Page 1

OEM FUNCTIONAL SPECIFICATION

ULTRASTAR XP (DFHC) S S A MODELS

1.12/2.25 GB - 1.0" HIGH

4.51 GB - 1.6" HIGH

3. 5 FORM FACTOR DISK DRIVE

VERSION 5.0

August 15, 1995

Publication number 3304

IBM Corporation

Source filename=STSSHEXT IBM Corporation Page 1 of 87

Page 2

USERRESPONSIBLEFORVERIFYINGVERSIONANDCOMPLETENESS

OEMFUNCTIONALSPECIFICATIONULTRASTARXP(DFHC)SSAMODELS1.12/2.25GB-1.0"HIGH

Thisdocumentispreliminaryandthecontentsaresubjecttochangewithoutnotice.Equiries,suggestions,

andrequestsforadditionalcopiesmaybedirectedto:

OEMEngineering

IBMCorporation

5600CottleRoad

SanJose,CA95193(USA)

IBMmayuseanyinformationthatyousupplywithoutincurringanyobligation.

IBMmayhavepatentsorpendingpatentapplicationscoveringsubjectmatterinthisdocument.Thefurnishingofthisdocumentdoesnotgiveyouanylicensetothesepatents.Youcansendlicenseinquiries,in

writing,to:

DirectorofCommercialRelations

IBMCorporation

ArmonkNY10577USA

CopyrightInternationalBusinessMachinesCorporation1994.Allrightsreserved.

NotetoU.S.GovernmentUsers—Documentationrelatedtorestrictedrights—Use,duplicationordisclosureossubjecttorestrictionssetforthinGSAADPScheduleContractwithIBMCorp.

Sourcefilename=PREFACEIBMCorporationPage2of87

Page 3

USER RESPONSIBLE FOR VERIFYING VERSION A ND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Preface

This document details the product hardware specification for the Ultrastar XP SSA family of Direct Access

Storage Devices. The capacity model offerings are 1.12, 2.25, and 4.51 GBytes (see 2.1.1, “Capacity

Equations” o n page 13 for exact capacities based on model and block size). The form factor offerings ar e

'Brick On Sled' carrier a n d 3.5-inch small form factor (refer to 4.1.1, “Weight and Dimensions” on page 51

for exact dimensions).

This document, in conjunction with the Ultrastar XP (DFHC) SS A Models Interface Specification, make

up the Functional Specification for t h e Ultrastar X P SSA (DFHC) product.

The product description a nd other data found in this document represent IBM's design objectives an d is

provided for information and comparative purposes. Actual results may vary based on a variety of factors

and the information herein is subject to change. T H IS PRODUCT DATA DOES NO T CONSTITUTE A

WARRANTY, EXPRESS O R IMPLIED. Questions regarding IBM's warranty terms or the methodology

used t o derive the data should be referred to your IB M customer representative.

Note: Not all mod els described in this document are in plan. Contact your IB M customer representative

for actual product plans.

Source filename=PREFACE IBM Corporation Page 3 of 87

Page 4

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Source filename=STSSHEXTIBM CorporationPage 4 of 87

Page 5

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Contents

1.0 Description .................................................... 9

1.1 Features ...................................................... 9

1.1.1 General Features .............................................. 9

1.1.2 Performance Summary .......................................... 9

1.1.3 Interface Controller Features ....................................... 9

1.1.4 Reliability Fea tu r es ...........................................

1.2 Models

..................................................... 10

2.0 Specifications .................................................. 11

2.1 General ..................................................... 11

2.1.1 Capacity Equations ........................................... 13

2.2 Power Requirements by Model ....................................... 15

2.2.1 C1x Models ................................................ 15

2.2.2 C2x Models ................................................ 21

2.2.3 C4x Models ................................................ 27

2.2.4 CxB Models ............................................... 33

2.2.5 Power Supply Ripple .......................................... 34

2.2.6 Grounding Requirements of the Disk Enclosure ........................... 34

2.2.7 Hot plug/unplug support ........................................ 34

2.2.8 Bring-up Sequence (and Stop) Times ................................. 36

10

3.0 Performance .................................................. 39

3.1 Environment Definition ........................................... 39

3.2 Workload Definition ............................................. 39

3.2.1 Sequential ................................................. 40

3.2.2 Random .................................................. 40

3.3 Command Execution Time ......................................... 40

3.3.1 Basic Component Descriptions ..................................... 40

3.3.2 Comments ................................................ 42

3.4 Approximating Performance for Different Environments ......................... 43

3.4.1 For Different Transfer Sizes ....................................... 44

3.4.2 When Read Caching is Enabled .................................... 44

3.4.3 When Write Caching is Enabled .................................... 44

3.4.4 When Adaptive Caching is Enabled .................................. 44

3.4.5 When Read-ahead is Enabled ...................................... 44

3.4.6 When N o Seek is Required ....................................... 45

3.4.7 For Queued Com mands ......................................... 45

3.4.8 Out of Order Transfers ......................................... 45

3.5 Skew ...................................................... 46

3.5.1 Cylinder to Cylinder Skew ....................................... 46

3.5.2 Track to Track Skew .......................................... 46

3.6 Idle Time Functions ............................................. 47

3.6.1 Servo R un Out Measurements ..................................... 48

3.6.2 Servo Bias Measurements ........................................ 48

3.6.3 Predictive Failure Analysis ....................................... 48

3.6.4 Channel Calibration ........................................... 48

3.6.5 Save Logs and Pointers ......................................... 49

3.6.6 Disk Sweep ................................................ 49

3.6.7 Summary ................................................. 49

3.7 Command Timeout Limits .......................................... 49

Source filename=STSSHEXT IBM Corporation Page 5 of 87

Page 6

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

4.0 Mechanical ................................................... 51

4.1 Small Form Factor Models (CxC) ..................................... 51

4.1.1 Weight and Dimensions ......................................... 51

4.1.2 Clearances ................................................. 51

4.1.3 Mounting ................................................. 51

4.1.4 Unitized Connector Locations ..................................... 55

4.2 Carrier Models (CxB) ............................................. 57

4.2.1 Weight and Dimensions ......................................... 57

4.2.2 Clearances ................................................. 57

4.2.3 Mounting ................................................. 57

4.2.4 Auto-docking Assembly Side Rails .................................. 60

4.2.5 Electrical Connector and Indicator Locations ............................ 62

5.0 Electrical Interface .............................................. 63

5.1 SSA Unitized Connector ........................................... 63

5.2 Carrier Connector ............................................... 64

5.3 SSA Link Cable ................................................ 66

5.4 SSA Link Electrical Characteristics ..................................... 66

5.5 Option Pins and Indicators .......................................... 66

5.5.1 - Manufacturing Test Mode (Option Port Pin 1) .......................... 66

5.5.2 - Auto Start P i n (Option Port Pin 2) ................................. 66

5.5.3 - Sync Pi n (Option Port Pin 3) ..................................... 66

5.5.4 - Write Protect (Option Port Pin 4) .................................. 67

5.5.5 - Ground long (Option Port Pin 5) .................................. 67

5.5.6 - Device Activity Pin/Indicator (Option Port Pin 6) ......................... 67

5.5.7 + 5V (Option Port Pin 7) ....................................... 67

5.5.8 - Device Fault Pin/Indicator (Option Port Pin 8) .......................... 67

5.5.9 Programmable pin 1 (Option Port Pin 9) ............................... 68

5.5.10 Programmable pin 2 (Option Port Pin 10) ............................. 68

5.5.11 - Early Power Off Warning or Power Fail (Power Port Pin 11) ................. 68

5.5.12 12V Charge and 5V Charge (Power Port pin 1 and 2) ....................... 68

5.6 Front Jumper Connector ........................................... 68

5.7 Spindle Synchronization ........................................... 69

5.7.1 Synchronization overview ........................................ 69

5.7.2 Synchronization Mode ......................................... 69

5.7.3 Synchronization time .......................................... 69

5.7.4 Synchronization with Offset ...................................... 69

5.7.5 Synchronization Route ......................................... 69

6.0 Reliability .................................................... 73

6.1 Error Detection ................................................ 73

6.2 Data Reliability ................................................ 73

6.3 Seek Error Rate ................................................ 73

6.4 Power On Hours Examples: ........................................ 73

6.5 Power on/off cycles .............................................. 74

6.6 Useful Life ................................................... 74

6.7 *Mean Time Between Failure (*MTBF) .................................. 75

6.7.1 Sample Failure Rate Projections .................................... 75

6.8 SPQL (Shipped product quality level) ................................... 75

6.9 Install Defect Free ............................................... 75

6.10 Periodic Maintenance ............................................ 76

6.11 ES D Protection ............................................... 76

6.12 Connector Insertion Cycles ......................................... 76

7.0 Operating Limits ............................................... 77

Source filename=STSSHEXTIBM CorporationPage 6 of 87

Page 7

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

7.1 Environmental ................................................. 77

7.1.1 Temperature Measurement Points ................................... 77

7.2 Vibration and Shock ............................................. 79

7.2.1 Drive Mounting Guidelines ....................................... 80

7.2.2 Output Vibration Limits ........................................ 80

7.2.3 Operating Vibration ........................................... 80

7.2.4 Operating Shock ............................................. 82

7.2.5 Nonoperating Shock ........................................... 82

7.3 Contaminants ................................................. 82

7.4 Acoustic Levels ................................................ 83

8.0 Standards .................................................... 85

8.1 Safety ...................................................... 85

8.2 Electromagnetic Compatibility (EMC) ................................... 85

Bibliography ..................................................... 87

Source filename=STSSHEXT IBM Corporation Page 7 of 87

Page 8

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Source filename=STSSHEXTIBM CorporationPage 8 of 87

Page 9

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

1.0 Description

1.1 Features

1.1.1 General Features

1.12/2.25/4.51 gigabytes formatted capacity (512 bytes/sector)

Serial Storage Architecture (SSA) attachment (dual port)

Brick On Sled carrier and 3.5" small form factor mod els

Rotary voice coil motor actuator

Closed-loop digital actuator servo (embedded sector servo)

Magnetoresistive (MR) heads

(0,8,6,infinity) 8/ 9 rate encoding

Partial Response Maximum Likelihood (PRML) data channel with digital filter

All mounting orientations supported

Jumperable au to spindle motor start

Jumperable write protection

Spindle synchronization

Two LED drivers

Bezel (optional)

1.1.2 Performance Summary

Average read seek time (1.12 GB): 6.9 milliseconds

Average read seek time (2.25 GB): 7.5 milliseconds

Average read seek time (4.51GB): 8.0 milliseconds

Average Latency: 4.17 milliseconds

Split read/write control

Media data transfer rate: 9.59 to 12.58 MegaBytes/second (10 bands)

SSA data transfer rate: 20 Megabytes/second

1.1.3 Interface Controller Features

Multiple initiator support

Supports blocksizes from 256 to 5952 bytes

512K byte, multi-segmented, dual port data buffer

Read-ahead caching

Adaptive caching algorithms

Write Cache supported (write back & write thru)

Tagged command queuing

Command reordering

Back-to-back writes (merged writes)

Split reads and writes

Nearly co ntig uou s read/write

Link error recovery procedure exit

Disable registration

Duplicate tags

Two byt e ULP message codes

SCSI response

Move data transfer messages

Multiple ULP's

Automatic retry and d at a correction on read errors

Source filename=DESCRIP IBM Corporation Page 9 of 87

Page 10

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Automatic sector reallocation

In-line alternate sector assignment for high-performance

Improved technique for down-loadable SSA firmware

1.1.4 Reliability Features

Self-diagnostics on power up

Dedicated head landing zone

Automatic actuator latch

Embedded Sector Servo for improving on-track positioning capability

Buffer memory parity

Longitudinal Redundancy Check (LRC) on Customer Data

ECC on the fly

Error logging and analysis

Data Recovery Procedures (DRP)

Predictive Failure Analysis (PFA &tm)

No preventative maintenance required

Tw o Field Replaceable Units (FRU's): Electronics Card and Head Disk Assembly (HDA)

Probability of n ot recovering data: 10 in 1015bits read

1.2 Models

The Ultrastar XP SSA disk drive is available in various models as shown below.

The Ultrastar XP SSA d at a storage capacities vary as a function of model and user block size. The

emerging industry trend is capacity poi nt s in multiples of 1.08GB (i.e. 1.08/2.16/4.32) at a block size of 512

bytes. Future IB M products will plan to provide capacities that are consistent with this trend. Users that

choose t o make full use of the Ultrastar XP SSA drive capacity above the standard capacity points may n ot

find equivalent capacity breakpoints in future products.

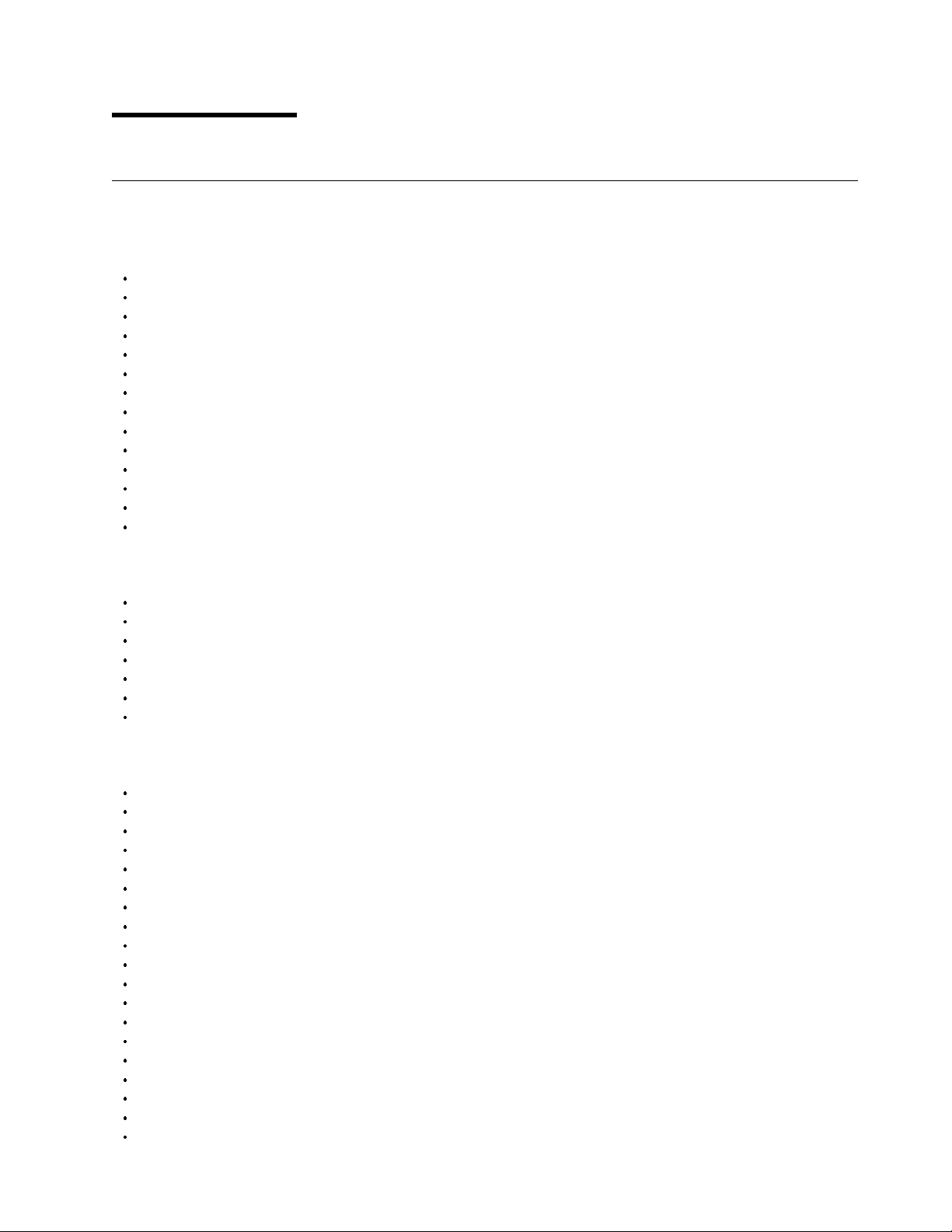

Model # Capacity GB (@512 Byte) Form Factor Connector Type

C1B 1.12 Brick O n Sled Carrier 128-pin HPC

C1C 1.12 3.5-inch Small FF 38-pin Unitized

C2B 2.25 Brick O n Sled carrier 128-pin HPC

C2C 2.25 3.5-inch Small FF 38-pin Unitized

C4B 4.51 Brick O n Sled carrier 128-pin HPC

C4C 4.51 3.5-inch Small FF 38-pin Unitized

Note: CxB models (C1B, C2B, and C4B) include a DC/DC converter, activity a nd check indicators.

