Page 1

BladeCenter JS12 Type 7998

Problem Determination and Service Guide

Page 2

Page 3

BladeCenter JS12 Type 7998

Problem Determination and Service Guide

Page 4

Note

Before using this information and the product it supports, read the general information in

Appendix B, “Notices,” on page 289 and the Warranty and Support Information document for your

blade server type on the Documentation CD.

Second Edition (November 2009)

© Copyright International Business Machines Corporation 2008, 2009.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety ...............v

Guidelines for trained service technicians ....vi

Inspecting for unsafe conditions ......vi

Guidelines for servicing electrical equipment . . vii

Safety statements ............viii

Chapter 1. Introduction ........1

Related documentation ...........1

Notices and statements in this documentation . . . 2

Features and specifications..........2

Supported DIMMs ............4

Blade server control panel buttons and LEDs . . . 5

Turning on the blade server .........7

Turning off the blade server .........8

System-board layouts ...........9

System-board connectors .........9

System-board LEDs ...........9

Chapter 2. Diagnostics ........11

Diagnostic tools .............12

Collecting dump data ...........13

Location codes .............14

Reference codes .............15

System reference codes (SRCs) .......16

1xxxyyyy SRCs ...........17

6xxxyyyy SRCs ...........22

A1xxyyyy service processor SRCs .....24

AA00E1A8 to AA260005 Partition firmware

attention codes ...........25

Bxxxxxxx Service processor early termination

SRCs ..............28

B200xxxx Logical partition SRCs .....29

B700xxxx Licensed internal code SRCs . . . 39

BA000010 to BA400002 Partition firmware

SRCs ..............48

POST progress codes (checkpoints) .....88

C1001F00 to C1645300 Service processor

checkpoints ............89

C2001000 to C20082FF Virtual service

processor checkpoints .........99

IPL status progress codes .......109

C700xxxx Server firmware IPL status

checkpoints ...........109

CA000000 to CA2799FF Partition firmware

checkpoints ............110

D1001xxx to D1xx3FFF Service processor

dump codes ............131

D1xx3y01 to D1xx3yF2 Service processor

dump codes ...........138

D1xx900C to D1xxC003 Service processor

power-off checkpoints ........140

Service request numbers (SRNs) ......141

Using the SRN tables .........142

101-711 through FFC-725 SRNs .....142

A00-FF0 through A24-xxx SRNs .....159

ssss-102 through ssss-640 SRNs for SCSI

devices .............180

Failing function codes 151 through 2D02 . . 184

Error logs ..............186

Checkout procedure ...........186

About the checkout procedure.......186

Performing the checkout procedure .....187

Verifying the partition configuration......189

Running the diagnostics program ......189

Starting AIX concurrent diagnostics .....189

Starting stand-alone diagnostics from a CD . . 190

Starting stand-alone diagnostics from a NIM

server ...............191

Using the diagnostics program ......192

Boot problem resolution ..........193

Troubleshooting tables ..........194

General problems ...........195

Hard disk drive problems ........195

Intermittent problems .........196

Keyboard problems ..........196

Management module service processor

problems ..............197

Memory problems ...........197

Microprocessor problems ........198

Monitor or video problems ........198

Network connection problems .......200

PCI expansion card (PIOCARD) problem

isolation procedure ..........200

Optional device problems ........201

Power problems ...........202

POWER Hypervisor (PHYP) problems ....203

Service processor problems ........205

Software problems...........217

Universal Serial Bus (USB) port problems . . . 217

Light path diagnostics ..........218

Viewing the light path diagnostic LEDs . . . 218

Light path diagnostics LEDs .......219

Isolating firmware problems ........222

Recovering the system firmware .......222

Starting the PERM image ........222

Starting the TEMP image ........223

Recovering the TEMP image from the PERM

image ...............223

Verifying the system firmware levels ....224

Committing the TEMP system firmware image 224

Solving shared BladeCenter resource problems . . 225

Solving shared keyboard problems .....226

Solving shared media tray problems.....226

Solving shared network connection problems 228

Solving shared power problems ......229

Solving shared video problems ......230

Solving undetermined problems .......231

Calling IBM for service ..........232

Chapter 3. Parts listing, Type 7998 235

© Copyright IBM Corp. 2008, 2009 iii

Page 6

Chapter 4. Removing and replacing

blade server components ......239

Installation guidelines ..........239

System reliability guidelines .......240

Handling static-sensitive devices ......240

Returning a device or component .....241

Removing the blade server from a BladeCenter

unit ................241

Installing the blade server in a BladeCenter unit 242

Removing and replacing Tier 1 CRUs .....244

Removing the blade server cover ......244

Installing and closing the blade server cover . . 245

Removing the bezel assembly .......246

Installing the bezel assembly .......247

Removing a SAS hard disk drive ......248

Installing a SAS hard disk drive ......249

Removing a memory module .......251

Installing a memory module .......251

Removing the management card ......253

Installing the management card ......254

Entering vital product data ........256

Obtaining a PowerVM Virtualization Engine

system technologies activation code .....257

Removing and installing an I/O expansion card 260

Removing a small-form-factor expansion card 260

Installing a small-form-factor expansion card 261

Removing a standard-form-factor expansion

card..............263

Installing a standard-form-factor expansion

card..............264

Removing a combination-form-factor

expansion card ...........265

Installing a combination-form-factor

expansion card ...........266

Removing the battery .........267

Installing the battery ..........268

Removing the hard disk drive tray .....270

Installing the hard disk drive tray .....271

Removing the expansion bracket ......272

Installing the expansion bracket ......273

Replacing the Tier 2 system-board and chassis

assembly ...............274

Updating the firmware ..........277

Configuring the blade server ........278

Using the SMS utility...........279

Starting the SMS utility .........279

SMS utility menu choices ........280

Creating a CE login ...........280

Configuring the Gigabit Ethernet controllers . . . 281

Blade server Ethernet controller enumeration . . . 282

MAC addresses for host Ethernet adapters . . . 282

Updating IBM Director ..........283

Appendix A. Getting help and

technical assistance ........285

Before you call .............286

Using the documentation .........286

Getting help and information from the Web . . . 287

Software service and support ........287

Hardware service and support .......287

IBM Taiwan product service ........287

Appendix B. Notices ........289

Trademarks ..............290

Important notes ............291

Product recycling and disposal .......291

Battery return program ..........293

Electronic emission notices .........295

Federal Communications Commission (FCC)

statement..............295

Industry Canada Class A emission compliance

statement..............295

Avis de conformité à la réglementation

d’Industrie Canada ..........296

Australia and New Zealand Class A statement 296

United Kingdom telecommunications safety

requirement .............296

European Union EMC Directive conformance

statement..............296

Taiwanese Class A warning statement ....297

Chinese Class A warning statement .....297

Japanese Voluntary Control Council for

Interference (VCCI) statement .......297

Chapter 5. Configuring .......277

iv

JS12 Type 7998: Problem Determination and Service Guide

Index ...............299

Page 7

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright IBM Corp. 2008, 2009 v

Page 8

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Guidelines for trained service technicians

Inspect the equipment for unsafe conditions and observe the servicing guidelines.

Inspecting for unsafe conditions

Identify potential unsafe conditions in an IBM®product that you are working on.

Each IBM product, as it was designed and manufactured, has required safety items

to protect users and service technicians from injury. This information addresses

only those items. Use good judgment to identify potential unsafe conditions that

might be caused by non-IBM alterations or attachment of non-IBM features or

options that are not addressed in this information. If you identify an unsafe

condition, you must determine how serious the hazard is and whether you must

correct the problem before you work on the product.

Consider the following conditions and the safety hazards that they present:

v Electrical hazards, especially primary power. Primary voltage on the frame can

cause serious or fatal electrical shock.

v Explosive hazards, such as a damaged CRT face or a bulging capacitor.

v Mechanical hazards, such as loose or missing hardware.

To inspect the product for potential unsafe conditions, complete the following

steps:

1. Make sure that the power is off and the power cords are disconnected.

2. Make sure that the exterior cover is not damaged, loose, or broken, and observe

any sharp edges.

3. Check the power cords:

v Make sure that the third-wire ground connector is in good condition. Use a

meter to measure third-wire ground continuity for 0.1 ohm or less between

the external ground pin and the frame ground.

v Make sure that the power cords are the correct type.

v Make sure that the insulation is not frayed or worn.

