Page 1

ERserver

7212 Model 102 External Storage Device Enclosure

7212 Model 102 Storage Device Enclosure

Service Guide

SY44-0084-04

Page 2

Page 3

ER s e r v e r

7212 Model 102 External Storage Device Enclosure

7212 Model 102 Storage Device Enclosure

Service Guide

SY44-0084-04

Page 4

©

US

Note!

Before using this information and the product it supports, be sure to read the general information

under “Notices” on page v.

Fifth Edition (May 2004)

This edition, SY44–0084–04, applies to Model 102 of the 7212 External Storage Device Enclosure and to all

subsequent releases and modifications until otherwise indicated in new editions. This edition applies only to the

specified model of the device.

Copyright International Business Machines Corporation 2001, 2004. All rights reserved.

Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

©

Contents

Notices . . . . . . . . . . . . . . .v

Safety and Environmental Notices . . . . . . .vi

Danger Notices . . . . . . . . . . . .vi

Caution Notices . . . . . . . . . . . . vii

Attention Notices . . . . . . . . . . . vii

Product Recycling and Disposal . . . . . . vii

Battery Return Program . . . . . . . . . viii

Environmental Design . . . . . . . . . viii

Electronic Emission Notices . . . . . . . . . viii

Federal Communications Commission (FCC)

