Page 1

ø22 HW Series Switches & Pilot Lights

Complete with finger-safe contact blocks

Ensure safety and save wiring time

• Finger-safe terminal blocks

• Self-cleaning rolling action contacts.

• Degree of protection: IP65 (except dual pushbutton: IP40)

• Dual pushbutton switches available with two pushbuttons and a pilot

light integrated into one space-saving unit.

• A wide range of operating voltages for worldwide application.

• UL, CSA rated, and EN compliant.

Standards and Approvals

Applicable Standards Mark File No. or Organization

UL508

UL Listing

File No. E68961

CSA C22.2

No.14

EN60947-5-1

GB14048.5 Contact IDEC for details.

• DC-DC converter types are not approved by standards.

• See website for details on approvals and standards.

CSA

File No. LR21451

TÜV Rheinland

EU Low Voltage Directive and

RoHS 2 Directive (except for DC-DC

coverter unit)

Specications and Ratings

Contact Ratings

Pushbuttons

Illuminated Pushbuttons

Dual Pushbuttons

Selector Switches

Illuminated Selector Switches

Selector Pushbuttons

Rated insulation voltage 600V

Rated continuous current 10A

Contact ratings by utilization category

IEC60947-5-1

Contact Ratings by Utilization Category

HW-U10 (NO contact), HW-U01 (NC contact)

Operating Voltage

AC-12 Control of resistive loads and solid state loads

AC-15 Control of electromagnetic loads (> 72 VA)

DC-12 Control of resistive loads and solid state loads

DC-13 Control of electromagnets

Operating

Current

AC

50/60 Hz

DC

Application for dual pushbuttons:

Ideal for use as power switches and start/stop switches (available

with I/ON and O/OFF markings on the buttons and a pilot light in

the center).

Interlock type prevents two pushbuttons from being pressed at the

same time, providing the best solution for up/down switches.

AC-15 (A600)

DC-13

24V 48V 50V 110V 220V 440V

10A − 10A 10A 6A 2A

10A − 7A 5A 3A 1A

10A 5A − 2.2A 1.1A −

5A 2A − 1.1A 0.6A −

HW-U10R (EM contact/NO contact), HW-U01R (LB contact/NC contact)

Operating Voltage

AC

Operating

Current

• The operating current represents the classication by making and breaking currents (IEC 60947-5-1).

• Contact materials: Silver contacts

• Minimum applicable load: 3V AC/DC, 5 mA (applicable range may vary with operating conditions and load types)

50/60 Hz

DC

AC-12 Control of resistive loads and solid state loads

AC-15 Control of electromagnetic loads (> 72 VA)

DC-12 Control of resistive loads and solid state loads

DC-13 Control of electromagnets

24V 48V 50V 110V 220V 440V

5A − 5A 5A 3A 1A

5A − 3.5A 2.5A 1.5A 0.5A

5A 2.5A − 1.1A 0.55A −

2.5A 1A

−

0.55A 0.3A

−

1

Page 2

ø22 HW Series Switches & Pilot Lights

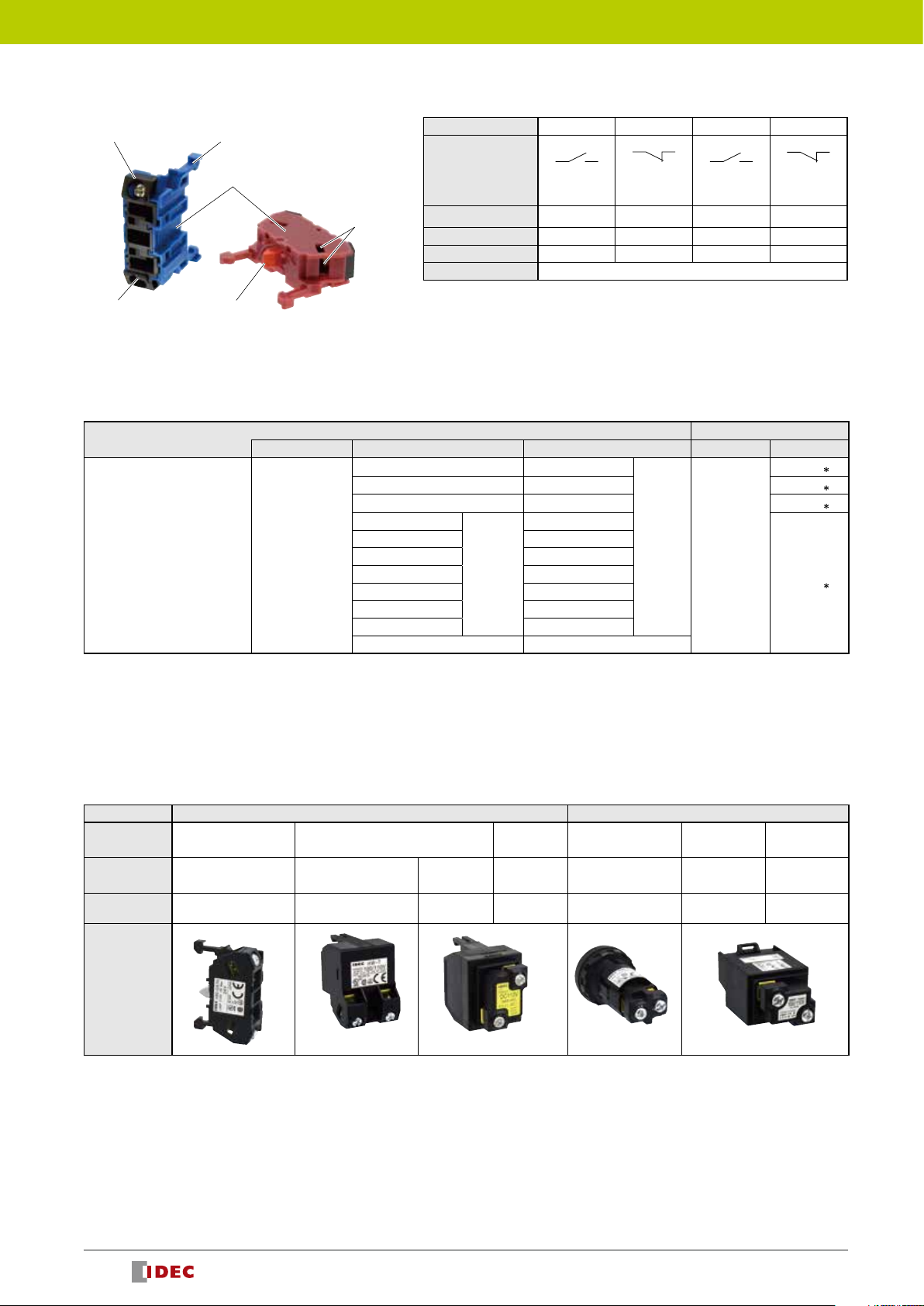

HW-U Contact Block

IP20 construction

No terminal cover necessary

Terminal

No. 4

Terminal

No. 3

Terminal screw

(M3.5)

HW-U10

(NO contact)

Snap-t latch

(To install/remove

the contact block)

Housing

Push rod

Terminal

No. 2

Two-way

wiring

Terminal

No. 1

HW-U01

(NC contact)

LED Specifications

Unit

Illuminated pushbutton

Illuminated selector switch

Pilot light

Dual pushbutton

(with pilot light)

• See page 3. for details on LED lamp ratings.

• For the LED lamp used in jumbo dome pilot lights, see page 3.

• Yellow (Y) cannot be used with dual pushbuttons.

• Color codes for units without LED lamps:

R (red), G (green), A (amber), Y (yellow), W (white), S (blue)

When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape. Make sure of

correct operation before installation. The operation of HW series cannot be guaranteed when a commercially available lamp is used.

Color Rated Voltage Operating Voltage Lamp Base Part No.

6V AC/DC 6V AC/DC

12V AC/DC 12V AC/DC

R (red)

G (green)

Y (yellow)

A (amber)

W (white)

S (blue)

PW (pure white)

24V AC/DC 24V AC/DC

100/110V AC

115/120V AC 115/120V AC (*1)

200/220V AC 200/220V AC

230/240V AC 230/240V AC (*1)

380V AC 380V AC

400/440V AC 400/440V AC

480V AC 480V AC

110V DC 90 to 140V DC

Part No. HW-U10 HW-U01 HW-U10R HW-U01R

Contact

1NO 1NC

EM (NO)

(early make)

(late break)

Contact No. 3-4 1-2 3-4 1-2

Housing Blue Purple red Blue Purple red

Push Rod Green Red Black White

Weight Approx. 11g

• Up to 2 layers (4 blocks) can be attached.

• Gold contacts available (gold-plated silver)

LED lamp

100/110V AC

±10%

BA9S/13

50/60 Hz

LB (NC)

LSTD-6

LSTD-1

LSTD-2

LSTD-6

Power Unit Terminal

Illuminated Unit Pilot Light

Power Unit Full voltage adapter Transformer

DC-DC

converter

Full voltage adapter Transformer

Rated Voltage 6, 12, 24V AC/DC 100 to 240V AC 380V AC min. 110V DC 6, 12, 24V AC/DC 100 to 480V AC 110V DC

Polarity None None None

X1

Shape/Terminal

X2

X2

X1

X1 (+)

X2 (–)

X2

None None

X1

X2

X1

DC-DC

converter

X1 (+)

X2 (–)

X1 X2

2

Page 3

ø22 HW Series Switches & Pilot Lights

X

X

Resistor

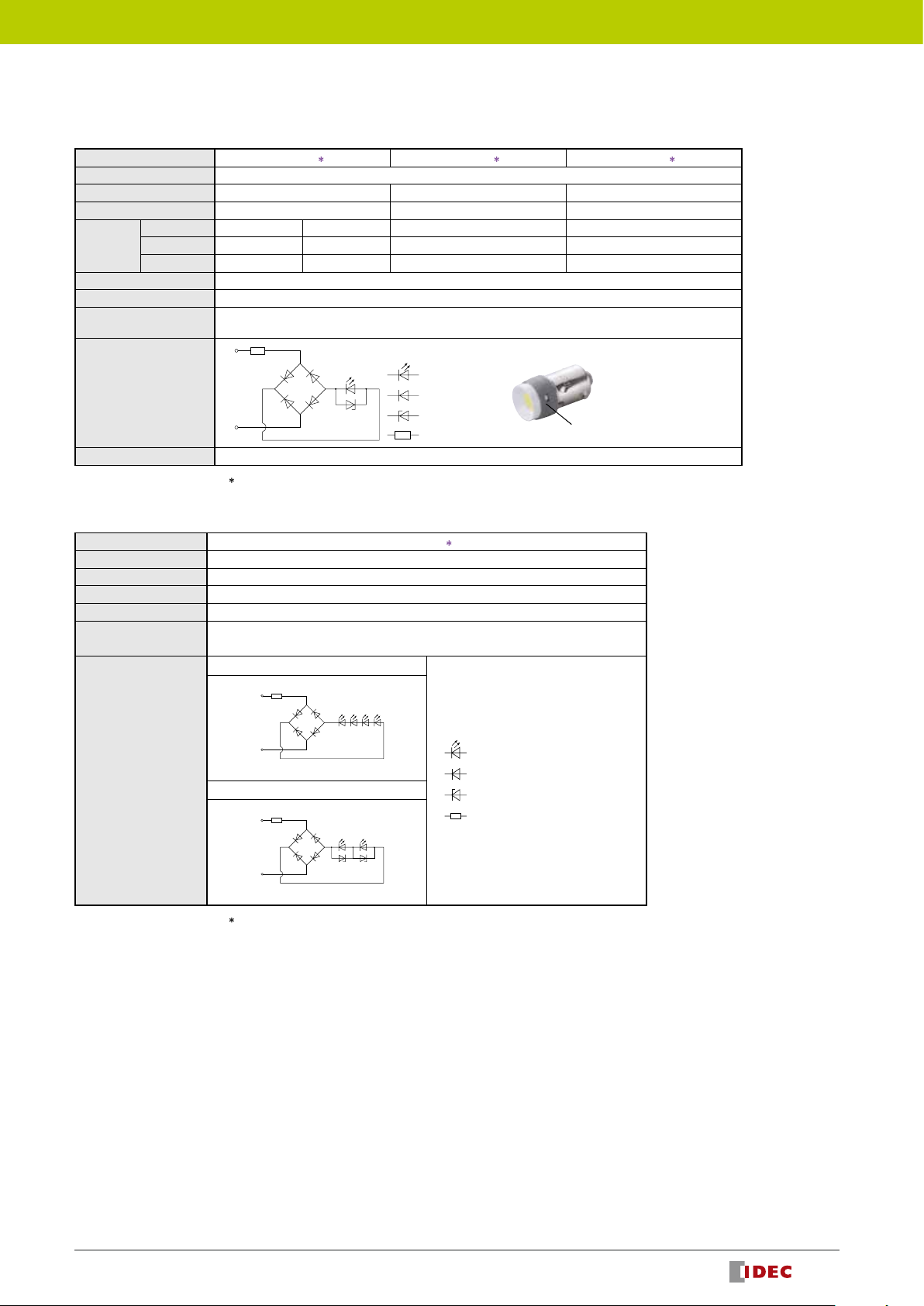

LED Lamp Ratings

LSTD (Except Jumbo Dome Pilot Lights)

Part No.