4. Remove the cover.

5. Check for any obvious non-IBM alterations. Use good judgment as to the safety

of any non-IBM alterations.

6. Check inside the computer for any obvious unsafe conditions, such as metal

filings, contamination, water or other liquid, or signs of fire or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Make sure that the power-supply cover fasteners (screws or rivets) have not

been removed or tampered with.

vi JS12 Type 7998: Problem Determination and Service Guide

Page 9

Guidelines for servicing electrical equipment

Observe the guidelines for servicing electrical equipment.

v Check the area for electrical hazards such as moist floors, nongrounded power

extension cords, and missing safety grounds.

v Use only approved tools and test equipment. Some hand tools have handles that

are covered with a soft material that does not provide insulation from live

electrical current.

v Regularly inspect and maintain your electrical hand tools for safe operational

condition. Do not use worn or broken tools or testers.

v Do not touch the reflective surface of a dental mirror to a live electrical circuit.

The surface is conductive and can cause personal injury or equipment damage if

it touches a live electrical circuit.

v Some rubber floor mats contain small conductive fibers to decrease electrostatic

discharge. Do not use this type of mat to protect yourself from electrical shock.

v Do not work alone under hazardous conditions or near equipment that has

hazardous voltages.

v Locate the emergency power-off (EPO) switch, disconnecting switch, or electrical

outlet so that you can turn off the power quickly in the event of an electrical

accident.

v Disconnect all power before you perform a mechanical inspection, work near

power supplies, or remove or install main units.

v Before you work on the equipment, disconnect the power cord. If you cannot

disconnect the power cord, have the customer power-off the wall box that

supplies power to the equipment and lock the wall box in the off position.

v Never assume that power has been disconnected from a circuit. Check it to

make sure that it has been disconnected.

v If you have to work on equipment that has exposed electrical circuits, observe

the following precautions:

– Make sure that another person who is familiar with the power-off controls is

near you and is available to turn off the power if necessary.

– When you are working with powered-on electrical equipment, use only one

hand. Keep the other hand in your pocket or behind your back to avoid

creating a complete circuit that could cause an electrical shock.

– When using a tester, set the controls correctly and use the approved probe

leads and accessories for that tester.

– Stand on a suitable rubber mat to insulate you from grounds such as metal

floor strips and equipment frames.

v Use extreme care when measuring high voltages.

v To ensure proper grounding of components such as power supplies, pumps,

blowers, fans, and motor generators, do not service these components outside of

their normal operating locations.

v If an electrical accident occurs, use caution, turn off the power, and send another

person to get medical aid.

Safety vii

Page 10

Safety statements

Important: Each caution and danger statement in this documentation is labeled

with a number. This number is used to cross reference an English-language caution

or danger statement with translated versions of the caution or danger statement in

the Safety Information document.

For example, if a caution statement is labeled, ″Statement 1,″ translations for that

caution statement are in the Safety Information document under ″Statement 1.″ Be

sure to read all caution and danger statements in this documentation before you

perform the procedures. Read any additional safety information that comes with

your blade server or optional device before you install the device.

Statement 1

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical storm.

v Connect all power cords to a properly wired and grounded electrical outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

viii JS12 Type 7998: Problem Determination and Service Guide

Page 11

Statement 2

CAUTION:

When replacing the lithium battery, use only IBM Part Number 16G8095 or an

equivalent type battery recommended by the manufacturer. If your system has a

module containing a lithium battery, replace it only with the same module type

made by the same manufacturer. The battery contains lithium and can explode if

not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable parts

inside the device.

v Use of controls or adjustments or performance of procedures other than those

specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser diode.

Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Safety ix

Page 12

Statement 4

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current from

the device, ensure that all power cords are disconnected from the power source.

1 2

Statement 8

x JS12 Type 7998: Problem Determination and Service Guide

Page 13

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component

that has this label attached. There are no serviceable parts inside these

components. If you suspect a problem with one of these parts, contact a service

technician.

Statement 10

CAUTION:

Do not place any object on top of rack-mounted devices.

Safety xi

Page 14

xii JS12 Type 7998: Problem Determination and Service Guide

Page 15

Chapter 1. Introduction

This problem determination and service information helps you solve problems that

might occur in your IBM BladeCenter®JS12 Type 7998 blade server. The

information describes the diagnostic tools that come with the blade server, error

codes and suggested actions, and instructions for replacing failing components.

Replaceable components are of three types:

v Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your

responsibility. If IBM installs a Tier 1 CRU at your request, you will be charged

for the installation.

v Tier 2 customer replaceable unit: You may install a Tier 2 CRU yourself or

request IBM to install it, at no additional charge, under the type of warranty

service that is designated for your blade server.

v Field replaceable unit (FRU): FRUs must be installed only by trained service

technicians.

For information about the terms of the warranty and getting service and assistance,

see the Warranty and Support Information document.

Related documentation

Documentation for the JS12 blade server includes documents in Portable Document

Format (PDF) on the IBM BladeCenter Documentation CD and the online information

center.

The most recent version of all BladeCenter documentation is in the BladeCenter

information center.

The online BladeCenter information center is available in the IBM Systems

Information Center.

You can find the following documents in PDF on the IBM BladeCenter

Documentation CD and in the online information center:

v Installation and User’s Guide

This document contains general information about the blade server, including

how to install supported options and how to configure the blade server.

v Safety Information

This document contains translated caution and danger statements. Each caution

and danger statement that appears in the documentation has a number that you

can use to locate the corresponding statement in your language in the Safety

Information document.

v Warranty and Support Information

This document contains information about the terms of the warranty and about

getting service and assistance.

© Copyright IBM Corp. 2008, 2009 1

Page 16

Additional documents might be included in the online information center and on

the IBM BladeCenter Documentation CD.

The blade server might have features that are not described in the documentation

that comes with the blade server. The documentation might be updated

occasionally to include information about those features, or technical updates

might be available to provide additional information that is not included in the

documentation that comes with the blade server.

Review the online information or the Planning Guide and the Installation Guide for

your IBM BladeCenter unit. The information can help you prepare for system

installation and configuration. The most current version of each document is

available in the BladeCenter information center.

Notices and statements in this documentation

The caution and danger statements in this document are also in the multilingual

Safety Information. Each statement is numbered for reference to the corresponding

statement in your language in the Safety Information document.

The following notices and statements are used in this document:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you

avoid inconvenient or problem situations.

v Attention: These notices indicate potential damage to programs, devices, or data.

An attention notice is placed just before the instruction or situation in which

damage might occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

Features and specifications

Features and specifications of the IBM BladeCenter JS12 Type 7998 blade server are

summarized in this overview.

2 JS12 Type 7998: Problem Determination and Service Guide

Page 17

The JS12 blade server is used in one of the following IBM BladeCenter units:

BladeCenter E (8677), BladeCenter H (8852), BladeCenter HT (8740 and 8750),

BladeCenter S (8886), and BladeCenter T (8720 and 8730) units.

Notes:

v Power, cooling, removable-media drives, external ports, and advanced system

management are provided by the BladeCenter unit.

v The operating system in the blade server must provide support for the Universal

Serial Bus (USB), to enable the blade server to recognize and communicate

internally with the removable-media drives and front-panel USB ports.

Microprocessor:

Support for one dual-core, 64-bit

POWER6

Support for Energy Scale thermal

management for power

management/oversubscription

(throttling) and environmental

sensing

Memory:

v Dual-channel (DDR2) with 8 slots

v Supports 1 GB, 2 GB, 4 GB, and 8

v Supports 2-way interleaved, DDR2,

Virtualization:

PowerVM Standard Edition hardware

feature supports Integrated

Virtualization Manager and Virtual

I/O Server

®

microprocessor; 3.8 GHz

for very low profile (18.3 mm)

DIMMs

GB DDR2 DIMMs for a maximum

of 64 GB

PC2-4200 or PC2-5300, ECC

SDRAM registered x4, memory

scrubbing, Chipkill, and bit steering

DIMMs

Integrated functions:

v Two 1 Gigabit Ethernet controllers

v Expansion card interface

v The baseboard management

controller (BMC) is a flexible

service processor with Intelligent

Platform Management Interface

(IPMI) firmware and SOL support

v ATI RN 50 ES1000 video controller

v SAS RAID controller

v Light path diagnostics

v RS-485 interface for

communication with the

management module

v Automatic server restart (ASR)

v Serial over LAN (SOL)

v Support for local keyboard and

video

v Four Universal Serial Bus (USB)

buses for communication with

keyboard and removable-media

drives

v Transferable Anchor function

(Renesas Technology HD651330

microcontroller) in the

management card

Storage:

Predictive Failure Analysis (PFA)

alerts:

v Microprocessor

v Memory

Electrical input: 12Vdc

Environment:

v Air temperature:

– Blade server on: 10° to 35°C (50°

to 95°F). Altitude: 0 to 914 m

(3000 ft)

– Blade server on: 10° to 32°C (50°

to 90°F). Altitude: 914 m to 2133

m (3000 ft to 7000 ft)

– Blade server off: -40° to 60°C (-40°

to 140°F)

v Humidity:

– Blade server on: 8% to 80%

– Blade server off: 8% to 80%

Size:

v Height: 24.5 cm (9.7 inches)

v Depth: 44.6 cm (17.6 inches)

v Width: 2.9 cm (1.14 inches)

v Maximum weight: 5.0 kg (11 lb)

Support for two internal

small-form-factor (SFF) Serial

Attached SCSI (SAS) drives

See the ServerProven Web site for information about supported operating-system

versions and all JS12 blade server optional devices.

