Page 1

FC9Y-B812

FC4A SERIES

Micro Programmable

Logic Controller

User’s Manual

Page 2

U

PDATE

I

NFO

« FC4A M

ICRO

S

MART

U

SER

’

S

M

ANUAL

»

M

ICRO

S

MART

U

SER

’

S

M

ANUAL

U

PDATE

Introduction

This manual includes additional descriptions of new modules and upgraded functionality of the FC4A

MicroSmart

CPU

modules with system program version up to 210 in detail.

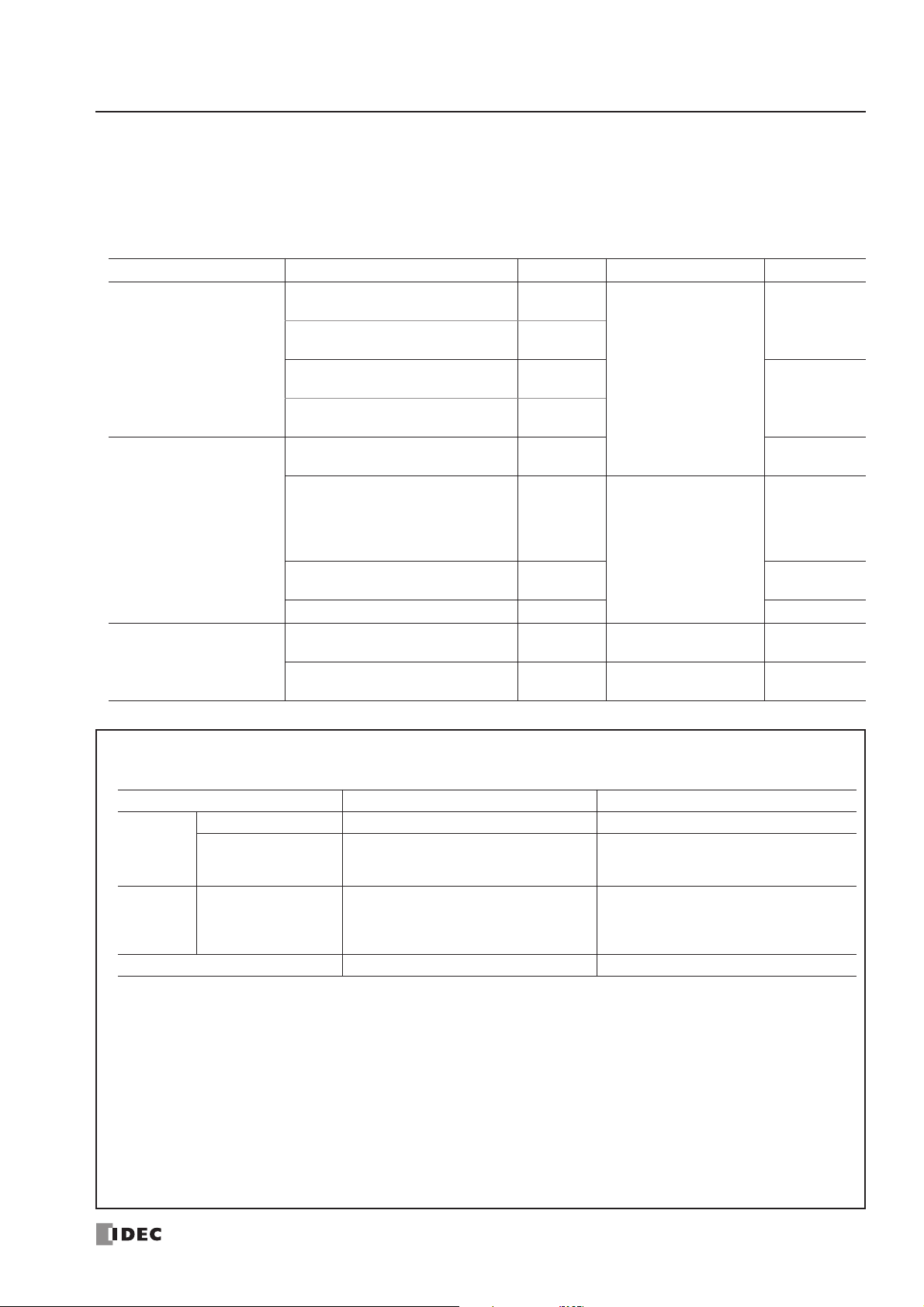

New Modules

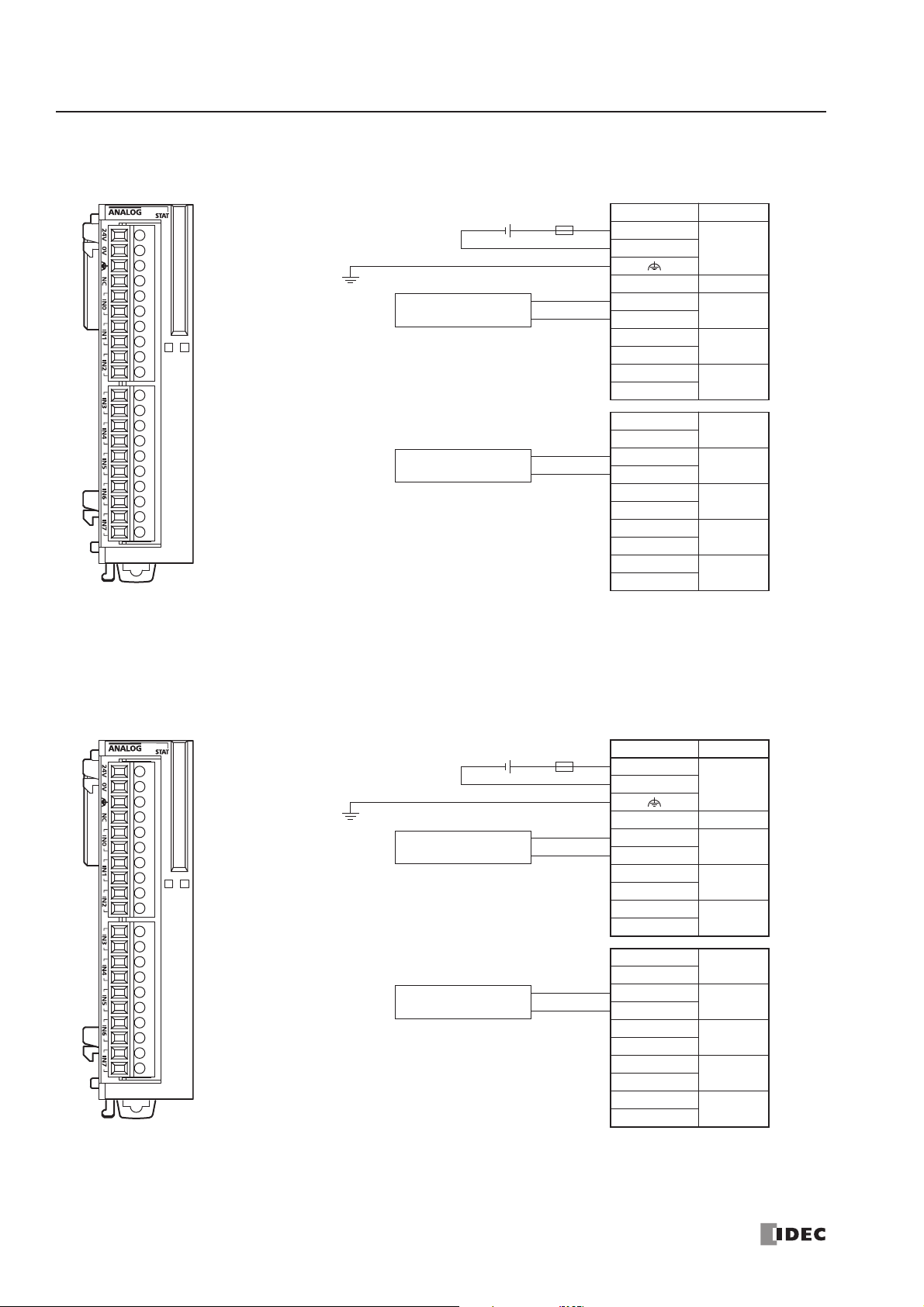

Analog I/O Modules (Ladder Refresh Type)

Upgraded Functionality

Twelve new functions have been implemented in the FC4A

MicroSmart

CPU modules. Availability of the twelve new

functions depends on the model and system program version of the CPU modules as listed below:

To confirm the system program version of the

MicroSmart

CPU module, use

WindLDR

on a computer connected with the

CPU module. Bring

WindLDR

into the online mode. The system program version is indicated on the PLC status dialog

box. For details about the procedure, see page 29-1.

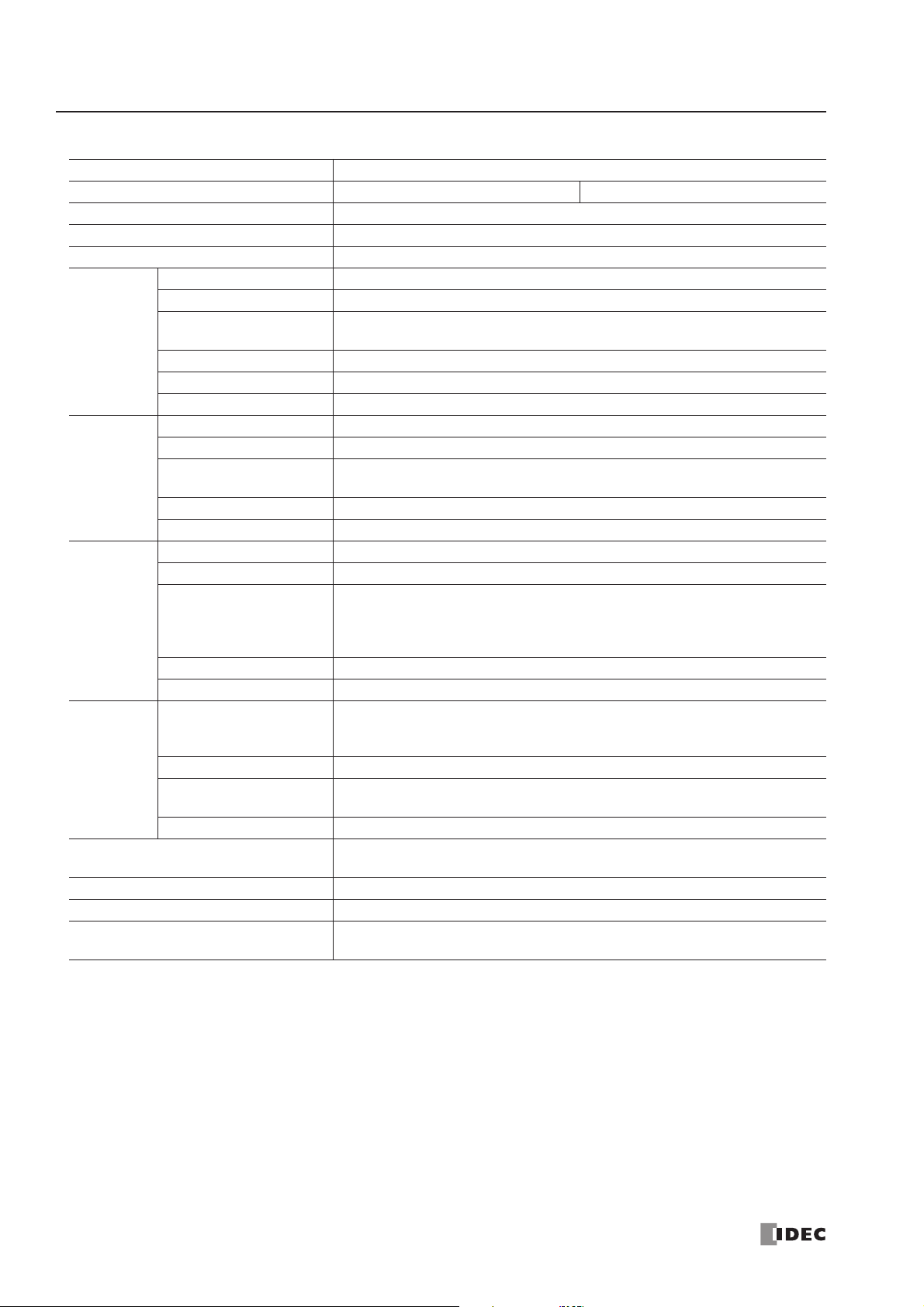

Name I/O Signal I/O Points Type No.

Analog Input Module

Voltage (0 to 10V DC) Current (4 to 20mA)

Thermocouple (K, J, T)

Resistance thermometer (Pt100, Pt1000, Ni100, Ni1000)

4 inputs FC4A-J4CN1

Voltage (0 to 10V DC) Current (4 to 20mA) 8 inputs FC4A-J8C1

Thermistor (NTC, PTC) 8 inputs FC4A-J8AT1

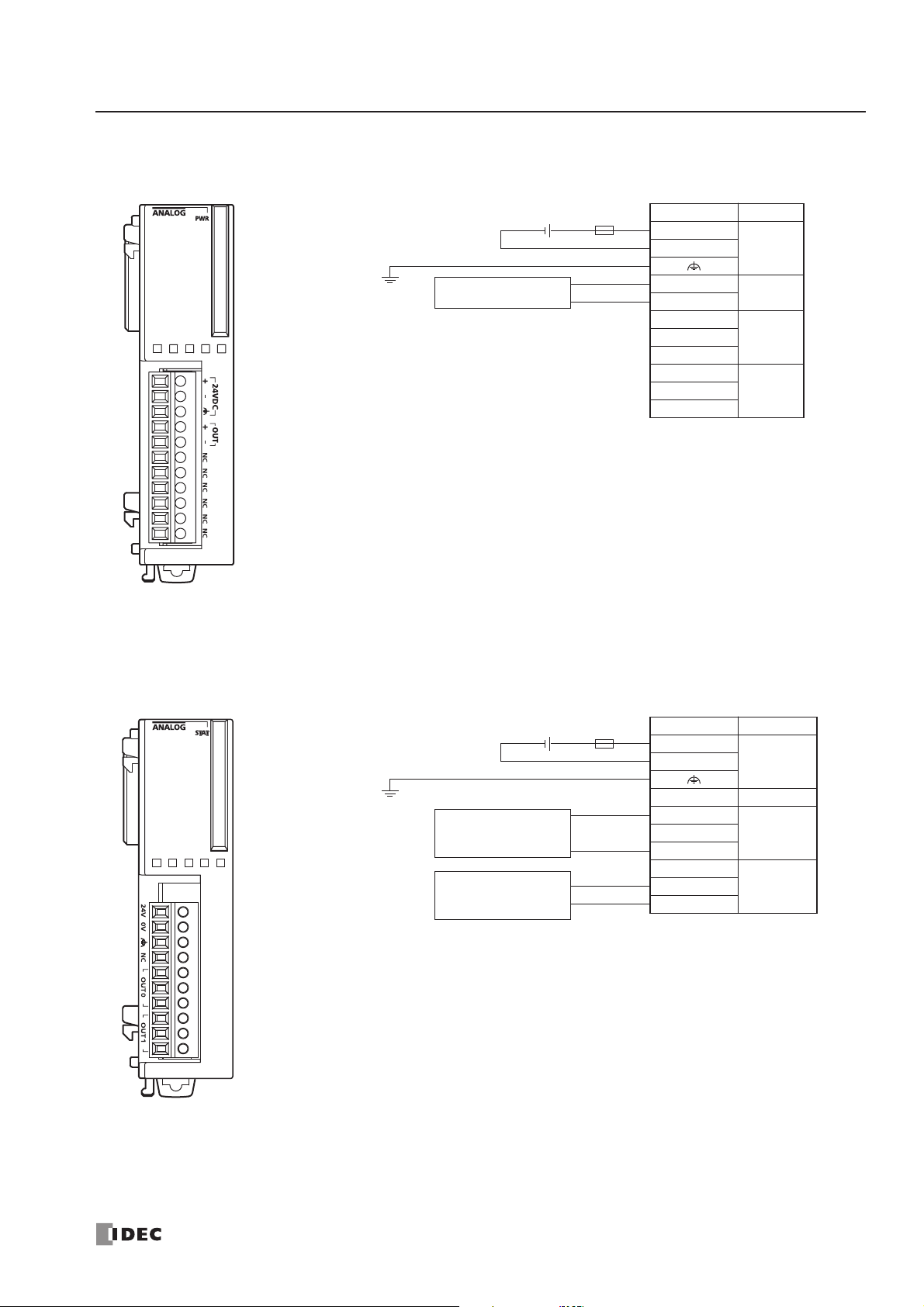

Analog Output Module Voltage (–10 to +10V DC) Current (4 to 20mA) 2 outputs FC4A-K2C1

CPU Module

All-in-One Type Slim Type

FC4A-C10R2

FC4A-C10R2C

FC4A-C16R2

FC4A-C16R2C

FC4A-C24R2

FC4A-C24R2C

FC4A-D20K3

FC4A-D20S3

FC4A-D20RK1

FC4A-D20RS1

FC4A-D40K3

FC4A-D40S3

Analog I/O Modules

(Ladder Refresh Type)

——204 or higher 204 or higher 203 or higher

AS-Interface Master Module

Compatibility

——

——

201 or higher

64KB Memory Cartridge

Compatibility

PID Instruction Upgrade

202 or higher 202 or higher

HMI Module Initial Screen

Selection

203 or higher 202 or higher

RS485 User Communication

Compatibility

—

204 or higher 204 or higher

204 or higher

202 or higher

User Communication BCC

Upgrade

(ADD-2comp, Modbus ASCII, and

Modbus RTU)

Pulse Instructions Upgrade

—

—

Coordinate Conversion

Instructions Upgrade

204 or higher 203 or higher

Intelligent Module Access

Instructions

Downloading from Memory

Cartridge to CPU Module

210 or higher 210 or higher 210 or higher 210 or higher

User Program Read Prohibit

Page 3

« FC4A M

ICRO

S

MART

U

SER

’

S

M

ANUAL

»P

REFACE

-1

S

AFETY

P

RECAUTIONS

• Read this user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance, and

inspection of the

MicroSmart

.

• All

MicroSmart

modules are manufactured under IDEC’s rigorous quality control system, but users must add a backup or

failsafe provision to the control system when using the

MicroSmart

in applications where heavy damage or personal injury

may be caused in case the

MicroSmart

should fail.

• In this user’s manual, safety precautions are categorized in order of importance to Warning and Caution:

•Turn off power to the

MicroSmart

before starting installation, removal, wiring, maintenance, and inspection of the

Micro-

Smart

. Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the

MicroSmart

. People without such expertise must not

use the

MicroSmart

.

• Emergency stop and interlocking circuits must be configured outside the

MicroSmart

. If such a circuit is configured inside

the

MicroSmart

, failure of the

MicroSmart

may cause disorder of the control system, damage, or accidents.