Statement . . . . . . . . . . . . . . viii

Trademarks . . . . . . . . . . . . . . .x

About This Guide . . . . . . . . . .xi

Related Publications . . . . . . . . . . .xi

How to send your comments . . . . . . . . xii

Chapter 1. General Information . . . . .1

System Requirement . . . . . . . . . . . .3

RS/6000 and pSeries Systems . . . . . . . .3

AS/400 and iSeries Systems . . . . . . . .4

SCSI Bus Cables . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . .8

Media Drive Environment and Use . . . . . . .9

Media Grades . . . . . . . . . . . . .9

Media Handling and Storage . . . . . . . .9

Environmental Issues . . . . . . . . . .9

Drive Cleaning . . . . . . . . . . . .9

SCSI Hardware Issues . . . . . . . . . .10

Microcode Updates . . . . . . . . . . .10

Summary . . . . . . . . . . . . . .10

Step 17 . . . . . . . . . . . . . . . .21

Step 18 . . . . . . . . . . . . . . . .21

Step 19 . . . . . . . . . . . . . . . .22

Step 20 . . . . . . . . . . . . . . . .23

Step 21 (AS/400 or iSeries Only) . . . . . . .23

Step 22 (AS/400 or iSeries Only) . . . . . . .24

Step 23 . . . . . . . . . . . . . . . .24

Step 24 . . . . . . . . . . . . . . . .25

Chapter 3. Removal and Replacement

Procedures . . . . . . . . . . . . .27

Handling Static-Sensitive Devices . . . . . . .27

Safety Considerations . . . . . . . . . . .27

Removing and Replacing the Cover . . . . . .28

Removing a Storage Device from the Enclosure . .29

Installing a Storage Device in the Enclosure . . .31

Removing and Replacing the Power Supply . . .33

Removing and Replacing the Cooling Fans . . . .35

Removing and Replacing the Power Switch

Assembly . . . . . . . . . . . . . . .36

Removing and Replacing the LED Status Light

Cable . . . . . . . . . . . . . . . .37

Removing and Replacing the Status Interface Card 38

Removing and Replacing the Power Distribution

Cable . . . . . . . . . . . . . . . .39

Removing and Replacing the SCSI Cable . . . .39

Installing a Split SCSI Bus Cable . . . . . .39

Installing a Single SCSI Bus Cable . . . . . .41

Securing the Internal SCSI Cables . . . . . .42

Removing and Replacing the SCSI Address Cables 44

Removing and Replacing the Audio Cable Assembly 45

Chapter 2. Maintenance Analysis

Procedures . . . . . . . . . . . . .11

Purpose of the MAPs . . . . . . . . . . .11

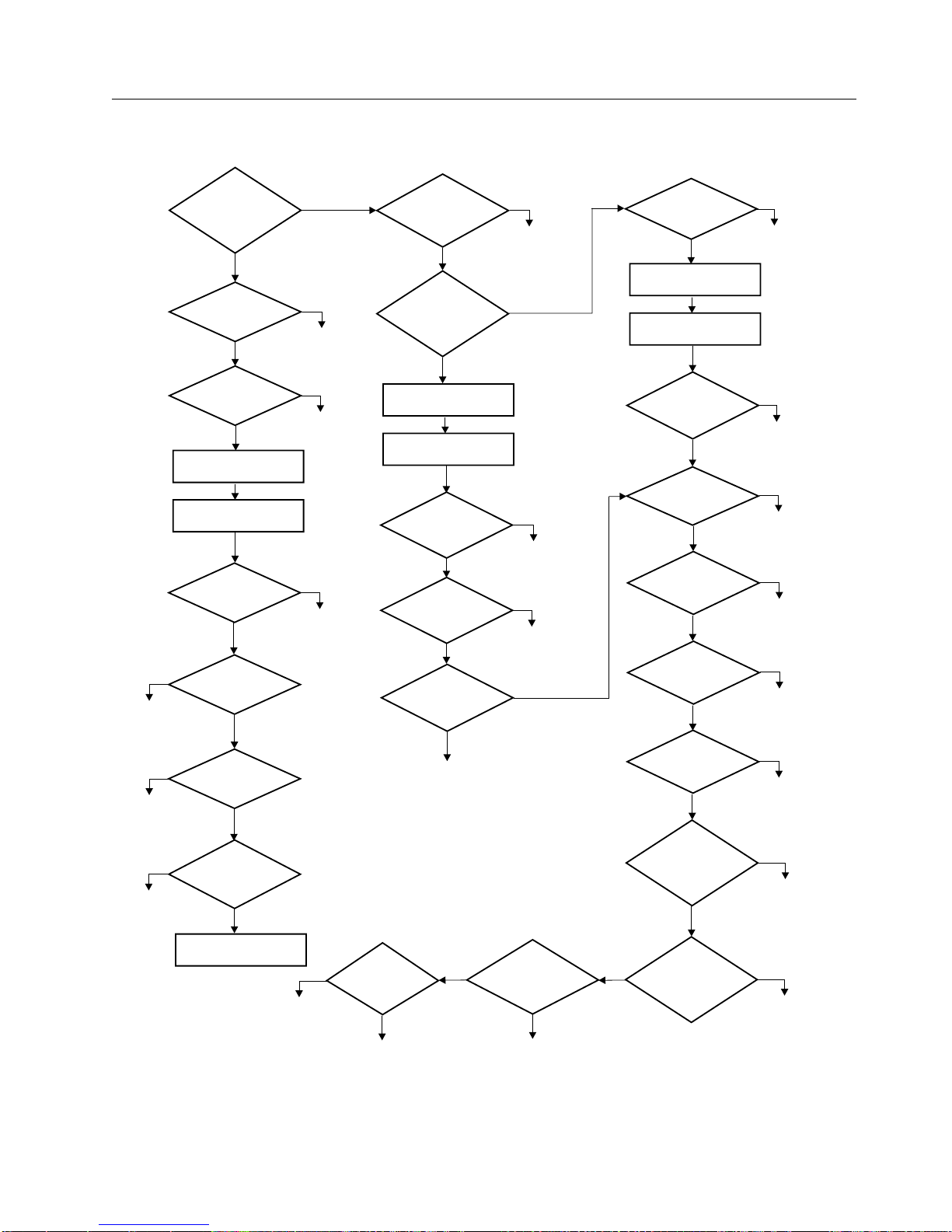

Flowchart of the MAPs (RS/6000 and pSeries

Systems) . . . . . . . . . . . . . . .12

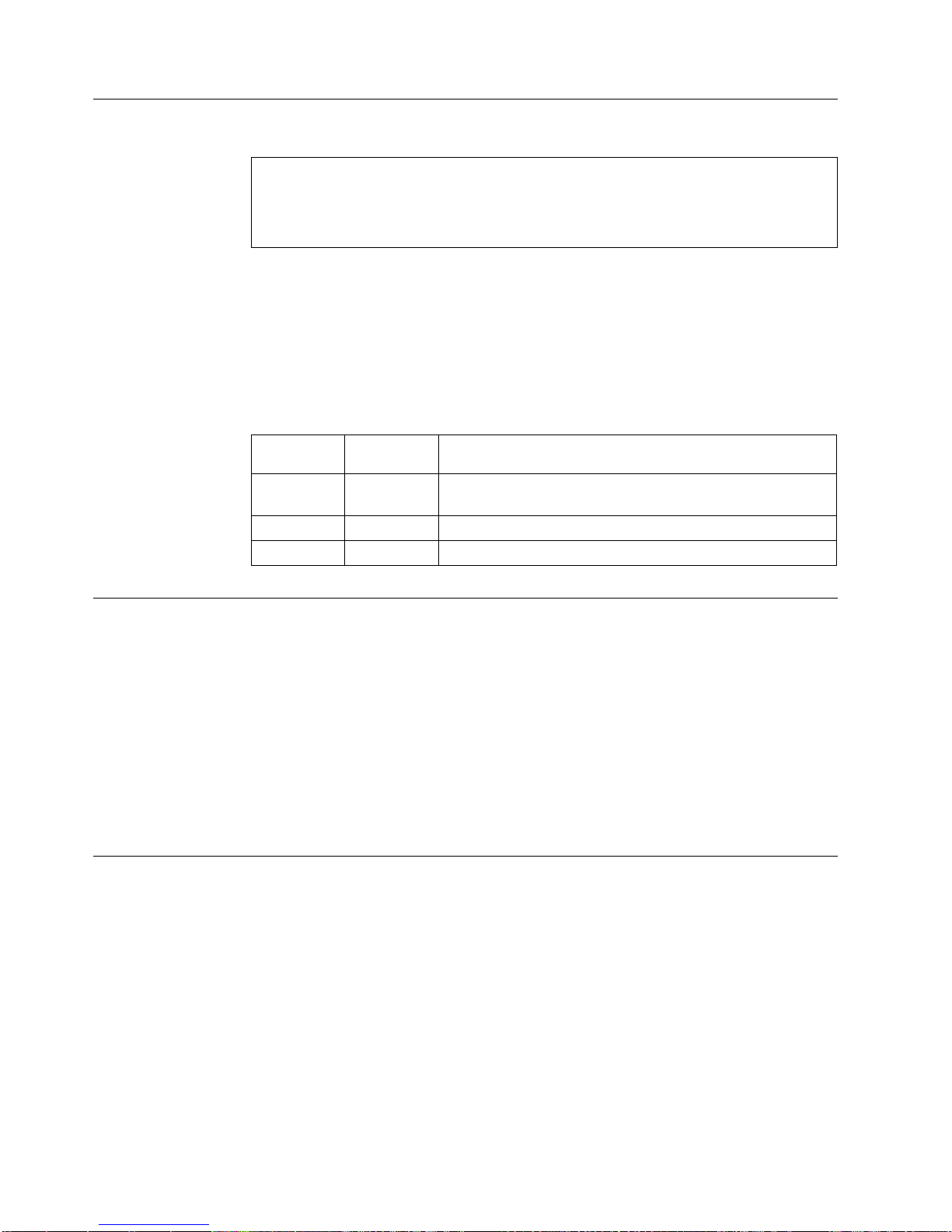

Flowchart of the MAPs (AS/400 and iSeries

Systems) . . . . . . . . . . . . . . .13

Step 1 . . . . . . . . . . . . . . . .14

Step 2 . . . . . . . . . . . . . . . .14

Step 3 . . . . . . . . . . . . . . . .14

Step 4 . . . . . . . . . . . . . . . .15

Step 5 . . . . . . . . . . . . . . . .15

Step 6 . . . . . . . . . . . . . . . .16

Step 7 . . . . . . . . . . . . . . . .16

Step 8 . . . . . . . . . . . . . . . .17

Step 9 . . . . . . . . . . . . . . . .17

Step 10 . . . . . . . . . . . . . . . .18

Step 11 . . . . . . . . . . . . . . . .18

Step 12 . . . . . . . . . . . . . . . .19

Step 13 . . . . . . . . . . . . . . . .19

Step 14 . . . . . . . . . . . . . . . .19

Step 15 . . . . . . . . . . . . . . . .20

Step 16 . . . . . . . . . . . . . . . .20

Copyright IBM Corp. 2001, 2004

Chapter 4. Servicing the DDS–4, 4mm

Tape Drive . . . . . . . . . . . . .47

Handling Static-Sensitive Devices . . . . . . .47

Manually Removing a Tape Cartridge . . . . .47

Chapter 5. Servicing the DAT 72, 4mm

Tape Drive . . . . . . . . . . . . .51

Handling Static-Sensitive Devices . . . . . . .51

Manually Removing a Tape Cartridge . . . . .51

Chapter 6. Servicing the VXA

Technology Tape Drive . . . . . . . .55

Handling Static-Sensitive Devices . . . . . . .55

Manually Removing a Tape Cartridge . . . . .55

Chapter 7. Servicing the SLR60 or

SLR100 Tape Drive . . . . . . . . .59

Handling Static-Sensitive Devices . . . . . . .59

Manually Removing a Tape Cartridge . . . . .59

iii

Page 6

iv

Chapter 8. Servicing the DVD-RAM

Drive . . . . . . . . . . . . . . .61

Handling Static-Sensitive Devices . . . . . . .61

Manually Removing a DVD Disc from the Drive . .62

Chapter 9. Servicing the DVD-ROM

Drive . . . . . . . . . . . . . . .63

Handling Static-Sensitive Devices . . . . . . .63

Manually Removing a DVD Disc from the Drive . .64

Chapter 10. Parts Diagram and Parts

List . . . . . . . . . . . . . . . .65

How To Use This Parts List . . . . . . . . .65

Example of Parts Listing . . . . . . . . .65

Assembly 1: Parts Diagram . . . . . . . . .66

Appendix A. Power Cables . . . . . .69

Appendix B. Safety Inspection

Procedures . . . . . . . . . . . . .71

7212 Storage Device Enclosure Service Guide

Page 7

be

to

©

Notices

This information was developed for products and services offered in the U.S.A.

IBM may not offer the products, services, or features discussed in this document in

other countries. Consult your local IBM representative for information on the

products and services currently available in your area. Any reference to an IBM

product, program, or service is not intended to state or imply that only that IBM

product, program, or service may be used. Any functionally equivalent product,

program, or service that does not infringe any IBM intellectual property right may

used instead. However, it is the user’s responsibility to evaluate and verify the

operation of any non-IBM product, program, or service.

IBM may have patents or pending patent applications covering subject matter

described in this document. The furnishing of this document does not give you

any license to these patents. You can send license inquiries, in writing, to:

IBM Director of Licensing

IBM Corporation

500 Columbus Avenue

Thornwood, NY 10594

U.S.A.

license inquiries regarding double-byte (DBCS) information, contact the IBM

For

Intellectual Property Department in your country or send inquiries, in writing, to:

World Trade Asia Corporation

IBM

Licensing

2-31 Roppongi 3-chome, Minato-ku

Tokyo 106-0032, Japan

following paragraph does not apply to the United Kingdom or any other

The

country where such provisions are inconsistent with local law:

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions, therefore, this statement may not apply

you.

This information could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will be

incorporated in new editions of the publication. IBM may make improvements

and/or changes in the product(s) and/or the program(s) described in this

publication at any time without notice.

Any references in this information to non-IBM Web sites are pro0vided for

convenience only and do not in any manner serve as an endorsement of those Web

sites. The materials at those Web sites are not part of the materials for this IBM

product and use of those Web sites is at your own risk.

Any performance data contained herein was determined in a controlled

environment. Therefore, the results obtained in other operating environments may

vary significantly. Some measurements may have been made on development-level

Copyright IBM Corp. 2001, 2004

v

Page 8

If

or in

A

on

vi

systems and there is no guarantee that these measurements will be the same on

generally available systems. Furthermore, some measurement may have been

estimated through extrapolation. Actual results may vary. Users of this document

should verify the applicable data for their specific environment.

Information concerning non-IBM products was obtained from the suppliers of

those products, their published announcements or other publicly available sources.

IBM has not tested those products and cannot confirm the accuracy of

performance, compatibility or any other claims related to non-IBM products.

Questions on the capabilities of non-IBM products should be addressed to the

suppliers of those products.

All statements regarding IBM’s future direction or intent are subject to change or

withdrawal without notice, and represent goals and objectives only.

This information contains examples of data and reports used in daily business

operations. To illustrate them as completely as possible, the examples include the

names of individuals, companies, brands, and products. All of these names are

fictitious and any similarity to the names and addresses used by an actual business

enterprise is entirely coincidental.

you are viewing this information softcopy, the photographs and color

illustrations may not appear.

The drawings and specifications contained herein shall not be reproduced in whole

part without the written permission of IBM.

IBM has prepared this publication for use by hardware service representatives in

the maintenance or repair of the specific machines indicated. IBM makes no

representations that it is suitable for any other purpose.

Safety and Environmental Notices

Danger Notices

danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people.

Use the following danger notices throughout this book.

DANGER

prevent a possible electrical shock from touching two surfaces with

To

different electrical grounds, use one hand, when possible, to connect or

disconnect signal cables. (RSFTD004)

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

7212 Storage Device Enclosure Service Guide

Page 9

to or

A

or

to

Do

An

DANGER

prevent a possible electrical shock when adding or removing any devices

To

from the system, ensure that the power cords for those devices are

unplugged before the signal cables are connected or disconnected. If possible,

disconnect all power cords from the existing system before you add or

remove a device. (RSFTD203)

DANGER

To prevent a possible electrical shock when installing the device, ensure that

the power cord for that device is unplugged before installing signal cables.

(RSFTD204)

DANGER

Do not attempt to open the covers of the power supply. Power supplies are

not serviceable and are to be replaced as a unit. (RSFTD217)

Caution Notices

caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition.

Use the following caution notices throughout this book.

CAUTION:

Ensure that all rack-mounted units are fastened in the rack frame. Do not extend

exchange any rack-mounted units when the stabilizer is not installed.

(RSFTC222)

CAUTION:

When the unit is extended, its weight can turn over a rack that is not steady.

Before you pull the unit out of the rack, ensure that a rack stabilizer is attached

the bottom front of the rack.

not pull out more than one unit at a time. The rack can turn over if you pull

out more than one unit at a time. (RSFTC224)

Attention Notices

attention notice indicates the possibility of damage to a program, device,

system, or data.

Product Recycling and Disposal

Components of the system, such as structural parts and circuit cards, can be

recycled where recycling facilities exist. IBM does not currently collect and recycle

used IBM products from customers in the United States other than those products

that are involved in trade-in programs. Companies are available to disassemble,

reutilize, recycle, or dispose of electronic products. Contact an IBM account

representative for more information.

The system unit contains batteries and circuit boards with lead solder. Before you

dispose of this unit, these batteries and circuit boards must be removed and

Notices

vii

Page 10

In

or

v

v

v

v

discarded according to local regulations or recycled where facilities exist. This book

contains specific information on each battery type where applicable.

Battery Return Program

the United States, IBM has established a collection process for reuse, recycling,

proper disposal of used IBM batteries and battery packs. For information on

proper disposal of the batteries in this unit, please contact IBM at 1-800-426-4333.

Please have the IBM part number that is listed on the battery available when you

make your call. For information on battery disposal outside the United States,

contact your local waste disposal facility.

Environmental Design

The environmental efforts that have gone into the design of the system signify

IBM’s commitment to improve the quality of its products and processes. Some of

these accomplishments include the elimination of the use of Class I

ozone-depleting chemicals in the manufacturing process, reductions in

manufacturing wastes, and increased product energy efficiency. For more

information, contact an IBM account representative.

Electronic Emission Notices

The following Statement applies to this IBM product. The statement for other IBM

products intended for use with this product will appear in their accompanying

manuals.

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

class B digital devices, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

Consult an IBM authorized dealer or service representative for help.

Properly

meet FCC emission limits. Proper cables and connectors are available from IBM

authorized dealers. IBM is not responsible for any radio or television interference

caused by using other than recommended cables or connectors or by unauthorized

changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

shielded and grounded cables and connectors must be used in order to

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interferences, and

(2) this device must accept any interferences received, including interference that

may cause undesired operation.

viii

7212 Storage Device Enclosure Service Guide

Page 11

EN

or

be

Responsible Party:

International Business Machines Corporation

New Orchard Road

Armonk, NY 10504

Telephone: 1-919-543-2193

Industry Canada Compliance Statement

This Class B digital apparatus meets the requirements of the Canadian

Interference-Causing Equipment Regulations.

Avis de conformité à la réglementation d’Industrie Canada

Cet appareil numérique de la classe B respecte toutes les exigences du Réglement

sur le matériel brouilleur du Canada.

European Community Compliance Statement

This product is in conformity with the protection requirements of EC Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM cannot accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-IBM option cards.

This product has been tested and found to comply with the limits for Class B

Information Technology Equipment according to CISPR 22 / European Standard

55022. The limits for Class B equipment were derived for typical residential

environments to provide reasonable protection against interference with licensed

communication devices.

Properly shielded and grounded cables and connectors (IBM part number 75G5958

its equivalent) must be used in order to reduce the potential for causing

interference to radio and TV communications and to other electrical or electronic

equipment. Such cables and connectors are available from IBM authorized dealers.

IBM cannot accept responsibility for an interference caused by using other than

recommended cables and connectors.

Germany Only: This product is in conformity with the EN55022 Class B emission

limits.

Japanese Voluntary Control Council for Interference (VCCI) Statement

This product is a Class B Information Technology Equipment and conforms to the

standards set by the Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). This product is aimed to be used in a domestic

environment. When used near a radio or TV receiver, it may become the cause of

radio interference. Read the instructions for correct handling.

Korean Government Ministry of Communication (MOC) Statement

Please note that this device has been approved for non-business purposes and may

used in any environment including residential areas.

Notices

ix

Page 12

e

x

Trademarks

The following terms are trademarks of International Business Machines

Corporation in the United States, or other countries, or both:

AIX

Application System/400

AS/400

(Stylized)

eServer

IBM

iSeries

Operating System/400

OS/400

pSeries

RISC System/6000

RS/6000

400

Other company, product, and service names may be the trademarks or service

marks of others.

7212 Storage Device Enclosure Service Guide

Page 13

It

a

v

v

©

About This Guide

This guide describes how to service the 7212 Model 102 Storage Device Enclosure.

contains the following chapters:

Chapter 1, “General Information,” describes the 7212 Storage Enclosure, gives the

system requirement, discusses SCSI bus cables, and lists hardware specifications.

Chapter 2, “Maintenance Analysis Procedures,” provides the maintenance analysis

procedures (MAPs) required to service the 7212 Model 102 Storage Device

Enclosure.

Chapter 3, “Removal and Replacement Procedures,” provides the removal and

replacement procedures required to service the 7212 Model 102 Storage Device

Enclosure.

Chapter 4, “Servicing the DDS–4, 4mm Tape Drive,” describes procedures to follow

when a problem is detected with an installed 4mm tape drive feature.

Chapter 5, “Servicing the DAT 72, 4mm Tape Drive,” describes procedures to

follow when a problem is detected with an installed DAT 72 tape drive feature.

Chapter 6, “Servicing the VXA Technology Tape Drive,” describes procedures to

follow when a problem is detected with an installed 4mm tape drive feature.

Chapter 7, “Servicing the SLR60 or SLR100 Tape Drive,” describes procedures to

follow when a problem is detected with an installed SLR tape drive feature.

Chapter 9, “Servicing the DVD–RAM Drive,” describes procedures to follow when

problem is detected with an installed DVD-RAM drive feature.

Chapter 10, “Servicing the DVD–ROM Drive,” describes procedures to follow

when a problem is detected with an installed DVD-ROM drive feature.

Chapter 11, “Parts Diagram and Parts List,” provides the parts diagram and parts

list required to service the 7212 Model 102 Storage Device Enclosure.

Appendix A, “Power Cables,” provides power cable information for different

countries.

Appendix B, “Safety Inspection Procedures,” provides procedures to identify

unsafe conditions when servicing the 7212 Storage Enclosure.

Store this guide with your system manuals.

Related Publications

7212 Model 102 Storage Device Enclosure Setup and Operator Guide, SA41-0054,

provides information about installing and operating the 7212 Storage Enclosure.

