Page 1

Managing Devices for the

M6-700 or M7-700

ESCALA Power7

REFERENCE

86 A1 84FF 00

Page 2

Page 3

ESCALA Power7

Managing Devices for the M6-700

or M7-700

This publication concerns the following models:

- Bull Escala E5-700 (Power 750 / 8233-E8B)

- Bull Escala M6-700 (Power 770 / 9117-MMB)

- Bull Escala M7-700 (Power 780 / 9179-MHB)

References to Power 755 / 8236-E8C models are irrelevant.

Hardware

March 2010

BULL CEDOC

357 AVENUE PATTON

B.P.20845

49008 ANGERS CEDEX 01

FRANCE

REFERENCE

86 A1 84FF 00

Page 4

The following copyright notice protects this book under Copyright laws which prohibit such actions as, but not limited

to, copying, distributing, modifying, and making derivative works.

Copyright

Suggestions and criticisms concerning the form, content, and presentation of this

book are invited. A form is provided at the end of this book for this purpose.

To order additional copies of this book or other Bull Technical Publications, you

are invited to use the Ordering Form also provided at the end of this book.

Bull SAS 2007-2010

Printed in France

Trademarks and Acknowledgements

We acknowledge the right of proprietors of trademarks mentioned in this book.

The information in this document is subject to change without notice. Bull will not be liable for errors

ontained herein, or for incidental or consequential damages in connection with the use of this material.

