Page 1

7012 G Series

Service Guide

Page 2

Third Edition (April 1997)

This edition notice applies to the

The following paragraph does not apply to the United Kingdom or any country where such

provisions are inconsistent with local law: THIS PUBLICATION IS PRINTED “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some

states do not allow disclaimer of express or implied warranties in certain transactions; therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made

to the information herein; these changes will be incorporated in new editions of the publication. The

manufacturer may make improvements and/or changes in the product(s) and/or program(s) described in this

publication at any time, without notice.

It is possible that this publication may contain reference to, or information about, products (machines and

programs), programming, or services that are not announced in your country. Such references or information

must not be construed to mean that such products, programming, or services will be offered in your country.

Any reference to a licensed program in this publication is not intended to state or imply that you can use only

the licensed program indicated. You can use any functionally equivalent program instead.

AIX is a registered trademark of International Business Machines Corporation.

Medeco is a trademark of Medeco Company.

Micro Channel is a registered trademark of International Business Machines Corporation.

SystemGuard is a trademark of International Business Machines Corporation.

Velcro is a trademark of Velcro Industries.

Copyright International Business Machines Corporation, 1994, 1997. All rights reserved.

Note to US Government Users – Documentation and programs related to restricted rights – Use, duplication,

or disclosure is subject to the restrictions set forth in the GSA ADP Schedule Contract.

7012 G Series Service Guide.

This edition obsoletes all previous editions.

Page 3

Table of Contents

Communications Statements vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notices xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Book xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1. Reference Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

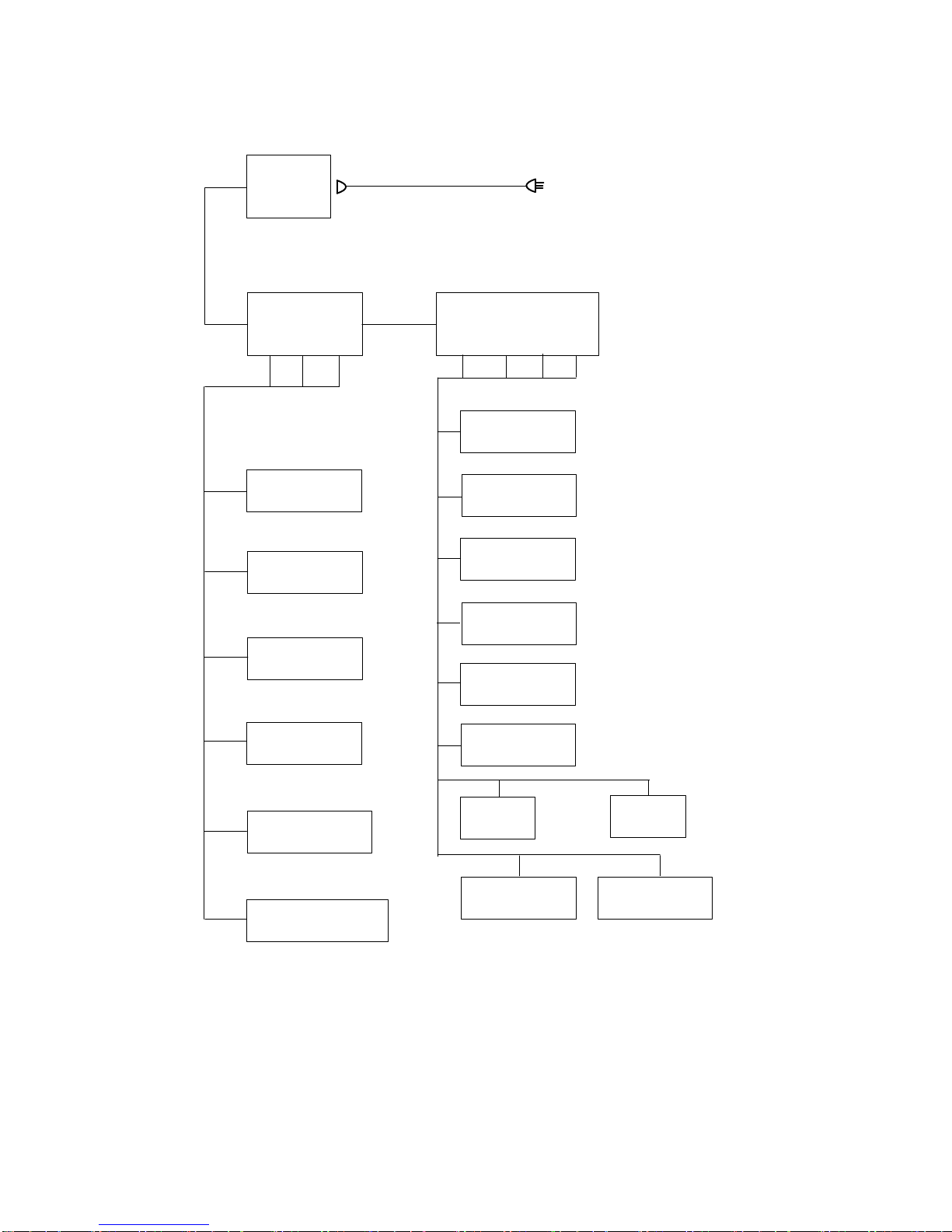

Base Unit System Unit Locations 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear View without Cover 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side View without Covers 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Cards 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Port Splitter Cable 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard / Mouse Card (KBD) 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Unit System Unit Locations 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of the Disk Expansion Unit 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cluster Power Control 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Planar Connector Locations 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Flow 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Flow 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Cable Routing 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cables 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Inspection Guide 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2. Using System Guard 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Power 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Components 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Bring-Up MicroProcessor Overview 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Operator Panel 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Consoles 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical and Electronic Key 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Phases 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand-By Phase 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Init Phase 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Phase 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boot Phase 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run-Time Phase 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Parameters and Flags 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Working with SystemGuard 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Menus 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Menu 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Configuration 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display BUMP Error Log 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable Service Console 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disable Service Console 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface iii

Page 4

Reset 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Off 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Boot 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Off-Line Tests 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Parameters 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set National Language 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Common SystemGuard Tasks 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customizing SystemGuard For Your Needs 2-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reloading the Flash EEPROM 2-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3. Maintenance Analysis Procedures (MAPs) 3-1520-1. . . . . . . . . . . . . . . . . . . . .

MAP 1520: 7012 G Series System Unit - Power Map 3-1520-1. . . . . . . . . . . . . . . . . . . . . . . . .

MAP 1540:7012 G Series Minimum Configuration 3-1540-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4. Removal and Replacement Procedures 4-1. . . . . . . . . . . . . . . . . . . . . . . .

Handling Static-Sensitive Devices 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Cover 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Cover 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Cover 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Unit Base 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Panel 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit Adapters 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Fan 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit Front Fan 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit CPU/Memory Card Retainers 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Drive 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit Diskette Drive 4-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Devices 4-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit CPU Card 4-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit Memory Card 4-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Modules 4-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Card 4-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit Battery 4-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 4-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Unit System Planar 4-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Lock 4-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Unit ECB Card 4-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Unit SCSI Cable 4-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5. System Installation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 1. Inventory 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 2. Observe this Safety Notice during Installation 5-2. . . . . . . . . . . . . . . . . . . . . . . . .

Step 3. Checking Customer Outlets 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 4. Setting Up the System Unit 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 5. Set Up Each Device Being Attached 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 6. Connecting Devices to Standard I/O Ports 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 7. Connecting Devices to the Adapters 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 8. Arranging the System Unit and Devices 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Checkout 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv Service Guide

Page 5

Chapter 6. Expansion Installation 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Cable Interconnection 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCSI Cable Connection 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recognizing the New Unit 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disconnecting Expansion Units 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7. Parts 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acronyms for FRU Parts 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Covers and Chassis 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics, Drives, and Power (1 of 2) 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics, Drives, and Power (2 of 2) 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7012 G Series Expansion Unit Unique Parts 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A. SystemGuard Test Groups A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Test Groups Table A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SystemGuard Test Group Descriptions A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BUMP Quick I/O Tests Group A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JTAG Test Group A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direct I/O Test Group A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Test Group A-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCB and Memory Test Group A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interrupt Tests Group A-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU MultiProcessor Test Group A-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B. Modifying SystemGuard Parameters B-1. . . . . . . . . . . . . . . . . . . . . . . . .

Default Parameter Values B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Flags and Parameters Under AIX Service Aids B-3. . . . . . . . . . . . . . . . . . . . .

Modifying the Remote Authorization Flag B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying the Dial-Out Authorization Flag B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying Dial-In Phone Numbers B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying Dial-Out Phone Numbers B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying the Electronic Mode Switch from Service Line Flag B-6. . . . . . . . . . . . . . . . . .

Reloading the Flash EEPROM B-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C. SystemGuard Remote Operation Configuration C-1. . . . . . . . . . . . . . .

Terminal Configuration C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flags and Parameters Settings C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modem Configuration Files C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initializing a Modem C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Dial-Out C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D. Off Line Diagnostic Error Codes D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Logging D-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E. System Power States E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power States E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary: Special Terms Used in SystemGuard X-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Index X-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface v

Page 6

vi Service Guide

Page 7

Communications Statements

The following statement applies to this product. The statement for other products intended

for use with this product appears in their accompanying manuals.

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC

emission limits. Neither the provider nor the manufacturer are responsible for any radio or

television interference caused by using other than recommended cables and connectors or

by unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

United Kingdom Telecommunications Safety Requirements

This equipment is manufactured to the International Safety Standard EN60950 and as such

is approved in the UK under the General Approval Number NS/G/1234/J/100003 for indirect

connection to the public telecommunication network.

The network adapter interfaces housed within this equipment are approved separately, each

one having its own independent approval number. These interface adapters, supplied by the

manufacturer, do not use or contain excessive voltages. An excessive voltage is one which

exceeds 70.7 V peak ac or 120 V dc. They interface with this equipment using Safe Extra

Low Voltages only. In order to maintain the separate (independent) approval of the

manufacturer’s adapters, it is essential that other optional cards, not supplied by the

manufacturer, do not use main voltages or any other excessive voltages. Seek advice from a

competent engineer before installing other adapters not supplied by the manufacturer.

International Electrotechnical Commission (IEC) Statement

This product has been designed and built to comply with IEC Standard 950.

Preface vii

Page 8

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council Directive

89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility .

Neither the provider nor the manufacturer can accept responsibility for any failure to satisfy

the protection requirements resulting from a non-recommended modification of the product,

including the fitting of option cards not supplied by the manufacturer.

This product has been tested and found to comply with the limits for Class A Information

Technology Equipment according to CISPR 22 / European Standard EN 55022. The limits

for Class A equipment were derived for commercial and industrial environments to provide

reasonable protection against interference with licensed communication equipment.

Attention: This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate measures.

Avis de conformité aux normes du ministère des Communications du

Canada

Cet appareil numérique de la classe A respecte toutes les exigences du Réglement sur le

matériel brouilleur du Canada.

Canadian Department of Communications Compliance Statement

This Class A digital apparatus meets the requirements of the Canadian

Interference-Causing Equipment Regulations.

VCCI Statement

The following is a summary of the VCCI Japanese statement in the box above.

This equipment is in the Class 1 category (information equipment to be used in

commercial and/or industrial areas) and conforms to the standards set by the Voluntary Control Council For Interference by Data Processing Equipment and Electronic Office Machines aimed at preventing radio interference in commercial and/

or industrial areas.

Consequently , when used in a residential area or in an adjacent area thereto, radio

interference may be caused to radios and TV receivers, etc.

Read the instructions for correct handling. VCCI–1.

viii Service Guide

Page 9

Radio Protection for Germany

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen EMVG vom 9.Nov.92

das EG-Konformitätszeichen zu führen.

Der Aussteller der Konformitätserklärung ist die IBM Germany.

Dieses Gerät erfüllt die Bedingungen der EN 55022 Klasse A. Für diese Klasse von Geräten

gilt folgende Bestimmung nach dem EMVG:

Geräte dürfen an Orten, für die sie nicht ausreichend entstört sind, nur mit besonderer

Genehmigung des Bundesministers für Post und Telekommunikation oder des Bundesamtes

für Post und Telekommunikation betrieben werden. Die Genehmigung wird erteilt, wenn

keine elektromagnetischen Störungen zu erwarten sind.

(Auszug aus dem EMVG vom 9.Nov.92, Para.3, Abs.4)

Hinweis:

Dieses Genehmigungsverfahren ist von der Deutschen Bundespost noch nicht veröffentlicht

worden.

Preface ix

Page 10

x Service Guide

Page 11

Safety Notices

Note: For a translation of these notices, see

SA23-2652.

Definitions of Safety Notices

A

danger

or serious personal injury.

A danger notice appears on the following pages:

A

caution

moderate or minor personal injury.

A caution notice appears on the following pages:

An

system, or data.

notice indicates the presence of a hazard that has the potential of causing death

3-1520-1

4-1

4-44

5-2

notice indicates the presence of a hazard that has the potential of causing

xi

3-1520-1

4-1

4-30

4-42

5-2

5-3

attention

notice indicates an action that could cause damage to a program, device,

System Unit Safety Information

, order number

CAUTION:

A lithium battery can cause fire, explosion, or a severe burn. Do not recharge,

disassemble, heat above 100°C (212°F), solder directly to cell, incinerate, or expose

cell contents to water. Keep away from children. Replace only with the part number

specified for your system. Use of another battery may present a risk of fire or

explosion.

The battery connector is polarized; do not attempt to reverse the polarity.

Dispose of the battery according to local regulations.

Preface xi

Page 12

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label that

identifies its classification. The label, located on the drive, is shown below.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

TO IEC 825:1984 CENELEC EN 60 825:1991

The optical drive in this system unit is certified in the U.S. to conform to the requirements of

the Department of Health and Human Services 21 Code of Federal Regulations (DHHS 21

CFR) Subchapter J for Class 1 laser products. Elsewhere, the drive is certified to conform to

the requirements of the International Electrotechnical Commission (IEC) 825 (1st edition

1984) and CENELEC EN 60 825:1991 for Class 1 laser products.

