Page 1

ø22mm

YW Series Switches & Pilot Lights

Page 2

Innovative Design, Space-Saving, Safety,

and Self-Cleaning Contacts

Emergency Stop Switches

Satisfy International Standards

• Safety Lock Mechanism

When the emergency stop signal has been generated during actuation of the emergency stop

device, the emergency stop function shall be maintained until the emergency stop device is

reset (disengaged)

(IEC 60947-5-5, 6.2).

• Direct Opening Action

Even if the contacts are welded, NC contacts are forced to open and break the circuit

(compliant to IEC 60947-5-1, Annex K, IEC 60947-5-5, 5.2).

Non-illuminated Illuminated

• Safe Pushbutton Design

The pushbutton is designed to ensure that an object cannot become trapped between the

mushroom button and the panel, disabling the button operation. In addition, the pushbutton is

designed to prevent removal from the front of the panel (IEC 60947-5-5, 6.3.2).

Easy Operation

• Push-to-lock, Pull/Turn-to-release

YW emergency stop switches can be unlatched by either

pulling or turning the operator.

Unibody Pilot Lights

Higher Brightness

Unibody pilot lights achieve high brightness.

Short Depth behind the Panel

Measures only 42mm depth behind the panel.

Four Lens Shapes

Flush, ush with marking, extended, and dome.

Panel Mounting

Unibody pilot lights can be mounted on panels by

tightening the locking ring.

Unlatching by pulling Unlatching by turning

Dome

Extended

Flush

w/marking

Key Selector Switches

Plastic Bezel

Metal Bezel

Flush

A variety of operations, key removal positions,

and circuits.

Wide range adds more options to choose from.

Page 3

Safety

Save

YW

series

Safety

Integrated Finger-safe Terminal Cover

Degree of Protection: IP20

(From panel front: IP65)

Save

New Contact Block Design

YW series

Reliable

Metal bezels are available for

pushbuttons, illuminated

pushbuttons, selector switches,

and key selector switches.

CB

FA

CB

1515

30

The contact block design reduces the depth

behind the panel.

CB FA CB

1010

10

30

CB: Contact block

FA: Full-voltage

adapter

Retained Locking Lever

Lock Unlock

An innovative plastic locking lever is retained and

eliminates the need for a separate lever lock.

Reliable

Heavy-Duty Rugged Construction

Self-Cleaning Wiping-Action Contacts with Scored

Contact Surfaces

Spring

Scored Surface

Movable

Contact

Stationary

Contact

(1) Normal State

(2) Wiping

(3) Fully Depressed

Page 4

YW Series Switches & Pilot Lights

•

•

•

•

•

•

Space-saving, 10-mm-thick contact blocks. Removable operator.

•Compact and light-weight

IP20 nger-safe screw terminals (IEC 60529)

Emergency stop switches feature safety lock mechanism, direct opening

action, and safe pushbutton design.

Separate contact block makes installation and removal easy.

Pilot lights feature a large lens for a wide viewing angle.

Matted surfaces on the buttons, lenses, and bezels reduce reection of

ambient light.

UL, c-UL listed, EN compliant, and CCC approved.

UL508, CSA C22.2 No. 14, EN 60947-1, EN 60947-5-1,

EN 60947-5-5, GB 14048.5

Contact Ratings (Contact Block)

Rated Insulation Voltage 600V

Rated Thermal Current 10A

Operating Voltage 24V 120V 240V 380V

AC

50/60 Hz

DC

Resistive Load (AC-12) 10A 10A 6A 2A

Inductive Load (AC-15) 10A 6A 3A 1.9A

Resistive Load (DC-12) 8A 2.2A 1.1A –

Inductive Load (DC-13) 4A 1.1A 0.55A –

(Emergency

Stop Switch)

LED Illuminated Unit Specifications

Pilot Light (removable lamp terminal type)

Illuminated Pushbutton

Unit LED Lamp

Unit Type Input Type Rated Voltage Operating Voltage Color Code

6V AC/DC

Pilot Light

(removable

lamp

terminal type)

Illuminated

Pushbutton

Note: Yellow LED lamps are used for white illumination.

Full Voltage

Transformer

(pilot light

only)

50/60 Hz

12V AC/DC

24V AC/DC

110V AC/DC

230/240V AC/DC 207 to 250V AC/DC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

100/110V AC

200/220V AC

115/120V AC

207 to 250V AC

±10%

±10%

A: amber

G: green

PW: pure white

R: red

S: blue

W: white (Note)

Y: yellow

Pilot Light (unibody type)

Unit Type Rated Voltage Operating Voltage Current Draw Color Code

6V AC/DC 6V AC/DC

Pilot Light

(unibody type)

12V AC/DC 12V AC/DC 20mA

24V AC/DC 24V AC/DC 20mA

100/110V AC (50/60 Hz sine wave) 100/110V AC 20mA

230/240V AC (50/60 Hz sine wave) 230/240V AC 207 to 250V AC 20mA

±10%

Lamp

Base

BA9S/13

16mA (A, R, W, Y)

13mA (G, PW, S)

Part No. Rated Voltage Current Draw Color

LSED-6

LSED-1

LSED-2

LSED-H

LSED-M3

LSED-6

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

230/240V AC/DC

6V AC/DC

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

10mA (A, R, Y)

7mA (G, PW, S)

14mA (A, R, Y)

13mA (G, PW, S)

14mA (A, R, Y)

13mA (G, PW, S)

5mA

3mA

10mA (A, R, Y)

7mA (G, PW, S)

A: amber

G: green

PW: pure white

R: red

S: blue

Y: yellow

Incandescent Illuminated Unit Specifications

Pilot Light (removable lamp terminal type)

Illuminated Pushbutton

Unit Incandescent Lamp

Unit Type Input Type Rated Voltage Operating Voltage Color Code Lamp Base Part No. Rating

(Pilot Light

(removable lamp

terminal type)

Illuminated

Pushbutton

Full Voltage

Transformer

(pilot light

only)

50/60 Hz

6V AC/DC 6V AC/DC

12V AC/DC 12V AC/DC LS-T8 1W (18V)

24V AC/DC 24V AC/DC LS-T3 1W (30V)

100/110V AC 100/110V AC

200/220V AC 200/220V AC

115/120V AC 115/120V AC

230/240V AC 207 to 250V AC

±10%

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

BA9S/13

LS-T6 1W (6.3V)

LS-T6 1W (6.3V)

4

Page 5

YW Series

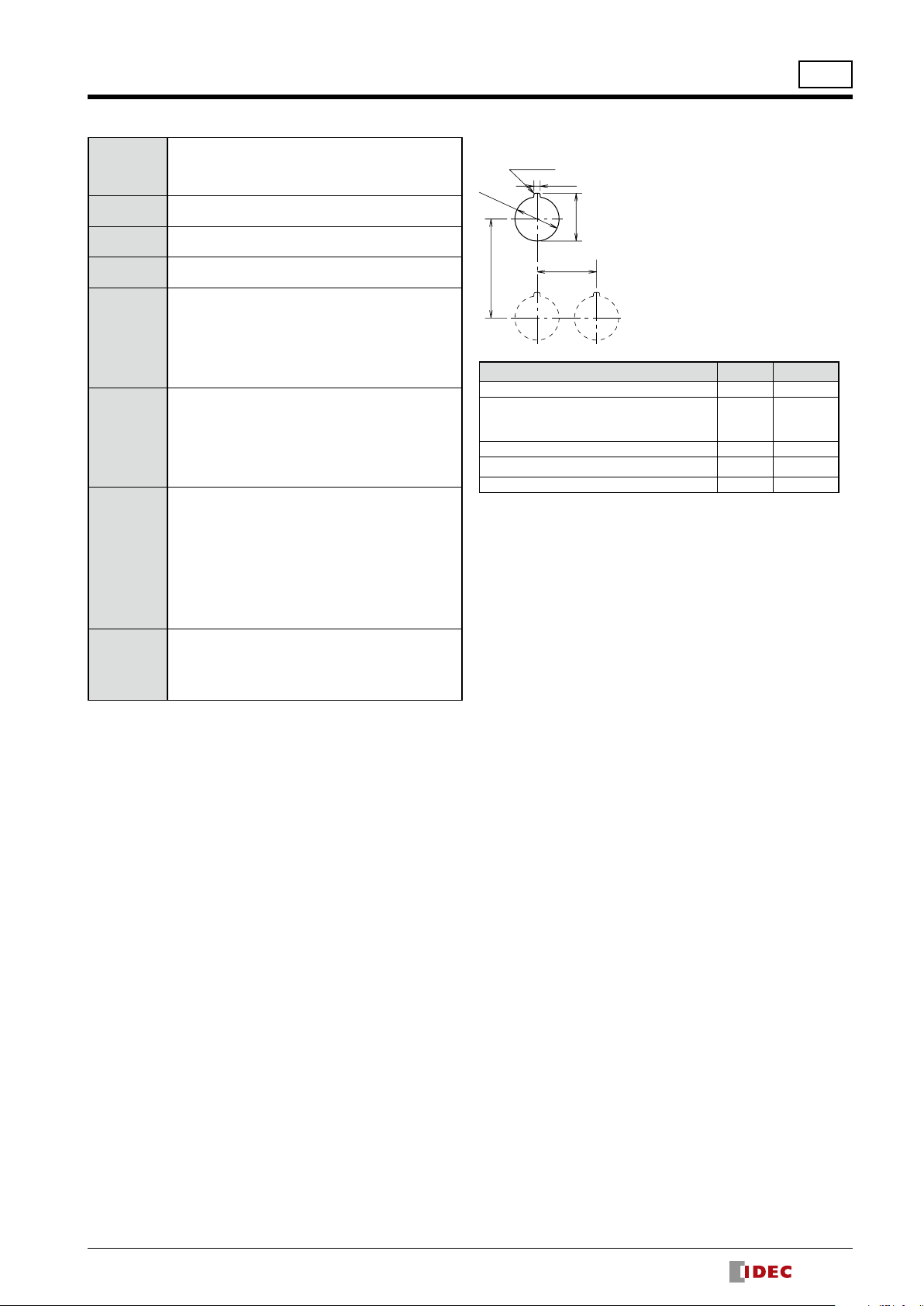

R0.8 max.

when the anti-rotation

ø22

Specifications

Operating

Conditions

Degree of

Protection

Insulation

Resistance

Dielectric

Strength

Vibration

Resistance

Shock

Resistance

Mechanical

Life (minimum

operations)

