Page 1

Store Systems:

ÉÂÔ

Installation and Operation Guide for

Point-of-Sale Input/Output Devices

GA27-4028-01

Created February 23, 1997

Page 2

Page 3

Store Systems:

ÉÂÔ

Installation and Operation Guide for

Point-of-Sale Input/Output Devices

GA27-4028-01

Created February 23, 1997

Page 4

Note

Before using this information and the product it supports, be sure to read the general information under “Notices” on page v.

Translations of the safety notices are found in the

60G1330, that is shipped with the point-of-sale terminal if required.

IBM 4693/4694 Point of Sale Terminals: Product Safety Information

, P/N

Created February 23, 1997

Second Edition (November 1995)

This is the second edition of the

edition replaces and obsoletes IBM Store Systems: Installation and Operation Guide for Point-of-Sale Input/Output Devices,

GA27-4028-00.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not stocked at the

address given below.

Forms for readers’ comments appear at the back of this publication. If the forms have been removed, address your comments to:

IBM Corporation, Information Development, Department CJMA

PO Box 12195

Research Triangle Park, North Carolina 27709-9990

USA

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1994, 1995. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

IBM* Store Systems: Installation and Operation Guide for Point-of-Sale Input/Output Devices

. This

Page 5

Created February 23, 1997

Contents

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

General Safety Information ............................................ vi

Electronic Emission Notices .......................................... vii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Related Diskettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Summary of Changes .............................................. ix

Chapter 1. Installing Input/Output Devices ................................ 1-1

Installing I/O Devices .............................................. 1-3

Installing the Cash Drawer and the System Unit ............................. 1-5

Installing the Compact Cash Drawer Coin Roll Cutter .......................... 1-6

Using the Compact Cash Drawer Coin Roll Cutter ............................ 1-6

Installing the 9-Inch Video Display ..................................... 1-7

Installing an Integrated Keyboard ...................................... 1-7

Installing the Fillers .............................................. 1-8

Installing the Printer .............................................. 1-9

Securing I/O Devices to the System Unit ................................ 1-10

Installing the Alphanumeric Display .................................... 1-10

Installing the 40-Character Liquid Crystal Display ........................... 1-11

Install 40-Character Vacuum Fluorescent Display II .......................... 1-12

Installing the Character Graphics Display ................................ 1-12

Installing the Shopper Display ....................................... 1-13

Installing a Flat Panel or Sure Point Touch Display .......................... 1-14

Installing the Distribution Kit ........................................ 1-15

Installing the Integration Kit ........................................ 1-15

Installing the Optional MSR Kit on the Sure Point Touch Display .................. 1-16

Installing the Signature Capture Device ................................... 1-17

Installing the RS232 Interface Model ................................... 1-17

Installing the RS485 Interface Model ................................... 1-17

Installing and Removing Keylocks ...................................... 1-18

Preparing to Install a Lock or a Blank Lock Insert ........................... 1-18

Installing a Lock Insert ........................................... 1-19

Removing a Lock Insert .......................................... 1-20

Installing a Blank Lock Insert ....................................... 1-20

Removing a Blank Lock Insert ....................................... 1-20

Installing the System Unit Rear Cover .................................. 1-21

Chapter 2. Operating Point-of-Sale I/O Devices ............................. 2-1

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjusting the Controls on Video Displays ................................. 2-3

Cash Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Keylock Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Document Storage Area Under Cash Till ................................. 2-5

Keyboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Manager’s Keylock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Keyboard Lights (Status Indicators) ..................................... 2-7

Copyright IBM Corp. 1994, 1995 iii

Page 6

Created February 23, 1997

Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Operating the Model 2 Point of Sale Printer ................................. 2-8

Opening/Closing the Document Insert Station ............................... 2-8

Inserting Documents in the Model 2 Printer ................................ 2-9

Advancing the Journal Paper on the Model 2 Printer .......................... 2-10

Advancing the Customer Receipt ..................................... 2-10

Tearing the Customer Receipt ....................................... 2-10

Unlocking the Journal Cover ........................................ 2-10

Testing the Model 2 Printer ........................................ 2-11

Operating the Model 3 or 4 Point of Sale Printer .............................. 2-11

Inserting Documents in the Model 3 or 4 Printer ............................ 2-11

Aligning the Print Line on an Inserted Document ............................ 2-13

Advancing the Customer Receipt Paper or Journal Paper ....................... 2-13

Unlocking the Journal Cover ........................................ 2-13

Testing the Model 3 or 4 Printer ..................................... 2-14

Model 4A Point of Sale Printer ........................................ 2-15

Model 3R and Model 4R Point of Sale Printers .............................. 2-15

Operating the Model 3R and Model 4R Printer ............................. 2-16

Entering Data at Your Terminal ........................................ 2-18

Operating Card Readers and Bar Code Readers ............................ 2-18

Cleaning the Card Reader ......................................... 2-19

Entering Data with the Hand-Held Bar Code Readers ......................... 2-19

Operating the Signature Capture Device .................................. 2-20

Signature Submission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Replacing the Pen Refill – Version 1 ................................... 2-20

Replacing the Pen Refill – Version 2 ................................... 2-20

Appendix A. Expendable Supplies and Replaceable Parts ...................... A-1

How to Order Expendable Supplies ...................................... A-1

Ribbon Cartridge for Point-of-Sale Printers ................................ A-1

Roll Paper for Point-of-Sale Printers .................................... A-2

Additional Forms for Point-of-Sale Printer Model 2 ............................ A-3

Additional Forms for Point-of-Sale Printer Model 3 or 4 ......................... A-4

Appendix B. Operator and Programmer Information .......................... B-1

Operator Techniques for the Point-of-Sale Printers ............................. B-1

Application Program Techniques for Point-of-Sale Printers ......................... B-1

Appendix C. Display Configurations and Controls ........................... C-1

Flat Panel Display Controls ........................................... C-1

Flat Panel Display Sleep Control ...................................... C-2

Sure Point Touch Display Controls ....................................... C-3

Sure Point Touch Display Beeper Controls ................................ C-3

Touch Display Sleep Control ........................................ C-4

Sure Point Touch Display Calibration .................................... C-5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

iv Installation and Operation for POS I/O Devices

Page 7

Created February 23, 1997

Notices

The following paragraph does not apply to the United Kingdom or any country where such provisions are

inconsistent with local law: INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied

warranties in certain transactions, therefore, this statement may not apply to you.

References in this publication to IBM products, programs, or services do not imply that IBM intends to

make these available in all countries in which IBM operates. Any reference to an IBM product, program,

or service is not intended to state or imply that only IBM’s product, program, or service may be used. Any

functionally equivalent product, program, or service that does not infringe any of IBM’s intellectual property

rights maybe used instead of the IBM program, product, or service. Evaluation and verification of

operation in conjunction with other products, except those expressly designated by IBM, are the user’s

responsibility.

IBM may have patents or pending patent applications covering subject matter in this document. The

furnishing of this document does not give you any license to these patents. You can send license

inquiries, in writing, to the IBM Director of Licensing, IBM Corporation, 500 Columbus Avenue, Thornwood,

NY 10594 USA.

Trademarks

The following terms, denoted by an asterisk (*) in this publication, are trademarks of the IBM Corporation

in the United States or other countries or both:

IBM PS/2 Sure Point Touch Screen

The following terms, denoted by a double asterisk (**) in this publication, are trademarks of other

companies:

Checkmate Checkmate Electronics Inc.

Cross A.T.X International Inc.

Contents v

Page 8

Created February 23, 1997

General Safety Information

The following general safety considerations should be observed whenever you work with electricity or with

any electronic equipment.

DANGER

Never work on equipment or connect or disconnect signal cables during periods of

lightning activity.

CAUTION:

For your safety, connect equipment requiring electrical power to a properly wired and grounded

outlet.

The following general safety considerations should be observed whenever you work with a point-of-sale

printer.

CAUTION:

For safety when running the printer test, make sure personal articles such as ties, necklaces, or

bracelets do not get caught in the moving print head.

The following general consideration should be observed whenever you replace batteries in a point-of-sale

terminal.

Return used Ni Cd (storage retention) batteries to IBM.

Replaceable Lithium Battery inside system unit.

Non-replaceable Lithium Battery inside adapter.

vi Installation and Operation for POS I/O Devices

Page 9

Created February 23, 1997

Electronic Emission Notices

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission

limits. IBM is not responsible for any radio or television interference caused by using other than

recommended cables and connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Canadian Department of Communications compliance statement

This equipment does not exceed Class A limits per radio noise emissions for digital apparatus, set out in

the Radio Interference Regulation of the Canadian Department of Communications. Operation in a

residential area may cause unacceptable interference to radio and TV reception requiring the owner or

operator to take whatever steps are necessary to correct the interference.

Avis de conformité aux normes du ministère des Communications du Canada

Cet équipement ne dépasse pas les limites de Classe A d'émission de bruits radioélectriques pour les

appareils numériques, telles que prescrites par le Règlement sur le brouillage radioélectrique établi par le

ministère des Communications du Canada. L'exploitation faite en milieu résidentiel peut entraîner le

brouillage des réceptions radio et télé, ce qui obligerait le propriétaire ou l'opérateur à prendre les

dispositions nécessaires pour en éliminer les causes.

United Kingdom Statement of Compliance

The United Kingdom Telecommunications Act 1984. This apparatus is approved under approval number

NS/G/1234/J/100003

for indirect connections to the public telecommunications systems in the United Kingdom.

Laser Product Identification

Some IBM Scanners are laser products. Where required, the scanner has a label that identifies its

classification. For example, information on the label in the U.S.A. is shown below.

Class IIa Laser Product -

Avoid Long-Term

Viewing of Direct Light

Contents vii

Page 10

Created February 23, 1997

Preface

This guide describes how to install and operate the Input/Output (I/O) devices on IBM point-of-sale

terminals. It also describes how to exchange expendable supply items, such as ribbons and paper. It

contains two chapters and three appendies.

It is written primarily for users who prepare training material and store procedures. Retain the guide for

future use when installing additional terminals or point-of-sale devices.

Chapter 1 Describes the procedures for installing I/O devices

Chapter 2 Provides illustrations of terminals and I/O devices and includes descriptions on how to use

the devices. on IBM point-of-sale terminals.

Appendix A Contains information for ordering customer replaceable parts and expendable supplies.

Appendix B Contains information for operators and programmers.

Appendix C Contains information on display configurations and controls.

Related Publications

Related Publication Name Form No.

IBM 4693 Point of Sale Terminals: Installation and Operation Guide

IBM 4694 Point of Sale Terminals: Installation and Operation Guide

IBM Store Systems: Hardware Service Manual for Point-of-Sale Input/Output Devices

IBM 4693, 4694, and 4695 Point of Sale Terminals: Hardware Service Manual

IBM 4693, 4694, and 4695 Point of Sale Terminals: Maintenance and Test Summary

IBM 4695 Point of Sale Terminals: Installation and Operation Guide

IBM Store Systems: Parts Catalog

IBM Store Systems: Supplement for Point of Sale Terminals – Installation, Operation,

and Service

SA27-3978

SA27-4005

SY27-0339

SY27-0337

SX27-3919

GA27-4031

S131-0097

GA27-4035

Related Diskettes

Related Diskettes Form No.

IBM 4693 Point of Sale Terminals: Reference Diskette

IBM 4693 Point of Sale Terminals: Diagnostic Diskette

IBM 4693 Point of Sale Terminals: Support Diskette for Medialess Terminals

IBM 4694 Point of Sale Terminals Service Diskette

IBM 4693/4694 Point of Sale Terminals Supplemental Drivers

IBM 4695 Point of Sale Terminals Service Diskette

IBM Point-of-Sale Subsystem for DOS

SX27-3961

IBM Point-of-Sale Subsystem for OS/2

SX27-3943

(1 of 2) SX27-3960

(1 of 2) SX27-3942

SX27-3918

SX27-3928

SX27-3929

SX27-3933

SX27-3934

SX27-3965

viii Installation and Operation for POS I/O Devices

Page 11

Created February 23, 1997

Summary of Changes

GA27-4028-01 (November 1995)

This edition includes installation and operation information about the following point-of-sale input/output

devices:

¹ 9–inch Video Display

¹ Sure Point Monochrome Touch Screen

¹ Sure Point Color Touch Screen

¹ Compact Cash Drawer

¹ Keyboard Filler Panel

¹ Special characters for the MICR Printer.

Copyright IBM Corp. 1994, 1995 ix

Page 12

Created February 23, 1997

x Installation and Operation for POS I/O Devices

Page 13

Created February 23, 1997

Chapter 1. Installing Input/Output Devices

Installing I/O Devices .............................................. 1-3

Installing the Cash Drawer and the System Unit ............................. 1-5

Installing the Compact Cash Drawer Coin Roll Cutter .......................... 1-6

Using the Compact Cash Drawer Coin Roll Cutter ............................ 1-6

Installing the 9-Inch Video Display ..................................... 1-7

Installing an Integrated Keyboard ...................................... 1-7

Installing the Fillers .............................................. 1-8

Installing the Keyboard Filler Panel ................................... 1-9

Installing the Printer .............................................. 1-9

Securing I/O Devices to the System Unit ................................ 1-10

Installing the Alphanumeric Display .................................... 1-10

Installing the 40-Character Liquid Crystal Display ........................... 1-11

Install 40-Character Vacuum Fluorescent Display II .......................... 1-12

Installing the Character Graphics Display ................................ 1-12

Installing the Shopper Display ....................................... 1-13

Installing a Flat Panel or Sure Point Touch Display .......................... 1-14

Installing the Distribution Kit ........................................ 1-15

Installing the Integration Kit ........................................ 1-15

Installing the Optional MSR Kit on the Sure Point Touch Display .................. 1-16

Installing the Signature Capture Device ................................... 1-17

Installing the RS232 Interface Model ................................... 1-17

Installing the RS485 Interface Model ................................... 1-17

Installing and Removing Keylocks ...................................... 1-18

Preparing to Install a Lock or a Blank Lock Insert ........................... 1-18

Installing a Lock Insert ........................................... 1-19

Removing a Lock Insert .......................................... 1-20

Installing a Blank Lock Insert ....................................... 1-20

Removing a Blank Lock Insert ....................................... 1-20

Installing the System Unit Rear Cover .................................. 1-21

Copyright IBM Corp. 1994, 1995 1-1

Page 14

Before You Start

These setup instructions describe how to install devices and connect cables on IBM 4693, 4694, and

4695 Point of Sale Terminals.

Your Store Planner should provide some instructions that show the devices your terminal has and

where you should connect them. If that arrangement is different than the one shown here, follow the

Planner’s instructions.

