ICP NHP260GKA1, NHP260AKA1, NHP248GKA1, NHP248AKA1, NHP242GKA1 Owner’s Manual

...

INSTALLATION INSTRUCTIONS

Split System

Premium Line

AC & HP Condensers

These instructions must be read and understood completely before attempting installation.

Installation / Startup Information & Warranty

CAUTION

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation MUST conform with local building

codes or, in the absence of local codes, with the

the National Electrical Code NFPA 70/ANSI

C1-1999 or current edition and Canadian

Electrical Code Part 1 CSA C.22.1.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in equipment

malfunction, property damage, personal injury

and/or death.

After uncrating unit, inspect thoroughly for hidden damage.

If damage is found, notify the transportation company im-

mediately and file a concealed damage claim.

Locating The Outdoor Unit:

Check local codes covering zoning, noise, platforms.

If practical, avoid locating next to fresh air intakes, vent or

bedroom windows. Noise may carry into the openings and

disturb people inside.

Placement of the unit should be in a well drained area or

unit must be supported high enough so runoffwill not enter

the unit.

Do not locate where heat, lint or exhaust fumes will be dis-

charged on unit (as from dryer vents).

Improper installation, adjustment, alteration, service or

maintenance can void the warranty.

The weight of the condensing unit requires caution and

proper handling procedures when lifting or moving to avoid

personal injury. Use care to avoid contact with sharp or

pointed edges.

Safety Precautions

1. Always wear safety eye wear and work gloves when

installing equipment.

2. Never assume electrical power is disconnected. Check

with meter and disconnect.

3. Keep hands out of fan areas when power is connected

to equipment.

4. R-22 causes frost-bite burns.

5. R-22 is toxic when burned.

NOTE TO INSTALLING DEALER: The Owners Instruc-

tions and Warranty are to be given to the owner or promi-

nently displayed near the indoor Furnace/Air Handler Unit.

Roof top installations are acceptable providing the roof will

support the unit and provisions are made for water drain-

age and the noise or vibration through the structure.

Do not install the unit in a recessed or confined area where

recirculation of discharge air may occur.

Heat Pumps Only: The top surface of platform must be

above average winter snow levels to prevent coil blockage.

Clearances:

Nominal operating clearances, where practical, are 48

inches (120 cm) above unit for discharge air and 18 inches

(40cm) around coil for intake air on three sides. Clearance

on one side (normally between unit and structure) may be

reduced to 6 inches (15cm). Nominal clearances are based

from a solid parallel object, wall, roof overhang, etc.

Do Not install under roof overhangs without guttering. A

minimum vertical clearance of 48" is required to overhang.

The clearance may be reduced from a single object with a

small surface area, such as the end of a wall, outside cor-

ner of a wall, fence section or a post, etc. As a general rule

the width ofthe object should equal the minimum clearance

from the unit. For example, a 4 inch (lOcm) fence post

could be 4 inches (lOcm) from the unit.

421 01 3202 02

Dec. 2004

_ Installation Instructions Split System Condensers I

Inside corner locations on single story structures require

evaluation. Large overhanging soffits may cause air recir-

culation in a corner area even though recommended clear-

ances are maintained. As a guide locate the unit far enough

out so that half of the discharge grille is out from under the

soffit.

Two or more units may be spaced with 18 inches (45cm)

between units.

Unit Support:

The unit must be level, and supported above grade by

beams, platform or a pad. Platform or pad can be of open or

solid construction but should be of permanent materials

such as concrete, bricks, blocks, steel or pressure treated

timbers approved for ground contact. Refer to Unit Clear-

ances to help determine size of supports etc. Soil condi-

tions should be considered so the platform or pad does not

shift or settle excessively and leave the unit only partially

supported.

CAUTION

Inadequate support could cause excessive vibration and

noise or binding and stress on refrigerant lines resulting in

equipment failure.

To minimize vibration or noise transmission, it is recom-

mended that supports not be in contact with the building

structure. However, slabs on grade constructions with an

extended pad are normally acceptable.

A, Ground Level Installation:

If beams or an open platform are used for support it is rec-

ommended that the soil be treated or area be graveled to

retard the growth of grasses and weeds.

A service clearance of 24 inches (60cm) is desirable from

control box end or side. Control box and corner panel be-

low it can be loosened and moved out to the side to facili-

tate servicing. Internal components can be accessed

through control box corner or top only.

B. Roof Top Installation:

This type of installation is not recommended on wood

frame structures where low noise levels are required.

