IDEAL Classic F 350 P, Classic F 360 P, Classic F 380 P, Classic FF 350 P, Classic FF 360 P User Manual

...Page 1

Page 2

2

Classic FF

- Propane Users

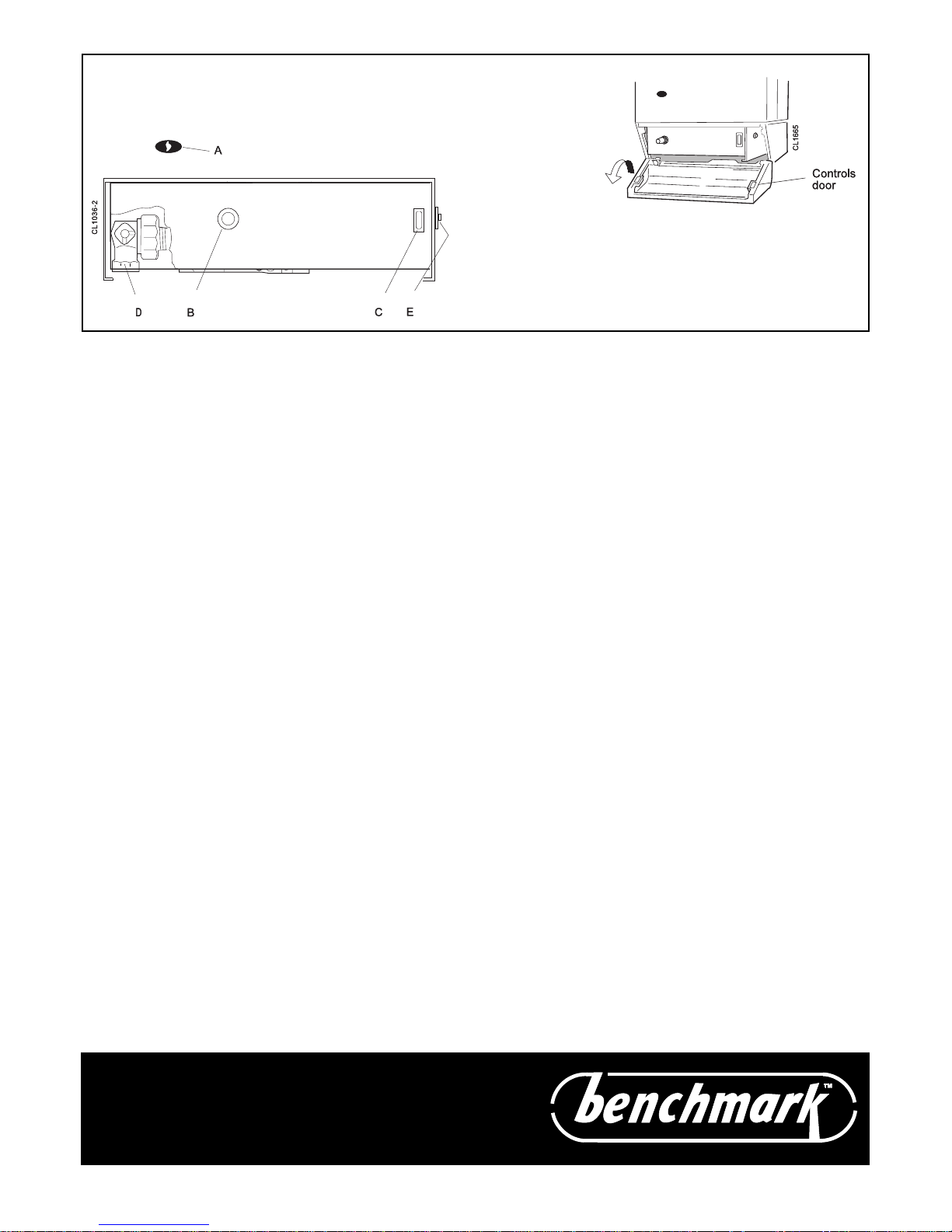

To light the boiler. Refer to Frame 1

1. CHECK THAT THE ELECTRICITY SUPPLY TO THE BOILER

IS OFF.

2. Open the controls access door by hinging downwards.

3. Ensure that the gas service cock (D) is OPEN.

4. Press the overheat reset button (E), located as shown in

Frame 1.

5. Ensure that the mains on/off switch (C) is in the OFF position.

6. Switch ON the electricity supply to the boiler. Check that all

external controls, e.g. room thermostat etc., are ON.

7. Turn the boiler thermostat knob (B) to position 6 and the

mains on/off switch (C) to ON. After about 15 seconds the

boiler will light automatically - this can be viewed through the

sight glass (A).

Set the boiler thermostat to the desired position.

8. Close the controls access door.

In winter conditions, i.e. central heating and domestic hot water,

the thermostat should be set at position 5 or 6.

For summer conditions, i.e. domestic hot water only, the

thermostat should be set at position 3.

