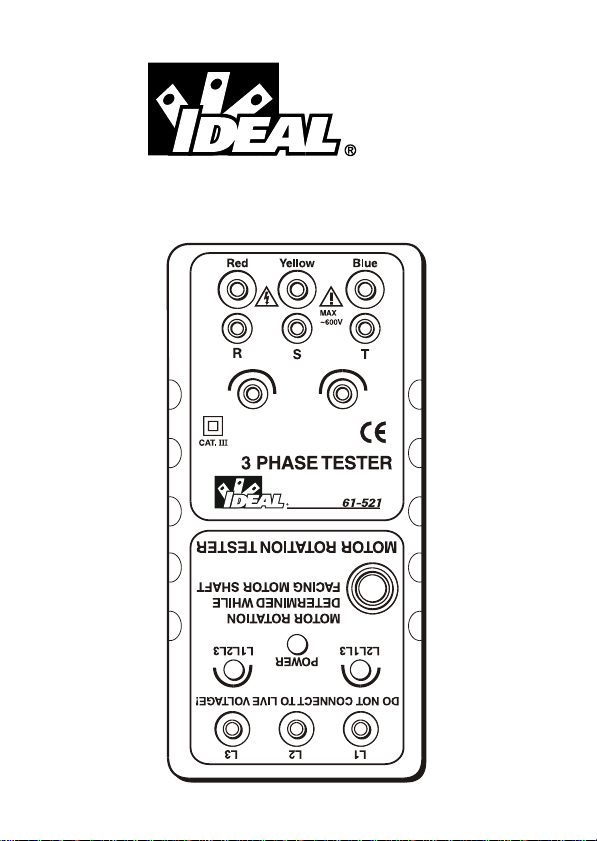

Page 1

#61-521

3-Phase Tester &

Motor Rotation Tester

Page 2

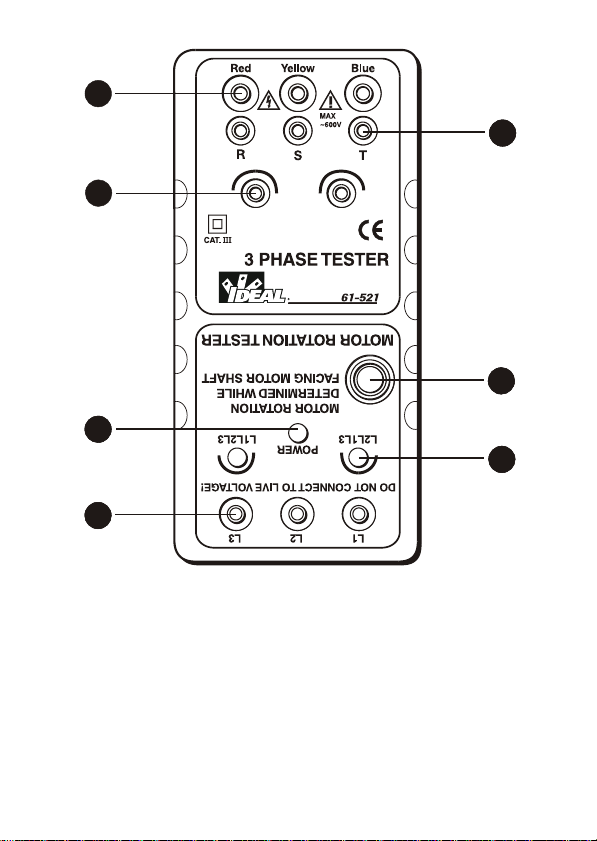

1

3 PHASE TESTER

&

MOTOR ROTATION TESTER

3

2

5

2

7

(1) PHASE ROTATION INPUT TERMINAL

(2) OPEN PHASE INDICATOR

(3) PHASE ROTATION INDICATOR

(4) MOTOR TESTER POWER SWITCH

(5) MOTOR TESTER POWER INDICATOR

(6) MOTOR ROTATION INDICATOR

(7) MOTOR ROTATION INPUT TERMINAL

2

2

2

4

26

Page 3

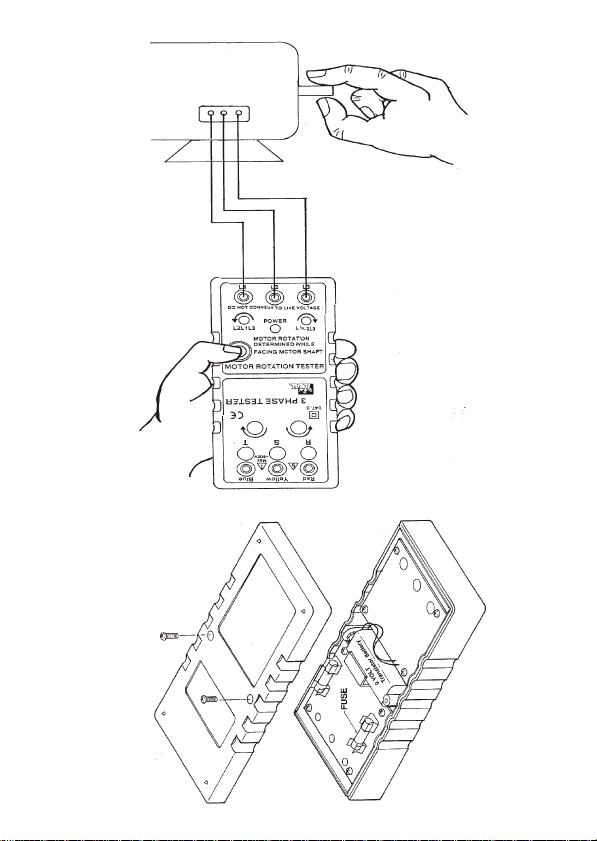

Fig.2

Fig.1

#6

1-

5

2

1

Page 4

1. Introduction

NOTE

This meter has been designed and tested

according to IEC Publication 348, Safety

Requirements for Electronic Measuring

Apparatus, IEC 1010 (En61010) and other

safety standards.

Follow all warnings to ensure safe operation.

CAUTION

READ "SAFETY NOTES" (NEXT PAGE)

BEFORE USING THE METER.

-1-

Page 5

2. Safety Notes

Read the following safety information carefully

before attempting to operate or service the

meter.

Use the meter only as specified in this manual;

otherwise the protection provided by the meter

may be impaired.

Rated environmental conditions :

(1) Indoor use.

(2) Installation Category lll.

(3) Pollution Degree 2.

(4) Altitude up to 2000 Meter.

(5) Relative Humidity 80% Max.

(6) Ambient Temperature 0~40 C.

Observe the International Electrical Symbols

Iisted below.

Meter is protected throughout by double

insulation or reinforced insulation.

o

2

Warning ! Risk of electric shock.

Caution ! Refer to this manual before using

the meter.

Alternating current.

~

-2-

Page 6

3. Features

Three functions in one unit, including open

phase, phase sequence and motor rotation

indication.

This model is ideal for installing conveyor lines,

pump systems and interconnected drivers.

Identifies 3-phase sequence and open phase

check.

Battery operated.

Meets IEC 1010(EN61010) safety requirements.

Complete with three large alligator clips.

-3-

Page 7

4. Measuring Methods

Operation of 3-Phase Rotation Tester :

(1) Connect the test lead to 3-phase input

terminals by R-S-T.

(2) Connect color alligator clips to the terminals

of a 3- phase power source. Connecting

order is optional.

(3) Make sure that all of the three lamps for open

phase check are on. If so, there is no open

phase. When any of the three lamps is not on,

there is open phase.

Open phase

check lamp

"R" is not on

Open phase

check lamp

"S" is not on

Open phase

check lamp

"T" is not on

(4) Check the rotating direction of the rotation

indicator.