Lamp Base BA9S/13

Rated Voltage 6V AC/DC 12V AC/DC 24V AC/DC

Voltage Range 6V AC/DC ±10% 12V AC/DC ±10% 24V AC/DC ±10%

Current

Draw

Color R, A, W G, S, PW R, G, A, W, S, PW R, G, A, W, S, PW

DC 7mA 5.5mA 10mA 10mA

AC 8mA 8mA 11mA 11mA

Lamp Base Color Same as illumination color (PW: gray)

Voltage Marking Die stamped on the base

Life (reference value)

Approx. 50,000 hours

(The luminance is reduced to 50% the initial intensity when used on complete DC at 25°C.)

1

Internal Circuit

2

Weight Approx. 2g

• Specify a color code in place of

. R (red), G (green), A (amber), W (white), S (blue), PW (pure white)

• Use a pure white (PW) LED for yellow (Y) illumination.

LSTD-6 LSTD-1 LSTD-2

Symbols

LED chip

Rectier diode

Zener diode

Example: LSTD-2PW

Base Color

LSTDB (For Jumbo Dome Pilot Lights HW1P-5Q4 Only)

Part No.

Lamp Base BA9S/13

Voltage Range 24V AC/DC±10%

Current Draw 15mA

Rated Voltage 24V AC/DC

Life (reference value)

Approx. 20,000 hours

(The luminance is reduced to 50% the initial intensity when used on complete DC at 25°C.)

R, A, W

X1

X2

Internal Circuit

X1

X2

G, S, PW

• Specify a color code in place of . R (red), G (green), A (amber), W (white), S (blue), PW (pure white)

• Use a pure white (PW) LED for yellow (Y) illumination.

LSTDB-2

LED chip

Rectier diode

Zener diode

Resistor

3

Page 4

ø22 HW Series Switches and Pilot Lights

R0.8 max.

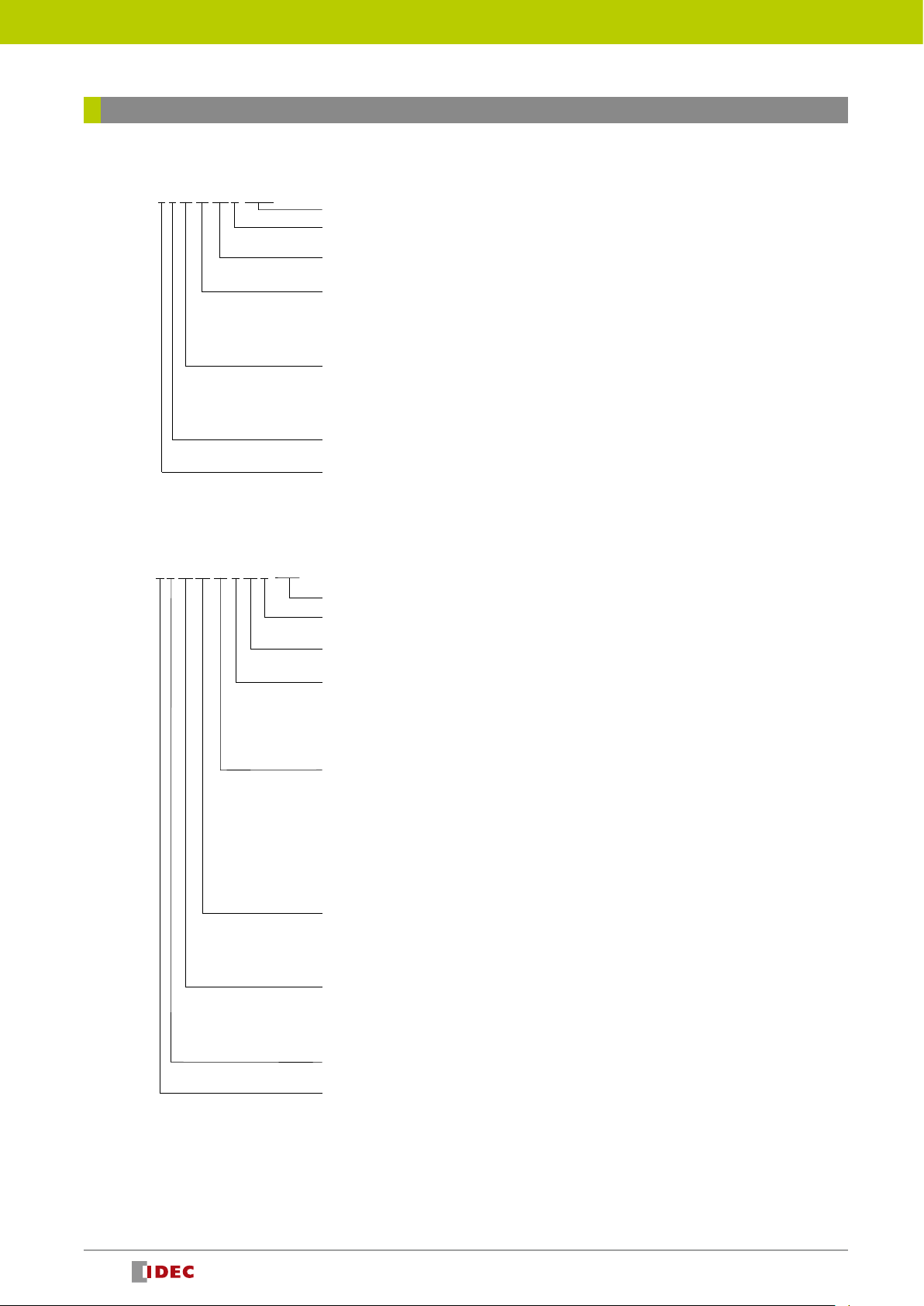

Specifications

Operating

Temperature

Operating Humidity 45 to 85% RH (no condensation)

Storage Temperature –40 to +80°C (no freezing)

Contact Resistance 50 mΩ maximum (initial value)

Insulation Resistance 100 MΩ minimum (500V DC megger)

Dielectric Strength

Vibration Resistance

Shock Resistance

Mechanical Life

(minimum

operations)

Electrical Life (*5)

Weight (Apporox.)

*1) Dielectric strength for dual pushbuttons are as follows:

Full voltage type: 1,000V AC, 1 minute (between live and dead metal parts)

Transformer and DC-DC converter types: 2,000V AC, 1 minute (between live

and dead metal parts)

*2) Switching frequency 1,800 operations/h, duty ratio 40%

*3) Switching frequency 1,200 operations/h, duty ratio 40%

*4) Switching frequency 900 operations/h, duty ratio 40%

*5) Load condition 220V AC, 3A (AC-15)

Non-illuminated: –25 to +60°C (no freezing)

Illuminated: –25 to +50°C (no freezing)

Jumbo dome pilot lights: –25 to +55°C (no freezing)

Between live and dead metal parts: 2,500V AC, 1 minute

(Full voltage and illuminated units: 2,000V AC, 1 minute)

(*1)

Damage limits: 30 Hz, amplitude 1.5 mm

Operating extremes: 5 to 55 Hz, amplitude 0.5 mm

Damage limits: 1,000m/s

Operating extremes: 100m/s

2

2

Pushbutton, Illuminated pushbutton

Momentary

Maintained 500,000

Dual pushbutton 500,000

Selector switch 500,000

Key selector switch (Disc tumbler) 500,000

Key selector switch (Pin tumbler) 100,000

Illuminated selector switch 500,000

Pushbutton selector 250,000

Mono-lever switches 250,000

Pushbutton, Illuminated pushbutton

Momentary

500,000 (*2)

Maintained 500,000 (*4)

Dual pushbutton 500,000 (*2)

Selector switch 500,000 (*3)

Key selector switch (Disc tumbler) 500,000 (*3)

Key selector switch (Pin tumbler) 100,000 (*3)

Illuminated selector switch 500,000 (*3)

Pushbutton selector 250,000 (*3)

Mono-lever switches 250,000 (*4)

66g (HW1B-M122)

20g (HW1P-1Q4)

84g (HW1L-M122Q4)

66g (HW1S-2T22)

94g (HW1K-2A22)

72g (HW1K-2JPC11)

84g (HW1F-222Q4)

71g (HW1R-2A22)

82g (HW1M-2222-22N9)

72g (HW7D-B111111)

90g (HW7D-L111111Q4)

5000,000

Mounting Hole Layout

All dimensions in mm.

Panel Cut (IEC60947-5-1)

+0.2

3.2

30

(*7)

+0.4

0

0

24.1

ø22.3

(*6)

+0.4

0

• The minimum mounting centers are applicable to switches with one layer of

contact blocks (one to two contact blocks). When two layers of contact blocks

are mounted, determine the minimum mounting centers in consideration of

convenience for wiring.

• When high temperature is expected, take necessary measures such as securing sufcient mounting centers or using a cooling fan.

Minimum Mounting Centers (Dimensions in mm)

Unit A (*6) B (*7)

ø40mm mushroom button 50 40

Pushbutton selector 50 50

Mono-lever switch 72 72

Pilot light 30 30

Jumbo dome pilot light 85 85

Dual pushbutton switch 55 30

Illuminated selector switch 50 50

• When using the safety lever lock, determine the vertical spacing (*6) in consideration of convenience for installing and removing the safety lever lock.

(Recommended vertical spacing: 100 mm)

The minimum length of vertical spacing (*6) is 45 mm when safety lever lock

is not used.

• The 3.2 mm recess is for preventing rotation and is not necessary when the

nameplate or anti-rotation ring is not used.

Degree of Protection

Unit IEC 60529

All units except dual pushbutton switches IP65 (*8)

Dual pushbutton switches IP40 (*9)

*8) When using a nameplate with the HW series, IP65 protection degree is

achieved only when nameplates shown on page 37 are used.

(IP40 when other ø22 namplates such as NWA are used)

*9) IP65 protection degree when HW9Z-D7D button cover is used.

Ordering Information

Standard models

• Specify Ordering No. when ordering.