Note: Please refer to section 2.1.1, “Capacity Equations” on page 13 fo r exact capacities based on user block size.

Source filename=DESCRIPIBM CorporationPage 10 of 87

Page 11

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.0 Specifications

All specifications are nominal values unless otherwise noted.

The Ultrastar XP SSA data storage capacities vary as a function of model and user block size. The

emerging Industry trend is capacity points in 1.08GB (i.e. 1.08/2.16/4.32) at a block size of 512 bytes. This

and future products will always p l a n to provide capacities that are consistent with this trend. Users that

choose t o make full use of the Ultrastar XP SSA drive capacity above the standard capacity poi n ts m a y n o t

find equivalent capacity breakpoints in future products.

2.1 General

Note: Th e recording band located nearest t he disk outer diameter (OD ) is referred to as 'Notch #1'. While

the recording band located nearest the inner diameter (ID) is called 'Notch #10'. 'Average' values are

weighted with respect to th e number of LBAs per notch when the drive is formatted with 512 byte blocks.

Data transfer rates

Notch #1 Notch #10 Average

Buffer to/from media 12.58 9.59 12.07 MB/s (instantaneous)

Host to/from buffer up to 20.0 MB/s (synchronous) (sustained)

Data Buffer Size (bytes) 512 K (See 3.0, “Performance” on page 39 for user data capacity.)

Rotational speed (RPM) 7202.7

Average latency (milliseconds) 4.17

Track Density (TPI) 4352

Minimum Maximum

Recording density (BPI) 96,567 124,970

Areal density (Megabits/square inch) 420.3 543.9

(model numbers - > ) C4x C2x C1x

Disks 842

User Data Heads (trk/cyl) 16 8 4

Seek times (in milliseconds)

Single cylinder (Read) 0.5 0.5 0.5

(Write) 2.0 2.0 2.0

Average (weighted) (Read) 8.0 7.5 6.9

(Write) 9.5 9.0 8.5

Full stroke (Read) 16.5 15.0 14.0

(Write) 18.0 16.5 15.5

Note: Times are typical for a drive population under nominal voltages

and casting temperature of 25˚C. Weighted seeks a r e seeks to the cylinders of random logical block addresses (LBAs).

Source filename=SPECS IBM Corporation Page 11 of 87

Page 12

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Total Cylinders (tcyl) All models C4x Models C2x Models C1x Models

& User Cylinders (ucyl) tcyl ucyl ucyl ucyl

Notch # 1 1893 1879 1877 1872

Notch # 2 956 955 955 955

Notch # 3 49 48 48 48

Notch # 4 310 309 309 309

Notch # 5 349 348 348 348

Notch # 6 116 115 115 115

Notch # 7 214 213 213 213

Notch # 8 190 189 189 189

Notch # 9 131 130 130 130

Notch #10 208 206 206 206

Sum of all Notches 4416 4392 4390 4385

Spares Sectors/cylinder (spr/cyl) C4x Models C2x Models C1x Models

Notch # 1 40 20 10

Notch # 2 40 20 10

Notch # 3 38 19 10

Notch # 4 37 19 9

Notch # 5 36 18 9

Notch # 6 34 17 9

Notch # 7 33 17 8

Notch # 8 32 16 8

Notch # 9 31 16 8

Notch #10 30 15 7

Last cylinder extra spares (lcspr) 60 30 14

User bytes/sector (ub/sct) 256 - 744 (even number of bytes only)

Sectors/logical block (sct/lba) 1-8

The lowest sct/lba that satisfies the following rules is used...

1. Block Length is evenly divisible by a number 2-8.

2. Quotient of previous equation is evenly divisible by 2.

3. Quotient must be ≥ 256 a nd ≤ 744.

User bytes/logical block (ub/lba) 256 - 5952 (See rules for determining sct/lba above for determining sup-

ported ub/lba values.)

Sectors/track (sct/trk) (See Table 1 o n page 13 o r contact an IB M Customer Representative

for other block lengths.)

Source filename=SPECSIBM CorporationPage 12 of 87

Page 13

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Notch #

User bytes /

logical block

256 216 216 216 202 195 180 180 180 180 162

512 135 135 130 126 120 115 112 108 105 100

520 128 128 128 123 115 112 108 105 102 99

522 128 128 128 122 115 112 108 105 102 90

524 128 128 128 120 115 112 108 105 102 90

528 128 128 126 120 112 112 108 105 101 90

600 115 115 115 110 102 101 97 90 90 90

688 102 102 102 98 90 90 90 90 81 78

744 96 96 96 90 90 90 81 78 77 73

1 2 3 4 5 6 7 8 9 10

Table 1. Gross sectors per track for several block lengths

C4x Models C2x Models C1x Models

User bytes /

logical block

formatted

capacity

(bytes)

logical

blocks /

drive

formatted

capacity

(bytes)

logical

blocks /

drive

formatted

capacity

(bytes)

logical

blocks /

drive

256 3,654,540,800 14,275,550 1,826,312,448 7,134,033 912,135,680 3,563,030

512 4,512,701,440 8,813,870 2,255,098,368 4,404,489 1,126,337,536 2,199,878

520 4,375,536,880 8,414,494 2,186,554,760 4,204,913 1,092,119,600 2,100,230

522 4,374,300,492 8,379,886 2,185,931,898 4,187,609 1,091,803,716 2,091,578

524 4,385,878,952 8,369,998 2,191,716,460 4,182,665 1,094,691,544 2,089,106

528 4,408,629,984 8,349,678 2,203,082,640 4,172,505 1,100,365,728 2,084,026

600 4,512,402,000 7,520,670 2,254,925,400 3,758,209 1,126,282,800 1,877,138

688 4,604,578,976 6,692,702 2,300,969,904 3,344,433 1,149,310,880 1,670,510

744 4,675,830,192 6,284,718 2,336,559,528 3,140,537 1,167,099,408 1,568,682

Table 2. User capacity for several block lengths

2.1.1 Capacity Equations

2.1.1.1 For Each Notch

The next group of equations must be calculated separately for each notch.

user bytes/sector (ub/sct) =

user sectors/cyl (us/cyl) = (sct/trk)(trk/cyl) - spr/cyl

spares/notch (spr/nch) = (spr/cyl)(ucyl)

Note: Add lcspr t o the equation above for the notch closest t o the inner diameter (#10).

user sectors/notch (us/nch) = (us/cyl)(ucyl)

Note: Subtract lcspr from the equation above for the notch closest to the inner diameter (#10).

Source filename=SPECS IBM Corporation Page 13 of 87

ub/lba

sct/l b a

Page 14

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.1.1.2 For Entire Drive

10

spares/drive (spr/drv) =

notch = 1

user sectors/drive (us/drv) =

∑

notch = 1

spr/nch

10

∑

us/nch

logical blocks/ drive (lba/drv) = I NT

user capacity (fcap) = (lba/drv)(ub/lba)

[

us/ drv

sct/l b a

]

Source filename=SPECSIBM CorporationPage 14 of 87

Page 15

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2. 2 Power Requirements by Model

2.2.1 C1x Models

The following voltage specifications apply at the drive power connector. There is no special power on/off

sequencing required. Th e extra power needed for Brick O n Sled mod els a nd t h e +38V power option are

described in 2.2.4, “CxB Models” on page 33.

Input Voltage

+ 5 Volts Supply 5V (± 5% during r un a n d spin-up)

+1 2 Volts Supply 12V (± 5% during ru n) ( +5 % / -7% during spin-up)

The following current values are the combination measured values of SCSI models an d SSA Cx4 model. T he

differences between SCSI and SSA is +5 V currents. Because of different interface electronics a n d speed, SSA

electronics card requires more +5 V current than SCSI. Read/Write Base Line is 290 m a higher. Idle

Average is 500 ma higher. (290ma an d 500ma differences were found by measuring SSA Cx4 model). SSA

+5V current numbers are derived from SCSI +5 V current numbers by adding 290ma a n d 500ma accordingly.

Population Population

Power Supply Current Notes Mean Stand. Dev.

+5VDC (power-up) Minimum voltage slew rate = 4.5 V/sec

+5VDC (idle avg) 1.23 Amps 0.02 Amps

+5VDC (R/W baseline) 1.25 Amps

1

0.05 Amps

+5VDC (R/W pulse) Base-to-peak .36 Amps 0.06 Amps

+12VDC (power-up) Minimum voltage slew rate = 7.4 V/sec

+12VDC (idle avg) 0.28 Amps 0.02 Amps

+12VDC (seek avg) 1 op/sec 0.0027 Amps 0.002 Amps

+12VDC (seek peak) 1.20 Amps

+12VDC (spin-up) 3.0 sec max 1.5 Amps

2

0.02 Amps

3

0.1 Amps

Drive power

Avg idle power 9.51 Watts .35 Watts

Avg R/W power 30 ops/sec 10.58 Watts .35 Watts

1

See Figure 1 on page 18 for a plot of ho w the read/write baseline a n d read/write pulse s um together.

2

Th e idle average an d seek peek should be added together to determine the total 12 volt peak current. See Figure 2

on page 19 for a typical buildup of these currents. Refer to examples on the following page to see how to combine

these values.

Source filename=POWER IBM Corporation Page 15 of 87

Page 16

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.1.1 Power Calculation Examples

Note: The following formulas assume all system ops as a 1 block read or write transfer from a random

cylinder while at nominal voltage condition.

Example 1. Calculate the mean 12 volt average current.

If we assume a case of 30 operations/second then to compute the sum of the 12 volt mean currents th e

following is done.

mean

+12VDC (idle average) 0.28 amps

+12VDC (seek average) 0.027 * 30 = 0.081 amps

TOTAL 0.361 amps

Example 2. Calculate the mean plus 3 sigma 12 volt average current.

To compute the sum of the 12 volt mean current's 1 sigma value assume all the distributions are normal.

Therefore the square root of the sum of the squares calculation applies. Assume a case of 30

operations/second.

sigma

+12VDC (idle average) 0.02 amps

+12VDC (seek average) sqrt(30*((0.0002)**2))= 0.001 amps

TOTAL sqrt((0.02)**2+(.001)**2))=0.02 amps

So the mean plus 3 sigma mean current is 0.361 + 3*0.02 = 0.42 amps

Example 3. Power Calculation.

Nominal idle drive power = (1.23 Amps * 5 Volts) + (0.28 Amps * 12 Volts) = 9.51 Watts

Nominal R/ W drive power at 30 ops/sec = (1.25 Amps * 5 Volts) + (0.361 Amps * 12 Volts) = 10.58

Watts

Mean plus 3 sigma drive power for 30 random R/W operations/second. Assume that the 5 volt a nd 12 volt

distributions are independent therefore the square root of the sum of the squares applies.

+5VDC (1 sigma power) 0.05 * 5 = 0.25 watts

+12VDC (1 sigma power) 0.02 * 12 = 0.24 watts

Total (1 sigma power) sqrt((0.25)**2+(0.24)**2) = 0.347 watts

Total power 9.13 + 3 * 0.347 = 10.2 watts

3

The current at start is the total 12 volt current required (ie. th e motor start current, module current a n d voice coil

retract current). See Figure 3 o n page 20 for typical 12 volt current during spindle motor start.

Source filename=POWERIBM CorporationPage 16 of 87

Page 17

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Example 4. Calculate the 12 volt peak current.

To compute the sum of the 12 volt peak currents the following is done.

mean

+12VDC (idle avg) 0.28 amps

+12VDC (seek peak) 1.2 amps

TOTAL 1.48 amps

Example 5. Calculate the mean plus 3 sigma 12 volt peak current.

To compute the sum of the 12 volt peak current's 1 sigma value assume all distributions are normal. Therefore the square root of the sum of the squares calculation applies.

sigma

+12VDC (idle avg) 0.02 amps

+12VDC (seek peak) 0.02 amps

TOTAL sqrt((0.02)**2+(0.02)**2)=0.028 amps

So the mean plus 3 sigma peak current is 1.48 + 3*0.028 = 1.56 amps

Things to check when measuring 12 V supply current:

Null the current probe frequently. Be sure to let it warm up.

Adjust the power supply t o 12.00 V at the drive terminals.

Use a proper window width, covering an integral number of spindle revolutions.

Measure values at 25 degree C casting temperature.

Get a reliable trigger for Seek Peak readings.

