Page 1

Hardware Maintenance Manual

xSeries 200

IBM

Page 2

Page 3

Hardware Maintenance Manual

xSeries 200

IBM

Page 4

Note: Before using this information and the product it supports, be sur e to read the general information under

“Notices” on page 141.

Second Edition (May 2001)

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION "AS IS" WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer of express or implied warranties in certain transactio ns, th erefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication. IBM may make improvements

and/or changes in the product(s) and/or the program( s) described in this publication at any time.

This publication was developed for products and services offered in the United States of America. IBM may not offer the

products, services, or features discussed in this document in other countries, and the information is subject to change

without notice. Consult your local IBM representative for information on the products, services, and features available in

your area.

Requests for technical information about IBM products sho uld be made to your IBM reseller or IBM marketing

representative.

© Copyright International Business Machines C orporation 2000. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract with

IBM Corp.

Page 5

About this manual

This manual contains dia gnost ic infor mat io n, a Symp tom -to- FR U index , servic e

information, error codes, error messages, and configuration information for the IBM

xSeries 200.

Important: This manual is intended for trained servicers who are familiar with IBM

PC Server products.

Important safety information

Be sure to read all caution and danger statements in this book befor e performing any

of the instructions.

Leia todas as instruções de cuidado e perigo antes de executar qualquer operação.

Prenez connaissance de toutes les consignes de type Attention et

Danger avant de procéde r aux opérations décrites par les instructions.

© Copyright IBM Corp. 2000 iii

Page 6

Lesen Sie alle Sicherheitshinweise, bevor Sie eine Anweisung ausführen.

Accertarsi di leggere tutti gli avvisi di attenzione e di pericolo prima di effettuare

qualsiasi operazi on e.

Lea atentamente todas las decl araciones de pr ecau ción y peligro ante de llevar a cabo

cualquier operación.

Online support

Use the W or ld Wide Web (WWW) to download Diagnostic, BIOS Flas h, Device Driver

files and docu me n ts .

The Web address is:

http://www.ibm.com/pc/support

iv Hardware Maintenance Manual: xSeries 200

Page 7

Contents

About this manual . . . . . . . . . . . . . . . . . . . iii

Important safety information . . . . . . . . . . . . . . . . . . . . . . iii

Online support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

General checkout. . . . . . . . . . . . . . . . . . . . . 1

General information. . . . . . . . . . . . . . . . . . . 3

Features and specifications . . . . . . . . . . . . . . . . . . . . . . . . 3

Server features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reliability, availability, and serviceability . . . . . . . . . . . . 5

Server controls and indicators. . . . . . . . . . . . . . . . . . . . . . 7

Turning on the server . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Turning off the server . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Diagnostic tools overview . . . . . . . . . . . . . . . . . . . . . . . . . 9

POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

POST beep code descriptions. . . . . . . . . . . . . . . . . . . . 9

POST error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Small computer system interface messages (some models)

10

Diagnostic programs and error messages . . . . . . . . . . . 10

Text messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Starting the diagnostic programs . . . . . . . . . . . . . . . 12

Using the diagnostics CD . . . . . . . . . . . . . . . . . . . 12

Downloading the diagnostics program. . . . . . . . 12

Using the diagnostic diskette . . . . . . . . . . . . . . . . 13

Viewing the test log . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Diagnostic error message tables . . . . . . . . . . . . . . . . 13

Power checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Recovering BIOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clearing CMOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Replacing the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Temperature checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Diagnosing errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting the Ethernet controller . . . . . . . . . . . . 18

Network connection problems. . . . . . . . . . . . . . . . . . 18

Ethernet controller troublesho oting cha r t . . . . . . . . 18

Ethernet controller messages. . . . . . . . . . . . . . . . . . . . . . 21

Novell NetWare or IntraNetWare system ODI driver

teaming messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NDIS 4.0 (Windows NT) d river mes sages . . . . . . . . 23

Ethernet teaming messages: . . . . . . . . . . . . . . . . . . . . 26

Configuring the server . . . . . . . . . . . . . . . 29

Using the Configuration/Setup Utility program . . . . 29

Starting the Configuration/Setup Utility program 29

Choices available from the Configuration/Setup main

menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Using passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Using the SCSISelect utility program (some models) . 32

Starting the SCSISelect utility program . . . . . . . . . . 33

Choices available from the SCSISelect menu . . . . . 33

Installing options. . . . . . . . . . . . . . . . . . . . 35

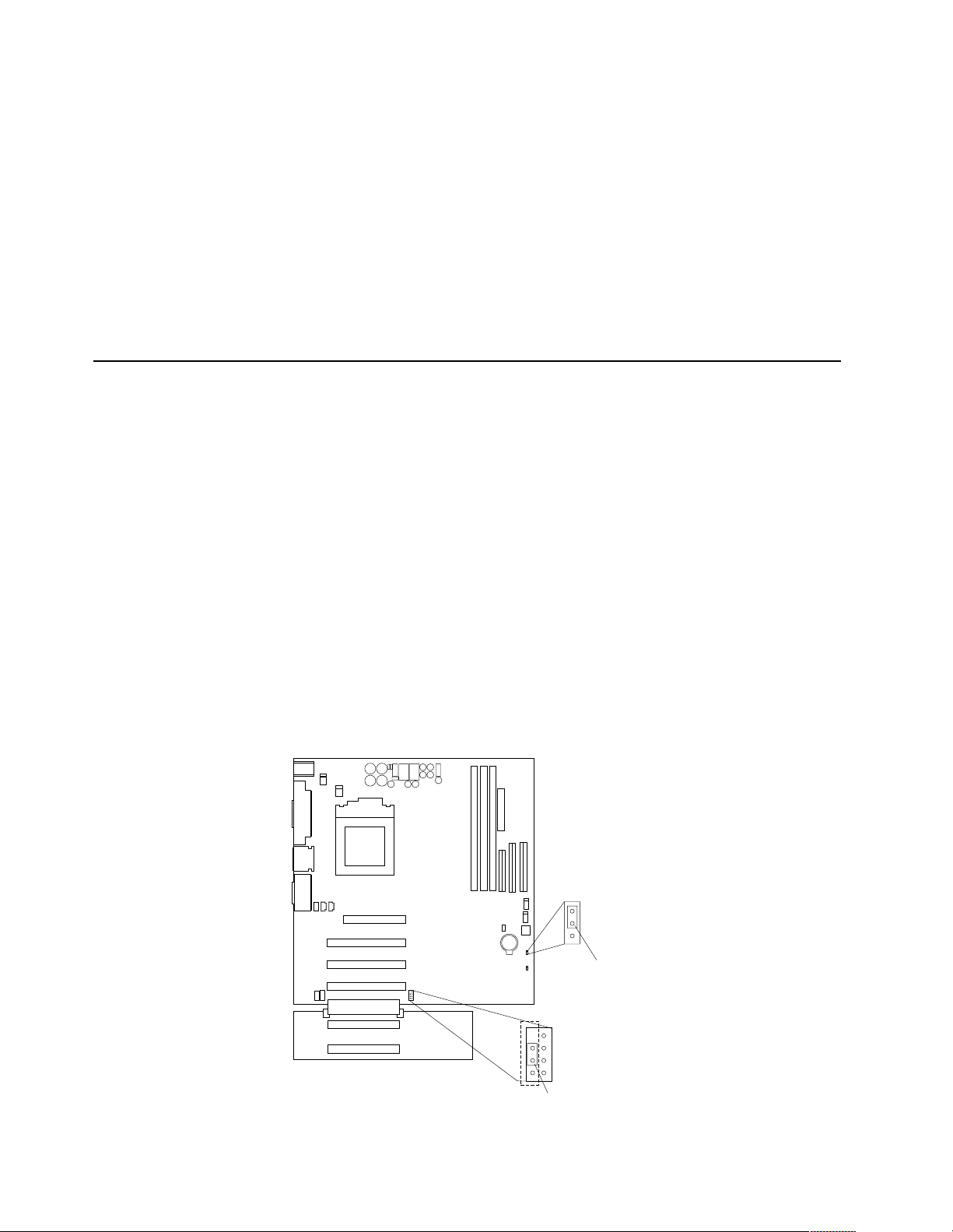

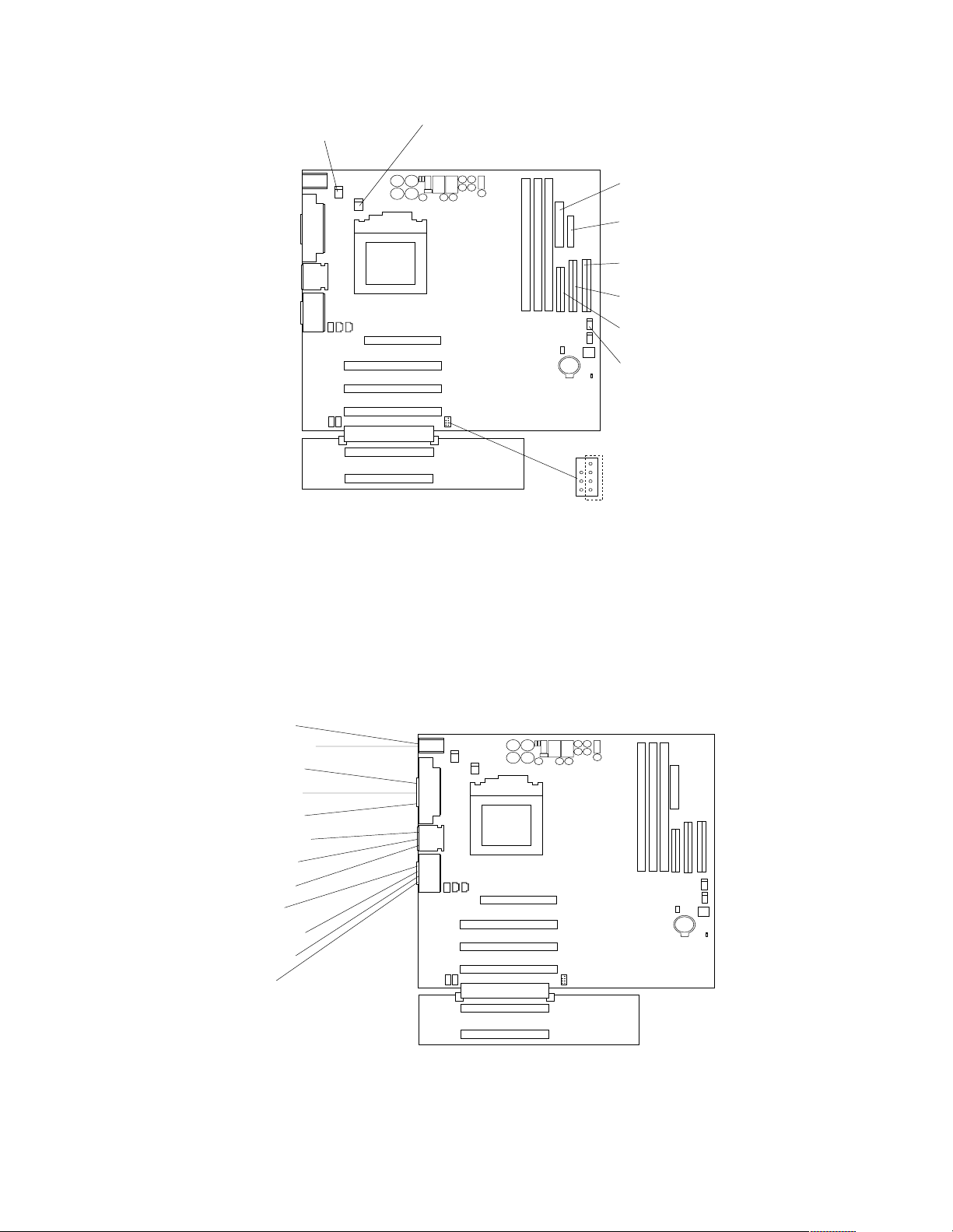

Expanded view of the xSeries 200. . . . . . . . . . . . . . . . . . 35

System and PCI extender board . . . . . . . . . . . . . . . . 35

System and PCI extender board options connectors

35

System board internal cable connectors . . . . . . . 36

System board extern a l co n nectors . . . . . . . . . . . . 37

System board switches and jumpers . . . . . . . . . . 38

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Working inside the server with the power on . . . . . 39

System reliability considerations. . . . . . . . . . . . . . . . 39

Handling static-sensitive devices. . . . . . . . . . . . . . . . 39

Moving the stabilizing feet. . . . . . . . . . . . . . . . . . . . . . . . 40

Removing the side cover . . . . . . . . . . . . . . . . . . . . . . . . . 40

Removing the bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Removing the support bracket assembly. . . . . . . . . . . . 42

Working with adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adapter considerations. . . . . . . . . . . . . . . . . . . . . . . . 44

Installing an adapter . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Installing a SCSI or ServeRAID adapter (some models) 46

Installing internal drives. . . . . . . . . . . . . . . . . . . . . . . . . . 47

Internal drive bays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Preinstallation steps (all bays) . . . . . . . . . . . . . . . . . . 49

Installing a drive in bay 2 or 4 . . . . . . . . . . . . . . . . . . 49

Installing a hard disk drive in bay 5, 6, or 7 . . . . . . . 51

Installing memory modules . . . . . . . . . . . . . . . . . . . . . . 52

Removing and installing a microprocessor. . . . . . . . . . 54

Removing a microprocessor . . . . . . . . . . . . . . . . . . . . 55

Installing a microprocessor. . . . . . . . . . . . . . . . . . . . . 56

Installing a security U-bolt. . . . . . . . . . . . . . . . . . . . . . . . 58

Completing the installation . . . . . . . . . . . . . . . . . . . . . . . 59

Installing the cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Updating the server configuration . . . . . . . . . . . . . . 60

Connecting external options. . . . . . . . . . . . . . . . . . . . 60

Installation procedure . . . . . . . . . . . . . . . . . . . . . . 60

I/O connector locations. . . . . . . . . . . . . . . . . . . . . . . . 60

Input/output ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mouse port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Keyboard port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Parallel connector . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Viewing or changing the conne ctor assignments

