Page 1

CF Series Scanner

Maintenance

Manual

Firmware Rev. S27G and up

Scanner Serial Number

The information contained herein is the property of SCAN-GRAPHICS, Inc., and shall not be reproduced

or copied, or used as the basis for the manufacture or sale of apparatus or service without the written

approval of SCAN-GRAPHICS, Inc., first being obtained.

Scan-Graphics, Inc.

700 Abbott Drive

Broomall, Pennsylvania 19008-4373 Part Number: A62950-6

Telephone: (610) 328-1040 Revision Number: 1

FAX: (610) 543-6257 Revision Date: 5/24/96

Email: support@scangraphics.com

Page 2

CF Series Scanner Maintenance Manual

(Firmware Rev. S27G and up)

©

1989-1996 Scan-Graphics, Inc.

All rights reserved. Printed in the United States of America. No part of this document may be used or reproduced in any

form or by any means, or stored in a database or retrieval system, without prior written permission of Scan-Graphics, Inc.

The information contained herein is the property of Scan-Graphics, Inc., and shall not be reproduced or copied, or used as the

basis for the manufacture or sale of apparatus or service without the written approval of Scan-Graphics, Inc., first being

obtained.

TRADEMARK NOTICE

Scan-Graphics, ScanView, Scangraphics, ScanMark, FRIENDS, FriendsPlus, CF ScanServ, ScanServ, ScanEdit, ScanPlot,

and CF Series Scanner are trademarks of Scan-Graphics, Inc.

IBM and DACU are registered trademarks of International Business Machines Corporation.

DEC, MicroVAX II, MicroVMS, and DR11W are registered trademarks of Digital Equipment Corporation.

PATENT NOTICE

This product is manufactured under U.S. Patent 4631598, U.S. Patent 4972273, and other patents pending.

AGENCY APPROVALS

This product is listed by Underwriters Laboratories, Inc. as the following:

UL File # E125596

This equipment complies with the FCC Rules for a Class "A" computing device. Operation of this equipment in a residential

area may cause unacceptable interference to Radio and TV reception requiring the operator to take whatever steps are

necessary to correct the interference.

CF Series Scanner Maintenance Manual

________________

Page 3

Preface

Purpose and Scope

The purpose of this manual is to provide the information necessary to keep the CF Series Scanner in proper working

order through regular preventive maintenance and provide the required information for a trained electronics technician to

effect repairs. This manual takes problem isolation and solution to the subassembly or board level.

Related Scangraphics Documentation

• CF Series Scanner User’s Manual (A62951-10)

This manual is available to factory-trained service technicians for the maintenance, troubleshooting, and

repair of CF Series Scanners.

• ScanServ User's Manual (A65352-04)

This manual is available to licensed users of ScanServ

personal computer to control the CF Series Scanner as a scan server.

Organization

The manual is organized into six sections and two appendices. The content of these divisions is as follows:

Section 1--System Overview

The System Overview provides a brief general discussion of the purpose and function of the subsystems comprising

the CF Series Scanner. Physical and performance specifications are also listed here.

Section 2--Installation

This section contains the procedures necessary for unpacking, choosing a location for, setting up, and applying

power to the scanner.

Section 3--System Description

This section goes into the details of the modules and components of the CF Series Scanner.

Section 4--Preventive Maintenance

This section lays out a regular program of maintenance which, if followed, w ill help keep the scanner trouble-free.

Section 5--Diagnostic Software

The program documented here tests the various modules of the scanner. It is accessible with an ANSI-type terminal

or a PC with terminal emulation software.

TM

- a Scangraphics' application program that allows a

Page 4

Section 6--Adjustment, Calibration, and Replacement

Contained in this section are the various procedures for adjusting and calibrating the scanner components. It also

covers replacement of some components. This treatment is task-oriented.

The two appendices are:

Appendix A--Terminal Setup

This appendix discusses settings required on terminals used with the CF Series Scanner.

Appendix B--Replacement Parts List

This appendix lists parts that may need replacement and their ordering numbers.

If You Have Questions

Should a question or problem arise that is not addressed in this or one of the SCAN-GRAPHICS scanning

publications, supervisors may contact SCAN-GRAPHICS, Inc. between 8:00 A.M. and 4:30 P.M. E.T., Monday through

Friday.

If you are calling to report a problem, be sure to have at hand error messages, printouts, or documents which

sequence the events leading up to the problem. The more specific the information, the faster the problem can be resolved.

Contact:

SCAN-GRAPHICS, Inc.

700 Abbott Drive

Broomall, Pennsylvania 19008

Telephone: (610) 328-1040

FAX: (610) 543-6257

Email: support@scangraphics.com

Page 5

Table of Contents

Preface

Table of Contents

Warranty

Revision Record

1 CF SERIES SCANNER: FEATURES AND SPECIFICATIONS

1.1 FEATURES

1.1.1 User Interface

1.1.2 Critical Calibration

1.1.3 Advanced Image Processing

1.1.4 Multiple Resolution

1.1.5 Preview Display Monitoring (option)

1.1.6 Diagnostics

1.1.7 Construction

1.2 SPECIFICATIONS

1.2.1 Functional Specifications

1.2.1.1 Scan Speed

1.2.1.2 Resolution

1.2.1.3 Accuracy/Repeatability

1.2.1.4 Imager Sensor

1.2.1.5 Transport

1.2.2 Input Characteristics

1.2.3 Physical Specifications

1.2.4 Power Specifications

1.2.5 Environmental Specifications

1.3 MAJOR SYSTEMS OF SCANNER

1.3.1 Scanner Control System

1.3.2 Document Transport System

1.3.3 Document Illumination System

1.3.4 Camera System

1.3.5 Data Handling System

1.3.6 Display System (optional)

1.3.7 User Interface System

1.3.8 Power Supply System

1.3.9 Ventilation System

2 INSTALLATION

2.1 UNPACKING

2.2 SETUP

2.2.1 Document Catch Installation

2.2.2 Environmental Concerns

2.2.2.1 Site

2.2.2.2 Airflow

2.2.2.3 Ambient Light

2.2.2.4 Vibration

2.2.2.5 Temperature

2.2.2.6 Humidity

Page 6

2.3 CONNECTIONS

2.3.1 A.C. Power

2.3.2 Video (Optional)

2.3.3 Host/Local Control and Diagnostics Terminal

2.4 POWER-UP

2.4.1 Check Line Voltage

2.4.2 Check Power Supply Voltage (Recommended)

2.5 SYSTEM CHECK

2.5.1 Check Line Splice

2.5.2 Check Merge

2.6 DE-INSTALLATION

3 SYSTEM DESCRIPTION

3.1 MAJOR SYSTEMS OF SCANNER

3.1.1 Scanner Control System

3.1.2 Document Transport System

3.1.3 Document Illumination System

3.1.4 Camera System

3.1.5 Data Handling System

3.1.6 Display System (Optional)

3.1.7 User Interface System

3.1.8 Power Supply System

3.1.9 Ventilation System

4 PREVENTIVE MAINTENANCE

4.1 DAILY

4.2 MONTHLY

4.2.1 Clean Filters

4.2.2 Clean Camera Lenses

4.3 ANNUALLY

4.3.1 Clean CCD Camera

4.3.2 Check Power Supply Voltages

4.3.3 Replace Lamps

4.3.4 Recalibrate Scanner

Page 7

5 ON-BOARD DIAGNOSTIC SYSTEM

5.1 DIAGNOSTICS TESTS

5.1.1 (1) : Set Global Parameters

5.1.2 (2) : Perform System Initialization

5.1.3 (3) : Parameter Backup

5.1.4 (4) : Set Motor Speed

5.1.5 (5) : Splice Counts

5.1.6 (6) : Focus and Magnification

5.1.6.1 Focus

5.1.6.2 Magnification

5.1.7 (7) : IP LUT

5.1.8 (8) : Merge and Splice Adjustment

5.1.8.1 Line Splice Adjustment

5.1.8.1.1 Adjusting Line Splice Mechanically

5.1.8.1.2 Adjusting Line Splice Electronically

5.1.8.2 Merge Adjustment

5.1.9 (9) : Autosize Parameters

5.1.10 (A) : Set CCB Registers

5.1.11 (B) : Test Frame Grabber

5.1.12 (C) : Test I/O Board

5.1.13 (D) : Page Offsets

5.1.14 (E) : Camera System Diagnostics

5.1.14.1 (E) : Exposure Memory

5.1.14.2 (NE) : Normalize Exposure

5.1.14.3 (G) : Gain Memory

5.1.14.4 (NG) : Normalize Gain

5.1.14.5 (D) : Display Calibration Memory

5.1.14.6 (F) : Fill Calibration Memory

5.1.14.7 (T) : Take Line

5.1.14.8 (Q) : Take Qualified Line

5.1.14.9 (A) : Autotake

5.1.14.10 (V) : Video Board Reset (Not used)

