Page 1

IBM 4400 Series Thermal Printer

User’s Guide

Form Number G544-5731-00

Page 2

SHIPPING INSTRUCTIONS: REMOVE MEDIA ANDRIBBON BEFORE MOVING OR

SHIPPING PRINTER.

INSTRUCTIONES DE TRANSPORTE: REMOV A O MEIO DE IMPRESSAO E A FITA ANTES DE

DESCLOCAR OU TRANSPORTAR A IMPRESSORA.

VERSANDHINWEISE: ENTFERNEN SIE MEDIUM UN FARBBAND BEVOR SIE

DEN DRUCKER TRANSPORTIEREN ODER VERSENDEN.

INSTRUCCIONES DE TRANSPORTE: RETIRAR EL MATERIAL Y LA CINTAANTES DE MOVER O

TRANSPORTAR LA IMPRESORA.

ISTRUZIONI PER IL TRASPORTO: RIMUOVERE LA CARTA E IL NASTRO PRIMA

DISPOSTARE O SPEDIRE LA STAMPANTE.

INSTRUCTIONS D’EXPEDITION: RETIRER LE SUPPORT ET LE RUBAN AVANT DE

DEPLACER OU DE RENVOYER L’IMPRIMANTE.

Page 3

IBM Thermal Printer

User’s Guide

G544-5731-00

Page 4

E

NERGYSTAR

The EPA ENERGY STAR** Computers program is a partnership effort with

manufacturers of data processing equipment to promote the introduction of

energy-efficient personal computers, monitors, and printers, and to reduce air

pollution caused by power generation.

IBM participates in this program by introducing printers that reduce power

consumption when they are not being used. This feature can cut energy use

by up to 50 percent.

Note: The

any product or service.

ENERGY STAR emblem does not represent EPA endorsement of

Notices

References in this publication to IBM products, programs, or services do not

imply that IBM intends to make these available in all countries in which IBM

operates. Any reference to an IBM licensed product, program, or service is

not intended to state or imply that only IBM’s product, program, or service

may be used. Any functionally equivalent product, program, or service that

does not infringe any of IBM’s intellectual property rights may be used instead

of the IBM product. Evaluation and verification of operation in conjunction with

other products, except those expressly designated by IBM, is the user’s

responsibility.

Any performance data contained in this document was obtained in a

controlled environment based on the use of specific data. The results that

may be obtained in other operating environments may vary significantly.

Users of this document should verify the applicable data in their specific

environment. Therefore, such data does not constitute a performance

guarantee or warranty.

IBM may have patents or pending patent applications covering subject matter

in this document. The furnishing of this document does not give you any

license to these patents. You can send license inquiries, in writing, to the IBM

Corporation, IBM Director of Licensing,208 Harbor Drive, Stamford,

Connecticut, United States, 06904.

Page 5

Communication Notices

Federal Communications Commission (FCC) Statement: This equipment

has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provided reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order

to meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and

connectors or by any unauthorized changes or modifications to this

equipment. Unauthorized changes or modifications could void the user’s

authority to operate the equipment.

Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Canadian Department of Communications Compliance Statement: This

Class A digital apparatus meets the requirements of the Canadian

Interference-Causing Equipment Regulations.

Avis de conformite aux normes du ministere des Communcations du

Canada: Cet appareil numerique de la classe A respecte toutes les

exigences du Reglement sur le materiel brouilleur du Canada.

The United Kingdom Telecommunications Statement of Compliance:

This apparatus is approved under the approval No. NS/G/1234/J/100003 for

the indirect connections to the public telecommunications systems in the

United Kingdom.

New Zealand: Warning - This is a Class A product. In a domestic

environment this product may cause radio interference in which case the user

may be required to take adequate measures.

Japanese VCCI:

Page 6

Communication Notices

European Union (EC) Electromagnetic Compatibility Directives: This

product is in conformity with the protection requirements of EC Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM cannot accept responsibility for

any failure to satisfy the protection requirements resulting from a nonrecommended modification of the product, including the fitting of non-IBM

option cards.

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen EMVG

vom 9.Nov.92 das EG-Konformitätszeichen zu furhren.

Properly shielded and grounded cables and connectors must be used in order

to reduce the potential for causing interference to radio and TV

communication and to other electrical or electronic equipment.

This product has been tested and found to comply with limits for Class A

Information Technology Equipment according to CISPR 22/European

Standard EN 55022. The limits for Class A equipment were derived for

commercial and industrial environments to provide reasonable protection

against interference with licensed communication equipment.

Warning: This is a Class A product. In a domestic environment this product

may cause radio interference in which case the user may be required to take

adequate measures.

Dieses Gerät erfüllt die Bedingungen der EN 55022 Klasse A. Für diese

Klasse von Geräten gilt folgende Bestimmung nach dem EMVG:

Geräte dürfen an Orten, für die sie nicht ausreichend entstört sind, nur mit

besonderer Genehmigung des Bundesminesters für Post und

Telekommunikation oder des Bundesamtes für Post und Telekommunikation

betrieben werden. Die Genehmigung wird erteilt, wenn keine

elektromagnetischen Störungen zu erwarten sind.

(Auszug aus dem EMVG vom 9.Nov.92, Para.3, Abs.4)

Hinweis: Dieses Genehmigungsverfahren ist von der Deutschen Bundespost

noch nicht veröffentlict worden.

Page 7

Electrical Safety

Electrical Safety

This printer is inspected and listed by recognized national testing laboratories,

such as Underwriters Laboratories, Inc. (UL) in the U.S.A. and Canadian

Standards Association (CSA) in Canada. Listing of a product by a national

testing laboratory indicates that the product is designed and manufactured in

accordance with national requirements intended to minimize safety hazards.

IBM equipment meets a very high standard of safety in design and

manufacture. Remember, however, that this product operates under

conditions of high electrical potentials and heat generation, both of which are

functionally necessary.

Trademarks and Service Marks

The following terms, denoted by an asterisk (*) in this publication, are

trademarks of IBM Corporation in the United States or other countries or both:

AS/400

IBM

IPDS

PC-DOS

Proprinter

RISC System/6000

SCS

The following terms, denoted by a double asterisk (**) in this publication, are

trademarks of other companies:

Acrobat Adobe Systems Incorporated

Adobe Adobe Systems Incorporated

Centronics Genicom Corporation

Code V Quality Micro Systems

Dataproducts Dataproducts Corporation

ECOS ECOS Electronics Corp., Inc., Oak Park, Ill.

EIA Electronic Industries Association

Energy Star United States Environmental Protection Agency

Epson Seiko Epson Corporation

Ethernet Xerox Corporation

Fluke John Fluke Manufacturing Co., Inc.

FX Seiko Epson Corporation

IEEE Institute of Electrical and Electronics Engineers, Inc.

IGP Printronix, Inc.

MS-DOS Microsoft Corporation

MTOS Industrial Programming, Inc.

PrintNet Printronix,Inc.

Printronix Printronix, Inc.

QMS Quality Micro Systems, Inc.

SureStak Printronix, Inc.

Torx Camcar/Textron Inc.

Page 8

Communication Notices

NOTE: Before using the information and the product it works with, make sure

that you read the general information under “Notices.”

First Edition (April 2000)

This edition applies to the IBM Thermal Printer.

The following paragraph does not apply to any other country where such

provisions are inconsistent with local law:

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES

THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions; therefore, this statement may not

apply to you. Requests for IBM publications should be made to your IBM

representative or to the IBM branch office serving your locality. Publications

are not stocked at the address given below.

You may send your comments by facsimile to 1-800-524-1519, by E-mail to

print_pubs@vnet.ibm.com, or by mail to:

THE IBM PRINTING SYSTEMS DIVISION

INFORMATION DEVELOPMENT

DEPARTMENT H7FE, BUILDING 003G

P.O. BOX 1900

BOULDER, CO 80301-9191

USA

When you send information to IBM or IBM Printing Systems Division, you

grant a nonexclusive right to use or distribute the information in any way IBM

or IBM Printing Systems Division believes appropriate without incurring any

obligation to you.

© Copyright International Business Machines Corporation 2000. All

rights reserved.

Note to U.S. Government Users - Documentation related to restricted rights Use, duplication or disclosure is subject to restrictions set forth in GSA ADP

Schedule Contract with IBM Corp.

Page 9

Table of Contents

1 Introduction..........................................................13

Notes and Notices ............................................................................... 13

Requesting IBM Service................................................................ 15

Printing Conventions in This Manual............................................. 16

The 4400 Thermal Label Printer.......................................................... 17

Features........................................................................................ 17

Thermal Printer Technology ................................................................ 18

The Printing Process..................................................................... 18

Dynamic Print Control ................................................................... 19

Thermal Consumables......................................................................... 19

Media Selection............................................................................. 19

Ribbons......................................................................................... 20

Thermal Features ................................................................................ 21

Emulations .................................................................................... 21

Hardware Options ......................................................................... 21

Setting Up The Printer ......................................................................... 22

Unpacking The Printer .................................................................. 22

Check List ..................................................................................... 24

Installation..................................................................................... 25

2 Operation..............................................................31

Using The Printer................................................................................. 31

Controls & Indicators..................................................................... 31

The POWER Switch and Indicator ................................................ 34

Powering On The Printer............................................................... 34

Operating Modes........................................................................... 35

Loading Media and Ribbon.................................................................. 36

Loading Roll Media ....................................................................... 37

Loading Fanfold Media.................................................................. 44

Loading Ribbon............................................................................. 48

Print Option.......................................................................................... 50

Label Peel Off ............................................................................... 50

Printing Adjustments............................................................................ 54

Printhead Pressure Adjustment..................................................... 54

Printhead Pressure Block Adjustments......................................... 55

Label Variations and the TOF/Paper Out Sensor.......................... 56

Page 10

Table of Contents

TOF/Paper Out Sensor Horizontal Adjustment............................. 56

Calibrating the TOF/Paper Out Sensor......................................... 57

Calibrate Procedure ...................................................................... 58

Cleaning............................................................................................... 60

General ......................................................................................... 60

Printhead....................................................................................... 60

