Page 1

IBM

ELECTRIC TYPEWRITER

MODEL

CUSTOMER ENGINEERING

REFERENCE MANUAL

Mechanical Principles

CONTENTS

NelV JPeatures _________________________________ 3

Case

and

~otor

Keylevers,

Resilient

~aper.nent

Space

ldargin

!4argbl

Line

Carriage

Paper

I>ecelerator ___________________________________ 22

Tabulation

Backspace

-Carriage

Shut

Ribbon,

Ribbon,

Covers

and

])rive

Letter

Keyboard

Bar

_____________________________________

Reset

Release

Lock

_____________________________________

and

Feed

Return

_________________________________________

Carbon

Fabric

______________________________ 3

____

~__________________________

Cams,

___________________________________

Rails _____________________________ 18

____________________________________

___________________________________ 25

____________________________________ 30

Control

__________________________________ 15

________________________________ 16

and

Line

________________________________ 36

________________________________ 39

C-l

and

Adjustments

Type

Bars

____________ 7

____________________ 10

Space

_______________ 31

P"g.

34

•

11

13

17

21

:INTERNATIONAL

NelV

Form

241-5002-0

BUSINESS

York

22, NelV

(this

MACHINES

York

section

only)

CORP.

/

Page 2

INTERNATIONAL

590

MADISON A VENUE.

Printed

© 1958

BUSu\ESS

NEW

In

U. S.

Form

241-5002-0

MACHINES CORP.·

YORK

22.

NEW

A.

1958

YOBK

(

I

Page 3

IBM ELECTRIC

STANDARD TYPEWRITER

MODEL

This

Model

above.

APPEARANCE.

been

tional

DECELERATOR.

quiets

riage

operate

RESILIENT KEYBOARD CONTROL.

pos~tions

mits

individual

SHIFT.

operation

MARGIN RESET.

been

malfunction

PLATEN

enclosed

RIBBON

feed

provide

feeding.

RIBBON

bon

typewriter

easier

CARRIAGE.

in

section

C1

completely

and

the

return

during

the

The

made

within

mechanism

cleaner,

mechanism

threading

13, 17, 20, 24

describes

typewriter,

The

case

redesigned

aesthetic

carriage

by

spring

operator

requirements.

and

easier

eliminated.

RATCHET.

MECHANISM-FABRIC.

MECHANISM-CARBON.

case

enabling

either

fingers

to

shift

the

the

has

faster

is

and

and

The

and

The

action

mechanism

adjustments

The

to

completely

Model C

improvements.

operation.

set

operate

left-hand

been

has

more

30

C-l

the

serial

numbers

and

to

decelerator

during

the

centrifugal

under

the

the

touch

margin

and

The

platen

carriage-end

completely

ribbon

been

accurate

inch

changing,

typewriter

carriage

new

features

cover

include

tabulation

key

to

has

been

simplified.

reset

the

ratchet

7he

The

contained

improved

feeding.

of

1,100,000

sections

many

improves

and

governor

This

levers

suit his

mechanism

lengths.

control

and

or

improved

possibility

has

cover.

fabric

and

carbon

within

to

is

available

ribbon

positive

provide

redesigned

the

and

have

func-

and

car-

to

per-

her

in

has

of

been

to

rib-

the

CASE AND COVER SECTIONS

The

typewriter

tion

or

case

and

Bristo

Four

shell. A

is

down

corner

in

the

are

rubber

with

screws

tom

section

latched

front

Lugs

Carriage-end

tons

by

rear

two

hinged

over

of

bottom

covers

secured

mounts,

is

contained

cover-section

long

to

the

the

the

keyplate

bottom

case-section

contain

over

inside

of

in a bottom

screws.

bottom

case-section

anchor

the

carriage-release

each

the

end

screwed

3

mounts

The

front

case-section

by a latch

the

end

of

the

covers.

to

the

case-sec-

to

the

bot-

cover-

and

at

each

(Figure

typewriter

1).

keyplate.

but-

carriage

Page 4

MODEl

CI

CUSTOMER ENGINEERING

side frames

through

mcunts. This gives

ing when in

desk

and

ing.

A locking

chors

the

desk. By sliding

machine

removed from

A removable bottom

case section

This

panel

ments

working

the

typewriter

the

typewriter

may

and

may also

on

set

into

bottom case

its

case

bar

be

the

and

can

be

the

machine.

the

bottom case. Base feet pass

and

the

typewriter

and

when

inside

to two desk mounts, secured to

the

quickly

desk.

panel

serves

easily removed

be

used

screw into

provides protection

it

the

locking

and

to

a resilient mount-

is removed

bottom case-section

easily attached to

slides into

protect

to

protect

bar

the

to

make

the

the

for

laterally

the

typewriter.

desk

r~

I .. '

rubber

to

the

servic-

anthe

bottom-

adjuat-

whell

.'

...

---

or

Figll"

1.

CdS'

"nil

COfl81'

Meeh""isfIJ

Removal

CASE

aDeI

COVERS

1.

Release

2.

Remove

mounting screws. (

3.

Disconnect

sembly,

the

C clips

the

front cover.

the

the

on

each side

and

front

rear

the

hinges from

pushing

cover-latch

cover by removing

of

in

the

on

4

••

the

ann

machine,

the

arms,

and

shatt

by

remcwinl

and

its

w..

u-

remove

Page 5

REFERENCE

4.

Remove

MANUAL

the

mounting-brackets

keyplate.

5. Disconnect

separating

6.

Turn

base

feet,

free

of

the

CARRIAGE

roll-release,

two

end-cover

TOP

PAPER

the

the

male

the

machine

and

allow

base section.

END

or

detent-release

mounting-screws.

TABLE.

ward.

CASE

and

1.

KEYPLATE.

COVERS

mounting-brackets

front

case-section smoothly.

operate

2.

tion

section

The

freely

HINGES.

when

the

to

clear

front

case

without

Adjust

latches

shall

raiserl position .

.3. LATCHES.

keyplate

and

line

and

up

the

by

raising

cord

female

on

its back.

power

removing

the

at

COVERS. Remove

lever

Pull

the

rear

Adjustments

Adjust

the

Adjust

so

that

binding.

so

there

are

bottom

not

by

forming

the

The

is sufficient

released

case

contact

by

positioning

the

front

the

typewriter

plug.

unscrew

frame

the

platen.

and

edie

the

keyplate

keybuttons

for

the

at

the

the

bail

MODEl

keyplate

edge

of

the

to

tip

loosen

up

and

keyplate

joins

vertical

front

front

roll

in

the

Cl

the

by

four

back

feed-

the

for-

the

shall

mo-

case-

edge.

full

latch

Latch

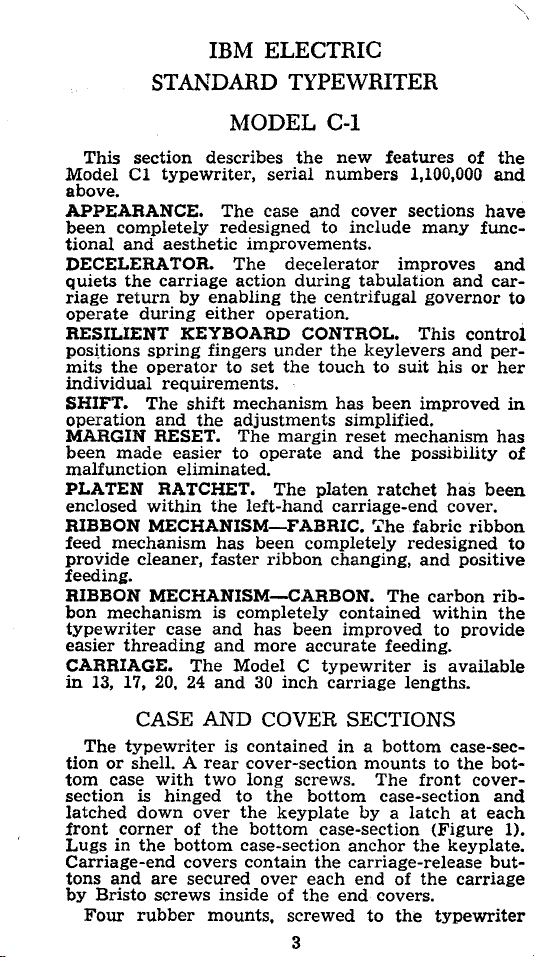

Figure 2. Front Cover Latch

5

Page 6

MODEl

Cl

CUSTOMER

ENGINEERING

mounting

the

~2"-O.

the

(Figure

4.

ance

of

%2"

The

main

bracket

front-case-section

There

front

and

2).