5.1.14.11 (L0) : Lights Off

5.1.14.12 (L1) : Lights On

5.1.14.13 (U) : Uniformity Check (Not used)

5.1.14.14 (K) : Calibration Check

5.1.14.15 (M) : Mirror Control

5.1.14.16 (T) : Test Pattern Control

5.1.14.17 (Y) : Camera Delay (Factory Use ONLY)

5.1.14.18 (C) : Calibration Memory Test

5.1.14.19 (R) : Camera Response Curves

5.1.14.20 (H) : Histogram

5.1.14.21 (X) : Exit

5.1.15 (F) : Resolution Control

5.1.16 (G) : Document Sizes

5.1.17 (H) : Run Self Tests

5.1.18 (I) : Restore NVRAM

5.1.19 (J) : Binary Filter Parameters

5.1.20 (K) : IP Averager LUT

5.1.21 (L) : Autocalibration

5.1.22 (M) : SCSI Buffer Parameters

5.1.23 (X) : Exit

Page 8

5.2 SAVING PARAMETER CHANGES TO NON-VOLATILE MEMORIES

5.2.1 Pixel Correction and Exposure Values

5.2.2 System Parameters

6 REPLACEMENT : COMPONENT AND SUB-ASSEMBLY

6.1 Task -- Removing Scanner Covers and Panels

6.2 Task -- Belt Replacement and Tension Adjustment

6.3 Task -- Lamp Installation and Replacement

6.4 Task -- Replacement of White Background

6.5 Task -- Camera Assembly Removal and Replacement

6.6 Task -- Camera Calibration

6.6.1 Video Board Adjustment

6.6.2 Camera Board Offset

6.6.3 Exposure Calibration

6.6.4 Gain Calibration

6.7 Task -- Checking and Adjusting Voltages

6.8 Task -- Fan Replacement

6.9 Task -- Filter Cleaning and Replacement

A TERMINAL SETUP

A.1 Using The Windows Terminal Emulator

A.2 Saving The Setup

A.3 Host Serial Cable Connections

B REPLACEMENT PARTS LIST

Page 9

Scangraphics warrants its Scanner Products against defective workmanship and materials for a period of ONE (1) YEAR

from date of shipment. Software and MK35 Products are warranted for a period of Ninety (90) days from date of shipment.

Scangraphics must be advised in writing, during the warranty period, of any defect or non-conformity within thirty (30) days

after discovery of defect. Products or components thereof shall not be returned for inspections, replacement, or repair

without the Buyer having first obtained a specific Return Material Authorization (RMA) number from Scangraphics, AND

Scangraphics shall have the final determination as to the existence and cause of the defect. Authorization to return defective

product must be received from the factory prior to shipping the Product.

The Buyer shall bear the expense of returning the Product to the factory with the subsequent return shipment charges paid for

by Scangraphics if, in the event such defect or non-conformity is established by Scangraphics. Air filters, fuses, and lamps

are excluded from the provisions of this warranty. Scangraphics assumes no responsibility for obsolescence of its Software.

Software is furnished "AS IS" without warranty of any kind and without any representation regarding quality, performance,

or suitability. Scangraphics does not warrant the Software free from defects or that the support services will correct all

defects which might exist. Scangraphics warrants for the benefit only of the Buyer, that the Scangraphics Software shall

conform in material respects to the Scangraphics Software User's Manual provided by Scangraphics, except with respect to

subsequent modifications, if any, made by the Buyer.

This WARRANTY shall not apply to any Product or parts thereof rendered defective by negligence, accident, or subjected to

electrical, thermal, or mechanical conditions in excess of the maximum values established by Scangraphics specification; or

misuse in handling, transportation, storage; or by performance of repairs, installation, or alterations outside the factory except

when performed by Scangraphics accredited service representatives. Scangraphics reserves the right to inspect the Product

on the premises of the Buyer or the third party thereof. Inspection or repair at any location other than the Scangraphics

factory if carried out by Scangraphics at the request of the Buyer shall be at the then current published repair service labor

rates plus reimbursement of applicable travel costs. Scangraphics may, however, at its sole option, perform repair of

Products in the Buyer's or third party's plant at Scangraphics' expense.

Scangraphics reserves the right to make changes, additions, or improvements in its Products without assuming any

obligation to incorporate such change, addition, or improvement on its Products previously manufactured.

Scangraphics shall not be liable to the Buyer or any third party for any loss of production time or profits, or any

consequential damages whatsoever resulting from use of the purchased product; or any failure in the performance of other

product to which the purchased product is connected; or the functioning of an entire system, or parts of any parts of any

system of which the purchased product may be a part, including the effect that other parts of such system may have upon the

purchased product. Scangraphics

sole and exclusive remedy and entire liability here

under shall be the repair or replacement

of component parts or software proving defective, and limited to the value of the product subject to the remedy regardless of

the form of action whether it is in contract or in tort including negligence.

Scangraphics MAKES NO REPRESENTATION OR WARRANTY OTHER THAN THOSE SET FORTH IN THIS

AGREEMENT. THE WARRANTY STATED HEREIN IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND SUCH WARRANTY CONSTITUTES

THE ONLY WARRANTY MADE BY Scangraphics WITH RESPECT TO THIS AGREEMENT OR THE PRODUCTS,

ARTICLES, MATERIALS, REPLACEMENT PARTS, OR SERVICES TO BE SUPPLIED HEREBY. Scangraphics

SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

Page 10

Revision Record

Rev. No. Date Action

0 12-10-95 Original draft.

1 05-24-96 Added sections 1-4 and Appendices A & B

1 SYSTEM OVERVIEW

The CF Series Scanner is a highly versatile data capture device, providing choices in speed and

resolution and producing high quality data. It also allows a choice between using a fixed threshold or an

adaptive threshold. An adaptive threshold takes into account variations in the shading of the media to

yield consistently good results, even from less than optimal documents. See Figure 1-1 for an

illustration of the scanner.

SCAN-GRAPHICS accomplished this in a way which makes the CF Series Scanner as easy to

use and maintain as possible. Care has been taken in the design and manufacture of the unit to build in a

strength which will keep the scanner operating reliable for years.

The CF Series Scanner can accommodate documents with widths up to 44 inches (the maximum

active scan area is 43 inches). The scanner does not limit the length of the document.

Although the technology employed by the CF Series Scanner is very complex, its function can be

described in quite simple terms. It consists of a set of cameras focused on a narrow window; lamps to

illuminate the document; a transport system which moves the document past the window; and the

electronics to convert the data captured by the cameras into a useful form.

Page 11

1 CF Series Scanner: Features and Specifications

This chapter provides a brief overview of the features available and the specifications that apply

to the various CF Series Scanner models.

1.1 Features

The CF Series Scanners offer a wide range of features that permit the user to set up an ideal

configuration for today's needs as well as providing the capability to adapt to new needs in the

future.

User Interface

• Operable from host CPU through software

• Operable from scanner keypad (option)

Critical Calibration

• Electronic alignment of Y-axis (merge)

• Electronic alignment of X-axis (splice)

Advanced Image Processing

• Speckle Removal

• Gap Filling

• Patented Local Area Adaptive Thresholding with Limit Option

• Contrast Enhancement

• Polarity reversible to scan both positive and negative images

• Image mirroring

Multiple Resolution

• Available resolutions range from 1600 to 100 dpi

Refer to Table 1-A for available resolution values.

• Patented True Resolution Control, using the averaging method of eight-bit video data to

avoid dropping pixels

• Up to eight resolutions for the CF 1000/44

Preview Display Monitoring (option)

• High-resolution Preview Display for precise monitoring of image quality

• Real-time monitoring of the captured image on a scrolling display

• Zoom-in, zoom-out, and pan capabilities

• Echo Scan

Echo Scan is a special feature that allows intermittent repetitive scanning of specific image

areas. It rescans the document area visible in the Preview Display repeatedly, forward and

backward, until you give the signal to continue scanning the rest of the document. With

Page 12

Echo Scan, you can fine tune the scan parameters for the best possible image quality in all

areas of the document.

Diagnostics

• Self-diagnostic tests are performed at power-up and on rebooting, unless manually

overridden.

• More powerful, menu-driven, internal diagnostic software is available for use by factory-

trained technicians.

Construction

• Solid construction based on the 1000 dpi model

• Casters for easy placement of the scanner

Page 13

1.2 Specifications

The scanner is designed to operate in a typical office environment, with options available for

different user needs.

Functional Specifications

• Scan Speed

Speed can range from 3.9 to 138.5 inches per minute, depending on the selected scan resolution.