Electrical Life

(minimum

operations)

Operating temperature: –20 to +55°C (no freezing)

Operating humidity: 45 to 85% RH (no condensation)

Storage temperature: –45 to +80°C

Storage humidity: 95% RH maximum

From panel front: IP65 (IEC 60529)

Terminal: IP20 (IEC 60529)

100 MΩ

Contact block: 2,500V, 1 minute

Pilot light: 2,000V, 1 minute

<Emergency stop switch>

Operating extremes / Damage limits:

10 to 500 Hz, amplitude 0.35 mm. acceleration 50 m/s

<Pushbutton, pilot light, illluminated pushbutton, selector

switch, and key selector switch>

Operating extremes: 5 to 55 Hz, amplitude 0.5 mm

Damage limits: 30 Hz, amplitude 1.5 mm

<Emergency stop switch>

Operating extremes: 150 m/s

Damage limits: 1,000 m/s2 (100G)

<Pushbutton, pilot light, illluminated pushbutton, selector

switch, and key selector switch>

Operating extremes: 100 m/s2 (10G)

Damage limits: 1,000 m/s2 (100G)

<Emergency stop switch>

250,000 (single contact block)

<Pushbutton and illuminated pushbutton>

Momentary: 5,000,000 (single contact block)

1,000,000 (double contact block)

Maintained: 250,000 (single contact block)

100,000 (double contact block)

<Selector switch and key selector switch>

250,000 (single contact block)

100,000 (double contact block)

<Emergency stop switch>

100,000 (single contact block)

<Pushbutton, selector switch, and key selector switch>

100,000 (single contact block)

50,000 (double contact block)

2

(10G)

2

(5G)

Mounting Hole Layout

The 3.2-mm-wide key recess

+0.2

ø22.3

3.2

+0.4

0

A

Emergency stop switch 50 min. 50 min.

Pushbutton

Selector switch

Key selector switch

Mushroom pushbutton 50 min. 40 min.

Pilot light (with removable lamp terminal)

Pilot light (unibody) 50 min. 30 min.

∗ Keep a minimum spacing of 50 mm when using a lamp of over 1W.

is necessary

0

ring is used.

0

+0.4

24.1

B

Unit A (mm) B (mm)

50 min. 30 min.

30 min.∗

30 min.

5

Page 6

ø22

28.6

30

ø40

M3.5 Terminal Screw

Contact Block

101010

Panel Thickness 0.8 to 6

32.545.8

Locking Ring

Gasket

41.4

28.6

101010

30

ø40

M3.5 Terminal Screw

M3.5 Terminal Screw

Full-Voltage Adapter

Contact Block

Locking Ring

Panel Thickness 0.8 to 6

45.8

32.5

Gasket

41.4

YW Series Emergency Stop Switches

Emergency Stop Switches (Pushlock Pull/Turn Reset)

Contact Block Mounting Position

1 2 3

ø40mm Mushroom

Style Contact

1NC — — NC YW1B-V4E01R

2NC NC — NC YW1B-V4E02R

Package Quantity: 1

Part No. Button Color Code

3NC NC NC NC YW1B-V4E03R

1NO-1NC NO — NC YW1B-V4E11R

1NO-2NC NO NC NC YW1B-V4E12R

2NO-1NC NO NC NO YW1B-V4E21R

• When pressed, the button is locked in the depressed position, and is reset when either pulled or turned clockwise.

Dimensions

Illuminated Emergency Stop Switches (Pushlock Pull/Turn Reset)

Contact Block Mounting

Style Lamp Contacts

ø40mm Mushroom

Without

Lamp

1NC — FA NC

2NC NC FA NC

1NO-1NC NO FA NC

1NC — FA NC

LED

2NC NC FA NC

1NO-1NC NO FA NC

1NC — FA NC

Incandescent

2NC NC FA NC

1NO-1NC NO FA NC

• Specify an operating voltage code in place of

in the Part No. FA: Full voltage adapter

➂

• When pressed, the button is locked in the depressed position, and is reset when either pulled or turned clockwise.

Dimensions

Position

1 2 3

Part No.

YW1L-V4E01Q0R

YW1L-V4E02Q0R

YW1L-V4E11Q0R

YW1L-V4E01Q

YW1L-V4E02Q

YW1L-V4E11Q

YW1L-V4E01Q

YW1L-V4E02Q

YW1L-V4E11Q

Contact Block Mounting Position

➂

Voltage Code

0: without lamp

250V AC/DC max.

2: 6V AC/DC

R

➂

➂

➂

➂

➂

➂

3: 12V AC/DC

4: 24V AC/DC

R

H: 110V AC/DC

R

M3: 230/240V AC/DC

R

5: 6V AC/DC

6: 12V AC/DC

R

7: 24V AC/DC

R

Contact Block Mounting Position

3

2

1

Operating

2

1

Red only

Package Quantity: 1

Lens Color

Code

Red only

3

6

Page 7

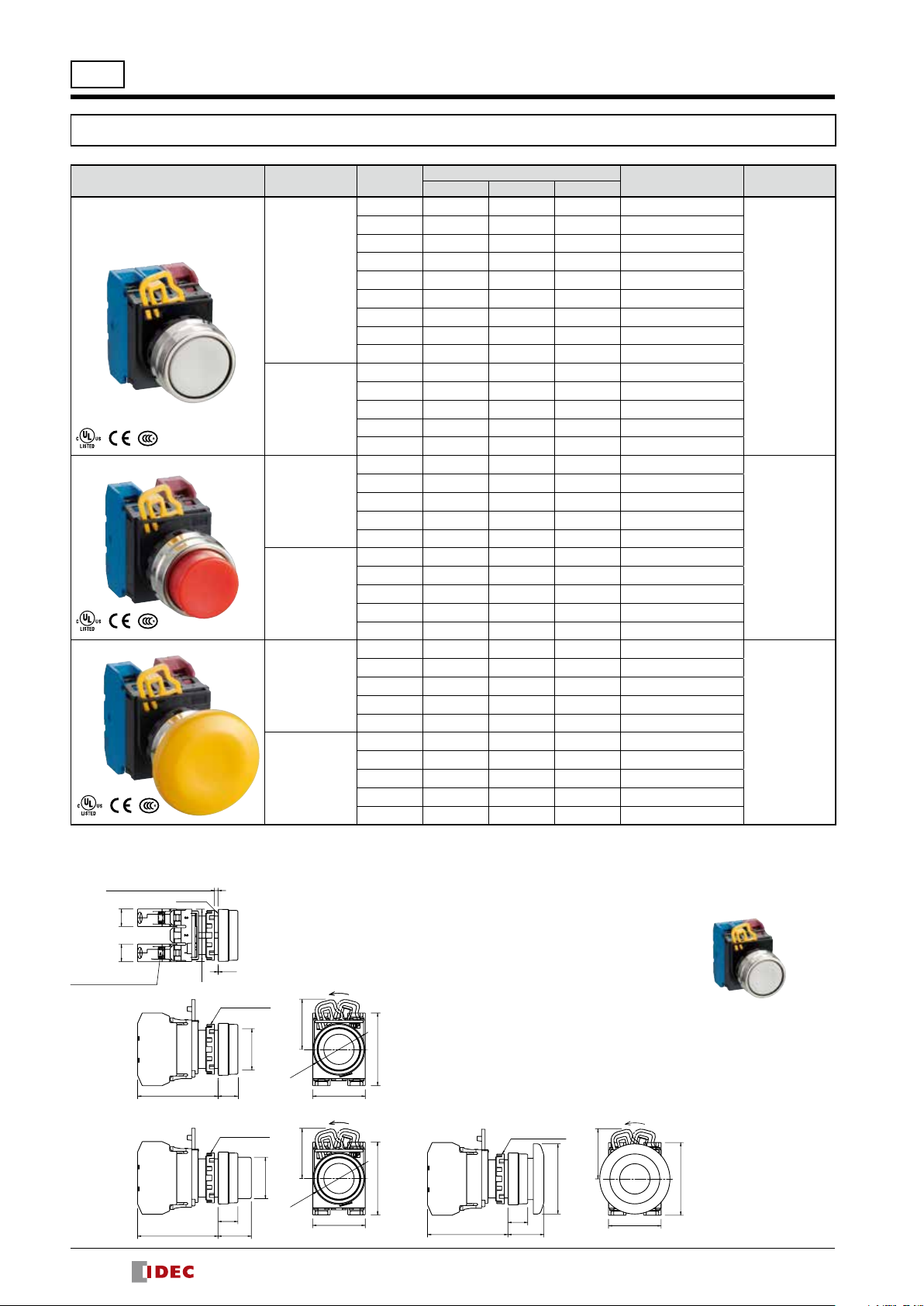

Pushbuttons with Plastic Bezel

Contact Block

M3.5

Panel Thickness: 0.8 to 6

Shape Operation Contact

Flush

Momentary

Maintained

Extended

Momentary

Maintained

Mushroom ø40mm

Momentary

Maintained

Note: Specify a button color code in place of ➀ in the Part No.

YW Series Pushbuttons

Contact Block Mounting Position

1 2 3

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

3NO NO NO NO

3NC NC NC NC

2NO-1NC NO NC NO

1NO-2NC NO NC NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

Part No.

YW1B-M1E10➀

YW1B-M1E01➀

YW1B-M1E20➀

YW1B-M1E02➀

YW1B-M1E11➀

YW1B-M1E30➀

YW1B-M1E03➀

YW1B-M1E21➀

YW1B-M1E12➀

YW1B-A1E10➀

YW1B-A1E01➀

YW1B-A1E20➀

YW1B-A1E02➀

YW1B-A1E11➀

YW1B-M2E10➀

YW1B-M2E01➀

YW1B-M2E20➀

YW1B-M2E02➀

YW1B-M2E11➀

YW1B-A2E10➀

YW1B-A2E01➀

YW1B-A2E20➀

YW1B-A2E02➀

YW1B-A2E11➀

YW1B-M4E10➀

YW1B-M4E01➀

YW1B-M4E20➀

YW1B-M4E02➀

YW1B-M4E11➀

YW1B-A4E10➀

YW1B-A4E01➀

YW1B-A4E20➀

YW1B-A4E02➀

YW1B-A4E11➀

ø22

Package Quantity: 1

Button Color

➀

Code

B: black

G: green

R: red

S: blue

W: white

Y: yellow

B: black

G: green

R: red

S: blue

W: white

Y: yellow

B: black

G: green

R: red

S: blue

W: white

Y: yellow

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

Dimensions

Terminal Screw

Flush

Extended

Gasket

10 10

45.811

45.8

0.5

Locking Ring

ø23.6

11

19

28.6

ø29

(Button Diameter)

28.6

ø23.6

ø29

(Button Diameter)

Lock

41.4

30

Mushroom

41.4

30

45.8

ø40

11

20.5

(Button Diameter)

Contact Block Mounting Position

28.6

41.4

30

3

2

1

All dimensions in mm.

