Page 1

Installation Instructions

PHM3 SERIES

PACKAGE HEAT PUMPS

TABLEOFCONTENTS

SAFETYLABELINGANDSIGNALWORDS ....................... 2

UNITDIMENSIONS......................................... 3

SAFEINSTALLATIONREQUIREMENTS ......................... 3

LOCATINGTHE UNIT ....................................... 3

CLEARANCES ............................................ 4

INSTALLATION............................................ 4

INSTALLINGDUCTCOLLARS................................. 4

CONDENSATEDRAIN....................................... 5

UNITELECTRICALWIRING .................................. 5

LINEVOLTAGE............................................ 5

CONVERTING230VTO208V ................................. 6

LOWVOLTAGEWIRING ..................................... 6

THERMOSTATCONNECTIONS................................ 6

FINALELECTRICALCHECK.................................. 6

CONTROLBOXCONFIGURATIONANDWIRING ................... 7

WIRINGDIAGRAMS ........................................ 8

RAINSHIELDINSTALLATION................................ 10

AIR DISTRIBUTIONSYSTEM................................. 10

DUCTWORK............................................. 10

FILTERS................................................ 10

UNITELECTRICALWIRING ................................. 10

START-UP PROCEDURES.................................. 1!

SPEEDTAPS ............................................ 1!

CHECKBEFORESTARTING................................. 1!

DEFROSTINTERVAL ...................................... 12

SEQUENCEOFOPERATION................................. 13

OPERATION............................................. 14

LISTED

Printed in U.S.A. 11/8/05 427 O1 1101 OO

Page 2

1. Safety Labelinq and Siqnal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAUTION are

used to identify levels of hazard seriousness. The signal

word DANGER is only used on product labels to signify an

immediate hazard. The signal words WARNING and

CAUTION will be used on product labels and throughout

this manual and other manuals that may apply to the

product.

Signal Words

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which MAY result

in minor personal injury or product or property damage,

Signal Words in Manuals

Danger Label

White lettering on a black background except the word

DANGER which is white with a red background.

Warning Label

White lettering on a black background except the word

WARNING which is black with an orange background,

The signal word WARNING is used throughout this manual

in the following manner:

The signal word CAUTION is used throughout this manual

in the following manner:

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels. Following are examples of

product labels with explanations of the colors used,

Caution Label

White lettering on a black background except the word

CAUTION which is black with a yellow background,

2 427 01 1101 00

Page 3

2. Dimensions

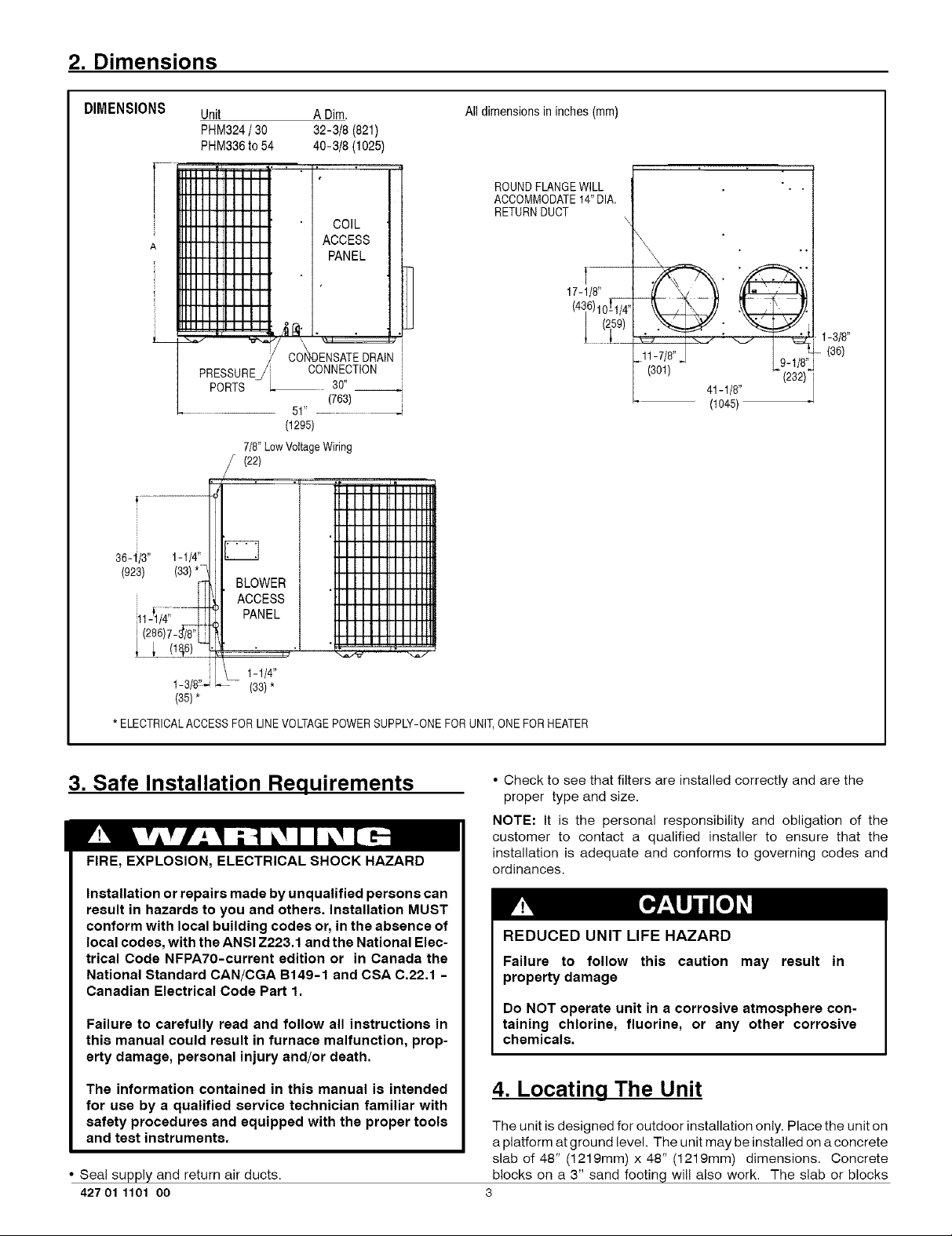

DIMENSIONS

36-1/3" 1-1/4"

(923)

Unit

PHM324 / 30

PHM336 to 54

IIIIII I Iil I I

RlllllllilII

RIIIIIIIilII

BIIIIIIIilII

_IIIIIII'III

RIIIIIIIIII

RIIIIIII,III

_lllllllilII

_lllllllilII

lllllllllilII

,.,,,,,,.,, _.

