INSTALLATION INSTRUCTIONS

R−410A Ducted Horizontal Heat Pump

Product Family: HC4H3

Figure 1 - HC4H3

NOTE: Read the entire instruction manual before starting

the installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1........................

INSTALLATION 2−6..................................

Step 1 − Complete Pre−Installation Checks 2........

Step 2 − Rig and Mount Unit 6.....................

Step 3 − Complete Refrigerant Piping Connections 6..

Step 4 − Make Electrical Connections 7.............

START−UP 10.......................................

SERVICE 10........................................

MAINTENANCE 15...................................

TROUBLESHOOTING 16−17..........................

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, or other conditions which may cause death, personal

injury, or property damage. Consult a qualified installer,

service agency, or your distributor or branch for information

or assistance. The qualified installer or agency must use

factory−authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes and National Electrical Code (NEC) for

special requirements.

Recognize safety information. This is the safety−alert

symbol

instructions or manuals, be alert to the potential for personal

injury. Understand these signal words; DANGER,

WARNING, and CAUTION. These words are used with the

safety−alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe

practices which would result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

!

!

When you see this symbol on the unit and in

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in

personal injury or death.

Before installing, modifying, or servicing system,

main electrical disconnect switch must be in the

OFF position. There may be more than 1

disconnect switch. Lock out and tag switch with a

suitable warning label.

WARNING

428 01 9700 03 Sep 2010

INSTALLATION

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could result in personal

injury or equipment damage.

R−410A refrigerant systems operate at higher

pressures than standard R−22 systems. Do not use

R−22 service equipment or components on R−410A

refrigerant equipment.

PERSONAL INJURY AND EQUIPMENT DAMAGE

HAZARD

Failure to follow this caution may result in personal

injury and / or equipment damage.

DO NOT operate the unit without a filter or with grille

removed.

Step 1 —Complete Pre−Installation Checks

Unpack Unit

Move the unit to final location. Remove unit from carton,

being careful not to damage service valves and grilles.

Inspect Shipment

File a claim with the shipping company if shipment is

damaged or incomplete. Check the unit nameplates to

ensure units match job requirements.

WARNING

!

CAUTION

Consider System Requirements

Consult local building codes and NEC for special installation

requirements.

Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Figure 3.

Locate unit so that condenser airflow is unrestricted on both

sides. Refer to Figure 3.

Unit may be mounted on a level pad directly on base legs or

mounted on raised pads at support points. See Figure 3 for

center of gravity.

Matching the Heat Pump to an Indoor Unit

The HC4H3 ducted heat pump units can be matched to

corresponding indoor units. The HC4H3 unit can be

matched with underceiling and residential fan coils and

evaporator coils. Refer to separate indoor unit literature for

more information.

Expansion Device − Cooling Mode

A hard shutoff, thermostatic expansion valve (TXV) is

required at the indoor section of the system for proper

operation of these products. If the indoor section of the

system is not equipped with a hard shutoff TXV, refer to

Spec Sheet for the correct TXV kit to be installed. Follow

the instructions in the kit for proper installation.

