Integrated

Circuit

Systems, Inc.

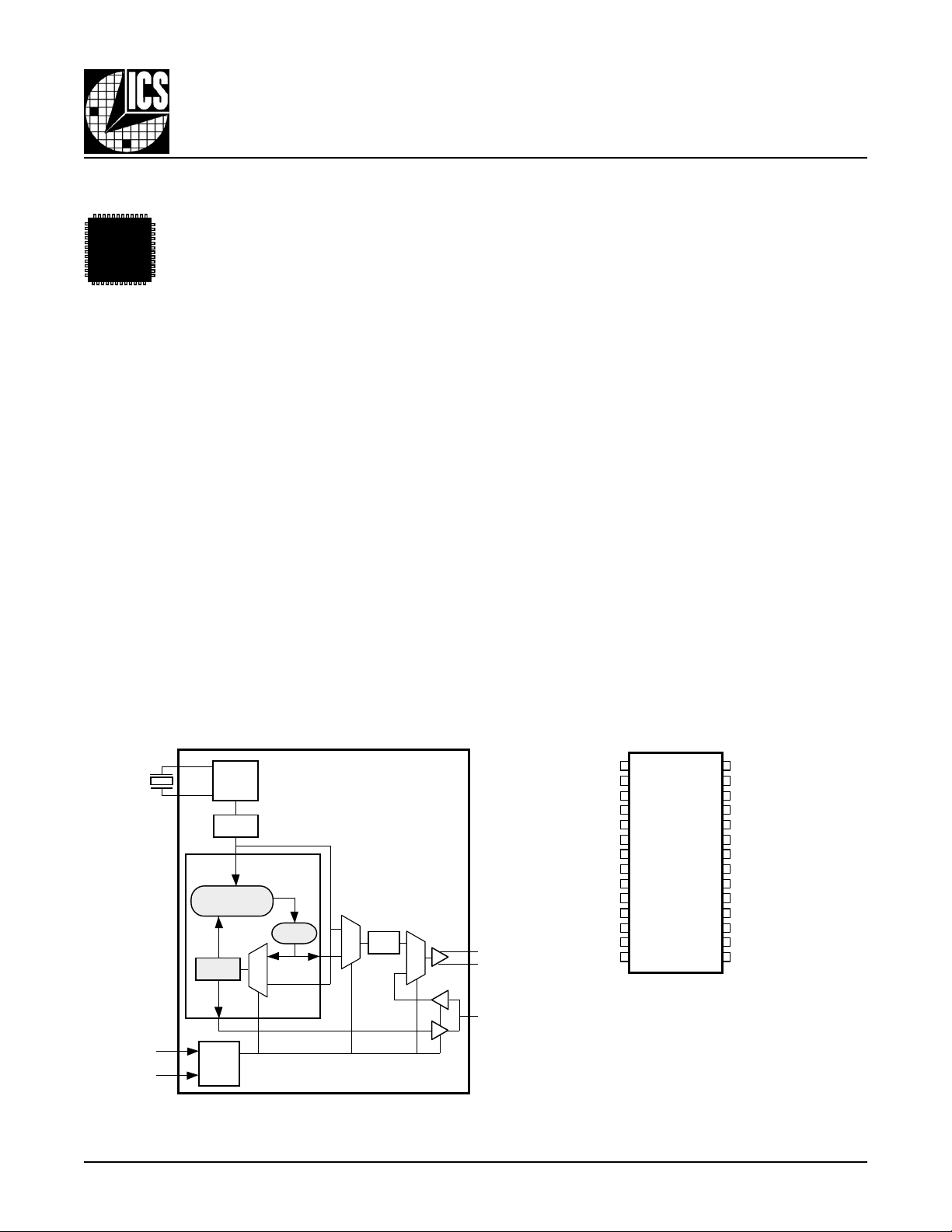

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

GENERAL DESCRIPTION

,&6

HiPerClockS™

bandwidth PLL timing channel. A 16.666MHz crystal is used

as the input to the on-chip oscillator. The M is configured to

produce a fixed output frequency of 200MHz.

Programmable features of the ICS8431-01 support four

operational modes. The four modes are spread spectrum

clocking (SSC), non-spread spectrum clock and two test

modes which are controlled by the SSC_CTL[1:0] pins. Unlike other synthesizers, the ICS8431-01 can immediately

change spread-spectrum operation without having to reset

the device.

In SSC mode, the output clock is modulated in order to

achieve a reduction in EMI. In one of the PLL bypass test

modes, the PLL is disconnected as the source to the

differential output allowing an external source to be

connnected to the TEST_I/O pin. This is useful for incircuit testing and allows the differential output to be driven

at a lower frequency throughout the system clock tree. In the

other PLL bypass mode, the oscillator divider is used as the

source to both the M and the Fout divide by 2. This is useful

for characterizing the oscillator and internal dividers.

