Page 1

Intel® Server Compute Blade SBX82:

Hardware Maintenance Manual and

Troubleshooting Guide

A Guide for Technically Qualified Assemblers of Intel Identified Subassemblies &

Products

Order Number C90896-001

Page 2

12

1

Disclaimer

Information in this document is provided in connection with Intel

or otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel's Terms and

Conditions of Sale for such products.

Intel assumes no liability whatsoever, and Intel disclaims any express or implied w arranty, relating to sale and/or use of

Intel products including liability or warranties relating to fitness for a particular purpose, merchantability, or infringement

of any patent, copyright or other intellectual property right.

Intel products are not designed, intended or authorized for use in any medical, life saving, or life sustaining applications

or for any other application in which the failure of the Intel product could create a situation where personal injury or

death may occur. Intel may make changes to specifications and product descriptions at any time, without notice.

Intel, Pentium, Itanium and Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the

United States and other countries.

© Copyright Intel Corporation 2004

2

ii Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

®

products. No license, express or implied, by estoppel

Page 3

Contents

Safety and regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Electrical Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Handling electrostatic discharge-sensitive devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Regulatory specifications and disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Electromagnetic compatibility notices (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Electromagnetic compatibility notices (International) . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Introducing the Intel

Features and specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reliability, availability, and serviceability features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intel® Server Compute Blade SBX82 features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Intel® Server Compute Blade SBX82 specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Notices and statements used in this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Using power, controls, jumpers, switches, and indicators . . . . . . . . . . . . . . . . . . . . . . . . 9

Turning on the blade server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Turning off the blade server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Understanding the control panel and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System board illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using system board switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using switch block 2 (SW2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using Light Path Diagnostics to troubleshoot the system board. . . . . . . . . . . . . . . . . 15

®

Server Compute Blade SBX82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Customer replaceable units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System reliability considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Handling static-sensitive devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Major components of the blade server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Removing the blade server from the SBCE unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Opening the blade server cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removing the blade server bezel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installing a SCSI hard disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Removing a SCSI hard disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing memory modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing an additional processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing an I/O expansion card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installing a small form-factor expansion card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing a standard form-factor expansion card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the Intel® Blade Server SCSI Expansion Module SBESCSI . . . . . . . . . . . . . . . . 32

Installing a SCSI storage expansion unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing a SCSI disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Opening the SCSI storage expansion unit cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installing an I/O expansion card in the SCSI storage expansion unit. . . . . . . . . . . . . . . . . . 38

Replacing the battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Completing the installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing the blade server bezel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Closing the blade server cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

iii

Page 4

Installing the blade server in the SBCE unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Updating your blade server configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Field replaceable units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Microprocessor removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removal Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removal procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

System board assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

System board component locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

System board LED locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

System board replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5 Configuring the blade server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Using the Configuration/Setup Utility program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Starting the Configuration/Setup Utility program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Configuration/Setup Utility menu choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Using passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Using the PXE boot agent utility program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Firmware updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configuring the Gigabit Ethernet controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Blade server Ethernet controller enumeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configuring a SCSI RAID array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Using the LSI Logic Configuration Utility program. . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

General checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Diagnostic tools overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

POST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

POST error logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Viewing error logs from the Configuration/Setup Utility program . . . . . . . . . . . . . . . . 63

Diagnostic programs and error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Starting the diagnostic programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Viewing the test log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Diagnostic error message tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Error symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Error symptom charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Small computer system interface messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Light Path Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Memory errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Recovering the BIOS code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Automatic BIOS recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Backup page jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7 BIOS, Diagnostics and Firmware update procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Updating the BIOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Updating the Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Updating the BMC and SDR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Online (OS Present) BIOS Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

BIOS Update from Windows Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

GUI operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Steps to perform update (GUI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

iv Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 5

Steps to extract the Windows Update to the hard drive (GUI) . . . . . . . . . . . . . . 72

Steps to extract DOS update files to diskette (GUI). . . . . . . . . . . . . . . . . . . . . . 72

Command Line Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Steps to perform update in Unattended Mode (Command Line) . . . . . . . . . . . . 73

Steps to extract the Windows Update to the hard drive in Unattended Mode

(Command Line) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Steps to extract DOS update files to diskette in Unattended Mode (Command

Line). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

BIOS Update from Linux Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

GUI operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Command Line Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Steps to perform update in Unattended Mode (Command Line) . . . . . . . . . . . . 74

Steps to extract the Windows Update to the hard drive in Unattended Mode

(Command Line) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Steps to extract DOS update files to diskette in Unattended Mode (Command

Line). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

System Event Log messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

SEL Viewer utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

SEL Viewer command-line arguments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Graphical User Interface (GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

SEL Viewer Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Pull-Down Menu – File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

File Menu Item – Open... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

File Menu Item – Save As... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

File Menu Item – Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Pull-Down Menu – SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SEL Menu Item – Reload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SEL Menu Item – Properties.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

SEL Menu Item – Clear SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

SEL Menu Item – Sort By. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Pull-Down Menu – View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

View Menu Item – Hide SEL Info Window/View SEL Info Window. . . . . . . . . . . 83

View Menu Item – Display In Hex/Display In Text. . . . . . . . . . . . . . . . . . . . . . . . 83

View Menu Item – Resolution Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Pull-Down Menu – Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Help Menu Item – General Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Help Menu Item – About. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

OEM SEL data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

SEL Viewer display information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

OEM SEL entry definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

POST OEM SEL formats with timestamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

SMI OEM SEL formats with timestamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

POST OEM SEL formats without timestamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

POST processor event/error SEL format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

SMI OEM SEL formats without timestamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SMI processor event/error SEL format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

SMI memory event/error SEL format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

SMI bus event/error SEL format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

SMI chipset event/error SEL format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

8 Symptom-to-FRU index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Beep symptoms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Contents v

Page 6

No-beep symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Diagnostic error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

POST error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Light Path Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Error symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Service processor error codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

SCSI error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Temperature error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Power error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

System shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

System errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Temperature-related system shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

DASD checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Undetermined problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Problem determination tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

9 Parts listing, Intel

®

Server Compute Blade SBX82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

A Getting help and technical assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Before you call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Using the documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Getting help and information from the World Wide Web . . . . . . . . . . . . . . . . . . . . . . . . . . 131

vi Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 7

Safety and regulatory information

W

✏ NOTE

The service procedures are designed to help you isolate problems. They are written with the

assumption that you have model-specific training on all computers, or that you are familiar

with the computers, functions, terminology, and service information provided in this

manual.

Important Safety Instructions

Read all caution and safety statements in this document before performing any of the

instructions. See Intel Server Boards and Server Chassis Safety Information on the

Resource CD and/or at http:\\support.intel.com

ichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warn- und Sicherheitshinweise in diesem Dokument, bevor

Sie eine der Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise

zu Intel-Serverplatinen und -Servergehäusen auf der Ressourcen-CD oder unter

http:\\support.intel.com

重要安全指导

.

在执行任何指令之前,请阅读本文档中的所有注意事项及安全声明。参见 Resource

CD(资源光盘) 和/或 http:\\support.intel.com

Chassis Safety Information(《Intel 服务器主板与服务器机箱安全信息》)。

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce

document avant de suivre toute instruction. Consultez Intel Server Boards and Server

Chassis Safety Information sur le CD Resource CD ou bien rendez-vous sur le site

http:\\support.intel.com

.

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de

realizar cualquiera de las instrucciones. Vea Intel Server Boards and Server Chassis

Safety Information en el CD Resource y/o en http:\\support.intel.com

.

上的 Intel Server Boards and Server

.

vii

Page 8

xx

General Safety

Follow these rules to ensure general safety:

• Observe good housekeeping in the area of the machines during and after maintenance.

• When lifting any heavy object:

1. Ensure you can stand safely without slipping.

2. Distribute the weight of the object equally between your feet.

3. Use a slow lifting force. Never move suddenly, or twist, when you attempt to lift.

4. Lift by standing or by pushing up with you leg muscles; this action removes the strain from the

muscles in your back. Do not attempt to lift any object that weighs more than 16 kg (35lb) or any

object that you think is too heavy for you.

• Do not perform any action that causes hazards to the customer, or makes the equipment unsafe.

• Before you start the machine, ensure that other service representatives and the customer’s

personnel are not in a hazardous position.

