Page 1

Installation

Instructions

For

R410-A

Refrigerant

SPLIT SYSTEM

Premium Line

AC CONDENSERS

Save This Manual for Future Reference

421 01 3204 03

Dec. 2004

Page 2

I Installation Instructions R410-A Split System Condensers I

Installation/Startup Information

These instructions must be read and understood com-

pletely before attempting installation.

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation MUST conform with local building

codes or, in the absence of local codes, with the

the National Electrical Code NFPA 70/ANSI

C1-1999 or current edition and Canadian

Electrical Code Part 1 CSA C.22.1.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in equipment

malfunction, property damage, personal injury

and/or death.

After uncrating unit, inspect thoroughly for hidden damage.

If damage is found, notify the transportation company im-

mediately and file a concealed damage claim.

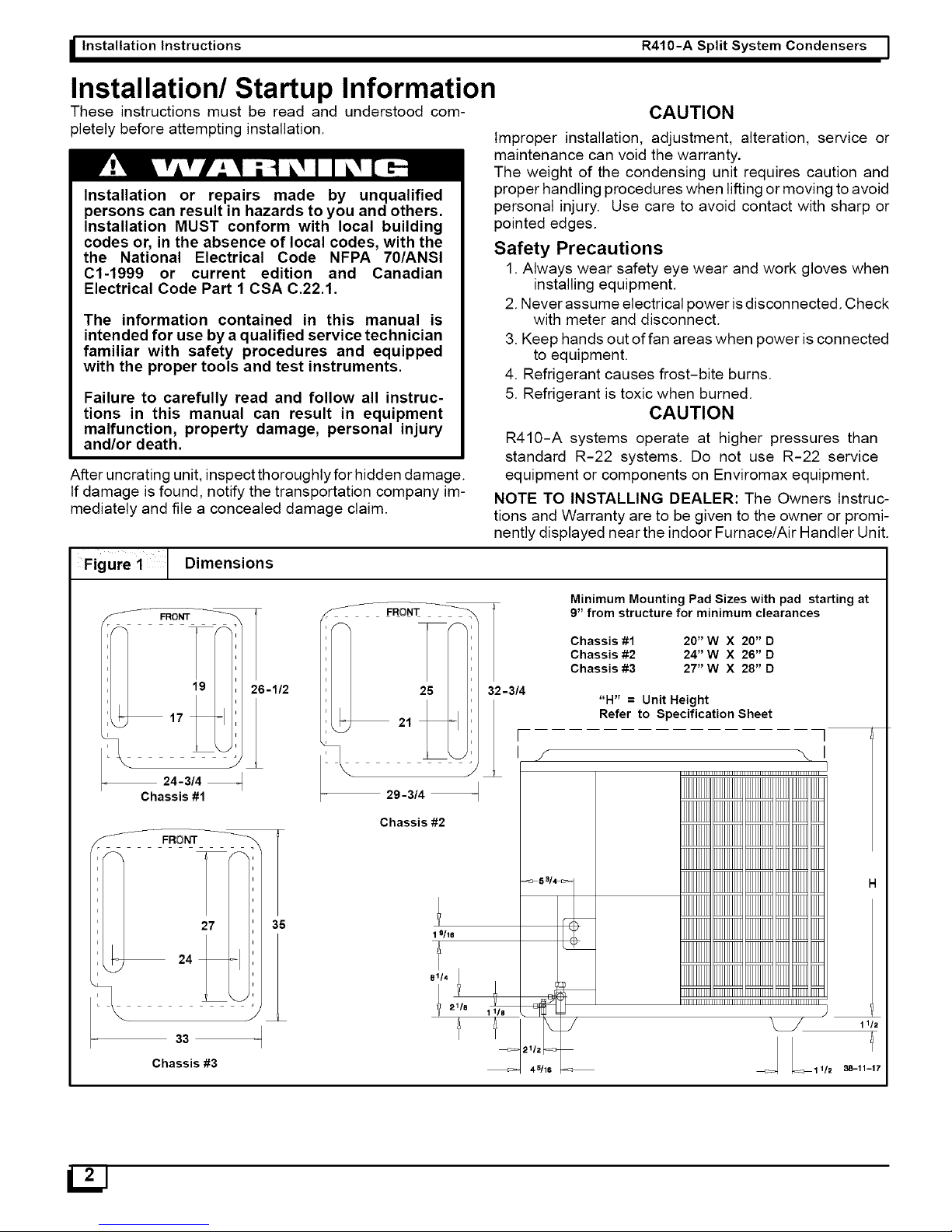

Figure 1 1 Dimensions

-- 24-3/4

Chassis #1

6-1/2

FRONT

36

33

Chassis #3

CAUTION

Improper installation, adjustment, alteration, service or

maintenance can void the warranty.