3 Configuring the Printer......................................... 63

Overview.............................................................................................. 63

Menu Navigation.................................................................................. 63

Setting Printer Configuration Parameters ..................................... 64

Moving Within the Configuration Menu ......................................... 64

Selecting a Menu Option............................................................... 65

Changing Printer Settings ............................................................. 66

Configuration Options.......................................................................... 68

Saving a Configuration.................................................................. 68

Modifying a Saved Configuration .................................................. 69

Printing a Configuration................................................................. 71

Menu Overview.................................................................................... 75

Menu Options ...................................................................................... 76

Printer Configuration Menu Items........................................................ 82

Control Functions.......................................................................... 82

Emulation Setup Functions ........................................................... 103

Diagnostics Functions................................................................... 150

Parallel Port Functions .................................................................. 152

Serial Port Functions..................................................................... 154

Optional Ports Functions............................................................... 160

Downloading True Type Fonts...................................................... 163

4 Interfaces........................................................... 165

Overview.............................................................................................. 165

Auto Switching..................................................................................... 165

Centronics Parallel Interface................................................................ 166

Centronics Parallel Interface Signals ............................................ 167

IEEE 1284 Parallel Interface................................................................ 168

Compatibility Mode........................................................................ 168

Nibble Mode.................................................................................. 168

Byte Mode..................................................................................... 168

Signals .......................................................................................... 169

Terminating Resistor Configurations............................................. 171

RS-232 and RS-422 Serial Interfaces ................................................. 172

RS-232.......................................................................................... 172

RS-422.......................................................................................... 173

Page 11

Table of Contents

5 Diagnostics and Troubleshooting ......................175

Requesting IBM Service ...................................................................... 175

Printer Self-Test................................................................................... 176

Troubleshooting Common Situations................................................... 177

Improving Processing Time........................................................... 177

Data Exchange.............................................................................. 177

Controlling Print Quality................................................................. 179

Determining Printhead Wear......................................................... 180

Replacing The Printhead ..................................................................... 181

Prepare the Printer........................................................................ 181

Replace the Printhead................................................................... 182

Restore the Printer to Operation ................................................... 185

Other Printer Problems.................................................................. 186

Printer Alarms ............................................................................... 191

Fault Messages............................................................................. 191

A Specifications.................................................... 201

Standard.............................................................................................. 201

Print Method.................................................................................. 201

Media ............................................................................................ 202

Ribbon........................................................................................... 204

Indicators and Switches ................................................................ 204

Memory ......................................................................................... 204

Host Interfaces.............................................................................. 205

Power............................................................................................ 205

Environmental ............................................................................... 205

Physical......................................................................................... 205

Acoustic Specifications ................................................................. 206

Options ................................................................................................ 206

B Printer Options ...................................................207

C Setting the Label Length................................... 209

D ASCII Control Codes..........................................211

E Glossary ............................................................ 213

Page 12

Table of Contents

Page 13

1 Introduction

Notes and Notices

For your safety and to protect valuable equipment, it is very important that you

read and comply with all information highlighted under notes and notices:

<#> The word Danger next to the lightning slash indicates the

DANGER

presence of a hazard that could cause death or serious

personal injury. Danger and Caution notices are numbered to

help you find the translated versions in the

Notices

booklet.

IBM 4400 Safety

CAUTION

<#> The word Caution next to the exclamation point (!) indicates the

presence of a hazard that could cause moderate or minor

personal injury.

CAUTION

<#> The word Caution next to this symbol indicates a heavy

assembly that requires two or more persons to lift or hold.

13

Page 14

Chapter 1 Notes and Notices

CAUTION

<#> The word Caution next to this symbol indicates a part or

assembly that is hot enough to burn you.

CAUTION

<#> The word Caution next to this symbol indicates a part or

assembly that is sharp enough to cut you.

ATTENTION

The wo rd Attention indica tes the possibility of damage to a program,

device, system, or data.

IMPORTANT

The word Important indicates information vital to proper operation of

the printer.

NOTE:

A note gives you helpful information and tips about printer operation

and maintenance.

14

Page 15

Requesting IBM Service

Requesting IBM Service

Follow the actions in the troubleshooting tables in chapter 5, Diagnostics and

Troubleshooting. Most problems can be easily resolved using these tables. If

you are unable to resolve the problem, you may want to request service from

your IBM service team. To request service on your IBM 4400 Series Thermal

Printer in the U.S. or Canada, call 1-800-358-6661. Service is available from 8

a.m. to 8 p.m. eastern time. To request service in other countries, call your

countryCall Center.

You may call for service free of charge during the printer's warranty period.

You can obtain service after the warranty period has expired if you sign a

service contract agreement with an authorized service provider.

You also can obtain service on a billable-per-call basis after the warranty

period has expired. Please have your service contract information and printer

serial number available when you call. The four digit machine type is 4400.

Please enter this number when prompted.

NOTE: Technical support is also available from the IBM Printing Systems

Division home page at:

http://www.printers.ibm.com

15

Page 16

Chapter 1 Notes and Notices

Printing Conventions in This Manual

Operator panel keys and LCD messages are set off from regular text in this

manual:

• Operator panel keys and indicators are printed boldface.

Example: Press the Cancel key, then press the Pause key.

• Liquid Crystal Display (LCD) messages are printed in capital letters inside

quotationmarks(“”).

Key combinations are denoted by the + (plus) symbol.

Example: Press ↑ + ↓

means

Press the Up↑key and the Down↓key at the same time.

16

Page 17

The 4400 Thermal Label Printer

NOTE: As used in this manual, the terms “4400” and “printer” refer to all

models within the 4400 series.

The printer series consists of a family of high quality, direct thermal and

thermal transfer printers specifically designed for printing labels and tags,

from any MS-DOS

option) based compatible computer.

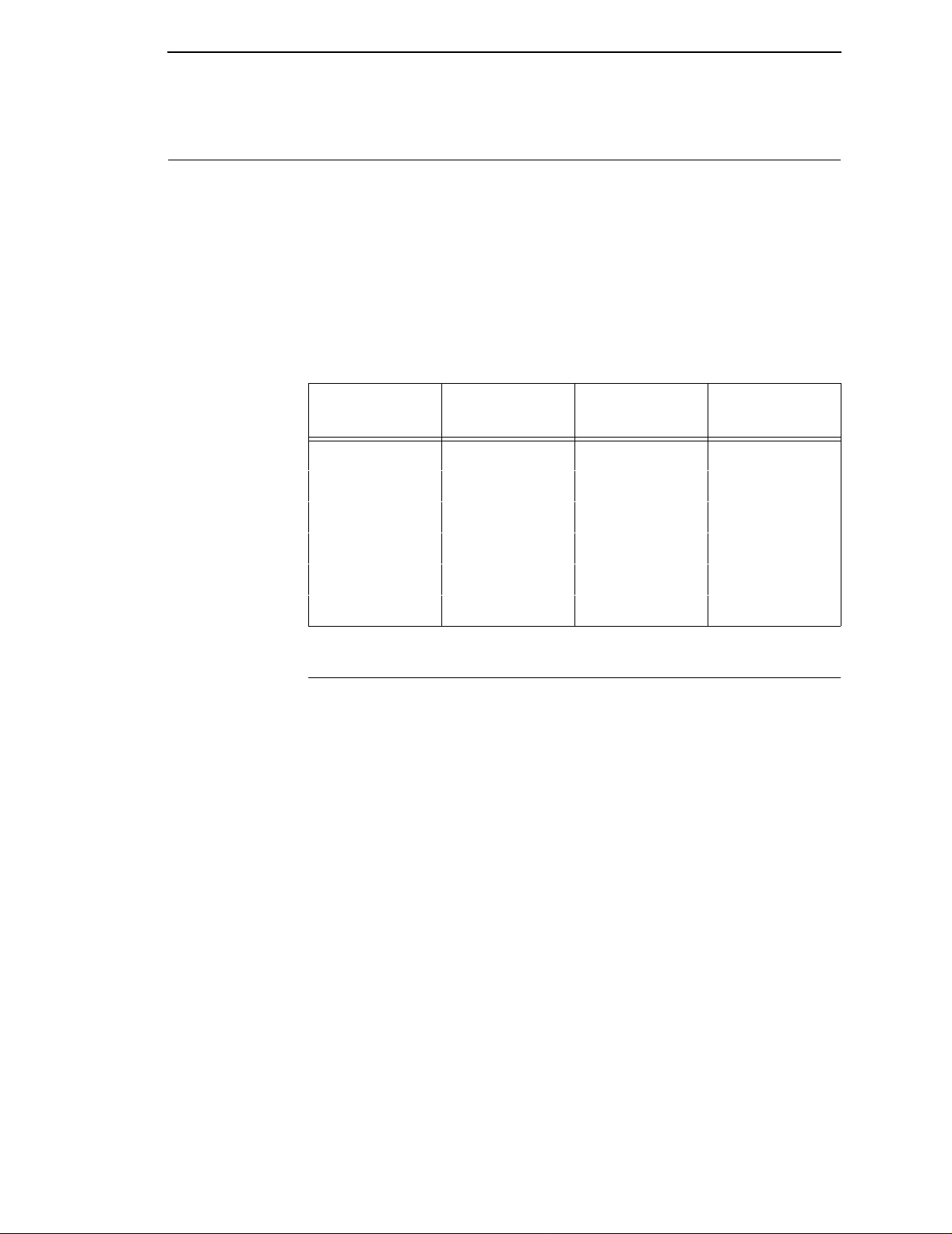

The IBM thermal printer series is comprised of the products detailed in Table

1.

**

, Windows**, ASCII or EBCDIC (with the Coax/Twinax

Table 1. The IBM thermal printer Series

Features

Model

4400-004 10 203 4.1

4400-004 8 300 4.1

4400-006 10 203 6.6

4400-006 8 300 6.6

4400-008 8 203 8.5

4400-008 6 300 8.5

Max Print

Speed (ips)

Printing

Density (dpi)

Max Print

Width (inches)

Features

• Thermal transfer and direct thermal printing.

• Supports over 20 types of bar codes.

• Download forms, fonts and graphics to printer memory.

