Page 1

7013 J Series

Operator Guide

SA23-2724-02

Page 2

Third Edition (April 1997)

This edition notice applies to the

7013 J Series Operator Guide.

This edition obsoletes all previous editions

.

The following paragraph does not apply to the United Kingdom or any country where such

provisions are inconsistent with local law: THIS PUBLICATION IS PRINTED “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some

states do not allow disclaimer of express or implied warranties in certain transactions; therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made

to the information herein; these changes will be incorporated in new editions of the publication. The

manufacturer may make improvements and/or changes in the product(s) and/or program(s) described in this

publication at any time, without notice.

It is possible that this publication may contain reference to, or information about, products (machines and

programs), programming, or services that are not announced in your country. Such references or information

must not be construed to mean that such products, programming, or services will be offered in your country.

Any reference to a licensed program in this publication is not intended to state or imply that you can use only

the licensed program indicated. You can use any functionally equivalent program instead.

AIX is a registered trademark of International Business Machines.

Medeco is a trademark of Medeco Company.

Micro Channel is a trademark of International Business Machines.

SystemGuard is a trademark of International Business Machines.

Velcro is a trademark of Velcro Industries.

Copyright International Business Machines Corporation, 1994, 1997. All rights reserved.

Note to U.S. Government Users – Documentation and programs related to restricted rights – Use,

duplication, or disclosure is subject to the restrictions set forth in the GSA ADP Schedule Contract.

Page 3

Preface iii

Table of Contents

Communications Statements ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notices xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Book xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1. Description of the 7013 J Series System 1-1. . . . . . . . . . . . . . . . . . . . . . .

Description of the Base Unit 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit Without Covers 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Controls 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Devices 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of the Expansion Unit 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Unit 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Power Switch Module 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Unit Main Switch 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Codes 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Code Format for SCSI Devices 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Code Format for Non-SCSI Devices 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Code Format for 7135, 9333, and 9334 Expansion Units 1-10. . . . . . . . . . .

Location Code Table for SCSI and Non-SCSI Devices 1-11. . . . . . . . . . . . . . . . . . . . . .

Cluster Power Control 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2. Using the System Unit 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Power Switch Module 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Operator Panel 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Controls 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Key Mode Switch 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping the System Unit 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Methods of Starting the System Unit 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manually Starting the System Unit 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manually Stopping the System Unit 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information about Multiple Systems 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminals and Printers 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Consoles 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Internal Mass Storage Devices 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the 8 mm Tape Drive 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Lights 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Write-Protect Tab on 8 mm Tape Cartridges 2-17. . . . . . . . . . . . . . . . . . . . .

Performance 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usage 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the 8 mm Tape Cartridge 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the 8 mm Tape Cartridge 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of 8 mm Tape Cartridges 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

iv Operator Guide

Preventive Maintenance 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Tape Path on the 5GB 8 mm Tape Drive 2-20. . . . . . . . . . . . . . . . . . . . . .

Loading the 8 mm Cleaning Cartridge 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Handling 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information for 4.0GB 4 mm Tape Drive 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommendations 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of 4 mm Tape Cartridges 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Cartridge Compatibility 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Write-Protect Tab on 4 mm Tape Cartridges 2-26. . . . . . . . . . . . . . . . . . . . .

Environmental Considerations for 4 mm Data Cartridges 2-26. . . . . . . . . . . . . . . . . . .

Operating in Harsh Environments 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 mm Data Cartridge Erasure 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Cartridge Data Capacity 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the 4.0GB 4 mm Tape Drive 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Lights 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the 4 mm Tape Cartridge 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the 4 mm Tape Cartridge 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Tape Path on the 4.0GB 4 mm Tape Drive 2-32. . . . . . . . . . . . . . . . . . . .

Using the 1/4-Inch Tape Drive 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Cartridge Compatibility 2-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the 1/4-Inch Tape Cartridge 2-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the 1/4-Inch Tape Cartridge 2-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Write-Protect Tab on 1/4-Inch Tape Cartridges 2-37. . . . . . . . . . . . . . . . . .

Cleaning the 1/4-Inch Cartridge Drive 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Considerations for 1/4-Inch Tape Cartridges 2-38. . . . . . . . . . . . . . . . .

Using the CD-ROM Drives 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the CD-ROM Disc Caddy (Type B Bezel Only) 2-40. . . . . . . . . . . . . . . . . . . . .

Loading the CD-ROM Drive (Type C Bezel Only) 2-40. . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the CD-ROM Disc Caddy 2-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading the CD-ROM Drive (Type C Bezel Only) 2-41. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the CD-ROM Drive 2-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emergency Eject (Type C Bezel Only) 2-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the 3.5-Inch Diskette Drive 2-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions 2-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling Your Diskettes 2-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of 3.5-Inch Diskettes 2-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Write-Protect Tab 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading and Unloading the 3.5-Inch Diskette 2-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Internal Disk Drives 2-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Controls of a Disk Device 2-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Preface v

Chapter 3. Using SystemGuard 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Power 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Components 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Bring-Up MicroProcessor Overview 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Operator Panel 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Consoles 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical and Electronic Key 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Phases 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand-By Phase 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Init Phase 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Phase 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boot Phase 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run-Time Phase 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Parameters and Flags 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Working with SystemGuard 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Menus 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Menu 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Configuration 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display BUMP Error Log 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable Service Console 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disable Service Console 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Off 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Boot 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Off-Line Tests 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Parameters 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set National Language 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Common SystemGuard Tasks 3-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customizing SystemGuard For Your Needs 3-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reloading the Flash EEPROM 3-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4. Removal and Installation Procedures 4-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Removability Capability 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Highly Removable Disks 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locating a Micro Channel Adapter 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locating a Disk or Media Drive 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Codes 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Bus Controllers 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Locations 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Converting a Software Location Code to a Physical Drive Location 4-6. . . . . . . . . . .

Unconfiguring or Configuring a Drive 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unconfiguring 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing or Installing a Front Media or Disk Device 4-8. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing or Installing a Rear Drive 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

vi Operator Guide

Chapter 5. Using Diagnostics 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Programs Operating Considerations 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics on a System Unit Attached to Another System 5-1. . . . . . . . . . . . . . . . . .

Selecting a Console Display 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identifying the Terminal Type to the AIX Operating System 5-1. . . . . . . . . . . . . . . . . .

Running Diagnostic Programs from CD-ROM 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Diagnostic Programs from Disk or From a Server 5-2. . . . . . . . . . . . . . .

Running the Diagnostic Programs from the Network 5-3. . . . . . . . . . . . . . . . . . . . . . .

Running the Diagnostic Programs from a TTY Terminal 5-3. . . . . . . . . . . . . . . . . . . . .

Diagnostic Modes of Operation 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Mode 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Concurrent Mode 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standalone Mode 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Exerciser 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading a Flashing 888 Message on a Multi-Line Operator Panel Display 5-11. . . . . . .

Step 1. Determine the Type of Message 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 2. Reading the Type 102 Message 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crash Codes 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dump Progress Indicators (Dump Status Codes) 5-12. . . . . . . . . . . . . . . . . . . . . . . . . .

Step 3. Reading the Type 103 and 105 Message 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 4. Other Numbers 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6. Introduction to Tasks and Service Aids 6-1. . . . . . . . . . . . . . . . . . . . . . . .

T asks 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Diagnostics Task 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Error Log Analysis Task 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display or Change Diagnostic Run Time Options Task 6-2. . . . . . . . . . . . . . . . . . . . . .

Process Supplemental Media Task 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Aids 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIX Shell Prompt Service Aid 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup/Restore Media Service Aid 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Error Rate Service Aid 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BUMP (Bringup Micro–Processor) Service Aids (Display or Change BUMP Configuration

Task) 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Package Utility Service Aid 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dials and LPFK Configuration Service Aid 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dials and LPFKs Configuration Service Aid Before Version 4.2 6-5. . . . . . . . . . . . . .

Configure Dials and LPFKs Task Version 4.2+ 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Based Diagnostic Update Service Aid and Update Disk Based Diagnostic Task 6-6

Disk Based Diagnostic Update Service Aid Before Version 4.2 6-6. . . . . . . . . . . . . .

Update Disk Based Diagnostic Task Version 4.2 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Maintenance Service Aid 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk to Disk Copy Service Aid 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display/Alter Sector Service Aid 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Media Service Aids 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optical Disk Service Aids 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diskette Media Service Aid 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display/Alter Bootlist Service Aid 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display or Change Configuration or Vital Product Data (VPD) Service Aid 6-9. . . . . . .

Display Vital Product Data (VPD) Service Aid and Display Hardware Vital Product Data

Task 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Preface vii

Display Software Product Data Pre-version 4.2 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Software Product Data Beginning with Version 4.2 6-10. . . . . . . . . . . . . . . . . .

Display Configuration Service Aid and Display Configuration and Resource List Task 6-10

Change Hardware Vital Product Data Task 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display and Change Diagnostic Test List Service Aid 6-10. . . . . . . . . . . . . . . . . . . . . . . . .

Display or Change Key Modes (Display or Change Electronic Mode Switch Task) 6-11

Display Previous Diagnostic Results Service Aid 6-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Test Patterns Service Aid 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generic Microcode Download Service Aid 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Error Report Service Aid and Display Hardware Error Log Task 6-12. . . . . . .

Local Area Network Service Aid and Local Area Network Analyzer Task 6-12. . . . . . . . .

Microcode Download Service Aid 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiprocessor Service Aid (Display or Change Multiprocessor Configuration Task) 6-12

Periodic Diagnostics Service Aid 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Topology Service Aid 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Bus Service Aid and SCSI Bus Analyzer Task 6-13. . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Tape Utilities Service Aid 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Aids for use with Ethernet 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Hints Service Aid 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SSA Service Aid 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trace Service Aid 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7318 Serial Communications Network Server Service Aid 6-16. . . . . . . . . . . . . . . . . . . . .

Chapter 7. Using the System Verification Procedure 7-1. . . . . . . . . . . . . . . . . . . . . . .

System Verification Procedure 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 1. Considerations before Running This Procedure 7-1. . . . . . . . . . . . . . . . . . . . . . .

Step 2. Loading the Diagnostic Programs 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 3. Running System Verification 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 4. Additional System Verification 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 5. Stopping the Diagnostics 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8. Hardware Problem Determination 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9. Expansion Unit 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedures 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Operations 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Cover 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Cover 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top Cover 9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Connection 9-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Securing the Units at the Bottom 9-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Units Interconnection 9-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FXE Cable Interconnection 9-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Cables Interconnection 9-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Interface Card Interconnection 9-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Terminators 9-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recognizing the New Unit 9-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Units Disconnection 9-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Disconnection 9-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

viii Operator Guide

Chapter 10. Moving the System Unit 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving the System Unit Safely 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A. SystemGuard Test Groups A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Test Groups Table A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Test Group Descriptions A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B. Modifying SystemGuard Parameters B-1. . . . . . . . . . . . . . . . . . . . . . . . .

Default Parameter Values B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Flags and Parameters Under AIX Service Aids B-3. . . . . . . . . . . . . . . . . . . . .

Modifying the Remote Authorization Flag B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying the Dial-Out Authorization Flag B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying Dial-In Phone Numbers B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying Dial-Out Phone Numbers B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying the Electronic Mode Switch from Service Line Flag B-6. . . . . . . . . . . . . . . . . .

Reloading the Flash EEPROM B-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C. SystemGuard Remote Operation Configuration C-1. . . . . . . . . . . . . . .

