ICT ICT240DB-8IRC Instruction Manual

Innovative Circuit

Technology Ltd.

Front Access Distribution

Panel Series

INSTRUCTION MANUAL

855-154-000

Model: ICT240DB-8IRC

2 Innovative Circuit Technology Ltd.

WARNING

Risk of serious personal injury or damage to equipment and property! Always

observe the following:

Use an appropriately rated over-current protection device in line with the

main battery connections to the panel

Use an appropriately rated disconnect switch or circuit breaker in line with

the dc inputs to enable installation and service of the panel with the dc

source disconnected

Shut off or disconnect all dc power sources before connecting or

disconnecting wiring

Use wire and connectors rated for the maximum load current and size of

fuse or circuit breaker, and keep cable lengths as short as practical

Carefully observe wiring polarity when making input and output connections

Securely tighten all connections

Do not attempt to service any internal parts. Refer all product service to an

authorized ICT Ltd. service facility

CAUTION

Risk of personal injury or damage to equipment! Always observe the following:

Install unit in a restricted access location (such as an equipment rack) to limit

unintentional contact with terminals and wiring

Ensure the total power consumption of the loads does not exceed the 100A

(continuous) rated capacity of each power bus

Ensure load current through each output channel does not exceed 30A max,

25A continuous

Do not block air inlet or outlet openings in the panel sides and back

Innovative Circuit Technology Ltd. 3

Contents

PRODUCT DESCRIPTION ....................................................................... 4

INSTALLATION ..................................................................................... 5

OPERATION ......................................................................................... 9

Status Indicators and Alarms ...................................................... 9

TCP/IP WEB BASED INTERFACE ........................................................... 10

Status and Control ...................................................................... 11

Device Setup ............................................................................... 12

Bus Setup ..................................................................................... 15

Output Setup ............................................................................... 16

Network setup ............................................................................ 18

E-mail Setup ................................................................................ 20

Alarm setup ................................................................................. 22

User Setup ................................................................................... 23

Maintenance................................................................................ 24

MOBILE WEB INTERFACE .................................................................... 24

PASSWORD RESET .............................................................................. 25

ROUTER CONFIGURATION .................................................................. 26

TEXT MESSAGE ALARM NOTIFICATIONS .............................................. 28

TROUBLESHOOTING ........................................................................... 28

PRODUCT SPECIFICATIONS ................................................................. 30

LIMITED WARRANTY .......................................................................... 32

4 Innovative Circuit Technology Ltd.

PRODUCT DESCRIPTION

The ICT Front Access Dual Bus Distribution Panel provides two 100A (continuous)

bus inputs with four independently controlled and monitored output channels

per bus in a compact 1U high chassis for 19 inch rack mounting. All connections

are located on the front panel for simple installation in tight cabinets, and over

current protection and manual on/off control for each output is provided by

65VDC user replaceable magnetic-hydraulic circuit breakers.

Each bus can accommodate a wide supply voltage from 10VDC to 60VDC, either

positive or negative polarity, with a peak input current of 120A to be distributed

at up to 30A peak on each of the 4 output channels. Each channel has

independent current sensing, over current protection, alarms, and output on/off

control.

Remote monitoring and control is available through the integrated security

protected Ethernet communications port on the front panel. The unit has a builtin web server with an embedded web-based graphical user interface (GUI) that

can be accessed using any standard commercial web browser, such as Internet

Explorer or Google Chrome. The web server displays all panel information, allows

full access to channel configuration settings, provides remote channel on/off

control, and can be set up to send an alarm to user-defined email accounts in the

event a fault occurs. The web server can also be used to configure and download a data log of up to 30 days of time stamped event information. Full

monitoring and control is also available using an SNMP (v2) based management

system for larger installations.

Form-C alarm output contacts (C/NO/NC) are provided for each bus to indicate

all distribution panel alarms, while 4 additional alarm inputs can be used to

monitor other dry-contact site sensors such as door/window opening, smoke

alarms, and water detectors etc. An optional remote temperature sensor (ICTTMP) can also be connected for remote monitoring of a battery pack or another

important temperature.