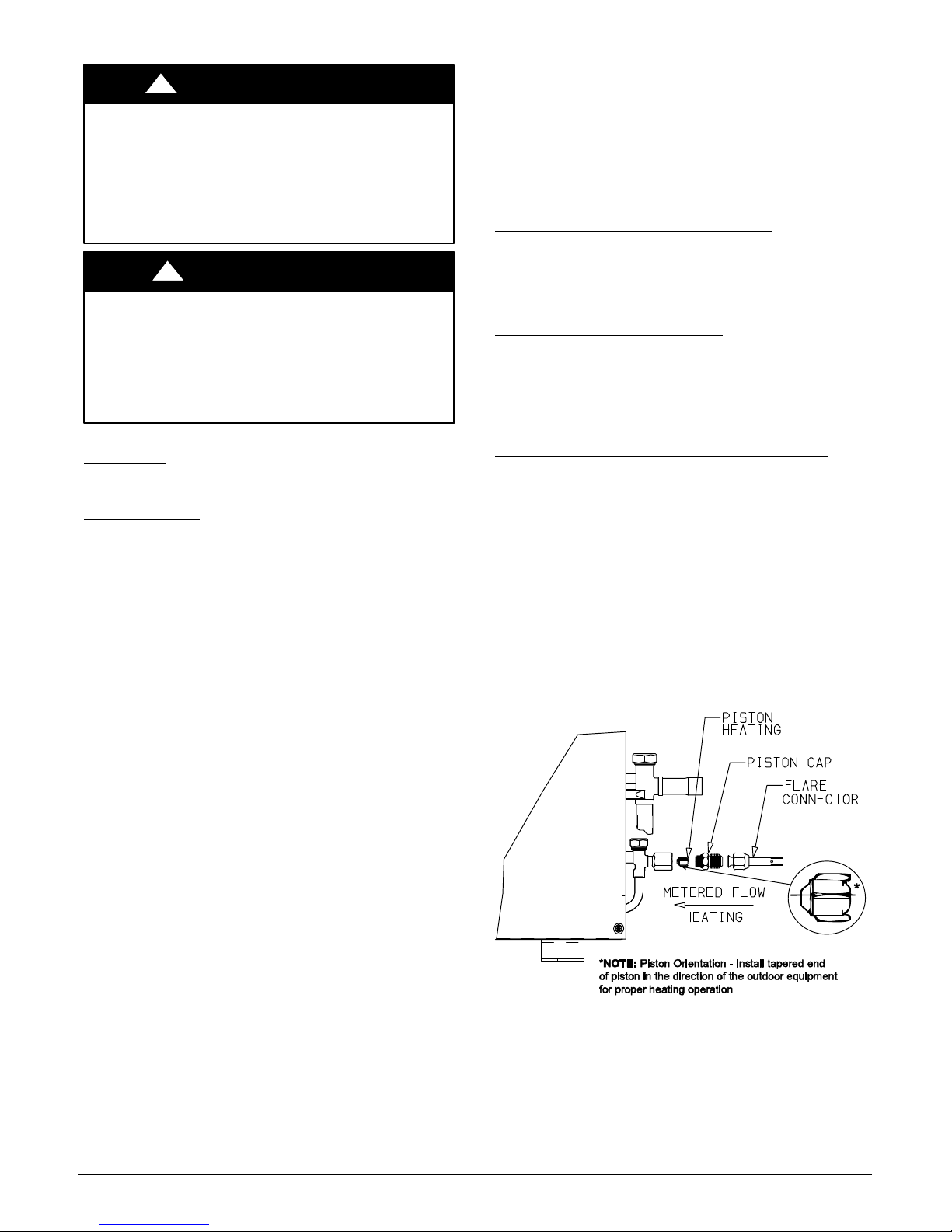

Check AccuRater Metering Device − Heating Mode

The correct AccuRater (bypass type) refrigerant control is

required for system capacity optimization. An AccuRater

device with field−replaceable piston is supplied with the

outdoor unit (see Figure 2).

Do not interchange components between the AccuRater

device types. Matching of outdoor unit with indoor unit may

require field replacement of piston. Replace piston, if

required, before connecting refrigerant lines. See Figure 2.

Piston replacement instructions are included in the indoor

unit installation instructions. After system installation is

complete, see the Refrigerant Charging section in this

document to check and/or adjust refrigerant charge.