• Place removed covers and other parts in a safe place, away from all personnel, while you are

servicing the machine.

• Keep your tool case away from walk areas so that other people will not trip over it.

• Do not wear loose clothing that can be trapped in the moving parts of a machine. Ensure that

your sleeves are fastened or rolled up above your elbows. If your hair is long, fasten it.

• Insert the ends of your necktie or scarf inside clothing, or fasten it with a nonconductive clip,

approximately 8 centimeters (3 inches) from the end.

• Do not wear jewelry, chains, metal-frame eyeglasses, or metal fasteners for your clothing.

Remember: Metal objects are good electrical conductors.

• Wear safety glasses when you are: hammering, drilling soldering, cutting wire, attaching

springs, using solvents, or working in any othe r conditions that might be hazardous to your e yes.

• After service, reinstall all safety shields, guards, labels, and ground wires. Replace any safety

device that is worn or defective.

• Reinstall all covers correctly before returning the machine to the customer.

Electrical Safety

CAUTIO N:

Electrical current from power, telephone, and communication cables can be hazard ous. To

avoid personal injury or equipment damage, disconnect the server system power cords,

telecommunication systems, networks, and modems before you open the server covers, unless

instructed otherwise in the installation and configuration procedures.

Important: Disconnect all power before performing a mechanical inspection.

Observe the following rules when working on electrical equipment.

• Use only approved tools and test equipment. Some hand tools have handles covered with a soft

material that does not protect you when working with live electrical currents.

• Many customers have rubber floor mats (near their equipment) that contain small conductive

fibers to decrease electrostatic discharges. Do not use this type of mat to protect yourself from

electrical shock.

viii Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 9

• Find the emergency power-off (E PO) switch, d isco n nect swit ch, or electrical outlet in the room.

If an electrical accident occurs, you can quickly turn off the switch or unplug the power cord.

• Do not work alone under hazardous conditions, or near equipment that has hazardous voltages.

• Disconnect all power before:

— Performing a mechanical inspection

— Working near power supplies

— Removing or installing main units

• Before you start to work on the machine, unplug the power cord. If you cannot unplug it, ask the

customer to power -of f the wall box (that supplies po wer to the machine) and to lock the w all box

in the off position.

• If you need to work on a machine that has exposed electrical circuits, observe the following

precautions:

— Ensure that another person, familiar with the power-off controls, is near you. Remember:

another person must be there to switch off the power, if necessary.

— Use only one hand when working with powered-on electrical equipment; keep the other

hand in your pocket or behind your back.

— Remember: There must be a complete circuit to cause electrical shock. By observing the

above rule, you may prevent a current from passing through your body.

• When using testers, set controls correctly and use the approved probe leads and accessories for

that tester.

• Stand on suitable rubber mats (obtained locally, if necessary) to insulate you from grounds such

as metal floor strips and machine frames.

• Observe the special safety precautions when you work with very high voltages; these

instructions are in the safety sections of the maintenance information. Use extreme care when

measuring high voltages.

• Regularly inspect and maintain your electrical hand tools for safe operational condition.

• Do not use worn or broken tools and testers.

• Never assume that power has been disconnected from a circuit. First, check that it has been

powered-off.

• Always look carefully for possible hazards in your work area. Examples of these hazards are

moist floors, nongrounded power extension cables, power surges, and missing safety grounds.

• Do not touch live electrical circuits with the reflective surface of a plastic dental inspection

mirror. The surf ace is conductive; such touching can cause personal injury and machine damage.

• When the power is on and power supply units, blowers and fans are removed from their normal

operating position in a machine, do not attempt to service the units. This practice ensures correct

grounding of the units.

• If an electrical accident occurs, use caution:

— Switch power off

— Send another person to get help/medical aid

ix

Page 10

Handling electrostatic dischar ge-sensitive devices

Any computer part containing transistors or integrated circuits (IC) should be considered sensiti v e to

electrostatic discharge (ESD). ESD damage can occur when there is a difference in charge between

objects. Protect against ESD damage by equalizing the charge so that the server, the part, the work

mat, and the person handling the part are all at the same charge.

✏ NOTE

Use product-specific ESD procedures when they exceed the requirements noted here.

Make sure that the ESD-protective devices you use have been certified (ISO 9000) as fully ef fective.

When handling ESD-sensitive parts:

• Keep the parts in protective packages until they are inserted into the product.

• Avoid contact with other people.

• Wear a grounded wrist strap against your skin to eliminate static on your body.

• Prevent the part from touching your clothing. Most clothing is insulative and retains a charge

even when you are wearing a wrist strap.

• Use the black side of a grounded work mat to provide a static-free work surface. The mat is

especially useful when handling ESD-sensitive devices.

• Select a grounding system, such as those in the following list, to provide protection that meets

the specific service requirement.

— Attach the ESD ground clip to any frame ground, ground braid, or green-wire ground.

— Use an ESD common ground or reference point when working on a double-insulated or

battery-operated system. You can use coax or connector-outside shells on these systems.

— Use the round ground-prong of the AC plug on AC-operated computers.

✏ NOTE

The use of a grounding system is desirable but not required to protect against ESD

damage.

DANGER

Electrical current from power, telephone and communication cables is hazardous.

To avoid a shock hazard:

• Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this

product during an electrical storm.

• Connect all power cords to a properly wired and grounded electrical outlet.

• Connect to properly wired outlets any equipment that will be attached to this product.

• When possible, use one hand only to connect or disconnect signal cables.

• Never turn on any equipment when there is evidence of fire, water, or structural damage.

• Disconnect the attached power cords, telecommunications systems, networks, and modems before you

open the device covers, unless instructed otherwise in the installation and confi guration procedures.

• Connect and disconnect cables as described in the following table when installing, moving, or opening

covers on this product or attached devices.

x Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 11

xx

xx

To Connect T o Disconnect

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

CAUTIO N:

If your system has a module containing a lithium battery, replace it only with the same or an

equivalent type battery recommended by the manufacturer. If your system has a module

containing a lithium battery, replace it only with the same module type made by the same

manufacturer. The battery contains lithium and can explode if not properly used, handled, or

disposed of.

•Do not:

• Throw or immerse into water

• Heat to more than 100 degrees C (212 degrees F)

• Repair or disassemble

• Dispose of the battery as required by local ordinances or regulations.

CAUTIO N:

When laser products (such as CD-ROMs, DVD-ROM drives, fiber optic devices, or

transmitters) are installed, note the following:

• Do not remove the co vers. Remo ving the cov ers of the laser product could result in e xposure to

hazardous laser radiation. There are no serviceable parts inside the device.

• Use of controls or adjustments or performance of procedures other than those specified herein

might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the

following:

Laser radiation when open. Do not stare into the beam, do not view directly with optical instruments,

and avoid direct exposure to the beam.

xi

Page 12

xx

xx

xx

xx

≥18 kg (37 lbs) ≥32 kg (70.5 lbs) ≥55 kg (121.2 lbs)

CAUTIO N:

Use safe practices when lifting.

CAUTIO N:

2

1

CAUTIO N:

The power control button on the device and the power switch on the power supply do not

turn off the electrical current supplied to the device. The device also might have more than

one power cord. To remove all electrical current from the device, ensure that all power cords

are disconnected from the power source.

Do not place any object weighing more than 82 kg (180 lbs.) on top of rack-mounted devices.

CAUTIO N:

Do not place any object weighing more then 82 kg (180lbs.) on top of rack-mounted devices.

xii Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 13

xx

xx

CAUTIO N:

To avoid personal injury, before lifting the unit, remove all the blades to reduce the weight.

CAUTIO N:

Hazardous energy is present when the blade is connected to the power source. Always

replace the blade cover before installing the blade.