Terminal Configuration C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flags and Parameters Settings C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modem Configuration Files C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initializing a Modem C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Dial-Out C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: Supplies D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Keys D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Reorder Form D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E. Three-Digit Display Numbers E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On (PON) Test Indicators E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Self-Test (POST) Indicators E-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Load Progress Indicators E-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Debugger Progress Indicators E-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing 888 Message Descriptions E-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix F. External SCSI Address Record F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix G. System Power States G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power States G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary: Special Terms Used in SystemGuard X-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Index X-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

Preface ix

Communications Statements

The following statement applies to this product. The statement for other products intended

for use with this product appears in their accompanying manuals.

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC

emission limits. Neither the provider nor the manufacturer are responsible for any radio or

television interference caused by using other than recommended cables and connectors or

by unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

United Kingdom Telecommunications Requirements

This equipment is manufactured to the International Safety Standard EN60950 and as such

is approved in the UK under the General Approval Number NS/G/1234/J/100003 for indirect

connection to the public telecommunication network.

The network adapter interfaces housed within this equipment are approved separately, each

one having its own independent approval number. These interface adapters, supplied by the

manufacturer, do not use or contain excessive voltages. An excessive voltage is one which

exceeds 70.7 V peak ac or 120 V dc. They interface with this equipment using Safe Extra

Low Voltages only. In order to maintain the separate (independent) approval of the

manufacturer’s adapters, it is essential that other optional cards, not supplied by the

manufacturer, do not use main voltages or any other excessive voltages. Seek advice from a

competent engineer before installing other adapters not supplied by the manufacturer.

International Electrotechnical Commission (IEC) Statement

This product has been designed and built to comply with IEC Standard 950.

Page 10

x Operator Guide

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council Directive

89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility .

Neither the provider nor the manufacturer can accept responsibility for any failure to satisfy

the protection requirements resulting from a non-recommended modification of the product,

including the fitting of option cards not supplied by the manufacturer.

This product has been tested and found to comply with the limits for Class A Information

Technology Equipment according to CISPR 22 / European Standard EN 55022. The limits

for Class A equipment were derived for commercial and industrial environments to provide

reasonable protection against interference with licensed communication equipment.

Attention: This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate measures.

Avis de conformité aux normes du ministère des Communications du

Canada

Cet appareil numérique de la classe A respecte toutes les exigences du Réglement sur le

matériel brouilleur du Canada.

Canadian Department of Communications Compliance Statement

This Class A digital apparatus meets the requirements of the Canadian

Interference-Causing Equipment Regulations.

VCCI Statement

The following is a summary of the VCCI Japanese statement in the box above.

This equipment is in the Class 1 category (information equipment to be used in

commercial and/or industrial areas) and conforms to the standards set by the Voluntary Control Council For Interference by Data Processing Equipment and Electronic Office Machines aimed at preventing radio interference in commercial and/

or industrial areas.

Consequently , when used in a residential area or in an adjacent area thereto, radio

interference may be caused to radios and TV receivers, etc.

Read the instructions for correct handling. VCCI–1.

Page 11

Preface xi

Radio Protection for Germany

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen EMVG vom 9.Nov.92

das EG-Konformitätszeichen zu führen.

Der Aussteller der Konformitätserklärung ist die IBM Germany.

Dieses Gerät erfüllt die Bedingungen der EN 55022 Klasse A. Für diese Klasse von

Geräten gilt folgende Bestimmung nach dem EMVG:

Geräte dürfen an Orten, für die sie nicht ausreichend entstört sind, nur mit besonderer

Genehmigung des Bundesministers für Post und Telekommunikation oder des Bundesamtes

für Post und Telekommunikation betrieben werden. Die Genehmigung wird erteilt, wenn

keine elektromagnetischen Störungen zu erwarten sind.

(Auszug aus dem EMVG vom 9.Nov.92, Para.3, Abs.4)

Hinweis:

Dieses Genehmigungsverfahren ist von der Deutschen Bundespost noch nicht veröffentlicht

worden.

Page 12

xii Operator Guide

Page 13

Preface xiii

Safety Notices

Note: For a translation of these notices, see the

System Unit Safety Information

, order

number SA23-2652.

Definitions of Safety Notices

A

danger

notice indicates the presence of a hazard that has the potential of causing death

or serious personal injury.

Danger

notices appear on the following pages:

4-1

9-2

10-1

10-1

A

caution

notice indicates the presence of a hazard that has the potential of causing

moderate or minor personal injury. A

caution

notice appears on the following page:

xiii

2-39

4-1

4-8

9-2

10-1

Lithium Battery

Note: For a translation of these notices, see

System Unit Safety Information

.

CAUTION:

A lithium battery can cause fire, explosion, or a severe burn. Do not recharge,

disassemble, heat above 100°C (212°F), solder directly to the cell, incinerate, or

expose cell contents to water. Keep away from children. Replace only with the part

number specified for your system. Use of another battery may present a risk of fire or

explosion.

The battery connector is polarized; do not attempt to reverse the polarity.

Dispose of the battery according to local regulations.

Page 14

xiv Operator Guide

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label that

identifies its classification. The label, located on the drive, is shown below.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

TO IEC 825:1984 CENELEC EN 60 825:1991

The optical drive in this system unit is certified in the U.S. to conform to the requirements of

the Department of Health and Human Services 21 Code of Federal Regulations (DHHS 21

CFR) Subchapter J for Class 1 laser products. Elsewhere, the drive is certified to conform to

the requirements of the International Electrotechnical Commission (IEC) 825 (1st edition

1984) and CENELEC EN 60 825:1991 for Class 1 laser products.

CAUTION:

A class 3 laser is contained in the device. Do not attempt to operate the drive while it

is disassembled. Do not attempt to open the covers of the drive as it is not

serviceable and is to be replaced as a unit.

Class 1 laser products are not considered to be hazardous. The optical drive contains

internally a Class 3B gallium-arsenide laser that is nominally 30 milliwatts at 830

nanometers. The design incorporates a combination of enclosures, electronics, and

redundant interlocks such that there is no exposure to laser radiation above a Class 1 level

during normal operation, user maintenance, or servicing conditions.

Page 15

Preface xv

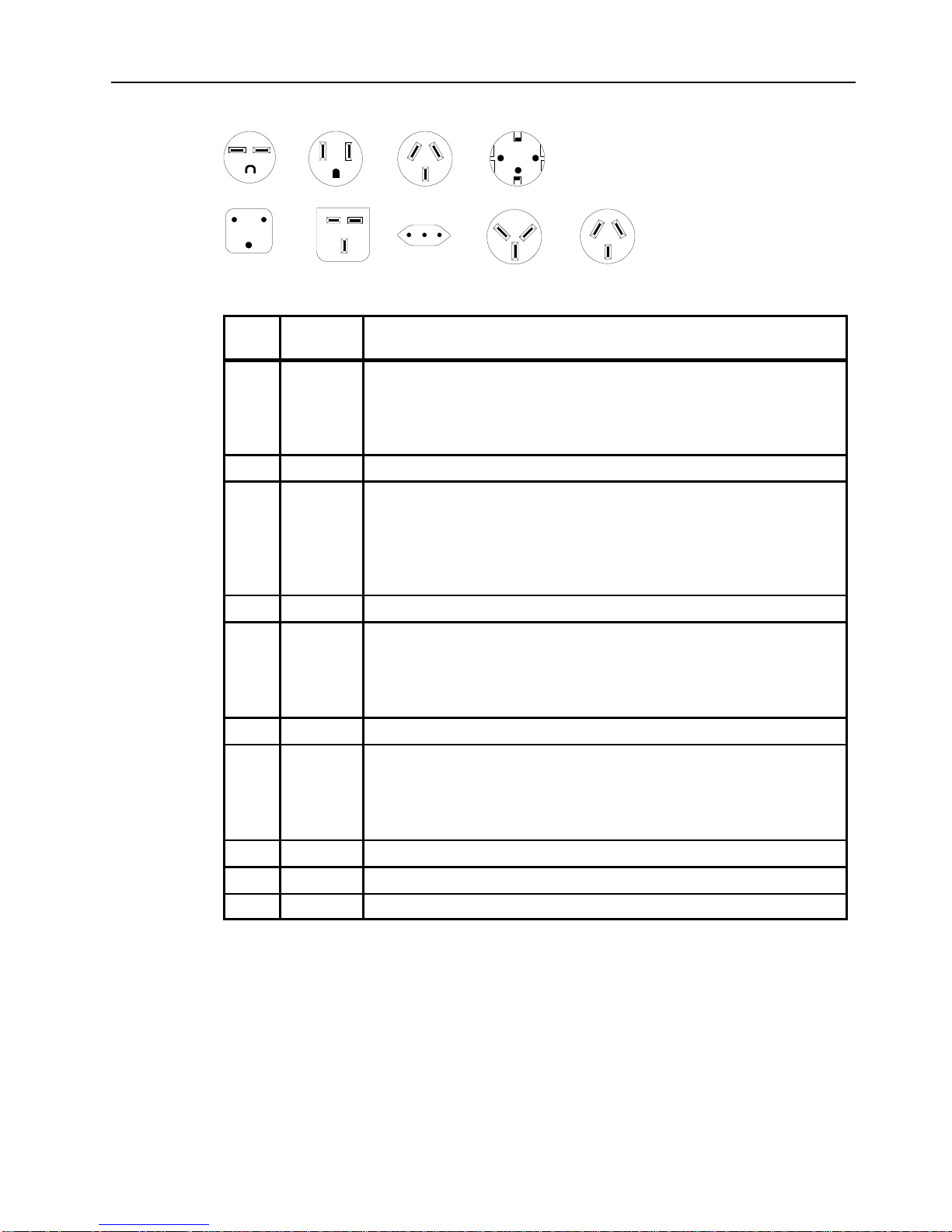

Power Cables and Plugs

1

23

4

5

6

7

89

Index

Part

Number

Country

1 14F1548 Bahamas, Barbados, Bolivia, Brazil, Canada, Costa Rica,

Dominican Republic, El Salvador, Ecuador, Guatemala, Guyana,

Haiti, Honduras, Jamaica, Japan, Netherlands Antilles, Panama,

Peru, Philippines, Taiwan, Thailand, Trinidad, Tobago, U.S.A.

(except Chicago), Venezuela

2 6427171 U.S.A. (Including Chicago)

2 6427168 Bahamas, Barbados, Bermuda, Bolivia, Brazil, Canada, Cayman

Islands, Colombia, Costa Rica, Dominican Republic, Ecuador, El

Salvador, Guatemala, Guyana, Haiti, Honduras, Jamaica, Japan,

Korea (South), Mexico, Netherlands Antilles, Nicaragua, Panama,

Peru, Philippines, Puerto Rico, Saudi Arabia, Suriname, Trinidad,

Taiwan, Venezuela

3 14F1559 Argentina, Australia, New Zealand,

4 14F1554 Abu Dhabi, Austria, Belgium, Bulgaria, Botswana, Denmark, Egypt,

Finland, France, Germany, Greece, Iceland, Indonesia, Korea

(South), Lebanon, Liechtenstein, Luxembourg, Macau, Netherlands,

Norway, Portugal, Saudi Arabia, Spain, Sudan, Sweden,

Switzerland, Turkey, Yugoslavia

5 14F1557 Bangladesh, Burma, Pakistan, South Africa, Sri Lanka

6 11H5086 Bahrain, Bermuda, Brunei, Channel Islands, Cyprus, Ghana, Hong

Kong, India, Iraq, Ireland, Jordan, Kenya, Kuwait, Malawi, Malaysia,

Nigeria, Oman, People’s Republic of China, Qatar, Sierra Leone,

Singapore, Tanzania, Uganda, United Arab Emirates (Dubai), United

Kingdom, Zambia

7 14F1560 Chile, Ethiopia, Italy

8 14F1561 Israel

9 14F1559 Paraguay, Colombia, Uruguay

Page 16

xvi Operator Guide

Page 17

Preface xvii

About This Book

This book contains information on 7013 J Series system and its operation together with a

description of the main operations that the operator may perform.

