Page 1

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

2

#61-492

490 Series

Industrial Grade Multimeter

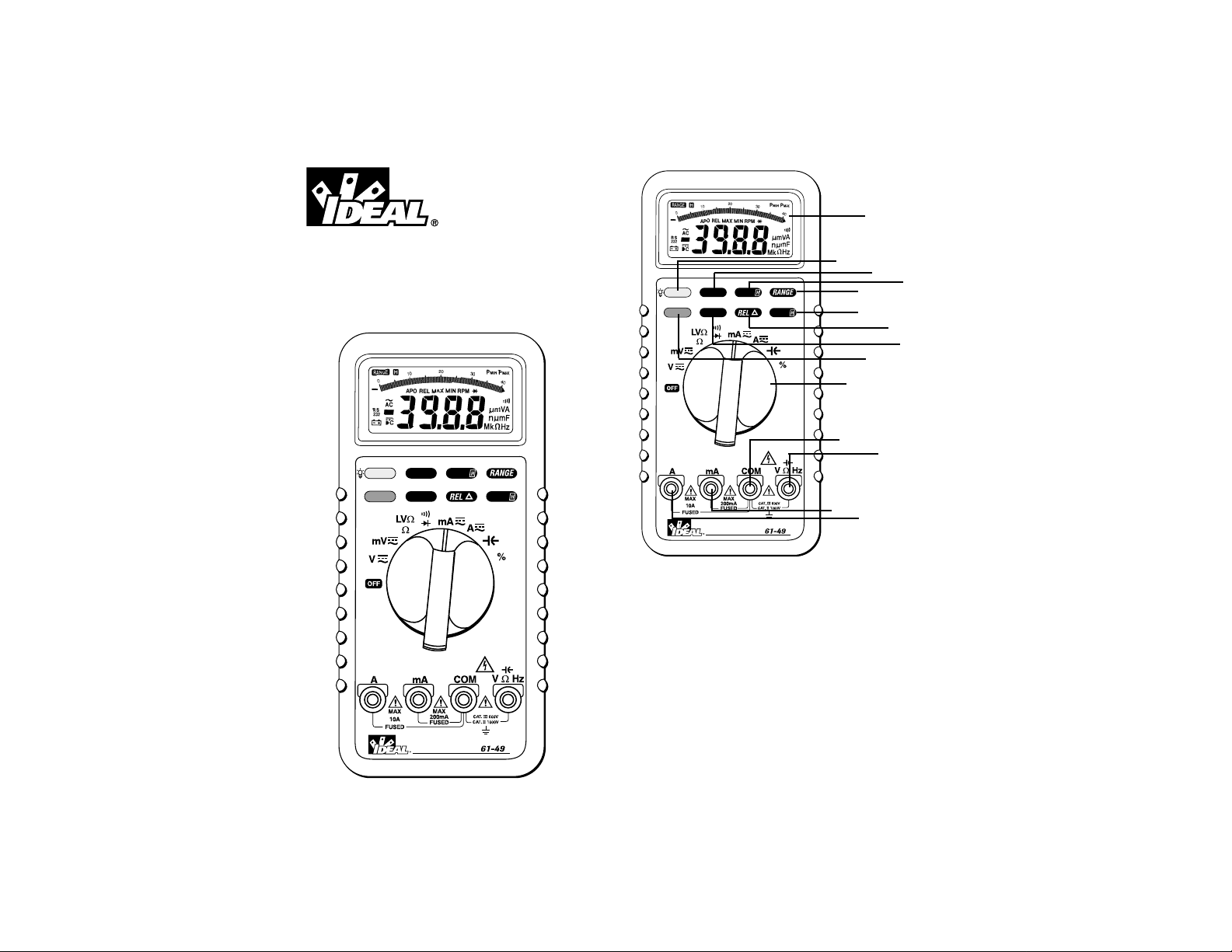

1. LCD Display

2. Rotary Function Switch

3. COM Input Terminal

4. VΩHz Input Terminal

5. mA Input Terminal

6. A Input Terminal

7. Backlight Button

8. ~Hz Button

9. Peak H Button

10.Range Button

11.Blue Switch Button

12.Min/Max Button

13.REL∆ Button

14.Hold Button

1

10

14

7

2

3

4

5

6

11

12

13

8

9

~Hz PEAK

MIN/MAX

Data Acquisition

HOLD

2

Page 2

4

Function Buttons

The meter beeps once for every valid key-press, and beeps

twice for every invalid key-press.