7

Page 8

ø22

Contact Block

M3.5

Panel Thickness: 0.8 to 6

YW Series Pushbuttons

Pushbuttons with Metal Bezel

Shape Operation Contact

Flush

Momentary

Maintained

Extended

Momentary

Maintained

Mushroom ø40mm

Momentary

Maintained

Note: Specify a button color code in place of ➀ in the Part No.

Contact Block Mounting Position

1 2 3

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

3NO NO NO NO

3NC NC NC NC

2NO-1NC NO NC NO

1NO-2NC NO NC NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

1NO NO — —

1NC — — NC

2NO NO — NO

2NC NC — NC

1NO-1NC NO — NC

Part No.

YW4B-M1E10➀

YW4B-M1E01➀

YW4B-M1E20➀

YW4B-M1E02➀

YW4B-M1E11➀

YW4B-M1E30➀

YW4B-M1E03➀

YW4B-M1E21➀

YW4B-M1E12➀

YW4B-A1E10➀

YW4B-A1E01➀

YW4B-A1E20➀

YW4B-A1E02➀

YW4B-A1E11➀

YW4B-M2E10➀

YW4B-M2E01➀

YW4B-M2E20➀

YW4B-M2E02➀

YW4B-M2E11➀

YW4B-A2E10➀

YW4B-A2E01➀

YW4B-A2E20➀

YW4B-A2E02➀

YW4B-A2E11➀

YW4B-M4E10➀

YW4B-M4E01➀

YW4B-M4E20➀

YW4B-M4E02➀

YW4B-M4E11➀

YW4B-A4E10➀

YW4B-A4E01➀

YW4B-A4E20➀

YW4B-A4E02➀

YW4B-A4E11➀

Package Quantity: 1

Button Color

➀

Code

B: black

G: green

R: red

S: blue

W: white

Y: yellow

B: black

G: green

R: red

S: blue

W: white

Y: yellow

B: black

G: green

R: red

S: blue

W: white

Y: yellow

Dimensions

Terminal Screw

Flush

Extended

8

Gasket

10 10

45.819

29.8

0.3

Locking Ring

11.345.8

Locking Ring

11.3

ø23.6

(Button Diameter)

ø23.6

(Button Diameter)

ø29.5

ø29.5

28.6

28.6

Lock

Lock

41.4

30

Mushroom

41.4

30

45.8

Locking Ring

11.3

20.5

ø40

(Button Diameter)

Lock

28.6

41.4

30

3

2

1

All dimensions in mm.

Contact Block Mounting Position

Page 9

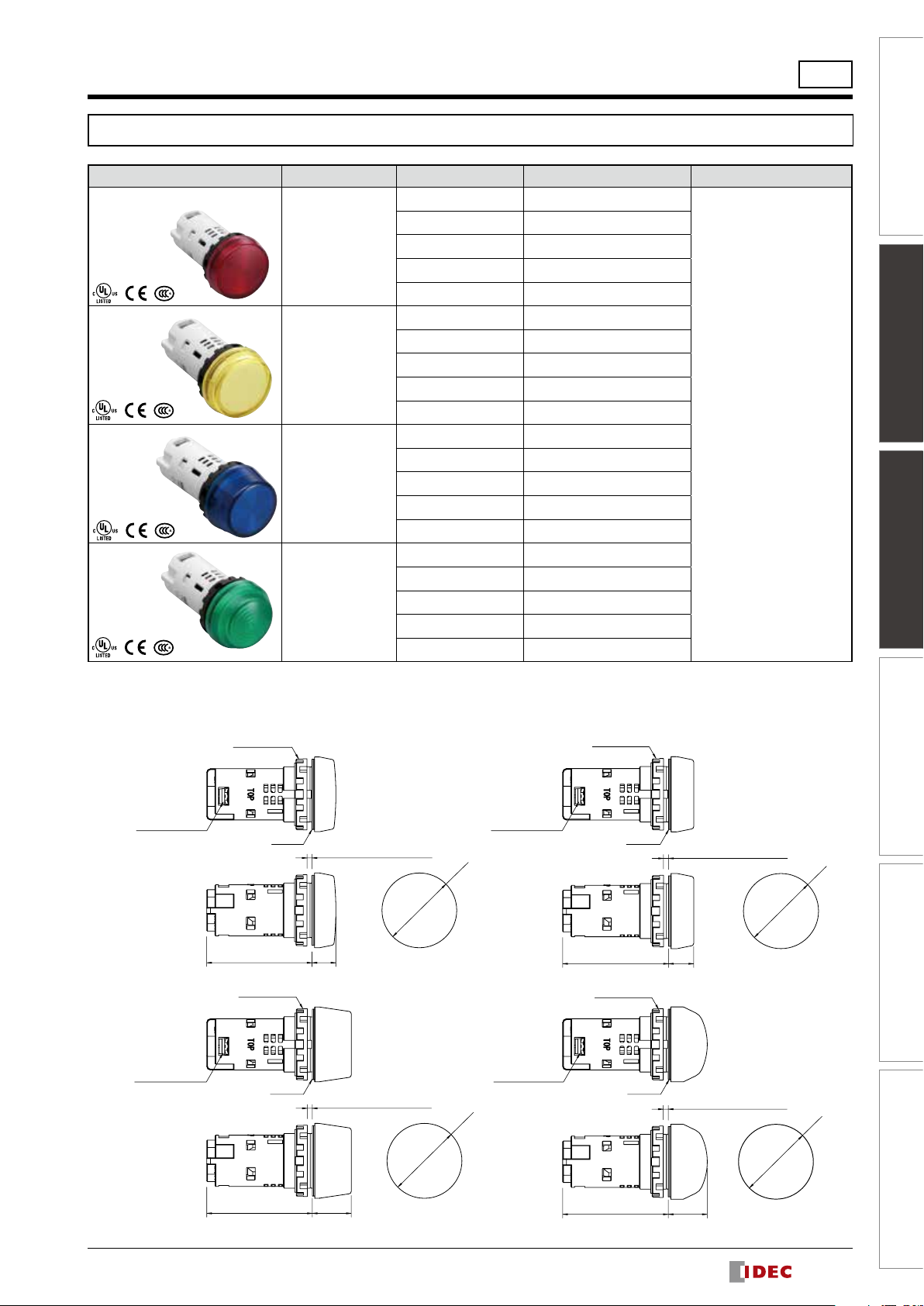

Pilot Lights (Unibody)

Flush

ø29.8

Extended

Flush Marking

Shape Lamp Operating Voltage Part No.

Flush

Full Voltage

Flush Marking

Full Voltage

Extended

Full Voltage

Dome

Full Voltage

LED

LED

LED

LED

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

230/240V AC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

230/240V AC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

230/240V AC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

230/240V AC

YW Series Pilot Lights

YW1P-1UQ2➁

YW1P-1UQ3➁

YW1P-1UQ4➁

YW1P-1UQH➁

YW1P-1UQM3➁

YW1P-1BUQ2➁

YW1P-1BUQ3➁

YW1P-1BUQ4➁

YW1P-1BUQH➁

YW1P-1BUQM3➁

YW1P-2TUQ2➁

YW1P-2TUQ3➁

YW1P-2TUQ4➁

YW1P-2TUQH➁

YW1P-2TUQM3➁

YW1P-2UQ2➁

YW1P-2UQ3➁

YW1P-2UQ4➁

YW1P-2UQH➁

YW1P-2UQM3➁

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Package Quantity: 1

Lens Color Code

➁

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

Dimensions

M3.5

Terminal Screw

M3.5

Terminal Screw

Locking Ring

Gasket

42.0 9.5

Locking Ring

Gasket

Panel Thickness 0.8 to 6

Panel Thickness 0.8 to 6

ø29.8

ø29.8

M3.5

Terminal Screw

Dome

M3.5

Terminal Screw

Locking Ring

Gasket

Locking Ring

Gasket

Panel Thickness 0.8 to 6

1042.0

Panel Thickness 0.8 to 6

ø29.8

15.542.0

15.542.0

All dimensions in mm.

9

Page 10

ø22

YW Series Pilot Lights

Pilot Lights (with Removable Lamp Terminal)

Shape Lamp Operating Voltage Part No.

Flush

Full Voltage

Flush

Transformer

Flush Marking

Full Voltage

Flush Marking

Transformer

Note: Specify a lens color code in place of ➁ in the Part No.

Clear lenses are used for PW (pure white) illumination of pilot lights.

Without Lamp 250V AC/DC max.

LED

230/240V AC/DC

Incandescent

LED

Incandescent

Without Lamp 250V AC/DC max.

LED

230/240V AC/DC

Incandescent

LED

Incandescent

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

YW1P-1EQ0➁

YW1P-1EQ2➁

YW1P-1EQ3➁

YW1P-1EQ4➁

YW1P-1EQH➁

YW1P-1EQM3➁

YW1P-1EQ5➁

YW1P-1EQ6➁

YW1P-1EQ7➁

YW1P-1EH2➁

YW1P-1EM2➁

YW1P-1EH22➁

YW1P-1EM42➁

YW1P-1EH5➁

YW1P-1EM5➁

YW1P-1EH25➁

YW1P-1EM45➁

YW1P-1BEQ0➁

YW1P-1BEQ2➁

YW1P-1BEQ3➁

YW1P-1BEQ4➁

YW1P-1BEQH➁

YW1P-1BEQM3➁

YW1P-1BEQ5➁

YW1P-1BEQ6➁

YW1P-1BEQ7➁

YW1P-1BEH2➁

YW1P-1BEM2➁

YW1P-1BEH22➁

YW1P-1BEM42➁

YW1P-1BEH5➁

YW1P-1BEM5➁

YW1P-1BEH25➁

YW1P-1BEM45➁

Package Quantity: 1

Lens Color Code

➁

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-➂

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

Built-in incandescent lamp: LS-T➂

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-6

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

Built-in incandescent lamp: LS-T6

A (amber), G (green), R (red),

S (blue), W (white), Y (yellow)

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-➂

A (amber), G (green), R (red),

S (blue), W (white), Y (yellow)

Built-in incandescent lamp: LS-T➂

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-6

A (amber), G (green), R (red),

S (blue), W (white), Y (yellow)

Built-in incandescent lamp: LS-T6

➁

➁

➁

➁

10

Page 11

YW Series Pilot Lights

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

Shape Lamp Operating Voltage Part No.

