Page 1

Pre-Insulated Crimp Application Machine (PCAM™)

Instruction Manual and Parts List

30-94 6, 3 0-947

1

Page 2

2

Warning and

Safety

Instructions

Please read, understand and follow the warnings and instructions in this manual and

on the machine. Failure to do so can result in serious personal injury.

■ Do not operate machine when any component is missing or damaged.

■ Do not perform any maintenance on the machine unless the electrical and air

supply to the machine are disconnected.

■ Do not operate machine without wearing proper eye protection.

■ Do not operate machine in a damp or wet location.

■ Do not operate if liquid is spilled on or in machine.

■ Do not operate machine on an ungrounded electrical system.

■ Do not alter, modify or misuse the machine.

■ Do not operate machine unless all instructions are read and understood.

■ Do not operate machine in a gaseous or hazardous environment.

Technical

Data

Description

Specifications

Total Cycle Time 4 Seconds

Electrical Supply 120 VAC 60 Hz

Compressed Air Supply 80-90 PSI Regulated & Dry

Dimensions 15” Deep x 13-5/8” Wide x 9-7/8” High

Shipping Weight 59 lbs.

For technical assistance with this machine, call:

1-877-201-9003

OEM Tech Support

Page 3

Table of Contents

Part I General Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. PCAM™ Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. PCAM™ Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

D. PCAM™ Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Part II Equipment Set-up Instructions . . . . . . . . . . . . . . . . . . . . . . . . 6

A. Unpacking PCAM™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Hand Gun Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

C. Console Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

D. Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

E. Mounting Hopper Unit to Console Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

F. Installing and Adjusting Hopper Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

G. Attaching Tool Balancer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

H. Assembling Bench Mounting Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

I. Loading Hopper Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

J. Checking Hopper Solenoid Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

K. Adjusting Hand Gun Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Part II I Operational Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Feed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part IV Maintenance Service Program . . . . . . . . . . . . . . . . . . . . . . 10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part V Service and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 10

Proper Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part VI Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-18

A. Hand Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

B. Console Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

C. Hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

D. Hopper Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

E. Bench Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Part VII PCAM Setup and Diagnostic Program . . . . . . . . . . . . . . . . . 19

Appendix A Service and Troubleshooting . . . . . . . . . . . . . . . . . . . . . 20-21

Appendix B1 Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Appendix B2 Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix C Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Addendum Figure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Addendum Figure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3

Page 4

Part I General Coverage

A. Introduction

The Pre-Insulated Crimp Machine (PCAM™) is especially designed to quickly and firmly apply IDEAL PreInsulated Crimp Connectors to a wide range of conductor types and sizes.

PCAM™ is a computer-controlled machine that insures integrity and consistency for each electrical connection.

PCAM™ is the only computer-controlled machine that applies "pig-tail" type crimp connectors, with precision,

faster than manual assembly operators.

