Page 1

NTGM/GNK Series

Upflow/Horizontal

NCGM/GCK Series

Downflow/Horizontal

SAFETY REQUIREMENTS

Recognize safety information. This is the safety-alert symbol _. When you see this symbol on the furnace and in instructions or

manuals be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER

identifies the most serious hazards, those that will result in severe personal injury or death. WARNING signifies a hazard that could

result in personal injury or death. CAUTION is used to identify unsafe practices that could result in minor personal injury or product and

property damage.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified person-

nel should install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations

must be performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the current edition National Fuel Gas Code (NFGC) NFPA

No. 54/ANStZ223.1. In Canada, refer tothe current edition ofthe National Standard Canada CAN/CGA-B149.1 - and .2-M91 Natural

Gas and Propane Installation Codes (NSCNGPIC). Wear safety glasses and work gloves. Have fire extinguisher available during start-

up and adjustment procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances, especially those that may not have kept up with changing residential

construction practices. We requre these instructions as a minimum for a safe installation.

Design Certified

byAGA

/X

Manufactured by:

International Comfort Products Corporation (USA)

Lewisburg, TN USA 37091

Table of Contents

1.SafeInstallationRequirements................ 2

2.Installation............................... 4

3.Combustion&VentilationAir ................ 9

4.Vent& CombustionAirPiping ................ 11

5.GasSupplyandPiping ...................... 19

6.ElectricalWiring ........................

7.DuctworkandFilter(Upflow/Horizontal)......

8.DuctworkandFilter(Downflow/Horizontal)....

9. ChecksandAdjustments.................

10.FurnaceMaintenance ...................

11.ConcentricVentTermination..............

Fire or Explosion hazard.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

Such use could result in death, bodily injury

and/or property damage.

LP1 6/9/2000 440 01 1002 01

22

23

25

28

30

30

Page 2

1.Safe InstallationRequirements

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities having jurisdiction.

The information contained in this manual is

intended for use by a qualified service technician

who is experienced in such work, who is familiar

with all precautions and safety procedures

required in such work and is equipped with the

proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in furnace

malfunction, death, personal injury and/or

property damage.

NOTE: This furnace is design certified by the American Gas

Association and the Canadian Gas Association for installation in

the United States and Canada. Refer to the appropriate codes,

along with Figure 1 or Figure 2 and this manual, for proper instal-

lation.

• This furnace is NOT approved for installation in mobile

homes, trailers or recreation vehicles.

Do NOT use this furnace as aconstruction heater or to heat

a building that is under construction.

Use only the Type of gas approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation. (Furnaces can

be converted to L.P. gas with approved kit.)

• Do NOT use open flame to test for gas leak.

• Ensure adequate combustion and ventilation air is pro-

vided to the furnace.

• Seal supply and return air ducts.

• The vent system MUST be checked to determine that it is

the correct type and size.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

NOTE: It is the personal responsibility and obligation of the end

user to contact a qualified installer to ensu rethat the installation is

adequate and conforms to governing codes and ordinances.

SafetyRules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. Consumer Product Safety Commission recom-

mends that users of gas-burning appliances install carbon

monoxide detectors. There can be various sources of car-

bon monoxide in a building or dwelling. The sources could

be gas-fired clothes dryers, gas cooking stoves, water

heaters, furnaces, gas-fired fireplaces, wood fireplaces,

and several other items. Carbon monoxide can cause seri-

ous bodily injury and/or death. Therefore, to help alert

people of potentially dangerous carbon monoxide levels,

you should have carbon monoxide detectors listed by a na-

tionally recognized agency (e.g. Underwriters Laboratories

or International Approval Services) installed and main-

tained in the building or dwelling (see Note below).

B. There can be numerous sources of fire or smoke in a build-

ing or dwelling. Fire or smoke can cause serious bodily inju-

ry, death, and/or property damage. Therefore, in order to

alert people of potentially dangerous fire or smoke, you

should have fire and smoke detectors listed by Underwrit-

ers Laboratories installed and maintained in the building or

dwelling (see Note below).

Note: The manufacturer of your furnace does not test any de-

tectors and makes no representations regarding any brand

or type of detector.

C. To ensure safe and efficient operation of your unit, you

should do the the following:

1. Thoroughly read this manual and labels on the unit.

This will help you understand how your unit operates and

the hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water.

Immediately call a qualified service technician to inspect

the unit and to replace any part of the control system and

any gas control which has been under water.

3. Never obstruct the vent grilles, or any ducts that pro-

vide air to the unit. Air must be provided for proper com-

bustion and ventilation of flue gases.

Carbon monoxide or "CO" is a colorless and odorless gas

produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

FreezingTemperaturesandYourStructure

Freeze warning.

Turn off water system.

If your unit remains shut off during cold weather

the water pipes could freeze and burst, resulting

in serious water damage.

Your unit is equipped with safety devices that may keep itfrom op-

erating if sensors detect abnormal conditions such as clogged ex-

haust flues.

Ifthe structure will be unattended during cold weather you should

take these precautions.

1. Turn off main supply water into the structure and drain the

water lines if possible. Open faucets in appropriate areas.

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Suggest they call qualified service agency, if

required.

[_ 44001 100201

Page 3

Dealer Name:

START-UP CHECK SHEET

(Keep this page for future reference)

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Type of Gas:

Blower Motor H.P.:

Supply Voltage:

Limit Opens at...(°F) or(°C)

Natural: _1 LP: _1

Business Card Here

Drip-Leg Upstream of Gas Valve?

Condensate Drain Connected? YES _1

Condensate Drain Trapped? YES _1

Horizontal Condensate Switch Installed? YES _1 NO _1

Blower Speed Checked? YES _1 NO _1

All Electrical Connections Tight? YES _1 NO _1

Gas Valve OK? YES _1 NO _1

Measured Line Pressure When Firing Unit:

YES _1 NO _1

NO_1

Noel

Limit Closes at._(°F) or(°C)

Which blower speed tap is used?

(Heating) (Cooling)

Temperature of Supply Air: (°F) or(°C)

Temperature of Return Air: (°F) or(°C)

Rise (Supply Temp.-Return Temp.): (°F) or(°C)

Filter Type and Size:

Fan "Time ON" Setting:

Fan "Time OFF" Setting:

Manual Gas Shut-Off Upstream

of Furnace/Drip-Leg? YES _1 NO _1

Dealer Comments:

Calculated Firing Rate: (See Checks and Adjustments Sec-

tion).

Measured Manifold Pressure:

Thermostat OK? YES _1

Subbase Level? YES _1

Anticipator Set? YES _1

Breaker On? YES _1

Date of Installation:

Date of Start-Up:

NOel

NO[_I

NO _1 Set At?:

NO_1

440 01 100201 [_

Page 4

2. Installation

Poison carbon monoxide gas Hazard.

This furnace can NOT be common vented or

connected to any type B, BW or L vent or vent

connector, nor to any portion of a factory-built or

masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be

necessary to resize the existing vent line and

chimney to prevent oversizing problems for the

other remaining appliance(s). See Venting and

Combustion Air Check in Gas Vent Installation

section. This furnace MUST be vented to the

outside,

Failure to properly vent this furnace or other

appliances can result in death, personal injury

and/or property damage.

*8" (200ram)Min.

20' (6m)Max.

in sameatmosphericzone

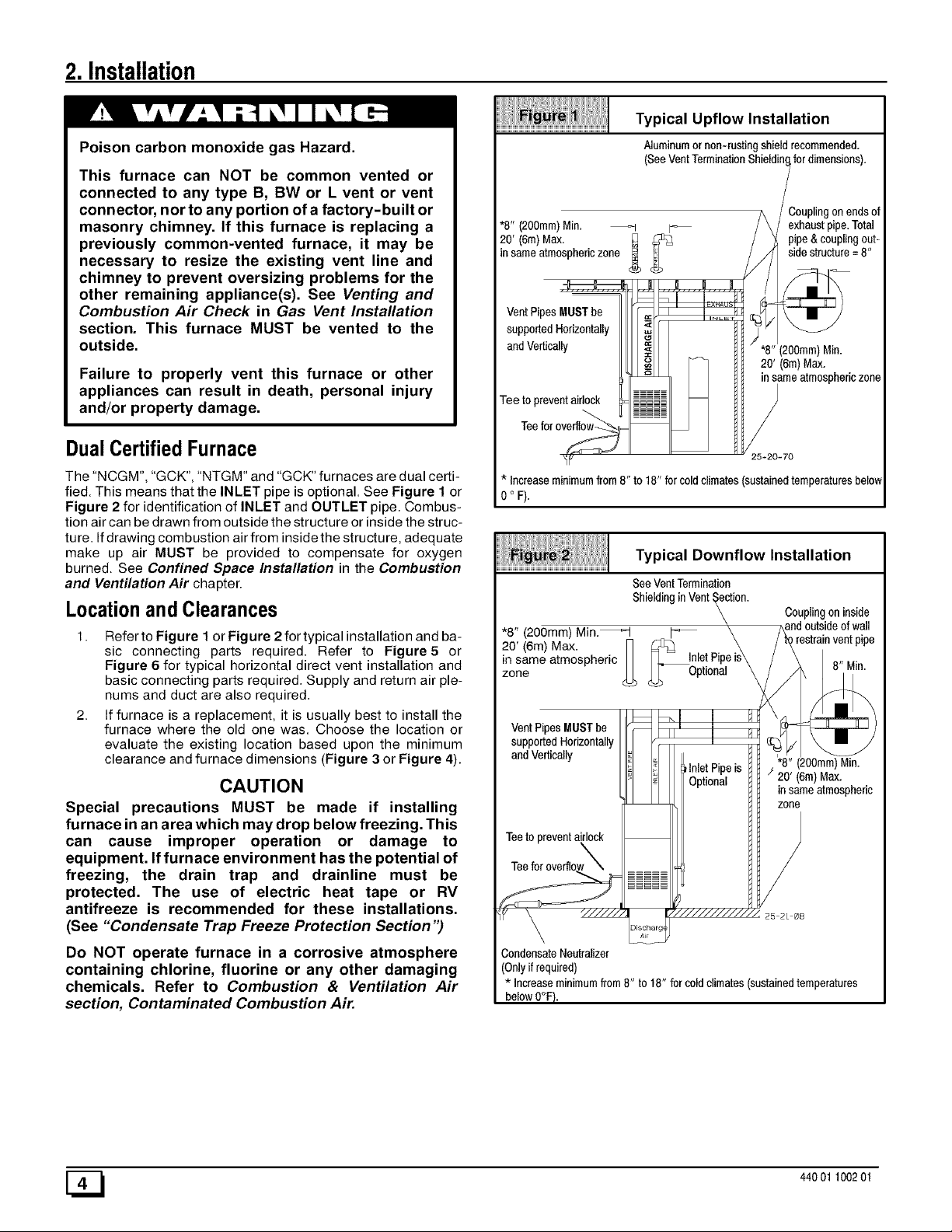

Typical Upflow Installation

Aluminumor non-rusting shieldrecommended.

(SeeVentTerminationShieldin fordimensions).

exhaustpipe.Total

pipe& couplingout-

sidestructure=8"

;ouplingon_nds of

'8" (200ram)Min.

20' (6m)Max.

insameatmosphericzone

DualCertifiedFurnace

The"NCGM", "GCK","NTGM"and"GCK"furnacesare dual certi-

fied. Thismeansthatthe INLET pipe isoptional.See Figure 1 or

Figure 2 for identificationof INLET and OUTLETpipe. Combus-

tion aircan bedrawnfrom outside thestructureorinsidethe struc-

ture. Ifdrawingcombustion airfrom insidethe structure, adequate

make up air MUST be provided to compensate for oxygen

burned. See Confined Space Installation in the Combustion

and Ventilation Air chapter.

