FC6A SERIES

All-in-One Type

Communication Manual

B-1730(3)

SAFETY PRECAUTIONS

Warning

Caution

• Read the "FC6A Series MicroSmart All-in-One Type Communication Manual" to ensure correct operation before starting installation, wiring,

operation, maintenance, and inspection of the FC6A Series MicroSmart.

• All FC6A Series MicroSmart modules are manufactured under IDEC’s rigorous quality control system, but users must add a backup or failsafe

provision to the control system when using the FC6A Series MicroSmart in applications where heavy damage or personal injury may be caused,

in case the FC6A Series MicroSmart should fail.

• In this manual, safety precautions are categorized in order of importance:

Warning notices are used to emphasize that improper operation may cause severe personal injury or death.

• The FC6A Series MicroSmart is not designed for use in applications requiring a high degree of reliability and safety. The FC6A Series MicroSmart

should not be used for such applications.

• When using the FC6A Series MicroSmart in applications (not described above) that require a high degree of reliability in terms of functionality

and precision, appropriate measures such as failsafe mechanisms and redundant mechanisms must be taken for the system containing the

FC6A Series MicroSmart. The following are specific examples.

• Emergency stop and interlocking circuits must be configured outside the FC6A Series MicroSmart.

• If relays or transistors in the FC6A Series MicroSmart output circuits should fail, outputs may remain at on or off state. For output signals

which may cause serious accidents, configure monitor circuits outside the FC6A Series MicroSmart.

• The FC6A Series MicroSmart self-diagnostic function may detect internal circuit or program errors, stop programs, and turn outputs off.

Configure circuits so that the system containing the FC6A Series MicroSmart is not jeopardized when outputs turn off.

• Turn off power to the FC6A Series MicroSmart before installation, removal, wiring, maintenance, and inspection of the FC6A Series MicroSmart.

Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the FC6A Series MicroSmart. People without such expertise must not use the

FC6A Series MicroSmart.

• Install the FC6A Series MicroSmart according to the instructions described in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

Improper installation will result in falling, failure, or malfunction of the FC6A Series MicroSmart.

Caution notices are used where inattention might cause personal injury or damage to equipment.

• The FC6A Series MicroSmart is designed for installation in a cabinet. Do not install the FC6A Series MicroSmart outside a cabinet.

• Install the FC6A Series MicroSmart in e nvironments described in the "FC6A Series MicroSmart All-in-One Type Us er’s Manual". If the FC6A Series

MicroSmart is used in places where the FC6A Series MicroSmart is subjected to high-temperature, high-humidity, condensation, corrosive gases,

excessive vibrations, or excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

• The environment for using the FC6A Series MicroSmart is "Pollution degree 2." Use the FC6A Series MicroSmart in environments of pollution

degree 2 (according to IEC 60664-1).

• Prevent the FC6A Series MicroSmart from falling while moving or transporting the FC6A Series MicroSmart, otherwise damage or malfunction of

the FC6A Series MicroSmart will result.

• Wiring must use lead sizes that are appropriate for the applied voltage and current. Terminal screws must be tightened with the prescribed

tightening torque.

• Prevent metal fragments and pieces of wire from dropping inside the FC6A Series MicroSmart housing. Put a cover on the FC6A Series

MicroSmart modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use an IEC 60127-approved fuse on the power line outside the FC6A Series MicroSmart. This is required when equipment containing the FC6A

Series MicroSmart is destined for Europe.

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the FC6A Series MicroSmart is destined for

Europe.

• Use an EU-approved circuit breaker. This is required when equipment containing the FC6A Series MicroSmart is destined for Europe.

• Make sure of safety before starting and stopping the FC6A Series MicroSmart or when operating the FC6A Series MicroSmart to force outputs on

or off. Incorrect operation of the FC6A Series MicroSmart may cause machine damage or accidents.

• Do not connect the ground wire directly to the FC6A Series MicroSmart. Connect a protective ground to the cabinet containing the FC6A Series

MicroSmart using an M4 or larger screw. This is required when equipment containing the FC6A Series MicroSmart is destined for Europe.

• Do not disassemble, repair, or modify the FC6A Series MicroSmart modules.

• The FC6A Series MicroSmart contains electronic parts and batteries. When disposing of the FC6A Series

MicroSmart, do so in accordance with national and local regulations.

Preface-1 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

ABOUT THIS MANUAL

This manual describes functions, specifications, installation, and operation basics of the FC6A Series MicroSmart. Also included is

information on the powerful communications tools of the FC6A Series MicroSmart, as well as troubleshooting procedures.

Chapter 1: General Information

General information about the FC6A Series MicroSmart with communication interfaces.

Chapter 2: Devices

Descriptions of the allocations of devices such as inputs, outputs, internal relays, registers, timers, and counters that are used in

the basic and advanced instructions, as well as details about the allocations of special internal relays and special data registers for

communication functions.

Chapter 3: Communication Settings

Functions for the FC6A Series MicroSmart communication, how to configure them, and examples of their use.

Chapter 4 through Chapter 8:

Various communication functions such as maintenance communication, user communication, Modbus communication, data link

communication and J1939 communication.

Chapter 9: PING Instruction

Descriptions of the PING instruction that sends a ping packet to the specified remote host to check if communication is possible at

the Internet Protocol (IP) layer.

Chanpter 10: Send E-mail Function

Descriptions of the EMAIL instruction that sends preregistered e-mails.

Chanpter 11: Web Server

Description of the Web server functions in the FC6A Series MicroSmart.

Index

Alphabetical listing of key words.

Publication history

December 2015 First Edition

February 2016 Second Edition

April 2016 Third Edition

March 2017 Fourth Edition

Trademarks

FC6A Series MicroSmart is a trademark of IDEC Corporation.

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 Preface-2

Regarding laws and compatible standards

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting from

the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all

programs, prior to installation, is the responsibility of the end user.

This product adheres to the laws and compatible standards of all countries involved, as shown below.

European laws and standards

This product complies with the following EU directives.

• Low Voltage Directive

• EMC Directive

To comply with these directives, this product has been designed and evaluated on the basis of the following international and

European standard.

• IEC/EN 61131-2: 2007

For details on the compatible standards and EU Directives, contact the distributor from which you purchased this product or visit our web site.

North America laws and standards

This product complies with the following standards.

• UL508

• CSA C22.2 No.142

• ANSI/ISA 12,12,01

• CAN/CSA C22.2 No.213

*1 Certain FC6A Series MicroSmart models are not compatible. For details, please contact IDEC Corporation.

For details on compatible standards and EU directives, please contact the dealer where purchased or check the IDEC website.

*1

*1

Preface-3 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

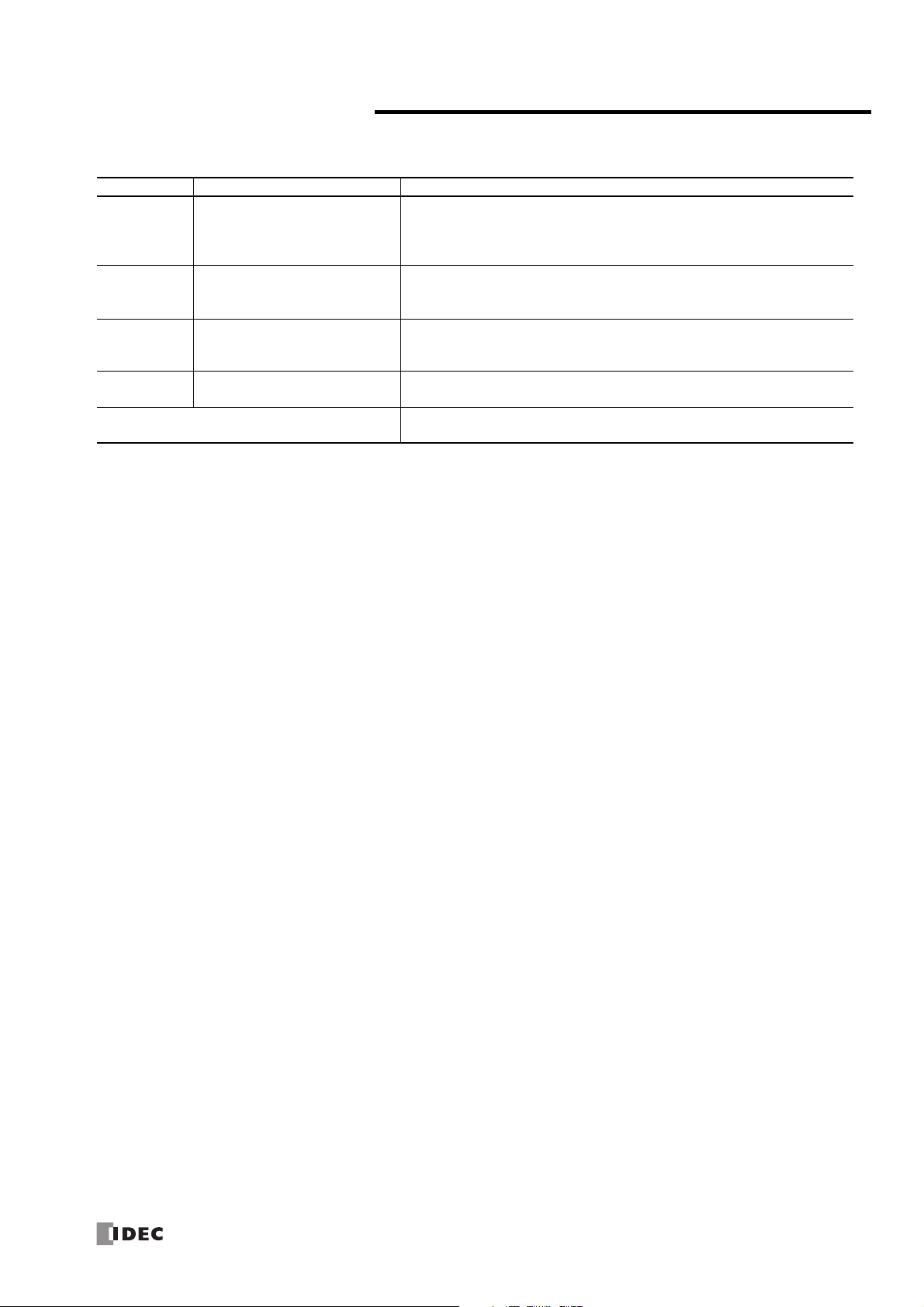

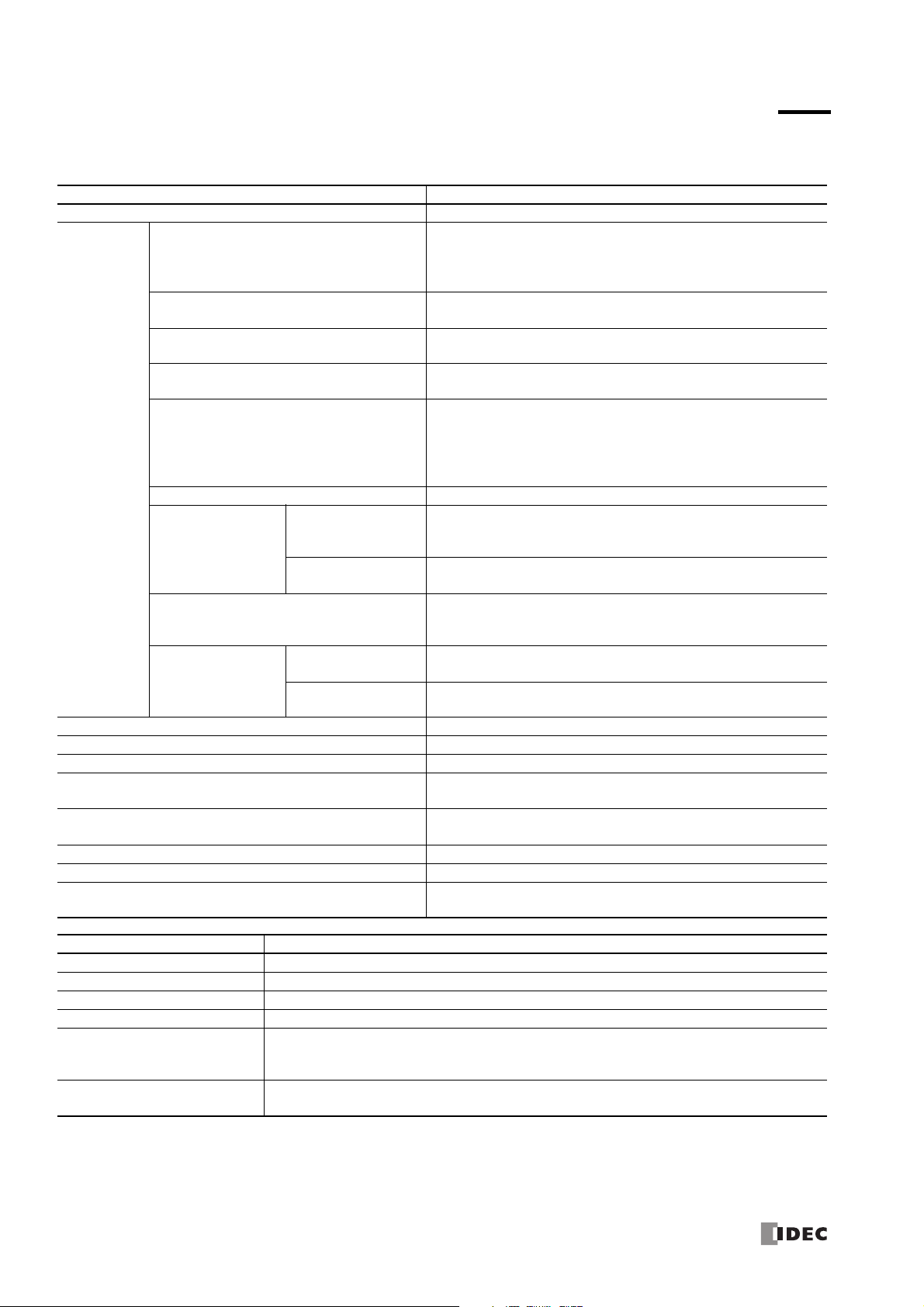

RELATED MANUALS

The following manuals related to the FC6A Series MicroSmart are available. Refer to them in conjunction with this manual.

Type No. Manual Name Description

Describes product specifications, installation and wiring instructions, instructions for

FC9Y-B1722

FC9Y-B1726

FC9Y-B1730

FC9Y-B1734

WindLDR Help

FC6A Series MicroSmart

All-in-One Type User’s Manual

FC6A Series MicroSmart

LAD Programming Manual

FC6A Series MicroSmart

All-in-One Type Communication

Manual (this manual)

FC6A Series MicroSmart

PID Module User's Manual

basic programming operations and special functions, device and instruction lists,

communication functions, and troubleshooting procedures for the FC6A Series

MicroSmart series.

Describes basic operations for programming with ladders on the FC6A Series

MicroSmart, monitoring methods, device and instruction lists, and details of each

instruction.

Describes specifications related to FC6A Series MicroSmart communication,

descriptions of functions, configuration methods, and usage examples.

Describes PID module specifications and functions.

Describes usage instructions for WindLDR, programming software for the FC6A

Series MicroSmart series.

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 Preface-4

NAMES AND ABBREVIATIONS USED IN THIS MANUAL

Model Names

Name Used in This Manual Type Number, Part Code, or Official Name

FC6A Series MicroSmart FC6A Series MICROSmart

FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C16K1CE, FC6A-C16P1CE,

All-in-One Type

CAN J1939 All-in-One Type

16-I/O type

24-I/O type

40-I/O type

CPU module

AC power type FC6A-C16R1AE, FC6A-C24R1AE, FC6A-C40R1AE, FC6A-C40R1AEJ

24V DC power type

DC power type

12V DC power type

Relay output type

Transistor sink output

Transistor output type

Expansion module Expansion I/O module, functional module

Expansion I/O module Input module, output module, mixed I/O module

Functional module Analog module, PID module

Analog module

Option module

Cartridge Analog cartridge, communication cartridge

WindLDR WindLDR application software

USB cable

type

Transistor protection

source output type

FC6A-C24R1AE, FC6A-C24R1CE, FC6A-C24K1CE, FC6A-C24P1CE,

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40K1CE, FC6A-C40P1CE,

FC6A-C40R1DE, FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE

FC6A-C40R1AEJ, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-C40R1DEJ, FC6A-C40K1DEJ, FC6A-C40P1DEJ

The general term for the model with 16 I/O points

(FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C16K1CE, FC6A-C16P1CE)

The general term for the model with 24 I/O points

(FC6A-C24R1AE, FC6A-C24R1CE, FC6A-C24K1CE, FC6A-C24P1CE)

The general term for the model with 40 I/O points

(FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40K1CE, FC6A-C40P1CE,

FC6A-C40R1DE, FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE,

FC6A-C40R1AEJ, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-C40R1DEJ, FC6A-C40K1DEJ, FC6A-C40P1DEJ)

FC6A-C16R1CE, FC6A-C24R1CE, FC6A-C40R1CE, FC6A-C16K1CE,

FC6A-C24K1CE, FC6A-C40K1CE, FC6A-C16P1CE, FC6A-C24P1CE,

FC6A-C40P1CE, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ

FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE, FC6A-C40R1DEJ,

FC6A-C40K1DEJ, FC6A-C40P1DEJ

FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C24R1AE, FC6A-C24R1CE,

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40R1DE, FC6A-C40R1AEJ,

FC6A-C40R1CEJ, FC6A-C40R1DEJ

FC6A-C16K1CE, FC6A-C24K1CE, FC6A-C40K1CE, FC6A-C40K1DE,

FC6A-C40K1CEJ, FC6A-C40K1DEJ

FC6A-C16P1CE, FC6A-C24P1CE, FC6A-C40P1CE, FC6A-C40P1DE,

FC6A-C40P1CEJ, FC6A-C40P1DEJ

Analog input module, analog output module,

mixed analog I/O module

HMI module, expansion interface module,

analog cartridge, communication cartridge

USB maintenance cable (HG9Z-XCM42),

USB Mini-B extension cable (HG9Z-XCE21)

Name Used in this Manual WindLDR Operating Procedure

Function area settings Configuration tab > Function Area Settings group

Monitors Select Online > Monitor > Start Monitor.

PLC status Select Online > PLC > Status.

Communication settings Select Online > Communication > Set Up.