• Specify a button or lens color code in place of ∗.

• Pilot lights, illuminated pushbuttons, and illuminated selector switches have an LED lamp installed.

• Nameplates and accessories for mono-lever switch are ordered separately. See page 37 to 39.

• Color codes for units without LED lamps:

R (red), G (green), A (amber), Y (yellow), W (white), S (blue)

When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of HW series cannot be guaranteed when a commercially available lamp is used.

4

Page 5

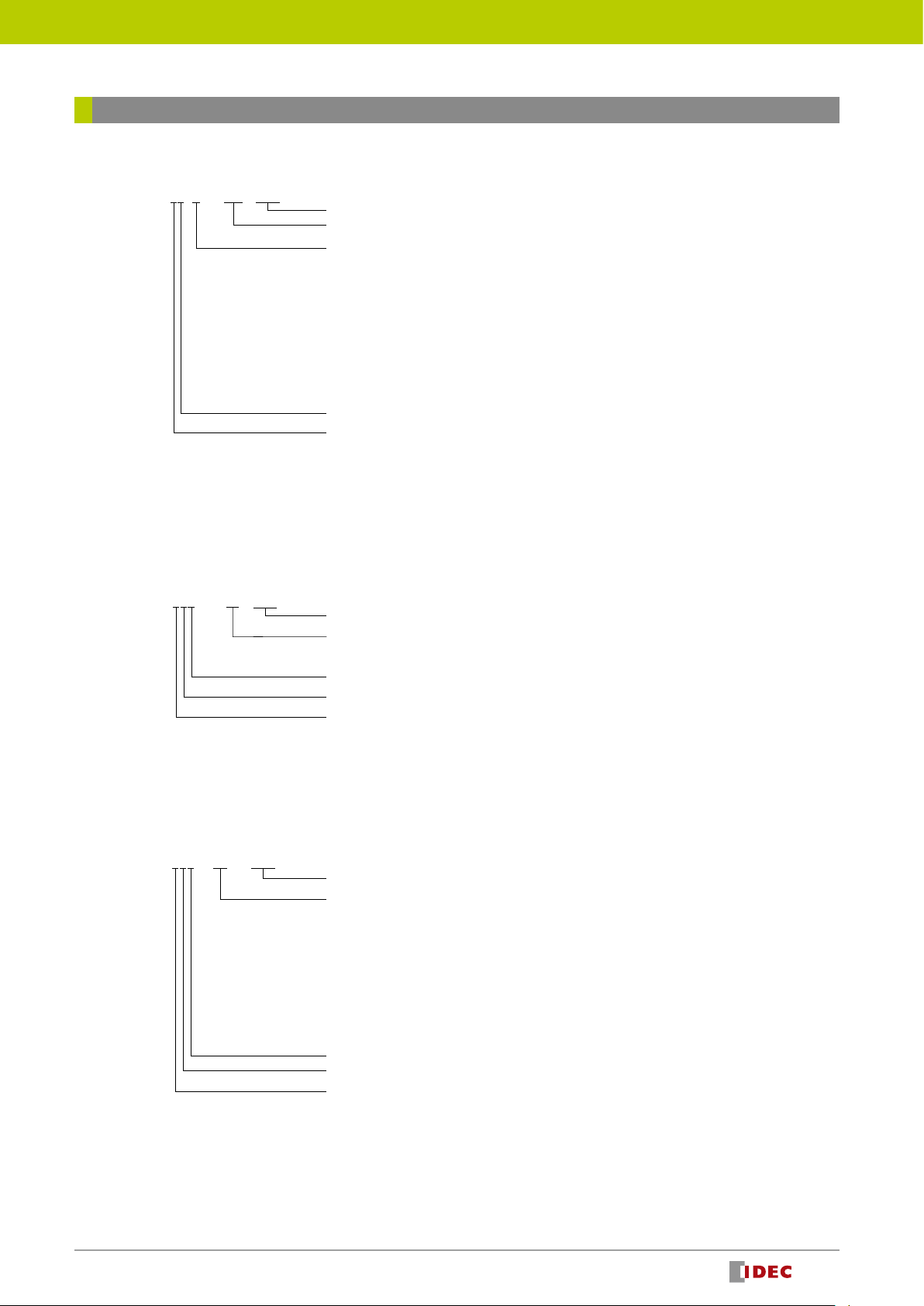

ø22 HW Series Ordering / Part No. Development

Ordering Information

Pushbuttons (Page 8 to 10)

When specifying gold-plated silver contact and contact conguration:

HW1B-M1 11 R -MAU

Optional contact

Contact conguration

Pilot Lights (Page 11)

When specifying LED operating voltage:

HW1P-1 H2 R

Operating voltage QO: Without LED lamp

Q2: 6V AC/DC

Q3: 12V AC/DC

Q4: 24V AC/DC

H2: 100/110V AC

H22: 115/120V AC

M2: 200/220V AC

M42: 230/240V AC

S2: 380V AC

T2: 400/440V AC

T82: 480V AC

D2: 110V DC

MAU: Gold contact

10: 1NO

01: 1NC

11: 1NO1NC

20: 2NO

02: 2NC

22: 2NO2NC

40: 4NO

04: 4NC

13: 1NO3NC

31: 3NO1NC

30: 3NO

03: 3NC

12: 1NO2NC

21: 2NO1NC

Note: Color codes for units without LED lamps: R (red), G (green), A (amber), Y (yellow), W (white), S (blue)

When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of HW series cannot be guaranteed when a commercially available lamp is used.

Illuminated Pushbuttons (Page 13 to 17)

When specifying gold-plated silver contact, contact conguration, and LED operating voltage:

HW1L-M1 11 H2 R - MAU

Optional contact

Operating Voltage

Contact conguration

Note:

• Color codes for units without LED lamps: R (red), G (green), A (amber), Y (yellow), W (white), S (blue)

When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape. Make sure of

correct operation before installation. The operation of HW series cannot be guaranteed when a commercially available lamp is used.

• Odd number of contact blocks, such as 1NO, 1NC, 3NO, 2NO-1NC, 1NO-2NC, and 3NC, is not available for transformer type or DC-DC converter type.

MAU Gold contact

QO: Without LED lamp

Q2: 6V AC/DC

Q3: 12V AC/DC

Q4: 24V AC/DC

H2: 100/110V AC

H22: 115/120V AC

M2: 200/220V AC

M42: 230/240V AC

S2: 380V AC

T2: 400/440V AC

T82: 480V AC

D2: 110V DC

10: 1NO

01: 1NC

11: 1NO1NC

20: 2NO

02: 2NC

22: 2NO2NC

40: 4NO

04: 4NC

13: 1NO3NC

31: 3NO1NC

30: 3NO

03: 3NC

12: 1NO2NC

21: 2NO1NC

5

Page 6

ø22 HW Series Ordering / Part No. Development

Ordering Information

Dual Pushbutton Switches [without pilot light] (Page 20)

When specifying gold-plated silver contact and contact conguration:

HW7D-B 1 1 10 02 GR 1−MAU

Optional contact

Button legends

Button color code

Contact Arrangement

(bottom button)

Lamp code

(top button)

Button style

Operation

MAU: Gold-plated silver

Blank: Without legend

1: I/ON + O/OFF

GR: Green (top) Red (bottom)

WB: White (top) Black (bottom)

10: 1NO

01: 1NC

11: 1NO1NC

20: 2NO

02: 2NC

10: 1NO

01: 1NC

11: 1NO1NC

20: 2NO

02: 2NC

1: Flush + Flush

2: Flush + Extended

1: Momentary

2: Interlock

Dual Pushbutton Switches [with pilot light] (Page 21)

When specifying gold-plated silver contact, contact conguration, and LED operating voltage:

HW7D-L 1 1 1 1 20 H2 R GR 1−MAU

Optional contact

Button legends

Button color code

Lamp color code

Lamp code

Contact arrangement code

(bottom button)

Contact arrangement code

(top button)

Button style

Operation

MAU: Gold-plated silver

Blank: Without legend

1: I/ON + O/OFF

GR: Green (top), Red (bottom)

WB: White (top), Black (bottom)

R: Red

G: Green

A: Amber

W: White

S: Blue

PW: Pure White

Q2: 6V AC/DC

Q3: 12V AC/DC

Q4: 24V AC/DC

H2: 100/110V AC

H22: 115/120V AC

M2: 200/220V AC

M42: 230/240V AC

S2: 380V AC

T2: 400/440V AC

T82: 480V AC

10: 1NO

01: 1NC

11: 1NO1NC

20: 2NO

02: 2NC

10: 1NO

01: 1NC

11: 1NO1NC

20: 2NO

02: 2NC

1: Flush + Flush

2: Flush + Extended

1: Momentary

2: Interlock

Note: Transformer type cannot have a contact arrangement of 3 contact blocks for the total of top and bottom.

6

Page 7

ø22 HW Series Ordering / Part No. Development

Ordering Information

Key Selector Switches (Pin Tumbler Key) (Pages 25 to 26)

When specifying gold-plated silver contact, key removal position, and key number:

HW1K- 2 JPA 01 -501 - MAU

Note:

• The key cannot be removed in a spring return position.

• The key number is engraved on the key cylinder.

(default key is not engraved with a number)

Optional contact

Different key number

Key removal position

Cam code

Operator position code

MAU: Gold-plated silver

-501 - 515

2-position A: Removable in all positions

B: Removable in the left only

C: Removable in the right only

3-position A: Removable in all positions

B: Removable in the left and center

C: Removable in the right and center

D: Removable in center only

E: Removable in right and left

G: Removable in left only

H: Removable in right only

Blank, J, or S

2: 2-position, maintained

21: 2-position, spring return from right

3: 3-position, maintained

31: 3-position, spring return from right

32: 3-position, spring return from left

33: 3-position, spring return two way

Key Selector Switches (Disc Tumbler Key) (Pages 27 to 28)

When specifying gold-plated silver contact, key removal position, and key number:

HW1K

3JA22 - 1H - MAU

-

Optional contact

Different key number

MAU: Gold-plated silver

-1H, -2H, -3H

Key removal position

Cam code

Operator position code

Note:

• The key cannot be removed in a spring return position.

• The key number is engraved on the key cylinder.

(default key is not engraved with a number)

(same as pin tumbler key shown above)

(same as pin tumbler key shown above)

(same as pin tumbler key shown above)

Illuminated Selector Switches (Pages 29 to 30)

When specifying gold-plated silver contact and LED operating voltage:

HW1F

Note: Color codes for units without LED lamps: R (red), G (green), A (amber), Y (yellow), W (white), S (blue)

When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of HW series cannot be guaranteed when a commercially available lamp is used.

