Page 1

ERserver

IBM xSeries 205

Type 8480

Hardware Maintenance Manual and Troubleshooting

Guide

Page 2

Page 3

ER s e r v e r

IBM xSeries 205

Type 8480

Hardware Maintenance Manual and Troubleshooting

Guide

Page 4

Note

Before using this information and the product it supports, read Appendix C, “Notices”, on page 151.

Fifth Edition (February 2003)

The following paragraph does not apply to the United Kingdom or any country where such provisions are

inconsistent with local law:

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION ″AS IS″ WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer of express or implied warranties in certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication. IBM may make

improvements and/or changes in the product(s) and/or the program(s) described in this publication at any time.

This publication was developed for products and services offered in the United States of America. IBM may not offer

the products, services, or features discussed in this document in other countries, and the information is subject to

change without notice. Consult your local IBM representative for information on the products, services, and features

available in your area.

Requests for technical information about IBM products should be made to your IBM reseller or IBM marketing

representative.

© Copyright International Business Machines Corporation 2002. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

About this manual

This manual contains diagnostic information, a Symptom-to-FRU index, service

information, error codes, error messages, and configuration information for the IBM

Eserver xSeries™205.

Important: The field replaceable unit (FRU) procedures are intended for trained

servicers who are familiar with IBM xSeries products. See the parts

listing in “System” on page 110 to determine if the component being

replaced is a customer replaceable unit (CRU) or a field replaceable

unit (FRU).

Important safety information

Be sure to read all caution and danger statements in this book before performing

any of the instructions. See “Safety information” on page 117.

Leia todas as instruções de cuidado e perigo antes de executar qualquer operação.

Prenez connaissance de toutes les consignes de type Attention et Danger avant de

procéder aux opérations décrites par les instructions.

®

Online support

Lesen Sie alle Sicherheitshinweise, bevor Sie eine Anweisung ausführen.

Accertarsi di leggere tutti gli avvisi di attenzione e di pericolo prima di effettuare

qualsiasi operazione.

Lea atentamente todas las declaraciones de precaución y peligro ante de llevar a

cabo cualquier operación.

You can download the most current diagnostic, BIOS flash, and device driver files

from http://www.ibm.com/pc/support on the World Wide Web.

© Copyright IBM Corp. 2002 iii

Page 6

iv IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 7

Contents

About this manual .......................iii

Important safety information ....................iii

Online support .........................iii

Chapter 1. General information...................1

Related publications .......................1

Notices and statements in this book .................2

Features and specifications .....................3

Server controls, LEDs, and connectors ................4

Server controls and LEDs ....................4

Server connectors .......................5

Server power features......................6

Chapter 2. Configuring your server .................9

Using the Configuration/Setup Utility program ..............9

Starting the Configuration/Setup Utility program ............9

Using passwords .......................10

Enabling Broadcom NetXtreme Gigabit Ethernet Boot Agent ........13

Using the ServerGuide Setup and Installation CD ............13

ServerGuide features .....................13

Setup and configuration overview .................14

Typical operating-system installation ................15

Setting up or updating multiple servers ...............16

Installing your operating system without ServerGuide ..........16

Configuring the Gigabit Ethernet controller ...............16

Using the SCSISelect Utility program .................17

Starting the SCSISelect Utility program ...............17

SCSISelect menu choices ....................18

Using the Boot Menu program ...................18

Chapter 3. Diagnostics .....................21

General checkout ........................21

Checkout procedure ......................22

Diagnostic tools overview .....................23

POST ............................23

POST beep codes ......................24

Error logs ..........................24

ServerGuide error symptoms ....................24

Small computer system interface messages ..............25

Diagnostic programs and error messages ...............25

Text messages ........................26

Starting the diagnostic programs .................26

Diagnostic error message tables .................28

Recovering from a POST/BIOS update failure .............29

Power checkout ........................29

Troubleshooting the Ethernet controller ................30

Network connection problems ..................30

Ethernet controller troubleshooting chart ..............31

Ethernet controller messages ..................32

Chapter 4. Installing options ...................33

System reliability considerations ..................33

Major components of the IBM Eserver xSeries 205 Type 8480 .......34

© Copyright IBM Corp. 2002 v

Page 8

System and PCI extender boards ..................35

System board internal cable connectors...............36

System board external connectors.................37

Optional system-management adapter component locations .......37

Installation guidelines ......................38

System reliability considerations .................38

Handling static-sensitive devices .................38

Moving the stabilizing feet .....................39

Removing the side cover .....................40

Removing the frame-support bracket .................41

Working with adapters ......................42

Adapter considerations .....................42

Installing an adapter ......................43

Installing a SCSI adapter ....................45

Cabling a RAID adapter or single SCSI channel using one hot-swap drive SCSI

backplane ..........................45

Installing internal drives ......................47

Internal drive bays ......................47

Preinstallation steps ......................48

Power and signal cables for internal drives .............49

Installing a drive in bay 1, 2, 3, or 4 ................50

Installing a non-hot-swap hard disk drive in bay 5, 6, or 7 ........52

Installing a hot-swap hard disk drive in bay 5, 6, or 7 ..........54

Installing memory modules ....................56

Installing a security rope clip ....................57

Replacing the side cover .....................59

Replacing the battery ......................60

Connecting external options ....................61

Video connector .......................62

Keyboard connector ......................62

Mouse connector .......................62

Parallel connector .......................62

Serial connectors .......................63

Gigabit Ethernet port ......................63

Universal Serial Bus (USB) connectors ...............64

Audio connectors .......................64

Optional system-management adapter ports .............65

Chapter 5. Field replaceable units .................67

Removing the front bezel .....................67

Power button .........................68

Microprocessor / fan sink .....................70

Hot-swap hard disk drive cage ...................71

Hot-swap backplane .......................72

Power supply .........................73

Rear fan ...........................74

Extender card .........................75

System board .........................77

CD-ROM drive .........................78

Diskette drive .........................79

Bezel release latch .......................80

Top/side cover .........................81

Handle assembly ........................82

Adapter retainer ........................83

Chapter 6. Symptom-to-FRU index .................85

vi IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 9

Beep symptoms ........................85

No-beep symptoms .......................87

Diagnostic panel system error LED .................87

Diagnostic error codes ......................89

Error symptoms ........................93

Power-supply LED errors .....................95

POST error codes ........................95

POST (ISPR) error procedures ...................98

ServeRAID error codes .....................100

Service processor error codes ...................102

SCSI error codes .......................102

Temperature error messages ...................102

Fan error messages ......................103

Power error messages .....................103

System shutdown .......................104

Voltage related system shutdown.................104

Temperature related system shutdown ...............104

DASD checkout ........................105

Host built-in self test (BIST) ....................105

Bus fault messages.......................105

Undetermined problems .....................106

Problem determination tips ....................107

Chapter 7. Parts listing xSeries 205 Type 8480............109

System ...........................110

Keyboard CRUs ........................111

Power cords .........................112

Appendix A. Getting help and technical assistance ..........115

Before you call ........................115

Using the documentation .....................115

Getting help and information from the World Wide Web .........115

Software service and support ...................116

Hardware service and support ...................116

Appendix B. Related service information ..............117

Safety information .......................117

General safety........................117

Electrical safety .......................118

Safety inspection guide ....................119

Handling electrostatic discharge-sensitive devices ..........120

Grounding requirements ....................121

Notice for customers in the State of California ............121

Safety notices (multilingual translations) ..............121

Appendix C. Notices ......................151

Edition notice .........................151

Trademarks..........................152

Important notes ........................152

Electronic emission notices ....................153

Federal Communications Commission (FCC) statement ........153

Industry Canada Class B emission compliance statement........154

Avis de conformité à la réglementation d’Industrie Canada .......154

European Union EMC Directive conformance statement ........154

Japanese Voluntary Control Council for Interference (VCCI) statement 154

Power cords .........................154

Contents vii

Page 10

viii IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 11

Chapter 1. General information

Your IBM Eserver xSeries 205 Type 8480 server is a high-performance server that

can be upgraded to a symmetric multiprocessing (SMP) server through a

microprocessor upgrade. It is ideally suited for networking environments that require

superior microprocessor performance, efficient memory management, flexibility, and

reliable data storage.

The xSeries 205 server contains several IBM X-Architecture

help increase server performance and reliability.

Your server comes with a limited warranty. If you have access to the World Wide

Web, you can obtain up-to-date information about your server model and other IBM

server products at http://www.ibm.com/pc/us/eserver/xseries/.

Your server serial number and model number are located on labels on the bottom of

the server and on the front below the bezel. You will need these numbers when you

register your server with IBM. The information label containing the serial number,

machine type, model number, and agency marks for your server is located on the

bottom of the server.

Related publications

This Hardware Maintenance Manual and Troubleshooting Guide contains

information to help you solve the problem yourself or to provide helpful information

to a service technician.

™

technologies, which

In addition to this Hardware Maintenance Manual and TroubleshootingGuide, the

following xSeries 205 Type 8480 documentation is provided with your server:

v Installation Guide

This printed publication contains setup and installation instructions.

v Rack Installation Instructions

This printed publication contains the instructions to install your server in a rack.

v Safety Book

This multilingual publication is provided in Portable Document Format (PDF) on

the IBM xSeries Documentation CD. It contains translated versions of the caution

and danger statements that appear in the documentation for your server. Each

caution and danger statement has an assigned number, which you can use to

locate the corresponding statement in your native language.

v User’s Guide

This publication is provided in PDF on the IBM xSeries Documentation CD. It

contains general information about your server, including information about

features, how to configure your server, how to use the ServerGuide

™

Setup and

Installation CD, and how to get help.

