Installation Instructions

I DIRECT DRIVE BLOWER

PH55/PYPA SERIES

U SINGLE PACKAGE HEAT

PUMPS c_

ELECTRIC HEAT

(OPTIONAL)

TABLEOFCONTENTS

1, SAFETYLABELINGANDSIGNALWORDS .................... 2

2. UNITDIMENSIONS ...................................... 2

3, SAFEINSTALLATIONREQUIREMENTS....................... 2

4. LOCATINGTHE UNIT .................................... 2

5, UNITELECTRICALWIRING................................ 4

6,WIRINGDIAGRAMS ..................................... 8

7, ELECTRICNEATINSTALLATIONGENERALINFORMATION ...... 10

8. INSTALLINGELECTRICHEATACESSORY................... 10

9. HEATERELECTRICALWIRING ........................... 11

10.RAIN SHIELDINSTALLATION............................ 15

11,AIR DISTRIBUTIONSYSTEM............................. 15

12.START-UPPROCEDURES.............................. 15

13.SEQUENCEOFOPERATION ............................ 17

14.OPERATION ......................................... 18

Printed in U.S.A. LP-1 1/23/03 427 01 1004 01

1. Safety Labelinq and Siqnal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAUTION are used to identi-

fy levels of hazard seriousness. The signal word DANGER is only used on

product labels to signify an immediate hazard. The signal words WARN-

ING and CAUTION will be used on product labels and throughout this

manual and other manuals that may apply to the product.

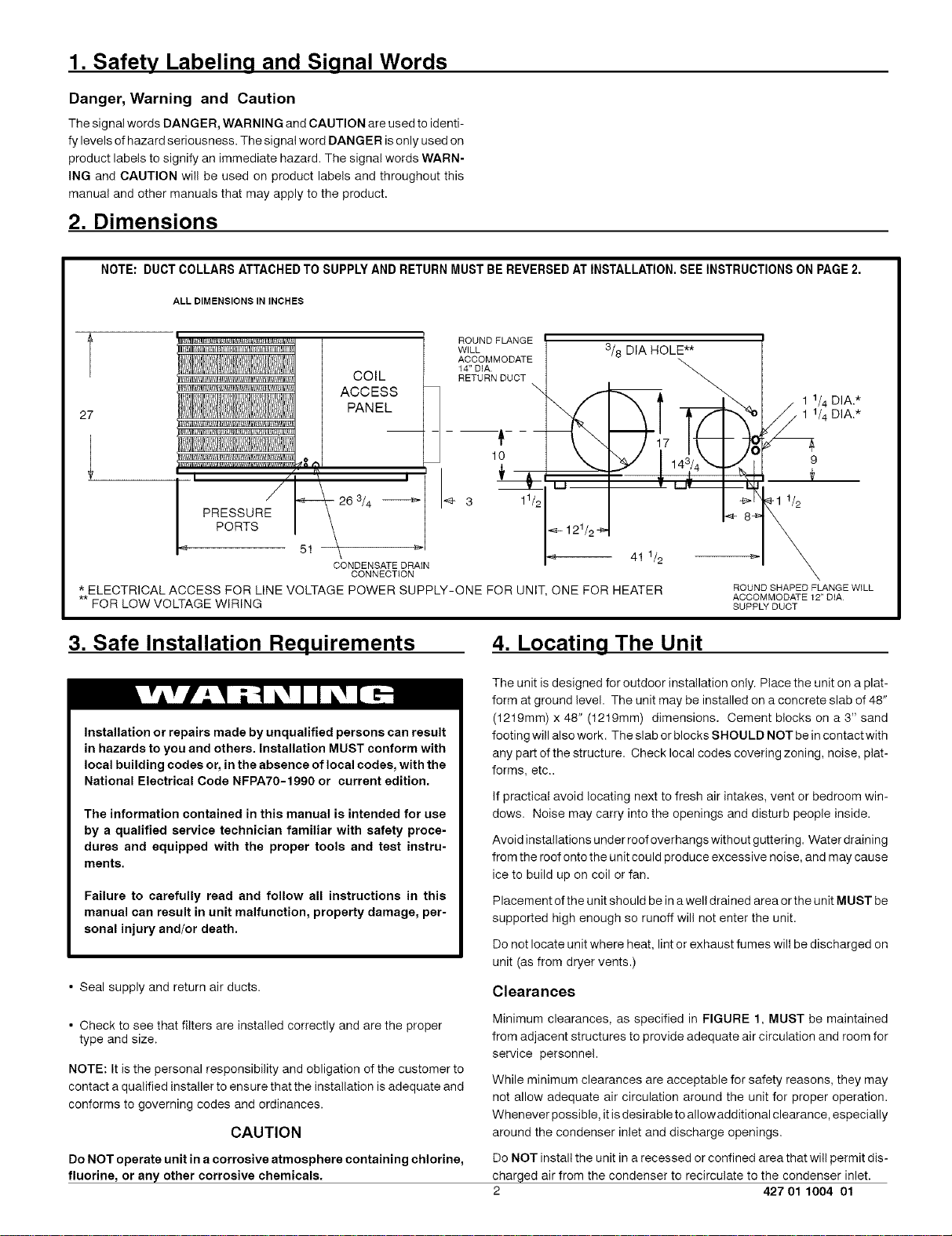

2. Dimensions

NOTE: DUCT COLLARS ATTACHED TO SUPPLY AND RETURN MUST BE REVERSED AT INSTALLATION. SEEINSTRUCTIONS ON PAGE 2.

ALL DIMENSIONS IN INCHES

ROUND FLANGE

WILL 3/8 DIA HOLE**

ACCOMMODATE

COIL

ACCESS

27

" tl_ I

PANEL

PRESSURE

26 3/4

<i PORTS

* ELECTRICAL ACCESS FOR LINE VOLTAGE POWER SUPPLY-ONE FOR UNIT, ONE FOR HEATER

** FOR LOW VOLTAGE WIRING

81 \

CONDENSATE DRAIN

CONNECTION

14" DIA.

RETURN DUCT

m___

10 9

3 11/2 I-1 1/2

41 1/2

ROUND SHAPED FLANGE WILL

ACCOMMODATE 12" DiA

SUPPLY DUCT

. 1 1/4 DIA.*

/ 1 1/4 DIA.*

3. Safe Installation Requirements 4. Locating The Unit

The unit is designed for outdoor installation only. Place the unit on a plat-

form at ground level. The unit may be installed on a concrete slab of 48"

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation MUST conform with

local building codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or current edition.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Failure to carefully read and follow all instructions in this

manual can result in unit malfunction, property damage, per-

sonal injury and/or death.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are the proper

type and size.

NOTE: It is the personal responsibility and obligation of the customer to

contact a qualified installer to ensure that the installation is adequate and

conforms to governing codes and ordinances.

CAUTION

Do NOT operate unit in a corrosive atmosphere containing chlorine,

fluorine, or any other corrosive chemicals.

(1219mm) x 48" (1219mm) dimensions. Cement blocks on a 3" sand

footing will also work. The slab or blocks SHOULD NOT be in contact with

any part ofthe structure. Check local codes covering zoning, noise, plat-

forms, etc..

If practical avoid locating next to fresh air intakes, vent or bedroom win-

dows. Noise may carry into the openings and disturb people inside.

Avoid installations under roof overhangs without guttering. Water draining

from the roof onto the unit could produce excessive noise, and may cause

ice to build up on coil or fan.

Placement ofthe unit should be in a well drained area or the unit MUST be

supported high enough so runoff will not enter the unit.

Do not locate unit where heat, lint or exhaust fumes will be discharged on

unit (as from dryer vents.)

Clearances

Minimum clearances, as specified in FIGURE 1, MUST be maintained

from adjacent structures to provide adequate air circulation and room for

service personnel.

While minimum clearances are acceptable for safety reasons, they may

not allow adequate air circulation around the unit for proper operation.

Whenever possible, itis desirable to allowadditional clearance, especially

around the condenser inlet and discharge openings.

Do NOT install the unit in a recessed or confined area that will permit dis-

charged air from the condenser to recirculate to the condenser inlet.

2 427 01 1004 01

Minimum Clearances to Combustible Construction

SERVICE ACCESS CLEARANCES

Blower Access Panel Side .......................... 30" (762mm)

Electrical Access Panel Side ........................ 30" (762mm)

OPERATIONAL CLEARANCES

Combustible Base

(Wood or Class A, B or C

roof covering material) ......................... 0"

Supply and Return Air Ducts ................................. 0"

Duct Connection Side

............................................. 0 !_

Clearance between Overhang

Clearance around Condenser Coil area to wall or shrubs ........ 10"

FIGURE i Minimum Clearances and Access Panels

Evaporator 48" Minimum Overhang Clearance

Access Panel

and Top of Unit ..................... 48" (1219mm)

Overhang

J

10"around

f condenser

coil area

Installing Duct Collars

Duct collars are supplied with the unit and are attached to the supply and

return openings with the flanges tothe inside and must be reversed before

unit's installation.

Blower/Electrical

Access Panel

,,_ Cover Plate

Installation

CAUTION

The unit must be installed with a slope no greater than 1/8" per foot

(10mm per meter), For side to side leveling, the condensate drain

side side MUST always be lower.

The unit MUST be situated in such a way as to provide safe access

for servicing.

The platform may be made of either concrete or pressure treated

wood and MUST be level and strong enough to support the unit's

weight.

1.Remove the screws from the collars and reverse them so the flange

is to the outside.

