Page 1

7206 Model 220 External 4mm Tape Drive

7206 M odel 220

4mm Tape Drive

Service Gui de

SY32-0409-01

Page 2

Page 3

7206 Model 220 External 4mm Tape Drive

7206 M odel 220

4mm Tape Drive

Service Gui de

SY32-0409-01

Page 4

Note!

Before using this information and the product it supports, be sure to read the general information under “Notices” on

page v.

First Edition (February, 2000)

This edition, SY32–0409–01, applies to Model 220 of the 7206 4mm Tape Drive and to all subsequent releases and

modifications until otherwise indicated in new editions. This edition applies only to the specified model of the

device.

© Copyright International Business Machines Corporation 2000. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Notices ...............v

Safety and Environmental Notices .......vi

Danger Notices ............vi

Caution Notices ............vii

Attention Notices ...........vii

Product Recycling and Disposal ......vii

Battery Return Program .........viii

Environmental Design .........viii

Electronic Emission Notices.........viii

Federal Communications Commission (FCC)

Statement..............viii

Trademarks...............x

About This Guide ..........xi

Related Publications ...........xi

How to send your comments ........xii

Chapter 1. Reference Information ....1

FrontView...............2

Operator Controls ...........2

Emergency Eject Feature .........3

Indicator Lights ............3

Rear View ...............6

Internal View ..............7

Rear View of the Drive ...........8

System Requirement ............9

Specifications ..............9

Cleaning the Tape Drive ..........10

Chapter 2. Using the Media ......13

Types of Tape Cartridges ..........13

Recommendations for Data Cartridge Usage . . . 14

Data Cartridge Erasure ..........14

Storage and Shipping Environments ......14

Tape Cartridge Storage .........15

Operating in Harsh Environments .......16

Setting the Write-Protect Switch .......16

Chapter 3. Maintenance Analysis

Procedures.............17

Purpose of the MAPs ...........17

Flowchart of the MAPs ..........18

Step 1: Power and Fan...........19

Step 2: Electrical Outlet Voltage........19

Step 3: Power Cable ...........20

Step 4: Power Supply, Fan, and Tape Drive ....20

Step 5: Cooling Fan............21

Step 6: Tape Drive ............21

Step 7: SCSI Address Switch.........22

Step 8: SCSI Address Cable .........22

Step 9: Tape Drive Status Lights .......22

Step 10: Power Supply Voltage Level ......23

Step 11: Reassembly ...........24

Step 12: External SCSI Cable Connection ....24

Step 13: Terminator Connection........25

Step 14: Configuration...........25

Step 15: AIX Diagnostics ..........26

Chapter 4. Removal and Replacement

Procedures.............27

Handling Static-Sensitive Devices .......27

Removing and Replacing the Cover ......28

Removing and Replacing the Drive ......30

Removing and Replacing the Power Supply . . . 32

Removing and Replacing the Cooling Fan ....34

Manually Removing a Tape Cartridge .....35

Chapter 5. Parts Diagram and Parts

List ................37

How To Use This Parts List .........37

Example of Parts Listing .........37

Assembly 1: Parts Diagram .........38

Appendix A. Power Cables ......41

Appendix B. Ordering Tape Cartridges 45

Appendix C. Safety Inspection

Procedures.............47

Readers’ Comments — We’d Like to

Hear from You ...........51

© Copyright IBM Corp. 2000 iii

Page 6

iv 7206 Model 220 Service Guide

Page 7

Notices

This information was developed for products and services offered in the U.S.A.

IBM may not offer the products, services, or features discussed in this document in

other countries. Consult your local IBM representative for information on the

products and services currently available in your area. Any reference to an IBM

product, program, or service is not intended to state or imply that only that IBM

product, program, or service may be used. Any functionally equivalent product,

program, or service that does not infringe any IBM intellectual property right may

be used instead. However, it is the user’s responsibility to evaluate and verify the

operation of any non-IBM product, program, or service.

IBM may have patents or pending patent applications covering subject matter

described in this document. The furnishing of this document does not give you

any license to these patents. You can send license inquiries, in writing, to:

IBM Director of Licensing

IBM Corporation

500 Columbus Avenue

Thornwood, NY 10594

U.S.A.

For license inquiries regarding double-byte (DBCS) information, contact the IBM

Intellectual Property Department in your country or send inquiries, in writing, to:

IBM World Trade Asia Corporation

Licensing

2-31 Roppongi 3-chome, Minato-ku

Tokyo 106, Japan

The following paragraph does not apply to the United Kingdom or any other

country where such provisions are inconsistent with local law:

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions, therefore, this statement may not apply

to you.

This information could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will be

incorporated in new editions of the publication. IBM may make improvements

and/or changes in the product(s) and/or the program(s) described in this

publication at any time without notice.

Any references in this information to non-IBM Web sites are provided for

convenience only and do not in any manner serve as an endorsement of those Web

sites. The materials at those Web sites are not part of the materials for this IBM

product and use of those Web sites is at your own risk.

© Copyright IBM Corp. 2000 v

Page 8

Any performance data contained herein was determined in a controlled

environment. Therefore, the results obtained in other operating environments may

vary significantly. Some measurements may have been made on development-level

systems and there is no guarantee that these measurements will be the same on

generally available systems. Furthermore, some measurement may have been

estimated through extrapolation. Actual results may vary. Users of this document

should verify the applicable data for their specific environment.

Information concerning non-IBM products was obtained from the suppliers of

those products, their published announcements or other publicly available sources.

IBM has not tested those products and cannot confirm the accuracy of

performance, compatibility or any other claims related to non-IBM products.

Questions on the capabilities of non-IBM products should be addressed to the

suppliers of those products.

All statements regarding IBM’s future direction or intent are subject to change or

withdrawal without notice, and represent goals and objectives only.

If you are viewing this information softcopy, the photographs and color

illustrations may not appear.

The drawings and specifications contained herein shall not be reproduced in whole

or in part without the written permission of IBM.

IBM has prepared this publication for use by hardware service representatives in

the maintenance or repair of the specific machines indicated. IBM makes no

representations that it is suitable for any other purpose.

Safety and Environmental Notices

Danger Notices

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people.

Use the following danger notices throughout this book.

DANGER

To prevent a possible electrical shock from touching two surfaces with

different electrical grounds, use one hand, when possible, to connect or

disconnect signal cables. (RSFTD004)

DANGER

Dangerous voltage being measured. (RSFTD005)

vi 7206 Model 220 Service Guide

Page 9

DANGER

Up to 240 V ac is present at the power module connectors when the main

power cord is connected to a power source. (RSFTD010)

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

DANGER

To prevent a possible electrical shock when adding or removing any devices

to or from the system, ensure that the power cords for those devices are

unplugged before the signal cables are connected or disconnected. If possible,

disconnect all power cords from the existing system before you add or

remove a device. (RSFTD203)

DANGER

To prevent a possible electrical shock when installing the device, ensure that

the power cord for that device is unplugged before installing signal cables.

(RSFTD204)

DANGER

Do not attempt to open the covers of the power supply. Power supplies are

not serviceable and are to be replaced as a unit. (RSFTD217)

Caution Notices

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition.

Use the following caution notices throughout this book.

Attention Notices

An attention notice indicates the possibility of damage to a program, device,

system, or data.

Product Recycling and Disposal

Components of the system, such as structural parts and circuit cards, can be

recycled where recycling facilities exist. IBM does not currently collect and recycle

used IBM products from customers in the United States other than those products

that are involved in trade-in programs. Companies are available to disassemble,

reutilize, recycle, or dispose of electronic products. Contact an IBM account

representative for more information.

The system unit contains batteries and circuit boards with lead solder. Before you

dispose of this unit, these batteries and circuit boards must be removed and

discarded according to local regulations or recycled where facilities exist. This book

contains specific information on each battery type where applicable.

Notices vii

Page 10

Battery Return Program

In the United States, IBM has established a collection process for reuse, recycling,

or proper disposal of used IBM batteries and battery packs. For information on

proper disposal of the batteries in this unit, please contact IBM at 1-800-426-4333.

Please have the IBM part number that is listed on the battery available when you

make your call. For information on battery disposal outside the United States,

contact your local waste disposal facility.

Environmental Design

The environmental efforts that have gone into the design of the system signify

IBM’s commitment to improve the quality of its products and processes. Some of

these accomplishments include the elimination of the use of Class I

ozone-depleting chemicals in the manufacturing process, reductions in

manufacturing wastes, and increased product energy efficiency. For more

information, contact an IBM account representative.

Electronic Emission Notices

The following Statement applies to this IBM product. The statement for other IBM

products intended for use with this product will appear in their accompanying

manuals.

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

class B digital devices, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

v Reorient or relocate the receiving antenna.

v Increase the separation between the equipment and receiver.

v Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

v Consult an IBM authorized dealer or service representative for help.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. Proper cables and connectors are available from IBM

authorized dealers. IBM is not responsible for any radio or television interference

caused by using other than recommended cables or connectors or by unauthorized

changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interferences, and

(2) this device must accept any interferences received, including interference that

may cause undesired operation.

Responsible Party:

viii 7206 Model 220 Service Guide

Page 11

International Business Machines Corporation

New Orchard Road

Armonk, NY 10504

Telephone: 1-919-543-2193

Industry Canada Compliance Statement

This Class B digital apparatus meets the requirements of the Canadian

Interference-Causing Equipment Regulations.

Avis de conformitéàla réglementation d’Industrie Canada

Cet appareil numérique de la classe B respecte toutes les exigences du Réglement

sur le matériel brouilleur du Canada.

European Community Compliance Statement

This product is in conformity with the protection requirements of EC Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM cannot accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-IBM option cards.

This product has been tested and found to comply with the limits for Class B

Information Technology Equipment according to CISPR 22 / European Standard

EN 55022. The limits for Class B equipment were derived for typical residential

environments to provide reasonable protection against interference with licensed

communication devices.

Properly shielded and grounded cables and connectors (IBM part number 75G5958

or its equivalent) must be used in order to reduce the potential for causing

interference to radio and TV communications and to other electrical or electronic

equipment. Such cables and connectors are available from IBM authorized dealers.

IBM cannot accept responsibility for an interference caused by using other than

recommended cables and connectors.

