Page 1

INSTALLATION

AND SERVICING

SOLAR THERMAL

When replacing any part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require.

Do not use reconditioned or copy parts that have not been clearly authorised by Ideal.

For the very latest copy of literature for specification and maintenance practices visit our

website www.idealheating.com where you can download the relevant information in PDF format.

For users guide see reverse of book

February 2012

UIN 207786 A02

Page 2

2

Solar Thermal - Installation and Servicing

GENERAL

Max. working excess pressure 6 bar

Max. working temperature 120

o

C

Safety valve 6 bar

Circulation pump Wilo ST25/7-ECO-3P

Nominal voltage AC 230 V

Power consumption Pump speed 1 39 W

Pump speed 2 47 W

Pump speed 3 53 W

Max. pump head 7 m

Max. pump capacity 4.5 m

3

/hr

Flow measuring device 2 – 12 l/min

TABLE 2 - GENERAL DATA - SOLAR PUMP STATION SPECIFICATION

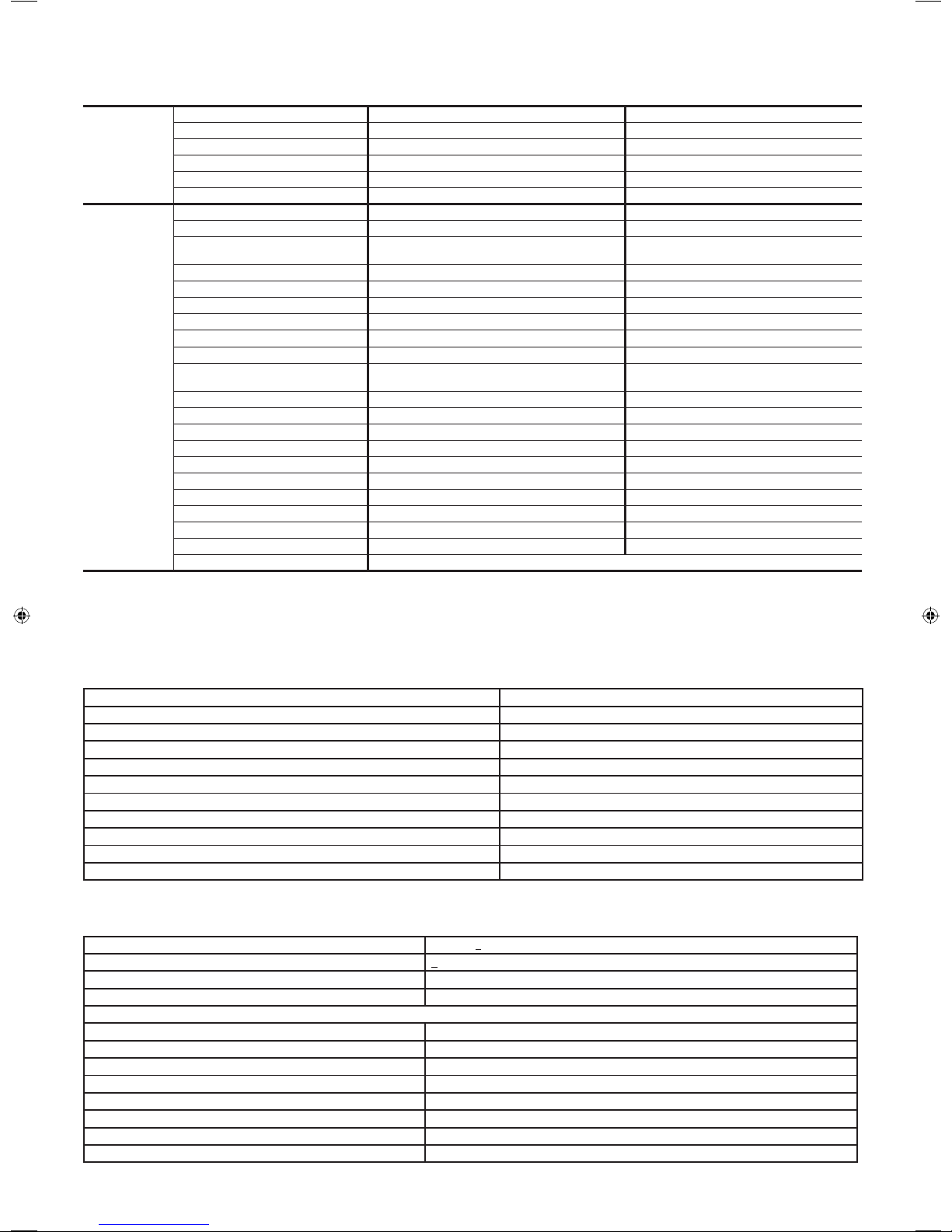

TABLE 1 - GENERAL DATA - SOLAR COLLECTOR SPECIFICATION

Operating voltage 230 Volt ( + 15%) 50Hz

Internal consumption

< 1W

3 inputs for recording temperatures PT1000

1 output Normally open relay, switching power max.800W, fuse:250V 4A MT

Output protected against overload and short circuits

Display Animated LCD display, 2 colour backlight

Appropriate protection IP 20/DIN 40050

Operation temperature range 0 to + 45

o

C

Installation Wall mounting

Weight 250 g

Housing Recyclable, 3 part plastic housing

Dimensions L x B x H (mm) 136 x 133 x 37

2 x PT1000 1.5m silicon cable, measuring range up to+ 180

o

C

TABLE 3 - GENERAL DATA - SOLAR CONTROLLER SPECIFICATION

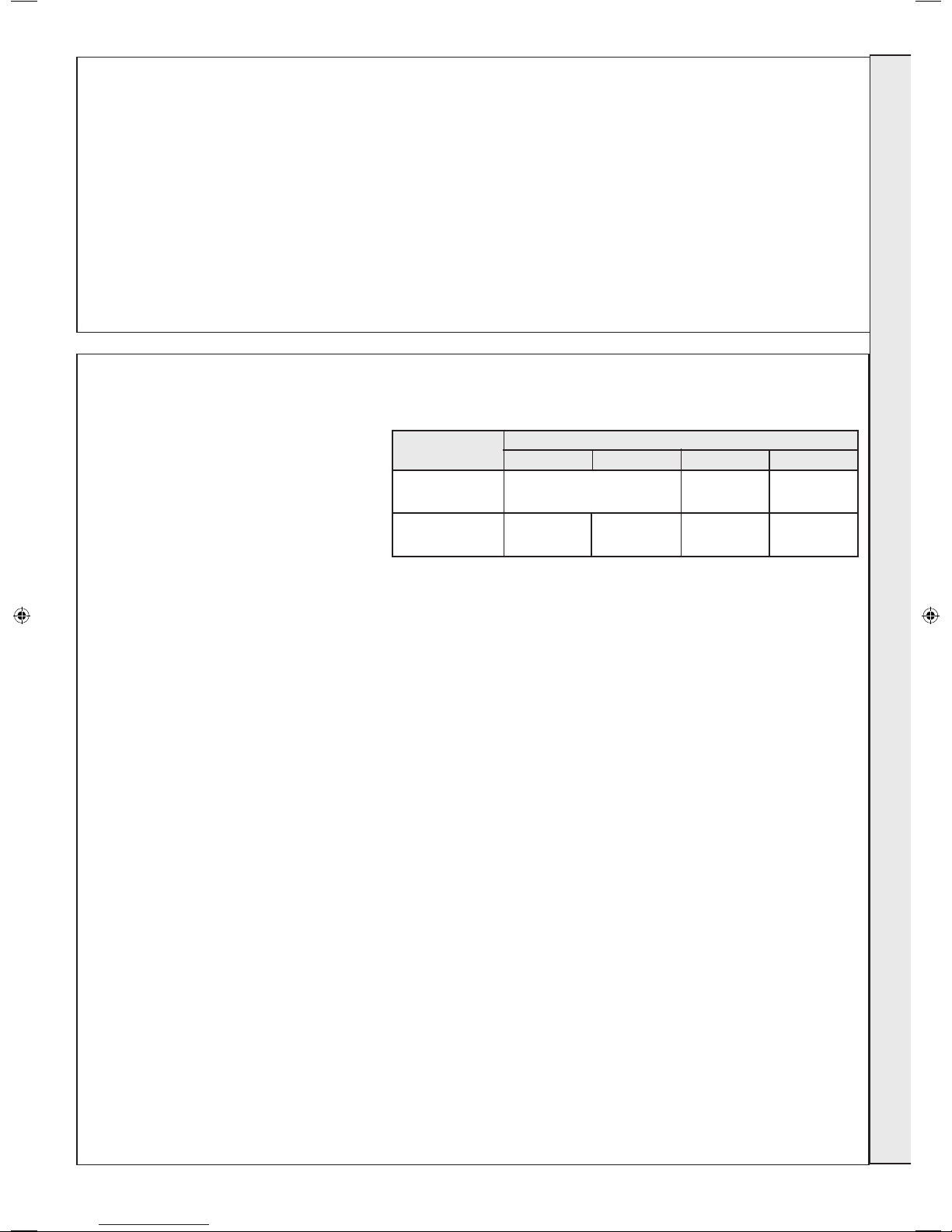

Model

TS 8000 TS 8001

Size

Collector type Roof-mounted collector In Roof-mounted collector

Overall area (m2) 2.02 2.51

Absorber area (m2) 1.84 2.28

Aperture area (m2) 1.91 2.32

L x W x H (mm) 1730 x 1170 x 83 2058 x 1227 x 105

Weight (kg) 35 49

Performance and

Installation

Absorber capacity (l) 1.4 1.7

Housing Al-frame Wooden frame

Surface

Al, natural or anodized

(Improved corrosion resistance)

Back plate Al-sheet

Absorber sheet Al highly selectively coated Al, highly selective vacuum coating

Absorption* (%) 95 95

Emission* (%) 5 5

ø manifold (mm) 18 or 22 (¾ or 1") 22 (1")

ø risers (mm) 8 8

Connections

Blank (compression joint),

coupling nut with at seal

Coupling nut with at seal

Glass 3.2 mm tempered solar safety glass 3.2 mm tempered solar safety glass

Transmittance of glass (%) 95 90.2

Insulation 40 mm mineral wool plate 50 mm mineral wool plate

Max. stagnation temperature 234˚C under test conditions 234˚C under test conditions

Max. operating pressure 10 bar 10 bar

Aperture area 1.922m² 2.33m²

Conversion factor N

0

0.769 0.776

Heat loss coefcient a

1

3.847W/m²K 3.293W/m²K

Proper heat transfer medium Polypropylene glycol/water mixture Polypropylene glycol/water mixture

Approved installation angle min. 15˚, max. 75˚ 15˚, max. 75˚

Certificate EN 1 2975-1.2 SOLAR KEYMARK

Sap Data TS8000 - On Roof TS8001 - In Roof

Aperture area 1.922m

2

Aperture Area 2.33m

2

Conversion Factor No 0.769 Conversion Factor No 0.776

Heat Loss coefcient a1 3.847W/m2K Heat loss Coefcient a1 3.293W/m2K

Heat Loss coefcient a2 0.0103W/m2K Heat loss Coefcient a2 0.011W/m2K

Page 3

3Solar Thermal - Installation and Servicing

GENERAL

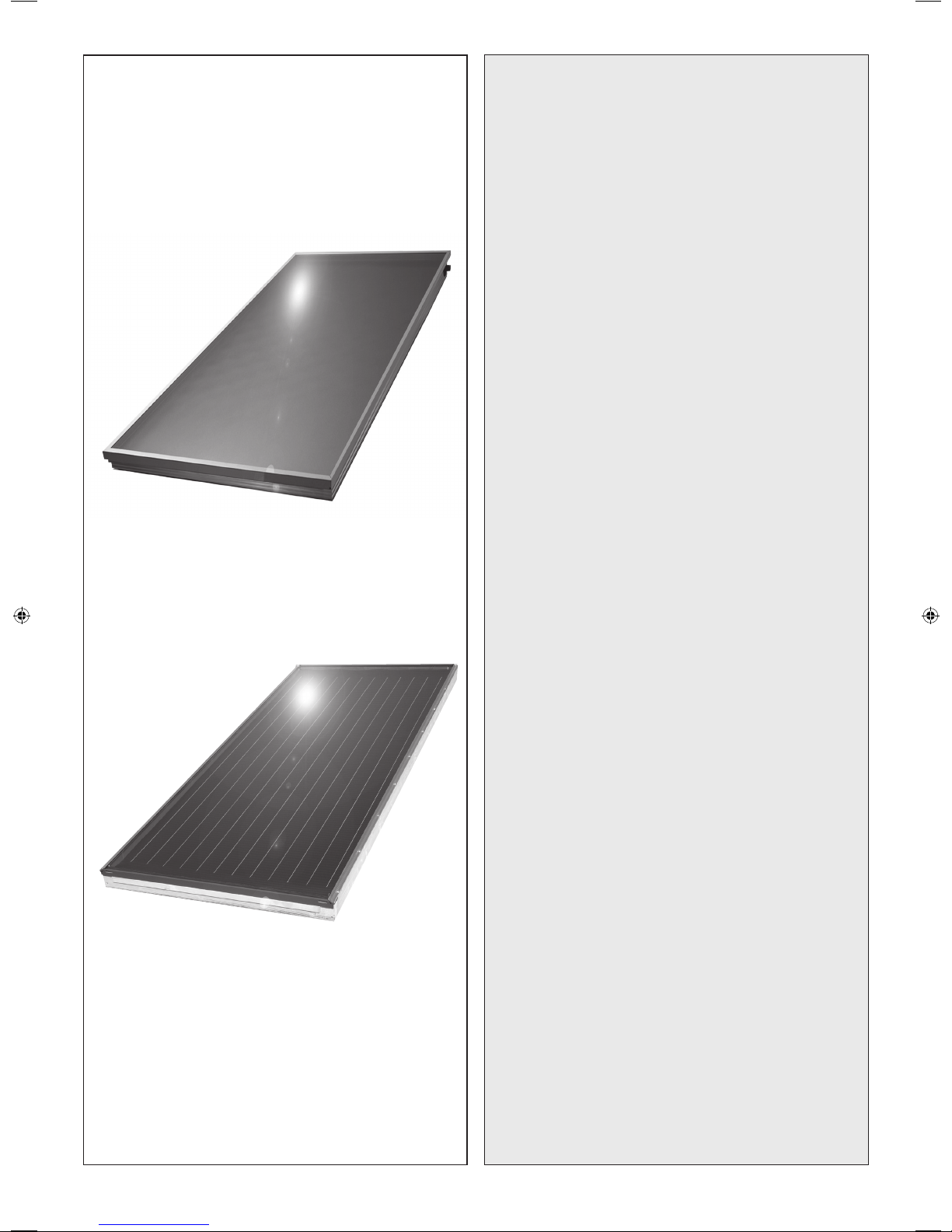

SOLAR THERMAL

Destination Country: GB, IE

TS8000 (on roof)

TS8001 (in roof)

CONTENTS

Commissioning Notes .......................................... 54, 55

Cylinders ....................................................................... 4

Fault Finding ............................................................... 58

Handing Over .............................................................. 56

Installation ................................................................... 12

Installation & Maintenance Checklist ........................ 57

Installation of On Roof Collector .............................. 12

Installation of In Roof Collector ................................. 21

Installation of Flat Roof Kit ......................................... 36

List of Parts ................................................................. 60

Planning Permission .................................................... 5

Pump Station ........................................................ 44, 45

Safe Handling ................................................................. 5

Solar Controller ..................................................... 46-53

Water Circuit Diagrams ............................................. 6, 7

Page 4

4

Solar Thermal - Installation and Servicing

GENERAL

INTRODUCTION

Ideal Solar is a range of solar water heating equipment for use

with twin coil storage cylinders only. The solar collectors come as

at plate type or evacuated tube and are suitable for use in new

and refurbishment installations.

