Page 1

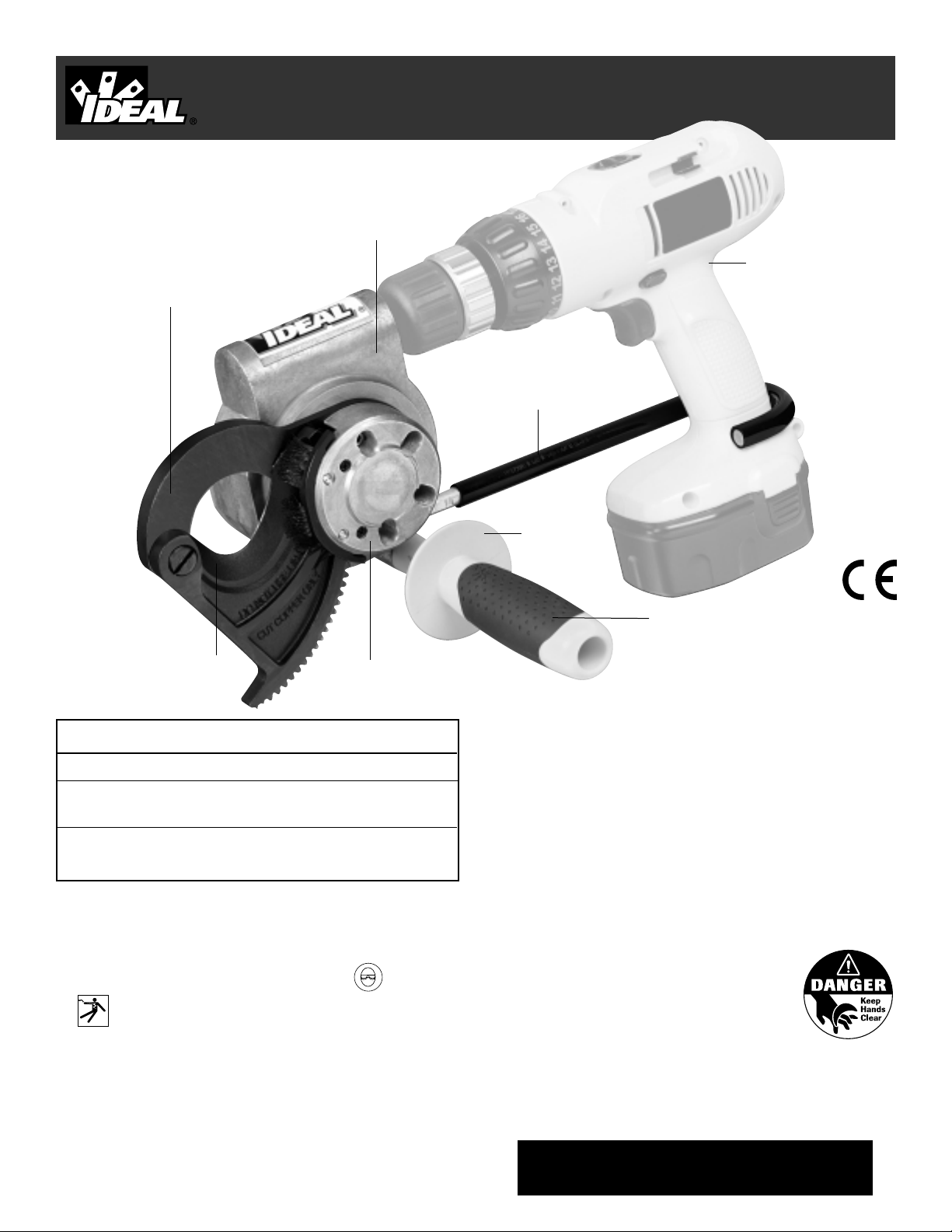

Po werBlade™Cable Cutter

Rugged metal housing

Replaceable hardened

steel blades ensure

consistent cuts and longterm durability

Contour blade design

minimizes cable distortion

Durable gears

Protective

shield

Ergonomically designed, textured

Santoprene

®

non-slip grip

Adjustable torque arm

holds drill in place

Acceptsalmost any

cordless or corded drill

Cable Cutter Assembly: 35-078

Drill Specifications: Any drill 12V or larger that accepts

3

⁄8 drive shaft

Cutting Capacity: 750 MCM Hard Drawn Copper

and up to 2 O.D. Aluminum

Specifications

Operating Precautions

1. Do not drop or abuse the unit.

2. Do not disassemble, repair or modify the assembly, except to

replace parts as shown on page 3.