Germany Only: This product is in conformity with the EN55022 Class B emission

limits.

Japanese Voluntary Control Council for Interference (VCCI) Statement

This product is a Class B Information Technology Equipment and conforms to the

standards set by the Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). This product is aimed to be used in a domestic

environment. When used near a radio or TV receiver, it may become the cause of

radio interference. Read the instructions for correct handling.

Korean Government Ministry of Communication (MOC) Statement

Please note that this device has been approved for non-business purposes and may

be used in any environment including residential areas.

Notices ix

Page 12

Trademarks

The following terms are trademarks of International Business Machines

Corporation in the United States, or other countries, or both:

AIX

IBM

RS/6000

Other company, product, and service names may be the trademarks or service

marks of others.

x 7206 Model 220 Service Guide

Page 13

About This Guide

Attention: Before attempting to work with the 7206 Tape Drive or using any of

the information in this guide, perform the safety inspection procedures described

in “Appendix C. Safety Inspection Procedures” on page 47.

Chapter 1, “Reference Information,” describes the operator controls, indicator

lights, connector locations, and hardware specifications of the 7206 Tape Drive. It

also tells how to clean the tape drive.

Chapter 2, “Using the Media,” describes the media to use in the 7206 Tape Drive.

Chapter 3, “Maintenance Analysis Procedures,” provides the maintenance analysis

procedures (MAPs) required to service the 7206 Tape Drive.

Chapter 4, “Removal and Replacement Procedures,” provides the removal and

replacement procedures required to service the 7206 Tape Drive.

Chapter 5, “Parts Diagram and Parts List,” provides a parts diagram and parts list

required to service the 7206 Tape Drive.

Appendix A, “Power Cables,” provides power cable information for different

countries.

Appendix B, “Safety Inspection Procedures,” provides steps to identify unsafe

conditions before working with the 7206 Tape Drive.

Store this guide with your system manuals.

Related Publications

v 7206 Model 220 4mm Tape Drive Setup and Operator Guide, SA26–2006, provides

information about installing and operating the 7206 Model 220 Tape Drive.

v IBM Externally Attached Devices Safety Information manual, SA26-2004, provides

translations of danger notices.

© Copyright IBM Corp. 2000 xi

Page 14

How to send your comments

Your feedback is important in helping to provide the most accurate and

high-quality information. If you have any comments about this book or any other

IBM documentation, fill out the readers’ comment form at the back of this book.

v If you prefer to send comments by mail, use the readers’ comment form with the

address that is printed on the back. If you are mailing a readers’ comment form

from a country other than the United States, you can give the form to the local

IBM branch office or IBM representative for postage-paid mailing.

v If you prefer to send comments by FAX, use either of the following numbers:

– United States and Canada: 1-800-937-3430

– Other countries: 1-507-253-5192

v If you prefer to send comments electronically, use one of these e-mail addresses:

– Comments on books:

RCHCLERK@us.ibm.com

IBMMAIL, to IBMMAIL(USIB56RZ)

Be sure to include the following:

v The name of the book.

v The publication number of the book.

v The page number or topic to which your comment applies.

xii 7206 Model 220 Service Guide

Page 15

Chapter 1. Reference Information

Attention: Before attempting to work with the 7206 Tape Drive or using any of

the information in this guide, perform the safety inspection procedures described

in “Appendix C. Safety Inspection Procedures” on page 47.

The 7206 Model 220 4mm Tape Drive is an external storage device that connects to

the IBM RS/6000

®

and stores additional data. The unit is a streaming tape drive

that uses Digital Data Storage (DDS) tape media.

|

|

|

|

The 7206 Tape Drive attaches to selected RS/6000 systems that use a low voltage

differential/single ended (LVD/SE) or SE Wide SCSI-2 interface which meets the

Small Computer System Interface-2 (SCSI-2) standard X3.131-1994 Rev. 10L of the

American National Standards Institute (ANSI).

The 7206 Tape Drive:

v Saves and restores system data files

v Archives important records

v Installs operating system software upgrades

The sections that follow describe the operator controls and indicator lights on the

7206 Tape Drive. This chapter also shows the connector locations, lists hardware

specifications, and describes how to clean the tape drive.

© Copyright IBM Corp. 2000 1

Page 16

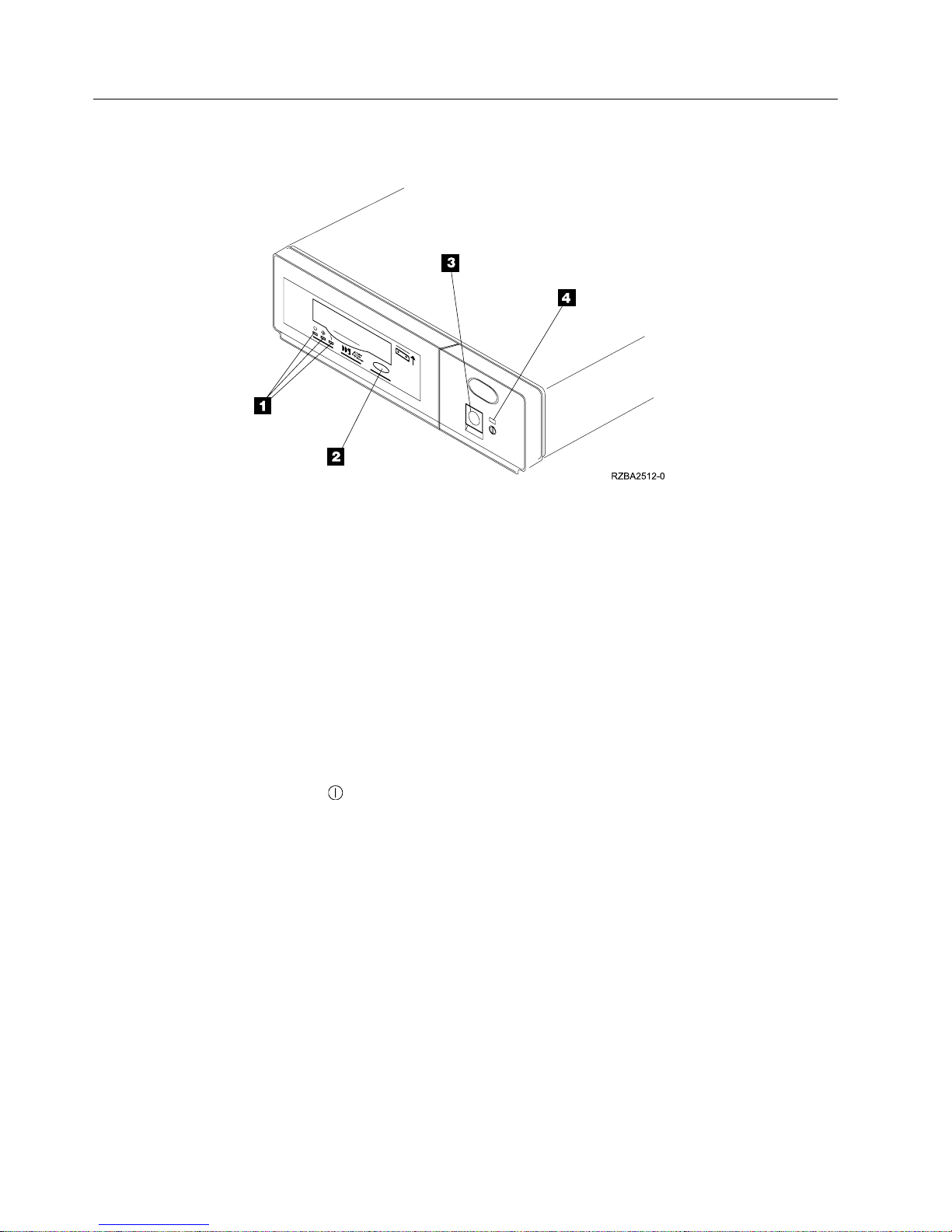

Front View

|

||||

||||

|

Figure 1 shows the front view of the 7206 Tape Drive.

Figure 1. Front View of the 7206 Model 220 4mm Tape Drive

1 Status lights 3 Power switch

2 Unload button 4 Power on light

|

Operator Controls

The 7206 Model 220 4mm Tape Drive has the following operator controls.

Power Switch

|

|

|

|

The power switch (3 in Figure 1) is a push button switch that enables the power

to be turned on or off. Push and release the button to turn the power on, when it

is off, or off when it is on. When the 7206 Tape Drive is on, the power-on light 4

is on.

Note: The

Organization for Standardization (ISO) symbol for a push button switch.

symbol located beside the power switch is an International

Unload Button

The unload button 2 enables the tape cartridge to be ejected. The unload button

operates only when the 7206 Tape Drive power is on. To remove a cartridge, press

and hold the unload button for about one second.

2 7206 Model 220 Service Guide

Page 17

Emergency Eject Feature

Attention: This procedure may result in loss of data.

|

|

|

|

|

|

The 7206 Tape Drive includes an emergency eject and reset feature that releases the

tape cartridge and resets the drive. Use the feature if the cartridge does not move

properly or if the unload process fails.

To perform an emergency eject of the tape cartridge or a reset of the drive, press

and hold the unload button for at least 5 seconds. If a cartridge is in the drive, it

automatically ejects without rewinding.

Indicator Lights

The 7206 Tape Drive has the following indicator lights.

Power-On Light

When the 7206 Tape Drive is turned on, the power-on light (4 in Figure 1 on

page 2) comes on and stays on.

Status Lights

Three status lights (1 in Figure 1 on page 2) and their ISO symbols appear on the

7206 Tape Drive as follows:

Ready (green)

Activity (green)

Fault (amber)

The combinations of the lights and their definitions are shown in Table 1 on page 4.