A range of packs are available providing all equipment (except

cylinders, pipework and insulation) for a range of properties. The

pack includes solar collector(s), mounting brackets, controller,

pump station, expansion vessel and system uid.

The solar collector is copper tube ultrasonically welded to

selectively coated absorber plates. This is housed in a sealed

casing with mineral wool insulation to rear and sides. It is sealed

into the casing with EPDM seals and a robust tempered glass

cover. Mounting kits are available to suit tiles, slates both on or

inset to roofs. In addition at roof mounting is provided.

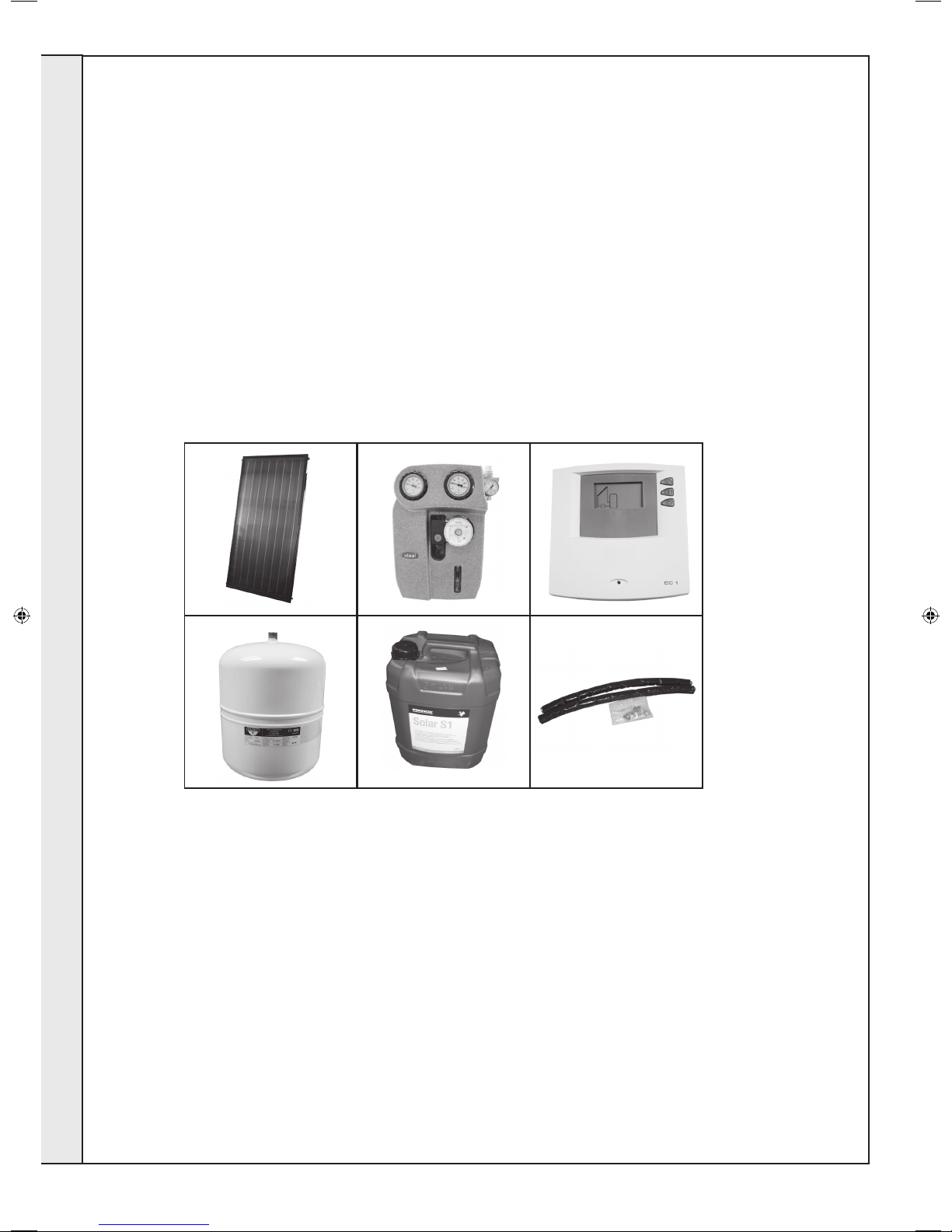

THE IDEAL SOLAR SYSTEM PACKAGE COMPRISES OF:

1. Ideal Solar Collector(s)

The TS800 solar collector panel(s) can be mounted directly

onto sloping roofs with a variety of xings for different roof

coverings or onto a support frame for at roofs.

The TS8001 is for inset applications only.

The Ideal Solar kit comprises of one, two or three high

performance at solar panel collectors.

Pressure loss (bends, valves, etc.)should be recognised when

specifying the pump arrangement.

2. Ideal Solar Twin Line Pump Station

The solar pump station is supplied with integrated pump

to provide circulation of the heat transfer uid, the main

components of the unit are:

A circulation pump.

A ow limiter with ll & drain valve shut-off valve.

Two ball valves with integral display thermometers and check

valves.

Safety relief valve/pressure gauge assembly.

Non-ow valve tted in both the ow and return circuit to

prevent the possibility of gravity circulation in the solar circuit.

3. Ideal Solar Controller EC1

The controller allows quick setting of functions and features

with LCD display to provide graphical information.

The controller allows the user to select the temperature

required at the hot water cylinder. The controller then

automatically determines when to run the pump to bring the

energy from the solar collector panel(s) to the cylinder.

The control uses a simple temperature difference to dene

when the pump runs. This ensures that the pump is running

only when the benet from the solar collectors is available.

OPERATION

The solar collector panel is mounted on a surface which is

selected for its exposure to sunlight and connected via pipe work,

to the lower coil of a twin-coil solar cylinder.

The solar controller monitors the temperature of the solar

collectors and the cylinder via its sensors.

The energy in the sun’s rays is absorbed by the solar collector’s

selective coated plate’s which is then transferred to the heat

transfer uid contained within the collector system pipe work.

When the solar collector sensor temperature is elevated 4

o

C

above the cylinder sensor temperature the controller activates the

circulating pump.

The pipe work is lled with a ready-mixed heat transfer uid

containing glycol and water, which is circulated by a pump to the

solar coil in the hot water cylinder. The heat is deposited in the

storage cylinder and the heat transfer uid returns to the collector

to absorb more free solar energy.

The circulation pump will continue to operate until the

cylinder sensor is satised (factory set 60

°

C) or the differential

temperature between the solar collector sensor and the cylinder

sensor reduces to 2°C.

With current recommendations to store water at 60

o

C it is

becoming more of a consideration to protect persons of reduced

physical, sensory or mental capabilities from scalding. A suitable

method to achieve this would be to t a Thermostatic Mixing

Valve (TMV) to the hot water outlet from the cylinder. If the TMV

is not tted with a line strainer, they must be tted on the hot and

cold supply lines.

IMPORTANT

Plastic Pipework is not suitable for the temperatures

possible in Solar circuits.

All connections and joints must be resistant to glycol and be

resistant to temperatures of up to 200°C.

OPTIONAL EXTRA KITS

• Flat Roof Frame Kit (1 and 2 collectors)

• Roof Fixing Kit (slates)

• Heat Transfer Fluid (10, 25 & 25 lt containers)

• Additional on roof and in roof at panel collectors

• Vacuum tube collectors

• Single line pump station

• First x kit - on roof

• First x kit - in roof

• Solar controller EC2 (controls East/West solar collector

orientation)

• Roof Inset Kit (1, 2, 3 and additional collectors) for tile roofs

• Roof Inset Kit (1, 2, 3 and additional collectors) for slate roofs

UNVENTED DHW CYLINDERS

When connecting the Ideal Solar System to an un-vented hot

water storage cylinder, it is recommended that the electrical

supply to the solar control system is taken via the thermal cut-out

device on the cylinder.

CYLINDERS

For your Ideal Solar System a dual coil hot water storage cylinder

must be used. Installation can be for both open vented and

sealed systems. If a sealed system is used then part G3 of the

Building Regulations must be observed.

When sizing the Dual Coil Hot Water Cylinder a minimum

dedicated solar volume must be either 25 litres per sq metre of

panel or 80% of the daily hot water used.

For reasonable efciency 35 litres per sq metre of panel should

be used.

For best practice a gure of 50 litres per square metre of

panel should be used. (These details are contained within the

Domestic Heating Compliance Guide).

Page 5

5Solar Thermal - Installation and Servicing

GENERAL

STANDARDS AND SAFETY INSTRUCTIONS

OVERVIEW OF EU STANDARDS

Solar Systems in General

EN ISO 9488

Thermal solar systems and components, terminology

(ISO/DIS 9488; 1995)

EN 12975-1

Thermal solar systems and components - Collectors Part 1: General requirements

EN 12975-2

Thermal solar systems and components - Collectors Part 2: Test Methods

ENV 1991-2-3

Eurocode 1 - Basis of design and actions on structures Part 2-3: Actions on structures - Snow Loads

EN 12976-1

Thermal solar systems and components - Factory made systems Part 1: General requirements

EN 12976-2

Thermal solar systems and components - Factory made systems Part 2: Testing Methods

ENV 12977-1

Thermal solar systems and components - Custom built systems

- Part 1: General requirements

ENV 12977-2

Thermal solar systems and components - Factory made systems Part 2: Testing Methods

ISO 9459-1: 1993

Solar heating - Domestic Water heating systems - Part 1:

Performance rating procedure using indoor test methods

ISO/TR 10217

Solar energy - Water heating systems - Guide to material

selection with regard to internal corrosion

Collectors and Collector Assembly

ENV 1991-2-4

Eurocode 1 - Basics of design and actions on structures Part 2-4: Actions on structures - Wind actions

Lightning Protection

ENV 61024-1

Protection of structures against lightning – Part 1: General

principles (IEC 1024-1: 1990; modied)

Building Regulation, dating from 1991 (England and Wales)

Requirement G3, L1 and Regulation 7

BS 7671

Requirements for electrical installations

(IEE Wiring Regulations, 16

th

edition

SAFE HANDLING OF SUBSTANCES

Heat Transfer Fluid

Use undiluted only.

Keep out of reach of children.

Avoid contact with skin and eyes.

If swallowed, seek medical advice immediately and show the label

adhered to the container.

Disposal

Any packaging contaminated or not along with Ideal Solar uid

must be disposed of at an appropriate waste site, whilst observing

local regulations.

PLANNING PERMISSION

Planning permission for the Ideal Solar System is generally only

required if you are in a conservation area or you are installing a

solar system on a listed building.

However it is prudent to seek the opinion of the local authority on

planning matters prior to starting work on the solar installation.

INSTALLATION REQUIREMENTS

The installation of the Ideal solar system must be carried

out in accordance with the relevant requirements for safety,

current Wiring Regulations, local Building Regulations, Building

Standards (Scotland), (Consolidation) Regulations and Bylaws

of the local water company and Health and Safety document No.

63S (Electricity at Work Regulations 1989).

It should be in accordance with the relevant recommendations of

the following British Standards and Regulations:

· BS 5918:1989

· The Health and Safety at Work Act 1974

· The Management of Health and Safety at Work Regulations

1999

· The Construction (Health, Safety and Welfare) Regulations

1996

· The Construction (Design and Management) Regulations

1994

· The Lifting Operations and Lifting Equipment Regulations

1998

The manufacturer’s notes must not be taken in any way as

overriding statutory regulations.

ELECTRICITY SUPPLY

All wiring must be performed in accordance with BS7671:

Requirements for Electrical Installations (IEE Wiring Regulations,

16th Edition).

A 3 amp fused three pin plug and un-switched shuttered socket

outlet (both complying with BS 1363) or preferably a double pole

isolator with a contact separation of 3mm in all poles supplying

the controller should be used. The controller must be earthed.

Earth Bonding

Ensure that the primary ow and return circuit is electrically

cross-bonded in accordance with BS 7676.

WARRANTY

The Ideal Solar system is supplied with a Comprehensive

Warranty cover of 10 years for the solar collector(s) and 2 years

for the pump station and controller.

For one off installers - products are sold with materials only

warranty

For Developers - Materials only warrantly. If labour required, to

be arranged and priced with the installer.

Ideal Solar Technical Support Line: 01482 498307.

HEAT TRANSFER FLUID

Solar panel collectors and system components should be used only

with the recommended heat transfer uid as supplied in the kit.

Recommended uid is supplied as:

10 Lt Container - Part No. UIN 206536

20 Lt Container - Part No. UIN 206537

25 Lt Container - Part No. UIN 206538

The heat transfer uid uses a proven concentration of anti-

freeze and water to give protection against freezing and provide

optimum performance from the solar panel collectors and system

components. Additional uid can be obtained via Ideal Solar

stockists.

The uid is pre-mixed to 60% concentration and is suitable for at

plate and vacuum tube collectors.