How to Use This Book

This book provides information about the operator controls, the internal and external devices

installed to the 7013 J Series system unit.

It is advisable to have one or more people beyond the system administrator be capable of:

• starting up and shutting down the system. See Chapter 2, “Using the System Unit”.

• assisting users who have problems with terminal configuration, connection, etc. See

“Terminal and Printers” in Chapter 2, “Using the System Unit”.

• operating, tape and CD-ROM units. See Chapter 2, “Using the System Unit”.

ISO 9000

ISO 9000 registered quality systems wer used in the development and manufacturing of this

product.

Related Publications

The

Problem Solving Guide and Reference

, order number SC23-2606 is the first book you

should use when you have a problem with the system unit. It contains procedures for

determining if the problem is hardware or software related.

The

7013 J Series Base Unit Hardware Setup Procedure,

order number SA23-2723

contains the procedures for the initial hardware setup of the 7013 J Series base unit.

The

7013 J Series Expansion Unit Hardware Setup Procedure,

order number SA23-2726

contains the procedures for the initial hardware setup of the 7013 J Series expansion unit.

Page 18

xviii Operator Guide

Page 19

Description of the 7013 J Series System 1-1

Chapter 1. Description of the 7013 J Series System

This chapter contains information to help you become familiar with the 7013 J Series

System.

This chapter groups miscellaneous reference information related to both the base and

expansion units.

It details the environmental specifications of the system.

In addition it shows each internal planar and card with the proper connectors and the

corresponding description, and then it shows the SCSI addresses related to both the

internal and external devices for each unit.

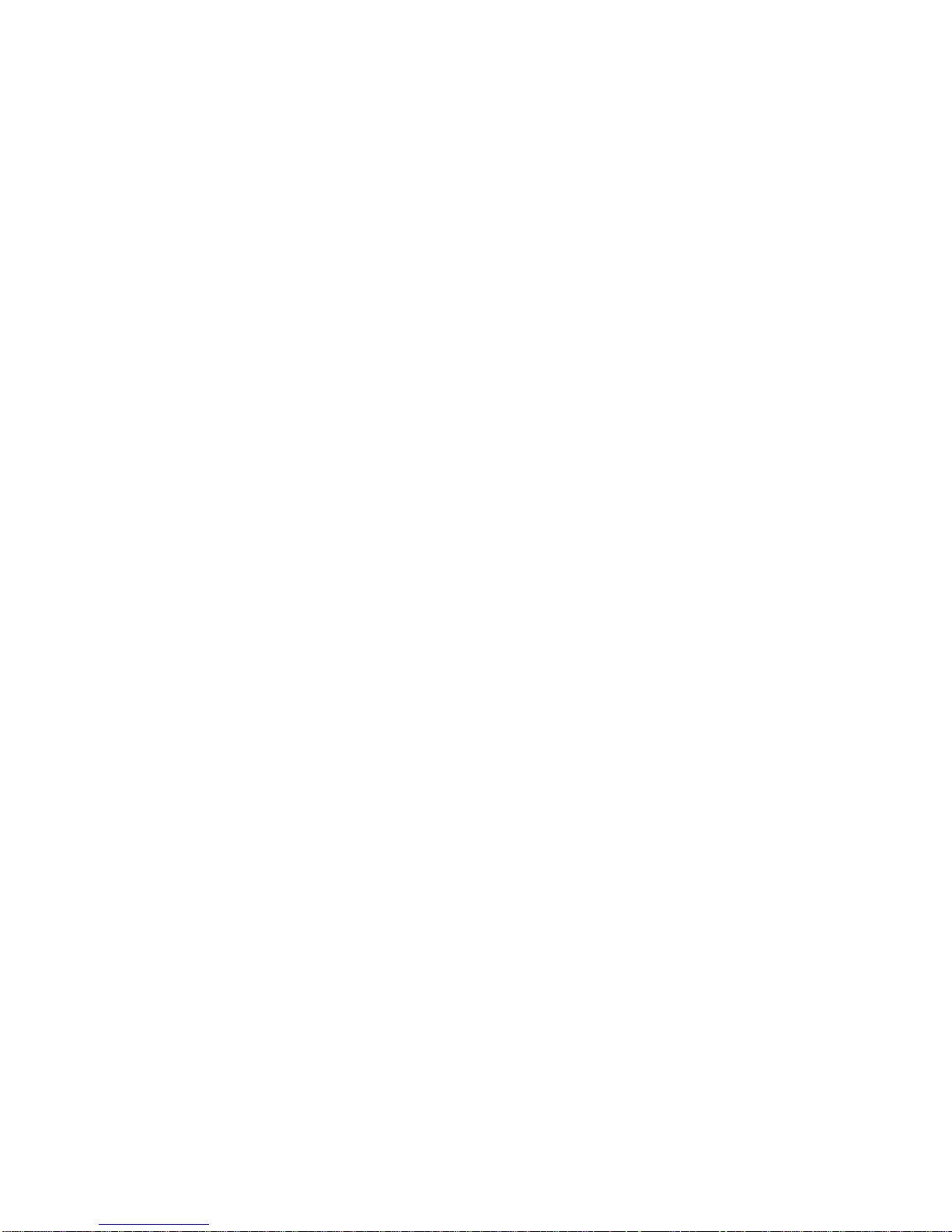

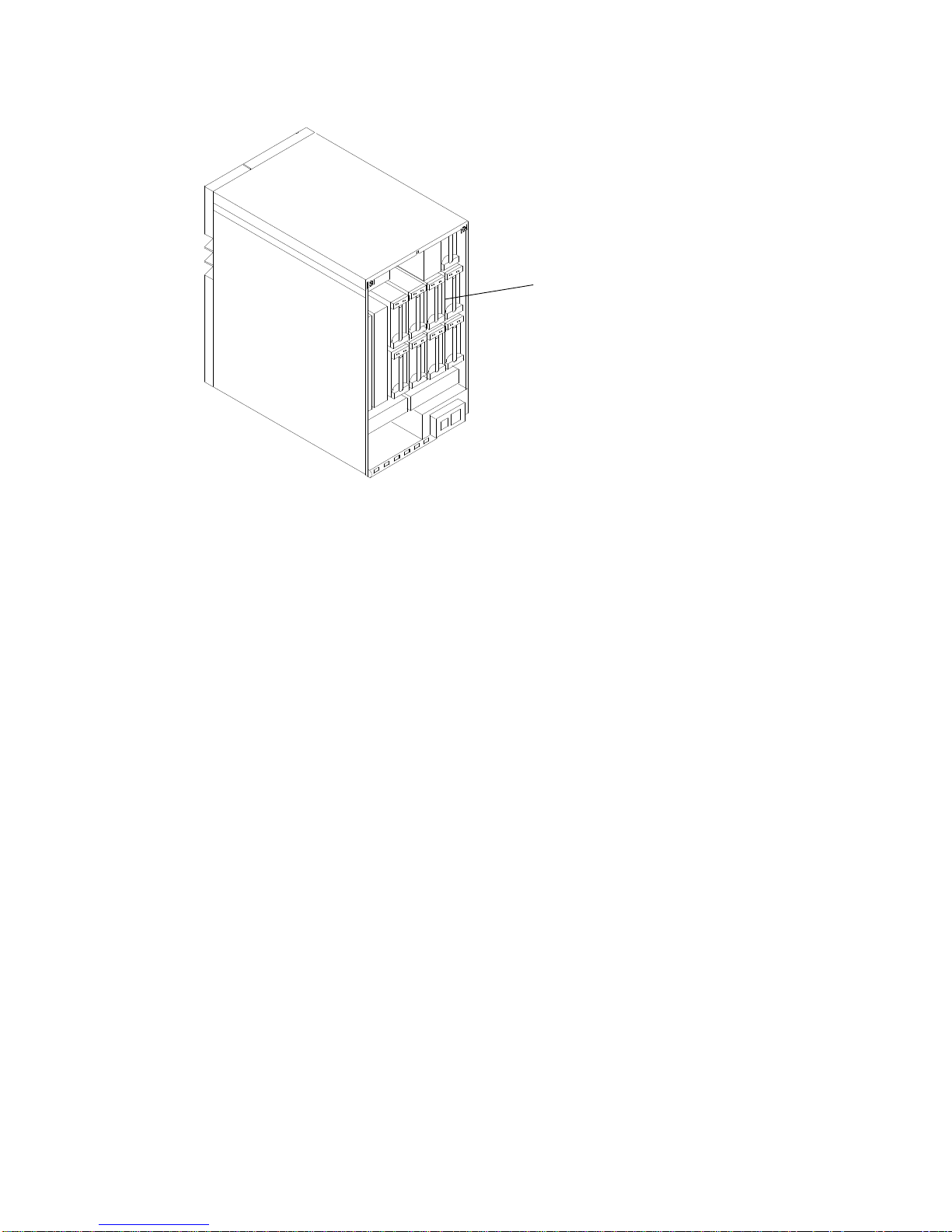

Description of the Base Unit

The 7013 J Series system is a multi-user system based on the PowerPC RISC-architecture.

It contains several types of input and output (I/O) adapters, memory, and media storage

devices. The hardware is controlled by the Operating System (OS).

The Operator Panel is accessible behind the front door of the system.

Front Door

Front View of the Base Unit

Page 20

1-2 Operator Guide

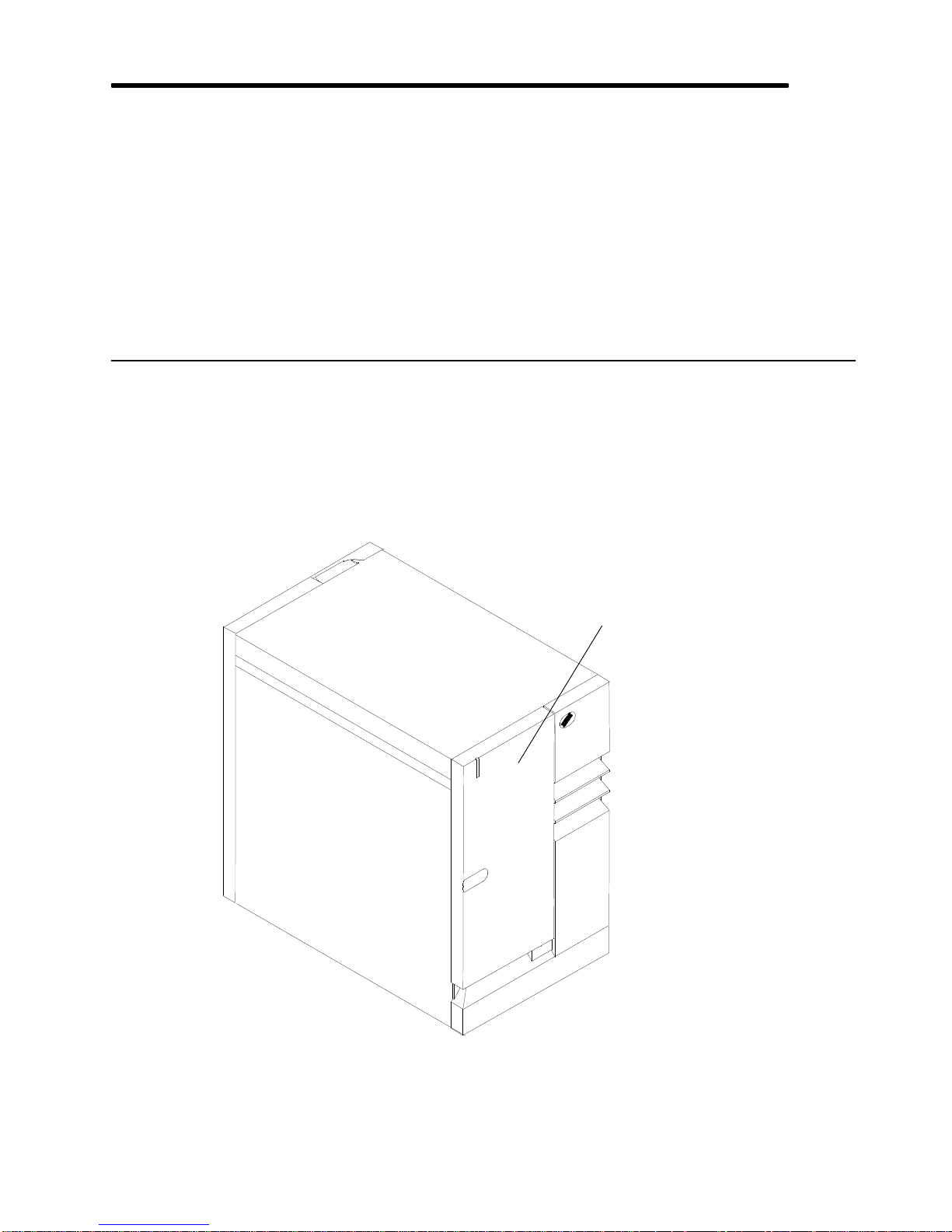

The base unit consists of a floor standing unit, which may be expanded with the addition of

an expansion unit, positioned to the left of the base unit.

