These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER - Immediate hazards which will result in

severe personal injury or death.

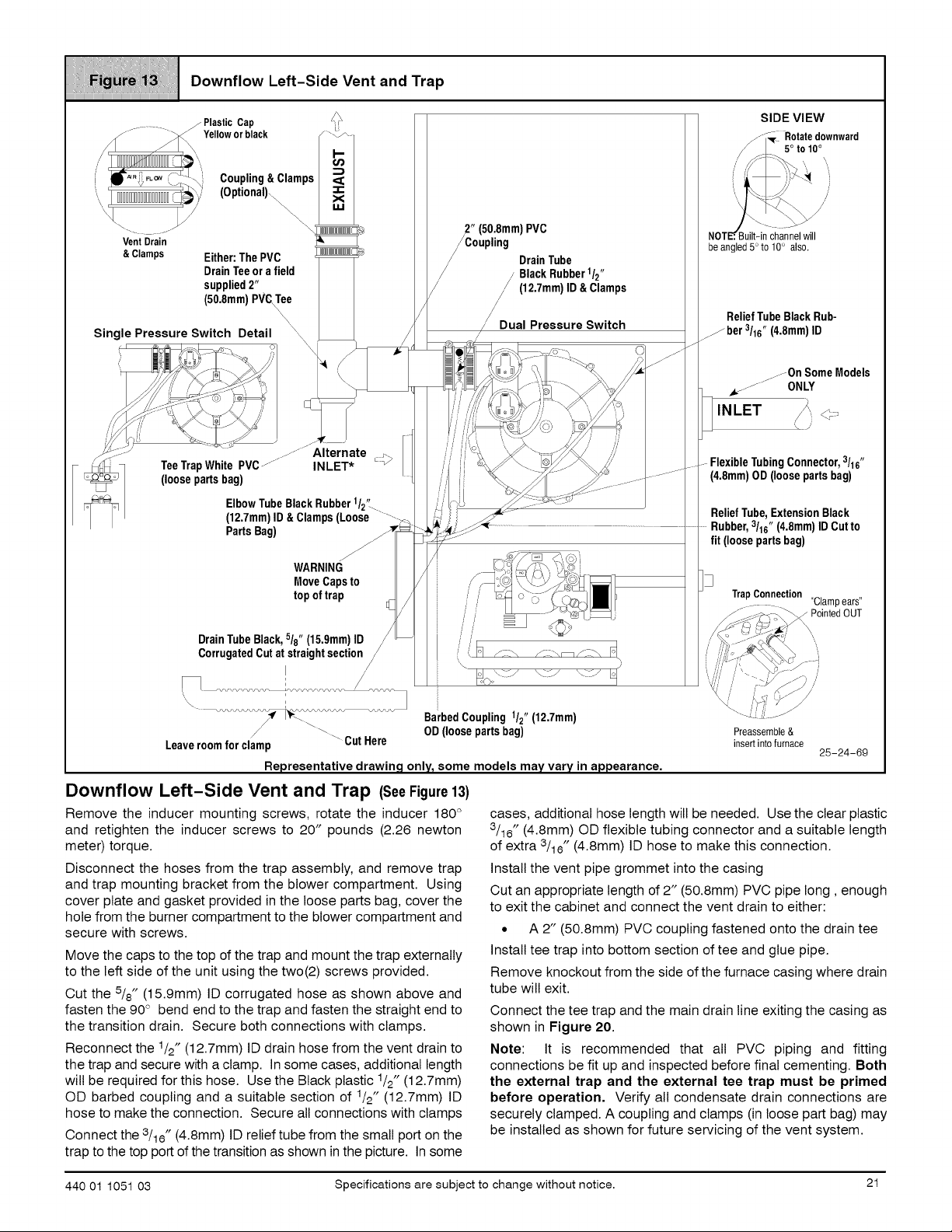

WARNING - Hazards or unsafe practices which

could result in severe personal injury or death.

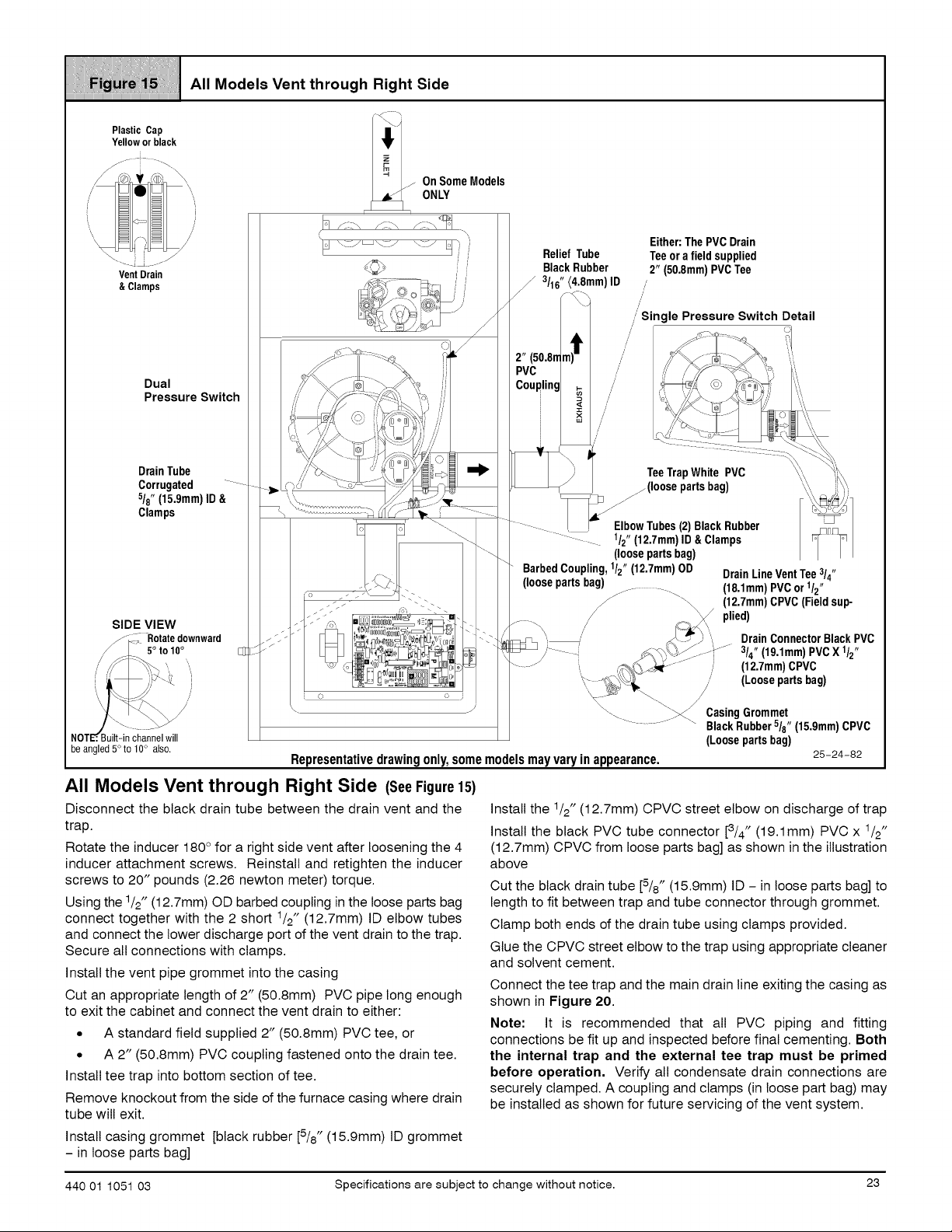

CAUTION - Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE - Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

The signal word CAUTION is used throughout

this manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

z_ Safety-alert symbol

When you see this symbol on the unit and in

instructions or manuals, be alert to the

potential for personal injury.

TABLE OF CONTENTS

Start-up Check Sheet ......................... 3

Safety considerations .......................... 4

Safe Installation Requirements .................. 4

Installation ................................... 6

Combustion & Ventilation Air .................... 10

Vent and Combustion Air Piping ................. 14

Concentric Termination ......................... 32

Gas Supply and Piping ......................... 32

Electrical Wiring ............................... 37

Ductwork and Filter ............................ 38

Checks and Adjustments ....................... 41

Furnace Maintenance .......................... 43

Sequence of Operation & Diagnostics ............ 44

Wiring Diagram (*9MPX) ....................... 46

Technical Support ............................. 47

Use of the AHRI Certified TM Mark indicates a

manufacturer's participation in the program.

For verification of certification for individual

products, go to www.ahridirectory.org .

International Comfort Products, LLC

Lewisburg, TN 37091 U.S.A.

www.icpusa.com

Portions of the text and tables are reprinted from NFPA 54/ANSI Z223.1-2009©, with permission of National Fire Protection Association, Quincy, MA 02269 and American Gas Association, Washington,

DC 20001. This reprinted material is not the complete and official position of the NFPA or ANSI, on the referenced subject, which is represented only by the standard in its entirety.

Printed in U.S.A. Specifications are subject to change without notice. 440 01 1051 03 Dec. 2010

PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning could

result in equipment malfunction, property damage,

3ersonal injury and/or death.

Installation or repairs made by unqualified persons could

result in equipment malfunction, property damage,

3ersonal injury and/or death.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

3rocedures and equipped with proper tools and test

instruments.

Installation must conform with local building codes and

with the Natural Fuel Gas Code (NFCG) NFPA 54/ANSI

Z223.1, and National standards of Canada

CAN/CSA-B149.1 and .2 Natural Gas and Propane

Installation Codes.

INSTALLER: Affix these instructions on or adjacent to the

furnace.

CONSUMER: Retain these instructions for future

reference.

Required Notice for Massachusetts Installations

Important

The Commonwealth of Massachusetts requires compliance with regulation 248 CMR as follows:

5.08: Modifications to NFPA-54, Chapter 10

2) Revise 10.8.3 by adding the following additional requirements:

(a)

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet

above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied:

1,

INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled equipment,

the installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on

the floor level where the gas equipment is to be installed, in addition, the installing plumber or gasfitter shall observe that a battery operated or

hard wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of qualified license

professionals for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall have a period

of thirty (30) days to comply with the above requirement; provided, however, that during said thirty (30) day period, a battery operated

carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight (8)

feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign

shall read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state of local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248

CMR 5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a) 1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the most current edition of NFPA 54 as adopted by the

Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c)

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the instructions provided by

the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d)

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a Product Approved

side wall horizontally vented gas fueled equipment does not provide the parts for venting the flue gases, but identifies "special venting systems", the

following requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a parts list and

detailed installation instructions.

(e)

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts

lists for venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of the installation.

For questions regarding these requirements, please contact the Commonwealth of Massachusetts Board of State Examiners of Plumbers and Gas

Fitters, 239 Causeway Street, Boston, MA 02114. 617-727-9952

44001 1051 03

Specifications are subject to change without notice.

Printed in U.S.A.

START-UP CHECK SHEET

For 95% Furnace

(This sheet is optional. Keep this page for future reference.)

Date of Start-Up:

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Setup Checks

Check the box when task is complete

Calculated Firing Rate:(See Checks and

Section)..

Heating Check

Measured Line Pressure when Firing Unit:

Measured Manifold Gas Pressure:

Temperature of Supply Air: (o)__

Temperature of Return Air: (o)__

Temperature Rise (supply-return temperature): (o)__

In Rise (see furnace rating plate)? (o)__

Static Pressure (Ducts): Supply Air Return __

Which blower speed tap is used? (Heating)

Optional Check: CO ? CO2 ?

Cooling Check

Temperature of Supply Air: (o)__

Adjustments

All Electrical Connections Tight?

Have hoses been relocated for furnace application

(upflow/horizontal)?

Condensate Drain Connected?

Condensate Drain Trapped?

Manual Gas Shut-Off Upstream of Furnace/Drip-Leg?LU

Gas Valve turned ON?

Type of Gas: Natural: Lj

Filter Type and Size:

440 01 1051 03 Specifications are subject to change without notice. 3

Propane: Lj

Temperature of Return Air: (o)__

Temperature Difference: (o)__

Static Pressure (Ducts) cooling: Supply Air Return

Blower Speed Tap used for cooling:

Dealer Comments:

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency,

or your distributor or branch for information or assistance. The

qualified installer or agency must use factory-authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for

brazing operations. Have fire extinguisher available.

Read these instructions thoroughly and follow all

warnings or cautions included in literature and attached

to the unit. Consult local building codes, the current

editions of the National Fuel Gas Code (NFCG) NFPA

54/ANSI Z223.1, and the National Electrical Code (NEC)

NFPA 70.

In Canada refer to the current editions of the National

standards of Canada CAN/CSA-B149.1 and .2 Natural

Gas and Propane Installation Codes, and Canadian

Electrical Code CSA C22.1.

Recognize safety information. This is the safety-alert

symbol z_. When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for

personal injury. Understand these signal words;

DANGER, WARNING, and CAUTION. These words are

used with the safety-alert symbol. DANGER identifies the

most serious hazards which will result in severe personal

injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is

used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, always turn off main power switch to unit and

install lockout tag. Unit may have more than one

power switch.

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow safety warnings could result in

personal injury, death, and/or property damage.

This furnace is not designed for use in mobile homes,

trailers or recreational vehicles.

CUT HAZARD

Failure to follow this caution may result in damage

personal injury.

Sheet metal parts may have sharp edges or burrs.

Use care and wear appropriate protective clothing,

safety glasses and gloves when handling parts and

servicin 9 furnaces.

Safe Installation Requirements

FIRE, EXPLOSION, AND ASPHYXIATION HAZARD

Improper adjustment, alteration, service,

maintenance or installation could cause personal

injury, death and/or property damage.