63

Parallel connector . . . . . . . . . . . . . . . . . . . . . . . 63

Serial connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Viewing or changing the serial-connector

assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Serial connectors . . . . . . . . . . . . . . . . . . . . . . . . 65

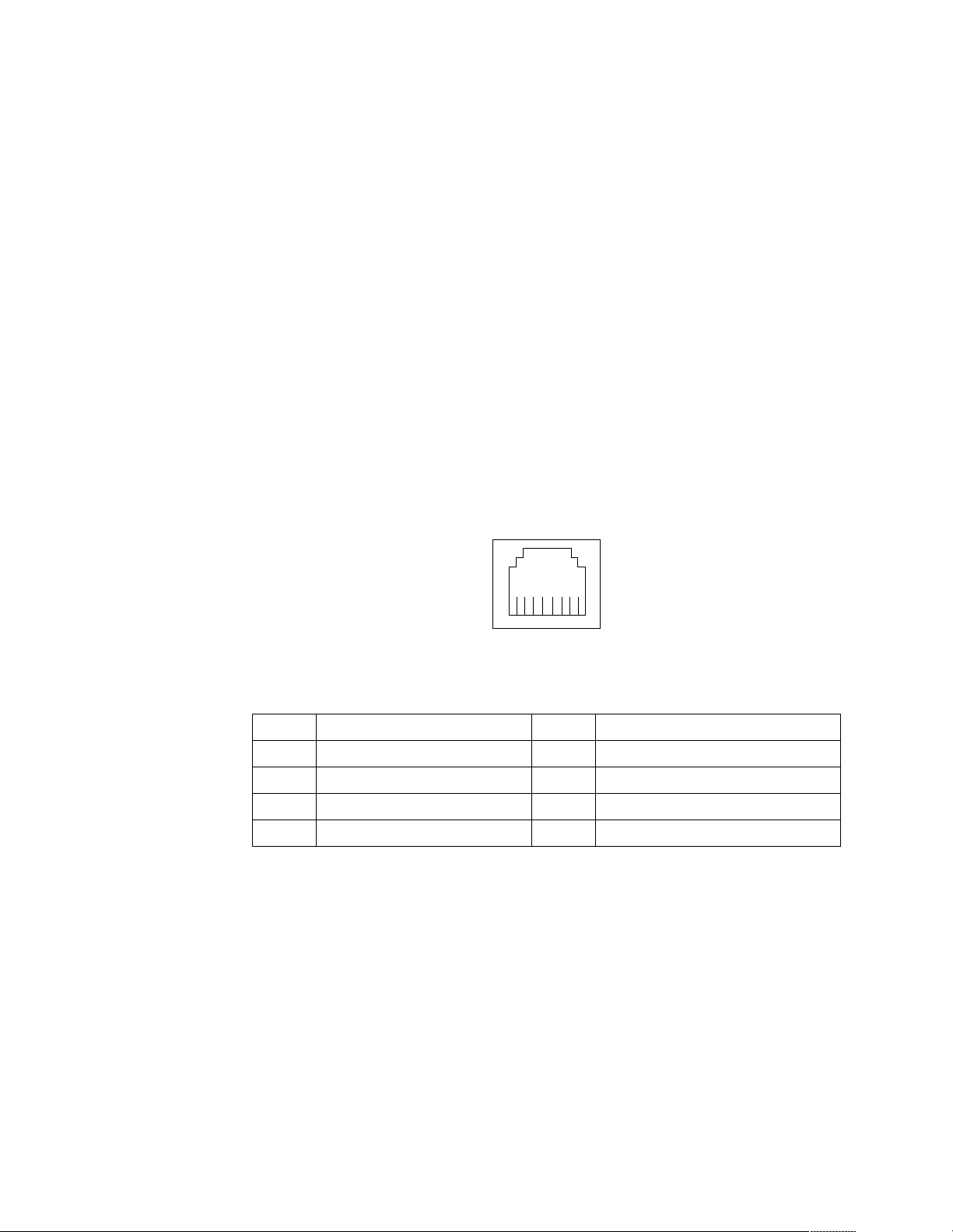

Ethernet connector . . . . . . . . . . . . . . . . . . . . . . . . . 65

Configuring the Ethernet controller . . . . . . . . 65

Failover for redundant Ethernet . . . . . . . . . . . 66

High Performance Ethernet Modes . . . . . . . . 66

Teaming Mode . . . . . . . . . . . . . . . . . . . . . . . 66

Priority Packet Mode . . . . . . . . . . . . . . . . . . 66

Virtual LAN Mode . . . . . . . . . . . . . . . . . . . . 67

Ethernet connector. . . . . . . . . . . . . . . . . . . . . . . 68

Universal Serial Bus connectors . . . . . . . . . . . . . . 68

USB cables and hubs . . . . . . . . . . . . . . . . . . . . . 69

USB connectors . . . . . . . . . . . . . . . . . . . . . . . . . 69

Audio connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Line out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Line in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Mic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

MIDI connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Video connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Ultra 3/1 6 0 SC SI connec tor (s om e mo de l s ) . . . . 70

SCSI cabling requirements . . . . . . . . . . . . . . . . 71

Setting SCSI IDs . . . . . . . . . . . . . . . . . . . . . . . . . 71

© Copyright IBM Corp. 2000 v

Page 8

FRU information (service only). . . . . . . . . 73

Hard disk drive cage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Rear fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

System board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

CD-ROM drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Floppy disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Button kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Guide assembly / speaker . . . . . . . . . . . . . . . . . . . . . . . . 78

Bezel release latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Top/side cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Handle assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Adapter retainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Symptom-to-FRU index. . . . . . . . . . . . . . . 85

Beep symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

No beep symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Diagnostic error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Error symptoms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

POST error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Processor board LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

ServeRAID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Undetermined problems . . . . . . . . . . . . . . . . . . . . . . . . 100

Parts listing . . . . . . . . . . . . . . . . . . . . . . . 101

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Keyboards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Related service information . . . . . . . . . . 105

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Electrical safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Safety inspection guide . . . . . . . . . . . . . . . . . . . . . . . 107

Handling electrostatic dischar ge-sensitive devices 108

Grounding requirements. . . . . . . . . . . . . . . . . . . . . . 109

Safety notices (multi-lingual translations) . . . . . . . 109

Send us your comments! . . . . . . . . . . . . . . . . . . . . . . . . 140

Problem determination tips . . . . . . . . . . . . . . . . . . . . . . 141

Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

vi Hardware Maintenance Manual: xSeries 200

Page 9

General checkout

The server diagnostic prog rams are stored in upgradable read-only memory (ROM)

on the system board. These programs are the primary method of testing the major

components of the server: The system board, Ethernet controller, video controller,

RAM, keyboard, mouse (pointing device), diskette drive, serial ports, hard drives,

and parallel port. You can also use them to test some external devices. See

“Diagnostic programs and error messages” on page 10.

Also, if you cannot determine whether a problem is caused by the hardware or by the

softw a re, you ca n run the diagnostic programs t o confirm that the hard wa re is

working properly.

When you run the diagnostic programs, a single problem might cause several error

messages. When this occurs, work to correct the cause of the first error message.

After the cause of the first error message is corrected, the other error messages might

not occur the next time you run the test.

A failed system might be par t of a shared DASD cluster (two or mor e systems sharing

the same external storage device(s)) . Prior to running diagnostics, verify that the

failing system is not part of a shared DASD cluster.

A system might be part of a cluster if:

• The customer identifies the system as part of a cluster.

• One or more external storage units are attached to the system and at least one of

the attached storage units is additionally attached to another system or

unidentifiable source.

• One or more sy stems are loca te d near the failing system.

If the failing system is suspected to be part of a shared DASD cluster, all diagnostic

tests can be run except diagnostic tests which test the storage unit (DASD residing in

the storage unit) or the storage adapter attached to the storage unit.

Notes:

1. For systems that are part of a shared DASD clus ter, run one test at a time in

looped mode. Do not run all tests in looped mode, as this could enable the DASD

diagnostic tests.

2. If multiple error codes are displayed, diagno se the firs t error code dis pla yed.

3. If the computer hangs with a POST error, go to the “Chapter . Symptom-to - FRU

index,” on page 85.

4. If the computer hangs and no error is displayed, go to “Undetermined problems”

on page 100.

5. Po wer supply problems, see “Chapter . Symptom-to-FRU index,” on page 85.

6. Safety information, see “Safety information” on page 105.

7. Fo r intermittent problems, check the error log; see “POST error mess ages” on

page 9.

1. IS THE SYSTEM PART OF A CLUSTER?

© Copyright IBM Corp. 2000 1

Page 10

YES. Schedule maintenance with the customer. Shut down all systems related to the

cluster. Run storage test.

NO. Go to step 2.

2. IF THE SY STEM IS NOT PART OF A CLUSTER:

• Power-off the computer and all external devices.

• Chec k al l cables an d power cords.

• Set all display controls to the middle position.

• Power-o n all ext e rna l devices.

• Power-on the computer.

• Record any POST error messages displayed on the screen. If an error is

displayed, look up the first error in the “POST error codes” on page 94.

• Check the System Error Log. If an error was recorded by the system, see

“Chapter . Symptom-to-FRU index,” on page 85.

• Start the Diagnostic Programs. See “Diagnostic p rograms and error

messages” on page 10.

• Check for th e following responses:

a. One beep.

b. Readable instructions or the Main Menu.

3. DID YOU RECEIVE BOTH OF THE CORRECT RESPONSES?

NO. Find the failure symptom in “Chapter . Symptom-to-FRU index,” on page 85.

YES. Run the Diagnostic Programs. If necessary, refer to “Diagnostic programs and

error messages” on page 10.

If you receive an error, go to “Chap te r . Sy m p to m-to-F R U i nd e x ,” on page 85.

If the diagnostics completed successfully and you still suspect a problem, see

“Undetermined problems” on page 100.

2 Hard ware Ma inte nance Manual: xSer ies 200

Page 11

General inf ormation

The IBM® xSeries 200 server delivers great value for general server

applications. It is ideally suited for networ king environm ent s that require superio r

microprocessor performance, efficient memory management, flexibility , and large

amounts of reliable data sto rag e .

The server serial number and model number are located on labels on the rear and

front of the server. With access to t he World Wide Web, up-to-date in f ormation abou t

the server model and other IBM server products is available at the following World

Wide Web address: http://www.ibm.com/pc/us/eserver/xseries

Features and specifications

The following provides a summary of the features and specification s for the xSeries

200 server. Depending on the server model, some features and specifications might

not apply.