Chapter 1. Reference Information 3

Page 18

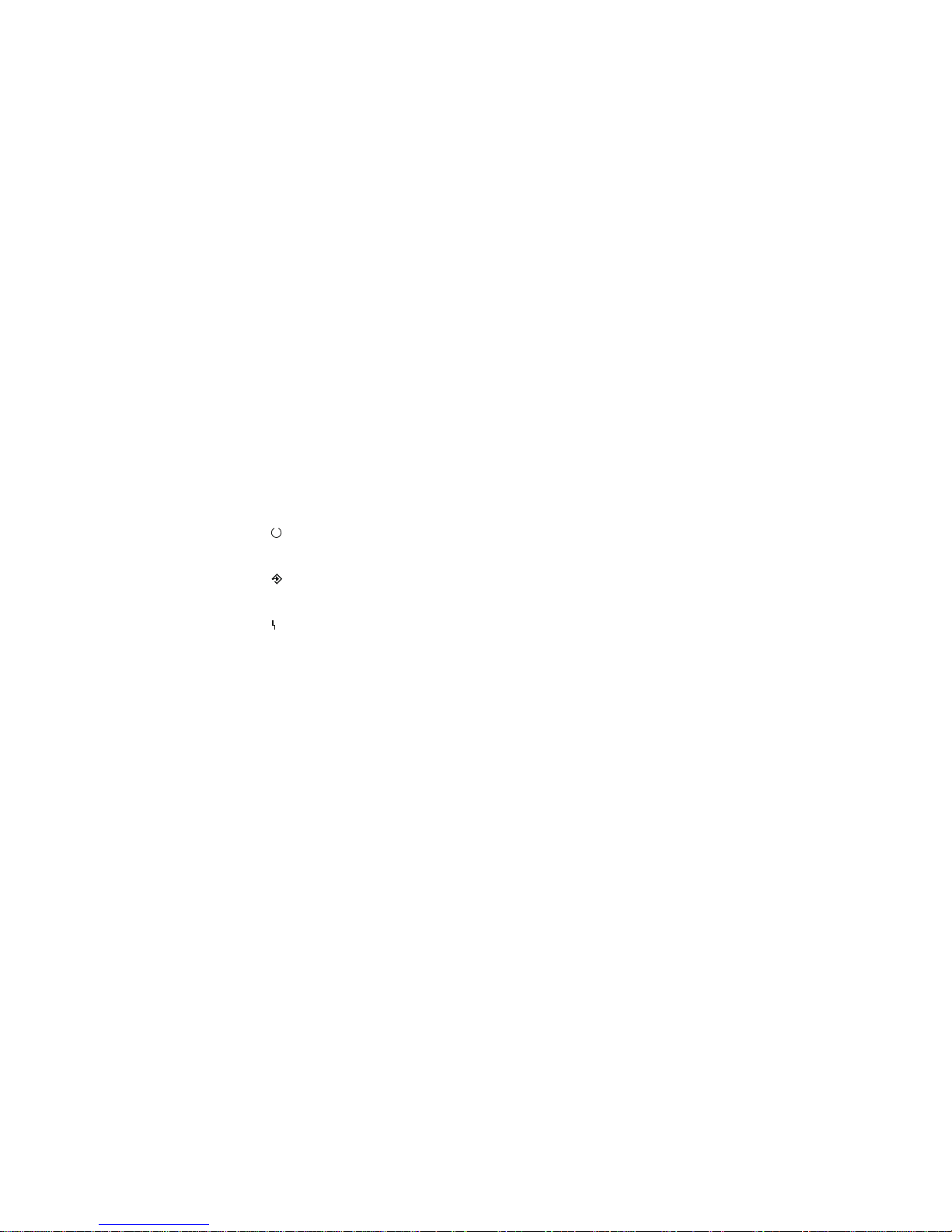

Table 1. Definition of Status Light Combinations

Ready

Flashing Off Off The Power-On Self Test (POST) is running or

Off or On On Off or Flashing The tape drive requires cleaning. See

Off Off or On Off One of the conditions exists:

On Off or On Off or Flashing A data cartridge has been inserted.

On Off or On Flashing The tape is in motion, and the 7206 Tape

Off Flashing Off The 7206 Tape Drive detected an internal

Fault Activity

Definition

the test cartridge is running.

“Cleaning the Tape Drive” on page 10.

v If the Ready light is on, a tape cartridge is

in the drive. If the light is off, a cartridge

is not in the drive.

v If the Activity light flashes, a tape

cartridge is in the drive and tape

movement is occurring. If the light is off,

no tape movement is occurring.

v The power is off (Fault light is off).

v The POST completed successfully, but no

tape cartridge has been inserted.

v If the Fault light is on, cleaning is

required. See “Cleaning the Tape Drive”

on page 10.

v The 7206 Tape Drive is ready to receive

commands from the system (whether the

Fault light is on or off).

v If the Fault light is on, cleaning is

required. See “Cleaning the Tape Drive”

on page 10.

v If the Activity light flashes, a tape

cartridge is in the drive and tape

movement is occurring. If the light is off,

no tape movement is occurring.

Drive is running an operation or is cleaning.

fault that requires corrective action.

v Reset the error by turning the power off to

the 7206 Tape Drive, then turning it back

on, or by holding down the open/close

button for 8 seconds.

v If the Fault light still flashes after the reset,

contact your service representative.

4 7206 Model 220 Service Guide

Page 19

Notes:

1. The 7206 Tape Drive needs cleaning when the tape drive turns on the Fault

status light (solid amber). The light turns on when:

v The 7206 Tape Drive determines that its soft error rate (recovered errors)

exceeds a preset soft-error rate limit, or

|

|

|

v The 7206 Tape Drive has been used for 50 tape motion hours without

cleaning. Tape motion hours are defined as the time the tape drive is moving

tape.

When the Fault light turns on (solid amber), the 7206 Tape Drive causes AIX to

log an information error (TAPE_ERR6) in the AIX log, indicating that the tape

drive needs to be cleaned.

|

2. IBM only supports the use of IBM media.

3. The 7206 Tape Drive is designed to operate in normal office environments.

Dirty environments or other poor environments may damage the tape drive. It

is the responsibility of the customer to provide the proper operating

environment.

4. When the tape drive indicates that the drive needs to be cleaned, it is the

responsibility of the customer to clean the tape drive with the recommended

cleaning cartridge.

5. If a DDS2 diagnostic cartridge (P/N 8191146) is used in the 7206 Tape Drive,

that cartridge will do automatic diagnostics.

6. If a DDS1 diagnostic cartridge (P/N 21F8762) is used, that cartridge will be

immediately ejected as an incorrect cartridge type.

Chapter 1. Reference Information 5

Page 20

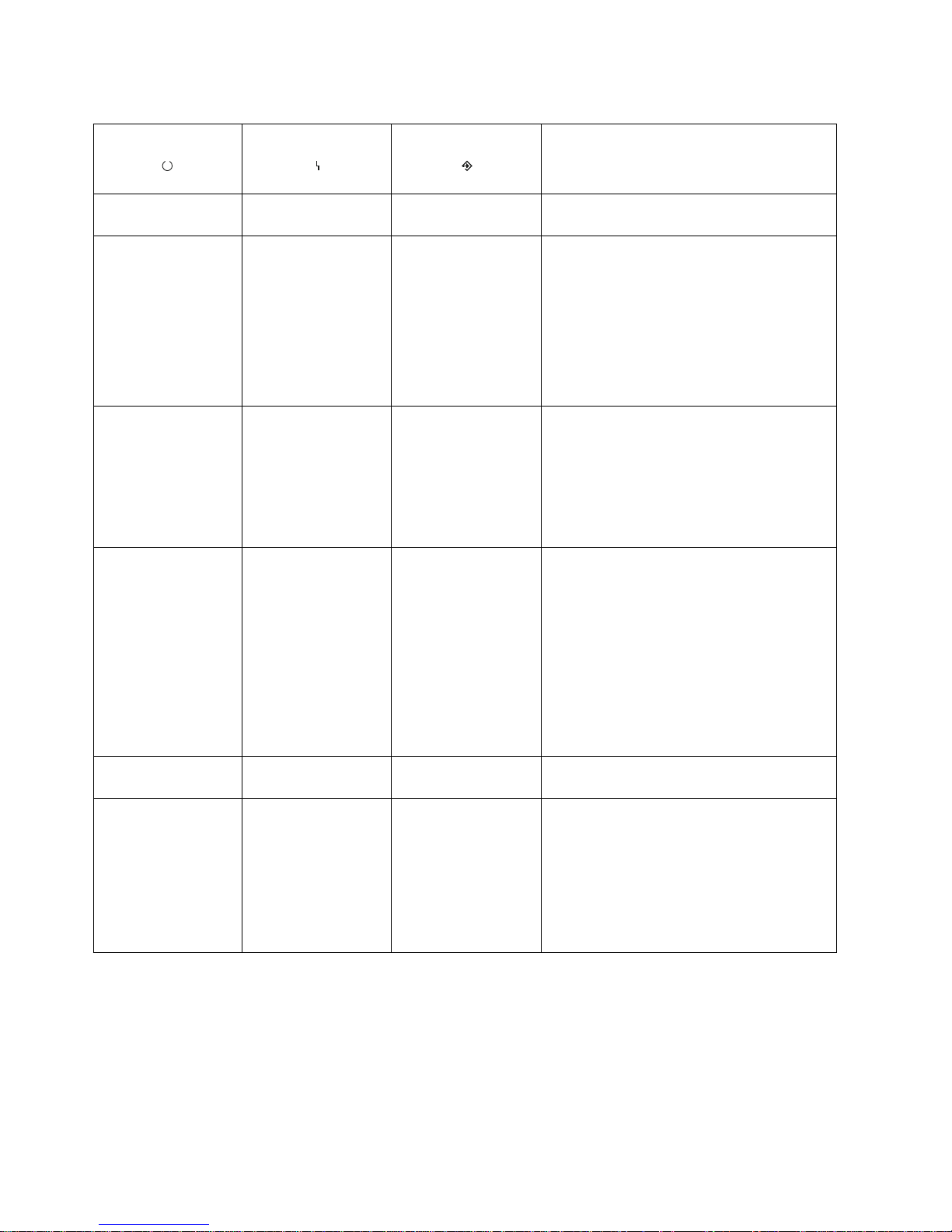

Rear View

Figure 2 shows the elements on the rear of the 7206 Model 220 Tape Drive.

1 SCSI address switch 3 Cooling fan

2 SCSI bus cable connectors 4 Power cable connector

Figure 2. Rear View of the 7206 Model 220 Tape Drive

6 7206 Model 220 Service Guide

Page 21

Internal View

Figure 3 shows the inside of the 7206 Model 220 Tape Drive.

