IDEC ID MW9ZT1 Datasheet

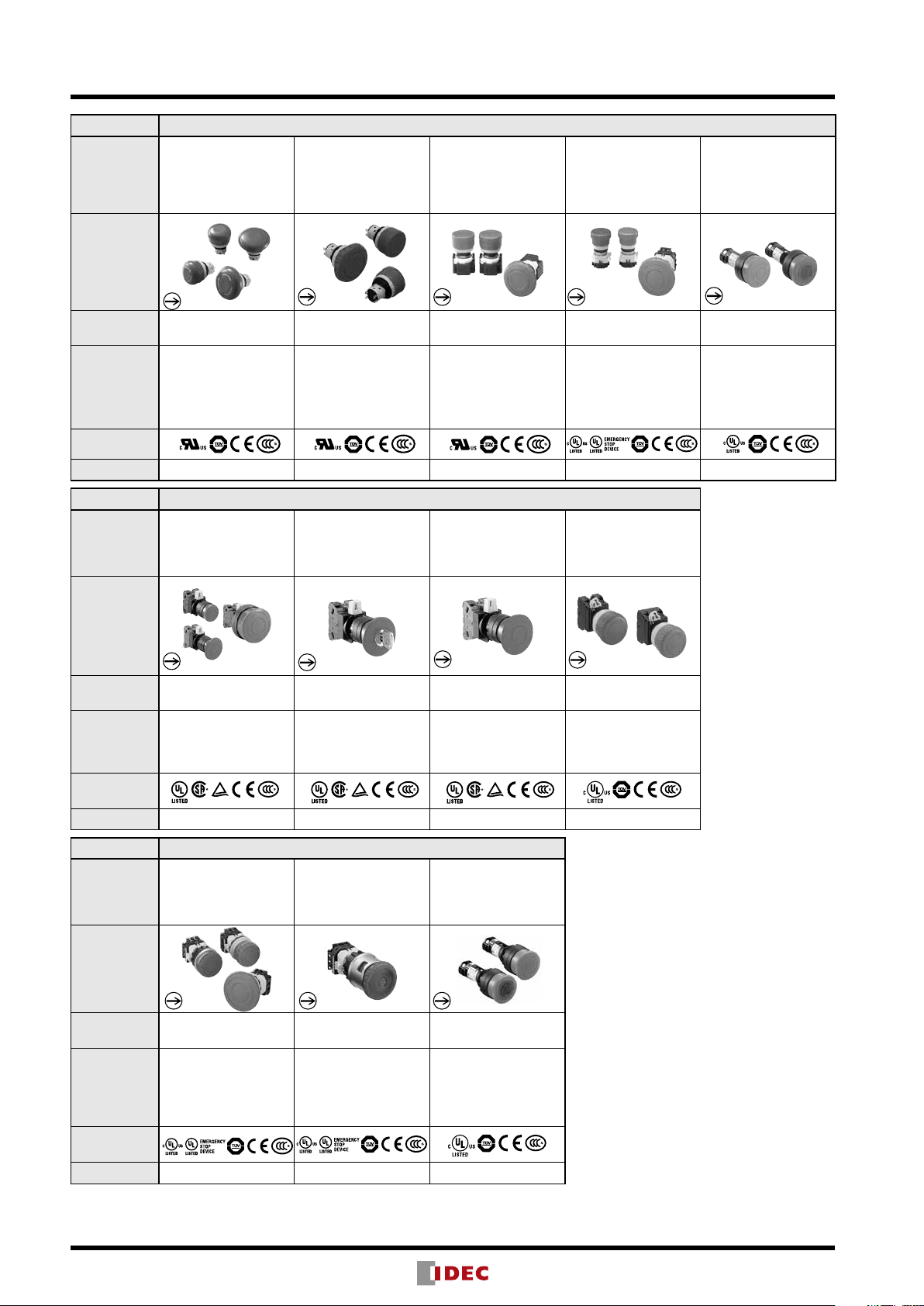

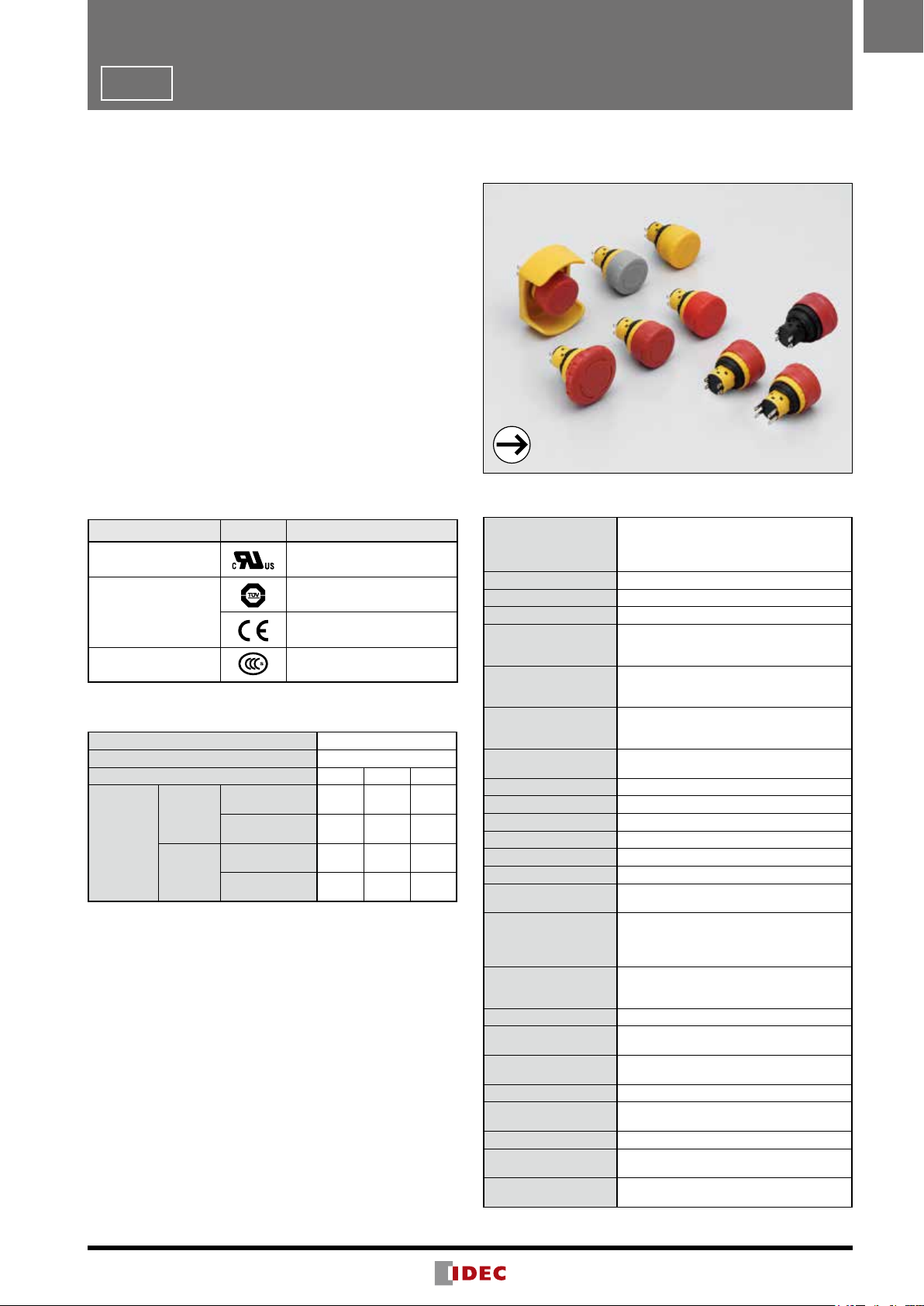

Emergency Stop Switches

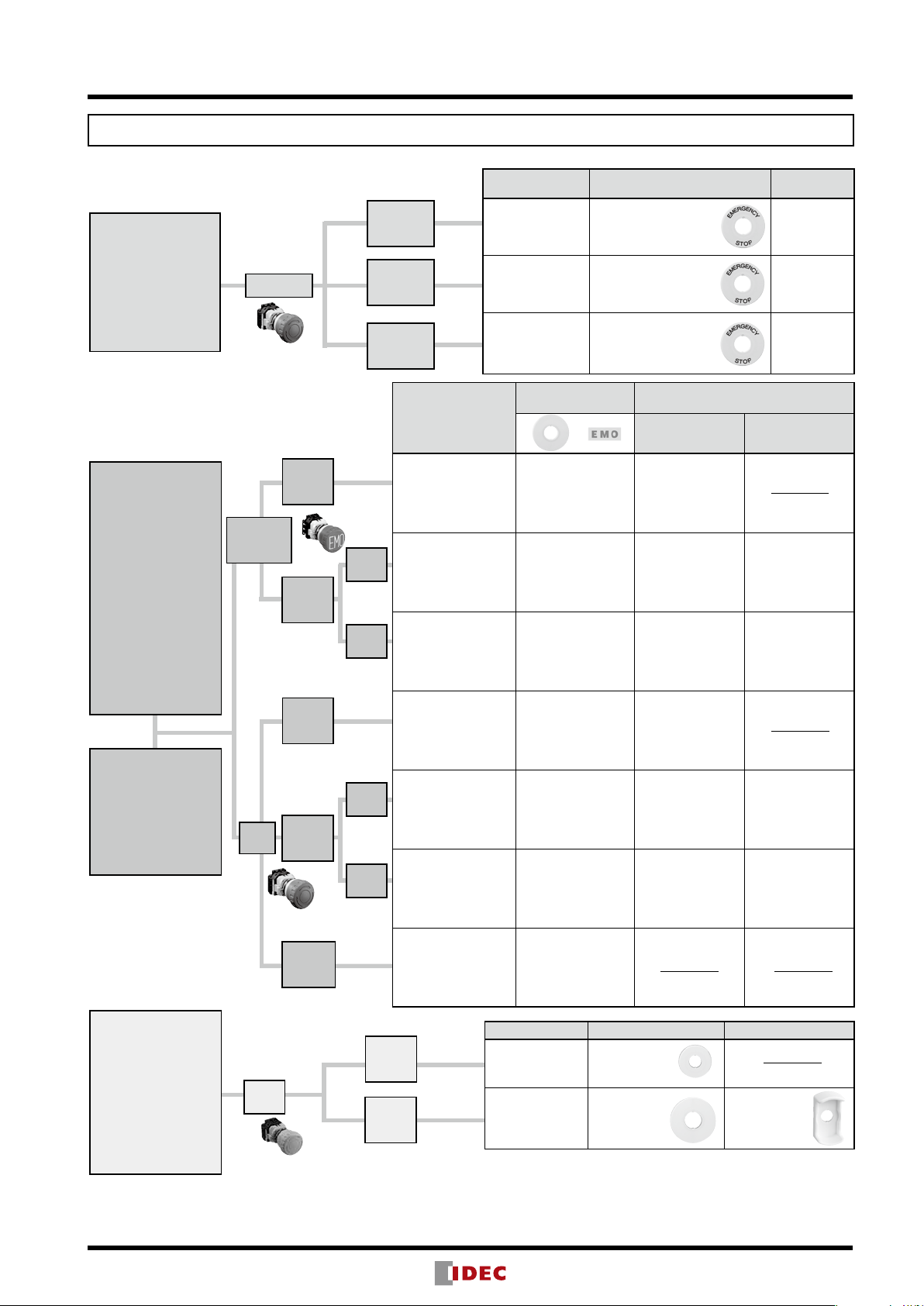

Emergency Stop Switches (Selection Guide)

Series Emergency Stop Switch

Name

Shape

ø16mm X6 Series

Pushlock Pull /

Turn Reset

(Unibody)

ø16mm XA Series

Pushlock Pull /

Turn Reset

(Unibody)

ø16mm XA Series

Pushlock Pull /

Turn Reset (with

Removable Contact

Block)

ø22mm XW Series

Pushlock Pull /

Turn Reset

ø22mm HW Series

Pushlock Turn Reset

(Unibody)

(Plastic/Flush Bezel)