Page 6

6

Solar Thermal - Installation and Servicing

GENERAL

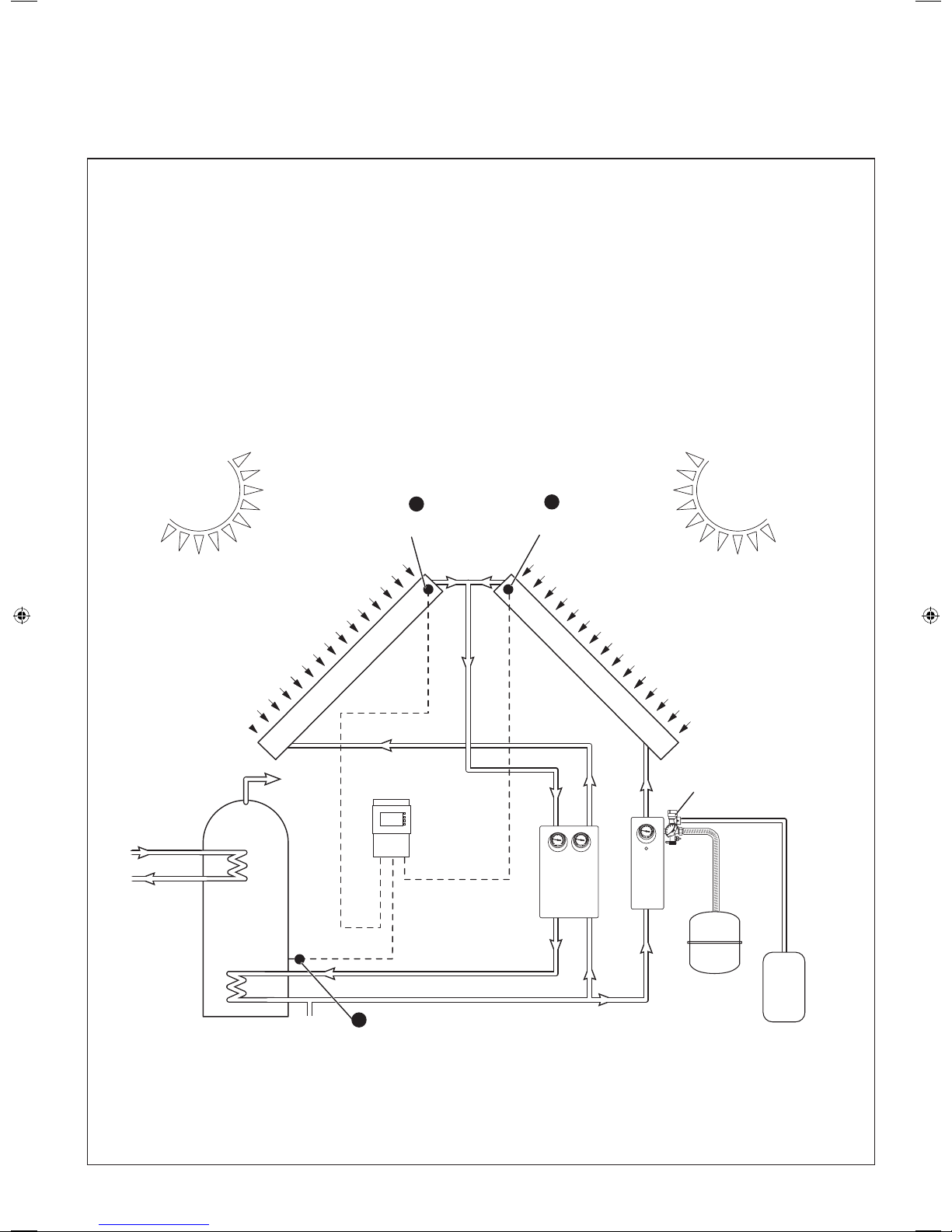

2

5

7

9

12

15

L/MIN

bar

6

0

2

4

?C

0

20

40

60

80

100

120120

100

80

60

40

20

0

?C

Drain

Sun

Solar

Cylinder

Twin Line

Pump

Station

Expansion

Vessel

*Solar

Cont-

ainer

Safety Relief

Valve / Pressure

Gauge Assembly

Solar

Collector

Panel

T1

Solar

Collector Sensor

T2 Solar

Cylinder Sensor

sol8618-1

Hot Water to Supply

Back Up

from Boiler or

Immersion Heater

Solar

Controller EC1

*Important: solar fluid container should be manufactured from a material

capable of withstanding the high temperatures at which solar fluid operates.

1A

INDIRECT PRESSURISED SOLAR CIRCUIT

The Ideal Solar System features high performance solar panel collectors with highly advanced features. The collector has been

awarded the Solar Keymark, the EUs quality mark for solar collectors. The collectors are mounted on a fast-to-t frame and a solar

pump station is also supplied to provide all the safety features required for a pressurised circuit. The Ideal Solar Controller EC1

ensures efcient use of the available solar energy at any given time and features several extra functions.

INSULATION

Exposed pipe work should be insulated according to the high temperatures that the collectors are able to generate. This should be high

temperature Armalfex or similar grade.

Suitable insulation is available from Armacell UK Ltd., Mars Street, Oldham, Lancashire OL9 6LY.

Page 7

7

INSTALLATION

Solar Thermal - Installation and Servicing

2

5

7

9

12

15

L/MIN

bar

6

0

2

4

?C

0

20

40

60

80

100

120

2

5

7

9

12

15

L/MIN

?C

0

20

40

60

80

100

120120

100

80

60

40

20

0

?C

Drain

SunSun

Solar

Cylinder

Expansion

Vessel

*Solar

Cont-

ainer

Safety Relief

Valve / Pressure

Gauge Assembly

Solar

Collector

Panel

Solar

Collector

Panel

T2

Solar

Collector Sensor

T1

Solar

Collector Sensor

sol8618-1

Hot Water to Supply

Back Up

from Boiler or

Immersion Heater

Solar

Cylinder

Sensor

Single

Line

Pump

Station

Twin Line

Pump

Station

Solar

Controller EC2

T3

*Important: solar fluid container should be manufactured from a material

capable of withstanding the high temperatures at which solar fluid operates.

1B

EAST WEST SOLAR PANEL CIRCUIT

Solar panels can be located in an East - West orientation. In this conguration single line pump station (Ideal part No. UIN 207072)

in addition to the twin line pump station should be employed. Control between the panels located in different orientations can be

achieved by specifying the solar controller EC2, (Ideal Part No. UIN 207754), which has the capability to control panels located in

East - West conguration. Controller, installation and operating instructions are provided with the Solar controller EC2 kit.

Page 8

8

INSTALLATION

Solar Thermal - Installation and Servicing

2

SOLAR PACK CONTENTS

PARTS NOT INCLUDED IN THE SOLAR PACK

You will have to provide all pipework, ttings and insulation. The following specications are required for items provided by the

installer:

Pipework: This should be 15 mm or 22mm copper or exible stainless on both ow and return, depending on number of solar

collectors and pipework (see Frame 4). Plastic pipework is not suitable for the temperature extremes possible in solar circuits. Pipe

clips must withstand the temperatures of up to 200°C. (We recomend annular twin pipes PART No’s. 206519 - DN16x15m long &

206520 - DN20x15m long). A rst x kit is provided with each solar pack. This comprises exible through roof hoses (insulated)

one metre in length, collector panel angle couplings with bre seals and a separate solar controller ow sensor.

Fittings: Brass olive compression ttings must be used . Unleaded solder is not designed for solar circuits. Alternatively, high

performance crimped ttings or similar performance ttings can be used. Teon or similar type tape is not to be used although

a proprietary liquid type suitable for solar conditions may be used. Any drain valves etc. must be capable of handling the

temperatures indicated above. Any ttings and pipework must be capable of withstanding 1.5 times the safety valve pressure.

Insulation: This should be High Temperature Armaex or similar grade insulation or above. Class O Armaex is not UV-resistant

or designed for the temperatures realised in the solar primary circuit. Polythene insulation will melt on a solar primary circuit. All

external items such as cable clips to hold the collector sensor must be UV-resistant.

Flexible stainless steel hose is available in pre-insulated form using suitable high temperature UV-resistant insulation and a suitable

two-core cable for the solar collector sensor. This hose is specically designed for solar applications.

1.

3.

4. 5.

2.

6.

Before starting any work check the solar pack contents. Please note, dependent upon specic solar pack, ordered contents may vary.

ON ROOF SOLAR PACK

1. On roof solar collector(s)

2. Twin line pump station with expansion vessel installation

hardware

3. Solar controller EC1

4. Solar expansion vessel

5. Solar uid

6. First x connection pack containing angle through roof

exi hoses, panel angle couplings and solar controller

ow sensor.

7. Basic on roof collector ;mounting set - see frame seven

for detail

8. collector support rails - see frame seven for details.

IN ROOF SOLAR PACK

1. In roof solar collector(s)

2. Twin line pump station with expansion vessel installation

hardware

3. Solar controller EC1

4. Solar expansion vessel

5. Solar uid

6. First x connection pack containing angle through roof

exi hoses, panel angle couplings and solar controller

ow sensor.

7. Basic on roof collector ;mounting set - see frame seven

for detail

8. Wooden wedges for collectors ashing - see Frame 16

for detail.

9. In roof ashing set - see Frame 16 for detail.

INSTALLATION

Page 9

9

INSTALLATION

Solar Thermal - Installation and Servicing

3

COLLECTOR SIZING AND LOCATION

Typically, approximately 1 square meter of solar collector should be supplied for each house occupant. Each Ideal Solar

Collector panel has an external area of 2.02m2 (TS8000) and 2.51 m2 (TS8001). Therefore, the Ideal 2 collector array is ideal

for a 3 to 4 person household and the Ideal 3 collector array for a 5 to 6 person household. The collector array should be

located between 30o East and 40o West of South and at an inclination between 20o to 45o within these bands there is no more

than a 10% loss in efciency from the optimum south facing at an inclination of 35o. For an East-West roof, either an EastWest application can be installed with a collector on each pitch or additional collector(s) can be tted on either the East-West

roof. For example, a 3 collector array on an East facing roof would be ideal for 4 to 5 occupants where there is a 20 % loss in

performance as compared to the ideal South facing 30° pitch. There should be no signicant over-shading of buildings, trees or

other obstructions. Even obstructions to the north of the collector can block a signicant proportion of the diffuse solar radiation.

Signicant overshading can be compensated by over-sizing the solar system.

4

INSTALLATION OF THE COLLECTOR AND EXTERNAL COMPONENTS

The ow and return pipework can be passed

through the roof either with a proprietary

roof penetration tile or a Code 4 lead custom

made roof penetration tile. Ventilation tiles

can sometimes be adapted for this purpose.

Alternatively a silicon “dektite” can be used.

Optional lead pipe ashing tile kits which can be

adapted to suit most roof tiles are available. Any

exposed elements of the roof penetration must be

carefully sealed with exterior grade low modulus

silicone.

IMPORTANT

All connections and joints must be resistant to temperature of up to 200°C and resistant to glycol.

During installation and servicing means for covering the solar collectors will be required to avoid burns. In direct sunlight, the solar

collectors can reach temperatures of 200°C.

Note. It is recommended that you select the pipework in accordance with this table. If the system provides additional pressure loss

(bends, valves, etc.), you should consider selecting pipe with larger diameter.

The nal part of the roof installation is the insertion of the silicon PT1000 Collector Sensor into its mounting pocket in the Flow

Connector and feeding of the cable through or under the ow roof penetration and through the felt or timber sarking so that the

sensor cable is visible in the loft space.

Wiring run lengths and cross sectional areas for low voltage collector sensor wire:

Lengths up to 50m: 0.75mm

2

Lengths up to 100m: 1.5mm

2

Number of Single Pipe Length

Solar Collectors Up to 6m Up to 15m up to 20m up to 25m

to 5 Ø 15mm (DN12) Ø 22 mm Ø 22 mm

(DN 15) (DN 20)

to 9 Ø 22 mm Ø 22 mm Ø 28 mm Ø 28 mm

(DN15) (DN20) (DN25) (DN25)

INSTALLATION

Page 10

10

INSTALLATION

Solar Thermal - Installation and Servicing

5

ASSEMBLY INSTRUCTIONS

General and Transport Instructions

The mounting system is suitable for tiled roofs only. Installation must only be carried out by qualied personnel. The entire

information in these instructions is intended exclusively for such qualied personnel. Only the supplied material should be used for

the installation. Prior to starting installation and operation of the solar collector system, please inform yourself about the applicable

local standards and regulations. The use of a carrying strap is recommended for transporting the collector. The collector must

not be lifted at the connections or on the threading. Avoid impacts and mechanical inuences on the collector, in particular on the

solar glass, the rear panel and pipe connections.

Statics - tiled roofs

The collectors may only be mounted on sufciently load-bearing roof surfaces and substructures. It is imperative that the static

load bearing capacity of the roof or substructure is checked in terms of local and regional conditions prior to installation of the

collectors by the customer, if necessary through the involvement of a structural engineer. Particular attention should be paid to the

quality of the (timber) substructure in terms of the stability of the screw connections necessary for fastening the collectors. The

checking of the entire collector structure by the customer as per DIN 1055 part 4 and 5 or as per the applicable country-specic

regulations is particularly important in areas with heavy snowfall (note: 1 m³ powder snow ~ 60 kg / 1 m³ wet snow ~ 200 kg) or

in areas exposed to high wind speeds. The assessment should also take into account any particular circumstances at the place

of installation (foehn wind, air jets or eddy formation etc.) which can lead to increased loads. When selecting the installation site

it should be ensured that the maximum load is not exceeded either by snow or wind forces. As a rule, collector arrays must be

installed such that any possible collection of snow is prevented from reaching the collectors by snow barriers (or through special

forms of installation). The distance to roof ridges/edges must be at least 1 m.

Note: Installing a collector array signies an intervention into an (existing) roof. Roof coverings, e.g. tiles, shingle and slate,

especially in the case of converted and inhabited loft spaces or roofs with less than the minimum slope (with regards to the

covering) require additional measures by the customer, e.g. sarking membranes, as security against water penetration caused by

wind pressure and driving snow.

Lightning protection / Equipotential bonding of the building

In accordance with the lightning protection standard ÖVE/ÖNORM EN 62305 Part 1-4 the collector array cannot be connected

to the building’s lightning protection. A safety distance of at least 1 m must be maintained from any possible adjacent conducting

object. For installations on metal substructures at the installation site, generally qualied electricians must be consulted. To carry

out a building potential equalisation, the metal tubes of the solar circuit and all collector cases or fastenings must be connected

to the main potential equalisation bus by a qualied electrician in accordance with ÖVE/ÖNORM E 8001-1 or the country-specic

standards.

Connections

Depending on the design, the collectors must be connected with one another and/or the connection pipes using screw

ttings (1” internal/external thread) with at-face sealing. Ensure correct placement of the at gaskets. If exible pipes are

not used as connectors, precautions must be taken to protect the connection pipes against temperature uctuations caused

by heat expansion, e.g. expansion bends and exible piping (see Connecting the collectors to one another/Operational

recommendations). Larger collector arrays must be assembled with expansion bends or exible members inserted in the links.

(IMPORTANT: check the pump design). When tightening the union nuts, always balance (counter) the torque with a pipe wrench

or another spanner to prevent damage to the absorber.

Collector inclination / General notes

The collector is suitable for angles between 20° (minimum) and 65° (maximum). The collector must be installed so that rear

ventilation for preventing the diffusion of moisture in the collector is guaranteed. The collector connections and the ventilation

openings must be protected against the penetration of water as well as contamination such as dust etc.