2.Make sure when pushing the collars into place that the "V" flange of

the collars seats into the supply and return holes securely.

3.Re-install screw in each collar so it goes through both of the holes in

the collar end. It does not matter how the ends of the collar overlap

in order to accomplish this.

FIGURE ;3 I Duct Collar Installation

Position platform separate from the building's foundation.

Install in a well-drained area, with the top surface of the platform

above grade level and above the average winter snow levels to

prevent coil blockage.

Platform MUST be high enough to allow for proper condensate

drainage.

3 427 01 1004 01

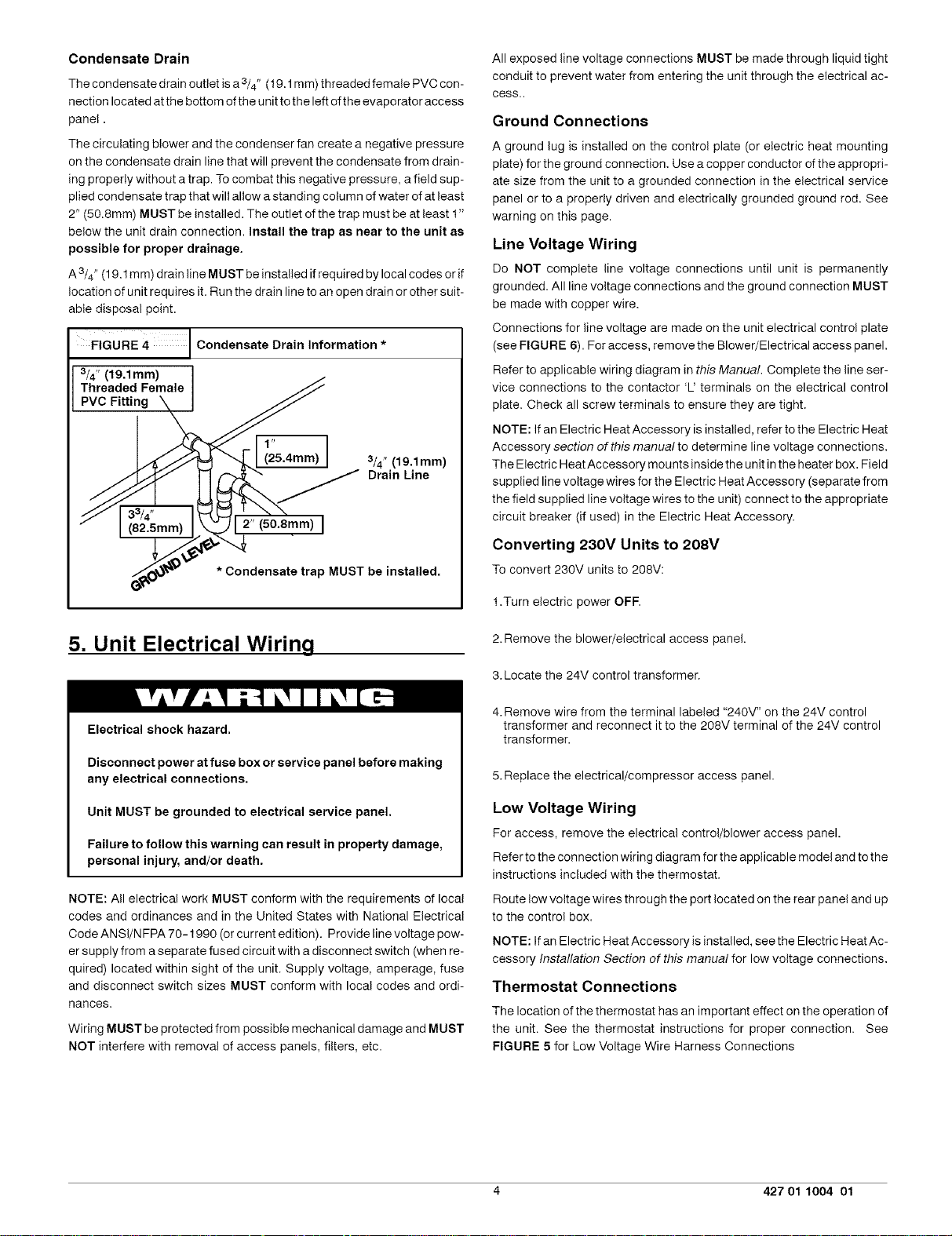

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) threaded female PVC con-

nection located at the bottom ofthe unit to the left of the evaporator access

panel.

The circulating blower and the condenser fan create a negative pressure

on the condensate drain line that will prevent the condensate from drain-

ing properly without a trap. To combat this negative pressure, a field sup-

plied condensate trap that will allow a standing column of water of at least

2" (50.8mm) MUST be installed. The outlet of the trap must be at least 1"

below the unit drain connection. Install the trap as near to the unit as

possible for proper drainage.

A 3/4" (19.1 mm) drain line MUST be installed ifrequired by local codes or if

location of unit requires it. Run the drain line to an open drain or other suit-

able disposal point.

FIGURE 4 J Condensate Drain information*

3/4" (19,1mm)

Threaded Female

PVC Fitting

i

1,, I

(25.4mm)

3/4" (19.1mm)

Drain Line

All exposed line voltage connections MUST be made through liquid tight

conduit to prevent water from entering the unit through the electrical ac-

cess..

Ground Connections

A ground lug is installed on the control plate (or electric heat mounting

plate) for the ground connection. Use a copper conductor of the appropri-

ate size from the unit to a grounded connection in the electrical service

panel or to a properly driven and electrically grounded ground rod. See

warning on this page.

Line Voltage Wiring

Do NOT complete line voltage connections until unit is permanently

grounded. All line voltage connections and the ground connection MUST

be made with copper wire.

Connections for line voltage are made on the unit electrical control plate

(see FIGURE 6). For access, remove the Blower/Electrical access panel.

Refer to applicable wiring diagram in this Manual. Complete the line ser-

vice connections to the contactor 'U terminals on the electrical control

plate. Check all screw terminals to ensure they are tight.

NOTE: If an Electric Heat Accessory is installed, refer to the Electric Heat

Accessory section of this manual to determine line voltage connections.

The Electric HeatAccessory mounts inside the unit in the heater box. Field

supplied line voltage wires for the Electric Heat Accessory (separate from

the field supplied line voltage wires to the unit) connect to the appropriate

circuit breaker (if used) in the Electric Heat Accessory.

* Condensate trap MUST be installed.

5. Unit Electrical Wiring

Electrical shock hazard.

Disconnect power at fuse box or service panel before making

any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

NOTE: All electrical work MUST conform with the requirements of local

codes and ordinances and in the United States with National Electrical

CodeANSI/NFPA 70-1990 (orcurrent edition). Providelinevoltage pow-

er supply from a separate fused circuit with a disconnect switch (when re-

quired) located within sight of the unit. Supply voltage, amperage, fuse

and disconnect switch sizes MUST conform with local codes and ordi-

nances.

Wiring MUST be protected from possible mechanical damage and MUST

NOT interfere with removal of access panels, filters, etc.

Converting 230V Units to 208V

To convert 230V units to 208V:

1.Turn electric power OFF.

2.Remove the blower/electrical access panel.

3. Locate the 24V control transformer.

4. Remove wire from the terminal labeled "240V" on the 24V control

transformer and reconnect it to the 208V terminal of the 24V control

transformer.

5. Replace the electrical/compressor access panel.

Low Voltage Wiring

For access, remove the electrical control/blower access panel.

Referto theconnectionwiringdiagramfor the applicablemodeland tothe

instructions included with the thermostat.

Route low voltage wires through the port located on the rear panel and up

to the control box.

NOTE: Ifan Electric Heat Accessory is installed, see the Electric Heat Ac-

cessory Installation Section of this manual for low voltage connections.

