Page 1

Save these instructions for future reference.

Printed in Canada

MULTI POSITION

WARM AIR

FURNACE

02/05/22 X40094 Rev. A

445 01 4094 00

Page 2

1)

INSTALLATION

SAFETY LABELLING AND SIGNAL WORDS

PART 1

2) SAFE INSTALLATION REQUIREMENTS

Installation or repairs made by unqualified persons

can result in hazards to you and others. Installation

MUST conform with codes or, in the absence of

local codes, with codes of the country having

jurisdiction.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped with

the proper tools and test instruments.

Failure to carefully read and follow all instructions

in this manual can result in furnace malfunction,

property damage, personal injury and/or death.

1.1) Danger, Warning and Caution:

The signal words DANGER, WARNING and CAUTION are used to

identify levels of hazard seriousness. The signal word DANGER is

only used in product labels to signify an immediate hazard. The signal

words WARNING and CAUTION will be used on product labels and

throughout this manual and other manuals that may apply to the

product.

1.2) Signal Words:

DANGER - Immediate hazards which WILL result in death or serious

injury.

WARNING - Hazards or unsafe practices which COULD result in

death or injury.

CAUTION - Hazards or unsafe practices which COULD result in

personal injury or product or property damage.

1.3) Signal Words in Manuals:

The signal word WARNING is used throughout this manual in the

following manner:

The signal word CAUTION is used throughout this manual in the

following manner:

CAUTION

Fire hazard

The furnace must be installed in a level position,

never where it will slope to the front.

If the furnace were installed in that position, oil

could drain into the furnace vestibule and create a

fire hazard, instead of draining properly into the

combustion chamber.

NOTE: It is the personal responsibility and obligation of the customer

to contact a qualified installer to ensure that the installation is

adequate and conforms to governing codes and ordinances.

a. This furnace is NOT approved for installation in mobile homes,

trailers or recreation vehicles.

b. You must have a sufficient supply of fresh air for combustion and

ventilation to the area in which the furnace is located,

c, Do NOT use this furnace as a construction heater or to heat a

building that is under construction,

d. Use only the Type of fuel oil approved for this furnace (see

Rating Plate on unit). Overfiring wilt result in failure of heat

exchanger and cause dangerous operation.

e, Visually check all oil line joints for signs of wetness, which would

indicate a leak,

f, Connect furnace to the chimney,

g. The points in Part 2 "Operation" are vital to the proper and safe

operation of the heating system, Take the time to be sure they

are all done.

h. Follow the rules of the NFPA Pamphlet No.31 (for USA) and 13-

139 (for Canada) or local codes for locating and installing the oil

storage tank.

i. Follow a regular service and maintenance schedule for efficient

and safe operation.

Page 3

j. Beforeservicing,allowfurnacetocool.Alwaysshutoffelectricity

andfueltofurnacewhenservicing.ThiswilIpreventelectrical

shockorburns.

k. Sealsupplyandreturnairducts.

I. TheventsystemMUSTbecheckedtodeterminethatitisthe

correcttypeandsize.

m. Installcorrectfiltertypeandsize.

n. UnitMUST be installed so electrical components are protected

from direct contact with water.

2.1) Safety Rules:

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and create

hazards for you, the owner.

The U.S. Consumer Product Safety Commission recommends

that users of oil-burning appliances install carbon monoxide

detectors. There can be various sources of carbon monoxide in

a building or dwelling. The sources could be gas-fired clothes

dryers, gas cooking stoves, water heaters, furnaces, gas-fired

fireplaces, wood fireplaces, and several other items. Carbon

monoxide can cause serious bodily injury and/or death.

Therefore, to help alert people d potentially dangerous carbon

monoxide levels, you should have carbon monoxide detectors

listed by a nationally recognised agency (e.g. Underwriters

Laboratories or International Approval Services) installed and

maintained in the building or dwelling (see Note).

b.

There can be numerous sources of fire or smoke in a building or

dwelling. Fire or smoke can cause serious bodily injury, death,

and/or property damage. Therefore, in order to alert people of

potentially dangerous fire or smoke, you should have fire and

smoke detectors listed by Underwriters Laboratories installed

and maintained in the building or dwelling (see Note below).

Your unit is equipped with safety devices that may keep it from

operating if sensors detect abnormal conditions such as clogged

exhaust flues.

If the structure will be unattended during cold weather you should take

these precautions.

a. Turn off main water supply into the structure and drain the water

lines if possible. Open faucets in appropriate areas.

b.

Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes from

freezing. Suggest they call a qualified service agency, if

required.

2.3) Installation regulation:

All local and national code requirements governing the installation of

oil burning equipment, wiring and flue connections MUST be followed.

Some of the codes that may be applicable are:

CSA B139 INSTALLATION CODE FOR OIL

BURNING EQUIPMENT

NFPA31 INSTALLATION OF OIL BURNING

ANSI/NFPA90B WARM AIR HEATING AND AIR

ANSI/NFPA 70 NATIONAL ELECTRICAL CODE

CSA C22.2 No3 CANADIAN ELECTRICAL CODE

ANSI/NFPA 211 CHIMNEYS, FIREPLACES, VENTS

EQUIPMENT

CONDITIONING SYSTEMS

AND SOLID FUEL BURNING

APPLIANCES

and makes no representations regarding any brand or type of

I NOTE: The manufacturer of your furnace does not test any detectors

detector.

Insure that the area around the combustion air intake

I CAUTION

terminal is free of snow, ice and debris.

2.2) Freezing Temperature and Your

Structure:

Freeze warning.

Turn off water system.

If your unit remains shut offduring cold weather the

water pipes could freeze and burst, resulting in

serious water damage.

Only the latest issues of the above codes should be used.

3) LOCATING THE FURNACE

CAUTION

Check carefully your furnace upon delivery for any

evidence of damage that may have occurred during

shipping and handling. Any claims for damages or lost

parts must be made with the Transport Company.

