Page 1

4560SLX Tape Libr ary

User’ s Guide

Important:

To maintain your new IBM 4560SLX Tape Library at peak performance and reliability,

follow the maintenance procedures described in Chapter 5, “Maintenance” on page 43.

Failure to do so may impact your product warranty.

Page 2

Page 3

4560SLX Tape Libr ary

User’ s Guide

Page 4

Note: Before using this information and the product it supports, read the information in

Appendix E, “Warranty information” on page 99 and Appendix F, “Notices” on page 111.

First Edition (August 2002)

© Copyright International Business Machines Corporation 2002. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety ...............v

Preface ..............vii

Product Registration ...........vii

Chapter 1. Introduction ........1

Contents................1

Configurations..............1

Library interfaces .............2

Front panel ...............2

Magazine doors .............3

Magazines ...............4

Mailslots...............4

Power supply ..............5

Tapedrives...............6

Library controller board ..........6

Robotics ................7

Multi-module library systems.........8

Chapter 2. Installation ........11

Setup................11

Attaching the slide members to the library . . . 12

Attaching the slide members to the rack....13

Installing a library in the rack .......14

SCSI cable configurations..........15

SCSI interface connectors .........15

Interface cable specifications........15

SCSI configuration ...........16

Turning on your library ..........19

Chapter 3. Library configuration ....21

Setting a SCSI ID ............21

Setting up reserved tape cartridge slots .....23

Chapter 4. Operation .........27

Usingthetouchscreen ..........27

Technical support information .......27

Mail Slot Access (left magazine only) .....27

Magazine Access ...........28

MoveMedia.............28

LCDcontrastcontrols..........30

Menu...............30

Online...............39

Status...............39

Power...............40

Using tape cartridges ...........40

Removing magazines ..........40

Inserting cartridges into a magazine .....41

Using the mail slot (left magazines only) . . . 41

Barcodelabels............42

Chapter 5. Maintenance .......43

Supported media ............43

Running a cleaning cartridge ........43

Automatically running a cleaning cartridge. . . 43

Manually running a cleaning cartridge ....44

Replacing a cleaning cartridge in a reserved slot . . 45

Replacing a cleaning cartridge in the right

magazine ..............45

Replacing a cleaning cartridge in the mail slot . . 45

Chapter 6. Troubleshooting ......47

Platformproblems............47

Error recovery procedures (ERPs) .......47

Fault symptom codes (FSCs).........49

Chapter 7. Using the NeoCenter utility 55

Establishing communication with your host . . . 55

Setting IP addresses ...........55

Setting an access password .........56

Setting SNMP traps............57

Setting e-mail addresses ..........57

Setting remote FTP server parameters .....57

Setting SCSI parameters .........58

Setting the SCSI identification .......58

Setting library parameters ........58

Setting the drives ...........58

Uploading data .............58

Downloading data ............60

Rebootingthelibrary...........61

Chapter 8. Web TLC .........63

Operation...............64

Web TLC access ............64

Status...............65

Movemedia.............65

Setup...............66

Functions..............66

History ...............66

Appendix A. Adding a tape drive . . . 67

Appendix B. Adding a library module 69

Planning your installation .........69

Positioning the modules ..........70

Cartridge elevator router ..........70

Routerinstallation............70

Installing the cartridge elevator........72

Cartridge elevator extension assembly .....75

Components .............75

Assembly ..............76

Module configuration ...........82

Configuring the primary master module....83

Configuringslavemodules........84

Cabling and interface connections .......85

Verifying firmware level of the slave modules . . . 87

Fail-overoperation............88

Cartridge elevator terms .........88

© Copyright IBM Corp. 2002 iii

Page 6

Cabling considerations for fail-over operation . . 88

Fail-over initiation ...........88

Restoringnormaloperation........89

Appendix C. Specifications ......91

Hardware...............91

Environmental .............92

Safety ...............92

Electromagnetic emissions ........92

Electrostatic discharge ..........92

Temperature, humidity, and altitude .....93

Shock ...............93

Vibration..............94

Primarypower.............94

Voltagelimits.............95

Frequencylimits............95

Powerrequirements ..........95

Sag/Surge protection ..........95

Power line disturbance .........95

Cooling................96

Installationconsiderations.........96

Rackmounting............96

Input supply .............96

Grounding..............96

Appendix D. Field replaceable units

(FRUs)...............97

Appendix E. Warranty information . . . 99

Warranty period .............99

Service and support ...........99

Warranty information on the World Wide Web . 99

Online technical support .........99

Telephone technical support ........99

IBM Statement of Limited Warranty Z125-4753-06

8/2000 ...............101

Part1-GeneralTerms.........101

Part 2 - Country-unique Terms ......103

Appendix F. Notices.........111

Trademarks..............112

Electronic emission notices .........112

Federal Communications Commission (FCC)

statement..............112

iv 4560SLX Tape Library: User’s Guide

Page 7

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Pred inštaláciou tohto zariadenia si pečítaje Bezpečnostné predpisy.

Antes de instalar este producto lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

© Copyright IBM Corp. 2002 v

Page 8

vi 4560SLX Tape Library: User’s Guide

Page 9

Preface

This manual provides step-by-step installation instructions and information

required for ongoing use and maintenance of the IBM®4560SLX Tape Library. This

manual is written for the installer and user of this equipment. The following

information is contained in this manual:

v Chapter 1, “Introduction” provides an introduction to the 4560SLX Tape Library,

along with a brief description of the library parts.

v Chapter 2, “Installation” provides installation procedures and descriptions of

interface connections and configuration options.

v Chapter 3, “Library configuration” explains how to configure the 4560SLX Tape

Library for normal operation.

v Chapter 4, “Operation” explains how to use the touch screen and tape

cartridges.

v Chapter 5, “Maintenance” explains how to run and replace a cleaning cartridge.

v Chapter 6, “Troubleshooting” provides problem diagnosis, error recovery

procedures, and fault symptom codes to aid in troubleshooting potential error

conditions.

v Chapter 7, “Using the NeoCenter utility” explains how to configure the

4560SLX Tape Library using the NeoCenter utility. Sections in this chapter

include setting IP addresses, passwords, and parameters.

v Chapter 8, “Web TLC” describes the web-based graphical interface that enables

you to monitor and control your automated tape library through any terminal

connected on your network or the Internet.

v Appendix A, “Adding a tape drive” contains procedures for adding an

additional tape drive.

v Appendix B, “Adding a library module” contains procedures for adding an

additional library module.

v Appendix C, “Specifications” contains specific device specifications and EMI

compliance information.

v Appendix D, “Field replaceable units (FRUs)” provides a list of field

replaceable units (FRUs).

v Appendix E, “Warranty information” provides warranty information.

v Appendix F, “Notices” contains trademarks and legal notices.

Product Registration

Thank you for purchasing this IBM®product. Take a few moments to register your

product and provide us with information that will help IBM to better serve you in

the future. Your feedback is valuable to us in developing products and services

that are important to you, as well as in developing better ways to communicate

with you. Register your option on the http://www.ibm.com/pc/register/ IBM

Web site.

IBM will send you information and updates on your registered product unless you

indicate on the Web site questionnaire that you do not want to receive further

information.

© Copyright IBM Corp. 2002 vii

Page 10

viii 4560SLX Tape Library: User’s Guide

Page 11

Chapter 1. Introduction

The IBM 4560SLX Tape Library is a backup and restore solution for high-end

xSeries™servers. The library provides many features and functions not normally

found in similarly classed products. Please read this document in its entirety before

attempting to install or use the library.

This chapter provides an introduction to the 4560SLX Tape Library. Sections in this

chapter include:

v Contents

v Configurations

v Library interfaces

v Front panel

v Magazine doors

v Magazines

v Mail slots

v Power supply

v Tape drives

v Library controller board

v Robotics

v Multi-module library systems

Contents

Configurations

In addition to this CD, you should have received the following:

v Base library module

v External SCSI cable

v External SCSI terminator

v Power cord

v Rack installation hardware

v Cleaning cartridge

v 4560SLX Tape Library Quick Installation Guide

Depending on your final configuration, the following options might be used with

the 4560SLX Tape Library, but are purchased separately:

v SDLT drive upgrade option (Part number: 59P6660)

– Base SDLT drive sled

– SCSI jumper cable

– 4560SLX Tape Library Quick Installation Guide

v LTO drive upgrade option (Part number: 59P6658)

– Base LTO drive sled

– SCSI jumper cable

– 4560SLX Tape Library Quick Installation Guide

v Fibre channel option (Part number: 59P6657)

© Copyright IBM Corp. 2002 1

Page 12

– Fibre Channel Option (FCO) card

– Interface cables (two)

– Fibre Option User Guide

v SDLT magazine option (Part number: 59P6661)

– Left magazine

– Right magazine

– Barcode pack

– 4560SLX Tape Library Quick Installation Guide

v LTO magazine option (Part number: 59P6659)

– Left magazine

– Right magazine

– Barcode pack

– 4560SLX Tape Library Quick Installation Guide

v Cartridge elevator option (Part number: 59P6662)

– Ethernet router

– Base mechanism

– Interconnect cables (three)

– 4560SLX Tape Library Quick Installation Guide

v Cartridge elevator extension option (Part number: 59P6663)

– Base mechanism

– 4560SLX Tape Library Quick Installation Guide

Note: You may also purchase additional 4560SLX Tape Libraries to construct

Contact your place of purchase if an item is missing or damaged. Be sure to retain

your proof of purchase. It might be required to receive warranty service. See

“Service and support” on page 99 for technical support information.

Library interfaces

The 4560SLX Tape Library includes a SCSI interface-to-host system that supports

Low Voltage Differential (LVD). The tape drives and robotics use separate SCSI

connections and SCSI ID addresses. The drive SCSI I/O is provided through

VHDCI 68-pin SCSI connectors located at the rear of the unit directly under the

tape drives. The Robotics SCSI I/O are provided through VHDCI 68-pin SCSI

connectors located on the library controller board.

The library can also be attached to fibre channel networks using a Fibre Channel

Option (FCO) card (part number: 59P6657).

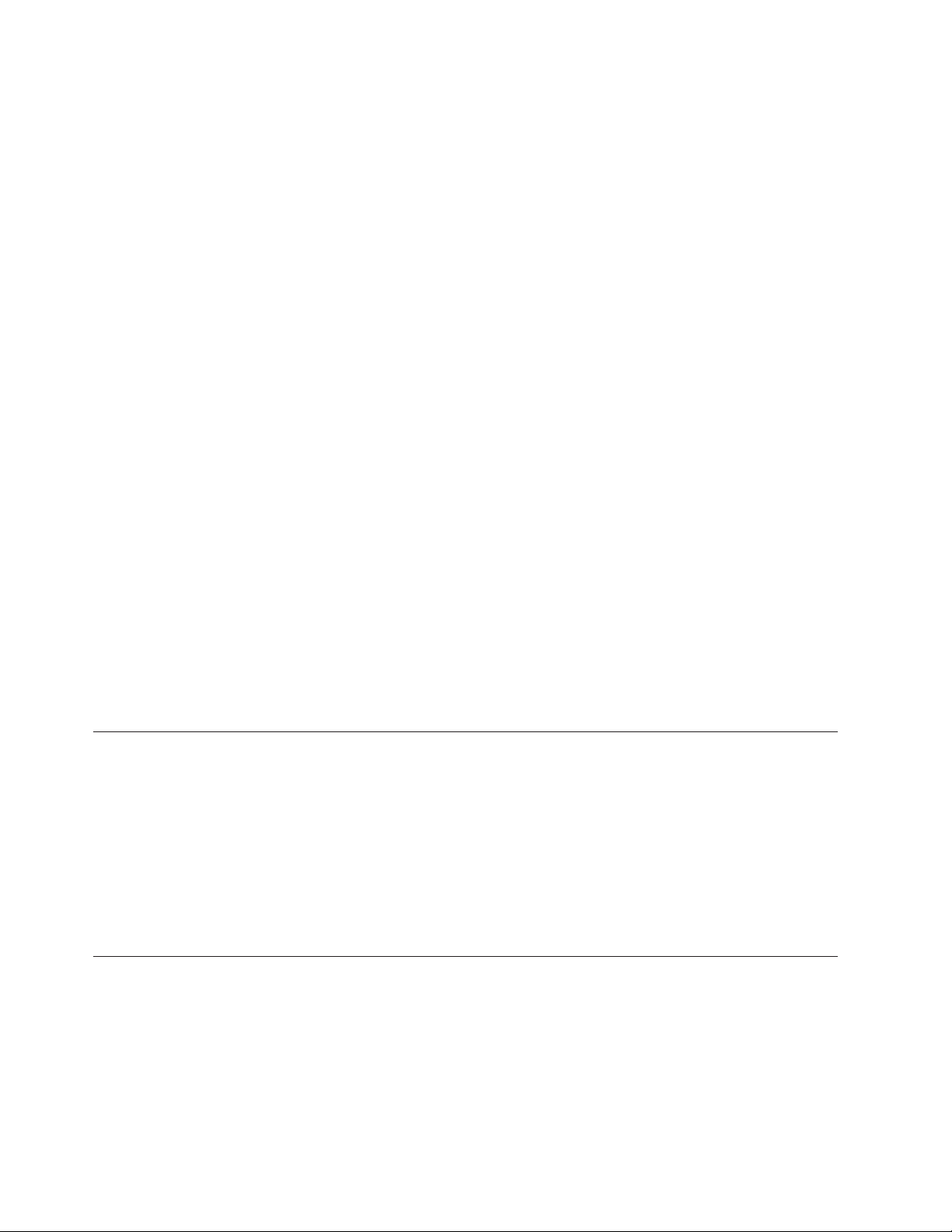

Front panel

The front panel of the library includes the left and right magazine doors, an

internal viewing window, a touch screen, and a library status LED as shown in

Figure 1 on page 3.

multi-module library configurations.

2 4560SLX Tape Library: User’s Guide

Page 13

1 Left magazine door

2 Internal viewing window

3 Touch screen

4 Library status LED

5 Right magazine door

Figure 1. Library front panel

Table 1 describes the different indicator settings of the library status LED.

Magazine doors

The magazine doors have an electrical release on the touch screen and a manual

release (1 and 3 in Figure 2). Always open the doors using the touch screen. In

an emergency, the doors can be manually opened by pushing in on the mechanical

releases directly behind the front panel.

Table 1. Library front panel indicators

Library Indicators

Solid Green The library is operating correctly under normal conditions.

Flashing Green The library is operating correctly. However, a change is being

made through the touch screen that is interrupting the current

library operation.

Solid Amber The library is in a fault state as indicated by the fault message on

the touch screen.