Locationand Clearances

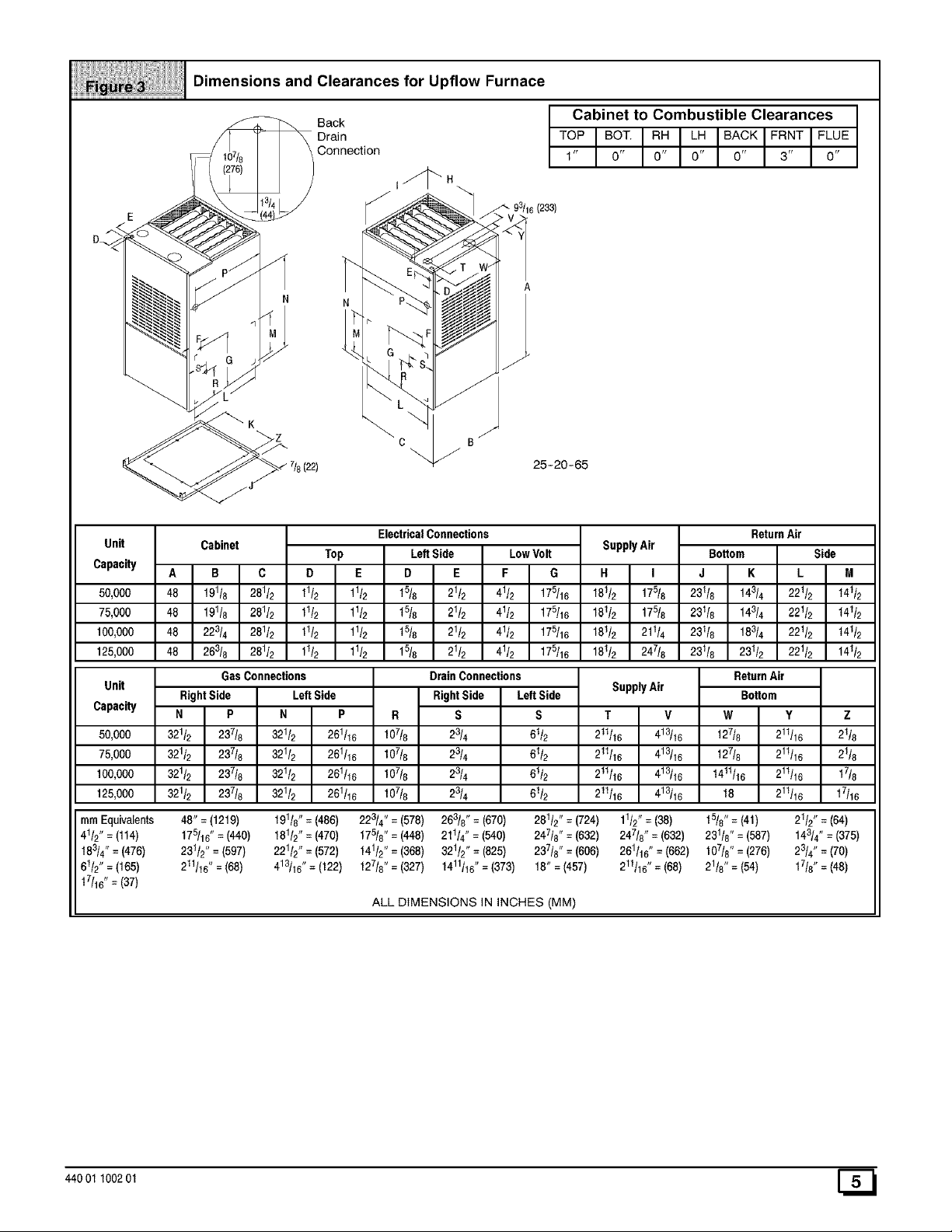

1. Refer to Figure 1or Figure 2 for typical installation and ba-

sic connecting parts required. Refer to Figure5 or

Figure 6 for typical horizontal direct vent installation and

basic connecting parts required. Supply and return air ple-

nums and duct are also required.

2. If furnace is a replacement, it is usually best to install the

furnace where the old one was. Choose the location or

evaluate the existing location based upon the minimum

clearance and furnace dimensions (Figure 3 or Figure 4).

CAUTION

Special precautions MUST be made if installing

furnace in an area which may drop below freezing. This

can cause improper operation or damage to

equipment. If furnace environment has the potential of

freezing, the drain trap and drainline must be

protected. The use of electric heat tape or RV

antifreeze is recommended for these installations.

(See "Condensate Trap Freeze Protection Section ")

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals. Refer to Combustion & Ventilation Air

section, Contaminated Combustion Air.

25-20-70

* Increaseminimumfrom8" to 18" forcoldclimates(sustainedtemperaturesbelow

0 ° F).

Typical Downflow Installation

See VentTermination

Shielding inVent _ction.

*8" (200mm) Min._ _

20' (6m)Max. _> ___ InletPip

Zoiqe

in same atmospheric _ Optional\

supportedHorizontally

andVertically

\

is

Couplingon inside

_re d outsideof wall

strainventpipe

"8"(200mm)Min.

/ 20' (6m)Max.

insameatmospheric

zone

Teeto preventairlock

\

CondensateNeutralizer

(Onlyifrequired)

*Increaseminimumfrom8"to18"forcoldclimates(sustainedtemperatures

belowO°F}.

[_ 44001 100201

Page 5

iiiiiii!!i!liiiii/l;i!iiiii/!iiiiiiii!liil;iii/iiiiiiiiii'ii!iii!!///!i

!! !!!!OimensionsandC,earances,orUp.owFurnace

__ Back Cabinet to

Drain TOPIBOT"I

Connection 1 ' 0'

"""'-_ 718 (22) _' _ 25-20-65

Combustible Clearances

i I'C IF= TI 'OE0' 0' 0' 3' 0"

Unit

Capacity

50,000

75,000

100,000

125,000

Unit

Capacity

50,000

75,000

100,000

125,000

turnEquivalents 48" = (1219) 191/8" = (486) 228/4"= (578) 263/8" = (670) 281/2"= (724) 11/2"= (38) 15/8" = (41) 21/2"= (64)

41/2"= (114) t75/16" = (440) 181/2"= (470) 175/8"= (448) 211/4"=(540) 247/8"= (632) 247t8" = (632) 231/8" =(587) t43/4" = (375)

t83/4" = (476) 231/2"=(597) 221/2" = (572) 141/2" = (368) 321/2"= (825) 237/8"= (606) 261/16"=(662) 107/8" = (276) 23/4" = (70)

61/2" = (165) 211/16"=(68) 4131_6"= (122) 127/8" = (327) 1411/16"= (373) 18" = (457) 2_1/16"= (68) 21/8" = (54) 17/8"= (48)

t7/16" = (37)

Cabinet

B

48 191t8 281_

48 19118 281_

48 223/4 281_

48 26_8 281_

GasConnections

RightSide LeftSide

N P N P R

321/2 237t8 321/2 261/16 107/8

321/2 237/8 321/2 261/16 107/8

321/2 237t8 321/2 261/16 107/8

321/2 237t8 321/2 261/16 107/8

Top LeftSide LowVolt

D E D E F G

11/2 11/2 t5/8 21/2 41/2 17_16

11/2 11/2 t5/8 21/2 41/2 17_16

11/2 11/2 t5/8 21/2 41/2 17_16

11/2 11/2 t518 21/2 41/2 17_16

ElectricalConnections

DrainConnections

RightSide LeftSide

S S

23/4 61t2

23/4 61/2

23/4 61/2

23/4 61/2

ALL DIMENSIONS IN INCHES (MM)

SupplyAir

H I

18112 175/8

181/2 175/8

181/2 211/4

181/2 247/8

SupplyAir

T V

211116 413/16

211/16 413/16

211/16 413/16

211/16 413/16

J K L

231/8 143/4 221/2 t41t2

231f8 143/4 221/2 t41/2

231/8 183/4 221/2 t41t2

231/8 231/2 221/2 t41t2

ReturnAir

Bottom Side

M

ReturnAir

Bottom

W Y Z

127/8 211/16 21/8

127/8 211/16 21/8

t411116 211/16 17/8

18 211/16 17/16

440 01 100201 [_

Page 6

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

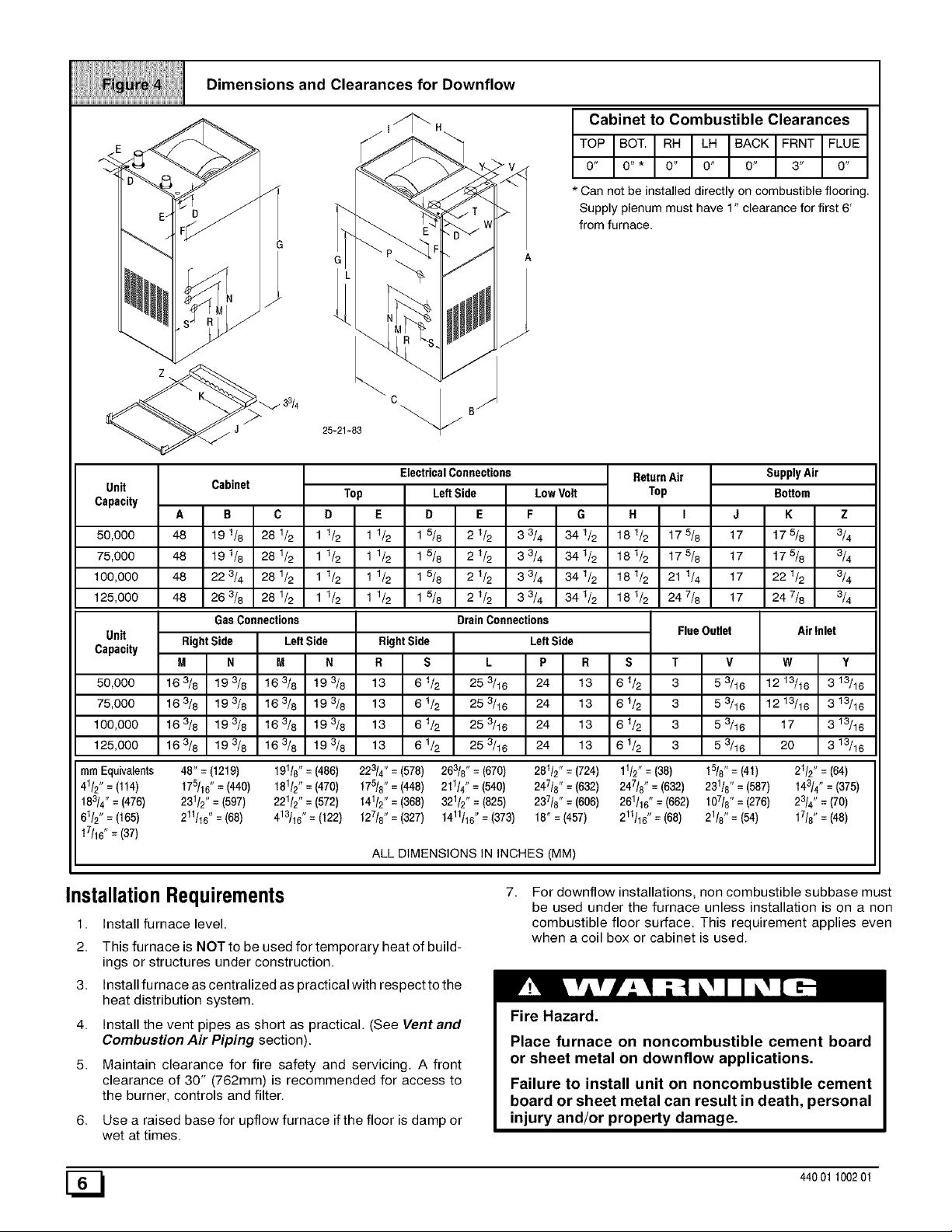

Dimensions and Clearances for Downflow

¥ v

Cabinet to Combustible Clearances

TOP BOT. RH LH BACK FRNT FLUE

0" 0"* 0" 0" 0" 3" O"

* Can not be installed directly on combustible flooring.

