Page 1

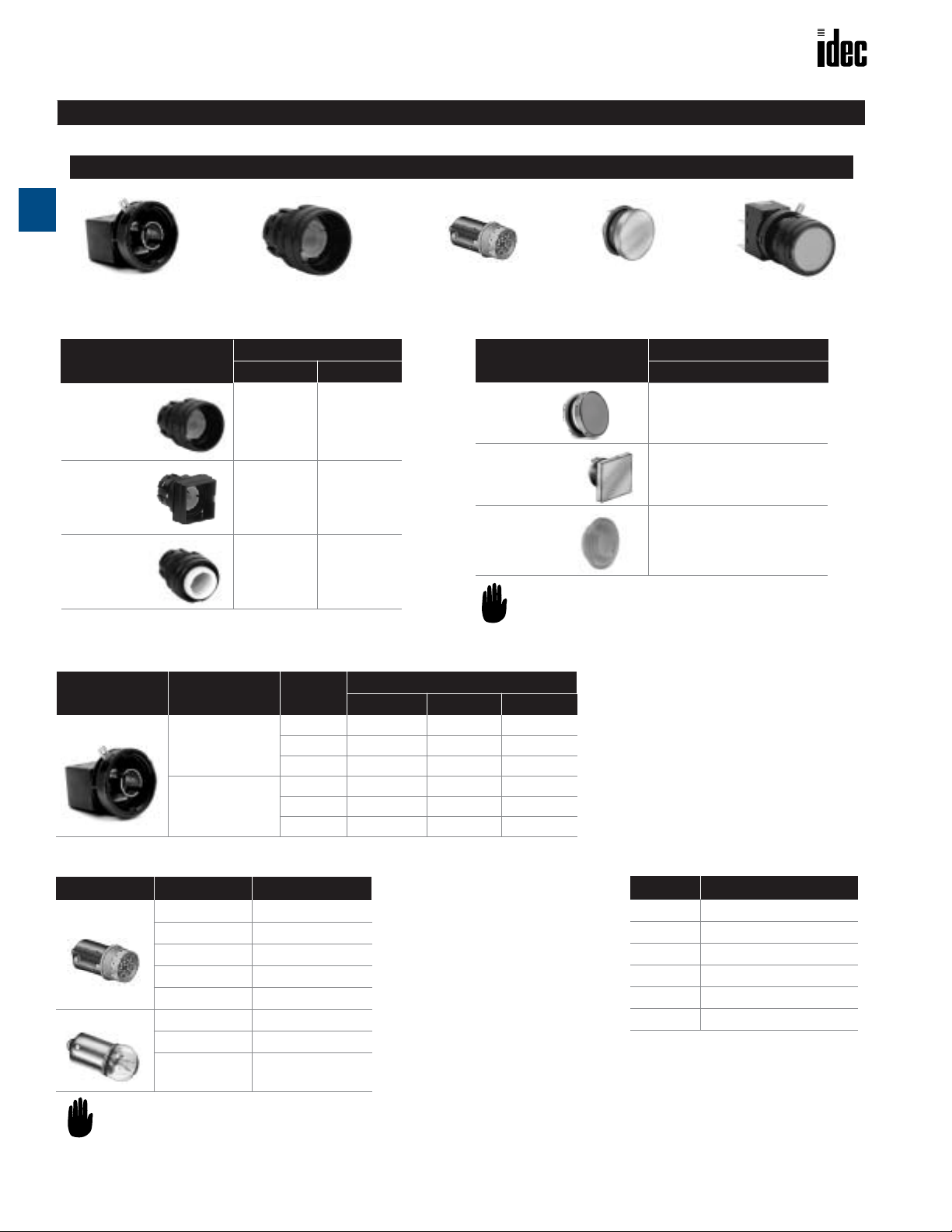

Oiltight Switches and Pilot Devices LW Series: 22mm

LW Series — Switches and Pilot Devices: 22mm

A

Switches & Pilot Devices

LW Series offer flexibility in space-saving package

Key features include:

• PC board mount, solder or screw terminal

•Collective mounting saves space

•Non-reflective lens

•Highly visible marking plate

•Tamper proof construction

•Light touch reduces strain

•Gold or silver contacts

•Removable contacts simplify wiring

and facilitate PCB applications

LW Series switches and pilot lights can be mounted collectively on 1.0"

centers. Combined with pcb terminals and locking lever removable

contacts, this eases manufacture of pre-fab pushbutton arrays (as

pictured). PC Board tracing/soldering of contacts can be done in tandem

with panel cutting/operator installation.

All LW series units mount by means of a locking ring that comes on from

the rear of the panel, as such they can not be removed from outside the

panel and are relatively tamperproof.

Combining the snap action and tactile feel of miniature commercial

pushbuttons with the size and ruggedness of industrial pushbuttons,

LW pushbuttons are a unique solution to many applications.

Choose from standard silver contacts or low-level gold plated contacts.

Ter minals available in .110" solder tab, M3 screw, or pcb pins.

UL Recognized

File # E55996

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-57

CSA Certified

File No. LR21451

Registration

No. J9551801

Page 2

LW Series: 22mm Oiltight Switches and Pilot Devices

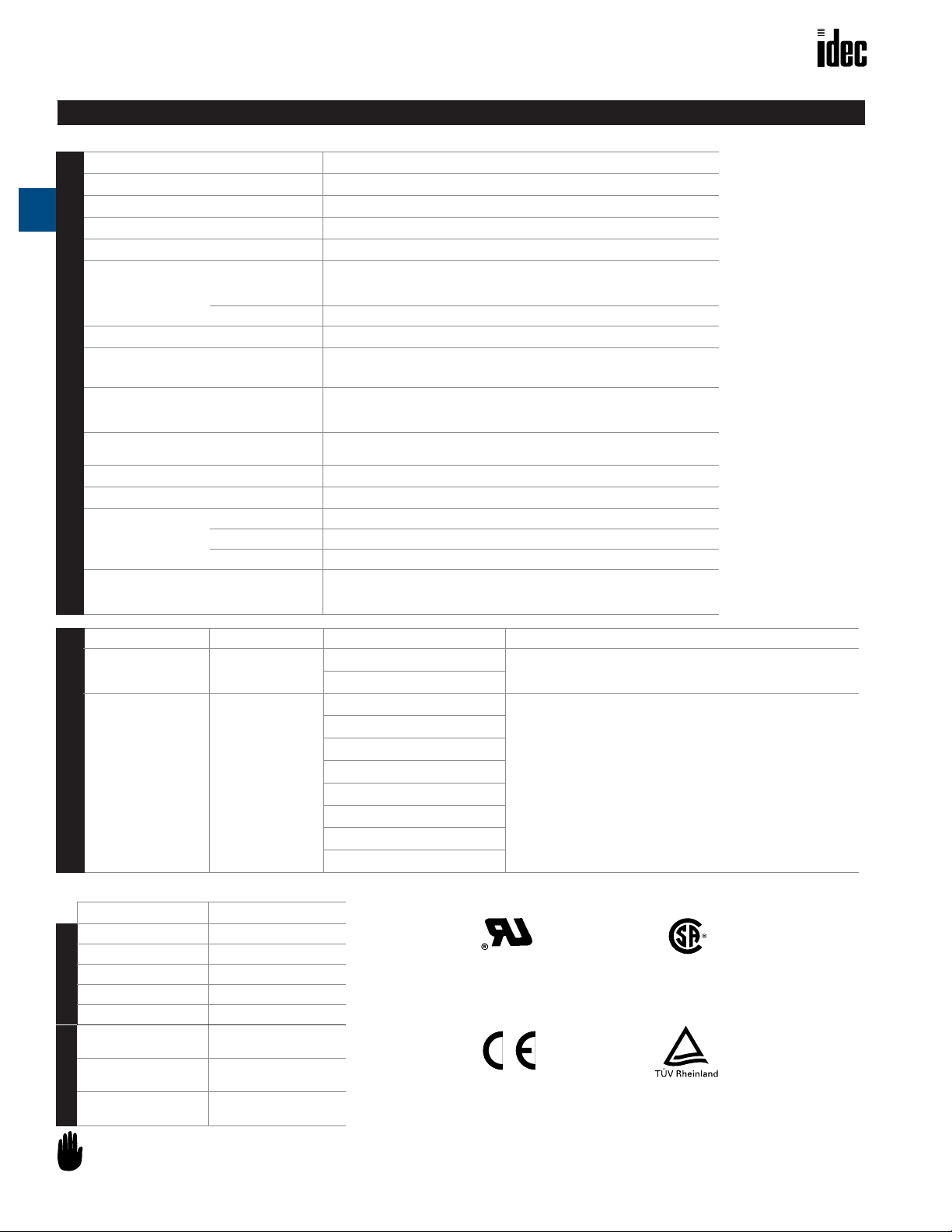

Specifications

Operating Temperature

Storage Temperature

A

Operating Humidity

Contact Resistance

Insulation Resistance

Dielectric Strength

Switch Unit

Illumination Unit Between live part and ground: 2,500V AC, 1 minute

Vibration Resistance

Shock Resistance

Mechanical Life

Specifications

Electrical Life

Degree of Protection

Switches & Pilot Devices

Insulation Voltage

Materials

Terminal Style

Lenses polyarylate

Operators polyacetate

Marking Plates acrylic resin

–25 to +60°C (without freezing) LED illuminated type: –25 to +50°C

–40 to +80°C

45 to 85% RH

50mΩ maximum (initial value)

