Page 1

IBM Storage Networking SAN192C-6, SAN384C-6 and

SAN768C-6

IBM

Installation, Service, and User Guide

MTM Service information: 8978-E04, 8978-E08, 8978-E16

SC27-9276-00

Page 2

Page 3

IBM Storage Networking SAN192C-6, SAN384C-6 and

SAN768C-6

IBM

Installation, Service, and User Guide

MTM Service information: 8978-E04, 8978-E08, 8978-E16

SC27-9276-00

Page 4

Read Before Using

This product contains software that is licensed under written license agreements. Your use of such software is subject to the

license agreements under which they are provided.

Before you use the information in this publication, be sure to read the general information under “Notices” on page 125.

Page 5

Contents

Figures ............... v

Tables ............... vii

Read this first ............ ix

Getting help .............. ix

Accessibility features ........... ix

How to send your comments ......... x

Safety and environmental notices ... xi

Safety notices and labels .......... xi

Caution notices ............. xi

Danger notices ............. xiii

Safety labels .............. xvi

Attention notices ............ xvii

ESD precautions ............ xviii

Rack safety .............. xviii

Rack installation ........... xviii

Rack relocation (19" rack)......... xx

Product recycling and disposal ........ xx

About this document ........ xxi

Product documentation .......... xxi

IBM and Cisco product matrix ........ xxi

Chapter 1. Introducing the IBM c-type

SAN Directors ............ 1

IBM SAN768C-6 ............. 1

IBM SAN384C-6 ............. 2

IBM SAN192C-6 ............. 2

Supported Components........... 3

Supported Components on the SAN768C-6 ... 3

Supported Components on the SAN384C-6 ... 3

Supported Components on the SAN192C-6 ... 4

Chassis Description ............ 4

SAN768C-6 Chassis ........... 4

SAN384C-6 Chassis ........... 7

SAN192C-6 Chassis ........... 9

System LEDs ............. 11

Supervisor Modules ........... 12

IBM Supervisor-1E Module ........ 12

IBM Supervisor-1 Module ........ 16

Crossbar Fabric Modules .......... 19

SAN768C-6 Crossbar Fabric Modules ..... 20

SAN384C-6 Crossbar Fabric Modules ..... 22

SAN192C-6 Crossbar Fabric Modules ..... 24

Fibre Channel Switching Modules ....... 27

IBM 48 port 32 Gbps Fibre Channel Switching

Module............... 27

LEDs on the 48 port 32 Gbps Fibre Channel

Switching Modules ........... 28

SAN Extension Modules .......... 29

IBM c-type SAN Director 24/10 port SAN

Extension Module ........... 29

LEDs on the 24/10 Port SAN Extension Module 30

Fan Modules .............. 32

SAN768C-6 Fan Modules ......... 32

SAN384C-6 Fan Modules ......... 33

SAN192C-6 Fan Modules ......... 34

Power Supplies ............. 35

Power Modes............. 38

Supported Transceivers .......... 40

Fibre Channel SFP+ Transceivers ...... 40

Chapter 2. Rack Installation ...... 41

Rack Requirements ............ 41

General Requirements for Open Four-Post Racks 41

General Rack and Cabinet Requirements for IBM

c-type SAN switches and directors ..... 41

Rack and Cabinet Requirements for the

SAN768C-6 Chassis........... 42

Rack and Cabinet Requirements for the

SAN384C-6 Chassis........... 42

Rack and Cabinet Requirements for the

SAN192C-6 Chassis........... 43

Clearance Requirements for IBM c-type SAN

switches and directors .......... 43

Rack-Mounting Guidelines ......... 45

Before Installing the Rack-Mount Support

Brackets .............. 45

Installing and Removing the Brackets...... 45

Required Equipment .......... 45

Installing the IBM c-type SAN Director Shelf

Bracket Kit into a Rack ......... 46

Installing the Switch on the Brackets ..... 46

Chapter 3. Installing the IBM c-type

SAN Device............. 49

Precautions for Installation ......... 49

Preparing for Installation .......... 49

Unpacking and Inspecting the Switch .... 50

Required Equipment .......... 51

Installation Guidelines.......... 51

Attaching Bottom-Support Rails to a Two-Post Rack

for the SAN192C-6 Director ......... 52

Attaching Bottom-Support Rails to a Four-Post Rack 53

Installing the SAN192C-6 Chassis in a Two-Post

Rack................. 58

Installing the SAN384C-6 or SAN768C-6 Device on

a Four-Post Rack or Cabinet ......... 62

System Grounding ............ 71

Proper Grounding Practices ........ 71

Preventing Electrostatic Discharge Damage ... 72

Installing, Removing and Verifying Field

Replaceable Units ............ 75

Installing Supervisor Modules ....... 76

Removing Supervisor Modules ....... 76

Installing a Switching Module ....... 77

Removing a Switching Module ....... 78

© Copyright IBM Corp. 2018 iii

Page 6

Verifying Installation of the Supervisor and

Switching Modules ........... 79

Installing and Removing a Crossbar Fabric

Module............... 79

Installing and Removing a Power Supply ... 81

Installing and Removing Fan Modules .... 86

Starting Up the Switch .......... 87

Verifying Component Installation ...... 87

Powering Up the Switch ......... 88

Console Port Pinouts .......... 113

Connecting the Console Port to a Computer

Using the DB-25 Adapter ........ 113

MGMT 10/100/1000 Ethernet Port ...... 114

Supported Power Cords and Plugs ...... 115

Power Cords ............. 115

Supported Plugs for 3000 W AC Power Supplies 116

Power Supply AC Power Cords ...... 117

AC Power Cord Illustrations ....... 117

Chapter 4. Connecting the IBM c-type

SAN Director ............ 91

Connection Guidelines........... 91

Preparing for Network Connections ...... 91

Connecting to the Console Port........ 91

Connecting to the MGMT 10/100/1000 Ethernet

Port ................. 92

Connecting to a Fibre Channel Port ...... 93

Removing and Installing SFP+ and QSFP+

Transceivers ............. 93

Maintaining SFP+ and QSFP+ Transceivers and

Fiber-Optic Cables ........... 97

Appendix A. Product Specifications .. 99

Switch Specifications ........... 99

SAN768C-6 Director Specification ...... 99

SAN384C-6 Director Specification ..... 100

SAN192C-6 Director Specification ..... 100

Module Specifications .......... 100

Power Specifications for the IBM c-type SAN

Director ............... 102

Power Supply Specifications ....... 102

Component Power Requirements and Heat

Dissipation ............. 103

AC Power Consumption for the SAN768C-6

Director .............. 105

AC Power Consumption for the SAN384C-6

Director .............. 105

AC Power Consumption for the SAN192C-6

Director .............. 106

AC Power Supply Requirements for Grid

Redundancy............. 106

SFP+ Transceiver Specifications ....... 107

Fibre Channel SFP+ Transceivers ...... 107

Maximum Environmental and Electrical Ratings

for Fibre Channel SFP+ Transceivers..... 112

Appendix C. Site Planning and

Maintenance Records ........ 121

Contacting Customer Service ........ 121

Finding the Chassis Serial Number ...... 121

Site Preparation Checklist ......... 121

Appendix D. IBM c-type SAN Director

Accessory Kit Contents ....... 123

Notices .............. 125

Trademarks .............. 126

Homologation statement ......... 126

Electronic emission notices ......... 126

Federal Communications Commission Statement 126

Industry Canada Compliance Statement ... 127

Australia and New Zealand Class A Statement 127

European Union Electromagnetic Compatibility

Directive .............. 127

Germany Electromagnetic Compatibility

Directive .............. 128

People's Republic of China Class A Statement 130

Taiwan Class A Statement ........ 130

Taiwan Contact Information ....... 130

Japan Voluntary Control Council for Interference

Class A Statement ........... 130

Japan Electronics and Information Technology

Industries Association Statement ...... 131

Korean Communications Commission Class A

Statement ............. 131

Russia Electromagnetic Interference Class A

Statement ............. 132

Index ............... 133

Appendix B. Cable and Port

Specifications ........... 113

Cables and Adapters Provided........ 113

Console Port.............. 113

iv SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 7

Figures

1. SAN768C-6 Chassis Front View ...... 5

2. SAN768C-6 Chassis Rear View ...... 6

3. SAN384C-6 Chassis Front View ...... 8

4. SAN384C-6SAN384C-6 Chassis Rear View 9

5. SAN192C-6 Chassis Front View ...... 10

6. SAN192C-6 Chassis Rear View ...... 11

7. IBM Supervisor-1E Module ....... 13

8. IBM Supervisor-1 Module ........ 16

9. SAN768C-6 Crossbar Fabric Module .... 20

10. SAN384C-6 Crossbar Fabric Module .... 22

11. SAN192C-6 Crossbar Fabric Module .... 25

12. IBM 48 port 32 Gbps Fibre Channel Switching

Module .............. 27

13. IBM c-type SAN Director 24/10 Port SAN

Extension Module .......... 30

14. SAN768C-6 Fan Modules External and Internal

View............... 33

15. SAN384C-6 Fan Modules External and Internal

View............... 34

16. SAN192C-6 Fan Modules External and Internal

View............... 35

17. 3000 W AC Power Supply ....... 36

18. 3000 W DC Power Supply ....... 37

19. SAN768C-6 Grid-PSU Connections ..... 39

20. SAN384C-6 Grid-PSU Connections ..... 40

21. SAN192C-6 Grid-PSU Connections ..... 40

22. Clearance Requirements for IBM c-type SAN

switches and directors (Top View) ..... 44

23. Installing the Shelf Bracket Kit into a Rack 46

24. Attaching Bottom-Support Rails to a Rack 53

25. Positioning Bottom-Support Rail - SAN384C-6

Chassis .............. 55

26. Positioning Bottom-Support Rail - SAN768C-6

Chassis .............. 56

27. Attaching Bottom-Support Rails to a Rack -

SAN384C-6 Chassis .......... 57

28. Attaching Bottom-Support Rails to a Rack -

SAN768C-6 Chassis .......... 57

29. Moving a Chassis onto a Rack or Cabinet 60

30. Attaching the Chassis to the Rack ..... 61

31. Chassis onto a Rack or Cabinet - SAN384C-6

Chassis .............. 66

32. Moving a Chassis onto a Rack or Cabinet -

SAN768C-6 Chassis .......... 67

33. Attaching the Chassis to the two vertical the

Chassis to the Rack - SAN384C-6 Chassis .. 68