CAUTION:

A class 3 laser is contained in the device. Do not attempt to operate the drive while it

is disassembled. Do not attempt to open the covers of the drive as it is not

serviceable and is to be replaced as a unit.

Class 1 laser products are not considered to be hazardous. The optical drive contains

internally a Class 3B gallium-arsenide laser that is nominally 30 milliwatts at 830

nanometers. The design incorporates a combination of enclosures, electronics, and

redundant interlocks such that there is no exposure to laser radiation above a Class 1 level

during normal operation, user maintenance, or servicing conditions.

xii Service Guide

Page 13

About This Book

This book provides maintenance information that is specific to the 7012 G Series system

unit, adapters, and attached devices that do not have their own service information. It also

contains Maintenance Analysis Procedures (MAPs) that are not common to other systems.

MAPs that are common to all systems are contained in

Channel Bus Systems

This book is used by the service technician for initial installation and to repair system

failures. This book assumes that the service technician has had training on the

Series

system unit.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing of

this product.

Related Information

The

Diagnostic Information For Micro Channel Bus Systems

contains the maintenance information and procedures that are common to all systems. The

information and procedures in this book apply to any system unit that uses the diagnostic

programs.

Adapters, Devices, and Cable Information

information about adapters, devices, and cabling for the system units. This manual also

contains the removal and replacement procedures for the logic boards on the disk drives.

This manual provides the service representative pin-out lists and cabling information to use

in isolating problems with customer cabling.

System Unit Safety Information

the danger and caution notices.

Diagnostic Information For Micro

.

7012 G

, order number SA23-2765,

, order number SA23-2764 contains reference

, order number SA23-2652, contains translated versions of

7012 G Series Setup Procedure,

The

the hardware setup of the base unit.

The

7012 G Series Expansion Unit Setup Procedure,

information about the hardware setup of the expansion unit.

7012 G Series Operator Guide,

The

the controls and features of the system unit.

Each attached device has a

the information needed for that device.

Setup and Operator Guide

order number SA23-2739, provides information about

order number SA23-2754, provides

order number SA23-2740, provides information about

and a

Service Guide

that provides

Preface xiii

Page 14

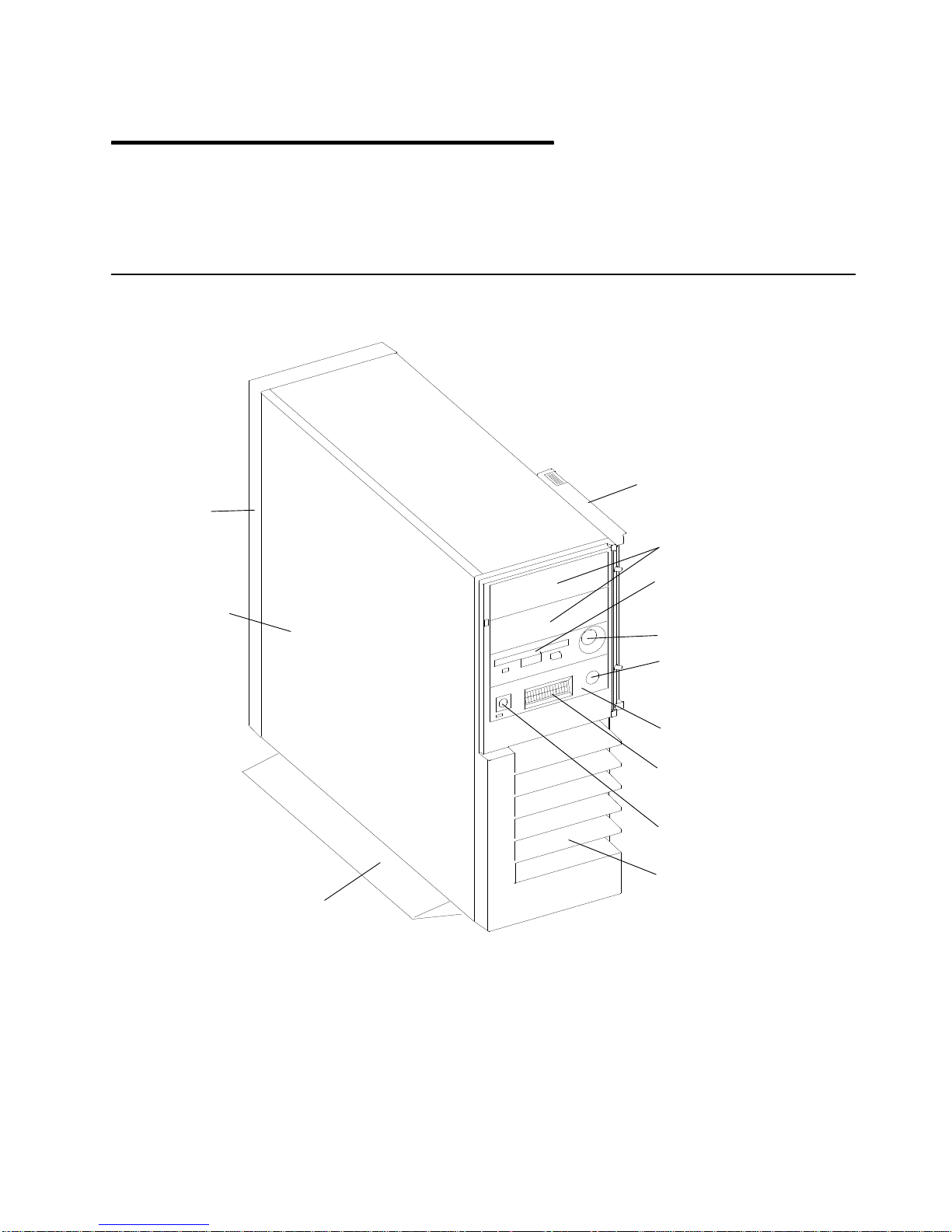

Chapter 1. Reference Information

Use the following views of the system unit to locate the feature positions, connectors, and

system board slot positions.

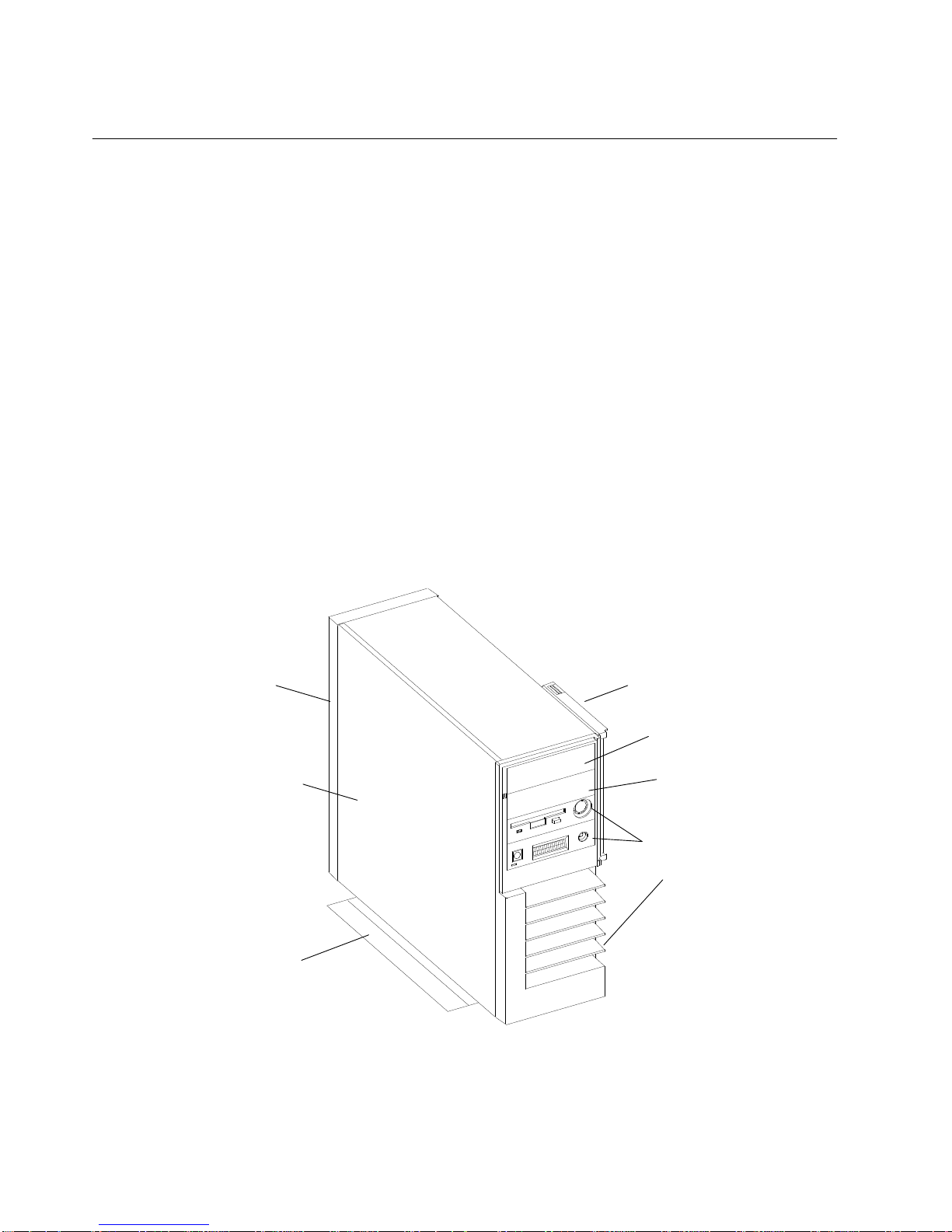

Base Unit System Unit Locations

Rear

Cover

Left Side

Cover

Front Door

Media Bays

3.5-Inch

Diskette

Drive

Key Mode Switch

Base

Reset

Button

Operator

Panel

Operator

Panel

Display

Power

Button

Front Cover

Reference Information

1-1

Page 15

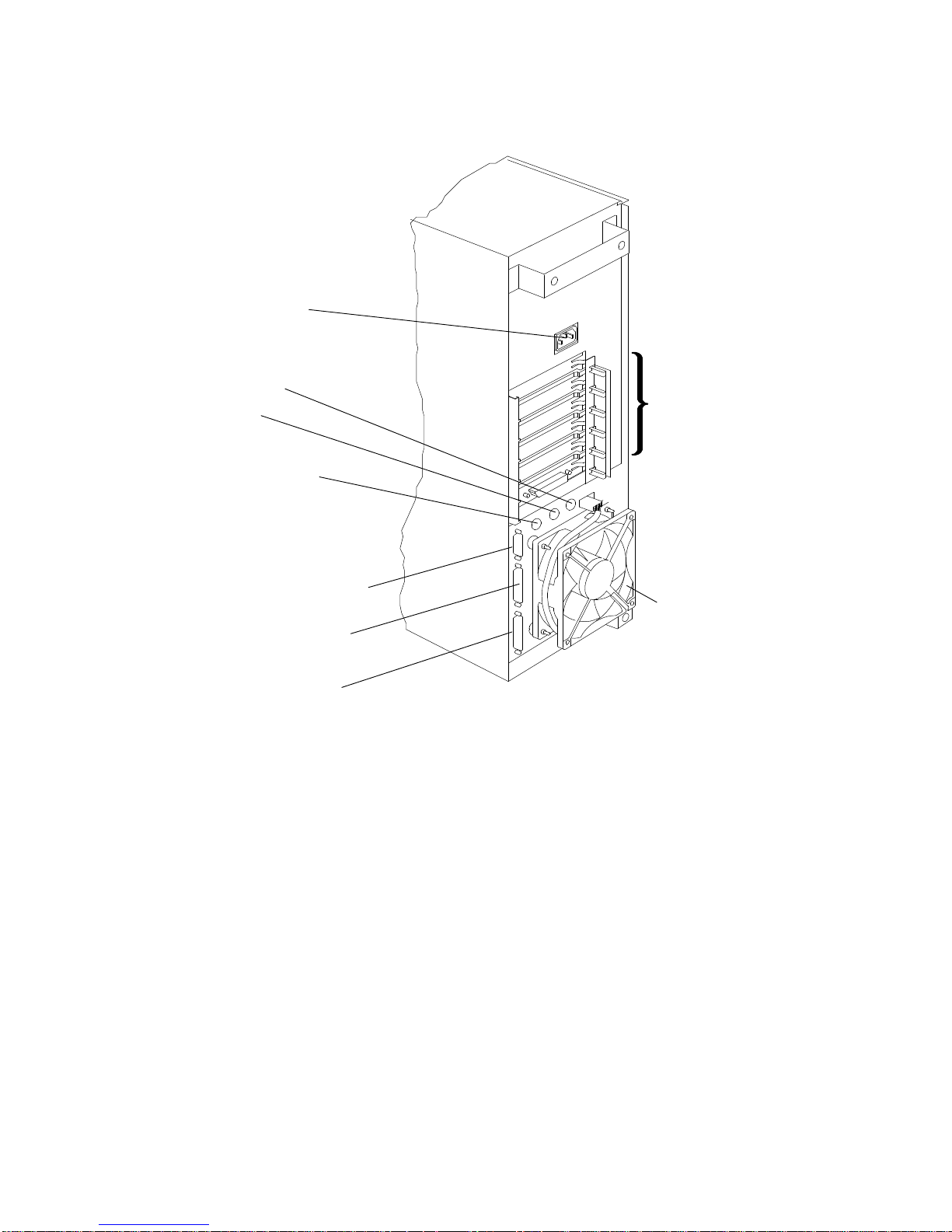

Rear View without Cover

Power Cord

Receptacle

Keyboard

Mouse

Power Control Port

(RS-485)

Adapters

9-Pin Serial Port (S3)

25-Pin Serial Port

(S1/S2)

Parallel Port (P1)

Rear

Fan

1-2 Service Guide

Page 16

Side View without Covers

Power

Supply

Micro

Channel

Adapter

Cards

RS-485

Card

Rear

Fan

1

...........

