Page 1

FC6A SERIES

LAD Programming Manual

B-1726(2)

Page 2

SAFETY PRECAUTIONS

Warning

Caution

• Read the "FC6A Series MicroSmart LAD Programming Manual" to ensure correct operation before starting installation, wiring, operation,

maintenance, and inspection of the FC6A Series MicroSmart.

• All FC6A Series MicroSmart modules are manufactured under IDEC’s rigorous quality control system, but users must add a backup or failsafe

provision to the control system when using the FC6A Series MicroSmart in applications where heavy damage or personal injury may be caused,

in case the FC6A Series MicroSmart should fail.

• In this manual, safety precautions are categorized in order of importance:

Warning notices are used to emphasize that improper operation may cause severe personal injury or death.

• The FC6A Series MicroSmart is not designed for use in applications requiring a high degree of reliability and safety. The FC6A Series MicroSmart

should not be used for such applications.

• When using the FC6A Series MicroSmart in applications (not described above) that require a high degree of reliability in terms of functionality

and precision, appropriate measures such as failsafe mechanisms and redundant mechanisms must be taken for the system containing the

FC6A Series MicroSmart. The following are specific examples.

• Emergency stop and interlocking circuits must be configured outside the FC6A Series MicroSmart.

• If relays or transistors in the FC6A Series MicroSmart output circuits should fail, outputs may remain at on or off state. For output signals

which may cause serious accidents, configure monitor circuits outside the FC6A Series MicroSmart.

• The FC6A Series MicroSmart self-diagnostic function may detect internal circuit or program errors, stop programs, and turn outputs off.

Configure circuits so that the system containing the FC6A Series MicroSmart is not jeopardized when outputs turn off.

• Turn off power to the FC6A Series MicroSmart before installation, removal, wiring, maintenance, and inspection of the FC6A Series MicroSmart.

Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the FC6A Series MicroSmart. People without such expertise must not use the

FC6A Series MicroSmart.

• Install the FC6A Series MicroSmart according to the instructions described in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

Improper installation will result in falling, failure, or malfunction of the FC6A Series MicroSmart.

Caution notices are used where inattention might cause personal injury or damage to equipment.

• The FC6A Series MicroSmart is designed for installation in a cabinet. Do not install the FC6A Series MicroSmart outside a cabinet.

• Install the FC6A Series MicroSmart in env ironments described in the "FC6A Series MicroSmart All-in-One Type User ’s Manual". If the FC6A Series

MicroSmart is used in places where the FC6A Series MicroSmart is subjected to high-temperature, high-humidity, condensation, corrosive gases,

excessive vibrations, or excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

• The environment for using the FC6A Series MicroSmart is "Pollution degree 2." Use the FC6A Series MicroSmart in environments of pollution

degree 2 (according to IEC 60664-1).

• Prevent the FC6A Series MicroSmart from falling while moving or transporting the FC6A Series MicroSmart, otherwise damage or malfunction of

the FC6A Series MicroSmart will result.

• Wiring must use lead sizes that are appropriate for the applied voltage and current. Terminal screws must be tightened with the prescribed

tightening torque.

• Prevent metal fragments and pieces of wire from dropping inside the FC6A Series MicroSmart housing. Put a cover on the FC6A Series

MicroSmart modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use an IEC 60127-approved fuse on the power line outside the FC6A Series MicroSmart. This is required when equipment containing the FC6A

Series MicroSmart is destined for Europe.

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the FC6A Series MicroSmart is destined for

Europe.

• Use an EU-approved circuit breaker. This is required when equipment containing the FC6A Series MicroSmart is destined for Europe.

• Make sure of safety before starting and stopping the FC6A Series MicroSmart or when operating the FC6A Seri es MicroSmart to force outputs on

or off. Incorrect operation of the FC6A Series MicroSmart may cause machine damage or accidents.

• Do not connect the ground wire directly to the FC6A Series MicroSmart. Connect a protective ground to the cabinet containing the FC6A Series

MicroSmart using an M4 or larger screw. This is required when equipment containing the FC6A Series MicroSmart is destined for Europe.

• Do not disassemble, repair, or modify the FC6A Series MicroSmart modules.

• The FC6A Series MicroSmart contains electronic parts and batteries. When disposing of the FC6A Series

MicroSmart, do so in accordance with national and local regulations.

Preface-1 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 3

ABOUT THIS MANUAL

This manual describes functions, specifications, installation, and operation basics of the FC6A Series MicroSmart. Also included is

information on the powerful communications tools of the FC6A Series MicroSmart, as well as troubleshooting procedures.

Chapter 1: Operation Basics

General information about setting up the basic FC6A Series MicroSmart system for programming, starting and stopping the FC6A

Series MicroSmart operation, and simple operating procedures. Everything from creating a user program using WindLDR on a

computer to monitoring the FC6A Series MicroSmart operation.

Chapter 2: Devices

Descriptions of the allocations of devices such as inputs, outputs, internal relays, registers, timers, and counters that are used in

the basic and advanced instructions, as well as details about the allocations of special internal relays and special data registers.

Chapter 3: Installation and Wiring

Methods and precautions for installing and wiring the FC6A Series MicroSmart.

Chapter 4: Instructions Reference

List of basic and advanced instructions to program the FC6A Series MicroSmart and general rules of using advanced instructions.

Chapter 5: Basic Instructions

Programming of the basic instructions, available devices, and sample programs.

Chapter 6 through Chapter 27:

Detailed descriptions for advanced instructions.

Appendix

Additional information about execution times and byte sizes for instructions.

Index

Alphabetical listing of key words.

Publication history

December 2015: First Edition

December 2016: Second Edition

March 2017: Third Edition

Trademarks

FC6A Series MicroSmart is a trademark of IDEC Corporation.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 Preface-2

Page 4

Regarding laws and compatible standards

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting from

the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all

programs, prior to installation, is the responsibility of the end user.

This product adheres to the laws and compatible standards of all countries involved, as shown below.

European laws and standards

This product complies with the following EU directives.

• Low Voltage Directive

• EMC Directive

To comply with these directives, this product has been designed and evaluated on the basis of the following international and

European standard.

• IEC/EN 61131-2: 2007

For details on the compatible standards and EU Directives, contact the distributor from which you purchased this product or visit our web site.

North America laws and standards

This product complies with the following standards.

• UL508

• CSA C22.2 No.142

• ANSI/ISA 12,12,01

• CAN/CSA C22.2 No.213

*1 Certain FC6A Series MicroSmart models are not compatible. For details, please contact IDEC Corporation.

For details on compatible standards and EU directives, please contact the dealer where purchased or check the IDEC website.

*1

*1

Preface-3 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 5

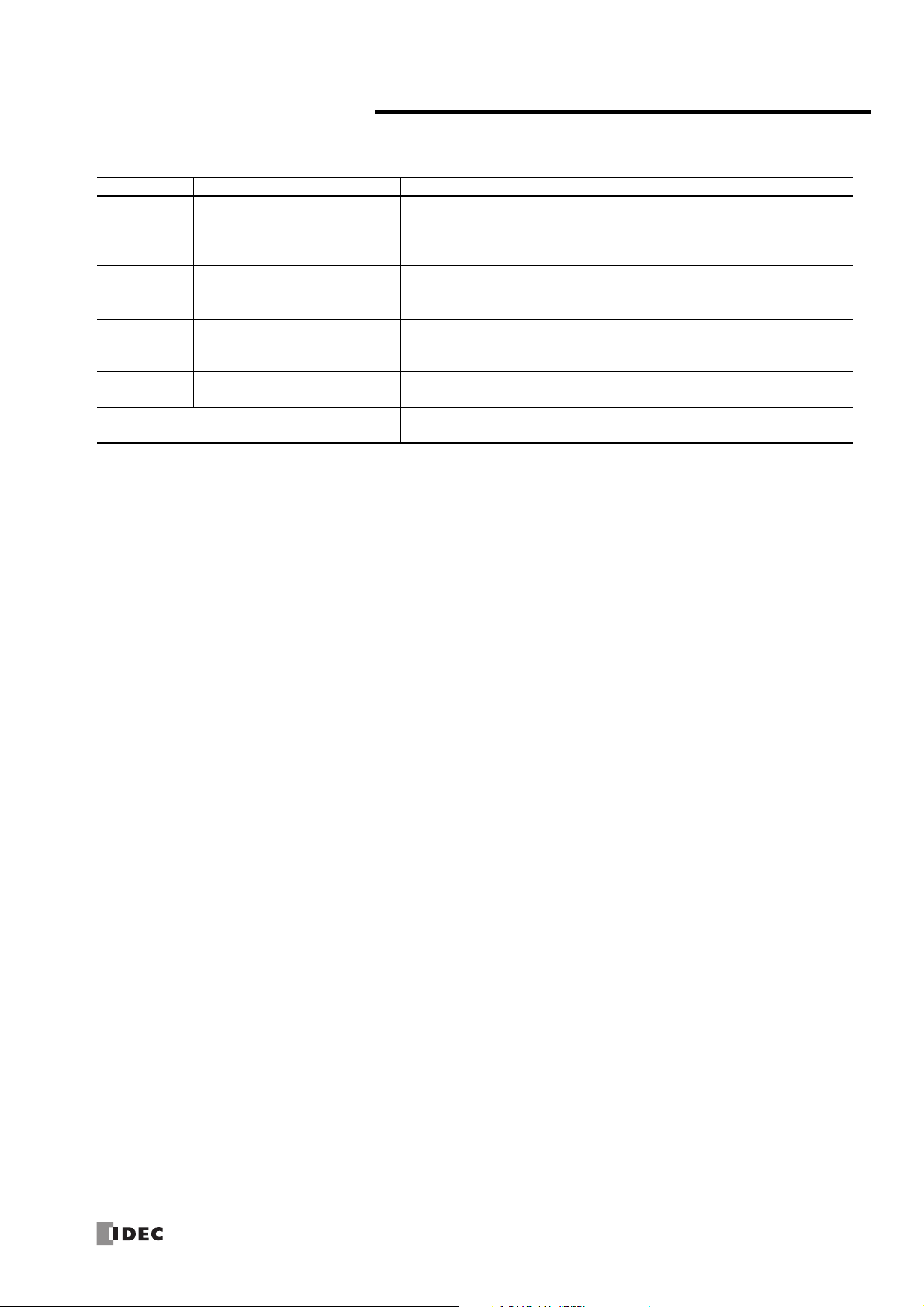

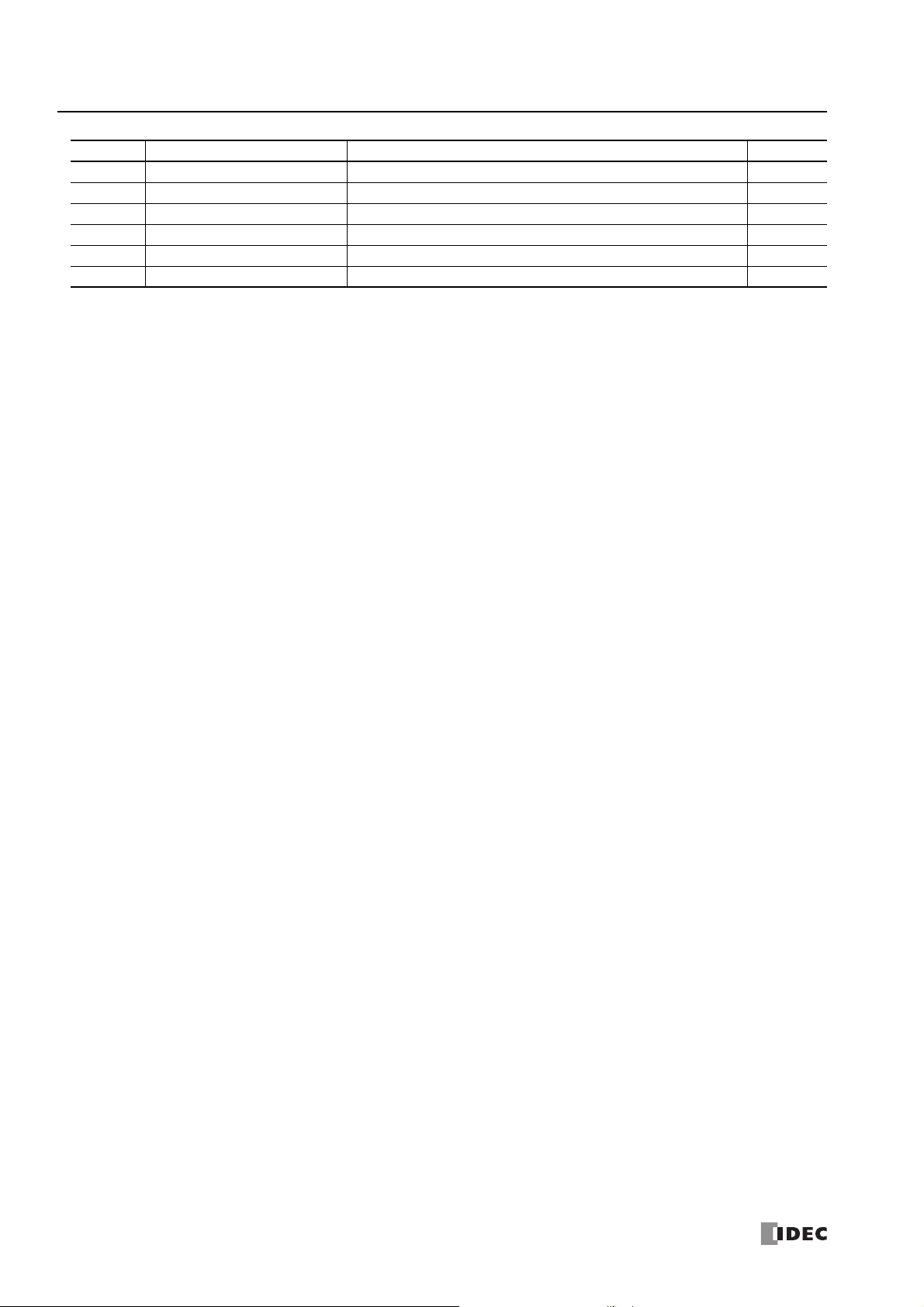

RELATED MANUALS

The following manuals related to the FC6A Series MicroSmart are available. Refer to them in conjunction with this manual.

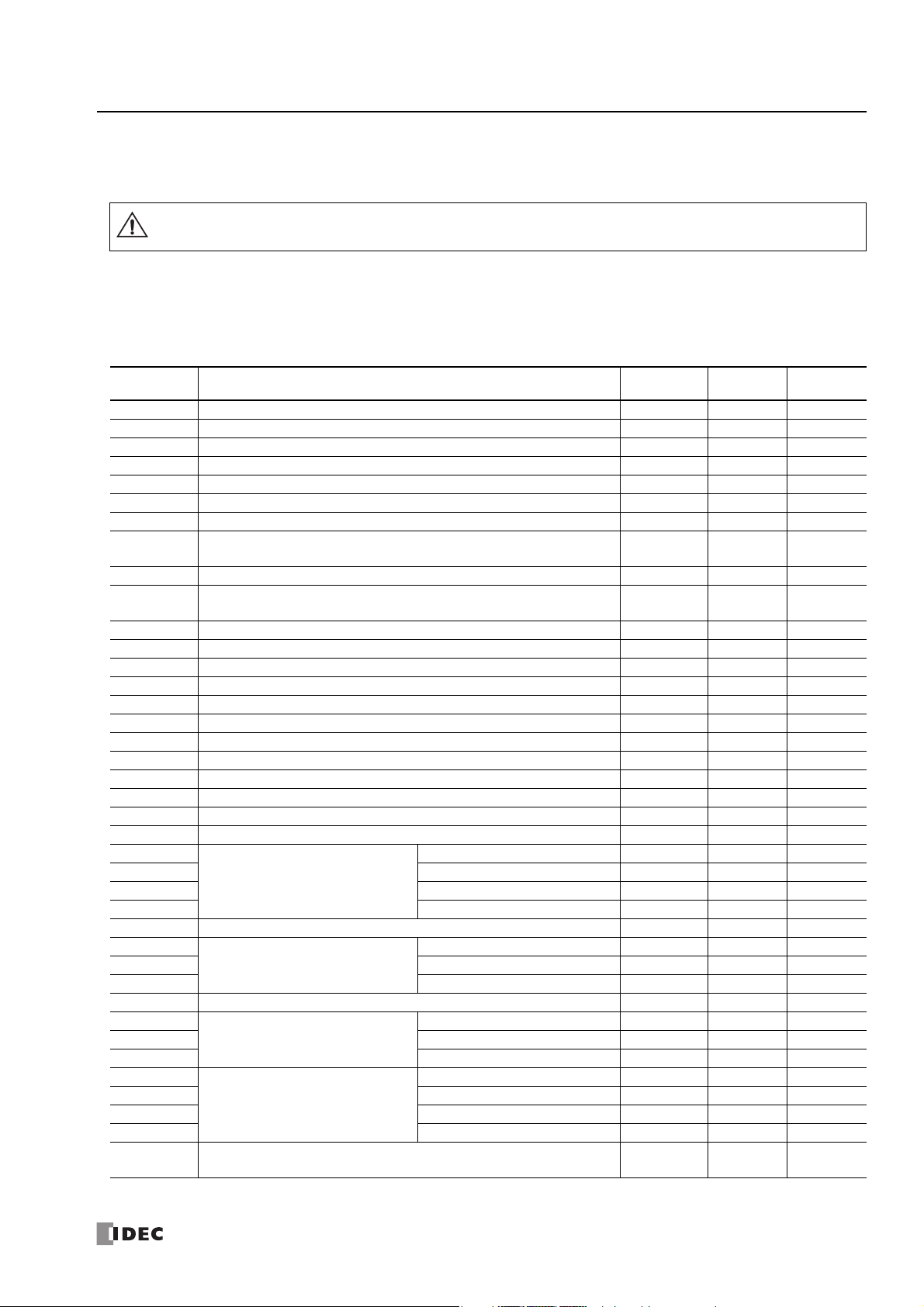

Type No. Manual Name Description

Describes product specifications, installation and wiring instructions, instructions for

FC9Y-B1722

FC9Y-B1726

FC9Y-B1730

FC9Y-B1734

WindLDR Help

FC6A Series MicroSmart

All-in-One Type User’s Manual

FC6A Series MicroSmart

LAD Programming Manual

(this manual)

FC6A Series MicroSmart

All-in-One Type Communication

Manual

FC6A Series MicroSmart

PID Module User's Manual

basic programming operations and special functions, device and instruction lists,

communication functions, and troubleshooting procedures for the FC6A Series

MicroSmart series.

Describes basic operations for programming with ladders on the FC6A Series

MicroSmart, monitoring methods, device and instruction lists, and details of each

instruction.

Describes specifications related to FC6A Series MicroSmart communication,

descriptions of functions, configuration methods, and usage examples.

Describes PID module specifications and functions.

