ICP PHX324000K00A1, PHX330000K00A1, PHX336000K00A1, PHX342000K00A1, PHX348000K00A1 Installation Guide

...Page 1

Installation Instructions

PHX3 Series

2 to 5 TON

PACKAGE HEAT PUMPS

TABLEOFCONTENTS

UNITDIMENSIONS ...................................... 2 - 3

SAFEINSTALLATIONREQUIREMENTS ......................... 4

LOCATINGTHE UNIT ....................................... 4

CLEARANCES ............................................ 4

INSTALLATION............................................ 5

GROUNDLEVELINSTALLATION .............................. 5

RooftopINSTALLATION..................................... 5

HOISTING................................................ 5

DOWNFLOWCONVERSION .................................. 5

CONDENSATEDRAIN....................................... 5

_ CLIS_IEDUS

ELECTRICALWIRING................................... 6

DUCTWORK.......................................... 7

FILTERS ............................................. 7

AIRFLOWADJUSTMENT ................................ 8

START-UPPROCEDURES ............................... 9

SEQUENCEOFOPERATION.............................. 9

MAINTENANCE ...................................... 10

RIGGING ........................................... 12

WIRINGDIAGRAMS ................................... 13

Printed in U.S.A.

CODE: PHX3

518 O1 1301 OO 1-4-O6

Page 2

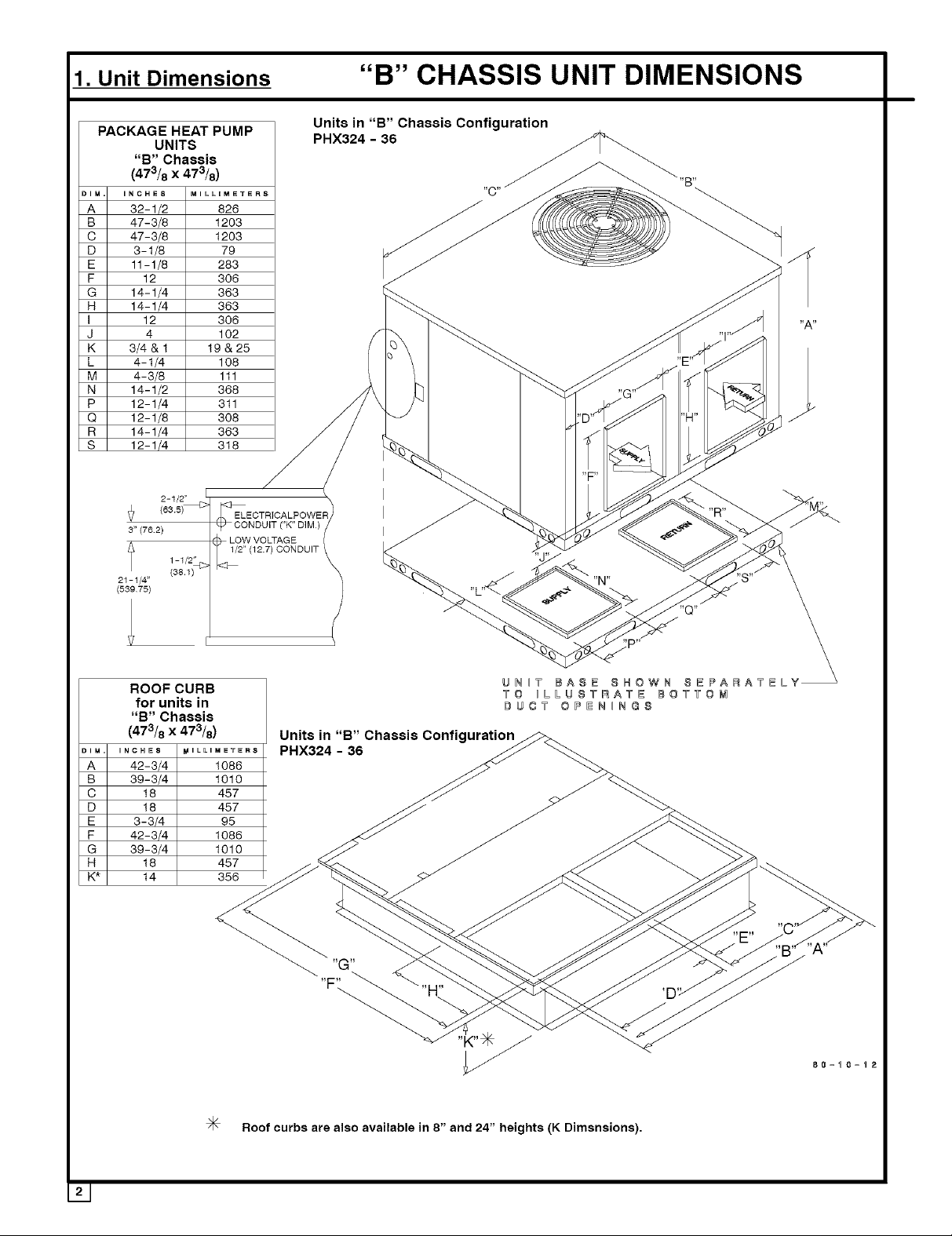

1. Unit Dimensions "B" CHASSIS UNIT DIMENSIONS

PACKAGE HEAT PUMP

DIM.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

Q

R

S

UNITS PHX324 - 36

"B" Chassis

(473/8 x 473/8)

INCHES MILLOMETERS

47-3/8 1203

47-3/8 1203

3-1/8 79

32-1/2 826

11-1/8 283

12 306

14-1/4 383 .¢-..... _

14-1/4 363 _ _

12 308 "4 _ _1 "A"

4 102 "1''/

314_I19_28 f_ _ _I _J'"_

4-1/4 lO8 [ _ \ _ _ .;E'_

I1_% ;_1 ._ _ __ ....._ <. _.