1 Drive 4 Cooling fan

2 SCSI address switch 5 Power supply

3 SCSI bus cable

Figure 3. Internal View of the 7206 Model 220 Tape Drive

Chapter 1. Reference Information 7

Page 22

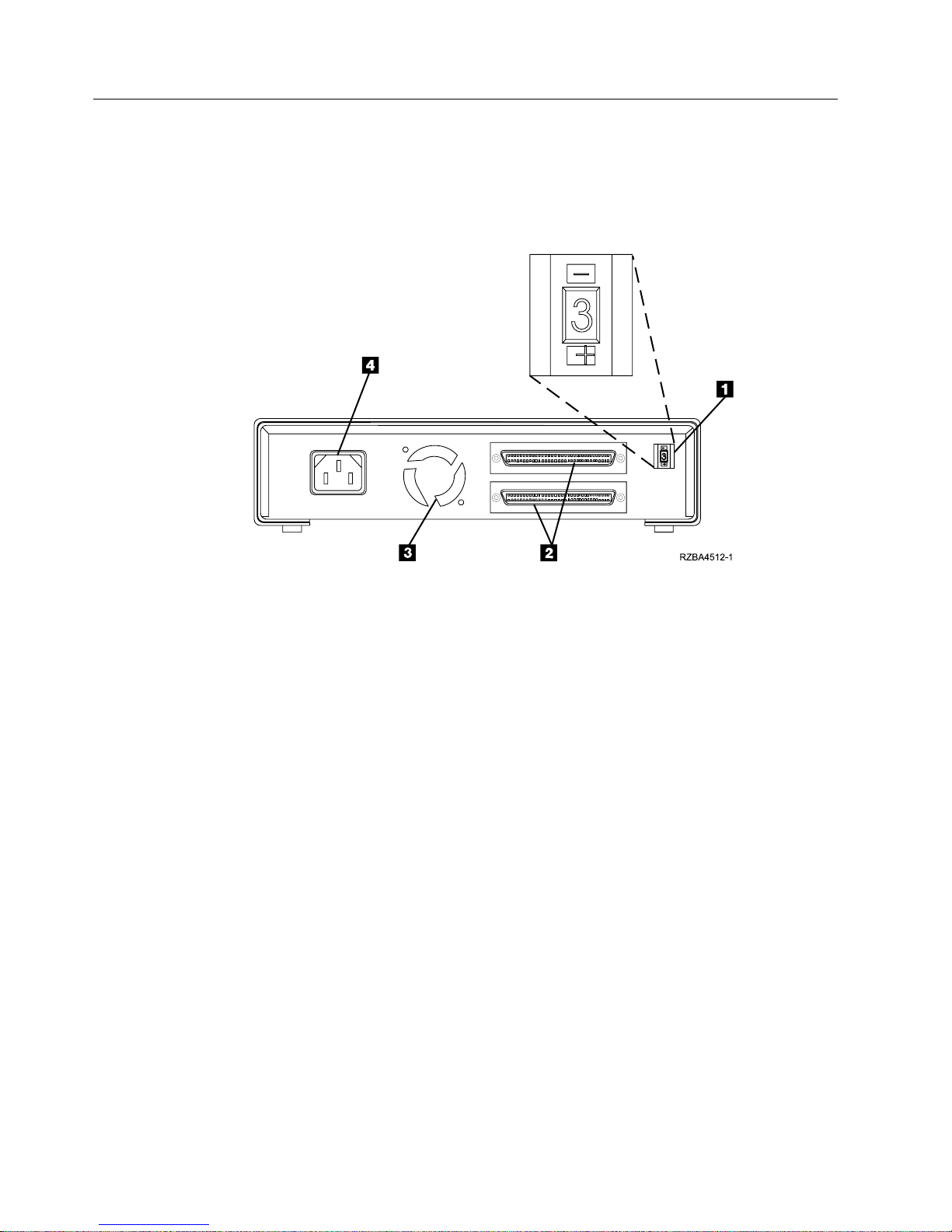

Rear View of the Drive

Figure 4 shows the connector locations on the drive.

1 SCSI address connector 3 Power supply connector

2 SCSI bus connector

Figure 4. Connector Locations on the Drive

8 7206 Model 220 Service Guide

Page 23

System Requirement

|

|

|

|

|

|

|

|

|

|

Specifications

The 7206 Tape Drive attaches to selected RS/6000 systems that uses a Wide Fast-20

LVD SCSI or single-ended FW SCSI adapter interface which meets the Small

Computer System Interface-2 (SCSI-2) standard X3.131-1994 Rev 10L of the

American National Standards Institute (ANSI).

The 7206 Tape Drive must be attached to a supported RS/6000 processor and

adapter with an AIX operating system at level:

v 4.1.5 (when installed with authorized program analysis report (APAR) #IX69941)

v 4.2 (when installed with APAR #IX69950) or higher

v 4.3 or higher

Table 2. Specifications for the 7206 Model 220 4mm Tape Drive

Physical Specifications

Width 250 mm (9.8 in.)

Depth 275 mm (10.8 in.)

Height 55 mm (2.2 in.)

Weight 3.7 kg (8 lb)

Power Specifications

kVA (typical) .03 @120 V ac

V ac Input 100 to 125

200 to 240

V dc Output +5 and +12

Frequency 50 to 60 Hz

Heat Output 77 Btu/hr (23 watts) @ 240 V ac

Power Factor .4 to .6

Other Specifications

Altitude 2135 m (7000 ft)

Recommended Environment

Environmental Factor Operating Non-operating

Temperature

16 to 32°C

(60 to 90°F)

Relative Humidity

20 to 80% 20 to 90%

(noncondensing)

23°C

Maximum Wet Bulb

(73°F)

10 to 43°C

(50 to 110°F)

27°C

(80°F)

Chapter 1. Reference Information 9

Page 24

Cleaning the Tape Drive

Clean the 7206 Tape Drive whenever the Fault status light comes on or a system

I/O error related to that device occurs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Attention: Use only the recommended cleaning cartridge to clean the tape drive.

Use of other than recommended cleaning cartridges can damage your drive and

may void the warranty.

To clean the 7206 Tape Drive tape drive:

1. Make sure that the power is on to the 7206 Tape Drive. (The power-on light

should be on.)

2. If a tape cartridge is in the 7206 Tape Drive, eject and remove the cartridge.

Note: The IBM cleaning cartridge has 50 white dots on the window side that

are designed to be used to log the use of the cartridge. Each time the

cartridge is used, mark one of the dots on the cartridge with a pen or

marker. When all of the dots have been marked, discard the cleaning

cartridge.

3. Grasp the cleaning cartridge (1 in Figure 5) by the outer edges, with the

window side up and the write-protect switch 2 facing you.

4. Lift the door on the front of the 7206 Tape Drive and slide the cartridge into

the opening on the front of the 7206 Tape Drive until the loading mechanism

pulls the cartridge into the drive and the drive door closes.

Figure 5. Loading the Cleaning Cartridge

|

10 7206 Model 220 Service Guide

Page 25

After the cleaning cartridge has been inserted, the remainder of the cleaning

process is automatic. The 7206 Tape Drive:

1. Loads the cleaning cartridge into the tape drive

2. Cleans the drive by moving the cleaning tape forward for approximately 30

seconds

3. Unloads the cleaning cartridge when the cleaning operation is complete

4. Indicates a successful cleaning operation by turning off the Fault status light (if

the Fault light was on prior to the cleaning process; otherwise, the Fault light

remains solid to indicate that the cleaning cartridge is no longer usable)

If a system error occurs, clean the drive and retry the operation. If the operation

fails, replace the data cartridge, clean the drive again, then retry the operation.

To determine how many times a cleaning cartridge may be used, check the

information printed on the cartridge. If you attempt to use a depleted cleaning

cartridge, the 7206 Tape Drive automatically detects the error and ejects the

cartridge. If the Fault status light was on prior to the cleaning process, it stays on;

if the Fault light was off, the depleted cartridge causes the light to come on.

Chapter 1. Reference Information 11

Page 26

12 7206 Model 220 Service Guide

Page 27

Chapter 2. Using the Media

The 7206 Tape Drive uses 4mm data cartridges for saving and restoring system

data. It is designed to use only DDS (Digital Data Storage) data cartridges. The

cartridges are identified by one of the following DDS symbols:

|

|

|

|

|

|

|

The 7206 Tape Drive only reads and writes data to tape cartridges that are DDS-2,

3, or 4 format.

Note: The 7206 Model 220 Tape Drive only supports DDS-2, 3, and 4 tape

cartridges.

The 7206 Tape Drive has been designed to operate with DDS media that meet the

following standards of the European Computer Manufacturers Association

(ECMA):

v ECMA-198 DDS-2 format

v ECMA-236 DDS-3 format

v ECMA-288 DDS-4 format

Note: IBM only supports the use of IBM media.

Types of Tape Cartridges

The 7206 Tape Drive is shipped with the following media cartridges.

Data Cartridge Use the 4mm data cartridge to save or restore

Test Cartridge Use the specially labeled 4mm test cartridge to run

programs or data.

®

the AIX

running diagnostics, refer to your AIX manuals).

The test cartridge should not be used to save or

restore customer programs or data.

system diagnostics (for information about

Cleaning Cartridge Attention: Use of other than the IBM 4mm

To order additional cartridges, refer to “Appendix B. Ordering Tape Cartridges” on

page 45.

© Copyright IBM Corp. 2000 13

cleaning cartridge can damage your 7206 Tape

Drive and may void your warranty.

Use the specially labeled cleaning cartridge (part

number 21F8763) to clean the 7206 Tape Drive. For

instructions about how to clean the 7206 Tape

Drive, see “Cleaning the Tape Drive” on page 10).