1 Left magazine door release

2 Touch screen

3 Right magazine door release

Figure 2. Magazine door mechanical release

Chapter 1. Introduction 3

Page 14

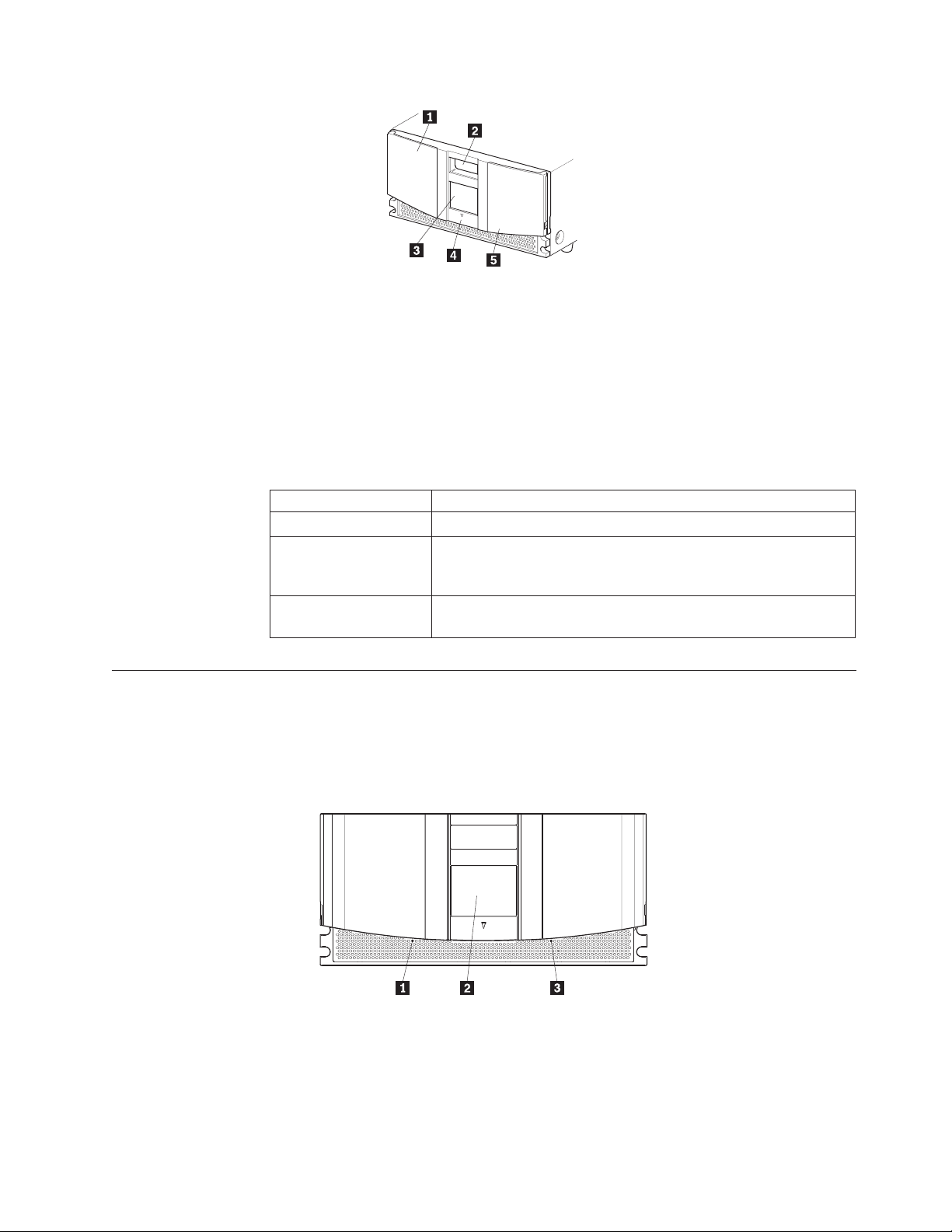

Magazines

The 4560SLX Tape Library contains two removable tape cartridge magazines that

are accessible through the magazine doors as shown in Figure 3. The magazine

doors are opened using the touch screen.

Note: The magazine must match the installed tape drive. For example, an LTO

magazine should be installed on an LTO drive and an SDLT magazine

should be installed on an SDLT drive.

1 Left magazine with integrated mail slot

2 Right magazine

Figure 3. Magazines

Mail slots

As viewed from the front of the 4560SLX Tape Library, the left tape magazine

includes a mail slot, which is accessible when the left magazine slot door is open as

shown in Figure 4. This mail slot enables you to insert or remove a single media

cartridge without interrupting library operation. If a full tape cartridge magazine is

required, you can configure the library to disable the mail slot feature. The right

tape magazine contains fixed cartridge slots (no mail slot feature), so it retains its

full capacity at all times.

Figure 4. Mail slot

4 4560SLX Tape Library: User’s Guide

Page 15

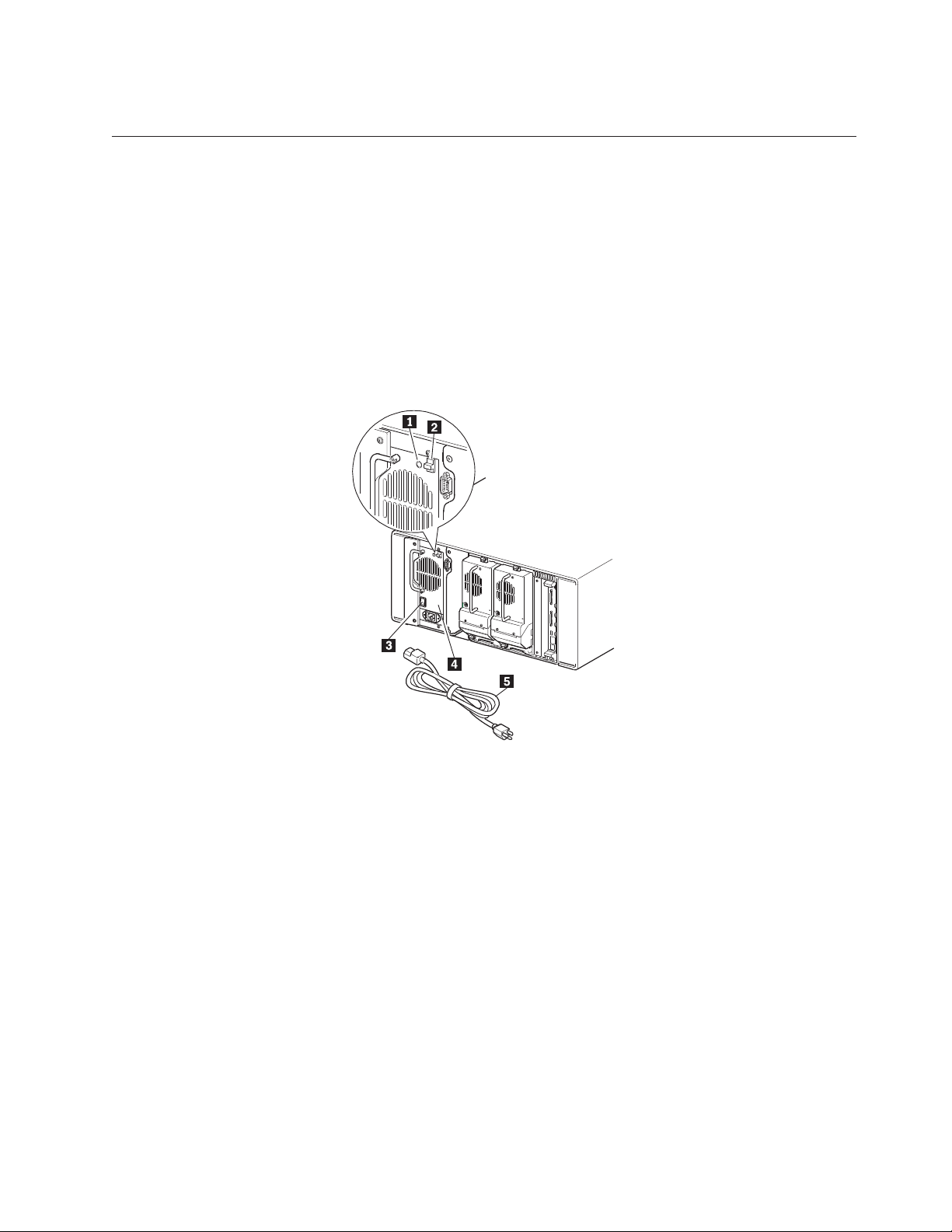

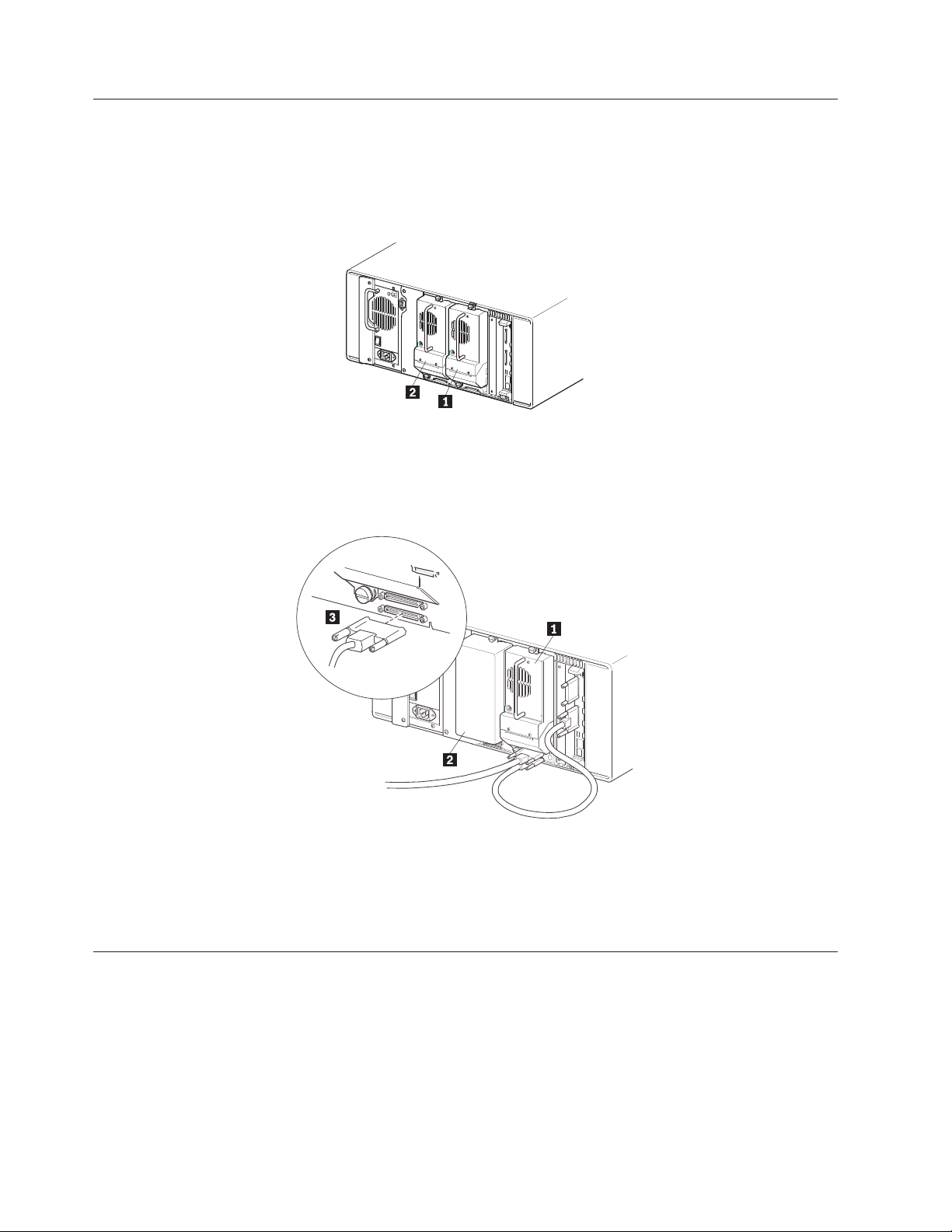

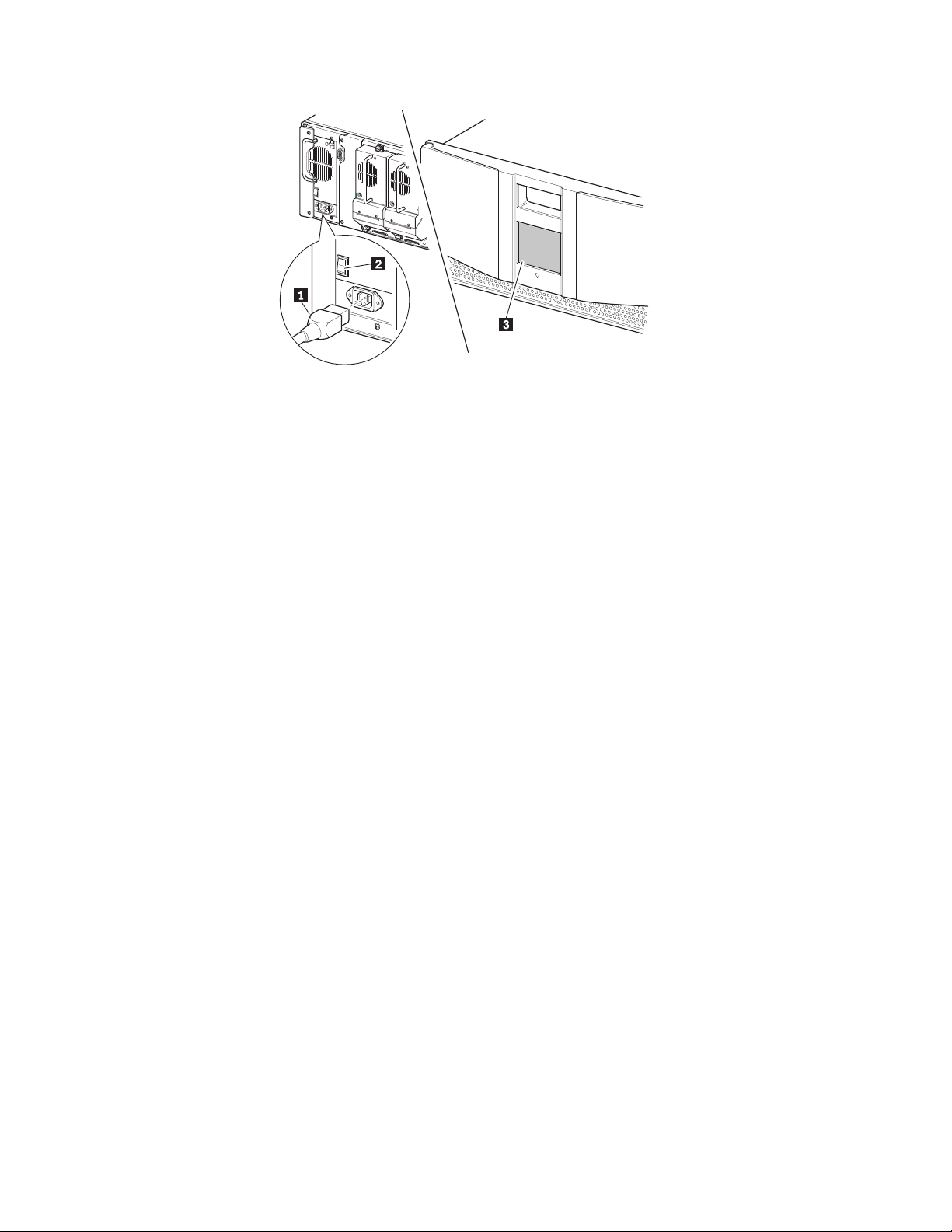

Power supply

The power supply is accessible from the rear of the library as shown in Figure 5.

These auto-ranging power supplies are capable of using any nominal ac voltage

between 100 and 240 V power at 50 Hz or 60 Hz.

Power to the library is supplied through the cord on the rear panel of the power

supply. Library power is controlled from the touch screen. However, a manual

power disconnect switch, located on the rear of the power supply, can also be

used.

Note: Only trained service personnel should remove the power supply. Hazardous

voltage is present in the cavity if the power cord is removed.