Source filename=POWER IBM Corporation Page 17 of 87

Page 18

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

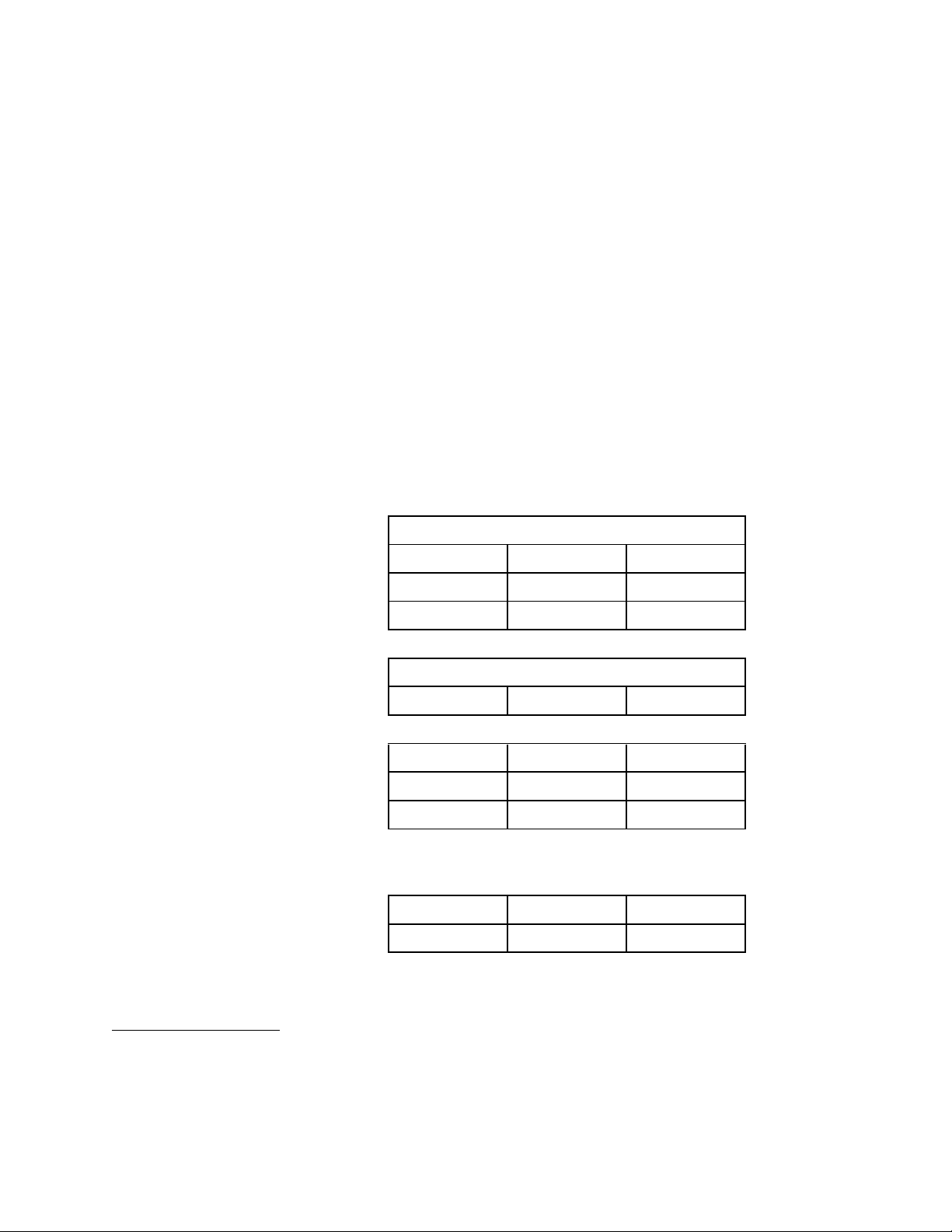

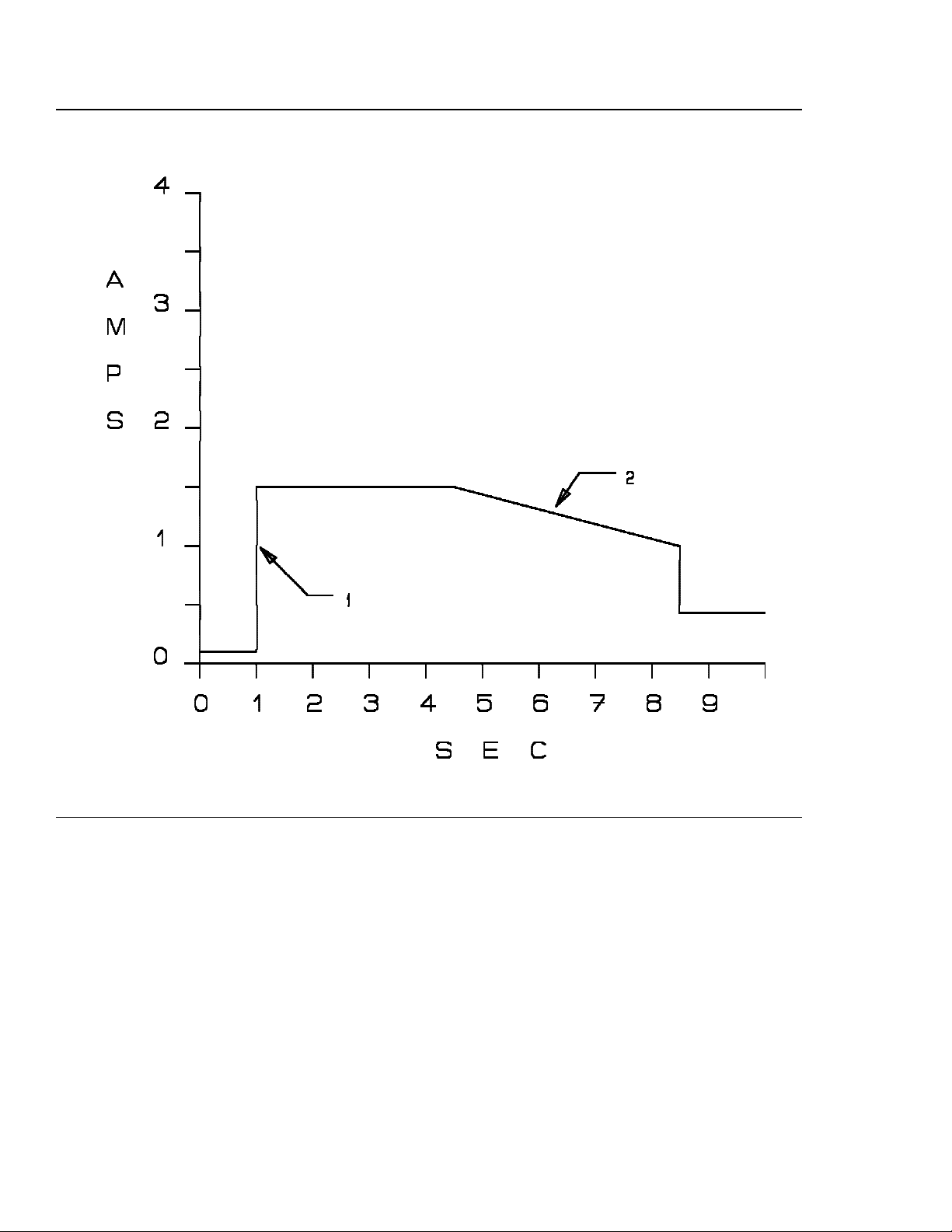

Figure 1. 5 volt current during read/write operations — C1x Models

1. Read/write baseline voltage.

2. Read/write pulse. T he width of the pulse is proportional to the number of consecutive blocks read or

written. The 5 volt supply must be able to provide the required current during this event.

Source filename=POWERIBM CorporationPage 18 of 87

Page 19

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

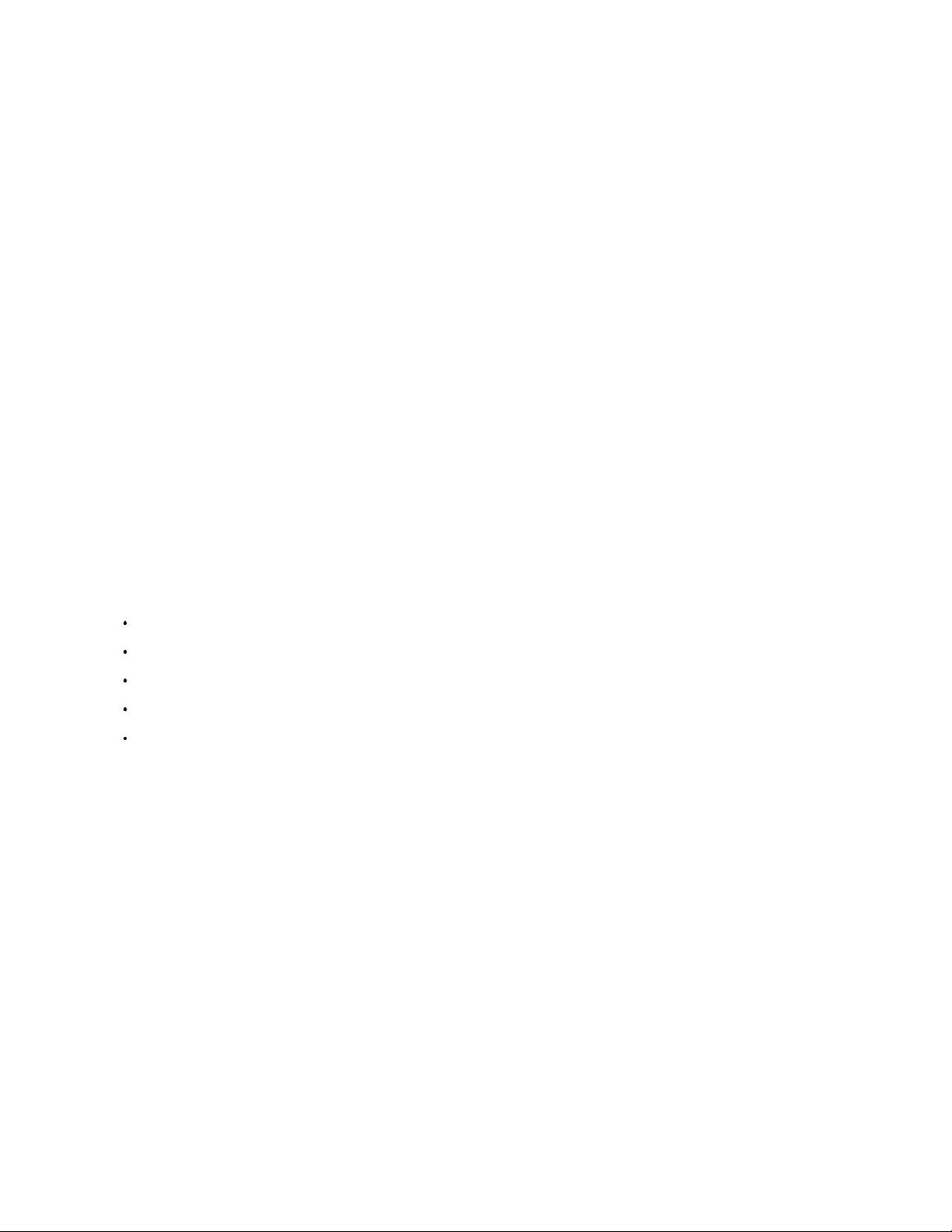

Figure 2. Typical 12 volt current —C1x Models

1. Maximum slew rate is 7 amps/millisecond.

2. Maximum slew rate is 100 amps/millisecond.

3. Maximum slew rate is 7 amps/millisecond.

4. Maximum slew rate is 3 amps/millisecond.

Source filename=POWER IBM Corporation Page 19 of 87

Page 20

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Figure 3. Typical 12 volt spin-up current — C1x Models

1. Maximum slew rate is 20 amps/millisecond.

2. Current drops off as motor comes up t o speed.

Source filename=POWERIBM CorporationPage 20 of 87

Page 21

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.2 C2x Models

The following voltage specifications apply at the drive power connector. There is no special power on/off

sequencing required. T h e extra power needed for Brick O n Sled models an d t he +38V power option are

described in 2.2.4, “CxB Models” on page 33.

Input Voltage

+ 5 Volts Supply 5V (± 5% during r un a n d spin-up)

+1 2 Volts Supply 12V (± 5% during ru n) ( +5 % / -7% during spin-up)

The following current values are the combination measured values of SCSI models an d SSA Cx4 model. T he

differences between SCSI and SSA is + 5V currents. Because of different interface electronics and speed, SSA

electronics card requires more +5 V current than SCSI. Read/Write Base Line is 290 m a higher. Idle

Average is 500 m a higher. (290ma and 500ma differences were found by measuring SSA Cx4 model). SSA

+5V current numbers are derived from SCSI + 5V current numbers by adding 290ma and 500ma accordingly.

Population Population

Power Supply Current Notes Mean Stand. Dev.

+5VDC (power-up) Minimum voltage slew rate = 4.5 V/sec

+5VDC (idle avg) 1.23 Amps 0.02 Amps

+5VDC (R/W baseline) 1.25 Amps

4

0.05 Amps

+5VDC (R/W pulse) Base-to-peak .36 Amps 0.06 Amps

+12VDC (power-up) Minimum voltage slew rate = 7.4 V/sec

+12VDC (idle avg) 0.41 Amps 0.02 Amps

+12VDC (seek avg) 1 op/sec 0.0031 Amps 0.0002 Amps

+12VDC (seek peak) 1.20 Amps

+12VDC (spin-up) 4.2 sec max 1.5 Amps

5

0.02 Amps

6

0.1 Amps

Drive power

Avg idle power 11.07 Watts .35 Watts

Avg R/W power 30 ops/sec 12.25 Watts .35 Watts

4

See Figure 4 on page 24 for a plot of ho w the read/write baseline a n d read/write pulse s um together.

5

Th e idle average a n d seek peek should be added together to determine the total 12 volt peak current. See Figure 5

on page 25 for a typical buildup of these currents. Refer to examples on the following page to see how to combine

these values.

6

The current at start is the total 12 volt current required (ie. the motor start current, module current a nd voice coil

retract current). See Figure 6 o n page 26 for typical 12 volt current during spindle motor start.

Source filename=POWER IBM Corporation Page 21 of 87

Page 22

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.2.1 Power Calculation Examples

Note: The following formulas assume all system ops as a 1 block read or write transfer from a random

cylinder while at nominal voltage condition.

Example 1. Calculate the mean 12 volt average current.

If we assume a case of 30 operations/second then to compute the sum of the 12 volt mean currents the

following is done.

mean

+12VDC (idle average) 0.41 amps

+12VDC (seek average) 0.0031 * 30 = 0.09 amps

TOTAL 0.50 amps

Example 2. Calculate the mean plus 3 sigma 12 volt average current.

To compute the sum of the 12 volt mean current's 1 sigma value assume all the distributions are normal.