c

Page 5

Contents

Safety notices .................................v

Chapter 1. What’s new in Managing devices ....................1

Chapter 2. Managing tape drives .........................3

Tape drives ....................................3

Tape drive media ..................................5

Preparing the tape drive for installation ..........................9

800/1600 GB Ultrium 4 SAS tape drive (FC 5746).......................10

Eject button functions on the tape drive (FC 5746) .....................11

Status lights (FC 5746) ...............................12

Tape cartridges (FC 5746) ..............................14

Setting the write-protect switch (FC 5746) ........................15

Cleaning the tape drive (FC 5746) ...........................15

Maintenance mode (FC 5746) ............................16

Resetting the tape drive ..............................18

Performing the internal self-test (FC 5746) ........................18

200/400 GB Half High Ultrium 2 tape drive (FC 5755) .....................20

Cleaning the tape drive (FC 5755) ...........................20

Setting the write-protect switch (FC 5755) ........................21

Status lights (FC 5755) ...............................22

Tape cartridges (FC 5755) ..............................25

Resetting the tape drive (FC 5755) ...........................26

Performing the internal self-test (FC 5755) ........................26

160/320 GB internal tape drive VXA-320 (FC 6279) ......................28

Cleaning the tape drive (FC 6120 and 6279)........................29

Loading and unloading cartridges ...........................30

Loading a cartridge...............................30

Unloading a cartridge ..............................30

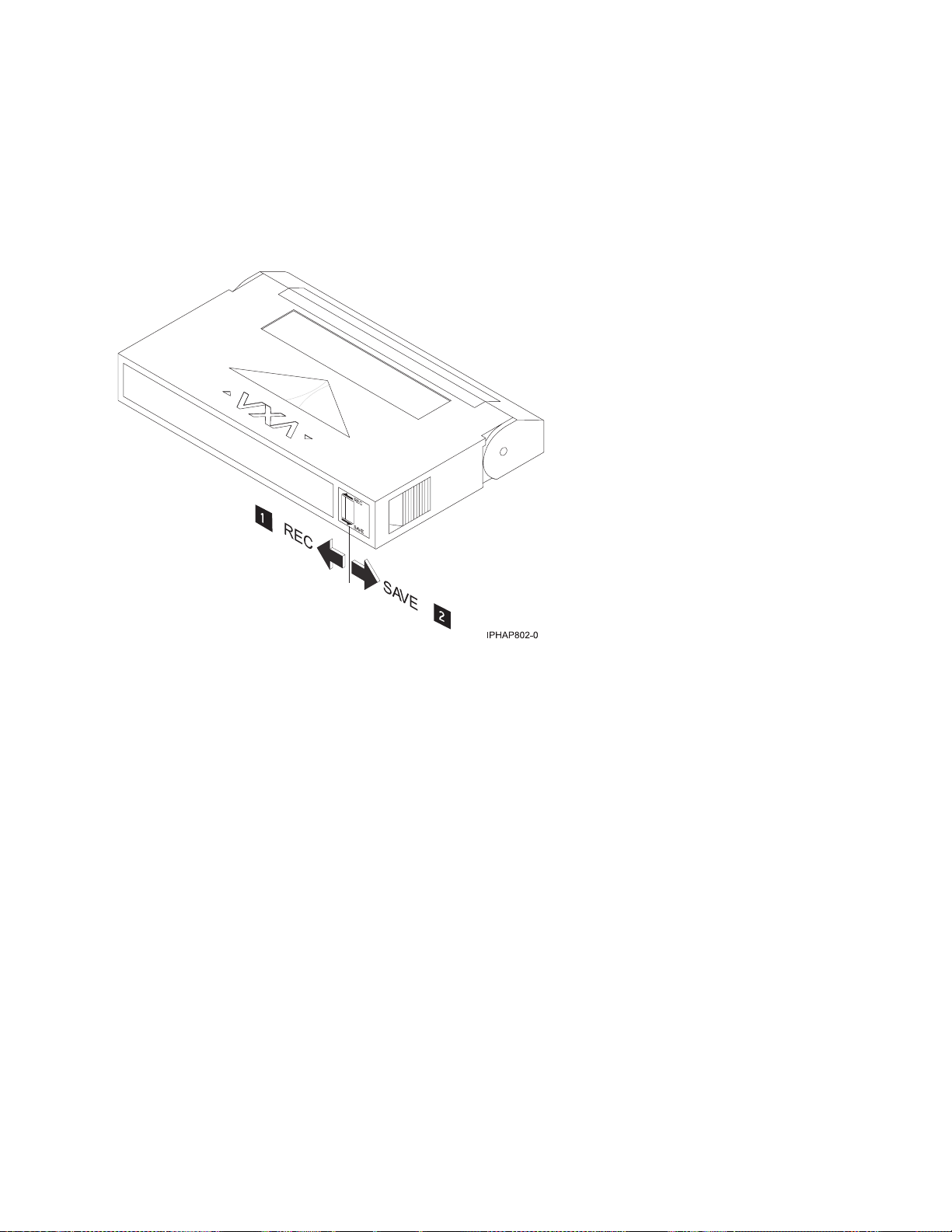

Setting the write-protect switch (FC 6279) ........................30

Status lights (FC 6279) ...............................31

Performing the internal self-test (FC 6120 or 6279) .....................33

Tape cartridges (FC 6279) ..............................34

Resetting the tape drive ..............................35

80/160 GB internal tape drive VXA-2 (FC 6120) .......................35

Cleaning the tape drive (FC 6120 and 6279)........................36

Loading and unloading cartridges ...........................37

Loading a cartridge...............................37

Unloading a cartridge ..............................37

Setting the write-protect switch (FC 6120) ........................38

Status lights (FC 6120) ...............................38

Performing the internal self-test (FC 6120 or 6279) .....................40

Tape cartridges (FC 6120) ..............................41

Resetting the tape drive ..............................42

60/150 GB 16-bit 8-mm internal tape drive (FC 6134) .....................43

Cleaning the tape drive (FC 6134) ...........................43

Loading and unloading cartridges ...........................45

Loading a cartridge...............................45

Unloading a cartridge ..............................45

Setting the write-protect switch (FC 6134) ........................45

Status lights (FC 6134) ...............................46

Tape cartridges (FC 6134) ..............................47

Resetting the tape drive ..............................48

36/72 GB Data72 4 mm internal tape drive (FC 6258 or 5907)...................48

Cleaning the tape drive (FC 6258 or 5907) ........................49

© Copyright IBM Corp. 2010 iii

Page 6

Loading and unloading cartridges ...........................50

Loading a cartridge...............................50

Unloading a cartridge ..............................51

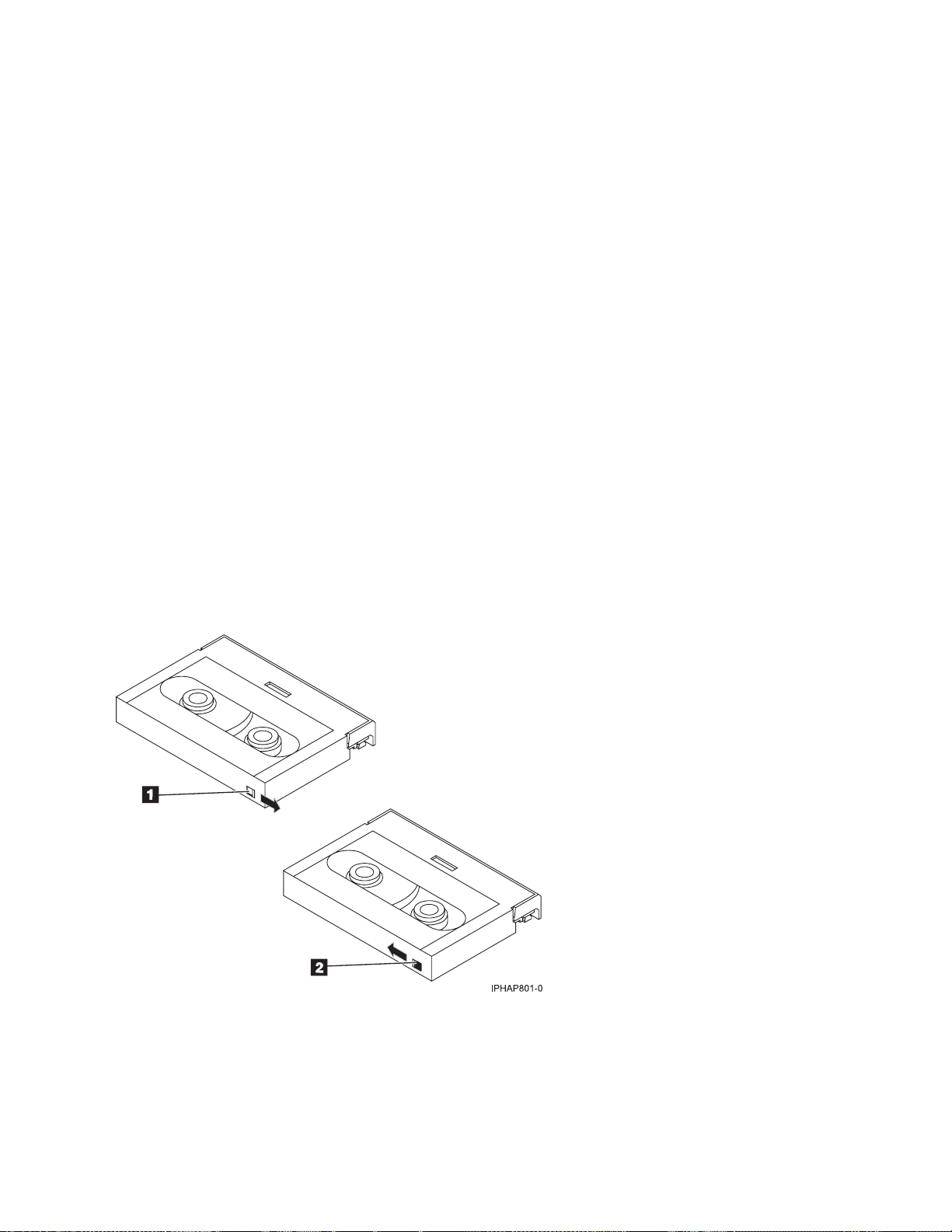

Setting the write-protect switch (FC 6258 or 5907) .....................51

Status lights (FC 6258 or 5907) ............................52

Tape cartridges (FC 6258 or 5907) ...........................54

Resetting the tape drive ..............................54

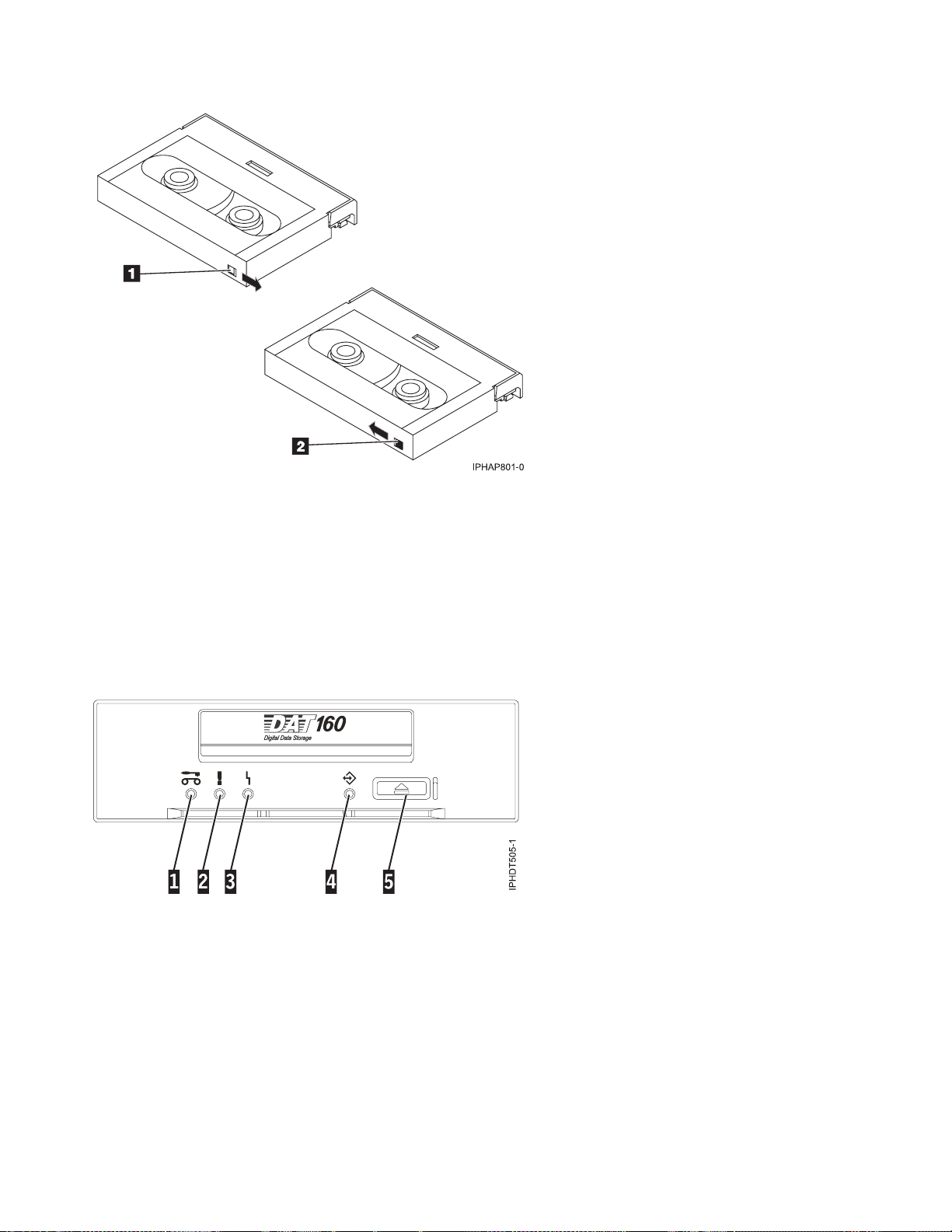

80/160 GB DAT160 SAS Tape Drive (FC 5619) ........................54

Cleaning the tape drive (FC 5619) ...........................55

Loading and unloading cartridges ...........................57

Loading a cartridge...............................57

Unloading a cartridge ..............................57

Setting the write-protect switch (FC 5619) ........................57

Status lights (FC 5619) ...............................58

Tape cartridges (FC 5619) ..............................60

Resetting the tape drive ..............................60

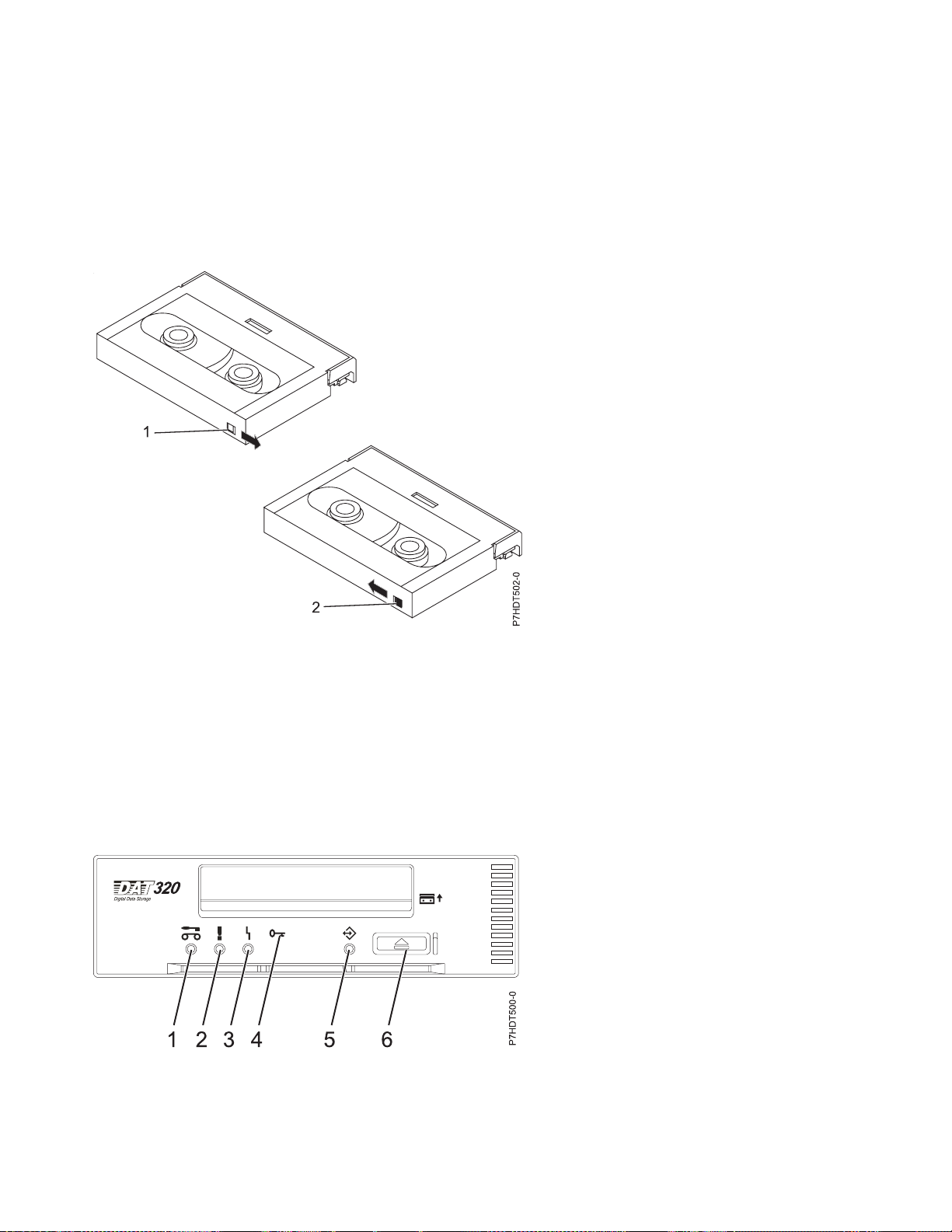

160/320 GB DAT320 SAS Tape Drive (FC 5661) .......................61

Cleaning the tape drive (FC 5661) ...........................62

Loading and unloading cartridges ...........................63

Loading a cartridge...............................63

Unloading a cartridge ..............................63

Setting the write-protect switch (FC 5661) ........................64

Status lights (FC 5661) ...............................64

Tape cartridges (FC 5661) ..............................67

Resetting the tape drive ..............................68

Chapter 3. Managing DVD drives ........................69

SATA Slimline DVD-RAM Drive (FC 5762) .........................69

Handling and storing the DVD media ..........................69

Opening a DVD tray manually .............................70

DVD-RAM type II disc ...............................70

Chapter 4. Managing diskette drives .......................73

External USB 1.44 MB diskette drive (FC 2591) .......................73

Chapter 5. Managing disk devices ........................75

Chapter 6. Managing removable disk drives ....................77

USB Removable Disk Drive (FC 1103, 1104, 1106, 1107) .....................77

Chapter 7. Managing communications devices ..................83

LAN-Attached Remote Asynchronous Node 16 (model 7036-P16) .................83

7036-P16 description and overview ..........................83

Installing 7036-P16 hardware ............................85

Installing Digi RealPort software for the 7036-P16 device ...................86

Configuring the 7036-P16 device and tty.........................88

Configuring the 7036-P16 into the network ........................90

Using diagnostic aids for the 7036-P16 .........................93

Replacing and reconfiguring the 7036-P16 ........................94

Field replacement units for the 7036-P16 .........................97

Appendix. Notices ...............................99

Trademarks ...................................100

Electronic emission notices ..............................100

Class A Notices.................................100

Terms and conditions................................104

iv Power Systems: Managing devices

Page 7

Safety notices

Safety notices may be printed throughout this guide:

v DANGER notices call attention to a situation that is potentially lethal or extremely hazardous to

people.

v CAUTION notices call attention to a situation that is potentially hazardous to people because of some

existing condition.

v Attention notices call attention to the possibility of damage to a program, device, system, or data.

World Trade safety information

Several countries require the safety information contained in product publications to be presented in their

national languages. If this requirement applies to your country, a safety information booklet is included

in the publications package shipped with the product. The booklet contains the safety information in

your national language with references to the U.S. English source. Before using a U.S. English publication