12-1/4 311 y/_, /"J _/ _.,_'G_,_ T _ '/

12-1/8 308 y / _ 'U'_" JJ "H" -"_J J

14-1/4 363 / / '_ _ ' J_

12-1/4 318 i_-_ _ _

2-1/2" I

,_ 1/2" (12.7) CONDUIT \ _/" ,_, ,,, __- _ _ /_ "X_YfX

1-1/2" "d"

Units in "B" Chassis Configuration

_O _

ROOFCURB vo ILLUSTRATE IOTVO_I

for units in #UO7 OPENINGS

"B" Chassis

(473/8 X 473/8) Units in "B" Chassis ConfigurationF_.

DIM.

'NCHEI_ _ ......... 8 PHX324 -- 36 // _

A

42-3/4 1086 _ _x

B

39-3/4 1010 _ _

C

D

E

F

G

H

K*

18 457 _ _ _

18 457 j_ _

3-3/4 98 _ _ j_._

42-3/4 1086 _ _ _ _._

"F'_ 80=_o=I_

J< Roof curbs are also available in 8" and 24" heights (K Dimsnsions).

Page 3

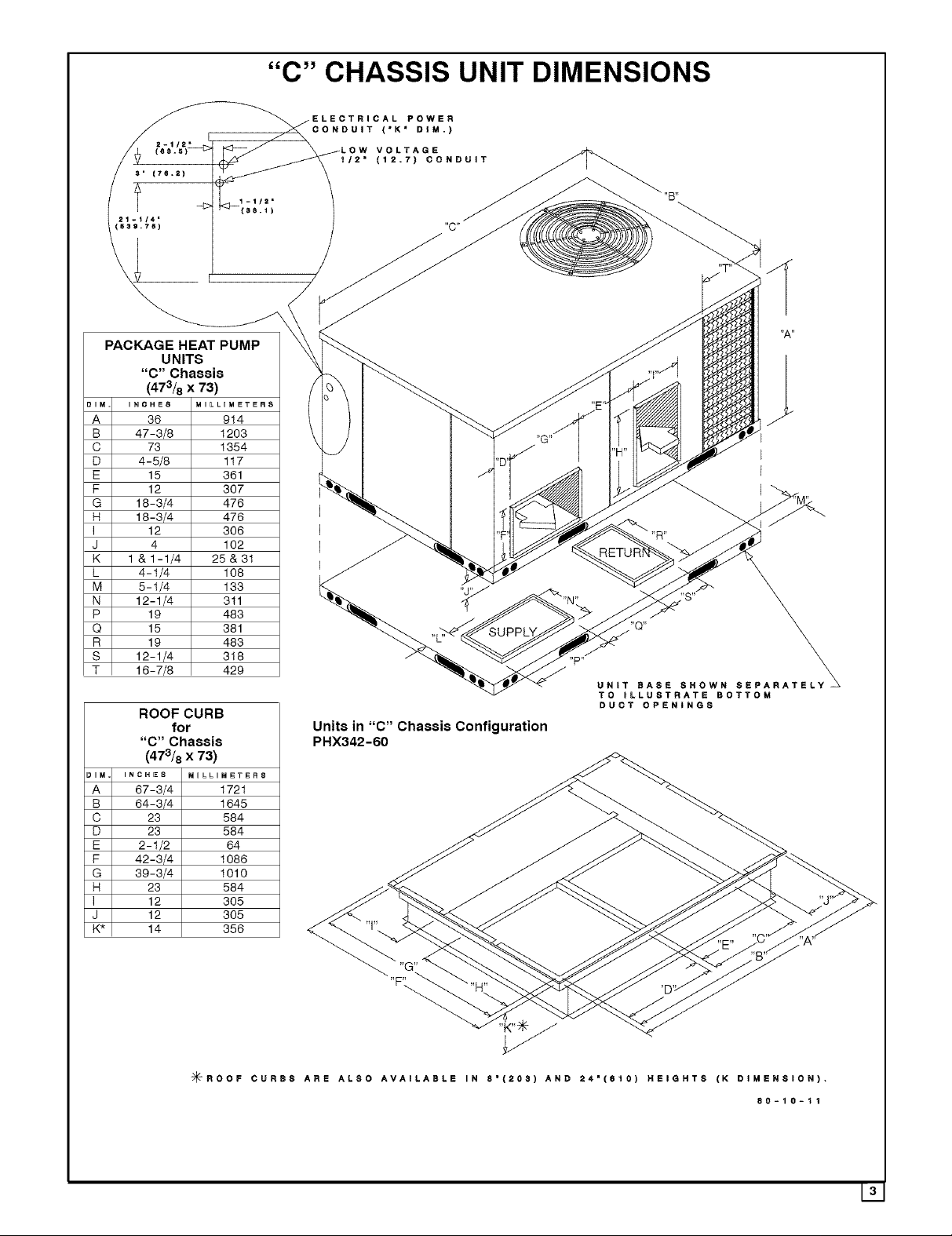

"C" CHASSIS UNIT DIMENSIONS

PACKAGE HEAT PUMP

UNITS

"C" Chassis

(473/8 x 73)