The weight of the condensing unit requires caution and

proper handling procedures when lifting or moving to avoid

personal injury. Use care to avoid contact with sharp or

pointed edges.

Safety Precautions

1. Always wear safety eye wear and work gloves when

installing equipment.

2. Never assume electrical power isdisconnected. Check

with meter and disconnect.

3. Keep hands out of fan areas when power is connected

to equipment.

4. Refrigerant causes frost-bite burns.

5. Refrigerant is toxic when burned.

CAUTION

R410-A systems operate at higher pressures than

standard R-22 systems. Do not use R-22 service

equipment or components on Enviromax equipment.

NOTE TO INSTALLING DEALER: The Owners Instruc-

tions and Warranty are to be given to the owner or promi-

nently displayed near the indoor Furnace/Air Handler Unit.

FRONT

26 '

29-3/4 _

Chassis #2

T

32-3/4

Minimum Mounting Pad Sizes with pad starting at

9" from structure for minimum clearances

Chassis #1 20" W X 20" D

Chassis #2 24" W X 26" D

Chassis #3 27" W X 28" D

f

"H" = Unit Height

Refer to Specification Sheet

]

I

IIIIIIIIIIIIIIIIIIIIIIIIIIIIII

IIIIIIIIII IIIIIIIIII IIIIIIIIII q_T T_ ]q_

11/2

L1 1/2 38-11-17

Page 3

I Split System Condensers R410-A Installation Instructions I

Locating The Outdoor Unit:

Check local codes covering zoning, noise, platforms.

If practical, avoid locating next to fresh air intakes, vent or

bedroom windows. Noise may carry into the openings and

disturb people inside.

Placement of the unit should be in a well drained area or

unit must be supported high enough so runoffwill not enter

the unit.

Do not locate where heat, lint or exhaust fumes will be dis-

charged on unit (as from dryer vents).