The ICS8431-01 is a general purpose clock

frequency synthesizer for IA64/32 application and

a member of the HiPerClockS™ family of High

Performance Clock Solutions from ICS. The

ICS8431-01 consists of one independent low

FEATURES

• Fully integrated PLL

• Differential 3.3V L VPECL output

• 200MHz output frequency

• 48% to 52% duty cycle

• Crystal oscillator interface

• Spread Spectrum Clocking (SSC) fixed at 1/2% modulation

for environments requiring ultra low EMI. T ypical10dB EMI

reduction can be achieved with spread spectrum modulation

• LVTTL / L VCMOS control inputs

• PLL bypass modes supporting in-circuit testing and on-chip

functional block characterization

• 28 lead SOIC

• RMS cycle-to-cycle jitter of 2ps

• Typical cycle-to-cycle jitter of 18ps

• 0° to 85°C ambiant operating temperature

BLOCK DIAGRAM PIN ASSIGNMENT

nc

XTAL1

XTAL2

SSC_CTL0

SSC_CTL1

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

OSC

÷ 16

PHASE

DETECTOR

÷ M

SSC

Control

Logic

PLL

VCO

÷ 2

FOUT

nFOUT

TEST_I/O

1

SSC_CTL0

SSC_CTL1

TEST_I/O

1

nc

2

nc

3

nc

4

nc

5

nc

6

nc

7

nc

8

nc

9

10

11

VEE

12

13

VDD

14

ICS8431-01

28-Lead SOIC

M Package

Top View

28

27

26

25

24

23

22

21

20

19

18

17

16

15

nc

VDDI

XTAL2

XTAL1

nc

nc

VDDA

VEE

RESERVED

nc

VDDO

FOUT

nFOUT

VEE

Integrated

Circuit

Systems, Inc.