1 Power on LED (lights after touching the touch screen)

2 Power supply release latch

3 Power switch

4 Power supply

5 Power cord

Figure 5. Power supply

Chapter 1. Introduction 5

Page 16

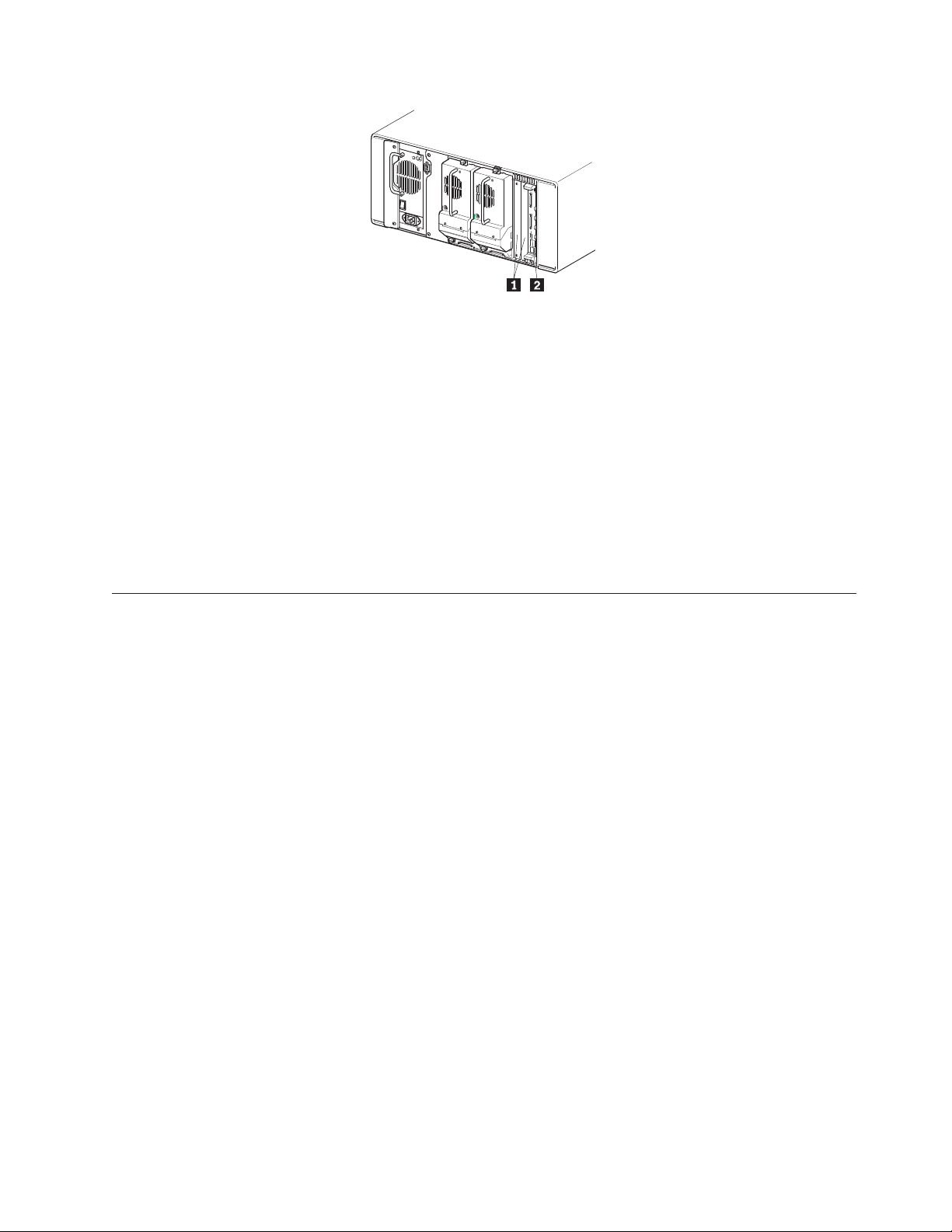

Tape drives

The 4560SLX Tape Library supports a 0-drive, 1-drive, or 2-drive configuration as

shown in Figure 6. All inactive tape drives are hot-swap capable. SCSI I/O is

accomplished through two VHDCI-series 68-pin SCSI connectors located on the

rear of the library directly under each tape drive as shown in Figure 7.

1 Tape drive 1

2 Tape drive 2

Figure 6. Tape drive locations

1 Drive 1

2 Drive 2 bay

3 VHDCI 68-pin connectors

Figure 7. Tape drive connectors

Library controller board

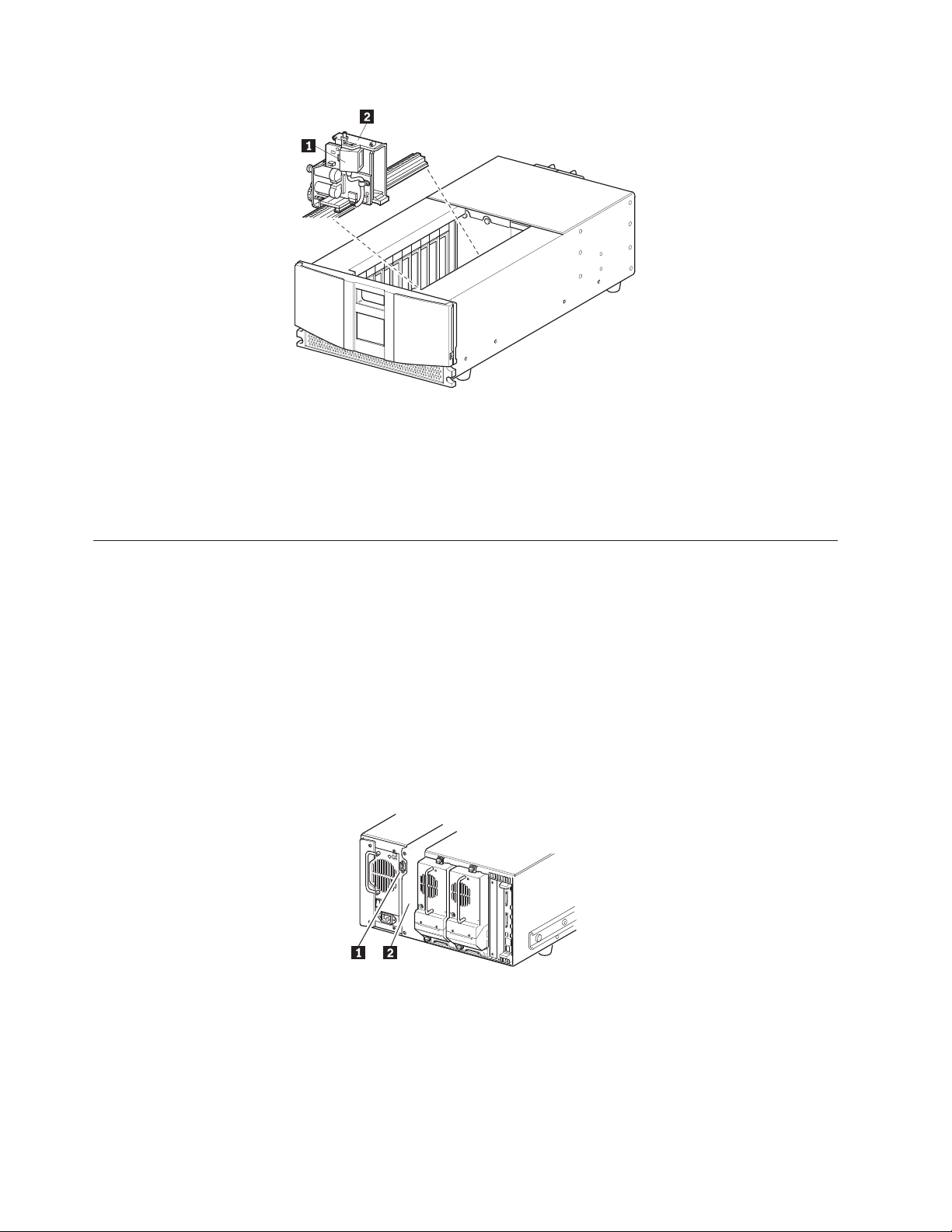

The library contains a rear-access adapter cage (see Figure 8 on page 7) and a PCI

backplane. This backplane contains the plug-in connectors for the library controller

board and FCO card.

6 4560SLX Tape Library: User’s Guide

Page 17

1 Rear access card cage

2 Library controller board

Figure 8. Library controller adapter and PCI slots

The library controller board contains a single microprocessor and associated logic

devices to control all robotics operations and manage overall library functions. The

microprocessor enables the SCSI interface between the library and the host system,

including Web TLC (Total Library Control).

Web TLC is built into the library controller board. Web TLC enables you to

remotely monitor and control the tape library from any terminal on a local

network or access the internet. For more information on Web TLC, see Chapter 8,

“Web TLC” on page 63.

Robotics

The library contains robotics which consist of a cartridge shuttle, motor hardware,

motor drives, and other support electronics. The robotics can pick up and place

tapes throughout a 180° arc that consists of the tape drives, tape cartridge

magazines, and an optional cartridge elevator.

The cartridge shuttle assembly includes a mounted bar code reader for scanning

tape cartridges installed in the magazines and tape drives as shown in Figure 9 on

page 8.

A full bar code reader scan and a physical scan are conducted each time the library

is powered up or a tape magazine is exchanged.

Chapter 1. Introduction 7

Page 18

1 Bar code reader

2 Cartridge shuttle assembly

Figure 9. Library robotics

Multi-module library systems

The 4560SLX Tape Library is an expandable tape library that can be configured in

a variety of module and drive combinations. The drives are mounted in a

removable drive shoe that enables easy installation and removal. Therefore, a failed

drive can be swapped without the server or library power needing to be cycled.

The library can be stacked with additional library modules to form a

multi-module, rack-mounted configuration. All multi-module libraries in the stack

can operate together as a single virtual library system through a rear-mounted

cartridge elevator as shown in Figure 10. Stacked units are interconnected through

their rear panel Ethernet connections and an external Ethernet router mounted to

the rack.

1 Interface connector

2 Cartridge elevator location

Figure 10. Cartridge elevator mounting location and connector

Any combination of modules, not exceeding a height of 40U can comprise a library

module system. A library module system appears to the host computer system and

8 4560SLX Tape Library: User’s Guide

Page 19

library control software as a single library. For multi-module applications, the top

library module becomes the primary master module and all other libraries become

slave modules.

The library robotics pick up and place tape cartridges into an elevator so that

individual tapes can be passed up or down between libraries in a multi-unit

library configuration.

The 4560SLX Tape Library supports fail-over protection for multi-unit library

configurations. In the event of a master module failure, a pre-selected slave

module can become the fail over master. For example, if the primary master library

fails, you can invoke the library system fail-over mode. In this mode, one of the

connected slave units serves as the secondary master library, communicating with

the host system through the SCSI interface. The source of power to the cartridge

elevator drive motor is switched from the original primary master library to the

newly-assigned secondary master library.

Chapter 1. Introduction 9

Page 20

10 4560SLX Tape Library: User’s Guide

Page 21

Chapter 2. Installation

This chapter explains how to install the 4560SLX Tape Library. Sections in this

chapter include:

v Setup

v SCSI cable configurations

v Turning on the library

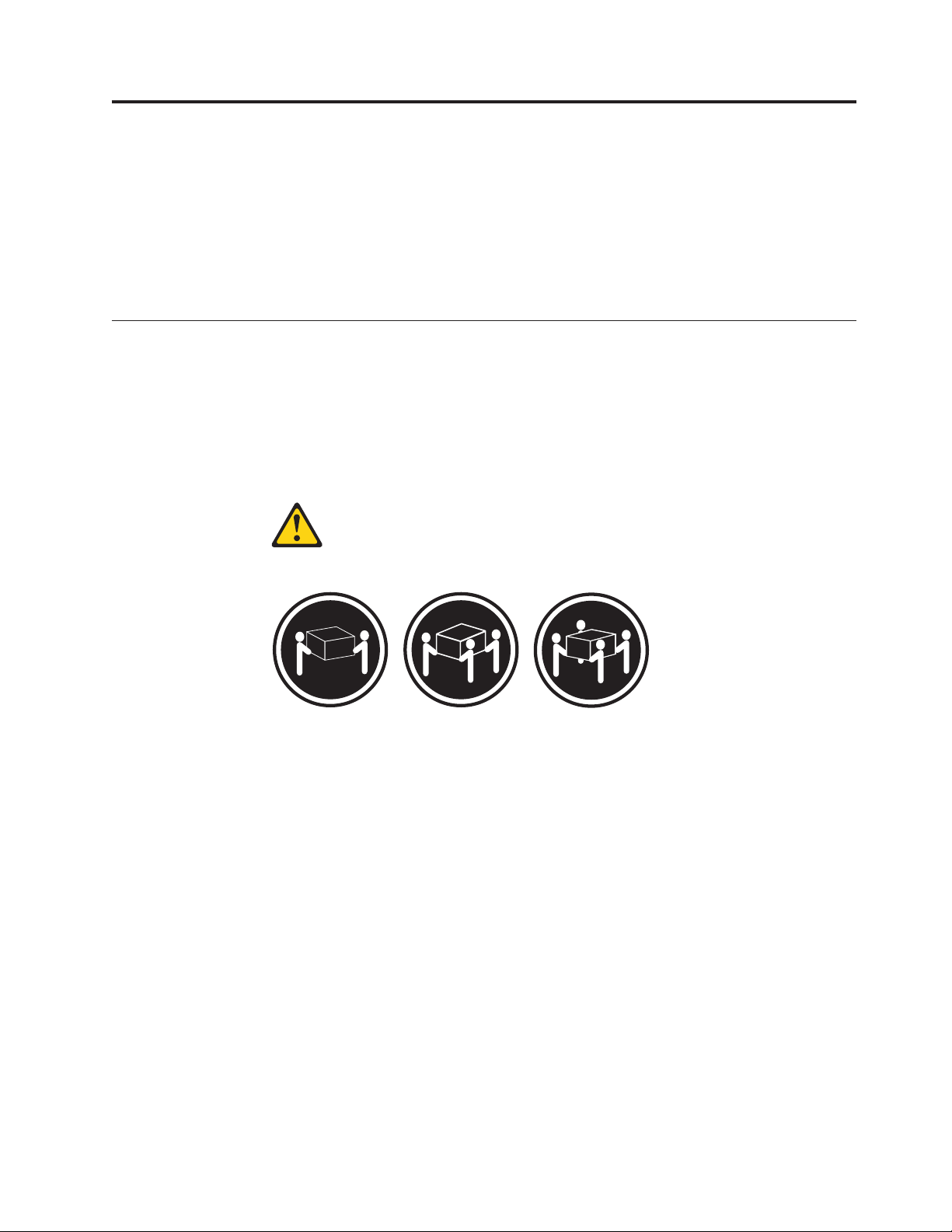

Setup

Before rack mounting the library, make sure there is adequate space available in

the rack. See “Installation considerations” on page 96, for considerations relating to

multi-unit rack-mounted environments.

Note: When lifting the library use a mechanical lifter or a two person minimum.

Statement 4

CAUTION:

≥18 kg (37 lbs) ≥32 kg (70.5 lbs) ≥55 kg (121.2 lbs)

Use safe practices when lifting.