2 428 01 9700 03

A07407b

Figure 2 - AccuRater (bypass type)

Metering Device Components

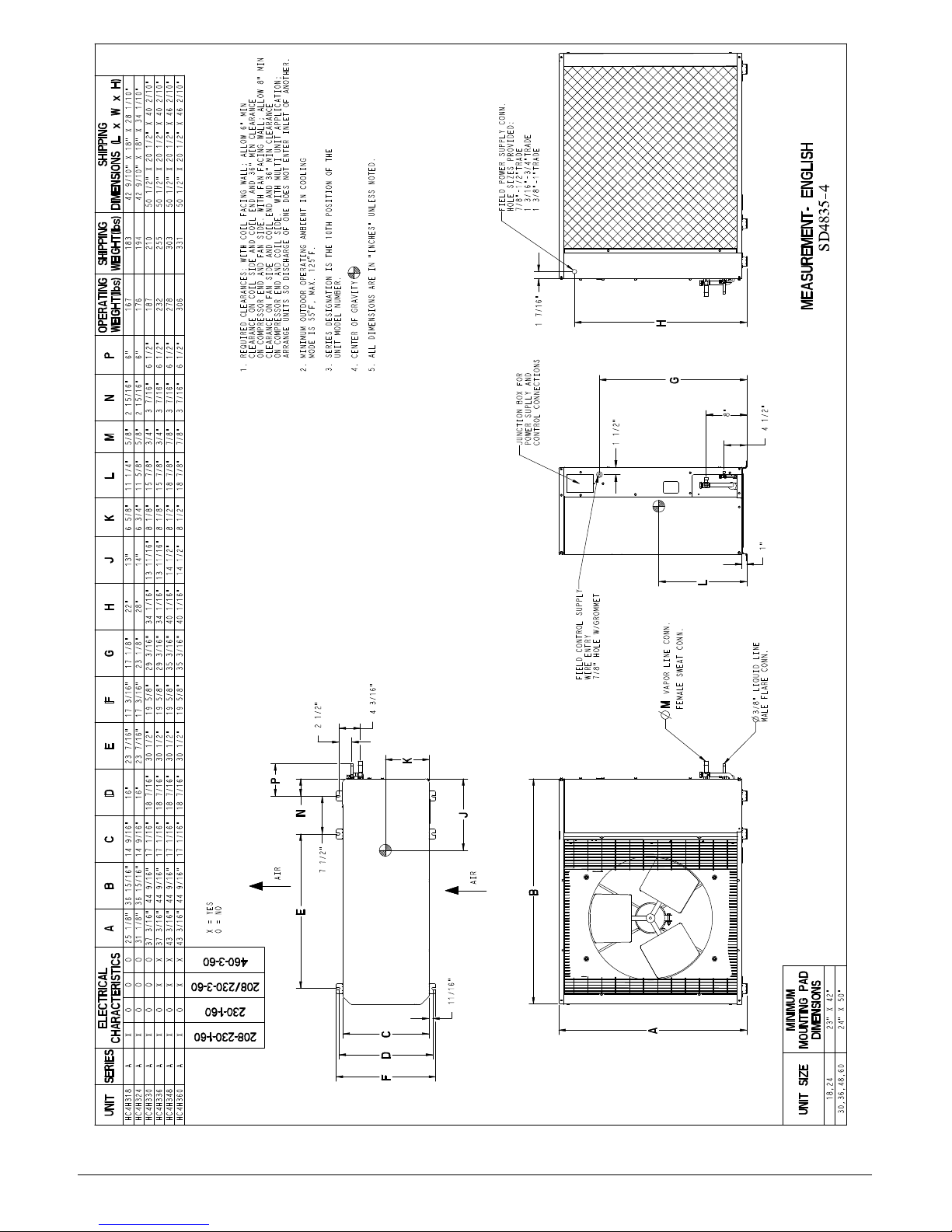

1. REQUIRED CLEARANCES: WITH COIL FACING WALL; ALLOW 6 MIN

CLEARANCE ON COIL SIDE AND COIL END AND 36 MIN CLEARANCE

ON COMPRESSOR END AND FAN SIDE. WITH FAN FACING WALL; ALLOW 8 MIN

CLEARANCE ON FAN SIDE AND COIL END AND 36 MIN CLEARANCE

ON COMPRESSOR END AND COIL SIDE. WITH MULTI UNIT APPLICATION;

ARRANGE UNITS SO DISCHARGE OF ONE DOES NOT ENTER INLET OF ANOTHER.