Safety

Category

Applicable

Standards

Mark

Page 8 13 15 21 32

Series Emergency Stop Switch

Name

Shape

Safety

Category

Applicable

Standards

4 4 4 4 4

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

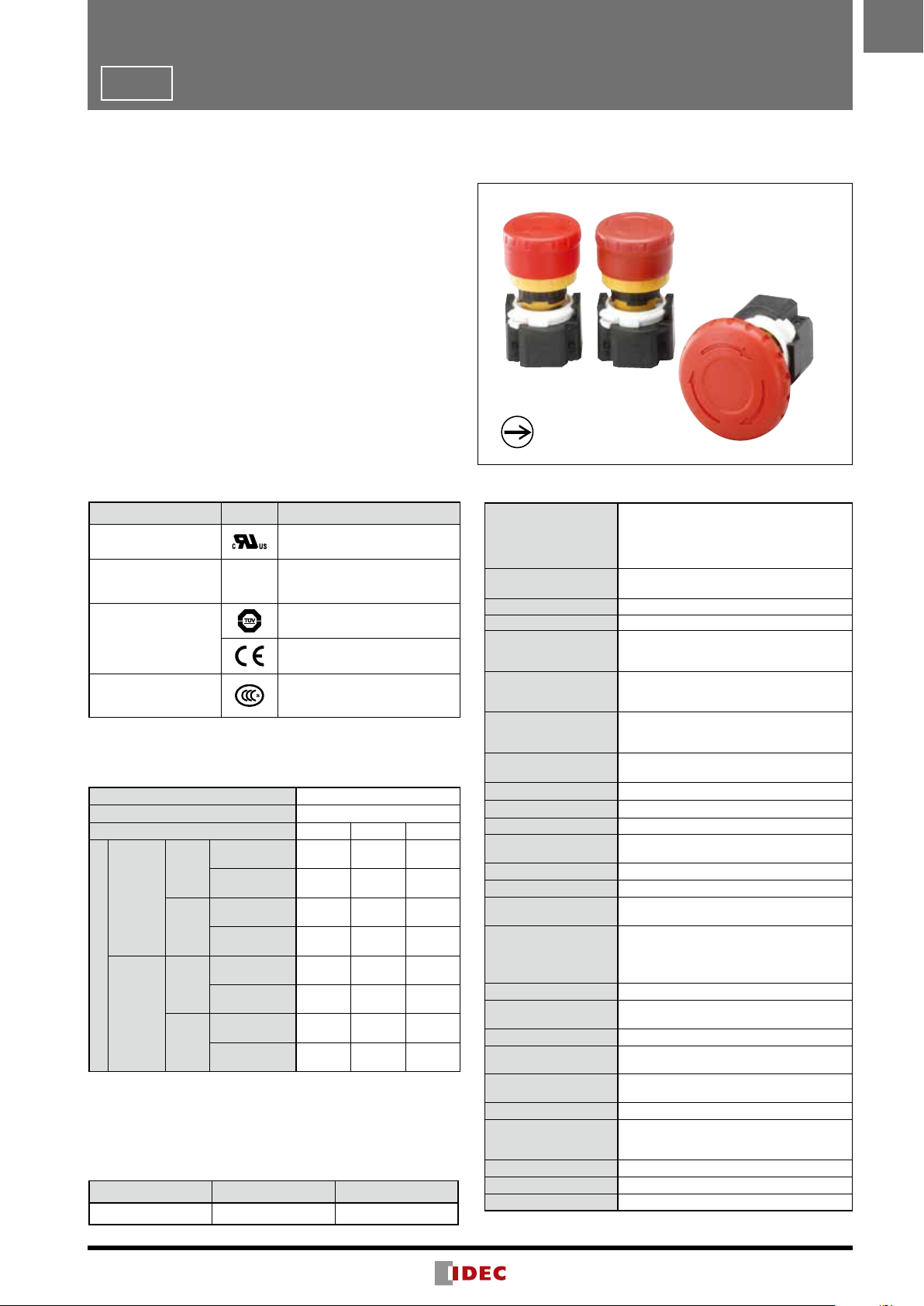

ø22mm HW Series

Pushlock Turn Reset

(with Removable

Contact Block)

4 4 4 4

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

ø22mm HW Series

Pushlock Key Reset

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

UL991

NFPA79

CSA C22.2 No.14

GB14048.5

ø22mm HW Series

Push-Pull

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

UL991

NFPA79

CSA C22.2 No.14

GB14048.5

ø22mm YW Series

Pushlock Pull /

Turn Reset

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

Mark

Page 34 35 35 40

Series Emergency Stop Switch

Name

Shape

Safety

Category

Applicable

Standards

Mark

Page

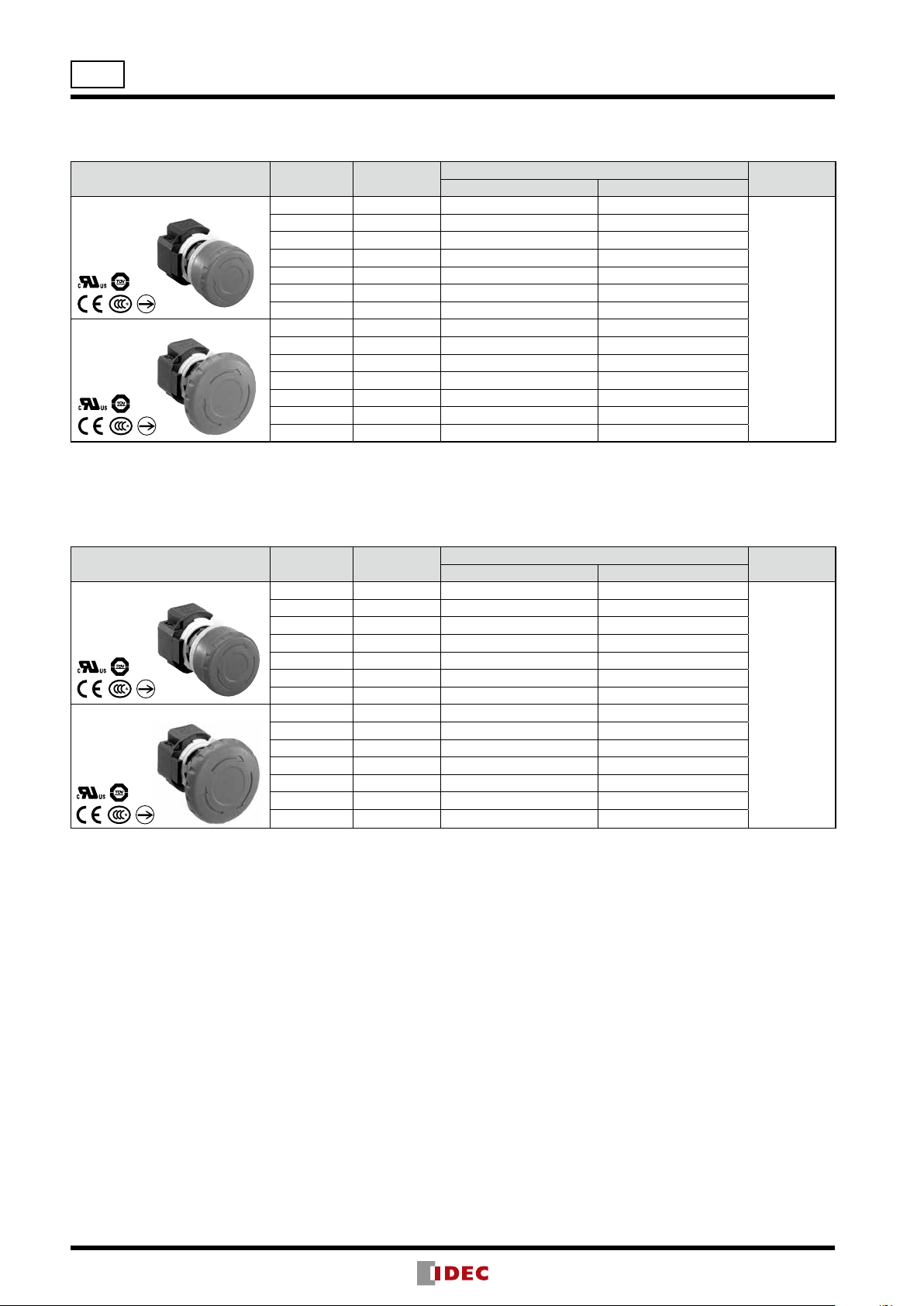

ø30mm XN Series

Pushlock Pull /

Turn Reset

(Plastic/Flush Bezel)

4 4 4

EN60947-5-5

UL508

UL991

NFPA79

CSA C22.2 No.14

GB14048.5

48

ø30mm XN Series

Pushlock Turn Reset

(Padlockable)

EN60947-5-5

UL508

UL991

NFPA79

CSA C22.2 No.14

GB14048.5

50 55

ø30mm HN Series

Pushlock Turn Reset

(Unibody)

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

2

Emergency Stop Switches (Selection Guide)

Series SEMI Emergency Off (EMO) Switch

Name

Shape

ø16mm XA Series

EMO Switch

Pushlock Pull /

Turn Reset

ø22mm XW Series

EMO Switch

Pushlock Pull /

Turn Reset

ø22 HW Series

EMO Switch

Pushlock Turn Reset

Switch Guard for

ø16mm XA Series

ø22mm HW/XW

Series

Safety

Category

Applicable

Standards

Mark —

Page 58 58 58 60

Series Stop Switch

Name

Shape

Safety

Category

Applicable

Standards

4 4 4 —

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

ø16mm XA Series

Pushlock Pull /

Turn Reset

(with Removable

Contact Block)

EN60947-5-1

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

ø16mm XA Series

Pushlock Pull /

Turn Reset

(Unibody)

