Page 1

LD6A

Unique Striped Design Improves Visibility

Key features of the LD6A LED SignaLight Towers include:

• The striped design with non-illuminated area between the lenses

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

makes the illuminated color very visible.

• Unique oval lens shape provides high-visibility from different

directions.

• Five different mounting styles available: frame mount, wall mount,

direct mount and pole mount (round or L-shaped bracket).

• Clear lens models available to clearly distinguish between illuminated and non-illuminated lenses.

• Custom conguration is possible.

• Flashing cycle: 1.75Hz (approx. 105 ashes per minute) conforms to

international standard IEC 60073.

• Alarm (3.3kHz, 2 different styles) can be heard in 360º degrees.

Adjustable volume (70 to 90dB).

• Degree of protection: IP65 Steady units and IP54 Flashing units

(using frame, wall, direct and pole mount with round base), IP23

Steady and Flashing units using pole mount with L-shaped bracket.

Signaling Lights

LD6A LED SignaLight Towers

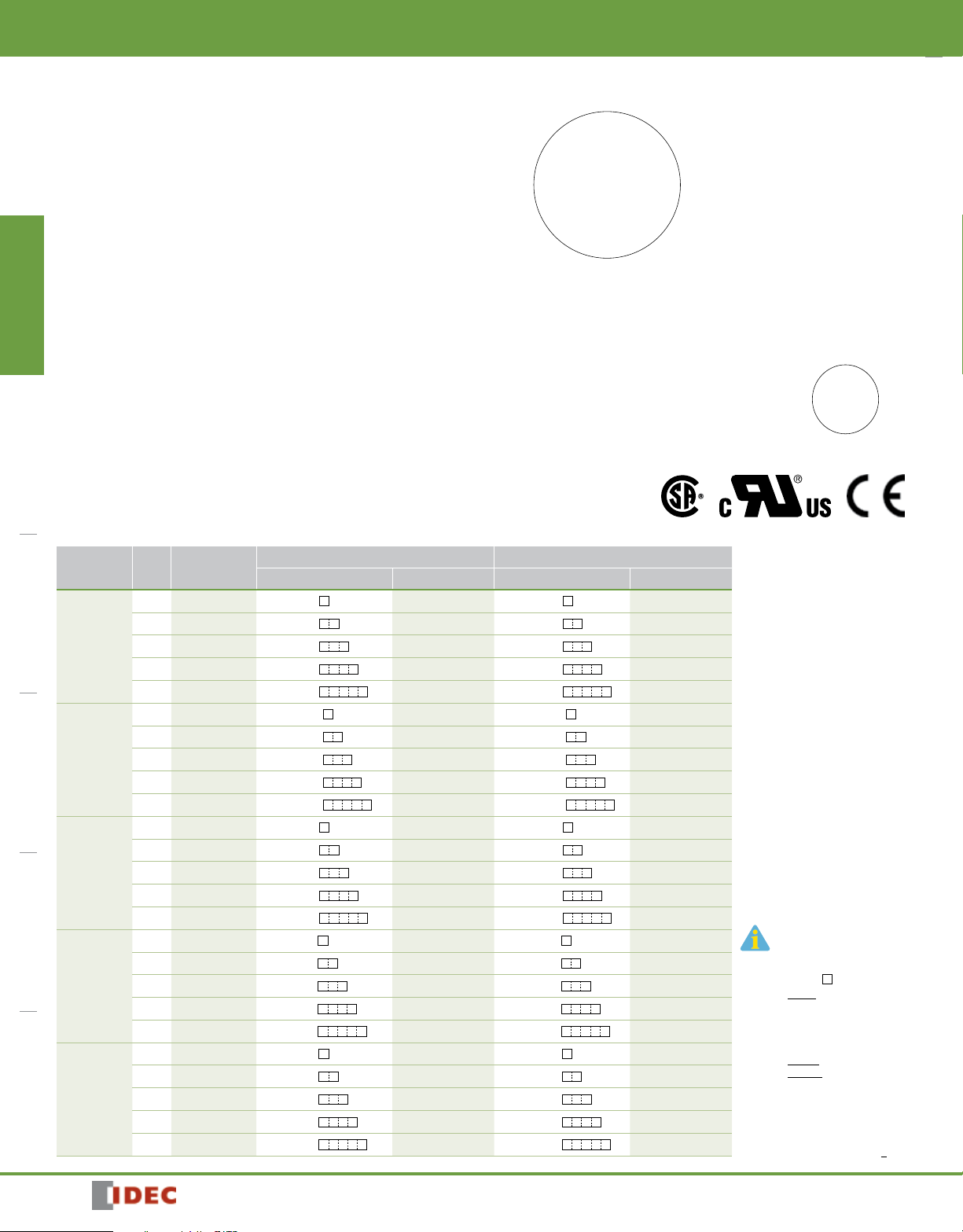

Frame mount

Direct mount

Pole mount

(w/Base)

Wall mount

(w/L-shaped bracket)

Mounting

Style

G: Frame

Mount

W: Wall

Mount

D: Direct

Mount

P: Pole Mount

(with base)

K: Pole

Mount

(with

L-shaped

bracket)

Tiers

LED Color

Code

1 R, Y, S, G, W

2 RY, RG

3 RYS, RYG

4 RYSG

5 RYSGW

1 R, Y, S, G, W

2 RY, RG

3 RYS, RYG

4 RYSG

5 RYSGW

1 R, Y, S, G, W

2 RY, RG

3 RYS, RYG

4 RYSG

5 RYSGW

1 R, Y, S, G, W

2 RY, RG

3 RYS, RYG

4 RYSG

5 RYSGW

1 R, Y, S, G, W

2 RY, RG

3 RYS, RYG

4 RYSG

5 RYSGW

Assembled Products

Steady Steady/Flashing/Alarm

Part Number Weight (approx.) Part Number Weight (approx.)

