ICP C8DNL050B12B1, C8DNL075F16B1, C8DNL100F14B1, C8DNL100L20B1, C8DNL125L20B1 Installation Guide

...Page 1

80+SingleStage

DedicatedDownflow

*8DNL

CategoryI Furnace

See section 4 for Category I definition.

* Denotes Brands (C, H, T)

SAFETY REQUIREMENTS

Recognize safety information. This is the safety-alert symbolZl._. When you see this symbol on the furnace and in instruction manuals be alert

to the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the

most serious hazards, those that will result in severe personal injury or death. WARNINGsignifiesahazardthatcouldresultinpersonalinjuryor

death. CAUTIONis used to identify unsafe practices that may result in minor personal injury or product and property damage. NOTE is used to

highlight suggestions that will result in enhanced installation, reliability, or operation.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel should

install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels at-

tached to or shipped with the furnace and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the National Fuel Gas Code (NFGC) ANSI Z223.1-2002/NFPA

54-2002. In Canada, refer to the National Standard of Canada Natural Gas and Propane Installation Code (NSCNGPIC) CSA B149.1-05. Wear

safety glasses and work gloves. Have fire extinguisher available during start-up and adjustment procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these instruc-

tions exceed certain local codes and ordinances, especially those that may not have kept up with changing residential construction practices. We

require these instructions as a minimum for a safe installation.

International Comfort Products, LLC

Lewisburg, TN 37097

INSTALLER: Affix these instructions on

or adjacent to the furnace.

CONSUMER: Retain these instructions

for future reference.

Table of Contents

1. Safe Installation Requirements ................ 3

2. Installation ............................... 4

3. Combustion & Ventilation Air ................. 6

4. Gas Vent Installation ........................ 9

5. Horizontal Venting ......................... 11

6. Masonry Chimney Venting ................... 13

Portions ofthe textand tablesare reprinted from NFPA54 / ANSI Z223,1-2002©, with permission ofNational Fire Protection Association, Quincy, MA 02269 andAmerican Gas Association,

Washington, DC 20001. Thisreprinted material is not the complete and official position ofthe NFPA or ANSI, on the referenced subject, which is represented only by the standard in its

entirety.

PrintedinU.S.A. 11/10/2005 441 01 2314 (02)

7. GasSupplyandPiping ....................... 16

8. ElectricalWiring ........................... 18

9. Ductworkand Filter ......................... 19

10.Checks and Adjustments..................... 23

11.FurnaceMaintenance........................ 27

12.Sequence of Operation&Diagnostics ........... 28

TechSupportand Parts......................... 31

CARBON MONOXIDE POISONING AND FIRE

HAZARD.

Failure to follow safety warnings exactly could

result in serious injury, death, and/or property

damage.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

Page 2

START-UP CHECK SHEET

(Keep this page for future reference)

Recommended, but not required,

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Type of Gas:

Blower Motor H.P,:

Supply Voltage:

Limit Opens at...(°F) or(°C).

Natural: _1 LP: _1

Business Card Here

Manual Gas Shut-Off Upstream

of Furnace/Drip- Leg?

Drip-Leg Upstream of Gas Valve?

Blower Speed Checked? YES _1

All Electrical Connections Tight?

Gas Valve turned ON? YES _1

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See Checks and Adjustments

Section).

YES_I NO_I

YES_I NO_I

NO [_I

YEs_I NO[31

NO[_I

Limit Closes at,,,(°F)___or(°C)

Which blower speed tap is used?

(Heating) (Cooling).

Temperature of Supply Air: (°F)___or(°C)

Temperature of Return Air: (°F) or(°C)__

Rise (Supply Temp.-Return Temp.): (°F) or(°C)__

Filter Type and Size:

Fan "Time ON" Setting:.

Fan "Time OFF" Setting:

Dealer Comments:

Measured Manifold Pressure:

Thermostat OK? YES _1

Subbase Level? YES _1

Anticipator Set? YES _1

Breaker On? YES _1

Date of Installation:

Date of Start-Up:

NOE_

NOE_I

NO E_ Set At?:

NoE_I

441 01 2314 02

Page 3

1. Safe Installation Requirements

FIRE, EXPLOSION, AND ASPHIXIATION HAZARD

Improper adjustment, alteration, service,

maintanence or installation could cause death,

personal injury, and/or property damage.

Installation or repairs made by unqualified

persons could result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities havingjurisdiction.

The information contained in this manual is

intended for use by a qualified service agency that

is experienced in such work, is familiar with all

precautions and safety procedures required in

such work, and is equipped with the proper tools

and test instruments.

• This furnace is NOT approved for installation in mobile

homes, trailers or recreation vehicles.

• Seal around supply and return air ducts.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

Safety Rules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A,

The U.S. Consumer Product Safety Commission encourages

installation of carbon monoxide alarms. There can be various

sources of carbon monoxide in a building or dwelling. The

sources could be gas-fired clothes dryers, gas cooking

stoves, water heaters, furnaces, gas-fired fireplaces, wood

fireplaces.

NOTE: This furnace is design-certified by CSA International (for-

merly AGA and CGA) for installation in the United States and Can-

dada. Refer to the appropriate codes, along with this manual, for

proper installation.

Use onlythe Type of gas approved for this furnace (see Rat-

ing Plate on unit). Overfiring will result in failure of heat ex-

changer and cause dangerous operation. (Furnaces can be

converted to L.P. gas with approved kit.)

Install this furnace only in a location and position as speci-

fied in "2. Installation"of these instructions.

Provide adequate combustion and ventilation air to the fur-

nace as specified in "3. Combustion and Ventilation Air" of

these instructions.

Combustion products must be discharged outdoors. Con-

nect this furnace to an approved vent system only, as speci-

fied in "4. Gas Vent Installation, 5, Horizontal Venting and 6.

Masonry Chimney Venting"of these instructions.

Never test for gas leaks with an open flame. Use a commer-

cially available soap solution made specifically for the detec-

tion of leaks to check all connections, as specified in "7. Gas

Supply and Piping, Final Check"of these instructions.

Always install furnace to operate within the furnace's in-

tended temperature-rise range with a duct system which

has an external static pressure within the allowable range,

as specified in" Technical Support Manual"of these instruc-

tions. See furnace rating plate.

Carbon monoxide can cause serious bodily injury and/or

death. Carbon monoxide or "CO" is a colorless and odorless

gas produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

Therefore, to help alert people of potentially dangerous ca rbon

monoxide levels, you should have a commercially available

carbon monoxide alarm that is listed by a nationally recog-

nized testing agency in accordance with Underwriters Labora-

tories Inc. Standard for Single and Multiple Station Carbon

Monoxide Alarms, ANSI/UL 2034 or the CSA 6.19-01 Resi-

dential Carbon Alarming Devices installed and maintained in

the building or dwelling concurrently with the gas- fired furnace

installation (see Note below). The alarm should be installed as

recommended by the alarm manufacturer's installation in-

structions.

B,

There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

people of potentially dangerous fire or smoke, you should have

fire extinguisher and smoke alarms listed by Underwriters Lab-

oratories installed and maintained in the building or dwelling

(see Note below).

Note: The manufacturer of your furnace does not test any alarms

and makes no representations regarding any brand or type

of alarms.

C. To ensure safe and efficient operation of your unit, you should

do the following:

When a furnace is installed so that supply ducts carry air cir-

culated by the furnace to areas outside the space containing

the furnace, the return air shall also be handled by a duct(s)

sealed to the furnace casing and terminating outside the

space containing the furnace.

A gas-fired furnace for installation in a residential garage

must be installed as specified in "2. Installation"of these in-

structions.

• This furnace is not to be used for temporary heating of build-

ings or structures under construction. See "2, Installation,

item 10 "

441 01 2314 02

1. Thoroughly read this manual and labels on the unit. This

will help you understand how your unit operates and the haz-

ards involved with gas and electricity.

Do not use this unit if any part has been under water. Im-

mediately call a qualified service agency to inspect the unit and

to replace any part of the control system and any gas control

which has been under water.

3. Never obstruct the vent grilles, or any ducts that provide

air to the unit. Air must be provided for proper combustion and

ventilation of flue gases.

Page 4

Frozen Water Pipe Hazard .yourfurnace remains off for an extended time, the pipes in your

WATER DAMAGE TO PROPERTY HAZARD

Failure to protect against the risk of freezing could

result in property damage.

Do not leave your home unattended for long

periods during freezing weather without turning off

home could freeze and burst, resulting in serious water damage.

If the structure will be unattended during cold weather you should

take these precautions.

Turn off the water supply to the structure and drain the water

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

-or-

water supply and draining water pipes or otherwise

protecting against the risk of frozen pipes and

resultant damage.

Your furnace is designed solely to provide a safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety de-

vices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

-or-

3. Install a reliable remote sensing device that will notify some-

body of freezing conditions within the home.

2. Installation

Do NOT install furnace directly on carpeting, tile or other com-

bustible material. See 9, Ductwork and Filter Sub-base for

CARBON MONOXIDE POISONING HAZARD.

Failure to properly vent this furnace or other

appliances could result in death or personal injury.

If this furnace is replacing a previously common-

vented furnace, it may be necessary to resize the

existing vent system to prevent oversizing prob-

lems for the other remaining appliances(s). See

Venting and Combustion Air Check in the 4. Gas

Vent Installation section of this instruction.