Thermostat Connections

The location of the thermostat has an important effect on the operation of

the unit. See the thermostat instructions for proper connection. See

FIGURE 5 for Low Voltage Wire Harness Connections

4 427 01 1004 01

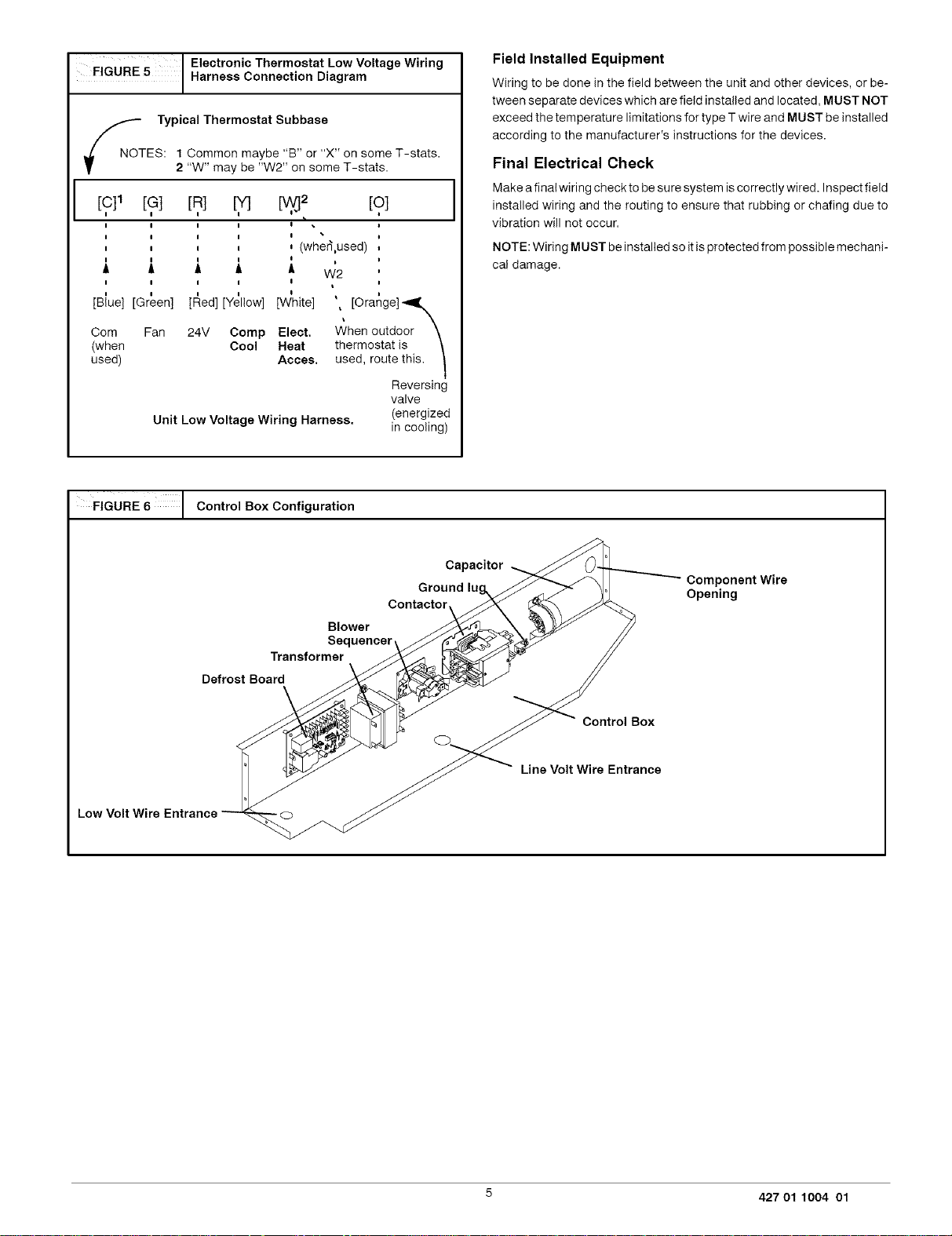

FIGURE5 I HarnessElectr°niCconnectionTherm°statDiagramL°WVoltage Wi ri ng

_NOT Typical Thermostat SubbaseES: 1 Common maybe "B" or "X" on some T-stats.

[c]1

I

i

I I I I

I I I I /

A A A A

I I I I I

[Blue] [Green] [F_ed] [Yellow] [W_hite]

Corn Fan 24V Comp Elect.

(when Cool Heat

used) Acces.

FIGURE 6 I Control Box Configuration

2 "W" may be "W2" on some T-stats.

[?] [,R] [O]

I I I I

I I I I

Unit Low Voltage Wiring Harness.

i (wher],used)

A

W2

',, [Orange] "_,Xk

When outdoor \

thermostat is \

used, route this. I

valve

Reversing

(energized

in cooling)

Field Installed Equipment

Wiring to be done in the field between the unit and other devices, or be-

tween separate devices which are field installed and located, MUST NOT

exceed the temperature limitations for type T wire and MUST be installed

according to the manufacturer's instructions for the devices.

Final Electrical Check

Make a final wiring check to be sure system is correctly wired. Inspect field

installed wiring and the routing to ensure that rubbing or chafing due to

vibration will not occur.

NOTE: Wiring MUST be installed so itis protected from possible mechani-

cal damage.

i

Low Volt Wire Entrance

Capacitor_

Ground lug%__ _oJ Component Wire

Contaotor Opening

Blower J___ _ //

Sequencer __;_ /_

Transformer\ ____. F //

oooooox

,neVo,We n,anoe

5 427 01 1004 01

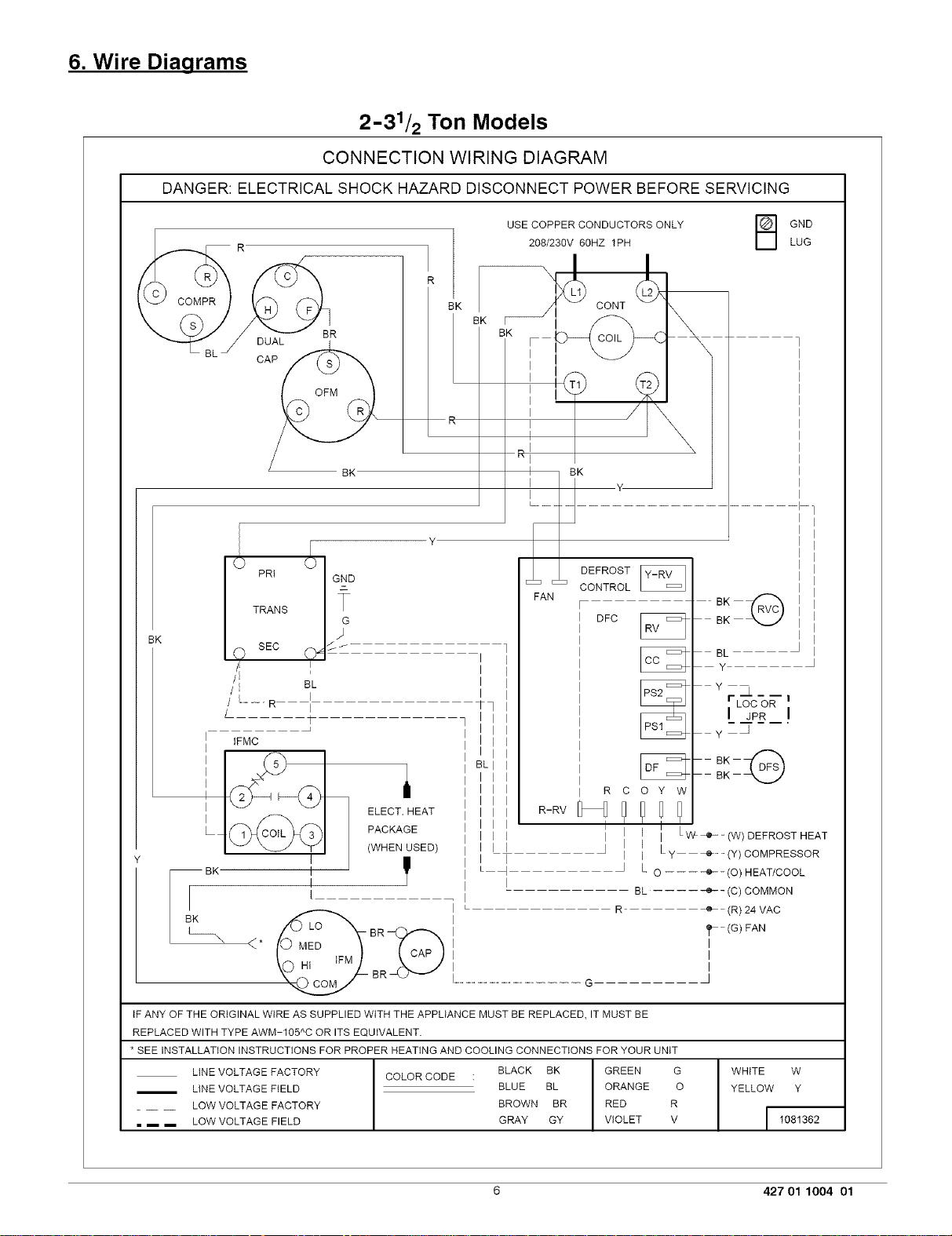

6. Wire Diagrams

DANGER: ELECTRICAL SHOCK HAZARD DISCONNECT POWER BEFORE SERVICING

DUAL

CAP

2-31/2 Ton Models

CONNECTION WIRING DIAGRAM

USE COPPER CONDUCTORS ONLY

208/230V 60HZ 1PH

EK

_ CONT

BK

BK

BK

B ND

LUG

4-

BK

PRt

TRANS

SEC

I...........R I

I IFMC

I

Ltc 3b

BK I

BK

I

BL

I

ELECT. HEAT

PACKAGE

(WHEN USED)

I

I

I

I

I

I

_q

I

L _ J

I

FAN

R-RV

DEFROST

CONTROL

DEC

R C

O Y W

I

I I

I I Lw+_ (w) DEFROST HEAT

I

I

I L y (y) COMPRESSOR

L O -------e--(O) HEAT/COOL

BL .... -e-- (C) COMMON

R e- (R) 24 VAC

<*

BR

tF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, IT MUST BE

REPLACED WITH TYPE AWM-105 C OR ITS EQUIVALENT.

* SEE INSTALLATION INSTRUCTIONS FOR PROPER HEATING AND COOLING CONNECTIONS FOR YOUR UNIT

LINE VOLTAGE FACTORY COLOR CODE : BLACK BK GREEN G

/ LINE VOLTAGE FIELD BLUE BL ORANGE O

LOW VOLTAGE FACTORY BROWN BR RED R

= i i LOW VOLTAGE FIELD GRAY GY VIOLET V

A

...............................................................................................G •

BL

Y

Yr&---i

LOC OR

L_P___!

y •

(G) FAN

I

I

I

WHITE W

YELLOW Y

6 427 01 1004 01

Wire Diaqrams (Cont'd...)