LD6A-1GQ*-

LD6A-2GQ*-

LD6A-3GQ*-

LD6A-4GQ*-

LD6A-5GQ*-

LD6A-1WQ*-

LD6A-2WQ*-

LD6A-3WQ*-

LD6A-4WQ*-

LD6A-5WQ*-

LD6A-1DQ*-

LD6A-2DQ*-

LD6A-3DQ*-

LD6A-4DQ*-

LD6A-5DQ*-

LD6A-1PQ*-

LD6A-2PQ*-

LD6A-3PQ*-

LD6A-4PQ*-

LD6A-5PQ*-

LD6A-1KQ*-

LD6A-2KQ*-

LD6A-3KQ*-

LD6A-4KQ*-

LD6A-5KQ*-

220g

260g

300g

340g

380g

225g

265g

305g

345g

385g

185g

225g

265g

305g

345g

645g

685g

725g

765g

805g

640g

680g

720g

760g

800g

LD6A-1GZQ*-

LD6A-2GZQ*-

LD6A-3GZQ*-

LD6A-4GZQ*-

LD6A-5GZQ*-

LD6A-1WZQ*-

LD6A-2WZQ*-

LD6A-3WZQ*-

LD6A-4WZQ*-

LD6A-5WZQ*-

LD6A-1DZQ*-

LD6A-2DZQ*-

LD6A-3DZQ*-

LD6A-4DZQ*-

LD6A-5DZQ*-

LD6A-1PZQ*-

LD6A-2PZQ*-

LD6A-3PZQ*-

LD6A-4PZQ*-

LD6A-5PZQ*-

LD6A-1KZQ*-

LD6A-2KZQ*-

LD6A-3KZQ*-

LD6A-4KZQ*-

LD6A-5KZQ*-

310g

350g

390g

430g

470g

315g

355g

395g

435g

475g

275g

315g

355g

395g

435g

735g

775g

815g

855g

895g

730g

770g

810g

850g

890g

Specify housing color code in

place of *: B (black),

W (light gray)

Specify illumination color in

place of starting with the

top tier. State the LED color

code from the left.

R (red), Y (yellow), S (blue),

G (green), W (pure white)

Example: When the LED color is

RYGSW => LD6A-5GQW-

RYGSW

Clear lens type also available.

Specify “C” after the LED

color code.

Example:

LD6A-5GQW-RYSGW =>

LD6A-5GQW-RYSGWC

778

1607302105

Page 2

•

Signaling Lights

LD6A

Combination of LED Color and Lens Color

LED Color Color Lens Type Clear Lens Type

R: Red Red lens Clear lens

Y: Yellow Yellow lens Clear lens

S: Blue Blue lens Clear lens

G: Green Green lens Clear lens

W: White Clear lens

For white (W) LED, a clear lens is used in both color and

clear lens congurations.