Backlight Button

• The light button is used to turn the backlight on or off.

~ Hz Button

• Pressing the ~Hz button in AC voltage or current mode

enters frequency counter mode with automatic range

selection.

• Pressing range switch in VAHz mode also changes the full

scale range of the original voltage or current mode after

VAHz mode is cancelled.

Peak Hold Button

• The peak hold button toggles the peak hold function on or

off.

• The precision of peak hold measurement can be enhanced

by calibration.

• Peak hold can be calibrated by pressing the peak hold button for > 2 seconds. “caL will be shown on the main display.

• Press the peak hold button to toggle between PMAX and

PMIN.

• Press peak hold for > 2 seconds to escape the peak hold

measurement.

Range Button

• Pressing the range button changes the unit to manual

ranging and toggles between the ranges of the measurement function.

• Pressing the range button for > 2 seconds returns the unit

to auto ranging.

Blue Button

• The blue button toggles between the black and blue functions on the dial.

3

WARNING!

1. DO NOT UNDER ANY CIRCUMSTANCES EXCEED THESE

RATINGS:

- Voltage is not to exceed 1000 Volts.

- Resistance, Capacitance, Logic and Continuity functions are not to be performed on circuits capable of delivering greater than 600 Volts.

- Current measurements are not to be performed on circuits capable of delivering greater than 500 Volts

2. To avoid electrical shock hazards and/or damage to the

meter:

- Do not exceed the voltage ratings for the meter. Use

caution when measuring voltage.

- Do not use during electrical storms. AC power sources

with inductive loads or electrical storms may result in high

voltage. High energy transients can damage meter and

present a dangerous shock hazard.

- Turn off power to the circuit or device being measured

before taking resistance and capacitance measurements.

Fully discharge all capacitors before measuring.

3. Ensure meter is in proper working order before using.

Visually inspect meter for damage. Performing a continuity check can verify proper operation. If the meter reading

goes from overload to zero, this typically means the meter

is in proper working order.

4. Visually inspect leads for damage before using. Replace if

insulation is damaged or leads appear suspect.

5. Never ground yourself when taking electrical measurements. Do not touch exposed metal pipes, outlets, fixtures

etc. Keep your body isolated from ground by using dry

clothing, rubber shoes, mats, or any other approved insulating material. Keep your fingers behind the finger

guards on the probes. Work with others.

6. Before beginning all unknown measurements, set meter to

highest possible range.

7. Before breaking a circuit for testing, turn off the power to

the circuit. When disconnecting from a circuit, disconnect

the hot lead first, then the common lead.

8. Disconnect the meter from the circuit before turning off

any indicator, including motors, transformers, and solenoids.

Page 3

6

Auto Power Off Feature

• If the meter is idle for more than 30 minutes, power is

automatically turned off.

• The APO annunciator on the display indicates that this feature is enabled.

• To disable this feature, power up the meter while pressing

the MIN/MAX, REL , or Hold button.

• The meter will give an audible indication 15 seconds prior

to powering down the meter.

• Power can be restored, with the display in the saved state

by pressing any of the buttons.

• Power can also be restored by changing the rotary switch.

5

MIN MAX Button

• The MIN/MAX button toggles between the stored minimum, and maximum values.

• Pressing the button the first time displays the minimum

value, the second time displays the maximum value, and

pressing the third time displays the actual measurement

with the MIN and MAX annunciators blinking.

• Pressing hold while in this function stops the meter from

updating the minimum and maximum values.

• To escape this function, press the MIN/MAX button for 2

seconds.

REL Button

• This function displays the differential between the actual

measurement and the last value displayed before pressing

the REL button.

• Pressing the hold button while in this function stops the

display from updating the new differential value.

• Pressing the REL button for >2 seconds enables the

recall function.