DANGER: ELECTRICAL SHOCK HAZARD DISCONNECT POWER BEFORE SERVICING

2-31/2 Ton Models

LADDER WIRING DIAGRAM

Lt _!1 GNU L2

(OPTIONAL) CRANKCASE HEATER

L1 CONTACTOR T1 CONTACTOR L2

208/230 VAC, 60 HZ, 1PH m

CAP

COMPR

DFC

_ OFM

<*

_CAP

IFM

230V

_...___) 208V TAP

TRANS

O

+

I

I

I

TRANS....TRANSFORMER

COMPR....COMPRESSOR

CAP ........ CAPACITOR

CONT......CONTACTOR

JPR ........ JUMPER WIRE

FAN

DEFROST

CONTROLDFs _

F ...................................................................................

R-_ i I f O Y W

mv _U I_

I L_--e- .... (W) DEFROST HEAT

I j ....

I e- .... (Y) COMPRESSOR

L

................................e ................................(O) HEAT/COOL

(C) COMMON -_.

(G) FAN .....

[ ,_EGE,,,o]

GND.......GROUND

LOC.......LOSS OFCHARGE

PRESSURESWtTCH

DFS ........ DEFROST SENSOR

DFC ........ DEFROST CONTROL

24V

......!_ LOC OR_ I

[ I JPR _i

ZZZZ@ _

e- .... (R) 24 VAC

E

IFMC......tNDOOR FAN MOTOR CONTROL

IFM ........ iNDOOR PAN MOTOR

RVS ........ REVERSING VALVE SOLENOID

OFM ........ OUTDOOR PAN MOTOR

TC .......... TERMINAL CONNECTOR

+

GND _

I 1081362

7 427 01 1004 01

Wire Diaqrams (Cont'd...)

DANGER: ELECTRICAL SHOCK HAZARD DISCONNECT POWER BEFORE SERVICING

4 & 5 Ton Model

CONNECTION WIRING DIAGRAM

R

BL _ C,_

_) {} Y

TRANS

BK

--BK I

BK

O SEC O _ _/

/I t

//EE BL

/ L_ R- I

I IPMC

I

I ELECT. HEAT

L_ PACKAGE

L

\

PRI GND

J

I

I

I

BK

G

(WHEN USED)

BR

USE COPPER CONDUCTORS ONLY

208/230V 6OHZ 1PH

BK

BK

BK

I I

I I

I I

I I

BK

i• L>--'@,--C \

I

FAN

I

Tq I

1 I I

I I I

I I I

I I I

i BLI I

I I I I

I I I I

I I I

I I I

I I I

I I Lw+ (W) DEFROSTHEAT

I I I

I I I

I I

L

I ] L O --- ÷- (O) HEAT/COOL

I

I BL .... ÷ (C) COMMON

I

I L R ....................................................................._ (R) 24 VAC

I

I _ (G)FAN

I I

I I

R-RV

I

CONT '_

DEFROST

CONTROL

r

ii DFC _

I

I

I

I

I

I

I

I

I

I

I

I

I

I R C O Y W

I

I

J

Ly + (Y) COMPRESSOR

BK

y--_

I I

I G I

B

GND

LUG

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

IF ANY OF THE ORIGINAL WiRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, IT MUST BE

REPLACED WITH TYPE AWM-165 C OR ITS EQUIVALENT.

* SEE INSTALLATION INSTRUCTIONS FOR PROPER HEATING AND COOLING CONNECTIONS FOR YOUR UNIT

LINE VOLTAGE FACTORY COLOR CODE : BLACK BK GREEN G

LINE VOLTAGE FIELD ..................................................................BLUE BL ORANGE O

LOW VOLTAGE FACTORY BROWN BR RED R

= m m LOW VOLTAGE FIELD GRAY GY VIOLET V

^

8 427 01 1004 01

WHITE W

YELLOW Y

I 1081364

Wire Diagrams (Cont'd...)

DANGER: ELECTRICAL SHOCK HAZARD DISCONNECT POWER BEFORE SERVICING

4 & 5 Ton Model

LADDER WIRING DIAGRAM

L1

(OPTIONAL) CRANKCASE HEATER I _ I

L1 CONTACTOR T1 COMPR T2 CONTACTOR L2

O---_ II GND L2

208/230 VAC, 60 HZ, 1PH |

4 CA H

O _ C FM

DFC SCO

[ <

TRANS

TRANS....TRANSFORMER

COMPR....COMPRESSOR

CAP ........ CAPACITOR

CONT......CONTACTOR

JPR ........ JUMPER WIRE

FAN

DEFROST

CONTROLDFs _

F

R-[_R If O Y W

RV _1_

(C) COMMON ..... -e

GND.......GROUND

LOC_.....LOSS OF CHARGE

PRESSURE SWITCH

DFS ........ DEFROST SENSOR

DFC ........ DEFROST CONTROL

I I ...............e ...........................(W) DEFROST HEAT

I

I _ (Y) COMPRESSOR

L .... -e- .... (O) HEAT/COOL

(G) FAN .........................................._ ............................................................................................................................

LEGEND

jq _2P2_ )

ZZZZ@ _

4_ (R) 24 VAC

J

IFMC......tNDOOR FAN MOTOR CONTROL

IFM........ INDOOR FAN MOTOR

RVS ........REVERSING VALVE SOLENOID

OFM ........ OUTDOOR FAN MOTOR

TC.......... TERMINAL CONNECTOR

}

/

()

(,)

GND L

I 1081364

9 427 01 1004 01

7. Electric Heat Installation General

Information

8. Installing Electric Heat Accessory

General Information

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation must conform with

local building codes or, in the absence of local codes, with

National Electrical Code ANSI/NFPA 70-1990 or current

edition.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety

procedures, equipped with the proper tools and test

instruments.

Failure to carefully read and follow all instructions in this

manual can result in malfunction, property damage, personal

injury, and/or death.

When an electric heat accessory is installed, two separate field power

supplies MUST be provided - one or more for the electric heat accessory

and one for the unit.

Electrical shock hazard.

Shut OFF electric power at unit disconnect and/or service

panel before beginning the following procedures.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

1. Shut OFF electric power at unit disconnect switch or service panel.

2. Remove the blower access panel from unit.

NOTE: Installation of field wiring and conduit for heaters to the

unit prior to installing the heater will simplify wiring of heaters.

3. From inside the blower compartment, remove the six screws on the

heater cover plate and save the screws. Discard the heater cover

plate.

The screws will be used later to mount the electric heat accessory

and its cover.

4. Remove the cardboard wrapper from the heater's elements.

5.Insert the heater into the heater/blower box. Exercise caution to

prevent damage to heater elements.

&Secure heater to heater/blower box with four of the six screws re-

moved in Step 3.

FIGURE 7 The Electric Heat Accessory

Breaker-

FIGURE 8 Installing The Electric Heat Accessory

10 427 01 1004 01

9. Heater Electrical Wirinq

Electrical shock hazard.

Shut OFF electric power at unit disconnect or service panel

before making any electrical connections.

Unit MUST be grounded before making line voltage connec-

tions. Do NOT fuse ground or neutral conductors.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

NOTE: All electrical work MUST conform with the requirements of local

codes and ordinances and in the United States with National Electrical

Code ANSI/NFPA70-1990 or current edition. Provide line voltage power

supply from a separate protected circuit with a disconnect switch (when

required) located within sight ofthe unit. Supply voltage, amperage, fuse

and disconnect switch sizes MUST conform with all technical specifica-

tions in this manual and on the unit rating plate and local codes.

Wiring MUST be protected from possible mechanical damage and MUST

NOT interfere with removal of access panels, filters, etc.

All exposed wiring or connections MUST be made with weatherproof

cable or wire unless installed in conduit.

All line voltage connections and the ground connection MUST be made

with copper wire.

The power supply wiring MUST have overcurrent protection. This can be

either fuses or circuit breakers. The maximum size for the overcurrent

protection is shown in the column labeled "Max. Fuse or NEC HACR

Breaker (Amps)" in the Electrical Data Table in FIGURE 10 or on the unit

rating plate.

Grounding

Permanently ground the electric heat accessory in accordance with local

codes and ordinances and in the United States with National Electrical

Code ANSI/N FPA70-1990 or current edition. Use a copper conductor of

the appropriate size from the electric heat accessory to the ground lug on

the circuit breaker panel as shown in FIGURE 9.

Adjusting Thermostat Anticipator

Set theheatanticipator of the thermostattothe propervalue. See instruc-

tions providedwith the thermostat before making this adjustment.

Model Number Anticipator

AMMK05AHB/A .18

AM MK07AH B/A .36

AMMK10AH B/A .36

AMMK15AH B/A .36

AM MK20AH B/A .54

Setting

Limit Controls

The limit controls are mounted on the face of the heater and are wired into

the supply wires to each element. If there is not enough air flow through

the heater, the limit will open and break the power circuit. The limit will re-

set when the electric accessory cools down.

Time Delay Operation

The heater elements are switched ON and OFF through one or more con-

trois which operate through the low voltage thermostat circuit.

These controls consist of a number of time delays depending on the spe-

cific heater model. An electric heat accessory has 1,2 or 3 of these con-

trois. The first time delay is activated when the thermostat contacts close.

Approximately 1 to 20 seconds later the indoor blower and the first heater

bank are energized. Approximately 70 seconds after the first heater bank

is energized the remaining time delays and heater banks are energized.

Staging

Some electric utilities require staging on electric heaters larger than 6 kilo-

watts. Therefore, the heater elements are turned on in 5 or 10 kW incre-

ments under control of the sequencers.