The printer, short keyboard, displays, and fillers can be placed on the left or on the right.

Video displays should be placed on the left side of the Model 3R and 4R printers.

To install the terminal:

1 Get the cables from the OPEN FIRST box as needed.

2 Follow the directions of your Store Planner in arranging the devices.

Created February 23, 1997

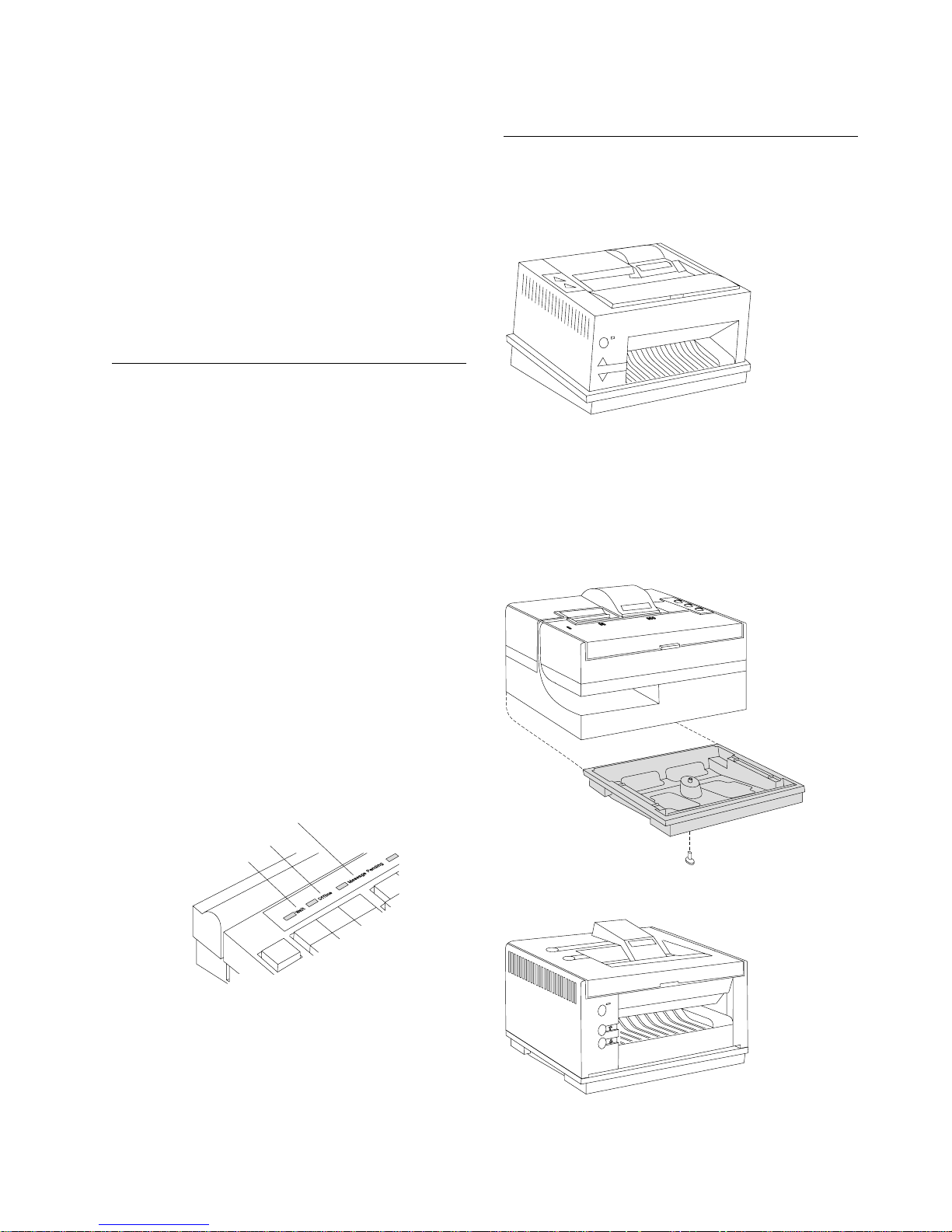

Figure 1-1. Point-of-Sale Terminal with I/O Devices

1-2 Installation and Operation for POS I/O Devices

Page 15

Created February 23, 1997

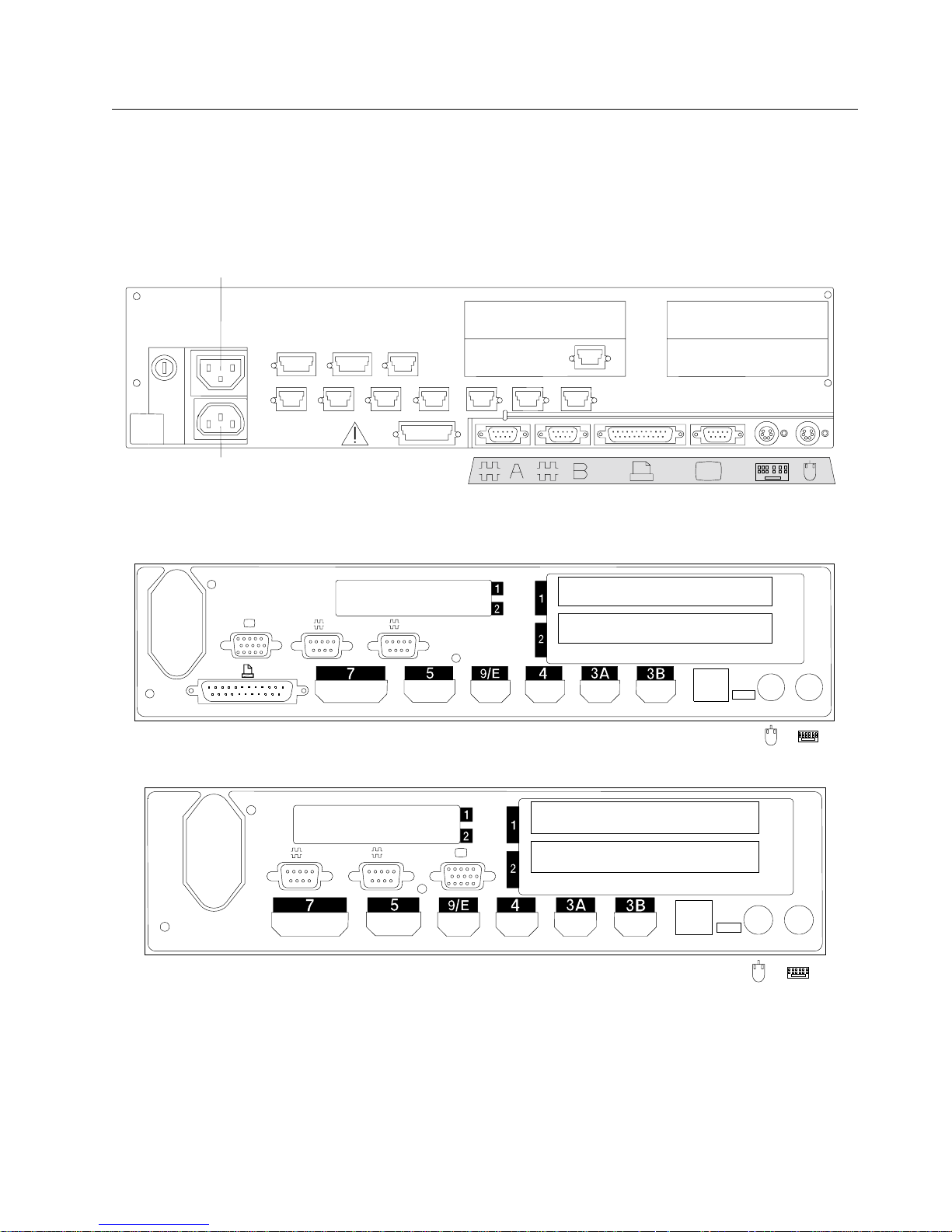

Installing I/O Devices

Note: This section provides information to set up I/O devices most often found on point-of-sale terminals.

The figure below shows typical socket panels at the rear of the system unit. The panels differ slightly,

depending on the model of your terminal. Refer to Table 1-1 on page 1-4 when plugging your cables.

VideoAC PowerOutlet

34

Power

Connector

ACin

5A 5B 9C

3A 3B 4A 4B 9A 9B 11

7

38V

Typical 4693

PCMCIASlots

A

B

4694 Model 041, 044 or 144

12

SerialBSerialA

Parallel Video Auxiliary

Keyboard

1234

Power

Connector

A

Chapter 1. Installing Input/Output Devices 1-3

PCMCIASLOTS

B

1234

4694 Model 001, 004 or 024

Page 16

Table 1-1. Plug Locations for I/O Devices

Type of Device Box No. Cable No. System Unit

Socket

Cash Drawer 3 3 3A or 3B 1

40-Character Vacuum Fluorescent Display

40-Character VFD II,

40-Character Liquid Crystal Display,

Character/Graphics Display,

Shopper Display

Flat Panel Display LCD 4 and LCD

Video Display

4 4 4, 4A, 4B, 9A, 9B 1

4 and

Created February 23, 1997

Notes

2

Keyboard 5 5

Printer 7 7 7

Scanner or Hand-held Bar Code Reader 9, 9C, or 9/E 1

4693 Model 202 (satellite terminal) 11 11

RS232C Device

Parallel Printer

Mouse

Option Adapters 2

Notes: :

1. Plug the cables according to your Store Planner’s instructions.

2. Your terminal may have one or more option adapters installed at the time of manufacture. Follow your Store

Planner’s instructions for connecting any cables to these adapters.