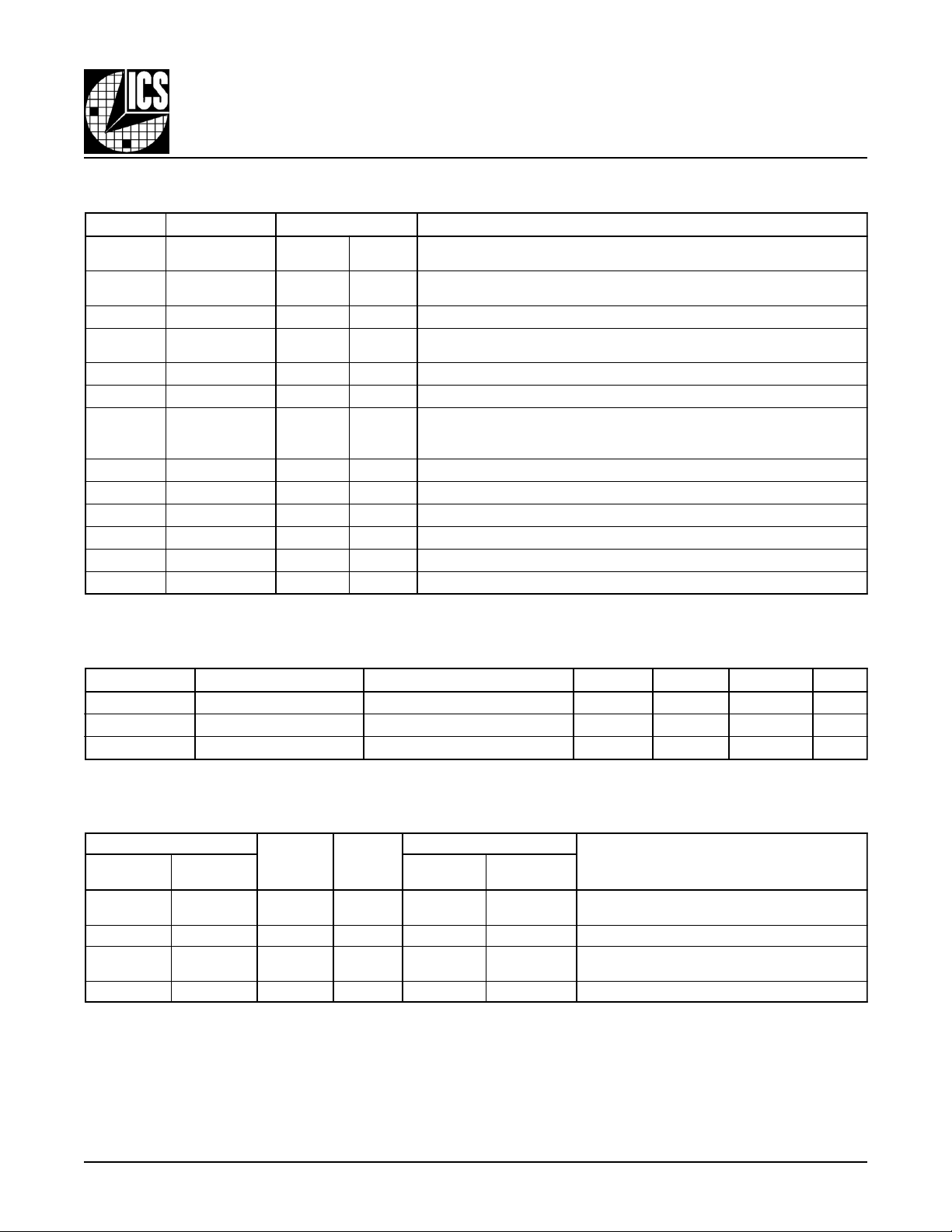

TABLE 1. PIN DESCRIPTIONS

rebmuNemaNepyTnoitpircseD

,91,9-1

82,42,32

11,01

21DNGrewoP.tuptuotsetdnaerocrofnipdnuorG

31O/I_TSET

72,41DDVrewoP.tuptuotsetdnaerocrofnipylppusrewoP

51DNGrewoP.tuptuorofnipdnuorG

71,61TUOF,TUOFntuptuO

81ODDVrewoP.tuptuorofnipylppusrewoP

02DEVRESERevreseR.nipevreseR

12EEVrewoP.nipdnuorG

22ADDVrewoP.nipylppusrewopLLP

62,522LATX,1LATXtupnI.tupnirotallicsolatsyrC

72IDDVrewoP.V3.3ottcennoC.nipylppusrewoperocdnatupnI

cndesunU.snipdesunU

,0LTC_CSS

1LTC_CSS

tupnIpulluP.slevelecafretniSOMCVL/LTTVL.sniplortnocCSS

/tupnI

tuptuO

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

..elbaTnoitcnuF3elbaTnidenifedsademmargorP

.rezisehtnysehtrofsrevirdtuptuoniamerastuptuolaitnereffidesehT

LCEPVLdecnereferevitisopdetanimrethtiwelbitapmocerayehT

.cigol

TABLE 2. PIN CHARACTERISTICS

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

NICecnaticapaCniPtupnI 4Fp

PULLUPRrotsiseRpulluPtupnI 15KΩ

NWODLLUPRrotsiseRnwodlluPtupnI 15KΩ

TABLE 3. SSC CONTROL INPUTS FUNCTION TABLE

stupnI

1LTC_CSS0LTC_CSS

00 lanretnIdelbasiDLATXf ÷ 23

01LLPdelbanEzHM002Z-iHtnecreP½=rotcaFnoitaludoM;CSStluafeD

10 lanretxEdelbasiDklCtseTtupnI

11LLPdelbasiDzHM002Z-iHnoitaludoMCSSoN

O/I_TSET

ecruoS

CSS

,TUOF

TUOFn

.noitaziretcarahcdnagubedesuohnirofdesU:1ETON

stuptuO

LATXf ÷ 61

÷ M

sedoMlanoitarepO

O/I_TSET

1ETON.edomtsetsredivid

1ETON;edoMcitsongaiD

zHM1( ≤ klCtseT ≤ )zHM002

NdnaM,rotallicso,rotallicsO;ssapybLLP

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

2

Integrated

Circuit

Systems, Inc.