DIM INCHES MILLOMETER8

A 36 914

B 47-3/8 1203

C 73 1354

D 4-5/8 117

E 15 361

F 12 307

G 18-3/4 476

H 18-3/4 476

I 12 306

J 4 102

K 1 &1-1/4 25&31

L 4-1/4 108

M 5-1/4 133

N 12-1/4 311

P 19 483

Q 15 381

R 19 483

S 12-1/4 318

T 16-7/8 429

ROOF CURB

for

"C" Chassis

(473/8 x 73)

DIM INCHES MOLLIM_T_RS

A 67-3/4 1721

B 64-3/4 1645

C 23 584

D 23 584

E 2-1/2 64

F 42-3/4 1086

G 39-3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

CONDUIT ('K" DIM.)

CAL POWER

VOLTAGE

_/2 = (12.7) CONDUIT

Units in "C" Chassis Configuration

PHX342-60

,,p,,

UNIT BASE SHOWN SEPARATELY

TO BLLUSTRATE BOTTOM

DUCT OPENINGS

"F\

=_ROOF CURBS ARE ALSO AVAILABLE IN 8"(203) AND 24"(fl10) HEIGHTS (K DIMENSION),

80-10-11

Page 4

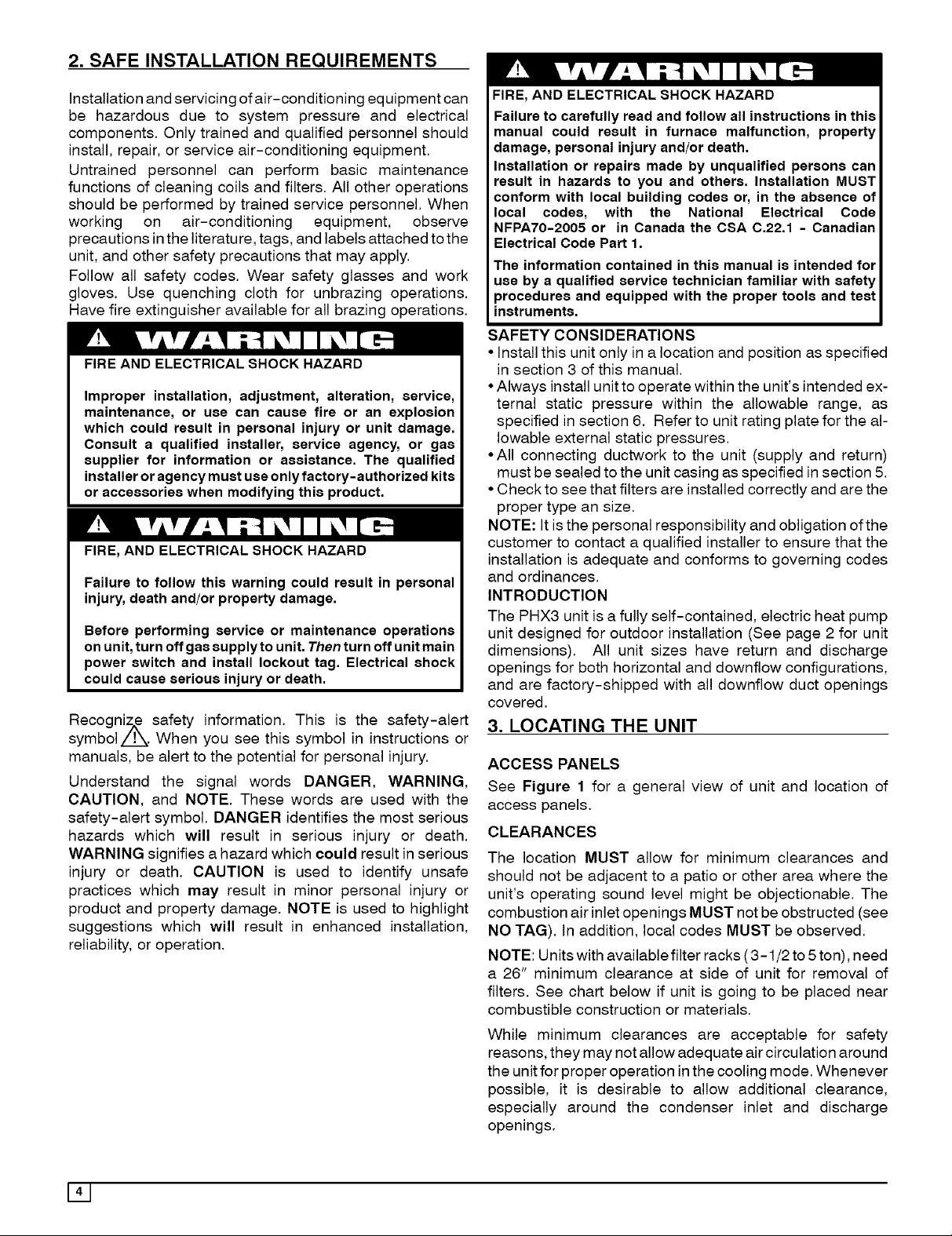

2. SAFE INSTALLATION REQUIREMENTS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical

components. Only trained and qualified personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance

functions of cleaning coils and filters. All other operations

should be performed by trained service personnel. When

working on air-conditioning equipment, observe

precautions inthe literature, tags, and labels attached to the

unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available for all brazing operations.

FIRE AND ELECTRICAL SHOCK HAZARD

Improper installation, adjustment, alteration, service,

maintenance, or use can cause fire or an explosion

which could result in personal injury or unit damage.

Consult a qualified installer, service agency, or gas

supplier for information or assistance. The qualified

installer or agency must use only factory-authorized kits

or accessories when modifying this product.

FIRE, AND ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Before performing service or maintenance operations

on unit, turn off gas supply to unit. Then turn off unit main

power switch and install lockout tag. Electrical shock

could cause serious injury or death.

RecognizAe safety information. This is the safety-alert

symbol/.Vk,. When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety-alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

FIRE, AND ELECTRICAL SHOCK HAZARD

Failure to carefully read and follow all instructions in this

manual could result in furnace malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the National Electrical Code

NFPA70-2005 or in Canada the CSA C.22.1 - Canadian

Electrical Code Part 1.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test

instruments.

SAFETY CONSIDERATIONS

• Install this unit only in a location and position as specified

in section 3 of this manual.

•Always install unit to operate within the unit's intended ex-

ternal static pressure within the allowable range, as

specified in section 6. Refer to unit rating plate for the al-

lowable external static pressures.

•All connecting ductwork to the unit (supply and return)

must be sealed to the unit casing as specified insection 5.

•Check to see that filters are installed correctly and are the

proper type an size.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

INTRODUCTION

The PHX3 unit is a fully self-contained, electric heat pump

unit designed for outdoor installation (See page 2 for unit

dimensions). All unit sizes have return and discharge

openings for both horizontal and downflow configurations,

and are factory-shipped with all downflow duct openings

covered.

3. LOCATING THE UNIT

ACCESS PANELS

See Figure 1 for a general view of unit and location of

access panels.

CLEARANCES

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable. The

combustion air inlet openings MUST not be obstructed (see

NO TAG). In addition, local codes MUST be observed.

NOTE: Units with available filter racks (3-1/2 to 5 ton), need

a 26" minimum clearance at side of unit for removal of

filters. See chart below if unit is going to be placed near

combustible construction or materials.

While minimum clearances are acceptable for safety

reasons, they may not allow adequate air circulation around

the unit for proper operation in the cooling mode. Whenever

possible, it is desirable to allow additional clearance,

especially around the condenser inlet and discharge

openings.

141

Page 5

Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet,

UNIT DAMAGE HAZARD

Failure to follow this caution may result in shorten life

of unit components.

Do NOT operate unit in a corrosive atmosphere

containing chlorine, fluorine, or any other corrosive

chemicals.

Minimum Clearances to Combustible Construction

DuctSide .................. 2" (6" on largechassis models)

Condenser Inlet .................................... 30"

BlowerService (Side) ............................... 30"

Control Service Side

(Front Combustion Air Inlet) .............. 30"

Clearance between 3 Ft. Overhang

and Top of Unit ......................... 30"

Combustible Base

(Woodor ClassA, B or C

roof covering material) ..................... 0"

Minlmomc,earoooosoodAooesspano,sCho si Shownl

Biower Compartment Panel

B Chassis - 2"

C Chassis - 6"

- Platform must be high enough to allow for proper

condensate trap installation and drainage. See Figure

2 and associated text for more information about

condensate drainage.

Rooftop Installation

Rooftop platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structu reif necessary. See page 12 of this

manual for unit weights.

- Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a

platform or a combination of platform and roof beams or

curb.

- See Hoisting section for hoisting instructions.

HOISTING

NOTE: All access panels MUST be secured in place before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings, Make sure that all equipment is adequate to

handle the weight ofthe unit and that the slings will not allow

the unit to shift,

Refer to NO TAG on page 12 of this manual for illustrated

rigging instructions and weight chart,

DOWNFLOW CONVERSION

80"

80-00-01

Control Panet

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed lev-

el front to rear and side to side. The slope MUST NOT be

greater than /8 perfoot (10mm per meter). For side to

1 ,

side leveling, the drain side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support unit weight.

Position platform separate from building foundation.

Install in well-drained area, with top surface of platform

above grade level.

NOTE: In downflow applications with roof curbs or jack

stands, the center rail under the unit must be removed. The

center rail is attached to the base rail with screws.

These units are adaptable to downflow use, To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten

with screw.

2. Install the removed plates on the horizontal return and

supply air openings.