Model Numbers: (covered in this manual)

ICT240DB-8IRC Intelligent Dual 120A Bus Distribution Panel for +/-12, 24 or

48VDC Systems

Innovative Circuit Technology Ltd. 5

INSTALLATION

Inspect your distribution panel to ensure it was not damaged in shipping, and has

all accessories:

2 clear snap on covers to insulate main dc power connections (shipped

on unit)

4 clear snap on covers for the 4 position output terminal blocks (shipped

on unit)

2 seven pin alarm output, remote sensor input connector plugs (shipped

on unit)

Circuit Breaker label sheet (apply output number label below each

breaker rocker once breakers installed)

This Instruction Manual

To complete the installation you will also need to order circuit breakers

appropriately sized for your requirements, and blanking plugs for any un-used

positions. Order these separately from ICT per the following list:

Breakers:

ICT Model

Rating (65VDC)

Mfg. Part Number

ICT-CB5

5A

Carling MA1-B-14-450-1-A26-2-J

ICT-CB15

15A

Carling MA1-B-14-615-1-A26-2-J

ICT-CB25

25A

Carling MA1-B-14-625-1-A26-2-J

ICT-BLP

Blanking Plug

CBI “B” series rocker handle circuit breakers with 0.25” tab terminals and current

ratings up to 25A may also be used, consult ICT for suitable part numbers.

CAUTION

Risk of personal injury or damage to equipment! Always observe the following:

Install unit in a restricted access location (such as an equipment rack) to limit