• Install the

MicroSmart

according to the instructions described in this user’s manual. Improper installation will result in fall-

ing, failure, or malfunction of the

MicroSmart

.

• The

MicroSmart

is designed for installation in a cabinet. Do not install the

MicroSmart

outside a cabinet.

• Install the

MicroSmart

in environments described in this user’s manual. If the

MicroSmart

is used in places where the

MicroSmart

is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive vibrations, and

excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

• The environment for using the

MicroSmart

is “Pollution degree 2.” Use the

MicroSmart

in environments of pollution

degree 2 (according to IEC 60664-1).

• Prevent the

MicroSmart

from falling while moving or transporting the

MicroSmart

, otherwise damage or malfunction of

the

MicroSmart

will result.

• Prevent metal fragments and pieces of wire from dropping inside the

MicroSmart

housing. Put a cover on the

MicroSmart

modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use an IEC 60127-approved fuse on the power line outside the

MicroSmart

. This is required when equipment containing

the

MicroSmart

is destined for Europe.

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the

MicroSmart

is des-

tined for Europe.

• Use an EU-approved circuit breaker. This is required when equipment containing the

MicroSmart

is destined for Europe.

• Make sure of safety before starting and stopping the

MicroSmart

or when operating the

MicroSmart

to force outputs on or

off. Incorrect operation on the

MicroSmart

may cause machine damage or accidents.

• If relays or transistors in the

MicroSmart

output modules should fail, outputs may remain on or off. For output signals

which may cause heavy accidents, provide a monitor circuit outside the

MicroSmart

.

• Do not connect the ground wire directly to the

MicroSmart

. Connect a protective ground to the cabinet containing the

MicroSmart

using an M4 or larger screw. This is required when equipment containing the

MicroSmart

is destined for

Europe.

• Do not disassemble, repair, or modify the

MicroSmart

modules.

• Dispose of the battery in the

MicroSmart

modules when the battery is dead in accordance with pertaining regulations.

When storing or disposing of the battery, use a proper container prepared for this purpose. This is required when equipment

containing the

MicroSmart

is destined for Europe.

• When disposing of the

MicroSmart

, do so as an industrial waste.

Warning

Caution

War ning notices are used to emphasize that improper operation may cause

severe personal injury or death.

Caution notices are used where inattention might cause personal injury or

damage to equipment.

Page 4

P

REFACE

-2 « FC4A M

ICRO

S

MART

U

SER

’

S

M

ANUAL

»

About This Manual

This user’s manual primarily describes entire functions, installation, and programming of the FC4A

MicroSmart

CPU and

all other modules. Also included are powerful communications of the

MicroSmart

and troubleshooting procedures.

C

HAPTER

1: G

ENERAL INFORMATION

General information about the MicroSmart, features, brief description on special functions, and various system setup configurations for communication.

CHAPTER 2: MODULE SPECIFICATIONS

Specifications of CPU, input, output, mixed I/O, analog I/O, and other optional modules.

CHAPTER 3: INSTALLATION AND WIRING

Methods and precautions for installing and wiring the MicroSmart modules.

CHAPTER 4: OPERATION BASICS

General information about setting up the basic MicroSmart system for programming, starting and stopping MicroSmart

operation, and simple operating procedures from creating a user program using WindLDR on a PC to monitoring the

MicroSmart operation.

CHAPTER 5: SPECIAL FUNCTIONS

Stop/reset inputs, run/stop selection at memory backup error, keep designation for internal relays, shift registers, counters,

and data registers. Also included are high-speed counter, catch input, interrupt input, timer interrupt, input filter, user program read/write protection, constant scan time, partial program download, and many more special functions.

CHAPTER 6: ALLOCATION NUMBERS

Allocation numbers available for the MicroSmart CPU modules to program basic and advanced instructions. Special internal relays and special data registers are also described.

CHAPTER 7: BASIC INSTRUCTIONS

Programming of the basic instructions, available operands, and sample programs.

CHAPTER 8: ADVANCED INSTRUCTIONS

General rules of using advanced instructions, terms, data types, and formats used for advanced instructions.

CHAPTER 9 THROUGH CHAPTER 23:

Detailed descriptions on advanced instructions grouped into 15 chapters.

CHAPTER 24 THROUGH CHAPTER 28:

Analog I/O control and various communication functions such as data link, computer link, modem mode, and AS-Interface.

CHAPTER 29: TROUBLESHOOTING

Procedures to determine the cause of trouble and actions to be taken when any trouble occurs while operating the Micro-

Smart

.

APPENDIX

Additional information about execution times for instructions, I/O delay time, and MicroSmart type list.

INDEX

Alphabetical listing of key words.

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting

from the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all programs,

prior to installation, is the responsibility of the end user.

Page 5

« FC4A MICROSMART USER’S MANUAL »PREFACE-3

Revision Record

The table below summarizes the changes to this manual since last printing of FC9Y-B812-0A in June, 2006.

Revision Description of Change Page

Analog I/O Modules

(Ladder Refresh Type)

Four analog input and output modules are added.

2-43, 6-5,

24-1

AS-Interface Master Module

Compatibility

AS-Interface master module is added.

2-58, 6-5,

28-1

RS485 User Communication

Compatibility

These functions are now available for FC4A-C16R2, FC4AC16R2C, FC4A-C24R2, FC4A-C24R2C, FC4A-D20K3, and

FC4A-D20S3.

17-1

User Communication BCC Upgrade

(ADD-2comp, Modbus ASCII, and Modbus RTU)

Pulse Instructions Upgrade

These functions are now available for FC4A-D20K3 and FC4AD20S3.

20-1

Coordinate Conversion Instructions

Upgrade

These functions are now available for FC4A-C24R2C, FC4AD20K3, and FC4A-D20S3.

19-1

Intelligent Module Access Instructions 23-1

Downloading from Memory Cartridge to

CPU Module

A user program can be downloaded from a memor y cartridge

to the CPU module.

2-66

User Program Read Prohibit

Read protection is upgraded and this option prevents copying

of the user program completely.

5-25

Analog I/O Modules Upgrade

(Version 200 or higher)

Four END refresh type analog input and output modules are

upgraded.

2-44

Page 6

PREFACE-4 « FC4A MICROSMART USER’S MANUAL »

Page 7

« FC4A MICROSMART USER’S MANUAL »i

TABLE OF CONTENTS

C

HAPTER 1: GENERAL INFORMATION

About the MicroSmart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

C

HAPTER 2: MODULE SPECIFICATIONS

CPU Modules (All-in-One Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

CPU Modules (Slim Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Mixed I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Analog I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

AS-Interface Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

HMI Base Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

Communication Adapters and Communication Modules . . . . . . . . . . . . . . . . . . . . 2-62