Extended

Full Voltage

Extended

Transformer

Dome

Full Voltage

Dome

Transformer

Note: Specify a lens color code in place of ➁ in the Part No.

Clear lenses are used for PW (pure white) illumination of pilot lights.

Without Lamp 250V AC/DC max.

LED

230/240V AC/DC

Incandescent

LED

Incandescent

Without Lamp 250V AC/DC max.

LED

230/240V AC/DC

Incandescent

LED

Incandescent

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

6V AC/DC

12V AC/DC

24V AC/DC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

100/110V AC

200/220V AC

115/120V AC

230/240V AC

YW1P-2TEQ0➁

YW1P-2TEQ2➁

YW1P-2TEQ3➁

YW1P-2TEQ4➁

YW1P-2TEQH➁

YW1P-2TEQM3➁

YW1P-2TEQ5➁

YW1P-2TEQ6➁

YW1P-2TEQ7➁

YW1P-2TEH2➁

YW1P-2TEM2➁

YW1P-2TEH22➁

YW1P-2TEM42➁

YW1P-2TEH5➁

YW1P-2TEM5➁

YW1P-2TEH25➁

YW1P-2TEM45➁

YW1P-2EQ0➁

YW1P-2EQ2➁

YW1P-2EQ3➁

YW1P-2EQ4➁

YW1P-2EQH➁

YW1P-2EQM3➁

YW1P-2EQ5➁

YW1P-2EQ6➁

YW1P-2EQ7➁

YW1P-2EH2➁

YW1P-2EM2➁

YW1P-2EH22➁

YW1P-2EM42➁

YW1P-2EH5➁

YW1P-2EM5➁

YW1P-2EH25➁

YW1P-2EM45➁

Lens Color Code

➁

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-➂➁

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

Built-in incandescent lamp: LS-T➂

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-6➁

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

Built-in incandescent lamp: LS-T6

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-➂➁

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

Built-in incandescent lamp: LS-T➂

A (amber), G (green),

PW (pure white), R (red),

S (blue), W (white), Y (yellow)

Built-in LED lamp: LSED-6➁

A (amber), C (clear),

G (green), R (red), S (blue),

W (white), Y (yellow)

Built-in incandescent lamp: LS-T6

11

Page 12

ø22

M3.5

Panel Thickness 0.8 to 6

Panel Thickness 0.8 to 6

YW Series Pilot Lights

Dimensions (Pilot Lights with Removable Lamp Terminal)

Flush

Full Voltage

M3.5 Terminal Screw

Transformer

Terminal Screw

Gasket

Locking Ring

46.29.5

Panel Thickness 0.8 to 6

Gasket

Locking Ring

29.6

ø29.8

ø29.8

Flush Marking

Full Voltage

M3.5 Terminal Screw

24

Gasket

Locking Ring

46.2 10

ø29.8

24

29.6

Transformer

Panel Thickness 0.8 to 6

M3.5 Terminal Screw

24

Gasket

Locking Ring

ø29.8

24

Extended

Full Voltage

M3.5 Terminal Screw

Transformer

M3.5 Terminal Screw

63.3

Panel Thickness 0.8 to 6

Gasket

Locking Ring

46.2

Panel Thickness 0.8 to 6

Gasket

Locking Ring

9.5

15.5

29.6

29.6

ø29.8

ø29.8

63.3

10

29.6

Dome

Full Voltage

M3.5 Terminal Screw

24

Panel Thickness 0.8 to 6

Gasket

Locking Ring

46.2

15.5

ø29.8

24

29.6

Transformer

Panel Thickness 0.8 to 6

M3.5 Terminal Screw

Gasket

Locking Ring

ø29.8

12

63.3

15.5

29.6

24

63.3

15.5

29.6

24

Page 13

YW Series Illuminated Pushbuttons

ø22

Illuminated Pushbuttons with Plastic Bezel

Package Quantity: 1

Contact Block Mounting

Shape Lamp Operation Contact

Extended

Momentary

Without

Lamp

Maintained

Momentary

LED

Maintained

Momentary

Incandescent

Maintained

Extended with

Full Shroud

Momentary

Without

Lamp

Maintained

Momentary

LED

Maintained

Momentary

Incandescent

Maintained

Note: Specify a lens color code in place of ➁ in the Part No. FA: Full voltage adapter

Specify an operating voltage code in place of ➂ in the Part No.

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

Position

1 2 3

Part No.

YW1L-M2E10Q0➁

YW1L-M2E01Q0➁

YW1L-M2E20Q0➁

YW1L-M2E02Q0➁

YW1L-M2E11Q0➁

YW1L-A2E10Q0➁

YW1L-A2E01Q0➁

YW1L-A2E20Q0➁

YW1L-A2E02Q0➁

YW1L-A2E11Q0➁

YW1L-M2E10Q➂➁

YW1L-M2E01Q➂➁

YW1L-M2E20Q➂➁

YW1L-M2E02Q➂➁

YW1L-M2E11Q➂➁

YW1L-A2E10Q➂➁

YW1L-A2E01Q➂➁

YW1L-A2E20Q➂➁

YW1L-A2E02Q➂➁

YW1L-A2E11Q➂➁

YW1L-M2E10Q➂➁

YW1L-M2E01Q➂➁

YW1L-M2E20Q➂➁

YW1L-M2E02Q➂➁

YW1L-M2E11Q➂➁

YW1L-A2E10Q➂➁

YW1L-A2E01Q➂➁

YW1L-A2E20Q➂➁

YW1L-A2E02Q➂➁

YW1L-A2E11Q➂➁

YW1L-MF2E10Q0➁

YW1L-MF2E01Q0➁

YW1L-MF2E20Q0➁

YW1L-MF2E02Q0➁

YW1L-MF2E11Q0➁

YW1L-AF2E10Q0➁

YW1L-AF2E01Q0➁

YW1L-AF2E20Q0➁

YW1L-AF2E02Q0➁

YW1L-AF2E11Q0➁

YW1L-MF2E10Q➂➁

YW1L-MF2E01Q➂➁

YW1L-MF2E20Q➂➁

YW1L-MF2E02Q➂➁

YW1L-MF2E11Q➂➁

YW1L-AF2E10Q➂➁

YW1L-AF2E01Q➂➁

YW1L-AF2E20Q➂➁

YW1L-AF2E02Q➂➁

YW1L-AF2E11Q➂➁

YW1L-MF2E10Q➂➁

YW1L-MF2E01Q➂➁

YW1L-MF2E20Q➂➁

YW1L-MF2E02Q➂➁

YW1L-MF2E11Q➂➁

YW1L-AF2E10Q➂➁

YW1L-AF2E01Q➂➁

YW1L-AF2E20Q➂➁

YW1L-AF2E02Q➂➁

YW1L-AF2E11Q➂➁

Operating

➂

Voltage Code

0: without lamp

250V AC/DC max.

2: 6V AC/DC

3: 12V AC/DC

4: 24V AC/DC

H: 110V AC/DC

M3: 230/240V

AC/DC

5: 6V AC/DC

6: 12V AC/DC

7: 24V AC/DC

0: without lamp

250V AC/DC max.

2: 6V AC/DC

3: 12V AC/DC

4: 24V AC/DC

H: 110V AC/DC

M3: 230/240V

AC/DC

5: 6V AC/DC

6: 12V AC/DC

7: 24V AC/DC

Lens Color Code

➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Built-in LED lamp:

LSED-➂➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

Built-in

incandescent

lamp:

LS-T

➂

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Built-in LED lamp:

LSED-➂➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

Built-in

incandescent

lamp:

LS-T➂

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

13

Page 14

ø22

Panel Thickness: 0.8 to 6

Extended

Mushroom

All dimensions in mm.

M3.5

Contact Block

M3.5

Full-voltage

YW Series Illuminated Pushbuttons

Shape Lamp Operation Contact

Mushroom ø40mm

Without

Lamp

LED

Incandescent

Momentary

Maintained

Momentary

Maintained

Momentary

Maintained

Contact Block Mounting

Position

1 2 3

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

Part No.

YW1L-M4E10Q0➁

YW1L-M4E01Q0➁

YW1L-M4E20Q0➁

YW1L-M4E02Q0➁

YW1L-M4E11Q0➁

YW1L-A4E10Q0➁

YW1L-A4E01Q0➁

YW1L-A4E20Q0➁

YW1L-A4E02Q0➁

YW1L-A4E11Q0➁

YW1L-M4E10Q➂➁

YW1L-M4E01Q➂➁

YW1L-M4E20Q➂➁

YW1L-M4E02Q➂➁

YW1L-M4E11Q➂➁

YW1L-A4E10Q➂➁

YW1L-A4E01Q➂➁

YW1L-A4E20Q➂➁

YW1L-A4E02Q➂➁

YW1L-A4E11Q➂➁

YW1L-M4E10Q➂➁

YW1L-M4E01Q➂➁

YW1L-M4E20Q➂➁

YW1L-M4E02Q➂➁

YW1L-M4E11Q➂➁

YW1L-A4E10Q➂➁

YW1L-A4E01Q➂➁

YW1L-A4E20Q➂➁

YW1L-A4E02Q➂➁

YW1L-A4E11Q➂➁

Operating

➂

Voltage Code

0: without lamp

250V AC/DC max.

2: 6V AC/DC

3: 12V AC/DC

4: 24V AC/DC

H: 110V AC/DC

M3: 230/240V

AC/DC

5: 6V AC/DC

6: 12V AC/DC

7: 24V AC/DC

Lens Color

➁

Code

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Built-in LED

lamp:

LSED-➂➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

Built-in

incandescent

lamp:

LS-T➂

Note: Specify a lens color code in place of ➁ in the Part No. FA: Full voltage adapter

Specify an operating voltage code in place of ➂ in the Part No.

