Page 1

International Technical Support Organization

8260 Multiprotocol Intelligent Switching Hub

May 1995

GG24-4370-00

Page 2

Page 3

IBML

International Technical Support Organization

8260 Multiprotocol Intelligent Switching Hub

May 1995

GG24-4370-00

Page 4

Take Note!

Before using this information and the product it supports, be sure to read the general information under

“Special Notices” on page xv.

First Edition (May 1995)

This edition applies to the 8260 Multiprotocol Intelligent Switching Hub family.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications

are not stocked at the address given below.

An ITSO Technical Bulletin Evaluation Form for reader′s feedback appears facing Chapter 1. If the form has been

removed, comments may be addressed to:

IBM Corporation, International Technical Support Organization

Dept. 545 Building 657

P.O. Box 12195

Research Triangle Park, NC 27709-2195

When you send information to IBM, you grant IBM a non-exclusive right to use or distribute the information in any

way it believes appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1995. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is

subject to restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Abstract

This document describes the IBM 8260 Multiprotocol Intelligent Hub. It provides

information about the 8260 architecture as well as how to install, configure and

manage the 8260 Ethernet and token-ring media modules.

This document was written for customers, systems engineers, network

professionals and technical support personnel. Some knowledge of local area

networks, token-ring and Ethernet architecture is assumed.

(327 pages)

Copyright IBM Corp. 1995 iii

Page 6

iv 8260 Multiprotocol Intelligent Switching Hub

Page 7

Contents

Abstract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Special Notices

Preface

How This Document is Organized

Related Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

......................... xvii

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

International Technical Support Organization Publications

Acknowledgments

Chapter 1. An Overview of the IBM 8260 Hub

1.1 Introduction

1.2 8260 Hardware Description

1.2.1 IBM 8260 Model 017

1.2.2 The Intelligent Cooling Subsystem

1.2.3 8260 Model 010

1.3 8260 Modules and Daughter Cards

1.3.1 Ethernet Modules

1.3.2 Token-Ring Modules

1.3.3 Management and Controller Modules

Chapter 2. Backplane Architecture

2.1 LAN Segments on the Backplane

2.2 Ethernet Segments on the Backplane

2.2.1 Digital Collision Detection

2.2.2 Analog Collision Detection

2.2.3 Statistics Collection

2.3 Token-Ring Segments on the Backplane

2.4 FDDI Segments on the Backplane

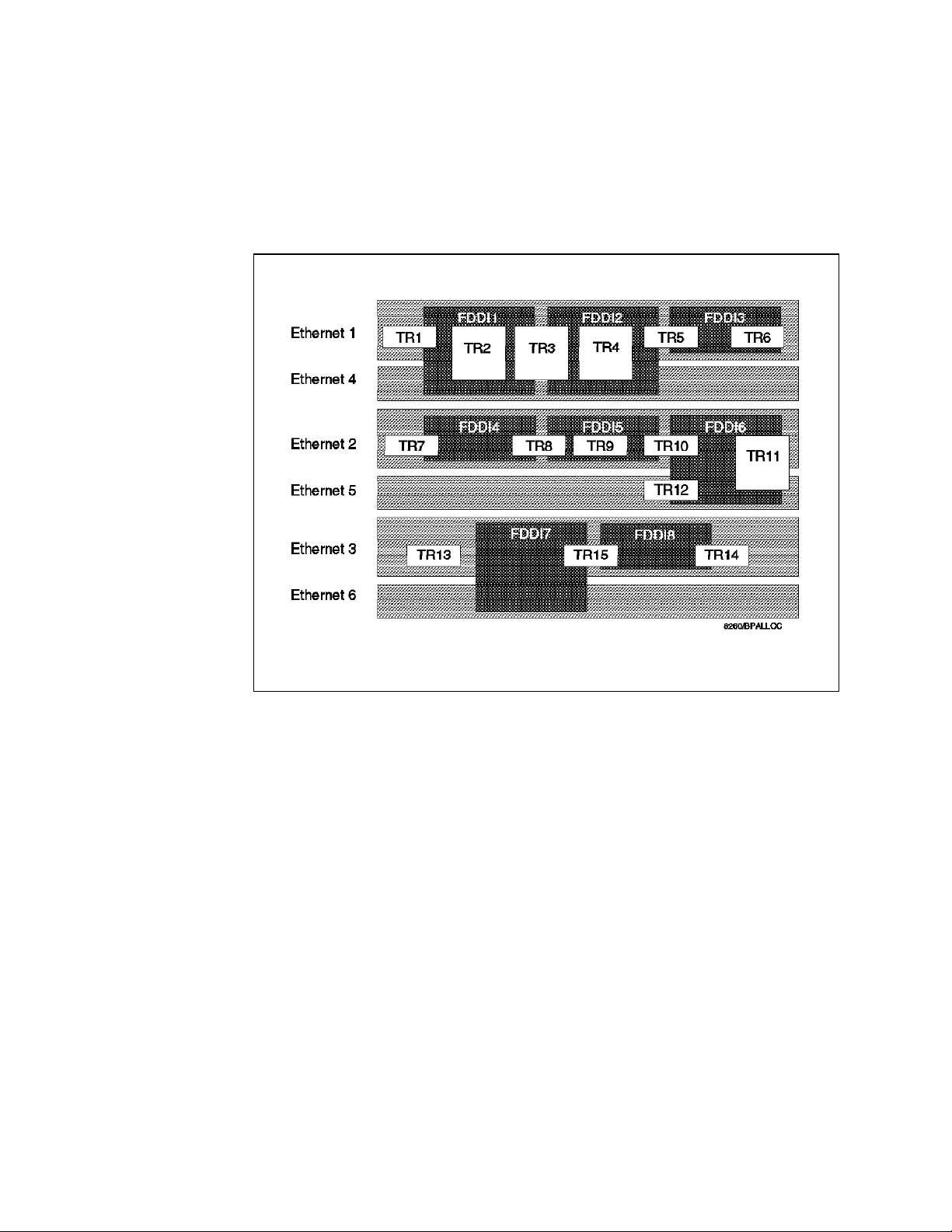

2.5 Network Allocations on the 8260 Backplane

2.5.1 Management Buses

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

................... 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

............................ 3

.............................. 3

..................... 7

................................ 7

....................... 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

................... 10

. . . . . . . . . . . . . . . . . . . . . . . . . . 13

........................ 13

...................... 15

.......................... 19

.......................... 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

.................... 19

........................ 22

.................. 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

.......... xviii

Chapter 3. 8260 Fault Tolerant Controller Module

3.1 8260 Fault Tolerant Controller Module Overview

3.1.1 The Controller Module Front Panel

3.1.2 Controller Module Fault Tolerance

3.1.3 Installing and Configuring the Fault Tolerant Controller Module

3.1.4 8260 Fault Tolerant Controller Module Considerations

Chapter 4. 8260 Distributed Management Architecture

4.1 8260 Distributed Management Architecture

4.1.1 I P Addressing for DMM

........................... 38

4.2 The Distributed Management Module (DMM)

4.2.1 Unpacking and Installing the DMM

4.2.2 DMM LED Indicators

4.2.3 Console and Auxiliary Ports

4.2.4 Configuring the DMM

............................. 40

......................... 41

............................. 43

4.3 The EC-DMM (Ethernet Carrier - Distributed Management Module)

4.3.1 Installing the EC-DMM

4.3.2 EC-DMM LED Description

4.4 MAC Daughter Cards

Copyright IBM Corp. 1995 v

............................ 59

.......................... 60

............................... 61

................. 29

............... 29

.................... 30

..................... 32

... 32

......... 33

.............. 35

.................. 35

................. 39

..................... 39

.... 58

Page 8

4.4.1 Ethernet MAC Daughter Card (E-MAC) .................. 64

4.4.2 Token-Ring MAC Daughter Card (T-MAC)

4.5 Managing 8260 Using DMM and 8250 xMM

4.5.1 Managing 8260 with DMM

4.5.2 Managing 8260 with 8250 xMM

.......................... 70

....................... 70

4.6 Overview of Management and Control Commands

................ 66

.................. 69

.............. 71

Chapter 5. 8260 Intelligent Power Management Subsystem

5.1 Intelligent Power Management Subsystem

5.2 Power Class

5.3 Configuring 8260 Power Supplies

5.3.1 Non-Fault Tolerant Mode

5.3.2 Fault Tolerant Mode

5.4 Managing Power in the 8260

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

........................ 76

........................... 78

............................. 79

........................... 81

.................. 73

5.4.1 Installing 8260 Module in an 8260 Managed by DMM

5.4.2 Installing 8260 Module in an 8260 Not Managed by DMM

5.4.3 Installing 8250 Module in a Hub Managed by DMM

5.4.4 Installing 8250 Module in a Hub Not Managed by DMM

5.5 Controlling Power to the 8260 Modules

5.6 Power Management Considerations

5.7 Power Management Scenarios

.......................... 86

5.8 Installing the 8260 Power Supply

Chapter 6. 8260 Intelligent Cooling Subsystem

6.1 Intelligent Cooling Subsystem

Chapter 7. 8260 Ethernet Modules

7.1 Ethernet LAN Overview

7.1.1 CSMA/CD

7.1.2 Frame Size

7.1.3 Data Integrity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.1.4 Ethernet Addressing Mode

.......................... 91

.......................... 97

.............................. 97

......................... 98

7.2 8260 Ethernet 24-Port 10Base-T Module

7.3 10Base-T Module Usage

............................ 104

7.4 Configuring the 10Base-T Module

7.5 8260 Ethernet 20/40-Port 10Base-T Module

7.6 Configuring the 20/40-Port 10Base-T Modules

7.7 8260 Ethernet 10-Port 10Base-FB Module

7.8 10Base-FB Module Usage

............................ 118

7.9 Configuring the 10Base-FB Module

7.10 8260 Ethernet Modules Summary

7.11 8260 Ethernet Security Daughter Card

7.11.1 Operation of Security Card

........................ 122

7.11.2 Configuring the Security Module

..................... 85

...................... 85

........................ 89

.................. 91

.................... 99

....................... 104

................. 106

................ 111

.................. 113

...................... 118

....................... 120

.................... 121

.................... 124

........... 73

.......... 81

....... 83

........... 83

........ 85

Chapter 8. 8260 Token-Ring Support

8.1 Token-Ring LAN Overview

8.1.1 Ring Operation

8.1.2 Ring Administration

8.1.3 Ring Errors

8.1.4 Differential Manchester Coding

8.1.5 Clock Recovery

8.1.6 Phase Jitter

8.2 8260 Backplane Signalling for TR Segments

8.3 Dual Phase Lock Loop

vi 8260 Multiprotocol Intelligent Switching Hub

........................ 129

........................... 129

................................ 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

...................... 132

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

................. 134

.............................. 138

Page 9

8.4 Jitter Attenuator Daughter Card (JADC) ................... 141

8.5 Passive Port Technology

8.6 Active Port Technology

8.6.1 Per-Port Switching on the Active Modules

8.6.2 Static Switch on the Per-Port Switching Modules

8.7 Signal Flow on the 8260 Token-Ring Modules

8.8 Speed Detection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.8.1 Speed Detection on Active Modules

8.8.2 Speed Detection on Passive Modules

8.9 Beacon Recovery

8.9.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

8.9.2 Beacon Recovery in the 8250

8.9.3 Beacon Recovery in the 8260

8.9.4 Beacon Recovery on the Module Switching Modules

8.9.5 Beacon Recovery on the Per-port Switching Modules

8.10 Address-to-Port Mapping for Module Switching Modules

8.11 Address-to-Port Mapping for Per-Port Switching Modules

............................ 142

............................. 142

............... 143

........... 145

................ 148

................... 149

.................. 149

....................... 151

....................... 155

......... 158

........ 159

........ 160

........ 164

8.12 IEEE 802.5C Recommended Practice for Dual Ring Wrapback

Reconfiguration

8.12.1 Trunk Wrapping on the Active Per-Port Switching Modules

8.12.2 Trunk Wrapping on the Active Module-Switching Modules

8.12.3 Merge Manager

8.12.4 Trunk Unwrapping on the Per-Port Switching Modules

8.12.5 Trunk Unwrapping on the Module-Switching Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

.... 168

..... 169

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

....... 170

........ 170

Chapter 9. 8260 Token-Ring Modules

9.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

9.2 Configuring Token-Ring Network Parameters

9.3 8260 18-Port Active Per-Port Switching Module

....................... 173

................ 173

............... 174

9.3.1 Configuring the 18-Port Active Per-Port Switching Module

9.4 8260 18-Port Active Module Switching Module

............... 180

9.4.1 Configuring the 18-Port Active Module Switching Module

9.5 8260 20-Port Passive Module Switching Module

9.5.1 Configuring the 20-Port Passive Module

9.6 8260 Dual Fiber Repeater Module

....................... 185

9.6.1 Configuring the Dual Fiber Repeater Module

Chapter 10. 8260 RMON Support

10.1 RMON Overview

10.1.1 Network Probes

10.1.2 RMON Manager

10.2 RMON Goals

10.2.1 Offline Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

10.2.2 Preemptive Monitoring

10.2.3 Problem Detection and Reporting

10.2.4 Value Added Data

10.2.5 Multiple Managers

10.3 Standards

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

.......................... 191

. . . . . . . . . . . . . . . . . . . . . . . . . . 194

.................... 194

............................. 194

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10.4 Managing the Ethernet LAN Environment