3. SERIES DESIGNATION IS THE 10TH POSITION OF THE

2. MINIMUM OUTDOOR OPERATING AMBIENT IN COOLING

UNIT MODEL NUMBER.

MODE IS 55 $

5. ALL DIMENSIONS ARE IN INCHES UNLESS NOTED.

FIELD POWER SUPPLY CONN.

HOLE SIZES PROVIDED:

7/8−1/2TRADE

1 3/16−3/4TRADE

1 3/8−1TRADE

F, MAX. 125 $F.

OPERATING

WEIGHT(lbs)

4. CENTER OF GRAVITY

14 1/2 8 1/2 18 7/8 7/8 3 7/16 6 1/2 278 303 50 1/2 X 20 1/2 X 46 2/10

14 1/2 8 1/2 18 7/8 7/8 3 7/16 6 1/2 306 331 50 1/2 X 20 1/2 X 46 2/10

11/16 8 1/8 15 7/8 3/4 3 7/16 6 1/2 187 210 50 1/2 X 20 1/2 X 40 2/10

3 11/16 8 1/8 15 7/8 3/4 3 7/16 6 1/2 232 255 50 1/2 X 20 1/2 X 40 2/10

6 5/8 11 1/4 5/8 2 15/16 6 167 183 42 9/10 X 18 X 28 1/10

14 6 3/4 11 5/8 5/8 2 15/16 6 176 194 42 9/10 X 18 X 34 1/10

4 3/16

2 1/2

1 7/16

JUNCTION BOX FOR

POWER SUPLLY AND

CONTROL CONNECTIONS

FIELD CONTROL SUPPLY

WIRE ENTRY

7/8 HOLE W/GROMMET

1 1/2

8

L

VAPOR LINE CONN.

M

FEMALE SWEAT CONN.