3. Do not expose the unit to water or solvents.

4. Do not cut cables larger than those listed in the specifications.

5. Do not use tool in the rain to prevent blade wear and malfunction.

6. Store cutter in case provided, in a dry, secure area.

7. We strongly recommend using a reversible drill to enable backing

out of a cut when necessary.

Do not cut steel, ACSR or any other

materials containing steel or damage

to blades will result.

Each unit is tested before shipment.

Copper residue on blades may remain

from the initial quality inspection test cut.

#35-078

Use and Care Manual

WARNINGS

1. Do not overreach. Keep proper footing and balance at all times.

2. Keep out of reach of children.

3. Always wear safety glasses when using this tool.

4. Do not use on live circuits. Always disconnect power before

using this tool.

5. Keep hands away from blades while operating unit.

6. Never operate tool without torque arm installed.

7. Blade is sharp; contact with blade can result in serious personal injury.

8. Disconnect drill from power source before servicing. Always remove drill

from unit before attempting to change blades.

Failure to heed all warnings and precautions outlined

in this manual may lead to serious personal injury.

Global Patents Pending

Page 2

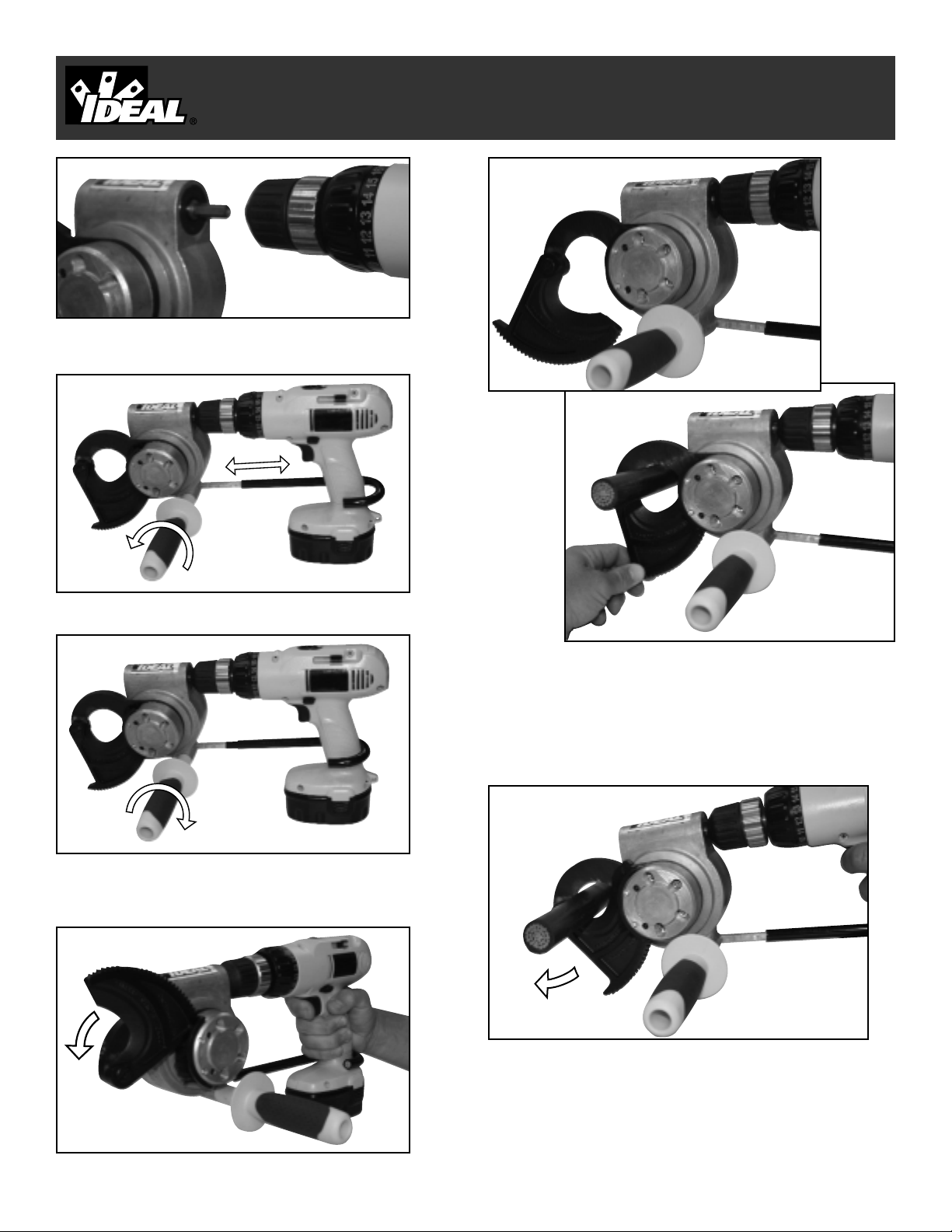

Operating Instructions

STEP 6: Press the drill trigger switch until cable is completely cut.

Reverse mode on drill can be used to back off blade if necessary.

STEP 8: When finished, remove any dust or particles that may

have become attached to the blade.

STEP 1: Attach cable cutter drive shaft to drill as shown

(Figure 1). Tighten drill chuck securely.

STEP 4: Activate the drill trigger switch to open the moving

blade (Figure 4).

Figure 1

Figure 2

Figure 3

Figure 4

Figure 7

Figure 6

Tighten

handle

Loosen

handle

STEP 2: Loosen handle so torque arm extends freely (Figure 2).

STEP 3: Loop torque arm around drill handle and tighten

handle into locking collar to lock torque arm in place (Figure 3).