These settings, however, are offered for general guidance only

and other settings may be found preferable, dependent upon the

type of system installed or as recommended by the installer.

Approximate flow temperatures for the boiler thermostat settings are:

CLASSIC FF

(

Propane Gas Models Only)

Classic G.C. No

FF 350 P .......... 41 392 06

FF 360 P .......... 41 392 07

FF 380 P ........... 41 392 08

Minimum clearances

A clearance of 533mm (21") MUST be available at the front of the

boiler for servicing.

The minimum clearances given below MUST be complied with in

order to maintain the safe running of the boiler and to facilitate

servicing.

Above the boiler 100 mm (4")

At each side of the boiler 5 mm (

1/4")

Underneath the boiler 100 mm (4")

In front of the boiler 450 mm (17 3 /4 ")

Introduction

It is essential that the instructions in this booklet are strictly

followed, for safe and economical operation of the boiler.

Gas Safety (Installation & Use)

Regulations or rules in force.

In your own interest, and that of safety, it is the law that this

boiler must be installed by a CORGI registered installer or in

IE a competent person, in accordance with the above

regulations.

Electricity Supply

This appliance must be efficiently earthed.

Supply: 230 V ~ 50 Hz. The fusing should be 3A.

Connection must be made in a way that allows complete

isolation of the electrical supply such as a double pole switch

having a 3mm (1/8") contact separation in both poles, or a plug

and socket, serving only the boiler and system controls. The

means of isolation must be accessible to the user after

installation.

Important notes

a.

This appliance must not be operated without the casing

correctly fitted and forming an adequate seal.

b.

If the boiler is installed in a compartment then the

compartment MUST NOT be used for storage purposes.

c.

The ventilation provided for the boiler during installation

MUST NOT be blocked, and a check should be made

periodically that the ventilation areas are free from any

obstruction.

d.

If it is known or suspected that a fault exists on the boiler

then it MUST NOT be used until the fault has been

corrected by a CORGI registered installer or in IE a

competent person.

e.

Inflammable materials must not be placed in close

proximity to the appliance. Materials giving off flammable

vapours must not be stored in the same room as the

appliance.

f.

Under NO circumstances should any of the sealed

components on this appliance be used incorrectly or

tampered with.

g. Where the boiler is fitted with a Vertex Flue System with a

draught diverter in the loft, the loft space MUST NOT be

used as a dwelling area.

To shut down the boiler

1. For short periods: Turn the boiler on/off switch (C)

to OFF. When heating is again required, restore the

switch to ON.

2. For longer periods: Turn the boiler on/off switch (C)

to OFF. Switch the electricity supply to OFF.

Knob Setting Flow Temperature

°C °F

1 56 133

2 61 142

3 66 152

4 72 161

5 77 170

6 82 180

CAUTION. To avoid the possibility of injury during the installation, servicing or cleaning of

this appliance care should be taken when handling edges of sheet steel components

Page 3

Classic FF

- Propane Users

3

1

BOILER CONTROLS

LEGEND

A Sightglass

B Thermostat knob

C Mains on/off switch

D Gas service cock (shown in the OPEN position)

E Overheat thermostat reset button

View inside boiler controls area

THE LOG BOOK SHOULD BE COMPLETED AFTER

EACH SERVICE AND KEPT WITH THESE

INSTRUCTIONS

Frost protection

If no frost protection is provided and frost is likely during a short

absence from home, leave the heating controls at a reduced

temperature setting.

For longer periods, the entire system should be drained - including

the domestic water supply. If the system includes a frost thermostat

then, during cold weather, the boiler should be turned OFF at the

time switch(es) ONLY. The mains supply should be left switched

ON, with the boiler thermostat left in the normal running position.

Boiler Overheat Thermostat

The boiler is fitted with a safety 'cutout' thermostat. This will shut

down the boiler in the event of overheating. Should this occur allow

the boiler to cool, press the reset button (E) then relight as detailed

in steps 1-8 in 'To light the boiler'.

If the cutout condition still persists turn off the boiler and consult a

CORGI registered installer or in IE a competent person.

Control of water temperature

1. Adjust the boiler thermostat (B) to give the required temperature

for central heating.

2. The boiler thermostat automatically switches the main burner

OFF and ON to maintain the selected temperature.

To relight the boiler

Repeat the procedure 1 - 8, detailed in 'To light the boiler'.

Loss of system water pressure

Boilers fitted with Classic Sealed System Units only

If the red arrow on the unit pressure gauge is set above zero and

the system pressure is seen to fall below this value over a period of

time then a water leak is indicated. In this event a CORGI registered

installer or in IE a competent person should be consulted.

DO NOT OPERATE THE BOILER IF THE PRESSURE HAS

REDUCED TO ZERO FROM THE ORIGINAL SETTING.

Escape of gas

Should a gas leak be suspected contact your local gas supplier

without delay.