PLATEN

between

to

3i14".

motor, drive,

essentially

B machine.

simplify

removal

conform to

The

motor

space for

The

the

to

simplify

ring

left

rear-rail

mount

mounting

so

that

the

latches

pin

by

shall

be a maximum

bottom

KNOBS.

the

left

case-sections

Adjust

and

stock

to

right

MOTOR AND DRIVE

and

the

Changes

the

new

is a

is

motor

and

new

the

has

removal

electrical

same

in

operation

have

been

adjustment

case design.

3" design

mechanisms

same

as

been

placed on

procedures

and

the

bottom

thickness

of

when

have

carriage-end

~"

equal

against

plus

between

latched

clear-

covers

mechanisms

as

the

in

allow

save

Model

design

and

more

weight.

made

procedures,

used

to

to

Model B; however,

the

rear

(Figure

frame

3).

re-

to

to

CAUTION:

motor,

LINE

The

drive,

CORD

line

cord

SwItch

IndIcator

Figul'e 3. Motol' and Dl'ive

Removal

Unplug

and

is

machine

when

electrical components.

removable

by

means

6

servicing

the-

of a pluggable

(

Page 7

REFERENCE

unit

attached

slot

low

CAUTION:

installing,

MANUAL MODEl

to

the

rear

in

the

Plug

to

prevent

rear

must

frame. Access

portion

be

properly

of

possible shock

MOTOR

1.

Remove complete case

2. Remove

screw

3. Disconnect

lever

4.

Remove

rear

frame

and

rear

from

spring,

frame.

the

the

to

and

the

the

belts

left

the

the

six

side-frame.

side frames,

and

and

the

tab-lever

tab-set

mounting

and

SWITCH

The

switch

frame

disconnecting

by

removing

may

the

be

removed

the

rear

switch

cover,

wiring.

POWER ROLL

1.

Remove complete case

2.

Refer

to

Model

The

lower

Note:

longer

ribbon

and

mechanism.

power-roll-bearing-retainer

serves

BI,

also as a

and

Power

Adjustments

1.

SWITCH.

Adjustment

2.

BEARINGS.

Adjustment

3. POWER ROLL END PLAY.

Motor

and

4. DRIVEN BELT.

Drive,

5.

tor

6.

Drive,

Adjustment

POWER ROLL SPEED.

and

DRIVE BELT.

Adjustment

7. MOTOR MOUNTINGS.

justed

without

bottom

screws

and

Refer

1.

Refer

2.

Drive,

Drive,

Adjustment

Adjustment

removing

case-section

repositioning

to

Refer

4.

Refer

6.

Model

to

Model

by

the

to

Refer

5.

to

Belt

the

loosening

motor.

the

bottom

seated,

hazard.

cover sections.

is

belt

tension

spring,

and

tab-clear

studs

remove

from

the

the

switch

cover

tab-actuating-

links.

that

right

sections.

Roll Removal.

spring

BI,

BI,

anchor

Motor

Motor

Refer

and

to

and

Model

3.

Model

Model

BI.

to

Model

BI.

tension

Motor

Motor

may

typewriter

the

Cl

through

case.

when

re-

adjusting-

hold

the

the

motor

side-

nut,

and

screw

for

the

Drive.

Drive.

BI,

and

BI,

Mo-

and

be

ad-

from

the

mounting

a

is

KEYLEVERS,C~S,TYPEBARS

The

keylever, cam.

Model C

is

B. However,

theoretically

the

and

typebar

the

same

keylevers, cams,

'I

operation

as

and

trip

on

the

levers

of

the

Model

have,

Page 8

MODEl

been

ration.

previous

underscore

provided

either

lever-bearing

crum

ing

frames

keylever

slightly

An

86

The

rod

support.

Cl

These

model

or

as

position

keylevers

held

and

to

'ij

redesigned

parts

typewriters.

88

character

is

the

only

standard

39

or

are

support

by

formed

The

assembly

is

adjustable

trip

lever

CUSTOMER ENGINEERING

in

order

to

are

not

keyboard

repeat/non-repeat

equipment

41.

mounted

and

fulcrum

lugs

in

clearance

improve

interchangeable

is

available.

and

is

available

in a redesigned

on a heavier

in

the

is

order

keylever-bear-

mounted

to

(Figure

to

obtain

4).

letter

their

the

proper

o~

with

The

key

in

key-

ful-

side

\-CIiP

PiK,,'e

4.

Keylefler Bearing

Each

row

of

spring. color coded for easy identification,

uniform

so

shift

sition.

the

guide-comb

available

. only.

been

with

touch.

that

all

are

Redesign

spring-loaded

Repeat/non-repeat

altered

a single piece

keylevers

The

functional

locked

of

the

to

be

for

carriage

by

replacing

when

repeat

plunger

redesigned.

keylever

has a different

keylever

and

letter

the

switch

letter

has

return,

letter

the

8

SII/Jpo,t

locking

containing

bar

keylevers

is

in

keylever

caused

Plunger

tab,

and

key

spring-loaded

operation

restoring

to

provide

is designed

except

the

OFF

to

eliminate

the

key

positions

an

lever

backspace

plunger

elongated

the

po-

are

has

Page 9

.£FERENCE MANUAL

MODEl

Cl

fulcrum-rod

keylever

(Figure

operation

the

the

places

erating

If

sired

keylever

The

operation

and a spring

5). .

takes

resistance

fulcrum

the

repeat

position.

Figlln 5.

additional

a two-piece

position.

letter

and

models.

KEYLEVEBS

1.

Remove

2.

Remove

3.

Disconnect

4. Remove

mounting

5.

6.

the

7.

lever

8.

and

keylever

9.

studs.

Disconnect

Insert

desired

a follow-up

keylever.

Remove

guide-comb

Lower

push

the

it

clears

Remove

hole. A

spring

is connected

bracket

As

the

keylever

place. As

of

the

point

upper

of

the

step

of

Rq,_/Non·Rej1UI

more

spring

keylever

the

trip-lever

is

repeat/non-repeat

cam

is

keylever

has

not

may

been

interchan~eable

reshaped

Removal

the

typewriter

the

resilient-keyboard-control

the

spacebar-switch-Iock shaft.

the

front

the

keylever

the

two

and

rear

the

of

the

the

guide-comb.

keylever

toward

from

frame

spring.

fulcrum

mounting

pivot

the

the

keylever

rear

of

by

9

by

the

pulling

above

the

keylever

depressed a single

between

pressure

is

applied

is overcome and

lowered.

lug

in

the

K~lwN

letter

cams

for

with

are

in

smoother

previous

section.

be

installed

the

base

indicator.

removing

rod

to

studs

guide-comb

between

machine

the

from

the

depth

the

forward.

the

cams

until

forward.

the

This

op-

de-

any

four

of

key-

the

Page 10

MODEL

Cl

CUSTOMER

ENGINEERING

LETTER

Refer

CAMS

to

Model

Bl,

Cam

Removal

Adjustments

1. CAM CLEARANCE

Bl

section.

2. KEYLEVER

sitioning

keylevers

plus

, guide-comb

or

the

trip

minus

(Figure

key

the

;.64"

3. INDIVIDUAL KEYLEVERS. Raise

conform

screwdriver

NOTE: Do

hammer

will

to

as

result.

adjustment

or

compress lugs

not

form

damage

•.

015"

BEARING

lever-bearing

cams

when

from

the

4).

2.

Spread

keylevers

to

the

to

.020".