Do not operate tool without torque arm in place.

Figure 5

STEP 5: Place the cable to be cut onto the stationary blade and

close the moving blade around the cable. Feed the moving blade

by hand until the first gear teeth are engaged (Figure 5 and 6).

STEP 7: To cut several small cables continuously, cut first cable as

described above, then reverse blade until opening is sufficient to

feed the next cable through. Continue to alternate between forward

and reverse modes until all cables are cut (Figure 7).

Page 3

Blade Replacement, Parts and Accessories

Blade Replacement (See exploded view above)

Your Drill-Powered Cable Cutter unit is designed for easy blade

replacement. If blade damage occurs that cannot be filed away, or if

blades are accidentally used on steel or ACSR, replace both blades

as described below:

1. Disconnect drill from power source or battery, then detach unit from

drill. Do not attempt blade replacement with drill attached.

2. Remove four hex screws from end cap that sits on top of the fixed

blade using a 5/32” hex wrench (Figure 8).

3. Remove end cap from unit (Figure 9).

4. Remove 6 hex screws attaching blade to body, using a

1

⁄8 hex

wrench (Figure 10).

5. Remove blade assembly.

6. Replace with a new blade set, IDEAL part #K-8906R.

7. Reinstall using screws removed earlier.

Always replace blades in sets for optimal performance. Replacing only

one side will increase wear and shorten overall blade life.

Handle Replacement

The comfort handle can be unscrewed and replaced if necessary.

Order IDEAL replacement handle part #K-8947R. Replacement torque

arm assemblies can also be ordered. IDEAL part #K-8909 includes

torque arm, locking collar and roll pin.

Warranty

One year limited warranty. Warranty limited solely to repair or replacement;

no warranty of merchantability, fitness for a particular purpose or

consequential damages. 90 day warranty on blades.

ITEM

PART NO. DESCRIPTION

H-3413-User

NO. Guide/QTY.

