Page 1

Model 7220

DSP Lock-in Amplifier

Instruction Manual

190171-A-MNL-C

Copyright © 1996 EG&G INSTRUMENTS CORPORATION

Page 2

FCC Notice

This equipment generates, uses, and can radiate radio-frequency energy and, if not

installed and used in accordance with this manual, may cause interference to radio

communications. As temporarily permitted by regulation, operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own facility

will be required to take whatever measures may be required to correct the interference.

Declaration of Conformity

This product conforms to EC Directives 89/336/EEC Electromagnetic Compatibility

Directive, amended by 92/31/EEC and 93/68/EEC, and Low Voltage Directive 73/23/EEC

amended by 93/68/EEC.

This product has been designed in conformance with the following IEC/EN standards:

EMC: BS EN55011 (1991) Group 1, Class A (CSPIR 11:1990)

BS EN50082-1 (1992):

IEC 801-2:1991

IEC 801-3:1994

IEC 801-4:1988

Safety: BS EN61010-1: 1993 (IEC 1010-1:1990+A1:1992)

Trademarks

IBM is a registered trademark of International Business Machines Corporation.

Microsoft, MS-DOS, GW-BASIC, QBASIC and QUICKBASIC are registered trademarks and Windows is a

trademark of Microsoft Corporation.

Page 3

Table of Contents

T able of Contents

Chapter One, Introduction

1.1 How to Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 What is a Lock-in Amplifier? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Key Specifications and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter T wo, Installation & Initial Checks

2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.02 Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.03 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.04 Line Cord Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.05 Line Voltage Selection and Line Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Initial Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.02 Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter Three, T echnical Description

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.01 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.02 Signal-Channel Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.03 Line Frequency Rejection Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.04 AC Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.05 Anti-Aliasing Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.06 Main Analog to Digital Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.07 Reference Channel DSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.08 Internal Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.09 Demodulator DSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.10 Output Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2.11 Main Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.01 Absolute Accuracy Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

i

Page 4

TABLE OF CONTENTS

3.3.02 Relative Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.4 Full-Scale Sensitivity and AC Gain Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.5 Dynamic Reserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.6 System Updates and Reference Frequency Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.7 Reference Phase and Phase Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.8 Output Channel Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8.01 Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8.02 Time Constants and Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.8.03 Output Offset and Expand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.9 Use of Magnitude and Signal Phase Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.10 Noise Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.11 Power-up Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.12 Auto Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.12.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.12.02 Auto-Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.12.03 Auto-Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.12.04 Auto-Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.12.05 Auto-Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.12.06 Default Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Chapter Four , Front and Rear Panels

4.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.01 A and B/I Signal Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.02 OSC OUT Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.03 REF IN Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.04 Left-hand LCD Display Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.05 MENU Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.1.06 90º Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.1.07 SET Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.1.08 Right-hand LCD Display Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.01 Line Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.02 Line Power Input Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.03 RS232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.04 AUX RS232 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.05 GPIB Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.06 DIGITAL OUTPUTS Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

ii

Page 5

TABLE OF CONTENTS

4.2.07 PREAMP POWER Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.08 REF MON Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.09 REF TTL Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.10 SIG MON Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.11 CH1, CH2 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.12 TRIG Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.13 ADC1, ADC2 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.14 DAC1, DAC2 Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.15 FAST X, FAST Y Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter Five, Front Panel Operation

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Setup Menu Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

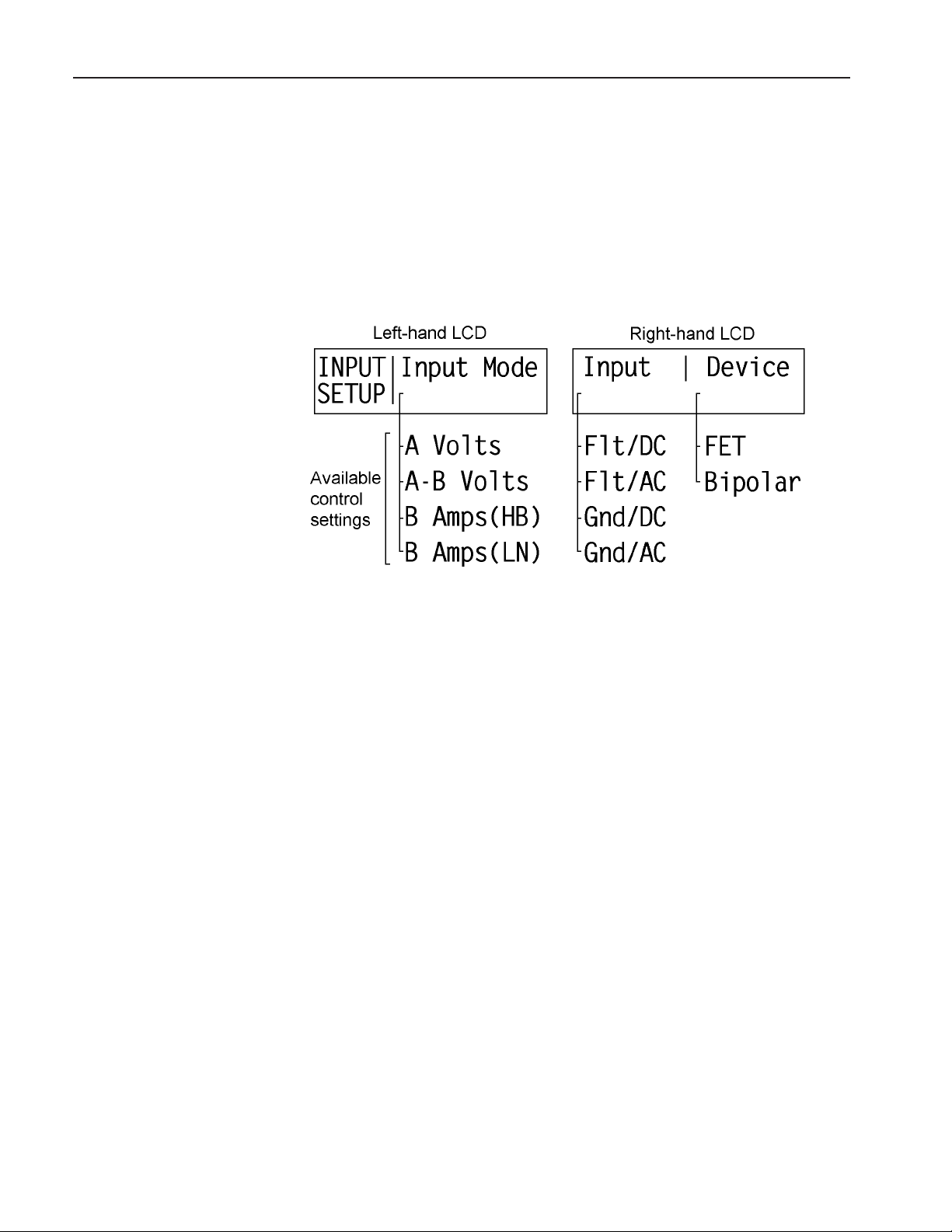

5.2.01 Input Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.02 Reference Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.03 Output Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.2.04 Control Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.05 Miscellaneous Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.2.06 RS232 Setup 1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.2.07 RS232 Setup 2 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.2.08 RS232 Setup 3 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.2.09 GPIB Setup 1 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.2.10 GPIB Setup 2 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.2.11 Digital Outputs Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.2.12 Control Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.3 Auto Functions Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4 Main Display Mode - Left-hand LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.5 Main Display Mode - Right-hand LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.6 Typical Lock-in Amplifier Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

