Page 1

featuring

Pentra

with Logic

Engine

IDEC MicroSmart

Page 2

IDEC Presents the MicroSmart Family of Micro-PLCs

A trusted name for over 60 years

IDEC has been a global leader in industrial

automation for over half a century. Our

customers know that they can trust IDEC to

provide high quality products, from simple

ON/OFF controls to complex HMIs, and to

maintain each product line with responsive

support and innovative design.

IDEC is committed to maintaining the same

excellence in products and services that we

have been known for since 1945.

“We value uptime. Our

machinery has to work for

Our promise is our performance

Micro-controllers play an increasingly central

role in today’s industrial applications. You

have many controllers to choose from, but

the one you turn to most often is the one

that fits best, physically and practically. You’ll

find IDEC PLCs in various applications from

water treatment plants to HVAC to printing

press operations and more. They’re always

dependable, easy to program and almost as

smart as you are.

at least 10-15 years, and we

want to invest in a versatile

controller that will really

last. The MicroSmart Pentra

is the answer for us.”

Machine Engineer

Packaging Manufacturer

2

Page 3

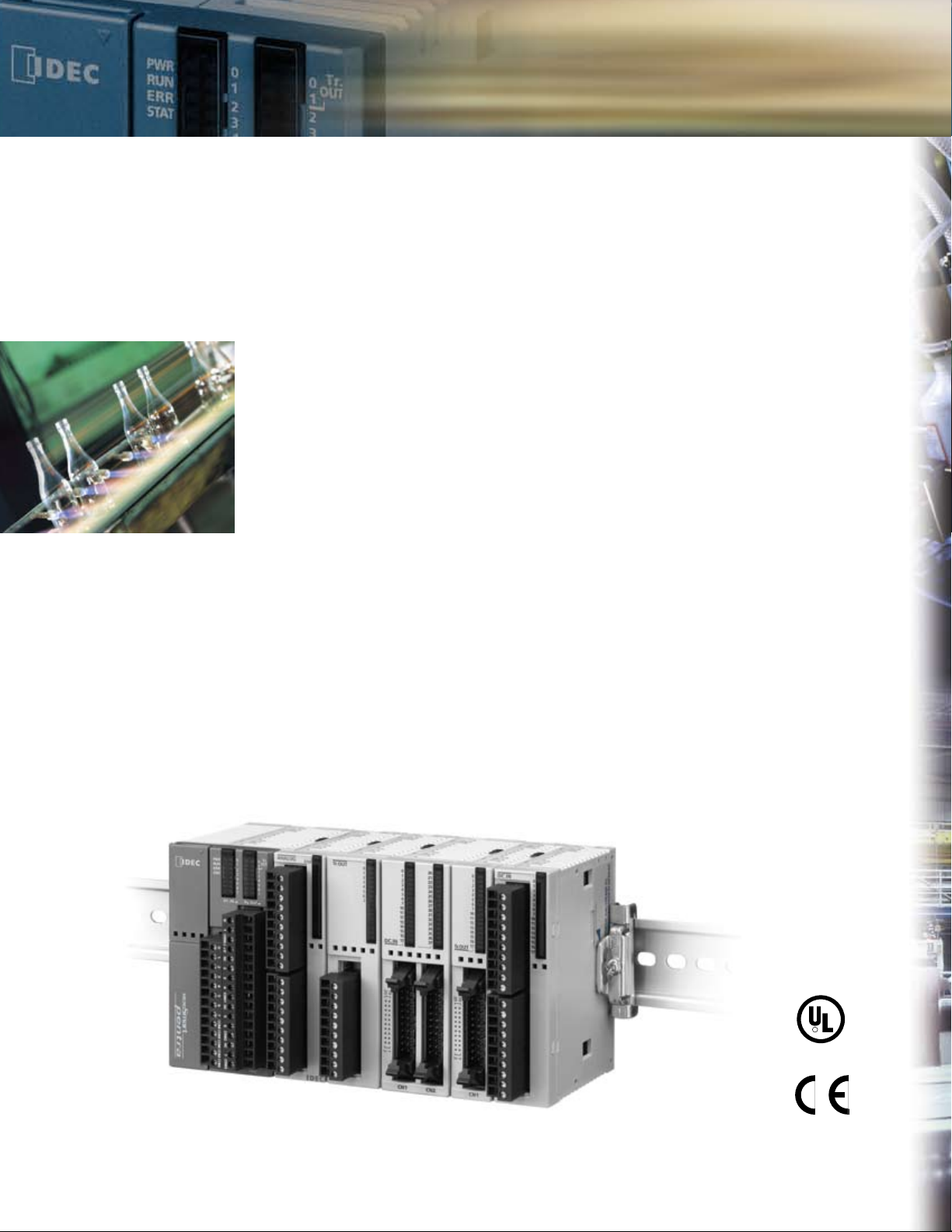

The world is moving into the

SPEED

POWER

PRECISION

future at an accelerated

pace, and the micro controller

market is no exception. Now

IDEC is bringing you controllers

so powerful that the only

limitation in your designs will

be the physical abilities of

your machines.

33

www. i d e c .com

Page 4

R

64

$

MicroSmart — One Controller Does it All

IDEC brought some of the first micro-PLCs to the market, and has been

meeting your changing control automation needs for decades. Our

controllers meet the highest standards for safety, flexibility and value.

International approvals

All MicroSmart controllers have regulatory

agency certifications for the worldwide

market including being cULus Listed for