Supp _'plenum must have 1" clearance for first 6'

from furnace.

_ 33/4

c B/

25-21-83 _"/

Unit

Capacity

50,000

75,000

100,000

125,000

Unit

Capacity

50,000

75,000

100,000

125,000

ram Equivalents 48" = (1219) 191/8" = (486) 223/4" = (578) 263/8" = (670) 281/2" = (724) 11/2" = (38) 15/8" = (41) 21/2" = (64)

41/2" = (114) t75/16" = (440) 181/2" = (470) 175/8" = (448) 211/4" =(540) 247/8" = (632) 247t8" = (632) 23118" = (587) t43/4 " = (375)

t83/4" = (476) 231/2" = (597) 221/2" = (572) 141/2" = (368) 321/2 ', = (825) 237/8" = (606) 261/16" = (662) 107/8" = (276) 23/4" = (70)

61/2" = (165) 211/16" = (68) 413/16" = (122) 127/8" = (327) 1411116"= (373) 18" = (457) 211t16" = (68) 21/8" = (54) 17/8" = (48)

t7/16" = (37)

Cabinet

A B C

48 191/8 28112

48 191/8 28112

48 223/4 28112

48 263/8 28112

Gas Connections

Right Side LeftSide

M N M N

163/8 193/8 163/8 t93/8

163/8 193/8 163/8 t93/8

163/8 193/8 163/8 t93/8

163/8 193/8 163/8 t93/8

D E D E F G

11/2 11/2 1 5/8 2 1/2 3 3/4 341/2

1 1/2 1 1/2 1 5/8 2 1/2 3 3/4 34 1/2

1 1/2 1 1/2 1 5/8 2 1/2 3 3/4 34 1/2

1 1/2 1 1/2 1 5/8 2 1/2 3 3/4 34 1/2

Top LeftSide LowVolt

ElectricalConnections

DrainConnections

RightSide LeftSide

R S L P R S

13 61& 25 _18 24 13 61&

13 61& 25 _18 24 13 61&

13 61_ 25 _16 24 13 61_

13 61_ 25 _16 24 13 61_

ALL DIMENSIONS IN INCHES (MM)

ReturnAir

Top

H I J

181/2 175/8 17

181/2 175/8 17

181/2 21 1/4 17

181/2 247/8 17

FlueOutlet

T

3

53/16

3

53/16

3

53/16

3

53/16

SupplyAir

Bottom

K Z

t75_ 3_

t75_ 3_

2216 3_

247_ 3_

AirInlet

v

W

1213/16

1213/16

17

20

Y

3 13/16

3 13/16

3 13/16

3 13/16

7.

InstallationRequirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of build-

For downflow installations, non combustible subbase must

be used under the furnace unless installation is on a non

combustible floor surface. This requirement applies even

when a coil box or cabinet is used.

ings or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4. Install the vent pipes as short as practical. (See Vent and

Combustion Air Piping section).

5. Maintain clearance for fire safety and servicing. A front

clearance of 30" (762mm) is recommended for access to

the burner, controls and filter.

6. Use a raised base for upflow furnace if the floor is damp or

Fire Hazard.

Place furnace on noncombustible cement board

or sheet metal on downflow applications.

Failure to install unit on noncombustible cement

board or sheet metal can result in death, personal

injury and/or property damage.

wet at times.

[_ 44001100201

Page 7

8. For horizontal installations, line contact is permissible only

between lines formed by intersection of back and two sides

of furnace jacket, and building joists, studs or framing.

9. Residential garage installations require:

• Burners and ignition sources installed at least

18" (457mm) above the floor.

• Located or physically protected from possible damage by a

vehicle.

10. Local codes may require a drain pan under the entire fur-

nace and condensate trap when the furnace is installed in

attic application.

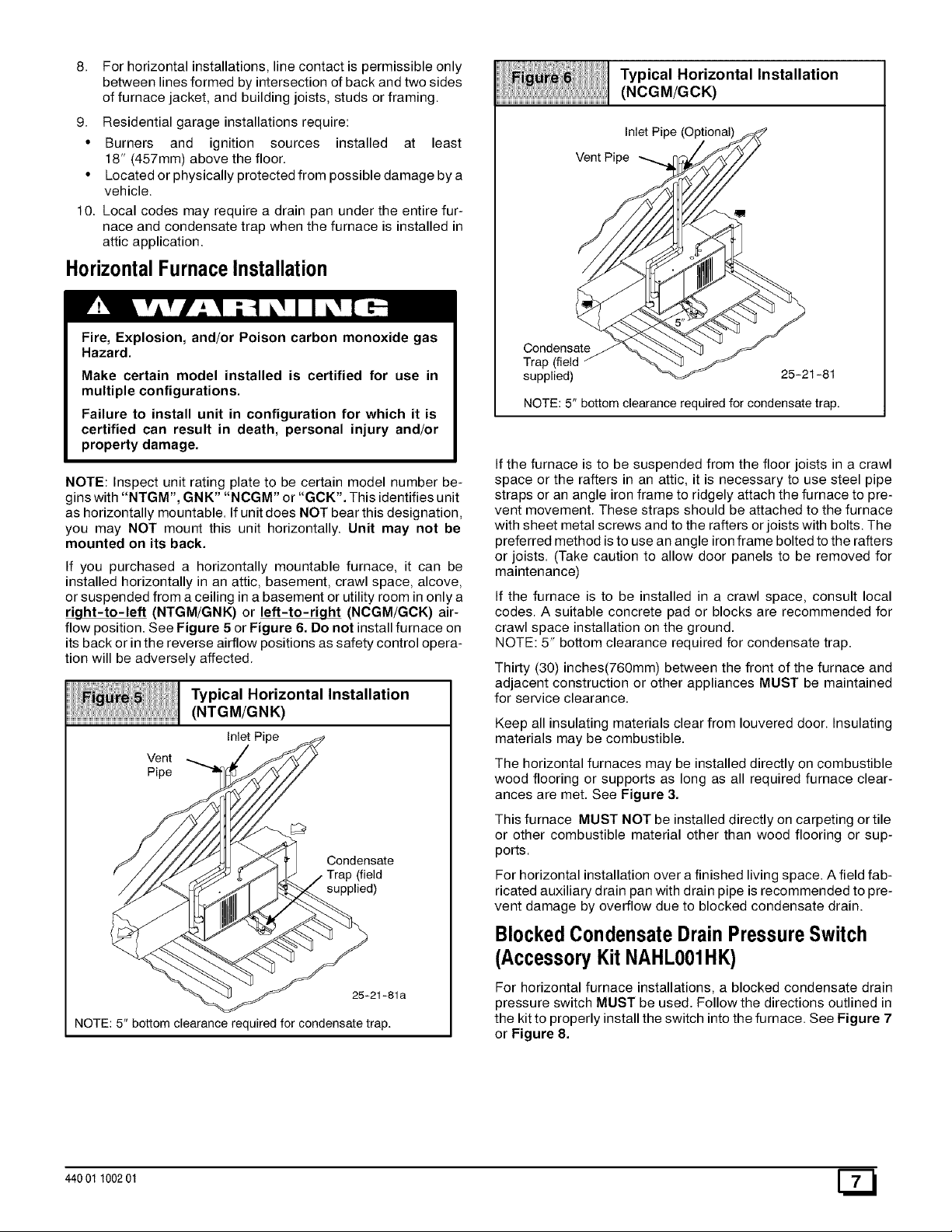

HorizontalFurnaceInstallation

Typical Horizontal Installation

(NCGM/GCK)

Inlet Pipe (Optional)

Vent Pipe

Fire, Explosion, and/or Poison carbon monoxide gas

Hazard.

Make certain model installed is certified for use in

multiple configurations.

Failure to install unit in configuration for which it is

certified can result in death, personal injury and/or

property damage.

NOTE: Inspect unit rating plate to be certain model number be-

gins with "NTGM", GNK" "NCGM" or "GCK'. This identifies unit

as horizontally mountable. Ifunit does NOT bear this designation,

you may NOT mount this unit horizontally. Unit may not be

mounted on its back.

If you purchased a horizontally mountable furnace, it can be

installed horizontally in an attic, basement, crawl space, alcove,

or suspended from a ceiling in a basement or utility room in only a

right-to-left (NTGM/GNK) or left-to-right (NCGM/GCK) air-

flow position. See Figure 5 or Figure 6. Do not install furnace on

its back or in the reverse airflow positions as safety control opera-

tion will be adversely affected.

Typical Horizontal Installation

(NTGM/GNK)

Inlet Pipe

Vent

Pipe

Condensate

Trap (field

supplied)

Condensate

Trap (field

supplied)

NOTE: 5" bottom clearance required for condensate trap.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to ridgely attach the furnace to pre-

vent movement. These straps should be attached to the furnace

with sheet metal screws and to the rafters or joists with bolts. The

preferred method is to use an angle iron frame bolted to the rafters

or joists. (Take caution to allow door panels to be removed for

maintenance)

If the furnace is to be installed in a crawl space, consult local

codes. A suitable concrete pad or blocks are recommended for

crawl space installation on the ground.

NOTE: 5" bottom clearance required for condensate trap.

Thirty (30) inches(760mm) between the front of the furnace and

adjacent construction or other appliances MUST be maintained

for service clearance.

Keep all insulating materials clear from Iouvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace clear-

ances are met. See Figure 3.

This furnace MUST NOT be installed directly on carpeting or tile

or other combustible material other than wood flooring or sup-

ports.

For horizontal installation over a finished living space. A field fab-

ricated auxiliary drain pan with drain pipe is recommended to pre-

vent damage by overflow due to blocked condensate drain.

25-21-81

BlockedCondensateDrainPressureSwitch

25-21-81 a

NOTE: 5" bottom clearance required for condensate trap.

440 01 100201

(AccessoryKitNAHL001HK)

For horizontal furnace installations, a blocked condensate drain

pressure switch MUST be used. Follow the directions outlined in

the kit to properly install the switch into the furnace. See Figure 7

or Figure 8.