Chapter Six, Computer Operation

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.01 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.02 Curve Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.03 Burst Mode Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.04 Internal Oscillator Frequency Sweep Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

iii

Page 6

TABLE OF CONTENTS

6.3 RS232 and GPIB Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.02 RS232 Interface - General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.03 Choice of Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.04 Choice of Number of Data Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.05 Choice of Parity Check Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.06 Auxiliary RS232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.07 GPIB Interface - General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.08 Handshaking and Echoes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.09 Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.10 Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.11 Delimiters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.12 Compound Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.13 Status Byte, Prompts and Overload Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.14 Service Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.4 Command Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4.01 Signal Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4.02 Reference Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.4.03 Signal Channel Output Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4.04 Signal Channel Output Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.05 Instrument Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4.06 Internal Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.4.07 Auxiliary Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.4.08 Auxiliary Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

6.4.09 Output Data Curve Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.4.10 Computer Interfaces (RS232 and GPIB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

6.4.11 Instrument Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

6.4.12 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.4.13 Default Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.5 Programming Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.5.01 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.5.02 Basic Signal Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.5.03 Frequency Response Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.5.04 X and Y Output Curve Storage Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.5.05 Transient Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.5.06 Frequency Response Measurement using Curve Storage and Frequency Sweep . . . . . . . . . . . . . 6-33

Appendix A, Specifications

iv

Page 7

TABLE OF CONTENTS

Appendix B, Pinouts

B.1 RS232 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 Preamplifier Power Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.3 Digital Output Port Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Appendix C, Demonstration Programs

C.1 Simple Terminal Emulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.2 RS232 Control Program with Handshakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.3 GPIB User Interface Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Appendix D, Cable Diagrams

D.1 RS232 Cable Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Appendix E, Alphabetical Listing of Commands

Appendix F, Default Settings

Default Setting Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Index

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . End of Manual

v

Page 8

TABLE OF CONTENTS

vi

Page 9

Introduction

1.1 How to Use This Manual

This manual gives detailed instructions for setting up and operating the EG&G

Instruments Model 7220 Digital Signal Processing (DSP) dual phase lock-in

amplifier . It is split into the following chapters:-

Chapter 1 - Introduction

Provides an introduction to the manual, briefly describes what a lock-in amplifier is

and the types of measurements it may be used for, and lists the major specifications

of the model 7220.

Chapter 2 - Installation and Initial Checks

Describes how to install the instrument and gives a simple test procedure which you

may perform to check that the unit has arrived in full working order.

Chapter 1

Chapter 3 - T echnical Description

Provides an outline description of the design of the instrument and discusses the effect

of the various controls. A good understanding of the design will enable you to get the

best possible performance from the unit.

Chapter 4 - Front and Rear Panels

Describes the connectors, controls and indicators which are to be found on the unit

and which are referred to in the subsequent chapters.

Chapter 5 - Front Panel Operation

Describes the capabilities of the instrument when used as a manually operated unit,

and shows how to operate it using the front panel controls.

Chapter 6 - Remote Operation

This chapter provides detailed information on operating the instrument from a

computer over either the GPIB (IEEE-488) or RS232 interfaces. It includes

information on how to establish communications, the functions available, the

command syntax and a detailed command listing.

Appendix A

Gives the detailed specifications of the unit.

Appendix B

Details the pinouts of the multi-way connectors on the rear panel.

Appendix C

Lists three simple terminal programs which may be used as the basis for more

complex user-written programs.

1-1

Page 10

Chapter 1, INTRODUCTION

Appendix D

Shows the connection diagrams for suitable RS232 null-modem cables to couple the

unit to an IBM-PC or 100 % compatible computer.

Appendix E

Gives an alphabetical listing of the computer commands for easy reference.

Appendix F

Provides a listing of the instrument settings produced by using the default setting

function.

If you are a new user, it is suggested that you unpack the instrument and carry out the

procedure in chapter 2 to check that it is working satisfactorily. You should then make

yourself familiar with the information in chapters 3, 4 and 5, even if you intend that

the unit will eventually be used under computer control. Only when you are fully

conversant with operation from the front panel should you then turn to chapter 6 for

information on how to use the instrument remotely. Once you are familiar with the

structure of the computer commands, appendix E will prove to be convenient as it

provides a complete alphabetical listing of these commands in a single easy-to-use

section.

1.2 What is a Lock-in Amplifier?

In its most basic form the lock-in amplifier is an instrument with dual capability. On

the one hand it can recover signals in the presence of an overwhelming noise

background or alternatively it can provide high resolution measurements of relatively

clean signals over several orders of magnitude and frequency .

Modern instruments, such as the model 7220, offer far more than these two basic

characteristics and it is this increased capability which has led to their acceptance in

many fields of scientific research, such as optics, electrochemistry, materials science,

fundamental physics and electrical engineering, as units which can provide the

optimum solution to a large range of measurement problems.

The model 7220 lock-in amplifier can function as a:-

n AC Signal Recovery Instrument n Transient Recorder

n V ector V oltmeter n Precision Oscillator

n Phase Meter n Frequency Meter

n Spectrum Analyzer n Noise Measurement Unit

These characteristics, all available in a single compact unit, make it an invaluable

addition to any laboratory.

1-2

Page 11

1.3 Key Specifications and Benefits

The EG&G Instruments Model 7220 represents the latest in DSP Lock-in Amplifier

technology at an affordable price, and offers:-

n Frequency range: 0.001 Hz to 120 kHz

n Voltage sensitivity: 20 nV to 1 V full-scale

n Current input mode sensitivities: 20 fA to 1 µA full-scale

n Line frequency r ejection filter

Chapter 1, INTRODUCTION

20 fA to 10 nA full-scale

n Dual phase demodulator with X-Y and R-

o

n Very low phase noise of < 0.0001

n 5-digit output readings

n Direct Digital Synthesizer (DDS) oscillator with variable output amplitude

and frequency

n Oscillator frequency sweep generator

n Output time constant: 10 µs to 5 ks

n 8-bit programmable digital output port for system control

n T wo external ADCs, two external DACs

n Full range of auto-modes

n Standard IEEE-488 and RS232 interfaces with RS232 daisy-chain

capability

rms

θθ

θ outputs

θθ

n Dual back-lit liquid crystal display (LCD) with variable contrast control

n 32768 point curve storage buffer

1-3

Page 12

Chapter 1, INTRODUCTION

1-4

Page 13

Installation &

Initial Checks

2.1 Installation

2.1.01 Introduction

Installation of the model 7220 in the laboratory or on the production line is very

simple. Because of its low power consumption, the model 7220 does not incorporate

forced-air ventilation. It can be operated on almost any laboratory bench or be rack

mounted, using the optional accessory kit, at the user’s convenience. With an ambient

operating temperature range of 0

variables, needing only to be protected from exposure to corrosive agents and liquids.