Supporting structure or platform for the unit must be level. If

installation is on a flat roof the unit should be 4 inches

(10cm.) above roof level. Four by four posts placed over a

load bearing wall make a suitable mounting platform.

If possible, place the unit over one or more load bearing

walls. If there are several units, mount them on platforms

that are self-supporting and span load bearing walls.

These suggestions are to minimize noise and vibration

transmission through the structure. If the structure is a

home or apartment, avoid (if practical) locating the unit

over bedrooms or study.

NOTE: When condensing unit is to be installed on a

bonded guaranteed roof, a release must be obtained from

the building owner to free the installer from all liabilities.

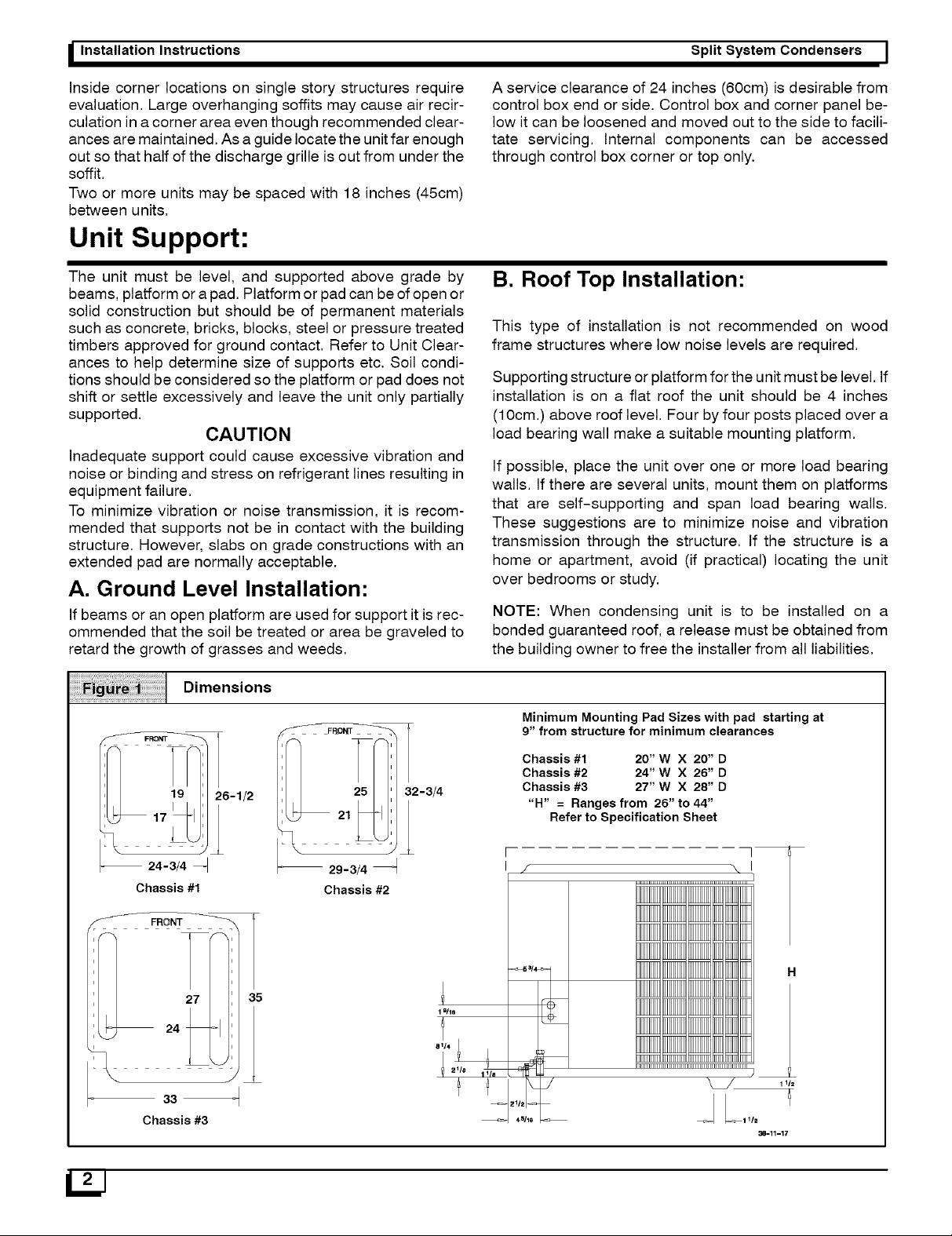

Dimensions

-- 24-3/4 --

Chassis #1

33

Chassis #3

6-1/2

Minimum Mounting Pad Sizes with pad starting at

9" from structure for minimum clearances

Chassis #1 20" W X 20" D

2-3/4

Chassis #2

Chassis #2 24" W X 26" D

Chassis #3 27" W X 28" D

"H" = Ranges from 26" to 44"