Hold Button

• Pressing the hold button stops the meter from updating

the LCD display.

• Enabling the hold function in normal measurement will

switch the meter from auto-ranging to manual ranging, but

will not change the full scale range. The meter can be

returned to auto-ranging by pressing the range, blue or

hold button.

• When the hold button is used in conjunction with the peak

hold, MIN/MAX, or RELr functions, the hold function must

be released by pressing the button prior to returning to

exiting the function.

Overload Protection

Function Overload Protection

VAC & VDC 1000V

AAC & ADC 1A/500V

10A/500V

Ohms (Ω) 600VAC/600VDC

Diode 600VAC/600VDC

Continuity 600VAC/600VDC

Unit of Measure Multipliers

For your reference, the following symbols are often used to

make measurement easier:

Symbol

Verbal Multiplier

M mega x 1,000,000

K kilo x 1,000

m milli ÷ 1,000

µ micro ÷1,000,000

Page 4

8

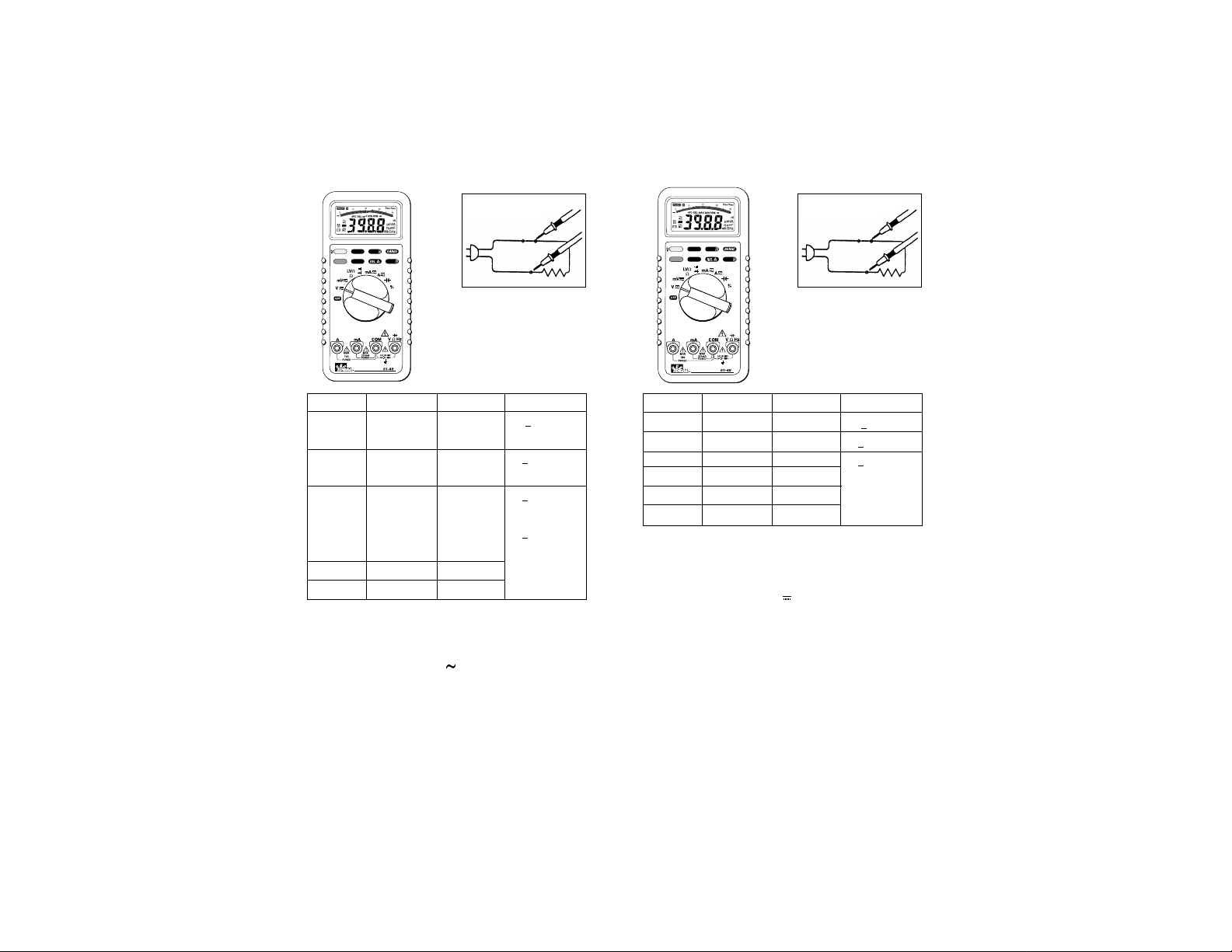

DC Volts

Range Resolution Max Display Accuracy

400mV 0.1mV 400.0 +

(1.5% +8)

400mV 100µV 400.0 +(0.3% +2)

4V 1mV 4.000 +

(0.1% +2)

40V 10mV 40.00

400V 100mV 400.0

1000V 1V 1000

To Measure DC Voltage:

1. Plug the Black test lead into the COM port and the Red

test lead into the Ω port.

2. Set the rotary switch to the V position.

3. Push the blue button until DC is shown on the display.

4. Connect the meter in parallel with the load or circuit.

5. Measure DC Voltage

Input Impedance: 10MΩ (over 1000MΩ in 400mV range)

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

7

AC Volts

Range Resolution Max Display Accuracy

400mV 0.1mV 400.0 +

(1.5% +8)

40Hz ~ 60Hz

4V 1mV 4.000 +(1.0% +5)

40Hz ~ 500Hz

40V 10mV 40.00 +(0.5% +5)

50Hz ~ 60Hz

+(1.0% +5)

40Hz ~ 1kHz

400V 100mV 400.0

750V 1V 750

To Measure AC Voltage:

1. The Plug the Black test lead into the COM port and the

Red test lead into the VΩHz port.

2. Set the rotary switch to the V position.