Memory Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-65

Clock Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

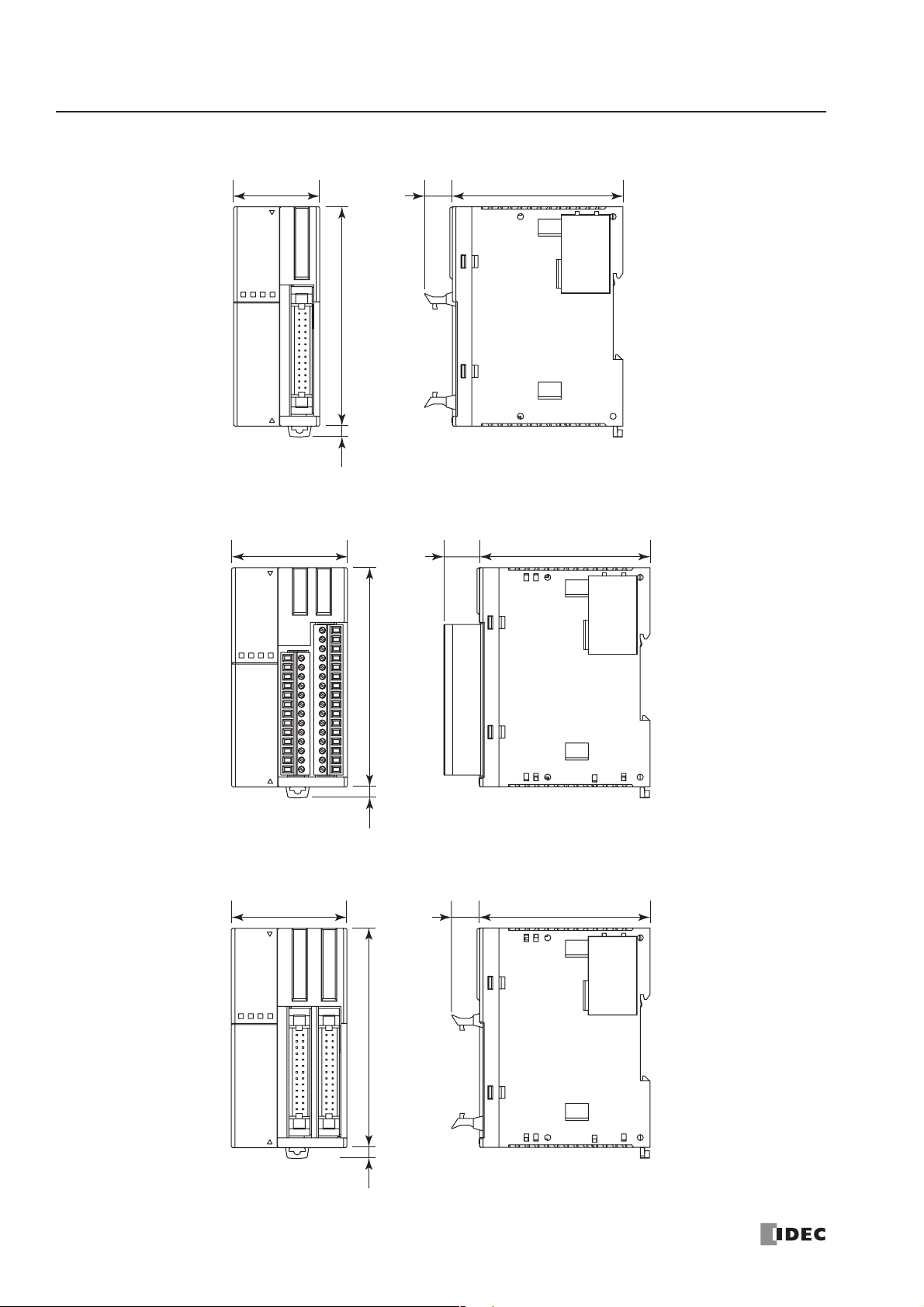

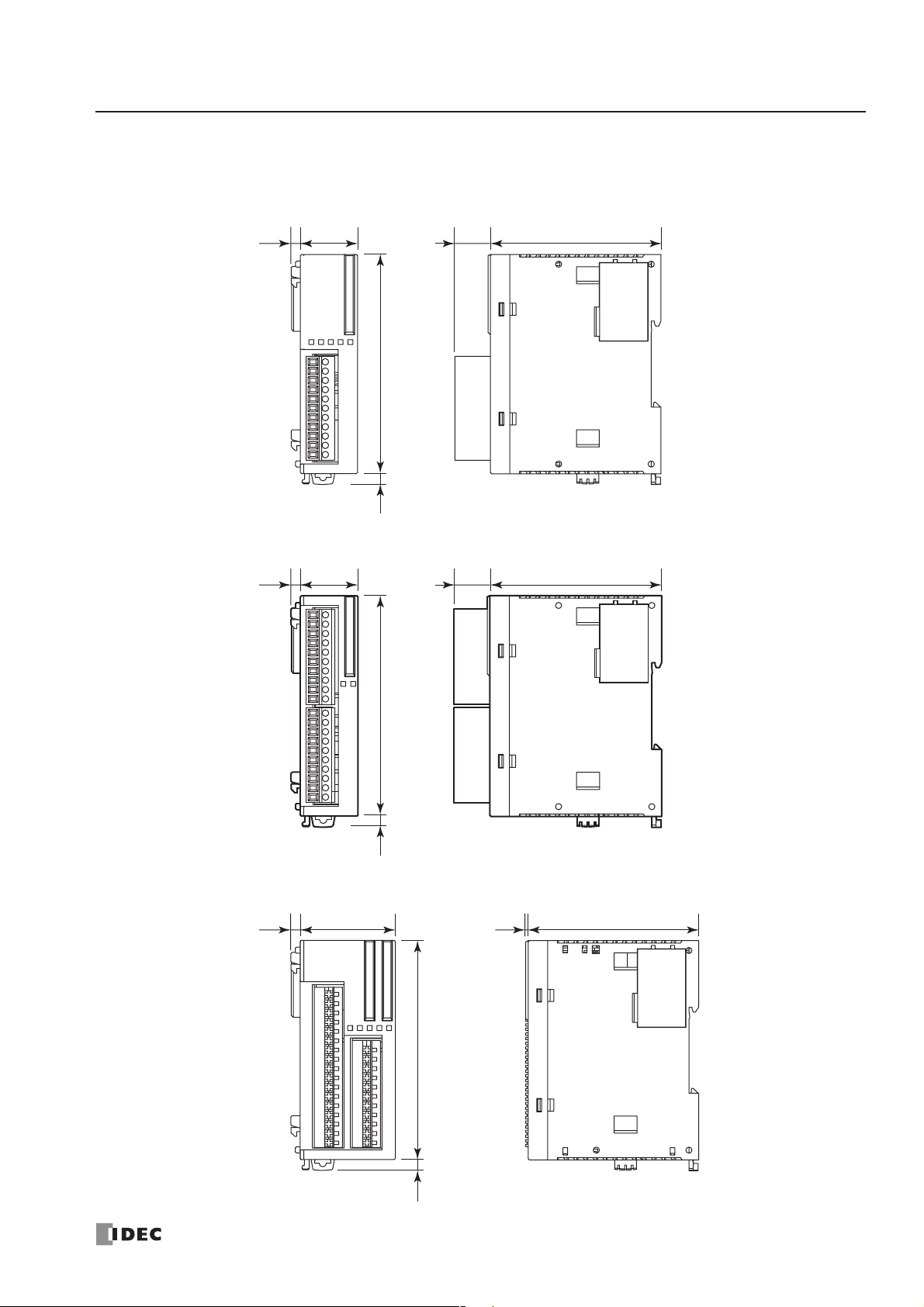

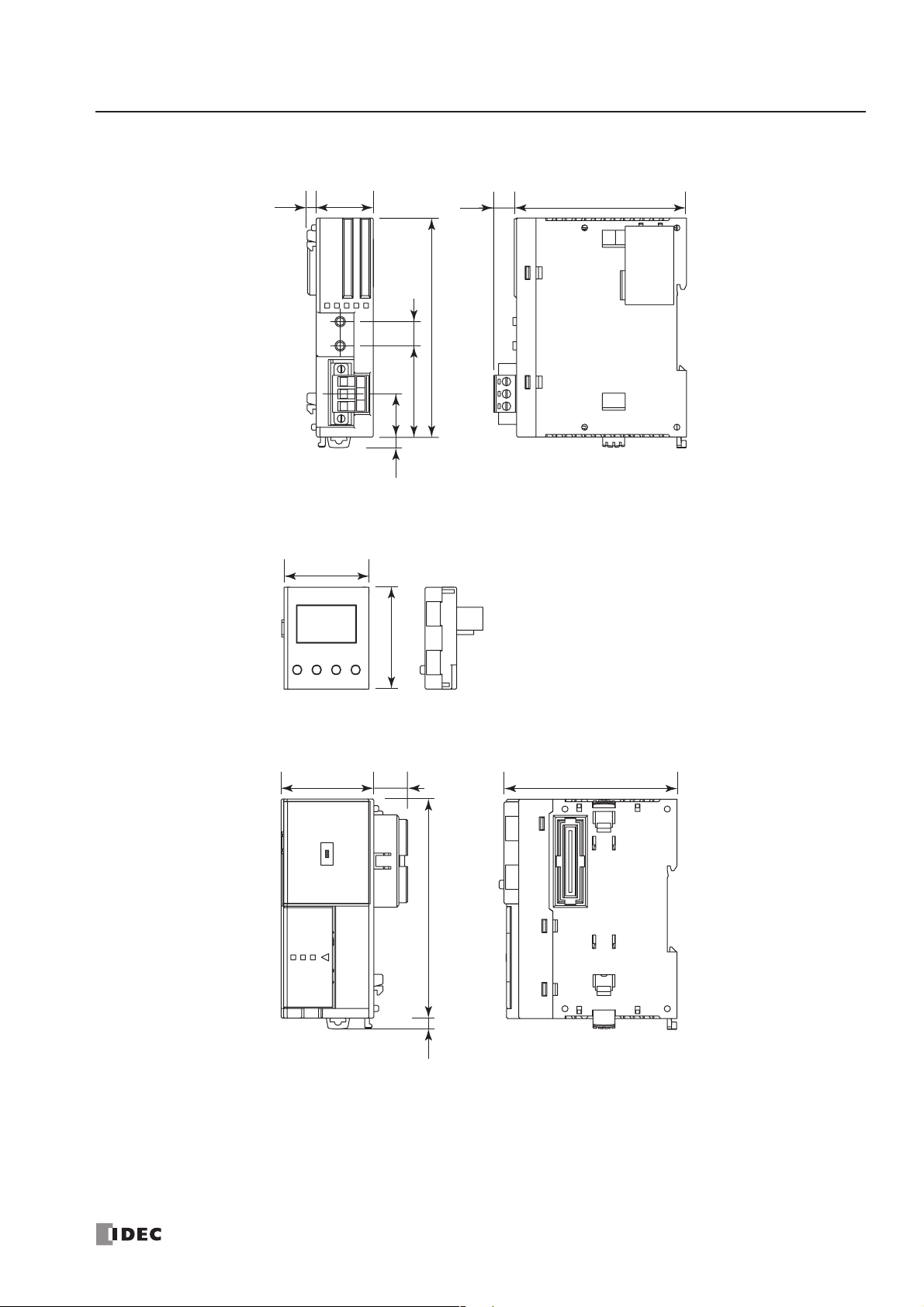

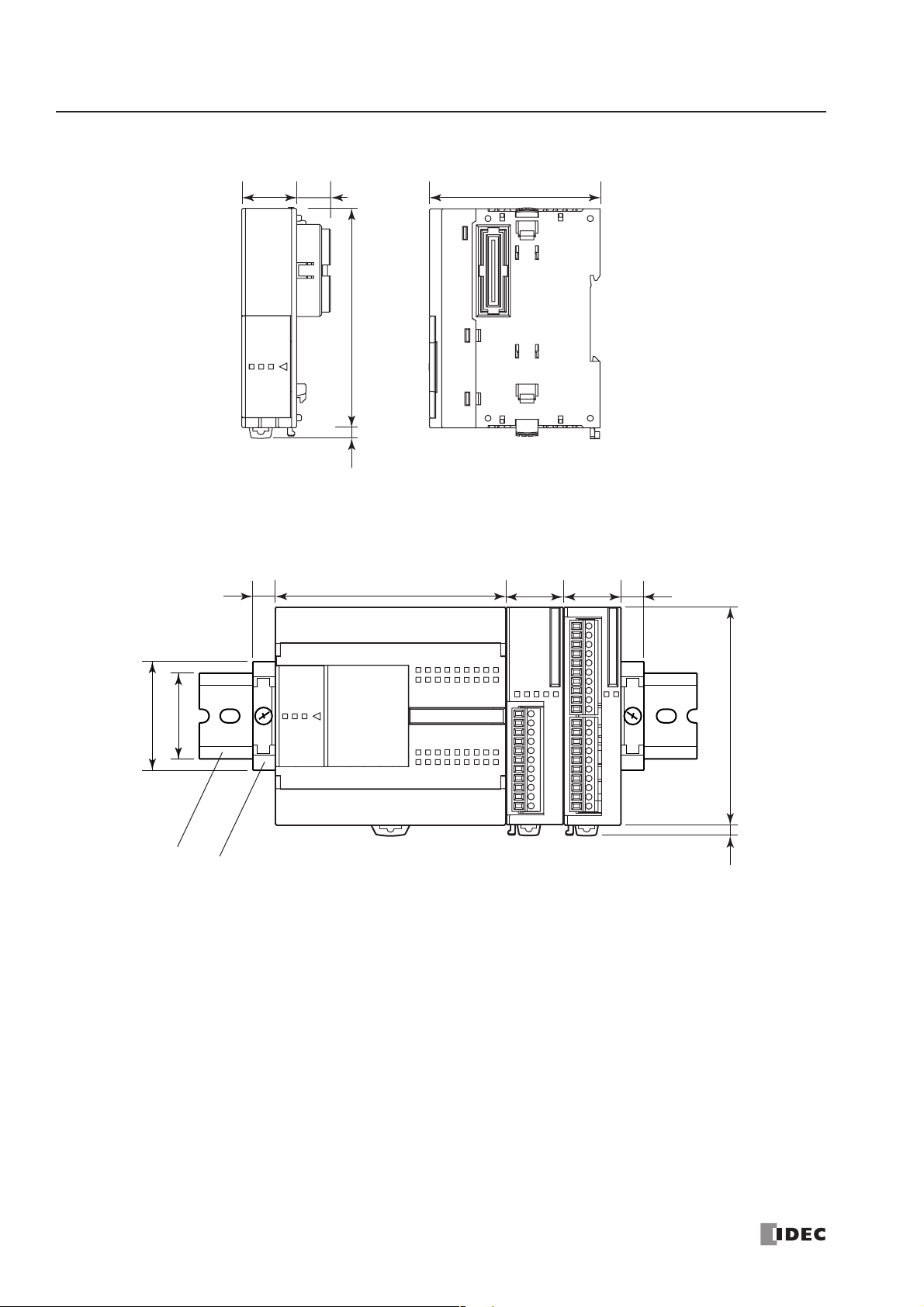

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

C

HAPTER 3: INSTALLATION AND WIRING

Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

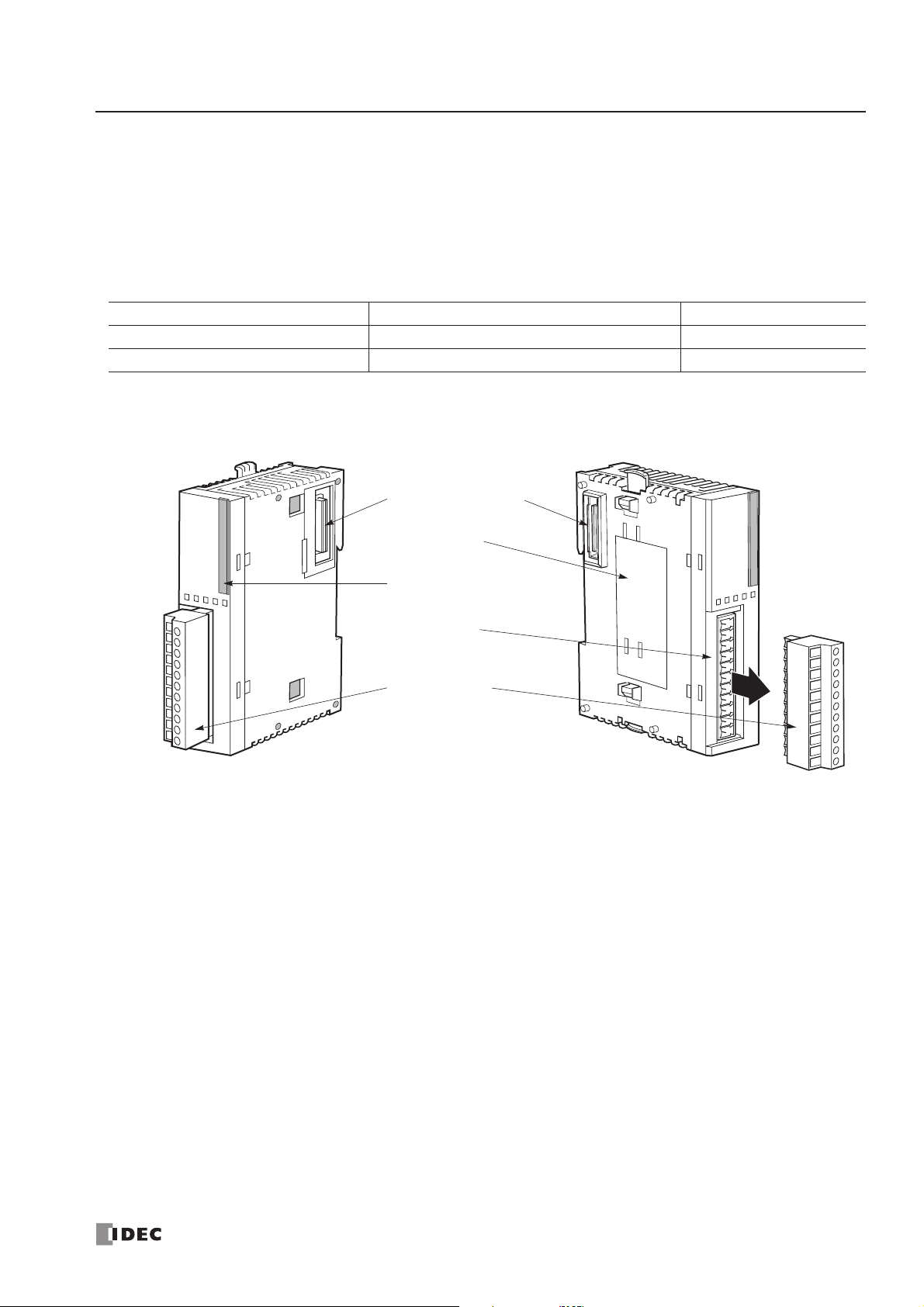

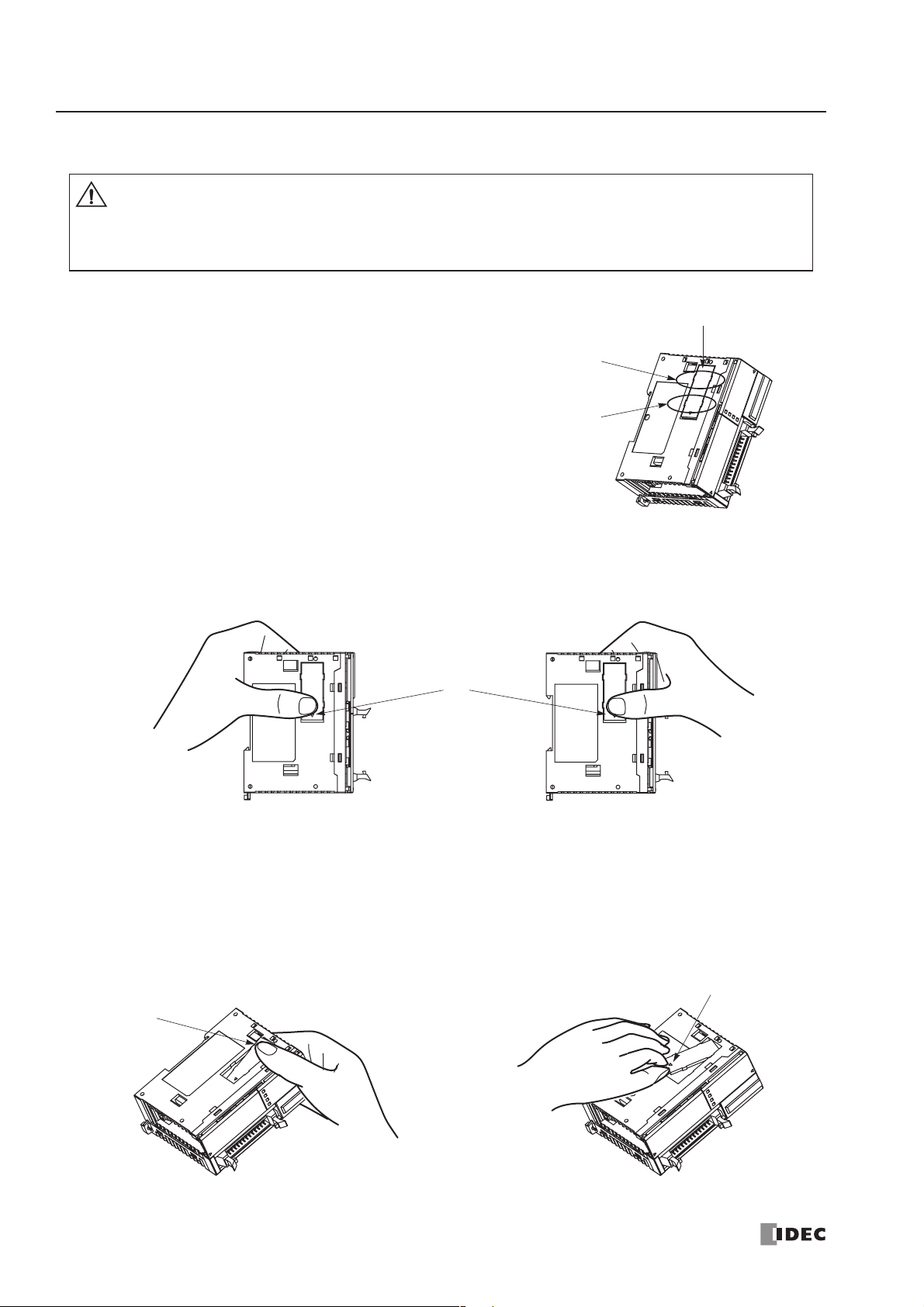

Assembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Disassembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing the HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing the HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Removing the Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Removing the Communication Connector Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

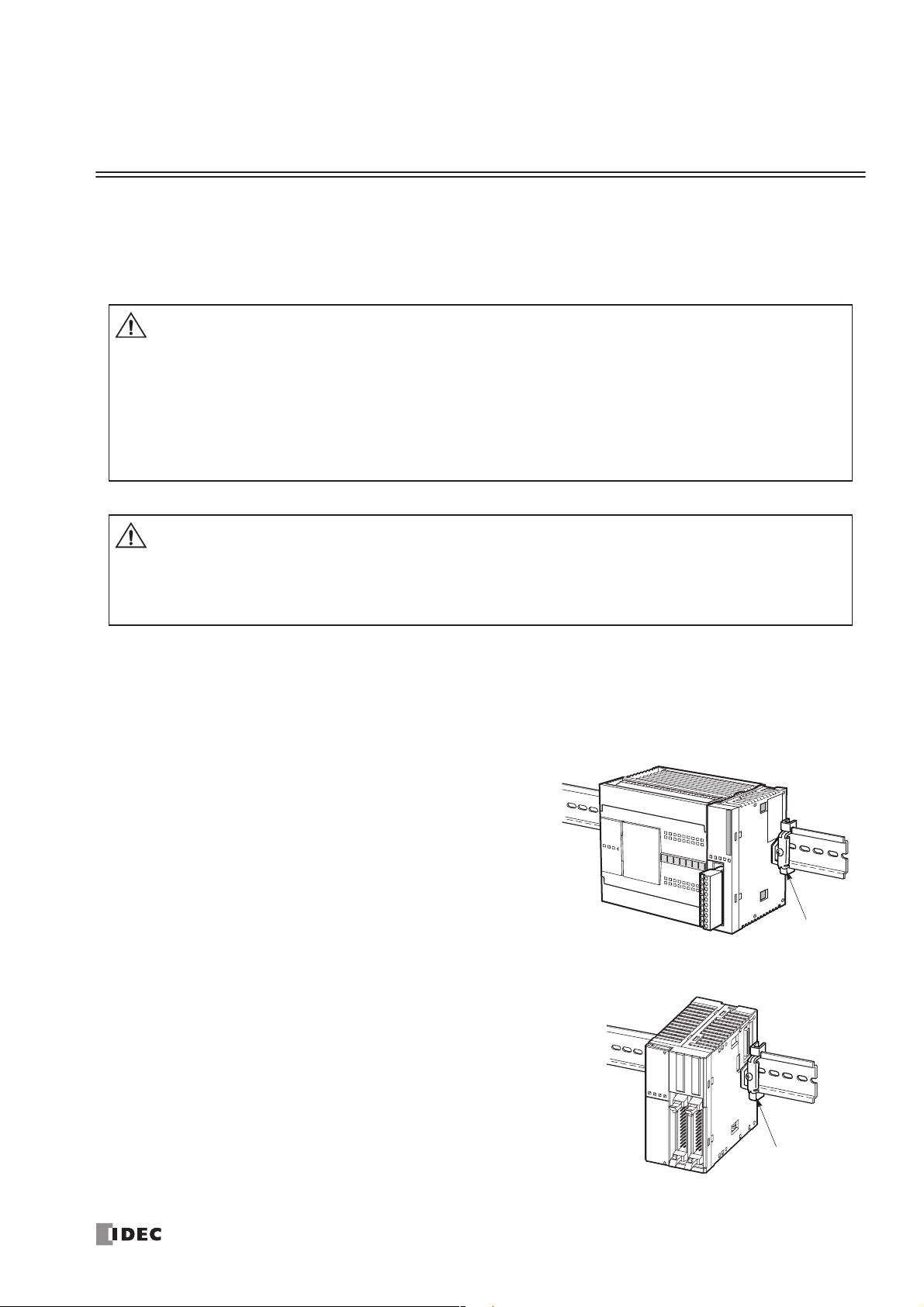

Mounting on DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Removing from DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Direct Mounting on Panel Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Installation in Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Mounting Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

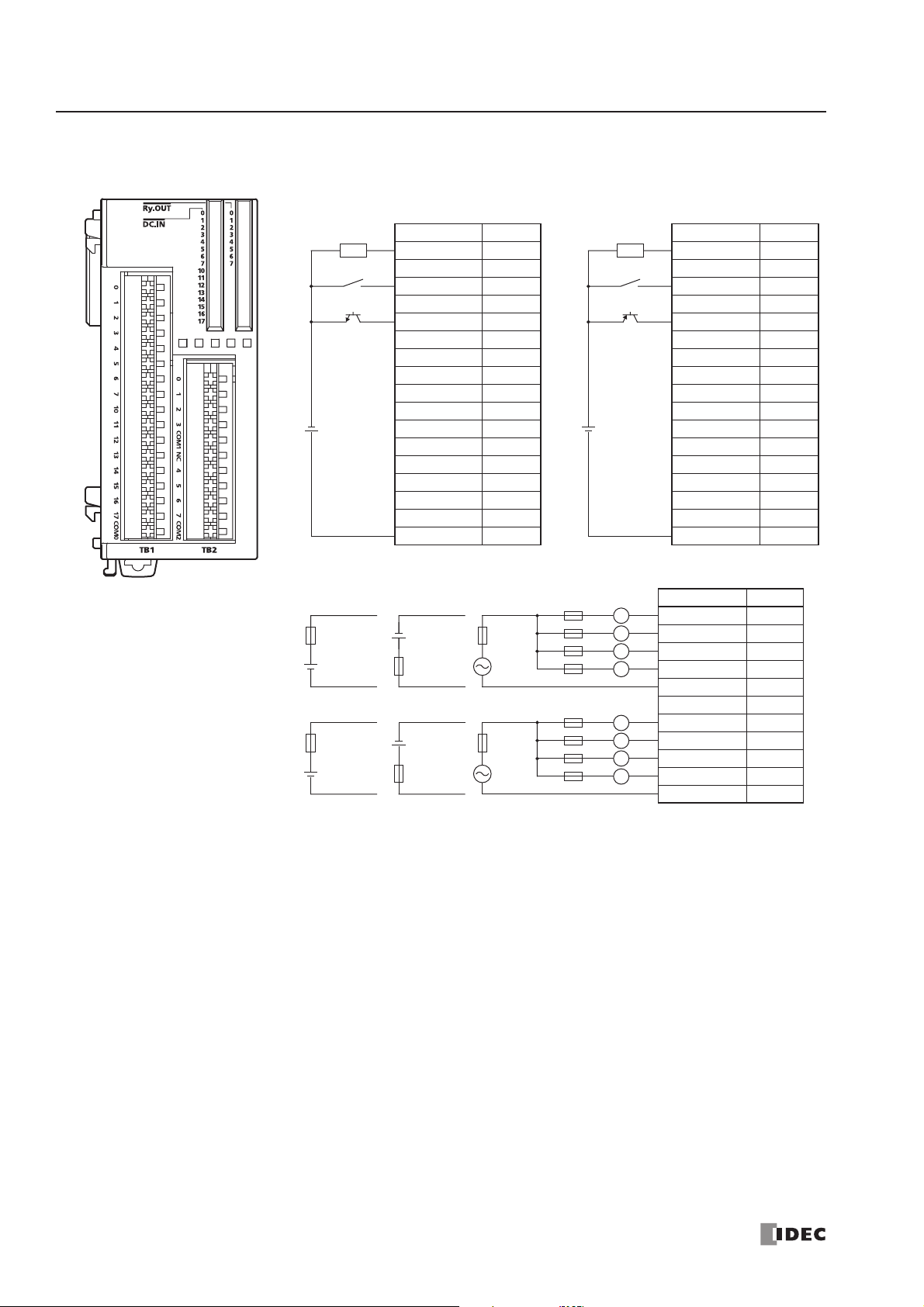

Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Terminal Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

C

HAPTER 4: OPERATION BASICS

Connecting MicroSmart to PC (1:1 Computer Link System) . . . . . . . . . . . . . . . . . . . 4-1

Start/Stop Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Simple Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Page 8

TABLE OF CONTENTS

ii « FC4A MICROSMART USER’S MANUAL »