Class 1 Division 2 Hazardous Locations, TUV

approved, and certified for marine use by

Lloyd’s Registry.

Rugged, compact, modular design

Every CPU module comes equipped with

embedded I/O points, and you can conveniently

add snap-on expansion modules for up to 512

I/Os based on your system requirements. All

MicroSmart controllers are DIN-rail and panel

mountable.

Write and run your programs now

Relax. Programming MicroSmart is fast and

straightforward. Use IDEC’s WindLDR Software to

configure, modify and monitor your MicroSmart

programs with ease. This powerful and intuitive

software makes it simple to get your system up

and running. See page 16-17 for more.

Upgrade without downtime

For added convenience, the same expansion I/O

modules and accessories can be used on both the

MicroSmart and MicroSmart Pentra controllers. In

fact, both controllers share the same architecture,

instruction set and programming software. The use

of a single platform for all IDEC PLCs means you

won’t have to reprogram or learn a new system to

move from one to another.

Make your choices

Feel the freedom. The ability to customize for the

functions you need allows you to create the perfect

system for your applications. Add an HMI module,

a RS232C/RS485 communications port, a Real Time

clock module or even an optional EEPROM module.

4

Page 5

StandardS

Value

Flexibility

Applications:

• Food and Beverage Equipment

• Packaging Machinery

• Textile Machinery

• Printing Press Equipment

• HVAC

• Conveyer Systems

• Car Wash Systems

• Doors/Gate Controls

• Environmental Rooms and Chambers

• Woodworking Machinery

• Water Pump Systems

• Water Treatment Plants & Systems

• Marine Industry

• Mail Sorting Equipment

• Oil & Gas Refinery Equipment

• Semiconductor Industry

• Building Management

www. i d e c .com

55

Page 6

MicroSmart Pentra — The New Standard for Micro Controllers

MicroSmart Pentra CPUs are the most full-featured

controllers in the IDEC family of PLCs. How many

different ways could you put them to use?