B. PCAM™ Models

Model 30-946

30-947

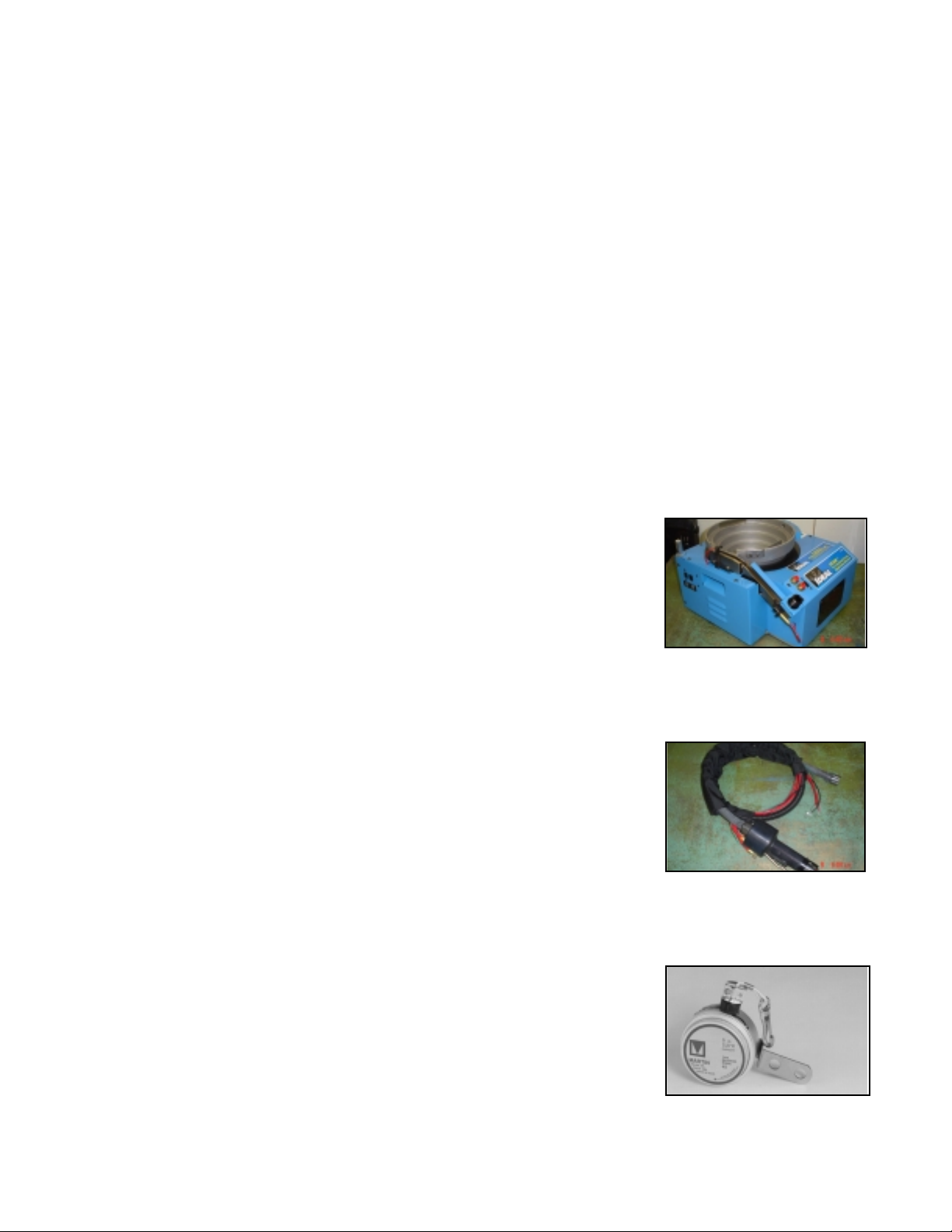

C. PCAM™ Components

Each PCAM™ model consists of the following components:

■ Console Unit

■ Hand Gun Assembly

■ Tool Balancer

The Console Unit contains the main control components, including the:

■ Electronics Modules

■ Pneumatic Components

■ Connector Feed Bowl

The Hand Gun Assembly applies the connector to the stripped conductor ends. It is

a lightweight hand-held unit that is controlled from the console unit. It contains the:

■ Hand Gun

■ Feed Hose

■ Pneumatic 1/4" Feed Tubes

The Tool Balancer is an adjustable counter balance for the Hand Gun. It allows the

Hand Gun to hang vertically weight free and locates the Hand Gun at a desired

height position.

D. PCAM™ Accessories

4

Page 5

1. Bench Mount and Foot Switch (30-930)

The Bench Mount and Foot Switch are used together. The Foot Switch can be used in place of hand gun

trigger. The Bench Mount holds and positions the Hand Gun. It is used for applications where the work can

be brought to the Hand Gun – usually small components that can be hand held.

2. Hopper Unit (30-951)

The Hopper Unit holds the wire connectors and feeds them to the feed bowl. This system is controlled by a

proximity sensor, which constantly monitors and maintains the correct level of connectors in the feed bowl

at all times.

5

Page 6

Part II Equipment Set-up Instructions

A. Unpacking PCAM™

Caution: Do Not use feeder bowl to lift console from carton.

Note: See assembly drawing on page 13 for item numbers.

Remove the following contents from carton:

■ Instruction Manual ■ 90º swivel air hose fitting (item #22)

■ Green ground wire (item #27) ■ 1/2" clear feed air hose (item #21)

■ 1/4" O.D. red air line tubing (item #14) (2) ■ Hand Gun (item #15)

■ Protective Sleeve (item #26) (2) ■ Tool Balancer (1161.033)

■ Power Cord (item #32)

■ Console Unit (30-947). Remove packing prior to lifting out unit.