© Copyright IBM Corp. 2000 3

Page 12

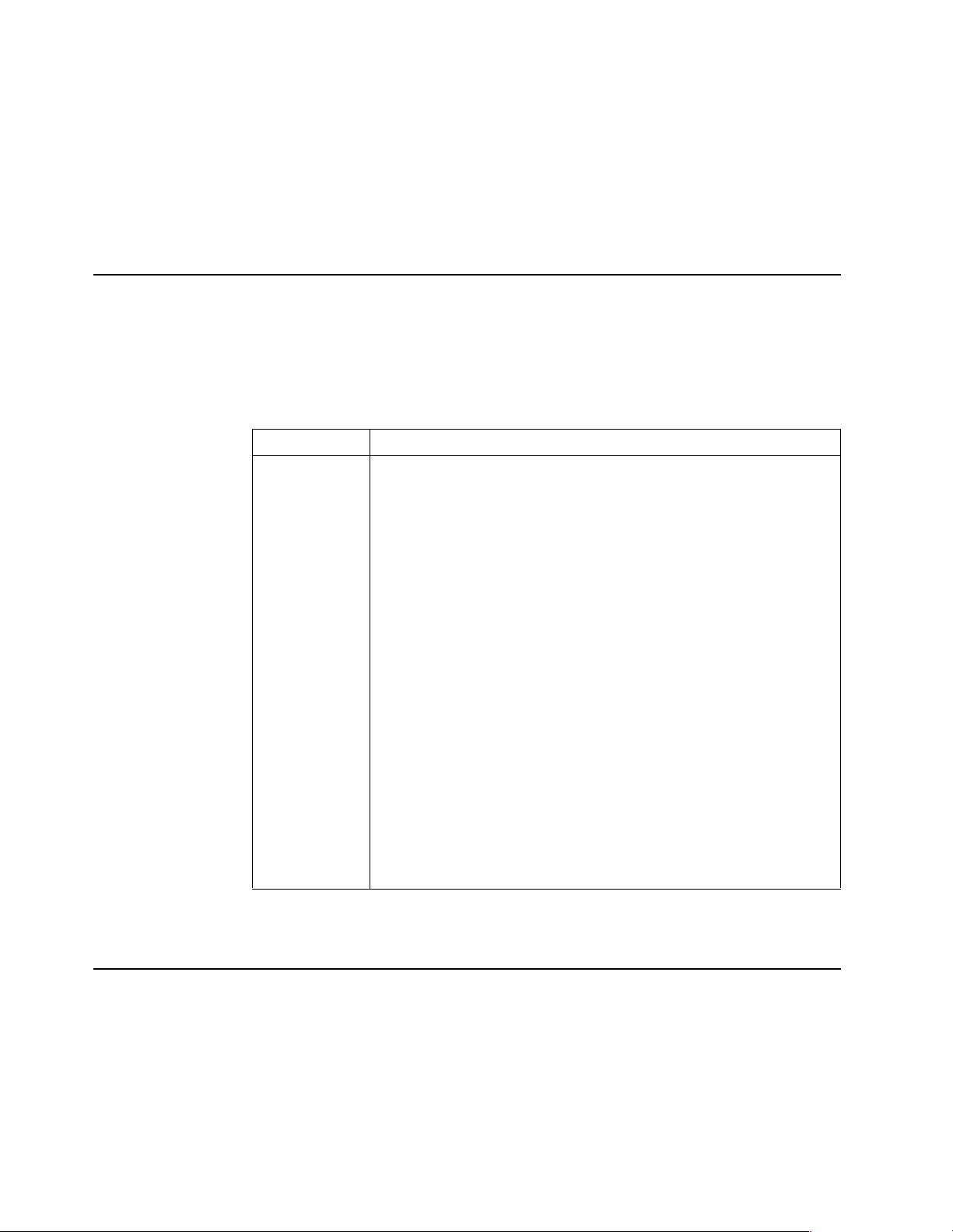

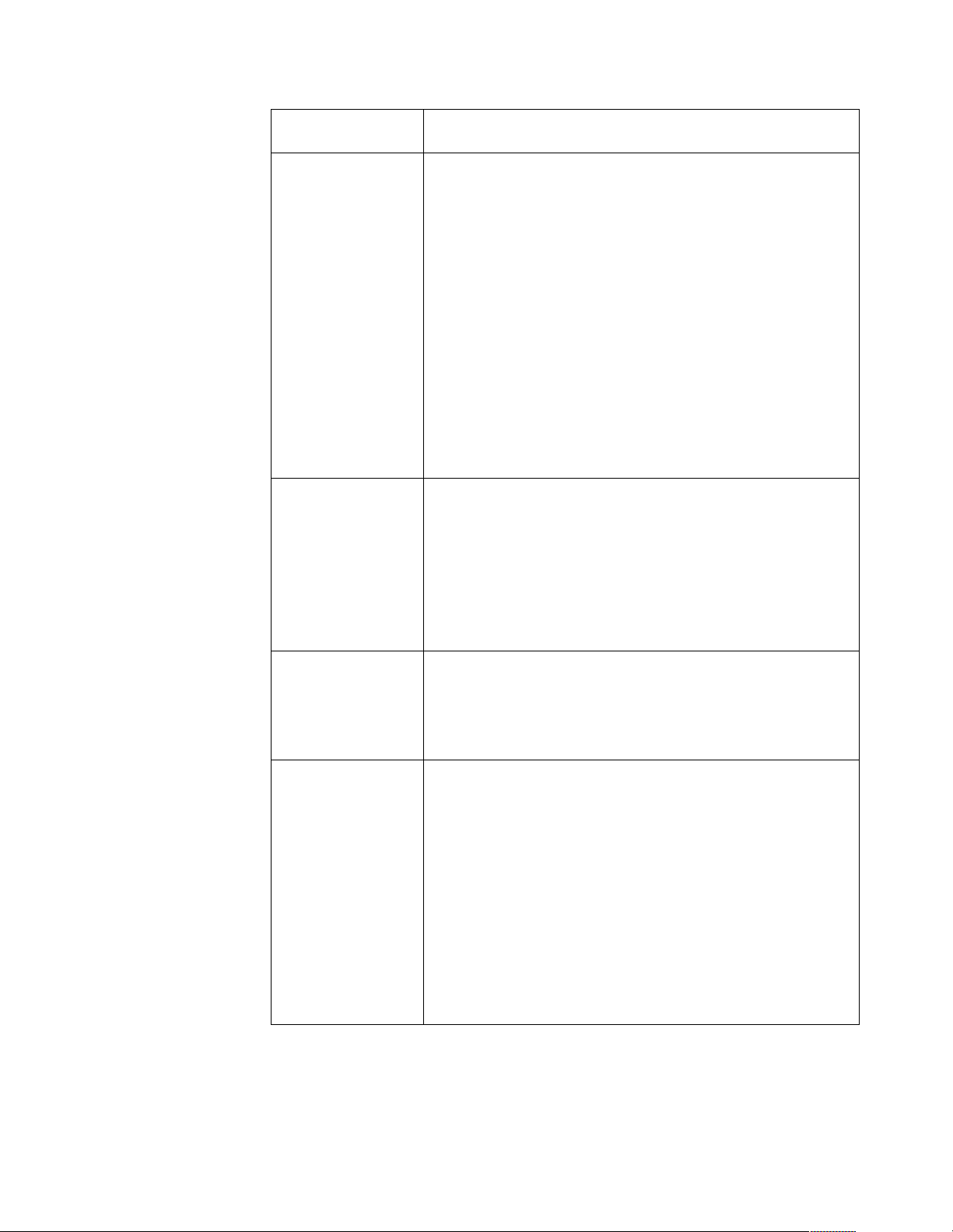

Table 1. Features and Specifications.

Microprocessor: Sup ports one

microprocessor (depending o n your

model)

• Intel

• Intel

Memory:

• Minimum: 64 MB

• Maximum: 1.5 GB

• Type: PC1 33 MHz, ECC SDRAM,

• Slots: 3 dual inline

Drives: (depending on your model)

• Diskette: 1.44 MB

• CD-ROM: IDE

• Hard disk drive

• Tape drive

Expansion bays:

• Two 5.25-in. bays (one CD-ROM

• Two 3.5-in. bays (one diskett e

• Three 3.5-in. slim-high bays

PCI expansion sl ots:

• Three 33 MHz/32-bit on the

• Two 33 MHz/32 -bit on the PCI

AGP slot : Accelerated graphics por t

(AGP)

®

Pentiu m® III with 256 KB

Level-2 cache and MMX™

(MMX2) technolo gy

or

®

Celeron® with 128 KB

Level-2 cache and MMX™

(MMX2) technolo gy

unregistered DIMMs only

drive installed)

drive installed)

available

system board ( some models come

with a SCSI adapter ins talled)

Bus extender board

Power supply:

One 330 watt (90-240 V ac)

Video:

• S3 Savage 4 AGP video adapter

• Compatible with SVGA and

VGA

• 8 MB SDRAM video memory

Size:

• Height: 470 mm (18.5 in.)

• Depth: 508 mm (19.9 in.)

• Width: 165 mm (6.5 in.)

• Weight: app roximately 19.5 Kg

(43 lb.) when fully configured or

15.9 Kg (35 lb.) mi ni mum

Integrated functions:

• 10BASE-T/100BASE-TX

Ethernet controller on the

system board

• Two se rial port s

• O ne parallel port

• Two USB ports

• Keyboard port

• Mouse port

• MIDI port

• Audio ports

— Line out

— Line in

— Mic

• Dual-channel bus mastering

IDE controller

Acoustical noise emissions:

• Sound p ower, idlin g : 6. 6 bel

maximum

• S o und pow e r, ope ra t i n g : 6.8 bel

maximum

Environment:

• Air temperature:

— Server on: 10° to 35° C (50.0°

to 95.0° F). Altitude: 0 to 914

m (2998.7 ft. )

— Server on: 10° to 32° C (50.0°

to 89.6° F). Altitude: 914 m

(2998.7 ft.) to 2133 m (6998.0

ft.)

— Server off: 10° to 43° C (50.0°

to 109.4° F). Maximum

altitude: 2133 m (6998.0 ft.)

• Humidity:

— Server on: 8% to 80%

— Server off: 8% to 80%

Heat output:

Approximate heat output in British

Thermal Units (Btu) per hour

• Minimum configuration: 341 Btu

(100 watts)

• Maximum configuration: 1604 Btu

(470 watts)

Electric al input:

• Sine-wave input (50-60 Hz)

required

• Input voltage low range:

— Minimum: 90 V ac

— Maximum: 137 V ac

• Input voltage high range:

— Minimum: 180 V ac

— Maximum: 265 V ac

• Input kilovolt-amperes (kVA)

approximately:

— Minimum: 0.08 kVA

— Maximum: 0.52 kVA

Server features

The design of the 200 takes a dvantage of advancements in data stor ag e and memory

management. The server combines:

• Impressive performance using an inno vative approach to micr oprocess or

utilization

The serve r comes with one Cel e ron

4 Hard ware Ma inte nance Manual: xSer ies 200

®

or Pentium® III microprocessor installed.

Page 13

• Large system memory

The memory bus in the server supports up to 1.5 gigabytes (GB) of system

memory. The memory controller provides error code correction (ECC) support

for up to three industry-standard PC133, 3.3 V, 168-pin, 133 megahertz (MHz),

unreg istered, synchronous dynamic random access memory (S DRAM) dual inline memory modules (DIMMs ).

• Systems-management capabilities

See the documentation provided with the systems-management software for

more information.

• Integrated network environment support

The server comes with an Ethernet controller on the system board. This Ethernet

controller has an interface for connecting to 10-Mbps or 100-Mbps netwo rks. The

server automatically selects between 10BASE-T and 100BASE-TX environments.

The controller provides full-duplex (FDX) capability, which allows simultaneous

transmission and recep tion of data on the Ethernet local area network ( LA N).

• IBM ServerGuide™ CDs

The ServerGuide CDs included with IBM servers provide programs to help set up

the server and install the network operating system (NOS). The ServerGuide

program detects the hardware options installed, and provides the correct

configuration program and device drivers. In addition, the ServerGuide CDs

include a variety of application programs for the server.

Note: The latest level of BIOS for the server is also available through the World

Wide Web. Refer to “Recovering BIOS ” on page 14 for the appro priate

World Wide Web addresses.

Reliability, availability, and serviceability

Three of the most important considerations in server design are reliability , availability ,

and serviceability (RAS). The RAS features help to ensure the integrity of the data

that is stored on the server, the availability of the server when needed, and the ease

with which you can diagnose and repair problems.

The following is an abbreviated list of the RAS features that the server supports.

Many of these features are explained in the following chapters of this book.

• Reliability features

— Boot block recovery

— Cooling fans with sp eed-sen sin g cap ability

— Customer-up gradable basic input/output system (BIOS)

— ECC front-s ide buses (FSBs)

— ECC L2 ca che

— ECC mem o ry

— Parity checking on t h e small computer system in terface (SCSI) and peripheral

component interconnect (PCI) buses

— Advanced conf igura tion an d power int erface ( ACP I)

— Power-on self-test (POST)

— Synchron ous dyn amic ran dom ac ces s memo ry (SDRA M) wit h se ria l presence

detect (SPD)

• Availability features

— Advanced desktop management interface (DMI) features

— Alarm on LAN ™ capa bilit y

– Chassis intrusio n

– Operating sy stem (OS) hangs

General information 5

Page 14

— Auto-restart initia l program load (IPL) p ower s upp ly

— Auto ma t i c e rro r retry or reco v e ry

— Automatic server restart

— Automatic restart afte r p ower failure

— Built-in, menu-driven configuration programs

— Built-in, menu-driven SCSI configuration programs (some models)

— Built-in, menu-driven setup programs

— Failover Etherne t support

— Menu-driven di agnostic programs on CD-ROM

— Monitoring support for temperature, voltage, and fan speed

— Server management

— ServeRAID™ adapter support

— Standard advanced system management (ASM) PCI adapter provides control

for remote system management

— Upgradable BIOS, diagnosti cs, ASM PCI adapter microcode, and POST

— Wake on LAN

— Microsoft

• Serviceability features

— 24/7 customer support

— 3-year warranty (parts: three (3) years; labor: one (1) year)

— Adaptec 29160 built-in self-test (BIST)

— Alert on LAN™ with optional IBM Ethernet adapter

— CD-ROM-based diagnostics

— Diagnostic support of Ethernet adapters

— Error cod e s and me s s ag e s

— Processor serial numbe r access

— Read-only memory (ROM) checksums

— Standard cables present detection

— Standby voltage for system management features and monitoring

— System error logging (ASM PCI adapter)

— Vital product data (VPD) (includes serial num ber info rm ation a nd

replacement part numbers, stored in nonvolat i le memory, for easier remote

maintenance)

®

(WOL) capability

®

Windows NT® failover support

6 Hard ware Ma inte nance Manual: xSer ies 200

Page 15

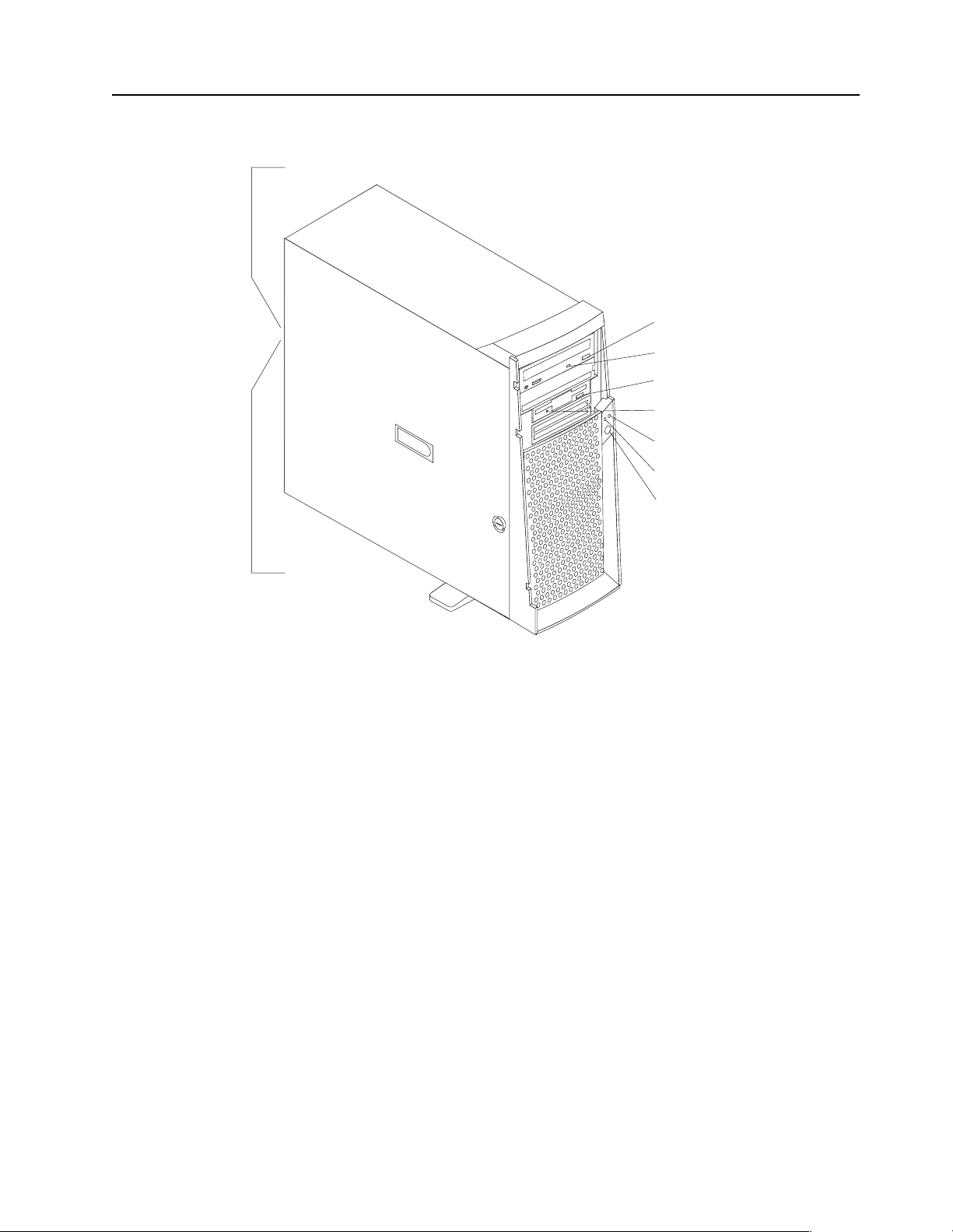

Server controls and indicators

Ethernet speed 100 Mbps

CD eject

button

CD-ROM drive

activity light

Diskette eject

button

Diskette drive

activity light

Hard disk drive

activity light

Power-on

light

Power control

button

Ethernet transmit/

receive activity

CD-ROM drive activity light: When this light is on, it indicates that the CD-ROM

drive is in use.

