ICP N8MPN, N8MPL, H8MPN, T8MPN, C8MPL Installation Instructions Manual

...

N8MPN&N8MPL

*8MPN&*8MPL

* Denotes Brands (C, H, T)

See section 5 for Category I definition.

SAFETY REQUIREMENTS

Recognizesafetyinformation. Thisisthesafety--alertsymbol!. Whenyouseethissymbolon thefurnaceand ininstructionmanualsbealert

to the potential for personal injury.

Understand thesignalwordsDANGER,WARNING,orCAUTION. Thesewordsareusedwiththesafety--alert symbol. DANGERidentifiesthe

mostserioushazards,thosethat will resultinsevere personalinjuryordeath. WARNING signifies ahazardthat couldresultin personalinjuryor

death. CAUTION is used toidentify unsafepractices that couldresultinminorpersonalinjuryorproductandproperty damage. Note is usedto

highlight suggestions that will result in enhanced installation, reliability, or operation.

Installingandservicingheatingequipment can behazardousdue to gasandelectrical components. Onlytrainedand qualifiedpersonnelshould

install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels attached to or shipped with the furnace and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the National Fuel Gas Code (NFGC) ANSI Z223.1--2002/NFPA

54--2002. InCanada,refertotheNational StandardofCanada Natural GasandPropaneInstallationCode(NSCNGPIC) CSAB149.1--00. Wear

safety glasses and work gloves. Have fire extinguisher available during start--up and adjustment procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these

instructions exceedcertainlocalcodesandordinances,especiallythosethatmaynothavekeptupwithchangingresidential constructionpractices. We require these instructions as a minimum for a safe installation.

International Comfort Products, LLC

Lewisburg, TN 37091

INSTALLER: Affix these instructions

on or adjacent to the furnace.

CONSUMER: Retain these

instructions for future reference.

Ò

1. Safe Installation Requirements 3...............

2. Installation 4..............................

3. Side Venting 8.............................

4. Combustion & Ventilation Air 9................

5. Gas VentInstallation 12.......................

6. Horizontal Venting 14.........................

7. Masonry Chimney Venting 16...................

8. Gas Supply and Piping 19.....................

!

WARNING

ELECTRIC SHOCK HAZARD

Failure to follow safety warnings

exactly could result in serious

injury, death, and/or property

damage.

Turn Off All Power Before

Servicing.

Portions of the textand tables are reprinted from NFPA54 / ANSI Z223.1--2002ã, withpermission of National Fire Protection Association, Quincy, MA 02269 andAmerican Gas Association,

Washington, DC20001. This reprinted material isnot the complete and official position of the NFPA or ANSI,on the referenced subject, which is represented only by the standard in its entirety.

Printed in U.S.A. 10/19/2004 441 01 2611 (06)

Table of Contents

9. Electrical Wiring 22.........................

10.Ductwork and Filter (Upflow/Horizontal) 23.......

11.Ductwork and Filter (Downflow) 25.............

12. Checks and Adjustments 29...................

13. Furnace Maintenance 33.....................

14. Sequence of Operation & Diagnostics 34.........

TechSupport and Parts 37.......................

!

CARBON MONOXIDE POISONING AND FIRE

HAZARD.

Failuretofollowsafetywarnings exactly could

result in serious injury,death, and/or property

damage.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

WARNING

WARNING

Ò

START--UP CHECK SHEET

(Keep this page for future reference)

Recommended, but not required. Checklist DOES NOT apply in Canada

Dealer Name:

Address: Business Card Here

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Type of Gas: Natural: LP:

Blower Motor H.P.:

Supply Voltage:

Limit Opens at...(°F) or(°C)

Limit Closes at...(°F) or(°C)

Which blower speed tap is used?

(Heating)

(Cooling)

Manual Gas Shut--Off Upstream

of Furnace/Drip--Leg? YES

Drip--Leg Upstream of Gas Valve? YES NO

Blower Speed Checked? YES NO

All Electrical Connections Tight? YES NO

Gas Valve OK? YES NO

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See Checks and Adjustments

Section).

Measured Manifold Pressure:

Thermostat OK? YES NO

NO

Temperature of Supply Air: (°F) or(°C)

Temperature of Return Air: (°F) or(°C)

Rise (Supply Temp.--Return Temp.): (°F) or(°C)

Filter Type and Size:

Fan “Time ON” Setting:

Fan “Time OFF” Setting:

Dealer Comments:

2

Subbase Level? YES NO

Anticipator Set? YES NO Set At?:

Breaker On? YES NO

Date of Installation:

Date of Start--Up:

441 01 2611 06

1. Safe Installation Requirements

!

WARNING

FIRE, EXPLOSION, AND ASPHIXIATION HAZARD

Improper adjustment, alteration, service,

maintance or installation could cause serious

injury, death and/or property damage.

Installationorrepairsmadeby unqualified persons

could result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities having jurisdiction.

The information contained in t his manual is

intended for use by a qualified service agency that

is experienced in such work, is familiar with all

precautions and safety procedures required in

such work, and is equipped with the proper tools

and test instruments.

NOTE: This furnace is design--certified by the CSA International

(formerly AGA and CGA) for installation in the United States and

Canada. Refer to the appropriate codes, along with this manual,

for proper installation.

· Use only the Type of gas approved for this furnace (see

RatingPlateon unit).Overfiringwill resultinfailure ofheat

exchanger and cause dangerous operation. (Furnaces

can be converted to LP gas with approved kit.)

· Installthisfurnaceonly in a location andpositionasspeci-

fied in “2. Installation” of these instructions.

· Provideadequatecombustionandventilationairtothefur-

naceasspecifiedin “4.CombustionandVentilationAir” of

these instructions.

· Combustionproductsmustbedischargedoutdoors.Con-

nectthisfurnacetoan approved vent systemonly,as specifiedin “5.GasVentInstallation,6.Horizontal Ventingand

7. Masonry Chimney Venting” of these instructions.

· Never test for gas leaks with an open flame. Use a com-

merciallyavailablesoapsolution made specifically for the

detectionofleakstocheckallconnections,asspecifiedin

“8. Gas Supply and Piping, Final Check” of these instructions.

· Always install furnace to operate within the furnace’s in-

tended temperature--rise range with a duct system which

hasanexternalstatic pressurewithintheallowablerange,

as specified in “Technical Support Manual” of these in-

structions.

· When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containingthe furnace,thereturnairshallalsobe handledbya

duct(s) sealed to the furnace casing and terminating outside the space containing the furnace.

· Agas--fired furnace for installation in a residential garage

must be installed as specified in “2. Installation” of these

instructions.

· This furnace is not to be used for temporary heating of

buildings or structures under construction.

See “2. Installation, Item 10”.

· This furnace is NOT approved for installation in mo-

bile homes, trailers or recreation vehicles.

· Seal around supply and return air ducts.

· Install correct filter type and size.

· Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

Safety Rules

Your unit is built to provide many years of s afe and dependable

serviceprovidingit is properly installedandmaintained.However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. ConsumerProduct Safety Commission encourages

installation of carbon monoxide alarms. There can be various

sources of carbon monoxide in a building or dwelling. The

sources could be gas--fired c lothes dryers, gas cooking

stoves, water heaters, furnaces, gas--fired fireplaces, wood

fireplaces, and several other items.

Carbon monoxide can cause serious bodily injury and/or

death. Carbon monoxide or “CO” is a colorless and odorless

gas produced when fuel is not burned completely or whenthe

flame does not receive sufficient oxygen.

Therefore,tohelpalertpeopleofpotentiallydangerouscarbon

monoxide levels, you should have a commercially available

carbon monoxide alarm that is listed by a nationally recognizedtestingagencyinaccordancewithUnderwritersLaboratories Inc. Standard for Single and Multiple Station Carbon

Monoxide Alarms, ANSI/UL 2034 or the CSA 6.19--01 Residential Carbon Alarming Devices installed and maintained in

thebuildingordwellingconcurrentlywiththegas--firedfurnace

installation(seeNote below).Thealarm shouldbeinstalledas

recommended by the alarm manufacturer’s installation instructions.

B. There can be numerous sources of fire or smokein a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

peopleofpotentiallydangerousfireorsmoke,youshouldhave

fireextinguisherandsmokealarmslistedbyUnderwritersLaboratories installed and maintained in the building or dwelling

(see Note below).

Note: The manufacturer of your furnace does not test any alarms

and makes no representations regarding any brand or type

of alarms.

C. To ensure safeandefficientoperationofyourunit,youshould

do the following:

1. Thoroughly read this manual and labels on the unit. This

will help you understand how your unit operates and the hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water. Immediatelycallaqualifiedserviceagencytoinspecttheunitand

to replace any part of the control system and any gas control

which has been under water.

3. Never obstruct the vent grilles, or any ducts that provide

airto theunit.Airmustbeprovidedforpropercombustionand

ventilation of flue gases.

441 01 2611 06

3

Frozen Water Pipe Hazard

Ifyour furnace remains off for an extended time, the pipes in your

home could freeze and burst, resulting in serious water damage.

!

WARNING

FROZEN AND BURST WATER PIPE HAZARD

FaiIure to protect against the risk of freezing could

result in property damage and/or personal injury.

Donotleaveyourhomeunattendedforlongperiods

during freezing weather without turning off water

supply and draining water pipes or otherwise

protecting against the risk of frozen pipes and

resultant damage.

Yourfurnaceisdesignedsolelytoprovidea safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety devices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

2. Installation

!

CARBON MONOXIDE POISONING HAZARD.

Failure to properly vent this furnace or other

appliances could result in death, personal injury

and/or property damage.

If this furnace is replacing a previously commonvented furnace, it may be necessary to resize the

existing vent system to prevent oversizing

problems for the other remaining appliances(s).

SeeVentingand CombustionAirCheckinthe5.Gas

Vent Installation section of this instruction.

Location and Clearances

If furnace is a replacement, it is usually best to install the furnace

wheretheoldone was. Choose the location or evaluate the existing location based upon the minimum clearance and furnace dimensions (Figure 1 or Figure 2).

!

CARBON MONOXIDE POISONING HAZARD.

Failure to follow safety warnings could result in

serious injury, death, or property damage.

Do NOT operate furnace in a corrosive

atmosphere containing chlorine, fluorine or any

other damaging chemicals which could harm the

furnace and vent system, and permit spillage of

combustion products into an occupied space.

Refer to 4. Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

Installation Requirements

1. Install furnace level.

2. ThisfurnaceisNOT to be usedfortemporaryheat of buildings

or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4

WARNING

WARNING

If the structure will be unattendedduring cold weather you should

take these precautions.

1. Turnoffthewater supplytothe structureanddrain thewater

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

-- o r --

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

-- o r --

3. Installareliableremotesensingdevicethatwillnotifysomebody of freezing conditions within the home.

4. Install the vent pipes as short as practical. (See 5. Gas Vent

Installation section).

5. DoNOTinstallfurnacedirectlyoncarpeting, tileorothercombustible material other than wood flooring.

6. Maintain clearance for fire safety and servicing. A front clearanceof30² is minimum for access to the burner, controls and

filter. See clearance requirements in Figure 1 or Figure 2.

7. Use a raised base if the floor is damp or wet at times.

8. Residential garage installations require:

· Burners and ignition sources installed at least 18² (457

mm) above the floor.

· Furnace must be located or physically protected from

possible damage by a vehicle.

9. Ifthefurnace is tobesuspendedfromthefloorjoistsin abasementoracrawlspaceortheraftersinanattic,it isnecessaryto

use steel pipe straps or an angle iron frame to attach the furnace. These straps should be attached to the furnace bottom

side with sheet metal screws and to the rafters or joists with

bolts. The preferred method is to use an angle iron frame

bolted to the rafters or joists.