unintentional contact with terminals and wiring

Ensure the total power consumption of the loads does not exceed the 100A

(continuous) rated capacity of each power bus

Channel output breakers must not exceed 30A max rating

Install only 65VDC rated breakers

Do not block air inlet or outlet openings in the panel sides and back

6 Innovative Circuit Technology Ltd.

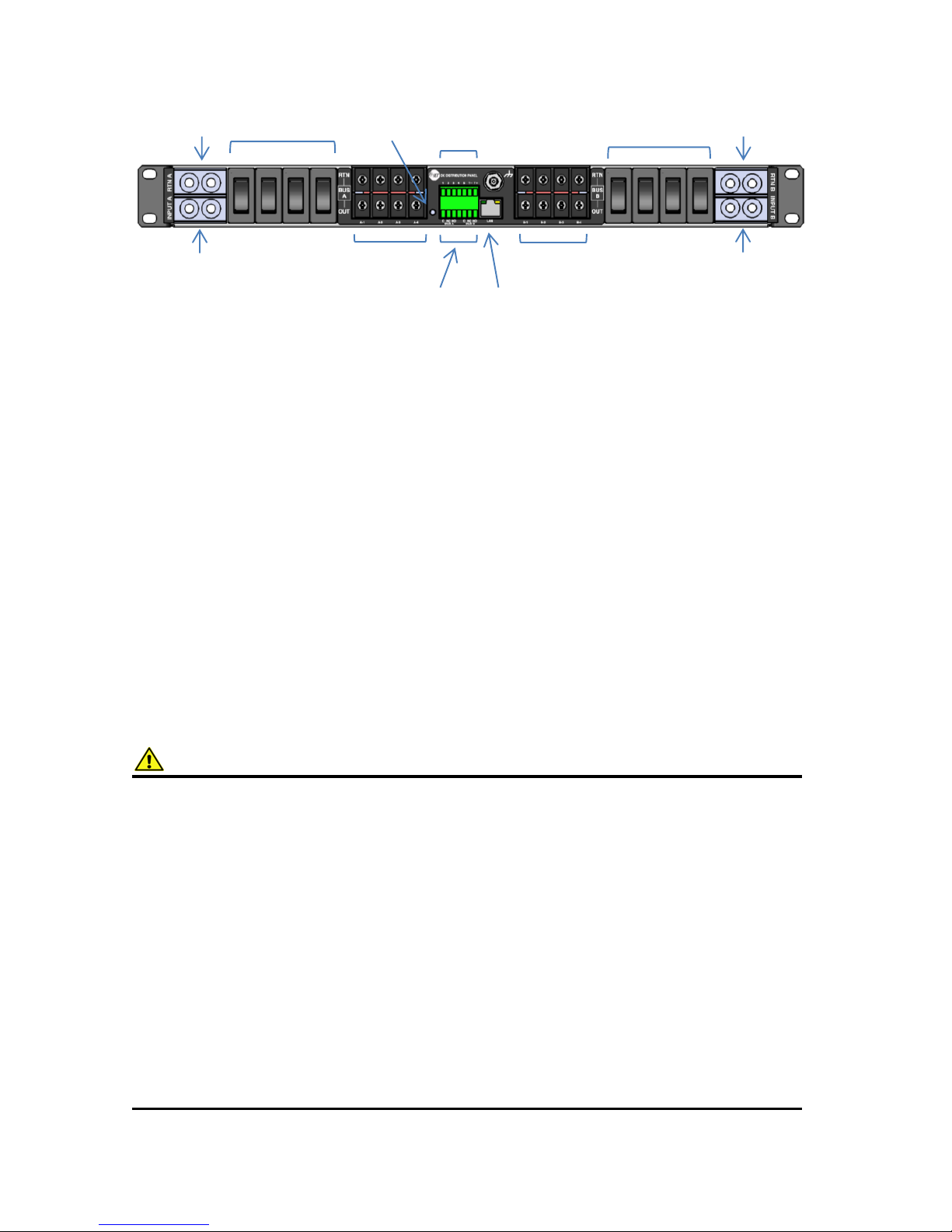

Figure 1: Front Panel Connections

Mount the Front Access Distribution Panel in a 19 inch equipment rack, using

standard rack mounting hardware. (Not provided)

Install appropriately rated circuit breakers in desired channel locations by

carefully inserting a breaker so that its mounting tabs securely snap into the

front panel (with “I/on” marking up). Install the breaker blanking plugs in any

unused locations. Breakers and plugs may be removed by using two small

screwdrivers or similar tools to press in the top and bottom mounting tabs

through the cover openings and gently prying out of the panel.

Label the output channel number of each breaker by applying one of the

supplied labels (A1 to A4, B1 to B4) below each breaker rocker.

WARNING

Risk of serious personal injury or damage to equipment and property! Always

observe the following:

Use an appropriately rated over-current protection device in line with the

main battery connections to the panel

Use an appropriately rated disconnect switch or circuit breaker in line with

the dc inputs to enable installation and service of the panel with the dc

source disconnected

Shut off or disconnect all dc power sources before connecting or

disconnecting wiring

Use wire and connectors rated for the maximum load current and size of

fuse or circuit breaker, and keep cable lengths as short as practical

Carefully observe wiring polarity when making input and output connections

Securely tighten all connections

Bus B Output

Breakers 1-4

Bus B Outputs

Channel 1-4

Bus B Return

(Common)

Bus A Return

(Common)

Site Alarm inputs

1-4, Temp Sense

Bus A, Bus B

Alarm out

C/NC/NO

LAN Port

10/100 Base-T

Bus A Output

Breakers 1-4

Bus A Outputs

Channel 1-4

Bus A Input

(100A cont)

Bus B Input

(100A cont)

Reset button

(recessed)

Innovative Circuit Technology Ltd. 7

Bond the panel chassis to the rack system ground, connecting a ground wire with

ring tongue to the front panel ground stud. (1/4-20 thread)

Connect Bus A loads to output channels A1 to A4 using suitably rated wire sized

for the breaker installed on the channel, with crimped on spade lug terminals

compatible with the output terminal block screws. Note which load is connected

to each channel, for future reference.

Repeat for the Bus B loads if required. The unit may be operated with either Bus

A or Bus B powered, or both.

NOTE!

All channel RTN lines, and the main high power Bus A and Bus B RTN terminals

are common, and tied to a single internal Return bus. Bus A and Bus B inputs can

be wired to a different dc voltage (10 to 60Vdc) of either polarity, but must share

a common RTN voltage, normally at earth potential.

Connect the main Bus A RTN line to the external battery or power supply return

using suitably sized wire and dual hole lug connector rated for up to 100A

continuous current. Connect the lug to the dual ¼-20 thread Bus A Rtn studs, and

then securely fasten with the supplied hardware.

Connect the Bus A Input through a suitably rated disconnect switch (set in the

open position) with a fuse or circuit breaker rated for 100A max continuous

operation to the external battery or power supply output, using suitably sized

wire and a dual-hole Lug connector rated for 100A continuous current. Connect

the Input lug to the dual ¼-20 thread Bus A Input studs, then securely fasten with

the supplied hardware. Snap the clear cover on to the Bus A input connector to

help prevent accidental contact with the input stud connections.