10.4.1 Managing Ethernet LANs with RMON

10.5 Managing the Token-Ring LAN Environment

10.5.1 Managing Token-Ring LANs with RMON

10.6 Monitoring Functions Supported In 8260

10.6.1 Monitoring Functions Supported by E-MAC

10.6.2 Monitoring Functions Supported by T-MAC

.............. 180

................ 183

.............. 188

.................. 195

................. 195

................ 201

................ 201

.................. 212

.............. 213

.............. 214

...... 177

...... 180

Contents vii

Page 10

10.6.3 SHOW COUNTER Command for Ethernet Networks ......... 215

10.6.4 Collecting and Displaying RMON Groups Using E-MAC

10.6.5 SHOW COUNTER Command for Token-Ring Networks

10.6.6 Collecting and Displaying RMON Groups Using T-MAC

10.7 Surrogate Functions Supported by T-MAC

10.7.1 Using T-MAC Surrogate Functions

................. 232

................... 233

10.7.2 Displaying the Information Collected by Surrogate Features

10.8 DOT5_Group Support by T-MAC

10.8.1 Using DOT5_Group Functions

10.9 Summary of T-MAC Monitoring Functions

....................... 237

...................... 237

................. 237

....... 218

....... 222

....... 230

.... 236

Chapter 11. 8260 Multiprotocol Interconnect Module

11.1 Introduction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

.............. 239

11.2 Power Requirements for Multiprotocol Interconnect Module

11.3 Bridging Functions

11.4 Routing Functions

11.4.1 IP Routing Support

11.4.2 IPX Routing Support

11.4.3 DECnet Phase IV Routing Support

11.5 Configuring Multiprotocol Interconnect Module

11.6 Local Management System (LMS)

11.7 SNMP Support

11.8 Configuring the Interconnect Module Using LMS

11.8.1 Configuring System Wide Parameters

11.8.2 Configuring Port Parameters

11.8.3 Port Configuration Summary

11.8.4 Configuring for Bridging Support

11.8.5 Filtering for Bridging Functions

11.8.6 Destination Address Filtering

11.8.7 Configuring for Routing Functions

11.8.8 Configuring for IP Routing

11.8.9 I P Security

11.8.10 Configuring for IPX Routing

11.9 Monitoring Multiprotocol Interconnect Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

............................. 245

............................ 246

................... 246

.............. 246

...................... 247

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

............. 251

................. 252

....................... 255

....................... 261

.................... 261

..................... 270

...................... 274

.................... 278

........................ 279

.................................. 304

....................... 308

............... 311

...... 242

Appendix A. Power Requirements for 8250/8260 Modules

A.1 Power Requirements for 8250 Ethernet Modules

A.2 Power Requirements for 8250 Token-Ring Modules

A.3 Power Requirements for 8250 FDDI Modules

A.4 Power Requirements for 8250 Internetworking Modules

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

viii 8260 Multiprotocol Intelligent Switching Hub

........... 315

.............. 315

............ 316

................ 316

......... 317

Page 11

Figures

1. IBM 8260 Model 017 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Components of the 8250 Adapter Kit

3. Enhanced TriChannel Bus

4. 8260 ShuntBus

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

............................ 14

5. Backplane Path Display for Ethernet Segments

6. Token-Ring Backplane Path Display

7. ShuntBus and Token-Ring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8. Backplane Path Display for FDDI Segments