100MΩ minimum (500V DC megger)

Between live part and ground: 2,500V AC, 1 minute

Between terminals of different poles: 2,500V AC, 1 minute

Between terminals of the same pole: 1,000V AC, 1 minute

Operating extremes: 5 to 55Hz, Amplitude 1.0mm p-p

Damage limits: 1,000 m/sec2 (Approx. 100G)

Operating extremes: 100 m/sec

Momentary: 1,000,000 operations minimum

Maintained: 500,000 operations minimum

Selectors: 250,000 operations minimum

Momentary: 100,000 operations minimum (at 1,800 operations/hour)

Maintained/Selector: 100,000 operations minimum (at 900 operations/hour)

Watertight/oiltight IP65 (IEC Pub529) (except key selectors)

250VAC/DC

.110" Solder tab/quick connect

PC board terminal (gold contacts only)

Screw terminal (DPDT units only)

2

(Approx. 10G)

Contact Material Thermal Current Contact Rating Remarks

Gold-clad cross-bar 3A

Silver Contact 5A

Contact Ratings

30VDC/0.1A resistive

125VAC/0.1A resistive

30VDC/2A resistive

30VDC/1A inductive

125VAC/3A resistive(50/60Hz)

125VAC/2A inductive (50/60Hz)

125VDC/0.4A resistive

125VDC/0.2A inductive

250VAC/2A resistive(50/60Hz)

250VAC/1.5A inductive (50/60Hz)

Lamp Ratings

Voltage Current/Wattage

6V AC/DC ±10% 17mA max

12V AC/DC ±10% 11mA max

24V AC/DC ±10% 11mA max

LED

120V AC ±10% 10mA max

240V AC ±10% 10mA max

6.3V AC/DC ±5% 1W

12V AC/DC ±10% 1W

Minimum applicable load (reference value): 5V, 1mA AC/DC.

(Applicable range is subject to the operating condition and load.)

AC inductive load: PF=0.6 to 0.7,

DC inductive load: L/R=7ms maximum.

UL Recognized

File # E55996

CSA Certified

File No. LR21451

Registration

No. J9551801

24V AC/DC ±10%

Incandescent

LED lamps contains a built-in current-limiting resistor and reverse polarity protection diode.

1W

A-58 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 3

Oiltight Switches and Pilot Devices LW Series: 22mm

① Button Color Code

Color Code

Black B

Green G

Red R

Blue S

White W

Yellow Y

(DC),

)

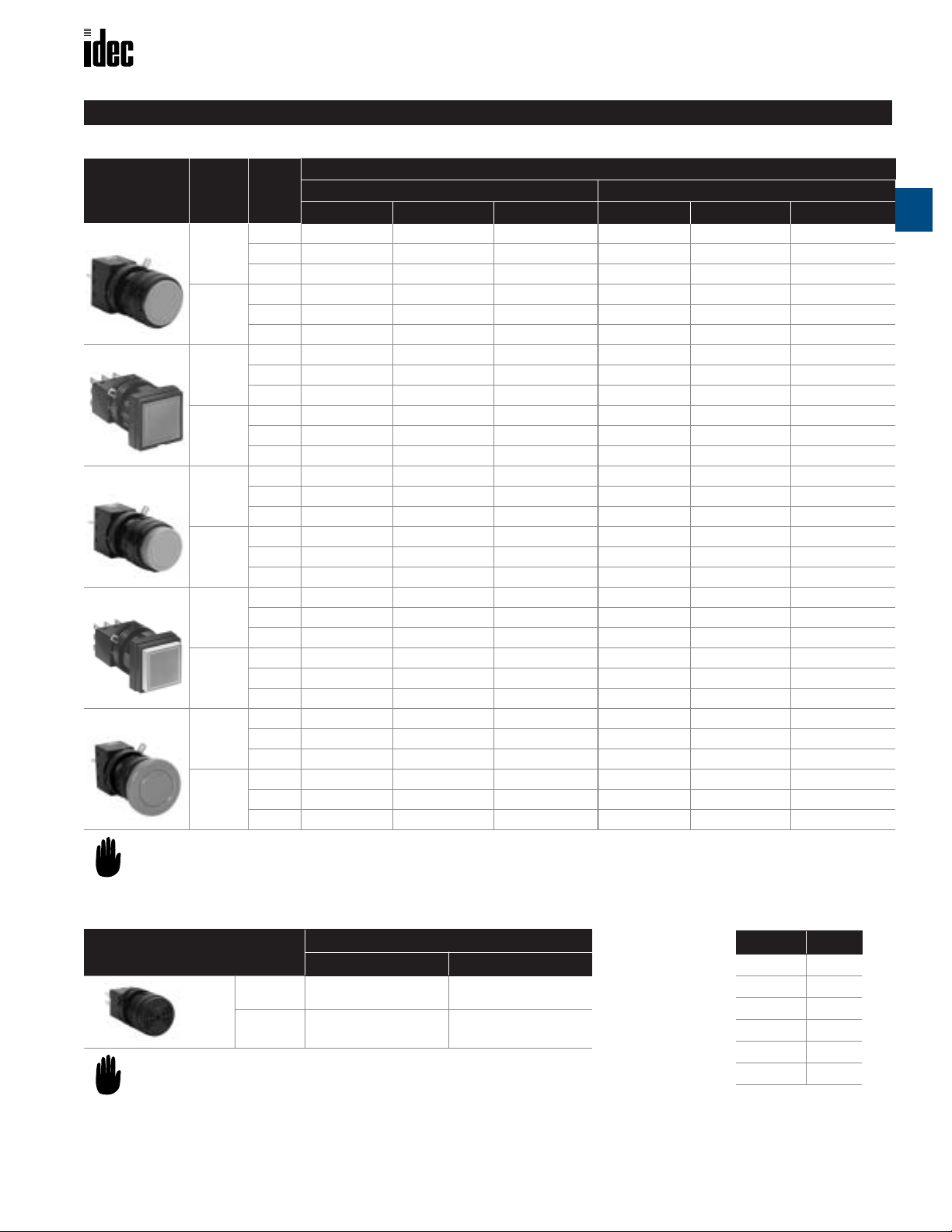

Part Numbers: LW1B/LW2B Pushbuttons

Style

Round Flush

Square Flush

Round Extended

Square Extended

Mushroom

1.In place of ①, specify Button Color Code from table below.

2.For sub-assembly part numbers, see page A-60.

3.For dimensions, see page A-69.

4.For accessories, see page A-68.

