Page 1

INSTALLATION

INSTRUCTIONS

Models

FCP2400D

FCP3000D

FCP3600D

FCP4200D

FCP4800D

FCP6000D

Use ONLY factory listed electric heaters.

Fan Coils

FCP2400C

FCP3000C

FCP3600C

FCP4200C

FCP4800C

FCP6000C

AMF001NHA

Accessory No Heat Kit

FCX2400C

FCX3600C

FCX4800C

FCX6000C

Require

General Information / Installation ............ 2

Upflow Installations ........................ 3

Horizontal Installations ..................... 3

Ductwork Connections ..................... 3

Filter Installation ........................... 4

Condensate Drain .......................... 5

Refrigerant Orifice and Lines ................ 5

Electrical Connections ...................... 6

Checks and Maintenance ................... 7

Blower Performance ........................ 8

Sequence of Operation ..................... 9

Wiring Diagram ............................ 10

Replacement Parts ......................... 11

FCP2405C

FCP2407C

FCP2410C

FCP3005C

FCP3007C

FCP3010C

FCP3605C

FCP3607C

5, 7, 10KW Heater

FCP3610C

FCP4205C

FCP4207C

FCP4210C

FCP4807C

FCP4810C

FCP6010C

With

Safety Labeling and Signal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAUTION

are used to identify levels of hazard seriousness. The

signal word DANGER is only used on product labels to

signify an immediate hazard. The signal words WARN-

ING and CAUTION will be used on product labels and

throughout this manual and other manuals that may ap-

ply to the product.

DANGER - immediate hazards which WILL result in se-

vere personal injury or death.

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property

damage.

Printed inU.S.A. 496 01 4111 03 June 2002

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

CAUTION

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels.

Page 2

_ Installation Instructions Fan Coils]

FigUre ! Dimensions and Clearances

14-3/8" (2-2 1/2 Ton)

17-7/8" (3-3 1/2 Ton)

21-1/2" (4 Ton FCP Only)

25-1/8" (5 Ton) (4 Ton FCX Only)

CLEARANCES

2"

8 1/2"

42"

(2-3 1/2 Ton)

52"

(4-5 Ton)

Filter Door

NO HEATERS

All Sides .................................. 0"

From Supply Duct .......................... 0"

Recommended Service From Front .......... 20"

(Service for blower, filter if installed)

WITH HEATERS

All Sides .................................. 0"

From First Three

Feet of Supply Duct to Combustibles ........ 1"

From Duct after Three Feet ................. 0"

Recommended Service From Front .......... 20"

(Service for blower, filter, heaters if installed)

21 1/2"

16-3/8" (2-2 1/2 Ton)

19-7/8" (3-3 1/2 Ton)

23-1/2" (4 Ton FCP Only)

27-1/8" (5 Ton) (4 Ton FCX Only)

38-20-17

General Information

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes and with the

National Electrical Code NFPA70 current edition.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in equipment malfunction,

property damage, personal injury and/or death.

The blower cabinet may be used for cooling or heat pump opera-

tion with or without electric heat. Installations without electric

heat, require a No Heat Kit.The cabinet can be installed in an up-

flow or horizontal position (Figure 2, 3). Horizontal installations

Fire Hazard

When heaters are installed maintain clear-

ances from combustible materials as speci-

fied on unit rating plate. Do not use plastic

lined or combustible flexible ducting within 36

inches of the supply end of the air handler.

Failure to do so can result in fire, property

damage, personal injury and/or death.

require a horizontal kit. Some models are shipped with the hori-

zontal kit already installed .These units are not shipped with air fil-

ters installed. Filter must be field supplied, either washable or

disposal type. Washable filters are available as an accessory.

Location

Select the best position which suits the installation site conditions.

The location should provide adequate structural support, space in

the front of the unit for service access, clearance for return air and

supply duct connections, space for refrigerant piping connections

and condensate drain line connections. If heaters are being

installed make sure adequate clearance is maintained from sup-

ply ductwork, See Clearances and Warning in Figure 1.

NOTE: Internal filter can be accessed from separate filter door. If

the filter can NOT be easily accessed, a remote filter is recom-

mended. Refer to ACCA Manual D for remote filter sizing.

Ifthe unit is located in an area of high humidity, nuisance sweating

of casing may occur. On these installations a wrap of 2" fiberglass

insulation with a vapor barrier should be used.