Diskette eject button: Push this b ut t on to install or remove a diskette from the dr ive.

Diskette drive activity light: When this light is on, it indicates that the diskette drive

is in use.

Hard disk drive activity light: When this light is on, it indicates that the hard disk

drive is in use.

Power-on light: This status indicator lights when you turn on your server.

Power control button: Press this button to man ually turn the serve r on or off.

See “I/O conne ctor locations” on page 60 for the location of the input/output (I/O)

connectors on the rear of th e se r v er.

Turning on the server

After you plug one end of the server power cord into the power supply outlet on the

rear of the server, and the other end of the power cord into an electrical outlet, the

server can start as follows:

• You can press the power control button on the front of the server to start the

server.

• If the server is turned on and a power failure occurs, the server will start

automatically when power is restored.

General information 7

Page 16

CAUTION:

The power control butto n on the device and the power switch on the powe r supply do not

turn off the el ectr ical c urr ent suppl ied to t he dev ice. The device a lso might have m ore th an

one power cord. To remove all electri cal current from the device, ensure that all power

cords are disconnected from the power source.

2

1

Turning off the server

You can turn off the server in any of the following ways:

• You can press the power control button on the front of the server. This starts an

orderly shutdown of the operating system, if this feature is supported by your

operating system, and places the server in standby mode.

Note: After tu rning off the se rver, wait at least five seconds before you press the

power control button to turn on the server again.

• You can press and hold the power control button for more than four seconds to

cause an immediate shutdown of the server and place the server in standby

mode. Y ou ca n use this feature if the operating system stops functioning.

• You can disconnect the server power cords from the electrical outlets to shut off

all power to the server.

Note: After di sconnecting the power cords, wait appr oximately 15 seconds for

your system to stop running.

8 Hard ware Ma inte nance Manual: xSer ies 200

Page 17

Diagnostics

This section provides basic troubleshooting information to help you resolve some

common pr oblems that might occur wi th the server.

If you cannot locate and correct the problem using the information in this sec tion,

refer to “Symptom-to-F RU index” on page 85 for more information.

Diagnostic tools overview

The following tools are available to help you identify and resolve hardware-related

problems:

• POST bee p cod es

The power-on self-test (POST) generates beep codes and messages to indicate

successful test completion or the det e ction of a probl e m. See “POST” for more

information.

• Diagnostic programs and error messages

The server diagnostic programs are provided on the IBM Enhanced Diagnostics

CD. These programs test the major components of the server . See “Diagnostic

programs and error messages” on page 10 for more information.

POST

When you turn on the server, it performs a series of tests to check the operation of

server components an d some of the options installed in th e se rver. This se ries of tests

is called the power-on self-test or POST.

If POST finishes without detecting any problems, the first window of the operating

system or application program appears.

Note:

1. If you have a power-on passw ord or administrator password set, you

must type the password and press Enter, when prompted, before POST

will continue.

2. A single problem might cause several error messages. When this occurs,

work to correct the cause of the first error message. After you correct the

cause of the first error message, the other error messages usuall y will no t

occur the next ti m e y ou ru n th e tes t .

POST beep code descriptions

POST generates beep codes to indicate successful completion or the detection of a

problem.

• One short beep indicates the successful completion of POST.

• More than one beep indicates that POST detected a problem. For more

information, see “Beep symptoms” on page 85“.

POST error messages

The possible types of beep codes that your system might emit are:

© Copyright IBM Corp. 2000 9

Page 18

Repeating long beeps

Indicates th at a memory error has occurred. Ensure that all DIMM s are

correctly installed.

One long beep and two short beeps

Indicates that a video err or has occurred and the BIOS cannot initialize the

video screen to display any additional i nformation. Ensure that the video

adapter is correctly installed.

For a list of POST errors, see “POST error co de s” on page 94.

Small computer system interface messages (some models)

The following table lists actions to take if you receive a SCSI error message.

Note: If the server does not have a har d disk drive, i gnore any mess age that indicates

that the BIOS is not installed.

You will get these messages only when running the SCSI Select Utility.

SCSI Messages Description

All One or more of the following might be causing the problem.

• A failing SCSI device (adapter or drive)

• An improper SCSI configuration

• Duplicate SCSI IDs in the sam e SCSI chain

• A n improperly installed SCSI terminator

• A defectiv e SCSI terminator

• A n improperly installed cable

• A defectiv e cable

Action:

Verify th a t :

• The external SCSI devices are turned on. External SCSI devices must

be turned on before the server.

• The cables for all external SCSI devices are connected correctly.

• The last d e vice in each SCSI ch ai n i s terminated p r operly.

• The SCSI devices are configured correctly.

If the above items are correct, run the diagnostic programs to obtain

additional information about the failing device.

Table 2. SCSI messages.

Diagnostic programs and error messages

The server diagnost ic p rograms are stored on the IBM Enhanced Diagnostics CD. These

programs provide the primary methods of tes ting the major components of the server.

Diagnostic error messages indicate that a problem exists; they ar e not inten ded to be

used to identify a failing part. Troubleshooting and servicing of complex problems

that are indicated by error messages should be performed by trained service

personnel.

10 Hardware Maintenance Manual: xSeries 200

Page 19

Somet i m e s th e f i rs t e rro r to occur caus e s addition al errors. In th is ca s e , th e server

displays more than one error message. Always follow the suggested action

instructions for the first error message that appears.

The following sections contain the error codes that might appear in the detailed test

log and summary log when running the diagnostic programs.

The error code format is as follows:

fff-ttt-iii-date-cc-text message

where:

fff is the thre e -digit fun ction code that in di cates the function being

ttt is the thre e -digit failure code that indicates the exact test failu re that

iii is the thr e e-digit device ID.

date is the date that the diagnostic test was run and the error recorded.

cc is the check digit that is used to verify the validity of the information.

text message is the diagnostic message that indicates the rea son for the problem .

Text messages

tested when the error occurred. For example, function c od e 089 is for

the microprocessor.

was encou ntered.

The diagnostic text message format is as follows:

Function Name: Result (test specific string)

where:

Func tion Name

is the name of the function being tested when the error occurred. This

corresponds to the function code (fff) given in the previous list.

Result can be one of the fo llowing:

Passed This result occurs when th e di agnostic test completes without any

errors.

Failed This re sult occurs when th e di agnostic tes t di scovers an error.

User Aborted

This result occurs when you stop the diagnostic test before it is

complete.

Not Applicable

This result occurs when you specify a diagnosti c test for a device that

is not present.

Aborted This result occurs when the test could not proceed because of the

server configuration.

Warning This result occurs when a possible problem is reported during the

diagnosti c test, such as whe n a device that is to be tested is not

installed.

Te st Spec i fi c Stri ng

This is additional informa tion th at is used to analyz e the problem.

Diagnostics 11

Page 20

Starting the diagnostic programs

The IBM Enhanced Diagnostics programs will isolate your server hardware from

software that you have installed on your hard disk drive. The programs run

independently of the operating system, and must be run either from the CD or diskette.

This method of testing is generally used when other methods are not accessible or

have not been successful in isolating a problem suspected to be hardware related.

An IBM Enhanced Diagnostics CD comes with the server. You can also download the

latest image of the diagnostics from the World Wide Web at

http://www.ibm.com/pc/support.

Using the diagnostics CD

To start the IBM Enhanced Diagnostics using the CD, do the following:

1. Turn off your server and any peripheral devices.

2. Turn on all attached devices; then, turn your server on.

3. When you see Press F1 For Configuration/Setup, press the F1 key.

4. When the Configuration/Setup Utility menu appears, select Start Options.

5. From the Start Options menu, select Startup Sequence.

6. Note the device selected as the First Startup Device. Later, you must restore this

setting.

7. Select CD-ROM as the First Startup Device.

8. Press Esc two time s to return to the Configurati on/Setup Util ity menu.

9. Place the IBM Enhanced Diagnostics CD in the CD - ROM dr ive.

10. Select Save & Exit Setup and follow the p rompts. The diagnostics will load.

Follow the instructions on the screen to run the diagnostics.

Important

When you finish running the diagnostics and utilities, remove the CD from the CD-ROM

drive and turn off the server. You must restore the First Startup Device to the original setting.

Use steps 2 through 8 of this procedure to do this.

Downloading the diagnostics program

Do the following to download the latest image of the IBM Enhanced Diagnostics from

the World Wide Web and cr eate a startable Enha nced Diagnos t ics dis kette:

1. Go to the following World Wide Web site: http://www.ibm.com/pc/support/

2. Download the diagnostics file for your server to a hard disk drive directory (not

to a dis ke tte).

3. Go to a DOS prompt and change to the directory where the file was downloaded.

4. Insert a blank high-density diskette in diskette drive A.

5. Type in the following, and then press Enter: filename a:

where filename is the name of the file you downloaded from the Web.

The downloaded file is self-extracting and will be copied to the diskette. When the

copy completes, you have a startable IBM Enhanced Diagnostics diskette.

12 Hardware Maintenance Manual: xSeries 200

Page 21

Using the diagnostic diskette

Do the following to start the IBM Enhanced Diagnostics using the diagnostics

diskette, do the fol lowing:

1. Turn off your server and any peripheral devices.

2. Insert the IBM Enhanced Diag nostics diske tte into the diskette drive.

3. Turn on all attached devices; then, turn on the server.

4. Follow the instructions on the screen.

5. Place the IBM Enhanced Diagnostics CD in the CD-ROM drive. The diagnostics will

load. Follow the instructions on the screen to run the diagnosti cs.

When the tests have completed, you can view the Test Log by selectin g Utility from

the top of the screen.

If the hardware checks out OK but the problem persists during normal server

operations, a software error might be the cause. If you suspect a software problem,

refer to the information that comes with the software package.

Viewing the test log

The test log records data about syste m f a ilures and othe r pertinent i nformation. Th e

test log will not contain any information until after the diagnostic program has run.

Note: If you already are running the diagnostic programs, begin with step 4.

1. Insert the IBM Enhanced Diagnostics CD.

2. Turn on the system and watch the screen.

If the syst e m is on, shut down your operating system and restart the system.

3. If a power-on password is set, the system prompts you for it. Type in the

appropriate password; then, press Enter.

4. Run the appropriate diagnostics program and when the Diagnostic Programs

screen appears, select Utility.

5. Select View Test Log from the list that appears; then, foll ow the instr uctions on

the screen.

6. You ca n save the test log to a file on a diskette or to your hard di sk drive.

Note: The syst e m mai ntains the test -log data while th e system is power e d on.

When you turn off the power to the server, the test log is cleared.

Diagnostic error message tables

For descriptions of the error messages that might appear when you run the diagnostic

programs, see “Diagnost ic error codes” on page 89. If diagnostic error messages

appear that are not listed in those tables, make sure that the server has the latest levels

of BIOS, Advance d System Managemen t P rocessor, ServeRAID, and diagnostics

microcode installed.

Power checkout

Power problems can b e difficu lt to trou bleshoot. For instance, a short circui t can exist

anywhere on any of the power distributio n busses. Usually a short circuit will cause

the power su b s ystem to shut d own because of an overcurrent conditi o n.

A general procedure for troubleshooting power problems is as follows:

Diagnostics 13

Page 22

1. Power off the server and disconnect the AC cord(s).

2. Check for loose cables in the power subsystem. Also check for short circuits, for

3. Remove adapters and disconnect the cables and power connector s to al l internal

4. R econnect the AC cord and power on the server. If the server powers up

To use this method it is important to know the minimum configuration required for a

server to power up (see page 100).