to install, operate, or service this product, you must first become familiar with the related safety

information in the booklet. You should also refer to the booklet any time you do not clearly understand

any safety information in the U.S. English publications.

German safety information

Das Produkt ist nicht für den Einsatz an Bildschirmarbeitsplätzen im Sinne§2der

Bildschirmarbeitsverordnung geeignet.

Laser safety information

IBM®servers can use I/O cards or features that are fiber-optic based and that utilize lasers or LEDs.

Laser compliance

IBM servers may be installed inside or outside of an IT equipment rack.

© Copyright IBM Corp. 2010 v

Page 8

DANGER

When working on or around the system, observe the following precautions:

Electrical voltage and current from power, telephone, and communication cables are hazardous. To

avoid a shock hazard:

v Connect power to this unit only with the IBM provided power cord. Do not use the IBM

provided power cord for any other product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration

of this product during an electrical storm.

v The product might be equipped with multiple power cords. To remove all hazardous voltages,

disconnect all power cords.

v Connect all power cords to a properly wired and grounded electrical outlet. Ensure that the outlet

supplies proper voltage and phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product to properly wired outlets.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or structural damage.

v Disconnect the attached power cords, telecommunications systems, networks, and modems before

you open the device covers, unless instructed otherwise in the installation and configuration

procedures.

v Connect and disconnect cables as described in the following procedures when installing, moving,

or opening covers on this product or attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. Attach the power cords to the outlets.

5. Turn on the devices.

(D005)

DANGER

vi Power Systems: Managing devices

Page 9

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment–personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top

of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in

the rack cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device installed in one rack cabinet into a power

device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

CAUTION

v Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer’s recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not

blocked or reduced on any side, front, or back of a unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels located on the

equipment in the rack to determine the total power requirement of the supply circuit.

v (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer brackets

are not attached to the rack. Do not pull out more than one drawer at a time. The rack might

become unstable if you pull out more than one drawer at a time.

v (For fixed drawers.) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or completely out of the

rack might cause the rack to become unstable or cause the drawer to fall out of the rack.

(R001)

Safety notices vii

Page 10

CAUTION:

Removing components from the upper positions in the rack cabinet improves rack stability during

relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a

room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at the top of the rack

cabinet. When possible, restore the rack cabinet to the configuration of the rack cabinet as you

received it. If this configuration is not known, you must observe the following precautions:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

– Ensure that there are no empty U-levels between devices installed in the rack cabinet below the

32U level.

v If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet from

the suite.

v Inspect the route that you plan to take to eliminate potential hazards.

v Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to the

documentation that comes with your rack cabinet for the weight of a loaded rack cabinet.

v Verify that all door openings are at least 760 x 230 mm (30 x 80 in.).

v Ensure that all devices, shelves, drawers, doors, and cables are secure.

v Ensure that the four leveling pads are raised to their highest position.

v Ensure that there is no stabilizer bracket installed on the rack cabinet during movement.

v Do not use a ramp inclined at more than 10 degrees.

v When the rack cabinet is in the new location, complete the following steps:

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet.

– If you removed any devices from the rack cabinet, repopulate the rack cabinet from the lowest

position to the highest position.

v If a long-distance relocation is required, restore the rack cabinet to the configuration of the rack

cabinet as you received it. Pack the rack cabinet in the original packaging material, or equivalent.

Also lower the leveling pads to raise the casters off of the pallet and bolt the rack cabinet to the

pallet.

(R002)

(L001)

(L002)

viii Power Systems: Managing devices

Page 11

(L003)

or

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class

1 laser products. Outside the U.S., they are certified to be in compliance with IEC 60825 as a class 1 laser

product. Consult the label on each part for laser certification numbers and approval information.

CAUTION:

This product might contain one or more of the following devices: CD-ROM drive, DVD-ROM drive,

DVD-RAM drive, or laser module, which are Class 1 laser products. Note the following information:

v Do not remove the covers. Removing the covers of the laser product could result in exposure to

hazardous laser radiation. There are no serviceable parts inside the device.

v Use of the controls or adjustments or performance of procedures other than those specified herein

might result in hazardous radiation exposure.

(C026)

Safety notices ix

Page 12

CAUTION:

Data processing environments can contain equipment transmitting on system links with laser modules

that operate at greater than Class 1 power levels. For this reason, never look into the end of an optical

fiber cable or open receptacle. (C027)

CAUTION:

This product contains a Class 1M laser. Do not view directly with optical instruments. (C028)

CAUTION:

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the following

information: laser radiation when open. Do not stare into the beam, do not view directly with optical

instruments, and avoid direct exposure to the beam. (C030)

Power and cabling information for NEBS (Network Equipment-Building System)

GR-1089-CORE

The following comments apply to the IBM servers that have been designated as conforming to NEBS

(Network Equipment-Building System) GR-1089-CORE:

The equipment is suitable for installation in the following:

v Network telecommunications facilities

v Locations where the NEC (National Electrical Code) applies

The intrabuilding ports of this equipment are suitable for connection to intrabuilding or unexposed

wiring or cabling only. The intrabuilding ports of this equipment must not be metallically connected to the

interfaces that connect to the OSP (outside plant) or its wiring. These interfaces are designed for use as

intrabuilding interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE) and require isolation

from the exposed OSP cabling. The addition of primary protectors is not sufficient protection to connect

these interfaces metallically to OSP wiring.

Note: All Ethernet cables must be shielded and grounded at both ends.

The ac-powered system does not require the use of an external surge protection device (SPD).