10. This furnace maybeusedforconstruction heat provided that:

· The furnace is permanently installed with all electrical

wiring,piping,ventingandductinginstalledaccordingto

these installation instructions. A return air duct is provided,sealed to the furnace casing, and terminated outside the space c ontaining the furnace. This prevents a

negativepressurecondition ascreatedbythe circulating

air blower, causing a flame rollout and/or drawing combustion products into the structure.

· The furnace is controlled by a thermostat. Itmay not be

“hot wired” to provide heat continuously to the structure

without thermostatic control.

· Clean outside air is provided for combustion. This is to

minimizethecorrosiveeffectsofadhesives, s ealers and

otherconstruction materials. Italsopreventstheentrainmentofdrywalldustintocombustionair,whichcancause

fouling and plugging of furnace components.

· The temperature of the return air to the furnace is main-

tained between 55° F(13° C) and 80° F(27° C) , with no

evening setback or shutdown. The use of the furnace

whilethestructureisunderconstruction is deemed to be

intermittent operation per our installation instructions.

441 01 2611 06

· The air temperature rise is within the rated rise range on

Furnace

ReturnAir

thefurnace ratingplate,andthefiringratehasbeensetto

the rating plate value.

· The filters used to c lean the circulating air during the

construction process must be either changed or thoroughly cleaned prior to occupancy.

· The furnace, ductwork and filters are cleaned as neces-

sarytoremovedrywalldustandconstructiondebris from

all HVACsystemcomponentsafter construction is completed.

· Verifyproperfurnaceoperatingconditionsincluding igni-

tion,gas input rate, air temperature rise, and venting according to these installation instructions.

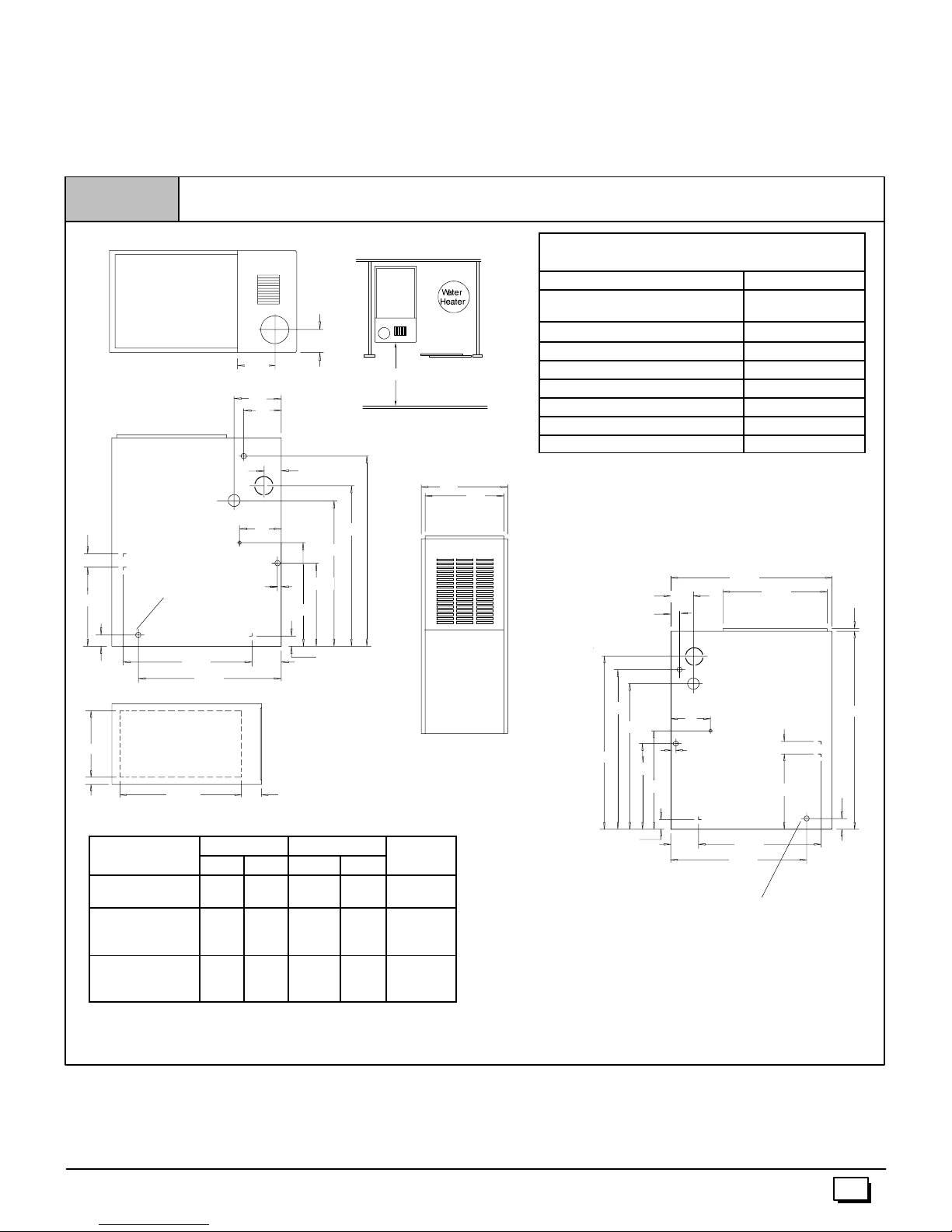

Figure 1

Dimensions and Clearances (N8MPN/L)

TOP

51/

3

61/

2

5

LEFT SIDE

7

21/

131/

4

4

17/

D

C

8

Plugged starting

hole tocutside

duct opening

213/

BOTTOM

231/

8

4

265/

1

47/

8

8

DIMENSIONAL INFORMATION

Furnace

Model

N8MPN/L050B12

N8MPN/L075B12

N8MPN/L075F16

N8MPN100F14

N8MPN/L100F20

N8MPN/L100J22

N8MPN/L125J20

N8MPN/L125J22

Cabinet Bottom

A B C D

151/

2 14

191/8175/

8

223/4211/4115/

MINIMUM CLEARANCES TO COMBUSTIBLE

REAR 0

FRONT (combustion air openings

in furnace and structure)

31/

4

30² Min.

33/

171/

131/

3

4

33

271/

2

241/

2

4

11/

2

A

B

FRONT

Drawing is representative, but some models may vary

41/

16

DIMENSIONS IN INCHES

Return Air

Opening

13/

21/

125/

8

143/

8

H

8

4

J

NOTE: Evaporator “A” coil drain pan dimensions may vary

183/

16

4

J

from furnace duct opening size. Always consult evaporator

specifications for duct size requirements.

Furnace is designed for bottom return or side return.

Return air through back of furnace is NOT allowed.

Required For Service

ALL SIDES Of SUPPLY PLENUM 1²

SIDES 0

VENT

Single--Wall Vent 6²

Type B--1 Double--Wall Vent 1²

TOP OF FURNACE 1²

*30² clearancerecommendedforcasing removal.

Horizontalposition: Linecontactis permissibleonlybetweenlines

formedbyintersectionsoftopandtwosidesof furnace jacket,and

buildingjoists, studsorframing.

MATERIALS FOR ALL FURNACES

3²

*24²

281/

2

181/

213/

2

21/

4

J

H

131/

4

4

8

33/

4

2

RIGHT SIDE

281/

2

253/

4

32

131/

11/

2

7

1

4

171/

3

47/

8

Plugged starting hole tocut

side duct opening

265/

3

/

4

35

17/

8

25--23--44a1

441 01 2611 06

5

Figure 2

Furnace

ReturnAir

21/

4

131/

4

TOP

51/

LEFT SIDE

Plugged starting

hole tocutside

duct opening

Dimensions and Clearances (*8MPN/L Models)

F

3

5

1

33/

4

7337

277/

175/

16

271/

2

321/

8

30² Min.

A

B

2

38

FRONT

MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS FOR ALL UNITS

REAR 0

FRONT (combustion air openings

3²

in furnace and structure)

Required For Service

*24²

ALL SIDES Of SUPPLY PLENUM 1²

SIDES 0

VENT

Single--Wall Vent 6²

Type B--1 Double Wall Vent 1²

TOP OF FURNACE 1²

*30² clearancerecommendedforcasing removal.

Horizontalposition: Linecontactis permissibleonlybetweenlines

formedbyintersectionsoftopandtwosidesof furnace jacket,and

buildingjoists, studsorframing.

281/

2

181/

33/

4

2

2

3

/

4

213/

17/

8

D

4

265/

BOTTOM

47/

8

11/

8

2

Drawing is representative some models may vary

231/

C

8

41/

16

DIMENSIONS IN INCHES

DIMENSIONAL INFORMATION

Furnace

Model

*8MPN/L050B12

*8MPN/L075B12

*8MPN/L075F16

*8MPN100F14

*8MPN/L100F20

*8MPN/L100J20

*8MPN/L125J20

*8MPN150J20

* Denotes Brand

Cabinet Top Bottom

A B F C D

151/214 6 13/8125/

191/8175/873/421/8143/

223/4211/491/2115/16183/

8

4

4

Return Air

Opening

H

J

J

NOTE: Evaporator “A” coil drain pan dimensions may

vary from furnace duct opening size. Always consult

evaporator specifications for duct size requirements.

Furnace is designed for bottom return or side return.

Return air through back of furnace is NOT allowed.

Furnace Installation

Inspecttheratingplatetobe certainthemodelnumberbegins with

“N8MP” or“*8MP”.Thisidentifies the unit as a multi--position furnaceandcan beInstalledina Upflow,HorizontalRight,Horizontal

Left or Downflow position.

RIGHT SIDE

1

37

303/

4

291/

1

/

2

175/

11/

2

7

J

21/

4

265/

H

131/

4

213/

4

8

Plugged starting hole to

cut side duct opening

2

16

47/

8

40

17/

8

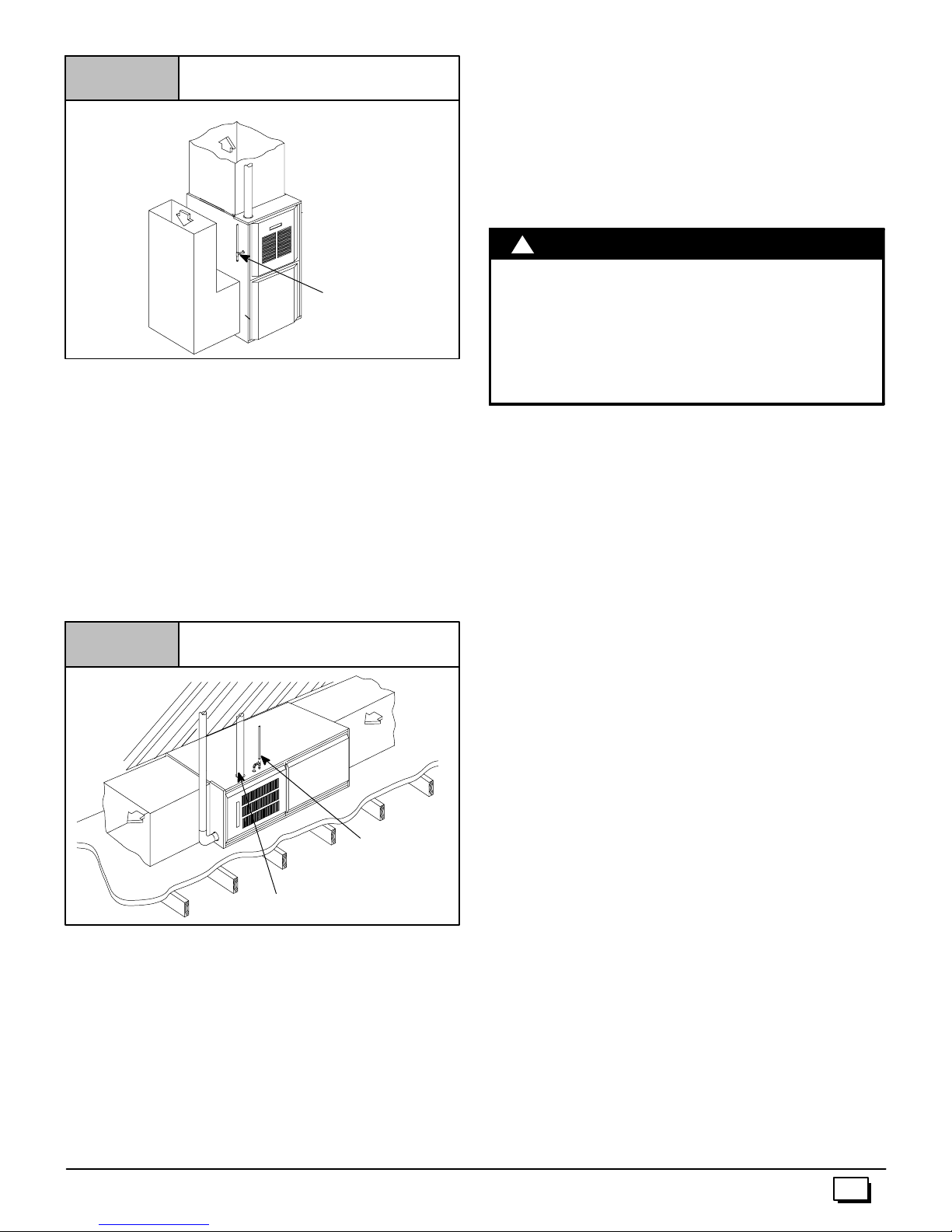

Upflow

No modifications are required for upflow installation. (See

Figure 3)