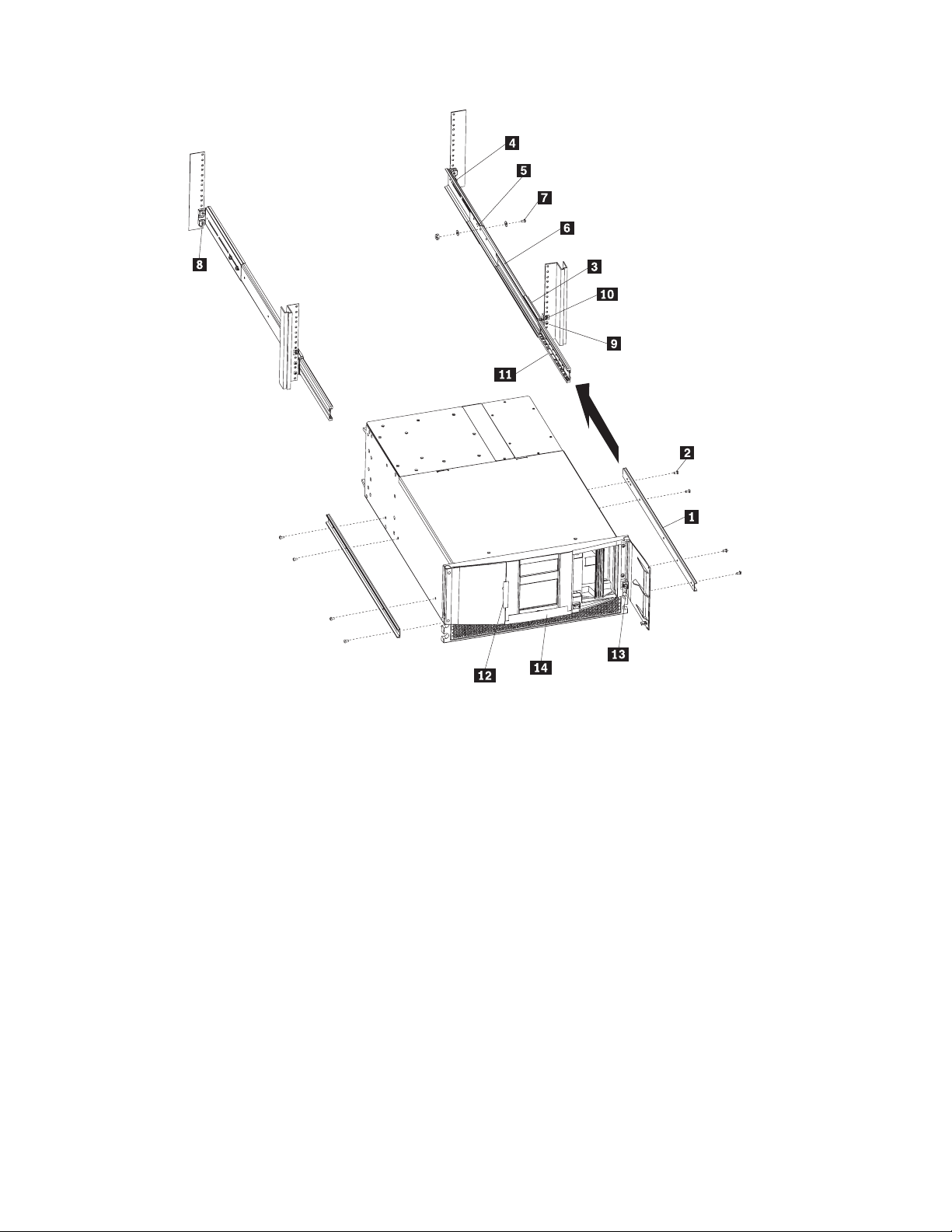

Figure 11 on page 12 identifies the parts needed for a rack-mount installation.

© Copyright IBM Corp. 2002 11

Page 22

1 Inner slide member 8 Clip or cage nut (eight 8-32)

2 Hex screw (eight M4 x 8mm) 9 Screw (eight 10-32 x 5/8)

3 Front mounting bracket 10 Clip or cage nut (two 10-32)

4 Rear mounting bracket 11 Ball bearing slide member

5 Outer slide member 12 Sticker

6 Middle slide member 13 Thumbscrew (two 10-32)

7 Screw, flat washer, lock washer, nut (eight sets) 14 Door latch insert

Note: If you are installing the library on the IBM Netbay42 Enterprise rack, clip nuts (8 and 10) are provided. If

you are installing a Netbay11, Netbay25, or Netbay42 standard rack, cage nuts are provided.

Figure 11. Rack mounting the library

Attaching the slide members to the library

To attach the slide members to the library, complete the following procedures:

1. Remove the inner slide member (1) from each rack-mount slide.

2. Attach the inner slide members to the sides of the chassis using eight hex

screws (2).

12 4560SLX Tape Library: User’s Guide

Page 23

Attaching the slide members to the rack

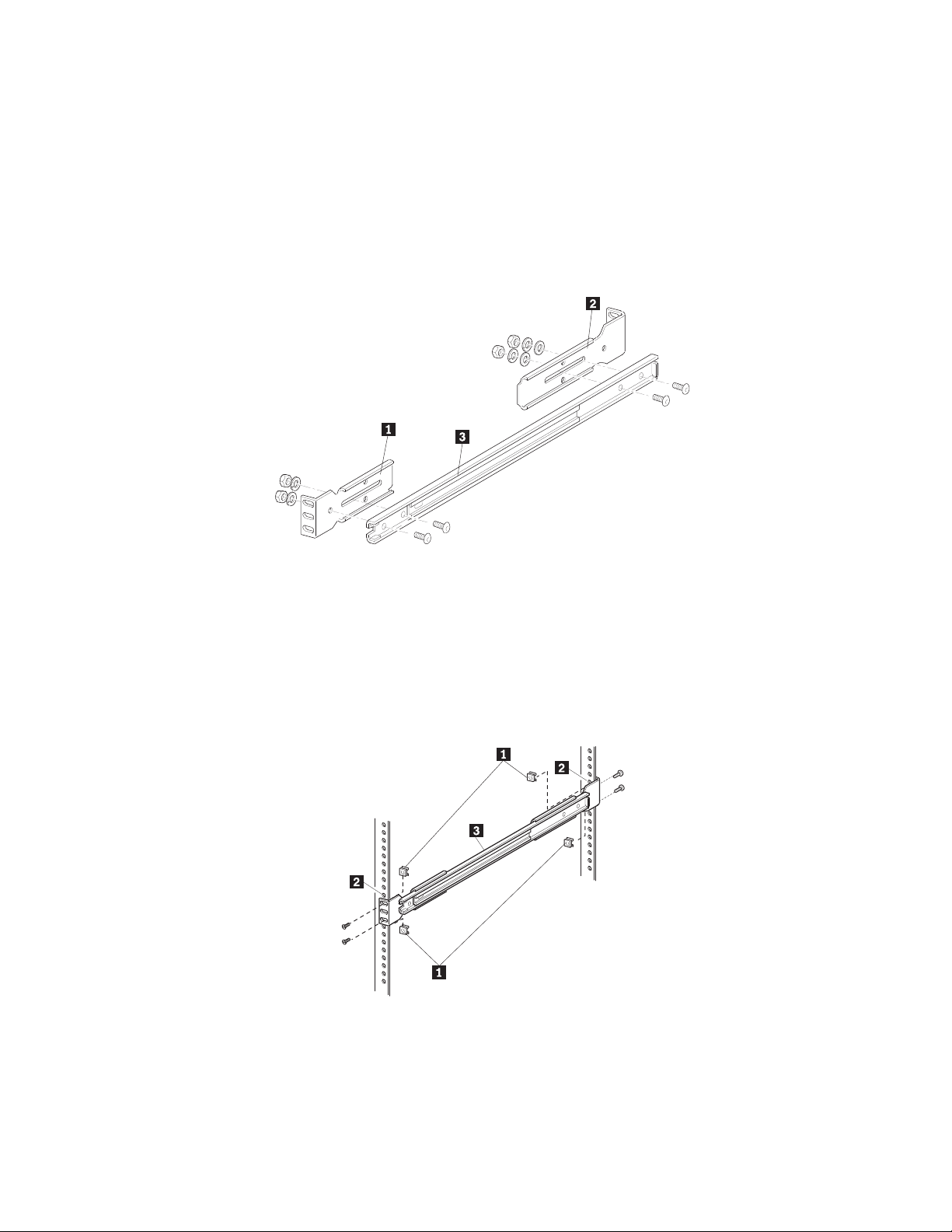

To attach the slide members to the rack, complete the following procedure:

1. Attach the front (shorter) and rear (longer) mounting brackets to the outer and

middle slide members as shown in Figure 12.

IMPORTANT: Fully tighten the front mounting bracket screws. Leave the rear

mounting bracket screws “finger tight” to prevent binding when mounting the

library module. Once the distance between rails is set, the screws should be

fully tightened.

1 Front mounting bracket

2 Rear mounting bracket

3 Middle slide member

Figure 12. Installing the slide members

2. Depending on the type of rack you are installing, use the clip or cage nuts to

attach the slide member assembly to the rack as shown in Figure 13.

1 Clip or cage nuts

2 Vertical member mounting holes

3 Middle slide member

Figure 13. Installing slide member fasteners

Chapter 2. Installation 13

Page 24

3. Push the middle slide member as far as possible to the front of the slide

member assembly.

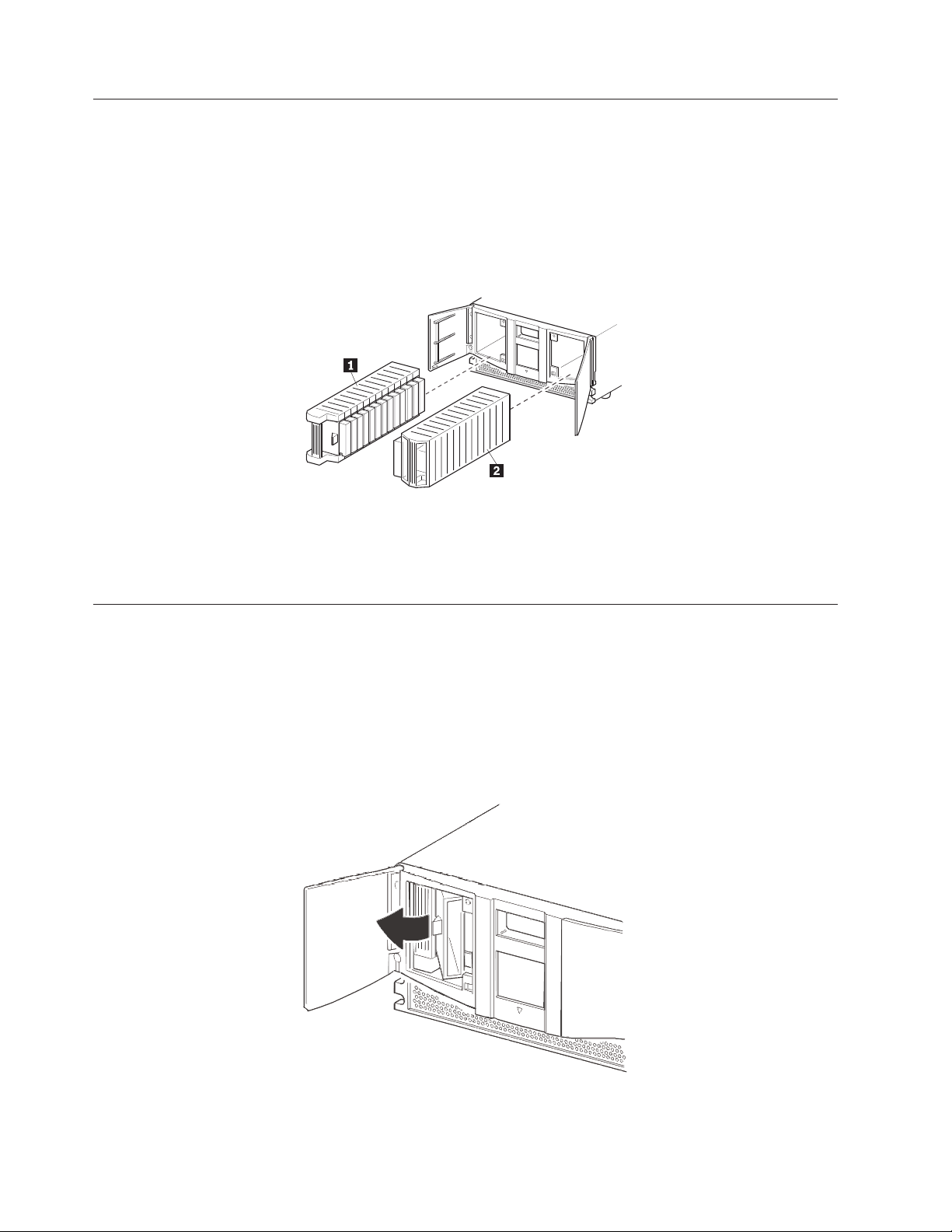

Installing a library in the rack

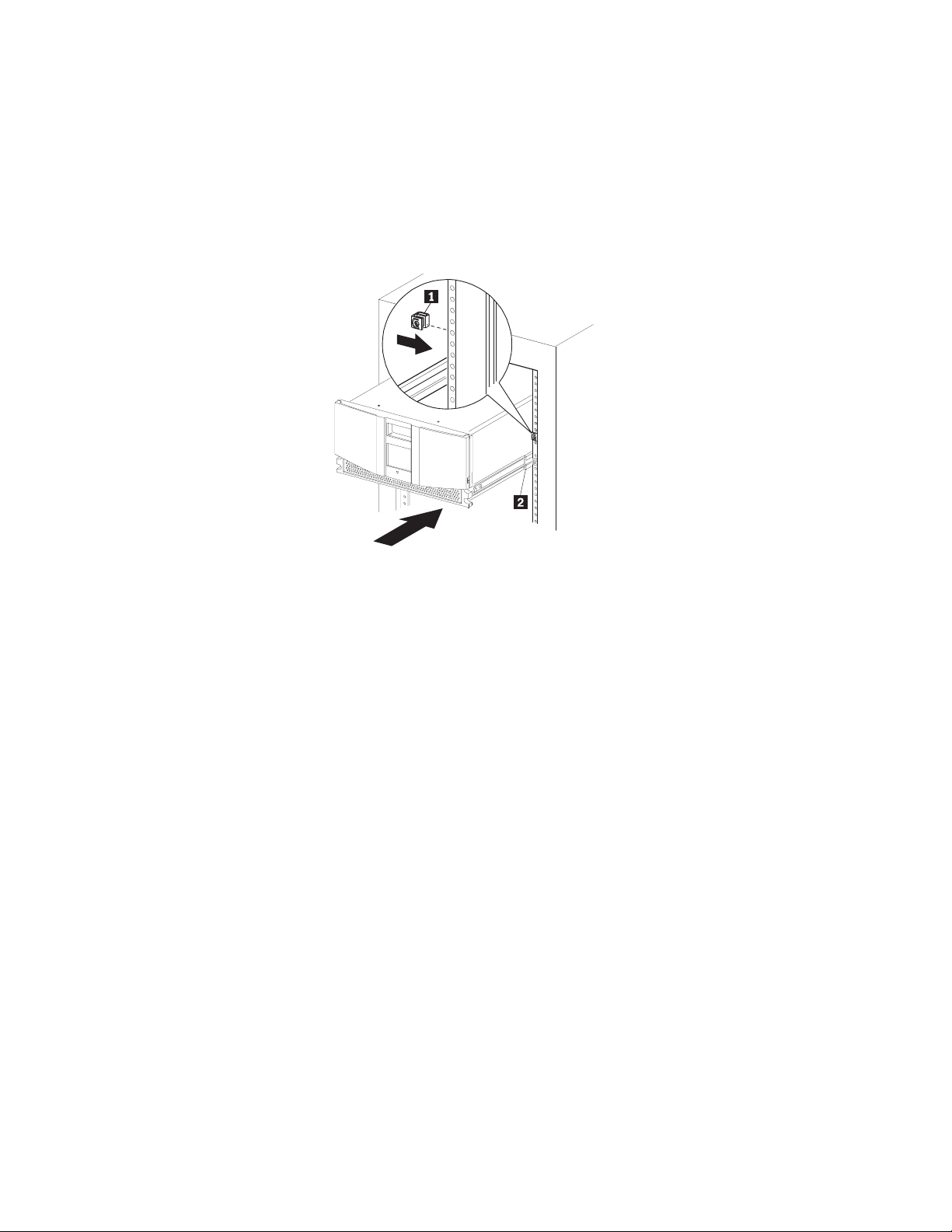

To install a library in the rack, complete the following procedure:

1. Install a clip or cage nut on each side of the front vertical rails as shown in

Figure 14.