Installation or repairs made by unqualified persons

could result in hazards to you and others.

Installation MUST conform to local codes or, in the

absence of local codes, with codes of all

governmental authorities having jurisdiction.

The information contained in this manual is

intended for use by a qualified service agency that

is experienced in such work, is familiar with all

precautions and safety procedures required in

such work, and is equipped with the proper tools

and test instruments.

NOTE: This furnace is design-certified by the CSA International

(formerly AGA and CGA) for installation in the United States and

Canada. Refer to the appropriate codes, along with this manual,

for proper installation.

• Use only the type of gas approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation. (Furnaces

can be converted to Propane gas with approved kit.)

• Install this furnace only in a location and position as

specified in "Installation" of these instructions.

• Provide adequate combustion and ventilation air to the

furnace as specified in "Combustion and Ventilation Air" of

these instructions.

Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only, as

specified in "Vent and Combustion Air Piping" of these

instructions.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for

the detection of leaks to check all connections, as

specified in "Gas Supply and Piping, Final Check" of these

instructions.

Always install furnace to operate within the furnace's

intended temperature-rise range with a duct system which

has an external static pressure within the allowable range,

as specified in "Technical Support Manual" of these

instructions. See furnace rating plate.

4 Specifications are subject to change without notice. 440 01 1051 03

• When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be handled

by a duct(s) sealed to the furnace casing and terminating

outside the space containing the furnace.

• A gas-fired furnace for installation in a residential garage

must be installed as specified in "Installation" of these

instructions.

• This furnace is not to be used for temporary heating of

buildings or structures under construction.

• This furnace is NOT approved for installation in

mobile homes, trailers or recreation vehicles.

• Seal around supply and return air ducts.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are

protected from direct contact with water.

SafetyRules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. Consumer Product Safety Commission encourages

installation of carbon monoxide alarms. There can be various

sources of carbon monoxide in a building or dwelling. The

sources could be gas-fired clothes dryers, gas cooking

stoves, water heaters, furnaces, gas-fired fireplaces, wood

fireplaces.

Carbon monoxide can cause bodily injury and/or death.

Carbon monoxide or "CO" is a colorless and odorless gas

produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

Therefore, to help alert people of potentially dangerous carbon

monoxide levels, you should have a commercially available

carbon monoxide alarm that is listed by a nationally

recognized testing agency in accordance with Underwriters

Laboratories Inc. Standard for Single and Multiple Station

Carbon Monoxide Alarms, ANSl/UL 2034 or the CSA 6.19-01

Residential Carbon Alarming Devices installed and

maintained in the building or dwelling concurrently with the

gas-fired furnace installation (see Note below). The alarm

should be installed as recommended by the alarm

manufacturer's installation instructions.

B. There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause bodily injury, death,

and/or property damage. Therefore, in order to alert people of

potentially dangerous fire or smoke, you should have fire

extinguisher and smoke alarms listed by Underwriters

Laboratories installed and maintained in the building or

dwelling (see Note below).

Note: The manufacturer of your furnace does not test any alarms

and makes no representations regarding any brand or type

of alarms.

C. To ensure safe and efficient operation of your unit, you should

do the following:

1. Thoroughly read this manual and labels on the unit. This

will help you understand how your unit operates and the

hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water.

Immediately call a qualified service technician to inspect the

unit and to replace any part of the control system and any gas

control which has been under water.

3. Never obstruct the vent grilles, or any ducts that provide

air to the unit. Air must be provided for proper combustion

and ventilation of flue gases.

FrozenWaterPipeHazard

WATER DAMAGE TO PROPERTY HAZARD

Failure to follow this caution may result in property

damage.

Do not leave your home unattended for long periods

during freezing weather without turning off water

supply and draining water pipes or otherwise

protecting against the risk of frozen pipes and result

in damage.

Your furnace is designed solely to provide a safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety

devices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

If your furnace remains off for an extended time, the pipes in your

home could freeze and burst, resulting in water damage.

If the structure will be unattended during cold weather you should

take these precautions.

1. Turn off the water supply to the structure and drain the water

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

-or-

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

-or-

3. Install a reliable remote sensing device that wilt notify

somebody of freezing conditions within the home.

WinterShutdown

If you go away during the winter months and do not leave the heat

on in your home, the plastic transition box and the condensate trap

on the furnace must be protected from freeze damage.(See

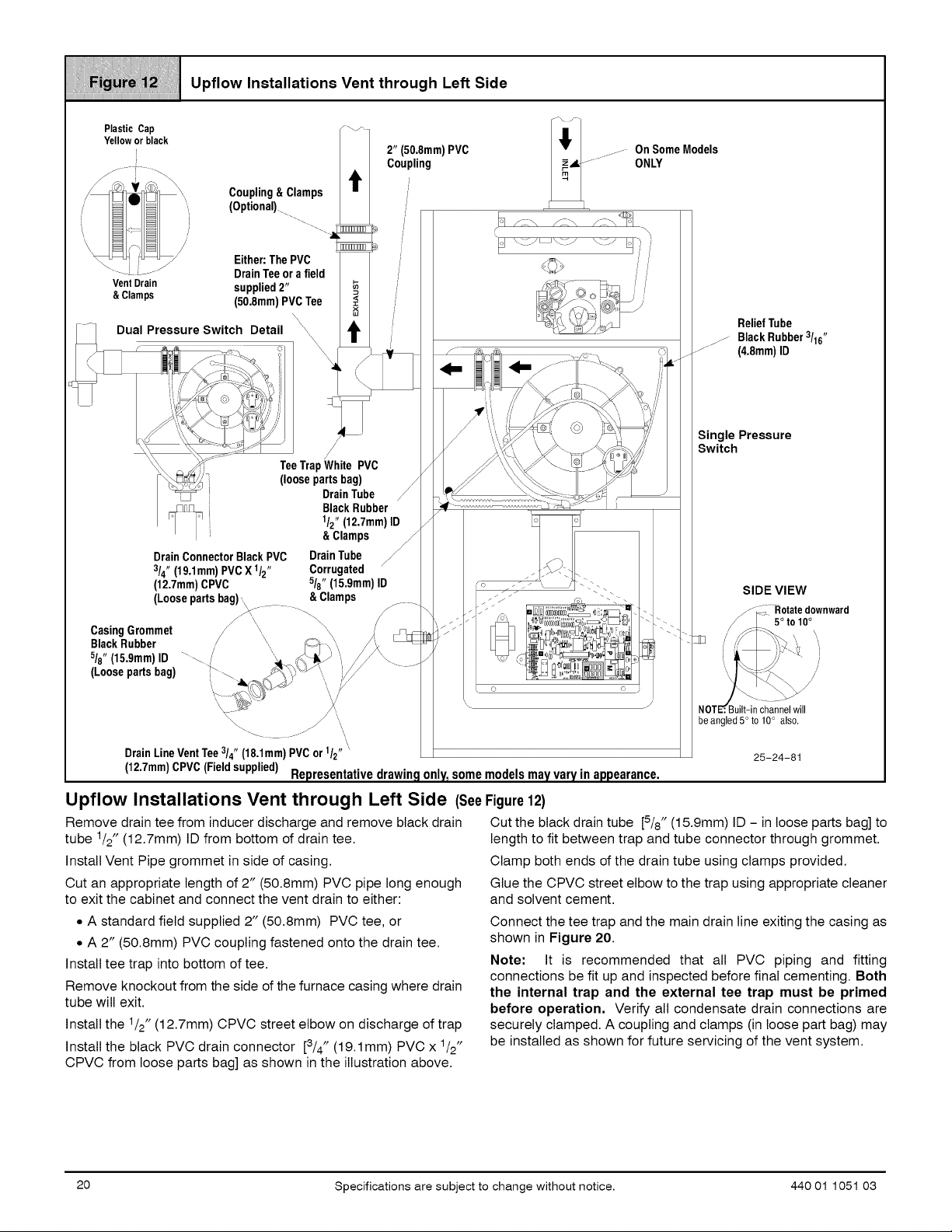

Figure 11 through Figure 20)

1. Disconnect the5/8"(15.9mm) OD rubber hose from the vent

drain fitting that is located downstream of the combustion

blower. Insert a funnel into the hose and pour four(4) ounces

of sanitary type (RV) antifreeze into the condensate trap.

Reconnect the 5/8" (15.9mm) OD rubber hose to the stub on

the vent drain fitting. Secure with the hose clamp.

2. Disconnect the 3/4" (19.1mm) OD rubber hose from the

condensate trap. Insert a funnel into the hose and and pour

four(4) ounces of sanitary type (RV) antifreeze into the

plastic Transition box. Squeeze the hose together near the

end and quickly reconnect the 3/4" (19.1mm) OD rubber

hose to the stub on the condensate trap. Secure with the

hose clamp.

When you return home, your furnace will be ready to start, as it is

not necessary to drain the antifreeze from the furnace.

440 01 1051 03 Specifications are subject to change without notice. 5

Installation

CARBON MONOXIDE POISONING HAZARD

Failure to properly vent this furnace or other

appliances could result in personal injury or death.

This furnace can NOT be common vented or

connected to any type B, BW or L vent or vent

connector, nor to any portion of a factory-built or

masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be

necessary to resize the existing vent and chimney

to prevent oversizing problems for the other

remaining appliance(s). See Venting and

Combustion Air Check in the Combustion &

Ventilation Air section. This furnace MUST be

vented to the outside.

InstallationPositions

This furnace can beinstalledin an upflow,horizontal (eitherleftor

right) or downflowairflow position. DONOT installthis furnace on

its back. For the upflow position, the return air ductwork can be

attachedto eitherthe left or rightside paneland/orthe bottom.For

horizontal and downflowpositions,the returnair ductworkmust be

attached to the bottom. The return air ductwork must never be

attachedto the back ofthefurnace.