■ Hose Assembly (item #13)

B. Hand Gun Assembly

■ Unwind switch cable from hand gun body

■ Screw black feed hose (item #13) into threaded fitting on back of hand gun body. Push both 1/4" O.D. red

air lines (item #14) into quick release air fittings on the hand gun adjacent to the black feed hose (item #13)

until they are fully seated. Notice dimple adjacent to quick release air fitting on back of the hand gun body.

■ Loosen screw adjacent to black feed hose (item #13) two to three turns. Slide spade terminal connector from

hand gun ground wire (item #27) under loosened screw. Tighten screw.

C. Console Unit Assembly

■ Screw black feed hose (item #13) into threaded adapter (item #12) on top front left of console unit.

■ Locate two quick release air fittings on the console adjacent to the black feed hose (item #13). Locate

dimple adjacent top quick release fitting. Push other end of 1/4" O.D. red air line (item #14) adjacent to the

dimple in hand gun into top quick release air fitting on console unit until it is fully seated.

■ Push second 1/4" red air line (item #14) into bottom quick release fitting adjacent to the black feed hose on

the console unit until it is fully seated.

■ Insert RJ-11 modular plug from hand gun switch into socket adjacent to the black hose on the console unit.

■ Loosen top screw of RJ-11 socket on console two to three turns. Slide spade terminal connector from hand

gun ground wire (item #27) under loosened screw. Tighten screw.

■ Install protective sleeves (item #26) by fastening hook, and loop material over red air lines, black feed tube,

ground wire, and switch cable.

D. Supply Assembly

Caution: A minimum 80 PSI clean dry compressed air is essential for the proper function of the PCAM™

machine. Failure to provide proper air supply will result in PCAM™ machine failure.

■ Apply a non-tape pipe thread sealant such as "Loctite®" #565 to threads of 90º swivel fitting (item #22).

Tighten 90º swivel fitting into brass bulkhead fitting on rear right side of console unit.

■ Insert 1/2" air hose (item #21) into the 90º swivel fitting above until it is fully seated.

■ With air supply shut off, connect 1/2" air hose above to clean dry regulated air supply.

■ Insert 120 VAC line cord socket (item #32) into on/off switch socket on right side of console unit.

■ With PCAM™ power switch in "off" position, plug power line cord into a 120 VAC supply.