3. Push the blue button until AC is shown on the display.

4. Connect the meter in parallel with the load or circuit.

5. Measure AC Voltage

Input Impedance: 10MΩ less than 100PF

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

Page 5

DC Current

Range Resolution Max Display Accuracy Voltage

Burden

40mA 10µA 40.00 +

(0.4% +2) 300mV max

400mA 0.1mA 400.0 +

(0.5% +2)

3V max

10A 10mA 10.00 +

(1.0% +3) 3V max

To Measure DC Current:

1. Plug the Black test lead into the COM port and the Red

test lead into the mA or A port.

2. Set the rotary switch to the mA or A position.

3. Push the blue button until DC is shown on the display.

4. Connect the meter in series with the load or circuit.

5. Measure DC Voltage.

Overload Protection: 1A, 600V IR 10kA fuse for mA input

15A, 600V IR 100kA fuse for A input

10

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

AC Current

Range Resolution Max Display Accuracy Voltage

Burden

40mA 1µA 40.00 +

(1.0% +5) 300mV max

400mA 0.1mA 400.0 3V max

10A 10mA 10.00 +(2.0% +5) 3V max

To Measure AC Current:

1. Plug the Black test lead into the COM port and the Red

test lead into the mA or A port.

2. Set the rotary switch to the mA or A position.

3. Push the blue button until AC is shown on the display.

4. Connect the meter in series with the load or circuit.

5. Measure AC Voltage.

Frequency Response: 40Hz ~ 1kHz

Overload Protection: 1A, 600V IR 10kA fuse for mA input

15A, 600V IR 100kA fuse for A input

9

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

Page 6

12

Resistance (Ohms)

Range Resolution Max Display Accuracy

400Ω 0.1Ω 400.0 ±(0.7% +3)

4kΩ 1Ω 4.000 ±(0.4% +2)

40kΩ 10Ω 40.00

400kΩ 100Ω 400.0

4MΩ 1KΩ 4.000 ±(0.6% +3)

40MΩ 10KΩ 40.00 ±(1.5% +5)

To Measure Resistance:

1. Turn the power off to the circuit or device that is to be

measured and discharge all capacitors before attempting a

measurement.

2. Plug the Black test lead into the COM port and the Red test

lead into the VΩHz port.