© Copyright IBM Corp. 2002 1

Page 12

v Option Installation Guide

This publication is provided in PDF on the IBM xSeries Documentation CD. It

contains instructions to install, remove, and connect optional devices supported

by your server.

Depending on your server model, additional publications might be included on the

IBM xSeries Documentation CD.

Notices and statements in this book

The caution and danger statements used in this book also appear in the multilingual

Safety Information book provided on the IBM xSeries Documentation CD. Each

caution and danger statement is numbered for easy reference to the corresponding

statements in the safety book.

The following types of notices and statements are used in this book:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

v Attention: These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

2 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 13

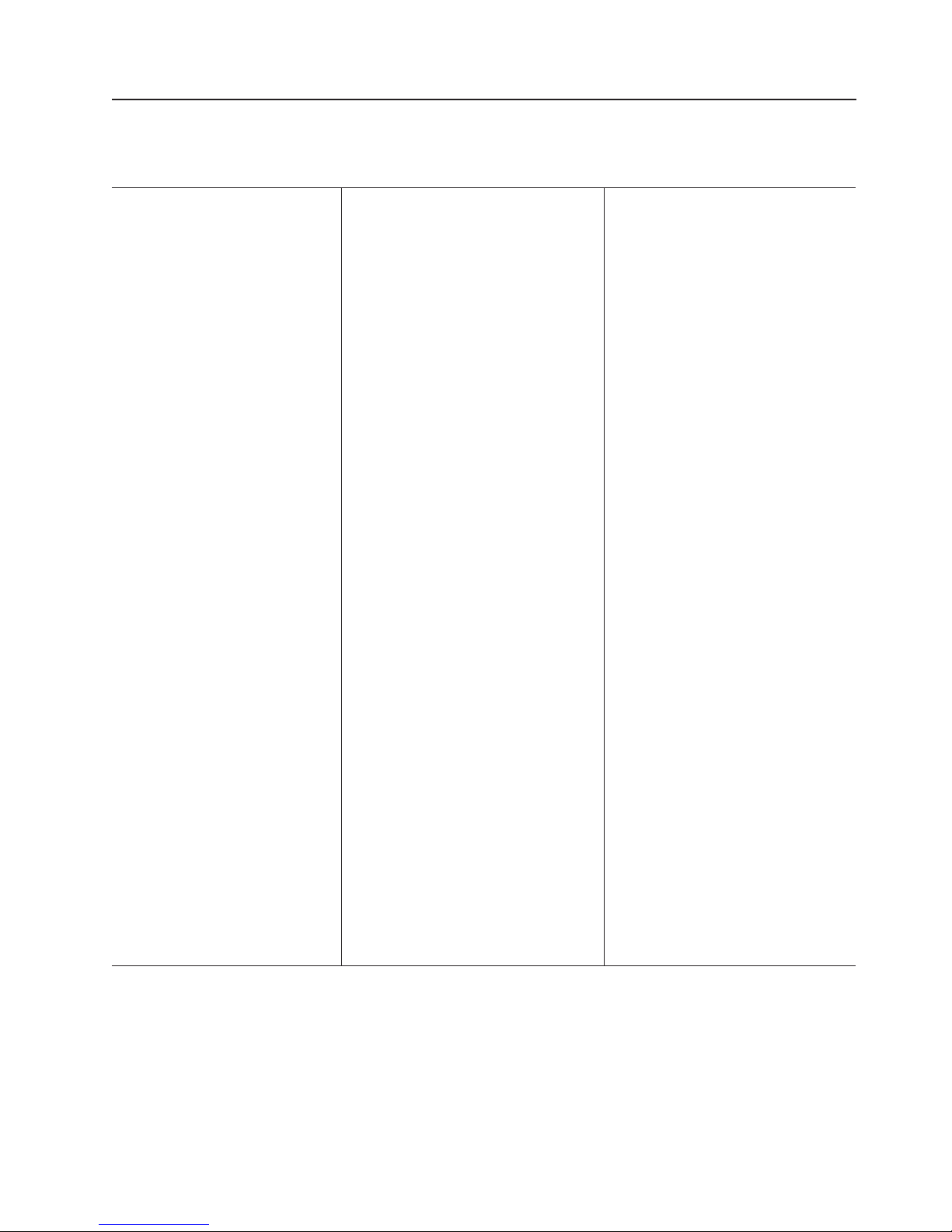

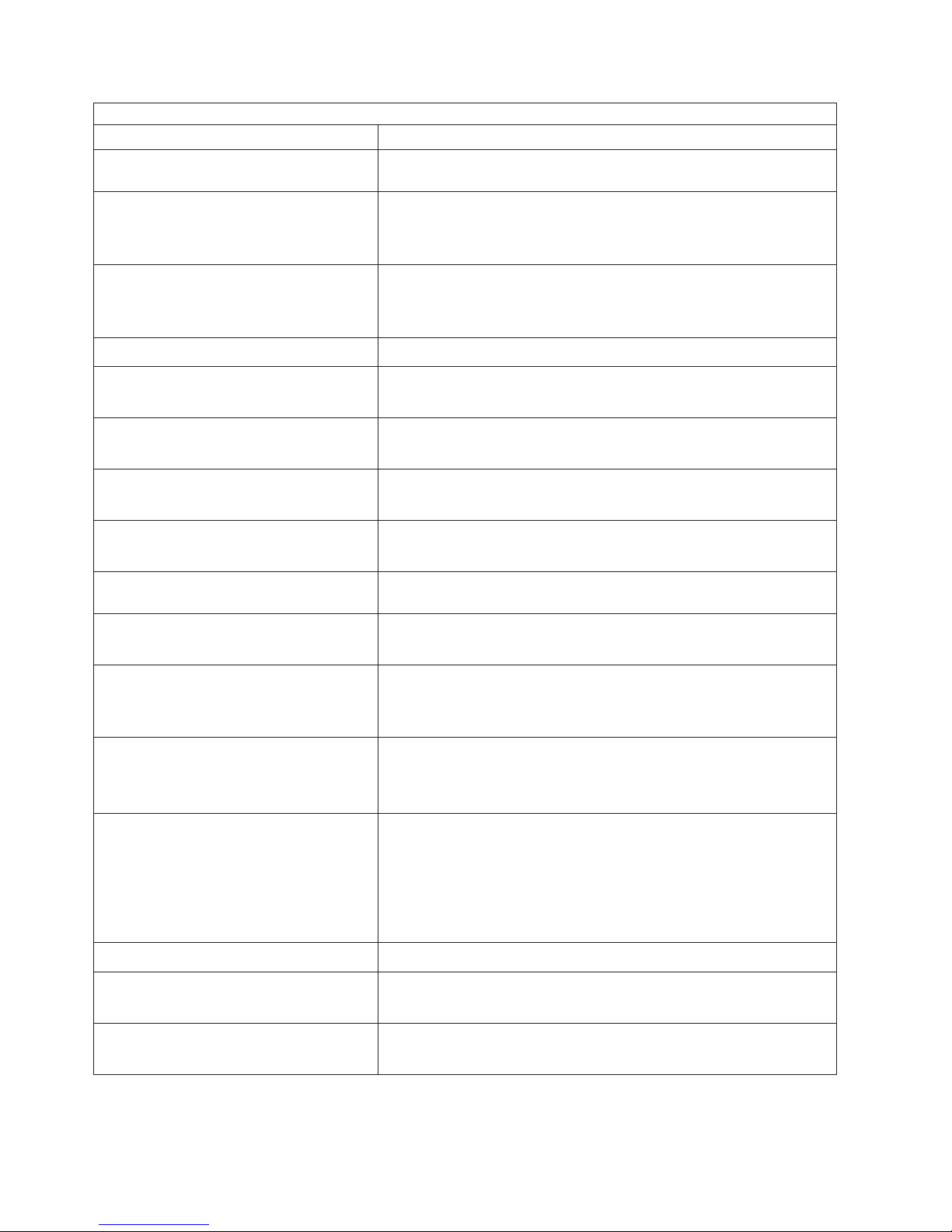

Features and specifications

The following table provides a summary of the features and specifications for your

server.

Microprocessor: Supports one

microprocessor — Intel Pentium

with 128 KB, 256 KB, or 512 KB

Level-2 cache and 400 MHz or 533

MHz front side bus (FSB) Memory:

v Minimum: 128 MB

v Maximum: 2.0 GB

v Type: PC2100 266 MHz

double-density RAM (DDR)

DIMMs

v Slots: Two dual inline

Drives: (depending on your model)

v Diskette: 1.44 MB

v Hard disk drive: IDE or SCSI

v One of the following:

– CD-ROM: IDE

– DVD-ROM: IDE

– CD-RW: IDE

Expansion bays: (depending on

your model)

v Two 5.25-in. bays (one CD-ROM

drive installed)

v Two 3.5-in. bays (one diskette

drive installed)

v Three 3.5-in. hard disk drive

bays: hot-swap drive bays (some

models) or non-hot-swap drive

bays with a hard disk drive

installed (some models)

PCI expansion slots:

v Three 33 MHz/32-bit on the

system board (some models

come with a SCSI adapter

installed)

v Two 33 MHz/32-bit on the PCI

extender board

Video controller: ATI Rage XL

video controller with 16 MB

SDRAM video memory on the PCI

extender card

®

Size and weight:

v Height: 445 mm (17.5 in.)