Page 4

As this unit may be installed as an upflow, counterflow or horizontal

furnace (right or left), it may be located in a basement, on the same

level as the area to be heated, suspended, or in a crawlspace. In any

case, the unit should always be installed level.

4) VENTING

In a basement, or when installed on the floor (as in a crawlspace), it

is recommended that the unit be installed on a concrete pad that is

1" to 2" thick.

When installed in the counterflow position, this furnace must not be

installed on combustible flooring, unless the approved sub-base is

used (Model # DFB-101). The flue pipe must exit the cabinet

through one of the panel opening, then extended up the side of the

furnace. Care must be taken to insure that the clearances from the

flue pipe to combustible construction are maintained.

Also, it is recommend to use the flue pipe guard kit

(Model # FPG-101 or # FPG102) to insure that a fire hazard

condition does not exist.

When installed in a horizontal position, the furnace may be

suspended by using an angle iron frame, as long as the total weight

of both the furnace and the frame are allowed for in the support

calculations. (Other methods of suspending are acceptable.) When

installed in the Horizontal Position, this furnace must not be installed

on combustible flooring, unless the approved sub-base is used

(Model # HFB-101).

This furnace is approved for reduced clearances to combustible

construction. Therefore, it may be installed in a closet or similar

enclosure.

The required minimum clearances for this furnace in all

positions are specified in tables # 3.2 and 3.3.

The furnace should be located as close as possible to the chimney

or vent in order to keep vent connections shorts and direct. The

furnace should also be located as near as possible to the center of

the air distribution system.

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

I CAUTION

chemicals. Refer to Part 1, section 5.2.

Poison carbon monoxide gas, fire and explosion

hazard.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in

property damage, personal injury and/or death.

CAUTION

When the furnace (chimney installation) is co-vented

with other combustion appliances such as a water

heater, the allowable venting materials (i.e. L-Vent etc.)

for use with those appliances should also be

investigated.

Poison carbon monoxide gas hazard

Never install a hand operated damper in the vent

pipe. However, any Underwriters Laboratories

listed electrically operated automatic type vent

damper may be installed if desired. Be sure to

follow instructions provided with vent damper.

Read and follow all instructions in this section.

Failure to properly vent this furnace or other

appliances can result in property damage, personal

injury and/or death.

Venting of the furnace should be to the outside and in accordance

with local codes or requirements d the local utility.

Electrical shock hazard.

This furnace is not watertight and is not designed

for outdoor installation. This furnace shall be

installed in such a manner as to protect the

electrical components from water.

Outdoor installation would lead to a hazardous

electrical condition and to premature furnace

failure, property damage, bodily injury or death.

OIL FIRED APPLIANCES SHALL BE CONNECTED TO FLUES

HAVING SUFFICIENT DRAFT AT ALL TIMES TO ENSURE SAFE

AND PROPER OPERATION OF APPLIANCE.

For additional venting information refer to ANSl/NFPA 211 Chimney,

Fireplaces, Vents and Solid Fuel Burning Appliances and/or CSA

B139 Installation Code.

This furnace is certified for use with Type '%" vent (maximum flue

gas temperature 575°F). The flue pipe clearance knockout in the

front top or side panel should be removed. Install the flue elbow so

that it exits the furnace cabinet through that opening.

Pre-instatlation vent system inspection:

Before this furnace is installed, it is highly recommended that any

existing vent system be completely inspected.

For any chimney or vent, this should include the following:

a. Inspection for any deterioration in the chimney or vent. If

deterioration is discovered, the chimney must be repaired or

the vent must be replaced.

Page 5

b. Inspection to ascertain that the vent system is clears and free

of obstructions. Any blockage must be cleared before installing

this furnace.

¢. Clearing the chimney or vent if previously used for venting a

solid fuel burning appliance or fireplace.

d. Confirming that all unused chimney or vent connections are

properly sealed.

e. Verification that the chimney is properly lined and sized per the

applicable codes, (Refer to list of codes on page 3.)

Masonry Chimney:

This furnace can be vented into an existing masonry chimney. This

furnace must not be vented into a chimney servicing a solid fuel-

burning appliance. Before venting this furnace into a chimney, the

chimney must be checked for deterioration and repaired if

necessary. The chimney must be properly lined and sized per local

or national codes.

Poison carbon monoxide gas hazard.

Comply with ANSI/NFPA (in U.S.) or CSA (in

Canada) standard for the installation of Oil Burning

Equipment and applicable provision of local

building codes to provide combustion and

ventilation air.

Failure to provide adequate combustion and

ventilation air can result in personal injury and/or

death.

If the furnace is vented into a common chimney, the chimney must

be of sufficient area to accommodate the total flue products of all

appliances vented into the chimney.

The following requirements are provided for a safe venting system:

a. Ensure that the chimney flue is clear of any dirt or debris.

b. Ensure that the chimney is not servicing an open fireplace.

C. Never reduce the pipe size below the outlet size of the furnace.

d. All pipes should be supported using the proper clamps and/or

straps. These supports should be at least every four (4) feet.

e. All horizontal runs of pipe should have at least a 1/4" per foot of

upward slope.

f. All runs d pipe be as short as possible with as few turns as

possible.

g. Seams should be tightly joined and checked for leaks.

h. The flue pipe must not extend into the chimney but be flush

with the inside wall.

i. The chimney must extend three (3) feet above the highest point

where it passes through a roof of a building and at least two (2)

feet higher than any portion of a building within a horizontal

distance of ten (10) feet. It shall also be extended at lest five

(5) feet above the highest connected equipment flue collar.

j. Check local codes for any variance.

Factory Built Chimneys:

May use listed factory built chimneys. Refer to chimney

manufacturer's instructions for proper installation.

5.1) General:

Oil furnaces must have an adequate supply of combustion air. It is

common practice to assume that older homes have sufficient

infiltration to accommodate the combustion air requirement for the

furnace. However, home improvements such as new windows, doors,

and weather stripping have dramatically reduced the volume of air

leakage into the home.