Dimensions

(Illuminated Pushbuttons with Plastic Bezel)

Terminal Screw

Adapter

10 1010

Terminal Screw

45.8

45.8

Gasket

0.5

ø23.6

(Lens Diameter)

11

19

ø40

(Lens Diameter)

11

20.5

28.628.6

ø29

Contact Block Mounting Position

3

2

1

41.441.4

30

Extended with Full Shroud

28.6

41.4

ø28.2

30

45.8

19

30

14

Page 15

YW Series Illuminated Pushbuttons

ø22

Illuminated Pushbuttons with Metal Bezel

Package Quantity: 1

Contact Block Mounting

Shape Lamp Operation Contact

Extended

Momentary

Without

Lamp

Maintained

Momentary

LED

Maintained

Momentary

Incandescent

Maintained

Extended with

Full Shroud

Momentary

Without

Lamp

Maintained

Momentary

LED

Maintained

Momentary

Incandescent

Maintained

Note: Specify a lens color code in place of ➁ in the Part No. FA: Full voltage adapter

Specify an operating voltage code in place of ➂ in the Part No.

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

Position

1 2 3

Part No.

YW4L-M2E10Q0➁

YW4L-M2E01Q0➁

YW4L-M2E20Q0➁

YW4L-M2E02Q0➁

YW4L-M2E11Q0➁

YW4L-A2E10Q0➁

YW4L-A2E01Q0➁

YW4L-A2E20Q0➁

YW4L-A2E02Q0➁

YW4L-A2E11Q0➁

YW4L-M2E10Q➂➁

YW4L-M2E01Q➂➁

YW4L-M2E20Q➂➁

YW4L-M2E02Q➂➁

YW4L-M2E11Q➂➁

YW4L-A2E10Q➂➁

YW4L-A2E01Q➂➁

YW4L-A2E20Q➂➁

YW4L-A2E02Q➂➁

YW4L-A2E11Q➂➁

YW4L-M2E10Q➂➁

YW4L-M2E01Q➂➁

YW4L-M2E20Q➂➁

YW4L-M2E02Q➂➁

YW4L-M2E11Q➂➁

YW4L-A2E10Q➂➁

YW4L-A2E01Q➂➁

YW4L-A2E20Q➂➁

YW4L-A2E02Q➂➁

YW4L-A2E11Q➂➁

YW4L-MF2E10Q0➁

YW4L-MF2E01Q0➁

YW4L-MF2E20Q0➁

YW4L-MF2E02Q0➁

YW4L-MF2E11Q0➁

YW4L-AF2E10Q0➁

YW4L-AF2E01Q0➁

YW4L-AF2E20Q0➁

YW4L-AF2E02Q0➁

YW4L-AF2E11Q0➁

YW4L-MF2E10Q➂➁

YW4L-MF2E01Q➂➁

YW4L-MF2E20Q➂➁

YW4L-MF2E02Q➂➁

YW4L-MF2E11Q➂➁

YW4L-AF2E10Q➂➁

YW4L-AF2E01Q➂➁

YW4L-AF2E20Q➂➁

YW4L-AF2E02Q➂➁

YW4L-AF2E11Q➂➁

YW4L-MF2E10Q➂➁

YW4L-MF2E01Q➂➁

YW4L-MF2E20Q➂➁

YW4L-MF2E02Q➂➁

YW4L-MF2E11Q➂➁

YW4L-AF2E10Q➂➁

YW4L-AF2E01Q➂➁

YW4L-AF2E20Q➂➁

YW4L-AF2E02Q➂➁

YW4L-AF2E11Q➂➁

Operating

➂

Voltage Code

0: without lamp

250V AC/DC max.

2: 6V AC/DC

3: 12V AC/DC

4: 24V AC/DC

H: 110V AC/DC

M3: 230/240V

AC/DC

5: 6V AC/DC

6: 12V AC/DC

7: 24V AC/DC

0: without lamp

250V AC/DC max.

2: 6V AC/DC

3: 12V AC/DC

4: 24V AC/DC

H: 110V AC/DC

M3: 230/240V

AC/DC

5: 6V AC/DC

6: 12V AC/DC

7: 24V AC/DC

Lens Color Code

➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Built-in LED lamp:

LSED-➂➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

Built-in

incandescent

lamp:

LS-T➂

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Built-in LED lamp:

LSED-➂➁

A: amber

G: green

R: red

S: blue

W: white

Y: yellow

Built-in

incandescent

lamp:

LS-T➂

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

15

Page 16

ø22

ø40

20.5

11.3

45.8

Locking Ring

Flush Mushroom

Extended

41.4

28.6

30

Lock

ø29.5

41.4

28.6

30

Lock

(Button Diameter)

(Button Diameter)

ø23.6

11.3

45.8 19

Locking Ring

(Button Diameter)

ø29.5

41.4

28.6

30

Lock

ø23.6

11.345.8

Locking Ring

29.8

10 10

0.3

Gasket

Panel Thickness: 0.8 to 6

YW Series Illuminated Pushbuttons

Contact Block Mounting

Style Lamp Operation Contact

1 2 3

ø40mm Mushroom

1NO NO FA —

1NC — FA NC

Momentary

2NO NO FA NO

2NC NC FA NC

Without

Lamp

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

Maintained

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

Momentary

2NO NO FA NO

2NC NC FA NC

LED

Incan-

Maintained

Momentary

descent

Note: Specify a lens color code in place of

Specify an operating voltage code in place of ➂ in the Part No.

Dimensions (Illuminated Pushbutton with Metal Bezel)

Panel Thickness: 0.8 to 6

M3.5 Terminal Screw

Full-voltage Adapter

Gasket

Maintained

in the Part No. FA: Full voltage adapter

➁

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

1NO NO FA —

1NC — FA NC

2NO NO FA NO

2NC NC FA NC

1NO-1NC NO FA NC

Position

Part No.

YW4L-M4E10Q0➁

YW4L-M4E01Q0➁

YW4L-M4E20Q0➁

YW4L-M4E02Q0➁

YW4L-M4E11Q0➁

YW4L-A4E10Q0➁

YW4L-A4E01Q0➁

YW4L-A4E20Q0➁

YW4L-A4E02Q0➁

YW4L-A4E11Q0➁

YW4L-M4E10Q➂➁

YW4L-M4E01Q➂➁

YW4L-M4E20Q➂➁

YW4L-M4E02Q➂➁

YW4L-M4E11Q➂➁

YW4L-A4E10Q➂➁

YW4L-A4E01Q➂➁

YW4L-A4E20Q➂➁

YW4L-A4E02Q➂➁

YW4L-A4E11Q➂➁

YW4L-M4E10Q➂➁

YW4L-M4E01Q➂➁

YW4L-M4E20Q➂➁

YW4L-M4E02Q➂➁

YW4L-M4E11Q➂➁

YW4L-A4E10Q➂➁

YW4L-A4E01Q➂➁

YW4L-A4E20Q➂➁

YW4L-A4E02Q➂➁

YW4L-A4E11Q➂➁

Operating

➂

➁

Voltage Code

A: amber

G: green

0: without lamp

250V AC/DC max.

R: red

S: blue

W: white

Y: yellow

A: amber

G: green

PW: pure white

R: red

S: blue

W: white

Y: yellow

Built-in LED

2: 6V AC/DC

3: 12V AC/DC

4: 24V AC/DC

H: 110V AC/DC

M3: 230/240V

AC/DC

lamp:

LSED-➂➁

A: amber

G: green

R: red

5: 6V AC/DC

6: 12V AC/DC

7: 24V AC/DC

S: blue

W: white

Y: yellow

Built-in

incandescent

lamp:

LS-T➂

Contact Block Mounting Position

3

2

1

Lens Color

Code

M3.5 Terminal Screw

Contact Block

Extended

Mushroom

16

10 1010

45.8 19

45.8

0.3

Locking Ring

11.3

Locking Ring

11.3

20.5

ø23.6

(Lens Diameter)

ø40

(Lens Diameter)

ø29.5

28.6

28.6

Lock

30

Lock

41.4

Extended with Full Shroud

Locking Ring

41.4

30

45.8 19.2

ø23.6

(Lens Diameter)

Lock

28.6

41.4

ø29.5

30

All dimensions in mm.

Page 17

Selector Switches with Plastic Bezel

LR

L

C

R

Shape

Knob

YW Series Selector Switches

Package Quantity: 1

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

No. of

Positions

90°

2-Position

No. of

Positions

45°

3-Position

Contact

Conguration

1NO

(10)

1NC

(01)

2NO

(20)

2NC

(02)

1NO-1NC

(11)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact

Conguration

2NO

(20)

2NO

(20N1)

2NC

(02)

2NC

(02N1)

1NO-1NC

(11)

1NO-1NC

(11N1)

1NO-1NC

(11N2)

1NO-1NC

(11N3)

1NO-1NC

(11N4)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

2

3

1

3 NC ●

1 NO ●

3 NO ●

1 NC ●

3 NC ●

1 NO ●

3 NC ●

1 NO ●

3 NO ●

1 NC ●

3 NC ●

1 NO ●

3 NO ●

1 NO ●

3 NC ●

Contact Block

Mounting Position

1 NO ●

2

3 NO ●

1

3 NO ●

1 NC

3 NC

1

3 NC

1 NO ●

3 NC

1 NC

3 NO ●

1 NO ●

3

1

3 NO ●

1

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

Operator Position

L R –

Operator Position

L C R

Maintained

YW1S-2E10 YW1S-21E10 — —

YW1S-2E01 YW1S-21E01 — —2

YW1S-2E20 YW1S-21E20 — —2

YW1S-2E02 YW1S-21E02 — —2

YW1S-2E11 YW1S-21E11 — —2

YW1S-2E30 YW1S-21E30 — —2 NO ●

YW1S-2E03 YW1S-21E03 — —2 NC ●

YW1S-2E21 YW1S-21E21 — —2 NC ●

YW1S-2E12 YW1S-21E12 — —2 NC ●

Maintained

YW1S-3E20 YW1S-31E20 YW1S-32E20 YW1S-33E20

YW1S-3E20N1 YW1S-31E20N1 YW1S-32E20N1 YW1S-33E20N12 NO ● ●

YW1S-3E02 YW1S-31E02 YW1S-32E02 YW1S-33E022

YW1S-3E02N1 YW1S-31E02N1 YW1S-32E02N1 YW1S-33E02N12 NC ●

YW1S-3E11 YW1S-31E11 YW1S-32E11 YW1S-33E112

YW1S-3E11N1 YW1S-31E11N1 YW1S-32E11N1 YW1S-33E11N12

YW1S-3E11N2 YW1S-31E11N2 YW1S-32E11N2 YW1S-33E11N22 NC ●

YW1S-3E11N3 YW1S-31E11N3 YW1S-32E11N3 YW1S-33E11N32 NC ●

YW1S-3E11N4 YW1S-31E11N4 YW1S-32E11N4 YW1S-33E11N42 NO ● ●

YW1S-3E30 YW1S-31E30 YW1S-32E30 YW1S-33E302 NO ● ●

YW1S-3E03 YW1S-31E03 YW1S-32E03 YW1S-33E032 NC ●

YW1S-3E21 YW1S-31E21 YW1S-32E21 YW1S-33E212 NC ●

YW1S-3E12 YW1S-31E12 YW1S-32E12 YW1S-33E122 NO ● ●

Spring Return

from Right

Spring Return

from Right

— —

Spring Return

from Left

Spring Return

Two-Way

17

Page 18

ø22

LR

L

C

R

YW Series Selector Switches

Selector Switches with Metal Bezel

Shape

Package Quantity: 1

Knob

No. of

Positions

90°

2-Position

No. of

Positions

45°

3-Position

Contact

Conguration

1NO

(10)