Describes usage instructions for WindLDR, programming software for the FC6A

Series MicroSmart series.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 Preface-4

Page 6

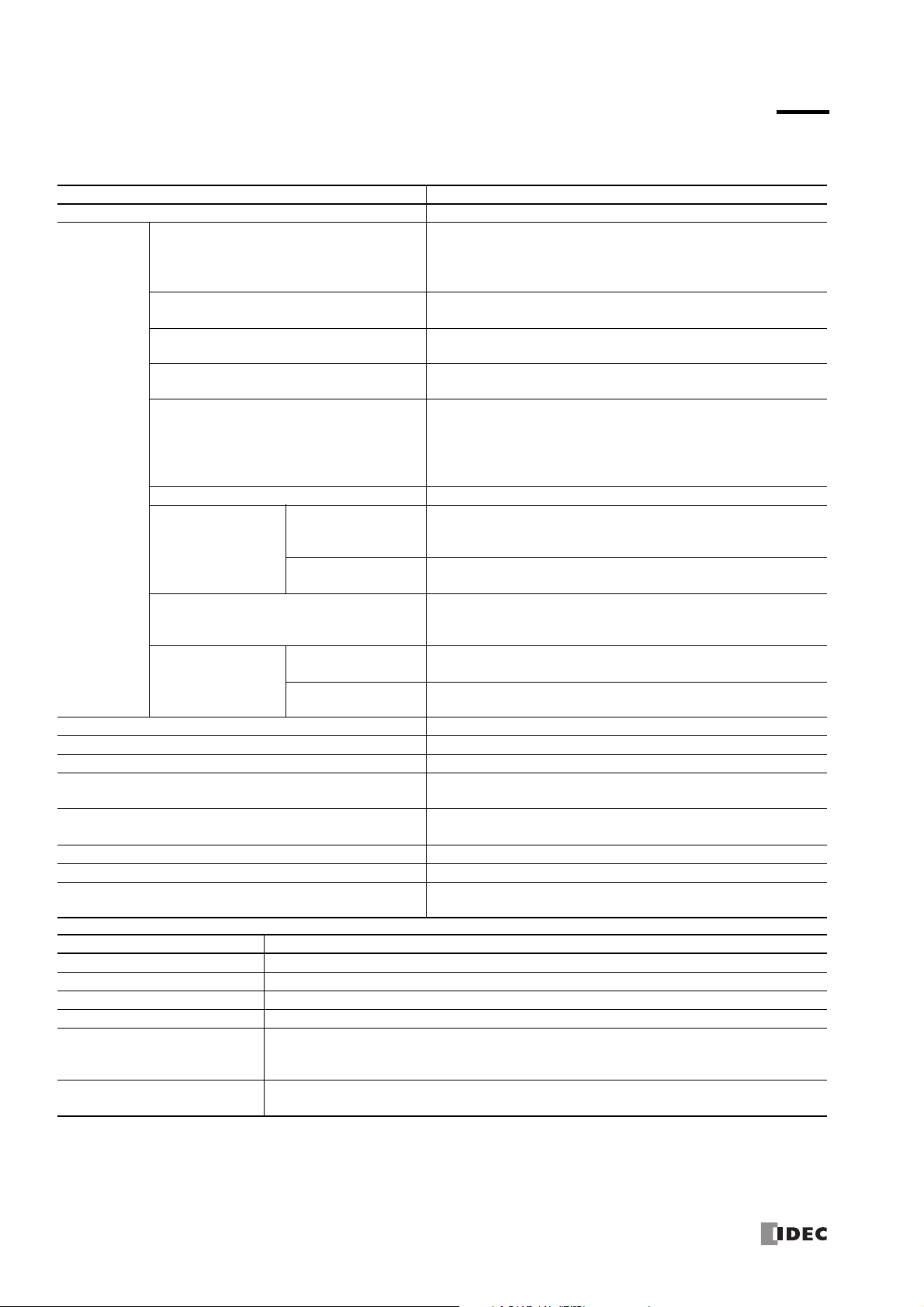

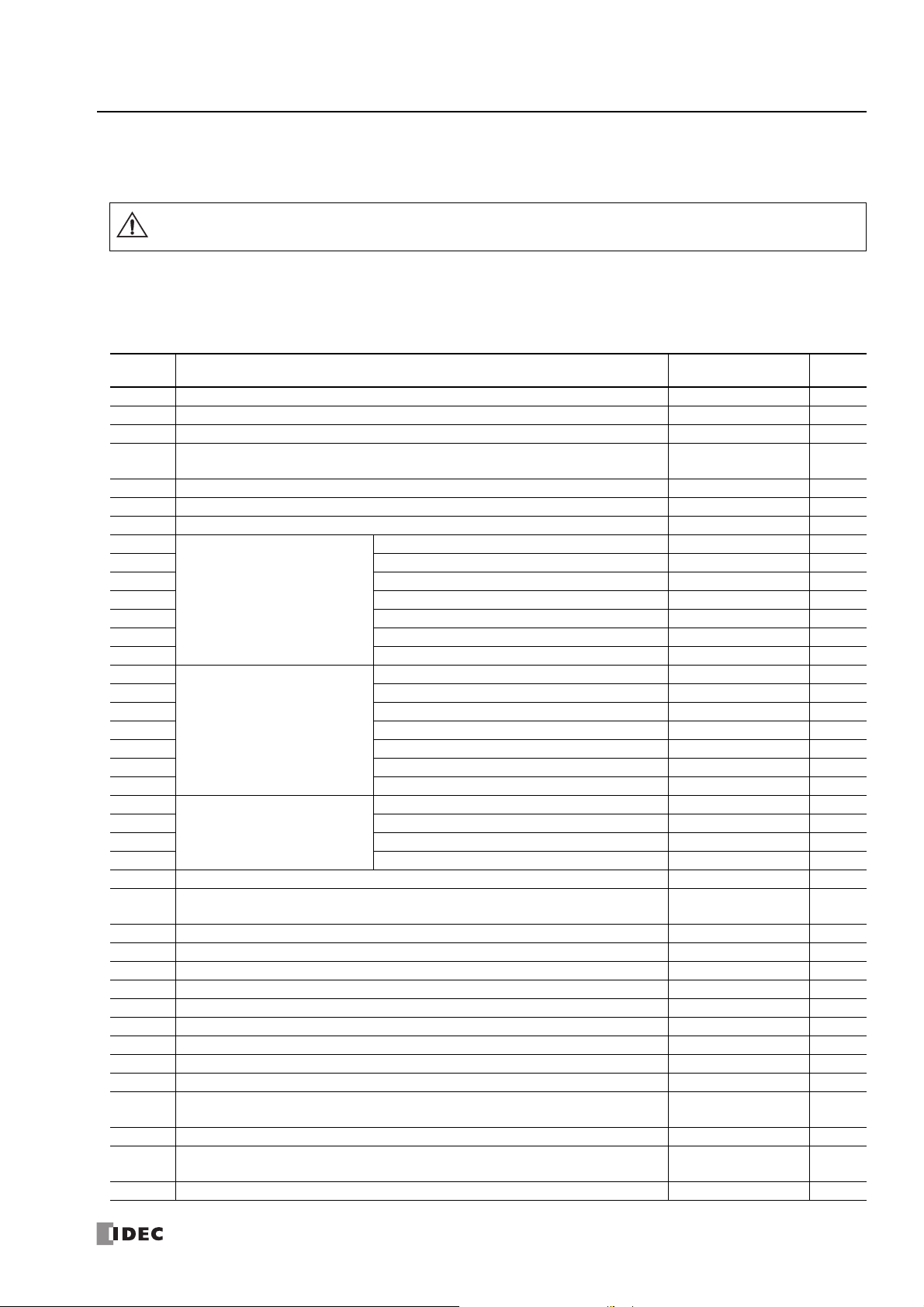

NAMES AND ABBREVIATIONS USED IN THIS MANUAL

Model Names

Name Used in This Manual Type Number, Part Code, or Official Name

FC6A Series MicroSmart FC6A Series MICROSmart

FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C16K1CE, FC6A-C16P1CE,

All-in-One Type

CAN J1939 All-in-One Type

16-I/O type

24-I/O type

40-I/O type

CPU module

AC power type FC6A-C16R1AE, FC6A-C24R1AE, FC6A-C40R1AE, FC6A-C40R1AEJ

24V DC power type

DC power type

12V DC power type

Relay output type

Transistor sink output

Transistor output type

Expansion module Expansion I/O module, functional module

Expansion I/O module Input module, output module, mixed I/O module

Functional module Analog module, PID module

Analog module

Option module

Cartridge Analog cartridge, communication cartridge

WindLDR WindLDR application software

USB cable

type

Transistor protection

source output type

FC6A-C24R1AE, FC6A-C24R1CE, FC6A-C24K1CE, FC6A-C24P1CE,

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40K1CE, FC6A-C40P1CE,

FC6A-C40R1DE, FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE

FC6A-C40R1AEJ, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-C40R1DEJ, FC6A-C40K1DEJ, FC6A-C40P1DEJ

The general term for the model with 16 I/O points

(FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C16K1CE, FC6A-C16P1CE)

The general term for the model with 24 I/O points

(FC6A-C24R1AE, FC6A-C24R1CE, FC6A-C24K1CE, FC6A-C24P1CE)

The general term for the model with 40 I/O points

(FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40K1CE, FC6A-C40P1CE,

FC6A-C40R1DE, FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE,

FC6A-C40R1AEJ, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ,

FC6A-C40R1DEJ, FC6A-C40K1DEJ, FC6A-C40P1DEJ)

FC6A-C16R1CE, FC6A-C24R1CE, FC6A-C40R1CE, FC6A-C16K1CE,

FC6A-C24K1CE, FC6A-C40K1CE, FC6A-C16P1CE, FC6A-C24P1CE,

FC6A-C40P1CE, FC6A-C40R1CEJ, FC6A-C40K1CEJ, FC6A-C40P1CEJ

FC6A-C40R1DE, FC6A-C40K1DE, FC6A-C40P1DE, FC6A-C40R1DEJ,

FC6A-C40K1DEJ, FC6A-C40P1DEJ

FC6A-C16R1AE, FC6A-C16R1CE, FC6A-C24R1AE, FC6A-C24R1CE,

FC6A-C40R1AE, FC6A-C40R1CE, FC6A-C40R1DE, FC6A-C40R1AEJ,

FC6A-C40R1CEJ, FC6A-C40R1DEJ

FC6A-C16K1CE, FC6A-C24K1CE, FC6A-C40K1CE, FC6A-C40K1DE,

FC6A-C40K1CEJ, FC6A-C40K1DEJ

FC6A-C16P1CE, FC6A-C24P1CE, FC6A-C40P1CE, FC6A-C40P1DE,

FC6A-C40P1CEJ, FC6A-C40P1DEJ

Analog input module, analog output module,

mixed analog I/O module

HMI module, expansion interface module,

analog cartridge, communication cartridge

USB maintenance cable (HG9Z-XCM42),

USB Mini-B extension cable (HG9Z-XCE21)

Name Used in this Manual WindLDR Operating Procedure

Function area settings Configuration tab > Function Area Settings group

Monitors Select Online > Monitor > Start Monitor.

PLC status Select Online > PLC > Status.

Communication settings Select Online > Communication > Set Up.

On the Configuration tab, in Function Area Settings, click Communication Ports, and in the

Modbus master request table

Application button

Preface-5 FC6A S

displayed Function Area Settings dialog box, for Communication Mode under Communication

Ports, select Modbus RTU Master or Modbus TCP Client

The button displayed on the left side of the menu bar. Click to display the menu with New, Save, and

Save As, recent projects, WindLDR Options, and Exit WindLDR.

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 7

T

ABLE OF

C

HAPTER

C

HAPTER

C

HAPTER

1: Operation Basics

2: Devices

3: Instructions Reference

C

ONTENTS

Safety Precautions............................................................................................................................. Preface-1

About This Manual............................................................................................................................. Preface-2

Related Manuals................................................................................................................................ Preface-4

Names and Abbreviations Used in this Manual ..................................................................................... Preface-5

Start WindLDR ............................................................................................................................................ 1-1

PLC Selection ..............................................................................................................................................1-2

Create Program...........................................................................................................................................1-3

Save Project................................................................................................................................................ 1-8

Simulate Operation ...................................................................................................................................... 1-9

Download Program .................................................................................................................................... 1-10

Monitor Operation ..................................................................................................................................... 1-12

Exit WindLDR ............................................................................................................................................ 1-12

Checking the WindLDR Version Number ...................................................................................................... 1-13

Ladder Program Operation ......................................................................................................................... 1-14

Start/Stop Operation.................................................................................................................................. 1-15

Device Addresses ........................................................................................................................................ 2-1

Special Internal Relay ..................................................................................................................................2-3

Special Data Register ................................................................................................................................. 2-13

Basic Instruction List....................................................................................................................................3-1

Advanced Instruction List ............................................................................................................................. 3-3

Structure of an Advanced Instruction ............................................................................................................3-6

Input Condition for Advanced Instructions..................................................................................................... 3-6

Source and Destination Devices .................................................................................................................... 3-6

Using Timer or Counter as Source Device ...................................................................................................... 3-6

Using Timer or Counter as Destination Device ............................................................................................... 3-6

Data Types for Advanced Instructions ........................................................................................................... 3-7

Discontinuity of Device Areas ..................................................................................................................... 3-11

NOP (No Operation) .................................................................................................................................. 3-11

C

HAPTER

4: Basic Instructions

LOD (Load) and LODN (Load Not) ................................................................................................................ 4-1

OUT (Output) and OUTN (Output Not) .......................................................................................................... 4-1

SET and RST (Reset) ...................................................................................................................................4-3

AND and ANDN (And Not)............................................................................................................................ 4-4

OR and ORN (Or Not) .................................................................................................................................. 4-4

AND LOD (Load) ......................................................................................................................................... 4-5

OR LOD (Load) ...........................................................................................................................................4-5

BPS (Bit Push), BRD (Bit Read), and BPP (Bit Pop) ......................................................................................... 4-6

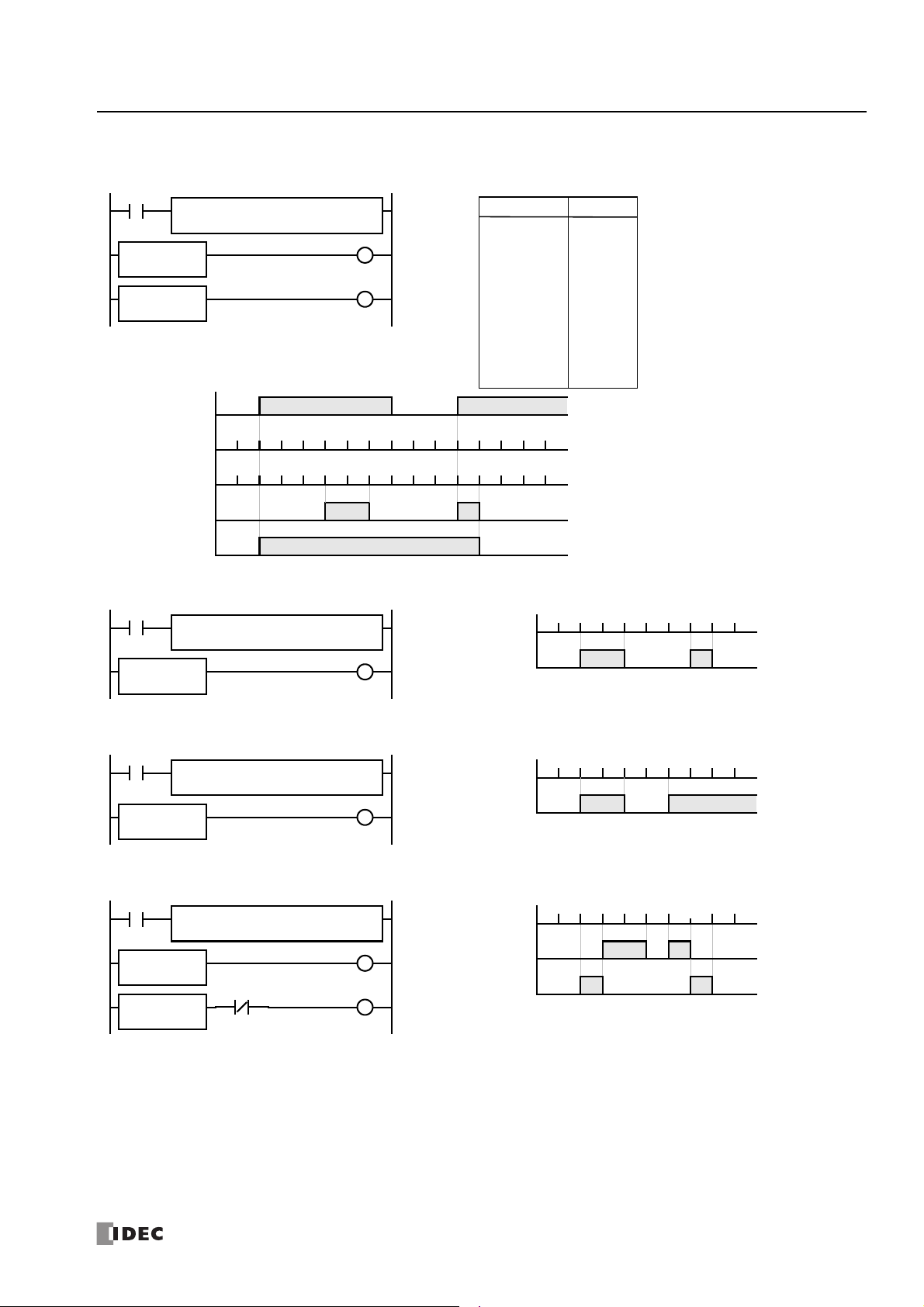

TML, TIM, TMH, and TMS (Timer) ................................................................................................................ 4-7

TMLO, TIMO, TMHO, and TMSO (Off-Delay Timer) ...................................................................................... 4-10

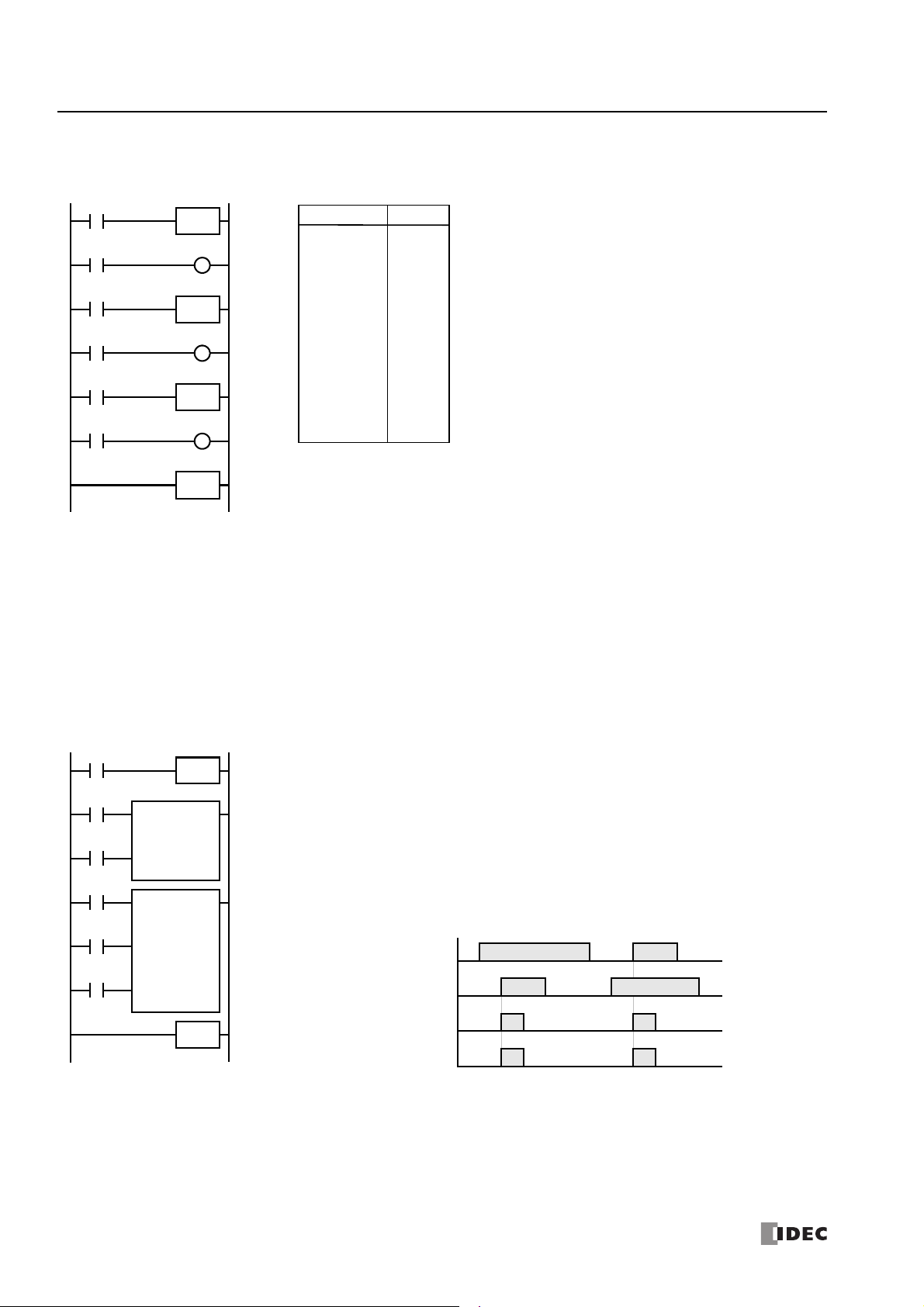

CNT, CDP, and CUD (Counter).................................................................................................................... 4-11

CNTD, CDPD, and CUDD (Double-Word Counter)......................................................................................... 4-14

CC= and CC>= (Counter Comparison) ........................................................................................................ 4-18

DC= and DC>= (Data Register Comparison) ............................................................................................... 4-20