IBM Externally Attached Devices Safety Information SA26-2004, provides

translations of danger and caution notices.

Copyright IBM Corp. 2001, 2004

xi

Page 14

v If

v If

–

–

If

v

v

v

How to send your comments

Your feedback is important in helping to provide the most accurate and

high-quality information. If you have any comments about this book or any other

IBM documentation, fill out the readers’ comment form at the back of this book.

you prefer to send comments by mail, use the readers’ comment form with the

address that is printed on the back. If you are mailing a readers’ comment form

from a country other than the United States, you can give the form to the local

IBM branch office or IBM representative for postage-paid mailing.

you prefer to send comments by FAX, use either of the following numbers:

United States, Canada, and Puerto Rico: 1-800-937-3430

Other countries: 1-507-253-5192

you prefer to send comments electronically, use the following e-mail address:

v

RCHCLERK@us.ibm.com

sure to include the following:

Be

The name of the book.

The publication number of the book.

The page number or topic to which your comment applies.

xii

7212 Storage Device Enclosure Service Guide

Page 15

in 1

v

v

v

v

v

v

in

v

v

is a

©

Chapter 1. General Information

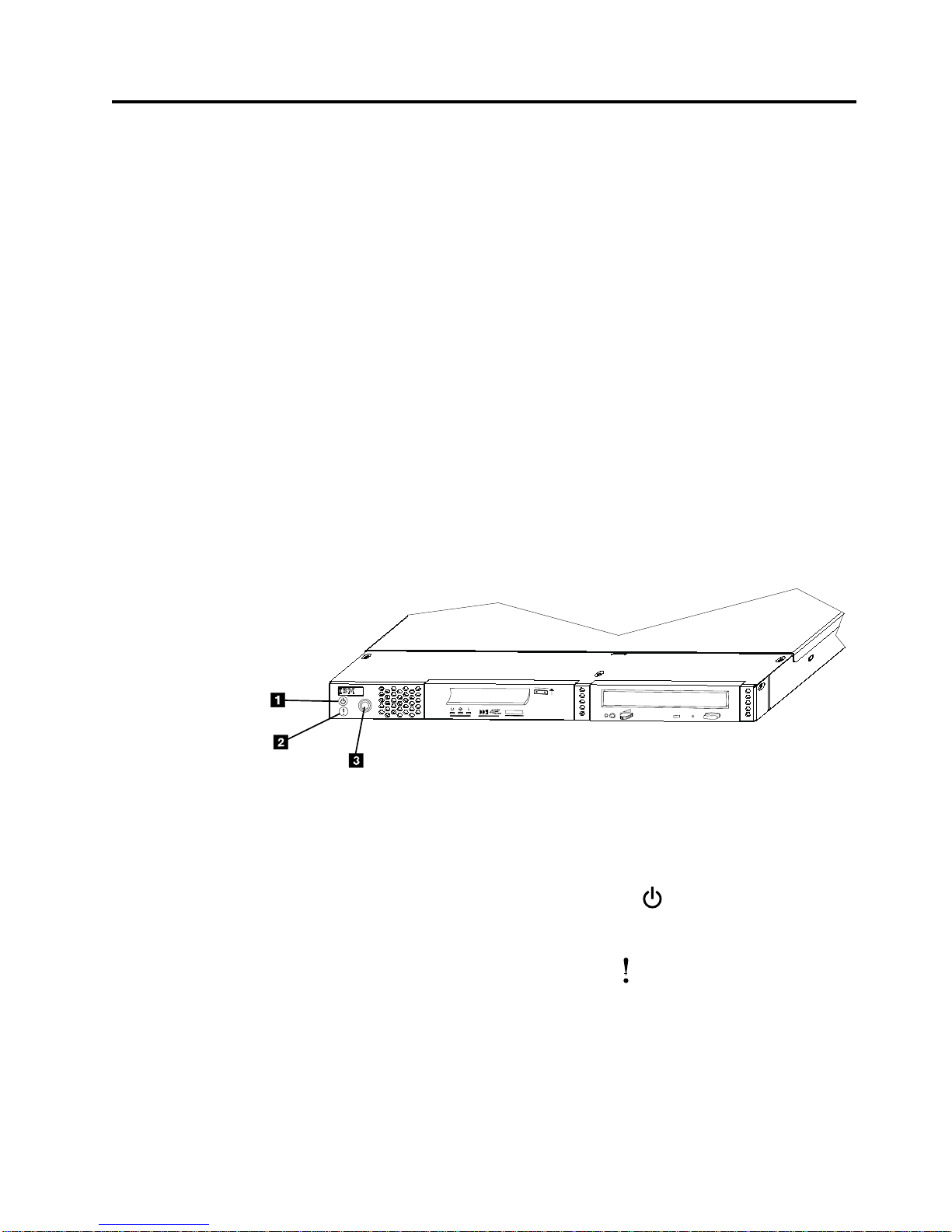

The 7212 Model 102 Storage Device Enclosure is an external enclosure that

provides convenient storage expansion capabilities for select IBM eServer, pSeries,

and RS/6000 computer systems. The 7212 Storage Enclosure is designed to mount

EIA Unit (1.75″) of a standard 19-inch rack using an optional rack mount

hardware feature kit, or be configured for desktop mounting. The design of the

7212 Storage Enclosure allows for easy customer setup and installation. The 7212

Storage Enclosure has two bays that can accommodate any two of the following

storage device features:

DDS-4, 4mm tape drive

DAT 72, 4mm tape drive

VXA technology tape drive

DVD-RAM drive

DVD-ROM drive

Bay Blank (to be used to cover an empty bay when only one drive is installed in

the 7212 Storage Enclosure)

Figure 1 shows the 7212 Storage Enclosure with a DDS-4 4mm tape drive installed

Bay A and a DVD-RAM drive installed in Bay B.

7212

RBBTW504-0

BAY A

BAY B

Figure 1. Front view of the 7212 Storage Enclosure

The 7212 Storage Enclosure has the following components on the front of the unit:

Status Lights

The following status lights are located on the left front of the enclosure:

The Power-on light 1 is a green symbol

that illuminated when the

7212 Storage Enclosure is powered on and no fault condition exists for

the enclosure.

The fault light 2 is an amber symbol

that is illuminated when there

fault condition with the 7212 Storage Enclosure cooling fans.

Power

Switch

Bay A Bay A, on the left front of the 7212 Storage Enclosure (see Figure 1), can

Copyright IBM Corp. 2001, 2004

The power switch 3 is a push button switch that enables the power to be

turned on or off. Push and release the button to toggle power to the 7212

Storage Enclosure on and off.

accommodate any one of the four storage devices or a bay blank.

1

Page 16

If a

to

To

2

Bay B Bay B, on the right front of the 7212 Storage Enclosure (see Figure 1 on

page 1), can accommodate any one of the four storage devices or a bay

blank.

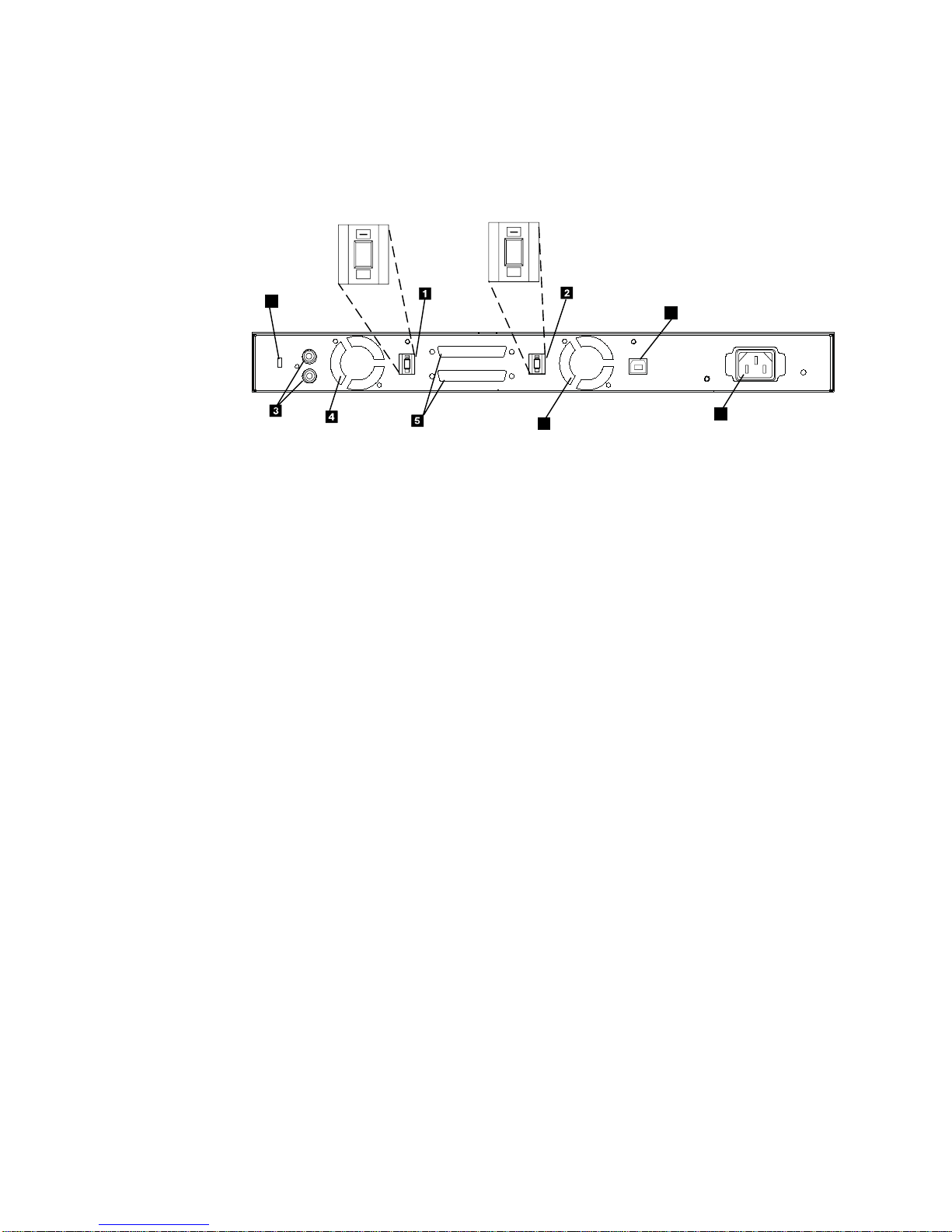

The rear of the 7212 Storage Enclosure has the following components:

3

+

5

+

9

3

+

5

+

6

Figure 2. Rear view of the 7210 DVD-RAM Drive

SCSI Address Switches

The Bay A 2 and Bay B 1 SCSI address switches are used to identify

the installed storage devices to the host system.

Note: The SCSI address switches are supplied as part of the device feature

kits since the various supported devices each have unique

requirements for the address switches. Therefore if no drive is

installed in a device bay, then no SCSI address switch is installed for

that bay.

Audio

Jack Connectors

DVD-ROM or DVD-RAM drive is installed in Bay B, the audio jack

connectors 3 can be used to attach the drive to a stereo amplifier.

7

8

RBBTV542-0

Note:

The audio jack connectors are supplied as part of the device feature

kits, since the various supported devices each have unique

requirements for the audio jack connectors. The audio jack

connectors are supplied only with the DVD-ROM Drive and the

DVD-RAM Drive feature kits. Audio jack connectors can only be

used for a DVD-ROM drive or DVD-RAM drive installed in device

bay B (see Figure 1 on page 1). If a DVD-ROM drive or DVD-RAM

drive is not installed in device bay B, no audio jack connectors are

installed in the 7212 Storage Enclosure.

Cooling Fans

The 7212 Storage Enclosure utilizes two internal cooling fans (4 and 6)

regulate the internal temperature of the enclosure. Air exits the 7212

Storage Enclosure at the two cooling fan locations.

Note:

the cooling fan exits at the rear of the enclosure and the air inlet

holes at the front of the enclosure have sufficient clearance to ensure

airflow.

7212 Storage Device Enclosure Service Guide

ensure proper operation, place the 7212 Storage Enclosure so that

Page 17

1.

2.

3.

4.