Regulatory specifications and disclaimers

Safety compliance

USA: UL 60950 - 3rd Edition/CSA 22.2. No. 60950

Canada: cUL certified - 3rd Edition/CSA 22.2. No. 60950- for

Canada (product bears the single cUL mark for U.S.

and Canada)

Europe: Low Voltage Directive, 73/23/EEC

TUV/CB to EN60950 3rd Edition

TUC/CB - EMKO-TSE (74-SEC) 207/94

International: TUVCB to IEC 60950, 3rd Edition plus all

international deviations

Australia/New Zealand: CB Report to IEC 60950, 3rd Edition plus

Australia/New Zealand deviations

xiii

Page 14

Electromagnetic compatibility (ECM)

USA: FCC CFR 47 Part 2 and 15, Verified Class A Limit

Canada: IC ICES-003 Class A Limit

Europe: EMC Directive, 89/336/EEC

EN55022, Class A Limit, Radiated & Conducted Emissions

EN55024 ITE Specific Immunity Standard

EN61000-4-2 ESD Immunity (Level 2 Contact Discharge, Level 3 Air Discharge)

EN61000-4-3 Radiated Immunity (Level 2)

EN61000-4-4 Electrical Fast Transient (Level 2)

EN61000-4-5 AC Surge

EN61000-4-6 Conducted RF

EN61000-4-8 Power Frequency Magnetic Fields

EN61000-4-11 Voltage Dips and Interrupts

EN6100-3-3 Voltage Flicker

Japan: VCCI Class A ITE (CISPR 22, Class A Limit)

IEC 1000-3-2 Limit for Harmonic Current Emissions

Australia/New

Zealand:

AS/NZS 3548, Class A Limit

Taiwan: BSMI Approval

Korea: RRL Approval

Russia: GOST Approval

Electromagnetic compatibility notices (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial env iron me nt. This

equipment generates, uses and can radiate radio frequency energy and if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his/her own expense.

✏ NOTE

Class A device definition: If a Class A device is installed within the is system, then the

system is to be considered a Class A system. In this configuration, operation of this

equipment in a residential area is likely to cause harmful interference.

✏ NOTE

This product is intended to be installed with CAT5 cable, or equivalent, to minimize

electrical interference.

xiv Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 15

Electromagnetic compatibility notices (International)

Europe (CE Declaration of Conformity): This product has been tested in accordance too, and

complies with the Low Voltage Directive (73/23/EEC) and EMC Directive (89/336/EEC). The

product has been marked with the CE Mark to illustrate its compliance.

Japan EMC Compatibility:

English translation of the notice above: This is a Class A product based on the standard of the

Voluntary Control Council for Interference by Information Technology Equipment (VCCI). If this

equipment is used in a domestic environment, radio disturbance may arise. When such trouble

occurs, the user may be required to take corrective actions.

ICES-003 (Canada): Cet appareil numérique respecte les limites bruits radioélectriques

applicables aux appareils numériques de Classe A prescrites dans la norme sur le matériel brouilleur:

"Appareils Numériques", NMB-003 édictée par le Ministre Canadian des Communications.

English translation of the notice above: This digital apparatus does not exceed the Class A limits

for radio noise emissions from digital apparatus set out in the interference-causing equipment

standard entitled "Digital Apparatus," ICES-003 of the Canadian Department of Communications.

BSMI (Taiwan): The BSMI Certification number and the following warning is located on the

product safety label which is located visibly on the external chassis.

xv

Page 16

RRL Korea:

English translation of the notice above:

Device User’s Information

Class A device This device complies with RRL EMC and is operated

in a commercial environment so that distributors or

users pay attention to this point.

If this product is sold or purchased improperly, please

exchange this product to one that can be used at

home.

Class B device This device complies with RRL EMC and is operated

in a residential area so that it can be used at all other

location as well as residential area.

✏ NOTE

Class A device: operated in a commercial area. Class B device: operated in a residential area.

xvi Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 17

1 Introducing the Intel® Server Compute Blade

SBX82

These high-performance blade servers are ideally suited for networking environments that require

superior processor performance, efficient memory management, flexibility , and reliable data storage.

This Hardware Maintenance Manual and Troubleshooting Guide provides information about:

• Setting up the blade server

• Starting and configuring the blade server

• Installing hardware options

• Installing the operating system

• Performing basic troubleshooting of the blade server

Record information about your Intel® Server Compute Blade SBX82 in the following table.

✏ NOTE

The model number and serial number are on the ID label that is behind the control panel

door on the front of the blade server, and on a label on the right side of the blade server that

is visible when the blade server is not in the SBCE unit.

Product name Intel® Server Compute Blade SBX82

Product code

Model number _____________________________________________

Serial number _____________________________________________

✏ NOTE

The illustrations in this document might differ slightly from your hardware.

1

Page 18

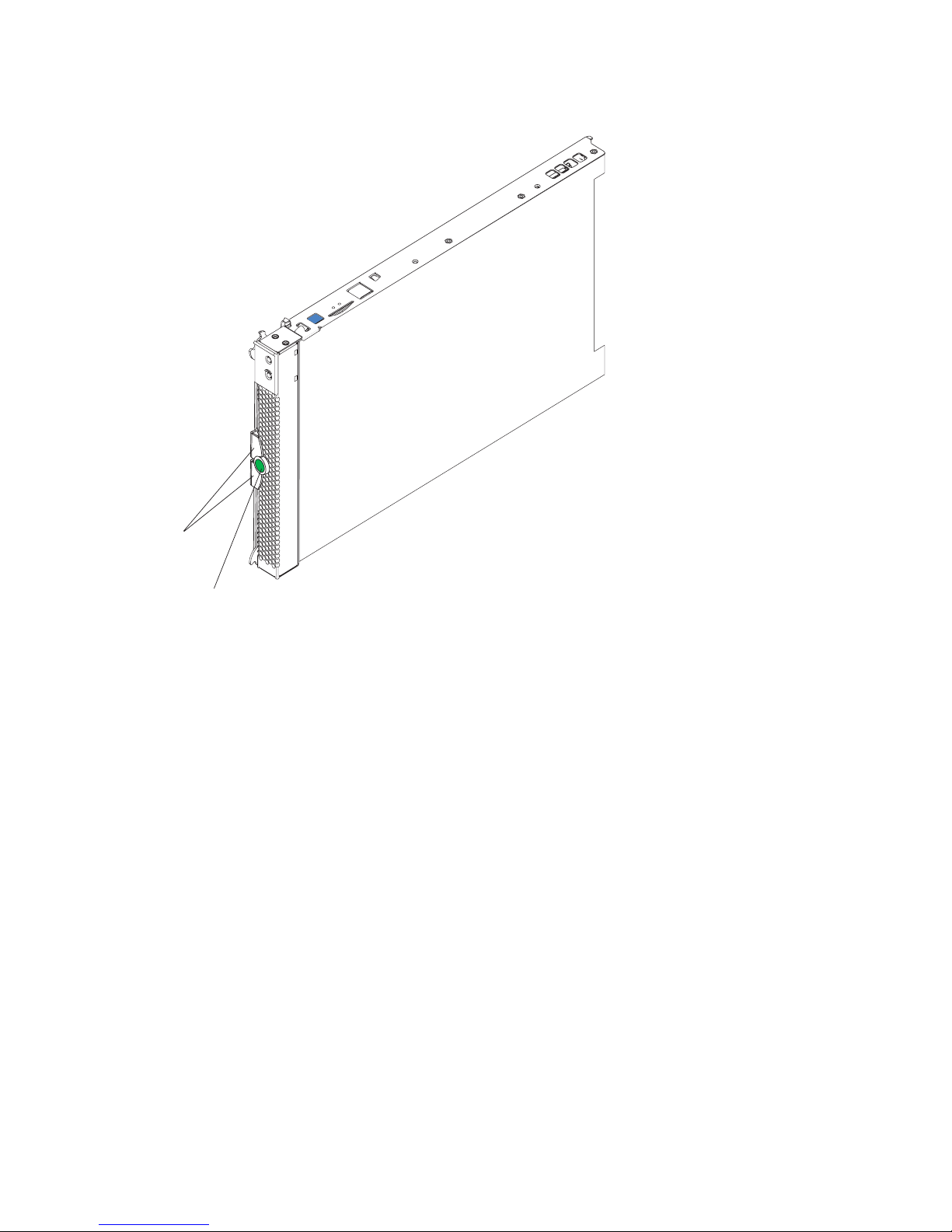

Figure 1. Blade server release levers

Release

levers

Release

button

A set of user labels comes with the Intel® Server Compute Blade SBX82. When you install the

blade server in the SBCE unit, write identifying information on a label and place the label on the

SBX82 unit bezel.

Figure 2 shows the placement of the label, just below the blade server, on the SBCE unit.