Locationand Clearances

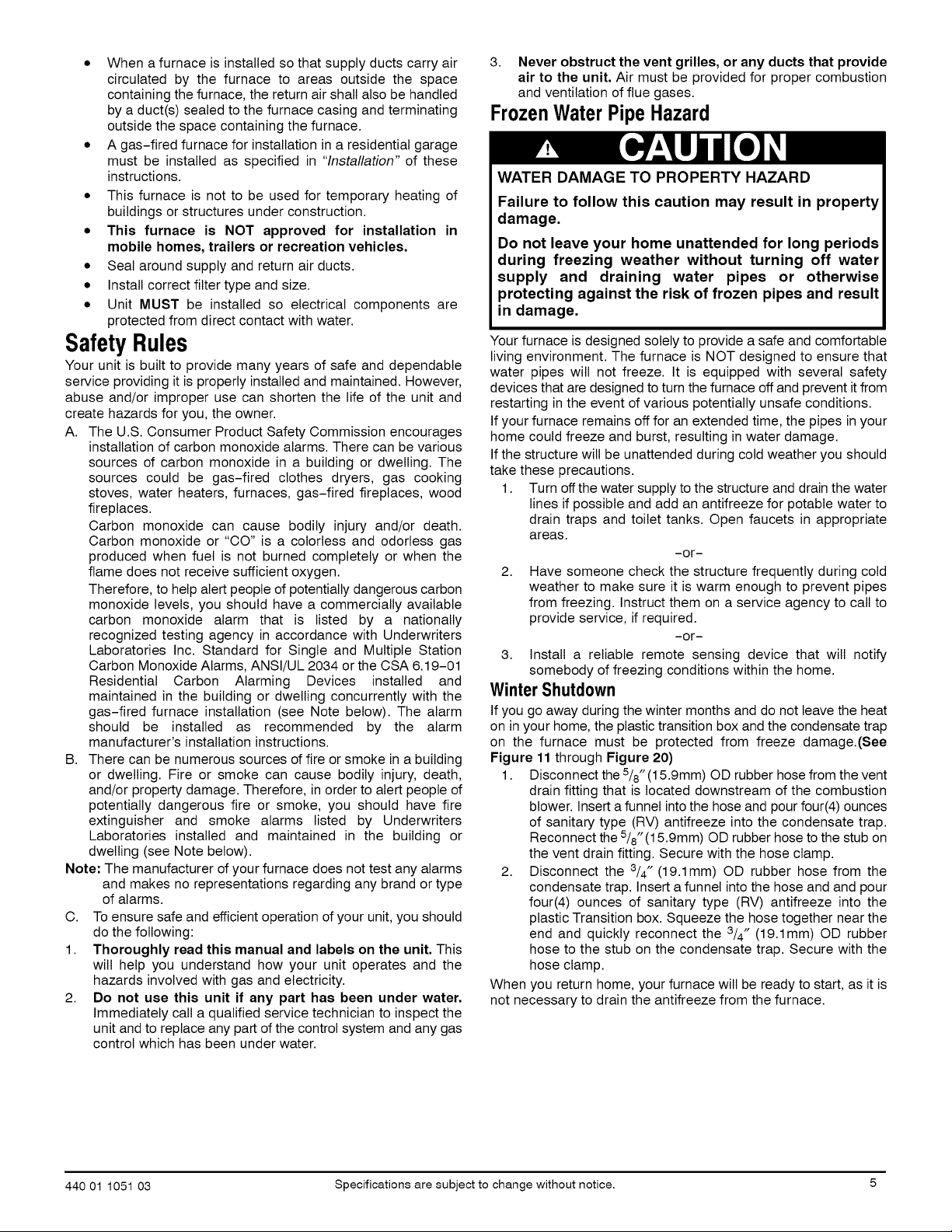

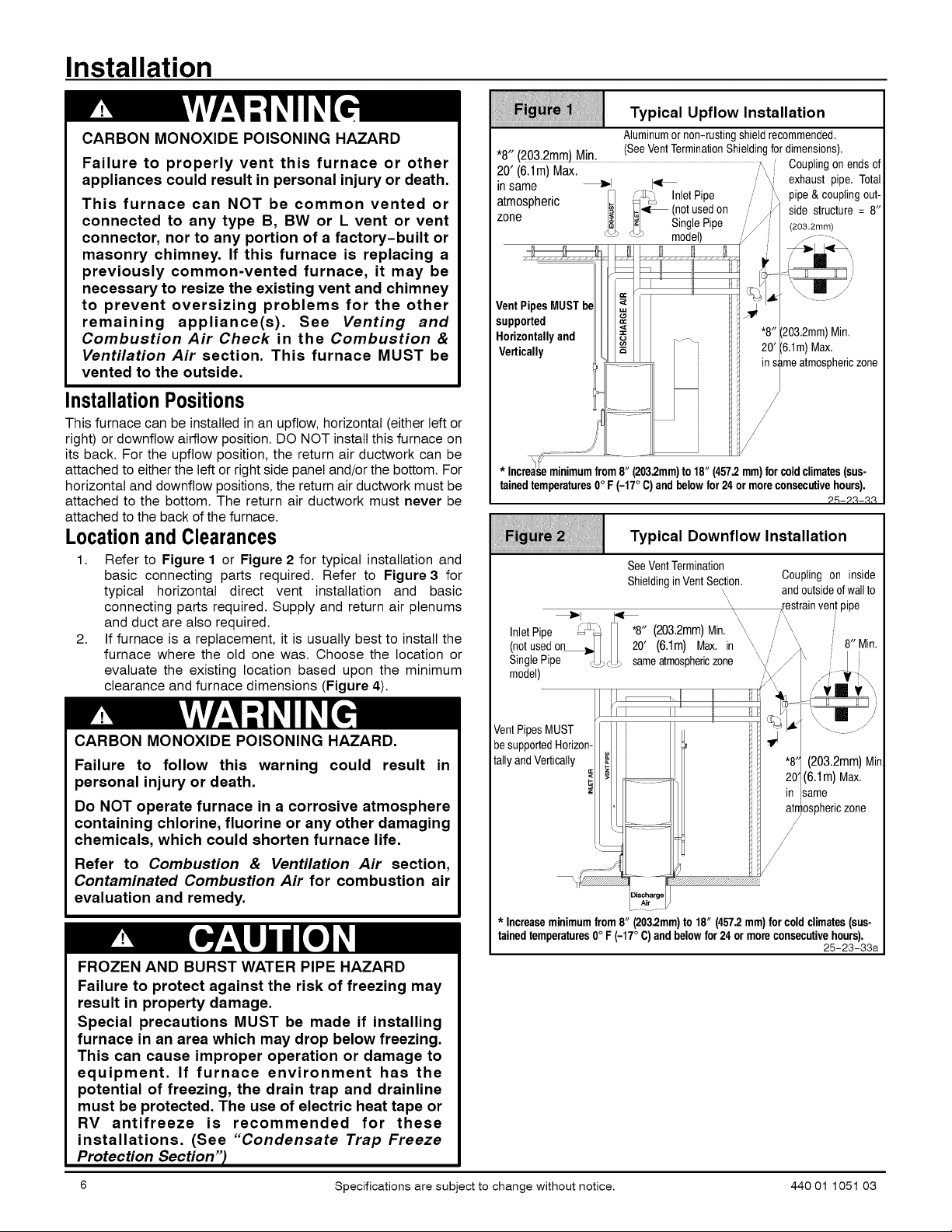

1. Refer to Figure 1 or Figure 2 for typical installation and

basic connecting parts required. Refer to Figure 3 for

typical horizontal direct vent installation and basic

connecting parts required. Supply and return air plenums

and duct are also required.

2. If furnace is a replacement, it is usually best to install the

furnace where the old one was. Choose the location or

evaluate the existing location based upon the minimum

clearance and furnace dimensions (Figure 4).

Typical Upflow Installation

• .... _H:_ (SeeVentTerminationShieldingfor dimensions)

8 (203 2...) iv,.

.... ,, ; _, ,, _ :__ Couplingon endsof

zU (b / m) tvlax '

in same ' _1 I_ _' exhaust pipe. Total

atmospheric _ (notusedon /' side structure = 8"

zone _Ii SinglePipe / (203.2mm)

Vent PipesMUST

supported

Horizontallyand

Vertically

* Increaseminimumfrom8" (203.2mm)to18" (457.2mm)forcoldclimates(sus-

tainedtemperatures0°F (-17°C)and belowfor24 or moreconsecutivehours),

Aluminumornon-rusting shieldrecommended.

_ InletPipe pipe& couplingout-

"_ : - model)

Max.

zone

25-2,!-,!3

Typical Downflow Installation

See VentTermination

Shieldingin VentSection.

_1 I_ '\_

InletPipe _ _ *8" (203.2mm) Min.

\

(notusedon_ _ 20' (6.1m) Max.in

Single Pipe _J_ sameatmosphericzone

model)

\

\

Coupling on inside

andoutsideofwallto

restrainyen!pipe

\ 8" Min.

CARBON MONOXIDE POISONING HAZARD.

Failure to follow this warning could result in

personal injury or death.

Do NOT operate furnace in a corrosive atmosphere

VentPipesMUST

besupportedHorizon-

tally andVertically _.

(203.2mm) air

(6.1m)Max.

same

osphericzone

containing chlorine, fluorine or any other damaging

chemicals, which could shorten furnace life.

Refer to Combustion & Ventilation Air section,

/

Contaminated Combustion Air for combustion air

evaluation and remedy.

* Increaseminimumfrom8" (203.2mm)to18" (457.2mm)for coldclimates(sus-

tainedtemperatures0°F (-17°C)andbelowfor 24 or moreconsecutivehours),

25-23-33a

FROZEN AND BURST WATER PIPE HAZARD

Failure to protect against the risk of freezing may

result in property damage.

Special precautions MUST be made if installing

furnace in an area which may drop below freezing.

This can cause improper operation or damage to

equipment. If furnace environment has the

potential of freezing, the drain trap and drainline

must be protected. The use of electric heat tape or

RV antifreeze is recommended for these

installations. (See "Condensate Trap Freeze

Protection Section"_

6 Specifications are subject to change without notice. 440 01 1051 03

InstallationRequirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of

buildings or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4. Install the vent pipes as short as practical, and in

accordance to these instructions. (See Vent and

Combustion Air Piping section).

5. Maintain clearance for fire safety and servicing. A front

clearance of 24" (609.6mm) required and 30" (762mm)

recommended for access to the burner, controls and filter.

See clearance requirements in Figure 4.

6. Use a raised base for upflow furnace if the floor is damp or

wet at times.

7. For downflow installations, non combustible subbase must

be used under the furnace unless installation is on a non

combustible floor surface. This requirement applies even

when a coil box or cabinet is used.

8. For horizontal installations, line contact is permissible only

between lines formed by intersection of back and two sides

of furnace jacket, and building joists, studs or framing.

9. Residential garage installations require:

• Burners and ignition sources installed at least 18"

(457.2mm) above the floor.

• Located or physically protected from possible damage by

a vehicle.

10. Local codes may require a drain pan under the entire

furnace and condensate trap when the furnace is installed in

attic application.

This furnace may be used for construction heat provided that all the

following conditions are met:

• The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is provided,

sealed to the furnace casing, and terminated outside the

space containing the furnace. This prevents a negative

pressure condition as created by the circulating air blower,

causing a flame rollout and/or drawing combustion products

into the structure.

• The furnace is controlled by a thermostat. It may not be "hot

wired" to provide heat continuously to the structure without

thermostatic control.

• Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which can

cause fouling and plugging of furnace components.

• The temperature of the return air to the furnace is

maintained between 55° F (13° C)and 80° F (27° C), with no

evening setback or shutdown. The use of the furnace while

the structure is under construction is deemed to be

intermittent operation per our installation instructions.

• The air temperature rise is within the rated rise range on the

furnace rating plate, and the firing rate has been set to the

rating plate value.

• The filters used to clean the circulating air during the

construction process must be either changed orthoroughly

cleaned prior to occupancy.

• The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

• After construction is complete, verify furnace operating

conditions including ignition, input rate, temperature rise

and venting according to these instructions.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals, which could shorten furnace life.

Refer to Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

FurnaceInstallationConsiderations

The installation of the furnace for a given application will dictate the

position of the furnace, the airflow, ductwork connections, vent and

combustion air piping. Consideration must be given to the

following:

CondensateTrap and Drain Lines

The supplied condensate trap must be attached to the furnace side

panel on either the left or right side. For horizontal installations, the

drain trap is vertically attached to the side panel below the furnace.

A minimum clearance of 6" (152.4mm) below the furnace is

required for the condensate trap. Downward slope of the

condensate drain line from the condensate trap to the drain

location must be provided. Adequate freeze protection of the drain

trap and the drain line must be provided. See "Condensate Drain

Trap" section for further details.

Leveling

Proper leveling of the furnace must be provided to insure proper

drainage of the condensate from the furnace. The furnace must be

level to within 1/4" (6.4mm) from front to back and from side to side

for upflow and downflow installations or top to bottom for horizontal

installations.

Vent and CombustionAir Connections

For venting information literature, call 931.270.4100 with the

complete model and serial number of the furnace.

Special Venting Requirements for Installations in Canada

Installation in Canada must conform to the requirements of CSA

B149 code. Vent systems must be composed of pipe, fittings,

cements, and primers listed to ULC $636. The special vent fittings

and accessory concentric vent termination kits and accessory

external drain trap have been certified to ULC $636 for use with

those Royal Pipe and IPEX PVC vent components which have

been certified to this standard. In Canada, the primer and cement

must be of the same manufacturer as the vent system - GVS-65

Primer (Purple) for Royal Pipe or IPEX System 636, PVC/CPVC

Primer, Purple Violet for Flue Gas Venting and GVS-65 PVC

Solvent Cement for Royal Pipe or IPEX System 636(1),M,PVC

Cement for Flue Gas Venting, rated Class IIA, 65 deg C. must be

used with this venting system - do not mix primers and cements

from one manufacturer with a vent system from a different

manufacturer. Follow the manufacturer's instructions in the use of

primer and cement and never use primer or cement beyond its

expiration date.

The safe operation, as defined by ULC $636, of the vent system is

based on following these installation instructions, the vent system

manufacturer's installation instructions, and proper use of primer

and cement. All fire stop and roof flashing used with this system

must be UL listed material. Acceptability under Canadian

standard CSA B149 is dependent upon full compliance with all

installation instructions. Under this standard, it is recommended

that the vent system be checked once a year by qualified service

personnel.

The authority having jurisdiction (gas inspection authority,

municipal building department, fire department, etc) should be

consulted before installation to determine the need to obtain a

permit.

(1) System 636 is a trademark of IPEX Inc.

440 01 1051 03 Specifications are subject to change without notice. 7

Consignes sp6ciales pour rinstallation de ventillation au

Canada

Uinstallation faite au Canada dolt se conformer aux exigences du

code CSA B149. Ce syst_me de ventillation dolt se composer de

tuyaux, raccords, ciments et appr_ts conformes au ULC S636. La

tuyauterie de ventillation des gaz, ses accessoires, le terminal

concentrique mural ainsi que I'ensemble du drain de condensat

exterieur ont et6 certifies ULCS 636 pour I'application des

composantes Royal Pipe, IPEX PVC qui sont certifiees & ce

standard. Au Canada, I'appr_t et le ciment doivent _tre du m_me

fabricant que le systeme d'evacuation. Uappr_t GVS-65 (Purple)

et le ciment-solvant GVS-65 doivent _tre utilise avec les Royal

Pipe. Systeme IPEX 636, appr_t PVC/CPVC, Purple pour

evacuation des gaz de combustion et systeme IPEX 636(1)'=,

ciment PVC pour evacuation des gaz de combustion, cots classe

IIA, 65 deg C. doivent _tre utitises avec le systeme d'evacuation

IPEX 636 - Ne pas combiner I'appr_t et le ciment d'un

manufacturier avec un systeme d'evacuation d'un manufacturier

different.

Bien suivre les indications du manufacturier Iors de t'utilisation de

I'appr_t et du ciment et ne pas utiliser ceux-ci si ladate d'expiration

est atteinte.

Uoperation securitaire, tel que definit par ULC S636, du systeme

de ventilation est base sur les instructions d'installation suivantes,

ainsi que I'usage approprie de I'appr_t et ciment. Tout arret feu et

solin de toit utilises avec ce systeme doivent _tre des materiaux

listes UL. L'acceptation du standard Canadien CSA B419 est

directement relie & I'installation conforme aux instructions ci- haut

mentionnees. Le standard Canadien recommande I'inspection

par un personel qualifie et ce, une fois par annee.

Les autoritees ayant juridiction (inspecteurs de gas, inspecteurs

en b&timents, departement des incendies, etc) devraient _tre

consultees avant I'instatlation afin de determiner si un permis est

requis.

On the Dual Certified furnace, the vent and combustion air pipes

attach to the furnace through the top panel for the upflow and

horizontal installations. For the downflow installation, the vent and

combustion air pipes attach to the furnace through the alternate

locations on the furnace side panels.

Note: On the Direct Vent furnace, the vent pipe attaches to the

furnace through the side panels. The combustion air pipe attaches

to the top panel or to the alternate location on the side panel.

On the Single Pipe furnace, the vent pipe attaches to the furnace

through the furnace side panels.

Note: Repositioning of the combustion blower is required for the

vent pipe connection to the furnace through the "right side" panel.

See "Vent and Combustion Air Piping" section for further details.