34. Attaching the Chassis to the Rack - SAN768C-6

Chassis .............. 69

35. Removing the Safety Cover for the Terminal

Box on the 3-kW DC Power Supply .... 84

36. SFP+ Transceiver with Mylar Tab Latch 94

37. SFP+ Transceiver with Bale-Clasp Latch 94

38. Alternate Removal Method for Bale Clasp

SFP+ or QSFP+ Transceivers ....... 95

39. Connecting the LC-Type Cable to a Fibre

Channel Port ............ 97

40. RJ-45 Interface Cable Connector ..... 114

41. Twisted-Pair 10/100/1000BASE-T Cable

Schematic ............. 115

42. 3000-W AC Power Supply Plugs ..... 116

43. Additional Power Supply Plug Supported for

3000 W 110 VAC Only ........ 117

44. AJK5 .............. 118

45. AJJX .............. 118

46. AJK4 .............. 118

47. AJK2 .............. 119

48. AJK1 .............. 119

49. AJJY .............. 119

50. AJJV .............. 120

© Copyright IBM Corp. 2018 v

Page 8

vi SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 9

Tables

1. Cisco and IBM product and model number

matrix .............. xxi

2. IBM c-type SAN switches and directors System

LEDs............... 11

3. IBM Supervisor-1E Module LEDs ..... 14

4. IBM Supervisor-1 Module LEDs...... 17

5. SAN768C-6 Crossbar Modules LEDs .... 21

6. SAN384C-6 Crossbar Modules LEDs .... 23

7. SAN192C-6 Crossbar Modules LEDs .... 26

8. IBM 48 Port 32 Gbps Fibre Channel Switching

Module LEDs ............ 28

9. IBM c-type SAN switches and directors 24/10

Port SAN Extension Module LEDs ..... 30

10. Power Supply LEDs.......... 37

11. Contents of Rack-Mount Support Brackets Kit 45

12. Contents of Shelf Bracket Kit....... 45

13. Best practices ............ 71

14. Specifications for the IBM c-type SAN

Directors ............. 99

15. Specifications for the SAN768C-6 Director

Director .............. 99

16. Specifications for the SAN384C-6 Director 100

17. Specifications for the SAN192C-6 Director 100

18. Supervisor-1 Module Specifications .... 100

19. Supervisor-1E Module Specifications 101

20. Fabric Switching Module Specifications 101

21. Extension Module Specifications ..... 101

22. IBM c-type SAN Director 48-Port 32-Gbps

Fibre Channel Switching

Module Specifications ........ 102

23. SAN c-type Director Power Supplies 102

24. Requirements for 3000 W AC Power

Supplies ............. 104

25. Dissipation for 3000 W AC Power Supplies

for Different Solutions with 32-G Fibre

Channel ports using IBM c-type SAN Director

48 port 32Gbps Switching Module and six

Fabric Modules............ 104

26. Consumption for SAN768C-6 Director 105

27. Consumption for SAN384C-6 Director 105

28. Consumption for SAN192C-6 Director 106

29. AC PSU Requirements for Grid Redundancy 106

30. Fibre Channel transceivers ....... 107

31. General Specifications for 32 Gbps Fibre

Channel SFP+ Transceivers ....... 108

32. Specification for 32 Gbps Fibre Channel SFP+

Transceivers ............ 109

33. Environmental Specifications for 32 Gbps

Fibre Channel SFP+ Transceivers ..... 109

34. General Specifications for 16 Gbps Fibre

Channel SFP+ Transceivers ....... 110

35. Specification for 16 Gbps Fibre Channel SFP+

Transceivers ............ 110

36. Environmental Specifications for 16 Gbps

Fibre Channel SFP+ Transceivers ..... 111

37. General Specifications for 8 Gbps Fibre

Channel SFP+ Transceivers ....... 111

38. Specification for 8 Gbps Fibre Channel SFP+

Transceivers ............ 112

39. Specifications for 8 Gbps Fibre Channel SFP+

Transceivers ............ 112

40. Maximum Environmental and Electrical

Ratings for Fibre Channel SFP+ Transceivers . 112

41. Console Port Pinouts ......... 113

42. Port Mode Signaling and Pinouts with the

DB-25 Adapter ........... 114

43. 10/100/1000BASE-T Management Port Cable

Pinout (MDI)............ 114

44. Power Cords for the IBM c-type Director 115

45. Power Supply AC Power Cords ..... 117

46. IBM c-type SAN Director Accessory Kit

Contents ............. 123

© Copyright IBM Corp. 2018 vii

Page 10

viii SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 11

Read this first

Getting help

Summary of changes

This is the first edition of the IBM®Storage Networking SAN192C-6, SAN384C-6

and SAN768C-6 Installation, Service, and User Guide.

For the latest version of your product documentation, visit the web at

http://www.elink.ibmlink.ibm.com/public/applications/publications/cgibin/

pbi.cgi.

For more information about IBM SAN products, see the following Web

site:http://www.ibm.com/servers/storage/san/

For support information for this product and other SAN products, see the

following Web site:http://www.ibm.com/servers/storage/support/san

For detailed information about the Fibre Channel standards, see the Fibre Channel

Industry Association (FCIA) Web site at: www.fibrechannel.org/

Visit www.ibm.com/contact for the contact information for your country or region.

You can also contact IBM within the United States at 1-800-IBMSERV

(1-800-426-7378). For support outside the United States, you can find the service

number at: http://www.ibm.com/planetwide/.

Accessibility features

Accessibility features help users who have a disability, such as restricted mobility

or limited vision, to use information technology products successfully.

Accessibility features

The following list includes the major accessibility features in this product:

v Light emitting diodes (LEDs) that flash at different rates, to represent the same

information as the colors of the LEDs

v Industry-standard devices for ports and connectors

v Management of the product through management applications is available

through Web and Graphical User Interface (GUI) options

Keyboard navigation

This product does not have an attached or integrated keyboard. Any keyboard

navigation is provided through the management software and GUI.

Vendor software

This product includes certain vendor software that is not covered under the IBM

license agreement. IBM makes no representation about the accessibility features of

© Copyright IBM Corp. 2018 ix

Page 12

these products. Contact the vendor for the accessibility information about its

products.

Related accessibility information

You can view the publications for this product in Adobe Portable Document

Format (PDF) using the Adobe Acrobat Reader. The PDFs are provided on a

product documentation CD-ROM that is packaged with the product. The CD-ROM

also includes an accessible HTML version of this document.

IBM and accessibility

See the IBM Human Ability and Accessibility Center website at

www.ibm.com/able/ for more information about the commitment that IBM has to

accessibility.

How to send your comments

Your feedback is important in helping us provide the most accurate and

high-quality information. If you have comments or suggestions for improving this

document, send us your comments by email to starpubs@us.ibm.com. Be sure to

include the following information:

v Exact publication title

v Form number (for example, GC27-2270-00)

v Page numbers to which you are referring

You can also mail your comments to:

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744-0001 U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or

distribute the information in any way it believes appropriate without incurring any

obligation to you.

x SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 13

Safety and environmental notices

This section contains information about:

v “Safety notices and labels”

v “Rack safety” on page xviii

v “Product recycling and disposal” on page xx

Safety notices and labels

When using this product, observe the danger, caution, and attention notices

contained in this guide. The notices are accompanied by symbols that represent the

severity of the safety condition. The danger and caution notices are listed in

numerical order based on their IDs, which are displayed in parentheses, for

example (D004), at the end of each notice. Use this ID to locate the translation of

these danger and caution notices in the Safety Notices publication that is shipped

with this product.

The following notices and statements are used in IBM documents. They are listed

below in order of increasing severity of potential hazards. Follow the links for

more detailed descriptions and examples of the danger, caution, and attention

notices in the sections that follow.

v Note: These notices provide important tips, guidance, or advice.

v “Attention notices” on page xvii: These notices indicate potential damage to

programs, devices, or data.

v “Caution notices”: These statements indicate situations that can be potentially

hazardous to you.

v “Danger notices” on page xiii: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are also attached

directly to products to warn of these situations.

v In addition to these notices, “Safety labels” on page xvi may be attached to the

product to warn of potential hazards.

Caution notices

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition. A caution notice can be accompanied

by different symbols, as in the examples below:

Example

symbol Symbol meaning

A hazardous electrical condition with less severity than electrical danger.

A generally hazardous condition not represented by other safety

symbols.

© Copyright IBM Corp. 2018 xi

Page 14

Example

svc00169

55kg(121.2lbs)

P/N 18P5850-B

SJ000752

svc00169

55kg(121.2lbs)

symbol Symbol meaning

A specification of product weight that requires safe lifting practices. The

weight range of the product is listed below the graphic, and the wording

of the caution varies, depending on the weight of the device.

>55kg (121.2 lb)

A potential hazard of pinching the hand or other body parts between

parts.

A hazardous condition due to moving parts nearby.

A hazardous condition due to the use of a laser in the product. Laser

symbols are always accompanied by the classification of the laser as

defined by the U. S. Department of Health and Human Services (for

example, Class I, Class II, and so forth).