9. TriChannel Backplane Network Allocation

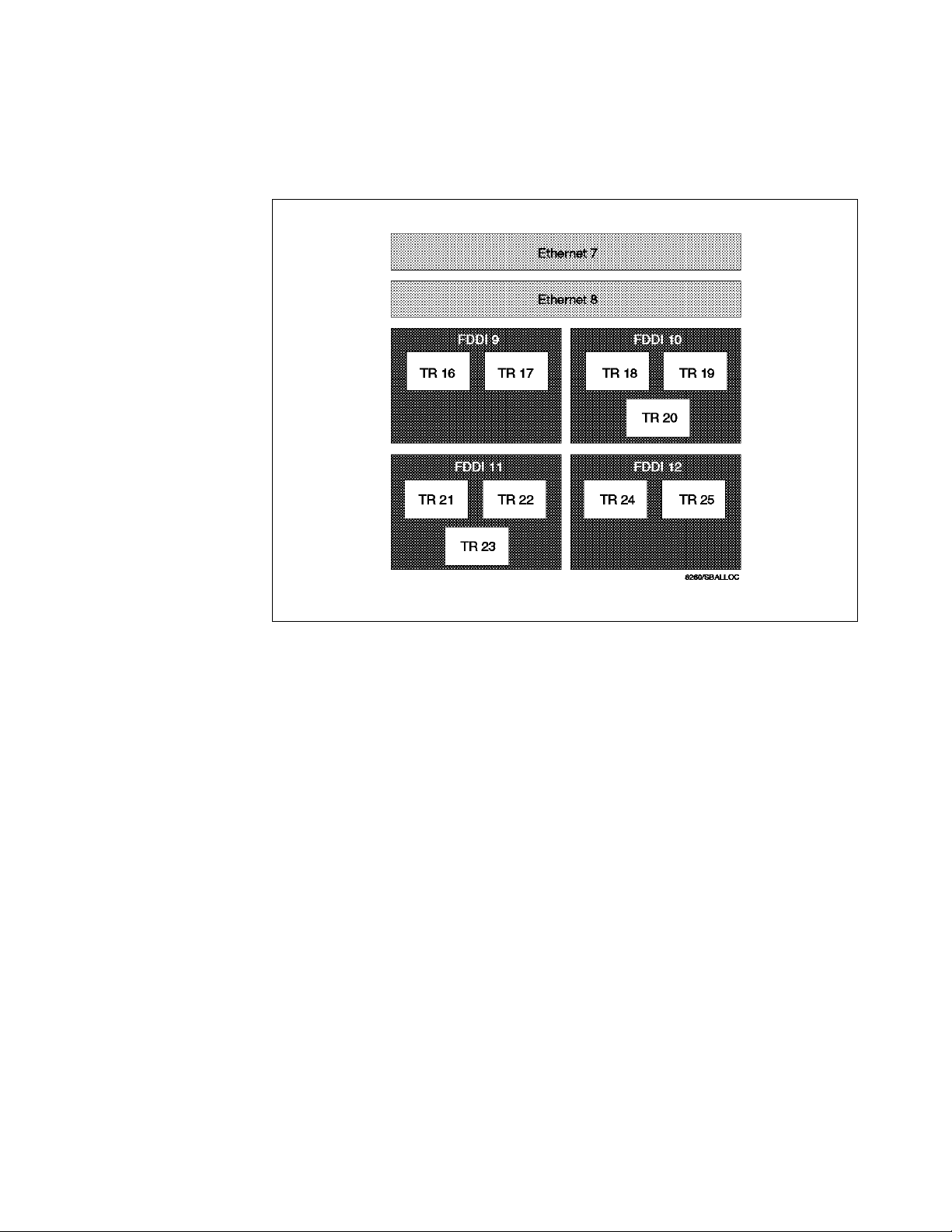

10. ShuntBus Backplane Network Allocation

11. The Backplane Relationship between TriChannel and ShuntBus

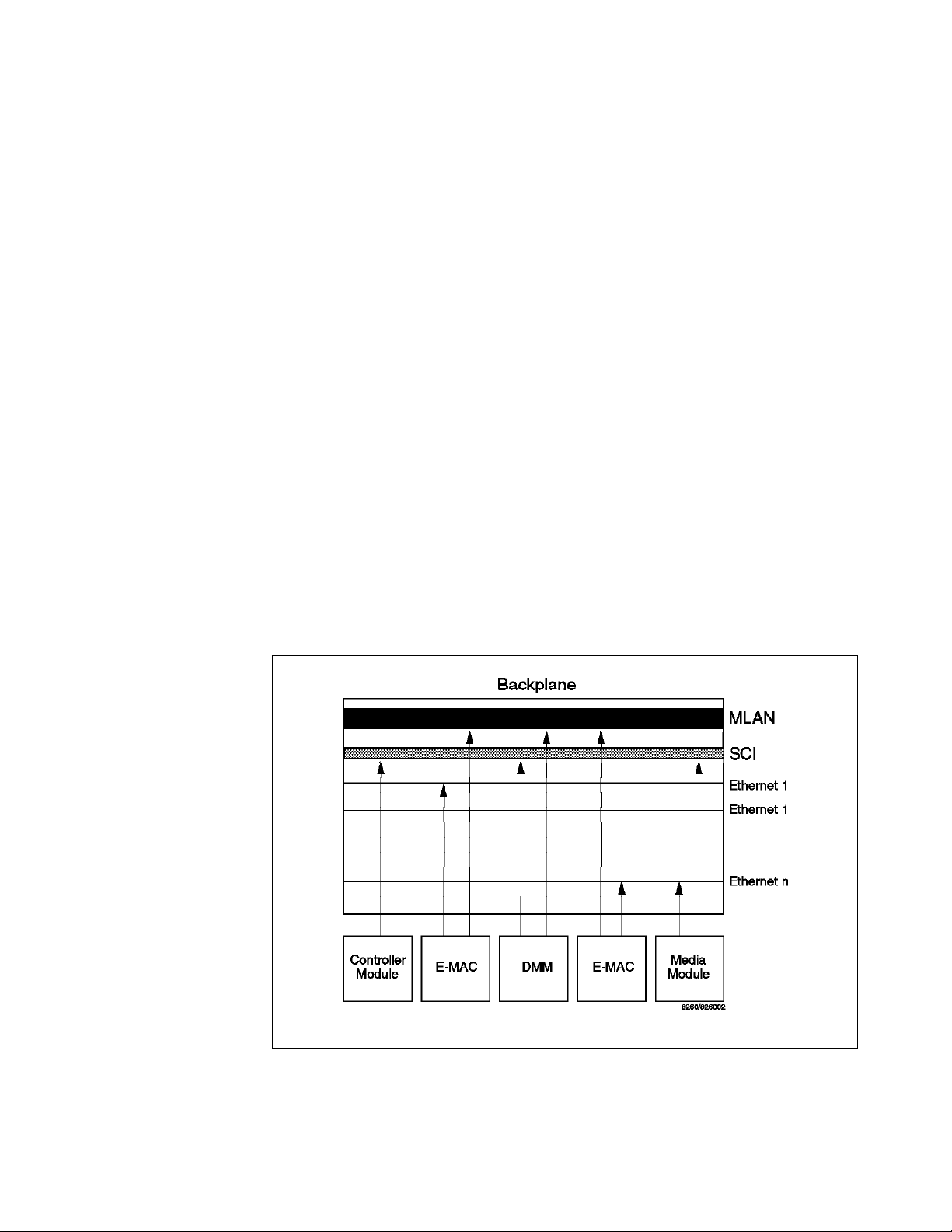

12. 8260 Management Buses

............................ 27

13. Front View of the Controller Module

14. Management Schematic

15. DMM Front Panel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

................................. 39

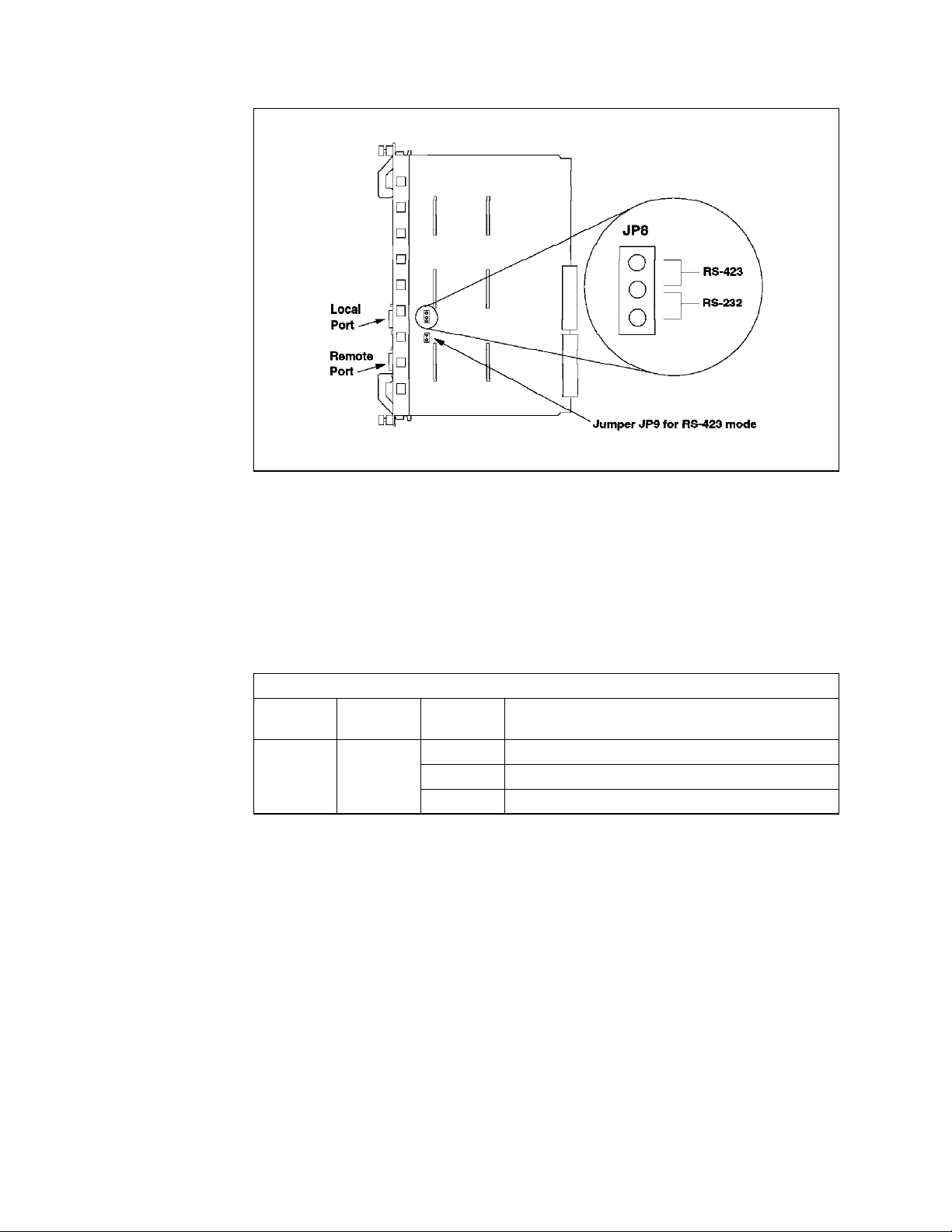

16. Jumpering for the DMM DB-9 Ports

17. DMM Login Message

............................... 44

18. Changing Superuser Password

19. Defining New DMM Superuser

20. Display of Defined DMM Users

21. Forced Termination of Existing DMM Users

22. Output from Show Terminal Command

23. Set Device Name Command for DMM

24. Set Device Location Command for DMM

25. Set Device Contact Command for DMM

26. Output from Show ARP_Cache Command with Canonical Setting

27. Output from Show ARP_Cache Command with Non-Canonical Setting

28. Output from Show Device Command

29. Output from Show IP Command

30. Output from Show Community Command

31. EC-DMM Front Panel

............................... 59

32. Jumpering for the EC-DMM DB-9 Ports

33. 24-Port Ethernet Module with E-MAC

34. EC-DMM Slots and Subslots

35. EC-DMM Display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

36. EC-DMM with Up to 6 EMACs

.......................... 63

.......................... 64

37. Assigning E-MAC to a Segment with an Active E-MAC

38. Output from E-MAC Display

........................... 66

39. Assigning T-MAC to a Segment with an Active T-MAC

40. Output from T-MAC Display

........................... 69

41. A Sample of Hierarchical Structure Command

42. 8260 with 4 Power Supplies

........................... 74

43. Set Power Class Command for 8250 Modules

44. Priorities of Modules to Be Powered-Up or Powered-Down

45. Output from Show Power Class Command

46. Output from Show Hub Command

47. Output from Show Power Budget Command

48. Output from Show Power Mode Command

49. Load Sharing Power Supplies

50. Output from Show Inventory Command

51. Installing 8260 Modules in an 8260 Managed by DMM

. . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . 24

................... 25

..... 26

...................... 30

...................... 40

......................... 45

......................... 45

......................... 46

................. 47

.................... 50

..................... 51

................... 51

................... 51

.... 52

. 52

..................... 54

........................ 55

.................. 57

.................... 60

..................... 62

........... 65

........... 68

............... 71

................ 75

........ 75

.................. 76

....................... 77

................. 78

.................. 79

......................... 80

.................... 82

........... 83

Copyright IBM Corp. 1995 ix

Page 12

52. Installing 8260 Modules in an 8260 Not Managed by DMM ........ 83

53. Installing 8250 Modules in an 8260 Managed by DMM

54. Installing 8250 Modules in an 8260 Not Managed by DMM

55. Messages Received when a Power Failure Occurs

56. Using the SHOW HUB Command

57. Using the SHOW POWER MODE Command

........................ 87

................. 87

58. Messages Received when the Power Mode Is Changed

59. Messages Received upon a Recovery of the Power Supply

60. 8260 Fan Units

61. Output from Show Hub Command

62. Output from Show Power Mode Command

63. 8260 Cooling Zones and Power Classes

64. Flow Chart for an Overheat Condition

65. Front View of 24-Port 10Base-T Module

66. 24-Port 10Base-T Module Side View

67. 24-Port 10Base-T DIP Switches

68. 24-Port 10Base-T Module Usage

69. Front View of 20/40-Port 10Base-T Modules

70. 20/40-Port 10Base-T Module Side View

71. 20/40-Port 10Base-T DIP Switches

72. Front View of 10-Port 10Base-FB Module

73. 10-Port 10Base-FB Module Side View

74. 10-Port 10Base-FB DIP Switches

75. 10-Port 10Base-FB Module Usage

................................... 91

....................... 92

.................. 93

................... 94

..................... 95

................... 101

..................... 102

........................ 103

....................... 104

................ 108

................... 109

...................... 110

.................. 115

.................... 116

....................... 117

...................... 118

76. Configuring Port Redundancy for 8260 Ethernet Modules

77. Default Security Settings

78. Network Security Address Table

79. Ethernet Security Intruder Table

80. Differential Manchester Coding

81. Self-Shorting Relays on the ShuntBus

............................ 124

....................... 125

....................... 127

........................ 132

.................... 135

82. 8260 Backplane Signalling for 4 Mbps Operation

83. 8260 Backplane Signalling for 16 Mbps Operation

84. Components of Dual Phase Lock Loop

85. DPLL Implementation on Active Ports

86. Components of DPLL Implemented on JADC

87. Token-Ring Per-Port Switching

........................ 144

................... 139

.................... 140

............... 141

88. Static Switch Display for Active Per-Port Switching Ports

89. Switching Ports with Enabled Static Switch

90. Port Switching with Source Routing Bridges

91. Port Display for Token-Ring Passive Ports

92. Show Device Command for TRMM

..................... 154

93. Recovery ASIC in Module Switching Module

94. Recovery ASIC in Per-Port Switching Module

95. Display Output for 20-Port Passive Module

................ 147

................ 148

................. 150

................ 155

............... 156

................. 156

96. Display Output for 18-Port Active Per-Port Switching Module

97. Beacon Recovery on the Module Switching Modules

98. Address-to-Port Map Display for a Module Switching Module

........... 84

........ 85

............. 86

.......... 88

........ 88

........ 119

............. 136

............ 137

........ 146

...... 157

.......... 159

..... 161

99. Address-to-port Mapping on Module Switching Modules for Fan-Out

Attached Devices

100. Address-to-Port Map Display for Fan-Out Attached Devices

101. Address-to-Port Map Display for MAC-less Stations

102. Address-to-Port Mapping on Per-Port Switching Modules

103. Address-to-Port Map Display for a Per-Port Switching Module

104. Dual-Ring Topology

105. Wrapback in Dual-Ring Topology

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

...... 163

........... 164

........ 164

..... 166

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

....................... 168

x 8260 Multiprotocol Intelligent Switching Hub

Page 13

106. Trunk Wrapping in Active Per-Port Switching Module .......... 169

107. Trunk Wrapping in Active Per-Port Switching Module

108. Front View of 18-Port Active Per-Port Switching Module

109. 18-Port Active Per-Port Switching Module Side View

110. Onboard Lobe/Trunk Jumpers on 18-Port

111. Front View of 20-Port Passive Module

112. 20-Port Passive Module Module Side View

113. Front View of Dual Fiber Repeater Module

114. Dual Fiber Repeater Module Side View

115. O SI Stack

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

116. A n Ex ample of RMON Implementation

117. Status Display for DMM Interfaces

118. Show Counter Ethernet

............................ 215

...................... 213

119. Show Counter Interface for Ethernet Segment

................. 178

.................... 182

................. 183

................. 186

................... 187

................... 193

............... 216

120. Show Counter Repeater for Ethernet Segment

121. Show Counter RMON Hosts

122. RMON Host Control Table

123. RMON Host Statistics Display

124. Show Counter for Token_Ring Segments

.......................... 218

........................... 221

......................... 222

.................. 223

125. Show Counter Interface for Token-Ring Segment

126. Show Counter RMON Hosts for Token_Ring Segments

127. Show Counter RMON Ring_station Using ″ring″ Option

128. Show Counter RMON Ring_station Using ″all″ Option

129. Show Counter RMON TR_MAC_LAYER

130. Show Counter RMON TR_MAC_LAYER

131. Show Counter RMON TR_SOURCE_ROUTING

132. Show Module Command for T-MAC

133. Displaying the Status of Surrogate Features

134. Displaying the Status of REM Options

135. Displaying the Status of CRS Options

................... 228

................... 229

............... 230

..................... 232

................ 234

.................... 235

.................... 235

136. Displaying the Status of CRS Stations Options

137. Front View of the Multiprotocol Interconnect Modules

138. LMS Initial Panel

139. LMS Short Cut Commands

140. LMS Jump Table

141. L MS C onfiguration Panel

142. LMS System Parameters Panel

143. LMS Trap Destination Panel

144. LMS Download Parameters Panel

145. LMS Port Menu Panel

................................ 247

.......................... 249

................................ 250

........................... 252

....................... 253

......................... 254

...................... 255

............................. 256

146. LMS Physical Port List for Ethernet Connections

147. LMS Physical Ports List for Token-Ring I/O Cards

148. LMS Physical Port Protocol Configuration Panel

149. LMS Logical Port Panel

150. LMS Bridge Menu Panel

151. LMS Bridging System Parameters

152. Transparent Bridging Port Parameters Panel

153. L MS STP System Parameters Panel

154. LMS STP Port Parameters Panel

155. LMS Source Routing Port Parameter

156. LMS Conversion System Parameters Panel

157. L MS C onfiguration Panel

158. LMS Custom Filter Test Table Panel

159. LMS Custom Filter Statement Table

160. LMS Protocols Menu Panel

............................ 260

............................ 261

...................... 262

............... 263

..................... 265

....................... 266

.................... 268

................ 269

........................... 271

.................... 275

..................... 277

.......................... 278

.......... 169

......... 175

........... 176

.............. 217

............. 224

......... 225

......... 226

.......... 227

.............. 236

.......... 241

............. 257

............ 258

............. 259

Figures xi

Page 14

161. LMS IP Panel .................................. 279

162. LMS IP Port Address Table Panel

163. LMS IP System Parameters Panel

164. LMS IP Port Parameter Panel

165. LMS IP Forwarding Table Panel

166. LMS IP Net To Media Table

.......................... 286

167. LMS Boothelper Parameters Panel

168. LMS OSPF Menu Panel

............................ 288

169. LMS OSPF System Parameter Panel

170. LMS OSPF Interface Table Panel

171. LMS OSPF Area Table Panel

172. LMS OSPF Area Default Metric Table

173. LMS OSPF Area Address Range Panel

174. LMS OSPF Interface Metric Table

175. LMS OSPF Virtual Interface Table Panel

176. LMS OSPF Neighbors Panel

177. LMS OSPF RIP Filter Table Panel

178. L MS C onfiguration Panel

........................... 300

179. L MS OS PF D efault RIP Convert Table Panel

180. LMS OSPF Static Filter Table Panel

181. L MS C onfiguration Panel

........................... 303

182. LMS OSPF Default Static Convert Table Panel

183. LMS IP Security Table Panel

184. LMS IP Security Access Panel

185. LMS IPX Menu Panel

.............................. 308

186. LMS IPX System Parameters Panel

187. LMS IPX Port Parameters Panel

...................... 280

...................... 281

........................ 283

....................... 284

..................... 287

.................... 289

....................... 290

......................... 293

.................... 294

................... 295

...................... 296

.................. 297

......................... 298

...................... 299

................ 301

..................... 302

.............. 304

......................... 305

........................ 307

..................... 309

....................... 310

xii 8260 Multiprotocol Intelligent Switching Hub

Page 15

Tables

1. Components of the 8250 Adapter Kit for 8260 . . . . . . . . . . . . . . . . 6

2. Ethernet Pins on the 8260 Backplane

3. 8260 controller Module LED Meaning

4. DMM Status LED

5. DMM LCD Display

6. Console Port Pinouts

7. Auxiliary Port Pinouts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

............................... 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8. Commands Required to Set Up the Modem for the Console Port

9. DMM Interface Configuration Quick Reference

10. DMM Terminal Defaults and Options

11. EC-DMM Status LED

12. EC-DMM LCD Display

............................... 60

.............................. 61

13. Power Available to Modules in Non-Fault Tolerant Mode

14. Power Available to Modules in Fault Tolerant Mode

15. Equivalent Distances for 24-Port 10Base-T Module

16. 24-Port 10Base-T Module LED Descriptions

17. 24-Port 10Base-T Module DIP Switch Settings

18. Equivalent Distances for 20/40 10Base-T Modules

19. 20/40-Port 10Base-T Module LED Descriptions

20. 20/40-Port 10Base-T Module DIP Switch Settings

21. Maximum Distances for 20/24-Port 10Base-T Modules

22. Equivalent Distances for Ethernet 10Base-FB Module

23. 10-Port 10Base-FB Module LED Descriptions

24. 10-Port 10Base-FB Module DIP Switch Settings

25. 8260 Ethernet Modules Summary

26. Lobe Distances Using 8260 Active TR Modules

27. Lobe Distances Using 8260 Passive TR Modules

28. 18-Port Active Per-Port Switching Module LED Descriptions

29. 18-Port Active Per-Port Switching Module

30. 20-Port Passive Module LED Descriptions

31. Dual Fiber Repeater Module LED Descriptions

32. MIB Structure for RFC 1271 - RMON MIB for Ethernet

. . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . 31

. . . . 42

. . . . . . . . . . . . . . . 43

..................... 43

......... 78

............ 79

............ 100

................ 101

............... 103

............ 107

.............. 108

............. 110

.......... 112

.......... 114

............... 115

.............. 117

...................... 120

.............. 143

............. 143

...... 176

................. 177

................. 182

.............. 186

.......... 196

33. MIB Structure for RFC 1513 - Token-Ring Extensions to the RMON MIB 202

34. Functions Supported by T-MAC V2.0

35. Functions Performed by T-MAC V2.0

36. Interconnect Module LED Description

37. Power Requirements for Interconnect Module IP Cards

38. Watts to Units Conversion Table

39. Custom Filter Test Table

............................ 276

40. Custom Filter Statement Table

41. Power Requirements for 8250 Ethernet Modules

42. Power Requirements for 8250 Token-Ring Modules

43. Power Requirements for 8250 FDDI Modules

44. Power Requirements for 8250 FDDI Modules

..................... 237

.................... 237

.................... 242

......... 242

....................... 243

........................ 278

............. 315

........... 316

............... 316

............... 317

Copyright IBM Corp. 1995 xiii

Page 16

xiv 8260 Multiprotocol Intelligent Switching Hub

Page 17

Special Notices

This publication is intended to help both IBM Customers and IBM System

Engineers to install and configure the IBM 8260 Multiprotocol Intelligent

Switching Hub. It contains description of the 8260 architecture as well as

information about how to install, configure and manage the the 8260 Ethernet

and token-ring modules. The information in this publication is not intended as

the specification of any programming interfaces that are provided by IBM 8260

Multiprotocol Intelligent Switching Hub. See the PUBLICATIONS section of the

IBM Programming Announcement for the 8260 for more information about what

publications are considered to be product documentation.