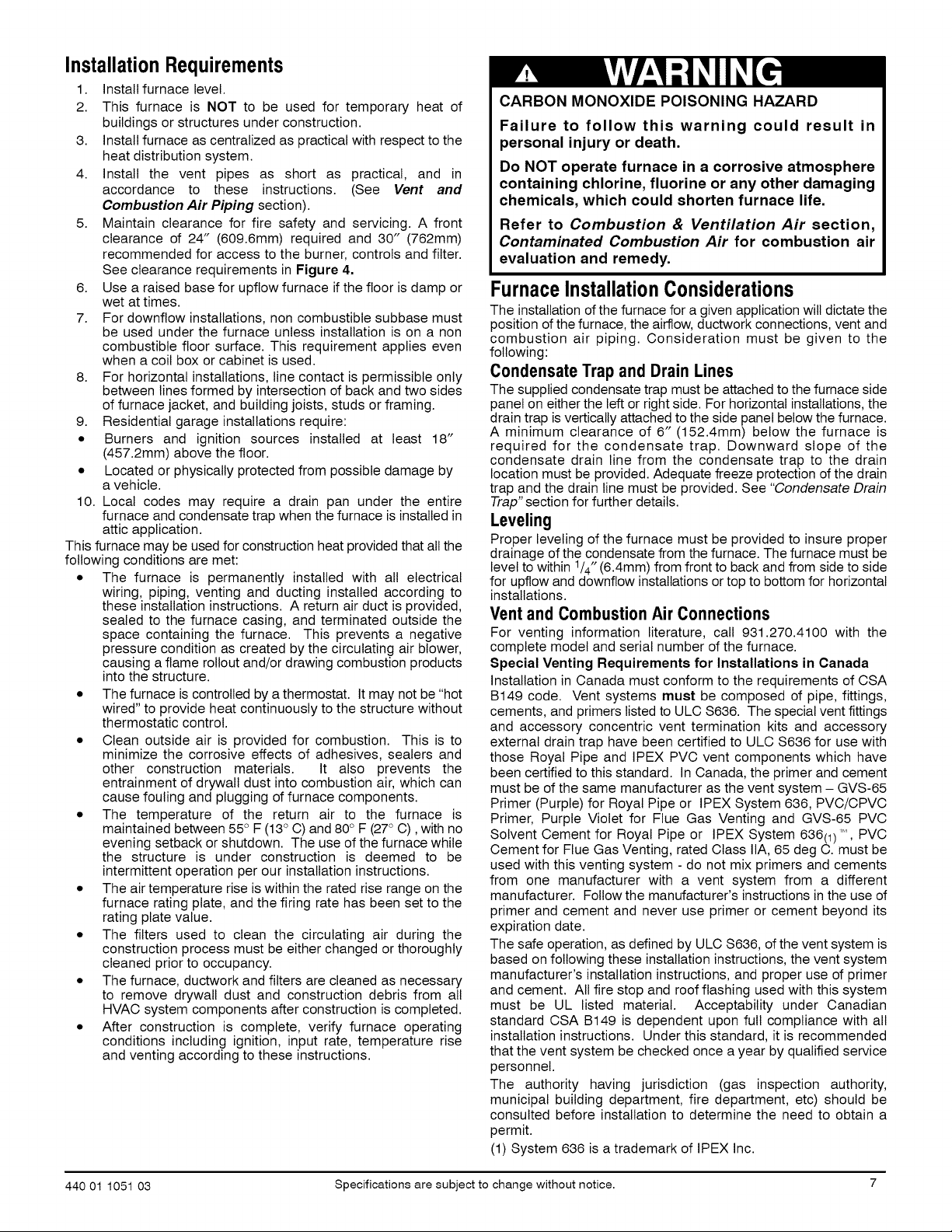

HorizontalFurnaceInstallation

Typical Horizontal Installation

Inlet Pipe (notusedonSinglePipemodel)

Vent

Pipe

_'] Condensate

__ Trap

\h --4:

25-23-34

NOTE:5" (127mm) bottom clearance required for condensatetrap.

This furnace can be installed horizontally in an attic, basement,

crawl space, alcove, or suspended from a ceiling in a basement or

utility room (See Figure 3). Do not install furnace on its back or in

the reverse airflow positions as safety control operation will be

adversely affected.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to rigidly attach the furnace to prevent

movement. These straps should be attached to the furnace bottom

side with sheet metal screws and to the rafters or joists with bolts.

The preferred method is to use an angle iron frame bolted to the

rafters or joists.

If the furnace is to be installed in a crawl space, consult local codes.

A suitable concrete pad or blocks are recommended for crawl

space installation on the ground.

NOTE: 6" (152.4mm) bottom clearance required for condensate

trap.

24" (609.6mm) inches between the front of the furnace and

adjacent construction or other appliances MUST be maintained for

service clearance. [30" (762mm) inches is required to remove

furnace].

Keep all insulating materials clear from Iouvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace

clearances are met. See Figure 3.

This furnace MUST NOT be installed directly on carpeting or tile or

other combustible material other than wood flooring or supports.

For horizontal installation over a finished living space. A field

fabricated auxiliary drain pan with drain pipe is required to prevent

damage by overflow due to blocked condensate drain.

8 Specifications are subject to change without notice. 440 01 1051 03

iiiiii;_iiiiiiiii!iiiiiiiiii_i_Xi:iiiiii!i!_iiiii_ii;¸;iiiiiii/!ii_;_;iiiiii!iiiiiiiiiiii;;i;;i;;iiiiii;iiiii/iiiiiiiiiiiii111i/ilil

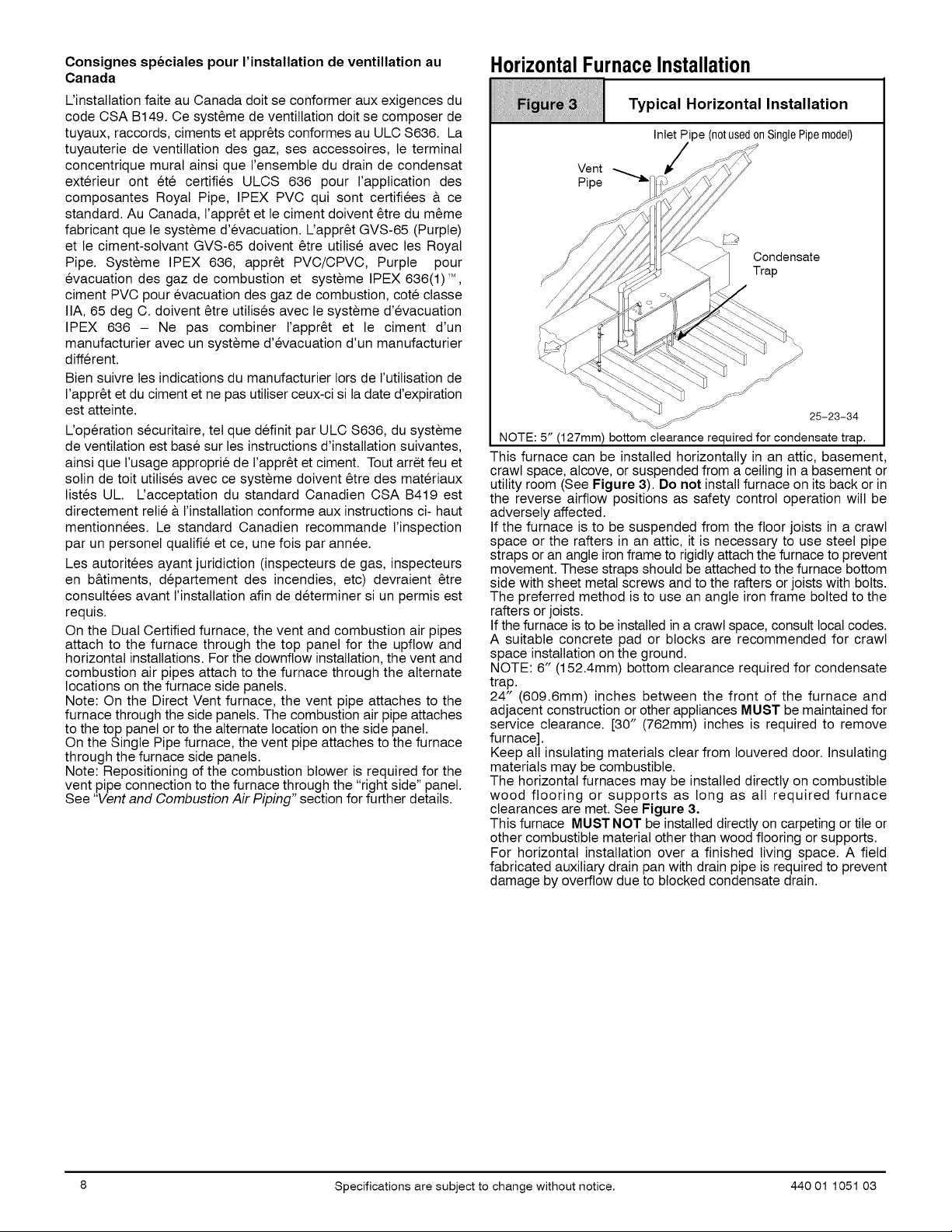

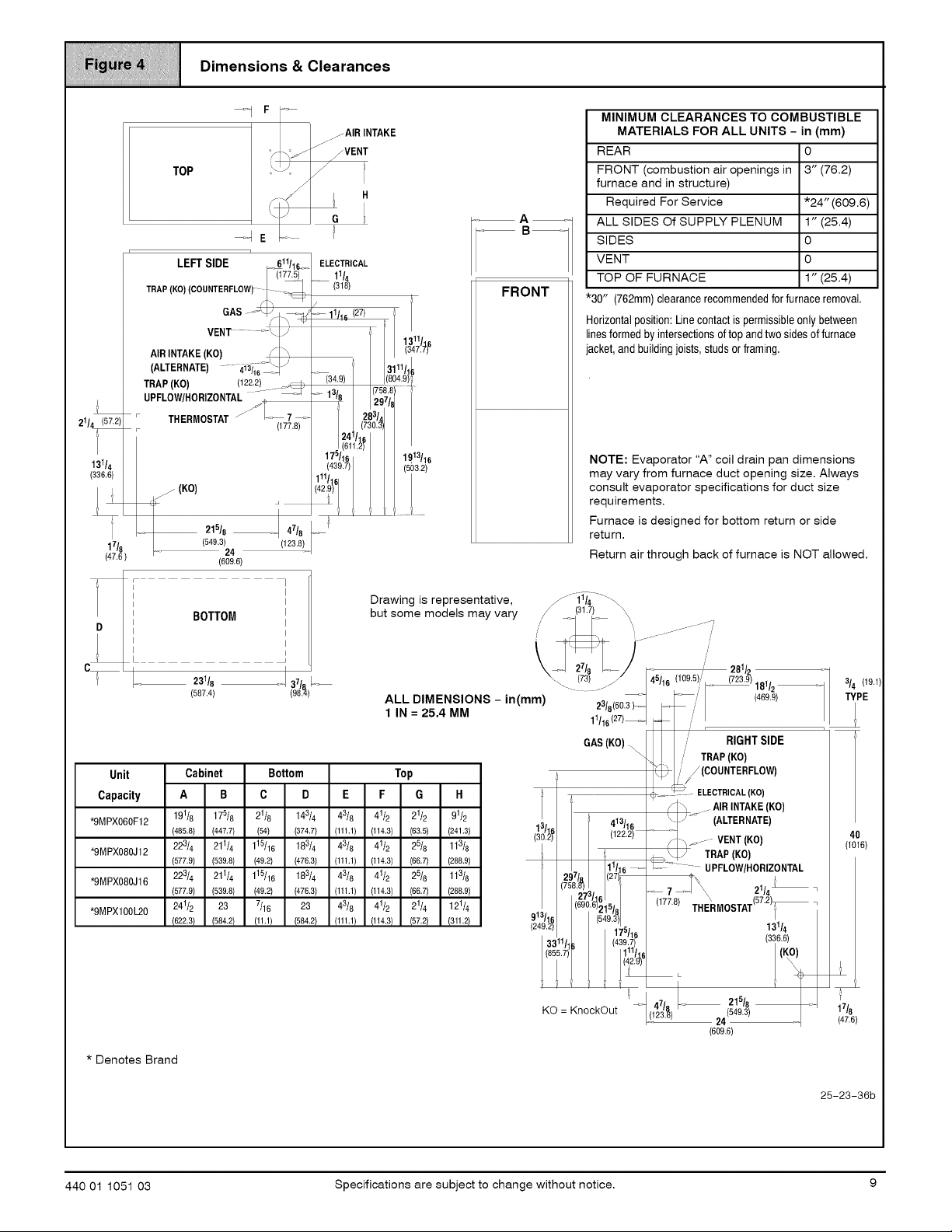

_!_i_:! I Dimensions & Clearances

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

---1 F --

_AIRINTAKE

J

J

FVENT

/

TOP

/

G

T

r n

LEFTSIDE 611/1__

TRAP (KO) (COUNTERFLOW)- (177.5t

r

ELECTRICAL

11/4

(318)

11/16(27) t

AIRINTAKE(KO) F _

TRAP (KO) (122.2) .... ,_)

UPFLOW/HORIZONTAL....._ _

21/4 (57.2)

• THERMOSTAT"j _.... 7....

