Page 1

B-1365(0)-1

INSTRUCTION SHEET

LF1D-F LED Illumination Unit

LF1D-F Series

Confirm that the delivered product is what you have ordered. Read this instruction sheet to

make sure of correct operation. Make sure that the instruction sheet is kept by the end user.

Safety Precautions

In this operation instruction sheet, safety precautions are categorized in order of importance to

Warning and Caution :

Warning notices are used to emphasize that improper operation may cause severe personal

injury or death.

Caution notices are used where inattention might cause personal injury or damage to

equipment.

· Before designing the final equipment and powering up the LF1D-F illumination unit,

confirm the specifications secribed on this sheet. If there is any uncertainty in the

description, contact IDEC before powering up the LF1D-F illumination unit.

· Do not disassemble, repair, or modify the LF1D-F illumination unit, otherwise severe

accidents may result, such as electric shocks, damage, fire, or malfunction.

· Turn off the power to the LF1D-F illumination unit before wiring. Make sure of correct

wiring, otherwise electric shocks or damage may result.

· Do not gaze into the LF1D-F illumination unit while it is lit, and do not project the light to

other people, otherwise eyes may be injured.

· Make sure that the LF1D-F illumination unit does not fall during transportation,

installation, and operation, otherwise damage may result.

· Do not pull out or push in the cable of the LF1D-F illumination unit, otherwise damage

may result. Give a slack to the cable while wiring.

· The LF1D-F illumination unit is a general-purpose and industrial electronic device. Do not

use the LF1D-F illumination unit for electronic equipment which may damage a human body

or threaten a life in case a malfunction or failure occurs.

· Make sure that the cable does not touch the LF1D-F housing.

· LED modules and illumination units may vary in illumination colors and illuminance.

· Apply a voltage within the rated value, otherwise the LED elements may be damaged.

· The LF1D-F illumination unit is vulnerable to static electricity. Take a sufficient measure for

protection against static electricity and surge voltages.

· Do not apply an excessive force to the LF1D-F illumination unit. Do not leave a damaged

LF1D-F illumination unit unattended or use a damaged LF1D-F.

· Make sure of the correct operating temperature, which is the temperature around the

LF1D-F illumination unit. Otherwise internal temperature rise may result in damage.

· Do not use or store the LF1D-F illumination unit in a place subjected to vibrations and

shocks.

· Do not use the LF1D-F illumination unit in the following places:

Exposed to direct sunlight, near heaters, and at high temperatures

Subjected to chemicals, and corrosire gases

(Plastic lens types: Iron powder and oil)

Basements, greenhouses, and other humid places

Cold storage warehouses and cooler exhaust outlets

(make sure that no freezing occurs)

· Do not loosen screws, otherwise the protection characteristics will be impaired.

Types

1

Lens Material

Reinforced Glass

Plastic

□ : Lens surface code ◇ : Accessory code

Accessories

Cable Gland

Mounting Bracket

Cable (5m)

Type No.

LF1D-F□F-2W-◇

LF1D-F□G-2W-◇

LF9Z-A11

LF9Z-B12

LF9Z-C05

Specifications

2

General Specifications

Applicable Standard

UL2108 , UL8750, CSA C22.2 No.250.0 *1

JIS C 8105-1 ,EN61000-6-2

Rated Voltage

Input Current (approx.)

Rated Power (approx.)

Operating Temperature

Storage Temperature

Operating Humidity

Storage Humidity

Life *2

Insulation Resistance

Dielectric Strength

Vibration Resistance

(damage limits)

Shock Resistance

(damage limits)

Material

24V DC (Operating voltage range: 21.6V to 26.4V DC)

520 mA typ. (625 mA maximum)

12.5W typ. (15W maximum)

-30 to +55ºC (no freezing)

-35 to +70ºC (no freezing)

45 to 85% RH (no condensation)

20 to 90% RH (no condensation)

50,000 hours minimum

(until the illuminance reduces to 70% the initial value in 25ºC environment)

1 MΩ minimum (500V DC megger)

1000V AC, 1minute

(between input terminal and ground terminal or housing)

5 to 55Hz, amplitude 0.5 mm

2

1000 m/s

Front Cover: SUS304

Housing: Diecast aluminium

Lens *3 : Reinforced Glass

Polycarbonate

Cable Gland: Brass

Mounting Bracket: SUS304

Cable: PVC

Weight (approx.)

Degree of Protection

800g (no accessories)

1000g (with cable gland, mounting bracket, cable)

LF1D-F□F-2W-◇: IP67, IP67F, IP69K *4

LF1D-F□G-2W-◇: IP67, IP69K

*1: Use Class 2 power supply when using the LF1D as UL / c-UL Listed Low voltage Luminaire.