Page 8

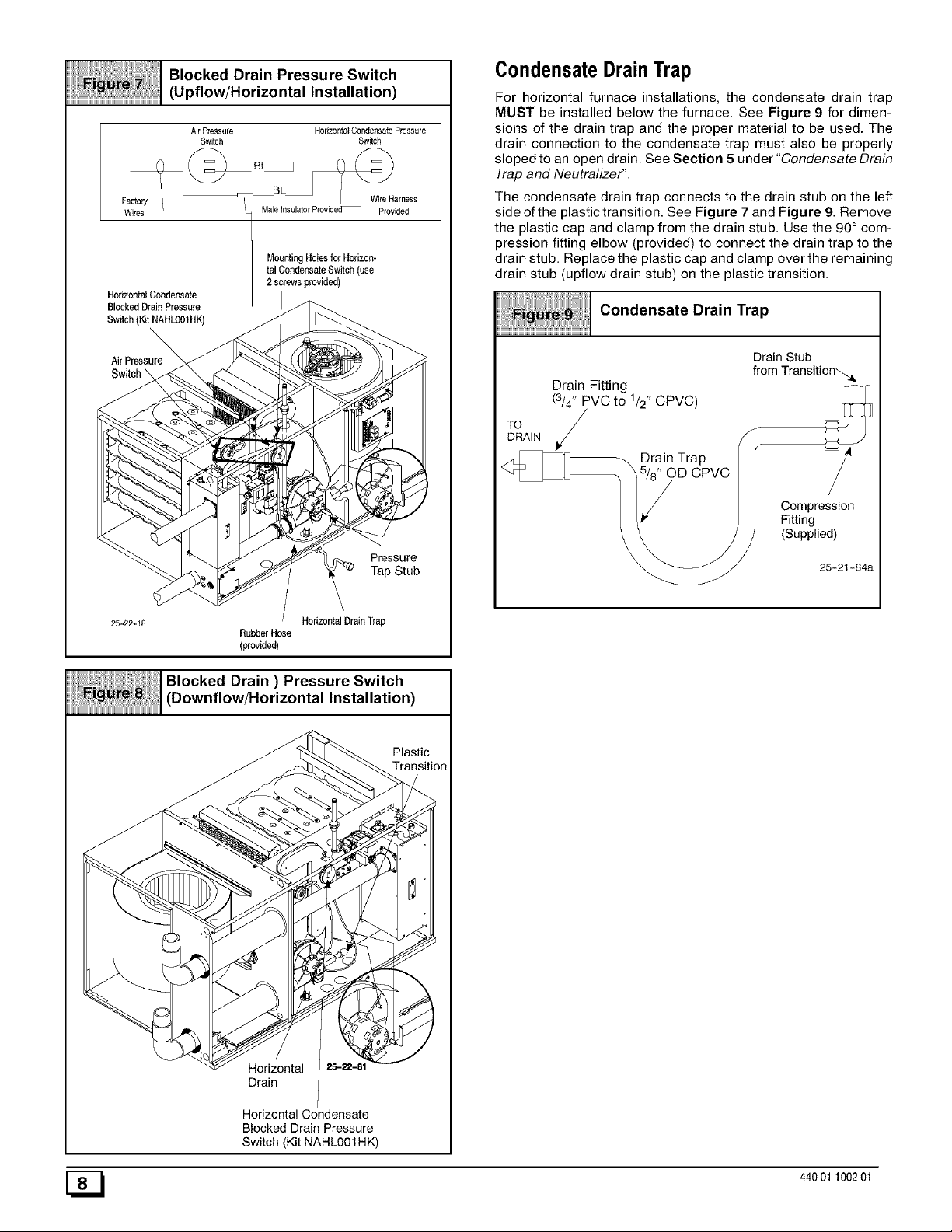

Blocked Drain Pressure Switch

(Upflow/Horizontal Installation)

Air Pressure Horn.offal Condensate Pressure

Switch Switch

W,res Mal_l_Prov_e_ V_ip_Hiadr_ss

MountingHolesforHorizon-

talCondensateSwitch (use

HorizontaJ Condensate

BlockedDrain Pressure

Switch(Kit NAHLO01HK)

Air Pressure_

2 screwsprovided)

CondensateDrainTrap

For horizontal furnace installations, the condensate drain trap

MUST be installed below the furnace. See Figure 9 for dimen-

sions of the drain trap and the proper material to be used. The

drain connection to the condensate trap must also be properly

sloped to an open drain. See Section 5 under "Condensate Drain

Trap and Neutralizer".

The condensate drain trap connects to the drain stub on the left

side of the plastic transition. See Figure 7 and Figure 9. Remove

the plastic cap and clamp from the drain stub. Use the 90° com-

pression fitting elbow (provided) to connect the drain trap to the

drain stub. Replace the plastic cap and clamp over the remaining

drain stub (upflow drain stub) on the plastic transition.

Condensate Drain Trap

Drain Stub

Drain Fitting

(3/4" PVC to 1/2" CPVC)

from Transition'_.&

25-22-18

Y

/ T ps,ub

RubberHsse

(provided)

Blocked Drain ) Pressure Switch

HorizontalDrainTrap

Installation)

Plastic

Transition

DRAIN

,/

Drain Trap

OD CPVC

S

Compression

Fitting

(Supplied)

25-21-84a

Horizontal

Drain

Horizontal Condensate

Blocked Drain Pressure

Switch (Kit NAHLOO1HK)

[_ 44001 100201

Page 9

3. Combustion&VentilationAir

Poison carbon monoxide gas Hazard.

Use methods described here to provide combustion

and ventilation air.

Failure to provide adequate combustion and ven-

tilation air can result in death and/or personal injury.

Ventingand CombustionAir Check

NOTE: The following information is supplied to allow the installer

to make adjustments to the setup of existing appliances, IF

REQUIRED, based on good trade practices, local codes, and

good judgement of the installer. Manufacturer does NOT take re-

sponsibility for modifications made to existing equipment.

NOTE: If this installation removes an existing furnace from a

venting system serving one or more other appliances, and to

make sure there is adequate combustion air for all appliances,

MAKE THE FOLLOWING CHECK.

1. Seal any unused openings in the venting system.

2. Visually inspect the venting system for proper size and hor-

izontal pitch to ensure there is no blockage or restriction,

leakage, corrosion or other deficiencies which could cause

an unsafe condition.

3. Insofar as is practical, close all doors and windows and all

doors between the space inwhich the appliance(s) remain-

ing connected to the venting system are located and other

spaces of the building.

4. Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

5. Follow the lighting instructions for each appliance being in-

spected. Adjust thermostat so appliance(s) will operate

continuously.

6. Allow 5 minutes of main burner operation, then check for

spillage at the draft hood relief opening of each appliance.

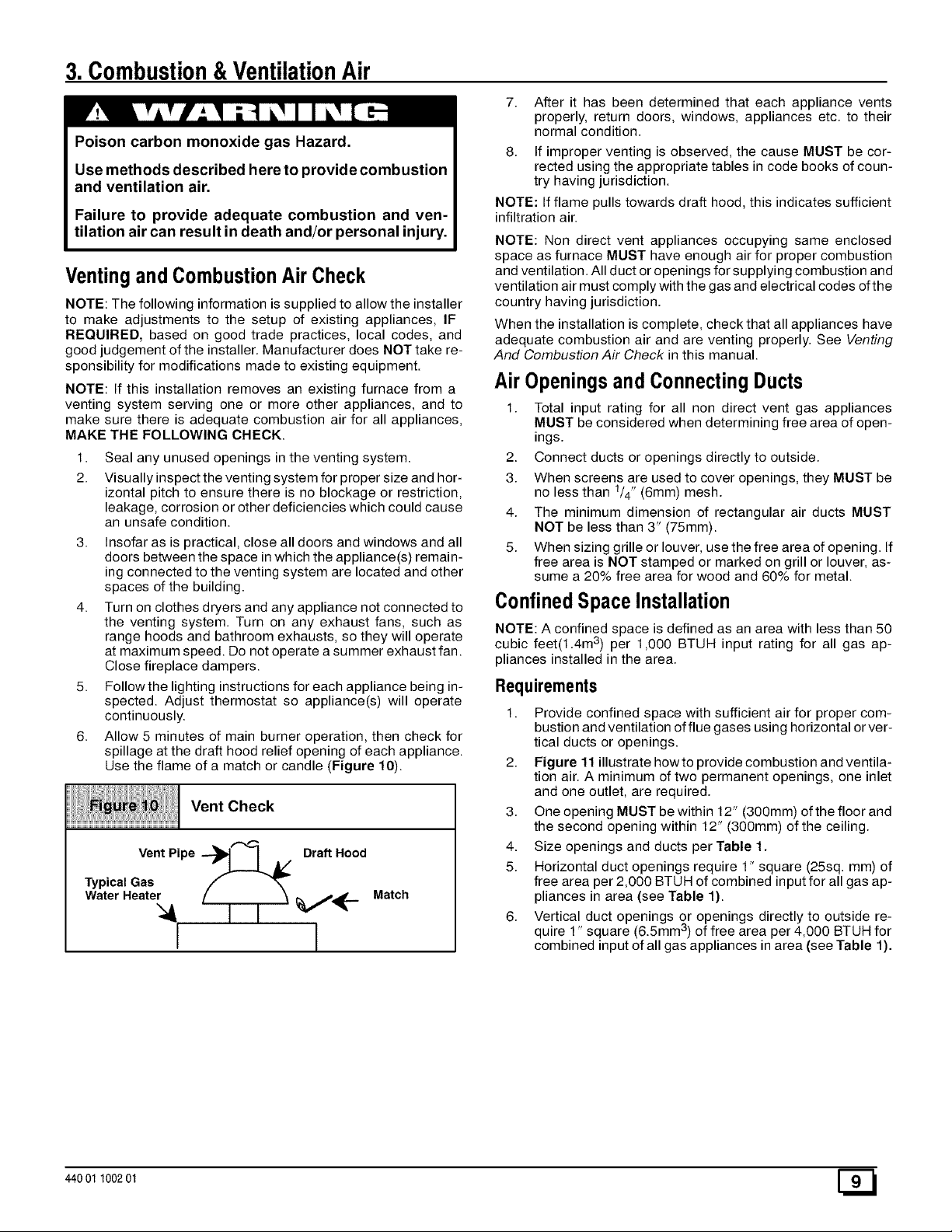

Use the flame of a match or candle (Figure 10).

Vent Check

Vent Pipe ---_t I A/ Draft Hood

Typical Gas

Water Heate_;_l / ] i _ V'_'-

Match

7. After it has been determined that each appliance vents

properly, return doors, windows, appliances etc. to their

normal condition.

8. If improper venting is observed, the cause MUST be cor-

rected using the appropriate tables in code books of coun-

try having jurisdiction.

NOTE: If flame pulls towards draft hood, this indicates sufficient

infiltration air.

NOTE: Non direct vent appliances occupying same enclosed

space as furnace MUST have enough air for proper combustion

and ventilation. All duct or openings for supplying combustion and

ventilation air must comply with the gas and electrical codes ofthe

country having jurisdiction.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

And Combustion Air Check in this manual.

Air Openingsand ConnectingDucts

1. Total input rating for all non direct vent gas appliances

MUST be considered when determining free area of open-

ings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, they MUST be

no less than 1/4" (6mm) mesh.

4. The minimum dimension of rectangular air ducts MUST

NOT be less than 3" (75mm).

5. When sizing grille or louver, use the free area of opening. If

free area is NOT stamped or marked on grill or louver, as-

sume a 20% free area for wood and 60% for metal.

ConfinedSpaceInstallation

NOTE: A confined space is defined as an area with less than 50

cubic feet(1.4m 3) per 1,000 BTUH input rating for all gas ap-

pliances installed in the area.

Requirements

1. Provide confined space with sufficient air for proper com-

bustion and ventilation of flue gases using horizontal or ver-

tical ducts or openings.