Refer to Table 1-A for a comparison of nominal speed to resolution. Interpolated resolutions are

available through Scangraphics ScanServ ver 3.0.0 or above.

Output Scanning Speed (in inches per minute)

Resolution CF1000/44 CF500/44 CF400/36 CF300/44

1600 dpi 3.91

1000 dpi 6.2 11.12 - -

800 dpi 7.7 - 17.33 700 dpi 8.8 - - 600 dpi 10.3 - - 23.14

500 dpi 12.3 22.2 - 400 dpi 15.4 27.7 34.6 300 dpi 20.5 36.9 46.2 46.2

200 dpi 30.8 55.4 69.2 69.2

100 dpi - 110.8 138.5 138.5

1

1600 (true longitudinal) x 1600 (software interpolated lateral)

2

1000 (true longitudinal) x 1000 (software interpolated lateral)

3

800 (true longitudinal) x 800 (software interpolated lateral)

4

600 (true longitudinal) x 600 (software interpolated lateral)

Table 1-A: Nominal Scan Speed/Resolution Chart

• Resolution

CF1000/44

200 to 1000 dpi

1600 dpi (true longitudinal and interpolated lateral)

CF500/44

100 to 500 dpi

1000 dpi (true longitudinal and interpolated lateral)

CF400/36

100 to 400 dpi

800 dpi (true longitudinal and interpolated lateral)

CF300/44

100 to 300 dpi

600 dpi (true longitudinal and interpolated lateral)

Page 14

• Accuracy/ Repeatability

.04% lateral

Note: Measured over 40 inches for CF Series 44 scanners, and over 35 inches for

CF400/36 scanner.

.04% longitudinal

Note: Measured over 20 inches for all CF Series scanners.

• Imager Sensor

Multiple CCD arrays

• Transport

Continuous feed

Input Characteristics

• Document Width

44 inches (111.8 centimeters)

• Active Scan Width

41 inches (104.1 centimeters) for models CF1000/44 and CF500/44

43 inches (109.2 centimeters) for model CF300/44

36 inches (91.4 centimeters) for model CF400/36

• Document Length

Unlimited (if operator-feed skew is zero)

• Document Thickness

.003 to .062 inches (.07 to 1.56 millimeters)

• Media Types

Media types include paper, mylar, vellum, sepia, bluelines, onionskin, cardboard-backed

paste-ups, and photographic negatives-among others

.

Physical Specifications

• Height

41 inches (112 centimeters)

• Width

53 inches (132 centimeters)

• Depth

20 inches (56 centimeters)

• Weight

380 pounds (172 kilograms)

• External Finish

Pearl Gray, Pebble Gray

• Internal Finish

Anodized or painted (as appropriate)

Power Specifications

• Power

600 watts maximum

Page 15

• Voltage

115 15% volts (a.c.)

220/240 15% volts (a.c.) (optional)

• Current

5.5 amps maximum (115 volts)

3.0 amps maximum (220/240 volts)

• Frequency

50/60 Hz ±5%

Environmental Specifications

• Operating Ambient Temperature

18 to 30C (64 to 86F)

• Non-Operating Temperature

5 to 40C (41 to 104F)

• Humidity

The scanner can operate at any humidity level, short of condensation.

• Other Environmental Limitations

The scanner is designed to operate in a typical office-type environment, although it can

operate in more industrial settings-provided that the area is kept clean.

• Clearance

A one-foot air space should be allowed at the rear of the scanner to allow adequate air

circulation.

Page 16

This page intentionally left blank.

Page 17

2 INSTALLATION

2.1 Unpacking

The CF Series Scanner comes in a corrugated paper crate mounted to a wooden pallet with four

"air-ball" cushions on the bottom. On the inside are packing materials which prevent the unit from

shifting around. Immediately upon receipt, check for shipping damage and report any found to the

shipper and SCAN-GRAPHICS. When unpacking, discard no materials until you have accounted for

the following contents of the box:

° Quantity 1 CF Series Scanner

° Quantity 1 Power Cord

° Quantity 1 CF Series Scanner Operations Manual (A62951-10)

° Quantity 1 Document Catch

In addition, those customers who purchase the optional display video monitor will receive a

corrugated paper box containing:

° Quantity 1 Video Monitor

° Quantity 1 Power Cable

° Quantity 1 Video Cable

The easiest method to remove the scanner from the crate is with a fork lift and a lot of caution. A

ramp is provided as part of the packing to allow the CF Series scanner to be removed from the pallet by

only two people. Remove the ramp from its storage location and attach it to the end of the pallet. One

person will guide the scanner down the ramp while the other pushes from the opposite end. Do not

attempt to lift the scanner by the top plate or lid.

Page 18

2.2 Setup

2.2.1 Document Catch Installation

The document catch has three keyhole type slots. Insert the studs on the rear of the

scanner (about an inch above the fan) into the three keyhole slots and push down firmly to seat

them in the slots.

2.2.2 Environmental Concerns

The following conditions must be met to ensure acceptable working conditions for the

scanner:

2.2.2.1 Site

The site has to be relatively dust free. The environment should also generate a

low degree of static electricity.

2.2.2.2 Airflow

There must be at least one foot of clearance in the rear of the scanner to allow for

proper airflow. Do not place the scanner near a heating panel or vent.

2.2.2.3 Ambient Light

In order to keep the light uniform on the document being scanned, no direct

sunlight or bright lights should fall on the unit.

2.2.2.4 Vibration

Excessive vibrations in the room should be avoided in order for the delicate

settings of the cameras to remain unchanged.

2.2.2.5 Temperature

The ambient temperature in the room should average between 18 and 30 degrees

C (64-86 degrees F). The maximum ambient temperature for a non-working scanner

must be between 5 and 40 degrees C (41-104 degrees F).

2.2.2.6 Humidity

The point of condensation should not be reached in the room.

2.3 CONNECTIONS

Page 19

See Figure xx for an illustration of the connector panel on the back of the scanner showing the

various points of connection for the following items. The appearance of the back panel may vary,

depending on the type of interface ordered.

2.3.1 A.C. Power

Check the line voltage to ensure that it is the proper level for the unit (either 110 or 220,

as ordered). Then connect the enclosed A.C. power cord to the scanner and to the wall outlet.

The 110 Volt model is not protected if it is connected to a 220 Volt circuit and major

damage will result.

2.3.2 Video (Optional)

The video connector is for the attachment of a cable from the scanner to the optional

display monitor. It has a 15-pin D sub-miniature connector. It is on the back panel, just to the

right of the Host Serial connector. Connect the other end to the monitor.

2.3.3 Host/Local Control and Diagnostics Terminal

The host serial control cable is attached to the scanner using this connector by means of

a D-type sub-miniature 9-pin male connector. This connector is also used for installation of the

local control and diagnostics terminal. Any ANSI-type terminal or personal computer with

terminal emulation can be used for local control and diagnostics. See Appendix xx for terminal

setup values. Only one source of control can be connected at any time.

2.4 POWER-UP

2.4.1 Check Line Voltage

If you have not done so already, check the line voltage to be sure it is at the proper level,

either 110 V A.C. or 220 V A.C., before turning on the scanner.

2.4.2 Check Power Supply Voltage (Recommended)

The power supply voltages should be checked to make sure that the voltages did not

change during shipment. This is quick and easy to do following the steps in task 6.7 (Checking

and Adjusting Voltages) for all voltages except the +120 volt lamp power (which is not

adjustable).

2.5 SYSTEM CHECK

Page 20

2.5.1 Check Line Splice

See Section 5.1.8.1 for details. A specific test document must be used for doing this

check.

2.5.2 Check Merge

See Section 5.1.8.2 for details. A specific test document must also be used for doing this

check.

2.6 DE-INSTALLATION

To de-install the CF Series Scanner, remove the cables from the rear of the scanner and lift the

document catch up and away from the scanner. If the scanner is to be shipped, replace the scanner in the

crate in which it came and include all the packing material.

Page 21

3 SYSTEM DESCRIPTION

The CF Series Scanner is a highly versatile data capture device, providing choices in speed and

resolution and producing high quality data. It also allows a choice between using a fixed threshold or an

adaptive threshold. An adaptive threshold takes into account variations in the shading of the media to

yield consistently good results, even from less than optimal documents.

SCAN-GRAPHICS accomplished this in a way which makes the CF Series Scanner as easy to

use and maintain as possible. Care has been taken in the design and manufacture of the unit to build in a

strength which will keep the scanner operating reliably for years.

The CF Series Scanner can accommodate documents with widths up to 44 inches (the maximum

active scan area is 43 inches). The scanner does not limit the length of the document.