When this furnace is installed in a closet or enclosure, two (2)

ventilation openings are required for combustion air. The openings

should be located about 6" from the top and the bottom of the

enclosure at the front of the furnace. Table # ! indicates the

minimum ventilation openings dimensions required.

TABLE # 1

Input Length Height

(MBTUH) (in,) (in,)

75- 105 16 8

120-155 20 10

Home air exhausters are common. Bathroom and kitchen fans, power

vented clothes dryers, and water heaters all tend to create a negative

pressure in the home. Should this occur, the chimney become less

and Iess effective and can easily downdraft.

4.1) BAROMETRIC DRART CONTROL

The barometric draft control shipped with furnace MUST be used with

furnace to ensure proper operation. Instructions for installing control

are packed with control.

5) AIR FOR COMBUSTION

Heat recovery ventilation (HRV) systems are gaining in popularity. The

HRVs are not designed to supply combustion air. If not properly

balanced, a serious negative pressure condition could develop in the

dwelling.

5.2) Contaminated Combustion Air :

Installation in certain areas or types of structures will increase the

exposure to chemicals or Halogens which may harm the furnace.

These instances will require that only outside air for combustion.

The following areas or types of structures may contain or have

exposure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air for

combustion.

a. Commercial building.

b. Building with indoor pools.

c. Furnaces installed near chemical storage areas.

Page 6

Exposuretothesesubstances:

a. Permanentwavesolutionsforhair.

b. Chlorinatedwaxesandcleaners.

c. Chlorinebasedswimmingpoolchemicals.

d. Watersofteningchemicals.

e. De-icingsaltsorchemicals.

f. Carbontetrachloride.

g. Halogentyperefrigerants.

h. Cleaningsolvent(suchasperchloroethylene).

i. Printinginks,paintremovers,varnishes,etc..

j. Hydrochloricacid.

k. Solventcementsandglues.

I. Antistaticfabricsoftenersforclothesdryers.

m. Masoneryacidwashingmaterials.

6) OIL TANKS AND LINES

Check your local codes for the installation of the tank and accessories.

A manual shut-off valve and an oil filter shall follow sequence from

tank to burner. Be sure that the oil line is clean before connecting to

the burner. The oil Iine should be protected to eliminate any possible

damage. Installations having the fuel oil tank below the burner level

must employ a two pipe fuel supply system with an appropriate fuel

pump (more than 8' lift use 2 stage pump and more than 16' an

auxiliary pump).

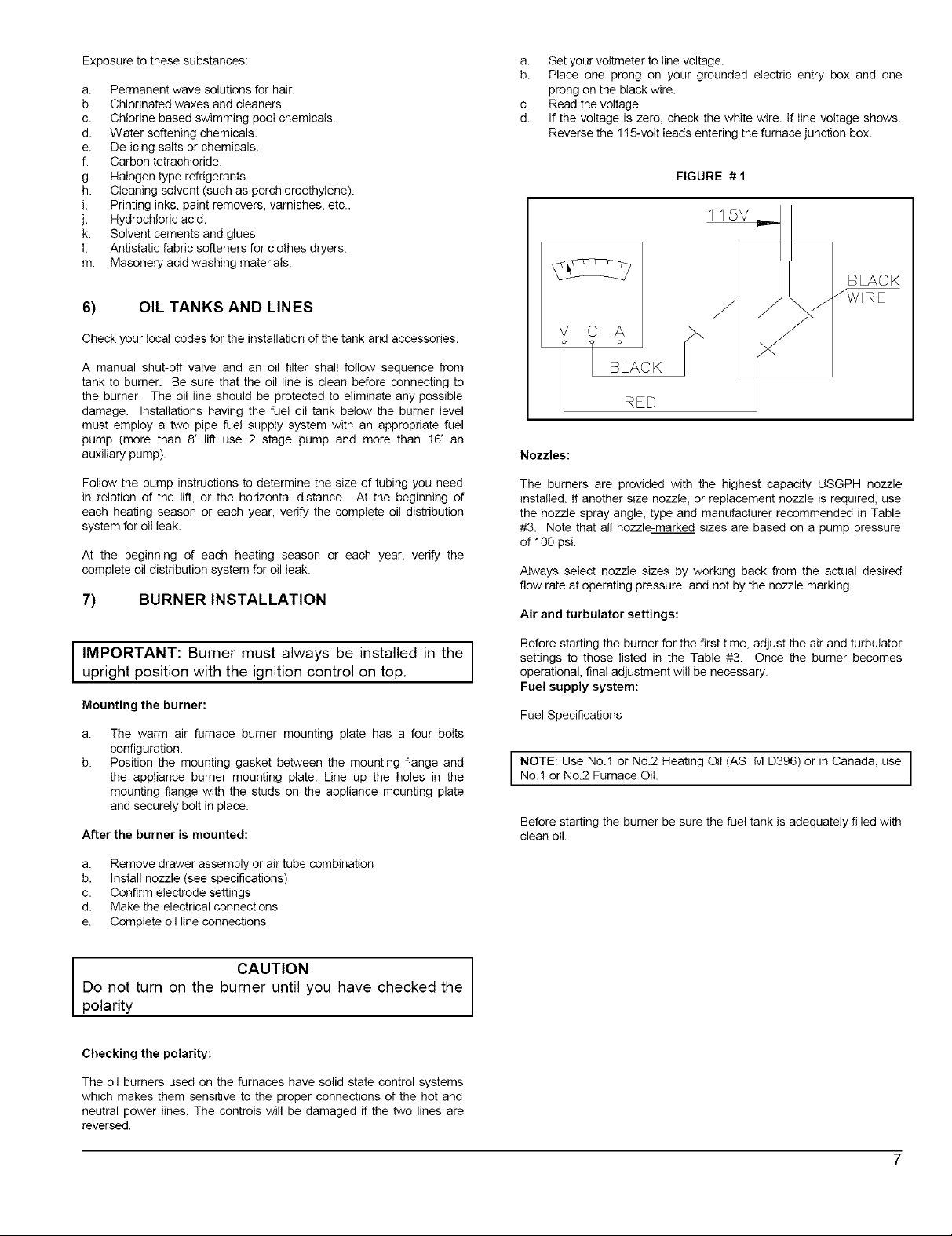

a. Set your voltmeter to line voltage.

b. Place one prong on your grounded electric entry box and one

prong on the black wire.

c. Read the voltage.

d. If the voltage is zero, check the white wire. If Iine voltage shows.