MEASUREMENT− ENGLISH

4 1/2

1

K

P

X = YES

O = NO

N

7 1/2

AIR

E

J

AIR

B

460−3−60

208/230−3−60

230−1−60

208−230−1−60

11/16

A

DIMENSIONS

FDC

UNIT SERIES ABC DE FG H J K L MNP

HC4H318 A XOOO25

HC4H324 A XOOO31

HC4H330 A XOOO37

HC4H336 A XOXX37

HC4H348 A XOXX43

HC4H360 A XOXX43

UNIT SIZE

Figure 3 - HC4A3 Unit Dimensions

428 01 9700 03 3

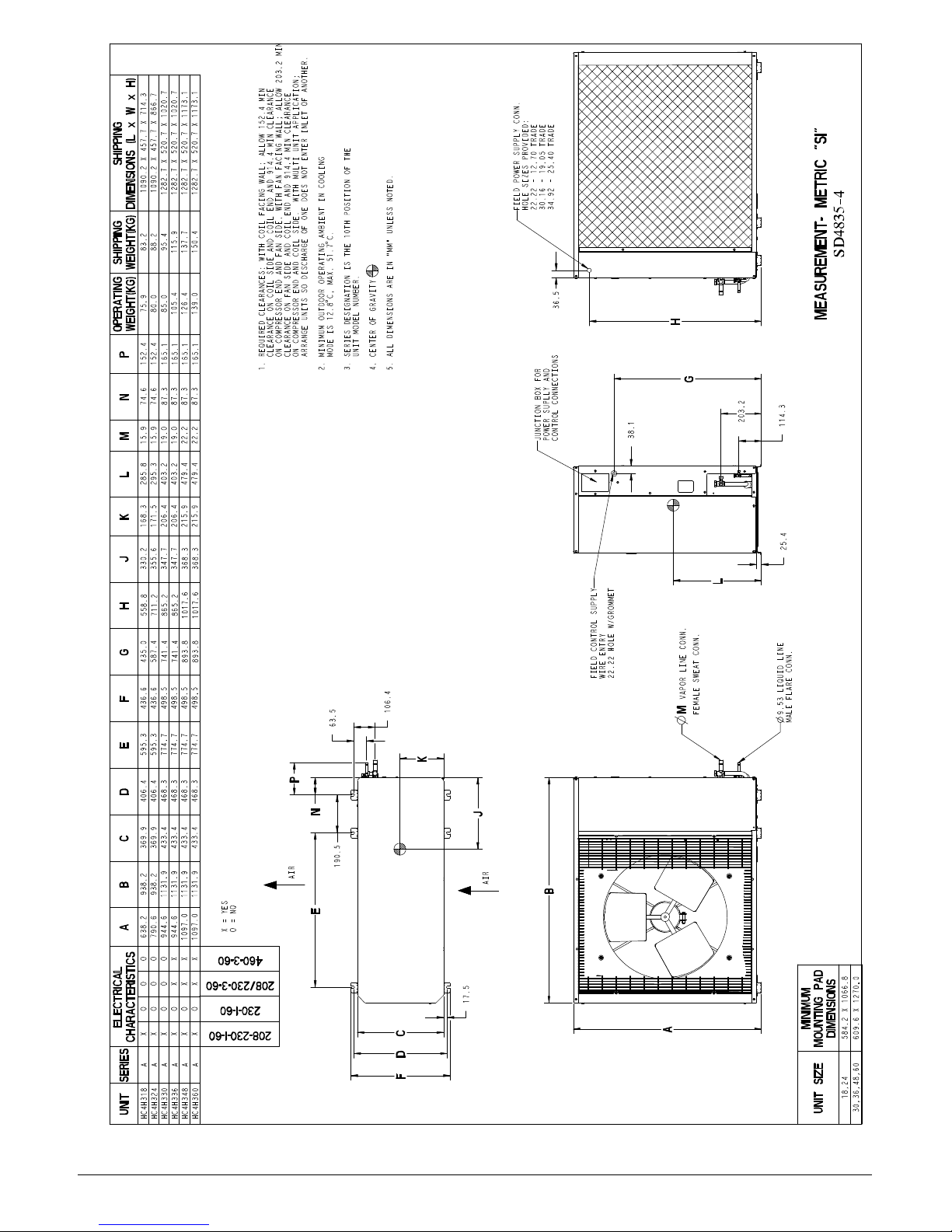

FIELD POWER SUPPLY CONN.

R

HOLE SIZES PROVIDED:

22.22 − 12.70 TRADE

30.16 − 19.05 TRADE

34.92 − 25.40 TRADE

1. REQUIRED CLEARANCES: WITH COIL FACING WALL; ALLOW 152.4 MIN

CLEARANCE ON COIL SIDE AND COIL END AND 914.4 MIN CLEARANCE

ON COMPRESSOR END AND FAN SIDE. WITH FAN FACING WALL; ALLOW 203.2 MIN

CLEARANCE ON FAN SIDE AND COIL END AND 914.4 MIN CLEARANCE

ON COMPRESSOR END AND COIL SIDE. WITH MULTI UNIT APPLICATION;

ARRANGE UNITS SO DISCHARGE OF ONE DOES NOT ENTER INLET OF ANOTHER.

85.0 95.4 1282.7 X 520.7 X 1020.7

105.4 115.9 1282.7 X 520.7 X 1020.7

126.4 137.7 1282.7 X 520.7 X 1173.1

WEIGHT(KG)

OPERATING

165.1

165.1

87.3 165.1

215.9 479.4 22.2 87.3

330.2 168.3 285.8 15.9 74.6 152.4 75.9 83.2 1090.2 X 457.7 X 714.3

355.6 171.5 295.3 15.9 74.6 152.4 80.0 88.2 1090.2 X 457.7 X 866.7

347.7 206.4 403.2 19.0

347.7 206.4 403.2 19.0 87.3

711.2

558.8

741.4 865.2

741.4 865.2

893.8 1017.6 368.3

3. SERIES DESIGNATION IS THE 10TH POSITION OF THE

2. MINIMUM OUTDOOR OPERATING AMBIENT IN COOLING

UNIT MODEL NUMBER.

MODE IS 12.8 $

C, MAX. 51.7 $C.

