Page 1

IBM Storage Networking SAN512B-6

IBM

Installation, Service, and User Guide

MTM Service information: 8961-F08

SC27-8966-02

Page 2

Page 3

IBM Storage Networking SAN512B-6

IBM

Installation, Service, and User Guide

MTM Service information: 8961-F08

SC27-8966-02

Page 4

Read Before Using

This product contains software that is licensed under written license agreements. Your use of such software is subject to the

license agreements under which they are provided.

Before you use the information in this publication, be sure to read the general information under “Notices” on page 251.

Copyright

Portions Copyright © 2016 Brocade Communications Systems, Inc. All Rights Reserved.

© Copyright IBM Corporation 2017.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures .............. vii

Tables ............... ix

Read this first ............ xi

Getting help .............. xi

Accessibility features ........... xi

How to send your comments ........ xii

Safety and environmental notices ... xiii

Safety notices and labels.......... xiii

Cautions ............... xiii

Danger notices ............. xv

Safety labels ............. xviii

Attention notices ............ xx

ESD precautions............. xx

Rack safety .............. xx

Environmental notices ........... xx

About this document ........ xxi

Product documents ........... xxi

Brocade documents ........... xxi

IBM and Brocade product matrix....... xxii

Chapter 1. Introducing the SAN512B-6 . 1

Product features ............. 1

Hardware components ........... 2

Port-side view of device .......... 3

Port-side slot numbering .......... 5

Nonport-side view of the device ........ 5

Chapter 2. Preparing for the Installation 7

Safety precautions ............ 7

Facility requirements ........... 10

Time and items required for installation ..... 11

Quick installation checklists ......... 13

Items shipped ............. 15

Assembling the rack hardware ....... 30

Installing the device in the rack....... 32

Removing the protective cover ........ 34

Chapter 4. Initial Setup and Verification 37

Configuration and verification task guide .... 37

Items required ............. 38

Providing power to the device ........ 39

Connecting power cord to AC power supplies.. 39

||

|

Connecting power cord to HVAC/HVDC power

supplies .............. 40

||

Establishing a serial connection to the device ... 46

Configuring the IP addresses ........ 48

Establishing an Ethernet connection to the device.. 49

Setting the domain ID ........... 50

Setting the date and time .......... 50

Setting the time zone .......... 51

Synchronizing local time with an external source 52

Customizing the chassis and switch name .... 53

Veifying the PID mode .......... 53

Verifying installed licenses and license key .... 54

Verifying correct operation ......... 54

Backing up the configuration ........ 55

Powering down the chassis ......... 56

Chapter 5. Installing Transceivers and

Cables ............... 57

Supported transceivers and cables ....... 57

Core routing blades........... 58

Time and items required .......... 60

Precautions specific to transceivers and cables ... 61

Cleaning the fiber-optic connectors ...... 61

Cable management ............ 62

Installing an SFP+ transceiver ........ 62

Replacing an SFP+ transceiver ........ 64

Installing a QSFP transceiver ........ 65

Replacing a QSFP transceiver ........ 66

Verifying the operation of new transceivers.... 68

Chapter 3. Mounting the Device .... 17

Mounting options ............ 17

Mounting precautions ........... 17

Unpacking and transporting the device ..... 19

Port-side slot numbering .......... 20

Installing the 14U Rack Mount Kit for Four-Post

Racks ................ 20

Time and items required ......... 20

Parts list .............. 21

||

Parts list – NEBS kit .......... 22

Assembling the rack hardware ....... 23

Installing the device in the rack....... 26

Installing the 14U Chassis Mid-Mount Rack Kit for

Two-Post Racks ............. 28

Time and Items required ......... 28

Parts list .............. 29

© Copyright IBM Corp. 2017 iii

Chapter 6. Monitoring the switch ... 69

Interpreting port blade LEDs ........ 69

Interpreting extension blade LEDs....... 72

Interpreting control processor blade LEDs .... 74

Interpreting core routing blade LEDs ...... 77

Interpreting WWN card LEDs ........ 78

Interpreting power supply LEDs ....... 79

Interpreting fan assembly LEDs ....... 82

Interpreting POST and boot results ...... 84

POST ............... 84

Boot ................ 85

Using monitoring commands ........ 85

chassisShow ............. 86

errDump and errShow.......... 89

fanShow .............. 90

haShow............... 90

Page 6

historyShow ............. 91

psShow............... 92

sensorShow ............. 92

slotShow .............. 92

sfpShow .............. 93

switchShow ............. 99

supportSave ............. 100

tempShow ............. 101

Running diagnostic tests.......... 103

Chapter 7. Port and Extension Blades 105

Port blade overview ........... 105

FC32-48 blade port numbering and trunking 105

Extension blade overview ......... 107

Extension features ........... 108

SX6 blade port numbering and trunking ... 109

Precautions specific to the blade ....... 110

Faulty blade indicators .......... 111

Time and items required for removal and

installation .............. 111

Removing a blade ............ 111

Installing a blade ............ 114

Verifying blade operation ......... 115

Chapter 8. Core Routing Blades ... 117

Core routing blade overview ........ 117

CR32-8 port numbering ......... 117

ICL trunking groups .......... 119

ICL cabling configurations ........ 120

Precautions specific to the blade ....... 122

Faulty core routing blade indicators ...... 123

||

Time and items required.......... 124

Removing a core routing blade ....... 124

Installing a core routing blade........ 127

Verifying blade operation ......... 128

Chapter 9. Control Processor Blades 129

Control processor blade overview ...... 129

CPX6 port identification ......... 130

Precautions specific to the blade ....... 131

Blade fault indicators ........... 131

Blade replacement task guide ........ 132

Time and items required for replacement .... 133

Preparing for replacement ......... 133

Replacing a CP blade........... 134

Hot-swap procedure .......... 135

Cold-swap procedure.......... 141

Completing the replacement ....... 143

Verifying blade operation ......... 144

Chapter 10. WWN Cards....... 147

WWN card overview........... 147

WWN card location and numbering..... 147

Precautions specific to WWN cards ...... 148

WWN card fault indicators ......... 148

WWN card replacement task guide ...... 150

Time and items required for replacement .... 150

Using the wwnrecover utility ........ 151

Preparing for WWN card replacement ..... 152

Hot-swap replacement .......... 153

Cold-swap replacement .......... 154

Removing the WWN card and bezel...... 156

Configuring airflow direction on WWN cards .. 157

Verifying WWN card operation ....... 159

Chapter 11. Power Supply Assemblies 161

AC power supply overview ........ 161

||

Fan and power supply airflow ...... 162

||

Power supply assembly numbering ..... 163

||

HVAC/HVDC power supply overview.... 164

||

Precautions specific to power supply assembly .. 166

Power supply assembly fault indicators .... 166

Power supply assembly task guide ...... 167

Time and items required.......... 168

Removing a power supply ......... 168

Installing a power supply ......... 169

Verifying power supply operation ...... 170

Chapter 12. Fan Assemblies ..... 173

Fan assembly overview .......... 173

Fan and power supply airflow ...... 174

Fan assembly numbering ........ 176

Precautions specific to fan assemblies ..... 176

Fan assembly fault indicators ........ 177

Fan assembly task guide ......... 177

Time and items required.......... 178

Removing a fan assembly ......... 178

Installing a fan assembly ......... 179

Verifying fan operation .......... 180

Chapter 13. Blade Filler Panels .... 181

Blade filler panel removal and replacement ... 181

Removing a filler panel .......... 181

Installing a filler panel .......... 182

Chapter 14. Cable management comb 185

Cable management comb overview ...... 185

Time and items required for removal and

installation .............. 185

Removing cable management comb ...... 185

Installing cable management comb ...... 186

Chapter 15. Chassis door ...... 187

Chassis door overview .......... 187

Time and items required.......... 187

Removing a chassis door ......... 187

Installing a chassis door .......... 188

Chapter 16. Replacing the Chassis 191

Chassis replacement overview........ 191

Precautions specific to chassis replacement ... 191

Chassis replacement task guide ....... 192

Customer replacement responsibilities .... 193

IBM service replacement responsibilities ... 203

Chapter 17. Removing the battery .. 207

Appendix A. SAN rack ....... 209

||

Installing the IBM SAN rack ........ 209

||

iv SAN512B-6 Installation, Service, and User Guide

Page 7

Step 1. Position the rack ......... 210

||

Step 2. Level the rack.......... 210

||

Step 3. Attach the stabilizers ....... 211

||

Step 4. Attach the rack to a concrete floor ... 212

||

Step 5. Attach the rack to a concrete floor

|

beneath a raised floor ......... 214

||

Step 6. Attach the mounting plates ..... 217

||

Step 7. Attach the front door ....... 217

||

Step 8. Check the customer's ac power source 218

||

Step 9. Check the intelligent power distribution

|

units ............... 219

||

Step 10. Connect switch and device cables... 221

||

Step 11. Power on the rack ........ 221

||

Service procedures ........... 222

||

Director power-off procedure ....... 222

||

Removing and replacing the iPDUs ..... 223

||

Removing and replacing the front or rear rack

|

door ............... 224

||

Relocating the rack .......... 225

||

Parts information ........... 226

||

SAN rack specifications ......... 233

||

Appendix B. Product specifications 235

Notices .............. 251

Trademarks .............. 252

Homologation statement ......... 252

Electronic emission notices ......... 252

Federal Communications Commission Statement 252