References in this publication to IBM products, programs or services do not

imply that IBM intends to make these available in all countries in which IBM

operates. Any reference to an IBM product, program, or service is not intended

to state or imply that only IBM′s product, program, or service may be used. An y

functionally equivalent program that does not infringe any of IBM′s intellectual

property rights may be used instead of the IBM product, program or service.

Information in this book was developed in conjunction with use of the equipment

specified, and is limited in application to those specific hardware and software

products and levels.

IBM may have patents or pending patent applications covering subject matter in

this document. The furnishing of this document does not give you any license to

these patents. You can send license inquiries, in writing, to the IBM Director of

Licensing, IBM Corporation, 500 Columbus Avenue, Thornwood, NY 10594 USA.

The information contained in this document has not been submitted to any

formal IBM test and is distributed AS IS. The information about non-IBM

(VENDOR) products in this manual has been supplied by the vendor and IBM

assumes no responsibility for its accuracy or completeness. The use of this

information or the implementation of any of these techniques is a customer

responsibility and depends on the customer′s ability to evaluate and integrate

them into the customer′s operational environment. While each item may have

been reviewed by IBM for accuracy in a specific situation, there is no guarantee

that the same or similar results will be obtained elsewhere. Customers

attempting to adapt these techniques to their own environments do so at their

own risk.

Any performance data contained in this document was determined in a

controlled environment, and therefore, the results that may be obtained in other

operating environments may vary significantly. Users of this document should

verify the applicable data for their specific environment.

Reference to PTF numbers that have not been released through the normal

distribution process does not imply general availability. The purpose of

including these reference numbers is to alert IBM customers to specific

information relative to the implementation of the PTF when it becomes available

to each customer according to the normal IBM PTF distribution process.

The following terms are trademarks of the International Business Machines

Corporation in the United States and/or other countries:

Copyright IBM Corp. 1995 xv

Page 18

AIX AIX/6000

IBM NetView

RS/6000

The following terms in this publication, are trademarks of other companies:

Windows is a trademark of Microsoft Corporation.

PC Direct is a trademark of Ziff Communications Company and is used by IBM

Corporation under license.

UNIX is a registered trademark in the United States and other countries licensed

exclusively through X/Open Company Limited.

DECnet, DEC VT100 and DEC VT220 Digital Equipment Corporation

Chipcom, ONline, ONcore Chipcom Corporation

Novell, NetWare and IPX Novell Corporation

Retix Retix Corporation

xvi 8260 Multiprotocol Intelligent Switching Hub

Page 19

Preface

This document is intended to assist customers and IBM system engineers to

implement local area networks based on the IBM 8260 Multiprotocol Intelligent

Switching Hub. It contains description of the 8260 architecture as well as

information about how to install, configure and manage the the 8260 Ethernet

and token-ring modules.

How This Document is Organized

The document is organized as follows:

•

Chapter 1, “An Overview of the IBM 8260 Hub”

This chapter is an introduction to the IBM 8260 Multiprotocol Intelligent

Switching Hub.

•

Chapter 2, “Backplane Architecture”

This chapter provides details of the 8260 backplane architecture.

•

Chapter 3, “8260 Fault Tolerant Controller Module”

This chapter provides information about the 8260 fault-tolerant controller

module.

•

Chapter 4, “8260 Distributed Management Architecture”

This chapter describes the 8260 Distributed Management architecture.

•

Chapter 5, “8260 Intelligent Power Management Subsystem”

This chapter describes the 8260 Intelligent Power Management Subsystem.

•

Chapter 6, “8260 Intelligent Cooling Subsystem”

This chapter describes the 8260 Intelligent Cooling Subsystem.

•

Chapter 7, “8260 Ethernet Modules”

This chapter provides detailed description and configuration information

about the 8260 Ethernet modules.

•

Chapter 8, “8260 Token-Ring Support”

This chapter provides a description of the advanced features supported by

the 8260 token-ring modules.

•

Chapter 9, “8260 Token-Ring Modules”

This chapter provides detailed description and configuration information

about the 8260 token-ring modules.

•

Chapter 10, “8260 RMON Support”

This chapter provides an introduction to RMON as well as the RMON support

by E-MAC and T-MAC daughter cards.

•

Chapter 11, “8260 Multiprotocol Interconnect Module”

This chapter provides details of routing and bridging support provided by the

8260 Multiprotocol Interconnect module.

•

Appendix A, “Power Requirements for 8250/8260 Modules”

Copyright IBM Corp. 1995 xvii

Page 20

Related Publications

The publications listed in this section are considered particularly suitable for a

more detailed discussion of the topics covered in this document.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

This appendix provides information about the power requirements of the

8250 modules.

IBM 8260/8250 PSPG

IBM 8260 Installation Guide

8260 TR Active Media Module Port Switching Guide

8260 Network Interconnect Module

IBM 8260 (DMM) User′s Guide

IBM 8260 Ethernet 24-Port 10BASE-T User′s Guide

IBM 8260 Ethernet Per Port User′s Guide

IBM 8260 Ethernet Security Module User′s Guide

8260 DMM Commands Guide

IBM 8260 DMM Quick Reference Commands

Passive Media Module User′s Guide

8260 Network Interconnect Module Reference Guide

8260 A4-FB100 Installation and User′s Guide

IBM 8260 A-CP Switch Installation and User′s Guide

,GA33-0285

, SA33-0251

, SA33-0256

, SA33-0258

, SA33-0259

, SA33-0260

, SA33-0261

, SA33-0262

, SA33-0275

, SA33-0276

, SA33-0286

, SA33-0288

, SA33-0324

, SA33-0326

International Technical Support Organization Publications

•

IBM 8250 Intelligent Hub and IBM Hub Management Program/6000

GG24-4033

A complete list of International Technical Support Organization publications, with

a brief description of each, may be found in:

International Technical Support Organization Bibliography of Redbooks,

GG24-3070.

To get listings of ITSO technical bulletins (redbooks) online, VNET users may

type:

TOOLS SENDTO WTSCPOK TOOLS REDBOOKS GET REDBOOKS CATALOG

How to Order ITSO Technical Bulletins (Redbooks)

IBM employees in the USA may order ITSO books and CD-ROMs using

PUBORDER. Customers in the USA may order by calling 1-800-879-2755 or by

faxing 1-800-284-4721. Visa and Master Cards are accepted. Outside the

USA, customers should contact their IBM branch office.

Customers may order hardcopy redbooks individually or in customized sets,

called GBOFs, which relate to specific functions of interest. IBM employees

and customers may also order redbooks in online format on CD-ROM

collections, which contain the redbooks for multiple products.

,

xviii 8260 Multiprotocol Intelligent Switching Hub

Page 21

Acknowledgments

The advisor for this project was:

Mohammad Shabani

International Technical Support Organization, Raleigh Center

The authors of this document are:

Mohammad Shabani

International Technical Support Organization, Raleigh Center

Nongyao Buranarachada

IBM Thailand

Mike Welsh

IBM Australia

This publication is the result of a residency conducted at the International

Technical Support Organization, Raleigh Center.

Thanks to the following people for the invaluable advice and guidance provided

in the production of this document:

Shawn Walsh

International Technical Support Organization, Raleigh Center

Haissam Alaiwan

8260 Product Planner, La Gaude

Theodore A. Makranczy

IBM Education and Training, USA

James J. Haefele

IBM Education and Training, USA

Benton R. Hobgood

IBM 8260 Development, RTP

Bradley S. Trubey

IBM 8260 Development, RTP

Victoria S. Thio

IBM 8260 Development, RTP

Walter G. Habermas

US National Technical Support, RTP

Preface xix

Page 22

xx 8260 Multiprotocol Intelligent Switching Hub

Page 23

Chapter 1. An Overview of the IBM 8260 Hub

This chapter is an introduction to the IBM 8260 Multiprotocol Intelligent Switching

Hub. It is intended to provide the reader with an overview of the following:

•

Hardware description

•

Backplane architecture

•

Fault-tolerant power subsystem

•

Intelligent cooling subsystem

•

Distributed management architecture

•

Hot pluggability

•

Fault-tolerant controller module

•

Compatibility with the 8250 family

1.1 Introduction

The 8260 is an intelligent managed hub which provides the platform to build local

area networks using various types of cabling systems (such as STP, UTP, fiber

and coax) and different types of LAN protocols (such as token-ring, Ethernet, and

FDDI). Additionally, the 8260 provides platform for the implementation of

high-speed networks based on Asynchronous Transfer Mode (ATM) technology.

The 8260 is a rack-mountable hub and depending on the model it allows you to

install up to 17 payload

modules

. These modules can be a combination of media

and management modules providing you with the flexibility to design networks

addressing the individual needs of your organization.

Media and management modules can be installed or removed from the 8260,

while the hub is operational. This allows you to modify the configuration of the

network with minimal disruption to the users.

The 8260 provides the room to install up to two controller modules. The second

controller module will be used to provide backup for the primary controller

module.

In addition to a wide range of 8260 media and management modules which are

specifically designed to take advantage of the features offered by the new

chassis, the 8260 supports all of the media and management modules from the

8250 (but not its controller module). This provides you with the ability to protect

your investment in the 8250 modules.

Note: As the 8260 is taller than the 8250, an optional adapter kit is required to

install the 8250 modules in an 8260.

The 8260 is designed to be a stand-alone unit or to be mounted in a standard 19″

rack. The 8260 is shipped with a rack mounting kit, a rubber feet kit and a cable

tray assembly.

When you order the 8260, the following components will be included in the 8260

chassis which is shipped to you:

•

One controller module

Copyright IBM Corp. 1995 1

Page 24

•

One power supply

•

One power supply bay cover

•

One AC power cord

•

Three fan units

•

One cable tray

•

One rack mount kit

•

One rubber feet kit

•

Six blank dual-slot filler plates

•

Three blank single-slot filler plates

Additionally, you can order the following features to be included in your 8260:

•

Up to three additional power supplies for 8260 Model 017 and Model 17 A or

up to two additional power supplies for the 8260 Model 010.

•

8250 adapter kit

− Distributed Management Module (DMM)

− Ethernet Carrier Distributed Management Module (EC-DMM)

− Ethernet Media Access Control (E-MAC) daughter card

− Token-ring Media Access Control (T-MAC) daughter card

•

Ethernet Modules:

− 8260 Ethernet 24-port 10Base-T module

− 8260 Ethernet 20-port 10Base-T module

− 8260 Ethernet 40-port 10Base-T module

− 8260 Ethernet 10-port 10Base-FB module

− 8260 Multiprotocol Interconnect module

− 8260 Ethernet Security daughter card

•

Token-ring modules:

− 18 port active per-port switching module

− 18 port active module-switching module

− 20 port passive module-switching module

− Dual fiber repeater module

− Jitter Attenuator daughter card

•

ATM modules:

− ATM Control Point and Switch module

− 4-port ATM Concentrator module

Note: This book will not discuss the ATM components of the 8260.

The 8260 can be managed out-of-band using an ASCII console attached locally or

via modem to the management module. Additionally, you may manage the 8260

via SNMP using the Hub Manager Program for AIX.

The following sections provide an overview of the various components of the

8260.

2 8260 Multiprotocol Intelligent Switching Hub

Page 25

1.2 8260 Hardware Description

There are three models of the 8260:

•

8260-017

•

8260-010

•

8260-17A

1.2.1 IBM 8260 Model 017

The 8260 Model 017 is a 17-slot module which allows you to install any

combination of 8260 and 8250 modules (except the 8250 Controller module) to set

up token-ring, Ethernet and/or FDDI networks. Additionally, it can be upgraded

with the ATM backplane to allow you to set up an ATM network.