Chapter 1. Introduction 3

Page 18

Supported DIMMs

The BladeCenter JS12 Type 7998 blade server contains eight memory connectors for

industry-standard registered, dual-inline-memory modules (RDIMMs). The DIMMS

are very low profile, which means that each DIMM has a height of 18.3 millimeters

(mm). Total memory can range from a minimum of 2 gigabytes (GB) to a

maximum of 64 GB.

See Chapter 3, “Parts listing, Type 7998,” on page 235 for memory modules that

you can order from IBM.

Memory module rules:

v Install DIMMs in pairs in the following connectors to have a supported (tested)

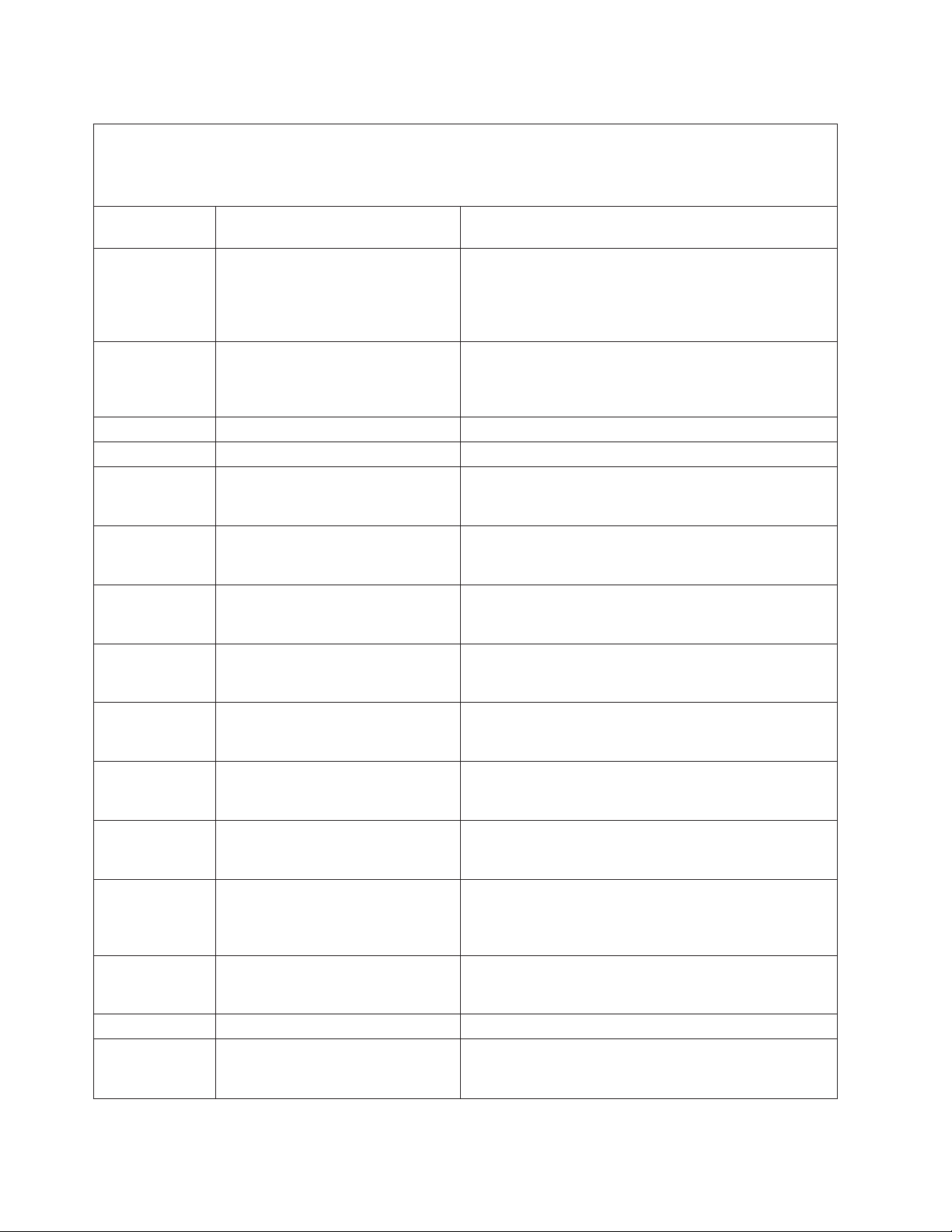

Table 1. Supported use of DIMMs

DIMM

Connectors

Pair 1 (DIMM 1

and DIMM 3)

Pair 2 (DIMM 6

and DIMM 8)

Pair 3 (DIMM 2

and DIMM 4)

Pair 4 (DIMM 5

and DIMM 7)

configuration:

Number of DIMMs in Use

Two Four Six Eight

Yes Yes Yes Yes

No Yes Yes Yes

No No Yes Yes

No No No Yes

See “System-board connectors” on page 9 for DIMM connector locations.

v Both DIMMs in a pair must be the same size, speed, type, technology, and

physical design. You can mix compatible DIMMs from different manufacturers.

Each DIMM in each of the following sets of four connectors must be the same

size:

Size 1 DIMM 1 and DIMM 3 (pair 1) and DIMM 2 and DIMM 4 (pair 3) when

using 6 or 8 DIMMs

Size 2 DIMM 5 and DIMM 7 (pair 4) and DIMM 6 and DIMM 8 (pair 2) when

using 8 DIMMs

v When using 4 DIMMs in DIMM 1 and DIMM 3 (pair 1) and DIMM 6 and

DIMM 8 (pair 2), DIMMs in the second pair can differ in size and speed from

the first pair.

v When using 8 GB DIMMs, all of the DIMMS used must be 8 GB.

®

v Install only supported DIMMs, as described on the ServerProven

Web site. See

http://www.ibm.com/servers/eserver/serverproven/compat/us/.

v Installing or removing DIMMs changes the configuration of the blade server.

After you install or remove a DIMM, the blade server is automatically

reconfigured, and the new configuration information is stored.

4 JS12 Type 7998: Problem Determination and Service Guide

Page 19

Blade server control panel buttons and LEDs

Blade server control panel buttons and LEDs provide operational controls and

status indicators.

Note: Figure 1 shows the control-panel door in the closed (normal) position. To

access the power-control button, you must open the control-panel door.

Keyboard/video select button

Media-tray select button

MT

Location LED

Activity LED

Power-on LED

Sleep (not used on

blade server)

Figure 1. Blade server control panel buttons and LEDs

Keyboard/video select button: When you use an operating system that supports a

local console and keyboard, press this button to associate the shared BladeCenter

unit keyboard and video ports with the blade server.

Information LED

Blade-error LED

Power-control button

NMI reset

Notes:

v The operating system in the blade server must provide USB support for the

blade server to recognize and use the keyboard, even if the keyboard has a

PS/2-style connector.

v The keyboard and video are available after partition firmware loads and is

running. Power-on self-test (POST) codes and diagnostics are not supported

using the keyboard and video. Use the management module to view

checkpoints.

The LED on this button flashes while the request is being processed, then is lit

when the ownership of the keyboard and video has been transferred to the blade

server. It can take approximately 20 seconds to switch control of the keyboard and

video to the blade server.

