Page 1

INSTRUCTION MANUAL

HF AUTOMATIC

ANTENNA TUNER

AT-141

Page 2

FOREWORD

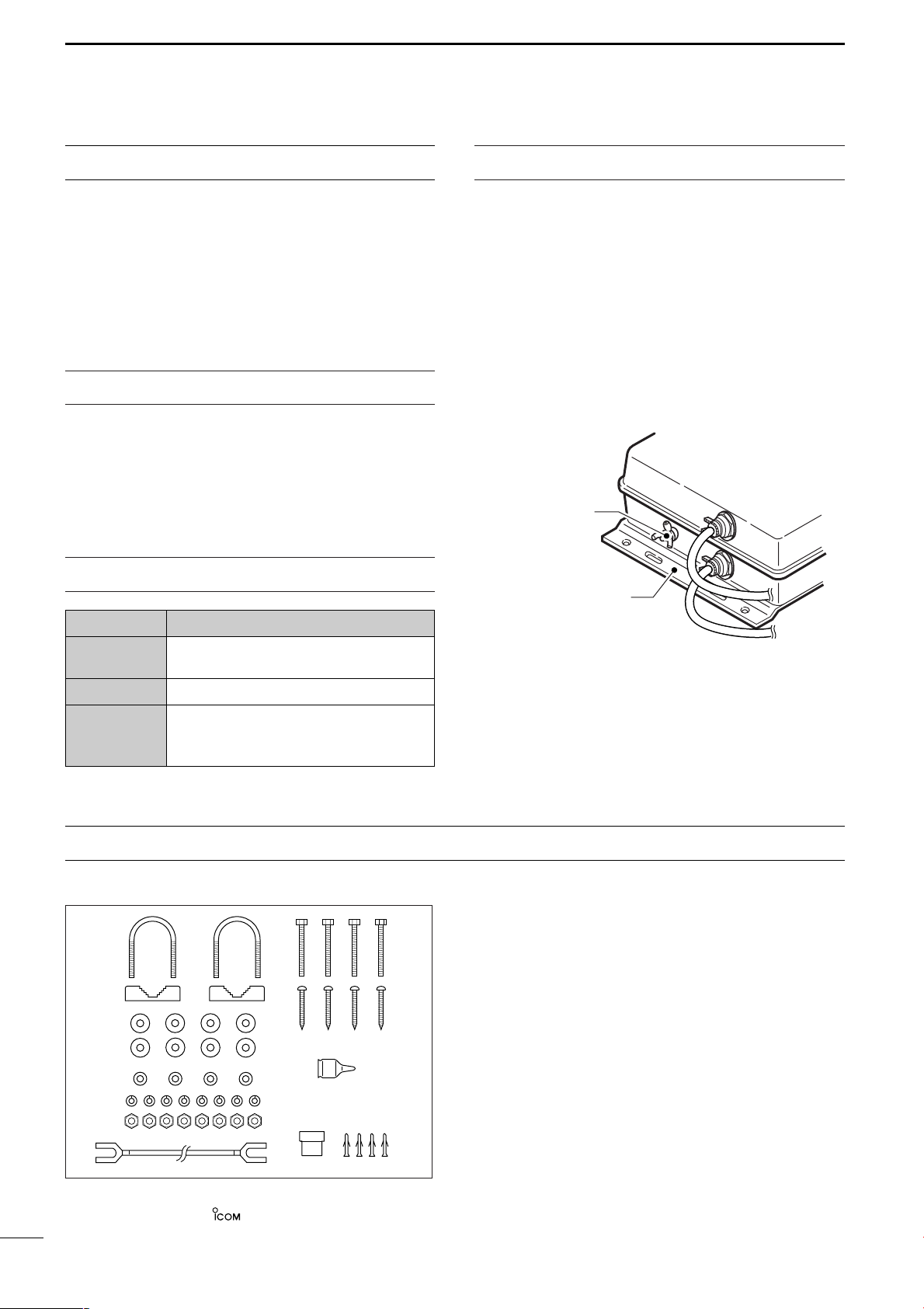

Ground terminal

Mounting plate

q

w

e

r

t

y

u

i

o

!0 !1

!2

PRECAUTIONS

Thank you for purchasing the AT-141 HF AUTO-

MATIC ANTENNA TUNER

The AT-141 is designed, primarily for use with Icom HF

transceivers.

Refer to your HF transceiver instruction manual for operation. If you have any questions, contact your dealer.

.

IMPORTANT

READ ALL INSTRUCTIONS carefully and com-

pletely before using the AT-141.