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

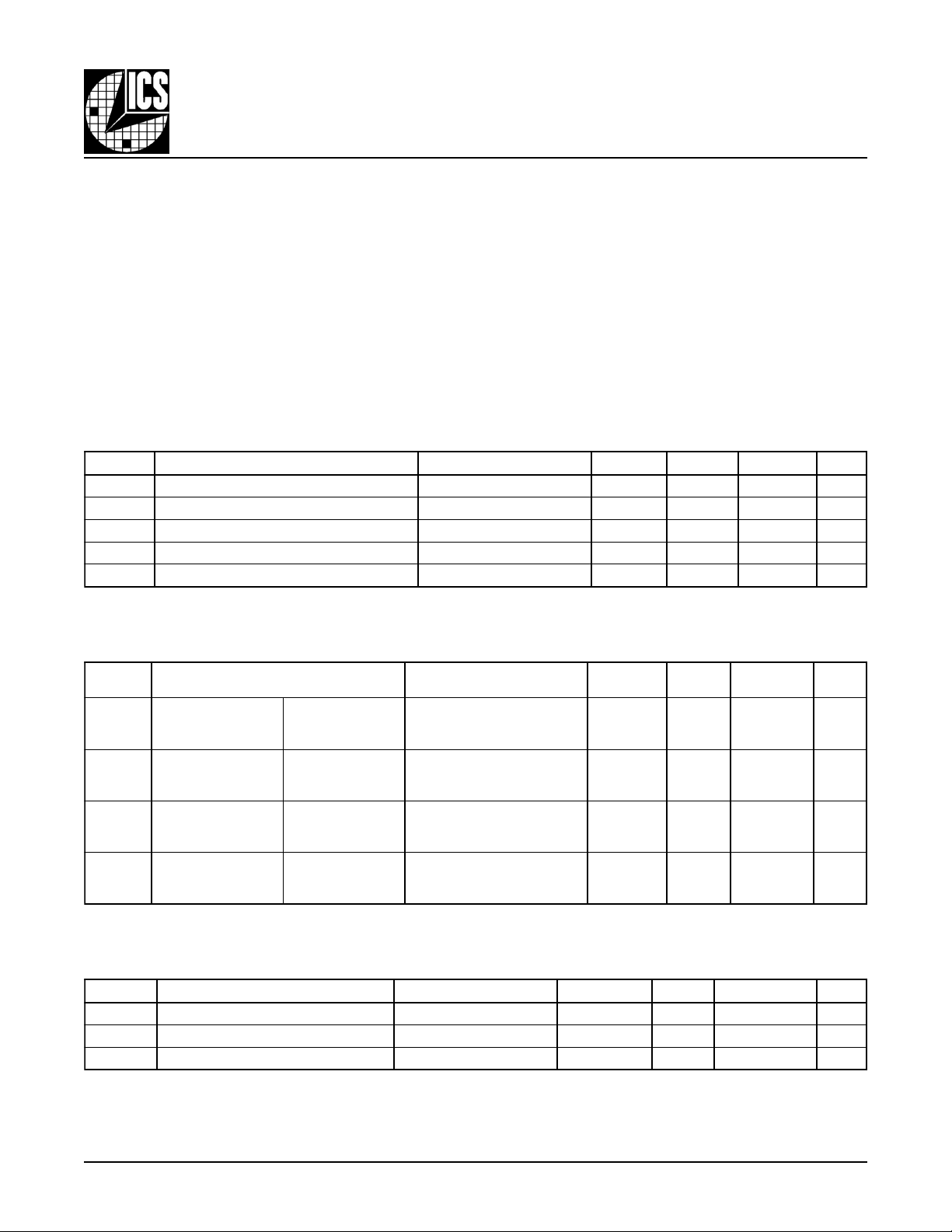

ABSOLUTE MAXIMUM RATINGS

Supply Voltage 4.6V

Inputs -0.5V to VDD + 0.5V

Outputs -0.5V to VDDO + 0.5V

Ambient Operating T emperature 0°C to 85°C

Storage T emperature -65°C to 150°C

Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These ratings

are stress specifications only and functional operation of product at these condition or any conditions beyond those listed in

DC Characteristics

the

periods may affect product reliability.

TABLE 4A. POWER SUPPLY DC CHARACTERISTICS, VDD = VDDA = VDDI = VDDO = 3.3V±5%, TA = 0°C TO 85°C

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

DDVegatloVylppuSrewoP 531.33.3564.3V

ODDVegatloVylppuSrewoPtuptuO 531.33.3564.3V

ADDVegatloVylppuSrewoPgolanA 531.33.3564.3V

IDDVegatloVylppuSrewoPtupnI 531.33.3564.3V

EEI 041Am

or

AC Characteristics

is not implied. Exposure to absolute maximum rating conditions for extended

TABLE 4B. L VCMOS / LVTTL DC CHARACTERISTICS, VDD = VDDA = VDDI = VDDO = 3.3V±5%, TA = 0°C TO 85°C

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

,0LTC_CSS

HIVegatloVhgiHtupnI

LIVegatloVwoLtupnI

HIItnerruChgiHtupnI

LIItnerruCwoLtupnI

,1LTC_CSS

O/I_TSET

,0LTC_CSS

,1LTC_CSS

O/I_TSET

,0LTC_CSS

,1LTC_CSS

OI_TSET

,0LTC_CSS

,1LTC_CSS

OI_TSET

V531.3 ≤ DDV ≤ V564.32 3.0+DDVV

V531.3 ≤ DDV ≤ V564.33.0-8.0V

V564.3=NIV=DDV5Aµ

V0=NIV,V564.3=DDV051-Aµ

TABLE 4C. L VPECL DC CHARACTERISTICS, VDD = VDDA = VDDI = VDDO = 3.3V±5%, TA = 0°C TO 85°C

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

HOV1ETON;egatloVhgiHtuptuO 82.1-ODDV089.0-ODDVV

LOVegatloVwoLtuptuO1ETON;0.2-ODDV7.1-ODDVV

GNIWSVgniwSegatloVtuptuOkaeP-ot-kaeP006007058Vm

05htiwdetanimrettuptuO:1ETON Ω .V2-ODDVot

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

3

Integrated

Circuit

Systems, Inc.