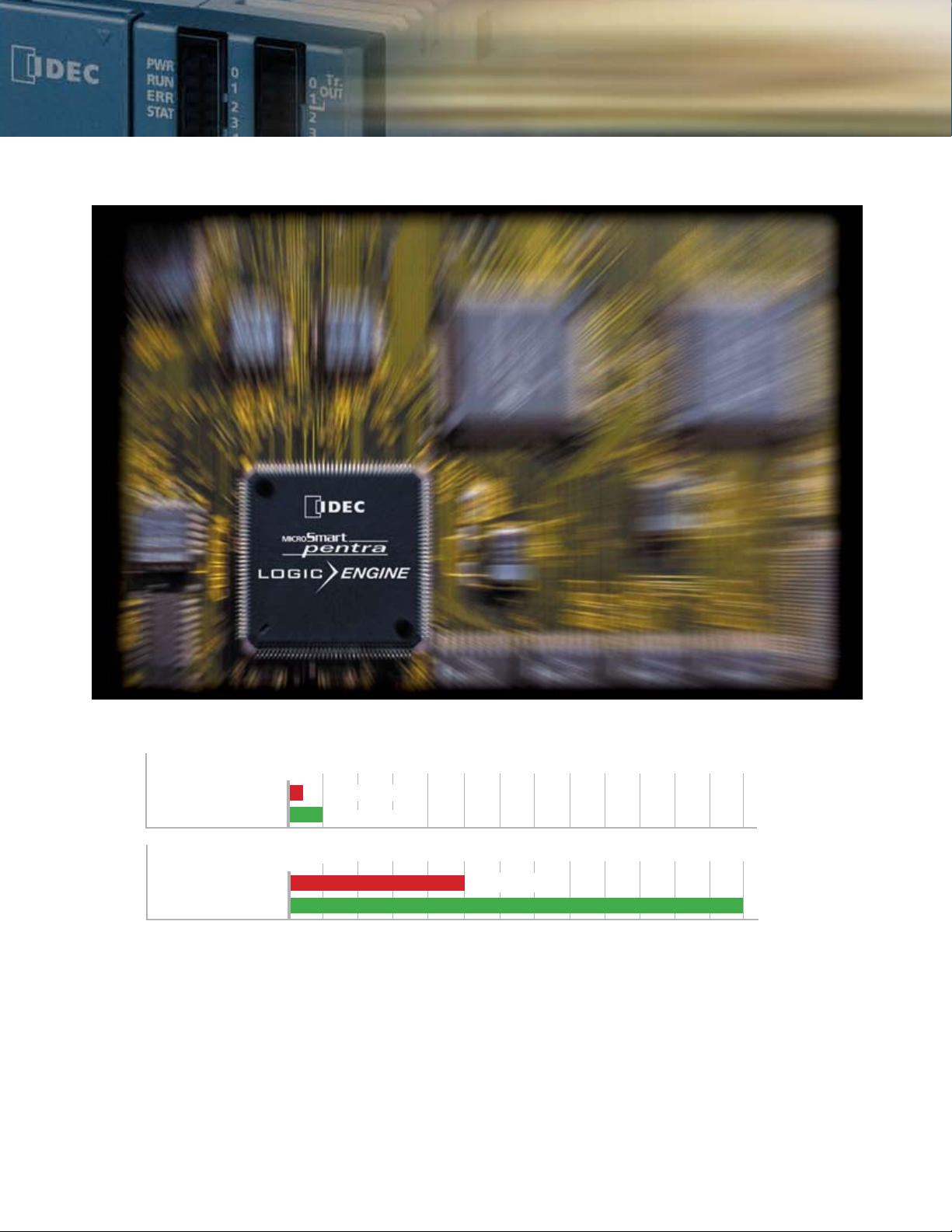

MicroSmart Pentra Speed Comparison

MicroSmart Pentra

LOD instructions

MOV instructions

Leading Competiors Controller

LOD instructions

MOV instructions

The Fastest Processing Speed

MicroSmart Pentra is the fastest micro

controller available in its class. The

overall processing speed of the new Logic

Engine CPU is 16 times faster than our

competitor’s average controller for simple

instruction execution, and more than 14

times faster when executing advanced

instruction sets.

Don’t wait for your old PLC to catch up to

today’s demands. Get faster scan times

and better throughput today.

6

0.056 μsec

0.167 μsec

0.9 μsec

Supports Double Word and

Floating Point Math

From billions to one-millionth, get the

numbers you need with 32-bit data

processing. MicroSmart Pentra supports

double-word and floating point math

operations, capturing and storing large

values, and returning computed results

accurate to seven decimal places. It’s

faster, it requires less maintenance and

gives you more precise data.

2.4 μsec

Built-in Modbus Master and

Slave

IDEC supports standard communication

protocols for industrial electronic devices.

See page 10 for more.

Field-Upgradeable Firmware

Extend the life of your PLC—upgrade your

unit’s firmware on-site as new functions

and versions become available.

Page 7

Maximum 512 I/O

fast

accurate

reliable

Choose from 23 different snap-on expansion

modules to create the perfect system.

100 kHz Counters and Outputs

MicroSmart has built-in high-speed inputs

with a maximum frequency of 100 kHz and

32-bit data processing capability, and can

configure up to three high-speed outputs.

Up to 56 Analog I/Os

Your options include 0-10V, 4-20mA, RTD,

thermocouple, thermistor inputs and ±10V

output.