5, 5A, 5B, or

or

, option adapter

slots 1 or 2

1

1

1-4 Installation and Operation for POS I/O Devices

Page 17

Created February 23, 1997

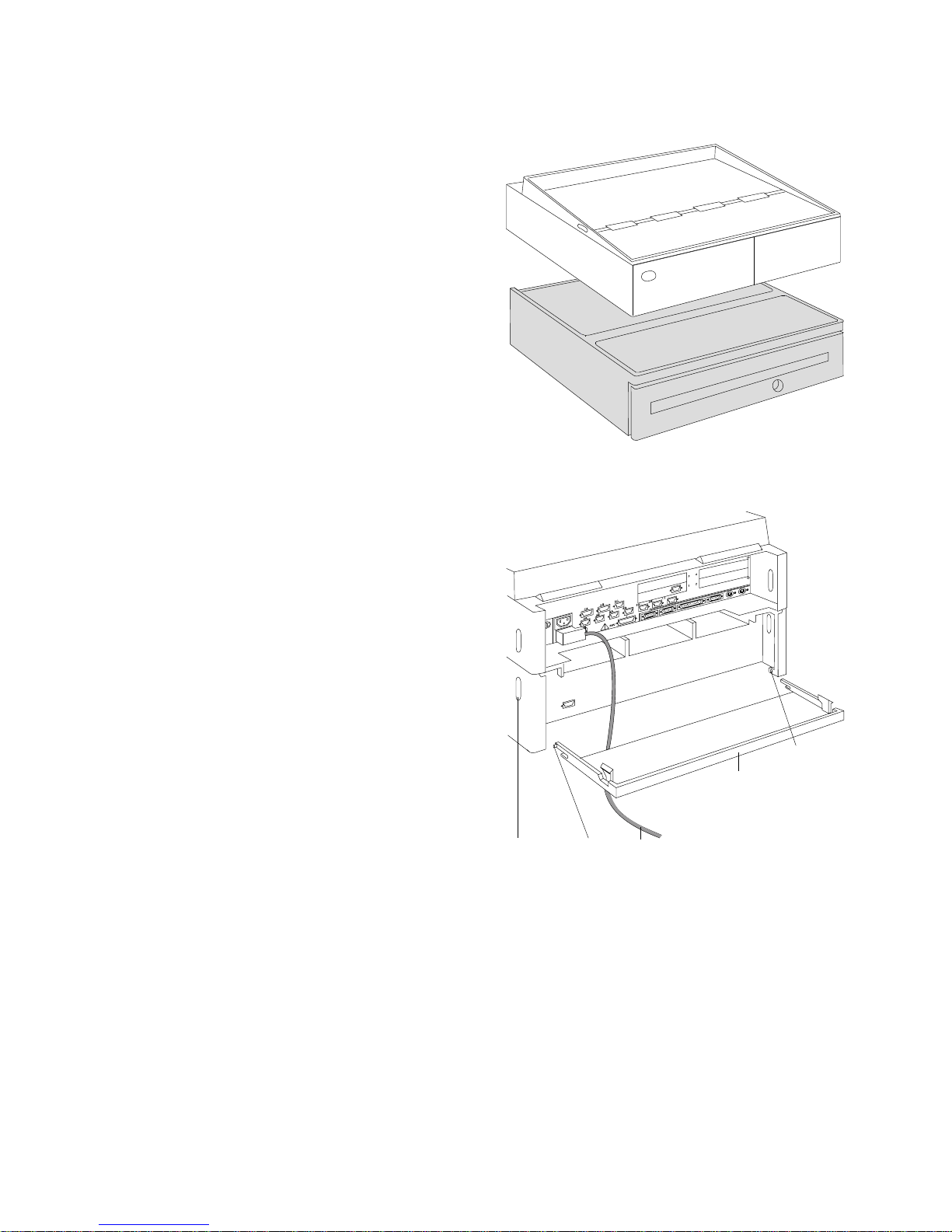

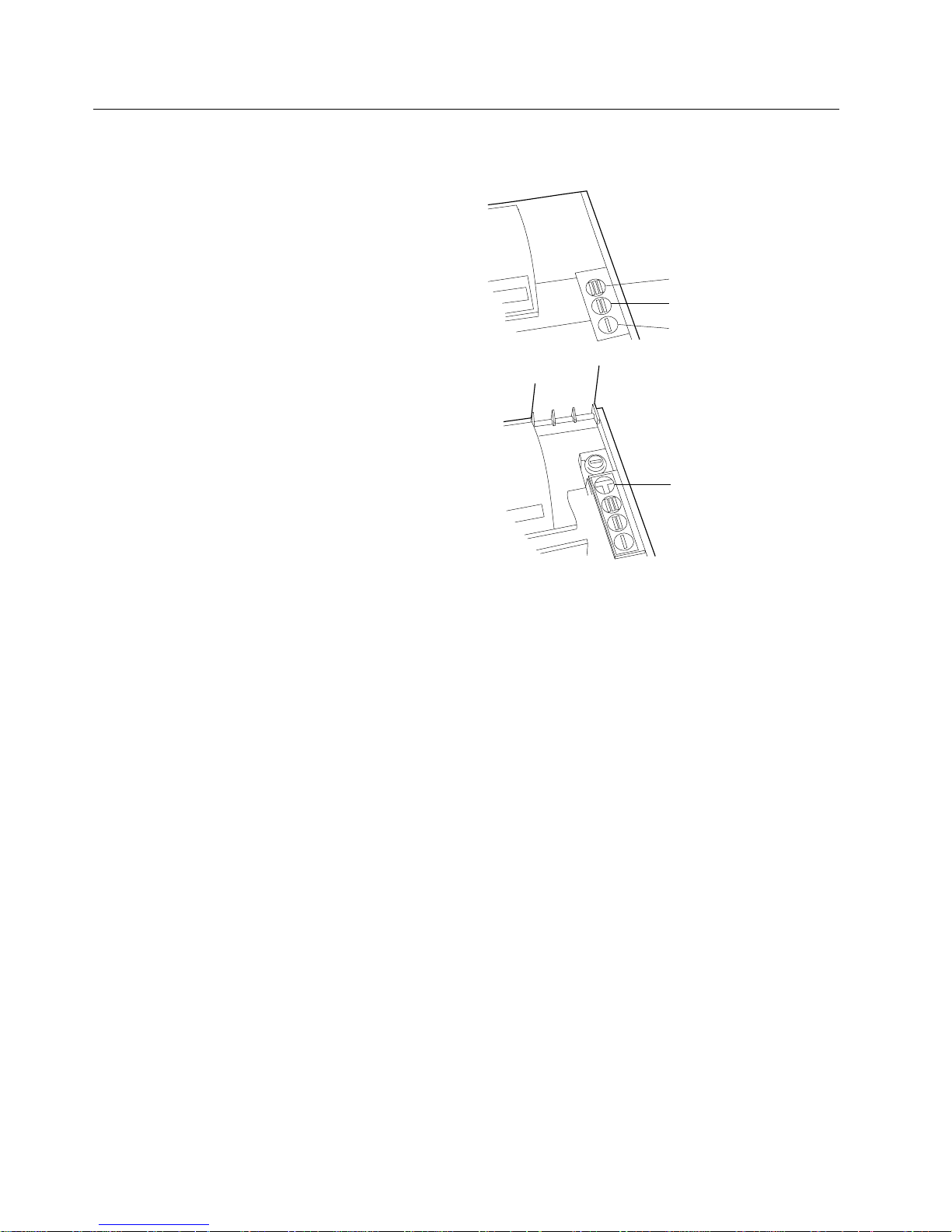

Installing the Cash Drawer and the System Unit

1 Place the cash drawer in the desired

location.

2 Place the system unit on top of the cash

drawer, if the unit is integrated.

3 Open the rear cover on the cash drawer and

remove it.

4 Connect the cash drawer cable to the 3A or

3B socket on the rear panel of the system

unit.

5 Connect the other end of the cable to the

rear of the cash draw (socket 3).

6 Connect the AC power cord to the system

unit.

Do not plug the other end of power cord

to an outlet yet.

7 Route the power cord down toward the

bottom of the cash drawer.

8 Install the cash drawer rear cover.

Note: Other models may vary.

9 The cash drawer is installed. Install any

other I/O devices at this time, otherwise go

to “Installing the System Unit Rear Cover” on

page 1-21.

3

Cover

Release

Button

(Both Sides)

Pin

Hole

Rear Cover

PowerCord

Chapter 1. Installing Input/Output Devices 1-5

Page 18

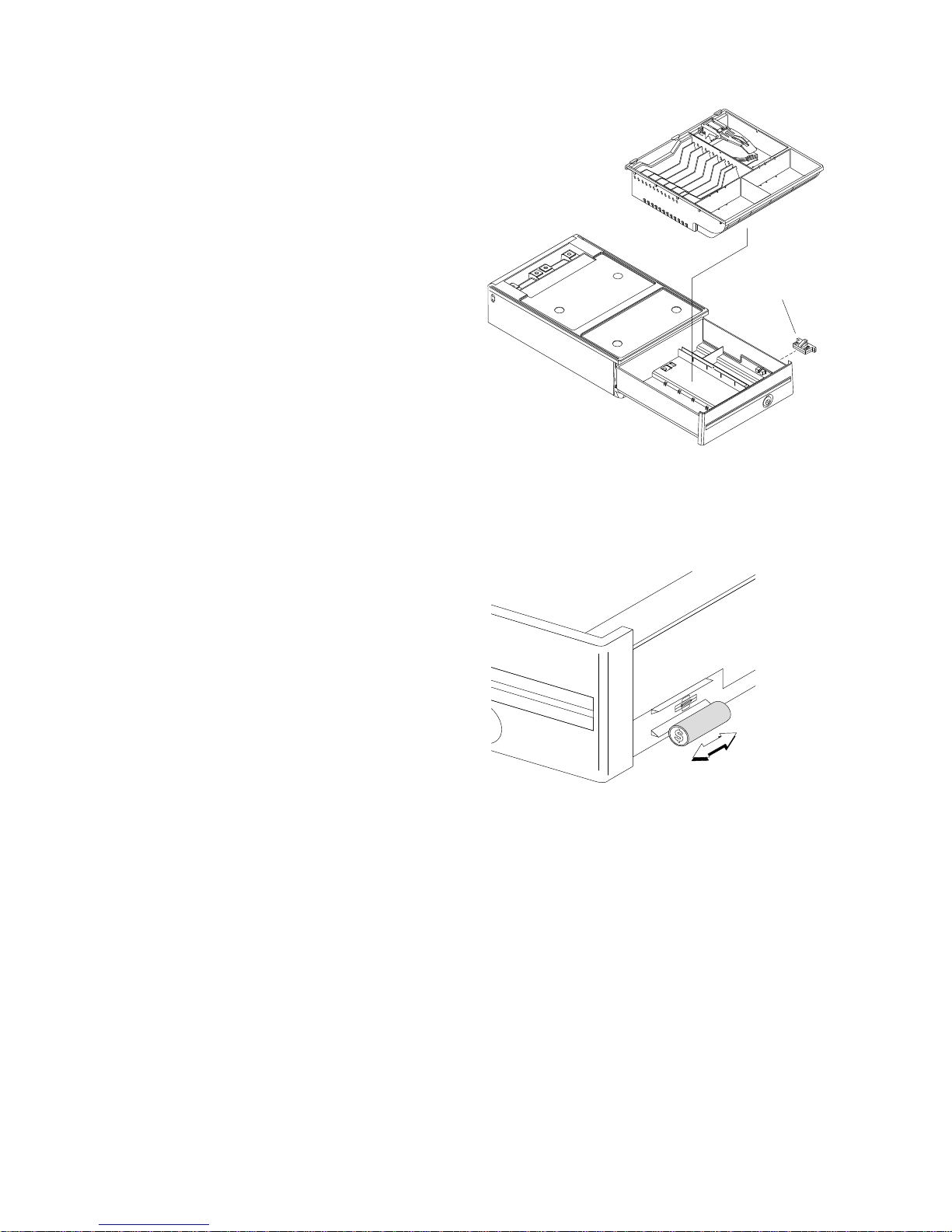

Installing the Compact Cash

Drawer Coin Roll Cutter

1 Open the cash drawer and pull it all the way

out.

2 Remove the till.

3 From inside the drawer, squeeze the cutter

latches together with your fingers and push

the cutter outward until it can be removed

from the outside.

4 To exchange the cutter, snap the new one

into position from the outside.

5Reassemble.

Created February 23, 1997

Coin Roll Opener

Using the Compact Cash Drawer

Coin Roll Cutter

1. Either push or pull the roll against the coin roll

cutter until a score is made in the outside

cover.

2. Then break roll open with your hands.

1-6 Installation and Operation for POS I/O Devices

Page 19

Created February 23, 1997

Installing the 9-Inch Video

Display

1 Hold the display and its base over the

system unit and route the two cables through

the opening at the rear of the base.

Tab

2 Ensure that two tabs at bottom rear of the

display base fit into slots in top of system

unit.

3 Place the display base over the three screw

holes in top of the system unit and tighten

the screws.

Note: The display should be mounted on

the left side when used with the Model 3R or

4R printer.

4 The display is installed. Install any other I/O

devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

Installing an Integrated Keyboard

Note: If your keyboard cable has a round plug

on one end, it may be easier to first connect the

round plug to the system unit and then route the

cable up through the opening of the system unit

that is inline with the keyboard socket. If the plug

is not round, follow these instructions.

Slot

Slots

1 Connect cable 5 to the keyboard.

2 Route the keyboard cable straight back and

through the nearest opening at the rear of

the system unit.

3 Place the keyboard so the slots in the front

of keyboard engage with tabs at the front

edge of system unit.

4 Be sure the side of the keyboard overlaps

the tabs on the side of the system unit.

5 Be sure the carder reader opening is aligned

with the slot in the system unit.

6 The keyboard is installed. Install any other

I/O devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

Chapter 1. Installing Input/Output Devices 1-7

Tabs

Card

Reader

Openings

Page 20

Installing the Fillers

Notes:

1. On an integrated unit, pull out on the locking

lever at the left side of system unit.

2. Ensure that the side of each filler overlaps the

tab on the side of the system unit.

1 If you have a video display on an integrated

terminal:

Created February 23, 1997

a Move the display on its arm to the side

and remove any tape holding the

alignment ring.

b Remove knockout section of display

filler.

c Align the display filler with the

alignment ring and slide the filler onto

the ring. Press the display filler into

place.

2 If you do not have a video display:

a Place the display filler on the system

unit. DO NOT REMOVE the knockout

section.

3 If you have a short keyboard:

a Place the keyboard filler beside the

keyboard. The fillers are installed.

Install any other I/O devices at this

time, otherwise go to “Installing the

System Unit Rear Cover” on

page 1-21.

Display

Filler

Knockout

Section

Alignment

Ring

DisplayFiller

Keyboard

Filler

1-8 Installation and Operation for POS I/O Devices

Page 21

Created February 23, 1997

Installing the Keyboard Filler Panel:

The keyboard filler panel is available on the

following models with a Sure Point Touch Screen:

4693, 4694 Models 041, 044, and on the Cash

Drawer I/O Integration Kit.

1 Place the filler so the slots in the front of

filler engage with tabs at the front edge of

system unit.

2 Make sure the side of the filler overlaps the

tabs on the side of the system unit.

3 Press in on the locking levers at the left side

of the integration kit so that its lugs engage

the filler. Check to be sure the locking lever

securely holds the filler to the integration kit.

Locking

Level

Tabs

Slots

Installing the Printer

1 Remove any packing material from inside or

under the printer.

2 Connect cable 7 at the bottom of the printer.

Route the cable through the center opening

and place the printer on the system unit.

3 Be sure the side of the printer overlaps the

tab on the side of system unit. On an

integrated unit pull out on the locking lever at

the left side of system unit. The printer is

installed. Install any other I/O devices at this

time, otherwise go to “Installing the System

Unit Rear Cover” on page 1-21.

Chapter 1. Installing Input/Output Devices 1-9

Page 22

Securing I/O Devices to the

System Unit

1 Press in on the locking lever at left side of

system unit so that its lugs engage the

keyboard, printer, and fillers.

2 Check to be sure that the locking lever

securely holds the I/O devices and fillers to

the system unit.

Installing the Alphanumeric

Display

Created February 23, 1997

Locking Lever

1 Plug display cable 4 to the display and route

it through the yoke and post as shown. The

end of the cable that has the round core

connects to the display.

2 Spread the arms of the yoke open slightly

and slide the display into the yoke.

3 Route the cable through opening in the

system unit at base of display.

4 Attach the display post to the system unit,

using two plastic thumbscrews. The notch in

the base of the post faces the rear.

5 The display is installed. Install any other I/O

devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

Core

Yoke

Front

Post

1-10 Installation and Operation for POS I/O Devices

Page 23

Created February 23, 1997

Installing the 40-Character Liquid Crystal Display

1 Slide the display up into its holder until it

latches securely in place.

2 Route display cable 4 up through the post.

The end of the cable that has the round core

connects to the display.

3 Plug the cable into the display unit.

4 Hold the display holder against the post as

shown so the interlocking surfaces contact

each other.

5 Rotate the display holder toward you to its

final position. Make sure the display is

securely attached to the post.

6 Snap the round top cover onto the post.

7 Route the cable through opening in the

system unit at the base of display.

8 Attach the display post to the system unit,

using two plastic thumbscrews. The notch in

the base of the post faces the rear.

9 The display is installed. Install any other I/O

devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

Notes:

a. Two displays can be stacked on a single

post. The displays can face toward the

front or the rear.

b. The optional ‘Y’ cable is required when

connecting two LCD displays to a 4694.