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

TABLE 5. CRYST AL CHARACTERISTICS

retemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

noitallicsOfoedoM latnemadnuF

ycneuqerF 666.61zHM

ecnareloTycneuqerF 05-05+mpp

ytilibatSycneuqerF 001-001+mpp

leveLevirD 001Wµ

)RSE(ecnatsiseRseireStnelaviuqE 05

ecnaiticapaCtnuhS 37Fp

ecnaiticapaCdaoL 018123Fp

ecnatcudnIniPseireS 37Hn

egnaRerutarepmeTgnitarepO 007C°

gnigAC°52@raeyreP5-5+mpp

TABLE 6. AC CHARACTERISTICS, VDD = VDDA = VDDI = VDDO = 3.3V±5%, TA = 0°C TO 85°C, 16.666MHZ CRYST AL

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

DOIREPt2ETON;doirePtuptuOegarevAzHM002=TUOF59945005sp

t

j)cc(ti

cdo;elcyCytuDtuptuO2ETONzHM002=TUOF8425%

Rt2,1ETON;emiTesiRtuptuO%08ot%02003054006sp

Ft2,1ETON;emiTllaFtuptuO%08ot%02003054006sp

latxFegnaRtupnIlatsyrC41666.6181zHM

mF

fmF

derCSS;noitcudeRlartcepS2,1ETON701Bd

ELBATSttuptuOkcolCelbatSotpu-rewoP 01sm

t

j.snoitinifed56DSEJCEDEJotmrofnoccdo,Ft,Rt,)cc(ti

2,1ETON

2,1ETON

2ETON;rettiJelcyC-ot-elcyCzHM002=TUOF8103sp

;ycneuqerFnoitaludoMCSS

;rotcaFnoitaludoMCSS

.delbanegnikcolcmurtcepSdaerpS:1ETON

05htiwdetanimretstuptuO:2ETON Ω .V2-ODDVot

0333.33zHK

4.06.0%

Ω

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

4

Integrated

Circuit

Systems, Inc.

PARAMETER MEASUREMENT INFORMATION

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

Clock Inputs

and Outputs

X_CLK, 1X_FOUT

nX_CLK, n1X_FOUT

nX_CLK, n1X_FOUT

X_CLK, 1X_FOUT

80%

20%

➤

➤

trise tfall

FIGURE 1 — INPUT AND OUTPUT SLEW RATES

➤

t

cycle n

t

jit(cc) = tcycle n –tcycle n+1

➤

➤

FIGURE 2 — CYCLE-TO-CYCLE JITTER

➤

Pulse Width (

➤

t

pw)

odc =

➤

t

PERIOD

t

pw

t

PERIOD

80%

➤

t

cycle n+1

➤

Vswing

20%

➤

➤

➤

➤

FIGURE 3 — odc & tPERIOD

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

5

Integrated

Circuit

Systems, Inc.

CRYSTAL INPUT AND OSCILLATOR INTERFACE

The ICS8431-01 features an internal oscillator that uses an

external quartz crystal as the source of its reference frequency .

A 16.666 MHz crystal divided by 16 before being sent to the phase

detector provides the reference frequency. The oscillator is a

series resonant, multi-vibrator type design. This design provides

better stability and eliminates the need for large on chip capacitors.

Though a series resonant crystal is preferred, a parallel resonant

crystal can be used. A parallel resonant mode crystal used in a

series resonant circuit will exhibit a frequency of oscillation a few

hundred ppm lower than specified. A few hundred ppm translates

to KHz inaccuracy. In general computing applications this level

of inaccuracy is irrelevant. If better ppm accuracy is required, an

external capacitor can be added to a parallel resonant crystal in

series to pin 25.

Figure 1A

Figures 1A, 1B, and 1C show various crystal parameters

which are recommended only as guidelines. Figure 1A shows

how to interface a capacitor with a parallel resonant crystal.

Figure 1B shows the capacitor value needed for the optimum

PPM performance over various parallel resonant crystals.

Figure 1C shows the recommended tuning capacitance for a

16.666MHz parallel resonant crystal.

shows how to interface with a crystal.

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

ICS8431-01

XTAL2

(Pin 26, SOIC)

XTAL1

(Pin 25, SOIC)

Quartz Crystal Selection:

(1) Raltron Series Resonant: AS-16.66-S-SMD-T -MI

(2) Raltron Parallel Resonant: AS-16.66-18-SMD-T -MI

FIGURE 1A. CRYSTAL INTERFACE

➤

Optional

FIGURE 1B. Recommended tuning capacitance for various parallel

resonant crystals.

60

14.318

50

40

30

20

10

Series Capacitor, C1 (pF)

0

15.000

16.667

14 15 16 17 18 19 20 21 22 23 24 25

Crys t al F requency (MHz )

19.440

20.000

24.000

IGURE 1C. Recommended tuning capacitance for 16.666MHz

F

parallel resonant crystal.