SCSI Bus Connectors

The 7212 Storage Enclosure provides two, 68 pin, rear mounted, SCSI bus

connectors 5 for attaching the 7212 Storage Enclosure to the host SCSI

bus. These two external SCSI connectors represent the two ends of the

internal SCSI bus cables. The internal SCSI bus cable can be configured to

support either a single SCSI bus with one host system or with a split SCSI

bus allowing SCSI connections to two hosts. Devices installed in the two

enclosure device bays are attached to the internal SCSI bus cables so that

the installed devices can be on a single or split SCSI bus.

Note: The SCSI interface mode (Low Voltage Differential or Single Ended)

that the 7212 Storage Enclosure will operate in, is dependent on the

type of drives installed in the 7212 Storage Enclosure and the host

system SCSI adapter type.

Signal USB Port

Fault

The rear of the 7212 Storage Enclosure has a Fault Signal USB Series B Port

7. This port is provided for installations that have provisions for remote

fault monitoring of devices. If the 7212 Storage Enclosure experiences a

fault condition (power loss or fan failure) the Pin 2 signal of the USB port

will go from a high state to a low state.

Power

Security Clip Hole

System Requirement

The following sections describe the host system requirements for the 7212 Model

102 Storage Enclosure:

Notes:

The USB port pin 2 is an open collector and must be connected to a

monitoring receiver that is active for the port to have a valid output

signal.

Pin 2 signal voltage is dependent on the electrical design of the

monitoring receiver.

Pin 4 is ground.

Pins 1 and 3 are not connected.

Cable Connector

The 7212 Storage Enclosure receives power through a cable connected to

the power cable connector 8.

The 7212 Storage Enclosure can be secured to a rack or other stationary

object using a security cable and clips that are inserted into the security

clip hole 9 and then attached to a secure object. Contact your IBM

marketing representative or business partner to purchase a security cable.

RS/6000 and pSeries Systems

The 7210 Model 025 DVD-RAM Drive requires a host system platform with an AIX

operating system at level 4.3.3 with update CD LCD4-0995-14 or AIX level 5.1 with

update CD LCD4-1103-01 or higher.

For a list of supported processors and adapters, contact your IBM marketing

representative or business partner.

Chapter 1. General Information

3

Page 18

1

3

No 10 m

No

No

No

No No 1

2

3

4

AS/400 and iSeries Systems

The 7212 Storage Enclosure requires only a supported AS/400 or iSeries system

processor with an OS/400 operating system at level V5R1 (or higher) and a PCI

Magnetic Media Controller (FC 2718 or FC 2768) or a PCI-X ULTRA TAPE

CONTROLLER (FC 5702) or PCI-X TAPE/DASD CONTROLLER (FC 5705). See the

order configurator information for the correct controller to be used for your host

system model.

For a list of supported processors and adapters, contact your IBM marketing

representative or business partner.

SCSI Bus Cables

The following table shows the various SCSI cable feature codes that can be ordered

depending on the host system adapter to which the product will be attached.

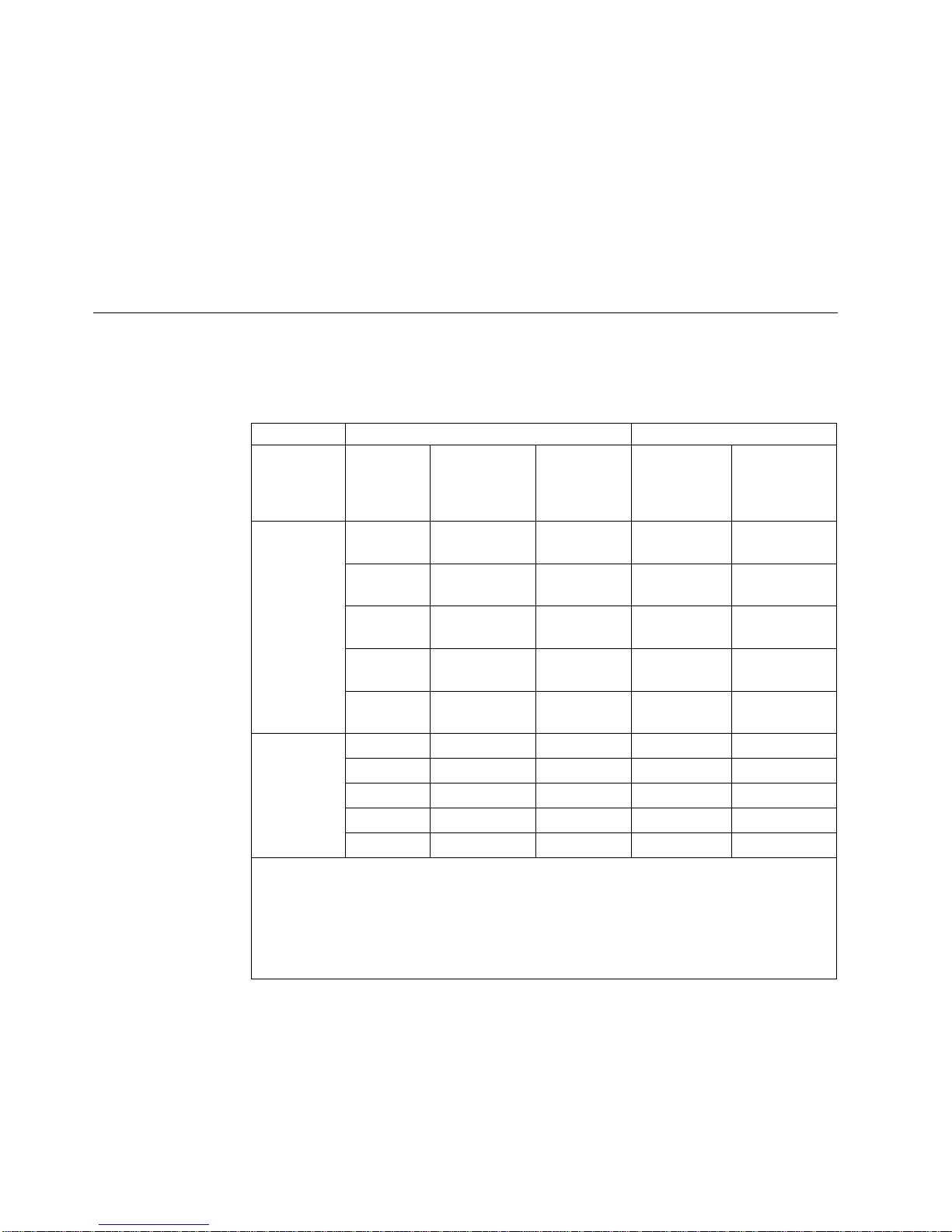

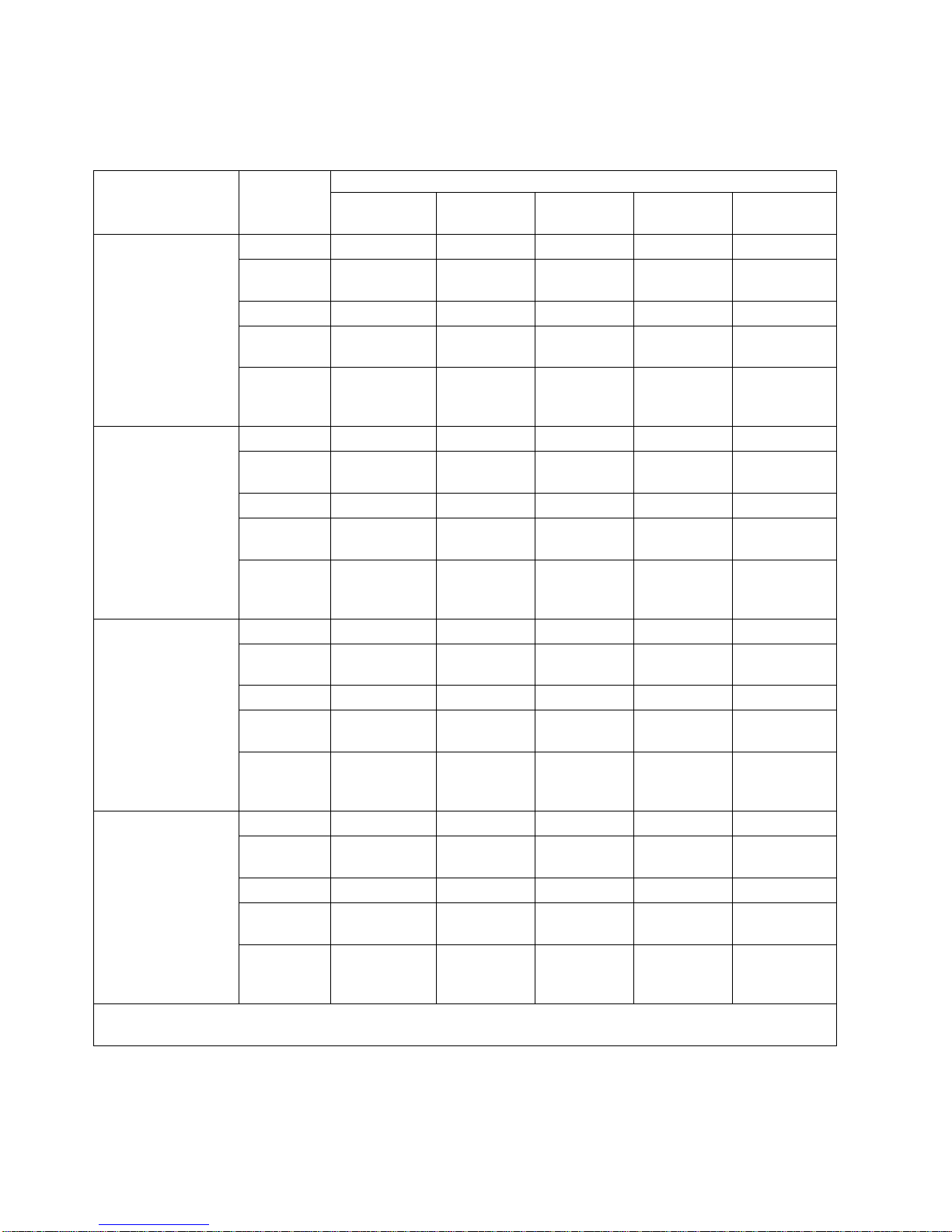

Table 1. SCSI Cable Features for pSeries or RS/6000

pSeries &

RS/6000

Adapter

Feature

6203, 6205,

Integrated

Ultra2 SCSI

Adapter, or

Integrated

Ultra3 SCSI

Adapter

(LVD/SE) or

5703, 5710,

5711, 5712

PCI-X

Adapter

6206 Ultra

SCSI Adapter

(SE)

configuration.

SCSI Cable Description

Length

0.5 m

1.5 m

2.5 m

4.5 m

Connectors MES Feature

VHDCI/HD68 5600/9765

VHDCI/HD68 5601/9761

VHDCI/HD68 5602/9762

VHDCI/HD68 5604/9764

VHDCI/HD68 5610/9760

0.5 m

0.7 m

1.5 m

2.5 m

5.0 m

HD68/HD68 5303/9733

HD68/HD68 5301/9751

HD68/HD68 5300/9750

HD68/HD68 5302/9752

HD68/HD68 5305/9755

Cable

SCSI Cable Application

Adapter to

7212-102

7212-102 to

2nd Device

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Use Table 3 on page 6 to determine the maximum SCSI cable length per SCSI bus

Yes

Yes

Yes

Yes

Yes

The SCSI Terminator feature for all 7212 cable configurations is 5097.

Attaching a second device to the SCSI bus after the 7212 Storage enclosure is only

supported when the internal SCSI cable is configured with a single SCSI bus.

Note: For more detailed descriptions of these cables, contact your IBM marketing

representative or business partner.