Base Module

Style Mounting Style

Frame Mount LD6A-0GQ* LD6A-0GZQ*

Wall Mount LD6A-0WQ* LD6A-0WZQ*

Direct Mount LD6A-0DQ* LD6A-0DZQ*

Pole Mount (with base) LD6A-0PQ* LD6A-0PZQ*

Mounting Parts Included

Mounting Style Supplied Parts

G: Frame mount

W: Wall mount

D: Direct mount

P: Pole mount

(with base)

K: Pole mount

(with L-shaped bracket)

*For black housing, black screws and washers are supplied. For light gray housing, silver screws and washers are supplied.

M4 screw (4 pcs)*, M4 spring washer (4 pcs)*, M4 plain washer (4 pcs)*, M5 screw (2 pcs),

M5 spring washer (2 pcs), M5 plain washer (2 pcs), bracket (1 pc)

M4 screw (20 mm) (4 pcs), M4 screw (8 mm) (4 pcs)*, M4 spring washer (8 pcs)*

M4plainwasher (8 pcs)*, M4 nut (4 pcs), bracket (1 pc), gasket (1 pc)

M5 screw (4 pcs)*, M5 spring washer (4 pcs)*, M5 plain washer (4 pcs)*, M5 nut (4 pcs)*,

O-ring (4 pcs), gasket (1 pc)

M5 screw (4 pcs), M5 spring washer (4 pcs), M5 plain washer (4 pcs), M5 nut (4 pcs),

O-ring (4 pcs), gasket (1 pc)

M22 plain washer 2 (pcs), M22 nut (2 pcs), bracket (1 pc)

Part Number

Steady Steady/Flashing/Alarm

Notes

A top cap is supplied.

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

Pole Mount (with L-shaped bracket) LD6A-0KQ* LD6A-0KZQ*

Specify a housing color code in place of *: B (black), W (light gray)

Do not supply power to the base module without connecting LED modules.

LED Module

Style Lens Part Number LED Color Code

Black

Light gray

Specify an LED color code in place of : R (red), Y (yellow), S (blue), G (green), W (white)

When using white (W) with a clear lens, order LD9Z-6ALB-W (black housing) or LD9Z-6ALW-W (light gray housing).

Color lens

Clear lens

Color lens

Clear lens

LD9Z-6ALB-

LD9Z-6ALB-

LD9Z-6ALW-

LD9Z-6ALW-

C

C

R, Y, S, G, W

R, Y, S, G

R, Y, S, G, W

R, Y, S, G

Center Set Screw

Item Part Number Notes

1 tier LD9Z-6AC1

2 tiers LD9Z-6AC2

3 tiers LD9Z-6AC3

4 tiers LD9Z-6AC4

5 tiers LD9Z-6AC5

A plain washer and spring washer are supplied.

1607302105

779

Page 3

LD6A

Signaling Lights

Ordering Examples

[Ex. 1] When ordering LD6A-3PQW-RYG as sub-component parts, specify the following:

Pole mount (with base), steady, light gray housing, 3 tiers, color lens LED modules with Red, Yellow, and Green LED

Base module (pole mount with base, steady, light gray housing) LD6A-0PQW 1 piece

LED module (red LED with color lens, light gray housing) LD9Z-6ALW-R 1 piece

LED module (yellow LED with color lens, light gray housing) LD9Z-6ALW-Y 1 piece

LED module (green LED with color lens, light gray housing) LD9Z-6ALW-G 1 piece

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

Center screw set (3 tiers) LD9Z-6AC3 1 piece

[Ex. 2] When ordering LD6A-5WZQB-RYSGWC as sub-component parts, specify the following:

Wall mount, steady/ashing/alarm, black housing, 5 tiers, clear lens LED modules with Red, Yellow, Blue, Green, and Pure white LED

Base module (wall mount, steady/ashing/alarm, black housing) LD6A-0WZQB 1 piece

LED module (red LED with clear lens, black housing) LD9Z-6ALB-RC 1 piece

LED module (yellow LED with clear lens, black housing) LD9Z-6ALB-YC 1 piece

LED module (blue LED with clear lens, black housing) LD9Z-6ALB-SC 1 piece

LED module (green LED with clear lens, black housing) LD9Z-6ALB-GC 1 piece

LED module (pure white LED with clear lens, black housing) LD9Z-6ALB-W 1 piece

Center screw set (5 tiers) LD9Z-6AC5 1 piece

Replacement Parts

Item Description Part Number Notes

Black LD9Z-6ATB

Top Cap

Light gray LD9Z-6ATW

A top cap is supplied with a base module.