Contact

Material

Gold

Silver

Gold

Silver

Gold

Silver

Gold

Silver

Gold

Silver

Contact

Solder/Tab PC Board Screw Solder/Tab PC Board Screw

SPDT LW1B-M1C1-① LW1B-M1C1V-① —LW1B-A1C1-① LW1B-A1C1V-① —

DPDT LW1B-M1C2-① LW1B-M1C2V-① LW1B-M1C2M-① LW1B-A1C2-① LW1B-A1C2V-① LW1B-A1C2M-①

3PDT LW1B-M1C3-① LW1B-M1C3V-① —LW1B-A1C3-① LW1B-A1C3V-① —

SPDT LW1B-M1C5-① ——LW1B-A1C5-① ——

DPDT LW1B-M1C6-① —LW1B-M1C6M-① LW1B-A1C6-① —LW1B-A1C6M-①

3PDT LW1B-M1C7-① ——LW1B-A1C7-① ——

SPDT LW2B-M1C1-① LW2B-M1C1V-① —LW2B-A1C1-① LW2B-A1C1V-① —

DPDT LW2B-M1C2-① LW2B-M1C2V-① LW2B-M1C2M-① LW2B-A1C2-① LW2B-A1C2V-① LW2B-A1C2M-①

3PDT LW2B-M1C3-① LW2B-M1C3V-① —LW2B-A1C3-① LW2B-A1C3V-① —

SPDT LW2B-M1C5-① ——LW2B-A1C5-① ——

DPDT LW2B-M1C6-① —LW2B-M1C6M-① LW2B-A1C6-① —LW2B-A1C6M-①

3PDT LW2B-M1C7-① ——LW2B-A1C7-① ——

SPDT LW1B-M2C1-① LW1B-M2C1V-① —LW1B-A2C1-① LW1B-A2C1V-① —

DPDT LW1B-M2C2-① LW1B-M2C2V-① LW1B-M2C2M-① LW1B-A2C2-① LW1B-A2C2V-① LW1B-A2C2M-①

3PDT LW1B-M2C3-① LW1B-M2C3V-① —LW1B-A2C3-① LW1B-A2C3V-① —

SPDT LW1B-M2C5-① ——LW1B-A2C5-① ——

DPDT LW1B-M2C6-① —LW1B-M2C6M-① LW1B-A2C6-① —LW1B-A2C6M-①

3PDT LW1B-M2C7-① ——LW1B-A2C7-① ——

SPDT LW2B-M2C1-① LW2B-M2C1V-① —LW2B-A2C1-① LW2B-A2C1V-① —

DPDT LW2B-M2C2-① LW2B-M2C2V-① LW2B-M2C2M-① LW2B-A2C2-① LW2B-A2C2V-① LW2B-A2C2M-①

3PDT LW2B-M2C3-① LW2B-M2C3V-① —LW2B-A2C3-① LW2B-A2C3V-① —

SPDT LW2B-M2C5-① ——LW2B-A2C5-① ——

DPDT LW2B-M2C6-① —LW2B-M2C6M-① LW2B-A2C6-① —LW2B-A2C6M-①

3PDT LW2B-M2C7-① ——LW2B-A2C7-① ——

SPDT LW1B-M3C1-① LW1B-M3C1V-① —LW1B-A3C1-① LW1B-A3C1V-① —

DPDT LW1B-M3C2-① LW1B-M3C2V-① LW1B-M3C2M-① LW1B-A3C2-① LW1B-A3C2V-① LW1B-A3C2M-①

3PDT LW1B-M3C3-① LW1B-M3C3V-① —LW1B-A3C3-① LW1B-A3C3V-① —

SPDT LW1B-M3C5-① ——LW1B-A3C5-① ——

DPDT LW1B-M3C6-① —LW1B-M3C6M-① LW1B-A3C6-① —LW1B-A3C6M-①

3PDT LW1B-M3C7-① ——LW1B-A3C7-① ——

Non-Illuminated Pushbuttons (Assembled)

Part Number

Momentary Maintained (Latching)

A

Switches & Pilot Devices

Part Numbers: Buzzers

12-24V AC/DC+/- 10%

80 dB (at 0.1m)

7mA

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-59

Style

20mA (AC

Part Number

Solder Tab PCB

Basic LW1Z-1X4 LW1Z-1X4V

With LED LW1Z-1X4D LW1Z-1X4DV

Page 4

LW Series: 22mm Oiltight Switches and Pilot Devices

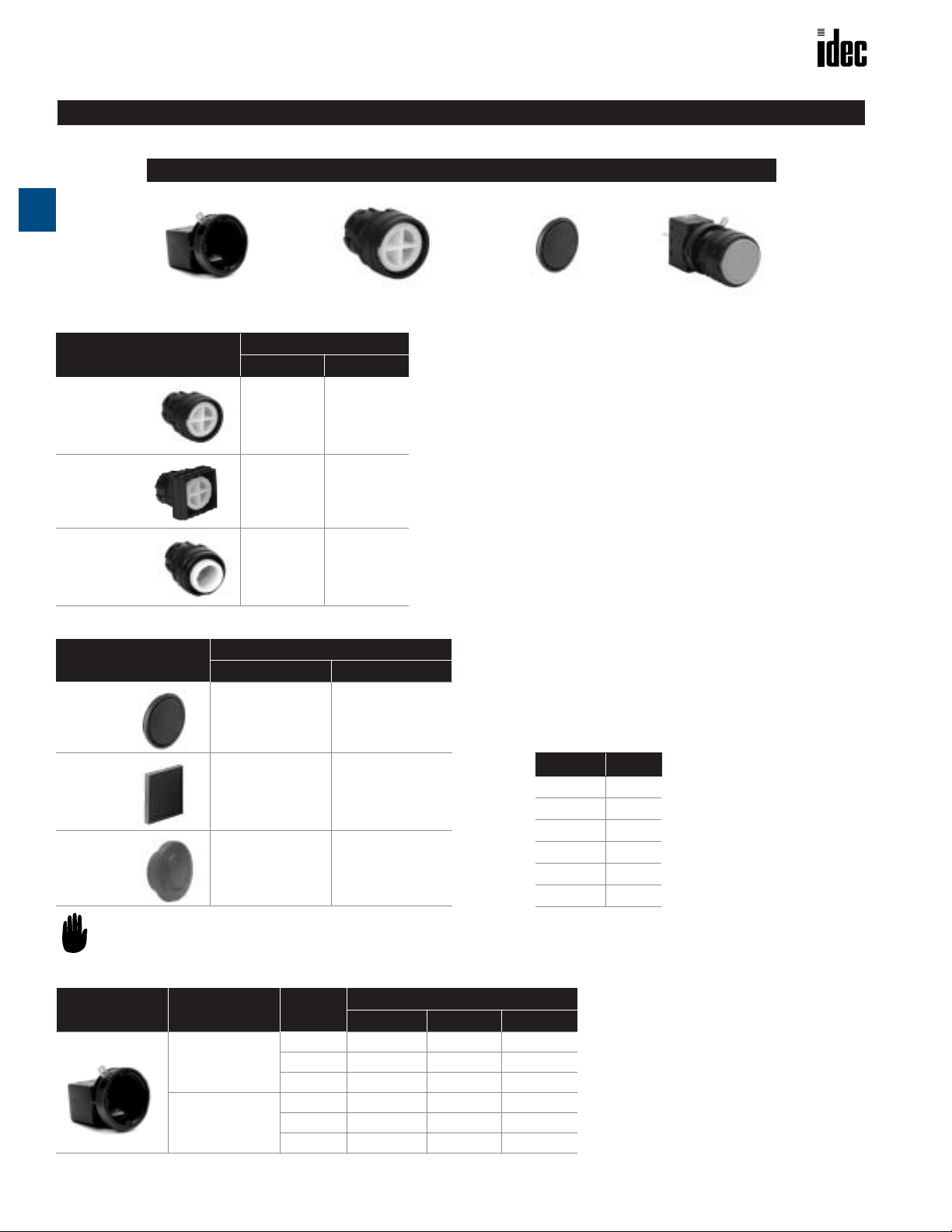

Non-Illuminated Pushbuttons (Sub-Assembled)

Contact Block + Operator + Button = Completed Unit

A

Part Numbers: Operators

Style

Round

Square

Switches & Pilot Devices

Part Number

Momentary Maintained

LW1B-M0 LW1B-A0

LW2B-M0 LW2B-A0

Mushroom

LW1B-M0L LW1B-A0L

Part Numbers: Buttons

Type

Flush Extended

Part Number

Round

LW1A-B1-① LW1A-B2-①

Square

LW2A-B1-① LW2A-B2-①

Mushroom

—LW1A-B3-①

In place of ①, specify Button Color Code from table at

right.