2 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 19

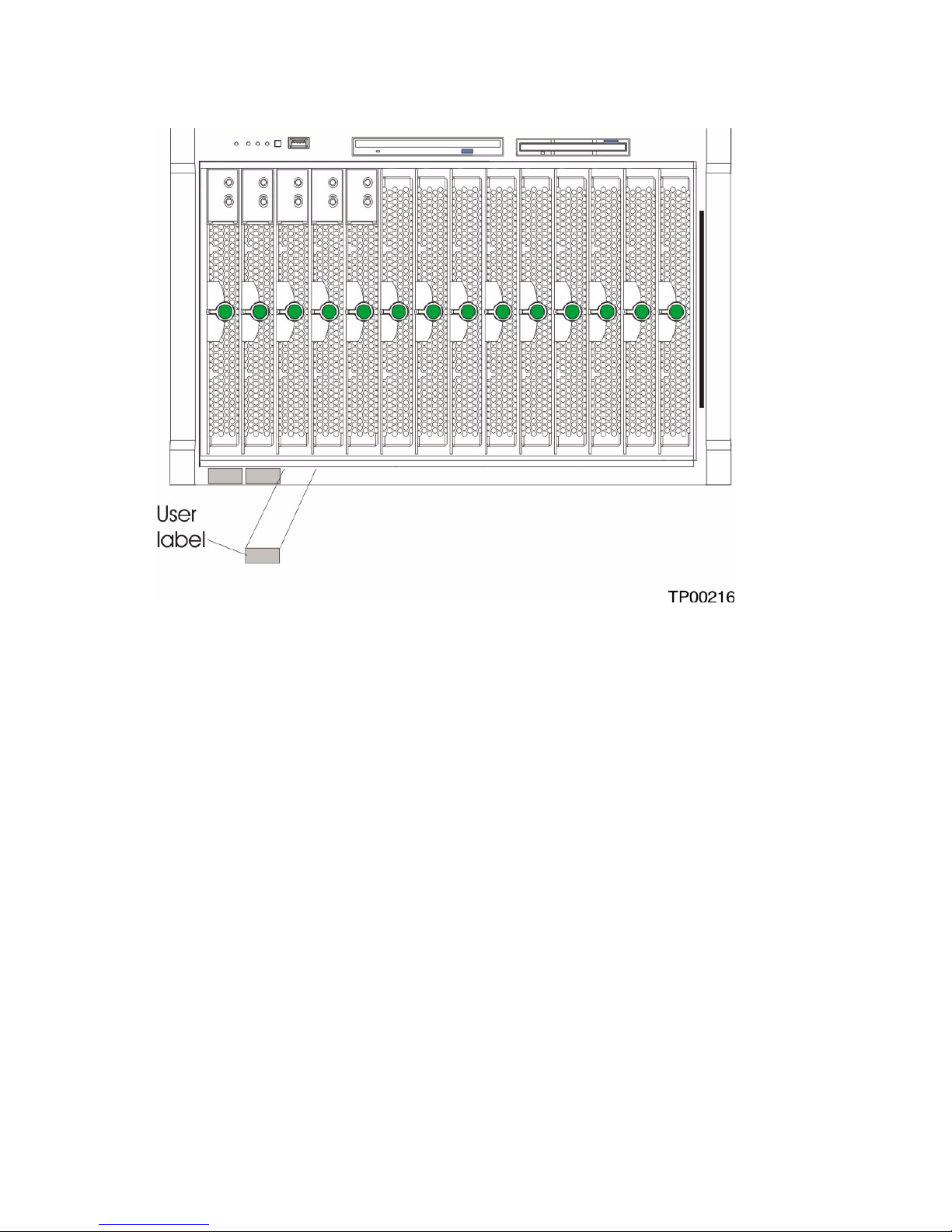

Figure 2. Label placement on the SBCE unit

Important: Do not place the label on the blade server itself or in any wa y block the ventilation holes

on the blade server.

3

Page 20

Features and specifications

This section provides a summary of the features and specifications of your blade server. Use the

Configuration/Setup Utility program to determine the specific type of processor that is in the blade

server.

Reliability, availability, and serviceability features

Three of the most important features in server design are reliability, availability, and serviceability

(RAS). These RAS features help to ensure the integrity of the data stored on the blade server; that

the blade server is available when you want to use it; and that should a failure occur, you can easily

diagnose and repair the failure with minimal inconvenience.

The blade server has the following RAS features:

• Advanced Configuration and Power Interface (ACPI)

• Automatic error retry or recovery

• Automatic server restart

• Built-in monitoring for temperature, voltage, hard disk drives, and flash drives

• Chipkill* memory for DIMMs with a capacity of 512 MB or greater

• Customer upgradeable basic input/output system (BIOS) code

• Diagnostic support of Ethernet controllers

• Error codes and messages

• ECC protection on the L2 cache

• ECC memory

• Failover Ethernet support

• Hot-swap drives on optional small computer system interface (SCSI) storage expansion unit

• Light Path Diagnostics* feature

• Power-on self-test (POST)

• Predictive Failure Analysis* (PFA) alerts

• Processor serial number access

• Service processor that communicates with the management module to enable remote blade

server management

• SDRAM with serial presence detect (SPD) and vital product data (VPD)

• System error logging

• VPD (includes information stored in nonvolatile memory for easier remote viewing)

• Wake on LAN* capability

4 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 21

Intel® Server Compute Blade SBX82 features

The design of your blade server takes advantage of advancements in memory management and data

storage. Your blade server uses the following features and technologies:

• Disk drive support

The blade server supports up to two 2.5-inch SCSI disk drives.

• Intel Architecture

Intel architecture technology leverages proven innovative technologies to build powerful,

scalable, reliable Intel-processor-based servers. The technology includes features such as Light

Path Diagnostics, Predictive Failure Analysis (PFA), and Advanced System Management.

• Impressive performance using the latest processor technology

Your blade server supports up to two Intel

least one processor installed; you can install an additional processor to further enhance

performance and symmetric multiprocessing (SMP) capability.

• Integrated network environment support

The blade server comes with two integrated dual Gigabit Ethernet controllers. Each Ethernet

controller has an interface for connecting to 10/100/1000-Mbps networks through an Ethernet-

compatible switch module on the SBCE unit. The blade server automatically selects between

10BASE-T and 100/1000BASE-TX environments. Each controller provides full-duplex (FDX)

capability, which enables simultaneous transmission and reception of data on the Ethernet local

area network (LAN). The controllers support Wake on LAN technology.

®

Xeon™ processors. The blade server comes with at

• I/O expansion

The blade server comes with two connectors on the system board for an optional expansion card,

such as the Intel

®

Blade Server Fibre Channel Expansion Card or the Intel® Blade Server

Ethernet Expansion Card, for adding more network communication capabilities to the blade

server.

• Large system memor y

The memory bus in your blade server supports up to 8GB of system memory. The memory

controller provides support for up to four industry-standard 1.8 V, 184-pin, double-data-rate

(DDR2-400), PC3200, registered synchronous dynamic random-access memory (SDRAM) with

error correcting code (ECC) DIMMs.

• Light Path Diagnostics

The Light Path Diagnostics feature provides light-emitting diodes (LEDs) to assist in isolating

problems with the blade server. An LED on the blade server control panel is lit if an unusual

condition or a problem occurs. If this happens, you can look at the LEDs on the system board to

locate the source of the problem.

• PCI Express*

PCI Express* is a fully serial interface that can be used for universal connectivity for use as a

chip-to-chip interconnect, I/O interconnect for adapter cards, and an I/O attachment point to

Gigabit networking devices. PCI Express bridges a PCI Express bus to a PCI-X bus and converts

the transactions on the PCI bus to transactions on the PCI-X bus. Using the expansion card

connector you can add additional LAN interfaces. The expansion card connector supports PCIX 133 and bridges PCI Express into PCI-X 133.

5

Page 22

• Power throttling

Each blade server is powered by two SBCE unit redundant 2000 W power supply modules. By

enforcing a power policy known as oversubscription, the SBCE unit can load-share power

between two power modules to ensure efficient power for each device in the SBCE unit. This

policy is enforced when the initial power is applied to the SBCE unit or when a blade server is

inserted into the SBCE unit.

The possible settings for this policy are:

— Redundant without performance impact

— Redundant with performance impact

— Non-redundant

You can configure an d monitor the po wer en vironment using the management module. For more

information about configuring and using power throttling, refer to your management module

manual.

Intel® Server Compute Blade SBX82 specifications

The following table provides a summary of the features and specifications of the Intel® Server

Compute Blade SBX82.

✏ NOTE

Power, cooling, removable-media drives, extern al por ts, and advanced system management

are provided by the SBCE unit.