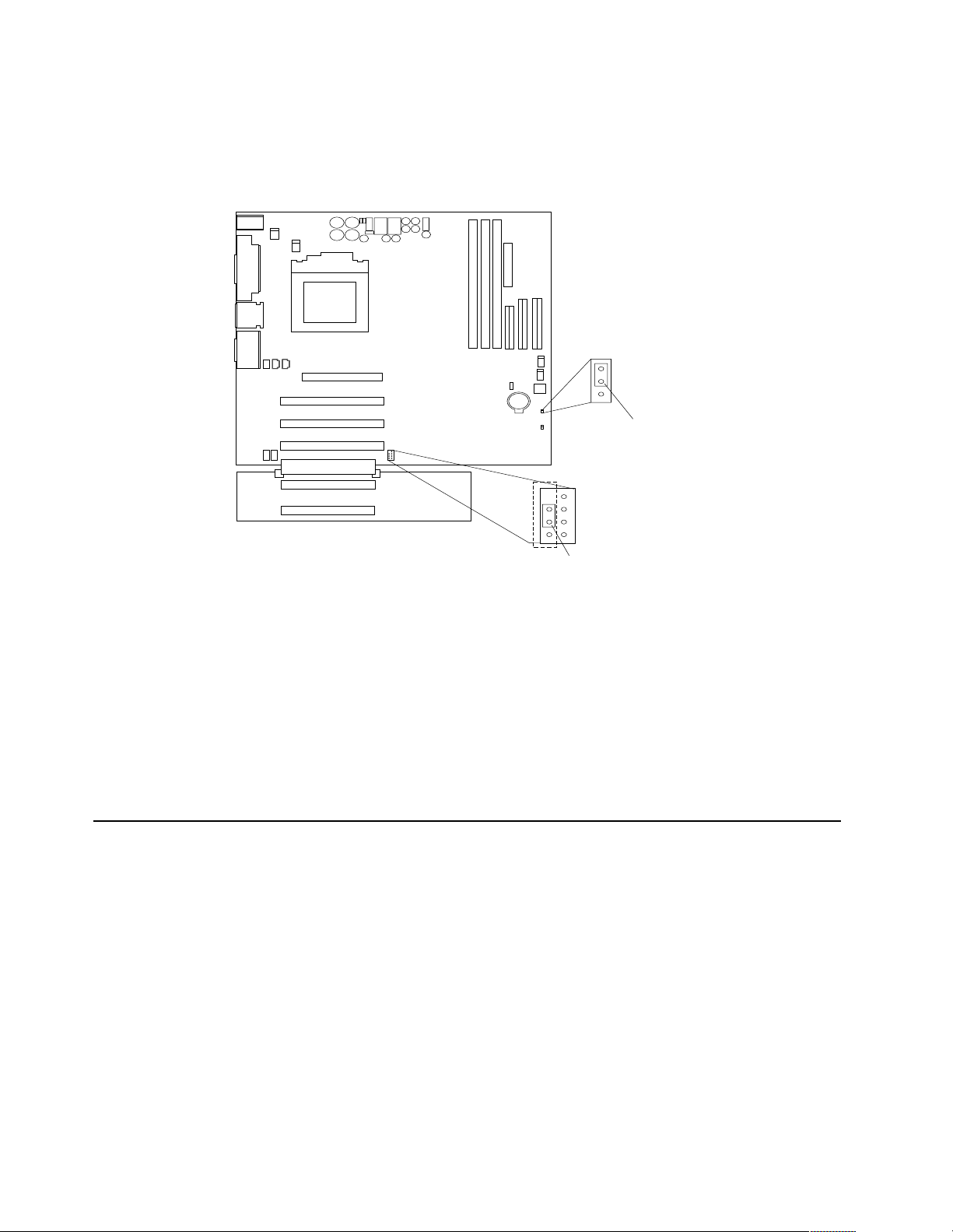

Recovering BIOS

If the BI O S has bec ome c orr up t ed, su ch as fr om a pow er f ai lu r e du ri n g a fl ash up dat e,

you can recover the BIOS using the boot block jumper and a BIOS flash diskette. The

boot block jumper selects which of two BIOS images to use. In the normal position,

the jumper will be installed on pins 2 and 3. In the alternate block position, the jumper

will be installed on pins 1 and 2.

Note: You can obtain a BIOS flash diskette fr om one of the following sources:

instance if there is a loose screw causing a short circuit on a circuit board.

and external devices until server is at minimum configuration required for power

on (see "Minimum operating requirements" on page 100).

successfully, replace adapters and devices one at a time until the problem is

isolated. If server does not power up from minimal configuration, replace FRUs

of minimal configuration one at a time until the problem is isolated.

• Use the ServerGuide program to make a BIOS flash diskette.

• Download files to make a BIOS flash dis kette from the World Wide Web.

Go to http://www.ibm.com/support/ select IBM System Support, and

then make the selections for your system.

Do the following to recover the BIOS:

1. Turn off the server and periphera l devic e s and disconnect all external cables and

power cords; then, r emo ve t he side cov er, see “Removing the side cover” on page

40.

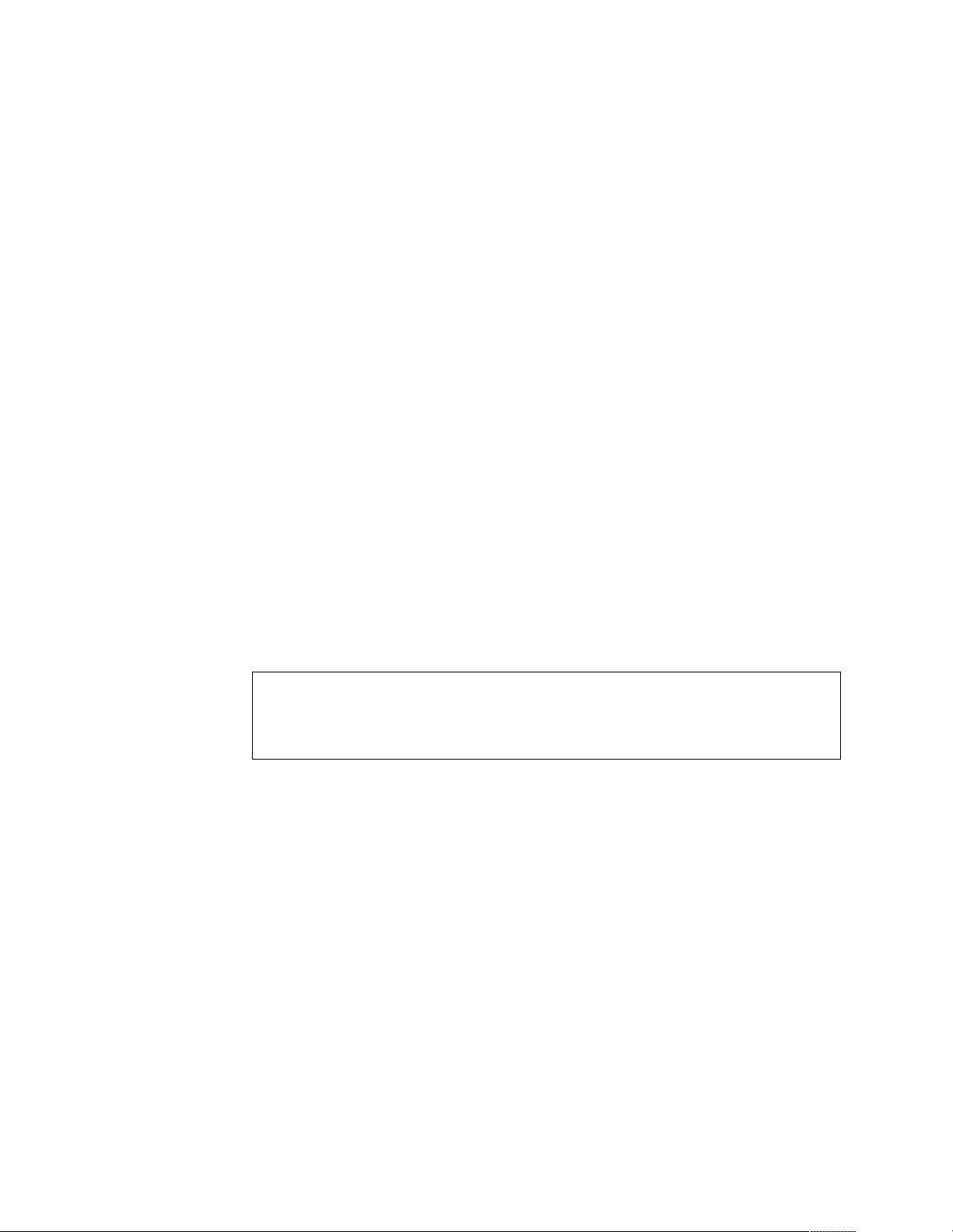

2. Locate jumper JROM1 on the system board.

1

2

3

CMOS jumper

(JBAT1)

3

2

1

p

14 Hardware Maintenance Manual: xSeries 200

Page 23

3. Move the JROM1 jumper to the alternate position (pins 1 and 2) to enable the

BIOS recovery mode.

4. Reinstall the side cove r, see “Installing the cover” on page 59.

5. Reconnect all external cables an d pow er cords and turn on the peripheral devices.

6. Insert the BIOS flash diskette in the diskette drive.

7. Restart the server. The BIOS begins the power-on self-test.

8. Select 1 - Update POST/BIOS from the menu that contains various flash (update)

options.

9. When prompted as to whether you want to save the current code to a diskette,

select N.

10. When prompted to choose a language, select a language (from 0 to 7) and press

Enter to accept your choice.

11. Do not restart your server at this time.

12. Remove the BIOS flash diskette from the diskette drive.

13. Turn off the server and peripheral devices and disconnect all external cables and

power cords; then, r emo ve t he side cov er, see “Removing the side cover” on page

40.

14. Move the JROM1 ju mper to the normal position (pin s 2 and 3) to return to normal

startup mode.

15. Reinstall the side cover, see “Installing the cover” on page 59.

16. Reconnect all external cables and power cords and turn on the peripheral devices.

17. Restart the se rver, which should start up normally.

Clearing CMOS

If you need to erase configuration information, you must move the CMOS jumper. See

the illustration in “Recovering BIOS” on page 14 for the location of the CMOS jumper.

The default position is a jumper installed on pins 1 and 2. Before you change the

position of this jumper , you must turn off the server and peripheral devices, and

disconnect all external cables and power cords . Remove the cover and then move the

jumper to pins 2 and 3.

After moving the jumper, wait at least 5 minutes for the CMOS information to clear.

Changing the position of this jumper erases all configuration and setup information,

including the power-on and administrator passwords. Therefore, you must

reconfigure the server after clearing CMOS memory (see “Ch apter . Configuring th e

server,” on page 29). If possible, record your server configuration information before

moving the CMOS jumper.

After you clear the CMOS information, move the jumper back to its normal position

(pins 1 and 2). Reconnect the external cables and power cords; then, turn on the

peripheral devices and the server.

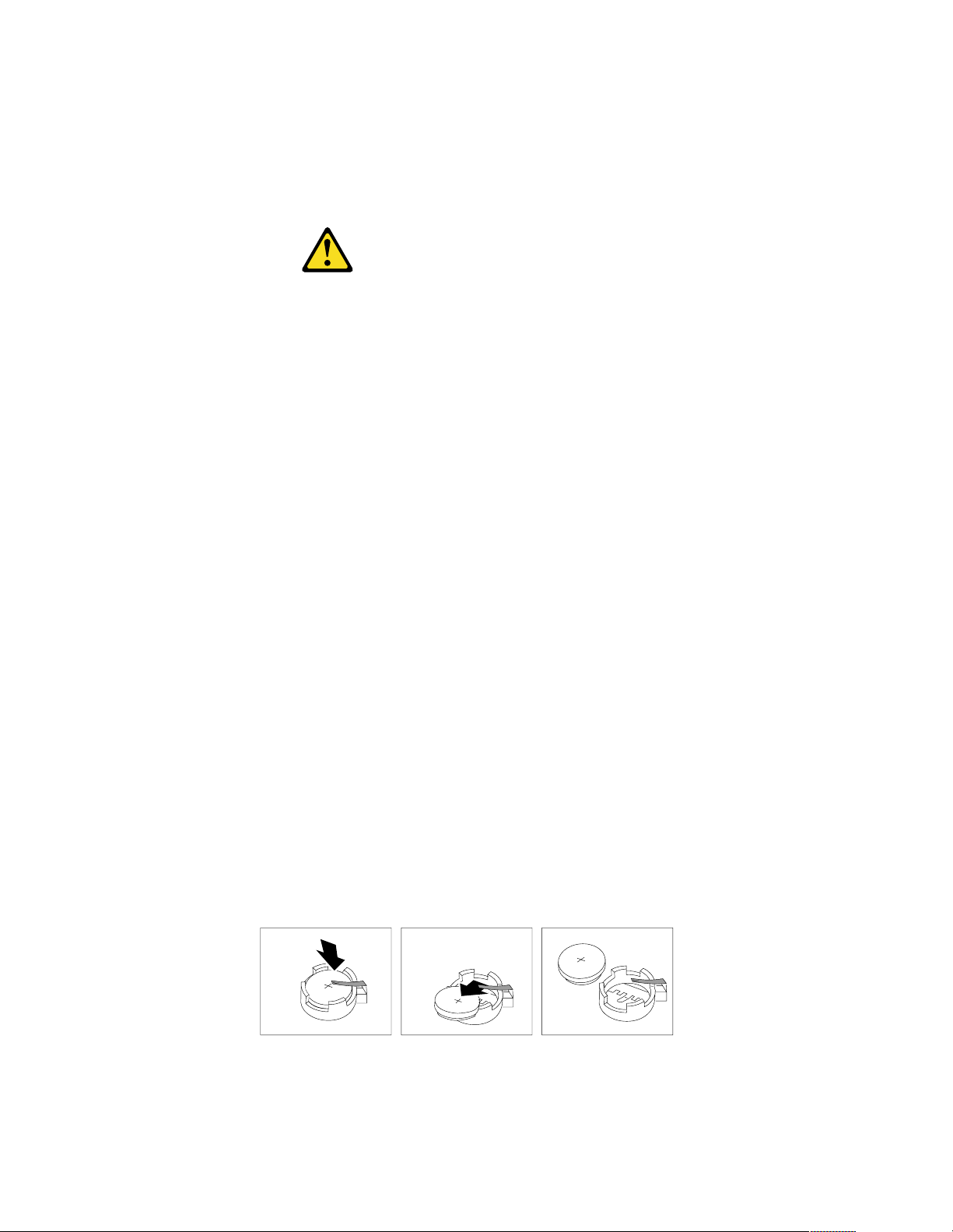

Replacing the battery

When replacing the battery, you must replace it with a lithium battery of the same

type from the same manufacturer. To avoid possible danger, read and follow the

safety statement below.

Diagnostics 15

Page 24

To order repl acement batteries, call 1-800 -772-2227 within the United States, and 1800-465-7999 or 1-80 0-465- 6666 withi n Cana da. Ou tside t he U.S. and Canada, call your

IBM reseller or IBM marketing representative.

Note: After you replace the battery, you must reconfigure your system and reset the

system date and time.