• High resolution printhead for sharp graphics and text.

• Built-in label rewinder for label Peel-Off operation.

• Label Taken Sensor for detecting removal of labels in Peel-Off or Tear-

Off modes.

• Peel-Off mode for peeling off labels one at a time, before printing the next

label.

• Tear-Off mode for positioning the label at the tear-off position and

detecting its removal before printing the next label.

• Tear-Off Strip mode for printing a specified number of labels and

positioning the last label at the tear-off position.

• 8MB DRAM memory (4MB for the 4400-004).

• 4MB Flash memory.

17

Page 18

Chapter 1 Thermal Printer Technology

Dynamic Print Control provides exceptional print quality. A circuit monitors the

data to be printed and automatically adjusts the energy applied to the thermal

printhead for maximum performance.

The printer can be connected to communicate with the host via RS-232 and

RS-422 serial, Centronics

parallel, and, optionally, coax/twinax host connections or Ethernet

Base-T. The interface cable needed to connect the printer to the host device

is supplied by the user.

Thermal Printer T echnolog y

Quiet and fast, with excellent print quality, the IBM multifunction thermal

printer uses an inline thermal printhead. The operation of a thermal printer is

different from that of a line-matrix or laser printer. The thermal printer uses a

printhead with heating elements and special paper or ribbon.

The Printing Process

The thermal printhead allows two modes of operation:

• Direct Thermal

direct

During

small, rectangular

paper, the dyes and developers in the coating react to the heat and

develop an image. This mode of printing is generally used for short-term

labeling applications.

thermal printing, the thermal printhead selectively heats

thermal

**

-compatible parallel, IEEE**1284 compliant

dots. When these contact the coated thermal

**

10/100

• Thermal Transfer

During thermal

thermal ribbon. The heat reacts with the ribbon and bonds the image to

the paper. This method is used especially for abrasive, long-storage

applications and for specialized applications, such as in extreme

environmental conditions or where tamper-proofing is required.

transfer

printing, the heated thermal dots contact a

18

Page 19

Dynamic Print Control

The thermal printer has a unique feature that provides excellent print quality

by preventing unevenness of print density. Unevenness is usually caused by

the stored heat from previous dots. Print quality largely depends on how the

thermal paper or the thermal ribbon and thermal transfer paper responds to

the heat of the thermal printhead.

During printing, the thermal printhead must reach a set temperature in the

shortest possible time. Then it must cool down to the original temperature in

the shortest possible time after printing. Thus print quality is dependent on the

precise control of the energy supplied to the thermal dots.

The Dynamic Print Control is a method for predicting the quantity of heat

required to print dots based on the results of the previous printing. This

prevents unevenness of print density and results in the printing of narrow-

ladder bar codes or vertical grid lines that are straight from the microscopic

viewpoint.

Thermal Consumables

Dynamic Print Control

Media Selection

Since there are two print modes of operation, there are two kinds of thermal

media:

• Direct thermal media

• Thermal transfer media

Direct thermal media is paper coated with special chemicals that act as an

accelerator, acceptor dye and binder. During direct thermal mode, the heat

from the thermal printhead contacts the paper and causes a chemical reaction

to take place.

There is a wide range of thermal transfer media available, such as film or

synthetic paper substitutes that are excellent in their ability to transfer an

image (print quality) and others in scratch resistance (long storage). Most of

these media options can be die-cut for easy label applications.

NOTE: The term “media” used in this manual refers to all the different kinds

of paper or tag stock that can be used in the printer.

19

Page 20

Chapter 1 Thermal Consumables

Ribbons

IBM offers a wide range of ribbons that have been specifically engineered to

enhance printing capabilities and to prevent premature printhead wear.

Therefore, it is strongly recommended that you use a Genuine IBM Thermal

Ribbon in your printer.

IBM 4400 TTW Thermal T ransf er Ribbon

This ribbon provides superior print quality on coated and uncoated thermal

transfer paper, labels and tags. IBM 4400 TTW ribbons are an excellent

choice for general-purpose applications.

IBM 4400 TTB Thermal T ransf er Ribbon

This ribbon provides excellent high-speed print quality with premium durability

and performance on a wide range of thermal transfer paper and synthetic

labels. IBM 4400 TTB ribbons are formulated to provide excellent print quality

at the highest IBM 4400 print speeds.

IBM 4400 TTR Thermal T ransf er Ribbon

Specifically designed for use with high-end synthetic labels. Provides the

highest heat, chemical, and abrasion resistance where toughness and label

durability are needed.

Ordering Ribbons (U.S. Only)

Ribbons may be purchased from Lexmark Authorized IBM Supplies Dealers

or directly from Lexmark by calling: 1-800-438-2468

Fax orders may be sent to: 1-800-522-3422

Mail orders may be sent to: Lexmark International, Inc., 1221 Alverser Drive,

Midlothian, VA 23113.

Ordering Ribbons (Outside of U.S.)

Order supplies by contacting your local Lexmark International distributor or by

writing to Lexmark International, Inc.

Lexmark International, Inc.

P.O. Box 11427

Lexington, KY, 40575-1427 USA

20

Page 21

Thermal Features

Emulations

The 4400 has the standard IBM ASCII Emulation which provides direct

compatibility with IBM series printers. In addition, the printer has co-resident

IGP and Code V emulations which provide printer system commands for text,

barcodes, graphics, lines, and boxes.

Hard ware Options

Ask your IBM representative about the following options, which can enhance

the versatility of your printer.

• Memory Expansion

16MB DRAM SIMM - Provides additional memory to accommodate

long label formats.

• Coax/Twinax Host Interface

Emulations

Provides connection to an IBM host computer system using a coax or

twinax interface.

• Ethernet** 10/100 BASE T

Allows the user to attach the printer to a LAN (Local Area Network)

rather than attaching it directly to a host system. This Ethernet

Interface server supports 10/100 Base T (UTP) only and is mounted

inside the printer.

21

Page 22

Chapter 1 Setting Up The Printer

:

Setting Up The Printer

CAUTION

<6> The printer weighs between 15.9 kg (35 lb.) and 22.7 kg

(50 lb.). Use two persons to carry the printer. Use

appropriate lifting precautions.

Unpacking The Printer

The printer is shipped in a carton and protective bag. Keep all packing

material in case you need to move or re-ship the printer. Avoid touching the

electrical connectors to prevent electrostatic discharge damage while setting

up the printer.

ATTENTION

ATTENTION

The discharge of electrostatic energy that accumulates on the surface

of the human body or other surfaces can damage or destroy the

printhead or electronic components used in this device.

Damage to the p rinter interface connector may result from placing the

printer on its backside during unpacking or handling.

22

Page 23

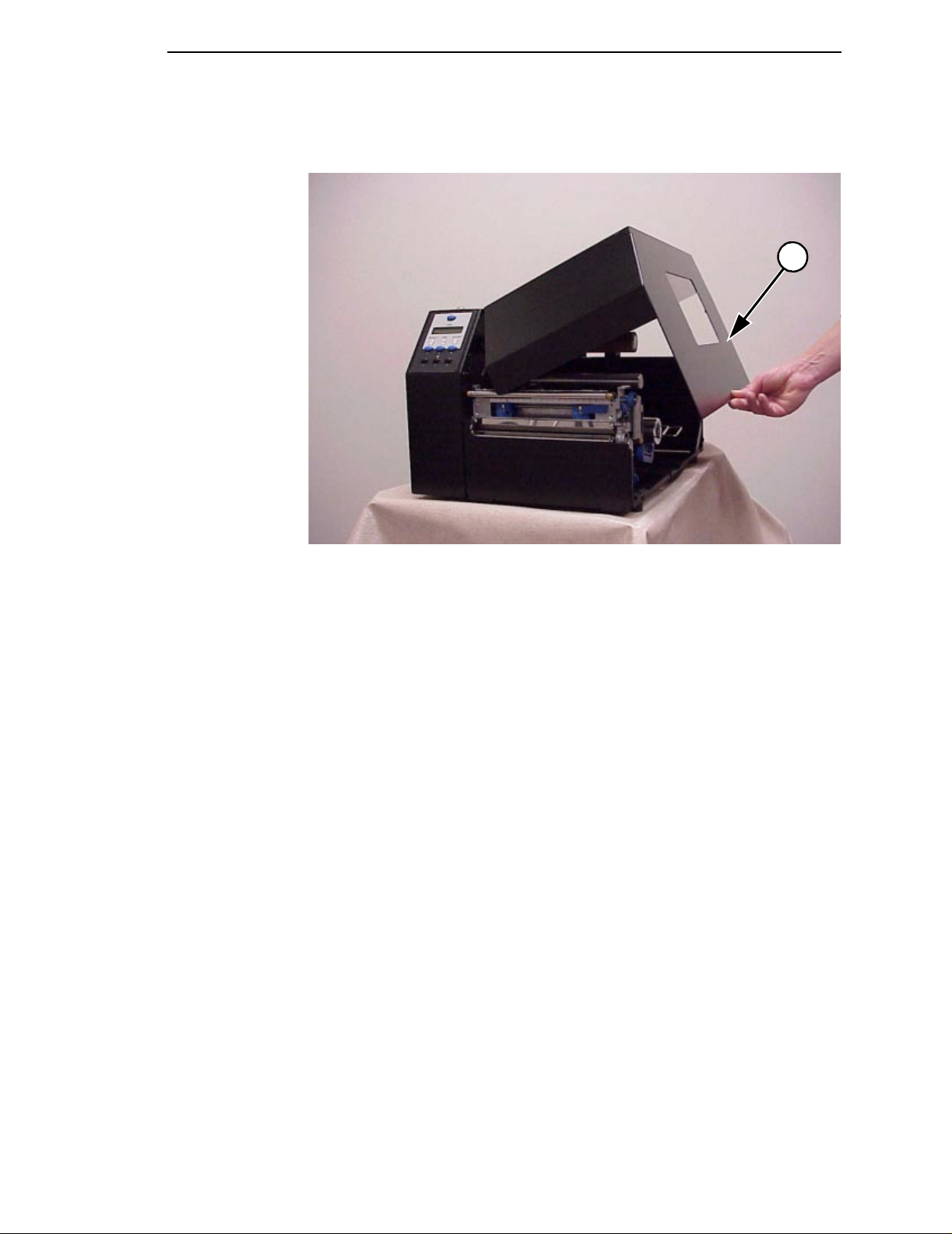

Unpacking The Printer

Open the media cover by lifting it in the center of its bottom right edge.