139.0 150.4 1282.7 X 520.7 X 1173.1

165.1

215.9 479.4 22.2 87.3

893.8 1017.6 368.3

4. CENTER OF GRAVITY

5. ALL DIMENSIONS ARE IN MM UNLESS NOTED.

36.5

JUNCTION BOX FOR

POWER SUPLLY AND

CONTROL CONNECTIONS

FIELD CONTROL SUPPLY

WIRE ENTRY

22.22 HOLE W/GROMMET

38.1

MEASUREMENT− MET

203.2

114.3

25.4

L

UNIT SERIES ABC DE FG H J K L MNP

XOOO 638.2 938.2 369.9 406.4 595.3 436.6 435.0

XOOO 790.6 938.2 369.9 406.4 595.3 436.6 587.4

HC4H318 A

HC4H324 A

XOOO 944.6 1131.9 433.4 468.3 774.7 498.5

HC4H330 A

XOXX 944.6 1131.9 433.4 468.3 774.7 498.5

HC4H336 A

XOXX 1097.0 1131.9 433.4 468.3 774.7 498.5

HC4H348 A

XOXX 1097.0 1131.9 433.4 468.3 774.7 498.5

HC4H360 A

X = YES

O = NO

VAPOR LINE CONN.M

63.5

106.4

FEMALE SWEAT CONN.

K

N

AIR

N

190.5

J

AIR

B

460−3−60

208/230−3−60

230−1−60

208−230−1−60

17.5

A

DIMENSIONS

FDC

UNIT SIZE

4 428 01 9700 03

Figure 4 - HC4A3 Unit Dimensions

Table 1—HC4H318−60 Physical Data

UNIT HC4H3 18 24 30 36 48 60

NOMINAL CAPACITY Tons 1.5 2.0 2.5 3.0 4.0 5.0

OPERATING WEIGHT lb (kg) 167 (75.75) 176 (79.83) 187 (84.82) 232 (105.23) 278 (126.10) 306 (138.80)

REFRIGERANT TYPE R-410A

METERING DEVICE TXV (Indoor Unit)

CHARGE* (lb) (kg) 6.8 (3.89) 7.0 (3.18) 12.0 (5.45) 12.5 (5.68) 12.2 (5.55) 12.8 (5.82)

COMPRESSOR

Type Scroll

Oil Charge (POE -oz) 25.0 25.0 25.0 25.0 42.0 42.0

Crankcase Heater (watts) — — 40 40 40 40

OUTDOOR FAN

Rpm/Cfm 840/1720 840/1720 850/3900 850/3900 850/3900 850/3900

Diameter in. (mm) 18 (457) 18 (457) 24 (610) 24 (610) 24 (610) 24 (610)

No. Blades 3 3 3 3 3 3

Motor (hp)

OUTDOOR COIL

Face Area sq. ft. (sq. m.) 5.8 (.54) 7.3 (.68) 12.1 (1.12) 12.1 (1.12) 14.1 (1.31) 14.1 (1.31)

No. Rows 3 3 2 3 3 3

FPI 20 20 20 20 20 20

HIGH PRESSURE SWITCH

Cut-In (psig) Cutout (psig)

LOW PRESSURE SWITCH

Low Cutout (psig)

Low Cut-in (psig)

REFRIGERANT LINES

Connection Type Sweat

Liquid Line (in.) OD

Vapor Line (in.) OD

Max Length ft (m) 200 (60.96)

Max Lift ft (m) 65 (19.81)

Max Drop ft (m) 150 (45.72)

CONTROLS

Fusible Plug F (C) 210 (98.89)

Control Voltage 24 vac

System Voltage 208/230 v 208/230 v 208/230 v 208/230 v, Single and 3 Phase, 460 v, 3 Phase

FINISH Gray

* Unit shipped with full factory charge. See ARI (Air Conditioning and Refrigeration Institute) capacity table for proper charge and piston for each fan coil type.

Valve connection size is 7/8 inch. Recommended line size is 1-1/8 inches.