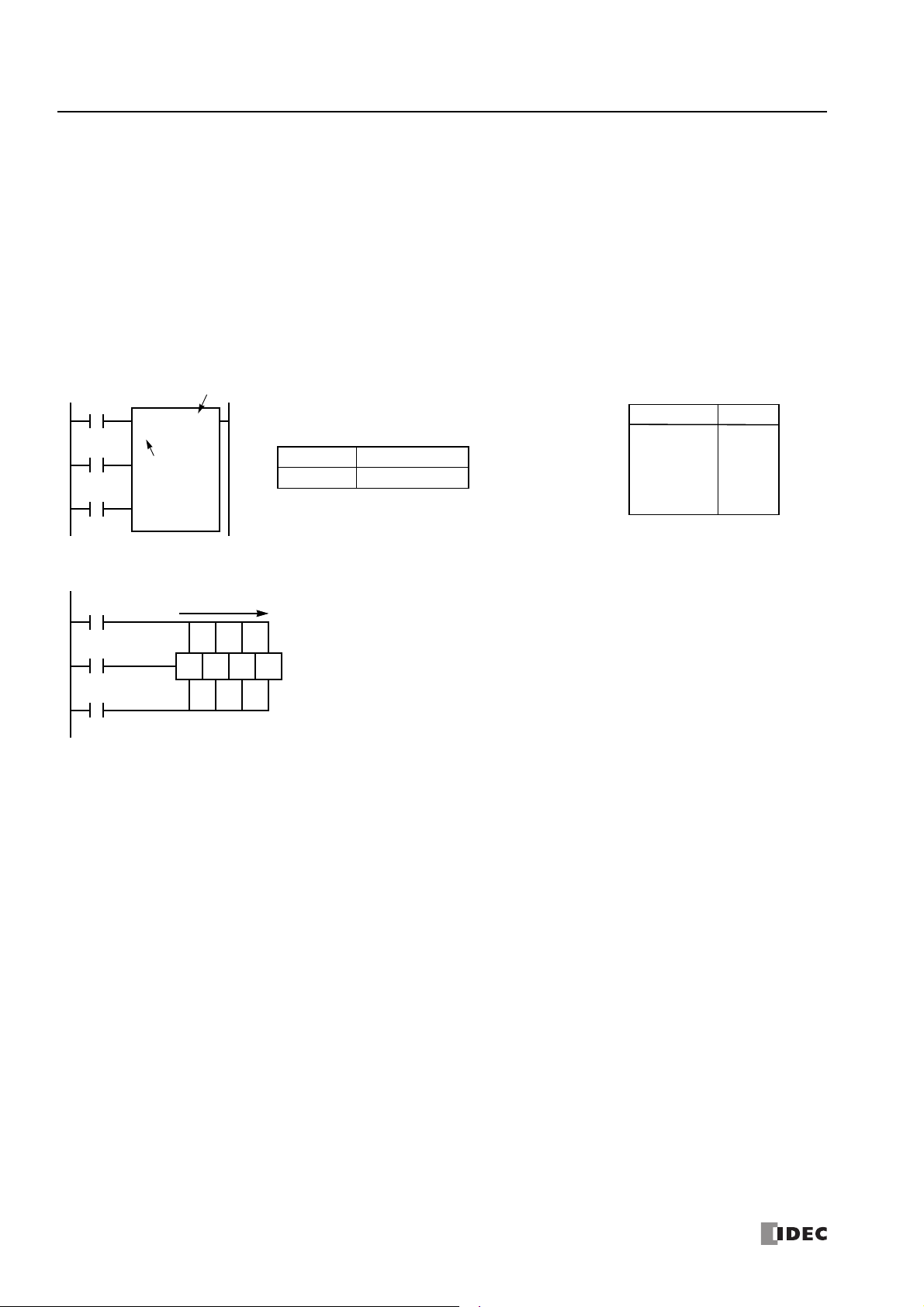

SFR and SFRN (Forward and Reverse Shift Register) .................................................................................... 4-22

SOTU and SOTD (Single Output Up and Down) ........................................................................................... 4-26

MCS and MCR (Master Control Set and Reset) ............................................................................................. 4-27

JMP (Jump) and JEND (Jump End) ............................................................................................................. 4-29

END ......................................................................................................................................................... 4-30

Restriction on Ladder Programming ............................................................................................................ 4-31

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 Preface-6

Page 8

T

ABLE OF CONTENTS

C

HAPTER

C

HAPTER

5: Move Instructions

6: Data Comparison Instructions

MOV (Move) ............................................................................................................................................... 5-1

MOVN (Move Not)....................................................................................................................................... 5-5

IMOV (Indirect Move).................................................................................................................................. 5-6

IMOVN (Indirect Move Not) ......................................................................................................................... 5-8

BMOV (Block Move) .................................................................................................................................... 5-9

IBMV (Indirect Bit Move) ............................................................................................................................5-10

IBMVN (Indirect Bit Move Not) ....................................................................................................................5-12

NSET (N Data Set) .....................................................................................................................................5-13

NRS (N Data Repeat Set)............................................................................................................................5-14

XCHG (Exchange) ......................................................................................................................................5-15

TCCST (Timer/Counter Current Value Store) ................................................................................................5-16

CMP= (Compare Equal To) .......................................................................................................................... 6-1

CMP<> (Compare Unequal To) .................................................................................................................... 6-1

CMP< (Compare Less Than) ........................................................................................................................ 6-1

CMP> (Compare Greater Than).................................................................................................................... 6-1

CMP<= (Compare Less Than or Equal To) .................................................................................................... 6-1

CMP>= (Compare Greater Than or Equal To) ............................................................................................... 6-1

ICMP>= (Interval Compare Greater Than or Equal To).................................................................................. 6-6

LC= (Load Compare Equal To)..................................................................................................................... 6-8

LC<> (Load Compare Unequal To) .............................................................................................................. 6-8

LC< (Load Compare Less Than) ................................................................................................................... 6-8

LC> (Load Compare Greater Than) .............................................................................................................. 6-8

LC<= (Load Compare Less Than or Equal To)............................................................................................... 6-8

LC>= (Load Compare Greater Than or Equal To) .......................................................................................... 6-8

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

7: Binary Arithmetic Instructions

ADD (Addition) ........................................................................................................................................... 7-1

SUB (Subtraction) ....................................................................................................................................... 7-1

MUL (Multiplication) .................................................................................................................................... 7-1

DIV (Division) ............................................................................................................................................. 7-1

INC (Increment) ........................................................................................................................................7-13

DEC (Decrement).......................................................................................................................................7-13

ROOT (Root) .............................................................................................................................................7-14

SUM (Sum)................................................................................................................................................7-15

RNDM (Random)........................................................................................................................................7-18

8: Boolean Computation Instructions

ANDW (AND Word) ..................................................................................................................................... 8-1

ORW (OR Word) ......................................................................................................................................... 8-1

XORW (Exclusive OR Word) ......................................................................................................................... 8-1

9: Shift / Rotate Instructions

SFTL (Shift Left) ......................................................................................................................................... 9-1

SFTR (Shift Right) ....................................................................................................................................... 9-3

BCDLS (BCD Left Shift)................................................................................................................................ 9-5

WSFT (Word Shift)...................................................................................................................................... 9-7

ROTL (Rotate Left)...................................................................................................................................... 9-8

ROTR (Rotate Right) ..................................................................................................................................9-10

10: Data Conversion Instructions

HTOB (Hex to BCD) ...................................................................................................................................10-1

BTOH (BCD to Hex) ...................................................................................................................................10-3

HTOA (Hex to ASCII) .................................................................................................................................10-5

ATOH (ASCII to Hex) .................................................................................................................................10-7

BTOA (BCD to ASCII) .................................................................................................................................10-9

ATOB (ASCII to BCD) ...............................................................................................................................10-12

ENCO (Encode)........................................................................................................................................10-15

DECO (Decode) .......................................................................................................................................10-16

Preface-7 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 9

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

BCNT (Bit Count)..................................................................................................................................... 10-17

ALT (Alternate Output) ............................................................................................................................ 10-18

CVDT (Convert Data Type)....................................................................................................................... 10-19

DTDV (Data Divide) ................................................................................................................................. 10-21

DTCB (Data Combine) ............................................................................................................................. 10-22

SWAP (Data Swap).................................................................................................................................. 10-23

11: Week Programmer Instructions

WEEK (Weekly Timer)................................................................................................................................ 11-3

YEAR (Yearly Timer) ................................................................................................................................ 11-16

12: Display Instructions

MSG (Message) ......................................................................................................................................... 12-1

DISP (Display)......................................................................................................................................... 12-20

DGRD (Digital Read) ................................................................................................................................ 12-22

13: Program Branching Instructions

LABEL (Label) ........................................................................................................................................... 13-1

LJMP (Label Jump) .................................................................................................................................... 13-1

LCAL (Label Call) ....................................................................................................................................... 13-3

LRET (Label Return) .................................................................................................................................. 13-3

DJNZ (Decrement Jump Non-zero) ............................................................................................................. 13-5

14: Refresh Instructions

IOREF (I/O Refresh) .................................................................................................................................. 14-1

HSCRF (High-speed Counter Refresh) ......................................................................................................... 14-3

FRQRF (Frequency Measurement Refresh) .................................................................................................. 14-4

COMRF (Communication Refresh) ............................................................................................................... 14-5

T

ABLE OF CONTENTS

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

15: Interrupt Control Instructions

DI (Disable Interrupt) ................................................................................................................................ 15-1

EI (Enable Interrupt) ................................................................................................................................. 15-1

16: Coordinate Conversion Instructions

XYFS (XY Format Set) ................................................................................................................................ 16-1

CVXTY (Convert X to Y) ............................................................................................................................. 16-2

CVYTX (Convert Y to X) ............................................................................................................................. 16-3

17: Average Instructions

AVRG (Average) ........................................................................................................................................ 17-1

18: Pulse Output Instructions

PULS (Pulse Output) .................................................................................................................................. 18-1

PWM (Variable Duty Cycle Pulse Output) ..................................................................................................... 18-8

RAMP (Trapezoidal Control) ..................................................................................................................... 18-15

ZRN (Zero Return)................................................................................................................................... 18-27

ARAMP (RAMP with Table) ....................................................................................................................... 18-37

ABS (Set Absolute Position) ...................................................................................................................... 18-59

JOG (JOG Operation) ............................................................................................................................... 18-63

19: PID Control Instruction

PID (PID Control) ...................................................................................................................................... 19-1

PIDA (PID Control) .................................................................................................................................... 19-3

PIDD (PID with Derivative Decay) ............................................................................................................. 19-26

PID Monitor ............................................................................................................................................ 19-36

Application Example ................................................................................................................................ 19-42

C

HAPTER

20: Dual / Teaching Timer Instructions

DTML (1-s Dual Timer) .............................................................................................................................. 20-1

DTIM (100-ms Dual Timer) ........................................................................................................................ 20-1

DTMH (10-ms Dual Timer) ......................................................................................................................... 20-1

DTMS (1-ms Dual Timer) ........................................................................................................................... 20-1

TTIM (Teaching Timer) .............................................................................................................................. 20-3

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 Preface-8

Page 10

T

ABLE OF CONTENTS

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

21: Trigonometric Function Instructions

22: Logarithm / Power Instructions

23: File Data Processing Instructions

24: Clock Instructions

RAD (Degree to Radian) .............................................................................................................................21-1

DEG (Radian to Degree) .............................................................................................................................21-2

SIN (Sine) .................................................................................................................................................21-3

COS (Cosine) .............................................................................................................................................21-4

TAN (Tangent)...........................................................................................................................................21-5

ASIN (Arc Sine) .........................................................................................................................................21-6

ACOS (Arc Cosine) .....................................................................................................................................21-7

ATAN (Arc Tangent)...................................................................................................................................21-8

LOGE (Natural Logarithm) ..........................................................................................................................22-1

LOG10 (Common Logarithm) ......................................................................................................................22-2

EXP (Exponent) .........................................................................................................................................22-3

POW (Power).............................................................................................................................................22-4

FIFOF (FIFO Format)..................................................................................................................................23-1

FIEX (First-In Execute) ...............................................................................................................................23-3

FOEX (First-Out Execute)............................................................................................................................23-3

NDSRC (N Data Search) .............................................................................................................................23-5

TADD (Time Addition) ................................................................................................................................24-1

TSUB (Time Subtraction) ............................................................................................................................24-5

HTOS (HMS to Sec)....................................................................................................................................24-9

STOH (S to HMS) .....................................................................................................................................24-10

HOUR (Hour Meter) .................................................................................................................................24-11

C

HAPTER

C

HAPTER

C

HAPTER

C

HAPTER

A

PPENDIX

25: Data Log Instructions

DLOG (Data Log) .......................................................................................................................................25-1

TRACE (Data Trace) ...................................................................................................................................25-7

26: Script

SCRPT (Script)...........................................................................................................................................26-1

Script Function Overview ............................................................................................................................26-3

Script Programming and Management .........................................................................................................26-5

Programming Scripts ................................................................................................................................26-12

Script Programming Examples...................................................................................................................26-19

Important Notes ......................................................................................................................................26-42

About the Priority of the Operator .............................................................................................................26-42

27: Flow Calculation Instructions

SCALE (Convert Analog Input) ....................................................................................................................27-1

FLWA (Analog Flow Totalizer) .....................................................................................................................27-9

FLWP (Pulse Flow Totalizer)......................................................................................................................27-18

28: User-defined Macro Instruction

UMACRO (User-defined Macro) ...................................................................................................................28-1

Execution Times for Instructions .................................................................................................................. A-1

Breakdown of END Processing Time ............................................................................................................. A-5

Differences between User-defined Macros and Subroutines ............................................................................ A-5

Instruction Bytes......................................................................................................................................... A-6

User Program Execution Error ...................................................................................................................... A-9

I

NDEX

Preface-9 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 11

1: O

Introduction

WindLDR (version 8.0.0 or later) is required for FC6A Series MicroSmart programming and maintenance. For details on how to

check the version, see "Checking the WindLDR Version Number" on page 1-13.

This chapter describes basic procedures for operating WindLDR, programming and maintenance software for the FC6A Series

MicroSmart.

PERATION

B

ASICS

Start WindLDR

■ Windows 8

Click WindLDR in the tiles on the Start screen.

■ Windows 7, Windows Vista

Click Start and then Programs > Automation Organizer V2 > WindLDR > WindLDR.

■ Windows XP

From the Start menu of Windows, select Programs > Automation Organizer V2 > WindLDR > WindLDR.

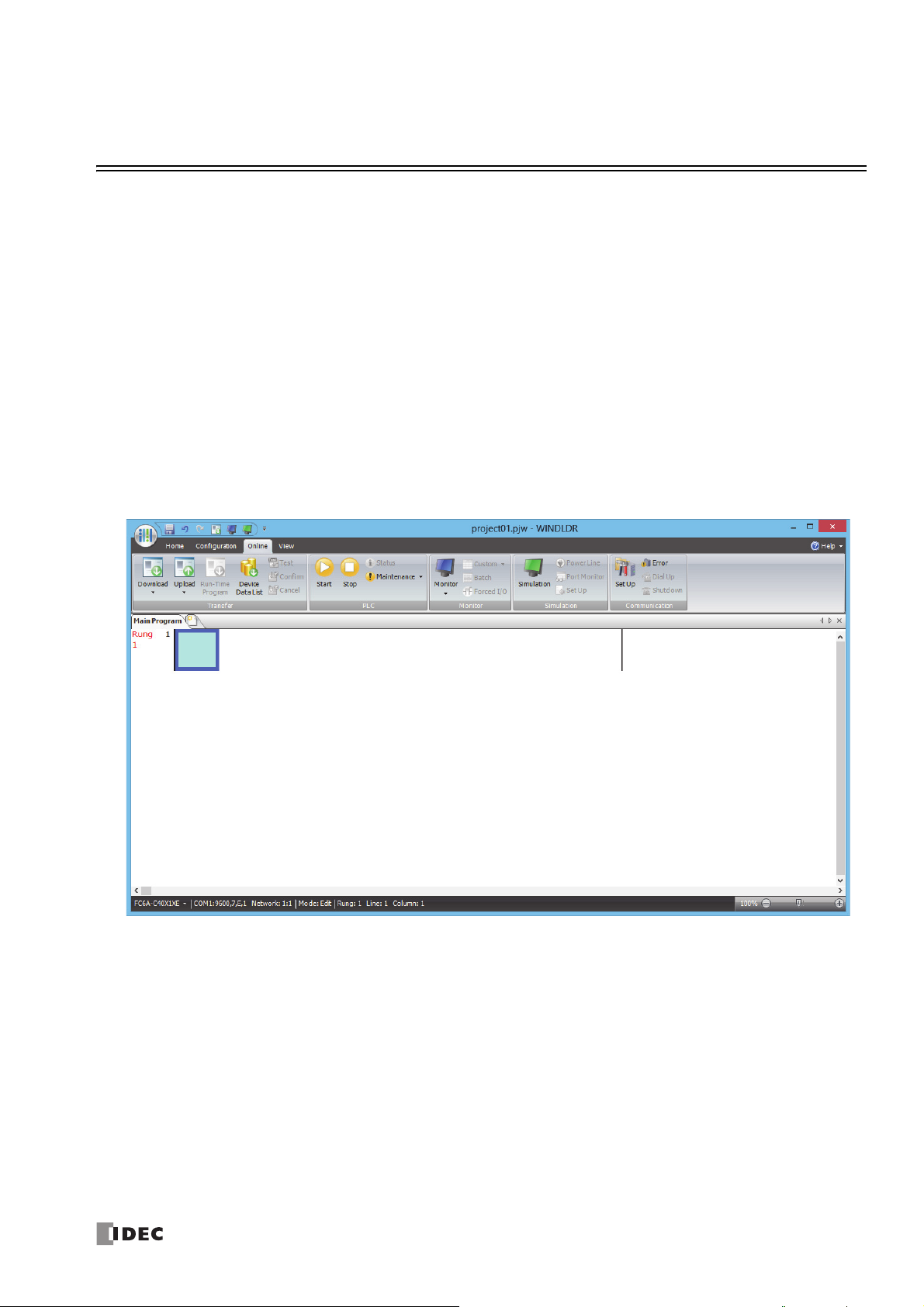

WindLDR starts and a blank ladder editing screen appears with menus and tool bars shown on top of the screen.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-1

Page 12

1: O

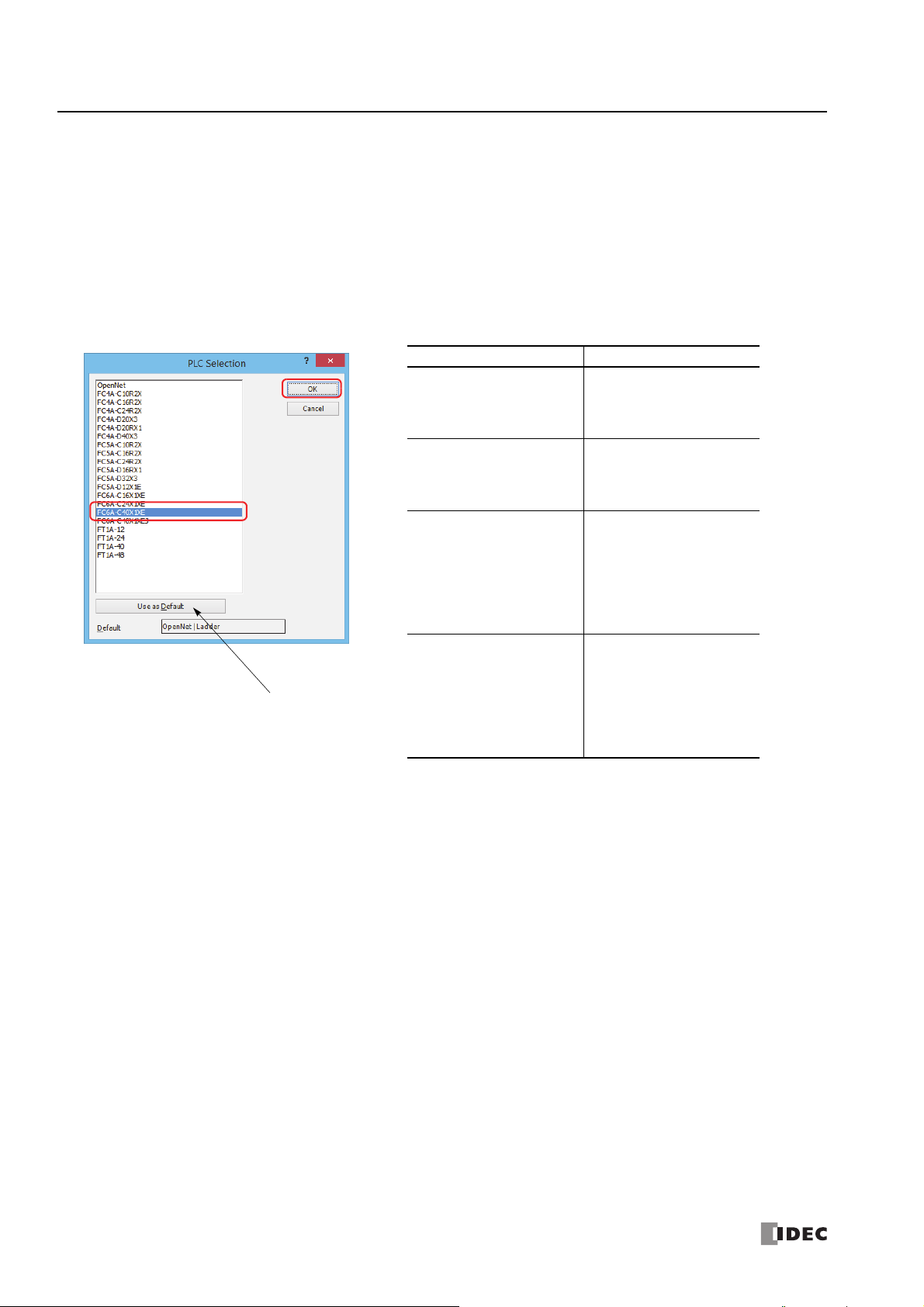

Select the PLC type from the list and click Use as

Default to set the selected PLC type as the default

type when WindLDR starts.