PRESSURE!

PORTS L_

(1295)

7/8"LowVoltageWiring

/ (22)

ADim.

32-3/8 (821)

40-3/8 (1025)

COIL

ACCESS

PANEL

CONNECTION

3O"

(763)

51"

Alldimensionsin inches(mm)

ROUNDFLANGEWILL

ACCOMMODATE14"DIA.

RETURNDUCT

1-3/8"

(36)

(301) (232)

41-1/8"

(lO45)

1-1/4"

(35)*

*ELECTRICALACCESSFOR UNEVOLTAGEPOWERSUPPLY-ONEFORUNIT,ONEFORHEATER

(33)*

3. Safe Installation Requirements

FIRE, EXPLOSION, ELECTRICAL SHOCK HAZARD

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the ANSI Z223.1 and the National Elec-

trical Code NFPA70-current edition or in Canada the

National Standard CAN/CGA B149-1 and CSA C.22.1 -

Canadian Electrical Code Part 1.

Failure to carefully read and follow all instructions in

this manual could result in furnace malfunction, prop-

erty damage, personal injury and/or death.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

• Seal supply and return air ducts.

42701 1101 oo

3

• Check to see that filters are installed correctly and are the

proper type and size.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes and

ordinances.

REDUCED UNIT LIFE HAZARD

Failure to follow this caution may result in

property damage

Do NOT operate unit in a corrosive atmosphere con-

taining chlorine, fluorine, or any other corrosive

chemicals.

4. Locating The Unit

The unit is designed for outdoor installation only. Place the unit on

a platform at ground level. The unit may be installed on a concrete

slab of 48" (1219mm) x 48" (1219mm) dimensions. Concrete

blocks on a 3" sand footing will also work. The slab or blocks

Page 4

SHOULD NOT be in contact with any part of the structure. Check Installation

local codes covering zoning, noise, platforms, etc..

Avoid locating next to fresh air intakes, vent or bedroom windows.

Noise may carry into the openings and disturb people inside.

Avoid installations under roof overhangs without guttering. Water

draining from the roof onto the unit could produce excessive

noise, and may cause ice to build up on coil or fan.

Placement of the unit should be in a well drained area or the unit

MUST be supported high enough so runoff will not enter the unit.

Do not locate unit where heat, lint or exhaust fumes wil! be

discharged on unit (as from dryer vents.)

Clearances

The unit must be installed with a slope no greater than 1/8"

per foot (10mm per meter). For side to side leveling, the

condensate drain side side MUST always be lower.

The unit MUST be situated in such a way as to provide safe

access for servicing.

The platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support the unit's weight.