2JL11 H2 R - MAU

-

Optional contact

Operating voltage

Operator shape

Cam code

Operator position code

MAU: Gold-plated silver

QO: Without LED lamp

Q2: 6V AC/DC

Q3: 12V AC/DC

Q4: 24V AC/DC

H2: 100/110V AC

H22: 115/120V AC

M2: 200/220V AC

M42: 230/240V AC

S2: 380V AC

T2: 400/440V AC

T82: 480V AC

Blank (Knob), L (Lever)

Blank, J, or S

2: 2-position, maintained

21: 2-position, spring return from right

3: 3-position, maintained

31: 3-position, spring return from right

32: 3-position, spring return from left

33: 3-position, spring return two way

7

Page 8

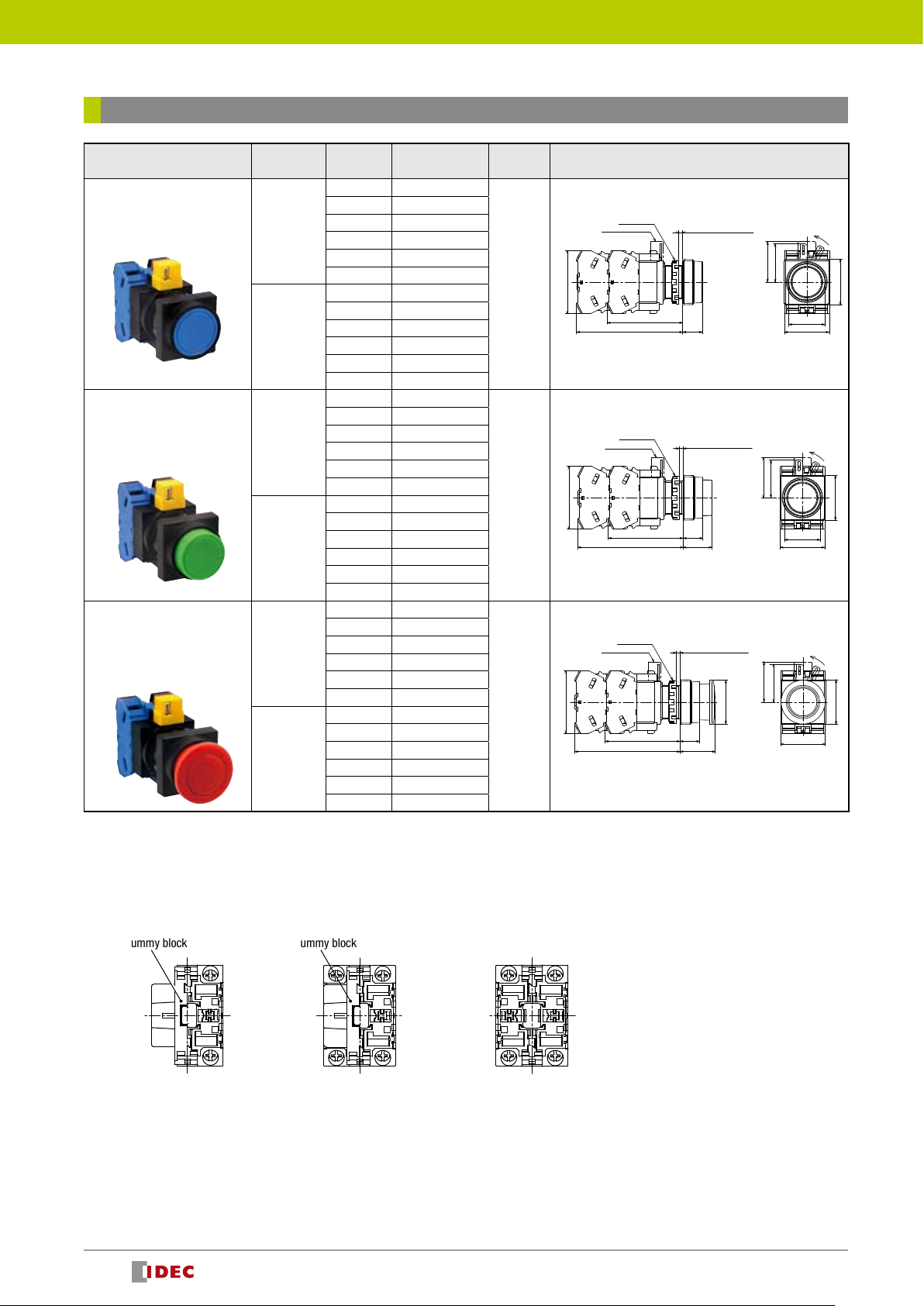

ø22 HW Series Pushbuttons

41.4

41.4

Locking Ring

41.4

41.4

Panel Thickness 0.8 to 6

Flush / Extended / Mushroom Pushbuttons

Shape Operation Contact Part No. Color Code Dimensions (mm)

Package Quantity: 1

Flush

HW1B-M1

HW1B-A1

Extended

HW1B-M2

HW1B-A2

ø29mm Mushroom

HW1B-M3

HW1B-A3

ø40mm Mushroom

HW1B-M4

HW1B-A4

ø60mm Mushroom

HW1B-M5

Momentary

Maintained

Momentary

Maintained

Momentary

Maintained

Momentary

Maintained

Momentary

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

HW1B-M110∗

HW1B-M101∗

HW1B-M111∗

HW1B-M120∗

HW1B-M102∗

HW1B-M122∗

HW1B-A110∗

HW1B-A101∗

HW1B-A111∗

HW1B-A120∗

HW1B-A102∗

HW1B-A122∗

HW1B-M210∗

HW1B-M201∗

HW1B-M211∗

HW1B-M220∗

HW1B-M202∗

HW1B-M222∗

HW1B-A210∗

HW1B-A201∗

HW1B-A211∗

HW1B-A220∗

HW1B-A202∗

HW1B-A222∗

HW1B-M310∗

HW1B-M301∗

HW1B-M311∗

HW1B-M320∗

HW1B-M302∗

HW1B-M322∗

HW1B-A310∗

HW1B-A301∗

HW1B-A311∗

HW1B-A320∗

HW1B-A302∗

HW1B-A322∗

HW1B-M410∗

HW1B-M401∗

HW1B-M411∗

HW1B-M420∗

HW1B-M402∗

HW1B-M422∗

HW1B-A410∗

HW1B-A401∗

HW1B-A411∗

HW1B-A420∗

HW1B-A402∗

HW1B-A422∗

HW1B-M510∗

HW1B-M501∗

HW1B-M511∗

HW1B-M520∗

HW1B-M502∗

HW1B-M522∗

Locking Ring

Safety Lever Lock

Panel Thickness 0.8 to 6

LOCK

B

G

R

Y

41.4

ø29

25

26.5

S

W

B

G

R

Y

S

W

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Locking Ring

Safety Lever Lock

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Safety Lever Lock

13

Panel Thickness 0.8 to 6

ø29

13

19

Panel Thickness 0.8 to 6

ø23.6

29.4

LOCK

25

26.5

ø23.6

29.4

LOCK

B

G

R

Y

25

26.5

ø29

S

W

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Locking Ring

Safety Lever Lock

13

23.2

Panel Thickness 0.8 to 6

B

G

R

Y

ø40

S

W

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Locking Ring

Safety Lever Lock

B

G

13

23.2

26.5

ø60

29.4

LOCK

25

26.5

29.4

LOCK

25

R

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

15

30.1

29.4

• Specify a color code in place of ∗ in Part No. B (black), G (green), R (red), Y (yellow), S (blue), W (white)

• Pushbuttons with 1 or 3 contact blocks have a dummy block.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Pushbuttons: M3.5 Terminal screws integrated terminal cover

8

Page 9

ø22 HW Series Pushbuttons

Square Flush / Square Flush Pushbuttons

Shape Operation Contact Part No. Color Code Dimensions (mm)

Package Quantity: 1

Square Flush

HW2B-M1

HW2B-A1

Square Extended

HW2B-M2

HW2B-A2

Momentary

Maintained

Momentary

Maintained

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

HW2B-M110*

HW2B-M101*

HW2B-M111*

HW2B-M120*

HW2B-M102*

HW2B-M122*

HW2B-A110*

HW2B-A101*

HW2B-A111*

HW2B-A120*

HW2B-A102*

HW2B-A122*

HW2B-M210*

HW2B-M201*

HW2B-M211*

HW2B-M220*

HW2B-M202*

HW2B-M222*

HW2B-A210*

HW2B-A201*

HW2B-A211*

HW2B-A220*

HW2B-A202*

HW2B-A222*

B

G

R

Y

S

W

B

G

R

Y

S

W

• Specify a color code in place of * in Part No. B (black), G (green), R (red), Y (yellow), S (blue), W (white)

• Pushbuttons with 1 or 3 contact blocks have a dummy block.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Pushbuttons: M3.5 Terminal screws

Locking Ring

Safety Lever Lock

41.4

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Locking Ring

Safety Lever Lock

41.4

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Panel Thickness 0.8 to 6

13

Panel Thickness 0.8 to 6

13

19

LOCK

25

26.5

29.6

24.8

29.4

LOCK

25

26.5

29.6

24.8

29.4

Bottom View

Dummy block Dummy block

1NO contact block 3 contact blocks 2/4 contact blocks

• For 1NC contact, the contact block will mount on the opposite side.

• See page 48 for wiring.

• Integrated terminal cover

9

Page 10

ø22 HW Series Pushbuttons

Locking Ring

41.4

41.4

Round Flush / Round Extended /Mushroom with Square Bezel

Shape Operation Contact Part No. Color Code Dimensions (mm)

Package Quantity: 1

Round Flush with Square Bezel

HW3B-M1

HW3B-A1

Round Extended

with Square Bezel

HW3B-M2

HW3B-A2

ø29mm Mushroom

with Square Bezel

HW3B-M3

HW3B-A3

Momentary

Maintained

Momentary

Maintained

Momentary

Maintained

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

HW3B-M110*

HW3B-M101*

HW3B-M111*

HW3B-M120*

HW3B-M102*

HW3B-M122*

HW3B-A110*

HW3B-A101*

HW3B-A111*

HW3B-A120*

HW3B-A102*

HW3B-A122*

HW3B-M210*

HW3B-M201*

HW3B-M211*

HW3B-M220*

HW3B-M202*

HW3B-M222*

HW3B-A210*

HW3B-A201*

HW3B-A211*

HW3B-A220*

HW3B-A202*

HW3B-A222*

HW3B-M310*

HW3B-M301*

HW3B-M311*

HW3B-M320*

HW3B-M302*

HW3B-M322*

HW3B-A310*

HW3B-A301*

HW3B-A311*

HW3B-A320*

HW3B-A302*

HW3B-A322*

B

G

R

Y

S

W

B

G

R

Y

S

W

B

G

R

Y

S

W

• Specify a color code in place of * in Part No. B (black), G (green), R (red), Y (yellow), S (blue), W (white)

• Pushbuttons with 1 or 3 contact blocks have a dummy block.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Pushbuttons: M3.5 Terminal screws

Safety Lever Lock

41.4

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Locking Ring

Safety Lever Lock

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Locking Ring

Safety Lever Lock

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Panel Thickness 0.8 to 6

13

Panel Thickness 0.8 to 6

13

19

Panel Thickness 0.8 to 6

ø29

13

23.2

LOCK

25

26.5

29.6

ø23.6

29.4

LOCK

25

26.5

29.6

ø23.6

29.4

LOCK

25

26.5

29.6

29.4

Bottom View

Dummy block Dummy block

1NO contact block 3 contact blocks 2/4 contact blocks

• For 1NC contact, the contact block will mount on the opposite side.

• See page 48 for wiring.

• Integrated terminal cover

10

Page 11

Round Flush / Dome / Square Flush / Jumbo Dome Pilot Lights

Shape Lamp Operating Voltage Part No. Color Code

Round Flush (marking type)

HW1P-1

24V AC/DC

LED

24V AC/DC

100/110V AC

ø22 HW Series Pilot Lights

Package Quantity: 1

HW1P-1Q4∗

R

G

Y

HW1P-1H2∗

A

W

S

PW

With transformer (100/110V AC)

Dome

HW1P-2

(24V AC/DC)

With transformer (100/110V AC)

Square Flush (marking type)

HW2P-1

(24V AC/DC)

LED

LED

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

HW1P-1M2∗

HW1P-2Q4∗

HW1P-2H2∗

HW1P-2M2∗

HW2P-1Q4∗

HW2P-1H2∗

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

200/220V AC

With transformer (100/110V AC)

Jumbo Dome Pilot Light (*1)

HW1P-5

LED 24V AC/DC

• Specify a color code in place of * in Part No. R (red), G (green), Y (yellow), A (amber) W (white), S (blue), PW (pure white)

• Pilot lights have an LED lamp installed.