L-shaped Bracket

Metal

(chrome-plated)

LD9Z-6AK Two plain washers and two nuts are supplied.

780

1607302105

Page 4

•

Signaling Lights

LD6A

Specications

Safety Standards

Operating Temperature –25 to +55ºC (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

Storage Temperature –40 to +75ºC (no freezing)

Overvoltage Category III (IEC60664-1)

Impulse Withstand

Voltage

Insulation Resistance 100 MΩ minimum (500V DC megger)

Dielectric Strength Between live and dead parts: 1000V AC, 1 minute

Pollution Degree 3

Corrosion Immunity Atmosphere free from corrosive gases

Vibration Resistance Operating extremes: 10 to 55Hz, amplitude 0.5 mm

Shock Resistance Operating extremes: 147 m/s

Degree of Protection

(IEC60529)

Housing Color Black, Light gray

Material

Wire 22AWG

IEC60947-5-1, EN60947-5-1, UL508,

CSA C22.2 No.14

800V (IEC60947-1)

2

, 6 shocks each in 6 axes

Steady

Steady pole mount with L-shaped bracket IP23

Flashing/

Alarm

Flashing/

Alarm

Housing: ABS resin

Lens: AS resin

Pole: Steel (nickel-chrome plated)

Pole base: Diecast aluminum

frame mount, wall mount, direct

mount, pole mount with base

frame mount, wall mount, direct

mount, pole mount with base

pole mount with L-shaped bracket IP23

Specications

External Contact Ratings

AC Contact Capacity

(per tier)

LED

DC Contact Capacity,

Transistor Capacity (per tier)

AC Contact Capacity

(per alarm)

DC Contact Capacity,

Alarm

Transistor Capacity

(per alarm)

IP65

IP54

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

Current Capacity 100mA min.

Dielectric Strength 35V AC min.

Current Capacity 100mA min.

Dielectric Strength 35V min.

Leakage Current 0.1mA max.

Current Capacity 400mA min.

Dielectric Strength 35V AC min.

Current Capacity 300mA min.

Dielectric Strength 35V min.

Leakage Current 0.1mA max.

Functional Specications

Rated Insulation Voltage 60V

Operating Voltage 24V AC/DC ±10%

Rated Voltage (Ue) 24V AC/DC

LED Color Code R (red), Y (yellow), S (blue), G (green), W (white)

Illumination Color R, Y S, G W

Rated Current (per tier) 25mA 30mA 20mA

LED

Power Consumption

(pertier)

LED Life (Note)

Flashing Cycle (IEC60073) Approx. 105 ashes per minute (1.75 Hz)

Alarm Cycle

Current Draw 110mA max.

Inrush Current AC: 400mA max. DC: 250mA max.

Alarm

Alarm Volume 70 to 90dB, at 1m (volume adjustable)

Acoustic Frequency Approx. 3.3kHz

Note: Life of the LED varies according to operating conditions and environment.

0.6W 0.75W 0.5W

Approx. 30,000 hours (until brightness is reduced

to 50% of the initial value in a 25ºC operating

environment)

Alarm 1: approx. 700 times per minute

Alarm 2: approx. 35 times per minute

1607302105

781

Page 5

LD6A

60

12.6

M20×P1.5

Power supply

Pure Whit

External contact

External transistor

External transistor

Dimensions (Steady Light)

Frame Mount Wall Mount Direct Mount Pole Mount (with base) Pole Mount (with L-shaped bracket)

60

2517.4

40

40

52.4

L1980

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

12.6

2517.4

Signaling Lights

60

ø94

L4730

40

40

80

40

12.6

60

2517.4

L580

60

40

53.4

40

60

12.6

40

2517.4

ø70

12.6

2517.4

L2

L31040

65

65

980

Conduit Port

Front Front Front

Dimension Table

Tiers

Frame Mount

(L1)

Wall Mount

(L2)

Direct Mount

(L3)

w/ base (L4) w/ L-shaped bracket (L5)

1 156 156 98 408 372

2 186 186 128 438 402

3 216 216 158 468 432

4 246 246 188 498 462

5 276 276 218 528 492

Pole Mount

Panel Cut-Out

Frame Mount Wall Mount Direct Mount* Pole Mount (with base)

2-M5

44.0

*Complies with IEC60947-5-1.