2.1.02 Rack Mounting

An optional accessory kit, part number K02002, is available from EG&G

Instruments to allow the model 7220 to be mounted in a standard 19-inch rack.

Chapter 2

o

C to 35 oC, it is highly tolerant to environmental

2.1.03 Inspection

Upon receipt the model 7220 Lock-in Amplifier should be inspected for shipping

damage. If any is noted, EG&G INSTRUMENTS should be notified immediately

and a claim filed with the carrier. The shipping container should be saved for

inspection by the carrier.

2.1.04 Line Cord Plug

A standard IEC 320 socket is mounted on the rear panel of the instrument and a

suitable line cord is supplied.

2.1.05 Line V oltage Selection and Line Fuses

Before plugging in the line cord, ensure that the model 7220 is set to the voltage of

the AC power supply to be used.

A detailed discussion of how to check and, if necessary , change the line voltage

setting follows.

CAUTION! The model 7220 may be damaged if the line voltage is set for 110 V

AC operation and it is turned on with 220 V AC applied to the power input

connector.

The model 7220 can operate from any one of four different line voltage ranges,

90-110 V, 110-130 V, 200-240 V, and 220-260 V, at 50-60 Hz. The change from one

range to another is made by repositioning a plug-in barrel selector internal to the Line

Input Assembly on the rear panel of the unit.

2-1

Page 14

Chapter 2, INSTALLATION AND INITIAL CHECKS

Instruments are normally shipped from the factory with the line voltage selector set to

110-130 V AC, unless they are destined for an area known to use a line voltage in the

220-260 V range, in which case, they are shipped configured for operation from the

higher range.

The line voltage setting can be seen through a small rectangular window in the line

input assembly on the rear panel of the instrument (figure 2-1). If the number

showing is incorrect for the prevailing line voltage (refer to table 2-1), the barrel

selector will need to be repositioned as follows.

Observing the instrument from the rear, note the plastic door immediately adjacent to

the line cord connector (figure 2-1) on the left-hand side of the instrument. When the

line cord is removed from the rear panel connector, the plastic door can be opened

outwards by placing a small, flat-bladed screwdriver in the slot on the right-hand side

and levering gently. This gives access to the fuse and to the voltage barrel selector ,

which is located at the right-hand edge of the fuse compartment. Remove the barrel

selector with the aid of a small screwdriver or similar tool. With the barrel selector

removed, four numbers become visible on it: 100, 120, 220, and 240, only one of

which is visible when the door is closed. T able 2-1 indicates the actual line voltage

range represented by each number . Position the barrel selector such that the required

number (see table 2-1) will be visible when the barrel selector is inserted and the door

closed.

Figure 2-1, Line Input Assembly

VISIBLE # VOLTAGE RANGE

100 90 - 110 V

120 110 - 130 V

220 200 - 240 V

240 220 - 260 V

Table 2-I, Range vs Barrel Position

Next check the fuse rating. For operation from a nominal line voltage of 100 V or

120 V, use a 20 mm slow-blow fuse rated at 1.0 A, 250 V. For operation from a

nominal line voltage of 220 V or 240 V, use a 20 mm slow-blow fuse rated at 0.5 A,

250 V.

To change the fuse, first remove the fuse holder by pulling the plastic tab marked with

an arrow . Remove the fuse and replace with a slow-blow fuse of the correct voltage

and current rating. Install the fuse holder by sliding it into place, making sure the

arrow on the plastic tab is pointing downwards. When the proper fuse has been

2-2

Page 15

installed, close the plastic door firmly . The correct selected voltage setting should now

be showing through the rectangular window . Ensure that only fuses with the required

current rating and of the specified type are used for replacement. The use of

makeshift fuses and the short-circuiting of fuse holders is prohibited and potentially

dangerous.

2.2 Initial Checks

2.2.01 Introduction

The following procedure checks the performance of the model 7220. In general, this

procedure should be carried out after inspecting the instrument for obvious shipping

damage (NOTE: any damage must be r eported to the carrier and to EG&G

INSTRUMENTS immediately; take care to save the shipping container for

inspection by the carrier).

Note that this procedure is intended to demonstrate that the instrument has arrived in

good working order, not that it meets specifications. Each instrument receives a

careful and thorough checkout before leaving the factory , and normally , if no shipping

damage has occurred, will perform within the limits of the quoted specifications. If

any problems are encountered in carrying out these checks, contact EG&G

INSTRUMENTS or the nearest authorized representative for assistance.

Chapter 2, INSTALLATION AND INITIAL CHECKS

2.2.02 Procedure

1) Ensure that the model 7220 is set to the line voltage of the power source to be

used, as described in section 2.1.05

2) With the rear panel mounted power switch (located at the extreme left-hand side

of the instrument when viewed from the rear) set to 0 (off), plug in the line cord

to an appropriate line source.

3) T urn the model 7220 power switch to the I (on) position.

4) The instrument’ s front panel displays will now briefly display the following

message:-

Figure 2-2, Opening Display

5) Press the key marked MENU twice to enter the setup menu screens. (N.B. on

early units this key was marked AUTO).

6) Press one of the keys on the left-hand side of the left-hand display repeatedly until

2-3

Page 16

Chapter 2, INSTALLATION AND INITIAL CHECKS

the CONTROL SETUP menu is displayed, which will look similar to the

following:-

7) Press one of the keys on the right-hand side of the left-hand display once. This

will set all the instrument’s controls and displays to a known state. The displays

will revert to the normal mode, with the left-hand panel showing the AC Gain and

Full Scale Sensitivity controls and the right-hand one the instrument’ s outputs in

the form of magnitude as a percentage of full-scale and phase in degrees.

8) The right-hand display should now look as follows:-

Figure 2-3, Control Setup Menu

Figure 2-4, Right-hand LCD - Main Display

9) Connect a BNC cable between the OSC OUT and A input connectors on the

front panel.

10) The right-hand display should now indicate a magnitude close to 100 % of fullscale (i.e. the sinusoidal oscillator output, which was set to 1 kHz and a signal

level of 0.5 V rms by the Default Setting key is being measured with a full-scale

sensitivity of 500 mV rms) and a phase of near zero degrees, if a short cable is

used.

This completes the initial checks. Even though the procedure leaves many functions

untested, if the indicated results were obtained the user can be reasonably sure that

the unit incurred no hidden damage in shipment and is in good working order .

2-4

Page 17

Technical Description

3.1 Introduction

The model 7220 lock-in amplifier is capable of outstandingly good signal recovery

performance, provided that it is operated correctly . This chapter describes the design

of the instrument, enabling the best use to be made of its facilities. Of particular

importance is the correct adjustment of the AC Gain parameter, described in section

3.2.04.