• See page 5 for other operating voltages.

• See page 12 for bottom view.

• See page 12 for how to specify units without LED lamps.

• When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of illuminated pushbutton switches cannot be guaranteed when a commercially available lamp is

used.

*1) Jumbo dome pilot lights contain an exclusive LED. See page 3 and 42.

HW2P-1M2∗

HW1P-5Q4∗

R

G

Y

A

W

S

PW

11

Page 12

ø22 HW Series Pilot Lights

+0.2

30 min.

+0.4

Panel Thickness 0.8 to 6

Panel Thickness 0.8 to 6

Panel Thickness 1 to 5

Dimensions

Pilot Lights

Round Flush Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp

Gasket

Locking Ring

Panel Thickness 0.8 to 6

ø29

100/110V AC, 200/220V AC (240V AC maximum) 110V DC, 380V AC minumum

Gasket

Locking Ring

Panel Thickness 0.8 to 6

ø

23.5

All dimensions in mm.

Gasket

29

ø

Locking Ring

ø23.5

ø29

ø

23.5

43.3

11.5

7

60.8 7

Extended Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp

Gasket

Locking Ring

43.3 17.5

Panel Thickness 0.8 to 6

ø23.6

11.5

ø29

100/110V AC, 200/220V AC (240V AC maximum) 110V DC, 380V AC minimum

Gasket

Locking Ring

60.8

Square Flush Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp

Gasket

Locking Ring

Panel Thickness 0.8 to 6

11.5

743.3

29.6

100/110V AC, 200/220V AC (240V AC maximum) 110V DC, 380V AC minimum

Gasket

Locking Ring

24.6

60.8 7

Jumbo Dome Pilot Light Terminal screws: M3.5, integrated terminal cover

ø23.6

17.5

Panel Thickness 0.8 to 6

29.6

29.6

29.6

24

76.2 7

Gasket

ø29

24

24.6

Locking Ring

76.2 17.5

Gasket

Locking Ring

76.2 7

Panel Thickness 0.8 to 6

ø23.6

Panel Thickness 0.8 to 6

24

29.6

ø29

24

29.6

24.6

29.6

Locking

Ring

Gasket

34.4

0.5

50.5

66

ø

Panel Cut-Out Pilot Light Bottom View

Mounting Centers

(Except jumbo dome)

Close mounting on 30 mm centers

0

ø22.3

30 min.

When mounting 100/110V AC, 200/220V

AC, 110V DC units on 30mm centers

vertically and horizontally, keep the

ambient temperature below 40°C.

Mounting Centers

(Jumbo dome)

R0.8 max.

+0.4

0

ø22.3

85 min.

Determine the minimum mounting centers

in consideration of convenience for wiring.

0

3.2

+0.4

85 min.

0

24.1

6, 12, 24V AC/DC

Without LED lamp

M3.5 Terminal Screw

X2

X2

X1

• For DC-DC Converter types, terminal X1 is ⊕, X2 is.

• See page 49 for wiring.

100/110V AC, 200/220V, 110V DC

X1

M3.5 Terminal Screw

X2

X2

X1

X1

12

Page 13

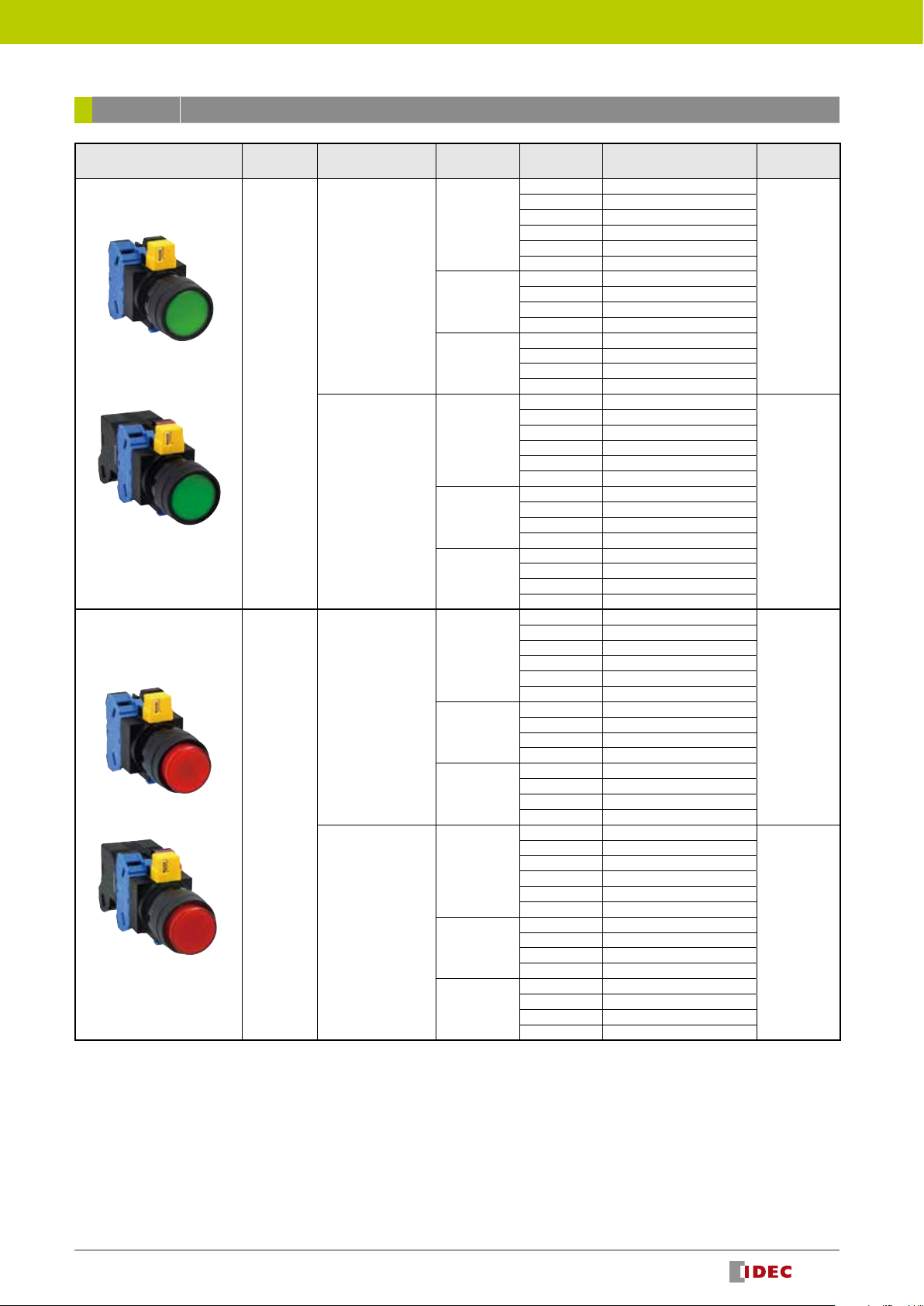

ø22 HW Series Illluminated Pushbuttons

LED Round Flush / Round Extended (Marking Type)

Package Quantity: 1

Shape Illumination Operation Rated Voltage

Round Flush (Marking type)

HW1L-M1

HW1L-A1

Momentary

(24V AC/DC)

LED

Maintained

With transformer

(100/110V AC)

Round Extended (Marking type)

HW1L-M2

HW1L-A2

Momentary

(24V AC/DC)

With transformer

(100/110V AC)

• Specify a color code in place of ∗ in Part No. R (red), G (green), Y (yellow), A (amber) W (white), S (blue), PW (pure white)

• Illuminated pushbuttons have an LED lamp installed.

• See page 5 for other operating voltage such as 6V AC/DC, 12V AC/DC, and 110V DC.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Illuminated pushbutttons of 24V AC/DC or below with 2 or 4 contact blocks have a dummy block.

• See page 19 for bottom view.

• See page 12 for how to specify units without LED lamps.

• When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of illuminated pushbutton switches cannot be guaranteed when a commercially available lamp is

used.

LED

Maintained

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220VAC

Contact

Conguration

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

Part No. Color Code

HW1L-M110Q4∗

HW1L-M101Q4∗

HW1L-M111Q4∗

HW1L-M120Q4∗

HW1L-M102Q4∗

HW1L-M122Q4∗

HW1L-M111H2∗

HW1L-M120H2∗

HW1L-M102H2∗

HW1L-M122H2∗

HW1L-M111M2∗

HW1L-M120M2∗

HW1L-M102M2∗

HW1L-M122M2∗

HW1L-A110Q4∗

HW1L-A101Q4∗

HW1L-A111Q4∗

HW1L-A120Q4∗

HW1L-A102Q4∗

HW1L-A122Q4∗

HW1L-A111H2∗

HW1L-A120H2∗

HW1L-A102H2∗

HW1L-A122H2∗

HW1L-A111M2∗

HW1L-A120M2∗

HW1L-A102M2∗

HW1L-A122M2∗

HW1L-M210Q4∗

HW1L-M201Q4∗

HW1L-M211Q4∗

HW1L-M220Q4∗

HW1L-M202Q4∗

HW1L-M222Q4∗

HW1L-M211H2∗

HW1L-M220H2∗

HW1L-M202H2∗

HW1L-M222H2∗

HW1L-M211M2∗

HW1L-M220M2∗

HW1L-M202M2∗

HW1L-M222M2∗

HW1L-A210Q4∗

HW1L-A201Q4∗

HW1L-A211Q4∗

HW1L-A220Q4∗

HW1L-A202Q4∗

HW1L-A222Q4∗

HW1L-A211H2∗

HW1L-A220H2∗

HW1L-A202H2∗

HW1L-A222H2∗

HW1L-A211M2∗

HW1L-A220M2∗

HW1L-A202M2∗

HW1L-A222M2∗

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

13

Page 14

ø22 HW Series Illluminated Pushbuttons

LED Round Extended with Full Shroud (Marking Type)

Shape Illumination Operation Rated Voltage Contact Part No. Color Code

Package Quantity: 1

Round Extended with Full Shroud

(Marking type)

HW1L-MF2

HW1L-AF2

Momentary

(24V AC/DC )

With transformer

(100/110V AC)

• Specify a color code in place of ∗ in Part No. R (red), G (green), Y (yellow), A (amber) W (white), S (blue), PW (pure white)

• Illuminated pushbuttons have an LED lamp installed.

• See page 5 for other operating voltage such as 6V AC/DC, 12V AC/DC, and 110V DC.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Illuminated pushbutttons of 24V AC/DC or below with 2 or 4 contact blocks have a dummy block.

• See page 19 for bottom view.

• See page 12 for how to specify units without LED lamps.

• When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of illuminated pushbutton switches cannot be guaranteed when a commercially available lamp is

used.

LED

Maintained

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

HW1L-MF210Q4∗

HW1L-MF201Q4∗

HW1L-MF211Q4∗

HW1L-MF220Q4∗

HW1L-MF202Q4∗

HW1L-MF222Q4∗

HW1L-MF211H2∗

HW1L-MF220H2∗

HW1L-MF202H2∗

HW1L-MF222H2∗

HW1L-MF211M2∗

HW1L-MF220M2∗

HW1L-MF202M2∗

HW1L-MF222M2∗

HW1L-AF210Q4∗

HW1L-AF201Q4∗

HW1L-AF211Q4∗

HW1L-AF220Q4∗

HW1L-AF202Q4∗

HW1L-AF222Q4∗

HW1L-AF211H2∗

HW1L-AF220H2∗

HW1L-AF202H2∗

HW1L-AF222H2∗

HW1L-AF211M2∗

HW1L-AF220M2∗

HW1L-AF202M2∗

HW1L-AF222M2∗

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

14

Page 15

ø22 HW Series Illluminated Pushbuttons

LED Square Flush / Round Flush with Square Bezel (Marking Type)

Shape Illumination Operation Illumination Contact Part No. Color Code

Package Quantity: 1

Square Flush (Marking type)

HW2L-M1

HW2L-A1

Momentary

(24V AC/DC)

With transformer

(100/110V AC)

Round Flush with Square Bezel

(Marking type)

HW3L-M1

HW3L-A1

(24V AC/DC)

With transformer

(100/110V AC)

• Specify a color code in place of ∗ in Part No. R (red), G (green), Y (yellow), A (amber) W (white), S (blue), PW (pure white)

• Illuminated pushbuttons have an LED lamp installed.