_J 49601 4111 03

Page 3

I Fan Coils

Installation Instructions I

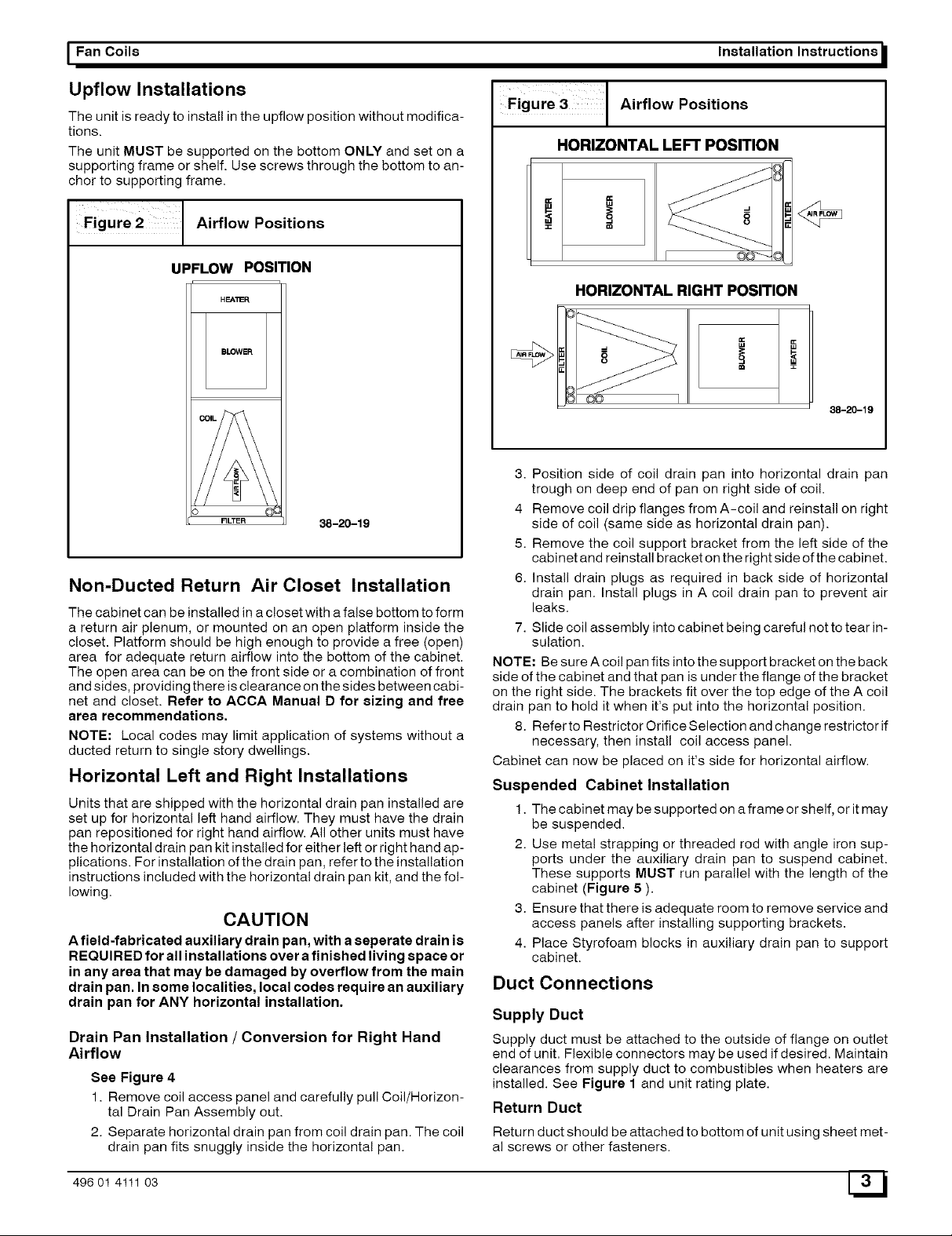

Upflow Installations

The unit is ready to install in the upflow position without modifica-

tions.

The unit MUST be supported on the bottom ONLY and set on a

supporting frame or shelf. Use screws through the bottom to an-

chor to supporting frame.

Figule 2 I

Airflow Positions

UPFLOW POSITION

HEARER

o

nLTER 38--20--19

Non-Ducted Return Air Closet Installation

The cabinet can be installed in a closet with a false bottom to form

a return air plenum, or mounted on an open platform inside the

closet. Platform should be high enough to provide a free (open)

area for adequate return airflow into the bottom of the cabinet.

The open area can be on the front side or a combination of front

and sides, providing there is clearance on the sides between cabi-

net and closet. Refer to ACCA Manual D for sizing and free

area recommendations.

NOTE: Local codes may limit application of systems without a

ducted return to single story dwellings.

Horizontal Left and Right Installations

Units that are shipped with the horizontal drain pan installed are

set up for horizontal left hand airflow. They must have the drain

pan repositioned for right hand airflow. All other units must have

the horizontal drain pan kit installed for either left or right hand ap-

plications. For installation of the drain pan, refer to the installation

instructions included with the horizontal drain pan kit, and the fol-

lowing.

CAUTION

Afield-fabricated auxiliary drain pan, with a seperate drain is

REQUIRED for all installations over a finished living space or

in any area that may be damaged by overflow from the main

drain pan. In some localities, local codes require an auxiliary

drain pan for ANY horizontal installation.

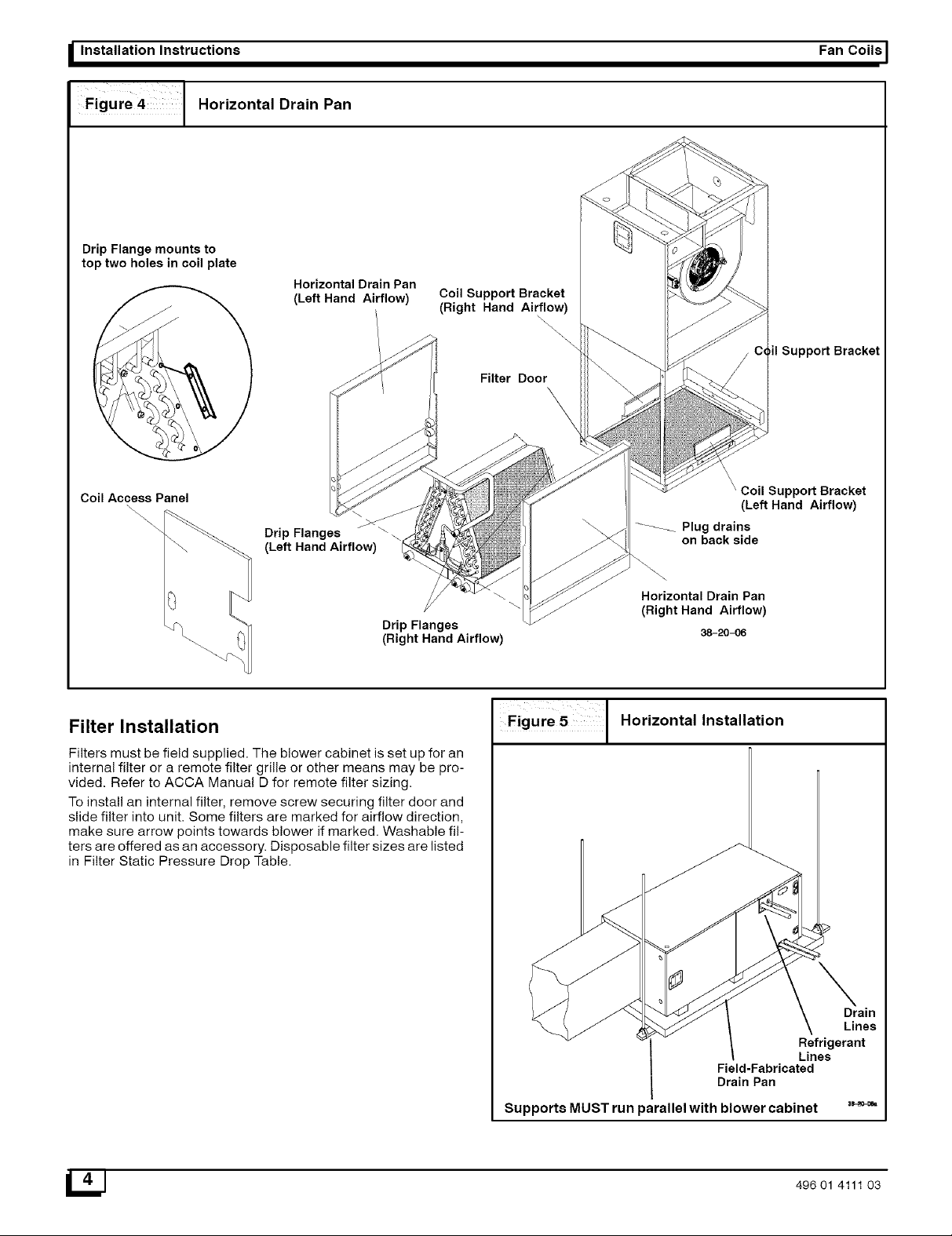

Drain Pan Installation / Conversion for Right Hand

Airflow

See Figure 4

1. Remove coil access panel and carefully pull Coil/Horizon-

tal Drain Pan Assembly out.