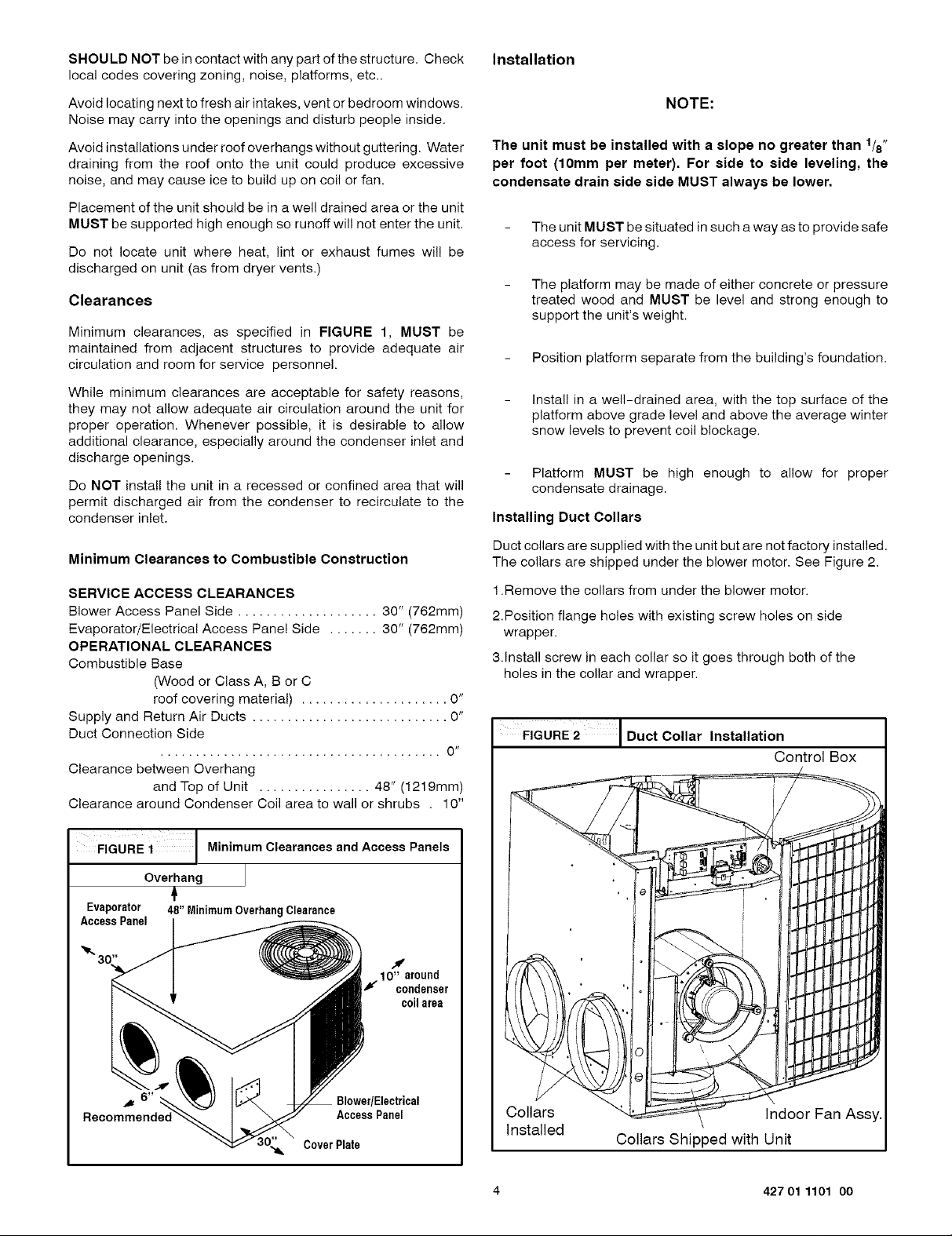

Minimum clearances, as specified in FIGURE 1, MUST be

maintained from adjacent structures to provide adequate air

circulation and room for service personnel.

Position platform separate from the building's foundation.

NOTE:

While minimum clearances are acceptable for safety reasons,

they may not allow adequate air circulation around the unit for

proper operation. Whenever possible, it is desirable to allow

additional clearance, especially around the condenser inlet and

discharge openings.

Do NOT install the unit in a recessed or confined area that will

permit discharged air from the condenser to recirculate to the

condenser inlet.

Minimum Clearances to Combustible Construction

SERVICE ACCESS CLEARANCES

Blower Access Panel Side .................... 30" (762mm)

Evaporator/Electrical Access Panel Side ....... 30" (762mm)

OPERATIONAL CLEARANCES

Combustible Base

(Wood or Class A, B or C

roof covering material) ..................... 0"

Supply and Return Air Ducts ............................ 0"

Duct Connection Side

........................................ 0 sl

Clearance between Overhang

and Top of Unit ................ 48" (1219mm)

Clearance around Condenser Coil area to wall or shrubs . 10"

FIGURE i Minimum Clearances and Access Panels

install in a well-drained area, with the top surface of the

platform above grade level and above the average winter

snow levels to prevent coil blockage.

Platform MUST be high enough to allow for proper

condensate drainage.

Installing Duct Collars

Duct collars are supplied with the unit but are not factory installed.

The collars are shipped under the blower motor. See Figure 2.

1.Remove the collars from under the blower motor.

2.Position flange holes with existing screw holes on side

wrapper.

3.Install screw in each collar so it goes through both of the

holes in the collar and wrapper.

FIGURE2 I Duct Collar Installation

Control Box

Overhang

Evaporator 48" MinimumOverhangClearance

AccessPanel

CoverPlate

10" around

f condenser

coilarea

BlowedElectrical

AccessPanel

Collars

Indoor Fan Assy.