C

HAPTER 5: SPECIAL FUNCTIONS

Function Area Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Stop Input and Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Run/Stop Selection at Memory Backup Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Keep Designation for Internal Relays, Shift Registers, Counters, and Data Registers 5-4

High-speed Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Catch Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Interrupt Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Timer Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Input Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

User Program Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Constant Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Partial Program Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Analog Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Analog Voltage Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

HMI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Expansion Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

C

HAPTER 6: ALLOCATION NUMBERS

Operand Allocation Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

I/O, Internal Relay, and Special Internal Relay Operand Allocation Numbers . . . . . . . 6-3

Operand Allocation Numbers for END Refresh Type Analog I/O Modules . . . . . . . . . 6-5

Operand Allocation Numbers for AS-Interface Master Module 1 . . . . . . . . . . . . . . . . 6-5

Operand Allocation Numbers for Data Link Master Station . . . . . . . . . . . . . . . . . . . 6-6

Operand Allocation Numbers for Data Link Slave Station . . . . . . . . . . . . . . . . . . . . . 6-6

Special Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Special Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Expansion I/O Module Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

C

HAPTER 7: BASIC INSTRUCTIONS

Basic Instruction List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

LOD (Load) and LODN (Load Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

OUT (Output) and OUTN (Output Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

SET and RST (Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

AND and ANDN (And Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

OR and ORN (Or Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

AND LOD (Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

OR LOD (Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

BPS (Bit Push), BRD (Bit Read), and BPP (Bit Pop) . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

TML, TIM, TMH, and TMS (Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

CNT, CDP, and CUD (Counter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

CC= and CC≥ (Counter Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

DC= and DC≥ (Data Register Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

SFR and SFRN (Forward and Reverse Shift Register) . . . . . . . . . . . . . . . . . . . . . . . 7-18

SOTU and SOTD (Single Output Up and Down) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

MCS and MCR (Master Control Set and Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

JMP (Jump) and JEND (Jump End) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Page 9

TABLE OF CONTENTS

« FC4A MICROSMART USER’S MANUAL » iii

C

HAPTER 8: ADVANCED INSTRUCTIONS

Advanced Instruction List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Advanced Instruction Applicable CPU Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Structure of an Advanced Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Input Condition for Advanced Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Source and Destination Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Using Timer or Counter as Source Operand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Using Timer or Counter as Destination Operand . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Data Types for Advanced Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Discontinuity of Operand Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

NOP (No Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

C

HAPTER 9: MOVE INSTRUCTIONS

MOV (Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

MOVN (Move Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

IMOV (Indirect Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

IMOVN (Indirect Move Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

BMOV (Block Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

IBMV (Indirect Bit Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

IBMVN (Indirect Bit Move Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

C

HAPTER 10: DATA COMPARISON INSTRUCTIONS

CMP= (Compare Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP<> (Compare Unequal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP< (Compare Less Than) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP> (Compare Greater Than) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP<= (Compare Less Than or Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP>= (Compare Greater Than or Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

ICMP>= (Interval Compare Greater Than or Equal To) . . . . . . . . . . . . . . . . . . . . . . 10-4

C

HAPTER 11: BINARY ARITHMETIC INSTRUCTIONS

ADD (Addition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

SUB (Subtraction) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

MUL (Multiplication) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

DIV (Division) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

ROOT (Root) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

C

HAPTER 12: BOOLEAN COMPUTATION INSTRUCTIONS

ANDW (AND Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

ORW (OR Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

XORW (Exclusive OR Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

C

HAPTER 13: SHIFT / ROTATE INSTRUCTIONS

SFTL (Shift Left) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

SFTR (Shift Right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

BCDLS (BCD Left Shift) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

WSFT (Word Shift) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

ROTL (Rotate Left) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

ROTR (Rotate Right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-7

Page 10

TABLE OF CONTENTS

iv « FC4A MICROSMART USER’S MANUAL »

C

HAPTER 14: DATA CONVERSION INSTRUCTIONS

HTOB (Hex to BCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

BTOH (BCD to Hex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

HTOA (Hex to ASCII) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

ATOH (ASCII to Hex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

BTOA (BCD to ASCII) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

ATOB (ASCII to BCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

ENCO (Encode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

DECO (Decode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-12

BCNT (Bit Count) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

ALT (Alternate Output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-14

C

HAPTER 15: WEEK PROGRAMMER INSTRUCTIONS

WKTIM (Week Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

WKTBL (Week Table) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-2

Setting Calendar/Clock Using WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

Setting Calendar/Clock Using a User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

Adjusting Clock Using a User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

Adjusting Clock Cartridge Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

C

HAPTER 16: INTERFACE INSTRUCTIONS

DISP (Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

DGRD (Digital Read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

C

HAPTER 17: USER COMMUNICATION INSTRUCTIONS

User Communication Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

User Communication Mode Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-2

Connecting RS232C Equipment through RS232C Port 1 or 2 . . . . . . . . . . . . . . . . 17-2

RS232C User Communication System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-3

Connecting RS485 Equipment through RS485 Port 2 . . . . . . . . . . . . . . . . . . . . . . 17-4

RS485 User Communication System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-4

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-5

TXD1 (Transmit 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-6

TXD2 (Transmit 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-6

RXD1 (Receive 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-15

RXD2 (Receive 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-15

User Communication Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-27

ASCII Character Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-28

RS232C Line Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-29

Sample Program – User Communication TXD . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-32

Sample Program – User Communication RXD . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-34

C

HAPTER 18: PROGRAM BRANCHING INSTRUCTIONS

LABEL (Label) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

LJMP (Label Jump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

LCAL (Label Call) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-3

LRET (Label Return) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-3

IOREF (I/O Refresh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-5

DI (Disable Interrupt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-7

EI (Enable Interrupt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-7

Page 11

TABLE OF CONTENTS

« FC4A MICROSMART USER’S MANUAL »v

C

HAPTER 19: COORDINATE CONVERSION INSTRUCTIONS

XYFS (XY Format Set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

CVXTY (Convert X to Y) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

CVYTX (Convert Y to X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-3

C

HAPTER 20: PULSE INSTRUCTIONS

PULS1 (Pulse Output 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

PULS2 (Pulse Output 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

PWM1 (Pulse Width Modulation 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-7

PWM2 (Pulse Width Modulation 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-7

RAMP (Ramp Control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-13

ZRN1 (Zero Return 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-24

ZRN2 (Zero Return 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-24

C

HAPTER 21: PID INSTRUCTION

PID (PID Control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-2

Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-14

C

HAPTER 22: DUAL / TEACHING TIMER INSTRUCTIONS

DTML (1-sec Dual Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

DTIM (100-ms Dual Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

DTMH (10-ms Dual Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

DTMS (1-ms Dual Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

TTIM (Teaching Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-3

C

HAPTER 23: INTELLIGENT MODULE ACCESS INSTRUCTIONS

RUNA READ (Run Access Read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-2

RUNA WRITE (Run Access Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-3

STPA READ (Stop Access Read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-4

STPA WRITE (Stop Access Write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-5

C

HAPTER 24: ANALOG I/O CONTROL

Applicable CPU Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-2

Analog I/O Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-7

Data Register Allocation Numbers for Analog I/O Modules . . . . . . . . . . . . . . . . . . 24-8

Analog Input Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-11

Analog Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-15

C

HAPTER 25: DATA LINK COMMUNICATION

Data Link Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-1

Data Link System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-2

Data Register Allocation for Transmit/Receive Data . . . . . . . . . . . . . . . . . . . . . . . 25-3

Special Data Registers for Data Link Communication Error . . . . . . . . . . . . . . . . . . 25-4

Data Link Communication between Master and Slave Stations . . . . . . . . . . . . . . . 25-5

Special Internal Relays for Data Link Communication . . . . . . . . . . . . . . . . . . . . . . 25-6

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-7

Refresh Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-9

Operating Procedure for Data Link System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-11

Data Link with Other PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-12

Page 12

TABLE OF CONTENTS

vi « FC4A MICROSMART USER’S MANUAL »

C

HAPTER 26: COMPUTER LINK COMMUNICATION

Computer Link System Setup (1:N Computer Link System) . . . . . . . . . . . . . . . . . . 26-1

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2

Monitoring PLC Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-3

RS232C/RS485 Converter FC2A-MD1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-4

C

HAPTER 27: MODEM MODE

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-1

Applicable Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-2

Special Internal Relays for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-2

Special Data Registers for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-3

Originate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-3

Disconnect Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-5

AT General Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-5

Answer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-6

Modem Mode Status Data Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-7

Initialization String Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-8

Preparation for Using Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-9

Programming Data Registers and Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . 27-9

Setting Up the CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-9

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-10

Operating Procedure for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-11

Sample Program for Modem Originate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-12

Sample Program for Modem Answer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-13

Troubleshooting in Modem Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-14

C

HAPTER 28: AS-INTERFACE MASTER COMMUNICATION

About AS-Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-1

Operation Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-6

Pushbuttons and LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-14

AS-Interface Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-18

Using Two AS-Interface Master Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-32

Using WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-34

SwitchNet Data I/O Port (AS-Interface Master Module 1) . . . . . . . . . . . . . . . . . . . 28-39

C

HAPTER 29: TROUBLESHOOTING

ERR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-1

Reading Error Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-1

Special Data Registers for Error Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-3

General Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-3

CPU Module Operating Status, Output, and ERR LED during Errors . . . . . . . . . . . . 29-4

Error Causes and Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-4

User Program Execution Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-6

Troubleshooting Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-7

Restriction on Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-22

A

PPENDIX Execution Times for Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1

Breakdown of END Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-2

I/O Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-2

Instruction Steps and Applicability in Interrupt Programs . . . . . . . . . . . . . . . . . . . . 30-3

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-4

Type List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-7

I

NDEX

Page 13

« FC4A MICROSMART USER’S MANUAL » 1-1

1: GENERAL INFORMATION

Introduction

This chapter describes general information for understanding the MicroSmart’s powerful capabilities and system setups to

use the MicroSmart in various ways of communication.

About the MicroSmart

IDEC’s MicroSmart is a new family of micro programmable logic controllers available in two styles of CPU modules; allin-one and slim types. The all-in-one type CPU module has 10, 16, or 24 I/O terminals and is equipped with a built-in universal power supply to operate on 100 to 240V AC or 24V DC. Using four 16-point I/O modules, the 24-I/O type CPU

module can expand the I/O points up to a total of 88 points. The slim type CPU module has 20 or 40 I/O terminals and

operates on 24V DC. The total I/O points can be expanded to a maximum of 264.

User programs for the MicroSmart can be edited using WindLDR on a Windows PC. Since WindLDR can load existing user

programs made for IDEC’s previous PLCs such as all FA series, MICRO-1, MICRO3, MICRO

3

C, and OpenNet Controller,

your software assets can be used in the new control system.

Program capacity of the all-in-one type CPU modules is 4,800 bytes (800 steps) on the 10-I/O type CPU module, 15,000

bytes (2,500 steps) on the 16-I/O type, and 27,000 bytes (4,500 steps) on the 24-I/O type. Slim type CPU modules have a

program capacity of 27,000 bytes (4,500 steps) or 31,200 bytes (5,200 steps). When using an optional 64KB memory cartridge on slim type CPU modules, the program capacity can be expanded up to 64,500 bytes (10,750 steps).

Features

Powerful Communication Functions

The MicroSmart features four powerful communication functions.

Communication Adapter (All-in-one 16- and 24-I/O type CPU modules)

Communication Module (Slim type CPU modules)

In addition to the standard RS232C port 1, the all-in-one 16- and 24-I/O type CPU modules feature a port 2 connector to

install an optional RS232C or RS485 communication adapter. All slim type CPU modules can be used with an optional

RS232C or RS485 communication module to add communication port 2. With an optional HMI base module mounted

with a slim type CPU module, an optional RS232C or RS485 communication adapter can also be installed on the HMI

base module.

Maintenance

Communication

(Computer Link)

When a MicroSmart CPU module is connected to a computer, operating status and I/O status

can be monitored on the computer, data in the CPU can be monitored or updated, and user

programs can be downloaded and uploaded. All CPU modules (except the all-in-one 10-I/O

type) can set up a 1:N computer link system to connect a maximum of 32 CPU modules to a

computer.

User Communication

All MicroSmart CPU modules can be linked to external RS232C devices such as computers,

printers, and barcode readers, using the user communication function. RS485 user communication is also available on upgraded CPU modules of slim 20-I/O relay output and 40-I/O

types.

Modem Communication

All MicroSmart CPU modules (except the all-in-one 10-I/O type) can communicate through

modems using the built-in modem protocol.

Data Link

All MicroSmart CPU modules (except the all-in-one 10-I/O type) can set up a data link system.

One CPU module at the master station can communicate with 31 slave stations through an

RS485 line to exchange data and perform distributed control ef fectively.

RS232C Communication Adapter

RS232C Communication Module

Used for computer link 1:1 communication, user communication, and modem

communication.

RS485 Communication Adapter

RS485 Communication Module

Available in mini DIN connector and terminal block styles. Used for computer link

1:1 or 1:N communication, user communication, and data link communication.

Page 14

1: GENERAL INFORMATION

1-2 « FC4A MICROSMART USER’S MANUAL »

HMI Module (all CPU modules)

An optional HMI module can be installed on any all-in-one type CPU module, and also on the HMI base module mounted

next to any slim type CPU module. The HMI module makes it possible to manipulate the RAM data in the CPU module

without using the Online menu options in WindLDR.

HMI module functions include:

• Displaying timer/counter current values and changing timer/counter preset values

• Displaying and changing data register values

• Setting and resetting bit operand statuses, such as inputs, outputs, internal relays, and shift register bits

• Displaying and clearing error data

• Starting and stopping the PLC

• Displaying and changing calendar/clock data (only when using the clock cartridge)

• Confirming changed timer/counter preset values

Clock Cartridge (all CPU modules)

An optional clock cartridge can be installed on the CPU module to store real time calendar/clock data for use with

advanced instructions to perform time-scheduled control.

Memory Cartridge (all CPU modules)

A user program can be stored on an optional memory cartridge using WindLDR. The memory cartridge can be installed on

another CPU module to replace user programs without the need for connecting to a computer. The original user program in

the CPU module is restored after removing the memory cartridge. The user program on the memory cartridge can also be

downloaded to the CPU module. The download option is selected using WindLDR.

Analog I/O Modules (all CPU modules except the all-in-one 10- and 16-I/O types)

Analog I/O modules are available in 3-I/O types, 2-input type, and 1-output type. The input channel can accept either voltage (0 to 10V DC) and current (4 to 20 mA) signals or thermocouple (types K, J, and T) and resistance thermometer (Pt

100) signals. The output channel generates voltage (0 to 10V DC) and current (4 to 20 mA) signals.

AS-Interface Master Module (slim type 20-I/O relay output and 40-I/O types)

Four upgraded slim type CPU modules (FC4A-D20RK1, FC4A-D20RS1, FC4A-D40K3, and FC4A-D40S3) with system

program ver. 201 and higher can use the AS-Interface master module, and have additional internal relays and data registers

to communicate with slaves, such as actuators and sensors, through the AS-Interface bus. For details about AS-Interface

module and AS-Interface communication, see page 2-58 and chapter 28.

Special Functions

The MicroSmart features various special functions packed in the small housing as described below. For details about these

functions, see the following chapters.

Stop and Reset Inputs

Any input terminal on the CPU module can be designated as a stop or reset input to control the MicroSmart operation.

RUN/STOP Selection at Startup when “Keep” Data is Broken

When data to be kept such as “keep” designated counter values are broken while the CPU is powered down, the user can

select whether the CPU starts to run or not to prevent undesirable operation at the next startup.

“Keep” or “Clear” Designation of CPU Data

Internal relays, shift register bits, counter current values, and data register values can be designated to be kept or cleared

when the CPU is powered down. All or a specified range of these operands can be designated as keep or clear types.

High-speed Counter

The MicroSmart has four built-in high-speed counters to make it possible to count up to 65,535 (FFFFh) high-speed pulses

which cannot be counted by the normal user program processing. One high-speed counter (all-in-one type CPU modules)

or two high-speed counters (slim type CPU modules) can be used as either two-phase or single-phase high-speed counters

at a maximum count input frequency of 20 kHz. Three or two others are single-phase high-speed counters with a maximum counting frequency of 5 kHz. The high-speed counters can be used for simple positioning control and simple motor

control.

Page 15

1: GENERAL INFORMATION

« FC4A MICROSMART USER’S MANUAL » 1-3

Catch Input

Four inputs can be used as catch inputs. The catch input makes sure to receive short input pulses (rising pulse of 40 µs or

falling pulse of 150 µs minimum) from sensors without regard to the scan time.

Interrupt Input

Four inputs can be used as interrupt inputs. When a quick response to an external input is required, such as positioning

control, the interrupt input can call a subroutine to execute an interrupt program.

Timer Interrupt

In addition to the interrupt input, slim type CPU modules FC4A-D20RK1, FC4A-D20RS1, FC4A-D40K1, and FC4AD40S1 have a timer interrupt function. When a repetitive operation is required, the timer interrupt can be used to call a

subroutine repeatedly at predetermined intervals of 10 through 140 ms.

Input Filter

The input filter can be adjusted for eight inputs to reject input noises. Selectable input filter values to pass input signals are

0 ms, and 3 through 15 ms in 1-ms increments. The input filter rejects inputs shorter than the selected input filter value

minus 2 ms. This function is useful for eliminating input noises and chatter in limit switches.

User Program Read/Write Protection

The user program in the CPU module can be protected against reading and/or writing by including a password in the user

program. Read protection without a password is also available to inhibit reading completely.

Constant Scan Time

The scan time may vary whether basic and advanced instructions are executed or not depending on input conditions to

these instructions. When performing repetitive control, the scan time can be made constant by entering a required scan

time value into a special data register reserved for constant scan time.

Partial Program Download

Normally, the CPU module has to be stopped before downloading a user program. All CPU modules (except the all-in-one

10-I/O type) have run-time program download capabilities to download a user program containing small changes while the

CPU is running in either 1:1 or 1:N computer link system. This function is particularly useful to make small modifications

to the user program and confirm the changes while the CPU is running.

Analog Potentiometer

All CPU modules have an analog potentiometer, except the all-in-one 24-I/O type CPU module has two analog potentiometers. The values (0 through 255) set with analog potentiometers 1 and 2 are stored to special data registers. The analog

potentiometer can be used to change the preset value for a timer or counter.

Analog Voltage Input

Every slim type CPU module has an analog voltage input connector. When an analog voltage of 0 through 10V DC is

applied to the analog voltage input connector, the signal is converted to a digital value of 0 through 255 and stored to a special data register. The data is updated in every scan.

Pulse Output

Slim type CPU modules have pulse output instructions to generate high-speed pulse outputs from transistor output terminals used for simple position control applications, illumination control, trapezoidal control, and zero-return control.

PID Control

All CPU modules (except the all-in-one 10- and 16-I/O types) have the PID instruction, which implements a PID (proportional, integral, and derivative) algorithm with built-in auto tuning to determine PID parameters. This instruction is primarily designed for use with an analog I/O module to read analog input data, and turns on and off a designated output to

perform PID control in applications such as temperature control. In addition, the PID instruction can also generate an analog output using an analog I/O module.