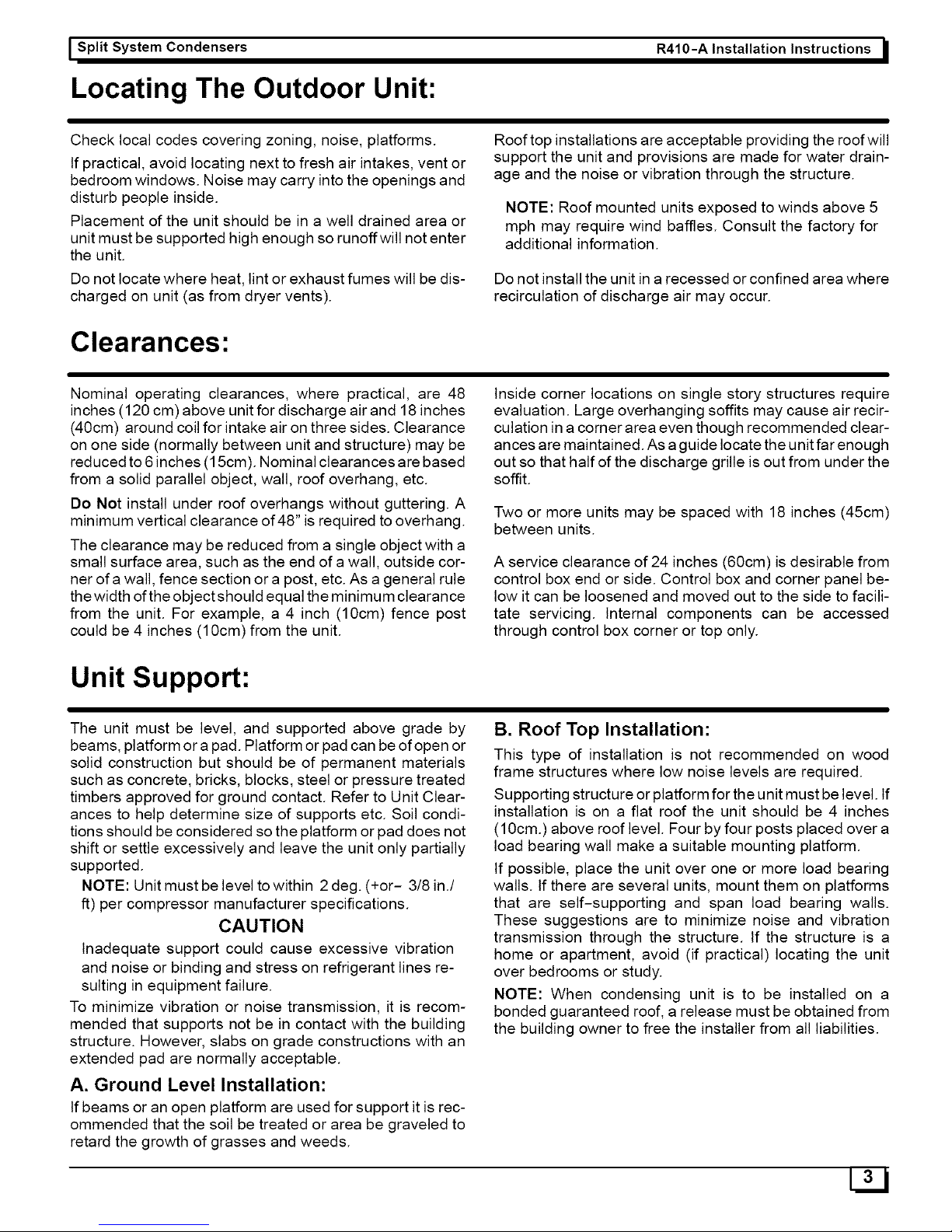

Clearances:

Rooftop installations are acceptable providing the roof will

support the unit and provisions are made for water drain-

age and the noise or vibration through the structure.

NOTE: Roof mounted units exposed to winds above 5

mph may require wind baffles. Consult the factory for

additional information.

Do not install the unit ina recessed or confined area where

recirculation of discharge air may occur.

Nominal operating clearances, where practical, are 48

inches (120 cm) above unit for discharge air and 18 inches

(40cm) around coil for intake air on three sides. Clearance

on one side (normally between unit and structure) may be

reduced to 6inches (15cm). Nominal clearances are based

from a solid parallel object, wall, roof overhang, etc.

Do Not install under roof overhangs without guttering. A

minimum vertical clearance of 48" is required to overhang.

The clearance may be reduced from a single object with a

small surface area, such as the end of a wall, outside cor-

ner of a wall, fence section or a post, etc. As a general rule

the width ofthe object should equal the minimum clearance

from the unit. For example, a 4 inch (10cm) fence post

could be 4 inches (10cm) from the unit.

Unit Support:

Inside corner locations on single story structures require

evaluation. Large overhanging soffits may cause air recir-

culation in a corner area even though recommended clear-

ances are maintained. As a guide locate the unit far enough

out so that half of the discharge grille is out from under the

soffit.

Two or more units may be spaced with 18 inches (45cm)

between units.

A service clearance of 24 inches (60cm) is desirable from

control box end or side. Control box and corner panel be-

low it can be loosened and moved out to the side to facili-

tate servicing. Internal components can be accessed

through control box corner or top only.

The unit must be level, and supported above grade by

beams, platform ora pad. Platform or pad can be of open or

solid construction but should be of permanent materials

such as concrete, bricks, blocks, steel or pressure treated

timbers approved for ground contact. Refer to Unit Clear-

ances to help determine size of supports etc. Soil condi-

tions should be considered so the platform or pad does not

shift or settle excessively and leave the unit only partially

supported.

NOTE: Unit must be level to within 2 deg. (+or- 3/8 in./

ft) per compressor manufacturer specifications.

CAUTION

Inadequate support could cause excessive vibration

and noise or binding and stress on refrigerant lines re-

suiting in equipment failure.

To minimize vibration or noise transmission, it is recom-

mended that supports not be in contact with the building

structure. However, slabs on grade constructions with an

extended pad are normally acceptable.

A. Ground Level Installation:

If beams or an open platform are used for support it is rec-

ommended that the soil be treated or area be graveled to

retard the growth of grasses and weeds.

B. Roof Top Installation:

This type of installation is not recommended on wood

frame structures where low noise levels are required.

Supporting structure or platform for the unit must be level. If

installation is on a flat roof the unit should be 4 inches

(10cm.) above roof level. Four by four posts placed over a

load bearing wall make a suitable mounting platform.

If possible, place the unit over one or more load bearing

walls. If there are several units, mount them on platforms

that are self-supporting and span load bearing walls.

These suggestions are to minimize noise and vibration

transmission through the structure. If the structure is a

home or apartment, avoid (if practical) locating the unit

over bedrooms or study.

NOTE: When condensing unit is to be installed on a

bonded guaranteed roof, a release must be obtained from

the building owner to free the installer from all liabilities.

3LjJ

Page 4

I Installation Instructions

Figuro2 C,oarancos

Recommended Clearances

R410-A Split System Condensers I

Minimum Clearances

24 _

24 _

24 _

24 _

Minimum Clearances

Minimum Clearances

18 _

Minimum Clearances

18 _

24 _

24 _

24 _

_J

Page 5

I Split System Condensers R410-A Installation Instructions I

Installing Refrigerant Lines

Component Matches

Check to see that you have the proper system compo-

nents. ONLY R410-A APPROVED MATCHED SYSTEM

COMPONENTS MAY BE USED. Refer to the Split Sys-

tem Summary or www.ariprimenet.org for match data

and orifice sizes.