Using a keyboard that is directly attached to the management module, you can

press keys in the following sequence to switch keyboard and video control

between blade servers:

NumLock NumLock blade_server_number Enter

Chapter 1. Introduction 5

Page 20

Where blade_server_number is the two-digit number for the blade bay in which

the blade server is installed. When you use some keyboards, such as the

28L3644 (37L0888) keyboard, hold down the Shift key while you enter this key

sequence.

If there is no response when you press the keyboard/video select button, you can

use the Web interface of the management module to determine whether local

control has been disabled on the blade server.

Media-tray select button: Press this button to associate the shared BladeCenter

unit media tray (removable-media drives and front-panel USB ports) with the

blade server. The LED on the button flashes while the request is being processed,

then is lit when the ownership of the media tray has been transferred to the blade

server. It can take approximately 20 seconds for the operating system in the blade

server to recognize the media tray.

If there is no response when you press the media-tray select button, use the

management module to determine whether local control has been disabled on the

blade server.

Note: The operating system in the blade server must provide USB support for the

blade server to recognize and use the removable-media drives and USB ports.

Information LED: When this amber LED is lit, it indicates that information about a

system error for the blade server has been placed in the management-module

event log. The information LED can be turned off through the Web interface of the

management module or through IBM Director Console.

Blade-error LED: When this amber LED is lit, it indicates that a system error has

occurred in the blade server. The blade-error LED will turn off after one of the

following events:

v Correcting the error

v Reseating the blade server in the BladeCenter unit

v Cycling the BladeCenter unit power

Power-control button: This button is behind the control panel door. Press this

button to turn on or turn off the blade server.

The power-control button has effect only if local power control is enabled for the

blade server. Local power control is enabled and disabled through the Web

interface of the management module.

Press the power button for 5 seconds to begin powering down the blade server.

6 JS12 Type 7998: Problem Determination and Service Guide

Page 21

NMI reset (recessed): The nonmaskable interrupt (NMI) reset dumps the partition.

Use this recessed button only as directed by IBM Support.

Power-on LED: This green LED indicates the power status of the blade server in

the following manner:

v Flashing rapidly: The service processor (BMC) is initializing the blade server.

v Flashing slowly: The blade server has completed initialization and is waiting for

a power-on command.

v Lit continuously: The blade server has power and is turned on.

Note: The enhanced service processor (BMC) can take as long as three minutes to

initialize after you install the BladeCenter JS12 blade server, at which point the

LED begins to flash slowly.

Activity LED: When this green LED is lit, it indicates that there is activity on the

hard disk drive or network.

Location LED: When this blue LED is lit, it has been turned on by the system

administrator to aid in visually locating the blade server. The location LED can be

turned off through the Web interface of the management module or through IBM

Director Console.

Turning on the blade server

After you connect the blade server to power through the BladeCenter unit, you can

start the blade server after the discovery and initialization process is complete.

You can start the blade server in any of the following ways.

v Start the blade server by pressing the power-control button on the front of the

blade server.

The power-control button is behind the control panel door, as described in

“Blade server control panel buttons and LEDs” on page 5.

After you push the power-control button, the power-on LED continues to blink

slowly for about 15 seconds, then is lit solidly when the power-on process is

complete.

Wait until the power-on LED on the blade server flashes slowly before you press

the blade server power-control button. If the power-on LED is flashing rapidly,

the service processor is initializing the blade server. The power-control button

does not respond during initialization.

Note: The enhanced service processor (BMC) can take as long as three minutes

to initialize after you install the BladeCenter JS12 blade server, at which point

the LED begins to flash slowly.

Chapter 1. Introduction 7

Page 22

v Start the blade server automatically when power is restored after a power

failure.

If a power failure occurs, the BladeCenter unit and then the blade server can

start automatically when power is restored. You must configure the blade server

to restart through the management module.

v Start the blade server remotely using the management module.

After you initiate the power-on process, the power-on LED blinks slowly for

about 15 seconds, then is lit solidly when the power-on process is complete.

Turning off the blade server

When you turn off the blade server, it is still connected to power through the

BladeCenter unit. The blade server can respond to requests from the service

processor, such as a remote request to turn on the blade server. To remove all

power from the blade server, you must remove it from the BladeCenter unit.

Shut down the operating system before you turn off the blade server. See the

operating-system documentation for information about shutting down the

operating system.

You can turn off the blade server in one of the following ways.

v Turn off the blade server by pressing the power-control button for at least 5

seconds.

The power-control button is on the blade server behind the control panel door.

See “Blade server control panel buttons and LEDs” on page 5 for the location.

Note: The power-control LED can remain on solidly for up to 1 minute after

you push the power-control button. After you turn off the blade server, wait

until the power-control LED is blinking slowly before you press the

power-control button to turn on the blade server again.

If the operating system stops functioning, press and hold the power-control

button for more than 5 seconds to force the blade server to turn off.

v Use the management module to turn off the blade server.

The power-control LED can remain on solidly for up to 1 minute after you

initiate the power-off process. After you turn off the blade server, wait until the

power-control LED is blinking slowly before you initiate the power-on process

from the advanced management module to turn on the blade server again.

Use the management-module Web interface to configure the management

module to turn off the blade server if the system is not operating correctly.

For additional information, see the online documentation or the User’s Guide for

the management module.

8 JS12 Type 7998: Problem Determination and Service Guide

Page 23

System-board layouts

Illustrations show the connectors and LEDs on the system board. The illustrations

might differ slightly from your hardware.

System-board connectors

Blade server components attach to the connectors on the system board.

Figure 2 shows the connectors on the system board in the blade server.

Control panel

connector

SAS drive (P1-D1)

DIMM 1 (P1-C1)

DIMM 2 (P1-C2)

DIMM 3 (P1-C3)

DIMM 4 (P1-C4)

SAS drive (P1-D2)

PCI-X expansion

card (P1-C10)

PCI-X expansion

card (P1-C10)

PCI-E high-speed

expansion card

(P1-C11)

Management

card (P1-C9)

Battery (P1-E1)

Figure 2. System-board connectors

System-board LEDs

Use the illustration of the LEDs on the system board to identify a light emitting

diode (LED).

DIMM 5 (P1-C5)

DIMM 6 (P1-C6)

DIMM 7 (P1-C7)

DIMM 8 (P1-C8)

Chapter 1. Introduction 9

Page 24

Remove the blade server from the BladeCenter unit, open the cover to see any

error LEDs that were turned on during error processing, and use Figure 3 to

identify the failing component.

Front SAS drive

error LED (P1-D1)

System board

error LED (P1)

Battery error

LED (P1-E1)

Figure 3. System-board LEDs

Power LED

(always on when plugged in)

PCIe high-speed

expansion card

error LED (P1-C11)

Management

card error LED

(P1-C9)

DIMM 1 error LED

(P1-C1)

DIMM 2 error LED

(P1-C2)

DIMM 3 error LED

(P1-C3)

DIMM 4 error LED

(P1-C4)

PCI-X expansion card

error LED (P1-C10)

DIMM 5 error LED

(P1-C5)

DIMM 6 error LED

(P1-C6)

DIMM 7 error LED

(P1-C7)

DIMM 8 error LED

(P1-C8)

10 JS12 Type 7998: Problem Determination and Service Guide

Page 25

Chapter 2. Diagnostics

Use the available diagnostic tools to help solve any problems that might occur in

the blade server.

The first and most crucial component of a solid serviceability strategy is the ability

to accurately and effectively detect errors when they occur. While not all errors are

a threat to system availability, those that go undetected are dangerous because the

system does not have the opportunity to evaluate and act if necessary. POWER6

processor-based systems are specifically designed with error-detection mechanisms

that extend from processor cores and memory to power supplies and hard drives.

POWER6 processor-based systems contain specialized hardware detection circuitry

for detecting erroneous hardware operations. Error checking hardware ranges from

parity error detection coupled with processor instruction retry and bus retry, to

ECC correction on caches and system buses.

IBM hardware error checkers have these distinct attributes:

v Continuous monitoring of system operations to detect potential calculation

errors

v Attempted isolation of physical faults based on runtime detection of each unique

failure

v Initiation of a wide variety of recovery mechanisms designed to correct a

problem

POWER6 processor-based systems include extensive hardware and firmware

recovery logic.

Machine check handling

Machine checks are handled by firmware. When a machine check occurs, the

firmware analyzes the error to identify the failing device and creates an error log

entry.