100

80

60

40

20

0

0 102030405060

-20

-40

-60

Frequency Accuracy (ppm)

-80

-100

16.666MHz

Series Capacit or, C1 (pF)

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

6

Integrated

Circuit

Systems, Inc.

SPREAD SPECTRUM

Spread-spectrum clocking is a frequency modulation technique for EMI reduction. When spread-spectrum is enabled, a

30KHz triangle waveform is used with 0.5% down-spread

(+0.0% / -0.5%) from the nominal 200MHz clock frequency.

An example of a triangle frequency modulation profile is shown

Figure 2

in

• Fnom = Nominal Clock Frequency in Spread OFF mode

• Fm = Nominal Modulation Frequency (30KHz)

• δ = Modulation Factor (0.5% down spread)

(1 - δ) fnom + 2 fm x δ x fnom x t when 0 < t < ,

(1 - δ) fnom - 2 fm x δ x fnom x t when < t <

Fnom

below. The ramp profile can be expressed as:

(200MHz with 16.666MHz IN)

1

2 fm

➤

1

2 fm

1

fm

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

The ICS8431-01 triangle modulation frequency deviation will

not exceed 0.6% down-spread from the nominal clock frequency (+0.0% / -0.5%). An example of the amount of down

spread relative to the nominal clock frequency can be seen in

the frequency domain, as shown in

width to the fundamental frequency is typically 0.4%, and will

not exceed 0.6%. The resulting spectral reduction will be

greater than 7dB, as shown in Figure 3. It is important to note

the ICS8431-01 7dB minimum spectral reduction is the component-specific EMI reduction, and will not necessarily be the

same as the system EMI reduction.

Figure 3.

∆ − 10 dBm

The ratio of this

(1 - δ) Fnom

0.5/fm

FIGURE 2. TRIANGLE FREQUENCY MODULATION

1/fm

POWER SUPPLY FILTERING TECHNIQUES

As in any high speed analog circuitry , the power supply pins

are vulnerable to random noise. The ICS8431-01 provides

separate power supplies to isolate any high switching noise

from the outputs to the internal PLL. VDD, VDDI, VDDA, and

VDDO should be individually connected to the power supply

plane through vias, and bypass capacitors should be used

for each pin. To achieve optimum jitter performance, better

power supply isolation is required.

10Ω along with a 10µF and a .01µF bypass capacitor should

be connected to each power supply pin.

Figure 4

illustrates how a

➤

B

A

δ = .4%

FIGURE 3. 200MHZ CLOCK OUTPUT IN FREQUENCY DOMAIN

(A) SPREAD-SPECTRUM OFF

(B) SPREAD-SPECTRUM ON

3.3V

VDD

.01µF

VDDA

.01µF

FIGURE 4. POWER SUPPLY FILTERING

10Ω

10 µF

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

7

Integrated

Circuit

Systems, Inc.

TERMINATION FOR PECL OUTPUTS

The clock layout topology shown below is typical for

IA64/32 platforms. The two different layouts mentioned are

recommended only as guidelines.

FOUT and nFOUT are low impedance follower outputs that

generate ECL/PECL compatible outputs. Therefore, terminating resistors (DC current path to ground) or current sources

must be used for functionality . These outputs are designed to

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

drive 50Ω transmission lines. Matched impedance techniques

should be used to maximize operating frequency and minimize signal distortion. There are a few simple termination

schemes.

Figures 5A and 5B

are recommended only as guidelines. Other suitable clock layouts may exist and it would be recommended that the board

designers simulate to guarantee compatibility across all printed

circuit and clock component process variations.

show two different layouts which

Zo = 50Ω

Zo = 50Ω

Zo = 50Ω

Zo = 50Ω

5

FINFOUT

Zo = 50Ω Zo = 50Ω

3.3V

5

Z

o

2

Z

o

2

FOUT FIN

RTT =

(VOH + VOL / VCC –2) –2

50Ω

1

Z

o

FIGURE 5A. L VPECL OUTPUT TERMINATION

RTT

50Ω

➤

VCC-2V

Z

= 50Ω Zo = 50Ω

o

3

Z

o

2

3

Z

o

2

FIGURE 5B. L VPECL OUTPUT TERMINATION

LAYOUT GUIDELINE

The schematic of the ICS8431-01 layout example used in this layout guideline is shown in

PCB board layout for this example is shown in

Figure 6B.

This layout example is used as a general guideline. The layout in the actual

system will depend on the selected component types, the density of the components, the density of the traces, and the stacking of

the P .C. board.