SAVE THIS INSTRUCTION MANUAL. This in-

struction manual contains important safety and installation instructions.

EXPLICIT DEFINITIONS

Word Definition

R WARNING

CAUTION Equipment damage may occur.

NOTE

Personal injury, fire hazard or electric

shock may occur.

If disregarded, inconvenience only. No

personal injury, fire hazard or electric

shock.

R DANGER HIGH VOLTAGE! NEVER touch

the antenna terminal, ground terminal, antenna or

counterpoise while transmitting. Place the AT-141, antenna and counterpoise in positions where no one can

touch them.

NEVER use without a ground connection.

NEVER transmit during internal adjustment. This may

cause an electric shock.

USE the ground terminal for ground connection.

The mounting plate is not connected internally.

DO NOT operate your HF marine transceiver without

running the boat’s engine.

AVOID using the AT-141 in areas where the temper-

ature is below –30°C or above +60°C.

SUPPLIED ACCESSORIES

The following accessories are supplied with the AT-141. Qty.

Icom, Icom Inc. and the logo are registered trademarks of Icom Incorporated (Japan) in the United States, the United Kingdom, Germany, France, Spain, Russia and/or other countries.

i

q U-bolts ……………………………………………… 2

w U-bolt plates ……………………………………… 2

e Flat washers (M6 large) ………………………… 8

r Flat washers (M6 small) ………………………… 4

t Spring washers (M6) ……………………………… 8

y Nuts (M6) …………………………………………… 8

u Hex head bolts (M6×50) ………………………… 4

i Self-tapping screws (A0 6×30) …………………… 4

o Weatherproof cap ………………………………… 1

!0 4-pin connector …………………………………… 1

!1 Connector pins …………………………………… 4

!2 Ground cable (OPC-412) ………………………… 1

Page 3

MISCELLANEOUS ITEMS

TABLE OF CONTENTS

The following parts are additionally required for installation, but are not supplied with the AT-141.

Purchase these parts locally.

q AWG 14×4-conductor shielded cable

*Icom offers an optional OPC-1465

Length: 10 m; 32.8 feet

w 50 Ω coaxial cable

e PL-259 connectors

CONTROL CABLE

.

FEATURES

Matches all bands

The AT-141 matches any frequency on every HF marine band. For example, the tuner matches a 7 m; 23 ft

long-wire antenna across 1.6–30 MHz.

Full automatic tuning

Just push the [TUNE] key on the transceiver, and the

AT-141 adjusts immediately to the minimum SWR of

any frequency on any HF marine band.

HF operation on any size ship

The AT-141 allows you HF operation where antenna

element length is restricted due to space.

Weather resistant

The AT-141 is housed in a durable, completely weather

resistant ASA case with a rubber gasket. The antenna

tuner can be conveniently installed both on the deck or

in the cabin near the antenna element.

FOREWORD …………………………………………… i

IMPORTANT …………………………………………… i

EXPLICIT DEFINITIONS ……………………………… i

PRECAUTIONS ……………………………………… i

SUPPLIED ACCESSORIES ………………………… i

MISCELLANEOUS ITEMS ………………………… ii

FEATURES …………………………………………… ii

TABLE OF CONTENTS ……………………………… ii

1 ANTENNA SYSTEM …………………………… 1–2

■ Antenna for ship ………………………………… 1

■ Coaxial cable …………………………………… 2

■ Ground and counterpoise ……………………… 2

2 INSTALLATIONS ………………………………… 3–5

■ Installation outline ……………………………… 3

■ Control cable……………………………………… 3

■ PL-259 connector………………………………… 4

■ Mounting ………………………………………… 4

■ Cable connections ……………………………… 5

3 CONTROL CABLE SIGNALS …………………… 6

■ Terminal information …………………………… 6

4 UNIT DESCRIPTION AND SPECIFICATIONS … 7

■ Unit description…………………………………… 7

■ Specifications …………………………………… 7

Simple installation

Installation is simple. Just connect the control and antenna cables. You never need to open the cover.

45 memories for shorter tuning time

To decrease the tune-up time, the AT-141 automatically

stores the matching conditions for up to 45 frequencies.

Re-tuning for a memorized frequency takes approx. 1

sec.

Super capacitor for memory backup

Even if the AT-141 is not used for approx. 1 week, the

built-in super capacitor backs up contents of the 45

memories.

Low power tune up

The AT-141 emits low output power during tuning. This

feature reduces the possibility of causing interference

to other stations.