Read and comply with the following caution notices before installing or servicing

this device.

CAUTION:

Energy hazard present. Shorting may result in system outage and

possible physical injury. Remove all metallic jewelry before servicing.

(C001)

>55kg (121.2 lb)

CAUTION:

The weight of this part or unit is more than 55 kg (121.2 lb). It takes

specially trained persons, a lifting device, or both to safely lift this

part or unit. (C011)

CAUTION:

The system contains circuit cards, assemblies, or both that may contain

lead solder. To avoid the release of lead (Pb) into the environment, do

not burn. Discard the circuit card as instructed by local regulations.

(C014)

CAUTION:

This product is equipped with a 3-wire (two conductors and ground)

power cable and plug. Use this power cable with a properly grounded

electrical outlet to avoid electrical shock. (C018)

xii SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 15

CAUTION:

This product might contain one or more of the following devices:

CD-ROM drive, DVD-ROM drive, DVD-RAM drive, or laser module,

which are Class 1 laser products. Note the following information:

v Do not remove the covers. Removing the covers of the laser product

could result in exposure to hazardous laser radiation. There are no

serviceable parts inside the device.

v Use of the controls or adjustments or performance of procedures

other than those specified herein might result in hazardous

radiation exposure.

(C026)

CAUTION:

The power-control button on the device does not turn off the electrical

current supplied to the device. The device might also have more than

one connection to dc power. To remove all electrical current from the

device, ensure that all connections to dc power are disconnected at the

dc power input terminals. (C031)

CAUTION:

Servicing of this product or unit is to be performed by trained service

personnel only. (C032)

Danger notices

CAUTION:

For CA residents only: IBM recommends installing this product in a room size

of 62 cubic meters (2190 cubic feet) or larger at 0.4 ACH ventilation rate to

reduce the concentrations of any chemicals emitted by the product.

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people. A lightning bolt symbol accompanies a danger notice to

represent a dangerous electrical condition. Read and comply with these danger

notices before installing or servicing this device.

DANGER

To prevent a possible shock from touching two surfaces with

different protective ground (earth), use one hand, when possible, to

connect or disconnect signal cables. (D001)

Safety and environmental notices xiii

Page 16

DANGER

Overloading a branch circuit is potentially a fire hazard and a

shock hazard under certain conditions. To avoid these hazards,

ensure that your system electrical requirements do not exceed

branch circuit protection requirements. Refer to the information

that is provided with your device or the power rating label for

electrical specifications. (D002)

DANGER

If the receptacle has a metal shell, do not touch the shell until you

have completed the voltage and grounding checks. Improper wiring

or grounding could place dangerous voltage on the metal shell. If

any of the conditions are not as described, STOP. Ensure the

improper voltage or impedance conditions are corrected before

proceeding. (D003)

DANGER

An electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the devices that

attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent

an electrical shock. (D004)

A general electrical danger notice provides instructions on how to avoid shock

hazards when servicing equipment. Unless instructed otherwise, follow the

procedures in this danger notice.

xiv SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 17

DANGER

When working on or around the system, observe the precautions:

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

v Connect power to this unit only with the IBM provided power

cord. Do not use the IBM provided power cord for any other

product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an

electrical storm.

v The product might be equipped with multiple power cords. To

remove all hazardous voltages, disconnect all power cords.

v Connect all power cords to a properly wired and grounded

electrical outlet. Ensure that the outlet supplies proper voltage

and phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product to

properly wired outlets.

v When possible, use one hand only to connect or disconnect

signal cables.

v Never turn on any equipment when there is evidence of fire,

water, or structural damage.

v Disconnect the attached power cords, telecommunications

systems, networks, and modems before you open the device

covers, unless instructed otherwise in the installation and

configuration procedures.

v Connect and disconnect cables as described below when

installing, moving, or opening covers on this product or attached

devices.

To disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices.

To connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. Attach the power cords to the outlets.

5. Turn on the devices.

(D005)

Delivery and subsequent transportation of the equipment

The customer should prepare his environment to accept the new product based on

the installation planning information provided, with assistance from an IBM

Safety and environmental notices xv

Page 18

> (> )500 lbs. 227 kg.

a69i0333

Safety labels

Installation Planning Representative (IPR) or IBM authorized service provider. In

anticipation of the equipment delivery, the final installation site should be prepared

in advance such that professional movers/riggers can transport the equipment to

the final installation site within the computer room. If for some reason, this is not

possible at the time of delivery, the customer will need to make arrangements to

have professional movers/riggers return to finish the transportation at a later date.

Only professional movers/riggers should transport the equipment. The IBM

authorized service provider will only perform minimal frame repositioning within

the computer room, as needed, to perform required service actions. The customer

is also responsible for using professional movers/riggers in the case of equipment

relocation or disposal.

DANGER

Heavy equipment—personal injury or equipment damage might

result if mishandled. (D006)

As an added precaution, safety labels are often installed directly on products or

product components to warn of potential hazards. These can be either danger or

caution notices, depending upon the level of the hazard.

The actual product safety labels may differ from these sample safety labels:

DANGER

Hazardous voltage, current, or energy levels are present inside

any component that has this label attached. Do not open any

cover or barrier that contains this label. (L001)

DANGER

Rack-mounted devices are not to be used as a shelf or work space.

(L002)

DANGER

Multiple power cords. The product might be equipped with

multiple power cords. To remove all hazardous voltages,

disconnect all power cords. (L003)

xvi SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 19

Attention notices

An attention notice indicates the possibility of damage to a program, device, or

system, or to data. An exclamation point symbol may accompany an attention

notice, but is not required. A sample attention notice follows:

Attention: Do not bend a fibre cable to a radius less than 5 cm (2 in.); you can

damage the cable. Tie wraps are not recommended for optical cables because they

can be easily overtightened, causing damage to the cable.

DANGER

Hazardous voltage present. Voltages present constitute a shock

hazard, which can cause severe injury or death. (L004)

CAUTION:

Hazardous moving parts nearby. (L008)

Safety and environmental notices xvii

Page 20

ESD precautions

Attention: Many of the field replaceable units (FRUs) are sensitive to electrostatic

discharge (ESD), and can potentially be damaged by improper handling. When

working with any FRU, use correct ESD precautions:

v Attach ground to the indicated area on the chassis

v Wear a wrist grounding strap connected to chassis ground (if the switch is

v Store ESD-sensitive components in antistatic packaging

Rack safety

Rack installation

DANGER

plugged in) or a bench ground.

Note: For safety reasons, the ESD wrist strap should contain a series 1

megaohm resistor.

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment—personal injury or equipment damage might result if

mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the

heaviest devices in the bottom of the rack cabinet. Always install servers and

optional devices starting from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place

objects on top of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all

power cords in the rack cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the

same rack cabinet. Do not plug a power cord from a device installed in one rack

cabinet into a power device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the

metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

(R001 part 1 of 2)

xviii SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 21

CAUTION:

v Do not install a unit in a rack where the internal rack ambient temperatures will

exceed the manufacturer’s recommended ambient temperature for all your

rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow

is not blocked or reduced on any side, front, or back of a unit used for air flow

through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit

so that overloading of the circuits does not compromise the supply wiring or

overcurrent protection. To provide the correct power connection to a rack, refer to the

rating labels located on the equipment in the rack to determine the total power

requirement of the supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature if the rack stabilizer

brackets are not attached to the rack. Do not pull out more than one drawer at a time.

The rack might become unstable if you pull out more than one drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be moved for servicing

unless specified by the manufacturer. Attempting to move the drawer partially or

completely out of the rack might cause the rack to become unstable or cause the

drawer to fall out of the rack.

(R001 part 2 of 2)

Safety and environmental notices xix

Page 22

Rack relocation (19" rack)

CAUTION:

Removing components from the upper positions in the rack cabinet improves

rack stability during relocation. Follow these general guidelines whenever you

relocate a populated rack cabinet within a room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at the

top of the rack cabinet. When possible, restore the rack cabinet to the

configuration of the rack cabinet as you received it. If this configuration is not

known, you must complete these steps:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack

cabinet.

– Ensure that there are no empty U-levels between devices installed in the

rack cabinet below the 32U level.

– If the rack cabinet you are relocating is part of a suite of rack cabinets,

detach the rack cabinet from the suite.

– Inspect the route that you plan to take when moving the rack to eliminate

potential hazards.

– Verify that the route that you choose can support the weight of the loaded

rack cabinet. Refer to the documentation that came with your rack cabinet

for the weight of a loaded rack cabinet.

– Verify that all door openings are at least 760 x 2030 mm (30 x 80 in.).

– Ensure that all devices, shelves, drawers, doors, and cables are secure.

– Ensure that the four leveling pads are raised to their highest position.

– Ensure that there is no stabilizer bracket installed on the rack cabinet

during movement.

– Do not use a ramp inclined at more than 10 degrees.

– Once the rack cabinet is in the new location, do the following:

- Lower the four leveling pads.

- Install stabilizer brackets on the rack cabinet.

- If you removed any devices from the rack cabinet, repopulate the rack

cabinet from the lowest position to the highest position.

– If a long distance relocation is required, restore the rack cabinet to the

configuration of the rack cabinet as you received it. Pack the rack cabinet in

the original packaging material, or equivalent. Also, lower the leveling

pads to raise the casters off of the pallet and bolt the rack cabinet to the

pallet.