3, Install roof curb on the building. Be sure to follow all

directions included with curb and all applicable building

codes in your installation.

Condensate Drain

The condensate drain outlet is a 3/4'' (19.1 mm) female PVC

connection located at the bottom on the left hand side (see

Figure 2),

151

Page 6

The circulating blower creates a negative pressure on the

condensate drain line that can prevent the condensate from

draining properly. To combat this negative pressure, a field

supplied condensate trap that will allow a standing column

of water of at least 2" (50.8mm) MUST be installed. Top of

outlet from trap MUST be at least 1" (25.4mm) below top of

outlet from unit. Install the trap as near to the unit as

possible for proper drainage.

A 3/4" (19.1 mm) drain line MUST be installed if required by

local codes or if location of unit requires it. Run the drain line

to an open drain or other suitable disposal point.

FIGURE 2 I Condensate Drain Information*

3/4" (19,1mm)

Threaded Female

PVC Fitting

b

25-1/2 ("B" Chassis)

32-1/4 ("C" Chassis)

(25.4mm)

/

2" (50.8mm)

* Condensate trap MUST be installed.

4. ELECTRICAL WIRING

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

The unit cabinet must have an uninterrupted,

unbroken electrical ground to minimize the possibility

of serious injury if an electrical fault should occur.

This ground may consist of an electrical wire

connected to the unit ground lug in the control

compartment, or conduit approved for electrical

ground when installed in accordance with National

Electric Code (NEC) NFPA 70, National Fuel Gas Code

NFPA 54-2005/ANSI Z223.1-2005 and local electrical

codes. In Canada, follow Canadian Electrical Code

CSA (Canadian Standards Association) C22.1 and

local electrical codes.

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow these precautions could result in

damage to the unit being installed.

1)Make all electricalconnections inaccordance with

NationalElectriccode (NEC)NFPa70 andlocalelectrical

codes governing such wiring. In Canada, all electrical

connections must be inaccordance with CSA standard

C22.1, Canadian Electrical Code Part 1, and applicable

local codes. Refer to unit wiring diagram.

2) Use only copper conductor for connections

betweenfield-supplied electricaldisconnectswitchand

unit. DO NOT USEALUMINUM WIRE.

3) Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4) Donot damageinternalcomponentswhendrilling

through any panel to mount electrical hardware,

conduit, etc. Consult local power company for

correction of improper voltage and/or phase imbalance.

Disconnect Switch

The unit must have separate electrical service with a

field-supplied, waterproof, disconnect switch mounted at,

orwithin sight from, the unit. Refer tothe unit rating plate for

maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing.

Ground Connections

Do NOT complete line voltage connections until unit is

permanently grounded. All linevoltage connections and the

ground connection MUST be made with copper wire.

A ground lug is installed in the control box area for the

ground connection. Use a copper conductor of the

appropriate size from the unit to a grounded connection in

the electrical service panel or a properly driven and

electrically grounded ground rod. See warning above.

Line Voltage Wiring - (Wiring Diagrams page 13)

Connections for line voltage are made in the unit control box

area. Refer to wiring diagram located on the Burner Access

panel. For access, remove the burner access panel.

1. Run the high voltage (L1, L2) and ground leads into the

control box.

2. Connect ground lead to chassis ground connection.

3. Connect L1 to pressure lug connection 11 of the

compressor contactor.

4. Connect L2 to pressure lug connection 23 of the

compressor contactor.

Thermostat / Low Voltage Wiring

Location of the thermostat has an important effect on home

comfort. FOLLOW THE THERMOSTAT INSTRUCTION

MANUAL FOR CORRECT LOCATION, MOUNTING, AND

WIRING.

All Models:

A two-stage thermostat is required for proper operation.

Thermostat should have the following terminals: "R',

"W/W1", "Y1 ", "O", and "G'. Some electronic thermostats

use low voltage from the unit for power for temperature

161

Page 7

display and programming. These electronic thermostats

will have a "C" terminal. The outdoor unit has color-coded

wires for easy connection. Using wire nuts, follow Figure 3

for proper connections:

FIGURE 3 2 to 5 Ton Thermostat Connections

fG_=

\-S

fO\,l .................................... /

'\ J........... _I

_\. j

Thermostat and subbase Unit Control Power

THERMOSTAT HEAT ANTICIPATOR

Some thermostats have an adjustable heat anticipator. The

heat anticipator prevents temperature overshoot in heating

mode. If the heat doesn't turn off until the set point

temperature on the thermostat is exceeded, then the

anticipator setting is too low. If the heat turns off before the

thermostat reaches the set point temperature on the

thermostat, then the anticipator setting is too high. Follow

the thermostat instruction manual for proper adjustment of

the heat anticipator.

Final Electrical Check

1, Make afinal wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to

ensure that rubbing or chafing due to vibration will not

occur.

NOTE: Wiring MUST be installed so it is protected from

possible mechanical damage.

5. DUCTWORK

Ductwork Sizing

The maximum recommended velocity in trunk ducts is 1000

feet per minute. The maximum recommended velocity in

branch ducts is 800 feet per minute.