Expanded Memory

• 48,000 Data Registers

• 2048 Internal Relays

• 256 Timers

• 256 Counters

• 62.4 K Programming Capacity

More MicroSmart Features

• Available in traditional brick style and

slimmer, space-saving book style

• Embedded I/O: each base model CPU is

equipped with built-in I/O configurations

of 10, 16, 20, 24, 32 and 40 I/O points.

• 100-240V AC or 24V DC power

• Optional memory cartridge for program

backup and transport

• Optional HMI module to easily monitor

and change your controller parameters

• Optional real-time clock cartridge for

time-based applications

• Built-in analog trim potentiometers

• Built-in 1-pt analog input

56 PID Loops with Auto-Tuning

Using MicroSmart in conjunction with PID

brings unparalleled accuracy and stability to

your process. See page 9 for more.

7 Communication Ports

RS232C is built in to every MicroSmart

CPU. If you need other ports, add one of the

available adapters or expansion modules;

MicroSmart Pentra models can accommodate

up to a total of seven communication ports.

Plug in bar code readers, printers or any

compatible devices, and go.

7

www. i d e c .com

Page 8

More Control — Pentra Gives You More Features

IDEC products live up to your exacting standards for motion control

and control in motion.

The success of your system might

be dependent on a few millimeters.

Most micro controllers lack the

necessary tools for accuracy at any

speed, much less at the very high

speeds modern applications require.

MicroSmart has always had the

capability to operate high speed

inputs and outputs, but MicroSmart

Pentra can go even faster, up to 100

kHz – and so can your productivity.

High speed counters

• Four high-speed inputs with

maximum frequency of 100 kHz

• Supports single or dual phase

counters

• 32-bit counting range up to

4,294,967,295 pulses

• Integrated Functions

- Execute Interrupt Programs

- Frequency Measurement

- High Speed Counter Refresh

- Multi Stage Comparison

High speed outputs

Configure as many as three high

speed pulse outputs, up to 100 kHz,

and get the simple position control

you want for stepper or servo motors.

8

8

Page 9

COMPACT

EFFECTIVE

ADVANCED

MicroSmart gives you all the benefits of PID quickly and easily—with none

of the drawbacks. No extra components required.

PID Implementations

Water level control

Environmental room

and chamber control

Flow Controls

Oven Controls

Speed Controls

PID creates a constant water level by

manipulating control valves

PID algorithm controls the temperature

PID is used to control the amount of air flow

through an air duct in a heating application.

PID is utilized to control the natural gas

burner for an oven system.

PID is used to maintain the speed of the motor

at a constant level.

PID (Proportional Integral Derivative) is

a common industrial control component

that uses loop feedback methods to

maintain a set process variable, such

as temperature or pressure control. This

loop allows accurate maintenance and

stabilization of the set point, adjusting

the control outputs based on history, or

rate of change on an error signal.

When you want the kind of stability PID

loops offer, but don’t have the kind of time or

experience that PID programming requires,

turn to IDEC. These powerful but simple to

use PID algorithms are included with the

MicroSmart controllers. You can select from

various control modes including Auto-tuning,

Advanced Auto-tuning or Manual. A wide

variety of alarms and conversion tools are

provided as well, and the software dialog

box is one of the easiest ways to implement

PID quickly.

• Program up to 56 loops with Pentra, up to

14 with MicroSmart

• PID dialog box walks you through algorithm

customization

• Advanced auto-tuning feature makes

programming PID instructions easy, even for

people with minimal algorithm experience

• Pre-defined parameters (such as time,

temperature or volume); avoid spending

extra time entering them manually

www. i d e c .com

9

Page 10

Networking Tools — Putting Everything Together is Easy With IDEC

PLCs don’t operate alone. Strong communication tools make everything in

your network work together.

RS485 Datalink

IDEC PLCs can create a master-slave system of

other IDEC controllers with up to 31 slave stations

over RS485, using the available communication

ports and RS485 modules. Plug in, attach two

simple wires, and you are on the way to an

effective, seamless network that can be extended

up to 200 meters.

All MicroSmart modules, as well as older IDEC

PLCs, support RS485 communication, so you can

include your existing IDEC controllers in a new,

more robust monitoring system.

10

10

Temperature Controllers

Modbus Master/Slave

Truly open standard, across devices and ideal

for wireless communication, Modbus messaging

protocol is a must-have for industrial networking.

If you need to establish communication between

multiple instruments from multiple manufacturers,

monitor remote devices through a PC or HMI, or

simply want to employ the most widely used

network protocol, you’re using Modbus.