Installed

Collars Shipped with Unit

4 427 01 1101 00

Page 5

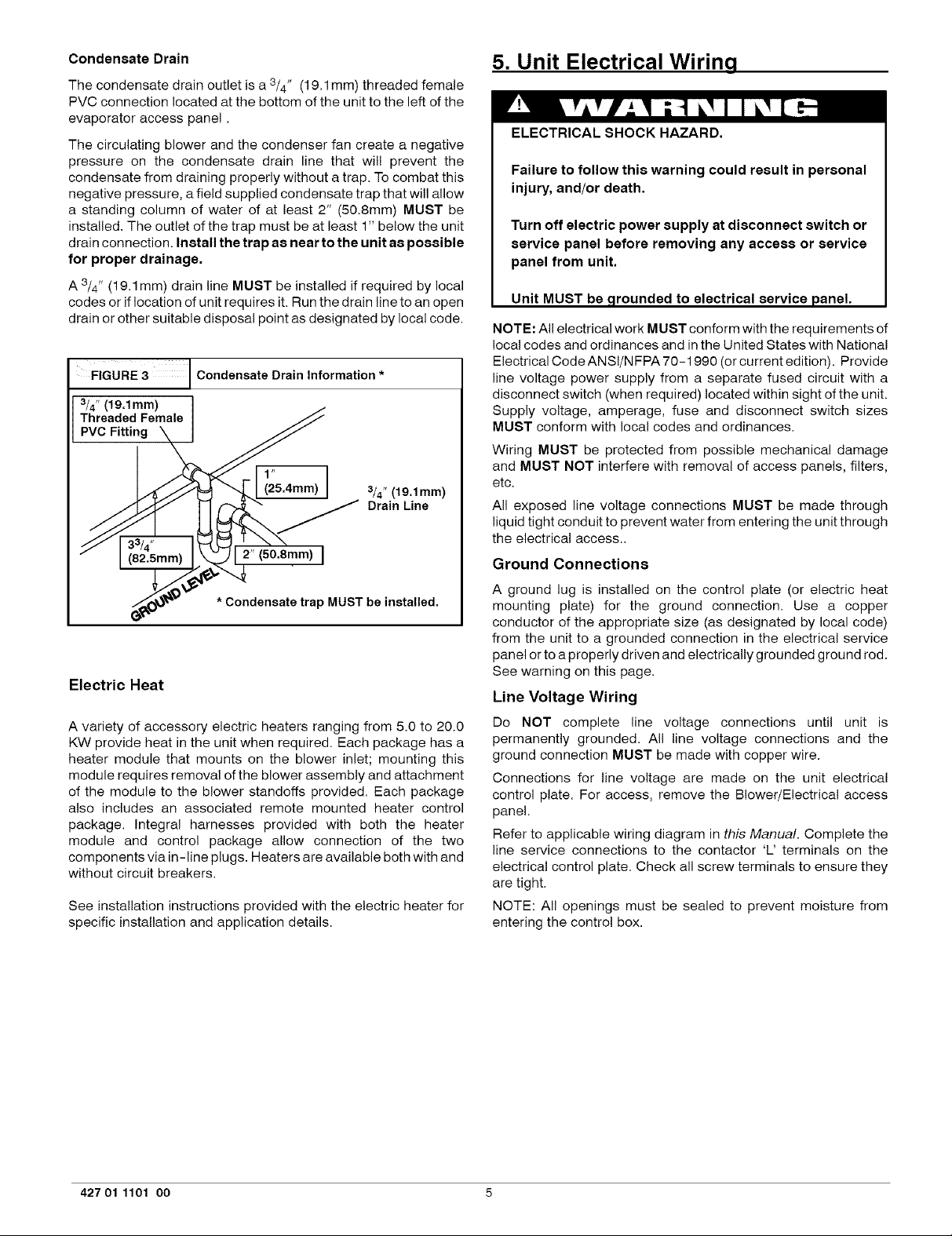

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) threaded female

PVC connection located at the bottom of the unit to the left of the

evaporator access panel.

The circulating blower and the condenser fan create a negative

pressure on the condensate drain line that wil! prevent the

condensate from draining properly without a trap. To combat this

negative pressure, a field supplied condensate trap that will allow

a standing column of water of at least 2" (50.Smm) MUST be

installed. The outlet of the trap must be at least 1" below the unit

drain connection. Install the trap as near to the unit as possible

for proper drainage.

A 3/4" (19.1 mm) drain line MUST be installed if required by local

codes or if location of unit requires it. Run the drain line to an open

drain or other suitable disposal point as designated by local code.

FIGURE 3 Condensate Drain Information *

3/4" (19,1mm)

Threaded Female

PVC Fitting

3/4" (19,1mm)

Drain Line

_4.Smm)

* Condensate trap MUST be installed.

mm>I

Electric Heat

A variety of accessory electric heaters ranging from 5.0 to 20.0

KW provide heat in the unit when required. Each package has a

heater module that mounts on the blower inlet; mounting this

module requires removal of the blower assembly and attachment

of the module to the blower standoffs provided. Each package

also includes an associated remote mounted heater control

package. Integral harnesses provided with both the heater

module and control package allow connection of the two

components via in-line plugs. Heaters are available both with and

without circuit breakers.

See installation instructions provided with the electric heater for

specific installation and application details.

5. Unit Electrical Wiring

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, and/or death.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Unit MUST be ,grounded to electrical service panel.

NOTE: All electrical work MUST conform with the requirements of

local codes and ordinances and in the United States with National

Electrical Code ANSI/NFPA 70-1990 (orcurrent edition). Provide

line voltage power supply from a separate fused circuit with a

disconnect switch (when required) located within sight of the unit.

Supply voltage, amperage, fuse and disconnect switch sizes

MUST conform with local codes and ordinances.

Wiring MUST be protected from possible mechanical damage

and MUST NOT interfere with removal of access panels, filters,

etc.

All exposed line voltage connections MUST be made through

liquid tight conduit to prevent water from entering the unit through

the electrical access..

Ground Connections

A ground lug is installed on the control plate (or electric heat

mounting plate) for the ground connection. Use a copper

conductor of the appropriate size (as designated by local code)

from the unit to a grounded connection in the electrical service

panel or to a properly driven and electrically grounded ground rod.

See warning on this page.

Line Voltage Wiring

Do NOT complete line voltage connections until unit is

permanently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

Connections for line voltage are made on the unit electrical

control plate. For access, remove the Blower/Electrical access

panel.

Refer to applicable wiring diagram in this Manual. Complete the

line service connections to the contactor 'L' terminals on the

electrical control plate. Check all screw terminals to ensure they

are tight.

NOTE: All openings must be sealed to prevent moisture from

entering the control box.

427 01 1101 00 5

Page 6

Converting 230V Units to 208V

To convert 230V units to 208V:

1.Turn electric power OFE

2.Remove the blower/electrical access panel.

3.Locate the 24V control transformer.

4.Remove wire from the terminal labeled "240V" on the 24V

control transformer and reconnect it to the 208V terminal of

the 24V control transformer.

5.Replace the electrical/compressor access panel.

Low Voltage Wiring

For access, remove the electrical control/blower access panel.

Refer to the connection wiring diagram for the applicable model

and to the instructions included with the thermostat.

Route low voltage wires through the port located on the rear panel

and up to the control box.

NOTE; If an Electric Heat Accessory is installed, see the Electric

Heat Accessory Installation manual for low voltage connections.

Thermostat Connections

GuRE4 I Electr°nic Therm°stat L°w V°ltage wiring

Harness Connection Diagram

PHM324-42 Units

©

@

O-

C>-

Thermostat and subbase

Unit Control Power

PHM348-54 Units

The location of the thermostat has an important effect on the

operation of the unit. See the thermostat instructions for proper

connection. See FIGURE 4 for Low Voltage Wire Harness

Connections

Field Installed Equipment

Wiring to be done in the field between the unit and other devices,

or between separate devices which are field installed and located,

MUST NOT exceed the temperature limitations for type T wire

and MUST be installed in accordance with manufacturer's

instruction and applicable local codes.

Final Electrical Check

Make a final wiring check to be sure system is correctly wired.

Inspect field installed wiring and the routing to ensure that rubbing

or chafing due to vibration will not occur.

NOTE: Wiring MUST be installed so it is protected from possible

mechanical damage.

@

@-

@-

Thermostat and subbase

Unit Control Power

6 427 01 1101 O0

Page 7

FIGURE 5 I Control Box Configuration

Indoor

Motor

Board

Defrost Board

Capacitor

Strap

/

POWER

PIGIAItS

WT)_LK_

_2b_K

Transformer Condenser Fan/

Compressor

Capacitor

/

Control Box

\

Contactor

Low Voltage Shield

Control Box Wiring for PHM024-42

[

0

II ......

• oD ;_ o

POWZR

PIGIAILS

MII IIi

24V

PIGTAI£$

Illlllll

Z4V

PIGIAILS

II .......