Refer to Specification Sheet

[][]

_ H

35

_ 11/2

38-11-17

I Split System Condensers

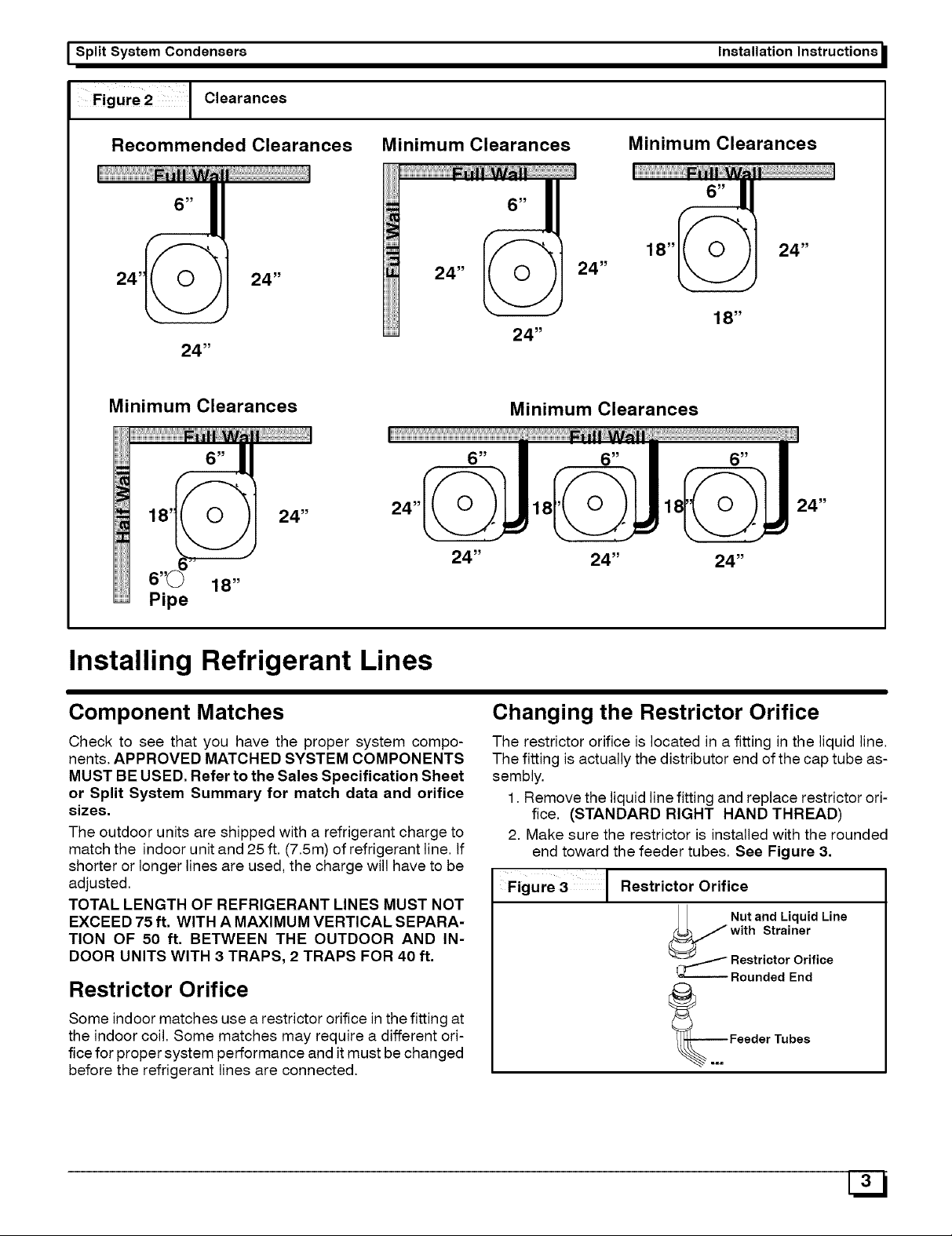

Figure 2 Clearances

Installation Instructions

Recommended Clearances Minimum Clearances

24"

24'_

24"

Minimum Clearances

24"

24" 24" 24"

18"

Minimum Clearances

18

Pipe

Minimum Clearances

24"

24"

18"

24"

Installing Refrigerant Lines

Component Matches

Check to see that you have the proper system compo-

nents. APPROVED MATCHED SYSTEM COMPONENTS

MUST BE USED. Refer to the Sales Specification Sheet

or Split System Summary for match data and orifice

sizes,

The outdoor units are shipped with a refrigerant charge to

match the indoor unit and 25 ft. (7.5m) of refrigerant line. If

shorter or longer lines are used, the charge will have to be

adjusted.