If staging based on heat loss or demand is required, the use of accessory

outdoor thermostats is recommended. The heat sequencer wiring is de-

signed to be staged by breaking the 24V "Common" Leg (normally brown

or gray). Outdoor thermostats available through your wholesale supplier

allow the control of two or four stages of electrical heat.

Some indoor electronic thermostats may provide for multiple stage of

electric heat. When this type thermostat is used, it may be necessary to

break the 24V"Hot" leg of the sequencer (asfed from the "W' circuit at the

thermostat). This will require field modification of the control wiring and

should only be done byan experienced controls technician/or electrician.

Installing Wiring

1.Shut OFF electric power at unit disconnect or service panel.

2.Install the appropriate field supplied conduit fitting into the heater

knockout located in the rear panel of the unit. The wiring entrance

hole is sized for 1" conduit.

11 427 01 1004 01

TypicalWiringInstallation(BreakerStyleHeaterShown-Pigtailstylealsoavailable)

UnitLineVoltageWires

3.Connect field installed copper ground wire(s) to the ground lug(s) on

the heater mounting plate. On models with more than one circuit, a

separate copper ground wire MUST be connected to a separate

ground lug for each circuit.

4. Route the field supplied line voltage wires for the heater to the line

side of the electric heat accessory's circuit breaker(s) or high voltage

wiring harness. Leave approximately 8" of excess wire so the break-

er or wiring harness may be moved to service. Make line voltage

connections to L3-L6 as appropriate. NOTE: If heaters without

breakers are used, route field wires to inside of unit and attach to

heater wires tagged L3-L6 as appropriate using supplied wire nuts.

5.Connect the black wire with terminal from the heater wire harness to

the loose black wire at the unit blower.

NOTE: Check FIGURE 11 for heater/speed combinations that are

unacceptable.

6 Connect the red wire with terminal in the heater wire harness to the

loose red wire from the unit sequencer.

7. Connect the white wire from the heater wire harness to the white wire

from the thermostat at the field supplied low volt wire harness in the

control box.

8. Connect the grey and brown wires from the heater wire harness to

the blue wire from the unit 24V common. NOTE: If outdoor thermo-

stats are used for staging electric heat, connect the grey and brown

wires according to the thermostat instructions. See "Staging" in

Electrical Wiring Section of this Manual.

After completing installation of the heater, install the breaker rain shield on

the blower access panel according to the following instructions on page

13. If using a pigtail style heater, proceed to Start-Up Procedures for Aux-

iliary Electric Strip Heat on page 14.

12 427 01 1004 01

FIGURE10 AccessoryElectricHeaterElectricalData

HEATER

MODEL

AMMK05AHA

AMMK05AHB

AMMK07AHA

AMMK07AHB

AMMK10AHA

AMMK10AHB

AMMK15AHB

AMMK20AHB

UsedWith

2-5 TON

2-5 TON

2-5 TON

21/2-5 TON

21/2-5 TON

Supply Voltage

240-1-60

208-1-60

240-1-60

208-1-60

240-1-60

208-1-60

240-1-60

208-1-60

240-1-60

208-1-60

KWRating

4.8

3.6

7.5

5.6

9.6

7.2

14.4

10.8

19.2

14.4

Nominal Heating

BTUH

16,382

12,287

25,598

19,113

32,765

24,574

49,147

36,860

65,530

49,147

Supply

Circuit No,

L3-L4

L3-L4

L3-L4

L3-L4

L3-L4

L5-L6

L3-L4

L5-L6

L3-L4

L5-L6

L3-L4

L5-L6

L3-L4

L5-L6

Heater

Amps

20.0

17.3

31.2

26.9

40.0

34.6

40.0

20.0

34.6

17.3

40.0

40.0

34.6

34.6

MininumCircuit

Ampacity

25.0

21.6

39.1

33.6

50.0

43.3

50.0

25.0

43.3

21.6

50.0

50.0

43.3

43.3

MaximumOvercurrent

ProtectiveDevice

(Amps)

3O

25

45

4O

6O

5O

6O

3O

5O

25

6O

6O

5O

5O

FIGURE 11

Accessory Electric Heater Heating Data

*TemperatureRise °F @CFM(ElectricHeatOnly)

Heater

Model

AMMK05AHA

AMMK05AHB

AMMK07AHA

AMMK07AHB

AMMK10AHA

AMMK10AHB

AMMK15AHB*

AMMK20AHB**

UseWith

2-5 TON

2-5 TON

2-5 TON

21/2-5 TON

21/2-5 TON

Supply Voltage

240-1-60

208-1-60

240-1-60

208-1-60

240-1-60

208-1-60

240-1-60

208-1-60

240-1-60

208-1-60

KWRating

4.8

3.6

5.6

9.6

14.4

10.8

19.2

14.4

7.5

7.2

Total Heating

BTUR 600 800

16,832 25.3 19.0

12,287 19.0 14.2

25,598 39.5 29.6

19,113 29.5 22.1

32,765 50.6 37.9

24,574 37.9 28.4

49,147 --- 56.9

36.860 56.9 42.7

65,530 ......

49,147 --- 56.9

* 15KW HEATERNOTTOBE OPERATEDONLOWTAPFOR 21/2 TONA/C ANDHE

** 20KW HEATERNOTTOBE OPERATEDONLOWOR MEDIUMLOWTAP FOR3 AND3 1/2A/C AND HE

1000 1200 1400 1600 1800 2000 2200

15.2 12.6 10.8 9.5 8.4 7.6 ---

11.4 9.5 8.1 7.1 6.3 5.7 ---

23.7 19.8 16.9 14.8 13.2 11.9 10.8

17.7 14.7 12.6 11.1 9.8 8.8 8.0

30.3 25.3 21.7 19.0 16.9 15.2 13.8

22.8 19.0 16.3 14.2 12.6 11.4 10.3

45.5 37.9 32.5 28.4 25.3 22.8 20.7

34.1 28.4 24.4 21.3 19.0 17.1 15.5

--- 50.6 43.3 37.9 33.7 30.3 27.6

45.5 37.9 32.5 28.4 25.3 22.8 20.7

13 427 O1 1OO4 O1

Wire Diagrams - Electric Heat Accessory

DESCRIPTION: IWIRING CODE_ REVISION_

AM[vlK 5_7.5,18 & 15 KS! ELECTRIC HEAT [ 2£18/23_1V88 HZ 1 PH

AHB HEATERS ONLY I • ] i

20B/24BV 1PH 60 HZ ] I I

USE COPPER CONDUCTORS ONLY I i!

FAN CONTACTOR _---_

CONTROL ?_ ....

TO U ; , ,

G s :I , _ ] ,,

:DMMON..... BL r • ' '

TO L2 BR ONO

COmnCTOR_ _ CONNEmlONS

_" TMERMOmAT

,,J/', i\N

ELECTRICAL SHOCK HAZARD

DISCONNECT ALL POWER SUPPLIES.

FAILURE TO DO SO COULD RESULT

SERIOUS INJURY OR DEATH.

EL .......... ELECTRIC ELEMENT

SEQ........SEQUENCER

HTR........HEATER

GND,,,,.,,,GROUND

LS .......... LIMIT SWITCH

[FM..,.....[NOOOR FAN MOTOR

GY

TRANS..,.TRANSFORMER

[FMC,.....,INDOOR FAN MOTOR CONTROL

FOLLOW HEATER INSTAL

LATIDN INSTRUCTIONS

ACCESSORYHEATER

WIRE MARNESS WIRING

LEGEND

LOW VOLTAGE

LINE VOLTAGE

HEATERABS¥ FORUSEW,TB,

MODEL NUMBER ELEMENTS _L3 L4 PA55, PA£5 & PH55

AMMKB5AHB 1 25A

AMMK_GAHA 24,30,36,42,48 & 60

AMMKO7AHB

AMMKO7AHA [,2 40A 24,30,36,42,4B & BO

AMMK]OAHB

AMMK]OAHA 1,2 50A 24,30,36,42,48 & 60

AMMK15AHB 112.3 3_,36,42,48 & BO

DESCRIPTION= WIRING CODE: REVISION: PART NUMBER:

AP1P1K 28 KW ELECTRZ8 HEAT 288/230v 1882113B

2BB/240V i PH 6B HZ ,

USE COPPER CONDUCTORS ONLY ,

INTERNALNTERNAL(WHEN_WHENRECOMMENDED

, , ÷ q

COLOR CODE

BLACK BK

BLUE BL

BROWN BR

GRAY GY

ORANGE 0

RED R

VIOLET V

WHITE W

YELLOW y

68 HZ 1 PH

1 ALL WIRING MUST BE DONE IN

2. WIRING THAT IS CIRCLED MUST

3 IF ANY WIRE MUST BE REPLACED,

IN SERIOUS INJURY OR DEATH.

NOTES

ACCORDANCE WITH NATIONAL

AND LOCAL ELECTRICAL CODES.

BE DONE BY INSTALLER

......

,, m /-x

ELECTRICAL SHOCK HAZARD

DISCONNECT ALL POWER SUPPLIES

FAILURE TO DO SO COULD RESULT

EL .......... ELECTRIC ELEMENT

SEO....,,..SEOUENCER

HTR........HEATER

GND....,,..GROUND

LS .......... LIMIT SWITCH

IFN........INDOOR FAN MOTOR

TRANS,...TRANSFORMER

IFMC.,.,...INDOOR FAN MOTOR CONTROL

FOLLOW HEATER INSTAL

LATION INSTRUCTIONS.