7212 Storage Device Enclosure Service Guide

Page 19

1

3

No

No

No

No 1

2

3

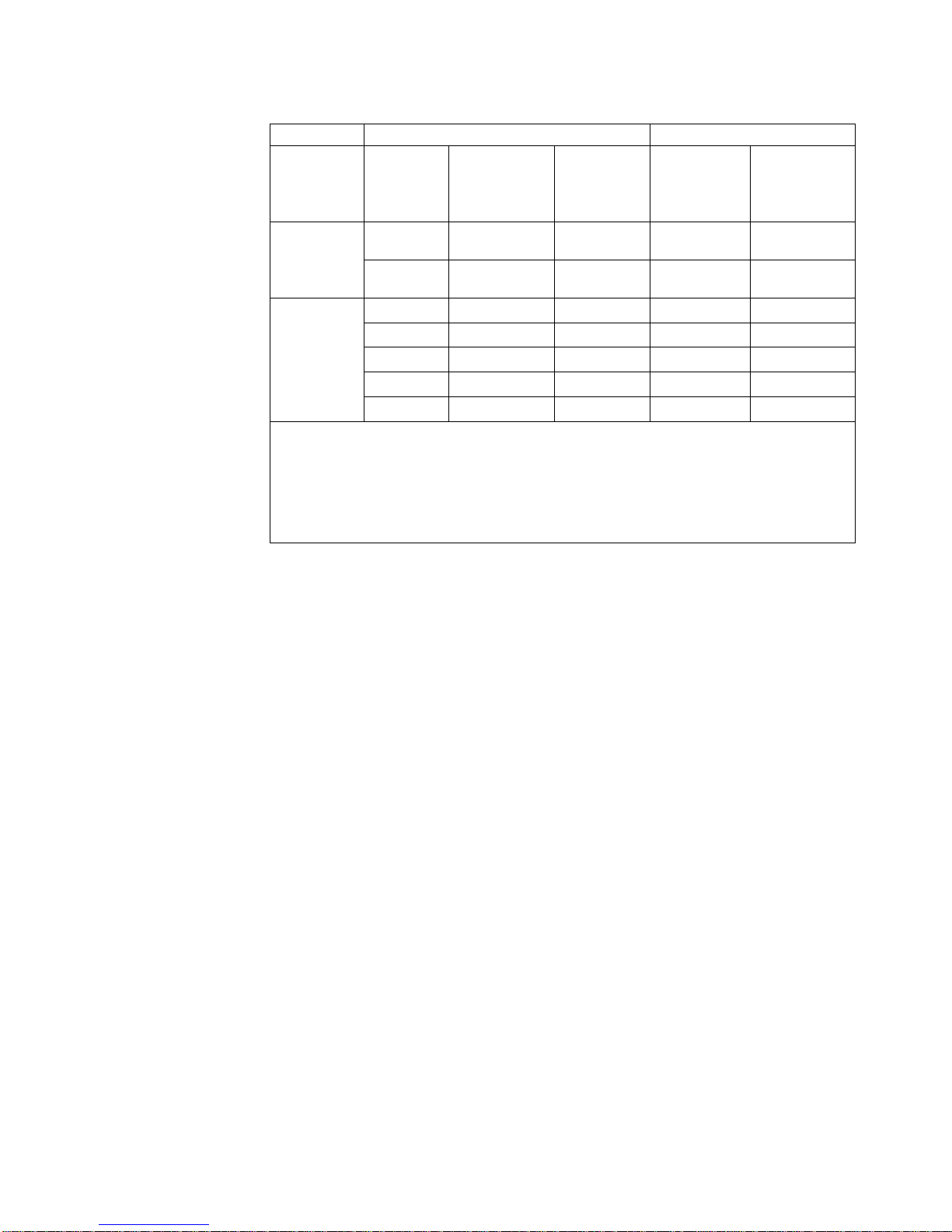

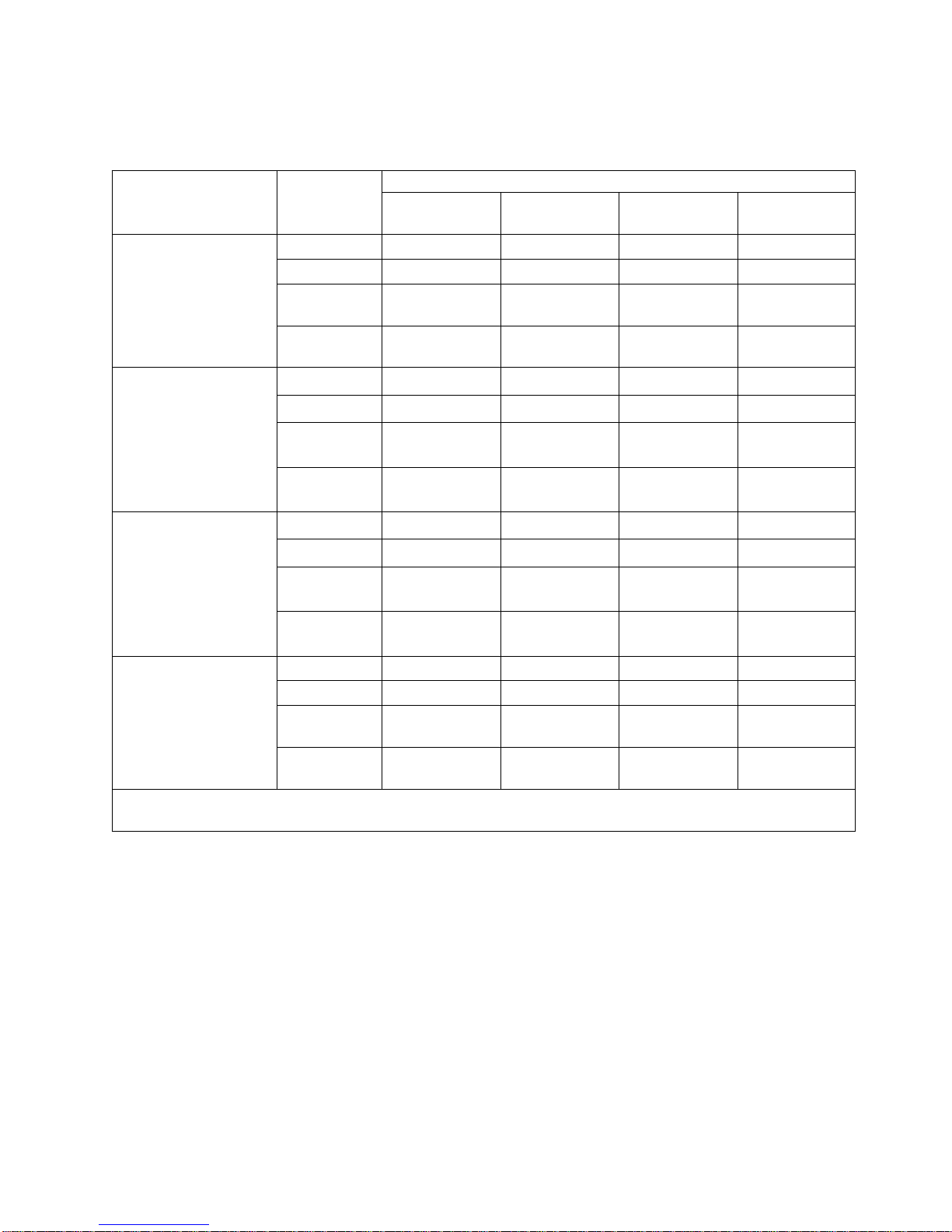

Table 2. SCSI Cable Features for iSeries or AS/400

iSeries &

AS/400

SCSI Cable Description

Length

Connectors MES Feature

Cable

SCSI Cable Application

Adapter to

7212-102

7212-102 to

2nd Device

Adapter

Feature

2718, 2768

1.5 m

HD68/HD68 5300/9750

Yes

Yes

Magnetic

Media

2.5 m

HD68/HD68 5302/9752

Yes

Controller

5702, 5703,

5705, 5710,

5711, 5712,

5715 PCI

Adapters

0.5 m

1.5 m

2.5 m

4.5 m

VHDCI/HD68 5600/9765

VHDCI/HD68 5601/9761

VHDCI/HD68 5602/9762

VHDCI/HD68 5604/9764

10.0 m VHDCI/HD68 5610/9760

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Use Table 4 on page 7 to determine the maximum SCSI cable length per SCSI bus

configuration.

The SCSI Terminator feature for all 7212 cable configurations is 5097.

Attaching a second device to the SCSI bus after the 7212 Storage enclosure is only

supported when the internal SCSI cable is configured with a single SCSI bus.

Note: For more detailed descriptions of these cables, contact your IBM marketing

representative or business partner.

Chapter 1. General Information

5

Page 20

NA

or

NA

or

1

NA 9 m 9 m 10 m 10 m

9 m 9 m 9 m 10 m 10 m

9 m 9 m 9 m 10 m 10 m

10 m 10 m 10 m 10 m 10 m

or

10 m 10 m

1

NA 10 m 10 m 10 m 10 m

10 m 10 m 10 m 10 m 10 m

10 m 10 m 10 m 10 m 10 m

10 m 10 m 10 m 10 m 10 m

or

10 m 10 m 10 m 10 m 10 m 1

6

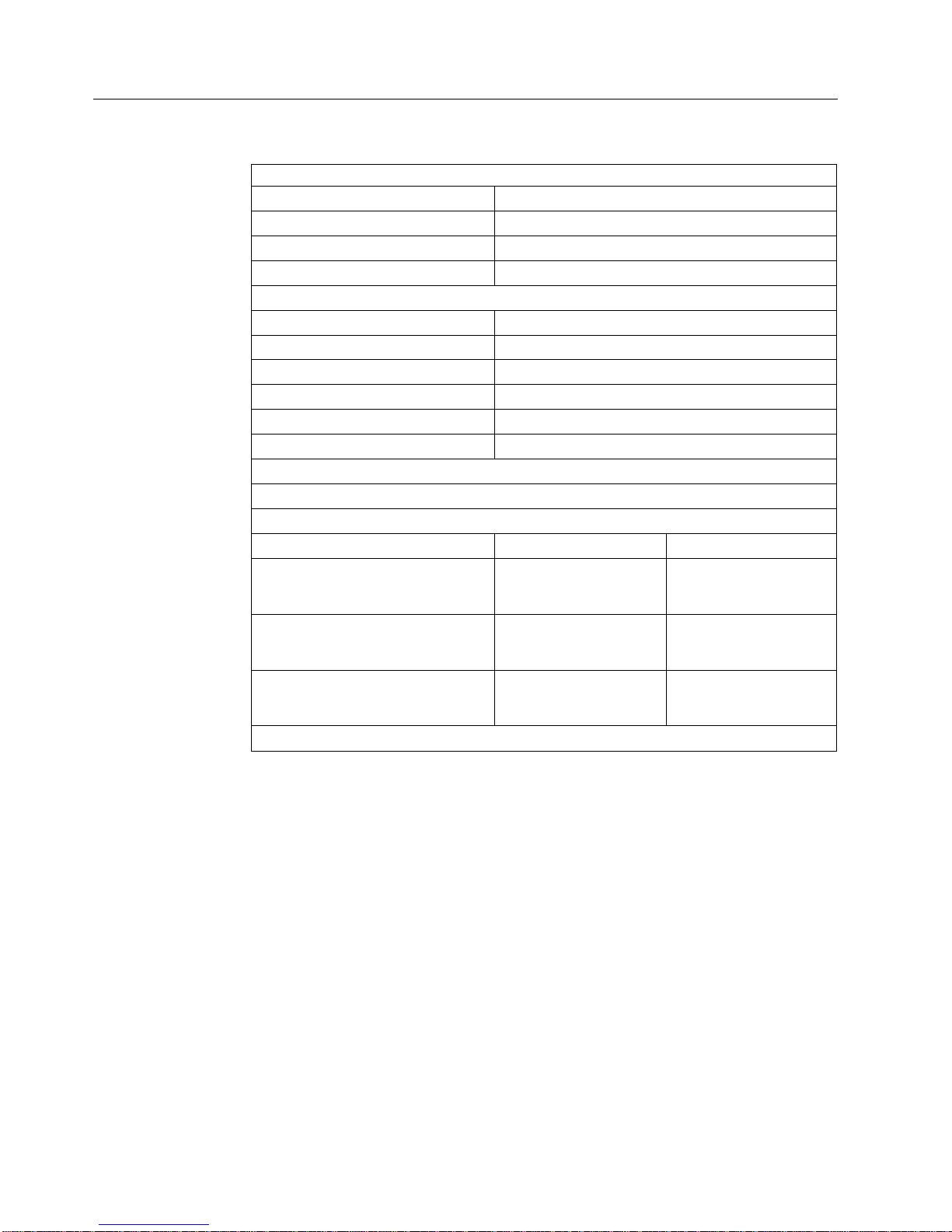

Table 3 details the maximum total length external SCSI cable for each configuration

supported on the 7212 Storage Enclosure connected to an RS/6000 or pSeries host.