Part Numbers: Contact Blocks

Appearance Contact Material Contact

SPDT LW-C1 LW-C1V —

Gold

Silver

DPDT LW-C2 LW-C2V LW-C2M

3PDT LW-C3 LW-C3V —

SPDT LW-C5 — —

DPDT LW-C6 — LW-C6M

3PDT LW-C7 — —

① Button Color Code

Color Code

Black B

Green G

Red R

Blue S

White W

Yellow Y

Part Number

Solder/Tab PC Board Screw

A-60 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 5

Oiltight Switches and Pilot Devices LW Series: 22mm

➁

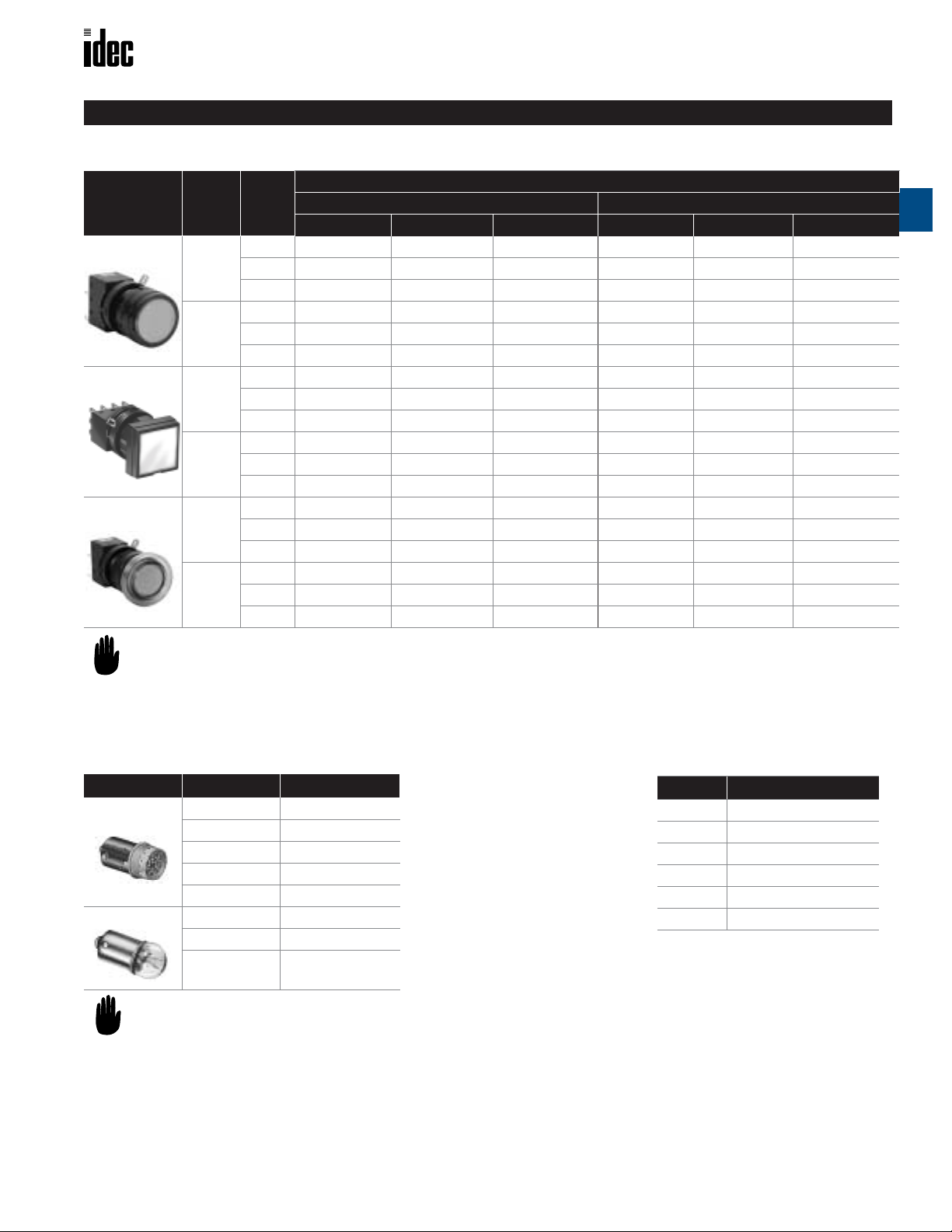

LED and Incandescent Illuminated Pushbuttons (Assembled)

Part Numbers: LW1L/LW2L Illuminated Pushbuttons (LED and Incandescent)

Style

Contact

Material

Contact

Solder/Tab PC Board Screw Solder/Tab PC Board Screw

Round

Square

Mushroom

1. In place of

2. Lamps must be ordered separately for all illuminated pushbuttons.

3. For marking plate size and engraving area, see page A-73.

4.For sub-assembly part numbers, see page A-62.

5.For dimensions, see page A-69.

5.For accessories, see page A-68.

Gold

Silver

Gold

Silver

Gold

Silver

SPDT

DPDT

3PDT

SPDT

DPDT

3PDT

SPDT

DPDT

3PDT

SPDT

DPDT

3PDT

SPDT

DPDT

3PDT

SPDT

DPDT

3PDT

, specify the Lens Color Code from table below.

LW1L-M1C10LW1L-M1C20LW1L-M1C30LW1L-M1C50LW1L-M1C60LW1L-M1C70LW2L-M1C10LW2L-M1C20LW2L-M1C30LW2L-M1C50LW2L-M1C60LW2L-M1C70LW1L-M3C10LW1L-M3C20LW1L-M3C30LW1L-M3C50LW1L-M3C60LW1L-M3C70-

➁ LW1L-M1C10V-➁

➁ LW1L-M1C20V-➁ LW1L-M1C20M-➁ LW1L-A1C20-➁ LW1L-A1C20V-➁ LW1L-A1C20M-➁

➁ LW1L-M1C30V-➁

➁

➁

➁

➁ LW2L-M1C10V-➁

➁ LW2L-M1C20V-➁ LW2L-M1C20M-➁ LW2L-A1C20-➁ LW2L-A1C20V-➁ LW2L-A1C20M-➁

➁ LW2L-M1C30V-➁

➁

➁

➁

➁ LW1L-M3C10V-➁

➁ LW1L-M3C20V-➁ LW1L-M3C20M-➁ LW1L-A3C20-➁ LW1L-A3C20V-➁ LW1L-A3C20M-➁

➁ LW1L-M3C30V-➁

➁

➁

➁

Momentary Maintained (Latching)

—

—

——

—

——

——

—

——

——

—

——

LW1L-M1C60M-

—

—

LW2L-M1C60M-

—

—

LW1L-M3C60M-

Part Number

➁ LW1L-A1C60-➁

➁ LW2L-A1C60-➁

➁ LW1L-A3C60-➁

LW1L-A1C10-

LW1L-A1C30LW1L-A1C50-

LW1L-A1C70LW2L-A1C10-

LW2L-A1C30LW2L-A1C50-

LW2L-A1C70LW1L-A3C10-

LW1L-A3C30LW1L-A3C50-

LW1L-A3C70-

➁ LW1L-A1C10V-➁

➁ LW1L-A1C30V-➁

——

➁

—

——

➁

➁ LW2L-A1C10V-➁

➁ LW2L-A1C30V-➁

——

➁

—

——

➁

➁ LW1L-A3C10V-➁

➁ LW1L-A3C30V-➁

——

➁

—

——

➁

—

—

LW1L-A1C60M-

—

—

LW2L-A1C60M-

—

—

LW1L-A3C60M-

A

Switches & Pilot Devices

➁

➁

➁

Part Numbers: Lamps (not included in assemblies)

Type Voltage Part Number

LED

Incandescent

1.In place of ➁, specify the LED Color Code.

2.The LED contains a current-limiting resistor

and reverse polarity protection diode.

6V AC/DC±10% LSTD-6➁

12V AC/DC±10% LSTD-1➁

24V AC/DC±10% LSTD-2➁

120V AC±10% LSTD-H2➁

240V AC ±10% LSTD-M4➁

6.3V AC/DC IS-6

12V AC/DC IS-12

24V AC/DC IS-24

➁ Lens/LED Color Code

Color Code

Amber A

Green G

Red R

Blue S

White W

Yellow Y

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-61

Page 6

LW Series: 22mm Oiltight Switches and Pilot Devices

LED and Incandescent Illuminated Pushbuttons (Sub-Assembled)

Contact Block + Operator + Lamp + Lens = Completed Unit

A

Part Numbers: Operators Part Numbers: Lenses

Style

Part Number

Momentary Maintained

Round

LW1L-M0 LW1L-A0

Square

Switches & Pilot Devices

LW2L-M0 LW2L-A0

Mushroom

LW1B-M0L LW1B-A0L

Type

Round

Square

Mushroom

In place of ➁, specify Lens Color Code from table below.

Part Number

Flush

LW1A-L1-➁

LW2A-L1-➁

LW1A-L3-➁

Part Numbers: Contact Blocks

Appearance Contact Material Contact

SPDT LW-C10 LW-C10V —

Gold

Silver

DPDT LW-C20 LW-C20V LW-C20M

3PDT LW-C30 LW-C30V —

SPDT LW-C50 — —

DPDT LW-C60 — LW-C60M

3PDT LW-C70 — —

Part Numbers: Lamps (not included in assemblies)

Type Voltage Part Number

LED

Incandescent

1.In place of ➁, specify the LED Color Code.

2.The LED contains a current-limiting resistor

and reverse polarity protection diode.