Industry Canada Compliance Statement ... 253

Australia and New Zealand Class A Statement 253

European Union Electromagnetic Compatibility

Directive .............. 253

Germany Electromagnetic Compatibility

Directive .............. 254

People's Republic of China Class A Statement 256

Taiwan Class A Statement ........ 256

Taiwan Contact Information ....... 256

Japan Voluntary Control Council for Interference

Class A Statement ........... 256

Japan Electronics and Information Technology

Industries Association Statement ...... 257

Korean Communications Commission Class A

Statement ............. 257

Russia Electromagnetic Interference Class A

Statement ............. 258

Index ............... 259

Contents v

Page 8

vi SAN512B-6 Installation, Service, and User Guide

Page 9

Figures

1. Port side of the SAN512B-6 (sample

configuration) ............ 4

2. Nonport side of the SAN512B-6 (sample

configuration) ............ 6

3. Rack kit parts ............ 22

4. NEBS kit parts list .......... 23

||

5. Left and right shelf brackets installed on rails 24

6. Nut and screw locations for mounting the

device .............. 25

7. Positioning the device for installation in a rack 27

8. Attaching port side of device to rack rails 28

9. Rack kit parts ............ 30

10. Attaching the rear tray to the rack rails 31

11. Attaching the front tray to the rack rails 32

12. Placing the device in the trays ...... 33

13. Attaching trays to the device....... 34

14. Removing protective cover from SAN512B-6 35

15. QSFP transceiver with separate cable .... 58

16. 2 km QSFP 16 Gbps with integrated cable 59

17. 2 km LWL QSFP transceiver with integrated

cable ............... 60

18. Female-to-female patch cable for QFSP

connections ............ 60

19. Optical transceiver extraction tool ..... 61

20. Installing an SFP+ transceiver with pull tab

into blade port ........... 63

21. Installing an SFP+ transceiver with bail latch

into blade port ........... 63

22. Replacing a SFP+ optical transceiver with pull

tab into blade port .......... 64

23. Installing an SFP+ transceiver with bail latch

into blade port ........... 65

24. Installing a QSFP transceiver into blade port 66

25. Installing a QSFP optical transceiver into blade

port ............... 67

26. FC32-48 port blade LEDs ........ 70

27. SX6 Extension blade LEDs ....... 72

28. Control processor blade (CPX6) ...... 75

29. CR32-8 core routing blade LEDs ..... 77

30. WWN card LEDs on bezel ....... 79

31. 2870 W AC Power supply LED ...... 79

32. Fan assembly LEDs .......... 83

33. FC32-48 blade port numbering...... 106

34. SX6 extension blade port numbering 109

35. Removing and replacing port or extension

blade .............. 113

36. CR32-8 core routing blade port numbering 118

37. ICL cable connections (sample configuration) 121

38. Core-edge ICL topology ........ 122

39. Removing and installing a core routing blade 126

40. CPX6 blade port identification ...... 130

41. Removal and replacement of the control

processor blade (CPX6) ........ 136

42. Removal and replacement of the control

processor blade (CPX6) ........ 142

43. WWN card location and numbering .... 148

44. Removing and installing WWN cards 157

||

45. AC power supply assembly....... 161

||

46. Airflow labels ........... 162

47. Power supply assembly numbering .... 163

||

48. HVAC/HVDC power supply assembly 165

||

49. Removing and installing power supply

assembly ............. 169

50. Fan assembly ........... 174

51. Airflow labels ........... 175

52. Fan assembly numbering ....... 176

53. Removing and installing a fan assembly 179

54. Removing and installing the blade filler panel 182

55. Removing and installing the blade filler panel 183

56. Removing or installing cable management

comb .............. 186

57. Removal and replacement of the chassis door 188

58. Removing protective cover from SAN512B-6

chassis .............. 189

59. Removal and replacement of the chassis door 190

60. Location of battery holder ....... 207

61. Caster wheel ............ 210

||

||

62. Adjusting the leveling feet ....... 211

||

63. Stabilizers............. 211

64. Attaching the rack to a concrete floor 212

||

65. Leveling the rack .......... 214

||

||

66. Attaching the rack to a raised floor .... 215

||

67. Leveling the rack .......... 216

68. Attaching the mounting plate ...... 217

||

69. Attaching the front door ........ 218

||

||

70. Power cord cabling (rack side view) .... 221

||

71. SAN rack with iPDU locations ...... 223

72. Removing the rack door ........ 225

||

73. iPDU locations ........... 232

||

||

74. iPDU (PN 00FW787) for director attachment 233

© Copyright IBM Corp. 2017 vii

Page 10

viii SAN512B-6 Installation, Service, and User Guide

Page 11

Tables

1. Brocade and IBM product and model number

matrix .............. xxii

2. Facility requirements ......... 10

3. Installation tasks, time, and items required 12

4. Installation prerequisites ........ 13

5. Installation and basic system configuration 13

6. Configuration and verification tasks .... 37

||

7. HVAC/HVDC power cable ....... 45

8. Example: tsTimeZone command parameter

selection for the US time zones ...... 52

9. Supported transceivers and cables ..... 57

10. Port blade LED descriptions ....... 70

11. Extension blade LED descriptions ..... 73

12. CP blade LED descriptions ....... 75

13. Core routing blade LED descriptions .... 78

14. WWN card LED descriptions ...... 79

15. 2870 W AC Power supply LED descriptions 81

16. 2870 W AC Power supply LED descriptions

(continued)............. 82

17. Fan assembly LED descriptions ...... 83

18. External port to slotShow port mapping for

core blades ............ 119

19. Messages that may indicate WWN card

failure .............. 149

20. RASlog messages from WWN card audit 151

||

21. HVAC/HVDC power cable wiring .... 166

22. Critical information checklist ...... 195

||

23. Power cables for side-mount iPDUs .... 231

|

24. Items supplied with the 14U director chassis

||

||

mount kit............. 231

25. IBM SAN rack specifications ...... 233

© Copyright IBM Corp. 2017 ix

Page 12

x SAN512B-6 Installation, Service, and User Guide

Page 13

Read this first

Getting help

Summary of changes

This is the first edition of the IBM®Storage Networking SAN512B-6 Installation,

Service, and User Guide.

For the latest version of your product documentation, visit the web at

http://www.elink.ibmlink.ibm.com/public/applications/publications/cgibin/

pbi.cgi.

For more information about IBM SAN products, see the following Web

site:http://www.ibm.com/servers/storage/san/

For support information for this product and other SAN products, see the

following Web site:http://www.ibm.com/servers/storage/support/san

For detailed information about the Fibre Channel standards, see the Fibre Channel

Industry Association (FCIA) Web site at: www.fibrechannel.org/

Visit www.ibm.com/contact for the contact information for your country or region.

You can also contact IBM within the United States at 1-800-IBMSERV

(1-800-426-7378). For support outside the United States, you can find the service

number at: http://www.ibm.com/planetwide/.

Accessibility features

Accessibility features help users who have a disability, such as restricted mobility

or limited vision, to use information technology products successfully.

Accessibility features

The following list includes the major accessibility features in this product:

v Light emitting diodes (LEDs) that flash at different rates, to represent the same

information as the colors of the LEDs

v Industry-standard devices for ports and connectors

v Management of the product through management applications is available

through Web and Graphical User Interface (GUI) options

Keyboard navigation

This product does not have an attached or integrated keyboard. Any keyboard

navigation is provided through the management software and GUI.

Vendor software

This product includes certain vendor software that is not covered under the IBM

license agreement. IBM makes no representation about the accessibility features of

© Copyright IBM Corp. 2017 xi

Page 14

these products. Contact the vendor for the accessibility information about its

products.

Related accessibility information

You can view the publications for this product in Adobe Portable Document

Format (PDF) using the Adobe Acrobat Reader. The PDFs are provided on a

product documentation CD-ROM that is packaged with the product. The CD-ROM

also includes an accessible HTML version of this document.

IBM and accessibility

See the IBM Human Ability and Accessibility Center website at

www.ibm.com/able/ for more information about the commitment that IBM has to

accessibility.

How to send your comments

Your feedback is important in helping us provide the most accurate and

high-quality information. If you have comments or suggestions for improving this

document, you can send us comments electronically by using the following

addresses:

v Internet: starpubs@us.ibm.com

v IBMLink from U.S.A.: STARPUBS at SJEVM5

v IBMLink from Canada: STARPUBS at TORIBM

v IBM Mail Exchange: USIB3VVD at IBMMAIL

You can also mail your comments by using the Reader Comment Form in the back

of this manual or direct your mail to:

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744–0001 U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or

distribute the information in any way it believes appropriate without incurring any

obligation to you.

xii SAN512B-6 Installation, Service, and User Guide

Page 15

Safety and environmental notices

This section contains information about:

v “Safety notices and labels”

v “Rack safety” on page xx

v “Environmental notices” on page xx

Safety notices and labels

When using this product, observe the danger, caution, and attention notices

contained in this guide. The notices are accompanied by symbols that represent the

severity of the safety condition. The danger and caution notices are listed in

numerical order based on their IDs, which are displayed in parentheses, for

example (D004), at the end of each notice. Use this ID to locate the translation of

these danger and caution notices in the Safety Notices publication that is shipped

with this product.