• (177.8)

i'

131/4

(336.6)

1 IKOl

17/6

(47.6

I

I

I BOTTOM

D I

I

I

I

L

_ 231/8

VENT......... \_ ./

..... 4i3116"_'\__ )(ALTERNATE)

./ /

215/8 _ 47/8

(549.3) (123.8)

24

(609.6)

(587.4)

_(34.9) (804.9)_

o_ 13/8 297/8

175/16 1913/16

(439.7) (503.2)

111/16

(42.9)

/

I i ;

]

i

I

I

I

I

I

1311/16

/

(347.7)

3111/1J

283/a

(730.3

Drawing is representative, _-1T//4---_

but some models may vary // ,(31.7!: _, ............ ii191/ " (7239

ALLO,MENS,ONS,°=

' IN = 25.4MM - ( ) 1_:/68((6_ '3 )_= _ ,/'

Unit Cabinet Bottom Top

Capacity A B C D E F G H

*9MPX060F12 191/8 175/6 21/6 143/4 43/8 41/2 21/2 91/2

*9MPX080J12 223/4 211/4 115/16 183/4 43/8 41/2 25/8 113/8

*9MPX080J16 223/4 211/4 115/16 183/4 43/8 41/2 25/8 113/8

*RMPXl00L20 241/2 23 7/16 23 43/6 41/2 21/4 121/4

(485,8) (447,7) (54) (374,7) (111,1) (1143) (63,5) (2413)

(577.9) (539.8) (49.2) (476.3) (111.1) (114.3) (66.7) (266.9)

(577,9) (539,8) (49,2) (4763) (111,1) (1143) (6&7) (28&9)

(6223} (584,2) (11,1} (5842) (111,1} (1143} (57,2) (311,2)

MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS FOR ALL UNITS - in (mm)

REAR 0

FRONT (combustion air openings in 3" (76.2)

furnace and in structure)

Required For Service

A

ALL SIDES Of SUPPLY PLENUM

SIDES

VENT

TOP OF FURNACE

FRONT

*30" (762mm)clearancerecommendedforfurnaceremoval.

Horizontalposition:Linecontactis permissibleonly between

linesformedbyintersectionsoftop and twosidesoffurnace

acket,and buildingjoists, studsor framing.

NOTE: Evaporator "A" coil drain pan dimensions

may vary from furnace duct opening size. Always

consult evaporator specifications for duct size

requirements.

Furnace is designed for bottom return or side

return.

Return air through back of furnace is NOT allowed.

/ _ _-_. --- 281/2

46/16 ,

GAS(KO)\

13/16

(30.2) (122,2)

297/.8

(758.6)

273/6

(690.61215/_

913/16 (549.3

(249.2)

3311h. (439.7)

(855._1' 1111/_e

Y v v _

KO= KnockOut (123.8)

\

.... ' TRAP(KO)

,_/ (COUNTERFLOW)

b_ _ / /

__, _ ELECTRICAL(KO)

/ \ _AIRINTAKE(KO)

413/16

"\J iS_-_ (ALTERNATE)

/ _. _.----VENT(KO)

<_ TRAPIKOI

_/6 _-

..... 7 _,I \_ 21/4 _

(177.8) THEXRMOSTAT(57.2)_

175/16

/14291

_- 47/8

/ RIGHTSIDE

UPFLOW/HORIZONTAL

131/4

336.6

215/8

(549.3) 17/8

24 (47.6)

(609.6)

*24" (609.6)

1" (25.4)

0

0

1" (25.4)

3/4 (19.1

TYPE

L

4O

(lO16)

* Denotes Brand

25-23-36b

440 01 1051 03 Specifications are subject to change without notice. 9

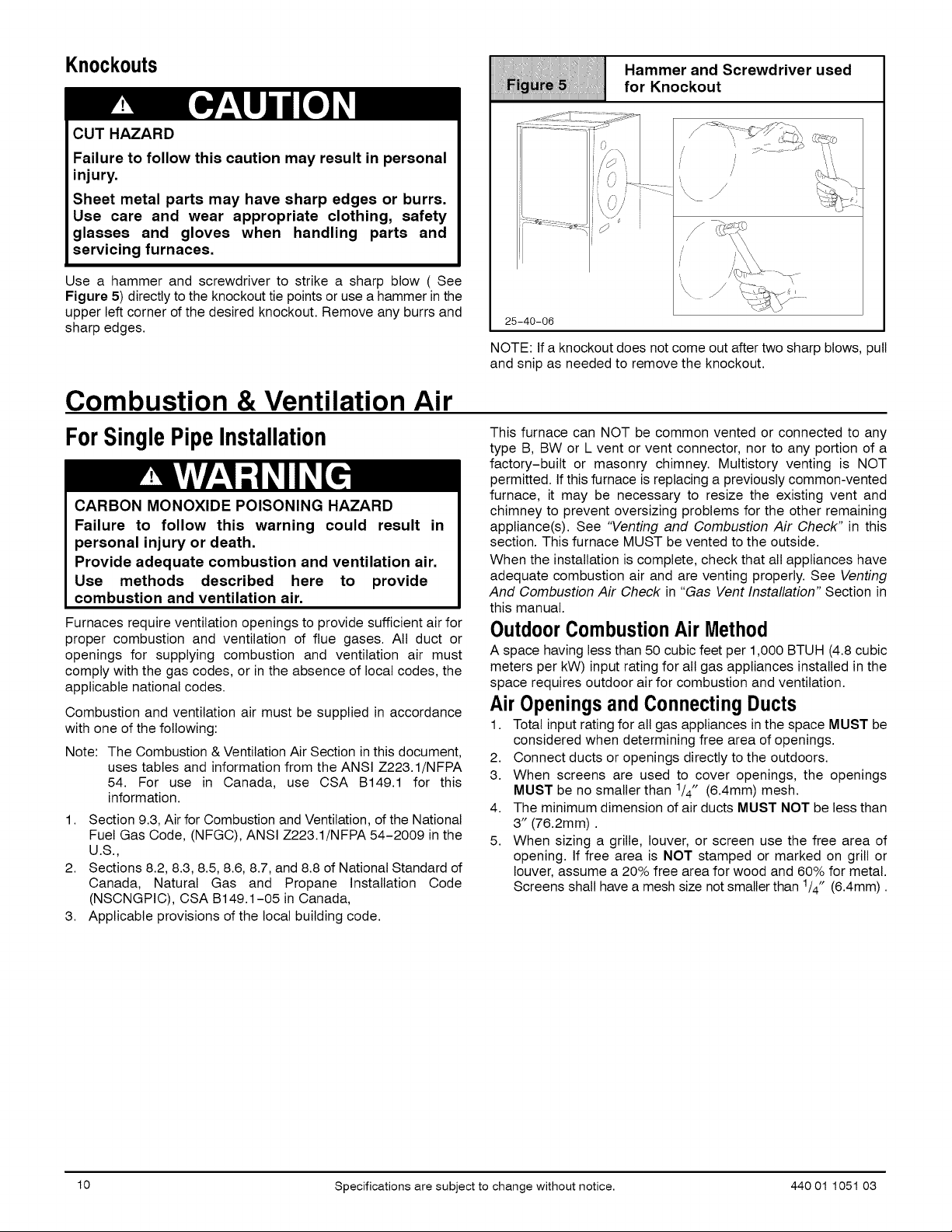

Knockouts

.........................................................................................................................................................for Knockout

Hammer and Screwdriver used

CUTHAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs.

Use care and wear appropriate clothing, safety

glasses and gloves when handling parts and

servicing furnaces.

Use a hammer and screwdriver to strike a sharp blow ( See

Figure 5) directly to the knockout tie points or use a hammer in the

upper left corner of the desired knockout. Remove any burrs and

sharp edges.

Combustion & Ventilation Air

ForSinglePipeInstallation

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Provide adequate combustion and ventilation air.

Use methods described here to provide

combustion and ventilation air.

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or

openings for supplying combustion and ventilation air must

comply with the gas codes, or in the absence of local codes, the

applicable national codes.

Combustion and ventilation air must be supplied in accordance

with one of the following:

Note: The Combustion & Ventilation Air Section in this document,

uses tables and information from the ANSI Z223.1/NFPA

54. For use in Canada, use CSA B149.1 for this

information.

1. Section 9.3, Air for Combustion and Ventilation, of the National

Fuel Gas Code, (NFGC), ANSI Z223.1/NFPA 54-2009 inthe

U.S.,

2. Sections 8.2, 8.3, 8.5, 8.6, 8.7, and 8.8 of National Standard of

Canada, Natural Gas and Propane Installation Code

(NSCNGPIC), CSA B149.1-05 in Canada,

3. Applicable provisions of the local building code.

I

i0 \

i / 'i

i f_ / ;;

/ /

\i

'\'9'!

i

25-40-06

NOTE: If a knockout does not come out after two sharp blows, pull

and snip as needed to remove the knockout.

This furnace can NOT be common vented or connected to any

type B, BW or L vent or vent connector, nor to any portion of a

factory-built or masonry chimney. Multistory venting is NOT

permitted. If this furnace is replacing a previously common-vented

furnace, it may be necessary to resize the existing vent and

chimney to prevent oversizing problems for the other remaining

appliance(s). See "Venting and Combustion Air Check" in this

section. This furnace MUST be vented to the outside.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

And Combustion Air Check in "Gas Vent Installation" Section in

this manual.

OutdoorCombustionAirMethod

A space having less than 50 cubic feet per 1,000 BTUH (4.8 cubic

meters per kW) input rating for all gas appliances installed in the

space requires outdoor air for combustion and ventilation.

AirOpeningsand ConnectingDucts

1. Total input rating for all gas appliances in the space MUST be

considered when determining free area of openings.

2. Connect ducts or openings directly to the outdoors.

3. When screens are used to cover openings, the openings

MUST be no smaller than 1/4" (6.4mm) mesh.

4. The minimum dimension of air ducts MUST NOT be less than

3" (76.2mm).

5. When sizing a grille, louver, or screen use the free area of

opening. If free area is NOT stamped or marked on grill or

louver, assume a 20% free area for wood and 60% for metal.

Screens shall have a mesh size not smaller than 1/4" (6.4mm).

/'

/

10 Specifications are subject to change without notice. 440 01 1051 03

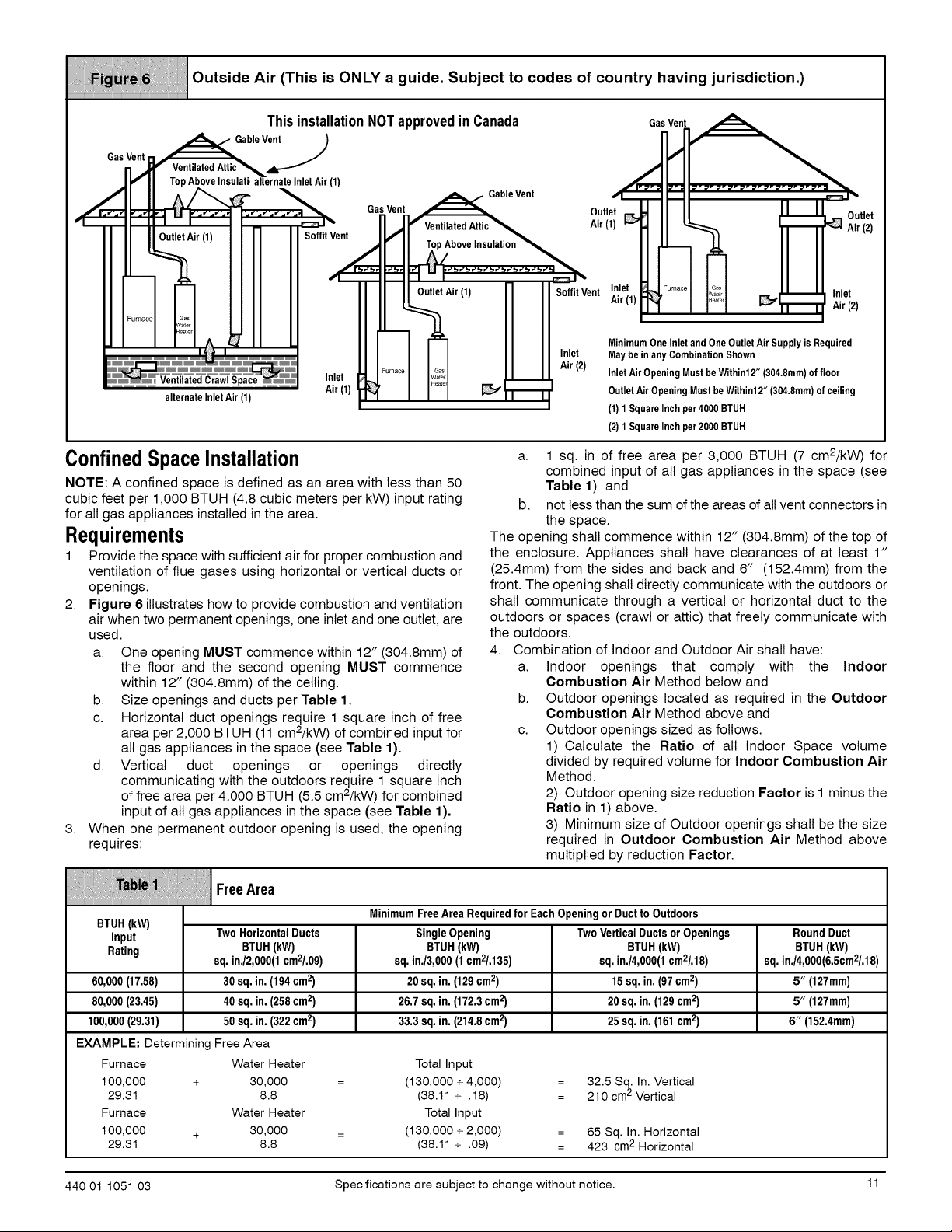

GasVent

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada GasVent

Above Insulati,alternateInletAir (1) _ _1 _ 1_- _- _- _- _- _- _- _- _- _- _-=_

_ GasVent _ Outlet _ _ II II JILL[-- ou

OutletAir (1) SoffitVent I1_11 _ I II 3| II II (2)

_ n _Vventilated Attic_ Air (,) I II Airtlet

._../ GableVent _ ;::1i lr _-

/,IFI1 p bovelnsulation IrU-1 II II

I II I10utletAir(1) SoffitVentI."leL,_Fu'_cd Iw_;I ___-[_LL Inlet

I LL_ -,rt,, ]_._ I p,°rl L,_IFI._ Air (2)

I I I _ MinimumOneInlet and OneOutletAir Supply is Required

I I I I I Inlet May be in anyCombinationShown

Inlet _ ...... IU _ InletAir OpeningMustbeWithin12"(304.8mm)°f fl°°r

alternatelnletAir (1) Air(l) _ I I_1 _1_ OutletAir OpeningMustbe Withinl2,, (304.8mm)of ceiling

ConfinedSpaceInstallation

NOTE: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH (4.8 cubic meters per kW) input rating

for all gas appliances installed in the area.