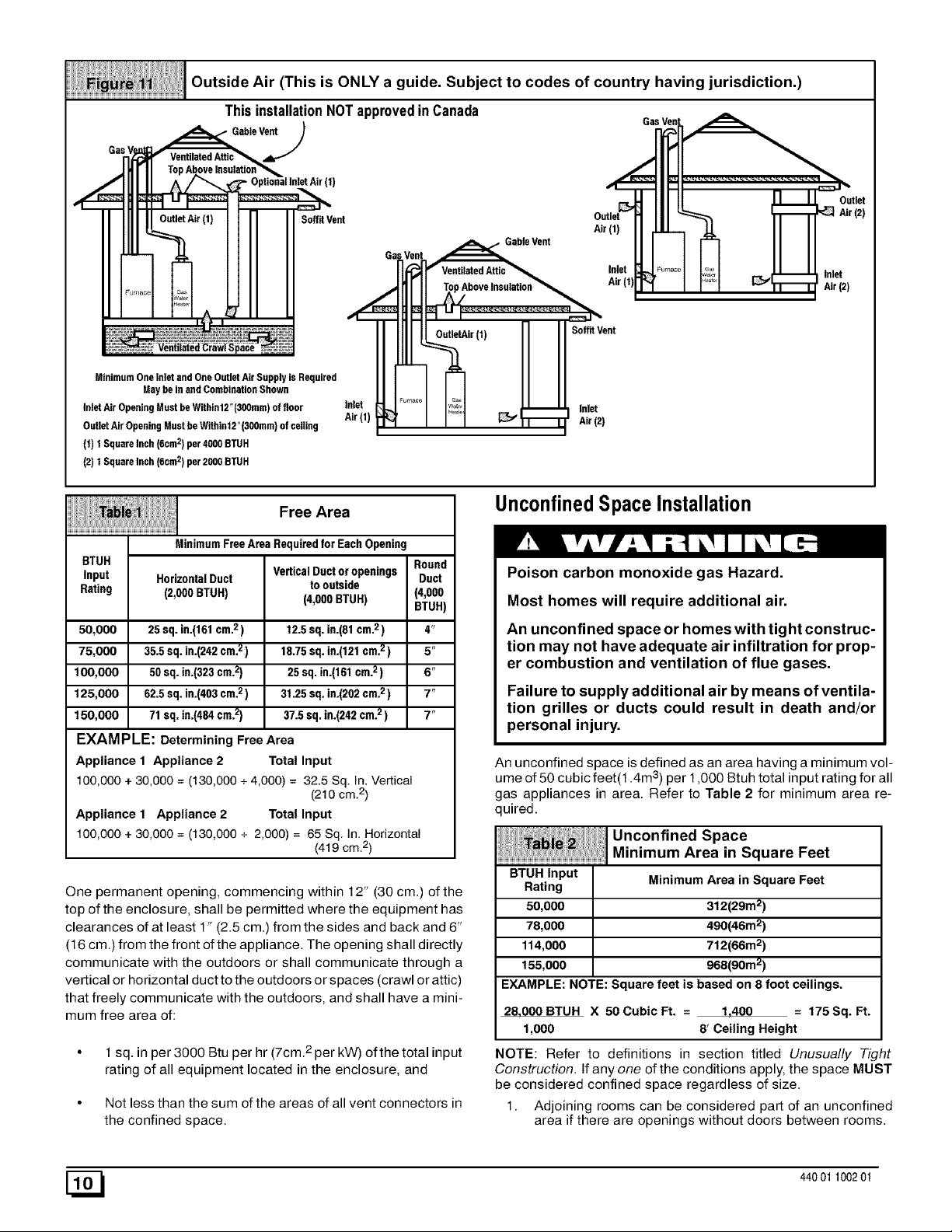

2. Figure 11 illustrate howto provide combustion and ventila-

tion air. A minimum of two permanent openings, one inlet

and one outlet, are required.

3. One opening MUST be within 12" (300mm) of the floor and

the second opening within 12" (300mm) of the ceiling.

4. Size openings and ducts per Table 1.

5. Horizontal duct openings require 1" square (25sq. mm) of

free area per 2,000 BTUH of combined input for all gas ap-

pliances in area (see Table 1).

6. Vertical duct openings or openings directly to outside re-

quire 1" square (6.5mm 3)of free area per 4,000 BTUH for

combined input of all gas appliances in area (see Table 1).

440 01 100201 [_

Page 10

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada

Gas V

- GableVe_

(1)

SoffitVent

GasVent

MinimumOneInletand OneOutletAir Supplyis Required

InletAir OpeningMustbeWithin12"(300mm)offloor

OutletAir OpeningMustbeWithin12"(300mm)ofceiling

(1) 1 SquareInch(6cm2) per4000BTUH

(2) 1 SquareInch(6cm2) per2000BTUH

Maybe in andCombinationShown

Inlet

Air(1

Free Area

MinimumFree AreaRequiredfor EachOpening

BTUH

input HorizontalDuct

Rating (2,000 BTUH)

50,000 25 sq. in.(161cm.2)

75,000 35.5 sq. in.(242cm.2)

100,000 50 sq. in.(323cm.2)

125,000 62.5sq. in.(403cm.2)

150,000 71 sq. in.(484cm.2)

EXAMPLE: Determining Free Area

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 4,000) = 32.5 Sq. In. Vertical

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 2,000) = 65 Sq. In. Horizontal

One permanent opening, commencing within 12" (30 cm.) of the

top of the enclosure, shall be permitted where the equipment has

clearances of at least 1" (2.5 cm.) from the sides and back and 6"

(16 cm.) from the front of the appliance. The opening shall directly

communicate with the outdoors or shall communicate through a

vertical or horizontal duct tothe outdoors or spaces (crawl or attic)

that freely communicate with the outdoors, and shall have a mini-

mum free area of:

1 sq. in per 3000 Btu per hr (7cm. 2 per kW) ofthe total input

rating of all equipment located in the enclosure, and

Not less than the sum of the areas of all vent connectors in

the confined space.

VerticalDuctoropenings Round

to outside Duct

(4,000BTUR) (4,000

12.5sq. in.(81cm.2) 4"

18.75 sq.in.(121cm.2) 5"

25 sq.in.(161cm.2) 6"

31.25 sq.in.(202cm.2) 7"

37.5sq. in.(242cm.2) 7"

(210 cm.2)

(419 cm 2)

BTUH)

GableVent

Air (1)

Inlet

Air(1)

Soft, Vent

Inlet

Air (2)

UnconfinedSpaceInstallation

Poison carbon monoxide gas Hazard.

Most homes will require additional air.

An unconfined space or homes with tight construc-

tion may not have adequate air infiltration for prop-

er combustion and ventilation of flue gases.

Failure to supply additional air by means of ventila-

tion grilles or ducts could result in death and/or

personal injury.

An unconfined space is defined as an area having a minimum vol-

ume of 50 cubic feet(1.4m 3) per 1,000 Btuh total in put rating for all

gas appliances in area. Refer to Table 2 for minimum area re-

quired.

_ _!i ii _iiJUnconfined Space

BTUH Input

Rating Minimum Area in Square Feet

50,000 312(29m2)

78,000 490(46m2)

114,000 712(66m2)

155,000 968(90m2)

EXAMPLE: NOTE:Square feet is based on 8 foot ceilings.

28,000BTUH X 50CubicFt. = 1,400 = 175Sq. Ft.

1,000 8' Ceiling Height

NOTE: Refer to definitions in section titled Unusually Tight

Construction. If any one of the conditions apply, the space MUST

be considered confined space regardless of size.

1. Adjoining rooms can be considered part of an unconfined

area if there are openings without doors between rooms.

Minimum Area in Square Feet

[_ 44001 100201

Page 11

2.

An attic or crawlspace may be considered an unconfined

space provided there are adequate ventilation openings di-

rectly to outdoors. Openings MUST remain open and NOT

have any means of being closed off. Ventilation openings to

outdoors MUST be at least 1"square (25mm 2) of free area

per 4,000 BTUH of total input rating for all gas appliances in

area.

3.

Install air intake a minimum of 12" (300mm) above maxi-

mum snow level and clear of any obstruction. Duct or ven-

tilation opening requires one square inch of free area per

4,000 BTUH of total input rating for all gas appliances in

area.

4.

Air inlet MUST be screened with not less than 1/4" (6mm)

mesh screen.

UnusuallyTight Construction

In unconfined spaces, infiltration may be adequate to provide air

for combustion, ventilation and dilution of flue gases. However, in

buildings with unusually tight construction, additional air MUST

4.VentandCombustionAir Piping

Poison carbon monoxide gas, fire and explo-

sion hazard.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in

death, personal injury and/or property damage.

DualCertifiedFurnace

This furnace is certified as a category IV appliance and is dual

certified as a direct vent furnace using outside air for combustion

or it can use air from inside the structure for combustion. The IN-

LET air pipe is optional. If combustion air comes from inside the

structure, adequate make up air MUST be provided to compen-

sate for oxygen burned. See Confined Space Installation in the

Combustion and Ventilation Air chapter. If combustion air is

drawn from outside the structure, it MUST be taken from the same

atmospheric pressure zone as the vent pipe.

ContaminatedCombustionAir

Installations in certain areas or types of structures will increase

the exposure to chemicals or halogens that may harm the fur-

nace.

The following areas or types of structures may contain or have ex-

posure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air

for combustion.

• Commercial buildings.

• Buildings with indoor pools.

• Furnaces installed in laundry rooms.

• Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De-icing salts or chemicals.

be provided using the methods described in section titled Con-

fined Space Installation:

Unusually tight construction is defined as: Construction with

1. Walls and ceilings exposed to the outside have a continu-

ous, sealed vapor barrier. Openings are gasketed or

sealed and

2. Doors and openable windows are weather stripped and

3. Other openings are caulked or sealed. These include joints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

VentilationAir

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air temper-

ature across the heat exchanger MUST not fall below 60°F (15° c)

or flue gases will condense in the heat exchanger. This will short-

en the life of the heat exchanger and possibly void your warranty.

• Carbon tetrachloride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

Vent and CombustionAir PipingGuidelines

NOTE: All vent piping MUST be installed in compliance with local

codes or ordinances, these instructions, good trade practices,

and codes of country having jurisdiction.

1. Determine the best routing and termination for the vent

pipe and air inlet pipe by referring to all of the instructions

and guidelines in this Section.

2. Determine the size required for the vent pipe and air inlet

pipe.

3. Loosely assemble all venting parts without adhesive (pipe

joint cement) for correct fit before final assembly.

4. Use of vertical piping is preferred because there will be

some moisture in the flue gases that may condense as it

leaves the vent pipe (See Special Instruction For Horizon-

tal Vents).

5. The vent MUST exit the furnace at the top left side.

6. The vertical vent pipe MUST be supported so that no

weight is allowed to rest on the combustion blower.

7. Exhaust vent piping or air inlet piping diameter MUST NOT

be reduced.

8. All exhaust vent piping from the furnace to termination

MUST slope upwards, away from furnace, a minimum of

1/4" per foot of run (6mm per 300mm).

9. Use DWV type long radius elbows whenever possible, as

they provide for the minimum slope on horizontal runs and

they provide less resistance in the vent system. If DWV el-

bows cannot be used, use two, 45 degree elbows when

possible. On horizontal runs the elbows can be slightly mis-

aligned to provide the correct slope.

440 01 100201 [_

Page 12

10. All horizontal pipe runs MUST be supported at least every

five feet with galvanized strap or other rust resistant materi-

al. NO sags or dips are permitted.

11. All vertical pipe runs MUST be supported every six feet

where accessible.

12. The maximum pipe length is 40' (12m) total in the inlet or

outlet side of the system. Up to five, 90 ° elbows can be

used on the inlet or the outlet. If more than five elbows are

required, reduce the length of both the inlet and exhaust

pipes 5' (1.5m) for each additional elbow used. (See Vent

Tables).