In WindLDR, the FC6A Series MicroSmart is categorized by the number of

inputs and outputs and the PLC type names are displayed as follows.

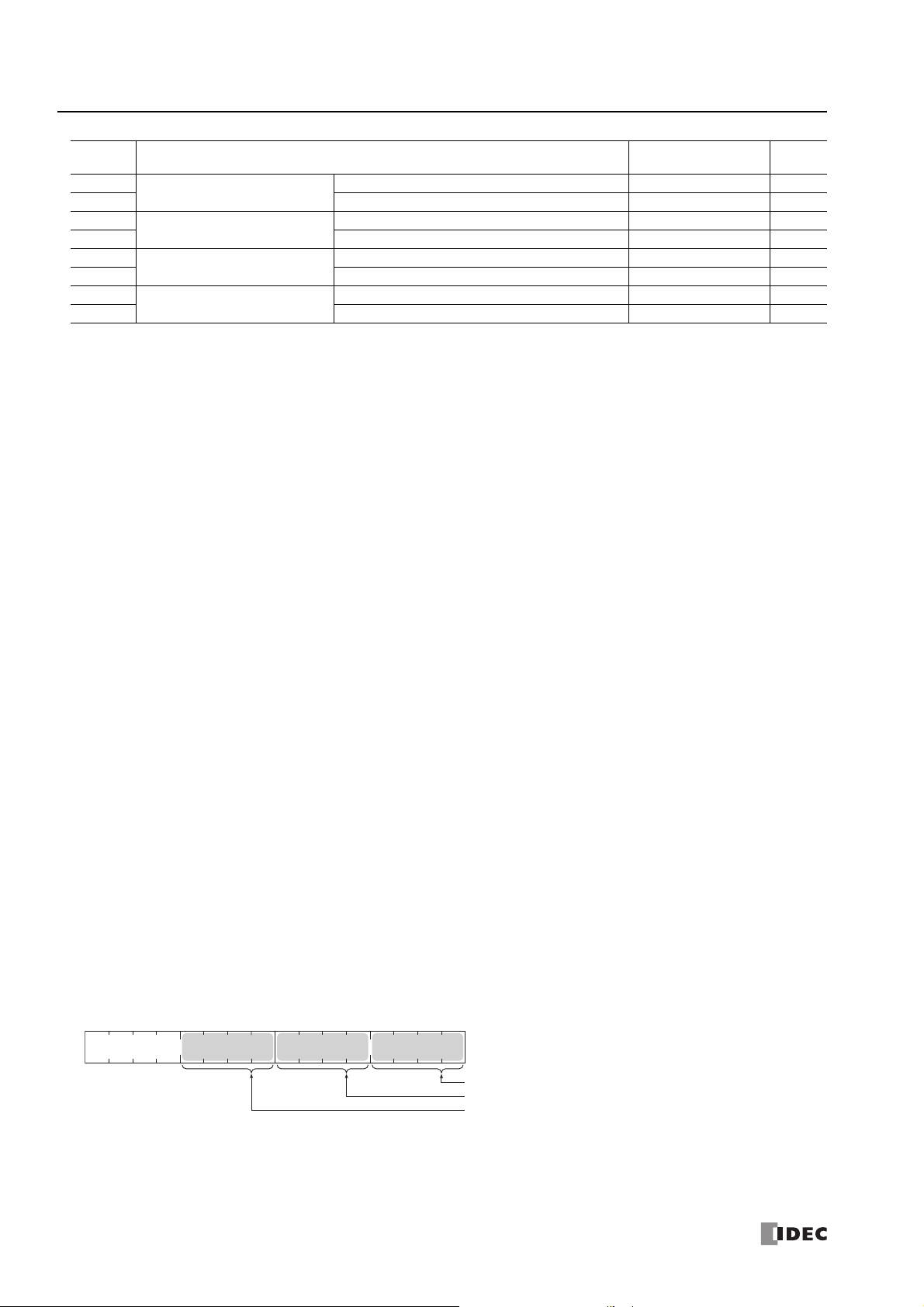

PLC Selection Option Type No.

FC6A-C16X1XE

FC6A-C16R1AE

FC6A-C16R1CE

FC6A-C16P1CE

FC6A-C16K1CE

FC6A-C24X1XE

FC6A-C24R1AE

FC6A-C24R1CE

FC6A-C24P1CE

FC6A-C24K1CE

FC6A-C40X1XE

FC6A-C40R1AE

FC6A-C40R1CE

FC6A-C40P1CE

FC6A-C40K1CE

FC6A-C40R1DE

FC6A-C40P1DE

FC6A-C40K1DE

FC6A-C40X1XEJ

FC6A-C40R1AEJ

FC6A-C40R1CEJ

FC6A-C40P1CEJ

FC6A-C40K1CEJ

FC6A-C40R1DEJ

FC6A-C40P1DEJ

FC6A-C40K1DEJ

PERATION BASICS

PLC Selection

Before programming a user program on WindLDR, select a PLC type.

1. Select Configuration from the WindLDR menu bar, then select PLC Type.

The PLC Selection dialog box appears.

2. Select a PLC type in the selection box and the programming language to use.

3. Click OK.

PLC selection is now complete. Next, create a ladder program.

1-2 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 13

1: O

PERATION BASICS

Create Program

Create Ladder Program

This section describes the operating procedure to create a ladder program in WindLDR.

Note: For details about devices, see "Devices" on page 2-1.

Sample User Program

Create a simple program using WindLDR. The sample program performs the following operation:

When only input I0 is turned on, output Q0 is turned on.

When only input I1 is turned on, output Q1 is turned on.

When both inputs I0 and I1 are turned on, output Q2 flashes in 1-s increments.

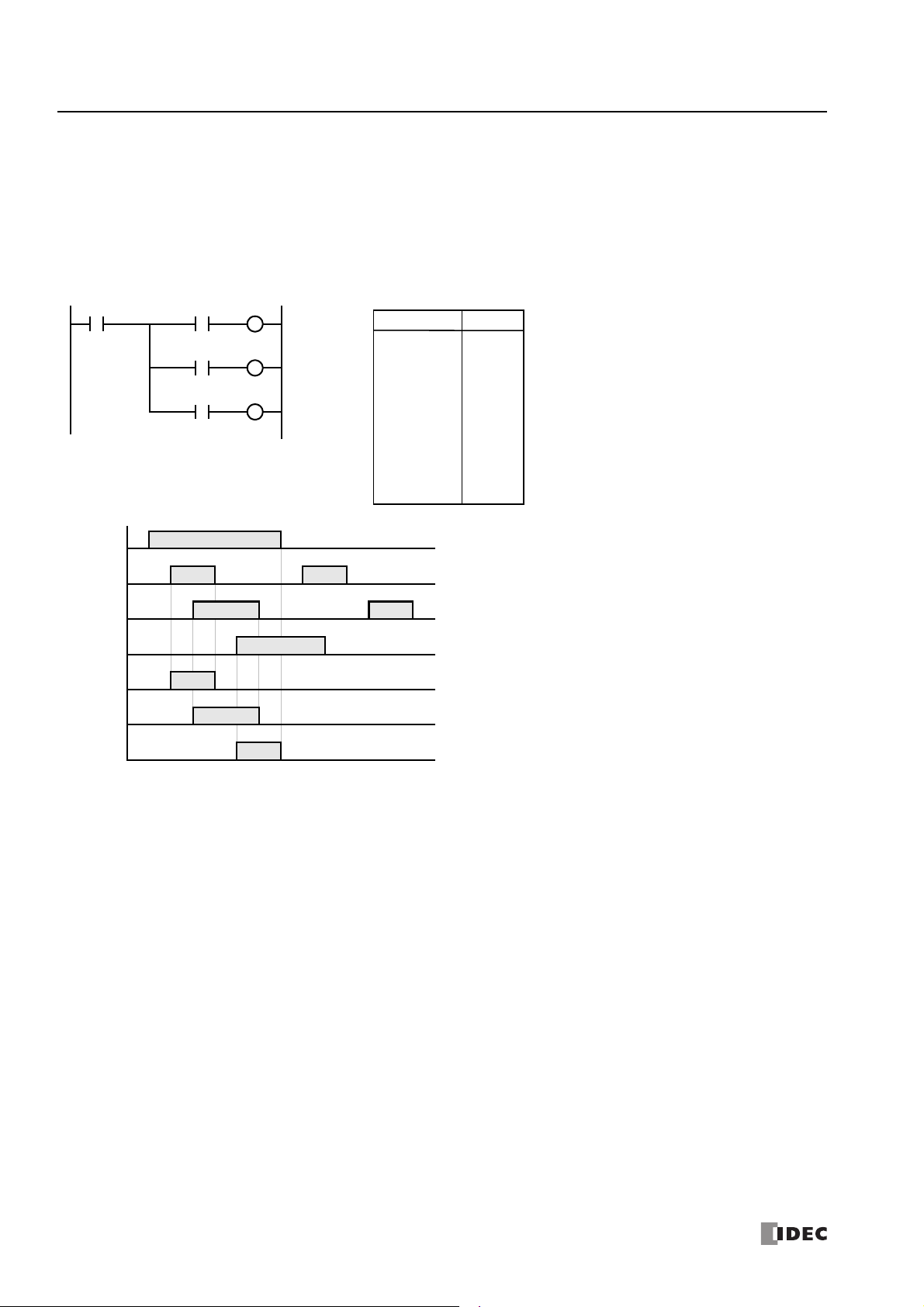

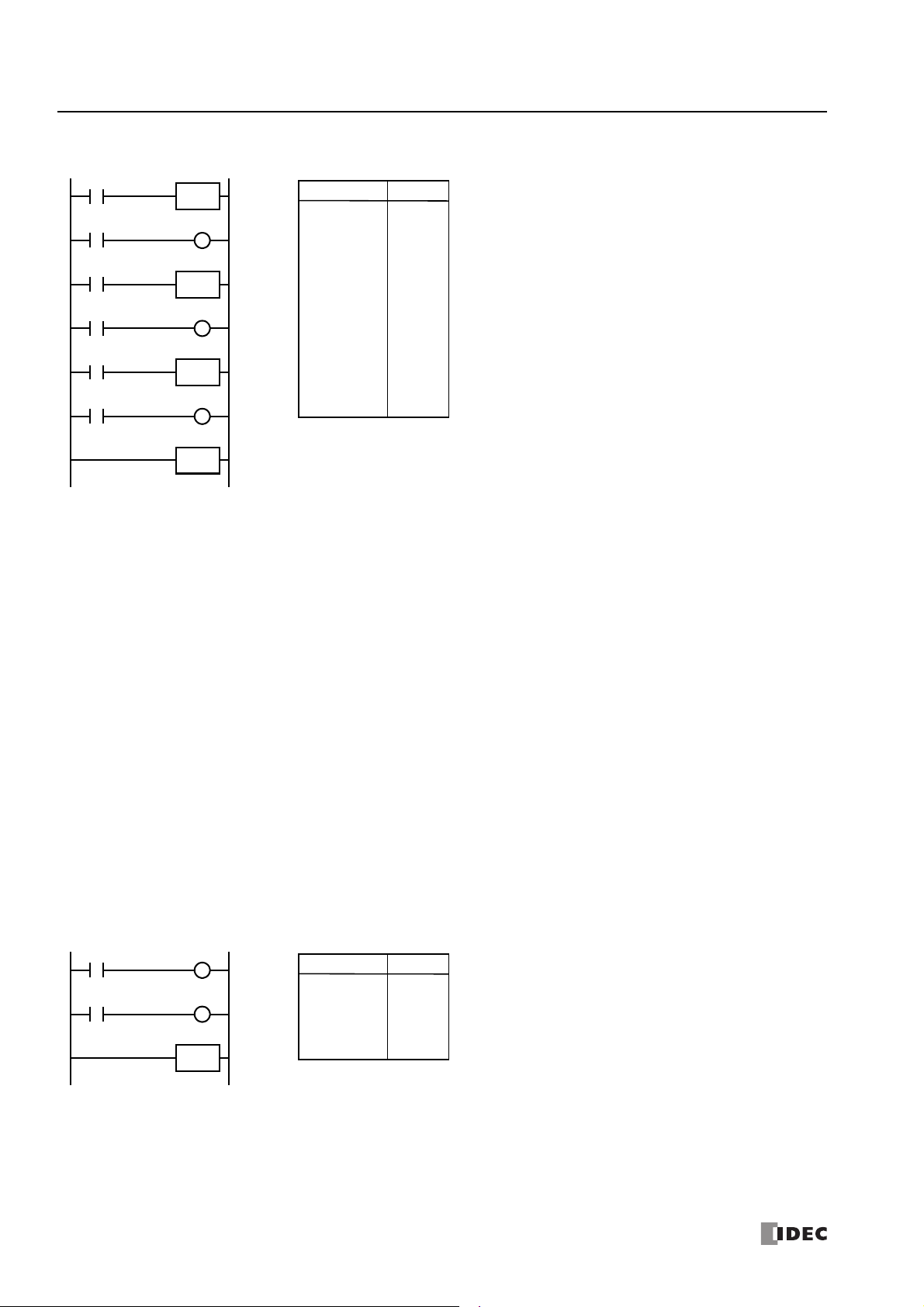

Rung No. Input I0 Input I1 Output Operation

1 ON OFF Output Q0 is turned ON.

2 OFF ON Output Q1 is turned ON.

3 ON ON Output Q2 flashes in 1-s increments.

Note: One collection of a group of instructions that control output or advanced instructions is called a rung. WindLDR manages programs in rung

units. Function descriptions can be configured as rung comments for individual rungs.

Start WindLDR

From the Start menu of Windows, select Programs > Automation Organizer V2 > WindLDR > WindLDR.

WindLDR starts and a blank ladder editing screen appears with menus and tool bars shown on top of the screen.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-3

Page 14

1: O

PERATION BASICS

Edit User Program Rung by Rung

Start the user program with the LOD instruction by inserting a NO contact of input I0.

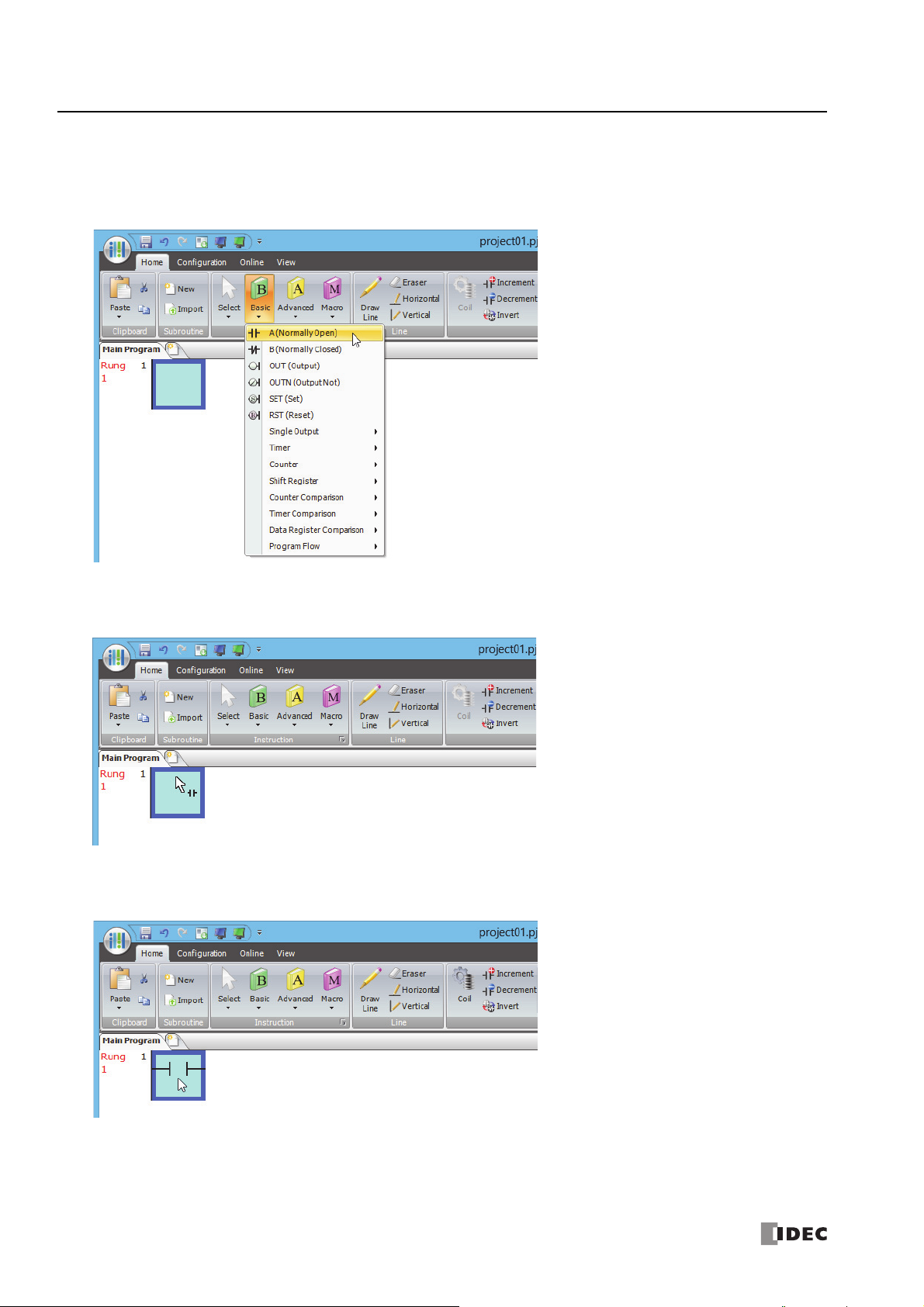

1. From the WindLDR menu bar, select Home > Basic > A (Normally Open).

2. Move the mouse pointer to the first column of the first line where you want to insert a NO contact, and click the left mouse

button.

3. Double-click Normally Open.

The A (Normally Open) dialog box is displayed.