4-ø4.5

Wire Entry

ø15

46

23

16

90°

Front

Pattern A* Pattern BPattern C

Front

4-ø5.5

ø54

Wire

Entry

ø15

ø40

120°

4-ø5.5

ø54

Wire Entry

ø15

3-ø4.5

120°

Wire

Entry

ø15

90°

FrontFrontFront

73032

Pole Mount

(with L-shaped bracket)

Pattern D

4-ø4.5

ø73

Wire

Entry

ø15

4-ø5.5

ø73

Wire Entry

ø15

w/ L-shaped

bracket

w/o L-shaped

bracket

2-ø11

35

+1

0

ø22

Wiring Example (Steady Light)

Mechanical Contacts NPN Transistors PNP Transistors

e

LED Red: Red

LED Yellow: Orange

LED Blue: Blue

LED Green: Green

Pure White

LED

Power supply line:

Yellow

Red

Yellow

Blue

Green

: White

for steady light

Fuse

1A

Power supply

24V

AC/DC

Red

Yellow

Blue

Green

Pure White

LED Red: Red

LED Yellow: Orange

LED Blue: Blue

LED Green: Green

Pure White

LED

: White

Power supply line:

Yellow

for steady light

Fuse

1A

(+)

(–)

Power supply

24V

DC

Red

Yellow

Blue

Green

Pure White

782

LED Red: Red

LED Yellow: Orange

LED Blue: Blue

LED Green: Green

LED

Pure White

: White

Power supply line:

Yellow

for steady light

(–)

Fuse

1A

(+)

24V DC

1607302105

Page 6

•

Signaling Lights

12.6

60

L580

M20×P1.5

Pattern A* Pattern BPattern C

Pattern D

LD6A

Dimensions (Steady/Flashing/Alarm)

Frame Mount Wall Mount Direct Mount Pole Mount (with base) Pole Mount (with L-shaped bracket)

60

2517.4

60

40

52.4

40

L1900

Conduit Port

12.6

2517.4

65

60

40

53.4

40

L2

900

60

12.6

40

ø70

12.6

2517.4

L3960

65

FrontFront Front

2517.4

40

ø94

12.6

2517.4

650 L4

40

32650

80

40

60

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

Dimension Table

Tiers

Frame Mount

(L1)

Wall Mount

(L2)

Direct Mount

(L3)

w/ base (L4) w/ L-shaped bracket (L5)

1 228 228 170 480 444

2 258 258 200 510 474

3 288 288 230 540 504

4 318 318 260 570 534

5 348 348 290 600 564

Pole Mount

Panel Cut-Out

Frame Mount Wall Mount Direct Mount* Pole Mount (with base)

2-M5

Wire Entry

ø15

44.0

*Complies with IEC60947-5-1.

4-ø4.5

Front

4-ø5.5

ø54

Wire

Entry

ø15

4-ø5.5

ø54

90°

Front

Wire Entry

ø15

46

23

16

3-ø4.5

120°

ø40

120°

Wire

Entry

ø15

90°

FrontFrontFront

Pole Mount

(with L-shaped bracket)

w/ L-shaped

4-ø5.5

ø73

Wire Entry

ø15

bracket

w/o L-shaped

bracket

4-ø4.5

ø73

Wire

Entry

ø15

2-ø11

35

+1

0

ø22

1607302105

783

Page 7

LD6A

Conduit por

(M20×P1.5

Signaling Lights

Wiring Example (Flashing Light and Alarm)