Expansion Data Register

Slim type CPU modules FC4A-D20RK1, FC4A-D20RS1, FC4A-D40K3, and FC4A-D40S3 have expansion data registers

D2000 through D7999. Numerical data can be set to expansion data registers using WindLDR. When downloading the user

program, the preset values of the expansion data registers are also downloaded to the EEPROM in the CPU module. Since

the data in the EEPROM is non-volatile, the preset values of the expansion data registers are maintained semi-permanently

and loaded to the RAM each time the CPU is powered up.

Page 16

1: GENERAL INFORMATION

1-4 « FC4A MICROSMART USER’S MANUAL »

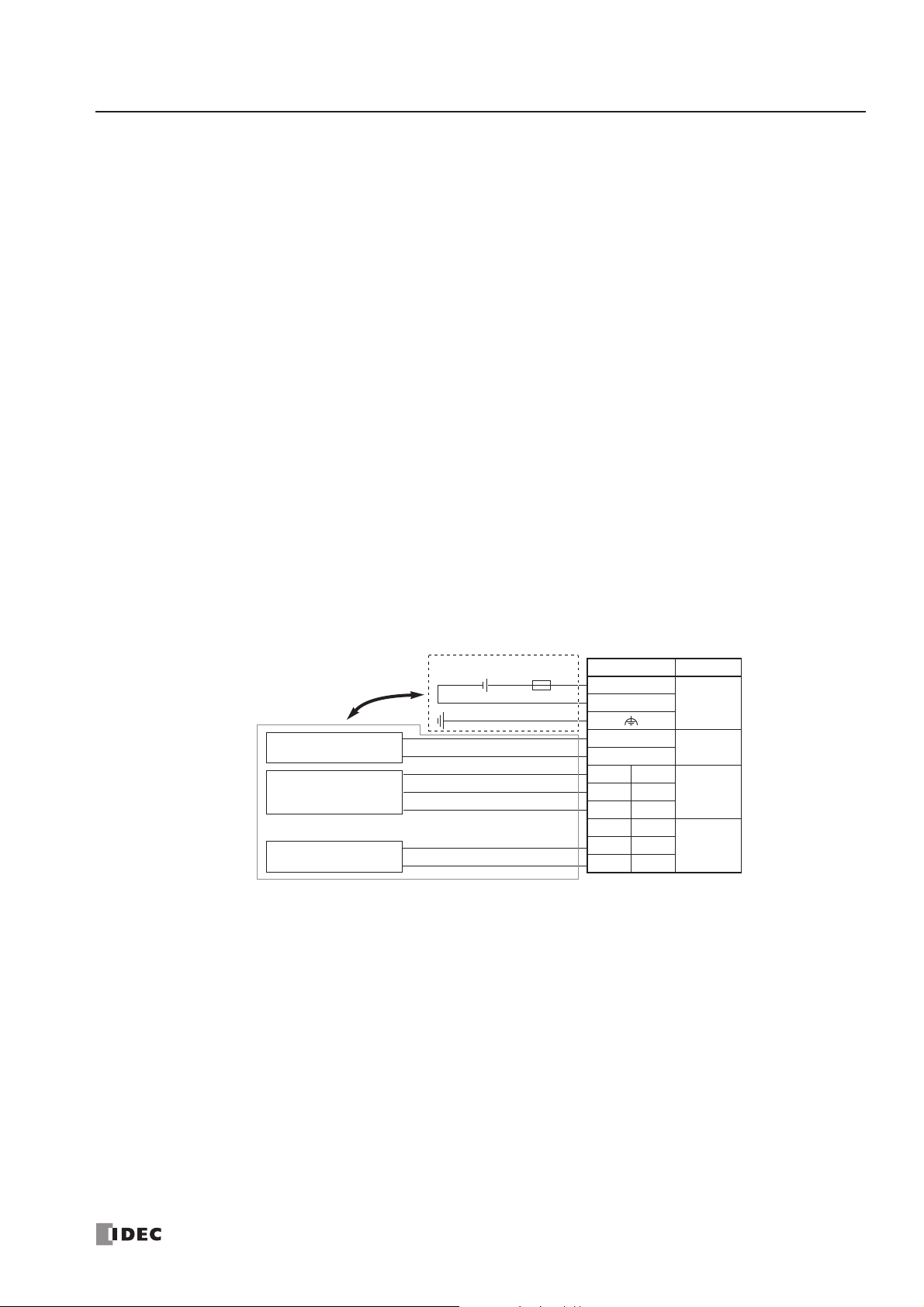

System Setup

This section illustrates system setup configurations for using powerful communication functions of the MicroSmart.

User Communication and Modem Communication System

The all-in-one 16- and 24-I/O type MicroSmart CPU modules have port 1 for RS232C communication and port 2 connector. An optional RS232C or RS485 communication adapter can be installed on the port 2 connector. With an RS232C communication adapter installed on port 2, the 16- or 24-I/O type MicroSmart CPU module can communicate with two

RS232C devices at the same time.

The figure below illustrates a system setup of user communication and modem communication. In this example, the operating status of a remote machine is monitored on a computer through modems connected to port 2 and the data is transferred through port 1 to a pager transmitter using the user communication.

The same system can be set up using any slim type CPU module and an optional RS232C communication module.

For details about the user communication, see page 17-1.

For details about the modem mode, see page 27-1.

All-in-One 16- or 24-I/O Type CPU Module

Pager Transmitter

Pager

Modem

Data

Communication

Modem

Computer

Data

Transmission

RS232C

Communication

Adapter on

Port 2 Connector

Port 1

Page 17

1: GENERAL INFORMATION

« FC4A MICROSMART USER’S MANUAL » 1-5

Computer Link System

When the MicroSmart is connected to a computer, operating status and I/O status can be monitored on the computer, data

in the CPU module can be monitored or updated, and user programs can be downloaded and uploaded. When an optional

RS485 communication adapter is installed on the port 2 connector of the all-in-one 16- or 24-I/O type CPU modules or

when an optional RS485 communication module is mounted with any slim type CPU modules, a maximum of 32 CPU

modules can be connected to one computer in the 1:N computer link system.

For details about the computer link communication, see pages 4-1 and 26-1.

Computer Link 1:1 Communication

Computer Link 1:N Communication

Slim Type CPU Module

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

All-in-One Type CPU Module

Port 1

RS232C Communication

Adapter on Port 2 Connector

Port 2

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

Port 1

RS232C Communication Module

RS232C/RS485 Converter

RS232C Cable

HD9Z-C52

1.5m (4.92 ft.) long

RS485 Communication

Adapter on Port 2 Connector

FC2A-MD1

Twisted-pair Shielded Cable

RS485 Communication Module

All-in-One 16- or 24-I/O Type CPU Module

Port 2

1st Unit

2nd Unit

Slim Type CPU Module

32nd Unit

Page 18

1: GENERAL INFORMATION

1-6 « FC4A MICROSMART USER’S MANUAL »

Data Link System

With an optional RS485 communication adapter installed on the port 2 connector, one 16- or 24-I/O type CPU module at

the master station can communicate with 31 slave stations through the RS485 line to exchange data and perform distributed control effectively. The RS485 terminals are connected with each other using a 2-core twisted pair cable.

The same data link system can also be set up using any slim type CPU modules mounted with RS485 communication

modules.

For details about the data link communication, see page 25-1.

Basic System

The all-in-one 10-I/O type CPU module has 6 input terminals and 4 output terminals. The 16-I/O type CPU module has 9

input terminals and 7 output terminals. The 24-I/O type CPU module has 14 input terminals and 10 output terminals. Only

the 24-I/O type CPU module has an expansion connector to connect I/O modules. When four 16-point input or output

modules are connected to the 24-I/O type CPU module, the I/O points can be expanded to a maximum of 88 points.

Any slim type CPU module can add a maximum of seven expansion I/O modules.

Master Station Slave Station 1 Slave Station 31

4 I/O modules maximumAll-in-One 24-I/O Type CPU Module

Page 19

1: GENERAL INFORMATION

« FC4A MICROSMART USER’S MANUAL » 1-7

Operator Interface Communication System

The MicroSmart can communicate with IDEC’s HG series operator interfaces through RS232C port 1 and port 2.

Optional cables are available for connection between the MicroSmart and HG series operator interfaces. When installing

an optional RS232C communication adapter on the all-in-one type CPU module or an optional RS232C communication

module on the slim type CPU module, two operator interfaces can be connected to one MicroSmart CPU module.

For details about communication settings, see the user’s manual for the operator interface.

Applicable Cables to Operator Interfaces

Operator Interface O/I Communication Cable For Use on MicroSmart

HG1B, HG2A Series

FC4A-KC1C RS232C port 1 and port 2

HG9Z-XC183 Port 2 only

HG2F, HG3F, HG4F Series

FC4A-KC2C RS232C port 1 and port 2

HG9Z-3C125 Port 2 only

HG series Operator Interface

To RS232C Por t 1 or 2

O/I Communication Cable

Page 20

1: GENERAL INFORMATION

1-8 « FC4A MICROSMART USER’S MANUAL »

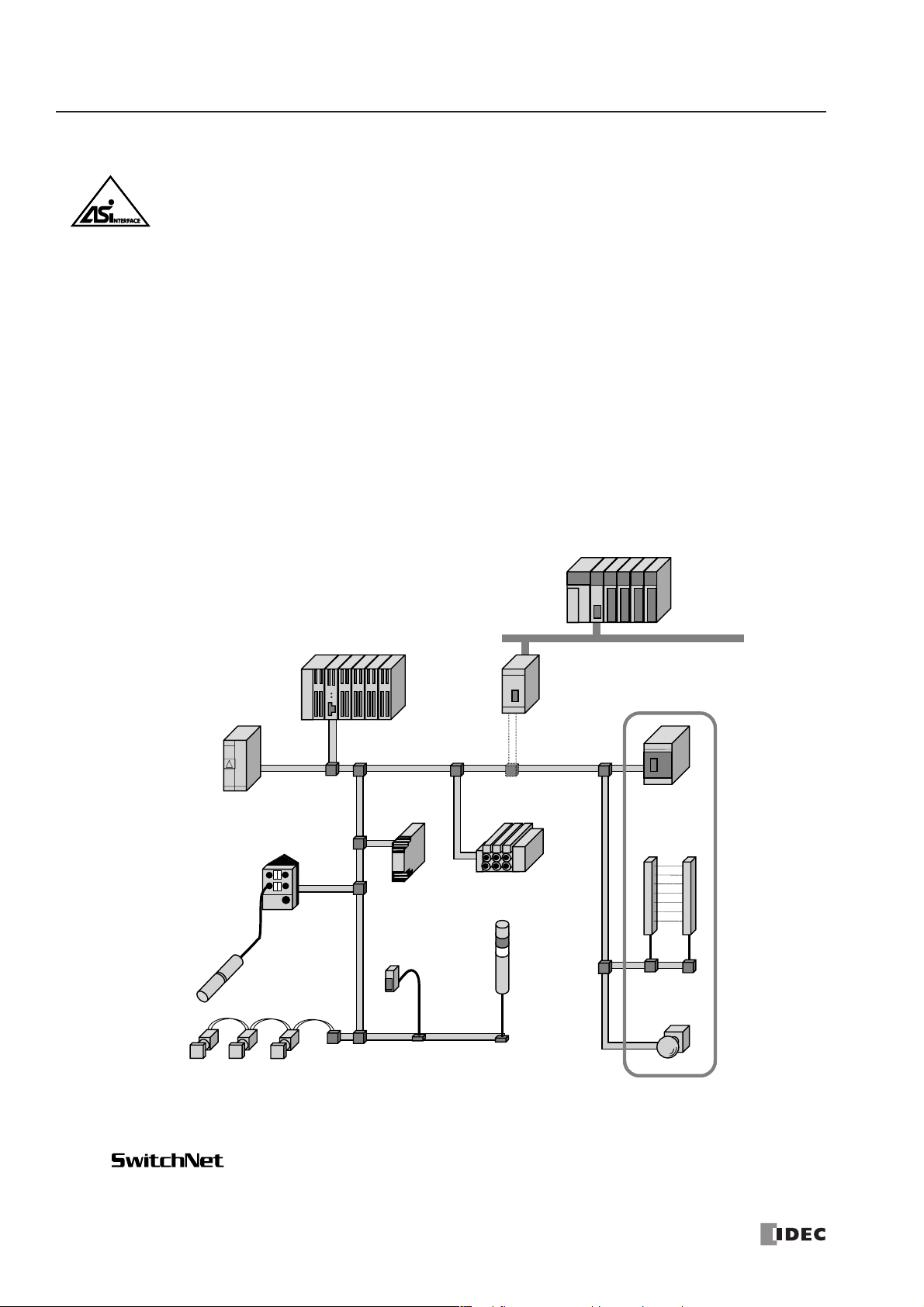

AS-Interface Network

The MicroSmart can be connected to the AS-Interface network using the AS-Interface master module (FC4A-AS62M).

AS-Interface is a type of field bus that is primarily intended to be used to control sensors and actuators. AS-Interface is a

network system that is compatible with the IEC62026 standard and is not proprietary to any one manufacturer. A master

device can communicate with slave devices such as sensors, actuators, and remote I/Os, using digital and analog signals

transmitted over the AS-Interface bus.

The AS-Interface system is comprised of the following three major components:

• One master, such as the MicroSmart AS-Interface master module

• One or more slave devices, such as sensors, actuators, switches, and indicators

• Dedicated 30V DC AS-Interface power supply (26.5 to 31.6V DC)

These components are connected using a two-core cable for both data transmission and AS-Interface power supply. ASInterface employs a simple yet efficient wiring system and features automatic slave address assignment function, while

installation and maintenance are also very easy.

For details about AS-Interface communication, see page 2-58 and chapter 28.

Light Curtain

Open Network (DeviceNet, CC-Link)

AS-Interface

Gateway

AS-Interface

Safety Monitor

AS-Interface Safety at Work

Emergency

Stop Switch

Manifold Solenoid Valve

Light Tower

(AS-Interface

Direct

Connection Type)

MicroSmart AS-Interface Master Module

PS2R AS-Interface Power Supply

SX5A AS-Interface

Communication Terminal

IP67 Outside-panel Type

SX5A AS-Interface

Communication Terminal

IP20 Inside-panel Type

SwitchNet Control Units

(AS-Interface Direct Connection Type)

Sensor

(AS-Interface Direct

Connection Type)

Sensor

The AS-Interface Safety Monitor is required

to connect safety devices, such as the light

curtain and emer gency stop switch, to the

AS-Interface line.

SwitchNet is an IDEC trademark for pushbuttons, pilot lights, and other control units

capable of direct connection to the AS-Interface. SwitchNet devices are completely

compatible with AS-Interface Ver. 2.1.

TM

Actuator-Sensor-Interface, abbreviated AS-Interface

Maximum Communication Distance

Without repeater: 100 m

With 2 repeaters: 300 m

Page 21

« FC4A MICROSMART USER’S MANUAL » 2-1

2: MODULE SPECIFICATIONS

Introduction

This chapter describes MicroSmart modules, parts names, and specifications of each module.

Available modules include all-in-one type and slim type CPU modules, digital input modules, digital output modules,

mixed I/O modules, analog I/O modules, HMI module, HMI base module, communication adapters, communication modules, memory cartridge, and clock cartridge.