24 v and a minimum of 40 va is provided in the fan coil unit.

FPI - Fins Per Inch

POE - Polyol Ester

1/8 1/8 1/4 1/4 1/4 1/4

420 ± 25

650 ± 10

20 ± 5

45 ± 25

420 ± 25

650 ± 10

20 ± 5

45 ± 25

5/8 3/4 7/8 7/8†

420 ± 25

650 ± 10

20 ± 5

45 ± 25

3/8

420 ± 25

650 ± 10

20 ± 5

45 ± 25

420 ± 25

650 ± 10

20 ± 5

45 ± 25

420 ± 25

650 ± 10

20 ± 5

45 ± 25

428 01 9700 03 5

Step 2 —RIG AND MOUNT UNIT

Mounting on Ground

Mount unit on a solid, level concrete pad. Position unit so

water or ice from roof does not fall directly onto unit. Use

field−provided snow stand or ice rack where prolonged

subfreezing temperatures or heavy snow occurs.

If conditions or local codes require unit be fastened to a pad,

6 field−supplied tiedown bolts should be used and fastened

through slots provided in unit mounting feet.

Mounting on Roof

Mount unit on a level platform or frame at least 6 in. (152.4

mm) above roof surface. Isolate unit and tubing from

structure.

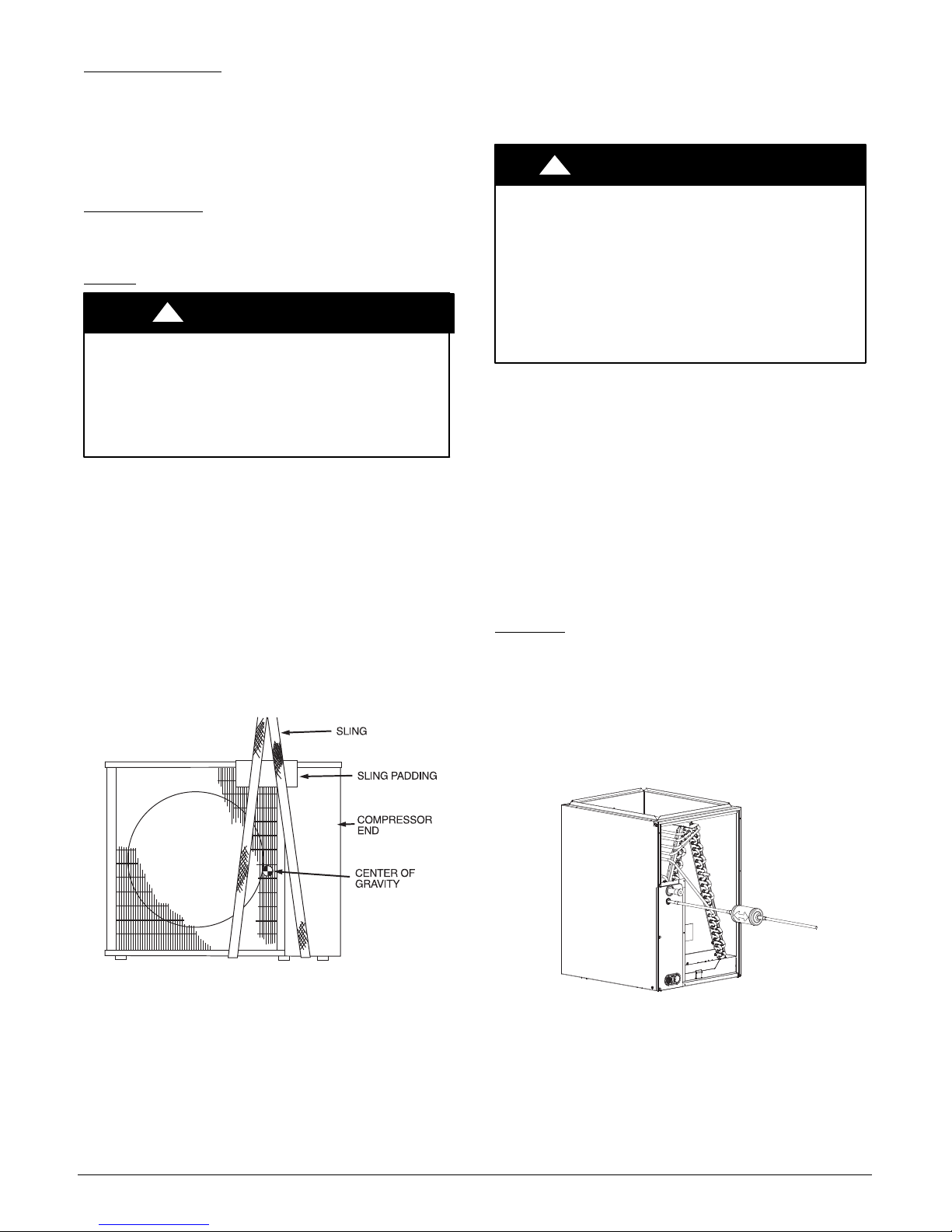

Rigging

!

PERSONAL INJURY AND/OR EQUIPMENT

DAMAGE HAZARD

Failure to follow this caution may result in personal

injury and/or equipment damage.

Be sure unit panels are securely in place prior to

rigging.

Keep the unit upright and lift unit using a sling. Use

cardboard or padding under the sling, and spreader bars to

prevent sling damage to the unit. See Figure 5. See

Figure 3 for center of gravity reference. Install the unit so

that the coil does not face into prevailing winds. If this is not

possible and constant winds above 25 mph are expected,

use accessory wind baffle. See installation instructions

provided with the accessory kit.

NOTE: Accessory wind baffles should be used on all units

with accessory low ambient temperature control.

Field−fabricated snow or ice stands may be used to raise

unit when operation will be required during winter months.

Units may also be wall mounted using the accessory wall

mounting kit.

CAUTION

Step 3 —COMPLETE REFRIGERANT PIPING

CONNECTIONS

Outdoor units may be connected to indoor units using