Filter Sizes

Ductwork sizing affects the discharge temperature, airflow

velocity, and efficiency of the system. Be sure to properly

size ductwork to the capacity of the unit and to the airflow

requirements of the conditioned space. Failure to properly

size ductwork can result in inadequate airflow and poor

efficiency. Undersized ductwork may result in tripped limit

controls and premature failure of compressors, motors and

other components.

Ductwork Insulation

Ductwork installed outdoors must have a minimum 2" thick

fiberglass "wrap" insulation and a weatherproof vapor

barrier installed around it. The insulation and vapor barrier

must be protected against potential damage. Caulking,

flashing, and other means of providing a permanent

weather seal must be used.

Ductwork Connections

The use of flexible, non-combustible connectors between

main trunk ducts and supply and return air plenums is

permitted. If flexible connectors are used, they should be

protected from potential mechanical damage such as

punctures and tears.

NOTE: When connecting the supply and return plenums to

the unit, make sure that the plenums are sealed against the

side casing of the unit and do not interfere with removal of

the top of the unit.

FILTERS

All return air MUST pass through a filter before entering the

unit. An electronic air cleaner, optional filter racks, or other

accessible filter arrangement must be installed inthe return

air ductwork. Minimum recommended filter sizes are listed

in FIGURE 4 and are based on maximum face velocities of

300 ft!min for disposable filters and 500 ft/min for washable

(high velocity) filters.

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this caution may result in improper

unit operation.

Do not operate the unit without a filter,

PHX3 Filter Data

Model

PHX324000K00A1

PHX330000K00A1

PHX336000K00A1

PHX342000K00A1

PHX348000K00A1

PHX360000K00A1

Disposable Filters

Nominal Size (Qty

xwxd)

1 x 20" x 20"

1 x 20" x 24"

2x 15"x20"

2x 18"x20"

2 x20" x20"

2 x20" x24"

Minimum Area (sc

inches)

384

480

576

672

768

960

Wasabte Filters

Nominal Size (Qty

xwxd)

1 x 10" x 20"

1 x 12" x 20"

1 x 15" x20"

1 x 18" x20"

1 x 20" x 20"

1 x 20" x 24"

Minimum Area (sq

inches)

192

24O

288

336

384

48O

171

Page 8

6. AIRFLOW ADJUSTMENT

CIRCULATING AIR BLOWER SPEEDS

ModelNumber PHX324 PHX330 PHX336

Torque(ox Ft.} 596 1098 1553 18.04 29.02 11.92 1302 18.04 23.06 29.02 1859 24.00 34.35 52.94

SpeedTap 1 2 3 4 5 1 2 3 4 5 1 2 3 4

AirDeliveryin CFM 04 252 564 768 858 I170 618 568 857 1017 I1C4 755 913 1179 I477

@VaryingExtemal 05 219 529 738 811 I199 584 530 828 992 I138 694 871 1150 I415

StaticPressure 08 188 481 584 775 I100 524 582 785 954 II12 651 841 1117 I354

(in.w c.} 07 431 550 733 I063 494 542 750 924 I077 598 793 1086 1287

ModelNumber PHX342 PHX349 PHX360

Torque(ox Ft.) 19.06 2306 34.12 41.98 44.00 26.99 3200 51.14 59.92 8000 30!2 3106 55.84 73.10 8000

SpeedTap 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

AirDeliveryin CFM 04 797 881 1179 1374 I463 1027 1187 1578 1732 I942 1189 1231 1735 I987 2039

@VaryingExternal 05 749 838 1138 1338 I423 983 1126 1544 1696 I878 1117 1197 1702 I935 1974

StaticPressure 08 702 789 1103 1298 I389 927 1077 1507 1661 I809 1073 1144 1567 I878 1905

(in.w c.} 07 642 731 1080 1263 I353 881 1028 1470 1621 I723 1028 1105 1629 I811 1827

Notes A9 Delivery@]isledexternalstaticpr_sslearetakenat230Vo0swh Dlycoil nofit_r and applovedb_aler

01 001 /1I 809 901 I201 /b4 /89 959 1100 I250 9(0 1026 12/0 1030

O2 478 655 842 914 I218 708 747 923 1080 I227 841 994 1242 I588

03 334 623 809 883 I194 671 714 894 1048 I201 794 949 1209 I526

O8 392 599 897 988 443 495 712 881 I027 543 735 1045 I216

09 334 569 858 871 382 460 861 838 934 499 583 998 I145

I 305 523 518 745 342 403 530 755 809 464 538 948 1070

O1 973 1028 1302 1481 I569 1173 1304 1680 1831 2103 1300 1388 1839 2091 2188

02 900 969 1280 1448 I537 1127 1256 1650 1797 2051 1253 1321 1807 2056 2140

03 853 924 1219 1412 I500 1085 1216 1614 1763 2001 1214 1283 1772 2023 2096

O8 581 680 1015 1228 I317 821 979 1427 1559 I632 975 1038 1590 I729 1745

09 529 617 963 1188 I278 784 921 1373 1446 I526 928 969 1535 1640 1642

I 476 582 923 1143 I298 710 875 1289 1339 I388 882 913 1460 1536 1537

Forwetcodadd 05in wc b Sta0cPlessuremeasur_mentNotefor208Vo0sappicatlons,reduceaflowby15%