6

441 01 2611 06

Figure 3

RETURN

AIR

T y pical Upflow Installation

SUPPLY

AIR

VENT

The horizontal furnaces may be installed directly on combustible

woodflooringorsupports, however,itisrecommendedforfurther

fireprotectioncementboardorsheetmetalisplacedbetweenthe

furnace and the combustible wood floor and extend 12² beyond

the front of the furnace louver door. (This is a recommendation

only, not a requirement).

This furnace MUST NOT be installed directly on carpeting, tile or

other combustible material other than wood flooring or supports.

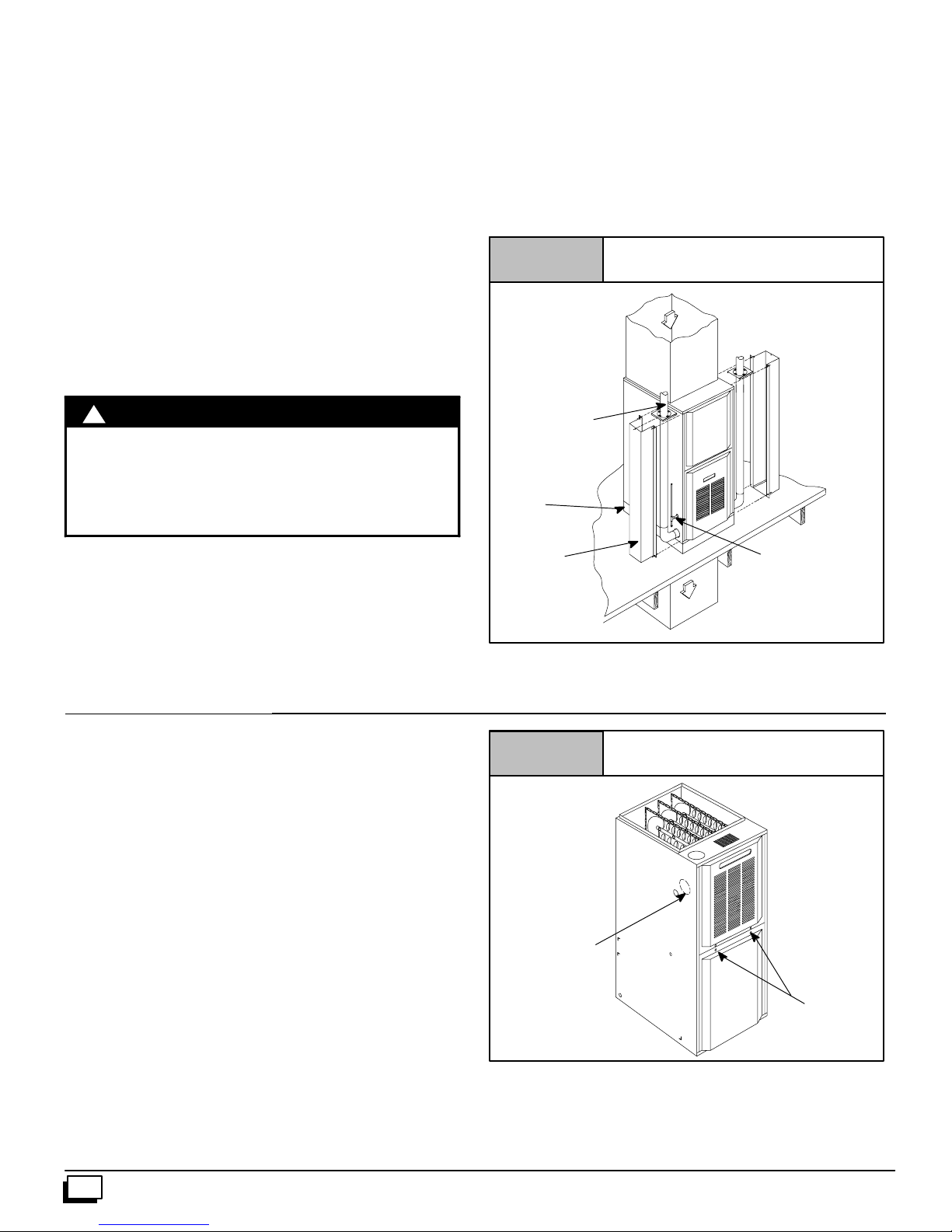

Downflow

GAS SUPPLY

25--23--17

Horizontal

Ifyou purchased a multi--position furnace, it can be installed horizontallyin an attic, basement, crawl space, alcove, or suspended

from a ceiling in a basement or utility room in either a right or left

airflow position. (see Figure 4)

Horizontally installed furnaces may be vented out the top of the

unitoroutthesidefacingup.See“Sideventing” forinstructionsto

rotate the vent to the side.

The minimum clearances to combustibles MUST be maintained

between the furnace and adjacent construction, as shown in

Figure 1 and Figure 2. ONLYthecornerofthecabinetisallowed

to contact the rafters as shown in Figure 4. All other clearances

MUST be observed as shown in Figure 1 and Figure 2.

Figure 4

SUPPLY

AIR

Ifthe furnaceisto besuspendedfromthefloorjoistsina basement

orcrawlspaceortheraftersinanattic,itis necessary to use steel

pipe straps or an angle iron frame to attach the furnace. These

straps should be attached to the furnace bottom side with sheet

metal screws and to the rafters or joists with bolts. The preferred

methodistouse an angle iron frame bolted to the rafters orjoists.

Ifthefurnaceistobeinstalledatgroundlevelinacrawlspace,consult local codes. A concrete pad 1² to 2² thick is recommended.

Thirtyinches(30²)isrequiredbetween thefrontofthe furnaceand

adjacent construction or other appliances. This should be maintained for service clearance.

Keep all insulating materials clear from louvered door.Insulating

materials may be combustible.

441 01 2611 06

T ypical Horizontal Installation

RETURN

AIR

VENT

VENT

GAS SUPPLY

OPTIONAL

VENT LOCATION

25-23-18a

!

WARNING

FIRE HAZARD.

Failure to install unit on noncombustible subbase

couldresultin death, personalinjuryand/orproperty

damage.

Place furnace on noncombustible subbase on

downflow applications, unless installing on

noncombustible flooring.

If you purchased a Multi--position furnace (*8MP) it may be

installed in a downflow configuration, (see Figure 5). The minimumclearancestocombustionconstructionMUST bemaintained

between the furnace and adjacent construction, as shown in

Figure 1 and Figure 2.

In addition to clearances in Figure 1 and Figure 2, c learance for

the vent pipe must be considered.

AsubbaseforcombustiblefloorsMUST beusedwhenthefurnace

isinstalledasa downflowoncombustiblematerial. See 11.“Duct-

work and Filter” (Downflow Section). The outlet flange must be

bent flat for downflow installation.

When installing a four--position furnace in the downflow position

(not the *8DNL furnace), the logo is to be repositioned so that it is

rightside--up as follows:

T8MPN/L

1. Find the door hardware kit that is stored in the furnace and

save it.

2. Carefullyremovelogofromtheoutsideof burnercompartment

door and save it.

3. Carefullyremovetwosmallplugbuttonsfromoutsideofblower compartment door and save them.

4. Removetwo thumbscrews from blower compartment door by

cutting apart metal retainer washers on inside of door with

smalldiagonalcuttingpliers.Theretainer washers will not unscrewfromthethumbscrews.Savethetwothumbscrewsand

two plastic washers.

5. Install two thumbscrews in holes at other end of blower

compartment door from where thumbscrews were removed.

a. A plastic washer should be on each of the two thumb-

screwsbeforeinsertingthe thumbscrews intotheblower

compartment door holes.

b. After inserting each thumbscrew into the proper hole in

the blower door,push a new metal retainer washer onto

each thumbscrew as far as it will go.

6. Install newstrip of rubber gasket on inside of blower compartment door on edge that does not already have a gasket.

7. Installlogoretainerpinsintoholesinblowercompartmentdoor

from which plug buttons were removed.

8. Installplugbuttonsintoholesin burnercompartmentdoorfrom

which logo was removed.

9. Install blower compartment door on furnace with bevel edge

and logo at top.

7

10. Install burner compartmentdooron furnacewithbeveledge at

bottom.

N8MPN/L, C8MPN/L, H8MPN/L

1. Carefully remove logo from burner compartment door and

save it.

2. Turn the logo rightside--up, and install the logo retainer pins

into holes in burner compartment door.

3. New labels for rightside--up application on outside of blower

compartmentdoormay bepurchasedina kit fromyourdistributor to cover upside--down labels.

locatetheswitch,locate2mountingholesordrillabovetheinducer

pressure tap. When drilling the 2 holes make sure to keep the

switch and tubing far enough away from the burners or hot surfacesastonot meltthehose,switch,or wires. Topreventpossible

kinking of the pressure switch hose, trim the hose to remove excess length.

Note:Whendrillingnewholesmakesuremetalshavingsdonotfall

on or in components, as this can shorten the life of the furnace.

Figure 5

T y pical Downflow Installation

Downflow Venting: The combustion venter MUST be rotated to

ventoutthesideforalldownflowinstallations,(seeFigure 5). Bottomventingisnotpermitted.See“Sideventing”forinstructionsto

rotatethe venttothe side.Inadditiontorotatingtheventtotheside

a Vent Pipe Shield (NAHA002VC) is required to shield the hot

vent pipe.

!

WARNING

BURN HAZARD.

Vent pipe is HOT and could cause personal injury.

Hot vent pipe is in reach of small children when

installed in downflow position.

Install vent pipe shield NAHA002VC.

Pressure Switch Relocation

Ifthe furnaceisinstalledintheupflowposition, thepressureswitch

will remain in the same position as installed by the factory unless

the inducer is rotated. If the furnace is installed in an orientation

that places the pressure switch below the pressure tap on the inducerhousing,thentheswitchMUST be relocated. In order to re-

3. Side Venting

This furnace is shipped from the factory with the venter assembly

in an upflow configurations (top vent). The venter assembly can

easily be rotated to a side vent configurations for use in upflow,

horizontal--flow, or downflow application.