6

Optional Second

CPU Card Position 0

or

Two Disk Drives

Positions F and G

(G30 only)

Media Drive

Position A

Media Drive

Position B

Key Mode Switch

Diskette Drive

Position C

Operator

Panel

Front Fan

First CPU Card

Position 1

System

Planar

Memory Card

Position A

Disk Drive

Positions

D and E

Reference Information

1-3

Page 17

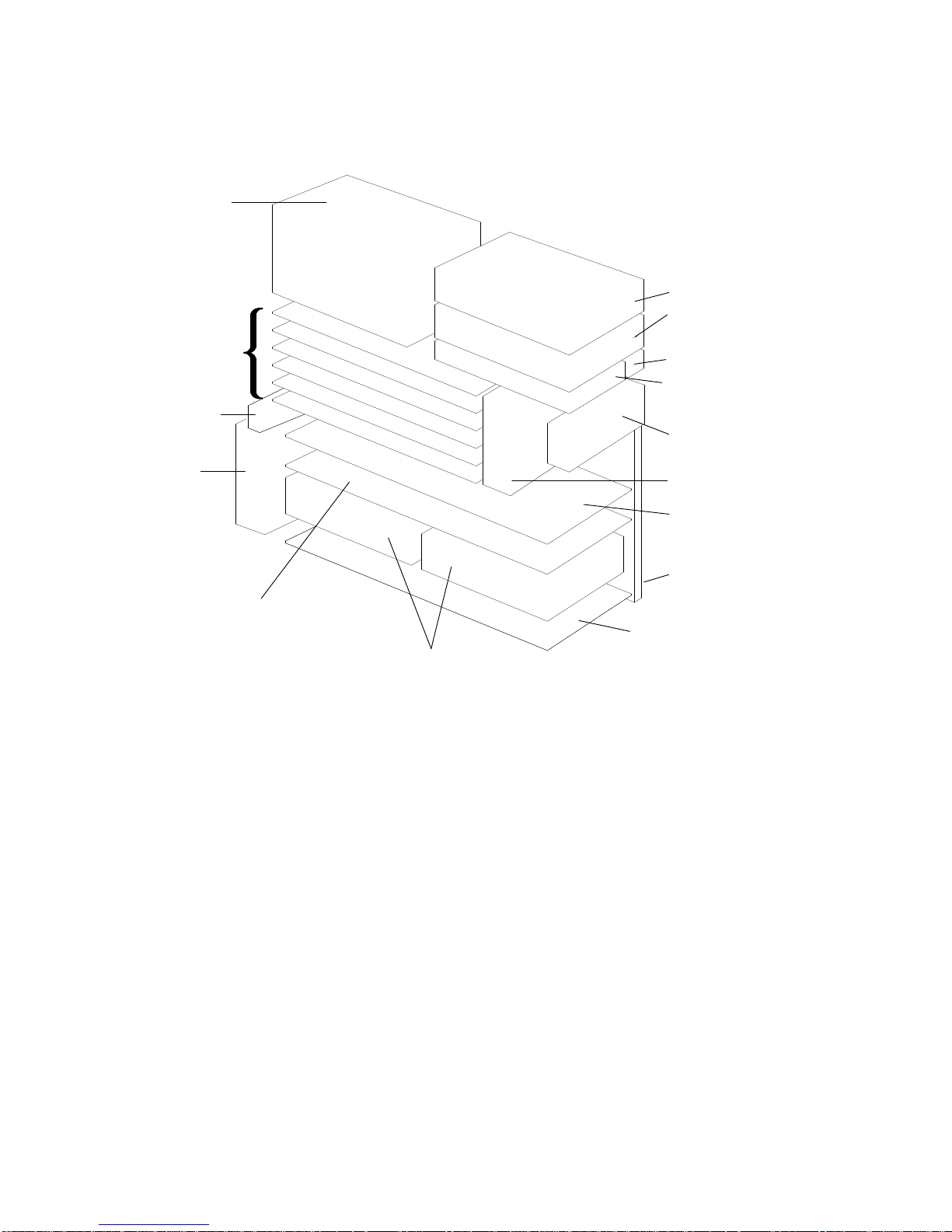

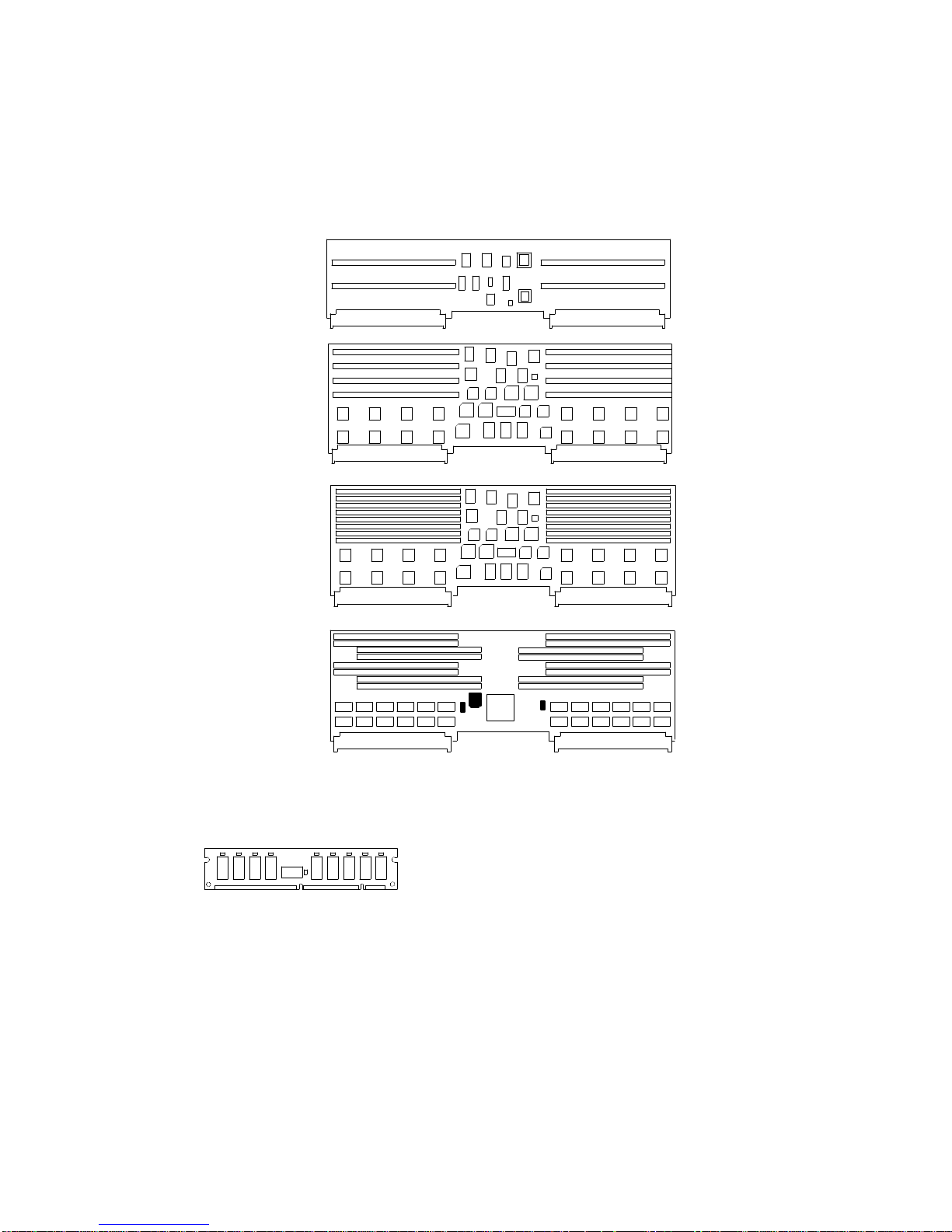

Memory Cards

There are four types of memory cards as shown below. Memory cards can house from one

to four memory module kits composed of four memory modules each, which comply with the

JEDEC standard for 68 pin, ECC, 60 ns, 5 volt memory modules. The figure below illustrates

the types of memory cards.

MRE

Memory Card

Two Bank RLX

Memory Card

Four Bank NFX

Memory Card

SF5

Memory Card

See page 4-38 for the location of the memory cards on the system planar.

The figure below shows a standard memory module.

The maximum memory reachable with this kind of memory module is 1024MB, because up

to four memory module kits can be installed on the memory card.

Modules from different size kits cannot be mixed on the same memory card.

According to both the kind and the number of memory module kits installed on the memory

cards, these can be divided into the following configurations:

• MM32, which gives 32MB memory contains four 8MB memory modules.

• MM64, which gives 64MB memory contains four 16MB memory modules.

• MM128, which gives 128MB memory contains four 32MB memory modules.

• MM256, which gives 256MB memory contains four 64MB memory modules.

1-4 Service Guide

Page 18

• NF256 board, based on 16M bit technology, which gives 256MB memory. It contains two

MM128 memory module kits.

• NF512 board, based on 16M bit technology, which gives 512MB memory. It contains four

MM128 memory module kits.

• NF1024 board, based on 16M bit technology, which gives 1024MB memory. It contains

four MM256 memory module kits.

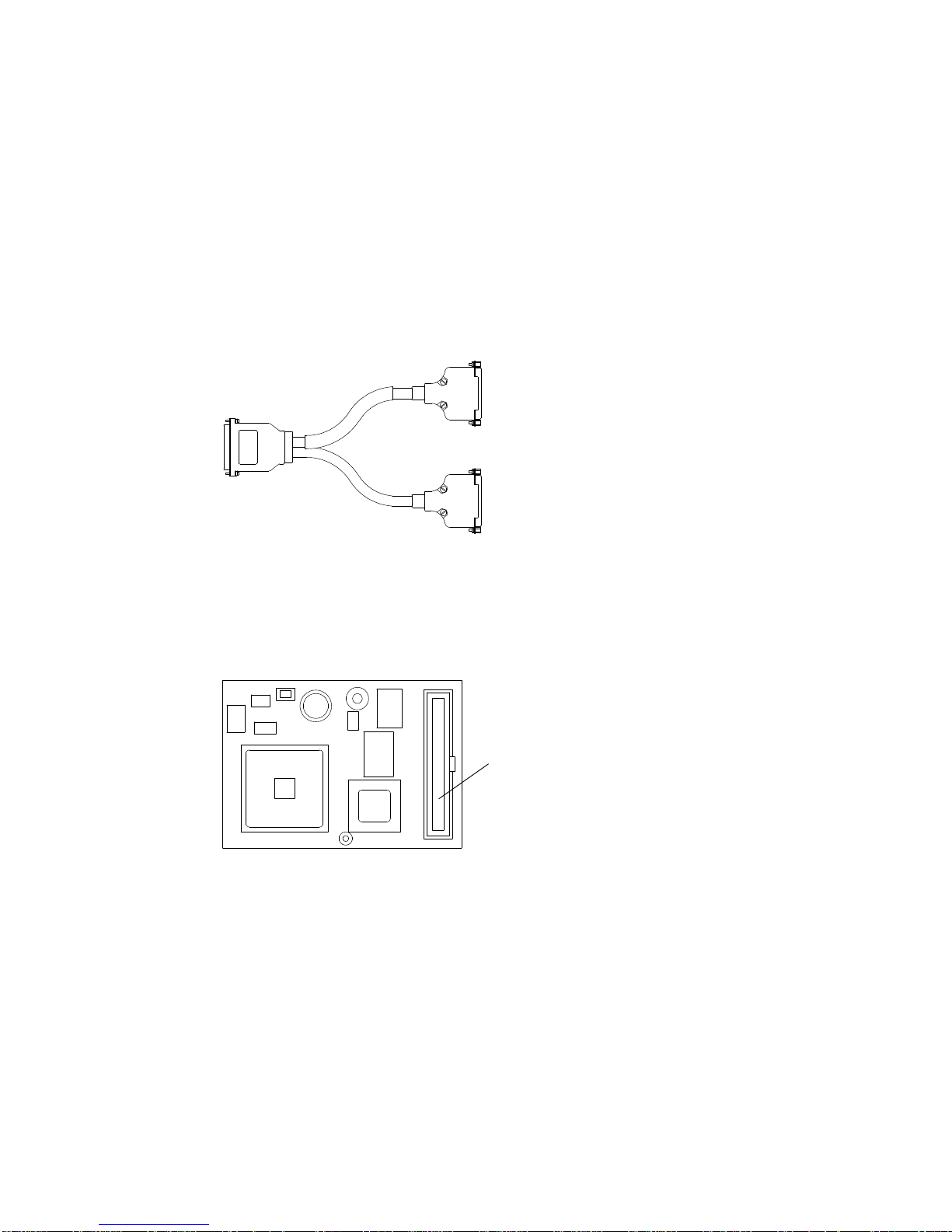

Serial Port Splitter Cable

The splitter cable is used to generate two 25-pin serial ports (S1 and S2 ports).

It is installed in the 25-pin serial port located in the rear of the base unit.

Keyboard / Mouse Card (KBD)

The KBD card is used to manage the connectors dedicated to the keyboard, mouse and

speaker capability, but not a key click option on the base unit. It must be placed on the

dedicated connector of the system planar (Y10 connector), but interfaces with the system

through the Micro Channel bus, which sees the card as occupying a Micro Channel slot.