✏ NOTE

The operating system in the blade server must provide USB support for the blade server to

recognize and use the keyboard, mouse, CD-ROM drive, and diskette drive. The SBCE unit

uses USB for internal communications with these devices.

6 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 23

Processor:

Supports up to two processors

®

• Intel

• Intel

Xeon™ processors with

an 800 MHz FSB at speeds

up to 3.6GHz

®

E7520 chipset

Memory:

• Dual channel 400 MHz

(DDR2) with four DIMM slots

(8 GB maximum)

• Type: 2-way interleaved,

DDR2, PC3200, ECC SDRAM

registered x4 (Chipkill*)

DIMMs only

• Supports 256 MB, 512 MB,

1 GB, and 2 GB DIMMs (four

DIMM slots)

Service Processor:

Renassas 2166 supports:

• RS-485 interface

• Serial over LAN (SOL)

•IPMI

Drives:

Support for two internal small

form-factor SCSI drives

Size:

• Height: 24.5 cm (9.7 inches)

• Depth: 44.6 cm (17.6 inches)

• Width: 2.9 cm (1.14 inches)

• Maximum weight: 5.4 kg

(12 lb)

Integrated functions:

• Dual Gigabit Ethernet

controllers

• Expansion card interface

• BMC with IPMI firmware

• ATI* 7000M video controller

• LSI* 1020 SCSI controller

• Light Path Diagnostics

• Local service processor

• RS-485 interface for

communication with the

management module

• Four USB buses for

communication with

keyboard, mouse, diskette

drive, and CD-ROM drive

Predictive Failure Analysis

(PFA) alerts:

• Processor

• Memory

Electrical Input:

12 V dc

Environment:

• Air temperature:

— Blade server on: 10° to 35°

C (50° to 95° F). Altitude: 0

to 914 m (2998.69 ft)

— Blade server on: 10° to 32°

C (50° to 89.6° F). Altitude:

914 m to 2134 m (2998.69

ft to 7000 ft)

— Blade server off: -40° to

60° C (-40° to 140° F)

•Humidity:

— Blade server on: 8% to

80%

— Blade server off: 5% to

80%

Related publications

In addition to this Hardware Maintenance Manual and Troubleshooting Guide, the following

documentation is provided in Portable Document Format (PDF) on the Intel Server Compute Blade

SBX82 Resource CD that came with your blade server.

• Intel® Server Compute Blade SBX82 Installation and User’s Guide

This document contains instructions for setting up and configuring the SBX82 unit and basic

instructions for installing some options. It also contains general information about the SBX82

unit.

7

Page 24

Notices and statements used in this document

The following notices and statements are used in the documentation:

• Note: These notices provide important tips, guidance, or advice.

• Important: These notices provide information or advice that might help you a vo id incon v enient

or problem situations.

• Attention: These notices indicate possible damage to programs, devices, or data. An attention

notice is placed just before the instruction or situation in which damage could occur.

• Caution: These statements indicate situations that can be potentially hazardous to you. A

caution statement is placed just before the description of a potentially hazardous procedure step

or situation.

• Danger: These statements indicate situations that can be potentially lethal or extremely

hazardous to you. A danger statement is placed just before the description of a potentially lethal

or extremely hazardous procedure step or situation.

8 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 25

2 Using power, controls, jumpers, switches, and

indicators

This chapter describes the power features, how to turn on and turn off the blade server, what the

controls and indicators mean, and where the system board jumpers and switches are located and how

to use them.

Turning on the blade server

After you connect the blade server to power through the SBCE unit, the blade server can start in any

of the following ways:

• You can press the power-control button on the front of the blade server (behind the control panel

door) to start the server.

✏ NOTE

Wait until the power-on LED on the blade server flashes slowly before pressing the blade

server power-control button. During this time, the service processor in the management

module is initializing; therefore, the power-control button on the blade server does not

respond.

✏ NOTE

While the blade server is powering up, the power-on LED on the front of the server is lit.

See “Understanding the control panel and LEDs” on page 11 for the power-on LED states.

• If a power failure occurs, the SBCE unit and then the blade server can start automatically when

power is restored if the blade server is configured through the management module to do so.

• You can turn on the blade serv er remo tely by means of the service processor in the management

module.

• If your operating system supports the Wake on LAN feature and the blade server power -o n LED

is flashing slowly, the Wake on LAN feature can turn on the blade server, if the Wake on LAN

feature has not been disabled through the management-module Web interface.

9

Page 26

Turning off the blade server

When you turn off the blade server, it is still connected to power through the SBCE unit. The blade

server can respond to requests from the service processor, such as a remote request to turn on the

blade server. To remove all power from the blade server, you must remove it from the SBCE unit.

Shut down your operating system before you turn off the blade server. See your operating-system

documentation for information about shutting down the operating system.

The blade server can be turned off in any of the following ways:

• You can press the power-control button on the blade server behind the control panel door. See

“Understanding the control panel and LEDs” on page 11. This starts an orderly shutdo wn of the

operating system, if this feature is supported by your operating system.

✏ NOTE

After turning off the blade server, wait at least 5 seconds before you press the powercontrol button to turn on the blade server again.

• If the operating system stops functioning, you can press and hold the power-control button for

more than 4 seconds to turn off the blade server.

• The management module can turn off the blade server.

✏ NOTE

After turning off the blade server, wait at least 30 seconds for its hard disk drives or flash

drives to stop before you remove the blade server from the SBCE unit.

10 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 27

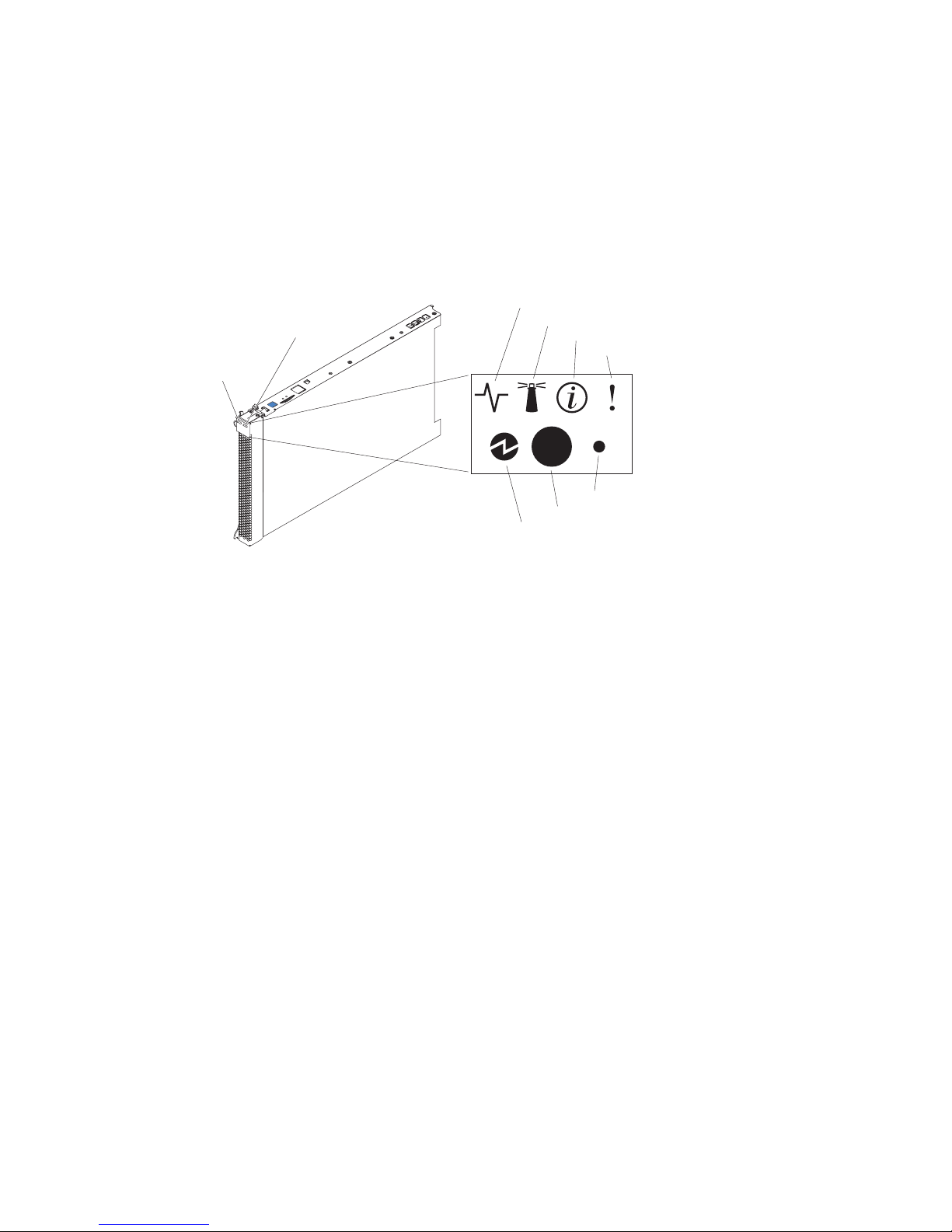

Understanding the control panel and LEDs

This section describes the controls and LEDs on your SBCE unit.