(R002)

Product recycling and disposal

Refer to the IBM Systems Environmental Notices and User Guide (Z125-5823) for

translated environmental statements and information regarding product recycling

and disposal. This document may be provided either in printed version or on the

product documentation CD. A more current version may be available through this

link ftp://public.dhe.ibm.com/systems/support/warranty/envnotices/

environmental_notices_and_user_guide.pdf.

xx SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 23

About this document

This document is intended for use by systems administrators and technicians

experienced with networking, Fibre Channel, and storage area network (SAN)

technologies. It describes how to install, service, and use the IBM Storage

Networking IBM SAN192C-6, SAN384C-6, and SAN768C-6 (machine type-models

8978 director). Throughout this document, the product is referred to as the IBM

SAN192C-6, SAN384C-6, and SAN768C-6, or simply the director.

This document has been created to include information specific to IBM

SAN192C-6, SAN384C-6, and SAN768C-6 switches running on NX-OS version

8.1(1b) or later. This document does not support all NX-OS versions. It is specific

to NX-OS version 8.1(1b) or later. Refer to the NX-OS version 8.1(1b) Release Notes

for more information.

Product documentation

The following documents contain information related to this product:

v IBM Storage Networking SAN192C-6, SAN384C-6 and SAN768C-6 Installation,

Service, and User Guide , (this document)

v IBM Systems Safety Notices, G229–9054

IBM and Cisco product matrix

The product matrix provides a cross-reference between the comparable IBM and

Cisco product models.

When you use any of the Cisco documents, such as the Fabric Configuration

Guide, you will notice that the model numbers reflect the corresponding Cisco

products. Table 1 provides a product matrix to correlate the Cisco products and

models to the IBM product names and machine types and model numbers.

Products withdrawn from marketing are not listed.

Table 1. Cisco and IBM product and model number matrix

IBM machine type and

Cisco product name IBM product name

9132T Fabric Switch SAN32C-6 8977 Model T32

9250i Multiservice Switch SAN50C-R 8977 Model R50

9706 Multilayer Director SAN192C-6 8978 Model E04

9710 Multilayer Director SAN384C-6 8978 Model E08

9718 Multilayer Director SAN768C-6 8978 Model E16

model number

© Copyright IBM Corp. 2018 xxi

Page 24

xxii SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 25

Chapter 1. Introducing the IBM c-type SAN Directors

The IBM c-type SAN directors includes the SAN768C-6, the SAN384C-6, and the

SAN192C-6.

This chapter has the following topics:

v “IBM SAN768C-6”

v “IBM SAN384C-6” on page 2

v “IBM SAN192C-6” on page 2

v “Supported Components” on page 3

v “Chassis Description” on page 4

v “Supervisor Modules” on page 12

v “Fibre Channel Switching Modules” on page 27

v “SAN Extension Modules” on page 29

v “Fan Modules” on page 32

v “Power Supplies” on page 35

v “Supported Transceivers” on page 40

IBM SAN768C-6

Key product features for the IBM SAN768C-6 device.

The SAN768C-6 includes the following components:

v An 18 slot chassis

v One to two supervisor modules

v 1 to 16 I/O modules

v Three fan modules

v 1 to 16 Power Supply Units

The SAN768C-6 delivers the following features:

v Port density of 768 line rate 32 and 16 Gbps Fibre Channel ports.

v Supports IBM c-type SAN Director 48 Port 32 Gbps Fibre Channel Switching

Module and IBM c-type SAN Director 24/10 port SAN Extension module.

v Reliability, high availability, and scalability through nondisruptive software

upgrades, stateful process restart and failover, and redundancy of all major

components including:

– Hot-swappable redundant supervisor modules

– Hot-swappable redundant crossbar fabric modules

– Hot-swappable redundant power supplies

– Hot-swappable fan modules with integrated temperature and power

management

– Hot swappable enhanced QSFP+, and SFP+ optics (2/4/8 Gbps, 4/8/16

Gbps, and 8/16/32 Gbps)

– Hot-swappable switching modules

v Powers storage environments with up to 48 Tbps of Fibre Channel bandwidth.

v Comprehensive security features

© Copyright IBM Corp. 2018 1

Page 26

IBM SAN384C-6

v Intelligent network services, including VSAN technology, IVR, and smart zoning

v SAN management tools including Data Center Network Manager (DCNM) and

the command-line interface (CLI)

v Online diagnostics (GOLD, Call Home, and so on)

v Multiprotocol architecture, including Fibre Channel.

Key product features for the IBM SAN384C-6 device.

The SAN384C-6 is a high-performance SAN switch that is designed to meet the

requirements of enterprise data center storage environments. The SAN384C-6

includes the following components that are designed specifically for deployment in

the IBM c-type SAN switches and directors:

v A ten-slot chassis

v A crossbar switching fabric module

v A supervisor module

v A 48 Port 32 Gbps Fibre Channel Switching Module

v A 24/10 port SAN Extension module

The SAN384C-6 delivers the following features:

v Up to 24 Tbps of Fibre Channel switching bandwidth

v Reliability, high availability, and scalability through nondisruptive software

upgrades, stateful process restart and failover, and redundancy of all major

components including:

– Hot-swappable redundant supervisor modules

– Hot-swappable redundant crossbar fabric modules

– Hot-swappable redundant power supplies

– Hot-swappable fan modules with integrated temperature and power

management

– Hot swappable enhanced QSFP+, and SFP+ optics (2/4/8 Gbps, 4/8/16

Gbps)

– Hot-swappable switching modules

v Intelligent network services, including VSAN technology, IVR, and smart

zoning

v Comprehensive security features

v SAN management tools including Data Center Network Manager (DCNM) and

the command-line interface (CLI)

v Online diagnostics

v Multiple protocol support, including Fibre Channel.

IBM SAN192C-6

Key features for the IBM SAN192C-6 device.

The SAN192C-6 is designed for deployment in small- to medium-sized storage

networks that can support enterprise clouds and business transformation.

The SAN192C-6 includes the following components:

v A 6-slot chassis

2 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 27

v A crossbar switching fabric module

v A supervisor module

v A 48 Port 32 Gbps Fibre Channel Switching Module

v A 24/10 port SAN Extension module

The SAN192C-6 supports up to 192 ports in a 6-slot modular chassis, with up to

768 ports in a single rack. The ports can be configured as Fibre Channel (2/8/4

Gbps, 4/8/16 Gbps, or 8/16/32 Gbps). The SAN192C-6 supports the same Fibre

Channel switching modules as the SAN768C-6 and SAN384C-6 for a high degree

of system commonality.

The following are the major features offered by SAN192C-6.

v Up to 192 32 Gbps Fibre Channel

v Up to 12 terabits per second (Tbps) front-panel, Fibre Channel, line-rate,

nonblocking system-level switching capacity

v Exceptional capabilities with intelligent fabric services

v Virtual SANs (VSANs) for consolidating individual physical SAN islands while

maintaining logical boundaries

v Inter-VSAN routing (IVR) for sharing resources across VSANs

Supported Components

v “Supported Components on the SAN768C-6”

v “Supported Components on the SAN384C-6”

v “Supported Components on the SAN192C-6” on page 4

Supported Components on the SAN768C-6

The SAN768C-6 director supports the following components:

v SAN768C-6 Chassis

v IBM c-type SAN switches and directors Supervisor-1E Module

v IBM c-type SAN Director 48 Port 32 Gbps Fibre Channel Switching Module

v IBM c-type SAN Director 24/10 port SAN Extension module

v SAN768C-6 Crossbar Switching Fabric1 Module

v SAN768C-6 Fan Module

v IBM c-type SAN Director 3000W AC power supply

v IBM c-type SAN Director 3000W DC power supply

v SAN768C-6 Accessory Kit

Supported Components on the SAN384C-6

The SAN384C-6 Director supports the following components:

v SAN384C-6 Chassis

v IBM c-type SAN Director Supervisor-1 Module

v IBM c-type SAN Director 48 Port 32 Gbps Fibre Channel Switching Module

v IBM c-type SAN Director 24/10 port SAN Extension module

v SAN384C-6 Crossbar Switching Fabric1 Module

v SAN384C-6 Fan Module

v IBM c-type SAN Director 3000W AC power supply

v IBM c-type SAN Director 3000W DC power supply

Chapter 1. Introducing the IBM c-type SAN Directors 3

Page 28

v IBM c-type SAN Director 3500W High-Voltage power supply

v SAN384C-6 Accessory Kit

Supported Components on the SAN192C-6

The SAN192C-6 director supports the following components:

v SAN192C-6 Chassis

v IBM c-type SAN Director Supervisor-1 module

v IBM c-type SAN Director 48 Port 32 Gbps Fibre Channel Switching Module

v IBM c-type SAN Director 24/10 port SAN Extension module

v SAN192C-6 Crossbar Switching Fabric1 Module

v SAN192C-6 Fan Module

v IBM c-type SAN Director 3000W AC power supply

v IBM c-type SAN Director 3000W DC power supply

v IBM c-type SAN Director 3500W High Voltage power supply

v SAN192C-6 Accessory Kit

Chassis Description

This section describes the chassis in the IBM c-type SAN directors:

v “SAN768C-6 Chassis”

v “SAN384C-6 Chassis” on page 7

v “SAN192C-6 Chassis” on page 9

SAN768C-6 Chassis

The SAN768C-6 has 18 slots for up to two supervisor modules and up to 16 I/O

modules. The chassis also holds up to six fabric modules, up to 16 AC or DC 3 kW

power supplies, and three fan modules. To group the many networking cables for

each I/O module on this chassis, you can install cable management frames on the

chassis. Figure 1 on page 5 shows the standard hardware features seen from the

front of the chassis.

4 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 29

Figure 1. SAN768C-6 Chassis Front View

1. I/O modules (slots 1-8 and 11-18)

2. Supervisor modules (slots 9 and 10)

3. Power supplies (16 bays)

4. Chassis mounting brackets

5. Chassis handles

6. System LEDs

7. Ground point

8. Grid A PSU bays

Chapter 1. Introducing the IBM c-type SAN Directors 5

Page 30

9. Grid B PSU bays

Note: Handles are to be used only for positioning empty chassis.