Open phase on

terminal where

RED alligator clip

is connected

Open phase on

terminal where

YELLOW alligator

clip is connected

Open phase on

terminal where

BLUE alligator

clip is connected

-4-

Page 8

If the counter clockwise indicator is lit, alternate

the connection two of the three alligator clips.

When the clockwise indicator is lit and the

power source terminals are connected by the

RED, YELLOW and BLUE alligator clips, the

phase sequence indicators (R, S and T) shall

be lit respectively.

2

Operation of Motor Rotation Tester :

(1) Make sure there is no voltage present.

(2) Connect the test leads to motor input

terminals by L1-L2-L3, and press the power

button (Fig1). The power indicator green

lamp is lit. (If the clockwise or counter

clockwise red indicator is lit before rotating

the motor shaft, it means voltage is present.

Stop measuring. Take off the test leads and

turn off the external power). Rotate the

motor shaft clockwise. If the clockwise

indicator is lit, it means there is a 3-phase

motor connection to the power supply by L1L2-L3. The 3-phase motor should be rotated

clockwise.

(3) Connect the leads to 3-phase motor by

L1-L2-L3, and press the power button. The

power indicator green lamp is lit.

2

-5-

Page 9

Rotate the motor shaft counter clockwise.

If counter clockwise indicator is lit, it means

there is a 3-phase motor connection to the

power supply by L1-L2-L3. The 3-phase

motor should be rotated clockwise.

(4) If you require the motor to rotate counter

clockwise, you should change the

connection to L1-L2-L3. The motor should

be rotated counter clockwise.

2

-6-

-6-

Page 10

5. Specifications

Input Voltage : 100V AC up to 600V AC

max.

Frequency : 45 to 70 Hz.

Circuit Structure : All electronic (not

mechanical).

Power Requirement : 006P DC9V battery.

Power Consumption : Consumption current

approx. 14mA of motor

rotation field of tester.

AC power consumption

approx. 7mA per phase

rotation field of indicator.

Installation Category : IEC 1010 600V Cat. III.

Dimension : 153(L)

(6.02

Weight : Approx. 182g

Included battery.

Accessories : Test Leads(red, yellow &

blue), Soft Vinyl Case,

Instruction Manual, Battery.

x72(W)x35(D)mm.

x2.83x1.37 inch).

-7-

Page 11

6. Maintenance

Battery Replacement :

(1) It is necessary to replace battery, when green

lamp is dull lit.

(2) Use a screwdriver to unscrew the screw on

the back then open the case(Fig.2), remove

the battery and replace with new battery (type

006P, DC9V).

(3) Reinstall the case.

Fuse Replacement :

(1) It is necessary to replace fuse, when lamp

indicator R or T show no connection, and

change R-S-T is the same.

(2) Use a screwdriver to unscrew the screws on

the back then open the case(Fig.2), remove

the broken fuse and replace with new fuse

(200mA, 250V).

(3) Reinstall the case.

Cleaning and Storage :

WARNING

To avoid electrical shock or damage to the meter,

do not get water inside the case.

2

Periodically wipe the case with a damp cloth and

detergent. Do not use abrasives or solvents.

-8-

Page 12

If the meter is not in use for periods of longer than

60 days, remove the battery and store them

separately.

7. Warranty

This meter is warranted to the original purchaser

against defects in material or workmanship for one

year following the purchase of the tester. IDEAL

INDUSTRIES, INC. will, at its option, replace or

repair the defective unit, subject to verification of

the defect or malfunction.

Warranty limited solely to repair or replacement; no

warranty of merchantability, fitness for a particular

purpose or consequential damages.

IDEAL INDUSTRIES, INC.

Sycamore, IL 60178, U.S.A.

800-304-3578 Customer Assistance

www.testersandmeters.com

ND 2869-1

Made in Taiwan

Loading...

Loading...