*2: Life of the LED is greatly attected by the operating conditions.

*3: The reinforced glass and polycarbonate lenses have the same appearance, but have

the different degrees of protection (IP67F or IP67).

*4: IP67 is tested to IEC 60529 , IP67F is tested to JIS C 0920 , IP69K is tested to DIN 40050-9.

Do not assure protection against all actual operating conditions. For illumination units

without accessories, use a cable gland and cable that satisfy IP67f or IP67 degrees

of protection.

LED Optical Specifications

Illumination Color

Color Temperature (typ.)

Total Luminous Flux (typ.)

Reference Illuminance (typ.) at 1.0m (perpendicular)

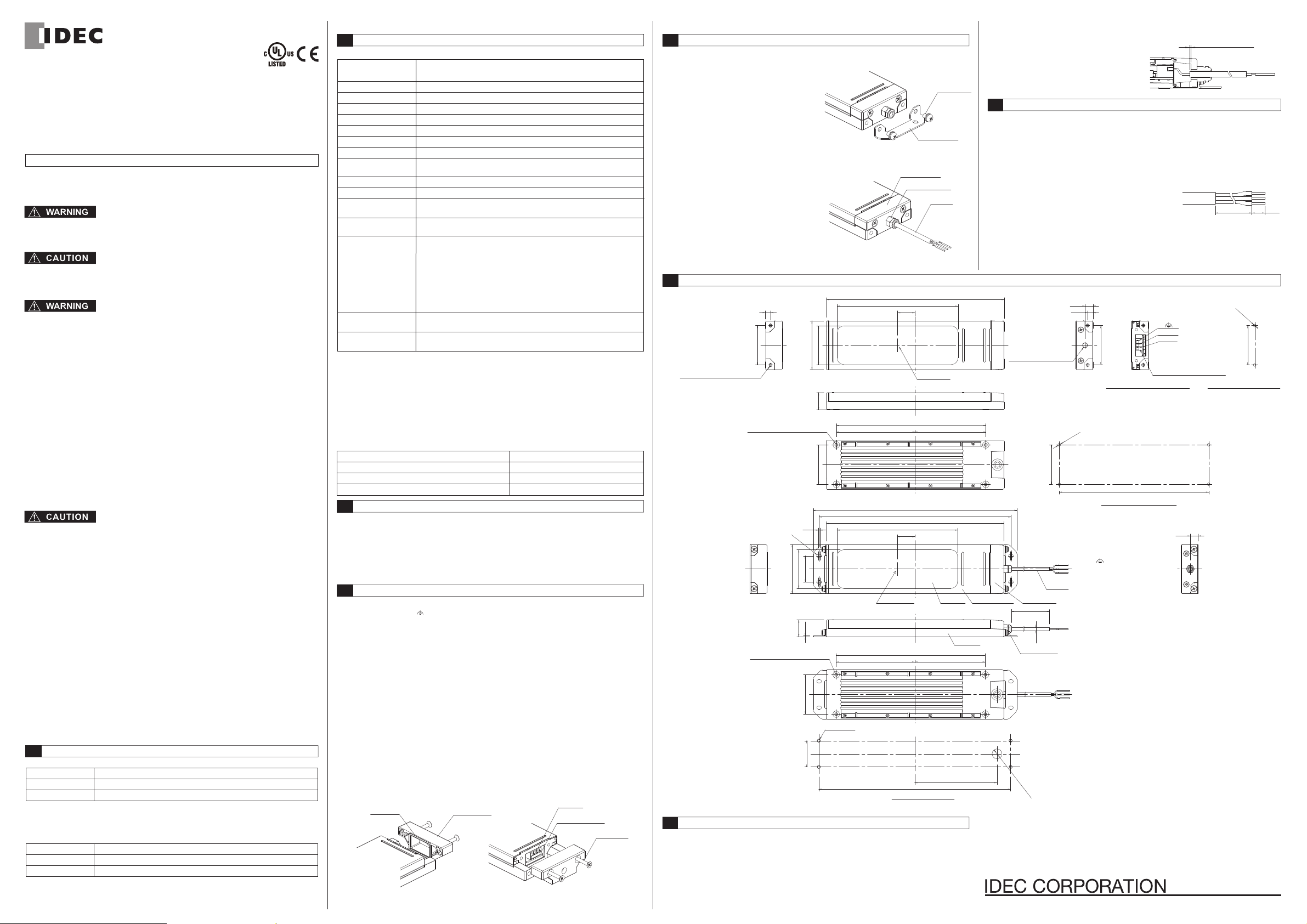

Installation

3

White

5700K

840 lm

1100 lx

Wall and ceiling Surface Mount

Mounting Centers (see Demensions)

· Direct Mount, Bracket Mount

Mount the LF1D-F illumination unit using four M5 screws. Tighten the screws to the torque

shown below.