EN60947-5-1

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

ø22 XW Series

Pushlock Pull /

Turn Reset

—

EN60947-5-1

UL508

CSA C22.2 No.14

GB14048.5

SEMI S2 0706

ø22 HW Series

Pushlock Turn Reset

Pushlock Pull

UL508

CSA C22.2 No.14

EN60947-5-5

GB14048.5

White Switch Guard

for ø22mm HW/XW

Series

—

Mark —

Page 62 62 63 63 64

3

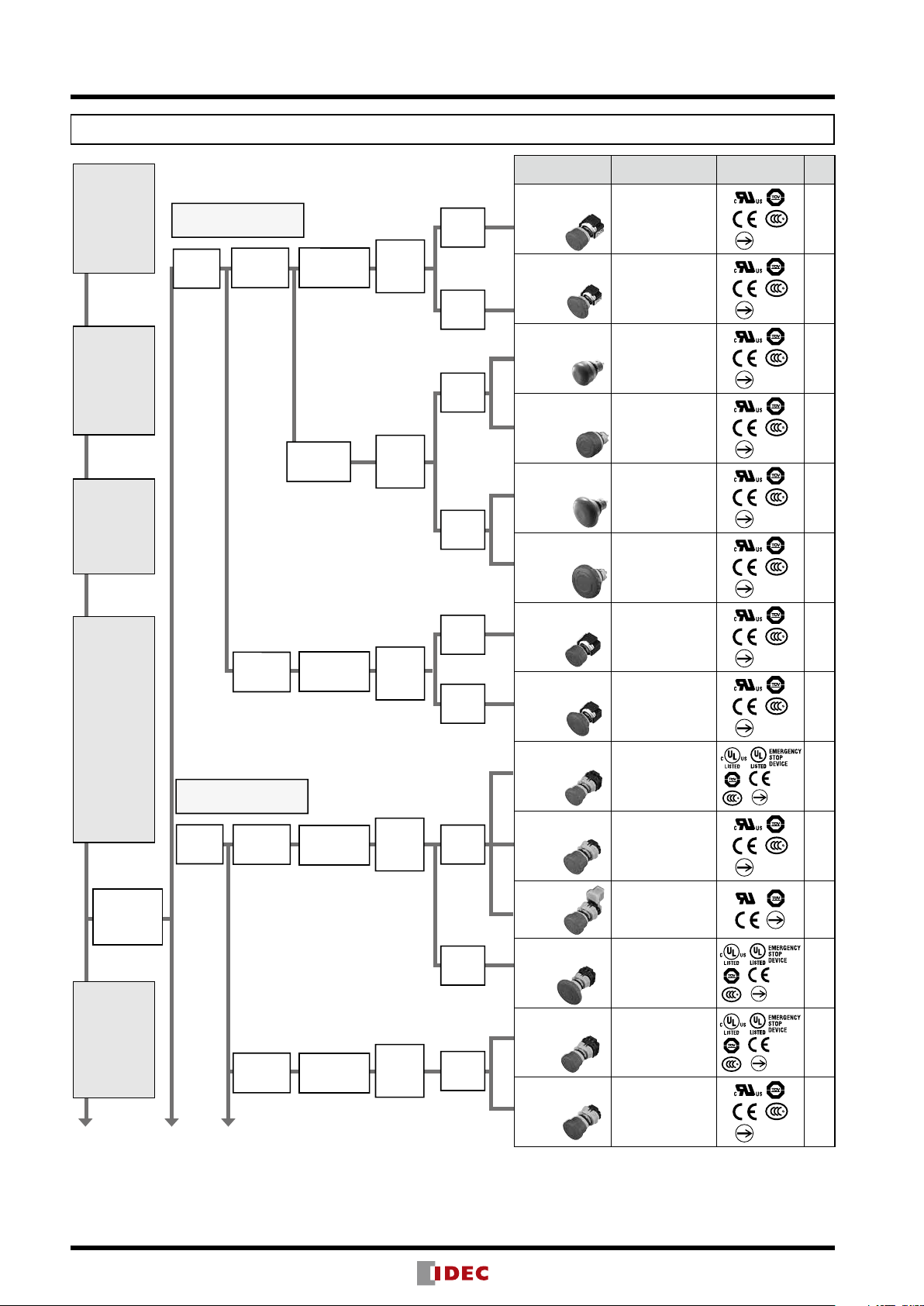

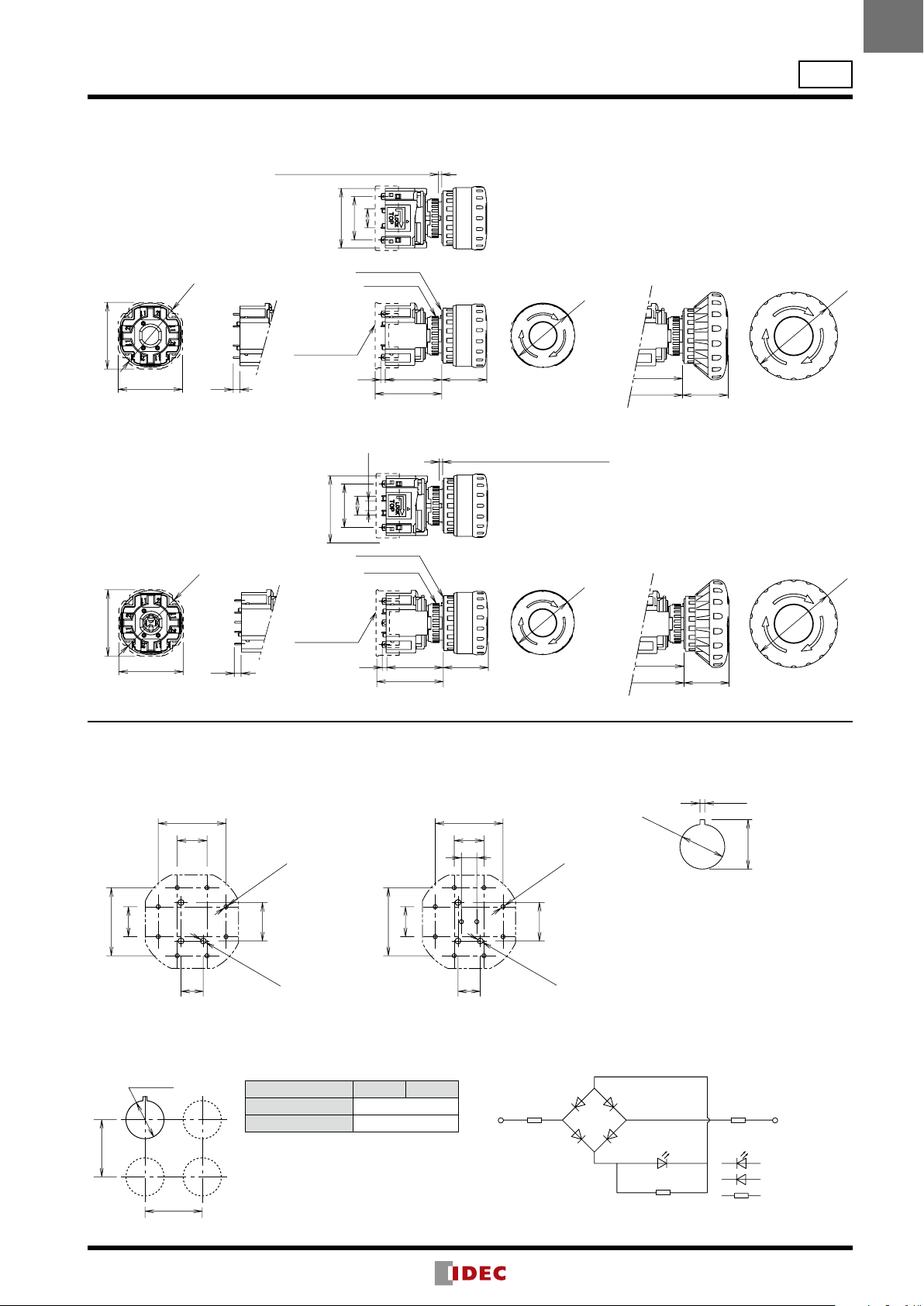

Emergency Stop Switches Selection Diagram

ISO / IEC Standards and Emergency Stop Switches

ISO 13850

4.4.1

mushroom-type

push-buttons

ISO 13850

4.4.4

The command

shall be

maintained

by engagement

(latching-in)

of the actuating

means.

ISO 13850

4.4.4

The actuator of

the emergency

stop device

shall be colored

red.

IEC 60947-5-5

5. Electrical

requirements

5.2 All normally

closed contact

elements of an

emergency stop

device shall

have a direct

opening action

(positive

opening action,

according to

annex K of IEC

60947-5-1.

Emergency

Stop Switch

Reverse Energy Structure

Safe Break Action

ø16mm

Mount

Hole

Reverse Energy Structure

Safe Break Action

ø22mm

Mount

Hole

Non

illuminated

Illuminated

Non

illuminated

(no safe break

action)

Detachable

Contact Block

Unibody

Detachable

Contact Block

Detachable

Contact Block

Pushlock

Pull or

Turn

Reset

Pushlock

Pull or

Turn

Reset

Pushlock

Pull or

Turn

Reset

Pushlock

Pull or

Turn

Reset

ø29mm

Button

ø40mm

Button

ø29mm

Button

ø40mm

Button

ø29mm

Button

ø40mm

Button

ø40mm

Button

Model

XA1E-BV3

(Solder, PC Board

Terminal)

XA1E-BV4

(Solder, PC Board

Terminal)

AB6E-3BV

(Solder Terminal)

XA1E-BV3U

(Solder, Solder/

Tab #110

Terminal)

AB6E-4BV

(Solder Terminal)

XA1E-BV4U

(Solder, Solder/

Tab #110

Terminal)

XA1E-LV3

(Solder, PC Board

Terminal)

XA1E-LV4

(Solder, PC Board

Terminal)

XW1E-BV4

(Screw Terminal)

XW1E-BV4

(Solder, PC Board

Terminal)

XW1E-BV4

(Connector)

Applicable

Standards

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508

Mark

Page

16

16

9

14

9

14

16

16

22

22

22

ISO 13850

4.4.6

As far as a

background

exists behind

the actuator

and as far as

is practicable, it

shall be colored

yellow.

Continued on Next Page

4

Illuminated

Detachable

Contact Block

Pushlock

Pull or

Turn

Reset

ø60mm

Button

ø40mm

Button

XW1E-BV5

(Screw Terminal)

XW1E-LV4

(Screw Terminal)

XW1E-LV4

(Solder, PC Board

Terminal)

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2 No.14

GB14048.5

22

23

23

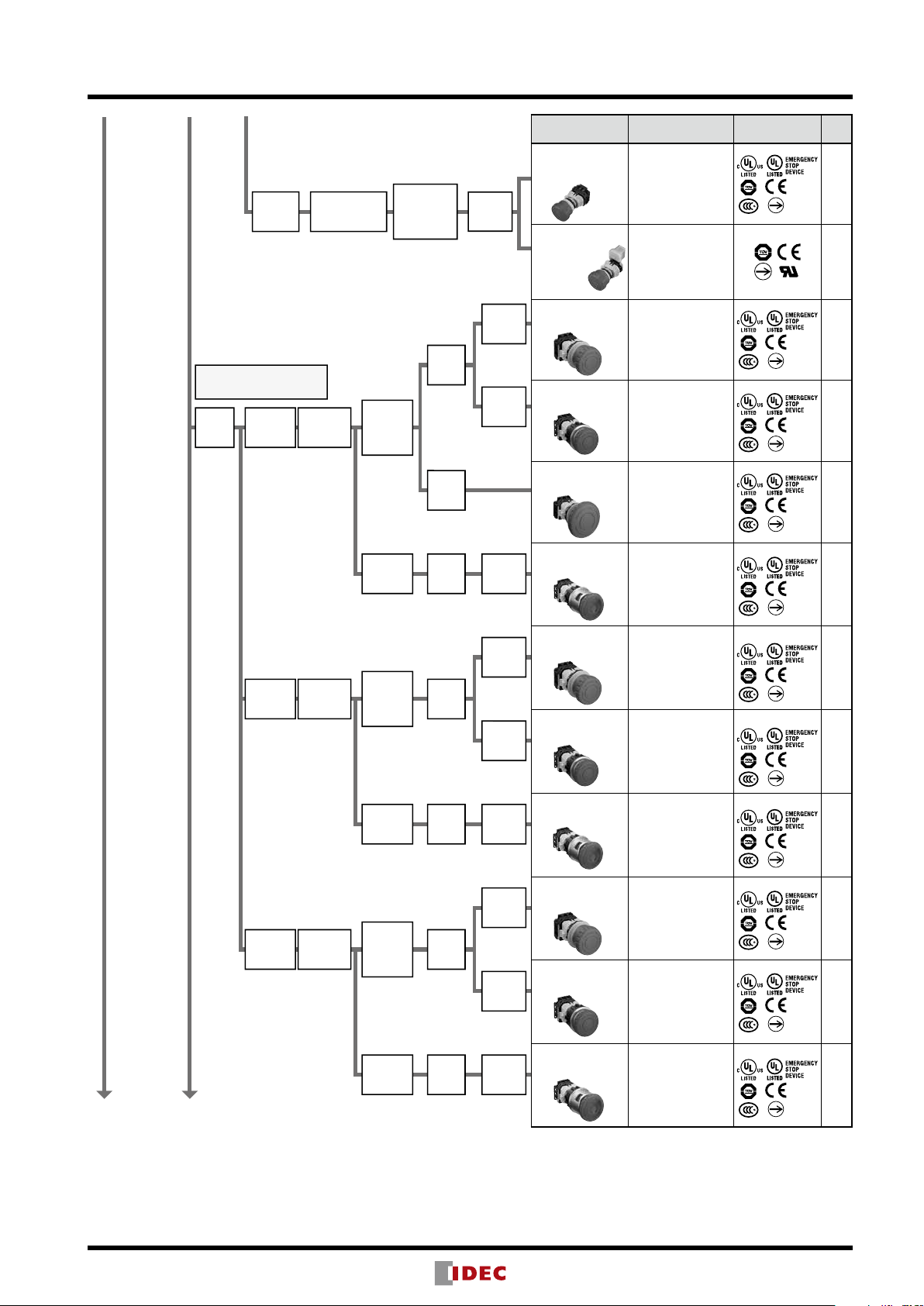

Emergency Stop Switches Selection Diagram

Continued on Next Page

Push-ON

Reverse Energy Structure

Safe Break Action

ø30mm

Mount

Hole

Non

illuminated

Illuminated

Push-ON

Detachable

Contact

Detachable

Contact

Detachable

Contact

Detachable

Contact

Block

Block

Block

Block

Pushlock

Pull or

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Pull or

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Pull or

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Pull or

Turn Reset

ø40mm

Button

ø60mm

Button

ø44mm

Button

ø40mm

Button

ø44mm

Button

ø40mm

Button

ø44mm

Button

ø40mm

Button

Plastic

Bezel

Flush

Bezel

Padlockable

Plastic

Bezel

Flush

Bezel

Padlockable

Plastic

Bezel

Flush

Bezel

Padlockable

Model

XW1E-TV4

(Screw Terminal)

XW1E-TV4

(Connector)

XN1E-BV4

(Plastic Bezel)

XN5E-BV4

(Flush Bezel)

XN1E-BV5

(Plastic Bezel)

XN4E-BL4

(Padlockable)

XN1E-LV4

(Plastic Bezel)

XN5E-LV4

(Flush Bezel)

XN4E-LL4

(Padlockable)

XN1E-TV4

(Plastic Bezel)

XN5E-TV4

(Flush Bezel)

XN4E-TL4

(Padlockable)