6

Page 7

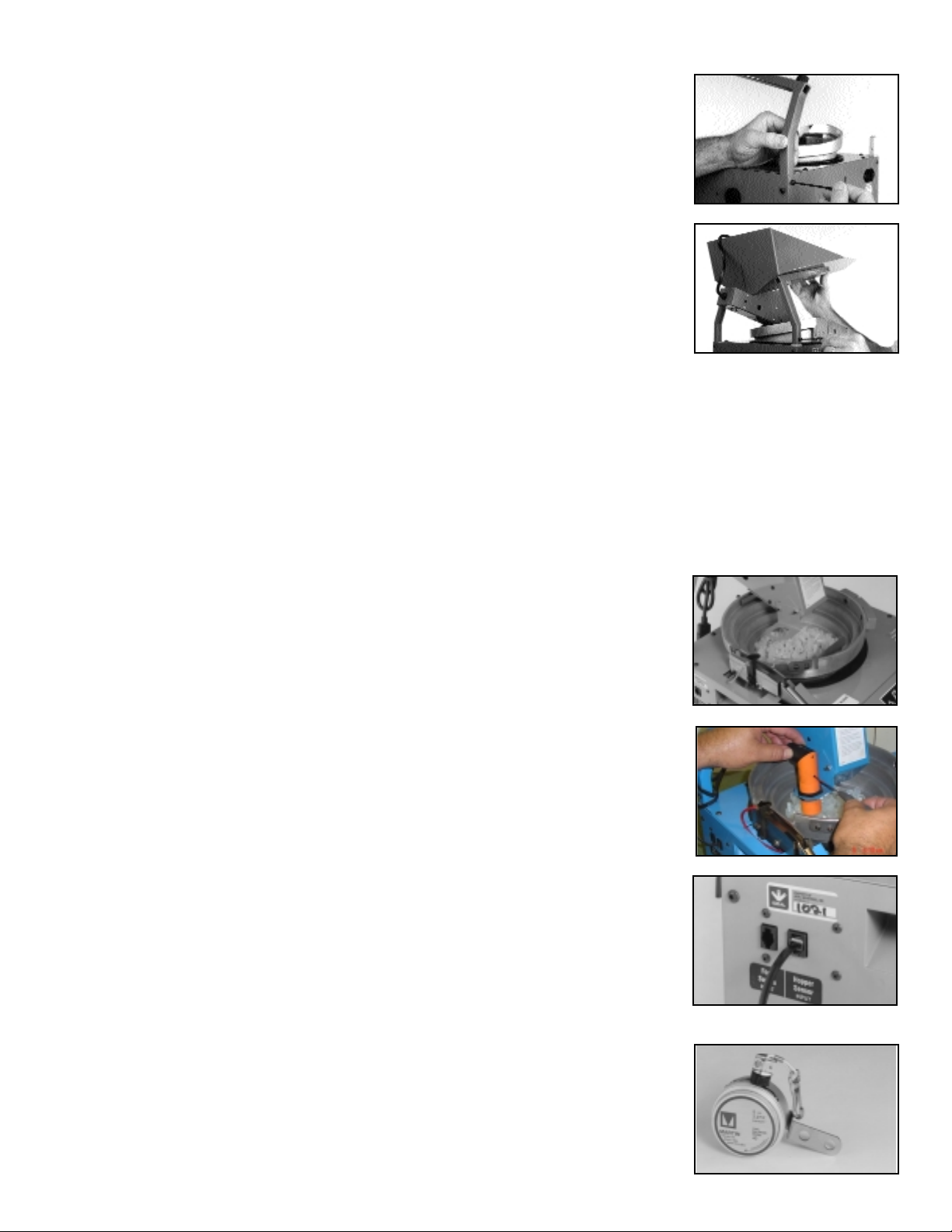

E. Mounting Hopper Unit to Console Unit

■ Mount hopper arm with rubber bumpers to right rear corner of Console Unit

using four 10-24 screws provided.

■ Slide arm attached to hopper over left rear Hopper mount post.

■ Secure with 10-24 x 1/2" screw.

■ The PCAM can be operated without the Hopper in place. To disable proximity sensor, access the display

board by removing the red bezel located at the front of the console. Rotate switch SW3 to the #5 position

and press button SW1 until the display reads "HOP OFF." This indicates that the automatic feed from the

hopper is turned off. Turn switch SW3 to the #0 position, resume normal operation without Hopper.

Note: See Part VII (page 19) for switch position description.

F. Installing and Adjusting Hopper Level Sensor

■ Fill bottom of feed bowl with connectors to about one inch depth.

■ Adjust sensor nuts to allow sensor to protrude through bracket about two

inches.

■ Plug proximity sensor into Hopper sensor connector located on left side of

Console Unit.

■ Plug Hopper power cord into outlet on back of Console Unit.

■ Turn power "ON." Switch located on right side of console.

■ If sensor light is on, turn adjustment screw counterclockwise until light just

goes off.

■ With sensor light off, turn adjustment screw clockwise until light just comes

on.

The level sensor is now adjusted. Slight adjustments can be made to the

connector level by turning adjusting screw counterclockwise to increase the level

and clockwise to decrease the level.

G. Attach Tool Balancer

■ A counter balance is supplied with each unit to locate hand tool to desired

height position. Swivel hook on counter balance can be attached to mounting

eye on hand tool.

7

Page 8

H. Assembling Bench Mounting Stand (optional).

■ Place Hand Gun in Bench Mount Stand.

■ Secure by tightening clamp collar screw.

■ Position Hand Gun and Bench Mount Stand in convenient working location

on bench.

■ Fasten Mounting Stand to bench securely.

■ Insert male plug from Foot Switch Control into Foot Switch INPUT jack on

rear left side of Console Unit.

I. Loading Hopper Unit

■ Fill Hopper.

■ IMPORTANT – Use only IDEAL Pre-Insulated Crimp Connectors in PCAM™.

Do not mix different size connectors in PCAM™.