SUPPORT.

support

the

bottom

key

with

pliers.

with

keylever-bearing

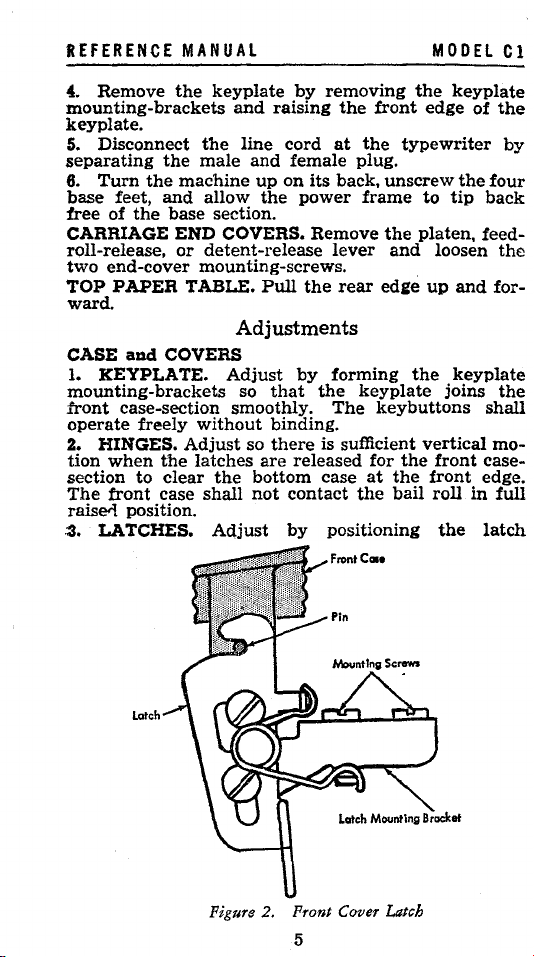

RESILIENT KEYBOARD CONTROL

The

resilient-keyboard

of

the

impression

erator

with a means

keylevers

resistance

path

of

varying

settings

travel

are

1. L - No

2.

3.

to

suit

is supplied

of

the

position

available

M -

H -

control

her

the

Some

Maximum

control, located

indicator, provides

of

varying

touch

by

flat

keylevers,

of

the

to

the

flat

flat

(Figure

springs,

flat

operator:

spring

spring

flat

the

and

springs.

contact.

spring

resistance

is

contact.

Procedure.

Refer

to

Adjust

so

that

keylever

of

the

key

or

lower

lever

lugs

"T"

bender

support

to

the

the

6).

This

mounted

determined

Three

contact.

Model

by

po-

the

is

¥.!2'"

lever

to

with

or

left

op-

of

the

added

in

the

by

major

Figure

6.

Resilient Keyboard Control

10

Page 11

REFERENCE

1.

Remove

2.

Remove

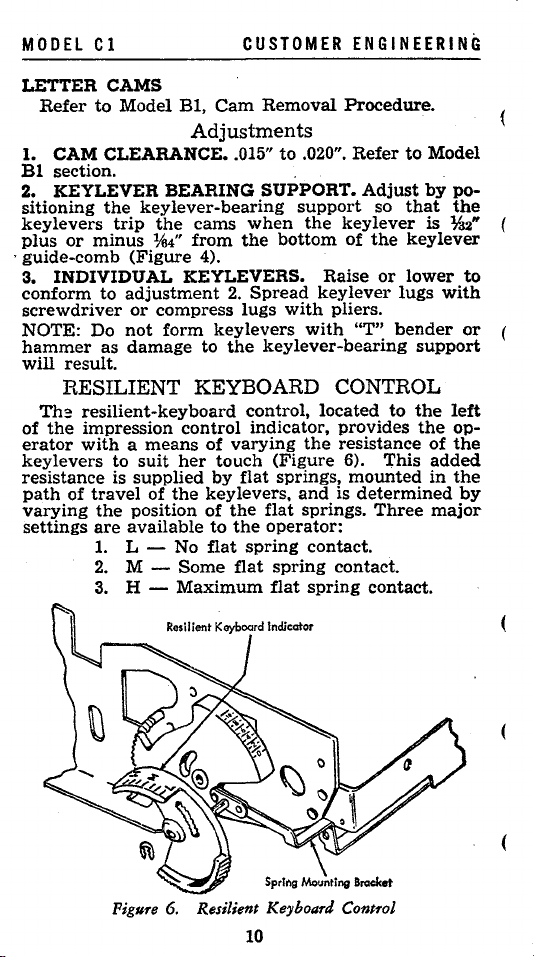

SPRING

mounting

the

key

:tween

the

FINGERS.

bracket

levers

the

spring

Figure

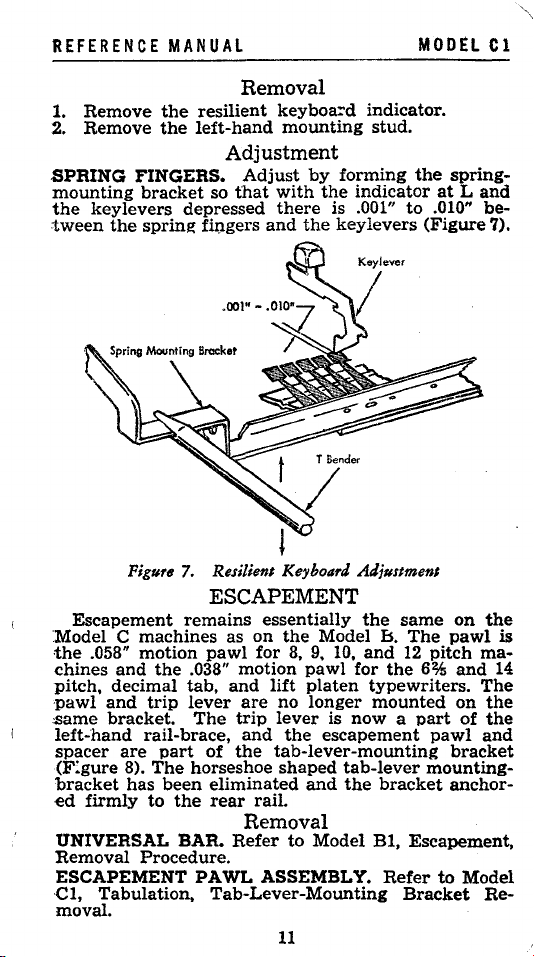

Escapement

Model C

the

chines

pitch,

'pawl

same

left-hand

spacer

(F:gure

bracket

ed

UNIVERSAL

Removal

ESCAPEMENT

Cl,

machines

.058"

motion

and

the

decimal

and

trip

bracket.

rail-brace,

are

8).

The

has

firmly

to

Procedure.

Tabulation,

part

moval.

MANUAL

Removal

the

resilient

left-hand

keyboa=d

mounting

Adjustment

Adjust

so

that

depressed

fingers

7.

Resilient Keyboard Adjustment

with

there

and

by

the

the

ESCAPEMENT

remains

.038"

tab,

lever

The

horseshoe

been

the

essentially

as

on

pawl

for

motion

and

lift

are

trip

lever

and

of

the

tab-lever-mounting

eliminated

rear

rail.

the

Model B.

8, 9, 10,

pawl

platen

no

longer

the

escapement

shaped

and

Removal

BAR.

Refer

to

Model

PAWL

ASSEMBLY.

Tab-Lever-Mounting

11

indicator.

stud.

forming

indicator

is .001"

keylevers

the

and

for

the

typewriters.

mounted

is

now a part

tab-lever

the

bracket

Bl,

Refer

MODEl

the

spring-

at

Land

H

to

.010

be-

(Figure

same

on

pawl

pitch

and

the

ma-

The

12

6%

The

on

the

of

the

pawl

and

bracket

mounting-

anchor-

Escapement,

to

Model

Bracket

Re-

Cl

7).

is

14

Page 12

MODEl

I.

be

injury

riage

drum.

follQwing

Cl

MAIHSPRING.

exercised

resulting

Tension

tension-tape

This

steps:

A.

Position

tab

check-lever

stop

on

B.

Set

C.

Hold

and

latch

D.

Gently

tab-check

Figure

8.Escllpemenl Mech,,,,istn

Adjustments

when

is

adjusted

adjustment

the

the

the

CAUTION:

servicing

from a disengaged

on

the

carriage

is

right

end

last

tab-stop.

carriage

the tab

position

lever

and

CUSTOMER

by

placing

various

may

directly

of

to

lever

the

release

12

this

lugs

be

checked

so

opposite

the

rack.

prevent

out.

set

tab-stop

the

ENGINEERING

Extreme

assembly

mainspring.

the

loop

of

the

through

that

the

the

any

carriage.

care

must

to

avoid

of

the

mainspring

against

car-

the

tip

of

the

last

tab-

movement

the

Page 13

IE

FE R ENe E MAN

E.

The

sion

to

A push-pull scale

tension

a slow

tion

erator

13" Carriage --

in

the

and

to

the

range). Tension shall

U A l

main

unlatch

spring should have suflicient

the

tab.

may

following manner.

steady

extreme

21h

rate

right

lbs. +

from

be

used

to

measure carriage

Pull

the

extreme

position, (excluding decel-

be

as follows:

Jf.&

- 0 Ibs.

lbs. maximum.