Tuner through function

The tuner through function is built into the AT-141. This

function helps improve receiver gain, depending on the

antenna element length used, and operating frequency.

ii

Page 4

1

Insulator

Backstay operates as

a long-wire antenna.

Insulator

Whip antenna

L =

300

16

×

1

2

n

×

9.4, 18.8, ...

1 m

39 inches

L =

300

f

×

1

2

n

×

ANTENNA SYSTEM

■ Antenna for ship

Required antenna element length

Required antenna element length to achieve full performance varies according to the lowest frequency:

The lowest frequency Required antenna element length

1.6 MHz band 7 m; 23.0 feet or longer

4 MHz band 3 m; 9.8 feet or longer

The longer the antenna element, the better the antenna efficiency.

Undesirable antenna element lengths

AVOID

tenna element lengths, since tuning becomes difficult.

L : Antenna element length to be avoided [m]

f : Operating frequency [MHz]

n : Natural number (n = 1, 2, 3, ...)

multiples of 1⁄2λ (half wavelength) for an-

[Example]

At an operating frequency of 16 MHz, avoid the following antenna element lengths:

For example, if 15 m is selected for an antenna element length, you have no problem in the 1.6–25 MHz

marine bands range.

NOTE: Keep antennas as far away from other objects

as possible, especially metal objects.

1

Page 5

■ Coaxial cable

ANTENNA SYSTEM

1

Insulate the lead-in cable of the AT-141 antenna terminal and antenna element from other metal objects.

To prevent interference, keep cables as far as possible from an antenna, electric pump and other electronic equipment.

■ Ground and counterpoise

Why a ship’s ground is required

The AT-141’s ground terminal MUST be connected

to your ship’s ground. Grounding prevents electric

shocks, interference to other equipment and other

problems. Grounding also ensures effective signal

transmission.

DANGER! NEVER connect the ground terminal to

the following points. These connections may cause

an explosion or electric shocks:

– Gas or electrical pipe

– Fuel tank or oil-catch pan

IMPORTANT! The mounting plate is NOT con-

nected to the AT-141’s internal ground.

Ideal ground points

One of following points is ideal:

– External ground plate

– External copper screen

– External copper foil

Good ground points

If electrically connected to sea water, one of the following points is usable:

– Stainless steel stanchion

– Through mast

– Through hull

– Metal water tank

Undesirable ground points

AVOID the following points, if possible. These con-

nections may cause noise or electrolysis:

– Engine block

– Ship’s DC battery ground

Electrolysis

All ground cables from the AT-141, HF transceiver,

etc. on your ship should be connected to only 1 ship’s

ground.

AVOID connection to 2 or more points. Voltage dif-

ference between 2 or more ship’s grounds may cause

electrolysis.

AVOID connection between dissimilar metals where

an electric current is present. These connections may

cause electrolysis.

To prevent erroneous indications, keep cables as far

away as possible from the flux gate compass.

Use suitable noise filters for alternators, fluorescent

lights, etc. Ask your Dealer for details.

Counterpoise

If your ship is made of FRP, etc. and a good ship’s

ground is not available, connect a counterpoise.

1

⁄4λ radial for

each band

Ground terminal

AT-141

1

⁄4λ (quarter wavelength) radial for each band is suit-

able for a counterpoise. Install the counterpoise directly below the AT-141’s ground terminal. Insulate

the ends of each radial from other metal objects. Layout the radial horizontally and as straight as possible.

L : Counterpoise length for the operating frequency [m]

f : Operating frequency [MHz]

300

L =

[Example]

At an operating frequency of 16 MHz, use a counterpoise with the following length:

300

L =

16

1 m

×

f

×

39 inches

1

4

1

4.7 [m]

4

Ground cable

For best results, use the heaviest gauge wire or metal

strap available. Make the distance between the AT141’s ground terminal and ship’s ground as short as

possible.

Supplied ground cable can be used for ground connection to a through mast. Confirm that the through

mast is electrically connected to sea water.

R WARNING!— When grounding to metal hull

Use a Zinc anode to protect the hull from

sis.

Ask your technical dealer, installer or refer to a tech-

nical book, etc., for RF ground details.

electroly-

2

Page 6

2

D When connecting to Icom IC-M801E

[GND]

To AT-141

[ANTC] : Black

[13.6] : Red

[STAR] : White

[KEY] : Green

Use the optional OPC-1465, or assemble the desired length 4-conductor shielded cable and the connector kits supplied with the transceiver and the tuner.