3. Set the rotary switch to the Ω position.

4. For correct reading, ensure that the device being tested

contains no voltage.

5. Press the range button to select the proper range of the

meter.

Overload Protection: 600V

Open Circuit Voltage: -1.3V (approx.)

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

11

Frequency/RPM

Range Resolution Max Display Sensitivity Accuracy

4kHz/40kRPM 1Hz/30RPM 4.000/40.00 150mV Frequency:

≥2.0 Hz 0.01% +1

1.5V < 20 Hz RPM:

0.01% + 10

40kHz/400kRPM 10Hz/300RPM 40.00/400.0

400kHz/4MRPM 100Hz/3KRPM 400.0/4.000

4MHz/40MRPM 1kHz/30KRPM 4.000/40.00 300mV

40MHz/400MRPM 10kHz/300KRPM 40.00/400.0 1V

400MHz/4000MRPM 100kHz/3MRPM 400.0/4000 ***

*This spec is not guaranteed.

To Measure Frequency:

1. Plug the Black test lead into the COM port and the Red

test lead into the VΩHz port.

2. Set the rotary switch to the HZ RPM position.

3. For RPM, Push the blue button until RPM is shown on the

display.

4. Connect the meter in parallel with the load or circuit.

5. Measure Frequency or RPM.

Overload Protection: 600V

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

Page 7

14

Diode Testing

Function Resolution Accuracy Max. Test Max. Open

Current Circuit

Voltage

1mV +

(1.5% +5) 1.5mA 3V

* For 0.4V to 0.8V.

Diode Check:

1. Turn off power to the device or circuit that is being tested

and discharge all capacitors.

2. Plug the Black test lead into the COM port and the Red

test lead into the VΩHz port.

3. Set the rotary switch to the Ω position.

4. Press the blue button until is shown on the display

5. Connect the test leads to the diode. Normally the forward

voltage drop of a good silicone diode is shown between

400V and 0.9V. If the diode under test is defective, “000”

(short circuit) or “OL” (non-conductive) is displayed.

Overload Protection: 600V max

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

Capacitance

Range Resolution Max Display Accuracy

4nF 1pF 4.000 +

(3.0% +10)

40nF 10pF 40.00 +(3.0% +5)

400nF 100pF 400.0

4µF 1nF 4.000

40µF 10nF 40.00

400µF 100nF 400.0

4mF 1µF 4.000 +

(5.0% +20)*

40mF 10µF 40.00

* In these two ranges the reading may be rolling within specification

To Measure Capacitance:

1. Turn the power off to the circuit or device that is to be measured

and discharge all capacitors before attempting a measurement.

2. Plug the Black test lead into the COM port and the Red test lead

into the VΩHz port.

3. Set the rotary switch to the position.

4. Connect the leads to the circuit to be measured.

5. Measure Capacitance

In order to ensure the best accuracy in measurement of low capacitance,

open the test leads before measurement and

memorize the test probe capacitance. It is necessary to

subtract the capacitance of the test probes themselves, or use the relative mode to compensate for the test leads.

Overload Protection: 600V

13

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

Page 8

16

PEAK Hold Measurements

Function Range Accuracy Function Range Accuracy

DC 400mV unspecified AC 400mV unspecified

Voltage Voltage

4V +

(1.5% +300) 4V +(1.5% +300)

40V +

(1.5% +60) 40V +(1.5% +60)

400V 400V

1000V 750V

DC 40mA +

(3% +60) AC 40mA +(3% +60)

Current Current

400mA 400mA

10A +

(1.5% +60) 10A +(1.5% +60)

Note: With zero calibrated before measurement

4V ranges specify readings above 10% of full scale

Current ranges specify reading <90% of full scale

Noise generating fields may affect intervals

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Continuity Check

To Verify Continuity:

1. A continuity test ensures that all circuit connections are

intact.

2. Plug the Black test lead into the COM port and the Red

test lead into the Ω port.

3. Set the rotary switch to the Ω position.

4. Press the blue button until is shown in the display.

5. Connect the test leads to the circuit to be measured. The

buzzer will sound if the resistance of the circuit measured

is lower than 30Ω.