Repeat input wiring for the Bus B input, its power source and over current

protection device, if the Bus B outputs are to be used. Bus A and Bus B Input and

output Return lines are internally connected together, so will share a common

ground. The Bus A and Bus B Input terminals are isolated, and support operation

from separate + or – 10 to 60V power sources, as long as they share a common

Return potential.

Connect the two form-C relay bus alarm outputs to an external monitoring

system if needed, by stripping and terminating 16-28AWG alarm wiring in the

Alarm 7-pin connector plug (lower), and installing in the front panel. Each Bus

Alarm output will trigger for any breaker open, or other alarm related to any

channel on that bus (Factory Default). Most alarm conditions can be masked off

so that they will not trigger the Alarm output if required, using the web based

graphical interface.

8 Innovative Circuit Technology Ltd.

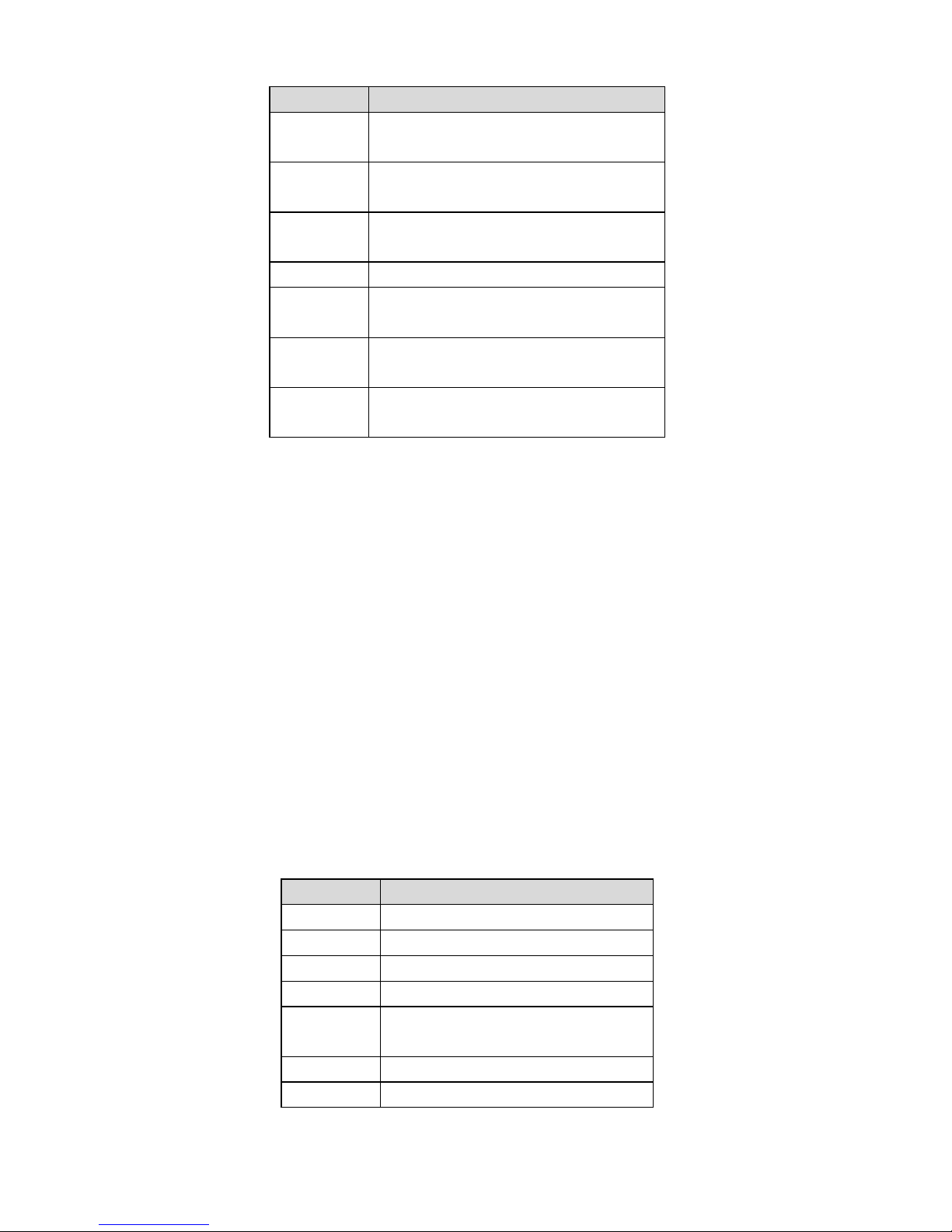

Bus Alarm Connector: (Lower connector plug)