4

v Depth: 498 mm (19.6 in.)

v Width: 165 mm (6.5 in.)

v Weight: approximately 19.5 kg (43 lb)

when fully configured or 15.9 kg (35

lb) minimum

Integrated functions:

v Broadcom 5702 10/100/1000

Ethernet controller on the system

board with RJ-45 Ethernet port

v Two serial ports

v One parallel port

v Two USB ports

v Keyboard port

v Mouse port

v Audio ports

– Line out

–Linein

–Mic

v Dual-channel bus mastering IDE

controller

v Support for IBM Remote Supervisor

Adapter

Acoustical noise emissions:

v Sound power, idling: 5.1 bel

maximum

v Sound power, operating: 5.3 bel

maximum

Environment:

v Air temperature:

– Server on: 10° to 35°C (50.0° to

95.0°F). Altitude: 0 to 2133 m

(6998.0.7 ft)

– Server off: 10° to 43°C (50.0° to

109.4°F). Maximum altitude: 2133

m (6998.0 ft)

v Humidity:

– Computer on: 8% to 80%

– Computer off: 8% to 80%

Heat output: Approximate heat output

in British thermal units (Btu) per hour

v Minimum configuration: 341 Btu

(100 watts)

v Maximum configuration: 1604 Btu

(470 watts)

Electrical input:

v Sine-wave input (50-60 Hz) required

v Input voltage low range:

– Minimum: 90 V ac

– Maximum: 137 V ac

v Input voltage high range:

– Minimum: 180 V ac

– Maximum: 265 V ac

v Input kilovolt-amperes (kVA)

approximately:

– Minimum: 0.095 kVA

– Maximum: 0.470 kVA

Notes:

1. Power consumption and heat

output vary depending on the

number and type of optional

features installed and the

power-management optional

features in use.

2. These levels were measured in

controlled acoustical environments

according to the procedures

specified by the American National

Standards Institute (ANSI) S12.10

and ISO 7779 and are reported in

accordance with ISO 9296. Actual

sound-pressure levels in a given

location might exceed the average

values stated because of room

reflections and other nearby noise

sources. The declared

sound-power levels indicate an

upper limit, below which a large

number of computers will operate.

Power supply: One 330 watt

(90-240 V ac)

Chapter 1. General information 3

Page 14

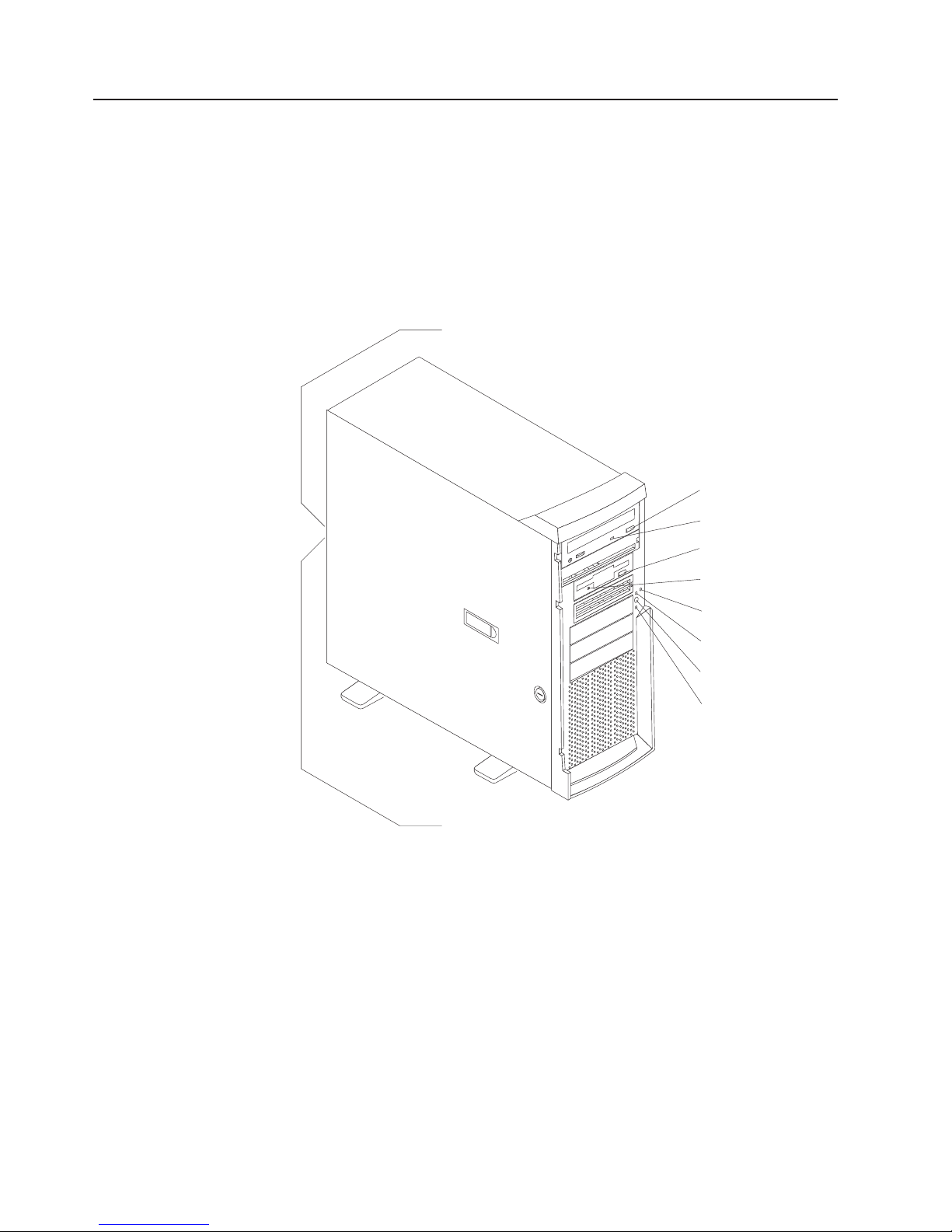

Server controls, LEDs, and connectors

This section describes the controls, light-emitting diodes (LEDs), and connectors on

your server.

Server controls and LEDs

The following illustration shows the controls and LEDs on the server.

Note: The front bezel door is not shown so that the drive bays are visible.

Front View:

Ethernet speed 1 Gbps LED

CD-eject

button

CD-ROM drive

activity LED

Diskette-eject

button

Diskette drive

activity LED

Hard disk drive

activity LED

Power-on

LED

Power-control

button

System error

LED

Ethernet speed 1 Gbps LED: When this LED on the Ethernet connector is lit, it

indicates that the Ethernet network speed is 1 Gbps. When this LED is off, it

indicates that the Ethernet network speed is 10 Mbps or 100 Mbps.

CD-eject button: Press this button to release a CD from the CD-ROM drive.

CD-ROM drive activity LED: When this LED is lit, it indicates that the CD-ROM

drive is in use.

Diskette-eject button: Press this button to release a diskette from the diskette

drive.

Diskette drive activity LED: When this LED is lit, it indicates that the diskette drive

is in use.

4 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Ethernet transmit/receive activity LED

Page 15

Hard disk drive activity LED: When this LED is flashing, it indicates that the hard

disk drive is in use.

Power-on LED: When this LED is lit, it indicates that the server is turned on.

Power-control button: Press this button to turn the server on and off manually.

Ethernet transmit/receive activity LED: When this LED on the Ethernet connector

is lit, it indicates that there is activity between the server and the network.