13. The minimum pipe run length is 2' (.6m).

14. The piping can be run in the same chase or adjacent to sup-

ply or vent pipe for water supply or waste plumbing. It can

also be run in the same chase with a vent from another 90+

furnace.

NOTE: In NO case can the piping be run in a chase where

temperatures can exceed 140° F. or where radiated heat

from adjacent surfaces would exceed 140° F.

15. The vent outlet MUST be installed to terminate in the same

atmospheric pressure zone as the combustion air inlet.

16. The vent system can be installed in an existing unused

chimney provided that:

• Both the exhaust vent and air intake run the length of the

chimney.

• No other gas fired appliance or fireplace (solid fuel) is

vented into the chimney.

• The top of the chimney MUST be sealed flush or crowned

up to seal against rain or melting snow so ONLY the piping

protrudes.

• The termination clearances shown in Figure 12 are main-

tained.

17. Horizontal furnace applications with vertical vents requir-

ing vent diameter increaser fittings must have increaser fit-

tings installed in vertical portion of the vent after a 2" elbow

turns upward. Condensate will be trapped in the vent if the

vent diameter is increased prior to having an elbow turned

upward. This could cause nuisance tripping of the pressure

switch. (This does not apply to horizontal venting.)

Piping Insulation Guidelines

NOTE: In general, chimneys on an outside wall and attics are ex-

posed to cold conditions which can cause the vent pipe to sweat

from condensation. This can lead to moisture damage to living

spaces. It is highly recommended that piping in these cases be

insulated to insure proper protection from condensation damage.

Use closed cell, neoprene insulation or equivalent. If Fiberglass

or equivalent insulation is used it must have a vapor barrier. Use R

values of 7 up to 10', R-11 if exposure exceeds 10L If Fiberglass

insulation is used, exterior to the structure, the pipe MUST be

boxed in and sealed against moisture.

1. Insulate pipe when the exhaust vent passes through an un-

conditioned space or raceway.

2.

If situations require pipe to be run on the exterior wall to

reach a suitable termination point, it MUST be properly in-

sulated.

3. If it is necessary to insulate piping when an inactive chim-

ney is used as a chase, the top of the chimney MUST be

sealed flush or crowned up to seal against rain or melting

snow so ONLY the piping protrudes.

4. When the vent or combustion air pipe height above the roof

exceeds 30" (760mm), or if an exterior vertical riser is used

on a horizontal vent to get above snow levels, the exterior

portion MUST be insulated.

5. When combustion air inlet piping is installed above a sus-

pended ceiling, the pipe MUST be insulated with moisture

resistant insulation such as Armaflex or other equivalent

type of insulation.

6. Insulate combustion air inlet piping when run in warm, hu-

mid spaces such as basements.

SizingCombustionAir andVent Pipe

1. Consult Table 4 to select the proper diameter exhaust and

combustion air piping. Exhaust and combustion air piping

is sized for each furnace Btuh size based on total lineal vent

length (on inlet or outlet side), and number of 90 ° elbows

required.

1. Single Pipe Installation-If installing as a non-direct vent

appliance, (single outlet pipe and no inlet pipe) refer to

Table 3. The table shows the maximum number of elbows

allowed with any given pipe diameter and length of run.

2. Double Pipe Installation-If installing as a direct-vent ap-

pliance, consult Table 4 to select the proper diameter ex-

haust and combustion air piping. Exhaust and combustion

air piping is sized for each furnace Btuh size based on total

lineal vent length (on inlet or outlet side), and number of 90°

elbows required.

2. Use of Elbows-Two 45 ° elbows can be substituted for one

90° elbow. The elbow or elbows used for vent termination

outside the structure ARE counted, including elbows need-

ed to bring termination above expected snow levels.

EXAMPLE: Refer to, 75,000 Btuh Furnace, Table 4.

• Avent system uses 25' of Inlet pipe and 24' of Outlet pipe. Use

the maximum length found in your system, so 25' is the length to

use in these tables.

• There are 4 elbows on the Outlet and 2 elbows on the Inlet. Use

the 4 elbows row because that is the maximum number of elbows

on any one side (Inlet or Exhaust).

• In this example, combinations C or F are allowed. Using the

legend at the bottom of the table, combination C is 3" Inlet with a

21/2'' Exhaust. Combination F is a 3" Inlet with a 3" Exhaust. Ei-

ther combination is allowed together, but they can NOT be mixed.

In other words, part ofa C combination can NOT be used with part

of an F combination just because they are listed together in the

same block.

[_ 44001 100201

Page 13

Pipe Diameter Table

i_ I Pipe Diameter Table

Single Piping ONLY

50,000 & 75,000 Btuh Furnaces

MaxNo.0f Feet of Pipe*

Elbows in

onosi°e 00110141151012024125201303413540

UP TO 5 All combinations use "A" a 2" Exhaust

100,000 Btuh Furnace

Feet of Pipe*

0-9 10-14 15-19 20-24 25-29 30-34 35-40

1 A A A A A A B,C

2 A A A A A B,C B,C

3 A A A A B,C B,C B,C

4 A A A B,C B,C B,C B,C

5 A A B,C B,C B,C B,C B,C

125,000 Btuh Furnace

Feet of Pi >e*

0-9 10-14 15-19 20-24 25-29 30-34 35-40

1 A A B,C B,C B,C B,C C

2 A B,C B,C B,C B,C C C

3 B,C B,C B,C B,C C C C

4 B,C B,C B,C C C C C

5 B,C B,C C C C C C

Possible combination legend:

A = 2" Exhaust

B = 21/2" Exhaust

C = 3" Exhaust

Elbows are DWV Long Radius Type for 2" and 3" vents.

Schedule 40 (sharp radius) for 21/2 `'

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5' (1.5m) for each additional

elbow used.

I OTE: It is allowable to use larger diameter pipe and fitting thanshown in the tables but not smaller diameters than shown.

MaxNo.Of Feet of Pipe*

Elbowsin

0neSide_ 0-9 110-14115-19120-24125-29130-34135-40

UP TO 5 All combinations use "A" a 2" Exhaust and 2" Air

0-9 10-14 15-19 20-24 25-29 30-34 35-40

1 A A A A D,B E,B E,B

2 A A A D,B E,B E,B C,F

3 A A D,B E,B E,B C,F C,F

4 A D,B E,B E,B C,F C,F C,F

5 D,B E,B E,B C,F C,F C,F C,F

0-9 10-14 15-19 20-24 25-29 30-34 35-40

1 A A A D,B E,B E,B C,F

2 A A D,B E,B E,F C,F C,F

3 A D,B E,B E,F C,F C,F C,F

4 D,B E,B E,F C,F C,F C,F C,F

5 D,B E,F C,F C,F C,F C,F C,F

0-9110-14115-10120-24125-20130-34135-40

UP TO 5 All combinations use "F" a 3" Exhaust and 3" Air

Possible combination legend:

A = 2" Inlet with a 2" Exhaust

B = 3" Inlet with a 2" Exhaust

C = 3" Inlet with a 21/2" Exhaust

D = 21/2" Inlet with a 2" Exhaust

E = 21/2`'Inlet with a 21/2 " Exhaust

F = 3" Inlet with a 3" Exhaust

Elbows are DWV Long Radius Type for 2" and 3" vents.

Schedule 40 (sharp radius) for 21/2"

- Signifies the maximum number of elbows, including the

termination elbow(s), on any one part of the system. Exam-

ple: 4 elbows on the exhaust and 5 elbows on the inlet would

use the chart showing 5 elbows, because 5 is the maximum

number on any one side.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5' (1.5m) for each additional

elbow used.

* Feet of pipe is whichever pipe run is the longest, either inlet

or outlet side.

For "Concentric Termination Kit" Venting table, see

"Section 10" in this manual,

Dual Piping ONLY

50,000 Btuh Furnaces

Inlet Pipe

75,000 Btuh Furnace

Feet of Pipe*

100,000 Btuh Furnace

Feet of Pi )e*

125,000 Btuh Furnace

Feet of Pipe*

Inlet Pipe

Vent Termination Clearances

Poison carbon monoxide gas, fire and explo-

sion hazard.

Inlet and outlet pipes may NOT be vented

directly above each other.

Failure to properly vent this furnace can result in

death, personal injury and/or property damage.

440 01 100201 [_

Page 14

1. Determine termination locations based on clearances spe-

cified in following steps and as shown in Figure 12,

Figure 16, Figure 17, Figure 18.

For "Concentric Termination Kit" clearances, see Figure 45,

Figure 46, Figure 47, Figure 48 and Figure 49 in "Section 10"

in this manual.

2. The vent termination must be located at least 12" (300mm)

above ground or normally expected snow accumulation

levels.

3. Do NOT terminate over public walkways. Avoid areas

where condensate may cause problems such as above

planters, patios, or adjacent to windows where steam may

cause fogging.

4. The vent termination shall be located at least 4' (1220mm)

horizontally from any electric meter, gas meter, regulator,

and any relief equipment. These distances apply ONLY to

U.S. installations.

5. The vent termination is to be located at least 3' (914mm)

above any forced air inlet located within 10' (3m) ; and at

least 10' (3m) from a combustion air intake of another ap-

pliance, except another direct vent furnace intake.

6. In Canada, the Canadian Fuel Gas Code takes prece-

dence over the preceding termination instructions.

Vent Termination Clearances

(United States Only)

In Canada See Canadian Fuel Gas Code

OtherThan

DirectVent

Terminal

Direct Vent

Termi_lal

50,000 Btuh

or less

Other Than

DirectVent ForcedAir

Terminal 12" Inlet

DirectVent Terminal

MoreThan 50,0008tub

OtherThan

DirentVent

10-11-36

CondensateDrainTrap and Neutralizer

This furnace removes both sensible and latent heat from the com-

bustion flue gases. Removal of latent heat results in condensation

of flue gas (water vapor). This condensed water vapor drains from

the secondary heat exchanger, through a built-in drain trap tran-

sition, and out of the unit. Condensate line can exit from the right

side, left side, or rear of the cabinet.

NOTE: The 90° compression fitting elbow (provided), requires the

drain line to be 1/2" (13mm) CPVC* ( 5/8" OD). 5/8" (16mm) I.D.

vinyl tubing may be used outside the furnace cabinet to connect to

the drain line. Internal trap assembly provides the required 4" wa-

ter column, so no additional trap is required.

* Make sure the 1/2" CPVC is 5/8" OD as there is also a sched-

ule 40 available that will not work.

1. Do NOT put a loop in the drain piping. This would cause an

extra water column pressure in addition to the pressure in-

side the built-in drain trap.

2. Drains must terminate at an inside drain to prevent freezing

of condensate and possible property damage.

3. Consideration MUST be given to type of filter being

installed. A 125,000 Btuh furnace may require

2-16"x25"x1" filters(one on each side of furnace). This

configuration does NOT allow the condensate drain line to

be run out the side of furnace. If line MUST be run out the

side, an optional standoff filter rack with one 20"x25"x1 "fil-

ter is needed. Install optional filter rack on side of furnace

opposite the side where condensate drain line will exit.

4. A condensate or sump pump MUST be used if required by

local codes, or if no indoor floor drain is available. A con-

densate neutralizer cartridge must be used if the pump is

not approved for use with acidic condensate. Neutralizer

cartridges MUST be installed in the drain line in a horizontal

position ONLY.