Applicable

Standards

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508/UL991

NFPA79

CSA C22.2

No.14

GB14048.5

Mark

Page

23

23

48

49

48

50

48

49

50

48

49

50

5

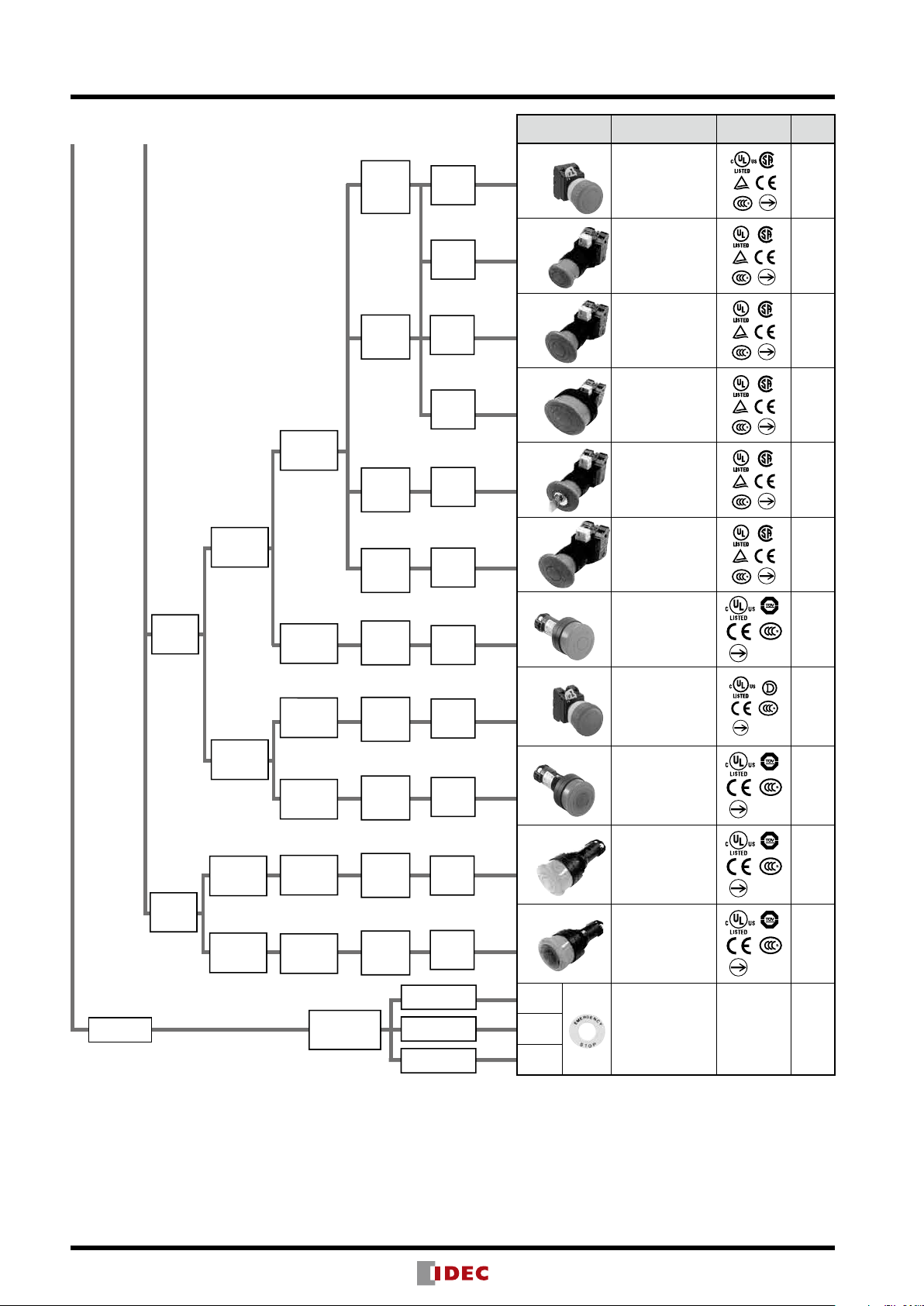

Emergency Stop Switches Selection Diagram

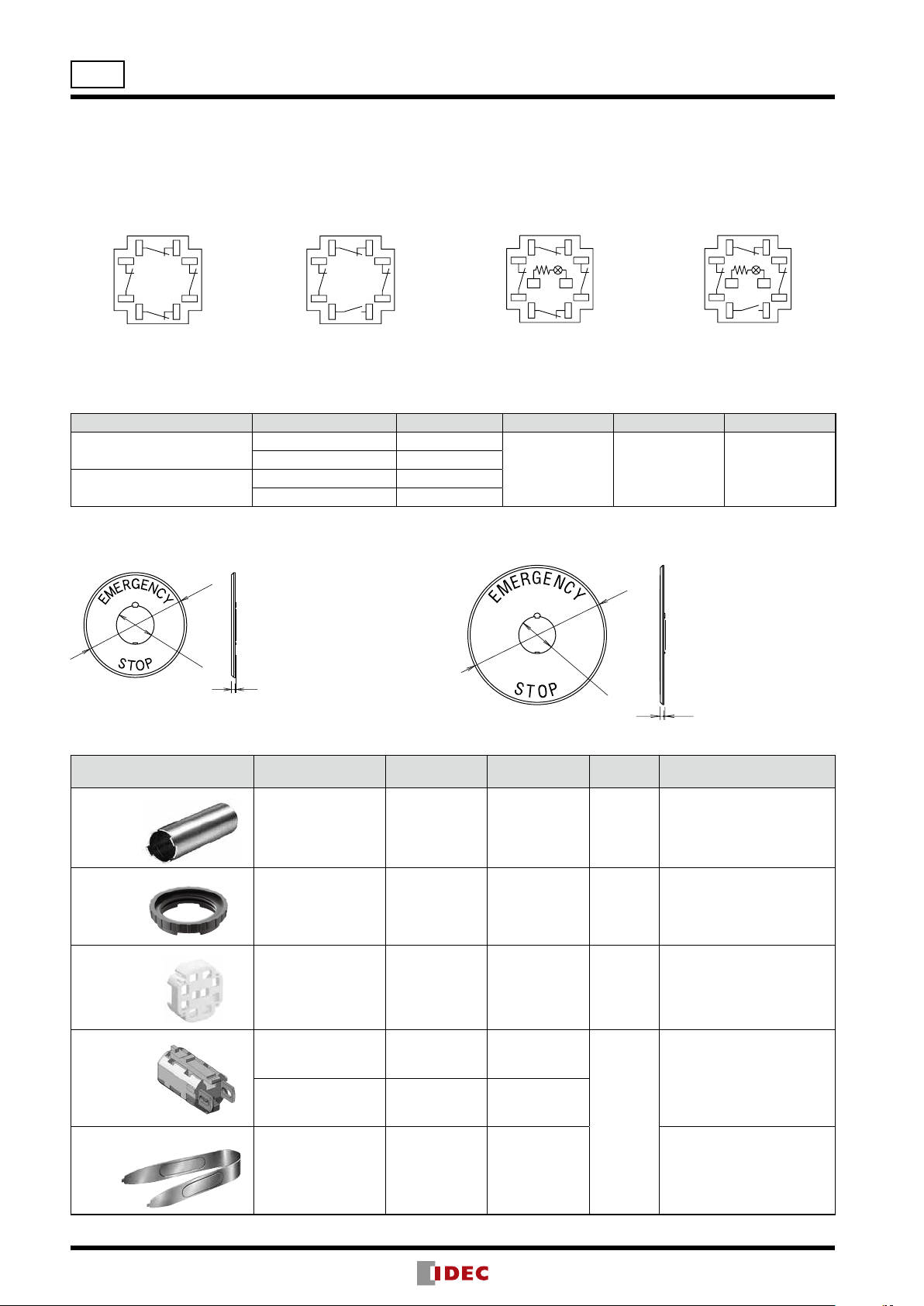

Accessories

ø22mm

Mount

Hole

ø30mm

Mount

Hole

Non

illuminated

Illuminated

Non

illuminated

Illuminated

Detachable

Contact

Block

Unibody

Detachable

Contact

Block

Unibody

Unibody

Unibody

Emergency

Stop

Nameplate

Pushlock

Pull or

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Key

Reset

Pushlock

Pull

Reset

Pushlock

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Turn

Reset

Pushlock

Turn

Reset

ø40mm

Button

ø29mm

Button

ø40mm

Button

ø60mm

Button

ø40mm

Button

ø40mm

Button

ø40mm

Button

ø40mm

Button

ø40mm

Button

ø40mm

Button

ø40mm

Button

ø16mm

Mount Hole

ø22mm

Mount Hole

ø30mm

Mount Hole

Model

YW1B-V4

HW1B-V3

HW1B-V4

HW1B-V5

HW1B-X4

HW1B-Y2

HW1E-BV4

YW1L-V4

HW1E-LV4

HN1E-BV4

HN1E-LV4

HAAV

HWAV

HNAV

Applicable

Standards

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

EN60947-5-5

UL508

CSA C22.2

No.14

GB14048.5

IEC 60947-5-5

IEC 60204-1

Mark Page

41

34

34

34

35

35

32

41

32

55

55

11

—

28

53

6

SEMI EMO Switch Guards

Switch and Background Color Selection Chart (IEC/SEMI/SEMATECH)

Emergency Stop

IEC 60947-5-5

IEC 60204-1

ISO 13850

•Red colored

•Mushroom

•Yellow background

•Shall be positioned

for easy access

Emergency Off

(EMO)

SEMATECH Application Guide for SEMI

S2-93

Red and mushroom

shaped button

•Yellow background

•EMO or Emergency

Off labeled

When installing a

guard

•Guard diameter

ø75mm minimum

•Button recessed from

the guard no more

than 3mm

Emergency Off

(EMO)

SEMI S2-0706

•Red and mushroom

shaped button

•Yellow background

•EMO or Emergency

Off labeled

Red button

Red button

(EMO

marking)

Red

button

ø16mm

mounting hole

ø22mm

mounting hole

ø16mm

mounting hole

ø22mm

mounting hole

Yellow

guard

White

guard

Yellow

guard

White

guard

Switch Applicable Nameplate (Note 1)

ø16mm

mounting

hole

ø22mm

mounting

hole

ø30mm

mounting

hole

XA1E

HA1E

HA1B-V

XW1E

HW1E

HW1B-V, HW1B-X

HW1B-Y

XN1E

XN4E

XN5E

HN1E

HAAV-0, HAAV-27

HAAV4-0

HAAV4-27

HWAV-0-Y, HWAV-27-Y

HWAV5-0

HWAV5-27

HWAV5F-27

HNAV-0

HNAV-27

Applicable Nameplate

(Note 1) / EMO label

Switch

SEMI SEMATECH

XA1E-BV4∗∗RH-EMO HAAV4-0 XA9Z-KG1 (Note 2)

HW9Z-KG1 (Note 2)

XW1E-BV4∗∗RH-EMO

HW1B-V4∗∗R-EMO

XW1E-BV4∗∗RH-EMO

HW1B-V4∗∗R-EMO

XA1E

HA1E

HA1B-V

XW1E

HW1E

HW1B-V (Note 4)

HW1B-X

HW1B-Y

XW1E

HW1E

HW1B-V (Note 4)

HW1B-X

HW1B-Y

HWAV-0-Y

HWAV-0-Y HW9Z-KG5-W HW9Z-KG5-W

HAAV-0, HAAV4-0

in combination with

HW9Z-EMO-NPP

HWAV-74-Y,

HWAV-0-Y

in combination with

HW9Z-EMO-NPP

HWAV-74-Y,

HWAV-0-Y

in combination with

HW9Z-EMO-NPP

HW9Z-KG2 (Note 2)

HW9Z-KG3 (Note 2)

HW9Z-KG4 (Note 2)

HW9Z-KG5

XA9Z-KG1 (Note 2)

HW9Z-KG1 (Note 2)

HW9Z-KG2 (Note 2)

HW9Z-KG3 (Note 2)

HW9Z-KG4 (Note 2)

HW9Z-KG5 (Note 3)

HW9Z-KG5-W

(Note 3)

Applicable

Switch Guard

N/A

N/A

N/A

Applicable Switch Guard

HW9Z-KG2 (Note 2)

HW9Z-KG4 (Note 2)

HW9Z-KG5

HW9Z-KG2 (Note 2)

HW9Z-KG4 (Note 2)

HW9Z-KG5 (Note 3)

HW9Z-KG5-W

(Note 3)

Local/Partial

Shut Down

SEMI S26-0308

•Should not use the

combination of red

button with yellow

background

•Should not be labeled as "EMO" or

"Emergency Off," or

the equivalent.

Note: Stop switch (yellow button) should not be labeled as

“EMS” or “Emergency Stop.”

Yellow

Button

ø30mm

mounting

hole

XN1E

XN4E

XN5E

HN1E

ø16mm

mounting hole

ø22mm

mounting hole

HNAV-0

in combination with

HW9Z-EMO-NPP

Switch Applicable Nameplate Applicable Switch Guard

XA1E-BV

HA1E-V2S∗Y

XW1E-BV4∗∗Y

HW1B-V

HW1B-Y2∗∗Y

Note 1: Marking plate legend

Note 2: Cannot be used with a nameplate.

Note 3: Cannot be used with HWAV5-∗.

Note 4: HW1B-V5 switch cannot be used with a switch guard.

Y

Y

HAAV-0-W

HAAV4-0-W

HWAV-0-W

HWAV5-0-W

HW9Z-KG4-W

(Note 2)

HW9Z-KG5-W

(Note 3)

∗∗∗

∗∗∗

-0 (blank), -27 (EMERGENCY STOP), -74 (EMERGENCY OFF)

7

ø16

X6 Series Emergency Stop Switches (Unibody)

Third-generation emergency stop switch with Reverse Energy Structure

Smallest in its class

• Two button sizes—ø30mm and ø40mm

• Two button colors—red for emergency stop and yellow for

stop switch

• Two ways of resetting —pulling and turning.

• Solder/tab terminal #110 makes for easy connections.

• UL, c-UL recognized, EN compliant.

• Safety lock mechanism (IEC 60947-5-5; 6.2)

• Direct opening action (IEC 60947-5-5; 5.2, IEC 60947-5-1,

Annex K)

• IP65 degree of protection (IEC 60529)

Standards

Standard Mark

UL508

CSA C22.2 No.14

EN60947-5-1

EN60947-5-5 (Note)

GB14048.5

• Stop switch (yellow button) is EN60947-5-1

Approval Organization/

File No.

UL/c-UL File No.E68961

TÜV SÜD

European Commission's Low

Voltage Directive

CCC No. 2012010305525957

(Stop switch: CCC No.