2. Separate horizontal drain pan from coil drain pan. The coil

drain pan fits snuggly inside the horizontal pan.

Figure 3

Airflow Positions

HORIZONTAL LEFT POSITION

,,=,

HORIZONTAL RIGHT POSITION

,,=,

m

38-20-19

3. Position side of coil drain pan into horizontal drain pan

trough on deep end of pan on right side of coil.

4 Remove coil drip flanges from A-coil and reinstall on right

side of coil (same side as horizontal drain pan).

5. Remove the coil support bracket from the left side of the

cabinet and reinstall bracket on the right side of the cabinet.

6. Install drain plugs as required in back side of horizontal

drain pan. Install plugs in A col! drain pan to prevent air

leaks.

7. Slide coil assembly into cabinet being careful not to tear in-

sulation.

NOTE: Be sure A coil pan fits into the support bracket on the back

side of the cabinet and that pan is under the flange of the bracket

on the right side. The brackets fit over the top edge of the A coil

drain pan to hold it when it's put into the horizontal position.

8. Refer to Restrictor Orifice Selection and change restrictor if

necessary, then install coil access panel.

Cabinet can now be placed on it's side for horizontal airflow.

Suspended Cabinet Installation

1. The cabinet may be supported on aframe or shelf, or itmay

be suspended.

2. Use metal strapping or threaded rod with angle iron sup-

ports under the auxiliary drain pan to suspend cabinet.

These supports MUST run parallel with the length of the

cabinet (Figure 5 ),

3. Ensure that there is adequate room to remove service and

access panels after installing supporting brackets,

4. Place Styrofoam blocks in auxiliary drain pan to support

cabinet.

Duct Connections

Supply Duct

Supply duct must be attached to the outside of flange on outlet

end of unit. Flexible connectors may be used if desired. Maintain

clearances from supply duct to combustibles when heaters are

installed. See Figure 1 and unit rating plate.

Return Duct

Return duct should be attached to bottom of unit using sheet met-

al screws or other fasteners.

496 01 4111 03 _L_

Page 4

_ Installation Instructions

FigUre 4 Horizontal Drain Pan

Drip Flange mounts to

top two holes in coil plate

Horizontal Drain Pan

(Left Hand Airflow)

Coil Support Bracket

(Right Hand Airflow)

Filter Door

\

Fan Coils I

il Support Bracket

Coil Access Panel

Drip Flanges

(Left Hand Airflow)

Drip Flanges

(Right Hand Airflow)

Filter Installation

Filters must be field supplied. The blower cabinet is set up for an

internal filter or a remote filter grille or other means may be pro-

vided. Refer to ACCA Manual D for remote filter sizing.

To install an internal filter, remove screw securing filter door and

slide filter into unit. Some filters are marked for airflow direction,

make sure arrow points towards blower if marked. Washable fil-

ters are offered as an accessory. Disposable filter sizes are listed

in Filter Static Pressure Drop Table.

Coil Support Bracket

(Left Hand Airflow)

--_ Plug drains

on back side

Horizontal Drain Pan

(Right Hand Airflow)

38-20-06

Figure 5 Horizontal Installation

Drain Pan

Field-Fabricated

Supports MUST run parallel with blower cabinet =_-o=

_J 49601 4111 03

Page 5

I Fan Coils

Installation Instructions

Condensate Drain Connections

The unit is provided with 3/4" National Pipe Thread (NPT) con-

densate drains. (Figure 1). Any drain can be used as a primary or

secondary drain. Condensate drain lines should be installed in a

manner that does not obstruct access to the filter.

There is a secondary drain fitting supplied with the unit that will

convert any of the primary condensate drain connections into a

secondary drain connection. This fitting should be installed in any

of the primary drain connections to convert it to a secondary drain.

1. Connect the drain lines to the appropriate drain fittings. 3/4"

PVC or other type of drain line may be used. The drain line

must not be smaller than the drain fitting.

2. Install a trap in the drain line below the bottom of the drain

pan and pitch the drain lines down from the coil at least I/4"

per foot of run. Horizontal runs over 15 feet long must also

have an anti-siphon air vent (stand pipe), installed ahead

of the horizontal run. An extremely long horizontal run may

require an oversized drain line to eliminate air trapping.

3. Routetotheoutsideortoafloordrain, laundrytrayorwaste

line (sewer). Check local codes before connecting to a

sewer line.

4. Insulate drain lines where sweating could cause water

damage.

Restrictor Orifice Selection

A restrictor orifice is located in a fitting at the distributor. The facto-

ry installed restrictor orifice is identified on the unit rating plate.

The restrictor orifice may require changing to obtain best perfor-

mance. Refer to the restrictor charts furnished with the outdoor

unit.

5. If a gravity drain cannot be used, install a condensate

pump. Install the pump as close to the indoor section as

possible.