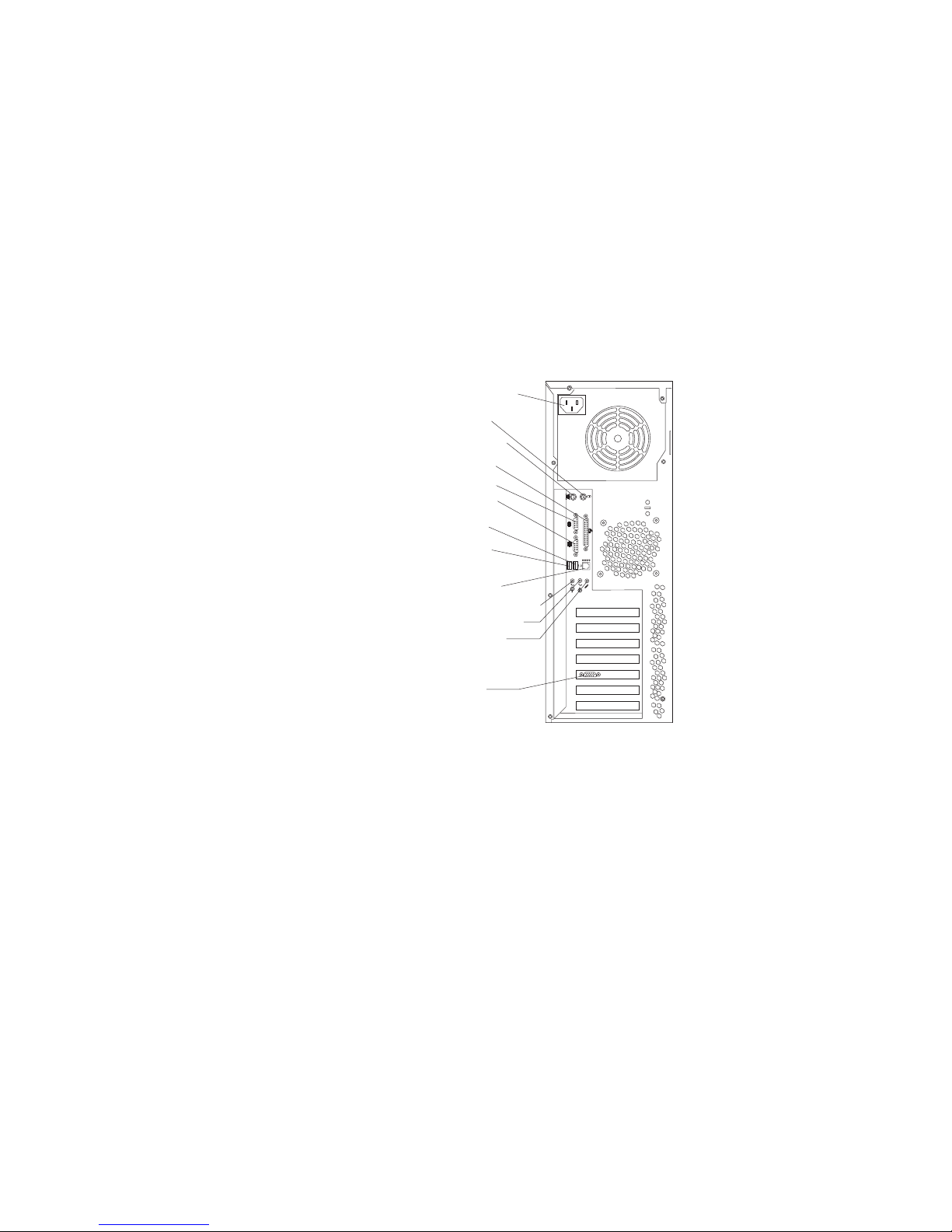

Server connectors

The following illustration shows the connectors on the rear of the server.

Rear View:

Power cord

Mouse

Keyboard

Parallel

Serial 1

Serial 2

USB 1

USB 2

Ethernet

Line out (green)

Line in (blue)

Mic (pink)

1

2

2

1

Video

Power-cord connector: Connect the power cord to this connector.

®

Mouse connector: Connect a mouse or other PS/2

device to this connector.

Keyboard connector: Connect a PS/2 keyboard to this connector.

Parallel connector: Connect a parallel device to this connector.

Serial 1 connector: Connect a 9-pin serial device to this connector.

Serial 2 connector: Connect a 9-pin serial device to this connector

USB 1 connector: Connect a USB device to this connector.

USB 2 connector: Connect a USB device to this connector.

Ethernet connector: Use this connector to connect the server to a network.

Mic connector (pink): Connect a microphone to this connector.

Chapter 1. General information 5

Page 16

Line out connector (green): Connect an audio output device, such as speakers, to

this connector.

Line in connector (blue): Connect an audio input device, such as a stereo, to this

connector.

Video connector: Connect a monitor to this connector.

If you have an optional Remote Supervisor Adapter (system-management adapter)

installed in PCI slot 1, your server has additional connectors and LEDs. See the

Option Installation Guide for more information about these connectors and LEDs.

Server power features

When you connect the server to an ac power source, the server goes into Standby

mode. After approximately 20 seconds, the power-control button becomes active,

and you can turn on the server and start the operating system by pressing the

power-control button. The following section describes other ways in which the

server can be turned on.

A power-control-button shield comes with your server. You can install this

disk-shaped shield to prevent the server from being turned off accidentally.

Turning on the server

After the server is connected to an ac power source, it can be turned on in any of

the following ways:

v You can press the power-control button.

v If a power failure occurs while the server is turned on, the server will restart

automatically when power is restored.

v If your operating system supports the system-management software for an

optional Remote Supervisor Adapter, the system-management software can turn

on the server.

v If your operating system supports the Wake on LAN

feature can turn on the server.

®

feature, the Wake on LAN

Turning off the server

Some operating systems require an orderly shutdown before you turn off the server.

See your operating-system documentation for information about shutting down the

operating system.

Statement 5:

6 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 17

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

The server can be turned off in any of the following ways:

v You can press the power-control button to start an orderly shutdown of the

operating system, if your operating system supports this feature, and turn off the

server.

v If the operating system stops functioning, you can press and hold the

power-control button for more than 4 seconds to turn off the server.

v If the Wake on LAN feature turned on the server, the Wake on LAN feature can

turn off the server.

v You can remove all power from the computer by disconnecting the server from

the ac power source.

Standby mode

When the server is connected to an ac power source but has not been turned on, it

is in Standby mode. When the server is in Standby mode, the operating system is

not running, and all core logic except for the service processor is shut down. The

power-on LED flashes to indicate that the server is in Standby mode. The server

can respond to requests from the service processor, such as a remote request to

turn on the server.

To put the server into Standby mode when the server is turned on, shut down the

operating system (see your operating-system documentation), and press the

power-control button.

You can also put the server into Standby mode through a request from the service

processor.

Chapter 1. General information 7

Page 18

8 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 19

Chapter 2. Configuring your server

You can use the following configuration programs to customize your server

hardware:

v Configuration/Setup Utility program

The Configuration/Setup Utility program is part of the basic input/output system

(BIOS) code that comes with your server. You can use this program to configure

serial port assignments, change interrupt request (IRQ) settings, change the

device startup sequence, set the date and time, and set passwords.

v Broadcom NetXtreme Gigabit Ethernet Boot Agent

The Broadcom NetXtreme Gigabit Ethernet Boot Agent is part of the BIOS code

that comes with your server. You can enable the Broadcom NetXtreme Gigabit

Ethernet Boot Agent in the Configuration/Setup Utility program. The Broadcom

NetXtreme Gigabit Ethernet Boot Agent enables you to configure the network as

a startable device and customize where the network option appears in your

startup sequence.

v ServerGuide Setup and Installation CD

The ServerGuide Setup and Installation CD provides software setup tools and

installation tools that are specifically designed for your IBM server. Use this CD

during the initial installation of your server to configure basic hardware features

and to simplify your network operating system (NOS) installation. See “Using the

ServerGuide Setup and Installation CD” on page 13 for more information.

v Ethernet controller configuration process

To configure the Ethernet controller, see “Configuring the Gigabit Ethernet

controller” on page 16.

v SCSISelect Utility program (some models)

If your server comes with a SCSI controller on the PCI extender card, you can

use the SCSISelect Utility program to configure devices that are attached to the

SCSI controller. Use this program to change default values, resolve configuration

conflicts, and perform a low-level format on a SCSI hard disk drive.

v Boot Menu program

The Boot Menu program is part of the BIOS code that comes with your server.

You can use the Boot Menu program to change startup sequence for one startup

session without changing settings in the Configuration/Setup Utility program.

Using the Configuration/Setup Utility program

This section provides the instructions for starting the Configuration/Setup Utility

program and descriptions of the menu choices that are available.

Starting the Configuration/Setup Utility program

The Configuration/Setup Utility program starts automatically when POST detects

that newly installed or removed hardware is not reflected in your current

configuration. A power-on-self-test (POST) error message is displayed. See the

Hardware Maintenance Manual and Troubleshooting Guide for details about the

POST error messages.

© Copyright IBM Corp. 2002 9

Page 20

Complete the following steps to start the Configuration/Setup Utility program:

1. Turn on the server and watch the monitor screen. If your server is already on

when you start this procedure, you must shut down the operating system, turn

off the server, wait a few seconds until all in-use LEDs go off, and restart the

server. Do not use Ctrl+Alt+Del to restart the server.

2. When the message Press F1 for Configuration/Setup, Press F12 for Boot

Menu appears at the bottom of the screen during startup, press F1. (This prompt

appears on the screen for only a few seconds. You must press F1 quickly.)

Note: If you have set both administrator and user passwords, you must type

the administrator password to access the full Configuration/Setup Utility

menu.

3. Follow the instructions that appear on the screen.

Use the Up Arrow (↑)and Down Arrow (↓) keys to select menu choices in any

Configuration/Setup Utility menu. Some menu choices provide information only.

Some menu choices show fields that you can change. These fields are enclosed by

square brackets. You can change the settings in these fields by using Left Arrow (←)

and Right Arrow (→) keys to change the settings, or you can type information in the

field.

To reload the current setting for a menu item, press F9. To reload the default setting

for a menu item, press F10.

Using passwords

The System Security choice appears only on the full Configuration/Setup Utility

menu. After you select this choice, you can implement an administrator password.

The administrator password provides access to all choices on the

Configuration/Setup Utility main menu. You can set, change, or delete the

administrator password.

The administrator password has the following features:

v No password is required to start the system.

v Type the password to access the Configuration/Setup Utility program.

v All choices are available on the Configuration/Setup Utility main menu.