2012010305525958)

Contact Ratings

Rated Insulation Voltage (Ui) 250V

Rated Thermal Current (Ith) 5A

Rated Operating Voltage (Ue) 30V 125V 250V

Resistive Load

AC

50/60 Hz

rent (Note)

DC

Main Contacts

Rated Operating Cur-

• Minimum applicable load: 5V AC/DC, 1 mA (reference value)

(May vary depending on the operating conditions and load)

• Operational current represents the classication by making and

breaking currents (IEC 60947-5-1).

Note:

TÜV/CCC rating: AC-15 0.75A/250V, DC-13 1A/30V

UL rating: Standard Duty AC 0.75A/250V

Standard Duty DC 1A/30V

(AC-12)

Inductive Load

(AC-15)

Resistive Load

(DC-12)

Inductive Load

(DC-13)

– 5A 3A

– 1.5A 0.75A

2A 0.4A 0.2A

1A 0.22A 0.1A

Specifications

IEC 60947-5-1, EN 60947-5-1

Applicable Standards

Operating Temperature –25 to +60°C (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

Storage Temperature –45 to +80°C (no freezing)

Operating Force

Minimum Force

Required for Direct

Opening Action

Minimum Operator

Stroke Required for

Direct Opening Action

Maximum Operator

Stroke

Contact Resistance 50 mΩ maximum (initial value)

Insulation Resistance 100 MΩ minimum (500V DC megger)

Overvoltage Category II

Impulse Withstand

Voltage

Pollution Degree 3

Operation Frequency 900 operations/hour

Shock Resistance

Vibration Resistance

Mechanical Life 100,000 operations minimum

Electrical Life 100,000 operations minimum

Degree of Protection IP65 (IEC 60529)

Short-circuit Protection

Conditional Shortcircuit Current

Terminal Style Solder terminal, Solder/tab terminal #110

Recommended Tight-

ening Torque for Locking Ring

Applicable Wire Size 1.25 mm

Terminal Soldering

Condition

Weight (approx.)

Note: Except for stop switch (yellow button)

IEC 60947-5-5 (Note), EN 60947-5-5 (Note)

JIS C8201-5-1, JIS C8201-5-5, UL508

CSA C22.2 No.14, GB14048.5

Push to lock: 10.5N

Pull to reset: 8.8N

Turn to reset: 0.17 N·m

40N

4.5 mm

4.5 mm

2.5 kV

Operation extremes: 150 m/s

Damage limits: 1000 m/s

Operation extremes: 10 to 500 Hz

amplitude 0.35 mm, acceleration 50 m/s

Damage limits: 10 to 500 Hz,

amplitude 0.35 mm, acceleration 50 m/s

250V/10A fuse

(Type aM IEC 60269-1/IEC 60269-2)

1000A

0.88 N·m

2

maximum (AWG16 maximum)

310 to 350°C, within 3 seconds

ø30mm button: 13g

ø40mm button: 16g

2

2

2

2

8

X6

X6 Series Emergency Stop Switches (Unibody)

Unmarked

Pushlock Pull/Turn Reset Switch

Shape Main Contact (NC)

ø30mm Mushroom

1NC AB6E-3BV01PRH AB6E-3BV01PTRH

2NC AB6E-3BV02PRH AB6E-3BV02PTRH

ø40mm Mushroom

1NC AB6E-4BV01PRH AB6E-4BV01PTRH

2NC AB6E-4BV02PRH AB6E-4BV02PTRH

• Pushlock pull/turn reset switches are locked when pressed, and reset when pulled or turned clockwise.

Solder Terminal Solder/tab Terminal #110

Arrow Marked

Part No.

ø16

Package quantity: 1

Pushlock Pull/Turn Reset Switch

Shape Main Contact (NC)

ø30mm Mushroom

1NC AB6E-3BV01PRM AB6E-3BV01PTRM

2NC AB6E-3BV02PRM AB6E-3BV02PTRM

ø40mm Mushroom

1NC AB6E-4BV01PRM AB6E-4BV01PTRM

2NC AB6E-4BV02PRM AB6E-4BV02PTRM

• Pushlock pull/turn reset switches are locked when pressed, and reset when pulled or turned clockwise.

Solder Terminal Solder/tab Terminal #110

Part No.

Stop Switch

Unmarked, Yellow Button, Pushlock Pull/Turn Reset Switch

Shape Operator

ø30mm Mushroom

ø30mm but-

ton

Main Contact

(NC)

1NC AB6E-3BV01PY AB6E-3BV01PTY

2NC AB6E-3BV02PY AB6E-3BV02PTY

Solder Terminal Solder/tab Terminal #110

Package quantity: 1

Package quantity: 1

Part No.

ø40mm but-

ton

• Pushlock pull/turn reset switches are locked when pressed, and reset when pulled or turned clockwise.

• Do not use the stop switch as an emergency stop switch.

1NC AB6E-4BV01PY AB6E-4BV01PTY

2NC AB6E-4BV02PY AB6E-4BV02PTY

9

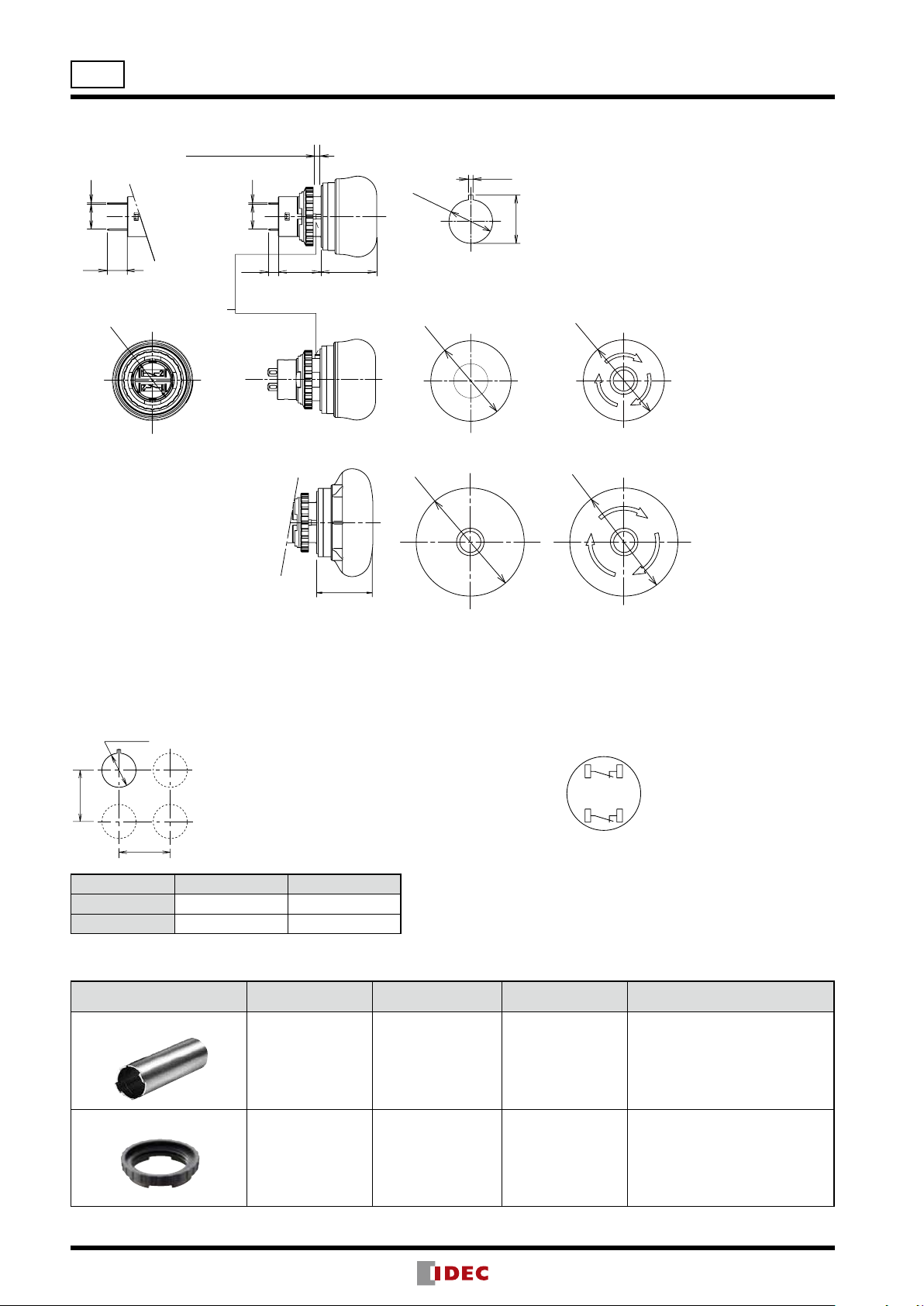

ø16

+0.2

Y

ø40mm Button

Panel thickness 0.8 to 4.5

Solder/tab terminal #110

(Depth behind the panel: 23.9 mm)

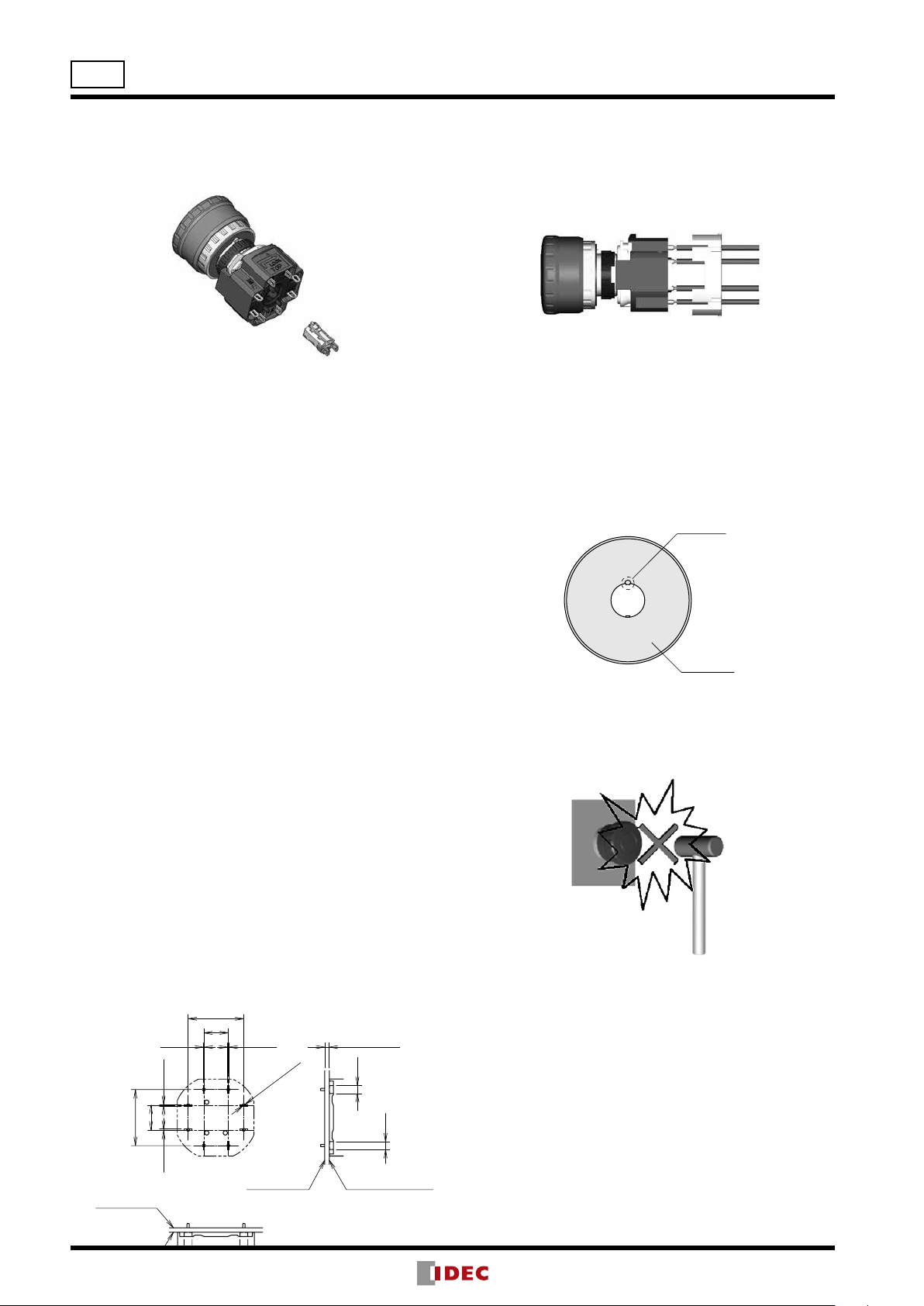

X6 Series Emergency Stop Switches (Unibody)

Dimensions

0.59.2

+0.2

0

+0.2

0

1.7

+0.2

0

17.9

0.59.2

ø16.2

8.0

Anti-rotation projection

ø15.8

Mounting Hole Layout

ø16.2

0

X

ø30 mm Button 40 mm min. 40mm min.

ø40 mm Button 50 mm min. 50mm min.

Accessories

Shape Material Part No. Package Quantity Remarks

Locking Ring Wrench

3.6

15.9

Solder terminal

(Depth behind the panel: 19.5 mm)

The values shown on the left are the

minimum dimensions for mounting

with other ø16 mm pushbuttons. For

other control units of different sizes and

styles, determine the values according to

dimensions, operation, and wiring.