Reverse the 115-volt leads entering the furnace junction box.

FIGURE # 1

BLACK

V C A

o o

\

BLACK

RED

Nozzles:

Follow the pump instructions to determine the size of tubing you need

in relation of the lift, or the horizontal distance. At the beginning of

each heating season or each year, verify the complete oil distribution

system for oil leak.

At the beginning of each heating season or each year, verify the

complete oil distribution system for oil leak.

7) BURNER INSTALLATION

I IMPORTANT: Burner must always be installed in the

upright position with the ignition control on top.

Mounting the burner:

a.

The warm air furnace burner mounting plate has a four bolts

configuration.

b.

Position the mounting gasket between the mounting flange and

the appliance burner mounting plate. Line up the holes in the

mounting flange with the studs on the appliance mounting plate

and securely bolt in place.

After the burner is mounted:

a. Remove drawer assembly or air tube combination

b. Install nozzle (see specifications)

c. Confirm electrode settings

d. Make the electrical connections

e. Complete oil line connections

The burners are provided with the highest capacity USGPH nozzle

installed. If another size nozzle, or replacement nozzle is required, use

the nozzle spray angle, type and manufacturer recommended in Table

#3. Note that all nozzle-marked sizes are based on a pump pressure

of 100 psi.

Always select nozzle sizes by working back from the actual desired

flow rate at operating pressure, and not by the nozzle marking.

Air and turbulator settings:

Before starting the burner for the first time, adjust the air and turbulator

settings to those listed in the Table #3. Once the burner becomes

operational, final adjustment will be necessary.

Fuel supply system:

Fuel Specifications

I NOTE: Use No.1 or No.2 Heating Oil (ASTM D396) or in Canada, useNo.! or No.2 Furnace Oil.

Before starting the burner be sure the fuel tank is adequately filled with

clean oil.

Do not turn on the burner until you have checked the

I CAUTION

polarity

Checking the polarity:

The oil burners used on the furnaces have solid state control systems

which makes them sensitive to the proper connections of the hot and

neutral power lines. The controls will be damaged if the two lines are

reversed.

Page 7

Fire and explosion hazard.

Use only approved heating type oil in this furnace.

DO NOT USE waste oil, used motor oil, gasoline or

kerosene.

NOTE: THE BACK SHOULD NOT BE CUT OUT FOR

RETURN AIR

Provision is also made on this furnace for a bottom return air duct.

Knockouts are provided on the floor of the furnace to facilitate the

cut out requirement to assembly d air filter rack and return

ductwork. (We recommend the use of this opening for horizontal

installations).

Use of these will result in death, personal injury

and/or property damage.

operated. This will soon disappear. It is only the oil used on the parts

I NOTE: You may notice a slight odor the first time your furnace is

during manufacturing.

8) INSTALLING ACCESSORIES

Electrical shock hazard.

Turn OFF electric power at fuse box or service

panel before making any electrical connections and

ensure a proper ground connection is made before

connecting line voltage.

Failure to do so could result in property damage,

bodily injury or death.

8.1) Air conditioning:

An air conditioning coil may be installed on the _side only.

Also, a minimum clearance must be allowed between the bottom of

the coil drain pan, and the top of the heat exchanger according to the

coil manufacturer instruction. Wire the thermostat and condensing unit

contactor as indicated in the wiring diagram (figures # 4 and # 4.! ).

When furnace supply ducts carry air outside furnace area, seal return

air duct to furnace casing and terminate duct outside furnace space.

Install air conditioning cooling coil (evaporator) on downstream (in the

supply air plenum) or furnace.

If separate evaporator and blower unit is used, install good sealing

dampers for air flow control. Cold air from the evaporator coil going

through the furnace could cause condensation and shorten furnace

life.

I CAUTION

Dampers (purchased locally) MUST be automatic.

Poison carbon monoxide gas hazard.

Do NOT draw return air from inside a closet or

utility room. Return air duct MUST be sealed to

furnace casing.

Failure to properly seal duct can result in death,

personal injury and/or property damage.

Poison carbon monoxide gas hazard.

8.2) Ductwork and Filter:

Installation:

Design and install air distribution system to comply with Air

Conditioning Contractors of America manuals or other approved

methods that conform to local codes and good trade practices.

Knockouts are provided on both sides of the furnace to cut the

required size opening for the installation of the return ductwork. This

can be done on either the right or the left side of the furnace. See

Figure # 3 and 3.1 for location and dimensions.

Install evaporator coil on the supply side of the

furnace ducting.

Evaporator coil installed in return side ducting can

cause condensation to form inside heat exchanger

resulting in heat exchanger failure. This could

result in death, personal injury and/or property

damage.

Page 8

PART 2

OPERATION

1) SEQUENCE OF OPERATION

1.1) Sequence of operation - Beckett AFG:

1. Normally open contact (T-T) on primary relay closed when

thermostat calls for heat.

2. The motor starts and spark is established. The pump pressure

builds and the poppet valve opens admitting fuel to the nozzle.

Pressure builds and poppet valve opens, allowing oil to flow

through nozzle.

3. Spark ignites oil droplets.

4. Cad cell senses flame and burner continues to fire.

5. After 60 sec., the fan control starts the circulating air blower and

electronic air cleaner.

6. The circulating air blower and burner motor remain on until the

thermostat is satisfied. The ignition transformer continues to

spark.

7. Thermostat is satisfied.

8. Primary relay contacts open and the burner fan motor shuts

down. The ignition transformer ceases sparking.