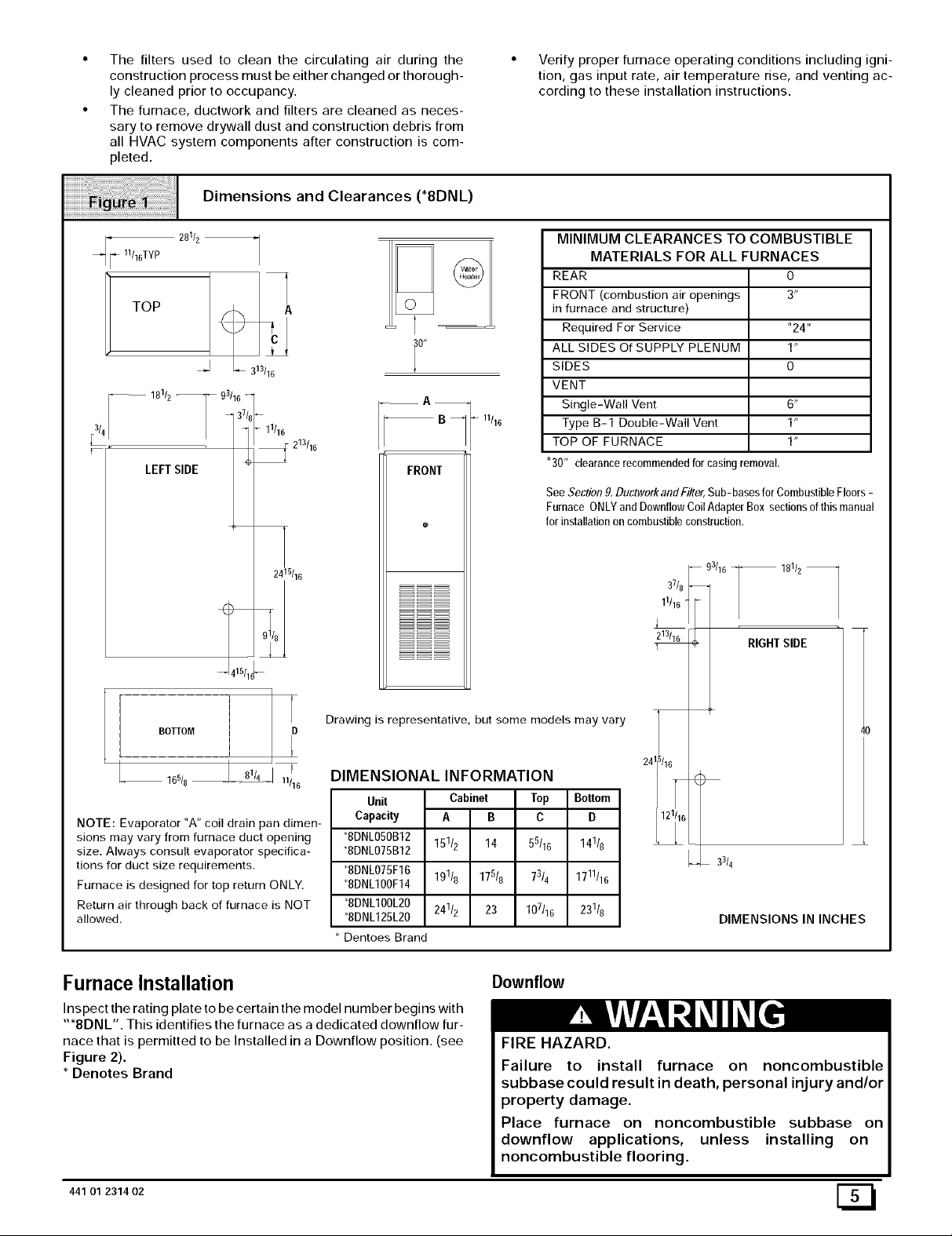

Location and Clearances

If furnace is a replacement, it is usually best to install the furnace

where the old one was. Choose the location or evaluate the exist-

ing location based upon the minimum clearance and furnace di-

mensions (Figure 1).

CARBON MONOXIDE POISONING HAZARD.

Failure to follow safety warnings exactly could

result in death or personal injury.

Do NOT operate furnace in a corrosive

atmosphere containing chlorine, fluorine or any

other damaging chemicals, which could shorten

furnace life.

Refer to 3. Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

Installation Requirements

1,

Install furnace level.

2.

This furnace is NOT to be used for temporary heat of buildings

or structures under construction.

3.

Install furnace as centralized as practical with respect to the

heat distribution system.

4.

Install the vent pipes as short as practical. (See 4. Gas Vent

Installation section).

Combustible Floors.

6. Maintain clearance for fire safety and servicing. A front clear-

ance of 24" is minimum for access to the burner, controls and

filter. See clearance requirements in Figure 1.

7. Use a raised base if the floor is damp or wet at times.

8. Residential garage installations require:

• Burners and ignition sources installed at least 18" (457

mm) above the floor.

• Furnace must be located or physically protected from

possible damage by a vehicle.

9. If the furnace is to be suspended from the floorjoists in a base-

ment or a crawl space or the rafters in an attic, it is necessary to

use steel pipe straps or an angle iron frame to attach the fur-

nace. These straps should be attached to the furnace bottom

side with sheet metal screws and to the rafters or joists with

bolts. The preferred method is to use an angle iron frame

bolted to the rafters or joists.

10. This furnace may be used for construction heat provided that:

• The furnace is permanently installed with all electrical wir-

ing, piping, venting and ducting installed according to

these installation instructions. A return air duct is provided,

sealed to the furnace casing, and terminated outside the

space containing the furnace. This prevents a negative

pressure condition as created by the circulating air blower,

causing a flame rollout and/or drawing combustion prod-

ucts into the structure.

The furnace is controlled by a thermostat. It may not be

"hot wired" to provide heat continuously to the structure

without thermostatic control.

• Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the entrain-

ment of drywall dust into combustion air, which can cause

fouling and plugging of furnace components.

• The temperature of the return air to the furnace is main-

tained between 55 ° F (13 ° C) and 80 ° F (27 ° C), with no

evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to be

intermittent operation per our installation instructions.

• The air temperature rise is within the rated rise range on

the furnace rating plate, and the firing rate has been set to

the rating plate value.

441 01 2314 02

Page 5

The filters used to clean the circulating air during the

construction process must be either changed or thorough-

ly cleaned prior to occupancy.

The furnace, ductwork and filters are cleaned as neces-

sary to remove drywall dust and construction debris from

all HVAC system components after construction is com-

pleted.

Dimensions and Clearances (*8DNL)

Verify proper furnace operating conditions including igni-

tion, gas input rate, air temperature rise, and venting ac-

cording to these installation instructions.

281/2

_-J 313116

LEFT SIDE

fl°'T i

11/16

_ 213/16

2415/16

0"

FRONT

MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS FOR ALL FURNACES

REAR 0

FRONT (combustion air openings 3"

in furnace and structure)

_E

11/16

Required For Service *24"

ALL SIDES Of SUPPLY PLENUM 1"

SIDES 0

VENT

Single-Wall Vent 6"

Type B-1 Double-Wall Vent 1"

TOP OF FURNACE 1"

"30" clearancerecommendedfor casingremoval.

See Section9.DuctworkandFiiter, Sub-basesforCombustibleFloors-

FurnaceONLYandDownflowCoilAdapterBox sectionsofthismanual

for installationoncombustibleconstruction.

-- 181/2

RIGHTSIDE

Drawing is representative, but some models may vary

165/8 nil 6

NOTE: Evaporator "A" coil drain pan dimen-

sions may vary from furnace duct opening

size. Always consult evaporator specifica-

tions for duct size requirements.

Furnace is designed for top return ONLY.

Return air through back of furnace is NOT

allowed.

DIMENSIONAL INFORMATION

Unit Cabinet Top Bottom

Capacity A B C D

*8DNL050B12 151/2 14 5

*8DNL075B12

*8DNLO75F16 191/8 175/8 73/4 1711116

*8DNL1OOF14

8DNL1OOL20 241/2 23 107116 231/8

*8DNL125L20

Dentoes Brand

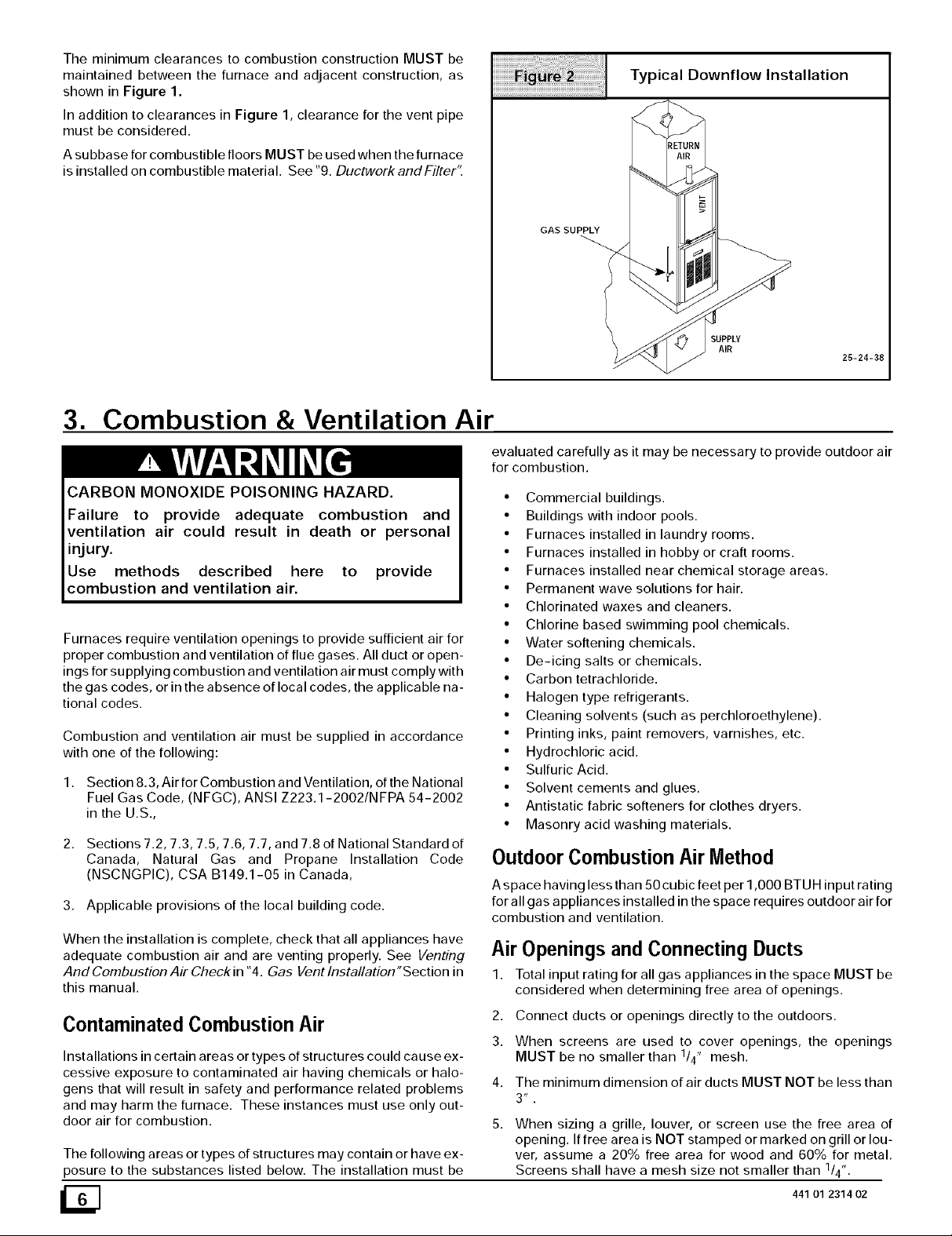

Furnace Installation

Inspect the rating plate to be certain the model number begins with

"*8DNL". This identifies the furnace as a dedicated downflow fur-

nace that is permitted to be Installed in a Downflow position. (see

Figure 2).