20.6

20.6

X Y

Metal

(nickel-plated brass)

MT-001 1

Mounting Hole Layout

ø30.0

Unmarked

ø40.0

Unmarked

ø30.0

ø30mm Button

Arrow Marked

ø40.0

Arrow Marked

Terminal Arrangement

(Bottom View)

TOP

2

1

1

2

1NC type: Terminals located near

the TOP marking

• Used to tighten the locking ring

when installing the X6 switch onto

a panel.

• Recommended tightening torque:

0.88 N·m maximum

All dimensions in mm.

Locking Ring

Plastic XA9Z-LNPN10 10

• Black

10

t

ø16

1.7 0.3

Projection

Projection

X6

X6 Series Emergency Stop Switches (Unibody)

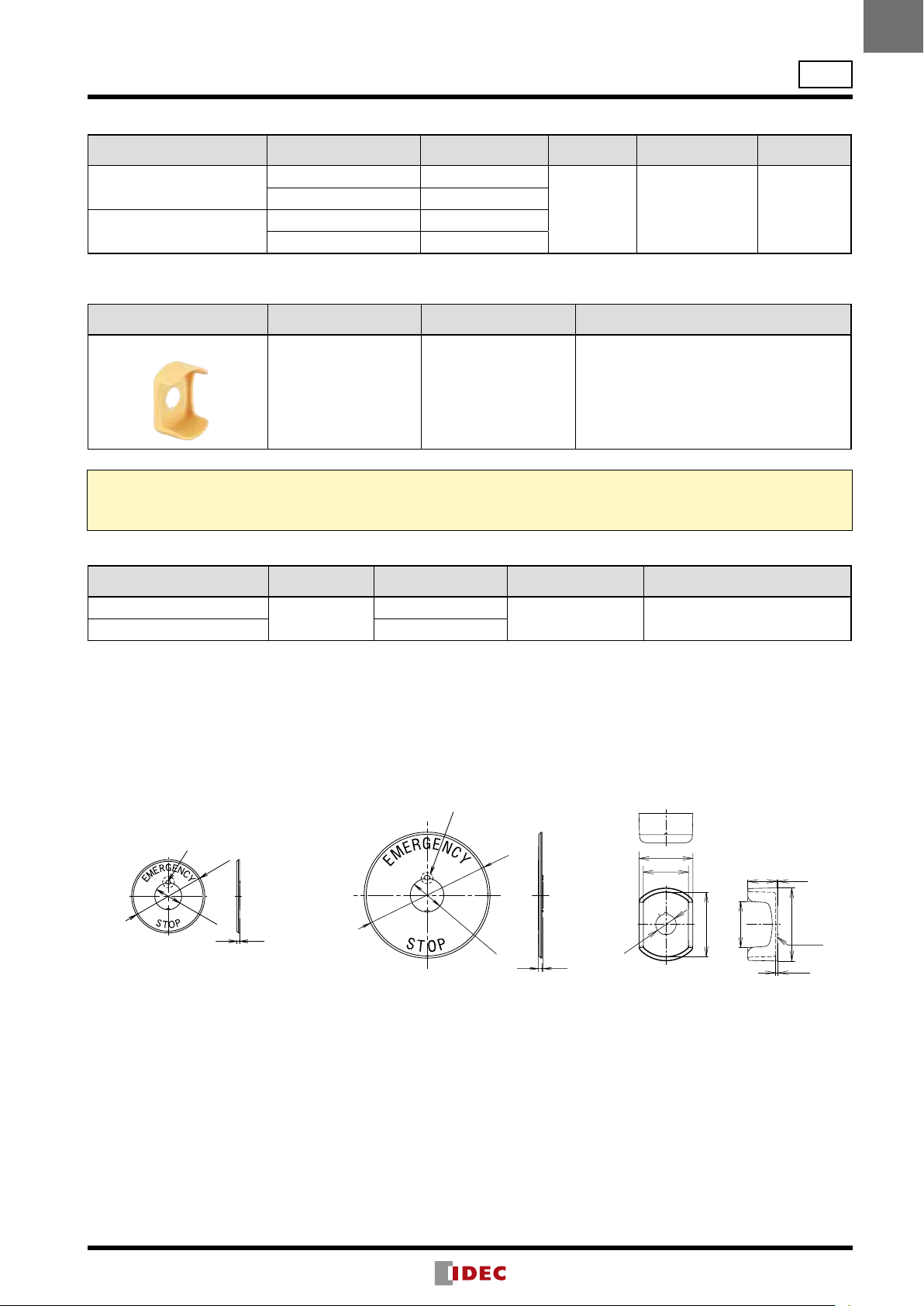

Nameplate (for emergency stop switch)

Description Legend Part No. Material Background Color Legend Color

For ø30mm Button

For ø40mm Button

• Cannot be used with switch guard.

Blank HAAV-0

EMERGENCY STOP HAAV-27

Blank HAAV4-0

EMERGENCY STOP HAAV4-27

Polyamide Yellow Black

SEMI S2 Compliant Switch Guard

Shape Material Part No. Remarks

Switch Guard

• IP65 degree of protection

Polyamide (PA6) XA9Z-KG1

Note:

Switch guards have been designed for applications in semiconductor manufacturing equipment only. Do not use the switch guards with emergency stop

switches which are installed on other machines such as machine tools or food processing machines. Machinery Directive of the European Commission and

IEC 60204-1 require that emergency stop switches be installed in a readily accessible area, and the usage of switch guards is not permitted.

• Color: yellow (Munsell 2.5Y8/10 or equivalent)

• Cannot be used with nameplate.

Package quantity: 1

Package quantity: 1

ø16

White Nameplate (for stop switch)

Description Legend Part No. Material Background Color

For ø30mm Button

For ø40mm Button HAAV4-0-W

Blank

HAAV-0-W

Polyamide White (Munsell N9.5)

Dimensions

Nameplate for ø30mm Button

•

HAAV-∗

ø43.5

ø16

• Remove the projection from the nameplate using pliers, otherwise the switch cannot be installed.

• Panel thickness when using a nameplate: 0.5 to 3 mm

Nameplate for ø40mm Button

•

HAAV4-∗

ø60

ø16

0.51.7

Package quantity: 1

Switch Guard

•

XA9Z-KG1

42

35

36

ø50

• Panel thickness when using a nameplate:

0.5 to 3 mm

23.1

(0.2)

ø57

Gaske

(1.7)

11

ø16

Projection

Rubber Gaske

Locking Ring

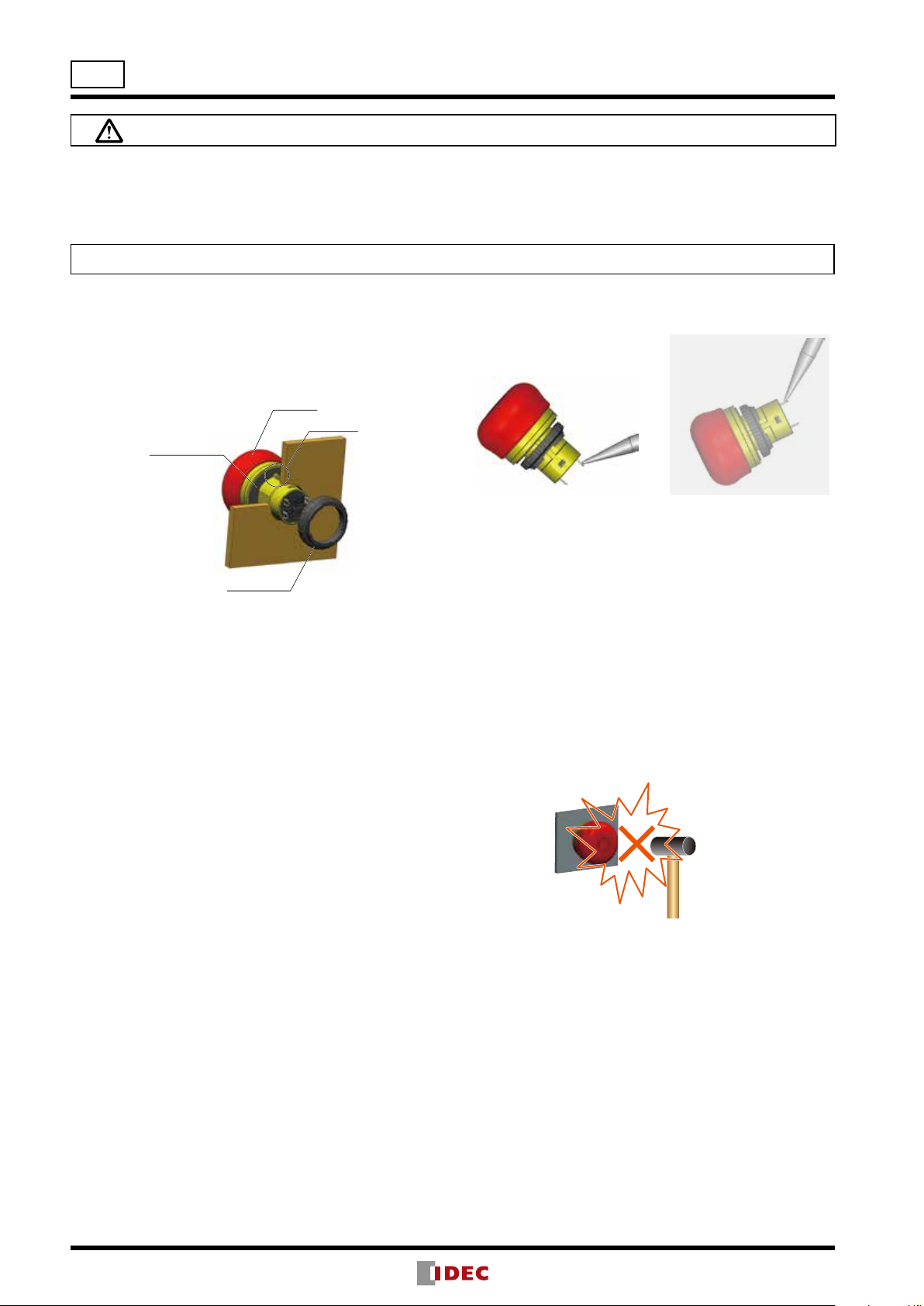

Operator

X6 Series Emergency Stop Switches (Unibody)

Safety Precautions

•Turn off power to the X6 series units before installation, removal,

wiring, maintenance, and inspection. Failure to turn power off

may cause electrical shocks or re hazard.

Instructions

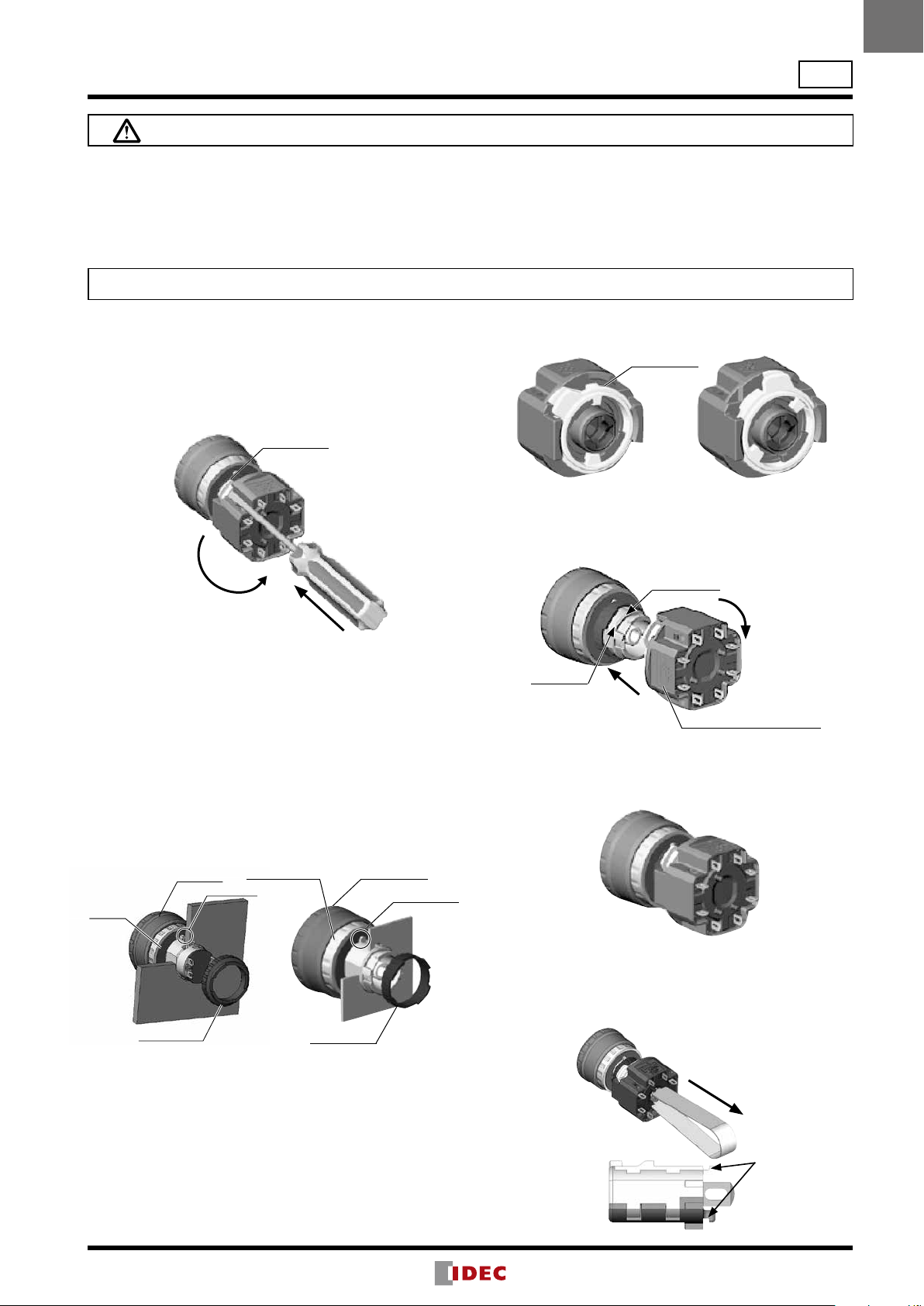

Panel Mounting

Remove the locking ring from the operator and check that

the rubber gasket is in place. Insert the operator from panel

front into the panel hole. Face the side with the projection

upward, and tighten the locking ring using the locking ring

wrench MT-001.

t

•For wiring, use wires of proper size to meet the voltage

and current requirements and solder properly. Improper

soldering may cause overheating and create re hazards.