Although the technology employed by the CF Series Scanner is very complex, its function can be

described in quite simple terms. It consists of a set of cameras focused on a narrow window; lamps to

illuminate the document; a transport system which moves the document past the window; and the

electronics to convert the data captured by the cameras into a useful form.

To provide a deeper understanding of the CF Series Scanner works, the remainder of this section

will discuss the various systems that comprise the scanner in technical detail.

Page 22

3.1 MAJOR SYSTEMS OF SCANNER

To provide a general overview of how the CF Series Scanner works, the remainder of this

section will discuss the various systems that comprise the scanner.

3.1.1 Scanner Control System

The CF Series Scanner may be controlled by the host computer, by the optional keypad

on the scanner itself, or a combination of the two.

Another option is the use of a separate "local terminal." Used primarily for diagnostic

purposes, this ANSI-type terminal takes the place of the host computer. It is the only means of

accessing the Diagnostics program.

Once initiated, the Central Processor (CPU) Board and the Camera Controller Board

(CCB) control the functions of the CF Series Scanner for the most part.

1. The CPU Board controls the general operations of the electronics of the scanner, contains

the firmware which operates the scanner, and other functions.

2. The Camera Controller Board (CCB) provides timing for all the other boards and handles

the merging of the input data from the cameras. Other functions include setting the

number of active cameras, the sequencing of the cameras, and document size. It also

sends data from the scanner to the host or optional interface board in on-line scanning.

3.1.2 Document Transport System

The document transport system is comprised of a motor driver, a stepper motor, a set of

pulleys, a set of belts, and two drive rollers. The Video Board controls the system. The motor

driver operates a stepper motor. The stepper motor turns a set of pulleys connected by belts.

The belts turn two drive rollers located on the bed of the scanner, which move the document past

the scan window.

1. The Video Board passes control signals to the motor driver and receives signals from the

document sensors.

2. The motor driver translates the control signals it receives from the Video Board.

3. The bi-directional stepping motor drives the document transport system.

4. A set of pulleys reduces the rpms.

5. Two timing belts connect the pulleys.

Page 23

6. Two pulley-driven drive rollers, one on each side of the scan window, are located on the

bed of the scanner. Applying pressure against these two drive rollers are two free-turning

rollers mounted in the lid of the scanner.

7. Three light sensitive sensors determine the position of the document.

3.1.3 Document Illumination System

The Document Illumination System employs one green florescent imaging lamp along

with a ballast. The Video Board controls these. Their purpose is to shed an even stable light on

the document.

1. The Video Board controls the imaging lamp.

2. One green florescent imaging lamp provides the light.

3. The florescent lamp operates with a 25 KHz high frequency solid state ballast, operated

on a linear voltage of 120 V D.C.

3.1.4 Camera System

The Camera System is comprised of the CCD Cameras, the Video Board, and the

Calibration and Line Splice Board (CALSB).

1. The CF XXXX/44 employs from three to eight CCD cameras.

Model # of Cameras

CF300 3

CF400 3

CF500 4

CF1000 8

2. The Video board converts all video analog signals to digital signals and corrects for gain

and offset.

3. The Calibration and Line Splice Board (CALSB) splices the scanning line together,

camera by camera.

3.1.5 Data Handling System

Page 24

In detecting data, the system simply distinguishes between black and white or dark and

light. The number of data samples taken per inch determines the resolution of the scan.

The data handling system also includes several data formats as an option. For example,

RLE (Run-Length Encoded), Group 4, and Greensheet. The standard output format of scanned

data is 8-bit gray scale or thresholded binary bit stream.

1. The Image Processor Board (IP) provides a Spatial Compressor function that allows the

scanner to sample documents at variable frequencies through the electronics.

2. The Image Processor Board (IP) also provides an Adaptive Threshold function that

provides several choices in setting the threshold value.

3.1.6 Display System (Optional)

A display monitor is an option to the scanner to allow you to view data as it is scanned.

This is very helpful in setting thresholds and other scanning parameters. This option requires an

additional board -- the Display Board.

1. The optional Display Board provides a Display Compressor function that buffers data and

reduces the image resolution to match the video display.

2. The Display Board also acts as a Frame Grabber that structures the pixels to a format

usable by the video display.

3.1.7 User Interface System

The SCAN-GRAPHICS CF Series Scanner may be controlled by the host computer or by

the optional keypad mounted on the scanner. A combination of both is often used.

Another option for the system is a control terminal which provides a third means of

system control and the only way to access the diagnostics program.

3.1.8 Power Supply System

1. The CF Series Scanner operates on 110 or 220 V.A.C. (determined at the time of

purchase).

2. A circuit breaker on the rear panel provides protection on the A.C. input line.

Page 25

3. The scanner has a switching power supply which provides an output of

+5 V.D.C. for both the front-end video camera system and the Multibus card cage.

4. The scanner has three linear power supplies which provide outputs of +12 V and -12 V

for both the front-end video camera system and the Multibus card cage; +46 V for the

stepper motor driver; and +120 V for the illumination system.

3.1.9 Ventilation System

The logic boards, 100 Watt lamps, and power supplies produce significant amounts of

heat.

1. A series of vents in the left side cover of the scanner allow air to enter the scanner for

cooling purposes.

2. A metal mesh air filter covers the air intake vent.

3. The scanner uses three cooling fans, one mounted on the back panel of the scanner, one

mounted on the bottom of the card rack and another one on the top of the power supply

cover.

Page 26

This page intentionally left blank.

Page 27

4 PREVENTATIVE MAINTENANCE

4.1 DAILY

As a start-up check each day, inspect the scan window daily (or more often if conditions warrant

it). If dirty, clean it using a clean soft lint-free cloth and glass cleaner. When cleaning the scan window,

great care should be taken to not use so much glass cleaner that it could seep down the edge of the scan

window glass. This could result in it accumulating on the underside of the window, drying, and leaving

a residue that would require cleaning the underside of the scan window.

Also, each day, with the scanner powered-on, be sure all cooling fans are operating. It is very

important that all these fans are operating. One fan is located on the back panel and two are inside the

unit. One is mounted under the card rack and the other is mounted on the cover for the power supply

assembly.

4.2 MONTHLY

4.2.1 Clean Filters

Once a month (or more often if conditions warrant it), remove the metal mesh filter located in the

bracket on the left inside panel of the scanner. Wash the filters in warm water, air dry them, spray them

all over lightly with filter spray (A64168), and reinstall them.

4.2.2 Clean Camera Lenses

Each month, clean the camera lenses with regular photographic camera lens brush or air duster.

Be sure you do not hold the lens while cleaning.

4.3 ANNUALLY

Each year, on the anniversary of the initial installation, perform the following tasks in order.

4.3.1 Clean CCD Camera

Clean the CCD array on the camera, located in the center of the Camera Board with an air duster

or cotton swab.

Page 28

4.3.2 Check Power Supply Voltages

Open the front of the scanner cabinet, refer to the Figure of the Power Supply Assembly found in

this manual and Section 6.7, and check the voltages at the test points on the power supply.

4.3.3 Replace Lamps

To assure adequate and consistent illumination of the document, replacement of the lamp

annually is recommended. Depending on the amount of usage, however, replacement may not be

necessary that often. If you decide to keep the lamp in longer, look for darkening around the ends of the

tube. This indicates disintegration of the filament and the lamp should be replaced. The lamp

replacement procedure is covered in Section 6.3.

4.3.4 Recalibrate Scanner

1. Every twelve months, recalibrate the scanner by adjusting the camera system's offset,

exposure, and gain. See Section 5.1.14.