* Denotes Brand

24 3/16

5/16 141/8

121/16 _3

3/4

DIMENSIONS IN INCHES

Downflow

FIRE HAZARD.

Failure to install furnace on noncombustible

subbase could result in death, personal injury and/or

property damage.

Place furnace on noncombustible subbase on

downflow applications, unless installing on

noncombustible flooring.

40

441 O1 231402 [_

Page 6

The minimum clearances to combustion construction MUST be

maintained between the furnace and adjacent construction, as

shown in Figure 1.

In addition to clearances in Figure 1, clearance for the vent pipe

must be considered.

A su bbase for combustible floors MUST be used when the furnace

is installed on combustible material. See "9. DuctworkandFilter't

3. Combustion & Ventilation Air

CARBON MONOXIDE POISONING HAZARD.

Failure to provide adequate combustion and

ventilation air could result in death or personal

injury.

Use methods described here to provide

combustion and ventilation air.

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or open-

ings for supplying combustion and ventilation air must comply with

the gas codes, or in the absence of local codes, the applicable na-

tional codes.

Combustion and ventilation air must be supplied in accordance

with one of the following:

1. Section 8.3, Air for Combustion and Ventilation, of the National

Fuel Gas Code, (NFGC), ANSI Z223.1-2002/NFPA 54-2002

in the U.S.,

2. Sections 7.2, 7.3, 7.5, 7.6, 7.7, and 7.8 of National Standard of

Canada, Natural Gas and Propane Installation Code

(NSCNGPIC), CSA B149.1-05 in Canada,

3. Applicable provisions of the local building code.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

And Combustion Air Check in "4. Gas Vent Installation "Section in

this manual.

Contaminated Combustion Air

Installations in certain areas or types of structures could cause ex-

cessive exposure to contaminated air having chemicals or halo-

gens that will result in safety and performance related problems

and may harm the furnace. These instances must use only out-

door air for combustion.

The following areas or types of structures may contain or have ex-

posure to the substances listed below. The installation must be

Typical Downflow Installation

RETURN

AIR

GAS SUPPLY

SUPPLY

AIR

25-24-38

evaluated carefully as it may be necessary to provide outdoor air

for combustion.

• Commercial buildings.

• Buildings with indoor pools.

• Furnaces installed in laundry rooms.

• Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De-icing salts or chemicals.

• Carbon tetrachloride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

Outdoor Combustion Air Method

A space having less than 50 cubic feet per 1,000 BTUH input rating

for all gas appliances installed in the space requires outdoor air for

combustion and ventilation.

Air Openings and Connecting Ducts

1. Total input rating for all gas appliances in the space MUST be

considered when determining free area of openings.

2. Connect ducts or openings directly to the outdoors.

3. When screens are used to cover openings, the openings

MUST be no smaller than 1/4" mesh.

4. The minimum dimension of air ducts MUST NOT be less than

3 _ .

When sizing a grille, louver, or screen use the free area of

opening. If free area is NOT stamped or marked on grill or lou-

ver, assume a 20% free area for wood and 60% for metal.

Screens shall have a mesh size not smaller than 1/4".

441 01 2314 02

Page 7

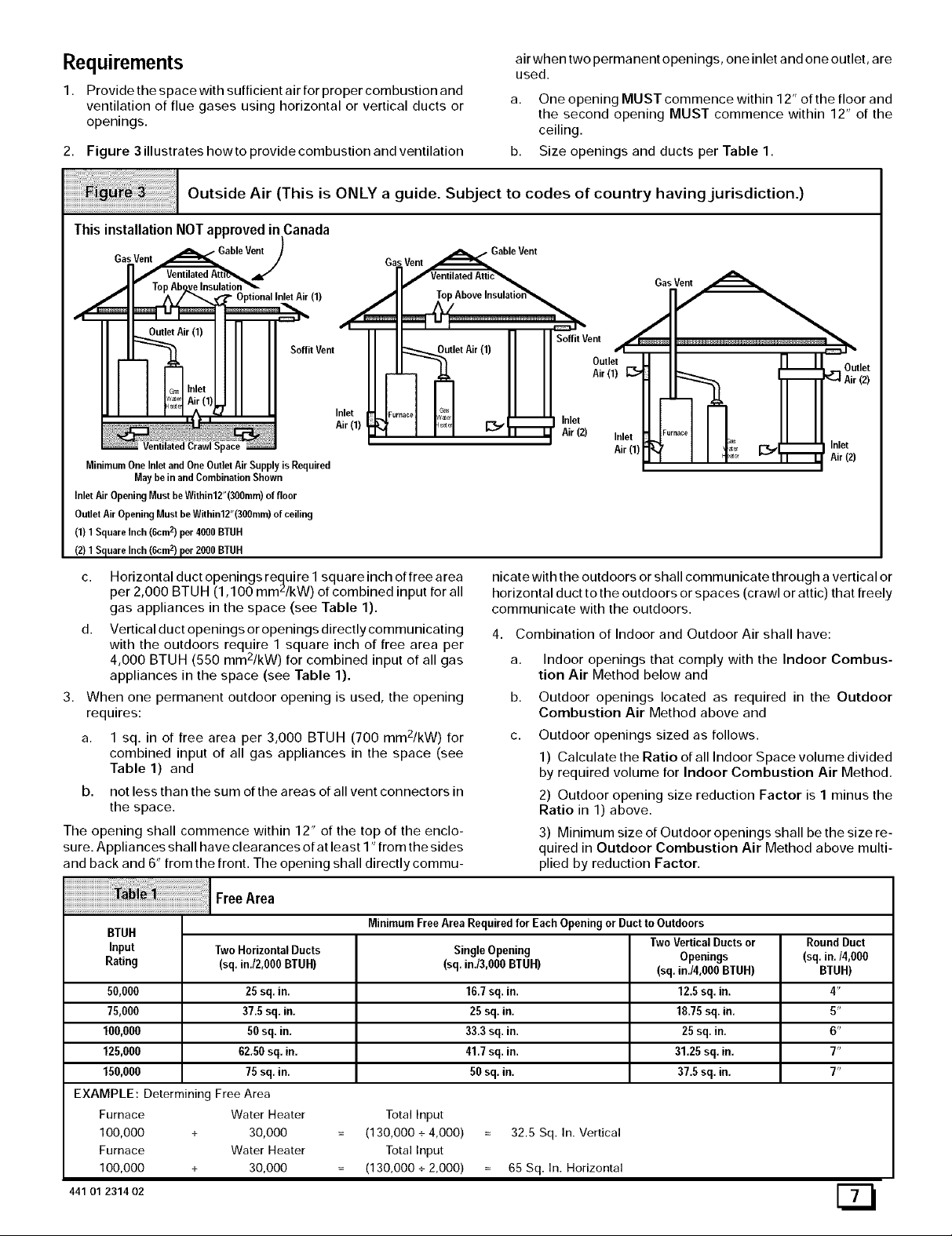

Requirements

1. Provide the space with sufficient air for proper combustion and

ventilation of flue gases using horizontal or vertical ducts or

openings.

2. Figure 3 illustrates how to provide combustion and ventilation

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

air when two permanent openings, one inlet and one outlet, are

used.

a. One opening MUST commence within 12" of the floor and

the second opening MUST commence within 12" of the

ceiling.

b. Size openings and ducts per Table 1.

ThisinstallationNOTapprovedinCanada

GasVent • GableVent)

/

.,1'

Gas Vent j_Gable Vent

VentilatedAttic'S.

SoffitVent J_utlet Air(1) Outle_

II _. Air(1) [_

I F...... _G%

Air(1) _' _ _ -- Inlet

;pace

MinimumOne InletandOneOutlet AirSupply is Required

May be in andCombination Shown

Inlet Air OpeningMustbeWithin12"(300mm)offloor

OutletAir OpeningMustbe Within12"(300mm)ofceiling

(1) 1 SquareInch (6cm2) per 4000 BTUH

(2) 1 Square Inch(6cmz) per 2000 BTUH

c. Horizontal duct openings require I square inch of free area

per 2,000 BTUH (1,100 mmZ/kW) of combined input for all

gas appliances in the space (see Table 1).

d. Vertical duct openings or openings directlycommunicating

with the outdoors require 1 square inch of free area per

4,000 BTUH (550 mm2/kW) for combined input of all gas

appliances in the space (see Table 1).

3. When one permanent outdoor opening is used, the opening

requires:

a. 1 sq. in of free area per 3,000 BTUH (700 mm2/kW) for

combined input of all gas appliances in the space (see

Table 1) and

b. not less than the sum of the areas of all vent connectors in

the space.

The opening shall commence within 12" of the top of the enclo-

sure. Appliances shall have clearances of at least I "from the sides

and back and 6" from the front. The opening shall directly commu-

II " SoffitVent

-- Air (2) Inlet

nicate with the outdoors or shall communicate through a vertical or

horizontal duct to the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

4. Combination of Indoor and Outdoor Air shall have:

a.

Indoor openings that comply with the Indoor Combus-

-, i I I,n,e`

Air(1)

_ '_ _ _ Air (2)

tion Air Method below and

b.

Outdoor openings located as required in the Outdoor

Combustion Air Method above and

C.

Outdoor openings sized as follows.