15

MIN/MAX

~Hz PEAK

HOLD

Data Acquisition

2

Circuit Connection:

Page 9

18

The function packet indicates the measurement mode of

the meter. Status, option 1 and option 2 gives the status of

the meter. CR and LF are delimiters used to separate the

blocks.

The meter always outputs the current input value to the

serial port. Each block is repeated twice in one conversion

cycle. The detailed data format of each packet is listed

below.

- Function

This packet indicates the measurement mode of the meter.

The following table summarizes the transmitted code for

each mode.

Code Measurement Mode

0111011 Voltage

0111101 µA Current

0111001 mA Current

0111111 A Current

0110011 Ω

0110101 Continuity

0110001 Diode

0110010 Frequency / RPM

1

0110110 Capacitance

Note 1: The judge bit in the Status packet determines whether it is frequency

mode or RPM mode.

17

Data Acquisition Function

1. Auto Power Off (APO)

The APO sign on the LCD panel indicates the meter is

working in the Auto Power Off mode. If the meter idles for

more than 30 minutes, the meter automatically turns the

power off. When this happens, the state (non-logic

measurement) of the meter is saved, the meter can be

turned back on by pushing any key switch, except back

light switch, or changing the rotary switch. If the meter is

Re-Powered on by pushing key switch, the LCD displays

the saved state when meter auto power off itself, pushing

Hold key switch to disable the hold state. The meter will

give periodic alarm in 15 seconds before automatically

turns power off by itself, any key press or rotary change

reset Auto Power Off.

2. Disable Auto Power Off

In order to disable auto power off function, power on the

meter with pressing anyone of the switches, except the

HOLD switch, back light switch or BLUE switch (for

function change) is pressed down.

3. RS232

Sent a single pulse to the multimeter to enable or disable

the RS232 when enable the RS232 the LCD display shows

the RS232 annunciator

The serial data is sent from RS232 cable twice every A/D

conversion cycle. The data format complies with JIS 7BIT

transmission code with a baud rate of 2400. The user can

use RS232 interface to read the data. A single dada packet

includes a start bit (always 0), 7 data bits, an odd parity

check bit, and a stop bit (always 1). The following figure

shows the data format of a single packet. The LSB is sent

first and the MSB is sent last.

One data block consists of 11 packets, or 110 bits. The

following figure shows the format of a data block. The

range packet indicates the full scale range of the meter.

Digit 3 through digit 0 is just the digits on the LCD panel.

Page 10

20

- Digit 3 - Digit 0

Digit 3 i the most significant digit on the LCD panel, and

digit 0 is the least significant digit. When the LCD panel

shows OL, the serial port outputs 4000.

Digit Code

0 0110000

1 0110001

2 0110010

3 0110011

4 0110100

5 0110101

6 0110110

7 0110111

8 0111000

9 0111001

- Status

The format of this packet is shown below. The Judge field

is meaningful only when the Function packet indicates

Frequency / RPM mode.

In Frequency / RPM mode, judge is 1 if the meter operates

in Frequency mode; otherwise, it is 0. Sign field indicates

whether the minus sign on the LCD panel is on or off.

BATT field is 1 if battery low condition is true. OL indicates

input overflow.

0 1 1 Judge Sign BATT OL

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

19

- Range

This packet indicates the full scale range of the meter.

When the meter operates in continuity mode, diode mode

or current (A) mode, this packet is always 0110000 since

the full scale range in these modes are fixed. The following

table lists the code for each range in each measurement

mode.

Code V mA Ω Frequency RPM Capacitance

0110000 400.0mV 40.00mA 400.0Ω 4.000KHz 40.00KRPM 4.000nF

0110001 4.000V 400.0mA 4.000KΩ 40.00KHz 400.0KRPM 40.00nF

0110010 40.00V 40.00KΩ 400.0KHz 4.000MRPM 400.0nF

0110011 400.0V 400.0KΩ 4.000MHz 40.00MRPM 4.000µF

0110100 4000V 4.000MΩ 40.00MHz 400.0MRPM 40.00µF

0110101 40.00MΩ 400.0MHz 4000MRPM 400.0µF

0110110 4.000mF

0110111 40.00mF

Page 11

22

21

- Option 1

This packet contains information on special measurement

modes. The format of this packet is shown below. The

three non-constant fields is set to one when the meter

operates in the corresponding special modes.