2. Check the line splice and merge and adjust if necessary. See Section 5.1.8.

3. Check the motor speed and adjust if necessary. See Section 5.1.4.

Page 29

5 DIAGNOSTIC SOFTWARE

5.1 On-Board Diagnostic System

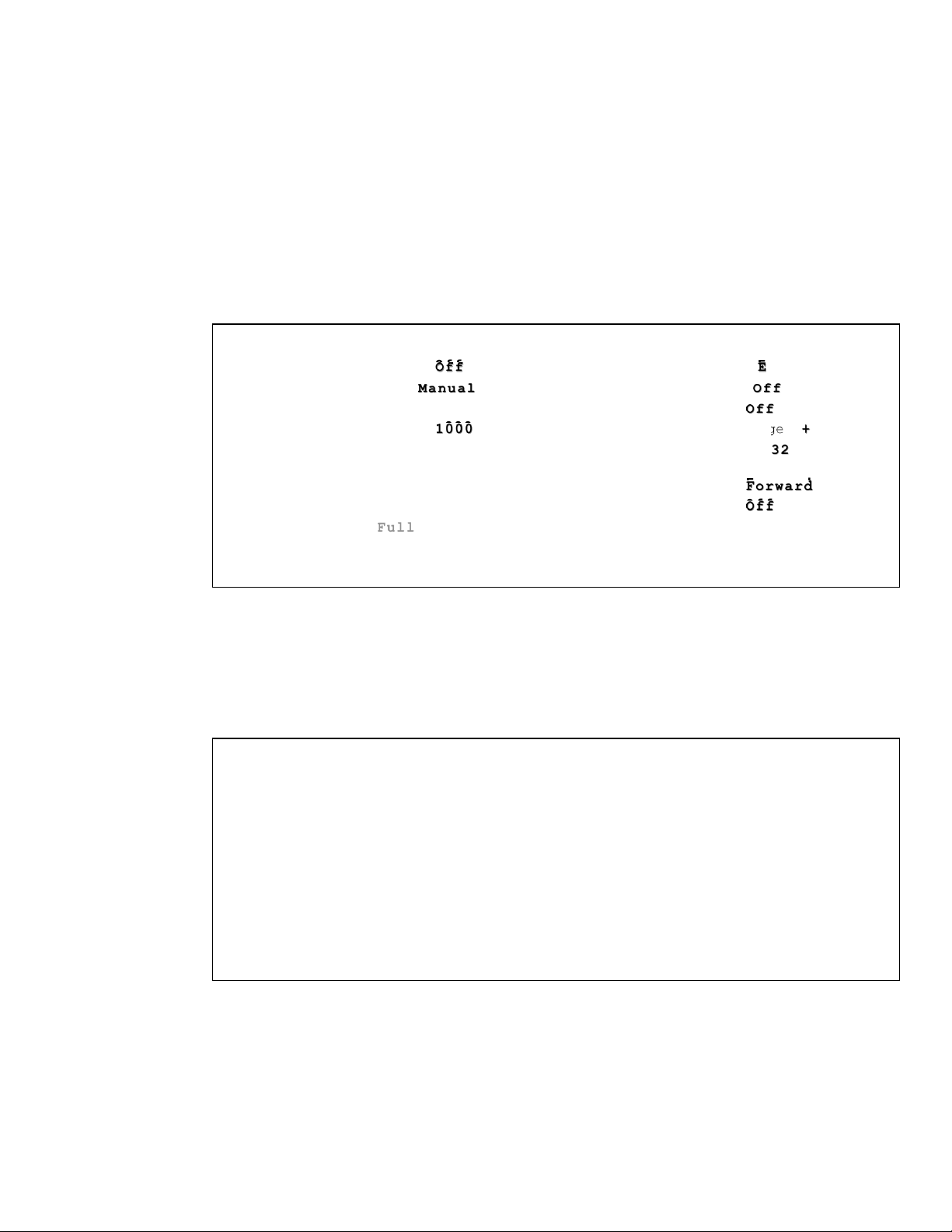

The Main Menu shown in Figure 5-7 is typical for a CF Series 1000 scanner. The Main Menus

for the other CF Series Scanners are similar. The functions on the Main Menu are the same as

those on the keypad and the scanner can be operated from either device.

M A I N M E N U

1 - Scan Off 3 - Set Document Size E

2 - Scan Mode Manual 4 - Filter Off

7 - Diagnostic Tests 5 - Tracking Off

8 - Set Resolution 1000 6 - Positive/Negative Image +

Z - Display Zoom In up - Increase Threshold 32

H - Display Zoom Out dn - Decrease Threshold

X - Select Area R - Scan Direction Forward

Y - Repeat Area G - Gray Scale Off

S - Speed Full I - Fast In

F - Binary Filter O - Fast Out

<- - Move Displayed Area Left -> - Move Displayed Area Right

Ready

Figure 5-7 CF Series Scanner Main Menu

To access the Diagnostic Tests program form the Main Menu, press <7> and the menu

illustrated in Figure 5-8 will appear. At this point, keypad control from the scanner is disabled

until you exit the Diagnostic Tests program.

DIAGNOSTIC TESTS

--------------- 1 Set Global Parameters 2 Perform System Init

3 Parameter Backup 4 Set Motor Speed

5 Splice Counts 6 Focus and Magnification

7 IP LUT 8 Merge & Splice Adjustment

9 Autosize Parameters A Set CCB Registers

B Test Frame Grabber C Test I/O Board

D Page Offsets E Camera System Diagnostics

F Resolution Control G Set Document Sizes

H Run Self Tests I Restore NVRAM

J Binary Filter Parameters K IP Averager LUT

L Autocalibration M SCSI Buffer Parameters

X Exit

Ready

Figure 5-8 Diagnostic Tests Menu

Page 30

Menus pop up in response to most choices on the Diagnostic Tests menu. Simply enter the

desired value or parameter and the function will be performed or its menu will be accessed.

Page 31

This page intentionally left blank.

Page 32

5.1.1 Set Global Parameters (1)

The Global Paramerters affect all scanner operations and will affect your entries in other

menus.

When you press <1> for “Set Global Parameters,” a menu display similar to that in Figure 5-9

appears. The values shown in this example are typical for a CF Series 1000 scanner.

----- SET GLOBAL PARAMETERS -----

0 MAXIMUM RESOLUTION 1000

1 NUMBER OF CAMERAS 8

2 SPLICE ON/OFF On

3 PIXEL SOURCE Cameras

4 NUMBER OF RESOLUTIONS 8

5 GRAY SCALE ON/OFF Off

6 NUMBER OF DOCUMENT SIZES 5

7 CCB WINDOW START 0258

8 DISPLAY SYSTEM In

9 MIRROR Off

A DEFAULT ZOOM STATE Zoomed In

B AUDIO LEVEL F

S : SET X : EXIT CHOICE: X

Ready

Figure 5-9 Global Parameters Menu

If you do not want to change anything, press <X> to exit and return to the Diagnostic Tests

Menu.

If you press <S> for “Set,” the prompt, “Parameter Number,” will appear. Enter the number

for the parameter you wish to change and a prompt will appear, allowing you to change its

value.

<0> MAXIMUM RESOLUTION: In the example, the scanner has a maximum

resolution of 500 dpi. (do not alter this parameter)

<1> NUMBER OF CAMERAS: In the example shown, four cameras are installed. (do

not alter this parameter)

<2> SPLICE ON/OFF: This switch controls the electronic line splice adjustment function

of the CALS Board. When the scanner is received from the factory, this function is

Page 33

turned off since the splice has been adjusted to the sub-pixel level at the factory. Note

that the host scan software can override this scanner setting.

<3> PIXEL SOURCE: The two choices are the cameras and a bar generator. The bar

generator is located on the CALS Board and produces a set test pattern for diagnostic

purposes. The host scan software can change this setting.

NOTE: The bar pattern is useful for troubleshooting because it isolates the “front end”

electronics -- the CCD cameras and the Video Board from the rest of the scanner. If the

bar pattern is good, the problem is either in the cameras or Video Board. If the pattern is

bad, the problem most likely occurs after that point.

<4> NUMBER OF RESOLUTIONS: The scanner can store upto 8 preset resulutions.

The number of resolution stored is depends on the model. (do not alter this parameter)

<5> GRAY SCALE ON/OFF: When gray scale is on, the scanner will output eight bit

data for each pixel. Otherwise, it will output binary data with one bit per pixel. The host

scan software can change this setting.

<6> NUMBER OF DOCUMENT SIZES: The scanner can store upto 8 preset

document sizes (active scan widths). Typically, five of these values are set for standard

document sizes A through E, while the remaining three are not used. The actual

document sizes are defined under option G of the Diagnostic Tests menu. The host scan

software can override this setting.

<7> CCB WINDOW START: This parameter adjusts the starting location of line scans.

It is adjusted to start scanning at the zero line on the document table at the factory. (do

not alter this parameter)

<8> DISPLAY SYSTEM: This parameter indicates if the scanner is equipped with a

display system.

<9> MIRROR: This parameter when active outputs the mirrored image. This is controlled

by the host scan software.

<A> DEFAULT ZOOM STATE: The scanner display option can be set to be either

“zoomed in” or “zoomed out” as the default.

<B> AUDIO LEVEL: This sets the audio level of the scanner. It has a range of 0 to F.

The factory defalt is A.

Page 34

5.1.2 Perform System Initialization (2)

When you press <2> to select this option, all parameters and register values are reset to those

stored in the NVRAM Boot Parameter File on the CALS Board. The Main Menu then returns.

5.1.3 Parameter Backup (3)

This option, <3>, provides a safe storage location in NVRAM on the CALS Board for the

factory-set or permanent parameter file values. It is accessible only through the local control

terminal. Should the boot parameter file become corrupted, this backup parameter file can be

used to restore the original values.

Should the customer's application require or benefit from permanent changes in their boot

parameter file, this option also allows the values in the backup locations to be replaced.