Therefore the square root of the sum of the squares calculation applies. Assume a case of 30

operations/second.

sigma

+12VDC (idle average) 0.02 amps

+12VDC (seek average) sqrt(30*((0.0002)**2))= 0.001 amps

TOTAL sqrt((0.02)**2+(.001)**2))=0.02 amps

So the mean plus 3 sigma mean current is 0.50 + 3*0.02 = 0.56 amps

Example 3. Power Calculation.

Nominal idle drive power = (1.23 Amps * 5 Volts) + (0.41 Amps * 12 Volts) = 11.07 Watts

Nominal R /W drive power at 30 ops/sec = (1.25 Amps * 5 Volts) + (0.50 Amps * 12 Volts) = 12.25

Watts

Mean plus 3 sigma drive power for 30 random R/W operations/second. Assume that the 5 volt a nd 12 volt

distributions are independent therefore the square root of the sum of the squares applies.

+5VDC (1 sigma power) 0.05 * 5 = 0.25 watts

+12VDC (1 sigma power) 0.02 * 12 = 0.24 watts

Total (1 sigma power) sqrt((0.25)**2+(0.24)**2) = 0.35 watts

Total power 10.8 + 3 * 0.35 = 11.9 watts

Source filename=POWERIBM CorporationPage 22 of 87

Page 23

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Example 4. Calculate the 12 volt peak current.

To compute the sum of the 12 volt peak currents the following is done.

mean

+12VDC (idle avg) 0.41 amps

+12VDC (seek peak) 1.20 amps

TOTAL 1.61 amps

Example 5. Calculate the mean plus 3 sigma 12 volt peak current.

To compute the sum of the 12 volt peak current's 1 sigma value assume all distributions are normal. Therefore the square root of the sum of the squares calculation applies.

sigma

+12VDC (idle avg) 0.03 amps

+12VDC (seek peak) 0.02 amps

TOTAL sqrt((0.03)**2+(0.02)**2)=0.036 amps

So the mean plus 3 sigma peak current is 1.61 + 3*0.036= 1.72 amps

Things to check when measuring 12 V supply current:

Null the current probe frequently. Be sure to let it warm up.

Adjust the power supply t o 12.00 V at the drive terminals.

Use a proper window width, covering an integral number of spindle revolutions.

Measure values at 25 degree C casting temperature.

Get a reliable trigger for Seek Peak readings.

Source filename=POWER IBM Corporation Page 23 of 87

Page 24

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

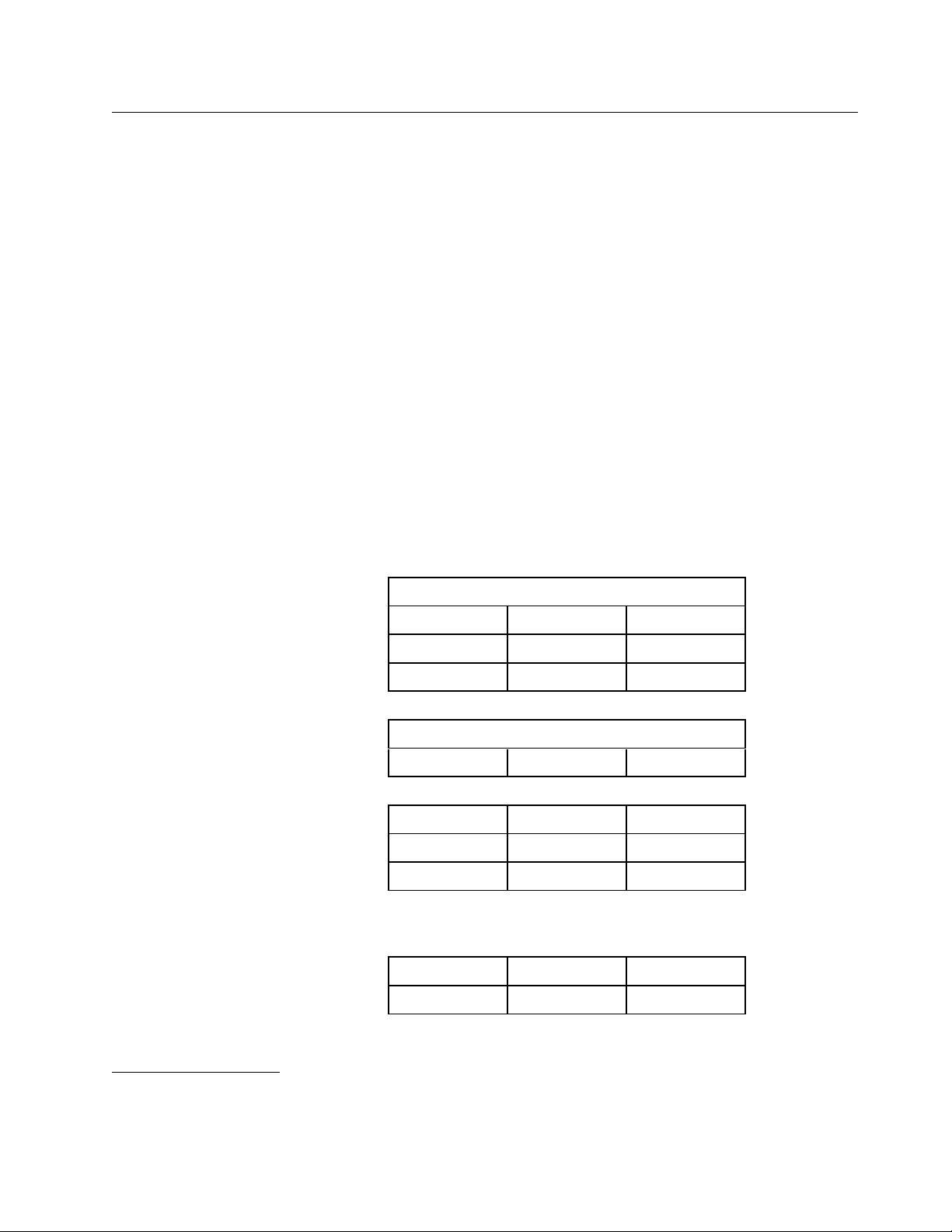

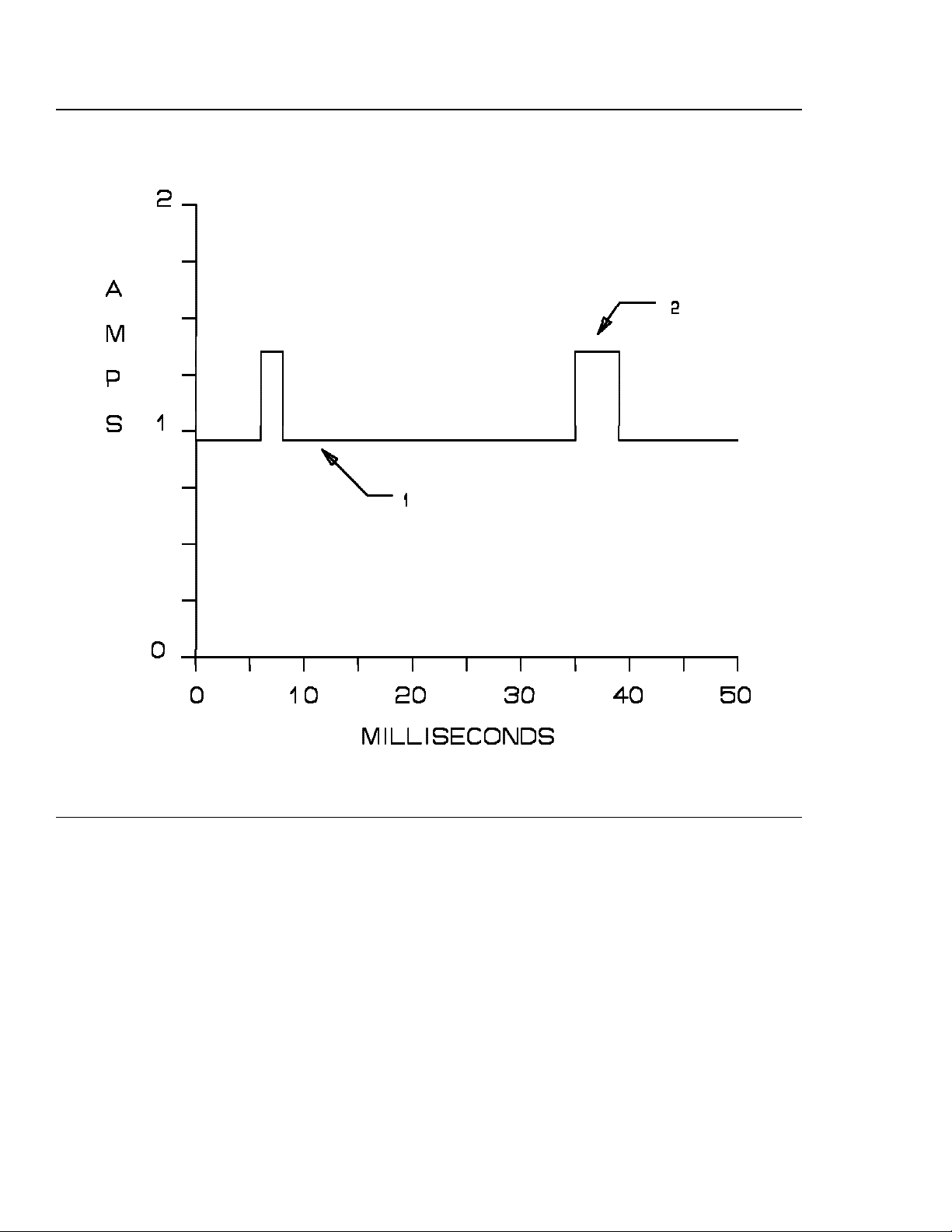

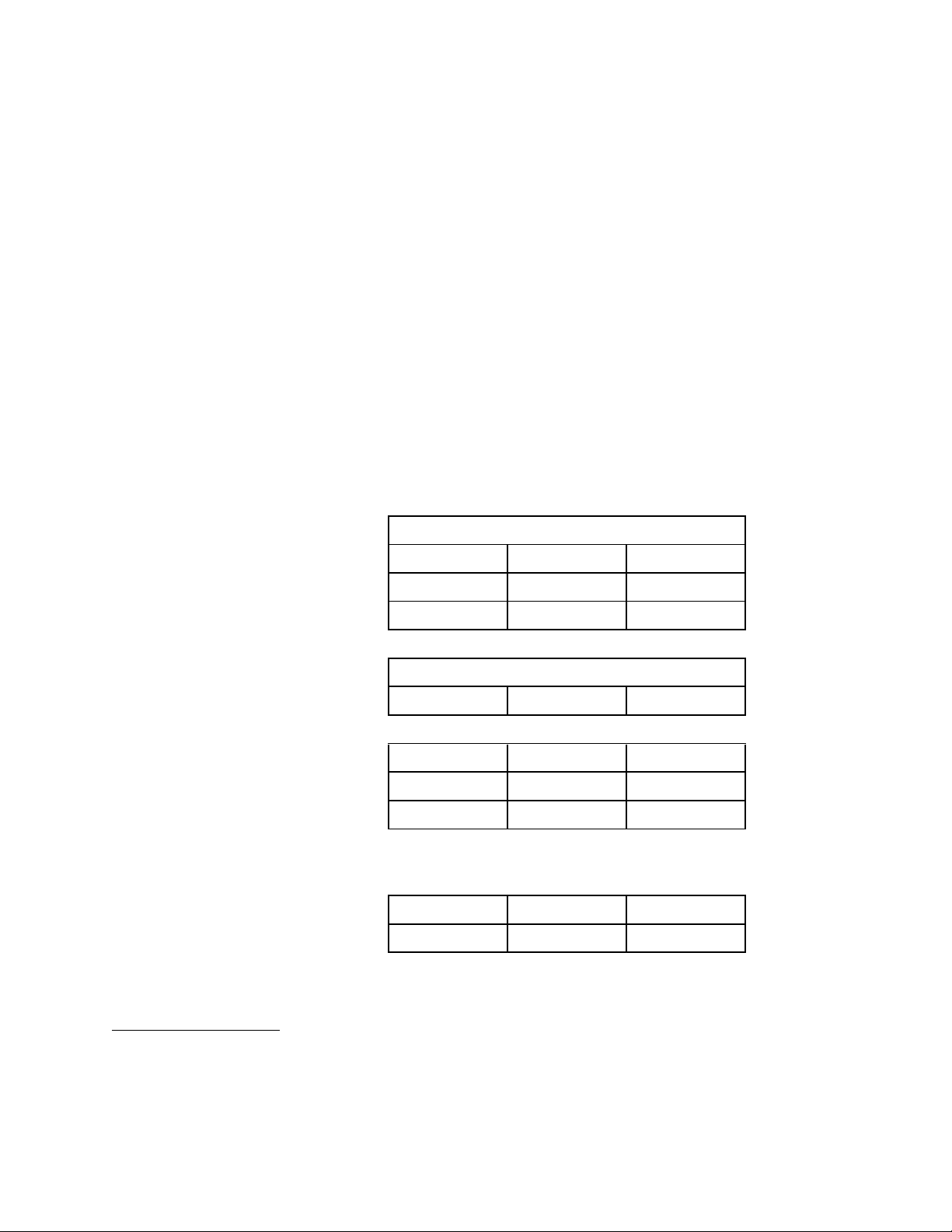

Figure 4. 5 volt current during read/write operations — C2x Models

1. Read/write baseline voltage.

2. Read/write pulse. T he width of the pulse is proportional to the number of consecutive blocks read or

written. The 5 volt supply must be able to provide the required current during this event.