Requirements

1.

Provide the space with sufficient air for proper combustion and

ventilation of flue gases using horizontal or vertical ducts or

openings.

2. Figure 6 illustrates how to provide combustion and ventilation

air when two permanent openings, one inlet and one outlet, are

used.

a. One opening MUST commence within 12" (304.8mm) of

the floor and the second opening MUST commence

within 12" (304.8mm) of the ceiling.

b. Size openings and ducts per Table 1.

c. Horizontal duct openings require 1 square inch of free

area per 2,000 BTUH (11 cm2/kW) of combined input for

all gas appliances in the space (see Table 1).

d. Vertical duct openings or openings directly

communicating with the outdoors require 1 square inch

of free area per 4,000 BTUH (5.5 cm2/kW) for combined

input of all gas appliances in the space (see Table 1).

3. When one permanent outdoor opening is used, the opening

requires:

Air (2)

(1) 1SquareInch per4000 BTUH

(2) 1SquareInch per2000 BTUH

a. 1 sq. in of free area per 3,000 BTUH (7 cm2/kW) for

combined input of all gas appliances in the space (see

Table 1) and

b. not less than the sum of the areas of all vent connectors in

the space.

The opening shall commence within 12" (304.8mm) of the top of

the enclosure. Appliances shall have clearances of at least 1"

(25.4mm) from the sides and back and 6" (152.4mm) from the

front. The opening shall directly communicate with the outdoors or

shall communicate through a vertical or horizontal duct to the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

4. Combination of Indoor and Outdoor Air shall have:

a. Indoor openings that comply with the Indoor

Combustion Air Method below and

b. Outdoor openings located as required in the Outdoor

Combustion Air Method above and

c. Outdoor openings sized as follows.

1) Calculate the Ratio of all Indoor Space volume

divided by required volume for Indoor Combustion Air

Method.

2) Outdoor opening size reduction Factor is I minus the

Ratio in 1) above.

3) Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor.

Free Area

STUB(kW)

MinimumFreeAreaRequiredfor EachOpeningorDuctto Outdoors

Input TwoHorizontalDucts SingleOpening TwoVerticalDuctsorOpenings RoundDuct

Rating BTUH(kW) BTUH(kW) BTUH(kW) BTUH(kW)

sq.in./2,000(1cm2/,09) sq.in./3,000(1cm2/,135) sq.in./4,000(1cm2/,18) sq. in./4,000(6,5cm2/,18)

60,000(17.58) 30sq.in.(194cm2) 20sq.in.(129cm2) 15sq.in.(97cm2) 5" (127mm)

80,000(23.45) 40sq.in.(258cm2) 26.7sq.in.(172.3cm2) 20sq.in.(129cm2) 5" (127mm)

100,000(29.31) 50sq.in.(322cm2) 33.3sq.in.(214.8cm2) 25sq.in.(161cm2) 6" (152.4mm)

EXAMPLE: Determining Free Area

Furnace Water Heater Total Input

100,000 + 30,000 = (130,000 + 4,000) 32.5 Sq. In. Vertical

29.31 8.8 (38.11 + .18) 210 cm_ Vertical

Furnace Water Heater Total Input

100,000 + 30,000 = (130,000 + 2,000) 65 Sq. In. Horizontal

29.31 8.8 (38.11 + .09) 423 cm2 Horizontal

440 01 1051 03 Specifications are subject to change without notice. 11

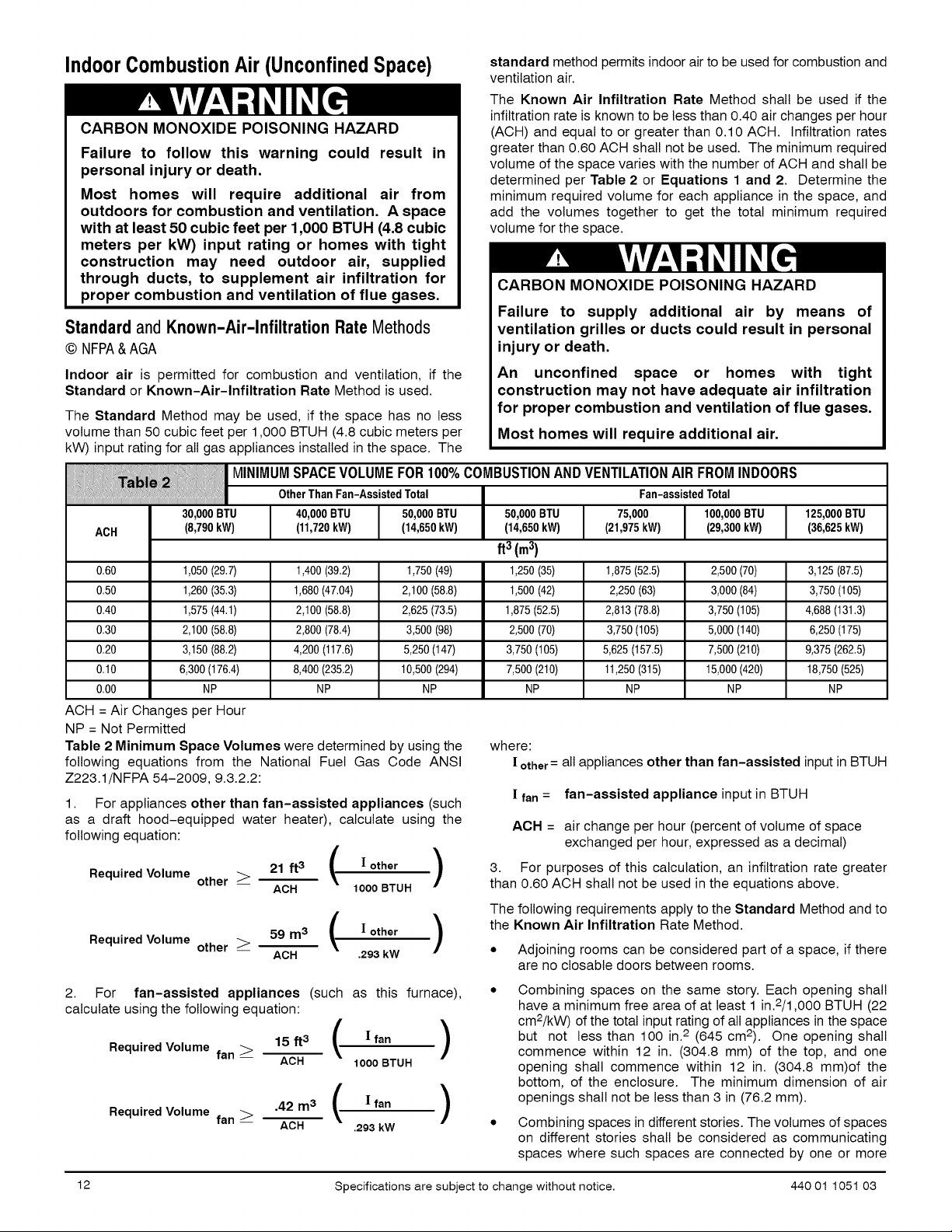

IndoorCombustionAir(UnconfinedSpace)

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Most homes will require additional air from

outdoors for combustion and ventilation. A space

with at least 50 cubic feet per 1,000 BTUH (4.8 cubic

standard method permits indoor air to be used for combustion and

ventilation air.

The Known Air Infiltration Rate Method shall be used if the

infiltration rate is known to be less than 0.40 air changes per hour

(ACH) and equal to or greater than 0.10 ACH. Infiltration rates

greater than 0.60 ACH shall not be used. The minimum required

volume of the space varies with the number of ACH and shall be

determined per Table 2 or Equations 1 and 2. Determine the

minimum required volume for each appliance in the space, and

add the volumes together to get the total minimum required

volume for the space.

meters per kW) input rating or homes with tight

construction may need outdoor air, supplied

through ducts, to supplement air infiltration for

CARBON MONOXIDE POISONING HAZARD

proper combustion and ventilation of flue gases.

Failure to supply additional air by means of

Standardand Known-Air-lnfiltrati0n Rate Methods

© NFPA &AGA

Indoor air is permitted for combustion and ventilation, if the

Standard or Known-Air-Infiltration Rate Method is used.

The Standard Method may be used, if the space has no less

volume than 50 cubic feet per 1,000 BTUH (4.8 cubic meters per

kW) input rating for alt gas appliances installed in the space. The

i .-,-,_ =. MINIMUM SPACE VOLUME FOR 100% COMBUSTION AND VENTILATION AIR FROM INDOORS

OtherThanFan-AssistedTotal Fan-assistedTotal

30,000BTU 40,000BTU 50,000BTU 50,000BTU 75,000 100,000BTU 125,000BTU

ACH (8,790kW) (11,720kW) (14,650kW) (14,650kW) (21,975kW) (29,300kW) (36,625kW)

0.60 1,050(29.7)

0.50 1,260(35.3)

0.40 1,575(44.1)

0.30 2,100(58.8)

0.20 3,150(88.2)

0.10 6,300 (176.4)

0.00 NP

ACH= Air Changes per Hour

NP = Not Permitted

Table 2 Minimum Space Volumes were determined by using the

following equations from the National Fuel Gas Code ANSI

Z223.1/NFPA 54-2009, 9.3.2.2:

1. For appliances other than fan-assisted appliances (such

as a draft hood-equipped water heater), calculate using the

following equation:

Required Volume other _ 21ft3 ( .°ther )

-- ACH 1000 BTUH

1,400(39.2) 1,750(49) 1,250(35) 1,875(52.5) 2,500(70) 3,125(87.5)

1,680(47.04) 2,100(58.8) 1,500(42) 2,250(63) 3,000(84) 3,750(105)

2,100(58.8) 2,625(73.5) 1,875(52.5) 2,813(78.8) 3,750(105) 4,688(131.3)

2,800(78.4) 3,500(98) 2,500(70) 3,750(105) 5,000(140) 6,250(175)

4,200(117.6) 5,250(147) 3,750(105) 5,625(157.5) 7,500(210) 9,375(262.5)

8,400 (235.2) 10,500 (294) 7,500 (210) 11,250 (315) 15,000 (420) 18,750 (525)

NP NP NP NP NP NP

/ \

Required Volume other _ 59 m3 _k [ other )

2. For fan-assisted appliances (such as this furnace),

calculate using the following equation:

RequiredVolume fan_ 15ft3 ( !fen )

-- ACH .293 kW

ACH 1000 BTUH

/ \

RequiredVolume fan _ .42 m3 _k ! fan )

ACH .293 kW

ventilation grilles or ducts could result in personal

injury or death.

An unconfined space or homes with tight

construction may not have adequate air infiltration

for proper combustion and ventilation of flue gases.

Most homes will require additional air.

ft3(m3)

where:

! other= all appliances other than fan-assisted input in BTUH

! fan = fan-assisted appliance input in BTUH

ACH= air change per hour (percent of volume of space

exchanged per hour, expressed as a decimal)

3. For purposes of this calculation, an infiltration rate greater

than 0.60 ACH shall not be used in the equations above.

The following requirements apply to the Standard Method and to

the Known Air Infiltration Rate Method.

. Adjoining rooms can be considered part of a space, if there

are no ctosable doors between rooms.

Combining spaces on the same story. Each opening shall

have a minimum free area of at least 1 in.2/1,000 BTUH (22

cm2/kW) of the total input rating of all appliances in the space

but not less than 100 in.2 (645 cm2). One opening shall

commence within 12 in. (304.8 mm) of the top, and one

opening shall commence within 12 in. (304.8 mm)of the

bottom, of the enclosure. The minimum dimension of air

openings shall not be less than 3 in (76.2 mm).

Combining spaces in different stories. The volumes of spaces

on different stories shall be considered as communicating

spaces where such spaces are connected by one or more

12 Specifications are subject to change without notice. 440 01 1051 03

openings in doors or floors having a total minimum free area of

2 in.2/1,000 BTUH (44 cm2/kW) of total input rating of all

appliances.

An attic or crawl space may be considered a space that freely

communicates with the outdoors provided there are adequate

ventilation openings directly to outdoors. Openings MUST

remain open and NOT have any means of being closed off.

Ventilation openings to outdoors MUST be at least 1 square

inch of free area per 4,000 BTUH (5.5cm2/kW) of total input

rating for all gas appliances in the space.

In spaces that use the Indoor Combustion Air Method,

infiltration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

with unusually tight construction, additional air MUST be

provided using the methods described in section titled

Outdoor Combustion Air Method:

• Unusually tight construction is defined as Construction with:

1. Walls and ceilings exposed to the outdoors have a

continuous, sealed vapor barrier. Openings are gasketed

or sealed and

2.

Doors and openable windows are weather stripped and

3.

Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between walt-ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

VentilationAir

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as

replacement air. Whichever method is used, the mixed return air

temperature across the heat exchanger MUST not fall below 60°

so that flue gases wilt not condense excessively in the heat

exchanger. Excessive condensation will shorten the life of the heat

exchanger and possibly void your warranty.