1) Calculate the Ratio of all Indoor Space volume divided

by required volume for Indoor Combustion Air Method.

2) Outdoor opening size reduction Factor is 1 minus the

Ratio in 1) above.

3) Minimum size of Outdoor openings shall be the size re-

quired in Outdoor Combustion Air Method above multi-

plied by reduction Factor.

Area

BTUH MinimumFree Area RequiredforEachOpeningor Ductto Outdoors

Input TwoHorizontalDucts SingleOpening Openings (sq. in./4,000

Rating (sq.in./2,000BTUH) (sq. in./3,000BTUH) (sq.in./4,000 BTUH) BTUH)

50,000 25sq. in. 16.7sq. in, 12.5sq. in, 4"

75,000 37,5 sq. in. 25sq. in. 1825 sq. in. 5"

100,000 50sq, in. 33.3sq.in, 25sq. in. 6"

125,000 62.50sq. in. 41.7sq. in. 31.25 sq. in. 7"

150,000 75sq. in. 50sq. in. 37.5sq. in. 7"

EXAMPLE: Determining Free Area

Furnace Water Heater Total Input

100,000 + 30,000 (130,000 + 4,000) 32.5 Sq. In. Vertical

Furnace Water Heater Total Input

100,000 + 30,000 (130,000 + 2,000) 65 Sq. In. Horizontal

44101 231402

TwoVerticalDuctsor RoundDuct

Page 8

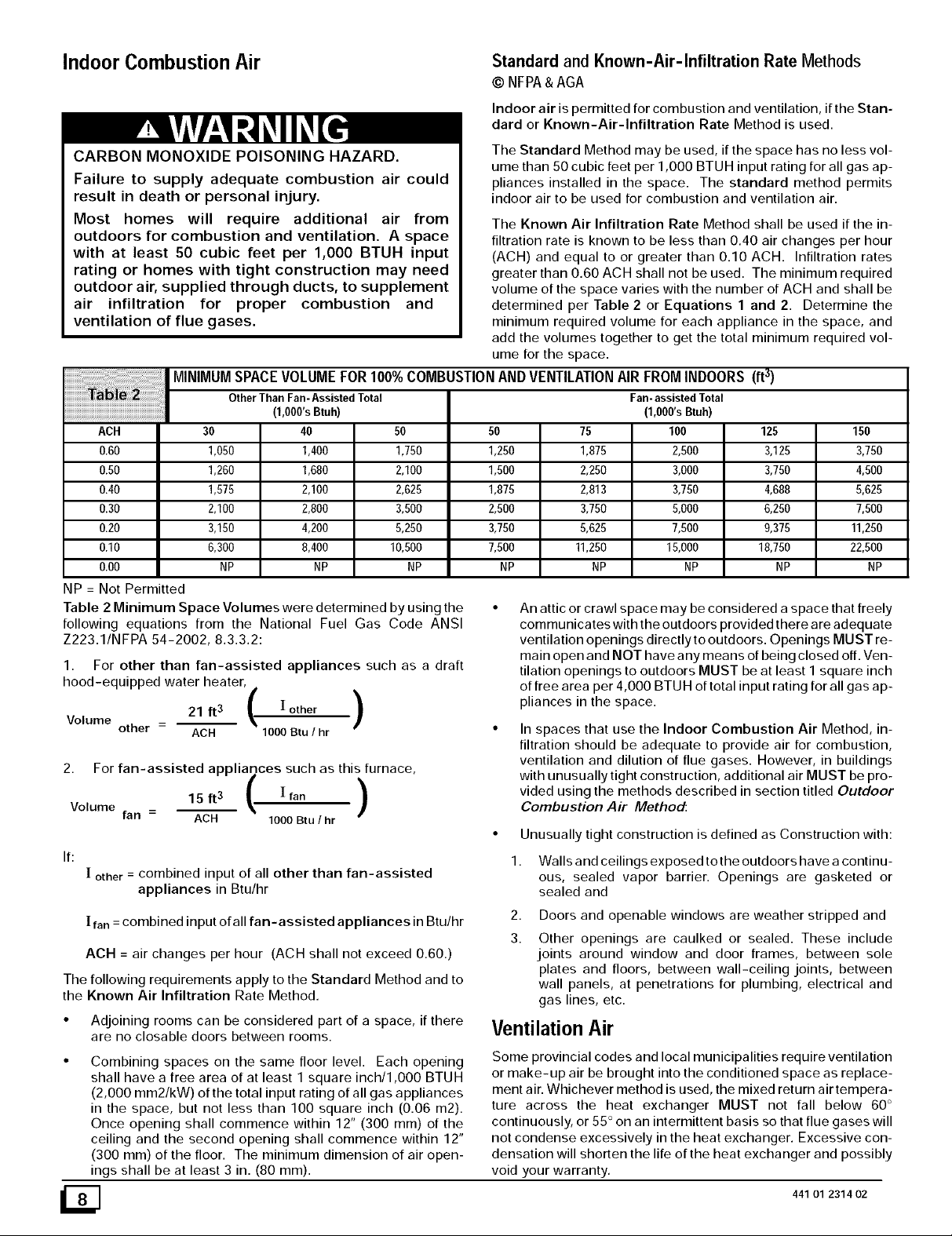

Indoor Combustion Air Standard and Known-Air-Infiltration Rate Methods

© NFPA&AGA

Indoor air is permitted for combustion and ventilation, if the Stan-

dard or Known-Air-Infiltration Rate Method is used.

CARBON MONOXIDE POISONING HAZARD.

Failure to supply adequate combustion air could

result in death or personal injury.

Most homes will require additional air from

outdoors for combustion and ventilation. A space

with at least 50 cubic feet per 1,000 BTUH input

rating or homes with tight construction may need

outdoor air, supplied through ducts, to supplement

air infiltration for proper combustion and

ventilation of flue gases.

iiiiiiiiiiiiiiiiiiiii_i;_;:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_i:_:i_!!!!_ii!#_;i!_#_;i!i!;i_iiiii_ii_iiiiiiiiiii;i#;ii;ii;ii;ii;ii;i

ACH

0.60 1,050 1,400 1,750 1250 3,125 3,750

0.50 1,260 1,680 2,100 1,500 3,750 4,500

0.40 1,575 2,100 2,625 1,875 4,688 5,625

0.30 2,100 2,800 3,500 2,500 6250 7,500

0.20 3,150 4200 5,250 3,750 9,375 11,250

0.10 6,300 8,400 10,500 7,500 18,750 22,500

0.00 NP NP NP NP NP NP

MINIMUM SPACE VOLUME FOR 100% COMBUSTION AND VENTILATION AIR FROM INDOORS (ft 3)

Other Than Fan-Assisted Total

(1,OOO'sBtuh)

30 40 50 50 125 150

The Standard Method may be used, if the space has no less vol-

ume than 50 cubic feet per 1,000 BTUH input rating for all gas ap-

pliances installed in the space. The standard method permits

indoor air to be used for combustion and ventilation air.

The Known Air Infiltration Rate Method shall be used if the in-

filtration rate is known to be less than 0.40 air changes per hour

(ACH) and equal to or greater than 0.10 ACH. Infiltration rates

greater than 0.60 ACH shall not be used. The minimum required

volume of the space varies with the number of ACH and shall be

determined per Table 2 or Equations 1 and 2. Determine the

minimum required volume for each appliance in the space, and

add the volumes together to get the total minimum required vol-

ume for the space.

Fan-assistedTotal

(1,000'sBtuh)

75 100

1,875 2,500

2,250 3,000

2,813 3,750

3,750 5,000

5,625 7,500

11,250 15,000

NP NP

NP = Not Permitted

Table 2 Minimum Space Volumes were determined by using the

following equations from the National Fuel Gas Code ANSI

Z223.1/NFPA 54-2002, 8.3.3.2:

1. For other than fan-assisted appliances such as a draft

hood-equipped water heater,

Volume other - ACH 1000Btu / hr

2. For fan-assisted appliances such as this furnace,

Volume fan = ACH 1000Btu ! hr

21 ft 3 ( ! other )

15ft3 ( Iran )

If:

[ other = combined input of all other than fan-assisted

appliances in Btu/hr

[ ran = combined input of all fan-assisted appliances in Btu/hr

ACH = air changes per hour (ACH shall not exceed 0.60.)

The following requirements apply to the Standard Method and to

the Known Air Infiltration Rate Method.

• Adjoining rooms can be considered part of a space, if there

are no closable doors between rooms.

• Combining spaces on the same floor level. Each opening

shall have a free area of at least 1 square inch/1,000 BTUH

(2,000 mm2/kW) of the total input rating of all gas appliances

in the space, but not less than 100 square inch (0.06 m2).

Once opening shall commence within 12" (300 mm) of the

ceiling and the second opening shall commence within 12"

(300 mm) of the floor. The minimum dimension of air open-

ings shall be at least 3 in. (80 mm).

An attic or crawl space may be considered a space that freely

communicates with the outdoors provided there are adequate

ventilation openings directly to outdoors. Openings MUST re-

main open and NOT have any means of being closed off. Ven-

tilation openings to outdoors MUST be at least I square inch

of free area per 4,000 BTUH of total input rating for all gas ap-

pliances in the space.

In spaces that use the Indoor Combustion Air Method, in-

filtration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

with unusually tight construction, additional air MUST be pro-

vided using the methods described in section titled Outdoor

Combustion Air Method:

• Unusually tight construction is defined as Construction with:

1. Walls and ceilings exposed to the outdoors have a continu-

ous, sealed vapor barrier. Openings are gasketed or

sealed and

2,

Doors and openable windows are weather stripped and

3.

Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall-ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air tempera-

ture across the heat exchanger MUST not fall below 60 °

continuously, or 55 ° on an intermittent basis so that flue gases will

not condense excessively in the heat exchanger. Excessive con-

densation will shorten the life of the heat exchanger and possibly

void your warranty.

441 O1 2314 02

Page 9

4. Gas Vent Installation

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to properly vent this furnace could result in

death, personal injury and/or property damage.

Read and follow all instructions in this section.

Install the vent in compliance with codes of the country havingju-

risdiction, local codes or ordinances and these instructions.

This Category ] furnace is fan-assisted. A fan assisted appliance

is an appliance equipped with an integral mechanical means to ei-

ther draw or force products of combustion through the heat ex-

changer.