CAUTION:

When replacing the battery, use only IBM Part Number 33F8354 or an equivalent

type battery recommended by the manufacturer. If your server has a module

containing a lithium battery, replace it only with the same module type made by

the same manufacturer. The battery contains lithium and can explode if not

properly used, handled, or disposed of.

Do not:

• Throw or immerse into water

• Heat to more than 100°C (212°F)

• Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Do the following to replace the battery:

1. Read “Before you begin” on page 38, and follow any special handling and

installation instructions supplied with the replacement battery.

2. Turn off the server and periphera l devic e s and disconnect all external cables and

power cords; then, remove the server cover.

3. Remove the battery:

a. Use one finger to lift the battery clip over the battery.

b. Use one finger to slightly slide the battery out from its socket. The spring

mechanism will push the battery out toward you as you slide it from the

socket.

c. Use your thumb and index finger to pull the battery from under the battery

clip.

d. Ensure that the battery clip is touching the base of the battery socket by

pressing gently on the clip.

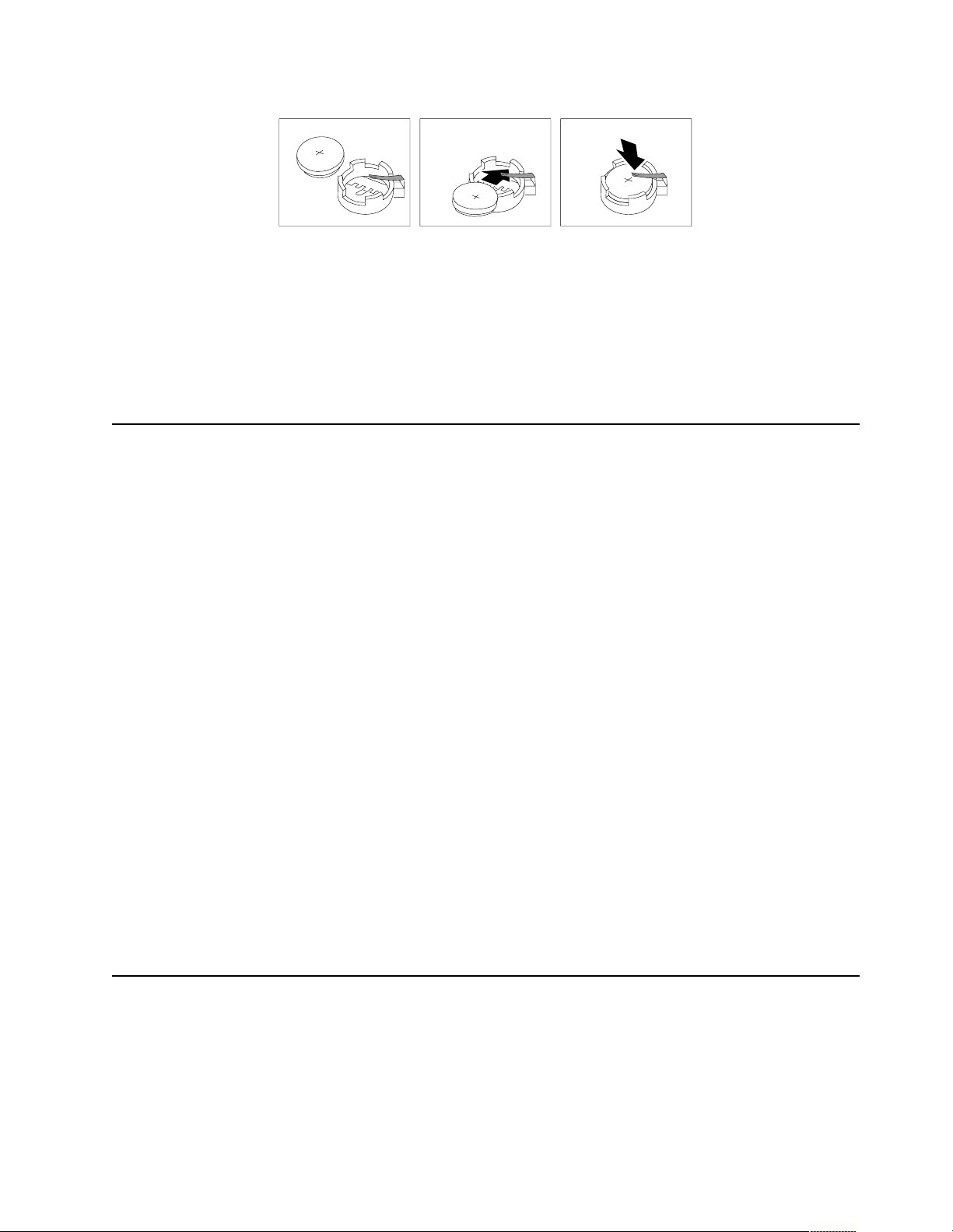

4. Do the following to insert the new battery:

a. Tilt the battery so that you can insert it into the socket under the battery clip.

b. As you slide it under the battery clip, press the battery down into the socket.

16 Hardware Maintenance Manual: xSeries 200

Page 25

5. R einstall the server cover and connect the cables.

6. Turn on the se rver.

7. Start the Configuration/Setup Utility program and set configuration parameters.

• Set the server date and time.

• Set the power-on password.

• Reconfigure your server.

Temperat ur e checkou t

Proper cooling of the server is important for proper operation and server reliability.

For a typical xSeries ser ve r, you should make sure:

• Each of the drive bays has either a drive or a filler panel installed

• Each of the power supply bays has either a power supply or a filler panel installed

• The server cover is in place during normal operation

• There is at l east 50 mm (2 inches) of ventilated space at the sides of t he se rv er and

100 mm (4 inches) at the rear of the server

• The server cover is removed for no longer than 30 minutes while the server is

operating

• The processor housing cover covering the proc essor and memory area is r emoved

for no longer that ten minutes while the server is operating

• A removed hot-swap drive is replaced within two minutes of removal

• Cables for optional adapters are routed according to the instructions provided

with the adapters (ensure that cables are not restricting air flow)

• The fans are operati ng correctly and the air flow is good

• A failed fan is replaced within 48 hours

In addition, ensure that the environmental specifi cat i on s for the server are met. See

“Features and specifications” on page 3“Features and specifications” on page 3.

Note: The speed of the fans will increase if:

• One fan fails.

• Ambient temperature gets too high.

Diagnosing errors

To find solutions to problems that have definite symptoms, see “Error symp t o ms” on

page 92.

If you cannot find the problem there, go to “Starting the diagnost ic programs” on

page 12 to test the se rver.

Diagnostics 17

Page 26

If you ha ve jus t ad de d new soft ware or a n ew opt ion and the se rver i s not wo rkin g, d o

the following before using the error symptoms table:

• Remove the software or dev ice that you just added.

• Run the diagnostic tests to determine if the serve r is running correctly.

• Reinstall the new softwa re or new device.

Troubleshooting the Ethernet controller

This section provides troubleshooting information for problems that might occur with

the 10/100 Mbps Ethernet controller.

Network connection problems

If the Ethernet controller ca nnot connec t to the network, check the following:

• Make sure that the cable is installed correctly.

The network cable must be securely attached at all connections. If the cable is

attached but the problem persists, try a different cable.

If you set the Ethernet contr oll er to operate at 100 Mbps, you must use Cate gory 5

cabling.

If you directly connect two workstations (without a hub), or if you are not using a

hub with X ports, use a crossover cable.

Note: To determine whether a hub has an X port, check the port label. If the label

contains an X, the hub has an X port.

• Determine if the hub suppo rts auto-negotiation. If not, try configuring the

integrated Ethernet controller manually to match the speed and duplex mode of

the hub.

• Check the LAN activity light (if available) on the front of the server. The LAN

activity light illuminates when the Ethernet controller sends or receives data over

the Ethernet network. If the LAN activity light is off, make sure that the hub and

network are operating and that the correct device drivers are loaded.

• Make sure that you are using the correct device drivers, supplied with your

server.

• Check for operating server-specific causes for the problem.

• Make sure that the device drivers on the client and server are using the same

protocol.

• Test the Ethernet controller.

The way you test the Ethernet controller depends on which operating system you

are using (see the Ethernet controller device driver README file).

Etherne t controller troubleshooting chart

You can use the following troubleshooting chart to fi nd sol u ti ons to 10/100 Mbps

Ethernet controller problems that have definable symptoms.

18 Hardware Maintenance Manual: xSeries 200

Page 27

Ethernet controller

problem

Suggested Action

The server stops

running when loading

device drivers.

The LAN activity light

(when available ) does

not light.

The PCI BIOS interrupt settings are incorrect.

Check the following:

• D ete rm in e if the IRQ sett ing assi gned to the Ether net co ntrolle r

is also assigned to another device in the Configuration/Setup

Utility program.

Although interrupt sharing is allowed for PCI devices, some

devices do not functi on well wh en the y share an interr up t with

a dissimilar PCI device. Try changing the IRQ assigned to the

Ethernet controller or the other device. For exa mple, for

NetWare Ve rs ions 3 and 4 it is recommended that disk

controllers not share interrupts with LAN controllers.

• Make sure that you are using the most recent device driv er

available from the World Wide Web.

• Run the network diagnostic program.

If the problem remains, call for service.

Check the following:

• Make sure that you have loaded the network device drivers.

• The network might be idle. Try sending data from this

workstation.

• Run diagnostics on the LEDs.

• The function of this LED can be changed by device driver load

parameters. If necessary, remove any LED parameter settings

when you load the device drivers.

Data is incorrect or

sporadic.

Check the following:

• Make sure that you are using Category 5 cabling when

operating the server at 100 Mbps.

• Make sure that the cables do not run close to noise-inducing

sources like fluorescent lights.

The Ethernet

controller stopped

working when

another adapter was

added to the server.

Check the following:

• Make sure that the cable is connected to the Ethernet controller.

• Make sure that your PCI server BIOS is current.

• Reseat the adapter.

• Determine if the IRQ setting assigned to the Ethernet adapter is

also assigne d to another device in the Con fi guration/Setu p

Utility program.

Although interrupt sharing is allowed for PCI devices, some

devices do not functi on well wh en the y share an interr up t with

a dissimilar PCI device. Try changing the IRQ assigned to the

Ethernet adapter or the other device.

If the problem remains, call for service.

Table 3. Ethernet troubleshooting cha rt.

Diagnostics 19

Page 28

Ethernet controller

problem

The Ethernet

controller stopped

working w ith ou t

apparent cause.

Check the following:

• Run diagnostics for the Ethernet controller.

• Try a different connector on the hub.

• Reinstall the device drivers. Refer to your operating system

documentation and to the ServerGuide information.

If the problem remains, call for service.

Table 3. Ethernet troubleshooting cha rt.

Suggested Action

20 Hardware Maintenance Manual: xSeries 200

Page 29

Ethernet controller messages

The integrated Ethernet controller might display messages from the following device

drivers:

• Novell NetWare

• Network driver interface specification (NDIS) adapter for level 4.0 (Windows NT)

Novell NetWare or IntraNetWare system ODI driver teaming messages

This section provides explanations of the error messages for the Novell NetWare or

IntraNe tWare system ODI driver, and suggested actions to resolve eac h problem.

™

or IntraNetWar e syst em open data-link interface (ODI)

Diagnostics 21

Page 30

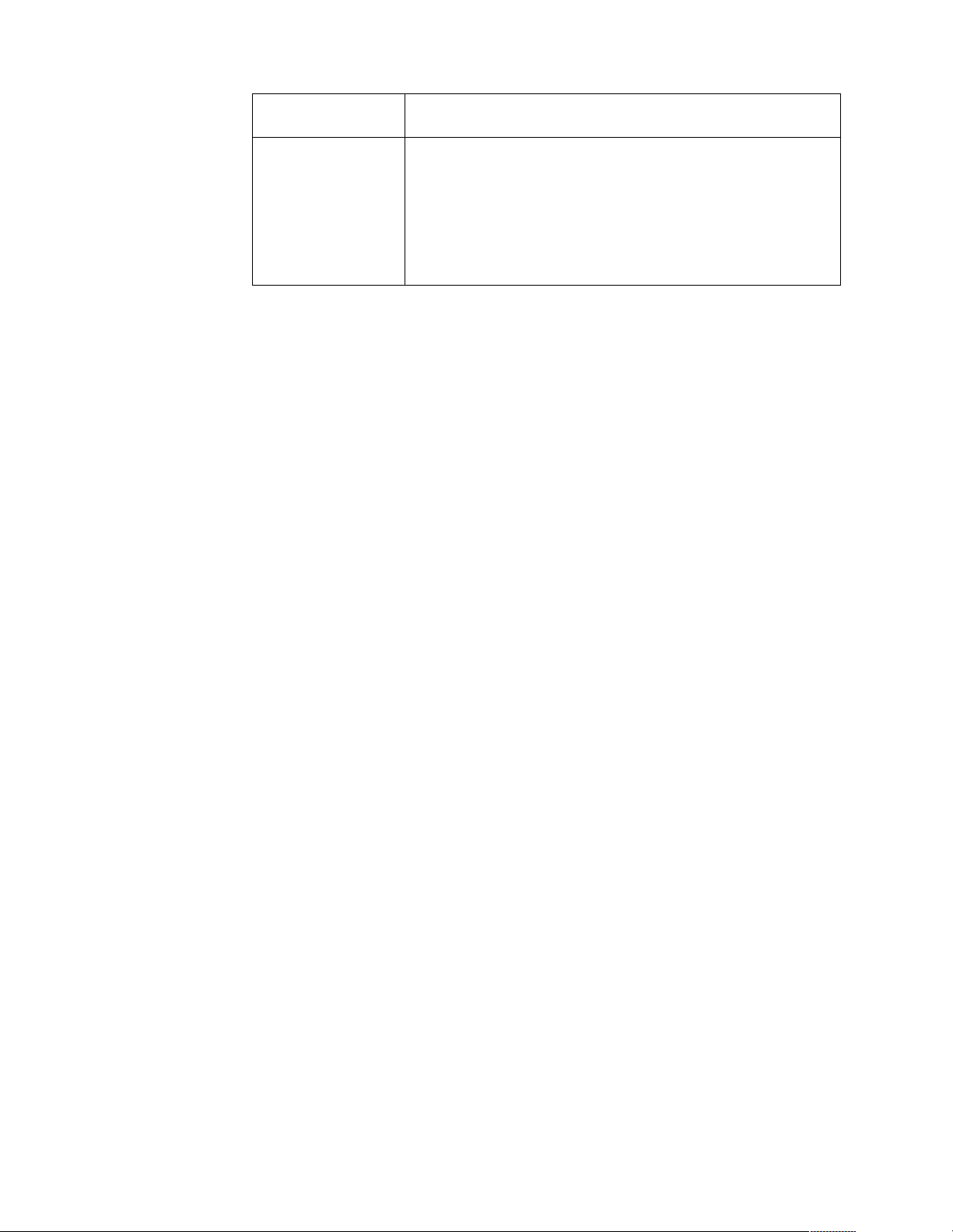

Message Description

Couldn’t allocate resources. Explanation: An unknown error has occurred when trying to

allocate needed resources for the AFT Module.