17" Carriage --

Ibs. maximum.

H

20

Carriage

lbs. maximum.

J4" Carriage

21h

lbs. +

'14

-0

lbs.

.-

2%

-.

lbs.+

23,4

Ibs. +

Jf.&

- 0 lhs.

¥.&

- 0 Ibs.

Ibs. maximum.

80'" Carriage •• 3 Ibs; +

Ibs. maximum.

2. UNIVERSAL BAR. Refer

Adjustment

men!;

I.

ADJUSTING PLATE ON UNIVERSAL

Refer

to Model

4.

TRIP

LINK:. Refer to Model

Adjustment

2.

Bl,

4.

~

- 0 lbs.

to

Model

~apement.

Adjustment

Bl,

SPACEBAR

The

repeat

tion

release

Depression of

spacebar features a controlled

action.

has

link

The

been

connected directly

spacebar cam release-lever rota-

reversed

the

spacebar

to

permit

to

through

the

the

its

MODEl

tl

ten-

the

at

at

at

at

at

start

stan

start

start

Bl,

carriage

left

start:to

at

posi-

to

3%

to

31h

3%

to

a~

to

,,~

lI:seape-

BAR.

3-

Escapement,

repeat/non·

use

of

a longer

spacebar shaft.

non;nal

travel

PigNr.

Front Fr

...

e

9.

SplU.hllr MechfItJum

18

Page 14

MODEl

trips

as

its

frame

against

spacebar-stem

determines

The second stop is

the

adjustable-shouldered-mounting

elongated holes

and

peat

the

bar

spring

er

below

the

switch is

Cl

the

cam

position

by

an

the

spacebar

travel

which

by

adjustable support,

is limited

in

previous machines.

rest

Spacebar

stop is fixed

the

upper,

The

repeat

spacebar

slide controls

during

in

screw into

slide

repeat

stem

tension

arm

of

A locking

the

switch lever, locking

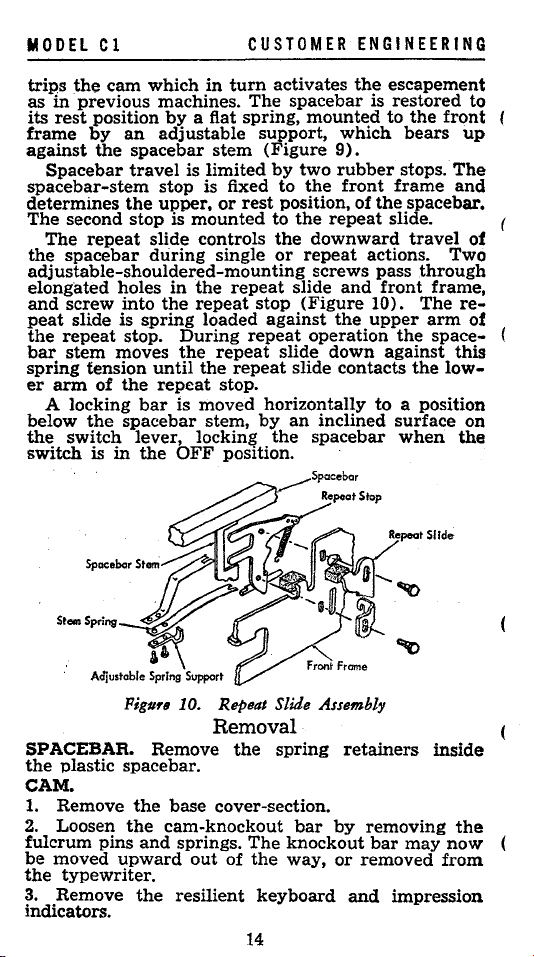

Spacobar Stam

the

is

spring

stop.

moves

until

the

repeat

bar

spacebar

in

the

During

the

is moved horizontally

OFF

CUSTOMER

in

turn

activates

The

a fiat spring,

stem

spacebar

(Figure

by

to

or

rest

mounted

single

the

repeat

loaded against

to

repeat

stop

position, of

the

or

slide

repeat

repeat

the

repeat

slide

slide contacts

stop.

stem,

by

an

the

position.

ENGINEERING

the

escapement

is

which

restored

to

the

bears

mounted

9).

two

rubber

the

the

repeat

downward

repeat

screws pass

(Figure

the

operation

down

stops.

front

frame

the

spacebar.

slide.

travel

actions. Two

front

10).

upper

through

The

and

the

against

the

to

a position

arm

inclined surface on

spacebar

when

to

front

up

The

and

of

frame,

re-

of

space-

this

low-

the

Figure

10. Repeat Slide Assembly

SPACEBAR. Remove

the

plastic spacebar.

CAM.

1.

Remove

2.

Loosen

fulcrum pins

be

moved

the

typewriter.

3.

Remove

indicators.

the

base cover-section.

the

cam-knockout

and

springs.

upward

the

out

resilient

Removal

the

spring

The

knockout

of

the

way,

keyboard

14

bar

retainers

by

removing

bar

or

removed

and

impression

may

inside

the

now

from

Page 15

REFERENCE MANUAL

4.

Remove

up

out

5.

D:Sconnect

lease link.

6.

Move

to

free

by

a C clip

the

left

of

the

the

its

the

cam.

side

impression-control

fulcrum

the

operating

operational

The

between

frame.

Adjustments

1.

CAM

clearance

screw

the

on

2.

when

rest

3.

ing, so

rest

4.

ing

bar

contact

s.

ment

reached.

be

CLEARANCE.

at

.010"

(Figure

power

the

CAM-RELEASE

SPRING-RETURN

position.

REPEAT

the

between

OPERATING

no

OFF.

rear

the

keylever

position.

the

spring

mounting

of

the

pawl

With

choking

9).

half

STOP.

the

repeat

just

the

to

Check

The

of

the

will

screws,

non-repeat

LINK.

before

cam

off.

has

slots.

cam

left

fulcrum

the

cam

Adjust

.015" using

by

release-lever

cam

lug.

LINK.

slide

Adjust

been

SUPPORT.

just

restore

Adjust

so

is

.015"

Adjust

the

high

on

its

shaft

link

and

fulcrum

rod

bearing

cam

the

releasing

so

depressed

Adjust

the

by

vertically

the

travel

tripping

to

.025"

to

point

high

point

MODEL

by

lifting

the

cam

rod

held

sUl}j)ort

to

power

the

should

the

cam

'is"

of

the

point

(Figure

the

of

the

there

enough

in

place

cam

with

trips

from

by

form-

to

position-

space-

and

escape-

cam

should

and

rest

is

adjustable-stop

lug

spacebar

trip

Cl

it

re-

roll

its

its

the

10).

is

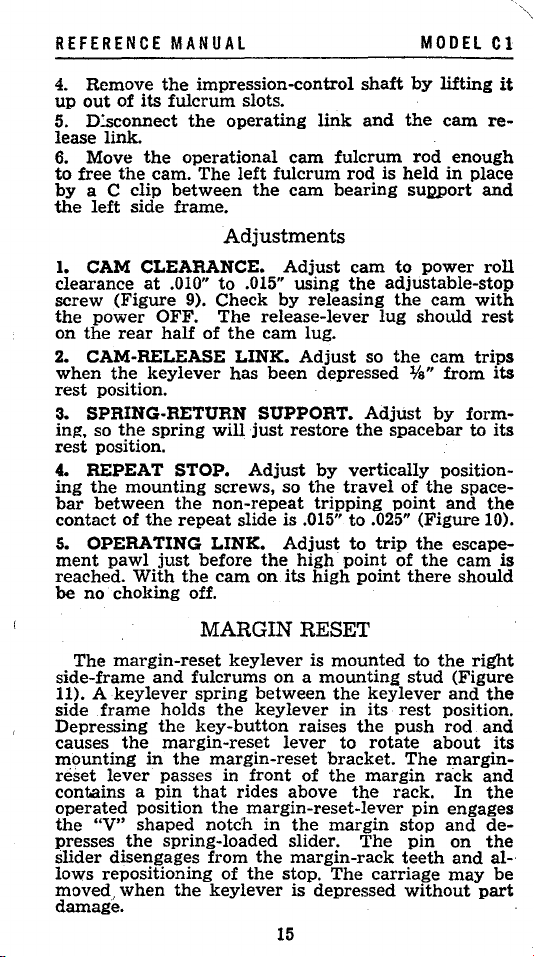

MARGIN RESET

The

margin-reset

side-frame

11). A

side

Depressing

causes

mounting

reset

contains a

operated

the

presses

slider

lows repositioning

moved,

damage.