----- PARAMETER BACKUP ---- !===========! !===========!

! Backup ! ! Boot !

! Parameter ! <-------- ! Parameter !

! File ! ! File !

!===========! !===========!

D : SET DIRECTION T : START TRANSFER X : EXIT

S : SAVE CURRENT SETUP TO BOOT FILE

Figure 5-10 Parameter Backup Menu

Figure 5-10 illustrates the menu for the parameter backup option. The direction of the

operation being carried out is indicated graphically.

The arrow between the two boxes represents the direction of the transfer -- from the backup

location to the boot up location or from the boot up location to the backup location. The

direction of transfer is changed by toggling with the <D> key. Once the desired direction is

set, press <T> to begin the transfer. When the transfer is complete, or if you wish to abort the

operation before pressing <T>, press <X> to exit back to the Diagnostic Tests menu. The <S>

command allows current system parameters to be saved to the boot parameter file prior to

backup. This has the same effect as the Save command described in section 5.2. The write

protect switch on the CALS Board must always be set to "Write Enable".

CAUTION: Changing the contents of the backup parameter storage locations should be

performed only by an authorized technician. Further, if alteration is necessary, as a

precaution, power the scanner off and then on again to reset all the current parameter

values. Then change only those which need changing. Then commit them to the backup

memory. This will prevent other values being inadvertently changed.

Page 35

This page intentionally left blank.

Page 36

5.1.4 Set Motor Speed (4)

Press option <4> to set the motor speeds to be used for each resolution. The Resolution Index

is a common index which combines a set of parameters -- resolution (samples taken per inch),

motor speed, and the splice count.

Lower resolutions run at a faster speed than high resolutions. The motor speed is inversely

proportional to the value in the speed table. When you select this option, the menu illustrated

in Figure 5-11 will appear.

----- SET MOTOR SPEEDS ---- RESOLUTION SPEED

---------- ------

A 61D6

B 4E44

C 446A

D 3AC2

E 30EB

F 2722

G 1D56

H 1391

S : SET ANY SPEED T : TUNE RESOLUTION A SPEED

C : CALCULATE OTHER SPEEDS FROM RESOLUTION A SPEED

X : EXIT CHOICE :

The entries illustrated in the figure are typical for a CF 1000/44. You may set any speed you

wish for any Resolution Index or you can fine-tune the motor speed for Resolution Index A

and then, using that value as a reference, the system will modify all the other motor speeds for

the other Resolution Indices. Even for the same model scanners, these values may vary

slightly.

Pressing <S> for "Set any Speed" will result in the prompt, "Resolution." Press the appropriate

letter, A-E, to select the Resolution Index for which you wish to change the speed.

Upon entering the single character for the Resolution Index, the prompt "Speed" will appear.

Enter the four-digit hex value corresponding to the speed you wish to use. When you enter the

speed, the Set Motor Speeds menu will return, from which you can exit back to the Diagnostic

Tests menu.

Figure 5-11

Set Motor Speed Menu

Page 37

The number of resolutions entered in the Global Parameters will determine the functionality of

this table. For example, the CF 300 with three resolutions will use motor speed values entered

in A through C when different resolutions are selected from the Main Menu.

If you press <T> to tune the speed for Resolution Index A, you will receive the prompt,

"Actual [*]," where "*" is the value entered the last time this option was used. Enter the actual

measured size of a target you have scanned. You may use any scale of measurement you wish

as long as the same units are used to measure the actual target as are used in measuring the

scanned image of the target. The measurement may be up to five digits. If it is less than five,

press <CR> after entering the value. Then, in response to the next prompt, "Scanned [*],"

enter the corresponding measurement of the scanned image.

After entering these two values, the calculated percentage error will appear, followed by the

prompt, "Update Resolution A Speed [Y/N]?" An error of .04% or less meets specifications. If

the error is greater, reply with "Y" to the prompt to automatically update the Resolution Index

A speed.

Press <C> if you wish to recalculate the speeds for the other resolutions based on the value for

Resolution Index A.

Press <X> to exit and return to the Diagnostic Tests menu.

Page 38

5.1.5 Splice Counts (5)

The Splice Counts option provides a method to list and modify line splice settings. The counts

are usually set interactively through choice 8, "Merge & Splice Adjustment," on the Diagnostic

Tests menu ( see 5.1.8 ) .

When you press <5>, a display similar to Figure 5-12 will appear. This particular figure is

from a CF 1000/44. The number of entries under Resolution Index depends on the value

entered in Global Parameters. The number of entries under cameras depends on the number of

cameras in your system -- from three to eight.

The <S> command allows you to specify the splice count for Resolution A for a selected

camera. Counts for lower resolutions are calculated and displayed automatically.

The <Z> command sets the splice counts of all cameras to zero.

This command is the easiest way to set splice values to the factory default setting.

The <X> command returns to the Diagnostic Tests menu.

----- SPLICE COUNTS ---- RESOLUTION PIXELS PER CAMERA

INDEX INCH 0 1 2 3 4 5 6 7

---------- ---------- --------------------- A 1000 0 0 0 0 0 0 0 0

B 800 0 0 0 0 0 0 0 0

C 700 0 0 0 0 0 0 0 0

D 600 0 0 0 0 0 0 0 0

E 500 0 0 0 0 0 0 0 0

F 400 0 0 0 0 0 0 0 0

G 300 0 0 0 0 0 0 0 0

H 200 0 0 0 0 0 0 0 0

Splice Count Listing Example from a CF 1000/44

"Pixels Per Inch" is the same as resolution or DPI .

The columns under "Camera" show the number of lines of data the CALS Board delays before

sending the data to the Image Processor Board. The range of possible delays is 0-5. The delay

decreases as the resolution decreases for he same camera

Figure 5-12

Page 39

This page intentionally left blank.

Page 40

5.1.6 Focus and Magnification (6)

When you press <6> to select the "Focus and Magnification" option, the sub-menu shown in

Figure 5-14 will appear. From here, you may press <F> to select "Focus", <M> to select

"Magnification," or

F : Focus

M : Magnification

X : Exit

Choice : X

Figure 5-14

Focus and Magnification Menu

you may press <X> to exit this submenu and return to the Diagnostic Tests menu.

NOTE: Focus, magnification, merge, and splice functions are intertwined. If you adjust one,

you must test and, if necessary, adjust the other functions. This must be done in the following

order:

1. Focus

2. Magnification

3. Merge

4. Splice

Equipment, Tools & Materials Required:

• Standard Target Document -- Scangraphics part number 64361-50X, with last digit

depending on scanner model.

• A white background strip that is the same size as the scan window.

• A weight to keep the target document flat and in proper position.

Page 41

This page intentionally left blank.

Page 42

5.1.6.1 <F> Focus

When adjusting the focus, the local control terminal acts as a digital oscilloscope, graphically

representing the voltage level output by the CCD.

When you press <F> for Focus, a display similar to that in Figure 5-15 will appear.

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

&

Pixel 2634 in Camera 2 Take Mode : Auto Minimum : 23 H for Help

The menu and status line at the bottom of the screen allow you to specify which camera to

check, to start the data capture display at a specific pixel within the selected camera, and to

choose the method of data sampling. You may also search for an event, such as the transition

from a dark mark to light background, where the voltage would increase. You can also display

an absolute pixel position, defined in terms of the distance from the beginning of the scan line.

The current settings are displayed at the bottom of the screen.

Press <C> to select the "Current Camera" (the one you wish to view). The cursor will then be

positioned over the camera number and you may enter the new numerical value (0 through 7,

depending on your system).

Figure 5-15

Sample Focus Display

Page 43

Press <P> to specify the pixel from which you wish to begin your display, and then enter a

four-digit decimal value where the cursor appears. The ampersand (&) at the top of the screen

will represent this pixel.

Press <T> to choose between the three data sampling methods. The choices are "Single,"

which will take a sample when the space bar is pressed; "Auto," which will sample

continuously; and "Lock," which will lock on to a drifting object and keep it on the screen.

Press <S> to search for an event where the voltage level changes, as will occur when a change

in brightness or darkness is detected by the CCD camera. Press any key to abort the search.

Pressing <CTRL-A> will display the absolute pixel position, in hex notation, from the

beginning of the scan line.

The image on the screen represents 24 consecutive pixels at a time with the pixel number

increasing from the top of the screen to the bottom. The left side of the screen represents less

light; the further right, the more light. For total darkness, the digital output would be 00 in hex

notation. For total white, the digital value would be FF.

To view more pixels, use the "Up" arrow to scroll the display up and the "Down" arrow to

scroll down.

Press <X> to return to the Diagnostic Tests menu.