Cleaning

Clean the water courses of the sheet metal edging at least once per year (or more often if required).

Legal guarantee

Legal guarantee claims can only be made if the supplier’s own antifreeze has been used and maintenance has been carried out

correctly. Installation by qualied personnel with absolute adherence to the instructions is a prerequisite for the justication of

claims.

ASSEMBLY

Page 11

11

INSTALLATION

Solar Thermal - Installation and Servicing

6

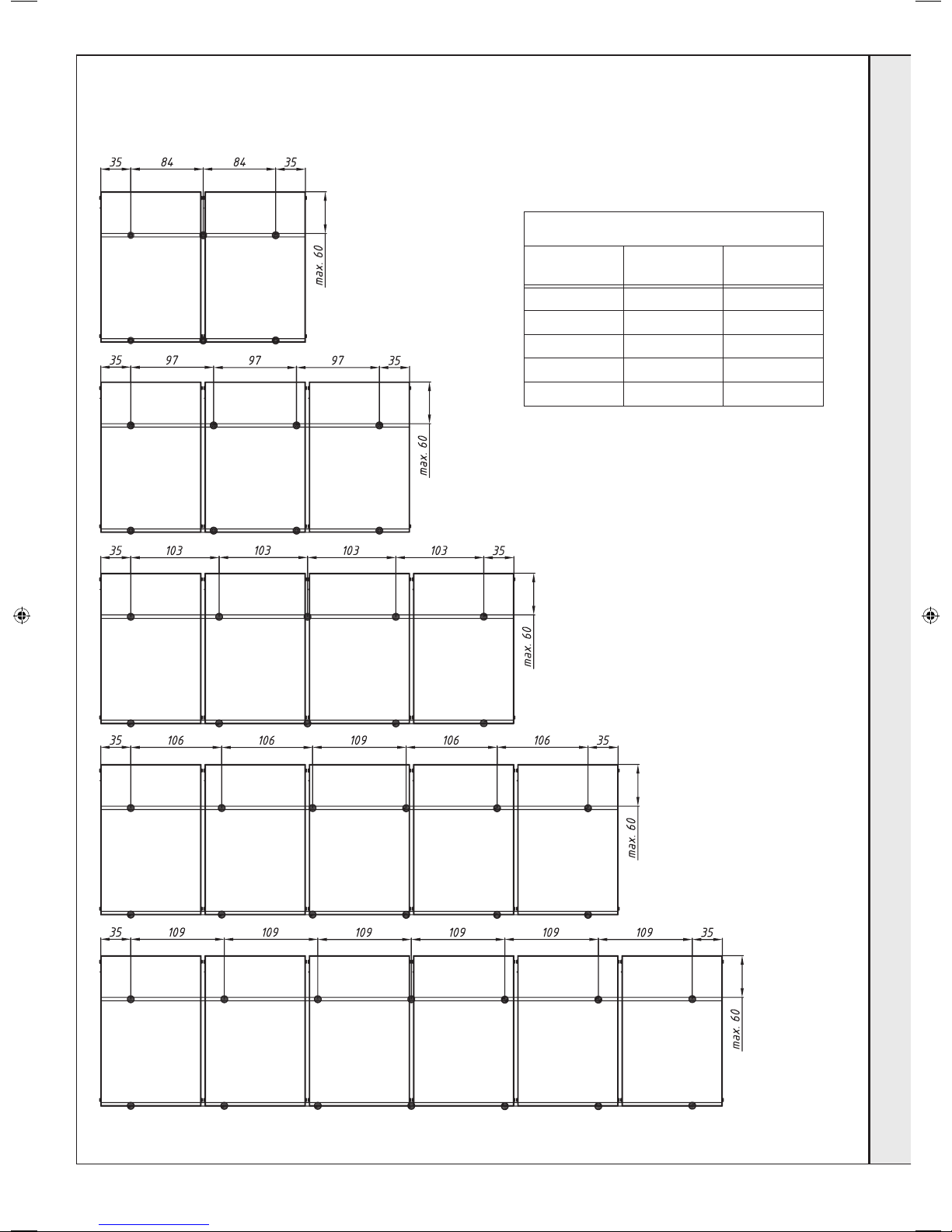

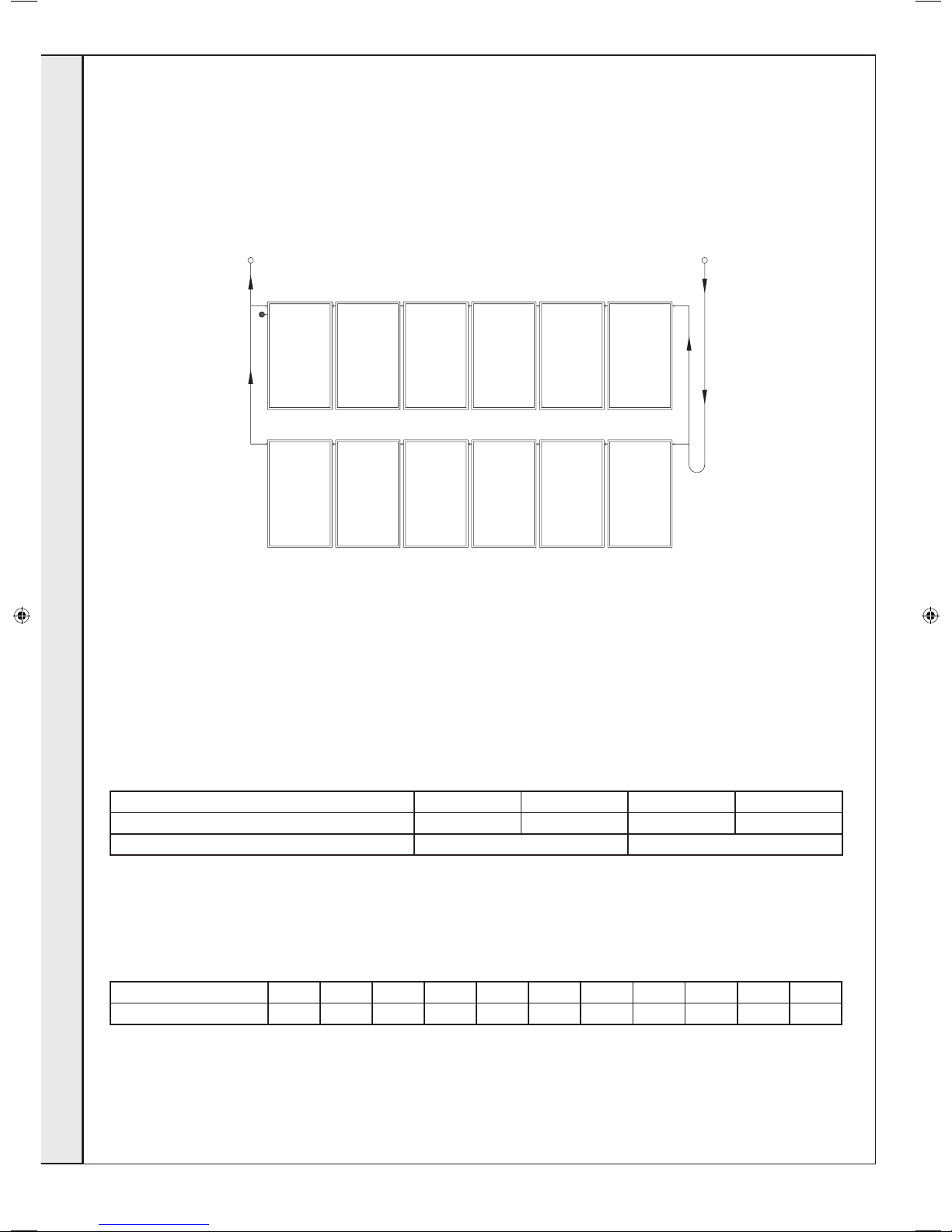

SUGGESTION FOR ATTACHMENT POINTS

Additional mounting structures must be provided in

areas with high snow and wind loads!

(Observe DIN 1055 or country-specific regulations)

•.....Atachment points

Collector Vertical

Collectors Total length

Atachment

points

2 239cm 6

3 361cm 8

4 482cm 10

5 603cm 12

6 724cm 14

ASSEMBLY

Page 12

12

INSTALLATION

Solar Thermal - Installation and Servicing

7

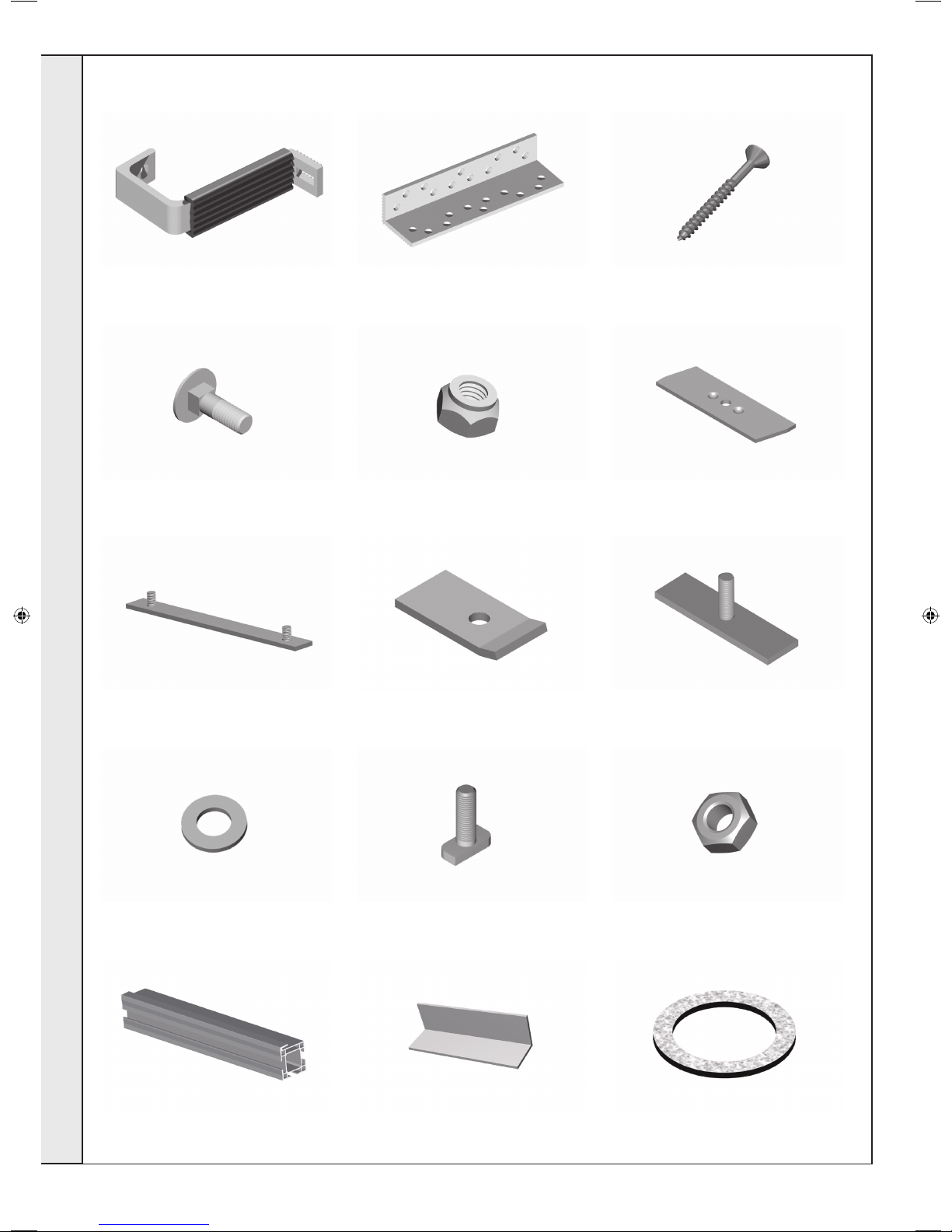

OVERVIEW OF MATERIALS - ON ROOF

Roof bracket Roof bracket console Self-tapping screws 6*60

Cup square bolt 8*25 M8 hex self-securing nut Clamping piece

Clamping piece extension Mounting part, top Mounting part extension

M8 washer M8*30 hammer-head bolt M8 hex nut

Support rail Mounting jig Flat gasket

INSTALLATION

Page 13

13

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

8

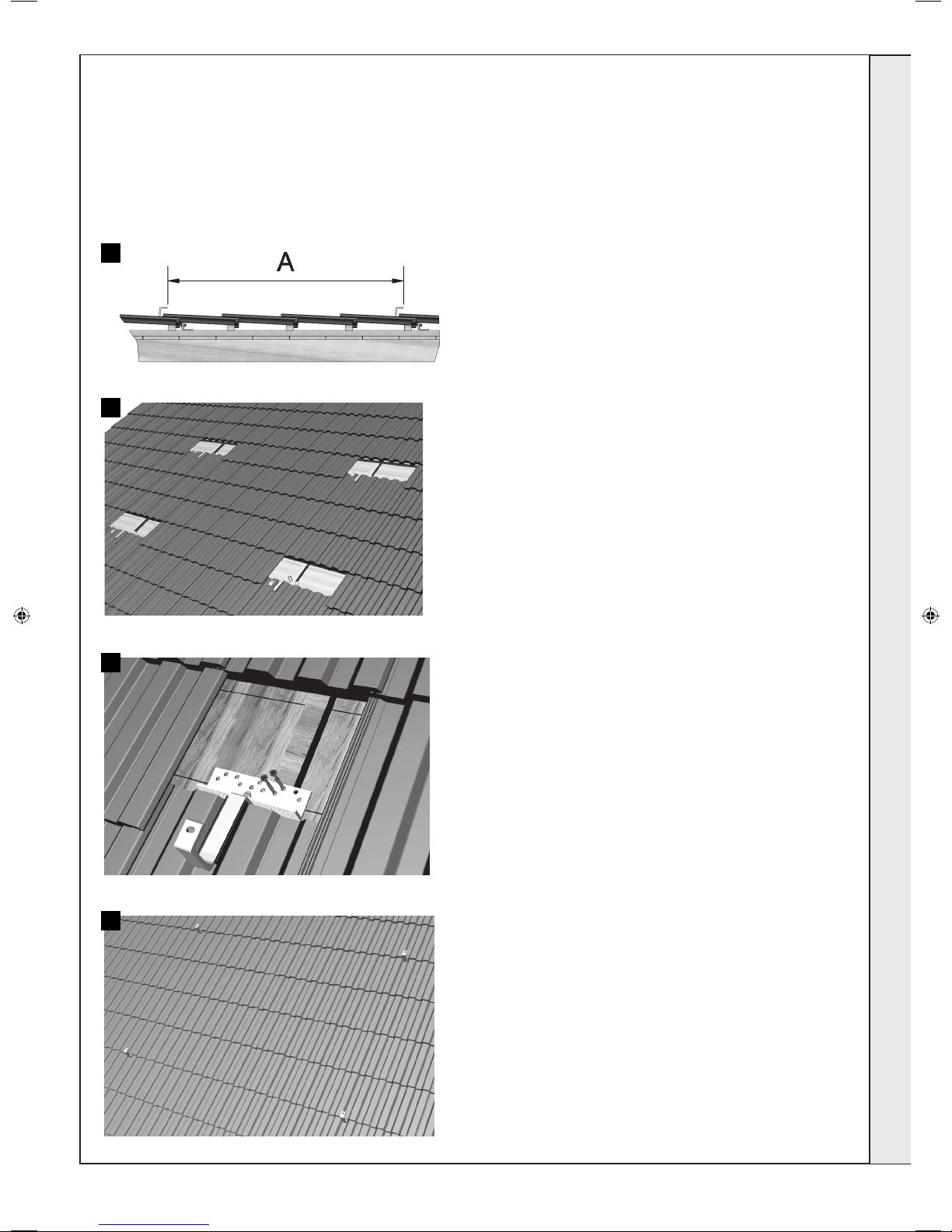

MOUNTING SYSTEM, PARALLEL

General Note:

Points 8-11, 16 and 17 of these instructions only apply when mounting more than two collectors.