VentingandCombustionAirCheck

NOTE: If this installation replaces an existing furnace from a

commonly vented system, the original venting system may no

longer be sized to properly vent the attached appliances. An

improperly sized venting system may cause the formation of

condensate in the vent and the leakage or spillage of vent gases.

To make sure there is adequate combustion air for all appliances,

MAKE THE FOLLOWING CHECK.

1111111111111111111111111111111111!]iili111iiiiililiiiliiliii!]Iiiliiliiii!iiiililliiiii

I I ontO.o°=

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation, could result in carbon

monoxide poisoning or death:

The following steps shall be followed for each

appliance connected to the venting system being

placed into operation, while all other appliances

connected to the venting system are not in

operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or CSA B149.1, Natural Gas and

Propane Installation Code and these instructions. Deter-

mine that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an

unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are

operating at maximum speed. Do not operate a summer

exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

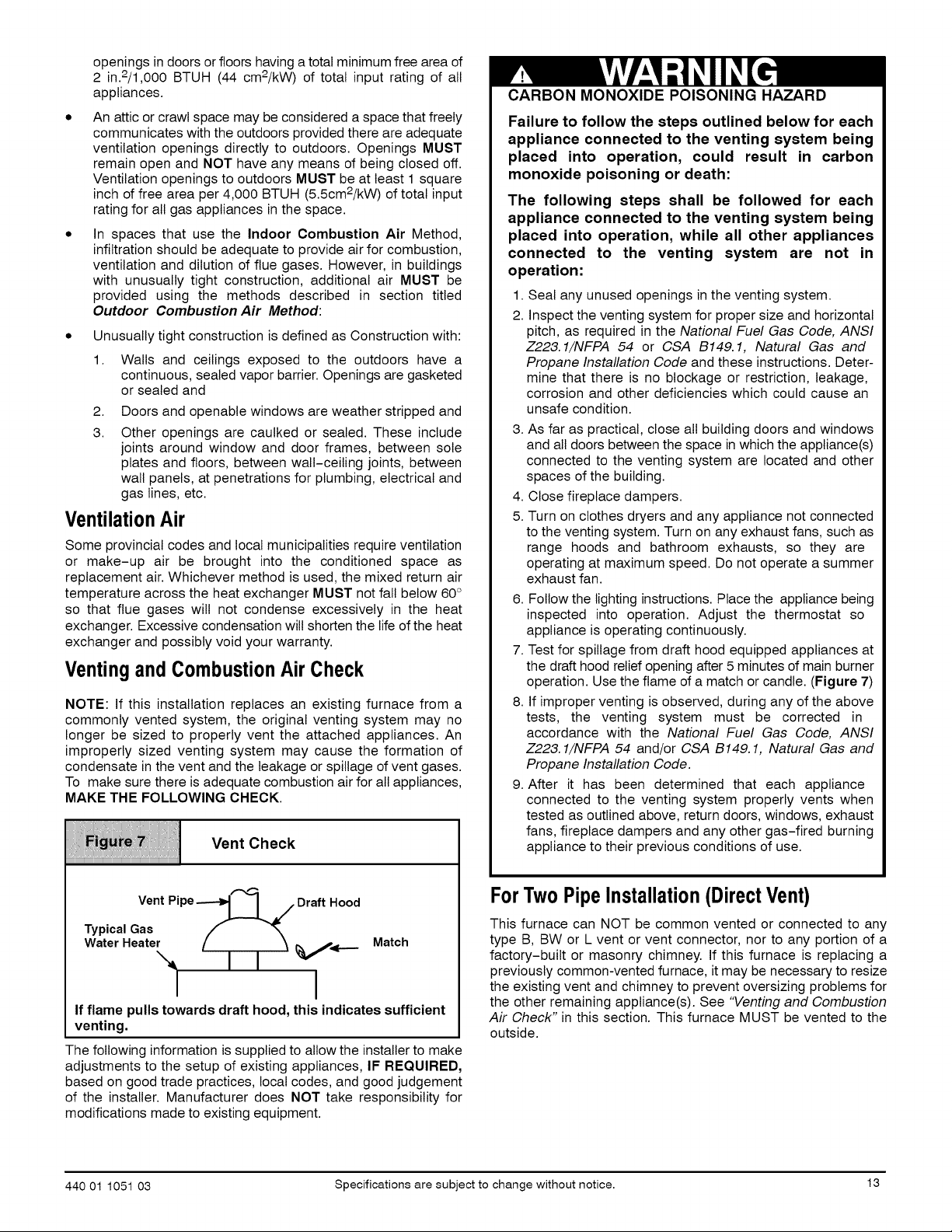

7. Test for spillage from draft hood equipped appliances at

the draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle. (Figure 7)

8. If improper venting is observed, during any of the above

tests, the venting system must be corrected in

accordance with the National Fuel Gas Code, ANSI

Z223. 1/NFPA 54 and/or CSA B149.1, Natural Gas and

Propane Installation Code.

9. After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows, exhaust

fans, fireplace dampers and any other gas-fired burning

appliance to their previous conditions of use.

Vent Pipe "--'_1 I / Draft Hood

wTyPtieCra/eGatSr [ I I/ V,<.__" Match

If flame pulls towards draft hood, this indicates sufficient

venting.

The following information is supplied to allow the installer to make

adjustments to the setup of existing appliances, IF REQUIRED,

based on good trade practices, local codes, and good judgement

of the installer. Manufacturer does NOT take responsibility for

modifications made to existing equipment.

440 01 1051 03 Specifications are subject to change without notice. 13

ForTwo PipeInstallation(DirectVent)

This furnace can NOT be common vented or connected to any

type B, BW or L vent or vent connector, nor to any portion of a

factory-built or masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be necessary to resize

the existing vent and chimney to prevent oversizing problems for

the other remaining appliance(s). See "Venting and Combustion

Air Check" in this section. This furnace MUST be vented to the

outside.

Vent and Combustion Air Piping

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in

personal injury or death.

Use methods described here to provide combustion

and ventilation air.

DualCertified(*9MPXModels)

This furnace is certified as a category iV appliance. This furnace

can be installed as a direct vent furnace using outside air for

combustion or the furnace can use air from inside the structure for

combustion. The INLET air pipe is optional. If combustion air

comes from inside the structure, adequate make up air MUST be

provided to compensate for oxygen burned. See Confined Space

Installation in the Combustion and Ventilation Air chapter. If

combustion air is drawn from outside the structure, it MUST be

taken from the same atmospheric pressure zone as the vent pipe.

ContaminatedCombustionAir

Installations in certain areas or types of structures will increase the

exposure to chemicals or halogens that may harm the furnace.

The following areas or types of structures may contain or have

exposure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air

for combustion.

* Commercial buildings.

* Buildings with indoor pools.

* Furnaces installed in laundry rooms.

* Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De-icing salts or chemicals.

• Carbon tetrachloride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

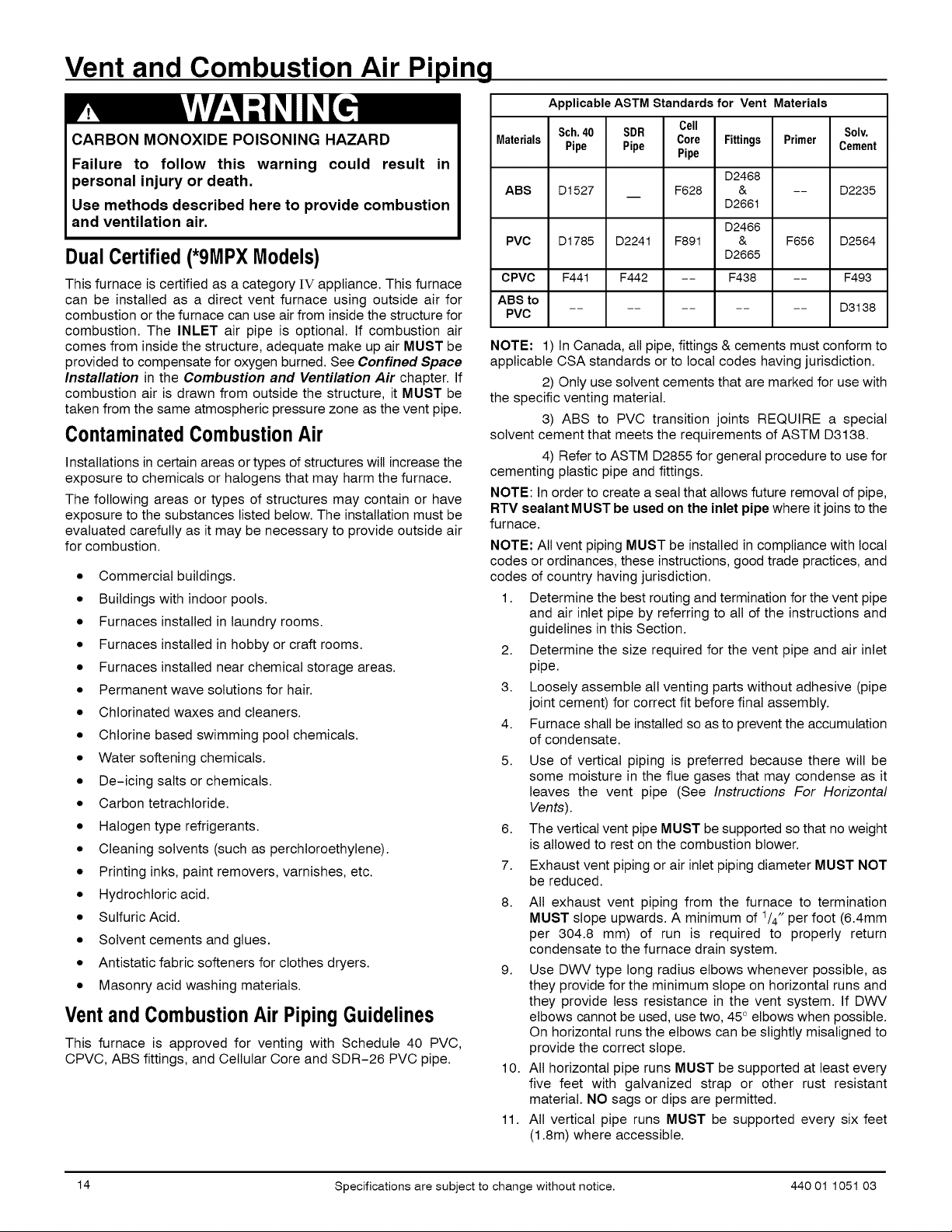

Ventand CombustionAirPiping Guidelines

This furnace is approved for venting with Schedule 40 PVC,

CPVC, ABS fittings, and Cellular Core and SDR-26 PVC pipe.

Applicable ASTM Standards for Vent Materials

Sch.40 SDR Cell Solv,

Materials Pipe Pipe Core Fittings Primer Cement

ABS D1527 F628 & -- D2235

PVC D1785 D2241 F891 & F656 D2564

CPVC F44t F442 -- F438 -- F493

ABS to

PVC

NOTE: 1) In Canada, all pipe, fittings & cements must conform to

applicable CSA standards or to local codes having jurisdiction.

the specific venting material.

solvent cement that meets the requirements of ASTM D3138.

cementing plastic pipe and fittings.

NOTE: In order to create a seal that allows future removal of pipe,

RTV sealant MUST be used on the inlet pipe where it joins to the

furnace.

NOTE: All vent piping MUST be installed in compliance with local

codes or ordinances, these instructions, good trade practices, and

codes of country having jurisdiction.

1. Determine the best routing and termination for the vent pipe

2. Determine the size required for the vent pipe and air inlet

3. Loosely assemble all venting parts without adhesive (pipe

4. Furnace shall be installed so as to prevent the accumulation

5. Use of vertical piping is preferred because there will be

6. The vertical vent pipe MUST be supported so that no weight

7. Exhaust vent piping or air inlet piping diameter MUST NOT

8. All exhaust vent piping from the furnace to termination

9. Use DWV type long radius elbows whenever possible, as

10. All horizontal pipe runs MUST be supported at least every

11. All vertical pipe runs MUST be supported every six feet

.......... D3138

2) Only use solvent cements that are marked for use with

3) ABS to PVC transition joints REQUIRE a special

4) Refer to ASTM D2855 for general procedure to use for

and air inlet pipe by referring to all of the instructions and

guidelines in this Section.

pipe.

joint cement) for correct fit before final assembly.

of condensate.

some moisture in the flue gases that may condense as it

leaves the vent pipe (See Instructions For Horizontal

Vents).

is allowed to rest on the combustion blower.

be reduced.

MUST slope upwards. A minimum of 1/4" per foot (6.4mm

per 304.8 mm) of run is required to properly return

condensate to the furnace drain system.

they provide for the minimum slope on horizontal runs and

they provide less resistance in the vent system. If DWV

elbows cannot be used, use two, 45° elbows when possible.

On horizontal runs the elbows can be slightly misatigned to

provide the correct slope.

five feet with galvanized strap or other rust resistant

material. NO sags or dips are permitted.

(1.8m) where accessible.

Pipe

D2468

D2661

D2466

D2665

14 Specifications are subject to change without notice. 440 01 1051 03

12.

The minimum vent length is 5' (1.5m) of PVC.

13.

The piping can be run in the same chase or adjacent to

supply or vent pipe for water supply or waste plumbing. It

can also be run in the same chase with a vent from another

90+ furnace.

NOTE: In NO case can the piping be run in a chase where

temperatures can exceed 140° F(60°C). or where radiated

heat from adjacent surfaces would exceed 140 ° F(60°C).

14. The vent outlet MUST be installed to terminate in the same

atmospheric pressure zone as the combustion air inlet.