@

I

SINGLECAPACITYCONTROLBOX - 208/230/1

Control Box Wiring for PHM048-54

D[TAIL -a-

o

o _ °i

. _

I I

i _E_ _EtECTC_TERminaL_EO_IR_S

_ELOC_IO_OH_OW_SITES

CT4_i

TIGO_I

_ROST TIWER_OB_ SE__r _o WIWUT_S

427 01 1101 O0 7

DUAL CAPACITY CONTROL BOX 208123D/1

Page 8

2-31/2 Ton Models

FIELD SCHEMATIC

SUPPLY CCH

POWER /"--X ,, v BL_LNr_ DR @ DB _08/230"1"G0

MAXIMUM WIRE I F-_ OPM

size2,,G.--'-_ W,4TEL F/m--_ ,,.vTEL . ,.4-_1

L i n Iv/ '= ,$'_--M._

EOUIP.GNoT I ] f] I _ .] Cl r ................cc,,_',Es_PEu_

.,,AM y . I Illl , II

ccEsso iii-_ I_1 EL-T----k7%MTRll IIII I I I--I/ I \

ELECTRIC MEAT I m V ' ] III ] I L_ YEL _ }

w_oce's I _ / _ I]l ' W3YEL ] L I -I\ [ ]

'15-20 -- -

KW-- -- -

',-- I I -- __ -- WE_ REO W23 BRN _ "]

UNIT COMPONENT ARRANGEMENT

_|DOOR FAN

SECII_

C_PEES$_

SECTION

I#_ FAN

SECT]_

r_

1_

r_

COMP

R

m

I,,,I

Y -i-.._V-.3_ y E Li

0 ---ItR--ORM--

W2--"_ WHT i

W3_VIO--

C -----_--."BRN

80A!{O COIITROL

80ARO

EOUiP,

/G.O

iE4V P_ER ENTRY

LEGEND

flEtO SPLICE

0 IE_#_ €WAR'E01 C C_T_T_

o I(RWINkL {UNNkR_ED) C(AP8 CAP_iTO_

o SPLICE ¢CH CRkW_CAS£H£AIER

OSPLICE _KEO} CO_P CO_ESSO_ _OTO_

i_CIORT |l_leG C_O CO_PRES_ _l_ _LAT

-- -FIEL_ C_T_ WIRl_ _ OEf_t _ARO

--_ tlEtO _R WIRl_ _T OEt_T I_{_TAT

l_l_ tC8 Fk_ CO_I_ _OARO

i TO I#OICATECOW_O_ _ HEATE__ELAY

_IEWIIAL _: I_# l#O00_ fAN V_IOR

_OT TO_[P_ESE_I I_I_ tPS LOI PRESSER{S|IICH

CI_Bi! 6_EA_ER

6WO G_#O

_VS REV[_SI_ WLV[ _E_ID

IRAW IRA#SrO_R

ACC[SSSORY [LrCtRIC HEAI------'_{W_

WHT _8N#i

HRI,_.3 _ _ (2O KW_ _RN

VIO

PN_ _BR_ i

6RY _

HR1 _ _ _I0 KWl/ BRN

DIP SWITCH SETTINGS

_lll(m

CtO (Tl,t2) COMPRESSOROELAY

CI Cl

CLOSES OPENS

_SAT

ALL EXCEPT 024

Pl_q324 42

8 427 01 1101 O0

Page 9

4 & 5 Ton Model

UNIT CO_IPONZNT ARRANGEMENT

SECTIOil

_i_O0_ FAN

C_PR£SSOR IN_ fAN

RE{IIOI SECTION

[_

1]]_]

¢_P

R

@

_ Fll_i tall

_AIIO ¢ONTIIOI

90Al(O

d--

BLU LPS BLU

ACCESSSORY ELECTRIC HEAT_

P#N _ORN--

DIP SWITCH SETTINGS

LEGEND

FIELR SPLICE

0 T[RHINAL {pARKER) C CO_T_l_

o TERWINAL(UNWARAER) CAP ¢AP_IX_

0 $PLI¢[ ¢8 ¢lnCUlT 9R£A_[R

OSPLICE (WARKER} ¢C_P¢¢_ _IPRES_RAWKCAt _EAT _

-- r_l_T I1111_ ¢_O ¢fflPRE$_ TI_ RELAT

-- lO PlRICA?ECr_'.l HR I!EA_TRREtAY

POTENTIALO_LY: I_11 IW_I_ lAW IIOT_

PO! TO REPR{SE_! |IRI_ tPS LOI PRESSURERIIt¢_

/EOIIIP. RV$ REVEI_$11_ VALVE$_I.E_IOIO

G#O TRA_ IRAWS_II[R

- II'$ (I_IWL(_I. FAW$EOUEWCE

_ _I[S:I. ir AI_ _ I,{ _lGl#_t IlR(S FUqi_{O X_E REPLIED.

iR_V _ER ENTRY 5. REL_A_I_ _ SPEERTAPS_t _E _(_I_R EgE_lEER_ RE'ENERGIZERu

_[i USIIG _I_Li) I§STALL[D[L[CT_IC H[AT[R$,

¢ols_ IWS_A_L_IO_ IIS_R_TI_ _o

O£T(_ll( COn£CTSPE[OT_P,_,l_TTll_.

_w _T_I_ raw _TOR

T_RO

F--

BLN

BLK

1

€TO (II,TR) C_R[S_ RELAY

0 *R RE¢ T T_5 WIW.

¢1 CI

CLOST$ GPE#R

TDAT

427 01 1101 O0 g

?H_348 54

Page 10

6. Rain Shield Installation

FIGURE 6 [ Installing The Rain Shield

RAIN SHIELD

requirements. If the unit is connected to an existing system, the

ductwork MUST be checked to make sure it is adequate. Extra

runs or larger duct sizes may have to be installed.

Maximum recommended velocity in trunk ducts is 1000 feet per

minute (5.08m/s). Velocity in branches should not exceed 800

feet per minute (4.06m/s). Refer to the Technical Data Label on

the unit for unit air volume requirements and system sizing

recommendations.