The 8260 Model 017 chassis is made up of 5 main areas:

•

The backplane

•

The payload area

•

The Controller module slots

•

The intelligent power subsystem

•

The intelligent cooling subsystem

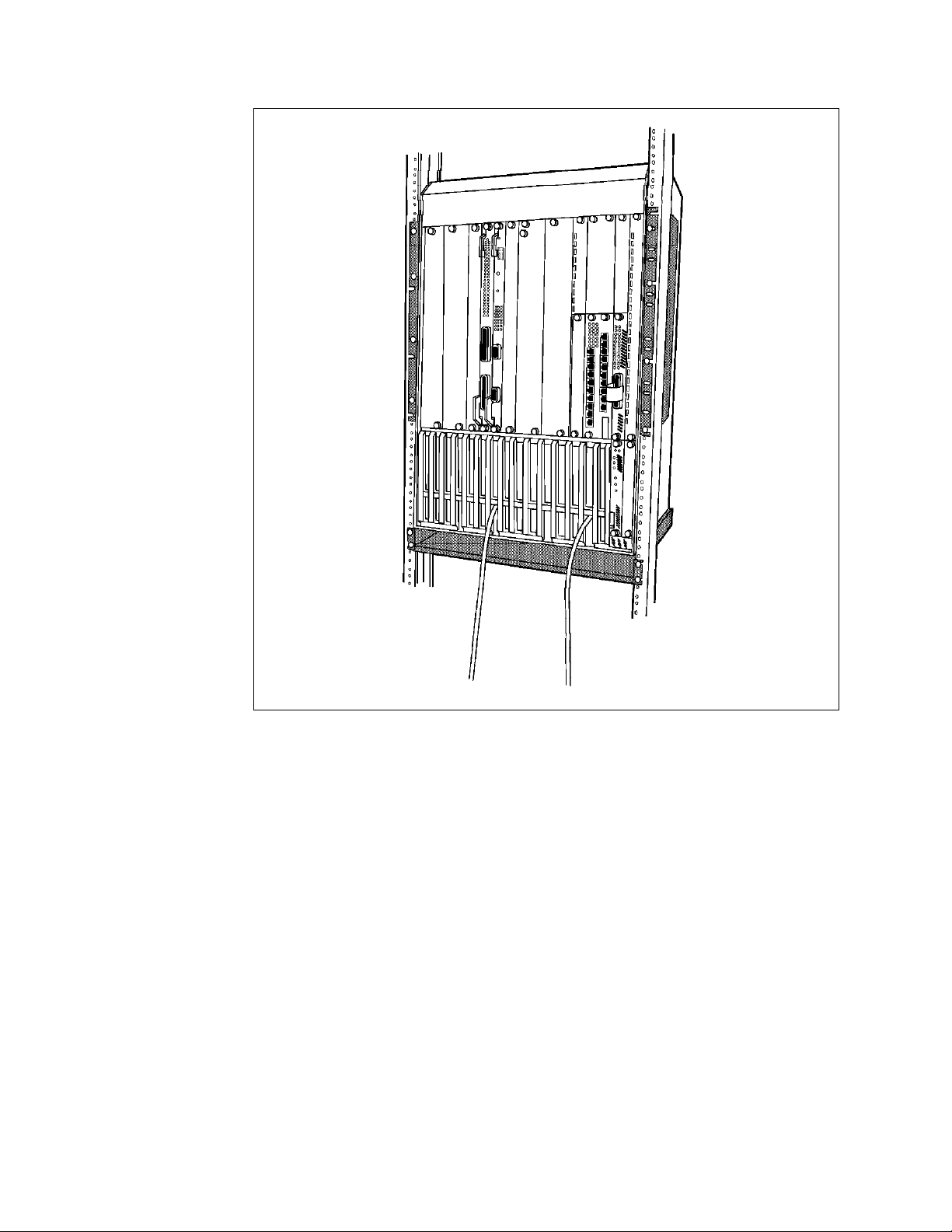

Figure 1 on page 4 provides a view of an 8260 multiprotocol intelligent switching

hub with both 8250 and 8260 modules installed.

1.2.1.1 8260 Backplane

The 8260 Model 017 has two standard backplane buses which are used to

provide you with the ability to configure token-ring, Ethernet, and/or FDDI

network segments. These two backplane buses are:

•

Enhanced TriChannel - Allows you to configure the following:

− Three Ethernet segments or

− Up to 7 token-ring segments or

− Up to 4 FDDI segments

You may also have a mixture of segments using different protocols. In that

case, the maximum number of permitted segments will depend on the

configuration of your hub.

•

ShuntBus - Allows you to configure the following:

− Two Ethernet segments and

− 10 token-ring segments (or 4 FDDI segments)

The Enhanced TriChannel and the ShuntBus are fully described in Chapter 2,

“Backplane Architecture” on page 13.

Chapter 1. An Overview of the IBM 8260 Hub 3

Page 26

Figure 1. IBM 8260 Model 017

1.2.1.2 Payload Area

The payload area provides the housing for 17 media and management modules.

In addition to the 8260 module, you may install all the 8250 modules (except the

Controller module) in an 8260. Once these modules are installed on the 8260,

they will be connected to the backplane.

Certain modules provide you with

to connect different ports on the same module to different backplane segments.

Other modules are

the module must be connected to the same network segment. The per-port

switching capability is available for both Ethernet and token-ring.

Since the 8260 modules are taller than the 8250 modules, when you install one or

more 8250 modules in the 8260 multiprotocol intelligent switching hub, you must

use the

kit enables you to install up to 4, 9 or 16 single-slot 8250 modules or a mixture of

single-slot and dual-slot 8250 modules.

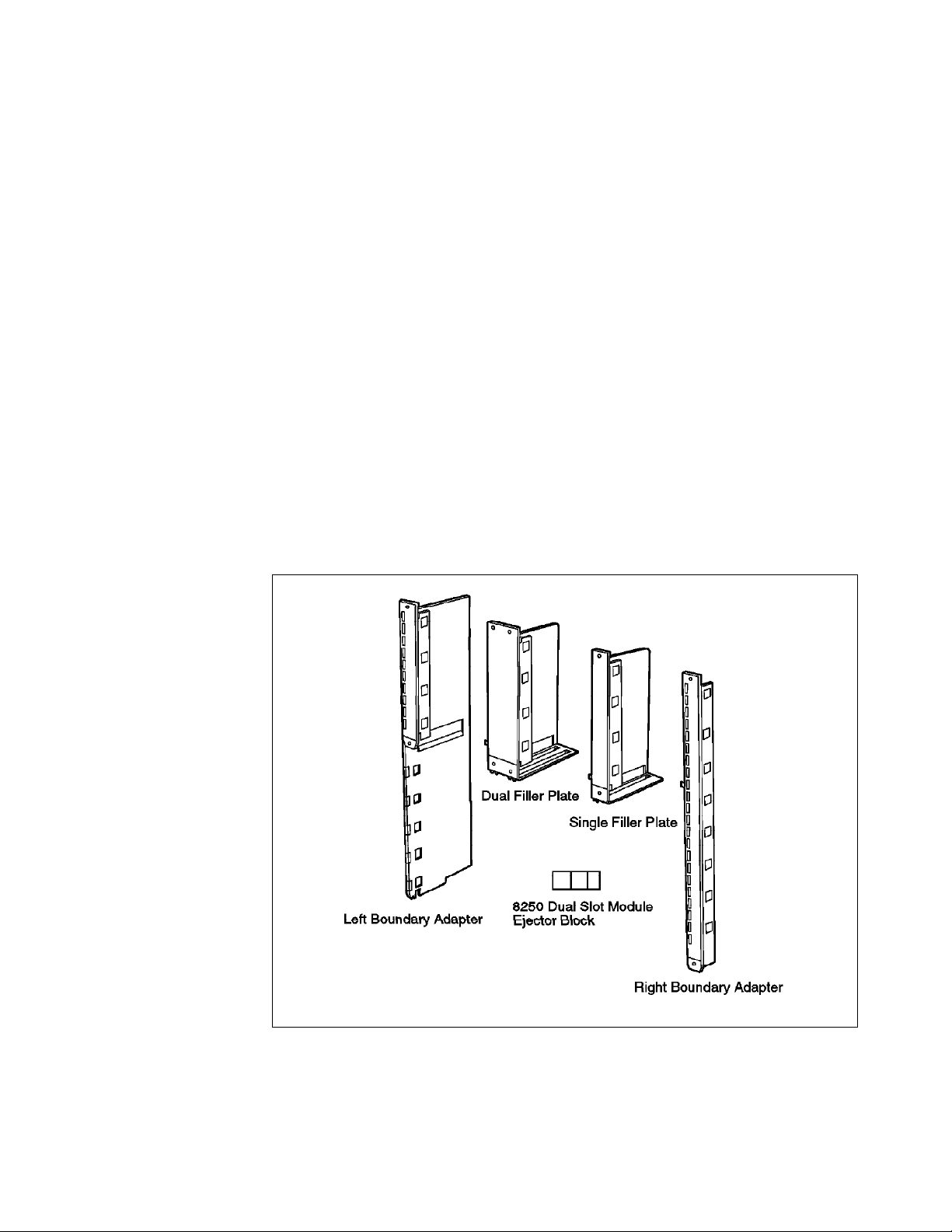

The 8250 adapter kit consists of the following:

8250 Adapter Kit

4 8260 Multiprotocol Intelligent Switching Hub

per-port switching

module-switching

. Depending on the kit that you order, the 8250 adapter

modules, which means that all the ports on

capability, which allows you

Page 27

•

Right Boundary Adapter: This adapter is a full length adapter and occupies

one slot. Installation of this adapter results in 16 slots remaining available in

the 8260 for the installation of media and management modules. It is

recommended that you install this adapter in slot 17. The reason for this is

that if an 8250 management module becomes the master management

module, it will always see the Controller module installed in slot 17.

Therefore, if there is any other module installed in this position, it will not be

recognized by the xMM.

Note: If a DMM is the master management module, it will always be able to

recognize the module installed in slot 17.

•

Left Boundary Adapter: This adapter will be installed on the left boundary of

the area occupied by the 8250 modules. The top portion of this adapter

provides a filler plate, while the bottom-portion will provide you with the

room to install an 8250 module.

•

Dual-slot Top Filler: This adapter provides the filler plate for two slots of the

8260 providing you with the room to install two single-slot (or one dual-slot)

8250 module.

•

Single-slot Top Filler: This adapter provides the filler plate for one slot of the

8260 providing you with the room to install a single-slot 8250 module. Note

that two of these adapters can be used to install a dual-slot 8250 module.

The components of the 8250 adapter kit are shown in Figure 2.

Figure 2. Components of the 8250 Adapter Kit

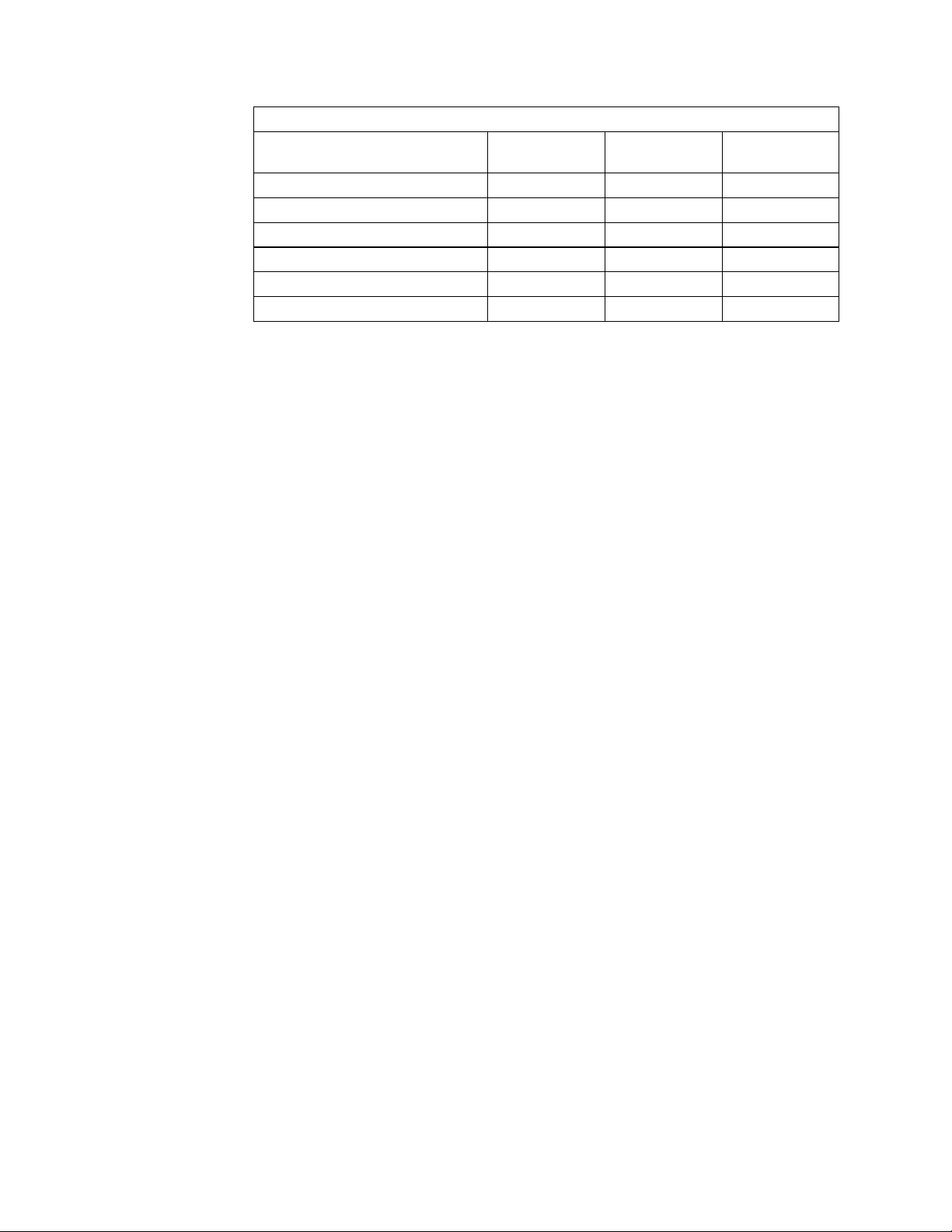

Table 1 on page 6 shows the quantity of each component for the various 8250

adapter kits:

Chapter 1. An Overview of the IBM 8260 Hub 5

Page 28

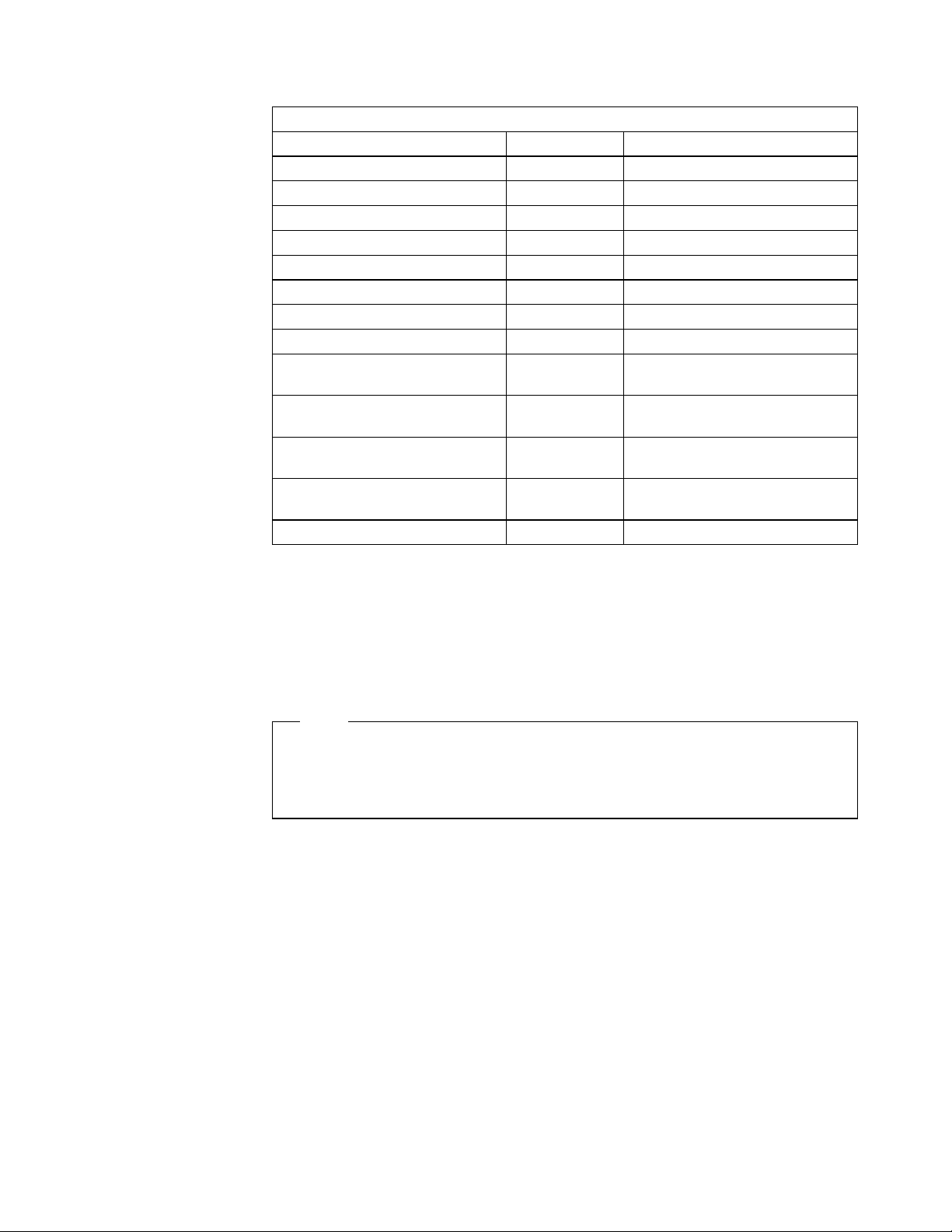

Table 1. Components of the 8250 Adapter Kit for 8260

Adapter kit Component 4-slot Feature 9-slot Feature 16-slot

Feature

Left Boundary Adapter 1 1 1

Right Boundary Adapter 1 1 1

Dual-Slot Top Filler 1 3 7

Single-Slot Top Filler 1 2 1

Dual-Slot Module Ejector Blocks 4 9 16

8250 Module Blank Faceplate 3 8 15

1.2.1.3 Fault-Tolerant Controller Module Slots

The Controller module provides all the clocking signals for the 8260. It is also

used to provide management of the power subsystem and the cooling

subsystem.

The 8260 chassis has two dedicated slots for the use of the Fault-Tolerant

Controller modules. These are referred to as slots 18 and 19. The 8260 Model

17 arrives with 1 Controller module as standard which is required for the

operation of the 8260. You may install a second Controller module which will be

used to back up the primary Controller module in case of failure. Fault tolerance

is established when there are two Controller modules installed. Either module

may be the master but in the event of the master Controller module failing and

will

the standby Controller module taking over, the network

be disrupted.

1.2.1.4 The Intelligent Power Subsystem

The power subsystem provides an easy access power bay which can support up

to four load-sharing, high capacity, managed power supplies. The 8260 Model

017 arrives with one power supply as standard and you may optionally install

three additional power supplies. Features of the power subsystem are:

•

Accessibility

The power bay is easily accessed from the front of the 8260.

•

Hot pluggability

You may install or remove power supplies while the hub is operating from

the other installed power supplies.

•

High capacity power supplies

Each power supply provides up to 295 watts of power.

•

Load sharing capability

The power consumption is evenly distributed over all the power supplies.

•

Power management

Using a combination of the DMM and the Controller module the power

subsystem can be monitored and controlled in either fault tolerant or

non-fault tolerant mode.

All of these features add up to a true seamless redundancy of the power

subsystem. The intelligent power subsystem is fully described in Chapter 5,

“8260 Intelligent Power Management Subsystem” on page 73.

6 8260 Multiprotocol Intelligent Switching Hub

Page 29

1.2.2 The Intelligent Cooling Subsystem

The cooling subsystem consists of 3 fans, each of which cools a specific area of

the hub. Each of the fans has a sensor to detect a slow or stopped condition and

a temperature sensor to detect an over temperature condition. In conjunction

with the Controller module and the DMM the hub environment can be monitored

and controlled for over temperature conditions. Fan and Temp LEDs on the

Controller module can also alert the user to potential problems. The intelligent

cooling subsystem is described in detail in Chapter 6, “8260 Intelligent Cooling

Subsystem” on page 91.

1.2.2.1 Distributed Management Architecture

To fully manage the 8260 and the installed modules, the 8260 uses a distributed

management architecture. In this architecture, the various tasks of managing

the various elements of the hub are distributed across the following elements:

•

Distributed management module

•

MAC daughter cards

•

Controller module

There are 2 types of distributed management module (DMM):

•

Stand-alone DMM

•

EC-DMM

In terms of management functions, DMM and EC-DMM are identical. The only

difference between these two cards is their ability to house Ethernet MAC

daughter cards.

The DMM, along with the fault-tolerant Controller module, manages and controls

the 8260 hub and its modules. However, to perform certain management

functions such as network traffic monitoring, there is a need for a daughter card

to assist DMM. There are two types of daughter cards:

•

•

The combination of DMM and daughter cards provides a cost efficient

management architecture that consolidates media management into a single

card, while distributing network monitoring across a series of protocol dependent

daughter cards. Detailed information about the distributed management

architecture of the 8260 and the management modules and daughter cards is

provided in Chapter 4, “8260 Distributed Management Architecture” on page 35.

1.2.3 8260 Model 010

The 8260 Model 010 is a 10-slot intelligent hub that shares many of the advanced

features of the 8260 Model 017. I t differs from the Model 017 in the following

areas:

•

•

Ethernet Media Access (E-MAC) daughter card

Token-ring Media Access (T-MAC) daughter card

It offers 10 payload slots, rather than 17.

It allows up to three power supplies, rather than four. The basic 8260 Model

010 is shipped with a single power supply, and up to two additional power

supplies can be added later. The same power supplies are used on both

models.

Chapter 1. An Overview of the IBM 8260 Hub 7

Page 30

•

Model 010 is shorter than the Model 017 (498 mm versus 673 mm), but has

the same depth and width.

•

Power supplies in the Model 010 are housed on the left side of the chassis

whereas in the Model 017 they are housed in the bottom section.

The 8260 Model 010 shares with the Model 017 all of the following benefits:

•

Supports three fan units.

•

Supports two Controller module slots for redundancy. The basic model is

shipped with one Controller module, and a second Controller module can be

added for redundancy.

•

It uses the same chassis accessories and chassis features:

− Rack mount kit

− Cable management tray

− Power supplies

− Fan units

− Controller module

•

Like the 8260 Model 017, the 8260 Model 010 is field upgradeable to support

ATM.

By sharing same chassis elements, networks can be built using a mixture of

Model 017s and Model 010s without an overhead for managing accessories and

spare parts.

Note

In the remainder of this book, the various components of the IBM 8260 are

explained assuming an 8260 Model 017.

1.3 8260 Modules and Daughter Cards

This section will give an overview of currently available 8260 modules and

daughter cards and a brief description of them. Details of individual modules,

the necessary steps required to configure them, and some testing scenarios will

be described in the following chapters. Currently, the available 8260 modules

and daughter cards can be classified as follows:

1.3.1 Ethernet Modules

1.3.1.1 8260 Ethernet 24-Port 10Base-T Module

The 8260 Ethernet 24-port 10Base-T module is single-slot module which provides

two Telco connectors for supporting 24 Ethernet ports. This module provides

per-port switching capability which enables you to connect each port to any of

the eight Ethernet segments on the backplane.

8 8260 Multiprotocol Intelligent Switching Hub

Page 31

1.3.1.2 8260 Ethernet 20-Port 10Base-T Module

The 8260 Ethernet 20-port 10Base-T module is single-slot module which provides

20 RJ-45 connectors for supporting 20 Ethernet ports. This module provides

per-port switching capability.

1.3.1.3 8260 Ethernet 40-Port 10Base-T Module

The 8260 Ethernet 40-port 10Base-T module is two-slot module which provides 40

RJ-45 connectors for supporting 40 Ethernet ports. This module provides

per-port switching capability.

1.3.1.4 8260 Ethernet 10-Base-FB Module

The 8260 Ethernet 10-Base-FB module is a single-slot module that provides 10

fiber ports which can be used to provide fiber backbone for Ethernet segments

using IEEE 10Base-F standard. You can also use these ports for connecting to

Ethernet ports using optical fiber cables. This module provides per-port

switching capability and can be ordered with one of the following connector

types:

•

ST

•

FC

•

SMA

1.3.1.5 8260 Multiprotocol Interconnect Module

The 8260 Multiprotocol Interconnect module is a one or two-slot module which

allows you to interconnect Ethernet, 802.3 and token-ring networks using bridging

and/or routing functions. Both models provide up to 6 logical ports for

attachment to Ethernet segments on the backplane, and the two-slot module

provides the capability to install two I/O cards which allow you to connect it to

external token-ring and Ethernet networks.

1.3.1.6 Ethernet Security Card

This is a daughter card that can be installed on any 8260 Ethernet media module

and provides you with the ability to perform intrusion protection and/or

eavesdropping protection for an Ethernet segment.

1.3.2 Token-Ring Modules

1.3.2.1 8260 TR 18 Port Active PPS Switch Module

The 8260 TR 18 Port Active PPS (Per-Port Switching) module is a single-slot

module which provides you with 18 RJ-45 connectors for attaching up to 18

workstations to the token-ring segments on the ShuntBus using both STP and

UTP cables. Using the per-port switching capability, any of the ports on this

module can be connected to any of the 10 token-ring segments on the ShuntBus

or 11 isolated segments on the module.

This module provides active re-timing and regeneration of the signal on every

port allowing you to have longer lobe distances for both STP and UTP cabling.

Ports 17 and 18 on this module can optionally be configured to act as fully

repeated RI/RO trunk ports.

Chapter 1. An Overview of the IBM 8260 Hub 9

Page 32

1.3.2.2 8260 TR 18 Port Active Module Switching Module

The 8260 TR 18 Port Active Module Switching module is a single-slot module

which provides attachment of up to 18 workstations to one of the 10 token-ring

segments on the ShuntBus using both STP and UTP cables. This module

provides active re-timing and regeneration of the signal on every port.

Ports 17 and 18 on this module can optionally be configured to act as fully

repeated RI/RO trunk ports.

1.3.2.3 8260 TR Dual Fiber Repeater Module

The 8260 TR Dual Fiber Repeater module is a single-slot module providing 10

lobe ports with RJ-45 connectors and two RI/RO trunk ports with ST fiber

connectors. Using the per-port switching feature, any of the lobes or any set of

RI/RO trunk ports can be connected to any of the 10 token-ring segments on the

ShuntBus.

Lobe ports support both UTP and STP cabling and each port provides active

re-timing and regeneration of the signal.

The fiber RI/RO trunk ports are fully repeated and can be used for connecting

your 8260 to other hubs over a distance of 2 km.

1.3.2.4 8260 TR 20 Port Passive Module-Switching Module

The 8260 TR 20 Port Passive Module-Switching module is a single-slot module

which allows you to attach up to 20 workstations, which can be switched on a

per module basis, to any of the 10 token ring networks on the backplane. This

module allows you to use either UTP or STP cabling. Unlike the active module,

it does not provide simultaneous support for both UTP and STP cabling.

1.3.2.5 8260 Jitter Attenuator Daughter Card

The 8260 Jitter Attenuator daughter card allows you to filter excessive amounts

of jitter that may have accumulated in other equipment, before passing the

signal to the 8260 backplane. The Jitter Attenuator daughter card can be

mounted on any 8260 token-ring media module.