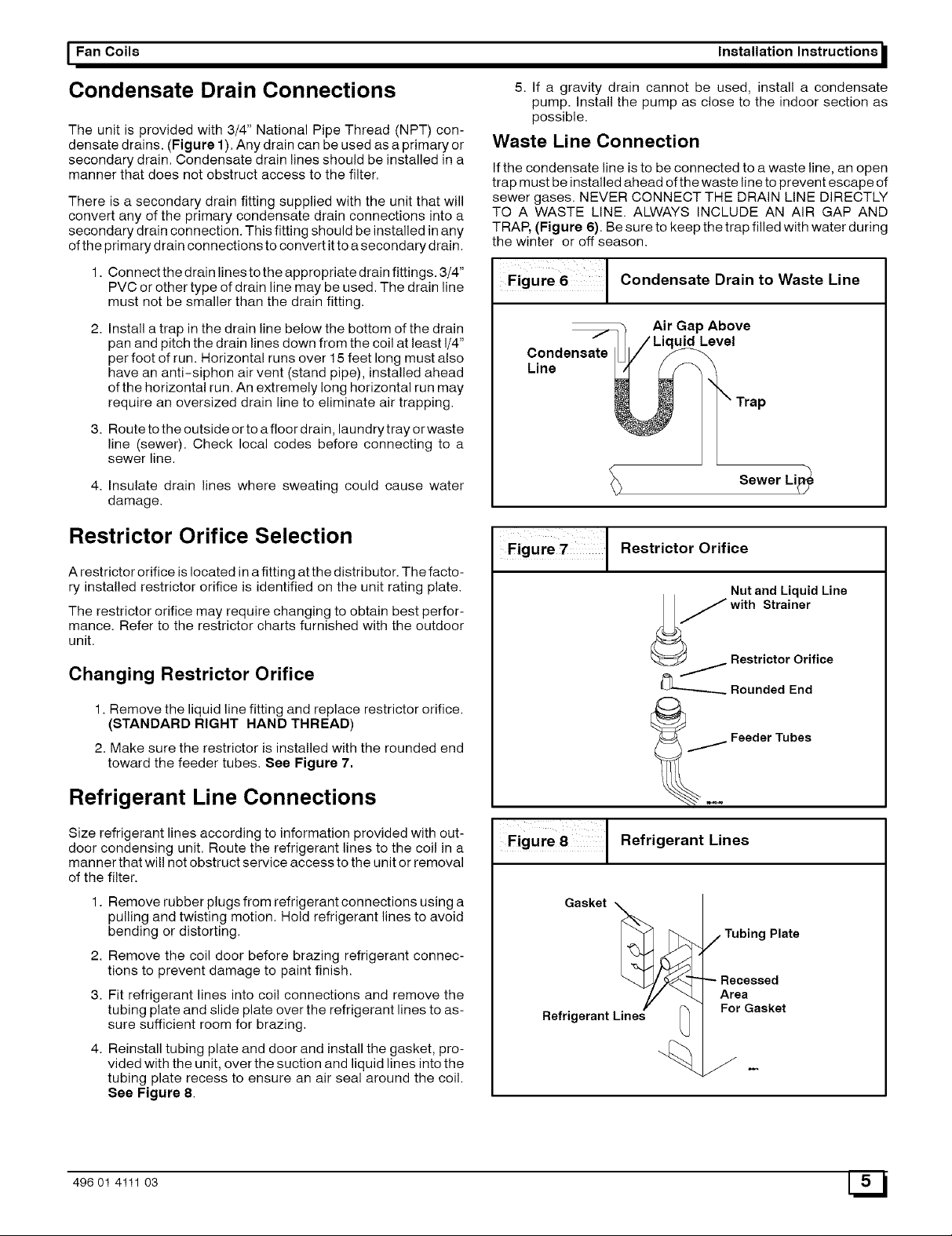

Waste Line Connection

If the condensate line is to be connected to a waste line, an open

trap must be installed ahead of the waste line to prevent escape of

sewer gases. NEVER CONNECT THE DRAIN LINE DIRECTLY

TO A WASTE LINE. ALWAYS INCLUDE AN AIR GAP AND

TRAP, (Figure 6). Be sure to keep the trap filled with water during

the winter or off season.

Figule 6 I Condensate Drain to Waste Line

Air Gap Above

Condensate

Line

Figule _ Restrictor Orifice

uid Level

Sewer Li_1_

Nut and Liquid Line

Changing Restrictor Orifice

1. Remove the liquid line fitting and replace restrictor orifice.

(STANDARD RIGHT HAND THREAD)

2. Make sure the restrictor is installed with the rounded end

toward the feeder tubes. See Figure 7.

Refrigerant Line Connections

Size refrigerant lines according to information provided with out-

door condensing unit. Route the refrigerant lines to the coil in a

manner that wil! not obstruct service access to the unit or removal

of the filter.

1. Remove rubber plugs from refrigerant connections using a

pulling and twisting motion. Hold refrigerant lines to avoid

bending or distorting.

2. Remove the coil door before brazing refrigerant connec-

tions to prevent damage to paint finish.

3. Fit refrigerant lines into coi! connections and remove the

tubing plate and slide plate over the refrigerant lines to as-

sure sufficient room for brazing.

4. Reinstall tubing plate and door and install the gasket, pro-

vided with the unit, over the suction and liquid lines into the

tubing plate recess to ensure an air seal around the coil.

See Figure 8.

_._ Rounded End

Figure 8 Refrigerant Lines

Gasket ,_

/ Tubing Plate

Recessed

Refrigerant k_ne_s__ '

Area

For Gasket

.%

Feeder Tubes

496 01 4111 03 5L_

Page 6

I Installation Instructions

Electrical Connections

Electrical shock hazard.

Fan Coils I

2. Connect line voltage to the lugs with the Black and Yellow

wires, or to circuit breakers or wire leads from heaters. Re-

fer to Figure 9 for FCP--D Series and Figure 10 for

FCP--C and FOX and wiring diagram.

Turn OFF electric power at fuse box or service

panel before making any electrical connections

and ensure a proper ground connection is made

before connecting line voltage.

Failure to do so can result in property damage,

personal injury and/or death.

All electrical work MUST conform with the requirements of local

codes and ordinances and the National Electrical Code NFPA 70

current edition.

The low voltage transformer and the fan control are standard on

all models and are prewired at the factory. Line voltage connec-

tions are made to the heater accessory or the wire pigtails in the

unit.

Low Voltage Control Connections

The 24 volt power supply is provided by an internally wired low

voltage transformer which is standard on all models. If power

supply is 208 volt, the low voltage transformer must be rewired to

the 208 volt tap. See the unit wiring label.

Field supplied low voltage wiring can enter the unit on the top left

hand corner or the left hand side panel. When using the left hand

side panel entrance, the low voltage wiring must be fed through

the entrance hole in the bottom of the control box.

Install the strain relief bushing (supplied with unit) in the selected

hole and a hole plug (supplied with unit) in the unused hole.

Connect the field wiring at the screw terminals of the control

board. Refer to Figures 9, 10.

Keep the low voltage wiring as short as possible inside the control

box.

Complete connections between indoor blower, outdoor section,

indoor thermostat and electronic outdoor thermostat (accessory)

according to instruction provided with the Condenser Installation

Instructions or those provided with the accessory and refer to Fig-

ures 11&12.

Overcurrent Protection

Figure 9 1 Electrical Controls - (FCP--D Series)

Low Voltage Matching Receptable

Connections For Electric Heater

Pigtails for

Line Voltage

(Yellow and Black) and

Ground Connection

en)

(Unplug Connector)

Figure 10 I Electrical Controls

Low Voltage

Connections

Matching Receptable

For No Heat Kit

or Electric Heater

The power supply wiring to the unit MUST be provided with over-

current protection. Governing codes may require this to be fuses

ONLY or circuit breakers.

For blower cabinets without heaters, a 15 amp circuit may be

used.

Line Voltage Connections

Line voltage wiring may be brought into the unit through the top

right-hand corner or the right-hand side panel. The correct hole

size required by the conduit fitting must be punched at the pilot

hole location. Plug the unused pilot hole with a hole plug (supplied

with unit).

Connect field wiring to appropiate terminals on electric heater or

the wire pigtails. All line voltage connections must be made with

copper wire.

Line Voltage Connection

1. Provide line voltage power supply (208V-240V) from a

separate circuit(s). Size per table or table in heater manual.

_J 49601 4111 03

Flanges Together

Adapter Plate

(FCP36-42, FCX36)_

No Heat Kit

Filler Plate

(FCP/X48-60)

Lugs for

Line Voltage

and Ground

Connections

Page 7

I Fan Coils

Installation Instructions

No Heat Kit Installation

(FCP --C and FCX)

If electric heat is not used, install accessory No Heat Kit.