3.2 Principles of Operation

3.2.01 Block Diagram

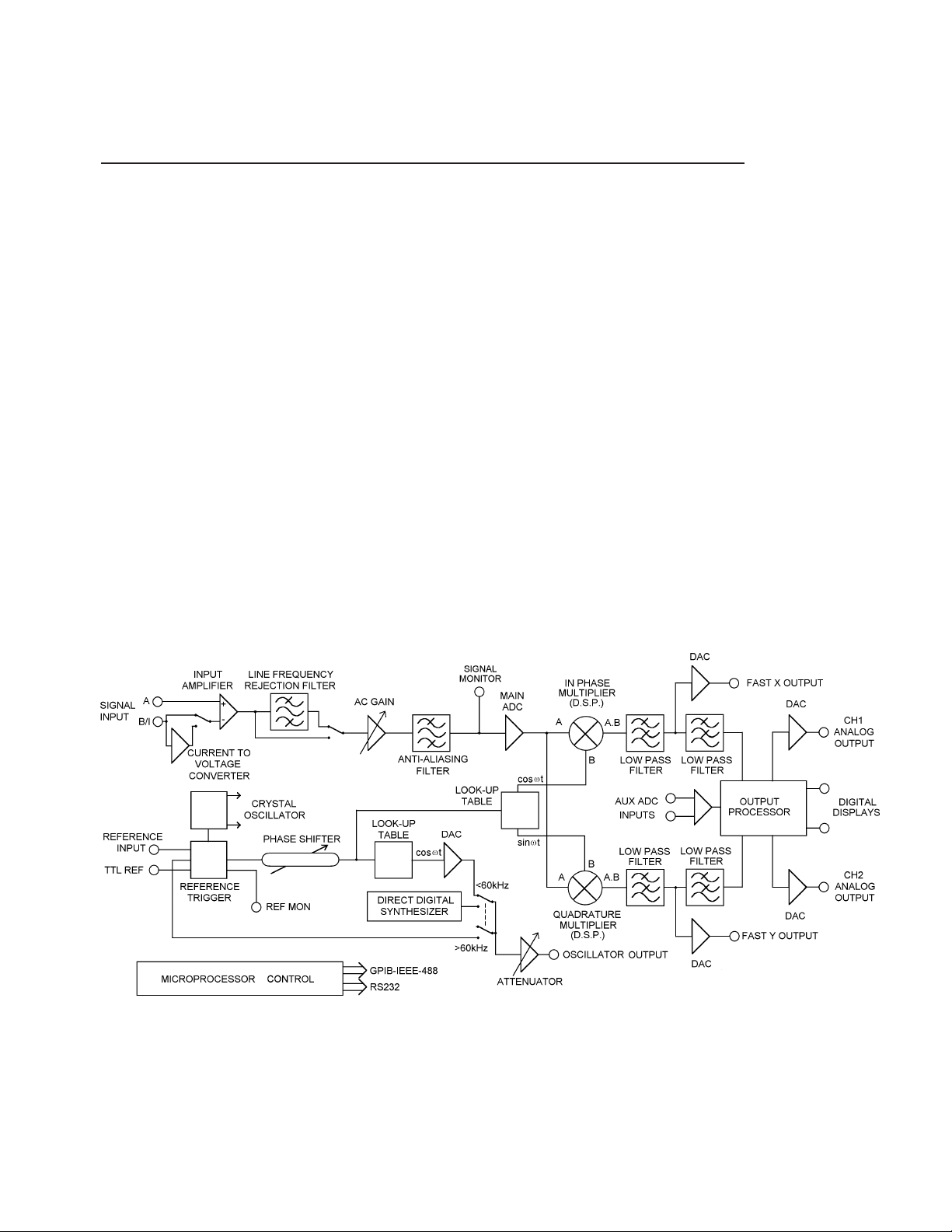

The model 7220 utilizes two digital signal processors, a microprocessor and a

dedicated digital waveform synthesizer, together with very low-noise analog

circuitry to achieve its specifications. A block diagram of the instrument is shown in

figure 3-1, and the sections that follow describe how each functional block operates

and the effect it has on the instrument’s performance.

Chapter 3

Figure 3-1, Model 7220 - Block Diagram

3-1

Page 18

Chapter 3, TECHNICAL DESCRIPTION

3.2.02 Signal-Channel Inputs

The signal input amplifier may be configured for either single-ended or differential

voltage mode operation, or single-ended current mode operation. In voltage mode a

choice of AC or DC coupling is available and the input may be switched between

FET and bipolar devices. In current mode two conversion gains are selectable to

allow for optimum matching to the signal input. In both modes the input connector

“shells” may be either floated or grounded to the instrument’ s chassis ground. These

various features are discussed in the following paragraphs.

Input Connector Selection, A / (A - B)

When set to the A mode, the lock-in amplifier measures the voltage between the

centre and the outer of the A input BNC connector, whereas when set to (A-B) mode

it measures the difference in voltage between the centre pins of the A and B input

connectors.

The latter, differential, mode is often used to eliminate ground loops, although it is

worth noting that at very low signal levels it may be possible to make a substantial

reduction in unwanted offsets by using this mode, with a short-circuit terminator on

the B connector, rather than by simply using the A input mode.

The specification defined as the Common Mode Rejection Ratio, CMRR, defines how

well the instrument rejects common mode signals applied to the A and B inputs when

operating in differential input mode. It is usually given in decibels. Hence a

specification of > 100 dB implies that a common mode signal (i.e. a signal

simultaneously applied to both A and B inputs) of 1 V will give rise to less than

10 µV of signal out of the input amplifier.

Input Connector Shell Ground / Float

The input connector shells may be connected either directly to the instrument’ s

chassis ground or they can be “floated” by being connected via a 1 kΩ resistor . When

in the float mode, the presence of this resistor substantially reduces the problems

which often occur in low-level lock-in amplifier measurements due to ground loops.

Input Device Selection, FET / Bipolar

The voltage preamplifier may be switched between bipolar and FET input devices.

The bipolar device, which has an input impedance of 10 kΩ, shows a relatively high

level of added current noise (2 pA/√Hz), but less than 50 percent of the voltage noise

of the FET device. As such, it is intended for use where the source impedance is

resistive or inductive with a resistance of 100 Ω or less, and there is no input voltage

offset.

WARNING: Signal channel overload may occur if the bipolar device is selected

and no DC bias path is provided.

3-2

The FET device provides an input impedance of 10 MΩ.

AC / DC Coupling

In normal operation, with reference frequencies above a few hertz, AC coupled

operation is always used.

Page 19

Chapter 3, TECHNICAL DESCRIPTION

The primary purpose of the DC coupling facility is to enable the use of the instrument

at reference frequencies below 0.5 Hz. It may also be used to reduce the effect of

phase and magnitude errors introduced by the AC coupling circuitry below a few

hertz.

However , the use of DC coupling introduces serious problems where the source has a

DC offset or is of such high impedance that bias currents cause significant offsets. In

these cases it may be necessary to include some form of signal conditioning between

the signal source and the lock-in amplifier.

The instrument always reverts to the AC coupled mode on power-up, to protect the

input circuitry.

Input Signal Selection, V / I

Although the voltage mode input is most commonly used, a current to voltage

converter may be switched into use to provide current mode input capability, in

which case the signal is connected to the B/I connector . High impedance sources

(> 100 kΩ) are inherently current sources and need to be measured with a low

impedance current mode input. Even when dealing with a voltage source in series

with a high impedance, the use of the current mode input may provide advantages in

terms of improved bandwidth and immunity from the effects of cable capacitance.