1

Legend:

1) Media Cover

Remove the tape securing the liner rewinder clamp to the rewinder spindle.

Slide the Media Hanger Guide outward to the end of the Media Hanger. Place

the Guide in the down (horizontal) position and remove the sample roll of

ribbon and media from the media hanger and set them to one side.

23

Page 24

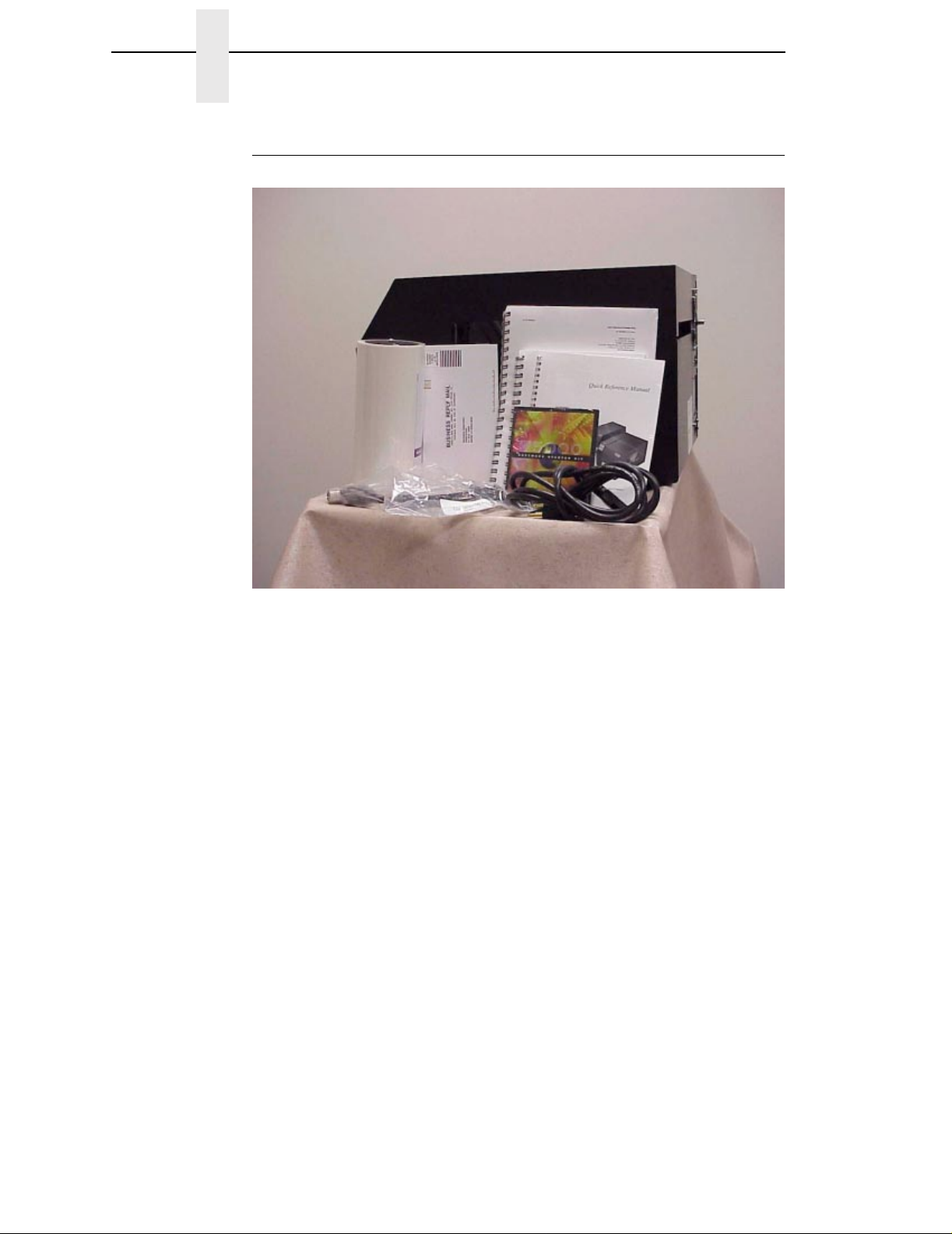

Chapter 1 Setting Up The Printer

Check List

Your thermal printer kit contains the items listed below.

• The thermal printer.

• AC Powercord

• User’s Manual

• Quick Reference Manual

• Printer Manual CD

• Terminating Resistor Packs

• Ribbon Take-Up Core (mounted in printer)

• Starter Kit Roll Media

• Sample Roll of IBM Thermal Transfer Wax Ribbon (wrapped inside media

roll)

• Printhead Cleaning Pen (wrapped inside media roll)

NOTE: If any items are missing, contact your dealer for replacement parts.

24

Page 25

Installation

Installation

The following sections will guide you through the installation of the printer.

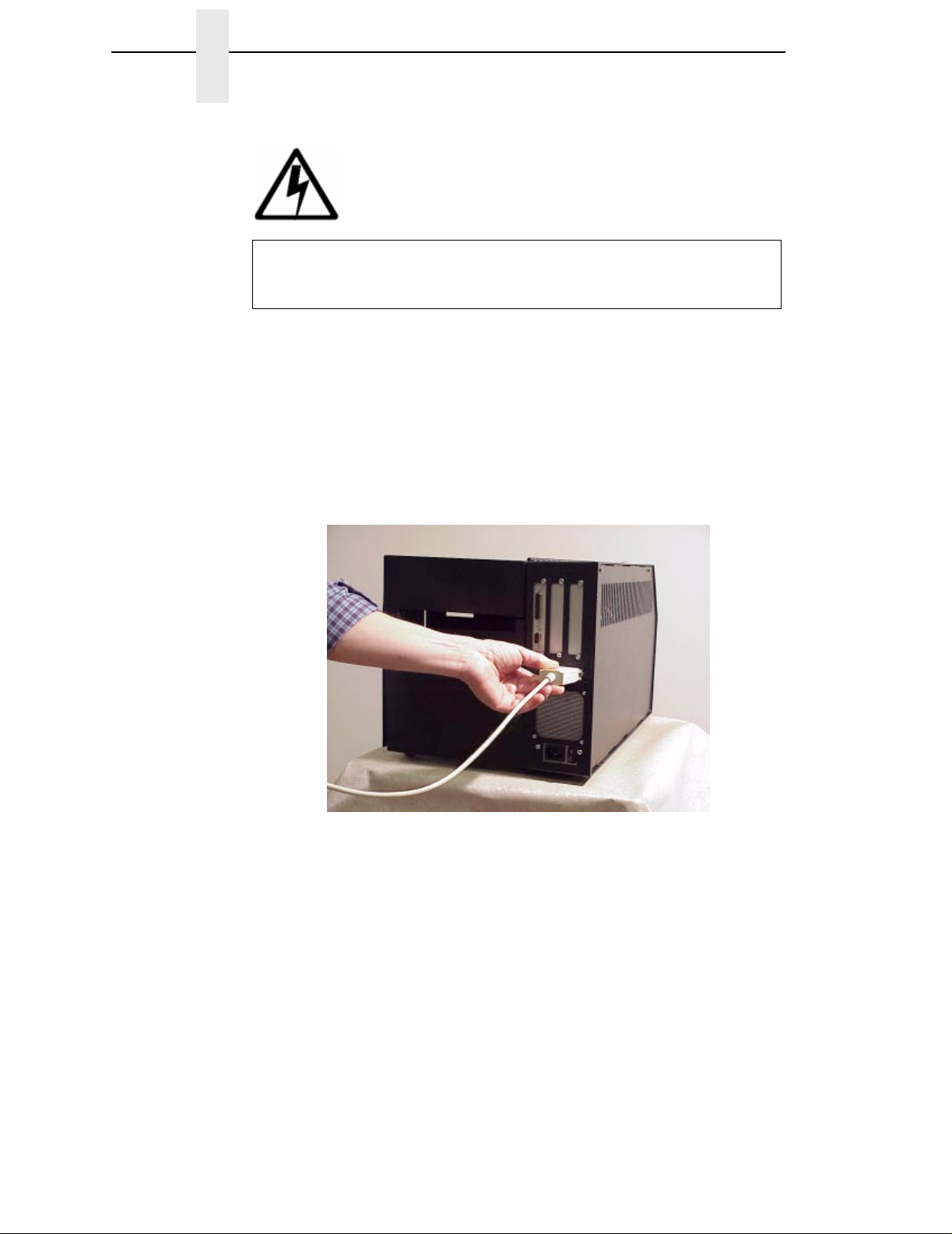

DANGER

<6> The printer should never be operated in a location where

the operator or printer can get wet.

1. Place the printer in a suitable location on a flat level surface that allows

easy access to all sides of the printer. The printer should never be

operated while resting on its side or upside down.

2. Check that the printer power switch is in the OFF (O) position.

Legend:

1) AC Power Receptacle

2) On/Off Power Switch

On Position Off Position

2

1

25

Page 26

Chapter 1 Setting Up The Printer

DANGER

<4>

The following sections will guide you through the installation of the printer.