LEGEND

L__<_ BK

HEATER ASSY.

MODEL NUMBER ELEMENTS

AMMKO20AHB 4 50A 50A 36,42 & 48

L3 L4 L5 L6

PA55

36,42,48 & 60

PAD5

PH55

36,42,48 & 80

ACCESSORYHEATEa

COLOR CODE

BLACK BK

BLUE BL

BROWN BR

GRAY GY

ORANGE 0

RED R

VIOLET V

WHITE W

YELLOW y

WIREHARNESS WIRING

1. ALL WIRING MUST BE DONE IN

ACCORDANCE WITH NATIONAL

AND LOCAL ELECTRICAL CODES

2. WIRING THAT IS CIRCLED MUST

BE DONE BY INSTALLER

3. IF ANY WIRE MUST BE REPLACED,

IT MUST BE REPLACED WITH ITS

EQUIVALENT, MIN RATING 105°C

NOTES

LOW VOLTAGE

LINE VOLTAGE

14 427 01 1004 01

10. Rain Shield Installation

121 Installing The Rain Shield

I

S,ZE.ADHES,VEBAO D.

l_f_SII I IIL_JI I _ PLACEINSIDE

HEATER PLUGS

RAIN SHIELD

connected to anexisting system, the ductwork MUST be checked to make

sure it is adequate. Extra runs or larger duct sizes may have to be

installed.

Maximum recommended velocity in trunk ducts is 1000 feet per minute

(5.08m/s). Velocity in branches should not exceed 800 feet per minute

(4.06m/s). Refer to the TechnicalData Label on the unit for unit air volume

requirements and system sizing recommendations.

NOTE: Ductwork sizing affects temperature rise and cooling temperature

differential. Be sure to properly size ductwork to the capacity and airflow

characteristics of your unit. Failure to do so can affect limit controls, com-

pressors, motors, and other components and will lead to premature failure

of components. This will also adversely affect day to day unit perfor-

mance.

Flexible Duct Kits are available from your supplier to effect proper sizing

and installation to Mobile Homes and other standard construction..

Refer to unit rating plate for proper Electric Heat Accessory sizing and see

the Temperature Rise Check section inthe Electric Heat Accessory Instal-

lation Section of this manual.

1.Removeallscrewsfrom the cover plateon Blower/ElectricalAccess Panel.

2. Install adhesive backed gasket on Blower/Electrical Access Panel.

3.Install lower frame of rain shield with 4 screws.

4.Install rain shield hinged cover with 4 screws.

5. Install circuit breaker filler plates (2 each per unused breaker slot.)

6. Re-install Blower/Electrical Access Panel.

NOTE: VERIFY ALL APPROPRIATE SEALS ARE IN PLACE. SEE

FIGURE 12,

11. Air Distribution System

For airflow data (blower performance data, blower speed tap settings,

etc.) see the Technical Data Sheet attached to the unit..

Ductwork

NOTE: The total heat gain of the structu reto be conditioned as expressed

in total Btu/hr should be calculated by manufacturer's method or in accor-

dance with "A.S.H.R.A.E. Guide" or "Manual J - Load Calculations" pub-

lished by the Air Conditioning Contractors of America. The total heat gain

calculated should be equal to or less than the cooling capacity output

based on D.O.E. test procedures, steady state efficiency times input.

Ductwork, supply registers, and return air grilles MUST be designed and

sized to handle the unit's cooling air volume requirements. If the unit is

FIGURE 13 Recommended Filter Sizes

NOTE: Some filters are marked with an arrow to indicate the proper direction of air flow through the filter. The air flow direction will be towards

Nominal Tons

Air Conditioning

2

2 1/2

3

3 1/2

4

5

the blower motor. Make sure filter is installed correctly.

Nominal Air Flow

Cubic Feet

per Minute

700-900

900-1100

1100-1300

1300-1500

1500-1700

1900-2100

Ductwork Insulation

It is recommended that ductwork installed outdoors have aminimum of 2"

(51mm) of fiberglass insulation and be covered by a weatherproof vapor

barrier that is protected against damage. Caulking and flashings, or other

means adequate to provide a permanent weather seal, must be used.

It is recommended that ductwork installed in attics orother areas exposed

to outdoor temperatures have a minimum of 2" (51mm) fiberglass insula-

tion and have an indoor type vapor barrier.

Ductwork Connections

The use of flexible, non-combustible connectors between main trunk

ducts and supply and return air plenums is recommended to minimize

vibration transmission.

NOTE: Connect supply and return air plenums to unit in a manner that will

allow the top of the unit to be removed without removing plenums. Ple-

nums MUST be individually sealed to unit casing. Ducts MUST be termi-

nated inside structure.

Filters

All return air MUST pass through a field supplied filter before entering the

unit. If used, an electronic air cleaner MUST be installed in the return air

ductwork. Minimum recommended filter areas are listed in FIGURE 13

and are based on a velocity of 300 ft/min (1.2m/s) for disposable filters

and 500 ft/min (2.54m/s) for washable high velocity filters.

CAUTION

Do NOT operate the unit without all filters in place.

Recommended Filter Sizes

Sq. In. Surface Area/Nominal Size

Disposable Filters

400 or 20 x 25

487 or 20 x 30

576 or 14 x 25 (2Req.)

665 or 16 x 25 (2Req.)

753 or 20 x 25 (2 Req.)

960 or 20 x 30 (2 Req.)

15

Cleanable Filters

246 or 15 x 20

301 or14x25

356 or16x25

411 or 20 x25

466 or 20 x 25

575 or 24 x 25

427 01 1004 01

12. Start-up Procedures

Electrical shock hazard.

Use extreme care during all of the following checks and pro-

cedures.

Make sure electric power is turned OFF as instructed in ap-

propriate steps.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

Circulating Air Blower

FIGURE 15 I Blower Motor Speed Taps

I

Blower Speed Tap Block

Yellow

Determining Blower Speed

1.Turn electric power OFF.

2. From the system design, determine the total external static pressure

(ESP) for the supply ducts, return ducts and registers, diffusers,

grilles, dampers, heaters and filters.

3.To your system ESP determined in Step 2, add 0.05 In. W.C. for a

wet coil.

4.From the system design, determine the desired cooling airflow in

cubic feet per minute (CFM).

5. Locate the unit's Blower Performance Data table on the tech data

label for the unit's voltage. (The tech data sheet is attached to the

evaporator access panel on the unit.) From the table, determine the

speed tap required to achieve the desired airflow.

6.See next section, Speed Taps, to set the blower motor speed termi-

nal block (speed taps) to the cooling speed determined in the pre-

vious steps.

Speed Taps

After determiningtherequired CFMandspeedtapdata fromthe tech data

sheet, follow the steps below to change speeds if necessary.

Auxiliary Electric Heat B

Wire (if used)

connects here

BE SURE TO CHECK BLOWER MOTOR SPEED DATA ON THE

UNITS TECHNICAL DATA LABEL LOCATED ON THE UNIT.

NOTE: On Heat Pumps Electric heater blower wire must be attached to

the same speed tap required for cooling/heat pump operation. See FIG-

URE 11 notes. The yellow lead MUST always be connected to the speed

tap block at the common quick connect terminal. The terminal is identified

as COM.

Refer to FIGURE 15 and the appropriate unit wiring diagram included in

this manual. Wire the black wire to the required speed tap terminal to

achieve required airflow determined in Step 5.

Cooling, Heating (Heat Pump) and Auxiliary

Electric Strip Heat

NOTE: The cooling, heat pump and strip heat airflows are all on the same

speed tap. The refrigerant system requires the same specific CFM for

proper operation in the cooling and the heat pump mode. For this reason,

cooling and heating airflow must be the same. DO NOT SPLIT OUT INTO

A COOLING SPEED AND HEATING SPEED. If auxiliary electric heat is

installed, the auxiliary electric heat blower speed wire must be connected

to the black wire insulated quick connect terminal.

FIGURE i4 L Blower Speed Tap Settings

10 SEER 2 TON MED

10 SEER 21/2 TON MED

10 SEER 3 TON LOW

10 SEER 31/2 TON MED HI

10 SEER 4 TON LOW

10 SEER 5 TON HI

Check Before Starting

1. Check that the blower motor speed terminal block is set to the prop-

er cooling speed. Refer to the unit wiring diagram and the various

airflow tables in this manual.

2. Check to see that clean, properly sized field supplied air filters are

installed in the return air duct.

3. Inspect the inside of the unit to be sure that all wires are in place and

all tools, etc. are removed.

4. Replace all service access panels.

Check the unit's operation as outlined in the following instructions. If any

unusual sparking, odors or noises are encountered, shut OFF electric

power immediately. Recheck for wiring errors, or obstructions in or near

blower motors.

16 427 01 1004 01

Circulating Air Blower

4.Set the thermostat temperature setting as high as it will go.

1.Be sure electric power is OFF.

2.Set thermostat Heat-Cool selector to OFF.

3.Set thermostat fan switch to AUTO.

4.Turn electric power ON. Nothing should start running.

5.Set thermostat fan switch to ON. The circulating air blower should

come ON after a 30 second delay.

6. Reset thermostat fan switch to AUTO. The circulating air blower

should go OFF after a 30 second delay. Nothing should be running.