1.3.3 Management and Controller Modules

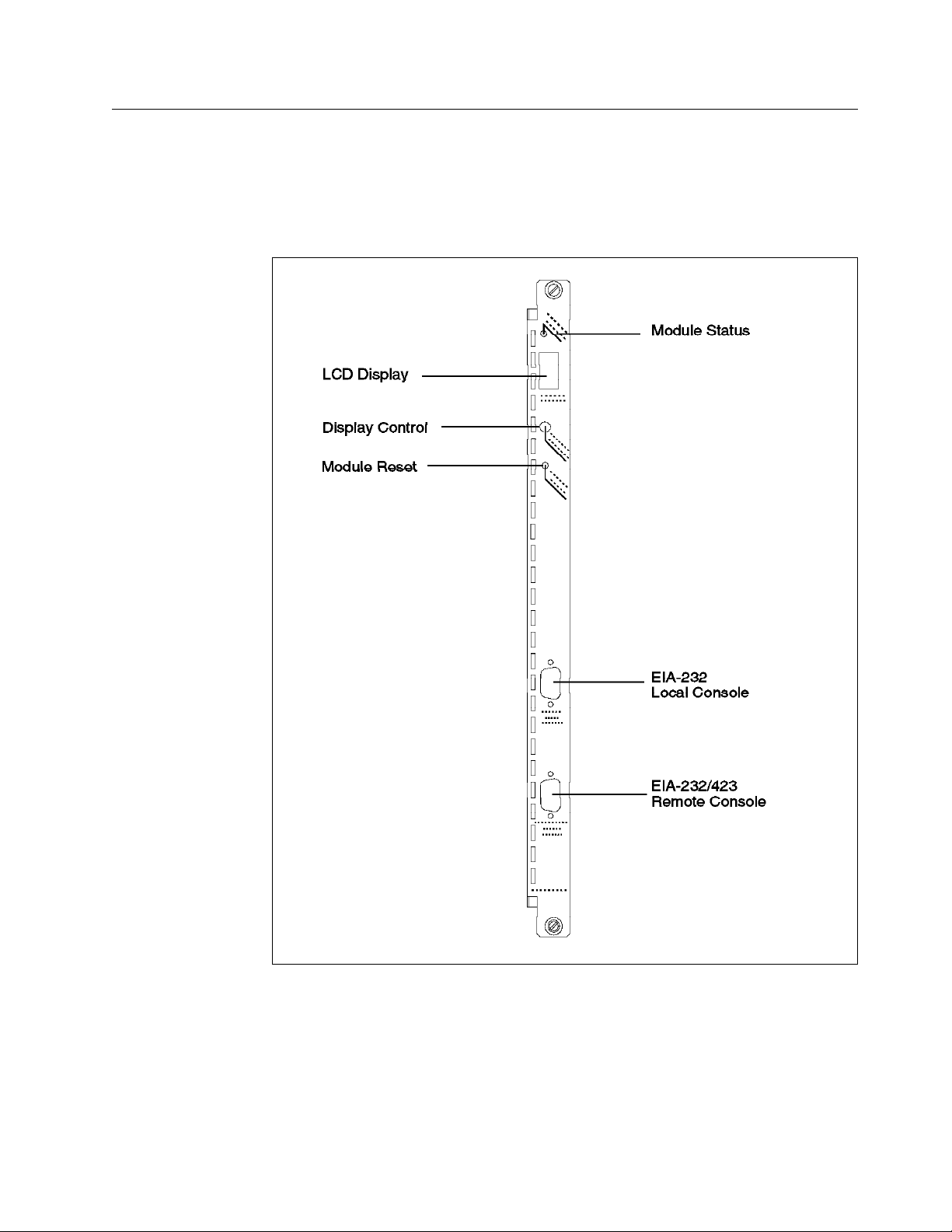

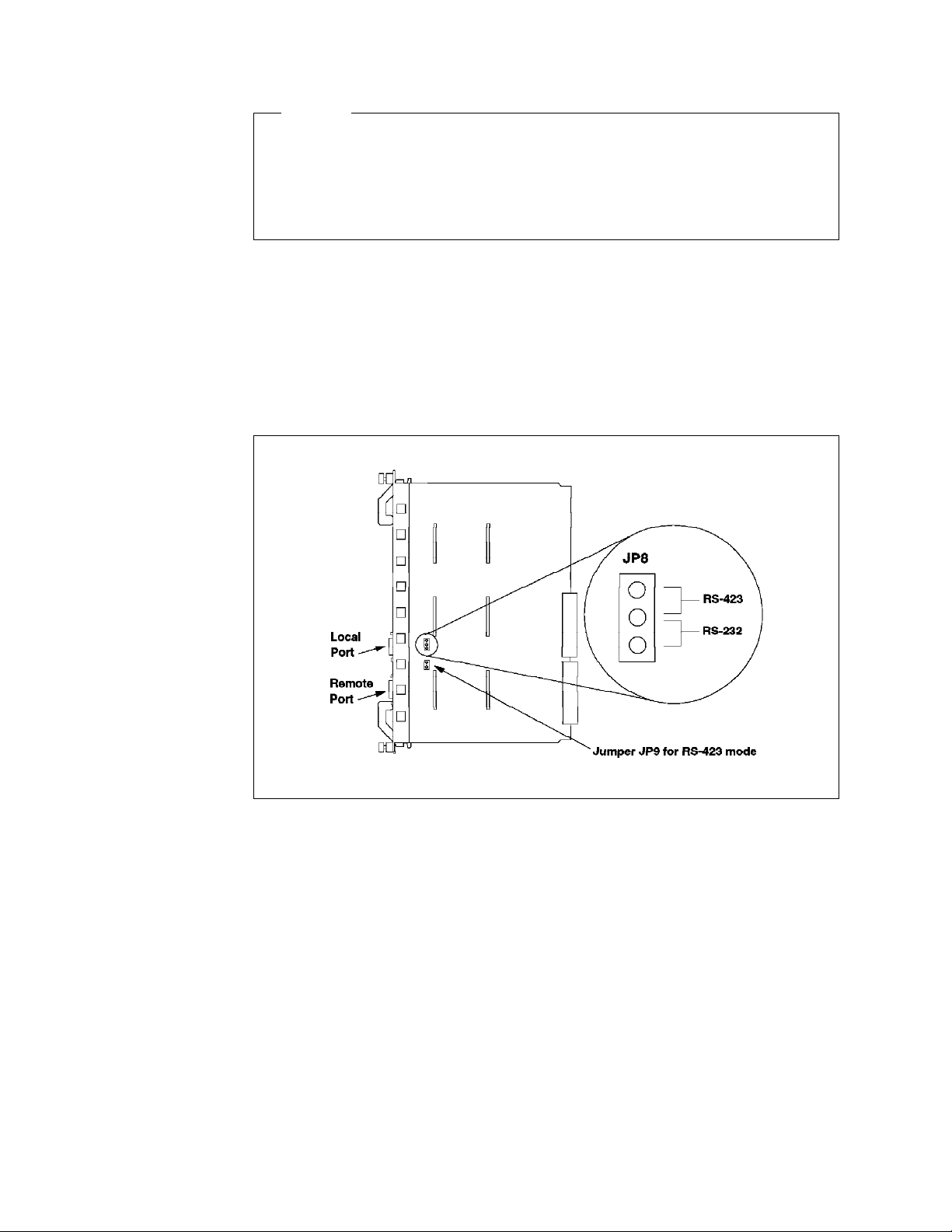

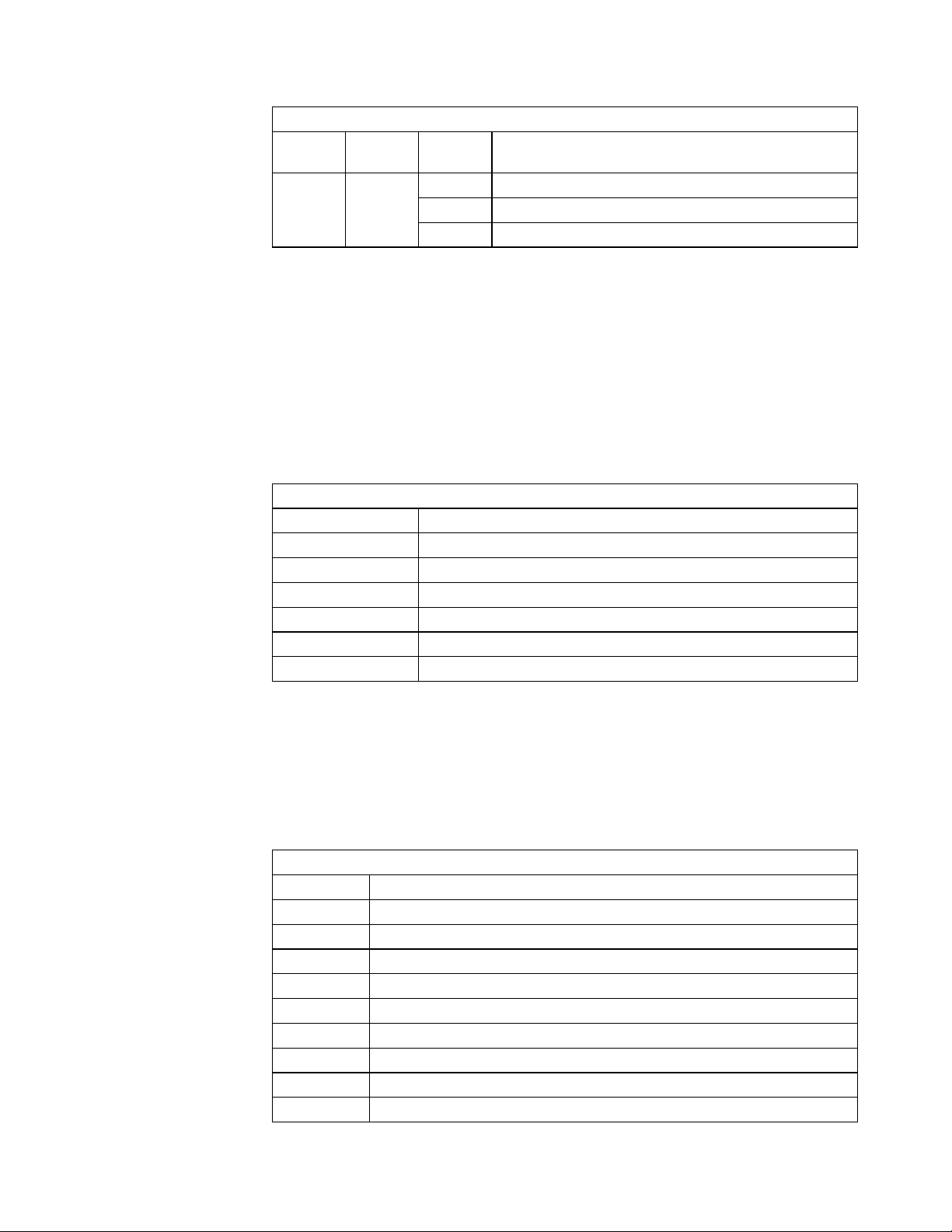

1.3.3.1 8260 Distributed Management Module (DMM)

The Distributed Management Module is an independent management module

which allows you to fully manage and control the 8260 Multiprotocol Intelligent

Hub and all the 8250/8260 modules. The DMM provides you with flexibility in

handling the management of network segments with different protocols and

media modules via a single management module using a single slot in the 8260

payload area. There are two different versions of DMM:

•

A Distributed Management Module with Ethernet Carrier - (DMM with Ethernet

Carrier) - The DMM with Ethernet Carrier module is a management module

which is capable of housing up to 6 Ethernet MAC daughter cards.

•

A Stand-alone Distributed Management Module (Stand-alone DMM ) - the

stand-alone DDM module is a management module which is not capable of

housing any Ethernet MAC daughter cards.

10 8260 Multiprotocol Intelligent Switching Hub

Page 33

1.3.3.2 8260 Fault-Tolerant Controller module

The 8260 Fault-Tolerant Controller Module synchronizes the operations of all

installed media and management modules by providing clocking and timing to

the 8260 Multiprotocol Intelligent Hub Backplane. The Controller module is also

responsible for managing the power and cooling subsystems.

1.3.3.3 Ethernet Media Access Daughter Card (E-MAC)

The E-MAC daughter card allows you to gather statistics for the network to which

it is attached. It can be physically mounted to either an 8260 Ethernet media

module or the 8260 EC-DMM.

1.3.3.4 8260 Token-Ring Media Access Daughter Card (T-MAC)

The T-MAC daughter card allows you to gather statistics for the network to which

it is assigned. It can be mounted on any 8260 token-ring media module.