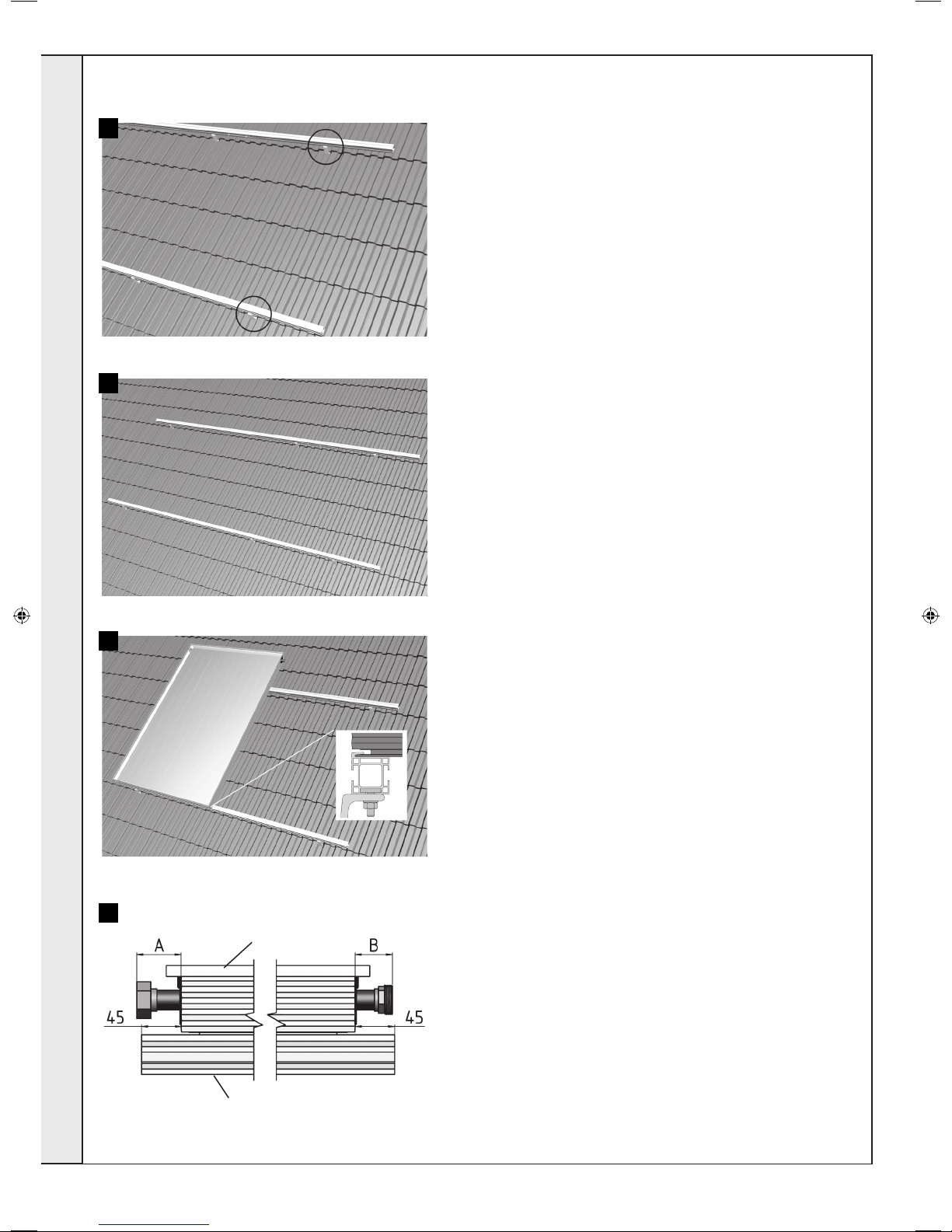

1. Measure distance between mounting bracket.

Distance should be between (125 - 155cm).

Remove appropriate roof tiles to t roof bracket

console.

2. A = 125 - 155cm - Distance between brackets

3. Fasten roof bracket console to rafters with provided self

tapping screws 6 x 60

4. Replace roof tile, cut tile to ensure correct t if necessary.

1

2

3

4

Page 14

14

INSTALLATION

Solar Thermal - Installation and Servicing

9

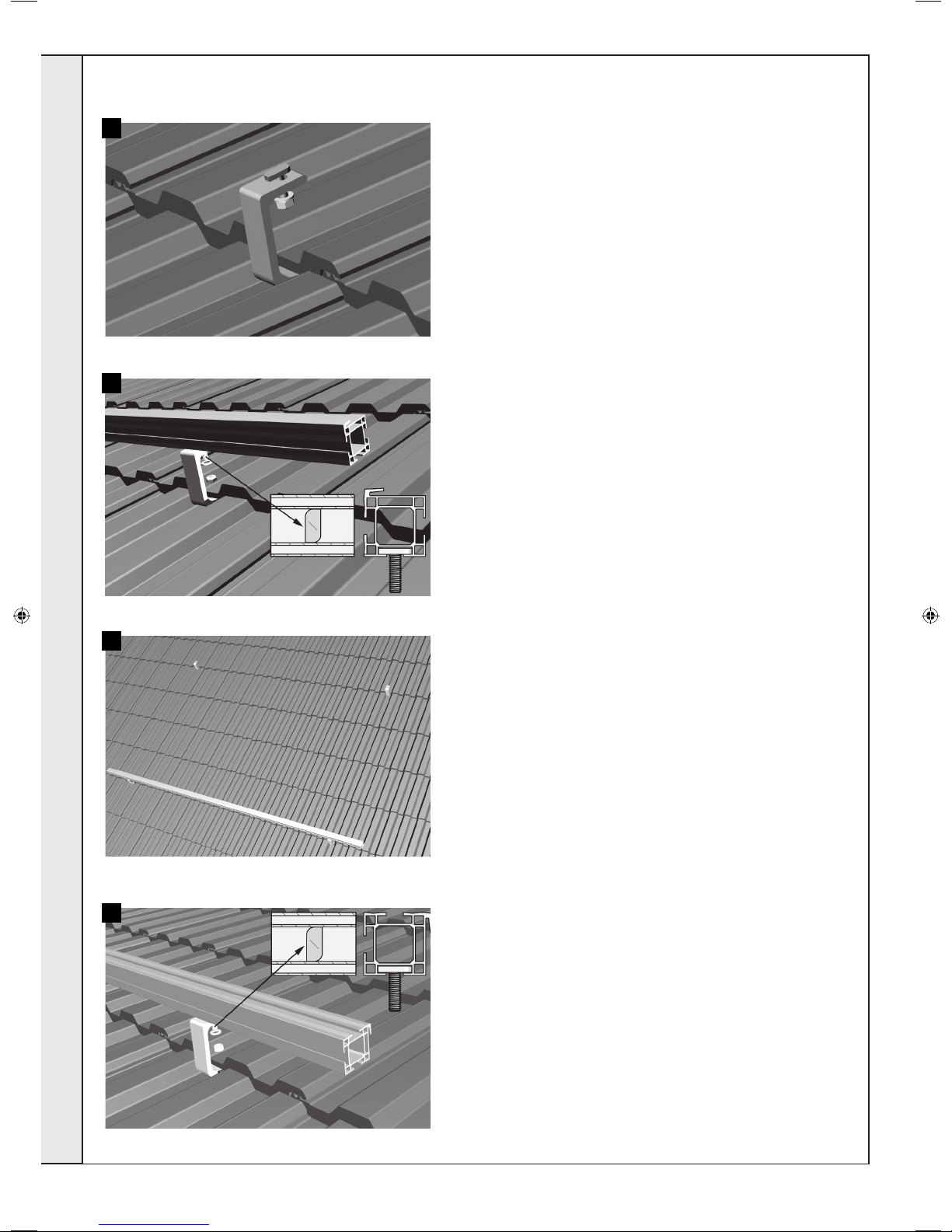

MOUNTING SYSTEM, PARALLEL

INSTALLATION

5. Insert the hammer-head bolt into the roof bracket and hand tighten

for now

Order:

hammer-head bolt - mounting bracket - washer - nut

6. Attach lower mounting rails (6a, 6b)

Order:

mounting rail - hammer-head bolt - roof bracket - washer - nut

7. Attach upper mounting rail (7a, 7b)

Order:

mounting rail - hammer-head bolt - roof bracket - washer - nut

5

6a

6b

7a

Page 15

15

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

10

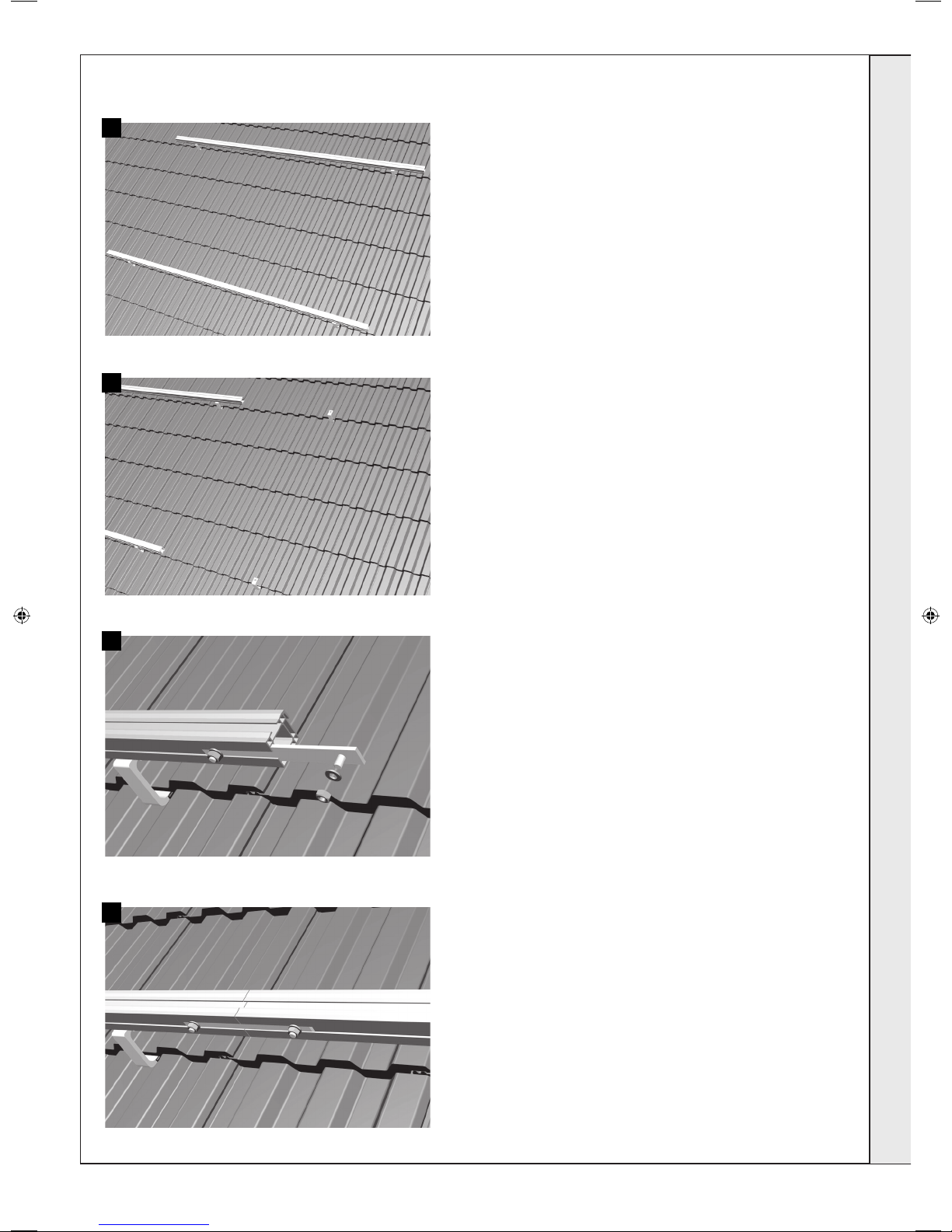

MOUNTING SYSTEM, PARALLEL

WARNING: Upper and lower mounting rails must be mounted

perfectly straight and parallel to one another!

8. Set addition mounting points as described in Points 1-4 if

additional collectors are to be tted.