1. Locate adapter and filler plates, with screws inside pack-

age.

2. Attach adapter plate and filler plate to bracket if required to

match cabinet, Refer to Figure 10.

3. Secure the electric heat accessory with four screws.

4. Connect the plug from No Heat Kit wiring into the recep-

tacle on the control board on the side of the cabinet.

CAUTION

Do not attempt to force plug as it only fits one way.

Grounding Connection

Use a copper conductor(s) from the Green ground wire on the unit

or ground lugs on the electric heater to a grounded connection in

the electric service panel or a properly installed grounding rod.

Figure !i Typical Low Voltage Schematic

Heat Pump with Electric Heat

Staging

_ermostat

R I

--i

G I

c I

---------t

o I

y I

=========4

w2 I

W 1 I--

Outdoor Unit

R

BL

W

-- y

O

Typ,ca,LowVo,tage

1

Thermostat

R

G --

Y

W

W 1 W2 G Y H O C R

000 00() () 1

Therrnoctat

R

W --

Cooling Only

Indoor Blower

Cooling with Electric Heat

Schematic

Outdoor Unit

Y

Y

Outdoor Unit

W t W2 G Y H O C

IndoorBlower

Electrical Data

Supply Maximum Branch Protective

SupplyCircuit Circuit Motor Total Circuit Device

Volts Phase Hertz No. AMPS. AMPS. Ampacity (AMPS.)

240 1 80 Single 60 60 75 15

208 1 60 Single 60 60 75 15

Nomi- Supply Heater Mexi- Branch

Heater Supply Heating Heat- KW Per Circuit KW Per Heater Motor Total Circuit

1086081 240 16,832 4.8 4.8 Single 48 200 60 26.0 325

05KW 208 12,287 3.6 3.6 Single 36 173 60 23.3 292

1086082 240 24573 7.2 3.6 Single 72 300 60 36.0 450

07KW 208 18430 5.4 2.7 Single 54 260 60 32.0 400

1086083 240 32,765 9.6 4.8 Single 96 400 60 46.0 575

10KW 208 24,574 7.2 3.6 Single 72 347 60 40.7 508

Voltage BTUH KW Element No. Circuit AMPS. AMPS. AMP Ampacity

Maximum

Overcurrent

o wo O

750C. Copper Ground

He. Size Length (Ft) No. Size

2 14 104 1 14

2 14 g0 1 14

Me,mum Recommended

Overcurrent Supply Wire

Protective 750 C. Copper Ground

Device Max. Wire

(AMPS.) No. Size Length (F No. Size

35 2 10 61 1 10

30 2 10 59 1 10

45 2 8 70 1 10

40 2 8 68 1 10

60 2 6 85 1 10

60 2 6 83 1 10

R

Recommended

SupplyWire

Max. Wire

496 01 4111 03 7L_

Page 8

_ Installation Instructions

Fan Coils I

Adjusting Thermostat Anticipator

Set the heat anticipator of the thermostat to the proper value. See

instructions provided with the thermostat before making this ad-

justment.

Heater Size - KW Anticipator Setting

05 .24

07, 10 .32

HEATER STAGING

ELECTRIC

HEATER

05KW

07KW

10 KW

ELECTRIC HEATER STATIC PRESSURE DROP - IN. WG.

CFM

6OO

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

VOLTAGE

208-240/1/60

208-240/1/60

208-240/1/60

TOTAL HEAT

208V 240V

3.6 4.8

5.4 7.2

7.2 9.6

5 KW

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.01

Staging

The heater elements are turned on in increments. Refer to Stag-

ing Table. In addition on heaters larger than 5KW, the heat can be

staged (1 st & 2nd) either through an indoor thermostat or by using

an outdoor thermostat. This satisfies staging requirements im-

posed by some electric utilities on heaters larger than 6 kilowatts.

A control signal (24V) from Wl on the Indoor T'stat to Wl on the

control board energizes the 1st stage of heat. A control signal

(24V) to W2 on the control board energizes the second stage of

electric heat. To turn ON both stages at the same time, using one

control signal, W1 and W2 are jumpered together.

Ifthe indoor thermostat does not have staging capabilities, acces-

sory electronic outdoor thermostats are available that wil! control

two stages of electric heat.

1st STAGE (W1)

208v 240v

3.6 4.8

2.7 3.6

3.6 4.8

7.5 KW

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.02

0.02

0.02

0.02

0.02

0.02

0.02

0.02

2nd STAGE (W2)

208V 240V

2.7 3.6

3.6 4.8

10 KW

0.01

0.01

0.01

0.01

0.01

0.01

0.01

0.02

0.02

0.02

0.02

0.02

0.02

0.02

0.02

_J 496 01 4111 03

Page 9

I Fan Coils Installation Instructions

Changing Motor Speed

The blower motor comes from the factory wired for high or Med

speed. To change the blower speed, disconnect the black wire at

the blower motor terminal block and reconnect at the desired

blower speed tap.

Air Flow Check

For proper system operation, the air flow through the indoor coil

should be between 350 and 450 cfm per ton of cooling capacity.

The air flow through the unit can be determined by measuring the

external static pressure to the unit and selecting the motor speed

tap that will most closely provide the required air flow.

1. Set up to measure external static pressure at the supply

and return duct connections (Figure 13).

2. Drill holes in the ducts for pressure taps, pitot tubes, or oth-

er accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer or draft

gauge.

4. Ensure the coil and filter are clean, and all the registers are

open.

Figure 13 Static Pressure Check

SupplYr____

e °on

5. Determine the external static pressure with the blower op-

erating.

6. Refer to the Air Flow Data tables, page 9 to find the speed

tap that will most closely provide the required air flow for the

system.

7. Refer to Changing the Motor Speed in these instructions if

the speed tap is to be changed.

8. Recheck the external static pressure with the new speed

tap, and confirm speed tap selection.

Temperature Rise Check

Temperature rise is the difference between the supply and return

air temperatures.

NOTE: The temperature rise can be adjusted by changing the

heating speed tap at the unit's blower terminal block. Refer to the

unit's Installation Instructions for airflow information.

A temperature rise greater than 60°F (33.3°C) is not recom-

mended.

1. To check the temperature rise through the unit, place ther-

mometers in the supply and return air ducts as close to the

unit as possible.

2. Open ALL registers and duct dampers.

3. Set thermostat Heat-Cool selector to NEAT.

4. Set the thermostat temperature setting as high as it wil! go.

5. Turn electric power ON.

6. Operate unit AT LEAST 5 minutes, then check tempera-

ture rise.

NOTE: The maximum outlet air temperature for all models is

200°F (93.3°C).

7. Set thermostat to normal temperature setting.

8. Turn electric power OFF

9. Be sure to seal all holes in ducts if any were created during

this process.