Complete the following steps to set an administrator password:

1. From the Configuration/Setup Utility main menu, select System Security and

2. Select Administrator Password and press the Right Arrow (→) key.

3. Type the password you want to set in the Enter Password field and press

4. Type the password again in the Enter Password again field and press Enter.

5. Press Enter to Set or Change Password. The setting in the Administrator

6. Press Esc until you return to the main menu.

7. Select Save Settings and Press Enter.

press Enter.

Enter.

Password field changes to Present.

After you have set an administrator password, you can then set a user password to

authorize a user to operate the server. You must set an administrator password to

set a user password.

10 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 21

You can use any combination of up to seven characters (A Z, a z, 0 9, and blanks)

for your user password. Keep a record of your password in a secure place. If you

forget the user password, you can regain access to the server through one of the

following methods:

v Type the administrator password at the power-on prompt. Start the

Configuration/Setup Utility program and change the user password.

v Change the position of the password check jumper (JP1) as described in “Setting

the password check jumper” on page 12.

v Remove the battery and then install the battery. See the Hardware Maintenance

Manual and Troubleshooting Guide for instructions.

To set a user password, complete the following steps:

1. Set an administrator password. See the instructions on page 10.

2. Select User Password and press the Right Arrow (→) key.

3. Type the password you want to set in the Enter Password field and press

Enter.

4. Type the password again in the Enter Password Again field and press Enter.

5. Press Enter to Set or Change Password. The setting in the User Password

field changes to Present.

6. Select Save Settings and press Enter.

If you set a user password, you can then enable Password on Boot. If you enable

this setting, you must type a user password when you start the server.

Chapter 2. Configuring your server 11

Page 22

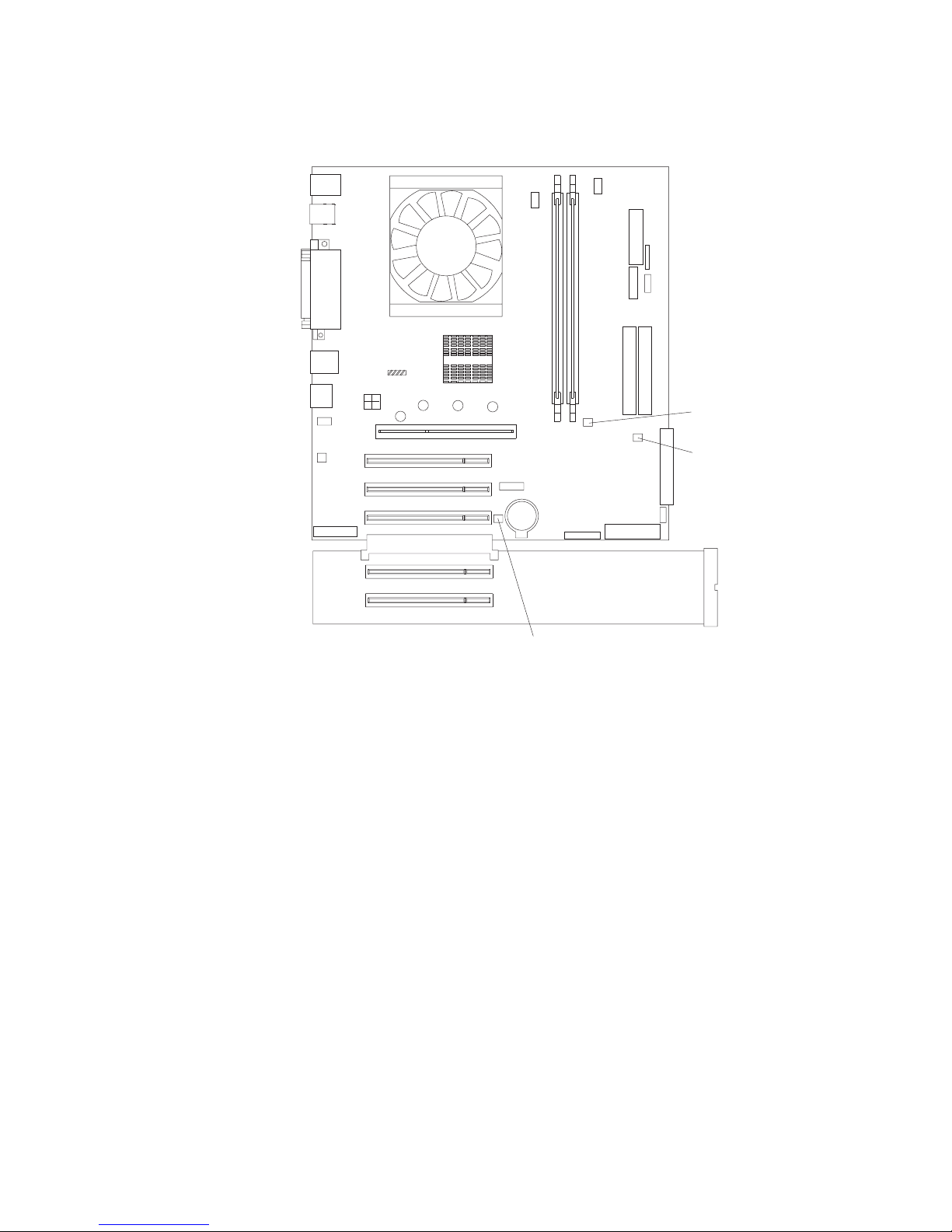

Setting the password check jumper

The following illustration shows the location of the password check jumper (JP1) on

the system board.

Password check

(JP1)jumper

CMOS clear

(JP3)jumper

Boot block

jumper (JP6)

Complete the following steps to set the password check jumper:

1. Review the “Safety information” on page 117.

2. Turn off the server and peripheral devices and disconnect all external cables

and power cords; then, remove the cover. See the Option Installation Guide for

instructions.

3. Move the jumper from pins 1 and 2 to pins 2 and 3. This clears the power-on

password for one boot cycle.

You can now start the server one time without having to use the user password,

but if you do not use the Configuration/Setup Utility program to change or delete

the password, the next time you start the server, the original power-on password

will be reinstated.

4. Connect the server to a power source, keyboard, monitor, and mouse.

5. Turn on the server.

You can now start the Configuration/Setup Utility program and either delete the old

password or set a new user password.

12 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 23

Enabling Broadcom NetXtreme Gigabit Ethernet Boot Agent

The Broadcom NetXtreme Gigabit Ethernet Boot Agent is part of the BIOS code

that comes with your server. You can enable the Broadcom NetXtreme Gigabit

Ethernet Boot Agent in the Configuration/Setup Utility program. The Broadcom

NetXtreme Gigabit Ethernet Boot Agent enables you to configure the network as a

startable device and customize where the network appears in your startup order.

To enable Broadcom NetXtreme Gigabit Ethernet Boot Agent, complete the

following steps:

1. From the Configuration/Setup Utility main menu, select Devices and I/O Ports

and press Enter.

2. Select System Board Ethernet PXE/DHCP and use the Right Arrow (→) key to

set it to Enabled.

3. Select Save Settings and press Enter.

Using the ServerGuide Setup and Installation CD

The ServerGuide Setup and Installation CD includes an easy-to-use setup and

installation program that is specifically designed for your server. The ServerGuide

program detects the server model and hardware options that are installed and uses

that information during setup to configure the hardware. The ServerGuide program

simplifies operating-system installations by providing updated device drivers and, in

some cases, installing them automatically.

If a later version of the ServerGuide program is available, you can download a free

image of the ServerGuide Setup and Installation CD, or you can purchase the CD.

To download the latest ServerGuide program, go to the IBM ServerGuide Web page

at http://www.ibm.com/pc/qtechinfo/MIGR-4ZKPPT.html. To purchase the latest

ServerGuide Setup and Installation CD, see the “ServerGuide Updates” flyer that

comes with your server library, or go to the ServerGuide fulfillment Web site at

http://www.ibm.com/pc/coupon/.

The ServerGuide program has the following features to make setup easier:

v An easy-to-use interface with online help

v Diskette-free setup, and configuration programs that are based on detected

hardware

v Performance Optimizer program, which easily tunes your SCSI RAID adapter

settings for your server environment

v A system BIOS update program, which updates the BIOS code directly from the

CD

v Device drivers that are provided for your server model and detected hardware

ServerGuide features

Features and functions can vary slightly with different versions of the ServerGuide

program. To learn more about the version that you have, start the ServerGuide

Setup and Installation CD and view the online overview. Not all features are

supported on all server models.

The ServerGuide program requires a supported IBM server with an enabled

startable (bootable) CD-ROM drive. In addition to the ServerGuide Setup and

Installation CD, you must have your operating-system CD to install your operating

system.

Chapter 2. Configuring your server 13

Page 24

The ServerGuide program has the following features:

v Sets system date and time.

v Detects the SCSI RAID adapter or controller and runs the SCSI RAID

configuration program.

v Updates the licensed internal code (firmware) level without diskettes.

v Checks the system BIOS code and microcode (firmware) levels of supported

options to determine whether a later level is available from the CD. You can

perform updates without using diskettes.

v Provides the Performance Optimizer program to easily tune your SCSI RAID

adapter settings for your server environment.

v Detects installed hardware options and provides updated device drivers for most

adapters and devices.

v Creates a setup-replication diskette for replicating setup selections for other

servers of the same model.

v Provides diskette-free installation for supported operating systems.

v Provides a replicated installation path for multiple installations of supported

operating systems.

v Includes an online README file with links to tips for your hardware and

operating-system installation.