Pin (L-R)

Alarm Function

1

Bus A - Alarm Output common

(0.5A 65Vdc max)

2

Bus A - Alarm Output normally

closed for alarm condition (NC)

3

Bus A - Alarm Output normally

open for alarm condition (NO)

4

No connection

5

Bus B - Alarm Output common

(0.5A 65Vdc max)

6

Bus B - Alarm Output normally

closed for alarm condition (NC)

7

Bus B - Alarm Output normally

open for alarm condition (NO)

Connect up to 4 dry contact type site sensors (such as door/window sensors,

smoke alarm, water detectors etc.) by stripping and terminating 16-28AWG

alarm wiring and connecting to the four Site Alarm Inputs on the 7 pin removable

Site Monitor Plug (upper), if desired. These inputs may be configured to activate

the panel Alarm outputs, or send an alarm e-mail on network connected units.

The external sensor contacts must be voltage free; as a small sense current is

supplied from the panel Alarm Input pins to detect the external contact open or

closed state. Refer to the Web Based Interface section for information on how to

configure and use the four Site Alarm inputs.

Connect an optional ICT external temperature sensor (ICT-TMP) to the two TMP

inputs if you need to remotely monitor the temperature of a battery pack or

enclosure.

Site Monitor Inputs: (Upper connector plug)

Pin (L-R)

Site Monitor Input Function

1

Contact Input 1

2

Contact Input 2

3

Contact Input 3

4

Contact Input 4

5

Monitor Return (common for

4 monitor inputs)

6

Remote Temperature Sense

7

Remote Temperature Sense

Innovative Circuit Technology Ltd. 9

Connect a standard 10/100 Base-T Ethernet cable to the RJ-45 LAN port on the

front panel to remotely monitor, control and reconfigure the panel settings from

a remote computer.

OPERATION

Ensure the correct circuit breakers are installed in each channel location that will

be used to power a load.

Energise each bus by closing the main external breaker or disconnect device on

the bus input lines. Switch on the front panel channel breakers for all connected

outputs, and check that the internal channel relays have closed by verifying that

the connected loads are energised. (Note that all output channels on a bus will

be disabled and network communication will be dropped if the bus voltage drops

below approximately 6V for more than 3s. Normal operation will be restored

once the bus voltage is above 8V)

Switch off any unused internal channel relays to reduce the power consumed by

the panel, using a networked computer and Web Browser. See the TCP/IP Web

Based Utility section, Output On/Off Buttons. (Each channel relay consumes

approximately 2W when closed; the factory default setting is for all outputs to be

on)