Inverters

With something this necessary, you should expect

it to be standard in all controllers. And with

MicroSmart Pentra, it is. IDEC offers support for

Modbus RTU and ASCII, allowing the MicroSmart to

be master or slave on any Modbus network. That’s

it. Don’t buy another converter when you can buy a

controller that does it all.

Page 11

If you link 32 MicroSmart Pentras,

COMMUNICATE

EXPAND

LINK

maxed out with expansion modules

and 512 I/Os per system, you can

create a daisy-chain of 16,384 I/O

points. Imagine what you could do

with all those inputs and outputs!

AS-interface master module

P/N FC4A-AS62M

AS-interface Networking

The Actuator Sensor-interface (AS-interface) is the

simplest and most cost-effective of the PLC-based,

industrial-networking protocols. This type of field

bus is primarily intended to be used to control

sensors and actuators at distances of up to 100

meters. IDEC supports this open technology, which

is in devices installed in automation systems

worldwide.

IDEC offers a plug-in AS-interface master module

(FC4A-AS62M) that is easy to configure; it can also

connect to up to 64 slaves. With this module, you’ll

reduce the amount of engineering needed, employ

simpler wiring and enhance your operations since

it requires less maintenance. With an average cost

savings of 15 to 40 percent compared with traditional

cabling methods, using an IDEC AS-interface module

is the easy choice.

www. i d e c .com

11

11

Page 12

Ethernet Networking — Be in Control Wherever You Are

The ability to communicate over an Ethernet network is no longer an option for

most industrial systems, it’s a must.

Ethernet is the fastest growing

segment of industrial networking,

allowing access-from-anywhere

capability and easy remote-data

archiving. It makes sense: You can’t

always be in the same location

as your machinery, but with IDEC

Web Server, you don’t need to be.

Monitor status in real-time, at a

lower cost than with any other

open standard or proprietary bus

network.

• Remote maintenance

Allows you to use IDEC software

(WindLDR or WindSRV) to

remotely monitor, download and

upload any ladder program.

Web monitoring

•

Lets you use Internet Explorer

or Netscape NavigatorTM to

monitor or update your PLC with

a custom, built-in, monitor dialog

box.

TM

Web Server Module

P/N FC4A-ENET

• Alarm messaging

You can send up to 32 customized

messages from the Web Server

Module to a maximum of 64 e-mail

addresses or cell phones. You can be

notified immediately of any error or

processing condition that arises.

• Data exchange

Enables communication between

several IDEC MicroSmart PLCs over an

Ethernet network.

Ethernet

• O/I connectivity

IDEC touchscreens and IDEC MicroSmart

PLCs can communicate even when

located in completely separate areas.

• Password protection

Secure your system by allowing you

to password protect any unauthorized

access.

12

12

Page 13

Choose the CPU that works for you.

ACCESS

CONNECT

COMPARE

Review specifications and select your part number

CPU Part

Number

FC5A-C10R2 100-240V AC

FC5A-C10R2C

FC5A-C16R2

FC5A-C16R2C 24V DC

FC5A-C24R2 100-240V AC

FC5A-C24R2C 24V DC

MicroSmart Pentra

FC5A-D16R*1

FC5A-D32*3 16in/16out Transistor 512

FC4A-C10R2 100-240V AC

FC4A-C10R2C

FC4A-C16R2

FC4A-C16R2C

FC4A-C24R2

FC4A-C24R2C 24V DC

FC4A-D20R*1

MicroSmart

FC4A-D20*3

FC4A-D40*3

Rated

Voltage

24V DC

100-240V AC

24V DC

24V DC

100-240V AC

24V DC

100-240V AC

24V DC

Embedded

I/Os

6in/4out

9in/7out 16 27K bytes –

14in/10out 88 54K bytes 32

8in/8out

6in/4out

9in/7out 16 15K bytes –

14in/10out 88 27K bytes 32

12in/8out

24in/16out 264

Output

Type

Relay

6-Relay

2-Transistor

Relay

6-Relay

2-Transistor

Transistor

Max.

Program

I/Os

Capacity

10

496

10 4.8K bytes –

244

148 27K bytes

13.8K

bytes

62.4K

bytes

31.2K

bytes

31.2K

bytes

Maximum

Analog I/O

Processing

Time

–

LOD: 0.7µs

MOV: 32µs

56

56 20kHz

LOD: 0.056µs

MOV: 0.167µs

LOD: 1µs

MOV: 46µs

32-bit and

Floating Pt.