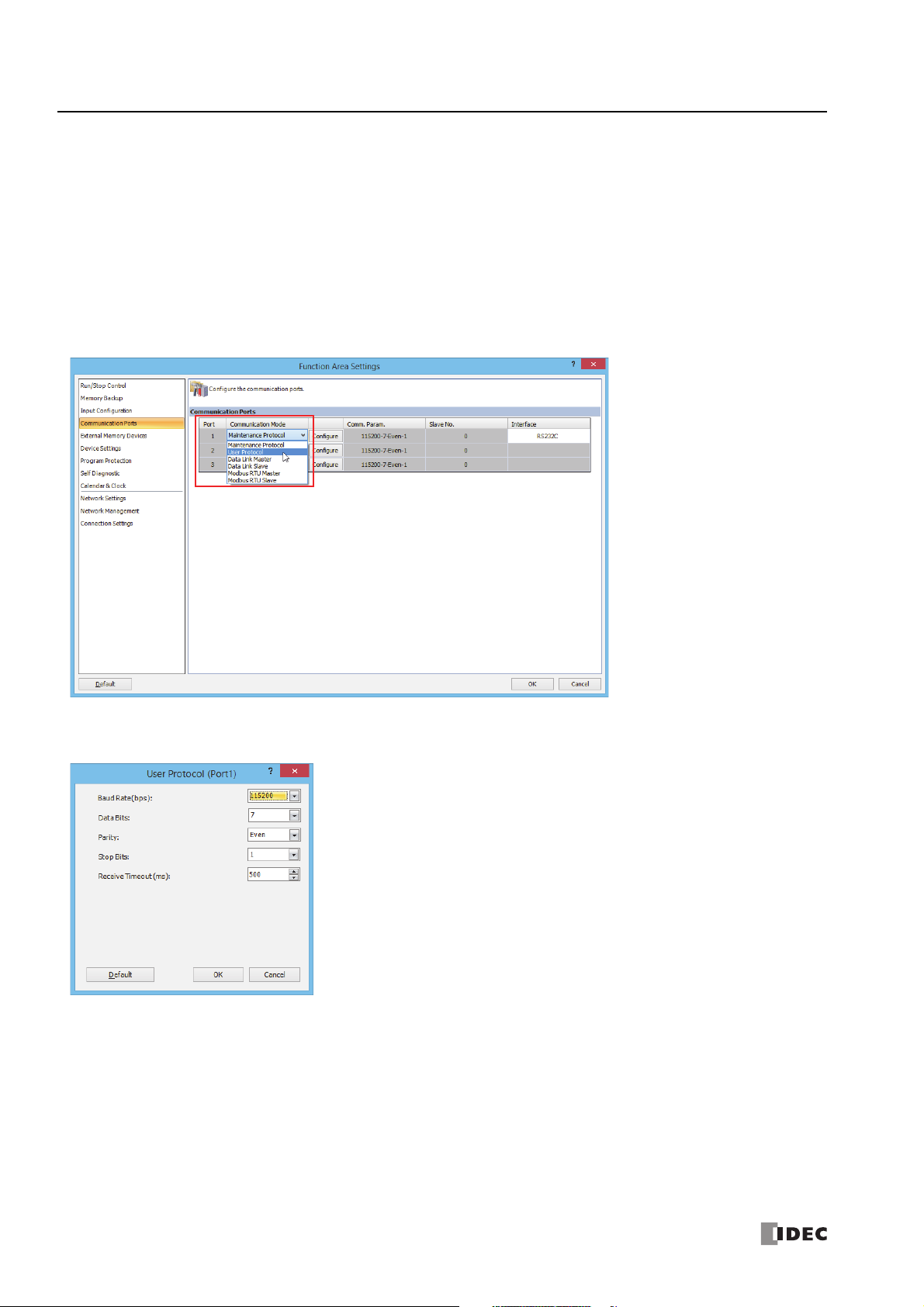

On the Configuration tab, in Function Area Settings, click Communication Ports, and in the

Modbus master request table

Application button

Preface-5 FC6A S

displayed Function Area Settings dialog box, for Communication Mode under Communication

Ports, select Modbus RTU Master or Modbus TCP Client

The button displayed on the left side of the menu bar. Click to display the menu with New, Save, and

Save As, recent projects, WindLDR Options, and Exit WindLDR.

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

T

ABLE OF

C

HAPTER

C

HAPTER

C

HAPTER

1: General Information

2: Device

3: Communication Settings

C

ONTENTS

Safety Precautions............................................................................................................................. Preface-1

About This Manual............................................................................................................................. Preface-2

Related Manuals................................................................................................................................ Preface-4

Names and Abbreviations Used in this Manual ..................................................................................... Preface-5

Description ................................................................................................................................................. 1-1

Communication Functions Overview .............................................................................................................. 1-5

Maintenance Communication........................................................................................................................ 1-5

User Communication.................................................................................................................................... 1-6

Modbus Communication ............................................................................................................................... 1-7

Data Link System ........................................................................................................................................ 1-7

Using J1939 Communication ........................................................................................................................ 1-8

Device Addresses ........................................................................................................................................ 2-1

Special Internal Relay .................................................................................................................................. 2-3

Special Data Register ...................................................................................................................................2-9

Setting List ................................................................................................................................................. 3-1

Communication Port Settings........................................................................................................................ 3-2

Network Settings ......................................................................................................................................... 3-3

Network Management.................................................................................................................................. 3-8

Connection Settings................................................................................................................................... 3-11

Remote Host List ....................................................................................................................................... 3-16

C

HAPTER

C

HAPTER

C

HAPTER

4: Maintenance Communication

Maintenance Communication via USB Port.....................................................................................................4-3

Maintenance Communication via Port 1 ......................................................................................................... 4-4

Maintenance Communication via Ethernet Port 1 ........................................................................................... 4-6

Maintenance Communication via a Communication Cartridge (Port 2, Port 3) ................................................. 4-11

Maintenance Communication via HMI-Ethernet port ..................................................................................... 4-13

5: User Communication Instructions

TXD (Transmit) ........................................................................................................................................... 5-2

RXD (Receive)........................................................................................................................................... 5-10

ETXD (User Communication Transmit over Ethernet) ................................................................................... 5-23

ERXD (User Communication Receive over Ethernet) ..................................................................................... 5-23

User Communication via Serial Communication ............................................................................................ 5-24

User Communication via Ethernet Communication ....................................................................................... 5-35

User Communication Error ......................................................................................................................... 5-43

ASCII Character Code Table ....................................................................................................................... 5-44

Sample Program – User Communication TXD............................................................................................... 5-45

Sample Program – User Communication RXD .............................................................................................. 5-47

6: Modbus Communication

Modbus RTU Communication via RS232C/RS485............................................................................................6-1

Modbus RTU Master Communication .............................................................................................................6-2

Modbus RTU Slave Communication ............................................................................................................... 6-8

Communication Format .............................................................................................................................. 6-12

Modbus TCP Communication via Ethernet Communication ............................................................................ 6-18

Modbus TCP Client .................................................................................................................................... 6-19

Modbus TCP Server ................................................................................................................................... 6-24

Modbus RTU Pass-Through Function ........................................................................................................... 6-27

C

HAPTER

7: Data Link Communication

Data Link System Setup ............................................................................................................................... 7-2

Data Link with Other PLCs.......................................................................................................................... 7-10

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 Preface-6

T

ABLE OF CONTENTS

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

I

NDEX

8: J1939 Communication

9: Send PING Function

10: Send E-mail Function

11: Web Server

Overview of J1939 Communication over CAN ................................................................................................ 8-1

J1939 Communication Settings .................................................................................................................... 8-7

PING (Ping) ................................................................................................................................................ 9-1

Overview...................................................................................................................................................10-1

EMAIL Instruction (Send E-mail) .................................................................................................................10-1

E-mail Address Book ..................................................................................................................................10-8

E-mail Editor............................................................................................................................................10-10

Attached File Editor ..................................................................................................................................10-13

Overview...................................................................................................................................................11-1

System Web Page ......................................................................................................................................11-8

User Web Pages ...................................................................................................................................... 11-12

Preface-7 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

1: G

ENERAL INFORMATION

Introduction

This chapter describes an overview of the FC6A Series MicroSmart, which is equipped with a communication interface.

Description

The FC6A Series MicroSmart can perform RS232C and RS485 communication using serial port 1. The communication ports can be

expanded by using communication cartridges to allow for multiple instances of RS232C and RS485 communication. The Ethernet

port is standard equipment to enable communication using Ethernet. Also, the Ethernet port can be expanded by using an HMI

module. The CAN J1939 All-in-One Type is equipped with a CAN port to enable J1939 communication.

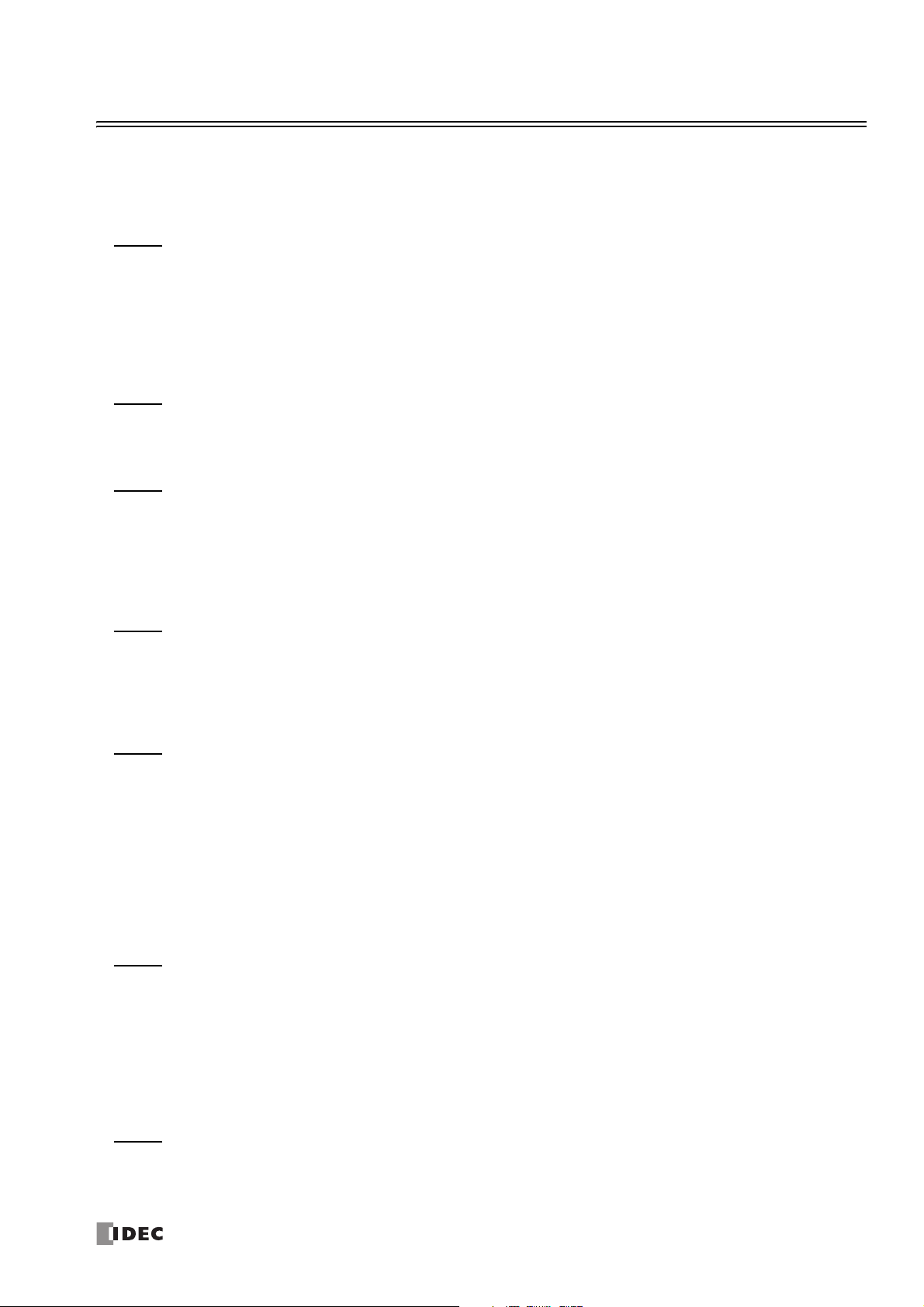

Communication Interfaces

An overview and the specifications of the communication interfaces are shown below.

USB Port

Maintenance communication can be performed by using this port to connect to a computer.

Communication Type USB2.0 Full speed, CDC class

Communication Functions Capable of maintenance communication with a PC, program downloads via USB power

Connector USB mini-B

Isolation between Internal Circuit Not isolated

Serial Port 1

This port can be used to communicate with RS232C/RS485 communication-compatible external devices such as computers,

operator interfaces, and printers.

Maintenance communication, user communication, Modbus RTU communication (master/slave), and data link communication

(master station/slave station) are possible.

Communication Type EIA RS-232C or RS-485 software selectable

Maximum Communication Speed 115,200 bps

Communication Functions

Connector RJ45

Cable

Maximum Cable Length

Isolation between Internal Circuit Not isolated

Maintenance communication, user communication, Modbus RTU communication, data link

communication

RS232C: Shielded multicore

RS485: Shielded twisted-pair

RS-232C: 5 m

RS-485 : 200 m

Ethernet Port 1

This port can be used to communicate with Ethernet communication-compatible external devices such as computers and operator

interfaces.

This port has eight connections that can be used with Ethernet communication. Each of these connections can simultaneously use

a different communication protocol. Each connection can be configured for maintenance communication (server), user

communication (server/client), or Modbus TCP communication (server/client).

Communication Type IEEE 802.3 compliant

Communication Speed 10BASE-T, 100BASE-TX

Number of Connections 8 maximum

Communication Functions Maintenance communication, user communication, Modbus TCP server/client

Connector RJ45

Cable CAT 5. STP

Maximum Cable Length 100 m

Isolation between Internal Circuit Pulse transformer isolated

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 1-1

1: G

ENERAL INFORMATION

Communication Cartridge

The communication cartridges can only be used when connected to cartridge slots 1 and 2 of the CPU module.

This port can be used to communicate with RS232C/RS485 communication-compatible external devices such as computers,

operator interfaces, and printers. Maintenance communication, user communication, Modbus RTU communication (master/slave),

and data link communication (master station/slave station) are possible.

Type No. FC6A-PC1 FC6A-PC3

Electrical Characteristics EIA RS232C EIA RS485

Maximum Communication Speed 115,200 bps 115,200 bps

Communication Functions Maintenance communication, user communication, Modbus communication, data link communication

Maximum Cable Length 5 m 200 m

Isolation between Internal Circuit Not isolated Not isolated

Cable

Recommended

Cable

Shielded multicore: 24 AWG Shielded twisted-pair: 24 AWG

CAN Port

The CAN J1939 All-in-One Type can use this port to perform J1939 communication.

Communication Type CAN bus communication

Communication Speed 250 kbps

Communication Functions J1939 communication

Connector FC6A-PMTE05PN02

Cable

Maximum Cable Length

Terminating Resistance 120 Ω (0.5 W or higher)

Isolation between Internal Circuit

SAE-J1939-11 : Shielded twisted-pair

SAE-J1939-15 : Unshielded twisted-pair

SAE-J1939-11 : 40 m, stub 1 m maximum

SAE-J1939-15 : 40 m, stub 3 m maximum

Power supply: Transformer isolated

Signal: Galvanic isolation, photocoupler isolated

HMI-Ethernet Port

The HMI-Ethernet port can only be used when a CPU module and an HMI module are connected.

This port can be used to communicate with Ethernet communication-compatible external devices such as computers and operator

interfaces.

This port has eight connections that can be used with Ethernet communication. Each connection can be configured for

maintenance communication (server).

This port also supports the web server function and the send E-mail function.

Communication Type IEEE 802.3 compliant

Communication Speed 10BASE-T, 100BASE-TX

Number of Connections 8 maximum

Communication Mode Maintenance Communication

Web Server Function Yes

Web Data Storage FROM

Web Data

Capacity

Send E-mail Function Yes

Connector RJ45

Cable CAT 5. STP or higher

Maximum Cable Length 100 m

Isolation between Internal Circuit Pulse transformer isolated

System Web Page Used Used Not used Not used

Web Page Editor Used Not used Used Not used

Area Available to User 2.5 MB 4.5 MB 3.0 MB 5.0 MB

Caution

• When accessing the FC6A Series MicroSmart over the Internet, adequate security measures for the network to prevent

unauthorized access are required. Be sure to consult your network administrator or Internet service provider. IDEC bears

no responsibility for damages or problems caused due to security in Ethernet communication.

• Restrict the access to FC6A Series MicroSmart with IP addresses and ports by using appropriate measures such as the

firewall.