If the system degrades to the point that the service processor cannot reach standby

state, the ability to analyze the error does not exist. If the error occurs during

POWER

In partitioned mode, an error that occurs during partition activity is surfaced to the

operating system in the partition.

®

hypervisor (PHYP) activities, the PHYP initiates a system reboot.

© Copyright IBM Corp. 2008, 2009 11

Page 26

Diagnostic tools

What to do if you cannot solve a problem

If you cannot locate and correct the problem using the diagnostics tools and

information, see Appendix A, “Getting help and technical assistance,” on page 285.

Tools are available to help you diagnose and solve hardware-related problems.

v Power-on self-test (POST) progress codes (checkpoints), error codes, and

isolation procedures

The POST checks out the hardware at system initialization. IPL diagnostic

functions test some system components and interconnections. The POST

generates eight-digit checkpoints to mark the progress of powering up the blade

server.

Use the management module to view progress codes.

The documentation of a progress code includes recovery actions for system

hangs. See “POST progress codes (checkpoints)” on page 88 for more

information.

If the service processor detects a problem during POST, an error code is logged

in the management module event log. Error codes are also logged in the Linux

syslog or AIX®diagnostic log, if possible. See “System reference codes (SRCs)”

on page 16.

The service processor can generate codes that point to specific isolation

procedures. See “Service processor problems” on page 205.

v Light path diagnostics

Use the light path diagnostic LEDs on the system board to identify failing

hardware. If the system error LED on the system LED panel on the front or rear

of the BladeCenter unit is lit, one or more error LEDs on the BladeCenter unit

components also might be lit.

Light path diagnostics help identify failing customer replaceable unit (CRUs).

CRU location codes are included in error codes and the event log.

LED locations

See “System-board LEDs” on page 9.

Front panel

See “Blade server control panel buttons and LEDs” on page 5.

v Troubleshooting tables

Use the troubleshooting tables to find solutions to problems that have

identifiable symptoms.

See “Troubleshooting tables” on page 194.

v Dump data collection

In some circumstances, an error might require a dump to show more data. The

Integrated Virtual Manager (IVM) sets up a dump area. Specific IVM

information is included as part of the information that can optionally be sent to

IBM support for analysis.

See “Collecting dump data” on page 13 for more information.

v Stand-alone diagnostics

The AIX-based stand-alone Diagnostics CD is in the ship package and is also

available from the IBM Web site. Boot the CD from a CD drive or from an AIX

network installation manager (NIM) server if the blade server cannot boot to an

operating system, no matter which operating system is installed.

®

12 JS12 Type 7998: Problem Determination and Service Guide

Page 27

Functions provided by the stand-alone diagnostics include:

– Analysis of errors reported by platform, such as microprocessor and memory

– Testing of resources, such as I/O adapters and devices

– Service aids, such as firmware update, format disk, and Raid Manager

v Diagnostic utilities for the AIX operating system

Run AIX concurrent diagnostics if AIX is functioning instead of the stand-alone

diagnostics. Functions provided by disk-based AIX diagnostic include:

– Automatic error log analysis

– Analysis of errors reported by platform, such as microprocessor and memory

– Testing of resources, such as I/O adapters and devices

– Service aids, such as firmware update, format disk, and Raid Manager

v Diagnostic utilities for Linux operating systems

Linux on POWER service and productivity tools include hardware diagnostic

aids and productivity tools, and installation aids. The installation aids are

provided in the IBM Installation Toolkit for Linux on POWER, a set of tools that

aids the installation of Linux on IBM servers with POWER architecture. You can

also use the tools to update the JS12 blade server firmware.

Diagnostic utilities for the Linux operating system are available from IBM at

https://www14.software.ibm.com/webapp/set2/sas/f/lopdiags/home.html.

v Diagnostic utilities for other operating systems

You can use the stand-alone Diagnostics CD to perform diagnostics on the JS12

blade server, no matter which operating system is loaded on the blade server.

However, other supported operating systems might have diagnostic tools that

are available through the operating system. See the documentation for your

operating system for more information.

Collecting dump data

A dump might be critical for fault isolation when the built-in First Failure Data

Capture (FFDC) mechanisms are not capturing sufficient fault data. Even when a

fault is identified, dump data can provide additional information that is useful in

problem determination.

All hardware state information is part of the dump if a hardware checkstop occurs.

When a checkstop occurs, the service processor attempts to dump data that is

necessary to analyze the error from appropriate parts of the system.

Note: If you power off the blade through the management module while the

service processor is performing a dump, platform dump data is lost.

You might be asked to retrieve a dump to send it to IBM Support for analysis. The

location of the dump data varies per operating system platform.

Chapter 2. Diagnostics 13

Page 28

v Collect an AIX dump from the /var/adm/platform directory.

v Collect a Linux dump from the /var/log/dump directory.

v Collect an Integrated Virtualization Manager (IVM) dump from the

IVM-managed JS12 blade server through the Manage Dumps task in the IVM

console.

Location codes

Location codes identify components of the blade server. Location codes are

displayed with some error codes to identify the blade server component that is

causing the error.

See “System-board connectors” on page 9 for component locations.

Notes:

1. Location codes do not indicate the location of the blade server within the

BladeCenter unit. The codes identify components of the blade server only.

2. For checkpoints with no associated location code, see “Light path diagnostics”

on page 218 to identify the failing component when there is a hang condition.

3. For checkpoints with location codes, use the following table to identify the

failing component when there is a hang condition.

4. For 8-digit codes not listed in Table 2, see “Checkout procedure” on page 186.

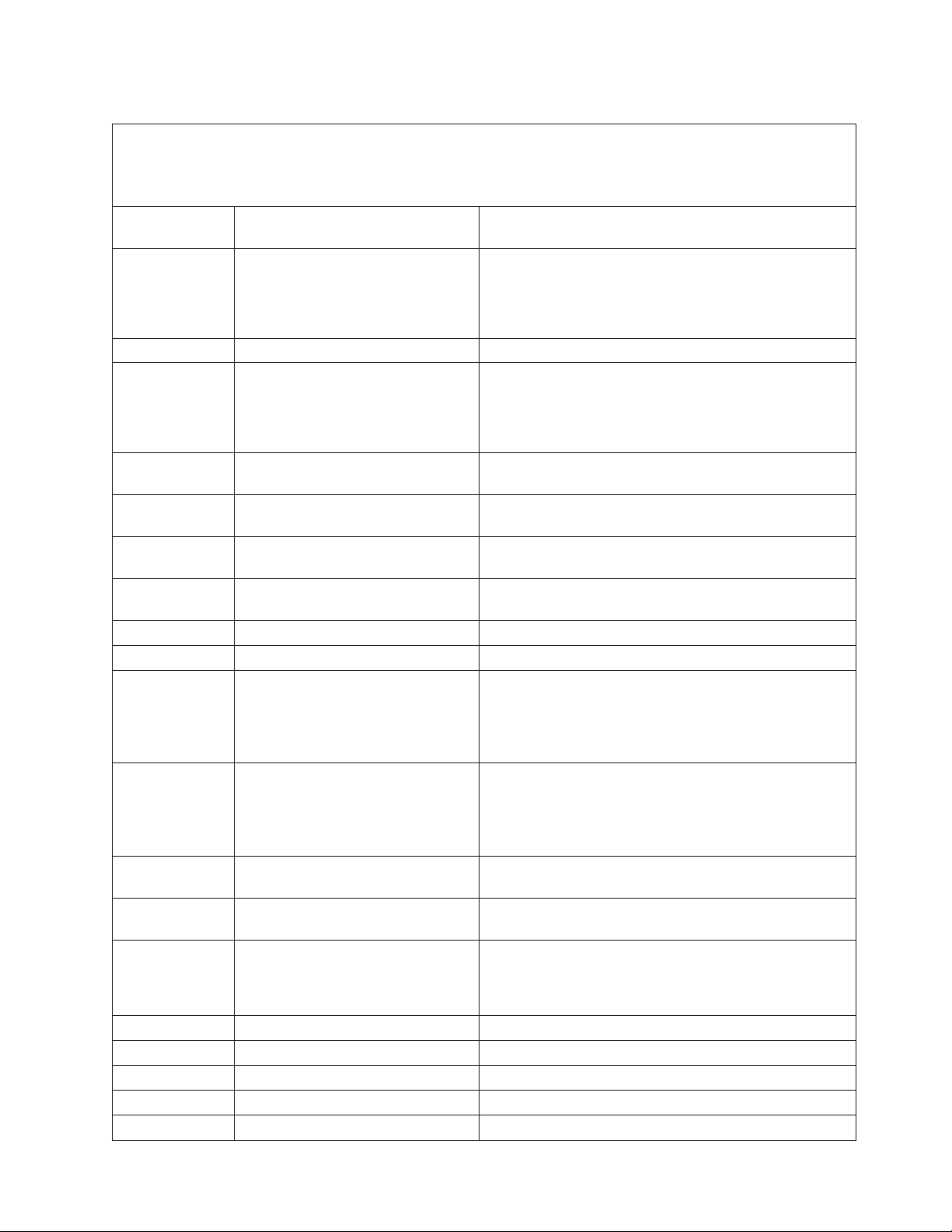

Table 2. Location codes

Location code Component

Un location codes are for enclosure and VPD locations.