The following notices and statements are used in IBM documents. They are listed

below in order of increasing severity of potential hazards. Follow the links for

more detailed descriptions and examples of the danger, caution, and attention

notices in the sections that follow.

v Note: These notices provide important tips, guidance, or advice.

v “Attention notices” on page xx: These notices indicate potential damage to

programs, devices, or data.

v “Cautions”: These statements indicate situations that can be potentially

hazardous to you.

v “Danger notices” on page xv: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are also attached

directly to products to warn of these situations.

v In addition to these notices, “Safety labels” on page xviii may be attached to the

product to warn of potential hazards.

Cautions

A Caution statement alerts you to situations that can be potentially hazardous to

you or cause damage to hardware, firmware, software, or data.

General cautions

CAUTION:

Changes or modifications made to this device that are not expressly

approved by the party responsible for compliance could void the

user's authority to operate the equipment.

CAUTION:

Disassembling any part of the power supply and fan assembly voids

the warranty and regulatory certifications. There are no

user-serviceable parts inside the power supply and fan assembly.

© Copyright IBM Corp. 2017 xiii

Page 16

CAUTION:

Make sure the airflow around the front, sides, and back of the device

is not restricted.

CAUTION:

Ensure that the airflow direction of the power supply unit matches

that of the installed fan tray. The power supplies and fan trays are

clearly labeled with either a green arrow with an "E", or an orange

arrow with an "I."

CAUTION:

To protect the serial port from damage, keep the cover on the port

when not in use.

CAUTION:

Never leave tools inside the chassis.

CAUTION:

Use the screws specified in the procedure. Using longer screws can

damage the device.

CAUTION:

To avoid damaging blade and chassis, do not push the blade into a

slot or pull the blade from a slot using the ejector handles.

CAUTION:

Remove the protective cover on the port side of chassis before

applying power. This cover is attached over the air vents. If not

removed, the chassis can overheat and will eventually shut down.

Electrical cautions

CAUTION:

Use a separate branch circuit for each power cord, which provides

redundancy in case one of the circuits fails.

CAUTION:

For the NEBS-compliant installation of a device with AC or DC

systems, use a ground wire of at least 2 AWG. The ground wire

should have an agency-approved crimped connector (provided with

the device) attached to one end, with the other end attached to

building ground. The connector must be crimped with the proper tool,

allowing it to be connected to both ground screws on the enclosure.

Before crimping the ground wire into the provided ground lug, ensure

that the bare copper wire has been cleaned and antioxidant is applied

to the bare wire. In addition, anti-rotation devices or lock washers

must be used with all screw connections for the grounding wire.

xiv SAN512B-6 Installation, Service, and User Guide

Page 17

CAUTION:

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

All devices with AC power sources are intended for installation in

restricted access areas only. A restricted access area is a location where

access can be gained only by service personnel through the use of a

special tool, lock and key, or other means of security.

CAUTION:

Before plugging a cable into any port, be sure to discharge the voltage

stored on the cable by touching the electrical contacts to ground

surface.

CAUTION:

Static electricity can damage the chassis and other electronic devices.

To avoid damage, keep static-sensitive devices in their static-protective

packages until you are ready to install them.

CAUTION:

If you do not install a module or a power supply in a slot, you must

keep the slot filler panel in place. If you run the chassis with an

uncovered slot, the system will overheat.

Cautions related to equipment weight

Danger notices

CAUTION:

Do not use the port cover tabs to lift the module. They are not

designed to support the weight of the module, which can fall and be

damaged.

CAUTION:

To prevent damage to the chassis and components, never attempt to

lift the chassis using the fan or power supply handles. These handles

were not designed to support the weight of the chassis.

A Danger statement indicates conditions or situations that can be potentially lethal

or extremely hazardous to you. Safety labels are also attached directly to products

to warn of these conditions or situations.

General dangers

DANGER

The procedures in this manual are for qualified service personnel.

DANGER

Be careful not to accidently insert your fingers into the fan tray

while removing it from the chassis. The fan may still be spinning

at a high speed.

Safety and environmental notices xv

Page 18

DANGER

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

This equipment is suitable for mounting on concrete or other

noncombustible surfaces only.

Dangers related to equipment weight

DANGER

Use safe lifting practices when moving the product.

DANGER

Make sure the rack housing the device is adequately secured to

prevent it from becoming unstable or falling over.

DANGER

Mount the devices you install in a rack as low as possible. Place

the heaviest device at the bottom and progressively place lighter

devices above.

DANGER

A completely empty chassis weighs approximately 35.61 kg (78.5 lb)

and requires a hydraulic or assisted lift to install it.

DANGER

A fully populated chassis weighs approximately 145.83 kg (321.5

lbs) and requires a hydraulic or assisted lift to install it.

xvi SAN512B-6 Installation, Service, and User Guide

Page 19

18-32kg(39.7-70.5lbs)

svc00167

DANGER

If a lift tool with a capacity of at least 350 lbs is not available, the

director chassis must be depopulated completely before installing

it into the rack. Remove the power supplies, fan modules, all of the

blades, the cable management comb, and the chassis door (if

equipped). Install the empty chassis into the rack following the

chassis installation instructions. The weight of the empty chassis is

78.5 lbs (35.6 kg) and must be lifted by minimum 3 people. After

securing the chassis to the rack, reinstall the power supplies, fan

modules, and the blades and proceed with the installation.

Electrical dangers

DANGER

Make sure that the power source circuits are properly grounded,

then use the power cord supplied with the device to connect it to

the power source.

DANGER

Before beginning the installation, see the precautions in “Power

precautions.”

DANGER

For safety reasons, the ESD wrist strap should contain a series 1

megaohm resistor.

DANGER

If the installation requires a different power cord than the one

supplied with the device, make sure you use a power cord

displaying the mark of the safety agency that defines the

regulations for power cords in your country. The mark is your

assurance that the power cord can be used safely with the device.

DANGER

Disconnect the power cord from all power sources to completely

remove power from the device.

Safety and environmental notices xvii

Page 20

Laser dangers

DANGER

High Touch Current. Earth connection essential before connecting

supply.

DANGER

All fiber-optic interfaces use Class 1 lasers.

DANGER

Use only optical transceivers that are qualified by IBM and comply

with the FDA Class 1 radiation performance requirements defined

in 21 CFR Subchapter I, and with IEC 825 and EN60825. Optical

products that do not comply with these standards might emit light

that is hazardous to the eyes.

Safety labels

DANGER

Laser Radiation. Do Not View Directly with Optical Instruments.

Class 1M Laser Products.

As an added precaution, safety labels are often installed directly on products or

product components to warn of potential hazards. These can be either danger or

caution notices, depending upon the level of the hazard.

The actual product safety labels may differ from these sample safety labels:

DANGER

Hazardous voltage, current, or energy levels are present inside

any component that has this label attached. Do not open any

cover or barrier that contains this label. (L001)

Do not service, there are no serviceable parts.

xviii SAN512B-6 Installation, Service, and User Guide

Page 21

DANGER

Use Only

Professional Movers!

Use Only Professional Movers!

> (> )500 lbs. 227 kg.

especializado

a69i0332

Rack-mounted devices are not to be used as a shelf or work space.

(L002)

DANGER

Multiple power cords. This product might be equipped with

multiple power cords. To remove all power to the device,

disconnect all power cords. (L003)

DANGER

High voltage present. Voltages present constitute a shock hazard,

which can cause severe injury or death. (L004)

CAUTION:

High energy present (L005)

DANGER

Heavy Equipment - Personal injury

or equipment damage may result if

mishandled (D006)

CAUTION:

Hazardous moving parts nearby (L008)

Safety and environmental notices xix

Page 22

or

Attention notices

An attention notice indicates the possibility of damage to a program, device, or

system, or to data. An exclamation point symbol may accompany an attention

notice, but is not required. A sample attention notice follows:

Attention: Do not bend a fibre cable to a radius less than 5 cm (2 in.); you can

damage the cable. Tie wraps are not recommended for optical cables because they

can be easily overtightened, causing damage to the cable.

ESD precautions

Attention: Many of the field replaceable units (FRUs) are sensitive to electrostatic

discharge (ESD), and can potentially be damaged by improper handling. When

working with any FRU, use correct ESD precautions:

v Attach ground to the indicated area on the chassis

v Wear a wrist grounding strap connected to chassis ground (if the switch is

CAUTION:

Pinch hazard. (L012)

plugged in) or a bench ground.

Note: For safety reasons, the ESD wrist strap should contain a series 1

megaohm resistor.

v Store ESD-sensitive components in antistatic packaging

Rack safety

Environmental notices

Use the environmental statements and warning in this section to guide you when

using this product and in properly disposing of the product and its components.

xx SAN512B-6 Installation, Service, and User Guide

Page 23

About this document

This document is intended for use by systems administrators and technicians

experienced with networking, Fibre Channel, and storage area network (SAN)

technologies. It describes how to install, service, and use the IBM Storage

Networking SAN512B-6 (machine type-models 8961-F08 Switch). Throughout this

document, the product is referred to as the SAN512B-6, or simply the switch.