Page 28

Recommendations for Data Cartridge Usage

The following list describes recommended guidelines that will help to protect your

data and prolong the life of your tape cartridges and the 7206 Tape Drive:

|

|

|

v Use only IBM 4mm DDS cartridges.

v Remove the tape cartridge from the drive when the drive is not in use.

v Back up and then discard any tape cartridge that repeatedly produces error

messages (the error information is in the System Error Log).

v On the data cartridge, do not open the door that covers the tape. The door

protects the tape from dirt, dust, and damage.

v Do not touch the tape. Any substance transferred to the tape by touching could

cause loss of data.

v Use only one label on a tape cartridge. Multiple or poorly placed labels can clog

the drive load mechanism.

v Do not use poor-quality tape cartridges. They can cause excessive read or write

errors, and may damage the tape drive.

v Discard any tape cartridges that are dropped, as the impact may damage the

tape’s internal mechanism.

v Make sure the environment is kept clean and constant. Do not operate in a

dusty environment and always maintain a constant environmental atmosphere.

A consistent storage and operating environment reduces media exposure to

climatic stress.

Attention: Use only the recommended cleaning cartridge to clean the tape drive.

Use of other than recommended cleaning cartridges can damage your drive and

may void the warranty.

v Printers and copiers can produce paper and toner dust. Locate the tape unit

away from these items. High traffic areas near hallways and doors can also

produce excess dust and dirt.

v All important information should be recorded on the tape label. Information,

such as the model and number of the system or tape drive, the date, the density,

any error statistics, and a log number should be included. The operating

environment and compression mode should also be noted.

Data Cartridge Erasure

|

|

|

Most bulk eraser devices do not have the capability to erase the 4mm data

cartridge. To properly erase a 4mm data cartridge with a bulk eraser device, the

erasure coercivity rating must be a minimum of 3900 Oersted.

Storage and Shipping Environments

Before using a tape cartridge, let it acclimate to the operating environment by

placing the cartridge in the operating environment for as long as it has been away

from the environment or for 24 hours, whichever is less. (To determine the

appropriate operating environment, see “Specifications” on page 9.)

Acclimation is necessary for any data cartridge exposed to a different humidity

environment or to temperature changes of 11°C (20°F) or more.

14 7206 Model 220 Service Guide

Page 29

Retrieval of archived data should be performed on a tape unit that is clean and

fully operational. Try to make the recovery environment the same as the operating

environment. Allow tapes at least 24 hours to acclimate to environment of the tape

unit.

The recommended environment for storage and shipment of 4mm data cartridges

is shown in Table 3.

Table 3. Recommended Environment for 4mm Data Cartridges

Environmental Factor Storage Shipping

Temperature

Relative Humidity

(noncondensing)

Maximum Wet Bulb

Tape Cartridge Storage

Tape drives record data using densities similar to hard disk drives. Because most

computer systems are not located in a dust-free, climate-controlled environment,

you must exercise special care when dealing with tape cartridges and tape drives.

They need to be treated as a valuable asset used to protect your business data.

5°Cto32°C

(41° to 90°F)

20 to 60% 5 to 80%

26°C

(79°F)

−40 to 52°C

(−40 to 125°F)

26°C

(79°F)

Use the following guidelines for storing your tape cartridges:

v Temperature and humidity should be kept constant at a level comfortable for

you.

v Tape cartridges should always be stored in their protective cases. The storage

case helps prevent damage from dust and physical misuse. When the tape

cartridges are not in use or being stored, they should be in their storage cases

and stood on edge in a designated storage location. Do not stack cartridges on

the flat side or stack other items on top of the tape cartridges. Handle your tape

cartridges with care to reduce archival problems.

v Stored tapes should be exercised at least once every 12 months. Run the tape

from Beginning of Data (BOD) to End of Data (EOD) and back to BOD at

normal operating speeds. Tapes stored in a warmer environment should be

exercised more frequently.

v Sunlight can damage the tape and the cartridge shell. Store tape cartridges out

of the direct sunlight

Attention: Operation outside of the environment can result in possible loss of

data or failure of the autoloader.

Chapter 2. Media 15

Page 30

Operating in Harsh Environments

Do not use as an archival tape any tape that has been used outside of the

operating ranges specified in Table 2 on page 9 for an extended period of time. The

magnetic and physical strength of the tape will have deteriorated as a result of its

exposure to the environment. Do not store important data on such a tape; transfer

the data to a newer tape for reliable archiving.

Attention: Do not operate the 7206 Tape Drive in a poor air-quality environment.

If your environment contains an excessive amount of particulates, contact your

service representative for more information.

Setting the Write-Protect Switch

The position of the write-protect switch on the 4mm tape cartridge determines

when you can write to the tape (see Figure 6).

v When the switch is set to the right 1, data can be written to and read from the

tape.

v When the switch is set to the left 2, data can only be read.

Figure 6. Setting the Write-Protect Switch

16 7206 Model 220 Service Guide

Page 31

Chapter 3. Maintenance Analysis Procedures

Purpose of the MAPs

Maintenance analysis procedures (MAPs) are used to check the:

Power cable SCSI address Drive

Power supply SCSI bus (signal) cable Fan

Terminator Configuration Drive head

If a problem is detected, the procedure isolates the problem to the failing field

replaceable unit (FRU), such as the 7206 Tape Drive drive, power supply, or

cooling fan. For instructions about removing or replacing a FRU, refer to

“Chapter 4. Removal and Replacement Procedures” on page 27.

Figure 7 on page 18 provides a flowchart to be used as a guide to the MAPs. For

detailed instructions on how to perform each procedure safely and correctly, refer

to the steps in this chapter.

© Copyright IBM Corp. 2000 17

Page 32

Flowchart of the MAPs

Figure 7. Flowchart of Maintenance Analysis Procedures (MAPs)

18 7206 Model 220 Service Guide

Page 33

Step 1: Power and Fan

This step verifies whether the power and the fan operate properly.

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

1. Make sure that the 7206 Tape Drive power cable is plugged into an electrical

outlet.

2. Make sure that the 7206 Tape Drive power is on by checking that:

v The power-on light is on.

v There is airflow from the fan at the rear of the unit.

Is the power-on light on and is there airflow from the fan?

NO While watching for the power-on light to come on, press the power switch

again. Repeat this procedure several times. If the power-on light fails to

come on or there is no airflow from the fan, go to Step 2: Electrical Outlet

Voltage.

YES Go to Step 7: SCSI Address Switch.

Step 2: Electrical Outlet Voltage

This step tests the voltage at the electrical outlet.

1. Do a controlled system shutdown (refer to the instructions in Chapter 2,

“Setting Up the 7206 Tape Drive,” in the 7206 Model 220 4mm Tape Drive Setup

and Operator Guide).

2. Ensure that the power to the system unit is off.

3. Press the 7206 Tape Drive power switch to turn off the power.

4. Unplug the 7206 Tape Drive power cable from the electrical outlet and from the

7206 Tape Drive.

DANGER

Dangerous voltage being measured. (RSFTD005)

5. Check the electrical outlets for proper voltage.

Is the voltage from the electrical outlet correct?

NO Contact your service personnel for further instructions.

YES Go to Step 3: Power Cable.

Chapter 3. Maintenance Analysis Procedures 19

Page 34

Step 3: Power Cable

This step determines whether the power cable is functional.

Make sure that all of the conductors in the power cable have continuity, and that

there are no short circuits.

Does the power cable have continuity and are there no short circuits?

NO Replace the power cable.

YES Go to Step 4: Power Supply, Fan, and Tape Drive.

Step 4: Power Supply, Fan, and Tape Drive

This step prepares the 7206 Tape Drive to determine whether the power supply,

fan, or tape drive is the cause of the problem.

1. Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

2. Plug the 7206 Tape Drive power cable into the 7206 Tape Drive and into the

electrical outlet.

3. Press the power switch to turn off the power.

DANGER

Up to 240 V ac is present at the power module connectors when the main

power cord is connected to a power source. (RSFTD010)

|

|

4. Disconnect the power supply connector (J1) from the drive (refer to Figure 3 on

page 7).

5. Disconnect the power supply connector (J2) between the power supply and the

cooling fan.

6. Press the power switch to turn on the power.

Does the power-on light come on and stay on?

NO Replace the power supply. Refer to “Removing and Replacing the Power

Supply” on page 32.

DANGER

Do not attempt to open the covers of the power supply. Power supplies are

not serviceable and are to be replaced as a unit. (RSFTD217)

YES Go to Step 5: Cooling Fan.

20 7206 Model 220 Service Guide

Page 35

Step 5: Cooling Fan

This step examines the cooling fan as the possible source of the problem.

1. Press the power switch to turn off the power.

DANGER

Up to 240 V ac is present at the power module connectors when the main

power cord is connected to a power source. (RSFTD010)

|

|

|

|

|

Step 6: Tape Drive

|

|

2. Reconnect the power supply connector (J2) to the cooling fan (refer to Figure 3

on page 7).

3. Press the power switch to turn on the power.

Does the power-on light come on and stay on, and is there airflow from the fan?

NO Power off the 7206 Tape Drive and then replace the cooling fan. Verify that

the power-on light comes on when power is restored to the device. Refer

to “Removing and Replacing the Cooling Fan” on page 34.

YES Go to Step 6: Tape Drive.

This step examines the drive as the possible source of the problem.

1. Press the power switch to turn off the power.

DANGER

Up to 240 V ac is present at the power module connectors when the main

power cord is connected to a power source. (RSFTD010)

2. Reconnect the power supply connector (J1) to the drive (refer to Figure 3 on

page 7).

3. Press the power switch to turn on the power.

Does the power-on light come on and stay on, and is there airflow from the fan?

|

|

|

|

|

NO Power off the 7206 Tape Drive and then replace the drive. Refer to

“Removing and Replacing the Drive” on page 30.

Note: If the media is still in the drive being replaced, it can be removed

manually. See “Manually Removing a Tape Cartridge” on page 35.

YES Go to Step 9: Tape Drive Status Lights.

Chapter 3. Maintenance Analysis Procedures 21

Page 36

Step 7: SCSI Address Switch

This step checks that the SCSI address switch setting is correct.

Is the SCSI address set correctly?

NO Set the SCSI address switch to the proper address, then go to Step 12:

External SCSI Cable Connection. To set the SCSI address switch, refer to

the instructions in Chapter 2, “Setting Up the 7206 Tape Drive,” in the 7206

|

Model 220 4mm Tape Drive Setup and Operator Guide.

|

|

|

YES Go to Step 8: SCSI Address Cable.