Setup and configuration overview

When you use the ServerGuide Setup and Installation CD, you do not need setup

diskettes. You can use the CD to configure any supported IBM server model. The

ServerGuide program checks your system BIOS, service processors, and other

system hardware to determine if system updates are available. The setup program

provides a list of tasks that are required to set up your server model. On SCSI

RAID servers, you can run the SCSI RAID configuration program to create logical

drives.

Note: Features and functions can vary slightly with different versions of the

ServerGuide program.

When you start the ServerGuide Setup and Installation CD, the program performs

the following tasks:

v The ServerGuide program prompts you for your language, country, and keyboard

layout. (This information is stored and later passed to the operating-system

installation program.)

v The ServerGuide program displays choices for running the configuration

programs. For example:

– The Express Configuration method runs the required programs for your

server, based on the hardware that is detected.

– The Custom Configuration method displays all programs that are available for

your server, and you decide which programs to run.

– The Replicated Configuration method provides the option of duplicating your

setup selections to other servers that are the same model.

v If you select the Custom Configuration method, the following features are

optional. If you select the Express Configuration method, some or all of these

features are run, depending on the hardware that is detected:

– The Set Date and Time feature is provided so that you do not have to use the

Configuration/Setup Utility program to access these settings.

14 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 25

– The Clear Hard Disks feature is provided so you can delete all partitions on all

hard disk drives. If the server has a SCSI RAID adapter installed, you can

select to restore the configuration on the SCSI RAID adapter to the factory

default settings.

– The ServerGuide program checks the system BIOS code and microcode

(firmware) levels for supported options and then checks the CD for a newer

level. The CD content might be newer than the BIOS code and firmware level.

The ServerGuide program can perform a flash update of the BIOS code and

supported microcode (firmware) options without using diskettes.

– The SCSI RAID configuration program starts, leading you through the entire

configuration process.

– The Performance Optimizer program easily tunes your server for your

environment.

v The ServerGuide program displays a confirmation summary, so that you will

know when you have completed all the required tasks. Then, you are ready to

install your operating system.

Notes:

1. Plug and Play adapters are configured automatically. Non-Plug and Play

adapters might require switch settings, additional device drivers, and installation

after the operating system is installed. See the documentation that comes with

the adapter.

2. Diagnostics for your server come in BIOS code or on a separate diagnostics

CD.

Typical operating-system installation

You can use the ServerGuide program to shorten your installation time. The

ServerGuide program provides the device drivers that are required for your

hardware and for the operating system that you are installing. This section

describes a typical ServerGuide operating-system installation.

Note: Features and functions can vary slightly with different versions of the

ServerGuide program.

1. After you have completed the setup process, the operating-system installation

program starts. (You will need your operating-system CD to complete the

installation.)

2. The ServerGuide program stores information about the server model, service

processor, hard disk drive controllers, and network adapters. Then, the program

checks the CD for newer device drivers. This information is stored and then

passed to the operating-system installation program.

3. With some operating-system installations, you can create an

operating-system-replication diskette for setting up additional servers. This

diskette contains the Internet protocol (IP) address, server name, and other

selections.

4. If you are installing the operating system from diskette, the ServerGuide

program lists the diskettes that you must create and the optional diskettes that

you might want to create. The diskettes that you can create are the

device-driver diskettes for the installed adapters or controllers.

5. The ServerGuide program prompts you to insert your operating-system CD and

restart the server. At this point, the installation program for the operating system

takes control to complete the installation.

Chapter 2. Configuring your server 15

Page 26

Setting up or updating multiple servers

You can use the ServerGuide program to create diskettes that help you set up or

update multiple servers. You can modify information on the diskettes as you use

them to set up or update other servers.

Note: Availability and function can vary by server model and by the hardware that

is installed.

You can create a setup-replication diskette, which contains your hardware

configuration selections. Use this diskette to replicate selections to other servers

that are of the same model.

You can create an operating-system-replication diskette, which contains information

that you need to complete multiple installations. Not all operating systems support

operating-system-replication diskettes.

Installing your operating system without ServerGuide

If you have already configured the server hardware and you decide not to use the

ServerGuide program to install your operating system, complete the following steps

to download the latest operating-system installation instructions from the IBM

Support Web page:

1. Go to http://www.ibm.com/pc/support/.

2. Under Browse, click Servers.

3. From the Family drop-down list, select your server model.

4. If NOS installation instructions are available for your server model, OS

installation is in the list in the upper-left corner of the Web page. Click OS

installation and select the instructions for your operating system.

Configuring the Gigabit Ethernet controller

The server comes with an integrated Ethernet controller. This controller provides an

interface for connecting to 10-Mbps, 100-Mbps, or 1000-Mbps networks and

provides full duplex (FDX) capability, which enables simultaneous transmission and

reception of data on the Ethernet local area network (LAN). You do not need to set

any jumpers or configure the Ethernet controller for your operating system before

you use the Ethernet controller. However, you must install a device driver to enable

your operating system to address the Ethernet controller. The device drivers are

provided on the Device Drivers and IBM Enhanced Diagnostics CD.

When you connect your server to the network, the Ethernet controller automatically

detects the data-transfer rate (10-Mbps, 100-Mbps, or 1000-Mbps) on the network

and then sets the controller to operate at the appropriate rate. In addition, if the

Ethernet ports that your server is connected to support auto-negotiation, the Gigabit

Ethernet controller will set the appropriate duplex state. That is, the Ethernet

controller will adjust to the network data rate, whether the data rate is standard

Ethernet (10BASE-T), Fast Ethernet (100BASE-TX/1000BASE-T), half duplex

(HDX), or full duplex (FDX). The controller supports half-duplex (HDX) and

full-duplex (FDX) modes at both speeds.

For information about configuring your Ethernet controller, see the Device Drivers

and IBM Enhanced Diagnostics CD that comes with your server. For updated

information about configuring your Ethernet controller, go to the IBM Support Web

site at http://www.ibm.com/pc/support/ and navigate to the area for your specific

server type. From this area you can download documentation, the most current

16 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 27

device drivers for your server, and software that supports advanced networking

functions. After downloading, run the downloaded program launch.exe.

You Ethernet controller supports optional modes, such as teaming, priority packets,

load balancing, fault tolerance, and virtual LANs, which provide higher performance,

security, and throughput for your server. These modes apply to the integrated

Ethernet controller and to the controllers on supported Ethernet adapters.

Using the SCSISelect Utility program

SCSISelect is a menu-driven configuration utility program for servers that come with

a SCSI adapter installed. You can use SCSISelect to:

v View the default SCSI IDs

v Locate and correct configuration conflicts

v Perform a low-level format on a SCSI hard disk

The following sections provide instructions for starting the SCSISelect Utility

program and descriptions of the menu choices available.

Starting the SCSISelect Utility program

Complete the following steps to start the SCSISelect utility program:

1. Turn on the server.

2. When the <<< Press <CTRL><A> for SCSISelect Utility! >>> prompt appears,

press Ctrl+A.

Note: If an administrator password has been set, you are prompted to type the

password to start the SCSISelect Utility program.

3. When the Would you like to configure the host adapter or run the SCSI

disk utility? question appears, make your selection and press Enter.

4. Use the arrow keys to select a choice from the menu.

5. Follow the instructions on the screen to change the settings of the selected

items, and press Enter.

Chapter 2. Configuring your server 17

Page 28

SCSISelect menu choices

The following choices appear on the SCSISelect Utility menu:

v Configure/View Host Adapter Settings

Select this choice to view or change the SCSI controller settings. To reset the

SCSI controller to its default values, press F6; then, follow the instructions that

appear on the screen.

You can view or change the following controller settings:

– Host Adapter SCSI ID

Select this choice to view the SCSI controller ID, normally 7.

– SCSI Parity Checking

This choice is set to Enabled and cannot be changed.

– Host Adapter SCSI Termination

This choice is set to Enabled and cannot be changed.

– Boot Device Options

Select this choice to configure startable device parameters. Before you can

make updates, you must know the ID of the device for which you want to

configure parameters.

– SCSI Device Configuration

Select this choice to configure SCSI device parameters. Before you can make

updates, you must know the ID of the device whose parameters you want to

configure.

Note: The Maximum Sync Transfer Rate represents the transfer rate for Ultra

SCSI devices.

- The transfer rate for Ultra3 SCSI LVD devices is 160 MBps.

- The transfer rate for Ultra2 SCSI LVD devices is 80 MBps.

- The transfer rate for Fast SCSI devices is 20 MBps.

– Advanced Configuration Options

Select this choice to view or change the settings for advanced configuration

options.

v SCSI Disk Utilities

Select this choice to view the SCSI IDs that are assigned to each device or to

format a SCSI device.

To use the utility program, select a drive from the list. Read the screens carefully

before making a selection.

Note: If you press Ctrl+A before the selected drives are ready, an Unexpected

SCSI Command Failure screen might appear. Restart the server and

watch the SCSISelect messages as each drive spins up. After the drive

that you want to view or format spins up, press Ctrl+A.