Connector used to place

the KBD card on the system

planar

Reference Information

1-5

Page 19

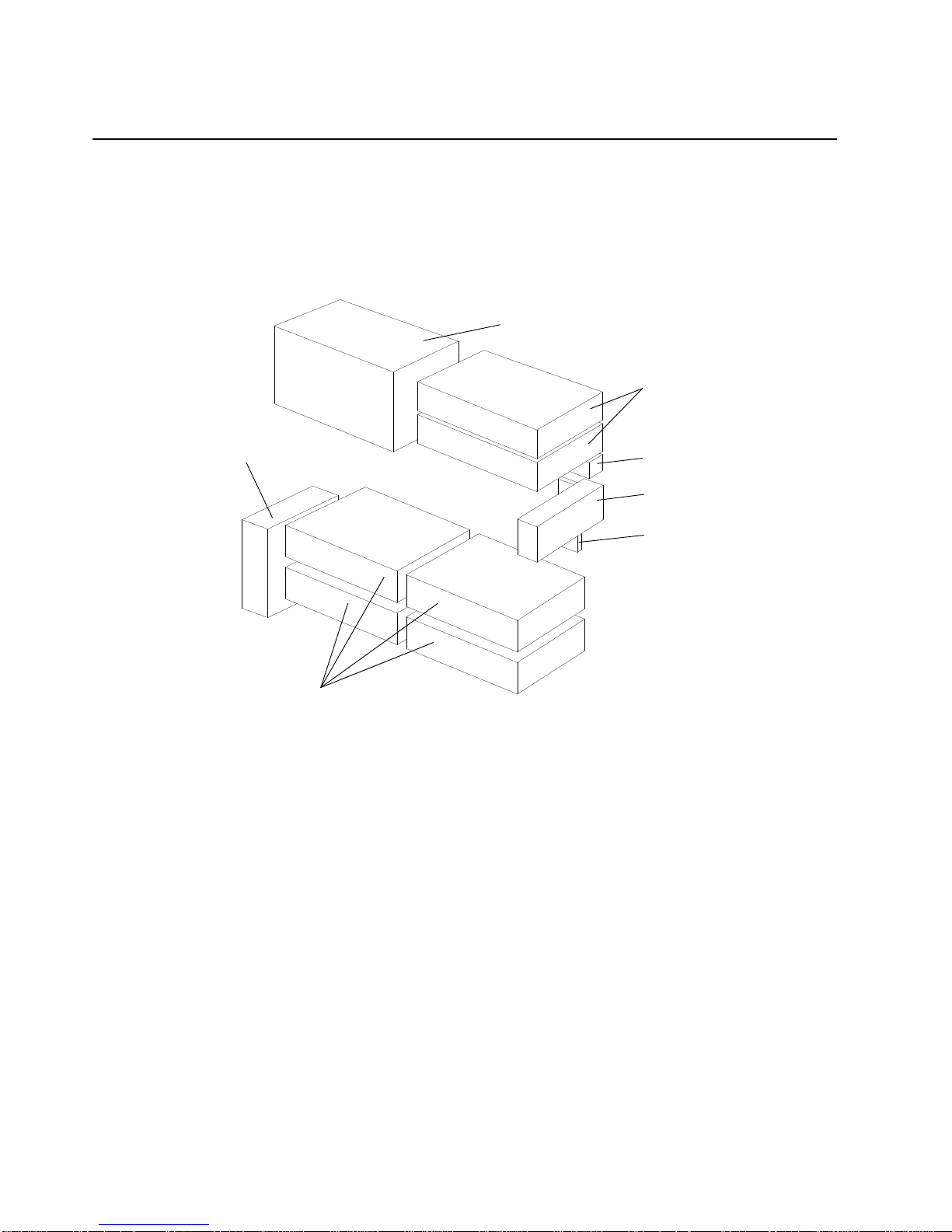

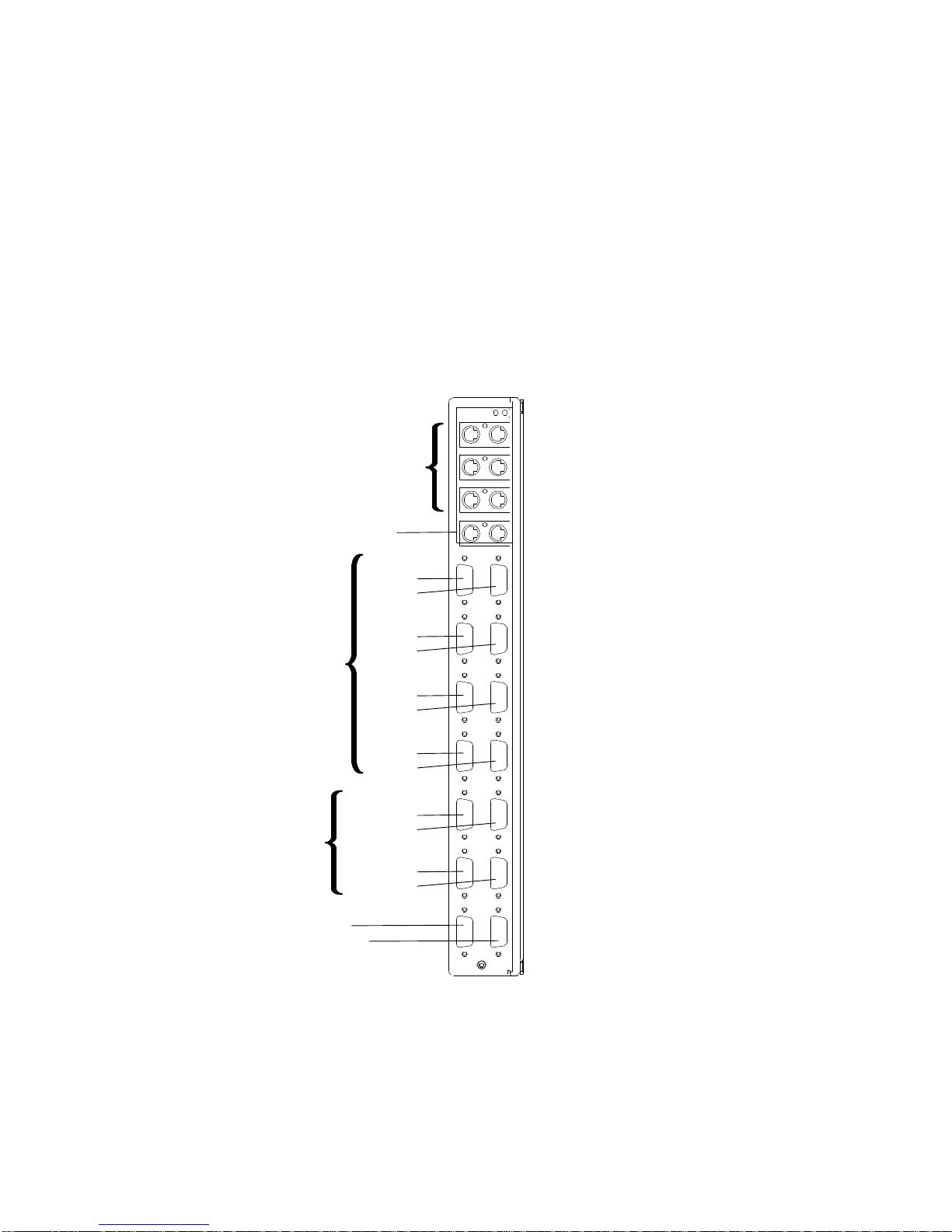

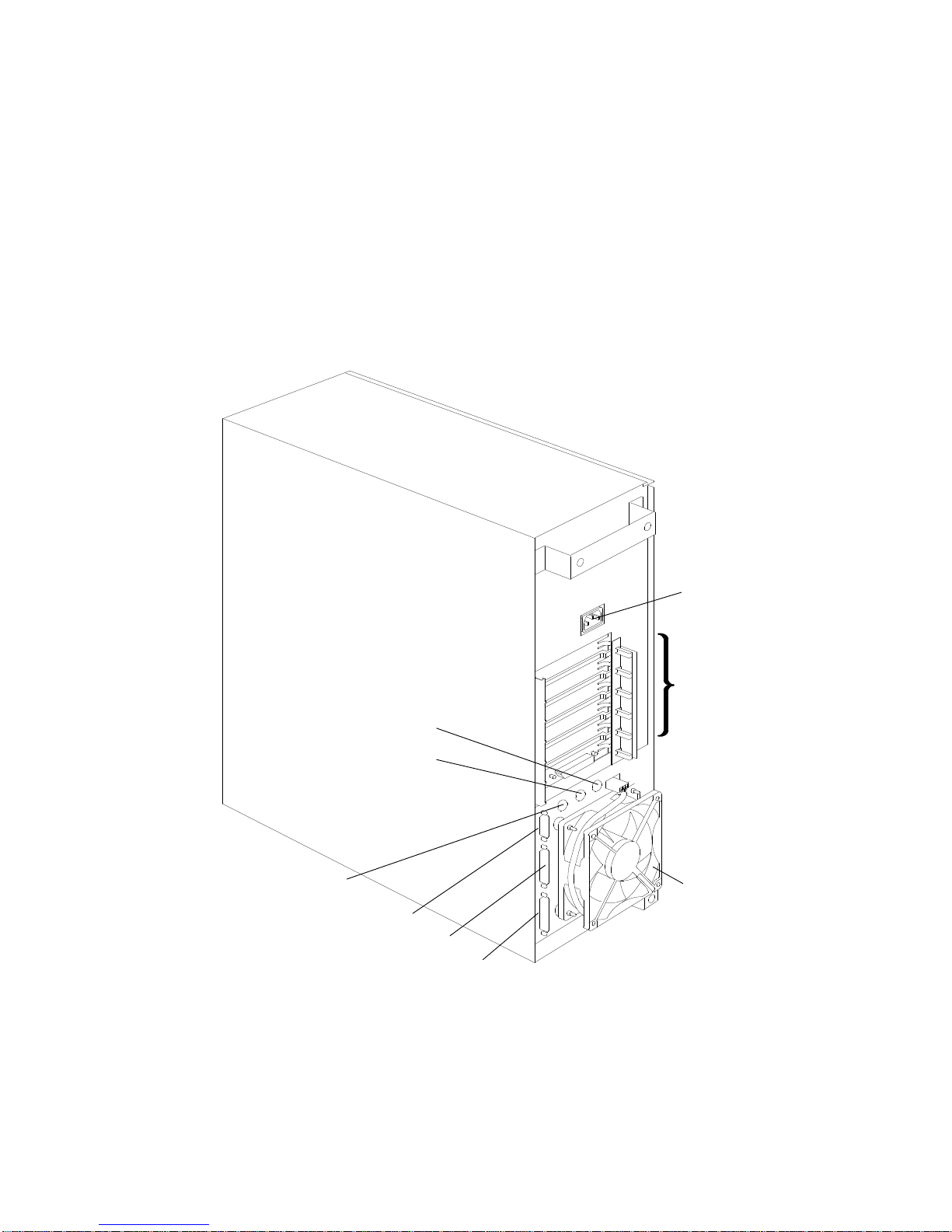

Expansion Unit System Unit Locations

Description of the Disk Expansion Unit

The disk expansion unit is used to increase the number of media devices and/or disk drives.

All hardware components inside the disk expansion unit are accessible from the left side

after having removed the unit covers.

Power Supply

Media Devices

or Disk Drives

Rear Fan

Disk Drives

From the left side of the disk expansion unit, the following modules are accessible:

• Up to two 5.25-inch half height media devices (optional). Up to two 3.5-inch half height

disk drive can be installed instead.

• The operator panel (mandatory)

• The key mode switch (mandatory)

• The ECB card (mandatory)

• Up to two disk drives (optional) in the bottom tray

Key Mode Switch

Operator Panel

ECB Card

• Up to two disk drives (optional) in the upper tray

• One external cooling fan (mandatory)

• The power supply (mandatory).

1-6 Service Guide

Page 20

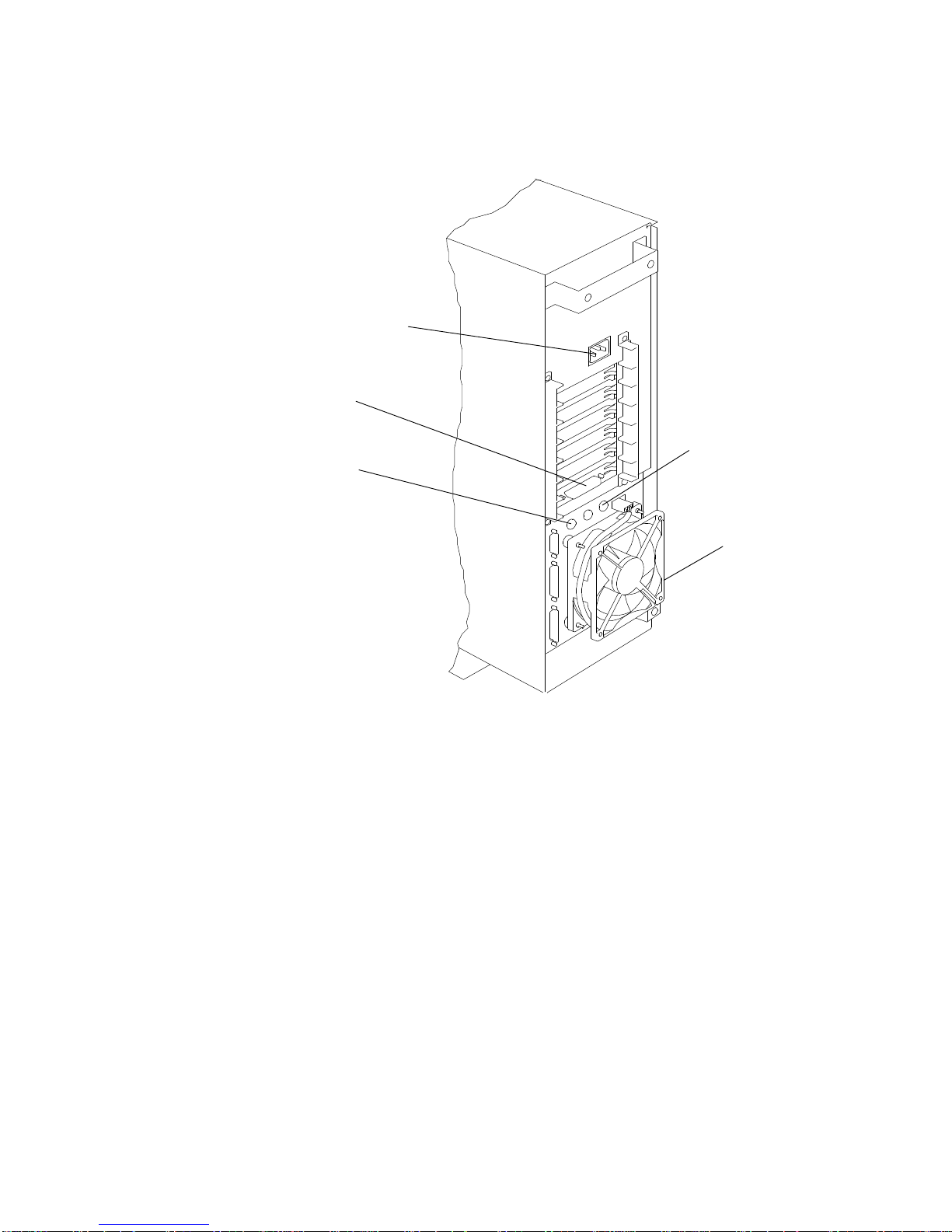

Rear Side

The following figure shows the rear side of the disk expansion unit.