Category ] furnace definition: A central furnace which operates 8.

with a non-positive vent static pressure and with a flue loss not

less than 17 percent. These furnaces are approved for common-

venting and multi-story venting with other fan-assisted or draft 9.

hood-equipped appliances in accordance with the NFGC or

NSCNGPIC.

Category [ Safe Venting Requirements

Category [ furnace vent installations shall be in accordance with

Parts 10 and 13 of the National Fuel Gas Code (NFGC), ANSI

Z223.1-2002/N FPA 54-2002; and/or Section 7 and Appendix C of

the CSA B149.1-05, National Standard of Canada, Natural Gas

and Propane Installation Code; the local building codes; furnace

and vent manufacturer's instructions.

NOTE: The following instructions comply with the ANSI

Z223.1/NFPA 54 National Fuel Gas Code and CSA B149.1 Natu-

ral Gas and Propane Installation code, based on the input rate on

the furnace rating plate.

1,

If a Category ] vent passes through an attic, any concealed

space or floor, use ONLY Type B or Type L double wall vent

pipe. If vent pipe passes through interior wall, use Type B vent

pipe with ventilated thimble ONLY.

2,

Do NOT vent furnace into any chimney serving an open fire-

place or solid fuel burning appliance.

3.

Use the same diameter Category ] connector or pipe as per-

mitted by:

• the National Fuel Gas Code Code (NFGC) ANSI

Z223.1-2002 / NFPA 54-2002 sections 10 and 13 venting

requirements in the United States

or

• the National Standard of Canada Natural Gas and Pro-

pane Installation Code (NSCNGPIC) CSA B149.1-05

section 7 and appendix C venting requirements in Canada.

Push the vent connector onto the furnace flue collar of the

venter assembly until it touches the bead (at least 5/8" overlap)

and fasten with at least two field-supplied, corrosion-resist-

ant, sheet metal screws located at least 140 ° apart.

5. Keep vertical Category [ vent pipe or vent connector runs as

short and direct as possible.

6,

Vertical outdoor runs of Type-B or ANY single wall vent pipe

below the roof line are NOT permitted.

7.

Slope all horizontal runs up from furnace to the vent terminal a

minimum of 1/4" per foot (21 ram/m).

Rigidly support all horizontal portions of the venting system ev-

ery 6' or less using proper clamps and metal straps to prevent

sagging and ensure there is no movement after installation.

Check existing gas vent or chimney to ensure they meet clear-

ances and local codes. See Figure 1

10.

The furnace MUST be connected to a factory built chimney or

vent complying with a recognized standard, or a masonry or

concrete chimney lined with a lining material acceptable to the

authority having jurisdiction. Venting into an unlined ma-

sonry chimney or concrete chimney is prohibited. See the

6. Masonry Chimney Venting section in these instruc-

tions.

11.

Fan-assisted combustion system Category [ furnaces shall

not be vented into single-wall metal vents.

12.

Category [ furnaces must be vented vertically or nearly verti-

cally, unless equipped with a listed mechanical venter.

13.

Vent connectors serving Category I furnaces shall not be con-

nected into any portion of mechanical draft systems operating

under positive pressure.

A 4-to-3 inch reducer is permitted at the flue collar when installing

a 50,000 Btuh gas input furnace, if the installation meets all the fol-

lowing requirements for sizing the vent connectors and vents:

1. The National Fuel Gas Code, ANSI

Z223.1/NFPA-54-2002, sections 10.5.3.1(1),

10.6.3.1(2), 10.10.3.1, 13.1.2, 13.1.10, and 13.2.21(1)

through (3) in the U.S. or

2. The Natural Gas and Propane Installation Code CSA

B149.1-05, sections 7.13.1 (b), 7.13.2(b), 7.18.5(b), and

Appendix C-GVR no. 2. in Canada.

441 01 2314 02 [_

Page 10

Venting and Combustion Air Check

NOTE: When an existing Category I furnace is removed or re-

placed, the original venting system may no longer be sized to prop-

erly vent the attached appliances, and to make sure there is

adequate combustion air for all appliances, MAKE THE FOL-

LOWING CHECK.

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being placed

into operation, could result in carbon monoxide

poisoning or death:

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1.Seal any unused openings in the venting system.

2.Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223. 1/NFPA 54 or CSA B 149. 1,Natural Gas a nd Propane

Installation Code and these instructions. Determine that

there is no blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe condition.

3.As far as practical, close all building doors and windows and

all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4.Close fireplace dampers.

5.Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, sothey are operating

at maximum speed. Do not operate a summer exhaust fan.

6.Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7.Test for spillage from draft hood equipped appliances at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle. (Figure 4)

8.If improper venting is observed, during any of the above

tests, the venting system must be corrected in accordance

with the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/or CSA B149, 1, Natural Gas and Propane Installation

Code.

9.After it has been determined that each applia nce connected

to the venting system properly vents when tested as out-

lined above, return doors, windows, exhaust fans, fireplace

dampers and any other gas-fired burning appliance to their

previous conditions of use.

Vent Check

VentPipe _1 I A/ Draft Hood

Typical Gas

Water Heater

! !

NOTE: If Elaine p_ulls towards draft hoo_, this indicates

sufficient infiltration air.

Venting to Existing Masonry Chimney

Dedicated venting of one fan assisted furnace into any ma-

sonry chimney is restricted. A chimney must first be lined with

either Type B vent sized in accordance with NFGC tables 13.1 or

13.2 or a listed metal lining system, sized in accordance with the

NFGC section 13.1.7 for a single appliance or 13.2.19 for multiple

appliances, or NSCNGPIC Appendix C, section 10. (See Section 6

Masonry Chimney Venting of these instructions.)

Listed, corrugated metallic chimney liner systems in masonry

chimneys shall be sized in the U.S. by using NFGC tables per

13.1.7 for dedicated venting and per 13.2.19 for common venting

with the maximum capacity reduced by 20% (0.80 X maximum ca-

pacity) and the minimum capacity as shown in the applicable table.

Corrugated metal vent systems installed with bends or offsets re-

quire additional reduction of 5% of the vent capacity for each bend

up to 45 ° and 10% of the vent capacity for each bend from 45 ° up to

90 °. In Canada, use the NSCNGPIC.

NOTE: Two(2) 45 ° elbows are equivalent to one (1) 90 ° elbow.

Combined Venting into a Masonry Chimney

Venting into a masonry or concrete chimney is only permitted

as outlined in the NFGC or NSCNGPIC venting tables. Follow

all safe venting requirements.

Note: See section "6. Masonry Chimney Venting'.

_] 441 01 2314 02

Page 11

5. Horizontal Venting

Category I Furnaces With External Power

Venters

In order to maintain a Category ] classification of fan-assisted fur-

naces when vented horizontally with sidewall termination, a power

venter is REQUIRED to maintain a negative pressure in the vent-

ing system.

In the U.S.: Per the NFGC, a listed power venter may be used,

when approved by the authority having jurisdiction.

In Canada: Only power venters approved by the appliance

manufacturer and where allowed by the authority having jurisdic-

tion may be used.

Please consult the Fields Controls Co. or Tjernlund Products, Inc.

for power venters certified for use with this furnaces.

Vent Termination

Venting Through a Non-Combustible and

Combustible Wall

Consult External Power Venter manufacturer instructions.

Select the power venter to match the Btuh input of the furnace be-

ing vented. Follow all of the power venter manufacturer's installa-

tion requirements included with the power venter for:

• venting installation,

• vent terminal location,

• preventing blockage by snow,

• protecting building materials from degradation by flue gases,

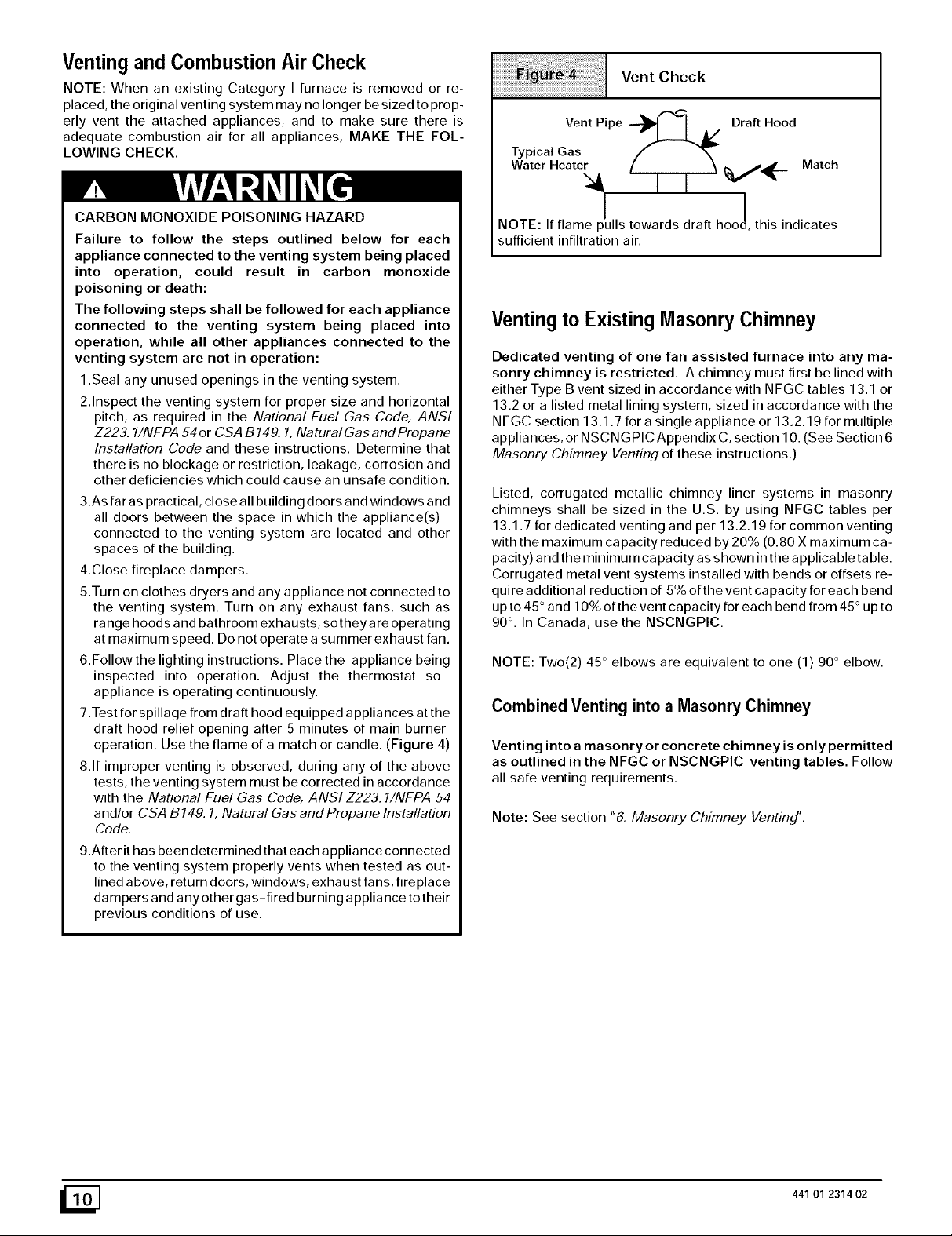

• see Figure 5 for required vent termination.