Using the Boot Menu program

The Boot Menu program is a built-in, menu-driven configuration utility program that

you can use to temporarily redefine the first startup device without changing

settings in the Configuration/Setup Utility program.

18 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 29

Complete the following steps to use the Boot Menu program to change the startup

sequence of your server:

1. Turn off the server.

2. Restart the server.

3. Press F12.

4. Select the startup device.

The next time the server is started, it returns to the startup sequence set in the

Configuration/Setup Utility program.

Chapter 2. Configuring your server 19

Page 30

20 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 31

Chapter 3. Diagnostics

This section provides basic troubleshooting information to help you resolve some

common problems that might occur with your server.

If you cannot locate and correct the problem using the information in this section,

see Appendix A, “Getting help and technical assistance”, on page 115 for more

information.

General checkout

The server diagnostic programs are stored on the IBM Enhanced Diagnostics CD.

These programs provide the primary methods of testing the major components of

the server.

If you cannot determine whether a problem is caused by the hardware or by the

software, you can run the diagnostic programs to confirm that the hardware is

working properly.

When you run the diagnostic programs, a single problem might cause several error

messages. When this occurs, work to correct the cause of the first error message.

After the cause of the first error message is corrected, the other error messages

might not occur the next time you run the test.

A failed system might be part of a shared DASD cluster (two or more systems

sharing one or more external storage devices). Before you run diagnostics, verify

that the failing system is not part of a shared DASD cluster.

A system might be part of a cluster if:

v The system is identified as part of a cluster.

v One or more external storage units are attached to the system and at least one

of the attached storage units is also attached to another system or unidentifiable

source.

v One or more systems are located near the failing system.

If the failing system is suspected to be part of a shared DASD cluster, you can run

all diagnostic tests except the diagnostic tests that test the storage unit (DASD

residing in the storage unit) or the storage adapter attached to the storage unit.

Notes:

1. For systems that are part of a shared DASD cluster, run one test at a time in

looped mode. Do not run all tests in looped mode, because this could enable

the DASD diagnostic tests.

2. If multiple error codes are displayed, diagnose the first error code that is

displayed.

3. If the computer stops with a POST error, go to “POST error codes” on page 95.

4. If the computer stops and no error is displayed, go to “Undetermined problems”

on page 106.

5. For power supply problems, see “Power checkout” on page 29.

6. For safety information, see “Safety information” on page 117.

7. For intermittent problems, check the error log.

© Copyright IBM Corp. 2002 21

Page 32

Checkout procedure

Follow the steps in this procedure to identify system problems.

001 IS THE SYSTEM PART OF A CLUSTER?

002 IF THE SYSTEM IS NOT PART OF A CLUSTER:

003 DID YOU RECEIVE BOTH OF THE CORRECT RESPONSES?

YES. Schedule maintenance for the system. Shut down all systems related

to the cluster. Run the storage test.

NO. Go to step 002.

1. Turn off the server and all external devices.

2. Check all cables and power cords.

3. Set all display controls to the middle position.

4. Turn on all external devices.

5. Turn on the server.

6. Record any POST error messages that are displayed on the screen. If

an error is displayed, look up the first error in the “POST error codes” on

page 95.

7. Check the System Error log. If an error was recorded by the system,

see Chapter 6, “Symptom-to-FRU index”, on page 85.

8. Start the diagnostic programs.

9. Check for the following responses:

v One beep.

v Readable instructions or the main menu.

NO. Find the failure symptom in Chapter 6, “Symptom-to-FRU index”, on

page 85.

YES. Run the diagnostic programs. If necessary, see “Diagnostic programs

and error messages” on page 25.

If you receive an error, see Chapter 6, “Symptom-to-FRU index”, on

page 85.

If the diagnostic programs were completed successfully and you still

suspect a problem, see “Undetermined problems” on page 106.

22 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 33

Diagnostic tools overview

The following tools are available to help you identify and resolve hardware-related

problems:

v POST beep codes and error messages

The power-on self-test (POST) generates beep codes and messages to indicate

successful test completion or the detection of a problem. See “POST” for more

information.

v Error log

The POST error log contains the three most recent error codes and messages

that the system has generated during POST. The System Error Log contains all

the error messages that were issued during POST.

To view the contents of the error logs, start the Configuration/Setup Utility

program; then, select Error Logs from the main menu. See “Viewing the System

Error log” on page 28 for more information.

v ServerGuide error symptoms

ServerGuide error symptoms are explained at “ServerGuide error symptoms” on

page 24.

v Diagnostic programs and error messages

The server diagnostic programs are stored on the IBM Enhanced Diagnostics

CD. These programs are the primary method of testing the major components of

your server. See “Diagnostic programs and error messages” on page 25 for more

information.

v Customized support page

You can create a customized support page that is specific to your hardware,

complete with Frequently Asked Questions, Parts Information, Technical Hints

and Tips, and Downloadable files. In addition, you can choose to receive

electronic mail (e-mail) notifications whenever new information becomes available

about your registered products.

After you register and profile your xSeries products, you can diagnose problems

using the IBM Online Assistant, and you can participate in the IBM discussion

forum. For more detailed information about registering and creating a customized

profile for your IBM products, go to the following addresses on the Web:

– http://www.ibm.com/pc/register

– http://www.ibm.com/pc/support

POST

When you turn on the server, it performs a series of tests to check the operation of

server components and some of the options installed in the server. This series of

tests is called the power-on self-test, or POST.

Notes:

1. If you have a user password or administrator password set, you must type the

password and press Enter, when prompted, before POST will continue.

2. A single problem might cause several error messages. When this occurs, work

to correct the cause of the first error message. After you correct the cause of

the first error message, the other error messages usually will not occur the next

time you run the test.

Chapter 3. Diagnostics 23

Page 34

POST beep codes

POST generates beep codes to indicate successful completion or the detection of a

problem.

v One short beep indicates the successful completion of POST.

v More than one beep indicates that POST detected a problem. For more

If POST detects a problem (more than one beep sounds), an error message

appears on your screen. See “Beep symptoms” on page 85 and “POST error codes”

on page 95 for more information.

Error logs

A POST error log is available when an optional service processor adapter has been

installed in the server.

The POST error log contains the three most recent error codes and messages that

the system generated during POST. The System Error log contains all messages

issued during POST and all system status messages from the service processor.

You can view the contents of the System Error log from the Configuration/Setup

Utility program or from the diagnostic programs.

Viewing error logs from the Configuration/Setup Utility program

Start the Configuration/Setup Utility program; then, select Error Logs from the main

menu. See Chapter 2, “Configuring your server”, on page 9 for more information.

information, see “Beep symptoms” on page 85.

Viewing error logs from diagnostic programs

Start the diagnostic programs; select Hardware Info from the top of the diagnostic

programs screen; select System Error Log from the list that appears; then, follow

the instructions on the screen. See “Starting the diagnostic programs” on page 26

for more information.

ServerGuide error symptoms

Look for the symptom in the left column of the chart. Probable solutions to the

problem are in the right column.

Table 1. ServerGuide Setup and Installation CD

Symptom Suggested action

The ServerGuide

Setup and

Installation CD will

not start.

The SCSI RAID

program cannot

view all installed

drives, or the NOS

cannot be installed.

The Operating

System Installation

program

continuously loops.

v Ensure that the server is supported and has a startable (bootable)

CD-ROM drive.

v If the startup (boot) sequence settings have been altered, ensure

that the CD-ROM drive is first in the startup sequence.

v If more than one CD-ROM drive is installed, ensure that only one

drive is set as the primary drive. Start the CD from the primary

drive.

v Ensure that there are no duplicate SCSI IDs or IRQ assignments.

v Ensure that the hard disk drive is connected properly.

Make more space available on the hard disk.

24 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 35

Table 1. ServerGuide Setup and Installation CD (continued)

Symptom Suggested action

The ServerGuide

program will not

start your NOS CD.

The NOS cannot

be installed; the

option is not

available.

Ensure that the NOS CD you have is supported by the ServerGuide

program. See the ServerGuide Setup and Installation CD label for a

list of supported NOS versions.

Ensure that the NOS is supported on your server. If the NOS is

supported, either there is no logical drive defined (SCSI RAID

systems) or the ServerGuide System Partition is not present. Run the

ServerGuide program, and ensure that setup is complete.

Small computer system interface messages

If you receive a SCSI error message, see “Diagnostic error codes” on page 89.

Note: If your server does not have a hard disk drive, ignore any message that

indicates that the BIOS is not installed.

Diagnostic programs and error messages

The server diagnostic programs are stored on the IBM Enhanced Diagnostics CD.

These programs are the primary method of testing the major components of your

server.

Diagnostic error messages indicate that a problem exists; they are not intended to

be used to identify a failing part. Troubleshooting and servicing of complex

problems that are indicated by error messages should be performed by trained

service personnel.

Sometimes the first error to occur causes additional errors. In this case, the server

displays more than one error message. Always follow the suggested action

instructions for the first error message that appears.

The following sections contain the error codes that might appear in the detailed test

log and summary log when the diagnostic programs are run.