• See page 5 for other operating voltage such as 6V AC/DC, 12V AC/DC, and 110V DC.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Illuminated pushbutttons of 24V AC/DC or below with 2 or 4 contact blocks have a dummy block.

• See page 19 for bottom view.

• See page 12 for how to specify units without LED lamps.

• When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of illuminated pushbutton switches cannot be guaranteed when a commercially available lamp is

used.

LED

Maintained

Momentary

LED

Maintained

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

HW2L-M110Q4∗

HW2L-M101Q4∗

HW2L-M111Q4∗

HW2L-M120Q4∗

HW2L-M102Q4∗

HW2L-M122Q4∗

HW2L-M111H2∗

HW2L-M120H2∗

HW2L-M102H2∗

HW2L-M122H2∗

HW2L-M111M2∗

HW2L-M120M2∗

HW2L-M102M2∗

HW2L-M122M2∗

HW2L-A110Q4∗

HW2L-A101Q4∗

HW2L-A111Q4∗

HW2L-A120Q4∗

HW2L-A102Q4∗

HW2L-A122Q4∗

HW2L-A111H2∗

HW2L-A120H2∗

HW2L-A102H2∗

HW2L-A122H2∗

HW2L-A111M2∗

HW2L-A120M2∗

HW2L-A102M2∗

HW2L-A122M2∗

HW3L-M110Q4∗

HW3L-M101Q4∗

HW3L-M111Q4∗

HW3L-M120Q4∗

HW3L-M102Q4∗

HW3L-M122Q4∗

HW3L-M111H2∗

HW3L-M120H2∗

HW3L-M102H2∗

HW3L-M122H2∗

HW3L-M111M2∗

HW3L-M120M2∗

HW3L-M102M2∗

HW3L-M122M2∗

HW3L-A110Q4∗

HW3L-A101Q4∗

HW3L-A111Q4∗

HW3L-A120Q4∗

HW3L-A102Q4∗

HW3L-A122Q4∗

HW3L-A111H2∗

HW3L-A120H2∗

HW3L-A102H2∗

HW3L-A122H2∗

HW3L-A111M2∗

HW3L-A120M2∗

HW3L-A102M2∗

HW3L-A122M2∗

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

15

Page 16

ø22 HW Series Illluminated Pushbuttons

LED Mushroom (ø29mm) / Mushroom (ø29mm) with Square Bezel (Marking Type)

Package Quantity: 1

Shape Illumination Operation Illumination Contact Part No. Color Code

ø29mm Mushroom

(Marking type)

HW1L-M3

HW1L-A3

Momentary

(24V AC/DC)

With transformer

(100/110V AC)

ø29mm Mushroom with Square

Bezel (Marking type)

HW3L-M3

HW3L-A3

(24V AC/DC)

With transformer

(100/110V AC)

• Specify a color code in place of ∗ in Part No. R (red), G (green), Y (yellow), A (amber) W (white), S (blue), PW (pure white)

• Illuminated pushbuttons have an LED lamp installed.

• See page 5 for other operating voltage such as 6V AC/DC, 12V AC/DC, and 110V DC.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Illuminated pushbutttons of 24V AC/DC or below with 2 or 4 contact blocks have a dummy block.

• See page 19 for bottom view.

• See page 12 for how to specify units without LED lamps.

• When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of illuminated pushbutton switches cannot be guaranteed when a commercially available lamp is

used.

LED

Maintained

Momentary

LED

Maintained

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

HW1L-M310Q4∗

HW1L-M301Q4∗

HW1L-M311Q4∗

HW1L-M320Q4∗

HW1L-M302Q4∗

HW1L-M322Q4∗

HW1L-M311H2∗

HW1L-M320H2∗

HW1L-M302H2∗

HW1L-M322H2∗

HW1L-M311M2∗

HW1L-M320M2∗

HW1L-M302M2∗

HW1L-M322M2∗

HW1L-A310Q4∗

HW1L-A301Q4∗

HW1L-A311Q4∗

HW1L-A320Q4∗

HW1L-A302Q4∗

HW1L-A322Q4∗

HW1L-A311H2∗

HW1L-A320H2∗

HW1L-A302H2∗

HW1L-A322H2∗

HW1L-A311M2∗

HW1L-A320M2∗

HW1L-A302M2∗

HW1L-A322M2∗

HW3L-M310Q4∗

HW3L-M301Q4∗

HW3L-M311Q4∗

HW3L-M320Q4∗

HW3L-M302Q4∗

HW3L-M322Q4∗

HW3L-M311H2∗

HW3L-M320H2∗

HW3L-M302H2∗

HW3L-M322H2∗

HW3L-M311M2∗

HW3L-M320M2∗

HW3L-M302M2∗

HW3L-M322M2∗

HW3L-A310Q4∗

HW3L-A301Q4∗

HW3L-A311Q4∗

HW3L-A320Q4∗

HW3L-A302Q4∗

HW3L-A322Q4∗

HW3L-A311H2∗

HW3L-A320H2∗

HW3L-A302H2∗

HW3L-A322H2∗

HW3L-A311M2∗

HW3L-A320M2∗

HW3L-A302M2∗

HW3L-A322M2∗

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

16

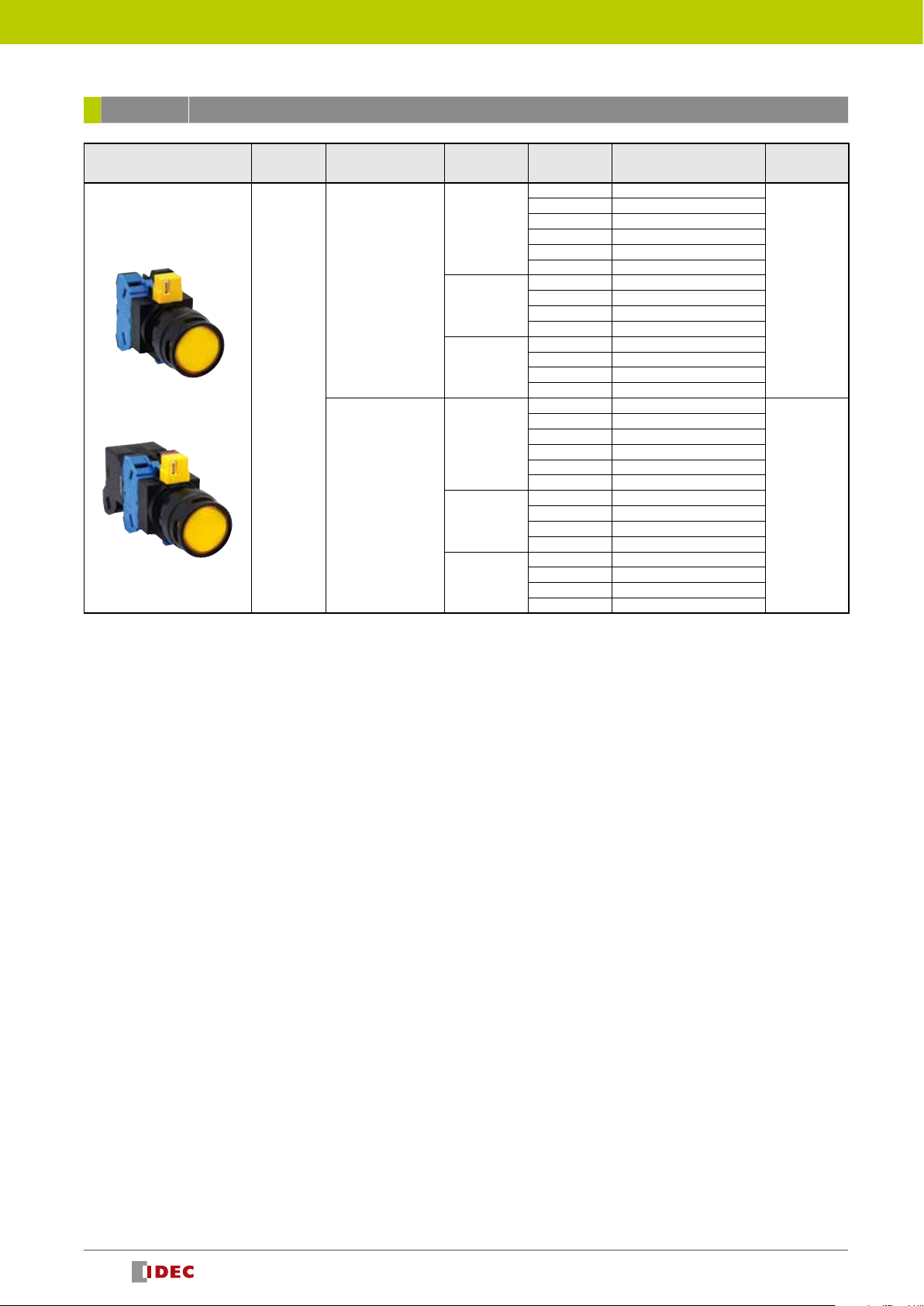

Page 17

ø22 HW Series Illluminated Pushbuttons

LED Mushroom (ø40mm) (Marking Type)

Package Quantity: 1

Shape Illumination Operation Illumination Contact Part No. Color Code

ø40mm Mushroom

(Marking type)

HW1L-M4

HW1L-A4

Momentary

(24V AC/DC)

With transformer

(100/110V AC)

• Specify a color code in place of ∗ in Part No. R (red), G (green), Y (yellow), A (Amber), W (white), S (blue), PW (pure white)

• Illuminated pushbuttons have an LED lamp installed.

• See page 5 for other operating voltage such as 6V AC/DC, 12V AC/DC, and 110V DC.

• See page 5 for other contact congurations and gold-plated silver contacts.

• Illuminated pushbutttons of 24V AC/DC or below with 2 or 4 contact blocks have a dummy block.

• See page 19 for bottom view.

• See page 12 for how to specify units without LED lamps.

• When using a commercially available lamp, choose a lamp with rated voltage 5 to 30V AC/DC and 1W maximum, and with the same base and shape.

Make sure of correct operation before installation. The operation of illuminated pushbutton switches cannot be guaranteed when a commercially available lamp is

used.