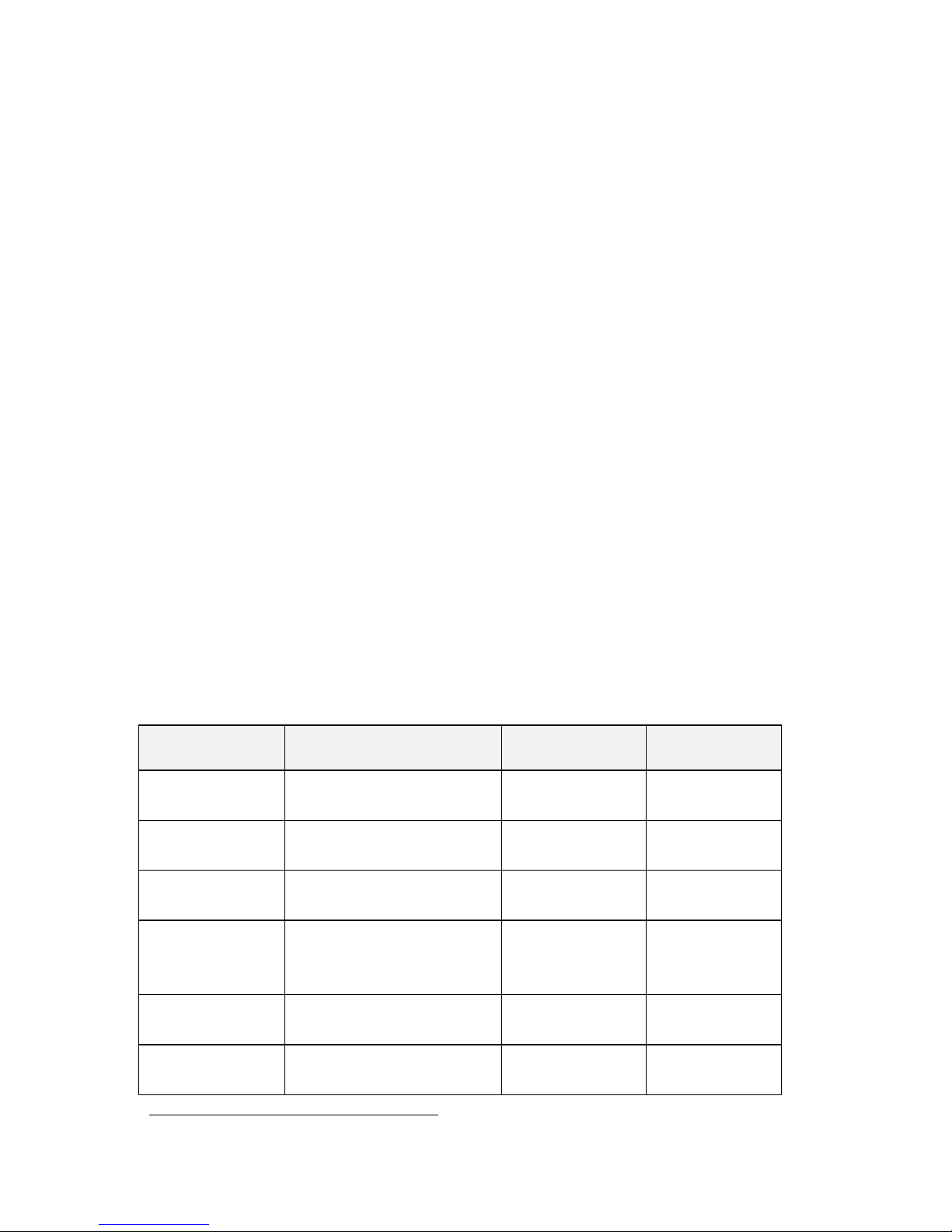

Status Indicators and Alarms

The Form-C Bus Alarm contacts are used to indicate an alarm condition.

Alarm

Trigger Condition

Channel Output

Bus Alarm

Contact

Breaker Off

Breaker opens or is

removed

Off

On

Bus Undervoltage

Bus V drops below UV

threshold

No change1

On

Bus Overvoltage

Bus V rises above the

OV threshold

No change

On

Bus Overcurrent

Bus current exceeds

the OC threshold

(default 100A)

No change

On

Output Overcurrent

Channel output current

exceeds OC threshold

Off2

On

No power to

Unit

Loss of bus input power

source

Off

On

1

All channel relays will be open if Bus Voltage is <6V, and recover for Bus Voltage >8V

2

The channel may be user configured to disable the output for an Over-current Alarm

10 Innovative Circuit Technology Ltd.

Alarm

Trigger Condition

Channel Output

Bus Alarm

Contact

Site Alarm

Input

Alarm contact on input

1 to 4

No change

On3

Remote Temp

Alarm

Adjustable over or

under temperature

threshold hit

No change

On3

The unit may also be configured to send an alarm e-mail to multiple user set email addresses for any of the alarm conditions, by enabling the e-mail function

on each alarm setup page on the web based interface. (no e-mail will be sent

when power is disconnected from the unit, due to loss of network control)