The dc-powered system employs an isolated DC return (DC-I) design. The DC battery return terminal

shall not be connected to the chassis or frame ground.

x Power Systems: Managing devices

Page 13

Chapter 1. What’s new in Managing devices

See what is new and what has changed in Managing devices since the last edition of this topic.

March 2010

v Added information on Handling and storing the DVD media.

February 2010

v Added information for IBM Power Systems™servers that contain the POWER7™processor.

© Copyright IBM Corp. 2010 1

Page 14

2 Power Systems: Managing devices

Page 15

Chapter 2. Managing tape drives

Learn about using and managing removable media devices. Find specifications and installation notes for

specific drives.

Tape drives

Learn general information about tape drives.

Select the appropriate information from this list:

v Tape drive overview

v Tape drive environment and use

v Tape handling and storage

v Environmental issues

v Tape drive cleaning

v SCSI hardware issues

v Microcode updates

Tape drive overview

Your tape drive must be installed in the cleanest possible environment. Additionally, tape drives require

high quality, data grade tapes and cleaning on a regular basis. Media must also be stored and handled

properly. Improper use, storage or handling of tape drives or media may void your warranty or service

agreement. If a tape drive stops functioning due to a component failure during the tape drive warranty

or maintenance time, the tape drive supplier will replace the tape drive unit. The tape drive supplier will

replace any defective tape drive under the terms and conditions of the warranty or service agreement.

The tape drive is a streaming device used primarily for:

v Saving and restoring system data files

v Archiving important records

v Distributing operating system software upgrades

Note: The following information describes hardware features and functions. While the hardware

supports them, the availability of these features and functions depends upon support from the operating

system. For information about support for features and functions, see the documentation for your

operating system.

Tape drive environment and use

Tape drives require specific maintenance and environmental conditions to operate well over time. Using

high-quality, data-grade media, handling and storing this media correctly, operating the tape drive in a

clean environment, and keeping the tape drive correctly cleaned can help you to avoid problems with

your tape drive.

If a tape drive stops functioning due to a component failure during the tape drive warranty or

maintenance time, the service provider will replace the tape drive unit. The service provider will replace

any defective tape drive under the terms and conditions of its warranty or service agreement. It is the

service provider’s objective to work with you to identify the cause of any tape-drive problem and provide

a solution.

© Copyright IBM Corp. 2010 3

Page 16

Tape handling and storage

Most tape is supplied in a sealed cartridge so that the tape will remain clean. Opening the cartridge

allows dirt and airborne particles to enter and then become a source of contamination. The cartridge

should only be opened by the tape drive and not an operator. The tape also is held under proper tension

inside the cartridge. If the cartridge is dropped, this tension will be relaxed.

Attention: Inserting a dropped cartridge into a tape drive can cause incorrect loading and result in a

jam. This action will ruin the tape and can cause physical damage if the cartridge is not removed

correctly.

When the tapes are stored, they must be replaced in their protective containers and stored on their end.

The storage area must be clean, dry, at normal room temperature, and away from any magnetic fields.

Improper use, storage, or handling of tape drives or media might void your warranty or service

agreement.

Environmental issues

Tape drives are designed to operate in a clean environment. Problems can be caused by dirt, dust, fibers,

and airborne particles. Airborne particles are the most difficult to address. When a tape is installed into

the tape drive, the clearance between the heads and the tape is measured in microns. Particles can

damage the tape or the head if they come in contact with either. Customers are responsible to provide a

clean operating environment for the tape drive and system.

Tape drive cleaning

No matter how clean the environment, debris can build up on the heads of any tape drive. Every time

tape motion occurs, some of the media surface comes off on the heads. Over time, this surface builds up

and causes errors in reading and writing. Customers are responsible to clean the tape drive in accordance

with the cleaning information that was provided with the tape drive.

Cleaning cartridges can be used a limited number of times. After a cleaning cartridge has been used to its

maximum number of times, the cartridge is considered expired. When cartridges expire, they must be

replaced. Never reuse an expired cleaning cartridge. Doing so allows previously removed dirt to be

reintroduced to the tape drive. Place a mark on the cleaning cartridge after each use, to best determine

when your cleaning cartridge has expired.

SCSI hardware issues

Note: If you are installing the auto-docking version of this device on your system, this section does not

apply to your system. For information about the auto-docking feature, see your system documentation.

SCSI bus cables and terminators can affect tape drive performance. Use cables and terminators that are

designed specifically to keep the SCSI bus as free of noise as possible. Generic cables or terminators can

adversely affect the SCSI bus performance. If your service provider’s analysis indicates a problem with

inferior cables, it might be necessary for the customer to replace them.

Microcode updates

To make certain that the tape drives work their best, your system supplier might release changed

microcode for the tape drives. When a microcode change is developed, your system supplier makes the

change available to you through its service organization or by electronic delivery. You might be

responsible for installing new microcode as it becomes available. However, microcode can be installed by

your service provider or your system administrator. For more information, contact your authorized

service provider.

4 Power Systems: Managing devices

Page 17

Tape drive media

Learn about using the different types of tape drive media.

Attention: Your system supplier might support only the media that it sells. If the supplier’s analysis

indicates that the problem is caused by using inferior media, it is the customer’s responsibility to replace

the inferior media.

Select the appropriate information from this list:

v Types of cartridges

v Recommendations for data cartridge usage

v Prolonging head life

v Storage and shipping environments

v Tape cartridge storage

v Operating in harsh environments

v Ordering tape cartridges

Types of cartridges

Tape devices use the following media cartridges.

Data cartridge

Use the data cartridge to save or restore programs or data.

Test cartridge

Use the specially labeled test cartridge to run the AIX

running diagnostics, refer to your AIX documentation). Do not use the test cartridge to save or

restore customer programs or data.

Cleaning cartridge

Use the specially labeled cleaning cartridge to clean the device.

Attention: Use of other than the IBM specified cleaning cartridge can damage your device and

might void your warranty.

To order additional cartridges, refer to Ordering tape cartridges.

®

system diagnostics (for information about

Recommendations for data cartridge usage

The following list describes recommended guidelines that will help to protect your data and prolong the

life of your tape cartridges and the device:

v Use only the tape cartridge specified for your type of tape device.

v Remove the tape cartridge from the drive when the drive is not in use.

v Back up and then discard any tape cartridge that repeatedly produces error messages (the error

information is in the System Error Log).

v On the data cartridge, do not open the door that covers the tape. The door protects the tape from dirt,

dust, and damage.

v Do not touch the tape. Any substance transferred to the tape by touching could cause loss of data.

v To avoid problems with loading and unloading, use only one label on a cartridge. Multiple or poorly

placed labels can clog the drive load mechanism.

v Do not use poor-quality tape cartridges. They can cause excessive read or write errors, and they might

damage the tape drive.

v Discard any tape cartridges that are dropped, because the impact might damage the tape’s internal

mechanism.

Chapter 2. Managing tape drives 5

Page 18

v Make sure the environment is kept clean and constant. Do not operate in a dusty environment and

always maintain a constant environment. A consistent storage and operating environment reduces

media exposure to climatic stress.

v Use only the recommended cleaning cartridge to clean the tape drive. Use of other than recommended

cleaning cartridges can damage your drive and might void the warranty.

v Printers and copiers can produce paper dust and toner dust. Locate the tape unit away from these

items. High traffic areas near hallways and doors can also produce excess dust and dirt.

v Record all important information on the tape label. Information, such as the model and number of the

system or tape drive, the date, the density, any error statistics, and include a log number. Also note the

operating environment and compression mode.

Prolonging head life

New technology found in the tape device is read and write compatible with newer tape cartridges. Due

to media characteristics, extended use of older tape cartridges might increase head wear on the drive. An

indication of this head wear is an increase in soft (recoverable) errors. Using newer tape cartridges may

have enhanced characteristics that can reduce drive head wear and maximize the overall advantages of

the tape device.

Storage and shipping environments

Before using a tape cartridge, let it acclimatize to the operating environment by placing the cartridge in

the operating environment for as long as it has been away from the environment or for 24 hours,

whichever is less. Acclimatization is necessary for any data cartridge exposed to an environmental change

in humidity or to temperature changes of 11°C (20°F) or more. To determine the appropriate operating

environment, see Tape drive environment and use.

Retrieval of archived data can be performed on a tape unit that is clean and fully operational. Try to

make the recovery environment the same as the operating environment. Allow tapes at least 24 hours to

acclimatize to the environment of the tape unit.

The recommended environment for storage and shipment of cartridges is shown in Table 1.

Table 1. Recommended environment for data cartridges

Environmental Factor Storage Shipping

Temperature 5°C to 32°C

(41° to 90°F)

Relative Humidity

(noncondensing)

Maximum Wet Bulb 26°C

20 to 60% 5 to 80%

(79°F)

-40 to 52°C

(-40 to 125°F)

26°C

(79°F)

Tape cartridge storage

Tape drives record data using densities similar to hard disk drives. Because most computer systems are

not located in a dust-free, climate-controlled environment, you must exercise special care when dealing

with tape cartridges and tape drives. They must be treated as a valuable asset used to protect your

business data.

Use the following guidelines for storing your tape cartridges:

v Keep temperature and humidity constant at the levels listed in Table 1.