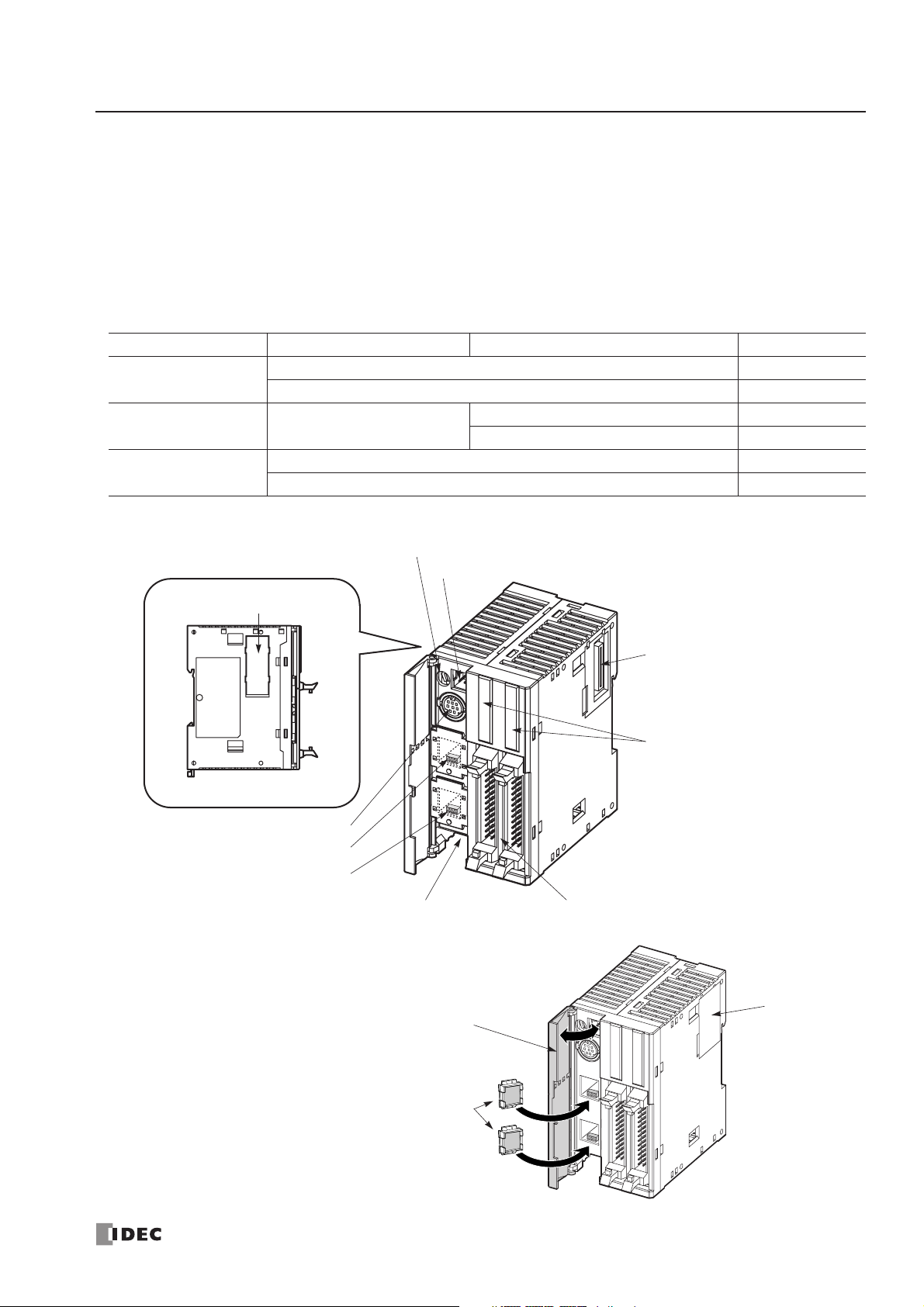

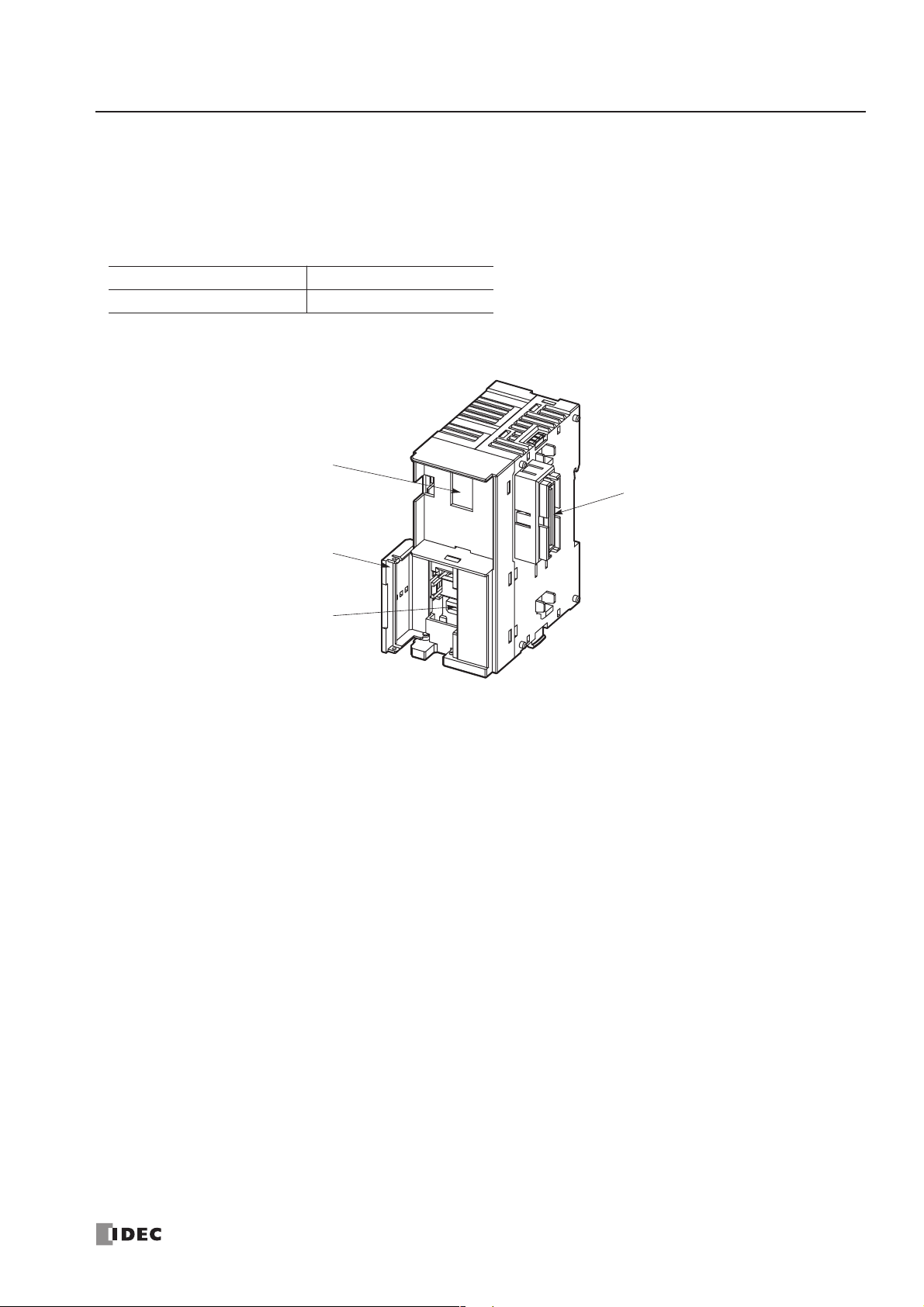

CPU Modules (All-in-One Type)

All-in-one type CPU modules are available in 10-, 16-, and 24-I/O types. The 10-I/O type has 6 input and 4 output terminals, the 16-I/O type 9 input and 7 output terminals, and the 24-I/O type 14 input and 10 output terminals. Every all-in-one

type CPU module has communication port 1 for RS232C communication. In addition, the 16- and 24-I/O type CPU modules have port 2 connector to install an optional RS232C or RS485 communication adapter for 1:N computer link, modem

communication, or data link communication. Every all-in-one type CPU module has a cartridge connector to install an

optional memory cartridge or clock cartridge.

CPU Module Type Numbers (All-in-One Type)

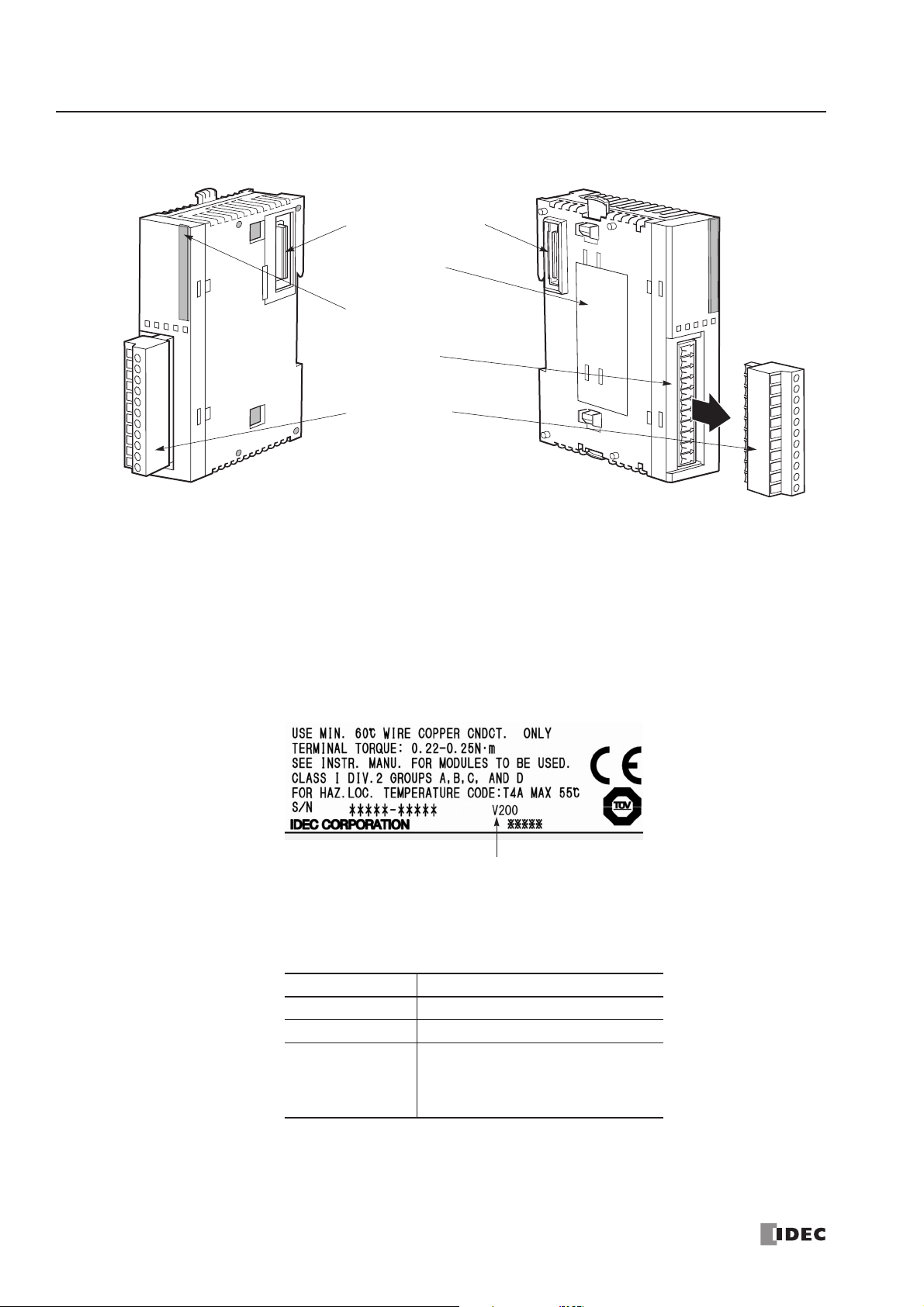

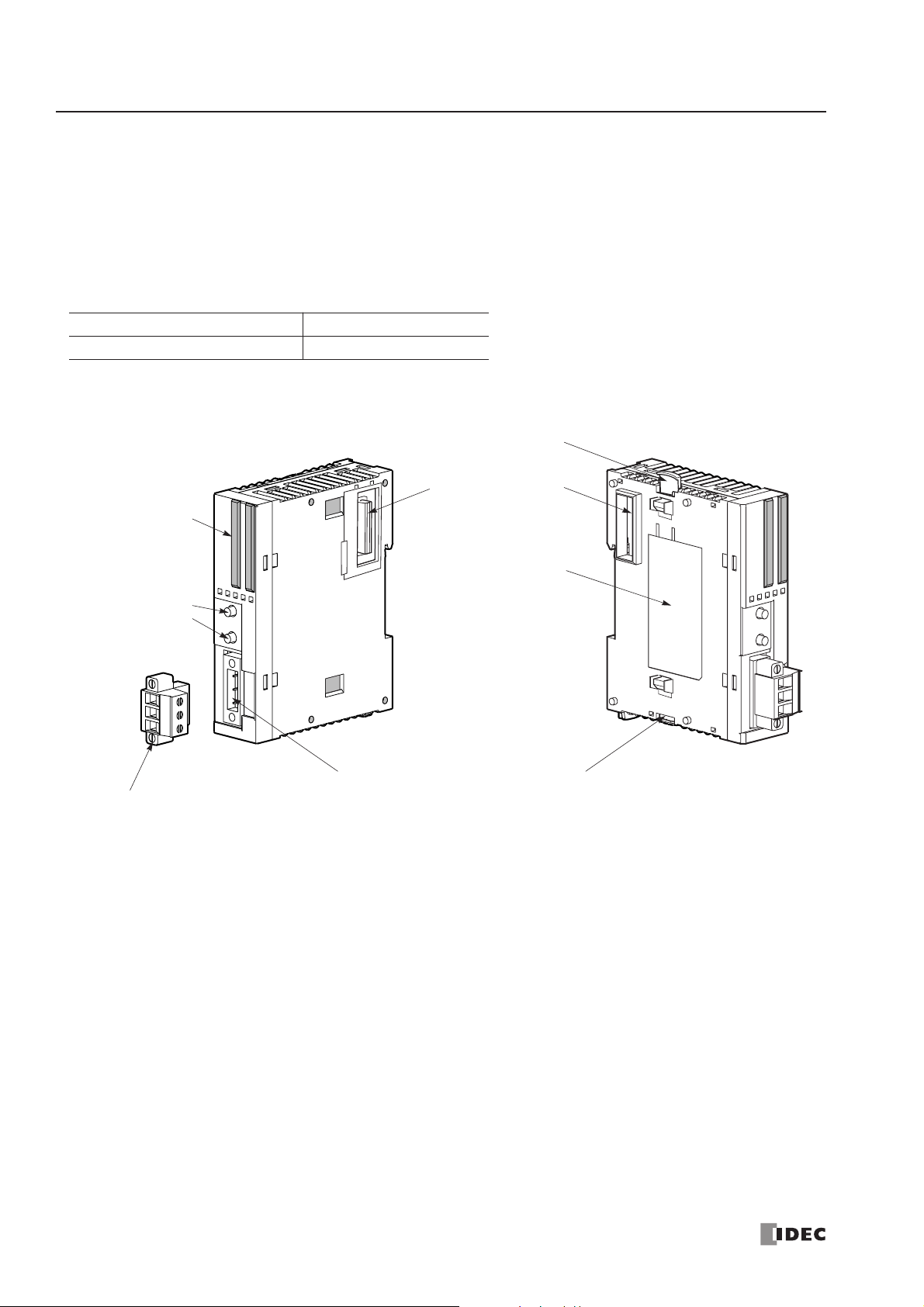

Parts Description (All-in-One Type)

Power Voltage 10-I/O Type 16-I/O Type 24-I/O Type

100 -240V AC (50/60 Hz) FC4A-C10R2 FC4A-C16R2 FC4A-C24R2

24V DC FC4A-C10R2C FC4A-C16R2C FC4A-C24R2C

(3) Input Terminals

(5) Expansion Connector

(6) Input LED (IN)

From Left:

(7) Power LED (PWR)

(8) Run LED (RUN)

(9) Error LED (ERR)

(10) Status LED (STAT)

(11) Output LED (OUT)

(2) Sensor Power Terminals

(12) Port 1

(13) Analog Potentiometer

(14) Port 2 Connector

Bottom View

(15) Cartridge Connector

(1) Power Supply Terminals

(16) Terminal Cover

(17) Hinged Lid

(4) Output Terminals

(20) Expansion

Connector

Seal

These figures illustrate the 24-I/O

type CPU module.

Functions of each part are described

on the following page.

(18) HMI Connector Cover

(16) Terminal Cover

(19) Dummy Cartridge

Page 22

2: MODULE SPECIFICATIONS

2-2 « FC4A MICROSMART USER’S MANUAL »

(1) Power Supply Terminals

Connect power supply to these terminals. Power voltage 100-240V AC or 24V DC. See page 3-16.

(2) Sensor Power Terminals (AC power type only)

For supplying power to sensors (24V DC, 250mA). These terminals can be used for supplying power to input circuits.

Use the sensor power supply only for supplying power to input devices connected to the MicroSmart.

(3) Input Terminals

For connecting input signals from input devices such as sensors, pushbuttons, and limit switches. The input terminals

accept both sink and source DC input signals.

(4) Output Terminals

For connecting output signals to output devices such as electromechanical relays and solenoid valves. The internal output relay is rated at 240V AC/2A or 30V DC/2A.

(5) Expansion Connector (24-I/O type CPU module only)

For connecting digital and analog I/O modules to the 24-I/O type CPU module.

(6) Input LED (IN)

Turns on when a corresponding input is on.

(7) Power LED (PWR)

Turns on when power is supplied to the CPU module.

(8) Run LED (RUN)

Turns on when the CPU module is executing the user program.

(9) Error LED (ERR)

Turns on when an error has occurred in the CPU module.

(10) Status LED (STAT)

The status LED can be turned on or off using the user program

to indicate a specified status.

(11) Output LED (OUT)

Turns on when a corresponding output is on.

(12) Port 1 (RS232C)

For connecting a computer to download a user program and

monitor the PLC operation on a computer using WindLDR.

(13) Analog Potentiometer

Sets a value of 0 through 255 to a special data register. The 10- and 16-I/O types have one potentiometer. The 24-I/O

type has two potentiometers. The analog potentiometer can be used to set a preset value for an analog timer.

(14) Port 2 Connector (16- and 24-I/O type CPU modules only)

For connecting an optional RS232C or RS485 communication adapter.

(15) Cartridge Connector

For connecting an optional memory cartridge or clock cartridge.

(16) Terminal Cover

For protecting the input and output terminals. When wiring the terminals, open the covers.

(17) Hinged Lid

Open the lid to gain access to the port 1, port 2 connector, and analog potentiometer.

(18) HMI Connector Cover

Remove the HMI connector cover when using an optional HMI module.

(19) Dummy Cartridge

Remove the dummy cartridge when using an optional memory cartridge or clock cartridge.

(20) Expansion Connector Seal (24-I/O type CPU module only)

Remove the expansion connector seal when connecting a digital or analog I/O module.