Chapter 1. Installing Input/Output Devices 1-11

Page 24

Install 40-Character Vacuum Fluorescent Display II

Note: The yoke for a two-sided display is taller

than the yoke for a single-sided display. The

installation procedure is the same for both.

1 Plug display cable 4 into the display. The

end of the cable that has the round core

connects to the display.

2 Spread the arms of the yoke open slightly

and slide the display into the yoke.

3 Route the cable through opening in the

system unit at the base of display.

4 Attach the display post to the system unit,

using two plastic thumbscrews. The notch in

the base of the post faces the rear.

Created February 23, 1997

Display

Yoke

5 The display is installed. Install any other I/O

devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

Installing the Character Graphics

Display

1 Press the release buttons at bottom of

display to open the rear cover.

2 Display cable 4 has a black core near one

end. Plug that end into the correct socket

on the system unit. See Table 1-1 on

page 1-4 for plug locations.

3 Route the cable up through the opening in

the system unit and up through the display

post.

4 Plug the cable into the display.

5 Attach the display post to the system unit,

using two plastic thumbscrews. The notch in

the base of the post faces the rear.

Release Buttons

Notch

Core

6 Snap the rear cover closed.

7 The display is installed. Install any other I/O

devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

1-12 Installation and Operation for POS I/O Devices

Page 25

Created February 23, 1997

Installing the Shopper Display

1 Route the cable through the post or arm.

2 Firmly press the display into the post or arm

until it snaps into place.

3 If the display is mounted on an arm, press

the cable into two notches on the underside

of the arm.

4 Route the cable through the opening in

system unit at the base of the display.

5 Attach the display post or arm to the system

unit, using two plastic thumbscrews.

Note: The notch in the base of post faces

the rear.

6 The display is installed. Install any other I/O

devices at this time, otherwise go to

“Installing the System Unit Rear Cover” on

page 1-21.

Post or Arm

Chapter 1. Installing Input/Output Devices 1-13

Page 26

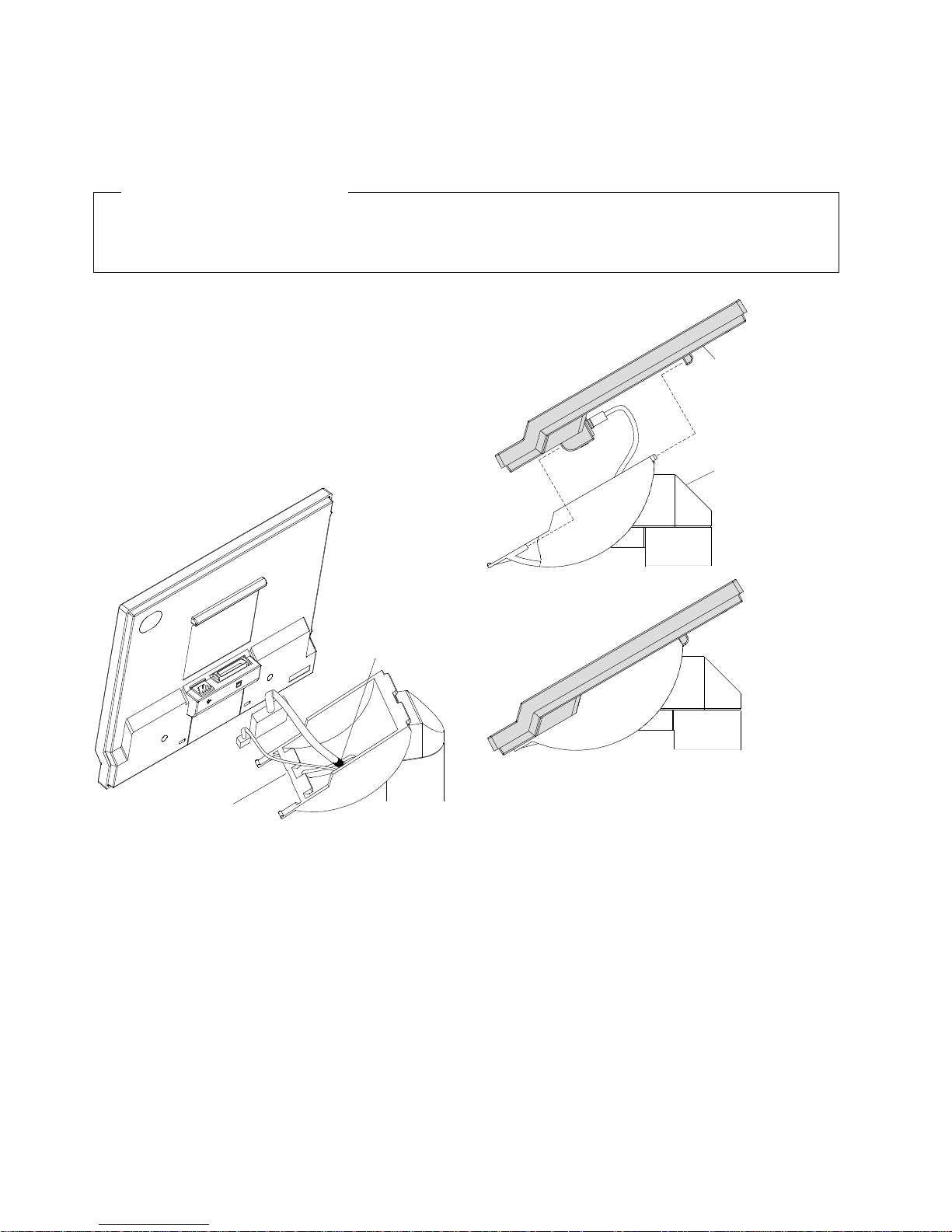

Installing a Flat Panel or Sure Point Touch Display

This section explains the installation of the flat panel or touch display and its accessory kits.

Before Installing the Display

The adapter for this display (if required), should be installed before setting up the display. See the

IBM Store System Adapters: Installation and Service

1 Connect the two cables to the connectors on

the rear of the touch display.

, GA27-4009.

Created February 23, 1997

2 Attach the display to the display holder. See

Figure 1-2.

3 Continue to page 1-15 and choose either the

integration or distribution installation

instructions.

Cable

Position

Mark

Display

Holder

Tilted Up

Display

Display

Holder

Figure 1-3. Installing the Display Unit

Figure 1-2. Display Holder Tilted Up

1-14 Installation and Operation for POS I/O Devices

Page 27

Created February 23, 1997

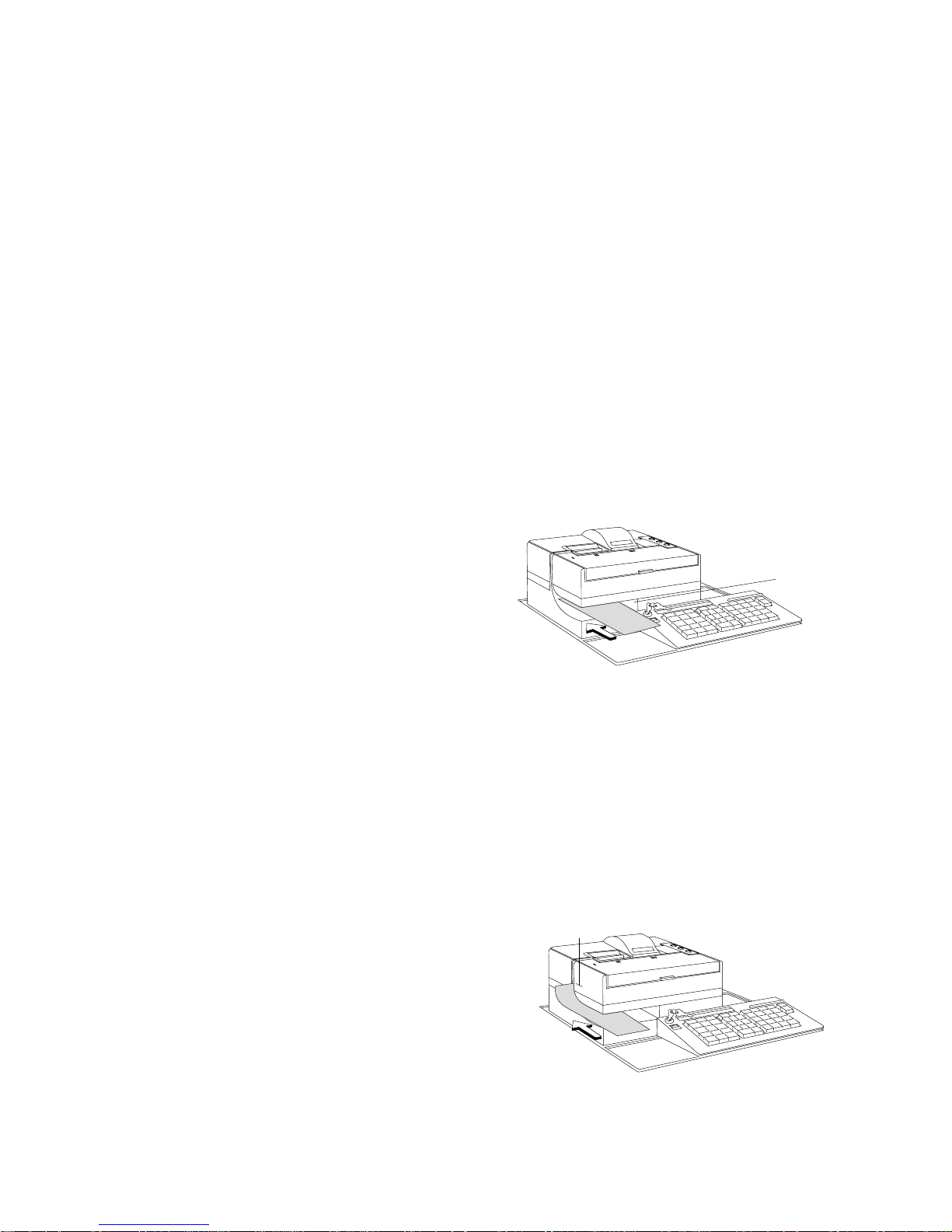

Installing the Distribution Kit

1 Place the distribution kit on the checkstand.

2 If required, install an M5 screw (not

provided) to the bottom to secure the

distribution kit to the checkstand.

Note: If it is necessary for the operator to

change the tilt and rotate positions of the

display, the distribution kit must be secured

to the checkstand.

3 Plug the large cable into the socket of the

adapter card or system unit LCD socket.

4 Plug the small cable into socket 4, 4A, 4B,

9A, or 9B.

5 Refer to testing information in the reference

documentation for your system and run the

Touch Display Test.

Installing the Integration Kit

1 Ask your Store Planner to determine whether

the integration kit should be installed on the

left or right side of the system unit or cash

drawer.

2 Hold the integration kit over the system unit

and route the two cables through the

opening at the rear. Be sure the cables are

completely pulled through the opening.

3 Place the integration kit over the two screw

holes of the system unit or cash drawer.

There are alignment slots to ensure proper

positioning of the integration kit.

4 Tighten two thumbscrews on the base to

secure the integration kit to the system unit.

5 Plug the large cable into the socket of the

adapter card or system unit LCD socket.

6 Plug the small cable into socket 4, 4A, 4B,

9A, or 9B.

Figure 1-4. Distribution Kit with Display Attached

7 To install the filler panel and rear panel, see

the

IBM Store Systems: Installation and

Operation Guide for Point-of-Sale

Input/Output Devices

, GA27-4028.

8 Refer to testing information in the reference

documentation for your system and run the

Touch Display Test.

Tabs

Alignment

Slots

Chapter 1. Installing Input/Output Devices 1-15

Figure 1-5. Integration Kit with Display Attached

Page 28

Installing the Optional MSR Kit on the Sure Point Touch Display

1 Remove the tab on the back of the touch display.

2 Plug in the MSR cable.

3 Align the MSR into position.

4 Slide it into the attached position.

5 Reinstall the MSR tab.

Created February 23, 1997

1 2

4

3

5

1-16 Installation and Operation for POS I/O Devices

Page 29

Created February 23, 1997

Installing the Signature Capture Device

There are two different models of the signature capture device that attach to an IBM 4683, 4684, 4693, or

a 4694 Point of Sale Terminal:

¹ Checkmate** 2020 Model A01 consists of an electromagnetic tablet, pen, and RS485 interface cable.

¹ Checkmate 2020 Model A02 consists of an electromagnetic tablet, pen, and RS232 interface cable

and AC adapter.

Note: The pen refill is a supply item that is exchanged by the user.