The outdoor units are shipped with a refrigerant charge to

match the indoor unit and 25 ft. (7.5m) of refrigerant line. If

shorter or longer lines are used, the charge will have to be

adjusted.

TOTAL LENGTH OF REFRIGERANT LINES MUST NOT

EXCEED 75 ft. WITH A MAXIMUM VERTICAL SEPARA-

TION OF 50 ft. BETWEEN THE OUTDOOR AND IN-

DOOR UNITS WITH 2 TRAPS,

NOTE: A crankcase heater must be used when refriger-

ant lines exceed 50 ft.

REFRIGERANT TUBING AND FLOW CONTROL (Fig. 3)

Field-supplied tubing must be of refrigerant grade. Suction tube

must be insulated. Do not use damaged, dirty, or contaminated

tubing because it may plug refrigerant flow-control device. AL-

WAYS evacuate the coil and field-supplied tubing to 500 microns

before opening outdoor unit service valves.

CAUTION: Braze with SiI-Fos or Phos-copper on copper to

copper joints and wrap a wet cloth around rear of fitting to

prevent damage to TXV.

Figure 3 I Refrigerant Flow-Control Device

Refrigeration Line Sets

Ifit is necessary toadd tubing inthe field, use dehydrated or

dry sealed deoxidized copper refrigeration tube. DO NOT

use copper water pipe.

CAUTION

If ANY refrigerant tubing is buried, provide a 6 in. verti-

cal rise at service valve. Refrigerant tubing lengths up

to 36 in. may be buried without further special consider-

ation. For lengths above 36 in., contact the factory.

It is important that notubing is cut or seals broken until

you are ready to actually make connections to the

evaporator and to the condenser section.

Do not remove rubber plugs or copper caps from the

tube ends until ready to make connections at evapora-

tor and condenser.

CAUTION

Do not leave system open to atmosphere any longer

than minimum required for installation. POE oil in com-

pressor is extremely susceptible to moisture absorp-

tion. Always keep ends of tubing sealed during

installation.

Be extra careful with sharp bends. This tubing can "kink"

very easily, and if this occurs, the entire tube length will

have to be replaced. Extra care at this time will eliminate

future service problems.

Suspension And Installation Of

Refrigeration Lines

DO NOT fasten liquid or suction lines indirect contact with

the floor or ceiling joist. Use an insulated or suspension

type of hanger. Keep both lines separate, and insulate the

suction line. Both lines should be insulated in long runs in

an attic or underground in a raceway.

Do not let refrigerant lines come in direct contact with

foundation. When running refrigerant lines through the

foundation or wall, the openings should be made large

enough to allow for a sound absorbing material to be

placed or installed between the tubing and the foundation.

This will prevent noise transmission between the tubing

and the wall section (foundation) or the building.

Installation Instructions For Condensing

Units That Are Higher Than Evaporator

It is recommended that vertical suction risers not be up-

sized. Proper oil return to the compressor should be main-

tained with suction gas velocity. If velocities drop below

1500 fpm (feet per minute), oil return will be decreased. An

oil trap should be installed every 20' of vertical suction line

riser (condenser above evaporator.) Refer to line sizing

charts.

Page 6

I Installation Instructions R410-A Split System Condensers I

Figure 4 I Oil Traps

10" Max

Min.

Line Valves

The outdoor condensing unit issupplied with straight sweat

brass service valves with copper stubs.

All line valves are positioned to seal the refrigerant in the

condensing unit with gauge ports open to connecting lines

when the schraeder valve is depressed. Gauge ports have

schraeders installed and require use of charging hoses

with depressors.

Brazing Connections

Fire Hazard

Refrigerant and oil mixture under pressure could

ignite as it escapes and contacts brazing torch

resulting in Fire. Make sure the refrigerant charge

is properly removed from both the high and low

sides of the system before brazing any compo-

nent or lines.

FAILURE TO DO SO COULD RESULT IN BODILY

INJURY OR DEATH.

Before making braze connections, be sure all joints are

clean. Before heat is applied for brazing, nitrogen should

be flowing through the tubing to prevent oxidation and

scale formation on the inside of the tubing.

Liquid & Suction Lines

Fully annealed refrigeration lines should be used when

installing the system.

The following is the recommended method for making

braze connections at the refrigerant line connections:

1. Clean refrigerant tube end with emery cloth or steel

brush.

2. Use a suitable brazing alloy for copper to copper joints.

3. Insert tubing into swage fitting connection.

4. Apply heat absorbing paste or heat sink product to pre-

vent damage to the service valve.