9. Depend on the delay of setting of the fan control, the circulating

air blower stop after 60, 90, !20 or 150 seconds. (See part 2,

section 2.4).

2) CHECKS AND ADJUSTMENTS

2.1) General:

IMPORTANT

The burner must be put in operation for at least 10

minutes before any test readings are taken. For new

installations, set up the burner to the settings (see table

# 3), before firing. These are rough adjustments but

they will ensure that the burner will start and run smoke-

free in advance of the fine adjustments being made.

Open the oil bleed port screw and start the burner. Allow the oil to

flush into a portable container for at least 10 seconds. Slowly close the

bleed screw - the oil should flow absolutely free of white streaks or

bubbles to indicate that no air is being drawn into the suction side of

the oil piping and pump. Tighten the bleed screw and the burner wilI

fire. Adjust the oil pressure as indicated in Table # 3.

2.2)

1.

2.

3.

4.

Restart if Burner Should Stop:

Set thermostat lower than the room temperature.

Press the reset button on the burner primary control (relay).

Set thermostat higher than the room temperature.

If the burner motor does not start or ignition fails, turn off the

disconnect switch and CALL YOUR SERVICEMAN

CAUTION

Do not attempt to start the burner when excess oil has

accumulated, when the furnace is full of vapour, or

when the combustion chamber is very hot.

During initial start-up and subsequent yearly maintenance calls, the

furnace must be thoroughly tested.

2.3) Perform the smoke / CO2 test:

1.

Pierce a test hole in the smoke pipe near the furnace breech.

Insert the smoke test instrument probe into the open hole.

2.

Starting with a zero smoke reading, gradually reduce the burner

air setting until just a trace (#1 on Bacharach Scale) of smoke

results.

3. Take a CO2 sample at the same test location where the smoke

sample was taken. Note the CO2 reading associated with the #!

smoke condition.

4.

Adjust the burner air setting to obtain a CO2 reading !% lower

than the reading associated with the #1 smoke.

5.

This method of adjusting the CO2 will allow adequate excess air

to ensure that the burner will burn clean for the entire heating

season.

Page 9

2.4) FAN ADJUSTMENT CHECK

This furnace is equipped with a 4 speed direct drive motor to deliver

a temperature rise within the range specified on the rating plate,

between the return and supply pressure at the external duct static

pressure noted on the rating label.

Adjust the fan speed ACCORDING TO THE OIL INPUT SELECTED

so that the temperature rise is within the rise specified on the rating

plate (see table # 3). Consult the wiring diagram for speed changes

on the direct drive motor.

To adjust fan OFF time, the DIP switches on the control board

adjusted to obtain the desired timing (See figure # 2).

Remove the restriction and the burner should come back on in a few

minutes.

For year round air conditioning:

The furnace is designed for use in conjunction with cooling

equipment to provide year round air conditioning. The blower has

been sized for both heating and cooling, however, the fan motor

speed may need to be changed to obtain the necessary cooling air

flow.

Heating:

The blower speed is factory set to deliver the required airflow at

normal duct static pressure.

FIGURE # 2

Delay off setting

60 Sec. 90 Sec. 120 Sec. 150 Sec.

DIP switchs

DNS-0378 Rev. A

2.5) Vent temperature test:

1. Place a thermometer in the test hole located in the breech pipe.

2. The vent temperature should be between 400 and 575°F. If

not, check for improper air temperature rise, pump pressure,

nozzle size, or for a badly sooted heat exchanger.

2.6) Limit control check

After the furnace has been in operation for at least 15 minutes,

restrict the return air supply by blocking the filters or closing the

return registers and allow the furnace to shut down on high limit.

The burner will shut OFF and the main blower should continue to

run.

MAINTENANCE

Cooling:

The blower speed may be adjusted in the field to deliver the required

airflow, for cooling application, as outlined in table # 3

Constant Blower Switch:

This furnace is equipped with a constant low speed blower option.

Whenever the room thermostat is not calling for heating or cooling,

the blower will run on low speed in order to provide air circulation. If

this constant blower option is not desired, the rocker switch on the

side of the control box can be used to 'turn off" the constant speed.

PART 3

1)

Preventive Maintenance:

"Preventive maintenance" is the best way to avoid unnecessary

expense and inconvenience, Have your heating system and

burner inspected at regular intervals by a qualified service man.

After inspection, a complete combustion test must be performed after

each annual service of the unit to maintain optimum performance and

reliability.

GENERAL

10

Electrical shock hazard.

Turn OFF power to furnace before any disassembly

or servicing.

Failure to do so can result in property damage,

bodily injury and/or death.

Page 10

Do not tamper with the unit or controls. Call your service

technician,

Before calling for service, check the following.

a. Check oil tank gauge and check if the oil tank valve is open.

b. Check fuse or circuit breaker.

c. Check ifshut-off switch is 'ON".

d. Reset thermostat above room temperature.

e. If ignition does not occur turn off the disconnect switch and call

your qualified service technician.

When ordering replacement parts, specify the complete furnace

model number and serial number.

1.1) Heat exchanger cleaning:

Ordinarily, it is not necessary to clean the heat exchanger or flue pipe

every year, but it is advisable to have your oil burner serviceman

check the unit before each heating season to determine whether

cleaning or replacement of parts is necessary.

If cleaning is necessary, the following steps should be perfomed:

1. Turn 'OFF" atl utilities upstream of the furnace.

2. Disconnect the flue pipe.

3. Remove the flue cellar panel located in the front part of the warm

air furnace.

4. Remove the radiator baffles.

5. Disconnect the oil Iine and remove the oil burner from the

furnace.

6. Clean the secondary tubes, and the primary cylinder with stiff

brush and vacuum cleaner.

7. After cleaning, replace the radiator baffles, flue collar plate and

oil burner.

8. Readjust burner for proper operation.

Soot will have collected in the first sections of the heat exchangers

only if the burner was started after the combustion chamber was

flooded with fuel oil, or if the burner has been operating in a severely

fouled condition.