✏ NOTE

The illustrations in this document might differ slightly from your hardware.

✏ NOTE

The control panel door is shown in the closed (normal) position in the illustration. To access

the power-control button, you must open the control panel door.

CD/diskette/USB

select button

eyboard/mouse/video

elect button

Activity LED

Location LED

Information LED

Blade-error LED

NMI

Power-control button

Power-on LED

Keyboard/mouse/video (KVM) select button: Press this button to associate the keyboard port,

mouse port, and video port with this blade server. The LED on this button flashes while the request

is being processed, then is lit when the ownership of the keyboard, mouse, and video has been

transferred to this blade server. It can take approximately 20 seconds to switch the keyboard, video,

and mouse control to the blade server.

Although the keyboard that is attached to the SBCE unit is a PS/2*-style keyboard, communication

with it is through the USB. The operating system in the blade server must provide USB support for

the blade server to recognize and use the keyboard and mouse. The SBCE unit uses USB for internal

communication with these devices. When you are running an operating system that does not have

USB device drivers, such as in the following situations, the keyboard responds very slowly:

• Running the blade server integrated diagnostics

• Running a BIOS update diskette on a blade server

• Updating the diagnostics on a blade server

• Running the Broadcom firmware CD for a blade server

If there is no response when you press the keyboard/mouse/video select button, you can use the

management-module Web interface to determine whether local control has been disabled on the

blade server.

11

Page 28

You can also press k eyboard k eys in the follo wing sequence to swit ch ke yboard/mouse/video control

between blade servers:

NumLock NumLock blade_server_number Enter

Where blade_server_number is the two-digit number for the blade bay in which the blade server

is installed.

CD/diskette/USB select button: Press this button to associate the CD-ROM drive, diskette drive,

and USB port with this blade server. The LED on this button flashes while the request is being

processed, then is lit when the ownership of the CD-ROM drive, diskette drive, and USB port has

been transferred to this blade server. It can take approximately 20 seconds for the operating system

in this blade server to recognize the CD-ROM drive, diskette drive, and USB port.

The operating system in the blade server must provide USB support for the blade server to recognize

and use the CD-ROM drive, diskette drive, and USB port. The SBCE unit uses the USB for internal

communication with these devices. If there is no response when you press the CD/diskette/USB

select button, you can use the management-module Web interface to determine whether local control

has been disabled on the blade server.

Activity LED: When this green LED is lit, it indicates that there is hard disk drive, flash drive, or

network activity.

Location LED: When this blue LED is lit, it has been turned on remotely by the system

administrator to aid in visually locating the blade server . The location LED on the SBCE unit will be

lit also. The location LED can be turned off through the management-module Web interface.

Information LED: When this amber LED is lit, it indicates that information about a system error

for this blade server has been placed in the system error log. The information LED can be turned off

through the management-module Web interface.

Blade Error LED: When this amber LED is lit, it indicates that a system error has occurred in the

blade server. The blade error LED will turn off only after the error condition is corrected.

Power-on LED: This green LED indicates the power status of the blade server in the following

manner:

• Flashing rapidly: The service processor on the blade server is handshaking with the management

module.

• Flashing slowly: The blade server has power but is not turned on.

• Lit continuously: The blade server has power and is turned on.

Power-control button: This button is behind the control panel door. Press this button to turn on or

turn off the blade server.

✏ NOTE

The power-control button has effect only if local power control is enabled for the blade

server. Local power control is enabled and disabled through the management-module Web

interface.

Non-maskable interrupt (NMI) button: Press this button to start diagnostic and debugging tests.

Use the tip of a paper clip or other pointed object to reset this button.

12 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 29

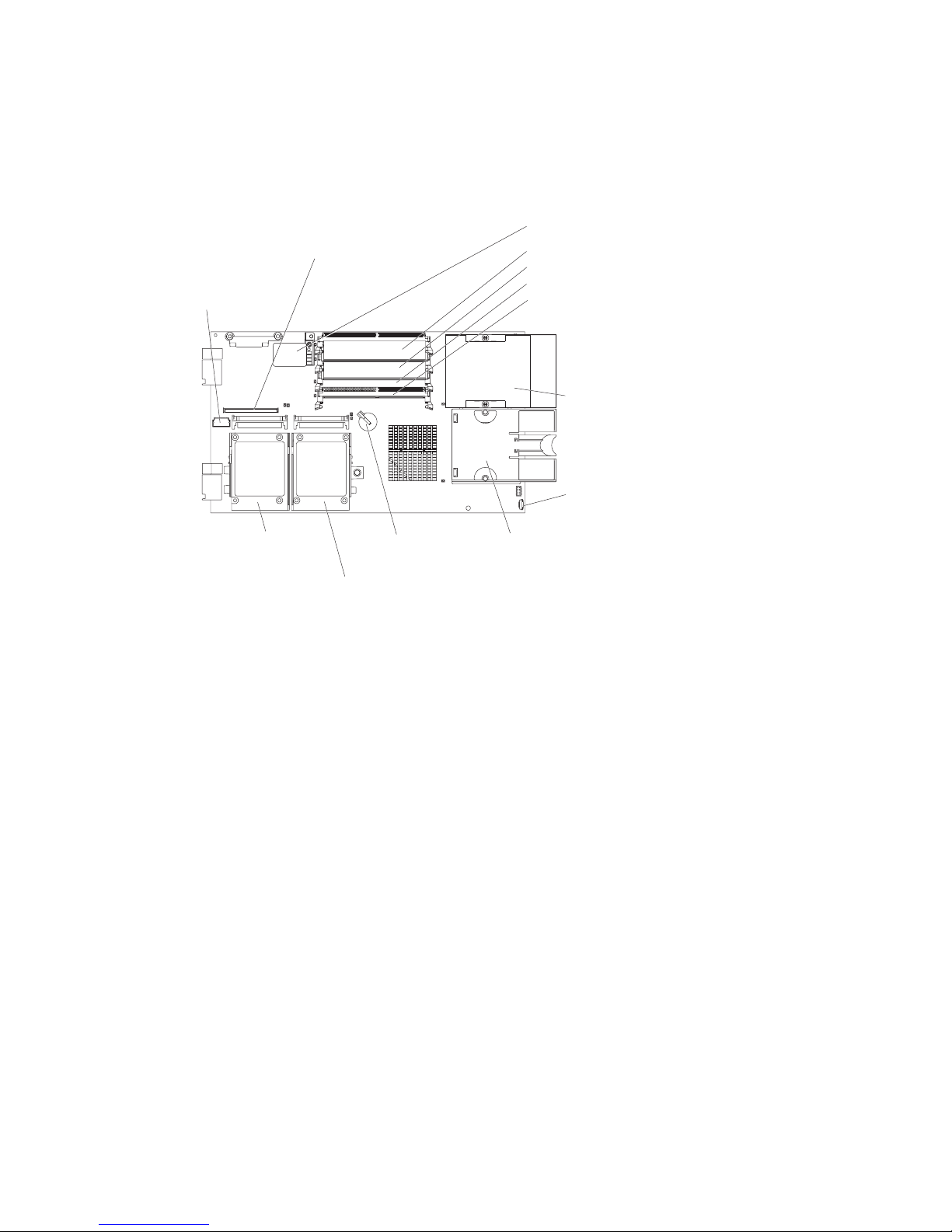

System board illustration

The following illustration shows the system-board components, including connectors for userinstallable options, for the blade server.