NOTE: It is the responsibility of the installer to properly terminate

the vent and provide adequate shielding. This is essential in order

to avoid water/ice damage to building, shrubs and walkways.

441 01 2314 02 [_

Page 12

iiiiiiiiiiiiiiiiii;ii_;;_i:_i:_i;!;!:;!_i_ii!_!ii_i:_:i::_;_i_!_!_i!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!_i!;iiiiiiiii_iiiiiiiiiiiiiiiiiiiiiii_!!!;!_i¸ii;ilililiiiiiiiiiiiiiiiiiiiiiiii_i_i_ii!!!iiiii

Other than Direct Vent Termination Clearance

r_ VENT TERMINAL

Item Clearance Descriptions

A Clearance above grade, veranda, porch, deck, balcony, or

anticipated snow level

B Clearance to a window or door that may be opened

(_ AIR SUPPLYINLET

Canadian Installation(1)

12" (30cm)#

6" (lfi cm) for appliances_<10,000BTUH(3kW), 12" (30

cm)forappliances> 10,000Btub(3kW) and _<100,000Btub

AREA WHERE TERMINAL IS NOT PERMITED

U.S. Installation (2)

12" (30 cm)

4' (1.2 m) below or to the side of the opening. 1' (30 cm)

above lhe opening.

(30 kW),36" (01 cm) forappliances> 100,000Btuh(30kW)

C

Clearance to a permanently closed window

D

Vertical clearance to a ventilated soffit located above the

terminal within a horizontal distance of 2' (61cm) from the

centedine of the terminal

E

Clearance to an unventilated soffit

F

Clearance to an outside corner

G

Clearance to an inside corner

H

Clearance to each side of the centefline extended above

electrical meter or gas service regulator assembly

I

Clearance to service regulator vent outlet

J

Clearance to non-mechanical air supply inlet to building or

the combustion air inlet to any other appliance

K

Clearanceto amechanicalair supplyinlet

L

Clearanceundera veranda,porch,deck,or balcony

M

Clearance to each side of the centefline extended above or

below vent terminal of the furnace to a dryer or water heater

vent, or other appliance's direct vent intake or exhaust.

N

Clearance from a plumbing vent stack

0

Clearanceabovea pavedsidewalkor paveddrivewaylocated

3' (91 cm) within 15' (4.5 m) above the meter/regulator

assembly

3' (01 cm)

6" (15cm)forappliances_<lO,OOOBTUH (3kW),12" (30

cm) for appliances > 10,000 Btuh (3 kW) and _<100,000 Btuh

(30 kW), 36" (01 cm) for appliances > 100,000 Btuh (30 kW)

6' (1.83 m)

12" (30 cm) +

3' (01cm)

7' (2.13m)

3' (91 cm) within 15' (4.5 m) above the meter/regulator

assembly

4' (1.2 m) below or to the side of opening: 1' (30 cm) above

opening.

3' (91 cm) above if within 10' (3m) horizontally

3' (01cm)

7' (2.13m)

on publicproperty.

(1.) In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

(2,) In accordance with the currem ANSI Z223.1/NFPA fi4, National Fuel Gas Code

# 18" (46 cm) above roof surface

+ Permitted only if veranda, porch, deck, or balcony isfully open on a minimum of two sides beneath the floor.

For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B140.1, clearances shall be in accordance with local installation codes and the requiremenls of the gas supplier and the manufacture's

installation instructions.

A vent shall nol terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings.

Notes:

1, The vent for this appliance shall not terminate

a. Over public walkways; or

b. Near soffit vents or crawl space vents or other areas where condensate or vapor could create a nusiance or hazard or property damage; or

c. Where condensate vapor could cause damage or could be detrimental to the operafion of regulators, relief valves, or other equipment.

2. When locating vent terminations, consideration must be given to prevailing winds, location, and other conditions which may cause recirculation of the combusfiob products of adjacent vents.

Recirculafion can cause poor combustion, inlet condensate problems, and accelerated corrosion of the heat exchangers.

441 01 2314 02

Page 13

6. Masonry Chimney Venting

Chimney Inspection

All masonry chimney construction must conform to Standard

ANSI/NFPA 211-2003 and to any state or local codes applicable.

The chimney must be in good condition and a complete chimney

inspection must be conducted prior to furnace installation. If the in-

spection reveals damage or abnormal conditions, make neces-

sary repairs or seek expert help. See "The Chimney Inspection

Chart" Figure 6. Measure inside area of tile-liner and exact height

of chimney from the top of the chimney to the highest appliance

flue collar or drafthood outlet.

Connector Type

To reduce flue gas heat loss and the chance of condensate prob-

lems, the vent connector must be double-wall Type B vent.

Venting Restrictions for Chimney Types

Interior Chimney - has no sides exposed to the outdoors below

the roofline. All installations can be single furnace or common

vented with another draft hood equipped Category ] appliance.

Exterior Chimney - has one or more sides exposed to the out-

doors below the roof line. All installations with a 99% Winter De-

sign Temperature* below 17°F must be common vented only with

a draft hood equipped Category I appliance.

The99%WinterDesignDry-Bulb(db)temperaturesarefoundinthe1993ASHRAE

FundamentalsHandbook,Chapter24, Table1(UnitedStates)and2(Canada),or

usethe99.6%heatingdbtemperaturesfound inthe1997or2001ASHRAEFunda-

mentalsHandbook,ClimaticDesignInformationchapter,Table1A (UnitedStates)

and 2A (Canada).

Ifa claytile-lined masonry chimney is being used and it is exposed

to the outdoors below the roof line, relining might be required.

Chimneys shall conform to the Standard for Chimneys, Fire-

places, Vents, and Solid Fuel Burning Appliances ANSI/NFPA

211-2003 in the United States and to a Provincial or Territorial

Building Code in Canada (in its absence, the National Building

Code of Canada) and must be in good condition.

U.S.A.- Refer to Sections 13.1.9 or 13.2.20 of the N FGC or the au-

thority having jurisdiction to determine whether relining isrequired.

If relining is required, use a properly sized listed metal liner,

Type-B vent, or a listed alternative venting design.

This model (*8DNL) is NOT listed for use with Chimney Adapter

kits. A multi-position furnace in the downflow position that is listed

for use with one of the Chimney Adapter Kits NAHAOOIDH or

NAHAOO2DH may be used with a masonry chimney.

Canada (and U.S.A.)-This furnace is permitted to be vented into a

clay tile-lined masonry chimney that is exposed to the outdoors

below the roof line, provided:

1. Vent connector is Type-B double-wall, and

2. This furnace is common vented with at least 1 draft hood-

equipped appliance, and

The combined appliance input rating is less than the maxi-

mum capacity given in Table A, and

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to properly vent this furnace could result in

death, personal injury and/or property damage.

These furnaces are CSA (formerly AGA and CGA

design-certified for venting into exterior clm

tile-lined masonry chimneys with a factory accesso

ry Chimney Adapter Kit. Refer to the furnace rating

31atefor correct kit usage. The Chimney Adapter Kits

are for use with ONLY furnaces having a Chimne_

Adapter Kit number marked on the furnace ratin i

plate.

The input rating of each space-heating appliance is greater

than the minimum input rating given in Table B for Masonry

Chimneys for the local 99% Winter Design Temperature.

Chimneys having internal areas greater than 38 square

inches require furnace input ratings greater than the input

ratings of these furnaces. See footnote at bottom of Table B,

and

5. The authority having jurisdiction approves.

If all of these conditions cannot be met, an alternative venting de-

sign shall be used, such as a listed chimney-lining system, or a

Type-B vent.

441 01 2314 02 [_

Page 14

Exterior Masonry Chimney,

FAN+NAT Installations with

Type-B Double-Wall Vent Connectors

© NFPA&AGA

Table A-

Combined Appliance

Maximum Input Rating in

Thousands of Btu per Hr

VENT

HEIGHT

(FT)

6

8

10

15

20

30

INTERNAL AREA OF

(SQ IN.)

12 19 28

74 119 178

80 130 193

84 138 207

NR 152 233

NR NR 250

NR NR NR

CHIMNEY

38

257

279

299

334

368

404

Table B-

Minimum Allowable Input Rating of

Space-Heating Appliance in

Thousands of Btu per Hr

VENT

HEIGHT

(FT)

Local 99% Winter Design Temperature: 17 to 26 ° F*

6

8

o 10

2O

30

Local 99% Winter Design Temperature: 5 to 16° F*

_" 10

0

,_ 15

20

30

Local 99% Winter Design Temperature: -10 to 4° F*

6

8

o 10

o is

i

2O

30

-11 ° F Local 99% Winter Design Temperature: -11 ° F or

or lower*

lower Not recommended for any vent configuration

The 99% Winter Design Dry-Bulb (db) temperatures are found in the

1993 ASHRAE Fundamentals Handbook, Chapter 24, Table 1

(United States) and 2 (Canada), or use the 99.6% beating db temper-

atures found in the 1997 or 2001 ASHRAE Fundamentals Handbook,

Climatic Design Information chapter, Table 1A (United States) and 2A

(Canada).