1-2 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

1: G

ENERAL INFORMATION

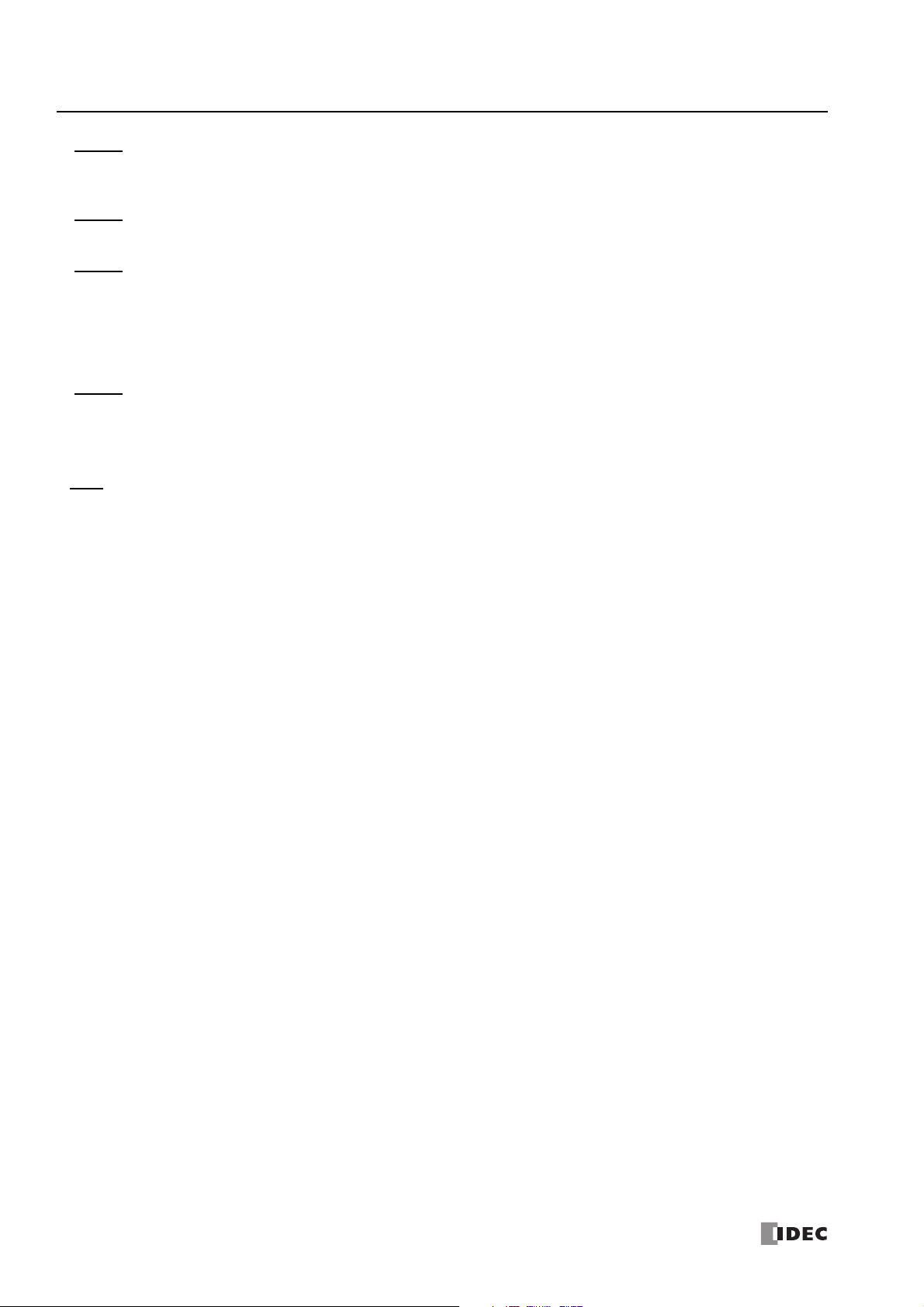

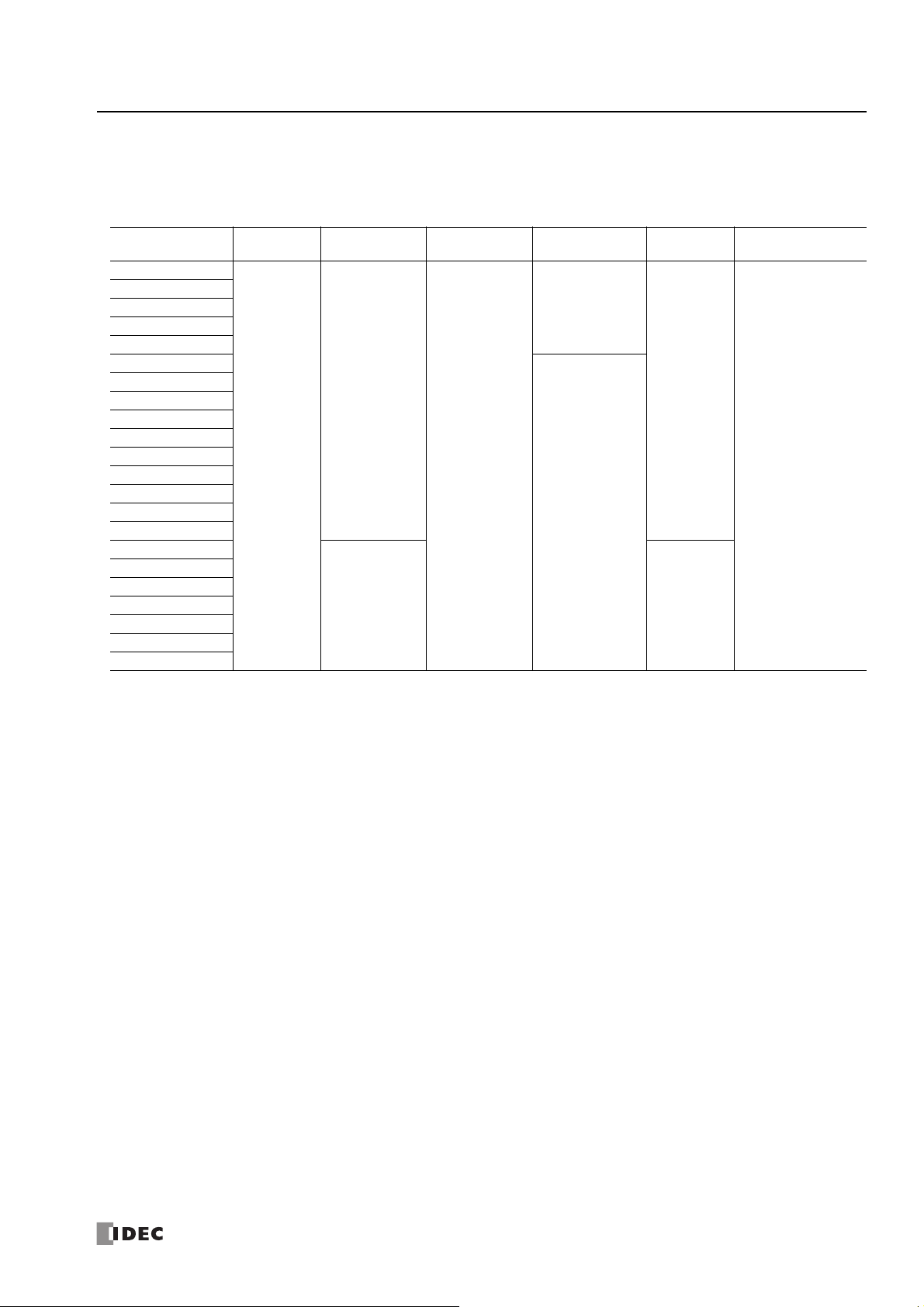

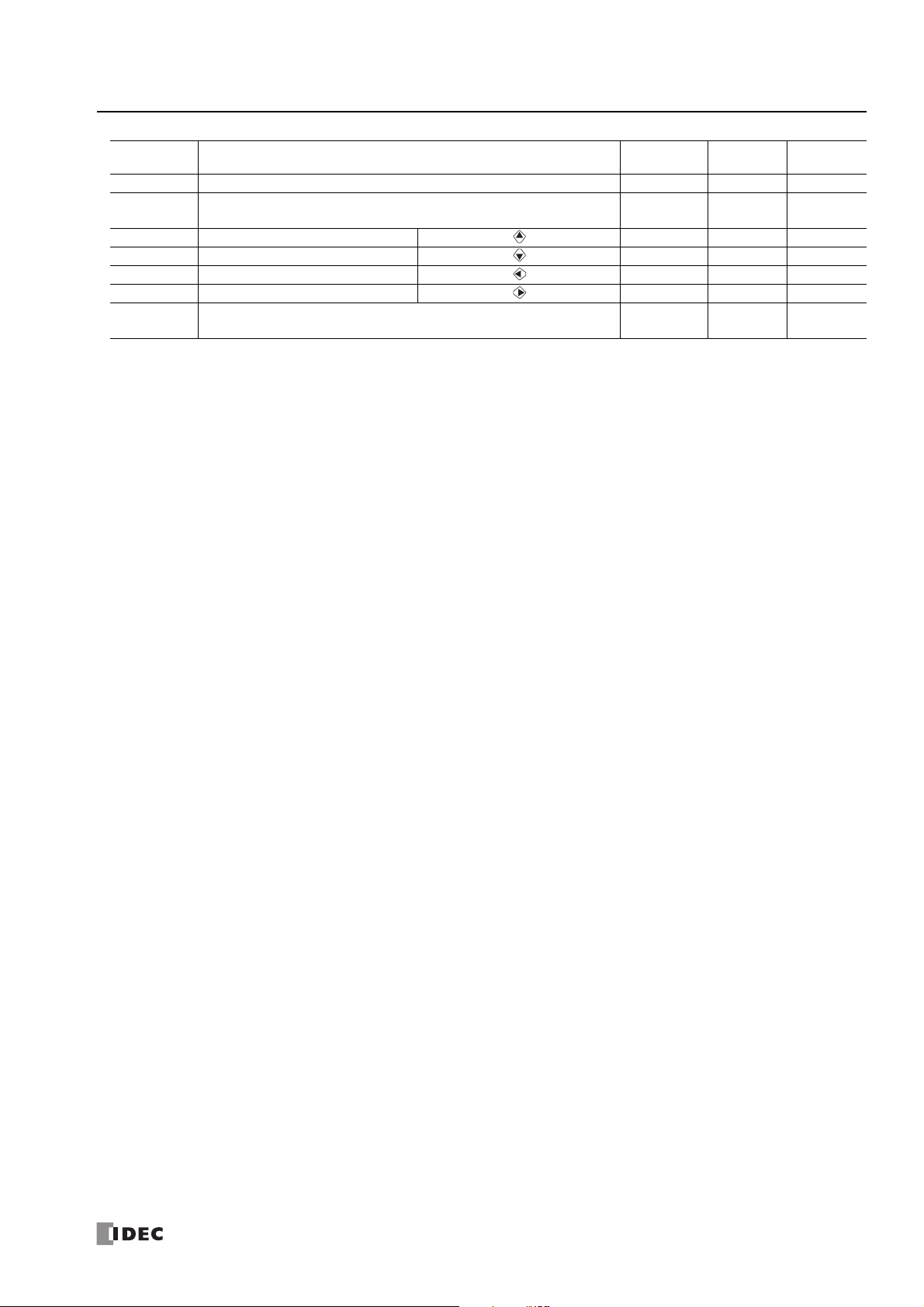

List of CPU Modules and Communication Interfaces

The following are the communication interfaces that the CPU modules are equipped with or can be expanded with.

For the locations of the communication interfaces in each module, see Chapter 2 "Product Specifications" in the "FC6A Series

MicroSmart All-in-One Type User's Manual".

Type No. USB Port Serial Port 1 Ethernet Port 1

FC6A-C16R1AE

FC6A-C16R1CE

FC6A-C16K1CE

FC6A-C16P1CE

FC6A-C24R1AE

FC6A-C24R1CE

FC6A-C24K1CE

FC6A-C24P1CE

FC6A-C40R1AE

FC6A-C40R1CE

FC6A-C40K1CE

FC6A-C40P1CE

FC6A-C40R1DE

FC6A-C40K1DE

FC6A-C40P1DE

FC6A-C40R1AEJ

FC6A-C40R1CEJ

FC6A-C40K1CEJ

FC6A-C40P1CEJ

FC6A-C40R1DEJ

FC6A-C40K1DEJ

FC6A-C40P1DEJ

*1 The communication cartridges can only be used when connected to cartridge slots 1 and 2 of the CPU module.

*2 The HMI-Ethernet port can only be used when a CPU module and an HMI module are connected.

1

1

1

— 1

Communication

Cartridge

1 maximum

2 maximum

*1

CAN Port HMI-Ethernet Port

—

*2

1 maximum

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 1-3

1: G

ENERAL INFORMATION

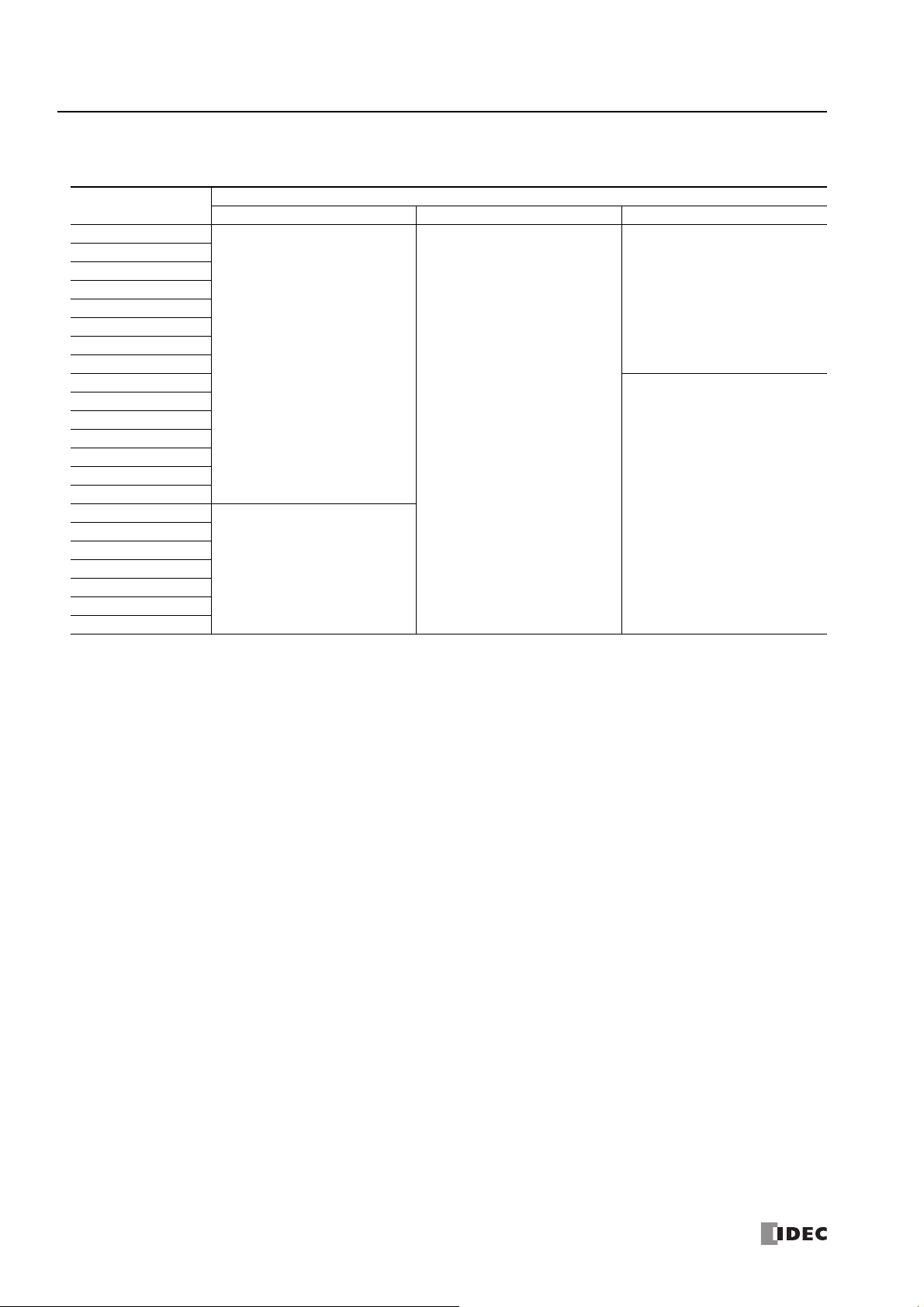

Communication Ports, Serial Port 1, Cartridge Slot 1 and 2 Corresponding Table

The communication ports that are used in serial communication support the following communication interfaces.

Type No.

Port 1 Port 2 Port 3

Serial Port

FC6A-C16R1AE

FC6A-C16R1CE

FC6A-C16K1CE

FC6A-C16P1CE

FC6A-C24R1AE

No supported communication

interface

FC6A-C24R1CE

FC6A-C24K1CE

FC6A-C24P1CE

Serial Port 1

*1

FC6A-C40R1AE

FC6A-C40R1CE

FC6A-C40K1CE

FC6A-C40P1CE

Cartridge Slot 1

communication cartridge*2

*4

FC6A-C40R1DE

FC6A-C40K1DE

FC6A-C40P1DE

FC6A-C40R1AEJ

Cartridge Slot 2

communication cartridge*3

*4

FC6A-C40R1CEJ

FC6A-C40K1CEJ

FC6A-C40P1CEJ

FC6A-C40R1DEJ

No supported communication

interface

FC6A-C40K1DEJ

FC6A-C40P1DEJ

*1 Can be used as port 1 for RS232C communication or RS485 communication.

To use, configure the interface under Communication Port in Function Area Settings.

*2 Can be used as port 2 by installing the RS232C communication cartridge (FC6A-PC1) or the RS485 communication cartridge (FC6A-PC3).

*3 Can be used as port 3 by installing the RS232C communication cartridge (FC6A-PC1) or the RS485 communication cartridge (FC6A-PC3).

*4 Cannot be set to "Data Bits: 7 bits" and "Parity: None".

Notes:

• For the locations of serial port 1, cartridge slot 1, and cartridge slot 2, see Chapter 2 "Parts Description" in the "FC6A Series MicroSmart All-

in-One Type User’s Manual".

• For serial port 1 wiring, see Chapter 2 "Other Inputs and Ports" in the "FC6A Series MicroSmart All-in-One Type User’s Manual". For

communication cartridge wiring, see Chapter 2 "Terminal Arrangement and Wiring Examples" in the "FC6A Series MicroSmart All-in-One Type

User’s Manual".

1-4 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

1: G

FC6A Series MicroSmart

Windows Computer

USB Port

(USB 2.0 Mini-B Connector)

USB Cable

HG9Z-XCM42 USB Maintenance Cable

Type A Plug Mini-B Plug

USB Port

O/I Communication Cable: FC6A-KC2C

(D-sub 9-pin connector style, cable length: 5 m)

Operator Interface

FC6A Series MicroSmart

Serial Communication Port

(RS232C)

Serial Port 1

(Port 1)

ENERAL INFORMATION

Communication Functions Overview

The FC6A Series MicroSmart supports maintenance communication, user communication, Modbus communication, data link

communication, and J1939 communication functions.

This section describes an overview of and connection examples for the communication functions.

Maintenance Communication

The maintenance communication of the FC6A Series MicroSmart enables you to check the operating status and I/O status of the

FC6A Series MicroSmart, monitor and change device values, and download and upload user programs with the PLC programming

software WindLDR installed on a computer. For details on maintenance communication, see "Maintenance Communication" on

page 4-1.

Supported ports

*1

USB Port Serial Port 1 Ethernet Port 1

Yes Yes Yes Yes No Yes

*1 Depending on the port that will be used, there are restrictions on the maintenance communication methods that can be used. For details on the

restrictions, see the "Maintenance Communication" on page 4-1.

Note: When an HMI module is connected, maintenance communication can be performed by using the HMI-Ethernet port. For details, see Chapter

7 "HMI Function" in "FC6A Series MicroSmart All-in-One Type User’s Manual".