Action:

• Check the server configuration. If the problem persists,

contact your net work supplier.

• Verify that the Ether net contr oller is enabled. If the

Ethernet controller is enabled , ru n the diagnost ic

programs.

AFT group for prima r y

adapter in slot nnn al ready

exists.

Error locating device control

table (DCT ) ad d resses in

internal table. Make sure that

you have loaded LAN

drivers after loading

AFT.NLM.

Insufficient number of

arguments specified.

Duplicate slot numbers

detected.

’xxx’ is not supported for

AFT team.

Explanation: An attempt was made to rebin d an ada pte r

already in an AFT group.

Action: Check the AFT slot numbers for existing AFT teams.

If the problem per s is ts, co nt ac t your network supplie r.

Explanation: The bind command was entered prior to

loading the device driver. The device driver must be loaded

after loading AFT.NLM, but before any bind command can be

issued.

Action: Load the driver for the supported adapter and try

loading the AF T module again. If the problem persists,

contact your net work supplier.

Explanation: The appropriate or expected number of

parameters was not enter ed in a command.

Action: Check the parameters required for the given

command . If the probl em persi sts , con ta ct you r ne twor k

supplier.

Explanation: An attempt has been made to bind the same slot

number more than once.

Action: Check the slot numbers entered during the bind.

Adapter slot numbers must be valid and unique. If the

problem persists, contact your network supplier.

Explanation: A bind command has been is sued fo r adapters

not supported by AFT.NLM.

Action: Make sure that you attempt to bind only adapters

supported by AFT.NLM.

Primary and Secondary

adapters do not match. AFT

group is not created.

Requested number of

Secondary cards are not

found.

Failed to create AFT group.

Make sure that the drive rs

for suppor t e d ad apte rs are

loaded, primary ada pte r i s

bound to protocols, and

secondary adapter is not

bound t o a ny protocols.

Explanation: A bind command was entered for an adapter

team that is a combination of server and client adapters. An

AF T tea m must be a group i ng of the same classification of

adapter.

Action: V e rify that all the adap ters bound in a team are of the

same classification.

Explanation: The number of adapters specified in the bind

command could not be located.

Action: Verify the numbers and slot locations of the adapters

to be bound. If the problem persists, contact your network

supplier.

Explanation: Binding of protocol failed. Protocol is ei ther not

bound to any adapter or is bound to more than one adapter in

the group.

Action: Ens u re that t he prot oc ol i s bou nd to on l y ad ap ter in

an AFT team.

Table 4. NetWare driver messages for the Ethernet controller.

22 Hardware Maintenance Manual: xSeries 200

Page 31

Message Description

Erro r i dent if ying s lot

numbers for the specified

board names.

Can’t unbind specified slot

from AFT group. Make sure

that the slot you specified is

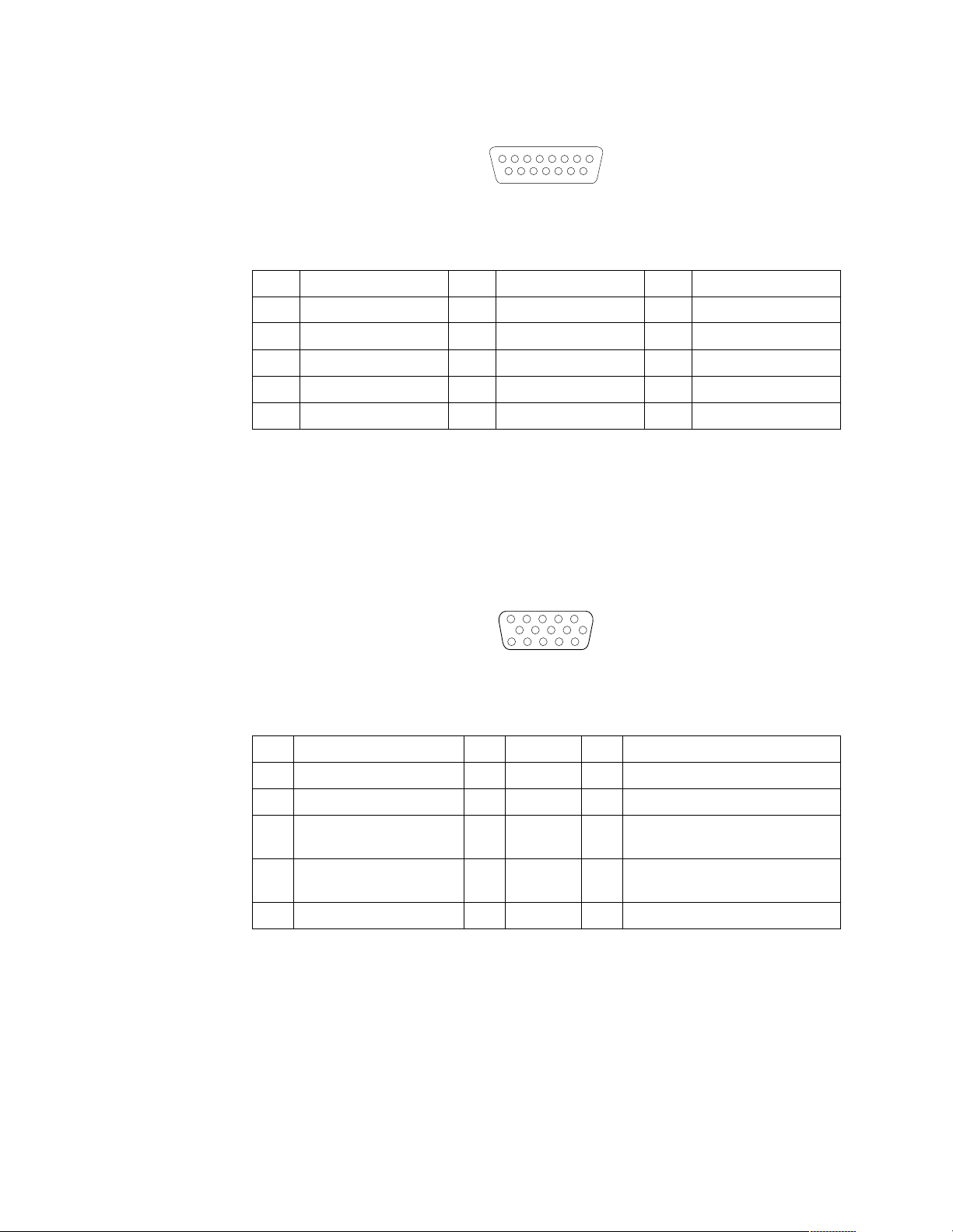

for the primary adapt e r in an

AFT group.

LAN adapter at slot nnnn

(Port 0xaa) failed to reset.

Check the state of the

adapter.

AFT is not supported on this

version of NetWare™.

Failed to allocate resources

tags.

Explanation: The mapping between the board name entered

and the slot number for an adapter could not be established.

Action: Check the board name for the adapter before issuing

the bind command. If the problem persists, contact your

network supplier.

Explanation: The number entered in the unbind command

was not the primary adap ter in an AFT group.

Action: Reissue the unbind command and specify the slot

number for the primary adapter.

Explanation: The adapter that you specified could not be

initialized.

Action:

1. Load the driver for the supported adapter.

2. Check that the adapter is seated prop erly in the sl ot and

try loading the AFT module again.

If the problem per s is ts, co nt ac t your network supplie r.

Explanation: The NetWare on your server is not a version

supported by AFT.

Action: Load and bind AFT only on supported versions of

NetWare (currently versi on 4.11 and above).

Explanation: An unknown error has occurred when trying to

allocate needed resources for the AFT module.

Action: Check server configuration. If the problem persists,

contact your net work supplier.

Please unload all LAN

drivers before unloading

AFT.NLM.

Explanation: An attempt was ma de to unloa d the A FT.NLM

module before unloading the adapter driver.

Action: Unload the adapter driver before unloading the AFT

module.

Table 4. NetWare driver messages for the Ethernet controller.

NDIS 4.0 (Windows NT) driver messages

This section contains t he erro r messages for the NDIS 4.0 driv ers. The explan ation and

recommended action are included with each message.

Diagnostics 23

Page 32

Error code

(hex)

0x00 Explanation: The driver could not register the specified interrup t .

Action: Using the Configuration/Setup Utility program, make sure that a

PCI interrupt is assigned to your Ethernet card, and that Ethernet is enabled.

0x01 Explanation: One of the PCI cards did not get the required resources.

Action: Using the Configuration/Setup Utility program, make sure that a

PCI interrupt is assigned to your Ethernet card, and that Ethernet is enabled.

0x02 Explanation: Bad node address (multicast address).

Action: Make sure the locally administered address is valid, if one is

specified. The address can no t be a multic ast address.

0x03 Explanation: Failed self-test.

Action: Make sure a cable is attached to the Ethernet connector. If the

problem persists, call for service.

0x0D Explanation: Could not allocate enough memory for transmit queues.

Action:

1. From the Windows NT desktop, se lect Start

Networks

2. Select your IBM Ethernet adapter from the list.

3. Select Properties

4. Lower the resource values that apply to the transmit queue.

0x0E Explanation: Could not allocate enough memory for receive queue.

Action:

1. From the Windows NT desktop, se lect Start

g

Networks gAdapters.

2. Select your IBM Ethernet adapter from the list.

3. Select Properties

4. Lower the resource values that apply to the receive queue.

g

Adapters.

g

Advanced.

g

Advanced.

Description

g

Control Panel g

g

Control Panel

0x0F Explanation: Could not allocate enough memory for other structures.

Action:

1. From the Windows NT desktop, se lect Start

Networks

2. Select your IBM Ethernet adapter from the list.

3. Select Properties

4. Lower the value for the resource named in the message.

0x10 Explanation: Did not find any Ethernet co ntrollers.

Action: Using the Configuration/Setup Utility program, make sure that

Ethernet is enabled.

0x11 Explanation: Multiple Ethernet controllers found, but none matched the

required ID.

Action: Using the Configuration/Setup Utility program, make sure that

Ethernet is enabled.

0x13 Explanation: Did not find any Ethernet controllers that matched the required

subven/subdev.

Action: Using the Configuration/Setup Utility program, make sure that

Ethernet is enabled.

g

Adapters.

g

Advanced.

g

Control Panel g

Table 5. NDIS (Windows NT or Windows 2000) driver messages for the Ethernet

controller.

24 Hardware Maintenance Manual: xSeries 200

Page 33

Error code

(hex)

0x16 Explanation: Single adapter found, but multiple instances tried to load.

Action: Using the Configuration/Setup Utility program, make sure that

Ethernet is enab l e d, and that the slot contai ning the IBM xSeries 200 10/100

Ethernet Adapter or the IBM 10/100 Etherjet PCI adapter is enabled.

0x17 Explanation: Slot parameter not specified in the registry.

Action: Remove the adapter driver and reinstall it. If the problem persists,

cal l for service.

Description

All other 4character

hexadecimal

codes

Action: Call for service.

Table 5. NDIS (Windows NT or Windows 2000) driver messages for the Ethernet

controller.

Diagnostics 25

Page 34

Ethernet teaming messages:

This section displays the messages associated with Ethernet teaming.