See side venting

for venter rotation

Combustible floor

base outlet flange

adapter

Vent Shield

Kit

Figure 6

RETURN

AIR

VENT

OPTIONAL VENT

SUPPLY

AIR

Furnace with Screws

GAS SUPPLY

MUST BE OPPOSITE

VENT DISCHARGE

SIDE

25--23--19

When using a side vent configuration (side outlet instead of top

outlet),it may be necessary to relocatethe pressure switch to the

alternatepositionontheoppositeside ofthetop panel. Twoscrew

holes are provided at the alternate position. Route the pressure

switch tubing so the tubing is not kinked and not touching the hot

collector box, venter housing, or motor. It may be necessary to

shorten the length of the tubing to properly route the tubing and

eliminate kinks.

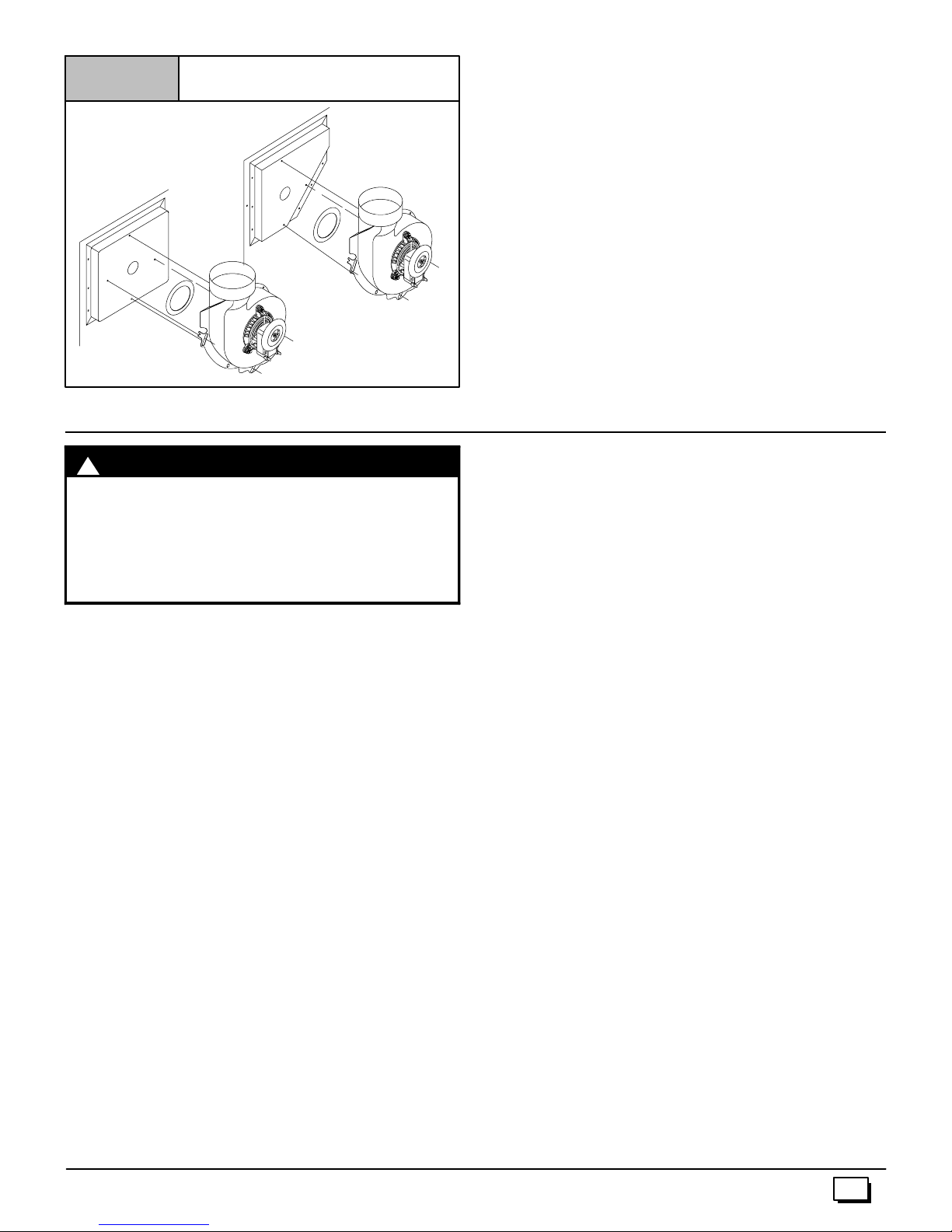

Rotating the Venter Assembly

1. If gas and electrical power have already been connected to

unitshutoff gasandremovepower fromunit.Unscrewscrews

onburner compartmentdoorandremoveburnercompartment

door. See Figure 6.

2. Disconnectpowerleadstotheventermotorandhosetopressureswitch.Removethree (3) orfour(4)screws which secure

the venter to the collector box, (see Figure 7).

3. Cut webbing with a pair of snips holding the vent plate to the

cabinetoneither the leftorrightside ofunitdependingonright

or left venting as desired. Discard vent plate, (see Figure 6).

8

Vent Plate

Screws (2)

25--23--45

441 01 2611 06

Figure 7

Venter Gasket

Entry

Main Line

25--23--52b

25--23--52c

4. Combustion & Ventilation Air

!

CARBON MONOXIDE POISONING HAZARD.

Failure to provide adequate combustion and

ventilationaircouldresultindeathand/orpersonal

injury.

Use methods described here to provide

combustion and ventilation air.

Furnaces require ventilation openings to provide sufficient air for

propercombustion and ventilation of flue gases. All duct or open ingsforsupplyingcombustionandventilationairmustcomplywith

thegascodes,orin the absenceoflocalcodes,the applicable national codes.

Combustion and ventilation air must be supplied in accordance

with one of the following:

1. Section8.3, AirforCombustionandVentilation,of theNational

Fuel Gas Code, (NFGC), ANSI Z223.1--2002/NFPA54--2002

in the U.S.,

2. Sections7.2,7.3,7.5, 7.6,7.7,and7.8 of NationalStandardof

Canada, Natural Gas and Propane Installation Code

(NSCNGPIC), CSA B149.1--00 in Canada,

3. Applicable provisions of the local building code.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

AndCombustionAirCheckin“5.GasVentInstallation” Section i n

this manual.

Contaminated Combustion Air

Installationsincertainareasortypes ofstructurescould causeexcessive exposure to contaminated air having chemicals or halogens that will result in safety and performance related problems

and may harm the furnace. These instances must use only outdoor air for combustion.

Thefollowingareasor types of structuresmaycontainorhave exposure to the substances listed below. The installation must be

441 01 2611 06

WARNING

4. Replace venter gasket (part # 1013540, if needed) to venter

assembly with adhesive in the same location as the old one.

5. Rotate venter assembly 90 ° right or left from original location

depending on venting configurations.

6. Tightenthe three (3) or four (4) screws that secure the venter

assembly to the collector box. Do tighten screws enough to

compress venter gasket.

7. Replace power leads to venter motor and reconnect hose to

pressure switch.

NOTE:Unused open vent hole must be covered. A VentCover is

suppliedwithVentPipeShieldKit NAHA002VC.A5

VentCoveri s availableseparatelyfromyourdistributor,or onecan

be fabricated with sheet metal for all side vent installations.

evaluated carefully as it may be necessary to provide outdoor air

for combustion.

5

/16² diameter

· Commercial buildings.

· Buildings with indoor pools.

· Furnaces installed in laundry rooms.

· Furnaces installed in hobby or craft rooms.

· Furnaces installed near chemical storage areas.

· Permanent wave solutions for hair.

· Chlorinated waxes and cleaners.

· Chlorine based swimming pool chemicals.

· Water softening chemicals.

· De--icing salts or chemicals.

· Carbon tetrachloride.

· Halogen type refrigerants.

· Cleaning solvents (such as perchloroethylene).

· Printing inks, paint removers, varnishes, etc.

· Hydrochloric acid.

· Sulfuric Acid.

· Solvent cements and glues.

· Antistatic fabric softeners for clothes dryers.

· Masonry acid washing materials.

Outdoor Combustion Air Method

Aspace havinglessthan50cubicfeetper1,000BTUHinputrating

forallgasappliancesinstalledin thespacerequiresoutdoorairfor

combustion and ventilation.

Air Openings and Connecting Ducts

1. Total input rating for all gas appliances in the space MUST be

considered when determining free area of openings.

2. Connect ducts or openings directly to the outdoors.

3. When screens are used to cover openings, the openings

MUST be no smaller than

4. The minimumdimensionof air ducts MUST NOT be less than

3² .

5. Whensizingagrille,louverorscreenusethefreeareaofopening. If free area is NOT stamped or marked on grill or louver,

assumea20%freeareafor woodand60%for metal. Screens

shall have a mesh size not smaller than

1

/4² mesh.

1

/4².

9

Requirements

BTU

H

1. Providethespacewithsufficientairforpropercombustionand

ventilation of flue gases using horizontal or vertical ducts or

openings.

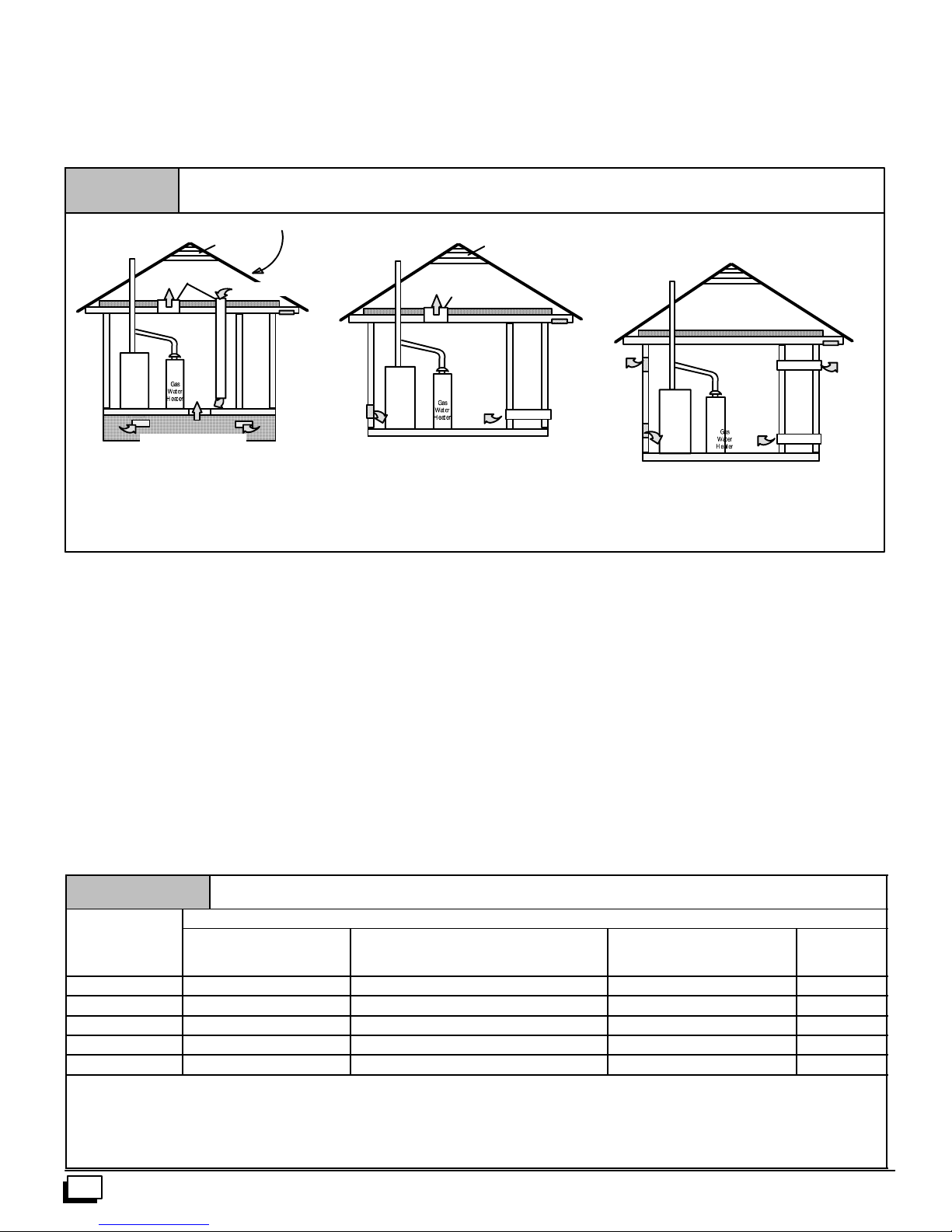

2. Figure 8illustrateshowtoprovidecombustionand ventilation

airwhentwopermanentopenings,oneinletandone outlet,are

used.

a. One opening MUST commencewithin12² of the floor

and the second opening MUST commence within 12² of

the ceiling.

b. Size openings and ducts per Table 1.