BlowerSpeedTapSe

Models LowCapacityAirflow RatedAirflow

PHX324 SpeedTap1 SpeedTap3

PHX330 SpeedTap1 SpeedTap4

PHX336 SpeedTap1 SpeedTap3

PHX342 SpeedTap1 SpeedTap4

PHX348 SpeedTap1 SpeedTap3

PHX360 SpeedTap2 SpeedTap

iin_ls

HighCapacityAirflow

SpeedTap5

SpeedTap5

SpeedTap5

SpeedTap5

SpeedTap5

SpeedTap5

Airflow Adjustment (cont,)

Verify that the proper blower speeds for heating and cooling

are selected on the blower motor by removing the blower

access panel and inspecting the blower motor. The motor

has 5 speeds numbered "1", "2", "3", "4" and "5". The wires

for the speed selection are as follows:

Red _ Heating

Black _ High Stage Cooling

Violet =1_ Low Stage Cooling (4 ton only)

Using the same speed for Heating and Cooling.

If the same speed is required for heating and low stage

cooling, the following procedure must be used:

1. Set Red wire on proper speed selection on blower

motor.

2. Remove Violet wire from "LO" on Blower Interface

Board. Tape end of Violet lead using electrical tape.

3. Jumper the Red wire to both the "Heat" terminal and the

"LO" terminal on the Blower Interface Board.

181

Page 9

7. START-UP PROCEDURES

CHECK BEFORE STARTING

1. Check that the blower motor speed terminal block is

running the correct heating and cooling speeds.

2. Check to see that clean, properly sized air filters are

installed.

3. Replace all service access panels.

Check the unit's operation as outlined in the following

instructions. If any unusual sparking, odors or unusual

noises are encountered, shut off electric power

immediately. Recheck for wiring errors, or obstructions in or

near blower motors.

1. Set thermostat Heat-Cool selector to OFE

2. Set thermostat fan switch to AUTO.

3. Turn electric power ON. Nothing should start running.

4. Set thermostat fan switch to ON,

5. Reset thermostat fan switch to AUTO.

8. SEQUENCE OF OPERATION

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Cooling Operation (PHX324 - 60)

These units utilize a 2 stage indoor thermostat. With a first

stage call for cooling (Y1), the indoor fan (low stage)

energizes immediately where as the contactor energizes

after a 5 minute time delay (incase of an initial start up)

starting the compressor (low stage) and the outdoor fan

motor. If the low stage operation cannot satisfy the cooling

demand, the second stage cooling (Y2) energizes

switching the compressor into high stage cooling through

energizing an internal solenoid valve inside the scroll

compressor and switching the indoor fan into high stage.

When second stage cooling is satisfied, Y2 de-energizes

switching the compressor and the indoor fan into low stage

cooling. When the low stage cooling demand is met, Y1

de-energizes shutting the compressor, indoor fan and the

outdoor fan.

Heating Operation (PHX324 - 60)

With a first stage call for heating (Y1), the indoor fan (low

stage) energizes immediately whereas the contactor

energizes after a 5 minute time delay (incase of an initial

start up) starting the compressor (low stage) and the

outdoor fan motor. If the low stage operation cannot satisfy

the heating demand, the second stage heating (Y2)

energizes switching the compressor into high stage heating

through energizing an internal solenoid valve inside the

scroll compressor and switching the indoor fan into high

stage. The auxiliary or back up heat is controlled by a third

stage (W2). If the demand is not met, W3 is energized

incase of staged heating. When heating demand is

satisfied, W3, W2 and Y2 sequentially de-energize

switching the compressor and the indoor fan into low stage

heating. When the low stage heating demand is met, Y1

de-energizes shutting the compressor, indoor fan and the

outdoor fan.

Scroll Recycle Delay timer

The defrost board is equipped with a recycle delay timer

which will delay the start of the compressor for 5 minutes in

the event of a power interruption. This sequences power

throughout the system and prevents possible reverse

rotation of the scroll compressor. The output of the timer

controls the compressor contactor via a normally open

contact of K3 (T2). The timer starts the delay cycle whenthe

compressor is turned off by removal of "Y." If application of

"Y" occurs before the timer has expired, the compressor

contactor will not be energized until the timer has expired.

CONTINUOUS FAN OPERATION

With the continuous Indoor fan option selected on the

thermostat, G is continuously energized. Incase of 024 -

042 units, the selected airflow setting is provided. Incase of

048 and 060 units, the system runs low stage (Y1) airflow for

continuous fan operation.

Defrost Mode

On a call for defrost:

When the defrost sensor closes in the heating mode, there

isa 30, 60, 90 or 120 minute delay before the defrost mode

begins. This delay is selected by the position of the

dipswitches on the defrost board. Defrost interval timing

can be configured by selection switch 1 and 2 on the

dipswitch per the following table: See Figure 6.

Switch 1

ON

OFF

OFF

ON

NOTES:

Switch 2 Time

OFF 30 Minutes

ON 60 Minutes

OFF 90 Minutes

ON 120 Minutes

1. The backup defrost terminate time is fixed at 10

minutes.