3. Use a non-corrosive rosin ux. To prevent the ux from

entering the switch while soldering, face the terminals

downward.

Correct

4. Because the terminal spacing is narrow, use protective

tubes or heat shrinkable tubes to avoid burning the wire

sheath or short circuit.

5. Apply force on the terminals in the vertical direction to the

panel only, otherwise the terminals will be damaged.

Incorrect

Notes for Panel Mounting

Using the locking ring wrench MT-001, tighten the locking

ring to a torque of 0.88 N·m. Do not use pliers. Do not apply

excessive force, otherwise the locking ring will become

damaged.

Wiring

1. Applicable wire size is 1.25 mm2 maximum.

2. Solder the terminals using a soldering iron at 310 to 350°C

for 3 seconds maximum. Do not use ow or dip soldering.

SnAgCu type lead-free solder is recommended. Make

sure that the soldering iron touches the terminals only, not

plastic parts. Do not apply external force such as bending

the terminals or applying tensile force on the wires.

Contact Bounce

When the button is reset by pulling or turning, the NC

contacts will bounce. When designing a control circuit, take

the contact bounce time into consideration (reference value:

20 ms).

Handling

Do not expose the switch to excessive shock and vibrations,

otherwise the switch may be deformed or damaged, causing

malfunction or operation failure.

12

ø16

XA Series Emergency Stop Switches (Unibody)

Small, unibody emergency stop switches suitable for equipment with small mounting space.

Requires only ø16mm × 19.5mm for installation.

•ø29mm and ø40mm mushroom operators

•Degree of protection IP65 and IP40 (IEC 60529)

•Dark red (Munsell 5R4/12) and bright red (Munsell

7.5R4.5/14) colors for operators of emergency stop

switches, and yellow/gray for stop switch operators.

•Gold-plated crossbar contacts

•Push-to-lock, pull or turn-to-reset operator

•UL, c-UL recognized. EN compliant.

•Safety lock mechanism (IEC 60947-5-5, 6.2)

•Direct opening action mechanism

(IEC 60947-5-5, 5.2, IEC60947-5-1, Annex K)

Solder Terminal

IP65

(body color: yellow)

Solder Terminal

IP40

(body color: black)

Solder/tab #110

XA

Standards

Applicable Standards Mark File No. or Organization

UL508

CSA C22.2 No.14

EN60947-5-1

EN60947-5-5 (note)

GB14048.5

Note: Except for stop switch (yellow and gray button)

UL/c-UL Recognition

File No.E68961

TÜV SÜD

EU Low Voltage Directive

CCC No. 2008010305286343

Contact Ratings

Rated Insulation Voltage (Ui) 250V

Thermal Current (Ith) 5A

Rated Operating Voltage (Ue) 30V 125V 250V

Resistive Load

AC

Rated

Operating

Current

•Minimum applicable load: 5V AC/DC, 1 mA (reference value)

(May vary depending on the operating conditions and load.)

•The rated operating currents are measured at resistive/inductive

loads as specied in IEC 60947-5-1.

50/60Hz

DC

(AC-12)

Inductive Load

(AC-15)

Resistive Load

(DC-12)

Inductive Load

(DC-13)

— 5A 3A

— 3A 1.5A

2A 0.4A 0.2A

1A 0.22A 0.1A

Specifications

IEC 60947-5-1, EN 60947-5-1

Applicable Standards

Operating Temperature −25 to +60°C (no freezing)

Storage Temperature −45 to +80°C (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

Operating Force

Minimum Force

Required for Direct

Opening Action

Minimum Operator

Stroke Required for

Direct Opening Action

Maximum Operator

Stroke

Contact Resistance 50 mΩ maximum (initial value)

Insulation Resistance 100 MΩ minimum (500V DC megger)

Overvoltage Category II

Impulse Withstand Voltage

Pollution Degree 3

Operating Frequency 900 operations/hour

Shock Resistance

Vibration Resistance

Durability

Degree of Protection IP65, IP40 (IEC 60529)

Short-circuit

Protection

Conditional

Short-circuit Current

Terminal Style Solder terminal, Solder/tab #110 terminal

Recommended Tightening

Torque for Locking Ring

Applicable Wire Size 1.25 mm

Terminal Soldering

Condition

Weight (approx.)

Note: Except for stop switches (operator color: yellow and gray)

IEC 60947-5-5 (Note), EN 60947-5-5 (Note)

JIS C8201-5-1, UL508, CSA C22.2 No.14

GB14048.5

Push-to-lock: 10.5N

Pull to reset: 10N

Turn to reset: 0.16 N·m

40N

4.0 mm

4.5 mm

2.5 kV

Operating extremes: 150 m/s

Damage limits: 1000 m/s

Operating extremes: 10 to 500 Hz,

amplitude 0.35mm, acceleration 50 m/s

Damage limits: 10 to 500 Hz,

amplitude 0.35 mm, acceleration 50 m/s

Mechanical: 250,000

Electrical: 100,000

250,000 (24V AC/DC, 100mA)

250V/10A fuse

(Type aM IEC 60269-1/IEC 60269-2)

1000A

0.88 N·m

2

maximum (AWG16 maximum)

310 to 350°C, within 3 seconds

ø29mm mushroom: 14g

ø40mm mushroom: 17g

2

2

2

2

13

ø29 mm Mushroom ø40 mm Mushroom

Solder/

Panel Thickness 0.8 to 4.5

TOP

1NC: Termimals on top

ø16.2

+0.2

Y

ø16

XA Series Emergency Stop Switches (Unibody)

XA Series

Pushlock Pull/Turn Reset (Solder Terminal)

Shape Contact

ø29mm Mushroom

1NC XA1E-BV3U01K

Part No.

IP40 (contact part: black) IP65 (contact part: yellow)

XA1E-BV3U01

Operator Color

Code

2NC XA1E-BV3U02K

ø40mm Mushroom

1NC XA1E-BV4U01K

2NC XA1E-BV4U02K

•Solder/tab #110 terminal is also available. Specify “T” before in the Ordering No.

XA1E-BV3U02KR → XA1E-BV3U02KTR

Dimensions

0.510.2

Tab Terminal #110

(Behind the panel: 23.9)

ø15.8

10.2 0.5

20.6

15.93.615.98.0

Solder Terminal

(Behind the panel: 19.5)

ø16.2

1.7

+0.2

0

Mounting Hole

ø29.0

+0.2

0

0

+0.2

17.9

20.6

XA1E-BV3U02

R: red

RH: bright red

XA1E-BV4U01

XA1E-BV4U02

Terminal Arrangement

(Bottom View)

1

2

21

Mounting Hole Layout

ø40

0

X

•Thevaluesshown

on the left are the

minimum dimensions

for mounting with other

ø16 mm pushbuttons.

For other control units

of different sizes and

styles, determine the

values according to the

dimensions, operation,

and wiring.

14

All dimensions in mm.

X Y

ø29mm Mushroom 40 mm minimum

ø40mm Mushroom 50 mm minimum

ø16

XA Series Emergency Stop Switches (w/Removable Contact Block)

The World’s First ø16 mm, 4-contact Emergency Stop Switch.

Compact size - only 27.9 mm deep behind the panel. Reliable “Safe break action.”

•The depth behind the panel is only 27.9 mm for 1 to 4

con tacts, both on illuminated and non-illuminated.

•IDEC’s original “Safe break action” ensures that the

contacts open when the contact block is detached from

the operator.

•1 to 4NC main contacts and 1NO monitor contact

•Push-to-lock, Pull or Turn-to-reset operator

•Direct opening action mechanism (IEC 60947-5-5, 5.2,

IEC60947-5-1, Annex K)

•Safety lock mechanism (IEC 60947-5-5, 6.2)

•Degree of protection IP65 (IEC 60529)

•Two operator sizes: ø29 and ø40 mm

•Dark red (Munsell 5R4/12) or bright red (Munsell

7.5R4.5/14) colors are available for the operator of nonilluminated emer gency stop switches, and gray for stop

switch operators.

•UL, c-UL recognized. EN compliant

Direct Opening Action

XA

Standards

Applicable Standards Mark File No. or Organization

UL508

CSA C22.2 No. 14

IEC60947-5-5 (Note)

UL991 (Note)

NFPA79 (Note)

EN60947-5-1

EN60947-5-5 (Note)

GB14048.5

Note: Except for stop switches (button color: gray).

UL/c-UL Recognized,

File No. E68961

— UL File No. E305148

TÜV SÜD

EU Low Voltage Directive

CCC No. 2005010305150899

(Stop switch:

CCC No. 2005010305150894)

Contact Ratings

NC main contacts (black) /NO monitor contact (blue)

Rated Insulation Voltage (Ui) 300V (illuminated part: 60V)

Rated Thermal Current (Ith) 5A

Rated Operating Voltage (Ue) 30V 125V 250V

Resistive Load

AC

(AC-12)

50/60

Inductive Load

Hz

DC

AC

50/60

Hz

DC

(AC-15)

Resistive Load

(DC-12)

Inductive Load

(DC-13)

Resistive Load

(AC-12)

Inductive Load

(AC-14)

Resistive Load

(DC-12)

Inductive Load

(DC-13)

Main

Contacts

Monitor

Rated Operating Current

Contacts

•Minimum applicable load: 5V AC/DC, 1 mA (reference value)

(Operating area may vary according to the operating conditions

and load types.)

•The rated operating currents are measured at resistive/inductive

load types specied in IEC 60947-5-1.

– 3A 3A

– 1.5A 1.5A

2A 0.4A 0.2A

1A 0.22A 0.1A

– 1.2A 0.6A

– 0.6A 0.3A

2A 0.4A 0.2A

1A 0.22A 0.1A

Illumination Ratings

Rated Voltage Operating Voltage Rated Current

24V AC/DC 24V AC/DC ±10% 11 mA

Specifications

IEC60947-5-1, EN60947-5-1

Applicable Standards

Operating

Temperature

Storage Temperature –45 to +80°C

Operating Humidity 45 to 85% RH (no condensation)

Operating Force

Minimum Force

Required for Direct

Opening Action

Minimum Operator

Stroke Required for

Direct Opening Action

Maximum Operator

Stroke

Contact Resistance

Insulation Resistance

Overvoltage Category II

Impulse Withstand

Voltage

Pollution Degree 3 (inside LED unit: 2)

Operation Frequency 900 operations/hour

Shock Resistance

Vibration Resistance

Mechanical Life 250,000 operations minimum

Electrical Life

Degree of Protection IP65 (IEC60529)

Short-circuit

Protection

Conditional

Short-circuit Current

Terminal Style Solder terminal, PC board terminal

Recommended

Tightening Torque

for Locking Ring

Connectable Wire 1.25 mm

Soldering Conditions 310 to 350°C, 3 seconds maximum

Weight ø29 mm: 23g, ø40 mm: 28g

Note: Except for stop switches (operator color: gray).

IEC60947-5-5 (Note), EN60947-5-5

(Note), JIS C8201-5-1, UL991 (Note),

NFPA79 (Note), UL508, CSA C22.2

No.14, GB14048.5

–25 to +60°C (no freezing)

Illuminated: –25 to +55°C (no freezing)

Push to lock: 10.5N

Pull to reset: 10N

Turn to reset: 0.16 N·m

60N

4.0 mm

4.5 mm

50 mΩ maximum (initial value)

100 MΩ minimum (500V DC megger)

2.5 kV

Operating extremes: 150 m/s

Damage limits: 1000 m/s

Operating extremes: 10 to 500 Hz,

amplitude 0.35 mm acceleration 50 m/s

Damage limits: 10 to 500 Hz,

amplitude 0.35 mm acceleration 50 m/s

100,000 operations min

250,000 operations min (24V AC/DC, 100 mA)

250V/10A fuse

(Type aM, IEC60269-1/IEC60269-2)

1000A

0.88 N·m

2

maximum (AWG16 maximum)

2

2

2

2

15

ø16

XA Series Emergency Stop Switches (w/Removable Contact Block)

Non-illuminated

Pushlock Pull/Turn Reset (Solder Terminal/PC Board Terminal)

Shape

ø29mm Mushroom

ø40mm Mushroom

•Specify a color code in place of ➀ in the Part No.