15. The vent system can be installed in an existing unused

chimney provided that:

• Both the exhaust vent and air intake run the length of the

chimney.

• No other gas fired appliance or fireplace (solid fuel) is

vented into the chimney.

• The top of the chimney MUST be sealed flush or crowned

up to seal against rain or melting snow so ONLY the piping

protrudes.

The termination clearances shown in Figure 8 & Figure 9

are maintained.

16.

Furnace applications with vertical vents requiring vent

diameter increaser fittings must have increaser fittings

installed in vertical portion of the vent. Condensate will be

trapped in the vent if the vent diameter is increased prior to

having an elbow turned upward. This could cause nuisance

tripping of the pressure switch.

CombustionAirandVentPiping Insulation

Guidelines

NOTE: Use closed cell, neoprene insulation or equivalent. If

Fiberglass or equivalent insulation is used it must have a vapor

barrier. Use R values of 7 up to 10' (3.1m), R-11 if exposure

exceeds 10' (3.1m). If Fiberglass insulation is used, exterior to the

structure, the pipe MUST be boxed in and sealed against

moisture.

1. When the vent or combustion air pipe height above the roof

exceeds 30" (76.2mm), or if an exterior vertical riser is used

on a horizontal vent to get above snow levels, the exterior

portion MUST be insulated.

2. When combustion air inlet piping is installed above a

suspended ceiling, the pipe MUST be insulated with

moisture resistant insulation such as Armaflex or other

equivalent type of insulation.

3. Insulate combustion air inlet piping when run in warm,

humid spaces.

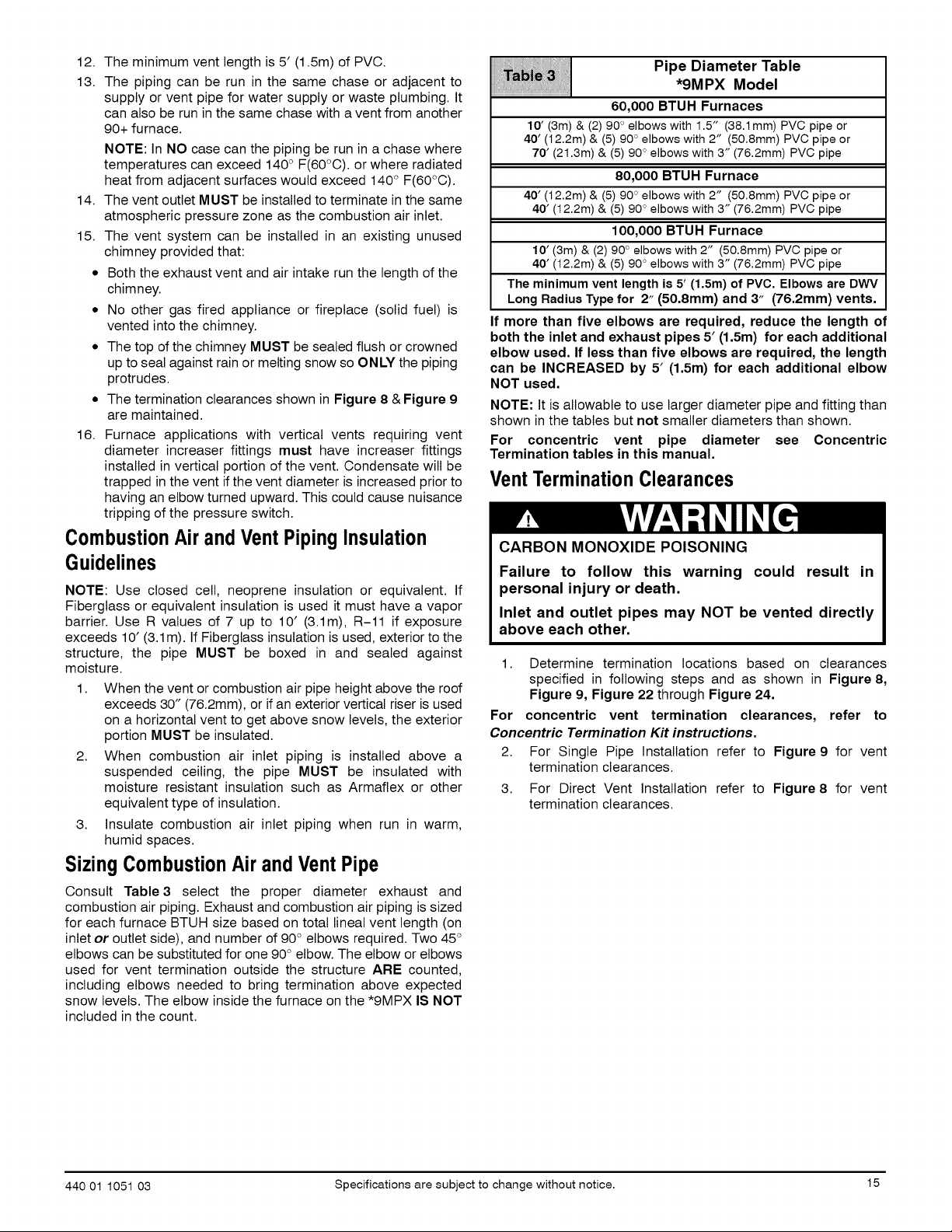

SizingCombustionAirandVentPipe

Consult Table3 select the proper diameter exhaust and

combustion air piping. Exhaust and combustion air piping is sized

for each furnace BTUH size based on total lineal vent length (on

inlet or outlet side), and number of 90 ° elbows required. Two 45 °

elbows can be substituted for one 90° elbow. The elbow or elbows

used for vent termination outside the structure ARE counted,

including elbows needed to bring termination above expected

snow levels. The elbow inside the furnace on the *9MPX IS NOT

included in the count.

Pipe Diameter Table

*9MPX Model

60,000 BTUH Furnaces

10' (3m)& (2) 90° elbows with 1.5" (38.1mm) PVC pipeor

40' (12.2m)& (5)90° elbowswith 2" (50.8mm) PVC pipe or

70' (21.3m)& (5) 90° elbows with 3" (76.2mm)PVCpipe

80,000 BTUH Furnace

40' (12.2m)& (5)90° elbowswith 2" (50.8mm) PVC pipe or

40' (12.2m)& (5) 90° elbows with 3" (76.2mm)PVCpipe

100,000 BTUH Furnace

10' (3m) & (2) 90° elbows with 2" (50.8mm) PVCpipe or

40' (12.2m)& (5) 90° elbows with 3" (76.2mm)PVCpipe

The minimum vent length is 5' (1.5m) of PVC. Elbows are DWV

Long Radius Type for 2" (50.8ram) and 3" (76.2mm) vents,

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5' (1.5m) for each additional

elbow used, If less than five elbows are required, the length

can be INCREASED by 5' (1.5m) for each additional elbow

NOT used,

NOTE: It is allowable to use larger diameter pipe and fitting than

shown in the tables but not smaller diameters than shown.

For concentric vent pipe diameter see Concentric

Termination tables in this manual,

VentTerminationClearances

CARBON MONOXIDE POISONING

Failure to follow this warning could result in

personal injury or death.

Inlet and outlet pipes may NOT be vented directly

above each other.

1. Determine termination locations based on clearances

specified in following steps and as shown in Figure 8,

Figure 9, Figure 22 through Figure 24.

For concentric vent termination clearances, refer to

Concentric Termination Kit instructions.

2. For Single Pipe Installation refer to Figure 9 for vent

termination clearances.

3. For Direct Vent Installation refer to Figure 8 for vent

termination clearances.

440 01 1051 03 Specifications are subject to change without notice. 15

Direct Vent Termination Clearance

/'

/

/

I_1 VENTTERMINAL \\\\\

(y AIR SUPPLY INLET

E_ AREAWHERE TERMINAL IS NOT PERMITED

Item ClearanceDescription CanadianInstallation(1) U.S. Installation(2)

A Clearanceabovegrade, veranda,porch, deck,balcony,or 12" (30cm)# 12" (30 cm)

anticipatedsnowlevel

B Clearanceto awindowordoorthat maybe opened 12" (30cm) forappliances> 10,000Btuh (3kW) and < 9" (23cm) for appliances > 10,000Btuh(3 kW)and < 50,000

100,000Btuh (30kW), 36" (91cm)for appliances > 100,000 Btuh(14.7 kW), 12" (30cm) forappliances > 50,000Btuh (14.7

Btuh(30 kW) kW)

C Clearanceto apermanentlyclosed window * *

D Verticalclearanceto a ventilatedsoffit locatedabovethe * *

terminalwithin a horizontaldistanceof 2' (61cm)from the

centedineofthe terminal

E Clearanceto an unventilatedsoffit * *

F Clearanceto an outsidecorner * *

G Clearanceto an insidecorner * *

H Clearanceto each side of the centedineextendedabove 3' (91cm) within 15' (4.5 m)abovethe meter/regulator *

electricalmeteror gasserviceregulatorassembly assembly

I Clearanceto seMce regulatorvent outlet 3' (91cm) *

J Clearanceto non-mechanicalair supplyinlet to buildingor 12" (30cm) for appliances > 10,000Btuh(3kW) and< 9" (23 cm)forappliances> 10,000Btuh(3 kW)and <

thecombustionair inlet to any otherappliance 100,000Btuh (30kW), 36" (91cm)forappliances > 50,000Btuh(15 kW),12" (30cm) for appliances> 50,000

100,000Btuh (30kW) Btuh(14.7 kW)

K Clearanceto a mechanicalair supplyinlet 6' (1.83 m) 3' (91 cm)aboveif within 10' (3m) horizontally

L Clearanceunder averanda,porch, deck,or balcony 12" (30cm)+ *

M Clearanceto each side of the centedineextendedaboveor 12" (30 cm) 12" (30cm)

belowventterminal ofthefurnace to a dryer or water heater

vent,orotherappliance'sdirectvent intake orexhaust.

N Clearanceto thevent terminalof a dryervent, water heater 3' (91cm) 3'(91 cm)

O Clearancefroma plumbing ventstack 3' (91cm) 3'(91 cm)

P Clearanceabovea pavedsidewalkor paveddrivewaylocated 7' (2.13m) ** *

onpublicproperty.

> greaterthan, _>greaterthan orequalto, < lessthan, _ lessthanor equalto

(1.) Inaccordancewith the currentCSAB149.1, NaturalGasandPropaneInstallationCode

(2.) Inaccordancewith the currentANSI Z223.1/NFPA54,NationalFuelGasCode

# 18" (46cm)aboveroof surface

+ Permittedonlyif veranda,porch,deck,or balconyis fully openon a minimumoftwo sides beneaththefloor.

Forclearancesnotspecifiedin ANSI Z223.1/NFPA54 or CSAB149.1,clearancesshall bein accordancewith local installationcodesand

the requirementsofthe gas supplierandthe manufacture'sinstallationinstructions.

** A ventshall notterminatedirectlyabovea sidewalkor paveddrivewaythat is locatedbetweentwo singlefamily dwellingsand servesboth dwellings.

Notes:

1. The ventfor this applianceshallnotterminate

a. Overpublicwalkways;or

b. Nearsoffitvents orcrawlspaceventsor other areas wherecondensateorvaporcouldcreate a nuisanceor hazardor propertydamage;or

c. Wherecondensatevapor could causedamage orcouldbe detrimentaltothe operationof regulators,relief valves, or other equipment.

2. When locatingventterminations,considerationmustbe givento prevailingwinds,location,and other conditionswhichmay causeredrcolation ofthe combustionproductsof adjacentvents.

Recirculationcan cause poor combustion,inletcondensateproblems,andacceleratedcorrosionofthe heatexchangers.

3. Avoidventingundera deck orlargeoverhang.Recirculationcouldoccur and cause performanceor system problems.

16 Specifications are subject to change without notice. 440 01 1051 03

Other than Direct Vent Termination Clearance

H

I_l VENT TERMINAL /')'_

\\

\X!" AIR SUPPLY INLET _ AREAWHERE TERMINAL IS NOT PERMITED

Item ClearanceDescriptions CanadianInstallation(1) U.S.Installation (2)

A Clearanceabovegrade, veranda,porch, deck,balcony,or 12" (30cm)# 12" (30 cm)

anticipatedsnowlevel

B Clearanceto awindowordoorthat maybe opened 12" (30cm) forappliances> 10,000Btuh (3kW) and < 4'(1.2 m) belowor to the side ofthe opening.1'(30 cm)above

100,000Btuh (30kW), 36" (91cm)for appliances > 100,000 the opening.

Btuh(30 kW)

C Clearanceto apermanentlyclosed window * *

D Verticalclearanceto a ventilatedsoffit locatedabovethe * *

terminalwithin a horizontaldistanceof 2' (61cm)from the

centerlineofthe terminal

E Clearanceto an unventilatedsoffit * *

F Clearanceto an outsidecorner * *

G Clearanceto an insidecorner *

H Clearanceto each side of the centerlineextendedabove 3' (91cm) within 15' (4.5 m)abovethe meter/regulator 3' (91cm)within15' (4.5 m)abovethemeter/regulator

electricalmeteror gasserviceregulatorassembly assembly assembly

I Clearanceto sewiceregulatorvent outlet 3' (91cm) *

J Clearanceto non=mechanicalairsupplyinlettobuildingor 12" (30cm)forappliances > 10,000Btuh (3kW) and < 4' (1.2 m) belowor to the side of opening: 1' (30 cm) above

thecombustionair inlet to any otherappliance 100,000Btuh (30kW), 36" (91cm)forappliances > opening.

100,000Btuh (30kW)

K Clearanceto a mechanicalair supplyinlet 6' (1.83 m) 3' (91 cm)aboveif within 10' (3m)horizontally