Power Cord Connector

SCSI Connector

To Base Unit

RS-485 In Port

RS-485 Out Port

Rear Fan

Disk Expansion Unit SCSI Bus

The disk expansion unit is equipped with one internal SCSI bus. It is driven by means of a

SCSI-2 single-ended controller via an external connection.

The SCSI bus features the following characteristics:

• SCSI-2 single-ended

• 16-bit wide data bus

• Support for single-ended devices (8/16 bits)

• 8bits and 16bits SCSI devices mixable on the same bus

• Fast data transfer (10MB per second for 8bits, 20MB per second for 16bits)

• Synchronous/Asynchronous data interchange.

Reference Information

1-7

Page 21

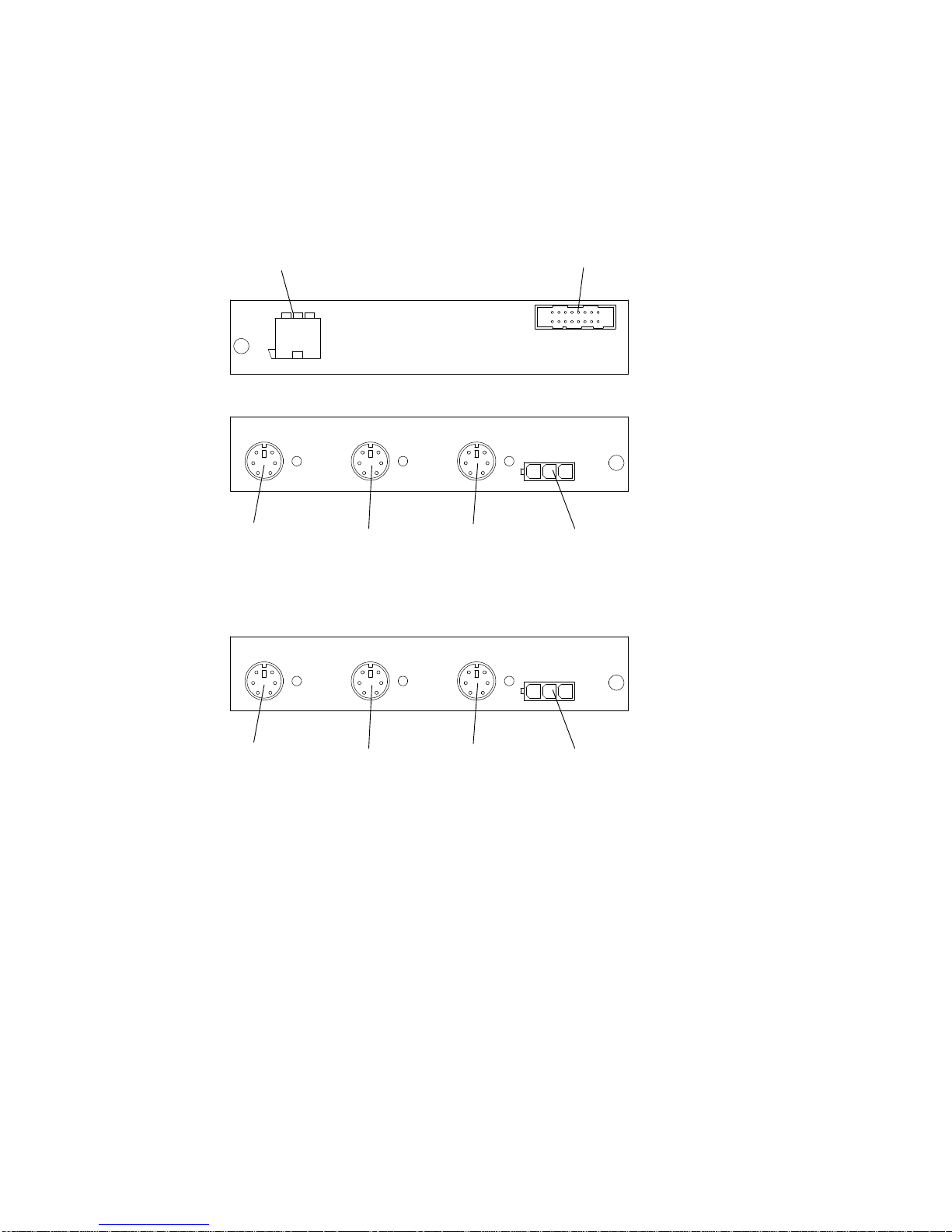

RS-485 Card

The RS-485 card is installed in the rear of both the base and the disk expansion units.

It is provided with a variety of connectors, whose functions are explained in the following

figures.

Power Connector

(Coming From the Power Supply

INTERNAL VIEW

EXTERNAL VIEW (BASE UNIT)

Mouse External FanKeyboardRS-485

EXTERNAL VIEW (DISK EXP ANSION UNIT)

Power/Signal Connector

(Coming From the Operator Panel)

1-8 Service Guide

Not Used External FanRS-485 InRS-485 Out

Page 22

Cluster Power Control

The cluster power controller (CPC) provides:

• Connectivity between the remote support facility and multiple CPUs through the modem

• Connectivity from any attached CPU to any disk drive drawer

• Central power-on and power-off through the TTY.

The CPC provides ports for connection of multiple 7012 G Series system units, 7013 J

Series system units, and 7015 Model R30, R40, and R50 CPU enclosures for interface

connection of CPUs and disk drive drawers. The CPC also contains ports for connection of a

modem and TTY.

For more information about the CPC, refer to

Guide

, order number SA23-2766.

Disk Drive Connectors

(PCI Connectors)

Disk Drive Connectors

(RS485 Connectors)

CPU A

1

2

CPU B

1

CPU

Connectors

2

CPU C

1

2

CPU D

1

2

Cluster Power Control Operator and Service

CPC

Expansion

Connectors

TTY Connector

Modem Connector

CPC

Left

CPC

Right

1

2

1

2

Reference Information

1-9

Page 23

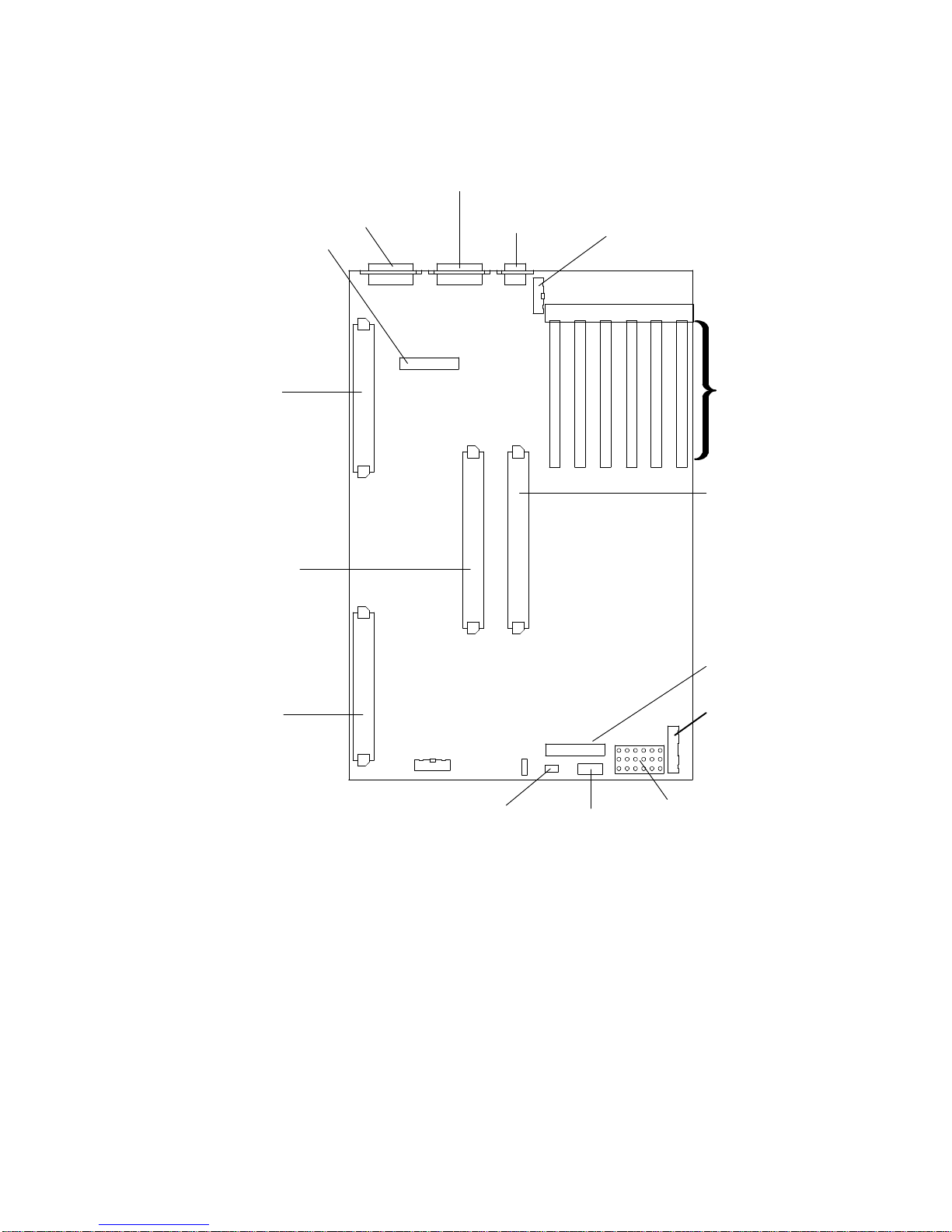

System Planar Connector Locations

Serial Ports 1 and 2

(with splitter)

Parallel

Port

Keyboard/Mouse

Card Connector

Serial Port 3

6 5 4 3 2 1

RS-485 Connector

Memory

Card

CPU Card

Position 0

Memory

Card

PQ

Battery

Connector

Operator

Panel

Connector

Micro Channel

Adapter Slots

CPU Card

Position 1

(Optional)