6V AC/DC±10% LSTD-6➁

12V AC/DC±10% LSTD-1➁

24V AC/DC±10% LSTD-2➁

120V AC±10% LSTD-H2➁

240V AC ±10% LSTD-M4➁

6.3V AC/DC IS-6

12V AC/DC IS-12

24V AC/DC IS-24

Part Number

Solder/Tab PC Board Screw

➁ LED/Lens Color Code

Color Code

Amber A

Green G

Red R

Blue S

White W

Yellow Y

A-62 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 7

Oiltight Switches and Pilot Devices LW Series: 22mm

LED and Incandescent Pilot Lights (Assembled)

Part Numbers: LW1P/LW2P Pilot Lights

Type Style

Round

Removable

Terminal Pilot Light

Square

Part Number

Solder/Tab PC Board Screw

—

LW1P-1C00V-

➁

A

Switches & Pilot Devices

—

Round

Monolithic

Pilot Light

1. In place of ➁, specify the Lens Color Code from table below.

2. For marking plate size and engraving area, see page A-73.

3. Lamps must be ordered separately, see table below.

4.For sub-assembly part numbers, see page A-64.

5.For dimensions, see page A-69.

6.For accessories, see page A-68.

Square

Part Numbers: Lamps (not included in assemblies)

Type Voltage Part Number

LED

Incandescent

6V AC/DC±10% LSTD-6➁

12V AC/DC±10% LSTD-1➁

24V AC/DC±10% LSTD-2➁

120V AC±10% LSTD-H2➁

240V AC ±10% LSTD-M4➁

6.3V AC/DC IS-6

12V AC/DC IS-12

—

LW1P-10-

LW2P-10-➁

LW2P-1C00V-

➁

➁

—

—

—

LW1P-10M-

LW2P-10M-

➁

➁

➁ Lens/LED Color Code

Color Code

Amber A

Green G

Red R

Blue

White W

Yellow Y

S

24V AC/DC IS-24

1.In place of ➁, specify the LED Color Code.

2.The LED contains a current-limiting resistor

and reverse polarity protection diode.

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-63

Page 8

LW Series: 22mm Oiltight Switches and Pilot Devices

1

LED and Incandescent Pilot Lights (Sub-Assembled)

Removable Terminal* + Operator + Lamp + Lens = Completed Unit

A

* Removable terminals are applicable for PCB terminated types only.

Part Numbers: Pilot Light Operators

Style

Round

Square

Switches & Pilot Devices

Solder PC Board Screw

LW1P-00

LW2P-00

Termination

LW1P-0

LW2P-0

†

†

LW1P-00M

LW2P-00M

. † Requires LW-C00V removable terminals in addition to operator.

2. Solder and screw terminals are monolithic (they do not use a removable terminal block).

Part Numbers: Lenses

Type Part Number

Round

LW1A-P1-➁

Square

LW2A-P1-➁

In place of ➁, specify Lens Color Code.

Part Numbers: Lamps (not included in assemblies)

Type Voltage Part Number

LED

Incandescent

6V AC/DC±10% LSTD-6➁

12V AC/DC±10% LSTD-1➁

24V AC/DC±10% LSTD-2➁

120V AC±10% LSTD-H2➁

240V AC ±10% LSTD-M4➁

6.3V AC/DC IS-6

12V AC/DC IS-12

➁ LED/Lens Color Code

Color Code

Amber A

Green G

Red R

Blue S

White W

Yellow Y

24V AC/DC IS-24

1.In place of ➁, specify the LED Color Code.

2.The LED contains a current-limiting resistor

and reverse polarity protection diode.

A-64 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 9

1

Oiltight Switches and Pilot Devices

Selector and Keylock Switches (Assembled)

Part Numbers: LW1S Selector Switches

Style

Round

1.Knob color: Black; Directional Indication Color: White

2.For contact operation, see next page.

3.For sub-assembly part numbers, see page A-67.

Part Numbers: LW1K Keylock Selector Switches

Style

Round

. Every key selector uses an identical key.

2. The key is removable in all positions.

3. If a different configuration is required, contact an IDEC representative for more information.

4.For contact operation, see next page.

5.For sub-assembly part numbers, see page A-67.

Position Contact Material Contact

90° 2-position

maintained

LR

45° 3-position

maintained

C

LR

Gold

Silver

Gold

Silver

SPDT LW1S-2C1 LW1S-2C1V —

DPDT LW1S-2C2 LW1S-2C2V LW1S-2C2M

3PDT LW1S-2C3 LW1S-2C3V —

SPDT LW1S-2C5 — —

DPDT LW1S-2C6 — LW1S-2C6M

3PDT LW1S-2C7 — —

DPDT LW1S-3C2 LW1S-3C2V LW1S-3C2M

3PDT LW1S-3C3 LW1S-3C3V —

DPDT LW1S-3C6 — LW1S-3C6M

3PDT LW1S-3C7 — —

Position Contact Material Contact

SPDT LW1K-2C1A LW1K-2C1VA —

90° 2-position

maintained

LR

45° 3-position

maintained

C

LR

Gold

Silver

Gold

Silver

DPDT LW1K-2C2A LW1K-2C2VA LW1K-2C2MA

3PDT LW1K-2C3A LW1K-2C3VA —

SPDT LW1K-2C5A — —

DPDT LW1K-2C6A — LW1K-2C6MA

3PDT LW1K-2C7A — —

DPDT LW1K-3C2A LW1K-3C2VA LW1K-3C2MA

3PDT LW1K-3C3A LW1K-3C3VA —

DPDT LW1K-3C6A — LW1K-3C6MA

3PDT LW1K-3C7A — —

Solder/Tab PC Board Screw

LW Series: 22mm

Part Number

A

Switches & Pilot Devices

Part Number

Solder/Tab PC Board Screw

Part Numbers: LW1F LED and Incandescent Illuminated Selector Switches

➁

➁

➁

➁

➁

➁

➁

➁

➁

➁

Part Numbers

LW1F-2C10VLW1F-2C20VLW1F-2C30V-

LW1F-3C20VLW1F-3C30V-

➁

➁

➁

——

—

——

➁

➁

—

——

—

LW1F-2C20M-

—

LW1F-2C60M-

LW1F-3C20M-

—

LW1F-3C60M-

➁

➁

➁

➁

Style

Round

1. In place of ➁, specify color code. See previous page for color codes.

2. Lamps must be ordered separately for all illuminated pushbuttons. See previous page.

3.For contact operation, see next page.

4.For sub-assembly part numbers, see page A-67.

www.idec.com

Position Contact Material Contact

SPDT

90° 2-position

maintained

LR

45° 3-position

maintained

C

LR

Gold

Silver

Gold

Silver

DPDT

3PDT

SPDT

DPDT

3PDT

DPDT

3PDT

DPDT

3PDT

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-65

Solder/Tab PC Board Screw

LW1F-2C10LW1F-2C20LW1F-2C30LW1F-2C50LW1F-2C60LW1F-2C70LW1F-3C20LW1F-3C30LW1F-3C60LW1F-3C70-

Page 10

C

NO NC

Left Center Right

C

NO NCCNO NC

Left Center Right

NO NC

C

C

NO NCCNO NC

LW Series: 22mm

Contact Operation: Selector and Keylock Switches

Position

A

LR

90°

2-Position

Maintained

Switches & Pilot Devices

Contact

SPDT _

DPDT _

Left Center Right

NO NC

3PDT _

Left Center Right

NO NC

C

Left Right

NO NC

C

NO NC

Oiltight Switches and Pilot Devices

Contact Operations

Operator Position and Contact Position (Top View)

NO NC

C

Left Right

NO NC

C

NO NC

NO NC

C

NO NC

C

C

Left Right

NO NC

C

NO NC

C

DPDT

C

LR

45°

3-Position

Maintained

3PDT

C

NO NC

Left Center Right

NO NC

Terminal Arrangements (Bottom View): LW

3 pole illuminated 3 pole non-illuminated2 pole illuminated

Lamp

Terminal

(+)

Lamp

Terminal

(—)

SPDT has C, NO and NC only on the center. DPDT has C, NO, and NC only

on the right and left.

X1X2X2

NCNOC

NCNOC

NCNOC

C

C

NO NC

CC

❏

L and LW

Lamp

Terminal

(+)

Lamp

Terminal

(—)

Left Right

NO NC

C

Left Center Right

NO NC

C

❏

B Pushbuttons

X1X2

NO NC

NO NC

C

NCNOC

C

NO NC

C

NCNOC

Left Right

NO NC

C

NO NC

C

NCNOC

NCNOC

SPDT has C, NO and NC only on the

right. DPDT has C, NO, and NC only

on the right and center.