1-4 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 15

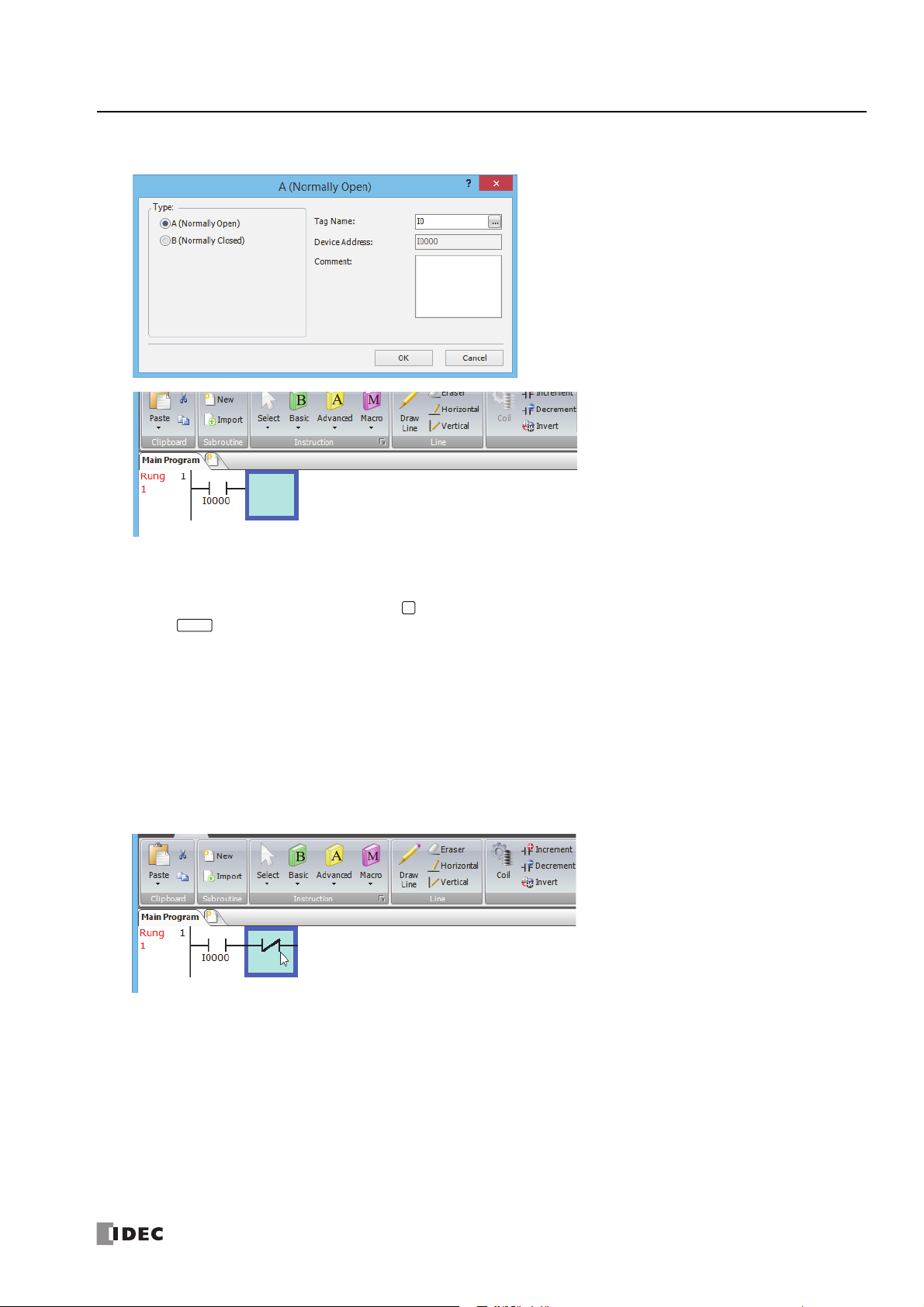

4. Enter I0 in the Tag Name field, and click OK.

A

Enter

1: O

PERATION BASICS

Note:

• To enter an NO contact from the right-click menu, right-click at the location to insert the NO contact, and on the right-click menu, click Basic

Instructions (B), then A (Normally Open).

• To enter an NO contact from the keyboard, press (A) to display the Coil Selection dialog box. Select A (Normally Open), and then

press (Enter).

A NO contact of input I0 is programmed in the first column of the first ladder line.

Next, program the ANDN instruction by inserting a NC contact of input I1.

5. From the WindLDR menu bar, select Home > Basic > B (Normally Closed).

6. Move the mouse pointer to the second column of the first ladder line where you want to insert a NC contact, and click the left

mouse button.

7. Double-click Normally Closed.

The B (Normally Closed) dialog box is displayed.

8. Enter I1 in the Tag Name field, and click OK.

An NC contact of input I1 is programmed in the second column of the first ladder line.

At the end of the first ladder line, program the OUT instruction by inserting a NO coil of output Q0.

9. From the WindLDR menu bar, select Home > Basic > OUT (Output).

10. Move the mouse pointer to the third column of the first ladder line where you want to insert an output coil, and click the left

mouse button.

Note: Another method to insert an instruction (either basic or advanced) is to type the instruction symbol, OUT, where you want to insert the

instruction.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-5

Page 16

1: O

To insert a new ladder line

without creating a new rung,

press the down arrow key when

the cursor is on the last line or

press the right arrow key when

the cursor is at the right-most

column of the last line.

PERATION BASICS

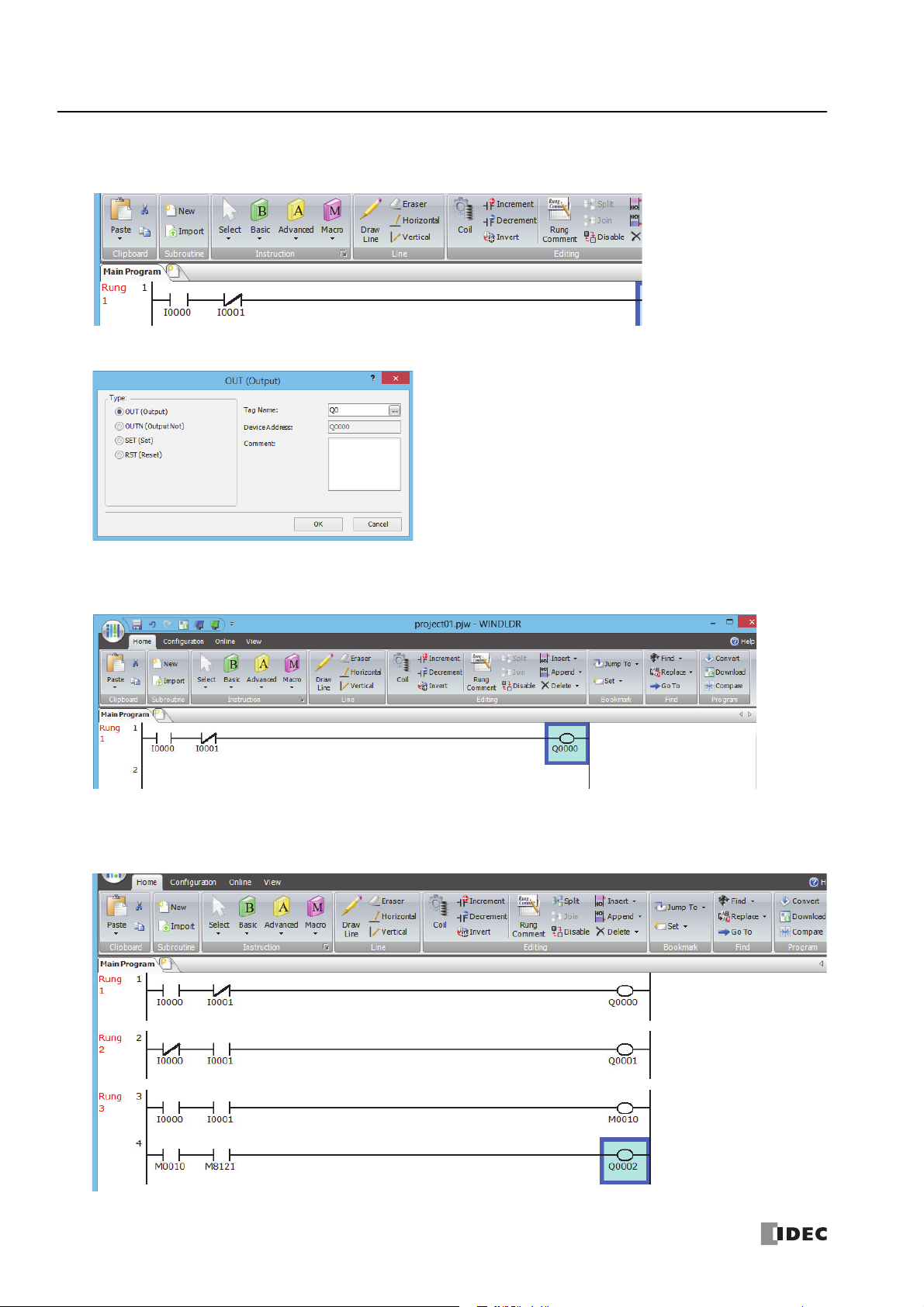

11. Double-click Output.

The Out (Output) dialog box is displayed.

12. Enter Q0 in the Tag Name field, and click OK.

A NO output coil of output Q0 is programmed in the right-most column of the first ladder line. This completes programming for

rung 1.

Continue programming for rungs 2 and 3 by repeating similar procedures.

A new rung is inserted by pressing the Enter key while the cursor is on the preceding rung. A new rung can also be inserted

by selecting Home > Append > Append a Rung.

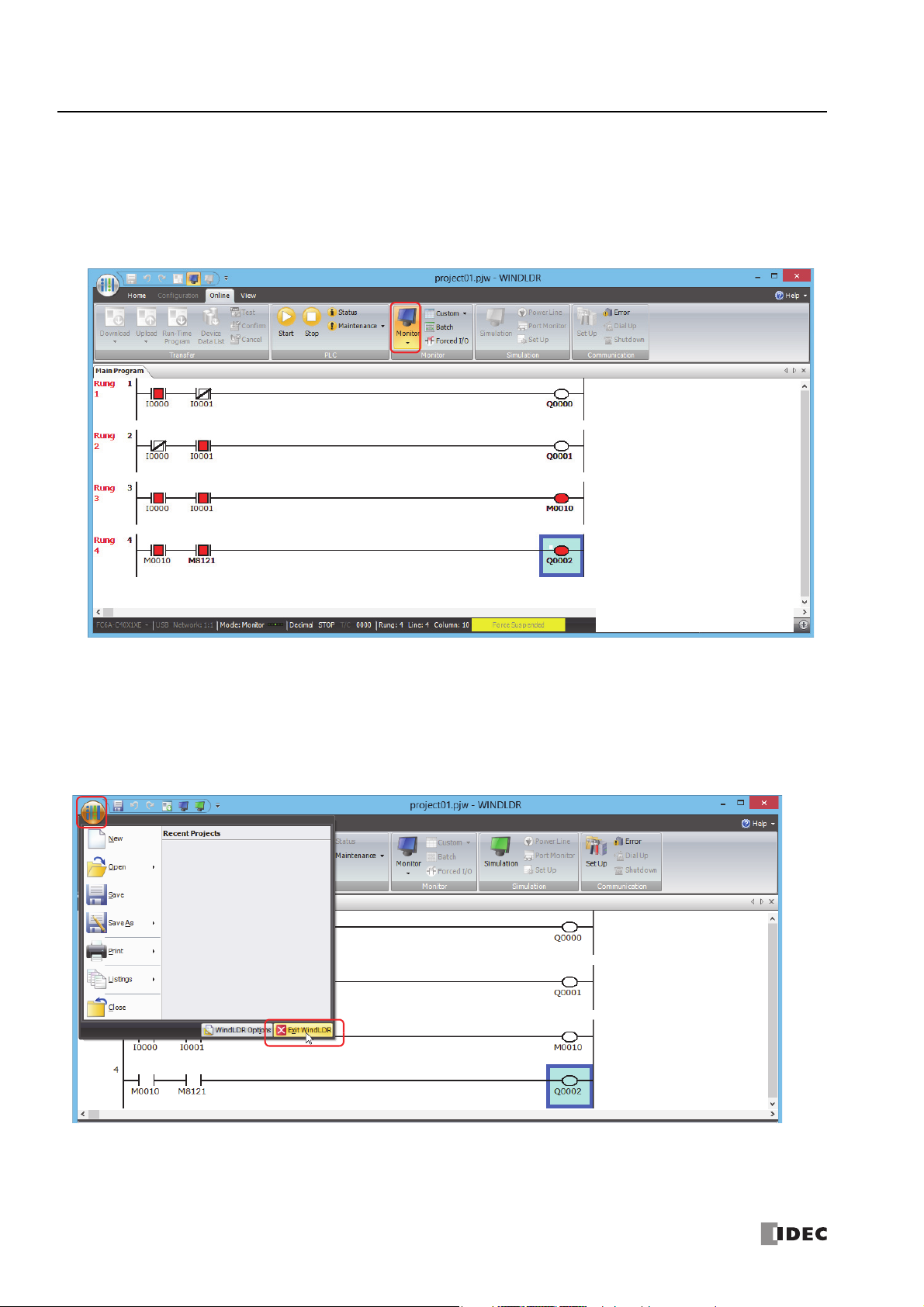

When completed, the ladder program looks like below.

1-6 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 17

1: O

Info Window

PERATION BASICS

Convert Program

The program can be checked whether it contains any user program syntax error.

From the menu bar, select Home > Convert (Program group).

When the instruction/FB symbols are connected correctly, the program conversion is completed successfully. If any error is found,

the errors are listed on the Info Window. Then, make corrections as necessary.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-7

Page 18

1: O

PERATION BASICS

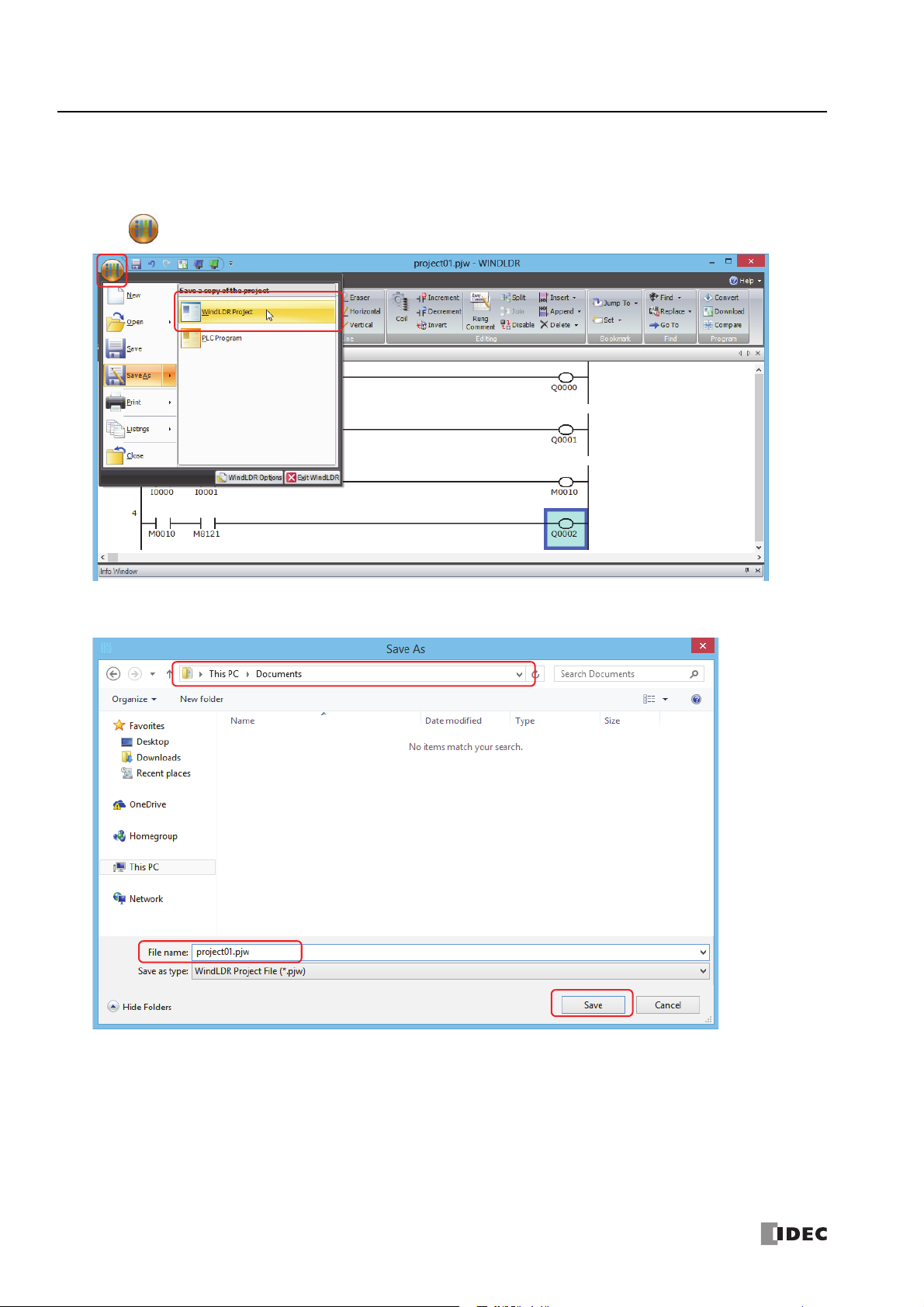

Save Project

This section describes the operating procedure to save the created ladder program as a project file.

1. Save the current project with a new name.

Click

2. Enter the file name in File name, specify the folder to save to, and click Save.

(application) button > Save As > WindLDR Project.

This completes the procedure to save a project to a file.

Note: The saved file is called a project file. The extension is ".pjw".

1-8 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 19

1: O

PERATION BASICS

Simulate Operation

This section describes the operating procedure to check the operation of the user program before transferring it to the FC6A Series

MicroSmart.

From the WindLDR menu bar, select Online > Simulation. The Simulation screen appears.

Select and right-click the input contact you want to change, and on the right-click menu, click Set or Reset.

To quit simulation, from the WindLDR menu bar, select Online > Simulation.

Notes:

• You can also change the status of an input contact by double-clicking it.

• To quit simulation, from the WindLDR menu bar, once more select Online > Simulation > Simulation.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-9