Diskette Drive

Connector

Power Supply

Signal Cable

Connector

Power Supply

Power Cable

Connector

1-10 Service Guide

Page 24

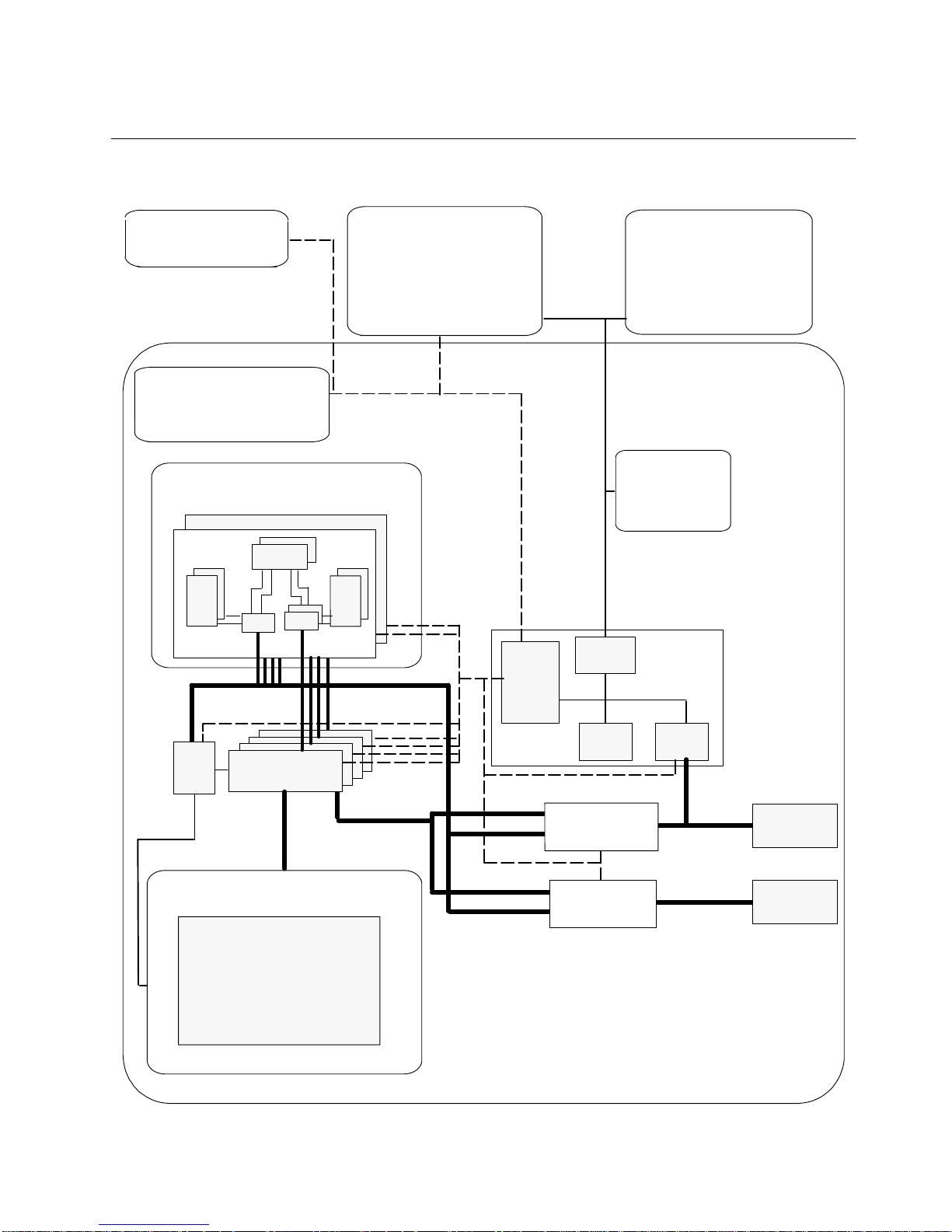

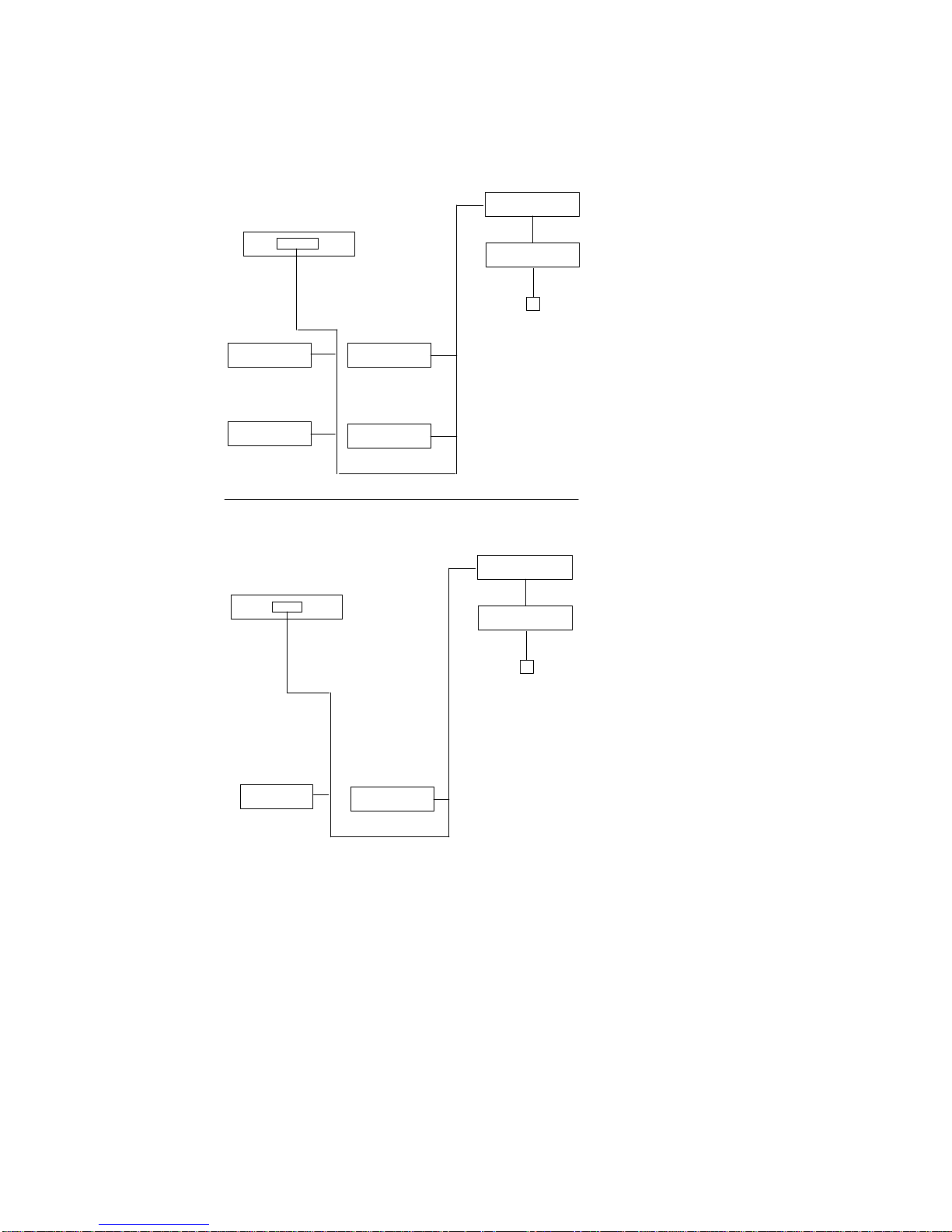

Data Flow

Power Supply

System EEPROMs

VPD EPROMs

CPU Array

CPU card

L2

Tag

SMC

CCA

60X

DCB

CCD

Operator Panel

Micro Processor

Battery

Reset/Scroll Button

LCD

Keylock

Diskette Drive

L2

CAC

Address bus

Data bus

JTAG bus

COP bus

I2C bus

BUMP

EPROM

RAM

Standard

IO

SS bus

System

IO

S1 BUMP Console

S2 Service Console

S3

Parallel Interface

System Planar

TOD Clock

NVRAM

Flash EPROM

Backup EPROM

SSGA

Memory bus

Memory Array

Memory card and DIMMs

Data bus

Base Unit I/O

Controller

Expansion Unit I/O

Controller

To

MCA bus

MCA bus

MicroChannel

Slots

To Expansion

MicroChannel

Planar

Reference Information

1-11

Page 25

Power Flow

Power

Supply

Standby

Voltages

+5

+12 –12

EEPROM

TOD

Operator

Panel

System AC Cable

PDU

+5 +3,3/3,6 –12

Rear Fan

Module

Front Fan

Module

Memory

Card

Power

Voltages

+12

3.5-inch

Diskette

System

Planar

1-12 Service Guide

System Guard

Processor

Local Console

Access

Remote

Console Access

CPU Cards

Disk

Media

Position A

Disk

Media

Position B

Page 26

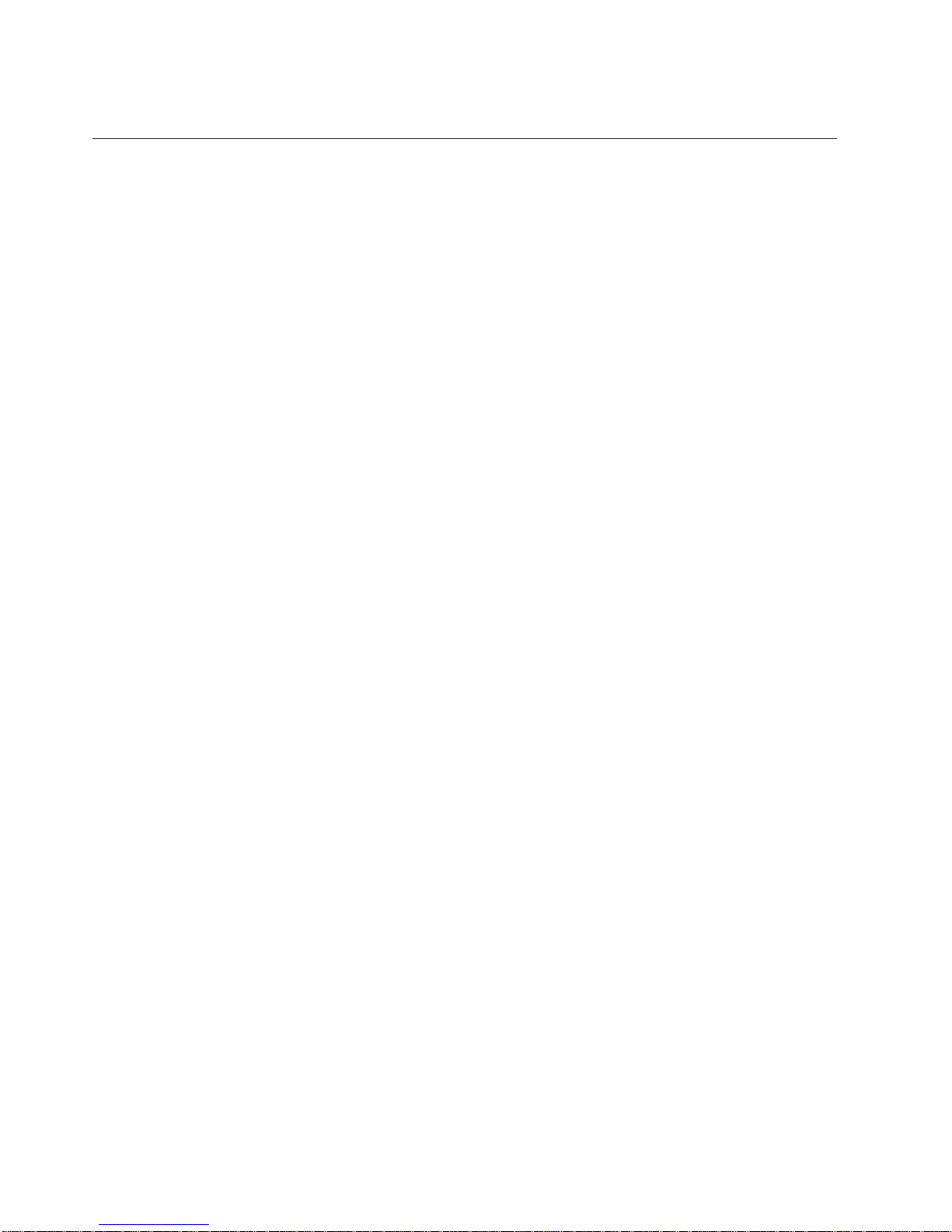

SCSI Cable Routing

SCSI controller

6-Position SCSI Cable

(4)

Upper dev.

(5)

Lower dev.

F (2)

3rd disk

D (0)

1st disk

SCSI controller

D (0)

1st disk

G (3)

4th disk

E (1)

2nd disk

4-Position SCSI Cable

E (1)

2nd disk

Terminator

(4)

Upper dev.

(5)

Lower dev.

Terminator

Reference Information

1-13

Page 27

Specifications

Dimensions (Vertical Position)

Height: 450mm (17.5 inches)

Depth: 613mm (28.2 inches)

Width: 173mm (6.9 inches)

Weight (Maximum)

19 kg to 25 kg (43 to 55 pounds)

Operating Environment – Class B

Temperature: 16

Humidity: 8% to 80%

Maximum Wet Bulb: 23

Maximum Altitude: 2133 m (7000 feet)

Power Source Loading

0.34 kVA

Power Supply

275 watts

Operating Voltage

100 V ac to 125 V ac; 50 to 60 Hz

200 V ac to 240 V ac; 50 to 60 Hz

° to 32° C (60° to 90° F)

° C (60° F)

Heat Output

1380 BTU per hour

1-14 Service Guide

Page 28

Power Cables

To avoid electrical shock, a power cable with a grounded attachment plug is provided. Use

only properly grounded outlets.

Power cables used in the U.S.A. and Canada are listed by Underwriter’s Laboratories (UL)

and certified by the Canadian Standards Association (CSA). These power cords consist of:

• Electrical cables, Type SVT or SJT.

• Attachment plugs complying with National Electrical Manufacturers Association (NEMA)

5-15P. That is:

“For 115 V operation, use a UL-listed cable set consisting of a minimum 18 AWG, Type

SVT or SJT three-conductor cord a maximum of 15 feet in length and a parallel blade,

grounding type attachment plug rated at 15 A, 125 V.”

“For 230 V operation in the U.S.A. use a UL-listed cable set consisting of a minimum 18

AWG, Type SVT or SJT three-conductor cable a maximum of 15 feet in length, and a

tandem blade, grounding type attachment plug rated at 15 A, 250 V.”

• Appliance couplers complying with International Electrotechnical Commission (IEC)

Standard 320, Sheet C13.

Power cables used in other countries consist of the following:

• Electrical cables, type HD21.

• Attachment plugs approved by the appropriate testing organization for the specific

countries where they are used.

“For units set at 230 V (outside U.S.A.): use a cable set consisting of a minimum 18

AWG cable and grounding type attachment plug rated 15 A, 250 V. The cable set should

have the appropriate safety approvals for the country in which the equipment will be

installed and should be marked ‘HAR’.”

Refer to the Parts Information section of this publication to find the power cables that are

available.

Reference Information

1-15

Page 29

Service Inspection Guide

Perform a service inspection on the system when:

• The system is inspected for a maintenance agreement.

• Service is requested and service has not recently been performed.

• An alterations and attachments review is performed.

• Changes have been made to the equipment that may affect the safe operation of the

equipment.

• External devices that have their own power cable are added.

If the inspection indicates an unacceptable safety condition, the condition must be corrected

before servicing the machine.

Note: The correction of any unsafe condition is the responsibility of the owner of the

system.

Do the following:

1. Check the covers for sharp edges and for damage or alterations that expose the internal

parts of the system unit.

2. Check the covers for proper fit to the system unit. They should be in place and secure

with the screws tight.

Rear cover

Side Cover

Base

3. Power down the system.

4. Set the power switch of the system unit to Off.

5. Unplug the power cord.

Front Door

Media Bay A

(optional)

Media Bay B

(CD-ROM

drive)

Operator Panel

Front Cover

6. Remove the covers.

1-16 Service Guide

Page 30

7. Check for alterations or attachments. If there are any, check for obvious safety hazards

such as broken wires, sharp edges, or broken insulation.

8. Check the internal cables for damage.

9. Check for dirt, water, and any other contamination within the system unit.

10.Check the voltage label on the back of the system unit to ensure that it matches the

voltage at the outlet.

11. Check the external power cable for damage.

12. With the external power cable connected to the system unit, check for 0.1 ohm or less

resistance between the ground lug on the external power cable plug and a jack screw on

the parallel port connector.