Figure 2 shows the standard hardware features seen from the rear of the chassis.

Figure 2. SAN768C-6 Chassis Rear View

1. Fan module

2. Fabric modules

3. Fan module handle

4. Fan module exhaust

5. Fan power connector

6. Fan and Fabric LEDs

7. Ground point

8. PSU exhaust

6 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 31

SAN384C-6 Chassis

The SAN384C-6 has a ten-slot chassis that supports two supervisor modules, up to

six fabric modules, three fan modules, and up to eight power supplies. Airflow is

front-to-back in the SAN384C-6 chassis.

Note: The base configuration of the SAN384C-6 ships with three fabric modules

and six power supplies.

The slots on the front of the chassis are numbered as follows:

v Line card slots 1 to 4 and 7 to 10 are numbered top to bottom. Each slot can

hold one SAN384C-6 48 port 32 Gbps Fibre Channel switching module.

v Slots 5 and 6 are side-by-side and numbered left to right. Each slot is half the

width of the chassis and each slot can hold one supervisor module.

v There are two rows of power supply bays at the bottom of the chassis. The top

row has bays 1 to 4, numbered left to right. The bottom row has bays 5 to 8,

numbered left to the right. Each bay can hold one power supply.

The slots on the rear of the chassis are numbered as follows:

v Fan modules 1 to 3 are numbered left to the right. When the fan modules are

installed, they cover the fabric modules.

v Fabric module slots 21 to 26 are numbered left to the right. Slots 21 and 22 hold

fabric modules 1 and 2; slots 23 and 24 hold fabric modules 3 and 4; and slots 25

and 26 hold fabric modules 5 and 6. The slots for the fabric modules are behind

the fan modules.

Figure 3 on page 8 shows the front view of the SAN384C-6 chassis.

Chapter 1. Introducing the IBM c-type SAN Directors 7

Page 32

Figure 3. SAN384C-6 Chassis Front View

1. System LEDs

2. Rack-mount bracket

3. Switching modules (1 to 4)

4. Supervisor modules (1 to 2)

5. Switching modules (5 to 8)

6. Power supply modules

7. Handles used for adjusting the chassis placement

Figure 4 on page 9 shows the rear view of the SAN384C-6 chassis.

8 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 33

Figure 4. SAN384C-6SAN384C-6 Chassis Rear View

1. Fan modules

2. Crossbar module

3. Midplane

4. Crossbar and fan LEDs

The SAN384C-6 chassis can be mounted on a standard 19-inch EIA equipment rack

by using the standard rack-mount hardware, or mounted on a standard two-post

Telco rack, with mounting rails.

SAN192C-6 Chassis

The SAN192C-6 has a six-slot chassis that supports one or two supervisor

modules, up to six fabric modules, three fan modules, and up to four AC or DC 3

kW power supplies. Airflow is front-to-back in the SAN192C-6 chassis.

Note: The base configuration of the SAN192C-6 ships with two supervisor

modules, three cross bar fabric modules, and four 3K AC power supplies.

Chapter 1. Introducing the IBM c-type SAN Directors 9

Page 34

Figure 5 shows the front view of the SAN192C-6 chassis.

Figure 5. SAN192C-6 Chassis Front View

1. System LEDs

2. Rack-mount brackets

3. Cable management frame

4. Switching modules (1 to 4)

5. Supervisor module (1 to 2)

6. Power supply modules (up to 4)

7. Handles used for adjusting the chassis placement

Figure 6 on page 11 shows the rear view of the SAN192C-6 chassis.

10 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 35

Figure 6. SAN192C-6 Chassis Rear View

1. Fan modules

2. Crossbar modules

3. LEDs for fan module and fabric modules

4. Handles used for adjusting the chassis placement

5. Vertical mounting brackets

System LEDs

Table 2 describes the System LEDs for the IBM c-type SAN switches and directors.

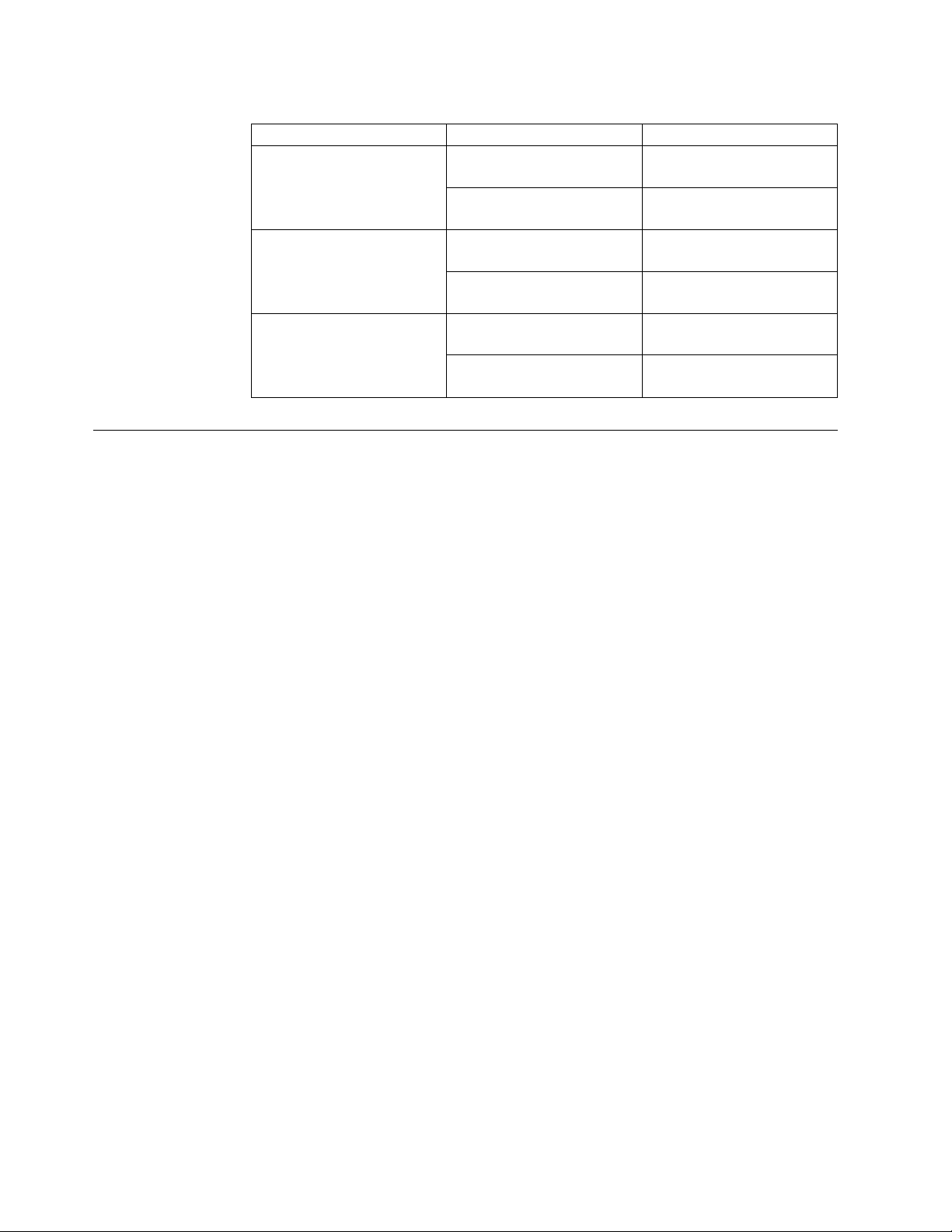

Table 2. IBM c-type SAN switches and directors System LEDs

LED Status Description

PSU Green Power supply units are

FAN Green Fan modules are operational.

operational.

Amber One of the following

problems has occurred:

v Any power supply unit

LED is red.

v Any power supply unit is

down.

Amber At least one I/O module has

a red STATUS LED.

Chapter 1. Introducing the IBM c-type SAN Directors 11

Page 36

Table 2. IBM c-type SAN switches and directors System LEDs (continued)

LED Status Description

SUP Green Supervisor modules are

FAB Green Fabric modules are

IOM Green Switching modules are

Supervisor Modules

This section describes supervisor modules supported by different IBM c-type SAN

switches and directors:

v “IBM Supervisor-1E Module”

v “IBM Supervisor-1 Module” on page 16

operational.

Amber At least one I/O module has

a red STATUS LED.

operational.

Amber At least one I/O module has

a red STATUS LED.

operational.

Amber At least one I/O module has

a red STATUS LED.

IBM Supervisor-1E Module

The Supervisor-1E Module is designed specifically for the SAN768C-6. This

supervisor module delivers the latest advanced switching technology and resources

to support the 18 slot chassis.

This supervisor module supports the following features:

v Nondisruptive software upgrades

v Stateful process restart and failover

v Fully redundant operation

v Support for up to 768 2/4/8 Gbps, 4/8/16 Gbps, or 8/16/32 Gbps full line-rate

autosensing Fibre Channel ports in a single chassis

v Support for up to 48 Tbps of Fibre Channel system bandwidth

v Multipathing based on Fabric Shortest Path First (FSPF)

v Ability to dynamically reroute traffic in the event of a switch failure

v Network management through the command-line interface (CLI) and through

Data Center Network Manager (DCNM)

v Extensive security features including RADIUS and TACACS+, Fibre Channel

Security Protocol (FC-SP), Secure File Transfer Protocol (SFTP), Secure Shell

(SSH) Protocol, and Simple Network Management Protocol Version 3 (SNMPv3)

implementing Advanced Encryption Standard (AES), VSANs, hardware-enforced

zoning, ACLs, and per-VSAN role-based access control (RBAC)

v Support for virtual SAN (VSAN) technology and inter-VSAN routing (IVR)

v Network services such as access control lists (ACLs) and quality of service (QoS)

v Smart zoning

v Power-on self-test (POST) and diagnostics

v Switched Port Analyzer (SPAN) and Remote Switched Port Analyzer (RSPAN)

12 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 37

Figure 7 shows the IBM c-type SAN switches and directors Supervisor-1E Module.