5. A plugged condensate drain line or a failed condensate

pump will allow condensate to spill. If the furnace is

installed where a condensate spill could cause damage,

then it is recommended that an auxiliary safety switch be

installed to prevent operation of the equipment in the event

of pump failure or plugged drain line. If used, an auxiliary

safety switch should be installed in the R circuit (low volt-

age) ONLY.

6. Install an overflow line if routing to floor drain or sump

pump. See Figure 1 or Figure 2 for example of proper

routing and installation of overflow line.

7. Install an overflow line if routing to floor drain or sump

pump. See Figure 1 for example of proper routing and

installation of overflow line.

Frozen water pipe hazard.

When activated an auxiliary safety switch wil cause

a furnace not to operate.

During freezing temperatures the water pipes in

your home could freeze and burst causing water

damage to the home.

Do not leave the home unattended during freezing

temperatures, or shut off the water supply and

drain the pipes before leaving.

Condensate DrainTrap FreezeProtection

Special precautions MUST be made if installing furnace in an

area which may drop below freezing. This can cause improper op-

eration or damage to the equipment. If the the furnace environ-

ment has the potential of freezing, the drain trap and drain line

must be protected. Use 3 to 6watt per foot at 115 volt, 40° F self-

regulating shielded and waterproof heat tape. Wrap the drain trap

and drain line with the heat tape and secure with the ties. Follow

the heat tape manufacturer's recommendations.

Connecting Furnaceand Piping

Poison carbon monoxide gas hazard.

Cement or mechanically seal all joints, fittings, etc.

to prevent leakage of flue gases.

Failure to properly seal vent piping can result in

death, personal injury and/or property damage.

1. Preassemble the exhaust and combustion air piping from

the furnace to the vent termination. Do NOT cement any

joints together until the preassembly process is complete.

[_ 44001 100201

Page 15

VentPipe Connection

1.

Install the vent pipe to the combustion blower using the

flexible coupling and clamps (provided). On the downflow

models remove the three screws holding the vent collar to

the top panel. Remove the vent collar. Remove the two

screws in the chase tube. Squeeze the chase tube together

and slide the chase tube through the top panel. The blower

snout is now accessible for installing the ABS pipe. See

Figure 13, Figure 14, or Figure 15. Reassemble in re-

verse order.

Vent Trap and Furnace Connections (Upflow)

Vent pipe MUST be installed

with the flexible coupling and

clamps (supplied) at the com-

bustion blower.

RTV sealant used to join

Air Inlet Pipe to Combustion

Air Inlet.. See Figure 6.

Proper Sealing Procedure for

Combustion Blower

Vent Pipe

Clamps_

Blower_

25-21-86

Condensate compression fitting

can be turned to exit out the left

side, rig ht side, or rear of cabinet.

If piping is exiting out the right

side of cabinet, it is necessary to

use an elbow to run pipe in front

of electronic module. Cabinet

entrance hole is offset enough to

allow adequate clearance.

Rubber Coupling

pe

440 01 100201 [_

Page 16

Vent Trap and Furnace Connections (Downflow)

Vent pipe MUST be installed

with flexible coupling and

clamps (supplied) at the com-

bustion blower.

Chase

Tube

Horizontal Drain Stub

(Left side only)

RTV sealant used to join Ail

Inlet Pipe to Combustion

Inlet..

Downflow Drain

Vent Pipe

Air Intake Pipe

y)

2" to 2 1/2" or 3" Adaptor

required (Field Supplied)

2" Plastic Pipe (Field Supplied)

Condensate compression

fitting can be turned to exit out the

side or right side (downflow).

Reducer Bushing (Supplied)

Air Inlet Pipe Connection

NOTE: Air Inlet Collar is sized for 3" PVC pipe. If2" (50mm) or 2

1/2" (64mm) combustion air piping is used, a 3" (75mm) to 2"

(50mm) or 3" (75mm) to 2 1/2" (64mm) reducer fitting is required.

The reducing section can be before the 90° elbow in a horizontal

section.

1. On the downflow models, install 3" to 2" pipe/reducer fitting

(supplied) to the inlet collar using RTV sealant ONLY to

provide for future serviceability.

2. On the downflow models, connect 2" plastic pipe into the

fitting using RTV sealant ONLY. Pipe must be long enough

to extend outside the furnace casing.

NOTE: Ifclearance is limited above the furnace, use two pieces of

pipe joined (RTV only) with a coupling to reach from the Combus-

tion Air Box to outside of casing.

3. Connect required size Air Intake Pipe using coupling or

adaptor as required, using RTV sealant ONLY to provide

for future serviceability.

Joining Pipe and Fittings

Fire hazard.

Provide adequate ventilation and do NOT

assemble near heat source oropen flame. Do NOT

smoke while using solvent cements and avoid

contact with skin or eyes.

Observe all cautions and warnings printed on

material containers to prevent possible death,

personal injury and/or property damage.

This furnace is approved for venting with Schedule 40 PVC,

CPVC, ABS, Cellular Core pipe fittings and SDR-26 PVC.

NOTE: SDR pipe is not approved for use in Canada.

NOTE: All PVC, CPVC, ABS, and Cellular Core pipe fittings, sol-

vent cement, primers and procedures MUST conform to Ameri-

can National Standard Institute and American Society for Testing

and Materials (ANSI/ASTM) standards.

• Pipe and Fittings -ASTM D1785, D2241, D2466, D2661,

D2665, F-891, F-628

• PVC Primer and Solvent Cement - ASTM D2564

• Procedure for Cementing Joints - Ref ASTM D2855

NOTE: Inorder to create a seal that allows future removal of pipe,

RTV sealant MUST be used on the inlet pipe where it joins to the

furnace. PVC, CPVC, ABS, and Cellular Core pipe and cement

may be used on all other joints.

CAUTION

Do NOT use solvent cement that has become curdled,

lumpy or thickened and do NOT thin. Observe precau-

tions printed on containers. For applications below

32 ° F., use only low temperature type solvent cement.

1. Cut pipe end square, remove ragged edges and burrs.

Chamfer end of pipe, then clean fitting, socket and pipe

joint of all dirt, grease, or moisture.

NOTE: Stir the solvent cement frequently while using. Use a natu-

ral bristle brush orthe dauber supplied with the cement. The prop-

er brush size is one inch.

2. After checking pipe and socket for proper fit, wipe socket

and pipe with cleaner-primer. Apply a liberal coat of primer

to inside surface of socket and outside of pipe. Do NOT al-

low primer to dry before applying cement.

3. Apply a thin coat of cement evenly in the socket. Quickly

apply a heavy coat of cement to the pipe end and insert

pipe into fittings with a slight twisting movement until it bot-

toms out.

NOTE: Cement MUST be fluid while inserting pipe. If NOT, recoat

pipe.

4. Hold the pipe in the fitting for 30 seconds to prevent the ta-

pered socket from pushing the pipe out of the fitting.

[_ 44001 100201

Page 17

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time varies according to fit,

temperature and humidity.

ConnectingVent PipesandTermination

NOTE: Combustion air intake and vent MUST terminate in the

same atmospheric pressure zone. If installation is in a cold cli-

mate (sustained temperatures below 0°F), increase the minimum

distance between vent pipe and air intake from 8" to 18".

CAUTION

Maintain a minimum of 36" (lm) between combustion

air inlet and clothes dryer vent. Terminate the combus-

tion air intake as far as possible from any air condition-

er, heat pump, swimming pool, swimming pool

pumping, chorlinator or filtration unit.

Poison carbon monoxide gas hazard.

Inlet and outlet pipes may NOT be vented

directly above each other

Failure to properly vent this furnace can result in

death, personal injury and/or property damage.

HorizontalTermination

1. Cut two holes. 21/2" (67mm) for 2" (50mm) pipe, 3"(75mm)

for 21/2,,(67mm) pipe, or 31/2,,(90mm) for 3" (75mm) pipe.

Do NOT make the holes oversized, or itwill be necessary to

add a sheet metal or plywood plate on the outside with the

correct size hole in it.

2. Check hole sizes by making sure it is smaller than the cou-

plings or elbows that will be installed on the outside. The

couplings or elbows MUST prevent the pipe from being

pushed back through the wall.

3. Extend vent pipe and combustion air pipe through the wall

3/4" to 1"(19 to 25mm) and seal area between pipe and

wall.

4. Install the couplings, nipple and termination elbows as

shown and maintain spacing between vent and combus-

tion air piping as indicated in Figure 16 through Figure 18.

_ :i i Sidewall Termination with Exterior

_1 _ Risers to Get Above Snow Level or

Grade Level

8" * "18" Minimum for coJd cJimates

MiN. "_ _ (substained below0 ° F)

/// 20' J

/.MAX j

t.

Install all couplings, nipples and elbows using proper pro-

cedures for Joining Pipe and Fittings and maintain spac-

ing between vent and combustion air piping as indicated in

Figure 16 through Figure 13.

Sidewall Termination 12" or More

Above Snow Level or Grade Level

8" * (substained below 0 ° F)

MIN.

"18" Minimum for cold ctimates

VerticalTermination

t.

Figure 18 shows the proper installation and clearances for

vertical vent termination. The vertical roof termination

should be sealed with a plumbing roof boot or equivalent

flashing. The inlet of the intake pipe and end of the exhaust

vent must be terminated no less than 12" (300mm) above

the roof or snow accumulation level, and 12" (300mm)

away from a vertical wall or other protrusion.

2.

If the vent system is installed in an existing chimney make

sure clearances shown in Figure 18 are maintained. Hori-

zontal section before the termination elbow can be ex-

tended on the inlet air to provide necessary clearance.

440 01 100201

__ 25=00=G4F

Using Exterior Risers

1. Install elbows and pipe toform riser as shown inFigure 17.

2. Secure vent pipe to wall with galvanized strap or other rust

resistant material to restrain pipe from moving.

3. Insulate pipe with Armaflex or equivalent moisture resis-

tant closed cell foam insulation or Fiberglass insulation if

boxed in and sealed against moisture.

Rooftop Termination

B

A = 12"Above roof or snow accumulation level

B = 8" Min., 20' Maximum, except in areas with extreme

cold temperatures (sustained below0°F), the 18" Min.

Optional Vent Screens

To prevent unwanted pests or foreign material from entering ter-

minated pipes, plastic vent screens are available in 2" and 3"

Page 18

sizes(checkpartslist).Useofthesescreensisrecommendedex-

ceptincoldclimateareaswhereiceislikelytoformonthem.Use

RTVsealantONLYonthescreeninsidetheterminationelbowus-

ingpipecement.Screensshouldbeinspectedmonthlyforblock-

ageandcleanedyearlypriortostartup.

VentTermination Shielding

Under certain wind conditions some building materials may be af-

fected by flue products expelled in close proximity to unprotected

surfaces. Sealing or shielding of the exposed surfaces with acor-

rosion resistant material (such as aluminum sheeting) may be re-

quired to prevent staining or deterioration. The protective material

should be attached and sealed (if necessary) to the building be-

fore attaching the vent terminal.

A metal shield is recommended 18" x 18" (457mm x 457mm) min.

or 18" (457mm) min. diameter around the vent termination at the

exterior wall to protect the house exterior materials from flue prod-

uct or condensation (freezing) damage.

MultiVent TerminationClearances

When two (2) or more furnaces are vented near each other, each

furnace must be individually vented.

Concentric Vent and Combustion-

Air Roof Termination

Figure 20, Figure 21, Figure 22and Figure 23, but the next vent

termination must be at least 36" away from first 2 terminations. It

is important that vent terminations be made as shown to avoid re-

circulation of flue gases.