TOTAL LENGTH OF REFRIGERANT LINES MUST NOT

EXCEED 75 ft. WITH A MAXIMUM VERTICAL SEPARA-

TION OF 50 ft. BETWEEN THE OUTDOOR AND IN-

DOOR UNITS WITH 3 TRAPS, 2 TRAPS FOR 40 ft.

Restrictor Orifice

Some indoor matches use a restrictor orifice in the fitting at

the indoor coil. Some matches may require a different ori-

fice for proper system performance and it must be changed

before the refrigerant lines are connected.

Changing the Restrictor Orifice

The restrictor orifice is located in a fitting in the liquid line.

The fitting is actually the distributor end of the cap tube as-

sembly.

1. Remove the liquid line fitting and replace restrictor ori-

fice. (STANDARD RIGHT HAND THREAD)

2. Make sure the restrictor is installed with the rounded

end toward the feeder tubes. See Figure 3.

Figure 3 I Restrictor Orifice

Nut and Liquid Line

with Strainer

!

_Feeder Tubes

I Installation Instructions Split System Condensers I

Refrigeration Line Sets

Ifit is necessary to add tubing in the field, use dehydrated or

dry sealed deoxidized copper refrigeration tube. DO NOT

use copper water pipe.

It is important that no tubing is cut or seals broken until

you are ready to actually make connections to the

evaporator and to the condenser section,

Do not remove rubber plugs or copper caps from the

tube ends until ready to make connections at evapora-

tor and condenser,

PLEASE! UNDER NO CIRCUMSTANCES LEAVE THE

LINES OPEN TO THE ATMOSPHERE FOR ANY

PERIOD OF TIME,

Be extra careful with sharp bends. This tubing can "kink"

very easily, and if this occurs, the entire tube length will

have to be replaced. Extra care at this time will eliminate

future service problems.

Suspension And Installation Of

Refrigeration Lines

DO NOT fasten liquid or suction lines in direct contact with

the floor or ceiling joist. Use an insulated or suspension

type of hanger. Keep both lines separate, and insulate the

suction line. Both lines should be insulated in extremely

long runs in an attic or underground in a raceway, 50' or

more.

Do not let refrigerant lines come in direct contact with

foundation. When running refrigerant lines through the

foundation or wall, the openings should be made large

enough to allow for a sound absorbing material to be

placed or installed between the tubing and the foundation.

This will prevent noise transmission between the tubing

and the wall section (foundation) or the building.