This document has been created to include information specific to SAN512B-6

switches running on Fabric OS version 8.0.1 or later. This document does not

support all Fabric OS versions. It is specific to Fabric OS v8.0.1 or later. Refer to the

Fabric OS Release Notes for more information.

Product documents

The following documents contain information related to this product. The

documentation may be printed material or may be on the documentation CD that

is shipped with the product.

v IBM Storage Networking SAN512B-6 Installation, Service, and User Guide, SC27-8966

(this document)

v IBM Storage Networking SAN512B-6 Quick Start Guide, GI13-4550

v Safety Notices

v IBM Systems Environmental Notices and User Guide, Z125-5823

v Warranty Information, 45W6626

Newer versions of product documentation may be available through the IBM

Publications Center website www.ibm.com/shop/publications/order. Search by

publication title or publication number.

Newer versions may also be available through the IBM Support Portal

www.ibm.com/supportportal. Enter your product machine type (8961) or product

name in the search field, and then select Documentation from the displayed page.

Brocade documents

IBM b-type switches use software licensed from Brocade Communications Systems,

Inc. You can find information related to the software that supports the switch in

the following documents on the CD-ROM supplied with this product:

Brocade Fabric OS

v EZSwitchSetup Administrator's Guide

v Fabric OS Administrator's Guide

v Fabric OS Command Reference Manual

v Fabric OS MIB Reference Manual

v Fabric OS Message Reference Manual

v Fabric OS Troubleshooting and Diagnostics Guide

Brocade Fabric OS optional features

v Fabric Watch Administrator's Guide

© Copyright IBM Corp. 2017 xxi

Page 24

v Web Tools Administrator's Guide

IBM and Brocade product matrix

The product matrix provides a cross-reference between the comparable IBM and

Brocade product models.

When you use any of the Brocade documents, such as Fabric Operating System

(FOS) publications, you will notice that the model numbers reflect the

corresponding Brocade products. Table 1 provides a product matrix to correlate the

Brocade products and models to the IBM product names and machine types and

model numbers. Products withdrawn from marketing are not listed.

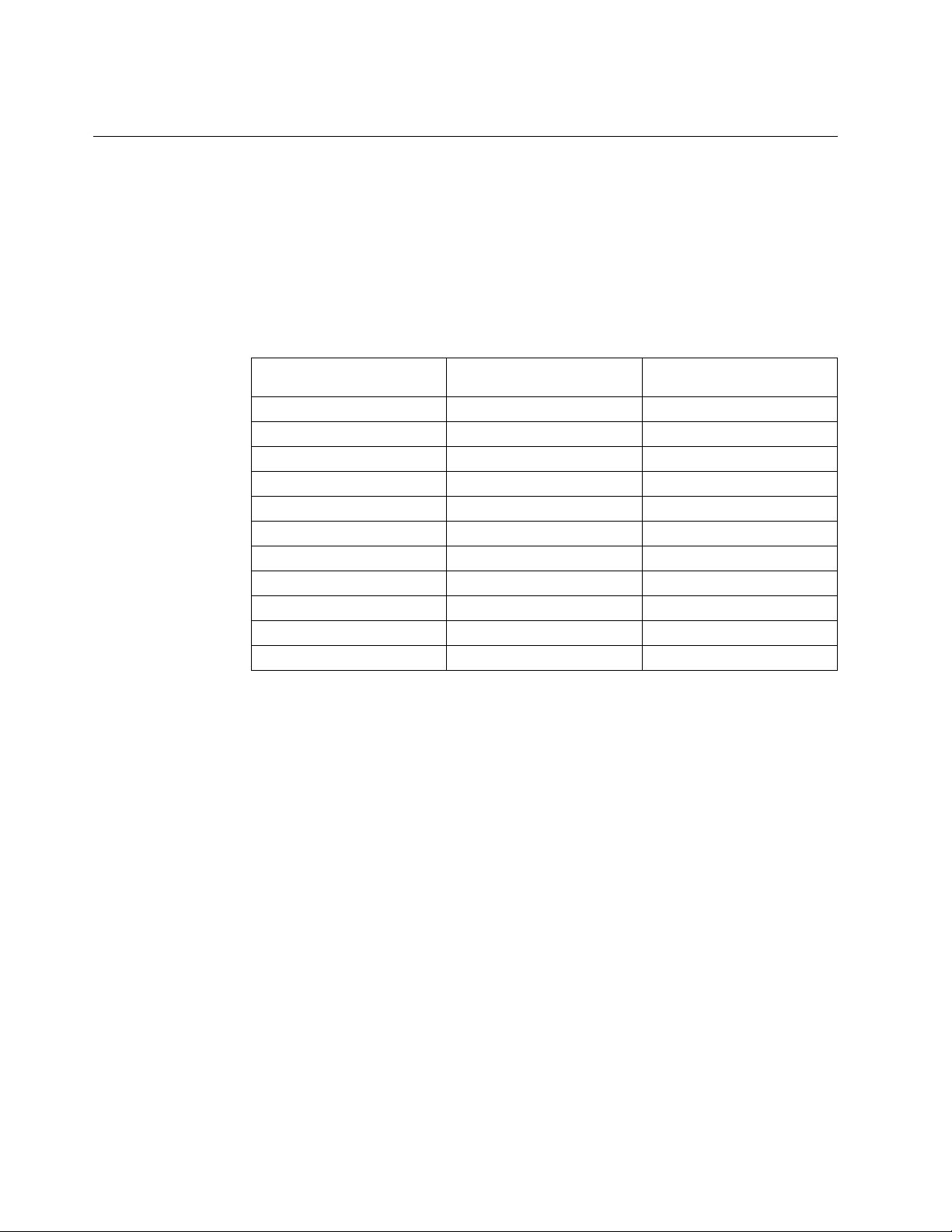

Table 1. Brocade and IBM product and model number matrix

Brocade product name IBM product name

Brocade G620 SAN64B-6 8960 Models F64 and N64

Brocade X6-4 Director SAN256B-6 8961 Models F04

Brocade X6-8 Director SAN512B-6 8961 Models F08

Brocade 6520 SAN96B-5 2498 Models F96 and N96

Brocade 6505 SAN24B-5 2498 Model X24

Brocade 6510 SAN48B-5 2498 Model F48

Brocade DCX 8510-4 SAN384B-2 2499 Model 416

Brocade DCX 8510-8 SAN768B-2 2499 Model 816

Brocade 7800 SAN06B-R 2498 Model R06

Brocade 7840 SAN42B-R 2498 Model R42

Brocade 300 SAN24B-4 2498 Models B24 and 24E

IBM machine type and

model number

xxii SAN512B-6 Installation, Service, and User Guide

Page 25

Chapter 1. Introducing the SAN512B-6

This chapter provides the following information:

v “Product features”

v “Hardware components” on page 2

v “Port-side view of device” on page 3

v “Port-side slot numbering” on page 5

v “Nonport-side view of the device” on page 5

Product features

Key product features for this device include the following:

v Redundant and hot-swappable SFP, SFP+, SFP28, and QSFP+ transceivers; port,

extension, control processor (CP) and core routing (CR) blades; power supply

assemblies, fan assemblies, and WWN cards that enable a high availability

platform and allow nondisruptive software upgrades for mission-critical SAN

applications.

v Up to 384 32-Gbps external ports and 32 4x32-Gbps QSFP (ICL) ports in a single

chassis, enabling high density SAN configurations with reduced footprint.

v Up to 192 32-Gbps external ports and 16 4x32-Gbps QSFP (ICL) ports in a single

chassis, enabling high density SAN configurations with reduced footprint.

v Support for 48 4-, 8-, 16-, and 32-Gbps autosensing Fibre Channel ports on

FC32-48 port blades. Trunking technology groups up to eight ports to create

high performance 256-Gbps ISL trunks between switches using 32-Gbps ports.

v 10-Gbps FC-type SFPs on FC32-48 port blades and 10-GbE SFPs on the SX6

application blades. The two types of SFPs are not interchangeable. The 10-Gbps

transceivers can be used for any port on the FC32-48 port blades.

v Support for 16 Fibre Channel ports supporting 4-, 8-, 16-, and 32-Gbps; 16 GbE

ports supporting 1 or 10 Gbps; and two GbE ports supporting 40 Gbps on SX6

extension blades. Trunking technology groups up to eight ports to create high

performance 256-Gbps ISL trunks between switches using 32-Gbps ports.

v Support for FC quad SFP (QSFP) ports supporting 4x16 Gbps and 4x32 Gbps on

core CR blades. Up to nine chassis in a full-mesh topology and 12 chassis in a

core-to-edge topology can be connected using these Fibre Channel ports for

inter-chassis links (ICLs).

v Universal ports that self-configure as E_Ports, F_Ports, EX_Ports, M_Ports

(mirror ports), and FICON ports. The 10-Gbps ports on the port blade can

function as E_Ports only.

v ClearLink Diagnostic port (D_Port) functionality on Fibre Channel ports.

v Data compression capabilities through the port blades when ports are configured

as ISLs.

v The SX6 blades perform as extension platforms to support Fibre Channel (FC)

and FICON data flows and IP-based storage data flows over an IP WAN.