Page 20

1: O

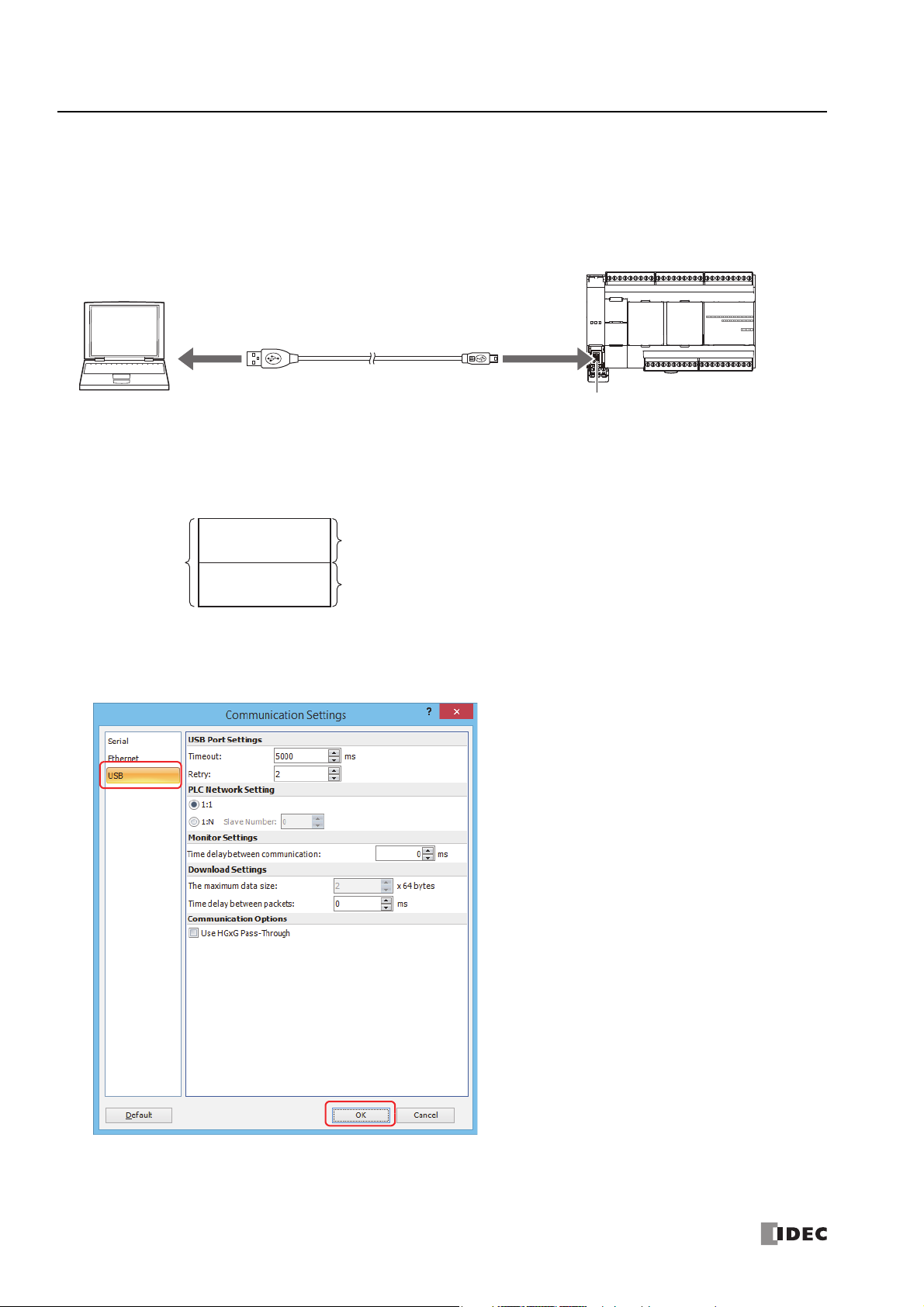

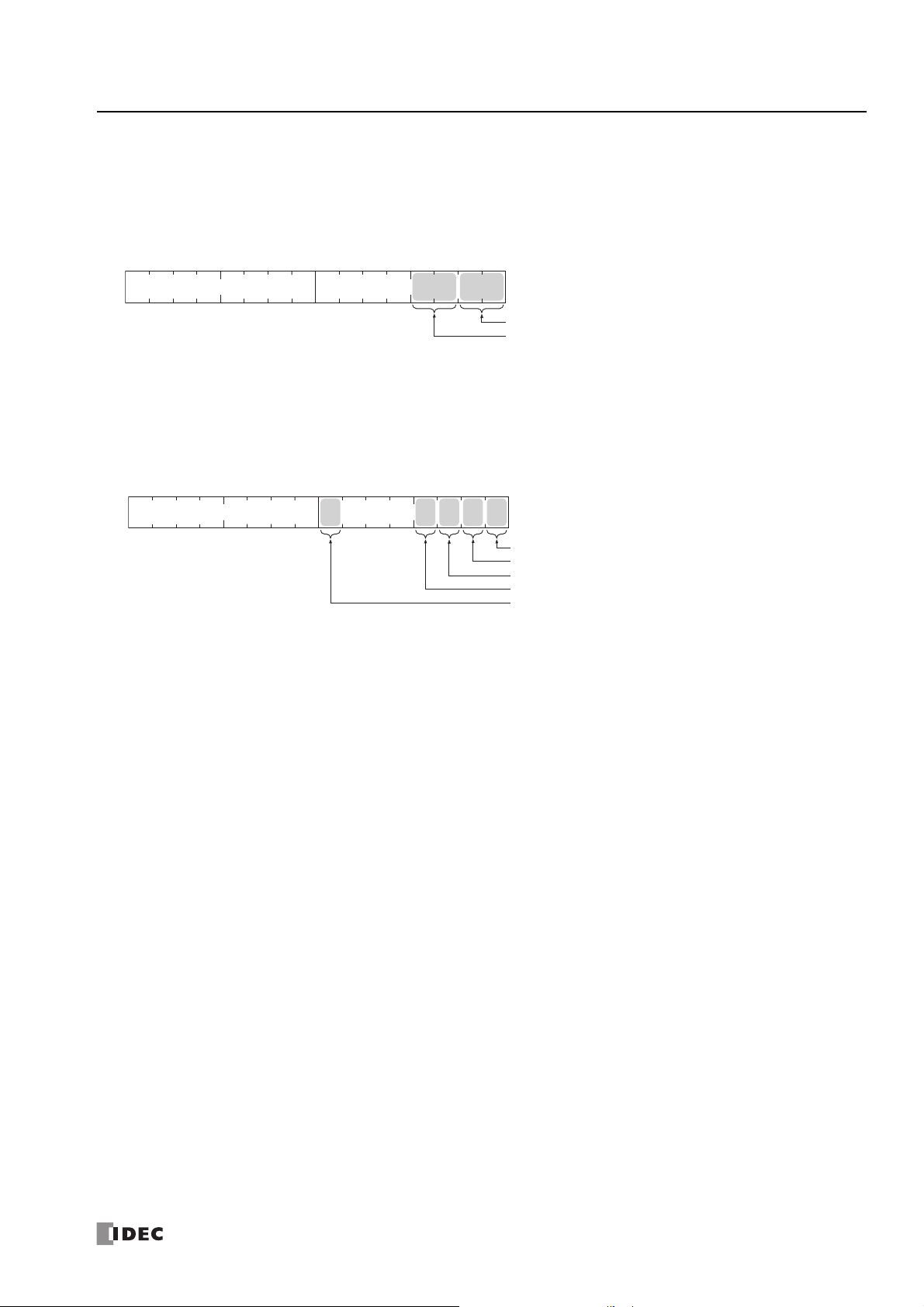

Windows Computer

USB Port

USB Cable

HG9Z-XCM42 USB Maintenance Cable

FC6A Series MicroSmart

Type A Plug Mini-B Plug

USB Port

(USB 2.0 Mini-B Connector)

Ladder Program

Function Area Settings

User Program

Details programmed with a ladder diagram

Details of the FC6A Series MicroSmart settings

The majority of these items are those set on the Configuration tab.

PERATION BASICS

Download Program

While WindLDR is running on a PLC, you can download the user program to the FC6A Series MicroSmart.

User programs can be downloaded to the FC6A Series MicroSmart from WindLDR using USB or Ethernet.

This section describes the operating procedure from configuring communication settings to downloading the user program using a

USB connection as an example.

Notes:

• In order for WindLDR to communicate with the FC6A Series MicroSmart via USB, a dedicated USB driver must be installed on the computer.

See Appendix "USB Driver Installation Procedure" in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

• A user program is a combination of a ladder program and the setting details (Function Area Settings).

1. From the WindLDR menu bar, select Online > Set Up.

The Communication Settings dialog box is displayed.

2. Click the USB tab and then click OK.

1-10 FC6A S

The communication method is now set to USB. Next, download a user program.

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 21

1: O

PERATION BASICS

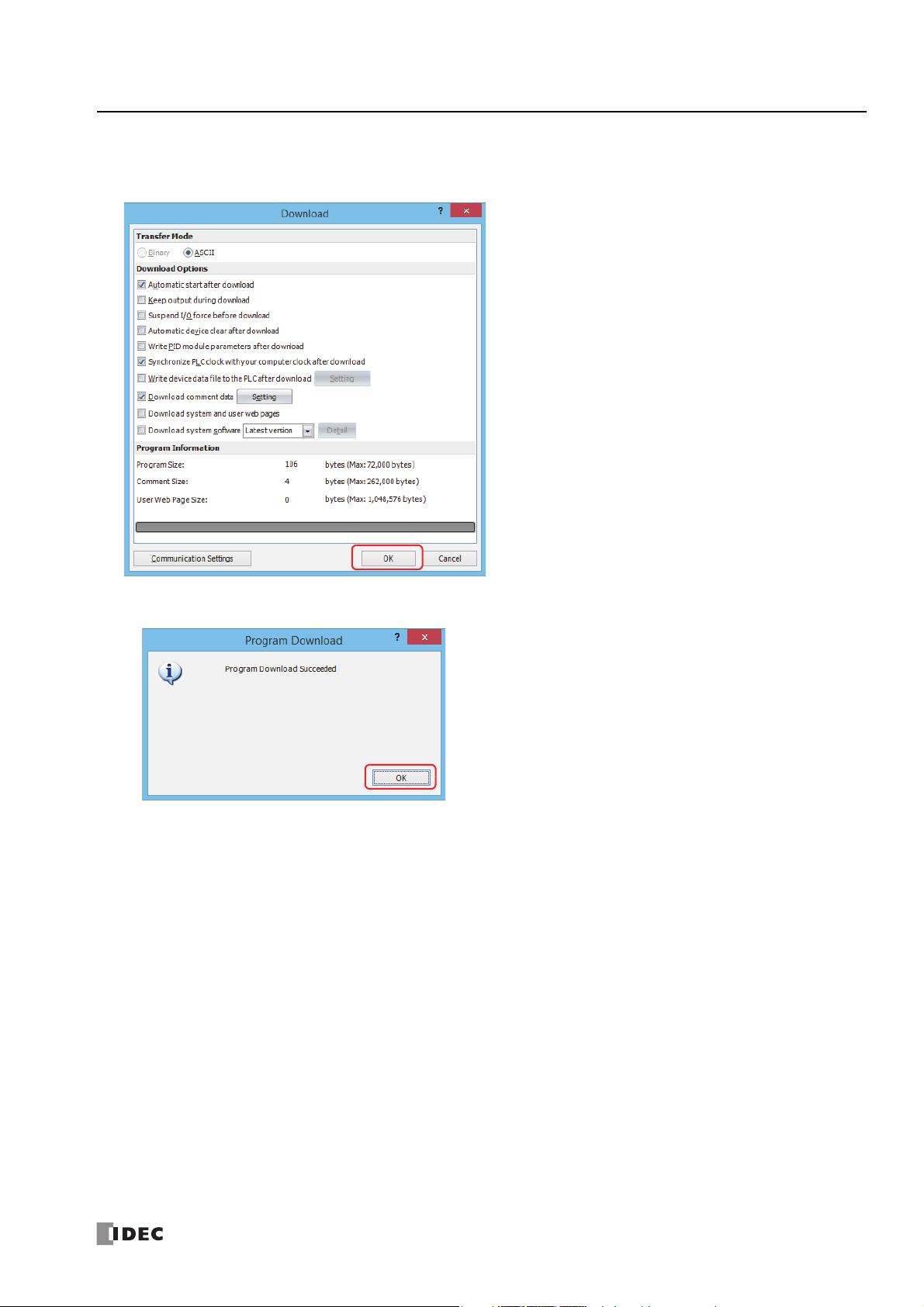

3. From the WindLDR menu bar, select Online > Download. The Download dialog box appears, then click OK. The user

program is downloaded to the FC6A Series MicroSmart.

Note: The Download dialog box can also be opened by

selecting Home > Download.

Note: When downloading a user program, all values and

selections in the Function Area Settings are also

downloaded to the FC6A Series MicroSmart. For details on

function settings, see Chapter 5 "Functions and Settings" in

the "FC6A Series MicroSmart All-in-One Type User’s Manual".

When the following message appears, the download has completed successfully. Click OK.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-11

Page 22

1: O

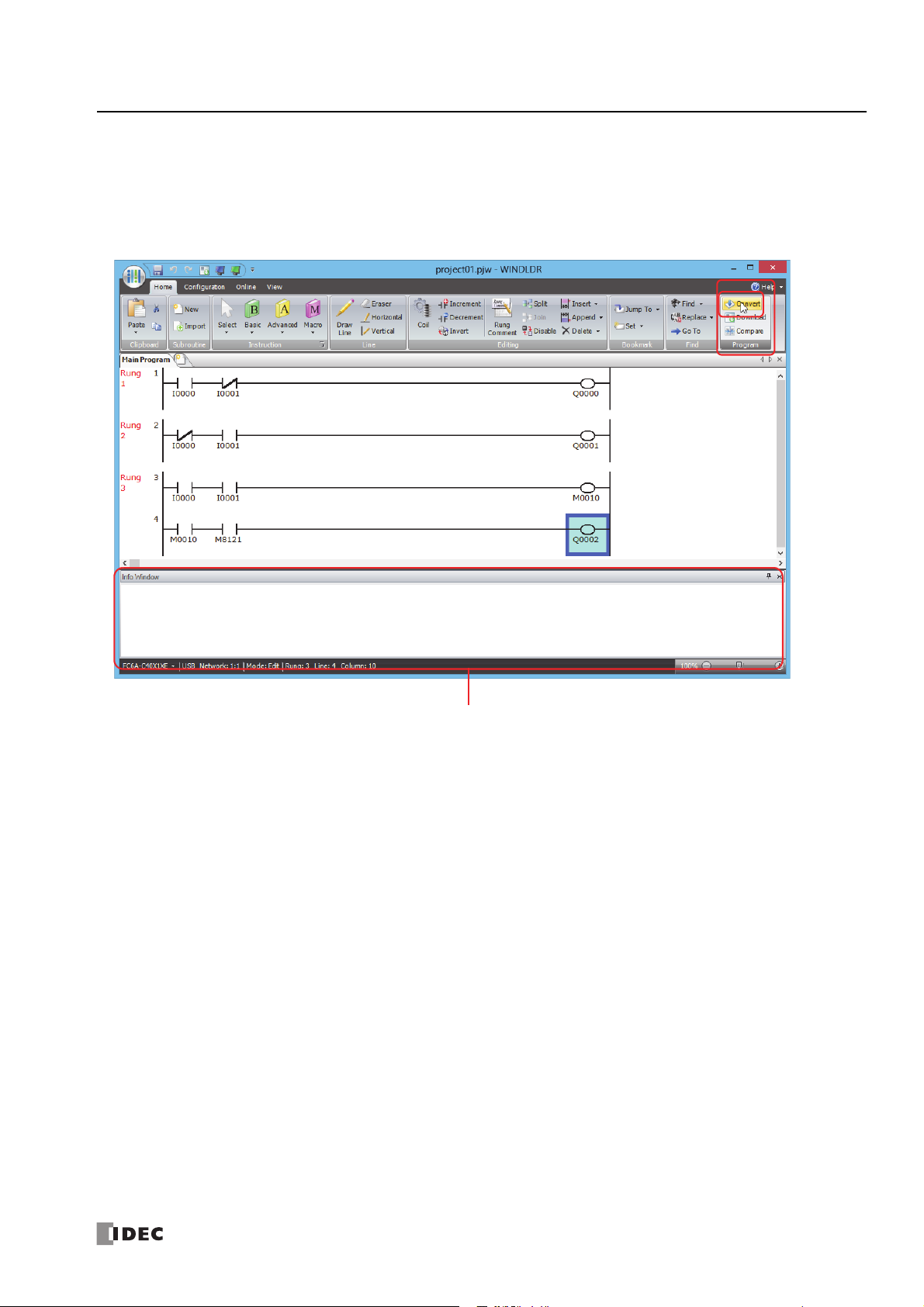

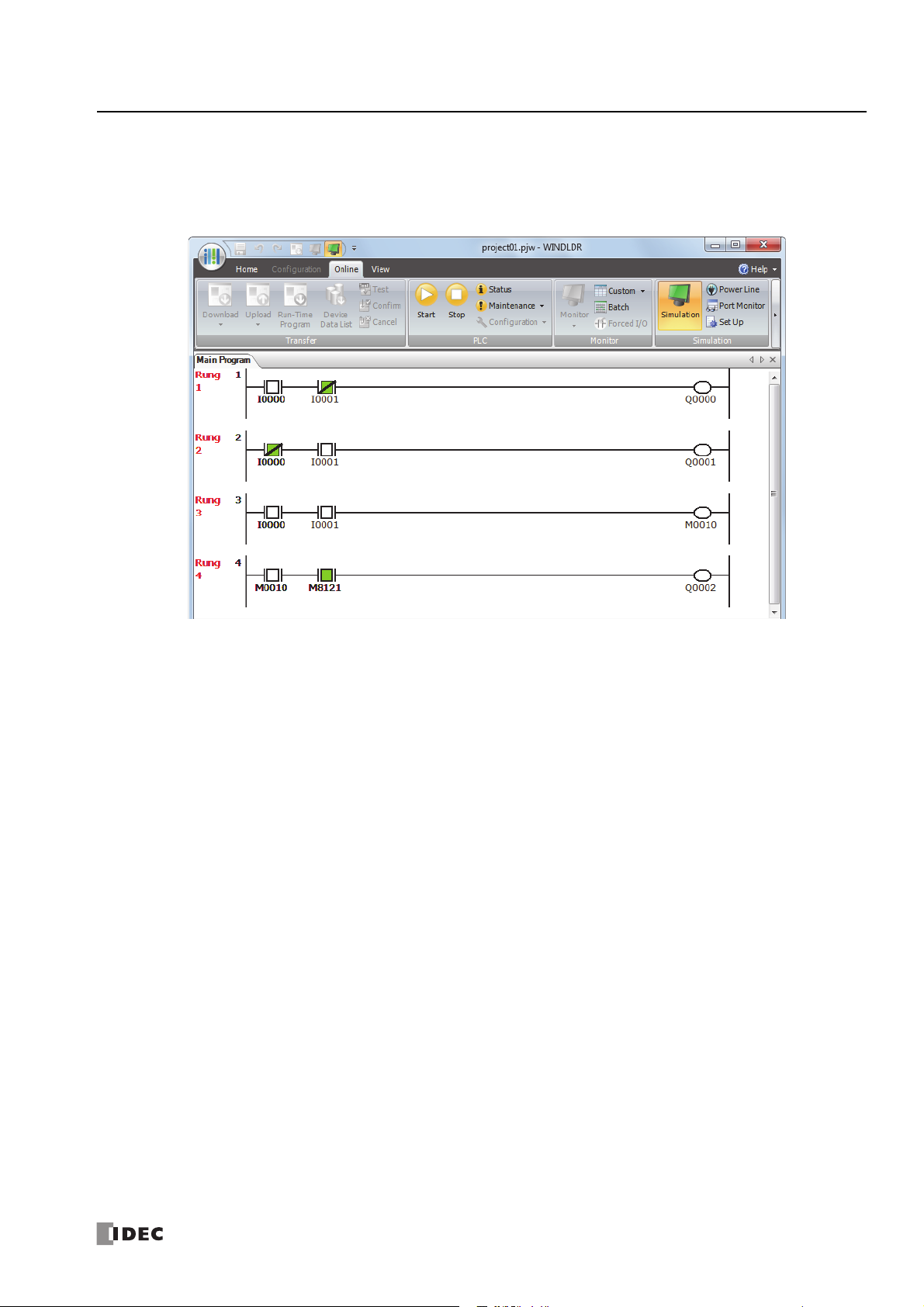

Rung 1:

When both inputs I0 and I1 are on,

output Q0 is turned off.

Rung 2:

When both inputs I0 and I1 are on,

output Q1 is turned off.

Rung 3:

When both input I0 and I1 are on,

internal relay M10 is turned on.

M8121 is the 1-s clock special

internal relay.

While M10 is on, output Q2 flashes

in 1-s increments.

PERATION BASICS

Monitor Operation

Another powerful function of WindLDR is to monitor the PLC operation on the computer. The input and output statuses of the

sample program can be monitored in the ladder diagram.

From the WindLDR menu bar, select Online > Monitor > Monitor.

When both inputs I0 and I1 are on, the ladder diagram on the monitor screen looks as follows:

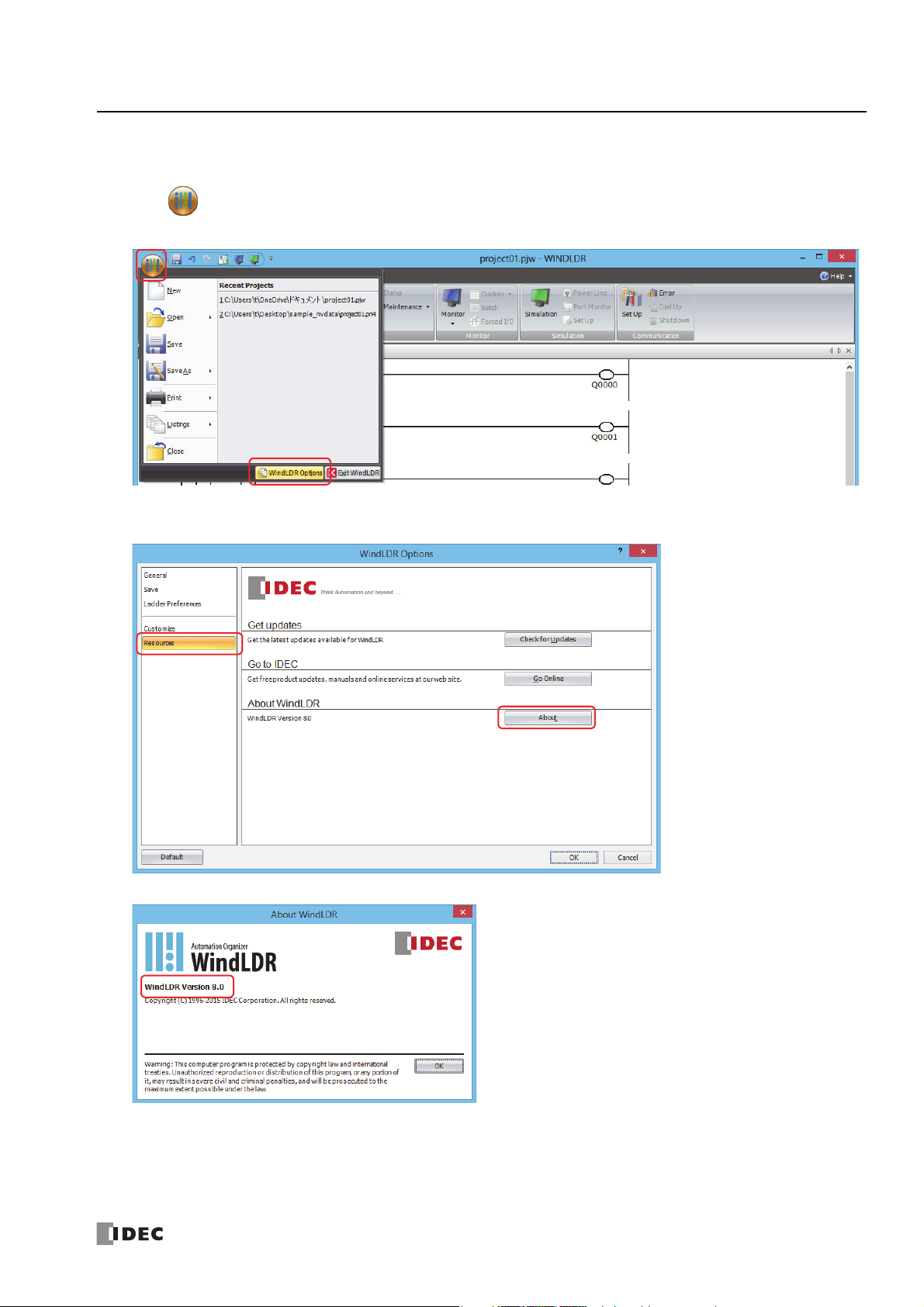

Exit WindLDR

This section describes the operating procedure to exit WindLDR.