HELP: Press <H> to display help text on the screen. This text provides you with helpful

reminders about how to reply to the various screen prompts and details the choices available

for each option. Press any key to clear the help text from the screen.

Procedure for Adjusting the Camera Focus: The first four steps of this procedure -- as well

as the required equipment, tools, and materials -- are the same as for adjusting the

magnification of the camera.

NOTE: In practice, both the focus and magnification of a given camera should be set before

moving on to the next camera because of the need for precise placement of the Standard Target

Document. Since focus and magnification interact, it is necessary to check magnification

whenever the focus is changed.

The camera assembly is composed of the camera board, the camera block, the collar, and the

lens. The collar is held on to the camera block by a bracket held by two screws. The lens

screws onto the collar.

Page 44

1. Open the scanner top cover and remove the rollers and document plate.

2. Place the Standard Target Document upside down on top of the scan window. The center

line of the target (barbell shape) should be directly above the center of the camera being

tested.

3. Place the white background strip on top of the Standard Target Document.

4. Place the weight on top of the white background strip.

5. Enter the focus software by pressing <F>.

6. Use the <C> command to select the appropriate camera.

7. Use the <T> command to set the take mode to "AUTO."

8. Use the <P> command to set the display at pixel 2200.

9. Use the <S> command to search for the target center line.

10.The <S> command will search forward from pixel 2200, looking for asignificant event. If

the target is properly centered, the event will be the center line and its position will be near

pixel 2650. (The center of a 5312 pixel camera is at 2656). The wave form displayed

should be similar to the one illustrated in Figure 5-15.

11.Move the target to the left or right until the position is as close to 2650 as possible.

12.Once you have the wave form on the screen, loosen the screws locking the adjustment of

the lens and then adjust the focus by moving the lens and collar up or down. Your goals is

to get the sharpest rising and falling edges possible on the displayed wave form.

Changing the focus does affect the magnification.

Page 45

This page intentionally left blank.

Page 46

5.1.6.2 <M> Magnification

The magnification (maximum physical resolution) is set by the distance of the camera from the

window. The closer the camera is to the window, the high the resolution. The farther the

camera is from the window, the lower the resolution.

Adjusting the magnification is a tedious and lengthy process; however, it is only necessary

when you replace a camera board. The camera board is a simple and very reliable circuit that

will rarely need replacement.

For testing magnification, this option scans precisely drawn lines on a test chart and calculates

the distance between them as perceived by the scanner. This value is then compared to the

actual known value.

Each CCD camera contains an array of 5312 pixels. When operating within specification, each

camera should detect at least 5100 pixels. The end camera CCD arrays are electronically

truncated to stay within the active scan area.

The status and prompt line allows you to see what the current settings are, the following key

actions will allow you to change the settings.

Press <C> to select the number of the camera you wish to check. Then, enter the camera

number (0 to 7, with the highest number dependent on the resolution of your scanner).

Press <T> to toggle between the two choices for sampling the signal. "Single" will take a

sample when the space bar is pressed. "Auto" will sample continuously.

Press <R> to toggle between the two choices for reporting information.

• The "Short" report will display the number of pixels within the target.

• The "Long" report will list the following items: (1) the memory address in which the start

of each line is recorded; (2) the width of each line in mils, along with whether that

measurement is good, too wide, or too narrow, and (3) a summary of information including

the memory address where the beginning of the first "good" or complete bar was noted and

stored, and the distance or difference between the two addresses translated into a decimal

number of pixels.

Press the Up and Down arrows to adjust the threshold. The Threshold is a number used to

decide whether to classify pixels as black (a mark) or white (background). The threshold range

is 00-63 decimal. Up arrow increases the threshold, down arrow decreases the threshold.

Page 47

Procedure for Adjusting Camera Magnification:

The first four steps of this procedure -- as well as the required equipment, tools, and materials -

- are the same as for adjusting the focus of the camera.

NOTE: In practice, both the focus and magnification of a given camera should be set before

moving on to the next camera because of the need for precise placement of the Standard Test

Document. Since focus and magnification interact, it is necessary to go back and re-check

focus whenever the magnification is changed.

1. Open the top cover and remove the rollers and document plate.

2. Place the Standard Target Document upside down on top of the scan window. The center

line of the target (barbell shape) should be directly above the center of the camera being

tested.

3. Place the white background strip on top of the Standard Target Document.

4. Place the weight on top of the white background strip.

5. Enter the magnification software by pressing <M>.

6. Use the <C> command to select the appropriate camera.

7. Use the <T> command to set the take mode to "AUTO."

8. Check the result display by the software.

• If the message "Can't Find Two Good Bars" is displayed, try adjusting the threshold up or

down. If that is unsuccessful, check the placement of the target document. When

successful, a distance is reported, and you can go on to the next step.

• If a distance is reported, the check is successful, and you can go on to the next step.

9. The magnification software locks its focus on the two rows of parallel lines on the target

document. It reports the distance between the leftmost and rightmost lines seen by the

camera. Since the lines within each of the two rows are each 50 pixels apart, the distance

reported must be a multiple of 50 when the magnification is correct.

Page 48

NOTE: On CF 300/44 models, the multiple should be 60, rather than fifty. If you have this

model, please use the following table to find the values.

Magnification Values for CF300

3540 4020 4500 4980

3600 4080 4560 5040

3660 4140 4620 5100

3720 4200 4680 5160

3780 4260 4740 5220

3840 4320 4800 5280

3900 4380 4860

3960 4440 4920

For example, the magnification is correct if the distance reported is 5150, 5200, or 5250.

Which multiple is reported depends on the placement of the target document and is at its

maximum when the target is precisely centered over the camera.

If the distance is not a multiple of 50, the magnification must be adjusted up or down to the

closest multiple. For example, if 5144 is reported, magnification must be adjusted up to 5150.

- When the discrepancy is less than 5 pixels, the magnification is fine-tuned by raising or

lowering the collar within the range that does not affect the camera's focus.

- When the discrepancy is larger than 5 pixels, the magnification is adjusted by changing

the thickness of the shims under the camera block. Reducing the shim thickness reduces

camera magnification, and increasing the shim thickness increases magnification.

Page 49

This page intentionally left blank.

Page 50

5.1.7 IP LUT For the Image Processor Board (7)

The incoming pixel value serves as the address to the LUT. The value residing at that table

A positive LUT is used for scanning positive documents (dark lines on a light background).

incoming outgoing

00 00

01 01

: :

FE FE

FF FF

A negative LUT is used for scanning negative documents (light lines on a dark background).

incoming outgoing

00 FF

01 FE

: :

FE 01

FF 00

The <C> command allows you to apply scaling and offset adjustments to the LUT. Two

When you select option <7>, a display similar to Figure 5-16 will appear. This display is the

Look-Up Table (LUT) for the image processor board. The values in the LUT table are used to

scale incoming pixels before they undergo image processing operations. The first entry is in

Address 00 (top left corner) and the last entry is in Address FF (bottom right corner).

location ( the value looked-up ) is sent through the image processor in place of the incoming

pixel value.

The values looked-up are non-inverted. In the default positive LUT the incoming pixel values

and the outgoing looked-up values are the same:

The values looked-up are inverted. In the default negative LUT the outgoing values are binary

complements of the incoming pixel values:

parameters are required: Step Size and Offset.

• Step Size: This is the value difference between successive table locations. For example, a

step size of 4 will generate the sequence 00,04,08,0C,..

• Offset: Specifies where in the table value stepping begins. For example , if offset is set to

40H in a positive LUT, the first 40H locations are set to zero and the stepping sequence

begins at address 40H.

Page 51

LUT customization is useful for scanning low contrast documents. It allows the small dynamic

range of a low contrast document to be expanded to full size.

----- POSITIVE LUT -----

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 04 08 0C 10 14 18 1C 20 24 28 2C 30 34 38 3C

40 44 48 4C 50 54 58 5C 60 64 68 6C 70 74 78 7C

80 84 88 8C 90 94 98 9C A0 A4 A8 AC B0 B4 B8 BC

C0 C4 C8 CC D0 D4 D8 DC E0 E4 E8 EC F0 F4 F8 FC

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

Step Size = 4 Offset = 40H

Figure 5-16

Example of an Image Processor Board Look-Up Table (IP LUT)

The <P> command writes a positive LUT into the table. If the LUT has been customized, the

custom parameters are used to calculate the table values. If not, the default positive LUT is

used. ( Note that the default LUT is equivalent to a customized LUT with Step Size = 1 and

Offset = 0 . )

The <N> command writes a negative LUT into the table, also using custom parameters if set.

The <D> command writes either the default positive LUT or the default negative LUT into the

table, depending on which is currently selected ( as shown at top of screen.)

The <X> command returns to the Diagnostic Tests menu. Any changes you make in the table

will remain active when you exit to the Main Menu.