J. Check Hopper Solenoid Adjustment

■ Gate should clear the connector entry path with the solenoid plunger

completely seated in the solenoid coil. Gate should not touch bottom of

Hopper Chute when in the open position.

Note: Improper solenoid adjustment will result in premature solenoid

failure.

■ To correct solenoid position, loosen mounting screws, slide solenoid

forward or back as required, retighten screws and double check adjustment.

K. Adjusting Hand Gun Sensor

■ The Hand Gun sensor is set at the factory. Due to changing Hand Gun housing, the sensor may need to be

adjusted to match the new housing.

■ Remove the six screws holding the red bezel to the front of the console.

Note: See Part VII (page 19) for switch position description.

■ Rotate switch “SW3” to the #6 position. The display will show "ADJ TOOL" (adjust tool). Hand Gun will

release the connector.

■ Push the connector back into the Hand Gun about 3-4".

■ The Hand Gun sensor adjustment can be reached with a small slotted screwdriver through a small hole

located on the front panel adjacent to the red air hoses.

■ Rotate the potentiometer counterclockwise until the warning beeper stops. Rotate the potentiometer

clockwise until the warning beeper has a consistent beep.

■ Rotate switch “SW1” to the #0 position. The PCAM will blow and the Hand Gun will clamp onto the

connector.

8

Page 9

Part II I Operation Instructions

■ Follow Equipment Set-up Instructions (Part II) to complete the assembly of the PCAM™.

■ Turn on the air supply and power. The display will momentarily show the current software version and then

will show the cycle counter. The Feed Bowl will vibrate the connectors up to the ramps. Once the stationary

ramp fills with connectors up to the upper sensor, the Feed Bowl will cease vibrating. When connectors are

removed from the stationary ramp past the lower sensor, the Feed Bowl will again begin to vibrate until the

upper sensor is again blocked. The air stream located at the top of the Feed Bowl will prevent improper

stacking of connectors. This air stream will blow any time the Feed Bowl is vibrating.

■ Fill the Hopper with connectors. The Hopper will continue to dump connectors every 15 seconds until the

Feed Bowl is filled to the proper operating level. The system will automatically keep the vibratory Feed

Bowl at this level at all times. If the Hopper becomes empty, the system will keep trying to dump connectors

every 15 seconds. If this occurs four times and the Feed Bowl has not been filled, a "Parts LO" (parts low)

message will be displayed and an audible alarm will beep. Momentarily press the trigger on the Hand Gun

to turn off the alarm. The machine remains operational during this condition. The operator will not have to

stop while the Hopper is being filled. The PCAM™ can be operated without the Hopper.

(See Part II "E" Pg 7)

■ When the PCAM™ is first set up, it is unlikely that a connector will be present in the Hand Gun. To send a

connector to the gun, press the switch level located on the Hand Gun. The following will occur:

- The escapement on the console will allow one connector into the feed chamber.

- A blast of air will send the connector to the Hand Gun.

- The crimp jaws will hold the connector in place without distorting it.

■ The PCAM™ is now ready for operation. Insert the wires fully into the connector exposed at the end of the

Hand Gun. With wires properly located, depress the switch lever momentarily and the crimp cycle will

begin. In the act of crimping, the jaws will push the connector out of the Hand Gun and then pull it back.

Once it is back in, the operator should remove the connector by pulling it straight out of the Hand Gun. The

next connector will automatically be sent to the Hand Gun.

■ If the switch lever is repeatedly depressed without wire in the connector, the connector(s) will become stuck

in the Hand Gun. To remove stuck connector(s), follow procedure 8 on page 20. Following procedure 8,

complete above process to send a connector to Hand Gun.

Feed Control

■ The connector feed rate is preset at the factory for normal applications and

installations. Due to variations in voltages and/or mounting practices, it may

be necessary to change the feeder bowl vibration rate to obtain the desired

feed rate. This should be set so that movement of the connectors is observed

but not to the extent that they bounce. The control for this adjustment can be

reached with a screwdriver through a small hole located on the right side

panel of the Console Unit. Clockwise rotation of the control shaft will

increase the vibration rate of the feeder bowl.