Communication

Cartridge

CAN Port

HMI-Ethernet

Port

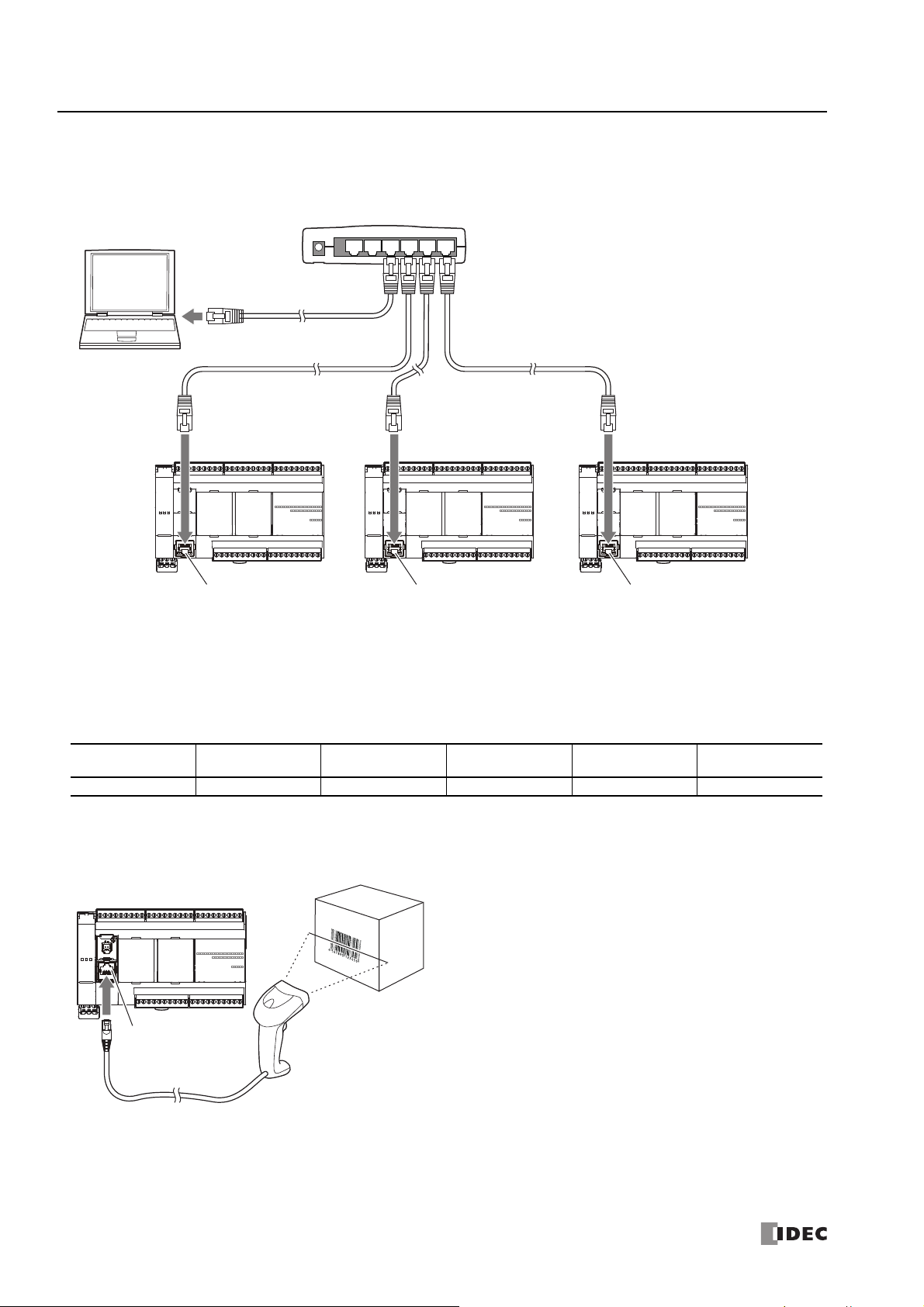

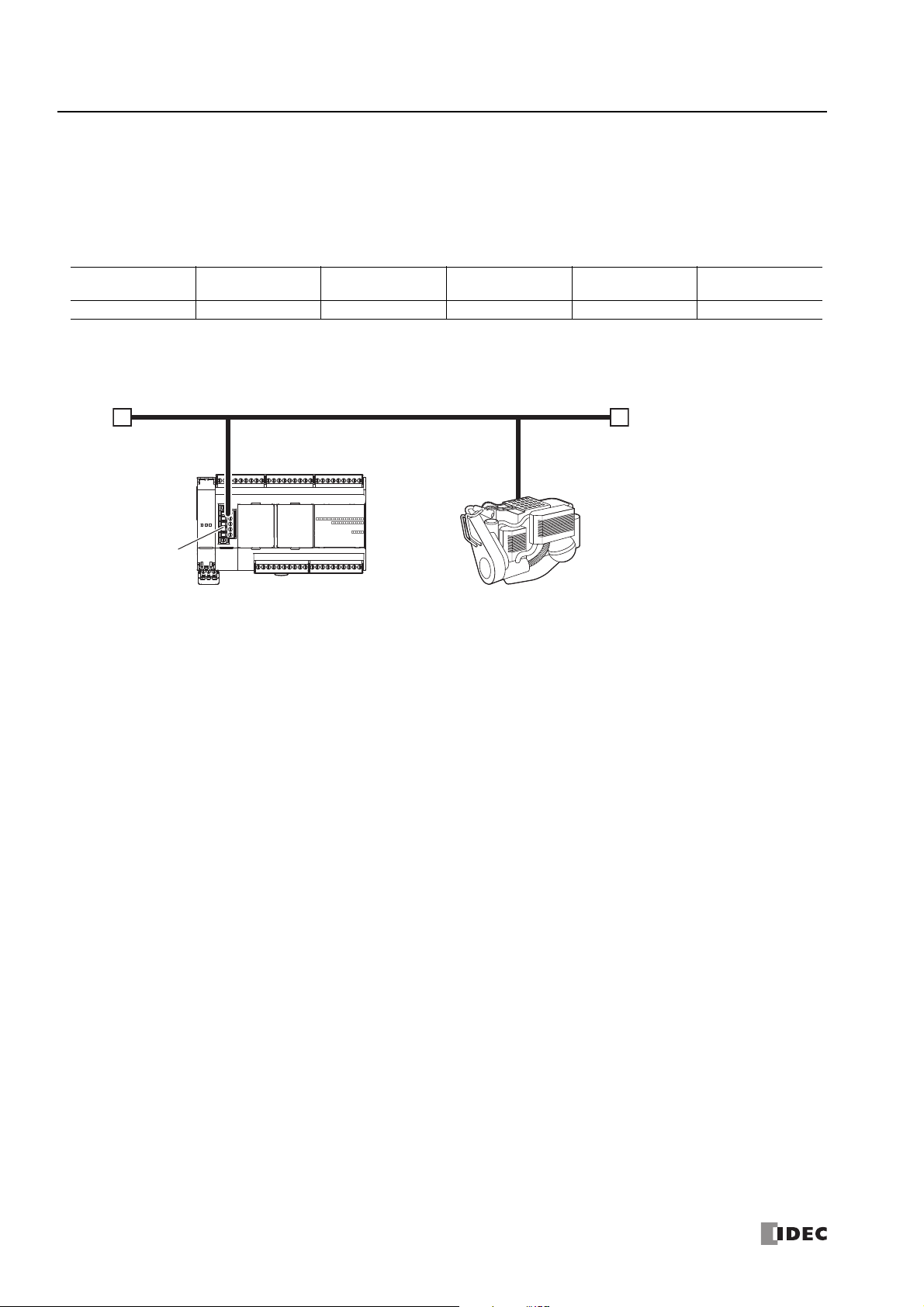

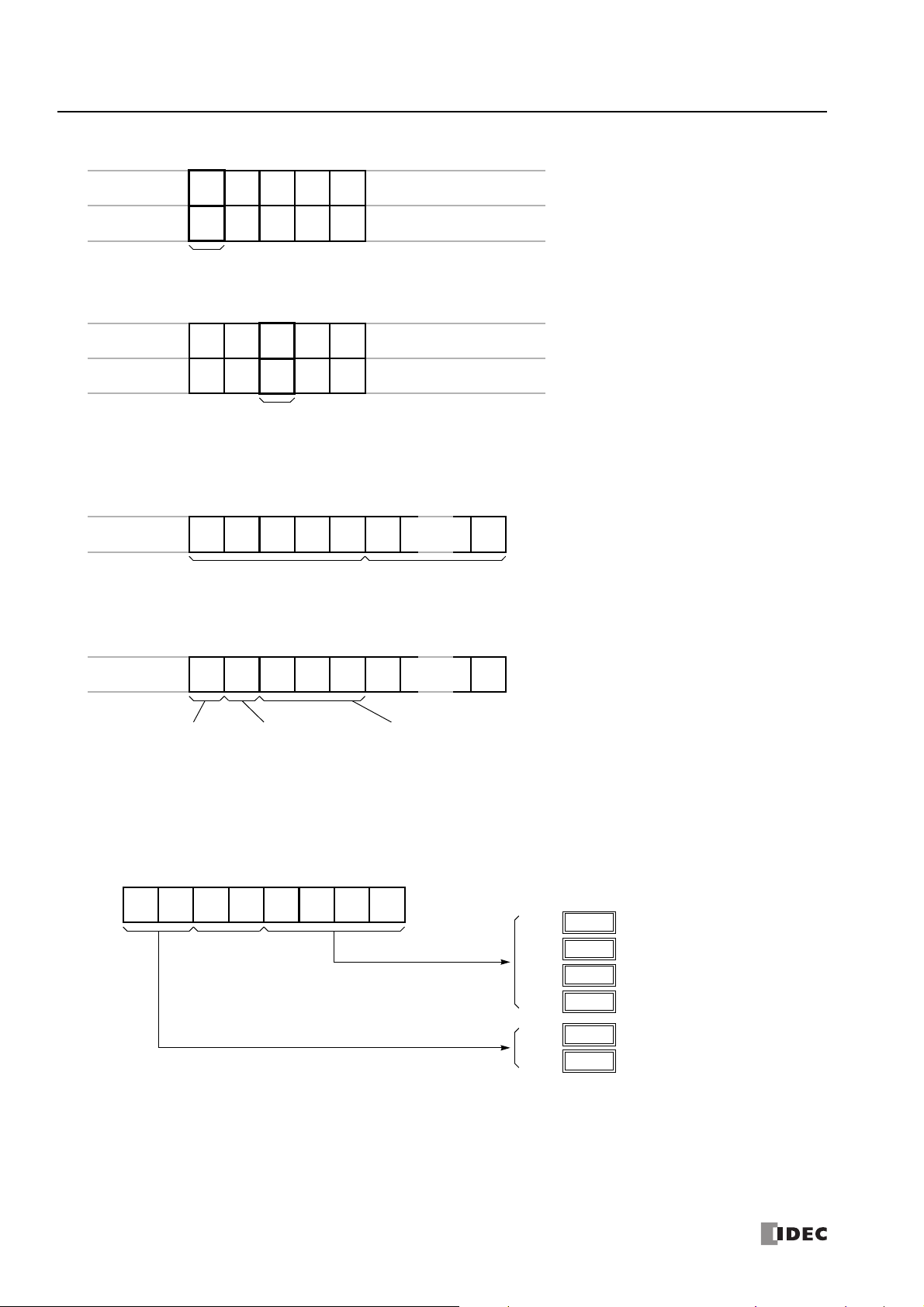

■ 1:1 Maintenance Communication System

This example shows a 1:1 maintenance communication system in which a FC6A Series MicroSmart and a computer are connected

with USB. The USB maintenance cable (HG9Z-XCM42) is used.

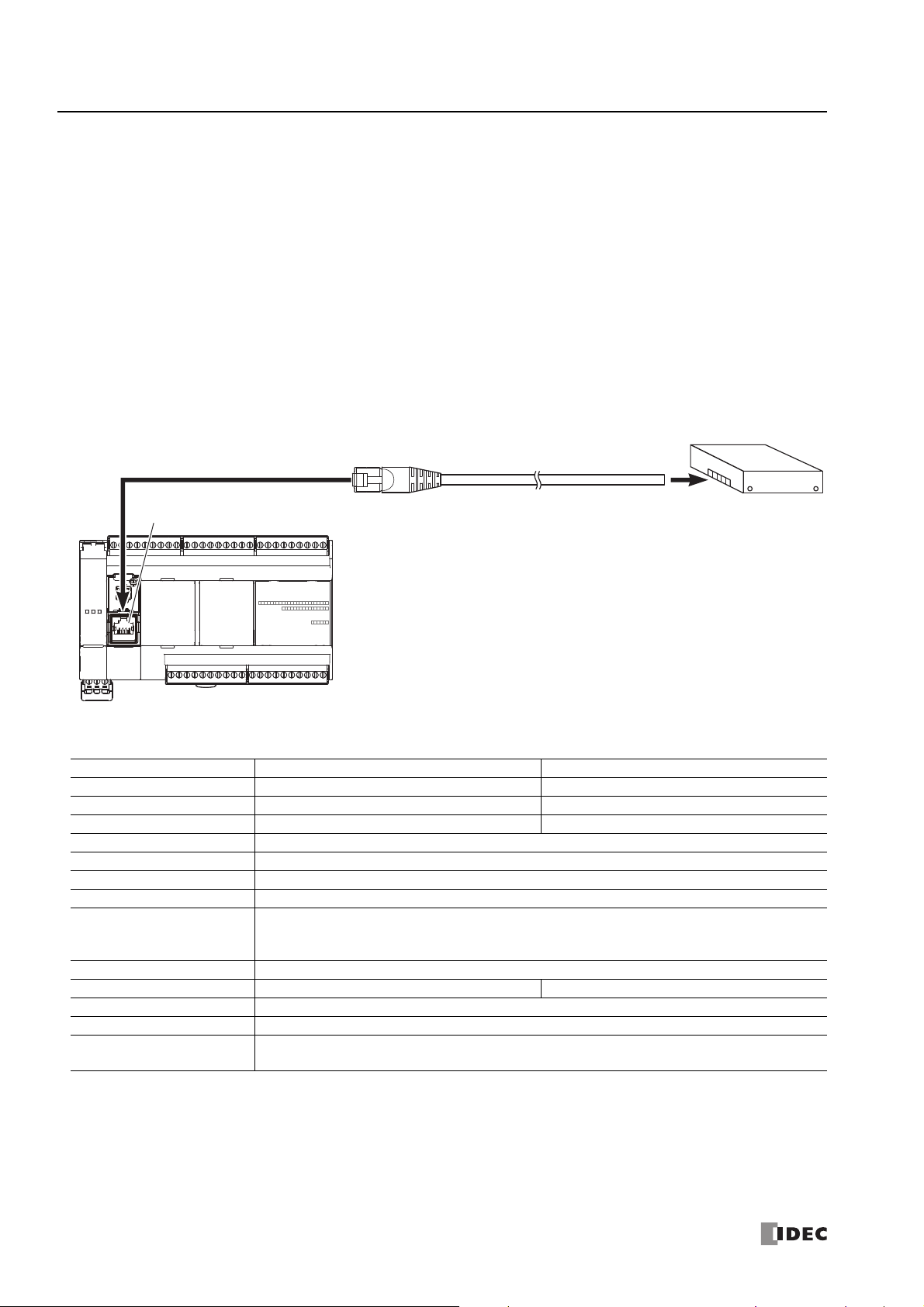

■ 1:1 Maintenance Communication Example with an IDEC Operator Interface Using Serial Port 1

This example shows maintenance communication between the FC6A Series MicroSmart and an operator interface, as well as

monitoring and changing FC6A Series MicroSmart device values using the operator interface. An IDEC operator interface is

connected to serial port 1 of the FC6A Series MicroSmart.

*1 For details on O/I communication cables, see Appendix "Cables" in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 1-5

1: G

Windows Computer

FC6A Series MicroSmart FC6A Series MicroSmart FC6A Series MicroSmart

Ethernet Hub

Ethernet Port 1 Ethernet Port 1Ethernet Port 1

Serial Port 1

(Port 1)

Barcode Reader

FC6A Series MicroSmart

ENERAL INFORMATION

■ 1:N Maintenance Communication System

This example shows a 1:N maintenance communication system in which three FC6A Series MicroSmart and a computer are

connected over Ethernet. The Ethernet cables are connected to the Ethernet port 1 of three FC6A Series MicroSmart, and those

FC6A Series MicroSmart are connected to the computer via an Ethernet hub.

User Communication

The user communication of the FC6A Series MicroSmart enables you to control external devices such as computers, printers, and

barcode readers. For details on user communication, see "User Communication Instructions" on page 5-1.

Supported ports

USB Port Serial Port 1 Ethernet Port 1

■ User Communication Using Serial Port 1

This example shows a system in which a FC6A Series MicroSmart receives the data read by a barcode reader. A barcode reader is

connected to port 1 of the FC6A Series MicroSmart.

Communication

Cartridge

No Ye s Yes Yes N o No

CAN Port

HMI-Ethernet

Port

1-6 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

1: G

INVERTER

RUN

RVS

ALM

COM

Temperature Controller

Inverter

Serial Port 1

(Port 1)

FC6A Series MicroSmart

FC6A Series MicroSmart

(Slave Station 1)

FC6A Series MicroSmart

(Slave Station 31)

Serial Port 1

(Port 1)

FC6A Series MicroSmart

(Master Station)

ENERAL INFORMATION

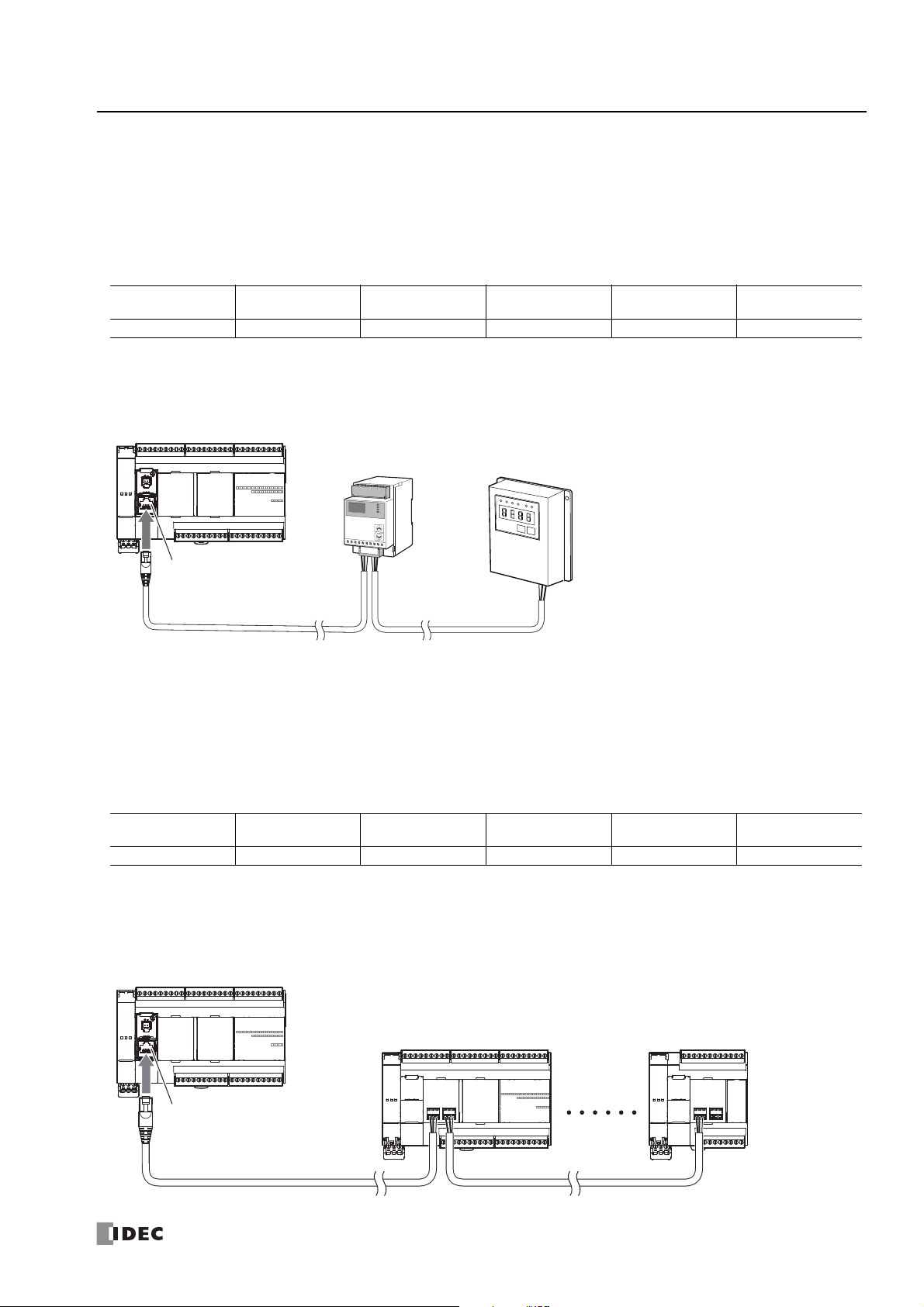

Modbus Communication

The FC6A Series MicroSmart is compliant with Modbus RTU protocol and can be used as either a Modbus communication master or

slave. With Modbus communication, the FC6A Series MicroSmart can monitor and modify the data of inverters and temperature

controllers.

For details on Modbus communication, see "Modbus Communication" on page 6-1.

Supported ports

USB Port Serial Port 1 Ethernet Port 1

Communication

Cartridge

CAN Port

HMI-Ethernet

Port

No Ye s Yes Yes N o No

■ Modbus RTU Communication Using Serial Port 1

This example shows a system in which a FC6A Series MicroSmart is communicating with a temperature controller and an inverter

that support Modbus RTU. The A temperature controller is connected to port 1 of the FC6A Series MicroSmart.

Data Link System

The FC6A Series MicroSmart supports data link communication, and it can share data between CPU modules using serial port 1

and cartridge slots. The FC6A Series MicroSmart can also share data with FC5A Series and FC4A Series CPU modules. Configure

the settings in WindLDR to enable distributed control of a maximum of 31 CPU modules.

For details about the data link communication, see "Data Link Communication" on page 7-1.

Supported ports

■ Data Link Communication Using Serial Port 1

This example shows communication between multiple CPU modules with the FC6A Series MicroSmart as the master station. A

slave station CPU module is connected to port 1 of the FC6A Series MicroSmart.

USB Port Serial Port 1 Ethernet Port 1

Communication

Cartridge

CAN Port

No Yes No Yes No No

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 1-7

HMI-Ethernet

Port

1: G

Engine

FC6A Series MicroSmart

(CAN J1939 All-in-One Type)

CAN Port

CAN

ENERAL INFORMATION

Using J1939 Communication

The CAN J1939 All-in-One Type can be connected to a J1939 communication network using the CAN port and it can communicate

with other J1939 communication-compatible devices. Messages that conform to the SAE J1939 standard can be sent and received.

For details on J1939 communication, see "J1939 Communication" on page 8-1.