6 Power Systems: Managing devices

Page 19

v Always store tape cartridges in their protective cases. The storage case helps prevent damage from dust

and physical misuse. When the tape cartridges are not in use or being stored, keep them in their

storage cases and stand on edge in a designated storage location. Do not stack cartridges on the flat

side or stack other items on top of the tape cartridges. Handle your tape cartridges with care to reduce

archival problems.

v Keep protective cases for tape cartridges closed except when inserting or removing a cartridge.

Contamination can build up and be transferred to the tape cartridge if the protective case is left open.

v Exercise stored tapes at least once every 12 months. Run the tape from Beginning of Data (BOD) to

End of Data (EOD) and back to BOD at normal operating speeds. Exercise tapes stored in a warmer

environment more frequently.

v Sunlight can damage the tape and the cartridge shell. Store tape cartridges out of the direct sunlight.

Attention: Operation outside of the recommended environment can result in possible loss of data or

failure of the drive.

Operating in harsh environments

The device is suited to streaming operations, as opposed to multiple stop-and-start, random-search tape

operations. When the tape is used for frequent stop-and-start operations, it is beneficial to still have as

much streaming movement as possible. This can be accomplished by ensuring that any save or restore

operation is the only active operation being performed.

Do not use any tape for archival purposes if it has been used outside of the ranges specified in Table 1 on

page 6 for an extended period of time. The magnetic and physical strength of the tape will have

deteriorated as a result of its exposure to the environment. Do not store important data on such a tape;

transfer the data to a newer tape for reliable archiving.

Ordering tape cartridges

All tape cartridges are not alike. The tape composition and length, and the construction of the cartridge

itself can all affect the quality and capacity of the recording and the performance of your tape drive. A

poor quality tape cartridge might appear to work adequately in your system, yet it can leave

contamination in the tape path or impede the speed of the recording.

The length and composition of the tape, and the size, shape, and construction of the cartridge shell must

all be considered when selecting the tape cartridge to be used with your system. IBM supports using only

data and cleaning cartridges supplied by IBM. Use only data-grade tape media for backup and data

processing.

To order cartridges in the United States and Canada, call 1-888-IBM-MEDIA or, on the internet, see

www.storage.ibm.com/media/

To order cartridges in other locations, contact your local provider of IBM storage products.

Table 2. Recommended test, cleaning, and 4mm data cartridges for the specific type of tape drive

Tape Drive Part Number Type of Cartridge

DDS3 59H3466 Test Cartridge 11.5m

21F8763 Cleaning Cartridge 50 cleanings

59H3465 Data Cartridge 12 GB

DDS4 59H4457 Test Cartridge 11.5m

21F8763 Cleaning Cartridge 50 cleanings

59H4458 Data Cartridge 20 GB

.

Chapter 2. Managing tape drives 7

Page 20

Table 2. Recommended test, cleaning, and 4mm data cartridges for the specific type of tape drive (continued)

Tape Drive Part Number Type of Cartridge

DAT72 59H4457 Test Cartridge 11.5m

21F8763 Cleaning Cartridge 50 cleanings

18P7912 Data Cartridge 36 GB

DAT160 23R5636 Test Cartridge 155m

23R5638 Cleaning Cartridge 25 cleanings (minimum)

23R5635 Data Cartridge 80 GB

DAT320 46C1938 Test Cartridge 153m

46C1937 Cleaning Cartridge 27 cleanings (minimum)

50 cleanings (average)

70 cleaning (maximum)

46C1936 Data Cartridge 160 GB

Table 3. Recommended 8-mm data cartridges

Part Number Type of Cartridge Length

35L1044 20 GB AME with SmartClean Data Cartridge 75 m (246 ft)

09L5323 40 GB AME with SmartClean Data Cartridge 150 m (492 ft)

18P6484 60 GB AME with SmartClean Data Cartridge 225 m (738 ft)

35L1409 Cleaning Cartridge

Table 4. Recommended VXA X-type data cartridges

Part Number Type of Cartridge Length

24R2137 80/160 GB X23 VXA Data Cartridge 230 m (754 ft)

24R2136 40/80 GB X10* VXA Data Cartridge 124 m (406 ft)

24R2134 20/40 GB X6* VXA Data Cartridge 62 m (203 ft)

24R2135 VXA X6* Test Cartridge 62 m (203 ft)

24R2138 VXA 20 X Cleaning Cartridge

Note: *X type media requires a minimum microcode level of 2105.

Table 5. Recommended VXA V Type data cartridges

Part Number Type of Cartridge Length

19P4876 80/160 GB V23 VXA Data Cartridge 230 m (754 ft)

24R2136 40/80 GB V10 VXA Data Cartridge 124 m (406 ft)

19P4878 20/40 GB V6 VXA Data Cartridge 62 m (203 ft)

19P4879 VXA V6 Test Cartridge 62 m (203 ft)

19P4880 VXA 20 V Cleaning Cartridge

Note: V cartridges are the original VXA cartridge.

8 Power Systems: Managing devices

Page 21

Table 6. LTO Ultrium data cartridges

Part Number Type of Cartridge Length

08L9120 100/200GB LTO Ultrium 1 Data

Cartridge

08L9870 200/400GB LTO Ultrium 2 Data

Cartridge

24R1922 LTO-3 Data Cartridge (400GB/800GB)

96P1203 LTO-3 Worm Data Cartridge

95P4436 LTO-4 Data Cartridge (800GB/1.6TB)

95P4450 LTO-4 Worm Data Cartridge

45E1129 LTO-4 Test Cartridge

24R0395 LTO Gen-2 Test Cartridge 610 m (2000 ft )

35L2086 Universal Cleaning Cartridge

610 m (2000 ft )

610 m (2000 ft )

Preparing the tape drive for installation

Find what you need to know before you install a SCSI tape drive.

Select the appropriate information from this list:

v “Handling recommendations”

v “Planning your serial-attached SCSI (SAS) device layout”

v “Configuring the tape drive” on page 10

v “Updating microcode levels” on page 10

Handling recommendations

Attention: Be sure to read these instructions before you remove the device from its anti-static bag or

any time you handle it.

For optimum performance, always follow these recommendations:

v Handle the drive carefully and by its external metal chassis. Keep your hands away from the printed

circuit boards, components, and printed circuit (flex) cables.

v If possible, work on a cushioned surface, and do not drop the device onto the work surface.

v If you move the device to an environment that is colder or warmer than its previous environment,

keep the drive in its package and allow the package to reach the current room temperature. This action

prevents potential data loss or damage to the device. Allow one hour of acclimatization for each 10

degrees C (18 degrees F) difference between the ship or storage temperature and the room temperature.

Note: If you are installing the auto-docking version of this device on your system, the remainder of this

information does not apply to your system. For information about the auto-docking feature, see your

system documentation.

Planning your serial-attached SCSI (SAS) device layout

SAS devices do not require you to set a SCSI address before connecting to a SAS bus.

Chapter 2. Managing tape drives 9

Page 22

Configuring the tape drive

To configure the drive after installation, boot your system unit. Device drivers are provided in the

operating systems that support the drive. Your operating system recognizes the drive and automatically

updates your system unit configuration.

Updating microcode levels

Media devices contain microcode that you can update. Contact your authorized service provider for

instructions on how to obtain and install the latest microcode levels for your device.

800/1600 GB Ultrium 4 SAS tape drive (FC 5746)

Learn about the features of this media device.

Description The Ultrium 4 serial attached SCSI (SAS) tape drive is a half-high tape drive designed for

Open Systems backup and restore applications. The tape drive is an LTO Ultrium 4 standard

interchange device. The drive will read tapes written by other Ultrium 4 drives, and will

write to tapes readable by other Ultrium 4 drives. For an illustration of the drive, see Figure 1

on page 12.

Characteristics:

v FRU part number is 45E1127. For media part numbers, see “Tape cartridges (FC 5746)” on

page 14.

v Custom card identification number (CCIN) number is 63A0

v Data transfer rate: 120 MB per second native mode, 240 MB per second at 2:1 compression

v Bootable device, depending on the host system configuration

v Operation: Streaming

v Form Factor: 5.25-inch half high

v Attributes required: One 1.6-inch (41 mm) half-high media bay and one integrated, internal

SAS controller

Tools The following tools and documentation are needed to complete the installation:

v A flat-blade screwdriver (if this device is not an auto-docking feature on your system)

v Your system unit documentation, including any service documentation

v Your operating system documentation

Contact the place of purchase if an item is missing or damaged.

Note: If you are installing the auto-docking version of this device on your system, see your

system documentation for information about the auto-docking feature.

Media The drive will read and write on Ultrium 4 and Ultrium 3 cartridges, and read Ultrium 2

cartridges. The drive will not write on Ultrium 2 cartridges. or read or write on Ultrium 1

cartridges.

Each Ultrium 4 tape cartridge can store up to 800 GB of uncompressed data, or up to 1600 GB

of compressed data.

Note: The actual capacity varies depending on the application, the type of data, and the tape

cartridge. When data compression is activated, 800 GB is typical and 1600 GB is possible. The

default setting of data compression is controlled by the host system. The user and the

application software can control the activation or deactivation of the data compression setting.