[ANTC] : Black

[13.6] : Red

[STAR] : White

[KEY] : Green

To transceiver

[GND]

INSTALLATIONS

■ Installation outline

q Connect a control cable and 4-conductor shielded

cable.

• Refer to “Control cable” below.

w Connect and solder the PL-259 connector to the

coaxial cable.

• Refer to p. 4 “PL-259 connector.”

e Mount the AT-141 in the desired location.

• Refer to p. 4 “Mounting.”

■ Control cable

Between the AT-141 and HF marine transceiver, connect 4 control signal lines as shown below. To prevent

RF feedback, use a 4-conductor shielded cable. Connect the shield line to the [GND] terminal on the transceiver. Icom offers 10 m (32.8 ft) long optional control

cables as at right.

r Connect the control and the coaxial cables be-

tween the transceiver and the AT-141.

• Refer to p. 5 “Cable connections.”

t Connect an antenna, ship’s ground or counter-

poise.

• Refer to p. 1 “Antenna for ship” and p. 2 “Ground and

counterpoise.”

OPC-1465 : for IC-M801E

Refer to p. 6 “Terminal information” for details.

3

Page 7

■ PL-259 connector

Solder

Solder

1–2 mm

10 mm

soft solder

10 mm

3

⁄8 inches

Coupling

30 mm

10 mm (soft solder)

Nut

Spring

washer

Flat

washer(L)

Flat

washer(L)

Hex head

bolt

Drill a hole here

Diameter:7–8 mm;

9

⁄32–5⁄16 inches

Weatherproof cap

Flat

washer(S)

Using self-tapping

screws

Using nuts and bolts

INSTALLATIONS

2

q Slide the coupling ring over the coaxial cable. Strip

the cable jacket and pull back to reveal 10 mm of

braid.

•

Soft solder the exposed braid and then pull out the jacket.

w Strip the cable as shown below. Soft solder the cen-

ter conductor the entire length of the exposed braid.

■ Mounting

Attach the AT-141 either horizontally or vertically with

one of the water drains facing downwards. After

mounting, remove the screw in the water drain.

Mounting on a Mast/Metal pole

e Slide the connector body over the cable and sol-

der as shown below.

r Screw the coupling ring onto the connector body.

Mounting on a flat surface

Mast/

Metal pole

Using U-bolts

U-bolt

U-bolt plate

Flat washer(L)

Spring washer

Flat washer(S)

Nut

WARNING: Mount the AT-141 securely with the

supplied nuts and bolts. Otherwise, vibrations and

shocks due to waves, etc. could loosen the antenna

tuner making if fall, causing personal injury.

4

Page 8

2

Ground terminal

Mounting plate

Rubber vulcanizing tape

INSTALLATIONS

■ Cable connections

q Connect the coaxial cable and the control cable to

the AT-141 as illustrated below.

w Cover both the antenna and the control cable con-

nectors with rubber vulcanizing tape and fix it with

a vinyl tape to prevent water seeping into the connector.

e Fix both of the coaxial and control cables to pro-

tect the inside connections.

DO NOT pull the antenna and control cable receptacles. This may cause disconnection (in the

AT-141), internal connector damaged or bad

connection.

Icom’s HF transceiver

r Connect the coaxial cable and the control cable to

the transceiver as illustrated below.

t Ground the transceiver, AT-141 and shield cable of

the control cable via the ground terminal.

• See p. 2 for grounding details.

IMPORTANT!— AT-141

NEVER ground the AT141 via the mounting

plate. It is not connected to ground internally.

AT-141

Grounding

Grounding

5

Page 9

■ Terminal information

8

6

4

2

0

Time

Key

voltage

[V]

Grounded

Approx. 7.5 V

During automatic tuning

8

6

4

2

0

Time

More than

350 msec.*

Approx. 7.5 V

Less than 1 V to

start tuning

Start

voltage

[V]

*For tuner through operation; Less than 250 msec.

[KEY]

[STAR]

[13.6]

[ANTC]

CONTROL CABLE SIGNALS

3

Consider the following points when using a non-Icom

transceiver.

Terminal Description

[KEY] Key voltage. Grounded during tuning.

Max. current drain 100 mA.

[13.6] 13.6 V DC + input terminal.

Max. current drain 2 A

[STAR] Receives start voltage.

Max. current drain 1 mA

[ANTC] Antenna current detector output.

Start voltage [STAR]

When a start voltage (less than 1 V) is received, the

AT-141 begins automatic tuning.

Key voltage [KEY]

During automatic tuning, the AT-141 grounds the key

voltage line, and the HF transceiver reduces output

power.