Sidewall Inlet Vent and Exhaust-

Air Termination

8" Min.

8"Min.

20' Max.

18" Min. for

Cold Climates

12" Min. Grade /_

or Snow Level

(Substained BeLow 0° F)

-/ Dimension "A" is touching or2" maximum separation.

Sidewall Inlet Vent and Exhaust-Air

Termination with Exterior Risers

18" Min. for Cold Ci|mates

F)

8" Min.

12" Min. Grade

or Snow Level

Combustior

Air

Dimension "A" is touching or 2" maximum separation.

Concentric Vent and Combustion-

Air Sidewall Termination

Exhaust

Vent 25-22-02d

Dimension "A" is touching or 2" maximum separation.

When two (2) or more furnaces are vented near each other, two

(2) vent terminations may be installed as shown in Figure 19,

12" Min.

Grade or

Snow Level

Inlet Snow Level

Dimension "A" is touching or 2" maximum separation.

Rooftop Inlet Vent and Exhaust-

Air Termination

18" Min, for Cold Climates

(Substained Below 0° F)

Inlet 20' Max.

8" Min,

Exhaust

12"Min,

Grade or

f

25-22-43

[_ 44001 100201

Page 19

5. GasSupplyandPiping

Poison carbon monoxide gas, fire and explosion

hazard.

Models designated for Natural Gas are to be used

with Natural Gas Only, unless properly converted

to use with LP gas.

Failure to properly vent this furnace can result in

death, personal injury and/or property damage.

NOTE: The rating plate is stamped with the model number, gas

type and gas input rating. In addition, models manufactured for

sale in Canada have orifice size information stamped on the rat-

ing plate.

SupplyPressure

Fire hazard.

Do NOT set input rating above that shown on

rating plate.

Failure to properly set input pressure can result in

death, personal injury and/or property damage.

1. Supply pressure can be checked using the 1/8"(3.2mm )

NPT port on the supply side of the gas valve.

2. Gas input to burners MUST NOT exceed the rated input

shown on rating plate.

3. Do NOT allow minimum gas supply pressure to vary down-

ward. Doing so will decrease input to furnace. Refer to

Table 6 for normal gas supply and manifold pressures.

Gas Pressures Above 2000'

AlternateBTUHInput Ratings(USA Only)

The input rating of these furnaces can be changed from the stan-

dard input rating to the alternate input rating shown in Table 5, by

changing the main burner orifices. Changing of burner orifices

MUST be done by a qualified service technician. See section on

changing orifices.

_le5 Alternate Input Ratings, USA ONLY.

BTUH BTUH Natural LP

Standard Alternate Gas Gas

Rating Rating Orifice Orifice

50,000 40,000 #44 #55

75,000 60,000 #44 #55

100,000 80,000 #44 #55

125,000 100,000 #44 #55

Gas

Type

Natural 4.5" 3.5"

• If Propane gas has a different BTU content, orifices

• Measured input can NOT exceed rated input.

• Combustion Air Box Cover MUST be removed when

• Any major change in gas flow requires changing burn-

Recommended Max.

(1.7 kPa) (3.5 kPa)

LP 11" 10"

(2.7 kPa) (3.5 kPa)

With Propane gas, the rated input is obtained when the

BTU content is 2,500 BTU per cubic foot and manifold

pressure set at 10" W.C.

MUST be changed by licensed Propane installer.

adjusting manifold pressure.

er orifice size.

Supply Pressure

Min. Pressure

7" 14"

(1.1 kPa) (0.9 kPa)

11" 14"

(2.7 kPa) (2.5 kPa)

Important Notes

MANIFOLD PRESSUREAND ORIFICESIZE FOR HIGH ALTITUDE APPLICATIONS

H`i_HiHiH`iHi`_`iHiHiHiHiHiHiHiHiHiHiHiHiHiHH`iHH`iHH`iHH`iHH`iHH`iHH`iHH`iHH`iHH`iHH`i.....

Heat Value

Btu!Cu.Ft. 0-1999 2000-2999 3000-3999 4000-4999 5000-5999 6000-6999 7000-7999

800 3.5 3.5 3.5 3.5 3.5 3.5 3.5

850 3.5 3.5 3.5 3.5 3.5 3.5 3.5

900 3.5 3.5 3.5 3.5 3.5 3.5 3.4

950 3.5 3.5 3.5 3.5 3.3 3.2 3.1

1000 3.5 3.4 3.3 3.2 3.0 2.9 2.8

1050 3.2 3.t 3.0 2.9 2.7 2.6 2.5

1100 2.9 2.8 2.7 2.6 2.5 2.4 2.3

Orifice Size #42 #42 #42 #42 #42 #42 #42

(".wc) (" .wc) (".wc) (" .wc) (" .wc) (".wc) (" .wc)

NATURAL GAS

ElevationAbove Sea Level

Manifold

ManifoldGas PressureAdjustment

NOTE: Gas supply pressure MUST be within minimum and maxi-

mum values listed on rating plate. Pressures are usually set by

gas suppliers.

440 01 100201 [_

Make adjustment to manifold pressure with burners operating

and combustion air box cover removed.

1. Remove combustion air box cover.

Page 20

Connect manometer to the tapped opening on the outlet

2 ChangingOrificesfor HighAltitude

side of gas valve or on the manifold pipe. Use manometer

with a 0-min.12" water column range.

3.

Turn gas ON, fire the furnace and remove adjustment

screw cover on gas valve.

4.

Turn counterclockwise to decrease pressure and clock-

wise to increase.

5. Set pressure to value shown in Table 6. Refer to Important

Notes in Table 6. Pressure is also listed on furnace rating

plate.

6. When pressure is set, replace adjustment screw cover on

gas valve.

Electrical shock, fire or explosion hazard.

Turn OFF electric power (at disconnect) and gas

supply (at manual valve in gas line) when

installing orifices. Installation of orifices requires

a qualified service technician.

Failure to properly install orifices can result in

death, personal injury and/or property damage.

7. Replace combustion air box cover.

NOTE: Main burner orifices can be changed for high altitudes.

NOTE: Adjustment screw cover MUST be replaced on gas valve

BEFORE reading manifold pressure and operating furnace.

General DeratingRules

1. Disconnect gas line from gas valve.

2. Remove combustion box front cover and manifold from fur-

Dace.

3. Remove the orifices from the manifold and replace them

1.

For operation with natural gas at altitudes above 2,000',

orifice change and/or manifold pressure adjustment may

with properly sized orifices.

4. Tighten orifices so it is seated and gas tight. Figure 24.

be required to suit gas supplied. Check with gas supplier. If

orifice sizing is needed, it should be based on reducing the

input rating by 2% (natural) or 4% (LP) for each 1,000'

Changing Orifices

above sea level. See Table 7 and Figure 24 for required

pressure change and/or orifice change for high altitudes.

2.

For operation with LP gas at altitudes above 2,000', gas ori-

fices MUST be changed and manifold pressure MUST be

Measure from face of orifice

to the back side of the

manifold.

maintained as per Table 6. Orifice sizes for 0-2000' above

sea level are #54. 2000-7000' above sea level, use #55.

7000-8000' above sea level, use #56 orifices. Orifices can

be ordered through your distributor.

HighAltitudeAir PressureSwitch

Altitudes over 4,000' require a different air pressure switch than

the one installed at the factory. Check parts list for pressure switch

and consult your distributor for part number and availability. In

Canada, provincial codes may govern installation of switch.

Check with governing authorities.

Typical Gas Piping for Upflow

Drip Leg and

Union, Union* should

be outside the cabi-

net. Manual shut-off

valve MUST be up-

stream of dripleg,

union, and furnace.

LP Low

pressure

switch. 0

tional on

some models.

t,ll" = (28.2mm)

t.21" = (30.amm)

5. Reinstall manifold and combustion air box cover. Ensure

burners do NOT bind on new orifices.

Air Intake Pipe

'Direct-Vent

Installation only)

Use elbows to

connect valve to

piping when us-

ht side

gas pipe entry.

25-20-73

* Union may be installed inside the cabinet when necessary because of clearances.

[_ 44001100201

Page 21

NaturalGas InputRatingCheck

NOTE: The gas meter can be used to measure input to furnace.

Rating is based on a natural gas BTU content of 1,000 BTU's per

cubic meter. Check with gas supplier for actual BTU content.

1. Make sure combustion air box cover is in place and closed

before performing the following steps.

2. Turn OFF gas supply to all appliances and start furnace.

3. Time how many seconds it takes the smallest dial on the

gas meter to make one complete revolution. Refer to Ex-

ample.

Typical Gas Piping for Downflow

Drip Leg and

Union, Union* should be

outside the cabinet. Manual

shut-off valve MUST be up-

stream of dripleg, union,

and

LP Low

pressure switch. Optional LP

conversion'X

Example

NaturalGas | No.ofSeconds TimePerCubic | BTUPer

BTUContent t PerHour FootinSecondst Hour1,000 3,600 48 75,000

1,000 x 3,600 +48 = 75,000 BTUH

4. Relight all appliances and ensure all pilots are operating.

NOTE: If meter uses a 2 cubic foot dial, divide results (seconds)

by two.

Air Intake Pipe

Direct-Vent Installation only)

Optional Gas Line Entrance.

Use when furnace has been

Jconverted to LP gas and LP

Low Pressure Switch is

used.

*Union may be installed inside the cabinet

when necessary because of clearances.

GasPiping Requirements

1.

Properly size gas pipe to handle combined appliance load

or run gas pipe directly from gas meter or LP gas regulator.

Refer to NFGC and ANSI Z223.1 for proper gas pipe size.

2. Install correct pipe size for run length and furnace rating.

3. Measure pipe length from gas meter or LP second stage

regulator.

NOTE: Refer to Figure 25 or Figure 26 for the general layout at

the furnace. The rules listed apply to natural and LP gas pipe

installations.

NOTE: Refer to Figure 25 for the general layout at the furnace.

The rules listed apply to natural and LP gas pipe installations.

4. Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

5. Use ground joint unions and install adrip leg no less than 3"

long to trap dirt and moisture before it can enter gas valve.

6. Use two pipe wrenches when making connections to pre-

vent gas valve from turning.

7. Install a manual shut-off valve external to furnace casing

and tighten all joints securely.

Additional LP Connection Requirements

1. Have a licensed LP gas dealer make all connections at

storage tank and check all connections from tank to fur-

nace.

25-21-13

2. Ifcopper tubing is used, it MUST comply with limitation set

in National Fuel Gas Code or CGA codes.

3. Two-stage regulation of LP gas is recommended.

FinalCheck

1. The furnace and its individual shut-offvalve must be discon-

nected from the gas supply piping system during any pres-

sure testing of that system at test pressures in excess of

1/2" PSIG (3.5 kPa).

The furnace must be isolated from the gas supply piping

system by closing its individual manual shut-off valve dur-

ing any pressure testing of the gas supply piping system at

test pressures equal to or less than /2" PSIG (3.5 kPa).

2. Test all pipes for leaks.

3.

Gas pressure MUST NOT exceed 1/2" PSIG to gas valve.

Checking gas piping above 1/2"PSIG requires the furnace

and manual shut-off valve to be disconnected during test-

ing.

4. Apply soap suds (or a liquid detergent) to each joint.

Bubbles forming indicate a leak.

5. Correct even the smallest leak at once.

6. If orifices were changed, make sure they are checked for

leakage.

1

440 01 100201 [_

Page 22

6. ElectricalWiring

Electrical shock hazard.

Turn OFF electric power at fuse box or service pan-

el before making any electrical connections and