The error code format is as follows:

fff-ttt-iii-date-cc-text message

where:

fff is the three-digit function code that indicates the function being

tested when the error occurred. For example, function code 089 is

for the microprocessor.

ttt is the three-digit failure code that indicates the exact test failure that

was encountered. (These codes are for trained service personnel;

see “Diagnostic error codes” on page 89).

iii is the three-digit device ID. (These codes are for trained service

personnel; see “Diagnostic error codes” on page 89).

date is the date that the diagnostic test was run and the error recorded.

cc is the check value that is used to verify the validity of the

text message is the diagnostic message that indicates the reason for the problem.

information.

Chapter 3. Diagnostics 25

Page 36

Text messages

The diagnostic text message format is as follows:

Function Name: Result (test specific string)

where:

Function Name

is the name of the function being tested when the error occurred. This

corresponds to the function code (fff) shown in the error code format in the

previous section.

Result

can be one of the following:

Passed This result occurs when the diagnostic test

is completed without any errors.

Failed This result occurs when the diagnostic test

discovers an error.

User Aborted This result occurs when you stop the

diagnostic test before it is complete.

Not Applicable This result occurs when you specify a

diagnostic test for a device that is not

present.

Aborted This result occurs when the test could not

proceed, for example, because of the

system configuration.

Warning This result occurs when a possible problem

test specific string

is additional information that you can use to analyze the problem.

Starting the diagnostic programs

The IBM Enhanced Diagnostics programs will isolate your server hardware from

software that you have installed on your hard disk drive. The programs run

independently of the operating system, and must be run either from the CD or

diskette. This method of testing is generally used when other methods are not

accessible or have not been successful in isolating a problem suspected to be

hardware related.

An IBM Enhanced Diagnostics CD comes with the server. You can also download

the latest image of the diagnostics from the World Wide Web at

http://www.ibm.com/pc/support.

Note: When using diagnostics with a USB Keyboard and Mouse attached, go into

Setup and enable USB emulation.

1. Press F1 Config/Setup

2. Select Devices and I/O Ports

3. Select USB Setup

4. Make sure USB Keyboard and Mouse are enabled.

is reported during the diagnostic test, such

as when a device driver is not found.

26 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 37

Using the diagnostics CD

To start the IBM Enhanced Diagnostics using the CD, do the following:

1. Turn off your server and any peripheral devices.

2. Turn on all attached devices; then, turn your server on.

3. When you see Press F1 For Configuration/Setup, press the F1 key.

4. When the Configuration/Setup Utility menu appears, select Start Options.

5. From the Start Options menu, select Startup Sequence.

6. Note the device selected as the First Startup Device. Later, you must restore

this setting.

7. Select CD-ROM as the First Startup Device.

8. Press Esc two times to return to the Configuration/Setup Utility menu.

9. Place the IBM Enhanced Diagnostics CD in the CD-ROM drive.

10. Select Save & Exit Setup and follow the prompts. The diagnostics will load.

Follow the instructions on the screen to run the diagnostics.

Important: When you finish running the diagnostics and utilities, remove the

CD from the CD-ROM drive and turn off the server. You must

restore the First Startup Device to the original setting. Use steps 2

through 8 of this procedure to do this.

Downloading the diagnostics program

Do the following to download the latest image of the IBM Enhanced Diagnostics

from the World Wide Web and create a startable Enhanced Diagnostics diskette:

1. Go to the following World Wide Web site: http://www.ibm.com/pc/support/

2. Download the diagnostics file for your server to a hard disk drive directory (not

to a diskette).

3. Go to a DOS prompt and change to the directory where the file was

downloaded.

4. Insert a blank high-density diskette in diskette drive A.

5. Type in the following, and then press Enter: filename a: where filename is the

name of the file you downloaded from the Web.

The downloaded file is self-extracting and will be copied to the diskette. When the

copy completes, you have a startable IBM Enhanced Diagnostics diskette.

Using the diagnostic diskette

Do the following to start the IBM Enhanced Diagnostics using the diagnostics

diskette, do the following:

1. Turn off your server and any peripheral devices.

2. Insert the IBM Enhanced Diagnostics diskette into the diskette drive.

3. Turn on all attached devices; then, turn on the server.

4. Follow the instructions on the screen.

5. Place the IBM Enhanced Diagnostics CD in the CD-ROM drive. The diagnostics

will load. Follow the instructions on the screen to run the diagnostics.

When the tests have completed, you can view the Test Log by selecting Utility from

the top of the screen.

If the hardware checks out OK but the problem persists during normal server

operations, a software error might be the cause. If you suspect a software problem,

refer to the information that comes with the software package.

Chapter 3. Diagnostics 27

Page 38

Viewing the test log

The test log records data about system failures and other pertinent information. The

test log will not contain any information until after the diagnostic program has run.

Note: If you already are running the diagnostic programs, begin with step 4

1. Insert the IBM Enhanced Diagnostics CD.

2. Turn on the system and watch the screen.

If the system is on, shut down your operating system and restart the system.

3. If a power-on password is set, the system prompts you for it. Type in the

appropriate password; then, press Enter.

4. Run the appropriate diagnostics program and when the Diagnostic Programs

screen appears, select Utility.

5. Select View Test Log from the list that appears; then, follow the instructions on

the screen.

6. You can save the test log to a file on a diskette or to your hard disk drive.

Note: The system maintains the test-log data while the system is powered on.

When you turn off the power to the server, the test log is cleared.

Viewing the System Error log

With the optional service processor adapter, you can also view the System Error log

from the diagnostic programs. See the instructions in “POST” on page 23.

Diagnostic error message tables

For descriptions of the error messages that might appear when you run the

diagnostic programs, see “Diagnostic error codes” on page 89.

Notes:

1. Depending on your server configuration, some of the error messages might not

appear when you run the diagnostic programs.

2. If diagnostic error messages appear that are not listed in the tables, make sure

that your server has the latest levels of BIOS, Advanced System Management

Processor, ServeRAID

™

, and diagnostics microcode installed.

28 IBM xSeries 205 Type 8480: Hardware Maintenance Manual and Troubleshooting Guide

Page 39

Recovering from a POST/BIOS update failure

If power to your server is interrupted while POST/BIOS is being updated (flash

update), your server might not restart correctly. If this happens, perform the

following procedure:

1. Turn off the server and all attached devices.

2. Unplug all power cords from electrical outlets and remove the server cover and

the support bracket. See the Option Installation Guide for instructions.

3. Locate the boot block and password check jumpers on the system board,

removing any adapters that impede access to the jumpers. See “System and

PCI extender boards” on page 35 for the location of the boot block and

password check jumpers.

4. Move the jumper to the adjacent pair of jumper pins.

5. Replace any adapters that were removed and replace the support bracket and

the cover. See the Option Installation Guide for instructions. Reconnect the

power cords for the server and monitor to electrical outlets.

6. Insert the POST/BIOS update (flash) diskette into drive A, and turn on the

server and monitor.

7. After the update session completes, remove the diskette from the diskette

drive, and turn off the server and monitor.

8. Unplug all power cords from electrical outlets, and remove the cover.

9. Remove any adapters that impede access to the boot block and password

check jumpers.

10. Replace the boot block and password check jumpers to their original positions.

11. Replace any adapters that were removed.

12. Replace the cover, and reconnect all cables that were disconnected.

13. Turn on the server to restart the operating system.

Power checkout

Power problems can be difficult to solve. For example, a short circuit can exist

anywhere on any of the power distribution buses. Usually a short circuit will cause

the power subsystem to shut down because of an overcurrent condition.

A general procedure for troubleshooting power problems is as follows:

1. Turn off the server and disconnect all ac power cords.

2. Check for loose cables in the power subsystem. Also check for short circuits, for

example, if there is a loose screw causing a short circuit on a circuit board.

3. Remove adapters and disconnect the cables and power connectors to all

internal and external devices until the server is at the minimum configuration

required to start the server (see “Minimum operating requirements” on page 95).

4. Reconnect all ac power cords and turn on the server. If the server starts up

successfully, replace adapters and devices one at a time until the problem is

isolated. If the server does not start up from the minimal configuration, replace

FRUs of minimal configuration one at a time until the problem is isolated.

To use this method, it is important to know the minimum configuration required for a

system to start (see page 95).

Chapter 3. Diagnostics 29

Page 40

Troubleshooting the Ethernet controller

This section provides troubleshooting information for problems that might occur with

the 10/100/1000 Mbps Ethernet controller.

Network connection problems

If the Ethernet controller cannot connect to the network, check the following

conditions:

v Make sure that the cable is installed correctly.

The network cable must be securely attached at all connections. If the cable is

attached but the problem remains, try a different cable.

If you set the Ethernet controller to operate at either 100 Mbps or 1000 Mbps,

you must use Category 5 or higher cabling.

v Determine whether the hub supports auto-negotiation. If it does not, try

configuring the integrated Ethernet controller manually to match the speed and

duplex mode of the hub.

v Check the Ethernet controller LEDs on the operator information panel and on the

rear of the server.

These LEDs indicate whether a problem exists with the connector, cable, or hub.

– The Ethernet transmit/receive activity LED, on the operator information panel,

is lit when the Ethernet controller sends or receives data over the Ethernet

Network. If the Ethernet transmit/receive activity LED is off, make sure that

the hub and network are operating and that the correct device drivers are

installed.

– The Ethernet link status LED, on the rear of the server, is lit when the

Ethernet controller receives a LINK pulse from the hub. If the LED is off, there

might be a defective connector or cable or a problem with the hub.

v Make sure that you are using the correct device drivers which are supplied with