INTERNAL AREA OF CHIMNEY

(SQ IN.)

12 19 28 38

0 55 99 141

52 74 111 154

NR 90 125 169

NR NR 167 212

NR NR 212 258

NR NR NR 362

NR 78 121 166

NR 94 135 182

NR 111 149 198

NR NR 193 247

NR NR NR 293

NR NR NR 377

NR NR 145 196

NR NR 159 213

NR NR 175 231

NR NR NR 283

NR NR NR 333

NR NR NR NR

Inspections before the sale a nd at the time of installation will deter-

mine the acceptability of the chimney or the need for repair and/or

(re)lining. Refer to the Chimney Inspection Chart to perform a

chimney inspection.

If the inspection of a previously used tile-lined chimney:

a. Shows signs of vent gas condensation, the chimney should

be relined in accordance with local codes and the authority

having jurisdiction. The chimney should be relined with a

listed metal liner or Type-B vent to reduce condensation. If

a condensate drain is required by local code, refer to the

NEGC, Section 10.9 for additional information on conden-

sate drains.

b. Indicates the chimney exceeds the maximum permissible

size in the tables, the chimney should be rebuilt or relined to

conform to the requirements of the equipment being

installed and the authority having jurisdiction.

A chimney without a clay tile liner, which is otherwise in good con-

dition, shall be rebuilt to conform to AN SI/N FPA 211 or be lined with

a UL listed (ULC listed in Canada) metal liner or UL listed Type-B

vent. Relining with a listed metal liner or Type-B vent is consid-

ered to be a vent-in-a-chase.

If a metal liner or Type-B vent is used to line a chimney, no other

appliance shall be vented into the annular space between the

chimney and the metal liner.

APPLIANCE APPLICATION REQUIREMENTS

Appliance operation has a significant impact on the performance

of the venting system. If the appliances are sized, installed, ad-

justed, and operated properly, the venting system and/or the ap-

pliances should not suffer from condensation and corrosion. The

venting system and all appliances shall be installed in accordance

with applicable listings, standards, and codes.

The furnace should be sized to provide 100 percent of the design

heating load requirement plus any margin that occurs because of

furnace model size capacity increments. Heating load estimates

can be made using approved methods available from Air Condi-

tioning Contractors of America (Manual J); American Society of

Heating, Refrigerating, and Air-Conditioning Engineers; or other

approved engineering methods. Excessive oversizing of the fur-

nace could cause the furnace and/or vent to fail prematurely.

When a metal vent or metal liner is used, the vent or liner must be in

good condition and be installed in accordance with the vent or liner

manufacturer's instructions.

To prevent condensation in the furnace and vent system, the fol-

lowing precautions must be observed:

1. The return-air temperature must be at least 60°F db except

for brief periods of time during warm-up from setback at no

lower than 55°F db or during initial start-up from a standby

condition.

Adjust the gas input rate per the installation instructions.

Low gas input rate causes low vent gas temperatures, ca us-

ing condensation and corrosion in the furnace and/or vent-

ing system. Derating is permitted only for altitudes above

2000'.

3. Adjust the air temperature rise to the midpoint of the rise

range or slightly ahove. Low air temperature rise ca n ca use

low vent gas temperature and potential for condensation

problems.

4. Set the thermostat heat anticipator or cycle rate to reduce

short cycling.

Air for combustion must not be contaminated by halogen com-

pounds which include chlorides, fluorides, bromides, and iodides.

These compounds are found in many common home products

such as detergent, paint, glue, aerosol spray, bleach, cleaning sol-

vent, salt, and air freshener, and can cause corrosion of furnaces

and vents. Avoid using such products in the combustion-air sup-

441 01 2314 02

Page 15

ply. Furnace use during construction of the building could cause

the furnace to be exposed to halogen compounds, causing prema-

ture failure of the furnace or venting system due to corrosion.

Vent dampers on any appliance connected to the common vent

CHIMNEY INSPECTION CHART

Foradditionalrequirementsreferto theNationalFuelGasCodeNFPA54/ANSIZ223.1-2002 andANSIINFPA211-2003Chimneys,Fire-

places,Vents,andSolid Fuel BurningAppliancesintheU.S.A. orto theCanadianInstallationCodeCSAB149.1-05 in Canada.

condition: Rebuild

Missing mortar crown

orbrick?

I

,_ withclay tile No

Yes

can cause condensation and corrosion in the venting system. Do

not use vent dampers on appliances common vented with this fur-

Race.

linerand top

sealingood

metalvent, fuel oil

residue?

Remove metal vent or liner.

_,,_stile n_isalignrnent, Yes p-

ingsections,

No No adapter venting Not Suitable

lineror top seal

orreline chimnei'as_

IRepair

Reline

Mortar or Remove mortar

file debris? and tile debris?

- _ instructions for / i,

/ _ \ application/

Condensate /,sObi e, " tab,iy

drainage atbottom _ < _:_r _'-]Vl Suitable

ofchimney? _ TvDe-Bven_/ vo_[ _ Linechim!ywitbpropedy

"' / '_[ InstallchimneyI sized,listedflexiblemetal

_. / I adaprerper I linerorType-BventperNFGCor

No Tv^_ I andlinerorventmanufacturer's

T. I _ NSCNGPICVentSizingTables

._ [ /_ Not Suitable instal]ationinstructions.

Chimney . , / IsChimnevto _ t,,_J_ /PartCofchimney_

be,owroof,ine? Yes _. U_nUalUe'_u;nace./ j_rT-"_, _ ,nstructionsfor |

/ _ , / Consul__

_.3,_ _ _2_uT ' _ adapter venting S_le

\ _ / I \ apl_!ica!i°n / _'

/ [ _,uitability/ I installchimney

441 01 2314 02 [_

Page 16

7. Gas Supply and Piping

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to follow safety warnings exactly could

result in death, personal injury and/or property

damage.

Models designated for Natural Gas are to be used

with Natural Gas ONLY, unless properly

converted to use with LP gas.

Listed Flexible

GasAppliance

Connector if

11o4

Se_c%

IO]

Typical Gas Piping ('8DNL)

GasSupply Requirements

• Use only the Type of gas approved for this furnace. See rating

plate for approved gas type.

• Gas input must not exceed the rated input shown on the rating

plate. Overfiring will result in failure of heat exchanger and

cause dangerous operation.

Do not allow minimum supply pressure to vary downward. Do-

ing so will decrease input to furnace. Refer to Table 3 for gas

supply. Refer to Table 5 or Table 6 for manifold pressures.

i I Pressures

Gas Type Supply Pressure

Recommended Max.

Natural 7" 14"

Propane 11" 14"

GasPiping Requirements

NOTE: The gas supply line must be installed bya qualified service

technician in accordance with all building codes.

NOTE: In the state of Massachusetts.

a. Gas supply connections MUST be performed by a li-

censed plumber or gas fitter).

b. When flexible connectors are used, the maximum length

shall not exceed 36" (915 ram).

c. When lever handle type manual equipment shutoff valves

are used, they shall be T-handle valves.

d. The use of copper tubing for gas piping is NOT approved.

1,

Install gas piping in accordance with local codes, or in the ab-

sence of local codes, the applicable national codes.

2.

It is recommended that a manual equipment shutoff valve be

installed in the gas supply line outside the furnace. Locate

valve as close to the furnace as possible where itis readily ac-

cessible. Refer to Figure 7.

Min,

4,5"

11"

union

Drip leg &

pipe cap _.

\

Gas control

valve

Elbows & 25-25-17

short nipples

3. Use black iron or steel pipe and fittings or other pipe approved

by local code.

4. Use pipe thread compound which is resistant to natural and LP

gases.

5. Use ground joint unions and install a drip leg no less than 3"

long to trap dirt and moisture before it can enter gas control

valve inside furnace.

6. Provide a 118" NPT plugged tapping for test gauge connection

immediately up stream of gas supply connection to furnace.

7. Use two pipe wrenches when making connections to prevent

gas valve from turning.

NOTE: If local codes allow the use of a flexible gas appliance con-

nector, always use a new listed connector. Do not use a connector

which has previously served another gas appliance.

8. Flexible corrugated metal gas connector may NOT be used in-

side the furnace or be secured or supported by the furnace or

ductwork.

9. Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or LP gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. Measure pipe length from gas meter or LP second stage regu-

lator to determine gas pipe size.

Left Side Gas Supply Piping

Gas line can be installed directly to the gas valve through the hole

provided in the left side of the cabinet. See Figure 7

Right Side Gas Supply Piping

FIRE HAZARD

Failure to follow safety warnings exactly could

result in death, personal injury and/or property

damage.

Use wrench to hold furnace gas control valve when

turning elbows and gas line to prevent damage to the

gas control valve and furnace.

_] 441 01 2314 02

Two(2) 90 ° street elbows or two(2) 90 ° standard elbows and

two(2) close nipples are required for right side gas supply. See

Figure 7.

Piping with Street Elbows

1. Assemble the elbows so that the outlet of one(l) elbow is 90 °

from the inlet of the other. The elbows should be tight enough

to be leak proof. An additional 1/4 turn will be required at the

end of step 2, see Figure 8.

Page 17

2. Screw elbow assembly into gas valve far enough to be leak

proof. Position el bow assembly so that the inlet of the el bow is

at the bottom of the gas valve. An additional 1/2 turn will be re-

quired in step 3. Turn open end of inlet elbow to face the right

side of the furnace (1/4 turn), see Figure 9.

3. Turn assembly an additional 1/2 turn to position inlet near the

top of the gas valve and in line with gas opening on right side of

furnace, see Figure 7 and Figure 10.

iiiiiiiiiiiiiiiiiiiiiiiii:iiiiiii;;;i_i¸!!iii!ilil!!!!!!!i!!!iiiii¸;I i!iliiii¸i¸Ii;¸

E,bows *aDNL

25-23-23c

Gas Valve with Elbows (*8DNL)

25-25-03

Gas Valve with Elbows (*aDNL)

FIRE OR EXPLOSION HAZARD.

Failure to properly install metal gas connector could

result in death, personal injury and/or property

damage.

A flexible corrugated metal gas connector must be

properly installed, shall not extend through the side

of the furnace, and shall not be used inside the

furnace.