Figure 8

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada

Gas Vent

Minimum OneInlet and One Outlet AirSupply isRequired

Inlet Air OpeningMust be Within12²(300mm) of floor

Outlet Air OpeningMust be Within12²(300mm) of ceiling

(1) 1 Square Inch(6cm

(2) 1 Square Inch(6cm

VentilatedAttic

TopAbove Insulation

Outlet Air (1)

Furnace

VentilatedCrawl Space

May bein and Combination Shown

2

2

c. Horizontal duct openings require 1 square inch of free

areaper2,000BTUH(1,100mm2/kW)ofcombinedinput

for all gas appliances in the space (see Table 1).

d. Verticalduct openings oropeningsdirectlycommunicat-

ing with the outdoors require 1 square inch of free area

per4,000 BTUH (550 mm

gas appliances in the space (see Table 1).

3. When one permanent outdoor opening is used, the opening

requires:

a. 1 sq. in of free area per 3,000 BTUH (700 mm

combined input of all gas appliances in the space (see

Table 1) and

Gable Ve nt

Inlet

Air (1)

) per 4000BTUH

) per 2000BTUH

Optional InletAir (1)

Soffit Vent

2

/kW)for combined input of all

b. notlessthanthesumoftheareasofallventconnectorsin

the space.

The opening shall commence within 12² of the top of the enclosure.Appliancesshallhaveclearancesofatleast1² fromthesides

andbackand6² from the front.Theopeningshalldirectly commu-

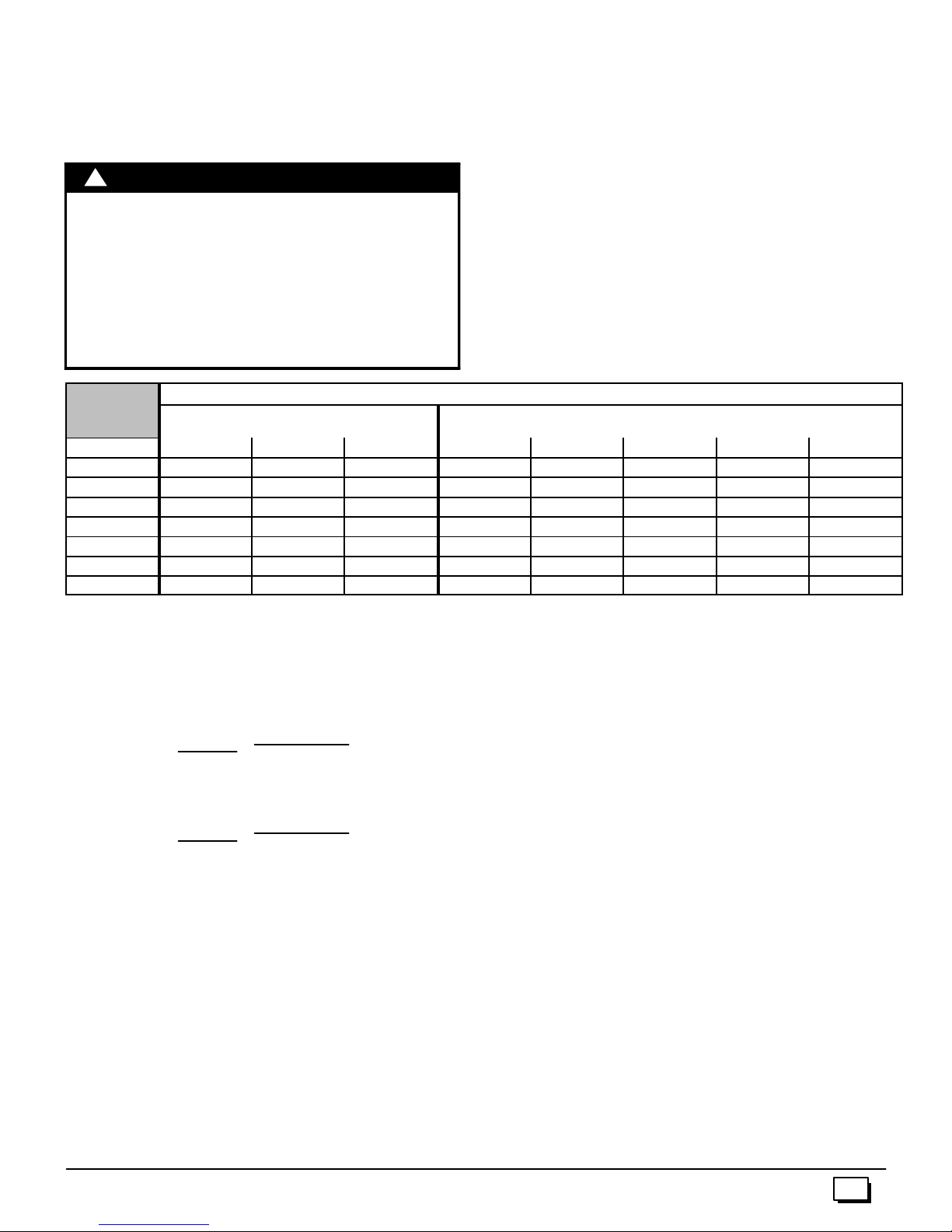

Table 1

Input

Rating

50,000 25 sq. in. 16.7 sq. in. 12.5 sq. in. 4²

75,000 37.5 sq. in. 25 sq. in. 18.75 sq. in. 5²

100,000 50 sq. in. 33.3sq.in. 25 sq. in. 6²

125,000 62.50 sq. in. 41.7 sq. in. 31.25 sq. in. 7²

150,000 75 sq. in. 50 sq. in. 37.5 sq. in. 7²

EXAMPLE: Determining Free Area

Furnace

100,000

Furnace

100,000

Free Area

TwoHorizontal Ducts

(sq. in./2,000 BTUH)

Water Heater

+

+

30,000

Water Heater

30,000

10

Gable Ve nt

Soffit Vent

Inlet

Air (2)

Outlet

Air (1)

Inlet

Air (1)

Inlet

Air (1)

Gas Vent

VentilatedAttic

TopAbove Insulation

Outlet Air (1)

Furnace

nicatewiththeoutdoorsorshallcommunicatethroughaverticalor

horizontalductto the outdoorsorspaces(crawlor attic)thatfreely

communicate with the outdoors.

4. Combination of Indoor and Outdoor Air shall have:

a. Indoor openings that comply with the Indoor Combus-

tion Air Method below and

b. Outdoor openings located as required in the Outdoor

Combustion Air Method above and

2

/kW) for

c. Outdoor openings sized as follows.

1) Calculate the Ratio of all Indoor Space volume dividedby requiredvolumeforIndoorCombustionAirMethod. Outdoor openings sized as follows.

2) Outdooropeningsizereduction Factor is1 minusthe

Ratio in 1) above.

3) Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor.

Minimum FreeAreaRequiredfor Each Opening or Duct to Outdoors

Single Opening

(sq. in./3,000 BTUH)

Total Input

=

(130,000 ¸ 4,000)

Total Input

=

(130,000 ¸ 2,000)

==32.5 Sq. In. Vertical

65 Sq. In. Horizontal

Gas Vent

Furnace

TwoVertical Ducts or Openings

(sq. in./4,000BTUH)

Outlet

Air (2)

Inlet

Air (2)

Round Duct

(sq. in./4,000

BTUH)

441 01 2611 06

Indoor Combustion Air

Standard and Known--Air--Infiltration Rate Methods

ã NFPA&AGA

Indoor air is permitted for combustion and ventilation, if the

Standard or Known--Air--Infiltration Rate Method is used.

!

CARBON MONOXIDE POISONING HAZARD.

Failure to supply adequate combustion air could

result in death and/or personal injury.

Mosthomeswillrequireadditionalairfrom outdoors

for combustion and ventilation. A space with atleast

WARNING

The Standard Method may be used, if the space has no less volumethan50cubicfeetper1,000BTUHof the maximum input ratings for all gas appliances installed in the space. The standard

method permits indoor air to be used for combustion and ventilation air.

The Known Air Infiltration Rate Method shall be used if the infiltration rate is known to be less than 0.40 air c hanges per hour

(ACH) and equal to or greater than 0.10 ACH. Infiltration rates

greater than 0.60 ACH shall not be used. The minimum required

volume of the space varies with the number of ACH and shall be

determined per Table 2 or Equations 1 and 2. Determine the

minimum required volume for each appliance in the space, and

add the volumes together to get the total minimum required volume for the space.

50 cubic feet per 1,000 BTUH input rating or homes

with tight construction may need outdoor air to

supplement air infiltration for proper combustion

and ventilation of flue gases.

MINIMUM SPACE VOLUME FOR 100% COMBUSTION AND VENTILATION AIR FROM INDOORS (ft3)

Table 2

ACH

0.60 1,050 1,400 1,750 1,250 1,875 2,500 3,125 3,750

0.50 1,260 1,680 2,100 1,500 2,250 3,000 3,750 4,500

0.40 1,575 2,100 2,625 1,875 2,813 3,750 4,688 5,625

0.30 2,100 2,800 3,500 2,500 3,750 5,000 6,250 7,500

0.20 3,150 4,200 5,250 3,750 5,625 7,500 9,375 11,250

0.10 6,300 8,400 10,500 7,500 11,250 15,000 18,750 22,500

0.00 NP NP NP NP NP NP NP NP

Other Than Fan-Assisted Total

(1,000’sBtuh)

30 40 50 50 75 100 125 150

Fan-assistedTotal

(1,000’sBtuh)

NP = Not Permitted

Table 2MinimumSpaceVolumesweredetermined by usingthe

following equations from the National Fuel Gas Code ANSI

Z223.1/NFPA 54--2002, 8.3.3.2:

1. For other than fan--assisted appliances such as a draft

hood--equipped water heater,

(

1000 Btu / hr

(

1000 Btu / hr

I

I

other

fan

)

)

3

Volume

other

2. For fan--assisted appliances such as this furnace,

Volume

If:

I

I

ACH = air changes per hour (ACH shall not exceed 0.60.)

The following requirements apply to the Standard Method and to

the Known Air Infiltration Rate Method.

=

fan

= combined input of all other than fan--assisted

other

appliances in Btu/hr

=combinedinputofallfan--assisted appliancesinBtu/hr

fan

21 ft

=

ACH

3

15 ft

ACH

· Adjoining rooms can be considered part of a space, if there

are no closable doors between rooms.

· An attic orcrawlspacemaybeconsidered a space thatfreely

communicateswiththeoutdoorsprovidedthereareadequate

ventilationopeningsdirectly tooutdoors.Openings MUST remainopenandNOThaveanymeansofbeingclosed off.Ven-

tilation openings to outdoors MUST be at least 1 square inch

offreeareaper4,000BTUH of totalinputratingforall gas appliances in the space.