Yes

– – 20kHz

Modbus HSC

Master

and

Slave

Pulse

Outputs

50KHz –

100kHz 100kHz

–

Data **

Memory

DR: 2000

TIM: 256

CNT: 256

IR: 2048

DR: 48000

TIM: 256

CNT: 256

IR: 2048

DR: 400

TIM: 32

CNT: 32

IR: 256

DR: 1300

TIM: 100

CNT: 100

IR: 1024

DR: 7300

TIM: 100

CNT: 100

IR: 1584

DR: 1300

TIM: 100

CNT: 100

IR: 1024

DR: 7300

TIM: 100

CNT: 100

IR: 1584

= K or S, Where K = sink and S = source outputs

*

**DR=Data Registers, TIM=Timers, CNT=Counters, IR=Internal Relays

www. i d e c .com

13

13

Page 14

Analog and Digital Options — Choose Your Expansion Needs

Wiring and programming analog signals could not be any

easier. With IDEC, it takes just three steps.

Wire your device to the snap-on

1

expansion module.

Analog Controls

For heightened precision and accuracy,

you need analog controls, and IDEC

can deliver. We offer a wide range of

solutions, including 0-10V, 4-20mA, RTD,

Thermocouple, Thermistor input modules

and ± 10V output modules; there are

8 different modules to choose from, with

12-bit or 16-bit resolution.

The expansion units snap on easily to the

MicroSmart CPU. Then configure the analog

signal using the built-in macro instructions

from the WindLDR programming software.

The range of values in the analog signals

can be combined with the PID algorithm to

manage the desired response and outcome.

Select the device type in WindLDR.

2

Analog Controls in Action

To control pressure, time, and temperature

cycles in an industrial autoclave, multiple

analog sensors feed input to the PLC. With

analog expansion modules, these values are

registered and translated into data accessible

by the MicroSmart and, in many cases, sent

through the built-in PID algorithm. Using a

feedback loop, the PLC can control various

elements that maintain the target values,

and keep the entire process running at peak

performance with no interruptions.

You’re up and running!

3

Digital Controls

To incorporate your sensors, switches,

pushbuttons and other digital controls,

IDEC offers an array of digital expansion

modules with DC inputs, AC inputs, relay

outputs and transistor outputs. Like all

MicroSmart expansion modules, they snap

on to the CPU with no extra cables.

Analog Expansion Modules

Part Number Description

FC4A-L03A1 2-pt 0-10V, 4-20mA in; 1-pt 0-10V out

FC4A-L03AP1

FC4A-J2A1

FC4A-K1A1

FC4A-J4BN1

FC4A-J8B1

FC4A-J8BT1

FC4A-K2B1

14

2-pt RTD, Thermocouple in/ 1-pt 0-10V out

2-pt 0-10V, 4-20mA in

1-pt 0-10V out

4-pt 0-10V, 4-20mA, RTD, Thermocouple in

8-pt 0-10V, 4-20mA in

8-pt thermistor in

2-pt ± 10V out

Digital Expansion Modules*

Part Number Description

FC4A-N08A11 8-pt AC input module

FC4A-N08B1

FC4A-N16B1

FC4A-R081

FC4A-R161

FC4A-M08BR1

FC4A-T08K1

FC4A-T08S1

* Other modules also available

8-pt DC input module

16-pt DC input module

8-pt Relay output module

16-pt Relay output module

4-pt DC input, 4-pt Relay output

8-pt Sink output

8-pt Source output

Page 15

“There’s no uncertainty with

MONITOR

CONTROL

RESPOND

IDEC products. We always

get the right product, and if

we need help I know we’ll

be able to get answers from

the right people, too.”

Business Manager

Water Treatment

Systems Manufacturer

www. i d e c .com

15

15

Page 16

WindLDR Software — Ladder Programming Made Easy

Don’t lose valuable hours programming your PLC when IDEC’s WindLDR®

software for Windows can get you up and running in no time!

Time is money. An IDEC PLC will save you both.

All IDEC micro controllers are programmable with

WindLDR ladder logic software. This icon-driven

programming tool combines logic and intuition

with an incredibly easy-to-use interface to allow

you to take advantage of every MicroSmart feature.