CAUTION

Be sure the blower is adequately supported when

sliding out of the mounting rails, especially in the

horizontal, in order to prevent dropping the blower and

injuring yourself or damaging the blower!

To remove the blower from the furnace:

1. Turn 'OFF" all utilities upstream of the furnace.

2. Remove the burner access door and blower door.

3. Remove the blower retaining screw (on the blower partition

panel).

4. Remove cover from control box and disconnect the thermostat

and power wires from the board.

5. Slide the blower forward on the rails toward the front of the unit.

6.

Reverse the above steps to reinstall the blower. (Refer to

wiring diagram figures # 4 a 4.1 of this instruction or the

diagram located on the inside of the blower door to properly

rewire the unit.)

1.3) Burner drawer assembly:

Remove the drawer assembly. Clean all foreign matter from the

retention head and electrodes. If a Beckett AFG burner has been

installed, the burner will have to be removed to check the retention

head and to check for proper "Z" dimension with the Beckett "T" gauge

supplied with every burner. Check for any sign of oil boiling out d the

nozzle and caulking - the solenoid valve could be leaking (if

applicable).

1.4) Nozzle:

Replace the nozzle with the one specified in table # 3.

1.5) Oil filter:

Tank filter:

The tank filter should be replaced as required.

Secondary filter:

The 10 micron (or less) filter cartridges should be replaced annually.

1.2) BLOWER REMOVAL

To remove the blower from the furnace:

1. Turn 'OFF" all utilities upstream of the furnace.

2. Remove the burner access door and blower door.

3. Remove the blower retaining screw (on the blower rails).

4. Remove cover from control box and disconnect the thermostat

and power wires from the board.

5. Slide the blower forward on the rails toward the front of the unit.

6. Reverse the above steps to reinstall the blower. (Refer to

wiring diagram figures # 4 a 4.1 of this instruction or the

diagram located on the inside of the blower door to properly

rewire the unit.)

1.6) Air filters:

Air filters are the disposable types. The disposable filters should be

replaced on at least an annual basis. Dusty conditions, presence of

animat hair etc. may demand much more frequent filter changes. Dirty

filters will impact furnace efficiency and increase oil consumption.

1.7) Motor lubrication:

Do not lubricate the oil burner motor or the direct drive blower motor

as they are permanently lubricated.

11

Page 11

PART 4

INFORMATION

Model:

Date of installation of the furnace :

Service telephones -day :

Dealer's name and address :

RESULT OF START-UP TEST

Nozzle:

Burner adjustments :

002 :

Gross stack temperature:

Ambiant temperature:

Primary air

Fine air

Draw Assembly

Smoke scale :

Seria! number:

Pressure :

Night :

psi

(Bacharach)

oF

oF

Chimney draft:

Overfire draft :

Test made by :

"C.E.

"C.E.

12

Page 12

TABLE#3

Technicalspecifications, NOMF

Model : NOMF .1 75 J 90 [ 105 [ 120 ..[ 140 J 155

RATING AND PERFORMANCE

Firing rate (USGPH) 0.5 0.65 0.75 0.85 1 1.!

Input (BTU/h) 70 000 91 OOO 105 0go 119 O00 140 0go 154 O00

Heating capacity (BTU/h) 57 00O 74 OOO 85 00O 97 OOO 1!5 0go 126 O00

AFUE % 80 80 80 80 80 80

Heating temperature rise (Degr. F) 55 - 85 Degr. F 55 - 85 Degr. F

BECKETr BURNER; MODEL AFG (3450 rpm) AFG-F3 AFG-F3 AFG-F6

Low firing rate baffle YES YES YES

Static disc, model 3 3/8" # 31646 2 3/4" # 3383 2 3/4" # 3383

Nozzle - 100 PSIG pump pressure (Detavan) 0.50 - 7OW 0.65 -70W 0.75 - 7OB 0.85 - 70B I 1.00 - 7OW 1.!0 - 70W

Combustion air adjustment (band/shutter) O/ 5 0 / 7 O/ 8 1/ 8 / 4 / 4 2 / 8

ELECTRICAL SYSTEM

Volts - Hertz - Phase 115-60-1 115-60- !

Operating voltage range 104 - ! 32 104 - 132

Rated current (Amps) 12.2 15.7

Minimum ampacity for wiring sizing 13.7 18. !

Max. w ire Ienght (ft) 26 26

Max. fuse size (Amps) 15 20

Control transformer 40 VA 40 VA

External control pew er available Heating 40 VA 40 VA

Cooling 30 VA 30 VA

BLOWER DATA

Blow erspeepat0.5"W.C, static pressure MED-LOW I MED-HIGH I HIGH MED-LOW I MED-HIGH I HIGH

Motor (HP) / number of speeds 1/3 HP / 4 speeds 3/4 HP / 4 speeds

Blow er w heel size (in) 10 X !0 12 X 10

Filter quantity and size 16 X 24 20 X 30

DIMENSIONS

Overall W x L x H ( in ) 20 x 35 x 48.75 20 x 39.50 x 53

Shipping w eight (Lbs) 220 250

Supply air duct (in) 19 x 20 19 x 24

Return air duct (in ) 15 x 23 17 x 29

TABLE # 3.1

Air delevery - CFM with air filter

NOM F105D12A

EXTERNAL STATIC PRESSURE WITH AIR FILTER

SPEED 0.2 0.3 0.4 0.5

HIGH 1425 1350 1305 1250

MED- HIGH 1130 1045 1000 950

MED-LOW 840 810 770 740

NOM F155E19A

EXTERNAL STATIC PRESSURE WITH AIR FILTER

SPEED 0.2 0.3 0.4 0.5

HIGH 2080 2041 1965 1864

MED- HIGH 1892 1859 1770 1675

MED-LOW 1556 1475 1394 1318

13

Page 13

(n

8o

Be

,,ll_

BLUE

VERSION EN FRANCAIS INCLUS DANS MANUEL

D'INSTALLATION.