Un = Utttt.mmm.sssssss

tttt = system machine type

mmm = system model number

sssssss = system serial number

Un-P1 System-board and chassis assembly (Planar, FSP, SPCN,

CP0, P5IOC2)

Un-P1-C1 DIMM 1 (DIMM1A)

Un-P1-C2 DIMM 2 (DIMM1B)

Un-P1-C3 DIMM 3 (DIMM0A)

Un-P1-C4 DIMM 4 (DIMM0B)

Un-P1-C5 DIMM 5 (DIMM3B)

Un-P1-C6 DIMM 6 (DIMM3A)

Un-P1-C7 DIMM 7 (DIMM2B)

Un-P1-C8 DIMM 8 (DIMM2A)

Un-P1-C9 Management card (MGMT CRD)

Un-P1-C10 PCI-X expansion card (PIOCARD)

Un-P1-C11 PCIe high-speed expansion card (PIOCARD)

Un-P1-D1 Front SAS hard disk drive (SFF0)

Un-P1-D2 Rear SAS hard disk drive (SFF1)

Un-P1-E1 Battery (BATT)

14 JS12 Type 7998: Problem Determination and Service Guide

Page 29

Table 2. Location codes (continued)

Location code Component

Um codes are for firmware. The format is the same as for a Un location code.

Um = Utttt.mmm.sssssss

Um-Y1 Firmware version

Reference codes

Reference codes are diagnostic aids that help you determine the source of a

hardware or operating system problem. To use reference codes effectively, use them

in conjunction with other service and support procedures.

The BladeCenter JS12 Type 7998 blade server produces several types of codes.

Progress codes: The power-on self-test (POST) generates eight-digit status codes

that are known as checkpoints or progress codes, which are recorded in the

management-module event log. The checkpoints indicate which blade server

resource is initializing.

Error codes: The First Failure Data Capture (FFDC) error checkers capture fault

data, which the baseboard management controller (BMC) service processor then

analyzes. For unrecoverable errors (UEs), for recoverable events that meet or

exceed their service thresholds, and for fatal system errors, an unrecoverable

checkstop service event triggers the service processor to analyze the error, log the

system reference code (SRC), and turn on the system attention LED.

The service processor logs the nine-word, eight-digit per word error code in the

BladeCenter management-module event log. Error codes are either system reference

codes (SRCs) or service request numbers (SRNs). A location code might also be

included.

Isolation procedures: If the fault analysis does not determine a definitive cause,

the service processor might indicate a fault isolation procedure that you can use to

isolate the failing component.

Viewing the codes

The JS12 blade server does not display checkpoints or error codes on the remote

console. The shared BladeCenter unit video also does not display the codes.

If the POST detects a problem, a 9-word, 8-digit error code is logged in the

BladeCenter management-module event log. A location code that identifies a

component might also be included. See “Error logs” on page 186 for information

about viewing the management-module event log.

Service request numbers can be viewed using the AIX diagnostics CD, or various

operating system utilities, such as AIX diagnostics or the Linux service aid

“diagela”, if it is installed.

Chapter 2. Diagnostics 15

Page 30

System reference codes (SRCs)

System reference codes indicate a server hardware or software problem that can

originate in hardware, in firmware, or in the operating system.

A blade server component generates an error code when it detects a problem. An

SRC identifies the component that generated the error code and describes the error.

Use the SRC information to identify a list of possibly failing items and to find

information about any additional isolation procedures.

The following table shows the syntax of a nine-word B700xxxx SRC as it might be

displayed in the event log of the management module.

The first word of the SRC in this example is the message identifier, B7001111. This

example numbers each word after the first word to show relative word positions.

The seventh word is the direct select address, which is 77777777 in the example.

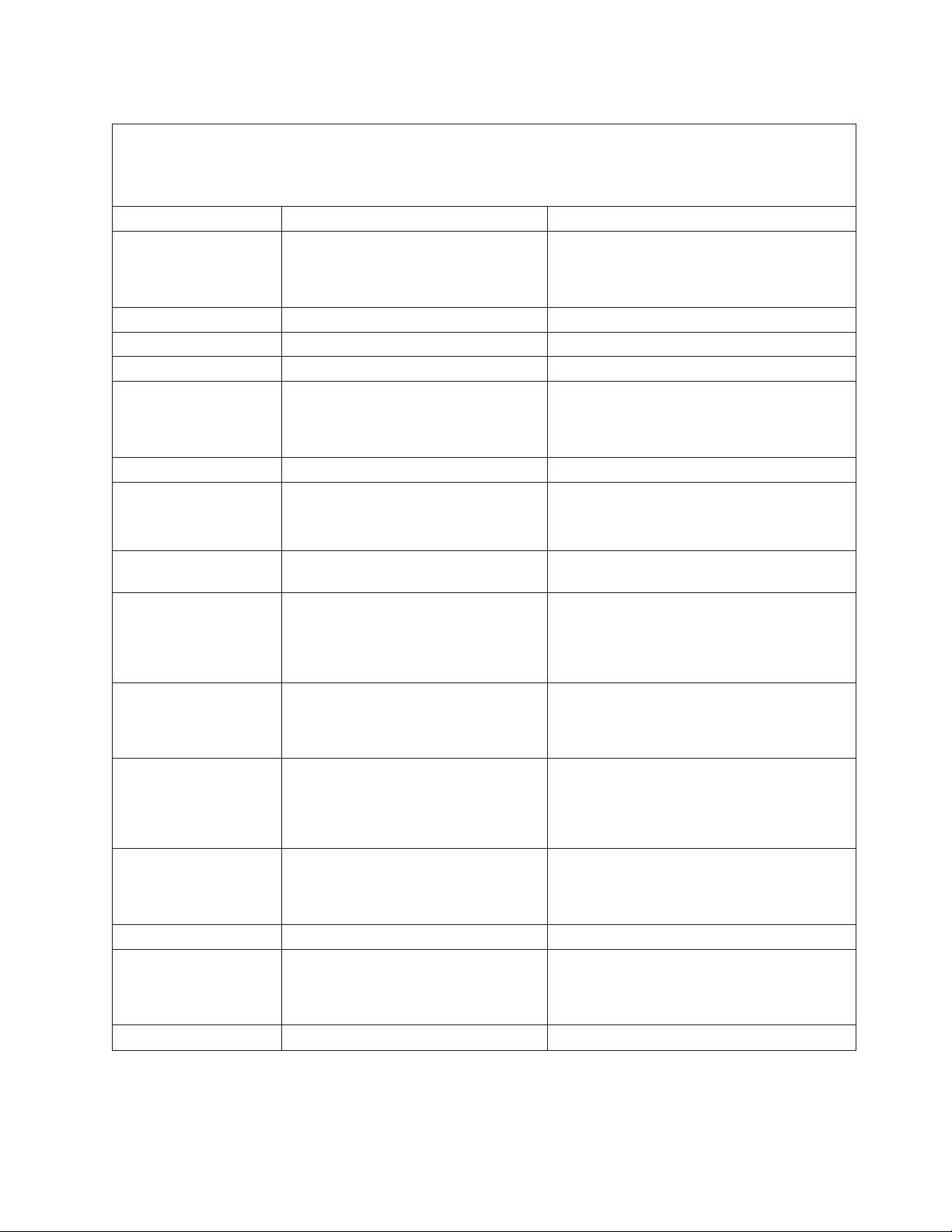

Table 3. Nine-word system reference code in the management-module event log

Index Sev Source Date/Time Text

(JS12-BC1BLD5E) SYS F/W: Error. Replace UNKNOWN

(5008FECF B7001111 22222222 33333333 44444444 55555555

66666666 77777777 88888888 99999999)

1 E Blade_05

Depending on your operating system and the utilities you have installed, error

messages might also be stored in an operating system log. See the documentation

that comes with the operating system for more information.