1 Clip or cage nut

2 Vertical member mounting holes

Figure 14. Installing the library module

2. Lighten the library module by removing the drives.

3. Lift the library and visually align the inner and middle slide members. (It is

good practice to use a mechanical lifter to lift the library.)

4. Carefully insert the chassis inner slide members into the extended

rack-mounted middle slide members. Ensure that the ball bearing slide

members are located in the front position.

5. Slide the library completely into the rack until the front panel touches the

rack.

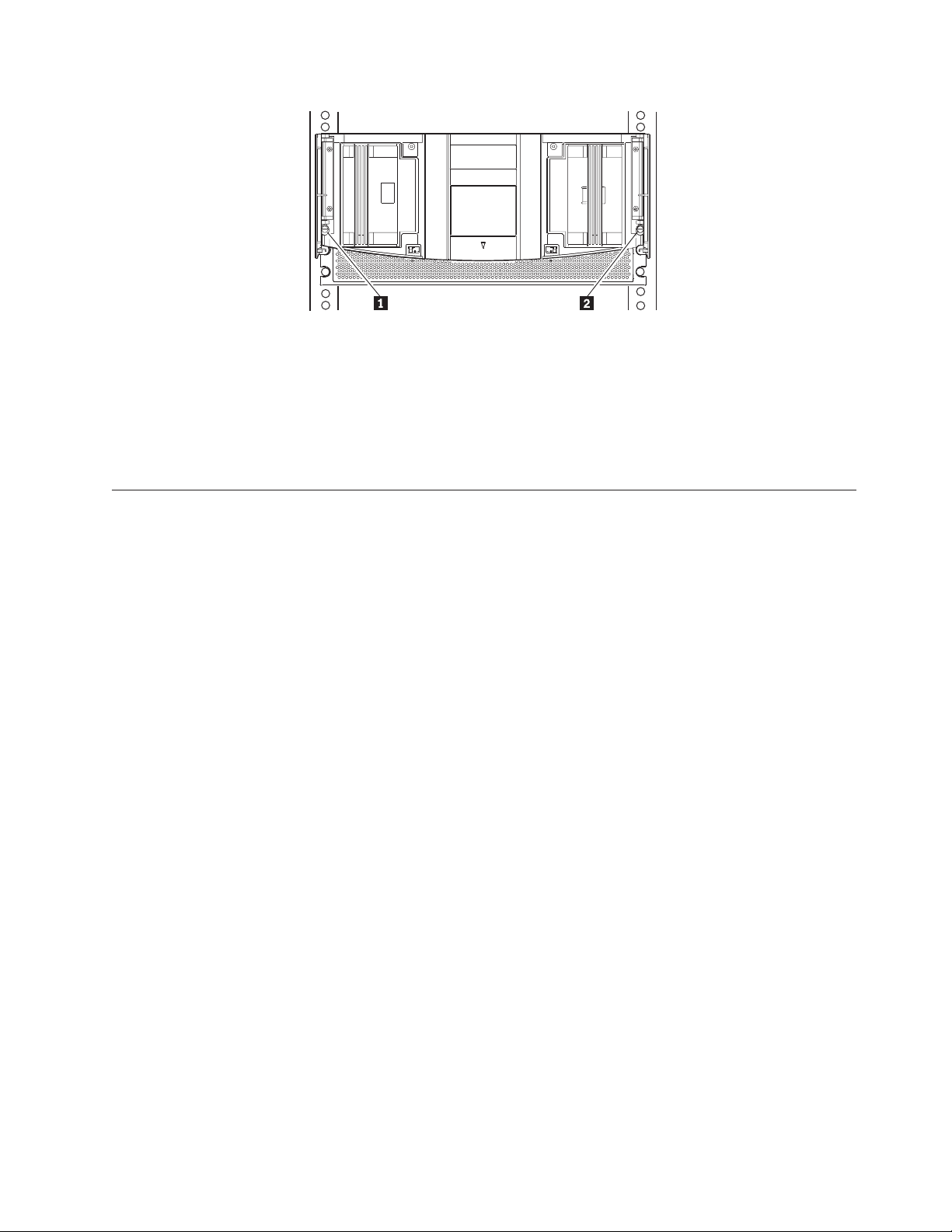

6. Remove the stickers that hold the doors in a closed position.

7. With the doors open, attach the library to the rack using two 10-32 captive

thumbscrews (located on the front panel inside the front doors). (See 1 and

2 in Figure 15 on page 15.)

14 4560SLX Tape Library: User’s Guide

Page 25

Figure 15. Retaining screws

8. Remove the door latch insert (the red tab located on the front panel).

9. Re-insert the drives.

10. Fully tighten the rear mounting bracket screws.

11. Close the doors.

12. Connect the ac power supply to the library.

SCSI cable configurations

The 4560SLX Tape Library supports multiple SCSI cable configurations on single

and dual host systems.

SCSI interface connectors

The library should be attached to a low voltage differential SCSI bus. Each tape

drive in the library and its robotics is a separate SCSI device. When two or more

devices are connected to the same SCSI bus, each SCSI device must be assigned a

unique SCSI ID. For information on assigning SCSI IDs, see “Setting a SCSI ID” on

page 21.

To connect a library to a host system, the host system must have at least one wide

LVD controller and the appropriate device driver software.

Interface cable specifications

The library is a high-performance system. To avoid degradation of performance,

use the highest quality interface cables from a reputable manufacturer of computer

cables. All SCSI cables used with the library should meet the following cable

specifications:

v Shielded or double-shielded as required to meet EMI specifications

v Impedance match with cable terminators that meet current SCSI specifications

v Characteristic impedance 115 ohms

All SCSI cables used with the library should meet the following usage guidelines:

v Each end of a twisted pair ground connected to chassis ground

v Maximum cable length of 39 ft. (12 m) for an LVD SCSI bus

v Cables of different impedances should not be used together

Additional specifications to ensure the highest SCSI performance can be found in

the current version of ANSI X3.131.

Chapter 2. Installation 15

Page 26

SCSI configuration

Your specific configuration will depend on the speed of your host and SCSI

controller. The library uses high performance tape drives. The tape drive

performance might be degraded if you attach too many drives to a single SCSI

host controller.

One tape drive on a single host system

Figure 16 shows a typical SCSI cable configuration for a library with one tape drive

(drive 1) installed.

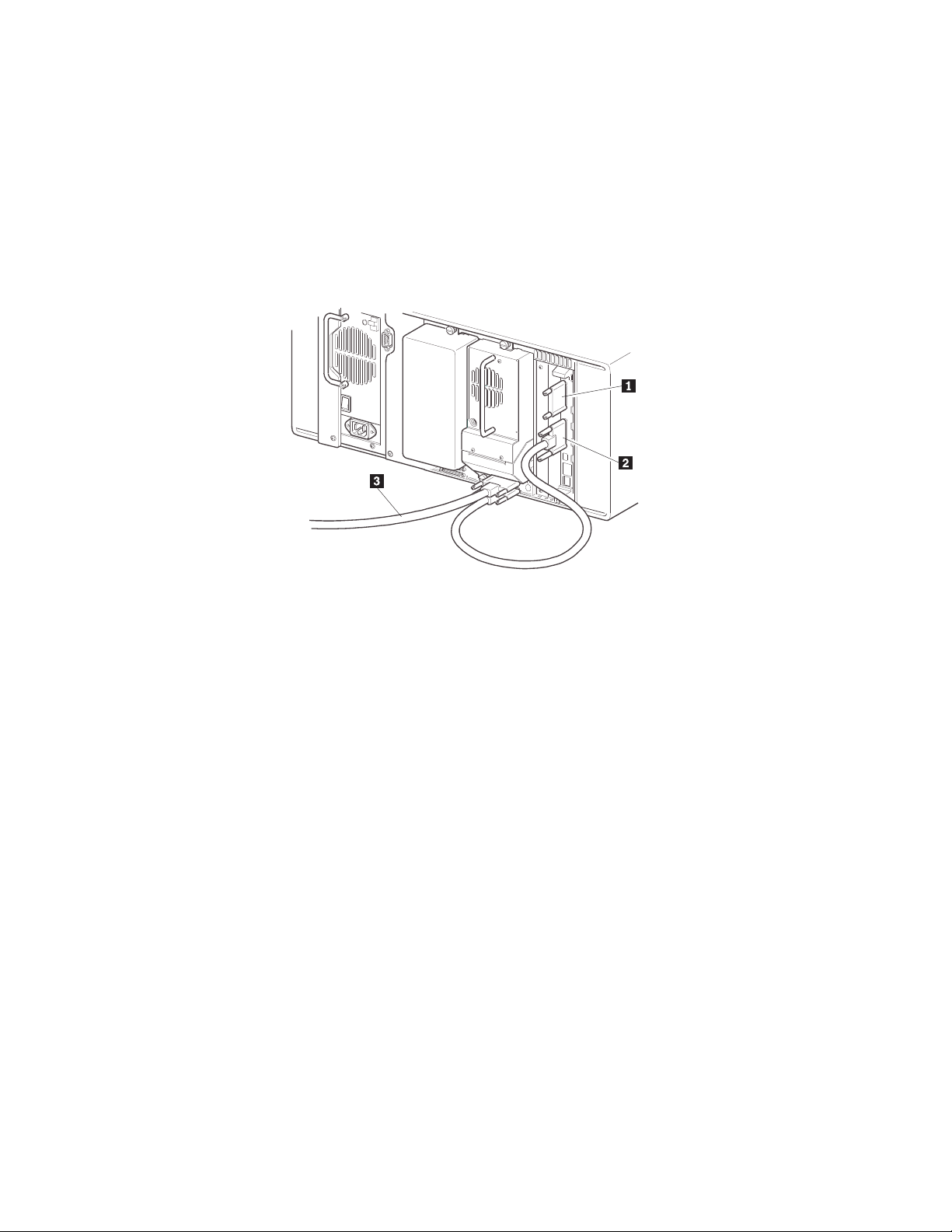

1 SCSI terminator

2 To library controller card

3 To host system

Figure 16. One tape drive single host

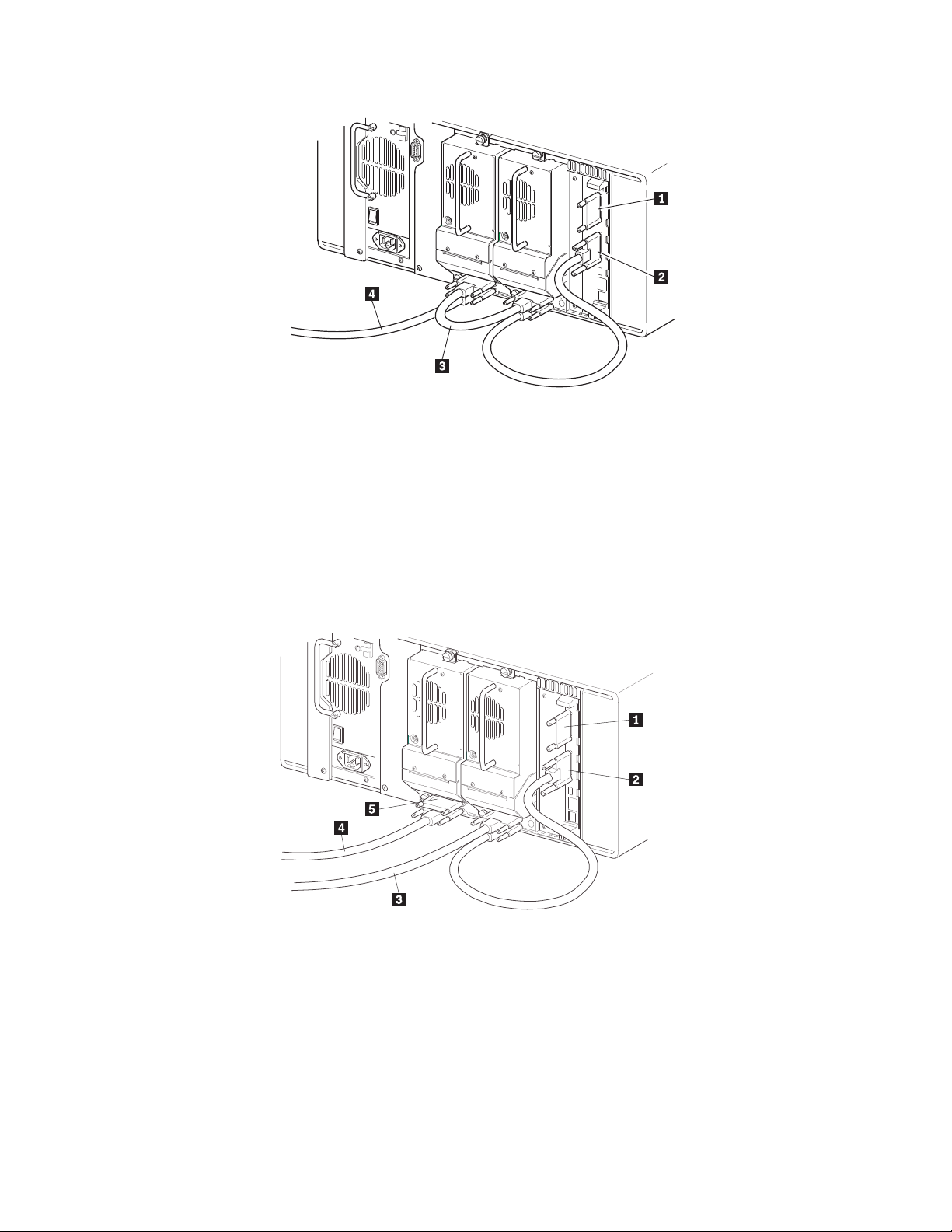

Two tape drives on a single host system

Figure 17 on page 17 shows a typical SCSI cable configuration for a library with

two tape drives installed using a single host system.

16 4560SLX Tape Library: User’s Guide

Page 27

1 SCSI terminator 3 Jumper cable

2 To library controller card 4 To host system

Figure 17. Two tape drives single host

Two tape drives on a dual host system

Figure 18 shows a typical SCSI cable configuration for a library with two tape

drives installed using a dual host system.