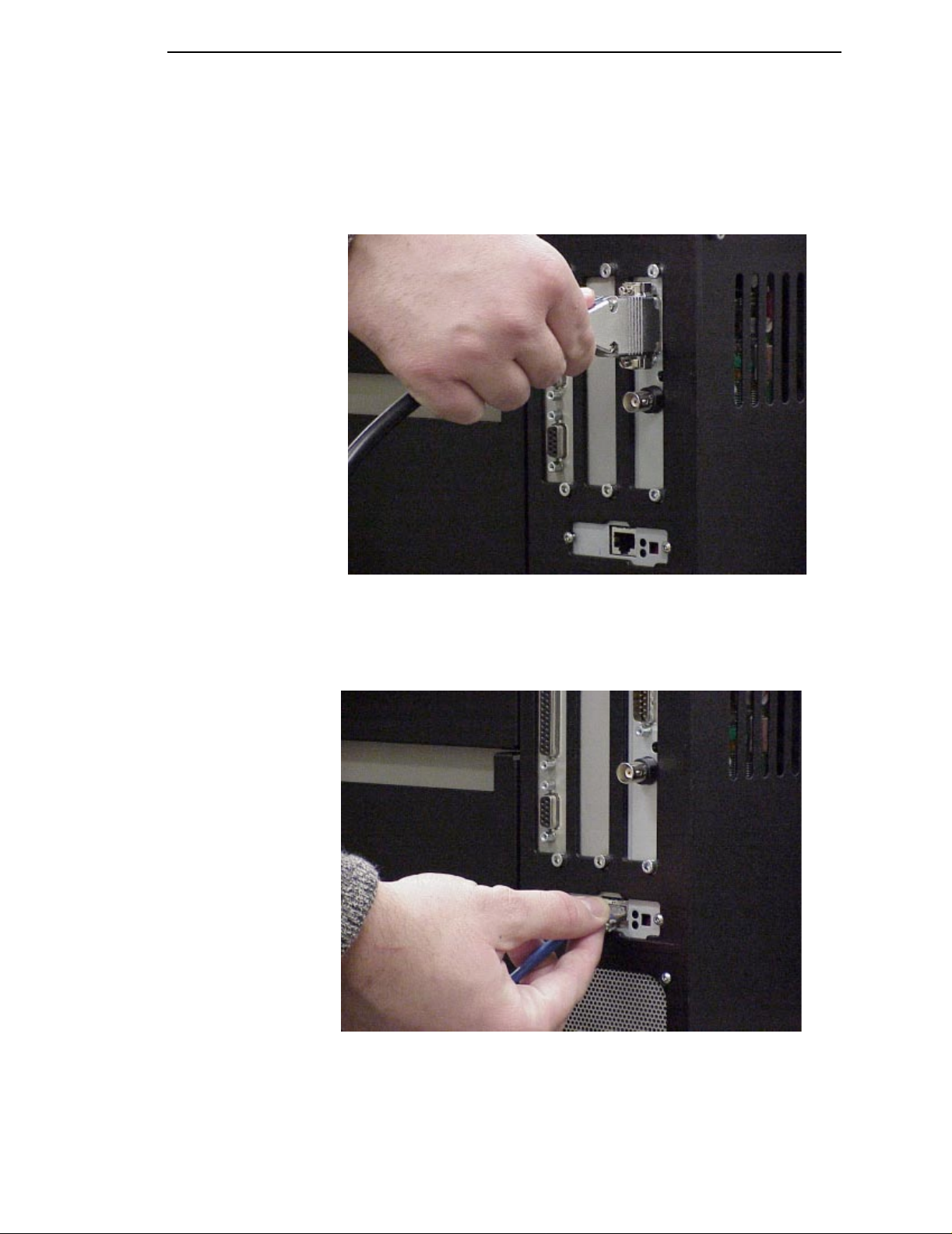

3. Attach Interface

a. Parallel Interface

Do not connect or disconnect any communication port,

teleport, attachment connector, or power cord during an

electrical storm.

Attach a suitable parallel printer cable from the computer to the

Centronics interface connector at the back of the printer. Snap the

bail locks to the Centronics connector to secure the interface cable to

the printer.

26

Page 27

Installation

b. Serial Interface

Attach a suitable serial printer cable from the computer to the DB-25

RS-232 Serial interface connector at the back of the printer. For

additional information on serial cable wiring, refer to “Diagnostics and

Troubleshooting” on page 175.

NOTE: The printer supports simultaneous connection of the Parallel and

Serial interfaces using the Auto Switching feature. See Auto

Switching described on page 165.

27

Page 28

Chapter 1 Setting Up The Printer

If your printer is equipped with the Coax/Twinax and ethernet interfaces, the

rear I/O panel will look like the picture below.

c. Coax Interface

Attach a suitable coaxial cable from the computer to the coax

connector located in the I/O plate in the back of the printer.

28

Page 29

d. Twinax Interface

Attach a suitable twinax cable from the computer to the twinax

connector located in the I/O plate in the back of the printer.

Installation

e. Ethernet Interface

Insert a suitable ethernet cable from your hub or switch to the

ethernet connector located in the I/O panel in the rear of your printer.

29

Page 30

Chapter 1 Setting Up The Printer

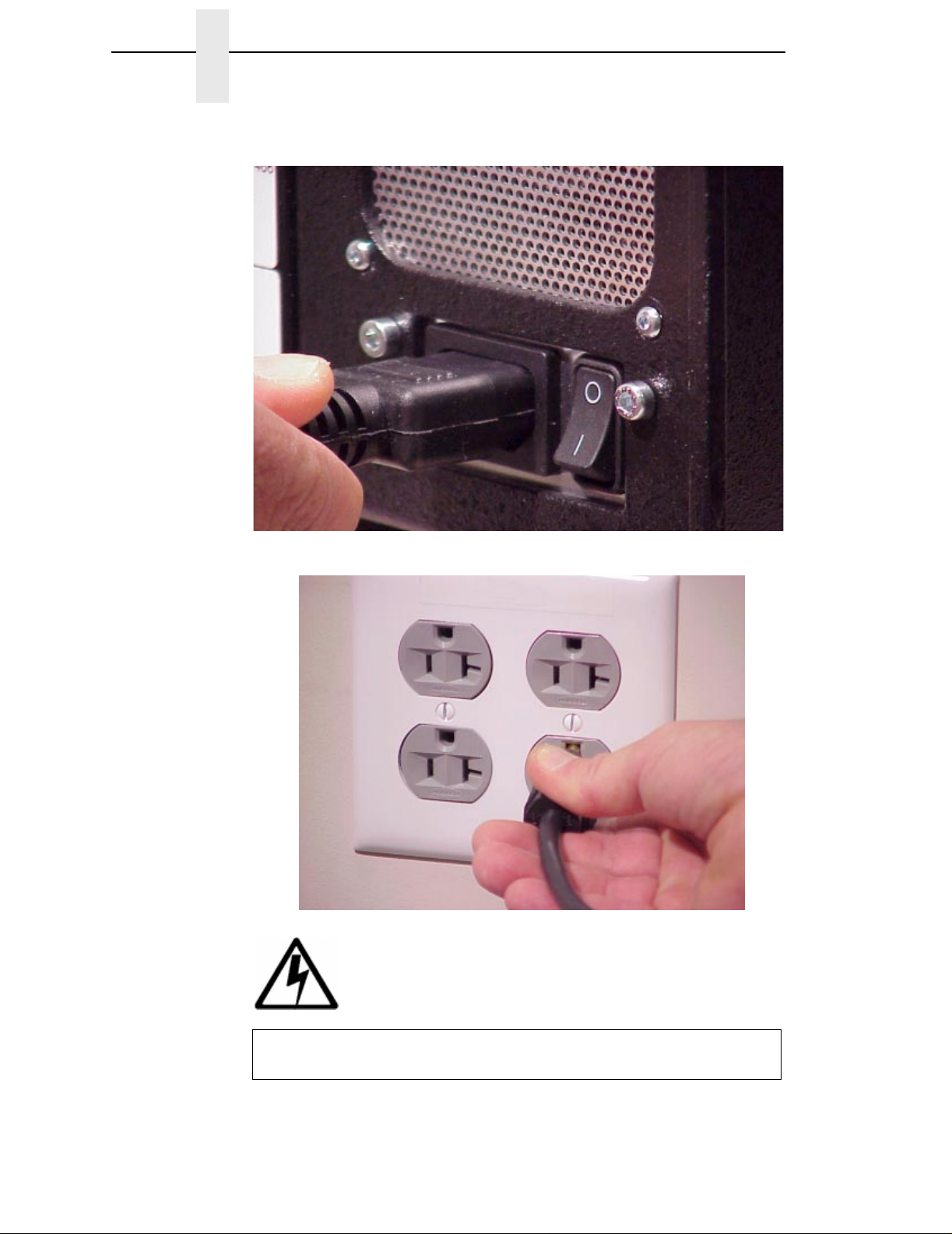

4. Attach the AC power cord to the AC power receptacle in the rear of the

printer.

Attach the AC power cord to a grounded (three prong) electrical outlet of the

proper voltage.

DANGER

30

<1>

Before powering on the printer, ensure that the printer is

plugged into the appropriate power source.

Page 31

2 Operation

Using The Printer

Controls & Indicators

All printer controls and indicators, except for the power switch and ONLINE

status indicator, are located on the front panel of the printer. The power switch

is located in the bottom left hand corner at the rear of the printer. The ONLINE

status indicator is located on top of the printer, directly above the control

panel.

The Control Panel is located at the top left of the printer. The panel has a

back-lighted Liquid-Crystal Display (LCD) with 2 rows of 16-characters each.

The Control Panel also contains the printer control keys. A summary of each

key’s function is provided on the following pages. Detailed descriptions of key

functionality are provided in Chapter 3.

31

Page 32

32

Chapter 2 Using The Printer

Button Description

PAUSE Key

Toggles the printer between

online and offline modes.

JOB SELECT Key None Selects a pre-stored

-

ñ

Decrement Key

FEED Key

Up Key

TEST PRINT Key

Pressing the↵ (Enter) key with

a Diagnostic Test displayed

initiates the test. Pressing the

(Enter) key again terminates the

test.

Function in Online

Mode

Sets printer to Offline

Mode.

Advances the media

one form length.

None Navigates the Test

↵

Function in Offline

Mode

Sets printer to Online

Mode.

printer configuration.

Advances the media

one form length.

Print pattern.

Function in Menu

Mode

Sets printer to Offline

Mode.

Decrements values in

the current menu

selection, or navigates

through selections to

the left.

Navigates the current

menu selection one

level up.

Increments values in

the current menu

selection, or navigates

through selections to

the right.