· In spaces that use the Indoor Combustion Air Method, in-

filtration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

withunusuallytightconstruction,additional air MUST beprovided using the methods described in section titled Outdoor

Combustion Air Method:

· Unusually tight construction is defined as Construction with:

1. Wallsand ceilings exposed to the outdoors have a continuous,sealed vapor barrier.Openingsaregasketed or

sealed and

2. Doors and openable windows are weather stripped and

3. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall--ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Someprovincialcodesandlocal municipalities requireventilation

ormake--up airbe brought into the conditioned space asreplacementair.Whichevermethodisused,the mixedreturnairtemperature across the heat exchanger MUST not fall below 60°

continuously,or55° onanintermittentbasis so that flue gases will

not condense excessively in the heat exchanger.Excessive condensation will shorten the life of the heat exchanger and possibly

void your warranty.

441 01 2611 06

11

5. Gas Vent Installation

!

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to properly vent this furnace could result in

death, personal injury and/or property d amage.

Read and follow all instructions in this section.

Install the vent in compliance with codes of the country having jurisdiction, local codes or ordinances and these instructions.

This Category I furnace is fan--assisted. Afan assisted appliance

isanapplianceequipped withanintegralmechanicalmeans toeither draw or force products of combustion through the heat exchanger.

Category I furnace definition: A central furnace which operates

with a non--positive vent static pressure and with a flue loss not

lessthan17percent. These furnaces are approved forcommon-venting and multi--story venting with other fan--assisted or draft

hood--equipped appliances in accordance with the NFGC or

NSCNGPIC

Category I Safe Venting Requirements

Category I furnace vent installations shall be in accordance with

Parts 10 and 13 of the National Fuel Gas Code (NFGC), ANSI

Z223.1--2002/NFPA54 --2002;and/orSection7andAppendixCof

the CSA B149.1--00, National Standard of Canada, Natural Gas

and Propane Installation Code; the local building codes; furnace

and vent manufacturer’s instructions.

NOTE: The following instructions comply with the ANSI

Z223.1/NFPA54 National Fuel Gas Code and CSA B149.1Natural Gas and Propane Installation code, based on the input rate on

the furnace rating plate.

1. If a Category I vent passes through an attic, any concealed

space or floor, use ONLY Type B or Type L double wall vent

pipe.Ifventpipepasses through interior wall, useTypeB vent

pipe with ventilated thimble ONLY.

2. Do NOT vent furnace into any chimney serving an open fireplace or solid fuel burning appliance.

3. Use the same diameter Category I connector or pipe as permitted by:

· the National Fuel Gas Code Code (NFGC) ANSI

· the NationalStandard of Canada Natural Gas and Pro-

4. Push the vent connector onto the furnace flue collar of the

venterassemblyuntilittouchesthebead(atleast

and fasten with at least two field--supplied, corrosion--resistant, sheet metal screws located at least 140° apart.

5. Keep vertical Category I vent pipe or vent connector runs as

short and direct as possible.

6. Verticaloutdoor runs of Type--B or ANY single wall vent pipe

below the roof line are NOT permitted.

7. Slopeallhorizontalruns upfromfurnace totheventterminal a

minimum of

WARNING

Z223.1--2002 / NFPA54--2002 sections 10 and 13 venting requirements in the United States

or

pane Installation Code (NSCNGPIC) CSA B149.1--00

section7andappendixCventing requirements inCanada.

5

/8² overlap)

1

/4² per foot (21 mm/m).

8. Rigidlysupportallhorizontalportionsoftheventingsystemevery6¢ orlessusingproperclampsandmetalstrapsto prevent

sagging and ensure there is no movement after installation.

9. Checkexistinggas ventorchimneyto ensuretheymeetclearances and local codes. See Figure 1

10. The furnace MUST be connected to a factorybuilt chimney or

vent complying with a recognized standard, or a masonry or

concretechimneylined withaliningmaterialacceptable tothe

authority having jurisdiction. Venting into an unlined ma-

sonrychimneyor concretechimneyis prohibited.Seethe

6. Masonry Chimney Venting section in these instructions.

11. Fan--assisted combustion system Category I furnaces shall

not be vented into single--wall metal vents.

12. Category I furnaces must be vented vertically or nearly vertically, unless equipped with a listed mechanical venter.

13. VentconnectorsservingCategoryIfurnaces shallnotbeconnectedintoanyportionofmechanical draft systems operating

under positive pressure.

A4--to-- 3 inchreducerispermitted attheflue collarwheninstalling

a50,000Btuhgasinputfurnace, iftheinstallationmeets allthefollowing requirements for sizing the vent connectors and vents:

1. The National Fuel Gas Code, ANSI

Z223.1/NFPA--54--2002, sections 10.5.3.1(1),

10.6.3.1(2), 10.10.3.1, 13.1.2, 13.1.10, and 13.2.21(1)

through (3) in the U.S. or

2. The Natural Gas and Propane Installation Code CSA

B149.1--00, sections 7.13.1(b), 7.13.2(b), 7.18.5(b),

and Appendix C--GVR no. 2. in Canada.

12

441 01 2611 06

Venting and Combustion Air Check

NOTE: When an existing Category I furnace is removed or replaced,theoriginalventingsystemmaynolongerbesizedtoprop erly vent the attached appliances, and to make sure there is

adequate combustion air for all appliances, MAKE THE FOL-

LOWING CHECK.

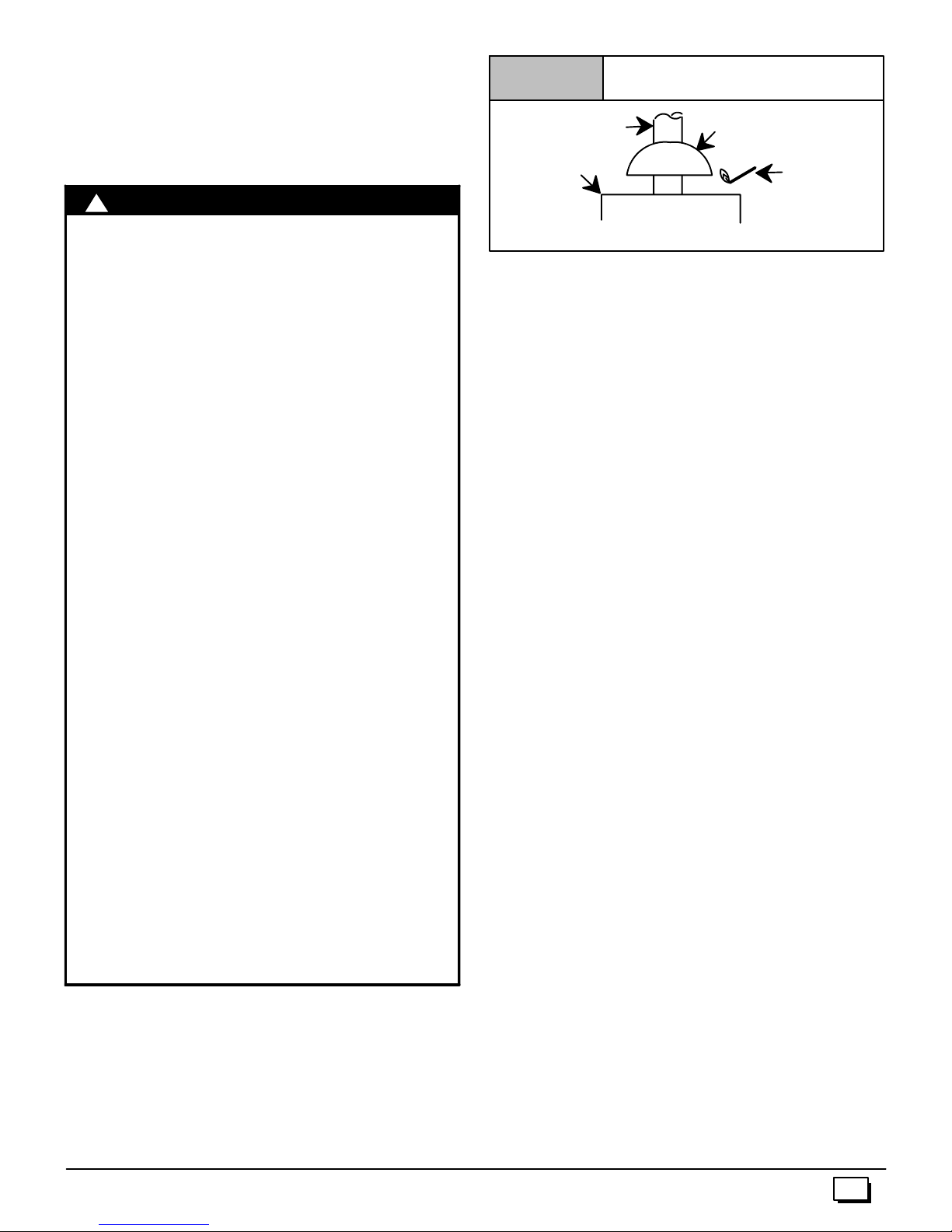

Figure 9

Typical Gas

Water Heater

Vent Check

Draft HoodVent Pipe

Match

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

applianceconnectedtothe venting systembeingplaced

into operation, could result in carbon monoxide

poisoning or death:

The followingsteps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1.Seal any unused openings in the venting system.

2.Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or CSA B149.1, Natural Gas and

Propane Installation Code and these instructions. Deter -

minethatthereisnoblockageorrestriction,leakage,corrosionandotherdeficiencieswhichcouldcauseanunsafe

condition.

3.As far as practical, close all building doors and windows

andalldoors between thespaceinwhich theappliance(s)

connected to the venting system are located and other

spaces of the building.

4.Close fireplace dampers.

5.Turnonclothesdryersandanyappliancenotconnectedto

the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are

operating at maximum speed. Do not operate a summer

exhaust fan.

6.Followthelightinginstructions.Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7.Test for spillage from draft hood equipped appliances at

thedraft hoodreliefopeningafter5minutesof mainburner

operation.Use the flame of a matchor candle. (Figure 9)

8.If improper venting is observed, during any of the above

tests,the ventingsystemmustbecorrectedinaccordance

with the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/orCSAB149.1,NaturalGasand PropaneInstallation

Code.

9.After it has been determined that each appliance con nected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas--fired burning

appliance to their previous conditions of use.

WARNING

NOTE: If flame pulls towards draft hood, this indicates

sufficient infiltration air.

Venting to Existing Masonry Chimney

Dedicated venting of one fan assisted furnace into any masonry chimney is restricted. A chimney must first be lined with

either Type B vent sized in accordance with NFGC tables 13.1 or

13.2 or a listed, metal lining system, or venting into a masonry

chimneyispermittedasoutlinedwith use of an optional listed masonry chimney kit. (See Section 7 Masonry Chimney Venting of

these instructions.)

Listed, corrugated metallic chimney liner systems in masonry

chimneysshallbesizedbyusing NFGC tables per13.1.7fordedicated venting and per 13.2.19 for common venting with the maximum capacity reduced by 20% (0.80 X maximum capacity) and

theminimumcapacityasshownintheapplicabletable.InCanada,

use the NSCNGPIC, appendix C, section 10. Corrugated metal

vent systems installed with bends or offsets require additional reductionof 5%oftheventcapacityforeach bendupto45° and10%

of the vent capacity for each bend from 45° up to 90°.

NOTE:Two(2)45° elbows are equivalent to one (1) 90° elbow.

Combined Venting into a Masonry Chimney

Ventingintoamasonryorconcretechimneyisonlypermitted

as outlined in the NFGC or NSCNGPIC venting tables. Follow

all safe venting requirements.

Note: See section “7. Masonry Chimney Venting”.