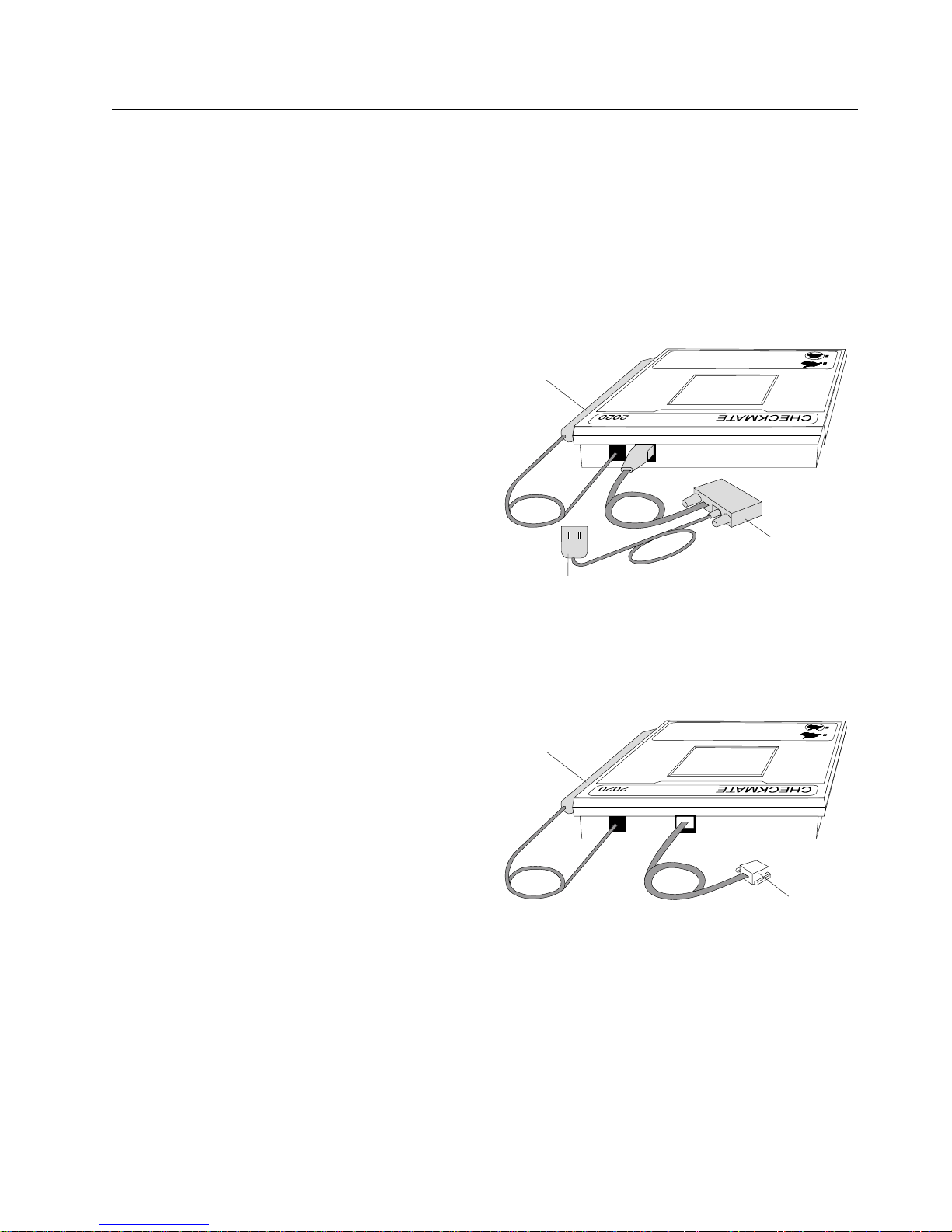

Installing the RS232 Interface

Model

1 Connect the pen cable to the rear four-pin

modular socket.

2 Connect the RS232 interface cable to the

remaining rear socket. Connect the other

end of the cable to an available RS232 port

on the point-of-sale terminal.

3 Connect the AC adapter cable to the RS232

connector.

Pen

RS232

Interface

Cable

AC Adapter

4 Plug the AC adapter in the upright position

into an AC electrical outlet.

Installing the RS485 Interface

Model

1 Connect the pen cable to the rear four-pin

modular socket.

2 Connect the RS485 cable to the remaining

rear socket.

3 Connect the other end of the cable to an

available port on the rear panel of the

point-of-sale terminal: 4B, 9A, 9B, 9C, or

9/E.

Figure 1-6. Signature Capture Device RS232 Interface

Model

Pen

RS485

Interface

Cable

Figure 1-7. Signature Capture Device RS485 Interface

Model

Chapter 1. Installing Input/Output Devices 1-17

Page 30

Created February 23, 1997

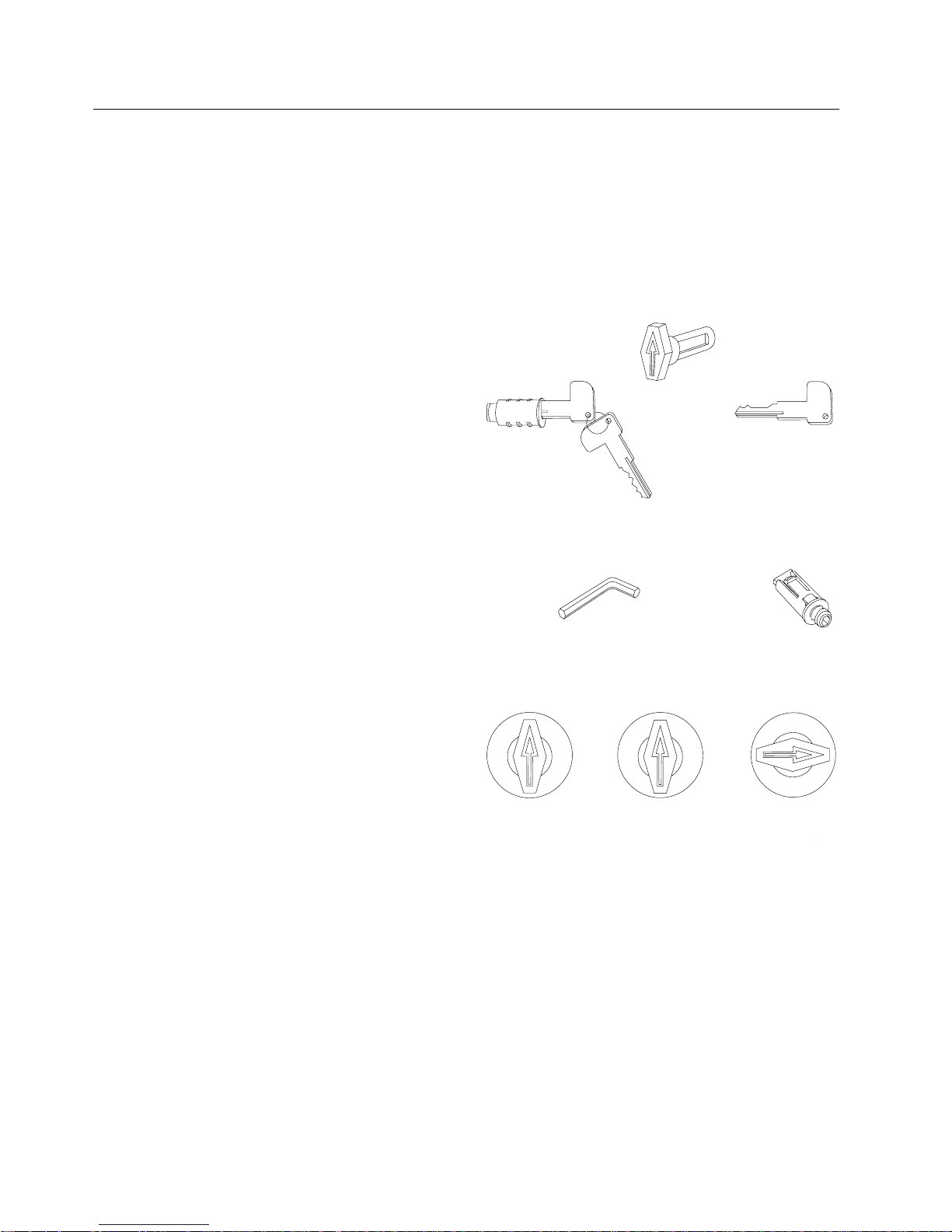

Installing and Removing Keylocks

The system unit, cash drawer, keyboard, and printer can have optional keylocks that prevent unauthorized

persons from using the terminal. If no lock is installed, a blank lock insert can be used to cover the

opening made for the lock.

Preparing to Install a Lock or a Blank Lock Insert

To install a lock insert, you need the following

items:

Aligner

Lock insert and keys

Brass installation/removal key

LockInsertand Keys

Aligner

BrassInstallation/

RemovalKey

To install a blank lock insert, you need the

following items:

Blank lock installation handle

Blank lock insert

The aligner is a tool used to ensure that the slot at

the bottom of the lock cylinder aligns with the lock

insert being installed.

The figure shows the aligner in place in the lock

cylinder of different devices. Note that when the

aligner is in place, the arrow points in different

directions, depending on the kind of device. Refer

to this figure for reference when you install a lock

in the different devices.

InstallationHandle

Keyboard

BlankLock

CashDrawer

Blank

LockInsert

Printer

1-18 Installation and Operation for POS I/O Devices

Page 31

Created February 23, 1997

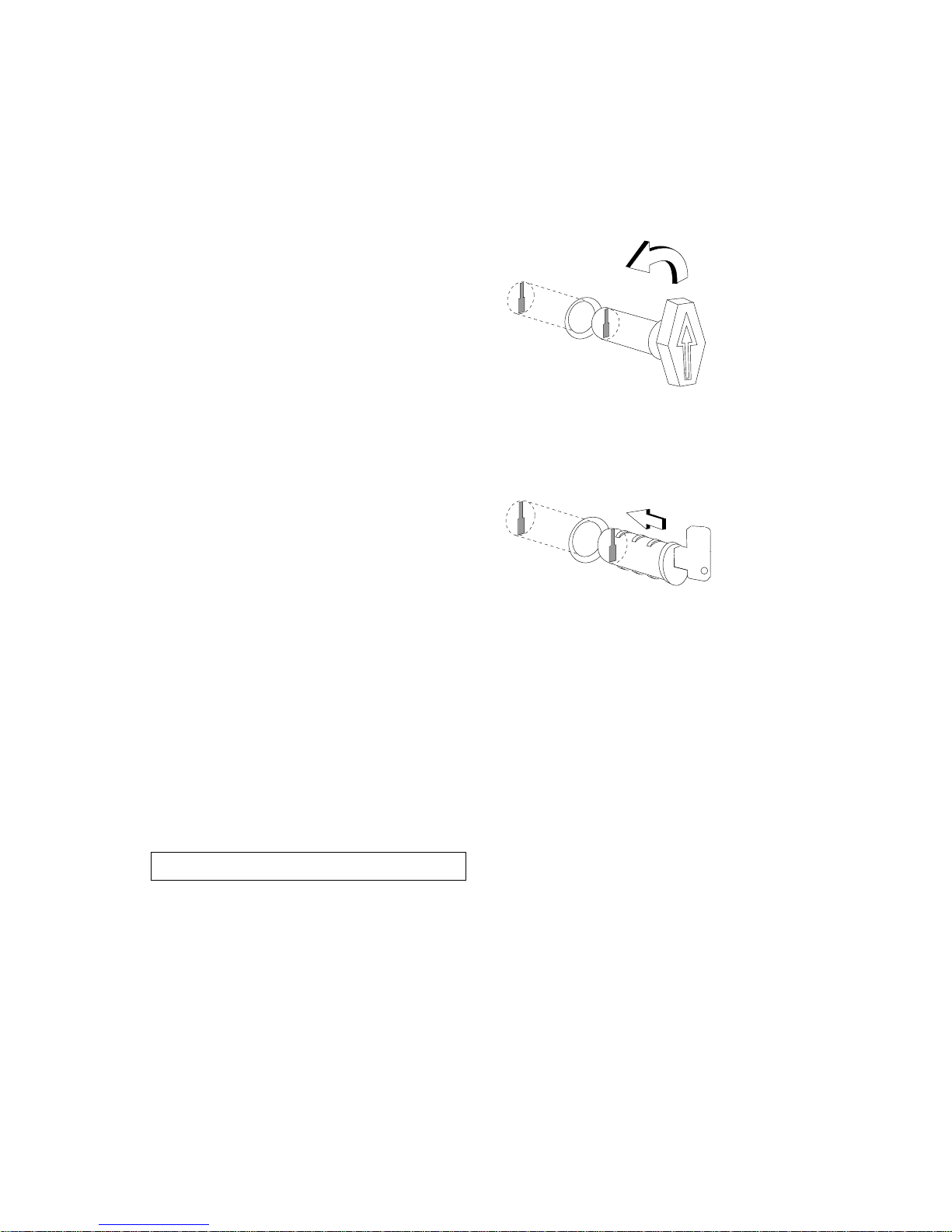

Installing a Lock Insert

The example shows how to install a lock insert in

a cash drawer. However, the procedure is the

same for installing a lock in any device. To check

that the slot at the bottom of the lock cylinder

aligns with the end of the lock insert:

1 Put the aligner into the empty lock cylinder.

2 Gently turn the aligner until you feel it go into

the slot at the bottom of the lock cylinder.

3 Turn the aligner so that the arrow points in

the proper direction for this device.

4 Remove the aligner.

Note: Some cash drawers may have a different

style lock. If the lock for your cash drawer is

different than the one described here, refer to the

instructions that came with the lock.

Be sure each lock and its keys have matching

numbers. To install the lock insert:

1 Remove the keys from the lock insert.

2 Push the brass installation/removal key fully

into the lock insert.

3 Hold the lock and brass key so that the key

points in the same direction as did the

aligner.

4 Push the lock insert and brass key fully into

the empty lock cylinder.

5 Hold the lock insert in place with your finger

and remove the brass key.

The lock insert is now installed.

6 Test the lock to be sure it operates correctly

with the keys.

7 Return the brass installation/removal key, the

aligner, and blank lock installation handle to

your supervisor for safekeeping.

Chapter 1. Installing Input/Output Devices 1-19

Page 32

Removing a Lock Insert

To remove a lock insert:

1 Put the brass installation/removal key into

the lock until you hear it click into place.

2 Gently pull the brass key.

The brass key and the lock insert should

come out of the lock cylinder together.

Pressing down on the brass key as you pull

makes it easier for the lock insert to come

out along with the brass key.

Installing a Blank Lock Insert

Blank lock inserts are used to cover the opening

at the lock cylinder if no lock has been installed.

Created February 23, 1997

1 Hold the blank lock insert so that the lug is

aligned with the slot in the lock cylinder.

2 Push the blank lock insert into the empty

lock cylinder until it is flush with the top of

the lock cylinder.

3 Use the blank lock installation handle to turn

the locking screw clockwise until it reaches

the bottom of the hole. Do not overtighten.

The blank lock insert is now installed.

4 Return the brass installation/removal key,

aligner, and blank lock installation handle to

your supervisor for safekeeping.

Removing a Blank Lock Insert

To remove a blank lock insert:

Use the blank lock installation handle to turn

the locking screw counterclockwise until you

can lift the blank lock insert out of the lock

cylinder.