NCNOC

A-66

www.idec.com

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 11

Oiltight Switches and Pilot Devices

Selectors and Key Switches (Sub-Assembled)

Contact Block

*Lens for illuminated units only

Part Numbers: Operators

Unit Position Part Number

Non-Illuminated

Selector Switch

Key Switch

Illuminated

Selector Switch

* Lens must be purchased separately for illuminated units.

+ Operator + Lens* = Completed Unit

2-position LW1S-2Y

3-position LW1S-3Y

2-position LW1K-2A

3-position LW1K-3A

2-position LW1F-20*

3-position LW1F-30*

LW Series: 22mm

A

Switches & Pilot Devices

Part Numbers: Knob (Lens)

Style Part Number

Illuminated Selector Switches

LW1A-F-➁

In place of ➁, specify LED/Lens Color Code from table below.

Part Numbers: Contact Blocks

Appearance

Part Numbers: Lamps (not included in assemblies)

Type

LED

Incandescent

Voltage Part Number

6V AC/DC±10% LSTD-6 ➁

12V AC/DC±10% LSTD-1 ➁

24V AC/DC±10% LSTD-2 ➁

120V AC±10% LSTD-H2 ➁

240V AC ±10% LSTD-M4 ➁

6.3V AC/DC IS-6

12V AC/DC IS-12

Style Contact Material Contact

Gold

Illuminated

Selector Switches

Silver

Gold

Non-Illuminated

Selector Switches

Silver

Part Number

Solder/Tab PC Board Screw

SPDT LW-C10 LW-C10V —

DPDT LW-C20 LW-C20V LW-C20M

3PDT LW-C30 LW-C30V —

SPDT LW-C50 — —

DPDT LW-C60 — LW-C60M

3PDT LW-C70 — —

SPDT LW-C1 LW-C1V —

DPDT LW-C2 LW-C2V LW-C2M

3PDT LW-C3 LW-C3V —

SPDT LW-C5 — —

DPDT LW-C6 — LW-C6M

3PDT LW-C7 — —

➁ LED/Lens Color Code

Color Code

Amber A

Green G

Red R

Blue S

White W

Yellow Y

24V AC/DC IS-24

1.In place of ➁, specify the LED Color Code.

2.The LED contains a current-limiting resistor

and reverse polarity protection diode.

www.idec.com

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-67

Page 12

0.137"

g

LW Series: 22mm

Style

Ring Wrench (optional)

A

Lamp Holder Tool (optional)

Terminal Cover

(for solder tab terminal)

Terminal Cover

(for screw terminal)

Switches & Pilot Devices

Terminal Cover

(for short body pilot light with solder tab terminal)

Oiltight Switches and Pilot Devices

Accessories — LW Series

Description/Usage Part Number

1. Metallic tool used for tightening the plastic locking ring when installing the LW series on a panel.

2. Tightening torque should not exceed 1.2N-m

(12 kgf-cm) when tightening a locking ring.

Rubber tool used for replacing incandescent or LED lamps installed in

illuminated switches and pilot lights and pilot lights

ø0.452"

(ø11.6mm)

2.301" (59mm)

Nylon cover for pushbuttons and selectors with solder terminals snaps

onto contact block.

(Insert the lead wires through terminal

cover holes before wiring.)

Nylon cover for pushbuttons and selectors for screw terminals snaps

onto contact block.

(Insert the lead wires through terminal

cover holes before wiring.)

Nylon cover for short body pilot lights with solder terminals. LW-PVL

ø0.546"

(ø14mm)

LW9Z-T1

OR-55

LW-VL2

LW-VL2M

Terminal Cover

(for short body pilot light with screw terminal)

Rubber Mounting Hole Plug

Metallic Mounting

Hole Plug

Replacement

Marking Plates

Anti-Rotation Ring

Replacement

Keys

Nylon cover for short body pilot lights with screw terminals. LW-PVLM

Black rubber plug fills unused 22mm panel cutouts.

ø1.131" (ø29mm)

0.137"

(3.5mm)

1. Used for plugging unnecessary mounting holes in the panel. Tighten

the attached locking ring to a torque of 1.2N-m (12kgf-cm) maximum

2. Degree of Protection: IP66

White plastic engraving plate for use on all illuminated units (included

in each lens).

May be used to capture printed mylar insert (not supplied by IDEC)

under lens face.

Prevents rotation of switches in panel.

(included with all selector and key switches only)

One pair of keys. (#231) KG9Z-SK-231PN02

0.468"

(12mm)

ø1.0" (ø25.8mm)

(3.5mm)

ø0.975" (ø25mm)

0.117" (3mm)

Locking Rin

OB-31

LW9Z-BM

LW9Z-P1-W (round)

LW9Z-P2-W (square)

ALW3B (mushroom)

LW9Z-L

Replacement

Locking Ring

For replacement lamps, see previous page.

A-68

www.idec.com

Use to secure operator to panel.

(included with all assembled switches and operators)

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

LW9Z-LN

Page 13

LW

❏

L & LW

M3 Screw Terminal

Terminal Cover

6.2

8.2

2.0

23.2

Oiltight Switches and Pilot Devices

Dimensions: Pushbuttons

❏

B: Illuminated & Non-Illuminated Pushbuttons

Terminal Cover

LW-VL2

LW-VL2M

4.85

R18

NCNO

C

LOCK

6.8

6.8

66

18.2

1.2

∗

16.2

Solder/Tab Terminal

Solder/Tab Terminal

Width 2.8 × 0.5t

Solder/Tab TerminalScrew Terminal PC Board Terminal

6.8

4.85

6.8

54.9

LOCK

R18

16.2

25.4

Screw Terminal

53.5 36

PC Board Terminal

PC Board Terminal

Width 0.8 × 0.5t

1.2

55

5.4

X1

NC

X2

NO

C

X2

25

Gasket

Locking Ring

OTP

47

LOCK

R18

25

26.5

8.5 11.7

2.6

9369

Panel Thickness: 0.8 to 6 mm

LOCK

ø25.8

Round Square

12.6

Round

w/Square Bezel

25.825.8

LW Series: 22mm

Extended

9

A

Switches & Pilot Devices

Mushroom

9

17

ø30

2.6

1.0

1.2

2-R0.6

M3 Screw terminal

Terminal Cover

LW-VL2M

8.2

2.0 6.2

23.2

25.4

53.5

54.9

LOCK

R18

PC Board Terminal

0.8 × 0.5t

55

5.4

1.2

16.2

Terminal Cover

LW-VL2

6.5

6.8

18.2

16.2

6.8

4.85

25

4.85 6.5

6.8 6.8

LOCK

R18

X1

NC

NC

X2

NO

NO

C

C

X2

25

Locking Ring

LOCK

R18

Gasket

OTP

47

Panel Thickness: 0.8 to 6 mm

LOCK

9

12.6

9

Extended

Mushroom

ø30

17

26.5

Solder/Tab TerminalScrew Terminal PC Board Terminal

Tab Terminal (solder)

Width 2.8 × 0.5t

66

1.2

8.5 11.7

36

9369

∗

Round Square

ø25.8

25.8

Round

w/Square Bezel

25.8

2.6

1.0

1.2

2-R0.6

Screw Terminal

PC Board Terminal

www.idec.com

Solder/Tab Terminal

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-69

Page 14

LW Series: 22mm

LW1P/LW2P Pilot Lights

M3 Screw terminal

Terminal Cover

A

LW-PVLM

P

O

36

7.2

4.5

26.8

7.7

Switches & Pilot Devices

Terminal Cover

LW-PVL

Oiltight Switches and Pilot Devices

Dimensions: Pilot Lights

Gasket

Locking Ring

5.95

∗

Tab Terminal (solder)

Width 2.8 × 0.5t

6.0

6.75

∗

7.5 27 9

Solder/Tab TerminalScrew Terminal PC Board Terminal

TPO

36

19

1.0

Panel Thickness: 0.8 to 6 mm

11.35

5

1.2

5

5.5

2.6

Locking Ring

LOCK

OTP

Gasket

PC Board Terminal (solder)

0.8 × 0.5t

2

11.7

8.5

36

Panel Thickness: 0.8 to 6 mm

Round Square

ø25.8

9

Round

w/Square Bezel

25.825.8

1.2

2-R0.6

A-70

www.idec.com

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 15

Oiltight Switches and Pilot Devices

Dimensions: Selector and Keylock Switches

LW1S and LW1K Selector and Keylock Switches

M3 Screw Terminal

Terminal Cover

LW-VL2M

2.0 6.2

8.2

54.9

53.5

Screw Terminal PC Board Terminal Solder/Tab Terminal

4.85

6.8 6.8

55

Terminal Cover

LW-VL2

PC Board Terminal

Width 0.8 × 0.5t

1.2

2

5.4

36

6.8

6.8

4.85

1.2

66

∗

Gasket

Locking Ring

OTP

Anti-Rotation Ring

47

2.6

Tab Terminal (solder)