Even without ladder program experience, you can

use the built-in editors, shortcuts and debuggers

to configure programs. Lose the extra costs of

engineering, installation and maintenance and get

right to work!

WindLDR is an excellent, long-term investment for

your control solutions. It programs every IDEC PLC,

so it’s adaptable to whatever hardware you need

today and down the road. Software upgrades are

always free for registered users.

WindLDR 5 runs on Windows 95, 98, 2000, NT

and XP and is available in five languages: English,

Japanese, Spanish, German and Chinese.

Online editing and programming

Shutting down for minor changes can be a major

hassle, so WindLDR allows you to edit and download

programs while the PLC is still in Run mode. You’ll be

able to write new values to counters, timers and registers at any time without switching between editor

mode (for programming) and monitor mode.

Simulation mode

Test your program in WindLDR to guarantee that it

works the way you expected, rather than downloading

it to your PLC for a test run.

Custom monitor dialog box

Compile and enter a list of parameters you want to

monitor, then save it and access it again and again,

instead of re-entering your data every time.

16

16

Page 17

Simple-to-use editors

MONITOR

RESPOND

CONTROL

Use the tag editor to access and edit coil

data. Edit comments and rung comments.

Comment download

When you transfer your program to the

PLC, you have the option to include

any accompanying comments too. User

programs can be downloaded with the

comments attached to operands and

rungs; the documentation is stored in the

processor. With comment data, you can

review programming codes for clarification

and streamlined maintenance.

Verify Program

This great debugging tool allows you to run

a comparison without uploading the whole

program from the PLC back to your PC. If

there’s a chance your program has been

corrupted or tampered with, that’s a chance

you don’t want to take.

User-friendly interfaces

Icon-based toolbars and drag-and-drop

functionality make basic ladder programming

accessible to anyone. But WindLDR also

shows you how to display parameters and

settings and how to input your parameters,

and the built-in shortcuts and tutorials will

keep you on the right track.

Part Number Description

FC9Y-LP2CDW WindLDR PLC Programming Software

“Building an entirely new production

line from the ground up is challenging,

especially on a budget. I like IDEC

controllers because I know they’ll

work and I know I’ll be able to program

them myself.”

Electrical Engineering Manager

Material Handling Equipment

17

www. i d e c .com

Page 18

HG Family HMIs — Control at Your Fingertips

Get the whole picture with an IDEC HMI. Now available in special

package deals with the MicroSmart Pentra!

18

Operator Interfaces

In today’s market, effective monitoring and

control of your manufacturing environment

is critical to your bottom line. In order to

stay ahead of the competition, you need to

constantly look for new ways to increase

productivity and lower your costs, while

maintaining quality control and safety. A

typical manufacturing control panel has an

overwhelming array of buttons, switches,

relays and other devices that make it

cumbersome and hard to manage. Change

all that with a simple solution: connect an

operator interface to your MicroSmart PLC.

Full color, monochrome, text-only,

high-resolution, large, small... there’s an

interface that can help you control your

production and let your workers manage

any situation quickly and safely.

• HG4F 12” TFT touchscreens

• HG3F 10” TFT touchscreens

• HG2F 5.7” STN color or monochrome touchscreens

• HG1F 4.6” monochrome touchscreen

• HG1X text message displays

More information online at:

www.idec.com/usa/smarttouch

IDEC touchscreens are programmable

with WindO/I-NV2 software, which helps

you create the right graphic interfaces

to visualize operating conditions. Use

the intuitive drag and drop programming

with built-in set-up wizards, or script your

processes in “C” to reduce the amount

of time spent programming connected

controllers.

Page 19

Starter Kits

BRIGHT

SIMPLE

QUALITY

Get your MicroSmart Pentra today, and

take your applications to the next level

with this fantastic micro controller. We’ll

send you everything that’s necessary to

integrate a new PLC into your systems: the

MicroSmart Pentra, a programming cable

and WindLDR software.

Starter Kit Packages

Part Numbers Controller Type Software Cable

MM-PENTRA-16 16 I/Os Slim CPU FC5A-D16RS1 WindLDR Programming

MM-PENTRA-24

24 I/Os All-in-One CPU FC5A-C24R2 WindLDR Programming

Solution Packages

Whether you’re new to IDEC or looking for

a quick way to put together a new system,

you’ll find a great deal in our solution

packages. Each package includes an IDEC

operator interface, a MicroSmart Pentra

slim CPU, a 24VDC slim power supply,

cables and software. It’s all you need in

just one step!