1NC

(01)

2NO

(20)

2NC

(02)

1NO-1NC

(11)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact

Conguration

2NO

(20)

2NO

(20N1)

2NC

(02)

2NC

(02N1)

1NO-1NC

(11)

1NO-1NC

(11N1)

1NO-1NC

(11N2)

1NO-1NC

(11N3)

1NO-1NC

(11N4)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

2

3

1

2

3 NC ●

1 NO ●

2

3 NO ●

1 NC ●

2

3 NC ●

1 NO ●

2

3 NC ●

1 NO ●

2 NO ●

3 NO ●

1 NC ●

2 NC ●

3 NC ●

1 NO ●

2 NC ●

3 NO ●

1 NO ●

2 NC ●

3 NC ●

Contact Block

Mounting Position

1 NO ●

2

3 NO ●

1

2 NO ● ●

3 NO ●

1 NC

2

3 NC

1

2 NC ●

3 NC

1 NO ●

2

3 NC

1 NC

2

3 NO ●

1 NO ●

2 NC ●

3

1

2 NC ●

3 NO ●

1

2 NO ● ●

3 NC

1 NO ●

2 NO ● ●

3 NO ●

1 NC

2 NC ●

3 NC

1 NO ●

2 NC ●

3 NO ●

1 NC

2 NO ● ●

3 NC

Operator Position

L R –

Operator Position

L C R

Maintained

YW4S-2E10 YW4S-21E10 — —

YW4S-2E01 YW4S-21E01 — —

YW4S-2E20 YW4S-21E20 — —

YW4S-2E02 YW4S-21E02 — —

YW4S-2E11 YW4S-21E11 — —

YW4S-2E30 YW4S-21E30 — —

YW4S-2E03 YW4S-21E03 — —

YW4S-2E21 YW4S-21E21 — —

YW4S-2E12 YW4S-21E12 — —

Maintained

YW4S-3E20 YW4S-31E20 YW4S-32E20 YW4S-33E20

YW4S-3E20N1 YW4S-31E20N1 YW4S-32E20N1 YW4S-33E20N1

YW4S-3E02 YW4S-31E02 YW4S-32E02 YW4S-33E02

YW4S-3E02N1 YW4S-31E02N1 YW4S-32E02N1 YW4S-33E02N1

YW4S-3E11 YW4S-31E11 YW4S-32E11 YW4S-33E11

YW4S-3E11N1 YW4S-31E11N1 YW4S-32E11N1 YW4S-33E11N1

YW4S-3E11N2 YW4S-31E11N2 YW4S-32E11N2 YW4S-33E11N2

YW4S-3E11N3 YW4S-31E11N3 YW4S-32E11N3 YW4S-33E11N3

YW4S-3E11N4 YW4S-31E11N4 YW4S-32E11N4 YW4S-33E11N4

YW4S-3E30 YW4S-31E30 YW4S-32E30 YW4S-33E30

YW4S-3E03 YW4S-31E03 YW4S-32E03 YW4S-33E03

YW4S-3E21 YW4S-31E21 YW4S-32E21 YW4S-33E21

YW4S-3E12 YW4S-31E12 YW4S-32E12 YW4S-33E12

Spring Return

from Right

Spring Return

from Right

— —

Spring Return

from Left

Spring Return

Two-Way

18

Page 19

L

C

R

Panel Thickness: 0.8 to 6

3-Position

Diameter

2-Position

L

C

R

ø40

20.5

11.3

45.8

Extended

Extended

Gasket

Full-voltage Adapter

M3.5 Terminal Screw

10 1010

0.3

Panel Thickness: 0.8 to 6

Contact Block

M3.5 Terminal Screw

Extended with Full Shroud

41.4

ø29.5

28.6

30

Lock

ø23.6

(Lens Diameter)

Locking Ring

45.8 19.2

41.4

28.6

30

ø29.5

41.4

28.6

30

Lock

(Button Diameter)

(Button Diameter)

Mushroom

41.4

28.6

30

Lock

ø40

20.5

11.3

45.8

Locking Ring

(Lens Diameter)

ø23.6

11.3

45.8 19

Locking Ring

(Button Diameter)

ø29.5

41.4

28.6

30

Lock

ø23.6

11.3

45.8 19

Locking Ring

(Lens Diameter)

ø29.5

41.4

28.6

30

ø23.6

11.345.8

Contact Block Mounting Position

Selector Switch with Plastic Bezel

Contact Block

Mounting Position

3

2

1

Operator Position

YW Series Selector Switches

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

Dimensions

Selector Switch with Plastic Bezel

10 10

M3.5 Terminal Screw

Contact Block

Gasket

45.8

0.5

Locking Ring

11

24

45°

90°

Lock

45°

Selector Switch with Metal Bezel Selector Switch with Metal Bezel

Contact Block

Mounting Position

2

1

3

Operator Position

0.3

Locking Ring

11.3

24

M3.5 Terminal Screw

Contact Block

Panel Thickness: 0.8 to 6

10 10

Gasket

45.8

28.6

45°

41.4

ø27.6

Knob

2-position

41.4

ø29

30

90°

Lock

28.6

ø29.5

30

45°

Lock

28.6

3-position

41.4

ø29.5

30

All dimensions in mm.

19

Page 20

ø22

LR

LR

YW Series Key Selector Switches

Key Selector Switches (90° 2-Position)

Operator Position

Package Quantity: 1

Part No.

Plastic Bezel Metal Bezel

No. of Positions

90° 2-position

Maintained

90° 2-position

Spring Return from Right

• On the spring-returned types, the key can be removed only from the maintained position. On the maintained types, the key can be removed from every position.

Key retained positions are also available. See Part No. Development shown on page 21.

• Each key selector switch is supplied with two identical keys.

Contact

Conguration

1NO

(10)

1NC

(01)

2NO

(20)

2NC

(02)

1NO-1NC

(11)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

1NO

(10)

1NC

(01)

2NO

(20)

2NC

(02)

1NO-1NC

(11)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

3

1

3 NC ●

1 NO ●

3 NO ●

1 NC ●

3 NC ●

1 NO ●

3 NC ●

1 NO ●

3 NO ●

1 NC ●

3 NC ●

1 NO ●

3 NO ●

1 NO ●

3 NC ●

1 NO ●

3

1

3 NC ●

1 NO ●

3 NO ●

1 NC ●

3 NC ●

1 NO ●

3 NC ●

1 NO ●

3 NO ●

1 NC ●

3 NC ●

1 NO ●

3 NO ●

1 NO ●

3 NC ●

L R

YW1K-2AE10 YW4K-2AE102

YW1K-2AE01 YW4K-2AE012

YW1K-2AE20 YW4K-2AE202

YW1K-2AE02 YW4K-2AE022

YW1K-2AE11 YW4K-2AE112

YW1K-2AE30 YW4K-2AE302 NO ●

YW1K-2AE03 YW4K-2AE032 NC ●

YW1K-2AE21 YW4K-2AE212 NC ●

YW1K-2AE12 YW4K-2AE122 NC ●

YW1K-21BE10 YW4K-21BE102

YW1K-21BE01 YW4K-21BE012

YW1K-21BE20 YW4K-21BE202

YW1K-21BE02 YW4K-21BE022

YW1K-21BE11 YW4K-21BE112

YW1K-21BE30 YW4K-21BE302 NO ●

YW1K-21BE03 YW4K-21BE032 NC ●

YW1K-21BE21 YW4K-21BE212 NC ●

YW1K-21BE12 YW4K-21BE122 NC ●

20

Page 21

L

C

R

L

C

Key Selector Switches (45° 3-Position)

YW Series Key Selector Switches

Operator Position

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

Package Quantity: 1

Part No.

Plastic Bezel Metal Bezel

No. of Positions

45° 3-position

Maintained

• On the maintained types, the key can be removed from every position. Key retained positions are also available. See Part No. Development below.

• Each key selector switch is supplied with two identical keys.

Contact

Conguration

2NO

(20)

2NO

(20N1)

2NC

(02)

2NC

(02N1)

1NO-1NC

(11)

1NO-1NC

(11N1)

1NO-1NC

(11N2)

1NO-1NC

(11N3)

1NO-1NC

(11N4)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

3 NO ●

1

3 NO ●

1 NC

3 NC

1

3 NC

1 NO ●

3 NC

1 NC

3 NO ●

1 NO ●

3

1

3 NO ●

1

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

L C R

YW1K-3AE20 YW4K-3AE202

YW1K-3AE20N1 YW4K-3AE20N12 NO ● ●

YW1K-3AE02 YW4K-3AE022

YW1K-3AE02N1 YW4K-3AE02N12 NC ●

YW1K-3AE11 YW4K-3AE112

YW1K-3AE11N1 YW4K-3AE11N12

YW1K-3AE11N2 YW4K-3AE11N22 NC ●

YW1K-3AE11N3 YW4K-3AE11N32 NC ●

YW1K-3AE11N4 YW4K-3AE11N42 NO ● ●

YW1K-3AE30 YW4K-3AE302 NO ● ●

YW1K-3AE03 YW4K-3AE032 NC ●

YW1K-3AE21 YW4K-3AE212 NC ●

YW1K-3AE12 YW4K-3AE122 NO ● ●

Part No. Development Contact Block Mounting Position

YW1K-2 A E21

Key removal position code

2-position

A: Removable in all positions

B: Removable in left only

C: Removable in right only

3-position

A: Removable in all positions

B: Removable in left and center

C: Removable in right and center

D: Removable in center only

E: Removable in right and left

G: Removable in left only

H: Removable in right only

Contact Block Mounting

Position

3

2

1

R

Operator Position

21

Page 22

ø22

L

C

R

YW Series Key Selector Switches

Key Selector Switches (45° 3-Position)

Operator Position

Package Quantity: 1

Part No.