2. The compressor recycle delay timer is 5 minutes.

3, The power interrupt response is minimum 17 msec, to

maximum 35 msec.

4. Quite shift compressor recycle delay is 30 seconds.

In normal defrost mode, the following sequence will occur

after the set delay:

1. Condenser fan off.

2,

Reversing valve energized to cooling and auxiliary

electric heat (W2) is energized.

3.

After defrost sensor opens or a maximum of 10

minutes; the condenser fan is energized (after 20

seconds) and the reversing valve is de-energized to

the heat mode. Electric strip heat is also de-energized

(after 15 seconds) except as required by the

thermostat,

191

Page 10

4. Should the system indoor thermostat be satisfied

during the defrost cycle, the control will de-energize the

reversing valve and auxiliary heat outputs and "hold"

the defrost timer until the next call for heat, at which time

the defrost cycle will be completed.

Service testing: the pins marked "speed up" when

momentarilyshorted together (for 5seconds) and released,

will defeat the 5 minutes recycle delay timer and allow the

compressor contactor to be immediately energized, thus

forcing adefrost cycle. Termination of this forced mode will

be by the defrost thermostat or the 10 minute backup timer,

provided the defrost thermostat was closed when the

defrost was "forces." If the defrost thermostat was not

closed, at the time of the "forced defrost," the defrost mode

will remain for 30 seconds and then terminate.

FIGURE 6 Defrost Board & Dip Switches

Defrost Board

Dip Switch

9. MAINTENANCE

MONTHLY MAINTENANCE AND INSPECTION

CHECKS

Air Filters

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this cautions may result in damage to

the unit being installed.

Do not operate the unit without a filter.

Inspect filters at least monthly and replace or clean as

required. Washable filters may be cleaned by soaking in

mild detergent and rinsing with cold water. Replace filters

with the arrows on the side pointing in the direction of air

flow. Dirty filters are the most common cause of inadequate

heating or cooling performance, and of compressor

failures.

COOLING SEASON CHECKS (MONTHLY)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of

leaves, grass clippings or other debris. Grass should be

kept short in front of the condenser inlet. Shrubbery MUST

be trimmed back so it is no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

ANNUAL MAINTENANCE AND INSPECTION

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

The annual inspection should include cleaning as required

to ensure efficient operation of the unit. To simplify access,

remove all access panels and the top from the unit if

possible.

Condenser Fan Motor

Note: The condenser fan motor is permanently lubricated.

No further lubrication is required. Do not attempt to

lubricate the condenser fan motor.

Clean the surrounding area and the condenser and

evaporator coils. Use caution to avoid damage to coil fins.

BLOWER MOTOR ACCESS

Refer to Figure 1 for blower motor access panel and

compartment.

1. Remove the blower access panel

2. Remove the three screws securing the blower motor

housing. If unit has a support bracket, remove the two

screws securing the bracket.

3. Remove the two red wires attached to the limit

switchand remove the limit switch.

Motor removal and replacement

This method is required to replace or repair blower wheel,

blower housing, or any unreachable components behind

blower assembly.

1. Remove all screws around rim of unit top, (except

screws which are inaccessible because of proximity to

structure).

2. Raise unit top at corner of unit closest to blower at least

2" and place asturdy brace at least 2" thick between top

and unit corner. A 2X4 piece of wood is ideal for this.

3. Disconnect all wires from housing and slide housing out

of unit. Reverse this process to reinstall.

Circulating Air Blower

Visually inspect the blower wheel for accumulations of dirt

or lint. Clean the compartment and the blower wheel. If

accumulation is excessive on blower wheel, or does not

easily remove, it will be necessary to remove the blower

assembly.

Note: The blower motor is permanently lubricated. No

further lubrication is required. Do not attempt to lubricate

the blower motor.

Page 11

FIGURE 7 Control Box

Defrost

Board

Motor

Board

o

Transformer

Contactor

Run Capacitor

Capacitor Strap

Ill

Page 12

E

R GG NG INSTRUCTIONS __

fAiLURETOfOLLOW-_-SE_.STRUC-r_O_S

//_ WA_\ NO CAN RESULT IN PROPERTY DAMAGE,

BoD,_,_u_R_oRDEAT_

.o

:D

C:

m

QO

- ALL PANELS MUST BE IN PLACE WHEN RIGGING AND LIFTING.

- HOOK RIGGING SHACKLES THROUGH HOLES IN BASE RAIL, AS SHOWN IN DETAIL-A.

- USE SPREADER BARS, WHEN RIGGING, TO PREVENT UNIT DAMAGE.

- BE SURE RIGGING AND SHACKLES ARE SUFFICIENT TO HANDLE WEIGHT LISTED BELOW.

DETAIL-A

DER BARS

-¢

HEIGHT

_OR _

LENGTH WIDTH

tQ

t_

f-

0

m.

o

:3

Cabinet

Small

Large

Max. Length Max. Width

IN MM IN MM

52 1219 48 1219

73 1854 48 1219

Max. Height

IN MM

38 965

38 965

Max. Weight

LB KG

500 227

900 409

Page 13

11. Wiring Diagrams

2 to 5 Ton Wiring Diagram

SO Loading...

Loading...