Source filename=POWERIBM CorporationPage 24 of 87

Page 25

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

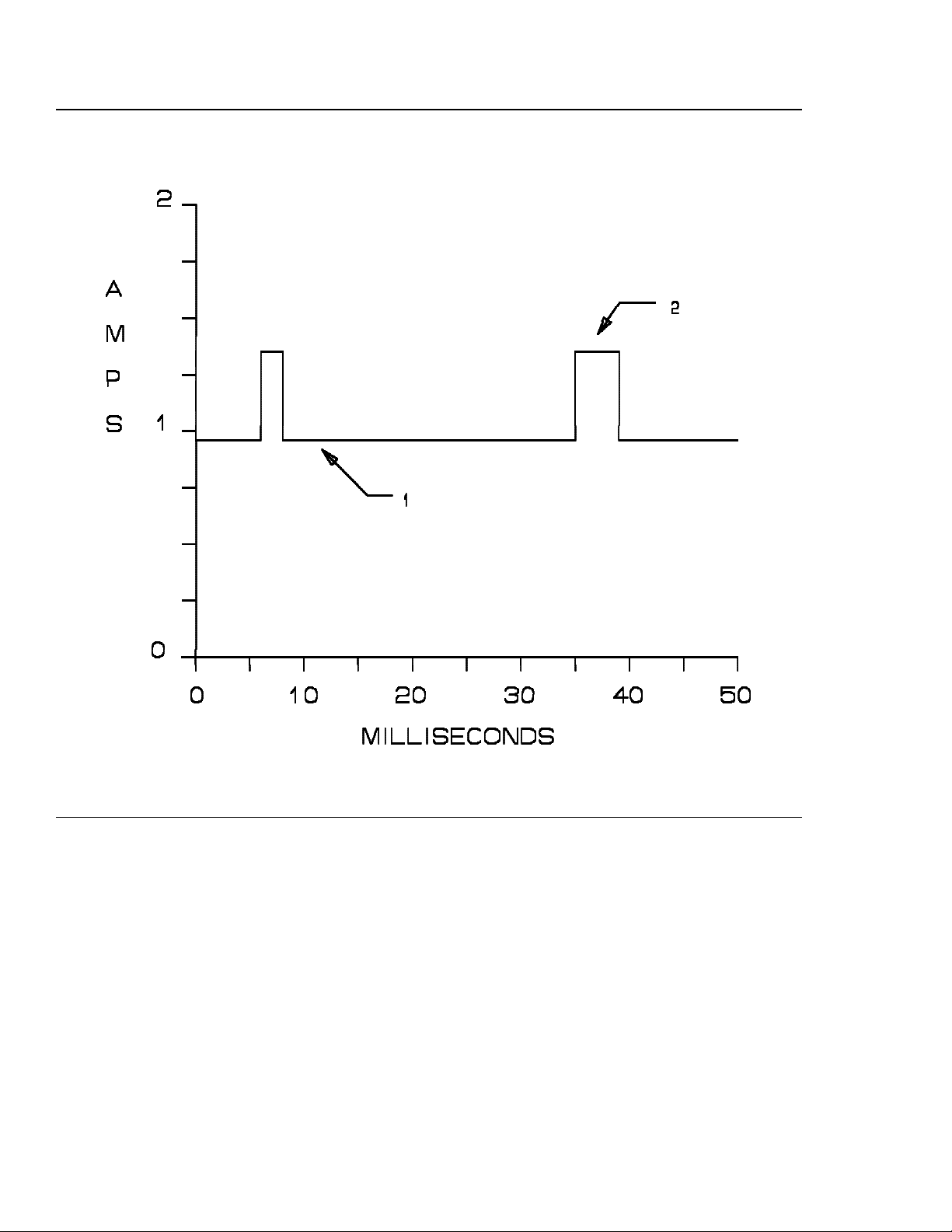

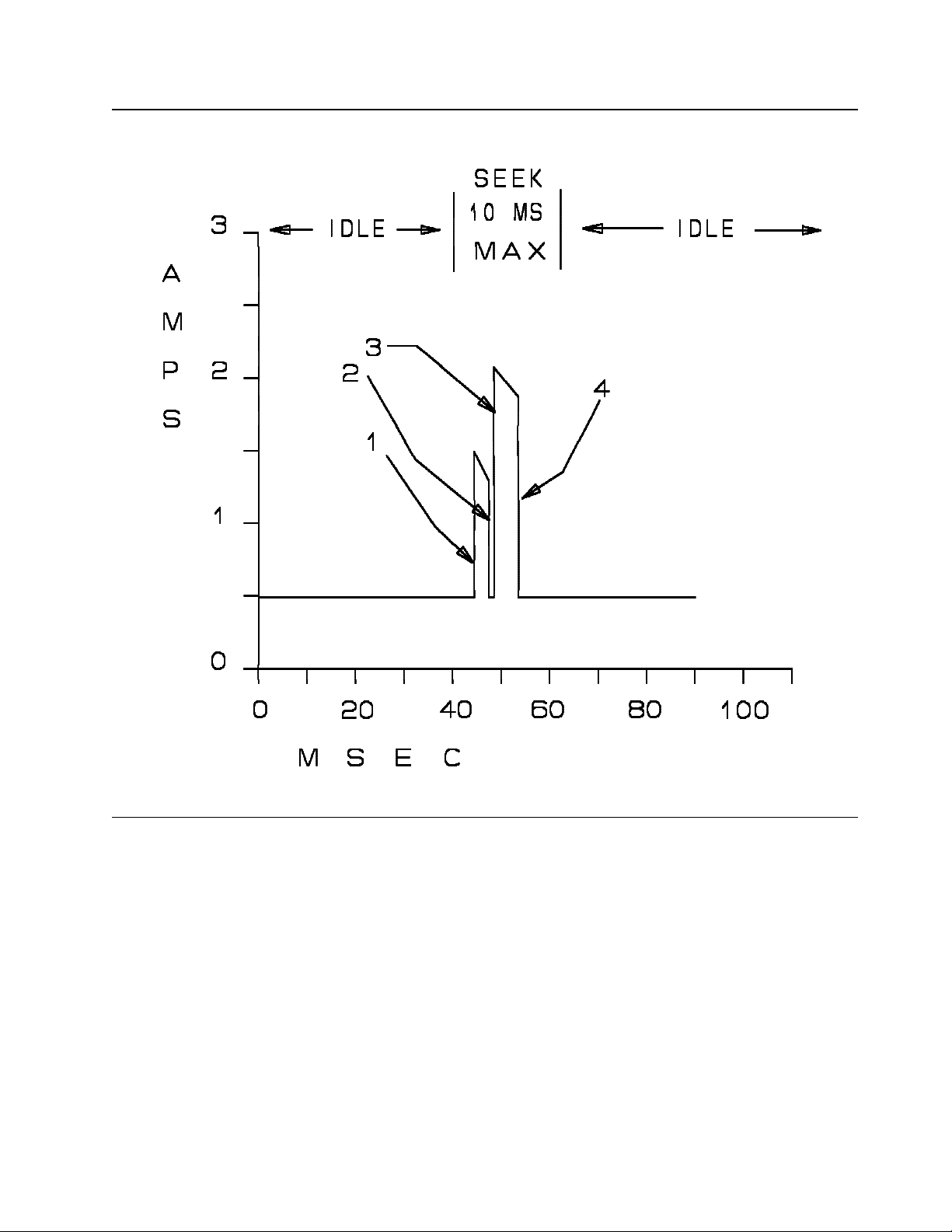

Figure 5. Typical 12 volt current —C2x Models

1. Maximum slew rate is 7 amps/millisecond.

2. Maximum slew rate is 100 amps/millisecond.

3. Maximum slew rate is 7 amps/millisecond.

4. Maximum slew rate is 3 amps/millisecond.

Source filename=POWER IBM Corporation Page 25 of 87

Page 26

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Figure 6. Typical 12 volt spin-up current — C2x Models

1. Maximum slew rate is 20 amps/millisecond.

2. Current drops off as motor comes up t o speed.

Source filename=POWERIBM CorporationPage 26 of 87

Page 27

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.3 C4x Models

The following voltage specifications apply at the drive power connector. There is no special power on/off

sequencing required. T h e extra power needed for Brick O n Sled models an d t he +38V power option are

described in 2.2.4, “CxB Models” on page 33.

Input Voltage

+ 5 Volts Supply 5V (± 5% during r un a n d spin-up)

+1 2 Volts Supply 12V (± 5% during ru n) ( +5 % / -7% during spin-up)

The following current values are the combination measured values of SCSI models an d SSA Cx4 model. T he

differences between SCSI and SSA is + 5V currents. Because of different interface electronics and speed, SSA

electronics card requires more +5 V current than SCSI. Read/Write Base Line is 290 m a higher. Idle

Average is 500 m a higher. (290ma and 500ma differences were found by measuring SSA Cx4 model). SSA

+5V current numbers are derived from SCSI + 5V current numbers by adding 290ma and 500ma accordingly.

Population Population

Power Supply Current Notes Mean Stand. Dev.

+5VDC (power-up) Minimum voltage slew rate = 4.5 V/sec

+5VDC (idle avg) 1.26 Amps 0.02 Amps

+5VDC (R/W baseline) 1.27 Amps

7

0.05 Amps

+5VDC (R/W pulse) Base-to-peak .36 Amps 0.06 Amps

+12VDC (power-up) Minimum voltage slew rate = 7.4 V/sec

+12VDC (idle avg) 0.77 Amps 0.03 Amps

+12VDC (seek avg) 1 op/sec 0.0036 Amps 0.0002 Amps

+12VDC (seek peak) 1.3 Amps

+12VDC (spin-up) 8.5 sec max 2.2 Amps

8

9

0.02 Amps

0.1 Amps

Drive power

Avg idle power 15.54 Watts .44 Watts

Avg R/W power 30 ops/sec 16.91 Watts .44 Watts

7

See Figure 7 on page 30 for a plot of ho w the read/write baseline a n d read/write pulse s um together.

8

Th e idle average a n d seek peek should be added together to determine the total 12 volt peak current. See Figure 8

on page 31 for a typical buildup of these currents. Refer to examples on the following page to see how to combine

these values.

9

The current at start is the total 12 volt current required (ie. the motor start current, module current a nd voice coil

retract current). See Figure 9 o n page 32 for typical 12 volt current during spindle motor start.

Source filename=POWER IBM Corporation Page 27 of 87

Page 28

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.3.1 Power Calculation Examples

Note: The following formulas assume all system ops as a 1 block read or write transfer from a random

cylinder while at nominal voltage condition.

Example 1. Calculate the mean 12 volt average current.

If we assume a case of 30 operations/second then to compute the sum of the 12 volt mean currents the

following is done.

mean

+12VDC (idle average) 0.77 amps

+12VDC (seek average) 0.0036 * 30 = 0.11 amps

TOTAL 0.88 amps

Example 2. Calculate the mean plus 3 sigma 12 volt average current.

To compute the sum of the 12 volt mean current's 1 sigma value assume all the distributions are normal.

Therefore the square root of the sum of the squares calculation applies. Assume a case of 30

operations/second.

sigma

+12VDC (idle average) 0.02 amps

+12VDC (seek average) sqrt(30*((0.0002)**2))= 0.001 amps

TOTAL sqrt((0.02)**2+(.001)**2))=0.02 amps

So the mean plus 3 sigma mean current is 0.88 + 3*0.02 = 0.94 amps

Example 3. Power Calculation.

Nominal idle drive power = (1.26 Amps * 5 Volts) + (0.77 Amps * 12 Volts) = 15.54 Watts

Nominal R /W drive power at 30 ops/sec = (1.27 Amps * 5 Volts) + (0.88 Amps * 12 Volts) = 16.91

Watts

Mean plus 3 sigma drive power for 30 random R/W operations/second. Assume that the 5 volt a nd 12 volt

distributions are independent therefore the square root of the sum of the squares applies.

+5VDC (1 sigma power) 0.05 * 5 = 0.25 watts

+12VDC (1 sigma power) 0.03 * 12 = 0.36 watts

Total (1 sigma power) sqrt((0.25)**2+(0.36)**2) = 0.44 watts

Total power 15.46 + 3 * 0.44 = 16.8 watts

Source filename=POWERIBM CorporationPage 28 of 87

Page 29

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Example 4. Calculate the 12 volt peak current.

To compute the sum of the 12 volt peak currents the following is done.

mean

+12VDC (idle avg) 0.77 amps

+12VDC (seek peak) 1.3 amps

TOTAL 2.07 amps

Example 5. Calculate the mean plus 3 sigma 12 volt peak current.

To compute the sum of the 12 volt peak current's 1 sigma value assume all distributions are normal. Therefore the square root of the sum of the squares calculation applies.

sigma

+12VDC (idle avg) 0.02 amps

+12VDC (seek peak) 0.02 amps

TOTAL sqrt((0.02)**2+(0.02)**2)=0.028 amps

So the mean plus 3 sigma peak current is 2.07 + 3*0.028= 2.1 amps

Things to check when measuring 12 V supply current:

Null the current probe frequently. Be sure to let it warm up.

Adjust the power supply t o 12.00 V at the drive terminals.

Use a proper window width, covering an integral number of spindle revolutions.

Measure values at 25 degree C casting temperature.

Get a reliable trigger for Seek Peak readings.

Source filename=POWER IBM Corporation Page 29 of 87

Page 30

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

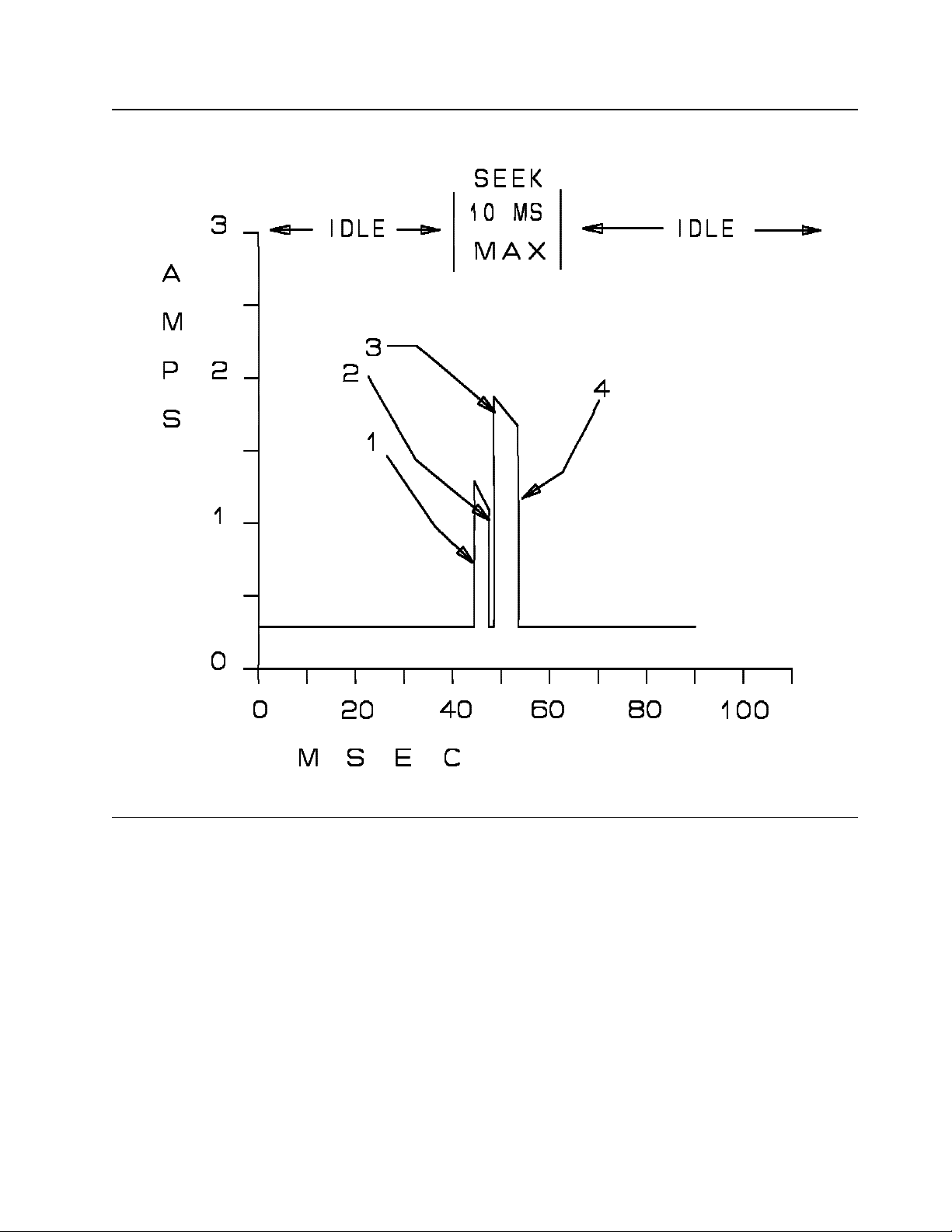

Figure 7. 5 volt current during read/write operations — C4x Models

1. Read/write baseline voltage.

2. Read/write pulse. T he width of the pulse is proportional to the number of consecutive blocks read or

written. The 5 volt supply must be able to provide the required current during this event.