U1

1

nc

2

nc

3

nc

4

nc

5

nc

6

nc

7

nc

8

nc

9

nc

10

SSC_CTL0

11

SSC_CTL1

12

VEE

13

VDD

C1

0.1uF

TEST_IO

14 15

VDD VEE

8431-01

VDDI

XTAL2

XTAL1

VDDA

VEE

VDDO

FOUT

nFOUT

28

nc

27

VDD

26

25

24

nc

23

nc

22

21

20

nc

19

nc

VDD

18

17

16

C2

0.1uF

X1

VDDA

C3

0.01uF

C6

0.01uF

R5

10

C4

10uF

Zo = 50 Ohm

TL1

Zo = 50 Ohm

TL2

Figure 6A.

Termination A

VDD0

R1

125

IN+

IN-

R2

84

The ICS8431-01 recommended

Termination

B (not shown

in the layout)

IN+

IN-

R3

125

R4

84

R1

R2

50

50

R3

50

FIGURE 6A. RECOMMENDED SCHEMATIC LAYOUT

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

8

Integrated

Circuit

Systems, Inc.

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

The following component footprints are used in this layout

example:

All the resistors and capacitors are size 0603.

The Crystal X1 is Raltron Part # AS-16.666-18-SMD.

POWER AND GROUNDING

Place the decoupling capacitors C1, C2 and C3, C4, C5, C6 as

close as possible to the power pins. If space allows, placing the

decoupling capacitor at the component side is preferred. This can

reduce unwanted inductance between the decoupling capacitor

and the power pin generated by the via.

Maximize the pad size of the power (ground) at the decoupling

capacitor. Maximize the number of vias between power (ground)

and the pads. This can reduce the inductance between the power

(ground) plane and the component power (ground) pins.

If VDDA shares the same power supply with VDD, insert the RC

filter R5, C3, and C4 in between. Place this RC filter as close to

the VDDA as possible.

CLOCK TRACES AND TERMINATION

The component placements, locations and orientations should

be arranged to achieve the best clock signal quality . Poor clock

signal quality can degrade the system performance or cause

system failure. In the synchronous high-speed digital system,

the clock signal is less tolerable to poor signal quality than other

signals. Any ringing on the rising or falling edge or excessive ring

back can cause system failure. The trace shape and the trace

delay might be restricted by the available space on the board and

the component location. While routing the traces, the clock signal

traces should be routed first and should be locked prior to routing

other signals traces.

• The traces with 50Ω transmission lines TL1 and TL2 at

FOUT and nFOUT should have equal delay and run adjacent to each other. Avoid sharp angles on the clock trace.

Sharp angle turns cause the characteristic impedance to

change on the transmission lines.

• Keep the clock trace on same layer. Whenever possible,

avoid any vias on the clock traces. Any via on the trace

can affect the trace characteristic impedance and hence

degrade signal quality.

• T o prevent cross talk, avoid routing other signal traces in

parallel with the clock traces. If running parallel traces is

unavoidable, allow more space between the clock trace

and the other signal trace.

• Make sure no other signal trace is routed between the

clock trace pair.

The matching termination resistors R1, R2, R3 and R4 should be

located as close to the receiver input pins as possible. Other termination scheme can also be used but is not shown in this example.

CRYSTAL

The crystal X1 should be located as close as possible to the pins

26 (XTAL1) and 25 (XTAL2). The trace length between the X1

and U1 should be kept to a minimum to avoid unwanted parasitic

inductance and capacitance. Other signal traces should not be

routed near the crystal traces.

C1

U1

ICS8431-01

C6

X1

C3

FIGURE 6B. PCB BOARD LAYOUT FOR ICS8431-01

C4

R5

C2

TL1 (50 Ohm)

TL2 (50 Ohm)

Close to the input

pins of the

receiver

IN+

IN-

GND

VDD

Signals

VIA

R1

R2

R3

R4

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

9

Integrated

Circuit

Systems, Inc.