Table 3. Maximum SCSI Cable Lengths per Configuration for RS/6000 or pSeries

pSeries or RS/6000

SCSI Bus

Configuration

6206 Ultra SCSI

adapter with one

7212 Enclosure per

adapter port

6203, 6205, Integrated

Ultra2 SCSI, or

Integrated Ultra3

SCSI adapter or 5703,

5710, 5711, 5712

PCI-X adapter with

one 7212 Enclosure

per adapter port

Device in

7212 Bay A

Blank

DDS-4 or

DAT 72

VXA

SLR60 or

SLR100

DVD-RAM

DVD-ROM

Blank

DDS-4 or

DAT 72

VXA

SLR60 or

SLR1000

DVD-RAM

Blank

1.5 m

1.5 m

1.5 m

1.5 m

10.5 m

10.5 m

10.5 m

1.5 m

DDS-4 or

DAT 72

1.5 m

1.5 m

1.5 m

1.5 m

1.5 m

10.5 m

10.5 m

10.5 m

10.5 m

1.5 m

Device in 7212 Bay B

VXA

1.5 m

1.5 m

1.5 m

1.5 m

1.5 m

10.5 m

10.5 m

10.5 m

10.5 m

1.5 m

SLR60 or

SLR100

1.5 m

1.5 m

1.5 m

1.5 m

1.5 m

10.5 m

10.5 m

10.5 m

10.5 m

1.5 m

DVD-RAM or

DVD-ROM

1.5 m

1.5 m

1.5 m

1.5 m

1.5 m

10.5 m

10.5 m

10.5 m

10.5 m

1.5 m

DVD-ROM

6203, 6205, Integrated

Ultra2 SCSI, or

Integrated Ultra3

SCSI adapter or 5703,

5710, 5711, 5712

PCI-X adapter with

two 7212 Enclosures

per adapter port

Blank

DDS-4 or

DAT 72

VXA

SLR60 or

SLR100

DVD-RAM

Not Supported

Not

Supported

Not

Supported

DVD-ROM

6203, 6205, Integrated

Ultra2 SCSI, or

Integrated Ultra3

SCSI adapter or 5703,

5710, 5711, 5712

PCI-X adapter with

one 7212 Enclosure

and one LVD Single

Device Bridge Box

Blank

DDS-4 or

DAT 72

VXA

SLR60 or

SLR100

DVD-RAM

per adapter port

DVD-ROM

Attaching a second device to the SCSI bus after the 7212 Storage enclosure is only supported when the internal

SCSI cable is configured with a single SCSI bus.

7212 Storage Device Enclosure Service Guide

Page 21

NA

NA

1

NA

1

NA

1

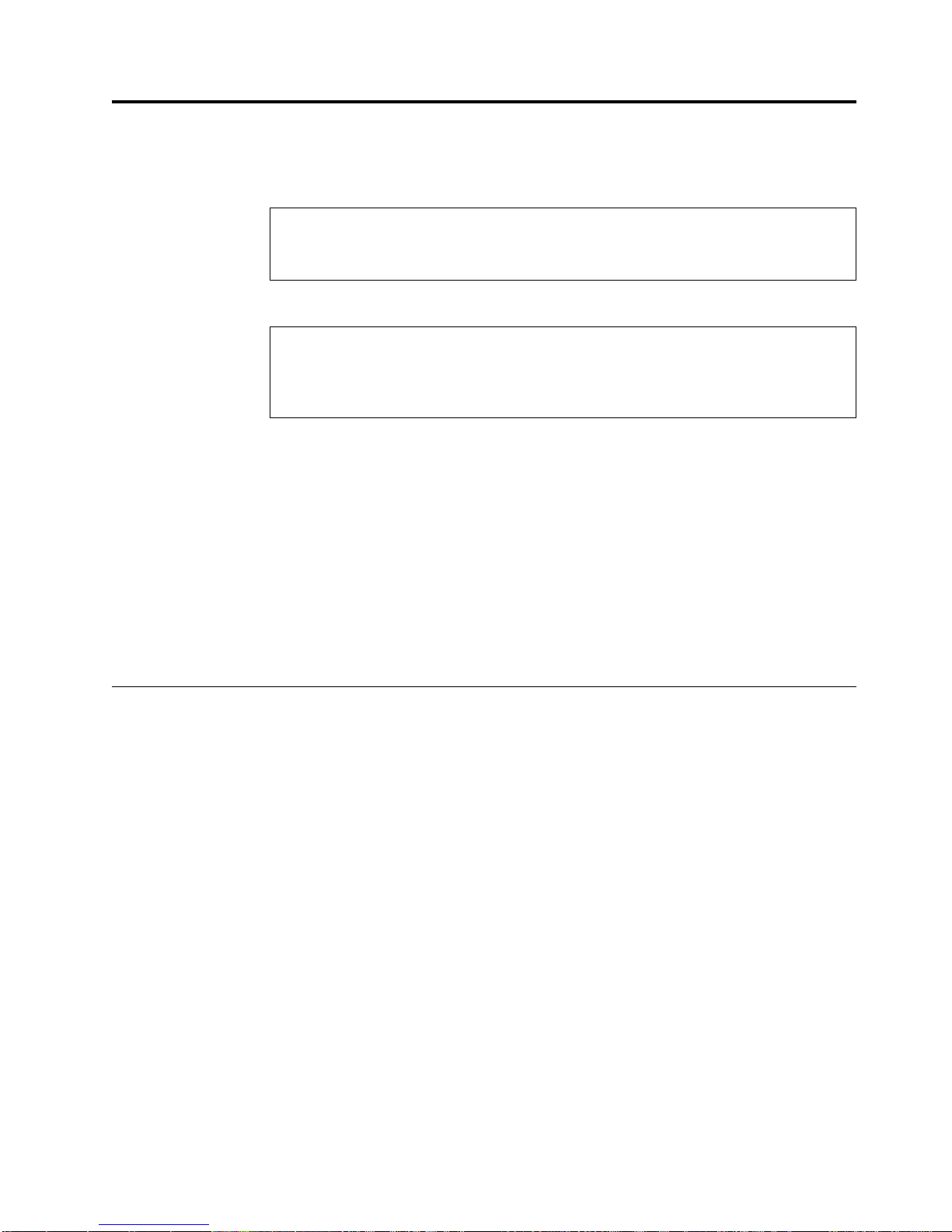

Table 4 details the maximum total length external SCSI cable for each configuration

supported on the 7212 Storage Enclosure connected to an AS/400 or iSeries host.

Table 4. Maximum SCSI Cable Lengths per Configuration for AS/400 or iSeries

iSeries or AS/400 SCSI

Bus Configuration

2718, 2768 Magnetic

Media Controller with

one 7212 Enclosure per

adapter port

6203, 6205, Integrated

Ultra2 SCSI, or

Integrated Ultra3 SCSI

adapter or 5702, 5703,

5710, 5711, 5712, 5715

PCIX adapter with one

7212 Enclosure per

adapter port

6203, 6205, Integrated

Ultra2 SCSI, or

Integrated Ultra3 SCSI

adapter or 5703, 5710,

5711, 5712, 5715 PCIX

adapter with two 7212

Enclosures per adapter

port

6203, 6205, Integrated

Ultra2 SCSI, or

Integrated Ultra3 SCSI

adapter with one 7212

Enclosure and one LVD

Single Device Bridge

Box per adapter port

Attaching a second device to the SCSI bus after the 7212 Storage enclosure is only supported when the internal

SCSI cable is configured with a single SCSI bus.

Device in 7212

Bay A

Blank

VXA

SLR60 or

SLR100

DVD-RAM or

DVD-ROM

Blank

VXA

SLR60 or

SLR100

DVD-RAM or

DVD-ROM

Blank

VXA

SLR60 or

SLR100

DVD-RAM or

DVD-ROM

Blank

VXA

SLR60 or

SLR100

DVD-RAM or

DVD-ROM

Blank

2.5 m

2.5 m

2.5 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

Device in 7212 Bay B

VXA

2.5 m

2.5 m

2.5 m

2.5 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

SLR60 or

SLR100

2.5 m

2.5 m

2.5 m

2.5 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

DVD-RAM or

DVD-ROM

2.5 m

2.5 m

2.5 m

2.5 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

10.0 m

Chapter 1. General Information

7

Page 22

44 mm

V AC

50 to 60

16 to

10 to

20 to

8 to

1

8

Specifications

Table 5. Specifications for the 7212 Model 102 Storage Device Enclosure

Physical Specifications

Width

Depth

Height

Weight

428 mm (16.85 in.)

483 mm (19.0 in.)

(1.72 in.)

8.3 kg (18.2 lb)

1

Power Specifications

kVA

0.047 @ 120 V AC

100 to 125, or 200 to 240

Hertz

Btu Maximum (watts)

Power Factor

Altitude

205 Btu/hr (60 watts) @ 240 V AC

0.8 to 0.9

2135 m (7000 ft)

Performance Specifications

Dependant on device, media type, and SCSI bus configuration.

Recommended Environment

Environmental Factor

Temperature

Operating

32°C

Non-operating

52°C

(60 to 90°F)

Relative Humidity

80%

(noncondensing)

Maximum Wet Bulb

23°C

(73°F)

Weight with two DDS-4, 4mm tape drives installed and no rack slides.

(50 to 126°F)

80%

23°C

(73°F)

7212 Storage Device Enclosure Service Guide

Page 23

a

to

a

we

it

is

a

No

Media Drive Environment and Use

IBM’s goal is to provide you with a product that you can configure and use

reliably. Removable media drives require specific maintenance and environmental

conditions to operate well over time. Using high quality, data grade media,

handling and storing this media properly, operating the removable media drive in

clean environment and keeping the removable media drive properly cleaned can

help you to avoid problems with your IBM product.

Media Grades

IBM may use two different grades of media. At the discretion of IBM, Program

Transmittal Fixes (PTFs) may be supplied on media that is designed to be written

only once and read from several times. This media is not designed to be used as

backup medium.

IBM also sells media designed to be used for storage. IBM supports the media that

sell. If IBM service personnel analysis indicates a problem with non-IBM media

may be necessary for the customer to replace the media.

Media Handling and Storage

Most media is supplied in a sealed cartridge. It is provided this way so that the

media will remain in a clean environment. Opening the cartridge allows dirt and

airborne particles to enter and then become a source of contamination. The

cartridge should only be opened by the drive and not an operator. The media also

held under proper tension inside the cartridge. If the cartridge is dropped, this

tension will be relaxed. Inserting a dropped cartridge into a drive can cause

incorrect loading and result in a jam. This will ruin the media and can cause

physical damage if the cartridge is not removed properly.

When the media is stored, it must be replaced in the protective containers and

stored on the end. The storage area must be clean, dry, normal room temperature

and away from any magnetic fields.

Environmental Issues

Removable media drives are designed to operate in a clean environment. Problem

factors are dirt, dust, fibers and airborne particles. Airborne particles are the most

difficult to address. When media is installed in the drive, the clearance between the

heads and the media is measured in microns. Particles can damage the media or

the head if they come in contact with either. Customers are responsible to provide

clean operating environment for the drive and system.

Drive Cleaning

matter how clean the environment, debris may build up on the heads of any

drive. Over time, this builds up and causes errors in reading and writing.

Customers are responsible to clean the drive in accordance with the cleaning

information provided with the drive.

IBM only supports the use of IBM cleaning cartridges for IBM drives.

Chapter 1. General Information

9

Page 24

If a

or

10

SCSI Hardware Issues

SCSI bus cables and terminators may affect drive performance. IBM cables and

terminators are designed specifically to keep the SCSI bus as free of noise as

possible. Use of non-IBM cables or terminators may adversely affect the SCSI bus

performance. If IBM service personnel analysis indicates a problem with non-IBM

cables, it may be necessary for the customer to replace them with the appropriate

IBM cables.

Microcode Updates

IBM constantly works to provide the best possible products. To make certain that

the drives work their very best, IBM occasionally releases changed microcode for

the drives. When a microcode change is developed, IBM makes it available to you

through the service organization or by electronic delivery.