26 Hardware Maintenance Manual: xSeries 200

Page 35

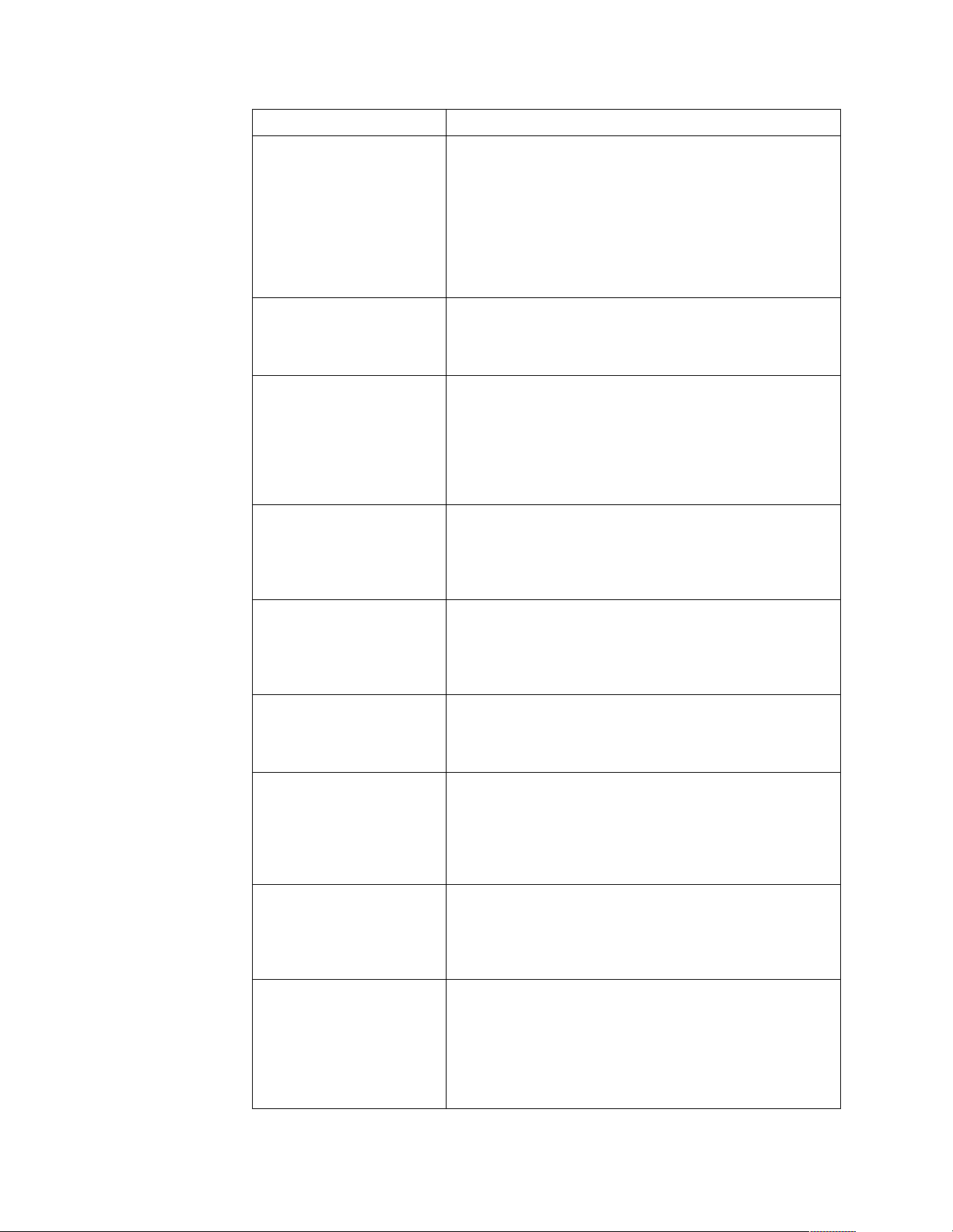

Even t ID Type Desc ri p tio n

01 Error Explanation: T eam name and physical adapter name are

the same. This is an invalid configuration.

Action: Reconfigure the adapter team by double-clicking

the PROSet icon in the control panel.

02 Error Explanation: Unable to allocate required resources.

Action: Free some memory resources and restart.

03 Error Explanation: Unable to read required registry parameters.

Action: Reconfigure the adapter team by double-clicking

the PROSet icon in the control panel.

04 Error Explanation: Unable to bind to physical adapter.

Action: Reconfigure the adapter team by double-clicking

the PROSet icon in the control panel.

05 Error Explanation: Unable to initialize an adapter team.

Action: Reconfigure the adapter team by double-clicking

the PROSet icon in the control panel.

06 Informational Explanation: Team nn. Primary adapter is initialized.

Action: None.

07 Informational Explanation: Team nn. Secondary adapter is initialized.

Action: None.

08 Informational Explanation: Team nn. V irtual adapter or Team is

initialized.

Action: None.

09 Informational Explanation: Team nn. Primary adapter is switching over.

Action: None.

10 Warning Explanation: Team nn. Adapter link down.

Action: Make sure the adapter is functioning properly.

11 Informational Explanation: Team nn. Secondary adapter took over.

Action: None.

12 Warning Explanation: Team nn. Secondary adapter is deactivated

from th e T eam.

Action: Make sure the secondary adapter is functio ning

properly and t hat t he adapt er c able is s ecur ely co nnec ted t o

the LAN.

13 Informational Explanation: Team nn. Secondary adapte r has r ejoi ned the

Team.

Action: None.

14 Informational Explanation: Team nn. Secondary adapter link is up.

Action: None.

15 Error Explanation: Team nn. The last adapter has lost its link.

Network connection has been lost.

Action: Shut down the server and replace the adapters;

then, restart the server to reestablish the connection.

16 Informational Explanation: Team nn. An adapter has reestablish e d the

link. Network connection has been restored.

Action: None.

Table 6. NDIS (Windows NT or Windows 2000) driver teaming messages for the

Ethernet controller.

Diagnostics 27

Page 36

Even t ID Type Desc ri p tio n

17 Informational Explanation: Team nn. Preferre d pri mary adap ter has been

detected.

Action: None.

18 Informational Explanation: Team nn. Preferred secondary adapter has

been detected.

Action: None.

19 Informational Explanation: Team nn. Prefe rre d prim ary ada pter took

over.

Action: None.

20 Informational Explanation: Team nn. Preferred secondary adapter took

over.

Action: None.

21 Warning Explanation: Team nn. Primary adapter does not sense any

Probe s . Possibl e reason: partitioned Team.

Action: Make sure the cables of the adapter team are

connected to the same LAN segment. Reconfigure the team

if necessary.

Table 6. NDIS (Windows NT or Windows 2000) driver teaming messages for the

Ethernet controller.

28 Hardware Maintenance Manual: xSeries 200

Page 37

Configuring the server

The following configuration programs ar e pro vided with the server:

• Configuration/Setup Utility

The Configura tion /S etup Utilit y program is part of the BIOS code that comes

with the server. You can use this program to configure serial- and parallelconnector assignments, change the drive startup sequenc e, set the date and time,

and set passwords. See “Using the Configuration/Setup Utility program” for

more information.

• SCSISelect Utility

With the SCSIS e le ct Uti l i ty p rogram, you ca n co n fi gu re the devices tha t a re

attached to the op tio nal SCSI adapter. Use this program to change defa ult value s,

resolve configuration conflicts, and perform a low-level format on a SCSI hard

disk drive. See “Using the SCSISelect utility program (some models)” on page 32

for more information.

• ServeRAID programs

The ServeRAID programs come with the optional ServeRAID adapters and with

server models that have a ServeRAID adapte r pr ei nstalled. If a ServeRAID

adapter has been installed in the server, you must use the ServeRAID

configuration program to define and configure the dis k-array s ubsyste m before

you install the operating system.

• ServerGuide CDs

The ServerGuide CDs include softwa re setup an d installa t io n tools spec if ically

designed for IBM 200 servers. You can use these CDs during the initial

installation of the server to configure the server hardware and simplify the NOS

installation. The ServerGuid e CDs also cont ain a collec tion of ap plicat io n

programs, which you can install after the server is up and running.

Using the Configuration/Setup Utility program

This section provides the instructions for starting the Configuration/Setup Utility

program and also provides descri ptions of the menu choices that are available.

Starting the Configuration/Setup Utility program

Complete the following steps to start the Configuration/Setup Utility program:

1. Turn on the server and watch the monitor screen.

2. When the message Press F1 for Configuration/Setup appears, press F1.

3. Follow the instructions that app ear on the screen.

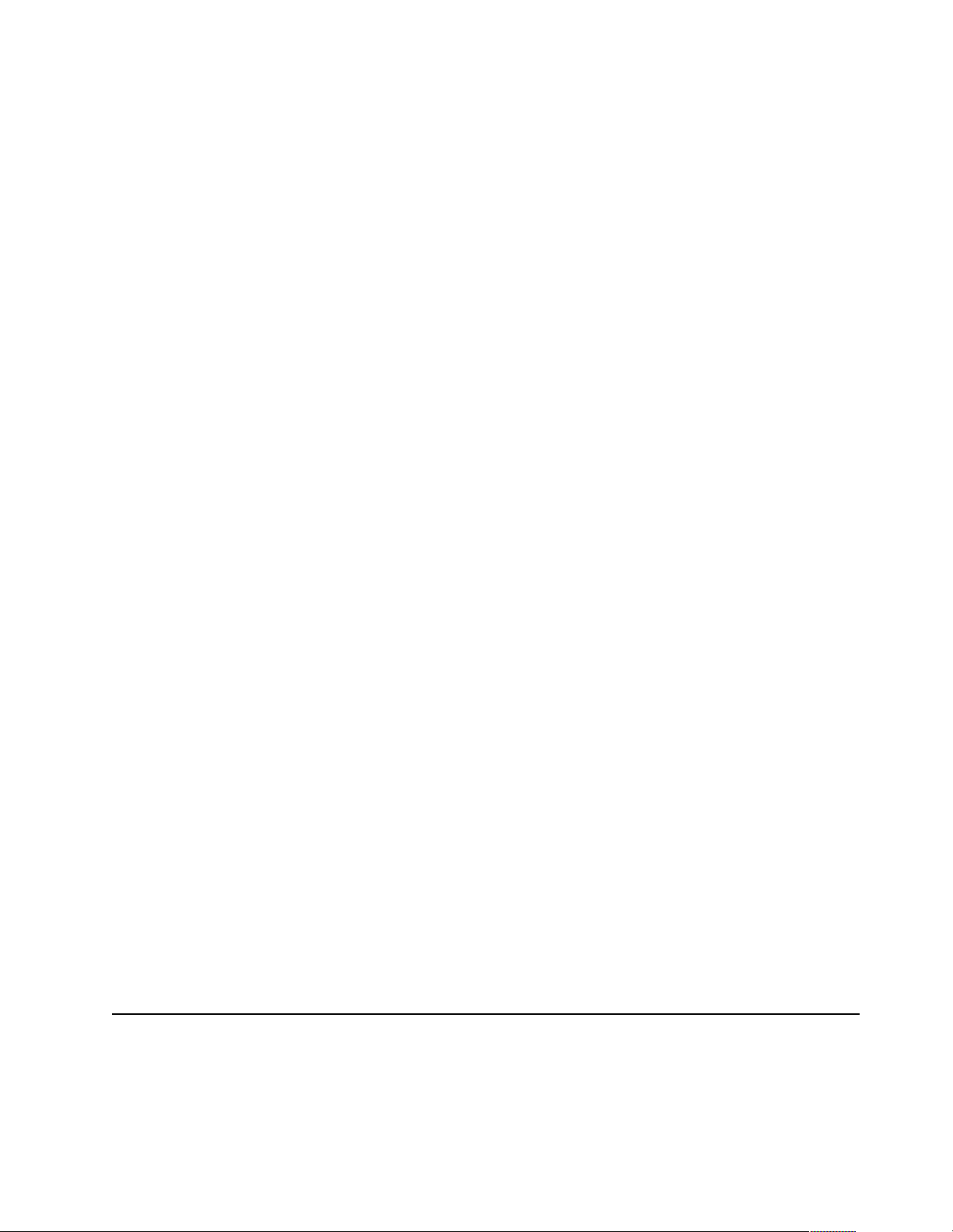

Choices avail able from the Configuration/Setup main menu

From the Configuration/S etup Ut ility main menu, you can select settings that you

want to change. The Configuration/Setup Utility main menu is similar to the

following illustration:

© Copyright IBM Corp. 2000 29

Page 38

CMOS Setup Utility - Copyright (c) 1984 - 2000 Award Software

Configuration/Setup Utility

Select Option:

System Summary

Product Data

Devices & I/O Ports

Start Options

Frequency Control

Date and Time

System Security

Advanced Setup

Power Management Setup

Save & Exit Setup

Load Optimized Defaults

Exit Without Saving

Move Enter: Select F1: General Help

F10: Save ESC: Exit

Note:

1. You can press F1 to display help information for a selected menu item.

2. The choices on some menus might diffe r sl ightly from the ones that are

described in this book, depending on the BIOS version in the server.

Descriptions of the choices that are available from the main menu are as follows:

• System summary

Select this choice to display configuration information. This includes the type and

speed of the microprocess ors and the amount of memory that is installed.

Changes that you make to configuration settings appear on this summary screen.

You cannot edit the fields.

This choice appears on both the full and limited Configuration/Setup Utility

menus.

• Product data

Select this choice to view system information, such as the machine type and

model, the server serial number, and the revision level or issue date of the BIOS

stored in the flash electronicall y eras abl e programmable read-only memory

(EEPROM).

• Devices and I/O port s

Select t his choic e to v ie w or chan ge th e as sig nmen ts fo r de vice s and input /out put

ports. This choice appears only on the full Configuration/Setup Utility main

menu.

• Start Options

Select thi s choice to view or ch ange the start opti on s. Start options tak e e ffect

when you start the server.

You can select keyboard operating characteristics, such as the keyboard speed.

You also can specify whether the server starts with the keyboard number lock on

or off.

The server uses a startup sequence to determine the device from which the

operating system starts. For example, you can define a startup sequence that

checks for a startable diskette in the diskette drive, then checks the hard disk

drive in bay 5, and then checks a network adapter.

30 Hardware Maintenance Manual: xSeries 200

Page 39

You can enable a virus-warning test that checks for changes in the master boot

record at startup. You also can choose to r un POST in the quick mode, and read

the microproce ssor serial number.

• Frequency Control

Select this choice to enable or disable the auto-detect DIMM/PCI clock.

• Date and Time

Select thi s choice to set the system date and time.

The system time is in a 24-hour format: hour:minute:second.

Note: You may also set the date and time using the procedures provided on the

ServerGuide CDs.

• System Security

Select this choice to set a power-on or an a dmi nistrator password.

See “Using passwords” on page 32 for more information.

• Advanced Setup

Select this choice to change values for advanced hardware features, such as Cache

Control and PCI configuration.

A message appears above the choices on this menu to alert you that the system

might malfunction if these options are configured incorrectly. Follow the

instructions on the screen carefully.

— Cache Control

Select this choice to enable or disable th e microprocessor cache.

Attention: Do not make changes to the Cache Control unless directed to do

so by an IBM authorized service representative.

— ROM Shadowing

Select thi s choice to enabl e or disable the state of a ROM shadowing.

— Chipset Feature

Select this choice to modify settings that control features of the core chip set

on the syste m board.

Attention: Do not m a k e changes to the Ch ipset Feature unless directed to d o

so by IB M .

— Memory Settings

If a memory error i s detected du ring POST or me mory configuration, the

serve r can automatically disa ble the fai ling memory bank and continue

operat ing with reduced memory capacity. If this occurs, you must manually

enable the memory bank after the problem is corrected. Select Memory

Settings from the Advanced Setup menu, use the arrow keys to highlight the

bank that you want to enable; then, use the arrow keys to select Enable.

• Power Manag em e n t Setup