Control Panel Keys

+

Increment K ey

Page 33

Button Description

Function in Online

Mode

Function in Offline

Mode

Function in Menu

Mode

33

Cancel Key

This key is set to disable from the

factory, except when the Coax/

Twinax option is present. In this

case, the factory default setting is

enable. CANCEL can also be

enabled in the PRINTER

CONTROL menu.

Down Key

Menu Key Sets the printer to

Enter Key

If the↵(Enter) key is locked, the

value will not be selected and an

“ENTER SWITCH LOCKED”

message displays for one second,

followed by a display of the

previously selected value. Pressing

the↓(Down) and↵(Enter) keys

unlocks the↵(Enter) key and

permits value selection. After

unlocking the↵(Enter) key, it is

then used to select the desired

value.

Clears all data in the

printer data buffer

when enabled.

Offline and selects the

Menu mode.

None None Selects the current

Clears all data in the

printer data buffer

when enabled.

Selects the Menu

mode.

Navigates the current

menu selection one

level down.

Navigatesbetween

top level menu

selections.

menu value and

displays an asterisk

(*) next to the value.

Controls & Indicators

Page 34

Chapter 2 Using The Printer

The POWER Switch and Indicator

The printer’s POWER SWITCH is located on the back panel of the printer, in

the bottom left corner. Placing this switch in the ON (|) position applies power

to the printer. Place this switch in the OFF (O) position to remove power when

you have finished using your printer. An illuminated LCD Message Display

indicates the printer power is ON.

Powering On The Printer

When you power on the printer, it executes a self-test. The default power-up

state is online. Once the printer has successfully initialized, the ONLINE

status indicator light illuminates, and the LCD indicates the communication

interface selected and the type of emulation installed.

If there is a fault during the self-test, the ONLINE status indicator flashes, and

a fault message appears on the display. The alarm may also sound, if it is

configured to do so.

34

Page 35

Operating Modes

Operating Modes

Online - In online mode, the printer can receive and print data sent from the

host. Pressing the PAUSE key toggles the printer between the online and

offline mode. The ONLINE status indicator is lit in online mode.

Offline - In offline mode, you may perform operator functions, such as loading

media, or navigating through the printer configuration menu to make changes

or verify option settings. Pressing the PAUSE key toggles the printer from

offline to online mode. The ONLINE status indicator is not illuminated in offline

mode.

Fault - In fault mode, a fault condition exists that must be cleared before

printing can continue. The ONLINE status indicator flashes, the alarm beeps

(if configured to do so) and a descriptive fault message displays.

The current operating mode can be selected through the control panel keys,

or may result from routine operations such as powering on the printer.

35

Page 36

Chapter 2 Loading Media and Ribbon

Loading Media and Ribbon

This section explains how to load roll media, fanfold media, and the ribbon.

The term “media” used in this manual refers to all the different kinds of paper,

label, or tag stock material that can be printed on by the printer.

Your thermal printer can print on continuous paper, adhesive backed labels or

non-adhesive tags packaged in roll or fanfold form.

ATTENTION

IMPORTANT

DO NOT TOUCH the Printhead or the electronic components under the

Printhead Assembly. The discharge of electrostatic energy that

accumulates on the surface of the human body or other surfaces can

damage or destroy the printhead or electronic components used in this

device.

Adhesive backed labels that DO NOT lay flat on the backing liner may

jam the printer. This can cause the label to peel off the liner. The

exposed edges may stick to the label guides and rollers inside the

printer.

If you run out of labels while printing, do not turn the power switch to

the O FF position while reloading labels. Lost data may result. Prior to

printing labels, it is also recommended you enable the Error Recover

sub-menu of the MEDIA CONTROL menu, and save it as the power-on

default. Error Recover forces the printer to automatically reprint a label

that may have been partially printed prior to the PAPER OUT fault

message, after additional labels are properly loaded.

36

Page 37

Loading Roll Media

Loading Roll Media

1. Open the media cover.

2. Slide the media hanger guide outward to the end of the media hanger,

and rotate it downward to a horizontal position.

1

Legend:

1) Media Hanger Guide

2) Media Hanger

2

37

Page 38

Chapter 2 Loading Media and Ribbon

3. Open the pivoting deck by rotating the deck lock lever clockwise to the

end of its travel. The pivoting deck will swing open.

1

Legend:

1) Pivoting Deck

2) Deck Lock Lever

2

38

Page 39

Loading Roll Media

4. Slide the media width guide located on the media damper outward to the

fully extended position.

1

Legend:

1) Media Damper

2) Media Width Guide

2

39

Page 40

Chapter 2 Loading Media and Ribbon

5. Slide a roll of media over the media hanger guide and onto the media

hanger. The media feeds from the top of the roll and towards the front of

the printer.

6. Push the roll to the back of the media hanger, rotate the media hanger

guide to its upright position and slide it inward against the outer edge of

the media roll.

3

Legend:

1) Media Roll

2) Media Hanger

3) Media Hanger Guide

2

1

40

Page 41

Loading Roll Media

7. Thread the media under the media damper and then between the platen

(drive roller) and the printhead. You can also ref er to the arrows on the

printer frame or the Ribbon and Media Loading instruction label inside the

media cover.

1

2

Legend:

1) Printhead Assembly

2) Platen (Drive Roller)

3) Media Damper

3

41

Page 42

Chapter 2 Loading Media and Ribbon

8. Push the media width guide inward until it is flush with the outer edge of

the media.

9. Check the location of the TOF (Top-of-Form)/Paper Out sensor (it is blue

in color and located just behind the platen), and refer to Top-of-Form

Sensor Horizontal Adjustment on page 56.

Legend:

1) Media Width Guide

1

42

Page 43

Loading Roll Media

10. Close the printhead by pressing down on both sides of the front of the

pivoting deck and rotating the deck lock lever counterclockwise against its

stop. This locks the pivoting deck and printhead assembly into the printing

position.

1

ATTENTION

2

Legend:

1) Pivoting Deck

2) Deck Lock Lever

Ensure the pivoting deck is down and locked before attempti ng to print.

Failure to do so will cause a premature failure of the printhead

assembly.

11. For direct thermal operation (no ribbon required) close the media cover

and go to step 12.

For thermal transfer operation (use of ribbon) complete the ribbon loading

procedure (See “Loading Ribbon” on page 48).

Verify that Print Mode in the Printer Configuration Menu is set for the

media type installed (Direct or Transfer). The Print Mode submenu is

located in the MEDIA CONTROL Main Menu. See “Menu Options” on

page 76 for details.

12. Press the FEED key once to verify that the media advances.

13. Press the PAUSE key to place the printer online.

The printer is now ready for printing.

43

Page 44

Chapter 2 Loading Media and Ribbon

Loading Fanfold Media

1. Open the media cover.

2. Slide the media hanger guide outward to the end of the media hanger,

and rotate it downward to a horizontal position.

3. Remove any roll media.

4. Place the fanfold media either behind or beneath the printer, depending

on the desired fanfold supply location. Insert the first few labels through

either the rear or bottom panel opening.

5. Place the media over the media hanger, flush against the back of the

printer.

6. Rotate the media hanger guide to its upright position and slide it inward

against the outer edge of the loaded media.

Legend:

1) Media Hanger Guide

2) Media Hanger

3) Fanfold Media

1

3

2

44

Page 45

Loading Fanfold Media

7. Rotate the fanfold tension arm down by pushing on it through the opening

at the top of the media hanger guide.

8. Open the pivoting deck by rotating the deck lock lever clockwise to the

end of its travel. The pivoting deck will swing upward.

1

2

3

Legend:

1) Fanfold Tension Arm

2) Pivoting Deck

3) Deck Lock Lever

45

Page 46

Chapter 2 Loading Media and Ribbon

9. Slide the media width guide outward to the end of the media damper.

10. Thread the media between the platen (drive roller) and the printhead. You

can also refer to the Ribbon and Media Loading instructions label inside

the media cover. The inner edge of the media should be positioned as far

inward as possible.

11. Slide the media width guide inward against the outer edge of the media.

12. Check the location of the TOF/Paper Out sensor, and refer to “TOF/Paper

Out Sensor Horizontal Adjustment” on page 56. The TOF/Paper Out

sensor is blue in color and located just behind the platen.

.

1

2

Legend:

1) Printhead Assembly

2) Platen

3) Media Width Guide

3

46

Page 47

Loading Fanfold Media

13. Close the printhead by pressing down on both sides of the front of the

pivoting deck and rotating the deck lock lever counterclockwise against its

stop. This locks the pivoting deck and printhead assembly into the printing

position.

Verify that Print Mode in the Printer Configuration Menu is set for the

media type installed (Direct or Transfer). If Thermal Transfer media is

installed, see “Loading Ribbon” on page 48. The Print Mode submenu is

located in the MEDIA CONTROL Main Configuration menu. See “Menu

Options” on page 76 for more information.

1

ATTENTION

2

Legend:

1) Pivoting Deck

2) Deck Lock Lever

Ensure the pivoting deck is down and latched before attempting to print.

Failure to do so may cause a premature failure of the printhead.

14. Press the FEED key once to verify that the labels advance.

15. Close the printer media cover if the thermal transfer operation is not

needed.

16. Press the PAUSE key to place the printer online.

The printer is now ready for printing.

47

Page 48

Chapter 2 Loading Media and Ribbon

Loading Ribbon

Skip this section when using Direct Thermal Printing

1. Slide the appropriate thermal transfer ribbon supply roll onto the ribbon

supply spindle until it is flush against the printer.

2. Open the pivoting deck by rotating the deck lock lever clockwise to the

end of its travel. The pivoting deck will swing upward.

3. Thread the end of the transfer ribbon below the rear ribbon guide and

continue threading between the platen (or media, if loaded) and the

printhead. You can also refer to the arrows on the printer frame or the

Ribbon and Media Loading Instruction label located inside the printer on

the media cover.

6

1

2

3

Legend:

1) Pivoting Deck

2) Platen

3) Deck Lock Lever

4) Rear Ribbon Guide

5) Ribbon Supply Spindle

6) Ribbon Supply Roll

5

4

48

Page 49

Loading Ribbon

4. Wrap the transfer ribbon from the front of the printhead assembly to the

front side of the ribbon take-up spindle. Attach the ribbon to the take-up

core (fiberboard tube) on the ribbon take-up spindle with tape.