The converter may be set to low-noise or wide bandwidth conversion settings, but it

should be noted that even at the wide bandwidth setting the -3 dB point is at 50 kHz.

Better performance may be achieved using a separate current preamplifier, such as

the EG&G Instruments Model 5182.

3.2.03 Line Frequency Rejection Filter

Following the signal input amplifier, there is an option to pass the signal through a

line frequency rejection filter, which is designed to give greater than 40 dB of

attenuation at the power line frequencies of 50 Hz or 60 Hz and their second

harmonics at 100 Hz and 120 Hz.

Early instruments use a simple single stage band-rejection filter, which has a

relatively broad bandwidth. This introduces significant gain and phase errors, at least

in the range 5 to 500 Hz, and this should be taken into account if it is used in

conjunction with reference frequencies in or near to this range. The filter control

settings for these units are simply “ON” or “OFF”.

Instruments manufactured after June 1996 use a more sophisticated type of filter,

which uses two cascaded rejection stages with “notch” characteristics. This allows

the filter to be set to reject signals at frequencies equal to either of, or both of, the

fundamental and second harmonic of the line frequency. Hence the filter control

settings for these instruments are “OFF”, “F”, “2F” or “F & 2F”.

Although instruments are supplied with the line frequency filter set to match the line

frequency of the country for which they are destined, it should be appreciated that if

a unit is moved from a 50 Hz area to a 60 Hz area then the filter will need to be

adjusted. The later instruments therefore respond to a computer command, LINE50,

which allows this to be done (see section 6.4).

3-3

Page 20

Chapter 3, TECHNICAL DESCRIPTION

3.2.04 AC Gain

The signal channel contains a number of analog filters and amplifiers, the gain of

which are defined by the “AC Gain” parameter , which is specified in terms of

decibels (dB). For each value of AC Gain there is a corresponding value of the

INPUT LIMIT parameter, which is the maximum instantaneous (peak) voltage or

current that can be applied to the input without input overload, as shown in table 3-1

below.

It is a basic property of the DSP lock-in amplifier that the best demodulator

performance is obtained by presenting as large a signal as possible to the main

analog to digital converter. Therefore, in principle, the AC Gain value should be made

as large as possible without causing amplifier or converter overload. This constraint

is not too critical however and the use of a value 10 or 20 dB below the optimum

value makes little difference.

Note that when signal overload occurs, the only action required is to reduce the

AC Gain value.

AC Gain (dB) INPUT LIMIT (mV)

10 1000

20 300

30 10

40 30

50 10

60 3

70 1

80 0.3

90 0.1

0 3000

3-4

Table 3-1, Input Limit vs AC Gain

Further information on the control of AC Gain is given in section 3.4

3.2.05 Anti-Aliasing Filter

Prior to the main analog to digital converter (ADC) the signal passes through an antialiasing filter to remove unwanted frequencies which would cause a spurious output

from the ADC due to the nature of the sampling process.

Consider the situation when the lock-in amplifier is measuring a sinusoidal signal of

frequency f

f

sampling

Hz. In order to ensure correct operation of the instrument the output values

representing the f

be measured, and not by any other process.

However , if the input to the ADC has, in addition, an unwanted analog sinusoid with

frequency f

appear in the output as a sampled-data sinusoid with frequency less than half the

sampling frequency, f

Hz, which is sampled by the main ADC at a sampling frequency

signal

frequency must have been uniquely generated by the signal to

signal

Hz, where f1 is greater than half the sampling frequency, then this will

1

= |f1 - nf

alias

sampling

|, where n is an integer.

Page 21

Chapter 3, TECHNICAL DESCRIPTION

This alias signal is indistinguishable from the output generated when a genuine signal

at frequency f

such that the alias signal frequency produced from it was close to, or equal to, that of

the wanted signal then it is clear that a spurious output would result.

For example, if the sampling frequency were 160 kHz then half the sampling

frequency would be 80 kHz. Let the instrument be measuring a signal of 55 kHz

accompanied by an interfering signal of 100 kHz. The output of the ADC would

therefore include a sampled-data sinusoid of 55 kHz (the required signal) and,

applying the above formula, an alias signal of 60 kHz (i.e. |100 kHz - 160 kHz|). If

the signal frequency were now increased towards 60 kHz then the output of the lockin amplifier would increasingly be affected by the presence of the alias signal and the

accuracy of the measurement would deteriorate.

T o overcome this problem the signal is fed through the anti-aliasing filter , which

restricts the signal bandwidth. When operating at reference frequencies below

60 kHz, the reference frequency is less than half the sampling frequency and a

conventional elliptic-type, low-pass anti-alias filter is used. This enables the system

to provide the lowest possible noise bandwidth. At frequencies above 60 kHz an

adaptive bandpass anti-alias filter is used. The noise bandwidth of this filter is

dependent on the reference frequency and is higher than that of the conventional

type of filter, but typically the noise penalty is negligible.

is sampled. Hence if the frequency of the unwanted signal were

alias

It should be noted that the dynamic range of a lock-in amplifier is normally so high

that practical anti-alias filters are not capable of completely removing the effect of a

full-scale alias. For instance, even if the filter gives 100 dB attenuation, an alias at

the input limit and at the reference frequency will give a one percent output error

when the dynamic reserve is set to 60 dB, or a full-scale error when the dynamic

reserve is set to 100 dB.

In a typical low-level signal recovery situation, many unwanted inputs need to be

dealt with and it is normal practice to make small adjustments to the reference

frequency until a clear point on the frequency spectrum is reached. In this context an

unwanted alias is treated as just another interfering signal and its frequency is

avoided when setting the reference frequency.

A buffered version of the analog signal just prior to the main ADC is available at the

rear panel signal monitor (SIG MON) connector; it may be viewed on an

oscilloscope to monitor the effect of the signal channel filters and amplifiers.

3.2.06 Main Analog to Digital Converter

Following the anti-alias filter the signal passes to the main 18-bit analog to digital

converter running at a sampling rate of 166 kHz. This rate is not fixed but is adjusted

automatically by up to ±1 %, as a function of the reference frequency , to ensure that

the sampling process does not generate a “beat” frequency close to zero hertz. For

example, if the reference frequency were 82.95 kHz and the sampling frequency were

not adjusted, a beat frequency of 50 Hz (|82.95 kHz - (166 kHz/2)|) would be

generated and would appear at the output if the time constant were not set to a large

enough value.

3-5

Page 22

Chapter 3, TECHNICAL DESCRIPTION

There is one situation where this automatic correction might not be sufficient to give

good performance. Consider the case where the signal being measured is at 73 kHz,

which is 10 kHz away from half the sampling frequency . If there were also a strong

interfering signal at 93 kHz (i.e. 166 kHz/2 + 10 kHz), then an alias of this would

give rise to a spurious output. Note that under these circumstances, the reference

frequency is not sufficiently close to half the sampling frequency to cause the latter to

be automatically adjusted. The problem is overcome by providing the Sample Rate

control which allows the user to adjust the main ADC sampling rate in steps of about

1 %. A 1 % change moves the alias by about 1 kHz, which is normally suf ficient to

ensure rejection by the output low-pass filters and thereby remove any error .