Note: You should turn the power to the 7206 Tape Drive off and then back

Step 8: SCSI Address Cable

This step checks whether the SCSI address switch is plugged into the drive.

1. Do a controlled system shutdown (refer to the instructions in Chapter 2,

“Setting Up the 7206 Tape Drive,” in the 7206 Model 220 4mm Tape Drive Setup

and Operator Guide).

2. Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

DANGER

To prevent a possible electrical shock from touching two surfaces with

different electrical grounds, use one hand, when possible, to connect or

disconnect signal cables. (RSFTD004)

Is the SCSI address switch plugged securely into the drive?

NO Ensure that the SCSI address switch is plugged securely into the drive,

then go to Step 11: Reassembly.

YES Go to Step 9: Tape Drive Status Lights.

on again to ensure the SCSI address setting is recognized.

Step 9: Tape Drive Status Lights

This step examines the drive as the possible source of the problem.

While pressing the power switch to turn on the power, watch to see if the three

status lights come on for approximately 10 seconds, then go out.

Did the three status lights come on for approximately 10 seconds, then go out?

NO Go to Step 10: Power Supply Voltage Level.

YES Go to Step 11: Reassembly.

22 7206 Model 220 Service Guide

Page 37

Step 10: Power Supply Voltage Level

This step checks the power supply voltage levels as the possible source of the

problem.

1. Press the power switch to turn off the power.

2. Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

3. Disconnect the power supply connector (J1) from the drive.

4. Disconnect the power supply connector (J2) between the power supply and the

cooling fan.

5. Connect the power cable to both the 7206 Tape Drive and the electrical outlet.

6. Press the power switch to turn on the power.

DANGER

Dangerous voltage being measured. (RSFTD005)

7. On the power supply connector J1 (see Figure 8), check the following:

v The +12V signal falls between a minimum of +11.5 volts and a maximum of

+12.6 volts

v The +5V signal falls between a minimum of +4.8 volts and a maximum of

+5.25 volts

Figure 8. Power Supply Connector J1

8. On the power supply connector J2 (see Figure 9), check that the +12V signal

falls between a minimum of +11.5 volts and a maximum of +12.6 volts.

Figure 9. Power Supply Connector J2

Are the voltages good?

NO Replace the power supply. Refer to “Removing and Replacing the Power

Supply” on page 32.

YES Replace the drive. See “Removing and Replacing the Drive” on page 30.

Note: If the media is still in the drive being replaced, it can be removed

manually. See “Manually Removing a Tape Cartridge” on page 35.

Chapter 3. Maintenance Analysis Procedures 23

Page 38

Step 11: Reassembly

This step describes the reassembly process.

1. Press the power switch to turn off the power.

2. Unplug the power cable from the electrical outlet.

3. Make sure that the power supply connector (J1) is plugged into the drive.

4. Make sure that the power supply connector (J2) is plugged into the cooling fan.

5. Make sure that all other cables are properly connected, and that the wires are

routed away from the cooling fan.

6. Perform the cover replacement procedure. Refer to “Removing and Replacing

the Cover” on page 28.

7. Plug the power cable into the electrical outlet.

8. Press the power switch to turn on the power.

Does the power-on light come and stay on, and is there airflow from the fan?

NO Verify that the 7206 Tape Drive was reassembled correctly. If the power-on

light still does not come on and there is no airflow from the fan, go to Step

1: Power and Fan.

YES Go to Step 12: External SCSI Cable Connection.

Step 12: External SCSI Cable Connection

This step ensures that the external SCSI bus cable connection is proper.

DANGER

To prevent a possible electrical shock when installing the device, ensure that

the power cord for that device is unplugged before installing signal cables.

(RSFTD204)

Ensure that the SCSI bus cable is properly connected to both the system unit and

to the 7206 Tape Drive.

Is the SCSI bus cable properly connected to the system unit and to the 7206

Tape Drive?

NO Plug the SCSI bus cable into the system unit and into the 7206 Tape Drive,

then go to Step 13: Terminator Connection.

YES Go to Step 13: Terminator Connection.

24 7206 Model 220 Service Guide

Page 39

Step 13: Terminator Connection

This step ensures that the terminator connection is proper.

DANGER

To prevent a possible electrical shock when installing the device, ensure that

the power cord for that device is unplugged before installing signal cables.

(RSFTD204)

Ensure that the terminator is properly connected to the last device on the SCSI bus.

Is the terminator properly connected to the last device on the SCSI bus?

NO Ensure that the terminator is properly connected to the last device on the

SCSI bus, then go to Step 14: Configuration.

YES Go to Step 14: Configuration.

Step 14: Configuration

This step verifies that the 7206 Tape Drive has been properly configured to the

RS/6000.

1. Clean the drive. See “Cleaning the Tape Drive” on page 10.

2. At the system prompt, type cfgmgr to configure the 7206 Tape Drive and make

it Available.

To ensure that 7206 Tape Drive has been correctly configured to the RS/6000, refer

to Chapter 2, “Setting Up the 7206 Tape Drive,” in the 7206 Model 220 4mm Tape

Drive Setup and Operator Guide.

Is the 7206 Tape Drive properly configured to the RS/6000?

NO Go to Step 15: AIX Diagnostics.

YES Go to Step 15: AIX Diagnostics.

Chapter 3. Maintenance Analysis Procedures 25

Page 40

Step 15: AIX Diagnostics

This step runs the AIX diagnostics to determine the problem.

|

|

|

|

|

|

|

|

|

Run the diagnostics on the 7206 Tape Drive. Have the test cartridge (part number

59H4457) available for when the diagnostics prompt you to load the cartridge.

From the AIX command prompt, type:

diag

and then press Enter. For additional instructions on running diagnostics, refer to

your AIX manuals.

Do all of the diagnostics routines pass?

NO Replace the FRU isolated by the diagnostics and identified by the service

request number.

Note: If the drive is the FRU isolated by the diagnostics, check that the J1

connector is properly seated. If the drive has recently been replaced

because of a similar problem, contact your service personnel.

YES If no problem was identified, the problem may be intermitant, related to

the tape quality, or relating to the environment. If a FRU was replaced or

changed and no more errors occur, the problem is fixed.

This completes the MAPs.

26 7206 Model 220 Service Guide

Page 41

Chapter 4. Removal and Replacement Procedures

This chapter describes the procedures to follow when removing and replacing the

field replaceable units (FRUs), such as the drive, power supply, and cooling fan for

the 7206 Model 220 Tape Drive. It also describes how to manually remove a tape

cartridge from the 7206 Tape Drive.

Before installing any FRU, let it acclimate to the operating environment for as long

as it has been away from the environment or for 24 hours, whichever is less.

Handling Static-Sensitive Devices

Attention: Tape drives are sensitive to static electricity discharge. To prevent

damage, when handling a tape drive wrap it in an antistatic bag.

Take the following precautions:

v Do not remove the drive from its antistatic bag until you are ready to install it.

v With the drive still in its antistatic bag, touch it to the metal frame of an

electrically grounded surface.

v Hold the drive by the frame. Avoid touching the solder joints or pins.

v Handle the drive carefully to prevent permanent damage.

© Copyright IBM Corp. 2000 27

Page 42

Removing and Replacing the Cover

To remove the cover from the 7206 Tape Drive:

1. If a tape cartridge is in the drive, eject it.

2. Do a controlled system shutdown (refer to the instructions in Chapter 2,

“Setting Up the 7206 Tape Drive,” in the 7206 Model 220 4mm Tape Drive Setup

and Operator Guide).

3. If it is on, turn off the power to the 7206 Tape Drive.

DANGER

To prevent a possible electrical shock when installing the device, ensure that

the power cord for that device is unplugged before installing signal cables.

(RSFTD204)

4. Unplug the 7206 Tape Drive power cable from the electrical outlet.

5. Disconnect the power cable from the 7206 Tape Drive.

6. Disconnect the SCSI bus cable from the 7206 Tape Drive.

7. Tilt the 7206 Tape Drive on its side and remove the four cover mounting screws

from the bottom. See Figure 10 on page 29.

8. Remove the cover by sliding it to the rear (see the directional arrow in

Figure 10 on page 29).

28 7206 Model 220 Service Guide

Page 43

To replace the cover, reverse the removal procedure.

Figure 10. Removing and Replacing the Cover. The 7206 Tape Drive is shown tilted on its

side.