Black iron pipe shall be installed at the furnace gas

control valve and extend a minimum of 2" outside

furnace.

Additional LP Piping Requirements

• Have a licensed LP gas dealer make all connections at storage

tank and check all connections from tank to furnace.

• If copper tubing is used, it MUST comply with limitation set in

Local Codes, orin the absence of local codes, the gas codes of

the country having jurisdiction.

• Two-stage regulation of LP gas is recommended.

FIRE OR EXPLOSION HAZARD.

A natural gas or LP gas leak ignited by an open

flame or spark could result in death, personal injury

and/or property damage.

Natural gas is lighter than air and will rise. Liquefied

petroleum (LP) gas is heavier than air and will settle

and remain in low areas and open depressions.

Thoroughly ventilate area and dissipate gas. Do

NOT use a match or open flame to test for leaks, or

attempt to start up furnace before thoroughly

ventilating area.

25-25-12

4. Gas supply line then can be run directly into opening of elbow.

Piping with Close Nipples and Standard Elbows

1. Assemble elbows and nipples similar to street elbows shown

in Figure 8.

2. Follow steps 2 through 4 Piping with Street Elbows.

FinalCheck

• Test all pipes for leaks.

• If orifices were changed, make sure they are checked for

leaks.

• During pressure testing of gas supply piping system:

a. If test pressure does not exceed 1/2 psi, isolate the

furnace from the gas supply piping system by closing the

equipment shutoff valve.

b. If test pressure exceeds 1/2 psi, the furnace and its

manual equipment shutoff valve must be disconnected

from the gas supply piping system.

• To check for leaks apply soap suds or a liquid detergent to

each joint. Bubbles forming indicate a leak.

• Do not use an open flame to test for gas leaks. Fire or explo-

sion could occur.

• Correct even the smallest leak at once.

441 01 2314 02 [_

Page 18

8. Electrical Wiring

ELECTRICALSHOCK HAZARD.

Failure to follow safety warnings exactly could

result in death or personal injury.

Turn OFF electrical power at fuse box or service

panel before making any electrical connections and

ensure a proper ground connection is made before

connecting line voltage.

7. Position all wires away from sharp edges and moving parts.

Do not pinch J-box or other wires when reinstalling blower

compartment door.

Thermostat

Thermostat location has an important effect on the operation of the

furnace. Follow instructions included with thermostat for correct

mounting and wiring.

Low voltage connections to furnace must be made on terminal

board of furnace control. (See Figure 11)

Power Supply Wiring

The furnace MUST be electrically wired and grounded in accor-

dance with local codes, or in the absence of local codes, with the

National Electrical Code (NEC), ANSI/NFPA 70-2002 in the U.S.,

or the Canadian Electrical Code (CEC), CSA C22.1 in Canada.

The power supply to the furnace connections must be between

104 VAC and 127 VAC during furnace operation for acceptable

performance.

Field wiring connections must be made inside the furnace connec-

tion box. A suitable strain relief should be used at the point the

wires exit the furnace casing.

Copper conductors shall be used. Line voltage wires should

conform to temperature limitation of 63 ° F (35 ° C) rise. Wire and

circuit breaker sizing shall be based on the ampacity of the furnace

electrical components plus the amps for all installed accessories

(1.0 amps toni for EAC and HUM). Ampacity can be determined by

using the NEC or CEC.

NOTE: Furnace will not have normal operation is line polarity is re-

versed. Check ALL field and control connections prior to opera-

tion.

Furnace must be installed so the electrical components are pro-

tected from water and connected to its own separate circuit.

J- Box Relocation

The J-box is installed on left side of casing. An alternate J-box

location on right side can be used.

1. Remove bag containing two hole plugs and two self-tapping

screws from loose parts bag in blower compartment.

2. Remove and discard two screws holding J-box to casing.

3. Move large hole plug from right to left J-box location.

4. Move J-box to alternate location and attach using two self-

tapping screws from bag.

5. A wire tie may need to be cut for additional wire length.

6. Apply two hole plugs from bag at left J-box location.

If cooling is used, the Y from the thermostat must be connected to

the control board Y to energize cooling blower speed.

Set thermostat heat anticipator in accordance with the Technical

Support Manual.

Heat anticipator setting will need to be measured if 24VAC humidi-

fier is installed. Measure currentin series from R to W at thether-

mostat. Be sure 24VAC humidifier is wired up to control. Allow

furnace to operate for 2 minutes before recording the AC amper-

age reading. Set anticipator on thermostat to recorded value.

Optional Equipment

All wiring from furnace to optional equipment MUST conform to lo-

cal codes or, in the absence of local codes, the applicable national

codes. Install wiring in accordance with manufacturer's instruc-

tions.

Humidifier/Electronic Air Cleaner

The furnace is wired for humidifier and/or electronic air cleaner

connection.

REDUCED FURNACE LIFEHAZARD

Failure to follow caution instructions may result in

reduced furnace life.

Do NOT exceed 115V/1.0 amp. maximum current

load for both the EAC terminal and the HUM

terminal combined.

HUMIDIFIER - The HUM (115VAC) is energized when the

pressure switch closes on a call for heat. The HUM is ener-

gized when the inducer is energized.

ELECTRONIC AIR CLEANER - EAC is energized when there

is a blower speed call, except is NOT energized when blower

operates in the hard-wired continuous fan mode.

_] 441 01 2314 02

Page 19

llSV. 60Hz.

-- BOX

Ground

_tat

Therm°_ i @

t i t i

i i i i

1 'I'

, I,I

Electrical Connections

24VAC

HUM_4 P

Jumperi

FUSE

Control Connections

%

DiagnosticLight

HUM

Low Voltage

Terminal Board

O

NOTE: 115 VAC/6OHz/single-phase 25-25-13

Operating voltage range*: 127 VAC max, 104 VAC min.

* Permissible limits of voltage at which unit will operate satisfactorily

Furnace Control

The furnace control is preset at the factory with ON delay of 30 sec-

onds in the heating mode. The blower OFF timing is preset at 140

seconds. If desired, the fan OFF delay can be reset to obtain the

longest delay times while still maintaining comfort levels. See

"Furnace Wiring Diagram".

9. Ductwork and Filter

CARBON MONOXIDE POISONING HAZARD.

Failure to properly seal duct could result in death or

personal injury.

Do NOT draw return air from inside a closet or

utility room where furnace is located. Return air duct

MUST be sealed to furnace casing.

FIRE HAZARD.

Failure to install furnace on noncombustible

subbase could result in death, personal injury

and/or property damage.

Place furnace on noncombustible subbase on

downflow applications, unless installing on

non-combustible flooring.

Duct Connections

This furnace may be installed in only a top return-air application.

Return air duct connection through the side(s) or back of the fur-

44101 231402

25-24-98

Furnace Control Fuse

The 24V circuit contains a 5-amp, automotive-type fuse located

on furnace control. (See Figure 12) Any electrical shorts of 24V

wiring during installation, service, or maintenance may cause fuse

to blow. If fuse replacement is required, use only a fuse of identical

size (5 amp.).

nace is NOT permitted. Supply duct connection is permitted to

ONLY the bottom of the furnace.

Duct Design

Design and install the air distribution system to comply with Air

Conditioning Contractors of America manuals or other approved

methods that conform to local codes and good trade practices.

When the furnace is located in an area near or adjacent to the living

area, the system should be carefully designed with returns to mini-

mize noise transmission through the supply and return air grilles.

Any blower moving a high volume of air will produce audible noise

which could be objectionable when the unit is located very close to

a living area. It is often advisable to route the supply air ducts un-

der the floor and return air ducts through the attic.

Refer to furnace Technical Support Manual (BlowerData) for

airflow information.

Size ductwork to handle airflow for heating and air conditioning

if used.

Duct Installation Requirements

When a furnace is installed so that supply ducts carry air circu-

lated by the furnace to areas outside of the space containing

the furnace, the return air shall also be handled by duct(s)

sealed to the furnace casing and terminating outside the space

containing the furnace.

Eil

Page 20

CARBON MONOXIDE POISONING HAZARD.

Failure to follow safety warning exactly could

result in death or personal injury.

Install cooling coil on furnace discharge. Cool air

passing over heat exchanger could cause

condensate to form resulting in heat exchanger

failure.

When the furnace is used with a cooling unit, the furnace shall

be installed parallel with or on the upstream side of the cooling

unit to avoid condensation in the heating element.

With a parallel flow arrangement, the dampers or other means

used to control flow of air shall be adequate to prevent chilled

air from entering the furnace. Chilled air going through the fur-

nace could cause condensation and shorten furnace life.

Dampers (purchased locally) can be either automatic or manu-

al. Manually or automatically operated dampers MUST be

equipped with a means to prevent furnace or air conditioning

operation, unless damper is in the full heat or cool position

Installation of locking-type dampers is recommended in all

branches, or in individual ducts to balance system's air flows.

Non-combustible, flexible duct connectors are recommended

for return and supply connections to furnace.

If air return grille is located close to the fan inlet, install at least

one, 90 ° air turn between fan and inlet grille to reduce noise.

• Ductwork installed in attic, or exposed to outside temperatures

requires a minimum of 2" of insulation with outdoor type vapor

barrier.

• Ductwork installed in an indoor unconditioned space requires

a minimum of 1" of insulation with indoor type vapor barrier.

Inspection Panel on Some Models

For a furnace not equipped with a cooling coil, the outlet duct shall

be provided with a removable access panel. This opening shall be

accessible when the furnace is installed and shall be of such a size

that the heat excha nger can be viewed for possible openings using

light assistance or a probe can be inserted for sampling the air

stream. This access cover shall be attached in such a manner as

to prevent air leaks.

Sub-Bases for Combustible Floors - Furnace Only

The Subbase for Combustible Floors MUST be used when a

downflow furnace is set on a combustible floor, even when the fur-

nace is installed on a coil box.

NOTE: Supply opening is 37/8" from the rear of the furnace.

Therefore maintain a 37/8 ', clearance from a wall behind the fur-

nace (where applicable).

1. Cut the opening in the floor according to the dimensions in

Table 4 because the base is equipped with locating tabs that

center the base over the opening.

The opening in the base is 11/4" shorter and 11/8" narrower