Both units have the same dimensions:

• Height: 610 mm (24.1 in.)

• Width: 360 mm (14.2 in.)

• Depth: 750 mm (29.5 in.).

Page 21

Description of the 7013 J Series System 1-3

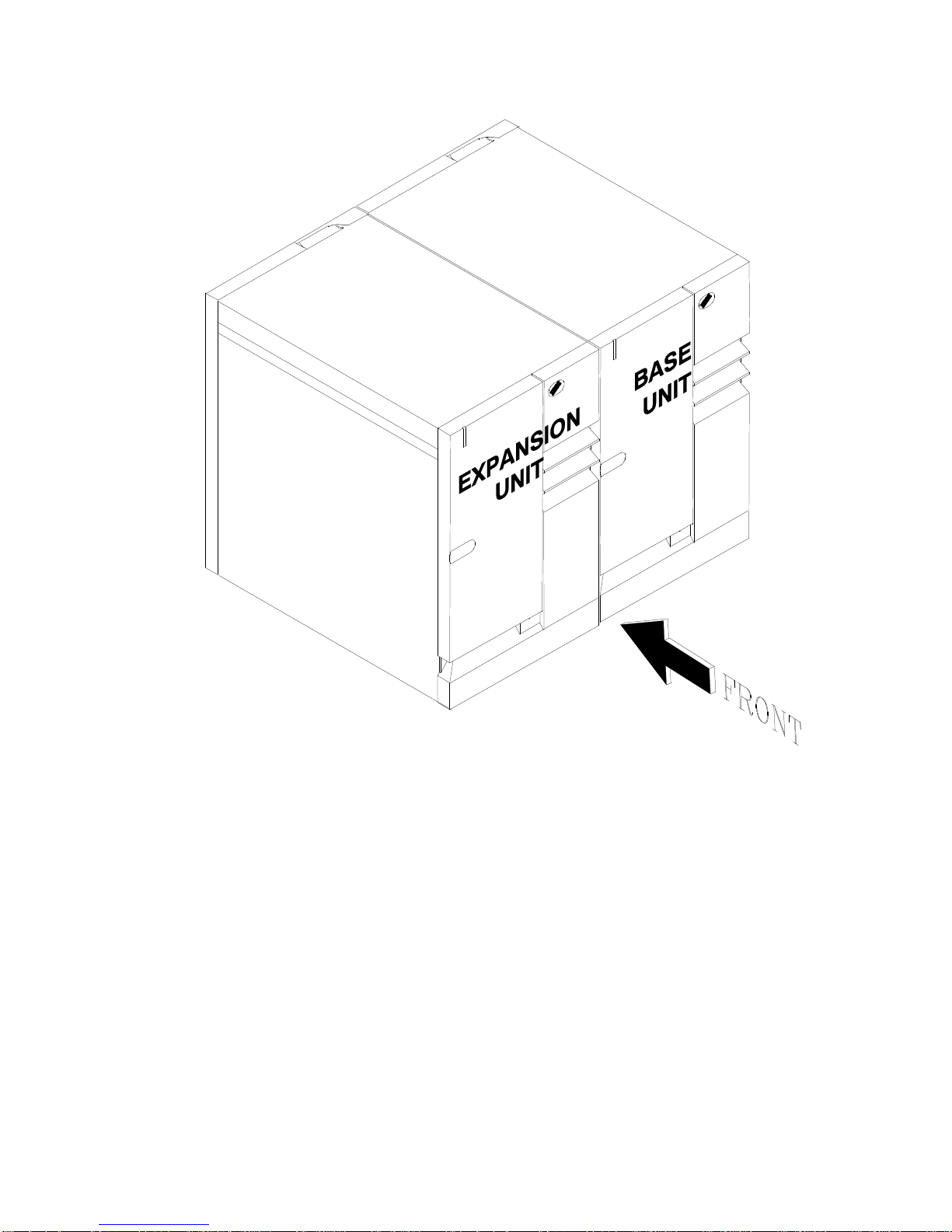

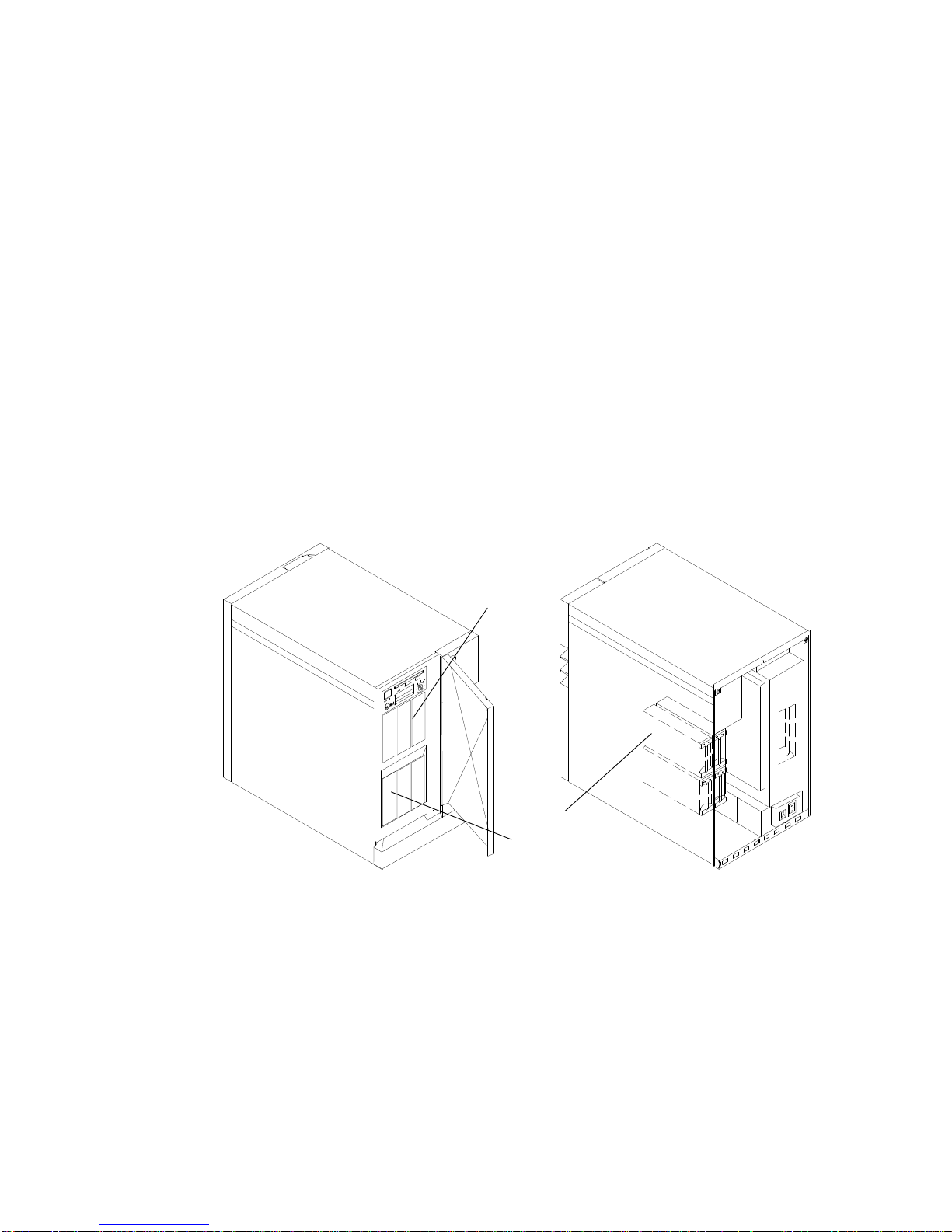

Base Unit Without Covers

The following figures show the base system unit with covers and doors removed.