Chapter 4. Removal and Replacement 29

Page 44

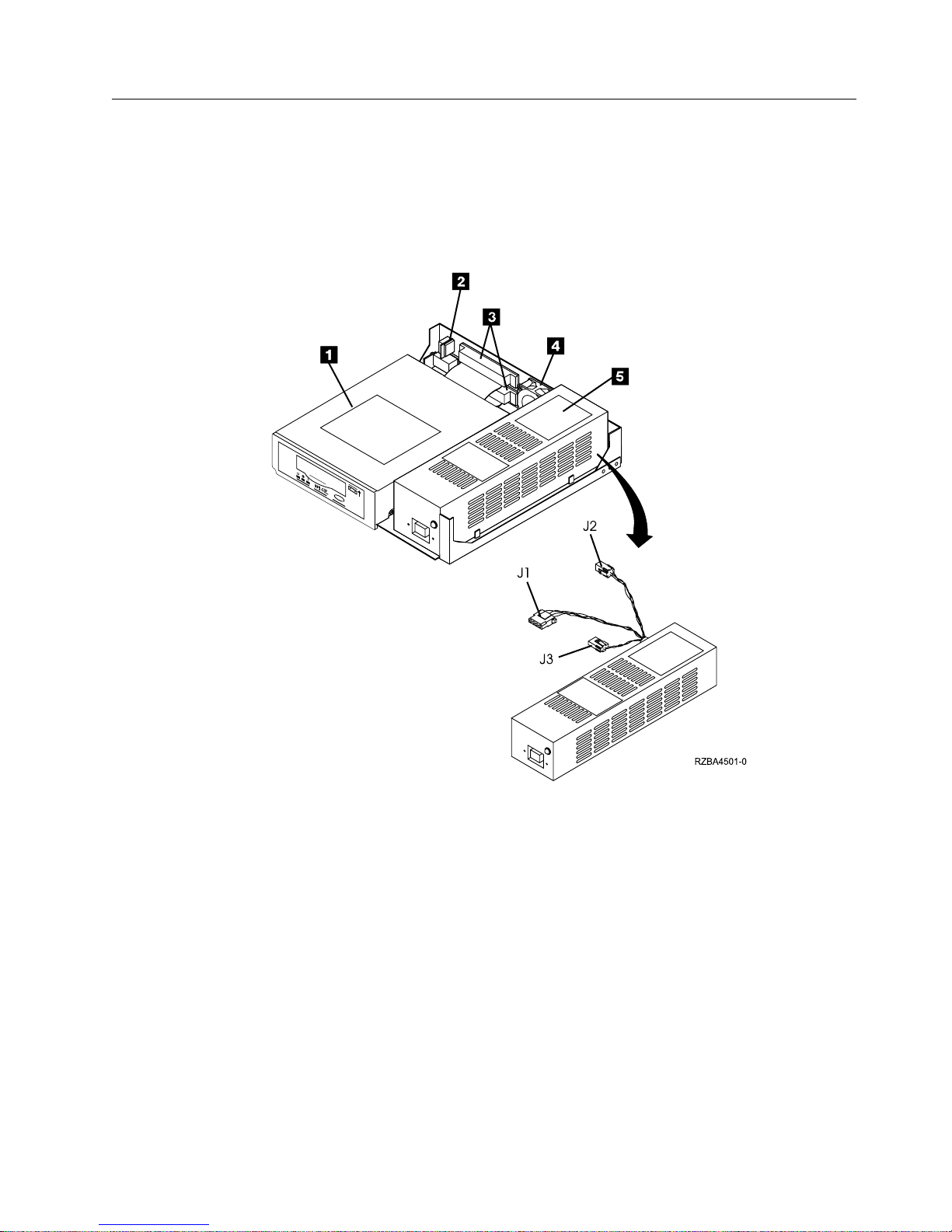

Removing and Replacing the Drive

To remove the drive from the 7206 Tape Drive:

1. Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

2. Disconnect the power supply connector (J1) (1 in Figure 11) from the drive.

3. Disconnect the SCSI bus cable 2 from the drive.

4. Disconnect the SCSI address cable 3 from the drive.

5. Tilt the 7206 Tape Drive on its side (see Figure 11). Support the drive 4 while

removing the four screws 5 that secure the drive to the chassis.

6. Support the drive while returning the 7206 Tape Drive to its original position.

7. Slide the drive out the front of the chassis.

Figure 11. Removing and Replacing the Drive

30 7206 Model 220 Service Guide

Page 45

To replace the drive, reverse the removal procedure. Make sure to

v Correctly insert and engage each cable to its proper connector.

v Arrange the cables so that they do not interfere with the cooling fan blades or

the replacement of the cover.

Note: The power supply connector J3 is not used in the 7206 Tape Drive.

Chapter 4. Removal and Replacement 31

Page 46

Removing and Replacing the Power Supply

DANGER

Do not attempt to open the covers of the power supply. Power supplies are

not serviceable and are to be replaced as a unit. (RSFTD217)

To remove the power supply from the 7206 Tape Drive:

1. Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

2. Tilt the 7206 Tape Drive on its side. Support the power supply (1 in

Figure 12) while removing the power supply mounting screw 2 from the

bottom.

3. Support the power supply while returning the 7206 Tape Drive to its original

position.

4. Disconnect the power supply connector (J1) (3 from the drive.

5. Disconnect the power supply connector (J2) 4 between the power supply and

the cooling fan.

6. Grasp the rear of the power supply and while pressing it toward the front

panel, lift the rear of the power supply from the chassis.

7. Push the power switch push button 5 out of the front panel and set it aside.

Figure 12. Removing and Replacing the Power Supply

32 7206 Model 220 Service Guide

Page 47

To replace the power supply, reverse the removal procedure. Make sure to:

v Align the power supply inside the two tabs (6 in Figure 12 on page 32) on the

base of the chassis.

v With its locking features in a horizontal position, insert the power switch push

button 5 into the front panel and press until it locks in place.

Note: If the power switch does not work properly, loosen the power supply

mounting screw, slide the power supply to the rear of the chassis, and

retighten the mounting screw.

v Arrange the cables so that they do not interfere with the cooling fan blades or

the replacement of the cover. Ensure that they do not obstruct airflow through

the fan.

|

|

|

Note: The power supply connector J3 is not used in the 7206 Tape Drive. Make

sure that the J3 connector is placed in a position so it will not interfere with

the operation of the drive or the fan.

|

Chapter 4. Removal and Replacement 33

Page 48

Removing and Replacing the Cooling Fan

To remove the cooling fan:

1. Perform the cover removal procedure. Refer to “Removing and Replacing the

Cover” on page 28.

2. Disconnect the power supply connector (J2) (1 in Figure 13) between the

power supply and the cooling fan.

3. Remove the two screws, lockwashers, and nuts 2 that secure the cooling fan

to the rear of the 7206 Tape Drive.

4. Lift the cooling fan out of the 7206 Tape Drive.

To replace the cooling fan, reverse the removal procedure. Make sure that the

cooling fan is oriented so that air blows out of the 7206 Tape Drive.

Figure 13. Removing and Replacing the Cooling Fan

34 7206 Model 220 Service Guide

Page 49

Manually Removing a Tape Cartridge

Attention: The procedure for manually removing a tape cartridge could damage

your tape cartridge, the 7206 Tape Drive, or both. Use this procedure only after

you have:

1. Turned the power to the 7206 Tape Drive off and on again to clear potential

hang conditions.

2. If available, issued the Unload SCSI command from your system command

menu.

3. Disconnected the 7206 Tape Drive from the system, and turned the power to

the 7206 Tape Drive on and off again several times.

|

|

|

4. Attempted an emergency eject of the cartridge by pressing and holding the

unload button for at least five seconds (see “Emergency Eject Feature” on

page 3).

|

|

The following procedure describes how to manually remove a data cartridge from

the 7206 Tape Drive. If this procedure is performed, replace the drive.

1. Remove the drive from the 7206 Tape Drive (see “Removing and Replacing the

Drive” on page 30).

2. Remove the mounting rails by removing the four screws (1 in Figure 14) near

the lower edge of the drive (two on each side). Access the screws through holes

in the side of each rail.

3. Remove the front bezel (the bezel snaps on) by doing the following:

a. Use a small screwdriver to depress one of the bezel tabs 2.

b. Pull the bezel down from the top.

c. Lift the bezel off the bottom locating tabs.

d. Remove the bezel from the unit.

Figure 14. Removing the Mounting Rails from the Drive

Chapter 4. Removal and Replacement 35

Page 50

4. Remove the top lid of the drive mechanism (4 screws).

5. Insert a 1.5 mm hexagonal key or a small Phillips screwdriver into the aperture

on the right side of the drive looking from rear. This gives you access to the

motor worm wheel, as shown in Figure 15. Turn the hexagonal key or small

screwdriver counter-clockwise to release the cartridge.

Note: This may take more than 1000 turns

Figure 15. Turning the Motor Worm Wheel to Release the Cartridge

6. Reassemble the drive in reverse order.

36 7206 Model 220 Service Guide

Page 51

Chapter 5. Parts Diagram and Parts List

How To Use This Parts List

AR (As Required) in the Units column indicates that the quantity is not

the same for all machines.

NP (Non-Procurable) in the Part Number column indicates that the part

is non-procurable and that the individual parts or the next higher

assembly should be ordered.

NR (Not Recommended) in the Units column indicates that the part is

procurable but not recommended for field replacement, and that

the next higher assembly should be ordered.

00 (Not Shown) in the Asm- Index column indicates that the part is

either not shown or not referenced in the illustration.

R (Restricted) in the Units column indicates that the part has a

restricted availability.

Indenture The indenture is marked by a series of dots located before the

parts description. The indenture indicates the relationship of a part

to the next higher assembly. For example:

Indenture Relationship of Parts

(No dot) MAIN ASSEMBLY

(One dot) v Detail parts of a main assembly

(One dot) v Sub assembly of the main assembly

(Two dots) vvDetail part of a one-dot sub assembly

(Two dots) vvSub assembly of a one-dot sub assembly

(Three dots) vvvDetail part of a two-dot sub assembly

Example of Parts Listing

AsmIndex

3- 2512667

-1 5373637 1 vSeal, Top

-2 5356429 2 vClip, Retaining

-3 1847630 1 vFinger Stock Asm

-4 1847602 NR vvChannel, Finger Stock

-5 5373639 AR vSeal, Bottom

-6 5356429 2 vClip, Retaining

-7 NP 1 vCover, Rear, Without Paint

-5 0416629 R vScrew, Panel

Part Number Units Description

2513714

1

1

Cover Asm, Rear, Red

Cover Asm, Rear, White

For Next Higher Asm, see Assembly 1-2.

© Copyright IBM Corp. 2000 37

Page 52

Assembly 1: Parts Diagram

38 7206 Model 220 Service Guide

Page 53

Assembly 1: (continued)

Asm–

Index

1–1 59H3760 1 Power supply

–2 46G2677 3 Screw, power supply, M3 x 6mm

–3 42F7300 1 Cooling fan

–4 46G2676 2 Screw, cooling fan

–5 1622401 2 Nut, cooling fan

–6 1622344 2 Washer, cooling fan, optional P/N 0338169

–7 59H2694 1 Cable, SCSI address

–8 59H2689 1 Chassis

–9 46G2677 2 Screw, cover, M3 x 6mm

–10 35L1162 1 Cable, 68–pin SCSI internal

–11 0251970 4 Screw, SCSI connectors

–12 46G2677 4 Screw, drive, M3 x 6mm

–13 34L3614 1 Tape drive, 4mm

–14 59H3847 1 Cover, includes feet

–15 74G8497 1 Push button, power supply

–00 52G4291 1 Device-to-device SCSI cable, .7 meter (2 ft) 68P to 68P

–00 06H6036 1 System-to-device SCSI cable, 1 meter (3 ft) 68P to 68P

–00 52G9501 1 System-to-device SCSI cable, 1.5 meter (5 ft) CC68 to 68P

–00 52G4337 1 System-to-device SCSI cable, 1.5 meter (5 ft)

–00 76H0518 1 Interposer, .3 meter (1 ft) VHDCI 68 to 68s

–00 52G9907 1 Terminator, SE 68 pin

–00 35L0145 1 Terminator, LVD/SE 68 pin

–00 59H4458 1 Data cartridge

–00 59H4457 1 Test cartridge

–00 21F8763 1 Cleaning cartridge

Part

Number Units Description

Chapter 5. Parts Diagram and List 39

Page 54

40 7206 Model 220 Service Guide

Page 55

Appendix A. Power Cables

To avoid electrical shock, a power cable with a grounded attachment plug has been

provided. Use only properly grounded outlets.