The output from the converter feeds the first of the digital signal processors, which

implements the digital multiplier and the first stage of the output low-pass filtering

for each of the X and Y channels.

3.2.07 Reference Channel DSP

The second DSP in the instrument is responsible for implementing the reference

trigger/phase-locked loop, digital phase shifter and internal oscillator look-up table

functional blocks on the block diagram. The processor generates two main outputs,

the first being a series of phase values which are used to drive the other DSP’s

reference channel input and the second being a sinusoidal signal which may be used

as the instrument’s internal oscillator output.

The normal operating mode of the instrument incorporates two reference frequency

ranges, namely the baseband from 1 mHz to 60 kHz and the highband from 60 kHz to

120 kHz. Different hardware configurations are used in the two bands, transitions

between which are made automatically according to the value of the reference

frequency. These transitions are generally transparent to the user.

External Reference Mode

In external reference mode at frequencies above 300 mHz, the reference source may

be applied to either a general purpose input, designed to accept virtually any periodic

waveform with a 50:50 mark-space ratio and of suitable amplitude, or to a TTL-logic

level input. At frequencies below 300 mHz the TTL-logic level input must be used.

Following the trigger buffering circuitry the reference signal is passed to a digital

phase-locked loop (PLL) implemented in the reference DSP. This measures the

period of the applied reference waveform and from this generates the phase values.

Internal Reference Mode

W ith internal reference operation in the baseband mode (i.e. at reference frequencies

< 60 kHz), the reference processor is free-running at the selected reference frequency

and is not dependent on a phase-locked loop (PLL), as is the case in most other lockin amplifiers. Consequently, the phase noise is extremely low, and because no time is

required for a PLL to acquire lock, reference acquisition is immediate. See appendix

A for numerical values of phase noise.

3-6

In the internal reference highband mode (i.e. reference frequencies > 60 kHz), the

instrument essentially operates as if in external mode, except that the reference

trigger input is now provided by an internal link from the output of the direct digital

synthesizer .

Page 23

Chapter 3, TECHNICAL DESCRIPTION

3.2.08 Internal Oscillator

The model 7220, in common with many other lock-in amplifiers, incorporates an

internal oscillator which may be used to drive an experiment. However, unlike most

other instruments, the oscillator in the model 7220 is digitally synthesized with the

result that the output frequency is extremely accurate and stable. The oscillator

operates over the same frequency range as the lock-in amplifier, 1 mHz to 120 kHz.

The source of the oscillator depends on whether the instrument is operating on

internal or external reference mode and on the selected frequency.

In internal reference baseband mode (< 60 kHz) the oscillator is derived from the

reference channel DSP. This outputs a series of digital values, corresponding to a

sinusoid at the required frequency, to a 16-bit DAC which in turn feeds a variable

attenuator. The output of the attenuator is the internal oscillator output.

In internal reference highband mode (> 60 kHz) and external reference mode, the

oscillator is derived from a dedicated direct digital synthesizer (DDS).

A further choice of output at the OSC OUT connector is offered when the unit is

operating in external reference mode. In this situation, if the synchronous oscillator

(also called the demodulator monitor) control is turned on, then the OSC OUT signal

becomes a direct analog representation of the sinusoidal signal at the reference input

to the X channel phase sensitive detector . Consequently it is affected by both the

reference phase shifter and harmonic controls of the reference channel.

For example, if an external reference at 1 kHz were applied, the unit were set to

operate in the 2F mode and the synchronous oscillator were turned on, then the signal

at the OSC OUT connector would be a 2 kHz sinusoid whose phase could be

adjusted using the reference phase shifter .

When used in the synchronous oscillator (demodulator monitor) mode, OSC OUT is

updated at the rate at which the reference channel generates new values for the

demodulators. Since this occurs approximately once every 6 µs, this should be taken

into account when viewing the waveform on an oscilloscope.

3.2.09 Demodulator DSP

The essential operation of the demodulator DSP is to multiply the digitized output of

the signal channel by data sequences called the X and Y demodulation functions and

to operate on the results with digital low-pass filters (the output filters). The

demodulation functions, which are derived by use of a look-up table from the phase

values supplied by the reference channel DSP, are sinusoids with frequency equal to

an integer multiple, nf

function is the X demodulation function delayed by a quarter of a period. The integer

n is called the reference harmonic number and in normal lock-in amplifier operation is

set to unity . Throughout the remainder of this text, the reference harmonic number

will be assumed to be unity unless specifically stated to have a non-unity value.

of the reference frequency f

ref,

The Y demodulation

ref.

The outputs from the X channel and Y channel multipliers feed the first stage of the X

3-7

Page 24

Chapter 3, TECHNICAL DESCRIPTION

and Y channel output filters. The outputs of these in turn drive two 16-bit digital to

analog converters (DACs) which generate the instrument’s F AST X and FAST Y

analog outputs. In addition, the signals are fed to further low-pass filters before

subsequent processing by the instrument’s host microprocessor.

3.2.10 Output Processor

Although shown on the block diagram as a separate entity, the output processor is in

fact part of the instrument’s main microprocessor. It provides more digital filtering of

the X and Y channel signals if required, calculates the vector magnitude, R, where

R = √(X

signals via two further 16-bit DACs to the unit’s CH1 and CH2 output connectors. It

also allows one of the two auxiliary analog inputs, ADC1 and ADC2, which are

digitized by a 16-bit analog to digital converter, to be used in ratio calculations.

2

+ Y2) and phase angle, θ, where θ = tan-1(Y/X), and routes any of these

3.2.11 Main Microprocessor

All functions of the instrument are under the control of a microprocessor which in

addition drives the front panel displays, processes front panel key operations and

supports the RS232 and GPIB (IEEE-488) computer interfaces. This processor also

drives the instrument’s 8-bit digital programmable output port, which may be used

for controlling auxiliary apparatus.

3.3 Accuracy

3.3.01 Absolute Accuracy Specifications

The microprocessor has access to memory which may be used for storage of the

instrument’s outputs as curves prior to transferring them to a computer via the

computer interfaces. In addition to using this function for the normal outputs, such as

the X and Y output signals, it may also be used with the auxiliary ADC inputs to

allow the instrument to operate as a transient recorder. The internal oscillator

frequency sweep function is also controlled by the microprocessor.

A particularly useful feature of the design is that only part of the controlling

firmware program code, which the microprocessor runs, is permanently resident in

the instrument. The remainder is held in flash EEPROM and can be updated via the

RS232 computer interface. It is therefore possible to change the functionality of the

instrument, perhaps to include a new feature or update the computer command set,

simply by connecting it to a computer and running an Update program.

When the demodulator is operating under correct conditions, the absolute gain

accuracy of the instrument is limited by the analog components in the signal channel,

and the absolute phase accuracy is limited by the analog components in both the

signal channel and the reference channel. The resulting typical accuracy is ±0.5

percent of the full-scale sensitivity and ±0.5 degree. When the higher values of AC

Gain are in use, the errors tend to increase in the upper part of the frequency range

(above 25 kHz).