The drive can optimally achieve a 2:1 compression ratio.

10 Power Systems: Managing devices

Page 23

Related information Your package contains the following items:

v The tape drive

v Media kit containing:

– One cleaning cartridge

– One test tape

v Specific hardware for attaching the drive to your specific system, as detailed on the parts

listing provided with your drive.

Eject button functions on the tape drive (FC 5746)

You might need to eject a tape, reset the drive, or place the drive in maintenance mode. Use the

information in this topic to perform these tasks.

The drive has an eject button that enables you to perform the functions shown in the following table. The

eject button is illustrated in Figure 1 on page 12.

Table 7. Eject button functions on the tape drive

Function How to start the function

Reset the drive Press and hold the eject button on the drive for 20

seconds. The drive saves a dump of the current drive

state, and then reboots to allow communication. Do not

cycle power because this will erase the contents of the

dump.

Rewind the tape into the cartridge and eject the cartridge

from the tape drive

Place the tape drive in maintenance mode Ensure that the tape drive is unloaded. Then, press the

Scroll through the maintenance functions While in maintenance mode, push the eject button once

Exit maintenance mode Press the eject button once per second until 0 displays.

Force a drive dump (part of the maintenance mode) Attention: If the tape drive detects a permanent error

Press the eject button once. The status light flashes green

while the tape drive is rewinding and unloading.

eject button three times within one second. You are in

maintenance mode when the light becomes solid amber

and 0 appears in the single-character display.

per second to increment the display characters by one.

When you reach the character of the diagnostic or

maintenance function that you want, press and hold the

eject button for 3 seconds. For a list of Maintenance

functions, see Table 10 on page 17.

Then press and hold the eject button for 3 seconds.

Maintenance mode is exited when the status light

becomes solid green and the single-character display

becomes blank.

and displays an error code, it automatically forces a

drive dump. If you force a drive dump, the existing

dump will be overwritten and data will be lost. After

you force a drive dump, do not turn off the power to the

tape drive or you might lose the dump data.

If the tape drive is in maintenance mode (status light is

solid amber), select function code 4. For a list of

Maintenance functions, see Table 10 on page 17.

If the tape drive is in operating mode (status light is

solid or flashing green), press and hold the eject button

for 10 seconds. If captured dump data exists, the tape

drive places the data into a dump area

Chapter 2. Managing tape drives 11

Page 24

Status lights (FC 5746)

You might need to read the status lights on your tape drive to determine the operating status of the

drive. Use the information in this topic to perform this task.

The following illustration shows a front view of the tape drive:

Figure 1. Front view of tape drive

1 Eject button

2 Ready LED

3 Fault LED

4 Single-character display (SCD)

5 SCD light

The combinations of the lights and their definitions are shown in the following table.

Table 8. Definition of Status Light Combinations

Operation Ready

Power-On Self-Test in

Off Off or on Segments flashing

progress

After Power-On

Self-Test and drive

2

reset

No cartridge is

3.0 seconds on

Off Off or on

2

loaded

Cartridge is loading

Flashing

1

or unloading

Cartridge loaded, no

On Off or on

activity

Data cartridge

Flashing

1

loaded, activity

Cleaning is required

On or off On

(clean bit is set)

Cleaning in progress Flashing Off C

Cleaning cartridge

Off On 6 or 7

loaded, clean failed

Fault Single character

display

3.0 seconds on

Offoron

Offoron

2

3

3

3

3

3

3.0 seconds on

OfforC

OfforC

OfforC

OfforC

1

2

3

3

3

3

3

C

3

4

Response

Wait 30 to 60 seconds.

Wait 30 to 60 seconds.

Wait 30 to 60 seconds.

Wait 30 to 60 seconds.

Wait 30 to 60 seconds.

Wait 30 to 60 seconds.

Clean drive as soon

as possible.

Wait for cleaning to

complete.

Replace cleaning

cartridge, which may

be expired.

12 Power Systems: Managing devices

Page 25

Table 8. Definition of Status Light Combinations (continued)

Operation Ready

Fault Single character

Response

display

Maximum operating

temperature exceeded

5

Off On 1 Reduce drive

temperature.

Input voltage failure Off On 2 Check input power

connections.

Drive firmware

6

failure

Drive firmware or

hardware failure

6

Unrecoverable drive

Off Flashing

Off Flashing

Off Flashing

failure

Drive or media

7

failure

Off On 6

Media error Off On 7

1

3 Update to latest level

firmware.

1

4 Clean drive, replace

cartridge, or both, if

1

5

4

needed. Retry

operation.

Replace cartridge.

Possible expired

cleaning cartridge.

SAS interface failure Off Flashing

1

8 Check SAS cable and

connector.

Recoverable drive

8

error

Off On A Clean drive and retry

operation.

Incorrect media Off On J Insert correct media

type.

Firmware update is in

progress

Incorrect firmware

update tape used

Firmware update

9

failed

Write operation was

attempted and media

Both LEDs flashing

together

Off On F

Off Flashing

Off On P

Both LEDs flashing

together

1

Off Wait for update to

complete.

4

Replace firmware

update tape.

H Retry firmware

update operation.

4

Use media that is not

write protected.

is write-protected

Drive is in service

Flashing rapidly

1

On On

10

mode

Self-test is in progress Flashing

1

On The number 1 is

flashing

Wait for test to

complete

Chapter 2. Managing tape drives 13

Page 26

Table 8. Definition of Status Light Combinations (continued)

Operation Ready

Fault Single character

Response

display

1

When used in this table, flashing refers toa1Hzflash rate (1 flash per second), and flashing rapidly refers toa4Hz

flash rate (4 flashes per second).

2

Immediately following a power-on self-test sequence or drive reset, both LEDs, all segments of the single-character

display, and the SCD dot will be on solid for approximately 3 seconds.

3

When a drive needs cleaning, the Fault LED will be on solid and a C will show on the single character display. In

most cases the drive will continue to function, but it should be cleaned as soon as possible. Do not ignore the

indicator by cycling the power to turn the LED off.

4

Error code on single-character display is cleared when cartridge is removed from drive.

5

The Fault LED will be on solid to indicate an over-temperature condition. If a tape is present it will be ejected.

This LED will remain on until the drive temperature drops below a lower secondary-temperature limit and one of

the following two conditions is also met:

v A data or cleaning cartridge is inserted.

v The drive is powered off and on.

6

A drive dump will be stored before the drive is powered off. The SCD light serves as a dump indicator. When this

light is lit, a dump file is stored in the drive and can be retrieved.

7

Failure cannot be isolated to either a faulty drive or faulty media.

8

Error condition will be cleared when the drive is powered off. The drive is not disabled.

9

The firmware update failed and the drive is not functional. The drive boot code is in control and you should retry

the firmware download.

10

When the drive is in maintenance mode, the Fault LED will be on solid and the single character display will

indicate the current maintenance mode state.

Tape cartridges (FC 5746)

Learn about the types of tape cartridges that are available for this drive.

Available tape cartridges

Table 9. LTO Ultrium data cartridges

Part number Type of cartridge

24R1922 LTO-3 Data Cartridge (400GB/800GB)

96P1203 LTO-3 Worm Data Cartridge

35L2086 LTO-4 Cleaning Cartridge

45E1129 LTO-4 Test Cartridge

95P4436 LTO-4 Data Cartridge (800 GB / 1.6 TB)

95P4450 LTO-4 Worm Data Cartridge

Attention: Do not attempt to bulk erase an LTO data cartridge for reuse. Bulk eraser devices cannot

properly erase an LTO data cartridge and cause permanent damage to the cartridge.

14 Power Systems: Managing devices

Page 27

Setting the write-protect switch (FC 5746)

You might need to set the write-protect switch on your tape drive. Use the information in this topic to

perform this task.

Attention: Do not attempt to change the write-protect settings after the tape cartridge is loaded in the

drive because this might cause unpredictable results and might damage the tape or the drive.

The position of the write-protect switch on the tape cartridge determines when you can write to the tape.

Before loading cartridges into magazines, set the write-protect switch of each cartridge to enable or

disable data recording. When the switch is set to the left, data can be written to the tape. When the

switch is set to the right, data cannot be written to the tape.

Cleaning the tape drive (FC 5746)

You will need to clean your tape drive. Use the procedure in this topic to perform this task.

Clean the device whenever the Fault status light comes on andaCisdisplayed in the single-character

display (SCD), or when a system I/O error occurs that is related to the device.

Attention: Use only the recommended cleaning cartridge to clean the tape drive. Use of other than

recommended cleaning cartridges can damage your drive and might void the warranty.

The tape drive will set the cleaning indicator when one of the following conditions occurs:

v The tape drive exceeds internal preset error thresholds in the drive.

v The tape drive exceeds the maximum recommended time between cleaning.

This is an internal drive calculation where the drive maintains information on the amount of data

written and read and when this value reaches a total of approximately 20 full tape writes or reads the

drive will request cleaning. The cleaning indicator will be turned on when the tape is ejected.

v There is a write or read failure of the tape drive to the data cartridge.