When you have completed monitoring, you can exit WindLDR either directly from the monitor screen or from the editing screen. In

both cases, from the WindLDR application button, click Exit WindLDR.

1-12 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 23

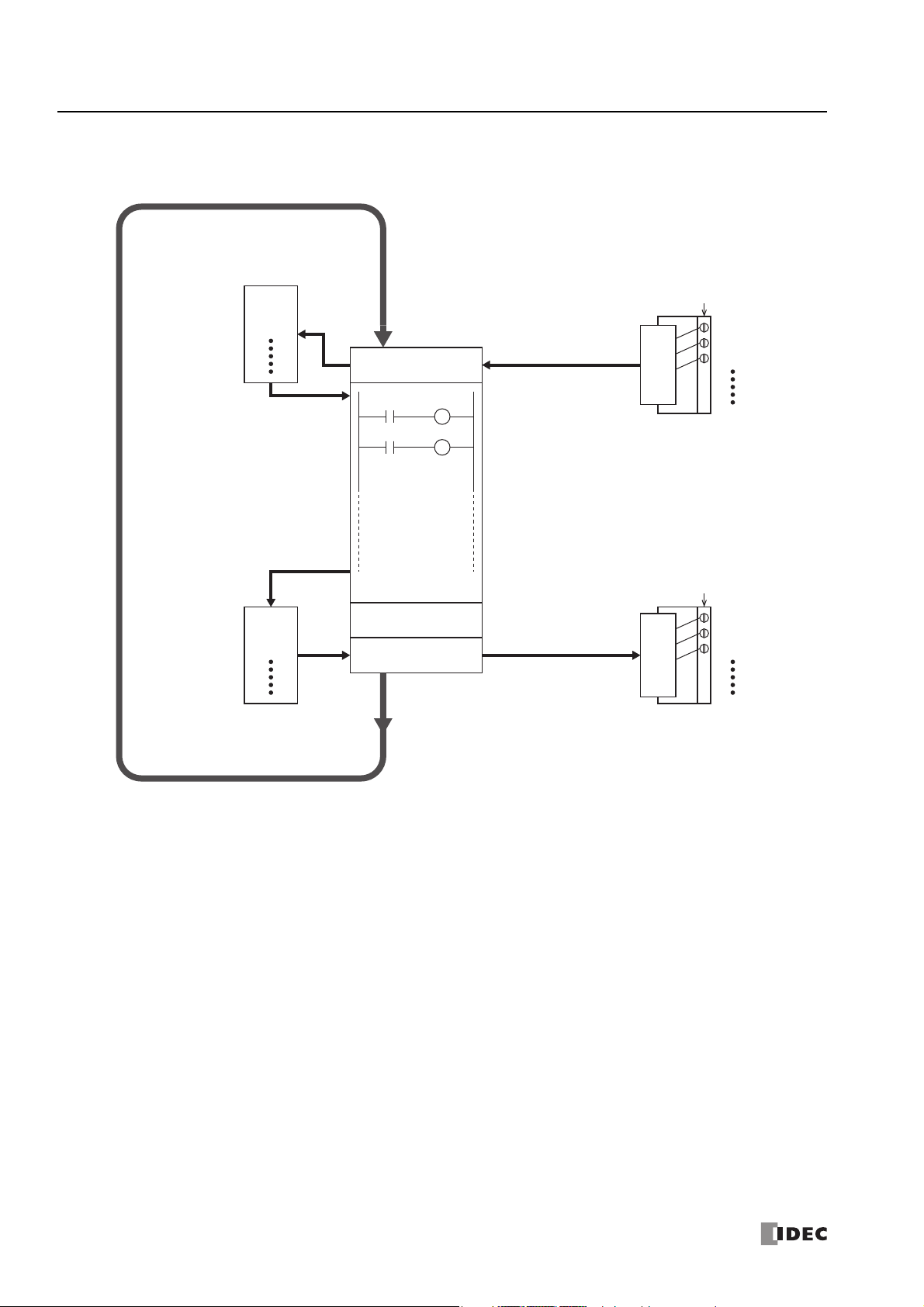

Checking the WindLDR Version Number

This section describes how to check the WindLDR version.

1. Click (application) button > WindLDR Options.

The WindLDR Options dialog box appears.

2. Click the Resources tab, and then click About.

The About WindLDR dialog box appears.

1: O

PERATION BASICS

You can check the WindLDR version. When finished, click OK.

Note: When using the FC6A Series MicroSmart, use version 8.0.0 or later of WindLDR.

If you are using a version of WindLDR that does not meet this condition, click Check for Updates on the Resources tab to obtain the latest

version of WindLDR.

This concludes the procedure for checking the WindLDR version.

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-13

Page 24

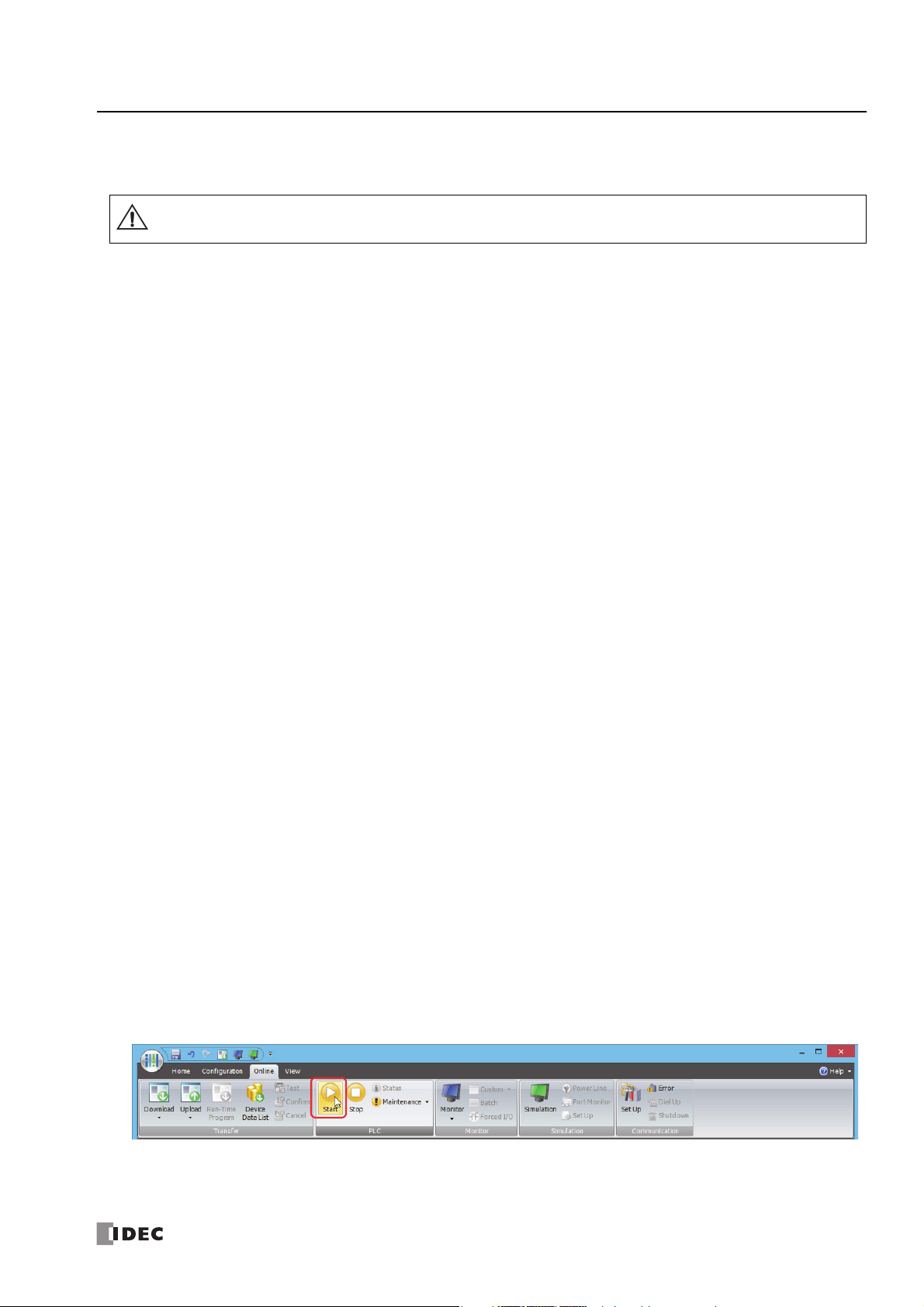

1: O

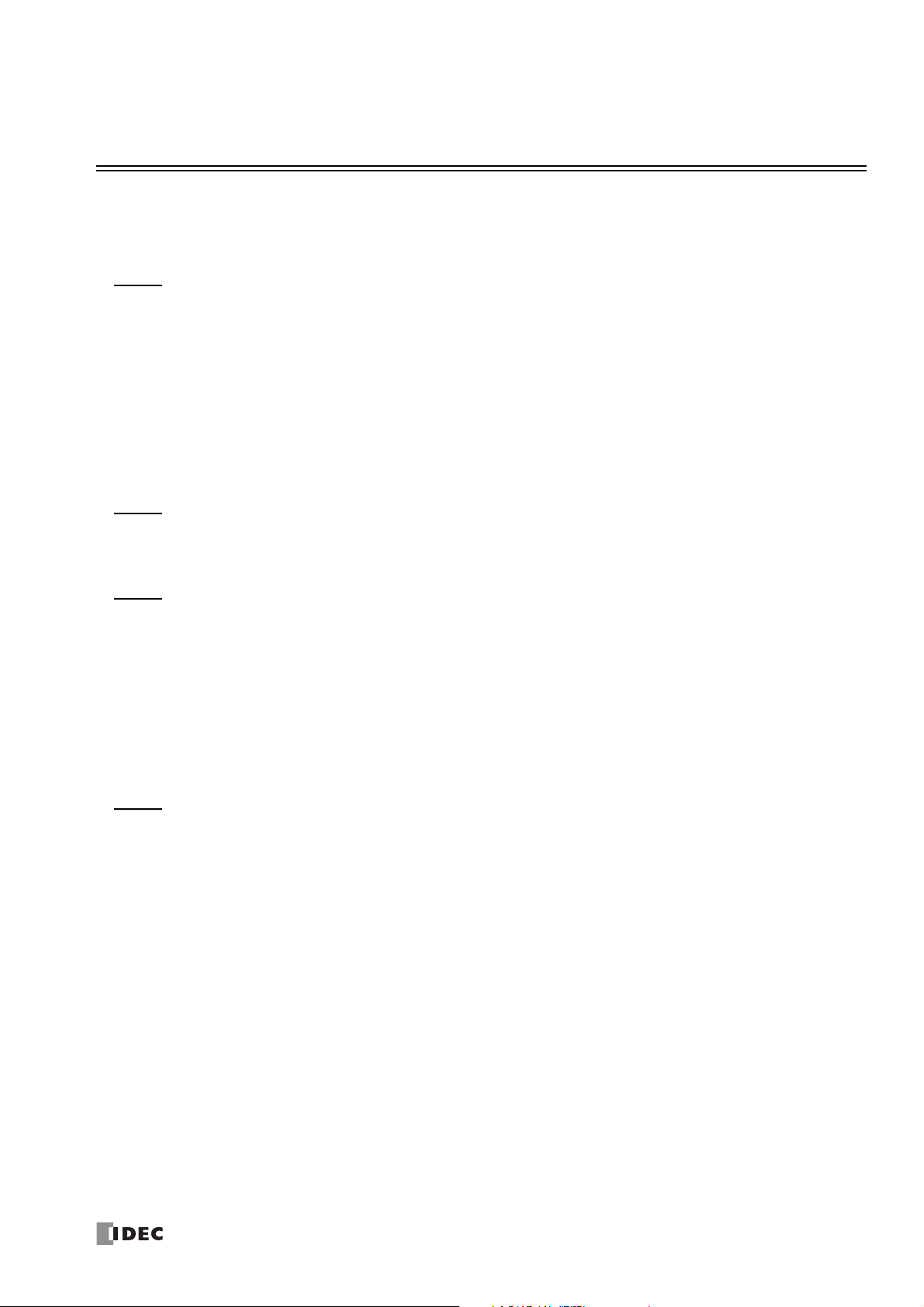

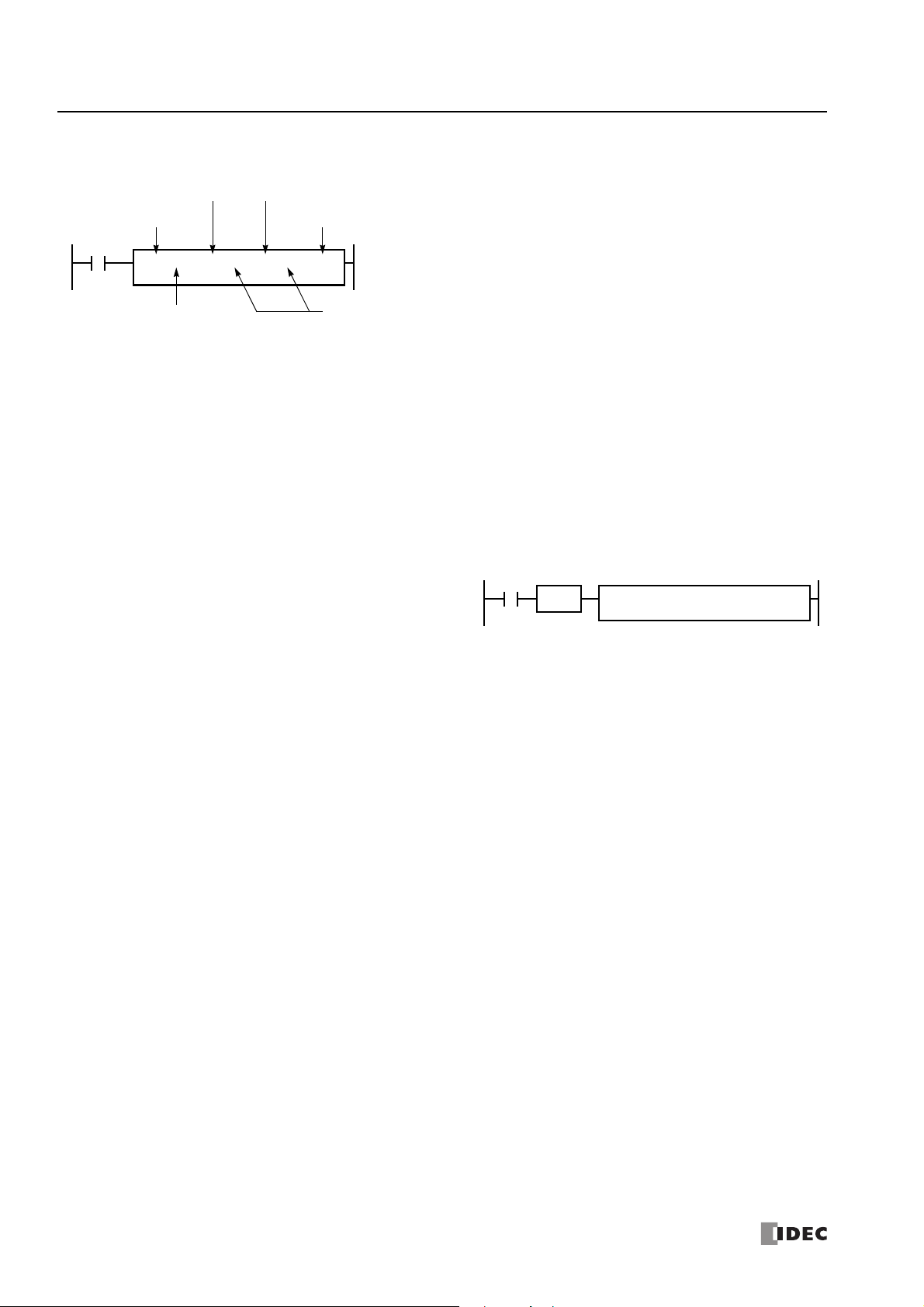

Input Refresh

Input Terminals

Input Device

Output Device

Ladder Processing

Output Refresh

Other Processing

Output Terminals

Input CircuitOutput Circuit

I0: ON

I1: OFF

I2: ON

Q0: ON

Q1: OFF

Q2: ON

0: ON

1: OFF

2: ON

0: ON

1: OFF

2: ON

Repeat operations

One sequence of operations is set as one

scan, and the time required is set as the

scan time.

The output devices are updated

according to the ladder program.

The input device values are applied to the

ladder program.

Processing other than the ladder

processing is called the END

processing.

The ON/OFF status of the input terminal

(external input) is applied to the input

circuit. The input refresh loads the external

input status into the input devices (I) by

way of the input circuit.

A delay occurs until the ON/OFF status of

the input circuit is applied to the input

devices (I). The delay time is equal to filter

time + 1 scan time.

The output refresh applies the status of the

output devices (Q) to the output circuit, and

then the ON/OFF status of the output

terminals (external input) is updated.

A delay occurs until the values of the output

devices (Q) are applied to the output circuit.

The delay time is at maximum 1 scan time.

PERATION BASICS

Ladder Program Operation

The FC6A Series MicroSmart performs the following operations to process ladder programs.

Notes:

• The delay time of the hardware is added to the actual input and output delay times.

For details on the hardware input/output delay times, see Chapter 2 "Product Specifications" in the "FC6A Series MicroSmart All-in-One Type

User’s Manual".

• The filter time differs depending on the input used.

• When the input is a CPU module input (I0 to I27)

See the input filter time configured in the WindLDR Function Area Settings. The initial value is 3 ms.

• When the input is an expansion input (I30 or greater)

There is no filter time.

1-14 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 25

1: O

Caution

PERATION BASICS

Start/Stop Operation

This section describes how to run and stop the FC6A Series MicroSmart.

Make sure of safety before starting and stopping the FC6A Series MicroSmart. Incorrect operation of the FC6A Series

MicroSmart may cause machine damage or accidents.

Start/Stop Schematic

You can start and stop FC6A Series MicroSmart operations by using WindLDR operations, FC6A Series MicroSmart operations,

function switch operations, menu operations using an HMI module, by turning the FC6A Series MicroSmart on or off, or by using

the stop/reset input function by way of external input.

• For operations using WindLDR, see "Start/Stop Operation Using WindLDR" on page 1-15.

• For operations using the FC6A Series MicroSmart power supply, see "Start/Stop Operation Using the Power Supply" on page

1-16.

• For operations using the function switch, see Chapter 5 "Function Switch Configuration" in the "FC6A Series MicroSmart All-inOne Type User’s Manual".

• For operations using an HMI module, see Chapter 7 "HMI Function" in the "FC6A Series MicroSmart All-in-One Type User’s

Manual".

• For the stop input settings, see Chapter 5 "Stop Input" in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

• For the reset input settings, see Chapter 5 "Reset Input" in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

The switch from start to stop is performed during the END processing of the user program, and the following functions are also

stopped when the user program is stopped. For details on END processing, see the "Breakdown of END Processing Time" on page

A-5.

High-speed counter/frequency measurement/user interrupt/catch input/timer interrupt/user communication/pulse output

• You can use M8025 (Maintain Outputs While Stopped) to select whether to maintain or clear the outputs while the CPU is

stopped.

For details on M8025 (Maintain Outputs While Stopped), see "M8025: Maintain Outputs While Stopped" on page 2-8.

• The current value of the timer instruction is reset.

For details on timer instructions, see "TML (1-s Timer)" on page 4-7".

Also, when you switch from stop to start, the device status is cleared or kept depending on Memory Backup in the Function

Area Settings. For details, see Chapter 5 "Memory Backup" in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

Start/Stop Operation Using WindLDR

The FC6A Series MicroSmart can be started and stopped using WindLDR run on a Windows computer connected to the FC6A

Series MicroSmart. When the

turned on to start the FC6A Series MicroSmart. When the

MicroSmart.

1. Connect the computer to the FC6A Series MicroSmart, start WindLDR, and power up the FC6A Series MicroSmart.

2. Check that a stop input is not designated using Configuration > Run/Stop Control > Stop and Reset Inputs. See

Chapter 5 "Stop Input and Reset Input" in the "FC6A Series MicroSmart All-in-One Type User’s Manual".

Note: When a stop input is designated, the FC6A Series MicroSmart cannot be started or stopped by turning start control special internal relay

M8000 on or off.

3. Select Online from the WindLDR menu bar.

The Online tab appears.