Supported ports

USB Port Serial Port 1 Ethernet Port 1

No No No No Yes No

Communication

Cartridge

CAN Port

HMI-Ethernet

Port

■ CAN Port Usage Example

This example shows the FC6A Series MicroSmart communicating with a J1939-compatible engine. The CAN port of the CAN J1939

All-in-One Type is connected to the engine.

1-8 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

2: D

EVICE

This chapter provides detailed descriptions of the allocations of devices such as inputs, outputs, internal relays, registers, timers,

and counters that are used in the basic and advanced instructions, as well as details about the allocations of special internal relays

and special data registers.

Please use this chapter as a reference when entering and editing devices in the user program.

Note: The entry and operation of FC6A Series MicroSmart user programs requires specialist knowledge.

Take the time to develop a thorough understanding of the contents and programs in this manual before using the FC6A Series MicroSmart.

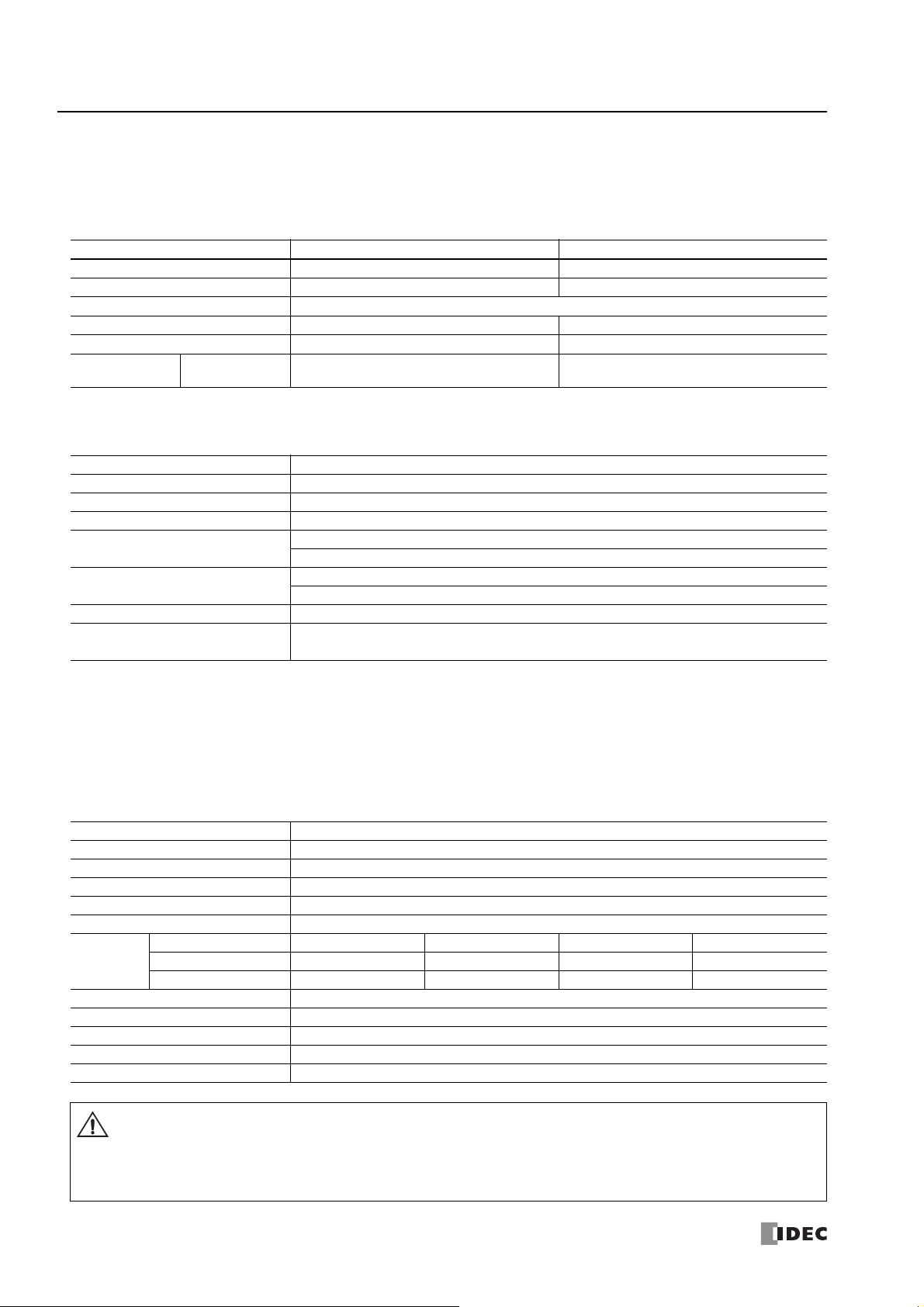

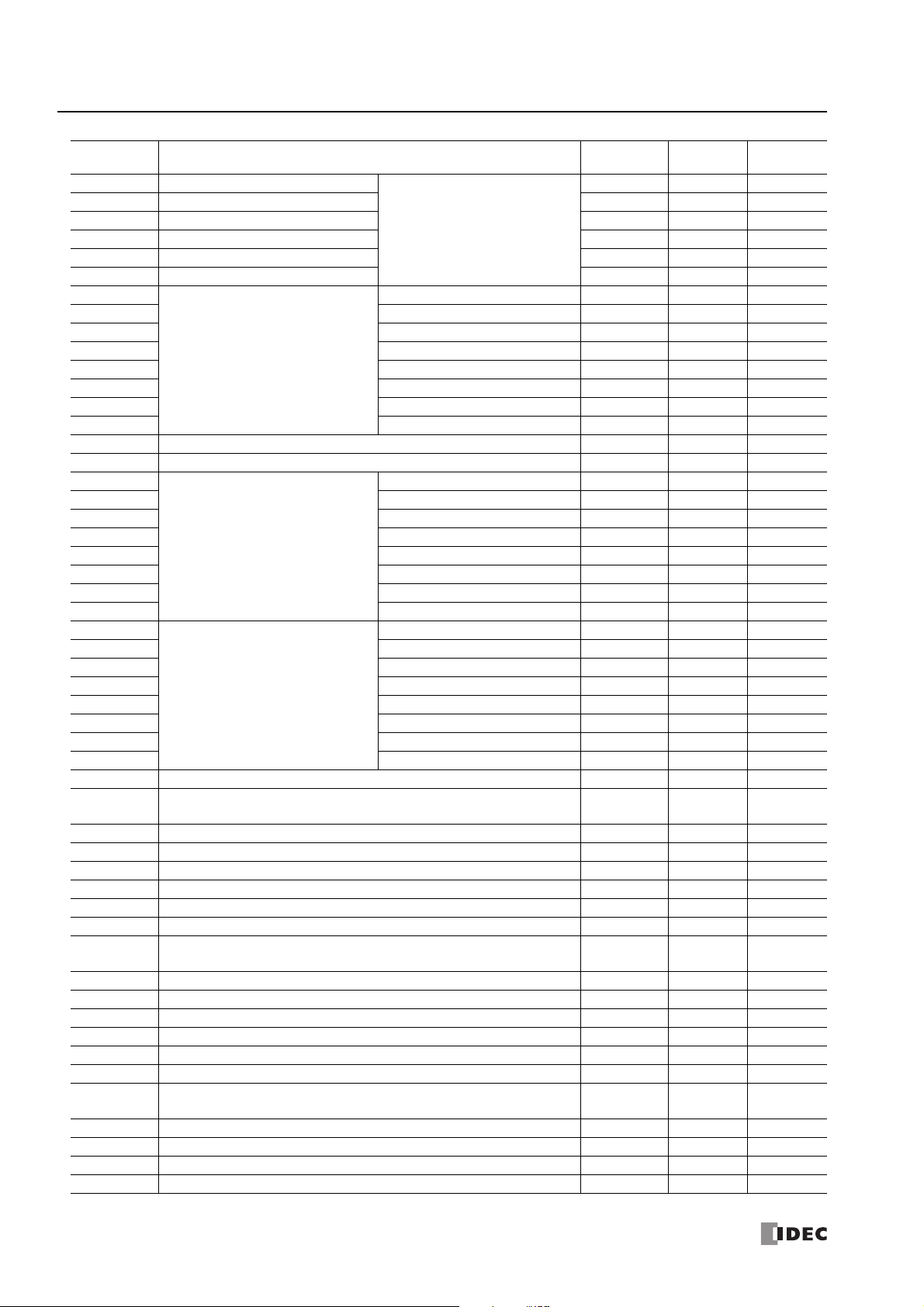

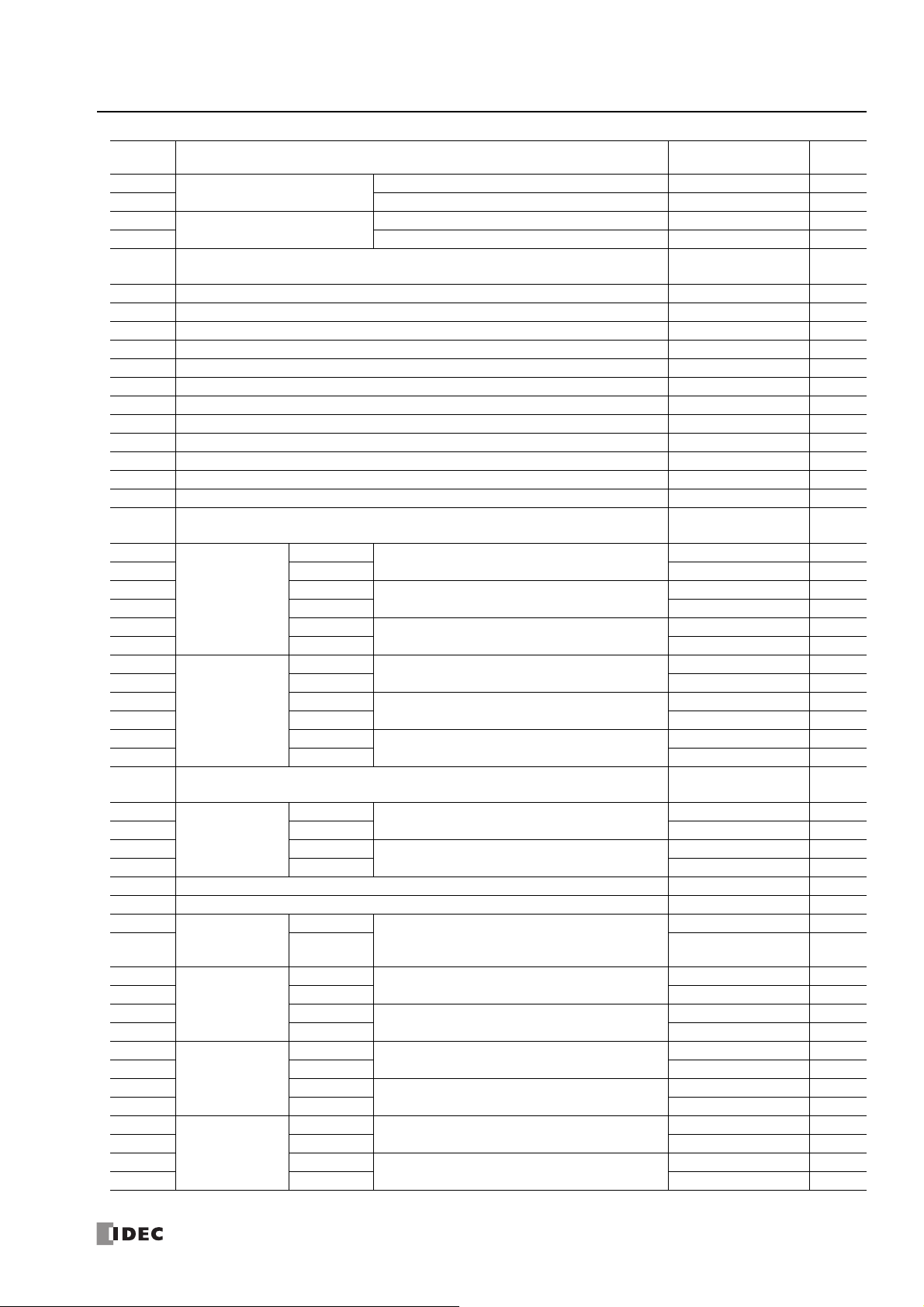

Device Addresses

Device Symbol Unit

*1

Inputs

Expansion Input Relays

*1

Output

Expansion Outputs

Internal Relay

Special Internal Relay

Shift Register R Bit

Timer T Bit/Word

Counter C Bit/Word

Data Register D Bit/Word

Special Data Register D Bit/Word

*1 The least significant digit of the device address is an octal number (0 to 7).

*2 I190 to I507 and Q190 to Q507 are devices that can only be used when an expansion module (expansion interface side) is connected using the

expansion interface module.

*3 I310 to I627 and Q310 to Q627 are devices that can only be used when an expansion module (expansion interface side) is connected using the

expansion interface module.

*1

*1

*1*3

*1

IBit

IBit

QBit

QBit

MBit

MBit

16-I/O Type 24-I/O Type 40-I/O Type

I0 - I10

(9 points)

I30 - I187

(128 points)

I190 - I507

(256 points)

(7 points)

Q30 - Q187

(128 points)

Q190 - Q507

(256 points)

*2

Q0 - Q6

*2

Range (Points)

I0 - I15

(14 points)

(224 points)

I310 - I627

(256 points)

Q0 - Q11

(10 points)

Q30 - Q307

(224 points)

Q310 - Q627

(256 points)

M0 - M7997

(6,400 points)

M10000 - M17497

(6,000 points)

M8000 - M8317

(256 points)

R0 - R255

(256 points)

T0 - T1023

(1,024 points)

C0 - C511

(512 points)

D0000 - D7999

(8,000 points)

D10000 to D55999

(46,000 points)

D8000 - D8499

(500 points)

I0 - I27

(24 points)

I30 - I307

*3

Q0 - Q17

(16 points)

*3

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 2-1

2: D

EVICE

■ Inputs (I), Expansion Inputs (I)

Devices that input on/off information from external devices to the FC6A Series MicroSmart.

■ Outputs (Q), Expansion Outputs (Q)

Devices that output on/off information from the FC6A Series MicroSmart to external devices.

■ Internal Relays (M)

Bit devices used internally on the FC6A Series MicroSmart.

■ Special Internal Relays (M)

Bit devices used internally on the FC6A Series MicroSmart. Special functions are assigned to each bit.

■ Shift Registers (R)

Bit devices that are used with the SFR instruction and the SFRN instruction. The bit sequence of the data is shifted according to

pulse input.

■ Timer (T)

Timers used internally in the FC6A Series MicroSmart. There are three devices: Timer bits (symbol: T, unit: bit), timer preset

values (symbol: TP, unit: word), and timer current values (symbol: TC, unit: word).

These can be used as an on-delay timer or an off-delay timer. For details on timers (T), see Chapter 3 "Using Timer or Counter

as Source Device" in the "FC6A Series MicroSmart LAD Programming Manual".

■ Counters (C)

Counters used internally in the FC6A Series MicroSmart. There are three devices: Counter bits (symbol: C, unit: bit), counter

preset values (symbol: CP, unit: word), and counter current values (symbol: CC, unit: word). These can be used as an adding

counter or a reversible counter. For details on counters (C), see Chapter 3 "Using Timer or Counter as Source Device" in the

"FC6A Series MicroSmart LAD Programming Manual".

■ Data Registers (D)

Word devices that are used for writing numerical data internally in the FC6A Series MicroSmart. These can also be used as bit

devices.

■ Special Data Registers (D)

Word devices that are used for writing numerical data internally in the FC6A Series MicroSmart. Special functions are assigned to

each data register. These can also be used as bit devices.

Notes:

• Although the device symbol for internal relays (M0000 to M7997, M10000 to M17497) and special internal relays (M8000 to M8317) is the

same ("M"), the device characteristics are different. Special functions are assigned to each bit of the special internal relays.

• Although the device symbol for the data registers (D0000 to D7999, D10000 to D55999) and special data registers (D8000 to D8499) is the

same ("D"), the device characteristics are different. Special functions are assigned to each special data register.