Operator Panel

Micro Channel Card

Cage Fan Module

Media Devices

Power Supply

Disk Devices

Main Fan Module

Front View

Back Plane

Micro Channel

Card Cage

Back Plane

System Interface

Board

CPU Complex

Main Power

Switch Module

Disk Fan Module

Disk Devices

Rear View

Micro Channel

Card Cage

Page 22

1-4 Operator Guide

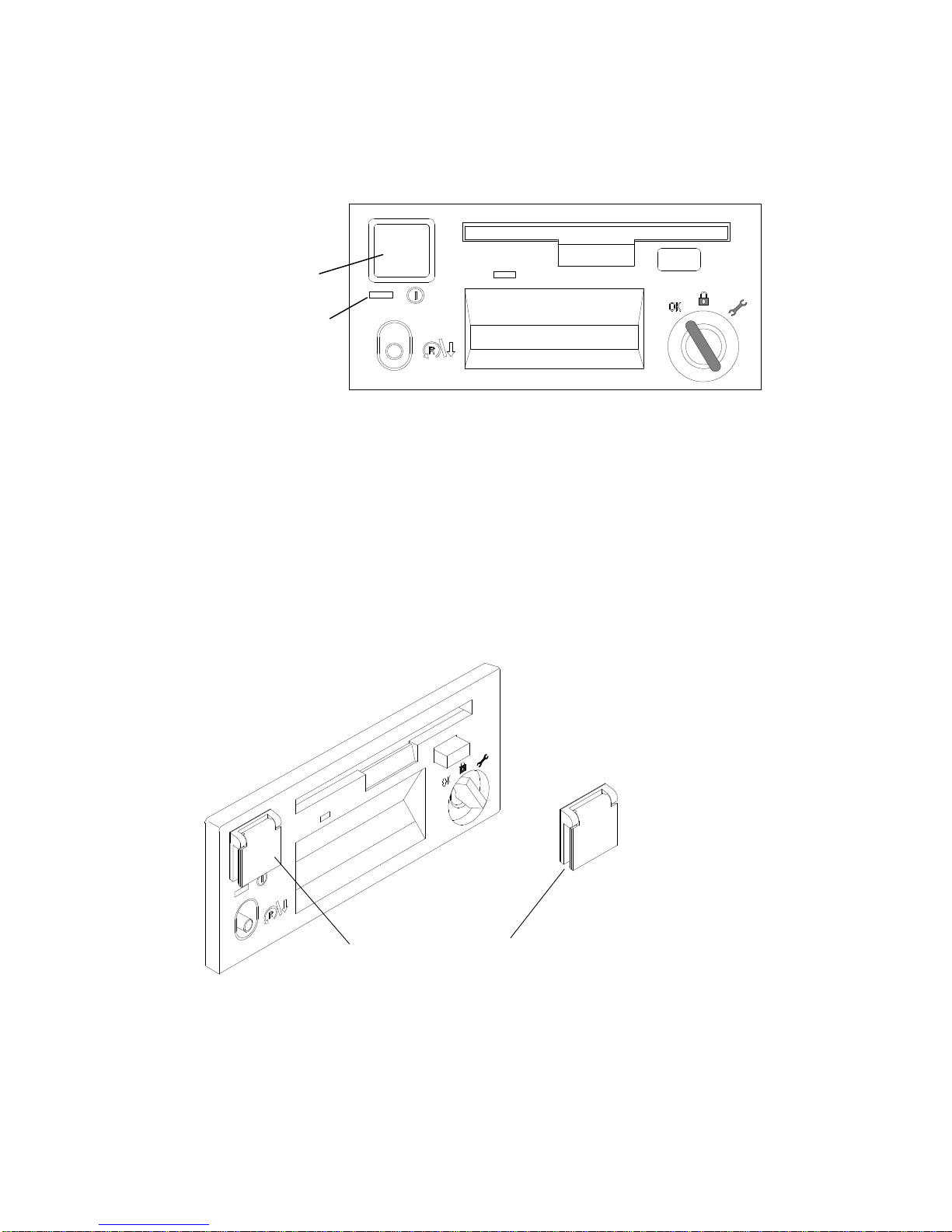

Operator Controls

The basic hardware interface between the user and the system unit, is the operator panel.

The operator panel is the primary hardware interface used by the system operator to bring

the system to an operable state. The interface with the user is provided via the system

console and/or terminal.

Power On Light

Power Button

Operator Panel with Power Controls

Power On Light Indicates that all voltages in the power supply are present and

within limits and that the fans are running. The power-on light is

used to help analyze power and cooling problems.

Power Button Controls the system power. This button enables the system to

automatically power itself back on if a power failure occurs.

The power supply has electric power as long as the power supply

cord is plugged into a working electrical outlet (even when the

power button has been pressed to turn of the system unit).

Power Button Cover This cover has been furnished as a method to prevent a person

from accidentally pressing the power button. It contains an

adhesive on the back, which enables you to attach it to the operator

panel as shown in the following diagram.

Power Button Cover

The system unit power cord must be plugged to the standard office wall outlet (1440 VA

maximum).

Page 23

Description of the 7013 J Series System 1-5

Media Devices

The SCSI interface is the main bus for the mass storage devices and is used to connect

disk drives, tapes and optical disks.

The SCSI bus internal to the unit is etched or embedded on the back plane, so it supports

device connection through direct insertion, without cables.

All the internal devices are included in a mechanical carrier that enables the devices to be

directly connected to the back plane. The carrier includes a SCSI converter board.

For the operator controls of the disk devices refer to “Using Internal Disk Drives” on page

2-47.

Base Unit

The base unit includes the basic SCSI device complex with 6 slots (SCSI bus A) and an

additional SCSI bus with 4 slots (SCSI bus B).

The media devices such as tape drives and CD-ROM drives are always located at the front

in the upper row of the base unit. This row can house three 5.25-inch half-high devices.

The lower device slots located at the front side are reserved for highly removable 3.5-inch

disk drives. See “Highly Removable Disks” on page 4-2, for more information about highly

removable disks.

Front View Rear View

Media

Devices

Disk

Devices

On the rear side of the system there are four 3.5-inch slots.

The disk devices connected to the slots at the rear of the unit should be accessed

only

for

maintenance or installation.

If you want to access the devices at the rear of your system unit, open the rear panel with

the operator panel key.

For more information about SCSI bus IDs and locating disk or media drives, see “Locating

a Disk or Media Drive” on page 4-4.

Page 24

1-6 Operator Guide

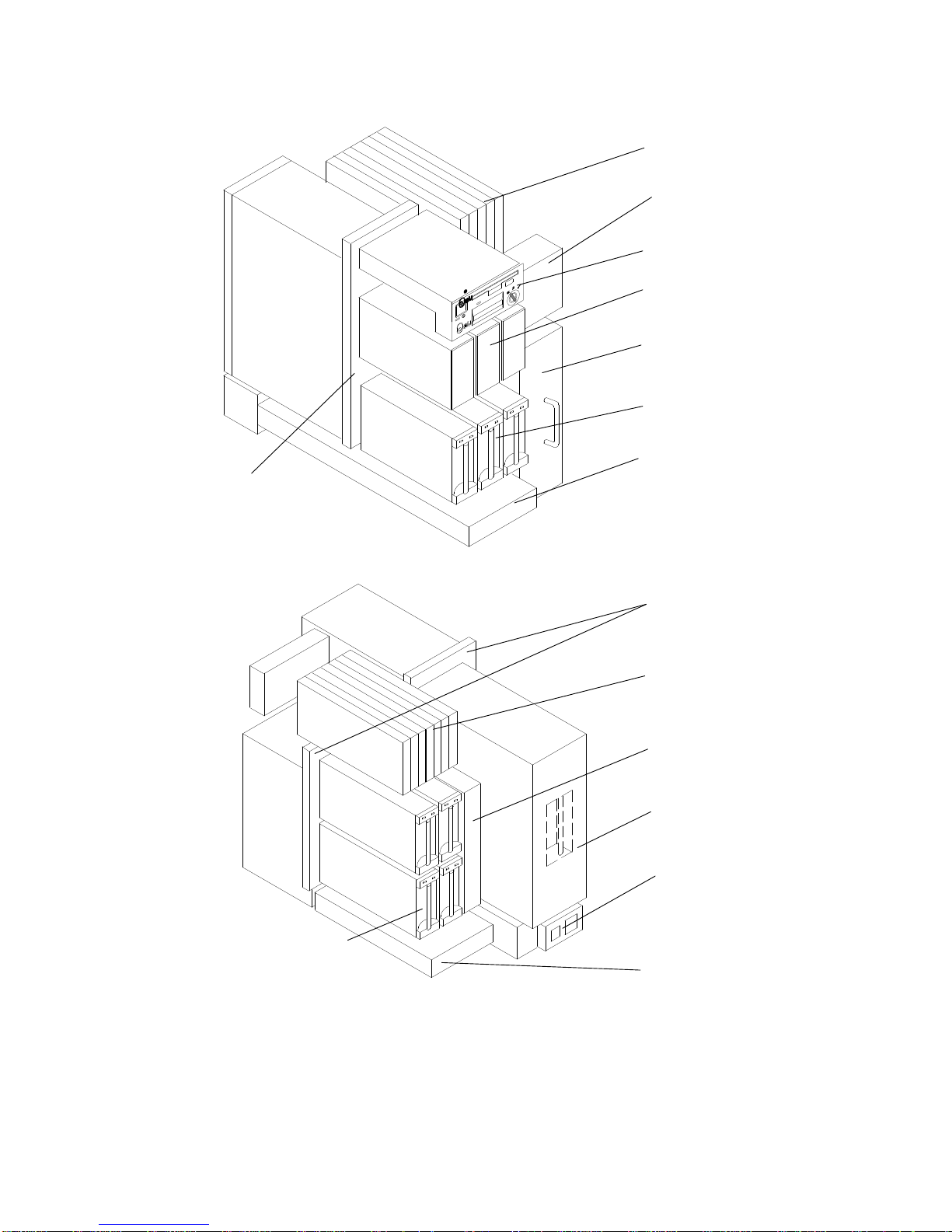

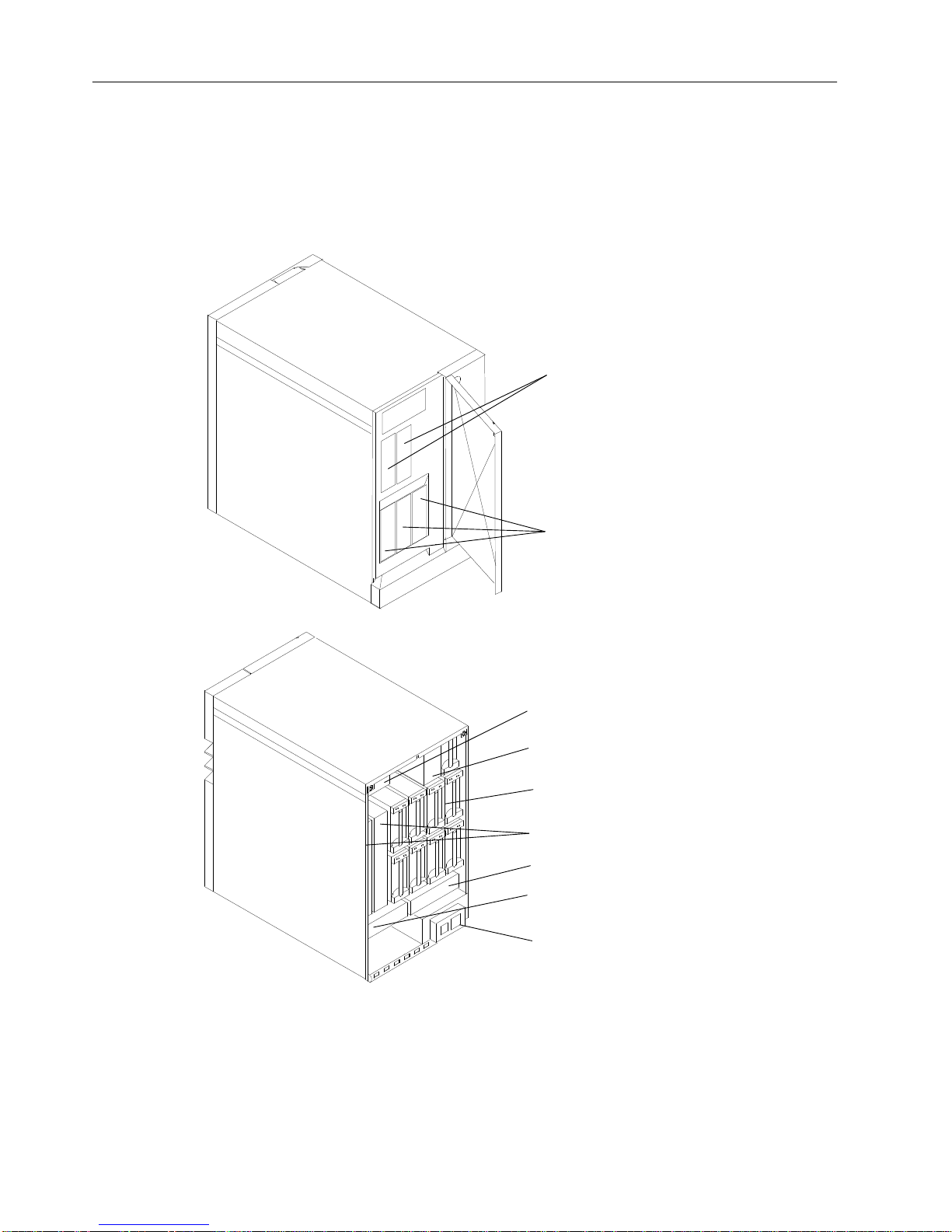

Description of the Expansion Unit

The expansion unit holds up to 14 Mass Storage Devices on the SCSI buses, one Micro

Channel Card Cage with eight slots, one or two System Interface Boards, one Power

Supply, and three Fan Modules.

Note: The Expansion Unit must always be positioned at the left side of the base system

unit.