9. Push the clamping piece extension halfway into the inner

groove of the mounting rails (upper and lower) and tighten

Order: mounting rail - clamping piece extension - washer - nut

10. insert the following mounting rails (upper and lower) and attach

them using the clamping piece extension

Order: mounting rail - clamping piece extension - washer - nut

7b

8

9

10

Page 16

16

INSTALLATION

Solar Thermal - Installation and Servicing

11

MOUNTING SYSTEM, PARALLEL

INSTALLATION

Solar Collector

Mounting Rail

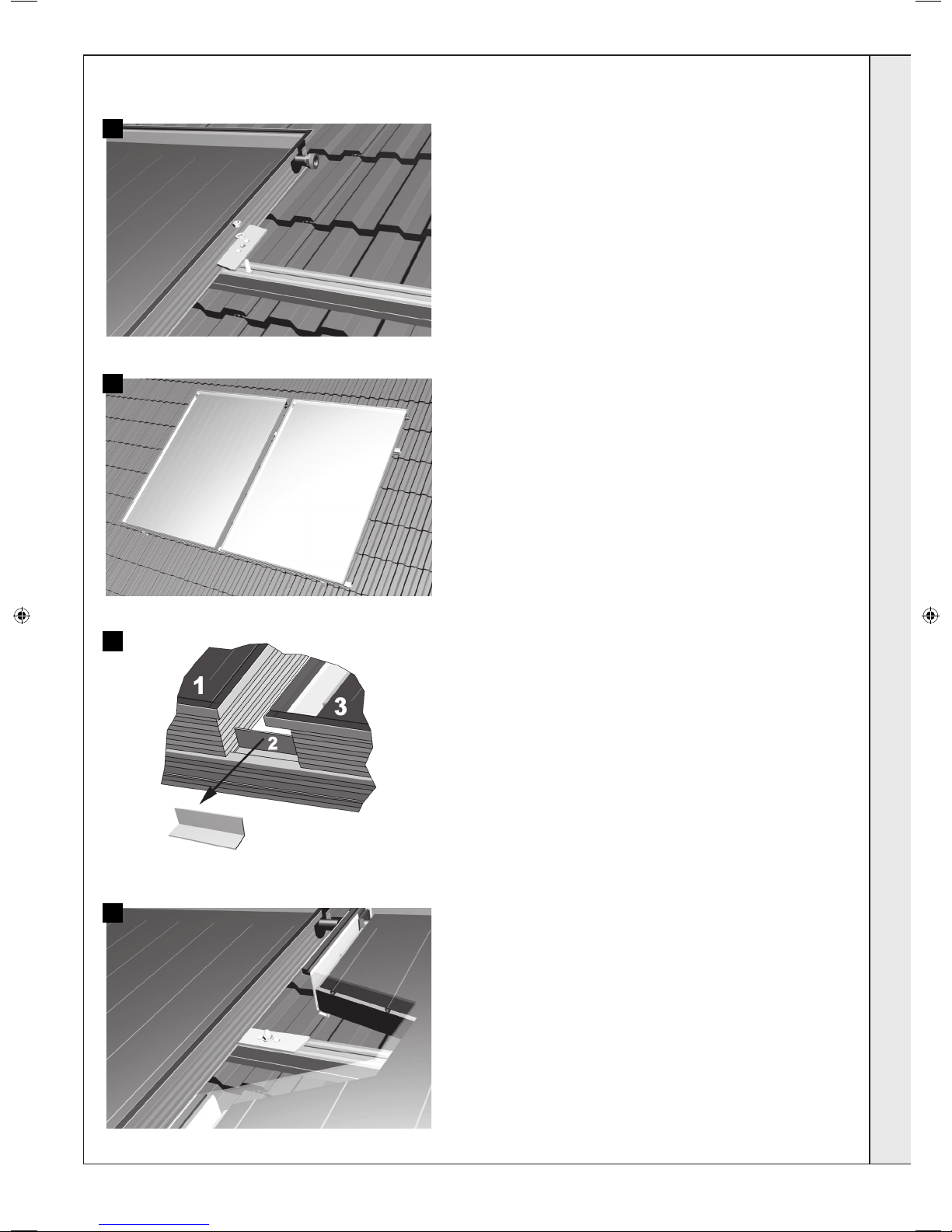

11. Attache the mounting rails (upper and lower) using the roof

bracket / clamping piece extension

Order:

mounting rail - hammer-head bolt - roof bracket - washer -nut

12. Hang the rst collector in the lower mounting rail and adjust

(12a + 12b)

Note: Distance between collector and end of moutning rails =

45mm. Measurement A = mesurement B.

11a

11b

12a

12b

Page 17

17

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

12

MOUNTING SYSTEM, PARALLEL

13. Place the clamping piece on the upper mounting rail and hand

tighten for now.

Order: upper mounting rail - hammer-head bolt - washer -

clamping piece - washer - nut

14. Attach the second collector (measurement A = measurement B as

shown in Figure 12b)

Please use the mounting jig (14b)

15. Rotate the clamping piece by 90º and screw it tight using a long

socket wrench

13

14a

14b

15

Page 18

18

INSTALLATION

Solar Thermal - Installation and Servicing

13

MOUNTING SYSTEM, PARALLEL

INSTALLATION

16. With clashing mounting rails, insert and position the mounting part

in the upper moutning rail

17. Attach additional clamping pieces / collectors as described in

Points 12-16.

18. Attach the mounting part on the upper left and right end of the

collector eld

Order:

mounting rail - hammer-head bolt - mounting part - washer - nut

19. Screw the collectors into place.

16

17

18

19

Page 19

19

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

14

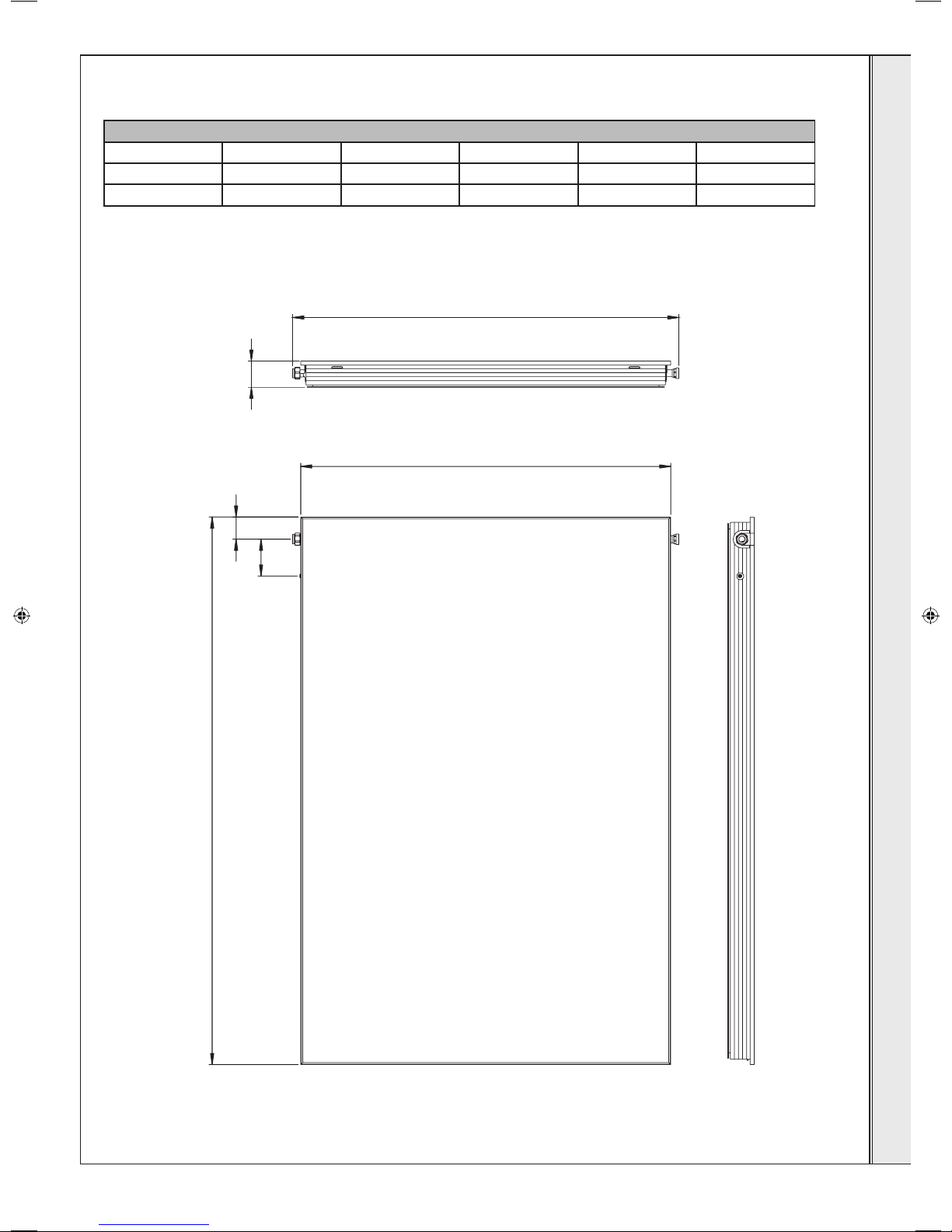

INFORMATION ABOUT THE COLLECTOR (TS 8000)

Technical Data

Gross area m

2

2,02 Weight (dry) kg 35

Net ara m

2

1,84 Contents 1 1, 4

Aperture m

2

1,91 Max. Pressure bar 10

1

2

2

1

38

611

70

1730

1

1

7

0

Page 20

20

INSTALLATION

Solar Thermal - Installation and Servicing

15

OPERATING TIPS - SOLAR POWER SYSTEM (TS 8000)

INSTALLATION

Connecting the collectors to one another

The diagram below is an example of how the collectors can be connected to one another. However, the actual connection may

be different depending on structural conditions. A maximum of 6 collectors may be connected in a series. If a collector panel is

made up of more than 6 collectors, the panel must be connected several times in parallel.

Mass Flow Rate

To ensure the performance of the collector, a specic ow rate of 30 l/m

2

h is to be selected up to a collector panel size of approx.

25m2.

Pipe Diameters

Dimensions table with a specic ow rate of 30 l/m

2

h

Collector panel size [m2] approx. 5 approx. 7.5 approx. 12.5 approx. 25

Pipe diameter / copper [mm] 10 - 12 15 18 22

Pipe diameter / stainless steel corrugated pipe DN16 DN20

Pressure loss collctor for anti-freeze / water mixture (40% / 60%) at a thermal conducting temperature of 50ºC

Pressure loss curve: ∆p = 0,000128x

2

+ 0,022931x

Mass ow rate [kg/h] 0 50 100 150 200 250 300 350 400 450 500

Pressure loss [mbar] 0 1,5 3,6 6,3 9,7 13,7 18,4 23,7 29,7 36,2 43,5

Supply

Return

Page 21

21

INSTALLATION

Solar Thermal - Installation and Servicing

16

OVERVIEW OF MATERIALS - IN ROOF (TS8001)

Installation batten 30x40x2450 Attachment bracket Self-trapping screws 5*60 / 5*40

Flat gasket

Front corner section right/left or middle

Connecting bend

Side piece right/left Side tin cover strip

Sealed plumping screw 4,5*35

Middle cover strip Sealed plumping screw 3,9*13 Wooden wedge

Self-trapping screws 6*120 Side piece connector right/left Middle cover right/left or middle

Rear corner section right/left or middle

Self-trapping screws 4*25 Metal retainer, roofing nail

Foam rubber wedge

INSTALLATION

Page 22

22

INSTALLATION

Solar Thermal - Installation and Servicing

17

IN ROOF MOUNTING (TS 8001)

1. Uncover the roof according to the collector surface area

Width: approx. 1.25m per collector + 1.5m

Height: approx. 3.0m for single row installation

Height: approx. 5.0 - 6.0m for double row installation

2a. Attach the installation batten below, self-taping screws 5*60

2b. Measurement A = 80mm for tile sheet metal edging

Measurement A = 50mm for shingle and crown tile sheet metal

edging

2c. Measurement B = 200mm or tile width + 50mm

1

2a

2b

2c

INSTALLATION

Page 23

23

INSTALLATION

Solar Thermal - Installation and Servicing

18

IN ROOF MOUNTING (TS 8001)

INSTALLATION

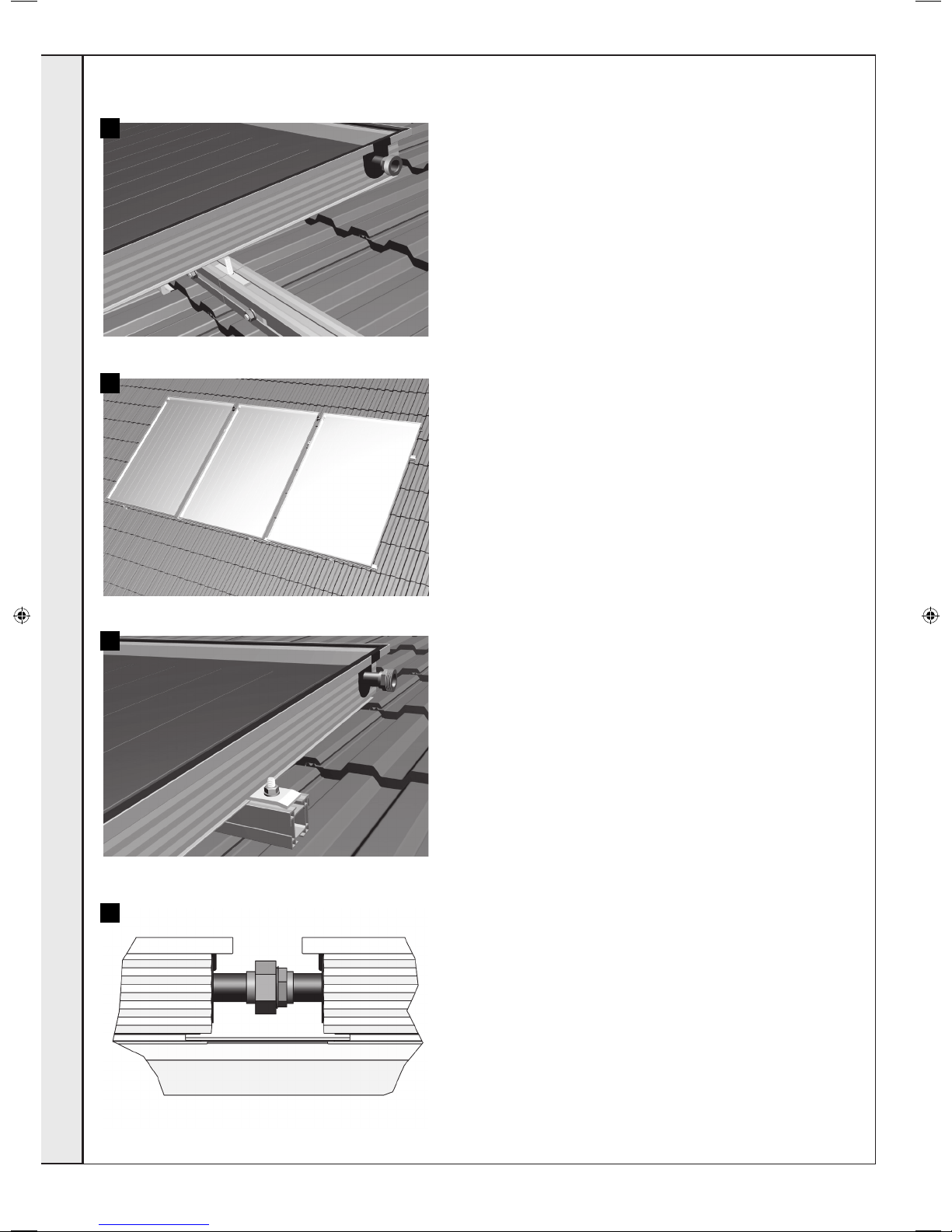

3. Fasten the attachment bracket on the installation batten as shown

on the attachment diagram (see Frame 28), self-tapping screws

5*40.