When installing a new roll of ribbon, attach the ribbon leader adhesive

strip to the ribbon take-up core. Manually rotate the spindle clockwise to

feed the unusable portion of the ribbon leader around the take-up spindle.

NOTE: Do not attach the ribbon to the ribbon take-up spindle without a core

installed. Proper ribbon tension and ribbon removal is based on use

of fiberboard core.

1

2

Legend:

1) Ribbon Take-up Spindle

2) Ribbon Take-up Core

5. Close the pivoting deck (see page 47).

6. Close the printer media cover if the rewinder is not needed.

7. Verify that Print Mode is set for Transfer in the Print Mode submenu

located in the MEDIA CONTROL Main Configuration menu. See “Menu

Options” on page 76 for more information.

8. The printer is now ready to print.

49

Page 50

Chapter 2 Print Option

Print Option

Label Peel Off

The printer can be set up to automatically peel off labels from the backing

liner and dispense them one at a time while rewinding the liner. This

configuration requires routing the liner through the rollers on the Peel/Tear

assembly properly and use of the printer’s internal rewinder.

1. Open the media cover.

2. Open the front cover.

3. Open the pivoting deck by rotating the deck lock lever clockwise to the

end of its travel. The pivoting deck will swing upward.

4. With the label stock already loaded and exiting from the front of the printer

(see “Loading Roll Media” on page 37), separate the labels from their liner

(about 20 inches worth).

50

Page 51

Label Peel Off

5. Thread the liner over the tear bar behind the top roller and around the

outside of the bottom of the Peel/Tear assembly.

51

Page 52

Chapter 2 Print Option

6. Manually position the leading edge of the first label to just behind the tear

bar of the Peel/Tear assembly.

7. Thread the liner counterclockwise around the rewinder and the rewinder

clamp as shown, and insert the liner end into one of the slots in the

rewinder. Make sure the rewinder clamp is pushed in against the

rewinder.

8. With one hand holding the liner in the slot, use the other hand on the

rewinder clamp and rotate the rewinder counterclockwise until the lever is

taught on the rewinder spindle.

Legend:

1) Rewinder Clamp

2) Rewinder

1

2

52

Page 53

Label Peel Off

9. Verify the leading edge of the first label is still behind the tear bar of the

Peel/Tear assembly.

10. Close the printhead by pressing down on both sides of the front of the

pivotingdeck and rotatingthe decklock counterclockwiseagainst its stop.

This locks the pivoting deck and printhead assembly into the printing

position.

11. Close the front door. The door must be closed for the Label Sensor to first

sense the label and then its removal.

1

2

3

Legend:

1) PIvoting Deck

2) Label Only

3) Deck Lock Lever

12. For automatic label peel-off mode, set Media Handling to Peel-Off under

the MEDIA CONTROL Main menu. See Chapter 3 for more information

on configuring the printer.

13. Close the media cover.

53

Page 54

Chapter 2 Printing Adjustments

Printing Adjustments

Printhead Pressure Adjustment

1

Legend:

1) Printhead Pressure Adjustment Dial

Adjustment of the printhead pressure is sometimes required to obtain

optimum printing results with variations in media thickness and width. The

printhead pressure adjustment dial is shown above.

In general, the printhead pressure should be adjusted to the minimum value

which produces the desired print quality. Following this procedure will help to

minimize printhead wear. The numbers on the Printhead Pressure Adjustment

Lever are relative only and do not indicate a specific printhead pressure.

54

Page 55

Printhead Pressure Block Adjustments

Printhead Pressure Block Adjustments

6

1

Legend:

1) Left Pressure Block

2) Left Pressure Block Handle

3) Pressure Block Adjustment Scale

4) Right Pressure Block

5) Right Pressure Block Pointer

6) Lead Screw Knob

The Printhead Pressure Pad Adjustments are used to obtain best printing

results under a variety of media and ribbon conditions.

Under normal printing conditions, the optimum position of the left pressure

block when its handle detent is positioned in the notch in the pivoting deck. If

media/ribbon widths of less than one-third the printer’s maximum printing

width are used, it may be necessary to move the left pressure block further

left by using the handle and overriding the detent. The left pressure block can

only be moved manually using its handle.

The proper setting for the pressure blocks is when they are evenly spaced

across the width of the media. The proper setting for the right pressure block

is with the right pressure block pointer positioned on the right edge of the

media in use. The right pressure block is adjusted by turning the Lead Screw

Knob located in the right side of the pivoting deck.

To check the correctness of the pressure block positions, print the grey test

pattern (see the DIAGNOSTICS/Printer Tests menu item). The pressure

blocks should then be positioned to obtain a uniform printing density across

the media. In most cases, only the right pressure block will need adjustment.

2

3 4

5

55

Page 56

Chapter 2 Printing Adjustments

Label V ariations and the TOF/Paper Out Sensor

Your printer is equipped with a sensor that is used to detect the TOF (Top-ofForm) position as well as a paper out condition. Depending on the type of

media used, the sensor will either “see through” the label liner, index hole or

notch in the media (

on the media with reflective label backing (

the correct option must be selected under the Gap Sense item in the MEDIA

CONTROL Main Menu. When Transmissive is selected, the TOF position is

based on the trailing edge of the gap, notch, or hole. When Reflective is

selected, the TOF position is based on the leading edge of the black stripe.

A third option, None, is also available under the Gap Sense item in the MEDIA

CONTROL menu. The None option must be selected when continuous media

with no gap, notch hole, or black stripe is installed. The TOF will be based on

the Label Length value set under the Media Control menu or by the Forms

Length command sent via host computer software.

NOTE: When Gap Sense = None, Calibrate should still be performed to

automatically establish the optimum Paperout Threshold value.

Transmissive

sensing) or detect a black horizontal stripe

Reflective

sensing). In either case,

TOF/Paper Out Sensor Horizontal Adjustment

In order to accurately detect the gap, hole, notch or narrow width black stripe,

the Top-of-Form sensor can be moved along the width of the media from the

inner media edge to within .65 inches from the maximum media width or the

right side. The position of the sensor is changed by using the handle at the

back of the sensor to slide the sensor to the desired position. The actual

location of the sensor is indicated by the notch located in the center in the

sensor visible when the pivoting deck is in the open position.

In the Transmissive Mode, the sensor should be located directly under the

inter-label gap, hole or notch, while in the Reflective mode it should be

positioned as close as possible in the middle of the width of the label black

stripe. For media with no gap and no black stripe, the sensor should be set

under the media to detect a paperout condition.

When using the TOF/Paper Out sensor, it is the responsibility of the user to

adhere to the media specifications described in Appendix A of this manual

and to ensure that the Label Length value set in the MEDIA CONTROL Main

Menu (or Label Length value sent via software command) matches the

physical length of the label or tag stock installed in the printer. In addition, the

operator should perform the TOF sensor Calibrate procedure described below

whenever a different type of media sensing will be required (Transmissive or

Reflective), when installing never-before-tried media, or when the printer is

experiencing loss of TOF position. Loss of Top-of-Form is usually followed by

a fault message on the LCD, such as “GAP NOT DETECTED See Manual” or

“PAPER OUT Load Paper.”

56

Page 57

Calibrating the TOF/Paper Out Sensor

Calibrating the TOF/Paper Out Sensor

Due to manufacturing differences in media, the TOF (Top-of-Form)/Paper Out

sensor may have difficulty distinguishing the difference between the label and

the liner (gap) or the label and the black stripe or a paperout condition. When

this occurs, the printer will display an error message on the LCD such as

“GAP NOT DETECTED See Manual” or “PAPER OUT Load Paper.” The

printer’s sensitivity for detecting the TOF position or paper out condition of the

media installed can be optimized by using the Calibrate feature of the printer.

TOF/Paper Out sensor sensitivity can be improved by changing the values of

Paper Calibrate/Gap Threshold and/or Paper Out Threshold. These values

can be changed manually within the MEDIA CONTROL menu, or can be

determined by the printer automatically by performing the Calibrate

procedure.

Any changes to sensor parameters which occur as a result of the Calibrate

procedure, regardless if performed automatically or manually, take effect

immediately within the current configuration menu, but are not automatically

saved. If the Calibrate is performed again the new values will overwrite the

previous values for the current menu.

The new values can be saved into non-volatile memory (menus 1-8 only) by

using the Save Configuration procedure. If the current menu in use is the

Factory menu, the values will take effect but will not be saved into memory

and will be lost when the printer is powered off.

When Paper Calibrate has completed successfully, the Sensed Distance

selection in the MEDIA CONTROL menu will display a distance in inches

based on the media type in use:

• transmissive media = the label length plus one gap length

• reflective media = the distance from the leading edge of one black

stripe to the leading edge of the next black stripe.

The Sensed Distance value can not be changed manually and is updated only

as a result of the Paper Calibrate procedure. The factory default value of

Sensed Distance is 0.00 inches.

If Calibrate fails to determine the proper values and ends with a fault message

displayed (GAP NOT DETECTED or LOAD PAPER), you can either try it

again or manually change the Gap Threshold and/or Paper Out Threshold

values under the Media Control/Paper Calibrate menu.

Once the correct values are determined and the Label Length setting in the

MEDIA CONTROL menu is equal to or slightly less than the physical label

length, press the FEED key to advance media and determine if it consistently

stops at the correct TOF position each time.

57

Page 58

Chapter 2 Printing Adjustments

Calibrate Procedure

Calibrate is enabled via the front panel by using the Menu Key and navigating

through the MEDIA CONTROL menu or by using the Test Print Key.

The Test Print Key requires the fewest key strokes to begin the Calibrate, but

the user must still navigate through the MEDIA CONTROL menu to view the

results regarding value changes to the Gap Threshold, Paper Out Threshold,

and Sensed Distance.

NOTE: Verify that the media installed in the printer matches the M EDIA

CONTROL menu Gap Sense option (Transmissive, Reflective, or

None).