1 SCSI terminator 4 To host (drive 2)

2 To library controller card 5 SCSI terminator

3 To host (drive 1)

Figure 18. Two tape drives dual host

Chapter 2. Installation 17

Page 28

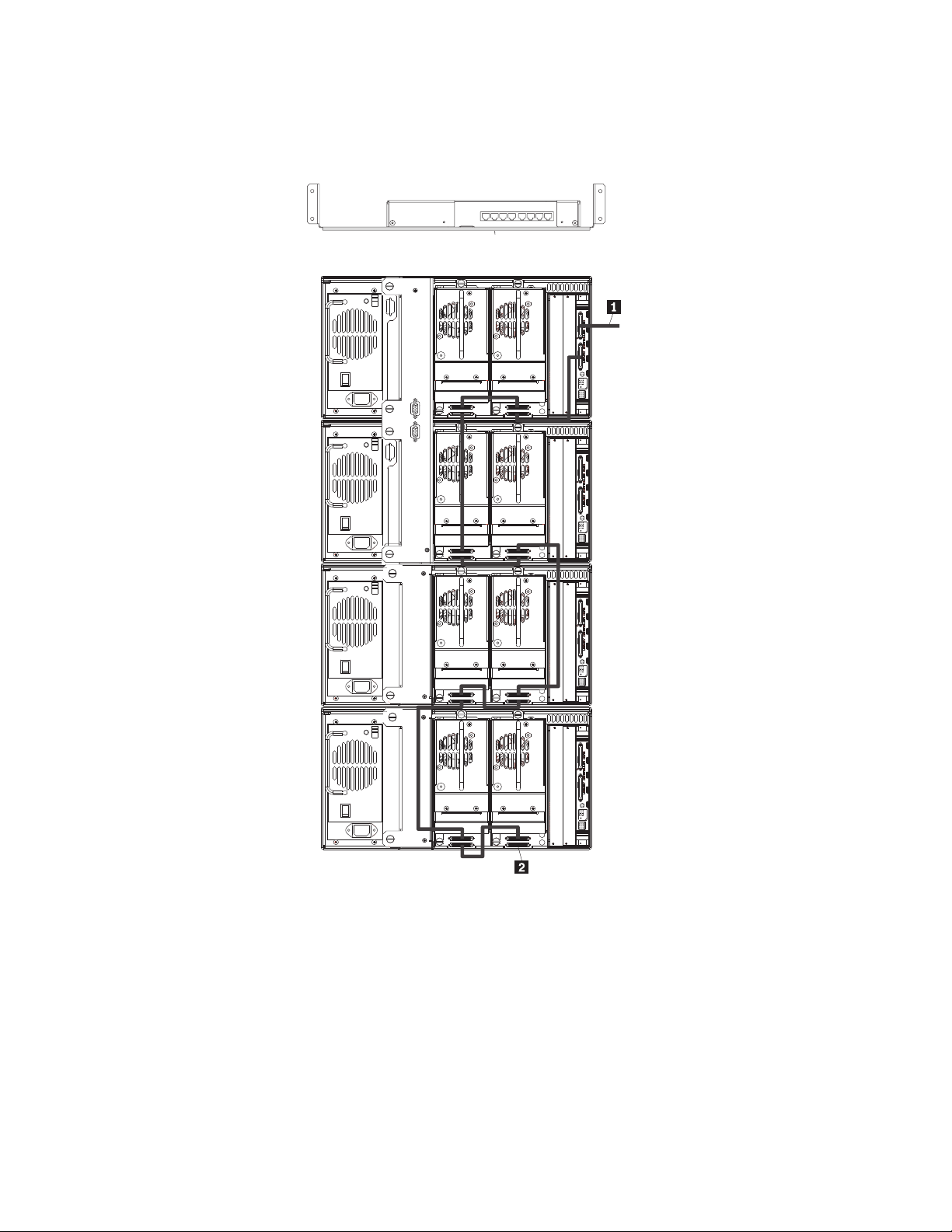

Multiple libraries on a single host system

Figure 19 shows a typical SCSI cable configuration for a multi-unit library with a

varying number of drives using a single host system.

WAN

567

432

1

1 To host system

2 SCSI terminator

Figure 19. Single host multi-unit system

18 4560SLX Tape Library: User’s Guide

Page 29

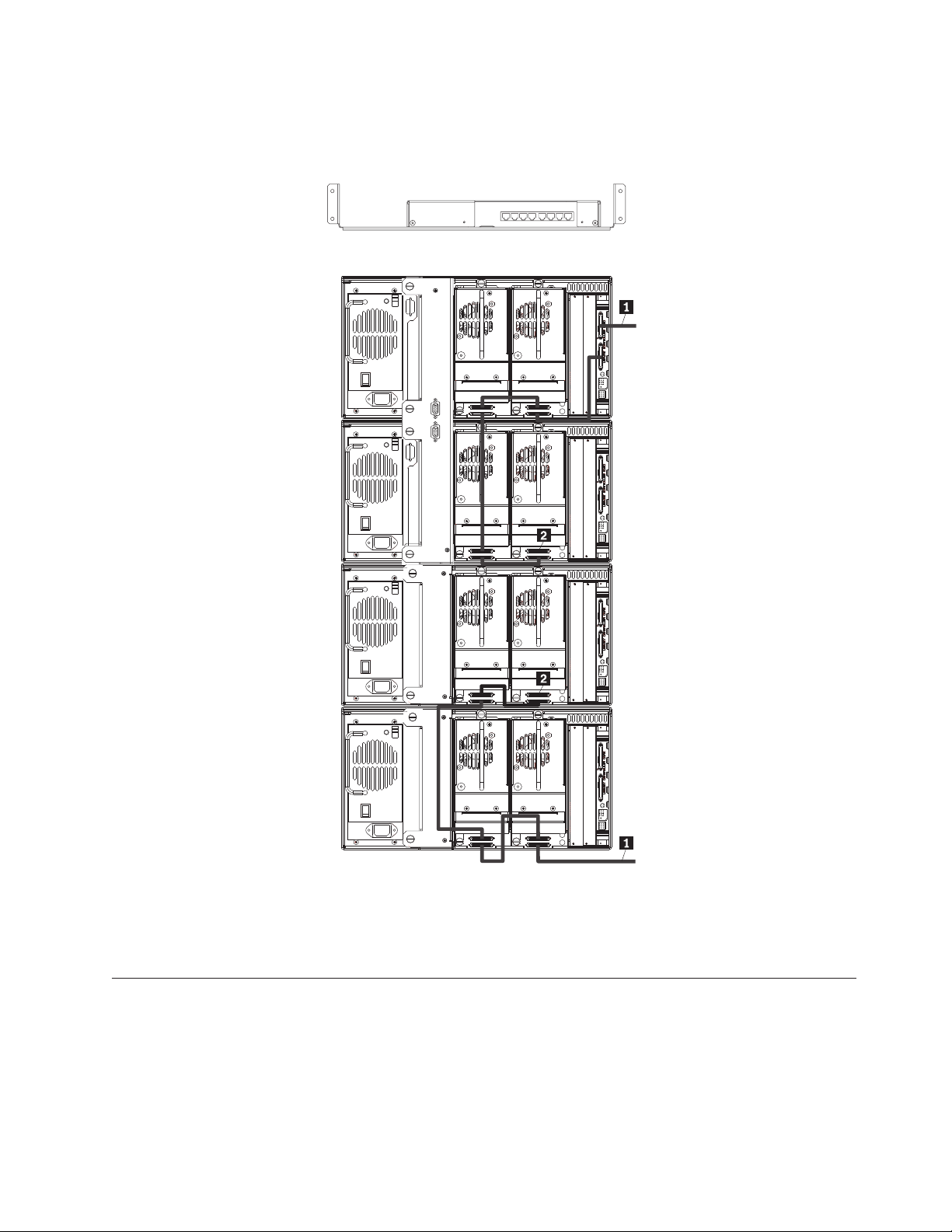

Multiple libraries on a dual host system

Figure 20 shows a typical SCSI cable configuration for a library with multiple

libraries and tape drives installed using a dual host system.

WAN

567

432

1

1 To host system

2 SCSI terminators

Figure 20. Dual host multi-unit system

Turning on your library

Use the following instructions to apply power to the library:

1. Connect the supplied power cord to the ac receptacle located on the back of the

library module as shown in Figure 21 on page 20.

Chapter 2. Installation 19

Page 30

1 Power cord

2 Power switch

3 Touch screen

Figure 21. Powering library module

2. Toggle the power switch to on “|”.

3. Press the touch screen to activate the display.

When power is first applied to the libraries, a series of Power-On Self Test

(POST) diagnostics are performed. After the POST completes, the Initialization

screen will appear.

4. Select Continue.

The library default screen will display.

20 4560SLX Tape Library: User’s Guide

Page 31

Chapter 3. Library configuration

The library provides several configuration options to support a variety of

applications and platforms. The settings for each of the available options are stored

in non-volatile memory in the library. For most applications, you do not have to

change the default settings. However, if you need to change the configuration, use

the instructions provided in the following sections. If you are uncertain whether

you need to change a setting, contact your authorized service provider.

You can change configuration settings using the touch screen. For information on

operating the touch screen, see Chapter 4, “Operation” on page 27.

Setting a SCSI ID

Each tape drive installed in the library requires a unique SCSI ID.

To set a SCSI ID, complete the following procedure:

1. Turn the library on and wait until the Power-On Self Test (POST) completes.

The library default screen appears on the display as shown in Figure 22.

Figure 22. Library default screen

2. Select the Menu option.

3. Enter the appropriate password. For instructions on how to set passwords, see

“Passwords” on page 38.

4. Select SCSI in the Edit Options area to display the screen shown in Figure 23

on page 22.

© Copyright IBM Corp. 2002 21

Page 32

Figure 23. SCSI ID selection screen

5. Select the button next to the SCSI ID you want to set. The screen will display

the current setting as shown in Figure 24.

Figure 24. SCSI ID editing screen

6. Enter a new value for the SCSI ID. This places your request in the New data

field.

7. Select Save. A confirmation screen appears on the display as shown in

Figure 25.

Figure 25. SCSI ID Confirmation screen

8. Select OK to confirm. The newly selected SCSI ID flashes for a few seconds

while the drive is being updated, then remains solid indicating that the

operation is complete.

22 4560SLX Tape Library: User’s Guide

Page 33

Figure 26. Drive 1 Bus 3 Data Field screen

9. Press the Back button to return to the Main menu screen. Repeat this procedure

to set any remaining SCSI IDs.

Setting up reserved tape cartridge slots

You might want to reserve tape cartridge slots to meet licensing requirements or

dedicate them as cleaning slots.

Standard tape cartridge slots are numbered from the front of the magazine to the

rear as shown in Figure 27 on page 24. When you reserve a slot, it becomes

reserved slot #1 in the last slot of the magazine. Additional reserved slots are

added in a rear-to-front pattern. If your software license limits you to less than the

full magazine capacity, reserved slot #1 always follows the last unreserved data

tape cartridge.

Chapter 3. Library configuration 23

Page 34

1 Reserved slot #1

2 Mail slot (left magazine only)

Figure 27. Slot numbering

#12

#11

#10

#9

#8

#7

#6

#5

#4

#3

#2

#1

MAIL SLOT

#25

#24

#23

#22

#21

#20

#19

#18

#17

#16

#15

#14

#13

To reserve a slot, complete the following procedure:

1. From the Menu screen, select the Library option from the Edit Options area.

2. From the Library options screen, press the down arrow to scroll to the screen

that contains the Total Reserved Slots option as shown in Figure 28.

Figure 28. Total Reserved Slots screen

3. Press the box next to the Total Reserved Slots option. A numeric keypad

appears on the display as shown in Figure 29 on page 25.

24 4560SLX Tape Library: User’s Guide

Page 35

Figure 29. Reserved slots numeric keypad

4. Enter a new value and select Save. A confirmation screen appears on the

display as shown in Figure 30.

Figure 30. Total Reserved Slots Confirmation screen

5. Press the Back button until you return to the Main menu screen. Your change

will take effect the next time you boot the library.

Chapter 3. Library configuration 25

Page 36

26 4560SLX Tape Library: User’s Guide

Page 37

Chapter 4. Operation

This chapter describes how to operate the 4560SLX Tape Library.

Using the touch screen

The touch screen enables you to set up and configure the library. This section

describes the following options that are available from the library default screen:

v Technical support information

v Mail slot access

v Magazine access

v Move media

v LCD contrast control

v Menu

v Online

v Status

v Power

Technical support information

Select the Contact IBM button on the top left corner of the library default screen to

display technical support information as shown in Figure 31.

Figure 31. Technical Support Assistance screen

Mail Slot Access (left magazine only)

Select this option to display the Mail Slot Access screen as shown in Figure 32 on

page 28. This option enables you to access the mail slot while the library is online.

Simply select the mail slot you want to open. The locked icon will change to

unlocked and the left side door of the selected library will open.

The mail slot is always the first tape cartridge slot in the left magazine. It can be

password protected.

© Copyright IBM Corp. 2002 27

Page 38

Figure 32. Mail Slot Access screen

Note: In a scaled multi-module library system, selecting the Mail Slot Access

button on the master library touch screen displays the mail slots of all the

libraries in the stack. This is the only way to access the mailslots of the other

libraries.

Magazine Access

Select this option to display the Magazine Access screen as shown in Figure 33.

The Magazine Access option enables you to access the magazine doors for tape

cartridge placement or removal. Access is gained by selecting the library you want

to access and then selecting left, right, or both. The lock icons will change to

unlocked and the doors of the selected library will open.

Magazine access can be password protected.

Figure 33. Magazine Access screen

Note: In a scaled multi-module library system, selecting the Magazine Access

button on the master library touch screen is the only way to access the left

and right magazines of all libraries in the stack.

Move Media

Select this option to display the Move Media screen as shown in Figure 34 on

page 29. The Move Media option enables you to remove cartridges from a tape

drive, load cartridges into a drive, or move cartridges within the library.

28 4560SLX Tape Library: User’s Guide

Page 39

Figure 34. Move Media screen

To move a cartridge, complete the following procedure:

1. Touch the Source box or Source Element Type from the Move Media screen.

The Source box will change from gray to an active state as shown in Figure 35.

Figure 35. Move Media screen (source)

2. From the Source Element Type area, select the element type you want to move.

Drive 2 is used for this example.

3. Touch the Destination box on the Move Media screen. The Destination box

will change from gray to an active state as shown in Figure 36.

Figure 36. Move Media screen (destination)

4. From the Destination Element Type area, select the element type you want to

move media to. Continue selecting the destination option until the desired

Chapter 4. Operation 29

Page 40

option is displayed in the Destination box. For example, touching Slot three

times displays Slot 3 in the Destination box.

5. Select the Execute Move button. The library robotics moves the cartridge to the

destination you selected.

LCD contrast controls

This option enables you to increase or decrease the contrast of the LCD display.

Incremental steps are set by adjusting the LCD contrast controls using the up and

down arrows from the upper right corner of the library default screen.

Menu

Select Menu on the library default screen to operate and configure the library.

Figure 37 shows the Menu option interface which displays three distinct areas:

v View System Data

v Utilities

v Edit Options

Figure 37. Menu screen

View System Data

The View System Data area enables you to view the following information:

v Library options

v SCSI options

v Network options

v Library information

v Cartridge map

Library Options: This option enables you to view, but not modify, the library

settings as defined in the Library option of the Edit Options area as shown in

Figure 38 on page 31. For descriptions of the available options, see Table 2.

Note: You can view the next sequential Library Options screen by selecting the

down arrow. To return to the Menu screen, press the Back button.

30 4560SLX Tape Library: User’s Guide

Page 41

Figure 38. View Library Options screen (initial screen)

Table 2 describes the available Library options.

Table 2. Library options

Option Description

Library Stays Offline After

Power-up Initialization

Auto Power-up an Installed

Drive

Unload Mode This option selects the unload mode for library tape drives.

Total Reserved Slots This option enables you to remove a specified number of

Auto Clean Mode This option enables you to establish an automatic cleaning

Drive and Slot Numbering This option enables you to specify SCSI elements in the

Library Mode This option enables you to set the robotics operating mode

Sequential Mode This option enables you to select a normal or recirculate

LCD Contrast Adjust This option enables you to increase or decrease the contrast

Mail Slot Mode This option enables the mail slots in a library. The default is

The library does not go online after power-up initialization.