Figure 7. IBM Supervisor-1E Module

1. Module retaining screw

2. ID: locator LED

3. Link: management port link status LED

4. MGMT Ethernet: system out of band Ethernet management port

5. ACT: management port packet activity LED

6. Console Serial Port: module serial console port

7. Eject Request: eject request button for USB1 device

8. USB1: usb1 status LED

9. USB1 USB port

10. Slot0: slot0 status LED

11. Eject Request: eject request button for slot0 device

12. Reset: module reset button

13. Module lock release button

14. Status: system diagnostic test status LED

15. System: system environment status LED

16. Active: supervisor redundancy status LED

17. PWR MGMT: system power status LED

18. Management port operational status LED

19. Module ejection lever

20. Slot0 USB port

Table 3 on page 14 describes the LEDs on the IBM c-type SAN switches and

directors Supervisor-1E Module.

Chapter 1. Introducing the IBM c-type SAN Directors 13

Page 38

Table 3. IBM Supervisor-1E Module LEDs

LED Status Description

ID Flashing blue A user has activated this

LED to allow a person to

find this module in the

chassis.

Off Location identification is

deactivated for this module.

Status Green All module diagnostics

passed. The module is

operational.

Red The module has detected an

error and cannot power on

or boot up.

The module is not properly

inserted.

A bootup or runtime

diagnostic test has failed.

Flashing Red Indicates one of the

following conditions:

The temperature of the

module has exceeded the

safe operating temperature

limits (a major temperature

alarm has occurred). The

module has been shut down

to prevent permanent

damage. The system will be

shut down after two minutes

if this condition is not

cleared.

Off The module is not receiving

System Green All environmental sensors in

Amber At least one power supply

Red The temperature of the

Off The slot has detected a slot

14 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

The module is resetting.

The ejector lever is open.

power.

the system are within

operational bounds.

has failed or the power

supply fan has failed.

supervisor module exceeded

the major threshold.

ID parity error

Page 39

Table 3. IBM Supervisor-1E Module LEDs (continued)

LED Status Description

Active Green The supervisor is operational

and in HA active state.

Amber The supervisor module is in

HA standby state.

Power Management Green There is sufficient power

available for all installed

modules.

Amber There is insufficient power

for all installed modules.

MGMT Ethernet Green The mgmt0 interface is

administratively active and

the supervisor is in HA

active state.

Amber The mgmt0 interface is

administratively active and

the supervisor is in the HA

standby state.

Flashing amber The management port link is

bad and has been disabled

due to a hardware failure.

Off The mgmt0 interface is

uninitialized. No signal is

detected.

ACT Flashing Green Frames are being transmitted

or received by the interface.

Off There is no activity on the

interface.

Link Green The management port link is

operational.

Off No link signal received.

LOG FLASH Green The log flash CompactFlash

or USB disk is being

accessed. Do not remove the

media until the LED is off..

Off The expansion flash

CompactFlash or USB disk is

not being accessed. You can

remove the media while this

LED is off.

Slot0 Green The log flash CompactFlash

or USB disk is being

accessed. Do not remove the

media until the LED is off.

Off The expansion flash

CompactFlash or USB disk is

not being accessed. You can

remove the media while this

LED is off.

Chapter 1. Introducing the IBM c-type SAN Directors 15

Page 40

IBM Supervisor-1 Module

The IBM Supervisor-1 Module is designed specifically for the SAN192C-6 and

SAN384C-6 chassis. This supervisor module provides control and management

functions for the switch and enables high-performance switching.

This supervisor module supports the following features:

v Nondisruptive software upgrades

v Stateful process restart and failover

v Fully redundant operation

v Support for up to 384 Fibre Channel ports in a single chassis and 1152 Fibre

Channel ports in a single rack

v Support for up to 24 Tbps of Fibre Channel system bandwidth

v Multipathing based on Fabric Shortest Path First (FSPF)

v Ability to dynamically reroute traffic in the event of a switch failure

v Network management through the command-line interface (CLI) and through

Data Center Network Manager (DCNM)

v Extensive security features including RADIUS and TACACS+, Fibre Channel

Security Protocol (FC-SP), Secure File Transfer Protocol (SFTP), Secure Shell

(SSH) Protocol, and Simple Network Management Protocol Version 3 (SNMPv3)

implementing Advanced Encryption Standard (AES), VSANs, hardware-enforced

zoning, ACLs, and per-VSAN role-based access control

v Support for virtual SAN (VSAN) technology and inter-VSAN routing (IVR)

v Network services such as access control lists (ACLs) and quality of service

(QoS)

v Smart zoning

v Power-on self-test (POST) and diagnostics

v Switched Port Analyzer (SPAN) and Remote Switched Port Analyzer (RSPAN)

Figure 8 shows the IBM c-type SAN switches and directors Supervisor-1 module.

Figure 8. IBM Supervisor-1 Module

1. Module retaining screw

2. ID: locator LED

16 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 41

3. Link: management port link status LED

4. MGMT Ethernet: system out of band Ethernet management port

5. ACT: management port packet activity LED

6. Console Serial Port: module serial console port

7. Eject Request: eject request button for USB1 device

8. USB1: usb1 status LED

9. USB1 USB port

10. Slot0: slot0 status LED

11. Eject Request: eject request button for slot0 device

12. Reset: module reset button

13. Module lock release button

14. Status: system diagnostic test status LED

15. System: system environment status LED

16. Active: supervisor redundancy status LED

17. PWR MGMT: system power status LED

18. Management port operational status LED

19. Module ejection lever

20. Slot0 USB port

Table 4 describes the LEDs on the IBM c-type SAN switches and directors

Supervisor-1 Module.

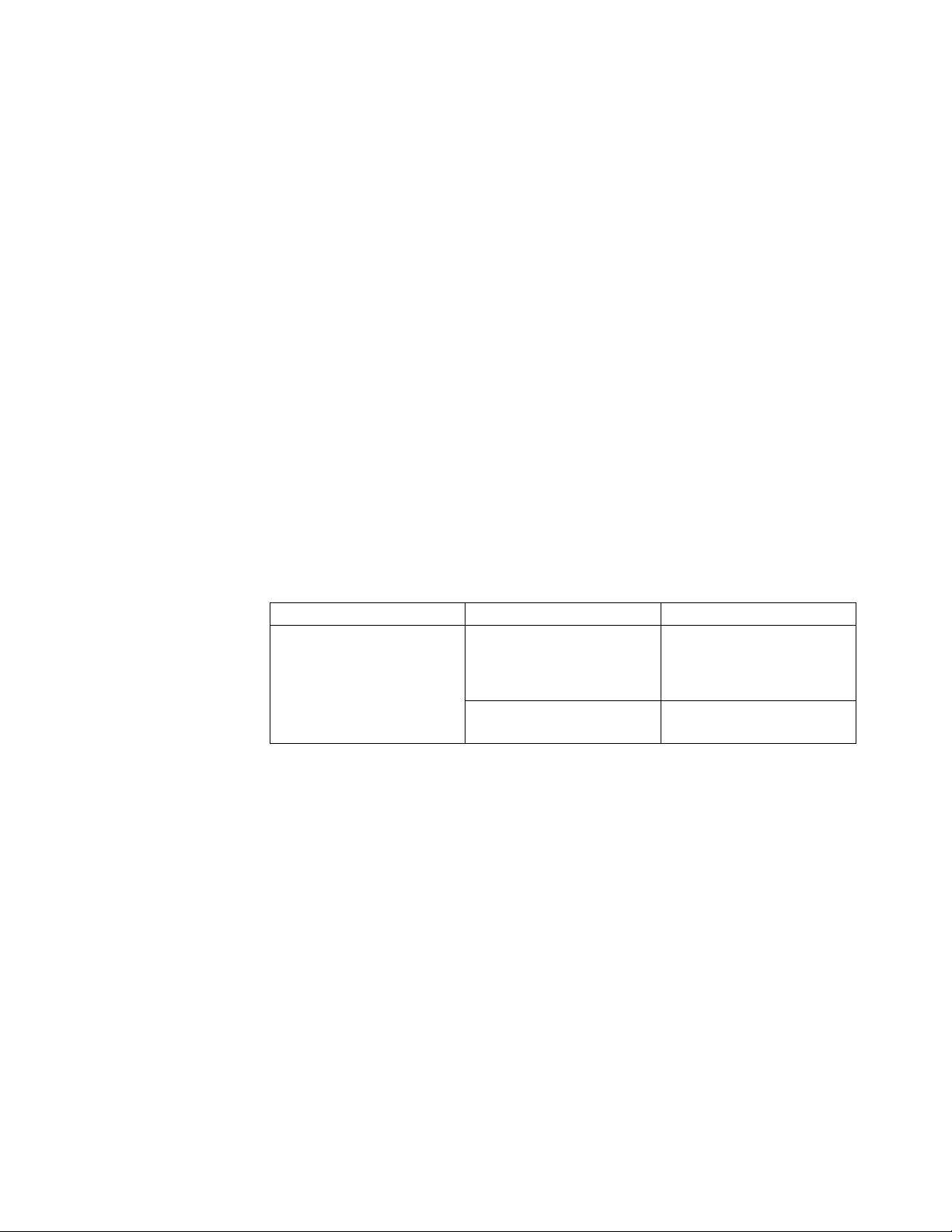

Table 4. IBM Supervisor-1 Module LEDs

LED Status Description

ID Flashing blue A user has activated this

LED to allow a person to

find this module in the

chassis.