9

Page 10

Part IV Maintenance Service Program

General

■ It is recommended that a regular prevention maintenance program be established to insure the utmost service

from the equipment. The schedule for such a program will largely depend upon the usage of the equipment.

The greater the use, the more frequent the maintenance schedule.

■ The IDEAL field sales engineer will train your personnel on the operation, care and maintenance of the

equipment at the time of installation; he will also establish a parts program.

■ See Appendix "C" for minimal recommended schedule.

Part V Service and Trouble Shooting

Proper Operation

■ When the machine is turned on, the machine will momentarily display the software version. If there is a

connector in the hose assembly or application tool, the machine will automatically advance it to the crimp

position. If no connector is visible at the crimp position, press the switch lever (25) momentarily to advance

the next connector. The display will show the cycle count. The machine is now ready to crimp.

■ See Appendix "A" for Trouble Shooting.

■ See Appendix "B" Functional Testing Descriptions.

10

Page 11

Part VI Parts Lists

A. Hand Gun

11

Page 12

12

B. Console Unit

Page 13

13

Page 14

14

C. Hopper

Page 15

15

Hopper

Item

Req Description Complete Unit

30-951

1 8 BHSC Screw #10-24 x .50 115.015

2 1 Hopper Sub Assembly K-6692

3 4 Phil Pan HD #6 x .25 501.055

4 2 Nut #6-32 371.003

5 2 BHSC Screw #6-32 x .50 115.003

6 1 Sensor Bracket LB1102

7 1 Hopper Sensor Assembly K-6693

8 1 Hopper Chute Assembly IA1165

9 1 Left Side Bracket Assembly IA1168

10 1 Right Side Bracket Assembly IA1169

11 2 Foot 081.009

Page 16

16

D. Hopper Chute

Page 17

17

Hopper Chute

Item

Req Description IA1165

1 1 Solenoid Cable Assembly K-6622

2 1 Gate Assembly K-6666

3 1 Strain Relief 272.004

4 1 Securing Plate L-7922

5 3 BHCS Screw #6-32 x .38 115.009

6 1 Nut #6-32 371.003

7 1 Int Washer #6 633.006

8 1 Side Cover K-5110

9 1 Chute Plate Assembly K-5112

10 1 Solenoid 1532.006

11 1 Feed Bracket L-9321

12 8 Phil Pan HD #6 x .25 501.055

13 1 Cotter Pin .090 x .75 283.001

14 1 Solenoid Mtg Plate K-5108

15 1 Spring L-6973

16 2 Washer 632.102

Page 18

18

E. Bench Mount

Bench Mount

Item

Req Description Part No.

1 1 Base Plate K-4703

2 1 Base K-7802

3 1 Mount LA-2884

4 3 SHCS Screw 1/4-28 x .38 113.172

5 4 Lockwasher 1/4 633.003

6 1 SHCS Screw 1/4-28 x 2.50 113.182

7 1 Carriage Bolt 5/16-18 x .75 051.004

8 1 Lockwasher 5/16 633.012

9 1 Nut 5/16-18 371.018

Page 19

19

Part VII PCAM™ Setup and Diagnostic Programs

To access set-up and diagnostic switches shown below, remove the six screws on the red faceplate bezel.

Setting Count

The count shown in normal RUN mode can be reset to zero by momentarily pushing push button "SW1."

Master Cycle Count

The total number of cycles run on the machine can be shown by turning switch “SW3” to position 1. Turn switch

“SW3” to 0 (zero) position to return to RUN Mode.

SW1

SW3

SW2

SW4

0

9

1

8

7

6

2

3

4

5

SW5

SW6

OFF

SW7

OFF

SW8

ON

6

7

2345

1

ON

2345

1

8

6

7

8

SW1

SW3

SW2

SW4

0

9

1

8

7

6

2

3

4

5

SW5

SW6

OFF

SW7

OFF

SW8

ON

6

7

2345

1

ON

2345

1

8

6

7

8

Page 20

Appendix A

Service and Troubleshooting

1. Machine does not power up.

2. Display and Operation sequence

3. Bowl feed does not feed connectors.

4. Front display panel does not display

cycle count.