© Copyright IBM Corp. 2017 1

Page 26

Hardware components

The device has a modular and scalable mechanical construction that allows a wide

range of flexibility in installation, fabric design, and maintenance. The device can

be mounted with the cables facing either the front or the rear of the equipment

rack, and consists of the following:

v Up to eight slots for hot-swappable port blade assemblies, providing up to 384

32-Gbps Fibre Channel ports.

v Two half-size slots for control processor (CP) blades:

– A single active CP blade can control all the ports in the device.

– The standby CP blade assumes control of the device if the active CP blade

fails.

v Two slots for core routing (CR) blades:

– CR blade interconnects all port blades.

– Up to 32 4x32-Gbps QSFP (ICL) ports.

– ICL ports allow interconnection with neighboring chassis

– Both CR blades are active.

v Up to four slots for modular, hot-swappable 34-port SX6 extension blades.

Blades provide 16 32– Gbps Fibre Channel (FC) ports supporting 8, 16, and 32

Gbps or 16 16-Gbps FC ports supporting 4, 8, and 16 Gbps; 16 GbE ports

supporting 1 or 10 Gbps; and 2 GbE ports supporting 40 Gbps. Extension blades

enable long-distance communication over an existing IP infrastructure.

v Modular, hot-swappable field-replaceable units (FRUs):

– Three fan assemblies, available with nonport-side intake (NPI) or

nonport-side exhaust (NPE) airflow.

– Up to four power supply assemblies, available with nonport-side intake (NPI)

or nonport-side exhaust (NPE) airflow. The power supplies are approved for

100–120 VAC and 200–240 VAC.

- At 100–120 VAC (nominal): Four power supply assemblies are required for

high availability. Refer to the "Power requirements" section in the

Appendix B, “Product specifications,” on page 235 for specific high

availability–requirements.

- 200–240 VAC (nominal) is recommended for efficiency. Depending on

quantity ordered, three or four power supply assemblies are provided.

Refer to the "Power requirements" section in the Appendix B, “Product

specifications,” on page 235 for specific high-availability requirements.

- Redundant AC primary power connections ensure high availability. Each

power supply assembly has its own connector, so four is the number of

primary power connections for optimum efficiency and redundancy.

– Two World Wide Name (WWN) cards located on the nonport side of the

device behind the WWN card bezel.

– Blades use small form-factor pluggable (SFP+ and QSFP+) optical

transceivers.

- The 10-Gbps speed must be manually set and requires special 10-Gbps FC

SFP+ transceivers.

- The 32-Gbps SFP+ transceivers support speeds of 8, 16, and 32 Gbps.

- The 16-Gbps SFP+ transceivers support speeds of 4, 8, and 16 Gbps.

- The 4x32-Gbps QSFP+ transceivers on the core routing blades provide four

32–Gbps inter-chassis links (ICL) clustered in a single quad connector and

cable.

2 SAN512B-6 Installation, Service, and User Guide

Page 27

- The 4x16-Gbps QSFP+ transceivers on the core routing blades provide four

16–Gbps inter-chassis links (ICL) clustered in a single quad connector and

cable).

v Chassis door. This door must be installed to meet EMI compliance certification.

v A cable management comb. These are installed on the chassis below the blades

for cable management.

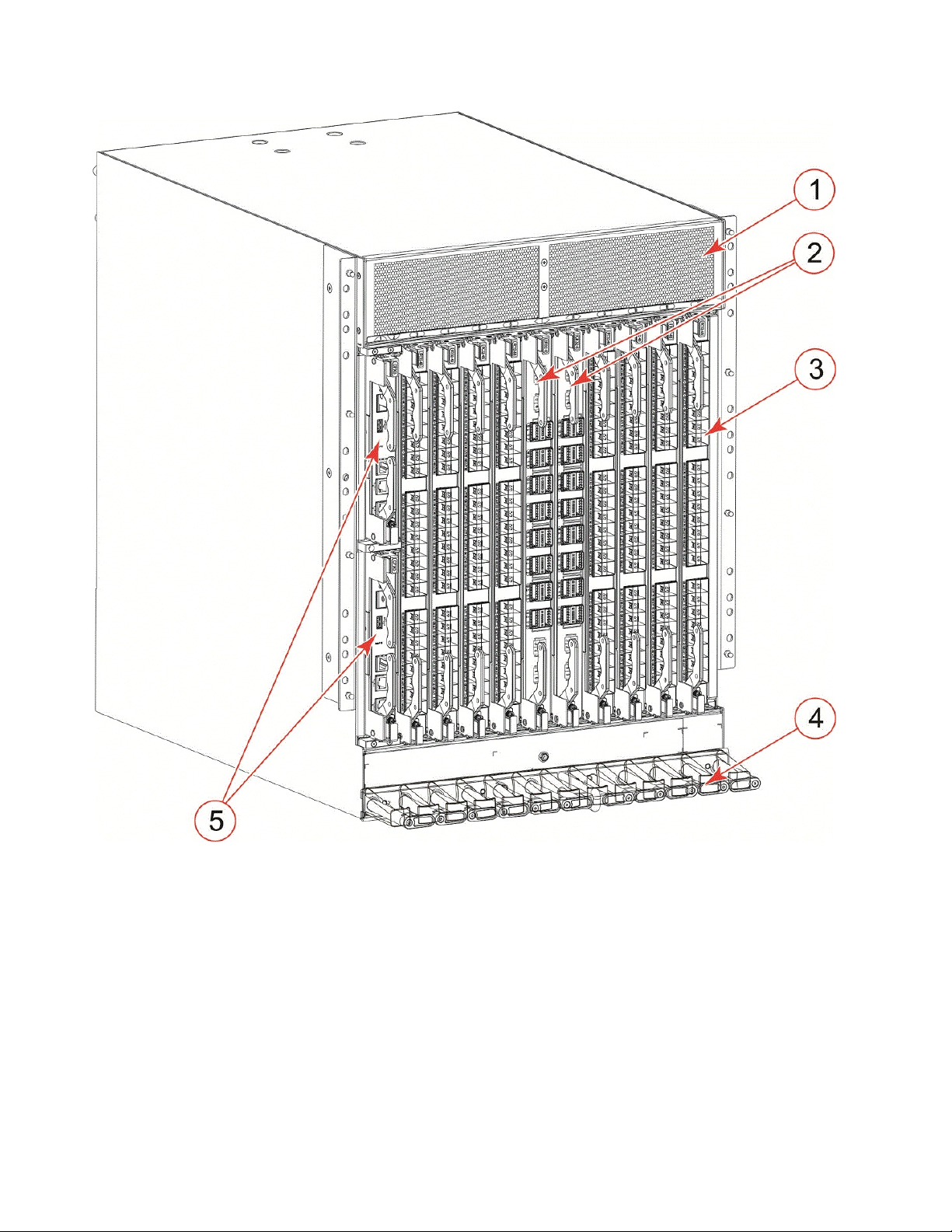

Port-side view of device

The following illustration shows the port-side view of the SAN512B-6 with

installed blades identified. Note that SX6 extension blades are not shown in the

following illustration, but would install in the same slots as the FC32-48 port blade.

A maximum of four SX6 blades are supported.

Chapter 1. Introducing the SAN512B-6 3

Page 28

1 - Air vent

2 - Core routing blades (CR32-8)

3 - Port blades (FC32-48)

4 - Cable management comb

5 - Control processor blades (CPX6) – slot 1 (upper), slot 2 (lower)

Figure 1. Port side of the SAN512B-6 (sample configuration)

Notes:

v Depending on the fans and power supplies installed, airflow can be from the

port side to the nonport side of chassis or from the nonport side to the port side

of the chassis.

v Do not attempt to lift the chassis by the protective cover attached over the air

vents at the top of the chassis.

4 SAN512B-6 Installation, Service, and User Guide

Page 29

Port-side slot numbering

The SAN512B-6 contains 10 full-height slots and two half-height slots, for a total of

12 slots. Facing the port side of the device, the half-height slots are on the left,

numbered 1 (top slot) and 2 (bottom slot). The remaining full-height slots are

numbered 3 through 12, counting from left to right of chassis.

Slots contain guide pins and connectors designed for specific blade types. Only

install the control processor (CP), core routing (CR), port, and extension blades into

slot numbers as follows:

v Slots 1– 2 are restricted to CP blades. Note that the blade installed in slot 1 will

be designated as CP0, while the blade in slot 2 will be designated as CP1 in CLI

command and message output.

v Slots 3–6 and slots 9–12 are restricted to port and extension blades.

v Slots 7– 8 are restricted to CR32-8 blades.