Note: When a cleaning cartridge that has been used the maximum number of times is inserted in the

drive, the drive will turn on the fault indicator. The SCD displays 6 or 7 to indicate that the cleaning

process is not done and the cleaning cartridge is no longer usable. If the fault indicator was on and a C

Chapter 2. Managing tape drives 15

Page 28

was in the SCD prior to the cleaning process, the indicators will stay on after the depleted cleaning

cartridge is removed. If these indicators were off prior to inserting the depleted cleaning cartridge, they

will turn off once the depleted cleaning cartridge is removed from the drive.

To clean the tape drive, complete the following steps:

1. Make sure that the power is on for the tape drive.

2. If a tape cartridge is in the tape drive, eject and remove the cartridge.

3. Grasp the cleaning cartridge by the outer edges, with the insertion arrow on top and the write-protect

switch facing you.

4. Slide the cartridge into the opening on the front of the drive until the loading mechanism pulls the

cartridge into the drive.

After the cleaning cartridge has been inserted, the remainder of the cleaning process is automatic. The

tape drive does the following actions:

v Loads the cleaning cartridge into the tape drive.

v Cleans the drive by moving the cleaning tape forward for approximately 30 seconds.

v Unloads the cleaning cartridge when the cleaning operation is complete.

v Indicates a successful cleaning operation by turning off the C in the SCD, if the C in the SCD was on

prior to the cleaning process.

Note: If the cleaning operation is completed but the C in the SCD remains on, the cleaning cartridge

might not be usable. Repeat the cleaning procedure with a new cleaning cartridge. If the C in the SCD

still remains on, contact your authorized service provider.

To determine how many times a cleaning cartridge can be used, check the information printed on the

cartridge. If you attempt to use a depleted cleaning cartridge the fault indicator will be turned on and the

SCD displays 6 or 7 to indicate that the cleaning process was not done and the cleaning cartridge is no

longer usable. If the fault indicator was on and a C was in the SCD prior to the cleaning process, the

indicators will stay on after the depleted cleaning cartridge is removed. If these indicators were off prior

to inserting the depleted cleaning cartridge, they will turn off once the depleted cleaning cartridge is

removed from the drive.

If a system error occurs, clean the drive and retry the operation. If the operation fails, replace the data

cartridge, clean the drive again, and then retry the operation.

Maintenance mode (FC 5746)

Learn about using maintenance mode functions on the 5746 tape drive.

Performing operations using the front panel

Perform maintenance operations by pushing the eject button while observing the status LED and the

single-character display.

Entering maintenance mode

To enter maintenance mode (if the drive is not already in maintenance mode and no cartridge is loaded),

press and hold the eject button for 6 seconds. While the drive is in maintenance mode, the status LED is

shows solid amber and the operator can perform maintenance or diagnostic functions. In maintenance

mode, the tape drive is offline to SCSI commands.

Note: If a tape is loaded, the eject button is interpreted as an eject request. The drive cannot be put into

maintenance mode while a tape is loaded.

16 Power Systems: Managing devices

Page 29

Scrolling through maintenance options

With the drive in maintenance mode, press the eject push button at a rate of once per second. The

single-character display code increments by one each time you press the eject push button.

Note: Do not press the eject push button more frequently than once per second or the selected

maintenance function will occur instead of the desired scrolling operation.

After the last maintenance function is reached, the display code wraps to 0. Unassigned digits (B, D, and

G) are not displayed when the options are incremented.

The following table lists the maintenance functions.

Table 10. Maintenance functions

Maintenance functions Display code

Normal mode None

Exit maintenance mode 0

Drive diagnostics 1

Update drive microcode from the firmware microcode

release (FMR) tape

Create FMR tape 3

Force a drive dump (same as pressing the eject button

for 10 or more seconds, except it does not cause a reset

operation)

Copy drive dump to tape at the beginning of tape 5

Copy drive dump to tape 5-1

Copy drive dump to flash memory 5-2

Clear flash dump 5-3

SCSI wrap test 6

SAS wrap test for port 1 6-1

SAS wrap test for port 2 6-2

SAS wrap test for both ports 6-3

RS-422 wrap test 7

Unmake FMR tape 8

Display error code log 9

Clear error code log A

Insert cartridge into tape drive C

Test cartridge and media E

Write performance test F

Test head H

Fast write test J

Load/unload test L

Enable post-error reporting P

Disable post-error reporting U

2

4

Chapter 2. Managing tape drives 17

Page 30

Running a maintenance function

To run the maintenance function indicated by the character on the single-character display, press and

hold the eject button for 2 seconds. The single digit flashes the selected maintenance function code during

the running of the operation. If the drive runs the function successfully, the single-character display

indicates 0. If the function fails, the status LED indicates continuous yellow and the single-character

display indicates the reason for the error by displaying an error code. For a list of error codes, see Table 8

on page 12.

Exiting maintenance mode

To exit maintenance mode, press the eject button twice within one second:

v While the single-character display indicates 0.

v When the selected maintenance function is completed either successfully or unsuccessfully.

v When the eject button is pressed during any currently running maintenance function.

Running a dump operation when not in maintenance mode

To perform a drive dump operation, press and hold the eject button for 10 or more seconds. The

microcode goes to its initialized state after a dump operation.

Note: Data from a dump operation is for use by trained personnel for problem determination.

Resetting the tape drive

You might need to reset your tape drive. Use the procedure in this topic to perform this task.

Use this information to reset your tape drive, without affecting server operation. Allow up to 2 minutes

for the entire tape drive process to complete.

Attention: Resetting a tape drive before the current backup operation has completed can cause loss of

customer data.

To reset the tape drive, follow these steps:

1. Press and hold the eject button for 20 seconds, and then release the button. The LEDs on the drive

will be flashing while the reset function is in process.

2. When the LEDs stop flashing, wait approximately one minute for the drive to complete the reset

operation. The drive will then be ready to use.

Performing the internal self-test (FC 5746)

Use the information in this section to perform an internal self-test on your tape drive.

This procedure is designed to allow you to quickly perform a complete set of diagnostic tests on your

LTO-4 tape drive, without impacting server operation. This 4-minute test can also be used to verify good

performance of individual LTO tape cartridges. For an illustration of the tape drive and the LED status

lights that are referred to in this procedure, see Figure 1 on page 12

Prerequisites

In order to perform the test you need a blank LTO-4 (Ultrium 4) data cartridge. If an Ultrium-4 data

cartridge is not available, an Ultrium-3 cartridge can be substituted.

18 Power Systems: Managing devices

Page 31

Performing the test

Follow these steps to perform the test:

Attention: Use a blank data cartridge to perform the test. During the test, the tape will be overwritten

with a test pattern and all data on the tape will be destroyed.

1. Enter diagnostic mode by doing the following steps:

a. Verify that a tape cartridge is not loaded in the drive. To unload a cartridge, press the eject button

on the front of the drive.

b. Press and hold the eject button for 7 seconds, until all LEDs become active, and then release the

button.

The Ready LED will continue flashing, the Fault LED will remain on, and a 1 is displayed in the

Single-character display (SCD). This combination indicates that the drive is waiting for a cartridge

to be inserted.

2. Start the self-test by inserting a blank, Ultrium 4 data cartridge into the drive.

If an Ultrium-4 data cartridge is not available, an Ultrium-3 cartridge can be substituted.

Notes:

v A cartridge must be loaded within 15 seconds or the drive will automatically revert back to normal

operation. If necessary, return to step 1 to reenter diagnostic mode.

v The test takes about 4 minutes.

v Use a cartridge that is not write-protected. If a write-protected cartridge is inserted while the drive

is in diagnostic mode, the cartridge will be ejected. See Table 11.

v Self-testing can only be performed using a write-compatible (either Ultrium-4 or Ultrium-3)

cartridge type, and with a cartridge that is not damaged. See Table 11.

v If a cleaning cartridge is inserted while the drive is in diagnostic mode, it will be ejected.

While self-testing is in progress, the LEDs will remain active and the following test steps are performed:

v The hardware test runs for about one minute. During that time, a static test is performed on the

electrical components of the drive, and proper operation of the cartridge load/unload mechanism is

verified.

v The write/read test runs for about three minutes.

Interpreting the results

Table 11. Interpreting the results of the self-test

Result Description

Test passed When self-testing has completed successfully and no problems were detected, the cartridge is

unloaded from the drive and all LEDs are off. Proper function of both the drive and tape

cartridge have been verified. The drive is no longer in diagnostic mode, and has been

returned to normal operation.

If the yellow Fault LED remains on and a C is displayed in the SCD, this combination

indicates that self-testing has completed successfully but that cleaning is required. Clean the

drive by inserting an IBM cleaning cartridge, part number 35L2086.

Drive failure When a drive problem is detected, the cartridge remains loaded inside the drive, the yellow

Fault LED flashes, and a 5 is displayed in the SCD. Replace the tape drive.

Media failure When a media problem is detected, the cartridge remains loaded inside the drive, the yellow

Fault LED remains on, and a 7 is displayed in the SCD. Repeat the self-test using another

blank tape cartridge and discard the defective media.

Chapter 2. Managing tape drives 19

Page 32

Table 11. Interpreting the results of the self-test (continued)

Result Description

Incorrect cartridge When an incorrect tape cartridge is used for the test, the cartridge is unloaded, the yellow

Fault LED remains on, and a P, 7,orJ is displayed in the SCD. This can happen if the

cartridge is:

v Write-protected (P is displayed in the SCD.)

v Damaged (7 is displayed in the SCD.)

v Not write-compatible with the drive (J is displayed in the SCD.)