Source filename=POWERIBM CorporationPage 30 of 87

Page 31

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Figure 8. Typical 12 volt current —C4x Models

1. Maximum slew rate is 7 amps/millisecond.

2. Maximum slew rate is 100 amps/millisecond.

3. Maximum slew rate is 7 amps/millisecond.

4. Maximum slew rate is 3 amps/millisecond.

Source filename=POWER IBM Corporation Page 31 of 87

Page 32

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

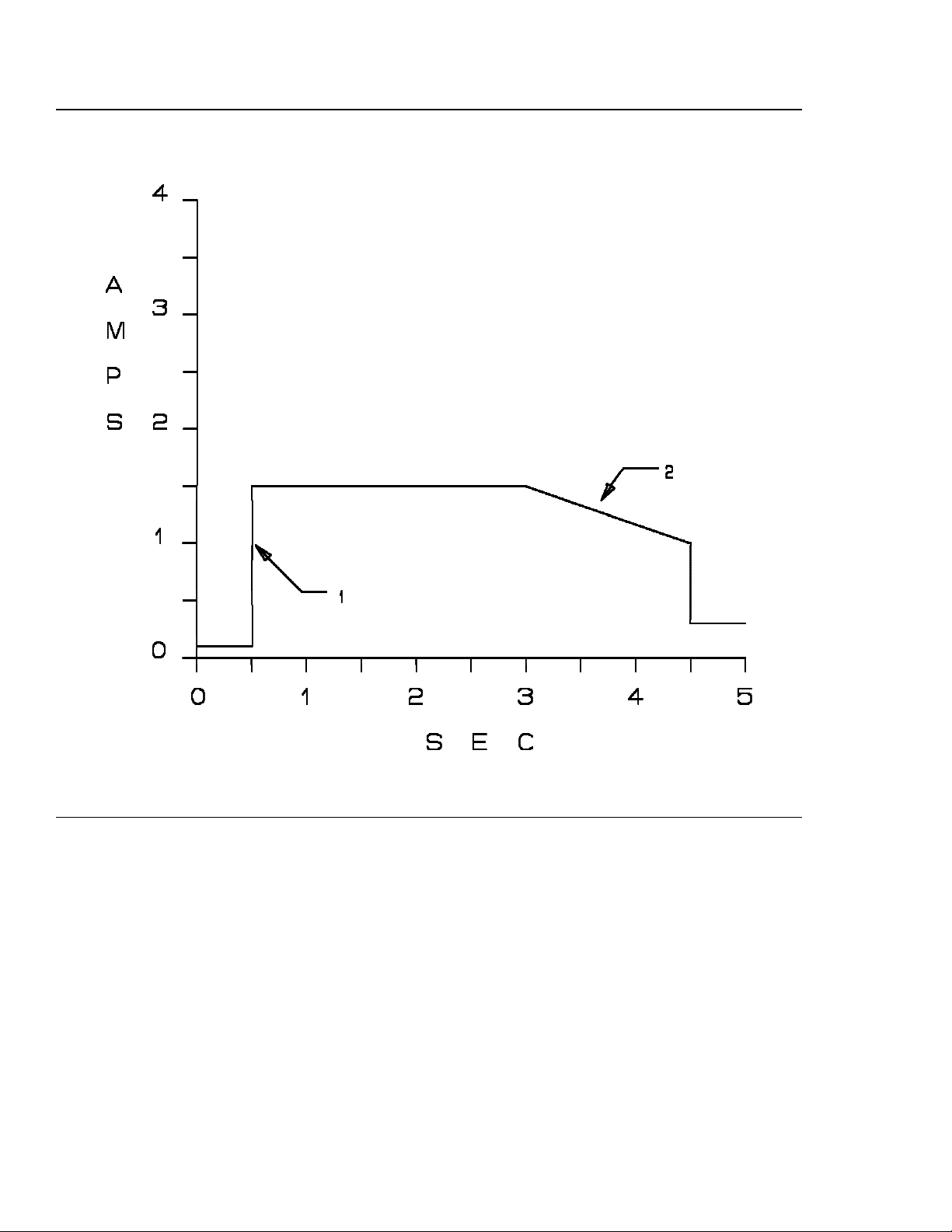

Figure 9. Typical 12 volt spin-up current — C4x Models

1. Maximum slew rate is 20 amps/millisecond.

2. Current drops off as motor comes up t o speed.

Source filename=POWERIBM CorporationPage 32 of 87

Page 33

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.4 CxB Models

Th e carrier m od el s include a DC/DC power converter, device activity and fault/service indicators. There is

no additional current required for +5 V or +12V.

2.2.4.1 Power supply methods

When +38V is applied to the interface connector pins +38V Source A, +38V Source B, and Ground, the

+ 38V supply is input to a DC/DC converter that provides +12V and + 5V t o t he drive electronics.

2.2.4.2 DC/DC Converter

Typical efficiency of this converter is 8 0% at maximum output load with input voltage at 38V.

There are tw o independent +38V power supply inputs o n the interface connector which supply two independent inputs to the DC/DC converter, +38V Source A and +38V Source B (refer to Table 12 on

page 65). The DC/DC converter will operate while one input voltage is i n th e range of +3 4V t o + 40V a n d

the other input voltage is in the range of 0 to +40 volts. Input voltage ripple must be less than 1.0 volts

peak-to-peak at the fundamental frequency of 420 H z maximum, less than 500mv at the frequency from

421hz to 1 kh z , less than 100mv at the frequency greater than 1 khz. The converter output is + 5 volts a t

0.3 amps to 2.6 amps and + 12 volts at 0.3 amps to 1.4 amps continuous current. Th e +12v output can

handle a surge current of 2.2 amps in 9 seconds.

The total input current to the converter is 1.6A amps when the highest input voltage on the power supply

input pins is +3 4 volts and t he converter outputs are operating at full load. Th e input current ripple, due to

converter switching is no more than 100 milliamps peak-to-peak at 1 M H z Maximum inrush current is

limited to 3 amps during turn on except for a maximum period of 2 microseconds (during h o t plugging)

where the current can exceed 3 amps bu t is less than 8 amps.

A DC/DC converter output enable is provided on the interface connector. This signal, +DC/DC Enable,is

pulled up within the converter. T o enable the DC outputs, this line must be at or above 2.4 volts. T o

disable t h e DC outputs, the signal must be at or below 1.4 volts.

The DC/DC converter has over-current, over-voltage, an d over-temperature detection. A ny of these conditions will latch off the converter. Th e latch is reset by insuring that both input voltages fall below + 5 volts

for a period greater than o r equal t o 10 milliseconds.

Refer to 5.5, “Option Pins and Indicators” on page 66 for descriptions of the Early Power Off Warning and

Loss of Redundancy fault signals associated wi th th e +3 8V supply inputs.

Source filename=POWER IBM Corporation Page 33 of 87

Page 34

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.5 Power Supply Ripple

Externally Generated Ripple

as seen at drive power connector Maximum Notes

+5VDC 150 mV 0-20 MHz

+12VDC 150 mV 0-20 MHz

During drive start u p a nd seeking, 12 volt ripple is generated by the drive (referred to as dynamic loading). If

several drives have their power daisy chained together then the power supply ripple plus other drive's

dynamic loading must remain within the regulation tolerance window of + /- 5%. A common supply with

separate power leads to each drive is a more desirable method of power distribution.

10

peak-to-peak

peak-to-peak

2.2.6 Grounding Requirements of the Disk Enclosure

Th e disk enclosure is at Power Supply ground potential. I t is allowable for the user mounting scheme to

common the Disk Enclosure to Frame Ground potential or t o leave it isolated from Frame Ground.

From a Electro-Magnetic Compatibility (EMC) standpoint it will, in most cases be preferable to common

the Disk Enclosure to the system's mounting frame. With this in mind, it is important that the Disk Enclosure not become an excessive return current path from the system frame t o power supply. Th e drive's

mounting frame must be within ± 150 millivolts of the drive's power supply ground. At no time should

more than 35 milliamps of current (0 t o 100Mhz) be injected into the disk enclosure.

Please contact your IB M Customer Representative if you have questions o n ho w to integrate this drive in

your system.

2.2.7 Hot plug/unplug support

Power supply and SSA link h ot plug and un-plug is allowed for all SSA models.

For Form Factor models, there is n o special sequence required for connecting 5 volt, 12 volt, or ground.

During a ho t plug-in event the drive being plugged will draw a large amount of current at the instant of

plug-in. This current spike is du e to charging the bypass capacitors o n th e drive. This current pulse may

cause t h e power supply to go out of regulation. If this supply is shared by other drives then a low voltage

power on reset ma y be initiated o n those drives. Therefore the recommendation for ho t plugging is to have

one supply for each drive. Never daisy chain the power leads if hot plugging is planned. H o t plugging

should be minimized to prevent wear o n the power connector.

The carrier models may be hot plugged ONLY IF the ground pins (longer pin) make contact first (before

other pins which are shorter). Vice versa, the carrier m ay be h ot unplugged ONLY IF the ground pins

(longer pins) are the last to remove (after other pins which are shorter). DAMAGE TO THE FILE ELEC-

TRONICS AND THE ADAPTER ELECTRONICS COULD RESULT IF THE ABOVE C OND IT ION S

ARE NO T MET. The mating HP C connector MUST HAVE PROGRAMMABLE PIN LENGTH. GN D

PINS MUST BE LONGER THAN SIGNAL AN D POWER PINS. THE GUIDE PIN S MUST BE TIED

TO THE DOKING ASSEMBLY FRAME GN D

10

This ripple must not cause the power supply to the drive to go outside of the ± 5% regulation tolerance.

Source filename=POWERIBM CorporationPage 34 of 87

Page 35

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Hot plugging t h e SSA link will be recognized by the n e x t node which will cause a configuration process to

be started by the Initiators.

During hot plugging, th e supplies must not go over the upper voltage limit. Th i s means that proper ESD

protection must be used during the plugging event.

During ho t un-plugging if the operating shock limit specification c a n be exceeded then the drive should be

issued a Start/Stop Unit command (spin down) that is allowed t o complete before un-plugging.

Source filename=POWER IBM Corporation Page 35 of 87

Page 36

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

2.2.8 Bring-up Sequence (and Stop) Times

Figure 10. Start Time Diagram

Note: BATS is the abbreviation for Basic Assurance Tests. Start-up sequence spins u p the spindle motor,

initializes the servo subsystem, up-loads code, performs BATS2 (verifies read/write hardware), resumes

"Reassign in Progress" operations, and more. Fo r more information on the start-up sequence, refer to the

Ultrastar XP (DFHC) SS A Models Interface Specification.

Note: If a RESET is issued before th e drive comes ready, the power on sequence will start again. In all

other cases when a RESET is issued the present state of the motor is not altered.

Note: Reference “Start/Stop Unit Time” o n page 49 for additional details.

Note: See 5.7, “Spindle Synchronization” on page 69 for details about Start-up time increases when the

device is requested via Mode Parameters to synchronize the spindle motor to another device.