Plastic Bezel Metal Bezel

No. of Positions

45° 3-position

Spring Return from

Right

• On the spring-returned types, the key can be removed only from the maintained position. Key retained positions are also available. See Part No. Development shown

on page 21.

• Each key selector switch is supplied with two identical keys.

Contact

Conguration

2NO

(20)

2NO

(20N1)

2NC

(02)

2NC

(02N1)

1NO-1NC

(11)

1NO-1NC

(11N1)

1NO-1NC

(11N2)

1NO-1NC

(11N3)

1NO-1NC

(11N4)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

3 NO ●

1

3 NO ●

1 NC

3 NC

1

3 NC

1 NO ●

3 NC

1 NC

3 NO ●

1 NO ●

3

1

3 NO ●

1

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

L C R

YW1K-31BE20 YW4K-31BE202

YW1K-31BE20N1 YW4K-31BE20N12 NO ● ●

YW1K-31BE02 YW4K-31BE022

YW1K-31BE02N1 YW4K-31BE02N12 NC ●

YW1K-31BE11 YW4K-31BE112

YW1K-31BE11N1 YW4K-31BE11N12

YW1K-31BE11N2 YW4K-31BE11N22 NC ●

YW1K-31BE11N3 YW4K-31BE11N32 NC ●

YW1K-31BE11N4 YW4K-31BE11N42 NO ● ●

YW1K-31BE30 YW4K-31BE302 NO ● ●

YW1K-31BE03 YW4K-31BE032 NC ●

YW1K-31BE21 YW4K-31BE212 NC ●

YW1K-31BE12 YW4K-31BE122 NO ● ●

22

Page 23

L

C

R

Key Selector Switches (45° 3-Position)

YW Series Key Selector Switches

Operator Position

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

Package Quantity: 1

Part No.

Plastic Bezel Metal Bezel

No. of Positions

45° 3-position

Spring Return from Left

• On the spring-returned types, the key can be removed only from the maintained position. Key retained positions are also available. See Part No. Development shown

on page 21.

• Each key selector switch is supplied with two identical keys.

Contact

Conguration

2NO

(20)

2NO

(20N1)

2NC

(02)

2NC

(02N1)

1NO-1NC

(11)

1NO-1NC

(11N1)

1NO-1NC

(11N2)

1NO-1NC

(11N3)

1NO-1NC

(11N4)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

3 NO ●

1

3 NO ●

1 NC

3 NC

1

3 NC

1 NO ●

3 NC

1 NC

3 NO ●

1 NO ●

3

1

3 NO ●

1

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

L C R

YW1K-32CE20 YW4K-32CE202

YW1K-32CE20N1 YW4K-32CE20N12 NO ● ●

YW1K-32CE02 YW4K-32CE022

YW1K-32CE02N1 YW4K-32CE02N12 NC ●

YW1K-32CE11 YW4K-32CE112

YW1K-32CE11N1 YW4K-32CE11N12

YW1K-32CE11N2 YW4K-32CE11N22 NC ●

YW1K-32CE11N3 YW4K-32CE11N32 NC ●

YW1K-32CE11N4 YW4K-32CE11N42 NO ● ●

YW1K-32CE30 YW4K-32CE302 NO ● ●

YW1K-32CE03 YW4K-32CE032 NC ●

YW1K-32CE21 YW4K-32CE212 NC ●

YW1K-32CE12 YW4K-32CE122 NO ● ●

23

Page 24

ø22

L

C

R

YW Series Key Selector Switches

Key Selector Switches (45° 3-Position)

Operator Position

Package Quantity: 1

Part No.

Plastic Bezel Metal Bezel

No. of Positions

45° 3-position

Spring Return Two-way

• On the spring-returned types, the key can be removed only from the maintained position. Key retained positions are also available. See Part No. Development shown

on page 21.

• Each key selector switch is supplied with two identical keys.

Contact

Conguration

2NO

(20)

2NO

(20N1)

2NC

(02)

2NC

(02N1)

1NO-1NC

(11)

1NO-1NC

(11N1)

1NO-1NC

(11N2)

1NO-1NC

(11N3)

1NO-1NC

(11N4)

3NO

(30)

3NC

(03)

2NO-1NC

(21)

1NO-2NC

(12)

Contact Block

Mounting Position

1 NO ●

3 NO ●

1

3 NO ●

1 NC

3 NC

1

3 NC

1 NO ●

3 NC

1 NC

3 NO ●

1 NO ●

3

1

3 NO ●

1

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

1 NO ●

3 NO ●

1 NC

3 NC

L C R

YW1K-33DE20 YW4K-33DE202

YW1K-33DE20N1 YW4K-33DE20N12 NO ● ●

YW1K-33DE02 YW4K-33DE022

YW1K-33DE02N1 YW4K-33DE02N12 NC ●

YW1K-33DE11 YW4K-33DE112

YW1K-33DE11N1 YW4K-33DE11N12

YW1K-33DE11N2 YW4K-33DE11N22 NC ●

YW1K-33DE11N3 YW4K-33DE11N32 NC ●

YW1K-33DE11N4 YW4K-33DE11N42 NO ● ●

YW1K-33DE30 YW4K-33DE302 NO ● ●

YW1K-33DE03 YW4K-33DE032 NC ●

YW1K-33DE21 YW4K-33DE212 NC ●

YW1K-33DE12 YW4K-33DE122 NO ● ●

24

Page 25

Dimensions (Key Selector Switch)

M3.5

Contact Block

Metal BezelPlastic Bezel

3-position

3-position

110

ø11.6

ø29

3.5

ø25.8

TOP

1.5

YW Series Key Selector Switches

Emergency Stop Switches Pushbuttons Pilot Lights Illuminated Pushbuttons Selector Switches Key Selector Switches

ø22

Panel Thickness 0.8 to 6

Terminal Screw

Gasket

45.8

0.5

Locking Ring

11

38

28.6

ø29.0

45°

90°

2-position

Lock

30.0

45°

41.4

Panel Thickness 0.8 to 6

M3.5 Terminal Screw

Contact Block

Gasket

45.8

0.3

Locking Ring

11.3

38

28.6

ø29.5

45°

90°

2-position

Lock

30.0

45°

41.4

All dimensions in mm.

Accessories

ø14

ø28

3.5

Package

Quantity

1

1

5

1

12 3

Name & Shape Part No. Description & Dimensions (mm)

Locking Ring Wrench

Metallic tool used to tighten the

plastic locking ring when installing

the YW series in a panel.

MW9Z-T1

Lamp Holder Tool

Made of rubber.

Used for replacing lamps.

OR-55

Rubber Mounting Hole Plug

Used for plugging unused mounting holes in the

panel.

OB-31PN05

Metallic Mounting Hole Plug

Color: Black

Used for plugging unused mounting holes in the

panel.

LW9Z-BM

Weight: Approx. 18g

59

ø25

Locking Ring

Anti-Rotation Ring

HW9Z-RLPN10

Prevents rotation of switches in panel.

Mainly used with selector switches when no

nameplate is used.

With waterproof gasket (IP65).

Made of plastic (black).

Applicable panel thickness: 1.2 to 4.5 mm

ø29

ø22

10

25

Page 26

ø22

70

82.5

Base BA9S/14

Base BA9S/13

M3.5

T

YW Series Accessories / Maintenance Parts

Name & Shape Part No. Description & Dimensions (mm)

Padlock Cover

Plastic hinged cover to protect pushbuttons,

illuminated pushbuttons, or selector switches.

Degree of protection: IP65.

Applicable panel thickness: 0.8 to 3.2 mm

HW9Z-KL1

30

ø50

Maintenance Parts

Name & Shape Part No. Description & Dimensions (mm)

LED Lamp

LSED-6➁

LSED-1➁

LSED-2➁

LSED-H➁

6V AC/DC

12V AC/DC

24V AC/DC

110V AC/DC

Specify a color code in place of ➁ in

the Part No.:

A (amber), G (green), PW (pure white),

R (red), S (blue), Y (yellow)

See page 4 for applicable units and

rated current.

Note: Yellow LED lamps are used for

white illumination of pilot lights

and illuminated pushbuttons.

Panel Thickness 0.8 to 3.2

ø22.2

Pad Lock Hole ø8

R66.5

29.5

30

20.8

93

24

Waterproof Gasket

Thickness 0.5

ø10.6

Package

Quantity

1

Package

Quantity

1

Incandescent Lamp

Single Contact Block

Double Contact Block

Spare Key

LSED-M3➁

LS-T6P 6.3V, 1W

230/240V AC/DC

One pack contains 100 incandescent

lamps.

LS-T3P 30V, 1W

YW-E10 Contact: 1NO Color: blue

YW-E01 Contact: 1NC Color: reddish purple

YW-EW20 Contact: 2NO Color: blue

YW-EW11 Contact: 1NO-1NC

Color: blue and

reddish purple

±1

ø11

41.4

erminal Screw

M3.5

Terminal Screw

±1

23

41.4

Note: Double contact blocks cannot be used

on emergency stop switches.

5

22.3

5

42.3

100LS-T8P 18V, 1W

10

10YW-EW02 Contact: 2NC Color: reddish purple

26

YW9ZSK00PN02

2

Page 27

Buttons, Lenses, and Marking Plates

ø23.6

ø40

ø29.8

ø29.8

ø29.8

ø29.8

ø23.6

ø40

ø22.7

ø17.2

Name Style Part No.

Button

(for pushbuttons)

Extended

Mushroom

ø40mm

Lens

(for pilot lights)

Flush

Flush Marking

YW9Z-B12➀

YW9Z-B14➀

YW9Z-PL11➁

YW9Z-PL11B➁

➀ ➁

Color Code

B: black

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

C: clear

G: green

R: red

S: blue

W: white

Y: yellow

A: amber

C: clear

G: green

R: red

S: blue

Y: yellow

YW Series Accessories

Dimensions (mm)

9.3

ø23.6

6

10.8

8.5

9

ø22

Package

Quantity

10

10

10

Lens

(for illuminated pushbuttons)

Marking Plate

(for pilot lights)

Marking Plate

(for illuminated pushbuttons)

Extended

YW9Z-PL12T➁

A: amber

C: clear

G: green

R: red

14.5

S: blue

W: white

Dome

Extended

YW9Z-PL12➁

YW9Z-L12➁

Y: yellow

A: amber

C: clear

14.5

9.3

G: green

R: red

S: blue

Mushroom

ø40mm

YW9Z-L14➁

— YW9Z-PP12 — 10

— YW9Z-P12 — 10

Y: yellow

15.2

ø23.6

6

10.8

ø21.8

21

2

4.4

ø16

1.4

5

10

10

10

27

Page 28

ø22

•

Marking Plate

30

30

Marking Plate

45

27

12

• Installing the marking plate

on a nameplate

• To remove the marking plate, insert the at screwdriver beween

YW Series Accessories

Nameplates

HWAM, HWAQ, HWAS, and HWAV

Name Legend Material Part No. Ordering No.