CAUTION

Do not heat valve body above 250 degrees F.

5. Braze joint.

6. Quench the joint and tubing with water using a wet rag.

Leave rag on fitting body and re-wet with water to help cool

area.

Evacuating Refrigerant Lines and Coil

NOTE

Intentional release of CFC, HFC or HCFC Refrigerants

to the Atmosphere violates Federal Law. It may also

violate State and Local Codes. Check all Federal, State

and Local Codes before proceeding.

These instructions are intended for use with condensing

units that are precharged at the factory with adequate re-

frigerant to handle 25 feet.

NOTE: Do not use any portion of the charge for purging or

leak testing. It is mandatory that a thorough evacuation of

the refrigerant in the piping and evaporator be performed.

The liquid line and suction line service valves have been

closed after final testing at the factory. Do not disturb

these valves until the lines have been leak checked

and evacuated or the charge in the unit may be lost.

CAUTION

Never use the system compressor as a vacuum pump.

Refrigerant lines and indoor coil should be evacuated us-

ing the recommended deep vacuum method of 500 mi-

crons. The alternate triple evacuation method may be used

if the procedure outlined below is followed. Always break a

vacuum with dry nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capa-

ble of pulling a vacuum of 500 microns and a vacuum gage

capable of accurately measuring this vacuum depth. The

deep vacuum method is the most positive way of assuring

a system is free of air and liquid water.

Figure 5

5000

4500

4000

3500

3000

2500

o

2000

1500

1000

50O

Deep Vacuum Graph

LEAKIN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

0 1 23 4 5 67

MINUTES

Page 7

I Split System Condensers R410-A Installation Instructions I

Triple Evacuation Method

The triple evacuation method should only be used when

vacuum pump is only capable of pumping down to 28 in. of

mercury vacuum and system does not contain any liquid

water. Refer to Fig. 8 and proceed is as follows:

1. Pump system down to 28 in. of mercury and allow

pump to continue operating for an additional 15 min-

utes.

2. Close service valves and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to system

and open until system pressure is 2 psig.

4. Close service valve and allow system to stand for 1hr.

During this time, dry nitrogen will be able to diffuse

throughout the system absorbing moisture.

5. Repeat this procedure as indicated in Fig. 6. System

will then be free of any contaminants and water va-

por.

The service valve cap is a primary seal for the valve and

must be properly tightened to prevent leaks. Make sure cap

is clean and apply refrigerant oil to threads and sealing sur-

face of cap.

For valves with retaining rings: Replace service valve

cap and torque to; 8-11 ft. Ibs. on 1/4" and 3/8" valves,

12-16 ft. Ibs. on 5/8" and 3/4", 15-21 ft. Ibs on 7/8" valves. If

torque wrench is not available, tighten cap finger tight and

then tighten one (1) additional wrench flat or 1/6 of a turn.

For valves with rolled tops: Replace service valve cap

tighten cap finger tight and then tighten one (1) additional

wrench fiat or 1/6 of a turn to properly seat the sealing sur-

faces. Subsequent installations will seat with 1/2 to 1

wrench flat of turning.

Gauge Ports: All Valves

Check for leaks at the schrader port and tighten valve core

if necessary. Install plastic caps finger tight.

gure 6[

Fi Triple Evacuation Chart

IEVACUATEI

IBREAK VACUUM WITH DRY NITROGEN

IEVACUATE I

IBREAK VACUUM WITH DRY NITROGEN

IEVACUATE I

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

I CHARGE SYSTEM J

Valve Actuation: Service Valves

Remove the service valve cap, if there is a male valve stem

see instructions for Ball Valves. For the standard service

valve there are two variations, but both have internal

stems. The first style uses an internal snap ring to retain the

valve stem and the second has a rolled top and also has

finer threads on the valve cap. NOTE: You may encounter

more than one type of valve on a unit.

For service valves fully insert a hex wrench into the stem. A

back-up wrench is required on the valve body to open the

valve stem. Backout counterclockwise until the valve stem

stops or just touches the retaining ring. NOTE: THIS IS

NOT A BACKSEATING VALVE. For valves with retainer

rings care must be taken to prevent dislodging them when

opening valve.

Ball Valves

On models with ball type valves use a 6" crescent wrench

to rotate the valve stem 90° counter clockwise. Retighten

valve cap to 6-8 ft. Ibs. If torque wrench is not available,

tighten cap finger tight and then tighten one (1/2) additional

wrench fiat.

REFRIGERATION PIPING & CHARGING

The recommended method of addition or removal of refrig-

erant is by weight.

Some matching coils may need more refrigerant than the

factory charge. If you can't determine charge by weight,

then check charge by superheat method and performance

curves. The oil charge is sufficient for 50 feet.