Mechanical Contacts NPN Transistors PNP Transistors

Red

Yellow

Blue

Green

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

Pure White

LED Red: Red

LED Yellow: Orange

LED Blue: Blue

LED Green: Green

Pure White

: White

LED

Alarm 1: Purple

Alarm 2: Light Blue

External contact

for steady light/alarm

External contact

for flashing light

Red

Yellow

Blue

Green

Pure White

LED Red: Red

LED Yellow: Orange

LED Blue: Blue

LED Green: Green

LED

Pure White

: White

Alarm1: Purple

Alarm 2 Light Blue

External contact

for steady light/alarm

External contact

for flashing light

Red

Yellow

Blue

Green

Pure White

LED Red: Red

LED Yellow: Orange

LED Blue: Blue

LED Green: Green

LED

Pure White

: White

Alarm1: Purple

Alarm 2 Light Blue

External contact

for steady light/alarm

External contact

for flashing light

Flashing COM: Brown

Power: Gray

Power: Yellow

Fuse 1A

Power supply

24V AC/DC

Flashing COM: Brown

Power: Gray

Power: Yellow

Safety Precautions

• Turn off the power to the LD6A before mounting, removing, wiring or assembling the LED module. Make sure the wiring is done correctly otherwise

electrical shock or re may result.

• Mount the LD6A on a solid surface not subject to vibrations.

• Do not mount the LD6A upside-down or horizontally.

• Do not leave the LD6A without a cap or unassembled.

• Install the supplied gasket, otherwise the waterproof seal will be

compromised.

• Do not apply any chemicals that may corrode the plastic materials.

• If the LD6A is subjected to strong vibrations, the hexagon socket screw may

Instructions

Mounting

• See drawing below regarding the mounting of the LD6A.

• For panel cut-out dimensions, see pages 9 and 10.

• Postion the LD6A to make sure the alarm sound is the loudest. (Steady/ashing/alarm type)

Frame Mounting

1. Insert two nuts in the frame, and attach the bracket using two M5 screws.

Recommended tightening torque: 2.6 to 2.7 N·m

2. Mount the LD6A to the bracket using four M4 screws.

Recommended tightening torque: 1.6 to 1.7 N·m

➀

➁

Bracket

Plain Washer

Spring Washer

M5 Screw

Frame (Note)

Frame Nut (Note)

Flashing COM: Brown

Fuse 1A

(–)

(+)

Power supply

24V DC

Power: Gray

Power: Yellow

Fuse 1A

become loose. Take measures to prevent loosening. (See the gure below.)

2-M4 holes for hexagon socket

set screws

(recommended tightening torque:

1.1 to1.2 N・m)

• Do not loosen any screws if the tightening torque is not specied.

Examples of recommended frames and frame nuts

Frame Size Frame Frame Nut Manufacturer

30 mm*

40 mm

SFF-302

SFF-402

*The mounting bracket for the housing is 40 mm.

When using a frame mount type, be sure to use

exible conduit, otherwise the waterproof seal will

be compromised.

Refer to the “Example of Flexible Conduit” shown on

the right.

SFB-001

SFB-4B5

SFB-101

SFB-008

SFB-4A5

SFB-108

(+)

Power supply

24V DC

(–)

SUS

Corporation

(Japan)

Gland

t

)

M4 Screw, Spring Washer, Plain Washer

Note: See table below for typical examples of frames and nuts. Consult the manufacturer of the frame

for the installation method of the frame nut.

784

Conduit

Example of Flexible Conduit

Conduit Port Size M20

Gland AL16/M20/A/BL

Conduit PAFS16BL

Manufacturer Adaptaex

1607302105

Page 8

•

Signaling Lights

Panel

M4 Screw (8 mm), Spring Washer, Plain Washer

Pane

M5 Screw

Nut

Hexagonal

nut

(M22)

Hexagonal

bolt

(M10)

∗

Insert flat screwdriver into recess

Recess

Top Cap

LD6A

Wall Mounting

1. Make four tapped holes in the mounting panel and mount the bracket

and gasket using four screws (M4 x 20).

Recommended tightening torque: 1.6 to 1.7 N·m

2. Mount the LD6A to the bracket using four screws (M4 x 8).

Recommended tightening torque: 1.6 to 1.7 N·m

Gasket

➀

➁

Direct Mounting

Recommended tightening torque: 2.6 to 2.7 N·m

Bracket

Plain Washer

Spring Washer

M4 Screw (20 mm)

Nut

Spring Washer

l

Plain Washer

O-ring

Base

Gasket

Pole Mounting (with base)

The pole mount type can be installed in four ways. The recommended mounting

method (pattern A from page 9 or 10) is described below.