01 1P

MAXPMAX

0 VAHZ

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

- Option 2

This packet contains information on the operations mode

of the meter. The format is shown below. The DC field

indicates that the meter operates in DC measurements

mode, either voltage or current. The AC field indicates that

the meter operates in AC measurement mode. The AUTO

field is set to 1 if the meter operates in automatic mode,

and is set to 0 when the meter operates in manual mode.

The APO field indicates whether Auto Power Off function is

enabled or not.

0 1 1 DC AC AUTO APO

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

-CR

Carriage return. The transmitted code is 0001101.

-LF

Line Feed. The transmitted code is 0001010.

CUS

General Specifications

Display: The Liquid Crystal Display (LCD)

with a maximum reading of 4000 and

82 segments bar graph.

Polarity Indication: Automatic, positive implied, negative

indicated.

Over range indication: (OL) or (-OL)

Low Battery Indication: is displayed when the battery

voltage drops below operating

voltage.

Sampling: 2 times/sec for digit.

12 times/sec for analog bargraph.

Auto Power Off: Approx 30 Minutes

Operating Ambient: 0°C - 30°C (≤80%R.H.),

30°C - 40°C (≤75%R.H.),

40°C - 50°C (≤45%R.H.)

Temperature Coefficient: 0.15 x (Spec Acc’y) / °C,

<18°C or >28°C.

Power Requirements: IEC LR03, AM4 or AAA size 1.5V x 2.

Battery Life: Alkaline 500 hours.

Dimensions (WxHxD):

90mmx200mmx42mm,

with out holster

100mmx212mmx55mm, with holster

Accessories: Protective Holster, battery (installed)

instruction manual, test leads.

Environmental Conditions

Indoor use.

Maximum Altitude: 2000 Meter.

Installation Category: IEC 1010, 1000V Cat. II, 600V Cat. III

Pollution Degree: 2

Page 12

23

Lifetime Limited Warranty

This meter is warranted to the original purchaser against defects in

material or workmanship for the lifetime of the meter. During this

warranty period, IDEAL INDUSTRIES, INC. will, at its option,

replace or repair the defective unit, subject to verification of the

defect or malfunction.

This warranty does not apply to defects resulting from abuse,

neglect, accident, unauthorized repair, alteration, or unreasonable

use of the instrument.

Any implied warranties arising out of the sale of an IDEAL product,

including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the above. The

manufacturer shall not be liable for loss of use of the instrument or

other incidental or consequential damages, expenses, or economic

loss, or for any claim or claims for such damage, expenses or economic loss.

State laws vary, so the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

IDEAL INDUSTRIES, INC.

Sycamore, IL 60178, U.S.A.

800-304-3578 Customer Assistance

www.testersandmeters.com

ND 2385-1 Made in Taiwan

Maintenance

Battery Installation or Replacement:

The #61-492 is powered by 2 1.5 volt batteries.

1. Remove the test leads from the front terminals and turn the

meter off.

2. Remove the screw from the battery cover and lift to

remove.

3. Replace batteries.

4. Make sure the battery box leads do not become pinched

between the case and battery cover before replacing the

battery cover and screw.

Fuse Replacement

1. Remove the test leads from the front terminals and turn the

meter off.

2. Remove the screw from the battery cover and lift to

remove.

3. Remove the battery.

4. Remove the two screws connecting the top and bottom

cases of the meter.

5. Remove the defective fuse by gently prying one end of the

fuse loose and sliding the fuse out of the fuse holder.

6. Install a new fuse of the same size and rating.

7. Make sure the fuse is centered in the fuse holder

8. Reconnect the top and bottom case.

9. Re-install the battery and batter y cover.

Warning

To avoid electrical shock, remove test lead before opening the

cover. Repairs or servicing not covered in this manual should

only be performed by qualified personnel.

Loading...

Loading...