For oil requirements refer to Figure 7. For piping lengths

up to 75 feet refer to Figure 8 for pipe size, and Figure 9 for

refrigerant adjustment.

On applications where liquid fioodback to the compressor

is likely to occur, use of a crankcase heater is recom-

mended.

Figure 7 - Addition of Refrigeration Oil

Distance

(Feet)

0-50

51

6O

75

Suction Line Size

5/8, 3/4, 7/8 1- 1/8

1 oz. 2 oz.

2 oz. 4 oz.

3 oz. 6 oz.

Figure 8 - LINE SIZING

Model Series

All Series

All Series

Size-ton Liquid Suction

1 1/2 to 3 3/8" 3/4"

3 1/2 to 5 3/8" 7/8"

Figure 9 Addition of Refrigeration Charge

Liquid Line Diameter oz. Per Linear Ft. *

3/8 .60

1/2 1.20

Page 8

I Installation Instructions R410-A Split System Condensers I

Electrical Wiring

A/C Control Box

Electrical Shock Hazard.

Shut off electric power at fuse box or service pan-

el before making any electrical connections.

Failure to shut off electric power can result in,

property damage, personal injury and/or death.

The supply voltage should be 208-230 volts (196 volt mini-

mum to 253 volts maximum) 60Hz single phase.

APPROVED FOR USE WITH COPPER CONDUCTORS

ONLY. DO NOT USE ALUMINUM WIRE.

REFER TO UNIT RATING PLATE FOR CIRCUIT

PROTECTION.

ALL Low Voltage

Connections MUST be

made in this AREA

Contactor

Low Voltage

Entrance

Ground Lug

Line Voltage

Entrance

Grounding

Permanently ground unit in accordance with the National

Electrical Code and local codes or ordinances. Use a cop-

per conductor of the correct size from the grounding termi-

nal in control box to a grounded connection in the service

panel ora properly driven and electrically grounded ground

rod.

Wiring Connections

Make all outdoor electrical supply (Line Voltage) connec-

tions with raintight conduit and fittings. Most codes require

a disconnect switch outdoors within sight of the unit.

Route Line Voltage wiring through entrance and through

hole in the bottom of the Control Box to connect to Contac-

tor and Ground Lug.

Route Low Voltage wiring through entrance ONLY and

make ALL low voltage connections to the low voltage pig-

tails in the area below the Control Box. (Two Yellow wires,

AC or W,Y,O,BL). The pigtail wires have 600V insulation

meeting approval for use in high voltage areas.

See Figures 10 thru 11 and Wiring Diagram on unit.

Use of Rigid Metal Conduit

It is recommended that wires be tied together or twisted to-

gether inside the conduit. This will minimize any buzzing

type sounds that could be produced with high current

loads, such as during starting. Under some conditions it

may be necessary to use a hard start kit to eliminate prob-

lem noises.

Control Box Access

Remove the four screws. Cover is notched so it will slide

out from under top edge of unit.

Figure 1 [ A/C Condenser Typical Low

! Voltage Connections

Indoor

Thermostat

( x2

R G

I I

(Compressor q

(Co

BL W

I J

Outdoor

Unit

ontactor)

Y--

nmon 24V)

A y _

INDOOR

GAS

BLOWER OR FURNACE

COIL

Start-Up Procedure

Start-up Procedure - Cooling Operation

1. Close electrical disconnects to energize system.

IJJ

.

Energize crankcase heater on units so equipped for

24Hrs, then proceed with Start UP.

Page 9

I Split System Condensers R410-A Installation Instructions I

3. Set Thermostat selector switch to OFF.

4. Set room thermostat at desired temperature. Be

sure setpoint is below indoor ambient temperature

for cooling and above indoor ambient for heating.

5. Set the system switch of the thermostat on COOL

and fan switch for continuous operation or AUTO, as

desired. Operate unit for 15-20 minutes, then check

the system refrigerant charge if it was necessary to

adjust.

6. After the refrigerant charge has been adjusted, the

system is now ready for continuous operation.

Final Refrigeration Charge Adjustment

Before any adjustment is made to the refrigerant charge, it

is imperative that the air flow characteristics of the indoor

blower be established.

When checking indoor air flow, it is important to remember

that the blower will deliver a higher quantity of air across a

dry coil versus a wet coil. Blower charts are calculated with

a dry coil.

Recommended air flow for installations of cooling units is

350-450 CFM per ton (12,000 BTUH) through a wet coil.

Refer to indoor unit installation instructions for proper

methods of determining air flow and blower perfor-

mance.