5. Connectors do not feed to Hand Gun

6. Stuck connectors in Hand Gun

7. Connector crimped without wires

inserted

8. Multiple connectors stuck in Hand Gun

9. "Parts LO" display indication

10. "LO PSI" or "HI PSI" display

indication

11. Warning beeper sounds when Hand

Gun switch lever is pressed

Check on/off switch. Set to "ON" position. Check 120 VAC supply.

Check power cord is properly seated at side of console.

See OPERATION page 9. Note: All switches are accessed by removing

six screws on red faceplate bezel. Switch “SW3” must be in "0"

position to operate PCAM™.

See page 9 – Feed control adjustment.

See page 19 – Setting Count. If count cannot be set, call IDEAL

Technical Support at 1-877-201-9003. (Assure “SW3” is set to “0”

position.)

Check connector blow off (item 5 pg 13) for stuck connector. Check

connector ramp and feed changer (item #16) for stuck connectors.

Recalibrate Hand Gun per procedure “K” on page 8.

Press Hand Gun switch lever (item #7 pg 11) until warning beeper

sounds. Pull out crimped connector with long nose pliers or remove

hose assembly (item #13 pg 13) from Hand Gun. Push crimped

connector out of Hand Gun with 8" wooden or plastic doll-rod.

Connect hose assembly to Hand Gun. Press Hand Gun switch lever to

advance next connector.

Follow above procedure except use long nose pliers to grip connector

and pull from Hand Gun.

Press Hand Gun switch lever (item #7 pg 11) until warning beeper

sounds. Remove hose assembly (item #13 pg 13) from Hand Gun.

Push crimped connectors out of Hand Gun with 8” wooden or plastic

doll-rod. Connect hose assembly to Hand Gun. Point Hand Gun away

from face and press both retainer arms (item #14 pg 11). Press Hand

Gun switch lever. Machine will clear hose and Hand Gun of all

connectors. Release retainer arms and press Hand Gun switch lever to

advance next connector.

Check feed bowl hopper for connectors. To silence warning beeper,

press Hand Gun switch lever (item #7). Fill hopper with connectors.

Check supply pressure. Pressure must be between 80 and 90 PSI.

Machine will not

operate unless air pressure of 80-90 PSI is

maintained. If pressure is too low or too high, warning beeper sounds

to alert operator when Hand Gun trigger is depressed.

Remove crimped connector from Hand Gun. Check I.D. of housing

assembly for exposed bare aluminum. Check Hand Gun sensor and

I.D. of housing assembly for damage. Recalibrate sensor per procedure

“K” on page 8.

20

Page 21

21

Appendix B

B-1 Functional Testing

In order to test the individual sensors and valves in the PCAM™, the red faceplate bezel must be removed. To

remove red faceplate bezel, unscrew the six retaining screws and remove bezel.

Once red faceplate bezel is removed, switch “SW3” must be set for position #2. Display will read "Unit."

Note: "SW3" must be returned to "0" position after testing for PCAM™ to function.

Only one test can be conducted at time. Return dip switch “SW7” to "OFF" position after each test.

Function Testing

1. Actuate connector "hold" solenoid

2. Actuate connector "crimp" solenoid

3. Actuate bowl blow off air blast at feed bowl

4. Actuate escapement air cylinder

5. Actuate air blast in feed chamber

6. Actuate hopper solenoid

7. Actuate vibrator on feed bowl

8. Actuate beeper

Move switch #1 on dip switch SW7 to ON position.

Move switch #2 on dip switch SW7 to ON position.

Move switch #3 on dip switch SW7 to ON position.

Move switch #4 on dip switch SW7 to ON position.

Move switch #5 on dip switch SW7 to ON position.

Move switch #6 on dip switch SW7 to ON position.

Move switch #7 on dip switch SW7 to ON position.

Move switch #8 on dip switch SW7 to ON position.

Appendix A (cont)

Service and Troubleshooting

12. Warning beeper sounds when Hand

Gun switch lever is pressed, but there is

no connector in Hand Gun

13. Cannot access the “ADJ TOOL”

during the “Adjusting Hand Gun Sensor”

procedure on page 8. (Cannot access any

Functional and/or Sensor Testing when

rotating the “SW3” switch.)

14. Audible alarm beeps and the crimp

does not advance to housing assembly

when Hand Gun trigger is cycled.

15. Crimp advances to Hand Gun, but the

indenters do not hold the crimp when

Hand Gun trigger is cycled.