2-2 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

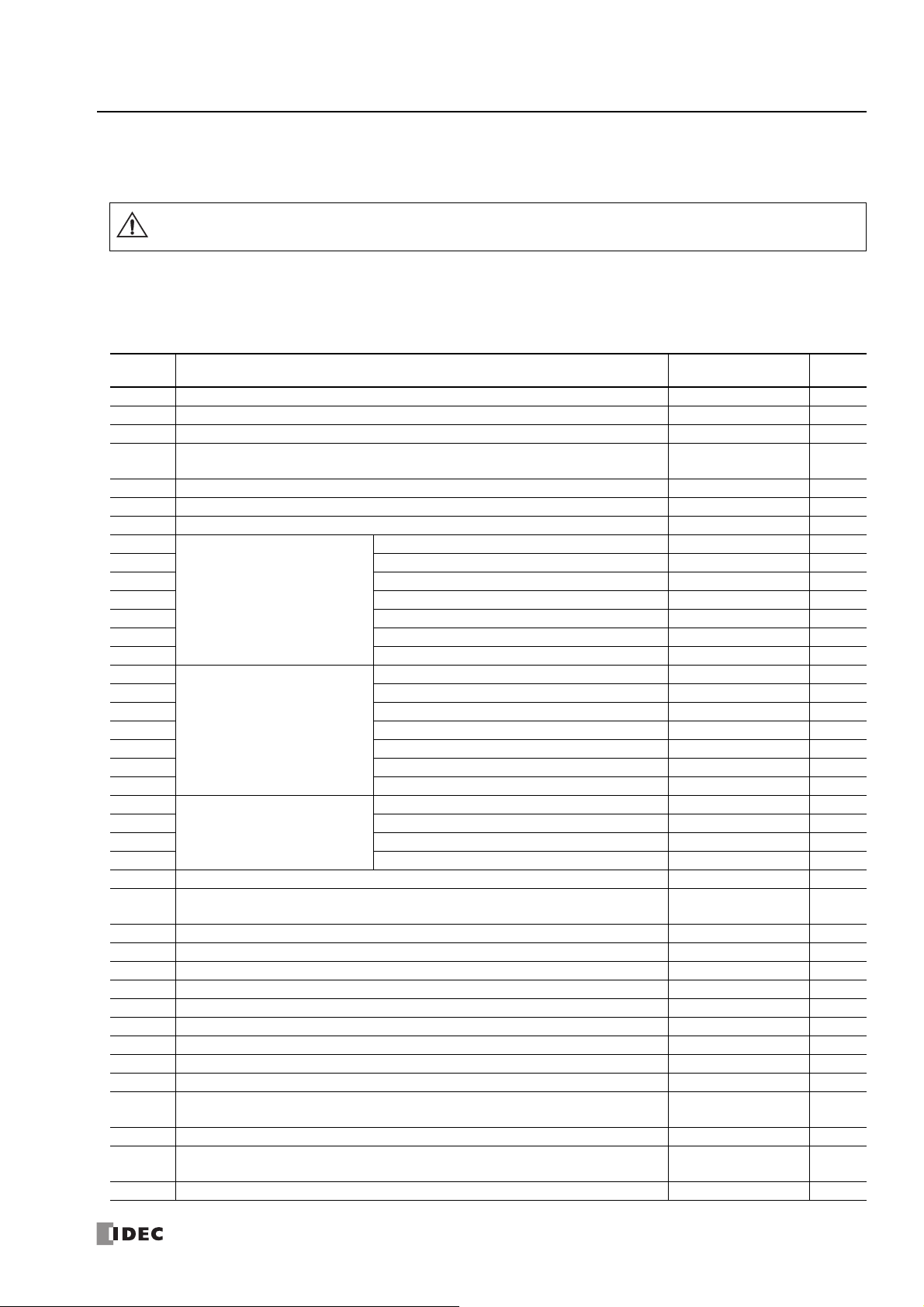

Special Internal Relay

Warning

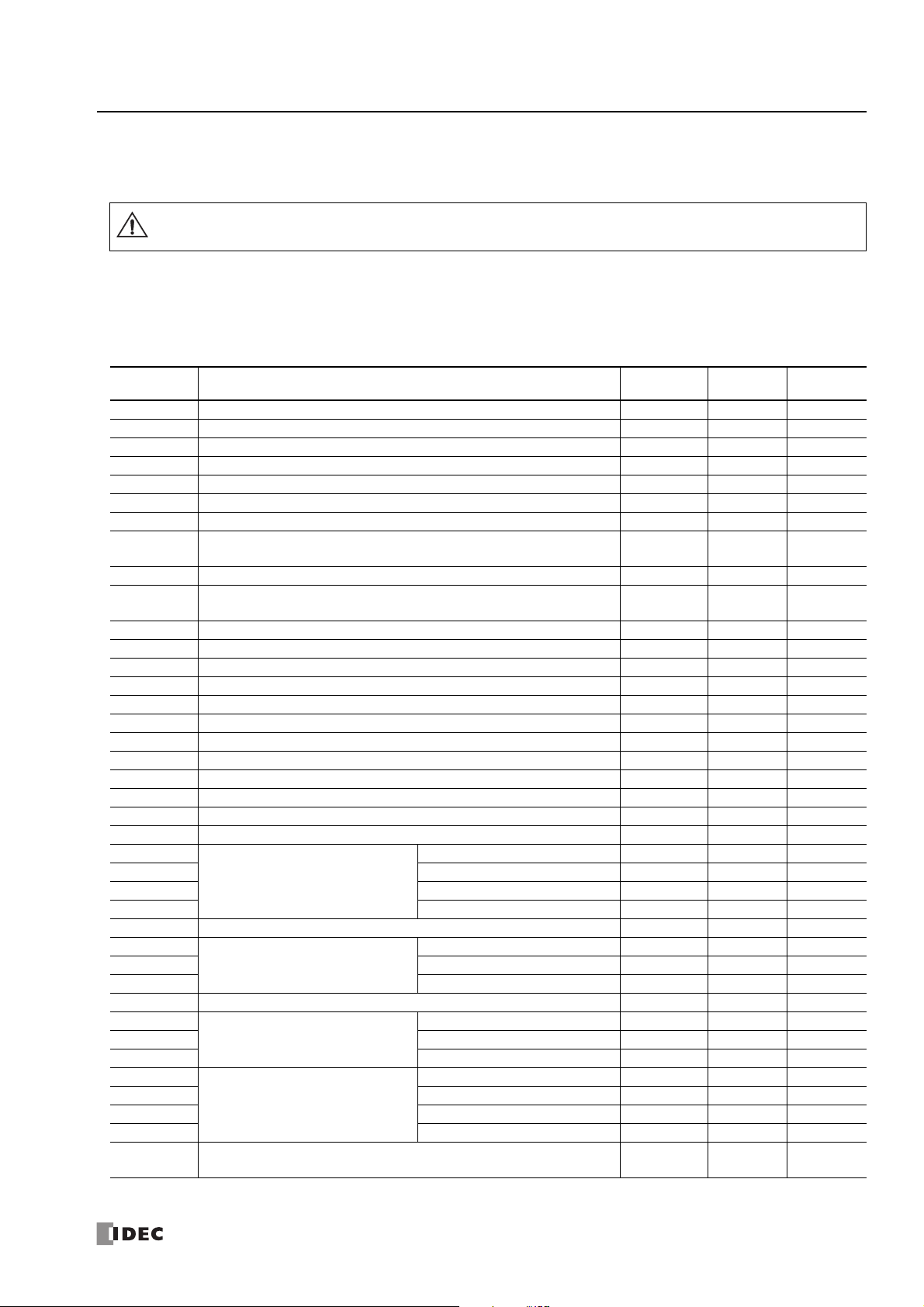

Special Internal Relay Device Addresses

Do not write to data in the area marked as reserved in the special internal relays list. Otherwise the system may not operate

correctly.

Note: R/W is an abbreviation for read/write.

The notation for the R/W field is as follows.

R/W: The device can be both read from and written to

R: Read-only

W: Write-only

2: D

EVICE

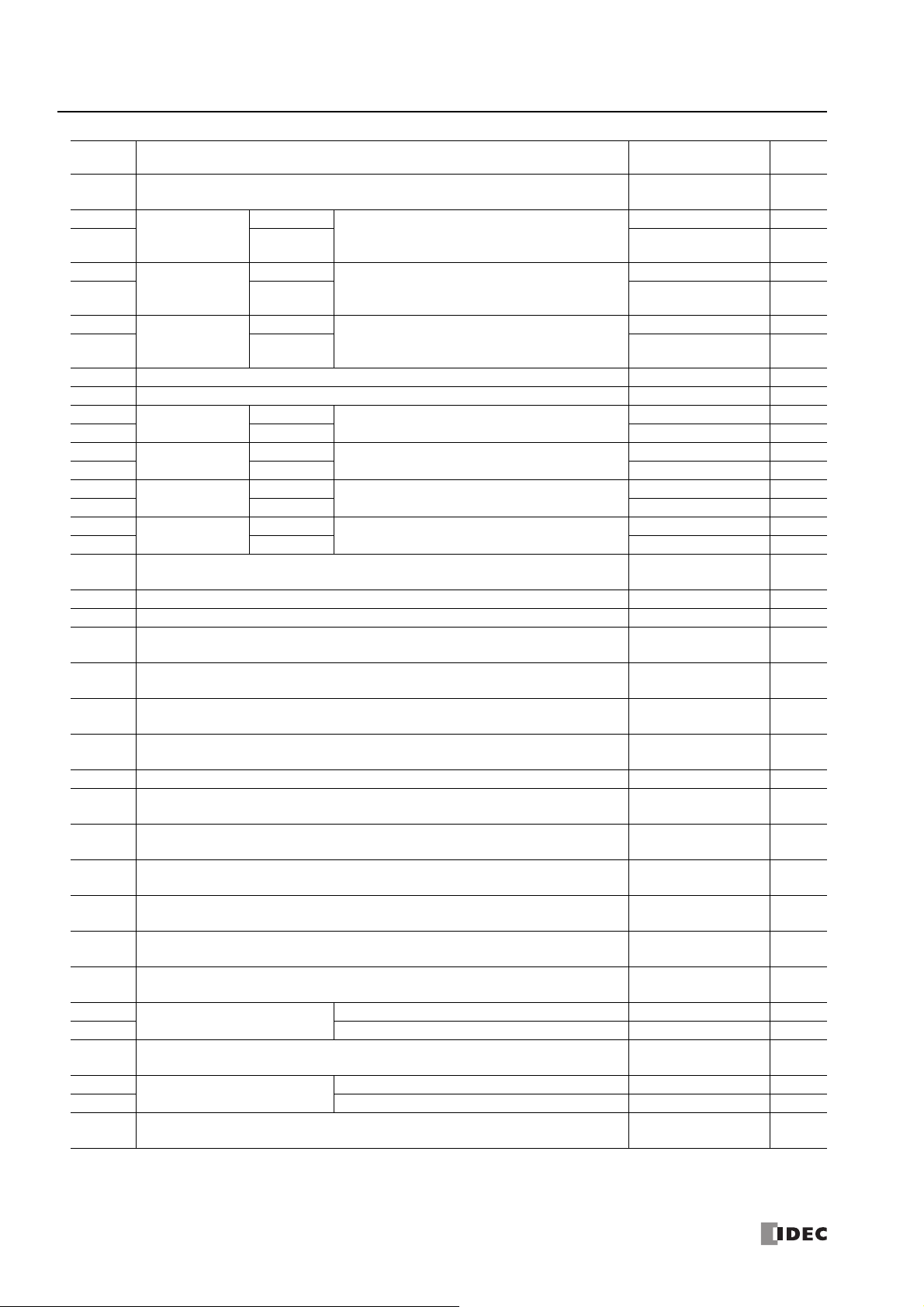

Device

Address

M8000 Start Control Maintained Maintained R/W

M8001 1-s Clock Reset Cleared Cleared R/W

M8002 All Outputs OFF Cleared Cleared R/W

M8003 Carry (Cy) or Borrow (Bw) Cleared Cleared R/W

M8004 User Program Execution Error Cleared Cleared R/W

M8005 Communication Error Maintained Cleared R/W

M8006 Communication Prohibited Flag (When Data Link Master) Maintained Maintained R/W

M8007

M8010 Status LED Operation Operating Cleared R/W

M8011

M8012

M8013 Calendar/Clock Data Write/Adjust Error Flag Operating Cleared R/W

M8014 Calendar/Clock Data Read Error Flag Operating Cleared R/W

M8015 — Reserved — — — —

M8016 Calendar Data Write Flag Operating Cleared R/W

M8017 Clock Data Write Flag Operating Cleared R/W

M8020 Calendar/Clock Data Write Flag Operating Cleared R/W

M8021 Clock Data Adjust Flag Operating Cleared R/W

M8022 User Communication Receive Instruction Cancel Flag (Port 1) Cleared Cleared R/W

M8023 User Communication Receive Instruction Cancel Flag (Port 2) Cleared Cleared R/W

M8024 BMOV/WSFT Executing Flag Maintained Maintained R/W

M8025 Maintain Outputs While Stopped Maintained Cleared R/W

M8026 User Communication Receive Instruction Cancel Flag (Port 3) Cleared Cleared R/W

M8027

M8030 Comparison Output Reset Cleared Cleared R/W

M8031 Gate Input Maintained Cleared R/W

M8032 Reset Input Maintained Cleared R/W

M8033 — Reserved — — — —

M8034

M8035 Gate Input Maintained Cleared R/W

M8036 Reset Input Maintained Cleared R/W

M8037 — Reserved — — — —

M8040

M8041 Gate Input Maintained Cleared R/W

M8042 Reset Input Maintained Cleared R/W

M8043

M8044 Comparison Output Reset Maintained Cleared R/W

M8045 Gate Input Maintained Cleared R/W

M8046 Reset Input Maintained Cleared R/W

M8047

M8050

Initialization Flag (When Data Link Master)/Stop Communication Flag (When

Data Link Slave)

— Reserved — — — —

High-speed Counter (Group 1/I0)

High-speed Counter (Group 3/I3)

High-speed Counter (Group 4/I4)

High-speed Counter (Group 5/I6)

— Reserved — — — —

Description

Count Direction Flag Maintained Cleared R/W

Comparison Output Reset Cleared Cleared R/W

Comparison Output Reset Cleared Cleared R/W

Count Direction Flag Cleared Cleared R/W

When

Stopped

Cleared Cleared R/W

Power

OFF

R/W

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 2-3

2: D

EVICE

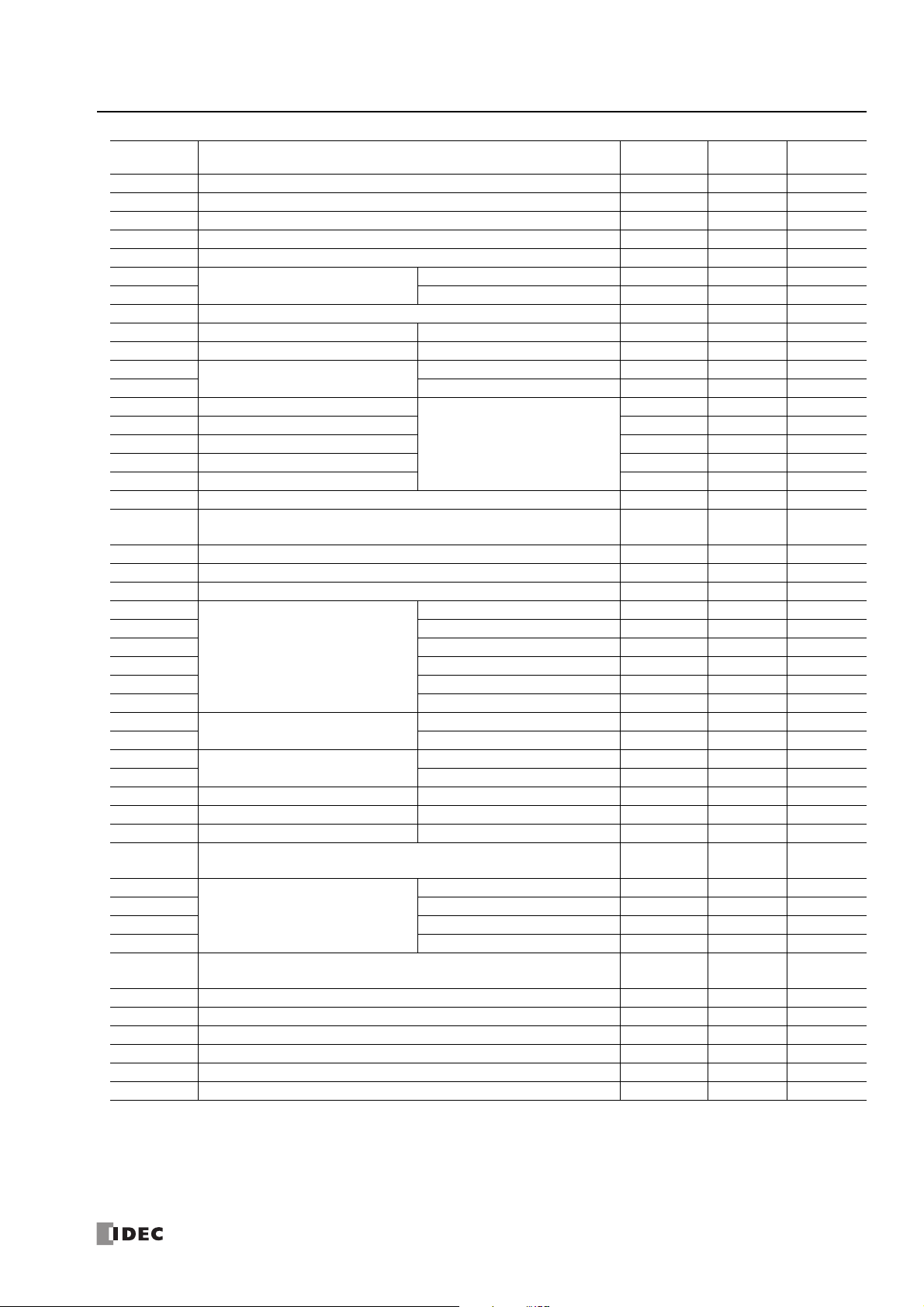

Device

Address

M8051

M8052 Gate Input Maintained Cleared R/W

M8053 Reset Input Maintained Cleared R/W

M8054 Comparison ON Status Maintained Cleared R

M8055 Overflow Maintained Cleared R

M8056 — Reserved — — — —

M8057

M8060 Gate Input Maintained Cleared R/W

M8061 Reset Input Maintained Cleared R/W

M8062 Comparison ON Status Maintained Cleared R

M8063 Overflow Maintained Cleared R

M8064 to

M8067

M8070 SD Memory Card Mount Status Maintained Cleared R

M8071 Accessing SD Memory Card Maintained Cleared R

M8072 Unmount SD Memory Card Operating Cleared R/W

M8073 Function Switch Status Operating Cleared R

M8074 Battery Voltage Measurement Flag Operating Cleared R/W

M8075 to

M8077

M8080 Data Link Slave 1 Communication Completed Relay (When Data Link Master) Operating Cleared R

M8081 Data Link Slave 2 Communication Completed Relay Operating Cleared R

M8082 Data Link Slave 3 Communication Completed Relay Operating Cleared R

M8083 Data Link Slave 4 Communication Completed Relay Operating Cleared R

M8084 Data Link Slave 5 Communication Completed Relay Operating Cleared R

M8085 Data Link Slave 6 Communication Completed Relay Operating Cleared R

M8086 Data Link Slave 7 Communication Completed Relay Operating Cleared R

M8087 Data Link Slave 8 Communication Completed Relay Operating Cleared R

M8090 Data Link Slave 9 Communication Completed Relay Operating Cleared R

M8091 Data Link Slave 10 Communication Completed Relay Operating Cleared R

M8092 Data Link Slave 11 Communication Completed Relay Operating Cleared R

M8093 Data Link Slave 12 Communication Completed Relay Operating Cleared R

M8094 Data Link Slave 13 Communication Completed Relay Operating Cleared R

M8095 Data Link Slave 14 Communication Completed Relay Operating Cleared R

M8096 Data Link Slave 15 Communication Completed Relay Operating Cleared R

M8097 Data Link Slave 16 Communication Completed Relay Operating Cleared R

M8100 Data Link Slave 17 Communication Completed Relay Operating Cleared R

M8101 Data Link Slave 18 Communication Completed Relay Operating Cleared R

M8102 Data Link Slave 19 Communication Completed Relay Operating Cleared R

M8103 Data Link Slave 20 Communication Completed Relay Operating Cleared R

M8104 Data Link Slave 21 Communication Completed Relay Operating Cleared R

M8105 Data Link Slave 22 Communication Completed Relay Operating Cleared R

M8106 Data Link Slave 23 Communication Completed Relay Operating Cleared R

M8107 Data Link Slave 24 Communication Completed Relay Operating Cleared R

M8110 Data Link Slave 25 Communication Completed Relay Operating Cleared R

M8111 Data Link Slave 26 Communication Completed Relay Operating Cleared R

M8112 Data Link Slave 27 Communication Completed Relay Operating Cleared R

M8113 Data Link Slave 28 Communication Completed Relay Operating Cleared R

M8114 Data Link Slave 29 Communication Completed Relay Operating Cleared R

M8115 Data Link Slave 30 Communication Completed Relay Operating Cleared R

M8116 Data Link Slave 31 Communication Completed Relay Operating Cleared R

M8117 Data Link All Slaves Communication Completed Relay Operating Cleared R

M8120 Initialize Pulse Cleared Cleared R

M8121 1-s Clock Operating Cleared R

M8122 100-ms Clock Operating Cleared R

High-speed Counter (Group 2/I1)

High-speed Counter (Group 6/I7)

— Reserved — — — —

— Reserved — — — —

Description

Comparison Output Reset Cleared Cleared R/W

Comparison Output Reset Cleared Cleared R/W

When

Stopped

Power

OFF

R/W

2-4 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

2: D

EVICE

Device

Address

M8123 10-ms Clock Operating Cleared R

M8124 Timer/Counter Preset Value Changed Maintained Cleared R

M8125 In-operation Output Cleared Cleared R

M8126 1 Scan ON After Run-Time Download Completes Cleared Cleared R

M8127 — Reserved — — — —

M8130

M8131 Comparison ON Status Maintained Cleared R

M8132 — Reserved — — — —

M8133 High-speed Counter (Group 3/I3) Comparison ON Status Maintained Cleared R

M8134 High-speed Counter (Group 4/I4) Comparison ON Status Maintained Cleared R

M8135

M8136 Comparison ON Status Maintained Cleared R

M8137 Interrupt Input I0 Status (Group 1/I0)