Factory charge is shown on unit information plate. R-410A

refrigerant cylinders contain a dip tube which allows liquid

refrigerant to flow from cylinder in upright position. Charge

R410-A units with cylinder in upright position and a com-

mercial-type metering device in manifold hose. Charge re-

frigerant into suction line.

NOTE: If superheat or subcooling charging conditions

are not favorable, charge must be weighed in accor-

dance with unit rating plate 0.5 oz/ft of 3/8-in. liquid line

above or below 25 ft respectively.

To Check System Refrigerant Charge

(Superheat Method), Cooling Only

NOTE: On units with two speed fan control the fan will be

on low speed if the temperature is below 83° E Pull one of

the yellow low voltage wires offthe fan control and the unit

will default to high speed fan for servicing. Reconnect wire

after checking.

Units with Cooling Mode TXV

Units installed with cooling mode TXV require charging by

the subcooling method.

1. Operate unit a minimum of 10 minutes before check-

ing charge.

2. Measure liquid service valve pressure by attaching

an accurate gage to service port.

3. Measure liquid line temperature by attaching an ac-

curate thermistor type or electronic thermometer to

liquid line near outdoor coil.

4. Refer to unit rating plate for required subcooling tem-

perature.

5. Refer to Figure 12. Find the point where required

subcooling temperature intersects measured liquid

service valve pressure.

6. To obtain required subcooling temperature at a spe-

cific liquid line pressure, add refrigerant if liquid line

temperature is higher than indicated or reclaim refrig-

erant if temperature is lower. Allow a tolerance of 3E

Page 10

I Installation Instructions R410-A Split System Condensers I

Figure 12

Required Liquid-Line Temperature (°F)

LIQUID

PRESSUREAT

SERVICEVALVE

(PSIG)

LIQUID

PRESSUREAT

REQUIREDSUBCOOLING

TEMPERATURE

(°F) SERVICEVALVE

8 1o 12 I 14 16 18 (PSIG)

58 56 54 52 50 48 326

60 58 56 54 52 50 335

62 60 58 56 54 52 345

64 62 60 58 56 54 354

66 64 62 60 58 56 364

68 66 64 62 60 58 374

70 68 66 64 62 60 384

72 70 68 66 64 62 395

74 72 70 68 66 64 406

76 74 72 70 68 66 416

78 76 74 72 70 68 427

80 78 76 74 72 70 439

82 80 78 76 74 72 450

84 82 80 78 76 74 462

86 84 82 80 78 76 474

88 86 84 82 80 78 486

90 88 86 84 82 80 499

92 90 88 86 84 82 511

REQUIREDSUBCOOLING

TEMPERATURE

(°F)

8 I 10 12

189 94 92 90

195 96 94 92

202 98 96 94

208 100 98 96

215 102 100 98 96

222 104 102 100 98

229 106 104 102 100

236 108 106 104 102

243 110 108 106 104

251 112 110 108 106

259 114 112 110 108

266 116 114 112 110

274 118 116 114 112

283 120 118 116 114

291 122 120 118 116

299 124 122 120 118

308 126 124 122 120

317 128 126 124 122

14 I 16 18

88 86 84

90 88 86

92 90 88

94 92 90

94 92

96 94

98 96

100 98

102 100

104 102

106 104

108 106

110 108

112 110

114 112

116 114

118 116

120 118

Figure 13

Superheat Charging

OUTDOOR EVAPORATORENTERINGAIR TEMPERATURE(°FWB)

TEMP

54 56 58 60 62 64 66 68 70 72 I 74 76

(°F)

55 14 17 20 23 26 29 32 35 37 40 42 45

60 12 15 18 21 24 27 30 33 35 38 40 43

65 10 13 16 19 21 24 27 30 33 36 38 41

70 7 10 13 16 19 21 24 27 30 33 36 39

75 e 9 I 12I 15 I 18 I 21 24 28 31 34 37

80 5 I 8 I 12 I 15 I 18 21 25 28 31 35

85 8 111115 19 22 26 30 33

90 5 I 9 I 13 16 20 24 27 31

95 6 I 10 14 18 22 25 29

100 8 12 15 20 23 27

105 5 9 13 17 22 26

110 6 11 15 20 25

115 8 14 18 23

--Where a dash appears,do nota_emptb charge sys_m underhese conditionsorretigerantslugging may occur. Charge mustbe

weighedin. NOTE:Superheat°F isatlow-side service port.

llj2J

Page 11

I Split System Condensers R410-A Installation Instructions I

Figure 14

Required Suction-Line Temperature

SUPERHEAT SUCTION PRESSURE ATSERVICE PORT(PSIG)