6

Page 10

4

Antenna terminal

Mounting plate

Control cable receptacleAntenna cable receptacle

Mounting plate

Water drain screw

Ground terminal

340 mm

230 mm

80 mm

91.5 mm

UNIT DESCRIPTION AND SPECIFICATIONS

■ Unit description

■ Specifications

• Frequency coverage : 1.6–30 MHz

• Power supply requirement : 13.6 V DC

• Current drain : Max. 2 A

• Operating temperature range : –30°C to +60°C

• Weight (approx.) : 2.5 kg

• Antenna connector : SO-239 (50 Ω)

• Max. Input power : 150 W

• Automatic tuning time : Approx. 2–3 sec. (general condition) Max. 15 sec.

Approx. 1 sec. (re-tuning for a memorized frequency)

• Automatic tuning accuracy : SWR 2.0:1 (after tuning, except for multiples of

(with 7 m or longer antenna element)

(supplied from HF transceiver)

(PEP) 100 W (continuous)

1

⁄2 λ)

All stated specifications are subject to change without notice or obligation.

7

Page 11

Icom America Inc.

<Corporate Headquarters>

2380 116th Avenue N.E., Bellevue, WA 98004, U.S.A.

Phone: +1 (425) 454-8155 Fax: +1 (425) 454-1509

URL: http//www.icomamerica.com

E-mail: sales@icomamerica.com

<Customer service>

Phone: (425) 454-7619

Icom Canada

Glenwood Centre #150-6165 Highway 17, Delta,

B.C., V4K 5B8, Canada

Phone: +1 (604) 952-4266 Fax: +1 (604) 952-0090

URL: http//www.icomcanada.com

E-mail: info@icomcanada.com

Icom (Europe) GmbH

Communication Equipment

Himmelgeister Str. 100,

D-40255 Düsseldorf, Germany

Phone: +49 0211 346047 Fax: +49 0211 333639

URL: http//www.icomeurope.com

E-mail: info@icomeurope.com

Icom Spain S.L.

Ctra. Rubi, No. 88 “Edificio Can Castanyer”

08190, Sant Cugat del Valles, Barcelona, Spain

Phone: +34 (93) 590 26 70 Fax: +34 (93) 589 04 46

URL: http//www.icomspain.com

E-mail: icom@icomspain.com

A-6472H-1EU

Printed in Japan

© 2005 Icom Inc.

Icom (Australia) Pty. Ltd.

A.B.N. 88 006 092 575

Unit 1/103, Garden Road, Clayton, Victoria, 3168,

Australia

Phone: +61 (03) 9549 7500 Fax: +61 (03) 9549 7505

URL: http//www.icom.net.au

E-mail: sales@icom.net.au

Icom New Zealand

146A Harris Road, East Tamaki, Auckland, New Zealand

Phone: +64 09 274 4062 Fax: +64 09 274 4708

URL: http//www.icom.co.nz

E-mail: inquiries@icom.co.nz

Asia Icom Inc.

6F No. 68, Sec. 1 Cheng-Teh Road, Taipei, Taiwan R.O.C.

Phone: +886 (02) 2559 1899 Fax: +886 (02) 2559 1874

URL: http//www.asia-icom.com

E-mail: sales@asia-icom.com

Icom (UK) Ltd.

Unit 9, Sea St., Herne Bay, Kent, CT6 8LD, U.K.

Phone: +44 01227 741741 Fax: +44 01227 741742

URL: http//www.icomuk.co.uk

E-mail: info@icomuk.co.uk

Icom France S.a

Zac de la Plaine, 1, Rue Brindejonc des Moulinais

BP 5804, 31505 Toulouse Cedex, France

Phone: +33 (5) 61 36 03 03 Fax: +33 (5) 61 36 03 00

URL: http://www.icom-france.com

E-mail: icom@icom-france.com

Icom Polska

Sopot, 3 Maja 54 Poland

Phone: +48 (58) 550 7135 Fax: +48 (58) 551 0484

E-mail: icompolska@icompolska.com.pl

Beijing Icom Ltd.

Room C01, 10th Floor, Long Silver Mansion, No.88

Yong Ding Road, Haidian District, Beijing, 100039,

China

Phone: +86

(010) 5889 4250

URL: http//www.bjicom.com

E-mail: bjicom@bjicom.com

Fax: +86

(010) 5889 4250

1-1-32 Kamiminami, Hirano-ku, Osaka 547-0003, Japan

Loading...

Loading...