Cooling

1. Be sure that electric power is OFF.

2. Set thermostat Heat-Cool select to COOL.

3. Adjust thermostat setting to below room temperature.

4. Turn electric power ON. During power application check the follow-

ing:

a. Contactor - Contacts closing

b. Compressor - ON

c. Condenser fan motor - ON

d. Circulating air blower - ON (after delay)

5.Switch the thermostat to OFF, check the following:

a. Contactor contacts opening.

b. Compressor - OFF

c. Condenser fan motor - OFF

d. Circulating blower - OFF (after delay)

5.Turn electric power ON.

6.Operate unit AT LEAST 5 minutes, then check temperature rise.

NOTE: The maximum outlet air temperature for all models is 200°F

(93.350). Maximum temperature rise for electric heat is 60°F (33.350)

If temperature rise is excessive, verify proper airflow through the unit. If

temperature rise is inadequate, check for proper electrical supply to the

heater and verify correct airflow.

7.Set thermostat to normal temperature setting.

8.Turn electric power OFF.

9.Change blower speed tap if 60°F (33.3°0) TemperatureRise was exceeded

andrepeat.

10.Be sure to seal all holes in ducts if any were created during this

process.

Defrost Control Time Interval Adjustment

Electrical shock hazard.

Turn OFF electric power supply at disconnect switch or ser-

vice panel before removing any access or service panel from

unit.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

To adjust defrost interval:

1.Turn off all power to Heat Pump.

2. Remove control box cover.

3. Locate electronic defrost control board.

4.The Defrost Control Board has a jumper plug that can be set at 30, 60,

90 or TEST. Remove the plug and insert on the appropriate 2 pins

indicated by ) on the board.

6.Turn electric power OFF

Auxiliary Heating

NOTE: Repeat circulating air blower procedure above ifAuxiliary Electric

Heat is being installed after unit has been installed and checked out.

Temperature Rise Check

Temperature rise is the difference between the supply and return air tem-

peratures. The temperature rise should be -+2°F (1.1°C) of the tempera-

ture rise shown in FIGURE 11 .

NOTE: The temperature rise can be adjusted by changing the heating

speed tap atthe unit's blower terminal block. Refer to the unit's Installation

Instructions for airflow information.

Atemperature rise greater than 60°F (33.3°C) is not recommended. (This

applies to electric heat only).

1.To check the temperature rise through the unit, place thermometers

in the supply and return air ducts as close to the unit as possible.

2.Open ALL registers and duct dampers.

3.Set thermostat Heat-Cool selector to HEAT.

13. Sequence of Operation

NOTE: If power to the unit has been interrupted, there will be a 3 minute

delay before the compressor starts.

Cooling Mode: Energized (R,G,Y, O) De-energized (N/A)

(a) When high and low voltage have been applied to unit

for more than 3 minutes:

(1)On a call for cooling ......... :

The compressor and condenser fan will energize. The evaporator

blower motor will have a delay on and will energize after 30 seconds.

17 427 01 1004 01

(2)When the cooling setpoint has been satisfied ......... :

The compressor and condenser fan will de-energize immediately.

The evaporator blower motor will have a delay off and will de-ener-

gize after 30 seconds.

Heat Mode (Heat Pump Only): Energized (R,G,Y)

De-energized (O)

NOTE: If the jumper on the defrost delay selection is left in the "TEST"

mode, the board will default to 90 min. delay until power is off.

(2) When defrost has been completed .........

This condition will be maintained until the defrost sensor opens or

until the defrost mode operates for 10 minutes (or2 seconds if test

pins are jumpered), whichever comes first.

(a) When high and low voltage have been applied to unit

for more than 3 minutes:

(1) On a call for heating ......... :

The compressor and condenser fan will energize (there will be a 3

minute delay on 4 Ton model with anti-cycle timer). The evapora-

tor blower motor will have a delay on and will energize after 30 se-

conds. The delay on for the compressor and the condenser fan can

be by-passed by jumpering the test pins on the defrost control

board.

(2) When the heating setpoint has been satisfied ......... :

The compressor and condenser fan will de-energize immediately.

The evaporator blower motor will have a delay off and will de-ener-

gize after 30 seconds.

Defrost Mode:Energized (R,G,Y) De-energized (O) Defrost

Sensor Closed

On a call for defrost .........

(1)

When the defrost sensor c!oses in the heating mode,there is a 30,

60 or 90 minute delay before the defrost mode begins. This delay

is selected by the position of a jumper on the defrost board

In normal defrost mode, the following sequence will occur after the

set delay:

1. Condenserfan off.

2. Reversing valve energized to cooling and auxiliary electric

heat ("W" circuit) is energized.

3. After defrost sensor opens or a maximum of 10 minutes; the

condenser fan is energized immediately. After a 10-12 second

delay the reversing valve is then de-energized to the heat mode.

Electric strip heat is also de-energized except as required by ther-

mostat.

To check out the defrost mode, place jumper across the two tabs

marked "DF". This simulates the defrost sensor closing. The delay

can be by- passed by jum pering the test pins on the defrost control

board (this reduces the delay from 30 minutes to 7 seconds, from

60 minutes to 14 seconds and from 90 minutes to 21 seconds). In

the defrost mode the reversing valve will energize and the con-

denser fan will de-energize.

Adding Accessories

Low/High Pressure Controls

This unit is equipped with extra !ow and high pressure ports located inside

the unit panel where the external high and low pressure ports are installed.

This allows for installation of high and low pressure controls or low ambi-

ent controls.

14. Operation

Scroll Anti-Cycle Timer (Where Applicable)

Single phase units with scroll compressors may be equipped with an anti-

cycle device which delays the start of the compressor in the event of a

power interruption. This equalizes pressure throughout the system and

prevents possible reverse rotation ofthe scroll compressor. Later produc-

tion scroll compressors are equipped with an anti-reverse device to pre-

vent the compressor from running backwards, so an anti-cycle timer is not

needed on these models.

CAUTION

Do NOT operate unit on cooling when the outdoor temperature is be-

low 60°F. This is necessary to prevent possible damage to the com-

pressor.

Loss of Charge Pressure Switch

Scroll compressor bearing units are equipped with a low pressure switch

on the liquid line (high side) which has been installed to prevent system

damage due to a loss of charge. The switch will open and de- energize the

contactor if the high side pressure drops below the set point of the switch.

18 427 01 1004 01

INTERNATIONAL COMFORT PRODUCTS

LIMITED WARRANTY CERTIFICATE

For Cooling & Heating Products

SAVE THIS CERTIFICATE. It gives you specific legal rights, and you may also have other rights which may vary from state to state and

province to province.

If your unit needs servicing, contact a qualified dealer or qualified service technician of your choice. When requesting service, please have the model

and serial number from each unit in your heating and/or cooling system readily available. Ifyour dealer needs assistance, the distributor is available to

provide support and we, in turn, support its efforts.

Fill in the installation date and model and serial numbers of the unit in the space provided below and retain this Limited Warranty for your files.

GENERAL TERMS

Subject to the conditions and limitations stated herein, during the term of this Limited Warranty, we will provide a replacement for any functional

component part (as defined below) of your unit found to be defective in materials or workmanship. The term ofthis Limited Warranty is five years from

installation on Residential Products and one year from installation on Commercial Products. Except as otherwise stated in the "Additional Terms"

section, this Limited Warranty covers only the original purchaser and subsequent transferees, and only while the unit remains at the site of the original

installation (except for mobile home installations), and onty if the unit is installed inside the continental United States, Puerto Rico, Alaska, Hawaii or

Canada. In addition, the Limited Warranty applies only if the unit is installed and operated in accordance with the printed instructions accompanying the

unit, and in compliance with alt applicable installation and building codes and good trade practices. As used in this Limited Warranty, "installation"

means the original installation of the unit.

TH ERE ARE EXCEPTIONS to this Limited Warranty as described on the reverse side of this page. All replacement parts will be warranted for the

unused portion of the warranty coverage period on the unit. The part to be replaced must be returned by the dealer to a distributor that sells products for

International Comfort Products, in exchange for the replacement part. In lieu of providing areplacement part, we may, at our sole option, refund to you

an amount equal to the distributor's component purchase price from us,or provide to you acredit equal to that amount to beapplied toward the purchase

of any new unit that we distribute. If a credit for a new unit is given in tieu of a replacement part, the rating plate from the unit being replaced must be

submitted on a warranty claim, and you r dealer must make the unit being replaced available to our distributor for disposition. As a condition towarranty

coverage, the unit must receive yearly maintenance, as described in the owner's manual, by a dealer. Satisfactory proof of yearly service by adealer

may be required.

"Functional component parts" include only the following: blower motor, unit-mounted sensors & timers, condenser motor, evaporator coil, condenser

coil, condenser fan, capacitor, transformer, single-phase strip heat elements, expansion device, reversing valve, solenoid valve, service valve,

electronic and electro-mechanical control board, ignitor, ignition module, draft inducer assembly, burner pilot, gas valve, limit control, pressure switch,

relays and contactors, blower wheel, interlock switch, crosslighter, pilot shield, gas & oil burners, oil pump assembly, accumulators and factory installed

driers and strainers.

This Limited Warranty DOES NOT COVER any labor, material, refractory chambers, oii nozzles, refrigerant, refrigerant inspection and refrigerant

reclaiming, freight and/or handling charges associated with any repair or replacement and such charges will be your responsibility.

Toestablish the installation date for any purpose under this Limited Warranty, you must retain the original records that can establish the installation date

ofyour unit. Ifyou donot providesuchdocumentsthe start dateoftheterm ofthis LimitedWarrantywillbe based uponthedate ofunit manufacture, ptus

thirty (30) days. In establishing that the required yearly service has occurred, you must furnish proof of yearly service by a qualified service technician.