Nonport-side view of the device

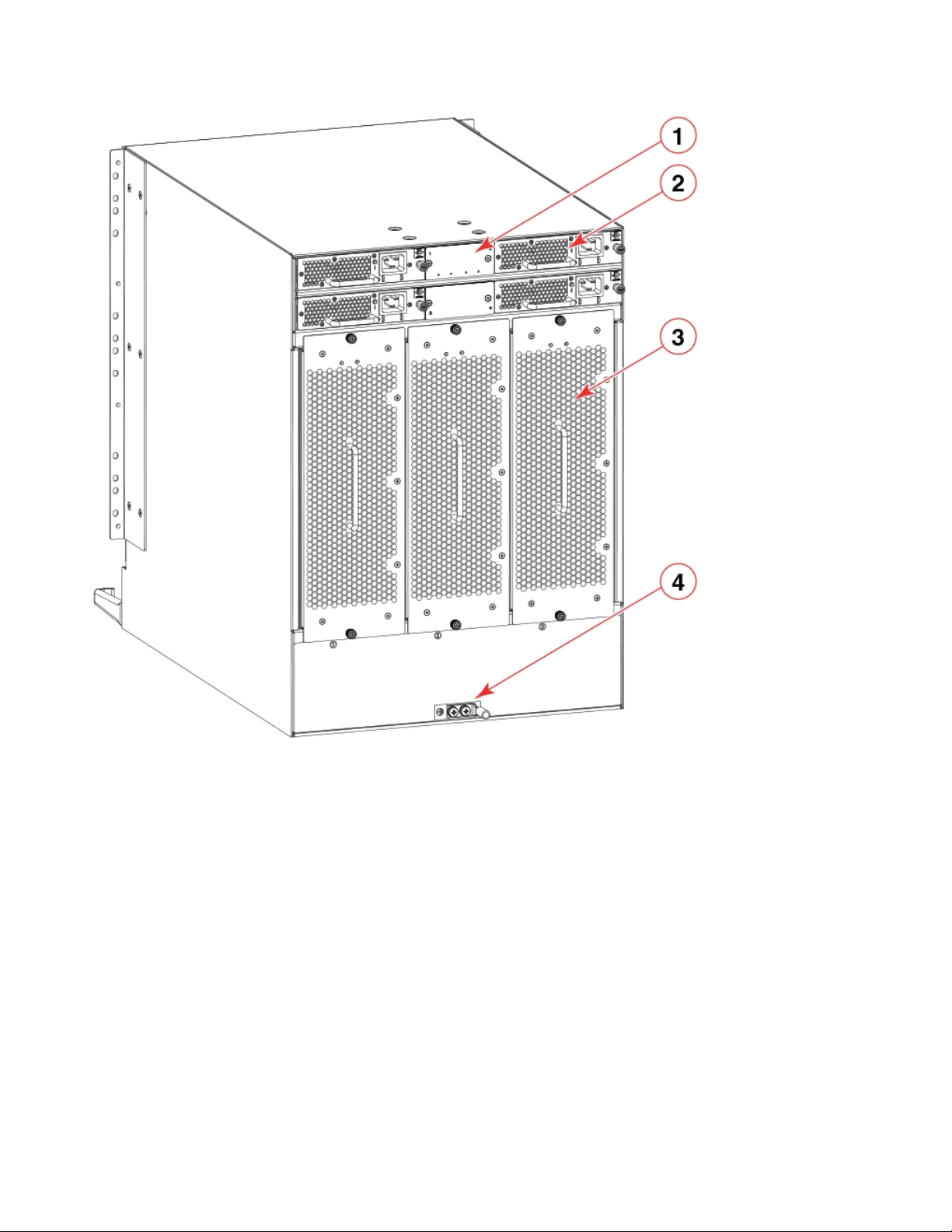

The following illustration shows the nonport-side view of the SAN512B-6 with all

fan and power supply assemblies installed.

Chapter 1. Introducing the SAN512B-6 5

Page 30

Figure 2. Nonport side of the SAN512B-6 (sample configuration)

1 - WWN bezel (WWN cards behind)

2 - Power supply assembly

3 - Fan assembly

4 - 2AWG Panduit LCD2-14AF lug for building ground connection

Depending on fans and power supplies installed, airflow can be from the port side

to the nonport side of the chassis or the nonport side to the port side of chassis.

Although not illustrated, the chassis label containing the serial number, SKU, and

WWN is located on the lower portion of the chassis, below the fan assemblies.

6 SAN512B-6 Installation, Service, and User Guide

Page 31

Chapter 2. Preparing for the Installation

This chapter provides the following information:

v “Safety precautions”

v “Facility requirements” on page 10

v “Time and items required for installation” on page 11

v “Quick installation checklists” on page 13

v “Items shipped” on page 15

Safety precautions

When using this product, observe all danger, caution, and attention notices in this

manual. The safety notices are accompanied by symbols that represent the severity

of the safety condition.

Refer to the Cautions and Danger Notices at the end of this guide for translations

of safety notices for this product.

General precautions

DANGER

The procedures in this manual are for qualified service personnel.

DANGER

Before beginning the installation, see the precautions in “Power

precautions.”

CAUTION:

Changes or modifications made to this device that are not expressly

approved by the party responsible for compliance could void the

user's authority to operate the equipment.

CAUTION:

Disassembling any part of the power supply and fan assembly voids

the warranty and regulatory certifications. There are no

user-serviceable parts inside the power supply and fan assembly.

CAUTION:

Make sure the airflow around the front, sides, and back of the device

is not restricted.

CAUTION:

To protect the serial port from damage, keep the cover on the port

when not in use.

© Copyright IBM Corp. 2017 7

Page 32

CAUTION:

Never leave tools inside the chassis.

CAUTION:

Use the screws specified in the procedure. Using longer screws can

damage the device.

ESD precautions

DANGER

For safety reasons, the ESD wrist strap should contain a series 1

megaohm resistor.

Power precautions

DANGER

For safety reasons, the ESD wrist strap should contain a series 1

megaohm resistor.

DANGER

If the installation requires a different power cord than the one

supplied with the device, make sure you use a power cord

displaying the mark of the safety agency that defines the

regulations for power cords in your country. The mark is your

assurance that the power cord can be used safely with the device.

DANGER

Make sure that the power source circuits are properly grounded,

then use the power cord supplied with the device to connect it to

the power source.

CAUTION:

Use a separate branch circuit for each power cord, which provides

redundancy in case one of the circuits fails.

DANGER

High Touch Current. Earth connection essential before connecting

supply.

8 SAN512B-6 Installation, Service, and User Guide

Page 33

Lifting precautions

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

CAUTION:

Use safe lifting practices when moving the product.

CAUTION:

A fully populated chassis weighs approximately 145.83 kg (321.5 lbs)

and requires a hydraulic or assisted lift to install it.

Note: Do not attempt to lift the device by the protective cover attached

to the air vents on the nonport-side of the chassis.

DANGER

If a lift tool with a capacity of at least 350 lb is not available, the

director chassis must be depopulated completely before installing

it into the rack. Remove the power supplies, fan modules, all of the

blades, the cable management comb, and the chassis door (if

equipped). Install the empty chassis into the rack following the

chassis installation instructions. The weight of the empty chassis is

78.5 lb (35.6 kg) and must be lifted by minimum 3 people. After

securing the chassis to the rack, reinstall the power supplies, fan

modules, and the blades and proceed with the installation.

Laser precautions

DANGER

All fiber-optic interfaces use Class 1 lasers.

DANGER

Laser Radiation. Do Not View Directly with Optical Instruments.

Class 1M Laser Products.

DANGER

Use only optical transceivers that are qualified by Brocade

Communications Systems, Inc. and comply with the FDA Class 1

radiation performance requirements defined in 21 CFR Subchapter

I, and with IEC 825 and EN60825. Optical products that do not

comply with these standards might emit light that is hazardous to

the eyes.

Chapter 2. Preparing for the Installation 9

Page 34

Facility requirements

Before installing the device, be sure the following facilities requirements are met.

Table 2. Facility requirements

Type Requirements

Device specifications Ensure that the facility can accommodate system, power, and

Electrical Ensure that there are dedicated electrical branch circuits with the

environmental specifications for this device as outlined in the

Appendix B, “Product specifications,” on page 235.

following characteristics are available:

v 200–240 VAC, 50-60 Hz, four branch circuits are recommended

for high availability and maximum blade usage.

v 110–120 VAC, 50–60 Hz, four branch circuits are highly

recommended.

v Four cables for 110–120 VAC or 200–240 VAC service.

v Protected by a circuit breaker in accordance with local electrical

codes.

v Supply circuit, line fusing, and wire size adequate to the

electrical rating on the chassis nameplate.

v Location close to the chassis and easily accessible.

v Grounded outlets installed by a licensed electrician and

compatible with the power cords.

Ensure that all equipment in rack is grounded through a reliable

branch circuit connection.

Make sure that power distribution units (PDUs) can handle

maximum input amperage of power supplies. Use cables with

adequate amperage rating from PDUs to power source.

Thermal Ensure that the air intake and exhaust vents have a minimum of

5.1 cm (2 in.) of airspace.

Ensure that the air intake temperature is less than 40°C (104°F)

during operation.

10 SAN512B-6 Installation, Service, and User Guide

Page 35

Table 2. Facility requirements (continued)

Type Requirements

Rack (when

rack-mounted)

Ensure that these airflow requirements are met:

v Plan to install the device with the air-intake side facing the cool

air aisle. The device can be installed facing either direction if

serviceability and cooling requirements are met.

v Ensure that the airflow available at the air vents meets the

minimum requirements for the device.

v Install the device with the airflow aligned with other devices in

the rack. Some devices have airflow running from port side to

nonport side and others have the opposite arrangement. Make

sure that the airflow for all devices moves in the same direction

to maximize cooling.