Media Devices

Disk Devices

Front View

MCA Complex

System Interface Board

Main Power

Switch Module

Disk Fan Module

Disk Devices

Bulkhead SCSI

Main Fan Module

Rear View

For more information about SCSI bus IDs and locating disk or media drives, see “Locating

a Disk or Media Drive” on page 4-4.

Page 25

Description of the 7013 J Series System 1-7

Expansion Unit

The expansion unit houses a device complex with 14 device slots. The media devices (tape

drives and a CD-ROM drive) are always located in the upper row at the front side of the

expansion unit. Two optional 5.25-inch half high media devices in two 5.25-inch half high

device slots may be installed.

The lower three 3.5-inch device slots in the front are reserved for highly removable disk

drives. For more information about highly removable disks, see “Highly Removable Disks”

on page 4-2.

Media Devices

Disk Drives

Installed Devices in the Front of the Expansion Unit

Page 26

1-8 Operator Guide

Nine slots for 3.5-inch disk drives are located in the rear of the expansion unit.

Disk Drives

Installed Devices in the Rear of the Expansion Unit

A SCSI-2 Differential Fast/Wide Adapter/A is required to support the drives installed in the

expansion unit. This adapter can be either:

• installed in the MCA card cage of the expansion unit where you are installing the disk

devices.

• installed in the base unit, and connected through an external connection.

In either case a dedicated SCSI-2 Differential Fast/Wide Adapter/A supports the input of the

SCSI-2 Differential Fast/Wide Adapter/A connection to the back plane.

To support the internal storage devices in the Expansion Unit one system interface board is

required, this services the A bus. If any device is placed on the B bus of the expansion unit,

you must connect an additional system interface board.

The expansion unit has two SCSI buses.

Page 27

Description of the 7013 J Series System 1-9

Main Power Switch Module

The power system provides power and power regulation for all units of the 7013 J Series.

It enables you to power on and power off (also under operating system control) individual

units. This is particularly useful for handling power outages or to gracefully shutdown the

system in case of problems.

The power supply complex consists of:

• the Main Power Switch Module

• the Power Supply.

Each unit is equipped with one power supply capable of powering the maximum number of

devices that can be configured in a unit.

Each system unit houses one Main Power Switch Module on the rear left corner in the lower

part of the unit; this module contains the unit main breaker for the general AC power

ON/OFF control.

Attention: Before powering on the base system unit, be sure that the expansion unit main

power switch is set to on (I). If you attempt to power the base unit on when the expansion

unit is set to off (O), the power on will fail and an error code will be displayed in the operator

panel display.

Main Power Switch

Module with System

Unit Main Switch

Rear View of Base Unit Showing Main Power Switch Module

System Unit Main Switch

Attention: Data can be lost if you use the basic unit main switch to turn off the power to the

system unit without first using an appropriate shutdown command to stop the operating

system. Refer to “Powering Down Procedure” on page 2-11 for more information about the

shutdown command.

The System Unit Main Switch at the rear of the system unit can be used to switch off power

to all the components of the system unit.

The switch has the symbols (I) for ON and (O) for OFF.

Page 28

1-10 Operator Guide

Location Codes

A location code is used to physically locate a failing device or unit. The location code is

displayed along with the service request number (SRN) when the diagnostic programs

isolate a failure. If the location code is not known, you can run the Display Previous

Diagnostic Results service aid to display the results of the last time the diagnostic programs

were run.

For more information about the location codes used in the base unit or the expansion unit,

see “Locating a Micro Channel Adapter” on page 4-3 and “Locating a Disk or Media Drive”

on page 4-4.

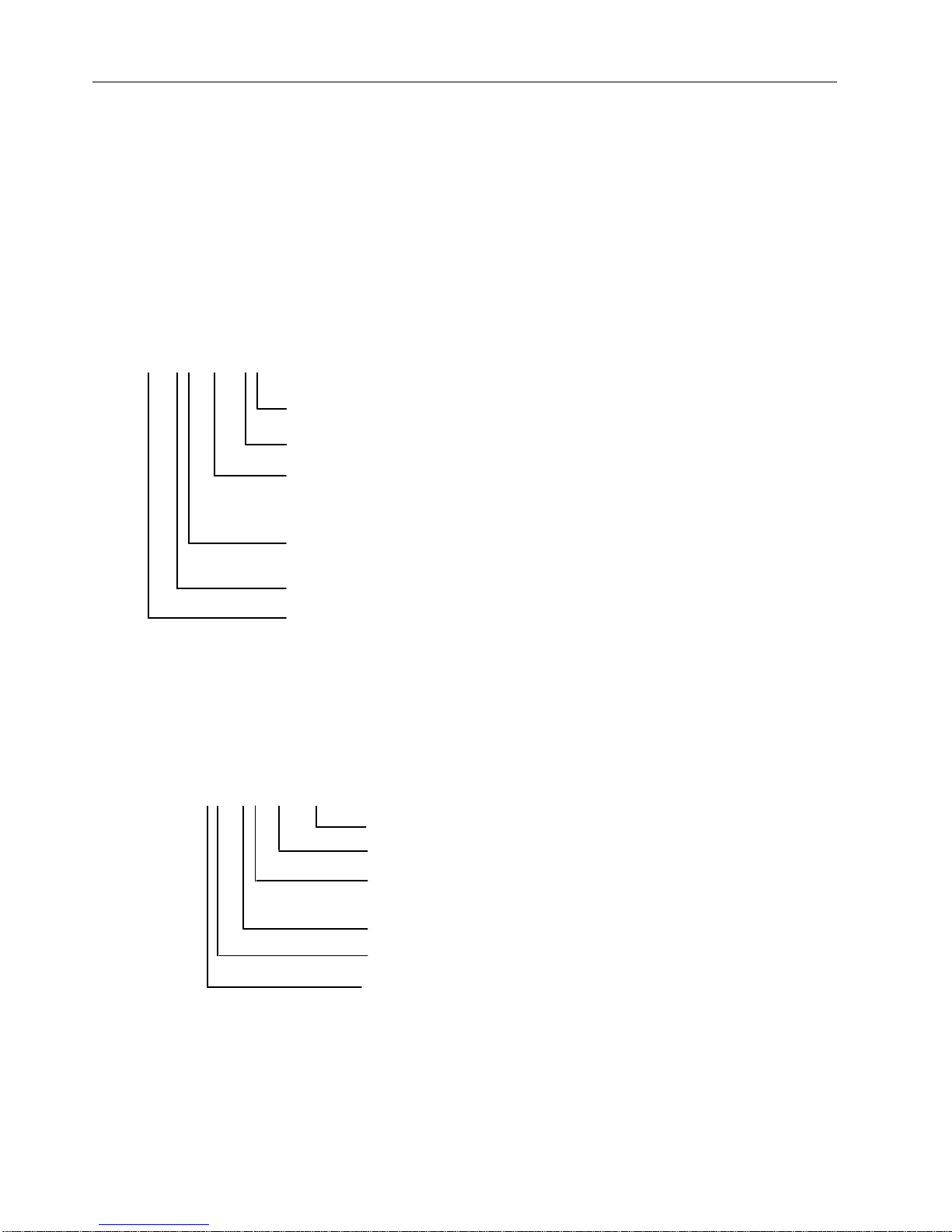

Location Code Format for SCSI Devices

AB - CD - EF - GH

Always 0.

Always 00.

Slot number of the SCSI controller.

00 - Internal SCSI bus connector.

01 - External SCSI bus connector of a non-integrated SCSI controller.

0S - External bus connector of an integrated SCSI controller,

SCSI address of the device.

,HHH is the logical unit number of the device shown in decimal.

Location Code Format for Non-SCSI Devices

The following example is for non-SCSI devices. These include planars, memory cards,

adapters, and async distribution boxes.

Use the example to determine the physical location of a device.

Note: The G and H fields each can contain one, two, or three characters.

AB - CD - EF - GH

Async port number or FRU location on a card or planar.

Connector number on an adapter or planar.

Slot number of the adapter, memory card, or adapter for

Always 0 on workstations.

the identified device

Always 0.

System I/O bus identifier.

Location Code Format for 7135, 9333, and 9334 Expansion Units

The location code formats for the 7135, 9333, and 9334 expansion units are described in

the publications for the 7135, 9333, and 9334 expansion units.