3-8

Page 25

Chapter 3, TECHNICAL DESCRIPTION

3.3.02 Relative Accuracy

The majority of lock-in amplifier measurements are concerned with the variation of

the input signal with time, temperature, etc. or with the comparison of two different

specimens. In these cases the absolute accuracy is of less importance than the

accuracy with which readings can be transferred from range to range.

A new feature of the model 7220 is the introduction of a separate control function

(“AC Gain”) for the gain of the signal channel. Where appropriate, this can be set to

accommodate the existing noise level and subsequent changes in the instrument’ s fullscale sensitivity do not cause any of the errors which might arise from a change in the

analog gain.

3.4 Full-Scale Sensitivity and AC Gain Control

The full-scale sensitivity is indicated as SEN on the left-hand LCD and is adjusted by

the use of the adjacent keys. The analog outputs and analog meter limit at a level a

few percent above the full-scale sensitivity value, but the digital displays do not limit

until a level of ±300 percent full-scale has been reached.

As stated in section 3.2.04, the best performance is obtained by making the AC Gain

value as large as possible without causing amplifier overload.

Note that the demodulator gain is adjusted automatically when the AC Gain value is

changed, in order to maintain the SEN value. However , the user is prevented from

setting an illegal AC Gain value, i.e. one that would result in overload on a full-scale

input signal. Similarly, if the user selects a SEN value which causes the present AC

Gain value to be illegal, the AC Gain will change to the nearest legal value.

In practice, this system is very easy to operate. However, the user may prefer to

make use of the AUTOM ATIC AC Gain facility which gives very good results in

most circumstances.

Note that when signal channel overload occurs, the only action required is to reduce

the AC Gain.

At reference frequencies above 1 Hz, the Auto-Sensitivity and Auto-Measure

functions can be used to adjust the full-scale sensitivity.

3.5 Dynamic Reserve

At any given setting, the ratio

DR = 0.7 (INPUT LIMIT) / (FULL-SCALE SENSITIVITY)

represents the factor by which the largest acceptable sinusoidal interference input

exceeds the full-scale sensitivity and is called the Dynamic Reserve of the lock-in

amplifier at that setting. (The factor 0.7 is a peak to rms conversion). The dynamic

3-9

Page 26

Chapter 3, TECHNICAL DESCRIPTION

reserve is often expressed in decibels, for which

DR( in dB) = 20 log(DR( as a ratio))

Applying this formula to the model 7220 we may put in the maximum value of

INPUT LIMIT (3 V) and the smallest available value of FULL-SCALE

SENSITIVITY (20 nV) to reach a value of about 1E8 or 160 dB for the maximum

available dynamic reserve. Figures of this magnitude are available from any DSP

lock-in amplifier but are based only on arithmetical identities and do not give any

indication of how the instrument actually performs. In fact, all current DSP lock-in

amplifiers become too noisy and inaccurate for most purposes at reserves of greater

than about 100 dB.

For the benefit of users who prefer to have the AC Gain value expressed in this form,

the model 7220 displays the current value of Dynamic Reserve in decibels on the

input full-scale sensitivity control.

3.6 System Updates and Reference Frequency Changes

Both the signal channel and the reference channel contain calibration parameters

which are dependent on the reference frequency. These include corrections to the

anti-alias filter and to the analog circuits in the reference channel.

In external reference operation the processor uses the reference frequency meter to

monitor the reference frequency and updates these parameters when a change of

about 2 percent has been detected.

All the parameters are also updated when the SET key is pressed or the LOCK

command is executed. Therefore if the most accurate and reproducible settings are

required, the SET key should be pressed or the LOCK command executed after

every intentional change in reference frequency, when in the external reference

modes. Note that sufficient time must be allowed for the frequency meter to give a

fully accurate value.

With internal reference operation, regardless of the frequency mode, the frequencydependent parameters are updated on any change of reference frequency, without the

need to press the front panel SET key or to issue the LOCK command.

3.7 Reference Phase and Phase Shifter

If the reference input is a sinusoid applied to the REF IN socket, the reference phase

is defined as the phase of the X demodulation function with respect to the reference

input.

This means that when the reference phase is zero and the signal input to the

demodulator is a full-scale sinusoid in phase with the reference input sinusoid, the X

output of the demodulator is a full-scale positive value and the Y output is zero.

3-10

Page 27

Chapter 3, TECHNICAL DESCRIPTION

The circuits connected to the REF IN socket actually detect a positive-going crossing

of the mean value of the applied reference voltage. Therefore when the reference input

is not sinusoidal, its effective phase is the phase of a sinusoid with positive-going zero

crossing at the same point in time, and accordingly the reference phase is defined with

respect to this waveform. Similarly , the effective phase of a reference input to the

TTL REF IN socket is that of a sinusoid with positive-going zero crossing at the

same point in time.

The reference phase is adjusted to its required value by the use of a digital phase

shifter, which is accessed from the front panel, by the REFP computer command or

with the use of the Auto-Phase function.

In basic lock-in amplifier applications the purpose of the experiment is to measure

the amplitude of a signal which is of fixed frequency and whose phase with respect

to the reference input does not vary. This is the scalar measurement, often

implemented with a chopped optical beam. Many other lock-in amplifier

applications are of the signed scalar type, in which the purpose of the experiment is

to measure the amplitude and sign of a signal which is of fixed frequency and whose

phase with respect to the reference input does not vary apart from reversals of phase

corresponding to changes in the sign of the signal. A well known example of this

situation is the case of a resistive bridge, one arm of which contains the sample to be

measured. Other examples occur in derivative spectroscopy, where a small

modulation is applied to the angle of the grating (in optical spectroscopy) or to the

applied magnetic field (in magnetic resonance spectroscopy). Double beam

spectroscopy is a further common example.

In this signed scalar measurement the phase shifter must be set, after removal of any

zero errors, to maximize the X or the Y output of the demodulator. This is the only

method that will give correct operation as the output signal passes through zero, and

is also the best method to be used in an unsigned scalar measurement where any

significant amount of noise is present.

3.8 Output Channel Filters

3.8.01 Slope

As with most lock-in amplifiers, the output filter configuration in the model 7220 is

controlled by the SLOPE variable. This may seem somewhat strange, and a few

words of explanation may be helpful.

In traditional audio terminology, a first-order low-pass filter is described as having

“a slope of 6 dB per octave” because in the high frequency limit its gain is inversely

proportional to frequency (6 dB is approximately a factor of 2 in amplitude and an

octave is a factor of 2 in frequency); similarly a second-order low-pass filter is

described as having “a slope of 12 dB per octave”. These terms have become part of

the accepted terminology relating to lock-in amplifier output filters and are used in the

model 7220 to apply to the envelope of the frequency response function of the digital

FIR (finite impulse response) output filters. Accordingly the front panel display

control which selects the configuration of the output filters is labelled SLOPE and the

options are labelled 6, 12, 18, 24 dB/octave.