Airflow220V/ 50 HzModels0nly

NOTES: Performance based on unit with horizontal drain pan installed, dry coil, no filter, Deduct Filter Static

MODEL BLOWER SPEED 0.1 0.2 0.3 0.4 0.5

FCP2400D HIGH 885 825 723 643 499 297

MEDIUM 873 811 708 573 380 266

LOW 775 728 645 558 416 188

FCP3000D HIGH 1,225 1,175 1,067 1,031 891 794

MEDIUM 1,160 1,115 1,014 980 847 747

LOW 1,034 1,001 919 886 765 667

FCP3600D HIGH 1,384 1,328 1,206 1,165 1,007 897

MEDIUM 1,311 1,260 1,146 1,107 957 844

LOW 1,168 1,131 1,038 1,002 865 754

FCP4200D HIGH 1,578 1,527 1,399 1,338 1,143 964

MEDIUM 1,446 1,402 1,288 1,224 1,037 876

LOW 1,198 1,184 1,111 1,073 927 805

FCP4800D HIGH 1,657 1,603 1,469 1,405 1,200 1,012

MEDIUM 1,518 1,472 1,352 1,285 1,089 920

LOW 1,258 1,244 1,167 1,128 973 845

FCP6000D HIGH 1,960 1,902 1,748 1,702 1,485 1,317

MEDIUM 1,869 1,815 1,670 1,626 1,419 1,252

LOW 1,759 1,715 1,585 1,545 1,351 1,202

496 01 4111 03 9L_

Page 10

I Installation Instructions Fan Coils J

Airflow Based on dry coil, no filter, no electric heat. Deduct heater static shown in heater static table.

Deduct filter static shown in filter static table. Deduct .05 for wet coil. Deduct .10 for Horizontal Kit (FCP) only.

i;[e,.]:,/.'_l SP IN. WG. l_[e,]_.-'[_l SP IN. WG.

SPEED VOLTAGE 0.1 0.2 0,3 0.4 0.5 0.6 0,7 SPEED VOLTAGE 0.1 0,2 0,3 0.4 0.5 0,6 0,7

LOW

MED

HIGH

230V 743 743 739 715 671 601 510 LOW

208V 561 561 561 560 544 512 459

230V 972 942 897 851 773 686 593 MED

208V 789 789 787 775 737 656 569

230V 1108 1052 992 936 859 765 653 HIGH

208V 1027 1027 974 910 836 751 651

230V 1643 1671 1670 1650 1607 1549 1474

208V 1337 1355 1369 1373 1360 1332 1282

230V 2059 2023 1974 1910 1827 1739 1635

208V 1735 1738 1728 1688 1636 1574 1483

230V 2453 2369 2272 2165 2056 1933 1813

208V 2339 2259 2167 2073 1971 1862 1741

I;[_:_[_1 sPIN. WG.

SPEED VOLTAGE 0.1 0.2 0,3 0.4 0.5 0.6 0,7

LOW 230V 1104 1069 1028 976 926 851 784

208V

MED

HIGH

230V

208V

230V

208V

I;[I,.]:_[.11 SP IN. WG.

SPEED VOLTAGE 0.1 0.2 0,3 0,4 0.5 0.6 0,7

LOW

MED

HIGH

230V

208V

230V

208V

230V

208V

I;[I.]'_PJI SP IN. WG.

SPEED VOLTAGE 0.1 0.2 0,3 0.4 0.5 0.6 0,7

LOW

MED

HIGH

230V

208V

230V

208V

230V

208V

940 908 870 832 780 723 666

1327 1277 1222 1161 1087 1022 940

1192 1153 1108 1049 989 930 834

1457 1396 1333 1267 1184 1107 1032

1378 1316 1260 1192 1117 1055 968

1111 1089 1059 1027 985 927 860

924 908 877 851 801 748 698

1415 1382 1341 1291 1232 1170 1092

1209 1185 1154 1120 1069 1019 937

1668 1611 1556 1486 1410 1330 1237

1494 1456 1410 1352 1283 1209 1130

1132 1129 1128 1105 1072 1026 944

929 926 922 908 886 841 802

1520 1489 1449 1400 1338 1269 1192

1279 1272 1255 1228 1187 1135 1055

1769 1711 1645 1569 1490 1406 1313

1618 1575 1524 1465 1402 1325 1239

l _[e.).:4,'_I

SPEED VOLTAGE 0.1

LOW 230V

208V

MED 230V

208V

HIGH 230V

208V

I ;[o.):_[.11

SPEED VOLTAGE 0,1

LOW 230V

208V

MED 230V

208V

HIGH 230V

208V

I ;[o.):__;I

SPEED VOLTAGE 0,1

LOW 230V

208V

MED 230V

208V

HIGH 230V

208V

SPIN, WG,

0,2 0,3 0,4 0,5 0,6 0.7

737 723 682 627 559 475 333

586 571 549 514 466 394 280

943 896 832 752 668 560 443

798 778 731 672 598 510 388

1092 1023 946 849 753 632 515

1015 955 888 800 704 596 489

SPIN, WG,

0,2 0,3 0,4 0,5 0,6 0,7

1069 1039 1004 956 898 825 740

898 861 827 785 730 675 599

1347 1302 1249 1187 1121 1041 946

1170 1129 1095 1037 975 909 817

1572 1504 1437 1362 1279 1186 1076

1423 1368 1313 1246 1176 1075 986

8PIN. WG.

0,2 0,3 0.4 0.5 0,6 0,7

1105 1093 1079 1066 1036 982 917

909 897 887 871 845 814 757

1501 1485 1456 1412 1358 1287 1196

1255 1243 1223 1206 1177 1127 1056

1870 1821 1758 1694 1598 1502 1390

1615 1597 1555 1509 1462 1386 1270

I_'_}:I SPIN. WG.

SPEED VOLTAGE 0.1 0.2 0,3 0.4 0.5 0.6 0,7

LOW 230V 1120 1113 1107 1094 1076 1045 1004

MED

HIGH

208V

230V

208V

230V

208V

913 903 889 876 865 845 810

1538 1531 1511 1479 1435 1380 1301

1257 1266 1256 1242 1215 1174 1122

1922 1877 1818 1751 1679 1590 1481

1653 1643 1617 1571 1517 1444 1366

FILTER STATIC PRESSURE DROP*

MODEL

FCP24 / FCX24 / FCP30

FCP36 / FCX36 / FCP42

FCP48

FOX48 / FOP60 / FCX60

*WASHABLE

FILTER SIZE

14 1/4 X 20 1/4

17 3/4 X 20 1/4

21 I/4 X 20 t/4

24 3/4 X 20 t/4

DISPOSABLE

FILTER SIZE

14X20

18X20

20 X 20

25 X 20

l_e.).:(_ll

SPEED VOLTAGE 0,1

LOW 230V

208V

MED 230V

208V

HIGH 230V

208V

1658 1642 1605 1543 1474 1393 1291

1370 1371 1358 1337 1291 1236 1150

1966 1905 1829 1740 1641 1527 1405

1733 1696 1645 1581 1502 1414 1310

2239 2137 2029 1916 1806 1683 1543

2141 2047 1952 1849 1739 1620 1495

SPIN, WG,

0,2 0,3 0,4 0,5 0,6 0.7

CFM

600 800 1000 1200 1400 1600 1800 2000

0.05 0.09 0.13 0.19 ............