Page 52

5.1.8 MERGE AND SPLICE ADJUSTMENT (8)

This feature lets you precisely adjust the effective camera position to eliminate discontinuities

across camera boundaries. Merging is adjustment along the scan line. Splicing is adjustment

perpendicular to the scan line.

______________________________________________________________________

NOTE: Focus, magnification, merge, and splice functions are intertwined. If you adjust one,

you must test and, if necessary, adjust the other functions. This must be done in the following

order:

1. Focus

2. Magnification

3. Merge

4. Splice

______________________________________________________________________

When you press <8> to select this option, the prompt, “ Use Electronic Splice ? [N]”, appears.

If you reply with <N>, you will be able to adjust only the merge. If you reply with <Y> and

electronic splice is enabled in Global Parameters, both merge and splice can be adjusted. (To

enable electronic splice, set global parameter 2 to “ON.”)

The prompt, “Use Bar Pattern? [N],” the appears. For the purpose of this test, reply to the

prompt with <N> or just a <CR> .

----- Merge and Splice Adjustment ---- Boundary Indicator

0 1 2 3 4 5 6 7

Threshold 35 Range 00-63 Decimal

Merge 2F Range 00-FF Hex

Splice 0 Range -5 to +5

Motor Full Forward

Status Paused

Delay Counts 00 00 00 00 00 00 00 00

------------------------- MENU------------------------ left arrow : Boundary Left right arrow : Boundary Right

up arrow : Threshold Up down arrow : Threshold Down

< or , : Increase Merge > or . : Decrease Merge

( or 9 : Increase Splice ) or 0 : Decrease Splice

space bar : Pause / Unpause

S : Select Scanning Speed R : Reverse Motor

F : Fast Paper Movement X : Exit

Figure 5-17 Merge and Splice Adjustment Menu

Page 53

At this point, the menu illustrated in figure 5-17 appears, although certain items on it may not

appear, depending whether or not you choose splice adjustment.

The top half of this menu screen displays a “boundary Indicator and provides a view of the

scanner current status. The bottom half displays the currently available keyboard commands

for adjusting the merge and splice. If you did choose splice adjustment, all of the items that

follow will appear in the top half of the Merge and Splice Adjustment Menu. If you did not

choose Splice Adjustment, those items marked with an asterisk (*) will not appear.

• Boundary Indicator: This item depicts which two cameras the boundary that you are

currently monitoring lies between.

• Threshold: This field shows the dividing points between marks and media. The range of

possible values is shown to the right.

• Merge: This field shows the number of pixel overlap between the two cameras in the

same axis as the row of the cameras. The range of possible values is showed to the right.

• Splice*: This field shows the number of sampling lines the data is advanced or delayed

to match the ad0jacent cameras in the axis perpendicular to the row of cameras. Again,

the range of possible values is show to the right.

• Delay counts*: This field shows the splice values between each camera in the scanner.

Place the standard test document, illustrated in figure 5-18, in the scanner to demonstrate the

camera merge and splice.

Viewing the scanned image on the monitor, you can operate and manipulate the scanner with

keyboard commands to fine-tune the merge and splice. Any changes you made are instantly

reflected on the monitor in real time. The currently available keyboard commands for

adjusting the merge and splice appear in the bottom half of the Merge and Splice adjustment

menu. If you did choose splice adjustment, all of the items below will appear in the bottom

half of the merge and splice adjustment menu. If you did not choose Splice Adjustment, those

items marked with an asterisk (*) will not appear.

• Left and Right Arrows Press these keys to move left or right to the boundaries

between cameras.

• Up and Down Arrows Used to increase or decrease threshold.

• < or , press either these keys to increase the merge.

• > or . press either these keys to increase the merge.

• ( or 9* press either these keys to increase the splice.

• ) or 0* press either these keys to increase the splice.

• Space Bar Press <space bar> to pause or restart the scanner.

• S (speed) Press <S> to set the scanning speed. The speed choices are full, 3/4, or 1/2.

Slower speeds worsen the problem of splicing because they make it easier to detect.

• R (reverse) Press <R> to change the direction of document travel.

Page 54

• F (fast) Allows you to speed up document travel to get to a specific place on the

document. It toggles between “fast” and the scanning speed previously set.

• X (exit) Press <X> to exit the Merge and Splice Adjustment menu and return to the

Diagnostic Test Menu.

Page 55

This page intentionally left blank.

Page 56

5.1.8.1 Line Splice Adjustment

Line splicing is matching or aligning the cameras so they all will encounter a line parallel to

the row of the cameras at the same times. If the cameras do not encounter the data at the same

times, the line will appear broken.

If one camera encounters data before adjacent cameras do, that means it is tilted too far

towards the front of the scanner. If it encounters data after its neighboring cameras, it is tilted

too far back.

In case of very slight misalignment, adjustment can be made electronically. For greater

misalignment, adjustment can be made mechanically by actually tilting the camera either

forward or backward. This is done by turning an adjustment screw on the camera block.

This adjustment can be made with any high contrast document containing parallel unbroken

lines. Any break appearing on the monitor will signal a line splice problem.

5.1.8.1.1 Adjusting Line Splice Mechanically

Procedure for Mechanical Line Splice Adjustment:

1. Using “Splice and Merge Adjustment” in the diagnostics software, scan a test document,

view each camera boundary, and then diagram the overall splice condition of the system

on a piece of paper. Each line represent a camera and the picture shows the splice

relationship among the cameras

2. Pick a reference camera by which you will adjust all the other cameras. Any camera can

be the reference camera; however, for ease of adjustment, use a camera which is located

roughly half way between the two extremes.

3. The splice is adjusted by turning an adjustment screw on the camera blocks. Turn the

screw clockwise to tilt it back, delaying the data, or turn it counterclockwise to tilt it

forward, to get the data earlier.

Adjust the camera closest to the reference camera first and then go on to the next closest

camera in that direction.

Page 57

5.1.8.1.2 Adjusting Line Splice Electronically

Procedure for Electronic Line Splice Adjustment:

1. Access the Diagnostic Tests Software and select “ Splice and Merge Adjustment.”

Answer “yes” to the prompt, “ Use Electronic Splice.”

2. Scan a test document and adjust each boundary.

3. Save the changes to non-volatile RAM (NVRAM). Refer to Section 5.2 for details about

the procedure for issuing the SAVE command.

5.1.8.2 Merge Adjustment

NOTE: Cameras must be properly spliced before they can be successfully merged.

Camera merging is the joining of data between adjacent cameras so that data is neither

duplicated nor lost between them. The system makes merge adjustment electronically and has

a design overlap of 64 to 128 pixels depending on the model of a scanner. To adjust merging,

you can delete up to 256 pixels from each camera’s data stream. Each merge adjustment is

independent so that adjusting the merge between one pair of cameras does not affect the merge

between any other pair of cameras.

Merge adjustment can be made with any high contrast document containing 45 degree lines

with clean line edges. (Standard Test Document-- Target area for merging). Any breaks

appearing on the monitor will signal a camera merge problem. The standard test document

contains a section of lines suitable for testing camera merge. The target area (of the Standard

Test Document) for merging is shown in Figure 5-21.

Procedure for Adjusting Camera Merge:

1. Select “Merge and Splice Adjustment” from the Diagnostic Tests Menu.

2. Scan the document and view each boundary. The merge problem will show at the center

of the display monitor as a broken line.

3. Adjust the merge using the “ < “ or “ > “ keys until the broken lines is stitched together.

Refer to figure 5-19 to see an example of incorrect merge that also shows whether an

increase or decrease in value is required to correct the problem.

4. Save the merge adjustment to the non-volatile memory. Refer to section 5.2 for details

about the procedure for issuing the SAVE command.

Page 58

5.1.9 AUTOSIZE PARAMETERS (9)

<This function is not implemented on any host scan softwares.>

When you press <9> to select auto size parameters, a menu similar to that shown in figure 5-24

will appear. This menu allows you to tune and test the scanner’s automatic sizing function.

----- AUTOSIZE PARAMETERS -----

0 DIFFERENCE THRESHOLD : 09

1 NUMBER IN ROW : 02

0 : SET PARAMETER 0 1 : SET PARAMETER 1

A : RUN AUTOSIZE SEQUENCE X : EXIT

CHOICE : X

Figure 5-24 Set Autosize Parameters Menu

Press <A> to run the auto sizing sequence. Feed in a document, then wait for the scanner to

analyze it and display its width on the display terminal.

• If the scanner is missing document edges and returning document width values that are

two narrow, one or both of the autosizing parameters may need to be decreased slightly.

• If the scanner is picking up false document edged and returning document width values

that are too wide, one or both autosizing parameters may need to be increased slightly.