You must select the online option from the menu screen on

the touch screen. The default is disabled.

This option enables a tape drive to be automatically

powered up after replacing a tape drive. The default is

disabled.

If the mode is implicit, the library unloads a tape drive

before attempting to move a cartridge from that tape drive.

If the mode is explicit, the host must issue a SCSI

UNLOAD command to a tape drive before each MOVE

MEDIUM command that removes a cartridge from that tape

drive. The default is implicit.

slots from use. Some host software impose size limits on

library magazines for licensing purposes. The default is 0.

cycle. To use this option, reserve a slot for a cleaning

cartridge using the Total Reserved Slots option. The default

is enabled.

library displayed as zero-based or one-based numbers. This

only affects the touch screen, not the actual SCSI addresses.

The default is one-based.

to random or sequential. The default is random.

frequency mode. The default is normal.

Note: This is only available if Library Mode is set to

sequential.

of the LCD display.

mail slot enabled.

Chapter 4. Operation 31

Page 42

Table 2. Library options (continued)

Option Description

Barcode Label Size This option enables you to limit the maximum number of

characters of the bar code label. Possible settings are 1

through 8. The default is 8.

Barcode Label Alignment This option enables you to specify the alignment of a bar

code label. The options are left or right. When used in

conjunction with the label size option, this option strips

unwanted trailing characters (left alignment) or leading

characters (right alignment). The default is left align.

Barcode Label Check Digit This option enables you to specify whether to enable or

disable the verification of a check digit character in the

barcode label. The default is disabled.

Barcode Reader This option enables you to specify whether the barcode

reader will retry reading barcode labels. The default is

retries enabled.

Module Configuration This option enables you to specify the library module

configuration. Three options are available:

v Standalone - This option is used when the library

contains a single module.

v Master - This option is used to select the module which

controls the pass-thru mechanism in a multi-module

library.

v Slave - This option is used to select the other modules in

a multi-module library.

SCSI Options: This option enables you to view the settings defined from the SCSI

option in the Edit Options area as shown in Figure 39.

Figure 39. View SCSI Options screen (initial screen)

Table 3 describes the available SCSI options.

Table 3. SCSI configuration options

Definition Option and default description Default value

Drive n Bus ID This option enables you to set the SCSI addresses of

the drives. The designators Drive 1 (outer tape

drive) through Drive n refer to the first through nth

drives. (one based default)

Library SCSI BusIDThis option enables you to set the SCSI addresses

for the library robotics.

Drive1=1

Drive2=2

6

32 4560SLX Tape Library: User’s Guide

Page 43

Table 3. SCSI configuration options (continued)

Definition Option and default description Default value

Library SCSI Bus

Parity

This option enables you to set the library robotics

SCSI bus parity checking.

Enabled

SCSI Mode This option defines the loader as SCSI-2 or SCSI-3. SCSI-3

Mailslot access This option defines when the mailslot is accessible. Prevent/Allow

Medium

Command

Determines

Access

Unit Attention

Reporting

This option enables you to select reporting of all or

only one stacked-unit attention conditions. If set to

Report All

all, the unit reports all unit attention conditions in

sequence. If set to one, the unit reports only the

highest priority condition.

Init Element Status This option enables you to specify the library

No Inventory

response to the SCSI INITIALIZE ELEMENT

STATUS command. The possible settings are no

inventory, force inventory, and force label scan.

Test Unit Ready

Reporting

This option enables you to specify the response to a

TEST UNIT READY command if the library is in

Standard

sequential mode. The possible settings are standard

or custom. Standard returns check condition not

ready and custom returns good status.

Device Capability

Page Length

This option enables you to choose between two

lengths of the mode sense/select device capabilities

Short (14 bytes)

page (SCSI page 1Fh), which are short (14 bytes)

and long (18 bytes), to accommodate different SCSI

device implementations of this page.

Transport Element

Base Address

Storage Element

Base Address

Transfer Element

Base Address

Import/Export

Element Base

This option enables you to set the base address for

the robotics mechanism.

This option enables you to set the base address for

the magazine slots.

This option enables you to set the base address for

the tape drives.

This option enables you to set the base address for

the mail slot.

0

20

1E0

1C0

Address

Product

Identification

This option enables you to specify the response of

the library robotics to the SCSI INQUIRY command

4560SLX

in the product ID fields.

Vendor

Identification

This option enables you to specify the response of

the library robotics to the SCSI INQUIRY command

IBM

in the vendor ID field.

Post Recovered

Errors

This option enables you to set the post recovered

errors.

Disabled

Chapter 4. Operation 33

Page 44

Table 3. SCSI configuration options (continued)

Definition Option and default description Default value

TapeAlert Mode This option enables you to specify the conditions

for logging and reporting the following tape alert

data options:

v Logging Disabled: Inhibits the logging feature.

v No Exceptions: Prohibits the library from

reporting information exceptions.

v Generate Unit Attention: Reports information

exceptions with a Unit Attention sense key and

an ASC/ASCQ of 5D/00.

v Conditionally Generate Recovered Error:

Reports information exceptions with a Recovered

Error sense key and an ASC/ASCQ of 5D/00, if

Recovered Error Reporting is enabled.

v Unconditionally Generate Recovered Error:

Reports information exceptions unconditionally

with a Recovered Error sense key and an

ASC/ASCQ of 5D/00.

v Generate No Sense: Reports information

exceptions with a No Sense sense key and an

ASC/ASCQ of 5D/00.

v Report on Unsolicited Request Sense: Reports

information exceptions with a No Sense sense

key and an ASC/ASCQ of 5D/00, only in

response to an unsolicited REQUEST SENSE

command.

Abort Move Status This option enables you to specify the SCSI

response while aborting a SCSI command. The

possible settings are busy or not ready.

Door Open

Response

Initiate Wide Data

Transfer

Negotiation

Data Speed

Transfer

This option enables you to specify the SCSI

response when a library door is open. The settings

are ready or not ready.

This option enables you to set the library to initiate

a SCSI synchronous and wide data transfer

negotiation with the host. The settings are do not

initiate or initiate.

This option enables you to set the SCSI data

transfer rate to Synchronous, 10 MB/sec, 5 MB/sec

or Asynchronous Only.

Logging

Disabled

Busy

Not Ready

Initiate

Synchronous, 10

MB/sec

Network Options: This option enables you to view the settings defined in the

Network option in the Edit Options area as shown in Figure 40 on page 35.

34 4560SLX Tape Library: User’s Guide

Page 45

Figure 40. View Network Options screen

Table 4 describes the available Network options.

Table 4. Network configuration options

Definition Option and default description Default value

IP Address

Determination

Private IP Base

Address

Private IP Subnet This option enables you to specify a private IP

Private IP

Gateway

Note: These options are only valid if the IP Address Determination Option is set to User

Specified IP Address.

This option enables you to set the way an IP

address is determined. The possible choices are:

Obtain An IP Address From a DHCP Server and

User Specified IP Address.

This option enables you to specify a private IP base

address.

Note: Master configurations only; ignored

otherwise.

subnet.

Note: Master configurations only; ignored

otherwise.

This option enables you to specify a private IP

gateway.

Note: Master configurations only; ignored

otherwise.

Obtain An IP

Address From a

DHCP Server

92.168.1.1

255.255.255.0

192.168.1.1

Library Info: This option enables you to display miscellaneous library

information. The Miscellaneous Library Info screen displays the library firmware

revision, IP address, and the library serial number as shown in Figure 41 on

page 36.

Chapter 4. Operation 35

Page 46

Figure 41. View Library Info screen

Cartridge Map: This option provides a visual indication of all library drives, mail

slots and magazine slots, including whether there is a cartridge present and

corresponding barcode label, if available.

Figure 42. Cartridge map

Utilities

The Utilities area contains the following screens:

v Maintenance

v Diagnostics

v Factory

v Security Level

Maintenance: This option enables you to:

v Set slave defaults

v Reboot server

v Fail-over to secondary master

Diagnostics: This option enables you to select and run several self-diagnostic

library tests.

Factory: This option is for factory use only.

Security Level: This option enables you to set passwords for one of the four

available security levels as shown in Figure 43 on page 37.

36 4560SLX Tape Library: User’s Guide

Page 47

Figure 43. Security Level screen

Table 5. Security level options

Security level Access

User Level 1 Mail slot access only

User Level 2 Mail slot and magazine access only

Service User and Service menus

Factory User, Service, and Factory menus

Edit Options

The Edit Options area contains the following screens:

v Library

v SCSI

v Network

v Passwords

Library: This option enables you to define the library options used to configure

the library for your specific needs. Defined options can be viewed in the View

System Data area as shown in Figure 44. For a description of the available Library

options, see Table 2 on page 31.

Figure 44. Edit Library Options screen

SCSI: Select this option to define the SCSI options used to configure the library

for your specific needs as shown in Figure 45 on page 38. For a description of the

available SCSI options, see Table 3 on page 32.

Chapter 4. Operation 37

Page 48

Figure 45. Edit SCSI Options screen

Network: This option enables you to define the network options used to

configure the library for your specific needs as shown in Figure 46. For a

description of the available network options, see Table 4 on page 35.

Figure 46. Edit Network Options screen

Passwords: This option enables you to define the password options used to

configure the library for your specific needs as shown in Figure 47 on page 39.

The Password screen offers three levels of security.

v User level 1 - This is the lowest level, which allows users access to the mail slot.

v User level 2 - This level allows magazine access and allows users to move

media.

v Service - This is the highest level, which allows users access to the menu that

enables them to view and edit library and SCSI options.

38 4560SLX Tape Library: User’s Guide

Page 49

Figure 47. Edit Passwords Options screen

Each password is represented by four decimal digits that are stored in NVRAM

(non-volatile memory) in a range of 0001 to 9999. 0000 is used to disable password

verification for that level.

Enabling a password causes all disabled higher levels to also be enabled to that

value. As a result, prior to accessing a higher level operation, you are prompted

first to enter the higher level password. This prevents someone from entering an

unprotected Menu mode and changing the lower-level password to defeat it.

You can also use a higher level password to gain access to a lower level operation.

For example, you can use the Service password to access the Move Media

operation. This gives full access (without validating) to the service operations.

Media can also be locked by software running on the host. The library does not

provide a touch screen override for this command. Usually, exiting the host

software restores media access. In the event of host failure, you can restore media

access by cycling the library power. Procedures for locking and unlocking

magazine doors and media are described later in this chapter.

Online

This option enables you to place the library online or offline. By default the library

comes online after a power-up initialization.

Status

This option displays the Library Initialization screen. You can identify a tape drive

type and view physical tape drive status, tape drive cleaning information, and tape

cartridge information by opening the corresponding areas on the screen as shown

in Figure 48 on page 40.

Chapter 4. Operation 39

Page 50

Figure 48. Status screen

Power

This option initiates a library power-down operation. Figure 49 shows the

confirmation screen that is displayed when this option is selected. The library

moves the shuttle assembly to the parked position before powering down.

Figure 49. Power Down Initiation screen

Using tape cartridges

This section describes how to remove magazines, insert cartridges into a magazine,

use the mail slot, and use bar codes.

Removing magazines

A magazine must be removed from the library in order to replace tape cartridges.

Before you remove a magazine, make sure the slot you want to use is not already

reserved for a tape cartridge that is in a tape drive. The safest way to do this is to

unload all tape drives before removing a magazine. You can unload all the tape

drives either through your host system software or by using the Move Media

option on the library default screen.

You must manually remove the library magazines. To access the magazines, use

the Magazine Access Option Default screen. This option enables you to open the

left or right magazine doors separately or both magazine doors at the same time.

After opening the appropriate magazine door, pull the magazine out and away

from the library chassis as shown in Figure 50 on page 41.

40 4560SLX Tape Library: User’s Guide

Page 51

1 Left magazine

2 Right magazine

Figure 50. Removing tape cartridge magazines

Inserting cartridges into a magazine

A full magazine is shown in Figure 51. Note that the lowest numbered tape

cartridge slot is the one closest to the front of the magazine.

Insert tape cartridges so that the bar code labels are facing outward.

Note: Handle and store tape cartridges in a clean and dust-free environment.

1 Lowest numbered tape cartridge slot

2 Bar code label

3 Highest numbered tape cartridge slot

Figure 51. Tape magazine with tape cartridges installed

Using the mail slot (left magazines only)

The mail slot is used only with host system software that supports this feature.

The mail slot feature enables you to insert or remove a single tape without

removing the entire magazine. You access the mail slot using the Mail Slot Access

option from the library default screen. This option enables you to open the left

Chapter 4. Operation 41

Page 52

magazine door for mail slot access. After opening the left magazine door, pivot the

mail slot forward to insert a tape cartridge as shown in Figure 52.

IMPORTANT: The mail slot must be enabled (factory default) using the Mail Slot

Mode option from the Edit Library Options menu. For more information on

Library options, see Table 2 on page 31.

1 Mail slot

2 Tape cartridge

Figure 52. Left magazine mail slot

Bar code labels

Sample bar code labels are included with your purchase. Also included are

instructions on ordering additional labels. Figure 53 shows you how to install a bar

code label onto a tape cartridge.

Figure 53. Bar code label installation

42 4560SLX Tape Library: User’s Guide

SDLT LTO

Page 53

Chapter 5. Maintenance

This chapter describes how to replace and run cleaning cartridges in the 4560SLX

Tape Library.

Note: Only qualified service technicians should perform the other menu options

contained in the Maintenance submenu.

Supported media

IBM supports the following brands of data and cleaning cartridges:

v SDLT data cartridges

– IBM (Part number: 35L1119)

– Maxell (Part number: SDLT1/1800)

– Quantum (Part number: MR-SAMCL-01)

v SDLT cleaning cartridges

– IBM (Part number: 19P4357)

– Quantum (Part number: MR-SACCL-01)

v LTO data cartridges

– IBM (Part number: 08L9120)

– Fuji (Part number: 26120010)

– Maxell (Part number: LTOU1/100)

– Imation (Part number: 0-51122-41089-5)

v LTO cleaning cartridges

– IBM (Part number: 08L9124)

Note: This list can change as new media is introduced. For a current list of

supported brands of data and cleaning cartridges, search for ″supported

media″ on the http://www.pc.ibm.com/support IBM Web site.

Running a cleaning cartridge

You can manage the cleaning of the installed tape drives automatically by enabling

Auto Clean mode or manually by selecting the Clean Drive menu option from the

Maintenance submenu on the front panel display.

Note: It is good practice to run a cleaning cartridge using the Auto Clean Mode.

Automatically running a cleaning cartridge

You can configure the library to automatically run the cleaning cartridge. If a tape

drive needs cleaning, it sends a message to the library. This activates an automatic

cleaning cycle (if the cleaning cartridge slot has been reserved and Auto Clean

mode has been selected from the Options menu).

To automatically run a cleaning cartridge using Auto Clean mode, reserve a

cleaning cartridge slot and enable the Auto Clean mode.

© Copyright IBM Corp. 2002 43

Page 54

Manually running a cleaning cartridge

You can manually run a cleaning cartridge from three locations:

v The mail slot - Running a cleaning cartridge from this location does not require

a magazine to be removed, a data cartridge slot to be used, or a cleaning

cartridge slot to be reserved.

v A data cartridge slot - Running a cleaning cartridge from this location requires a

magazine to be removed so that a cleaning cartridge can be inserted in a data

cartridge slot.

v The cleaning slot - Running a cleaning cartridge from this location requires the

last data cartridge slot be reserved for exclusive use as a cleaning cartridge slot.