....... 0.09 0.12 0.17 0.22 ......

............. 0.12 0.15 0.19 ---

............. 0.09 0.11 0.14 0.18

49601 4111 03

Page 11

I Blower Coils Installation Instructions

Sequence Of Operation

Mode /Thermostatto Con- / Control Control Function

[trol Board 24 volt [ State

Cooling Only Unit With Electric Heat

Constant Slower

Fan Switch ON)

Cooling Only Unit

(Thermostat calls for

Cooling)

Cooling Only Unit

(Thermostat calls for

Heat)

Heat Pump

(Thermostat calls for

Cooling)

Heat Pump Y & G

(Thermostat calls for

Heat)

Heat Pump cannot Y & G & Wl & W2

maintain proper temp.

Electric Heat Tempera-

ture satifised

Heat Pump

(Goes into Defrost

Mode)

Heat Pump Y & G

Room temp. satifised)

Y&G&O&Wl&W2

Heat Pump

(Emergency Heat)

G On

Y&G

G&Wl &W2

Y&G&O

G&Wl &W2

Off

On

Off

On

Off

Heat Pump With

On

Off

On

On

Off

On

Off

Off

On

Off

Fan On.

Fan Off.

Compressor On, Fan On.

Compressor Off, 60 Second Delay - Then Fan Off.

Fan On, 1st Stage Of Heat On, then 2nd Stage Of Heat On.

2rid thenlst Stage Of Heat Off. 6 sec delay, then Fan Off.

Electric Heat

Compressor On, Reversing Valve Energized, Fan On.

Compressor Off, 60 Second Delay And Then Fan Off.

Compressor On, Fan On

1st Stage Of Heat On, then 2nd Stage Of Heat On

2rid then 1st Stage Of Heat Off

Reversing valve switches unit to cooling, 1 st Stage Of Heat

On, then 2nd Stage Of Heat On

Reversing valve switches back to heating, 2nd then ! st Stage

Of Heat Off

Compressor Off, 60 Second Delay And Then Fan Off.

Fan On, 1st Stage Of Heat On, then 2nd Stage Of Heat On.

2nd then 1st Stage Of Heat Off. 6 sec delay, then Fan Off.

NOTE: Electric Heat Elements are controlled by relays with a delay sequence from the logic board to provide sequencing between elements.

LimitOperation

The temperature limit responds to over-temperature conditions in the air duct. If the temperature limit trips, the electric heater relays will

be de-energized and the fan relay will be energized. Once the limit resets, the control will resume normal operation. If the limit trips four

times during a single call for heat, the control will go into a 1 hour soft lockout. During the soft lockout, the fan relay will respond to

thermostat inputs but the heater relays are disabled. If the control detects a limit trip during the soft lockout, the control will go into a hard

lockout. Oncein a hard lockout, thefan relayislocked on andtheheater relaysaredisabled. Turningthepowertotheunit offand then on

wil! clear this state.

496 01 4111 03

Page 12

I Installation Instructions Fan Coils I

POWER SUPPLY: 208/230-1-60 USE COPPER CONDUCTORS ONLY.

KEY: HIGH VOLT; -- -- -- LOW VOLT.

_(1 CNTRL

I_ BRD

_ o[}_-

I=_ _ _q

o(] _ ;o

I

1 _-R--I

BL- I

20 Kw

r- _ L BL-

_o

s Y_

BASE UNIT WITH NO-HEAT KIT AMF001NH INSTALLED

*SEE INSTALLATION MANUAL FOR PROPER HEATING AND COOLING

FACTORY PRE-SET SPEED CONNECTIONS FOR YOUR UNIT.

G'_D

GRD

_V'_[_

_ B K'_[_[_

r-A

B_ll LIMIT

I r-J Z- q

"

II

G /I BK

BK]_Y

AMFK03CH/AMFK05CH ELECTRIC HEATER

o@oL'MtT%

@ F

BL_

II

II

II

_-=---L.L

0 5 Kw

_%

Y 3 Kw&

G_U

7.5& 10Kw

GRD

GRD

GRD

AMFK20CH ELECTRIC HEATER

BL

I

I

25 Kw

II IGYII II_ I _o

W_m_, --N-- I --

0 _ -- -- BK

AMFK25CH ELECTRIC HEATER

LIMIT

t I

_' AMFK07CH/AMFK10CH ELECTRIC HEATER

,_?_

30Kw

15 Kw

B

BK

l_J 49601 4111 03

AMFK14CH ELECTRIC HEATER

*AMFK15CH ELECTRIC HEATER (2 LIMITS)

BK

AMFK30CH ELECTRIC HEATER

GRD

GRD

GRD

sK_

1087757

Page 13

I Fan Coils

Installation Instructions

O

HI

19

DD

EE

Z2

J

W

15

1

18

17

14

Zl

12

\

Y

lO

AA

CC

7

JJ

496 01 4111 03 1L_

38-20-21

38-20-26

Page 14

I Installation Instructions Fan Coils I

KEY

NO,

1 Coil, Evaporator

2 Manifold, Evaporator

2

2

2

2

2

2

2

2

2

3 Housing, Flow Control

3

3 Distributor

4 Restrictor, .057

4 .065

4 .073

4 .078

4 .079

4 .092

4 Valve, Expansion

4

4

5 Adapter, Flow Control

5 with Liquid Tube

5

5

5

6 Distributor Assembly

7 Pan, Drain, 15"

7 19"

7 22"

7 26"

8 Pan, Drain Horizontal

8

g Control, Fan Timer

I0 Transformer

11 Motor, Blower

11

11

11

12 Mount, Blower Motor

12

12

13 Wheel, Blower

13

13

13

14 Capacitor, 5MFD, 370V

14 10MFD, 370V

14 15MFD, 370V

15 Block, Terminal

16 Heater, 5KW, W/Term. Bk

16 7KW, W/Term. Bk

16 1OKW, W/Term. Bk

17 Relay

18 Switch, Limit

19 Fuse Link

DESCRIPTION

Not Stocked

1082961

1085679

1082914

1082963

1082964

1082984

1087520

1083253

1083310

1083258

1082972

1082973

1062727

1085975

1093424

1054027

1053112

1053661

1053712

1082871

1082873

1087340

1082860

1082864

1082862

1082857

1082966

Not Stocked

1082775

1082776

1082777

1085353

1082619

1082621

1085914

1082611

1087048

1083044

1083045

1083046

1050254

1002801

609227

600585

600586

600587

96839

1094954

1094956

1094959

1087753

1087682

1087683

1087684

1084529

1084734

1087811

11111

11111

11111

11111

1111

111

I

I

I

I

I

-I-

I I

I

I I -

I1

I 1

111111111111111

111111111111

11111

11111

11111

11111

1111

111

I

-I-

I II1 1

I

I

I

I

I

-I-

I I I -

I1

I 1

1111111111

11111

11111

1111

111

1111111111

1111111111

1111

111

I 1 I I

1 1 -Ill

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 II1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 II1 1