Power Cord

Receptacle

Adapters

Keyboard Port

Mouse Port

Power Control

Port (RS-485)

Rear

Fan

9-Pin Serial Port (S3)

25-Pin Serial Ports (S1/S2)

Parallel Port (P1)

13. If the system unit passes the test in the previous step, install the covers.

14. Check each external device that has its own power cable:

a. For damage to the power cord.

b. For the correct grounded power cable.

c. With the external power cable connected to the device, check for 0.1 ohm or less

resistance between the ground lug on the external power cable plug and the metal

frame of the device.

Reference Information

1-17

Page 31

Chapter 2. Using System Guard

This chapter introduces the SystemGuard service processor which is included in all

Symmetric Multiprocessor models.

Introduction

SMP servers include a service processor, called SystemGuard, as a standard feature.

SystemGuard continually monitors the hardware as well as the operating system. If, for

instance, a CPU fails, the system detects this, reboots itself automatically and runs the

built-in diagnostics on the hardware. If the CPU is detected as bad during the initial program

load (IPL) or reIPL, the CPU is disabled. Likewise, if memory is detected as bad during IPL

or reIPL, it is disabled.

SystemGuard allows diagnostics and maintenance to be performed either locally or

remotely. The SystemGuard processor makes it possible for these remote systems to be

managed from a central location. SMP servers can even be set up to automatically call a

Service Center if they fail to boot successfully.

The main features of the SystemGuard are:

• Initialization process flow management

• Local as well as remote control of the system (turning power on or off, diagnostics,

reconfiguration, maintenance)

• Console mirroring to make remote actions visible and controllable by the customer

• Dial-out to a support center in case of system boot failure

• Run-Time surveillance

Using SystemGuard

2-1

Page 32

SystemGuard Power

SystemGuard has its own DC power boundary. This means that even if the system power is

off (power button of the system in the off position), SystemGuard is still powered on, as long

as the unit is still plugged into a power outlet. This allows control of the system even though

the system is down. The only way to turn off the SystemGuard power is to unplug the AC

power cord.

SystemGuard Components

SystemGuard introduces new hardware and firmware components:

• a microprocessor called the Bring-Up MicroProcessor (BUMP)

• a Flash EEPROM

• a Backup EPROM that enables the system to boot in case of a Flash EEPROM failure.

Part of the SystemGuard firmware is stored in the BUMP EPROM; part is in the Flash

EEPROM. The Backup EPROM contains a subset of the Flash EEPROM .

SystemGuard Bring-Up MicroProcessor Overview

The SystemGuard Bring-Up MicroProcessor (BUMP) controls the system when the power is

off or the AIX operating system is stopped. SystemGuard performs the following:

• Controls the power-on (PON) tests, the power-on self tests (POST) and loading of the

AIX operating system.

• Responds to local or remote BUMP console commands to set the mode or set system

parameters.

• Runs the SystemGuard programs using the STANDBY MENU or the MAINTENANCE

MENU.

• Monitors the “heartbeat” from AIX, if the feature is enabled and AIX is running.

SystemGuard releases control of the system to the AIX operating system after it is loaded. If

the AIX operating system stops or is shutdown, SystemGuard again controls the system.

The BUMP console (attached to S1 port) provides the normal input. The service console

(attached to S2 port) provides remote service access to the BUMP. Access to both of these

consoles is controlled by flags.

2-2 Service Guide

Page 33

The Operator Panel

The Operator Panel is the first level of user interface to SystemGuard.

The Operator Panel has the following features:

Power button It should generally stay pushed in all the time if you want to be able to

Reset button It resets SystemGuard to the Init phase and, depending on the key position,

power on or off the system remotely.

reboots the system to Maintenance or to AIX Multi-User.

LCD display It is made of two rows of sixteen characters. It displays the word

in the Stand-By phase, or it displays the usual three-digit boot up codes.

Physical Key It uses the international symbols for Normal, Secure and Service modes.

This key should generally stay in the Normal position because the modes

can be changed electronically when the physical key is in the Normal

position.

Diskette Eject Button

3.5-inch

Diskette

Drive

Power-on

Button

Power-on

Light

Key Mode Switch

Stand-By

Operator Panel Display

Note: In the 7012 G Series the system board contains the NVRAM, the NVRAM battery ,

and the TOD. You can drain NVRAM by disconnecting the NVRAM battery.

When NVRAM is drained it results in a reset of the TOD to 1969 which affects

applications. Draining NVRAM also causes a loss of configuration data.

Reset Button

Using SystemGuard

2-3

Page 34

SystemGuard Consoles

SystemGuard works with two types of consoles:

• The

• The

Bump Console

console provides the normal input to the BUMP. It can be local or remote. The line speed

for the BUMP console must be set to 9600 baud for either type of connection.

Service Console,

console is usually remote and located in a customer support center or a service support

center. This console enables the support center to work with SystemGuard and/or AIX.

The support center needs specific authorization from the customer to access

SystemGuard remotely .

, which is an ASCII terminal attached to the S1 serial port. This

which is an ASCII terminal attached to the S2 serial port. This

Physical and Electronic Key

Normal, Secure, Service modes can be set physically by turning the Physical Key or

electronically by executing the electronic key command. The Physical Key and the

Electronic Key together define a state called the

be turned if the Physical Key is in Normal position. Refer to “How to Set the Electronic Key”

on page NO TAG for details on how to set the Electronic Key.

Following are various Electronic and Physical Key combinations and the resultant System

Key position:

Physical Key

normal normal normal

normal service service

normal secure secure

secure not valid secure

service not valid service

Electronic Key System Key

System Key

. The Electronic Key can only

SystemGuard Phases

During boot up, SMP servers go through five different phases: Stand-By, Init, Maintenance,

Boot, and Run-Time.

Stand-By Phase

The Stand-By phase is present anytime the system unit power is off, and the SystemGuard

power is on.

At this phase, the AIX operating system is not yet loaded; the system unit power is not on,

and the word Stand-By is displayed on the Operator Panel display.

The SystemGuard is active, and it can receive commands from the BUMP console or

Service Console (either local or remote). You can enter the SystemGuard Stand-by menu

from this phase.

The Stand-By phase ends when the power button on the Operator Panel is pressed or the

power-on command is entered on the BUMP Console or Service Console.

2-4 Service Guide

Page 35

Init Phase

Init phase is entered when the power button on the Operator Panel is pressed on or when

the power-on command is entered on the BUMP Console or Service Console.

If the System Key is in Normal mode, the BUMP runs the built-in or resident power-on

(PON)-tests on the system hardware, IPLs on the first available processor, runs the

functional power on self-tests (POST) on the I/O subsystem to check the system, and finally

loads the AIX operating system.

If the System Key is in Service mode, and if several conditions are met, the system loads

the SystemGuard MAINTENANCE MENU. These conditions are: the Autoservice IPL flag

disabled, the BUMP console enabled, and a Valid Service Contract.

If the System Key is in Secure mode, the system enters the Stall state, and the LCD

displays the three-digit code 200. The initialization of the system stops until the Physical Key

is set to Normal or Service. The Stall state is exited, and control of the system is passed to

AIX.

Maintenance Phase

The maintenance phase is entered from the Init phase if the system key is in service mode.

If the BUMP console present flag is set, the MAINTENANCE MENU is displayed on the

BUMP console, and the system waits for an operator action. The maintenance menu

choices are described on page 2-21. Various maintenance tasks can be performed from this

menu. When maintenance tasks are complete, the system can be booted, powered down, or

reset.

Boot Phase

SystemGuard enters the Boot phase from either the Init phase or the Maintenance phase. In

this phase the system is initialized and control of the system is passed to the operating

system. Control of the two serial ports is switched to the operating system and the Run-Time

phase is entered. If a valid boot block is not found and the system key is set to Service,

SystemGuard returns to the Maintenance phase.

Run-Time Phase

This is the phase where the AIX operating system is in control of the system. The Run-Time

phase is entered once the AIX operating system is loaded and takes control of the consoles.

When AIX is stopped again, for example due to a shutdown, the system goes back to the

Stand-By phase.

Using SystemGuard

2-5

Page 36

Phase Change (Stand-By to Init Stage)

The phase change from Stand-By to Init is called crossing the power boundary. This is

achieved by pushing the power button on the Operator Panel or by typing the keyword

power at the Stand-By prompt (>). Note that if you type power while the power button is not

pushed in, nothing happens until you press the power button. In this case, the power

command has been taken into account by SystemGuard, and you don’t have to reenter it.

The power command is the default power on command sequence, which you can change

from the maintenance menu or AIX service aids.

SystemGuard, checks for a special downloadable diskette (if in Service mode), checks the

Flash EEPROM, and then produces an output. The following is an example of what appears:

BUMP FIRMWARE – February 16, 1995

ID 07.01 – POWER_ON in EPROM

#

FLOPPY NOT READY!

DO YOU WANT TO UPDATE FLASH FROM LINE S2[y/n]? n

BUMP FIRMWARE – May 19, 1995

ID xx.xx – POWER_ON in FLASH PROM

The message FLOPPY NOT READY! means that there is no downloadable diskette in the

diskette drive.

Note: This message is only displayed when IPLing in Service mode.

The special diskette could be:

• Code to be downloaded into Flash EEPROM

• Code to change the VPD in the EEPROMs of the SMP system

2-6 Service Guide

Page 37

Power-on (PON) Tests

PON tests are run by SystemGuard whenever the system power comes on. There are two

types of tests:

• A comprehensive set of tests are performed on the processors, cache, memory and

related hardware when the Fast-IPL flag is disabled.

• A minimum core set of tests are performed on the processors, cache, memory and

related hardware during fast-IPL which cannot be turned off.

Following is an example of PON test output for the Fast-IPL type of test.

BUMP FIRMWARE – February 16, 1995

ID 07.01 – POWER_ON in EPROM

BUMP FIRMWARE – May 19, 1995

ID 07.04 – POWER_ON in FLASH PROM

– Low Interleaving –

Initial test on CPU 0 – * OK !

Initial test on CPU 1 – * OK !

Initial test on CPU 2 – * OK !

Initial test on CPU 3 – * OK !

Init 1024kb L2 cache by processor 0 – * OK !

Init 1024kb L2 cache by processor 1 – * OK !

Init 1024kb L2 cache by processor 2 – * OK !

Init 1024kb L2 cache by processor 3 – * OK !

Clearing 128 Mb by processor 0 –> **** OK !

CPU FIRMWARE – August 4, 1994

Processor 0 on IPL INIT

{{ 216 }}

{{ 220 }}

{{ 288 }}

{{ 278 }}

{{ 292 }}

{{ 286 }}

{{ 292 }}

Processor 0 on IPL Start

{{223}}

{{299}}

A flashing 888 is displayed if PON tests cannot start. If the PON test hangs, a three-digit

code corresponding to a failed component will be displayed.

Note that the system IPLs on the first available physical processor. If for any reason

processor 0 is not available, the system IPLs on processor 1, and then on 2 so on until a

processor is available. If all the processors are disabled, the PON test fails, and

SystemGuard treats this as a hardware component failure and goes into the

MAINTENANCE MENU in Service mode. In Normal mode, the PON test initiates dial-out, if

possible, and goes into Stall state afterward. No IPL proceeds. Processors can be manually

enabled again in Service mode through the MAINTENANCE MENU. This can also be

repaired locally by:

• Turning the system power off

• Moving the Physical Key into Service position

Using SystemGuard

2-7

Page 38

• Enabling at least one processor from the STAND-BY MENU

There are other resident PON tests to check other system resources. These tests are a

subset of the SystemGuard maintenance offline tests, and reside within the flash EEPROM.

These tests are divided into the following groups:

BUMP Quick I/O Test Group

These tests check the accessibility and the functions of the

standard and direct I/O components from the BUMP: Async lines

(S1, S2, and S3), EEPROMs, NVRAM, Flash EEPROM, and TOD

(Time-Of-Day).

JTAG (Joint Tests Action Group) Test Group

These tests check the chip-to-chip connections using the JTAG

features.

Direct I/O Test Group These tests check the accessibility of the Standard and Direct I/O

components from the CPUs: IONIAN, NVRAM access, EPROM

access, TOD, and the diskette.

CPU Test Group These tests are performed by all of the processors and check the

status of the CPU cards: processor, address translation, L1 and L2

caches.

DCB (Data CrossBar) and Memory Test Group

These tests check the status of the system planar and memory

cards: data/address lines accessibility, memory components, ECC,

memory refresh (CPU checkstop).

Interrupt Test Group These tests collectively check the interrupt system: BUMP-CPU,

CPU-CPU (CPU checkstop).

MCA Test Group Not applicable

CPU Multiprocessor Test Group

These tests check the multiprocessor mechanisms, atomic

instructions, cache coherency, main memory sharing, and

multi-resources sharing.

2

I

C Bus Test Group

The following is an example of the output when running these PON tests:

***************

* PON TESTS *

***************

.. Bump [01.01.00] DEBUG LINE TEST OK

.. Bump [01.02.00] S1 ASL (BUMP) TEST OK

.. Bump [01.03.01] S2 ASL (REM.) TEST OK

.. Bump [01.04.00] S3 ASL (SPE.) TEST OK

.. Bump [01.05.00] FLASH EP. CONTENT TEST OK

.. Bump [01.06.00] NVRAM CONTENT TEST OK

.. Bump [01.07.00] EPROM CONTENT TEST OK

.. Bump [01.08.00] TOD TEST OK

.. Bump [01.09.00] FLOPPY–D CNT. TEST OK

.. Bump [01.10.00] BPP REGISTERS TEST OK

.. Bump [01.11.00] MISC. REGS TEST OK

.. Bump [06.05.00] TOD–BUMP IT TEST OK

Note that the PON test can be suppressed if the

fast IPL

flag is enabled through

SystemGuard.

2-8 Service Guide

Page 39

Phase Change (Init to Boot)

The maintenance phase is entered from the Init phase if the system key is in service mode.