field−supplied tubing of refrigerant grade and condition. See

Table 1 for correct line sizes. Do not use less than 10 ft

(3.05 m) of interconnecting tubing.

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

If any section of pipe is buried, there must be a 6 in.

(152.4 mm) vertical rise to the valve connections on

the outdoor unit. If more than the recommended

length is buried, refrigerant may migrate to cooler,

buried section during extended periods of system

shutdown. This causes refrigerant slugging and

could possibly damage the compressor at start−up.

When more than 80 ft (24.38 m) of interconnecting tubing

and more than 20 ft (6.10 m) of vertical lift is used, consult

the residential Long Line Application Guide for required

accessories. If either refrigerant tubing or indoor coil is

exposed to the atmosphere, the system must be evacuated

following good refrigeration practices.

Run refrigerant tubes as directly as possible, avoiding

unnecessary turns and bends. Suspend refrigerant tubes so

they do not damage insulation on vapor tube and do not

transmit vibration to structure. Also, when passing

refrigerant tubes through a wall, seal the opening so that

vibration is not transmitted to structure. Leave some slack in

refrigerant tubes between structure and outdoor unit to

absorb vibration. Refer to separate indoor unit installation

instructions for additional information.

Filter Drier

Refer to Figure 6 and install filter drier as follows:

1. Braze 5 in. (127 mm) liquid tube to the indoor coil.

2. Wrap filter drier with damp cloth.

3. Braze filter drier to 5 in. (127 mm) long liquid tube

from step 1.

4. Connect and braze liquid refrigerant tube to the filter

drier.

CAUTION

Figure 5 - Lifting Unit with Sling

6 428 01 9700 03

A07396

A05227

Figure 6 - Filter Drier Components

The filter drier must be replaced whenever the refrigeration

system is exposed to the atmosphere.

Only use factory specified liquid−line filter driers with rated

working pressures less than 600 psig.

NOTE: Do not install a suction−line filter drier in liquid line.

Loading...

Loading...