Do NOT search for gas leaks with a naked flame.

Cleaning

For normal cleaning simply dust with a dry cloth.

To remove stubborn marks and stains, wipe with a damp cloth

and finish off with a dry cloth.

Do NOT use abrasive cleaning materials.

Maintenance

The appliance should be serviced at least once a year by a CORGI

registered installer or in IE a competent person.

THE GAS SAFETY (INSTALLATION AND USE) REGULATIONS,

STATUTORY INSTRUMENT 1994, NO. 1886, AND AMENDMENTS

1996, IMPOSE CERTAIN LEGAL OBLIGATIONS ON GAS USERS.

Changing gas cylinders

a. Ensure that the replacement gas cylinder is the correct one for

the installation.

b. Extinguish any fire, flame or source of ignition (including

cigarettes, pipes and pilot lights) before changing the gas

cylinders.

c. Change cylinders with caution.

d. Ensure that the gas cylinder valve(s) is/are closed before

disconnecting an empty cylinder or before removing any plastic

cap or plug on the outlet connection of the replacement cylinder.

Never use tools on cylinder valves, hand wheels or levers.

Note.

Cylinders with threaded connections have a left hand

thread. For cylinders with self-sealing clip-on valves, ensure

that the regulator tap is closed before disconnection.

All CORGI registered installers carry a CORGI ID card, and have a registration number. Both should be recorded in

your Benchmark Log Book. You can check your installer by calling CORGI direct on 01563 72300

Page 4

GAS LEAK

(usually detected by a distinctive smell)

DO NOT

use electrical switches

DO NOT

look for a leak with a

naked flame

IMMEDIATE ACTION:

• CLOSE all supply valves.

• EXTINGUISH all sources of ignition.

• Open all doors and windows.

• If leakage cannot be stopped REMOVE CYLINDERS to a

safe place in the open air and advise the supplier. If this

is not possible, evacuate the premises and call the fire

brigade.

• Do not use the installation until it has been checked by a

CORGI registered installer or in IE a competent person.

EMERGENCY ACTION

EMERGENCY ACTION

FIRE

IMMEDIATE ACTION:

IF SAFE TO DO SO

, SHUT OFF THE GAS SUPPLY

Do not attempt to extinguish gas flame by any other means.

Raise the alarm and call the fire brigade stating that a liquefied

petroleum gas cylinder is involved, and give its location.

DO NOT GO NEAR A CYLINDER if a cylinder is being heated by

fire.

ALERT EVERYONE in the immediate area of the fire and

evacuate the building.

ADVISE THE FIRE BRIGADE on their ARRIVAL of the LOCATION

of the cylinder.

If a cylinder is not involved in the fire and it is SAFE TO DO SO,

close all cylinder valves and remove the cylinders to a safe

place.

e. Ensure that the replacement cylinder connections are gastight.

Any leaking vapour will have a distinctive odour. Test by using

leak detection solution around the connections - bubbles will

form if vapour is leaking.

NEVER USE A NAKED FLAME

f. It is essential that the correct pressure regulator, with the correct

pressure setting and capacity for the installation, is used in

accordance with the manufacturer's instructions.

g. In the case of a connection on a pressure regulator or gas

appliance which relies upon a sealing washer to maintain a

gastight joint, it is essential to check that the washer is

present and that it is sound and correctly positioned prior to

making the connection. Where the connection relies on a

metal-to-metal seating or bullnose connection to obtain a

gastight joint, it is essential that the mating surfaces be clean

and undamaged.

Under no circumstances should a damaged valve or

connection be used.

h. Where connections are designed to be tightened with a spanner,

it is essential that a spanner of the correct size is used and that

the union is firmly tightened - hand tightness is not sufficient.

When self sealing valves are incorporated in a gas cylinder,

connection should be made in accordance with the

manufacturer's instructions and tools should not be used.

i. If the continuation of supply is interrupted when a cylinder is

changed, it is essential that all appliance taps are turned off

before the change is made.

j. With bulk storage tanks always ensure that the site is kept clean

and clear of rubbish. Such vessels are designed to be filled on

site by the gas distributors.

Ideal Consumer Helpline

Tel: 01482 498 660

www.idealboilers.com

The code of practice for the installation,

commissioning & servicing of central heating systems

Caradon Ideal Limited. is a member of the Benchmark initiative

and fully supports the aims of the programme. Benchmark has

been introduced to improve the standards of installation and

commissioning of central heating systems in the UK and to

encourage the regular servicing of all central heating systems to

ensure safety and efficiency.

March 2003 UIN 157366 A02

Caradon Ideal Limited pursues a policy of continuing improvement

in the design and performance of its products. The right is therefore

reserved to vary specification without notice.

Ideal Boilers,

P.O. Box 103, National Ave, Kingston upon Hull,

HU5 4JN. Telephone: 01482 492 251 Fax: 01482 448 858.

Registration No. London 322 137.

Loading...

Loading...