Ensure that the following amount of space is available in the rack:

v 14 rack units (14U) high. 1U is equal to 4.45 cm (1.75 inches).

v 61.29 cm (24.09 inch) deep.

v 43.74 cm (17.22 inch) wide.

Ensure that the rack meets these additional requirements:

v Additional weight of chassis will not exceed the rack’s weight

limits.

v The rack is secured to ensure stability in case of unexpected

movement.

Time and items required for installation

You can set up and install the device in the following ways:

v As a standalone unit on a flat surface.

v In a 19-inch Electronic Industries Association (EIA) rack or in a

telecommunications (Telco) rack using a rack mount kit. Refer to“Mounting

options” on page 17 for applicable rack mount kits.

The following table describes the main installation and setup tasks, the estimated

time required for each, and the items required to complete the task for a device

that is fully populated with port blades. Configurations with fewer blades or ports

require less time. These time estimates assume a prepared installation site and

appropriate power and network connectivity.

Chapter 2. Preparing for the Installation 11

Page 36

Table 3. Installation tasks, time, and items required

Installation task Time estimate Items required

Site preparation and

unpacking the device.

Installing rack mount kit . 30 minutes Refer the procedures for

Mounting and securing the

device in rack.

Installing power cables and

powering on the device.

Establishing serial

connection, logging in to the

device, and configuring IP

addresses.

30 minutes 1/2-in. socket wrench

(optional).

#1 and #2 Phillips

screwdrivers.

Pallet jack.

Hydraulic or assisted lift

with a minimum raise of 140

cm (55 in.) and a minimum

capacity of 158.76 kg (350 lb)

To find the weight of your

device fully populated with

the required port blades,

refer to Appendix B,

“Product specifications,” on

page 235.

30 minutes

20 minutes Power cables. These are

20 minutes Serial cable (provided in the

your rack mount kit located

in this guide.

ordered and shipped

separately based on country

where device is installed.

accessory kit).

Workstation computer with a

serial port or terminal server

port and a terminal emulator

application (such as

HyperTerminal).

Installing an Ethernet cable,

opening a Telnet session, and

configuring the device

domain ID, date and time,

and additional system

parameters. Verify and back

up configuration.

Installing transceivers as

needed.

Attaching fiber-optic cables,

cable ties, and cable guides.

12 SAN512B-6 Installation, Service, and User Guide

Ethernet IP addresses for the

device and for both control

processor blades; total of

three addresses.

20 minutes Ethernet cabling (optional)

for Telnet access.

Refer to the Fabric OS

Administrator's Guide.

20-30 minutes or longer if

you are using high-density

port blades.

2-3 hours Fiber-optic cables, cable ties,

SFP+ and QSFP28 optical

transceivers as needed.

and cable management

comb.

Page 37

Quick installation checklists

These checklists provides a high-level overview of the basic installation process

from the planning stage to the point where the device comes online and is ready to

be deployed. Completing all the tasks in the suggested order ensures successful

installation. It is recommended that you print these checklists and take them to the

installation site.

Pre-installation tasks

Review all installation requirements ahead of time as part of your site preparation.

Careful planning and site preparation ensures seamless installation, especially

when installing multiple devices.

Table 4. Installation prerequisites

Task Task details or additional information Completed

Unpack the device. Take an inventory of the hardware components included in your

shipment. Refer to “Items shipped” on page 15.

Gather necessary components and

required tools.

Review the safety precautions. Refer to “Safety precautions” on page 7.

Plan the installation. Obtain the appropriate rack mount kit. Refer to “Mounting options”

Review and verify installation

requirements.

Gather network configuration

parameters.

Review the time and items required information at the beginning of

the following sections in this guide to ensure you have gathered all

necessary components required:

v Mounting the Device

v Initial Setup and Verification

v Port and Extension Blades (if required to install)

v Power Supplies (if required to install)

on page 17.

Verify that the following requirements are met. Refer to “Facility

requirements” on page 10.

v Electrical

v Environmental

v Rack

v Thermal

v IP address

v Subnet mask

v Default gateway

v Domain ID

v Time zone

Installation and initial configuration

The initial setup includes mounting the device on a flat surface or in a rack and

completing the configuration tasks necessary to bring the device online and verify

the operation.

Table 5. Installation and basic system configuration

Task Task details or additional information Completed

Install blades or power supply

assemblies

Install any blades or power supply assemblies that have shipped

separately from the chassis. Be sure to use a #1 Phillips screwdriver

for captive screws to lock these FRUs into place.

Chapter 2. Preparing for the Installation 13

Page 38

Table 5. Installation and basic system configuration (continued)

Task Task details or additional information Completed

Mount the device Choose one of the following mounting options:

v Mount the device in a four-post rack. Refer to the instructions in

this guide for mounting your device in a four-post rack.

v Mount the device in a two-post rack. Refer to the instructions in

this guide for mounting your device in a two-post rack.

Check the airflow of the power

supply and fan assembly

Gather all components required

for the initial setup

Provide power to the device Refer to “Providing power to the device” on page 39.

Attach a management station,

establish a serial connection, and

change the default passwords

(optional)

Set the IP address, subnet mask,

and the default gateway IP

address

Set the date and time

Customize the switch name and

chassis name

Establish an Ethernet connection By establishing an Ethernet connection, you can complete the

Optional: Configure the DNS

service

Optional: Customize the domainIDUse the configure command to change the domain ID (default ID

The airflow direction of the power supply and fan should match.

The power supplies and fan trays are clearly labeled with either a

green arrow with an "E", or an orange arrow with an "I." For more

details, refer to “Fan and power supply airflow” on page 162.

Refer to “Items required” on page 38.

Refer to “Establishing a serial connection to the device” on page 46.

After completing this task, log in to the serial port to configure the

device.

Use the ipaddrset command to configure a static device IP address,

subnet mask, and gateway IP address, or you can use a DHCP

server to obtain the information dynamically. Refer to “Configuring

the IP addresses” on page 48.

v Use the date command to display and set the date and time.

v Use the tstimezone command to display and set the time zone.

v Use the tsclockserver command to synchronize the time with an

external NTP server.

Refer to “Setting the date and time” on page 50 for more

information.

v Use the switchname command to change the default switch name.

v Use the chassisname command to change the default chassis

name.

Refer to“Customizing the chassis and switch name” on page 53 for

more information.

device configuration using a serial session, Telnet, or management

application, such as IBM Network Advisor. Refer to“Establishing an

Ethernet connection to the device” on page 49.

Use the dnsconfig command to create DNS server entries. Refer to

theFabric OS Administrator's Guide.

is 1). Refer to“Setting the domain ID” on page 50 for more

information.

14 SAN512B-6 Installation, Service, and User Guide

Page 39

Table 5. Installation and basic system configuration (continued)

Task Task details or additional information Completed

Verify that the device operates

correctly

Back up the configuration Use the interactive configupload command to back up the

Optional: Power off the devices Enter the shutdown command and wait for the device to power

v Check the LEDs to verify operation of functional parts. Refer to

the Monitoring the Device section of this guide.

v The following commands can be useful to establish an

operational baseline for the device. Refer to the Fabric OS

Command Reference for more information on these commands.

– psshow

– fanshow

– tempshow

– historyshow

– errdump

configuration. Refer to “Backing up the configuration” on page 55

for more information.

down, and then unplug the power cords. Refer to “Powering down

the chassis” on page 56 for more information.

Items shipped

When unpacking the device, follow procedures under "Unpacking and transporting

the device". Verify that you have the following items. Save shipping cartons and

packaging in the event you need to return the device.

Packaged in device shipping carton:

v SAN512B-6 switch with shipping tray

v Packing foam

v Antistatic plastic

v Inner foam

Packaged in device shipping carton or separate carton.

v Door (for EMI compliancy)

v Power cords as ordered for installed power supplies

v Serial cable

v ESD wrist strap

v SFP extraction tool

v Power cord retainer clips

v Cable management comb assembly

v China-RoHS Hazardous/Toxic Substance statement

v Network Advisor web pointer card

v IBM documentation web pointer card

v Rack mount kit for your device

v Ground lug kit

Chapter 2. Preparing for the Installation 15

Page 40

16 SAN512B-6 Installation, Service, and User Guide

Page 41

Chapter 3. Mounting the Device

18-32kg(39.7-70.5lbs)

svc00167

This chapter provides the following information:

v “Mounting options”

v “Mounting precautions”

v “Unpacking and transporting the device” on page 19

v “Port-side slot numbering” on page 5

v “Installing the 14U Rack Mount Kit for Four-Post Racks” on page 20

v “Installing the 14U Chassis Mid-Mount Rack Kit for Two-Post Racks” on page 28

v “Removing the protective cover” on page 34

Mounting options

You can mount the device in the following locations:

v In a four-post 19 in. (48.3 cm) EIA rack:

– Use the 14U rack mount kit for four-post racks (XBR-DCX-0120), which

contains shelf brackets that telescope from 27 in. (68.58 cm) to 31 in. (78.74

cm) to fit the majority of racks.