•Terminal cover (XA9Z-VL2) is ordered separately.

•For EMO Switches, see page 58.

NC Main

Contact

1NC —

2NC —

3NC —

4NC —

1NC 1NO

2NC 1NO

3NC 1NO

1NC —

2NC —

3NC —

4NC —

1NC 1NO

2NC 1NO

3NC 1NO

NO Monitor

Contact

Illuminated

Pushlock Pull/Turn Reset (Solder Terminal/PC Board Terminal)

Shape

ø29mm Mushroom

ø40mm Mushroom

•Terminal cover (XA9Z-VL2) is ordered separately.

NC Main

Contact

1NC — XA1E-LV301Q4R XA1E-LV301Q4VR

2NC — XA1E-LV302Q4R XA1E-LV302Q4VR

3NC — XA1E-LV303Q4R XA1E-LV303Q4VR

4NC — XA1E-LV304Q4R XA1E-LV304Q4VR

1NC 1NO XA1E-LV311Q4R XA1E-LV311Q4VR

2NC 1NO XA1E-LV312Q4R XA1E-LV312Q4VR

3NC 1NO XA1E-LV313Q4R XA1E-LV313Q4VR

1NC — XA1E-LV401Q4R XA1E-LV401Q4VR

2NC — XA1E-LV402Q4R XA1E-LV402Q4VR

3NC — XA1E-LV403Q4R XA1E-LV403Q4VR

4NC — XA1E-LV404Q4R XA1E-LV404Q4VR

1NC 1NO XA1E-LV411Q4R XA1E-LV411Q4VR

2NC 1NO XA1E-LV412Q4R XA1E-LV412Q4VR

3NC 1NO XA1E-LV413Q4R XA1E-LV413Q4VR

NO Monitor

Contact

Part No.

Solder Terminal PC Board Terminal

XA1E-BV301

XA1E-BV302

XA1E-BV303

XA1E-BV304

XA1E-BV311

XA1E-BV312

XA1E-BV313

XA1E-BV401

XA1E-BV402

XA1E-BV403

XA1E-BV404

XA1E-BV411

XA1E-BV412

XA1E-BV413

Solder Terminal PC Board Terminal

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

Part No.

XA1E-BV301V

XA1E-BV302V

XA1E-BV303V

XA1E-BV304V

XA1E-BV311V

XA1E-BV312V

XA1E-BV313V

XA1E-BV401V

XA1E-BV402V

XA1E-BV403V

XA1E-BV404V

XA1E-BV411V

XA1E-BV412V

XA1E-BV413V

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

➀

Operator

Color Code

R: Dark red

RH: Bright

red

Operator

Color

Dark red only

16

Solder Terminal

ø29mm Mushroom

ø40mm Mushroom

PC Board Terminal

3.1

Locking Ring

Rubber Gasket

Mounting Panel Thickness: 0.8 to 3.7

XA9Z-VL2

Terminal Cover

19.8

8.7

2.1

27.2

25.8 20.6

30.4

29.4

30.4

ø29.8

25.8

20.6

30.4

ø40

ø29

ø29mm Mushroom

Solder Terminal

27.2

19.8

8.7

4.5

Mounting Panel Thickness: 0.8 to 3.7

2.1

25.8

20.6

30.4

PC Board Terminal

3.1

29.4

30.4

ø29.8

Locking Ring

Rubber Gasket

XA9Z-VL2

Terminal Cover

25.8

20.6

30.4

ø40mm Mushroom

ø40

ø29

0

+0.2

ø16.2

0

+0.2

1.7

0

+0.2

17.9

8.7

19.8

8.7

19.8

10-ø1.2 holes

6.5

11.2

4.5

3-ø1.7 holes

3-ø1.7 holes

8.7

19.8

8.7

19.8

10-ø1.2 holes

6.5

11.2

ø16.2

+0.2

0

X

Y

X1

Protection diode

Resistor

XA

XA Series Emergency Stop Switches (w/Removable Contact Block)

Dimensions

Non-illuminated

Illuminated

ø16

PC Board Layout (Bottom View) Panel Cut-out

Non-Illuminated Illuminated

Mounting Hole Layout LED Unit Internal Circuit

X Y

R1 R2

LED

R3

ø29mm Mushroom 40 mm minimum

ø40mm Mushroom 50 mm minimum

•The values shown above are the minimum

dimensions for mounting with other ø16

mm pushbuttons. For other control units

of different sizes and styles, determine

the values according to the dimensions,

opera tion, and wiring convenience.

All dimensions in mm.

X2

LED chip

17

12

12

TOP

21

21

LeftRight

TOP

21

21

12

34

LeftRight

NC main contacts (black)

NC main contacts (black):

Terminals 1-2

1NC: Terminals on right

2NC: Terminals on right and left

3NC: Terminals on right, left, and top

Non-illuminated

LeftRight

TOP

21

21

12

12

X1 X2

TOP

LeftRight

21

21

12

34

X1 X2

LEDLED

For ø29mm Operator

ø43.5

ø16

1.70.3

0.5

1.7

ø60

ø16

Ring Wrench

Locking Ring

Terminal Cover

LED Unit

LED Unit Removal Tool

ø16

XA Series Emergency Stop Switches (w/Removable Contact Block)

Terminal Arrangement (Bottom View)

Illuminated

only

With NO monitor contacts (blue)

NC main contacts (black):

Terminals 1-2

NO monitor contacts (blue):

Terminals 3-4

1NC: Terminals on top

2NC: Terminals on right and left

NC main contacts only (black)

NC main contacts(black):

Terminals 1-2

1NC: Terminals on right

2NC: Terminals on right and left

3NC: Terminals on right, left, and top

Nameplates (for ø16 Emergency Stop Switches)

Description Legend Part No. Material Plate Color Legend Color

For ø29mm Operator

For ø40mm Operator

(blank) HAAV-0

EMERGENCY STOP HAAV-27

(blank) HAAV4-0

EMERGENCY STOP HAAV4-27

For ø40mm Operator

•Panel thickness when using

the nameplate: 0.5 to 2 mm

With NO monitor contacts (blue)

NC main contacts (black):

Terminals 1-2

NO monitor contacts (blue):

Terminals 3-4

1NC: Terminals on top

2NC: Terminals on right and left

Polyamide Yellow Black

•Panel thickness when using

the nameplate: 0.5 to 2 mm

Accessories and Replacement Parts

Description & Shape Material Part No. Ordering No.

Package

Quantity

•Used to tighten the locking

Metal

(nickel-plated brass)

MT-001 MT-001 1

ring when installing the XA

emer gency stop switch onto

a panel.

Polyamide XA9Z-LN XA9Z-LNPN10 10 •Black

•White

PBT XA9Z-VL2 XA9Z-VL2PN02 2

•Used for solder terminals.

•Also applicable to the XW

series.

For Solder Terminal XA9Z-LED2R XA9Z-LED2R

•Replacement LED unit for

illumi nated (for XA series

For PC Board

Terminal

XA9Z-LED2VR XA9Z-LED2VR

only).

1

All dimensions in mm.

Remarks

18

Stainless Steel MT-101 MT-101

•Used for removing the LED

unit.

Operator

Removing the Contact Block

First unlock the operator button. While pushing up the

white bayonet ring, using a small screwdriver (width: 2.5 to

3 mm) if necessary, turn the contact block

counterclockwise and pull out.

force when using a screwdriver, otherwise the bayonet

ring may be dam aged.

➁

Notes for Removing the Contact Block

1. When the contact block is removed, the monitor contact

2. While removing the contact block, do not exert excessive

Panel Mounting

Remove the locking ring from the operator and check

that the rubber gasket is in place. Insert the operator from

panel front into the panel hole. Face the side with the antirotation protrusion on the operator upward, and tighten the

locking ring.

Rubber Gasket

Notes for Panel Mounting

To mount the XA emergency stop switches onto a panel,

tighten the locking ring to a tightening torque of 0.88 N·m

maximum using ring wrench MT-001. Do not use pliers. Do

not exert excessive force, otherwise the locking ring may

be damaged.

Installing the Contact Block

Bayonet Ring

Unlocked Locked

marking on the edge of the operator base

con tact block onto the operator and turn the contact block

XA

XA Series Emergency Stop Switches (w/Removable Contact Block)

Safety Precautions

•Turn off power to the XA series emergency stop switch

before starting installation, removal, wiring, maintenance,

and inspection of the relays. Failure to turn power off may

cause electrical shock or re hazard.

•Use the LED unit removal tool when replacing the LED

unit to avoid burn on your hands.

Instructions

Do not exert excessive

Bayonet Ring

•Use wires of the proper size to meet the voltage and

cur rent requirements, and solder the wires correctly. If

solder ing is incomplete, the wire may heat during operation, causing re hazard.

First turn the bayonet ring to the unlocked position.

Align the small ▲

with the TOP marking on the contact block. Press the

ø16

Turn counterclockwise

Push

➀

(NO contact) is closed.

force, otherwise the switch may be damaged.

Gasket

Locking Ring

Projection

Contact BlockUnibody

Operator Unit

Locking Ring

clock wise until the bayonet ring clicks.

▲ marking

Press

➀

TOP marking

➁

TOP marking (contact block)

Notes for Installing the Contact Block

Check that the contact block is securely installed on the

opera tor. When the emergency stop switch is properly

assembled, the bayonet ring is in place as shown below.

Anti-rotation

Protrusion

Removing the LED Unit (Contact Block)

Pull out the LED unit while squeezing the latches on the

LED unit using the LED unit removal tool (MT-101).

Squeeze the

LED unit on the

latches and pull

out.

Tur n

TOP side

Latches

19

Installing the LED Unit (with Removable

Contact Block)

Align the to of the LED unit with the TOP marking on the

contact block. Push the LED unit into the contact block.

Wiring

1. The applicable wire size is 1.25 mm

2. Solder the terminal at a temperature of 310 to 350°C

3. Use a non-corrosive rosin ux.

4. Because the terminal spacing is narrow, use protective

Solder/Tab Terminal #110

1. Use #110 receptacles for 0.5mm-thick tabs.

2. Because the terminal spacing is narrow, use protective tubes

3. Do not apply force on the terminals in the direction

PC Board Terminal

1. When mounting a contact block on a PC board, provide

2. When mounting an XA emergency stop switch on a PC

About PC Board and Circuit Design

1.

2. PC boards and circuits must withstand rated voltage and

3. The minimum applicable load is 5V AC/DC, 1 mA. This value

4. Within the 2.8

Installing Insulation Terminal Cover

Projection

Nameplate

19.8

8.7

19.8

(0.5)

1.6 (PC Board)

(0.5)

(0.5)

2.8∗

2.8∗

(0.5)

10-ø1.2 holes

Solder Surface

Surface for installing

components

Solder Surface

Surface for installing

8.7

ø16

XA Series Emergency Stop Switches (w/Removable Contact Block)

TOP side

2

maximum.

within 3 seconds using a soldering iron. Sn-Ag-Cu type is

recommended when using lead-free solder. When soldering, do not touch the enabling switch with the soldering

iron. Also ensure that no tensile force is applied to the terminal. Do not bend the terminal or apply excessive force to

the terminal.

To install the terminal cover (XA9Z-VL2), align the TOP

marking on the terminal cover with TOP marking on the

con tact block, and press the terminal cover toward the

contact block.

Note: For wiring, insert the wires into the holes in the terminal cover before

soldering.

Contact Bounce

When the button is reset by pulling or turning, the NC main

contacts will bounce. When pressing the button, the NO

monitor contacts will bounce.

When designing a control circuit, take the contact bounce

time into consideration (reference value: 20 ms).

Nameplate

When anti-rotation is not required, remove the projection

from the nameplate using pliers.

tubes or heat shrinkable tubes to avoid burning of wire

coating or short circuit.

or heat shrinkable tubes of 0.5mm minimum in thickness.

other than vertical to the mounting panel, otherwise the

terminals will be damaged.

sufcient rotating space for the PC board when installing

and removing the contact block.

board, make sure that the operator is securely installed.

Use PC boards made of glass epoxy copper-clad lami nated

sheets of 1.6 mm in thickness, with double-sided through

hole.

current, including the instantaneous current and voltage

at switching.

may vary according to the operating environment and load.

∗ mm areas shown in the gure below,

ter minals touch the PC board, resulting in possible short

cir cuit on the printed circuit. When designing a PC board

pattern, take this possibility into consideration.

Handling

Do not expose the switch to excessive shock and vibration,

otherwise the switch may be deformed or damaged,

causing malfunction or operation failure.

20

Loading...

Loading...