Page 29

Description of the 7013 J Series System 1-11

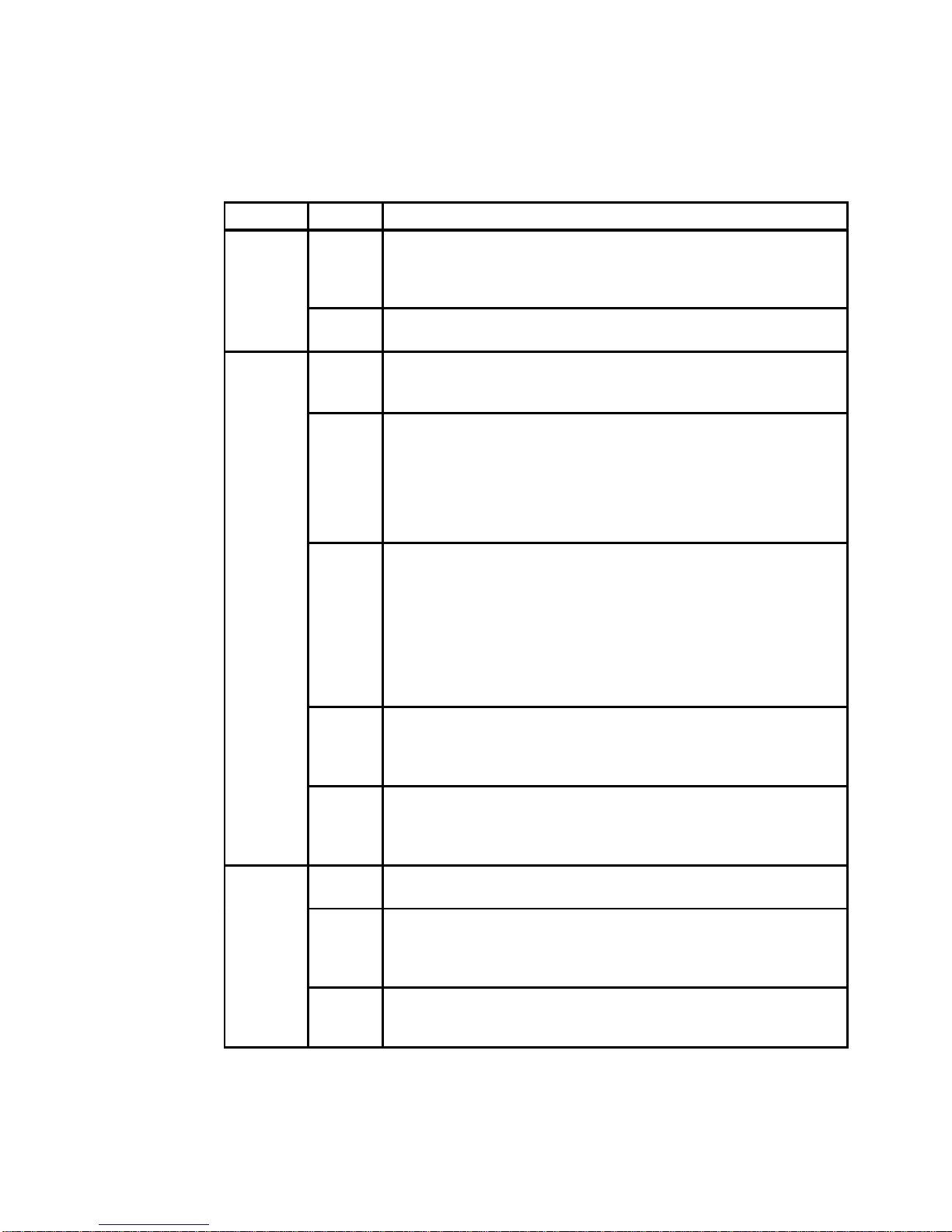

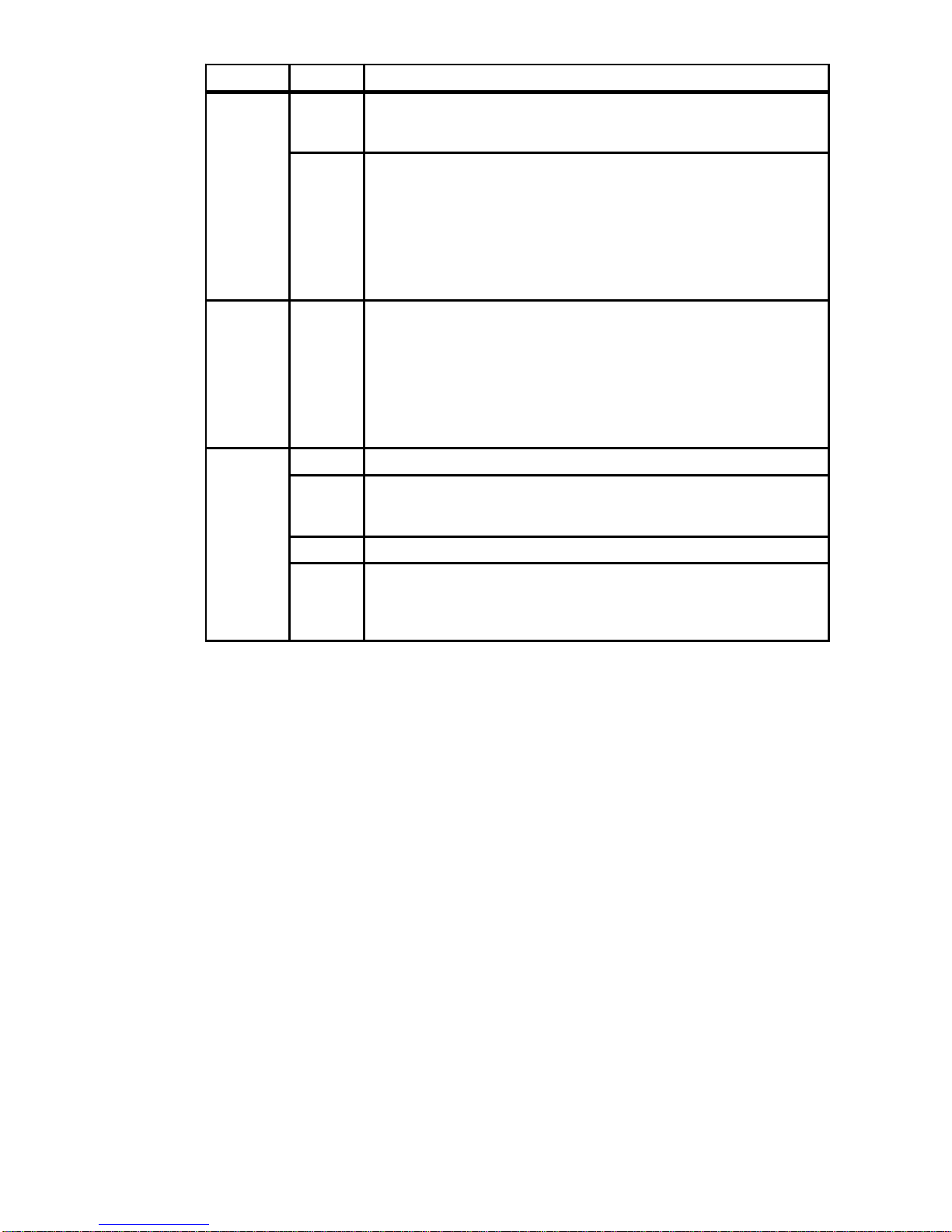

Location Code Table for SCSI and Non-SCSI Devices

Use the following table to determine the physical location of a device or unit.

Note: The location code format for 9333 devices is described on the previous page and in

9333 documentation.

Use the following example to identify these two-character pairs: AB-CD-EF-GH.

Pair

Value Description

AB 00

00

00

00

Workstation-type system unit.

CPU drawer or enclosure in a rack-type system unit.

SCSI device drawer in a rack-type system unit.

SCSI disk drawer in a rack-type system unit.

08 This is not an invalid number. Slot 8 contains a standard SCSI

adapter.

CD 00

00

00

CPU card.

MCA planar.

A device attached to the MCA planar.

01

02

03

04

05

06

07

Adapter in slot 1 of the MCA planar.

Adapter in slot 2 of the MCA planar.

Adapter in slot 3 of the MCA planar.

Adapter in slot 4 of the MCA planar.

Adapter in slot 5 of the MCA planar.

Adapter in slot 6 of the MCA planar.

Adapter in slot 7 of the MCA planar.

10

11

12

13

14

15

16

17

18

Second MCA planar.

Adapter in slot 1 of the second MCA planar or expansion cabinet.

Adapter in slot 2 of the second MCA planar or expansion cabinet.

Adapter in slot 3 of the second MCA planar or expansion cabinet.

Adapter in slot 4 of the second MCA planar or expansion cabinet.

Adapter in slot 5 of the second MCA planar or expansion cabinet.

Adapter in slot 6 of the second MCA planar or expansion cabinet.

Adapter in slot 7 of the second MCA planar or expansion cabinet.

Adapter in slot 8 of the second MCA planar or expansion cabinet.

CD 0A

0B

0C

0D

Memory card in slot A on the System planar.

Memory card in slot B on the System planar.

Memory card in slot C on the System planar.

Memory card in slot D on the System planar.

0P

0Q

0R

0S

CPU card located in slot P on the System planar.

CPU card located in slot Q on the System planar.

CPU card located in slot R on the System planar.

CPU card located in slot S on the System planar.

EF 00 Does not have a connector or software was not able to identify

the connector number.

01

02

03

04

The number of the connector on an adapter card, distribution

box, or planar. If needed, see Chapter 8 for the connector

numbering on your adapter.

0D

0E

0P

Internal diskette connector on the MCA planar.

Built-in Ethernet adapter.

Parallel printer connector.

Page 30

1-12 Operator Guide

Pair DescriptionValue

S1

S2

S3

Serial port 1 connector.

Serial port 2 connector.

Serial Port 3 connector.

11

12

13

14

21

22

23

24

Remote async node 1 on line 1.

Remote async node 2 on line 1.

Remote async node 3 on line 1.

Remote async node 4 on line 1.

Remote async node 1 on line 2.

Remote async node 2 on line 2.

Remote async node 3 on line 2.

Remote async node 4 on line 2.

GH 01

02

03

04

05

06

07

08

Memory SIMM or DIMM in location 1 on the memory card.

Memory SIMM or DIMM in location 2 on the memory card.

Memory SIMM or DIMM in location 3 on the memory card.

Memory SIMM or DIMM in location 4 on the memory card.

Memory SIMM or DIMM in location 5 on the memory card.

Memory SIMM or DIMM in location 6 on the memory card.

Memory SIMM or DIMM in location 7 on the memory card.

Memory SIMM or DIMM in location 8 on the memory card.

G,HHH 00 For devices other than those listed here

00

thru

15

Port addresses for 8-port async, 16-port async, and 16-port

concentrator distribution boxes.

01 Diskette drive 1

0,000

thru

F,255

SCSI address and logical unit number of the device shown in

decimal.

Note: When a comma appears between the G and H, digits

appearing to the right of the comma are represented in decimal.

Page 31

Description of the 7013 J Series System 1-13

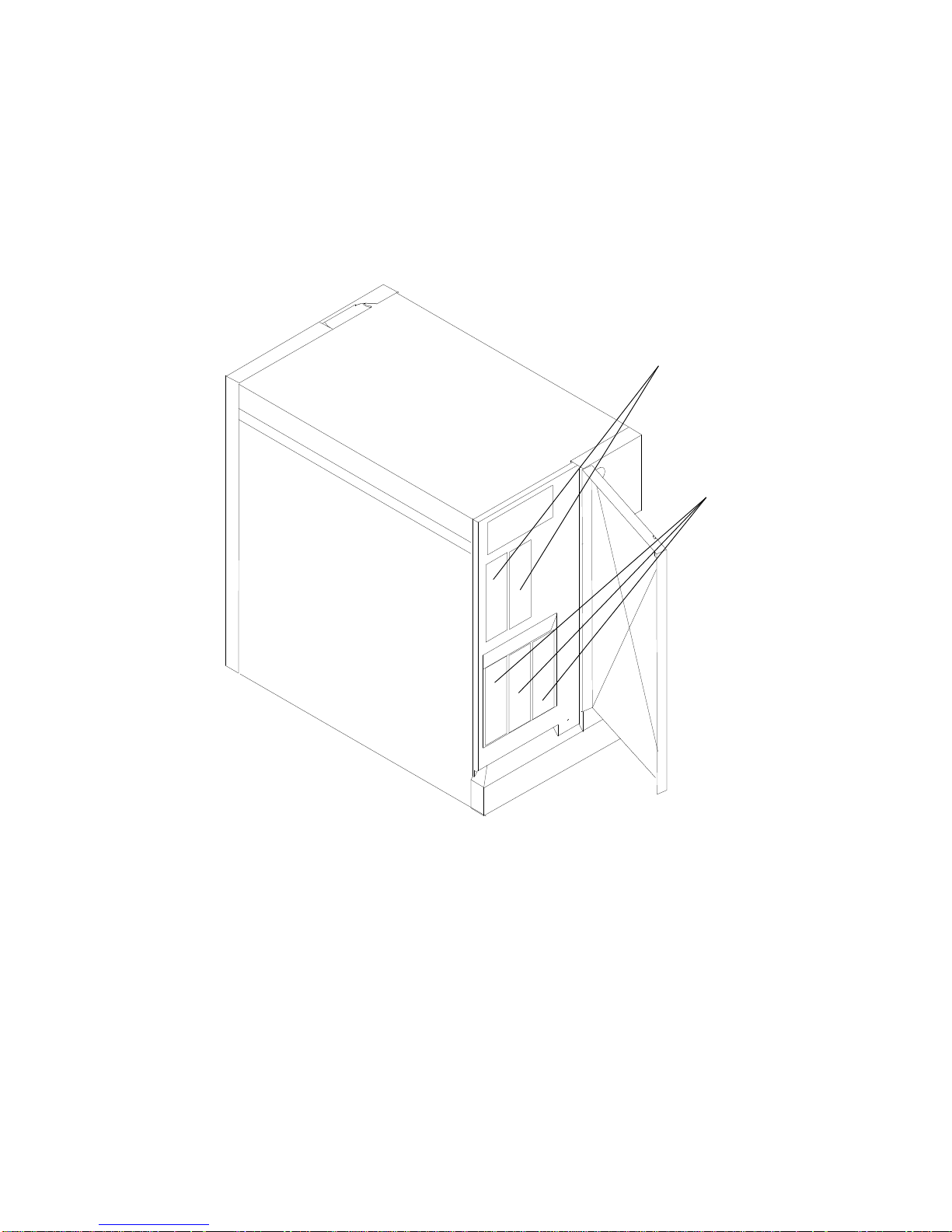

Cluster Power Control

The cluster power controller (CPC) is an external option which provides:

• Connectivity between a remote support facility and multiple CPUs through a modem

• Connectivity from any attached CPU to any disk drive drawer

• Central power-on and power-off through the TTY.