– Use the 14U rack mount kit for four-post racks (XBR-DCX-0152), which

contains 22 in. (55.88 cm) fixed shelf brackets designed for specific racks.

– Refer to “Installing the 14U Rack Mount Kit for Four-Post Racks” on page 20

for instructions.

v In a two-post Telco rack:

– Use the 14U mid-mount rack kit for two-post racks (XBR-DCX-0121).

– Refer to “Installing the 14U Chassis Mid-Mount Rack Kit for Two-Post Racks”

on page 28 for instructions .

Note: Review the “Mounting precautions” before mounting the device and ensure

that all “Facility requirements” on page 10 are met.

Mounting precautions

The following precautions specifically apply to mounting the device.

CAUTION:

Do not use the port cover tabs to lift the module. They are not

designed to support the weight of the module, which can fall and be

damaged.

DANGER

Make sure the airflow around the front, sides, and back of the

device is not restricted.

© Copyright IBM Corp. 2017 17

Page 42

18-32kg(39.7-70.5lbs)

svc00167

DANGER

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

Mount the devices you install in a rack as low as possible. Place

the heaviest device at the bottom and progressively place lighter

devices above.

DANGER

Use safe lifting practices when moving the product.

CAUTION:

To prevent damage to the chassis and components, never attempt to

lift the chassis using the fan or power supply handles. These handles

were not designed to support the weight of the chassis.

CAUTION:

Do not attempt to lift the chassis by the protective cover attached over

the air vents on the port side.

CAUTION:

You can connect the device to building ground by connecting an

appropriate 2 AWG wire from a grounded connection to the 2AWG

Panduit LCD2-14AF lug on the nonport-side of the device.

18 SAN512B-6 Installation, Service, and User Guide

Page 43

Unpacking and transporting the device

About this task

Use the following procedure to unpack and install your device.

DANGER

A fully populated chassis weighs approximately 145.83 kg (321.5 lbs) and

requires a hydraulic or assisted lift to install it.

If a lift tool with a capacity of at least 350 lb is not available, the director

chassis must be depopulated completely before installing it into the rack.

Note any possible interconnecting cables so that you will be able to reconnect

them correctly. Remove the power supplies, fan modules, all of the blades,

the cable management comb, and the chassis door (if equipped). Install the

empty chassis into the rack following the chassis installation instructions.

The weight of the empty chassis is 78.5 lb (35.6 kg) and must be lifted by

minimum 3 people. After securing the chassis to the rack, reinstall the power

supplies, fan modules, the blades and any possible interconnecting cables

and proceed with the installation.

Procedure

1. Unpack the device.

a. Cut the bands that encircle the packaging.

b. Open the top of the shipping box and remove accessory kit, rack mount

kits, and foam from the top of the device.

c. Lift the cardboard shipping container and inner cardboard sleeve off the

device.

d. Remove the antistatic plastic off the device.

e. Leave the device on top the foam shipping tray and wood pallet if the

device must be transported to the installation location.

f. Verify the contents of the shipping carton by referring to “Items shipped”

on page 15.

g. Save foam packing material and wooden pallet for reuse.

2. Use a pallet jack or other assisted lift to transport the device to the installation

area. Doorways must be wider than 36 in. (91 cm) to accommodate the device.

3. Remove the chassis door if installed.

4. Remove the cable management comb if attached to the device.

5. Use a lift to raise the device to the correct level. Use two people, one to

operate the lift and the other to secure the device on the lift.

Note: Do not attempt to lift the device by the protective cover attached to

over the air vents on the port side of the chassis.

Note: Orient the device on the lift so that you can slide it into correct side of

rack to provide cool air intake. Fans and power supply FRUs in this device

have a green "E" or "I" symbol on the FRU faceplate. An "E" indicates that the

FRU pulls air from the port side of the device and exhausts out the nonport

side. An "I" indicates that the FRU pulls air from the nonport side of the

device and exhausts out the nonport side. Fans and power supplies must have

Chapter 3. Mounting the Device 19

Page 44

the same airflow indicator. Be sure that you are pulling cool air into the air

intake side of the device. For more details, refer to“Fan and power supply

airflow” on page 162.

6. If applicable, lock the wheels of the lift.

7. Install the applicable rack mount kit in your equipment rack and mount the

device using the rack mount kit's installation instructions.

Note: When installing the device into the rack, use one person on each side of

the device to gently slide it onto the final installation surface and ensure that

it remains supported during the transfer.

8. Reinstall the cable management comb if you removed it.

9. Install the vertical cable management fingers on the rack's upright posts.

10. Reinstall the chassis door. The door must be installed to meet EMI

compliance.

Port-side slot numbering

The SAN512B-6 contains 10 full-height slots and two half-height slots, for a total of

12 slots. Facing the port side of the device, the half-height slots are on the left,

numbered 1 (top slot) and 2 (bottom slot). The remaining full-height slots are

numbered 3 through 12, counting from left to right of chassis.

Slots contain guide pins and connectors designed for specific blade types. Only

install the control processor (CP), core routing (CR), port, and extension blades into

slot numbers as follows:

v Slots 1– 2 are restricted to CP blades. Note that the blade installed in slot 1 will

be designated as CP0, while the blade in slot 2 will be designated as CP1 in CLI

command and message output.

v Slots 3–6 and slots 9–12 are restricted to port and extension blades.

v Slots 7– 8 are restricted to CR32-8 blades.

Installing the 14U Rack Mount Kit for Four-Post Racks

Use the following instructions to install a modular device in a 19-in. (48.3 cm) EIA

rack using the 14U Rack Mount Kit for Four-Post Racks. Any updates to these

instructions will be added to the hardware installation guide for your product.

Two rack-mount kits are available.

1. Contains shelf brackets that telescope from 27 in. (68.58 cm) to 31 in. (78.74 cm)

to fit the majority of racks.

2. Contains 22 in. (55.88 cm) fixed shelf brackets that are designed for specific

racks.

Note: Hardware devices illustrated in these procedures are only for reference and

may not depict the device you are installing into the rack.

Time and items required

Allow approximately one hour to unpack and install a device in a rack.

The following tools are required when installing the 14U Rack Mount Kit for

Four-Post Rack:

v Torque screwdriver with #2 Phillips screwdriver tip

20 SAN512B-6 Installation, Service, and User Guide

Page 45

v Slotted (flat blade) screwdriver

v Hydraulic or assisted lift with a minimum raise of 140 cm (55 in.) and a

Parts list

The following table lists the parts supplied in the 14U Chassis Rack Mount Kit. for

Four-Post Racks.

Note:

Depending on the device and installation, not all parts may be used on the device

type.

minimum capacity of 158.76 kg (350 lbs)

DANGER

If a lift tool with a capacity of at least 350 lbs is not available, the director

chassis must be depopulated completely before installing it into the rack.

Note any possible interconnecting cables so that you will be able to

reconnect them correctly. Remove the power supplies, fan modules, all of

the blades, the cable management comb, and the chassis door (if equipped).

Install the empty chassis into the rack following the chassis installation

instructions. The weight of the empty chassis is 78.5 lbs (35.6 kg) and must

be lifted by minimum 3 people. After securing the chassis to the rack,

reinstall the power supplies, fan modules, the blades and any possible

interconnecting cables and proceed with the installation.

Chapter 3. Mounting the Device 21

Page 46

1 - Left rack mount shelf bracket

2 - Right rack mount shelf bracket

3 - 10-32 x 5/8 in. (1.58 cm) panhead Phillips screw and washer

4 - 10-32 clip nut for racks that have rails with round holes

5 - 1/4-20 x 1/2 in. (1.27 cm) panhead Phillips screw with lock washer for racks that have rails with round holes

6 - 10-32 retainer nut for racks that have rails with square holes

7 - 1/4-20 x 1/2 in. (1.27 cm) panhead Phillips screw with thread locker for racks that have rails with square holes

8 - 3/8 in. (0.953 cm) alignment washer for racks that have rails with square holes

Figure 3. Rack kit parts

|

|

|

|

|

Parts list – NEBS kit

The following table lists the parts supplied in the NEBS KIT to help direct airflow

away from the rack area. This kit is only supported for specific devices, and may

not apply to the device that you are installing.

Note: Depending on the device and installation, not all of the parts may be used.

22 SAN512B-6 Installation, Service, and User Guide

Page 47

|

|

Verify that the items listed in the following figure are included in the NEBS kit.

|

|

Figure 4. NEBS kit parts list

|

|

|

|

|

|

|

|

|

Assembling the rack hardware

1. Left cable comb assembly (1)

2. Right cable comb assembly (1)

3. Air filter (1)

4. Chassis door (1)

5. Velcro strap (8)

6. Screw, 10-32 x .63-in., square cone washer (10)

7. Screw, 8-32 x .312 in., flathead (20)

8. Nut retainer (6)

About this task

Attach the left and right rack mount shelf brackets to the rack rails.

Chapter 3. Mounting the Device 23

Page 48

Note: If cables are to be routed down through the cable management comb, allow

space below the brackets for cable management.

Procedure

1. Locate the shelf brackets in the device.

2. Locate and loosen the screws on the adjustable ends of the brackets (see the

following figure) to allow for adjustment to rack depth.

Figure 5. Left and right shelf brackets installed on rails