Width 2.8 × 0.5t

9

36 17.5

8.5

Panel Thickness: 0.8 to 6 mm

LOCK

11.7

9

Round Round

ø25.8

w/Square Bezel

LW Series: 22mm

A

Switches & Pilot Devices

25.8

23.2

25.4

Screw Terminal

R18

LOCK

R18

NC

NC

X2 X1

NO

NO

16.2

C

C

X2

25

PC Board Terminal

LOCK

Terminal Cover

LW-VL2

6.8

4.85

6.8

66

∗

Locking Ring

Anti-Rotation Ring

2.6

Tab Terminal (solder)

Width 2.8 × 0.5t

1.2

9

Solder/Tab Terminal

2.6

1.0

1.2

Gasket

TOP

47

36

LOCK

8.5 11.7

2-R0.6

Panel Thickness 0.8 to 6 mm

0.5

10.5

37

Round Round

ø25.8

w/Square Bezel

25.8

LOCK

R18

18.2

16.2

25

26.2

Solder/Tab Terminal

www.idec.com

USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-71

Page 16

LW Series: 22mm Oiltight Switches and Pilot Devices

Dimensions: Selector and Keylock Switches, continued and Layouts

LW1F LED and Incandescent Illuminated Selector Switches

A

M3 Screw Terminal

Terminal Cover

LW-VL2M

8.2

54.9

53.5

Switches & Pilot Devices

Screw Terminal

4.85 6.5

6.8 6.8

PC Board Terminal (solder)

0.8 × 0.5t

55

1.2

5.4

PC Board Terminal

Terminal Cover

LW-VL2

6.8

6.8

6

6

36

Locking Ring

6.5

4.85

Anti-Rotation

Ring

Tab Terminal (solder)

Width 2.8 × 0.5t

1.2

2.6

9

Solder/Tab Terminal

Gasket

TOP

47

1.2

Panel Thickness: 0.8 to 6 mm

Round

ø25.8

LOCK

0.5

LOCK

R18

23.2

11.7

9

8.5

36

1.0

17.5

2.6

2-R0.6

25.4

Screw Terminal

Round

w/Square Bezel

25.8

R18

NC

NC

X2 X1

NO

NO

16.2

C

C

X2

25

PC Board Terminal

LOCK

18.2

16.2

26.2

Solder/Tab Terminal

LOCK

R18

25

Layouts

LW❏L PC Board Drilling Layout

PC Board Terminal

Bottom View

0.265"

0.189" (4.85mm)

0.254"

(6.5mm)

ø0.047" (ø1.2mm) holes

(6.8mm)

0.265" (6.8mm)

0.047"

(1.2mm)

0.195"

(5mm)

0.195"

(5mm)

Mounting Hole Layout

+0.02"

ø0.87"

- 0

+0.16"

(ø22.3

mm)

0

1.014" (26mm) Note 2

1.014" (26mm) Note 3

LW❏B PC Board Drilling Layout

PC Board Terminal

Bottom View

0.265"

0.189" (4.85mm)

(6.8mm)

ø0.047" (ø1.2mm) holes

1. When determining mounting centerlines, allow for easy operation.

2. Mushroom (Ø 1.17" (Ø 30mm)) = 1.248" (32mm)

Tab terminal = 1.014" (26mm) (with/without terminal cover)

PC board terminal = 1.014" (26mm)

Screw terminal = 1.56" (40mm)

3. Mushroom (Ø 1.17" (Ø 30mm) = 1.248" (32mm)

Tab terminal = 1.053" (27mm) (with terminal cover)

Tab terminal = 1.014" (26mm) (without terminal cover)

PC board terminal = 1.014" (26mm)

Screw terminal = 1.014" (26mm)

0.047"

(1.2mm)

0.265" (6.8mm)

0.195"

(5mm)

0.195"

(5mm)

Pilot Lights

PC Board Drilling Layout

PC Board Terminal

Bottom View

0.047" (1.2mm)

0.195"

(5mm)

0.195"

(5mm)

ø0.047" (ø1.2mm) holes

0.443" (11.35mm)

A-72 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 17

Oiltight Switches and Pilot Devices LW Series: 22mm

Engraving

Area

ø0.694" (ø17.8mm)

0.033"

(0.85mm)

Engraving

Area

ø0.683" (ø17.5mm)

0.033"

(0.85mm)

0.772"

(19.8mm)

0.69" (17.7mm)

Lens Marking Plate Lens Holder

For Round Lens

Film Housing

Top Marking Side

Lens Marking Plate Lens HolderFilm Housing

Top Marking Side

For Square Lens

Instructions — LW Series

Replacement of Lens & Marking Plate

Removing

1. Remove the operator (lens, marking plate, and lens holder) by inserting a

screwdriver into the recess of the lens through the bezel.

2. Remove the marking plate by pushing the lens from the rear to disengage

the latches between the lens and the lens holder, using the screwdriver as

shown below.

The translucent filter in the lens holder can

not be removed because this filter is sealed to

make the unit waterproof and oiltight.

Installing

For round lens types, place the marking plate on the lens holder with the antirotation projection engaged and press the lens onto the lens holder to engage

the latches. For square lens types, insert the marking plate into the lens, and

press the lens onto the lens holder to engage the latches.

Pay attention to the orientation of the marking plate.

Pay attention to the orientation of the

marking plate.

For Round Lens

Lens Marking Plate Lens Holder

For Square Lens

Lens Marking Plate Lens Holder

the same direction. Then push the lamp lightly and turn it clockwise.

Grooves in the

Operator Unit

Replacement of Lamps by Removing the Contact Block

The lamp can be replaced by removing the contact block without using the

lamp holder tool.

Marking Plates & Films

For LW series illuminated pushbuttons and pilot lights, legends and symbols

can be engraved on marking plates, or printed mylar can be inserted under the

lens for labelling purposes.

Marking Plate and Marking Film Size

Lens Style Round Lens Square Lens

Built-in

Marking

Plate

Engraving must be made on the engraving area within

0.02" (0.5mm) deep.

The marking plate is made of white acrylic resin.

0.772"

(19.8mm)

Applicable

Marking

Film

Insertion Order of Marking Plate & Film

Mylar for printing labels are not included and must be

provided and printed by user.

Two 0.004" (0.1mm)-thick films or one 0.008" (0.2mm)-thick

film can be installed in the lens.

Recommended marking film: Mylar

A

Switches & Pilot Devices

Replacement of Lamps

Lamps can be replaced using the lamp holder tool (OR-55) from the front of

the panel. Also by removing the contact block from the operator unit, the lamp

can be replaced.

Replacement of Lamps from the Front of the Panel.

(How to Remove)

1. Push and turn the lamp counterclockwise using the side A of the

lamp holder tool, and the lamp and the lamp holder can be removed.

(How to Install)

1. Insert the lamp into the lamp holder tool and hold the lamp as in the

following illustration.

2. Place the insertion guide of the lamp and the groove in the operator unit in

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-73

Lamp Lamp Holder Tool

Insertion Order of Marking Plate & Film.

1. Mylar is not included.

2. Pay attention to the orientation of marking plate.

Page 18

LW Series: 22mm Oiltight Switches and Pilot Devices

0.039"

(1mm)

0.078"

(2mm)

0.117"

(3mm)

0.156"

(4mm)

0.195"

(5mm)

0.234"

(6mm)

2000

1500

1000

500

0

Load (g)

Stroke

TW series pushbutton

(SPST-NO/SPST-NC)

LW series pushbutton

(Momentary DPDT)

LW series pushbutton

(Momentary SPDT)

0.117"

(3mm)

Stroke

Light Touch And High Reliability

Operating-force Snap Switching Mechanism

Instructions con’t

Panel Mounting

Remove the contact block from the operator. Insert the operator into the panel

cut-out from the front, then install the contact block to the operator.

Removing the Contact Block

A

Turn the locking lever on the contact block in the direction opposite to the

arrow on the housing. Then the contact block can be removed.

Installing the Contact Block

Insert the contact block, with the TOP markings on the contact block and the

operator placed in the same direction. Then lock the units, turning the locking

lever in the direction of the arrow.