Figure 3. System board components

I/O expansion

option connector (J34)

I/O expansion

option connector (J131)

Blade expansion

connector (J132)

DIMM 1 (J113)

DIMM 2 (J111)

DIMM 3 (J112)

DIMM 4 (J110)

Microprocessor 1

and heatsink (U66)

Control panel

connector (J64)

(J94)

BatterySCSI connector 2

SCSI connector 1

(J95)

Microprocessor socket 2

and heatsink (U70)

Using system board switches

This section describes the system board switches on your Intel® Server Compute Blade SBX82.

✏ NOTE

The illustrations in this document might differ slightly from your hardware.

Figure 4 on page 14 and Figure 5 on page 15 show the LEDs on the system board for the Intel®

Server Compute Blade SBX82. Refer to Table 1 and Table 2 on page 15 for more information about

the Light Path Diagnostics LED locations and settings. Refer to these illustrations and tables when

solving problems with the blade server.

✏ NOTE

Power is av ailable to relight the Light Path Diagnostics LEDs for a small period of time after

the blade server is removed from the SBCE unit. During that period of time, you can relight

the Light Path Diagnostics LEDs for a maximum of 25 seconds (or less, depending on the

number of LEDs that are lit and the length of time the blade server is removed from the

SBCE unit) by pressing the Light Path Diagnostics button. The Light Path Diagnostics

power present LED (CR111) lights when the Light Path Diagnostics button is pressed if

power is available to relight the blade-error LEDs. If the Light Path Diagnostics power

present LED does not light when the Light Path Diagnostics button is pressed, no power is

available to light the blade-error LEDs, and they will be unable to provide any diagnostic

information.

13

Page 30

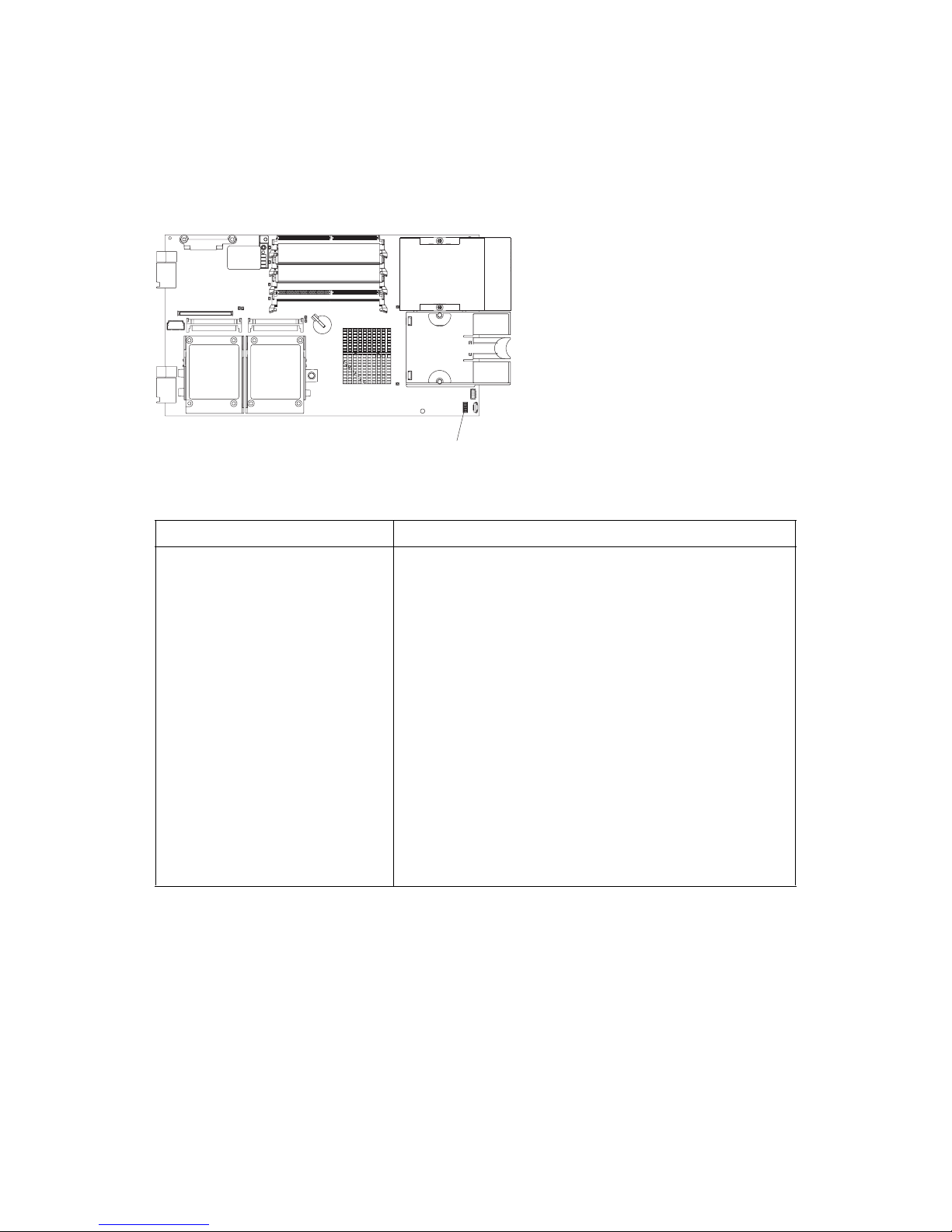

Using switch block 2 (SW2)

You must remove the blade server from the SBCE unit, open the cover, and press the Light Path

Diagnostics button to light any error LEDs that were turned on during processing. The following

illustration and Table 1 on page 14 show the location and the settings for SW2.

Figure 4. System board switch block (SW2) location

Switch block (SW2)

Table 1. Switch block 2 (SW2) and settings

Switch number Description

SW2 Switch block: Eight switches

• 1 - BIOS backup page jumper.

- Open: the BIOS boots from the Primary BIOS page.

- Closed: the BIOS boots from the backup BIOS page.

• 2 - Wake on LAN Bypass

- Open: Enabled

- Closed: Disabled (default)

•3 - Reserved

•4 - Reserved

•5 - Reserved

• 6 - Clear CMOS

- Open: Disabled

- Closed: Enabled

•7 - Reserved

• 8 - Bypass power-on password

- Open: Disabled (default)

- Closed: Enabled

14 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 31

Using Light Path Diagnostics to troubleshoot the system board

After the system board is removed from the chassis, you can press Light Path Diagnostics (SW4) to

troubleshoot system board component problems. See Figure 5 on page 15 and Table 2 on page 15 for

more information about locating Light Path Diagnostics LEDs and what to do if an error LED is lit.

Figure 5. Light Path Diagnostics switch (SW4) and error LEDs

SW4

DIMM 1 error LED

DIMM 2 error LED

DIMM 3 error LED

DIMM 4 error LED

Microprocessor 1 error LED

Microprocessor 2 error LED

Table 2. SW4 Light Path Diagnostics LED locations

LED name and location Description

DIMM 1 (CR6), DIMM 2 (CR5),

DIMM 3 (CR4), DIMM 4 (CR201) error

BMC fault (CR11) There is a problem with the corresponding BMC.

Processor 1 error (CR12)

Processor 2 error (CR13)

System board fault (CR30) There is a problem with the corresponding system board.

Light Path Diagnostics LED (CR111) Lights to show the circuit is active and functioning.

There is a problem with the corresponding DIMM.

There is a problem with the corresponding processor.

Figure 6. Light Path Diagnostics switch (SW4) and error LEDs

NMI

MIS

S BRD

TEMP

15

Page 32

Table 3. SW4 Light Path Diagnostics LED locations

LED error Action

NMI Check the error log for additional information. Reboot the

MIS Check the processors to make sure they are at the same

SBRD Reboot the blade server. If the error still exists, replace the

TEMP Check the SBCE unit blowers and air inlets. Check the room

Light Path Diagnostics LED Check the Light Path Diagnostics LED for errors

Light Path Diagnostics button (SW4) Press SW4 to locate faults on the system board. If the

See “Diagnosing problems using Light Path Diagnostics” on page 70 for informatio n on what

action to take if there is a component error.

blade server. If the error still exists, replace the system board.

speed.

system board.

temperature.

processor or memory LED is lit, reseat the component. If the

LED remains lit, replace the defective component.

16 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 33

3 Customer replaceable units

This chapter provides instructions for installing hardware options in your blade server. Some optionremoval instructions are provided in case you need to remove one option to install another.

Installation guidelines

Before you begin installing options in the blade server, read the following information:

• Read the safety information beginning on page vii and the guidelines in “Handling staticsensitive devices.” This information will help you work safely with your blade server and

options.