M8140 Interrupt Input I1 Status (Group 2/I1) Cleared Cleared R

M8141 Interrupt Input I3 Status (Group 3/I3) Cleared Cleared R

M8142 Interrupt Input I4 Status (Group 4/I4) Cleared Cleared R

M8143 Interrupt Input I6 Status (Group 5/I6) Cleared Cleared R

M8144 Timer Interrupt Status Cleared Cleared R

M8145 to

M8147

M8150 Comparison Result 1 Maintained Cleared R

M8151 Comparison Result 2 Maintained Cleared R

M8152 Comparison Result 3 Maintained Cleared R

M8153

M8154 Group 2/I1 Maintained Cleared R

M8155 Group 3/I3 Maintained Cleared R

M8156 Group 4/I4 Maintained Cleared R

M8157 Group 5/I6 Maintained Cleared R

M8160 Group 6/I7 Maintained Cleared R

M8161

M8162 Underflow Maintained Cleared R

M8163

M8164 Underflow Maintained Cleared R

M8165 High-speed Counter (Group 3/I3) Overflow Maintained Cleared R

M8166 High-speed Counter (Group 4/I4) Overflow Maintained Cleared R

M8167 Interrupt Input I7 Status (Group 6/I7) (ON: Allowed, OFF: Prohibited) Maintained Cleared R

M8170

M8171

M8172

M8173 Group 2 Operating Cleared R

M8174 Group 3 Operating Cleared R

M8175 Group 4 Operating Cleared R

M8176 to

M8183

M8184 Change HMI Module Network Settings Trigger Operating Cleared R/W

M8185 In Daylight Saving Time Period Operating Cleared R

M8186 Executing Auto Ping Operating Cleared R

M8187 Auto Ping Stop Flag Operating Cleared R/W

M8190 Change CPU Module Network Settings Trigger Operating Cleared R/W

M8191 SNTP Acquisition Flag Operating Cleared R/W

High-speed Counter (Group 1/I0)

High-speed Counter (Group 5/I6)

— Reserved — — — —

Catch Input ON/OFF Status

High-speed Counter (Group 1/I0)

High-speed Counter (Group 5/I6)

— Reserved — — — —

Transistor Source Output Overcurrent

Detection

— Reserved — — — —

Description

Reset Status Maintained Cleared R

Reset Status Maintained Cleared R

(ON: Allowed, OFF: Prohibited)

Group 1/I0 Maintained Cleared R

Overflow Maintained Cleared R

Overflow Maintained Cleared R

Group 1 Operating Cleared R

When

Stopped

Cleared Cleared R

Power

OFF

R/W

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 2-5

2: D

EVICE

Device

Address

M8192 Interrupt Input I0 Edge

M8193 Interrupt Input I3 Edge Cleared Cleared R

M8194 Interrupt Input I4 Edge Cleared Cleared R

M8195 Interrupt Input I6 Edge Cleared Cleared R

M8196 Interrupt Input I7 Edge Cleared Cleared R

M8197 Interrupt Input I1 Edge Cleared Cleared R

M8200

M8201 Connection 2 Cleared Cleared R/W

M8202 Connection 3 Cleared Cleared R/W

M8203 Connection 4 Cleared Cleared R/W

M8204 Connection 5 Cleared Cleared R/W

M8205 Connection 6 Cleared Cleared R/W

M8206 Connection 7 Cleared Cleared R/W

M8207 Connection 8 Cleared Cleared R/W

M8210 — Reserved — — — —

M8211 Send E-mail Server Settings Initialization Operating Cleared R/W

M8212

M8213 Connection 2 Operating Cleared R

M8214 Connection 3 Operating Cleared R

M8215 Connection 4 Operating Cleared R

M8216 Connection 5 Operating Cleared R

M8217 Connection 6 Operating Cleared R

M8220 Connection 7 Operating Cleared R

M8221 Connection 8 Operating Cleared R

M8222

M8223 Connection 2 Operating Cleared R/W

M8224 Connection 3 Operating Cleared R/W

M8225 Connection 4 Operating Cleared R/W

M8226 Connection 5 Operating Cleared R/W

M8227 Connection 6 Operating Cleared R/W

M8230 Connection 7 Operating Cleared R/W

M8231 Connection 8 Operating Cleared R/W

M8232 HMI Module Connection Information Reference Connection Status Operating Cleared R

M8233 to

M8247

M8250 Download from SD Memory Card Execution Flag Operating Cleared R/W

M8251 Upload to SD Memory Card Execution Flag Operating Cleared R/W

M8252 Executing SD Memory Card Download Operating Cleared R

M8253 Executing SD Memory Card Upload Operating Cleared R

M8254 SD Memory Card Download/Upload Execution Completed Output Operating Cleared R

M8255 SD Memory Card Download/Upload Execution Error Output Operating Cleared R

M8256

M8257

M8260 Write Recipe Execution Flag Operating Cleared R/W

M8261 Read Recipe Execution Flag Operating Cleared R/W

M8262 Executing Write Recipe Operating Cleared R/W

M8263 Executing Read Recipe Operating Cleared R/W

M8264 Recipe Execution Completed Output Operating Cleared R/W

M8265 Recipe Execution Error Output Operating Cleared R/W

M8266 to

M8297

M8300 J1939 Communication Permitted Flag Cleared Cleared R/W

M8301 J1939 Online Status Cleared Cleared R

M8302 J1939 Local Station Address Confirmation Status Cleared Cleared R

M8303 J1939 Communication Error Output Cleared Cleared R

User Communication Receive

Instruction Cancel Flag

Connection Status

(ON: Connected, OFF: Not Connected)

Disconnect User Communication

Connection

— Reserved — — — —

— Reserved — — — —

— Reserved — — — —

Description

On: Rising Edge

Off: Falling Edge

Connection 1 Cleared Cleared R/W

Connection 1 Operating Cleared R

Connection 1 Operating Cleared R/W

When

Stopped

Cleared Cleared R

Power

OFF

R/W

2-6 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

2: D

EVICE

Device

Address

M8304 J1939 Communication Bus Off Occurrence Output Cleared Cleared R

M8305 to

M8310

M8311 ESC+Key Input (Up) ESC+Key Input ( ) Cleared Cleared R

M8312 ESC+Key Input (Down) ESC+Key Input ( ) Cleared Cleared R

M8313 ESC+Key Input (Left) ESC+Key Input ( ) Cleared Cleared R

M8314 ESC+Key Input (Right) ESC+Key Input ( ) Cleared Cleared R

M8315 to

M8317

— Reserved — — — —

— Reserved — — — —

Description

When

Stopped

Power

OFF

R/W

Supplementary Descriptions of the Special Internal Relays Related to the Communication Functions

■ M8005: Communication Error

When an error occurs during data link communication, M8005 is turned on. The state is retained even when the error is cleared.

■ M8006: Communication Prohibited Flag (When Data Link Master)

During data link communication, communication is stopped while M8006 is on.

■ M8007: Initialization Flag (When Data Link Master)/Stop Communication Flag (When Data Link Slave)

When data link master:

When this flag is turned on in the run status, the data link is initialized just once to check the connection

status. Use this when the slave configured in the data link is powered at a timing slower than the master.

When data link slave : This flag is turned on when communication from the master is interrupted for 10 s or longer. This flag is

turned off when communication can be normally received.

■ M8022: User Communication Receive Instruction Cancel Flag (Port 1)

While M8022 is on, user communication (receive instruction) executing on Port 1 is canceled.

■ M8023: User Communication Receive Instruction Cancel Flag (Port 2)

While M8023 is on, user communication (receive instruction) executing on Port 2 is canceled.

■ M8026: User Communication Receive Instruction Cancel Flag (Port 3)

While M8026 is on, user communication (receive instruction) executing on Port 3 is canceled.

■ M8080 to M8117: Data Link Communication Completed Relay

Special internal relays used for data link communication. For details, see "Data Link Communication" on page 7-1.

■ M8184: Change HMI Module Network Settings Trigger

When M8184 is turned on, the values written to D8437 to D8456 are set as the HMI module IP address.

The IP address is not set just by changing the values of D8437 to D8456. For details on changing the HMI module network

settings, see "Network settings by HMI module special data registers" on page 3-5.

■ M8186: Executing Auto Ping

M8186 is on when auto ping is operating. M8186 is off when auto ping is stopped. For details on auto ping, see "Auto Ping

Function" on page 3-18.

■ M8187: Auto Ping Stop Flag

While M8187 is on, auto ping stops. While M8187 is off, auto ping is executed. At that time, auto ping is executed from the

smallest remote host number specified in the remote host list, regardless of the previous end status.

■ M8190: Change CPU Module Network Settings Trigger

When M8190 is turned on, the values written to D8304 to D8323 are set as the CPU module IP address.

The IP address is not set just by changing the values of D8304 to D8323. For details on changing the CPU module network

settings, see "Network settings by special data registers" on page 3-4.

■ M8191: SNTP Acquisition Flag

When M8191 is turned on, the time information is acquired from the SNTP server.

■ M8200 to M8207: User Communication Receive Instruction Cancel Flag

When M8200 to M8207 are turned on, the user communication receive instruction being executed is stopped.

M8200 = User communication receive instruction being executed on client connection 1

M8201 = User communication receive instruction being executed on client connection 2

M8202 = User communication receive instruction being executed on client connection 3

M8203 = User communication receive instruction being executed on client connection 4

M8204 = User communication receive instruction being executed on client connection 5

M8205 = User communication receive instruction being executed on client connection 6

M8206 = User communication receive instruction being executed on client connection 7

M8207 = User communication receive instruction being executed on client connection 8

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 2-7

2: D

EVICE

■ M8211: Send E-mail Server Settings Initialization

When M8211 is turned on, the send E-mail server settings are initialized.

■ M8212 to M8221: Connection Status

While connected to a network device via the maintenance communication server, user communication server/client, or Modbus

TCP server/client, the connection status is turned on. While not connected to a network device, the connection status is turned

off.

M8212 = Connection 1

M8213 = Connection 2

M8214 = Connection 3

M8215 = Connection 4

M8216 = Connection 5

M8217 = Connection 6

M8220 = Connection 7

M8221 = Connection 8

■ M8222 to M8231: Disconnect User Communication Connection

When connected to a remote host via user communication, the corresponding connection is disconnected when M8222 to

M8231 is turned on.

M8222 = Connection 1

M8223 = Connection 2

M8224 = Connection 3

M8225 = Connection 4

M8226 = Connection 5

M8227 = Connection 6

M8230 = Connection 7

M8231 = Connection 8

These relays are enabled only when a user communication client is used.

■ M8232: HMI Module Connection Information Reference Connection Status

M8232 is turned on when there is a connection with the connection number specified by D8429. M8232 is turned off when there

is no connection.

■ M8300 to M8304: J1939 Communication

Special data registers used in J1939 communication. For details, see "Special Internal Relay Allocations" on page 8-4.

2-8 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

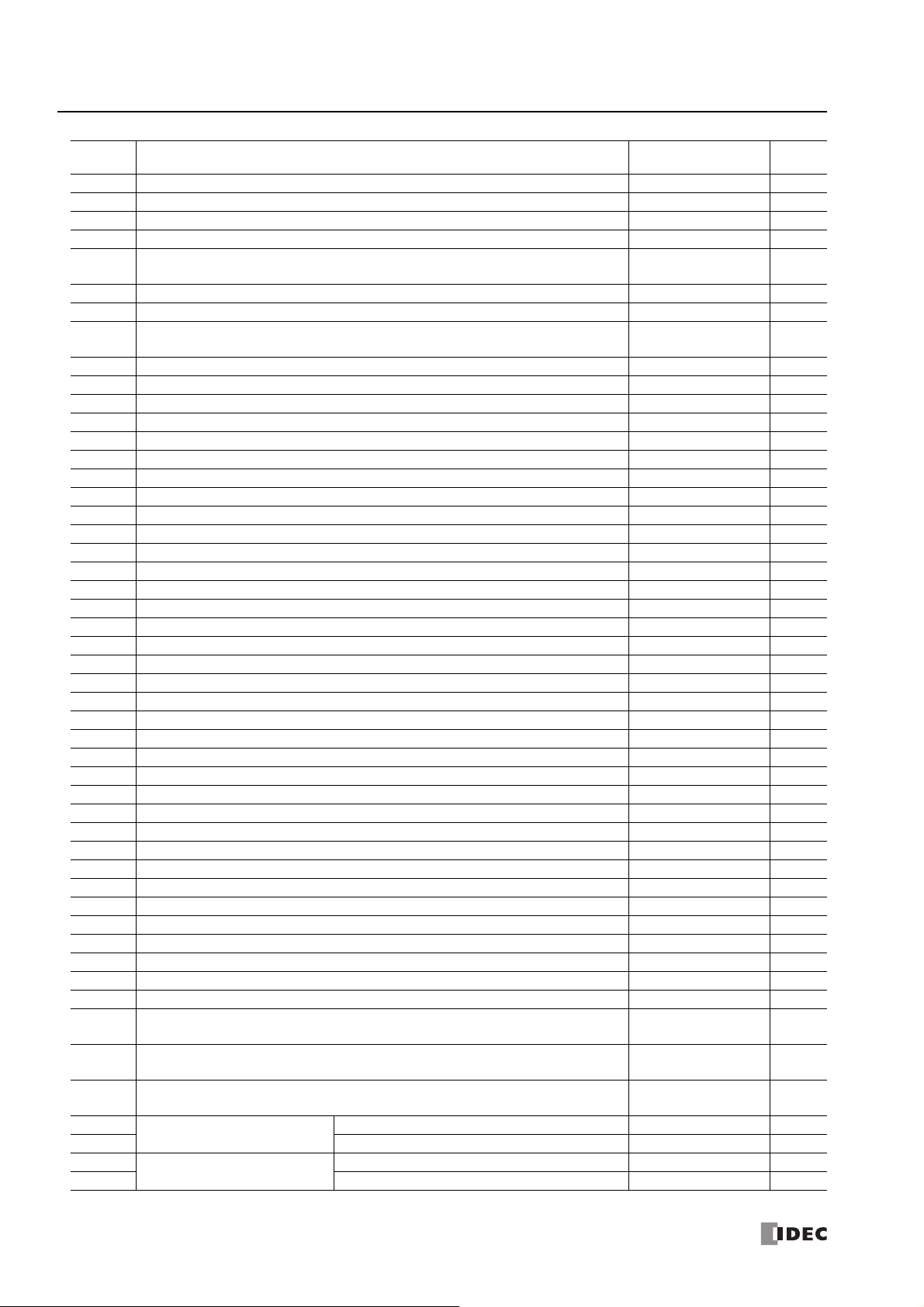

Special Data Register

Warning

Special Data Register Device Addresses

Do not write to data in the area marked as reserved in the special data registers list. Otherwise the system may not operate

correctly.

Note: R/W is an abbreviation for read/write.

The notation for the R/W field is as follows.

R/W: The device can be both read from and written to

R: Read-only

W: Write-only

2: D

EVICE

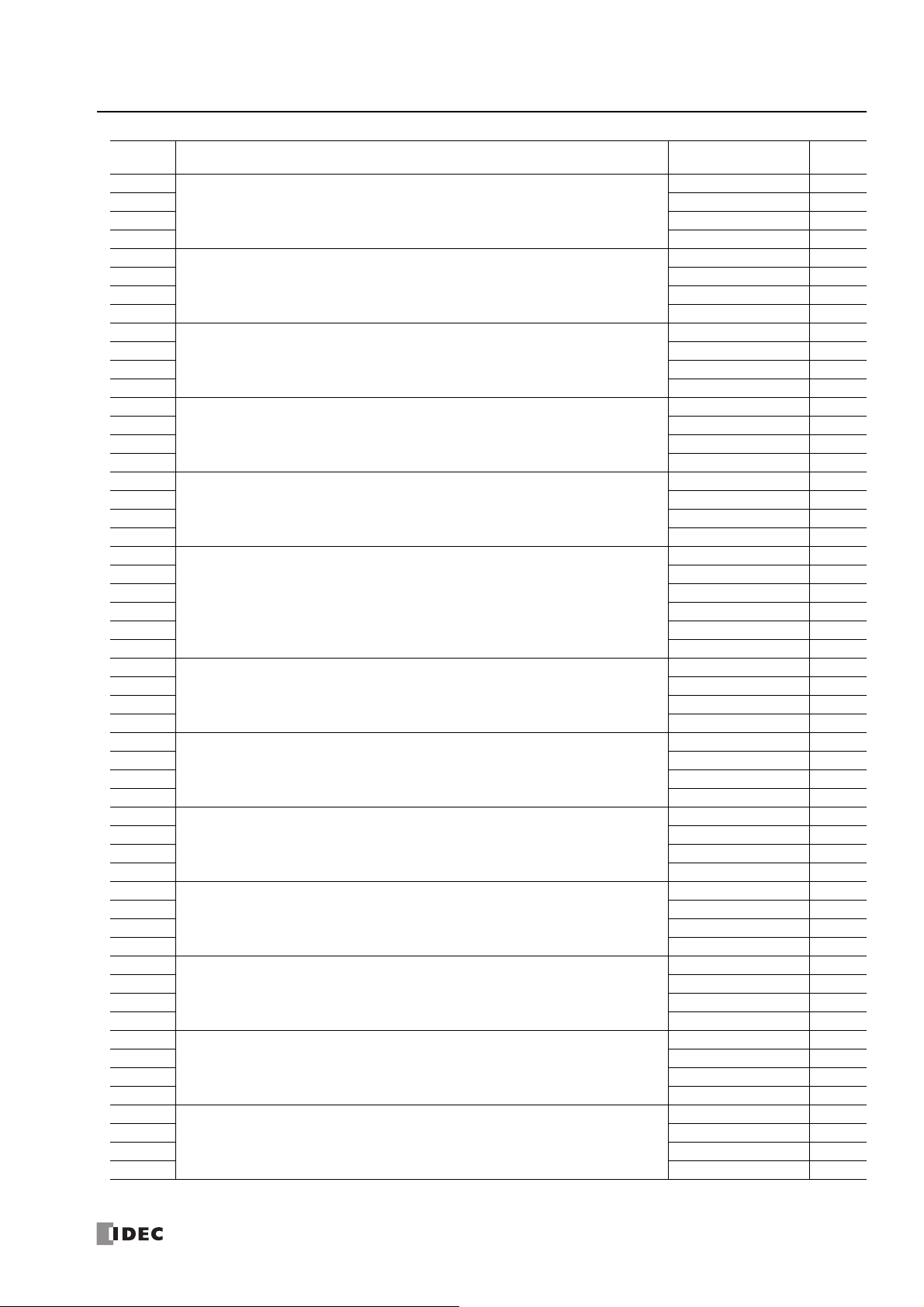

Device

Address

D8000 Quantity of Inputs When I/O initialized R

D8001 Quantity of Outputs When I/O initialized R

D8002 CPU Module Type Information Power-up R

D8003

D8004

D8005 General Error Code When error occurred R/W

D8006 User Program Execution Error Code When error occurred R

D8007 — Reserved — ― -

D8008

D8009 Month Every 500 ms R

D8010 Day Every 500 ms R

D8011 Day of the Week Every 500 ms R

D8012 Hour Every 500 ms R

D8013 Minute Every 500 ms R

D8014 Second Every 500 ms R

D8015

D8016 Month ― W

D8017 Day ― W

D8018 Day of the Week ― W

D8019 Hour ― W

D8020 Minute ― W

D8021 Second ― W

D8022

D8023 Scan Time Current Value (ms) Every scan R

D8024 Scan Time Maximum Value (ms) At occurrence R

D8025 Scan Time Minimum Value (ms) At occurrence R

D8026 Communication Mode Information (Port 1 to Port 3) Every scan R

D8027

D8028

D8029 System Software Version Power-up R

D8030 Communication Adapter Information Power-up R

D8031 Optional Cartridge Connection Information Power-up R

D8032 Interrupt Input Jump Destination Label No. (I1) ― R/W

D8033 Interrupt Input Jump Destination Label No. (I3) ― R/W

D8034 Interrupt Input Jump Destination Label No. (I4) ― R/W

D8035 Interrupt Input Jump Destination Label No. (I6) ― R/W

D8036 Timer Interrupt Jump Destination Label No. ― R/W

D8037 Number of Connected I/O Modules When I/O initialized R

D8038 to

D8051

D8052 J1939 Communication Error Code Every scan R/W

D8053 to

D8055

D8056 Battery Voltage ― R

— Reserved — ― -

Calendar/Clock Current Data

(Read only)