1 END CAP 1

2 K-8906R BLADE PAIR ASSEMBLY 1

3 K-8933 TORQUE ARM 1

4 LA-4192 LOCKING COLLAR 1

5 K-8947R HANDLE 1

6 K-9076 THRUST PLATE 1

7 113.161 6-32 HSCS X .375 LG. HEX SCREW 2

8 633.041 #6 LOCK WASHER 2

9 281.106 .125 DIA X .625 ROLL PIN 1

10 113.191 10-32X.500 SHCS HEX SCREW 4

11 633.059 #10 SPLIT LOCK WASHER 4

12 113.190 10-32X.375 FHMS HEX SCREW 6

13 GEARBOX ASSEMBLY 1

14 K-8926 CARRYING CASE

SCREWS

TO REMOVE

THRUST PLATE

SCREWS

TO REMOVE

END CAP

THRUST

PLATE

SCREWS

TO REMOVE

FIXED BLADE

87

END CAP

1110

6

2

BLADE

ASSEMBLY

12

13

GEARBOX

ASSEMBLY

4

3

5

1

TORQUE

ARM

LOCKING

COLLAR

HANDLE

FIGURE

8

FIGURE

10

ROLL PIN

9

FIGURE

9

Page 4

Maintenance and Inspection

Form No. ND 5095-3

©2004 IDEAL I NDUSTRIE S, INC.

Printed in U.S.A.

IDEAL INDUSTRIE S, INC.

Becker Place, Sycamore, IL 60178, USA / 815-895-5181 • 800-435-0705 in USA

33 Fuller Road, Ajax, Ontario, L1S 2E1, Canada / 905-683-3400 • 800-527-9105 in Canada

225 Europa Boulevard, Gemini Business Park, Warrington, Cheshire WA5 7TN, UK / +44-(0) 1925 444446

Gutenbergstrasse 10, 85737 Ismaning, Germany / +49-(0) 89 996860

Level 6, 75-85 Elizabeth Street, Sydney NSW 2000 Australia / 61300 765 800

Unit 505, Tower W1, The Towers, Oriental Plaza, No. 1 East Chang An Avenue,

Dong Cheng District, Beijing, 100738, China / 86-10-8518-3141

Condomínio América Business Park, Cj 201 Edifício Quebec,

Av. Marginal do Rio Pinheiros No. 5200,

CEP 05693-000 São Paulo - Brasil / 55-11-3759-8777

Prol. Americas 1600 4to. Piso, Col. Country Club / Guadalajara, Jal. 44610, Mexico

ph: 52-33-36789176 • 52-33-10688902 (mobile) • fax: 52-33-36789290

www.idealindustries.com

Innovation by I DEAL,

the Brand Electricians Trust

1. Frequent maintenance is important to keep the tool in good

working condition.

2. To ensure smooth operation and prevent rust, store the tool in

a cool, dry area.

3. Ensure that blades are clean and sharp for optimal performance.

4. Inspect blades for damage or burrs. If burrs exist, they can be

removed with a flat grinding stone or file on the back sides of

the blades.

5. Keep handle and torque arm dry, clean and free from oil or grease.

These can be cleaned with a soft cloth using mild soap and water.

Do not submerge gear box in water. Wipe unit completely dry

after cleaning.

6. Occasionally oil blades with a light cutting oil.

7. If the tool is maintained regularly, it should provide you with

trouble-free service.

8. The large shoulder screw used to attach the blades together may

loosen during use, especially when making many cuts on larger cable

sizes (750 MCM), or when blades become dull. Tighten shoulder

screw, then loosen 1/4 turn to adjust. If this screw loosens too

frequently, or if blades smash cable instead of cutting, replace blade

assembly as shown on page 3.

9. For best cutting results, we recommend replacing blades after

400-600 cuts on 750 MCM cable.

10. A generic shear pin locks the output gear to the output shaft. If too

much torque is placed on the pin and it is damaged, it can be

replaced with a standard 1/8 square key, available at your local

hardware store.

Gearbox is lubricated and sealed for the life of the tool. Do not open

the gearbox for any reason; opening will void all warranties.

Loading...

Loading...