Lightly tap housing of Hand Gun on bench to remove dirt or connector

fragments from sensor, or see Adjusting Hand Gun Sensor on page 8.

Check I.D. of housing assembly for exposed bare aluminum.

Check Hand Gun sensor and I.D. of housing assembly for damage.

Recalibrate sensor per procedure “K” on page 8.

Make sure “SW3” switch is in the “0” position. Using a small

electronic slotted screwdriver, rotate the potentiometer (located on

front panel adjacent to the red air hoses) clockwise while cycling the

Hand Gun until a crimp is advanced and the audible alarm stops

beeping. The crimp is viewed by the sensor and held by the indenters.

(The clockwise rotation of the potentionmeter must be performed

quickly prior to the cycle timing out.) Now, rotate the “SW3” to the

desired position.

Recalibrate Hand Gun sensor per procedure “K” on page 8.

Recalibrate Hand Gun sensor per procedure “K” on page 8.

Replace housing assembly, or entire Hand Gun, and recalibrate sensor

per procedure “K” on page 8.

Page 22

22

1. Test upper-end feed ramp (optical) sensor

2. Test lower-end feed ramp (optical) sensor

3. Test low and high pressure sensors

4. Test Hand Gun switch lever

5. Test Hand Gun sensor

6. Test hopper proximity sensor

Move switch #1 on dip switch SW7 to ON position.

Beeper will sound if object is in sensor's range.

Move switch #2 on dip switch SW7 to ON position.

Beeper will sound if object is in sensor's range.

Move switch #3 on dip switch SW7 to ON position.

Beeper will sound if pressure is below 75 PSI or

above 95 PSI.

Move switch #4 on dip switch SW7 to ON position.

Beeper will sound when Hand Gun switch lever is

activated.

Move switch #5 on dip switch SW7 to ON position.

Beeper will sound when a connector or something

reflective is placed near the sensor.

Move switch #6 on dip switch SW7 to ON position.

Beeper will sound when any object is within sensing

distance.

(refer to diagrams on page 19)

Appendix B

B-2 Sensor Tests

Follow instructions for "Functional Tests" except move switch SW3 to position #3. Display will read "Sensors."

Page 23

23

Appendix C

Preventive Maintenance

The following schedule is based on normal use in a clean environment. Conduct maintenance more often if

needed. Refer to page 11 parts list for the hand gun.

Every 5,000 cycles, perform the following.

■ Inspect Hand Gun visually for any sign of damage or wear. Contact IDEAL Technical Support at

1-877-201-9003 for assistance.

■ Inspect O-ring (item #30) for cracking. Replace if needed.

■ Apply a drop of medium weight machine oil to each end of each roller (item #28) to lubricate pins

(item #29).

■ Apply small amount of general purpose grease to both indenters (item #12). Apply grease where indenter

touches roller (item #28). (See PCAM Addendum Fig. 1)

Every 50,000 cycles, perform the following:

■ Remove crimp housing (item #16) from Hand Gun and blow out foreign matter with air hose.

(See PCAM Addendum Fig 2)

■ Crimp a connector without wires. Look into open end of connector. If daylight can be seen between inside

edges of ferule, replace Hand Gun housing subassembly (item #46 pg 11)

Page 24

24

PCAM Addendum – Fig. 1

Preventive Maintenance

Every 5,000 cycles apply a small amount of general-purpose grease to the indentor surface as indicated by

Balloon 1 above.

Bearing Orientation

Balloon 2 shows the Bearing in the correct orientation. The Bearings are marked with a notch to help check for

the correct orientation. Check the Bearings each time the Housing is screwed back into position.

Page 25

25

PCAM Addendum – Fig. 2

Must remove 4-40 button head with 1/16” Allen wrench and housing cover before housing can be removed.

Page 26

1330 E Lincoln Hwy, DeKalb, IL 60115 U.S.A.

Ajax, Ontario L1S 2E1 CANADA

Warrington, Cheshire WA5 5TN ENGLAND

Technical Assistance: 1-877-201-9003 – M-F 7:00 am - 3:30 pm CST

www.idealindustries.com

ND-854-2 7/04 Made in U.S.A.

Loading...

Loading...