LED

Maintained

24V AC/DC

100/110V AC

200/220V AC

24V AC/DC

100/110V AC

200/220V AC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

1NO-1NC

2NO

2NC

2NO-2NC

HW1L-M410Q4∗

HW1L-M401Q4∗

HW1L-M411Q4∗

HW1L-M420Q4∗

HW1L-M402Q4∗

HW1L-M422Q4∗

HW1L-M411H2∗

HW1L-M420H2∗

HW1L-M402H2∗

HW1L-M422H2∗

HW1L-M411M2∗

HW1L-M420M2∗

HW1L-M402M2∗

HW1L-M422M2∗

HW1L-A410Q4∗

HW1L-A401Q4∗

HW1L-A411Q4∗

HW1L-A420Q4∗

HW1L-A402Q4∗

HW1L-A422Q4∗

HW1L-A411H2∗

HW1L-A420H2∗

HW1L-A402H2∗

HW1L-A422H2∗

HW1L-A411M2∗

HW1L-A420M2∗

HW1L-A402M2∗

HW1L-A422M2∗

R

G

Y

A

W

S

PW

R

G

Y

A

W

S

PW

17

Page 18

ø22 HW Series Illluminated Pushbuttons

LOCK

26.5

25

29.6

29.6

24.6

LOCK

26.5

25

29.8

29.6

24.6

LOCK

26.5

25

29.4

ø23.5

29.6

LOCK

26.5

25

29.6

ø23.5

29.6

LOCK

26.5

25

29.8

ø23.5

29.6

LOCK

26.5

25

29.4

ø23.5

Locking Ring

LOCK

26.5

25

29.6

ø23.5

Panel Thickness

LOCK

26.5

25

29.8

ø23.5

26.5

26.5

25

29.4

ø23.5

LOCK

LOCK

26.5

25

29.6

ø23.5

LOCK

26.5

25

29.8

ø23.5

26.5

LOCK

26.5

25

29.4

ø23.5

LOCK

26.5

25

29.6

ø23.5

ø29.6

LOCK

26.5

25

29.8

ø23.5

ø29.6

26.5

LOCK

26.5

25

29.4

29.6

24.6

Dimensions

Illuminated Pushbuttons (Momentary / Maintained)

Round Flush Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Safety Lever Lock

41.4

Panel Thickness

0.8 to 6

ø29

41.4

Locking Ring

Safety Lever Lock

0.8 to 6

Safety Lever Lock

ø29

41.4

Locking Ring

Panel Thickness

0.8 to 6

ø29

All dimensions in mm.

LOCK

25

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

13

79.5(2 blocks), 99.5 (4 blocks)

0.5

13

89.5 (2 blocks), 109.5 (4 blocks)

Round Extended Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Locking Ring

Safety Lever Lock

41.4

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

Panel Thickness

0.8 to 6

13

18.5

ø29

41.4

79.5(2 blocks), 99.5 (4 blocks)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

13

18.5

Locking Ring

Safety Lever Lock

41.4

ø29

89.5 (2 blocks), 109.5 (4 blocks)

Round Extended with Full Shroud Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Locking Ring

Safety Lever Lock

41.4

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

Panel Thickness

0.8 to 6

18.5

41.4

79.5 (2 blocks), 99.5 (4 blocks)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

18.5

41.4

89.5 (2 blocks), 109.5 (4 blocks)

Locking Ring

Safety Lever Lock

0.5

13

Panel Thickness

0.8 to 6

13

18.5

Panel Thickness

0.8 to 6

18.5

ø23.5

29.8

LOCK

25

ø29

ø23.5

29.8

LOCK

25

ø29.6

ø23.5

29.8

Square Flush Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Locking Ring

Safety Lever Lock

41.4

49.4 (1 block)

69.4 (2, 3 blocks)

89.4 (4 blocks)

Panel Thickness

0.8 to 6

13

41.4

79.5 (2 blocks), 99.5 (4 blocks)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

13

41.4

89.5 (2 blocks), 109.5 (4 blocks)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

13

LOCK

25

26.5

29.6

24.6

29.8

Flush with Square Bezel Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Locking Ring

Safety Lever Lock

41.4

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

18

Panel Thickness

0.8 to 6

13

41.4

Locking Ring

Safety Lever Lock

79.5 (2 blocks), 99.5 (4 blocks)

Panel Thickness

0.8 to 6

13

41.4

89.5 (2 blocks), 109.5 (4 blocks)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

13

LOCK

25

26.5

29.6

ø23.5

29.8

Page 19

ø22 HW Series Illluminated Pushbuttons

26.5

25

41.4

29.4

LOCK

LOCK

26.5

25

29.6

Locking Ring

LOCK

26.5

25

29.8

26.5

LOCK

26.5

25

29.4

29.6

Locking Ring

LOCK

26.5

25

29.6

29.6

Locking Ring

LOCK

26.5

25

29.8

29.6

26.5

LOCK

29.4

25

26.5

Locking Ring

LOCK

29.6

25

26.5

Locking Ring

LOCK

29.8

25

26.5

26.5

Dimensions

Illuminated Pushbuttons (Momentary / Maintained)

ø29mm Mushroom Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

Safety Lever Lock

ø29

41.4

Panel Thickness

0.8 to 6

Safety Lever Lock

41.4

ø29

Locking Ring

Panel Thickness

0.8 to 6

All dimensions in mm.

LOCK

25

ø29

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

13

23.2

79.5 (2 blocks), 99.5 (4 blocks)

13

23.2

89.5 (2 blocks), 109.5 (4 contacts)

ø29mm Mushroom with Square Bezel Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Panel Thickness

Safety Lever Lock

41.4

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

0.8 to 6

13

23.2

41.4

ø29

Safety Lever Lock

79.5 (2 blocks), 99.5 (4 contacts)

Panel Thickness

0.8 to 6

13

23.2

ø29

41.4

89.5 (2 blocks), 109.5 (4 contacts)

Locking Ring

Safety Lever Lock

ø40mm Mushroom with Square Bezel Terminal screws: M3.5, integrated terminal cover

6, 12, 24V AC/DC, Without LED lamp 100/110V AC, 200/220V AC (240V maximum) 110V DC, 380V AC minimum

Panel Thickness

13

0.8 to 6

23.2

ø40

41.4

Safety Lever Lock

41.4

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

Safety Lever Lock

79.5 (2 blocks), 99.5 (4 blocks)

Panel Thickness

0.8 to 6

13

23.2

ø40

41.4

89.5 (2 blocks), 109.5 (4 blocks)

Locking Ring

Safety Lever Lock

13

23.2

Panel Thickness

0.8 to 6

13

23.2

Panel Thickness

0.8 to 6

13

23.2

29.8

LOCK

25

ø29

25

ø40

29.6

29.8

LOCK

29.8

Bottom View

6, 12, 24V AC/DC, Without LED lamp

Dummy block

X1

100/110V AC, 200/220V AC

(240V AC maximum)

Full voltage

adapter

X2X1

X2

1 contact block 3 contact blocks 2/4 contact blocks

• For DC-DC Converter types, terminal X1 is ⊕, X2 is

• See page 49 for wiring.

110V DC, 380V AC minimum

.

19

Page 20

ø22 HW Series Dual Pushbuttons

Dual Pushbuttons (without Pilot Light)

Specify a button color code in place of

HW7D

Shape

and legend code in place of

2

in the Part No. Package Quantity: 1

3

Operation Button Style

Flush (top)

Flush (bottom)

Momentary

Flush (top)

Extended (bottom)

Flush (top)

Flush (bottom)

Interlock (*1)

Flush (top)

Extended (bottom)

Contact

Top Button Bottom Button

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

Part No.

HW7D-B111001

HW7D-B111010

HW7D-B111111

HW7D-B112002

HW7D-B112020

HW7D-B121001

HW7D-B121010

HW7D-B121111

HW7D-B122002

HW7D-B122020

HW7D-B211001

HW7D-B211010

HW7D-B211111

HW7D-B212002

HW7D-B212020

HW7D-B221001

HW7D-B221010

HW7D-B221111

HW7D-B222002

HW7D-B222020

32

32

32

32

32

32

32

32

GR: Green (top)

32

Red (bottom)

32

WB: White (top)

32

Black (bottom)

32

32

32

32

32

32

32

32

32

2

Button Color Code

• For other contact arrangements, see Ordering Information on page 8 and Contact Arrangement Chart on page 23.

• Dual pushbuttons with 3 contact blocks have a dummy block.

• See page 23 for top and bottom button contact mounting positions.

*1) Interlock: Momentary operation. When one of the buttons is pressed, the other button cannot be operated.

Do not operate top and bottom buttons at the same time. Operating the buttons at the same time may lead to malfunctions.

3

Legend Code

Black: Without legend

1:

I / ON (top)

O / OFF (bottom)

20

Page 21

LED Dual Pushbuttons (with Pilot Light)

Specify a LED color code in place of

HW7D

LED: LSTD-2* (24V AC/DC)

Shape

1

button color code in place of

,

2 ,

and legend code in place of

ø22 HW Series Dual Pushbuttons

in the Part No. Package Quantity: 1

3

Contact

Operation Button Style Illumination

Flush (top)

Flush (bottom)

Momentary

Flush (top)

Extended (bottom)

Flush (top)

Flush (bottom)

Interlock (*1)

Flush (top)

Extended (bottom)

24V AC/DC

24V AC/DC

24V AC/DC

24V AC/DC

Top

Button

Bottom

Button

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

1NO 1NC

1NO 1NO

1NO-1NC 1NO-1NC

2NO 2NC

2NO 2NO

Part No.

HW7D-L111001Q4

HW7D-L111010Q4

HW7D-L111111Q4

HW7D-L112002Q4

HW7D-L112020Q4

HW7D-L121001Q4

HW7D-L121010Q4

HW7D-L121111Q4

HW7D-L122002Q4

HW7D-L122020Q4

HW7D-L211001Q4

HW7D-L211010Q4

HW7D-L211111Q4

HW7D-L212002Q4

HW7D-L212020Q4

HW7D-L221001Q4

HW7D-L221010Q4

HW7D-L221111Q4

HW7D-L222002Q4

HW7D-L222020Q4

LED

321

321

321

321

321

321

321

321

R

321

G

321

A

321

W

S

321

PW

321

321

321

321

321

321

321

321

• LED lamp code: R (red), G (green), A (amber), W (white), S (blue), PW (pure white)

• Only W (white) lens is available.

• See page 6 for other operating voltage such as 100/110V AC and 200/220V AC.

• See page 23 for other contact congurations

• See page 6 for gold-plated silver contacts.

• Illuminated pushbutttons of 24V AC/DC or below with 2 or 4 contact blocks have a dummy block.

• See page 23 for top and bottom button contact mounting positions.

*1) Interlock: Momentary operation. When one of the buttons is pressed, the other button cannot be operated.

Do not operate top and bottom buttons at the same time. Operating the buttons at the same time may lead to malfunctions.

2

Button Color

Code

GR: Green (top)

Red (bottom)

WB: White (top)

Black (bottom)

3

Legend Code

Black: Without

legend

1: I / ON (top)

O / OFF (bottom)

21

Page 22

ø22 HW Series Dual Pushbuttons

41.4

41.4

41.4

41.4

29.8

54.8

18.7

24.6

18.7

Dimensions

Dual Pushbuttons

All dimensions in mm.

Without Pilot Light Terminal screws: M3.5, integrated terminal cover

Flush (top), Flush (bottom)

Locking Ring

Safety Lever Lock

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Flush (top), Extended (bottom)

Locking Ring

Safety Lever Lock

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Flush (top), Extended (bottom) (with legend)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

14.5

Panel Thickness

0.8 to 6

14.5

20

Panel Thickness

0.8 to 6

54.8

18.7 18.7

24.6

29.8

18.7

54.8

18.7

24.6

29.8

With Pilot Light Terminal screws: M3.5, integrated terminal cover

Flush (top), Flush (bottom) (24V AC/DC)

Locking Ring

Safety Lever Lock

49.4 (1 block)

69.4 (2 or 3 blocks)

89.4 (4 blocks)

Flush (top), Flush (bottom) (240V AC maximum)

Locking Ring

Safety Lever Lock

79.5 (2 blocks), 99.5 (4 blocks)

Flush (top), Flush (bottom) (380V AC minimum)

Locking Ring

Safety Lever Lock

Panel Thickness

0.8 to 6

14.5

Panel Thickness

0.8 to 6

14.5

Panel Thickness

0.8 to 6

18.7 18.7

24.6

29.8

18.7 18.7

24.6

29.8

54.8

54.8

41.4

49.4 (1 or 2 blocks)

69.4 (3 or 4 blocks)

Bottom View

Without Pilot Light

Dummy Block

3 contact bocks

With Pilot Light

6, 12, 24V AC/DC

18.7

54.8

18.7

14.5

20

24.6

29.8

41.4

89.5 (2 blocks), 109.5 (4 blocks)

14.5

54.8

18.7 18.7

24.6

29.8

2/4 contact blocks

Dummy Block

100/110V AC, 200/220V AC

(240V maximum)

380V AC minimum

X1

X2X1

3 contact bocks

• See page 48 to 49 for wiring.