Notes on Mounting

Use the optional Ring Wrench (LW9Z-T1) to mount the operator onto a panel.

Tightening torque should not exceed 1.2N-m (12 kgf-cm). Do not use pliers.

Excessive tightening will damage the locking ring.

Switches & Pilot Devices

Wiring

1. Solder the terminals within 20W/5 seconds or 260°C/3 seconds without

exerting external force to the terminals. While soldering, do not touch the

soldering iron to the housing. While wiring, prevent tension from being

applied to the terminals. Do not bend or raise the terminals, nor exert

excessive force

to terminals.

2. Use a non-corrosive resin liquid flux.

Collective Mounting

As the locking lever can be turned easily from the rear of the units using a

screwdriver, the contact blocks can be removed even when

mounted collectively.

Connection

Positive-lock connector and easy-lock connector are applicable to

tab terminals.

One Board Mounting

Mounting the switches and pilot lights on one PC board offers the following

features.

1. Reduced installation labor, easy wiring, space saving, and standardization.

2. Since the contact blocks on the PC board can be removed easily using a

locking lever, the LW series switches and pilot lights are easy to maintain.

3. Because the LW series switches and pilot lights require no studs for fastening the control unit to a PC board, special preparation of operation panel is

not needed.

For details on one board mounting, contact IDEC.

Notes for Terminal Cover

(Solder/Tab Terminal)

Insert the terminal cover into the contact block with the TOP markings on the

contact block and the terminal cover in the same direction.

When wiring, insert the lead wires into the terminal cover holes

before wiring.

Notes for Wiring

When installing a terminal cover onto the solder/tab terminal contact block,

solder the inside of lamp terminal (toward the switch terminals) and wire.

(Screw Terminal Type)

Install a terminal cover to the control unit before wiring.

1. After wiring, terminal covers cannot be installed.

2. When terminal covers are used, round crimping terminals

cannot be used.

A-74 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Page 19

Switches and Pilot Devices General Information

General Information

Information About LED Lamps

Light-emitting diodes (LEDs) are P–N junction semiconductors with mechanisms called “junction electro-luminescence.” Application of direct current results in radiation or emission of a monochromatic light.

Different semiconductor materials produce different wavelengths of light as shown below:

Green Gallium Phosphide (GaP) 5600 Å

Yellow

Amber

Red

Specifications

Infrared Gallium Arsenide (GaAs) 9000 Å

Advantages of Using LEDs

• LEDs are used when heat generated by incandescent lamps would damage nearby equipment or interfere with

a precision process. This is particularly advantageous when multiple lights are grouped.

• LEDs can operate at low temperatures which would cause incandescent lamps to fail, since glass cracks during rapid cooling.

• LEDs consume 50 times less power than incandescent lamps, thereby reducing energy consumption.

• LEDs last 500 times longer than incandescent lamps. LEDs average a million hours (114 years) while incandescent lamps average 2000 hours.

• LEDs do not generally “blow out” unless subjected to a severe overvoltage. They exhibit a half-life type

dimishment in brightness over time. After 50,000 hours (6 years) of use, IDEC LEDs will retain approximately

half of their original intensity.

• IDEC’s SUPERBRIGHT LEDs have high visibility.

• LEDs require little or no maintenance because of long life and high reliability.

Gallium Arsenide

Phosphide (GaAsP)

Gallium Arsenide

Phosphide (GaAsP)

Gallium Arsenide

Phosphide (GaAsP)

5800 Å

6300 Å

6600Å

A

Switches & Pilot Devices

IDEC Recommendations

For optimum results, especially when using switches and pilot lights in operating environments which are conducive to overheating, use IDEC LED illuminated units. Transformers are available for use with incandescent illuminated units, which operate

at lower voltages to avoid overheating.

When IDEC’s L-120L lamp is used, make sure ambient temperatures do not exceed 30˚C (86˚F). If

a lamp from another supplier is used, it should be rated f or less than 1.8 watts (15mA at 120V A C),

with ambient temperatures as stated above.

Information About Incandescent Lamps

Filament-type incandescent lamps operate within the following parameters.

Light output and life expectancy depend on operating voltage. Light output varies to the 3rd or 4th power of the voltage. Life

expectancy varies inversely to the 12th power of voltage. In other words, over-voltage of 5% reduces life expectancy by 50%.

Under-voltage of 5% doubles life expectancy at the price of light output efficiency.

Inrush current (initial current through the filament) has an adverse effect on life expectancy. Cold resistance (room temperature)

will have a more detrimental effect than hot resistance to inrush current. Life expectancy of incandescent lamps can be maximized by reducing occurrences of cold resistance to inrush current.

Continued intermittent flashing will significantly reduce life expectancy. When using an incandescent lamp with a tungsten filament, flashing will not reduce life expectancy as long as light output does not exceed that of steady burning.

When an incandescent lamp must withstand shock and vibration, use low voltage/high amperage (5–6V/60–120mA) lamps.

These lamps have a short, thick filament with a high resonant frequency.

Provide cooling by using a heat sink, particularly when multiple incandescent lamps are grouped or when air circulation is limited. Make sure ambient temperatures do not exceed 100˚C (212˚F) for maximum life of incandescent lamps.

www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC A-11

Page 20

General Information Switches and Pilot Devices

Comparison: LED vs. Incandescent Lamps

Superbright LEDs Incandescent

A

Heat Dissipation

Life Expectancy

Reliability

Mechanical

Strength

Maintenance

Required

Operation at Low

Temps.

Characteristics

Inrush Current

Voltage Effects

on Life

Brightness

Very Low High

Very Long Short

Very High Low

Not Susceptible Susceptible to Shock/Vibration

Negligible Frequent

Possible Not Possible

Negligible Very Large

Insignificant Significant

Slightly Less Slightly More

Switches & Pilot Devices

1. IDEC offers assembled and sub-assembled switches and pilot lights for your convenience. In some cases there is a cost difference, with sub-assembled units

costing slightly less. Since assembled units are custom made to your order, a couple of days for assembly is added to delivery. To minimize delivery or inventory

requirements, it is recommended that switches and pilot lights be ordered as sub-components.

2. When ordering pilot lights or illuminated pushbuttons, make sure to specify the color code in place of the asterisk in the part number, (LED or incandescent lamp

included). Spare lamps can be ordered and are listed with sub-assembly components.

3. Accessories, such as locking ring wrench, lens removal tool, and lamp holder, are available to make installation and assembly easier. IDEC recommends using

these accessories and is not responsible for damage as a result of using the wrong tool.

4. Marking plates are available for switches and pilot lights which feature a flat lens. Printed mylar (not included) can also be inserted under lens for labeling purposes.

5. Nameplates are available for TW, 7/8" (22mm), HW 7/8" (22mm),and TWTD series, Ø1–13/64" (30mm). For prompt delivery, order standard legends. Custom

engraving is also offered for an additional charge.

1. Use the appropriate lamp holder to remove or install LED or incandescent lamps. Using pliers will damage the lamp.

2. When mounting switches and pilot lights into a panel, use locking ring wrench.Using pliers or tightening excessively will damage the locking ring.

3. A series, 21/64" (8mm), can be mounted on a panel 0.019" (0.5mm) to 0.236" (6mm) thick.

4. LW 7/8” (22mm), TW, 7/8" (22mm), and TWTD series, Ø1–13/64" (30mm), feature an adjustment ring for mounting on a panel 0.038" (1mm) to 0.236" (6mm)

thick. Using a nameplate or an anti-rotation ring adds 0.031" (0.8mm) to the panel thickness.

5. When applicable, solder terminals within 20W/5sec or 260˚/3sec without exerting external force to the terminals. Use a non-corrosive resin liquid flux.

6. The operating voltage for LED units represents a complete DC value. When using a pulsing voltage, such a full-wave rectification, keeppeak currents within the

forward current I

7. To avoid a short circuit, never connect NO and NC contacts to different voltages or power sources.

8. Optimum performance of TW and TWTD illuminated pushbuttons, selector switches, and pilot lights is obtained with IDEC LED and incandescent lamps.

9. For maximum life of incandescent lamps (approximately 2000 hours), use within the rated operating voltage. If it is necessary to use a higher voltage, keeping

ambient temperature below 30˚C (86˚F)will help prolong the life of an incandescent lamp.

. Peak currents exceeding If may shorten the life of the LED lamp.

f

Ordering Information

Installation and Operation

If excessive voltage is applied (over 50V), the lamp may blow and

the lens holder may pop out.

A-12 www.idec.com USA: (800) 262-IDEC or (408) 747-0550, Canada (888) 317-IDEC

Loading...

Loading...