Verify that the Top-of-Form sensor is horizontally positioned to permit

sensing of the notch, gap, or black stripe. (See “TOF/Paper Out

Sensor Horizontal Adjustment” on page 56.)

Running Calibrate via the MEDIA CONTROL Menu

1. Press and release the PAUSE key to place the printer Offline.

2. Press and release the↓and↵keys simultaneously to unlock the printer

menu. “ENTER SWITCH UNLOCKED” appears on the LCD.

.

3. Press the key until “MEDIA CONTROL” appears on the LCD.

4. Press the↓key until “Paper Calibrate/Run Calibrate” appears.

5. Press the↵key. The media will advance approximately 11 inches.

.

.

The procedure is completed successfully if no fault is displayed and the

Sensed Distance value is correct (See “Sensed Distance” on page 98).

Sensed Distance value will be updated only when Gap Sense =

Transmissive or Reflective. When Gap Sense = None, only Paper Out

Threshold will be updated.

If a fault message such as “GAP NOT DETECTED See Manual” or

“PAPER OUT Load Paper” appears while performing the Paper Calibrate

procedure, press the PAUSE key and perform the Calibrate procedure

again.

6. Press the PAUSE key until “OFFLINE” appears on the LCD.

7. Press the FEED key. The media should advance one forms length.

NOTE: If Clip Page = Enable (factory default) in the MEDIA CONTROL

menu, the printer will stop at the first TOF (Top Of Form) position of

the transmissive gap, notch, or hole, or reflective black strip that it

detects. This is regardless of the Label Length value selected under

the MEDIA CONTROL menu.

If Clip Page = Disable in the MEDIA CONTROL menu and the Label

Length value is longer than the physical label length of the media in

use, the printer will continue to advance media to achieve that Label

Length value and then stop at the next TOF position.

8. Press the PAUSE key to place the printer Online.

58

Page 59

Calibrate Procedure

NOTE: The amount of media advancement is also based on which Media

Handling selection is enabled under the MEDIA CONTROL Main

menu. ‘Tear-Off’ and ‘Tear-Off Strip’ will advance the media until the

Top-of-Form of the next label is positioned over the Tear bar. When

‘Continuous’ Media Handling is selected the media will advance only

until the Top-of-Form of the next label is positioned under the

printhead.

Running Calibrate Via The T est Print Key

1. Press and release the PAUSE key to place the printer Offline.

2. Press the Test Print Key until Printer Test/Calibrate appears on the LCD.

3. Press the

The procedure is completed successfully if no fault is displayed and the

Sensed Distance value is correct (See “Sensed Distance” on page 98).

Sensed Distance value will be updated only when Gap Sense =

Transmissive or Reflection. When Gap Sense = None, only Paper Out

Threshold will be updated.

4. Press the PAUSE key until “OFFLINE” appears on the LCD.

5. Press the FEED key. The media should advance one forms length.

NOTE: If Clip Page = Enable (factory default) in the MEDIA CONTROL

6. Press the PAUSE key to place the printer Online.

↵ key. The media will advance approximately 11 inches.

menu, the printer will stop at the first TOF (Top Of Form) position of

the transmissive gap, notch, or hole, or reflective black strip that it

detects. This is regardless of the Label Length value selected under

the MEDIA CONTROL menu.

If Clip Page = Disable in the MEDIA CONTROL menu and the Label

Length value is longer than the physical label length of the media in

use, the printer will continue to advance media to achieve that Label

Length value and then stop at the next TOF position.

The amount of media advancement is also based on which Media

Handling selection is enabled under the MEDIA CONTROL Main

menu. ‘Tear-Off’ and ‘Tear-Off Strip’ will advance the media until the

Top-of-Form of the next label is positioned over the Tear bar. When

‘Continuous’ Media Handling is selected the media will advance only

until the Top-of-Form of the next label is positioned under the

printhead.

59

Page 60

Chapter 2 Cleaning

Cleaning

Depending on the media used, the printer may accumulate residues (media

dust, adhesives, etc.) as a by-product of the normal printing process. To

maintain top printing quality, these residues should be removed by a periodic

cleaning of the printer.

General

Periodic cleaning should be performed on all rollers, guides, and assemblies.

Low pressure air can be used to remove dust in the printer. Isopropyl alcohol

and a cotton swab should be used to clean any areas where media dust,

adhesives, etc. have accumulated. This general cleaning will insure that all

parts are free of residue which may degrade print quality.

The media path and printhead should be cleaned each time a new roll of

media is installed in the printer.

Printhead

As you use your printer, the printhead may become dirty resulting in poor print

quality. You should clean the printhead when replacing the ribbon or installing

new media.Clean the printhead with the printhead Cleaning Pen supplied with

the printer. The printhead heating elements (light brown area) is most

important. Keeping your printhead clean will help to maintain its life.

60

Page 61

Printhead

1. Rotate the deck lock clockwise to open the pivoting deck and remove any

media and ribbon (if loaded) to gain access to the printhead assembly

heating element area.

1

2

Legend:

1) Pivot Deck

2) Deck Lock Lever

2. Gently rub the felt tip of the Cleaning Pen or a cotton swab with Isopropyl

alcohol across the printhead heating elements (light brown area).

Allow the printheadto dry for one minute before reloading the labels.

61

Page 62

Chapter 2 Cleaning

62

Page 63

3 Configuring the Printer

Overview

The configuration process is done using the printer configuration keys on the

control panel and includes the following:

• Configuring the printer for different host interface options

• Customizing label formats

• Checking printer status

• Running various maintenance tests

NOTE: Control codes sent by the host system will override the control panel

Menu Navigation

settings.

This section explains how to use the control panel to change individual

settings and save them as a customized configuration. For details on the

control panel keys and how they work, see “Controls & Indicators” on page

31.

Pressing↓and↵ together unlocks or locks the printer menu (offline mode

only) and permits value selection. This is the default key combination for

locking/unlocking the printer. You can change the key combination. See “Set

Lock Key” on page 101.

63

Page 64

Chapter 3 Menu Navigation

Setting Printer Configuration Parameters

Configuration parameters are set from the control panel or are retrieved from

the printer’s memory. The parameters define how the printer will respond to

command and interface signals from the host computer.

The configuration menu structure consists of top-level menus and various

parameter selections under each top-level menu.

NOTE: Many of the selectable configurations refer to printer options or

features that may or may not be present in your printer. Selecting an

option or feature that is not present will result in no action being

performed by the printer, or an ‘OPTION NOT INSTALLED’ message

displayed.

Moving Within the Configuration Menu

Movement within the configuration menus is controlled by using the

appropriate navigation keys. Figure 1 shows how to move through the menu

system. See “Controls & Indicators” on page 31, for more details on the

function of the operator panel keys.) This example configures the printer for

Direct Thermal operation.

Figure 2 is a configuration printout of a typical printer. This printout illustrates

some of the possible parameter selections which can be made from either the

printer configuration menu or a host computer.

Figure 3 shows the top level overview of the menu structure. A brief

description of the function of each top-level menu selection is given below

each top-level menu selection.

Figure 4 shows a more detailed view of the top level of the menu system. Not

all possible top-level menu selections are available simultaneously since their

presence depends on the installed options as well as specific selections made

in other areas of the menu system.

Use these basic guidelines to move throughout all the configuration menus.

You can select different options and save them as the power on default;

however, they can only be saved to configurations menus 1-8, as the factory

configuration menu can not be altered or saved over.

When the printer is online, the first line of the LCD indicates ONLINE and the

second line lists the active interface port and type of emulation.

To configure the printer, it must be offline. If the ONLINE indicator is lit, press

and release the PAUSE key to place the printer offline. When the printer is

offline, OFFLINE appears on the top line of the LCD. Pressing the key

causes the printer to enter the printer configuration menu system and

CONFIG. CONTROL appears on the next line. When in the printer

configuration menu system the LED indicator is illuminated.

.

.

.

64

Page 65

Selecting a Menu Option

Step Press LCD Notes

1. OFFLINE

2.

3. OFFLINE

4. OFFLINE

5.

6.

7.

Figure 1. Moving within the Configuration Menu

↓& ↵

.

.

.

.

.

.

↓ UNTIL

+or –

↵

ENTER SWITCH

UNLOCKED

CONFIG. CONTROL

MEDIA CONTROL

Print Mode

Transfer*

Print Mode

Direct

Print Mode

Direct*

Allows you to make

configuration changes.

Enables the printer

configuration menu.

Selects the MEDIA

CONTROL top level

menu.

Cycle through the

choices.

Selects the Direct transfer

mode.

Selecting a Menu Option

By default, the↵key is “locked” when the printer is turned on. The purpose of

this is to prevent accidental changes to the configuration menu. If you press

the↵key when the key is locked, the message ENTER SWITCH LOCKED is

displayed on the LCD for one second, and the value will not be selected.

To unlock the↵key, press the↓and↵keys simultaneously.

This toggles the enter lock function.

IMPORTANT

If this function is performed while the↵key is locked, the message

ENTER SWITCH UNLOCKED will be displayed for one second, and the

ENTER key will be unlocked.

If this function is performed while the↵key is unlocked, the message

ENTER SWITCH LOCKED will be displayed for one second, and the

key will be locked.

When the ↵ key is pressed (with the ↵ key unlocked), the value displayed is

entered and the configuration is changed immediately.

This c hange takes effect for all subsequent data and operations for the

printer as soon as ENTER Key is pressed and the asterisk (*) is

displayed. The configuration change(s), stay in effect only while the

printer is powered on. When the power is turned off, all current

configuration w ill be lost unless changes made to it are saved via the

CONFIG. CONTROL menu.

↵

65

Page 66

Chapter 3 Menu Navigation

To save configuration information permanently or to select it as the power-up

default, see “Saving a Configuration” on page 68.

Changing Printer Settings

Changing printer settings, such as print speed or emulation, is referred to as

configuration. Configure the printer through the control panel.

1. Make sure the printer is offline. If the ONLINE indicator is lit, press the

PAUSE key to enter the offline mode. The following message will display:

OFFLINE

.

2. Press key until the following message displays.

.

.

OFFLINE

MEDIA CONTROL