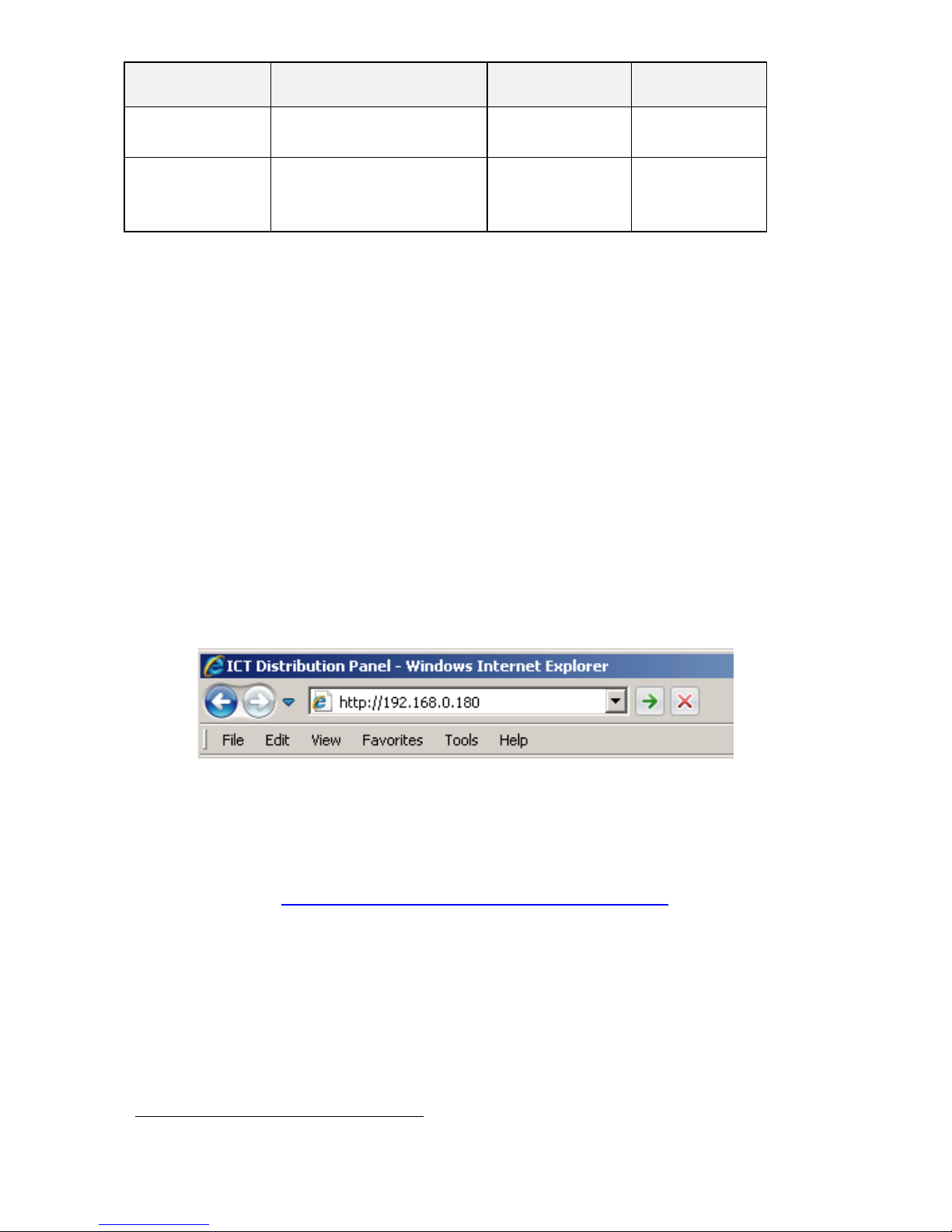

TCP/IP WEB BASED INTERFACE

These panels are equipped with a built in web server and Graphical User

Interface (GUI) to enable full remote monitoring and control using any standard

web browser, such as Microsoft Explorer, Google Chrome, or Mozilla Firefox. To

connect with your networked panel, do the following:

1. Start Your Browser.

2. Enter the IP address of the panel in the address field of your browser as

shown.

Typically your panel will be connected to a network with a DHCP server,

and will be assigned an IP address automatically. To find the current

address of your panel run the ICT IP Address Discovery tool, after

installing it on your Windows computer (tool available for download

from ICT http://www.ictcorporate.com/resources/tools/ ) otherwise the

panel will use the factory default IP address of 192.168.0.180, as shown

above.

3. Enter your user name and password. The default Administrator user

name is admin, with no password.

3

Use the web interface to configure each alarm input to trigger either Bus A, B or both

alarm contacts

Loading...

Loading...