BLACK

BLUE

RED

OIL INPU

L° FIoAPAc, oR

ML _z

MH _L

HI

c

J

115 VAC I_/60HZ pOWER SUPPLY

(FUSEO DISCONNECT ON HOT LEO]

GND ,llll<_ o N_

ED MOT LEAE _> ON

]6_1 _ CN6 2 CN6 4

l LIMIT

Q.

3

"11

COOLINO : 2 1/2

to 3 TONS

.,,&

r,a ,1_

tD

I

STANDARD HEAT / COOL WIRING DIAGRAM

WITH ST9103 ELECTRONIC FAN TIMER

OIL INPUT : 0.75 USGPH

COOLING CAPACITY ; 3 TONS MAX

Jumper : USE JUMPER ONLY WHEN THE COOLING AND

HEATING SPEEDS ARE SAME

FOR HUMIDIFIER AND EAC, REMOVE THE DUMMY TERMINAL MARKED HUM

FOR HUMIDIFIER OR EAC FOR ELECTRONIC AIR CLEANER

OIL INPUT : 0.50 USGPH

COOLING CAPACITY : 2 TONS

°b

UNUSED MOT LEAD>> "_J_BLFoCLwE LAqqON

o"

c

tD

Page 14

co

cu

LO Oz

ML

MH

HI

c

VERSION EN FRANCAIS INCLUS BANS MANUEL

D'INSTALLATION.

BLACK

TRA_

,lll_ GND

120

CAPACITOR

I BLACK

LI (H)

L2 (N) 120 VAC POWER SUPPLY

I CAPAC'TOR

LOMNN,MLc

115 VAC 1_' 60HZI pOICI_R SUPPLY

(FUSED DISCONNECT ON HOT LFG]

8 2

1

R99GO01

: 3 BT91

im

BLACK

BLUE

RED

(

BLUE

RED

OIL INPUT : 1,00 USGPH

COOLINO CAPACITY : 4 to 5

TONS MAX

F

<

5

LO _ <

ML _,

MH

_ WHITE

CAPACITOR

Oz

OL

_+

LIMIT(S) ___

CN6 8_CN6 5

a

t-

CAD CELLI

STANDARD HEAT / COOL WIRING DIAGRAM

WITH ST9105 ELECTRONIC FAN TIMER

OIL INPUT : 0.85 USGPH

COOLING CAPACITY ; 4 TONS MAX

* Jumper : USE JUMPER ONLY WHEN THE COOLING AND HEATING

SPEEDS ARE SAME

FOR HUMIDIFIER AND EAC, REMOVE THE DUMMY TERMINAL MARKED HUM

FOR HUMIDIFIER OR EAC ELECTRONIC AIR CLEANER

L BLACK

BLUE

OIL INPUT " 1.10 USGPH

COOLING CAPACITY : 5 TONS

UNUSED M O Sl LEAD>> _m_ ON

COOL L_

*Jumper [__@

UNUSED MOT >_ x"_B LRoCwUL_

LEAD IRCULAllON

Page 15

DNS-0832 Rev A

I

I o

I

7

I

,I

FIGURE # 3

Model: NOMF105D12A

3 2O

I

35

J

1663

LOCATION

FLUE PIPE

16

SIDE

BACK

TOP

BOTTOM

FRONT

TABLE # 3.2

Minimum clearances - combustion materials (in), MODEL: NOMF105D12A

APPLICATION

FURN ACE

SUPPLY PLENUM WITHIN 6 FT OF FURNACE

FURN ACE

FURNACE OR PLENUM

HORIZONTAL WARM AIR DUCT WITHING 6 FT OF FURNACE

FURNACE (**COMBUSTIBLE FLOOR WITH THE SUBBASE)

HORIZONTALLY OR BELOW FLUE PIPE

VERTICALLY ABOVE FLUE PIPE

FURN ACE

UPFLOW

0

1

0

2

2

0

4

9

8

DOWNFLOW

HORIZONTAL

2

2

1

2

2

**0

4

9

8

2

1

0

2

3

**0

4

9

24

Page 16

FIGURE # 3.1

Model: NOMF155E19A

1_oo

2900 _=_1259--

--j

_F

'#_J

l

2_00

FOR6_ DIA FLUE

TCPKN0CK OUT

--19.00--

DNS-0833 R@v. A

LOCATION

SIDE

BACK

TOP

BOTTOM

FLUE PIPE

FRONT

5&00

01LINLET

_(BOTH SIDE)

I

laD_

1_.75 |

TABLEAU # 3.3

Minimum clearances - combustion materials (in), MODEL: NOMF155E19A

APPLICATION

FURNACE

SUPPLY PLENUM WITHIN 6 FT OF FURNACE

FURNACE

FURNACE OR PLENUM

HORIZONTAL WARM AIR DUCT WITHING 6 FT OF FURNACE

FURNACE (**COMBUSTIBLE FLOOR WITH THE SUBBASE)