Recommended tightening torque: 2.6 to 2.7 N·m (M5 screw)

M5 Screw

O-ring

Pole Stand

Gasket

Panel

Plain Washer

Spring Washer

Nut

4-M5

Mounting

Hole

Pole Stand

4-M4 Mounting Hole

3-M4 Mounting Hole

4-M5 Mounting Hole

(recommended)

Pole Mounting (with L-shaped bracket)

1. Using L-shaped bracket

Recommended tightening torque: 10 to 11 N·m (M10)

Recommended tightening torque: 25 to 26 N·m (M22)

2. Not using L-shaped bracket

Remove the bushing, hexagonal nut (M22), plain washer, and L-shaped

bracket from the LD6A and install in the following order: plain washer, hexagonal nut (M22), and bushing.

Recommended tightening torque: 25 to 26 N·m (M22)

1. Using L-shaped bracket 2. Not using L-shaped bracket

∗

The parts marked with * are not supplied and should be provided by the user.

Hexagonal

nut∗

(M10)

Spring washer

Plain washer∗

Plain washer

Hexagonal nut

(M22)

Bushing

Replacement and Addition of LED Modules

• Make sure to turn power off.

• Insert a at screwdriver into the cap recess as shown below, lift up the cap,

and remove with your hands. Use a at screwdriver with maximum 1-mm

thick and 7-mm wide tip.

• Remove the center screw before reassembling the LED modules.

• When assembling the LED modules, make sure to align the recess of the cap

with the recess of the LED module. Otherwise, damage may result.

Recommended tightening torque: 0.4 to 0.5 N·m.

Recess

1

2

3

LED module

Recess

Gasket

Recess

• Note the correct orientation when assembling the LED modules.

• Tighten the screws to the recommended tightening torque. The LED module

may be damaged if the screw is loose during operation.

• Do not touch the metal plug on the LED module. Otherwise, LED elements

maybe damaged due to static electricity.

• Use a maximum of 5 tiers.

• Select the correct screw length depending on the number of tiers.

• Do not remove the gasket from the LED module. Otherwise, the waterproof

seal will be compromised.

Wiring

• For wiring, see the wiring diagrams on pages 782 and 784.

• Incorrect wiring may damage the internal circuit.

• Be sure to insulate unused wires.

• Connect a 1A fuse to the power line as shown in the Wiring Examples on

pages 782 and 784.

• Use a UL listed external fuse holder.

• Use a class 2 power supply only.

• When using LED modules of the same color for two or more tiers, determine

contact capacity in referencet to the LED current, because only one wire is

used to light all tiers of the same color.

• Do not apply voltage to ashing (brown) lines.

• Do not connect ashing (brown) line to the power lines. The internal circuit

may be damaged.

• Do not turn on steady and ashing circuits simultaneously.

• Do not turn on alarms 1 and 2 simultaneously.

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

1607302105

785

Page 9

LD6A

Wire Color

Wire Color Steady Steady, Flashing, Alarm

Red LED Module – Red LED Module – Red

Orange LED Module – Yellow LED Module – Yellow

Blue LED Module – Blue LED Module – Blue

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

Green LED Module – Green LED Module – Green

White LED Module – White LED Module – White

Purple — Alarm 1

Light Blue — Alarm 2

Brown — Flashing COM

Gray — Power Line

Yellow Power Line Power Line

For information on external contacts, see “External Contact Ratings” on page 781.

Alarm Volume Adjustment

• Move the volume adjustment to the right or left to change the volume.

• When the adjustment lever is all the way to the right the volume is at its

maximum.

• The adjustment lever may be damaged if forced open or closed.

Signaling Lights

Alarm volume

adjustment lever

Min.

Max.

High Temperature Limitations

The external temperature cannot exceed 50ºC when all tiers are lit at the same

time in the following combinations:

1. Three tiers

Two or more tiers of blue and green (example: Red-Green-Blue,

Green-Green-Red)

2. Four or ve tiers (example: Red-Yellow-Green-White, Red-Yellow-Blue-GreenWhite)

786

1607302105

Loading...

Loading...