4. Set and align collectors on the roof.

5. Fasten the collectors to the attachment bracket, self-tapping

screws 5*40.

6. Secure the collectors to the upper attachment bracket,

1 bracket in the centre of each collector glass, self-tapping

screws 5*40.If necessary, install upper installation batten, selftapping screws 5*60.

3

4

5

6

Page 24

24

INSTALLATION

Solar Thermal - Installation and Servicing

19

IN ROOF MOUNTING (TS 8001)

INSTALLATION

7. Hydraulically connect the collectors using short connecting bends.

8. Connect the roof-integrated connection set (8a/8b). Alternative:

Create a CU connection using a soldered connection. Install the

sensor with the sensor tube extension at the forward ow.

9. If installing a second row install the installtion batton for the

second row of collectors using the provided 5 x 60 self tapping

screws. The distance between the upper and lower rows

should be 200mm.

7

8a

8b

9

Page 25

25

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

20

IN ROOF MOUNTING (TS 8001)

Warning: The collector array must be checked for leaks before

installing the metal casing!

10. Slide the front corner section to the left into the required nut of the

glass lower bar. Note: Before installing the underside of the metal

casing, remove the collectors’ lower protection piece!

11. Slide the front section into the middle.

13. Secure the front section on the required positions (stampings)

using sealed plumbing screws 4.5*35.

12. Slide the front corner section to the right.

10

11

12

13

Page 26

26

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

21

IN ROOF MOUNTING (TS 8001)

14. Install the side pieces on the right and left. Upper edge of the

sheet metal ush with the upper edge of the collector.

Repeat steps 14, 15, 17, 18, 19 and 20 for second collector row accordingly

15. Secure the side pieces to the roof batten using metal retainers

and roong nails.

16. Place the metal wedge in the middle between the collector

rows and tighten it on the roof structure using self-tapping

screws 6*120. Install the side piece connector on the right and

left.

14

15

16

Page 27

27

INSTALLATION

Solar Thermal - Installation and Servicing

22

IN ROOF MOUNTING (TS 8001)

17. Attach the lateral cover strip on the right and left.

18. Attach the side tin cover strip to the front corner section on the

right and left at the collector using sealed plumbing screws 4.5*35.

20. Tighten the middle cover strips using two self-drilling sealed

plumbing screws and the lateral tin cover strip using one selfdrilling sealed plumbing screw 3.9*13.

19. Push the middle cover strip (between adjacent collectors) from

the bottom as far as it can go.

17

18

19

20

INSTALLATION

Page 28

28

INSTALLATION

Solar Thermal - Installation and Servicing

23

IN ROOF MOUNTING (TS 8001)

21. Slide in the middle cover on the left.

22. Slide in the middle cover to the centre.

23. Slide in the middle cover on the right

24. Tighten the left and right middle cover to the side tin cover strip

and the collector on the required position using a self-drilling

sealed plumbing screw 4.5*35

21

22

23

24

INSTALLATION

Page 29

29

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

24

IN ROOF MOUNTING (TS 8001)

25. Place the metal wedge in the middle above the collector and tighten it on the roof structure, self-tapping screws 5*120. Hang the

left rear corner section (27b) in the collector.

27. Hang the middle rear section in the collector and connect the

rear left corner section. Tighten the sheet metal outside of the

rein-forcing seam using a self-tapping screw 4*25.

26. Tighten the left rear corner section outside of the reinforcing

seam on the wooden wedge, self-tapping screws 4*25

25a

25b

26

27

Page 30

30

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

25

IN ROOF MOUNTING (TS 8001)

28. Hang the right rear section in the collector and connect it to the

middle rear section

29. Tighten the rear section on the left and right side to the cover strip

and the collector using a sealed plumbing screw 4.5*35

30. Laterally secure the right and left rear corner section to the

roof batten using metal retainers and roong nails

31. Glue the foam rubber wedge on the side and the top (applies to sheet metal edgings for tile roofs only!)

28

29

30

31a

31b

Page 31

31

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

26

IN ROOF MOUNTING (TS 8001)

34. Note: When installing the side sections of the plain-tile metal

casing, the tiles and metal parts must always be alternately

co-vered!

32. Cover the collector eld. If necessary, the tile must be cut to

the appropriate size using an angle grinder. The top projecting

end of the tile must be 80 and 140mm over the metal edge.

33. Finally, adjust the lead skirting (for sheet metal edging with tile

roofs only) to the contour of the tile.

32

33

34

Page 32

32

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

27

INFORMATION ABOUT THE COLLECTOR (TS 8001)

Technical Data

Gross area m

2

2,52 Weight kg 47

Net ara m

2

2,32 Contents 1 1, 7

Aperture m

2

2,28 Max. Pressure bar 10

1130

2058

2104

1227 105

Page 33

33

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

28

IN ROOF MOUNTING (TS 8001)

Connecting bend

Installation batten

Attachment bracket

Page 34

34

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

Connecting the collectors to one another

The diagram below is an example of how the collectors can be connected to one another. However, the actual connection may

be different depending on structural conditions. A maximum of 6 collectors may be connected in a series. If a collector panel is

made up of more than 6 collectors, the panel must be connected several times in parallel.

Mass Flow Rate

To ensure the performance of the collector, a specic ow rate of 30 l/m

2

h is to be selected up to a collector panel size of approx.

25m2.

Pipe Diameters

Dimensions table with a specic ow rate of 30 l/m

2

h

Collector panel size [m2] approx. 5 approx. 7.5 approx. 12.5 approx. 25

Pipe diameter / copper [mm] 10 - 12 15 18 22

Pipe diameter / stainless steel corrugated pipe DN16 DN20

Pressure loss collctor for anti-freeze / water mixture (40% / 60%) at a thermal conducting temperature of 50ºC

Pressure loss curve: ∆p = 0,0001579x

2

+ 0,0274717x

Mass ow rate [kg/h] 0 50 100 150 200 250 300 350 400 450 500

Pressure loss [mbar] 0 1,8 4,3 7,7 11,8 16,7 22,5 29,0 36,3 44,3 53,3

Supply

Return

29

OPERATING TIPS - SOLAR POWER SYSTEM TS8001

Page 35

35

INSTALLATION

Solar Thermal - Installation and Servicing

30

OVERVIEW OF MATERIALS - FLAT ROOF KIT (TS8000)

Bench screw M12*350 Rubber seal M12 washer

M12 hex nut

Clamping piece Clamping piece extension

Mounting part, top Mounting part extension

M8 washer

M8*30 hex bolt M8*30 hammer-head bolt M8 hex nut

Attachment bracket Base bracket Support bracket

Support rail

Mounting jig Flat gasket

INSTALLATION

Page 36

36

INSTALLATION

Solar Thermal - Installation and Servicing

31

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

1. Measurement C = 148cm (A/B see previous side)

2. Drill holes in foundation / wood Ø 8mm, concrete as required

3. Attach the rubber seal, screw it in and then fasten

(minimum screw depth ≥ 100mm)

Order: rubber seal – washer – nut

4. Align the attachment brackets at the same height and fasten

Order: nut – washer – attachment bracket – washer – nut

1

2

3

4

INSTALLATION

General Note: Points 9,10,11,16 and 17 of these instructions only apply

when mounting more than two collectors!

Page 37

37

INSTALLATION

Solar Thermal - Installation and Servicing

32

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

INSTALLATION

5. Cut off any excess length from the bench screw.

(Measurement D = max 45mm)

6. Attach the rst mounting triangle as described in 6a-6c

6a. Screw the base bracket to the support bracket (A)

Order: screw – base bracket – support bracket - washer – nut

6b. Screw the base bracket to the attachment bracket on the front (B)

Order: screw – attachment bracket – base bracket – washer – nut

5

6

6a

6b

Page 38

38

INSTALLATION

Solar Thermal - Installation and Servicing

33

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

6c. Screw the support bracket to the attachment bracket on the back (C)

Order:

screw – attachment bracket – support bracket – washer – nut

6d. Attach the second mounting triangle as described in 6a-6c

7. Slit T-head bolt into the lower groove of the mounting rail and screw

it to the mounting part using a washer and hexagon nut.

Order:

mounting rail - hammer-head bolt - mounting part - washer - nut

8. Attach upper mounting rail as described in Point 7

Warning: Upper and lower mounting rails must be mounted perfectly

straight and parallel to one another!

6c

6d

7

8

INSTALLATION

Page 39

39

INSTALLATION

Solar Thermal - Installation and Servicing

34

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

INSTALLATION

9a. Push the clamping piece extension halfway into the inner groove

of the mounting rails (upper and lower) and tighten

Order: mounting rail – clamping piece extension – washer – nut

10. Insert the following mounting rails (upper and lower) and

attach them using the clamping piece extension

Order: mounting rail – clamping piece extension – washer –

nut

11. Attach the mounting rails (upper and lower) using the base brak-kets

Order:

support rail – hammer-head bolt – base bracket – washer – nut

9a

9b

10

11

Page 40

40

INSTALLATION

Solar Thermal - Installation and Servicing

35

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

12. Hang the rst collector in the lower mounting rail and adjust (12a +

12b!)

Note: Distance between collector and end of mounting rails = 45mm

13. Place the clamping piece on the upper mounting rail and hand

tighten for now

Order:

upper mounting rail – hammer-head bolt – clamp – washer – nut

14. Attach the second collector.

(measurement A = measurement B as shown in Figure 12b)

Please use the mounting jig (14b).

12a

12b

13

14a

INSTALLATION

Page 41

41

INSTALLATION

Solar Thermal - Installation and Servicing

36

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

INSTALLATION

15. Rotate the clamping piece by 90° (see gure 13) and screw it tight

using a long socket wrench

16. With clashing mounting rails, insert and position the mounting

part in the upper mounting rail

17. Attach additional clamping pieces / collectors as described in Points

12–16

14b

15

16

17

Page 42

42

INSTALLATION

Ideal Solar - Installation and Servicing

37

IN ROOF MOUNTING (TS 8001) - MOUNTING SYSTEM 45O ELEVATION

18. Attach the mounting part on the upper left and right end of the

collector eld

Order:

mounting rail – hammer-head bolt – mounting part – washer – nut

19. Screw the collectors into place with the proper torque

18

19

INSTALLATION

Page 43

43

INSTALLATION

Solar Thermal - Installation and Servicing

INSTALLATION

38

OPERATING TIPS (TS8000 & TS8001)

Flushing and Filling

For safety reasons, you should only ll the collectors when there is no direct irradiation from the sun (or cover thecollectors).

Especially in regions exposed to frost, for at plate collectors you should use a mixture of (FS) antifreeze with water (40%

antifreeze). The solar thermal system should be lled and commissioned within one week of installation, because heat buildup in the collector (array) can damage the at gaskets in empty systems. If this is not possible, the at gaskets should be

replaced before commissioning to prevent leakage.

Attention: Antifreeze that is not pre-mixed must be mixed with water prior to lling!

Recommended antifreeze for at plate collectors: TYFOCOR-L

40% proportion of antifreeze (60%/water) - freezing point: -22° C/solidication point: -26° C

50% proportion of antifreeze (50%/water) - freezing point: -32° C/solidication point: -44° C

It may not be possible to completely empty collectors once they have been lled. For this reason, collectors exposed to frost

should only be lled with a water/antifreeze mixture, also for pressure and function tests. Alternatively, the pressure test can

also be carried out using compressed air and leak detection spray.

Installing the Temperature Sensor

The temperature sensor should be installed in the sensor sleeve nearest to the collector array ow. To ensure optimal contact

between the sensor and the surrounding environment, the gap between the sensor sleeve and the sensor element should be

lled with a suitable conducting compound. All materials used for installing temperature sensors (sensor element, conducting

compound, cables, sealing and insulating materials) must be suitably temperature resistant (up to 250° C).

Operating Pressure

The maximum operating pressure is 10 bar.

Bleeding

The system must be bled:

- when commissioning the system (after lling the collectors)

- 4 weeks after commissioning

- when necessary, e.g. if there are malfunctions

Warning: Risk of scalding due to steam and hot heat transfer uid!

Only operate the bleeding valve if the temperature of the heat transfer uid is < 60° C.

When bleeding the system, the collectors must not be hot! Cover the collectors and, if possible, bleed the system in the

morning.

Check Heat Transfer Fluid

The heat transfer uid must be checked every two years with regard to its antifreeze and pH value.

- Check antifreeze using antifreeze tester and replace or rell if necessary!

Target value is ca. - 25° C and - 30° C depending on climatic conditions.

- Check pH value with a pH indicator rod (target value approx. pH 7.5):

If the limit pH value is less than ≤ pH 7, replace the heat transfer uid.

Maintenance of the Collector

The collector or the collector array must be inspected visually, once a year, for any damage, leaks and contamination.

Additional recommendations on operation and maintenance can be found in the supplier’s general documentation and

instructions on commissioning and maintenance.

Page 44

44

INSTALLATION

Solar Thermal - Installation and Servicing

PUMP STATION

39

PUMPING STATION 2-WAY “SOLAR 3”

EPP insulation box

Mesurements 277x425x150

side opening on the back part of

the insulation box for the security

unit. A special window allows to

read to adjust the ow without

taking off the cover. Back plate to

fasten the unit to the wall or to the

cylinder.

Back plate to fasten the unit to

the wall or to the cylinder

Fastening holes on the back xing

plate. special openings on the

insulation box allow the fastening

without disassembling the unit.

(1) - Filling the installation:

Remove the plugs from the side

valves and connect the hose unions.

Close the ball valve and open the side

lling valve and draining valve.

Directions for the use of the owmeter to ll the installation:

(2) - Starting the installtion working:

Open the ball valve and close the side

lling and draining valves. Remove the

hose unions and screw again the plugs.

to avoid any casual opening of the side

valves, it is better to stop the levers in

the close position, as shown here aside.

(3) - Regulate the ow rate using the

regulation rod until the right ow rate

is shown.

N.B. The ow rate is shwon taking

as reference the lower edge of the

sliding cursor. (see picture).

The vent air is a device that divides continually the air

that can be in circulation together with the uid. The

air goes to the upper part of the vent air and it can be

eliminated through the special drain while the installation

is working. unscrew of 360º the knurled metal ring lock.

This operation ahs to be done at intervals.

DANGER OF BURNS - To avoid any leakage of the

uid, taking into consideration the very high working

temperature, we recommend to fasten a pipe to the

end of the drain

Page 45

45

INSTALLATION

Solar Thermal - Installation and Servicing

PUMP STATION

Safety Relief Valve / Pressure Gauge Assembly

The Hydraulic solar pump station in the Ideal solar package is equipped with a 6 bar pressure relief valve which should be connected

via 22mm pipe work terminating in a suitable container. An empty canister of heat transfer uid can be used for this purpose .