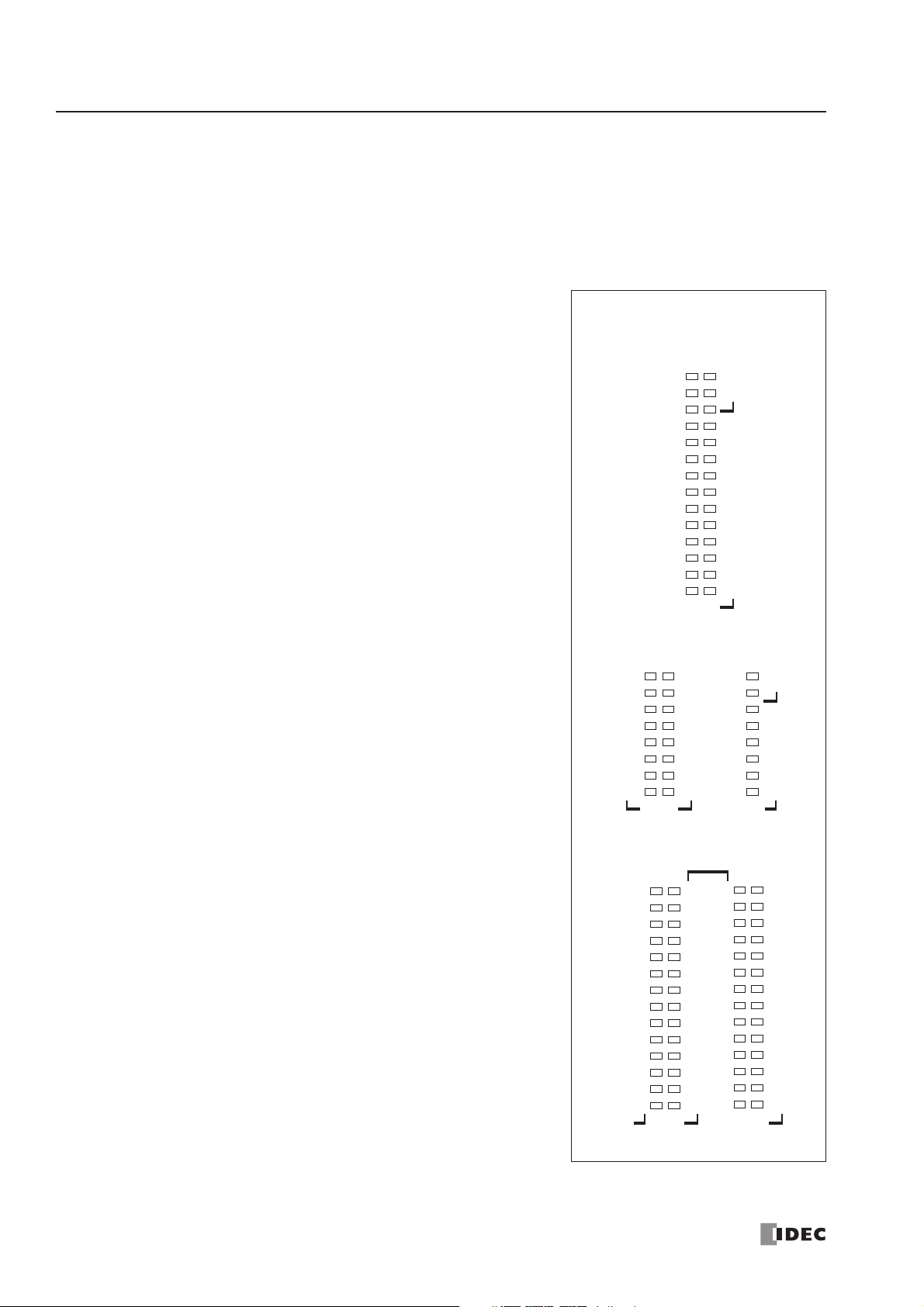

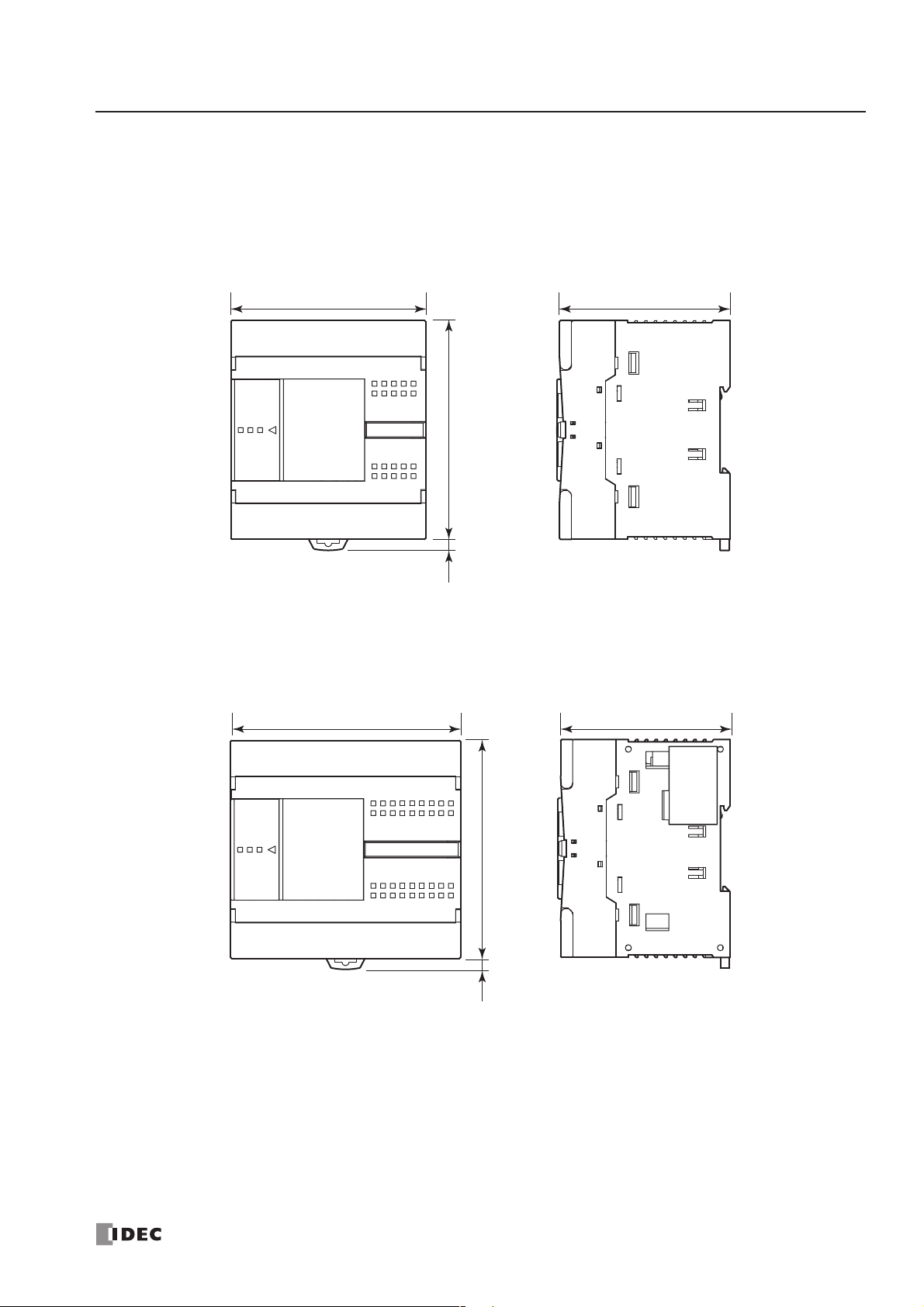

10-I/O Type

012345

IN

LED Indicators

16-I/O Type

PRES012 3

WRUNR

T

A

T

R

0123456710

OUT

IN

24-I/O Type

PRES0123456

WRUNR

01234567101112131415

T

A

T

R

OUT

PRES012345671011

WRUNR

T

A

T

R

IN

OUT

Page 23

2: MODULE SPECIFICATIONS

« FC4A MICROSMART USER’S MANUAL » 2-3

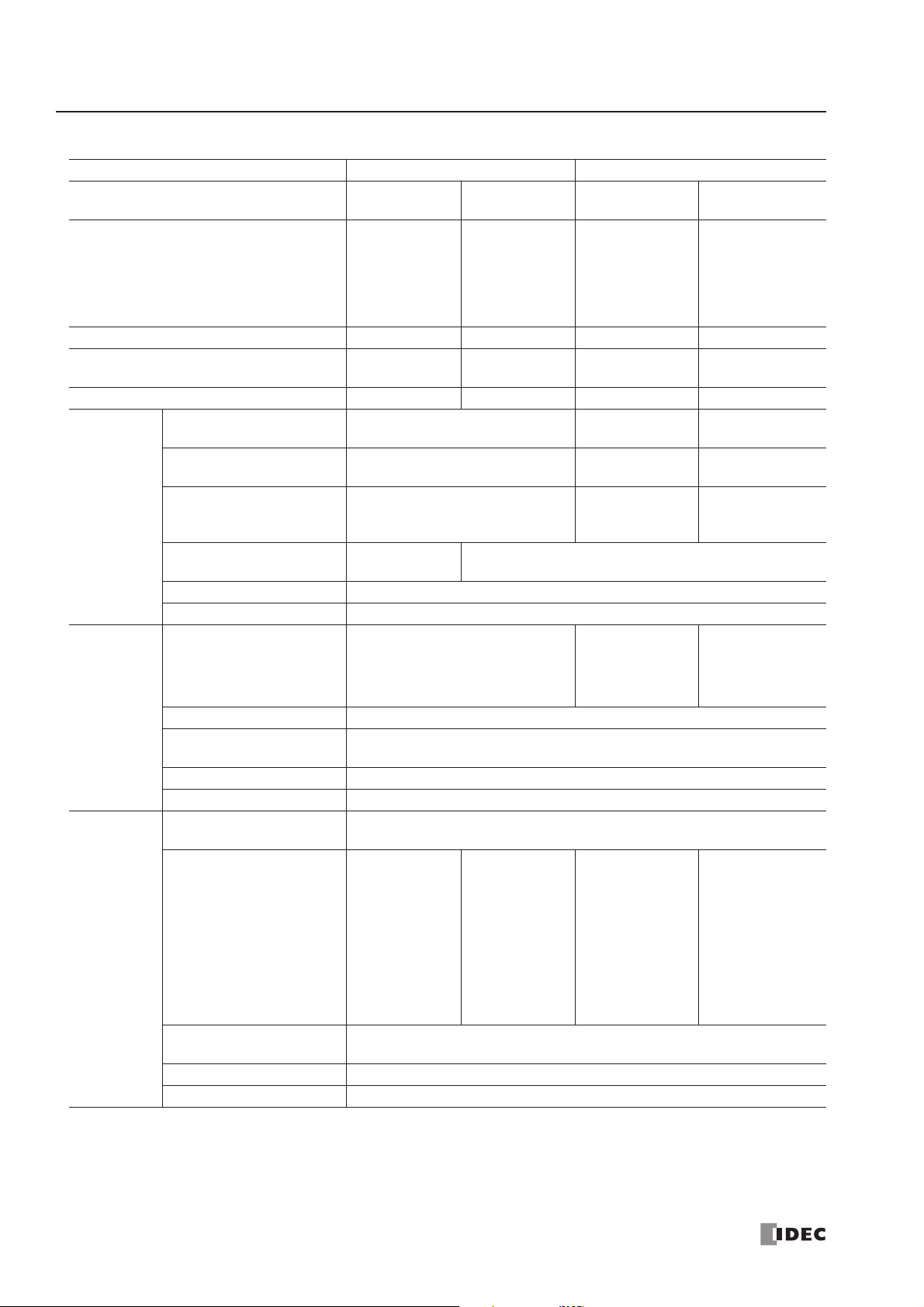

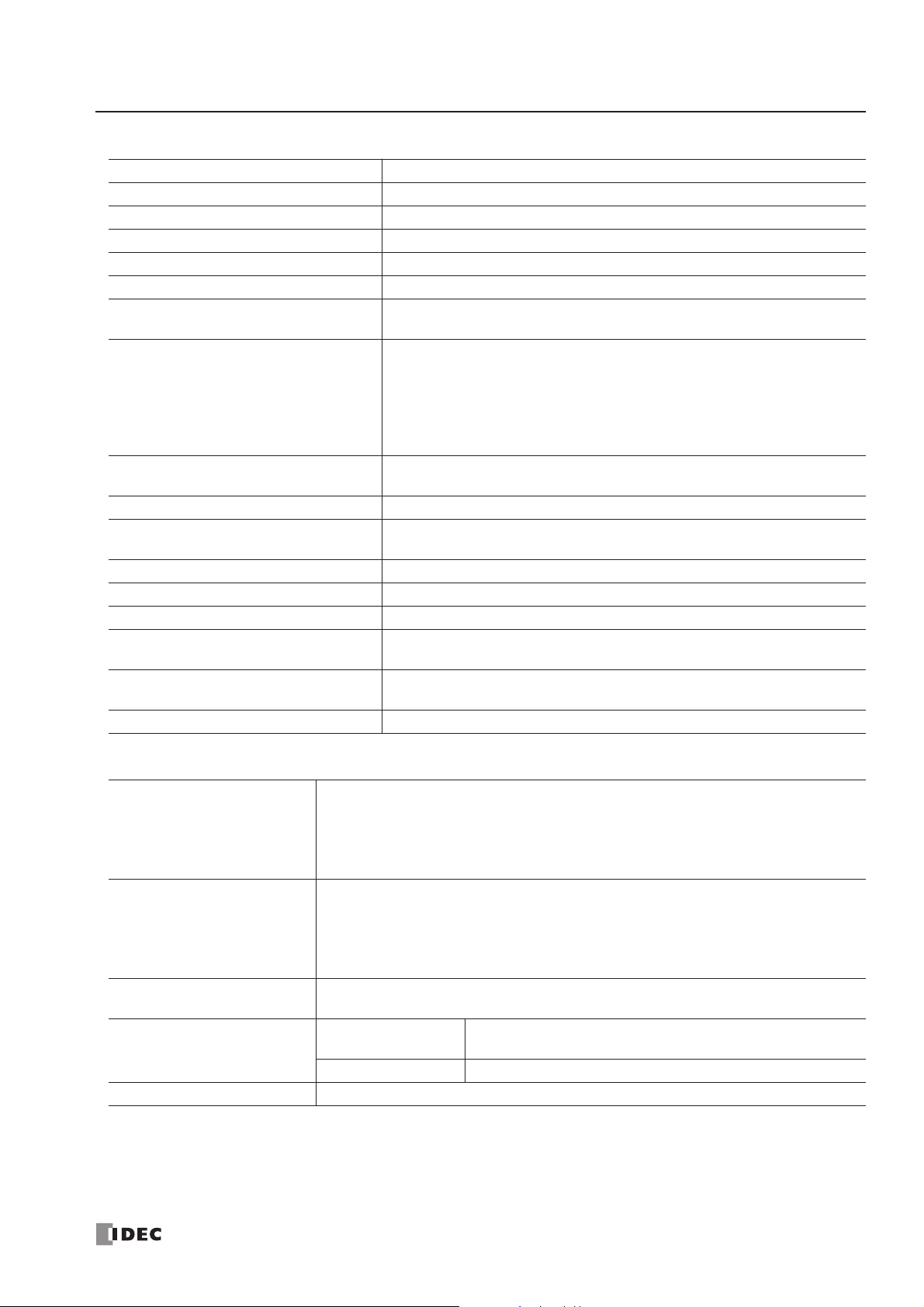

General Specifications (All-in-One Type CPU Module)

Normal Operating Conditions

Power Supply

Note: The maximum number of relay outputs that can be turned on simultaneously is 33 points (AC power type CPU module)

or 44 points (DC power type CPU module) including relay outputs on the CPU module.

CPU Module

AC Power Type FC4A-C10R2 FC4A-C16R2 FC4A-C24R2

DC Power Type FC4A-C10R2C FC4A-C16R2C FC4A-C24R2C

Operating Temperature 0 to 55°C (operating ambient temperature)

Storage Temperature –25 to +70°C

Relative Humidity 10 to 95% (non-condensing)

Pollution Degree 2 (IEC 60664-1)

Degree of Protection IP20 (IEC 60529)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Operation: 0 to 2,000m (0 to 6,565 feet)

Transport: 0 to 3,000m (0 to 9,840 feet)

Vibration Resistance

When mounted on a DIN rail or panel surface:

5 to 9 Hz amplitude 3.5 mm, 9 to 150 Hz acceleration 9.8 m/s

2

(1G)

2 hours per axis on each of three mutually perpendicular axes (IEC 61131-2)

Shock Resistance

147 m/s

2

(15G), 11 ms duration, 3 shocks per axis on three mutually perpendicular

axes (IEC 61131-2)

ESD Immunity Contact discharge: ±6 kV, Air discharge: ±8 kV (IEC 61000-4-2)

Weight

AC Power Type 230g 250g 305g

DC Power Type 240g 260g 310g

Rated Power Voltage AC power type: 100 to 240V AC, DC power type: 24V DC

Allowable Voltage Range AC power type: 85 to 264V AC, DC power type: 20.4 to 28.8V DC (including ripple)

Rated Power Frequency AC power type: 50/60 Hz (47 to 63 Hz)

Maximum Input Current

250 mA (85V AC)

160 mA (24V DC)

300 mA (85V AC)

190 mA (24V DC)

450 mA (85V AC)

360 mA (24V DC)

Maximum

Power

Consumption

AC Power Type

FC4A-C10R2: 30VA (264V AC), 20VA (100V AC) (CPU module*)

FC4A-C16R2: 31VA (264V AC), 22VA (100V AC) (CPU module*)

FC4A-C24R2: 40VA (264V AC), 33VA (100V AC) (CPU module* + 4 I/O modules)

*The CPU module power consumption includes 250mA sensor power.

DC Power Type

FC4A-C10R2C: 3.9W (24V DC) (CPU module)

FC4A-C16R2C: 4.6W (24V DC) (CPU module)

FC4A-C24R2C: 8.7W (24V DC) (CPU module + 4 I/O modules)

Allowable Momentary Power

Interruption

10 ms (at the rated power voltage)

Dielectric Strength

Between power and or terminals: 1,500V AC, 1 minute

Between I/O and or terminals: 1,500V AC, 1 minute

Insulation Resistance

Between power and or terminals: 10 MΩ minimum (500V DC megger)

Between I/O and or terminals: 10 MΩ minimum (500V DC megger)

Noise Resistance

AC or DC power terminals: 1.5 kV, 50 nsec to 1 µs

I/O terminals (coupling clamp): 1.5 kV, 50 nsec to 1 µs

Inrush Current 35A maximum 35A maximum 40A maximum

Grounding Wire UL1007 AWG16

Power Supply Wire UL1015 AWG22, UL1007 AWG18

Effect of Improper Power

Supply Connection

Reverse polarity: Normal operation (AC), No operation, no damage (DC)

Improper voltage or frequency: Permanent damage may be caused

Improper lead connection: Permanent damage may be caused

Page 24

2: MODULE SPECIFICATIONS

2-4 « FC4A MICROSMART USER’S MANUAL »