For RS/6000 and pSeries Host Systems

Microcode changes are available from the following IBM Web site:

http://techsupport.services.ibm.com/server/mdownload

Microcode can be installed by your IBM authorized service personnel or your

system administrator.

For AS/400 and iSeries Host Systems

AS/400 and iSeries system technical support is available from the following IBM

Web site:

http://www-912.ibm.com/

Microcode can be installed by your IBM authorized service personnel or your

system administrator.

Summary

Your drive must be installed in the cleanest possible environment. Additionally,

IBM drives require high quality, data grade media and cleaning on a regular basis.

Media must also be stored and handled properly. Improper use, storage or

handling of drives or media may void your IBM warranty or service agreement

defective drive under the terms and conditions of the IBM warranty or service

agreement. It is our objective to work with you to identify the cause of any drive

problems and provide a solution.

drive stops functioning due to a component failure during the drive warranty

maintenance time, IBM will replace the drive unit. IBM will replace any

7212 Storage Device Enclosure Service Guide

Page 25

on

or

to

Do

If a

to

©

Chapter 2. Maintenance Analysis Procedures

DANGER

prevent a possible electrical shock from touching two surfaces with

To

different electrical grounds, use one hand, when possible, to connect or

disconnect signal cables. (RSFTD004)

DANGER

electrical outlet that is not correctly wired could place hazardous voltage

An

metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

CAUTION:

Ensure that all rack-mounted units are fastened in the rack frame. Do not extend

exchange any rack-mounted units when the stabilizer is not installed.

(RSFTC222)

CAUTION:

When the unit is extended, its weight can turn over a rack that is not steady.

Before you pull the unit out of the rack, ensure that a rack stabilizer is attached

the bottom front of the rack.

not pull out more than one unit at a time. The rack can turn over if you pull

out more than one unit at a time. (RSFTC224)

Purpose of the MAPs

Maintenance analysis procedures (MAPs) are used to check the:

Power cable

Power supply

Terminator

problem is detected, the procedure isolates the problem to the failing field

replaceable unit (FRU).

SCSI address

SCSI cable

Configuration

Drive

Fan

For instructions about removing or replacing a FRU, refer to Chapter 3, “Removal

and Replacement Procedures,” on page 27

The following flowchart provides a graphic to be used as a guide to the MAP. For

detailed instructions on how to perform each procedure safely and correctly, refer

the steps in this chapter.

Copyright IBM Corp. 2001, 2004

11

Page 26

12

Flowchart of the MAPs (RS/6000 and pSeries Systems)

no

Replace power

switch and

return to Step 1

no

Replace power

supply and

return to Step 1

no

Replace status

interface card and

return to Step 1

Step 1

Does the

7212-102

power up?

no

Step 2

Electrical outlet

OK?

Contact service

yes

Step 3

Power cable

OK?

yes

Exchange

power cable

Shut the system down

and power off

Remove cover and

prepare unit

Step 4

Any visual

problem?

Fix problem and

no

Step 5

Power Switch

OK?

yes

Step 6

Power Supply

OK?

yes

Step 7

Status interface

card OK?

yes

Replace the LED cable

and return to Step 1

yes

no

personnel

no

yes

return to Step 1

Step 8

Are either of the

fans bad?

no

Step 9

Did drive

complete

POST?

Shut the system down

and power off

Remove cover and

prepare unit

Step 10

Any visual

problem?

Step 11

Power distribution

cable OK?

Step 12

Drives power

up normal?

Replace failing

drive and

return to Step 1

Fail

Replace FRU/contact

service personnel

yes

Replace

fans and

return to Step 1

no

yes

Fix problem and

return to Step 1

no

no

Replace power

distribution cable and

yes

return to Step 1

yes

no

Step 20

Run AIX

diagnostics

Problem fixed

yes

Pass

Step 13

Media

OK?

yes

and return to Step 1

Shut the system down

and power off

Remove cover and

prepare unit

Step 14

Any visual

problem?

Fix problem and

no

return to Step 1

Step 15

SCSI Address

OK?

yes

Step 16

Internal SCSI

cable OK?

Replace SCSI

yes

return to Step 1

Step 17

External SCSI

cable OK?

Replace SCSI

yes

return to Step 1

Step 18

Terminator

OK?

yes

terminator and

return to Step 1

Step 19

Run Configuration

Manager

no

Replace media

yes

no

Fix SCSI

address and

return to Step 1

no

cable and

no

cable and

no

Replace

RBBTW521-0

Figure 3. RS/6000 and pSeries Systems Flowchart of the Maintenance Analysis Procedures (MAPs)

7212 Storage Device Enclosure Service Guide

Page 27

Flowchart of the MAPs (AS/400 and iSeries Systems)

no

Replace power

switch and

return to Step 1

no

Replace power

supply and

return to Step 1

no

Replace status

interface card and

return to Step 1

Step 1

Does the

7212-102

power up?

no

Step 2

Electrical outlet

OK?

Contact service

yes

Step 3

Power cable

OK?

yes

Exchange

power cable

Shut the system down

and power off

Remove cover and

prepare unit

Step 4

Any visual

problem?

Fix problem and

no

Step 5

Power Switch

OK?

yes

Step 6

Power Supply

OK?

yes

Step 7

Status interface

card OK?

yes

Replace the LED cable

and return to Step 1

Retry and

replace

on failure

yes

no

personnel

no

yes

return to Step 1

no

Are either of the

Shut the system down

Remove cover and

Step 24

Did the Verify

test pass?

yes

Problem fixed

Step 8

fans bad?

no

Step 9

Did drive

complete

POST?

no

and power off

prepare unit

Step 10

Any visual

problem?

no

Step 11

Power distribution

cable OK?

distribution cable and

yes

Step 12

Drives power

up normal?

no

Replace failing

drive and

return to Step 1

fail

yes

Replace

fans and

return to Step 1

yes

yes

Fix problem and

return to Step 1

no

Replace power

return to Step 1

yes

Step 23

Clean the

drives and

retry

pass

Problem

fixed

Shut the system down

and power off

Remove cover and

prepare unit

Any visual

SCSI Address

Internal SCSI

cable OK?

External SCSI

cable OK?

Terminator

Are the devices

configured to

Are the devices

communicating with

yes

the system?

Step 13

Media

OK?

yes

Step 14

problem?

no

Step 15

OK?

yes

Step 16

yes

Step 17

yes

Step 18

OK?

yes

Step 21

system?

no

Step 22

RBBTW528-0

no

Replace media

and return to Step 1

yes

Fix problem and

return to Step 1

no

Fix SCSI

address and

return to Step 1

no

Replace SCSI

cable and

return to Step 1

no

Replace SCSI

cable and

return to Step 1

no

Replace

terminator and

return to Step 1

yes

Go to

Step 20

no

Contact support

personnel

Figure 4. AS/400 and iSeries Systems Flowchart of the Maintenance Analysis Procedures (MAPs)

Chapter 2. Maintenance Analysis Procedures

13

Page 28

on

1.

2.

3.

go to

On

On

1.

2.

3.

NO

Go to

NO

Go to

14

Step 1

DANGER

electrical outlet that is not correctly wired could place hazardous voltage

An

metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

This step verifies whether the power is operating properly.

Make sure that the 7212 Storage Enclosure power cable is plugged into an

electrical outlet.

Press the Power On button on the 7212 Storage Enclosure.

Check the state of the power On and Fault lights on the front of the 7212

Storage Enclosure.

Table 6. Status Light States

Power-On

Light Status

Off

Off

Fault Light

Status

Off

Off

Service Action

Repeat Step 1 several times. If neither light illuminates, then

Step 2.

This indicates normal operation. Go to Step 9.

This indicates that there may be a fan failure. Go to Step 8.

Step 2

Step 3

This step tests the voltage at the electrical outlet.

Press the 7212 Storage Enclosure power switch to turn off the power.

Unplug the 7212 Storage Enclosure power cable from the electrical outlet and

from the 7212 Storage Enclosure.

Measure the voltage at the electrical outlet.

the voltage from the electrical outlet correct?

Is

Contact your service personnel for further instructions.

YES

Step 3.

This step determines whether the power cable is functional.

Make sure that all of the conductors in the power cable have continuity, and that

there are no short circuits.

Does the power cable have continuity and are there no short circuits?

Replace the power cable, then go to Step 1.

YES

Step 4.

7212 Storage Device Enclosure Service Guide

Page 29

1. Do a

2.

3.

4.

5.

6.

7.

NO

If

1.

2.

On or In

3.

On

NO

in

to

Step 4

This step performs a visual and physical check in an attempt top fix the problem.

controlled system shutdown (refer to the instructions in the 7212 Model

102 Storage Device Enclosure Setup and Operator Guide).

Ensure that the power to the host is off.

Turn off the power to the 7212 Storage Enclosure.

Unplug the 7212 Storage Enclosure from the electrical source.

Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

Visually inspect all of the internal components in the enclosure. Look for any

signs of wear, damage, contamination, or excessive heat.

Physically check each cable connection and ensure all cables are fully seated

and secured.

Are their any signs of damage, wear, or loose cables?

Step 5

Plug the enclosure into an electrical source and press the power On

switch to determine if the connection inspection fixed the problem.

the enclosure does not power on, go to Step 5. If the enclosure

powers on and appears to run normally, reassemble the enclosure,

and then return to Step 1.

YES

Replace the damaged component or reseat the cable, reassemble

the enclosure and then return to Step 1.

This step checks the Power On/Off switch to determine if this is the source of the

problem.

Unplug the 7212 Storage Enclosure from the electrical source.

Press the power switch on the enclosure to determine whether it latches in the

position.

Unplug the power switch cable from the power supply and test the electrical

continuity of the cable pins, as illustrated in Table 7.

Table 7. Power Switch Cable Pin Continuity

Power button

position

Off (out)

(in)

Continuity between

cable pins 1 and 2

Open Circuit

Continuity

Continuity between

cable pins 3 and 4

Open Circuit

Continuity

Continuity between

other cable pin pairs

Open Circuit

Open Circuit

Does the power switch latch in the On position and support the continuity as

shown in Table 7?

YES

Adjust the power switch bracket to ensure the button moves freely

the chassis hole. If the power button does not latch in the On

position or if the cable does not have continuity, replace the power

switch assembly (see “Removing and Replacing the Power Switch

Assembly” on page 36), reassemble the enclosure, and then return

Step 1.

Reassemble the power switch assembly and then go to Step 6.

Chapter 2. Maintenance Analysis Procedures

15

Page 30

1.

2.

3.

4.

5.

6.

7. On

v

v

NO

1.

2.

3.

4.

5.

6.

16

Step 6

This step checks the power supply voltage levels as the possible source of the

problem.

Press the power switch to turn off the power to the 7212 Storage Enclosure.

Unplug the 7212 Storage Enclosure from the electrical outlet.

Disconnect the power supply connector (J1) from the internal power

distribution cable.

Connect the power cable to both the 7212 Storage Enclosure and to the

electrical outlet.

Press the power switch to turn on the power.

Ensure the fan is operating on the power supply.

the power supply connector J1 (see Figure 5), check the following:

The +12V signal falls between a minimum of +11.5 volts and a maximum of

+12.6 volts

The +5V signal falls between a minimum of +4.8 volts and a maximum of

+5.25 volts

Step 7

Figure 5. Power Supply Connector J1

Are the voltages good, and is the power supply fan operating?

Replace the power supply (see “Removing and Replacing the

Power Supply” on page 33), reassemble the enclosure, and then

return to Step 1.

YES

Reconnect the power supply to the internal power distribution

cable and then go to Step 7.

This step checks the LED cable as the possible source of the problem.

Press the power switch to turn off the power to the 7212 Storage Enclosure.

Unplug the 7212 Storage Enclosure from the electrical outlet.

Disconnect the LED cable from the status interface card.

Connect the power cable to both the 7212 Storage Enclosure and to the

electrical outlet.

Press the power switch to turn on the power to the enclosure.

Check the voltage on the status interface card J1 connector pins with the 7212

cooling fans set to the states listed in Table 8 on page 17. This table lists the

front panel status light states that would occur if the LED cable is plugged into

the J1 connector.

The fans can be turned to an OFF state by disconnecting the fan cable from

Note:

the status interface board.