441 01 2611 06

13

6. Horizontal Venting

Category I Furnaces With External Power

Venters

InordertomaintainaCategory Iclassificationof fan--assistedfurnaceswhenventedhorizontallywithsidewalltermination,apower

venter is REQUIRED to maintain a negative pressure in the venting system.

In the U.S.: Per the NFGC, a listed power venter may be used,

when approved by the authority having jurisdiction.

In Canada: Only power venters approved by the appliance

manufacturer and where allowed by the authority having jurisdiction may be used

PleaseconsulttheFieldsControlsCo. or Tjernlund Products, Inc.

for power venters certified for use with our furnaces.

Vent Termination

VentingThrough a Non--Combustible and

Combustible Wall

Consult External Power Venter manufacturer instructions.

SelectthepowerventertomatchtheBtuhinputofthefurnacebeingvented. Followallof thePowerVenter manufacturer’s installation requirements included with the power venter for:

· venting installation,

· vent terminal location,

· preventing blockage by snow,

· protecting building materials from degradation by flue gases,

· see Figure 1 0 for required vent termination.

NOTE: It is the responsibility of the installer to properly terminate

theventandprovideadequateshielding. This is essential inorder

to avoid water/ice damage to building, shrubs and walkways.

14

441 01 2611 06

Figure 10

Other than Direct Vent Termination Clearance

N

V

V

D

E

V

B

V

C

F

B

V

VENT TERMINAL

Item Clearance Descriptions Canadian Installation(1)

A Clearance above grade, veranda, porch,deck,balcony,or

anticipated snow level

B Clearance to awindowor door that may be opened 6² (15 cm) forappliances £ 10,000 BTUH (3kW), 12² (30

C Clearance toapermanently closed window

D Verticalclearance toa ventilated soffitlocatedabovethe ter-

minal within a horizontal distance of 2¢ (61cm) from thecenterline of theterminal

E Clearance to anunventilated soffit

F Clearance to anoutsidecorner

G Clearancetoan inside corner

H Clearance toeachside ofthecenterline extended above elec-

trical meter or gas service regulator assembly

I Clearance to service regulator vent outlet 3¢ (91cm)

J Clearance tonon--mechanical air supply inlet to building or the

combustion air inlet to anyotherappliance

K Clearance to amechanical air supply inlet 6¢ (1.83 m) 3¢ (91cm)aboveif within 10¢ (3mhorizontally)

L Clearance under a veranda, porch, deck, orbalcony 12² (30 cm) +

M Clearanceto eachsideofthe centerline extended above or

below vent terminal of thefurnace toadryer or water heater

vent, or otherappliance’s direct vent intake or exhaust.

N Clearance from aplumbingventstack 3¢ (91cm) 3¢ (91cm)

(1.) In accordance with the current CSAB149.1,Natural Gas andPropane Installation Code

(2.) In accordance with the currentANSIZ223.1/NFPA54, National Fuel Gas Code

#18² (46cm)aboveroof surface

+ Permitted only if veranda, porch, deck, or balcony is fully open ona minimum of twosides beneath thefloor.

B

V

B

B

X

AIR SUPPLYINLET

12² (30cm) # 12² (30cm)

cm) for appliances > 10,000Btuh(3 kW) and£ 100,000 Btuh

(30kW),36² (91 cm) for appliances > 100,000Btuh(30 kW)

* *

* *

* *

* *

* *

3¢ (91cm) within15¢ (4.5 m) above the meter/regulator

assembly

6² (15 cm) forappliances £ 10,000 BTUH (3kW), 12² (30

cm) for appliances > 10,000Btuh(3 kW) and £ 100,000 Btuh

(30kW),36² (91 cm) for appliances > 100,000 Btuh (30kW)

* *

B

X

J

A

H

I

L

K

AREA WHERE TERMINAL ISNOTPERMITED

G

X

V

4¢ (1.2m) below ortothe side of the opening. 1¢ (30 cm)

above theopening.

3¢ (91cm) within15¢ (4.5 m)abovethe meter/regulator

assembly

*

4¢ (1.2m) below ortothe side of opening: 1¢ (30cm) above

opening.

*

M

A

V

25--24--65--2

U.S. Installation (2)

* For clearances not specified in ANSI Z223.1/NFPA 54orCSA B149.1, clearances shall be inaccordancewithlocalinstallation codes andtherequirements of thegassupplier and themanufacture’s

installation instructions.

Notes:

1. The ventforthis appliance shall not terminate

a. Over public walkways; or

b. Near soffit vents orcrawlspacevents or otherareaswhere condensate orvapor could create anusiance or hazard orpropertydamage; or

c. Where condensate vapor could cause damage or could bedetrimental to theoperationof regulators, relief valves, or other equipment.

2. When locatingvent terminations,considerationmust begivento prevailingwinds,location, andother conditions which may causerecirculation of thecombustiob products of adjacent vents.

Recirculation can cause poor combustion, inlet condensate problems, and accelerated corrosion of the heatexchangers.

441 01 2611 06

15

7. Masonry Chimney Venting

Chimney Inspection

All masonry chimney construction must conform to Standard

ANSI/NFPA211--2003 and to any state or local codes applicable.

The chimney must be in good condition and a complete chimney

inspectionmustbeconductedpriortofurnace installation.Iftheinspection reveals damage or abnormal conditions, make necessary repairs or seek expert help. See Figure 11 “The Chimney

Inspection Chart”. Measure inside area of tile --liner and exact

height of chimney from the top of the c himney to the highest appliance flue collar or drafthood outlet.

Connector Type

To reduce flue gas heat loss and the c hance of condensate problems, the vent connector must be double--wall Type B vent.

VentingRestrictions for Chimney Types

Interior Chimney -- has no sides exposed to the outdoors below

the roofline. All installations can be single furnace or common

vented with another draft hood equipped Category I appliance.

Exterior Chimney -- has one or more sides exposed to the outdoors below the roof line. All installations with a 99% Winter Design Temperature*below17°F must be common vented only with

a draft hood equipped Category I appliance.

The 99% Winter Design Dry--Bulb (db) temperatures are found in the

*

1993 ASHRAE Fundamentals Handbook, Chapter 24, Table 1 (United

States)and2(Canada),orusethe99.6% heatingdb temperaturesfound

in the 1997 or 2001 ASHRAE Fundamentals Handbook, Climatic

Design Information chapter, Table 1A (United States) and 2A

(Canada).

!

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to properly vent this furnace could result in

death, personal injury and/or property d amage.

These furnaces are CSA (formerly AGA and CGA)

design--certified for venting into exterior clay

tile--lined masonry chimneys with a factory

accessory Chimney Adapter Kit. Refer to the

furnace rating plate for correct kit usage. The

Chimney Adapter Kits are for use with ONLY

furnaces having a Chimney Adapter Kit number

marked on the furnace rating plate.

WARNING

Ifa claytile--linedmasonrychimneyisbeingusedanditisexposed

to the outdoors below the roof line, relining might be required.

Chimneys shall conform to the Standard for Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances ANSI/NFPA

211--2003 in the United States and to a Provincial or Territorial

Building Code in Canada (in its absence, the National Building

Code of Canada) and must be in good condition.

U.S.A.--Refer toSections13.1.9or13.2.20ofthe NFGCortheauthorityhavingjurisdictiontodeterminewhetherreliningisrequired.

If relining is required, use a properly sized listed metal liner,

Type--B vent, or a listed alternative v enting design.

NOTE: See the NFGC, 13.1.9 and 13.2.20 regarding alternative

venting design and the exception, which cover installations such

as the Chimney Adapter Kits NAHA001DH and NAHA002DH.

The Chimney Adapter Kits are listed alternative v enting designs

for these furnaces. See the kit instructions for complete details.

Canada(and U.S.A.)--Thisfurnaceispermittedtobeventedintoa

clay tile--lined masonry chimney that is exposed to the outdoors

below the roof line, provided:

1. Ventconnector is Type--B double--wall, and

2. This furnace is common vented with at least 1 draft hood-equipped appliance, and

3. The combined appliance input rating is less than the maximum capacity given in Table A, and

4. Theinputratingofeachspace--heatingapplianceisgreater

than the minimum input rating given in Table B for Masonry

Chimneys for the local 99% Winter Design Temperature.

Chimneys having internal areas greater than 38 square

inches require furnace input ratings greater than the input

ratingsofthesefurnaces. SeefootnoteatbottomofTableB,

and

5. The authority having jurisdiction approves.

Ifall of these conditions cannot be met, an alternative venting design shall be used, such as the listed chimney adapter kit with a

furnace listed for use with the kit, a listed chimney--lining system,

or a Type--B vent.

These furnaces are CSA design--certified for use in exterior clay

tile--lined masonry chimneys with a factory accessory Chimney

AdapterKit. Refer to the furnace ratingplateforcorrectkitusage.

The Chimney Adapter Kits are listed alternative v enting designs

andarefor use withONLY furnaces having aChimneyAdapterKit

number marked on the furnace rating plate.

16

441 01 2611 06

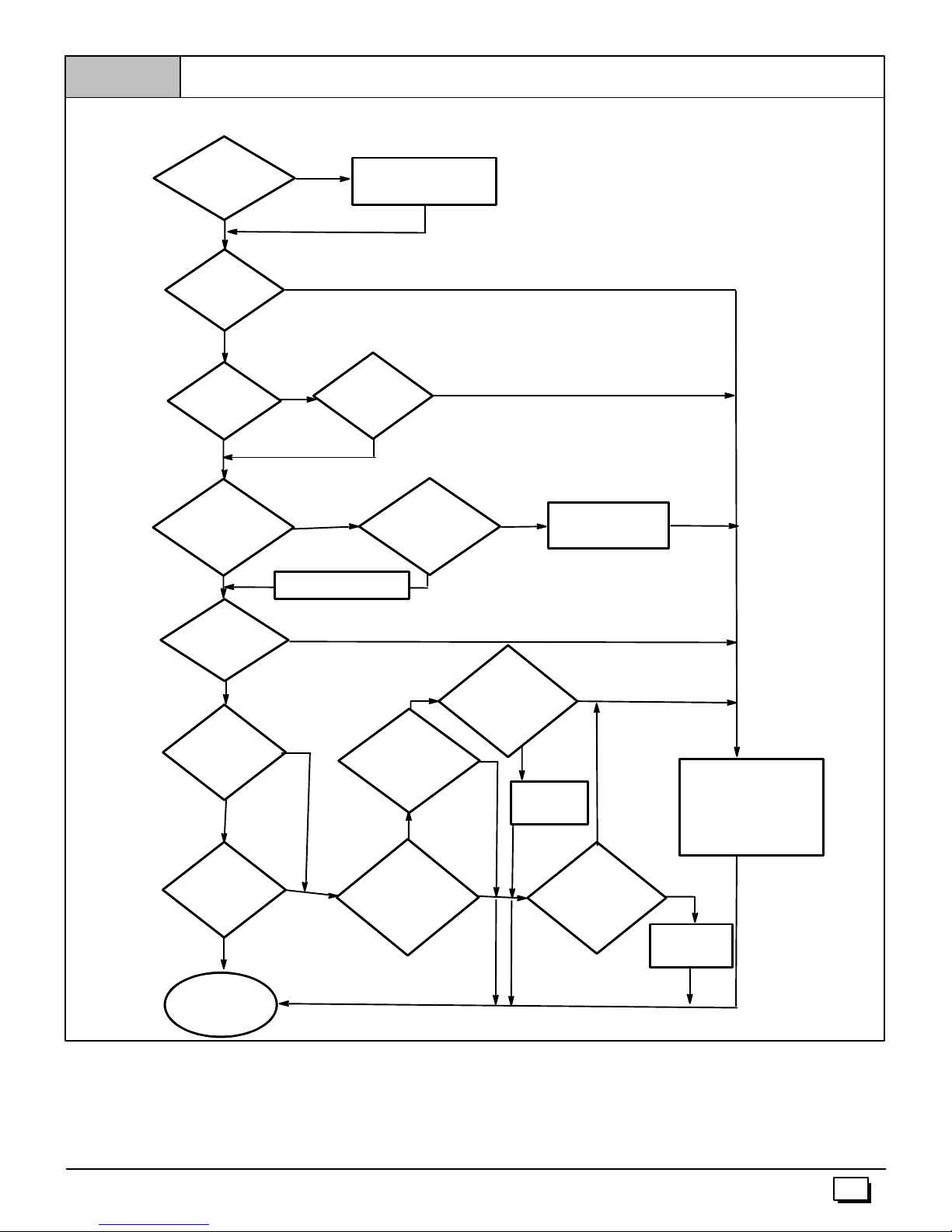

Figure 11

CHIMNEY INSPECTION CHART

ForadditionalrequirementsrefertotheNationalFuelGasCodeNFPA54/ANSIZ223.1--2002andANSI/NFPA211--2003Chimneys,Fireplaces, Vents,andSolidFuel

BurningAppliancesin the U.S.A. or to the Canadian InstallationCodeCSAB149.1--00 in Canada.