1-20 Installation and Operation for POS I/O Devices

Page 33

Created February 23, 1997

Installing the System Unit Rear

Cover

1 Hold the system unit rear cover in position

as shown.

2 Choose one end of the rear cover, insert the

pin on the cover into the hole in the system

unit.

3 At the other end of the cover, press the

flexible strip holding the pin to permit the

cover to snap into place.

4 Arrange the cables neatly and close the rear

cover.

Note: See “Installing and Removing Keylocks” on

page 1-18 to install any locks or blank lock inserts

that go in your I/O devices.

You have completed installation of the I/O

devices. Save any publications or diskettes that

came in the OPEN FIRST box.

Hole

Pin

If you have not yet configured the terminal, refer

to one of the following guides:

IBM 4693 Point of Sale Terminal: Installation

¹

and Operation Guide

¹

IBM 4694 Point of Sale Terminal: Installation

and Operation Guide

¹

IBM 4695 Point of Sale Terminals: Installation

and Operation Guide

, SA27-3978

, SA27-4005

, GA27-4031.

Chapter 1. Installing Input/Output Devices 1-21

Page 34

Created February 23, 1997

1-22 Installation and Operation for POS I/O Devices

Page 35

Created February 23, 1997

Chapter 2. Operating Point-of-Sale I/O Devices

This chapter describes and illustrates the input and output devices on point-of-sale terminals and tells how

to operate them. For illustration purposes, we show the devices on an IBM 4693 Point of Sale Terminal.

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Adjusting the Controls on Video Displays ................................. 2-3

Cash Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Keylock Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Document Storage Area Under Cash Till ................................. 2-5

Keyboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Enhanced Alphanumeric Keyboard ................................... 2-6

Manager’s Keylock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Keyboard Lights (Status Indicators) ..................................... 2-7

Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Operating the Model 2 Point of Sale Printer ................................. 2-8

Opening/Closing the Document Insert Station ............................... 2-8

Inserting Documents in the Model 2 Printer ................................ 2-9

Inserting a Document at the Front .................................... 2-9

Inserting a Document at the Side .................................... 2-9

Advancing the Journal Paper on the Model 2 Printer .......................... 2-10

Advancing the Customer Receipt ..................................... 2-10

Tearing the Customer Receipt ....................................... 2-10

Unlocking the Journal Cover ........................................ 2-10

Testing the Model 2 Printer ........................................ 2-11

Operating the Model 3 or 4 Point of Sale Printer .............................. 2-11

Inserting Documents in the Model 3 or 4 Printer ............................ 2-11

Inserting a Document at the Front ................................... 2-12

Inserting a Document at the Top .................................... 2-12

Aligning the Print Line on an Inserted Document ............................ 2-13

Advancing the Customer Receipt Paper or Journal Paper ....................... 2-13

Unlocking the Journal Cover ........................................ 2-13

Testing the Model 3 or 4 Printer ..................................... 2-14

Model 4A Point of Sale Printer ........................................ 2-15

Model 3R and Model 4R Point of Sale Printers .............................. 2-15

Operating the Model 3R and Model 4R Printer ............................. 2-16

MICR Read Head Cleaning ....................................... 2-16

Installing the Ribbon Cartridge ..................................... 2-16

Inserting MICR Checks in the Printer ................................. 2-16

Running the Stand-Alone MICR Test ................................. 2-16

Special MICR Characters ........................................ 2-18

Entering Data at Your Terminal ........................................ 2-18

Operating Card Readers and Bar Code Readers ............................ 2-18

Cleaning the Card Reader ......................................... 2-19

Entering Data with the Hand-Held Bar Code Readers ......................... 2-19

Operating the Signature Capture Device .................................. 2-20

Signature Submission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Replacing the Pen Refill – Version 1 ................................... 2-20

Replacing the Pen Refill – Version 2 ................................... 2-20

Copyright IBM Corp. 1994, 1995 2-1

Page 36

Created February 23, 1997

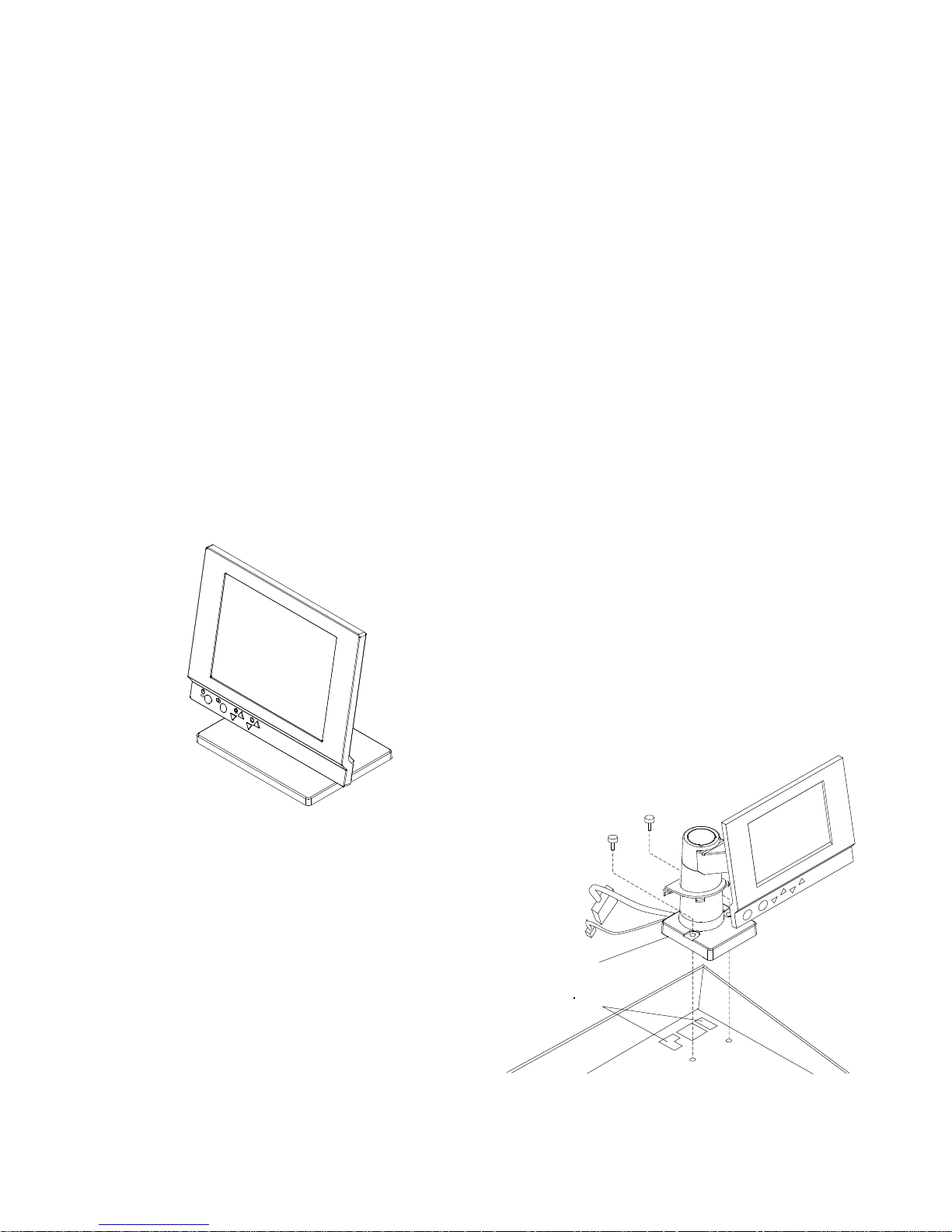

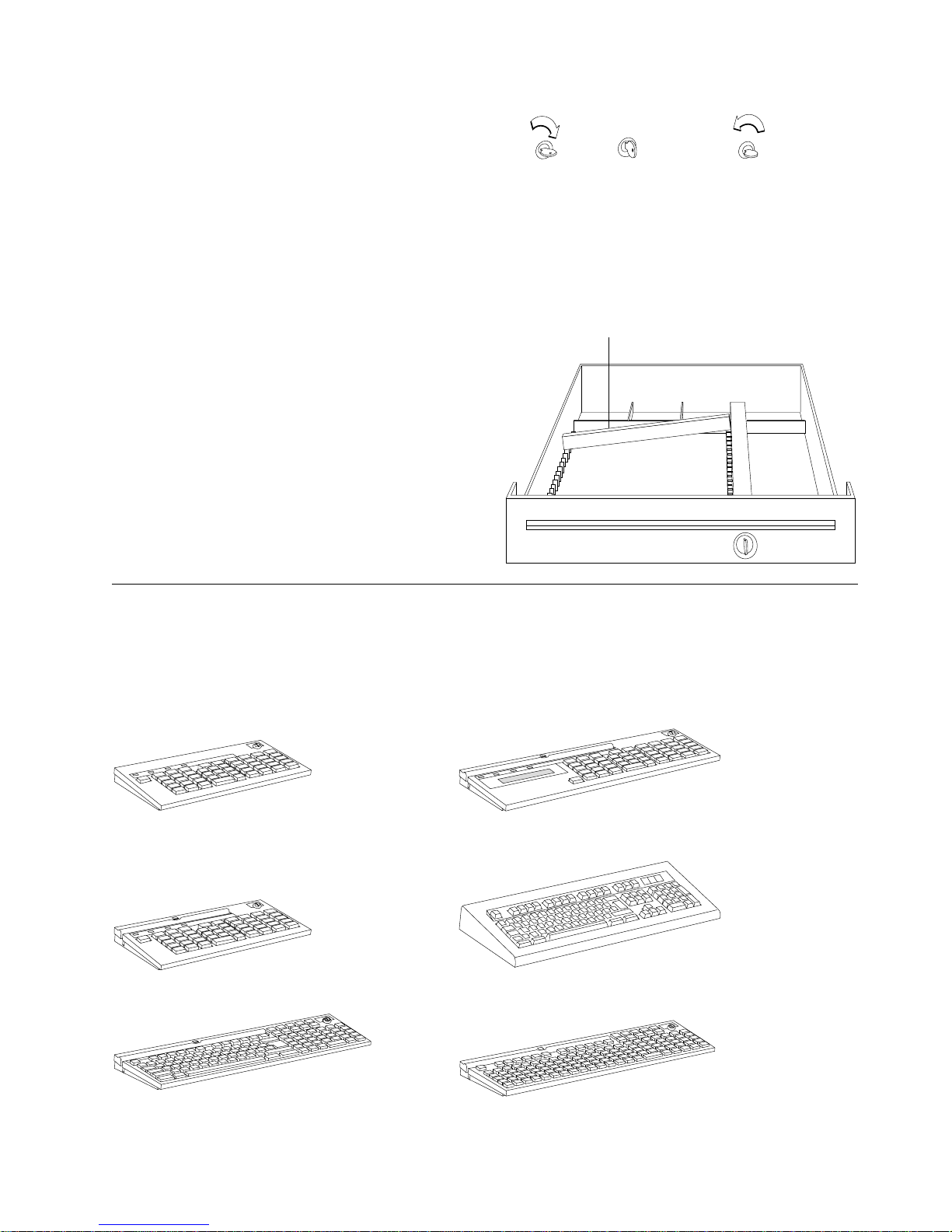

Displays

The 40-character vacuum fluorescent display,

40-character liquid crystal display, and the

character/graphics each displays two lines of 20

characters each. The 40-character display can be

used in graphic mode.

Alphanumeric Display

Character/Graphics Display

The terminal can have a 9 inch monitor; either

monochrome or color. The monitor can be

integrated with the terminal or distributed in a

desired location.

The flat panel display has 640(H) x 480(V) dots.

Distributed 9-Inch

Color Display

Distributed 9-Inch

Monochrome Display

40 Character Vacuum

Fluorescent

Display II (single sided)

Liquid Crystal Display

Vacuum Fluorescent

40 Character

Display II (Two sided)

Flat Panel Display

Monochrome and Color

Sure Point Touch Screen

The Sure Point Touch Screens are 9.5 inch liquid

crystal displays with a touch screen panel. They

can be setup in an integrated arrangement or they

can be placed by themselves in a distributed

arrangement.

2-2 Installation and Operation for POS I/O Devices

Page 37

Created February 23, 1997

The shopper display can display one row of eight

characters, with commas and decimal points. It

also has six indicator lights to further provide

information to the customer.

Shopper Display

on Post

Shopper Display

on Arm

Adjusting the Controls on Video

Displays

There are two versions of the 9-inch monochrome

display. One version has an ON/OFF switch and

has brightness and contrast controls. See

Figure 2-1. The other version has an ON/OFF

switch and has brightness contrast, vertical size,

and horizontal center controls. See Figure 2-2.

Video controls

are located under

the front edge.

Vertical

Size

Horizontal

Center

Contrast

Brightness

Off/On

Switch

Figure 2-2. Controls on 9-Inch Monochrome Display

The 9-inch color display has an ON/OFF switch

and has five video controls for adjusting the

screen.

Video controls

are located under

the front edge.

Horizontal

Center

Vertical

Size

Vertical

Center

Brightness

Contrast

Off/On

Switch

Figure 2-3. Controls on 9-Inch Color Display

Figure 2-1. Controls on 9-Inch Monochrome Display

Chapter 2. Operating Point-of-Sale I/O Devices 2-3

Page 38

Created February 23, 1997

Cash Drawers

There are three kinds of cash drawers. All three

cash drawers can have removable cash tills and

till covers with locks. Two cash drawers are

similar in size to the system unit and opens

toward the front. One fits wide system units and

one fits small systems. They can serve as the

base for the terminal in an integrated arrangement

or placed by themselves in a distributed

arrangement. An optional keylock permits them to

open under an application program control or by

means of a key.

The compact drawer, is smaller in size. It can

serve as the base for the terminal in an integrated

arrangement or it can be placed by itself in a

distributed arrangement. An optional keylock

permits it to open under application program

control or by means of a key.