Chapter 1. An Overview of the IBM 8260 Hub 11

Page 34

12 8260 Multiprotocol Intelligent Switching Hub

Page 35

Chapter 2. Backplane Architecture

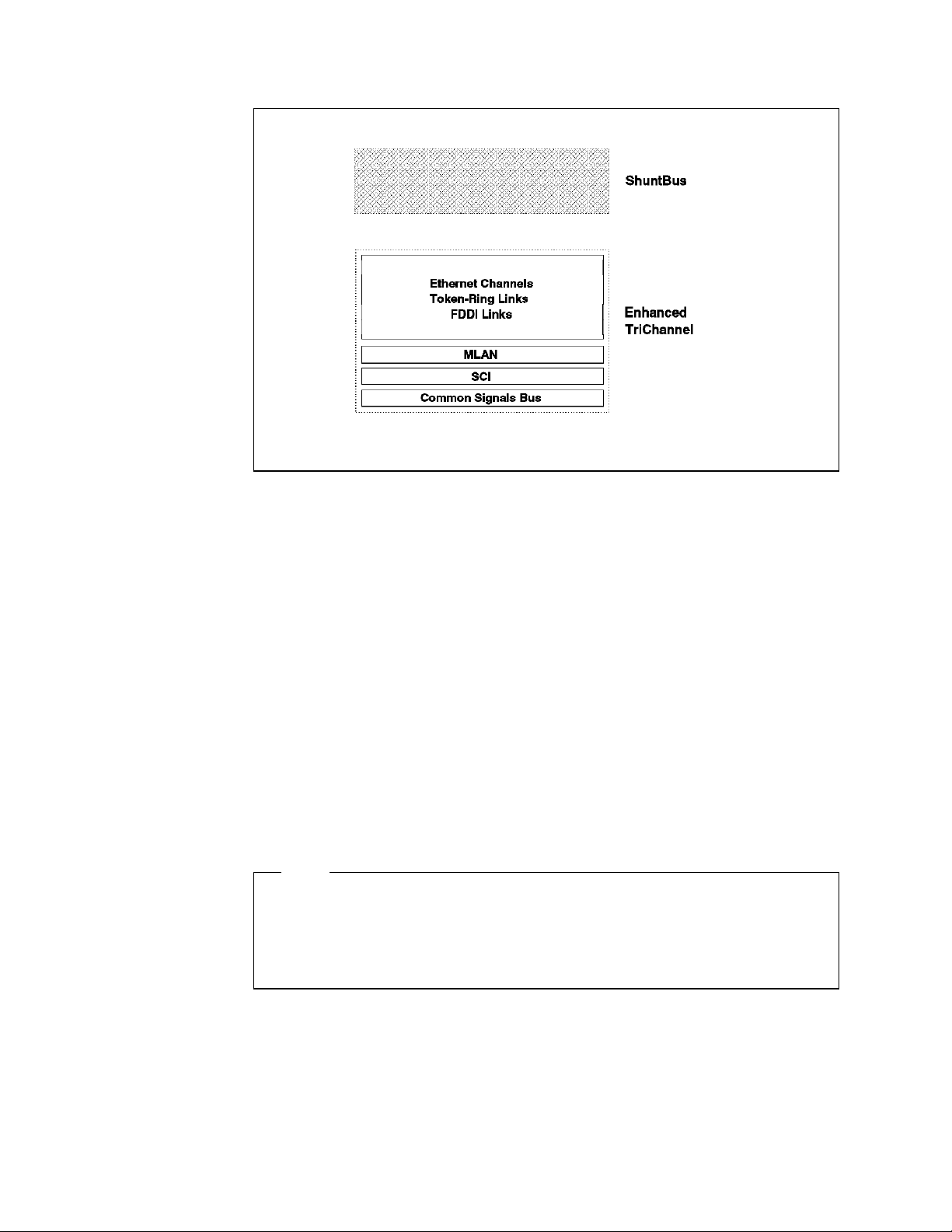

The 8260 backplane consists of the following two buses:

•

Enhanced TriChannel

•

ShuntBus

These two buses are standard features of all the 8260 models and are installed

on every 8260 shipped to the customers.

The following sections provide detailed information about the 8260 backplane

and how the backplane buses operate.

2.1 LAN Segments on the Backplane

On each backplane bus (both Enhanced TriChannel and ShuntBus) there are 96

pins

which are used for passing the network traffic between the media modules

installed in the hub as well as the control signals between the media modules,

fault-tolerant Controller module, and Distributed Management Module (DMM).

The control signals are used to carry clocking, voltage, status and other

information pertinent to the proper operation of the hub and the installed

modules.

On the Enhanced TriChannel, 54 pins are available to be used for passing

network traffic. the rest of the pins are used for non-data traffic signals. These

signals are used for passing control signals between the Controller module and

the media modules as well as signals between the Management module and the

media modules. More information about these non-data traffic signals are

provided in 2.5.1, “Management Buses” on page 26.

On the Enhanced TriChannel, the pins used for passing the network traffic are

not permanently allocated to a specific type of network. Instead a pin may be

configured to be used for passing either token-ring, Ethernet or FDDI packets at

any one time. This enables more efficient utilization of the backplane resources.

The following is the maximum number of permitted LAN segments when a single

protocol is used on the Enhanced TriChannel:

•

6 Ethernet segments or

•

7 token-ring segments or

•

4 FDDI segments

Note that you are allowed to have a mixture of token-ring, Ethernet and FDDI

segments on the Enhanced TriChannel. In this case, the exact number of each

network type which is allowed in a mixed protocol environment depends on the

configuration of your hub. For detailed information about the permitted

configurations in a mixed protocol environment please refer to 2.5, “Network

Allocations on the 8260 Backplane” on page 23.

Figure 3 on page 14 provides an overview of the Enhanced TriChannel bus.

Copyright IBM Corp. 1995 13

Page 36

Figure 3. Enhanced TriChannel Bus

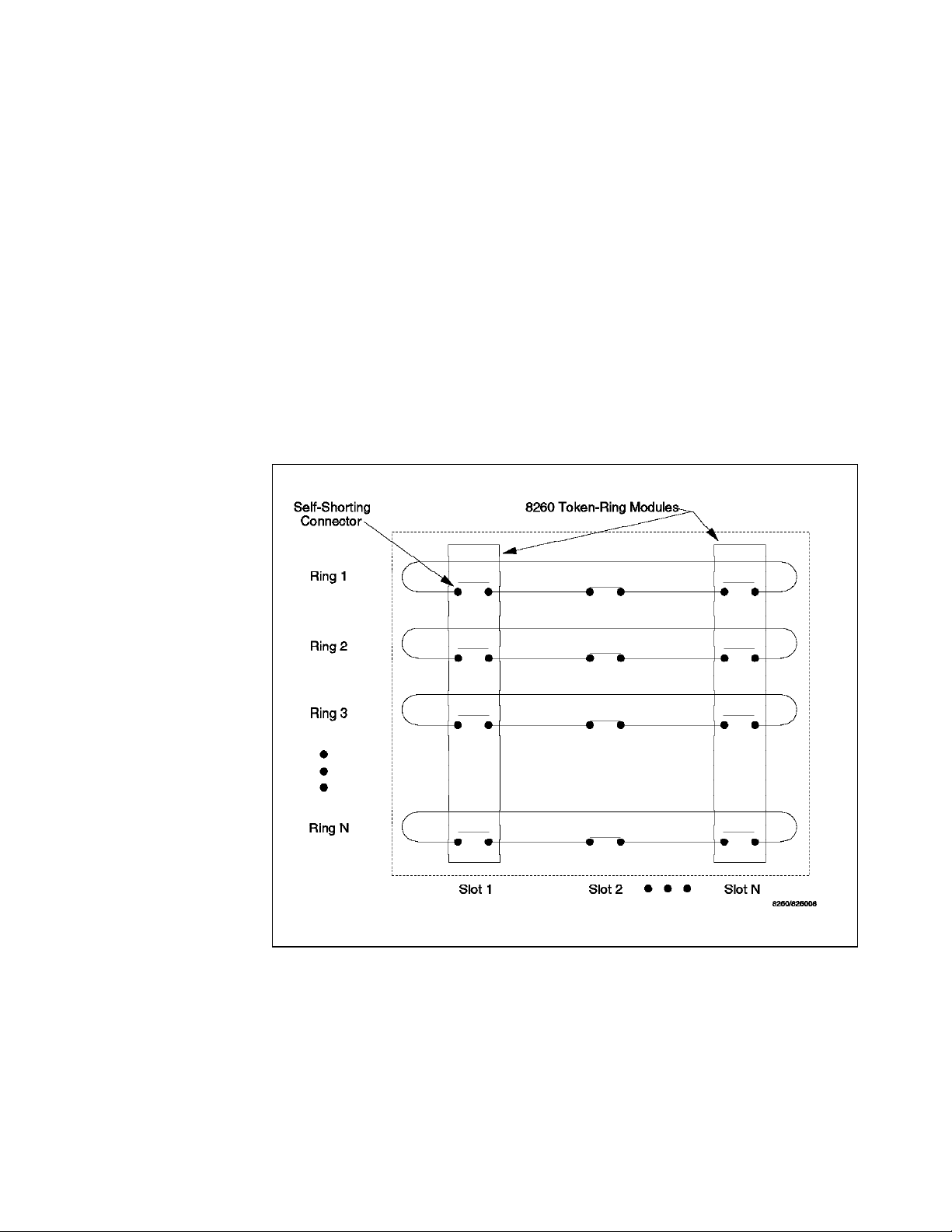

The number of pins available for user traffic on the ShuntBus is 72 pins. These

pins are used to set up 2 dedicated Ethernet segments as well as 10 token-ring

(or 4 FDDI) segments as shown in Figure 4 on page 15.

On the ShuntBus, 8 pins out of the 72 network traffic pins are dedicated to be

used by two Ethernet segments. These dedicated pins are not available to be

used by other segment types. The remaining 64 pins on the ShuntBus are

available to be used by token-ring and/or FDDI segments. This allows you to

have a mixture of token-ring and FDDI segments as well as two Ethernet

segments on the ShuntBus. The rules governing the maximum number of FDDI

and token-ring segments allowed in a mixed token-ring and FDDI environment

are discussed in 2.5, “Network Allocations on the 8260 Backplane” on page 23.

The following is the permitted maximum number of LAN segments on the

ShuntBus:

•

2 Ethernet and

•

10 token-ring or 4 FDDI

Note

At the time of writing this publication, there are no FDDI modules available

that can be assigned to the FDDI segments on the ShuntBus. Therefore,

practically, the ShuntBus allows you to have two Ethernet segments plus 10

token-ring segments.

14 8260 Multiprotocol Intelligent Switching Hub

Page 37

Figure 4. 8260 ShuntBus

2.2 Ethernet Segments on the Backplane

The 8260 allows you to set up a maximum of 6 Ethernet (ethernet_1 thru 6)

segments on the Enhanced TriChannel and two Ethernet segments (ethernet_7

and 8) on the ShuntBus. ethernet_1 thru 3 can consist of 8250 and/or 8260

Ethernet modules, whereas ethernet_4 thru 8 can consist of 8260 Ethernet

modules only.

Each Ethernet segment on the backplane uses a number of pins on the

backplane which is referred to as an

8 Ethernet paths (ethernet_path_1 thru 8) on and 8260. ethernet_path_1 thru 6

are on the Enhanced TriChannel whereas ethernet_path_7 and 8 are on the

ShuntBus.

Ethernet_path_1 thru 3 use 14 pins each to set up an Ethernet segment while

ethernet_path_4 thru 8 use 4 pins each.

The Ethernet segments on the Enhanced TriChannel use the same pins on the

backplane as are used by the token-ring and/or FDDI segments. Therefore,

simultaneous configuration of other types of networks (such as FDDI and/or

token-ring) on your hub′s Enhanced TriChannel will impact the number of

Ethernet networks available for use. However, the two Ethernet segments on the

ShuntBus have dedicated pins on the backplane and will not be impacted by the

configuration of other segment types (that is, token-ring and/or FDDI) on the

ShuntBus.

Ethernet Path

in this document. There are

Each Ethernet segment on the 8260 utilizes one of the Ethernet paths on the

backplane regardless of the number of Ethernet modules which constitute that

segment. You can choose the Ethernet network (hence the Ethernet path used

by your module) using the following management command:

Chapter 2. Backplane Architecture 15

Page 38

SET MODULE {slot.sublsot} NETWORK {ethernet_n} or

SET PORT {slot.port} NETWORK {ethernet_n}

Before assigning the port or module to a network you may use the following

management command to display the availability of the Ethernet segments on

the Enhanced TriChannel and the ShuntBus:

SHOW BACKPLANE_PATHS ETHERNET

An example of the output from this command is shown in Figure 5.

8260> show backplane_paths ethernet

Physical Path Logical Network

--------------- --------------ETHERNET_PATH_1 ETHERNET_1

ETHERNET_PATH_2 in use

ETHERNET_PATH_3 in use

ETHERNET_PATH_4 available

ETHERNET_PATH_5 ETHERNET_5

ETHERNET_PATH_6 ETHERNET_6

ETHERNET_PATH_7 ETHERNET_7

ETHERNET_PATH_8 ETHERNET_8

8260>

Figure 5. Backplane Path Display for Ethernet Segments

In this example, the Ethernet segments shown ″in use″ are not available to be

used for setting up Ethernet segments in this hub due to the backplane pins

corresponding to these segments being currently used by other segment types

such as token-ring and/or FDDI. Ethernet_1 and ethernet_5 through ethernet_8

are currently configured to be used by Ethernet modules in this hub. The pins

available to be used by ethernet_4 are not currently configured to be used by

any network type.

To connect and use the Ethernet segments on the backplane (Enhanced

TriChannel or ShuntBus) various techniques are used by the various 8250 and

8260 Ethernet modules. These techniques can be categorized into one of the

three following methods:

•

Method 1:

This method uses 14 pins on the backplane to set up an Ethernet segment.

In this method, each module attached to the Ethernet segment will send the

slot-id and port-id of the transmitting station in

The slot-id will use 5 pins and the port-id will use 4 pins on the backplane as

shown in Table 2 on page 17.

The slot-id will be used to perform

2.2.1, “Digital Collision Detection” on page 19. Additionally, the slot-id and

the port-id will be used by the management module to perform statistics

gathering about the segment as well as the individual ports and modules on

that segment as described in 2.2.3, “Statistics Collection” on page 19.

digital collision detection

parallel

over the backplane.

as described in

This method is used by all 8250 modules and is only allowed on ethernet_1,

ethernet_2, and ethernet_3 segments on the Enhanced TriChannel.

Therefore, the 8250 Ethernet modules installed in the 8260 can only be

assigned to these three segments and can not be assigned to Ethernet

16 8260 Multiprotocol Intelligent Switching Hub

Page 39

segments ethernet_4, ethernet_5 and ethernet_6 on the Enhanced TriChannel