7212 Storage Device Enclosure Service Guide

Page 31

J1

J1

3

0v

On On

0v

On

0v On

0v

Do

NO

to

1.

2.

3.

NO Go to

1.

2.

NO If

Go to

Table 8. Status Interface Card Voltages

voltage

between

pins 1 and 2

voltage

between pins

and 4

4.8v < x <

7212

Right-side

cooling fan

7212 Left-side

cooling fan

7212 front

panel power

light

Green

7212 front

panel fault

light

Off

5.4v

4.8v < x <

Off

Off

Yellow

5.4v

4.8v < x <

Off

Off

Yellow

5.4v

4.8v < x <

Off

Off

Off

Yellow

5.4v

the voltages measured on the status interface board J1 connector comply

with Table 8?

Replace the status interface card (see “Removing and Replacing the

Power Supply” on page 33), reassemble the enclosure, and then

return to Step 1.

Step 8

Step 9

YES

Replace the LED cable, reassemble the enclosure, and then return

Step 1.

This step examines the cooling fan as the possible source of the problem.

Press the power switch to turn on the power to the 7212 Storage Enclosure.

Observe the fault light on the front of the enclosure.

Observe the cooling fans on the rear of the enclosure. Ensure the fans are

blowing air out of the enclosure and that they are operating at a constant

speed, not making abnormal noises.

the fault light come on and stay on, or are either of the fans operating

Does

abnormally?

Step 9.

YES

Replace the failing cooling fan (see “Removing and Replacing the

Cooling Fans” on page 35), and then return to Step 1.

This step examines the drive as the possible source of the problem.

Press the power switch to turn on the power to the 7212 Storage Enclosure.

Observe each of the drive status indicator lights during & after POST.

the drives power up and complete the Power On Self Test (POST) normally?

Do

YES

the drives do not power up, go to Step 10. If the drives power

up, but with status lights reporting an error condition follow the

recommended drive service action as appropriate (refer to the

drive descriptive chapters in the 7212 Model 102 Storage Device

Enclosure Setup and Operator Guide), and then go to Step 1.

Step 13.

Chapter 2. Maintenance Analysis Procedures

17

Page 32

1. Do a

2.

3.

4.

5.

6.

7.

NO

If

1.

2.

3.

4.

5.

6.

7. On

v

v

18

Step 10

This step performs a visual and physical check in an attempt top fix the problem.

controlled system shutdown (refer to the instructions in the 7212 Model

102 Storage Device Enclosure Setup and Operator Guide).

Ensure that the power to the host is off.

Turn off the power to the 7212 Storage Enclosure.

Unplug the 7212 Storage Enclosure from the electrical source.

Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

Visually inspect all of the internal components in the enclosure. Look for any

signs of wear, damage, contamination, or excessive heat.

Physically check each cable connection and ensure all cables are fully seated

and secured.

Are their any signs of damage, wear, or loose cables?

Step 11

Plug the enclosure into an electrical source and press the power On

switch to determine if the connection inspection fixed the problem.

the enclosure does not power up normally, go to Step 11. If the

enclosure powers on and appears to run normally, reassemble the

enclosure, and then return to Step 1.

YES

Replace the damaged component or reseat the cable, reassemble

the enclosure and then return to Step 1.

This step checks the power distribution cable as the possible source of the problem.

Press the power switch to turn off the power to the 7212 Storage Enclosure.

Disconnect the power distribution cable from the device installed in Bay A.

Disconnect the power distribution cable from the device installed in Bay B.

Disconnect the power distribution cable from the status interface card.

Connect the power cable to both the 7212 Storage Enclosure and to the

electrical outlet.

Press the power switch to turn on the power.

each of the three device power distribution cable connectors (see Figure 6),

check the following:

The +12V signal falls between a minimum of +11.5 volts and a maximum of

+12.6 volts

The +5V signal falls between a minimum of +4.8 volts and a maximum of

+5.25 volts

Figure 6. Device Power Cable Connector

7212 Storage Device Enclosure Service Guide

Page 33

NO

1.

2.

3.

NO

1.

2.

3.

NO If

1. Do a

2.

3.

4.

Are the voltages good at each connector?

Replace the power distribution cable (see “Removing and

Replacing the Power Distribution Cable” on page 39), reassemble

the enclosure, and then return to Step 1.

Step 12

Step 13

YES

Reattach the power cables to the devices and then go to Step 12.

This step examines the drives as the possible source of the problem.

Press the power switch to turn off the power to the 7212 Storage Enclosure.

Disconnect the power distribution cable, SCSI cable, and SCSI address cable

from the drive in Bay A.

Press the power switch to turn on the power.

the drive in Bay B power up and complete the Power On Self Test (POST)

Does

normally?

Turn off the power, reconnect the cables to the drive in Bay A, and

then disconnect the cables from the back of the drive in Bay B. If

the drive in Bay A then powers on normally, replace the drive in

Bay B and then return to Step 1. If not, go to Step 15.

YES

Replace the drive in Bay A and then return to Step 1.

This step checks whether the media is the source of the problem.

Press the media unload button on the drive (refer to the drive descriptive

chapters in the 7212 Model 102 Storage Device Enclosure Setup and Operator

Guide).

Remove the used media. If the media fails to unload, refer to drive specific

chapters (4, 5, and 6) in this manual for manual media unload procedures.

Power the 7212 Storage Enclosure off and then back on. Insert new media and

then power the 7212 Storage Enclosure off and then back on.

the installed drives power up and complete the POST normally?

Do

YES

Step 14

This step performs a visual and physical check in an attempt top fix the problem.

102 Storage Device Enclosure Setup and Operator Guide).

Ensure that the power to the host is off.

Turn off the power to the 7212 Storage Enclosure.

Unplug the 7212 Storage Enclosure from the electrical source.

the drives do not power up, go to Step 11. If the drives power

up, but with status lights reporting an error condition, follow the

recommended drive service action (refer to the drive descriptive

chapters in the 7212 Model 102 Storage Device Enclosure Setup and

Operator Guide), and then go to Step 1.

Discard the used media and then go to Step 14.

controlled system shutdown (refer to the instructions in the 7212 Model

Chapter 2. Maintenance Analysis Procedures

19

Page 34

6.

7.

8.

NO

If

is

NO

To

to

Go to

1.

2.

3.

4.

Is

NO

to

20

5.

Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

Visually inspect all of the internal components in the enclosure. Look for any

signs of wear, damage, contamination, or excessive heat.

Physically check each cable connection and ensure all cables are fully seated

and secured.

Ensure that the internal SCSI cables are connected correctly for the desired SCSI

configuration (split or single SCSI bus.)

Are their any signs of damage, wear, or loose cables?

Plug the enclosure into an electrical source and press the power On

switch to determine if the connection inspection fixed the problem.

the enclosure does not power up normally, go to Step 15. If the

enclosure powers on and appears to run normally, reassemble the

enclosure, and then return to Step 1.

Step 15

Step 16

YES

Replace the damaged component or reseat the cable, reassemble

the enclosure and then return to Step 1.

This step checks that the SCSI address switch settings are correct and that the

address cables are plugged into the drives correctly.

Are the SCSI addresses set correctly with the SCSI cables plugged securely and

the cable in good condition?

Replace the cable, if necessary. Set the SCSI address switch to the

proper address and securely seat the cables, then return to Step 1.

set the SCSI address switch and secure the cables correctly, refer

the instructions in the 7212 Model 102 Storage Device Enclosure

Setup and Operator Guide.

YES

Step 16.

This step determines whether the internal SCSI bus cable is the source of the

problem.

Press the power switch to turn off the power to the 7212 Storage Enclosure.

Disconnect the internal SCSI cable from the drives.

Inspect the SCSI cable and connectors for signs of damage, such as bent pins or

damaged wires.

Ensure that the internal SCSI cables are connected correctly for the desired SCSI

configuration (split or single SCSI bus.)

the internal SCSI cable in good condition?

YES

7212 Storage Device Enclosure Service Guide

Replace the internal SCSI cable (see “Removing and Replacing the

SCSI Cable” on page 39), reassemble the enclosure, and then return

Step 1.

Reassemble the enclosure, and then go to Step 17.

Page 35

to

Is

NO

Go to

Is

NO

on

If

Go to

If

Step 17

This step ensures that the external SCSI bus cable connection is proper.

Inspect the SCSI bus cable for damage, such as bent pins or damaged wires.

Ensure that the SCSI bus cable is properly connected to both the host system and

the 7212 Storage Enclosure. Verify that the supported maximum SCSI bus length

and number of devices is not exceeded. Verify that a supported host adapter is

being used (see Table 1 on page 4 and Table 3 on page 6).

the SCSI bus cable properly connected to the host system and to the 7212

Storage Enclosure?

Replace the cable if it is damaged or too long. Remove any devices

from SCSI bus that are not supported by the configuration. Correct

any adapter problems. Plug the SCSI bus cable into both the host

system and the 7212 Storage Enclosure, then go to Step 18.

Step 18

YES

Step 18.

This step ensures that the external terminator connection is proper.

Inspect the terminator for damage and ensure it has the correct part number.

Ensure that the terminator is properly connected to the last device on the SCSI bus.

Note: If the enclosure is configured with a split SCSI bus, the terminators are

mounted inside the enclosure.

the terminator properly connected to the last device on the SCSI bus?

Replace the terminator if it is damaged or the wrong part number.

Ensure that the terminator is properly connected to the last device

the SCSI bus, then go to Step 19.

the host system is an AS/400 or iSeries system, go to Step 21

(AS/400 or iSeries Only).

YES

Step 19.

the host system is an AS/400 or iSeries system, go to Step 21

(AS/400 or iSeries Only).

Chapter 2. Maintenance Analysis Procedures

21

Page 36

by

1.

2. At

to

3.

v

v

v

If

Is

NO Go to

Go to

22

Step 19

You are here because the host system is an RS/6000 or pSeries host system.

This step verifies that the 7212 Storage Enclosure has been properly configured to

the host system.

Check the configuration of the 7212 Storage Enclosure to the host system software

doing the following:

Log into the host system (AIX operating system).

Note: You must have root authority to install or remove the 7212 Storage

Enclosure from the system. To obtain root authority, see your system

administrator.

the system prompt, type

lsdev -Cs scsi

and press Enter. The command lists all of the SCSI devices that are connected

the host system. Figure 7 shows an example of the screen that displays. The

screen lists:

1

2

3

Device name

Device Status

SCSI adapter slot number

4

5

SCSI address (begins with 7th digit)

Description of the SCSI device

hdisk0 Available 00-00-0S-0,0 2.0GB SCSI Disk Drive

hdisk1 Available 00-02-01-2,0 4.5GB 16 Bit SCSI Disk Drive

hdisk2 Available 00-02-01-3,0 16 Bit SCSI Disk Drive

rmt0 Available 00-02-01-4,0 Differential SCSI 8mm Tape Drive

rmt1 Available 00-02-01-5,0 4.0 GB 4mm Tape Drive

cd1 Available 00-03-01-1,0 SCSI Multimedia CD-ROM Drive

cd2 Available 00-03-01-2,0 16 Bit LVD SCSI DVD-ROM Drive

rmt2 Available 00-03-01-3,0 LVD SCSI 4mm Tape Drive

Figure 7. Screen Display of SCSI Devices Attached to the host system

From the list of SCSI devices, identify the 7212 Storage Enclosure drive

features. These are listed as:

Differential SCSI 4mm Tape Drive

SCSI 4mm Tape Drive

SCSI DVD-RAM Drive

the status of the 7212 Storage Enclosure drive feature is displayed as

Available, the device has successfully been configured. If the status is not

displayed as Available, refer to your host system manuals.

RBBTV547-1

the 7212 Storage Enclosure properly configured to the host system?

YES

7212 Storage Device Enclosure Service Guide

Step 20.

Step 20 to verify that the problem is fixed

Page 37

1.

2.

3.

4.

5.

NO

If

1. At

2. In

3. In

Step 20

This step runs the AIX diagnostics to determine the problem or to verify a fix.

Press the power switch to turn on the power.

Press the load/unload button to eject any media currently loaded in the

devices.

Obtain the appropriate test media for the device. Inspect the test media for

damage and debris. If the quality of the test media is questionable, replace it

with new test media.

Load the test media into the drive.