NOTE: Ductwork sizing affects temperature rise and cooling

temperature differential. Be sure to properly size ductwork to the

capacity and airflow characteristics of your unit. Failure to do so

can affect limit controls, compressors, motors, and other

components and will lead to premature failure of components.

This will also adversely affect day to day unit performance.

Flexible Duct Kits are available from your supplier to effect proper

sizing and installation to Mobile Homes and other standard

construction,.

Refer to unit rating plate for proper Electric Heat Accessory sizing

and see the Temperature Rise Check section in the Electric Heat

Accessory Installation manual.

1.Remove all screws from the cover plate on Blower/Electrical Access

Panel.

2.Install adhesive backed gasket on Blower/Electrical Access

Panel.

3.Install lower frame of rain shield with 4 screws.

4.Install rain shield hinged cover with 4 screws.

5.Install circuit breaker filler plates (2 each per unused breaker

slot.)

&Re-install Blower/Electrical Access Panel.

NOTE: VERIFY ALL APPROPRIATE SEALS ARE IN PLACE.

SEE FIGURE 6.

Ductwork Insulation

It is recommended that ductwork installed outdoors have a

minimum of 2" (51mm) of fiberglass insulation and be covered by

a weatherproof vapor barrier that is protected against damage.

Caulking and flashings, or other means adequate to provide a

permanent weather seal, must be used.

It is recommended that ductwork installed in attics or other areas

exposed to outdoor temperatures have a minimum of 2" (51mm)

fiberglass insulation and have an indoor type vapor barrier.

Ductwork Connections

The use offlexible, non-combustible connectors between main

trunk ducts and supply and return air plenums is recommended to

minimize vibration transmission.

7. Air Distribution System

NOTE: Connect supply and return air plenums to unit in a manner

that will allow the top of the unit to be removed without removing

For airflow data (blower performance data, blower speed tap

settings, etc.) see the Technical Data Sheet attached to the unit.

Duetwork

NOTE: The total heat gain of the structure to be conditioned as

expressed in total Btu/hr should be calculated by manufacturer's

method or in accordance with "A.S.H.R.A.E. Guide" or "Manual J

Load Calculations" published by the Air Conditioning

Contractors of America. The total heat gain calculated should be

equal to or less than the cooling capacity output based on D.O.E.

test procedures, steady state efficiency times input.

plenums. Plenums MUST be individually sealed to unit casing.

Ducts MUST be terminated inside structure.

Filters

All return air MUST pass through a field supplied filter before

entering the unit. if used, an electronic air cleaner MUST be

installed in the return air ductwork. Minimum recommended filter

areas are listed in FIGURE 7 and are based on a velocity of 300

ff./min. (1.2m/s) for disposable filters and 500 ft./min. (2.54m/s)

for washable high velocity filters.

NOTE:

Ductwork, supply registers, and return air grilles MUST be

designed and sized to handle the unit's cooling air volume

FIGURE 7 Recommended Filter Sizes

NOTE: Some filters are marked with an arrow to indicate the proper direction of air flow through the filter. The air flow direction wilI be towards

Nominal Tons

Air Conditioning

2

2 1/2

3

3 1/2

4

5

the blower motor. Make sure filter is installed correctly.

Nominal Air Flow

Cubic Feet

per Minute

700 - 900

875 - 1125

1050 -1350

1225 -1575

1400-1800

1750 - 2000

Do NOT operate the unit without all filters in place.

Recommended Filter Sizes

Sq. In. Surface Area/Nominal Size

Disposable Filters

400 or 20 x 25

487 or 20 x 30

576 or 14 x 25 (2Req.)

865 or 16 x 25 (2Req.)

753 or 20 x 25 (2 Req.)

960 or 20 x 30 (2 Req.)

10

Gleanable Filters

246 or 15 x 20

301 or 14x25

356 or 16x25

411 or 20 x25

486 or 20 x 25

575 or 24 x 25

427 01 1101 00

Page 11

8. Start-up Procedures

ELECTRICAL SHOCK HAZARD.

2. From the system design, determine the total external static

pressure (ESP) for the supply ducts, return ducts and

registers, diffusers, grilles, dampers, heaters and filters.

3.To your system ESP determined in Step 2, add 0.05 In. W.C.

for a wet coil.

Failure to follow this warning could result in personal

injury, and/or death.

Use extreme care during all of the following checks

and procedures.

Make sure electric power i8 turned OFF as instructed

in appropriate steps.

Circulating Air Blower

Determining Blower Speed

1.Turn electric power OFF.

FIGURE 8 Blower Speed Tap Settings and Blower Performance Data

Blower Speed Tap Settings

Rated Airflow High Airflow

2 TON Tap 1 Tap 2

21/2 TON Tap 2 Tap 3

3 TON Tap 1 Tap 2

31/2 TON Tap 3 Tap 4

4 TON Tap 3 (Hi); 1 (Lo) Tap 4 (Hi); 2 (Lo)

5 TON Tap 3 (Hi); 1 (Lo) Tap 4 (Hi); 2 (Lo)

See Figure 5 for Blower

Speed Tap Pigtail

4.From the system design, determine the desired cooling

airflow in cubic feet per minute (CFM).

5.Locate the unit's Blower Performance Data table in Figure 8.

From the table, determine the speed tap required to achieve

the desired airflow.

6.See next section, Speed Taps, to set the blower motor speed

terminal block (speed taps) to the cooling speed determined

in the previous steps.

Speed Taps

After determining the required CFM and speed tap data from the

Figure 8, follow the steps below to change speeds if necessary.