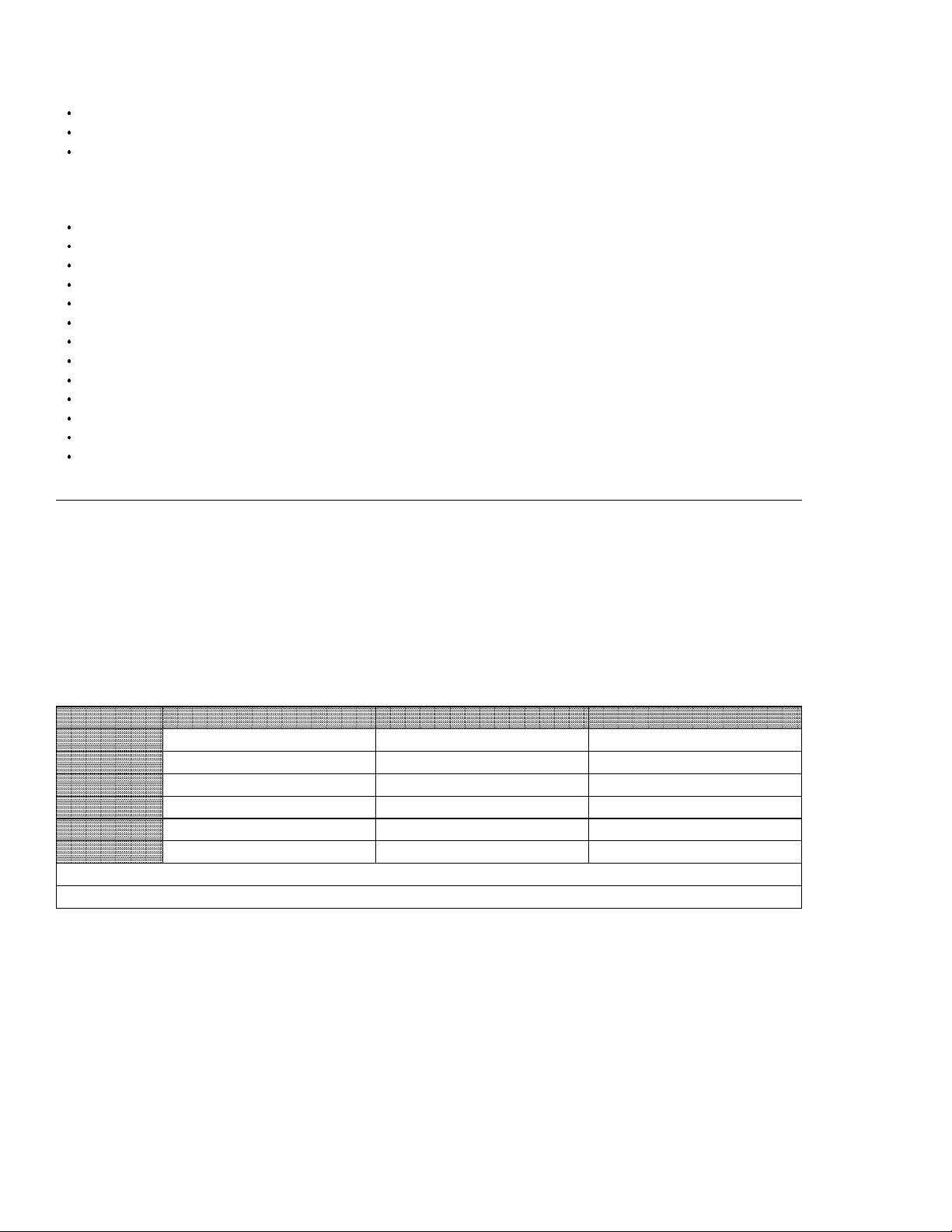

Event Nominal Maximum Notes

Power-up 1.5 sec 2.0 sec *see Figure 10

Start-up 12.4 sec 45 sec. *see Figure 10

Spin-up 8.2 sec 29.2 sec *see Figure 10

Spindle St o p 6.0 sec 12.0 sec

Table 3. Bring-up Sequence Times a nd Stop Time for C1x Models

Source filename=BRINGUPIBM CorporationPage 36 of 87

Page 37

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Event Nominal Maximum Notes

Power-up 1.5 sec 2.0 sec *see Figure 10

Start-up 17.6 sec 45 sec. *see Figure 10

Spin-up 13.2 sec 29.2 sec *see Figure 10

Spindle St o p 9.0 sec 12.0 sec

Table 4. Bring-up Sequence Times a nd Stop Time for C2x Models

Event Nominal Maximum Notes

Power-up 1.5 sec 2.0 sec *see Figure 10 o n page 36

Start-up 16.5 sec 45 sec. *see Figure 10 on page 36

Spin-up 11.17 sec 30.9 sec *see Figure 10 o n page 36

Spindle St o p 8.0 sec 12.0 sec

Table 5. Bring-up Sequence Times a nd Stop Time for C4x Models

Source filename=BRINGUP IB M Corporation Page 37 of 87

Page 38

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Source filename=PERFORMIBM CorporationPage 38 of 87

Page 39

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

3.0 Performance

Drive performance characteristics are dependent upon the workloads ru n and the environments in which

they are run.

All times listed in this chapter are typical values provided for information only, so that the performance for

environments and workloads other than those shown as examples can be approximated. Actual minimum

and maximum values will vary depending upon factors such as workload, logical and physical operating environments.

3.1 Environment Definition

Drive performance criteria is based on the following operating environment. Deviations from this environment may cause deviations from values listed in this specification.

Block lengths are formatted at 512 bytes per block.

The number of data buffer cache segments is 8. The total data buffer length is 512k bytes. Each

segment is of equal length. Therefore, each cache segment is 64k bytes.

The number of blocks of customer data that can fit into one segment is reduced because 2 bytes of L RC

information is also stored in th e segment for each block of customer data stored in the segment. Therefore, use t he following equation to determine how many blocks c an fit into one segment.

512KB

(

# of segments

ub/lba +2

Ten byte Read and Write commands are used.

SSA environment consists of a single initiator and single target with no SSA link contention.

The Initiator delay in responding t o messages from the Target is assumed to be zero.

All performance enhancing functions are disabled, except where noted. More specifically,

− Comman ds are no t queued

− Caching is disabled (RCD=1, WCE=0)

− Out of order transfers are not allowed (OOTM=0, OOTI=0)

The media is formatted with th e skew definition that optimizes the disk d a ta transfer rate for unsynchronized spindle operation.

All Current Mode Parameters are set to their Default values except where noted.

Averages are based on a sample size of 10,000 operations.

)

3.2 Workload Definition

Th e drive's performance criteria is based on the following command workloads. Deviations from these

workloads m ay cause deviations from this specification.

Operations are either all Reads or all Writes. The specifications for Command Execution Time with

Read Ahead describe exceptions to this restriction. F or that scenario all commands are preceded by a

Read command, except for sequential write commands.

The Data Transfer size is set to 64 Blocks.

Source filename=PERFORM IBM Corporation Page 39 of 87

Page 40

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

The time between the end of a n operation, and when the next operation is issued is 50 msec, +/ - a

random value of 0 to 50 msec, unless otherwise noted.

3.2.1 Sequential

N o Seeks. The target LBA for all operations is the previous L B A + 64.

3.2.2 Random

All operations are to random LBAs. The average seek is an average weighted seek.

3.3 Command Execution Time

Command execution, or service, times are th e su m of several Basic Components:

1. Seek

2. Latency

3. Command Execution Overhead

4. Data Transfer to/from Disk

5. Data Transfer to/from SSA Link

The impact or contribution of those Basic Components to Command Execution Time is a function of the

workload being sent to the drive a nd the environment in which the drive is being operated.

3.3.1 Basic Component Descriptions

Seek

The average time from the initiation of the seek, to the acknowledgement that the R/ W head is

on the track that contains the first requested L B A . Values are population averages, a nd vary as

a function of operating conditions. T h e values used t o determine Command Execution Times

for sequential commands is 0 milliseconds and th e values for random commands are shown in

section 2.0, “Specifications” on page 11.

Latency

The average time required from the activation of the read/write hardware until the target sector

has rotated to the head and the read/write begins. This time is 1/2 of a revolution of the disk, or

4.17 milliseconds.

Command Execution Overhead

The average time added to the Command Execution Time due to the processing of t he

command. It includes all ti m e the drive spends not doing a disk operation or SSA link data

transfer.

The following values are used whe n calculating the Command Execution Times.

Workload Command Execution

Sequential Read .65 ms

Sequential Write 1.00 ms

Random Read .25 ms

Random Write .30 ms

Table 6. Overhead Values

A number of Initiator controlled factors affect Command Execution Overhead. These are examined separately in 3.4, “Approximating Performance for Different Environments” on page 43.

Source filename=PERFORMIBM CorporationPage 40 of 87

Page 41

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

The Post Command Processing time of .26 ms is defined as the average time required for process

cleanup after the command has completed. If a re-instruct period faster tha n this time is used, the

difference is added t o th e Command Execution Overhead of the next operation.

Data Transfer to/from Disk

The average time used t o transfer th e data between th e media and t he drive's internal data buffer.

This is calculated from:

(Data Transferred)/(Media Transfer Rate).

There are four interpretations of Media Transfer Rate. H ow it is to be used helps decide which

interpretation is appropriate t o use.

1. Instantaneous Data Transfer Rate

The same for a given notch formatted at any of the supported logical block lengths. I t varies

by notch only and does no t include any overhead.

2. Track Data Sector Transfer Rate

Varies depending upon the formatted logical block length and varies from notch t o notch. It

includes t h e overhead associated with each individual sector. This is calculated from:

(user bytes/sector)/(individual sector time)

(Contact an IBM Customer Representative for individual sector times of the various for-

matted block lengths.)

3. Theoretical Data Sector Transfer Rate

Also includes t im e required for track and cylinder skew and overhead associated with each

track. (See 3.3.2.1, “Theoretical Data Sector Transfer Rate” on page 43 for a description on

how to calculate it.)

4. Typical Data Sector Transfer Rates

Also includes th e effects of defective sectors and skipped revolutions due to error recovery.

See Appendix B of the Ultrastar XP (DFHC) SSA Models Interface Specification for a

description of error recovery procedures.

Rates for drives formatted at 512 bytes/block are located in Table 7 on page 42.

Source filename=PERFORM IBM Corporation Page 41 of 87

Page 42

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

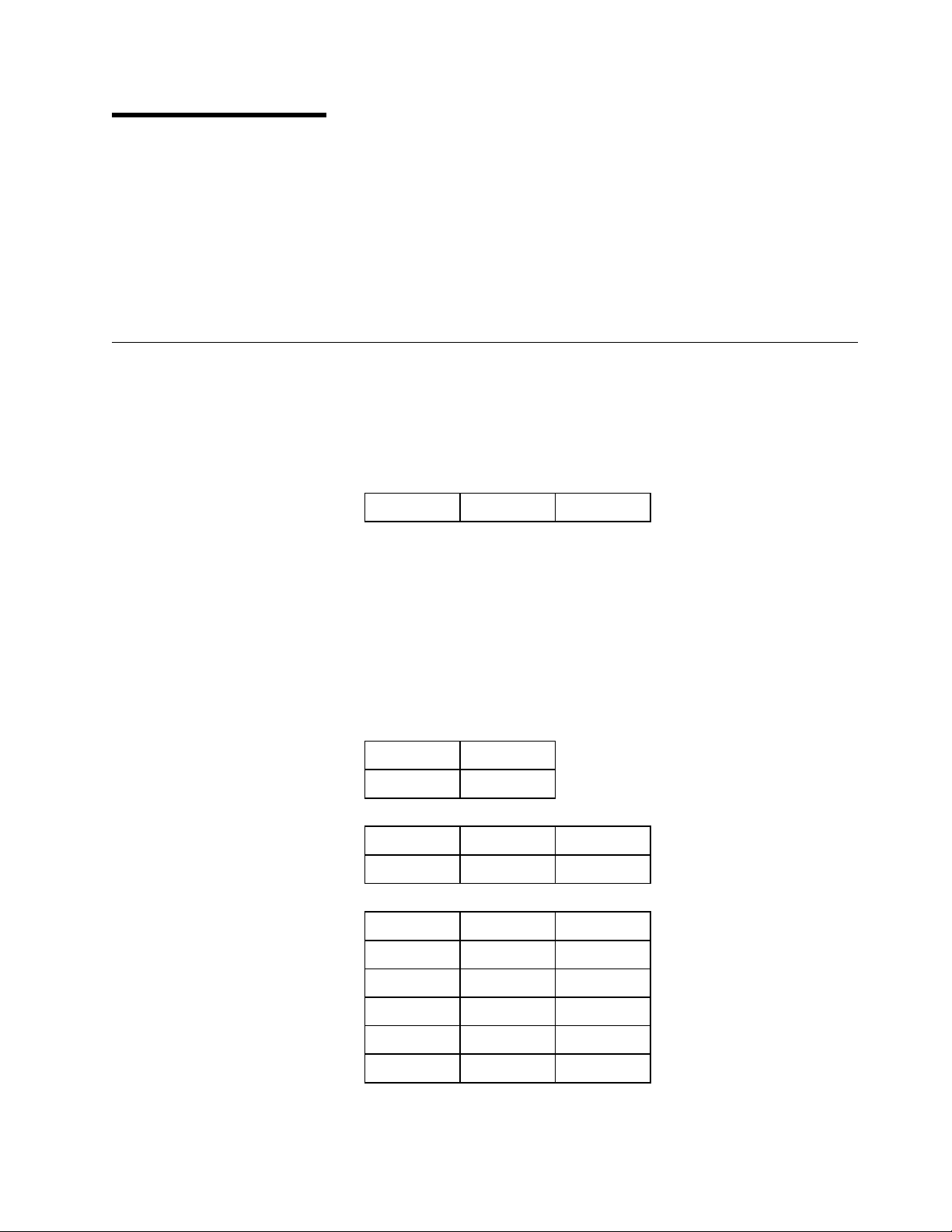

Model Type All C4x C2x C1x

Notch # Instant. Track Theoretical Typical Theoretical Typical Theoretical Typical

Average 12.07 7.91 7.17 7.13 7.13 7.10 7.06 7.03

1 12.58 8.30 7.52 7.48 7.48 7.44 7.40 7.37

2 12.58 8.30 7.52 7.48 7.48 7.44 7.40 7.37

3 12.51 7.99 7.22 7.18 7.18 7.15 7.11 7.08

4 11.96 7.74 7.02 6.99 6.99 6.95 6.92 6.89

5 11.26 7.38 6.66 6.63 6.63 6.60 6.57 6.54

6 11.05 7.07 6.41 6.38 6.38 6.35 6.31 6.28

7 10.64 6.88 6.23 6.20 6.19 6.16 6.13 6.10

8 10.29 6.64 6.03 6.00 6.00 5.97 5.94 5.91

9 10.01 6.45 5.85 5.83 5.83 5.80 5.77 5.74

10 9.59 6.15 5.55 5.53 5.53 5.50 5.48 5.45

Note: The values for Typical Data Sector Transfer Rates assume a typically worst case value of 3.16 errors in 109bits read at

nominal conditions for soft error rate.

Note: Contact an IBM Customer Representative for values when formatted at other block lengths.

Note: "Average" values a re sums of the individual notch values weighted by the number of LBAs in the associated notches.

Table 7. Data Sector Transfer Rates. (All rates are in MB/sec)

Data Transfer to/from SSA Link

The time required to transfer data between the SSA link an d the drive's internal dat a buffer, that

is n o t overlapped with t he time for the Seek, Latency or Data Transfer to/from Disk.

When the drive is reading, data is transferred from the medium to its data buffer an d from the

buffer across the SSA link simultaneously. However, data transfer t o the link from the data

buffer buffer lags transfer from the medium t o the buffer b y one block. At the e nd of the transfer

from the medium, one block still has to be transferred across the link.

For a write operation, the data is normally transferred t o the d at a buffer during the seek and

latency time. In the rare case that these are both zero, the write cannot begin until one sector is

transferred, a n d th e ti me t o do this becomes part of the overhead.

Each block of data is transferred as one or more frames on the SSA Link. Each frame requires

10 bytes of overhead and may contain up t o 128 bytes of data. The time to transfer one block

depends on the number of frames required. For example, a 744 byte block needs 6 frames (5 x

128 byte, 1 x 104). T his adds 60 bytes of overhead making 804 bytes total. At an instantaneous

transfer rate of 20MB/s, that is 40 microseconds per block (17.7MB/s sustained).

3.3.2 Comments

Overlap has been removed from the Command Execution Time calculations. The components of the

Command Execution Times are truly additive times to the entire operation. Fo r example,

The Post Command Processing times are n o t components of the Command Execution time therefore

they are not included in the calculation of environments where the re-instruct period exceeds the Post

Command Processing time.