TEMP(°F) 107.8 112.2 116.8 1212 126.0 130.8 138.8 140.8 145.8

0 35 37 39 41 43 45 47 49 51

2 37 39 41 43 45 47 49 51 53

4 39 41 43 45 47 49 51 53 55

6 41 43 45 47 49 51 53 55 57

8 43 45 47 49 51 53 55 57 59

10 45 47 49 51 53 55 57 59 61

12 47 49 51 53 55 57 59 61 63

14 49 51 53 55 57 59 61 63 65

16 51 53 55 57 59 61 63 65 67

18 53 55 57 59 61 63 65 67 69

20 55 57 59 61 63 65 67 69 71

22 57 59 61 63 65 67 69 71 73

24 59 61 63 65 67 69 71 73 75

26 61 63 65 67 69 71 73 75 77

28 63 65 67 69 71 73 75 77 79

30 65 67 69 71 73 75 77 79 81

32 67 69 71 73 75 77 79 81 83

34 69 71 73 75 77 79 81 83 85

36 71 73 75 77 79 81 83 85 87

38 73 75 77 79 81 83 85 87 89

40 75 77 79 81 83 85 87 89 91

To Check System Refrigerant Charge

(Heating Mode)

Maintenance

The recommended method of addition or removal of

charge in the heating mode is by weight. The system op-

eration may be checked against the performance charts.

Remember, indoor airflow must be approximately 400

CFM per ton to compare operation to performance charts.

In some areas, with high humidity, the temperature ter-

mination may require adjustment for complete removal of

ice from the coil. For best economy, always set to the low-

est temperature that will keep the coil clear of ice.

NOTE: The term ice means hard but not frost. During nor-

mal operation, the coils may become coated with frost until

they are solid white. The temperature for the defrost should

be set so the frost and ice melt off completely without hard

ice building up on the coil.

Electrical Shock Hazard.

Shut off electric power atfuse box or service pan-

el before making any electrical connections,

Failure to shut off electric power can result in,

property damage, personal injury and/or death.

Condensate Drain

During the cooling season check at least monthly for free

flow of drainage and clean if necessary.

Cleanliness

These tips will help you keep your air conditioner looking

better and working more efficiently:

1. Free air flow is essential. Keep the outdoor coil clean

and free of restrictions. Keep fences, shrubs, snow

drifts and any other obstructions at least two feet from

all coil air inlets.

Page 12

I Installation Instructions

2.

R410-A Split System Condensers I

Keep the coil free of grass clippings, weeds and other

debris. BE SURE TO TU RN OFF ELECTRICITY BE-

FORE CLEANING!

Coils may require cleaning. The coil should al-

ways be cold when cleaning. Use an alkaline

based cleaner only. Cleaning a hot coil or using

an acid based cleaner will remove the paint from

the fins and may clog the coil.

. Never use a weather cover over the outdoor unit un-

less itis aventilated type or made of breathable fabric

that will allow moisture to evaporate rapidly. A cover

that holds moisture in the unit will cause more rust

build-up and damage than normal exposure to

weather.

Page 13

I Split System Condensers R410-A Installation Instructions I

R410-A QUICK REFERENCE GUIDE

R-410A refrigerant operates at 50-70 percent higher pressures than R-22. Be sure that servic-

ing equipment and replacement components are designed to operate with R-410A.

R410-A refrigerant cylinders are rose colored.

R410-A refrigerant cylinders have a dip tube which allows liquid to flow out of cylinder in upright

position. Recovery cylinder service pressure rating must be 400 psig, DOT 4BA400 or DOT

BW400.

Enviromax systems should be charged with liquid refrigerant. Use a commercial type metering

device in the manifold hose. Manifold sets should be 800 psig high side and 250 psig low side with

550 psig low-side retard.

Use hoses with 800 psig service pressure rating.

Leak detectors should be designed to detect HFC refrigerant. R410-A, as with other HFCs, is

only compatible with POE oils. Vacuum pumps will not remove moisture from oil.

DO NOT use liquid-line filter driers with rated working pressures less than 600 psig. Do not install

a suction-line filter drier in liquid line.

POE oils absorb moisture rapidly. DO NOT expose oil to atmosphere. Wrap all filter driers and

service valves with wet cloth when brazing. A liquid-line filter drier is required on every unit.

DO NOT use an R-22 TXV.

If indoor unit is equipped with an R-22 TXV, it must be changed to a R410-A TXV. Never open

system to atmosphere while it is under a vacuum.

When system must be opened for service, evacuate then break vacuum with dry nitrogen and

replace filter driers. DO NOT vent R410-A into the atmosphere.

DO NOT use capillary tube coils.

Observe all warnings, cautions, and bold text.

Personal Injuury Hazard

Relieve pressure and recover all refrigerant be-

fore system repair or final unit disposal to avoid

personal injury or death. Use all service ports and

open all flow-control devices, including solenoid

valves.

Loading...

Loading...