The CPC provides ports for connection of multiple 7012 G Series system units, 7013 J

Series system units, and 7015 Model R30, R40, and R50 CPU enclosures for interface

connection of CPUs and disk drive drawers. The CPC also contains ports for connection of a

modem and TTY.

For more information about the CPC, refer to

Cluster Power Control Operator and Service

Guide

, order number SA23-2766.

Disk Drive Connectors

(PCI Connectors)

Disk Drive Connectors

(RS485 Connectors)

CPU

Connectors

CPU D

CPU C

CPU B

CPU A

1

2

1

2

1

2

1

2

CPC

Expansion

Connectors

CPC

Left

CPC

Right

1

2

1

2

TTY Connector

Modem Connector

Page 32

1-14 Operator Guide

Page 33

Using the System Unit 2-1

Chapter 2. Using the System Unit

This chapter explains how to use the operator panel and other devices for control, input,

display, and data storage in the 7013 J Series system unit.

CAUTION:

This product is equipped with a three-wire power cable and plug for the user’s

safety. Use this power cable in conjunction with a properly grounded electrical outlet

to avoid electrical shock.

Main Power Switch Module

Each system unit is equipped with a Main Power Switch Module containing the switch for

general AC power ON/OFF control, and the AC power cable connector.

Before performing the first startup of the machine being installed, the following steps must

be performed to give it AC power. Please note that this procedure must be repeated for

each system unit (expansion and base).

1. Press the Main Power Switch at the rear of each unit to the Off position “O”.

2. Connect the power cord connector to the connector present on the Main Power Switch

Module of the units, as shown in the figure.

Main Power Switch

Module with Power

Cord Connector

Page 34

2-2 Operator Guide

3. Plug the power cords into the elelectical outlet.

4. Perform this step first on the expansion unit if there is one attached. Press the switch

located on the Main Power Switch Module to on, switching it to the ”I” position.

Main Power

Switch

Page 35

Using the System Unit 2-3

The Operator Panel

The Operator Panel complex is installed on the front of the main unit. To access the

operator panel you have to open the front door.

The Operator Panel elements are controlled by the CPU and by a special microprocessor

located on the I/O card called SystemGuard.

Operator Controls

Operator Panel Display

Reset/Scroll

Button

Key Mode Switch

Power Light

Power Button

Diskette Drive

Normal

Secure

Service

Power Button Used to switch the power to the system on or off

Power Light Green LED: when lit, indicates all voltages in the power supply

are present and within specified limits and all fans are running.

The power-on light is also used to help analyze power and

cooling problems.

Reset/Scroll Button Used to reset the system unit, depending on the position of the

key mode switch. Also used to scroll the messages on the

Operator Panel Display.

Operator Panel Display Displays status indication of the system

Key Mode Switch Is a key controlled switch with three positions labeled:

, and .

Diskette Drive Used to read and write diskettes

The key mode switch functions are enabled only when power is present in the base unit,

that is, the base unit main power switch on the back of the unit is in the ON position.

Page 36

2-4 Operator Guide

Reading the Operator Panel Display

Attention: If you have a flashing 888 in the Operator Panel Display, do not push the

Reset/Scroll button before you carefully read the related documentation.

The Operator Panel Display has two 16 position rows. The display is used for:

• Event indications and problem reporting during Power-On-Self-Test (POST) and

Configuration Methods.

• Progress and command indications when loading diagnostics.

• Event indications during diagnostics when a Console-Display is not available.

• Problem reporting during diagnostics when a Console-Display is not available.

• Check Stop indications when the machine cannot recover from a Check Stop.

• Crash reporting when the machine cannot recover from a crash.

• Dump progress and command indications during dump.

• Problem reporting when there is a power problem.

During the POST, the numbers displayed indicate the progress of the testing. If an error that

requires attention is detected, the system unit stops and a flashing 888 is displayed in the

Operator Panel Display to identify the error.

When the self-tests and configuration methods complete without error, the display is blank.

Operator Panel Display

Please refer to the

Problem Solving Guide and Reference

for a detailed description of what

is displayed on the operator panel display.

Page 37

Using the System Unit 2-5

Using the Reset/Scroll Button

Attention: When the mode switch is in Normal or Service position, pressing the

Reset/Scroll button causes the unit to reset and do an IPL (Initial Program Load). Pressing

the Reset/Scroll button while the operating system is running can result in damaged or lost

data.

The Reset/Scroll button is used to:

• Reset the system unit and cause a boot when the mode switch is set to Normal or

Service. Pushing the Reset button once may cause an incomplete reset and the system

may not restart. Therefore it is recommended to push the reset button twice for a

complete reset.

• Read out messages (scroll) after a flashing 888 is displayed.

• Start the dump program when a manual dump is needed.

• Sequentially read system configuration in Stand-By Mode and with the key mode switch

in Service position.

Pushing the Reset button once causes an incomplete reset and the system may not restart.

Therefore it is recommended that you push it twice for a complete reset.

When the mode switch is in the Secure position, the Reset/Scroll button is disabled.

Reset/Scroll Button

Page 38

2-6 Operator Guide

Setting the Key Mode Switch

The key mode switch has three positions:

Normal Position

Secure Position

Service Position

The switch is used to establish the initial program load (IPL) path. The IPL loads the system

programs, checks the system hardware and prepares the system for user operation.

Before starting the system unit for normal day-to-day-operation, set the key mode switch to

the normal position. This permits the operating system to load after the power-on-self-tests

(POST’s) are completed.

Note: It is possible to set the Electronic Mode Switch (E-Key) through SystemGuard

firmware from the local or remote SystemGuard BUMP console. In Normal mode an

electronic key may be used to set Normal, Secure and Service modes. For remote

maintenance, see “Electronic Mode Switch” page 2-8. In Secure and Service

modes, the physical key setting prevails.

Operator Panel with Key Mode Switch in Normal Position

Key Mode Switch

The following table summarizes the possible operations for each key mode switch position:

Operation Key Mode Switch Position

Normal Secure Service

Reset Enabled Disabled Enabled

BUMP Console Active Enabled Enabled Enabled

BUMP Console Debug/

Dump

Disabled Disabled Enabled

Normal IPL Enabled Disabled Disabled

Service IPL Disabled Disabled Enabled

Note: In this information, the name SystemGuard BUMP Console refers to the Local

Console connected to the S1 port on the system interface board.

Page 39

Using the System Unit 2-7

The following list explains the uses of the key mode switch positions:

Attention: The Reset/Scroll button is active when the mode switch is in the Normal or

Service position, and pressing the Reset/Scroll button can cause data to be damaged or lost

if the operating system is still running.

OK The Normal Position is used for attended operation, which is the usual or

normal placement of the key mode switch when an operator is present and

in control of the operation of the system unit. The Reset/Scroll button is

active when the key mode switch is in the Normal position. The IPL

proceeds according to the Normal Mode Bootlist.

The Secure position prevents the system from booting. If the system is

already booted, this position does not lock the system console or block

system network communication. It also prevents an autoboot in case of a

system crash or checkstop condition.

When the operating system is up, turning the key to the Secure position

disables the Reset/Scroll button. With the key mode switch in this position,

a passerby cannot accidentally press the Reset/Scroll button and cause a

loss of data.

The Service position is used for attended operation when hardware or

software service is conducted. The Service position activates operating

system console sequences that support error determination (debug) and

storage printout (dump). In the Service position, the system unit attempts to

IPL from the media drive. The IPL proceeds according to the Service Mode

Bootlist.

The key mode switch is also used for the following:

• To indicate to the diagnostic programs that there is no console available. This is

done by setting the key mode switch from Service to Normal and then back to Service

when a c31 is displayed on the operator panel display.

• To start a dump. If the system is booted in Normal mode, a manual dump is started with

the key mode switch set to Service and pressing the Reset/Scroll button. If the system is

booted with the key mode switch set to the Service mode, a dump is started by setting

the key mode switch to Normal and pressing the Reset/Scroll button. If the Reset/Scroll

button is pressed twice, the system reboots.

If there is a problem with the system unit, refer to

the

Problem Solving Guide and Reference

before setting the mode switch to the Service position or pressing the Reset/Scroll button.

Attention: Do not set the key mode switch from Normal (OK) to Service while the system is

booting. Instead, wait until the boot is completed and then change the mode switch setting.

Page 40

2-8 Operator Guide

Electronic Mode Switch

The electronic mode switch (E-key) enables you to remotely change the status of the key

mode switch and:

• places the system for maintenance or debug purpose from a remote location, from

Normal to Service mode, without a person physically being present near the system to

change the key mode switch position,

• assists remote access and service of a customer installed machine from a central

customer hub (CH) or IBM service center and to run off-line and online diagnostics from a

remote location to isolate a problem to the FRU level,

• activates from an enabled terminal (via a software command) the use of the maintenance

features on the remote line

• breaks a remote maintenance session by the service people, if some intrusion attempt is

suspected

• prevents non-authorized access to the system setting the system in Secure mode.

The Electronic Mode Switch has validity only when the operator panel key mode switch is

set to the Normal position. It is able to electronically move the position of the ”key mode

switch” on the operator panel in the following way:

Key Mode

Switch

Electronic

Mode Switch

Status of the System (*)

Normal Normal Normal

Service Service

Secure Secure

Secure Set to any mode Secure

Service Set to any mode Service

Note: (*) The status of the system matters only during IPL and in off-line maintenance

mode; once the Operating System is up and running, the key mode status is

relavent only for maintenance application software and diagnostic aids.

The following functions of the key mode switch cannot be performed remotely by setting the

E-Key:

• Indicate to the diagnostic program that no console is available

• Start a manual dump.

See the

AIX Version 4 System Management Guide: Communications and Networks

and the

keycfg command for detailed information on the electronic mode switch.

Setting the Electronic Mode Switch (E-Key)

See “How to Set the Electronic Key” on page 3-39 for information about setting the

electronic key mode switch.

Page 41

Using the System Unit 2-9

Starting and Stopping the System Unit

Note: This section presents an overview of the procedures to follow when starting up and

shutting down the system. Before performing initial start up procedures, check with

the system administrator to determine if the system operating software has been

loaded and define the best startup and shut down procedures for the system. If the

system operating software must be loaded, refer to the

AIX Version 4 System

Management Guide: Operating System and Devices

.

Methods of Starting the System Unit

The four methods of starting the system unit are as follows:

Manually The power is switched on manually, and the

system unit does a normal or a service IPL

depending on the mode switch position. For further

explanation refer to page 2-10.

Remotely The power is switched on from another location,

and the system unit does a normal IPL. To use this

method, a modem or an equivalent device must be

attached to the system.

Programmed by date and time On a specific day and time, the power is switched

on and the system unit does a normal IPL. This

facility is available only with the system in stand-by

mode.

Recovery after a power failure When the power is restored, the power is switched

on and the system unit does a normal IPL.

The examples used in this section describe a manual start up procedure. Refer to the

AIX Version 4 System Management Guide: Operating System and Devices

, for more

information on all start up and shut down procedures. Also refer to “Chapter 3. Using

System Guard” and “Appendix G. System Power States” for additional start up and shut

down procedures.

When you press the power button, the power light comes on and the system starts its

power-on self-tests (POST). During the POST, messages warning that these tests are in

progress are displayed in the operator panel display. If an irrecoverable error occurs, its

error code is displayed in the operator panel display.

Page 42

2-10 Operator Guide

Manually Starting the System Unit

1. Set the power switches of the external devices to On (if connected).

2. If an expansion unit is attached, set the main power switch on the back of the unit to On.

Set the base unit main power switch at the rear side of the system to On.

3. The LCD display will display the message “Stand-By”, indicating that stand-by power is

turned on.