The effects of idle time functions are not included in the above examples. The 3.2.1, “Sequential” o n

page 40 and 3.2.2, “Random” on page 40 bot h define environments where the effects due to increased

command overhead of Idle Time Functions upon Command Execution time are less than 0.15%.

Source filename=PERFORMIBM CorporationPage 42 of 87

Page 43

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

3.3.2.1 Theoretical Data Sector Transfer Rate

This Rate does no t account for time required for error recovery or defective sectors (the Typical Data Sector

Transfer Rate described in 3.3.1, “Basic Component Descriptions” on page 40 does include those effects).

Each group of cylinders with a different number of gross sectors per track is called a notch. Th e following

shows values for notch #1 of C4x models. Th e "Average" values used in this specification are sums of the

individual notch values weighted b y the number of LBAs in the associated notches. Fo r the other notches

and block lengths use values that correspond to those notches and block lengths.

Data Sector Transfer Rate =

Bytes/cylinder

time for 1 cyl+ track skews + 1 cyl skew

Bytes/cylinder = {(tracks/cyl)(gross sectors/track) - spares/cyl}(user bytes/sector)

= {(16)(135) - 40}(512)

= 1,085,440 Bytes/cyl

time for 1 cyl of data = {(tracks/cyl)(gross sectors/track) - spares/cyl}(avg. sector time)

= {(16)(135) - 40}(.061705)

= 130.815 msec/cyl

time for track skews = (tracks/cyl - 1)(track skew)(avg. sector time)

= (16-1)(13)(.061700)

= 12.032 msec/cyl

time for 1 cyl skew = (cylinder skew)(avg. sector time)

= (25)(.061705)

= 1.543 msec/cyl

Data Sector Transfer Rate =

1,085,440 Bytes

130.815 msec + 12.032 msec + 1.543 msec

= 7.517 MB/sec (Notch #1)

Note: See 2.0, “Specifications” on page 11 for the descriptions of

tracks/cyl (trk/cyl)

gross sectors/track (gs/trk)

spares/cyl (b1spr/cyl an d b2spr/cyl)

user bytes/sector (ub/sct)

gross bytes/sector (gb/sct)

See 3.5, “Skew” o n page 46 for the descriptions of

track skew (tss)

cylinder skew (css)

Average sector times per notch can be calculated as follows:

average sector time (ast) =

1 sec

120.045 × gs/trk

3.4 Approximating Performance for Different Environments

Source filename=PERFORM IBM Corporation Page 43 of 87

Page 44

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

3.4.1 For Different Transfer Sizes

The primary performance change due to a change of transfer size is the Data Transfer to/from Disk parameter. See 3.3.1, “Basic Component Descriptions” on page 40 for an explanation of the calculation of this

parameter.

The Command Execution Overhead m ay also change if the transfer size is reduced to the point where certain

internal control functions can n o longer be overlapped with either t he SSA Link or Disk data transfer.

For example, a short read may incur u p t o .65ms extra overhead if t he Data Ready/Reply exchange does not

overlap th e disk transfer.

3.4.2 When Read Caching i s Enabled

For read commands with Read Caching Enabled Command Execution time can be approximated by

deleting Seek, Latency, and Data Transfer to/from Disk components if all of the requested data is available

in a cache segment (cache hit). Command Execution Overhead increases by approximately .1ms in this case

as there is n o overlap with seek/latency.

When some, bu t n o t all, of the requested data is available in a cache segment (partial cache hit) Data

Transfer to/from Disk will be reduced b u t n ot eliminated. Seek and Latency may or may n o t be reduced

depending upon the location of requested data not in the cache and location of the read/write heads at the

time the command was received.

The contribution of the Data Transfer to/from SSA link to the Command Execution time may increase since

a larger, or entire, portion of the transfer may no longer be overlapped with the components that were

reduced.

3.4.3 When Write Caching i s Enabled

For write commands with th e Write Caching Enabled (WCE) Mode parameter bit set, Command Execution

time can be approximated by deleting Seek, Latency, and Data Transfer to/from Disk components. The

contribution of the Data Transfer to/from SSA link to th e Command Execution time may increase since a

larger, or entire, portion of the transfer may no longer be overlapped with the components that were

reduced. T h e reduced times effectively are added to the Post Command Processing Time.

Command completion status is returned when data is completely stored in the buffer. T he time to transfer

this group of data to the disk will be added to the performance of any next command that was in the queue.

3.4.4 When Adaptive Caching is Enabled

The Adaptive Caching feature attempts to increase Read Cache hit ratios by monitoring workload and

adjusting cache control parameters, normally determined by the using system via th e Mode Parameters, with

algorithms using the collected workload information.

3.4.5 When Read-ahead is Enabled

If read-ahead is active, th e service tim e is affected i n several ways:

If the data requested by a read command is all in the data buffer already, t h e command can be serviced

very quickly.

If th e beginning of the requested dat a is in t he buffer, an d the read-ahead is still in progress, data transfer

Source filename=PERFORMIBM CorporationPage 44 of 87

Page 45

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

for the command can start immediately. This effectively avoids latency tim e for read operations sequential on a previous read.

If the data requested by a read operation is not in the read-ahead buffers, there is an increase in t h e

command overhead time due to the time spent searching t h e buffers. This time depends o n the number

of buffer segments selected by the Mode Select command.

If read-ahead is still in progress whe n the next command is received and th e data requested is not

sequential, the drive aborts read-ahead and starts the command. T he time t o perform this abort

increases t he Command Execution Overhead by .23ms.

3.4.6 When No Seek is Required

For a Read command, the additional Command Execution Overhead when no seek is required is approximately .50ms. For a Write, it is approximately .70ms.

3.4.7 For Queued Commands

If commands are sent t o the drive wh en it is busy performing a previous command, they can be queued. I n

this case, some of the command processing is performed during the previous command and the overhead for

the queued command is reduced by approximately .20 milliseconds.

3.4.7.1 Reordered Commands

If the Queue Algorithm Modifier Mode Parameter field is set to allow it, commands in the device command

queue may be executed in a different order than they were received. Commands are reordered so that the

seek portion of Command Execution time is minimized. The amount of reduction is a function of the

location of the 1st requested block per command and the rate at which t he commands are sent to th e drive.

A Queue Algorithm Modifier Mode Parameter value of 9 enables an algorithm that gives the using system

the ability t o place ne w commands into the drive command queue execution order relative to t h e outstanding commands in the queue. For example, if a request is sent to the drive that the using system prioritizes such that it's completion time is more important than one or more of the outstanding commands, the

using system can increase the likelihood that command is executed before those others by using a tag value

greater than those outstanding commands.

3.4.7.2 Back-To-Back Commands

If consecutive read/write commands access contiguous data, they can be serviced without incurring disk

latency between commands.

Note: There is a minimum transfer length for a given environment where continuous access to t he disk can

not be maintained without missing a motor revolution. For Write commands with Write Caching enabled

the likelihood is increased that shorter transfers c a n fulfill the requirements needed to maintain continuous

writing to the disk.

Back-to-back Read is only enabled if Read-ahead is disabled.

3.4.8 Out of Order Transfers

Tw o bits in th e SCSI Command message control out of order transfers. OOTM applies to transfers to/from

the media a nd OOTI applies to transfers to/from the interface (SSA Link).

Th e benefit from setting OOTM increases as t h e transfer length approaches o ne disk revolution. This affects

both reads an d writes and is du e to the reduction in latency.

Source filename=PERFORM IBM Corporation Page 45 of 87

Page 46

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

The full benefit of o ut of order transfers in only achieved if OOTI is also set. Read data is transferred on the

interface in t h e same order as it was read from the media.

3.5 Skew

3.5.1 Cylinder to Cylinder Skew

Cylinder skew is the s um of the sectors required for physically moving the heads (csms), which is a function

of the formatted block length and recording density (notch #), and reassign allowance sectors (ras = 3) used

to maintain optimum performance over t he normal life of the drive.

Note: The values in t h e Mode Page 3 'Cylinder Skew Factor' are notch specific non-synchronized spindle

mode values. The value for notch 1 is returned when the Active Notch is set to 0.

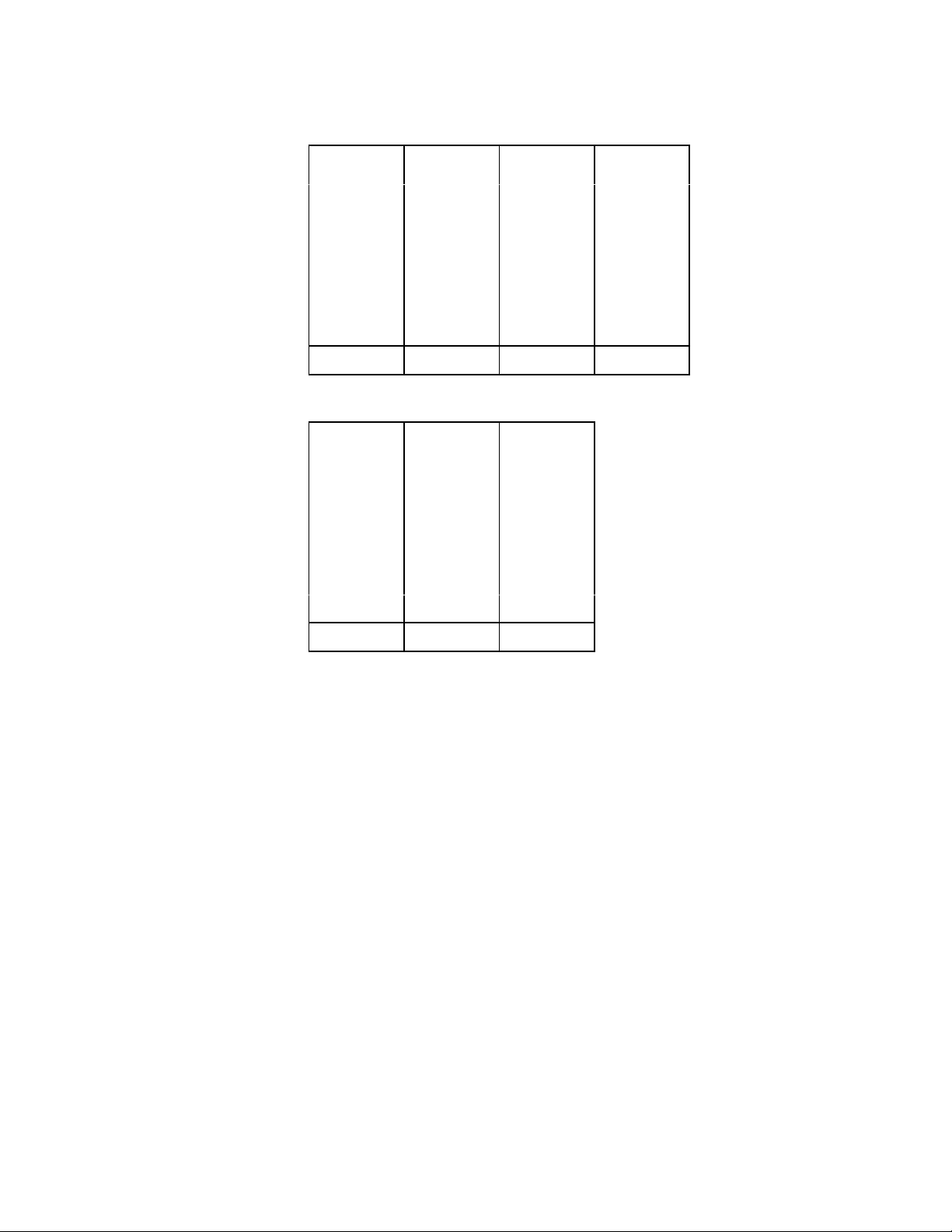

Notch #

User bytes / logical

block

256 42 42 42 40 38 36 36 36 36 32

512 28 28 27 26 25 24 24 23 22 21

520 26 26 26 26 24 24 23 22 22 21

522 26 26 26 25 24 24 23 22 22 20

524 26 26 26 25 24 24 23 22 22 20

528 26 26 26 25 24 24 23 22 22 20

600 24 24 24 23 22 22 21 20 20 20

688 22 22 22 21 20 20 20 20 18 18

744 21 21 21 20 20 20 18 18 17 17

Note: Contact an IBM Customer Representative for values at other formatted block lengths.

Table 8. Optimal Cylinder Skew for several block lengths

1 2 3 4 5 6 7 8 9 10

In order to increase th e likelihood that equivalent LBA's on two or more devices are located at the same

relative physical position when the devices ar e used in a synchronized spindle mode, cylinder skew is calculated differently. The cylinder skew calculations d o n o t take into account known defective sites. To prohibit

revolutions from being missed on cylinder crossings by drives formatted while i n a synchronized spindle

mode, an extra allowance for 6 defects is added that is not added when optimally formatted in a nonsynchronized mode.

3.5.2 Track t o Track Skew

Note: The values in t h e SCSI Mode Page 3 'Track Skew Factor' are notch specific values. The value for

notch 1 is returned when the Active Notch is set to 0.

Source filename=PERFORMIBM CorporationPage 46 of 87

Page 47

USER RESPONSIBLE FOR VERIFYING VERSION AND COMPLETENESS

OEM FUNCTIONAL SPECIFICATION ULTRASTAR XP (DFHC) SSA MODELS 1.12/2.25 GB - 1.0" HIGH

Notch #

User bytes / logical

block

256 20 20 20 19 19 17 17 17 17 15

512 13 13 13 12 12 11 11 10 10 10

520 12 12 12 12 11 11 10 10 10 10

522 12 12 12 12 11 11 10 10 10 9

524 12 12 12 12 11 11 10 10 10 9

528 12 12 12 12 11 11 10 10 10 9

600 11 11 11 11 10 10 10 9 9 9

688 10 10 10 10 9 9 9 9 8 8

744 9 9 9 9 9 9 8 8 8 7

Note: Contact an IBM Customer Representative for values at other formatted block lengths.

Table 9. Track (or Head) Skew f or several block lengths

1 2 3 4 5 6 7 8 9 10

3.6 Idle Time Functions

The execution of various functions by the drive during idle times may result in delays of commands

requested by initiators. ‘Idle time’ is defined as time spent by the drive n ot executing a command requested

by a initiator. Th e functions performed during idle time are:

1. Servo R un Out Measurements

2. Servo Bias Measurements

3. Predictive Failure Analysis (PFA)

4. Channel Calibration

5. Save Logs a nd Pointers

6. Disk Sweep

The command execution time for commands received while performing idle time activities may be increased

by the amount of time it takes t o complete the idle time activity. The messages and d a t a exchanged across

the SSA link are no t affected by idle time activities.

Note: Command Timeout Limits do no t change d ue to idle time functions.