Off Location identification is

deactivated for this module.

Chapter 1. Introducing the IBM c-type SAN Directors 17

Page 42

Table 4. IBM Supervisor-1 Module LEDs (continued)

LED Status Description

Status Green All module diagnostics

passed. The module is

operational.

Red Indicates one of the

following conditions:

The module has detected an

error and cannot power on

or boot up.

The module is not properly

inserted.

A bootup or runtime

diagnostic test has failed.

Flashing Red Indicates one of the

following conditions:

The temperature of the

module has exceeded the

safe operating temperature

limits (a major temperature

alarm has occurred). The

module has been shut down

to prevent permanent

damage. The system will be

shut down after two minutes

if this condition is not

cleared.

The module is resetting.

The ejector lever is open.

Off The module is not receiving

power.

System Green All environmental sensors in

the system are within

operational bounds.

Amber At least one power supply

has failed or the power

supply fan has failed.

Red The temperature of the

supervisor module exceeded

the major threshold.

Active Green The supervisor is operational

and in HA active state.

Amber The supervisor module is in

HA standby state.

Power Management Green There is sufficient power

available for all installed

modules.

Amber There is insufficient power

for all installed modules.

18 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 43

Table 4. IBM Supervisor-1 Module LEDs (continued)

LED Status Description

MGMT Ethernet Green The mgmt0 interface is

administratively active and

the supervisor is in HA

active state.

Amber The mgmt0 interface is

administratively active and

the supervisor is in the HA

standby state.

Off The mgmt0 interface is

uninitialized. No signal is

detected.

ACT Green Frames are being transmitted

or received by the interface.

Off There is no activity on the

interface.

Link Green The management port link is

operational.

Amber The management port link

has been disabled by

software.

Flashing amber The management port has

been disabled by a hardware

fault.

Off No link signal received.

USB1 Green The flash device is mounted.

Red The device is a valid device

type, but failed to be

mounted. This can be due to

an invalid file system format.

Off The flash device is not

mounted and can be safely

removed.

Slot0 Green The flash device is mounted.

Red The device is a valid device

type, but failed to be

mounted. This can be due to

an invalid file system format.

Off The flash device is not

mounted and can be safely

removed.

Crossbar Fabric Modules

This section describes the crossbar fabric modules supported by different IBM

c-type SAN director switches:

v “SAN768C-6 Crossbar Fabric Modules” on page 20

v “SAN384C-6 Crossbar Fabric Modules” on page 22

v “SAN192C-6 Crossbar Fabric Modules” on page 24

Chapter 1. Introducing the IBM c-type SAN Directors 19

Page 44

SAN768C-6 Crossbar Fabric Modules

The SAN768C-6 supports up to six crossbar fabric modules. There is a crossbar

fabric module designed specifically for the SAN768C-6. The crossbar fabric

modules are installed vertically in slots 21 through 26, numbered from left to right,

at the back of the chassis behind the fan modules.

Figure 9. SAN768C-6 Crossbar Fabric Module

1. Locking lever

2. Unlocking button

3. Fabric module LEDs

20 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 45

4. Connector pins

The fan modules cover the fabric modules in the back of the chassis. Fan module 1

must be removed to access fabric modules 1 and 2, fan module 2 must be removed

to access fabric modules 3 and 4, and fan module 3 must be removed to access

fabric modules 5 and 6.

The LEDs on the crossbar fabric modules indicate the status of the modules.

Table 5 describes the LEDs.

Table 5. SAN768C-6 Crossbar Modules LEDs

LED Status Description

Status Green All diagnostics pass. The

module is operational

(normal initialization

sequence).

Red Indicates one of the

following: The diagnostic test

has failed. The module is not

operational because a fault

has occurred during the

initialization sequence.

The inlet air temperature of

the system has exceeded the

safe operating temperature

limits of the card (a major

environmental warning). The

card has been shut down to

prevent permanent damage.

Flashing Red Indicates one of the

following: The fabric module

has just been inserted and is

booting up.

An overtemperature

condition has occurred and

the module has powered

down.

The power was turned off

with a CLI command. The

module is resetting and both

ejector levers are out.

Off The module is not receiving

power.

Locater ID Flashing Blue The operator has activated

this LED to identify this

module in the chassis.

Off Operator has not flagged this

card for identification.

Chapter 1. Introducing the IBM c-type SAN Directors 21

Page 46

SAN384C-6 Crossbar Fabric Modules

The SAN384C-6 supports up to six crossbar fabric modules. There is a crossbar

fabric module designed specifically for the SAN384C-6. The crossbar fabric

modules are installed vertically in slots 21 through 26, numbered from left to right,

at the back of the chassis behind the fan modules. A minimum of 3 crossbar fabric

modules are required to deliver full line rate and bandwidth for the switch. A

fourth crossbar fabric module is required for N+1 protection.

Figure 10. SAN384C-6 Crossbar Fabric Module

1. Locking lever

2. Unlocking button

3. Fabric module LEDs

4. Connector pins

22 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 47

Each crossbar fabric module connects to 8 switching modules and 2 supervisor

modules. In addition, each crossbar fabric module supports four 55 Gbps fabric

ports connected to each switching module and one 55 Gbps fabric port connected

to each supervisor module.

The fan modules cover the fabric modules in the back of the chassis. Fan module 1

must be removed to access fabric modules 1 and 2, fan module 2 must be removed

to access fabric modules 3 and 4, and fan module 3 must be removed to access

fabric modules 5 and 6.

The LEDs on the crossbar fabric modules indicate the status of the modules.

Table 6 describes the LEDs.

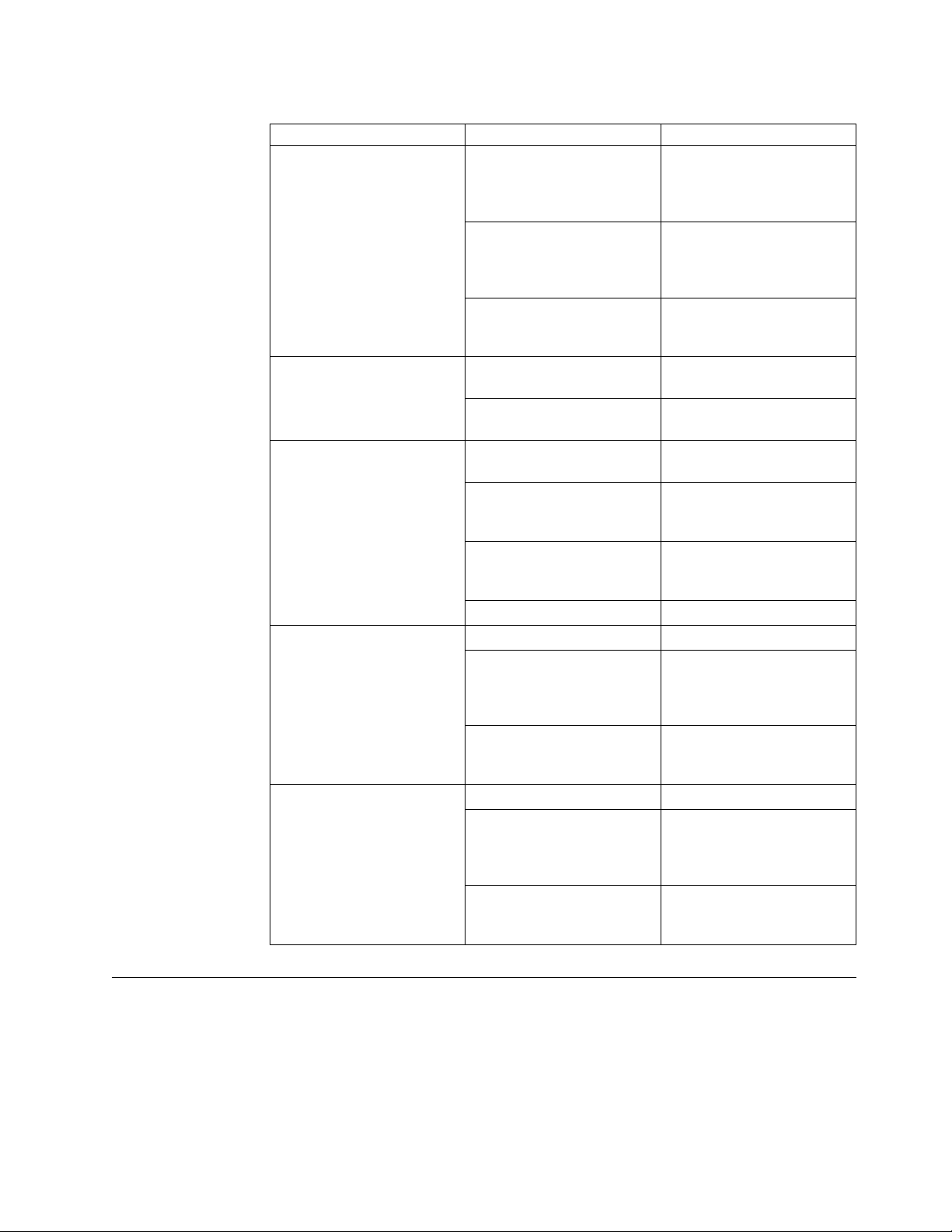

Table 6. SAN384C-6 Crossbar Modules LEDs

LED Status Description

Status Green All diagnostics pass. The

module is operational

(normal initialization

sequence).

Orange One of the following occurs:

The module is booting or

running diagnostics (normal

initialization sequence).

An over-temperature

condition occurred (a minor

threshold was exceeded

during environmental

monitoring).