and

keylever

frame

the

lever

"V"

the

disengages from

when

fulcrums

spring

holds

the

key-button

margin-reset

in

the

passes in

pin

that

position

shaped

spring-loaded

the

keylever

the

margin-reset

front

rides

the

margin-reset-Iever

notch

of

the

keylever

is

on a mounting

between

keylever

raises

lever

of

above

in

the

slider.

the

margin-rack

stop.

is

15

mounted

the

keylever

in

its

the

to

rotate

bracket.

the

margin

the

margin

The

The

carriage

depressed

to

stud

rest

push

about

The

rack.

pin

stop

pin

teeth

without

the

right

(Figure

and

the

position.

rod

and

margin-

nick

and

In

the

engages

and

de-

on

the

and

al-

may

part

its

be

Page 16

MODEL

C 1

CUSTOMER

ENGfNEERtIU

Adjustments

1. MARGIN·RESET LEVER.

clevi$ so

ance

the

margin

2. MARGIN-RESET BRACKET·ASSEMBLY. Posi-

tion

reset-lever

margin

a.

freely

that

with

of

.005"

reset-lever

stop.

left

or

right

pin

stoP.

MARGIN STOPS.

without

the

to

.015" between

pin

on

will

excessive

parts

and

the

rear

center

The

Adjust

at

rest

the

the

in

margin stops

play

bottom surface

top surface of

rail

so

the

"V" groove of

and

without

there

that

the

pusb-r04

is a clear-

the

margin-

shall

binding.

either

the

operate

of

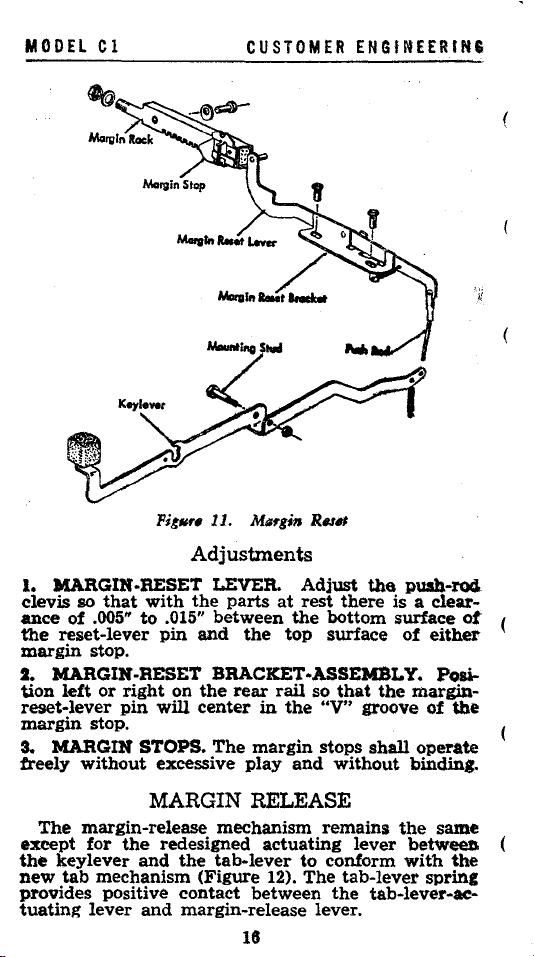

MARGIN RELEASE

The

margin-release mechanism remains

except for

the

keylever and

new

tab

provides positive contact between

tuating

the

redesigned actuating lever betwee!l

the

mechanism (Figure 12). The tab-lever spring

lever

and

tab·lever

margin-release lever.

to conform

18

the

tab-lever-ae-

the

with

same

the

Page 17

REFERENCE MANUAL

Acluating

Lev_er

__

Figure 12. Margin Release

Model

Bl,

the

typewriter

Refer

sary

to

to

remove

Pivot Stud

Tab

'1II~.a.

Removal

Margin

Release.

Lever

from

It

the

MODEL

is

not

base

Cl

neces-

section.

Adjustment

MARGIN RELEASE ECCENTRIC.

the

margin

margin

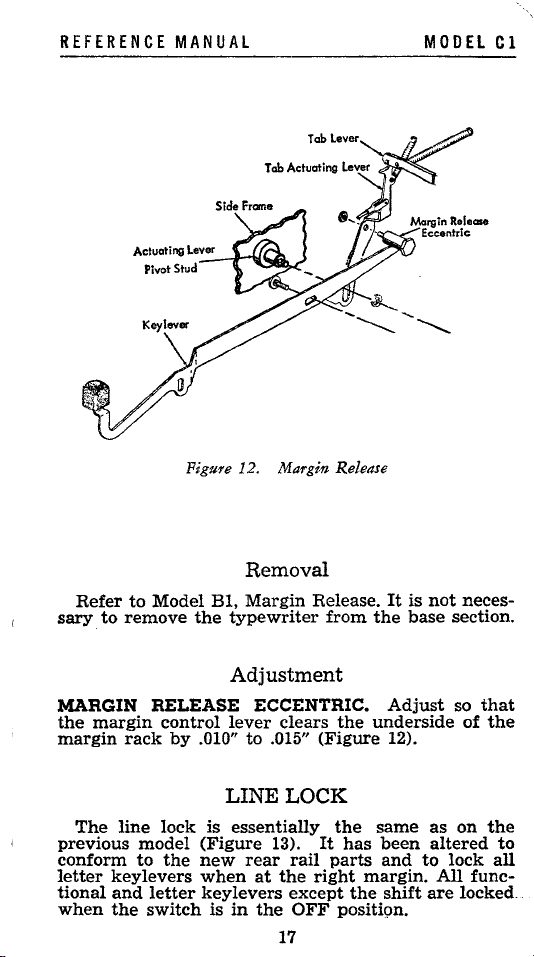

The

previous

conform

letter

tional

when

control

rack

by

line

lock

model

to

the

keylevers

and

letter

the

switch

lever

.010"

to

LINE

is

essentially

(Figure

new

rear

when

at

keylevers

is

in

the

clears

.015"

LOCK

13).

rail

the

except

OFF

17

the

(Figure

the

It

has

parts

right

the

position.

Adjust

underside

12).

same

been

and

to

margin.

shift

so

of

as

on

altered

lock

All

func-

are

locked.

that

the

the

to

all

Page 18

MODEL

Cl

PUSH ROD.

ment

2.

The

carriage

tion

and

changes

and

flexibility.

Model C

lengths:

tab-rack

anchors

margin

14).

lows

llny

operational

have

cover

13", 17", 20", 24"

center-support,

to

rack

It

mounts

the

operator

desired

CUSTOMER

Figure 13. Line Lock

Adjustment

Refer

to

Model

Bl,

Line

CARRIAGE AND RAILS

has

been

section

carriages

the

carriage

where

into

location

retained

characteristics.

made

design

are

it

is

the tab

to

position

on

its

to

conform

and

available

and

on

carriages

and

bridges

attached

rack

any

length

18

box-frame

to

to

increase

in

30".

The

up

at

the

as

before.

either

carriage.

17"

margin

ENGINEERING.

Lock,

Adjust-

construc-

The

following

the

new

case

machine

the

following

margin

and

and

rear ( Figure

longer,

over

This

stop

and

the

al-

at

Page 19

REFERENCE MANUAL

Pigu,.11

14.

Ma,.gin

Platen

locking.

on

Pulling

lever

in

15).

latches

The

eccentrics, connected

the

over

the

latch

Platen latch Lever

have

new

latch

latch

the

toward

platen

lever, locking

been

consists

shaft.

Rack

altered

by

a fiat

the

The

the

Cente,.

to

of

two

platen-latch

front

latch

two

together(

MODEL

Suppo,.t

make

them

levers,

pivots

the

engages a

Cl

self-

pivoting

link.

latch

notch

Figure

Figure

15.

Platen

Latches

The

multi-copy lever, fe!=!d-roll-release lever,

able-line-space

lever,

and

the

19

detent-release

varilever

Page 20

MODEl

Cl

CUSTOMER ENGINEERING

operate

form

The

buttons

Rails.

same

been

new

truck

as before.

to

the

new

cover

carriage-release

contained

trucks.

as

on

eliminated.

starwheels.

the

Model B.