4. Click the Start button to start operation, then the start control special internal relay M8000 is turned on.

Start button is pressed in the menu bar shown below, start control special internal relay M8000 is

Stop button is pressed, M8000 is turned off to stop the FC6A Series

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 1-15

Page 26

1: O

PERATION BASICS

5. Click the Stop button to stop operation, then the start control special internal relay M8000 is turned off.

The PLC operation can also be started and stopped while WindLDR is in the monitor mode. Select Online

> Monitor >

Monitor and click the Start or Stop button.

Note: Special internal relay M8000 is a keep type internal relay and stores the status when power is turned off. M8000 retains its previous status

when power is turned on again. However, when the backup battery is dead, M8000 loses the stored status, and can be turned on or off as

programmed when the FC6A Series MicroSmart is powered up. The selection is made in Configuration > Run/Stop Control > Run/Stop

Selection at Memory Backup Error. See Chapter 5 "Run/Stop Selection at Keep Data Error" in the "FC6A Series MicroSmart All-in-One Type

User’s Manual".

The backup duration is approximately 30 days (typical) at 25°C after the backup battery is fully charged.

Start/Stop Operation Using the Power Supply

The FC6A Series MicroSmart can be started and stopped by turning power on and off.

1. Power up the FC6A Series MicroSmart to start operation.

2. Turn power on and off to start and stop operation.

1-16 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 27

2: D

EVICES

This chapter provides detailed descriptions of the allocations of devices such as inputs, outputs, internal relays, registers, timers,

and counters that are used in the basic and advanced instructions, as well as details about the allocations of special internal relays

and special data registers.

Please use this chapter as a reference for the devices.

Note: The entry and operation of FC6A Series MicroSmart user programs requires specialist knowledge.

Take the time to develop a thorough understanding of the contents and programs in this manual before using the FC6A Series MicroSmart.

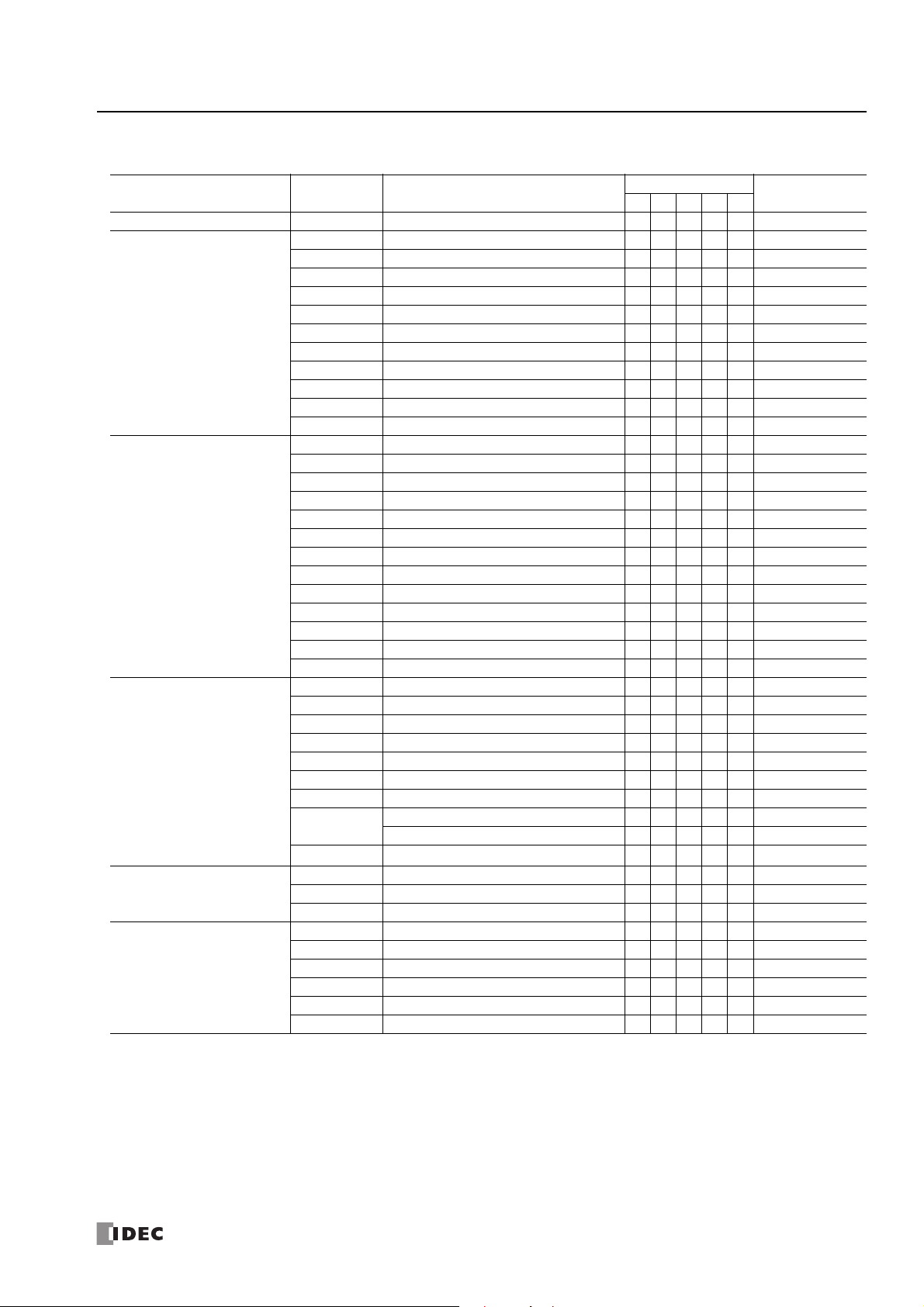

Device Addresses

Device Symbol Unit

*1

Inputs

Expansion Input Relays

*1

Output

Expansion Outputs

Internal Relay

Special Internal Relay

Shift Register R Bit

Timer T Bit/Word

Counter C Bit/Word

Data Register D Bit/Word

Special Data Register D Bit/Word

*1 The least significant digit of the device address is an octal number (0 to 7).

*2 I190 to I507 and Q190 to Q507 are devices that can only be used when an expansion module (expansion interface side) is connected using the

expansion interface module.

*3 I310 to I627 and Q310 to Q627 are devices that can only be used when an expansion module (expansion interface side) is connected using the

expansion interface module.

*1

*1

*1*3

*1

IBit

IBit

QBit

QBit

MBit

MBit

16-I/O Type 24-I/O Type 40-I/O Type

I0 - I10

(9 points)

I30 - I187

(128 points)

I190 - I507

(256 points)

(7 points)

Q30 - Q187

(128 points)

Q190 - Q507

(256 points)

*2

Q0 - Q6

*2

Range (Points)

I0 - I15

(14 points)

(224 points)

I310 - I627

(256 points)

Q0 - Q11

(10 points)

Q30 - Q307

(224 points)

Q310 - Q627

(256 points)

M0 - M7997

(6,400 points)

M10000 - M17497

(6,000 points)

M8000 - M8317

(256 points)

R0 - R255

(256 points)

T0 - T1023

(1,024 points)

C0 - C511

(512 points)

D0000 - D7999

(8,000 points)

D10000 to D55999

(46,000 points)

D8000 - D8499

(500 points)

I0 - I27

(24 points)

I30 - I307

*3

Q0 - Q17

(16 points)

*3

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 2-1

Page 28

2: D

EVICES

■ Inputs (I), Expansion Inputs (I)

Devices that input on/off information from external devices to the FC6A Series MicroSmart.

■ Outputs (Q), Expansion Outputs (Q)

Devices that output on/off information from the FC6A Series MicroSmart to external devices.

■ Internal Relays (M)

Bit devices used internally on the FC6A Series MicroSmart.

■ Special Internal Relays (M)

Bit devices used internally on the FC6A Series MicroSmart. Special functions are assigned to each bit.

■ Shift Registers (R)

Bit devices that are used with the SFR instruction and the SFRN instruction. The bit sequence of the data is shifted according to

pulse input.

■ Timer (T)

Timers used internally in the FC6A Series MicroSmart. There are three devices: Timer bits (symbol: T, unit: bit), timer preset

values (symbol: TP, unit: word), and timer current values (symbol: TC, unit: word).

These can be used as an on-delay timer or an off-delay timer. For details on timers (T), see "Using Timer or Counter as Source

Device" on page 3-6.

■ Counters (C)

Counters used internally in the FC6A Series MicroSmart. There are three devices: Counter bits (symbol: C, unit: bit), counter

preset values (symbol: CP, unit: word), and counter current values (symbol: CC, unit: word). These can be used as an adding

counter or a reversible counter. For details on counters (C), see "Using Timer or Counter as Source Device" on page 3-6.

■ Data Registers (D)

Word devices that are used for writing numerical data internally in the FC6A Series MicroSmart. These can also be used as bit

devices.

■ Special Data Registers (D)

Word devices that are used for writing numerical data internally in the FC6A Series MicroSmart. Special functions are assigned to

each data register. These can also be used as bit devices.

Notes:

• Although the device symbol for internal relays (M0000 to M7997, M10000 to M17497) and special internal relays (M8000 to M8317) is the

same ("M"), the device characteristics are different. Special functions are assigned to each bit of the special internal relays.

• Although the device symbol for the data registers (D0000 to D7999, D10000 to D55999) and special data registers (D8000 to D8499) is the

same ("D"), the device characteristics are different. Special functions are assigned to each special data register.

2-2 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 29

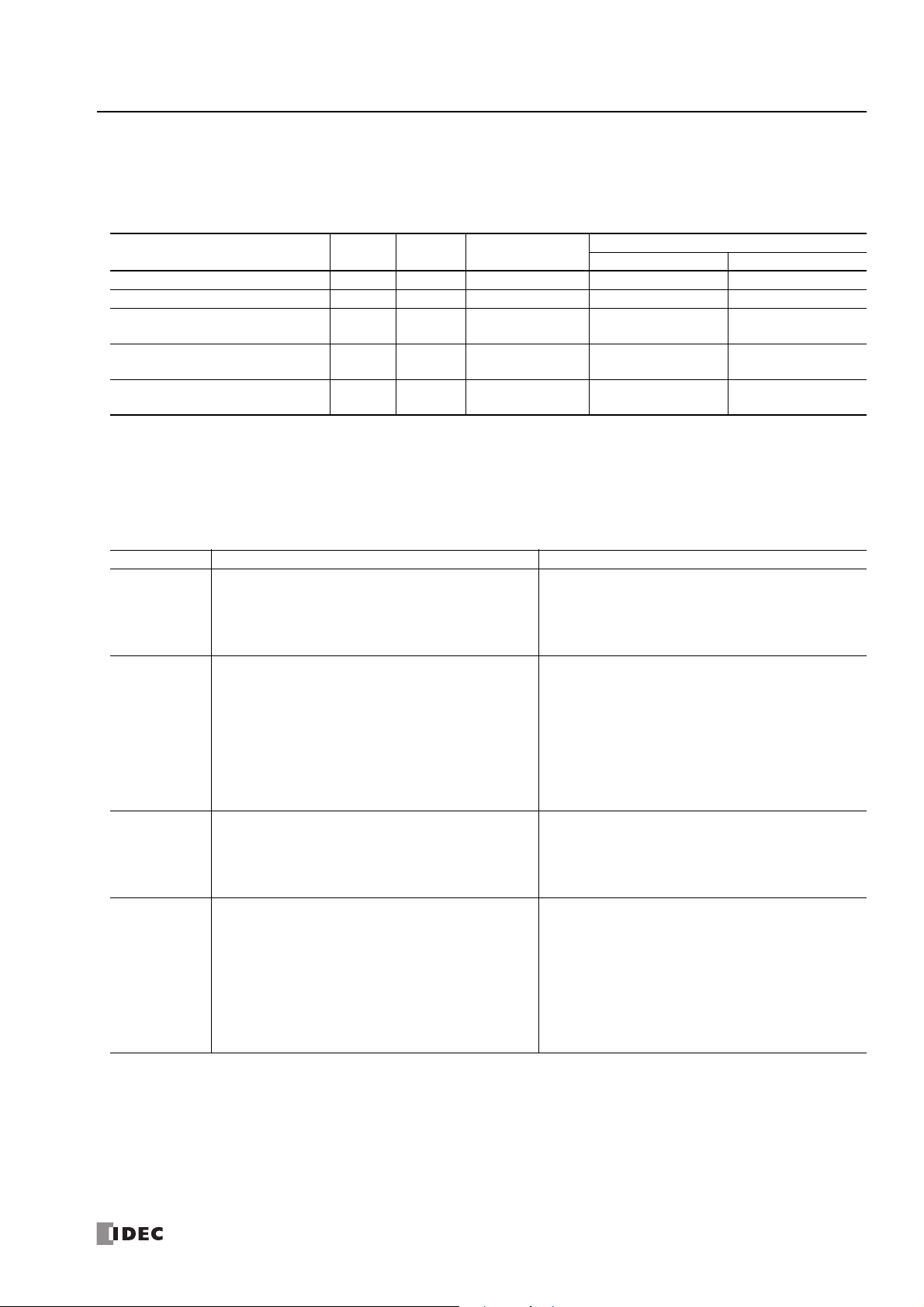

Special Internal Relay

Warning

Special Internal Relay Device Addresses

Do not write to data in the area marked as reserved in the special internal relays list. Otherwise the system may not operate

correctly.

Note: R/W is an abbreviation for read/write.

The notation for the R/W field is as follows.

R/W: The device can be both read from and written to

R: Read-only

W: Write-only

2: D

EVICES

Device

Address

M8000 Start Control Maintained Maintained R/W

M8001 1-s Clock Reset Cleared Cleared R/W

M8002 All Outputs OFF Cleared Cleared R/W

M8003 Carry (Cy) or Borrow (Bw) Cleared Cleared R/W

M8004 User Program Execution Error Cleared Cleared R/W

M8005 Communication Error Maintained Cleared R/W

M8006 Communication Prohibited Flag (When Data Link Master) Maintained Maintained R/W

M8007

M8010 Status LED Operation Operating Cleared R/W

M8011

M8012

M8013 Calendar/Clock Data Write/Adjust Error Flag Operating Cleared R/W

M8014 Calendar/Clock Data Read Error Flag Operating Cleared R/W

M8015 — Reserved — — — —

M8016 Calendar Data Write Flag Operating Cleared R/W

M8017 Clock Data Write Flag Operating Cleared R/W

M8020 Calendar/Clock Data Write Flag Operating Cleared R/W

M8021 Clock Data Adjust Flag Operating Cleared R/W

M8022 User Communication Receive Instruction Cancel Flag (Port 1) Cleared Cleared R/W

M8023 User Communication Receive Instruction Cancel Flag (Port 2) Cleared Cleared R/W

M8024 BMOV/WSFT Executing Flag Maintained Maintained R/W

M8025 Maintain Outputs While Stopped Maintained Cleared R/W

M8026 User Communication Receive Instruction Cancel Flag (Port 3) Cleared Cleared R/W

M8027

M8030 Comparison Output Reset Cleared Cleared R/W

M8031 Gate Input Maintained Cleared R/W

M8032 Reset Input Maintained Cleared R/W

M8033 — Reserved — — — —

M8034

M8035 Gate Input Maintained Cleared R/W

M8036 Reset Input Maintained Cleared R/W

M8037 — Reserved — — — —

M8040

M8041 Gate Input Maintained Cleared R/W

M8042 Reset Input Maintained Cleared R/W

M8043

M8044 Comparison Output Reset Maintained Cleared R/W

M8045 Gate Input Maintained Cleared R/W

M8046 Reset Input Maintained Cleared R/W

M8047

M8050

Initialization Flag (When Data Link Master)/Stop Communication Flag (When

Data Link Slave)

— Reserved — — — —

High-speed Counter (Group 1/I0)

High-speed Counter (Group 3/I3)

High-speed Counter (Group 4/I4)

High-speed Counter (Group 5/I6)

— Reserved — — — —

Description

Count Direction Flag Maintained Cleared R/W

Comparison Output Reset Cleared Cleared R/W

Comparison Output Reset Cleared Cleared R/W

Count Direction Flag Cleared Cleared R/W

When

Stopped

Cleared Cleared R/W

Power

OFF

R/W

FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726 2-3

Page 30

2: D

EVICES

Device

Address

M8051

M8052 Gate Input Maintained Cleared R/W

M8053 Reset Input Maintained Cleared R/W

M8054 Comparison ON Status Maintained Cleared R

M8055 Overflow Maintained Cleared R

M8056 — Reserved — — — —

M8057

M8060 Gate Input Maintained Cleared R/W

M8061 Reset Input Maintained Cleared R/W

M8062 Comparison ON Status Maintained Cleared R

M8063 Overflow Maintained Cleared R

M8064 to

M8067

M8070 SD Memory Card Mount Status Maintained Cleared R

M8071 Accessing SD Memory Card Maintained Cleared R

M8072 Unmount SD Memory Card Operating Cleared R/W

M8073 Function Switch Status Operating Cleared R

M8074 Battery Voltage Measurement Flag Operating Cleared R/W

M8075 to

M8077

M8080 Data Link Slave 1 Communication Completed Relay (When Data Link Master) Operating Cleared R

M8081 Data Link Slave 2 Communication Completed Relay Operating Cleared R

M8082 Data Link Slave 3 Communication Completed Relay Operating Cleared R

M8083 Data Link Slave 4 Communication Completed Relay Operating Cleared R

M8084 Data Link Slave 5 Communication Completed Relay Operating Cleared R

M8085 Data Link Slave 6 Communication Completed Relay Operating Cleared R

M8086 Data Link Slave 7 Communication Completed Relay Operating Cleared R

M8087 Data Link Slave 8 Communication Completed Relay Operating Cleared R

M8090 Data Link Slave 9 Communication Completed Relay Operating Cleared R

M8091 Data Link Slave 10 Communication Completed Relay Operating Cleared R

M8092 Data Link Slave 11 Communication Completed Relay Operating Cleared R

M8093 Data Link Slave 12 Communication Completed Relay Operating Cleared R

M8094 Data Link Slave 13 Communication Completed Relay Operating Cleared R

M8095 Data Link Slave 14 Communication Completed Relay Operating Cleared R

M8096 Data Link Slave 15 Communication Completed Relay Operating Cleared R

M8097 Data Link Slave 16 Communication Completed Relay Operating Cleared R

M8100 Data Link Slave 17 Communication Completed Relay Operating Cleared R

M8101 Data Link Slave 18 Communication Completed Relay Operating Cleared R

M8102 Data Link Slave 19 Communication Completed Relay Operating Cleared R

M8103 Data Link Slave 20 Communication Completed Relay Operating Cleared R

M8104 Data Link Slave 21 Communication Completed Relay Operating Cleared R

M8105 Data Link Slave 22 Communication Completed Relay Operating Cleared R

M8106 Data Link Slave 23 Communication Completed Relay Operating Cleared R

M8107 Data Link Slave 24 Communication Completed Relay Operating Cleared R

M8110 Data Link Slave 25 Communication Completed Relay Operating Cleared R

M8111 Data Link Slave 26 Communication Completed Relay Operating Cleared R

M8112 Data Link Slave 27 Communication Completed Relay Operating Cleared R

M8113 Data Link Slave 28 Communication Completed Relay Operating Cleared R

M8114 Data Link Slave 29 Communication Completed Relay Operating Cleared R

M8115 Data Link Slave 30 Communication Completed Relay Operating Cleared R

M8116 Data Link Slave 31 Communication Completed Relay Operating Cleared R

M8117 Data Link All Slaves Communication Completed Relay Operating Cleared R

M8120 Initialize Pulse Cleared Cleared R

M8121 1-s Clock Operating Cleared R

M8122 100-ms Clock Operating Cleared R

High-speed Counter (Group 2/I1)

High-speed Counter (Group 6/I7)

— Reserved — — — —

— Reserved — — — —

Description

Comparison Output Reset Cleared Cleared R/W

Comparison Output Reset Cleared Cleared R/W

When

Stopped

Power

OFF

R/W

2-4 FC6A S

ERIES MICROSMART

LAD P

ROGRAMMING MANUAL

FC9Y-B1726

Page 31

2: D

EVICES

Device

Address

M8123 10-ms Clock Operating Cleared R

M8124 Timer/Counter Preset Value Changed Maintained Cleared R

M8125 In-operation Output Cleared Cleared R

M8126 1 Scan ON After Run-Time Download Completes Cleared Cleared R

M8127 — Reserved — — — —

M8130

M8131 Comparison ON Status Maintained Cleared R

M8132 — Reserved — — — —

M8133 High-speed Counter (Group 3/I3) Comparison ON Status Maintained Cleared R

M8134 High-speed Counter (Group 4/I4) Comparison ON Status Maintained Cleared R

M8135

M8136 Comparison ON Status Maintained Cleared R

M8137 Interrupt Input I0 Status (Group 1/I0)

M8140 Interrupt Input I1 Status (Group 2/I1) Cleared Cleared R

M8141 Interrupt Input I3 Status (Group 3/I3) Cleared Cleared R