BLOWER PERFORMANCE DATA

Model Number PHM324K00A1 PHM330K00A1 PHM336K00A1 PHM342K00A1 PHM348K00A1 PHM354K00A1

Speed Tap 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

Air Delivery in 0.3 783 1052 1052 1184 1209 1387 1480 1620 909 1157 1601 1859 1228 1364 1963 2093

CFM@Varying 0.4 720 1006 - 1006 1152 1170 1334 1438 1583 825 1094 1542 1813 159 1296 1923 2049

External Static

Pressure (in, 0.7 489 881 881 1047 1065 1247 1318 1474 613 915 1390 1651 988 1129 1783 1921

w.c.) 0.8 435 838 838 1017 1011 1203 1268 1437 841 1324 1602 940 1083 1734 1877

Notes: Air Delivery @ listed external static pressre are taken at 230Volts with Dry coit, no filter and approved heater

NOTE: On Heat Pumps Electric heater blower wire must be

attached to the same speed tap required for cooling/heat pump

operation. The yellow lead MUST always be connected to the

speed tap block at the common quick connect terminal. The

terminal is identified as COM.

Refer to Figures 5 and 8 and the appropriate unit wiring diagram

included in this manual. Wire the black wire to the required speed

tap terminal to achieve required airflow determined in Step 5.

Cooling, Heating (Heat Pump) and Auxiliary

Electric Strip Heat

NOTE: The cooling, heat pump and strip heat airflows are all on

the same speed tap. The refrigerant system requires the same

specific CFM for proper operation in the cooling and the heat

pump mode. For this reason, cooling and heating airflow must be

the same. DO NOT SPLIT OUT INTO A COOLING SPEED AND

427 01 1101 oo

0.1 1078 1170 1170 1266 1420 1497 1559 1694 1213 1299 1698 1974 1389 1461 205C 2179

0.2 833 1102 1102 1221 1288 1433 1520 1657 1028 1226 1652 1924 1292 1417 2003 2132

0.5 681 964 964 1121 1153 1294 1401 1550 762 1037 1494 1761 104 1243 1874 2011

0.6 615 921 921 1089 1106 1292 1359 1514 667 961 1442 1706 1043 1180 1823 1968

0.9 378 789 789 985 967 1171 1218 1389 769 1265 1538 873 1026 168C 1830

1 317 684 684 951 910 1117 1181 719 1201 1485 828 978 162,2 1760

For wet coil add .05 in. wc to Static Pressure measurement Note for 208 Votts appIications, reduce airflow by 15%

HEATING SPEED, If auxiliary electric heat is installed, the

auxiliary electric heat blower speed wire must be connected to the

black wire insulated quick connect terminal.

Check Before Starting

1. Check that the blower motor speed terminal block is set to

the proper cooling speed. Refer to the unit wiring diagram

and the various airflow tables in this manual.

2. Check to see that clean, properly sized field supplied air

filters are installed in the return air duct.

3. Inspect the inside of the unit to be sure that all wires are in

place and all tools, etc. are removed.

4. Replace all service access panels.

Check the unit's operation as outlined in the following

instructions. If any unusual sparking, odors or noises are

11

Page 12

encountered, shut OFF electric power immediately. Recheck for

wiring errors, or obstructions in or near blower motors.

/

Figure 10 / Defrost Dip Switch Settings

Circulating Air Blower

1.Be sure electric power is OFE

2.Set thermostat Heat-Cool selector to OFE

3.Set thermostat fan switch to AUTO

4.Turn electric power ON. Nothing should start running.

5.Set thermostat fan switch to ON. The circulating air blower

should come ON.

6.Reset thermostat fan switch to AUTO. The circulating air

blower should go OFF after a 60 second delay for models

PHM324-42 and 90 second delay for PHM348-54. Nothing

should be running.

Cooling

1. Be sure that electric power is OFF.

2. Set thermostat Heat-Cool select to COOL.

3. Adjust thermostat setting to below room temperature.

4. Turn electric power ON. During power application check the

following:

DIP SWITCH SETTINGS

30 #lUUlrS S0WIHuI(S gO#IHuI(S 120WIHuI(S

SP((O_"I-------"_'I--_ JUIf(R(0 T(ST PINS (US( N(TAL 06J(¢f)

(D(TAULT)

FI(LD S(L(¢TASL( OPTIOUS F0R TIN[ P[UIO0

6(Tgt(ll KrROSI CTCL(S (NlUUI(S)

TH( CONPR(SSOR WILL SHUT OfT roll )o s(¢, oil 0(TIIOST

lUlIIATIOHAnDT(RWlUAIIORIn TH("OUI(I SHIRT"OI

POSlIIOR

f I(L0 SP((0-UP ¢lrCL(

1) NON[IITARILT SHORT PlUS All0 R(L(AS( TO IBTPASS

¢QMPRrSSOa OFT 0(LAlr.

21 SHOAT FOR S* S(C. AND II(L(AS( FOR FOUC(0 0(FROST.

)) P(RNAH(H! SKQRT WILL 8( IGIIOR(0,

0[reOST WILL T[RHIUAT( IH $0 S[¢, Ir OFT OP[N,

0[fROST gILL T[IZMIUAT( UORNALLY Ir 0rT IS ¢LOS[0,

D£FRO ST BOARD

a. Contactor - Contacts closing

b. Compressor - ON

c. Condenser fan motor - ON

d. Circulating air blower - ON (after delay)

5.Switch the thermostat to OFF, check the fol!owing:

a. Contactor contacts opening.

b. Compressor - OFF

c. Condenser fan motor - OFF

d. Circulating blower - OFF (after delay)

6.Turn electric power OFF

Defrost Control Time Interval Adjustment

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury and/or death.

Turn OFF electric power supply at disconnect switch

or service panel before removing any access or

service panel from unit.

To adjust defrost intervah

1.Turn off all power to Heat Pump.

2.Remove control box cover.

D]? SWITCES

3.Locate electronic defrost control board.

4.The Defrost Control Board has a dip switches that can be set

at 30, 60, 90 or 120 minutes. Factory setting is60 minutes.

See Figure 10 for Defrost settings. For service test, refer to

sequence of operation for defrost mode on next page.

12 427 01 1101 O0

Page 13

9. Sequence of Operation

Cooling Operation (PHM324-42)

(1)On a call for cooling (Y)

The indoor fan energizes immediately where as the contactor

energizes after a 5 minute time delay (in case of an initial

start up) starting the compressor and the outdoor fan motor.