Due

insertion

THIRTEEN

INCH

CARRIAGE

SEVENTEEN

TWENTY

INCH

INCH

CARRIAGE

CARRiAGE

They

in

the

method

have

design.

levers

carriage-end

RAILS

and

The

to

the

new

is

been

,altered

are

operated

rollers

carriage

carriage

used

(Figure

:..-..

covers.

remain

final-stop

lengths

Position No. I

to

con-

through

the

has

16).

a·

Figure 16.

Carriage

Removal

CARRIAGE AND RAILS.

may

be

1. Disconnect

removed

two

decelerator-arm

together

the

left-hand

springs.

20

Truck Insertion

The

an

assembly

carriage

as

tab-lever

as

spring

and

follows:

and

rails.

the

Page 21

REFERENCE MANUAL MODEl

2.

Unhook

margin-reset

3.

Unhook

the

backspace

lmk.

the

pawl-release

operating-link

and

clutch-unlatching

and

links.

4.

Unhook

ment-trip

5.

Remove

6.

Disconnect

sion

tapes.

7.

Remove

off

the

CARRIAGE.

between

1.

Remove

2.

Remove

3.

Disconnect

s.on

tapes

4.

Remove

5.

Move

the

margin-control

plate

6.

Remove

INNER

moved

justments

Model

the

link.

the

the

the

carriage

The

the

rails

the

the

the

at

the

the

the

carriage

to

pass

over

the

CARRIAGE.

without

by

following

BI

section

line

lock

push-rod

ribbon

from

the

carriage-return

four

rail-mounting

and

rails

assembly.

carriage

as

follows:

rear

cover.

right-hand

may

carriage

carriage-return

carriage.

margin-reset-Iever

to

the

lever

extreme

allowing

it.

carriage

disturbing

of

by

The

the

the

Reference

moving

inner

the

procedure

and

corner

and

screws

be

and

assembly.

left

the

it

carriage

rails

Manual.

the

escape-

ribbon

guides.

carriage-ten-

and

removed

end-cover.

carriage

and

depress

carriage

to

the

left.

may

or

carriage

outlined

be

in

Adjustments

1.

RAILS.

Adjustments

2.

PLATEN

so

that

the

eccentric

15).

3.

PLATEN

the

latch

4.

PLATEN

Carriage.

5.

PLATEN

BI,

Carriage,

S.

RING

riage,

7.

FEED-ROLL

el

Bl,

The

as

on

have

been

vent

paper

Refer

to

1,

2,

and

LATCH

the

platen

is

in

the

LATCH

firmly

engages

CONTROL-YOKES.

Adjustment

RETAINING-PLATES.

Adjustment

AND CYLINDER.

Adjustment

Carriage,

4.

CENTER-SUPPORT.

Adjustment

PAPER

paper-feed

the

Model B.

added

mechanism

to

slippage

Model

3.

LEVER

held

firm

forward

half

ECCENTRIC.

the

2.

3.

Refer

5.

FEED

is

An

additional

the

13"

on

and

these

BI,

Rail

Adjustments,

ECCENTRIC.

with

the

high

of

its

orbit.

Adjust

platen

latch

Refer

to

Refer

to

Model

Refer

the

same

set

17"

new

of feed

carriages

carriage

Adjust

point

(Figure

so

lever.

ModelBI,

to

Model

BI,

to

in

principle

to

lengths.

21

Cl

the

lift

from

ten~

end-

readthe

of

that

Car-

Mod-

rolls

pre-

Page 22

MODEL

Cl

CUSTOMER

ENGINEERING

FEED

FRONT

Model

Refer

ROLLS.

AND

Bl

to

Refer

REAR

section.

Model

Bl

DECELERATOR

The

centrifugal-governor.

clutches

centrifugal-governor

governor

the

tab

horseshoe

moves

spring

gear

governor

carriage, a spring

drum

assembly

utilizes a coiled

When

decelerator

and

cam

action

speed

of

rebound

The

assembly,

A

spring

the

check-lever,

shaped

centrifugal-governor

to

the

and

to

turned

left

drum

shaft.

rewind

andlor

clutch

which

in

arms

absorbs

moving

tab-lever

during

unwind

During

clutch

without

operating

is a

spring

one

Removal

to

Model

Bl

PRESSURE-LEVERS.

section.

Adjustment

section.

is a

control

It

consists

that

(Figure

carriage

carriage.

drives

left

allows

rotating

ratchet

fitted

direction

mechanism

of

17).

shock

air

rotate

the

pinion

to

right

the

the

governor.

like

closely

the

a series

the

The

It

cylinder

as

mainspring

mechanism

spring

control

the

mounting-bracket.

operates

tabulation.

they

the

Refer

to

for

the

of

spring

action

of

controls

the

and

carriage

main-

hub

and

on

the

of

and

and

gear

which

tightens

the

the

the

decelerator-

and

eliminates

the

As

the

the

gear

motion

hub

about a shaft.

Figure

(

17. Decelerator

22

Page 23

REFERENCE

about

the

turned

and

slips

CARRIAGE

During

up

the

causing

rotate

ure

18).

forces

tightening

hub

assembly.

pinion

creases

carriage

MANUAL

shaft

in

margin-control

the

the

the

gear

carriage

return

and

the

opposite direction

about

the

RETURN DECELERATION

carriage

margin-control

carriage-return-decelerator

The

carriage-return-decelerator-bellcrank

carriage-return-decelerator

its

spring

The

of

the

speed

operation.

+- Ccrrl"9$ Motion

Carriage

~rBellcrank

causes

shaft.

return

gear

Return

the

shaft

the

the

lever

clutch,

centrifugal-governor

during

left-margin-stop

and

moves

bellcrank

and

and

rotating

hub

the

assembly

last

MODEL

to

rotate.

spring

it

to

the

to

operate

bellcrank

arm

to rotate,

the

gear

drives

which

portion

Cl

When

relaxes

picks

right,

and

(Fig-

and

the

de-

of

the

Corrlage

Return

Decelerator

TABULATION DECELERATION

As

the tab

to

the

will

permit,

arm

spring. As a

lever

and

link

causes

Am

Figure 18. Carriage Return Deceleration

lever

right, as

under

moves

the tab

latches

far

set

it

the

as its

tension of

tab-stop

to

the

decelerator-bellcrank

tab

elongated

contacts

left,

23

the

check-lever

mounting-slots

tab-decelerator-

the tab

the tab

decelerator-

check-

to

moves

rotate

Page 24

MODEL

and

This

an

trifugal-governor.

carriage

absorbs

Cl

operate

action

increased

during

the

o

the

tightens

rotation

shock.

tab

decelerator-arm

the

tab

to

This

the

Tob

increased

last

portion

\

T

ob

Decelerator

Decelerator Bellerank

CUSTOMER ENGINEERING

spring-clutch

the

already

of a tabulation

Carriage Motion

Link

(Figure

operating

rotation

T

ob

Check

and

slows

Lever

19).

gives

cen-

the

and

The

decelerator,

spring

following

1.

2.

spring

wind

drum

Remove

Disconnect

drum.

slowly.

Figure 19. Tabulation Deceleration

Removal

gear

and

hub

may

these

steps:

typewriter

the

CAUTION:

be

removed

from

carriage-tension

24

assembly,

as a complete

the

base

Allow

tape

mainspring

and

section.

at

the

main-

unit

main-

to

by

un-

Page 25

REFERENCE MANUAL

3.

Loosen

sufficiently

4.

Unhook

tab

decelerator-arms.

5.

Remove

6.

Unscrew

shaft.

the

centrifugal-governor

to

prevent

the

springs

the

rear

the

spring-clutch

Adjustments

1.