• Back up all important data before you make changes to the disk drives.

• Before you remove a hot-swap blade server from the SBCE unit, you must shut down the

operating system and turn off the blade server. You do not have to shut down the SBCE unit

itself.

• Blue on a component indicates touch points, where you can grip the component to remove it

from or install it in the blade server, or open or close a latch.

• Orange on a component or an orange label on or near a component indicates that the component

can be hot-swapped, which means that if the blade server and operating system support hotswap capability, you can remove or install the component while the server is running. (Orange

can also indicate touch points on hot-swap components.) See the instructions for removing or

installing a specific hot-swap component for any additional procedures that you might have to

perform before you remove or install the component.

System reliability considerations

To help ensure proper cooling and system reliability, make sure that processor socket 2 always

contains either a processor heat sink filler or a processor and heat sink.

✏ NOTE

When using a single processor, you must install it into the CPU 1 socket.

Handling static-sensitive devices

Attention: Static electricity can damage electronic devices and your blade server. To avoid

damage, keep static-sensitive devices in their non-conductive packages until you are ready to install

them.

To reduce the possibility of damage from electrostatic discharge, observe the following precautions:

• When working on the SBCE unit, use an electrostatic discharge (ESD) wrist strap, especially

when you will be handling modules, options, and blade servers. To work properly, the wrist

strap must have a good cont act at both ends (touch ing your skin at o ne end and f irmly co nnected

to the ESD connector on the front or back of the SBCE unit).

• Limit your movement. Movement can cause static electricity to build up around you.

• Handle the device carefully, holding it by its edges or its frame.

• Do not touch solder joints, pins, or exposed printed circuitry.

17

Page 34

• Do not leave the device where others can handle and possibly damage it.

• While the device is still in its non-conductiv e package, touch it to an unpainted metal part of the

SBCE unit or any unpainted metal surface on any other grounded rack component in the rack

you are installing the device in for at least 2 seconds. This drains static electricity from the

package and from your body.

• Remove the device from its package and install it directly into the blade serv er without setting it

down. If it is necessary to set the device down, pl ace it back into its non-conductiv e package. Do

not place the device on your blade server cover or on a metal surface.

• Take additional care when handling devices during cold weather. Heating reduces indoor

humidity and increases static electricity.

Major components of the blade server

You must remove the blade server from the SBCE unit and remove the cover to see the components.

✏ NOTE

The illustrations in this document might differ slightly from your hardware.

The following figure shows the major components of the SBX82 unit.

Figure 7. Major components of the Intel

DIMM

Blade expansion

unit connector

SCSI hard

disk drives

Processor

heat sink filler

®

Server Compute Blade SBX82

Heat sink

Processor

Bezel

assembly

•

18 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 35

Removing the blade server from the SBCE unit

✏ NOTE

The illustrations in this section might differ slightly from your hardware.

The following figure shows how to remove the blade server from the SBCE unit.

✏ Attention

• To maintain proper system cooling, do not operate the SBCE unit for more than one minute

without either a blade server, expansion unit, or filler blade installed in each blade bay.

• Make note of the bay number. Reinstalling a blade server into a different bay than the one

from which it was removed could have unintended consequences. Some configuration

information and update options are established according to bay number; if you reinstall the

blade server into a different bay, you might need to reconfigure the blade server.

Complete the following steps to remove the blade server:

1. If the blade server is operating, shut down the operating system; then, press the power-control

button (behind the blade server control panel door) to turn off the blade server.

✏ Attention

Wait at least 30 seconds, until the drives st op spinning, before proceeding to the next step.

2. Open the two release levers (see figure above). The blade server moves out of the bay

approximately 0.6 cm (0.25 inch).

3. Pull the blade server out of the bay. Spring-loaded doors farther back in the bay move into place

to cover the bay temporarily.

4. Place either a filler blade or another blade server in the bay within one minute. The recessed

spring-loaded doors will move out of the way as you insert the blade server.

19

Page 36

xx

Opening the blade server cover

The following illustration shows how to open the cover on the blade server.

Blade-cover

release

Blade-cover

release

Complete the following steps to open the blade server cover:

1. Read the safety information beginning on page vii and “Installation guidelines” on page 17.

2. Carefully lay the blade server down on a flat, non-conducti ve surface, with the cover side up.

3. Press the blade-cover release on each side of the blade server and lift the co ver open, as shown in

the illustration.

4. Lay the cover flat, or lift it from the blade server and store for future use.

Statement 21:

CAUTIO N:

Hazardous energy is present when the blade server is connected to the power source. Always

replace the blade cover before installing the blade server.

20 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 37

Removing the blade server bezel assembly

To install certain options, you must first remove the blade server bezel assembly. The following

illustration shows how to remove the bezel assembly from the blade server.

Bezel-assembly

release

Bezel-assembly

release

Control panel

connector

Complete the following steps to remove the blade server bezel assembly:

1. Read the safety information beginning on page vii and “Installation guidelines” on page 17.

2. Open the blade server cover (see “Opening the blade server cover” on page 20 for instructions).

3. Press the bezel-assembly release and pull the bezel assembly away from the blade server

approximately 1.2 cm (0.5 inch).

4. Disconnect the control-panel cable from the control-panel connector.

5. Pull the bezel assembly away from the blade server.

6. Store the bezel assembly in a safe place.

Control-panel

cable

Installing a SCSI hard disk drive

The blade server has two connectors on the system board for installing optional Ultra320 SCSI hard

disk drives.

Each Ultra320 SCSI connector is on the same bus. Depending on your blade server, at least one

SCSI hard disk drive might alread y be installed . If your blade serv er is equipped with one SCSI hard

disk drive, you can install an additional SCSI hard disk drive. These two SCSI hard disk drives can

be used to implement and manage a redundant array of independ ent disks (RAID) level-1. See

“Configuring a SCSI RAID array” on page 59 for information about SCSI RAID configuration.

Attention: To maintain proper system cooling, do not operate the system unit without a blade

server, expansion unit, or filler blade installed in each blade bay.

The following illustration shows how to install a SCSI hard disk drive and tray in the blade server.

21

Page 38

Figure 8. Installing a SCSI drive

Hard

drive

release

lever

SCSI ID 1

SCSI ID 0

Hard drive

release

lever

✏ Note

Do not install a SCSI hard disk drive in SCSI connector 1 (SCSI ID 1) if you intend to also install an

optional standard expansion card. The standard expansion card occupies the same area as the second

drive.

To install a SCSI hard disk drive, complete the following steps:

1. Read the safety information beginning on page vii and “Installation guidelines” on page 17.

2. Shut down the operating system, turn off the blade server, and remove the blade server from the

SBCE unit (see “Removing the blade server from the SBCE unit” on page 19 for instructions).

3. Carefully lay the blade server on a flat, non-conductive surface.

4. Open the blade server cover (see “Opening the blade server cover” on page 20 for instructions).

5. Locate SCSI connector 0 (J95).

Attention: Do not press on the top of the drive. Pressing the top could damage the drive.

6. Place the drive into the tray and push it, from the rear edge of the drive, into the connector until

the drive moves past the lever at the back of the tray. The drive clicks into place.

7. If you have other options to install or remove, do so now; otherwise, go to “Completing the

installation” on page 41.

Removing a SCSI hard disk drive

To remove the SCSI hard disk drive, complete the following steps:

1. Read the safety information beginning on page vii and “Installation guidelines” on page 17.

2. Shut down the operating system, turn off the blade server, and remove the blade server from the

SBCE unit (see “Removing the blade server from the SBCE unit” on page 19 for instructions).

3. Carefully lay the blade server on a flat, non-conductive surface.

4. Open the blade server cover (see “Opening the blade server cover” on page 20 for instructions).

22 Intel® Server Compute Blade SBX82: Hardware Maintenance Manual and Troubleshooting Guide

Page 39

5. Locate SCSI connecto r 1 and sl owly pull the blue lever at the back of the hard disk drive tray to

disengage the drive from its tray.

6. From the rear edge of the drive, slide the drive out of the SCSI connector.

Attention: To maintain proper system cooling, do not operate the system unit without either a

blade server, expansion unit, or filler blade installed in each blade bay for more than 1 minute.

Installing memory modules

The following notes describe the types of dual inline memory modules (DIMMs) that the blade

server supports and other information that you must consider when installing DIMMs:

• The system board contains four DIMM connectors and supports two-way memory interleaving.