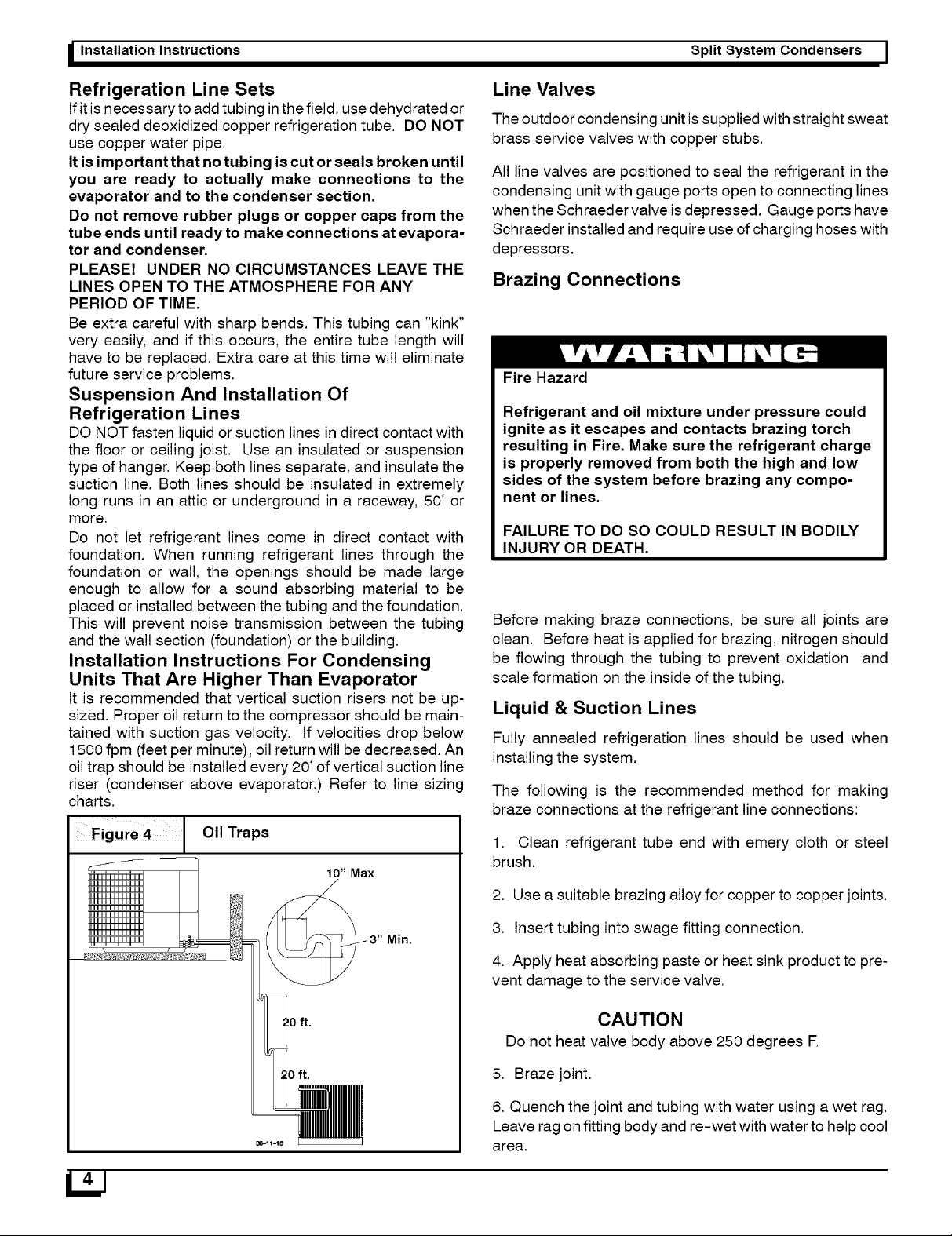

Installation Instructions For Condensing

Units That Are Higher Than Evaporator

It is recommended that vertical suction risers not be up-

sized. Proper oil return to the compressor should be main-

tained with suction gas velocity. If velocities drop below

1500 fpm (feet per minute), oil return will be decreased. An

oil trap should be installed every 20' of vertical suction line

riser (condenser above evaporator.) Refer to line sizing

charts.

Line Valves

The outdoor condensing unit is supplied with straight sweat

brass service valves with copper stubs.

All line valves are positioned to seal the refrigerant in the

condensing unit with gauge ports open to connecting lines

when the Schraeder valve is depressed. Gauge ports have

Schraeder installed and require use of charging hoses with

depressors,

Brazing Connections

Fire Hazard

Refrigerant and oil mixture under pressure could

ignite as it escapes and contacts brazing torch

resulting in Fire, Make sure the refrigerant charge

is properly removed from both the high and low

sides of the system before brazing any compo-

nent or lines.

FAILURE TO DO SO COULD RESULT IN BODILY

INJURY OR DEATH.

Before making braze connections, be sure all joints are

clean. Before heat is applied for brazing, nitrogen should

be flowing through the tubing to prevent oxidation and

scale formation on the inside of the tubing.

Liquid & Suction Lines

Fully annealed refrigeration lines should be used when

installing the system.

The following is the recommended method for making

braze connections at the refrigerant line connections:

Figure 4 [ Oil Traps

12J

0 ft.

10" Max

Min.

1. Clean refrigerant tube end with emery cloth or steel

brush.

2. Use a suitable brazing alloy for copper to copper joints.

3, Insert tubing into swage fitting connection.

4. Apply heat absorbing paste or heat sink product to pre-

vent damage to the service valve.

CAUTION

Do not heat valve body above 250 degrees F.

5, Braze joint.

6, Quench the joint and tubing with water using a wet rag.

Leave rag on fitting body and re-wet with water to help cool

area.

Loading...

Loading...