Drain Valve

It is good practice to install a suitable drain valve at the lowest point in the system to facilitate draining of the solar system if required.

Connecting the Solar Cylinder

Refer to solar cylinder manufacturer’s instructions for installation, observing the correct direction of ow through the cylinder coil. Refer

to Frame 1.

Double Return Kit

If additional ow capacity is requried the single line

pump station (Ideal Part No. UIN 207072) can be

employed. within this kit an additional collector

return pump and connector tee is provided. During

installation the safety relief valve and pressure

gauge is transferred from the twin line pump station

to the single line station.

A ow gauge is provided in the single line pump

station so the ow rate between the two ow rates

can be balanced.

The single line pump station is also employed when

installing solar panels in East-West conguration.

Twin line

pump station

Single line

pump station

Tee Connection

40

BRACKET AND CONNECTION KIT FOR THE EXPANSION VESSEL

A. 3/4” exible pipe connected to the security unit of the solar pumping

station (not included).

B. Fibre sealing joint inlcuded.

C. Connector with double check valve to disconnect the expansion vessel

in a reliable and fast way without any leakage.

D. Expansion vessel with 3/4” threaded connection (available on request).

E. Fixing bracket provided with plugs and screws to x it to the wall

Fix the bracket (E) to the wall with the plugs (centre distance 55mm)

Screw the expansion vessel (D) to the connector (C) and put it on the

xing bracket using the special groove then lock with the nut.

Put the sealing joint (B) and screw the exible pipe of the security unit (A)

to the connector.

Replacement of the Expansion Vessel

The connector (C) holds up the expansion vessel and allows a quick detachment of it avoiding

any leakage.

By unscrewing the nut (F) it is possible to disconnect one end of the connector that remains

screwed to the expansion vessel. The other end of the connector stays xed on the bracket

connected to the security unit.

both ends have a check valve that becomes operative at the time of the disconnection: this

prevents any leakage both from the expansion vessel and from the exible pipe.

To ret the expansion vessel connect the two ends of the connector and to x them by screwing

the nut (F). In that way the two check valves are disconnected and the expansion vessel is

again connected to the installation.

Page 46

46

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

41

IDEAL SOLAR CONTROLLER - SAFETY INSTRUCTIONS

1. Please see that re safety cable systems and similar systems

are not impaired.

2. The controller must not be installed and used in damp

areas (e.g. bathrooms) or in rooms in which ammable gas

mixtures (by gas bottles, paint solvents etc.) are likely to

occur.

3. Do not store any of the above or similar items in a room

where the solar controller is installed.

4. The controller must not be installed on a conductive base.

5. All operations must be conducted in accordance with the

national electrical regulations and local rules.

6. For your own safety please note the following for electrical

installation:

The controller has been built for the use at 230 V (±15 %) AC

at a frequency of 50 Hz. Using this controller for other voltage

values is not allowed. Please also note that the admissible

nominal currents must not be exceeded. If there is a

grounded conductor planned or laid down for pump or

reversing valve it MUST also be connected. There are

corresponding supply terminals. Please make sure that

the earthing contact is led to the controller also on the

power supply side.

7. Wires that are not permanently connected with the

building have to be equipped with a strain relief clamp

outside the controller. The controller is only for the

prescribed applications. No liability is taken over for

other utilization. All operations on an open controller

are only to be conducted cleared from the power

supply. All safety regulations for working on the power

supply are valid. Connecting and/or all operations that

require opening the controller (e.g. changing the fuse)

are only to be conducted by a Solar competent heating

engineer. The controller is protected against overload

and short circuit.

Installation Site

The controller is designed for assembly on vertical walls. Installation of the controller is only permitted in an area that provides

appropriate protection (see technical data). The ambient temperature at the installation site may never fall short of or exceed the

maximum ambient temperature allowed.

42

IDEAL SOLAR CONTROLLER - MOUNTING

Wall Mounting

1. The internal controller cover protects the controller’s

electronics and may not be removed for installation purposes.

2. Drill and plug the wall in the desired position. Afx the central

screw and place the controller in position.

3. The controller can be used as a template to mark both

additional mounting holes.

NOTE. Only use the controller as a marking template, never as a

drilling template.

2

3

3

1

sol8572

116.5mm

Fuse

105mm

124mm

129.5mm

Page 47

47

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

1. The cable can be fed through the underside of the controller

or back panel of the housing depending on the installation.

2. The cable entry in the housing tray must rst be cut out to

insert the cable from the underside of the controller.

3. Each cable inlet requires 2 vertical incisions in the wall of

the plastic tray. A cable knife or an electrician’s side cutting

pliers can be used as a cutting tool.

4. Flexible wiring must be secured in the controller with the

attached strain relief clamps.

5. If the controller must be wired through the back panel of the

housing tray, the punch out holes can be used for the cable

entry. For this, an external strain relief is provided.

43

IDEAL SOLAR CONTROLLER - CONNECTIONS

WARNING. THE CONNECTION WORK DESCRIBED

HERE IS ONLY POSSIBLE WHEN THE CONTROLLER’S

FRONT COVER IS OPEN. DISCONNECT THE MAINS! ALL

APPLICABLE INSTRUCTIONS FOR WORKING ON THE

MAINS MUST BE OBSERVED! THE MAINS MAY FIRST BE

SWITCHED ON WHEN THE CONTROLLER HOUSING IS

CLOSED. IN ADDITION, THE INSTALLER MUST ENSURE

NOT TO INFRINGE THE IP DEGREE OF PROTECTION

WHEN INSTALLING THE CONTROLLER.

The mains, pump and sensor connections must be connected

according to the terminal plan below. If an Earth conductor is

intended or required for the pump, the Earth conductor must be

connected. The corresponding Earth conductor wire terminals

are provided. Ensure that the ground contact is also connected

to the controller’s mains supply side.

sol8573

Cut out cable entry

2

1

5

sol8574

Actuating the

terminal clamp

sol8575

Each clamp may only be allocated one connecting cable (up to 2.5mm2). Connector sleeves must be used with nely stranded

cables.

Temperature Sensor

Warning. Only the original sensors permitted for the controller may be used. This is the PT1000 sensor type. Temperature sensors

and silicon cables are heat resistant up to +180°C. The polarity of the sensor contacts is irrelevant. All sensor leads are low voltage

and must be installed separately from the 230V or 430V lead sensors to prevent any inductive interference (at least 100mm apart).

If external inductive interference is to be expected, e.g. by heavy current cables, contact wires, transformer stations, radios and

television sets, amateur radio stations, microwave devices or similar devices, the conducting cables carrying the measuring signal

must be shielded. The sensor cable can be extended to a length of approximately 100m. Use cable of cross section 0.75mm

2

up

to 50m in length and 1.5mm2 up to 100m in length.

sol8576

Earth wire connection

solar circuit's pump

Output

Solar circuit's pump

Collector

temperature sensor

Storage tank temp.

sensor below

Storage tank temp.

sensor above

(optional

Mains voltage

230 V

PE LN

Page 48

48

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

44

IDEAL SOLAR CONTROLLER - OPENING AND CLOSING THE CONTROLLER

1. The front cover is secured by two holding bars on the top

edge of the controller and a screw on the housing.

2. Close the controller by angularly setting the front cover on

the controllers housing. The holding bars must be on the

corresponding hinge notches.

1. After the controller’s front cover has been closed, the power supply can be

turned on (refer to page 5, Electricity Supply)

2. To test if the solar circuit’s pump has been installed correctly (independent of

the controller’s functions), it is helpful to briey turn it on and off by hand. For

this purpose, there is a mode switch on the left side of the housing.

Note.

Every change of the switching position is followed by a 3 sec. lasting display of the

current control mode. (‘on’ / ‘Automatic’/ ‘off’).

45

IDEAL SOLAR CONTROLLER - COMMISSIONING

sol8577

1

2

4

3

3. Now, the front cover can be folded down and the push

buttons can be threaded through.

4. A fastening screw is used to securely close the housing.

sol8578

2

Switch in central position means automatic mode.

The backlight display is yellow.

Turn the switch to the upper position to start the pump.

The word ‘on’ flashes in the display as a reminder.

The backlight display is red.

Turn the switch to the lower position to switch off the pump.

The word ‘off’ flashes in the display as a reminder.

The backlight display is red.

sol8579

WARNING. If the system is ready for operation (system is lled, solar circuit is not blocked), the controller can be set to

automatic mode after commissioning.

Page 49

49

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

46

IDEAL SOLAR CONTROLLER - DISPLAY OVERVIEW

1

8

10

9

2

3

4

11

76 5

12

sol8580

1. Symbols for temperature sensors

2. Display for temperature values and error symbols e.g. short circuit, open circuit or ‘SYS‘ = system error (see Section A )

3. Holiday function (see section B)

4. Antifreeze function (not applicable see section C)

5. Change-over °C / °F (see section D)

6. Pipe collector function (not applicable see section E)

7. Setting of storage tank max. temperature (see section F)

8. Symbols for solar circuit (pump and circulation)

9. Symbol for storage tank max. temperature is reached (see section G)

10. Error icon e.g. short circuit, open circuit (see section A) or ‘SYS‘ = system error (see page 33)

11. Symbol for steam in collector (see section G)

12. Symbol for enough heat provided (see section G)

Page 50

50

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

47

IDEAL SOLAR CONTROLLER - OPERATING THE CONTROLLER

During normal operation the keys are used to browse

through the recorded temperature values. The (T1,T2,T3) sensor

symbols in the system diagram, show which measurement value

is currently being displayed.

sol8581

SOL8582

sol8583

The temperature in the upper part of the storage tank is only displayed if the T3 sensor has been connected.

In the event a sensor or its supply line short circuits, an animated Short Circuit Symbol is displayed instead of the

temperature.

In the event a sensor or its supply line is

interrupted, an animated Interruption Symbol is

displayed instead of the temperature.

If such a sensor fault occurs, the backlight

display alternately ashes red/yellow and a

warning symbol is displayed to indicate the fault.

sol8590

SECTION A

The holiday function can be activated with this setting. The holiday function

is a storage re-cool function. If the operator does not use the warm water, the

storage tank may reach its maximum temperature early in the day. In this case

vaporization may occur within the solar unit and thus subjecting the unit to a

higher thermal load.

Note: This function should only be used if you are not at home for an extended

period of time. Please deactivate this function after returning back home to

prevent unnecessary loses of energy!

If while the holiday function is activated, a temperature 10K below the maximum

storing temperature is reached, this is recognized by the controller. In order to be

able to charge the storage tank the next day for a longer time and thus subjecting

the unit to a lower thermal load, the storage tank (e.g. during the night) attempts

to cool down to 35°C. For this purpose, if the storage tank is 8K warmer than the

collector, the pump is activated. If the temperature difference between the pump

and the collector is only 4K, the pump is deactivated again.

To activate the holiday function: Press and hold the set button for 2 seconds.

Symbol boxes will appear. Use the and buttons to scroll until the holiday

symbol appears. Press and hold the set button until a tick is shown next to the

holiday symbol. The holiday function is now set.

Press the ‘SET’ button again to deactivate the holiday function.

Press the

button to reach the next setting.

SECTION B

continued . . . . .

Page 51

51

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

48

IDEAL SOLAR CONTROLLER - OPERATING THE CONTROLLER continued

The Ideal solar system is supplied with a ready-mixed heat transfer uid

containing glycol and water as its anti-freeze agent.

Note. The anti-freeze function is only helpful with systems that have solar

circuits without anti-freezing agents. This is not applicable to the Ideal Solar

System.

sol8591

SECTION C

SECTION D

sol8588

Changing the temperature display’s unit of measurement.

Press and hold the set button for 2 seconds. Use the and button to scroll to

the temperature unit function. Press and hold the set button to change.

Press the

button to reach the next setting.

SECTION E

sol8589

The vacuum collector function is only applicable for systems using Evacuated

tube collector type systems. This is not applicable with the ideal solar system.

continued . . . . .

Page 52

52

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

49

IDEAL SOLAR CONTROLLER - OPERATING THE CONTROLLER continued

SECTION F

SET

sol8587

Press the ‘SET’ button for 2 seconds to open the settings menu.

At rst, the current valid maximum storing temperature value is

displayed.

To illustrate which value is referred to, the ‘max’ indicator in the

storage tank symbol and the T2 sensor ash.

To alter the maximum storage temperature: - Press and hold the

set button for two seconds using the and buttons, select the

maximum storage temperature indicator. (value and T2 Flash) Using

the and buttons adjust the value. When the desired value is

showing, press and hold the set button for two seconds to save the

value.

Press the

button to reach the next setting.

sol8584

sol8585_1

VROB

SECTION G

The controller constantly compares the temperature on the collector (T1) and in the

lower part of the storage tank (T2). If while charging the storage tank, a sufcient

temperature difference (8K) is recognized, this is indicated by the sun in the display.

If no safety control or functions prohibit the pump operation, an animated pump

operation now begins to move in the display. If the temperature difference drops

below 4K, the pump operation is deactivated and the sun disappears.

If in the lower part of the storage tank (T2), the set maximum storing temperature

is reached (factory setting 60°C), the charging stops. (Pumps are stationary). A

new charging procedure is rst possible at a temperature of 4K under the maximum

storing temperature.

The ‘max’ indicator ashes in the storage tank symbol to illustrate that although the

sun is displayed, the pump is stationary.

If the solar circuit stops (e.g. due to a full tank) at a high irradiance, the solar uid in

the collector can assume a temperature higher than 130°C and vaporize. To protect the

pump, the pump operation is blocked until the temperature drops below 127°C (storage

tank cools down in the meantime).

THE STEAM INDICATOR FLASHES ON THE COLLECTOR SYMBOL TO ILLUSTRATE

THAT THERE IS STEAM IN THE COLLECTOR AND THE PUMP HAS SWITCHED

OFF.

WARNING. It is recommended that the solar store temperature set point is not set below 60°C as this temperature

facilitates the eradication of Legionella bacteria.

Risk of scalding from the solar storage tank if set above 60°C

It is recommended that a thermostatic mixing valve (TMV) is set to 60°C or below and is tted local to the solar

cylinder.

Page 53

53

INSTALLATION

Solar Thermal - Installation and Servicing

SOLAR CONTROLLER

50

IDEAL SOLAR CONTROLLER - NOTES ON TROUBLESHOOTING

WARNING. BEFORE OPENING THE FRONT COVER, THE POWER MUST BE DISCONNECTED FROM THE DEVICE.

The controller was designed to be continually used for several years. Nevertheless, faults may occur. Most of the time, the fault’s

cause is not sought in the controller, rather in the peripheral system elements. The following description of a few common faults

should help the installer and the operator to isolate the fault and activate the system as quickly as possible to avoid unnecessary