Crown

condition:

Missingmortar

or brick?

No

Is

Chimney properly lined

with clay tile

liner?

Yes

Is

liner and top

seal in good

condition

Yes

Debris in

cleanout? Mortar,tile,

metal vent, fuel oil

residue?

No

Yes

No

Repair

No

liner or topseal

or reline chimney as

necessary.

Yes

Remove metal vent orliner.

Repair

Rebuild

crown

Mortar or

tile debris?

Reline

No

Yes

Remove mortar

and tile debris?

Clay

tile misalignment,

missingsections,

gaps?

No

Condensate

drainage at bottom

of chimney?

No

Chimney

exposed to outdoors

below roof line?

No

Chimneyis

acceptable for use

Yes

Yes

Yes

No

Is Chimney

lined with properly

sized, listed liner or

Type--B vent?

Yes

Is Chimney to

be dedicated toa

single furnace?

Consult

Part B ofchimney

adapter venting

instructionsfor

application

suitability.

Suitable

Yes

Install chimney

adapter per

instructions.

No

Not Suitable

Not Suitable

Consult

Part C ofchimney

adapter venting

instructionsfor

application

suitability.

Line chimney with properly

sized, listed flexible metal

liner or Type--B vent per NFGC or

NSCNGPIC VentSizing Tables

and liner orventmanufacturer’s

installation instructions.

Suitable

Install chimney

adapter per

instructions.

441 01 2611 06

17

Exterior Masonry Chimney,

G

6

o

7

o

5

4

t

1

o

r

FAN+NAT Installations with

Type--B Double--Wall Vent Connectors

ã

ã NFPA&AGA

ãã

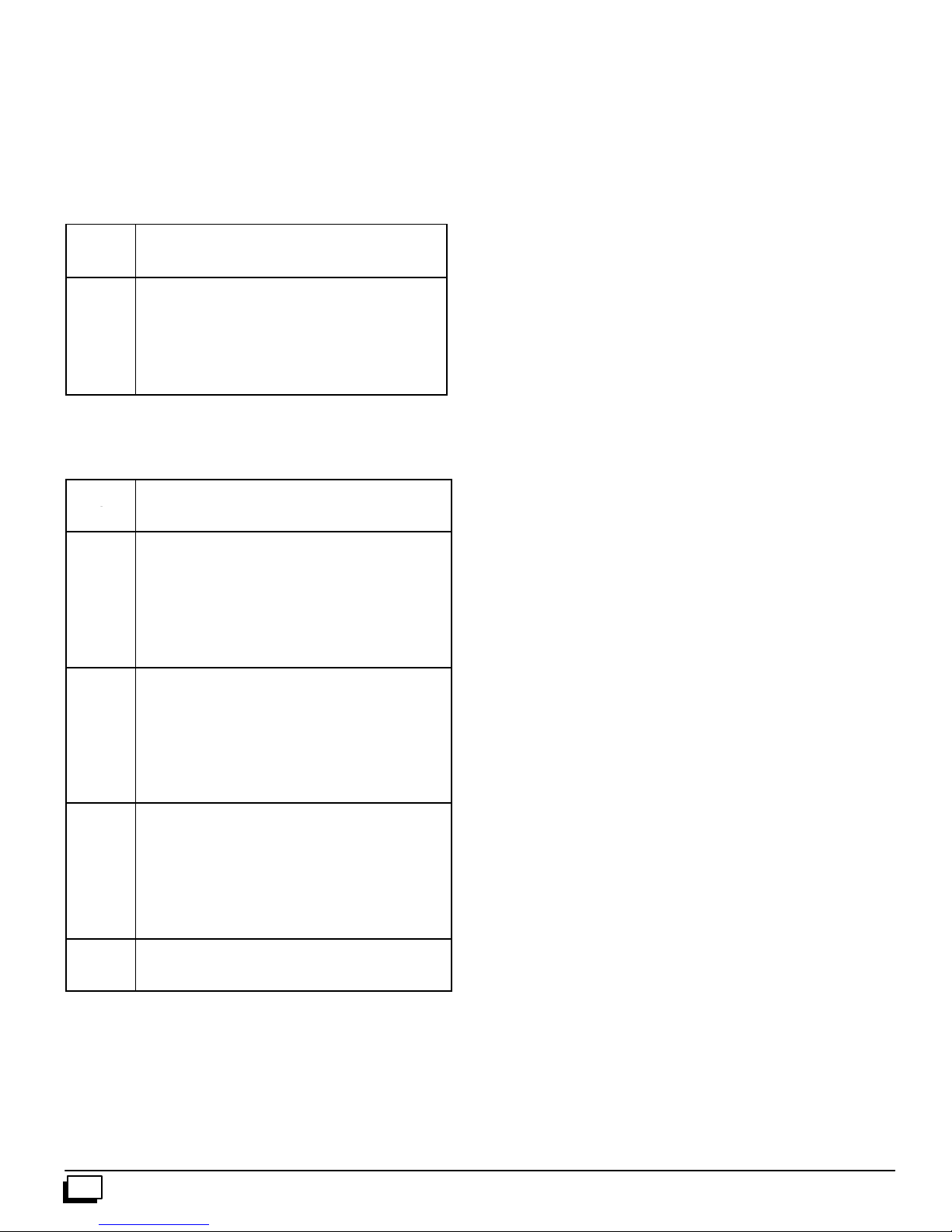

Table A--

Combined Appliance

Maximum Input Rating in

Thousands of Btu per Hr

VENT

HEIGHT

(FT)

6 74 119 178 257

8 80 130 193 279

10 84 138 207 299

15 NR 152 233 334

20 NR NR 250 368

30 NR NR NR 404

INTERNAL AREA OF CHIMNEY

(SQ IN.)

12 19 28 38

Table B--

Minimum Allowable Input Rating of

Space--Heating Appliance in

Thousands of Btu per Hr

VENT

HEIGHT

(FT)

Local 99% Winter Design Temperature: 17 to 26°°°° F*

6 0 55 99 141

°

°F

°

°

8 52 74 111 154

6

10 NR 90 125 169

o2

15 NR NR 167 212

7t

1

20 NR NR 212 258

30 NR NR NR 362

Local 99% Winter Design Temperature: 5 to 16°°°° F*

6 NR 78 121 166

8 NR 94 135 182

°

°F

°

°

16

10 NR 111 149 198

15 NR NR 193 247

5t

20 NR NR NR 293

30 NR NR NR 377

Local 99% Winter Design Temperature: --10 to 4°°°° F*

6 NR NR 145 196

°

°F

°

°

8 NR NR 159 213

4

10 NR NR 175 231

to

15 NR NR NR 283

10

--

20 NR NR NR 333

30 NR NR NR NR

-- 1 1 °°°° F

lower

Local 99% Winter Design Temperature: --11°°°° For

or

INTERNAL AREA OF CHIMNEY

(SQ IN.)

12 19 28 38

lower*

Not recommended for any vent configuration

* The 99% Winter Design Dry--Bulb (db) temperatures are found in the

1993 ASHRAE Fundamentals Handbook, Chapter 24, Table 1

(United States) and 2 (Canada), or use the 99.6% heating db

temperaturesfound in the 1997 or 2001 ASHRAE Fundamentals

Handbook, Climatic Design Information chapter, Table 1A (United

States) and 2A (Canada).

Inspectionsbeforethesaleandatthetimeofinstallationwilldeterminetheacceptabilityofthechimney or the need for repair and/or

(re)lining. Refer to the Chimney Inspection Chart to perform a

chimney inspection.

18

If the inspection of a previously used tile--lined chimney:

a. Showssignsof ventgascondensation,thechimneyshould

be relined in accordance with local codes and the authority

having jurisdiction. The chimney should be relined with a

listed metal liner, Type--B vent, or a listed chimney adapter

kittoreducecondensation. Ifacondensatedrainisrequired

bylocalcode,refer totheNFGC,Section 10.9foradditional

information on condensate drains.

b. Indicates the chimney exceeds the maximum permissible

sizeinthe tables, thechimneyshould berebuiltorrelined to

conform to the requirements of the equipment being

installed and the authority having jurisdiction.

Achimneywithoutaclaytileliner,which is otherwise in good condition,shallberebuilttoconformtoANSI/NFPA211orbelinedwith

a UL listed (ULC listed in Canada) metallinerorULlistedType--B

vent. Relining with a listed metal liner or Type--B vent is considered to be a vent--in-- a--chase.

If a metal liner or Type--B vent is used to line a chimney,no other

appliance shall be vented into the annular space between the

chimney and the metal liner.

APPLIANCE APPLICATION REQUIREMENTS

Appliance operation has a significant impact on the performance

of the venting system. If the appliances are sized, installed, adjusted, and operated properly, the venting system and/or the appliances should not suffer from condensation and corrosion. The

ventingsystemandallappliancesshall beinstalledinaccordance

with applicable listings, standards, and codes.

The furnace should be sized to provide 100 percent of the design

heating load requirement plus any margin that occurs because of

furnace model size capacity increments. Heating load estimates

can be made using approved methods available from Air Conditioning Contractors of America (Manual J); American Society of

Heating, Refrigerating, and Air--Conditioning Engineers; or other

approved engineering methods. Excessive oversizing of the furnace could cause the furnace and/or vent to fail prematurely.

Whena metalventormetallinerisused,thevent orlinermustbein

goodcondition andbeinstalled inaccordancewiththevent orliner

manufacturer’s instructions.

To prevent condensation in the furnace and vent system, the following precautions must be observed:

1. Thereturn--airtemperaturemustbe at least60°Fdbexcept

forbriefperiodsoftimeduringwarm--up from setback atno

lower than 55°F db or during initial start--up from a standby

condition.

2. Adjust the gas input rate per the installation instructions.

Lowgas inputrate causeslowventgastemperatures,causing condensation and corrosion in the furnace and/orventing system. Derating is permitted only for altitudes above

2000¢.

3. Adjust the air temperature rise to the midpoint of the rise

rangeorslightly above. Lowairtemperaturerisecancause

low vent gas temperature and potential for condensation

problems.

4. Set the thermostat heat anticipator or cycle rate to reduce

short cycling.

Air for combustion must not be contaminated by halogen compoundswhichincludechlorides,fluorides, bromides, andiodides.

These compounds are found in many common home products

suchas detergent,paint,glue,aerosolspray,bleach,cleaningsolvent,salt, and air freshener, and can cause corrosion of furnaces

and vents. Avoidusing such products in the combustion--air supply. Furnace use during construction of the building could cause

thefurnace tobe exposedtohalogencompounds,causingpremature failure of the furnace or venting system due to corrosion.

441 01 2611 06

Loading...

Loading...