Cash Drawer

The flip-top cash drawer, is smaller in size. It can

be used in distributed arrangements where space

may be limited. Its top cover hinges up. It, too,

can have an optional keylock to permit the top

cover to open under application program control or

by means of a key.

Flip-top

Cash Drawer

2-4 Installation and Operation for POS I/O Devices

Page 39

Created February 23, 1997

Keylock Positions

The cash drawer keylock has three positions:

¹ Locked closed

¹ Operate

¹ Manual open/locked open

The Operate position permits the cash drawer to

open under application program control. The key

is normally turned to this position while the

terminal is in operation. The key can be removed

while in any of the three positions.

Document Storage Area Under

Cash Till

Space is available under the cash till for storing

documents. Use the slot at the front of the cash

drawer for depositing documents. An adjustment

bar inside lets you adjust the size of the document

storage area to suit your needs.

LockedClosed Operate ManualOpen/LockedOpen

Depth

Adjustment

Bar

Keyboards

Several kinds of keyboards are available with a variety of features. Most have a built-in magnetic card

reader.

RetailPointofSaleKeyboard

RetailPointofSaleKeyboard

withCardReader

RetailPointofSaleKeyboard

withCardReaderandDisplay

EnhancedAlphanumericKeyboard

RetailAlphanumericPointofSale

Keyboard withCardReader

Chapter 2. Operating Point-of-Sale I/O Devices 2-5

ModifiableLayoutKeyboard

withCardReader

Page 40

Function Keys

Function keys, such as S1 and S2, permit the

terminal to perform certain functions or operations

with few keystrokes by the operator.

On keyboards that have a Ctrl (Control) key, the

S1 and S2 functions require a combination of two

keys:

1 Press and hold the Ctrl key.

2 Then, press the S1 or S2 key.

If no Ctrl key is present, you need only to press

the S1 or S2 key. Figure 2-4 illustrates the keys

on a typical keyboard.

S2

S1

CtrlKey

Figure 2-4. Example of S1 and S2 Function Keys

Created February 23, 1997

Enhanced Alphanumeric Keyboard:

On the enhanced alphanumeric keyboard:

The ESC (Escape) key functions as S1.

The ENTER key functions as S2.

Manager’s Keylock

The keyboards can be equipped with a manager’s

keylock, for special override functions as

determined by your store procedures.

During normal operations, the keylock is in the

OFF position. When needed, it can be turned to

the ON position to enable special keying functions,

and then turned OFF again. The key cannot be

removed while it is in the ON position.

Enter(S2)

ESC(S1)

Figure 2-5. Example of Function Keys on Enhanced

Alphanumeric Keyboard

Manager's

Keylock

Figure 2-6. Manager’s Keylock

2-6 Installation and Operation for POS I/O Devices

Page 41

Created February 23, 1997

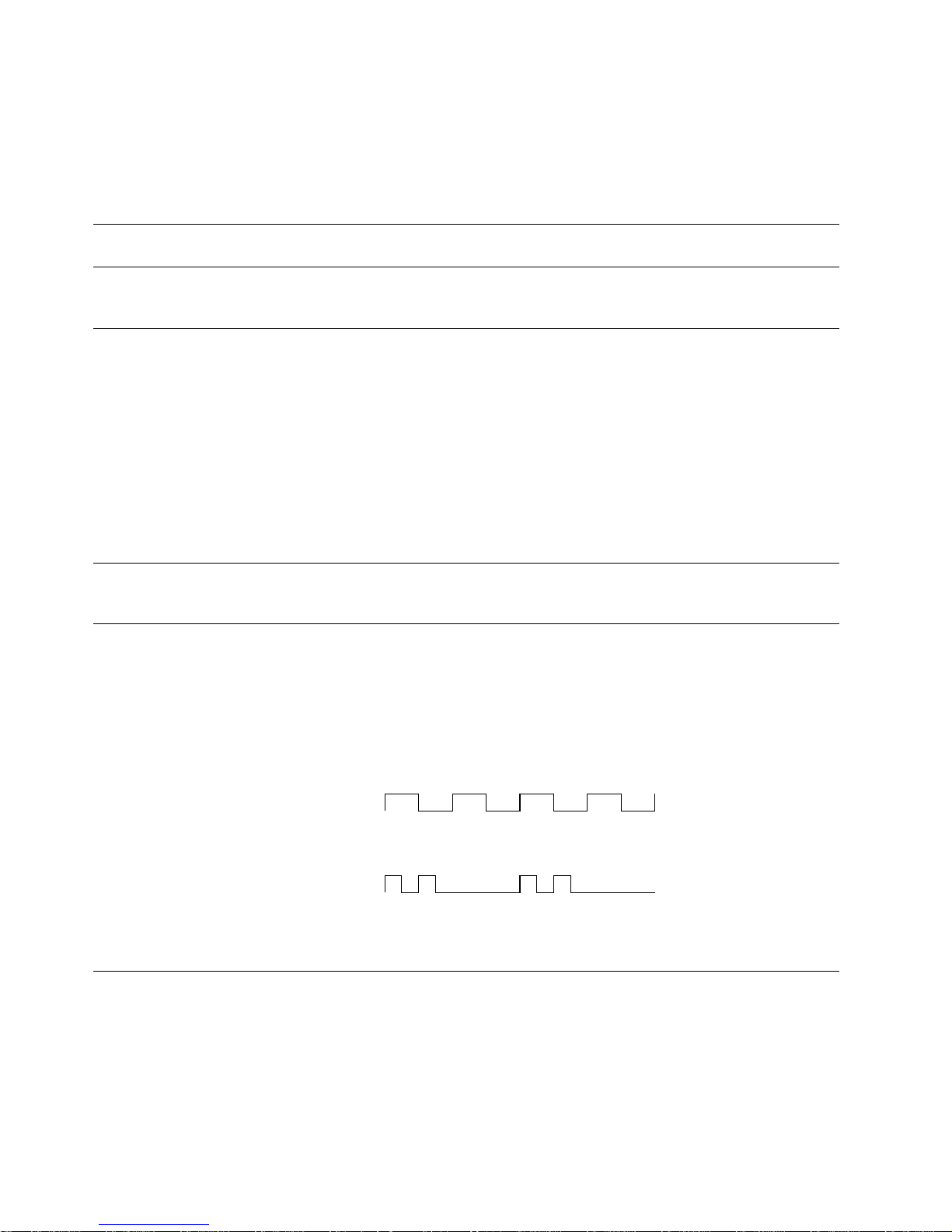

Keyboard Lights (Status Indicators)

Four lights, or status indicators, on the keyboard

provide information about the system. Three of

the lights are labeled: Wait, Offline, and Message

Pending. The fourth light is not labeled.

The lights operate under application program

control. The following table describes the typical

use of these lights. Refer to your store operating

procedures for specific information on how these

lights work.

Light Meaning

Wait The application program

running on the terminal is

waiting for an action to

complete (for example, waiting

for a program to load).

Offline Normal online operations have

been interrupted and you can

display an offline message

using system function keys. An

offline message gives you

information related to the offline

condition.

Message

Pending

Unlabeled Reserved

A system message is waiting to

be displayed on the terminal,

and can be displayed using

system function keys.

Printers

The Model 4 Printer is designed for a 4693

system unit that has a slanted fence on top.

Figure 2-8. Point-of-Sale Printer Model 4

A base is available for the Model 2 and 3 printers,

that allows them to be placed on an I/O integration

kit. The base holds the printer in a slanted

position, in the same manner in which a Model 4

printer is held.

Message Pending

Offline

Wait

Figure 2-7. Keyboard Status Lights

Chapter 2. Operating Point-of-Sale I/O Devices 2-7

Figure 2-9. Point-of-Sale Printer Model 2

Figure 2-10. Point-of-Sale Printer Model 3

Page 42

Operating the Model 2 Point of Sale Printer

Note: Consult your store procedures for information on the correct method of operating the document

insert station.

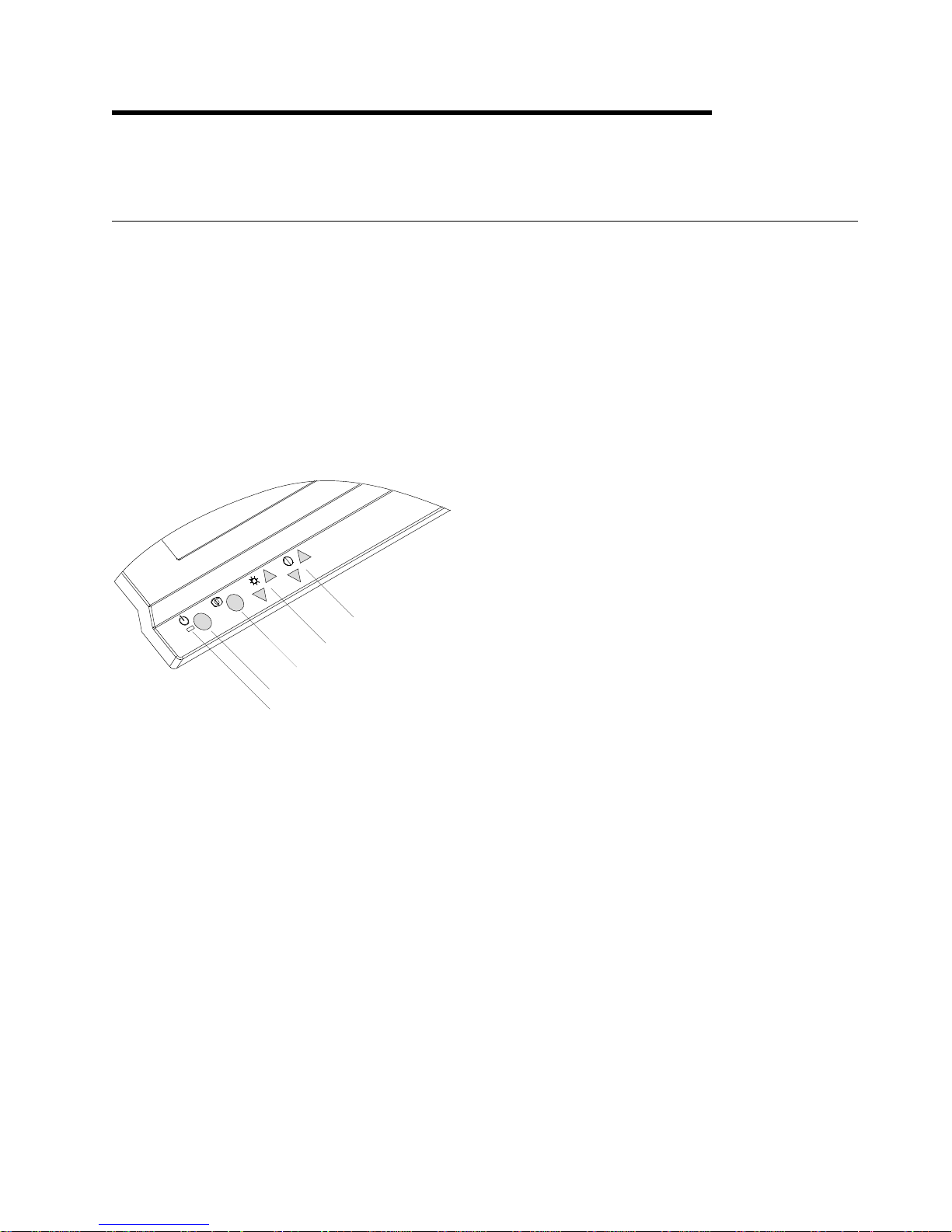

The Model 2 printer has four buttons located on

the top of the printer. These buttons are used to:

Created February 23, 1997

III Advance paper at the journal station

II Advance paper at the customer receipt

station

I Open and close the document insert

station

T Test the printer

Three of the buttons are visible when the printer

cover is closed. The test button is visible only

when the printer cover is raised.

Opening/Closing the Document

Insert Station

The document insert station can be opened or

closed under application program control or it can

be operated manually using the document insert

button.

JournalAdvanceButton

Customer ReceiptAdvanceButton

Document InsertButton

TestButton

Figure 2-11. Buttons on a Model 2 Printer

The document insert station is normally open and

ready for insertion of a document.

1 Insert the document. (The following sections

describe how to insert documents.)

2 Press the I button to manually close the

station.

Note: Pressing the I button is not

necessary if your printer has been

programmed to close the document insert

station automatically.

2-8 Installation and Operation for POS I/O Devices

Page 43

Created February 23, 1997

Inserting Documents in the Model 2 Printer

Note: Consult your store procedures for information on the correct method of operating the document

insert station.

When you want to print on a check or form, insert the document into the document insert station. You can

insert the document at either the front or the side. Consult your store procedures or authorized personnel

at your store for information on inserting documents. You can insert documents that are fastened

together, provided they are not fastened together on the right side.

Note: Do not insert a document with staples, metal inserts, or holes in the area to be printed.

Inserting a Document at the Front

1 Insert the document with the side to be

printed facing up.

2 Push the document against the right wall of

the insert station and forward until it comes

to a stop.

Inserting a Document at the Side

Your store procedures or a message on your

terminal display may tell you which documents

should be inserted at the side. Use the raised

mark on the left side of the printer to help you line

up documents.

1 Insert the document, sliding it to the right as

far as it can go.

2 Be sure to line up your document correctly;

the first line of printing begins where the

mark is located.

3 Press the document insert button marked I

to manually close the station after the

document is lined up correctly. Pressing the

I button is not necessary if the printer has

been programmed to close automatically.

If the document needs to be adjusted after

you have closed the document insert station,

press the document insert button marked I

and adjust the document. Press the button

marked I again to close the document insert

station.

Right Wall

Figure 2-12. Inserting a Document at the Front of

Model 2 Printer

Raised

Mark

Chapter 2. Operating Point-of-Sale I/O Devices 2-9

Figure 2-13. Inserting a Document at the Side of

Model 2 Printer

Page 44

Created February 23, 1997

Advancing the Journal Paper on

the Model 2 Printer

To advance the journal paper:

1 Press the III button.

2 The journal roll advances one line each time

you press the button, or it continues to

advance if you press and hold the button.