SPRING

and

carriage-return

positioned

tor

arms

play

of

SPRING-CLUTCH

2.

the

end

tates

freely

- CLUTCH COLLARS.

on

the

rotate

arms

so

with

shaft

freely

on

that

end

to

the

collar

TABULATION

Tabulation

to

incorporate

on

the

the

stripping

to

the

frame.

spring-clutch

so

without

the

shaft

SHAFT.

the

play

Model C

advantages

decelerator-mounting

as

to

(Figure

Adjust

hub

and

not

to

has

MODEl

mounting-screws

gear

teeth.

carriage-return

The

their

17).

by

assembly

been

the

tabulation

should

decelera.003"

positioning

.003".

redesigned

decelerator

collars

allow

exceeding

gear

exceed

of

\

Cl

and

be

end

ro-

Figure

20. Tabukltion

25

Page 26

MODEL

Cl

C U S

TOM

E R

EN

GI

NEE

R I N G

(Figure

Model C

space

with

set

second

all

adjustable

tension

lever

tab

tab

other

The

lever

20). One

Typewriters.

on

standard

the

operation.

stop

on

tab

stoP.

standard

tab

latch

eccentric

of

the

works

against a lug

unlatching.

tab

pitch

the

when

pitches.

is

mounted

tab

lever

Tab

machines

Tabulation

6%

pitch

consecutive stops

and

works

lever

(Figure

Removal

TAB

LEVER

1.

Remove

It

is

ever,

cedure

2.

Remove

3.

Remove

4.

Disconnect

and

the

5.

Remove

6.

Remove

the

rear.

Reassembly

above

ing

nut

binding

TAB

1.

Remove

2. Remove

3. Disconnect

4.

Disconnect

pawl

5.

Remove

6.

Remove

7.

Block

the

tab-lever

8.

Remove

mounting-bracket

bracket.

Replacement

the

above

spacer

Care

,must

ing.screws

reassembly

bellcrank

the

paper

not

necessary

it

may

aid

to

do so.

the

the

the

decelerator-bellcrank

the

the

procedure. Avoid

LEVER MOUNTING BRACKET

spring.

must

may

on

the

tab-lever-pivot

of

the tab

the

the

the tab

the

the

the

the

carriage

mounting-bracket

three

procedure.

be

in

also

be

as

their

may

and

intermediate-pawl-release

table

to

remove

the

removal

margin

line-lock operating-lever.

tab-lever-pivot

tab

rear

carriage

margin-control

line-lock operating-lever.

may

tab-lever

lever

be

accomplished

lever.

cover.

tab-lever

screws

to

the

be

The

front

exercised

shoulder

result

rack.

over-tightening

from

operating

to

accomplished

of

in

assembly

stops

may

without

is possible

machine

atop

the

against a lower

<17).

on

the

tab

and

carriage

the

and

spring,

link.

stud.

by

lifting

stud

between

link.

spring

bellcrank.

prevent

is

that

secure

rear

rail

escapement

the

escapement

in

replacing

depths

binds

in

26

serves

be

set

interfering

and

are

rear

rail

The

tab-check

latch

end-covers.

rear

cover;

reassembly

tab-latch

it

up

and

by

reversing

the

as

movement

removed.

and

the

self-lock-

this

may

the

and

escapement

the

remove

by

pawl

and

trip-lever.

the

vary.

Improper

pawl-release

lever.

all

pitch

at

every

to

each

to

every

set,

on

with

an

ex-

to

effect

how-

pro-

spring,

toward

the

cause

rails.

when

tab-lever

the

reversing

pawl

mount-

(

Page 27

REFERENCE MANUAL

CAM

Refer

to

the

manual.

Spacebar

cam

removal,

Adjustments

1.

CAM CLEARANCE.

Adjustment

2. CAM RELEASE LINK.

is

tripped

to % of

3. MARGIN CO:ITROL LEVER

to

Model C1.

4.

TAB RACK.

justed

A.

LEFT

justed

.015" ± .002"

escapement

the

tab-check

(Figure

(1) Depress

tate

the

its

high

(2) Allow

set

tab

treme

Observe

(3)

faces

rack

tooth.

when

its

to

satisfy

TO RIGHT.

left

21).

power

point.

the

stop

left

position.

of

the

1.

downward

Margin

three

or

right

between

pawl

and

lever

the

tab

roll

carriage

positions

the

clearance

escapement

the

The

so

is

cam

by

Refer

keylever

Release,

an

Adjust

travel.

tab

rack

conditions.

The

tab

that

there

the

working

escapement

in

its

with

until

to

move

tab-check

between

pawl

the

hand

the

Carriage Motion

to

Adjustment

MODEL

in

this

section

Model

Cl,

Spacebar,

so

is

must

extreme

to

and

that

depressed

ECCENTRIC~

rack

is a

power

the

the

the

be

carefully

should

clearance

surfaces

rack

tooth

left

OFF

tab

cam

left

lever

working

the

escapement-

1.

so

to

Cl

of

the

cam

from

lh

Refer

ad-

be

ad-

of

of

the

when

position

and

ro;'

is

near

that

its

ex-

sur-

a

Escapement

B.

PARALLEL

of

the tab

the

rack

.015" :t .002"

~--

Figure 21. Tab Rack Adjustment,

rack

is

parallel

--;---If--

Pawl

=

TO

in

its

~

___

=/

RAILS.

elongated

to

the

carriage

27

_

Position

mounting

rails.

Tab Check

4A

the

This

....

right

slot

so

may

ena

that

be

Page 28

MODEl

Cl

CUSTOMER ENGINEERING

checked

an

C.

the

a

lever

NOTE:

rack

end-plates.

5.

mounting-stud

'h

the

tric

23).

by

equal

bite

PARALLEL

tab

rack

set

tab

stop

(Figure

Tob

Check

Figure 22. Tab

Caution

mounting-nuts

TAB

LATCH.

to % of

tab

must

the

lever

be

Tob

observing

that

the

on

all

set

TO

about

22).

Lever

is

kept

Check

TAB

its

parallel

must

be

so

Adjust

that

latched.

in

the

Lever

axis

as

the

surface

is

so

exposed

'~·"-"~-~i~~~

tab-check

tab

stops.

CHECK

so

that

to

the

RAck

Adjustment, 4C

used

in

not

to

by

positioning

tab-check

of a set

The

high

left

half

.-

tip

tightening

spring

of

-:::s.=

LEVER.

the

front

of

the

the

the

lever

tab

side

of

its

orbit

lever

takes

Position

face

tab-check

the

carriage

eccentric

engages

stop

when

the

eccen-

(Figtfre

of

tab-

Figure 23. Tab Latch Adjustment (

6. TAB-LATCH.

contact

when

full

with

the tab

left-hand

the tab

check-lever

position

Form

the

check-lever,

(Figure

28

tab-latch,

so

is .040"

24.)

Tob

Latch Eccentric

at

the

the tab

to

.045"

Set Tob Stop

point

unlatches

from

of

its

)

Page 29

REFERENCE MANUAL

MODEl

Cl

Carriage Motion

'1.

TAB

CHECK-LEVER

check-lever

there

is a

working

stop

the

of

keeper

26.)

when

keeper.

.003"

with

surfaces

to

Tab Check Lever

Figu1'e

Tab Lever

~4"

••

Figuf'e

24.

Tab Latch Adjustment

KEEPER.

keeper

clearance

the

front

.010"

the tab

on

the

rear

of

.010"

of

the

parts

are

rear,

lever

at

the

to

between

Tab Check Lever Keeper

25. Tab Check Level' Adjustment

to

tab

check-lever

rest

so

that

tab

latched

rail,

.025"

(Figure

there

check-lever

to

Position

left

to

between

and a tab

25).

is a

the

rear

the tab

right,

so

the

Position

clearance

and

the

(Figure

Figu1'e

26. Tab Check Leflef' Adjustm8nt

29

Page 30

MODEl CI

8.

OPERATING

so

there

contact

when

9.

high

.005"

lever

this

10.

right-lug

ment

11. DECELERATOR

this

carriage

19).

12.

B1,

13.

B1,

is a

surfaces

the

cam

Pigu,s 27. Ope,ating Link Adjustmsnt

TAB-LEVER

point

between

keeper

clearance

PAWL

so

rack

link

to

without

CENTRIFUGAL

Tabulation,

TAB

SET

Tabulation,

LINK.

clearance

of

is

on

EXTENSION.

there

should

the

overthrow

and

the

by

forming

RELEASE

the

escapement

by

.010"

obtain

interfering

Adjustment

AND

Adjustments

BACKSPACE

The

Model

Removal

backspace

Bl.

and

mechanism

Refer

to

Adjustment

CUSTOMER ENGINEERING-

Adjust

of .015"

the

tab

its

high

tab-lever

LEVER.

to

.020".

LINK.

the

maximum

GOVERNOR.

TAB

that

the

length

to

.020",

latch

and

point

(Figure

With

be a clearance

stop

the

pawl

with

lOa.