This Limited Warranty does not cover: (a) failure or damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b)

damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals (other

than those found in a normal residential environment) (c) damages caused by an unauthorized alteration or repair of the unit affecting its stability or

performance (d) damages caused by improper matching or application of the unit or the unit's components (e) damages caused by failing to provide

proper maintenance and service to the unit in accordance with this Limited Warranty Certificate and the printed instructions originally provided with the

unit (f) any expenses incurred for erecting, disconnecting, or dismantling the unit (g) parts or supplies used in connection with service or maintenance,

such as refrigerant, refractory chambers, oil nozzles, filters, or belts (h) damage, repairs, inoperation or inefficiency resulting from faulty installation or

application (i) electricity or fuel costs or any increase in electricity or fuel cost whatsoever including additional or unusual use of supplemental electric

heat (j) units which have not had the required yearly maintenance described elsewhere in this limited warranty.

In no event shall we be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit.

We have not made. do not make. and hereby disclaim any implied condition or implied warranty of fitness for a particular use or purpose, and

anv implied condition or implied warrantv of merchantabilitv, to the fu Ilest extent allowed bv law. We make no express or implied warranties

except as stated in this Limited Warrantv certificate.

No one is authorized to change this Limited Warranty or to create for us any other obligation or liability in connection with this unit. Any implied

warranties shall last for the term of the expressed warranty contained herein. Some states and provinces do not allow the exclusion or limitation of

incidental or consequential damages or do not allow limitations on how long an implied warranty orcondition lasts, so the above limitations orexclusions

may not apply toyou. The provisions of this Limited Warranty are in addition to and not amodification of or subtraction from any statutory warranties and

other rights and remedies provided by law.

Please refer to reverse side of this page for additional terms.

Model No.

Serial No. Date Installed

Effective on units installed After July 1, 2002,

USA: International Comfort Products Corporation (USA) • 650 Hell-Quaker Avenue *P.O. Box 128 • Lewisburg, Tennessee 37091 • (931-270-4100)

CANADA: International Comfort Products division of UTC Canada Corporation • 6060 Burnside Court, Unit 1, Mississauga, Ontario L5T 2T5

(905-795-8113).

Manufacturers of Airquest, Arcoaire, Clare, Comfortmaker, Dettson, Hell, Keeprite, Lincoln, Tempstar and other quality brand name private label

products.

Part No. 401 06 1010 19 (Orig. 9/19/2002)

ADDITIONAL TERMS FOR RESIDENTIAL APPLICATIONS ONLY

The Additional Terms for the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

Warranty coverage is limited to parts that fail due to defect in materials or workmanship during the specified term.

CENTRAL GAS & OIL FURNACE HEAT EXCHANGERS*

Gas Model Series: C9MPV. HgMPV. TgMPV. CgMPT. H9MPT. T9MPT. C9MPD. HgMPD. TgMPD: Limited Lifetime Warranty on heat exchangers. If

a heat exchanger on one ofthese furnaces fails due to defect inthe part, we will provide a replacement part or, at our option, credit toward the purchase

of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tasts only for as tong as the originat

purchaser tives in the home where the furnace is initially installed.** Itis not transferable to any subsequent owner. Ifthe furnace was not installed in the

home owned by the original purchaser, if the original purchaser setls the home to a subsequent owner, or if proof of originat purchase cannot be

provided, then the limited warranty is only for 20 years from the date of original installation.

Gas Model Series: GDL. GNL. TNE. TDE. NTC7. NDC7. NTP6. NDP6. TDE. NTV6. VNE: A replacement heat exchanger will be provided for any

heat exchanger that fails in one of these furnaces due to defect for 25 years from the originat date of installation.

Gas Model Series: NTC6. GNE. GDE. NDN6. NTG3. NDN3. FBF. NBF. NDF. NTN3. NTN6. NNE. N9MPI. N9MP2. FUH: A replacement heat

exchanger witt be provided for any heat exchanger that faits in one of these furnaces due to defect for 20 years from original date of installation.

Oil Model Series: OLR(105, 160, 182), OCF, OLE OUF, NOLE NOUF, OLB, OHB, ODH, FLO, MBO, LBO, NOMF: Limited Lifetime Warranty on

heat exchangers. Ifa heatexchangerononeofthesefurnacesfailsduetodefectinthepart, wewitl provide a replacement part or, at our option, credit

toward the purchase of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tasts only for as

long as the original purchaser lives in the home where the furnace is initially installed.** It is not transferable to any subsequent owner. If the furnace

was not installed in the home of the original purchaser, if the original purchaser sells the home to a subsequent owner, or if proof of original purchase

cannot be provided, then the limited warranty is only for 20 years from the date of original installation.

Oil Fired Floor Furnace: NFO: A replacement heat exchanger witl be provided for any heat exchanger that faits due to defect for 10 years from

installation with the following limitation: during the sixth through tenth year, any credit toward your purchase of a component or toward the purchase of

any new unit wilI be in an amount equal to the distributor's purchase price reduced by 20 percent for each year after the fifth year.

ADDITIONAL TERMS FOR OIL FURNACE APPLICATIONS ONLY

1) OIL BURNERS - A replacement for 5 years from date of original installation for Oil Burner Parts.

2) OPTIONAL ACCESSORIES AND FUNCTIONAL PARTS: A replacement for 5 years from date of original installation. (Refractory and

oil nozzles not included)

GAS/ELECTRIC PACKAGED UNITS HEAT EXCHANGERS

Model series: PGAD. PGAA. PGMD. PGME. PGF. GPFM. PGC. GPCM: A replacement for 10 years from original date of installation.

COMPRESSORS:*

1) Premium Model Units: HAC0. HAC2. HAC4. CAC0. CAC2. CAC4. KAC0. TCA0. TCA2. TCA4. HHP0. HHP2. HHP4. CliP0. CliP2. CliP4.

TCH0. TCH2. TCH4. PGME. PYMC. PHAD. PGAD. PA95. PAPC. PAK. APK: Tothe original purchaser a replacement for 10 years from original date

of installation, only if the unit is installed with factory matched coils, except air conditioner condensing units with a nominal SEER of 10 may be matched

with evaporator coils of the same nominal tonnage regardless of manufacturer and in accordance to factory recommendations. This limited 10-year

warranty is not transferable to any subsequent owner. HOWEVER, if the unit was not installed in the home owned by the original purchaser, if the

purchaser sells the home to a subsequent owner, or if proof of original purchase cannot be provided, then the limited warranty is only for 5years from the

original date of installation.**

2) All Other Models: Air Conditioners. Heat PumPs. & Combination Gas/Electric Units: NAC0. NAC2. NHP0. NHP2. AO. A2. HO. H2. PGF.

PGC, GPFM, GPCM, PAE APFM, PHE HPFM, PGAA, PGMD, PA55, PH55, PAPA, PYPA: A replacement for 5 years from date of original

installation, onty if: (a) air conditioner condensing units with SEER rating in the range of 10 to 11SEER are matched with evaporator coils of the same

nominal tonnage regardless of manufacturer and in accordance to factory recommendations, or (b) heat pump condensing units are used with factory

matched coils, unless written approval to do otherwise is obtained from manufacturer.

ADDITIONAL TERMS FOR COMMERCIAL APPLICATIONS ONLY

For purposes of this warranty a commercial application isone in which: the product has over 5 tons nominal cooling capacity, or is designed

for operation with 3 phase electrical power, or is installed in a commercial establishment such as a beauty or hair salon, hospital, school,

restaurant, church, hotel etc..

3-Phase Models: PGF, GPFM, GPF, PGAD, PGME, PGB, PGMG, PGMF, PGS, PGE, APE, PAE, PAB, PAMD, PAS, PAl=,APFM, APF, PHB, PHE,

PYMD, HPB, PHS, CAC, ACC, CAE, ACE, CHC, HCC, CHE, HCE, CHB, YA:

The additional Terms of the components listed below are in addition to and subject to the General Terms on the reverse side of this page.

1) GAS FIRED HEAT EXCHANGERS (ALL MODELS):* A replacement for 10 years from date of originat installation.

2) COMPRESSORS (ALL MODELS):* A replacement for 5 years from date of original installation.

3) OPTIONAL ACCESSORIES AND FUNCTIONAL COMPONENT PARTS (ALL MODELS):*

A replacement for 1 year from date of original installation.

4) COMMERCIAL OIL MODELS: OLR210, OLR350, OTF210, AMT3, AMT4, AMP3: Ten(10) Year Limited Warranty on heat exchangers.

*To receive advantage of your limited warranty, you must provide proof of yearly service by a qualified service technician.

**To receive advantage of your warranty, you must retain the original records that can establish the installation date and proof of purchase of the unit.

MINI SPLITS:

Summary - Mini Splits Warranted for one (1) year on all replacement parts.

Additional terms for Mini Splits:

The additional Terms of the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

1) Compressors (All Models): A replacement compressor wili be provided for atI compressors that faii due to defect for 5 years from date of original

installation.

2) Optional Accessories and Functional Components Parts (All Models):

A replacement part will be provided for alt parts that fail due to defect for one (1) year from date of original installation.

Failu re to maintain the equipment through annual maintenance by a qualified service technician shall void the warranty. Proof of service wili berequired

with ati warranty claims. Proof of purchase and installation date must be submitted with ali claims.

Loading...

Loading...