Red, flashing One of the following occurs:

The diagnostic test failed.

The module is not

operational because a fault

occurred during the

initialization sequence.

An over-temperature

condition occurred (a major

threshold was exceeded

during environmental

monitoring).

Fabric module has been

manually powered off.

Red Bad slot ID parity.

Off The module is not receiving

power.

Locater ID Blue flashing Operator has flagged this

card for identification.

Off Operator has not flagged this

card for identification.

Since the crossbar fabric modules are located behind the fan modules in the

chassis, the LEDs on the crossbar fabric module are not easily visible from the back

Chapter 1. Introducing the IBM c-type SAN Directors 23

Page 48

of the chassis. So, crossbar fabric status LEDs are provided on the fan modules as

well. Since each fan module covers two fabric modules, the status LEDs for two

crossbar fabric modules are present on each fan module. If the fan module is

removed the status and locator LEDs on crossbar fabric modules will be visible.

When a fabric module needs to be located, the locator LED of the corresponding

fan module needs to be activated, followed by the locator LED of fabric module,

using CLIs locator-led fan <fan module number> and locator-led xbar <xbar

slot number>. For example, to locate crossbar fabric module 4, the locator LED of

fan module 2 needs to be activated followed by the locator LED of fabric module

4.

SAN192C-6 Crossbar Fabric Modules

The SAN192C-6 supports up to six crossbar fabric modules. There is a crossbar

fabric module designed specifically for the SAN192C-6. The crossbar fabric

modules are installed vertically at the back of the chassis behind the fan modules.

Fabric slots 1 and 2 are behind fan module slot 1, fabric slots 3 and 4 are behind

fan module slot 2, and fabric slots 5 and 6 are behind fan module slot 3.

24 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 49

Figure 11. SAN192C-6 Crossbar Fabric Module

1. Locking lever

2. Unlocking button

3. Fabric module LEDs

4. Connector pins

The LEDs on the crossbar fabric modules indicate the status of the modules.

Table 7 on page 26 describes the LEDs.

Chapter 1. Introducing the IBM c-type SAN Directors 25

Page 50

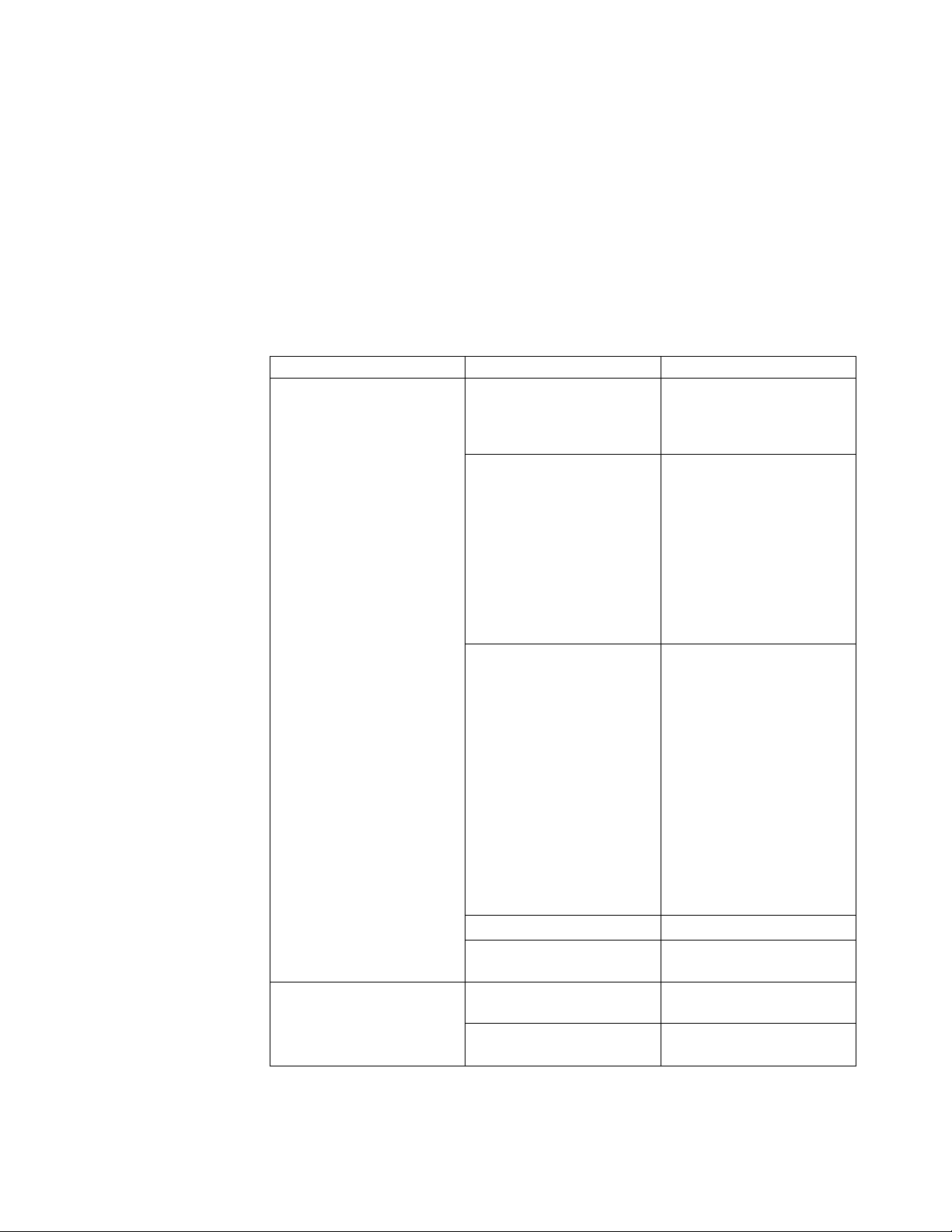

Table 7. SAN192C-6 Crossbar Modules LEDs

LED Status Description

Status Green All diagnostics pass. The

module is operational

(normal initialization

sequence).

One of the following occurs:

The module is booting or

running diagnostics (normal

initialization sequence).

An over-temperature

condition occurred (a minor

threshold was exceeded

during environmental

monitoring).

Red, flashing One of the following occurs:

The diagnostic test failed.

The module is not

operational because a fault

occurred during the

initialization sequence.

An over-temperature

condition occurred (a major

threshold was exceeded

during environmental

monitoring).

Fabric module has been

manually powered off.

Red Bad slot ID parity.

Off The module is not receiving

power.

Locater ID Blue flashing Operator has flagged this

card for identification.

Off Operator has not flagged this

card for identification.

Each crossbar fabric module connects to 4 switching modules and 2 supervisor

modules. In addition, each crossbar fabric module supports four 55 Gbps fabric

ports connected to each switching module and one 55 Gbps fabric port connected

to each supervisor module.

Since the crossbar fabric modules are located behind the fan modules in the

chassis, the LEDs on the crossbar fabric module are not easily visible from the back

of the chassis. So, crossbar fabric status LEDs are provided on the fan modules as

well. Since each fan module covers two fabric modules, the status LEDs for two

crossbar fabric modules are present on each fan module. If the fan module is

removed the status and locator LEDs on crossbar fabric modules will be visible.

26 SAN192C-6, SAN384C-6 and SAN768C-6 Installation, Service, and User Guide

Page 51

When a fabric module needs to be located, the locator LED of the corresponding

fan module needs to be activated, followed by the locator LED of fabric module,

using CLIs locator-led fan <fan module number> and locator-led xbar <xbar

slot number>. For example, to locate crossbar fabric module 4, the locator LED of

fan module 2 needs to be activated followed by the locator LED of fabric module

4.

Fibre Channel Switching Modules

This section describes “IBM 48 port 32 Gbps Fibre Channel Switching Module”

supported by the IBM c-type SAN switches and directors switches.

IBM 48 port 32 Gbps Fibre Channel Switching Module

The IBM 48 port 32 Gbps Fibre Channel switching module is designed specifically

for the IBM c-type SAN directors.

With 768 line-rate 32 Gbps Fibre Channel ports per director, the 32 Gbps 48 port

Fibre Channel switching module meets the high-performance needs for

flash-memory and Non-Volatile Memory Express (NVMe) over Fibre Channel

workloads. The switching module is hot swappable and compatible with 4 Gbps, 8

Gbps, 16 Gbps, and 32 Gbps Fibre Channel interfaces. This module also supports

hot swappable Enhanced Small Form-Factor Pluggable (SFP+) transceivers.

Individual ports can be configured with 32 Gbps, 16 Gbps, 8 Gbps and 4 Gbps

SFP+ transceivers. Each port supports 500 buffer credits for exceptional

extensibility without the need for additional licenses. With the Enterprise Package

license, up to 8191 buffer credits can be allocated to an individual port, enabling

full link bandwidth over long distances with no degradation in link utilization.

For more information on the IBM 48 port 32 Gbps Fibre Channel Switching

Module, see the IBM 48-Port 32-Gbps Fibre Channel Switching Module Data Sheet.

Figure 12 shows a IBM 48 port 32 Gbps Fibre Channel Switching Module.

Figure 12. IBM 48 port 32 Gbps Fibre Channel Switching Module

1. Captive screw

2. Unlock button

3. Unlocking lever

4. Status LED

5. ID LED

6. Fibre Channel ports

7. Link LEDs

8. Fibre Channel port group

Chapter 1. Introducing the IBM c-type SAN Directors 27

Page 52

LEDs on the 48 port 32 Gbps Fibre Channel Switching Modules

Table 8 describes the LEDs for the 48 port 32 Gbps Fibre Channel switching

module.

Table 8. IBM 48 Port 32 Gbps Fibre Channel Switching Module LEDs

LED Status Description

Status Green All diagnostics pass. The

module is operational

(normal initialization

sequence).