Press the eject button to end the self-test and return the drive to normal operating mode.

Then return to step 1 and run the self-test again using a suitable cartridge.

Returning to normal operation

When self-testing has completed successfully, the tape cartridge is unloaded. The drive is no longer in

diagnostic mode and returns to normal operation.

When self-testing fails, the tape cartridge remains loaded inside the drive, and the drive remains in

diagnostic mode. Press the eject button to unload tape cartridge and return drive to normal operation.

200/400 GB Half High Ultrium 2 tape drive (FC 5755)

Learn about the features of this media device.

The LTO half-high tape drive is a SCSI device that can be used for backing up, restoring and archiving

data. These files can include multimedia, imaging, transaction processing, large databases, and other

storage-intensive applications. Each tape cartridge can store up to 200 GB of data (uncompressed), or up

to 400 GB of data (compressed), assuminga2to1compression ratio.

Note: The actual capacity varies depending on the application, the type of data, and the tape cartridge.

200 GB is typical and 400 GB is possible when the Data Compression setting is activated. The default

setting of Data Compression is controlled by the host system. The user and the application software can

control the activation or deactivation of the data compression setting. The drive can optimally achieve a

2:1 compression ratio.

The LTO half-high tape drive FRU part number is 23R3248

The custom card identification number (CCIN): 63A0

The LTO half-high tape drive features:

v A sustained native data transfer rate of up to 24 MB per second, 48 MB per second at 2:1 compression

v Downward read and write compatibility with earlier LTO-type data cartridges.

v Uses the self-configuring SCSI device driver native to the host operating system.

v Can be used as an bootable device, depending on the host system configuration.

v 5.25-inch half-high form factor

v Streaming operation

Attributes required: One 1.6-inch (41 mm) half-high media bay and one SCSI-2 internal 16-bit address

Cleaning the tape drive (FC 5755)

You will need to clean your tape drive. Use the procedure in this topic to perform this task.

20 Power Systems: Managing devices

Page 33

Clean the device whenever the Fault status light comes on or a system I/O error related to the device

occurs.

Attention: Use only the recommended cleaning cartridge to clean the tape drive. Use of other than

recommended cleaning cartridges can damage your drive and might void the warranty.

The tape drive will turn on the cleaning indication for several reasons:

v - The tape drive exceeds internal preset error thresholds in the drive.

v - A cleaning cartridge that has been used the maximum number of times is inserted in the drive. The

cleaning indicator is turned on to indicate that the cleaning process was not done and the cleaning

cartridge is no longer usable.

v The tape drive exceeds the maximum recommended time between cleaning.

The maximum recommended time between preventive-maintenance cleaning is 100 tape motion hours.

Tape motion hours are defined as the time that the tape drive is moving tape. If the tape drive reaches

100 tape motion hours since the tape drive was last cleaned, the drive will turn on the cleaning required

LED to indicate the drive needs cleaning. The tape drive will continue to operate but it is recommended

the tape drive be cleaned at the next opportunity to insert a cleaning cartridge.

To clean the tape drive, complete the following steps:

1. Make sure that the power is on for the tape drive.

2. If a tape cartridge is in the tape drive, eject and remove the cartridge.

3. Grasp the cleaning cartridge by the outer edges, with the window-side up and the write-protect

switch facing you.

4. Slide the cartridge into the opening on the front of the drive until the loading mechanism pulls the

cartridge into the drive.

After the cleaning cartridge has been inserted, the remainder of the cleaning process is automatic. The

tape drive does the following actions:

v Loads the cleaning cartridge into the tape drive.

v Cleans the drive by moving the cleaning tape forward for approximately 30 seconds.

v Unloads the cleaning cartridge when the cleaning operation is complete.

v Indicates a successful cleaning operation by turning off the Cleaning status light (if the Cleaning light

was on prior to the cleaning process. Otherwise, the Cleaning light remains solid to indicate that the

cleaning cartridge is no longer usable. Obtain a new cleaning cartridge and repeat the process.)

Note: If the cleaning operation completes but the Cleaning light remains on, repeat the cleaning

procedure with a new cleaning cartridge. If the light still remain on, contact your authorized service

representative.

To determine how many times a cleaning cartridge may be used, check the information printed on the

cartridge. If you attempt to use a depleted cleaning cartridge, the drive automatically detects the error

and ejects the cartridge. If the Cleaning status light was on prior to the cleaning process, it stays on; if the

Cleaning light was off, the depleted cartridge causes the light to come on.

If a system error occurs, clean the drive and retry the operation. If the operation fails, replace the data

cartridge, clean the drive again, then retry the operation.

Setting the write-protect switch (FC 5755)

You might need to set the write-protect switch on your tape drive. Use the information in this topic to

perform this task.

Chapter 2. Managing tape drives 21

Page 34

Attention: Do not attempt to change the write-protect settings after the tape cartridge is loaded in the

drive because this might cause unpredictable results and might damage the tape or the drive.

The position of the write-protect switch on the tape cartridge determines when you can write to the tape.

Before loading cartridges into magazines, set the write-protect switch of each cartridge to enable or

disable data recording. When the switch is set to the left, data can be written to the tape. When the

switch is set to the right, data cannot be written to the tape.

Status lights (FC 5755)

You might need to read the status lights on your tape drive to determine the operating status of the

drive. Use the information in this topic to perform this task.

The following illustration shows a front view of the tape drive:

22 Power Systems: Managing devices

Page 35

Figure 2. Front view of tape drive

1 Eject button

2 Ready (green)

3 Active (green)

4 Cleaning (amber)

5 Fault (amber)

The status lights and their ISO symbols are on the device as follows:

Ready

Activity

Cleaning

Fault

(green)

(green)

(amber)

(amber)

The combinations of the lights and their definitions are shown in the following table.

Table 12. Definition of Status Light Combinations

Operation Ready

Power-On LED Test

Power-On Self-Test

(POST) is in progress

A cartridge is not

1

On for 2.0 seconds On for 2.0 seconds On for 2.0 seconds On for 2.0 seconds

2

Flashing Off Off Off

Off Off On

loaded

Activity Cleaning Fault

3

/Off Off

Chapter 2. Managing tape drives 23

Page 36

Table 12. Definition of Status Light Combinations (continued)

Operation Ready

Activity Cleaning Fault

Cartridge loaded, no

activity

Data cartridge

loaded, activity

Cleaning cartridge

loaded, activity

Cleaning cartridge

loaded, cleaning

failed

Cartridge is loading

or unloading

Unrecoverable drive

failure

Firmware download

is in progress

Firmware update is in

progress

Firmware download

6

failure

Maximum operating

temperature

exceeded

7

Diagnostics test is

in-progress

Media failure

Incorrect media

inserted in drive

8

8

On Off On3/Off Off

3

On Flashing On

/Off Off

On Flashing On Off

Off Off On

Off Flashing On

On/Off Off On

34

3

/Off Off

3

/Off Flashing

Off

Flashing Off On3/Off Off

3

Flashing Flashing On

/Off Off

Off Off On3/Off Flashing

Off Off On3/Off On

3

Flashing Off or Flashing On

/ Off Off

Off Off Flashing Off

Off Both LEDs Flashing Together Off

5

5

24 Power Systems: Managing devices

Page 37

Table 12. Definition of Status Light Combinations (continued)

Operation Ready

1

All 4 LEDs will be on solid for 2 seconds.

2

If the drive completes Power-On Self-Test (POST) within 2 seconds, no POST in progress indication is required.

3

A solid amber Clean LED indicates that the drive needs cleaning. In most cases the drive will continue to function,

Activity Cleaning Fault

but it should be cleaned as soon as possible.

4

If the cleaning function completes and the solid amber Clean LED remains lit, the cleaning function was not

successful. The cleaning cartridge may be depleted. Obtain a new LTO cleaning cartridge and use it to perform the

cleaning function again.

5

The Fault LED will flash to indicate an unrecoverable error. An unrecoverable error is an error condition that

results in the drive not being able to function unless initiator, operator, or service intervention is applied. An

unrecoverable drive failure is usually the result of a hardware error condition. One of the following actions will be

needed to clear the flashing Fault LED:

v Hard SCSI reset

v Cartridge eject

v Power cycle

v Retry microcode download

An unrecoverable cartridge (media) failure is usually the result of a defective cartridge, media, or cartridge state

and will require the drive to eject the cartridge (if possible) to clear the flashing LED.

6

The firmware download failed and the drive is not functional. The drive boot code is in control and the firmware

download must be retried.

7

When the Fault LED is solid, it indicates an over temperature condition. The drive has exceeded its preset

temperature limit, and if a tape is present in the drive it will be ejected. The Fault LED will remain solid until the

drive temperature drops below a secondary temperature limit, and a data or cleaning cartridge is inserted.

8

While running drive diagnostics (using either SEND DIAG or the Self-Test Procedure), a media-related problem

(hard media error or excessive soft error rate) will be reported as a media failure (with flashing Clean LED), and a