01/21/2008,

17:15:14

The management module can display the most recent 32 SRCs and time stamps.

Manually refresh the list to update it.

Select Blade Service Data → blade_name in the management module to see a list of

the 32 most recent SRCs.

Table 4. Management module reference code listing

Unique ID System Reference Code Timestamp

00040001 D1513901 2005-11-13 19:30:20

00000016 D1513801 2005-11-13 19:30:16

Any message with more detail is highlighted as a link in the System Reference

Code column. Click the message to cause the management module to present the

additional message detail:

D1513901

Created at: 2007-11-13 19:30:20

SRC Version: 0x02

Hex Words 2-5: 020110F0 52298910 C1472000 200000FF

16 JS12 Type 7998: Problem Determination and Service Guide

Page 31

SRC formats

SRCs are strings of either six or eight alphanumeric characters. The first four

characters designate the reference code type and the second four characters

designate the unit reference code (URC).

The first character indicates the type of error. In a few cases, the first two

characters indicate the type of error:

v 1xxxxxxx - System power control network (SPCN) error

v 6xxxxxxx - Virtual optical device error

v A1xxxxxx - Attention required (Service processor)

v AAxxxxxx - Attention required (Partition firmware)

v B1xxxxxx - Service processor error, such as a boot problem

v BAxxxxxx - Partition firmware error

v Cxxxxxxx - Checkpoint (must hang to indicate an error)

v Dxxxxxxx - Dump checkpoint (must hang to indicate an error)

To find a description of a SRC that is not listed in this JS12 blade server

documentation, refer to the POWER6 Reference Code Lookup page at

https://www-01.ibm.com/servers/resourcelink/lib03030.nsf/pages/eClipzML/

$file/refCode.html.

1xxxyyyy SRCs

The 1xxxyyyy system reference codes are system power control network (SPCN)

reference codes.

Look for the rightmost 4 characters (yyyy in 1xxxyyyy) in the error code; this is the

reference code. Find the reference code in Table 5.

Perform all actions before exchanging failing items.

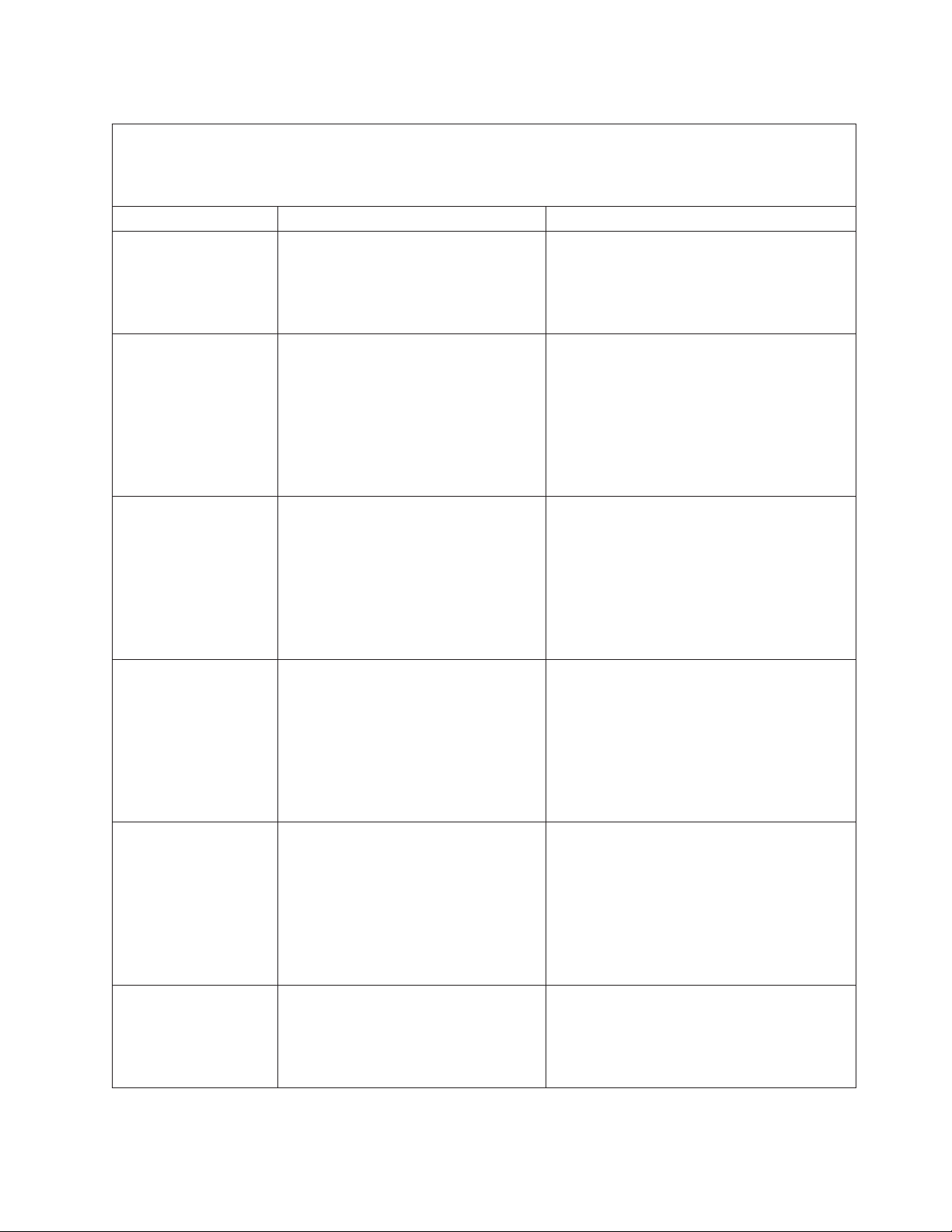

Table 5. 1xxxyyyy SRCs

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

1xxxyyyy

Error Codes

00AC Informational message: AC

00AD Informational message: A

1F02 Informational message: The

2600 pGood master fault

Description Action

No action is required.

loss was reported

No action is required.

service processor reset caused

the blade server to power off

No action is required.

trace logs reached 1K of data.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

Chapter 2. Diagnostics 17

Page 32

Table 5. 1xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

1xxxyyyy

Error Codes

2610 Power good (pGood) fault

2620 12V dc pGood input fault

2622 SMP expansion_comp_pgood

2623 mezzanine_comp_pgood fault

2624 mezzanine_12V_pgood fault

2625 PCIE_A0_PGOOD fault Perform the DTRCARD Symbolic CRU isolation procedure by

2626 PCIE_A1_PGOOD fault Perform the DTRCARD Symbolic CRU isolation procedure by

Description Action

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

completing the following steps:

1. Reseat the PCIe expansion card.

2. If the problem persists, replace the expansion card.

3. If the problem persists, go to “Checkout procedure” on page

186.

4. If the problem persists, replace the system board and chassis

assembly, as described in “Replacing the Tier 2 system-board

and chassis assembly” on page 274.

The DTRCARD Symbolic CRU isolation procedure is in “Service

processor problems” on page 205.

completing the following steps:

1. Reseat the PCIe expansion card.

2. If the problem persists, replace the expansion card.

3. If the problem persists, go to “Checkout procedure” on page

186.

4. If the problem persists, replace the system board and chassis

assembly, as described in “Replacing the Tier 2 system-board

and chassis assembly” on page 274.

The DTRCARD Symbolic CRU isolation procedure is in “Service

processor problems” on page 205.

18 JS12 Type 7998: Problem Determination and Service Guide

Page 33

Table 5. 1xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

1xxxyyyy

Error Codes

Description Action

2627 PCIE_B_PGOOD fault Perform the DTRCARD Symbolic CRU isolation procedure by

completing the following steps:

1. Reseat the PCIe expansion card.

2. If the problem persists, replace the expansion card.

3. If the problem persists, go to “Checkout procedure” on page

186.

4. If the problem persists, replace the system board and chassis

assembly, as described in “Replacing the Tier 2 system-board

and chassis assembly” on page 274.

The DTRCARD Symbolic CRU isolation procedure is in “Service

processor problems” on page 205.