11111 I- I -

1 1 1 1 1 1 1 1 1 1 I I -

111111111 I 1

111 I 1

11111 I I

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 II1

111 I1

11111 I- I -

11111 I

1 1 1 1 1 1 1 1 1 1 I I -

1 1 1 1 1 1 1 -I1 1

11111 I I

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 II1

111 -I-1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 II1 1

1 I 1 1 I

I I 1 1 1 I

1 I 1 I 1 I -I-

1 2 2 1 2 2 1 2 2 1 2 2 2 2 2 I

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -I-

1 2 2 1 2 2 1 2 2 1 2 2 2 2 2 I

I

I

I

I

-I -

I

I -I-

I I -

I

-I 1 1

I I I -

49601 4111 03

Page 15

I Fan Coils Installation Instructions

oo_ _

I.L I,L

1 1 1

2 2 2

4 2 2

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

2 2 2

1 1 1

1 1 1

2 2

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 1

1 1 t

1 1 1

1 1 1

2

1

1 1 1

1 1 1

1

1 1 1

o_

I.L LL LL

1

1 1

2 2 2

224222

111111

111111

1

11111

11111

11111

22222

11111

11111

22-22

11111

11111

11111

11111

11111

11111

11111

11111

11111

11111

11111

11111

11111

1

2

1

1

I.L I.L I,L

1 1 1

2 2 2

xx

I--I-

I I-

1 t 1 1 1 1 1 111 1 I-

I I1

21 I-

I--I-

12-1-

2222 I 1-

2422242414414

222-1-212

1111111111111

1111111111111

111-1-

1111111-1-111

1 1 111 111

11 I-

I1-1-

1111 ....... I--I-

111-1-111

11 I-

I1-1-

1111 ....... I--I-

111-1-111

2

21 I-

12-1-

2222 ....... I--I-

1

1111111111111

222-1-212

11 I-

1

I1 1-

1111 ....... I--I-

111-1-111

2

2-222 2-1--I-

1111 ....... I--I-

11 I-

1

I1 1-

1111 ....... I--I-

111-1-111

11 I-

I--I-

I1 I-

1 1 1 1 1 1 1 -I- 111

11 I-

I1 1-

1111111-1-111

1

1111 111 11t 111

1

1111111111111

1

1111111111111

11 I-

I1 1-

1111 ....... I--I-

111-1-111

11 I-

I1-1-

1111 ....... I--I-

111-1-111

11 I-

I1-1-

1111 I 1-

111-1-111

1 1 1 1 1 1 1 -I1 111

1 1 1 1 1 1 1 -I- 111

111 111

2 2 212 212

I- -I-

I- -I-

1 1 I 1-

1111111111111

1111111111111

1 1 I 1-

1111111111111

KEY

NO.

A

A

A

A

B

B

B

B

B

C

D

H

K

K

L

O

O

O

O

P

P

P

P

Q

Q

Q

Q

R

S

S

S

S

T

U

V

V

V

V

W

W

W

W

X

X

X

Y

Zl

Z2

AA

AA

AA

AA

BB

BB

BB

BB

CC

CC

CC

CC

DD

EE

FF

GG

HH

HH

HH

JJ

)(

)(

)(

DESCRIPTION NUMBER ,,_,,__-_u._____._u._u._u.____u.(_

Baffle, Top 1084530 1 1 1 1 1 1

Plate, Triangular 1082779 2 2 2 2 2

Plug, DrainPan 1083241 2 4 2 2 2 2 4 2 2 2 2

Plug, Drain Pan 1082965 1 1 1 1 1 1 1 1 1 1 1

Plate, Tubing 1085601 1 1 1 1 1 1 1 1 1 1 1

Grommet, Tubing Plate 1085683 t t 1 1 1 1 1 1 t 1 1

Bracket, Coil Hold Down 1082602 - 1 1

Panel, Rear Blower Deck 1082604 1 t 1 1 1 1 1 1 t 1

Panel, Front Blower Deck 1086694 1 1 1 1 1 1 1 1 1 1

Panel,Side Blower Deck 1082622 2 2 2 2 2 2 2 2 2 2

Bracket, Control Fan 1085371 t t 1 1 1 1 1 1 t 1 1

Bracket, Drain Pan 1082609 1 1 1 1 1 1 1 1 1 1

Stop, Coil 1083349 2 2 2 2 2 2 2 2 2

Adapter, Filter 1884788

Panel, Top 1087710 1 t 1 1 1 1 1 1 t 1

Housing, Blower 1087343 1 1 1 1 1

Panel, Blower Cutoff 1082607 1 1 1 1 1 1 1 1 1 1

Clamp, Capacitor 1095020 1 1 1 1 1 1 1 1 1 1 1

Rail, Blower R.H. 1085504 1 t 1 1 1 1 1 1 t 1 1

Rail, Blower L.H. 1085521 t 1 1 1 1 1 1 1 1 1 1

Door, Coil Access 1087718 1 1 1 1 1 1 1 1 1 1

Door, Blower Access 1087729 1 1 1 1 1 1 1 1 1 1

Door, Filter Access 1087730 1 1 1 1 1 1 1 1 1 1

Plate, Heater Adapter 1084686 t

Plate, Heater Filler 1084608

Clamp. Tube 10631 t 8

Shield, Condensate 1083333 2 2

Plate, Heater Closure 1084926 1 1

Adapter, Male (Drain) 1085010 1 1 1 1 1 1 1 1 1 1 1

Harness, Wire 1086021 1 1 1 1 1 1 1 1 1 1 1

Harness, Wire (Clos. Plate) 1084929 1 1

Manual, Installation 49601411100 t t 1 1 1 1 1 1 t 1 1

PA.T

1082954 1 1 1 1 1

1082955

1082956

1082780 2 2 2 2 2

1882924 2

1082904

1082782

1085602

1082844 1

1082845

1082846

1085372 1

1085373

1085374

1082847 2

1082848

1082849

1082927 1

1082928

1082929

1087711 1

1087712

1087713

1087195 1 1 1 1 1

1087193 1

1087194

1082616 1

1082949

1087719 1

1087720

1087721

1087726 1

1087727

1087728

1087731 1

1087732

1087733

1084927

1084928

496 01 4111 03

Loading...

Loading...