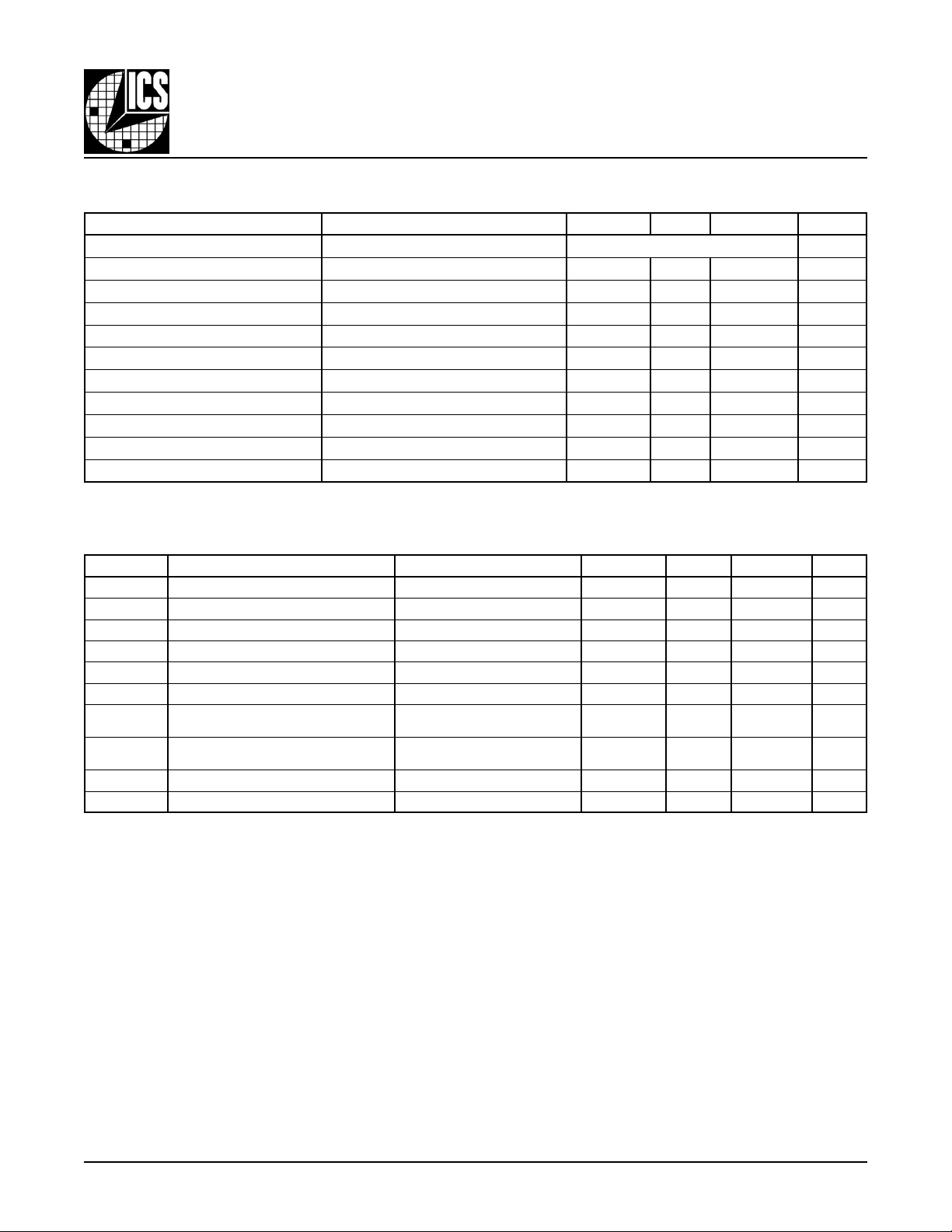

PACKAGE OUTLINE - M SUFFIX

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

N

1

D

A2

e

TABLE 7. PACKAGE DIMENSIONS

C

1528

H

E

14

h x 45º

A

A1

B

SEATING

PLANE

.10 (.004)

L

α

LOBMYS

N82

A--56.2--401.0

1A01.0--0400.0--

2A50.255.2180.0001.0

B33.015.0310.0020.0

C81.023.0700.0310.0

D07.7104.81796.0427.0

E04.706.7192.0992.0

eCISAB72.1CISAB050.0

H00.0156.01493.0914.0

h52.057.0010.0920.0

L04.072.1610.0050.0

α

REFERENCE DOCUMENT: JEDEC PUBLICATION 95, MS-013, MO-1 19

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

NIMXAMNIMXAM

°0 °8 °0 °8

sretemilliMsehcnI

10

Integrated

Circuit

Systems, Inc.

TABLE 8. ORDERING INFORMATION

rebmuNredrO/traPgnikraMegakcaPtnuoCerutarepmeT

10-MC1348SCI10-MC1348SCICIOSdaeL82ebuTreP62C°58otC°0

T10-MC1348SCI10-MC1348SCIleeRdnaepaTnoCIOSdaeL820001C°58otC°0

ICS8431-01

200MHZ, LOW JITTER,

L VPECL FREQUENCY SYNTHESIZER

While the information presented herein has been checked for both accuracy and reliability, Integrated Circuit Systems, Incorporated (ICS) assumes no responsibility for either its use

or for infringement of any patents or other rights of third parties, which would result from its use. No other circuits, patents, or licenses are implied. This product is intended for use

in normal commercial applications. Any other applications such as those requiring extended temperature range, high reliability, or other extraordinary environmental requirements are

not recommended without additional processing by ICS. ICS reserves the right to change any circuitry or specifications without notice. ICS does not authorize or warrant any ICS

product for use in life support devices or critical medical instruments.

ICS8431CM-01 www.icst.com/products/hiperclocks.html REV. A JUNE 5, 2001

11

Loading...

Loading...