• Mounting position of the dummy block may change according to the contact conguration of the top and bottom buttons.

22

2/4 contact blocks

X2

Page 23

ø22 HW Series Dual Pushbuttons

Contact Arrangement Chart

Contact Contact Block Top Button Bottom Button

Top

Button

1NO 1NO 1010

1NO 1NC 1001

1NC 1NO 0110

1NO 1NO-1NC 1011

2NO 2NO 2020

2NO 1NO-1NC 2011

2NO 2NC 2002

1NO-1NC 1NO-1NC 1111

1NO-1NC 2NC 1102

• Transformer types cannot mount 3 contact blocks.

• Contact blocks and are actuated by the top button. Contact blocks and are actuated

by the bottom button.

Bottom

Button

Contact

Code

Mounting

Position

➀ NC

Contact Normal Push Normal Push

NO

NO

NO

NC

NO

NO

NO

− Dummy Block

NC

NO

NO

NO

NO

NO

NO

NO

NC

NO

NC

NO

NC

NO

NO

NC

NC

NO

NC

NC

NC

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

Contact Block Mounting Position

Full Voltage Adapter

With Pilot Light

(Full Voltage Type)

With Pilot Light

(Transformer Type)

Part No. Example

HW7D-B121111GR

Contact Code

Contact Block Top Button Bottom Button

Mounting

Position

Contact Normal Push Normal Push

NO ●

NO ●

NC ●

NC ●

Button Position

Pushbutton Operation

23

Page 24

ø22 HW Series Selector Switches

12

12

1

0

1

0

1

0

102

Selector Switches (Knob Operator)

Knob Operator

HW1S

Shape

Package Quantity: 1

Contact Block Operator Position

Maintained (90°)

Contact

90°

2-position/

60°

2-position

Mounting

Position

1NO

(10)

1NO-1NC

(11)

2NO

(20)

2NO-2NC

(22)

Contact 1 2

NO

- Dummy Block

NO

NC

NO

NO

NO

NC

NO

NC

HW1S-2T10 HW1S-21T10

HW1S-2T11 HW1S-21T11

HW1S-2T20 HW1S-21T20

HW1S-2T22 HW1S-21T22

Maintained

Contact Block Operator Position

Contact

Mounting

Position

2NO

(20)

2NC

(02)

2NO-2NC

(22N1)

45°

3-position

4NO

(40)

4NC

(04)

2NO-1NC

(21N1)

Contact 1 0 2

NO

NO

NC

NC

NO

NO

NC

NC

NO

NO

NO

NO

NC

NC

NC

NC

●

NO

NO

NC

- Dummy Block

HW1S-3T20 HW1S-31T20 HW1S-32T20 HW1S-33T20

HW1S-3T02 HW1S-31T02 HW1S-32T02 HW1S-33T02

HW1S-3T22N1 HW1S-31T22N1 HW1S-32T22N1 HW1S-33T22N1

HW1S-3T40 HW1S-31T40 HW1S-32T40 HW1S-33T40

HW1S-3T04 HW1S-31T04 HW1S-32T04 HW1S-33T04

HW1S-3JT21N1 − − −

• Knob operator: white indicator on black body

• On the contact arrangement marked with

in the table above, the rated current (load switching current) is reduced to a half of the related current of the contact

block. The rated insulation voltage and the rated thermal current remain unchanged.

• For models with , contacts may overlap when the operator position is changed.

• Other contact arrangements are also available. See page 32 to 34.

• Selector switches with one or three contact blocks contain a dummy block.

• See page 6 for gold-plated silver contacts.

• Turn the operator to each position accurately.

Spring Return from

Right (60°)

Spring Return

from Right

2

2

− −

Spring Return

from Left

2

Spring Return

Two-way

Contact Block Mounting Position

24

Page 25

12

21

12

Key Selector Switches (Pin Tumbler Key)

12

Shape

Pin Tumbler Key

HW1K

• Each selector key switch is supplied with two keys.

• 15 types of key numbers are available in addition to standard (500) key. See below for details.

• Spring-return type is also available. See below for details.

• Key retained position can be selected. See below for details.

No. of

Positions

90°

2-position

Contact

1NC

(01)

1NO-1NC

(11)

2NC

(02)

2NO-1NC

(21)

3NC

(03)

2NO-2NC

(22)

Contact Block Operator Position

Mounting

Position

Contact 1 2

NC

− Dummy Block

NO

NC

NC

NC

NO

NO

NC

− Dummy Block

NC

NC

NC

− Dummy Block

NO

NC

NO

NC

ø22 HW Series Key Selector Switches

Package Quantity: 1

Cam Code

− HW1K-2PA01

− HW1K-2PA11

− HW1K-2PA02

− HW1K-2PA21

− HW1K-2PA03

− HW1K-2PA22

Maintained

Ordering Information

Example:

• For more contact arrangement, see page 32 to 34.

• Key selector switches with one or three contact blocks contain a dummy block.

• See page 7 for gold-plated silver contacts.

• Turn the operator to each position accurately.

HW1K-2JPA01-501

Not specied: 500 (default key)

501-515: The key number is engraved on the key cylinder.

(default key is not engraved with a number)

Cam code: Blank or J

Operator position code:

2: 2-position, maintained

21: 2-position, spring return from right

Maintained (90° 2-position)

Cam code: blank Cam code: J Cam code: blank

Contact Block Mounting Position

Spring Return

(60° 2-position)

Spring return

from right

Key removable/retained positions

A: Removable/retained in all positions

B: Removable in left theft only

C: Removable in right only

Key Retained Position

A (removable in

all positions)

A (removable in

all positions)

: Key removal position

B (removable in

left only)

Cam code: blank

Key Retained Position

B (removable in

left only)

Cam code: J

C (removable in

right only)

C (removable in

right only)

: Key retained position

Note: The key cannot be removed in a spring return

position.

25

Page 26

ø22 HW Series Key Selector Switches

0

12

0

12

0

12

0

12

0

12

Key Selector Switches (Pin Tumbler Key)

Shape

No. of

Positions

Contact Code

Pin Tumbler Key

HW1K

45°

3-position

• On the contact arrangement marked with

in the table above, the rated current (load switching current) is reduced to a half of the related current of the contact

block. The rated insulation voltage and the rated thermal current remain unchanged.

• For models with , contacts may overlap when the operator is changed.

• For contact block mounting position, see the gure on the right.

• Each key selector switch is supplied with two keys.

• 15 types of key numbers are available in addition to standard (500) key. See below for details.

• Spring-return type is also available. See below for details.

• Key retained position can be selected. See table below details..

Contact Conguration Operator Position

Mounting

Position

2NC

(02)

2NO-2NC

(22N1)

4NC

(04)

2NO-1NC

(21N1)

4NC

(04)

Contact 1 0 2

NC

NC

NO

NO

NC

NC

NC

NC

NC

NC

NO

NO

NC

− Dummy Block

NC

NC

NC

NC

Contact Block Mounting Position

Package Quantity: 1

Maintained

Cam

Code

− HW1K-3PA02

− HW1K-3PA22N1

− HW1K-3PA04

J HW1K-3JPA21N1

S HW1K-3SPA04

Ordering Information

Example: HW1K-3 SPA04-501

Not specied: 500 (default key)

501-515:

Operator position code:

3: 3-position, maintained

31: 3-position, spring return from right

32: 3-position, spring return from left

33: 3-position, spring return two way

Maintained

(45° 3-position)

Maintained Spring Return from

Cam code:

blank, J, or S

Spring Return (45° 3-position)

Spring Return from

Right

Cam code: blank

• For more contact arrangement, see page 32 to 34.

• Key selector switches with one or three contact blocks contain a dummy

block.

• See page 7 for gold-plated silver contacts.

• Turn the operator to each position accurately.

The key number is engraved on the key cylinder.

(default key is not engraved with a number)

Cam code: Blank, J, or S

Left

Spring Return

Two-way

Key removal/retained positions

A: Removable in all positions

B: Removable in left and center

C: Removable in right and center

D: Removable in center only

E: Removable in right and left

G: Removable in left only

H: Removable in right only

Note: The key cannot be removed in a spring return position.

Key Retained Position (45° 3-position)

A (removable in

all positions)

E (removable in

right and left only)

B (removable in

left and center)

G (removable in

left only)

C (removable in

right and center)

H (removable in

right only)

: Key removal position

: Key retained position

Note: The key cannot be removed in a spring return position.

D (removable in

center only)

26

Page 27

12

21

12

Key Selector Switches (Disc Tumbler Key)

21

12

Disc Tumbler Key

HW1K

No. of

Positions

ø22 HW Series Key Selector Switches

Package Quantity: 1

Contact Conguration

Contact Code

1NO

(10)

1NC

(01)

1NO-1NC

(11)

2NO

(20)

2NC

90°

2-position/

60°

2-position

• Each key selector switch is supplied with two keys.

• 3 types of key numbers are available in addition to standard key.

• Key retained position can be selected. See table below for key retained positions.

(02)

2NO-1NC

(21)

3NC

(03)

2NO-2NC

(22)

Mounting

Position

Contact

NO

− Dummy Block

NC

− Dummy Block

NO

NC

NO

NO

NC

NC

NO

NO

NC

− Dummy Block

NC

NC

NC

− Dummy Block

NO

NC

NO

NC

Operator Position

1 2

Ordering Information

Example: HW1K-2JA01-1H

Maintained (90° 2-position)

Cam code: blank Cam code: J Cam code: blank

• For more contact arrangement, see page 32 to 34.

• Key selector switches with one or three contact blocks contain a dummy block.

• See page 7 for gold-plated silver contacts.

• Turn the operator to each position accurately.

Not specied: 231 (default key)

1H

2H

3H

Cam code: Blank or J

Operator position code:

2: 2-position, maintained

21: 2-position, spring return from right

Spring Return

(60° 2-position)

Spring Return from Right

The key number is engraved on the key cylinder.

(default key is not engraved with a number)

Maintained (90°)

Cam Code

− HW1K-2A10 HW1K-21B10

− HW1K-2A01 HW1K-21B01

− HW1K-2A11 HW1K-21B11

− HW1K-2A20 HW1K-21B20

− HW1K-2A02 HW1K-21B02

− HW1K-2A21 HW1K-21B21

− HW1K-2A03 HW1K-21B03

− HW1K-2A22 HW1K-21B22

Spring Return from Right (60°)

Contact Block Mounting Position

Key removal/retained positions

A: Removable in all positions

B: Removable in left only

C: Removable in right only

Key Retained Position

A (removable in

all positions)

A (removable in

all positions)

: Key removal position

: Key retained position

Note: The key cannot be removed in a spring return position.

B (removable in

left only)

Cam code: blank

Key Removal Position

B (removable in

left only)

Cam code: J

C (removable in

right only)

C (removable in

right only)

27

Page 28

ø22 HW Series Key Selector Switches

0

12

0

12

0

12

0

12