Advancing the Customer Receipt

To advance the customer receipt:

1 Press the II button.

2 The customer receipt advances one line

each time you press the button, or it

continues to advance if you press and hold

the button.

Note: If you have a document inserted in the

document insert station, pressing the II button

advances the document. Be sure to remove all

documents from the document insert station

before pressing the II button to advance the

customer receipt.

Unlocking the Journal Cover

Your terminal may have an optional keylock for

securing the journal cover. This keylock is located

under the printer cover near the printer buttons.

To unlock the journal cover:

1 Raise the printer cover.

2 Insert the journal cover key into the journal

keylock and turn it to the unlocked position.

3 Open the journal cover.

4 To lock the journal cover, reverse these

steps. Be sure to remove the journal cover

key. The printer cover does not close until

the key is removed.

Locked

Unlocked

Tearing the Customer Receipt

To tear off the customer receipt, pull the paper

toward the front of the printer (not toward the

sides) and tear it against the tear bar.

2-10 Installation and Operation for POS I/O Devices

Page 45

Created February 23, 1997

Testing the Model 2 Printer

The printer test button is located under the printer

cover and can only be used when the cover is

open. This button runs a test that lets you know

that the print head is seated properly and the

printer is working correctly. Use this button each

time you install the paper, ribbon cartridge, or print

head.

CAUTION:

For safety when running the printer test, make

sure personal articles such as ties, necklaces,

or bracelets do not get caught in the moving

print head.

To run the printer test:

1 Raise the printer cover.

2 Press the T button.

Operating the Model 3 or 4 Point

of Sale Printer

Note: Consult your store procedures or

authorized personnel at your store for information

on inserting documents.

Model 3 and 4 printers have two buttons located

on the top and three on the front. These buttons

are used to:

Advance journal station paper

Advance customer receipt station paper

Advance an inserted document a preset

number of lines (Ready)

Advance an inserted document

Withdraw an inserted document

Run tests on the printer

The buttons on a Model 3 printer differ slightly in

appearance, but their function remains the same.

T

Figure 2-14. Test Button on Model 2 Printer

3 A test begins that prints two lines of 38

characters in both stations. A quick visual

scan verifies that the printer is printing

correctly.

IHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIH

IHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIH

Button

AdvanceJournalButton

CustomerReceiptAdvanceButton

ReadyButton

DocumentInsert Upbutton

DocumentInsert Downbutton

Figure 2-16. Buttons on Model 4 Printer

Inserting Documents in the Model

3 or 4 Printer

When you want to print on a check or form, insert

the document into the printer at the front or at the

top.

Figure 2-15. Printer Test Pattern

4 Tear off the customer receipt paper before

closing the cover.

Chapter 2. Operating Point-of-Sale I/O Devices 2-11

Page 46

Created February 23, 1997

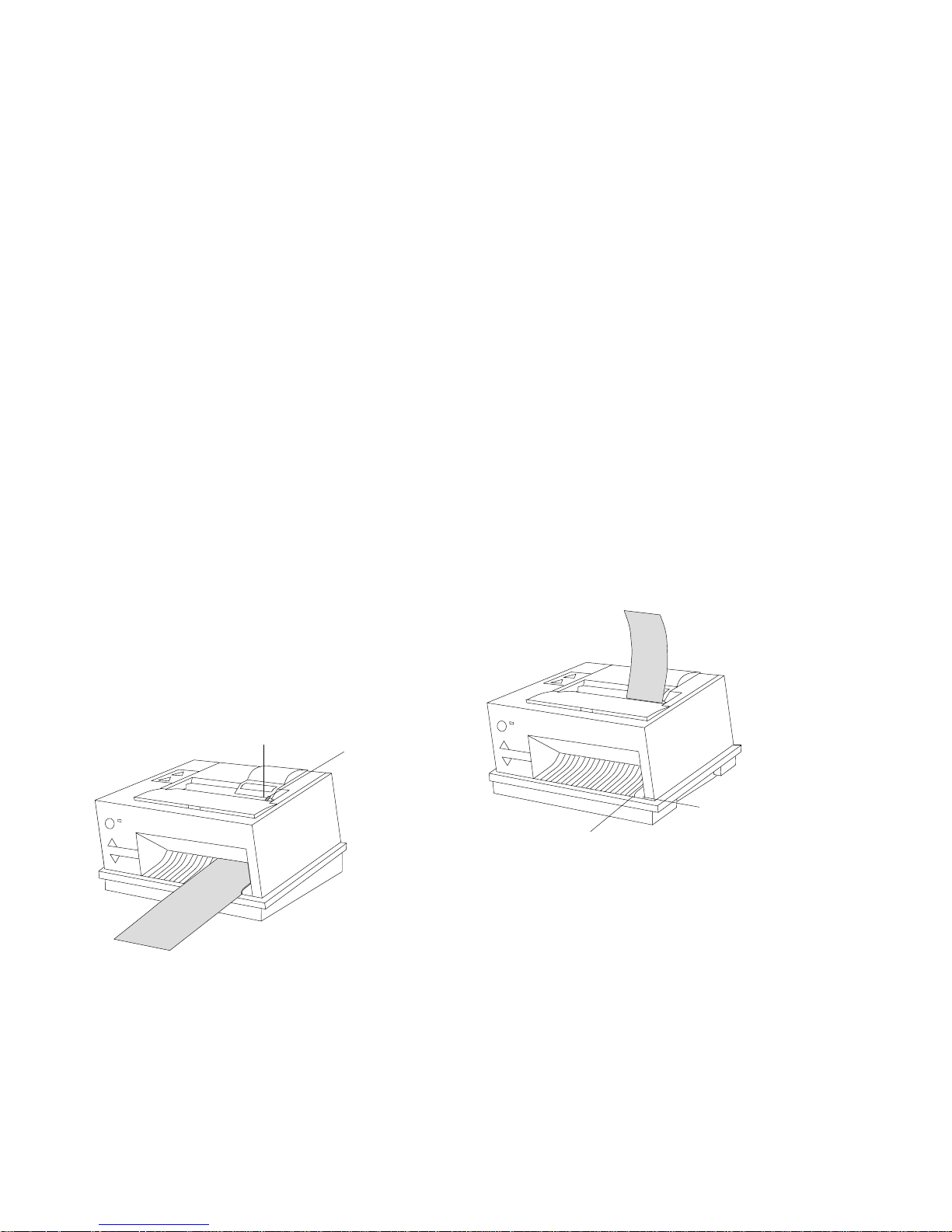

Inserting a Document at the Front

To insert a document at the front:

1 With the side to be printed facing up, insert

the document into the front of the document

insert station until it stops.

Note: The form must be inserted into the

document insert station with enough force so

that it moves between the rollers.

2 When the green light next to the Ready

button goes ON:

¹ Consult your store procedures or

authorized personnel at your store for

information on completing the document

insert transaction.

¹ Press the Ready button to move the

document a preset number of lines into

the printer.

¹ Press the document insert button Up

button to move the document into the

printer one line at a time.

Inserting a Document at the Top

1 With the side to be printed facing you, insert

the document into the top of the document

insert station until it stops.

2 When the green light next to the Ready

button goes ON:

¹ Consult your store procedures or

authorized personnel at your store for

information on completing the document

insert transaction.

¹ Press the Ready button to move the

document a preset number of lines into

the printer.

¹ Press the document insert button Down

button to move the document into the

printer one line at a time.

Note: If the document is not inserted

correctly, the document insert button Up

button to back it out. Return to Step 1 and

try again.

Note: If the document is not inserted

correctly, press the document insert button

Down button to back it out. Return to Step

1 and try again.

Top Load

Form Guide

Tab

Figure 2-17. Inserting a Document at the Front of

Model 4 Printer

MICR and Wide Load

Load Form Guide

Normal Front Load

Form Guide

Figure 2-18. Inserting a Document at the Top of

Model 4 Printer

2-12 Installation and Operation for POS I/O Devices

Page 47

Created February 23, 1997

Aligning the Print Line on an

Inserted Document

To align an inserted document:

Press the Ready button to move the

document a preset number of lines into the

printer.

- or -

Press the document insert button Up or the

document insert button Down to move the

document into the printer one line at a time.

Advancing the Customer Receipt

Paper or Journal Paper

To advance the customer receipt, press the

customer receipt button. To advance the journal

station, press the journal button. See page 2-11.

The customer receipt advances or the journal

station advances one line each time you press the

button with the cover open or 12 lines each time

you press the button with the cover closed. They

continue to advance if you press and hold the

button with the cover open or closed.

Unlocking the Journal Cover

Your terminal may have an optional keylock for

securing the journal cover. This keylock is located

under the printer cover, to the right of the journal

cover.

To unlock the journal cover:

1 Raise the printer cover.

2 Insert the journal cover key into the journal

keylock (on the right side of the journal

cover).

3 Turn the key to the unlocked position.

4 Open the journal cover.

To lock the journal cover, reverse these

steps. Be sure to remove the journal cover

key. The printer cover does not close until

the key is removed.

Locked

Note: If the document insert station is occupied,

you will be able to advance the customer receipt

paper or journal paper, but the printer does not

print at the customer receipt station.

Unlocked

Chapter 2. Operating Point-of-Sale I/O Devices 2-13

Page 48

Created February 23, 1997

Testing the Model 3 or 4 Printer

The printer test lets you know the printer is

working correctly. It can only be run when the

cover is open and the printer has power.

CAUTION:

For safety when running the printer test, make

sure personal articles such as ties, necklaces,

or bracelets do not get caught in the moving

print head.

To run the printer test on the journal station:

1 Close the printer cover. Then open the

cover to clear any outstanding journal errors.

2 Press and hold the Ready button and then

press the journal advance button.

3 The test begins and prints 50 lines of 38

characters at the journal station.

You can stop the test at any point by

pressing the Ready button.

IHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIH

IHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIHIH

Figure 2-19. Printer Test Pattern

A quick visual scan verifies that the printer is

printing correctly.

You can stop the test at any point by pressing

the Ready button.

To run the printer test on the customer receipt

station:

1 Raise the printer cover.

2 Press and hold the ready button and then

press the customer advance receipt button.

3 The test begins and prints 50 lines of 38

characters at the customer receipt station.

A quick visual scan verifies that the printer is

printing correctly. You can stop the test at

any point by pressing the Ready button. If

necessary, tear off the customer receipt paper

before closing the cover.

Note: Pressing the Ready button while the test is

running stops the test and causes the customer

receipt paper cutter to cut the paper. This verifies

that the cutter is functioning correctly.

To run the printer test on the document

station:

1 Raise the printer cover.

2 Insert a blank document into:

The top of the printer and move it into

the printer by pressing the document

insert button Down button.

- or -

The front of the printer and move it into

the printer by pressing the document

insert button Up button.

3 Press and hold the Ready button and then

press:

The document insert button Up button to

run the test and move the document out

the top of the printer.

- or -

The document insert button Down button

to run the test and move the document

out the front of the printer.

4 The test begins and prints 50 lines of 38 test

pattern characters on the inserted document.

5 Remove the document from the printer by

pressing:

The document insert button Up button to

move the document out the top of the

printer.

- or -

The document insert button Down button

to move the document out the front of

the printer.

A quick visual scan verifies that the printer is

printing correctly. You can stop the test at

any point by pressing the Ready button.

AdvanceJournalButton

CustomerReceiptAdvanceButton

ReadyButton

DocumentInsert Upbutton

DocumentInsert Downbutton

2-14 Installation and Operation for POS I/O Devices

Figure 2-20. Testing the Model 4 Printer

Page 49

Created February 23, 1997

Model 4A Point of Sale Printer

Installing a model 4A Printer

The Model 4A Point of Sale Printer is available on

the IBM 4693 and 4694 Point of Sale Terminal.

This model is similar to the Model 4, but in

addition, contains non-volatile (FLASH) memory.

FLASH memory provides the capability for the

user to download any country-specific character

sets (fonts) into the printer.

the

IBM 4693 Point of Sale Terminals:

Introduction and Planning Guide

, SA27-3977.

Operating the Model 4A Point of Sale Printer

For DOS systems, the FLASH memory loading

procedure is described in the FL.DOC file in the

\FL directory on diskette 2 of the

Subsystem/DOS Drivers

, SX27-3960 and

Point of Sale

SX27-3961, Version 1.20 or later.

There is no unique installation procedure or

planning required for the Model 4A Point of Sale

Printer. Use the

Terminals: Setup Instructions

IBM 4693 Point of Sale

, PN 73G1012 and

For POSS/2 systems, the FLASH memory loading

procedure is described in

Point of Sale

Subsystem/2 Programming Reference and User's

Guide

Version 1.1 (or later), SC30-3560.

Model 3R and Model 4R Point of Sale Printers

Introduction

Model 3R and Model 4R Point of Sale Printers read the magnetic ink characters printed at the bottom of

most checks, while maintaining the functions of the standard Model 3 and Model 4 printers. The Magnetic

Ink Character Recognition (MICR) device consists of a read head, located in the document insert station

and the associated circuitry on the printer extension card and printer logic card. Model 3R and 4R printers

are identified by the presence of a check orientation label at the front of the printer. Figure 2-21 shows

the location of the label on a Model 4R printer.

X

0103

Figure 2-21. Model 4R Printer With Check Orientation Label

Installing and Planning

Model 3R and 4R printers are designed to read

Model 3R and 4R printers automatically position checks for franking at the completion of a MICR read

operation. Franking is limited to a maximum of 20 characters per line at 15 characters per inch. If more

characters per line are required the check must be reinserted at the normal document stop.

Video Display Placement

Terminals should be configured with the video display to the left of the printer. If a video display is

installed too close to the right side of the Model 3R or 4R printer, check reading failures may occur. If

you experience this problem, move the display away from the printer as far as practical. A spacing of