If the BUMP console present flag is set, the MAINTENANCE MENU is displayed on the

BUMP console, and the system waits for an operator action. The maintenance menu

choices are described on page 2-21. Various maintenance tasks can be performed from this

menu. When maintenance tasks are complete, the system can be booted, powered down, or

reset.

Phase Change (Maint to Boot)

SystemGuard enters the Boot phase from either the Init phase or the Maintenance phase. In

this phase the system is initialized and control of the system is passed to the operating

system.

Phase Change (Boot to AIX Load and Run-Time)

Similar to the entry into the Init phase, there is a distinct line when entering this phase. At

this line, SystemGuard gives up control of the system and passes it to the loaded code

(AIX). This is indicated by the three-digit code 299 on the consoles and Operator Panel.

Since SystemGuard is also giving up control of the two serial lines, nothing can be displayed

on the consoles. The usual three-digit boot indicators are still displayed on the Operator

Panel. Note that the code 570 virtual SCSI devices being configured can take

several minutes for each card in the SMP system.

When the boot indicators have reached c33, AIX has progressed enough to display its own

boot messages on the system console. However, this is no longer the SystemGuard

Console; it is the AIX console.

SystemGuard Parameters and Flags

A certain number of SystemGuard parameters and flags can be changed through different

SystemGuard menus, from the Diagnostics interface and from AIX. Basically, there are four

different groups of flags:

Service contract flags These flags enable Service Console usage, maintenance usage

and determine if dial-out messages are sent to IBM or to a

Customer Service Center. These flags are stored in the SID

(System Identification) field of the System EEPROM.

Diagnostics flags These flags are used to control the service, diagnostics and

maintenance from a customer point of view. For example, the

customer can modify one of these flags to authorize setting the

Electronic Key from the Service Console or to authorize the dial-out.

Modem and Site Configuration flags

These flags allow the customer to customize modem configuration

for the Service Console.

Phone numbers flags These are the dial-in and dial-out phone numbers and the operator

voice number.

Using SystemGuard

2-9

Page 40

Working with SystemGuard

You can change SystemGuard parameters and flags from different locations They can be

changed from the SystemGuard STAND-BY MENU, the SystemGuard MAINTENANCE

MENU, the Diagnostics interface, and also from AIX.

When the key signal is received, SystemGuard clears the screen and displays the

SystemGuard prompt. At this point, a keyword can be entered. The supported keywords are:

power This keyword starts the system, exactly as if the power button is pushed.

You can change, disable or enable this keyword: see “Power-On Command

Parameters” on page 2-33 for details. Turning the system power on makes

the system enter the init phase. Thus, if the Key Mode Switch is in the

Service position, and if the

Maintenance Menu

sbb This keyword displays the STAND-BY menu.

It is important to understand the following flowchart.

AutoService IPL

.

flag is disabled, you enter the

Exit

Stand-

By

Menu

Normal and Secure

Service

System

Position

Key

Normal

Auto

Service IPL

Disabled

Enter “sbb”

Yes

No

“Stand-By”

on Operator

Panel Display

Press the Enter key

(>) Console Prompt

Enter “power”

System

Key

Position

Service

BUMP

Console

Enabled

No

Stand-By

Mode

Stall State

Secure

Multi-User

AIX

2-10 Service Guide

Yes

Maintenance

Menu

Diagnostics

Page 41

When the system is in Stand-By mode and the System Key (Physical or Electronic Key) is in

Service mode, the STAND-BY MENU can be accessed and SystemGuard executed.

If you turn the system unit power on from Stand-By mode with the System Key in the Normal

position, the system boots to AIX Multi-User.

If you turn the system unit power on with the System Key in the Service position, you can go

to the MAINTENANCE MENU or to Diagnostics, depending on the state of three flags:

SystemGuard Console Present, Autoservice IPL, and Service Contract Validity.

If you power on the system with the System Key in Secure, the system stalls.

Here is some information on the meaning of the different flags:

BUMP Console Present flag

When the BUMP console is enabled, the LED codes and System Guard

messages are displayed on the console during the Init phase. If the BUMP

console is not enabled, it is like a regular system; no codes and no

messages are displayed on the console during the Init phase. Only AIX

messages appear when the system starts loading AIX.

Note that if you are running the level 5 of the SystemGuard firmware, the

BUMP Console is disabled by default, and if you enable it, it is disabled after

every shutdown. If your system is in Service mode, you might go to

Diagnostics instead of Maintenance due the SystemGuard Console being

disabled by default.

If you are running level 7 or higher of the SystemGuard firmware, the BUMP

Console is enabled by default and stays enabled after a shutdown.

Autoservice IPL flag

Service Contract flag

SystemGuard Menus

SystemGuard menus are low-level menus; they make extensive use of abbreviations or

acronyms. Refer to the glossary on page X-1 for a full list of these acronyms and

abbreviations.

SystemGuard is menu-driven, and menu choices are usually numbered. Letters are

sometimes used and can be entered in either lowercase or uppercase (SystemGuard is

case insensitive). The letter x is often used to exit the current menu and return to the

previous menu (or leave SystemGuard, if given from the main menu). Commands are only

treated after you press the Enter key. Until you press the Enter key, you can use the

Backspace key to edit a command. If you enter a command that does not match the

available options, a beep signals that an invalid selection has been made.

If enabled, this flag means that you want to go to Diagnostics when booting

with the System Key in Service mode.

This flag is preset at the factory and is not variable. The Service Contract is

always valid. This flag allows the service center to access the system and

do some maintenance. The Service Contract is set by default to an

unlimited number of days (exactly 32767 days).

Using SystemGuard

2-11

Page 42

Stand-By Menu

The STAND-BY MENU can only be entered when the system is in Stand-By mode (the word

Stand-By must be displayed on the LCD display). Perform the following steps to bring up the

ST AND-BY MENU.

1. With Stand-By displayed on the LCD display press the Enter key on the BUMP console.

2. To enter the STAND-BY MENU from here, set the System Key into Service mode, either

3. Press the Enter key again.

4. Enter the keyword sbb to display the STAND-BY MENU.

The STAND-BY MENU appears with several options, as follows:

The Stand-By prompt is the greater than (>) sign.

by setting the Physical Key to Service or the Electronic Key to Service. To set the

Electronic Key to Service, follow the procedure on page 2-39.

For Details,

See the

Following STAND–BY MENU : rev xx.xx

Pages

2-13 0 Display Configuration

2-15 1 Set Flags

2-16 2 Set Unit Number

2-17 3 Set Configuration

2-18 4 SSbus Maintenance

2-19 5 I2C Maintenance

Select(x:exit): 0

Note: It is also possible to enter the ST AND-BY MENU from the Service Console if the

remote authorization flag is enabled. The Electronic Key can be set from the Service

Console with the same escape sequence.

The STAND-BY MENU allows the system administrator to display the physical configuration

of the system (CPUs, memory, I/O, and so on) and to set flags, such as the

and the

second phase of the power-on tests. The

console to be enabled or disabled during boot up. This menu also enables the service

representative to test the interconnection between the BUMP and different components

through the I2C bus or the SSbus. For instance, it is possible to send a specific string of

characters to the LCD and read the result on the Operator Panel display. Or, it is possible to

turn on the LEDs on the Operator Panel, or to turn on the power supplies and fans without

allowing the system to IPL.

BUMP Console Present

flag. The Fast IPL flag causes the system to skip the

BUMP Console Present

flag allows the BUMP

Fast IPL

flag,

2-12 Service Guide

Page 43

How to Display the System Configuration

The system configuration can be displayed through the STAND-BY MENU or through the

MAINTENANCE MENU.

Displaying Configuration through the Stand-By Menu

This option displays the system configuration table. This configuration can be viewed on the

LCD of the Operator Panel if the console is not configured. This is done by pressing the

reset button with the mode switch in the Service position.

To display the configuration of the system, enter the STAND-BY MENU, and from the Main

menu, select Display Configuration (option 0). The first-level screen is displayed with

features and devices that can be configured.

Here is an example of the display configuration screen for a 7013 J Series system. The

screens for the 7012 G Series are similar:

Display Configuration

SID TM 7013J30 45067 SID Y2 00045067

SID Y3 7fffff003935303730370000 UNIT PAAAAAAA 40

CPU conf CCCCAAAA MM conf CCAACCAAAAAAA

FLASH_FW 0704 MM size 0080 OP_KEY NRM E_KEY SRV

OPP D78610 19H0494

SP D78605 19H0471 IOC E38030 96G4400

CPU0 D78605 19H6472 CPU1 D78605 19H6472

CPU2 CPU3

MC0 D78605 19H0473 MC1 D78605 19H0473

MC2 MC3

SIB10 E38042 19H0310 PS0 D29655 11H5114

SIB11 PS1

SIB21

SIB12 PS2

SIB22

SIB13 PS3

SIB23

Hit Return

Using SystemGuard

2-13

Page 44

Display Configuration

SIB14 PS04

SIB24

SIB15 PS05

SIB25

SIB16 PS06

SIB26 fc8e000000000000

SIB17 PS07

SIB27

MP D78605 19H0464 MPe D78605

MCA 01 C fc8e000000000000 MCAe 01 C e1ff000000000000

MCA 02 C f48e000000000000 MCAe 02 C 708f000000000000

MCA 03 C fc8e000000000000 MCAe 03 C ec8f000000000000

MCA 04 C ffde000000000000 MCAe 04 C fc8e000000000000

MCA 05 C 14e0000000000000 MCAe 05 C f0ef000000000000

MCA 06 C fc8e000000000000 MCAe 06 C 7f8f000000000000

MCA 07 C fc8e000000000000 MCAe 07 C fc8e000000000000

MCA 08 A fc8e000000000000 MCAe 08 C fc8e000000000000

Hit Return

The meanings of the configuration display fields are as follows:

• SID Y2: This is the system identification information. It is automatically updated when the

operator panel is changed.

• SID TM: This indicates the type of the model.

• SID Y3: This parameter gives the maintenance contract information in order to enable

service facilities.

• FLASH_FW: This is the Flash EEPROM firmware release number. The corresponding

second column gives the memory size expressed in KB.

• CPU Conf: This gives the status information of the CPU module (present, absent,

deconfigured, or temporarily deconfigured).

• MM Conf: This is the status information for the memory DIMM.

• UNIT ssssssss: This gives the unit status information. The corresponding second column

displays the number of RDS devices present in each unit. Each unit is denoted by two

hexadecimal digits (the first stands for RDS1 and the second for RDS2).

• SIBx EC: This indicates the system interface board (SIB) status information and the vital

product data (VPD) identifier.

• PSx EC: The power supply status and the corresponding VPD identifier information is

provided.

• SP EC+s: This parameter gives the status information and the VPD identifier of the

system planar. The technical status information is also included.

• IOC EC+s: This parameter gives the status information and the VPD identifier of the I/O

card (IOC).

• OP EC+s: This field gives the operator panel (OP) VPD values and the corresponding

status information.

2-14 Service Guide

Page 45

Set Flags

• CPUx EC+s: The agent status information of the CPU cards and the VPD information is

given.

• MCx EC+s: This field gives the memory card VPD values.

• MCAx loc. code+status: This parameter contains the location code and the status

information of the Micro Channel adapters (MCA). The contents of the 8 programmable

option select (POS) registers are also displayed in the second column.

• MPx EC: This field displays the VPD identifier of the base unit MCA planars. This field

does not appear on 7012 systems.

• MPex EC: This field displays the VPD identifier of the expansion unit MCA planars. This

field does not appear on 7012 systems and appears on 7013 systems only if the system

is attached to a 7013 J01. For 7015 systems, the second MCA planar in the CPU

enclosure is identified in this field.

• OP_KEY xxx: This field gives the value of the physical operator panel key (Key Mode

Switch). The second column shows the value of the electronic key (E_KEY).

Use this option to manage miscellaneous flags. The default values are listed in the following

table:

Flag Parameter and Keyword Default Values

Name Default Value

Remote Authorization flag Disabled

BUMP Console Present flag Enabled

Autoservice IPL flag Disabled

Extended Tests parameter Disabled

Power-On Tests in Trace Mode flag Disabled

Power-On Tests in Loop Mode flag Disabled

Fast IPL flag Disabled

Set Electronic Mode Switch to Normal NRM

1. Enter 1 in the main menu to select this option. The following screen is displayed:

Set Flags

0 Remote Authorization Disabled

1 Bump Console Present Enabled

2 Autoservice IPL Disabled

3 Extended Tests Disabled

4 PowerOn Tests in Trace Mode Disabled

5 PowerOn Tests in Loop Mode Disabled

6 Fast IPL Disabled

7 Set Electronic Mode Switch to Normal NRM

select(x:exit):

2. To set or reset a particular flag, enter its menu number.

The value set for all flags is permanent until a new change is performed (except for FAST

IPL, which is automatically cleared at boot). For a complete list of default values for flags

Using SystemGuard

2-15

Page 46

and parameters (set during manufacturing), see the table in “Default Parameter Values” on

page B–1 of the service guide for your system. The following flags can be managed:

• Remote Authorization: Only the local operator can enable this flag to enable remote

maintenance to be performed. Both the local and remote operators can disable it.

• BUMP Console Present: If enabled, SystemGuard displays the MAINTENANCE MENU

on the BUMP console (line S1). If disabled, the MAINTENANCE MENU is not available

on the BUMP console.

• Autoservice IPL: When enabled, this flag enables an automatic IPL even if the Key Mode

Switch is in the Service position, thus avoiding the display of the MAINTENANCE MENU.

• Extended Tests: This parameter determines under what conditions extended power on

self-tests are run at IPL time, after the regular power on self-tests (POSTs). If the

parameter is enabled, the extended tests are run. If the parameter is disabled, the

extended tests are not run.

• Power-On Tests in Trace Mode: When enabled, supports the running of POST tests in

trace

mode, which gives extra information about how tests are conducted. A dedicated tty

line is required, this is to be used only when directed by service support personnel.