Solution Packages

Part Numbers Controller Type O/I Touchscreen Software Power Supply Cables

16 I/Os Slim CPU

FC5A-D16RS1

16 I/Os Slim CPU

FC5A-D16RS1

16 I/Os Slim CPU

FC5A-D16RS1

16 I/Os Slim CPU

FC5A-D16RS1

24 I/Os Brick CPU

FC5A-C24R2

24 I/Os Brick CPU

FC5A-C24R2

24 I/Os Brick CPU

FC5A-C24R2

24 I/Os Brick CPU

FC5A-C24R2

MM-PENTRA-16-HG1F

MM-PENTRA-16-HG2F-C

MM-PENTRA-16-HG3F

MM-PENTRA-16-HG4F

MM-PENTRA-24-HG1F

MM-PENTRA-24-HG2F-C

MM-PENTRA-24-HG3F

MM-PENTRA-24-HG4F

4.6” Monochrome HG1F

5.7” STN Color HG2F

10.2” TFT Color HG3F

12.1” TFT Color HG4F

4.6” Monochrome HG1F

5.7” STN Color HG2F

10.2” TFT Color HG3F

12.1” TFT Color HG4F

www. i d e c .com

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

WindLDR &

WindO/I-NV2

30W PS5R Slim

30W PS5R Slim

30W PS5R Slim

30W PS5R Slim

30W PS5R Slim

30W PS5R Slim

30W PS5R Slim

30W PS5R Slim

Programming &

Interface

Programming &

Interface

Programming &

Interface

Programming &

Interface

Programming &

Interface

Programming &

Interface

Programming &

Interface

Programming &

Interface

19

Page 20

Product Information

IDEC MicroSmart family:

www.idec.com/usa/microsmart

WindLDR software:

www.idec.com/software

Software demos, upgrades, manuals and documentation:

www.idec.com/manuals

Touchscreens/Operator Interfaces:

www.idec.com/oi

IDEC has made a commitment to provide you with top-notch customer service

at every step of your experience. This means you can get the support you need

from installation and setup to programming your system. Get help or extra

documentation online, on the phone or by email. Whatever you need, just ask

and IDEC can help!

Product Support

Technical support:

support@idec.com

Sales support:

sales@idec.com

USA

IDEC Corporation

Tel: (408) 747-0550

opencontact@idec.com

Canada

IDEC Canada Ltd.

Tel: (905) 890-8561

sales@idec.com

Australia

IDEC Australia Pty. Ltd.

Tel: +61-3-9763-3244

sales@au.idec.com

PLC Training:

www.idec.com/usa/training

Want more MicroSmart and WindLDR experience? Get hands-on guidance from

IDEC’s expert technical staff. These intensive, two-day sessions cover PLC and

touchscreen programming, setup, troubleshooting and more. Classes are held

throughout the year at various locations in the US and Canada. For the latest

schedule of upcoming classes, visit our web site.

Find your local IDEC Representative or Distributor

www.idec.com/usa/locator

800-262-IDEC

Think Automation and beyond...

www.idec.com

Japan

IDEC Corporation

Tel: +81-6-6398-2571

products@idec.co.jp

United Kingdom

IDEC Electronics Ltd.

Tel: +44-1256-321000

sales@uk.idec.com

Specifications and other descriptions in this catalog are subject to change without notice.

©2006 IDEC Corporation. All Rights Reserved.

Germany

IDEC Elektrotechnik GmbH

Tel: +49-40-253054-10

service@idec.de

Hong Kong

IDEC (H.K.) Co., Ltd.

Tel: +852-2803-8989

info@hk.idec.com

Catalog No. FC9Y-B100-0 9/06 10K

China/Beijing

IDEC (Shanghai) Corporation

Tel: +86-10-6599-5541

China/Shanghai

IDEC (Shanghai) Corporation

Tel: +86-21-5353-1000

idec@cn.idec.com

China/Shenzhen

IDEC (Shenzhen) Corporation

Tel: +86-755-8356-2977

Singapore

IDEC Asia Pte. Ltd.

Tel: +65-6746-1155

info@sg.idec.com

Taiwan

IDEC Taiwan Corporation

Tel: +886-2-2698-3929

service@idectwn.com.tw

Loading...

Loading...