Recommended tightening torque: 2.6 to 3.7 N·m

Wiring

4

Wiring

· Connect the ground ( ) terminal of the LF1D-F LED illumination unit to a proper ground for

protection against static electricity and surge voltages.

· The LF1D-F illumination unit is equipped with a cabtyre cable, RO-FLEX 725T AWG 24 x 3 c.

When wiring, use an appropriate connector, terminal, or wire to meet the specification values.

When soldering the wires of the cable, use a 20W soldering iron, with a tip temperature of

350ºC, and complete soldering within 3 seconds. Use Sn-Ag-Cu lead-free solder.

· Make sure that the cable does not touch the LF1D-F housing.

Cable Connection

· When connecting a cable to the terminal block, remove the side cover. Before removing the

side cover, wipe off water and oil from the housing, otherwise water or oil may enter the inside

of the housing.

· When reinstalling the side cover, clean the gasket. Any foreign object on the gasket may

impair the water-proof characteristics. Make sure that the cable is not caught between the

housing and the side cover.

· To install the side cover, tighten the two M4 screws to the torque shown below.

Recommended tightening torque: 1.4 to 2.0 N·m

· To remove the cable from the terminal block, push in the clamp and pull out the wire.

Gasket

Side Cover

Clamp

Terminal Block

M4 Screw

Accessories

5

When installing the optional mounting bracket, cable gland,

and cable, follow the steps shown below.

· Install the two mounting brackets using the

attached four M5 screws. Tighten the screws to

the torque shown below.

Recommended tightening torque: 2.6 to 3.7 N·m

· Tighten the cable gland to the torque shown below.

Installation into the side cover:

Recommended tightening torque: 1.5 N·m minimum

Tightening the cable:

Recommended tightening torque: 1.5 N·m minimum

· For cable connection, see [4] "Wiring."

Demensions

7

<No Accessories>

LF1D-F □* -2W

P0.8

4-M5

Effective Thread Length:

8

60

10mm

P0.8

4-M5

Effective Thread Length:

75

10mm

58.6

25.9

60

<with Cable Gland, Mounting Bracket, Cable>

LF1D-F □* -2W-A

Precautions for Disposal

8

P0.8

4-M5

Effective Thread Length:

R2.6

74.7

58.6

25.9

2

40

1.5

10mm

60

±0.2

40.0

· Dispose of the LF1D-F LED Illumination Unit as an industrial waste.

4-M5 Screw

Side Cover

Cable Gland

270

183.6

27

227

310

292

270

183.6

27

Optical Axis

227

±2.0

292.0

Mounting Hole Layout

M5 Screw

Mounting

Bracket

Cable

Optical Axis

(107)(120)

Lens

(107)(120)

Housing

124.8

· When installing a cable using the cable gland,

make sure that the cable sheath protrudes the

1.0mm minimum

gland as shown at right, otherwise the water-

proof characteristics may be impaired.

Recommended Parts

6

When using commercially available ferrules, cables, and cable glands, choose the

recommended parts shown below.

· Ferrule: AI 0.25-12BU, AI 0.34-12TQ

AI 0.5-12 WH, AI 0.75-12GY (Phoenix Contact)

Applicable ferrule thickness: 0.25 to 0.75mm

2

· Cable: RO-FLEX 725T AWG24 x 3c (NICHIGOH)

Use UL Listed cable Type CL2,CL3 or CM. (For UL / c-UL compliant product)

Strip the cable sheath and wire insulation as shown at right.

· Cable Gland: SKINDICHT MINI M8X1(LAPP)

When using a cable gland shown above, choose a cable of

φ

3.5 to 5.5 mm in order to

assure IP67.

Choose a cable gland in consideration of the thread size and effective thread length.

12

8

( )

N (-)

L (+)

Spring Cage Terminal Block

±0.2

227

All dimensions in mm.

Side Mounting Hole Layout

12

±1.0

M8

Effective Thread Length: 5mm

Front Cover

φ15.0

P1.0

4- φ5.2

±0.2

60

Cable

Side Cover

5m

φ5

Cable Gland

Note: When installing a rear wiring type, drill a hole in the panel.

Provide a proper sealing to the rear wiring hole in the panel.

+0.2

0

*

60

Terminal Block Wiring Diagram

Rear Mounting Hole Layout

Pink: ( )

Blue: (-)

Brown: (+)

2- φ5.2

±0.2

12.040.0

60

http://www.idec.com

2013.2.1 Ref.

Loading...

Loading...