(2)When the cooling setpoint has been satisfied

When the cooling demand is met, (Y) de-energizes, shutting

off the compressor, indoor fan and the outdoor fan.

(2) When the heating setpoint has been satisfied

When heating demand is satisfied, W3, W2 and Y2

sequentially de-energize switching the compressor and

the indoor fan into low stage heating. When the low stage

heating demand is met, Y1 de-energizes shutting off the

compressor, indoor fan and the outdoor fan.

Continuous Fan

With the continuous Indoor fan option selected on the thermostat,

G is continuously energized. On 024 - 042 units, the selected

airflow setting is provided. On 048 and 054 units, the system runs

low stage (Y1) airflow for continuous fan operation.

Cooling Operation (PHM348-54)

(1)On a call for cooling

These units utilize a 2 stage indoor thermostat. With a first

stage call for cooling (Y1), the indoor fan (low stage)

energizes immediately where as the contactor energizes

after a 5 minute time delay (incase of an initial start up)

starting the compressor (low stage) and the outdoor fan

motor. If the low stage operation cannot satisfy the cooling

demand, the second stage cooling (Y2) energizes switching

the compressor into high stage cooling through energizing an

internal solenoid valve inside the scroll compressor and

switching the indoor fan into high stage.

(2)When the cooling setpoint has been satisfied

When second stage cooling is satisfied, Y2 de-energizes

switching the compressor and the indoor fan into low stage

cooling. When the low stage cooling demand is met, Y1

de-energizes shutting off the compressor, indoor fan and the

outdoor fan.

Heating Operation (PHM324-42)

(1) On a call for heating ......... :

With a call for heating (Y), the indoor fan (low stage)

energizes immediately where as the contactor energizes

after a 5 minute time delay (incase of an initial start up)

starting the compressor and the outdoor fan motor. If (Y)

cannot satisfy the heating demand, the auxiliary or back up

heat (W2) energizes, incase of staged heating, W3 is

energized if the demand is not met. The highest airflow

selected is run while the electric heat is in operation.

(2) When the heating setpoint has been satisfied

When heating demand is met, W3, W2 and Y sequentially

de-energize shutting off the compressor, indoor fan and

the outdoor fan.

Heating Operation (PHM348-54)

(1) On a call for heating ......... :

With a first stage call for heating (Y1), the indoor fan (low

stage) energizes immediately whereas the contactor

energizes after a 5 minute time delay (in case of an initial

start up) starting the compressor (low stage) and the

outdoor fan motor. If the low stage operation cannot satisfy

the heating demand, the second stage heating (Y2)

energizes switching the compressor into high stage

heating through energizing an internal solenoid valve

inside the scroll compressor and switching the indoor fan

into high stage. The auxiliary or back up heat is controlled

by a third stage (W2). If the demand is not met, W3 is

energized in case of staged heating.

42701 1101 oo

Defrost Mode:

On a call for defrost .........

(1)

When the defrost sensor closes in the heating mode, there

is a 30, 60, 90 or 120 minute delay before the defrost mode

begins. This delay is selected by the position of the

dipswitches on the defrost board. Defrost interval timing

can be configured by selection switch 1 and 2. See Figure

10.

1. The backup defrost terminate time is fixed at 10

minutes.

2. The compressor recycle delay timer is 5 minutes.

3. The power interrupt response is minimum 17 msec. to

maximum 35 msec.

4. Quite shift compressor recycle delay is 30 seconds.

In normal defrost mode, the following sequence will

occur after the set delay:

1. Condenser fan off.

2. Reversing valve energized to cooling and auxiliary

electric heat (W2) is energized.

3. After defrost sensor opens or a maximum of 10 minutes;

the condenser fan is energized (after 20 seconds) and the

reversing valve is de-energized to the heat mode. Electric

strip heat is also de-energized (after 15 seconds) except

as required by the thermostat.

4. Should the system indoor thermostat be satisfied during

the defrost cycle, the control will de-energize the reversing

valve and auxiliary heat outputs and "hold" the defrost timer

until the next call for heat, at which time the defrost cycle

will be completed.

Service testing: the pins marked "speed up" when momentarily

shorted together (for 5 seconds) and released, will defeat the 5

minutes recycle delay timer and allow the compressor contactor

to be immediately energized, thus forcing a defrost cycle.

Termination of this forced mode will be by the defrost thermostat

or the 10 minute backup timer, provided the defrost thermostat

was closed when the defrost was "forces." If the defrost

thermostat was not closed, at the time of the "forced defrost," the

defrost mode wil! remain for 30 seconds and then terminate.

Adding Accessories

Low/High Pressure Controls

This unit is equipped with extra low and high pressure ports

located inside the unit panel where the external high and low

pressure ports are installed. This allows for installation of high

and low pressure controls or low ambient controls.

13

Page 14

10. Operation Pressure Switch

Scroll Recycle Delay Timer

The defrost board is equipped with a recycle delay timer which will

delay the start of the compressor for 5 minutes in the event of a

power interruption. This sequences power throughout the

system and prevents possible reverse rotation of the scroll

compressor. The output of the timer controls the compressor

contactor via a normally open contact of K3 (T2). The timer starts

the delay cycle when the compressor is turned off by removal of

"Y." If application of "Y" occurs before the timer has expired, the

compressor contactor will not be energized until the timer has

expired.

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this caution may result in premature

component failure.

Do NOT operate unit on cooling when the outdoor

temperature is below 45°F or PHM324 and 40°F for

PHM330-54. This is necessary to prevent possible

damage to the compressor.

Loss of Charge Pressure Switch: Units are equipped with a low

pressure switch on the liquid line (high side) which has been

installed to prevent system damage due to a loss of charge. The

switch will open and de-energize the contactor if the high side

pressure drops below the set point of the switch.

High Pressure Switch: The PHM348-54 are equipped with a high

pressure switch to protect the compressor.

14 427 01 1101 00

Loading...

Loading...