2629 1.5V reg_pgood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

262B 1.8V reg_pgood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

262C 5V reg_pgood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

262D 3.3V reg_pgood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

262E 2.5V reg_pgood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

2630 VRM CP0 core pGood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

2632 VRM CP0 cache pGood fault

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

Chapter 2. Diagnostics 19

Page 34

Table 5. 1xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

1xxxyyyy

Error Codes

2633 1.2V reg_pgood fault

2640 VRM CP1 core pGood fault

2642 VRM CP1 cache pGood fault

2643 1.2V power good signal fault

2647 No 12V dc coming to the

2648 Blade power latch fault

2649 Blade power fault

2670 The BladeCenter encountered

2671 12V power fault in the blade

Description Action

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

blade server from the

BladeCenter midplane

a problem, and the blade

server was automatically shut

down as a result

server

1. Check the management-module event log for errors that

indicate a power problem with the BladeCenter.

2. Resolve any problems that are found.

3. Reboot the blade server.

4. If the problem is not resolved, replace the system-board and

chassis assembly, as described in “Replacing the Tier 2

system-board and chassis assembly” on page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Check the management-module event log for entries that were

made around the time that the JS12 blade server shut down.

2. Resolve any problems that are found.

3. Reboot the blade server.

4. If the problem is not resolved, replace the system-board and

chassis assembly, as described in “Replacing the Tier 2

system-board and chassis assembly” on page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

20 JS12 Type 7998: Problem Determination and Service Guide

Page 35

Table 5. 1xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

1xxxyyyy

Error Codes

Description Action

2672 Blades PEU3 voltage alert Perform the DTRCARD Symbolic CRU isolation procedure by

completing the following steps:

1. Reseat the PCIe expansion card.

2. If the problem persists, replace the expansion card.

3. If the problem persists, go to “Checkout procedure” on page

186.

4. If the problem persists, replace the system board and chassis

assembly, as described in “Replacing the Tier 2 system-board

and chassis assembly” on page 274.

The DTRCARD Symbolic CRU isolation procedure is in “Service

processor problems” on page 205.

3134 I2C problem found with the

PEU3 hardware monitoring

chip

Perform the DTRCARD Symbolic CRU isolation procedure by

completing the following steps:

1. Reseat the PCIe expansion card.

2. If the problem persists, replace the expansion card.

3. If the problem persists, go to “Checkout procedure” on page

186.

4. If the problem persists, replace the system board and chassis

assembly, as described in “Replacing the Tier 2 system-board

and chassis assembly” on page 274.

The DTRCARD Symbolic CRU isolation procedure is in “Service

processor problems” on page 205.

8400 Invalid configuration decode

1. Check for server firmware updates.

2. Apply any available updates.

3. If the problem persists:

a. Go to “Checkout procedure” on page 186.

b. Replace the system-board and chassis assembly, as described

in “Replacing the Tier 2 system-board and chassis assembly”

on page 274.

8402 Unable to get VPD from the

concentrator

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

8413 Invalid processor 1 VPD

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

8414 Invalid processor 2 VPD

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

Chapter 2. Diagnostics 21

Page 36

Table 5. 1xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

1xxxyyyy

Error Codes

8423 No processor VPD was found

84A0 No backplane VPD was found

Description Action

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

1. Go to “Checkout procedure” on page 186.

2. Replace the system-board and chassis assembly, as described in

“Replacing the Tier 2 system-board and chassis assembly” on

page 274.

6xxxyyyy SRCs

The 6xxxyyyy system reference codes are virtual optical reference codes.

Look for the rightmost 4 characters (yyyy in 6xxxyyyy) in the error code; this is the

reference code. Find the reference code in Table 6.

Table 6. 6xxxyyyy SRCs

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

6xxxyyyy

Error Codes

632BCFC1 A virtual optical device cannot

632BCFC2 A non-recoverable error was

632BCFC3 The data in the list of volumes

632BCFC4 A virtual optical device cannot

632BCFC5 A non-recoverable error was

632BCFC6 The file specified does not

Description Action

632Byyyy codes are Network File System (NFS) virtual optical SRCs

On this partition and on the Network File System server, verify

access the file containing the

list of volumes.

detected while reading the list

of volumes.

is not valid.

access the file containing the

specified optical volume.

detected while reading a

virtual optical volume.

contain data that can be

processed as a virtual optical

volume.

that the proper file is specified and that the proper authority is

granted.

Resolve any errors on the Network File System server.

On the Network File System server, verify that the proper file is

specified, that all files are entered correctly, that there are no blank

lines, and that the character set used is valid.

On the Network File System server, verify that the proper file is

specified in the list of volumes, and that the proper authority is

granted.

Resolve any errors on the Network File System server.

On the Network File System server, verify that all the files specified

in the list of optical volumes are correct.

22 JS12 Type 7998: Problem Determination and Service Guide

Page 37

Table 6. 6xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

6xxxyyyy

Error Codes

632BCFC7 A virtual optical device

Description Action

Resolve any errors on the Network File System server.

detected an error reported by

the Network File System

server that cannot be

recovered.

632BCFC8 A virtual optical device

Install any available operating system updates.

encountered a non-recoverable

error.

632Cyyyy codes are virtual optical SRCs

632CC000 Informational system log entry

No corrective action is required.

only.

632CC002 SCSI selection or reselection

Refer to the hosting partition for problem analysis.

timeout occurred.

632CC010 Undefined sense key returned

Refer to the hosting partition for problem analysis.

by device.

632CC020 Configuration error. Refer to the hosting partition for problem analysis.

632CC100 SCSI bus error occurred. Refer to the hosting partition for problem analysis.

632CC110 SCSI command timeout

Refer to the hosting partition for problem analysis.

occurred.

632CC210 Informational system log entry

No corrective action is required.

only.

632CC300 Media or device error

Refer to the hosting partition for problem analysis.

occurred.

632CC301 Media or device error

Refer to the hosting partition for problem analysis.

occurred.

632CC302 Media or device error

Refer to the hosting partition for problem analysis.

occurred.

632CC303 Media has an unknown

No corrective action is required.

format.

632CC333 Incompatible media.

1. Verify that the disk has a supported format.

2. If the format is supported, clean the disk and attempt the

failing operation again.

3. If the operation fails again with the same system reference code,

ask your media source for a replacement disk.

632CC400 Physical link error detected by

Refer to the hosting partition for problem analysis.

device.

632CC402 An internal program error

Install any available operating system updates.

occurred.

632CCFF2 Informational system log entry

No corrective action is required.

only.

632CCFF4 Internal device error occurred. Refer to the hosting partition for problem analysis.

Chapter 2. Diagnostics 23

Page 38

Table 6. 6xxxyyyy SRCs (continued)

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved. If an action solves the problem, then you can stop performing the remaining actions.

v See Chapter 3, “Parts listing, Type 7998,” on page 235 to determine which components are CRUs and which

components are FRUs.

6xxxyyyy

Error Codes

632CCFF6 Informational system log entry

632CCFF7 Informational system log entry

632CCFFE Informational system log entry

632CFF3D Informational system log entry

632CFF6D Informational system log entry

Description Action

No corrective action is required.

only.

No corrective action is required.

only.

No corrective action is required.

only.

No corrective action is required.

only.

No corrective action is required.

only.

A1xxyyyy service processor SRCs

An A1xxyyyy system reference code (SRC) is an attention code that offers

information about a platform or service processor dump or confirms a control

panel function request.

Table 7 shows A1xxyyyy SRCs.

Table 7. A1xxyyyy service processor SRCs

Attention code Description Action

A1xxyyyy Attention code

1. Go to “Checkout procedure” on page 186.

2. Replace the system board and chassis

assembly, as described in “Replacing the Tier

2 system-board and chassis assembly” on

page 274.

A200yyyy Logical partition SRCs

An A200yyyy SRC is a logical partition reference code that is deprecated in favor

of a corresponding B2xx SRC. B2xx SRCs are described in “B200xxxx Logical

partition SRCs” on page 29.

Table 8. A200yyyy Logical partition SRCs

Attention code Description Action

A200yyyy See the description for the B200yyyy error

code with the same yyyy value.

Perform the action described in the B200yyyy

error code with the same yyyy value.

24 JS12 Type 7998: Problem Determination and Service Guide

Page 39

A700yyyy Licensed internal code SRCs

An A7xx SRC is a licensed internal code SRC that is deprecated in favor of a

corresponding B7xx SRC. B7xx SRCs are described in “B700xxxx Licensed internal