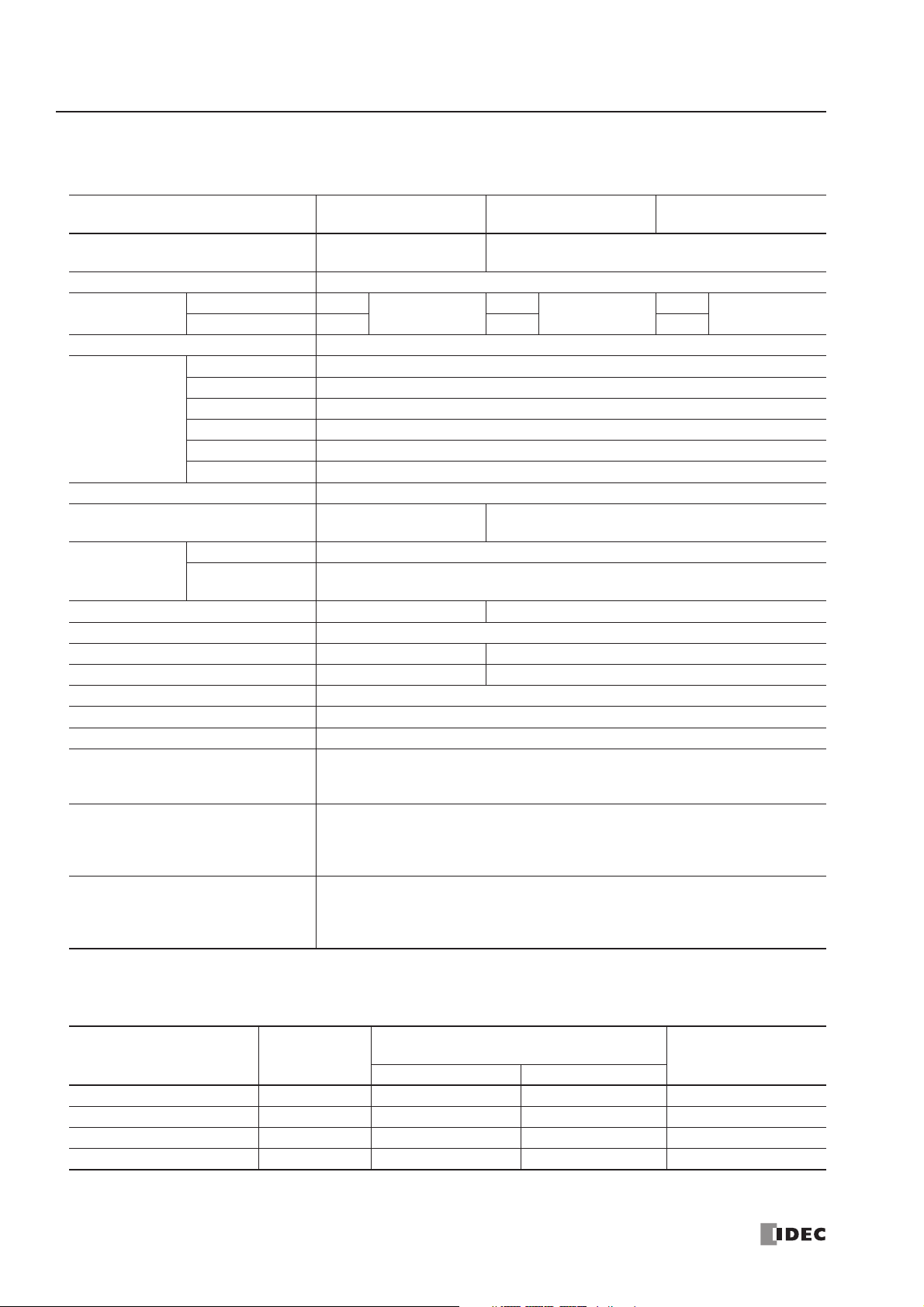

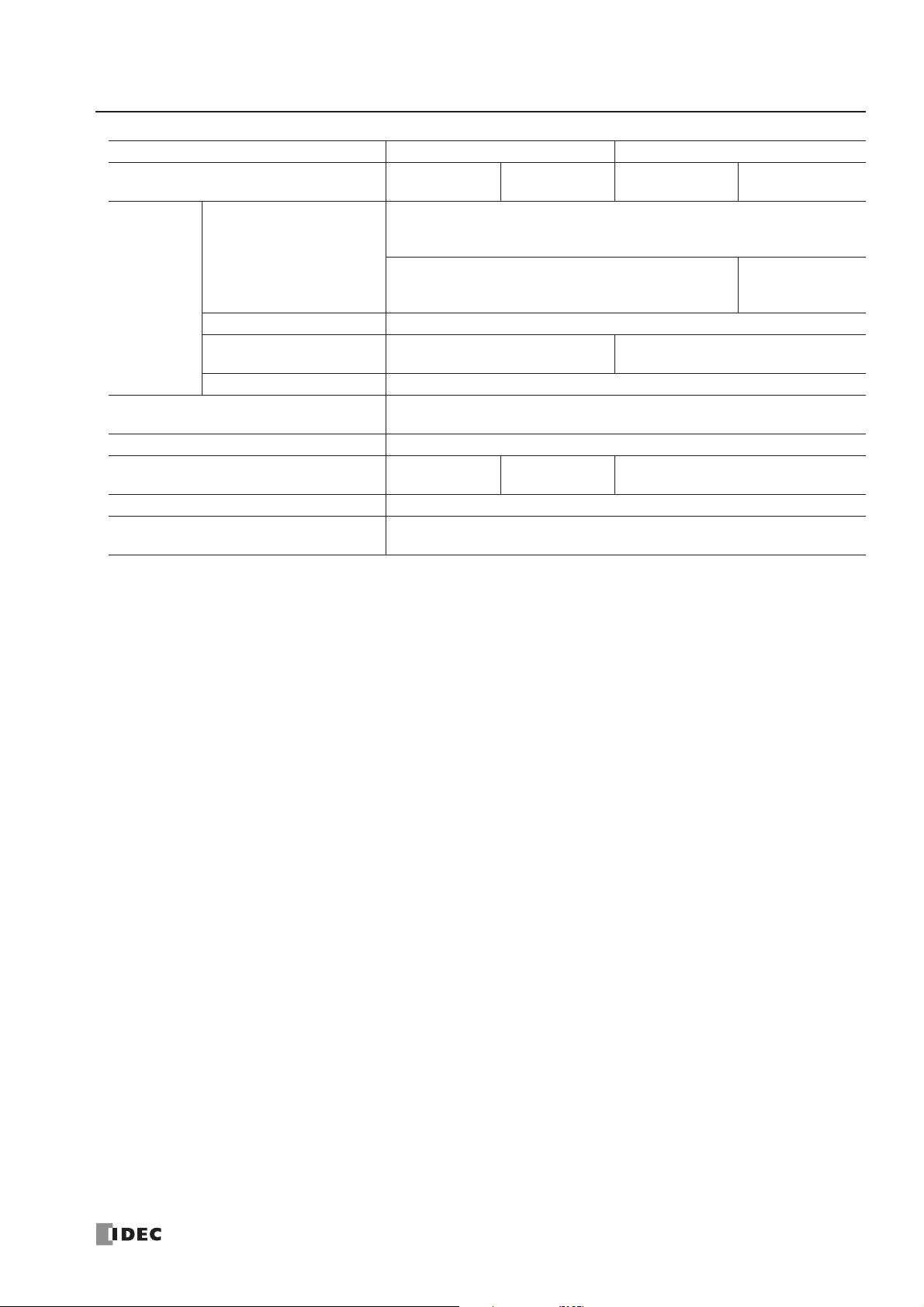

Function Specifications (All-in-One Type CPU Module)

CPU Module Specifications

System Statuses at Stop, Reset, and Restart

CPU Module

FC4A-C10R2

FC4A-C10R2C

FC4A-C16R2

FC4A-C16R2C

FC4A-C24R2

FC4A-C24R2C

Program Capacity

4,800 bytes

(800 steps)

15,000 bytes

(2,500 steps)

27,000 bytes

(4,500 steps)

Expandable I/O Modules ——4 modules

I/O Points

Input 6914

Expansion:

64

Output 4710

User Program Storage EEPROM

RAM Backup

Backup Duration Approx. 30 days (typical) at 25°C after backup batter y fully charged

Backup Data Internal relay, shift register, counter, data register

Battery Lithium secondary battery

Charging Time Approx. 24 hours for charging from 0% to 90% of full charge at 25°C

Battery Life Approx. 1000 cycles of discharging down to 10% and full charging

Replaceability Not possible to replace battery

Control System Stored program system

Instruction Words

35 basic

38 advanced

35 basic

40 advanced

35 basic

48 advanced

Processing

Time

Basic instruction 1.65 ms (1000 steps) See page A-1.

END processing

0.64 ms (not including expansion I/O service, clock function processing, data

link processing, and interrupt processing) See page A-2.

Internal Relay 256 1024 1024

Shift Register 64 128 128

Data Register 400 1300 1300

Counter

(adding, dual pulse reversible,

up/down selection reversible)

32 100 100

Timer

(1-sec, 100-ms, 10-ms, 1-ms)

32 100 100

Input Filter 3 to 15 ms (selectable in increments of 1 ms)

Catch Input

Interrupt Input

Four inputs (I2 through I5) can be designated as catch inputs or interrupt inputs

Minimum turn on pulse width: 40 µs maximum

Minimum turn off pulse width: 150 µs maximum

Self-diagnostic Function

Power failure, watchdog timer, data link connection, user program EEPROM sum

check, timer/counter preset value sum check, user program RAM sum check,

keep data, user program syntax, user program writing, CPU module, clock IC, I/O

bus initialize, user program execution

Start/Stop Method

Turning power on and off

Start/stop command in WindLDR

Turning start control special internal relay M8000 on and of f

Turning designated stop or reset input off and on

Mode Output

Internal Relay, Shift Register,

Counter, Data Register

Timer Current Value

Keep Type Clear Type

Run Operating Operating Operating Operating

Stop (Stop input ON) OFF Unchanged Unchanged Unchanged

Reset (Reset input ON) OFF OFF/Reset to zero OFF/Reset to zero Reset to zero

Restart Unchanged Unchanged OFF/Reset to zero Reset to preset

Page 25

2: MODULE SPECIFICATIONS

« FC4A MICROSMART USER’S MANUAL » 2-5

Communication Function

* Recommended cable for RS485: Twisted-pair shielded cable with a minimum core wire of 0.3 mm2.

Conductor resistance 85 Ω/km maximum, shield resistance 20 Ω/km maximum.

Built-in Functions

Memory Cartridge (Option)

Clock Cartridge (Option)

Communication Port Port 1 (RS232C)

Port 2 (RS232C)

Communication Adapter

Port 2 (RS485)

Communication Adapter

Standards EIA RS232C EIA RS232C EIA RS485

Maximum Baud Rate 19,200 bps 19,200 bps

Computer link: 19,200 bps

Data link: 38,400 bps

Maintenance Communication

(Computer Link)

Possible Possible Possible

User Communication Possible Possible Not possible

Modem Communication Not possible Possible Not possible

Data Link Communication Not possible Not possible Possible

Quantity of Slave Stations —— 31

Maximum Cable Length Special cable Special cable 200m *

Isolation between Internal Circuit

and Communication Port

Not isolated Not isolated Not isolated

High-speed Counter

Maximum Counting Frequency

and High-speed Counter Points

Total 4 points

Single/two-phase selectable: 20 kHz (1 point)

Single-phase: 5 kHz (3 points)

Counting Range 0 to 65535 (16 bits)

Operation Mode Rotar y encoder mode and adding counter mode

Sensor Power Supply

(AC power type only)

Output Voltage/Current 24V DC (+10% to –15%), 250 mA

Overload Detection Not available

Isolation Isolated from the internal circuit

Analog Potentiometer

Quantity

1 point (10- and 16-I/O type CPU)

2 points (24-I/O type CPU)

Data Range 0 to 255

Memory Type EEPROM

Accessible Memory Capacity 32 KB

Hardware for Storing Data CPU module

Software for Storing Data WindLDR

Quantity of Stored Programs One user program can be stored on one memor y cartridge.

Program Execution Priority

When a memory cartridge is installed, the user program on the memory cartridge is

executed.

Accuracy ±30 sec/month (typical) at 25°C

Backup Duration Approx. 30 days (typical) at 25°C after backup battery fully charged

Battery Lithium secondary battery

Charging Time Approx. 10 hours for charging from 0% to 90% of full charge

Battery Life Approx. 100 recharge cycles after discharging down to 10% of full charge

Replaceability Not possible to replace battery

Page 26

2: MODULE SPECIFICATIONS

2-6 « FC4A MICROSMART USER’S MANUAL »

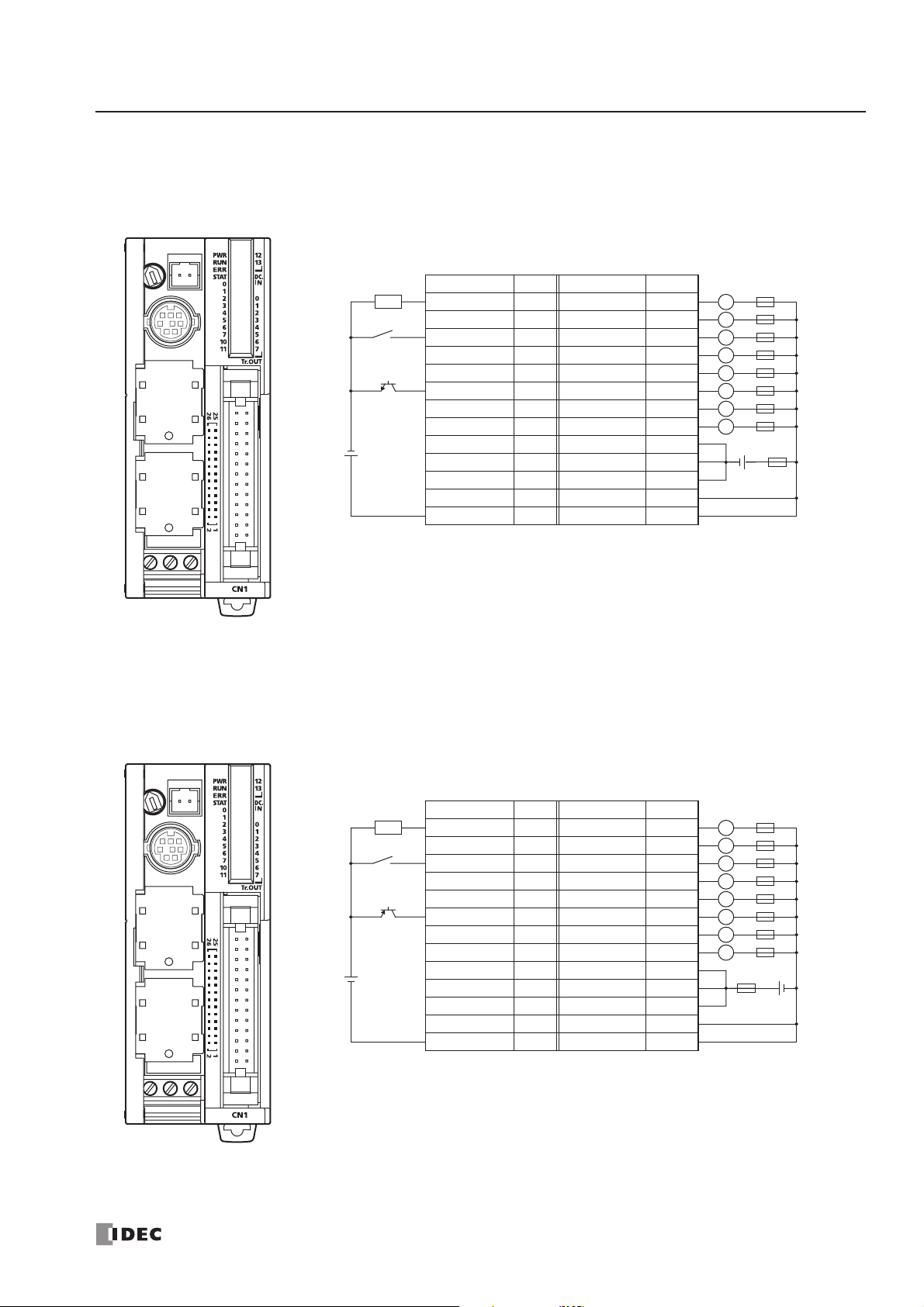

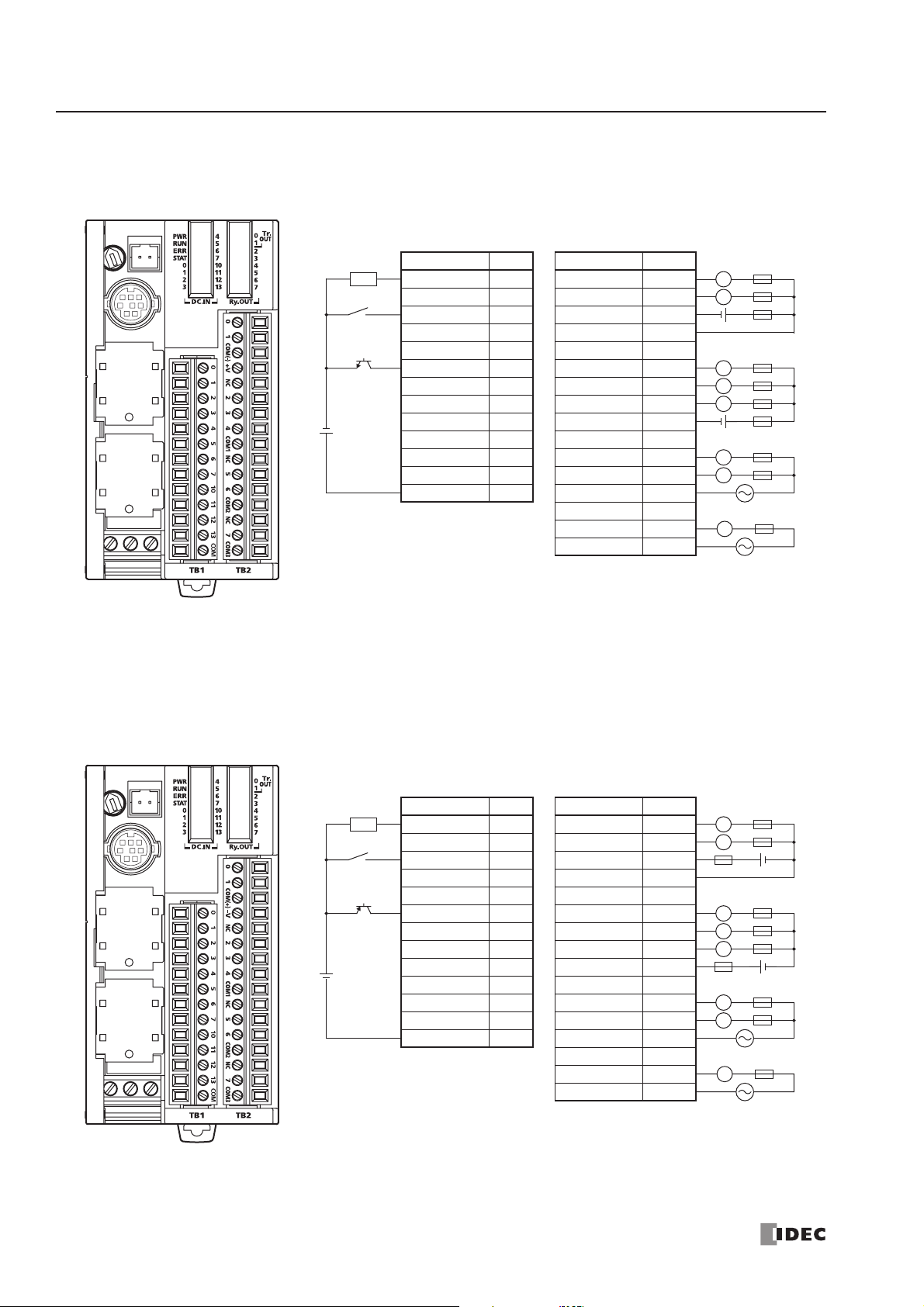

DC Input Specifications (All-in-One Type CPU Module)

Input Operating Range Input Internal Circuit

The input operating range of the Type 1

(IEC 61131-2) input module is shown

below:

CPU Module

FC4A-C10R2

FC4A-C10R2C

FC4A-C16R2

FC4A-C16R2C

FC4A-C24R2

FC4A-C24R2C

Input Points and Common Line

6 points

in 1 common line

9 points

in 1 common line

14 points

in 1 common line

Ter minal Arrangement See CPU Module Terminal Arrangement on pages 2-8 and 2-9.

Rated Input Voltage 24V DC sink/source input signal

Input Voltage Range 20.4 to 28.8V DC

Rated Input Current

I0 and I1: 11 mA

I2 to I7, I10 to I15: 7 mA/point (24V DC)

Input Impedance

I0 and I1: 2.1 kΩ

I2 to I7, I10 to I15: 3.4 kΩ

Turn ON Time

I0 to I5: 35 µs + filter value

I6, I7, I10 to I15: 40 µs + filter value

Turn OFF Time

I0 and I1: 45 µs + filter value