3-11

Page 28

Chapter 3, TECHNICAL DESCRIPTION

The 6 dB/octave filters are not satisfactory for most purposes because they do not

give good rejection of periodic components in the demodulator output, including the

inevitable component at double the reference frequency . However , the 6 dB/octave

filter finds use where the lock-in amplifier is incorporated in a feedback control loop,

and in some situations where the form of the time-domain response is critical. The

user is recommended to use 12 dB/octave unless there is some definite reason for not

doing so.

Note that the filter slope for the rear panel FAST X and FAST Y outputs is fixed at

6 dB/octave.

3.8.02 Time Constants and Synchronization

The output time constant can be varied between 10 µs and 5 ks. Values from 10 µs to

640 µs are available at the rear panel FAST X and FAST Y outputs, while values

from 5 ms to 5 ks apply to all other outputs, including CH1, CH2 and the digital

displays.

The filters are of the Finite Impulse Response (FIR) type with the averaging time of

each section being equal to double the nominal time constant.

These filters offer a substantial advantage in response time compared with analog

filters or digital Infinite Impulse Response (IIR) filters.

When the reference frequency is below 10 Hz the synchronous filter option is

available. This means that the actual time constant of the filter is not generally the

selected value T but a value which is equal to an integer number of reference cycles.

If T is greater than 1 reference cycle, the time constant is between T/2 and T.

Where random noise is relatively small, synchronous filter operation gives a major

advantage in low-frequency measurements by enabling the system to give a constant

output even when the output time constant is equal to only 1 reference cycle.

3.8.03 Output Offset and Expand

The output offset facility enables ±300 % full-scale offset to be applied to the X, Y or

both displays. Note however that the rear panel analog outputs limit at ±120 %

full-scale.

The output expand facility allows a ×10 expansion to be applied to the X, Y, both or

neither outputs, and hence to the analog meter indication and the CH1 and CH2

analog outputs, if these are set to output X or Y values.

3.9 Use of Magnitude and Signal Phase Outputs

If the input signal Vs(t) is a reference frequency sinusoid of constant amplitude, and

3-12

the output filters are set to a sufficiently long time constant, the demodulator outputs

are constant levels V

amplitude of the required signal V

and Vy. The function √(V

x

(t) (i.e. it is not dependent on the phase of Vs(t)

s

x

2

+ V

2

) is dependent only on the

y

Page 29

Chapter 3, TECHNICAL DESCRIPTION

with respect to the reference input) and is computed by the output processor in the

lock-in amplifier and made available as the “magnitude” output. The phase angle

between V

equal to the angle of the complex quantity (V

(t) and the X demodulation function is called the “signal phase”: this is

s

+ jVy) (where j is the square root of -1)

x

and is also computed by the processor by means of a fast arctan algorithm.

The magnitude and signal phase outputs are used in cases where phase is to be

measured, or alternatively where the magnitude is to be measured under conditions

of uncertain or varying phase.

One case of varying phase is that in which the reference input is not derived from the

same source as that which generates the signal, and is therefore not exactly at the

same frequency. In this case, if the input signal is a sinusoid of constant amplitude,

the X and Y demodulator outputs show slow sinusoidal variations at the difference

frequency, and the magnitude output remains steady.

However, the magnitude output has disadvantages where significant noise is present

at the outputs of the demodulator. When the required signal outputs (i.e. the mean

values of the demodulator outputs) are less than the noise, the outputs take both

positive and negative values but the magnitude algorithm gives only positive values:

this effect, sometimes called noise rectification, gives rise to a zero error which in

the case of a Gaussian process has a mean value equal to 0.798 times the combined

root-mean-square (rms) value of the X and Y demodulator noise. Note that unlike

other forms of zero error this is not a constant quantity which can be subtracted from

all readings, because when the square root of the sum of the squares of the required

outputs becomes greater than the total rms noise the error due to this mechanism

disappears.

A second type of signal-dependent error in the mean of the magnitude output occurs

as a result of the inherent non-linearity of the magnitude formula: this error is always

positive and its value, expressed as a fraction of the signal level, is half the ratio of

the mean-square value of the noise to the square of the signal.

These considerations lead to the conclusion that when the magnitude output is being

used, the time constants of the demodulator should be set to give the required signal/

noise ratio at the X and Y demodulator outputs; improving the signal/noise ratio by

averaging the magnitude output itself is not to be recommended.

For analogous reasons, the magnitude function also shows signal-dependent errors

when zero offsets are present in the demodulator. For this reason, it is essential to

reduce zero offsets to an insignificant level (usually by the use of the Auto-Offset

function) when the magnitude output is to be used.

Note that the majority of signal recovery applications are scalar measurements, where

the phase between the required signal and the reference voltage is constant apart from

possible phase reversals corresponding to changes in the sign of the quantity being

measured. In this situation the lock-in amplifier is used in the normal X-Y mode, with

the phase shifter adjusted to maximize the X output and to bring the mean Y output to

zero. (Refer to section 3.12.03 for further information on the correct use of the AutoPhase function for this purpose.)

3-13

Page 30

Chapter 3, TECHNICAL DESCRIPTION

3.10 Noise Measurements

The noise measurement facility is available only in the baseband mode (i.e. at

reference frequencies less than 60 kHz) and uses the output processor to perform a

noise computation on the Y output where it is assumed that the waveform is

Gaussian with zero mean. The zero mean is usually obtained by using the reference

phase control or the Auto-Phase function with a comparatively long time constant

(say 1 s) and the time constant is then reduced (to say 10 ms) for the noise

measurement.

The user is strongly advised to use an oscilloscope attached to the rear panel SIG

MON (signal monitor) output when making noise measurements as this is the best

way of ensuring that one is measuring a random process rather than line pick-up.

The indicated value of the noise (in V/√Hz or A/√Hz) is the square root of the mean

spectral density over the bandwidth defined by the setting of the output filter time

constant.

3.11 Power-up Defaults

All instrument settings are retained when the unit is switched off. When the

instrument is switched on again the settings are restored but with the following

exceptions:-

a) The signal channel reverts to AC coupling.

b) The GPIB mask byte is set to zero.

c) The REMOTE parameter is set to zero (front panel control enabled).

d) The curve buffer is cleared.

e) Any sweep that was in progress at switch-of f is terminated.

f) Synchronous time constants are enabled.

g) Display backlights are turned on

3.12 Auto Functions

3.12.01 Introduction

The auto functions are groups of control operations which can be executed by means

of a single command or two key-presses. The auto functions allow easier, faster

operation in most applications, however, direct manual operation or special purpose

control programs may give better results in certain circumstances. During application

of several of the auto functions, decisions are made on the basis of output readings

made at a particular moment. Where this is the case, it is important for the output

time constant set by the user to be long enough to reduce the output noise to a

sufficiently low level so that valid decisions can be made and suf ficient time is

allowed for the output to settle.

3-14

The following sections contain brief descriptions of the auto functions.

Page 31

Chapter 3, TECHNICAL DESCRIPTION

3.12.02 Auto-Sensitivity

This function only operates when the reference frequency is above 1 Hz. A single