Calendar/Clock New Data

(Write only)

Scan Time Data

— Reserved — ― -

— Reserved — ――

— Reserved — ――

Description Update Timing R/W

Year Every 500 ms R

Yea r ― W

Constant Scan Time Preset Value (1 to 1,000 ms) ― W

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 2-9

2: D

EVICE

Device

Address

D8057 Analog Potentiometer (AI0) Every scan R

D8058 Built-in Analog Input (AI1) Every scan R

D8059 Analog Input Status AI0 Every scan R

D8060 Analog Input Status AI1 Every scan R

D8061 to

D8066

D8067 Backlight ON Time ― R/W

D8068 — Reserved — ――

D8069

D8070 Slave 2 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8071 Slave 3 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8072 Slave 4 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8073 Slave 5 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8074 Slave 6 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8075 Slave 7 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8076 Slave 8 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8077 Slave 9 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8078 Slave 10 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8079 Slave 11 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8080 Slave 12 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8081 Slave 13 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8082 Slave 14 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8083 Slave 15 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8084 Slave 16 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8085 Slave 17 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8086 Slave 18 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8087 Slave 19 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8088 Slave 20 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8089 Slave 21 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8090 Slave 22 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8091 Slave 23 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8092 Slave 24 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8093 Slave 25 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8094 Slave 26 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8095 Slave 27 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8096 Slave 28 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8097 Slave 29 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8098 Slave 30 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8099 Slave 31 Communication Status/Error (When Data Link Master Mode) When error occurred R

D8100 Slave Number (Port 1) ― R/W

D8101 — Reserved — ――

D8102 Slave Number (Port 2) ― R/W

D8103 Slave Number (Port 3) ― R/W

D8104 Control Signal Status (Port 1 to 3) Every scan R

D8105 RS232C DSR Input Control Signal Option (Port 1 to 3)

D8106 RS232C DTR Output Control Signal Option (Port 1 to 3)

D8107 to

D8119

D8120

D8121 System Software Version ― R

D8122

D8123 System Software Version ― R

— Reserved — ――

Slave 1 Communication Status/Error (When Data Link Master Mode)

Slave Communication Status/Error (When Data Link Slave Mode)

— Reserved — ――

HMI Module Information

Cartridge Slot 1 Information

Description Update Timing R/W

When error occurred R

When sending/

receiving data

When sending/

receiving data

Typ e I D / S t a tus ― R

Typ e I D / S t a tus ― R

R

R

2-10 FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730

2: D

EVICE

Device

Address

D8124

D8125 System Software Version ― R

D8126

D8127 System Software Version ― R

D8128 to

D8169

D8170 Analog Cartridge I/O AI2/AQ2 Every scan R

D8171 Analog Cartridge I/O AI3/AQ3 Every scan R

D8172 Analog Cartridge Status AI2/AQ2 Every scan R

D8173 Analog Cartridge Status AI3/AQ3 Every scan R

D8174 Analog Cartridge I/O AI4/AQ4 Every scan R

D8175 Analog Cartridge I/O AI5/AQ5 Every scan R

D8176 Analog Cartridge Status AI4/AQ4 Every scan R

D8177 Analog Cartridge Status AI5/AQ5 Every scan R

D8178 Analog Cartridge I/O AI6/AQ6 Every scan R

D8179 Analog Cartridge I/O AI7/AQ7 Every scan R

D8180 Analog Cartridge Status AI6/AQ6 Every scan R

D8181 Analog Cartridge Status AI7/AQ7 Every scan R

D8182 to

D8191

D8192

D8193 Low Word Every scan R

D8194 High Word

D8195 Low Word ― R/W

D8196 High Word

D8197 Low Word ― R/W

D8198

D8199 Low Word Every scan R

D8200 High Word

D8201 Low Word ― R/W

D8202 High Word

D8203 Low Word ― R/W

D8204 to

D8209

D8210

D8211 Low Word Every scan R

D8212 High Word

D8213 Low Word ― R/W

D8214 Interrupt Input Jump Destination Label No. (I7) ― R/W

D8215 Interrupt Input Jump Destination Label No. (I0) ― R/W

D8216 High-speed

D8217 Low Word ― R/W

D8218

D8219 Low Word Every scan R

D8220 High Word

D8221 Low Word ― R/W

D8222

D8223 Low Word Every scan R

D8224 High Word

D8225 Low Word ― R/W

D8226

D8227 Low Word Every scan R

D8228 High Word

D8229 Low Word ― R/W

Cartridge Slot 2 Information

Cartridge Slot 3 Information

— Reserved — ――

— Reserved — ――

High Word

High-speed

Counter

(Group 2/I1)

High Word

High-speed

Counter

(Group 6/I7)

— Reserved — ――

High-speed

Counter

(Group 1/I0)

Counter

(Group 1/I0)

High-speed

Counter

(Group 3/I3)

High-speed

Counter

(Group 4/I4)

High-speed

Counter

(Group 5/I6)

High Word

High Word

High Word

High Word

High Word

Description Update Timing R/W

Type ID/Status ― R

Type ID/Status ― R

Current Value/Frequency Measurement (I1) Current

Value

Preset Value

Preset Value

Current Value/Frequency Measurement (I7) Current

Value

Preset Value

Preset Value

Current Value/Frequency Measurement (I0) Current

Value

Preset Value

Preset Value

Current Value/Frequency Measurement (I3) Current

Value

Preset Value

Current Value/Frequency Measurement (I4) Current

Value

Preset Value

Current Value/Frequency Measurement (I6) Current

Value

Preset Value

Every scan R

― R/W

― R/W

Every scan R

― R/W

― R/W

Every scan R

― R/W

― R/W

Every scan R

― R/W

Every scan R

― R/W

Every scan R

― R/W

FC6A S

ERIES MICROSMART ALL-IN-ONE TYPE COMMUNICATION MANUAL

FC9Y-B1730 2-11

2: D

EVICE

Device

Address

D8230

D8231

D8232 High-speed

D8233 Low Word ― R/W

D8234 High-speed

D8235 Low Word ― R/W

D8236 High-speed

D8237 Low Word ― R/W

D8238 — Reserved — ――

D8239 Absolute Position Control Status Every scan R

D8240

D8241 Low Word Every scan R

D8242

D8243 Low Word Every scan R

D8244

D8245 Low Word Every scan R

D8246

D8247 Low Word Every scan R

D8248

D8249

D8250 Read SD Memory Card Capacity Every scan R

D8251 Read SD Memory Card Free Capacity Every scan R

D8252

D8253

D8254 SD Memory Card Download/Upload Execution Information

D8255 SD Memory Card Download/Upload Execution Status

D8256 to

D8359

D8260 Recipe Block Number ― R/W

D8261 Recipe Execution Block Number

D8262 Recipe Execution Channel No.

D8263 Recipe Execution Operation

D8264 Recipe Execution Status

D8265 Recipe Execution Error Information

D8266 to

D8277

D8278

D8279 Connection 5 to 8 ― R

D8280 to

D8283

D8284

D8285 HMI Connection 5 to 8 ― R

D8286 to

D8303

— Reserved — ――

High Word

Counter

(Group 5/I6)

High Word

Counter

(Group 3/I3)

High Word

Counter

(Group 4/I4)

Absolute Position

Counter 1

Absolute Position

Counter 2

Absolute Position

Counter 3

Absolute Position

Counter 4

— Reserved — ――

— Reserved — ――

— Reserved — ――

— Reserved — ――

Communication Mode Information

(Client Connection)

— Reserved — ――

Communication Mode Information

(HMI Connection)

— Reserved — ――

High Word

High Word

High Word

High Word

Description Update Timing R/W

― R/W

Preset Value

― R/W

Preset Value

― R/W

Preset Value

Absolute Position

Absolute Position

Absolute Position

Absolute Position

Connection 1 to 4 ― R

HMI Connection 1 to 4 ― R

Every scan R

Every scan R

Every scan R

Every scan R

When processing has

completed

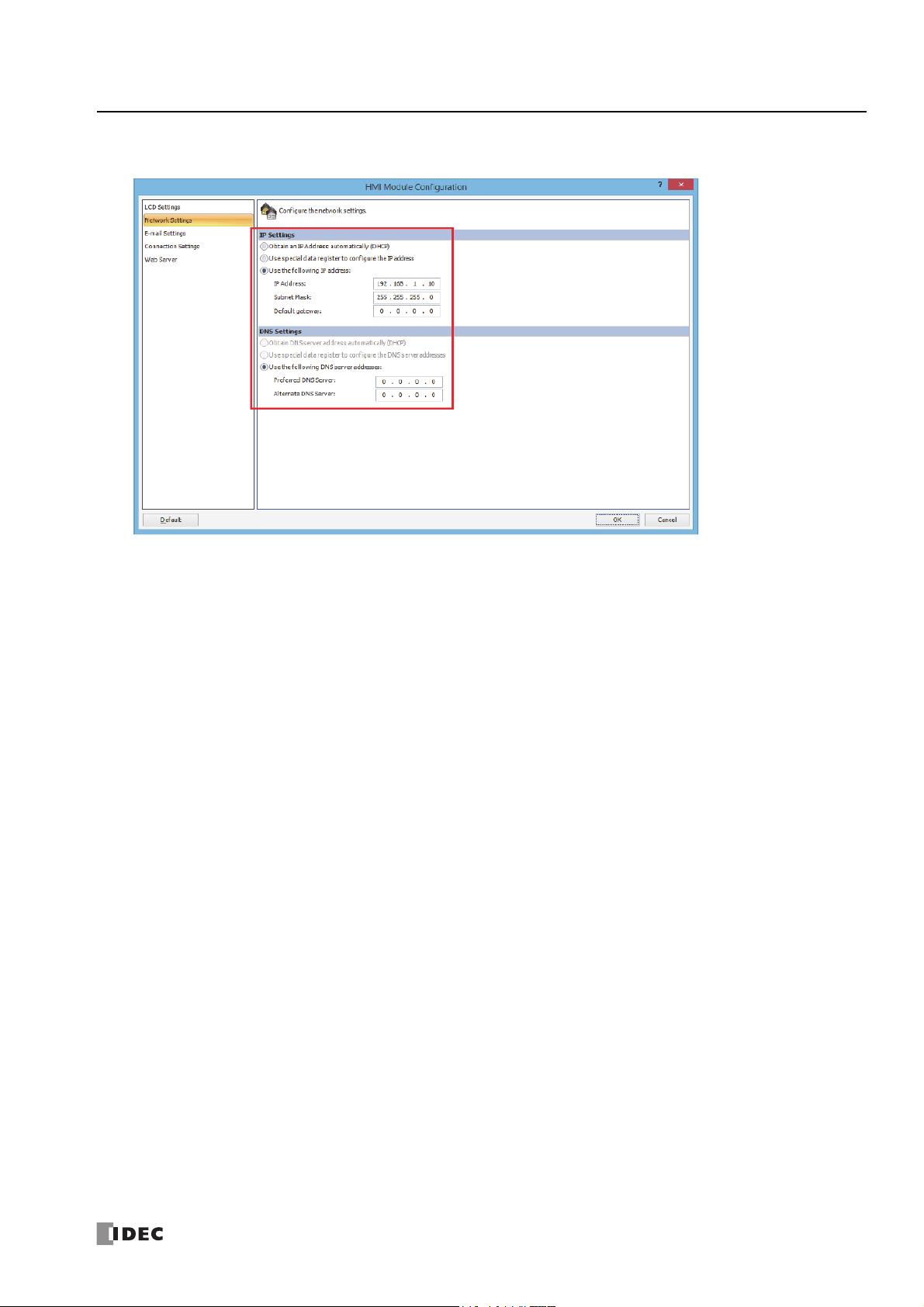

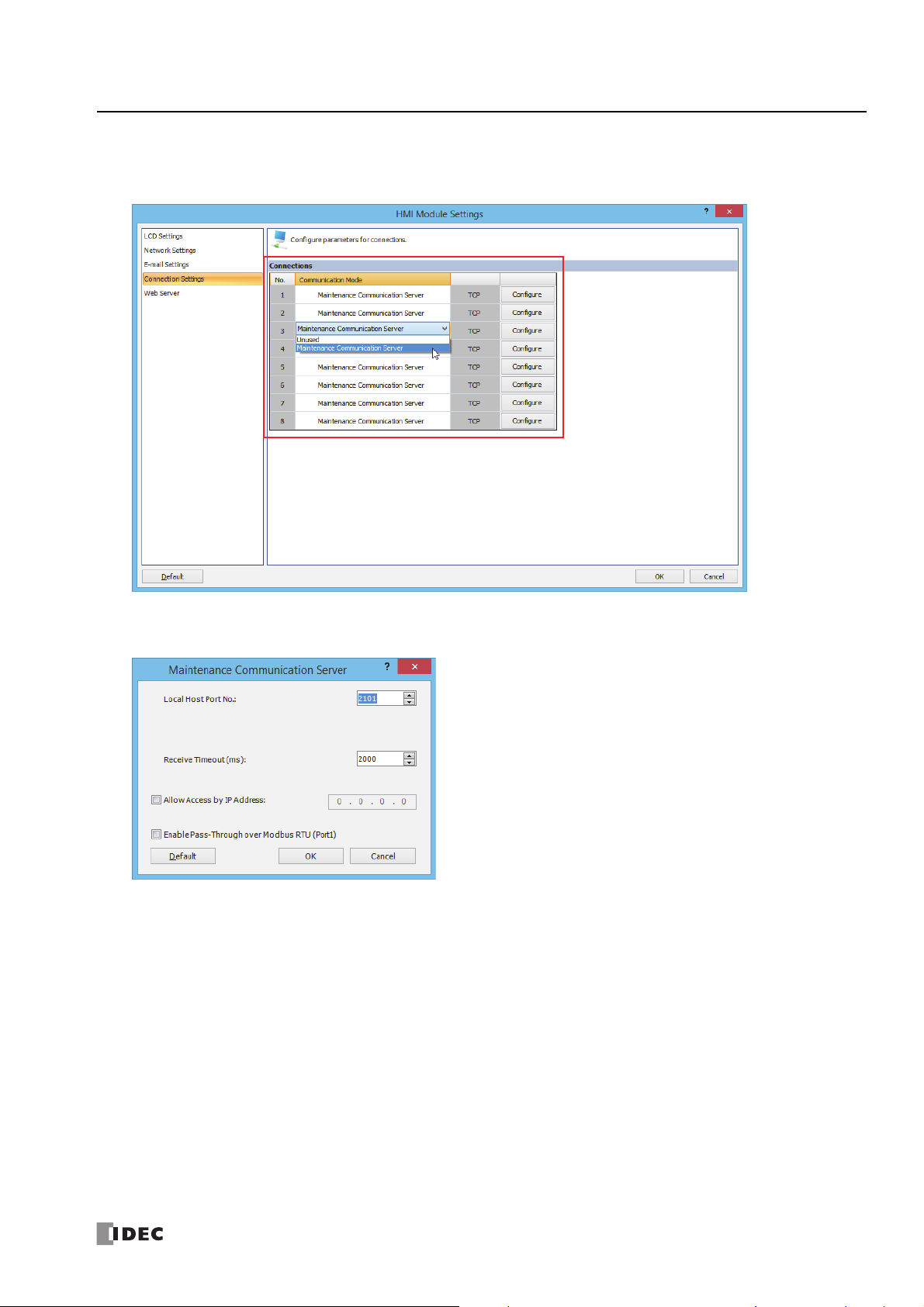

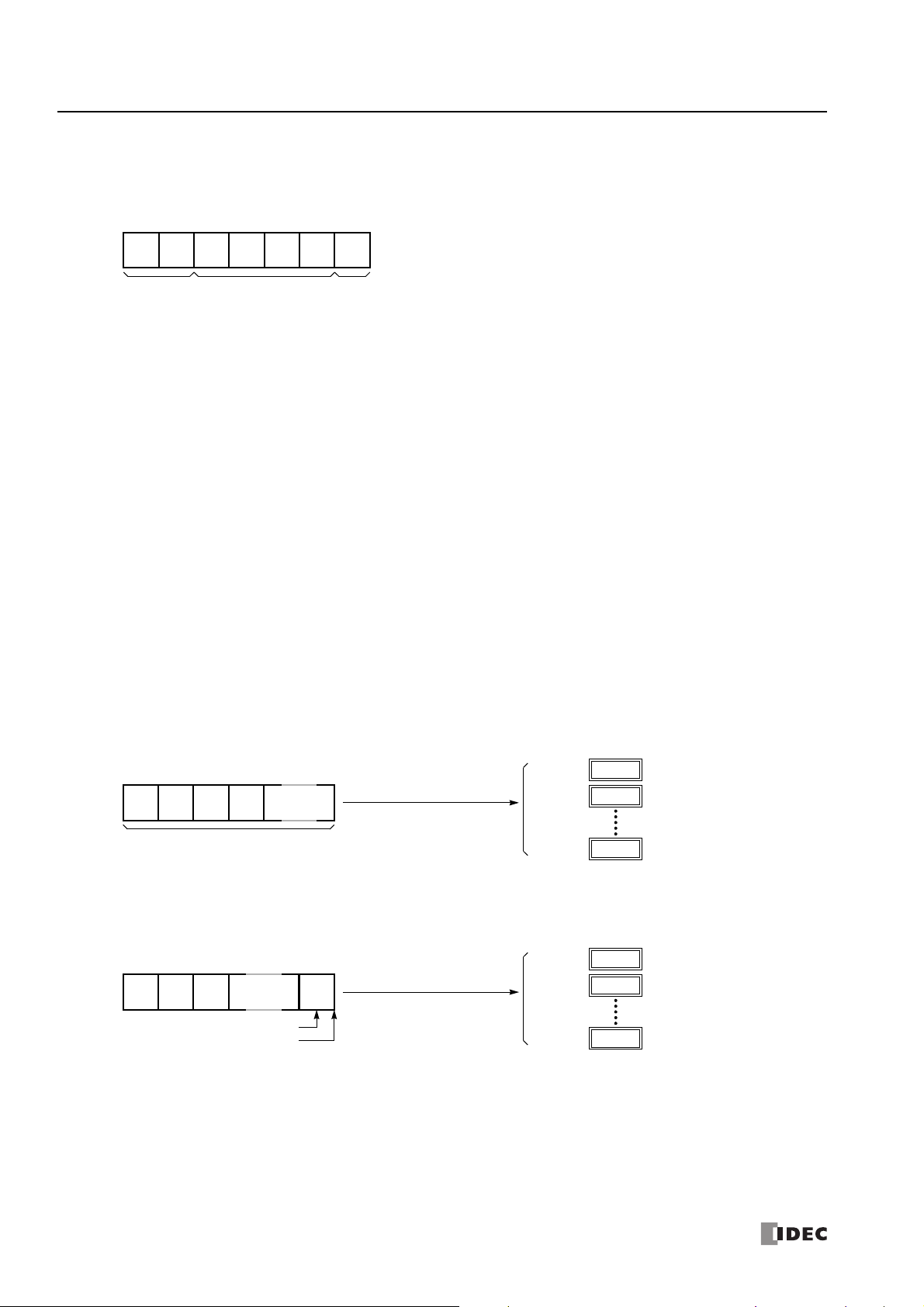

When processing has