HWAM 1

HWAM

HWAQ

Order marking plate

separately.

Order marking plate

separately.

HWAQ Blank

Plastic (black) 1.5

mm thick

Plastic (black) 1.5

mm thick

Plastic (black) 1.5

mm thick

HWAM

HWAMPN10 10

HWAQ 1

HWAQ

HWAQPN10 10

HWAS-0 1

HWAS-0

HWAS-0PN10 10

Package

Quantity

Dimensions (mm)

12.1

R14.9

ø22

12.1

R14.9

ø22

29

27

14.9

14.5

29

27

14.9

14.5

1.6

ø22

2.7

11.5

2.7

11.9

0.9

E

G

N

R

C

E

Y

M

E

HWAV

Blank

Plastic (yellow)

1.5 mm thick

HWAV-0 HWAV-0 1

S

P

T

O

EMERGENCY STOP HWAV-27 HWAV-27 1

Legend “Emergency Stop”

is indicated outside a ø44mm circle.

Making Plate

Description Material Part No. Ordering No. Package Quantity Dimensions (mm)

• White legend on black background.

HWNP

Aluminum (black)

1.0 mm thick

HWNP-∗

• Specify a legend code in place of ∗ in the Ordering No.

Legends

Code Legend

0 (blank)

1 ON

2 OFF

3 START

4 STOP

31 OFF-ON

35 HAND-AUTO

53 HAND-OFF-AUTO

Nameplate

➁

Marking Plate

➀

HWNP-∗

HWNP-∗PN10

1

10

the marking plate and nameplate.

Flat Screwdriver

Marking Plate

When requring no anti-rotation, remove the projection using pliers.

Nameplate

ø60

ø22

0.91.6

28

Note: When using an nameplate, the mounting panel thickness is decreased by 1.5 mm.

Page 29

YW Series Accessories

Secondary Ter minal

Primary Terminal

38

35

36.5

36.2

35

ø22

Switch Guards Package Quantity: 1

Part No. & Shape (mm) Dimensions Part No. & Shape Dimensions (mm)

HW9Z-KG1

EMO Switch Guard

SEMI S2 compliant (Note 1)

HW9Z-KG2

ø

22

ø22.2

64

47

ø66.8

22

32

ø76.1

HW9Z-KG4

ø80

EMO Switch Guard

SEMI S2 compliant (Note 2)

SEMATECH compliant (Note 3)

HW9Z-KG5

ø90

ø22

25

67

ø76

50

34.4

ø

22

27

33

40

76

ø90

ø90

EMO Switch Guard

SEMI S2 compliant (Note 1)

SEMATECH compliant (Note 3)

EMO Switch Guard

SEMI S2 compliant (Note 2)

SEMATECH compliant (Note 3)

75

HW9Z-KG3

25

52

ø74

EMO Switch Guard

ø22

ø66

42

SEMI S2 compliant (Note 2)

Material: Polyamide (PA6)

Color: Yellow, Munsell 2.5Y 8/10 equivalent

Degree of protection: IP65

• Degree of protection IP65 applies to the combination of an emergency stop switch and an EMO switch guard.

Note 1: SEMI S2-0703 12.5.1 compliant.

Note 2: The combination of IDEC’s emergency stop switches and EMO switch guards are approved by TÜV Rheinland for compliance with SEMI S2 standard.

Note 3: SEMATECH Application Guide for SEMI S2-93, 12.4.c. compliant.

Transformer

Din Rail Mount Transformer For 6V

Dimensions (mm)

Primary Voltage

(50/60 Hz)

110V AC TWR516

Part No. Applicable Lamp Rating

115V AC TWR5116

120V AC TWR5126

220V AC TWR526

230V AC TWR5236

240V AC TWR5246

380V AC TWR5386

440V AC TWR546

480V AC TWR5486

One full voltage type illuminated unit

containing LED lamp LSED-6 (6V

AC/DC) or incandescent lamp LS-T6

(6.3V)

Screws M3.5

2-ø3.5

Mounting Holes

40

48

52

Screws M3.5

30

22

41

40

Note: Finger-safe terminal cover is supplied with the transformer.

29

Page 30

ø22

Extended

Marking Plate

Flush

Extended

Dome

Flush Markin

Lens

YW Series Instructions

Safety Precautions

• Turn off the power to the YW series before starting installation, removal,

wiring, maintenance, and inspection of the products. Failure to turn power off

may cause electrical shocks or re hazard.

• To avoid burning your hand, use the lamp holder tool when replacing lamps.

Instructions

Panel Mounting

• Remove the contact block from the operator (for pilot lights, remove the

transformer or full voltage unit from the pilot light). Remove the locking ring

from the operator. Insert the operator into the panel cut-out from the front,

tighten the locking ring from the back, then install the contact block to the

operator.

Removing and Installing the Contact Block

➁

➀

➂

➀ Pull up the locking lever.

➁ Turn the lever to the left.

➂ Pull out the contact block

• For wiring, use wires of a proper size to meet the voltage and current

requirements. Tighten the M3.5 terminal screws to a tightening torque of 1.0

N·m. Failure to tighten the terminal screws may cause overheating and re.

Removing the Full Voltage Unit

➁

➀

1. To remove the full voltage unit, squeeze the full voltage unit from both sides

to disengage the latch as shown, and pull it out. Like the transformer unit, the

full voltage unit can also be pulled out by inserting a at screwdriver into the

latch hole as shown.

2. To reinstall, place the TOP markings on the operator and the latch on the full

voltage unit in the same direction, and insert the operator into the full voltage

unit.

Notes for Panel Mounting

1.

Use the optional locking ring wrench (MW9Z-T1) to mount the operator onto a

panel. Tightening torque must not exceed 2.0 N·m. Do not use pliers. Excessive

tightening will damage the locking ring.

2. For contact blocks and transformers housing LED and incandescent lamps,

make sure not to press the lamps too hard, otherwise the lamp socket may

be damaged.

1. To remove the operator from the contact block, pull up the locking lever and

turn it to the left. Then the operator can be pulled out.

2. To reinstall, place the TOP marking on the operator and the TOP marking

on the contact block mounting adapter in the same direction, and insert the

operator into the contact block mounting adapter. Then turn the locking lever

to the right.

Removing and Installing the Transformer

1. Insert a at screwdriver (5 mm wide at maximum) into the latch hole on the

transformer unit as shown in the photo below, and disengage the latch. Then

pull out the operator.

2. To reinstall, place the TOP marking on the operator and the latch in the same

direction, and push the operator into the transformer.

➀

➁

Insertion Order of Lens and Marking Plate

Illuminated Pushbutton Pilot Light

Marking Plate

Lens

With Full Shroud

Lens

Full Shroud

Mushroom

Marking Plate

Lens

g

Lens

Marking Plate

30

Page 31

YW Series Instructions

Lamp Lamp Removal Tool

Illuminated Pushbutton

Lamp

kk

king

P

P

0.8 to 6 mm

0.8 to 3.2 mm

ø21.0

2

1.2

Area

ø22

Marking

For YW series pilot lights and illuminated pushbuttons, legends and symbols can

be engraved on built-in marking plates, or printed mylar lm can be inserted

under the lens for labeling purposes. Mylar lm is not supplied with the YW

series and must be supplied by the end user.

Built-in Marking Plate and Marking Film Size

Unit Pilot Light Illuminated Pushbutton

ø15.

Engraving Area

20.8

1.0

0

-0.2

ø22.7

0

-0.2

Built-in Marking Plate

Engraving depth: 0.5 mm maximum

Marking plate material: White acrylic

0.1-mm-thick × 2 sheets or 0.2-mm-thick × 1 sheet

Applicable Marking Film

Film material: Mylar (recommended)

Note: Marking lm is not supplied with the pilot light or illuminated pushbutton.

Replacement (LED and incandescent lamps)

Lamps can be replaced using the lamp holder tool (OR-55) from the front of the

panel, or by removing the contact block from the operator unit.

15.0

Engraving

0

0

-0.2

-0.2

ø17.2

Removing Contact Blocks

and Full Voltage Adapters

Insert a at screwdriver between the latch and contact

block mounting adapter, and disengage the latch.

Make sure to remove the lamp and contact blocks

before removing the full voltage adapter.

j

Full Voltage Adapter

Contact Block

l

Tightening Torque for Terminal Screws

Tighten terminal screws to a torque of 1.0 N·m.

Anti-rotation Ring and Mounting Panel

Turn the TOP marking on the operator and the ▲ mark on the anti-rotation ring

to the recess on the mounting panel.

Projections ( mark)

Removing the Lamp from the Front of the Panel

To remove, gently insert the lamp holder tool onto the lamp head. Then push

slightly, and turn the lamp holder tool to the left.

Installing the Lamp from the Front of the Panel

1. To install, insert the lamp head into the lamp holder tool, and hold the lamp as

shown in the gure below.

2. Place the pins on the lamp base to the grooves in the lamp socket. Insert the

lamp and turn it to the right.

Pilot Light

Note: LED lamps in unibody pilot lights cannot be replaced.

Anti-rotation Ring Loc

anel Thickness 1.2 to 4.5 mm

Ring

Mounting Panel Thickness

The mounting panel must be 0.8 to 6.0 mm in thickness. When optional

accessories are added, the applicable panel thickness changes as shown below.

Padlock Cover

HW9Z-KL1P

anel Thickness

Panel Thickness

Contact Bounce

When pressing or turning the operator, the NC and NO contacts will

bounce. When designing a control circuit, take the contact bounce time into

consideration (reference value: 20 ms).

31

Page 32

ø22

+

–

R: Shunt resistor

Precautions for Noise

When using the unibody pilot light in an environment where it is subjected to

noise, connect a noise suppressor across terminals X1 and X2 as shown below.

Noise Suppressor

Key Selector Switch