Power cables used in the United States and Canada are listed by Underwriter’s Laboratories

™

) and certified by the Canadian Standards Association (CSA™). The power cables

(UL

consist of:

v Electrical cables, type SVT or SJT.

v Attachment plugs complying with National Electrical Manufacturers Association (NEMA)

5-15P, that is:

“For 115 V operation use a UL Listed Cable Set consisting of a minimum 18 AWG, Type

SVT or SJT three conductor cable a maximum of 15 feet in length and a parallel blade,

grounding type attachment plug rated at 15 A, 125 V.”

“For 230 V operation in the United States use a UL Listed Cable Set consisting of a

minimum 18 AWG, Type SVT or SJT three conductor cable a maximum of 15 feet in

length, and a tandem blade, grounding type attachment plug rated at 15 A, 250 V.”

v Appliance couplers complying with International Electrotechnical Commission (IEC)

Standard 320, Sheet C13.

Power cables used in other countries consist of:

v Electrical cables, type HD21.

v Attachment plugs approved by the appropriate testing organization for the specific

countries where they are used.

“For units set at 230 V (outside of U. S.): Use a Cable Set consisting of a minimum 18

AWG cable and grounding type attachment plug rated 15 A, 250 V. The Cable Set should

have the appropriate safety approvals for the country in which the equipment is to be

installed and marked 'HAR'.”

Table 4 on page 42 lists the power cable part number, the country where the power cable can

be used, and an index number to be matched with the receptacles shown in Figure 16 on

page 43. If your power cable does not match this information, contact your local dealer.

© Copyright IBM Corp. 2000 41

Page 56

Table 4. Power Cable Information

Part Number Country Index

1838574 Japan Bahamas, Barbados, Bolivia, Brazil, Canada, Costa

Rica, Dominican Republic, Ecuador, El Salvador,

Guatemala, Guyana, Haiti, Honduras, Jamaica,

Japan, Netherlands Antilles, Panama, Peru,

Philippines, Taiwan, Thailand, Tobago, Trinidad,

U.S.A. (except Chicago), Venezuela

6952300 US/Canada Bahamas, Barbados, Bermuda, Bolivia, Brazil,

Canada, Cayman Islands, Colombia, Costa Rica,

Dominican Republic, Ecuador, El Salvador,

Guatemala, Guyana, Haiti, Honduras, Jamaica,

Japan, Korea (South), Mexico, Netherlands

Antilles, Nicaragua, Panama, Peru, Philippines,

Puerto Rico, Saudi Arabia, Suriname, Taiwan,

Trinidad, U.S.A. (except Chicago), Venezuela

6952301 6 ft Chicago Chicago, U.S.A. 2

13F9940 Australia Argentina, Australia, New Zealand, Uruguay 3

13F9979 France Abu Dhabi, Austria, Belgium, Bulgaria, Botswana,

Egypt, Finland, France, Germany, Greece, Iceland,

Indonesia, Korea (South), Lebanon, Luxembourg,

Macau, Netherlands, Norway, Portugal, Saudi

Arabia, Spain, Sudan, Sweden, Turkey, Yugoslavia

13F9997 Denmark Denmark 5

14F0015 South Africa Bangladesh, Burma, Pakistan, South Africa, Sri

Lanka

14F0033 United

Kingdom

14F0051 Switzerland Liechtenstein, Switzerland 8

14F0069 Italy Chile, Ethiopia, Italy 9

14F0087 Israel Israel 10

6952291 Colombia Colombia, Paraguay 11

Bahrain, Bermuda, Brunei, Channel Islands,

Cyprus, Ghana, Hong Kong, India, Iraq, Ireland,

Jordan, Kenya, Kuwait, Malawi, Malaysia,

Nigeria, Oman, People’s Republic of China, Qatar,

Sierra Leone, Singapore, Tanzania, Uganda,

United Arab Emirates (Dubai), United Kingdom,

Zambia

1

2

4

6

7

42 7206 Model 220 Service Guide

Page 57

123

56 7 8

910 11

4

Figure 16. Types of Receptacles

Appendix A. Power Cables 43

Page 58

44 7206 Model 220 Service Guide

Page 59

Appendix B. Ordering Tape Cartridges

All tape cartridges are not alike. The tape composition and length, and the

construction of the cartridge itself can all affect the quality and capacity of the

recording and the performance of your tape drive. A poor quality tape cartridge

may appear to work adequately in your system, yet it can leave contamination in

the tape path or impede the speed of the recording.

The length and composition of the tape, and the size, shape, and construction of

the cartridge shell must all be considered when selecting the tape cartridge to be

used with your system. We recommend using only data and cleaning cartridges

supplied by IBM. Data grade tape media is the only type of tape media that

should be used for backup and data processing. Saving money by using generic

media for data purposes will do little to save your business if your data is

destroyed and your backup tapes fail because of inferior media.

Table 5 lists the tape cartridges that you can order for the 7206 Model 220 4mm

Tape Drive. To order cartridges in the United States and Canada, call

1-888-IBM-MEDIA. To order cartridges in other locations, contact your local

|

provider of IBM storage products.

|

|

|||

|||

|

|||

Table 5. Tape Cartridges for the 7206 Model 220 4mm Tape Drive

IBM Part Number Type of Cartridge Length

59H4458

4mm Data Cartridge

21F8763 4mm Cleaning Cartridge --

150 m

(492 ft)

|

© Copyright IBM Corp. 2000 45

Page 60

46 7206 Model 220 Service Guide

Page 61

|

Appendix C. Safety Inspection Procedures

Use the following procedures to identify unsafe conditions. Be cautious of potential

safety hazards not covered by the procedures. If unsafe conditions are present,

determine how serious the hazards are and whether you should continue before

correcting the problem.

Figure 17 shows the components to review during the service inspection.

Figure 17. Safety Inspection

Perform the following safety checks.

1. Do a controlled system shutdown (refer to the instructions in Chapter 2,

“Setting Up the 7206 Tape Drive,” in the 7206 Model 220 4mm Tape Drive Setup

and Operator Guide).

2. Turn off the power to all external devices connected to the system unit.

3. Turn off the power to the 7206 Tape Drive (1 in Figure 17).

4. Turn off the power to the system unit 2.

© Copyright IBM Corp. 2000 47

Page 62

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

5. Unplug the 7206 Tape Drive external power cable from the electrical outlet.

6. Unplug the system unit power cable from the electrical outlet.

7. Check the 7206 Tape Drive external power cable for damage.

DANGER

To prevent a possible electrical shock when adding or removing any devices

to or from the system, ensure that the power cords for those devices are

unplugged before the signal cables are connected or disconnected. If possible,

disconnect all power cords from the existing system before you add or

remove a device. (RSFTD203)

DANGER

To prevent a possible electrical shock from touching two surfaces with

different electrical grounds, use one hand, when possible, to connect or

disconnect signal cables. (RSFTD004)

8. Check the external SCSI bus (signal) cable 3 for damage.

9. Check the SCSI bus terminator for damage.

10. Check the covers for sharp edges, damage, or alterations that expose the

internal parts of the 7206 Tape Drive.

11. Check the covers for proper fit. They should be in place and secure.

12. Check the product label on the bottom of the 7206 Tape Drive to make sure it

matches the voltage at your outlet.

DANGER

Dangerous voltage being measured. (RSFTD005)

13. Check the voltage level at the outlet and also check for proper grounding (see

Figure 18 on page 49).

48 7206 Model 220 Service Guide

Page 63

Figure 18. AC Grounding Diagram (50 Hz and 60 Hz)

14. With the external power cable (1 in Figure 19) connected to the 7206 Tape

Drive, check to ensure 1.0 ohm or less resistance between the ground lug on

the external power cable plug and the metal frame.

Figure 19. Safety Inspection - Rear View of the 7206 Model 220 4mm Tape Drive

Note: Use an analog meter to measure grounding resistance; do not use a

digital multimeter.

Appendix C. Safety Inspection Procedures 49

Page 64

15. If the 7206 Tape Drive passes the test in the previous steps, plug its external

power cable into the electrical outlet. If the 7206 Tape Drive does not pass the

test, see “Chapter 3. Maintenance Analysis Procedures” on page 17 for more

information. If problems persist, contact your service representative.

Note: Safety Information Label, Part Number 85F7884, located on top of the power

supply under the top cover, shows the following symbol:

38M0010

This symbol indicates a hazard arising from dangerous voltage inside. Do not

open.

50 7206 Model 220 Service Guide

Page 65

Readers’ Comments — We’d Like to Hear from You

7206 Model 220 External 4mm Tape Drive

7206 Model 220

4mm Tape Drive

Service Guide

Publication No. SY32-0409-01

Overall, how satisfied are you with the information in this book?

Very Satisfied Satisfied Neutral Dissatisfied Very

Dissatisfied

Overall satisfaction hhhhh

How satisfied are you that the information in this book is:

Very Satisfied Satisfied Neutral Dissatisfied Very

Dissatisfied

Accurate hhhhh

Complete hhhhh

Easy to find hhhhh

Easy to understand hhhhh

Well organized hhhhh

Applicable to your tasks hhhhh

Please tell us how we can improve this book:

Thank you for your responses. May we contact you? h Yes h No

When you send comments to IBM, you grant IBM a nonexclusive right to use or distribute your comments in any

way it believes appropriate without incurring any obligation to you.

Name Address

Company or Organization

Phone No.

Page 66

___________________________________________________________________________________________________

Readers’ Comments — We’d Like to Hear from You

SY32-0409-01

_________________________________________________________________________________________

Fold and Tape Please do not staple Fold and Tape

NO POSTAGE

NECESSARY