CLEAR.

11, 12,

is

section

procedures.

30

the

on

the

extension.

tab-lever

Form

clears

Adjust

cushioning

tabulation

Refer

Refer

13,

the

same

of

this

the

the tab

of

the

between

lever

27).

cam

on

of

.001"

tab

check-

Obtain

extension.

the

rear

the

escape-

length

of

(Figure

to

Model

to

Model

and

14.

as

on

manual

link

the

..

its

to

up-

of

the

(

the

for

Page 31

REFERENCE MANUAL

CARRIAGE RETURN

The

to

permit

The

clutch

more

positive

28).

Release

lever

forward

velop a

space

as

on

the

As

the

margin

carriage

and

stop

the

latch

of

the

pull

on

pawl

Model

carriage

picks

Pawl

return

decelerator

has

latching

carriage-return

causing

the

release

Bl.

approaches

up

Relea

..

mechanism

to

replace

been

modified

and

unlatching

cam

the

clutch

carriage-return

operations

the

the

margin-control

Bellcronlc

has

the

pulls

to

engage

tape.

remain

left

MODEl

been

air

to

provide

action

the

The

margin

lever.

Cl

modified

cylinder.

(Figure

clutch

and

de-

line-

the

same

the

This

a

Keylever

Figflfe 28. Carriagl1 Return

31

Can

Page 32

MODEL

pivots

three

1.

latching

the

2.

turn-tab

3.

ing

return-decelerator

section

Cl

the

margin-control

actions:

Allows

the

escapement

the

intermediate-pawl-release

pawl-release

Unlatches

the

interlock.

Cushions

the

the

centrifugal-governor

of

this

manual).

bellcrank.

clutch

shock

bellcrank.

Removal

Refer

to

Model

Bl

section.

Adjustments

1. CAM CLEARANCE.

bar,

Adjustment

2. CAM-RELEASE

is

released

to

full

peat

3.

there

normal

when

FRONT

is a

clearance

1.

LINK.

when

the

travel.

the

keylever

This

plunger

CLUTCH-LEVER

of

.010"

Clutch

CUSTOMER

bellcrank

pawl

by

rotating

of

carriage

through

(Refer

Refer

to

Adjust

is

will

has

allow

been

LINK.

to

.030"

Latch

Link

ENGINEERING

which

to

restore

lever

the

carriage-re-

return

the

to

Decelerator

Model

so

Cl.

that

depressed

the

cam

depressed

Adjust

between

performs

by

from

by

operat-

carriage-

Space-

the

from

to

n".

so

the

con-

un-

cam

%

re-

that

Front

Clutch

Lever

Link

Figure 29. Front Clutch Lever Link Adjultment

32

(

Page 33

REFERENCE MANUAL

tact

surfaces

when

the

4.

REAR

in

the

with

the

bellcrank

S.

CLUTCH

of

the

latch

bellcrank

riage-return-tab

6.

CLUTCH

so

the

of

the

the

carriage

1.

PAWL

riage

Return,

8.

MARGIN-CONTROL-BELLCRANK

tion

the

of

the

cam

is on

CLUTCH-LEVER

center

bellcrank

clutch

is

parallel

LATCH

hole of

unlatched

and

is

in

interlock

clutch

UNLATCHING

unlatches

carriage

by

RELEASE

travel.

hand

Adjustment

eccentric

clutch

its

to

LINK.

adjust

line

to

LINK.

stop

lever

high

the

bell-crank

the

the

rear

with

when

during

Latch

observe

16.

to

permit

point

LINK.

Place

so

Refer

and

(Figure

Position

elongated

rail.

in

the

slot

the

hole

the

clutch

LINK.

the

last

the

clutch

this

to

maximum

MODEL

the

clutch

29).

the

and

adjust

hole

the

center

in

the

in

is

Adjust

.100"

and

condition.

Model

Bl.

STOP.

Cl

latch

clevis

in

the

hole

clutch-

the

car-

latched.

the

link

to

.050"

return

Car-

Posi-

move-

so

Figure

30.

Carriage

Return Tab Interlock Ad;ustmtml

33

/

Page 34

MODEL

ment

with

9.

Form

lease

the

2

Cl

of

the

the

linelock

INTERMEDIATE

the

upright

lever

touches

pawl-release

spaces

from

margin-control

operating-lever.

bellcrank

the

CUSTOMER

PAW

lug

so

the

the

margin-control

when

left-hand

lever

10. CARRIAGE-RETURN-TAB

the

interlock

A.

Disconnect

B.

Wij;h

terlock

when

the

margin-control

ll.

CLUTCH

B1,

Carriage

COMPRESSION

12.

will

return

along

the

lever

to

the

so

it

left-hand

to

writing

th~

as

follows:

the

carriage

clears

bellcrank

PLATE

Return,

the

rear.

clutch

the

at

tab-lever

lug

of

unlatching

the

left

the

(Figure

CLEARANCE.

Adjustment

SPRING.

left

margin,

line,

with

L -

intermediate

margin.

interlock

Adjust

the

ENGINEERING

without

interfering

RELEASE

bellcrank

the

carriage

INTERLOCK.

link.

margin

lug

by

form

.005"

contacts

30).

Refer

to

18.

so

from

the

any

variable

linespace

LEVER.

pawl-re-

and

is 1

Adjust

the

in-

to

.015"

the

Model

carriage

position

13. MARGIN-CONTROL-LEVER DECELERATORSCREW.

rest

increase

14.

right

over

control

position

Adjust

with a minimum

the

decelerator

OVERBANK.

and

observe

an

escapement-rack

lever

is

from

31).

Left

Margin Stop

(Figure

the

screw

of shock.

Move

that

.010"

so

action

the

the

escapement

tooth

to

.015"

the

carriage

Lower

(Figure

carriage

when

from

comes

the

screw

18).

from

left

pawl

its

drops

margin-

full

the

Carriage Motion

to

to

right

I

to

to

The

ally

and

ance

adjustment

gle

assembly

binding

Figure 31. Overbank Adjustment

SHIFT

shift

mechanism

to

simplify

of

the

to

shaft

has

been

adjustment.

has

been

simplify

relocated

adjustment

assembly. Eccentric

34 ,

improved

The

equal

on

the

and

operation-

pin-clear-

shift

minimize

studs

tog-

mount

Page 35

REFERENCE MANUAL

the

segment

ing

"even

out

upsetting

PUSHER

1.

Remove

2.

Remove

retahe.t".

3.

IJisconnect

4.

Unhook

5.

l)isconnect

6.

Remove

levers

to

top

and

the

AND

the

the

the

the

assembly

the

type

bottom"

pin

Segment

.Mountlng

LEVERS

auxiliary

retainer

the

operating

shift-pusher

the

shift-pusher-Iever

shoulder

through

Adjustments

Rin~

and

fore

making

I.

CAM CLEARANCE.

Mechanism.

2. CAM

Mechanism.

3.

EVEN

Shift

NOTE:

used

to

used

4. MOTION.

Adjustment

cylinder

any

adjustments

Adjustment

RELEASE

Adjustment

TOP-AND-BOTTOM.

MechanisIll

The

adjust

to

insure

Adjustment

eccentric

for

even

that

Refer

2.

basket

clearance

fe_Ie

during

SeS!!lent

and

manufacture

(Figure

~-.

Removal

ASSEMBLY

hairpin-spring.

mounting-screws

link

at

link

at

screw

right

be

properly

to

Refer

Refer

1.

and

and

the

to

to

Refer

bottom.

is

BI,

the

must

3.

LINK.

4.

segment-mountings

top

the

segment

to

Model

MODEl

aid

in

establish-

32).

the

rear.

the

key

lever.

spring.

the

pusher-and-

side-frame.

adjusted

shift

mechanism.

Model

Model

to

BI,

BI,

Model

Care

not

tilted.

Shift

Mechanism,

with-

and

may

must

Cl

the

be-

Shift

Shift

BI,

be

be

Page 36

MODEL

5.

screws

the

their

6.

anism.

7.

Mechanism.

8.

Shift

Cl

EQUAL

and

clearance

respective

PUSHER

Adjustment

OPERATING

SHIFT-LOCK

Mechanism,

CUSTOMER

PIN-CLEARANCE. Loosen

position

Figure 33. Pin Clearance Adjustmem

Adjustment

between

pusher

LINK.

6.

LINK.

BRACKET.