HORIZONTALLY OR BELOW FLUE PIPE

VERTICALLY ABOVE FLUE PIPE

FURNACE

UPFLOW

1

1

0

2

2

0

4

9

8

DOWNFLOW

HORIZONTAL

2

2

1

2

2

**0

4

9

8

2

1

0

2

3

**0

4

9

24

17

Page 17

Page 18

ModUle : NOMF105D12A

PARTS LIST

I=]=_._"_e,,];.41M/[e] _ _[I LV_l:!--;.i [.e,[e]Lv_ILv_I--_I Er_

Heat exchanger B01667

2 Back panel ass'y B01728 INCLUDES PANEL, INSULATION AND BAFFLE

3 Back panel insulation B01526-11

4 Left back baffle B01686-02

5 Right back baffle B01686-01

6 Right side panel ass'y B01885-01 INCLUDES PANEL, INSULATION AND BAFFLE

7 Right side panel insulation B01645-01

8 Right side baffle B01679-01

9 Front top panel ass'y B01861 INCLUDES PANELAND LATCHES

10 Front divider panel ass'y B01727 INCLUDES PANEL, INSULATION AND LABELS

11 Front divider panel insulation B01646

12 Flue pipe cover ass'y B01697

13 Front access door B40011-06 DOOR, LATCHE AND HANDLE INCLUDED

14 Recess handle Z99F050

15 Radiator baffle ass'y B01676 INCLUDES BAFFLES AND INSULATION

16 Blow er compartiment door ass'y B01883 INCLUDES DOOR AND LABELS

17 Junction box cover B01684

18 Junction box B01683 BOX ONLY

19 Junction box holder plate B01682

20 Blow er slides B01681 2 REQUIRED

21 Floor B01687

22 Blower slides support B01680 2 REQUIRED

23 Blow er divider panel B01846 PANEL ONLY

24 Left side baffle B01679-02

25 Left side panel ass'y B01885-02 INCLUDES PANEL, INSULATION AND BAFFLE

26 Left side panel insulation B01645-02

27 Hi limit 175-20 F, 1,75" R02R003

28 Gasket, flue pipe cover B01214

29 Gasket, burner flange N01Z026

30 Beckett Burner AFG-F3 B01536-01

3t Hexagon nut 3/8-16NC zinc F07F011

32 Capacitor holder B01024

33 5 MF capacitor L011001

34 1/3 HP direct drive motor B01890-01 INCLUDES MOTOR AND LEGS

35A Blower ass'y B01405-01 INCLUDES BLOWER, MOTOR, CAPACITOR

35B Blower 10 X 10 Z011004 INCLUDES BLOWER WHEEL AND HOUSING

36 Blower weel 10 X 10 Z01L002

37 Motor mounting, band Z01F012

38 Motor mounting, leg Z01 F013 3 REQUIRED

39 Screw for motor mount leg F03F023 3 REQUIRED

40 Washer for motor mount leg F03F010 3 REQUIRED

41 Nut for motor mount band F07J001

42 Bolt for motor mount band F05F015

43 Motor mount ass'y B01888

44 Hi limit 140-20 F, 7" R02R002

45 Observation door ass'y B01842

46 F-lectrical insulating barrier A00284

47 Rocker sw itch SPST L07F003

48 F-lectronic fan timer R99G002

49 Transformer 120/24 VAC / 40 VA K03040

50 Female latche Z99F003

5t Male latche Z99F038

52 Filter rack U frame B01695

53 Filter rack access B01696

54 Paper filter 16 x 24 x 1 Z04F007

55 F-lectrical kit B00203

19

Page 19

,7,

L,O

o

DETAIL "

DETAIL "A"

8

Page 20

PARTS LIST

ModUle : NOMF155E19A

1l]2_"[e_:ltUl [el_ !LIJLVil=!2=• =KO]Lv_hV_l=l_i IK

Heat exchanger B01787

2 Back panel ass'y B01877 INCLUDES PANEL, INSULATION AND BAFFLES

3 Back panel insulation B0!526-25

4 Left back baffle B0!806-02

5 Right back baffle B0!806-01

6 Right side panel ass'y B0!875-01 INCLUDES PANEL, INSULATION AND BAFFLES

7 Right side panel insulation B0!800-01

8 Right side baffle B01805

9 Front top panel ass'y B01874 INCLUDES PANEL AND LATCHES

10 Front divider panel ass'y B01878 INCLUDES PANEL, INSULATION AND LABELS

11 Front divider panel insulation B01853

12 Flue pipe cover ass'y B01747

13 Front access door B40014-06 INCLUDES PANEL, HANDLE AND LATCHES

14 Recess handle Z99F050

15 Radiator baffle ass'y B01751 INCLUDES INSULATION AND BAFFLE

16 Blow er compartiment door ass'y B01873 INCLUDES DOOR AND LABEL

17 Junction box cover B01684

18 Junction box B01683 BOX ONLY

19 Junction box holder plate B01682

20 B!ow er slides B01681 2 REQUIRED

21 Floor B01804

22 Blow er slides support B01794 2 REQUIRED

23 Blower divider panel B01795 PANEL ONLY

24 Left side baffle B01805

25 Left side panel ass'y B0!875-02 INCLUDES PANEL, INSULATION AND BAFFLES

26 Left side panel insulation B0!800-02

27 Hi limit 175-20 F, !.75" R02R005

28 Gasket, flue pipe cover B00205

29 Gasket, burner flange N04Z026

30 Beckett burner B0!537-01

31 Hexagon nut 3/8-16NC zinc F07F0! I

32 Capacitor holder B01024

33 15 MF capacitor L011005

34 3/4 HP direct drive motor L061004 MOTOR ONLY

35A Blower ass'y B0!406-01 INCLUDES BLOWER, MOTOR, CAPACITOR

35B Blow er 12 X !0 Z011008 INCLUDES WHEEL AND HOUSING

36 B!ow er w eel 12X10 Z01L003

37 Motor mounting, band Z0! F012

38 Motor mounting, leg Z01 !009

39 Screw for motor mount leg F03F023 3 REQUIRED

40 Washer for motor mount leg F03F0!0 3 REQUIRED

41 Nut for motor mount band F07J001 3 REQUIRED

42 Bolt for motor mount band F05F015

43 Motor mount ass'y B01889

44 Hi limit 140-20 F, 7" RO2R002

45 Observation door ass'y B01842

46 Electrical insulating barrier A00284

47 Rocker sw itch SPST L07F003

48 Electronic fan timer R99GO02

49 Transformer 120/24 VAC / 40 VA L01 F003-2

50 Female Iatche Z99F003

51 Mate latche Z99F038

52 Filter rack U frame (for 20" X 30" filter) B01809

53 Filter rack access (for 20" X 30" filter) B01808

54 Paper filter 20 x 30 x 1 Z04F013

55 Electrical kit B00203

21

Loading...

Loading...