The advantage of this method is that the cleaning cartridge is stored in the

library and is always available for use. It only needs to be handled when it

needs to be replaced.

Running a cleaning cartridge from the mail slot

To run a cleaning cartridge from the mail slot, complete the following procedure:

1. Install a cleaning cartridge into the mail slot.

2. Select the Clean Drive menu option from the Maintenance submenu on the

Menu screen.

3. Select Source and then Mail Slot in the Element Type box.

4. Select Cleaning. If the default entry is not the tape drive to be cleaned, select

Drive in the Destination Element Type box to sequence through the available

tape drive choices. You can also use the keypad to enter the tape drive number.

5. Select Execute Clean when the source and destination entries are correct. When

the cleaning cycle completes, the library returns the cleaning cartridge to the

mail slot.

6. Select Mail Slot Access from the Status screen to remove the cleaning cartridge.

Running a cleaning cartridge from a data cartridge slot

To run a cleaning cartridge from a data cartridge slot, complete the following

procedure:

1. Install a cleaning cartridge into the appropriate data cartridge slot.

2. Select the Clean Drive menu option from the Maintenance submenu on the

Menu screen.

3. Select Source. If the default entry is not the slot with the cleaning cartridge,

select Slot in the Element Type box to sequence through the available cartridge

slots. You can also use the Decimal Keypad Backspace and Numeric Keys to

enter the slot number.

4. Select Cleaning. If the default entry is not the tape drive to be cleaned, select

Drive in the Destination Element Type box to sequence through the available

tape drive choices. You can also use the Decimal Keypad Backspace and

Numeric Keys to enter the tape drive number.

5. Select Execute Clean when the source and destination entries are correct. When

the cleaning cycle completes, the library returns the cleaning cartridge to the

data cartridge slot.

6. Select Magazine Access from the Status screen to remove the cleaning

cartridge.

Running a cleaning cartridge from the cleaning slot

To run a cleaning cartridge from the cleaning slot, complete the following

procedure:

44 4560SLX Tape Library: User’s Guide

Page 55

1. Reserve the cleaning cartridge slot. For more information, see “Setting up

reserved tape cartridge slots” on page 23.

2. Install a cleaning cartridge in the reserved slot.

3. Select the Clean Drive menu option from the Maintenance submenu on the

Menu screen. The Source window defaults to the cleaning slot (cleaning slot 0).

4. Select Cleaning. If the default entry is not the tape drive to be cleaned, select

Drive in the Destination Element Type box to sequence through the available

tape drive choices. You can also use the Decimal Keypad Backspace and

Numeric Keys to enter the tape drive number.

5. Select Execute Clean, when the destination entry is correct. When the cleaning

cycle completes, the library returns the cleaning cartridge to the cleaning

cartridge slot.

Replacing a cleaning cartridge in a reserved slot

When the cleaning cartridge has been exhausted, a message appears on the touch

screen indicating that the cleaning cartridge has expired. Examine the Status screen

to make sure that the cleaning cartridge has been unloaded from the tape drive. If

not, unload the cleaning cartridge using the Move Media menu option from the

Status screen.

A cleaning cartridge can be removed and replaced by removing the right magazine

or by using the mail slot.

Replacing a cleaning cartridge in the right magazine

To replace a cleaning cartridge in the right magazine, complete the following

procedure:

1. Select Magazine Access from the Status screen.

2. Remove the magazine from the library.

3. Remove the expired cleaning cartridge from the last slot. Mark it EXPIRED and

then properly dispose of it.

4. Place a new cleaning cartridge in the last slot of the magazine.

5. Replace the right magazine.

Replacing a cleaning cartridge in the mail slot

To replace a cleaning cartridge in the mail slot, complete the following procedure:

1. Select the Move Media menu option from the Status screen.

2. Select Source and then select Cleaning Slot in the Source Element Type box.

3. Select Destination and then select Mail Slot in the Destination Element Type

box.

4. Select Execute Move to place the cleaning cartridge in the mail slot.

5. When the move completes, press the Back button to access the library default

screen.

6. Select Mail Slot Access from the Status screen.

7. Remove the expired cleaning cartridge. Mark it EXPIRED and then properly

dispose of it.

8. Place a new cleaning cartridge in the mail slot.

9. Select the Move Media option from the Status screen.

10. Select Source and then select Mail Slot in the Source Element Type box.

Chapter 5. Maintenance 45

Page 56

11. Select Destination and then select Cleaning Slot in the Destination Element

Type box.

12. Select Execute Move to put the new cleaning cartridge in the reserved slot.

46 4560SLX Tape Library: User’s Guide

Page 57

Chapter 6. Troubleshooting

The following information might be useful if you experience problems using the

4560SLX Tape Library.

Platform problems

Incorrectly installing or configuring the 4560SLX Tape Drive can cause platform

problems. In this occurs, the library appears to be operating normally, but no data

can be interchanged. An error code might be displayed on the touch screen. To

identify this type of problem, check your installation and configuration setup. For

information on how to correctly install and configure the library, see Chapter 2,

“Installation” on page 11.

General drive errors usually result from a miscommunication between the library

and tape drive, or from a mechanical malfunction within the library. The touch

screen displays error messages and fault symptom codes (FSCs) when platform

problems and general drive errors occur. Use the FSCs to report errors to IBM

technical support or to determine a recovery procedure.

Error recovery procedures (ERPs)

Figure 54 on page 48 outlines the troubleshooting steps for error recovery.

© Copyright IBM Corp. 2002 47

Page 58

TROUBLESHOOTING

AND ERROR RECOVERY

ERROR, FAULT,

MALFUNCTION

Determine Suspected

Error Type

PLATFORM

No FSC displayed.

Normal front panel operation

Cycle the power

to the library

Retry

Check configuration

(see Chapter 3)

Call Technical Support

CARTRIDGE ERROR

FSC might be displayed

Cartridge will not eject

Normal operation impossible

GENERAL DRIVE

FSC and ERP displayed

on touch screen

Follow the ERP on

touch screen

Find FSC in Table 7

Follow the ERP in Table 6

Call Technical Support

Figure 54. Troubleshooting flow chart

Table 6 lists ERPs reported on the touch screen of the library. This list includes only

those procedures that can be safely performed by a user. For a list of FSCs and

their related ERPs, see Table 7 on page 49.

Table 6. Error recovery procedures

ERP code Procedure/Description

C Cycle power to the library using the power option on the touch screen.

D Turn off power to the library and inspect connectors and cables.

F Invalid operation. Select parameters correctly and try again.

G Call IBM technical support.

48 4560SLX Tape Library: User’s Guide

Wait 30 seconds to power on again.

Page 59

Fault symptom codes (FSCs)

Table 7 lists the FSCs and their related ERPs that might be displayed on the touch

screen. If an FSC continues, report it to IBM technical support.

Table 7. Fault symptom codes

Message FSC ERP

OS Catastrophic Error 0901 G

OS Task Exit Error 0902 G

SCSI Firmware Error 1001 D,G

SCSI FIFO Empty 1002 D,G

SCSI FIFO Error 1003 D,G

SCSI Gross Error 1004 C,D,G

Illegal SCSI Cnt Cmd 1005 C,D,G

SCSI Message Error 1006 D,G

SCSI Invalid Element 1007 D,G

SCSI No Pending Int. 1008 D,G

SCSI Invalid Int. 1009 D,G

Illegal Move 2008 C,G

Door Open (status only) 2009 F

Menu Mode (status only) 200A F

Cart Unaccessible 200C F

Drive In Error 200D C,G

No Magazine 200E F

Removal Prevented 200F F

Ctl. Firmware Error 2010 C,G

Drive Code Update Command Error 2080 C,G

Move Command Failure 2081 C,G

Open Mail Slot Fault 2090 C,G

Open Left Door Fault 2091 C,G

Open Right Door Fault 2092 C,G

Open Doors Fault 2093 C,G

Open DLT Handle Fault 2094 C,G

No IP Address Found 20a0 C,G

No IP Address Mode Fault 20a1 C,G

No Gateway Address Found 20a2 C,G

Unknown Exchange For The Async message 20b0 C,G

Drive In Error 20c0 C,G

Drive In Error 20c1 C,G

Motor Fault Condition 3000 C,G

Shuttle Tach Errors 3001 C,G

Picker Tach Errors 3002 C,G

Rotary Tach Errors 3003 C,G

Chapter 6. Troubleshooting 49

Page 60

Table 7. Fault symptom codes (continued)

Message FSC ERP

Vertical Tach Errors 3004 C,G

Passthru Tach Errors 3005 C,G

Excessive Picker Friction Error 3006 C,G

Bin Fetch Failure 3011 C,G

Bin Stow Failure 3012 C,G

Drive Fetch Failure 3013 C,G

Drive Stow Failure 3014 C,G

Drive Timeout Failure 3015 C,G

Drive Status Failure 3016 C,G

Drive In Flux Timeout 3017 C,G

Drive Load Retry Failed 3018 C,G

Drive Open Door Failed 3019 C,G

Drive Close Door Failed 301A C,G

Drive Communication Error 301B C,D,G

Drive Get General Status Fail 301C C,D,G

Drive Get Status 3 Fail 301D C,D,G

Undefined Config 3020 C,G

Orphan Cartridge not flowed 3030 C,G

Chassis S/N Mismatch. Previous S/N retained 3031 G

Chassis S/N Character count is not correct 3032 G

Chassis S/N did not scan 3033 G

Chassis S/N save operation failed 3034 G

Motor Firmware Error 3040 C,G

Loader Received Invalid Command 3041 C,G

Motor Firmware Error 3042 C,G

Missing Magazine 3050 F

No Cartridges In Library 3051 F

Too Many Cartridges 3052 F

Need 3 Cartridges Minimum 3053 F

Need 1 Drive Minimum 3054 F

Need 5 Cartridge Minimum 3056 F

Invalid Magazine Type 3057 F

Magazine Type Change Not Handled 3058 F

Zone Sequence Error 3060 C,G

Drive Eject Fail 3070 C,G

Drive Eject Fail 3071 C,G

Drive Eject Fail 3072 C,D,G

Drive Eject Fail 3073 C,D,G

Soft Fetch Retry 3080 C,D,G

Soft Fetch Retry 3081 C,D,G

50 4560SLX Tape Library: User’s Guide

Page 61

Table 7. Fault symptom codes (continued)

Message FSC ERP

Drive Stow Failed, Media Returned to Source 3082 F

Drive Stow Failed, Media Remains in Drive 3083 F

Unsupported Drive For Requested Operation 3084 F

No Retry On Fetch/Stow 308F F

Picker Jammed 3100 C,G

Picker Jammed 2 3102 C,G

Picker Jammed 3 3103 C,G

Picker Jammed 4 3104 C,G

Picker Jammed 5 3105 C,G

Picker Jammed 6 3106 C,G

Picker Jammed 7 3107 C,G

Picker Jammed 8 3108 C,G

Picker Jammed 9 3109 C,G

Picker Jammed 10 310A C,G

Picker Jammed 11 310B C,G

Picker Jammed on Stow 310F C,G

Picker Retries Exceeded 3110 C,G

Picker Retries Exceeded 1 3111 C,G

Picker Retries Exceeded 2 3112 C,G

Picker Retries Exceeded 3 3113 C,G

Picker Retraction Error 3115 C,G

Shuttle Jammed 3200 C,G

Shuttle Jammed 3201 C,G

Shuttle Jammed 3202 C,G

Shuttle Jammed 3203 C,G

Shuttle Jammed 3204 C,G

Shuttle Jammed 3205 C,G

Rotary Jammed 3300 C,G

Shuttle on Wrong Side of the Rotary 3301 C,G

Rotary Cannot Find Zones 3302 C,G

Passthrough Elevator Jammed 3400 C,G

Vertical Elevator Jammed 3500 C,G

No DLTs Attached 5010 F

All Slots Empty 5011 F

DLT Already Loaded 5014 F

Expired Clean’g Cart 5015 F

Not a Clean’g Cart 5016 F

DLT Timeout Error 5035 C,D,G

Move Command Fail 503B F

Clean Operation Timeout 503C F

Chapter 6. Troubleshooting 51

Page 62

Table 7. Fault symptom codes (continued)

Message FSC ERP

Drive Status Fail 503D F

Command response from unexpected source 7001 D,G

Control command execution failed 7002 D,G

Control response not matched to a known command 7003 D,G

Loader response not matched to a known command 7004 D,G

Drive response not matched to a known command 7005 D,G

Flash response not matched to a known command 7006 D,G

Drive index on Update Status message was invalid 7007 C,D,G

The Drive response was not expected 7008 C,D,G

The opcode for a WORD message was unknown 7009 C,D,G

The opcode for a DWORD message was unknown 700A C,D,G

The button causing library to go offline was unknown 700B C,D,G

Destination Xchg was Null 700C C,G

Sending of a cmd failed 700D C,G

Deactivating a drive that is not attached 700E C,G

Deactivation of a drive failed 700F C,G

Drive removal failed 7010 C,G

HotPlug statue update failed 7011 C,G

Drive is Active failed 7012 C,G

Control Com Unidentified 7013 C,G

Drive status update failed 7014 C,G

Loader command execution failed 7015 C,G

Sequential command execution failed 7016 C,G

Destination Xchg for msg. was Null 7017 C,G

Bad src mod in peg msg 7018 C,G

Peg message wrapping a Null msg. ptr. 7019 C,G

Xchg conversion failed 701A C,G

Invalid L-drive number to convert 701B C,G

Invalid P-drive number to convert 701C C,G

Invalid mod number to convert 701D C,G

Cartridge reject recovery failed 8001 C,D,G

Drive Fan stalled 8002 C,D,G

Drive load did not complete 8003 C,D,G

Invalid drive was installed 8004 F

Orphan cartridge recovery failed 9001 C,D,G

Move operation failed 9002 C,D,G

SMX send error A001 C,G

SMX receive error A002 C,G

Comm free list empty A003 C,G

Invalid comm. put attempt A004 C,G

52 4560SLX Tape Library: User’s Guide

Page 63

Table 7. Fault symptom codes (continued)

Message FSC ERP

Invalid comm. get attempt A005 C,G

Comm initialization error A006 C,G

Put of a NULL comm A007 C,G

Msg contains no comm A008 C,G

Comm return address is unknown A009 C,G

Note: If an error message is displayed that is not included in Table 7, write down

the fault code number and follow the recovery procedure. If the same error

occurs again, call IBM technical support.

Chapter 6. Troubleshooting 53

Page 64

54 4560SLX Tape Library: User’s Guide

Page 65

Chapter 7. Using the NeoCenter utility

The NeoCenter utility enables you to configure the unit using the Windows

interface. The utility enables you to perform the following tasks:

v Establishing communication with your host

v Setting IP addresses

v Setting an access password

v Setting SNMP traps

v Setting e-mail addresses

v Setting remote FTP server parameters

v Setting SCSI parameters

v Setting the SCSI identification

v Setting library parameters

v Setting the drives

v Uploading data

v Downloading data

v Rebooting the library

Establishing communication with your host

To establish communication with your host, complete the following procedure:

1. Turn on the power.

2. Connect the RJ11-DB9 cable between the connector labeled RS232 on the library

and a COM port on the host computer. Note the port you select.

3. Power up the host computer and boot into Windows. Windows 95, Windows

98, Windows 2000, or Windows NT

4. Install the configuration utility from the included 3.5” diskette (A:\SETUP).

5. Launch the configuration utility. The Main screen is displayed.

6. Click Connect.

The Serial Port Setting screen is displayed.

7. Verify settings of the COM port and click OK.

®

®